Patents

Literature

92 results about "Rapid casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapid casting is an integration of conventional casting with rapid prototyping/3D printing. In this technique disposable pattern used for forming mold are created with 3d printing techniques like fused deposition, stereo lithography or any other 3d printing technique.

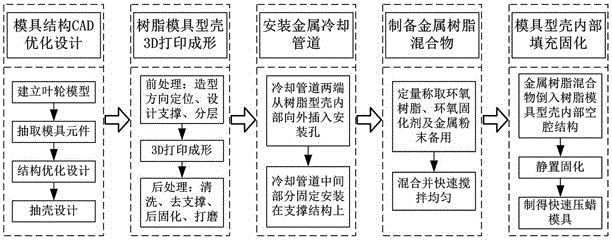

Rapid wax injection mold manufacturing process based on photo-curing 3D printing technique

InactiveCN106694804AEliminate processing and manufacturing linksReduce manufacturing costAdditive manufacturing apparatusFoundry mouldsEpoxyWax

The invention relates to a rapid wax injection mold manufacturing process based on a photo-curing 3D printing technique and belongs to the technical field of rapid manufacturing of molds. The rapid wax injection mold manufacturing process comprises the following steps: firstly building a mold component three-dimensional model and carrying out structure optimization design and shell-drawing design, secondly forming a mold shell three-dimensional model through photo-curing 3D printing to manufacture a resin mold shell, then mounting a metal cooling pipeline in the resin mold shell; finally preparing a metal resin mixture by taking epoxy resin, epoxy curing agents and metal powder as the raw materials, and filling the metal resin mixture in the resin mold shell and manufacturing the rapid wax injection mold after the metal resin mixture is completely cured. Through the rapid wax injection mold manufacturing process based on the photo-curing 3D printing technique, the manufacturing cost of the wax injection mold can be reduced; the manufacturing cycle of the wax injection mold is shortened; the manufactured wax injection mold is high in mechanical strength, high in heat conduction performance and long in service life; the practicability of the wax injection mold in the casting field can be effectively improved; the wax injection mold is conveniently popularized and applied in the field of single-piece, small-batch and rapid casting.

Owner:浙江省机电设计研究院有限公司 +1

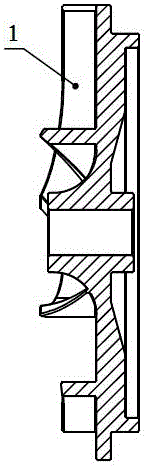

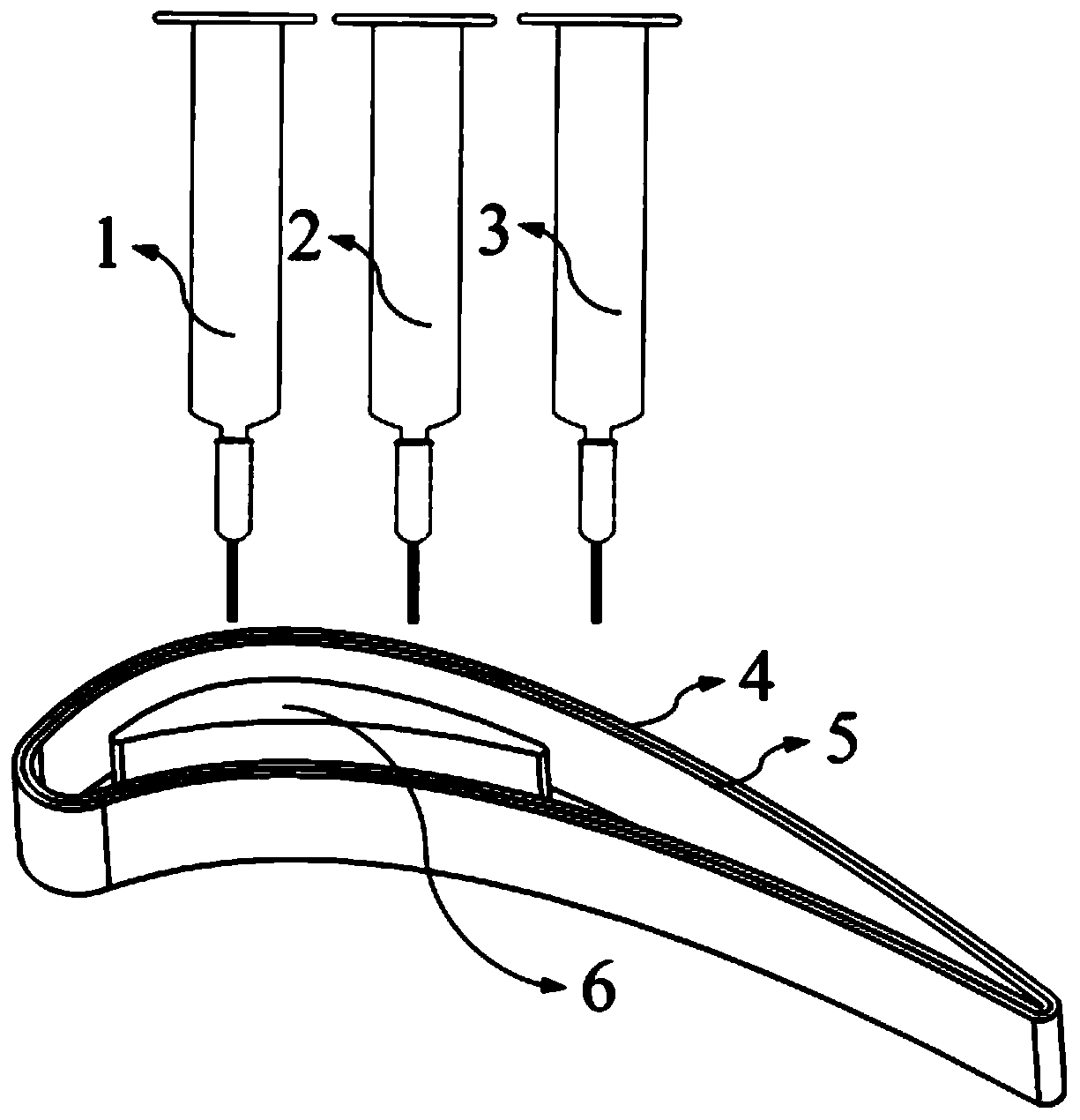

Method for three-dimensional jet-printing, forming and casting of core

ActiveCN105057601AHigh viscosityIncrease surface tensionFoundry mouldsFoundry coresFine structureThin layer

The invention discloses a method for three-dimensional jet-printing, forming and casting of a core. The method comprises the comprises the following steps: (1) spreading film covering sand to form a thin layer, and selectively injecting bonding liquid into the film covering sand by using a three-dimensional jet-printing device so that particles in the film covering sand can be bonded with one another to form a first layer; (2) forming a second layer by using the same method in the step (1), repeating the step (1) until a part is formed completely, and standing the part in a powder bed for a period of time so as to obtain an initially formed blank; and (3) heating the initially formed blank at the temperature of 170-220 DEG C until the bonding liquid completely volatilizes, and cross-linking and curing with phenolic resin, so that the casting of the core is finished. According to the method, the method for three-dimensional jet-printing, forming and casting of the core is simplified; the film covering sand can be accumulated layer by layer without drying conditions among layers, so that the fast casting forming of the core is finished; finally, a produced piece is relatively high in intensity, low in cost and high in efficiency; the method can be used for producing the casting core with the large size and a fine structure, and has a wide application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

Cast manufacturing method of rapid sand casting based on SLA prototype

ActiveCN103310068AImprove efficiencyHigh precisionFoundry mouldsFoundry coresShrinkage rateMaterial resources

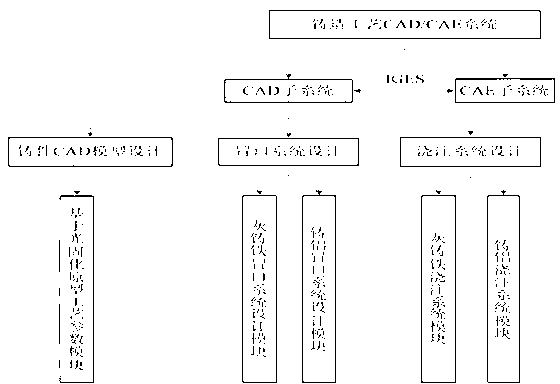

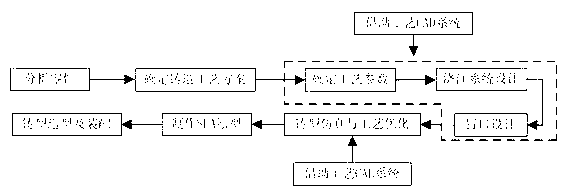

The invention discloses a cast manufacturing method of a rapid sand casting based on an SLA prototype, which combines the SLA rapid prototyping technology based on a conventional cast manufacturing method. The method comprises the following steps: in a whole cast design, exploiting a cast technology CAD system software as a main auxiliary application tool, and conducting cast simulating and technology optimization through a technology CAE system; and after finishing the cast design, manufacturing an SLA prototype piece through a light curing model mechanism, forming the cast by the modeling and the assembling of the cast, and manufacturing metal products by pouring. Meanwhile, by modifying the linear shrinkage and the draft angle of the cast, and adopting technical ways of phenol-urethane resin bonded sand molding, and the like, the efficiency and the accuracy of design and manufacturing of a casting technology designer are improved; manpower and material resources are saved; the engineering time is shortened, so as to facilitate the popularization and application of the rapid casting technology.

Owner:SOUTHWEAT UNIV OF SCI & TECH

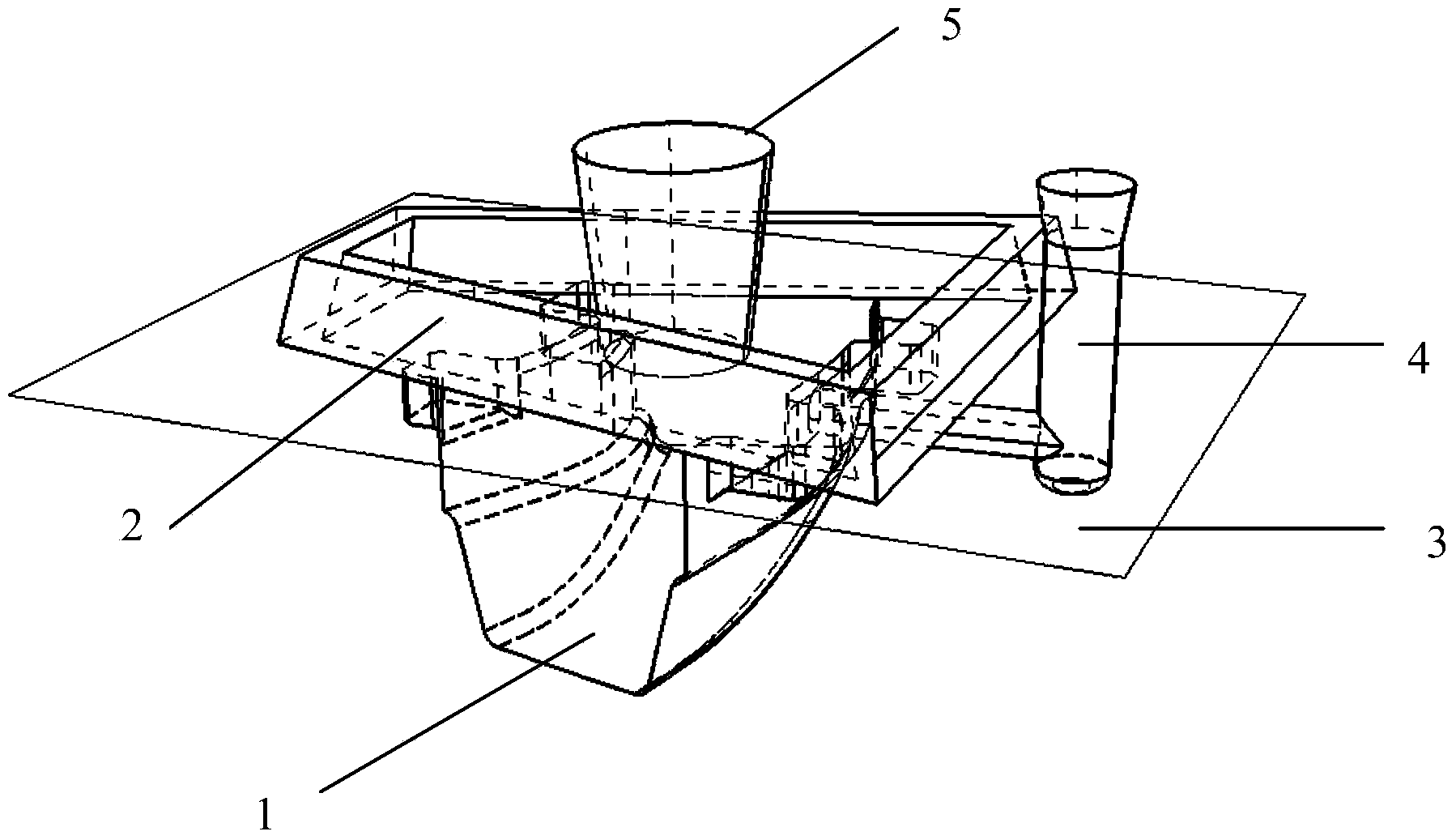

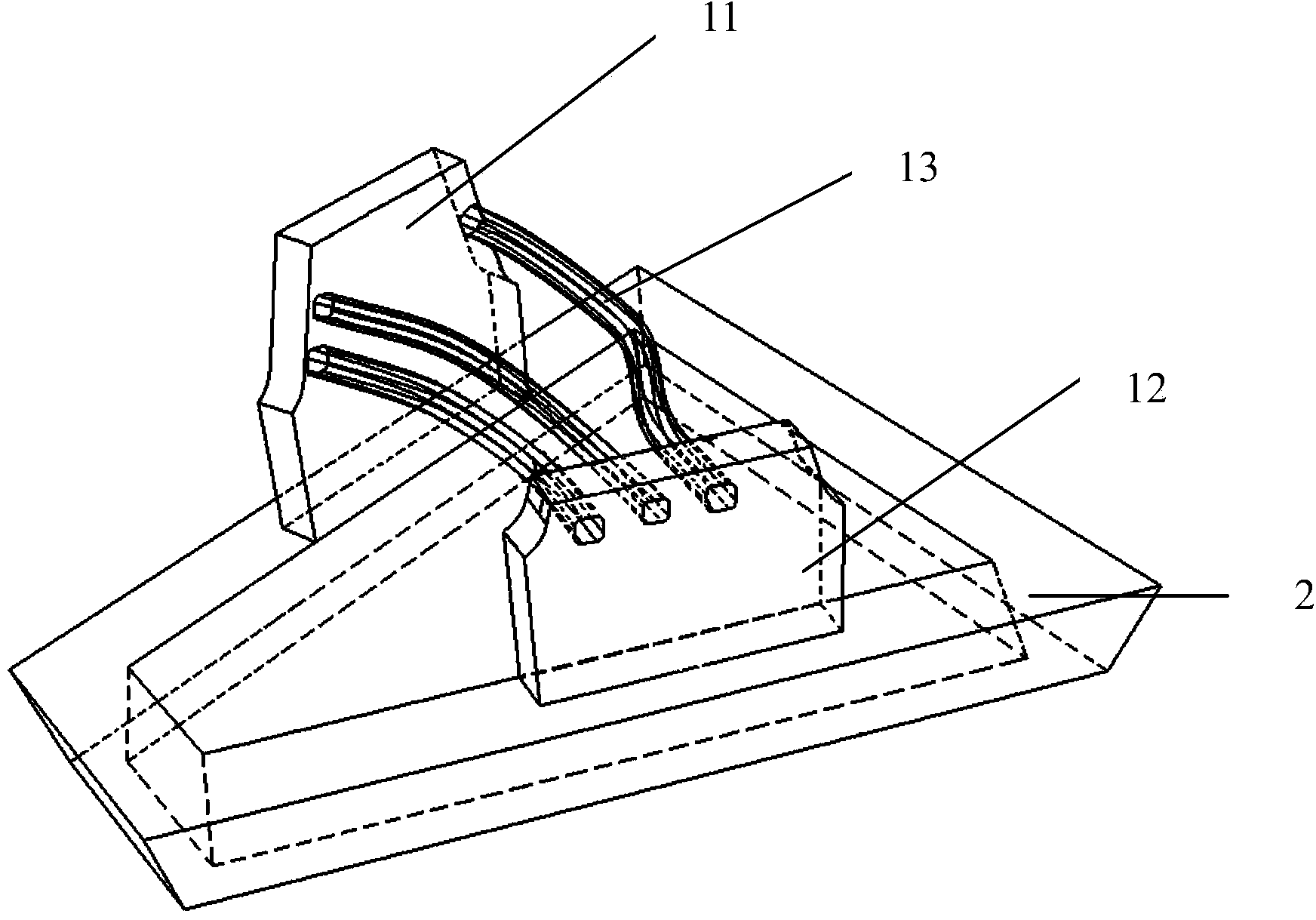

Non-pre-buried type abnormal-shaped bent water channel hot-work die and manufacturing method of non-pre-buried type abnormal-shaped bent water channel hot-work die

InactiveCN103522026AOvercoming cracks and leaksOvercome longevityShaping toolsFoundry mouldsWater channelHot work

The invention discloses a non-pre-buried type abnormal-shaped bent water channel hot-work die and a manufacturing method of the non-pre-buried type abnormal-shaped bent water channel hot-work die. The manufacturing method is characterized in that casting-state die workblank manufacturing is achieved by combining a ceramic core or a 3D printing core with a traditional sand casting method, and includes the steps of die workblank manufacturing, casting-state die workblank coarse machining and casting-state die workblank finish machining. The die workblank manufacturing includes the steps of manufacturing a cavity, an abnormal-shaped bent water channel core and a casting system, assembling the die, smelting steel, carrying out rapid casting, and carrying out cleaning, shot blasting, annealing, post-processing and flaw detection on the abnormal-shaped bent water channel core and a water collecting groove inlet-and-outlet core. The casting-state die workblank coarse machining includes the steps of casting-state die workblank profile coarse machining, quenching and tempering. The casting-state die workblank finish machining includes the steps of casting-state die workblank profile finish machining, casting-state die workblank matching face finish machining and profile PVD plating. The non-pre-buried type abnormal-shaped bent water channel hot-work die and the manufacturing method of the non-pre-buried type abnormal-shaped bent water channel hot-work die solve the problems that an abnormal-shaped bent water channel with optimized values cannot be achieved through a traditional mechanical drilling manner and the cooling rate of the traditional mechanical drilling manner is uneven, and have the advantages that the profile temperature is even, and the die machining cost is reduced.

