Patents

Literature

405 results about "Heat fusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat fusion (sometimes called heat welding, butt welding or simply fusion) is a welding process used to join two different pieces of a thermoplastic. This process involves heating both pieces simultaneously and pressing them together. The two pieces then cool together and form a permanent bond. When done properly, the two pieces become indistinguishable from each other. Dissimilar plastics can result in improper bonding.

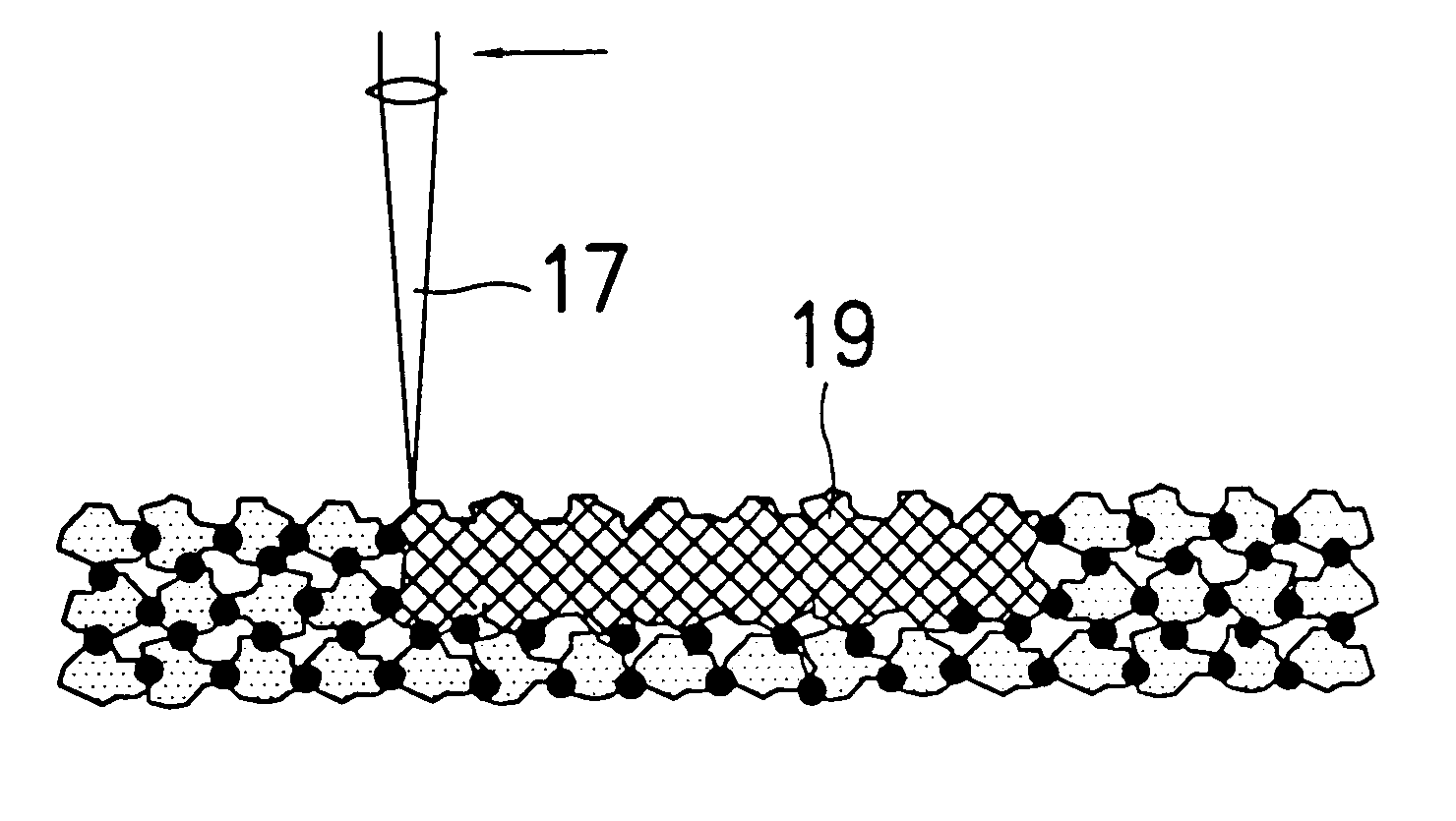

Method for rapid forming of a ceramic work piece

InactiveUS6217816B1Rapid productionPrevent dislocationAdditive manufacturing apparatusFeeding arrangmentsHeat fusionLaser beams

An inorganic binder and a dissolving agent are put into ceramic powder. They are mixed to form a plastic green mixture. Then the said mixture is formed into a thin green layer. Preferably, this thin green layer will be preheated and dried such that the thin green layer will be hardened due to the bonding effect of the inorganic binder. A portion of the thin green layer exposed under a directed high-energy beam is sintered, preferably by a laser beam, to cause ceramic molecules to bond together locally due to heat fusion. By controlling the scanning path of the high-energy beam, a two-dimensional thin cross section of the ceramic part in arbitrary form can be produced. A second thin ceramic layer can be built onto the first thin ceramic layer and bonded to it by the same method. After multiple repetitions of this procedure a three dimensional ceramic part can be fabricated layer upon layer. The green portion, which is not scanned by the high-energy beam, will be removed with suitable method. A ceramic part can be rapidly produced in this way.

