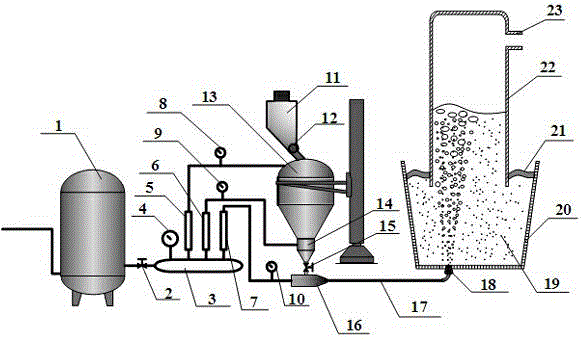

Device and method for single snorkel vacuum degassing refining of molten steel by employing bottom injection

A vacuum degassing and powder spraying technology, applied in the field of iron and steel refining, can solve problems such as splashing or secondary pollution of molten steel, shortening the service life of spray guns, and large end faces of dipping tubes, so as to achieve uniform removal of inclusions and improve operational safety , increase the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

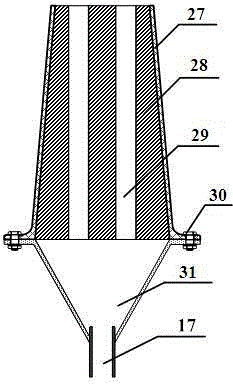

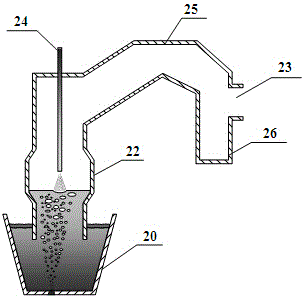

[0049] Using the above device, take 50t bottom powder spraying SSVD-BPI method for desulfurization and smelting ultra-low carbon steel as an example. The carrier gas is dry argon, the spraying powder is 600 mesh CaO powder, the powder-gas ratio is 0.8, and the spraying time is 10min. The bottom powder spraying element adopts a linear slit type powder spraying element, the slit width is 0.18mm, the length is 20mm, the number of slits is 20, and the number of powder spraying elements is 1. It is arranged in the ladle of the bottom powder spraying single nozzle vacuum degassing refining furnace The bottom is 0.5 times the radius from the center of the bottom. The single-nozzle vacuum degassing refining furnace inserts molten steel to a depth of 300mm, the molten steel rises to a height of 600mm in the vacuum chamber, and the injection pressure is 0.5Mpa. Specifically follow the steps below:

[0050] (1) When the steel is tapped from the primary smelting furnace, the steel ladle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com