Owner:DALIAN UNIV OF TECH

Die-free fast casting method based on fused deposition technology

ActiveCN105328121AImprove breathabilityHigh precisionMoulding toolsFoundry mouldsDeposition processRapid casting

The invention relates to a metal die-free fast casting method based on the fused deposition technology. The casting method is characterized by comprising the steps of 1, preparing mixed ceramic and plastic filamentous material; 2, preparing three-dimensional CAD data of cast shell molds; 3, printing the cast shell molds; 4, carrying out degreasing; 5, carrying out sintering; 6, pouring molten metal; 7, carrying out post-processing to obtain needed castings. The casting method has the advantages that needed equipment is simple, the cost is low, the production cycle is short, the accuracy of the castings is high and there is no need to set a draft angle or arrange a parting surface, can be used for casting formation of various kinds of metal and is especially suitable for fast casting formation of small and medium parts with complex cavities.

Owner:泰州市海通资产管理有限公司

Method for quickly casting large precision casting based on 3D printing technology

ActiveCN108907095ASimple processing technologyShort production timeAdditive manufacturing apparatusFoundry mouldsSlagDimensional modeling

The invention relates to the technical field of metal molding and casting, in particular to a method for quickly casting a large precision casting based on a 3D printing technology; through combination of a 3D printing and molding technology and a lost foam casting technology, by using special shell type coatings, a casting without the defects of recarburization, pores, slag inclusion or wrinkledskin can be cast, and the requirements of a high grade and complex structure and the precision casting can be met; and the method has the advantage of green, environmental protection and no pollution.The method comprises the steps of three-dimensional modeling, making of a fusible model and a special shell mold, boxing of the shell mold, negative pressure pouring and the like. The method has theadvantages of simple processing technology, no need of developing a mould, short production time, easy regulation and modification, low production cost, green, environmental protection and no pollution, and the molding process can be finished in real time; the requirements of individualization and customization cam be met; high quality products can be made, and massive casting and precision casting are both taken into consideration.

Owner:河南圣得威机械科技有限公司

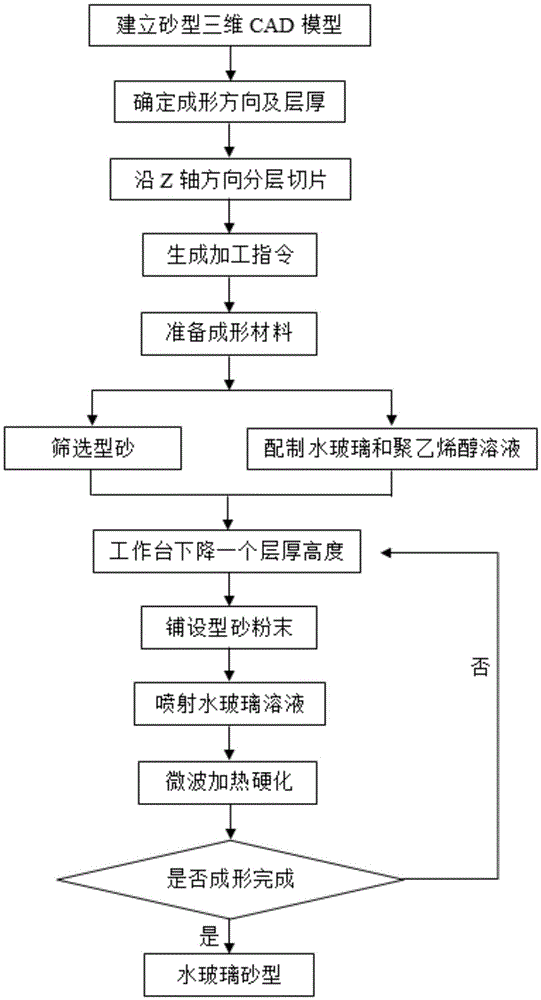

Rapid molding method of sodium silicate sand mould

ActiveCN105562623AFast bondingImprove liquidityAdditive manufacturing apparatusFoundry mouldsMicrowavePolyvinyl alcohol

The invention discloses a rapid molding method of a sodium silicate sand mould and belongs to the field of rapid casting. The rapid molding method comprises the following steps: (1), establishing a three-dimensional entity model of a sodium silicate sand mould to be molded, taking the Z axis as the molding direction, and setting molding layer thickness; (2), first, paving one layer of molding sand material, and then spraying an adhesive so as to form the current layer of outline pattern, wherein the adhesive is a mixed solution of sodium silicate and polyvinyl alcohol; (3), carrying out microwave heating on the current layer of outline pattern, and forming the current layer of sand mould outline; (4), stopping microwave heating, and lowering the work table for a height of one layer thickness along the Z axis; and (5), repeating steps (2-4) until the sodium silicate sand mould is molded. The method meets the high requirement of sodium silicate sand hardened through microwave heating on the mould, solves the problems that the surface of the sodium silicate sand mould becomes powdery due to overheating and easily absorbs moisture, and further overcomes the poor feasibility, difficult molding sand storage and difficult molding sand recycling defects of the existing micro-injection bonding sodium silicate sand rapid molding technology.

Owner:HUAZHONG UNIV OF SCI & TECH

Casting mold three-dimensional printing formation method

ActiveCN106799461AStable in natureAvoid easy cloggingFoundry mouldsFoundry coresWater basedMicrowave

The invention belongs to the technical field of rapid casting and discloses a casting mold three-dimensional printing formation method. The method comprises the following steps of 1, preparing a liquid binding agent; 2, preparing mixed powder; and 3, putting the liquid binding agent prepared in step 1 into an ink-jet printing head of rapid formation equipment, putting the mixed powder prepared in step 2 into a powder cylinder, starting the rapid formation equipment to conduct three-dimensional printing formation, in the printing process and / or after part printing is completed, solidifying a part through heating and / or microwave drying, and after solidification is completed, removing excessive powder, so that the needed casting mold part is obtained. According to the casting mold three-dimensional printing formation method, the liquid binding agent is a water-based binding agent and stable in property; the situation that a nozzle is blocked due to deterioration of the liquid binding agent cannot occur easily; technological stability of casting mold three-dimensional printing is improved; it is helpful to lower use cost; in addition, an inorganic binding agent material is adopted, and the gas generation amount of a casting mold is reduced; and it is helpful to reduce possibility of generation of defects such as air holes in a casting.