Owner:NAT SCI COUNCIL

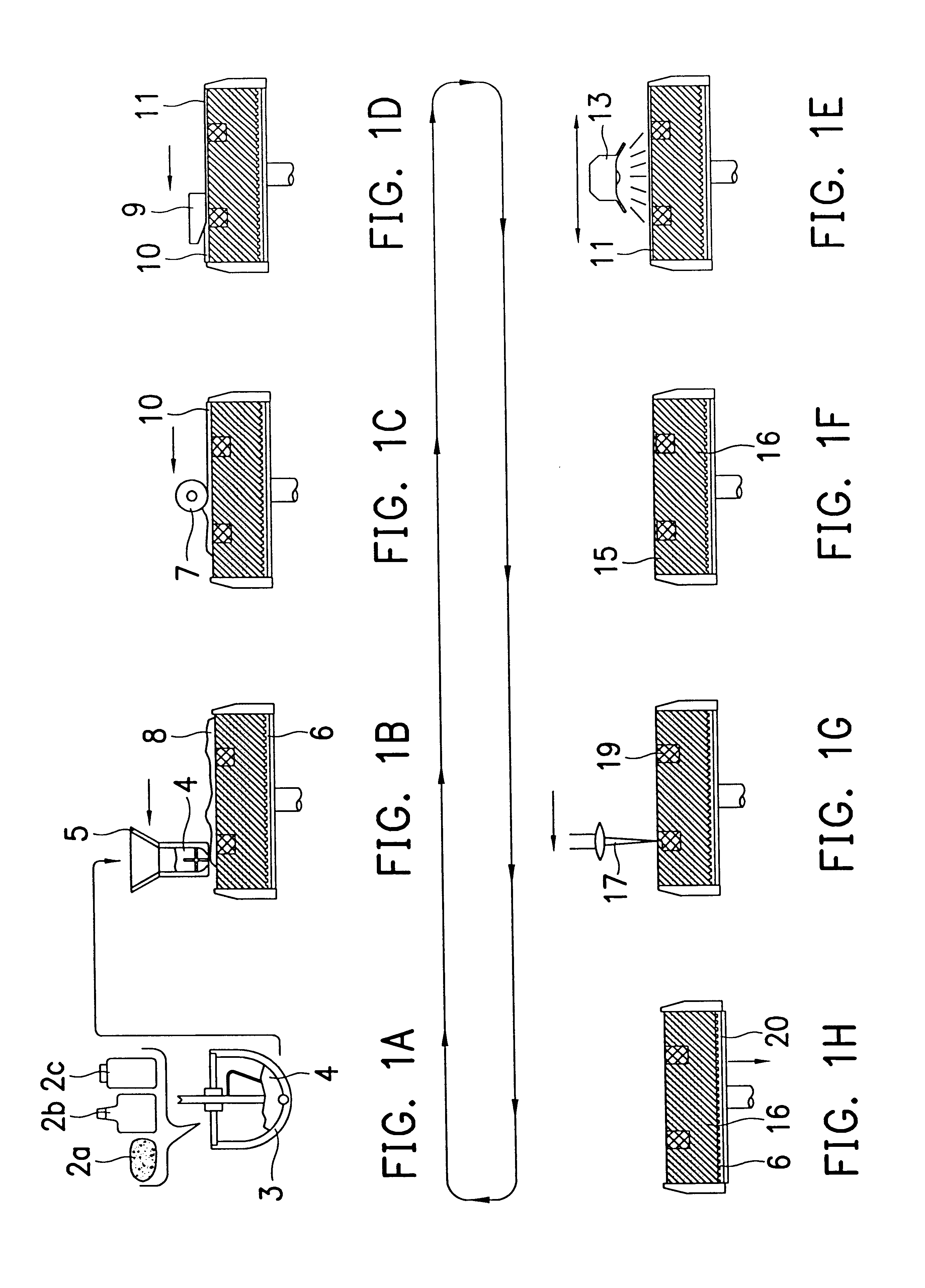

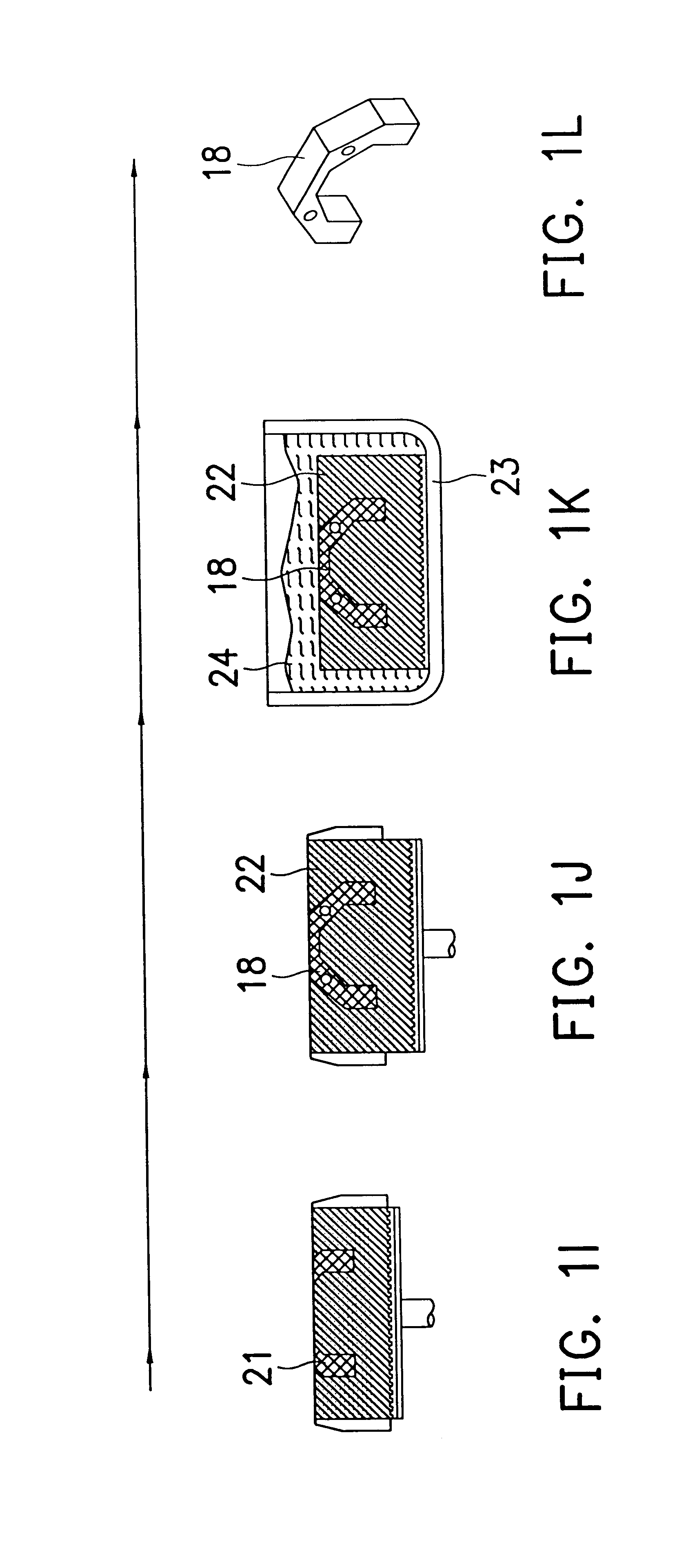

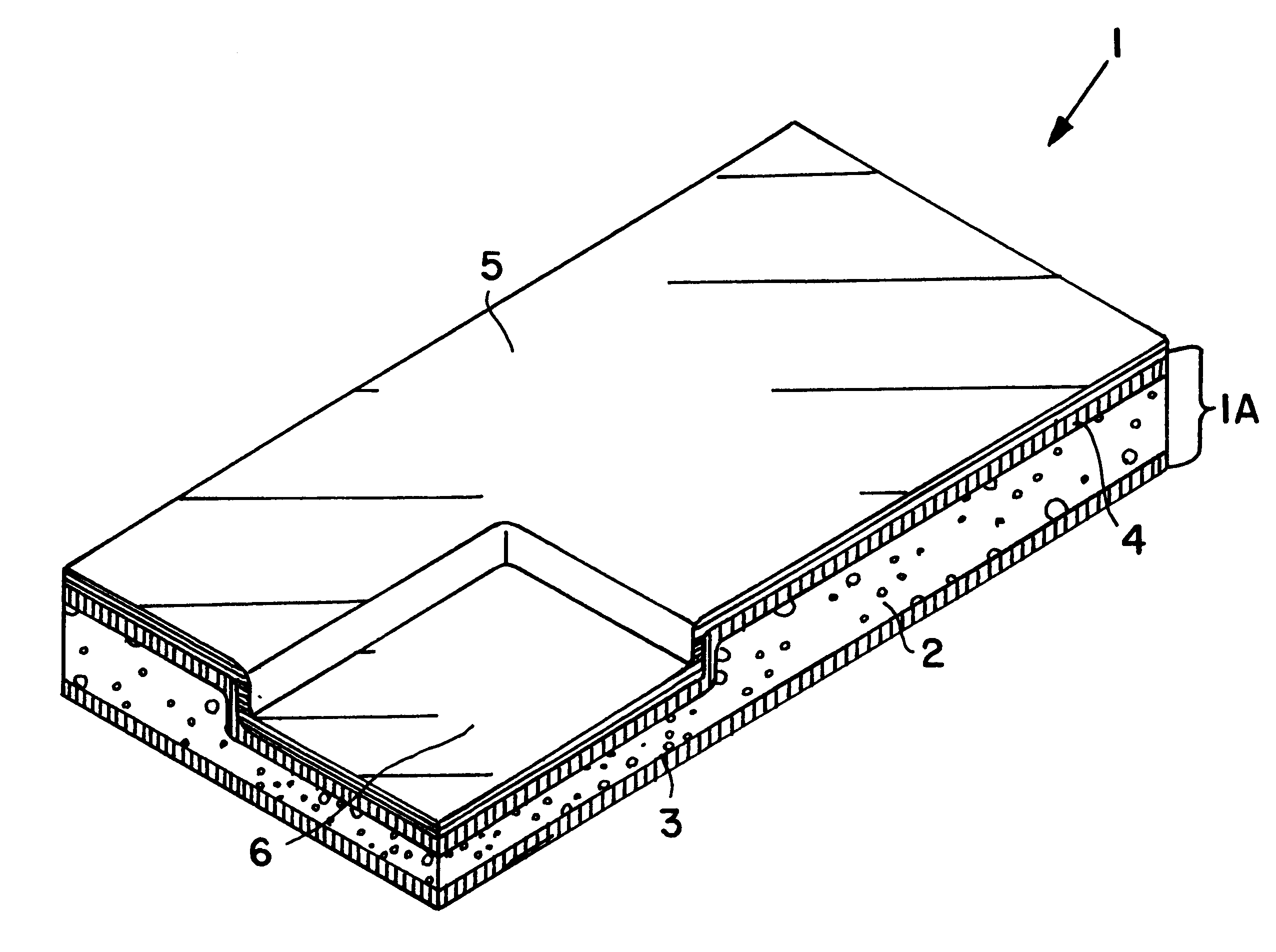

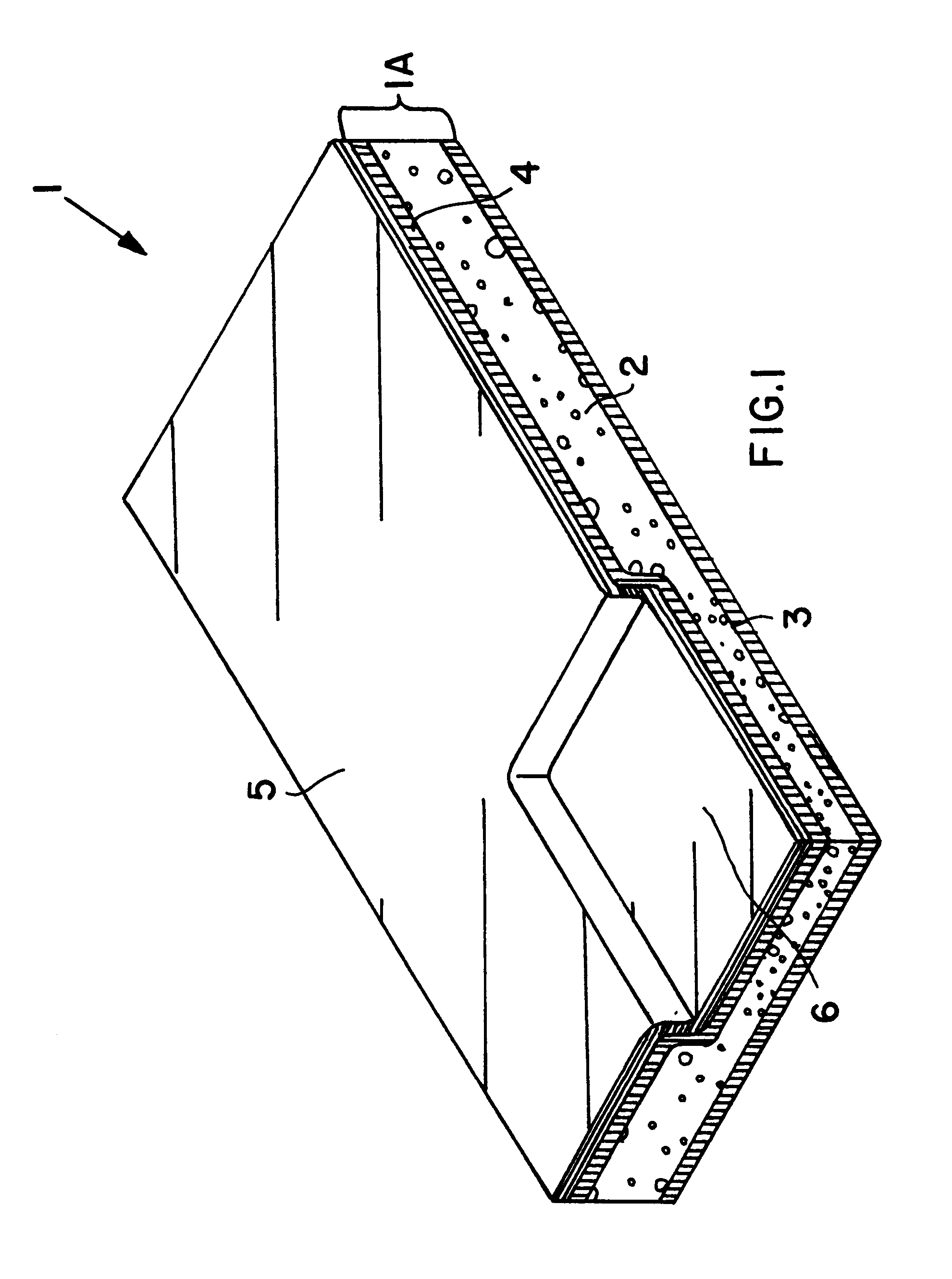

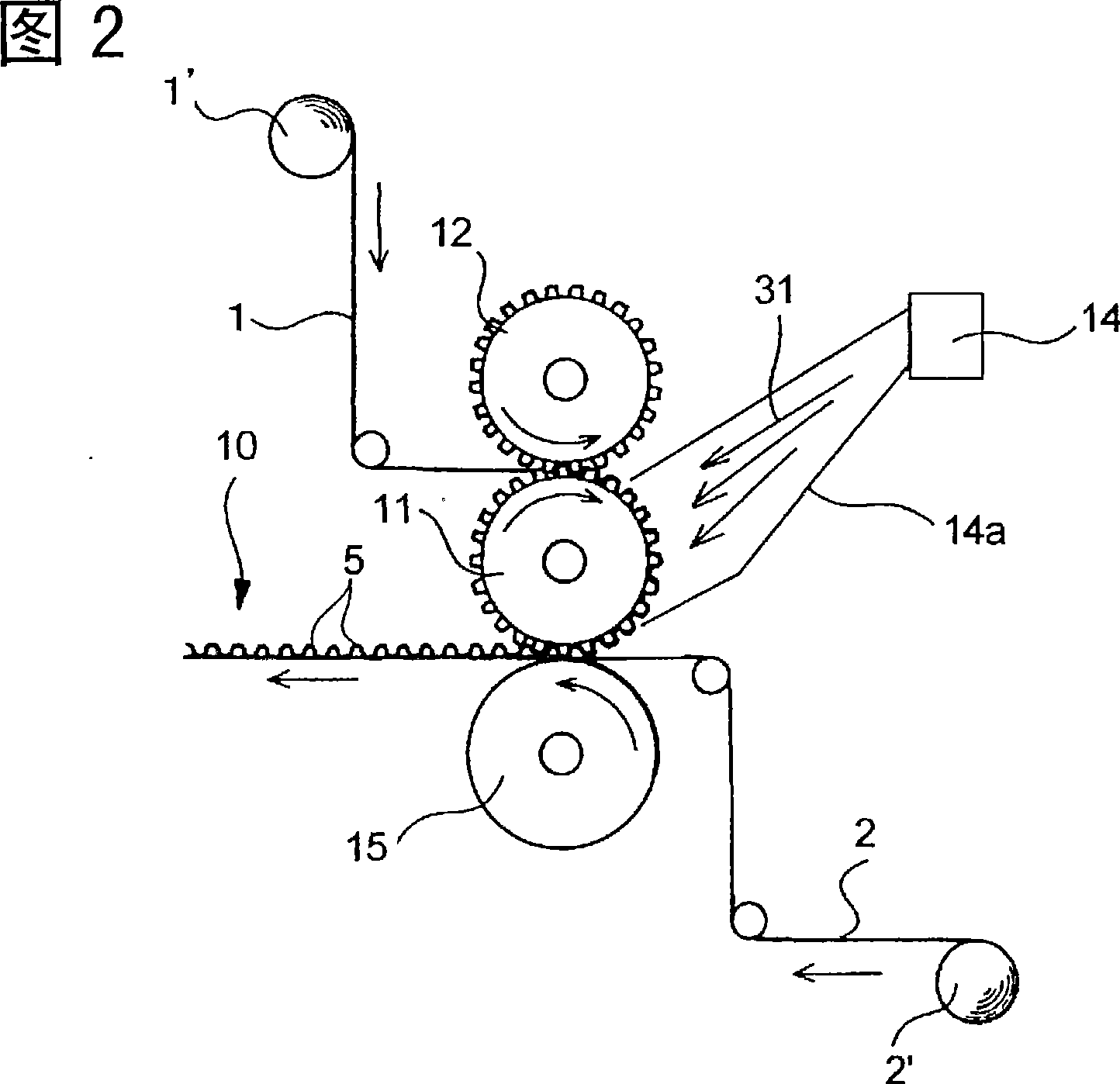

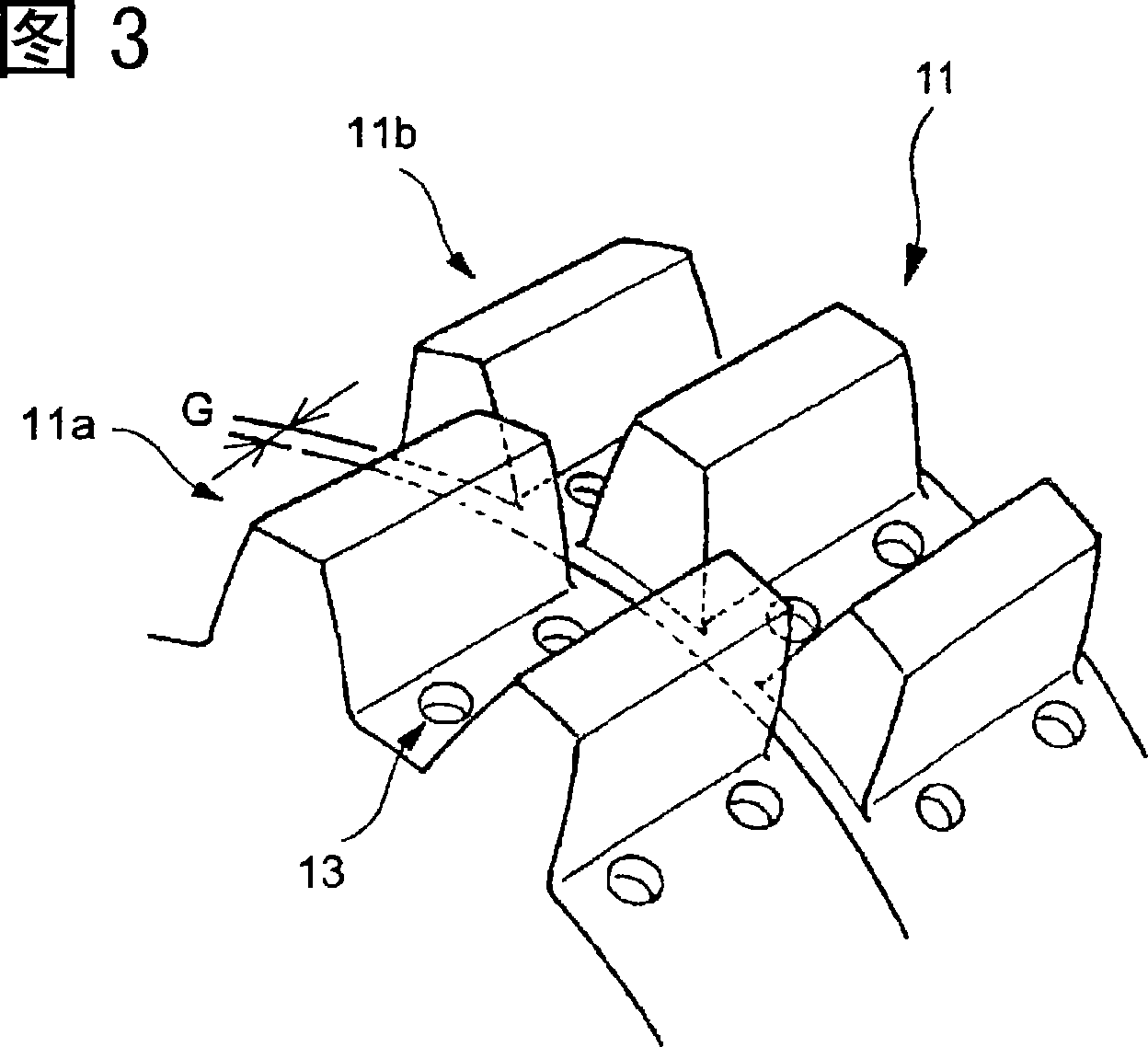

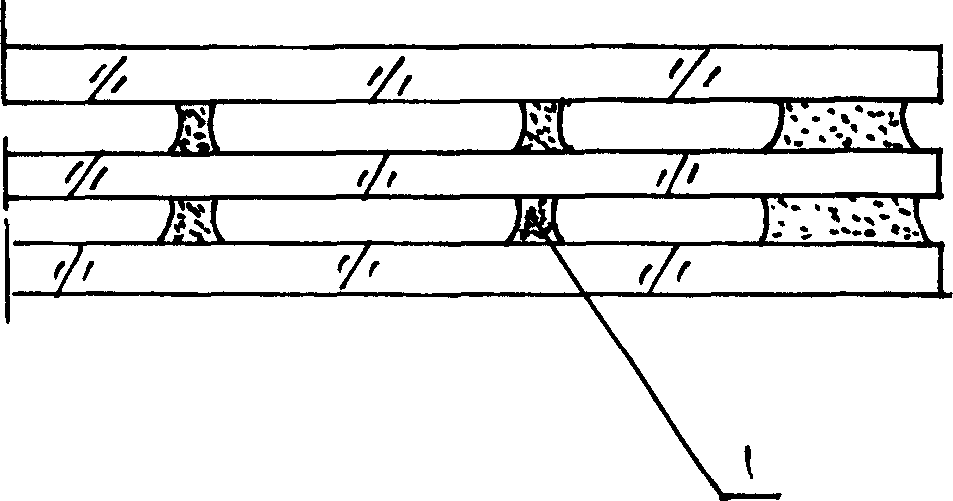

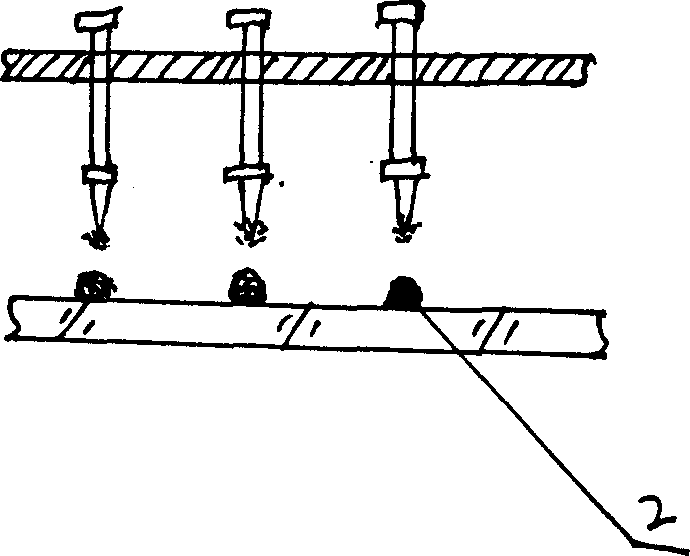

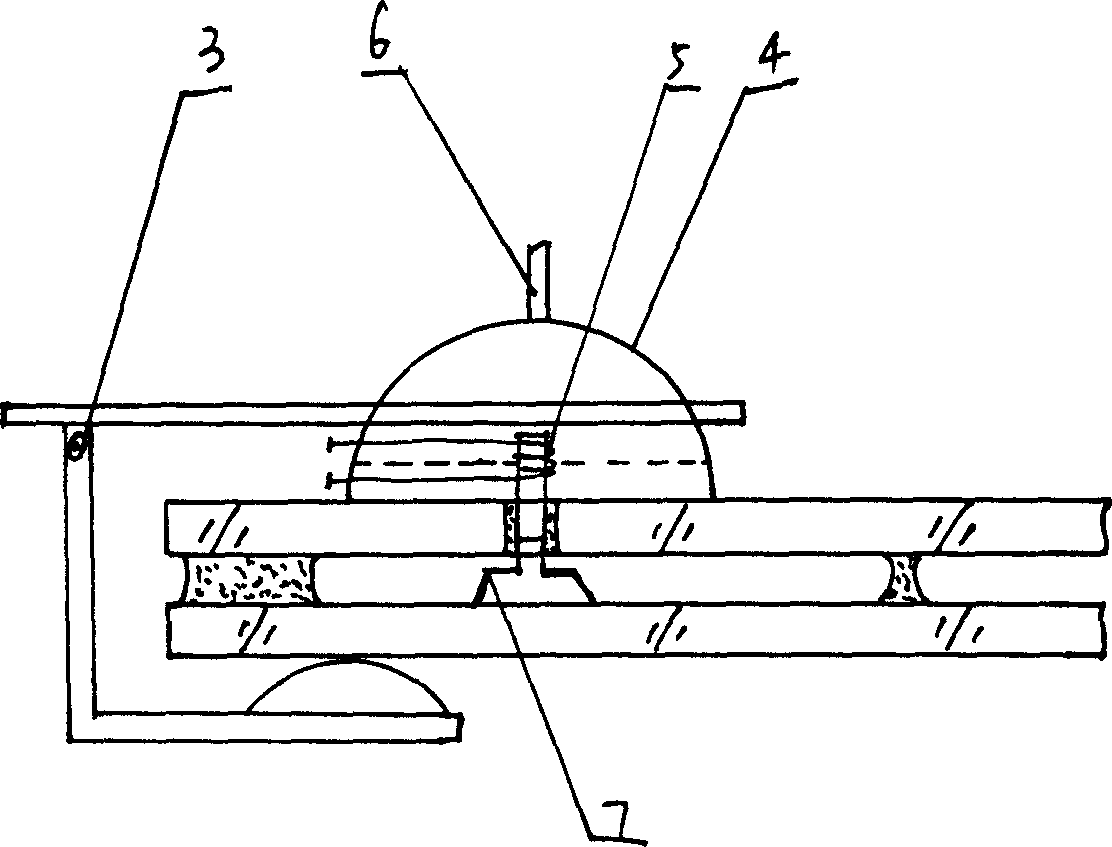

Composite structural panel with thermoplastic foam core and natural fibers, and method and apparatus for producing the same

InactiveUS6287678B1Easy to recycleEasily thermo-processedAdhesive processesLamination ancillary operationsComposite constructionShell molding

A composite structural panel includes a cover sheet laminated onto a three-layered substrate including a thermoplastic foam core sandwiched between two composite outer layers. Each composite outer layer includes natural fibers embedded in a thermoplastic matrix. The thermoplastic material of all layers is preferably polypropylene, and the core consists of an expanded cellular polypropylene rigid foam. In a method for forming the composite structural panel, a first preheated outer layer is laminated and molded onto the foam core in a first molding step, and then the second preheated outer layer and the cover sheet are laminated and molded onto the foam core in a second molding step, with a cooling-down time allowed between the two molding steps. In this manner, each preheated outer layer provides enough heat to thermally fuse the outer layer onto the foam core, without overheating the foam core to the point of softening or melting the foam core. The low density foam core provides a spacing distance between the strong composite outer layers, and therefore the finished composite structural panel has a high strength and rigidity, and a high strength-to-weight ratio. The structural panel can be molded into any desired three-dimensional contoured configuration during the molding process.

