Non-pre-buried type abnormal-shaped bent water channel hot-work die and manufacturing method of non-pre-buried type abnormal-shaped bent water channel hot-work die

A hot work mold, non-embedded technology, applied in the direction of forming tools, manufacturing tools, casting molds, etc., can solve the problems of mold damage, uneven cooling of the mold, and difficult processing of the outer surface, so as to ensure uniformity and good market Application value, good effect of significant industrialization significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Taking a typical car B-pillar reinforced beam mold punch block as an example, the blank of the non-pre-embedded special-shaped curved water channel hot working mold is formed by a casting method, which mainly includes the following steps:

[0048] A. Production of as-cast mold blanks:

[0049] ①Preliminary preparation:

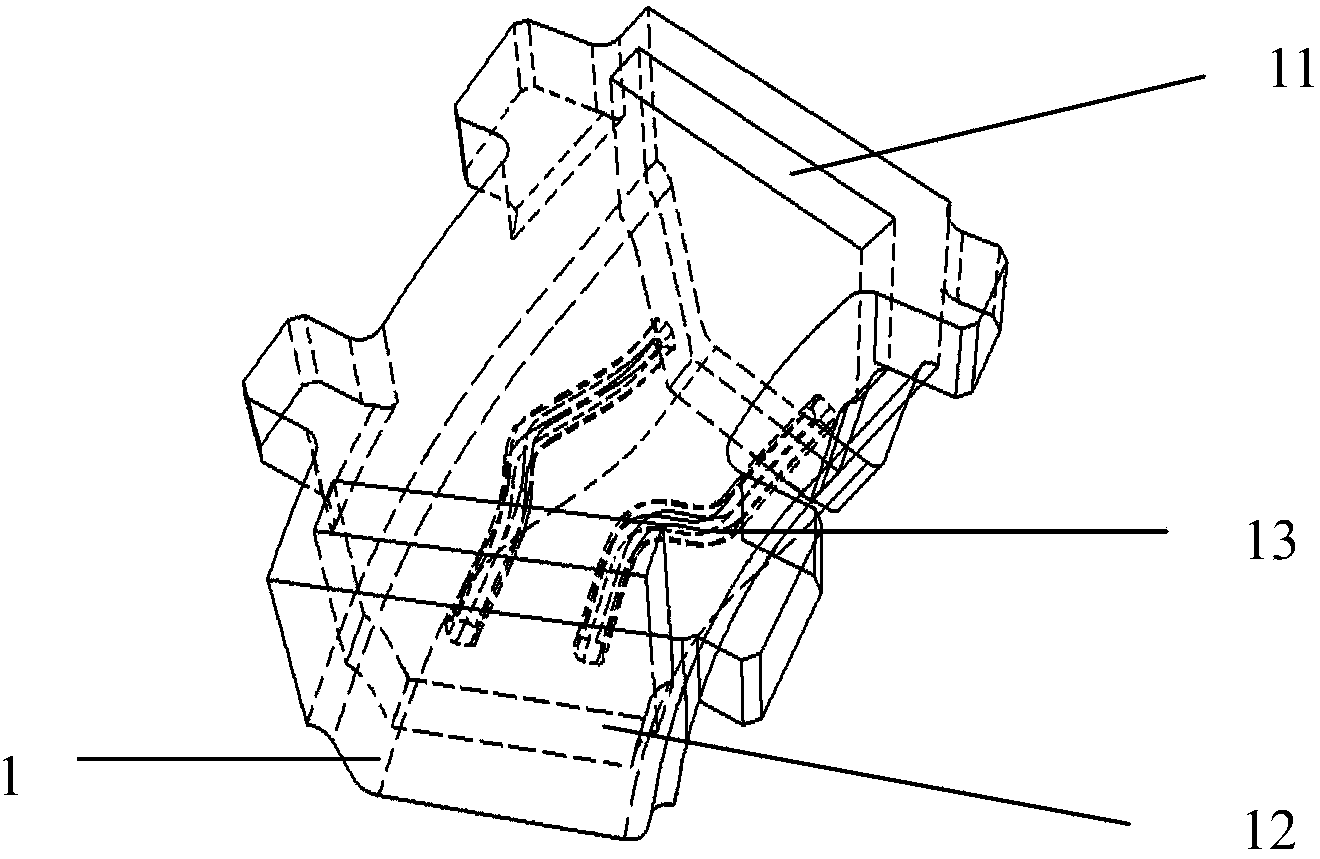

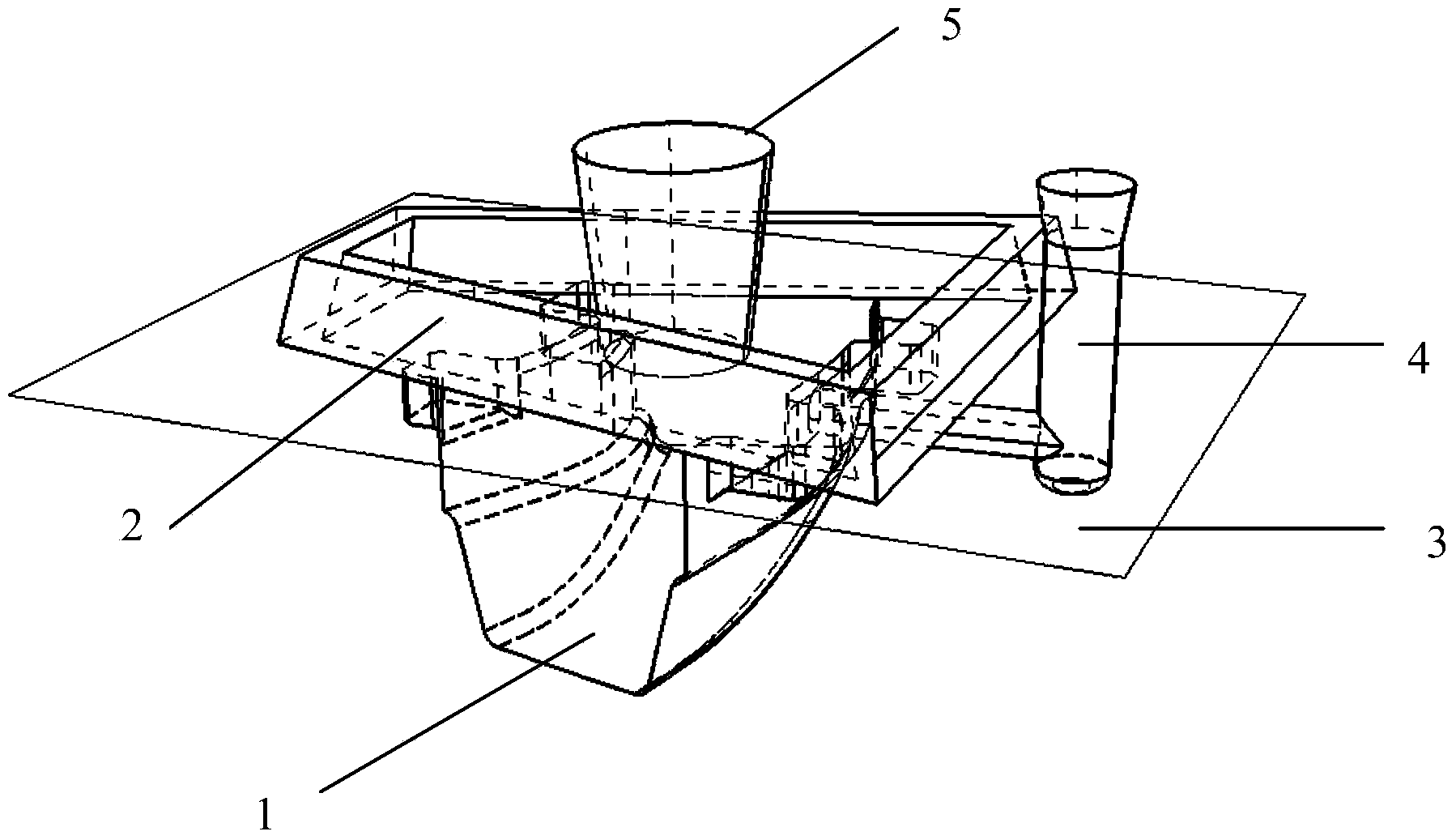

[0050] Make a male mold 1 with a mold blank shape (such as figure 1 Shown): The male mold 1 is mainly based on the three-dimensional digital model of the mold to make a wooden mold or an aluminum mold. The surface cavity of the mold is made of gemstone sand and used as the lower box during pouring.