Owner:HUAZHONG UNIV OF SCI & TECH

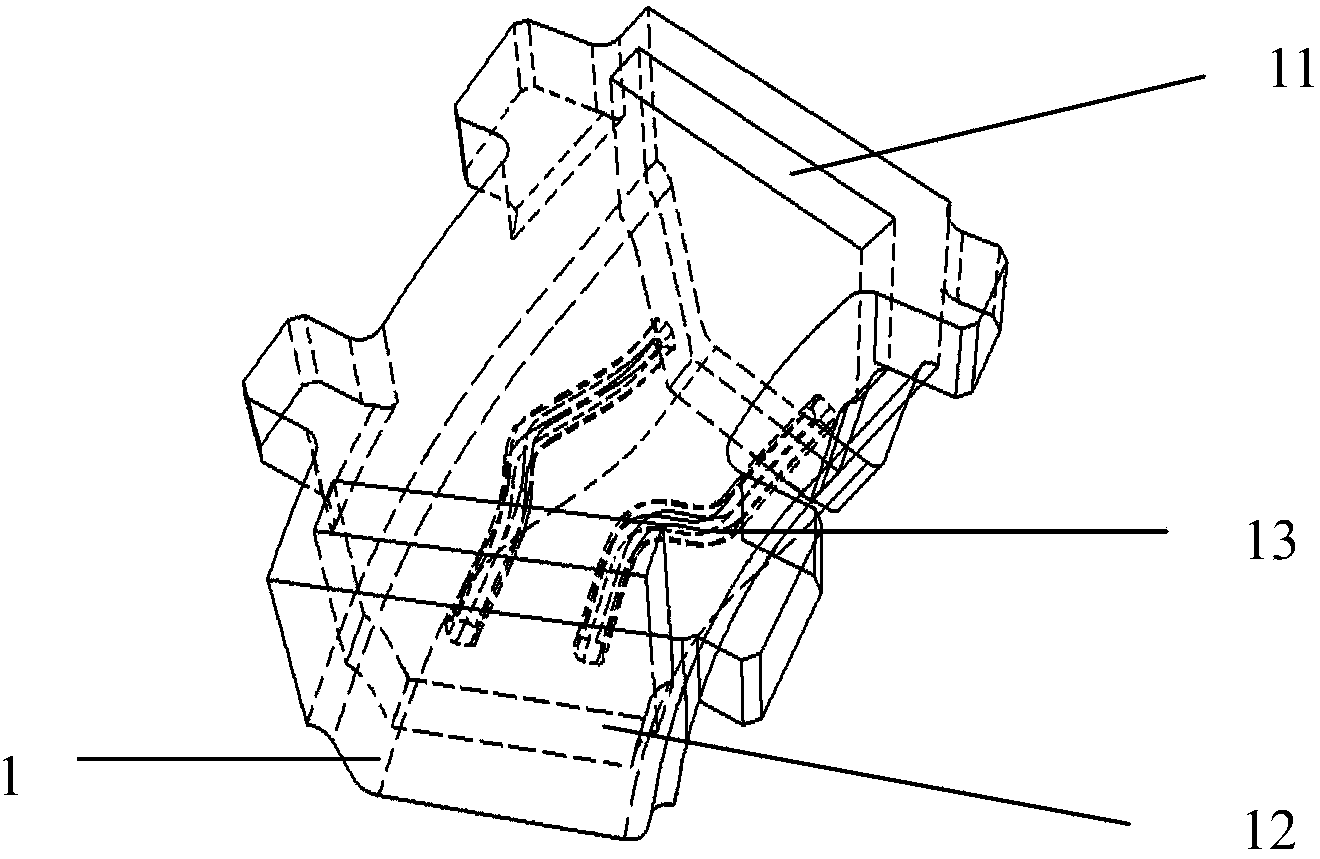

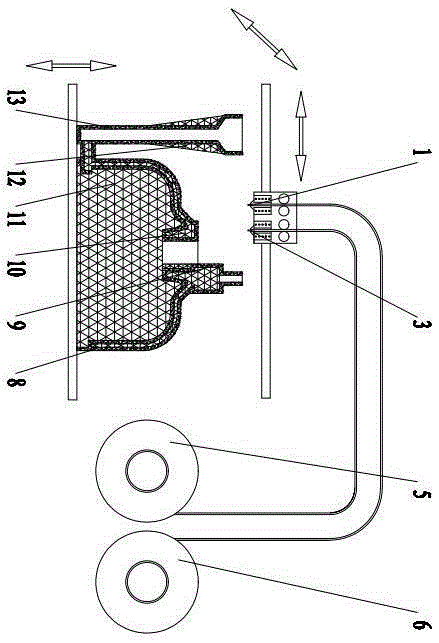

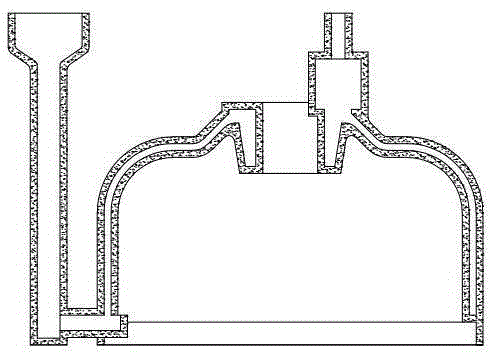

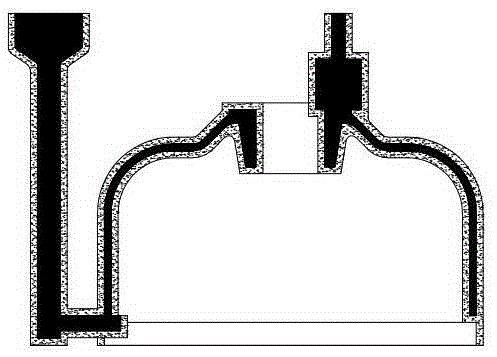

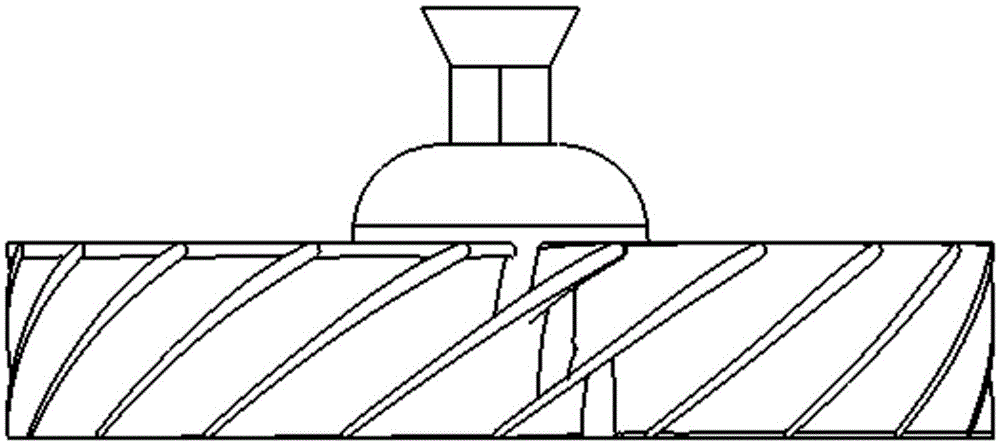

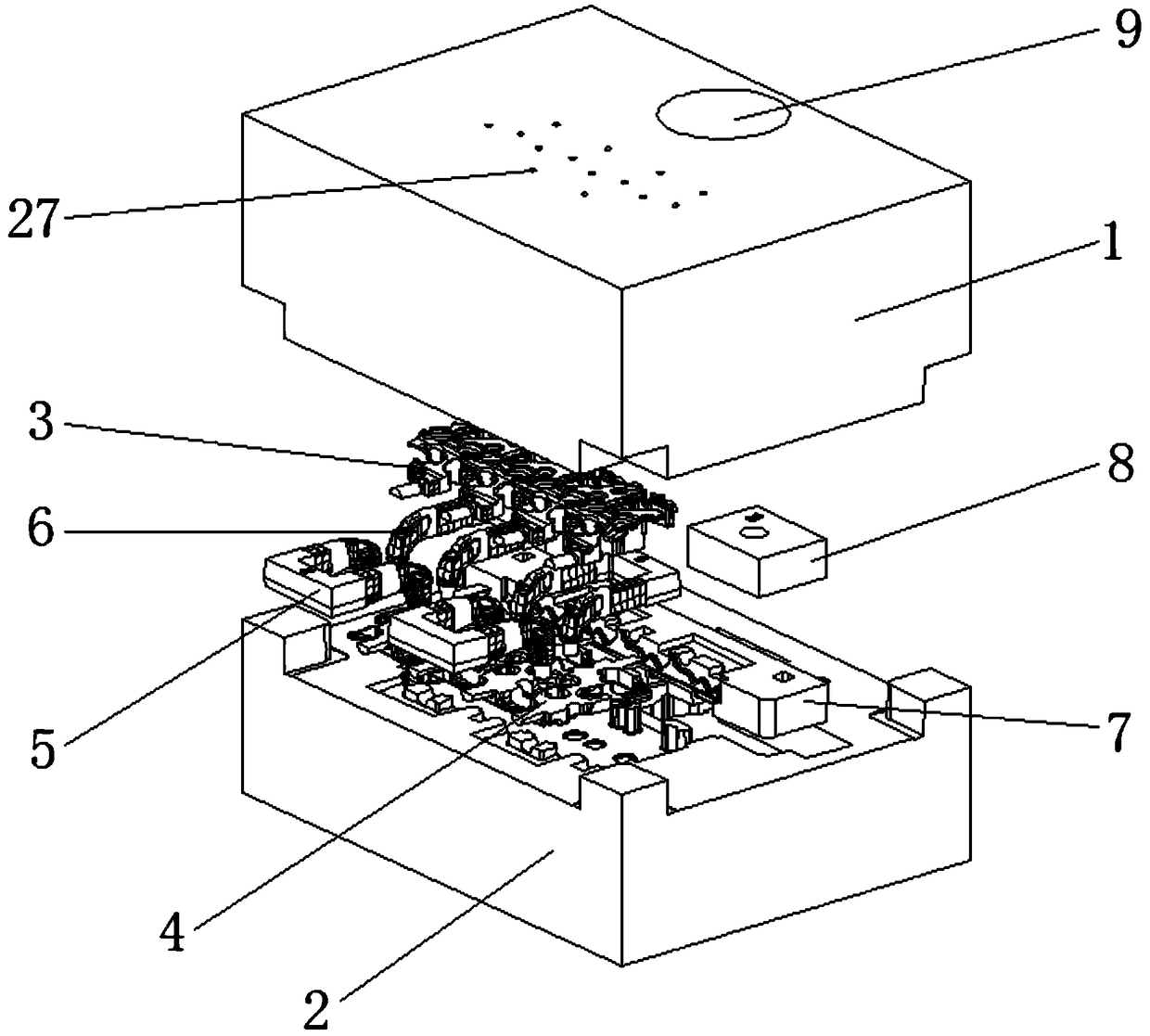

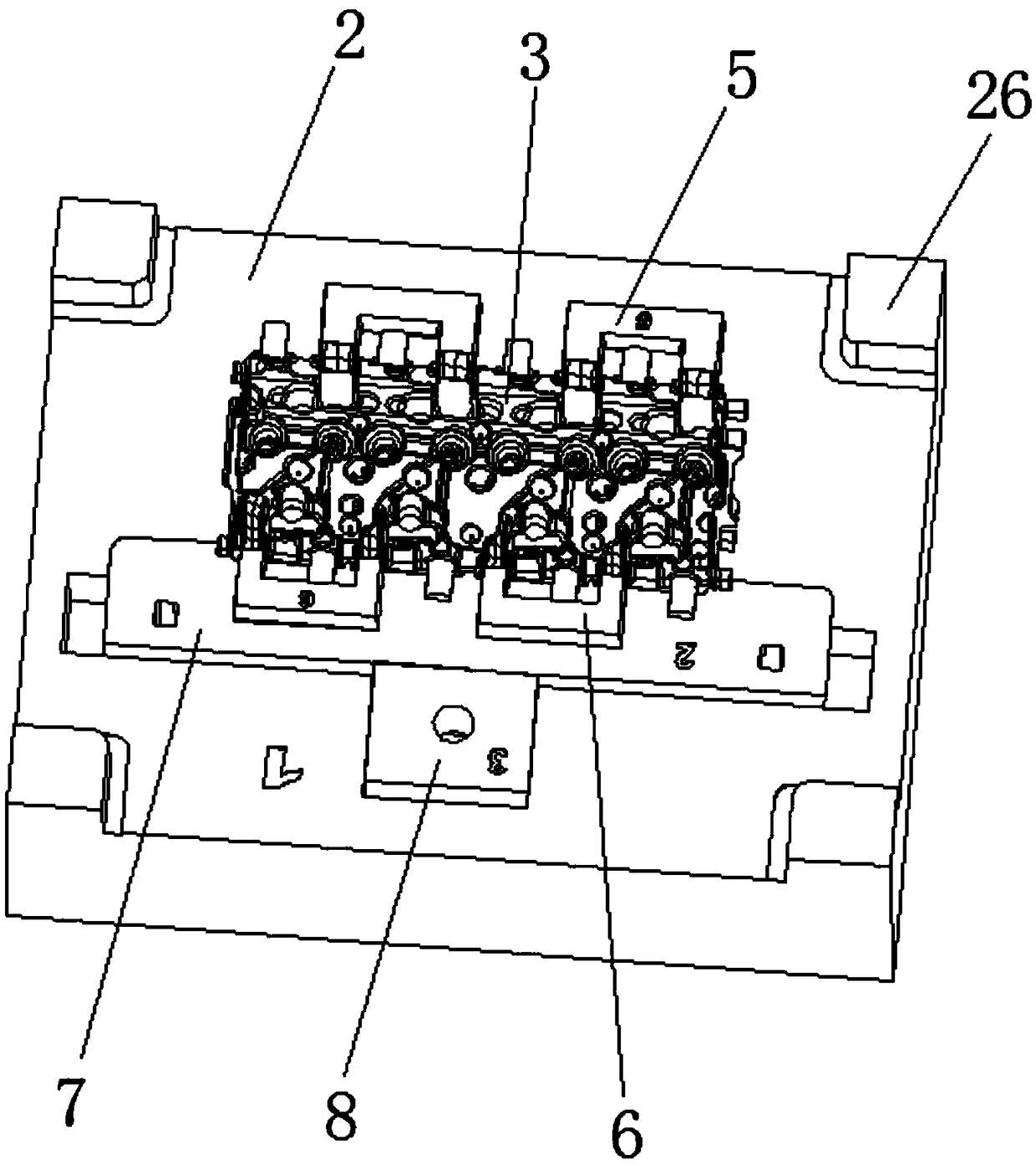

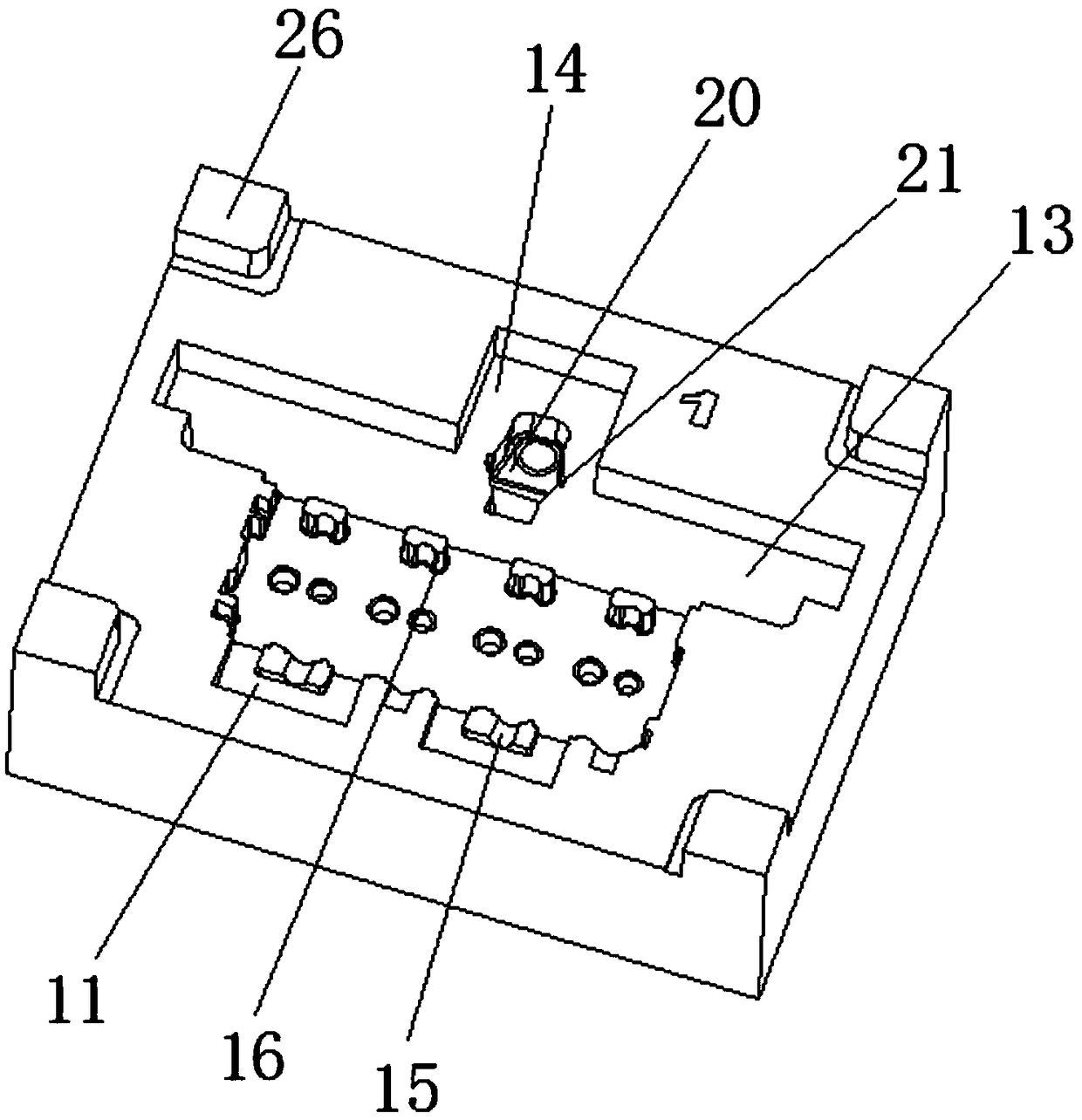

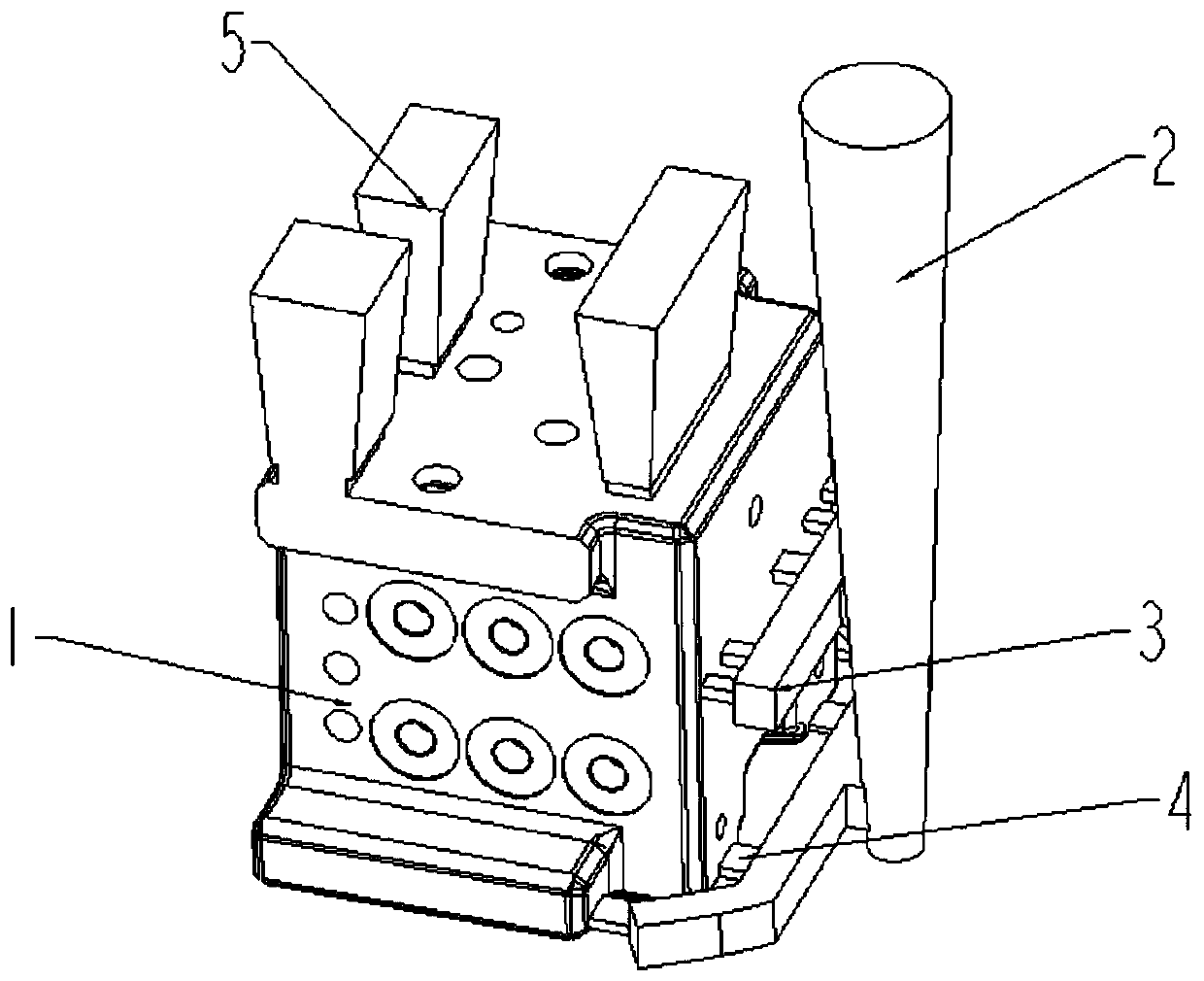

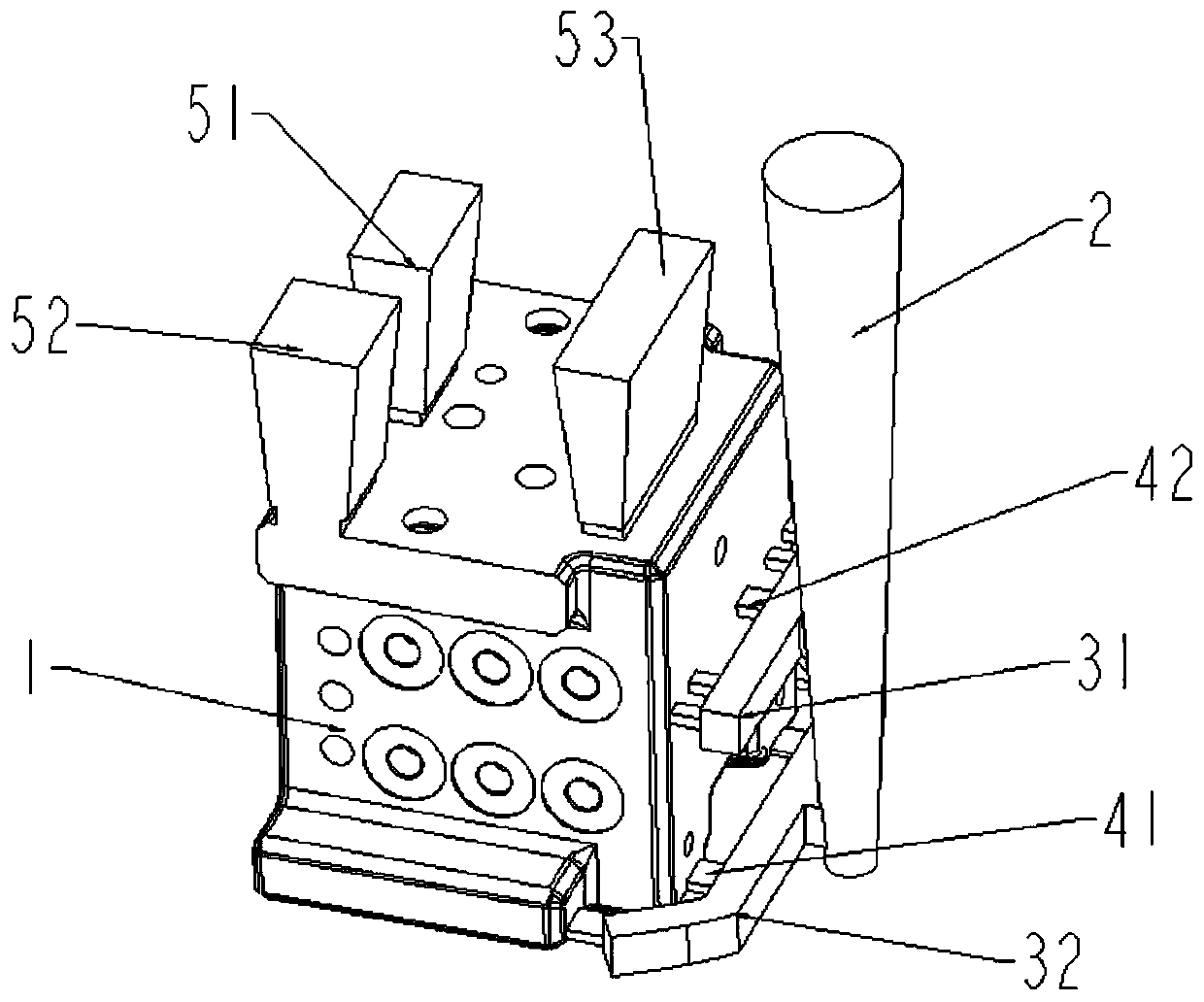

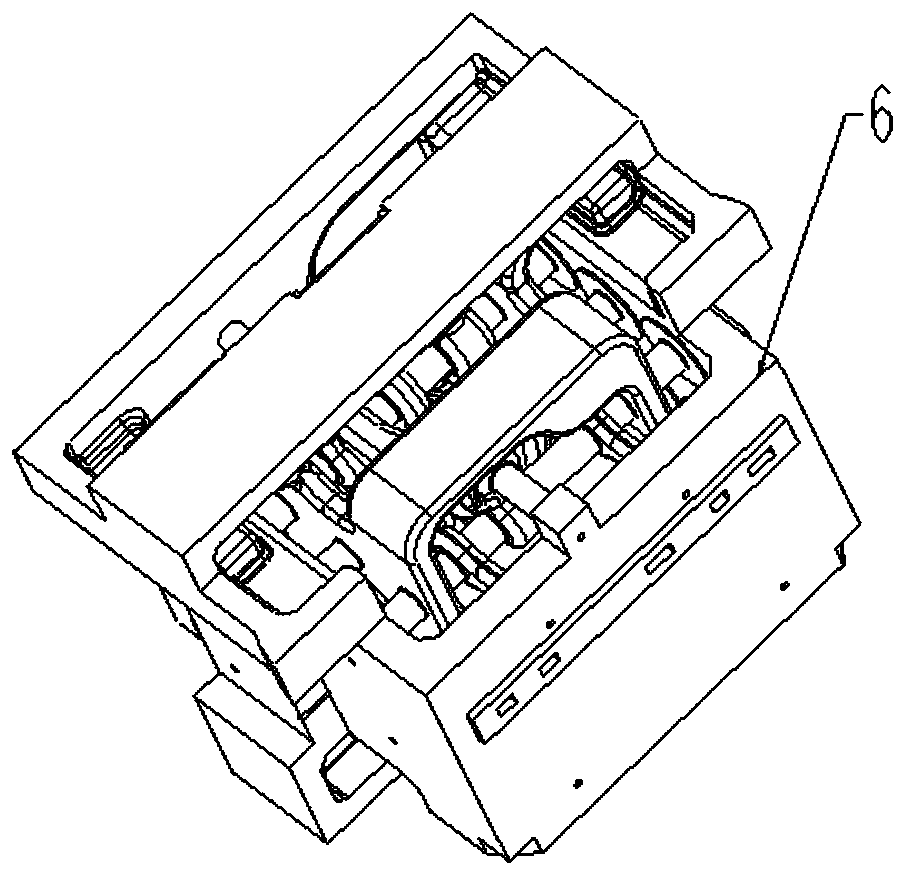

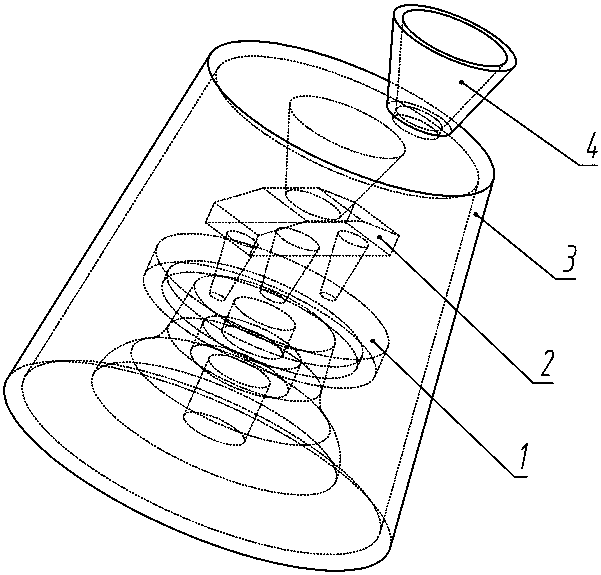

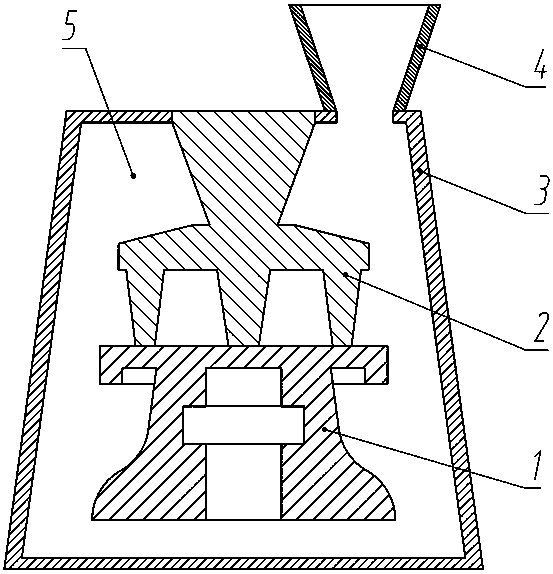

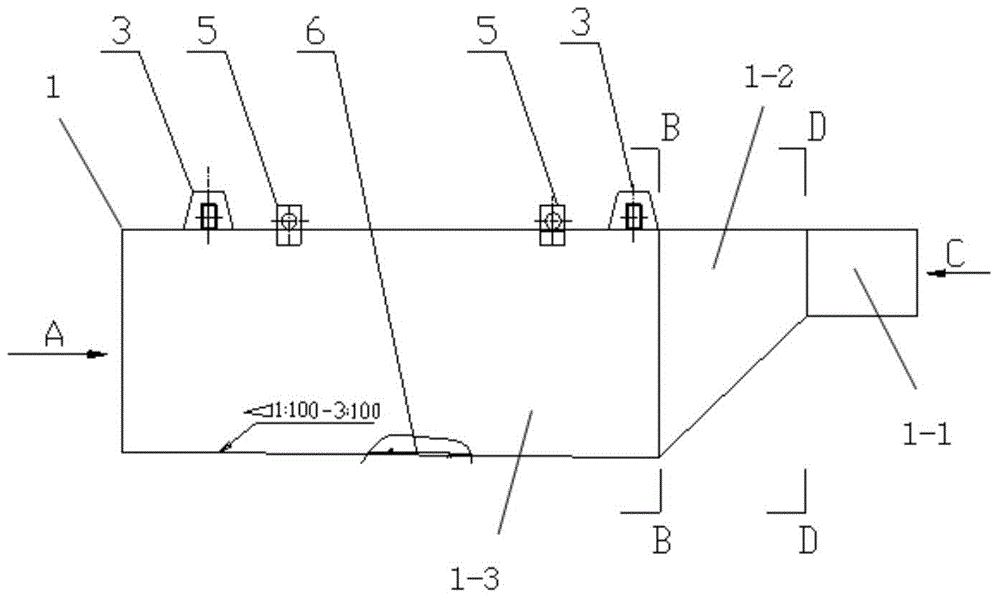

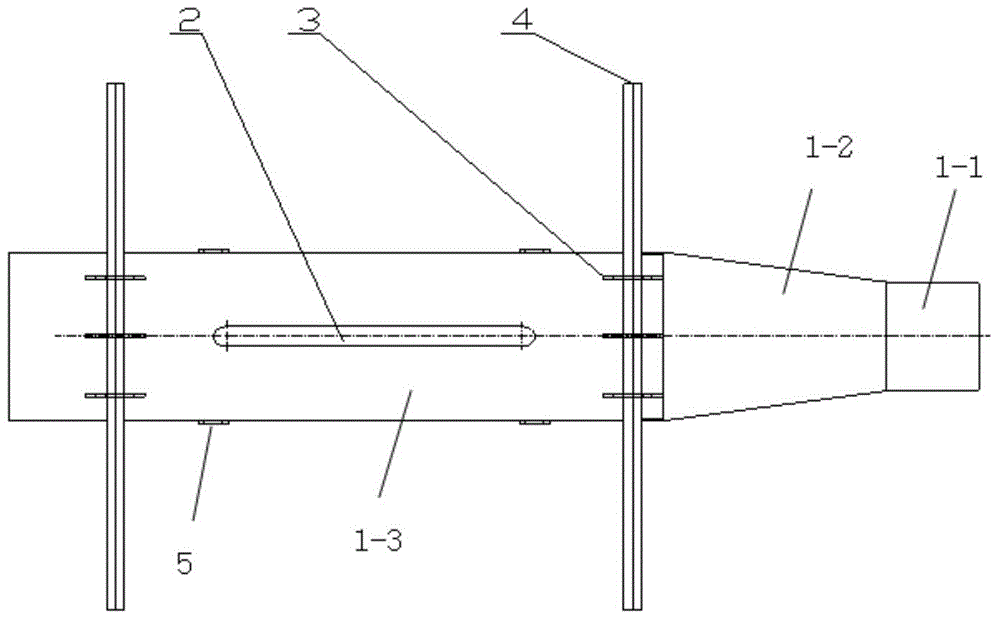

Rapid casting method for cylinder cover of diesel engine and sand core assembly

The invention discloses a rapid casting method for a cylinder cover of a diesel engine. According to the method, a one-box one-piece sand core assembly is adopted, by a lateral pouring and bottom injecting type casting mode, molten iron is poured from one side of the sand core assembly and enters the cavity of a cylinder cover of a sand core, and thus, the cavity of the cylinder cover is filled with the molten iron from bottom to top. The method is suitable for rapid casting of a new product, the product verification period is short, the cost is low, and the requirement of real-time changing of the new product is met. The invention further discloses a sand core assembly for rapidly casting the cylinder cover of the diesel engine. The sand core assembly is compact in structure and reasonable in design, when the cylinder cover of the diesel engine is casted by the sand core assembly, mold filling is stable, slag stopping performance is good, air is discharged smoothly, core assembling isfacilitated, a casting of which the wall thickness is uniform and accurate is easily obtained, and the product quality of the casting is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

Wax-containing 3D printing light-cured cast resin and preparation method thereof

InactiveCN109880272ALow viscosityImprove mechanical propertiesAdditive manufacturing apparatusMechanical propertyDefoaming Agents

The invention discloses wax-containing 3D printing light-cured cast resin and a preparation method thereof. The wax-containing 3D printing light-cured cast resin comprises the following components inparts by weight: 30-80 parts of oligomer resin, 15-60 parts of a reactive diluent, 1-10 parts of a photoinitiator, 1-10 parts of micro-powder wax, 0.1-5 parts of an organic pigment, 0.01-2 parts of adispersing agent, 0.1-5 parts of a defoaming agent and 0.1-5 parts of a flatting agent. The wax-containing 3D printing light-cured cast resin disclosed by the invention has the multiple advantages oflow viscosity, excellent mechanical property, low ash content, small linear shrinkage rate and the like, and can effectively ensure the dimensional precision and clean and smooth appearance of a casting. The invention provides the light-cured material with high printing precision, rapid casting and stable performance for the field of 3D printing and casting, greatly expands the advantages of a laser rapid prototyping technology in the field of casting, and remarkably improves the market competitiveness of products.

Owner:HANS LASER TECH IND GRP CO LTD

Casting method and system suitable for integral multi-way valve based on 3D printing

PendingCN111468678AReduce breakageImprove consistencyAdditive manufacturing apparatusFoundry mouldsMold fillingEngineering

