V-method mold for casting electronic appliance mold casting blank

A home appliance mold and mold technology, applied in the field of aluminum alloy casting, can solve the problems of increasing raw material consumption and production time, unable to achieve the advantages of the inner cavity surface of the casting billet, unable to cover the deep cavity in place, etc., so as to shorten the production cycle and save raw materials. and production time, the effect of canceling the labor of the wood mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

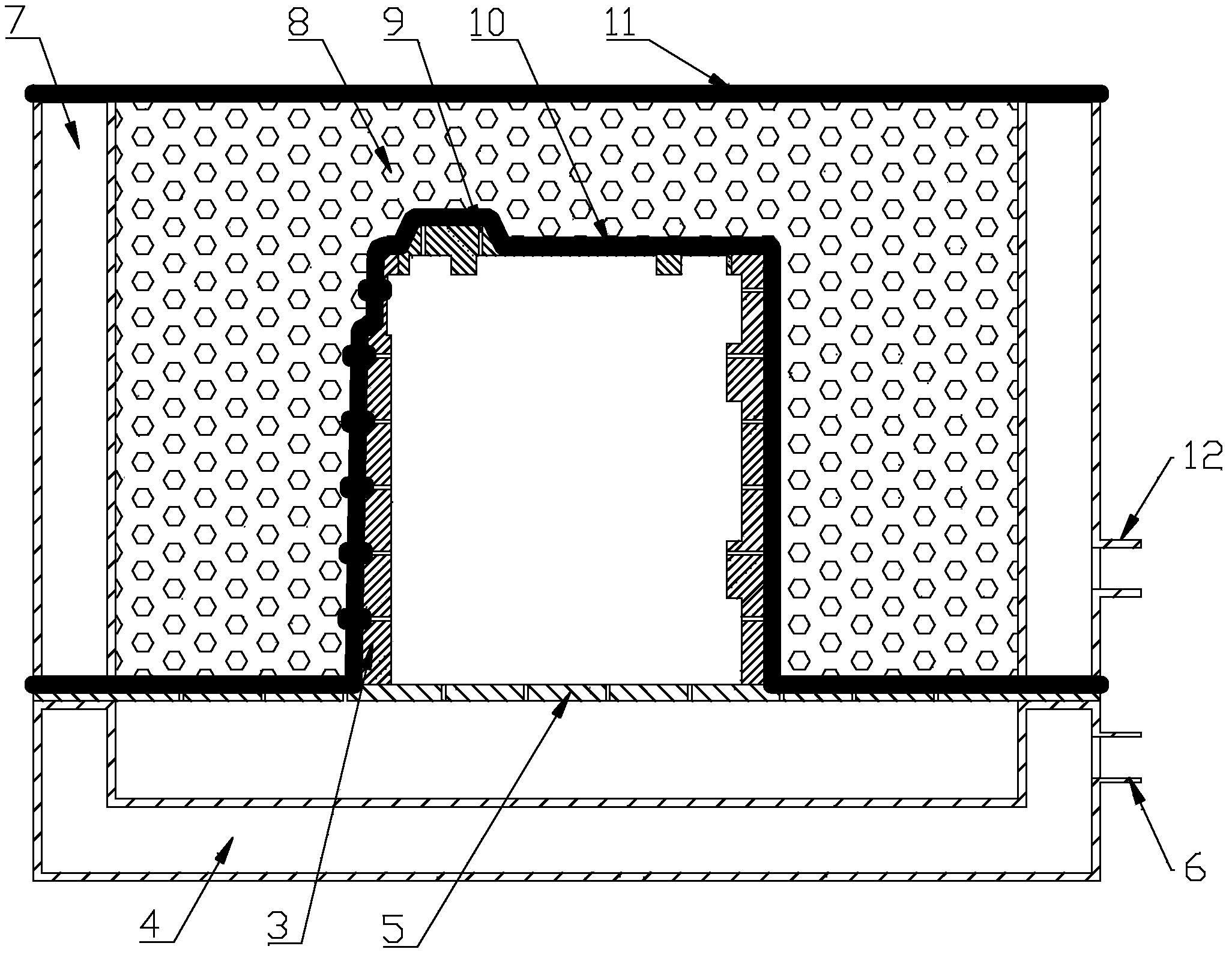

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

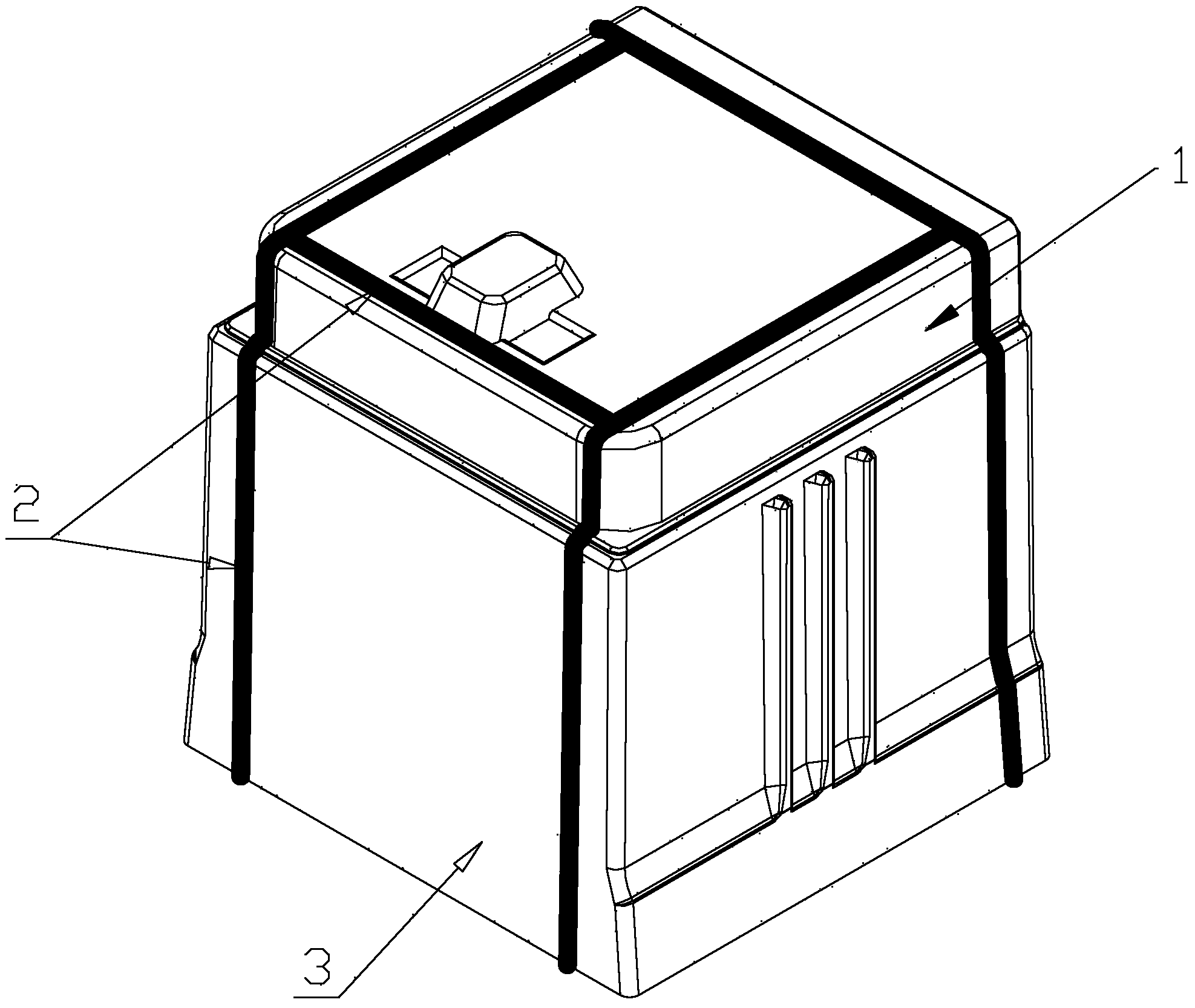

[0039] Such as Figure 1 to Figure 5 As shown, the embodiment is an example of using this case to cast a mold blank for the inner tank of a household appliance:

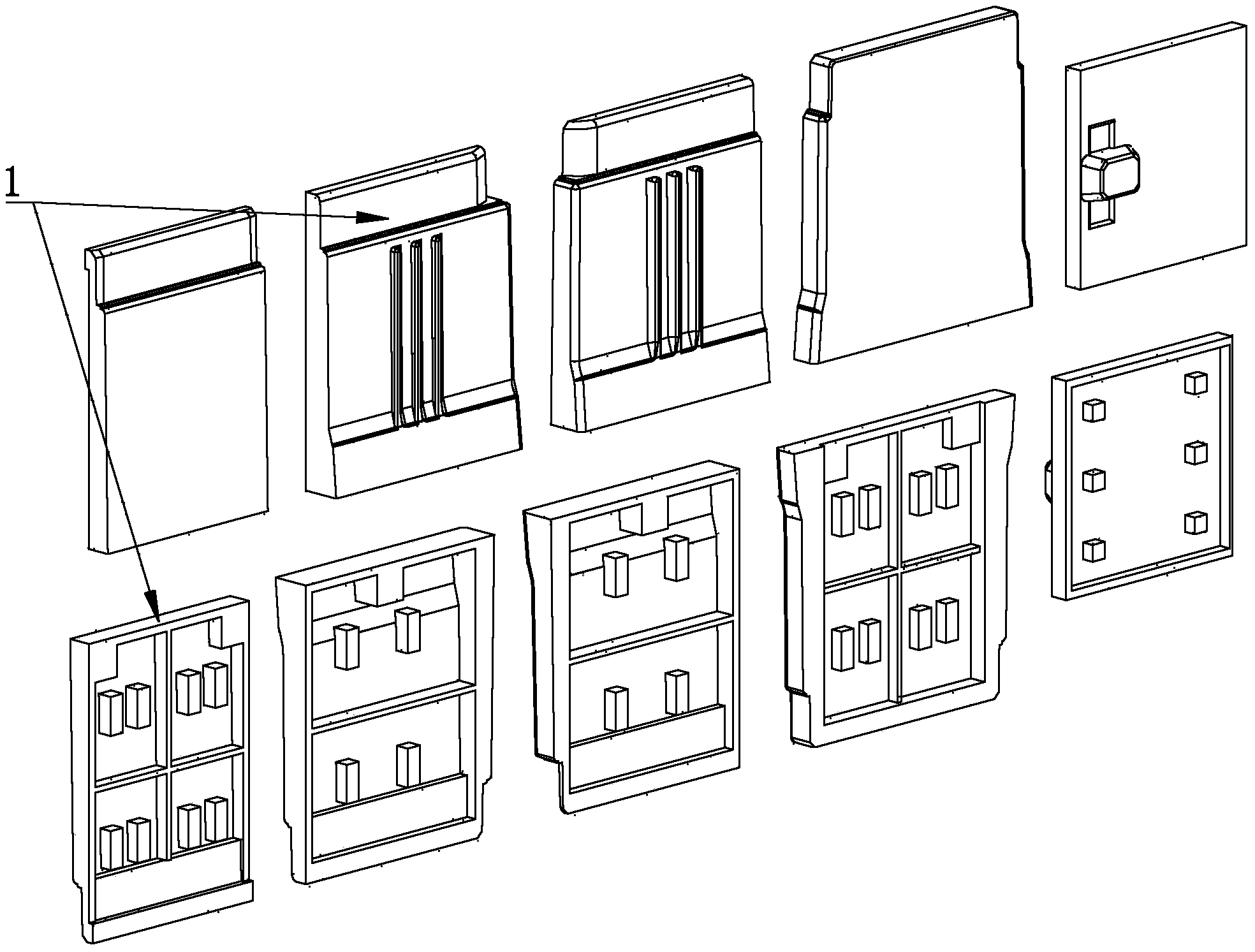

[0040] ①According to the requirements of the customer's drawings, use 3D software to shape and process the box body, cut the box body into 5 small pieces of modules 1, and then process each module 1 with CNC machine tools, figure 1 As shown, the module material is polyurethane foam with a density of 100;

[0041] ②Drill out several vacuum holes 9 of φ1mm in each module 1, and then use double-sided adhesive tape 2 to bond each module according to the shape, so as to obtain the V-method mold 3 for casting the box;

[0042] ③Paste the V-method mold 3 on the first panel 5 with double-sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com