Owner:HERBERT OLBRICH

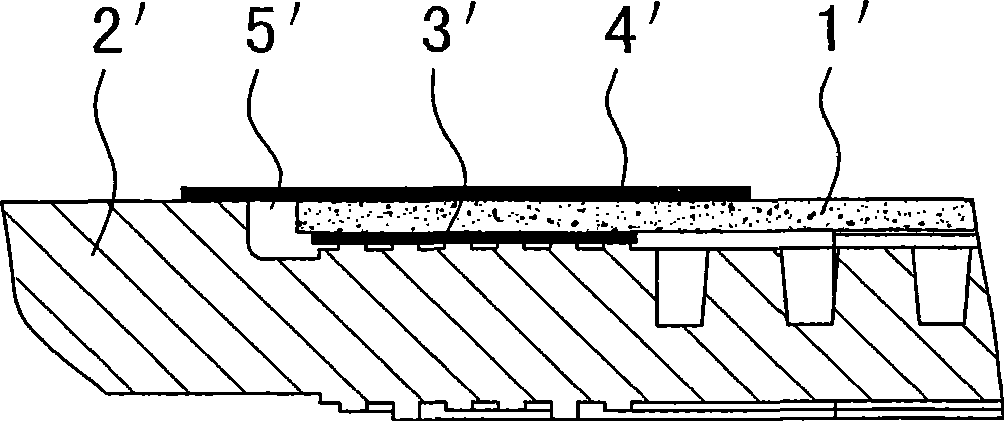

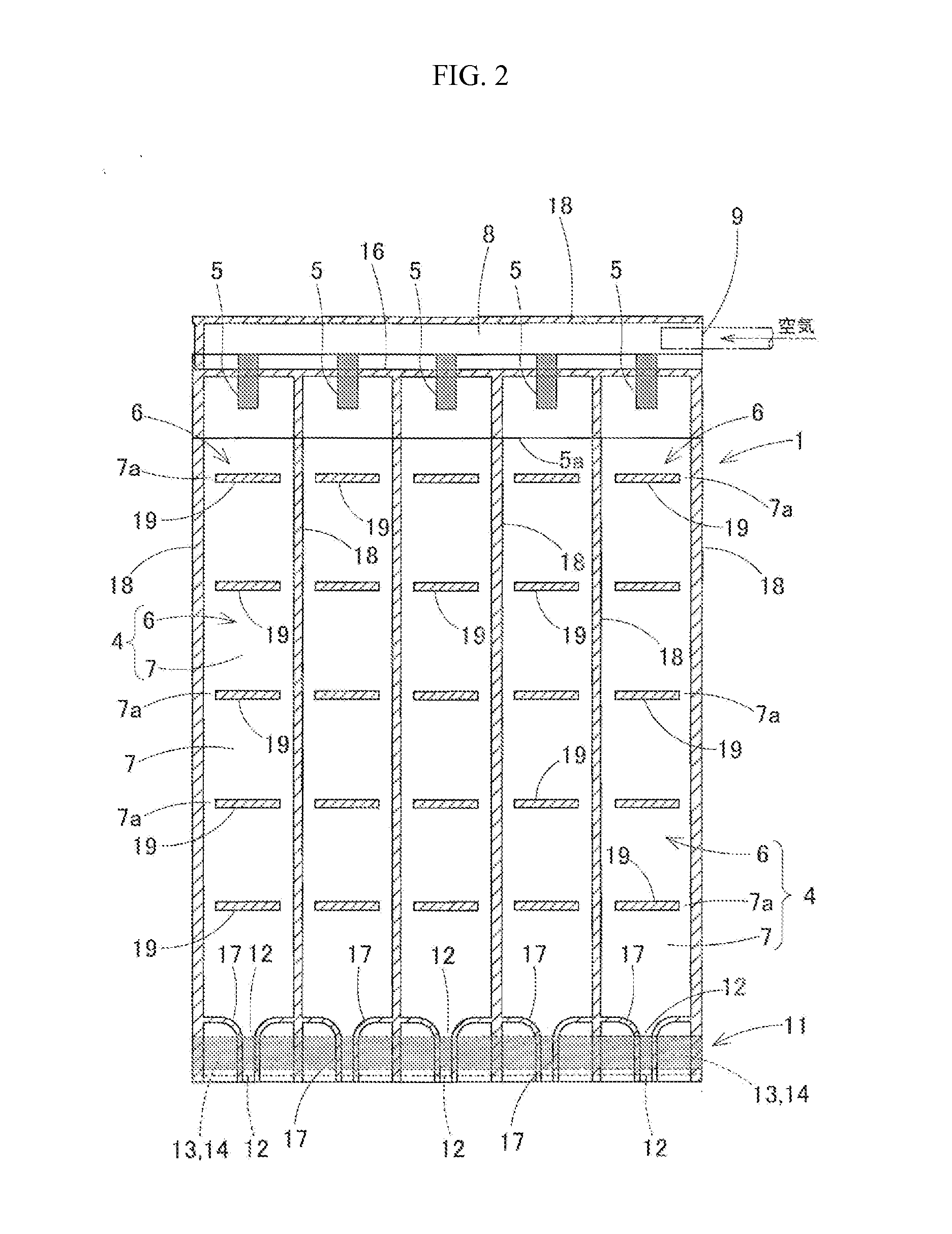

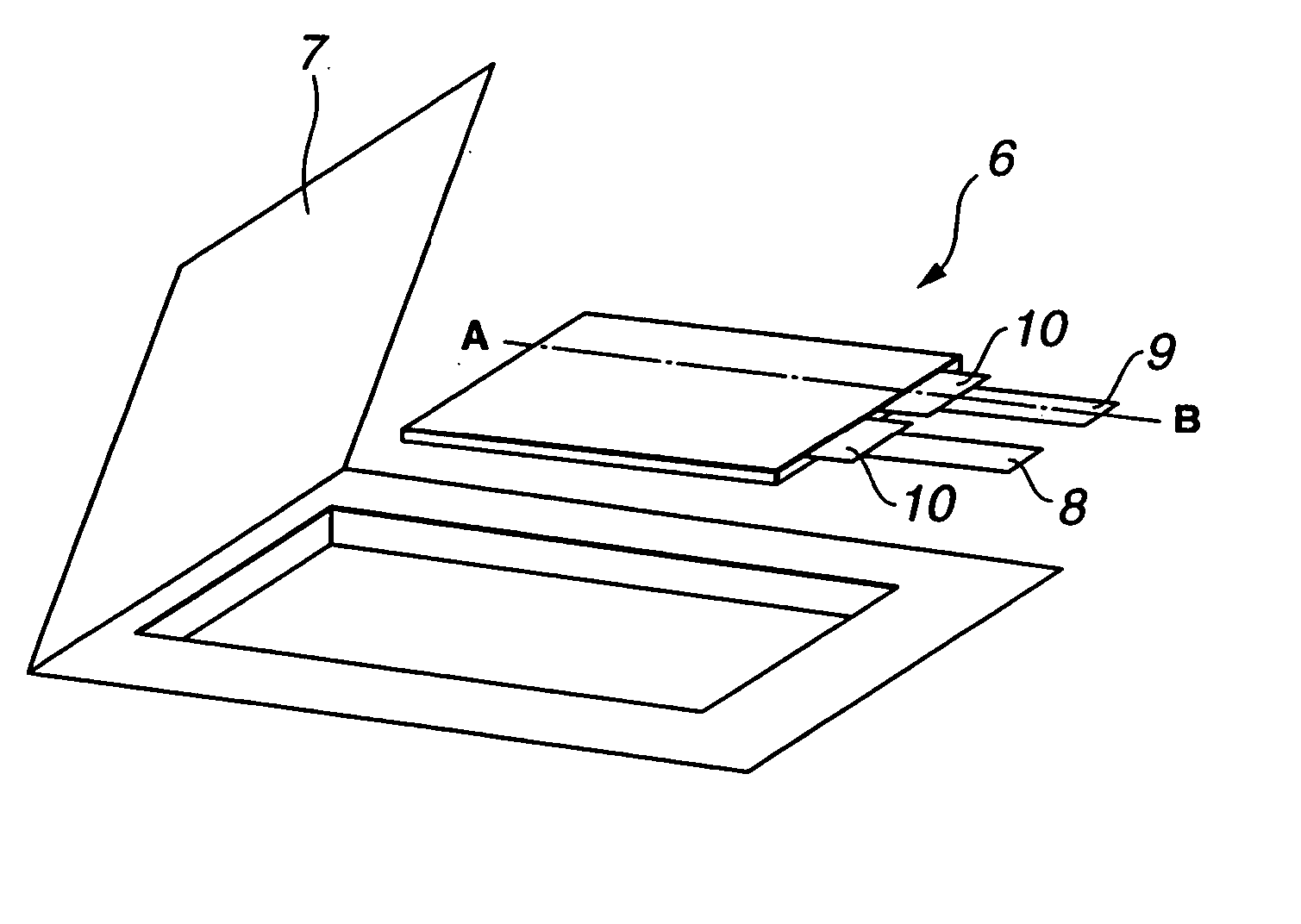

Flat oxygen-enriched membrane component

InactiveCN101544356AGuaranteed service lifeIncrease profitSemi-permeable membranesDispersed particle separationAdhesiveHeat fusion

The invention relates to a flat oxygen-enriched membrane component, which consists of an upper template, a middle template and a lower template which are fastened. One end of the upper template, one end of the middle template and one end of the lower template are provided with oxygen outlets A, B and C which are communicated; the insides of the upper template and the lower template are provided with oxygen-enriched membranes A and D respectively; two sides of the middle template are provided with oxygen-enriched membranes B and C respectively; air passages A and B are arranged between the adjacent oxygen-enriched membranes; one end of the air passage A and one end of the air passage B are communicated with the atmosphere, and the other end of the air passage A and the other end of the air passage B are communicated with the oxygen outlets A, B and C; the oxygen outlets B and C are provided with oxygen passage covers B and C of through holes; and the flat oxygen-enriched membrane component is characterized in that heat fused welding layers are arranged between the oxygen-enriched membranes A, B, C and D and the corresponding upper template, the middle template and the lower template respectively. The oxygen-enriched membranes are physically welded and fixed by adopting heat fusion, the defects of adhesion and fixation of adhesive are thoroughly changed, the service life is ensured, and the utilization ratio is improved.

Owner:周纪昌

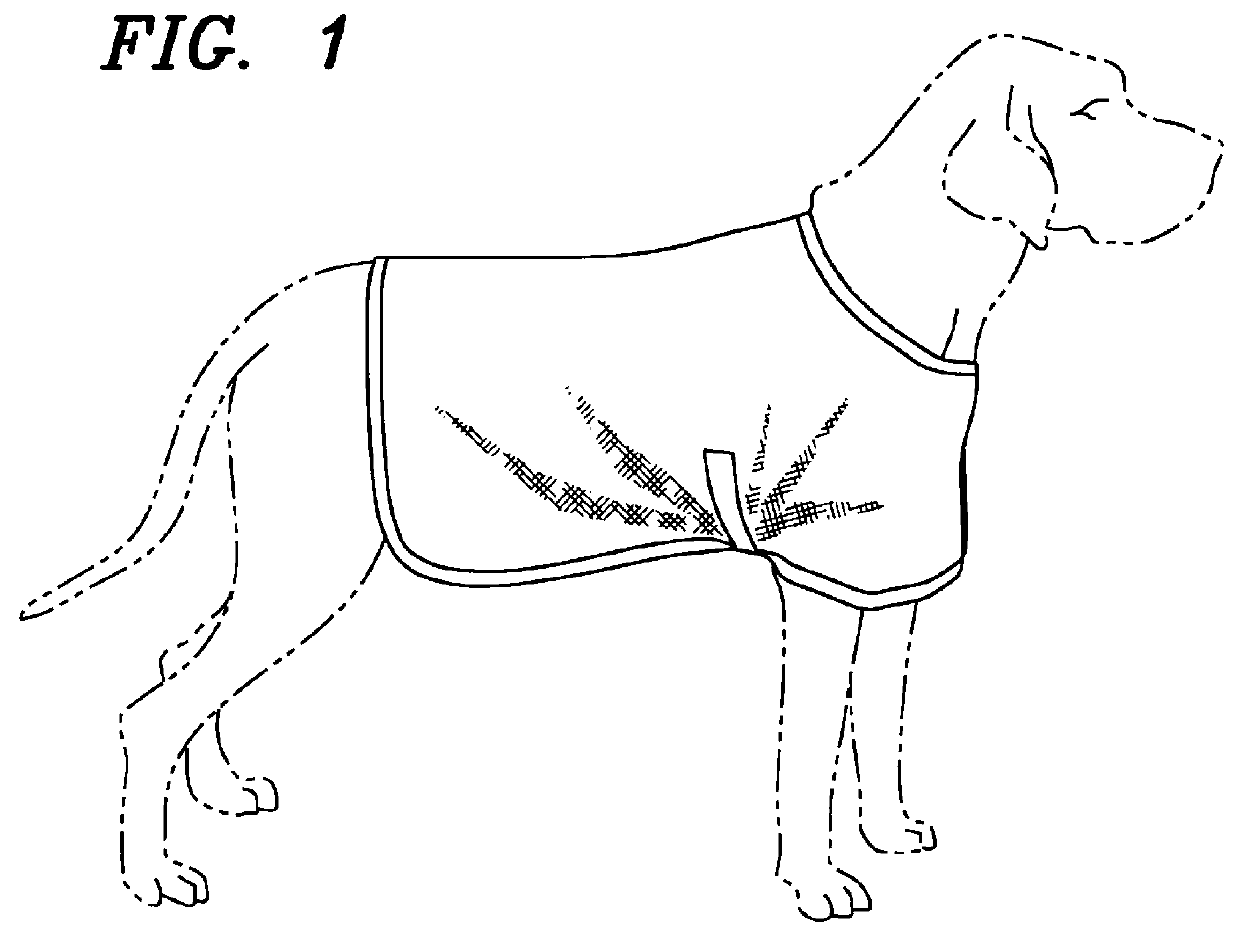

Reversible heat-reflective pet garment

InactiveUS6089194AGreat warmthImprove visibilityChemical protectionHeat protectionEngineeringThermal radiation

A protective coat for domestic animals, such as dogs, is reversible to alternatively protect against heat or cold. The coat is made of a light-weight flexible material that is preferably fastened with the use of hook-and-loop fastening strips. The coat is a two-ply garment, one ply providing a water-repellent surface, while the second ply provides a heat radiation-reflective surface. The preferred material used in constructing the pet garment is Astrolon TM . The coat is a lamination of two sheets providing the desired protective qualities. The first sheet is aluminized clear polyethylene, and the second sheet is a colored polyethylene. The two sheets are heat-fused together. A cloth piping is sewn around the side edges of the lamination.

Owner:LABELLE JUDY

Heater arrangement with connector or terminating element and fluoropolymer seal, and method of making the same

InactiveUS6423952B1Improve protectionGood flexibilityHeater elementsCouplings bases/casesCorrosive chemicalElectrical conductor

A heater arrangement such as a heating band is especially suitable for providing freeze protection for water pipes in an aircraft, because it is resistant to vibrations, greatly varying temperatures, low pressure conditions, and aggressive chemicals, while achieving a reliable seal against the penetration of moisture or liquid into the areas of the electrical connections. The heater arrangement includes a heating element with a heater band matrix and heating conductors extending therein, as well as a fluoropolymer protective layer thereover. A connecting element or a terminating element is connected to exposed ends of the heating conductors. To seal the area at which the connecting element or terminating element is connected to the heater arrangement, a fluoropolymer is extruded over this area, and / or a fluoropolymer molded part is used as a connection block or end cap. The fluoropolymer materials are thermally fused together to form a continuous integral seal.