The invention discloses a casting method and system suitable for an integral multi-way valve based on 3D printing, and belongs to the technical field of valve casting. According to the casting methodand system, inner sprues of multiple layers, multiple cross gates connected with the inner sprues of all the layers and a sprue connected with the multiple cross gates are determined according to thestructural parameters of the to-be-cast integral multi-way valve, and the integral sand mold is printed through 3D printing technology, so that the multi-layer combined type pouring casting method andthe corresponding casting system are achieved, the influences of gravity, scouring force and the like in the liquid mold filling process can be dispersed and balanced, and the casting defects of sandcore breakage, internal defect flashes, main valve hole bending and the like are reduced. And the consistency between the integral sand molds through 3D printing is good, no bonding gap exists in theintegral sand molds, the quality stability and the surface quality of a valve body casting obtained after pouring can be guaranteed, meanwhile, rapid casting of the integral hydraulic valve can be achieved, the integral hydraulic valve is suitable for batch and normalized manufacturing, and rapid upgrading of large-scale integral hydraulic multi-way valve products is better supported.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Aluminum-scandium alloy sputtering target material and preparation method thereof

PendingCN110527956ASolve difficultySolve the problem of low scandium contentVacuum evaporation coatingSputtering coatingLevitationIngot

The invention discloses an aluminum-scandium alloy sputtering target material and a preparation method thereof, and belongs to the technical field of high-performance aluminum-scandium alloy target materials. In the aluminum-scandium alloy target material, the content of scandium is 5 at%-50 at%, and the balance is aluminum. The preparation method comprises the following steps of 1, preparing materials; 2, smelting and casting ingots; 3, calcining or rolling; 4, sampling and detecting; 5, milling and cleaning; 6, carrying out vacuum packing. According to the present invention, the aluminum-scandium alloy target material is prepared through a vacuum induction levitation melting furnace and a rapid casting and rapid condensation technology, and the thickness of the prepared aluminum-scandiumalloy target material is 2-35 mm, the density is 99.9%, the scandium content is 5-50 at%, and the balance is the aluminum element. The preparation method is easy to operate, the alloy is uniform, theutilization rate of the expensive metal scandium is high, and the industrial application is facilitated. The characteristics of good component uniformity and good subsequent machinability satisfy therequirements of the semiconductors and the sputtering target materials in the special fields, and the defects in the prior art are overcome.

Owner:何午琳

Glass utensil mould production method

InactiveCN1876581ASimple designEasy to modifyGlass pressing apparatusDimensional modelingRapid casting

The invention provides the preparing method of glass die, comprising the following steps: 1. making glass die three-dimensional CAD modeling, and making resin master mold used for casting die blank by high-rate forming machine; 2. making resin master mold used for casting spark handling electrode; 3. making core and wood former used for casting die blank; 4. shaping and pouring glass die; 5. making ZrO2 molding pattern and casting spark handling electrode; 6. spark handing glass die, and getting glass die. The invention firstly carries out three-dimensional modeling and makes resin master mold, then uses gypsum model and resin to make core of die blank, and uses blank wood former to shape; the invention uses ZrO2 molding and resin master mold which enlarges the model size to 0.5 - 1.5mm to make spark handling electrode. The method can quickly get die blank and electrode.

