Silane crosslinked polyethylene pipe connecting piece

A technology of pipeline connectors and silane cross-linking, which is applied in the direction of pipeline connection layout, pipe/pipe joint/pipe fittings, mechanical equipment, etc. problem, to achieve the effect of improving low temperature cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

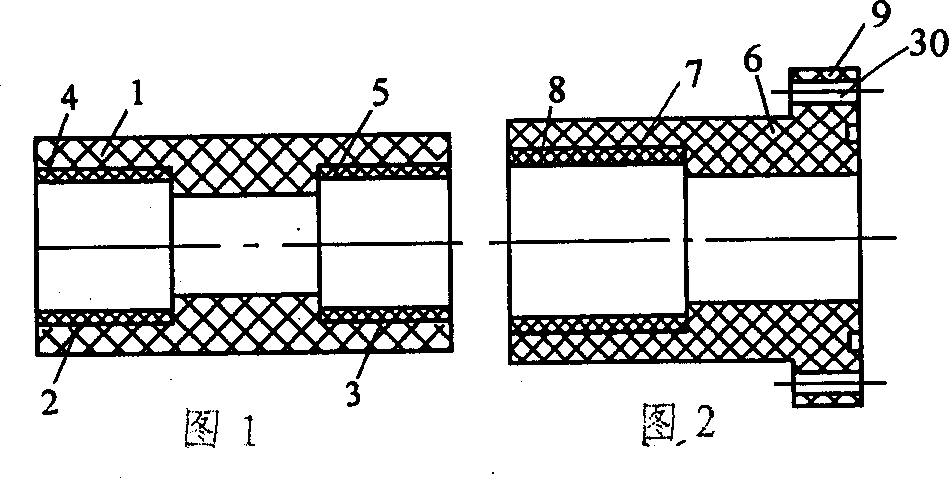

[0026] Fig. 1 is a schematic structural diagram of Embodiment 1 of the present invention. A two-way silane cross-linked polyethylene pipe body 1 is formed by extrusion molding (or injection molding) and cross-linking polycondensation reaction of a material composed of a silicone monomer grafting initiator, a hydrolysis polycondensation catalyst and polyethylene. Hot-melt adhesive layers 4, 5 are respectively distributed on the inner walls of the socket openings 2, 3 at both ends of the pipe body 1. In Example 1, the pipe connector is connected to the pipe through the sockets at both ends in a hot-melt manner.

Embodiment 2

[0028] FIG. 2 shows a schematic structural diagram of Embodiment 2 of the present invention. Embodiment 2 is basically the same as Embodiment 1. The difference is that the silane cross-linked polyethylene pipe body 6 only has a socket 7 at one end, and a hot-melt adhesive layer 8 is distributed on its inner wall. The other end of the pipe body 6 has a flange 9 with a connecting through hole 30 . In Example 2, the pipe connector is connected to the pipe through the socket at one end and the flange by means of heat fusion and connector connection.

Embodiment 3

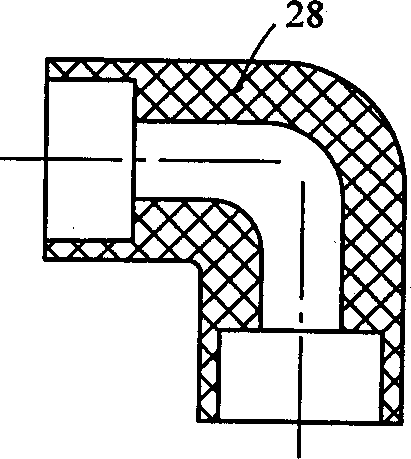

[0030] image 3 A schematic structural diagram of Embodiment 3 of the present invention is given. Embodiment 3 is basically the same as Embodiment 1. The difference is that the silane crosslinked polyethylene pipe body 10 is in the form of a 90° elbow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com