Owner:AIRBUS OPERATIONS GMBH

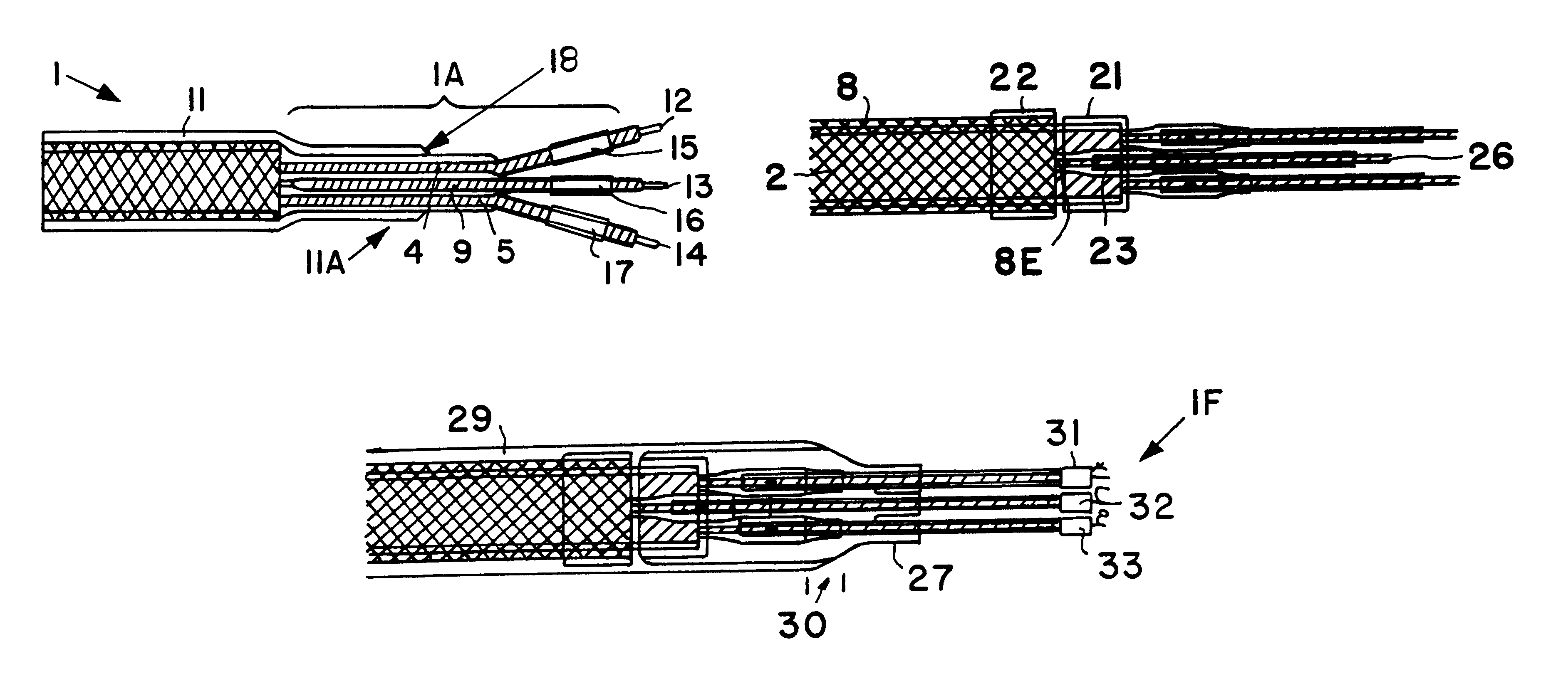

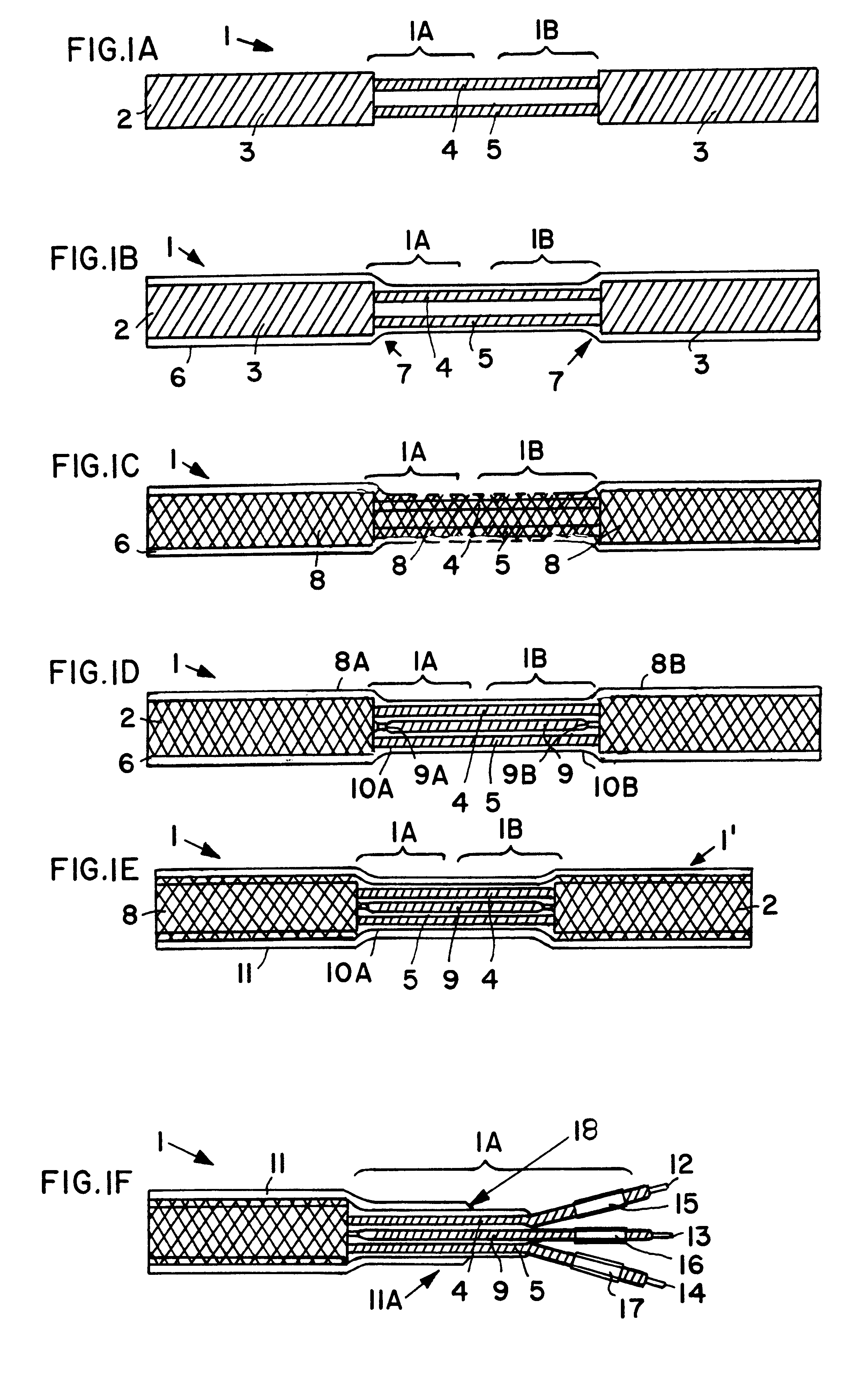

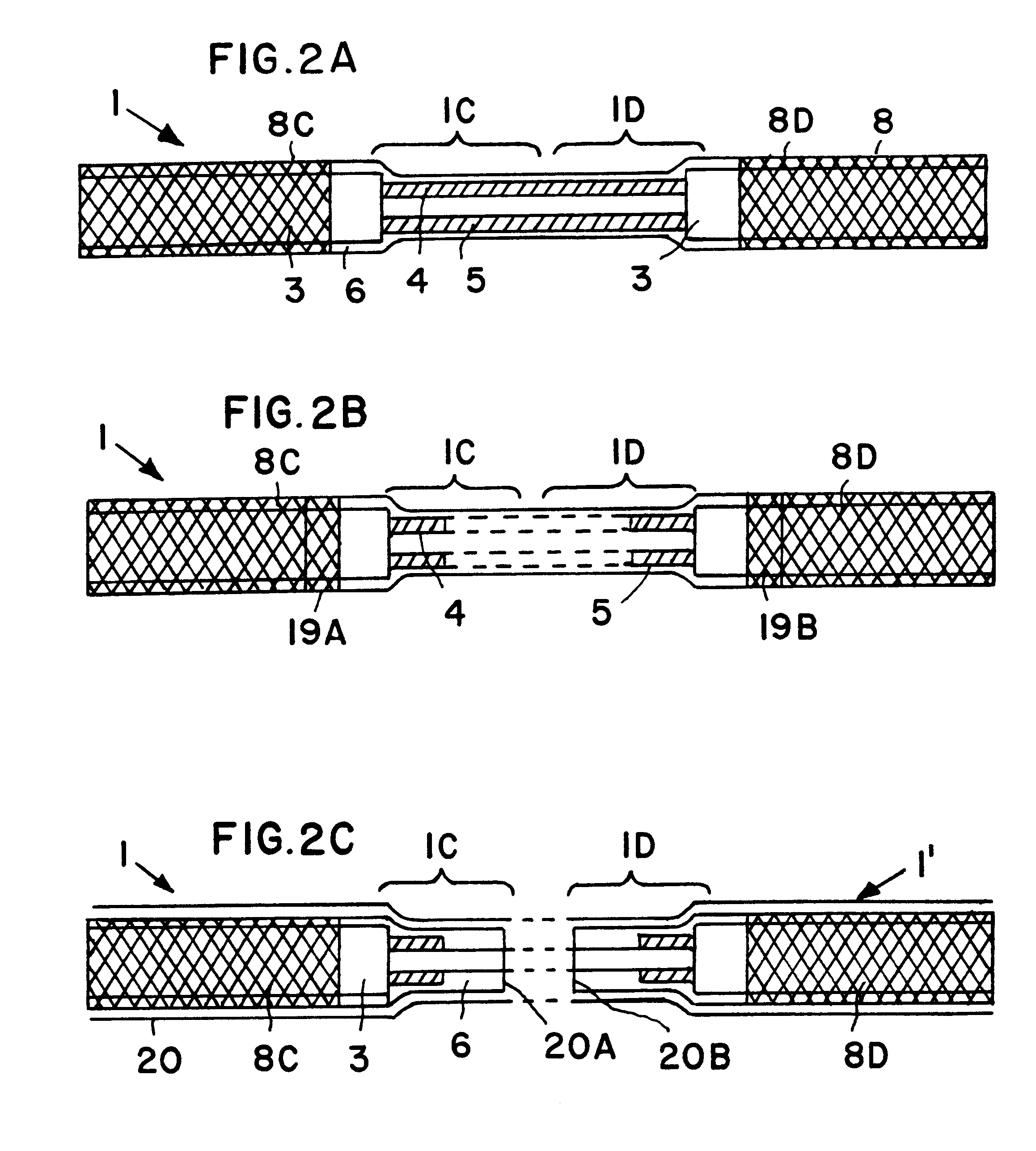

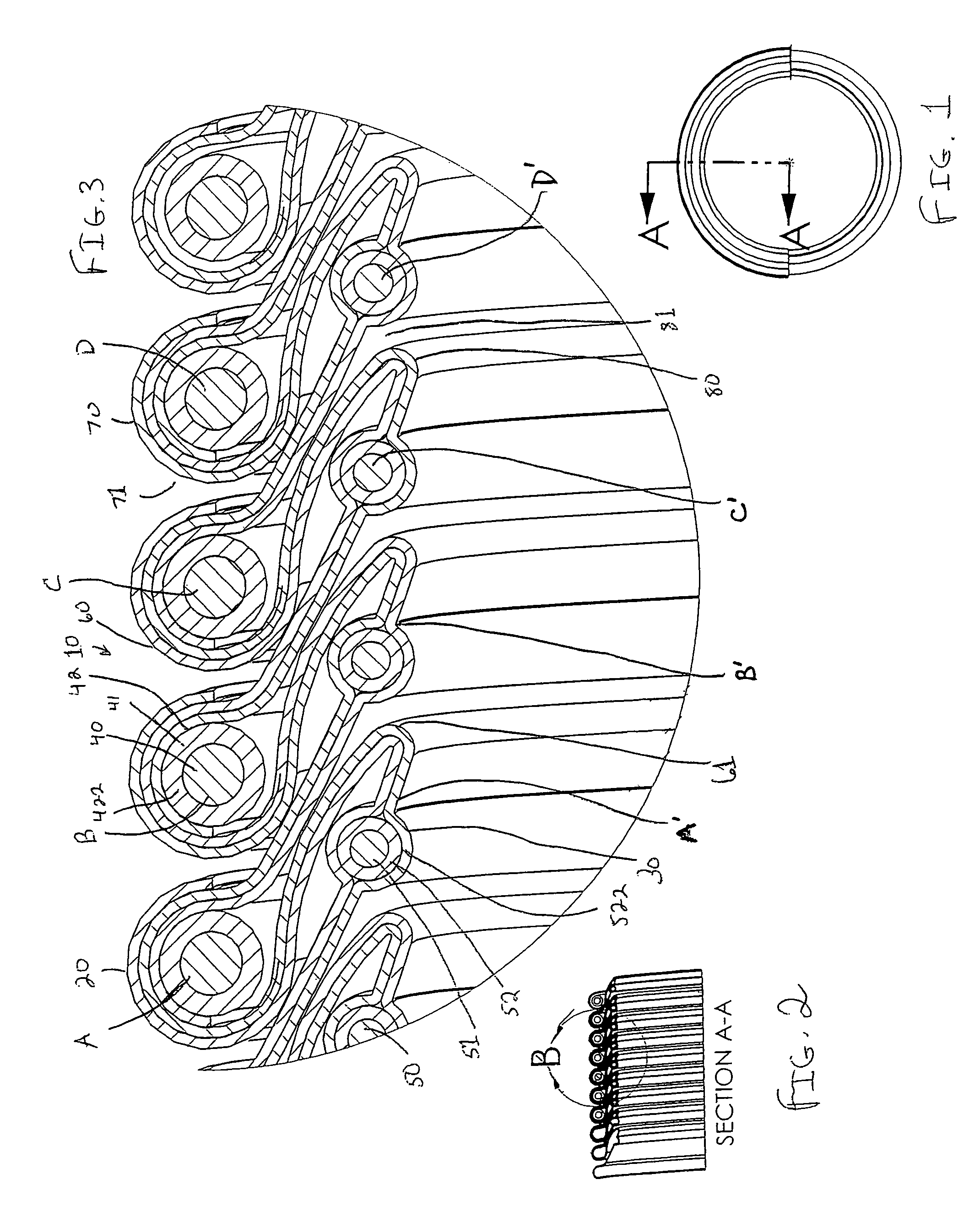

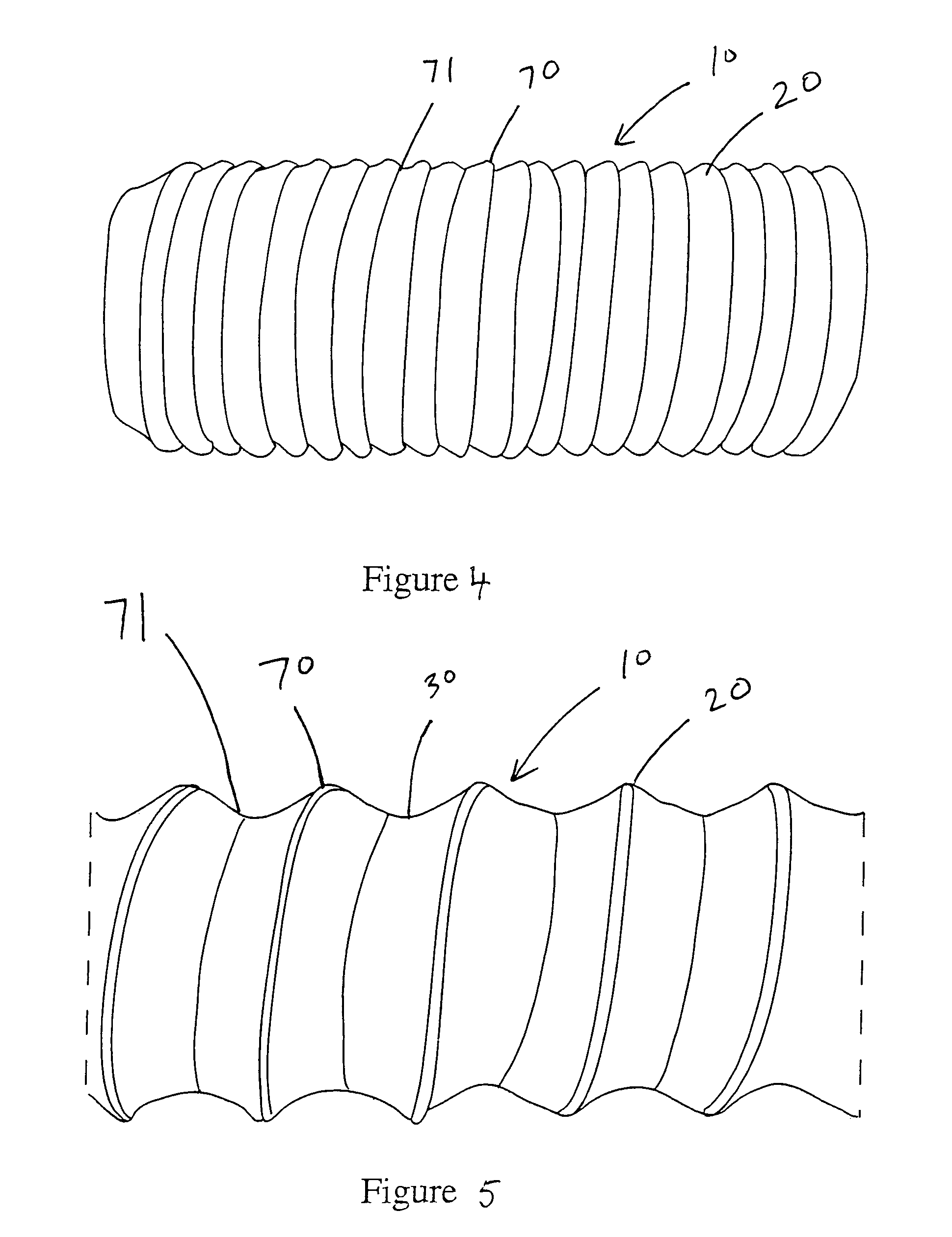

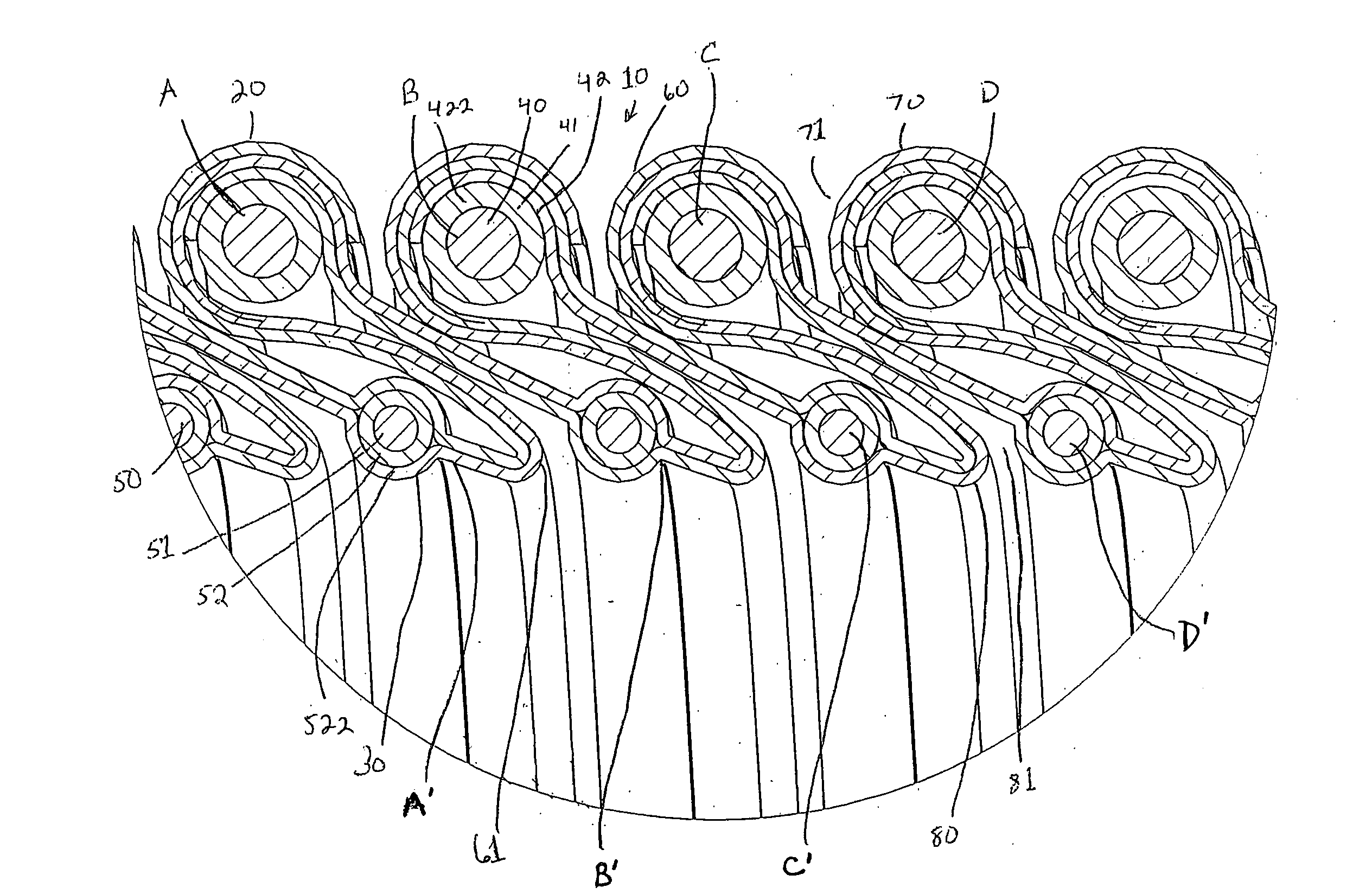

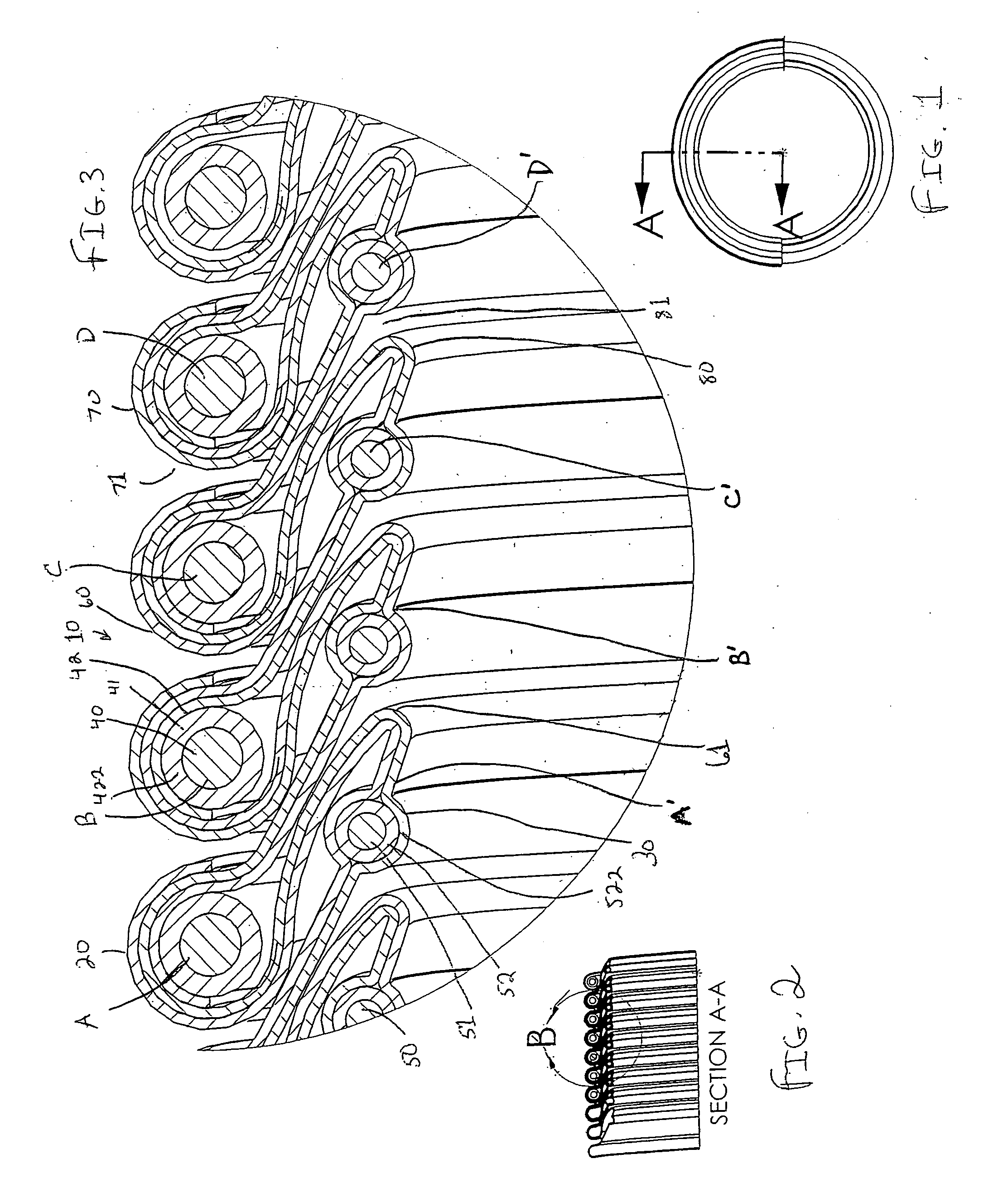

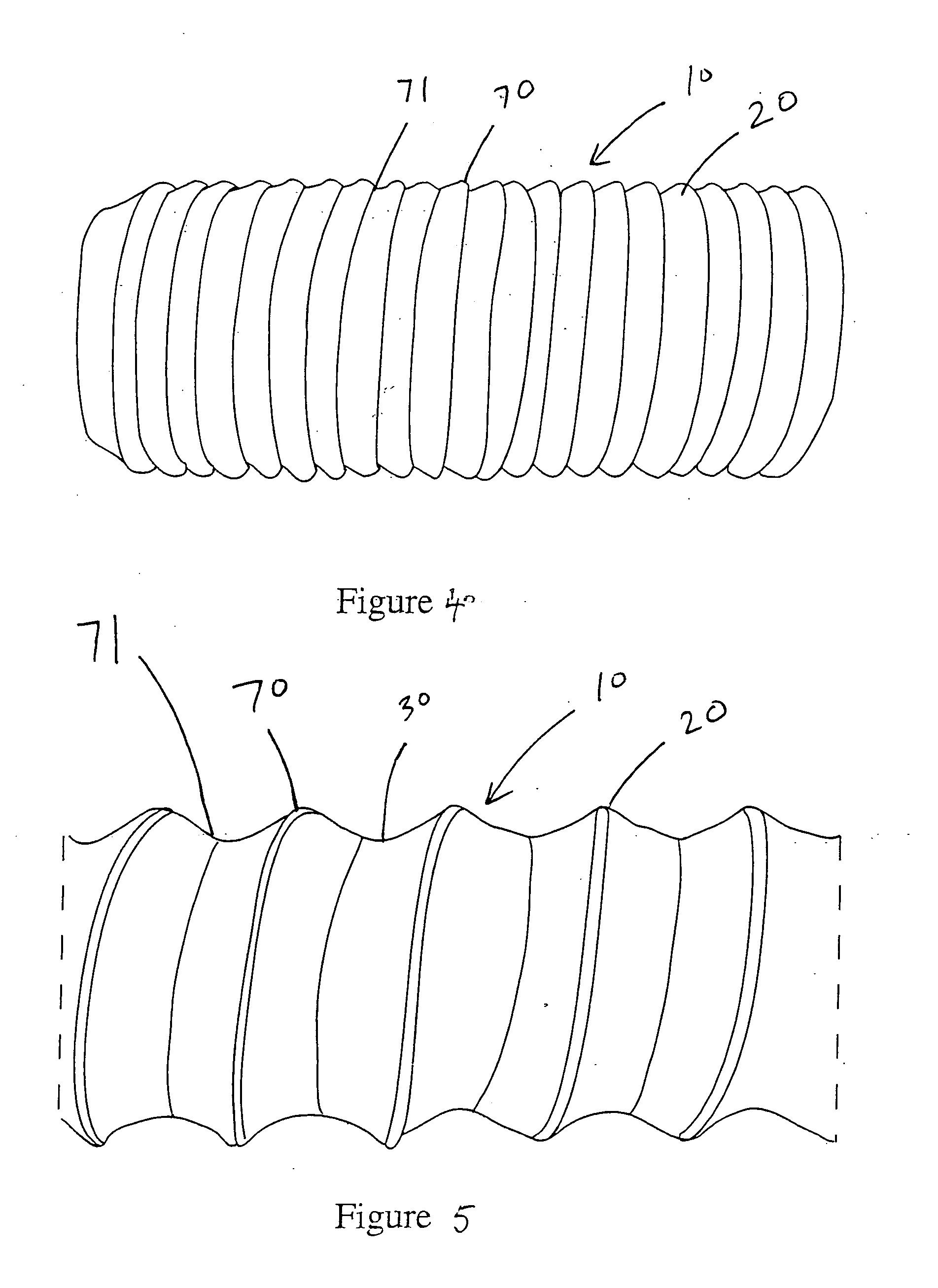

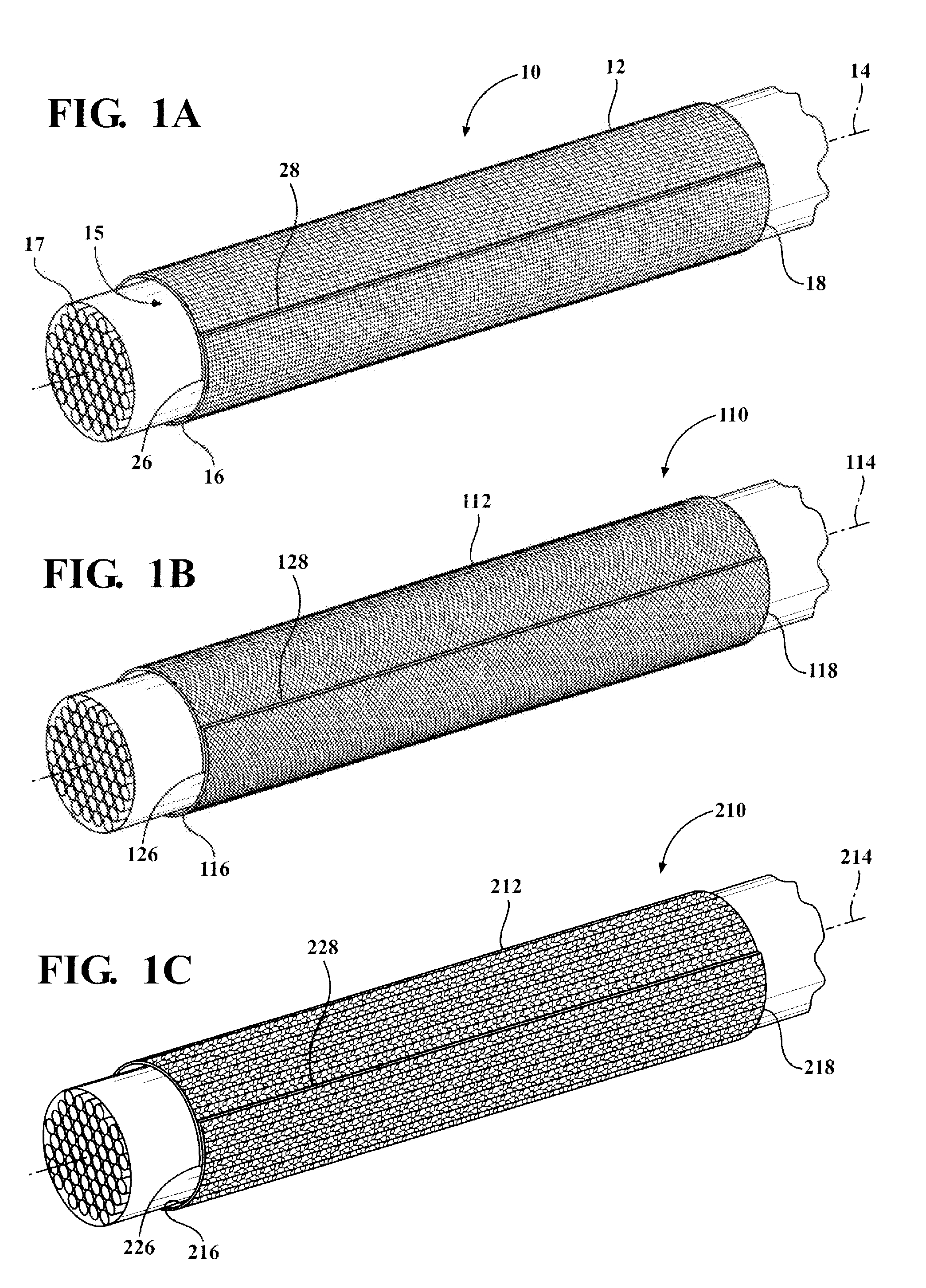

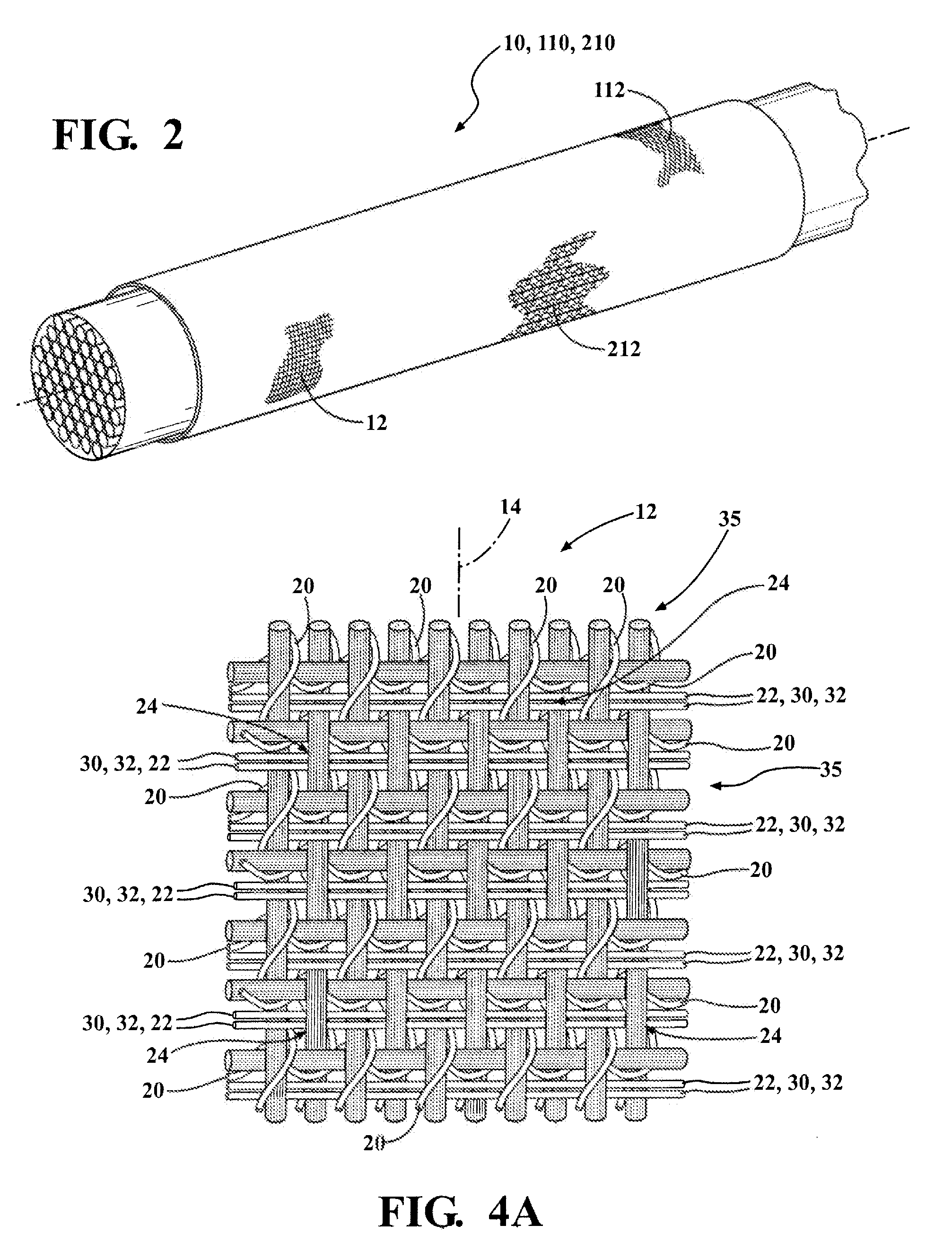

Electrical stretch hose

InactiveUS7520302B2Low costEasy to manufactureSuction cleanersInsulated cablesElectricityEngineering

The present invention is an electrical extensible hose that includes an outer shell, an inner core and at least one helical wire, which acts like a skeleton. In the present invention one implemented an additional wire that was conductive. The outer shell and inner core of the present invention may be bonded together via heat fusion. The helical wire is attached to the inner core via heat fusion. The helical wire supports the outer shell and inner core so as to form a tube. The outer shell and the inner core have a portion that forms an angular fold and have a portion that remains fixed. The second wire is attached at a point below the fixed portion of the electrical stretch hose so as to allow for maximum constriction caused by the shrinkable force created by the helical wire, thus increasing the stretch ratio of the hose.