Owner:SHANDONG UNIV OF TECH

Debris rapid casting blank method

InactiveCN1544907ANo escapeNo escape, in full compliance with oil drilling site safety regulationsWithdrawing sample devicesPreparing sample for investigationAdhesiveCoupling

The invention relates to a method to identifying slices of rock scraps and preparing the slice sample, specially applied to field fast sample fabrication for petroleum well drilling, washing the sample of petroleum drilling rock scraps by water and carbon tetrachloride, then making surface soak-modification processing by silane coupling agent or chrome complex coupling agent, filtering and drying and pouring in a container, adding in adhesive, solidifying agent and accelerant, uniformly blending, shaking on a shaker and then keep static for 20 minutes, and able to make field grinding to make slices at once. It need no open fire, has no pollution, simple and short-cut, heightens slice making efficiency by 4-6 times in comparison with existing slice making methods by examination, suitable for making sample on the spot for petroleum well drilling

Owner:JILIN UNIV

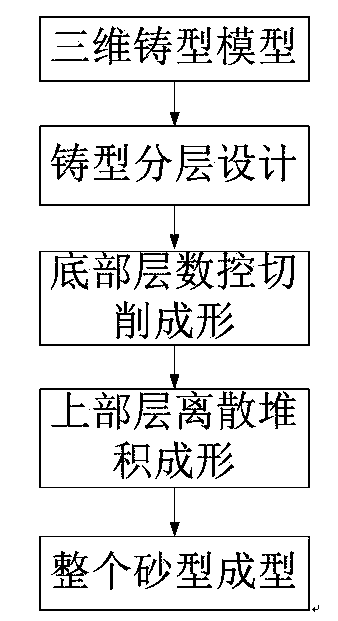

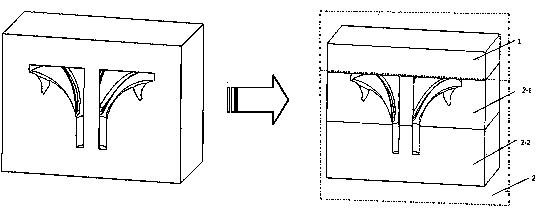

Sand mold composite molding method

ActiveCN103600028AFast processingImprove efficiencyFoundry mouldsFoundry coresSand castingCasting mold

The invention discloses a sand mold composite molding method, and belongs to the field of rapid casting. The method comprises the following steps: according to the complex structural characteristics of a casting mold, carrying out a layering process in the horizontal direction; according to the module structure of each divided area, determining the processing method: when a subarea of the casting mold contains a runner, the casting mold in the subarea is large and heavy and accounts for a large amount of volume, a digital control forming method is adopted; when a casting mold contains a complicated inner cavity structure, a dispersed / accumulated forming method is adopted; molding the lower part of the casting mold by cutting, after the molding of the lower part of the casting mold, molding the upper part of the casting mold by accumulating so as to finish the molding of the casting mold; and finally cleaning to remove the waste sands so as to obtain the sand casting mold. The method can achieve large and medium casting mold molding in any shape, and can improve the manufacturing speed and quality of casting mold by selecting proper partition positions.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Polyacrylamide gels for rapid casting, blotting, and imaging, with storage stability

ActiveUS20140262785A1Little or no deteriorationAbility to blotSludge treatmentVolume/mass flow measurementMedicineBlot

Owner:BIO RAD LAB INC

Quick casting cold crucible suspension furnace and alloy smelting method

PendingCN114294952AAvoid pollutionIncrease profitIncreasing energy efficiencyCrucible furnacesMold fillingCrucible

According to the rapid casting cold crucible suspension furnace and the alloy smelting method, a smelting crucible water cooling box, a smelting coil, a smelting crucible and a casting coil are arranged in a smelting chamber, the smelting crucible water cooling box is welded to the smelting crucible, the smelting crucible water cooling box is connected with a guide rail of the smelting chamber, and the guide rail is welded to the smelting chamber; the smelting crucible water cooling box moves up and down along a guide rail of the smelting chamber, the smelting coil is connected with the smelting chamber through an insulating material, the casting coil is connected with the smelting chamber through an insulating material, the casting chamber is connected with a casting chamber furnace door, a smelting chamber furnace cover is arranged on the lower portion of the gate valve, and a to-be-fused alloy material is arranged in the smelting crucible. The invention has the advantages of rapid melting and casting functions, good mold filling, uniform melting component and stable quality, can be used for melting high-purity, easily-oxidized and refractory alloy, reduces the production cost, and is applied to the technical fields of high-purity active light alloy material preparation and casting precision forming.

Owner:SHENYANG RES INST OF FOUNDRY

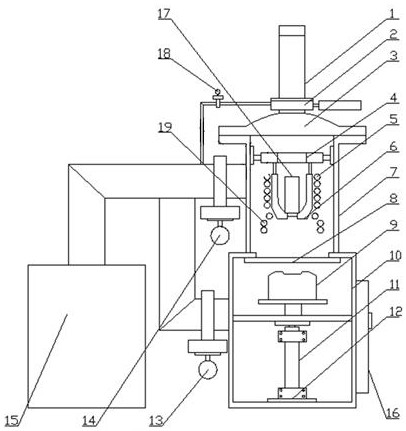

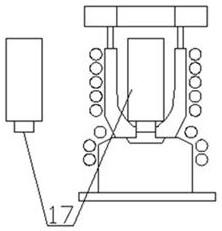

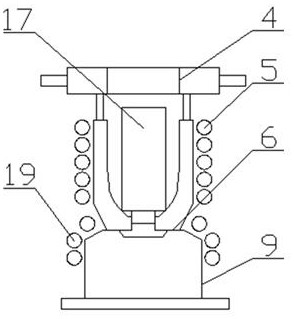

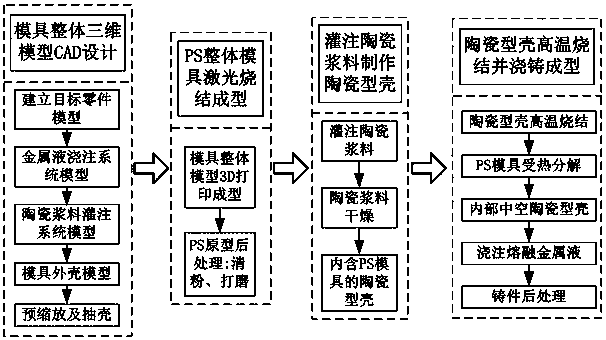

Ceramic mold casting PS (polystyrene) integral mold based on selective laser sintering and quick casting method of integral mold

PendingCN109158542AReduce manufacturing costShort manufacturing costFoundry mouldsFoundry coresSelective laser sinteringPolystyrene

The invention relates to a ceramic mold casting PS (polystyrene) integral mold based on selective laser sintering and a quick casting method of the integral mold, and belongs to the technical field ofprecision casting. The integral mold comprises a target spare part PS model, a molten metal pouring system PS model, a mold housing PS model, a ceramic slurry filling system PS model and a ceramic slurry filling cavity, wherein the molten metal pouring system PS model and the target spare part PS model are connected and fixed inside the mold housing PS model; and the ceramic slurry filling cavityis formed among outer walls of the molten metal pouring system PS model and the target spare part PS model and an inner wall of the mold housing PS model. The invention further provides the quick casting method of the integral mold. According to the invention, links of mold processing and manufacturing, and mold assembly in the traditional ceramic mold precision casting process are removed; a spare part manufacturing period is shortened; the product manufacturing cost is saved; the product development efficiency is improved; and a casting is high in dimensional precision and good in surface quality, and meets use requirements.

Owner:浙江省机电产品质量检测所有限公司 +1

Rapid continuous casting ceramic foam filter

The invention discloses a rapid casting ceramic foam filter which is directed to deficiencies of conventional ceramic foam filters of complex production and unstable performance. The rapid casting ceramic foam filter is prepared by taking soft polyurethane foam sponge as a carrier, making impregnated thixotropic ceramic slurry into blanks, drying and sintering. The thixotropic ceramic slurry is prepared by mixing ceramic powder, carboxymethyl cellulose, polyvinyl alcohol and water according to a certain proportion. The rapid casting ceramic foam filter prepared by the present invention is suitable for large-scale industrial production, and is stable in the overall performance.

Owner:TAIZHOU ZHUXIN NEW MATERIAL TECH CO LTD

Blast furnace front refractory casting mold and casting method

The invention relates to the technical field of blast furnace production, in particular to a blast furnace front refractory casting mold and a casting method. Rapid casting molding and reutilization can be realized, and the blast furnace production requirement is greatly met. According to the blast furnace front refractory casting mold and the casting method, a wedged segmented model is designed, the purposes of rapid casting, forming and demolding are achieved through rapid water cooling and grease lubrication, the operation is easy, the cost is low, and similar accidents such as manual blockage of slag iron can be avoided.

Owner:SHANDONG IRON & STEEL CO LTD

Self straggle fast casting method used for battlefield emergency fast shaping of armoured car component part

A self-spreading high-speed casting method for emergency manufacture of the parts for armoured car includes such steps as preparing aluminothermic welding flux, preparing mould from furan resin sand, loading said welding flux in resin crucible burying the igniting TiC flux in welding flux, igniting, self-spreading aluminothermic reaction to obtain molten iron, casting, and solidifying.

