Quick casting cold crucible suspension furnace and alloy smelting method

A rapid casting and cold crucible technology, applied in crucible furnaces, furnaces, furnace types, etc., can solve the problems of ceramic crucible waste, high-quality alloy pollution, melting high temperature, etc., to prevent pollution of alloy liquid, uniform melting components, and reduce condensation shell effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

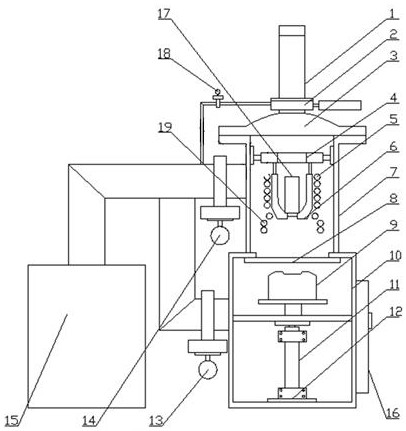

[0023] The melting of the titanium-based composite material is carried out by using a rapid casting cold crucible suspension furnace. The alloy composition of the titanium-based composite material is Ti: balance, Ni: 0.8%, C: 0.5%, Mo: 0.3%, Cr: 5%; the specific steps as follows:

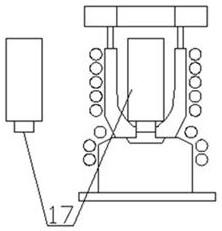

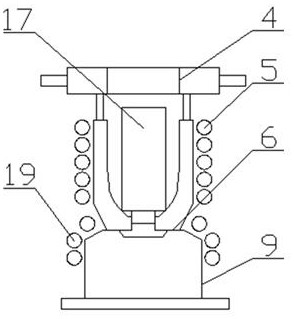

[0024] In the first step, put the standard alloy material 17 to be melted into the melting crucible 6, put the casting mold 9 into the casting chamber 10, close the furnace cover 3 of the melting chamber, start the vacuum unit 15, open the pneumatic valve 14 of the melting chamber and the casting chamber. Pneumatic valve 13 in the mold chamber, when the vacuum degree reaches ≤10-2Pa, start the lifting mechanism 11 to drive the mold 9 to the designated position in the melting chamber 7;

[0025] In the second step, the melting coil 5 is energized to generate an alternating magnetic field to rapidly heat the alloy material. The heating power is 200KW for 15-20 minutes. The walls are not in contact, t...

Embodiment 2

[0028] Use the rapid casting cold crucible suspension furnace to melt the aluminum-lithium alloy material, and add Ti: 0.3% to the aluminum-lithium alloy; the specific steps are as follows:

[0029] In the first step, put the pre-processed standard alloy ingot into the casting hole at the bottom of the melting crucible 6, mix the alloy material into the melting crucible 6, put the casting mold 9 into the casting chamber 10, and close the melting chamber Furnace cover 3, start the vacuum unit 15, open the pneumatic valve 14 of the smelting chamber and the pneumatic valve 13 of the casting chamber, wait for the vacuum degree to be ≤ 10-2Pa, start the lifting mechanism 11 to drive the mold 9 to the designated position in the smelting chamber 7 ;

[0030] In the second step, the melting coil 5 is energized to generate an alternating magnetic field to rapidly heat the alloy material. The melting power is 30KW and kept for 10-20 minutes. Under the action of the electromagnetic fiel...

Embodiment 3

[0033] Utilize rapid casting cold crucible suspension furnace to carry out the smelting of high entropy alloy material, Zr: 20%, Ti: 20%, Ni: 20%, W: 20%, Mo: 20%; Its specific steps are as follows:

[0034] In the first step, put the standard alloy material 17 to be melted into the melting crucible 6, put the casting mold 9 into the casting chamber 10, close the furnace cover 3 of the melting chamber, start the vacuum unit 15, open the pneumatic valve 14 of the melting chamber and the casting chamber. Pneumatic valve 13 in the mold chamber, when the vacuum degree reaches ≤10-2Pa, start the lifting mechanism 11 to drive the mold 9 to the designated position in the melting chamber 7;

[0035] In the second step, the melting coil 5 is energized to generate an alternating magnetic field to rapidly heat the alloy material. The heating power is 300KW for 25-35 minutes. The walls are not in contact, the casting coil 19 is started, and the heating power is 300KW for 5-10 minutes, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com