Rapid casing pipe type well digging device and method

A casing and fast technology, applied in drilling equipment and methods, drilling equipment, earthwork drilling and production, etc., can solve the problems of impracticability and difficulty in use, and achieve the effects of low cost, increased irrigated area of farmland, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

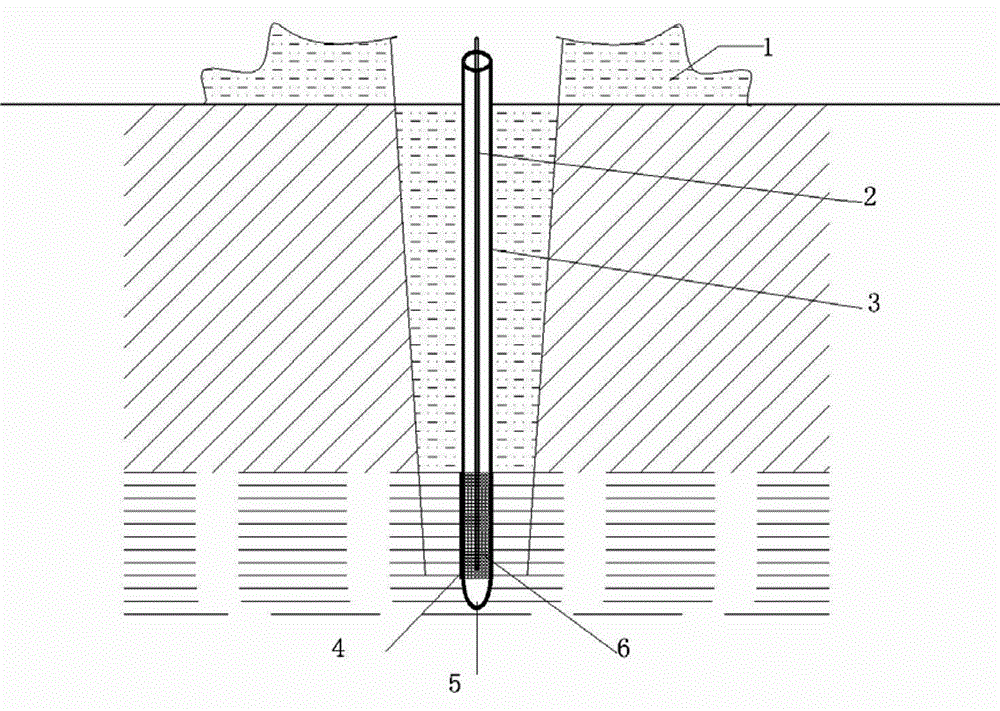

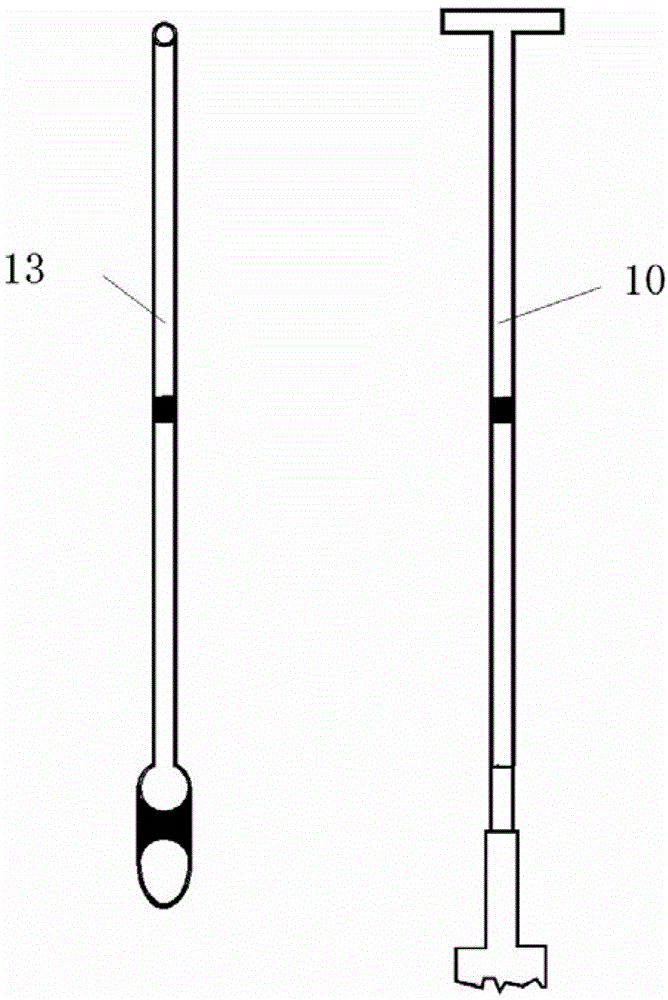

[0029] Such as Figure 1-3 As shown, the implementation area of the present invention is close to the Taklimakan Desert and belongs to the Tarim River Basin. This area is dry and rainless, with little precipitation and large evaporation. , the specific operation is as follows:

[0030] c), start to drill wells, drill holes from the ground with soil borrowing tubes, and drill wells to the depth of the submerged layer;

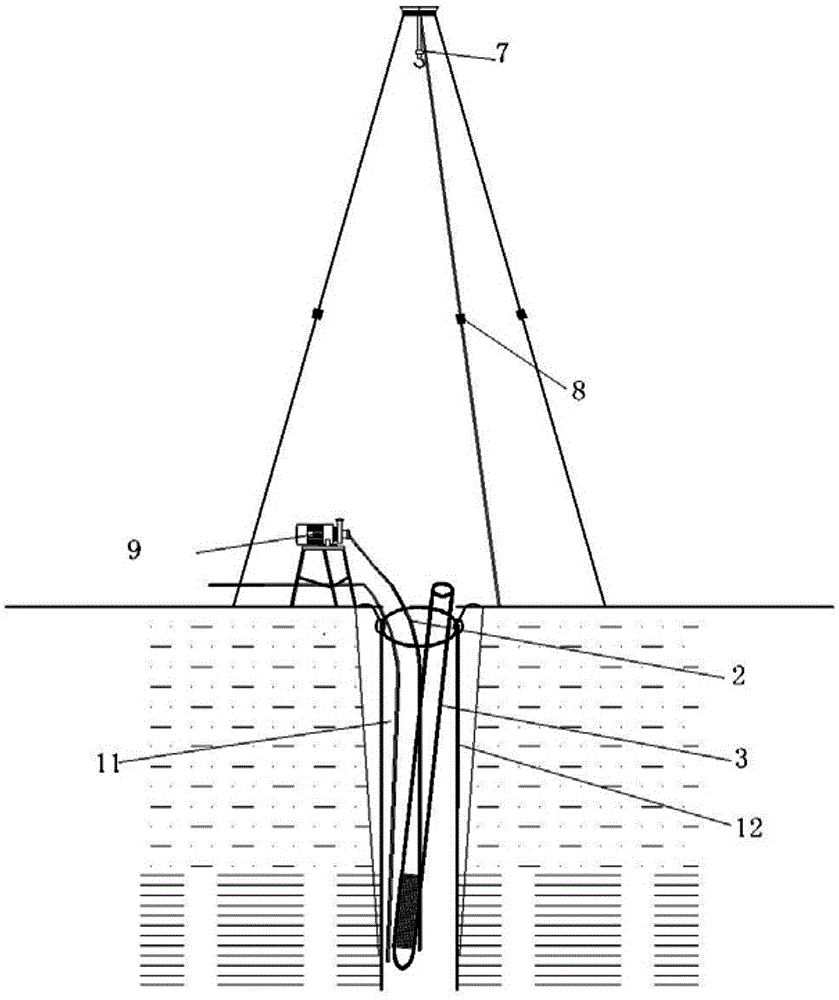

[0031] d) On the basis of step c, align the wellbore and erect the triangular bracket, align the pulley hook of the tripod bracket with the center of the wellbore, hook the upper end of the casing with the pulley hook of the tripod bracket, and align the center of the wellbore with the ground Put vertically into the casing;

[0032] e) Use the soil auger to drill the sediment in the casing, and the casing gradually descends as the sediment is taken out. In order to ensure that the soil auger can take soil vertically, it needs to be pulled by the pulley hook ...

Embodiment 2

[0036] The implementation area of the present invention belongs to the lower reaches of the Tarim River Basin. This area is dry and rainless, with little precipitation and large evaporation. The site conditions are sandy loam, the shallow groundwater level is 13 meters to 22 meters, and 3 wells are drilled. The specific operations are carried out according to the following steps :

[0037] c. Start to drill the well, and drill the hole from the ground with the soil borrowing tube, and drill the well to the depth of the submerged layer;

[0038] d. On the basis of step a, align the wellbore and set up the triangular support. The pulley hook of the tripod is aligned with the center of the wellbore. Use the pulley hook of the tripod to hook the upper end of the casing, and align the center of the wellbore to be perpendicular to the ground. into the casing;

[0039] e. Use the soil auger to drill the sand in the casing. As the sand is taken out, the casing gradually descends. I...

Embodiment 3

[0043] The implementation area of the present invention is in the transitional zone between oasis and desert, drought and little rain, less precipitation, large evaporation, site conditions are sandy loam and loam, shallow groundwater level 19 meters to 29 meters, 6 wells are drilled, and the specific operations are as follows conduct:

[0044] c. Start to drill the well, and drill the hole from the ground with the soil borrowing tube, and drill the well to the depth of the submerged layer;

[0045] d. On the basis of step a, align the wellbore and set up the triangular support. The pulley hook of the tripod is aligned with the center of the wellbore. Use the pulley hook of the tripod to hook the upper end of the casing, and align the center of the wellbore to be perpendicular to the ground. into the casing;

[0046] e. Use the soil auger to drill the sand in the casing. As the sand is taken out, the casing gradually descends. In order to ensure that the soil auger can take s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com