Owner:JIANGSU FASTEN TECH DEV CENT

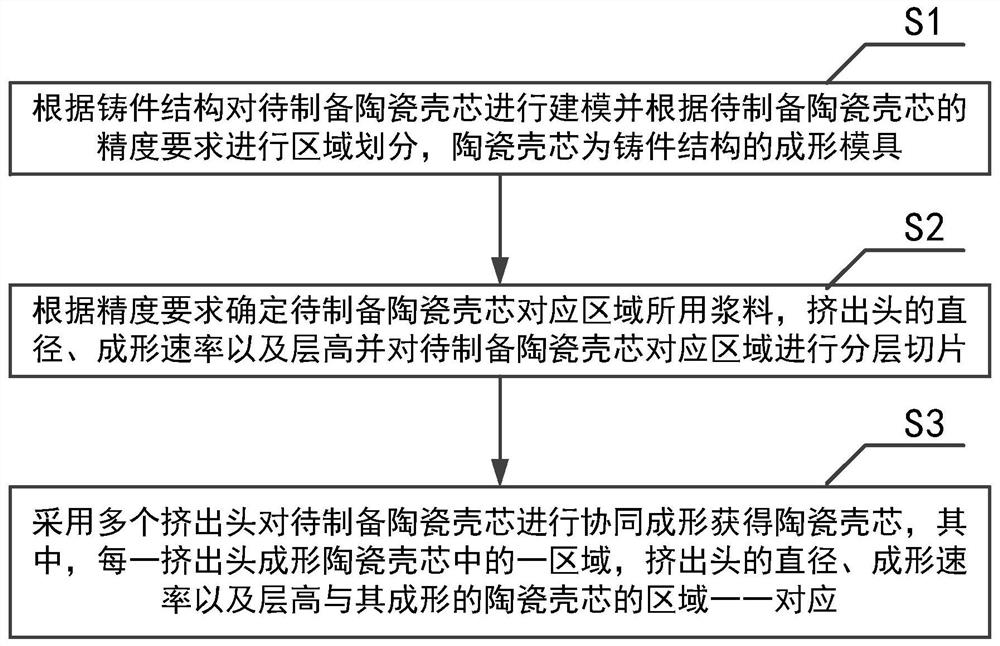

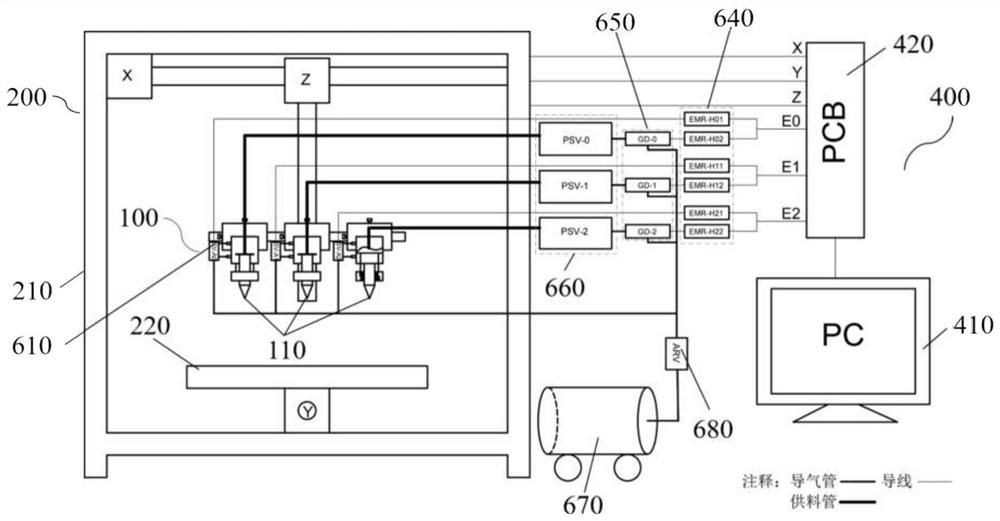

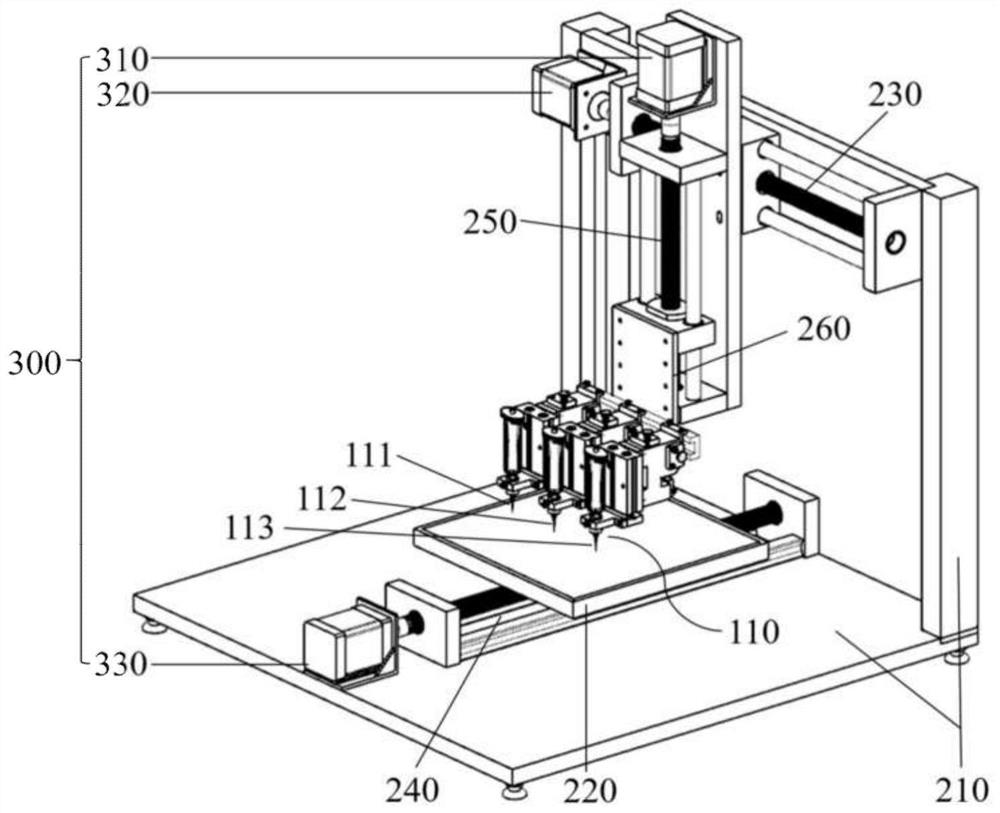

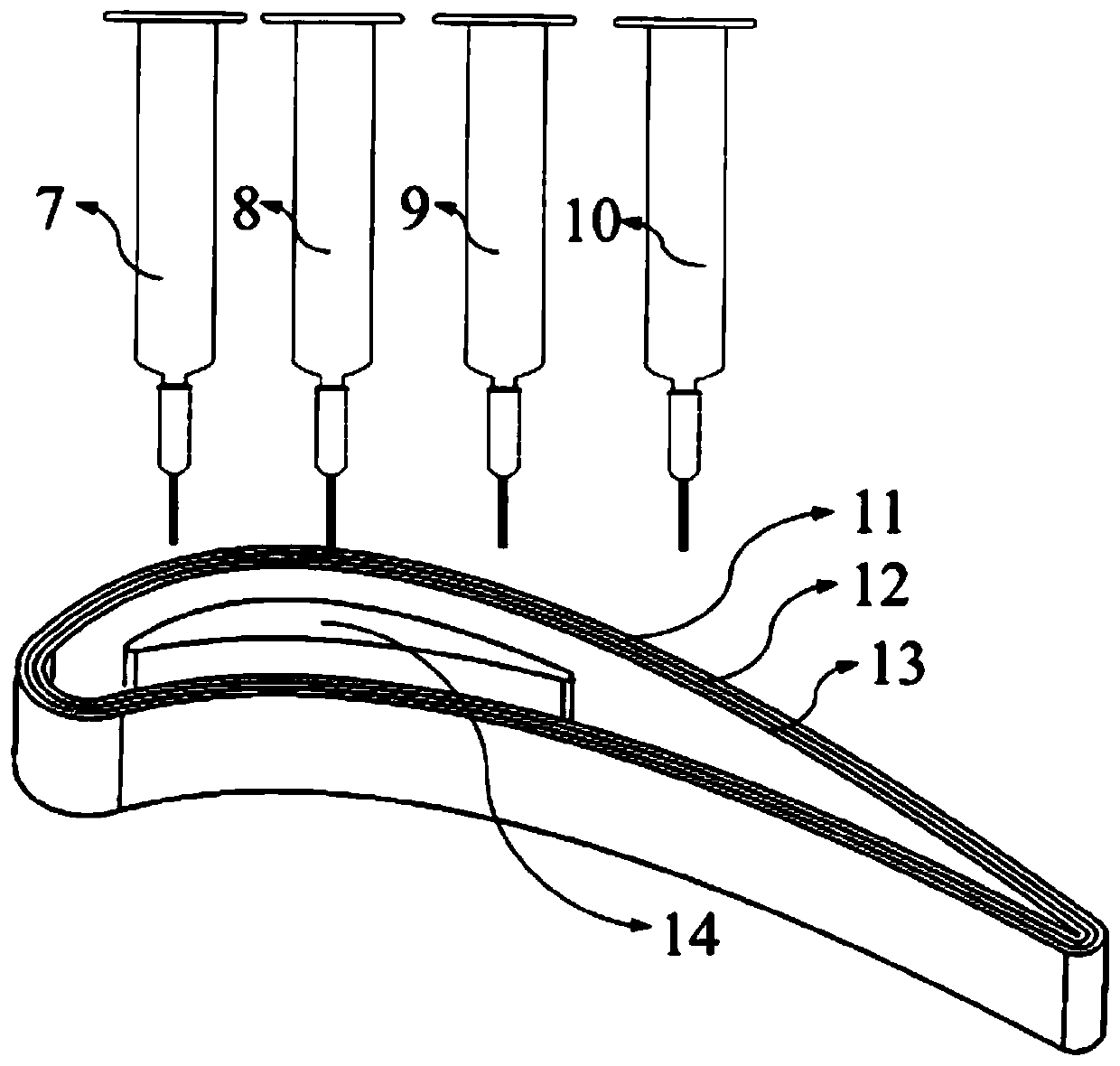

Manufacturing method and device for ceramic shell core for precision casting

ActiveCN111940683ARealize integrated formingMeet different precision requirements in different regionsFoundry mouldsMoulding machinesSlurryRapid casting

The invention belongs to the technical field related to rapid casting and discloses a manufacturing method for a ceramic shell core for precision casting. The method comprises the steps that firstly,modeling is carried out for a ceramic shell core to be manufactured according to a casting structure, and area division is carried out according to precision of the ceramic shell core to be manufactured; secondly, slurry used by corresponding areas of the ceramic shell core to be manufactured, the diameter of extruding heads, the forming speed and the layer height are determined according to the precision requirement, and layered slicing is carried out on the corresponding areas of the ceramic shell core to be manufactured; and thirdly, the multiple extruding heads are adopted for carrying outcollaborative forming on the ceramic shell core to be manufactured, so that the ceramic shell core is obtained. The invention further provides a device for realizing the manufacturing method. According to the device, the multiple extruding heads are arranged, and are controlled independently, the limitation that an existing rapid forming technology can only achieve mixed extrusion forming of a single material or two materials can be overcome, the problem that in the prior art, extruding heads cannot achieve precise positioning, and a blank is scratched can be solved, and forming efficiency and precision are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