Owner:FLEXIBLE TECH INC

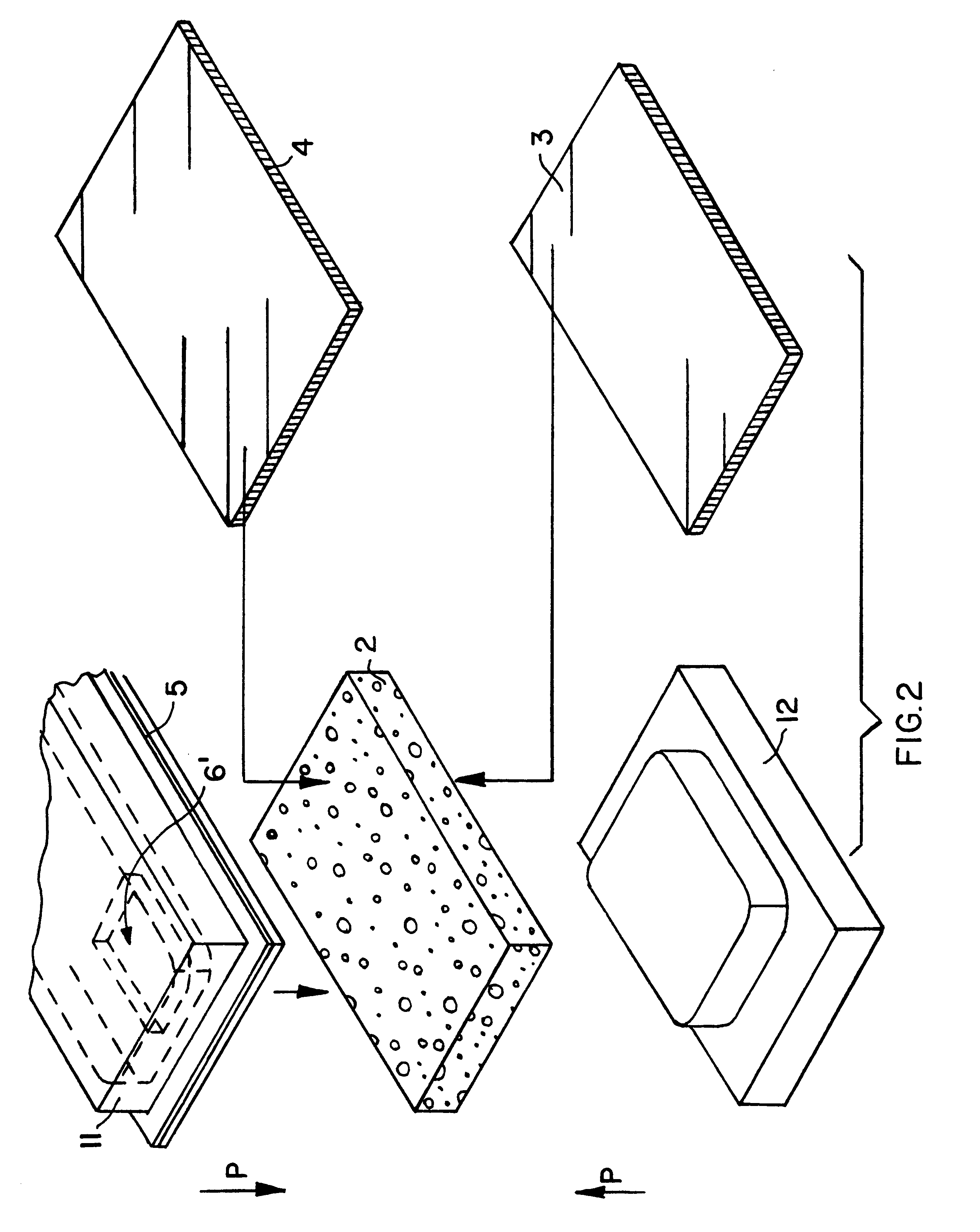

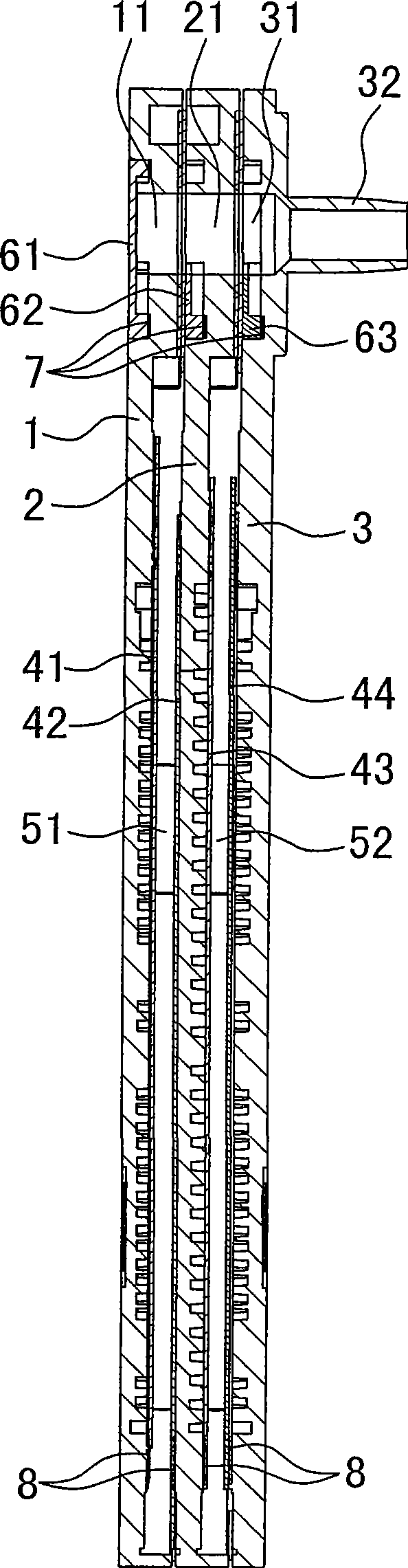

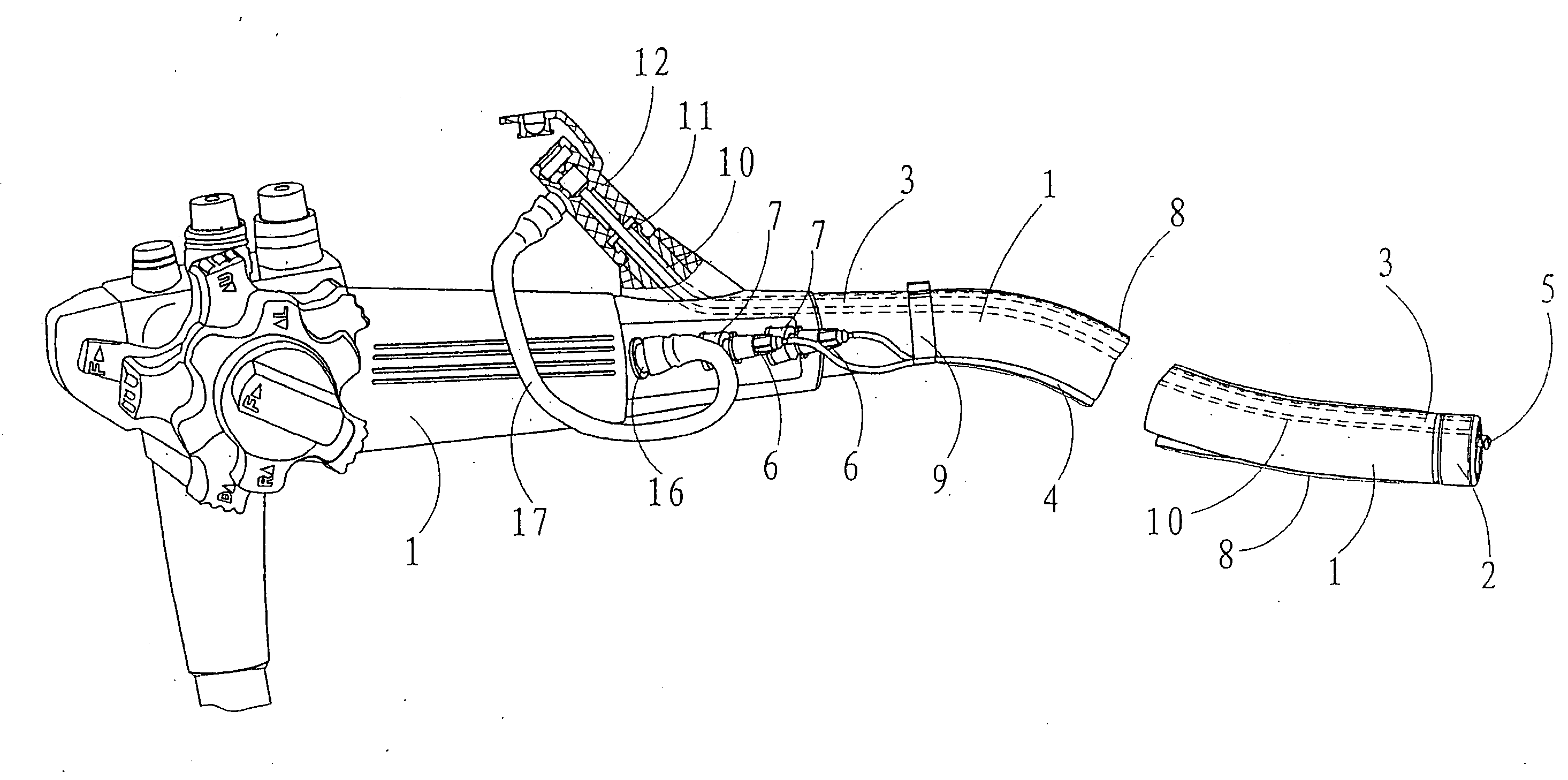

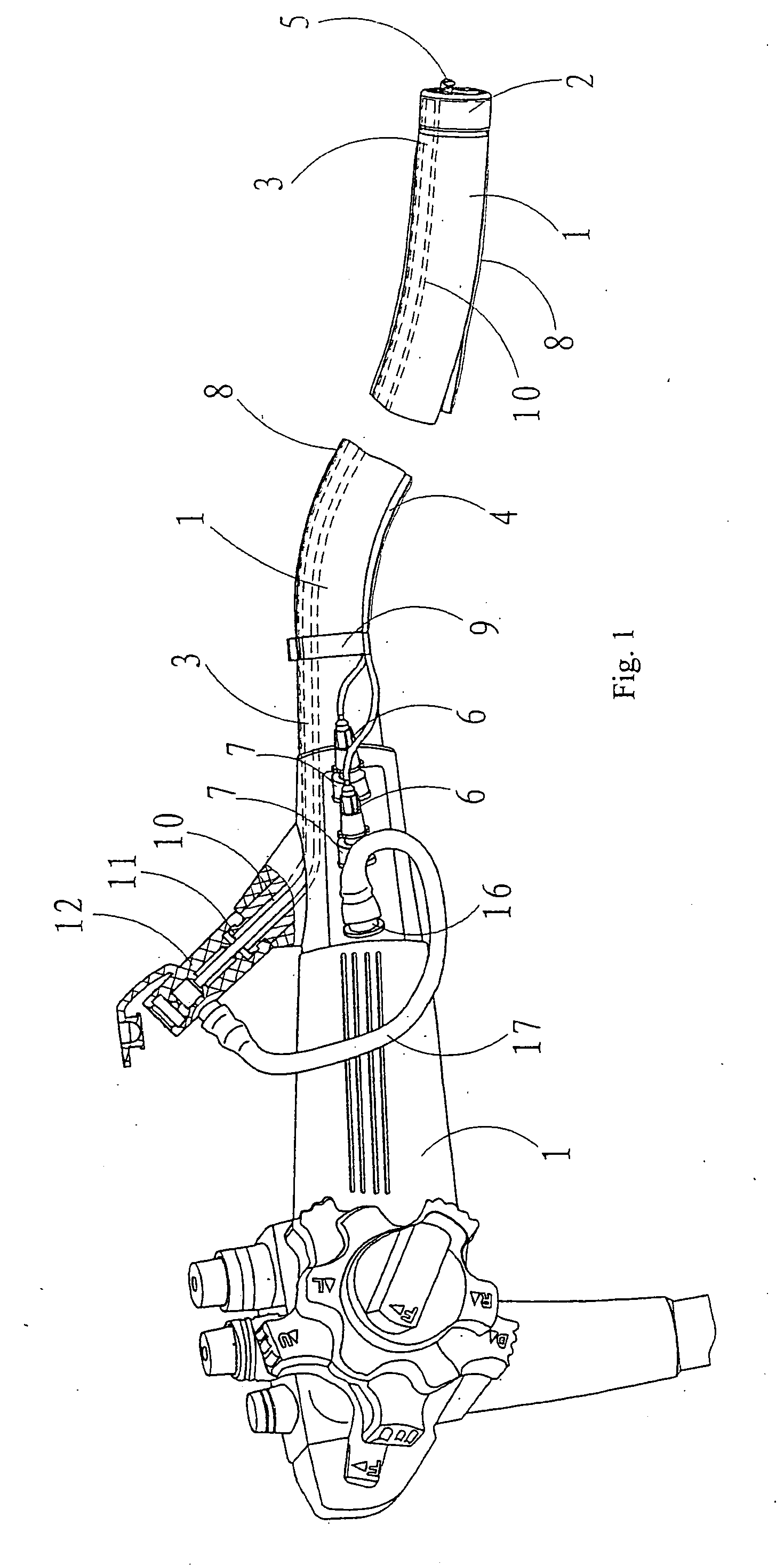

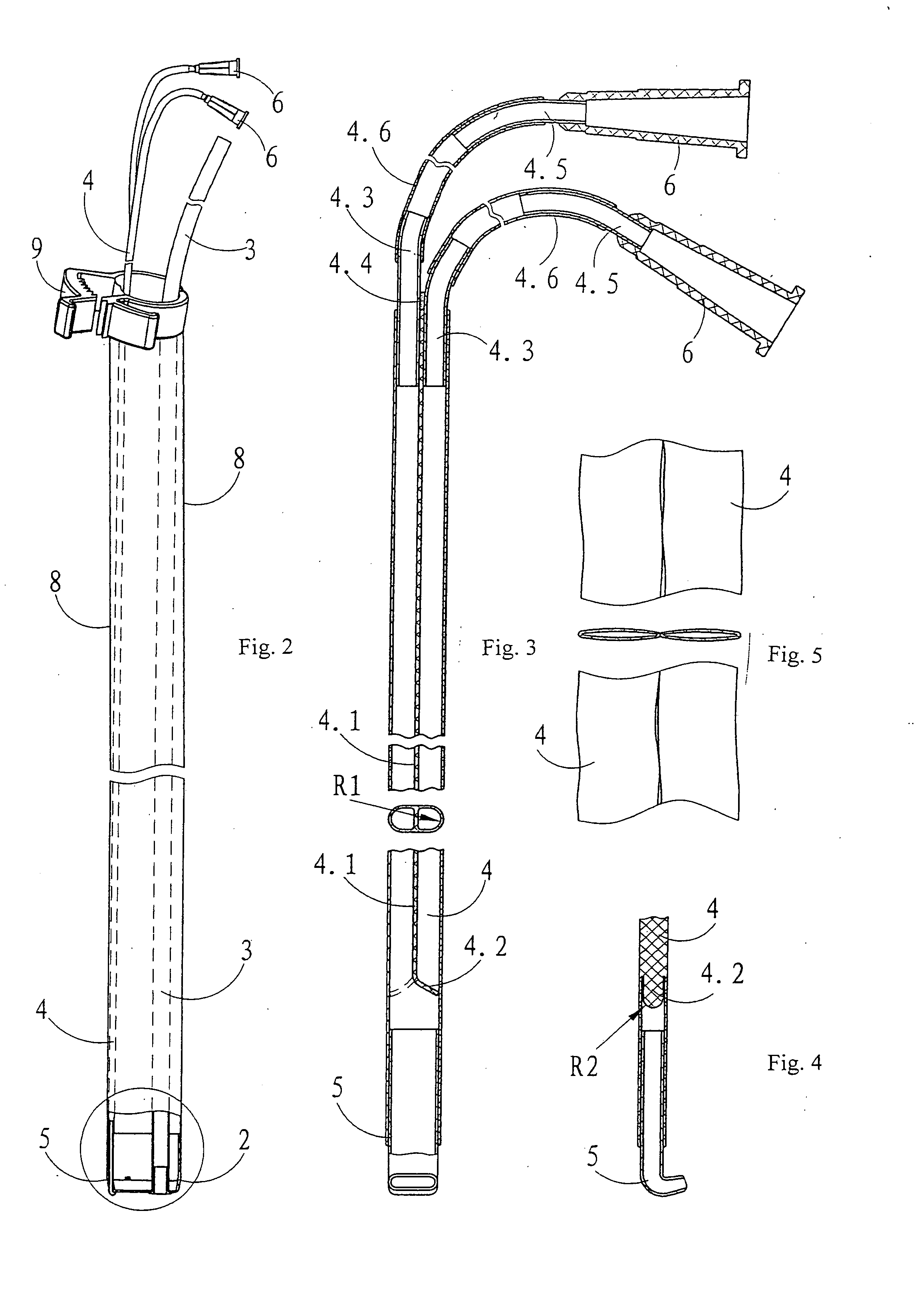

Endoscope System with a Disposal Sheath

InactiveUS20080249362A1Reduce spacingDecrease reflected complicated lightSurgeryEndoscopesCatheter blockageFlexible endoscope

The purpose of this invention is absolute elimination of medical cross-infection by endoscopy. It offers an endoscope system with a disposal sheath. The disposal sheath via anterior end cap connects the capsule which covers the outside of the endoscope and the disposal channel which sheathe in the endoscope channel and the fluid-air channel, and all these parts are joined together in a whole body. After the disposal channel is passed through the endoscope channel, its posterior disposal channel can be blocked into the elastic sealing cap via the guide tube, the posterior disposal channel's orifice need to be heated and melted and cut up simultaneously and its cut edge is in shape of V-shape by using one kind of heat fusion forceps after the use and before the retracting from the endoscope channel. A fluid-air exit and a sucking channel adapter are set on the posterior endoscope, convenience to connect with the fluid-air channel and the three-way sealing cap, the fluid-air channel may be single cavity channel or double cavity channel or two single cavity channels join in one channel together at nearing jet channel site, the channel sizes may be cylinders, or flat sizes. Both the outer surface of the endoscope and the inner surface of the endoscope channel are protected from pollution by the disposal sheath, thus ensures patients to safely use the permanent endoscope.

Owner:JIANG KERANG +1

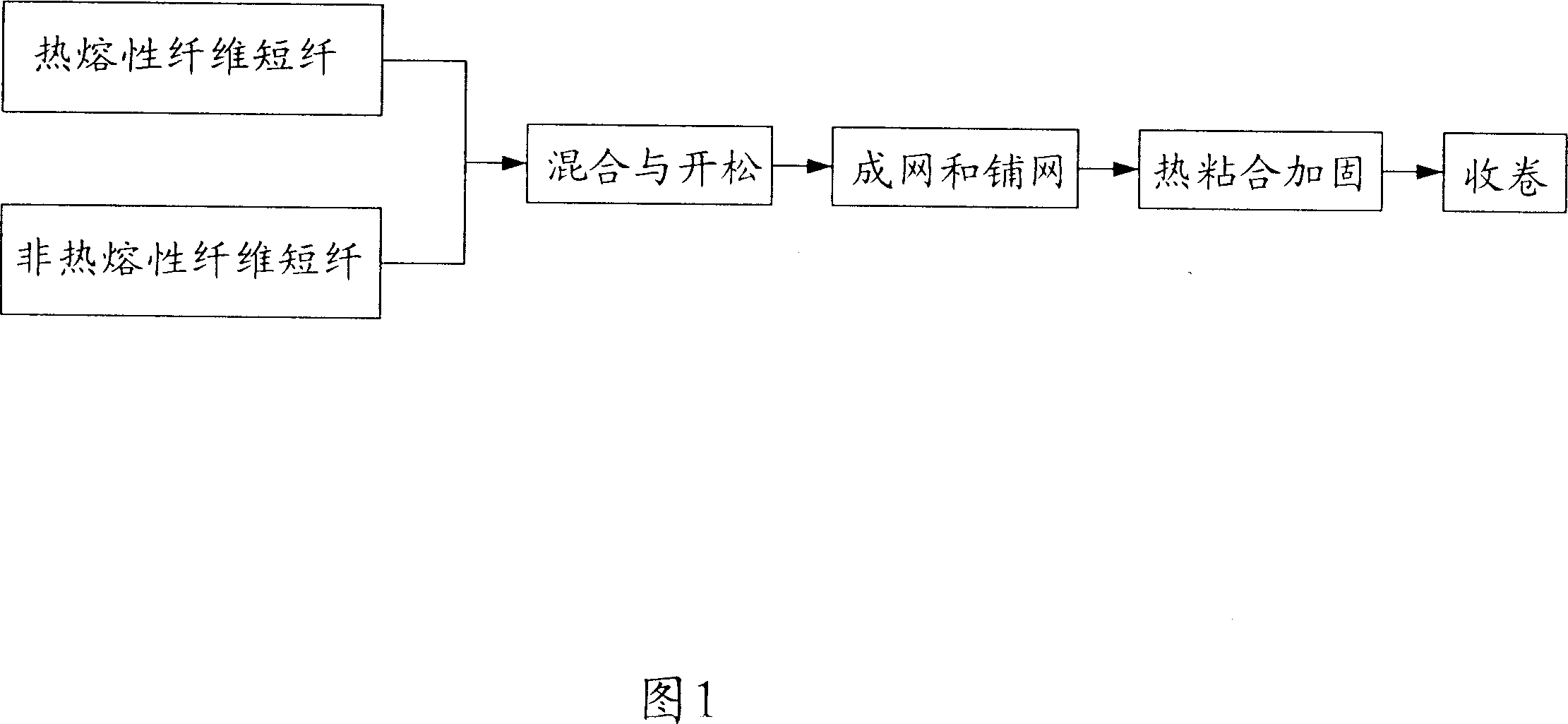

Nonwovens and machining method thereof

The invention discloses a non-woven cloth and relative production, wherein the non-woven cloth is formed by non-hot-melt staple fiber whose mass content is not lower than 30% and hot-melt composite staple fiber, via thermal adhesive fixing method. And the invention utilizes the character that the surface of the hot-melt composite staple fiber has heated fusion function, and the invention uses thermal adhesive fixing method to fuse the face of hot-melt composite staple fiber to adhere the non-hot melt staple fiber to form non-woven cloth, therefore, the produced non-woven cloth has damp adsorption property, soft property, and flexibility, without sensibility on human body. And the invention utilizes the hot-wind non-woven device or thermal rolling non-woven device with low energy consumption and low cost.

Owner:谢继华 +1

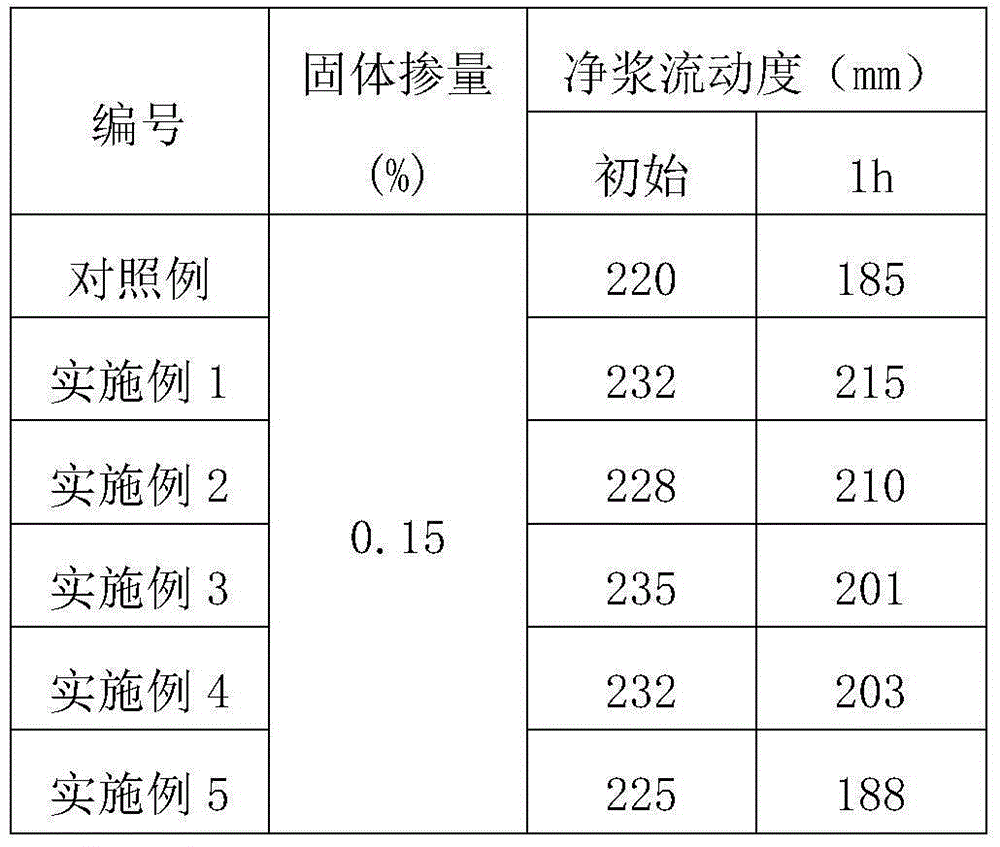

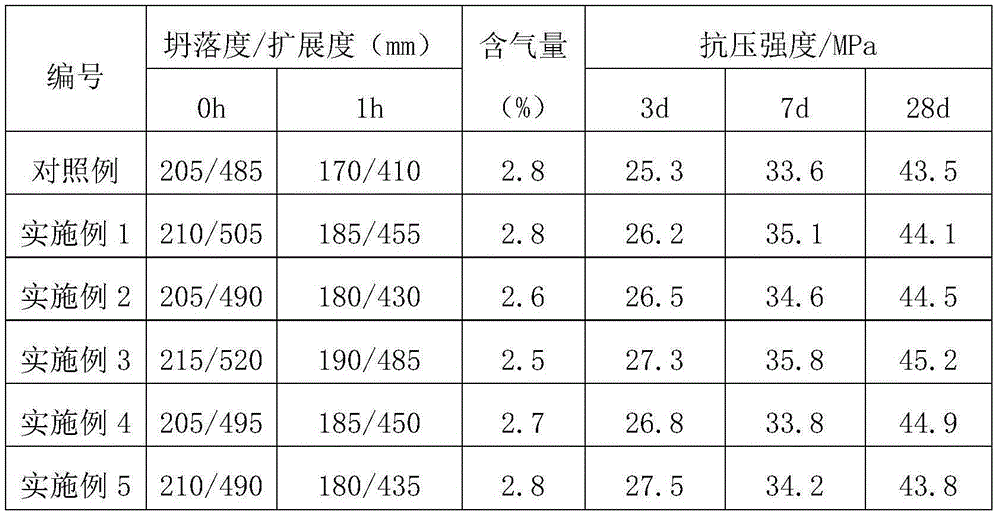

Preparation method for high performance water reducer made from high water reducing solid polycarboxylic acid

The present invention relates to a preparation method for high performance water reducer made from high water reducing solid polycarboxylic acid. The prepartion method specifically comprises the following steps: performing heat fusion on two unsaturated polyoxyethylene ether composite macromonomers with different molecular weights; then dropwise adding a mixed liquid of an unsaturated carboxylic micromonomer, an unsaturated amide micromonomer and a chain transfer agent under the reaction of an initiator; and preparing the water reducer through a free radical polymerization reaction, and after the reaction, using a neutralizing agent to adjust a pH value to 5-6 and then cooling and grinding the water reducer in a solid particulate shape. The preparation method provided by the present invention has advantages of being simple in process, high in conversion rate and environmental-friendly and free of pollution, and has the characteristics of high water reduction and low adulterate amount in concrete and dry-mixed mortar, and the transportation cost in long distance transportation is greatly lowered.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

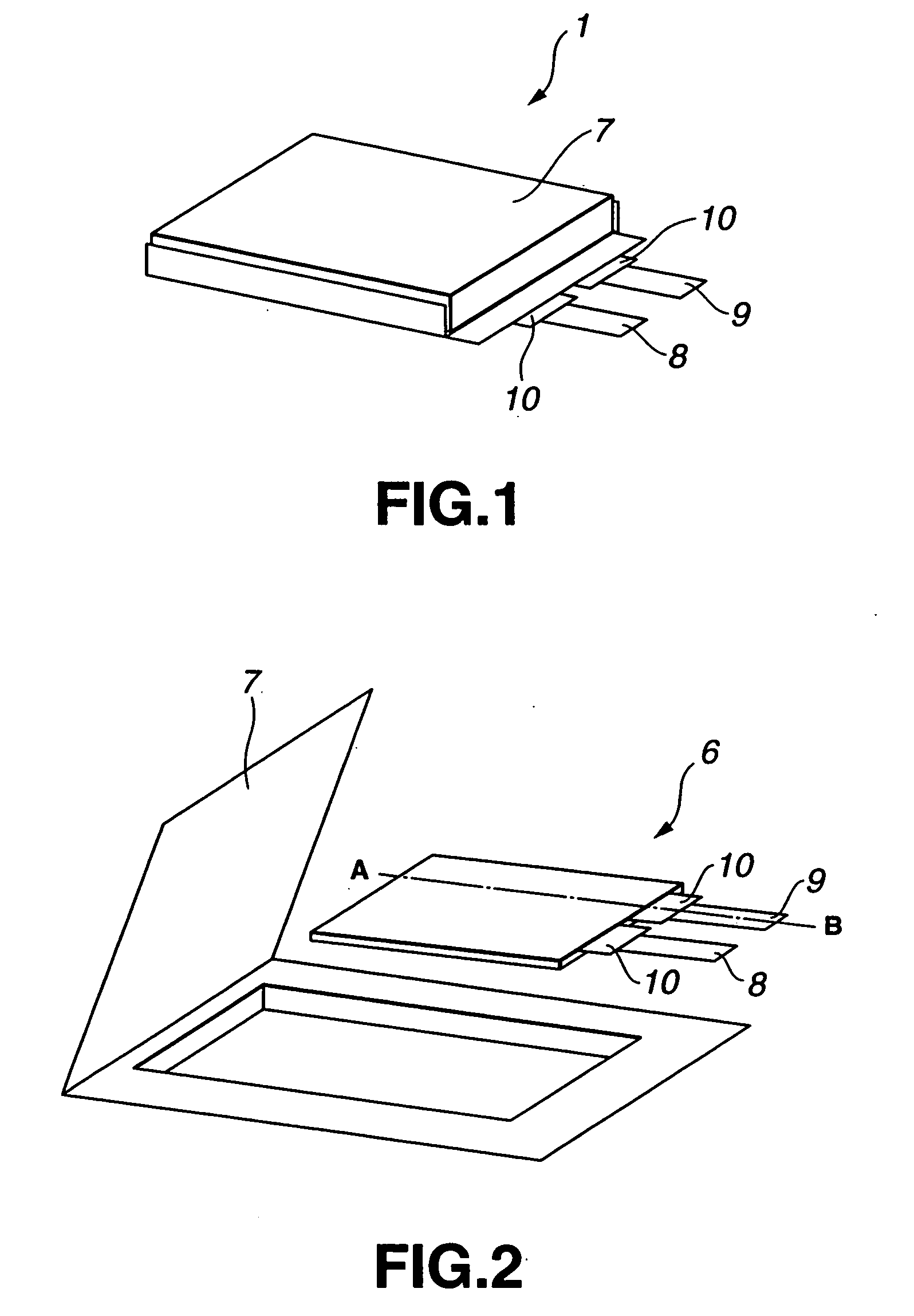

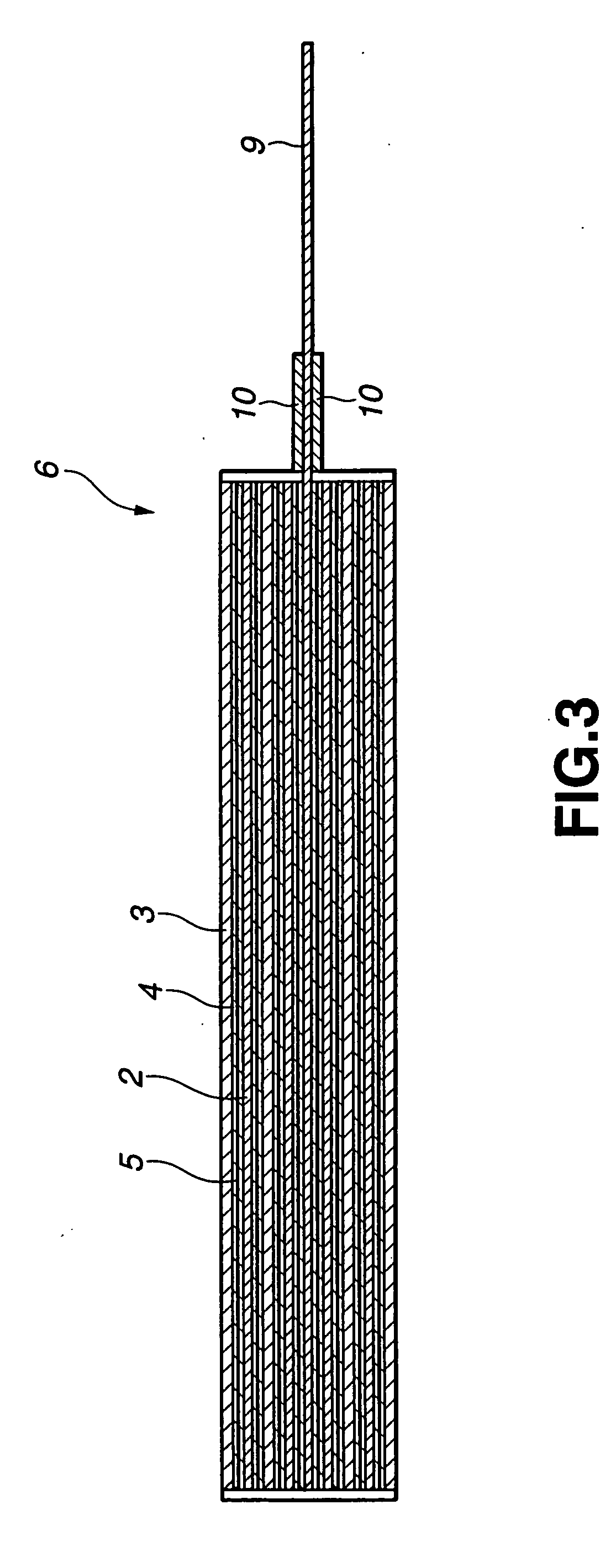

Light emitting device

A light emitting device in which a bonding pad is soldered to a mounting substrate, wherein the bonding pad may be formed in various shapes that can minimize the occurrence of voids during soldering or heat fusion.