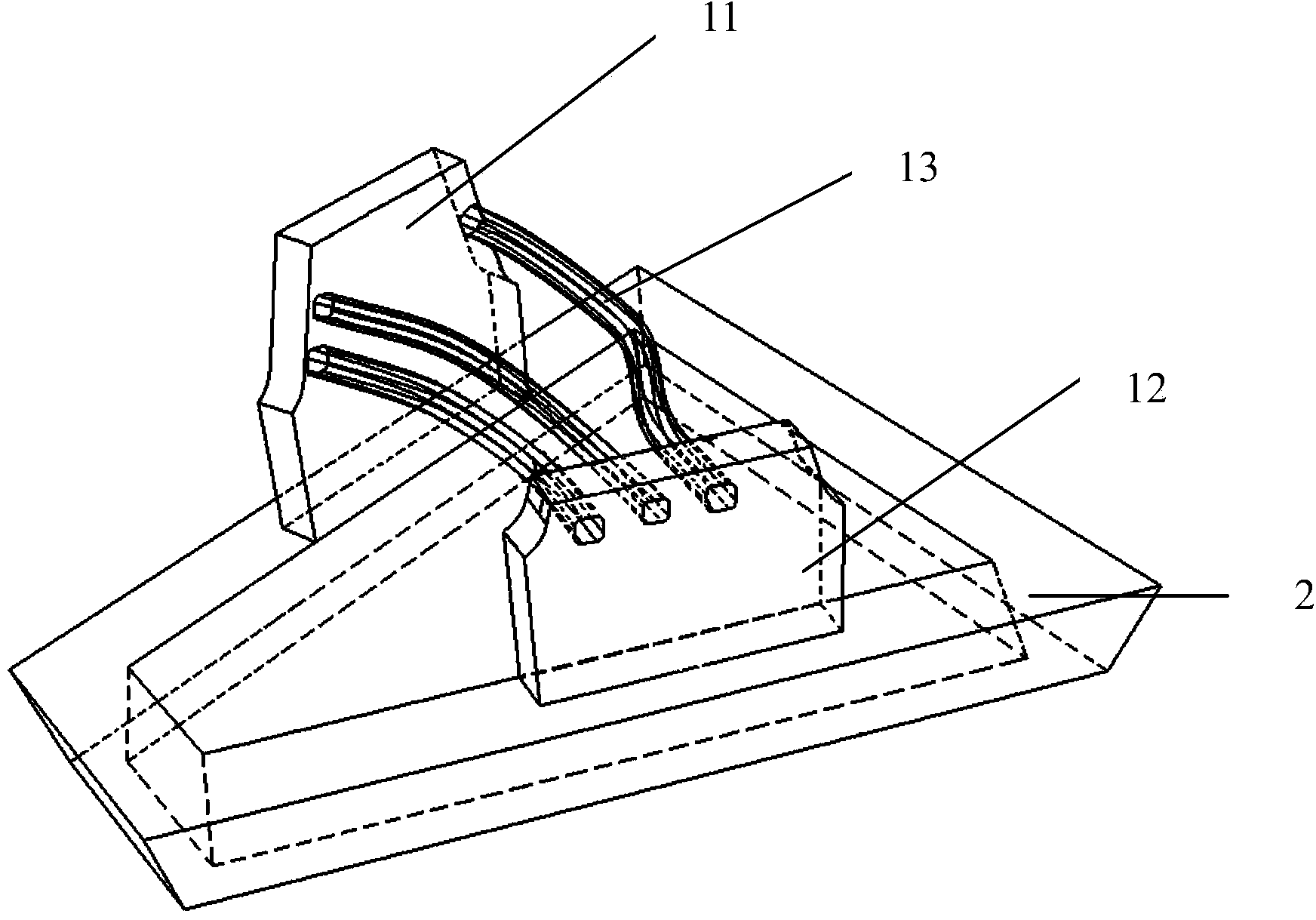

[0051] The overall structure of special-shaped curved water channel core (such as image 3 Shown): Including a number of special-shaped curved water channel cores 13 optimized and designed by numerical simulation, fixed cores 11 for the inlet and outlet troughs and fixed cores 12 for the inlet, fixed on both ends of the special-shaped curved water channel cores 13 ...

Embodiment 2

[0067] Taking the B-pillar reinforced beam mold punching block of a car as an example, the gating system and the overall structure of the special-shaped curved water channel core are made by 3D printing technology, including the following steps:

[0068] A. Production of as-cast mold blanks:

[0069] ①Preliminary preparation:

[0070] Make a male mold 1 with the shape of the mold blank (such as Figure 7 Shown): The male mold 1 is mainly based on the three-dimensional digital model of the mold, using 3D laser printing equipment to print the sand into the entire cavity containing the mold surface.

[0071] The overall structure of special-shaped curved water channel core (such as Picture 10 Shown): The sand structure made by 3D printing technology includes a number of special-shaped curved water channel cores 13 optimized and designed by numerical simulation, fixed cores 11 and fixed cores for the water collecting tank at both ends of the special-shaped curved water channel core 13 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com