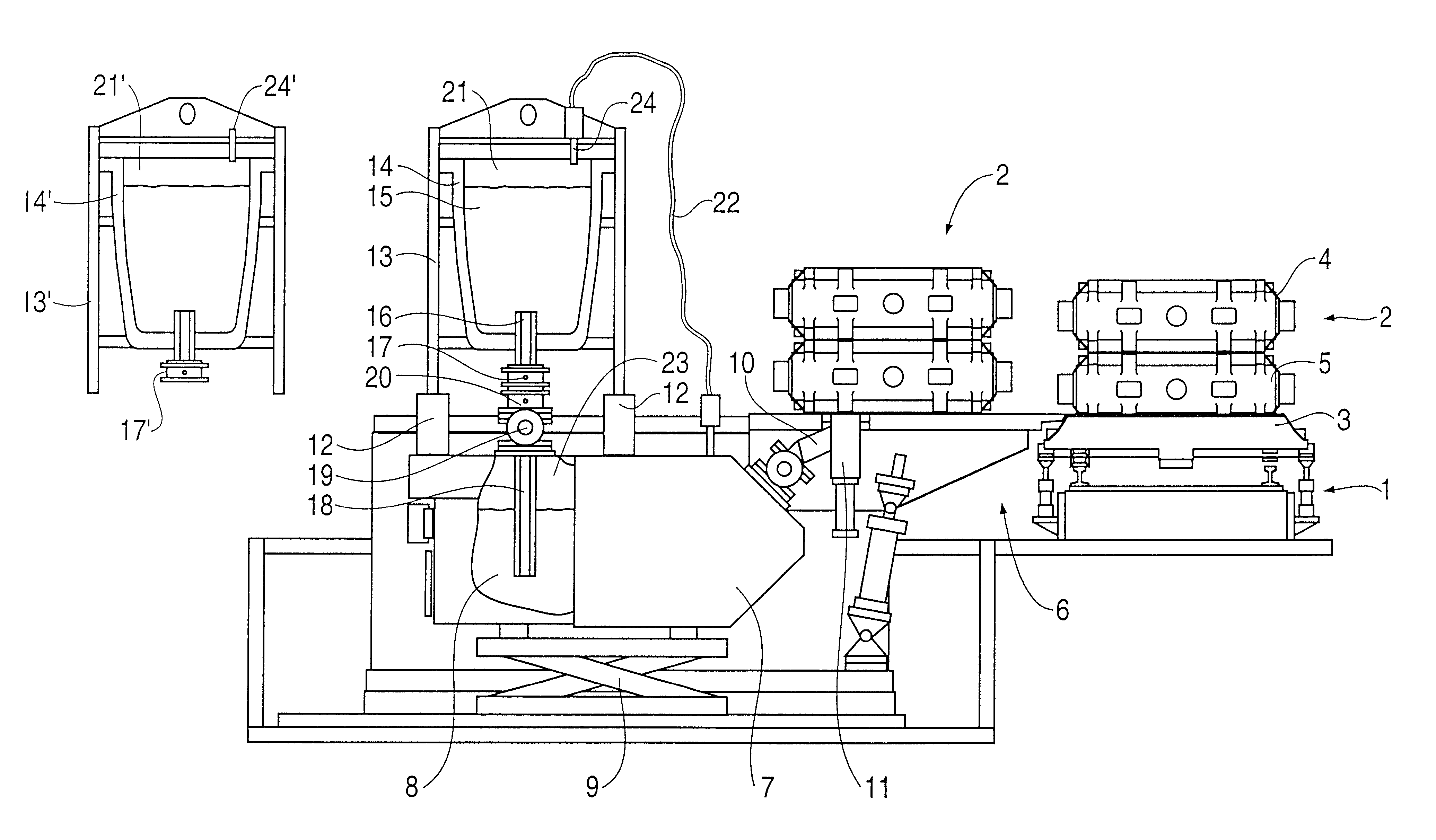

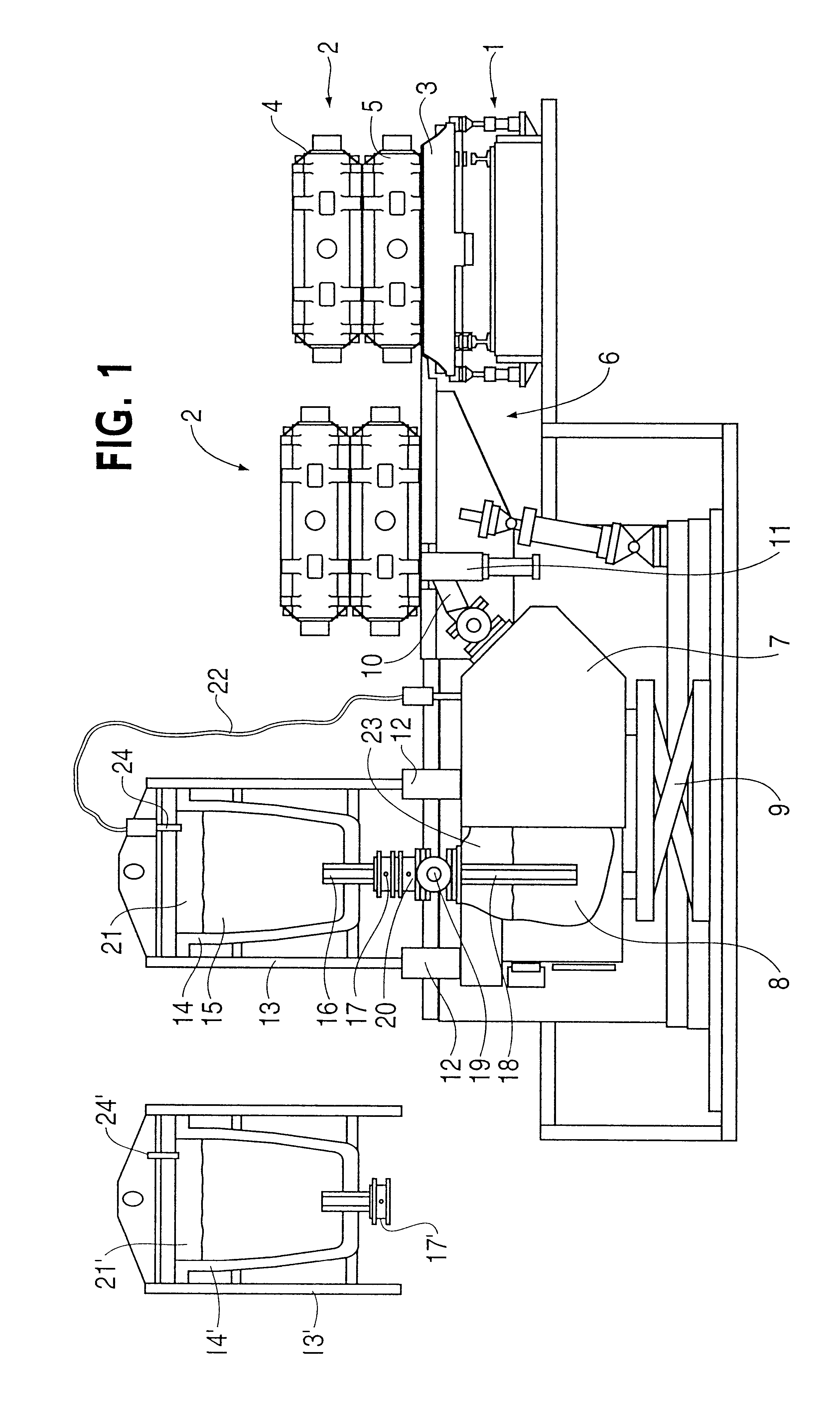

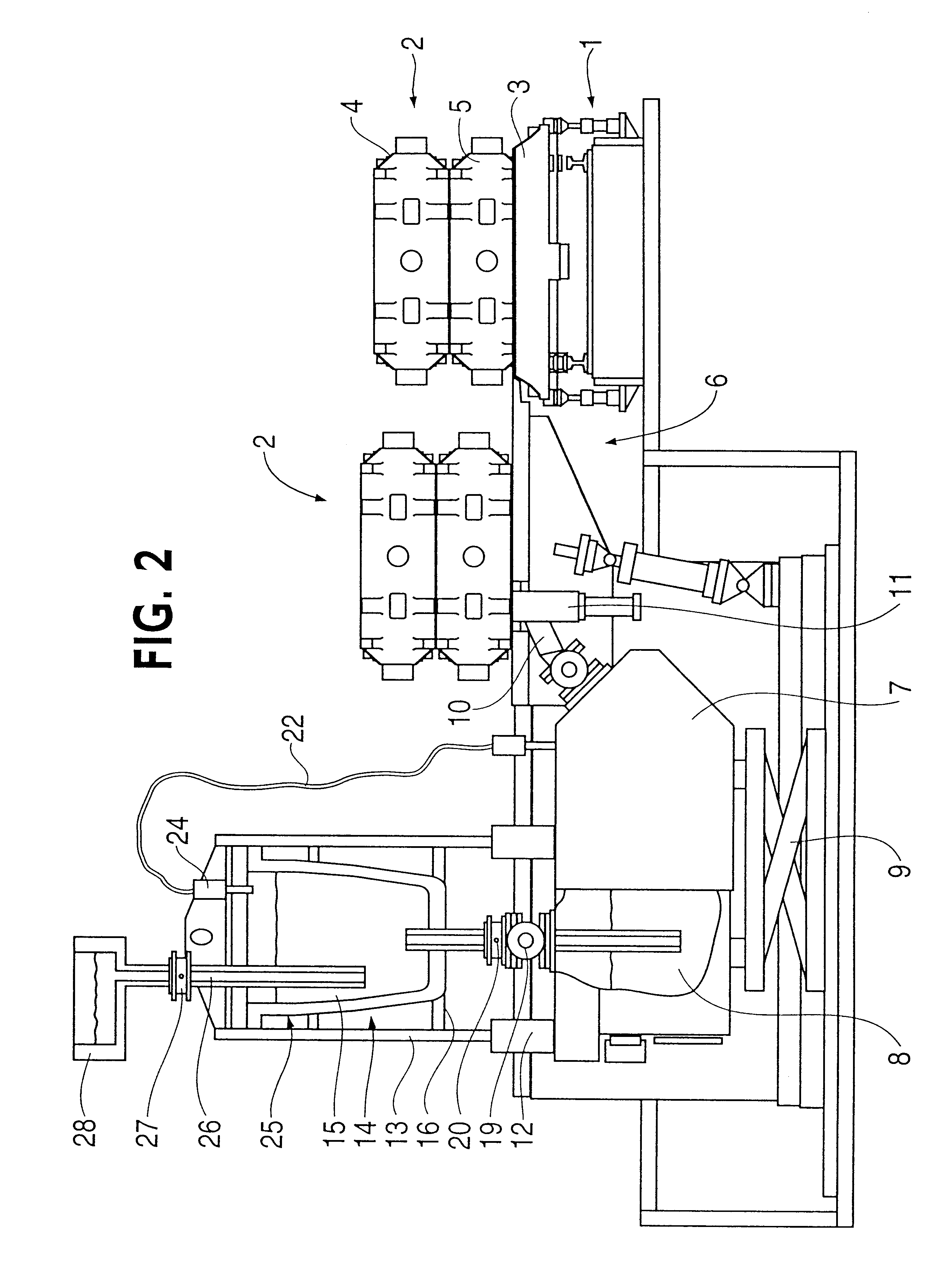

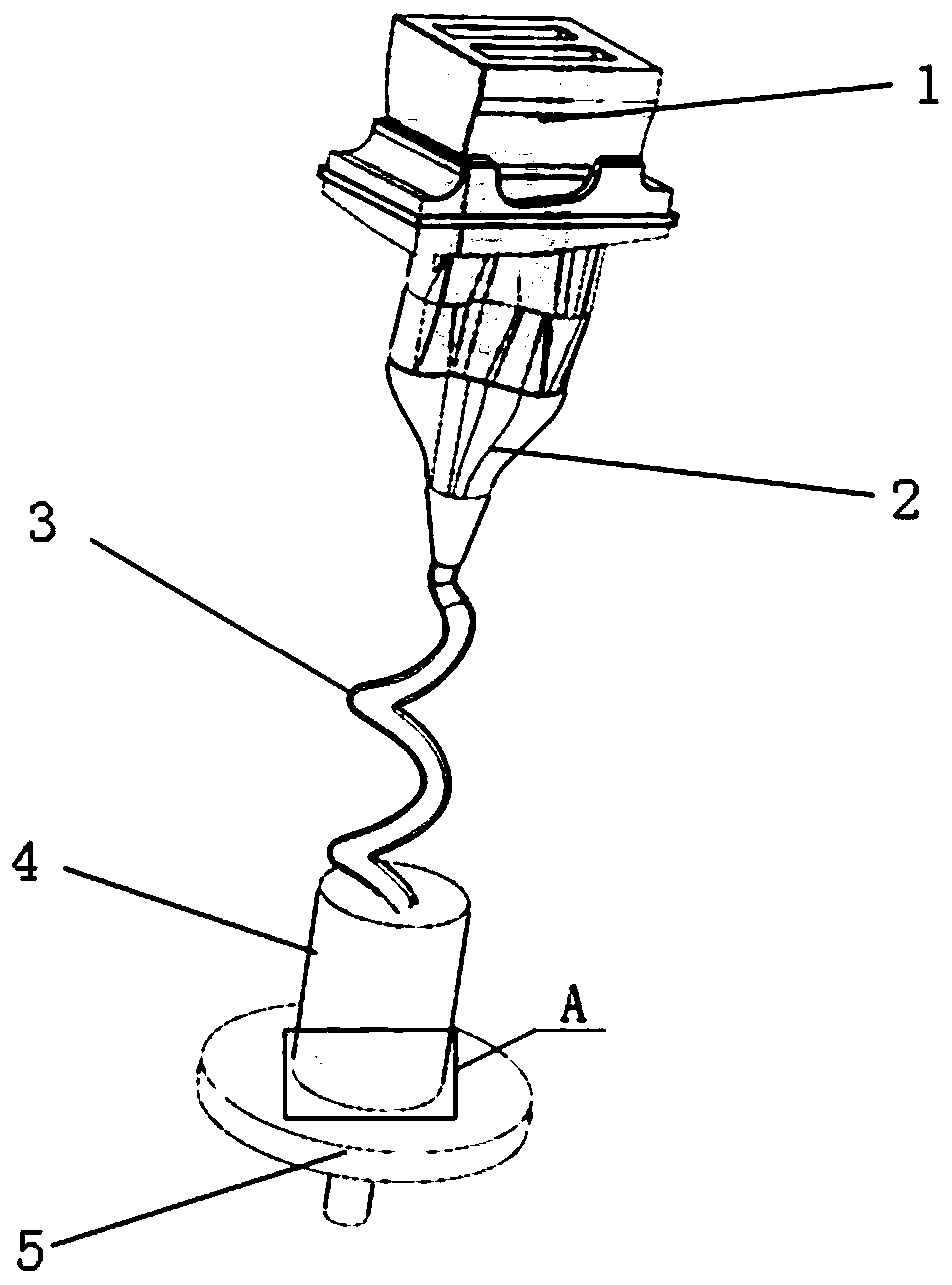

Apparatus for uphill low pressure casting of molten metal

InactiveUS6460604B1Avoid pressure dropAvoid accessMelt-holding vesselsCasting plantsMetallurgyPressure casting

An apparatus for uphill low pressure casting of molten metal in sand molds conveyed in synchronized manner with a casting station located at the conveyor, a gas pressure holding furnace containing the molten metal and located at the casting station with a rising casting tube connectable to the sand molds has a device for refilling the holding furnace with molten metal. To permit a rapid casting cycle and high casting capacities, the refilling device has at least one pressure-tight melt container and a filling tube located in the holding furnace with a seal positioned outside the same. The melt container is couplable in pressure-tight manner by means of its outlet to the holding furnace filling tube. The holding furnace is connected to the melt container by means of a pneumatic pressure compensating line.

Owner:GEORG FISCHER FAHRZEUGTECHNIK GMBH

Method for integrally casting and molding single crystal part based on gel-casting with seed crystal block embedded structure spiral crystal selector

ActiveCN111168004AImprove performanceQuality improvementPolycrystalline material growthFoundry mouldsPhysical chemistryCrystal structure

The invention discloses a method for integrally casting and molding a single crystal part based on the gel-casting with a seed crystal block embedded structure spiral crystal selector, and belongs tothe field of rapid casting based on photocuring molding technology. The method comprises the following steps that 1) the single crystal part and an integrated resin mold prototype with the seed crystal block embedded structure spiral crystal selector are manufactured through CAD design by using photo-curing rapid prototyping technology; (2) firstly, ceramic slurry is poured into the integrated resin mold prototype by adopting a gel-casting method, and then vacuum freeze drying and high-temperature sintering strengthening are adopted to obtain the integrated casting mold; and (3) after a seed crystal block is embedded, a directional solidification technology is adopted to realize high-quality molding of the single crystal part. According to the method, the epitaxial growth of the seed crystal block and the crystal selection effect of the spiral crystal selector are utilized, the primary dendrite orientation and the secondary dendrite orientation of the single crystal part are preciselycontrolled, meanwhile, an anti-hybrid crystal structure is arranged to improve the performance and quality of the single crystal part. According to the method, the design is reasonable, the manufacturing cycle of the single crystal part is greatly shortened, and the reliability of part manufacturing is improved.

Owner:XI AN JIAOTONG UNIV

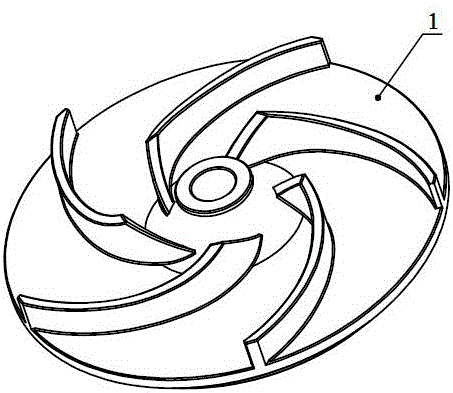

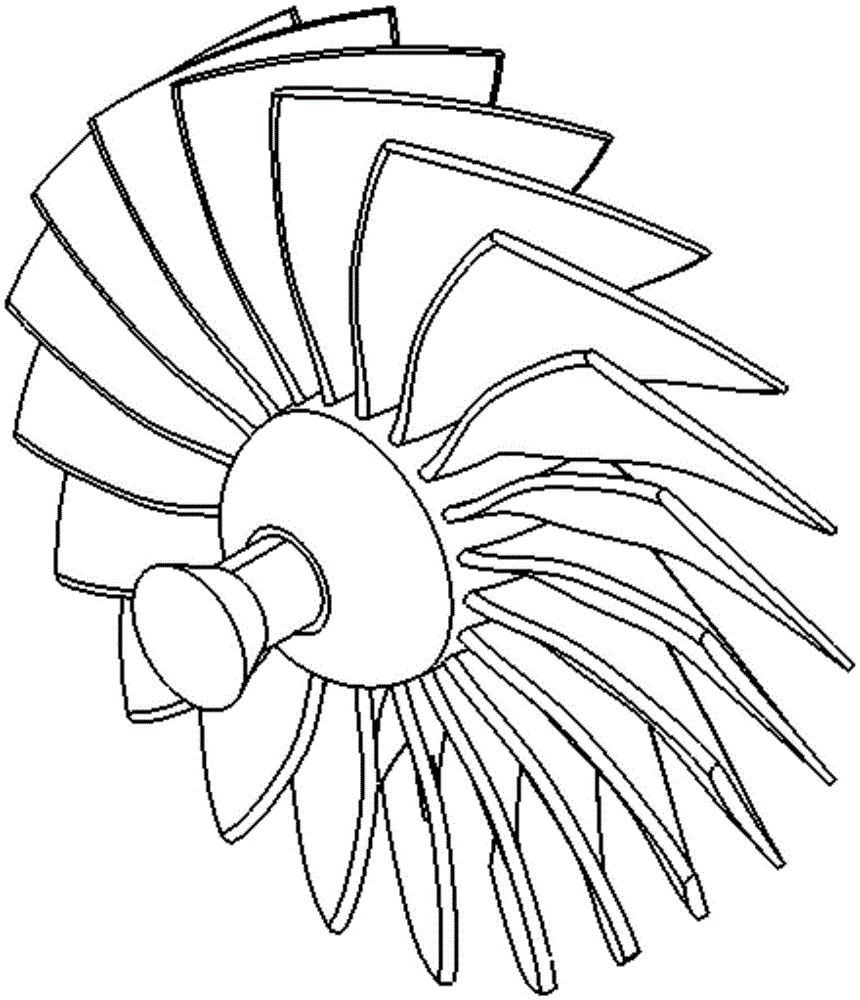

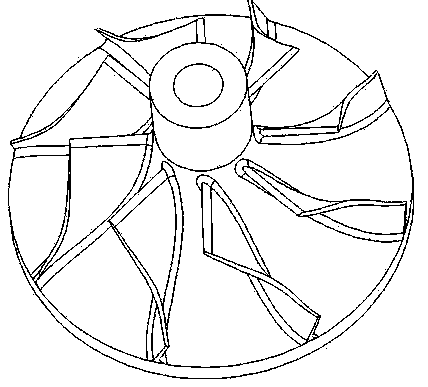

Fast investment casting technology of stainless steel impeller employing 3D printing solid mould

InactiveCN107297459AInhibit swellingHigh dimensional accuracyAdditive manufacturing apparatusFoundry mouldsImpellerWax

The invention discloses a fast investment casting technology of a stainless steel impeller employing a 3D printing solid mould in the field of the investment casting technology. The fast investment casting technology comprises the following steps: arranging a venting pore channel in the 3D printing solid mould, and then sealing the venting pore channel with ordinary wax; welding the solid mould and a molten mould into a whole to form a mould group; coating the surface of the mould group with modified silica sol to form an integral mould shell; removing a mould shell closing the venting pore channel from the integral mould shell, melting the molten mould and the ordinary wax; airing, putting the whole formed by the mould shell and the solid mould into a roasting furnace in a state that the solid mould is positioned on the upper part, ablating the solid mould in an oxygen-riched state, closing a furnace door after sufficient combustion, stopping the furnace after sufficient ablation, cooling and taking out the mould shell; washing the mould shell to remove residues and residual ash, and then sealing a part, removed in the former step, of the mould shell; putting the mould shell into the roasting furnace, roasting, and then casting high-temperature metal melt to obtain a cast. The fast investment casting technology has the advantages of low manufacturing cost, high production efficiency, low possibility of mould shell cracking and the like.

Owner:ZHANGJIAGANG FEILANG PUMP & VALVE

Rapid casting mold cooling method

InactiveCN106180579ASpeed up coolingGrain refinementFoundry mouldsFoundry coresCasting moldRapid casting

The invention discloses a rapid casting mold cooling method. The method comprises the following steps of production technology preparing, material preparing, sand making, modeling, drawing, mould assembling mold casting, melting, pouring cooling and shaking out after curing. According to the rapid casting mold cooling method, ventilation channels are manufactured in the casting modeling process, compressed air is blown in during pouring to conduct manual strengthened cooling, the casting cooling speed is increased, and a very good effect is achieved for relieving the sand mold heat effect; defects of a casting due to molding sand heating can be reduced, and therefore generation of defects of blade parts is reduced. Cooling is conducted while pouring is conducted, the grain of the casting is refined, the mechanical performance of the casting is also improved to a certain degree, the quality of the casting is improved, and especially the quality of partition plate blades for an H type compressor is obviously improved; and through the batched trial manufacturing, the partition plate casting produced by adopting the method for blowing the compressed air in the pouring process is subjected to nondestructive testing after grinding, and the quality situation meets the requirement and is greatly improved compared with original partition plate castings.