Owner:SEOUL VIOSYS CO LTD

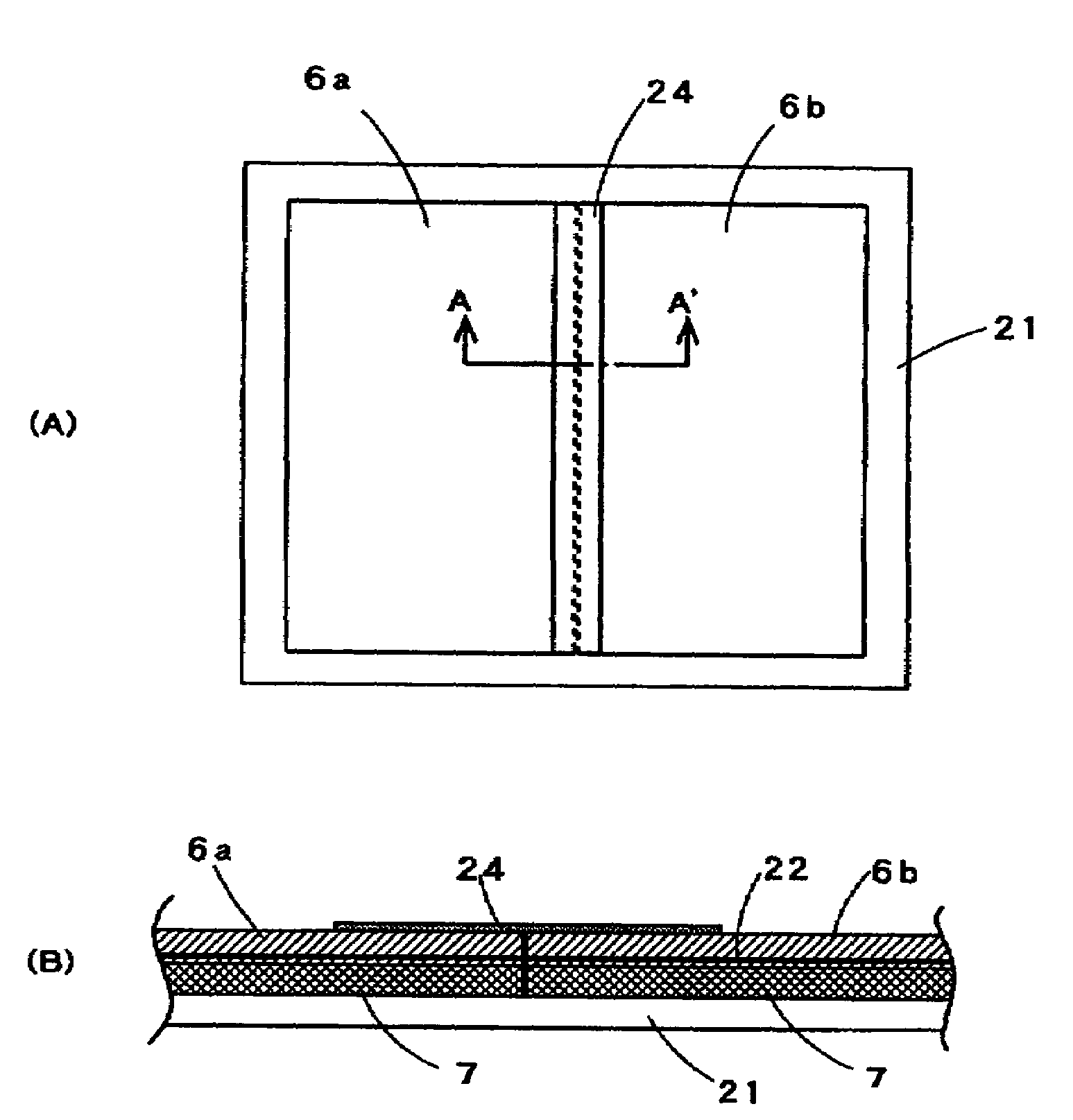

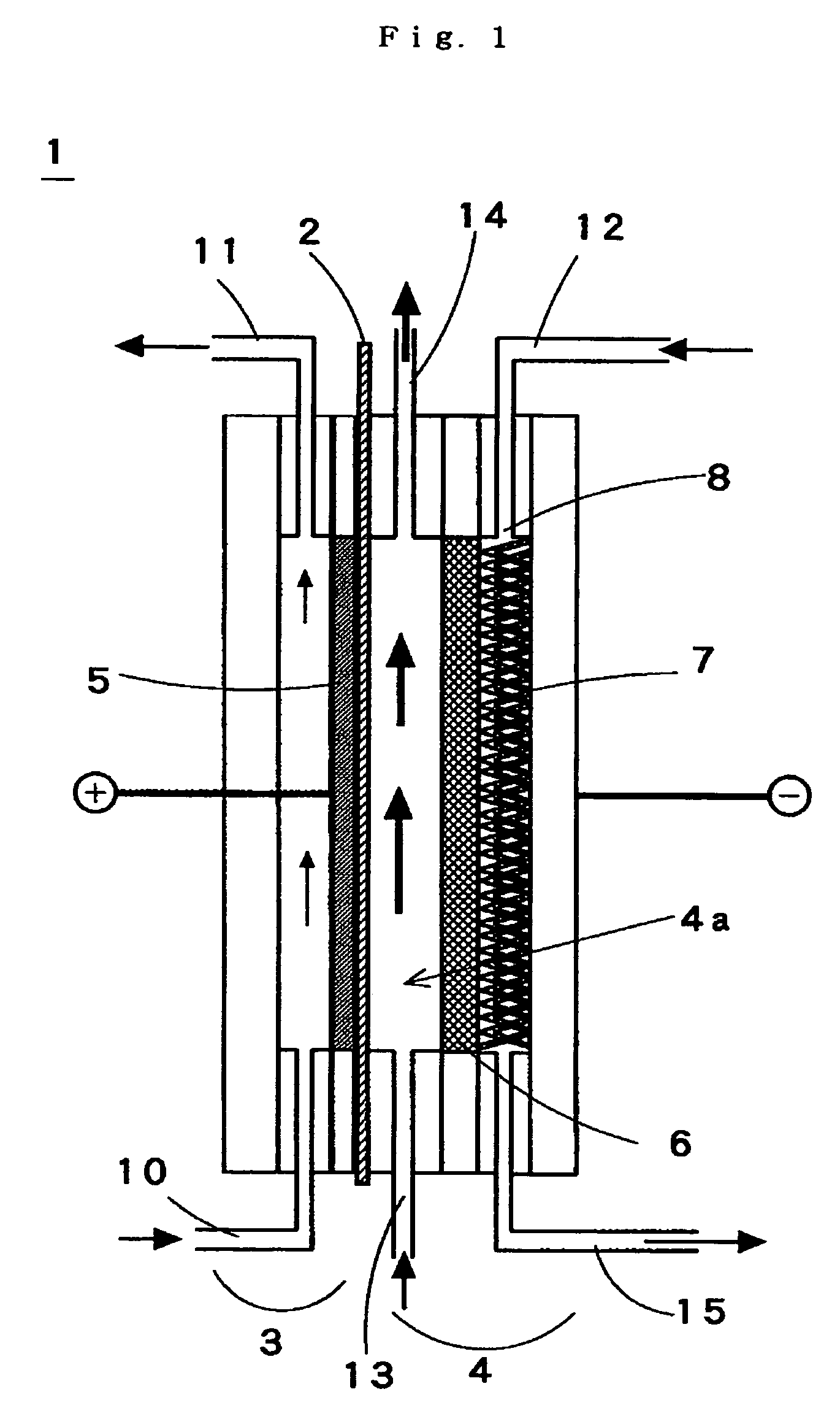

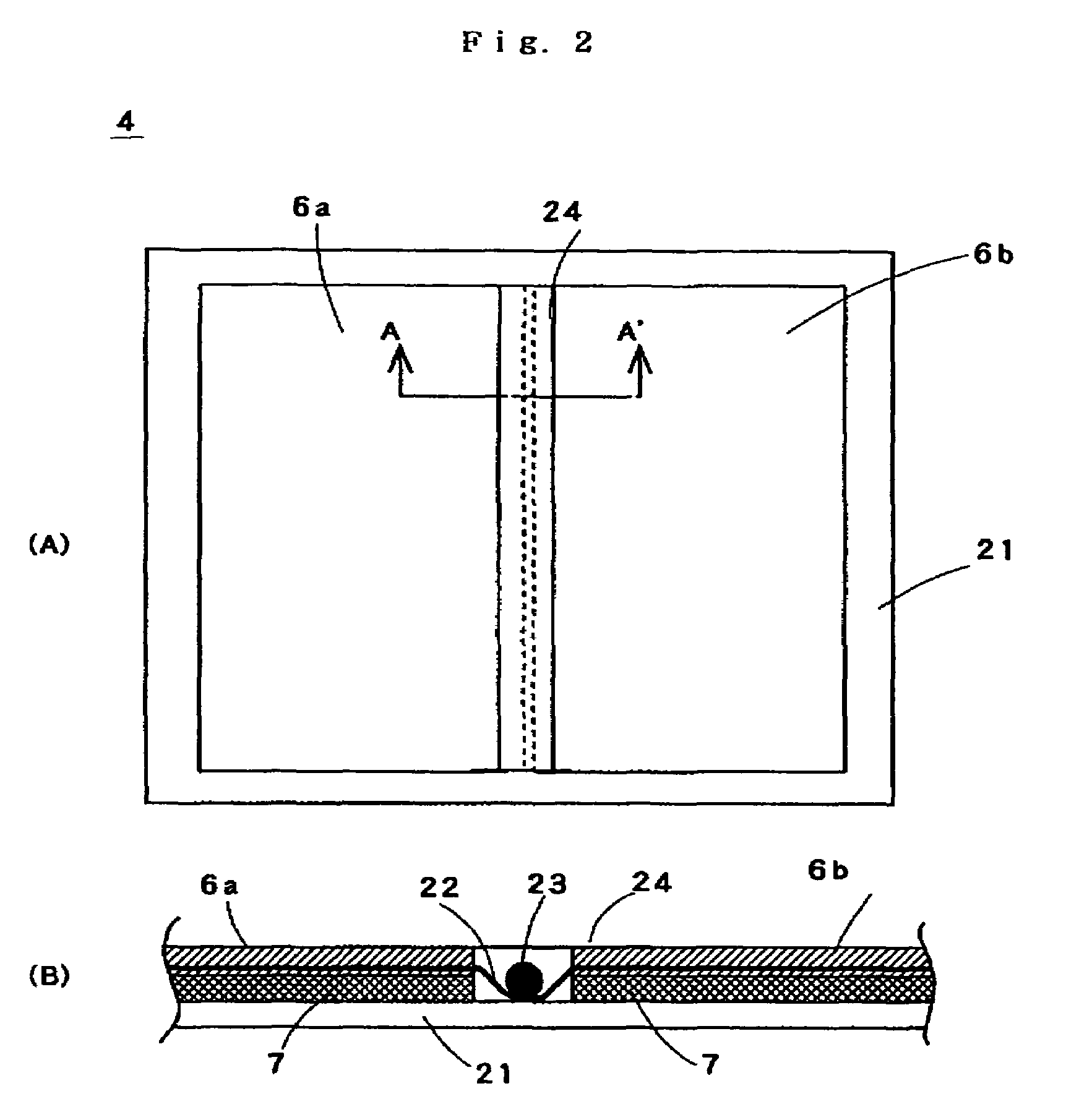

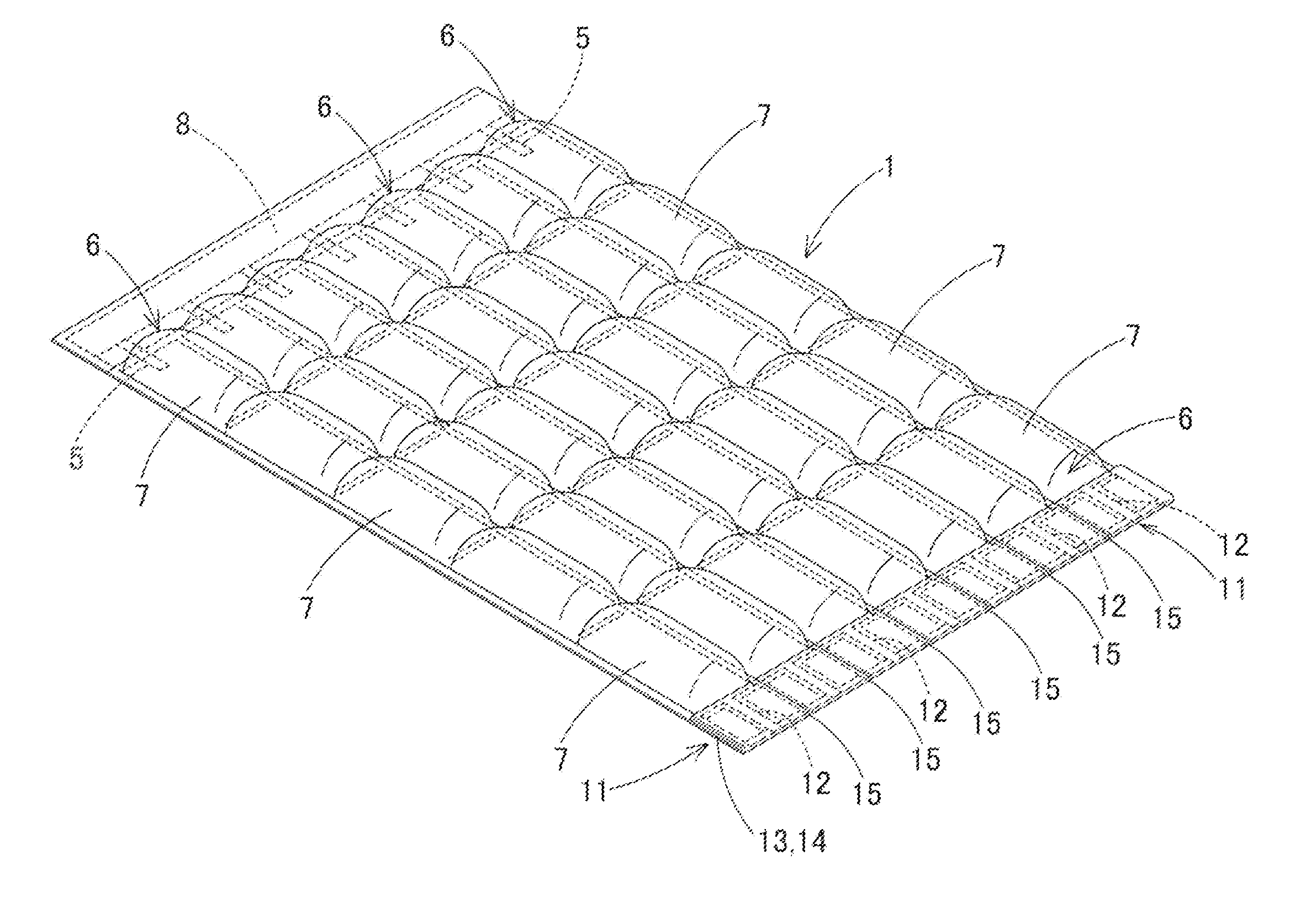

Gas diffusion electrode assembly, bonding method for gas diffusion electrodes, and electrolyzer comprising gas diffusion electrodes

In a gas diffusion electrode assembly, and in an electrolyzer using the same, a bonding piece having on at least one surface a perfluorosulfonic acid layer, a perfluorosulfonyl fluoride layer or an alkyl ester of perfluorocarboxylic acid layer is positioned at its perfluoro compound layer surface with respect to the gas diffusion electrode assembly. Adjacent gas diffusion electrodes are heat fusion bonded together, or heat fusion bonding is carried out using the bonding piece in a frame form. Adjacent gas diffusion electrodes are sealed up by heat fusion bonding, using a material that is similar to the material that forms the gas diffusion electrodes.

Owner:AGC INC +8

Exhaust valve apparatus and gas filled cushion

InactiveUS20160058218A1Easy dischargeEasy to usePaper/cardboard articlesDomestic upholsteryCushioningExhaust valve

A gas cushioning material preserved by easily discharging a gas from a bag part and used by filling the bag part with the gas when used again is provided. Gas cells are disposed in parallel in a gas cell row by forming heat-fusion parts in the transverse direction. A discharge valve part for discharging gas is formed at an end portion of each gas cell row. A narrowed discharge passage is formed in the discharge valve part. When the bag part is filled with a gas, the discharge valve part is bent to close the discharge passage, and in the state in which the discharge valve part is bent, a first surface fastener and a second surface fastener formed on a front surface and a rear surface of the discharge valve part are coupled to each other to maintain a closed state of the discharge passage.