Owner:HANGZHOU STEAM TURBINE CASTING & FORGING

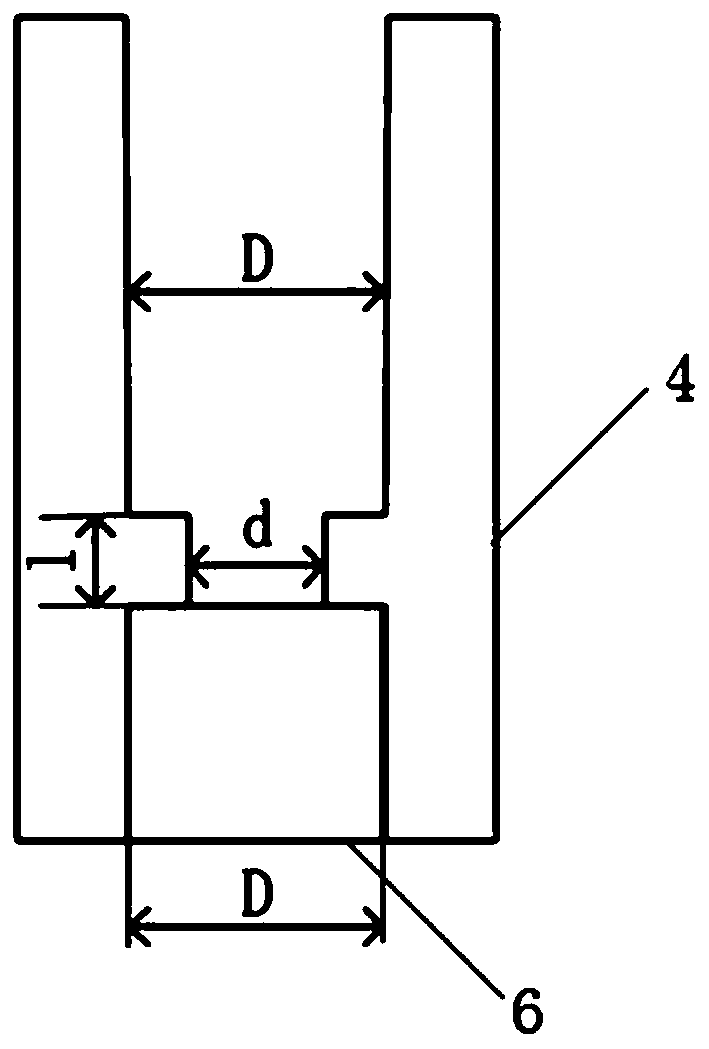

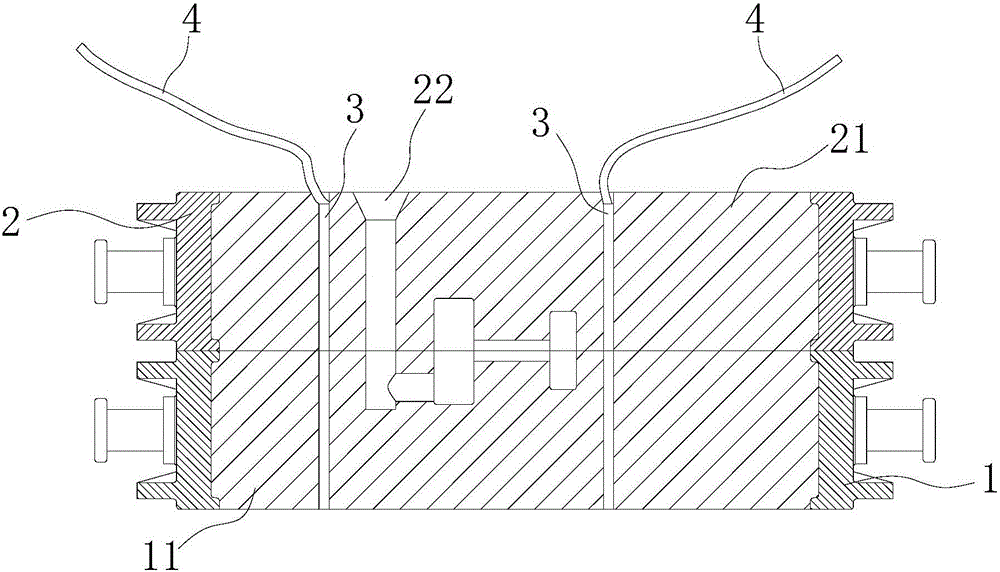

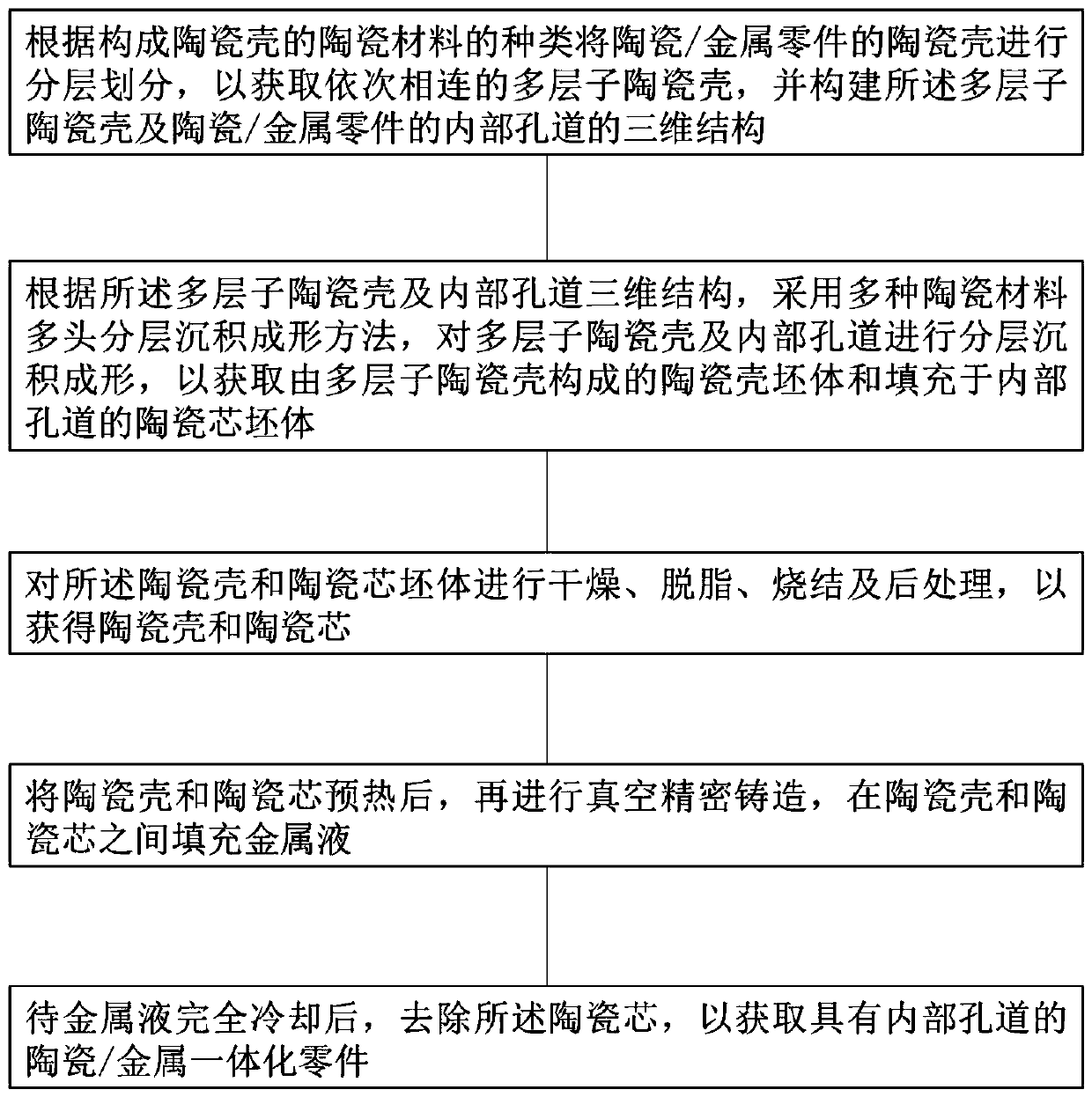

Casting method of ceramic/metal integrated part on basis of layering extrusion forming

ActiveCN110370423AImprove production efficiencyImprove high temperature resistanceAdditive manufacturing apparatusCeramic shaping apparatusAfter treatmentRapid casting

The invention belongs to the field of rapid casting and discloses a casting method of a ceramic / metal integrated part on the basis of layering extrusion forming. The method comprises the steps that 1,the three-dimensional structure of a ceramic shell and the three-dimensional structure of a ceramic core are designed according to the shape of the part; 2, a multi-ceramic-material and multi-head layering deposition forming method is adopted, and precision overall forming of multi-ceramic-material layer gradient structure shell is achieved; 3, blanks of the ceramic shell and the ceramic core aresubjected to drying, degreasing, sintering and after-treatment; 4, the treated ceramic shell and the ceramic core are preheated, and molten metal filling is completed through vacuum precise casting;and 5, after molten metal is cooled completely, the ceramic core is removed, an internal hole channel of the metal and ceramic part is formed, and the ceramic / metal integrated part is obtained. According to the method, by means of the layering extrusion forming method, double-layer or three-layer ceramic shells with different thicknesses and compactness degrees can be prepared, the vacuum precisecasting technology is combined, filling of the molten metal is completed, and precise casting forming of the ceramic / metal integrated part is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

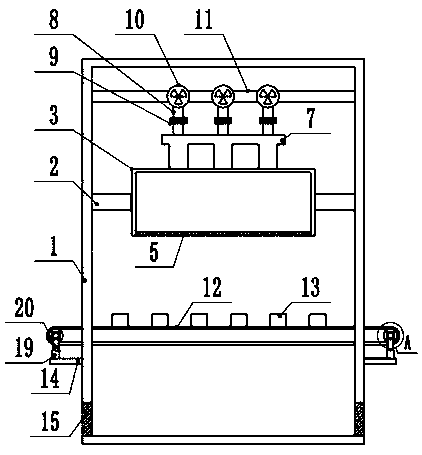

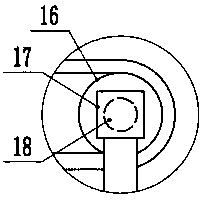

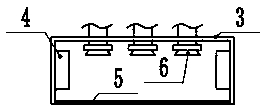

Rapid casting part cooling device for casting

The invention discloses a rapid casting part cooling device for casting and relates to the technical field of casting. The rapid casting part cooling device comprises a device box. A fixing frame is fixedly connected above the inner wall of the left side and the inner wall of the right side of the device box. A cooling box is fixedly installed in the middle of the fixing frame. Condensers are fixedly installed on the inner wall of the left side and the inner wall of the right side of the cooling box. A connecting pipeline is fixedly connected into the middle of a box body above the cooling box. A wind nozzle is fixedly installed at the lower end of the connecting pipeline. A fan pipe is fixedly connected to the upper surface of the connecting pipeline. A fan is connected to the upper end of the fan pipe. A filter screen is fixedly installed in the middle of the fan pipe. A base is fixedly connected below the outer wall of the left side and the outer wall of the right side of the devicebox. According to the rapid casting part cooling device, a casting part can be cooled rapidly, the cooling effect is good, by means of design of a conveying belt, the casting part can be conveyed automatically, cooling work of the casting part is facilitated, the automation level is improved, the cooling efficiency of the casting part is improved greatly, and practicality is high.

Owner:青岛全程源机械有限公司

Casting method for rapid casting of large precision castings based on 3D printing technology

ActiveCN108907095BSimple processing technologyShort production timeAdditive manufacturing apparatusFoundry mouldsMetal formingProcess engineering

The invention relates to the technical field of metal molding and casting, in particular to a method for quickly casting a large precision casting based on a 3D printing technology; through combination of a 3D printing and molding technology and a lost foam casting technology, by using special shell type coatings, a casting without the defects of recarburization, pores, slag inclusion or wrinkledskin can be cast, and the requirements of a high grade and complex structure and the precision casting can be met; and the method has the advantage of green, environmental protection and no pollution.The method comprises the steps of three-dimensional modeling, making of a fusible model and a special shell mold, boxing of the shell mold, negative pressure pouring and the like. The method has theadvantages of simple processing technology, no need of developing a mould, short production time, easy regulation and modification, low production cost, green, environmental protection and no pollution, and the molding process can be finished in real time; the requirements of individualization and customization cam be met; high quality products can be made, and massive casting and precision casting are both taken into consideration.

Owner:河南圣得威机械科技有限公司

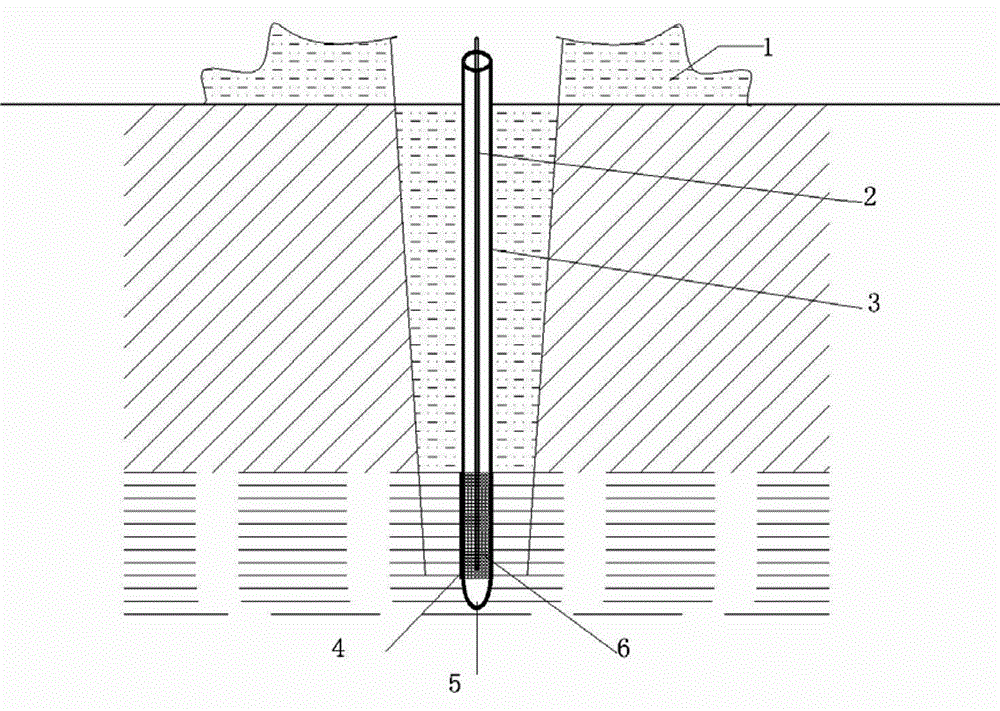

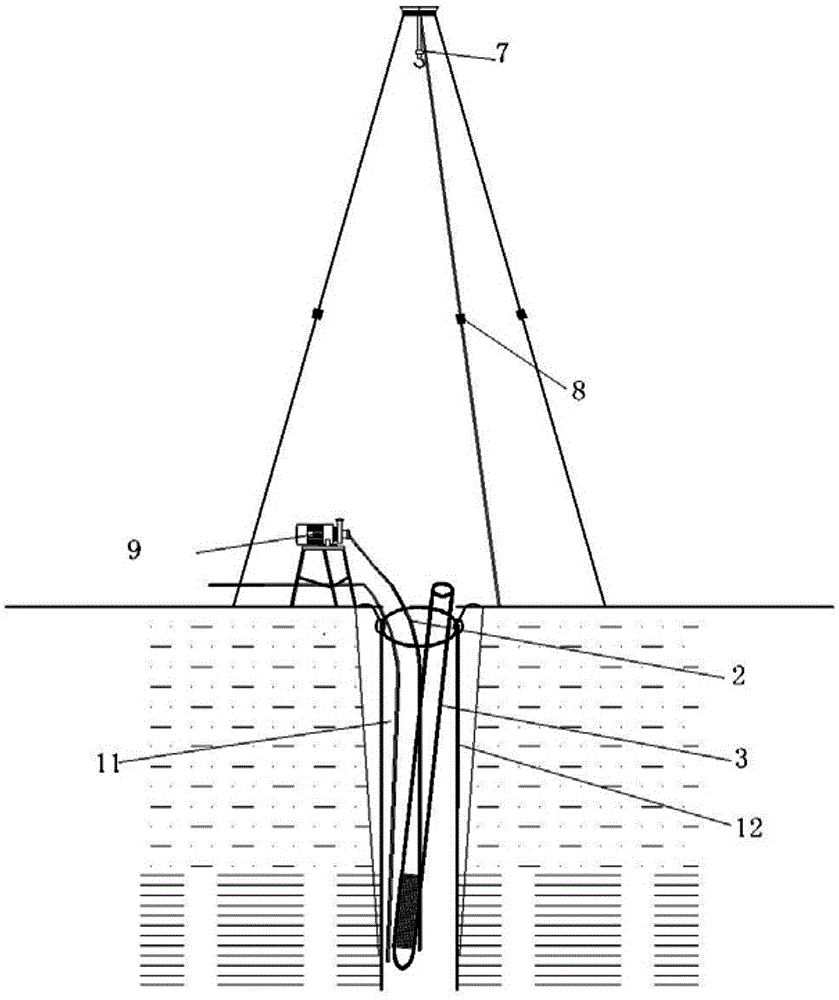

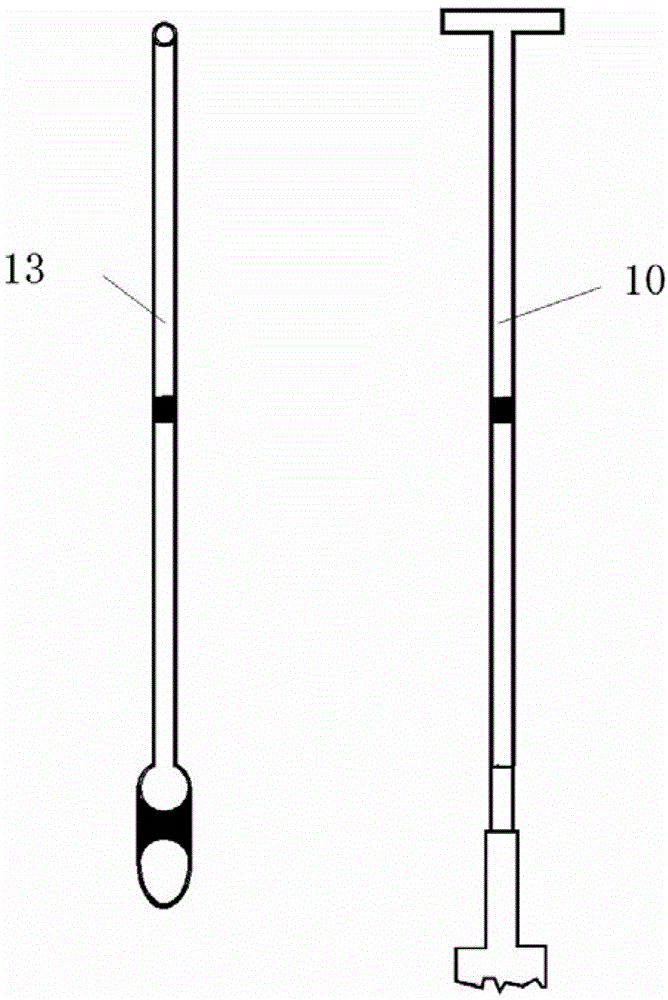

Rapid casing pipe type well digging device and method

InactiveCN104863507AExpand the irrigated areaThe process of forming a well is simpleDerricks/mastsDrilling machines and methodsWater tableEngineering

The invention discloses a rapid casing pipe type well digging device. The device comprises a support, a soil auger, an oil taking barrel, a small water pump, a water injection pipe, a casing pipe, a water seepage pipe and a silt sucking water pipe or a water sucking pipe. A rapid casing pipe well digging method comprises the steps that in a dry and sandy area sandy land or a windy desert area or a sandy land, the soil taking barrel is used for punching a hole in a phreatic layer, a pulley hook of the support is aligned to the center of a well hole and hooks the upper end of the casing pipe, the casing pipe is placed into the well hole, the soil auger is used for drilling and taking silt in the casing pipe or the silt sucking water pipe and the water injection pipe are inserted to the bottom of the casing pipe for sucking silt, the casing pipe gradually descends along with taking-out of the silt, a pulley hook rope of the support is used for pulling the top of the casing pipe to descend until reaching the place nearby the underground water line, the water seepage pipe is inserted into the bottom of the casing pipe, then a pulley of the support is used for lifting out the casing pipe, the water seepage pipe deeply penetrates into the underground water containing layer, the water sucking pipe is inserted into the internal area of the water seepage pipe, the upper portion of the water sucking pipe is fixedly connected with the small water pump, and rapid casting pipe type well digging work is completed.

Owner:XINJIANG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com