Owner:YOSHIFUSA KATSUTOSHI +3

Epoxy matrix resin and prepreg and preparation method thereof and device for preparation thereof

The invention discloses an epoxy matrix resin, a prepreg, a preparation method of the prepreg and a device for preparation of the prepreg, in order to solve the problem of poor performance of an epoxy matrix resin curing substance caused by uneven toughening phase state even no phase separation in the traditional epoxy matrix resin curing product, the problem of complex technique of the traditional preparation method of the prepreg and relatively imprecise control on the resin content in the prepreg, and the problem of high manufacturing cost of the traditional device for preparing the prepreg. The epoxy matrix resin is prepared from a phenolic epoxy resin, a bisphenol A epoxy resin, a core shell polymer, a curing agent and a curing accelerator; the prepreg is prepared from the epoxy matrix resin and fiber woven cloth; and the prepreg is prepared through the device for producing the prepreg by a heat fusion method. After and before the resin is cured, the toughening phase state is not changed and is uniformly dispersed; and the toughening phase state effect is good and stable. The mechanical property of the composite material obtained by curing with the prepreg is high.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

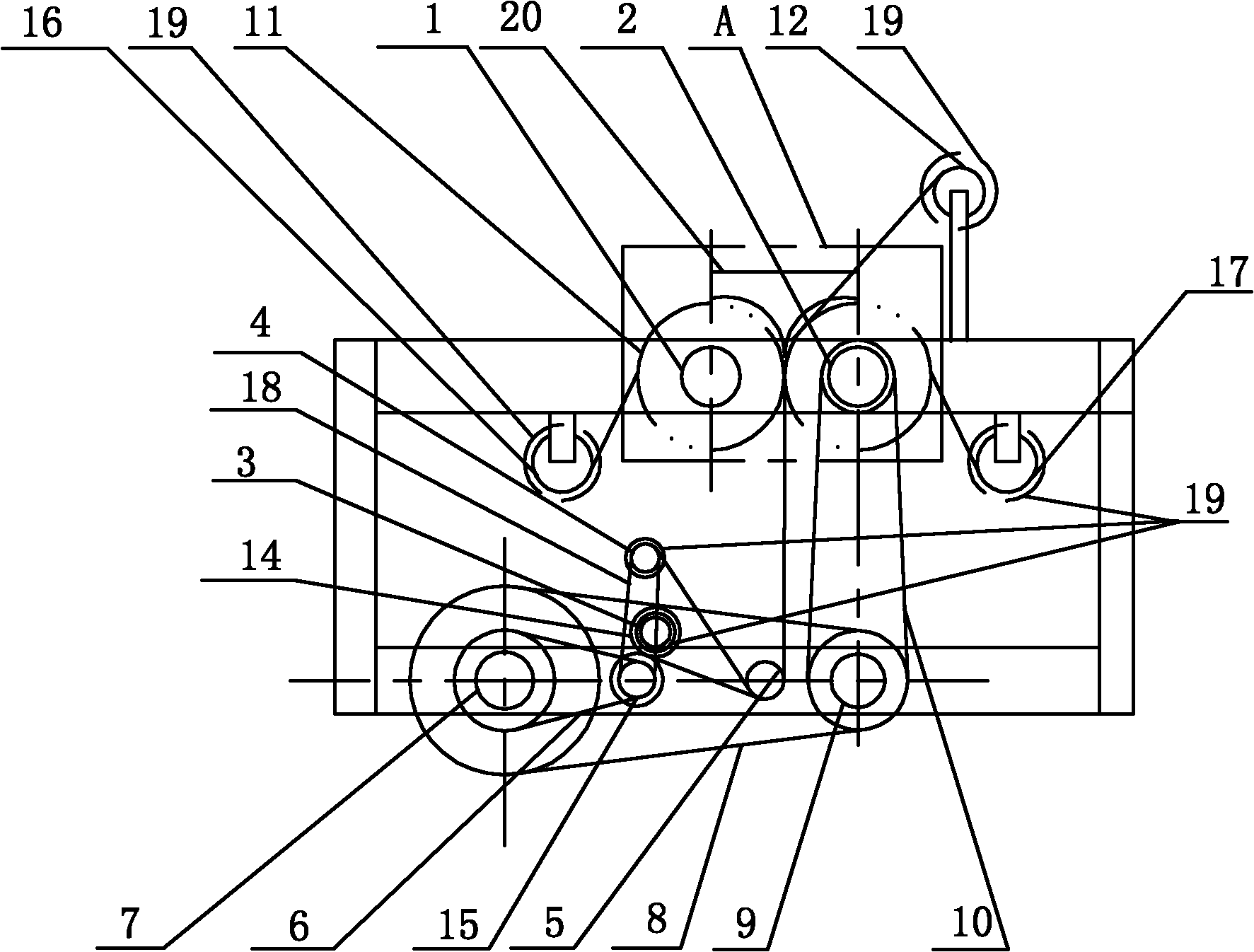

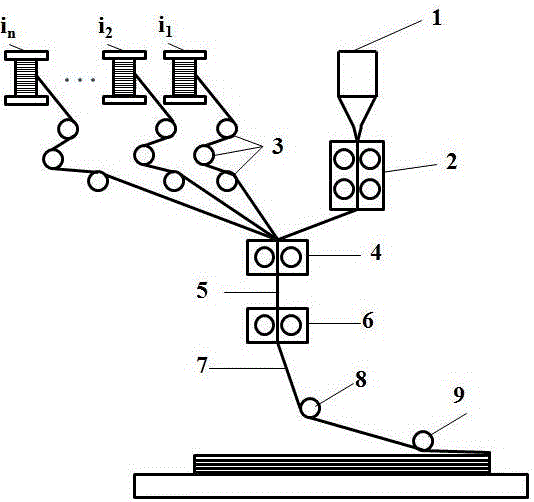

Three-dimensional printing forming method of long fiber thermoplastic composite material component

InactiveCN106515041AFully infiltratedEnhanced interface bindingAdditive manufacturing apparatusManufacturing material handlingYarnThermoplastic composites

The invention discloses a three-dimensional printing forming method of a long fiber thermoplastic composite material component, and belongs to the field of composite material forming technologies. A reinforced yarn is expanded as a thinner yarn strip, and is fully infiltrated with a drawn resin strip to form a single-layer prepreg yarn; the single-layer prepreg yarn is extruded by a shaping device to form a prepreg tow with appointed shape and size; and the prepreg tow is guided by a guide device to bond with a previous layer of composite material to form a composite material laminating structure after heating fusion by a compaction device. Through unfolding of continuous fibers and drawing of a basal body material, the method effectively improves the infiltration effect of the yarn and the resin so as to improve the interface bonding strength of the fiber and the basal body; the prepreg tow can be printed by any angle; and meanwhile, after the prepreg tow is compacted by the compaction device, the fiber volume fraction is prominently increased, so that the added material manufacturing of a high-performance composite material component with complex structure can be realized.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

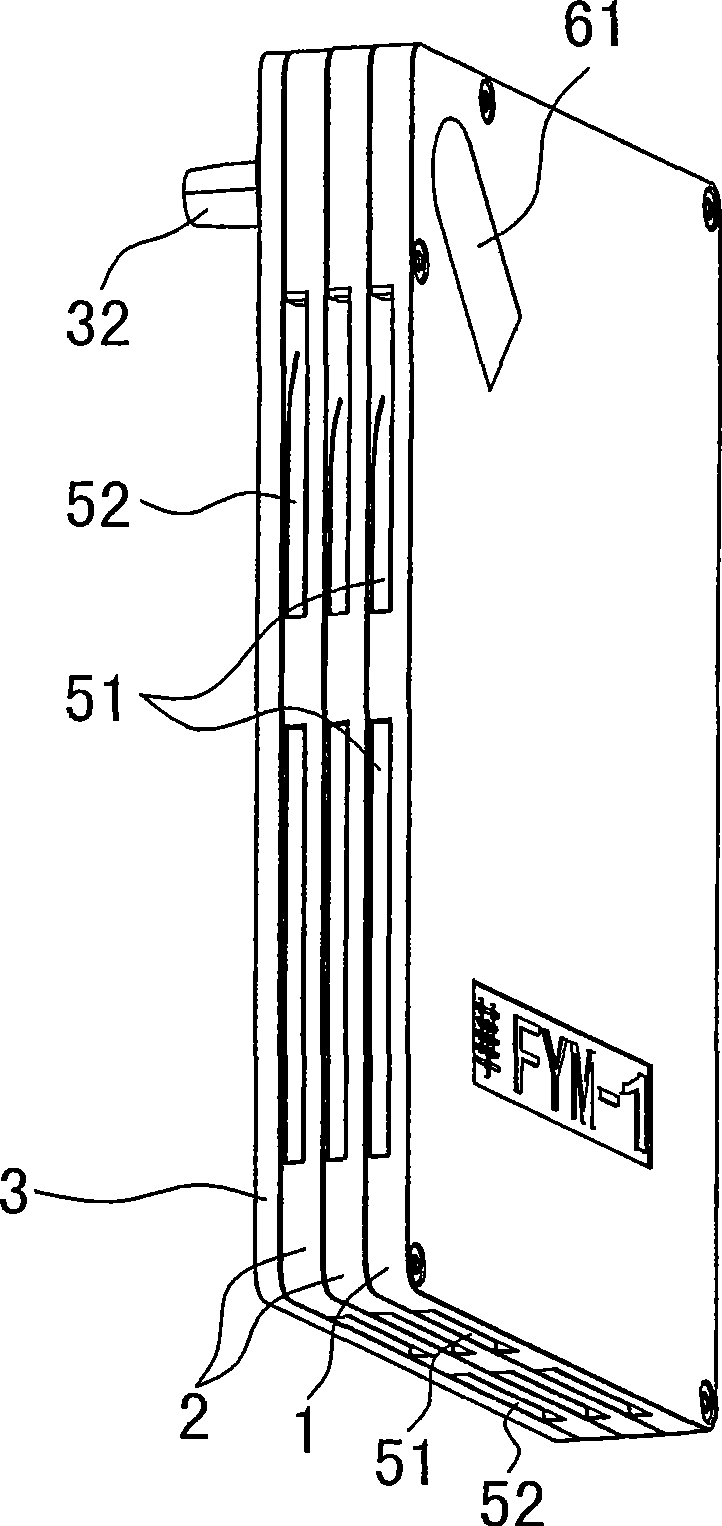

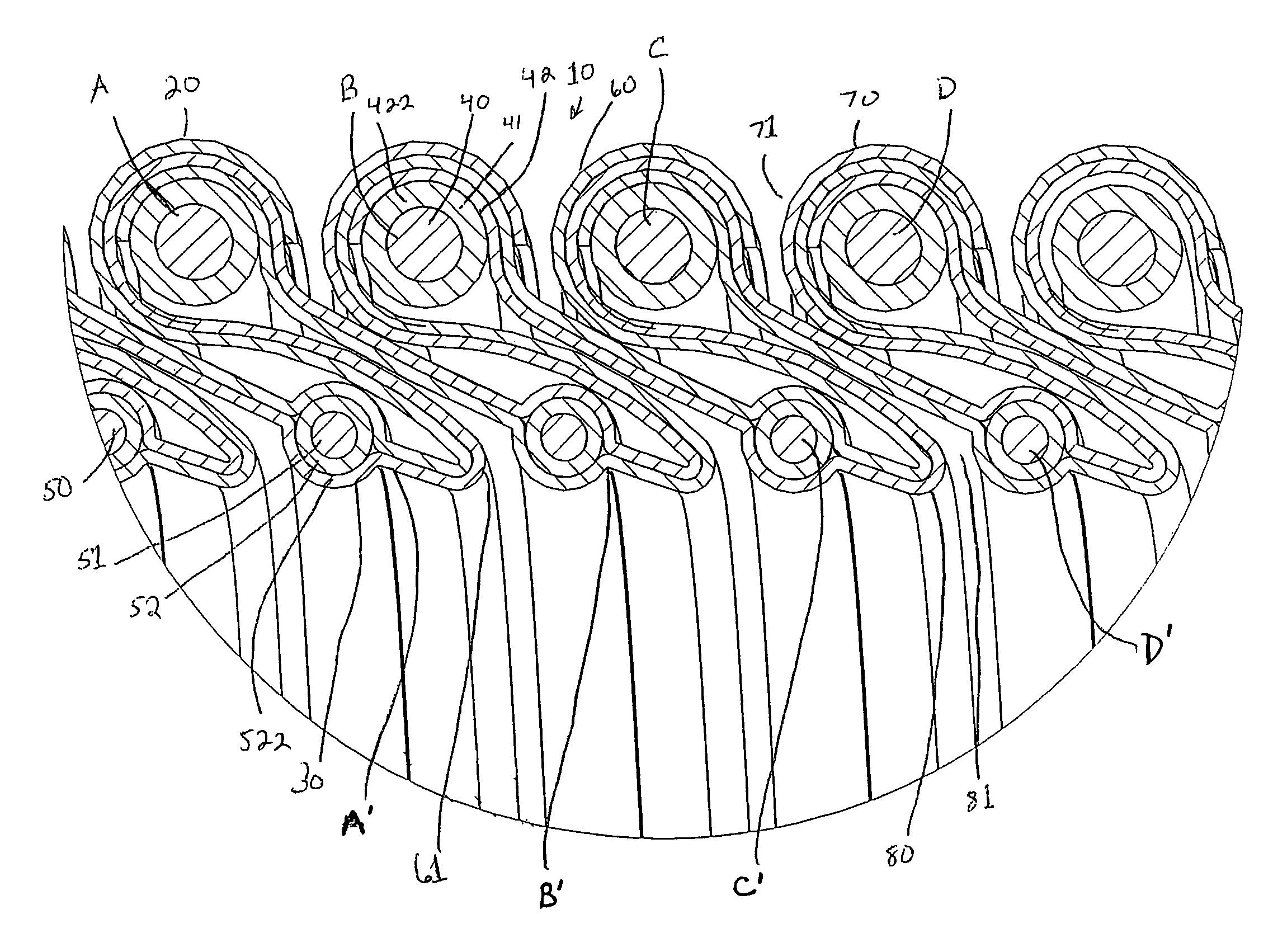

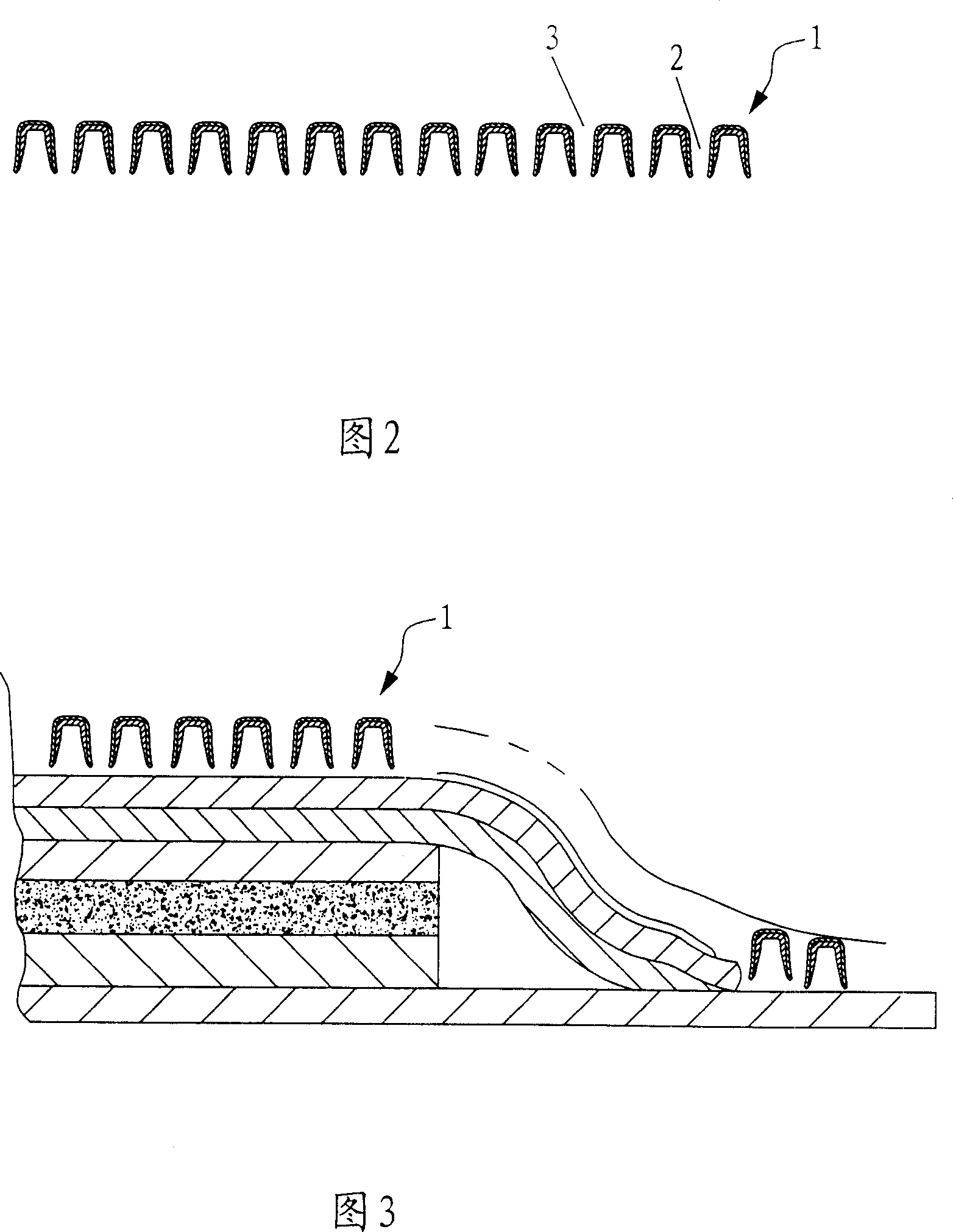

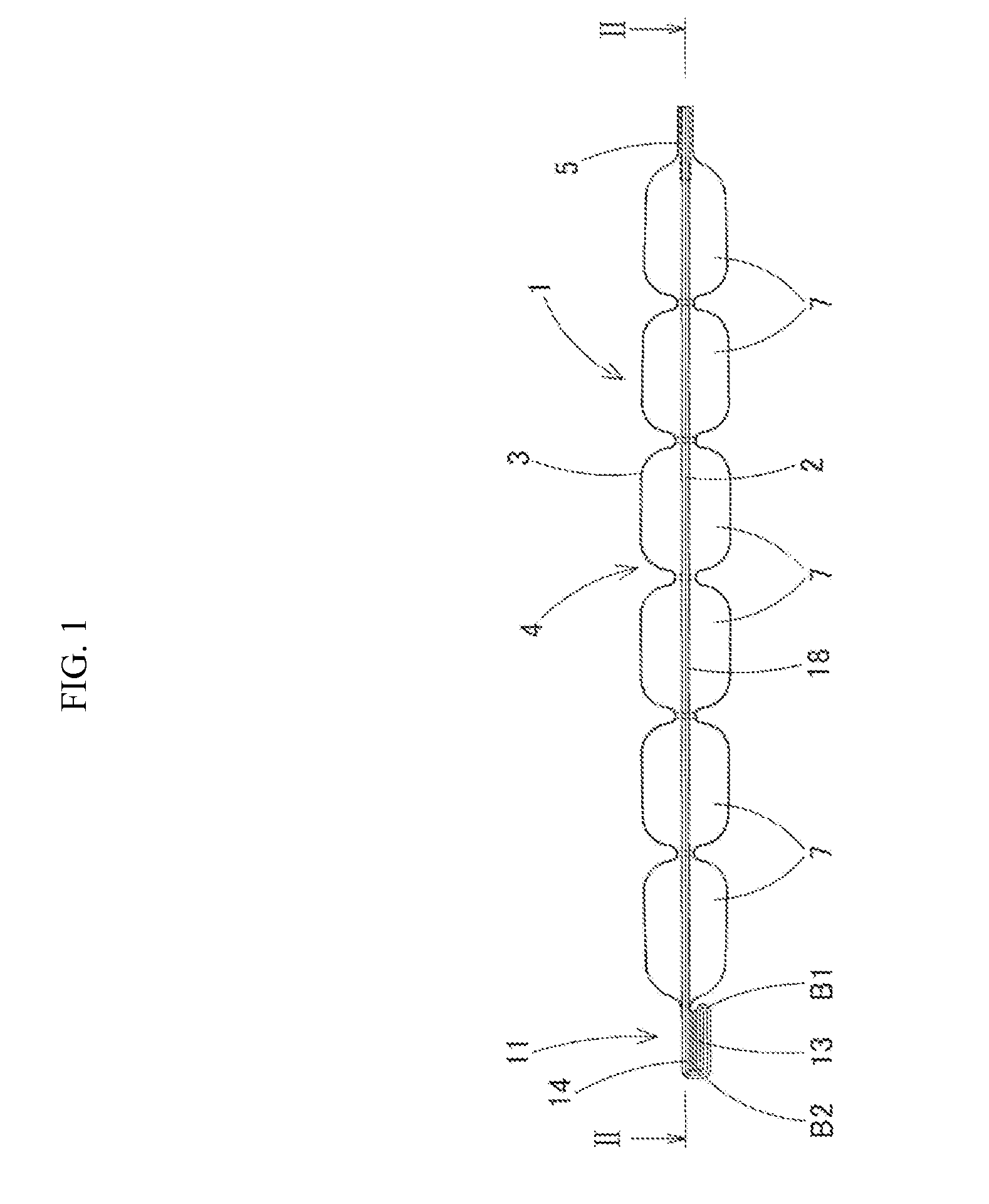

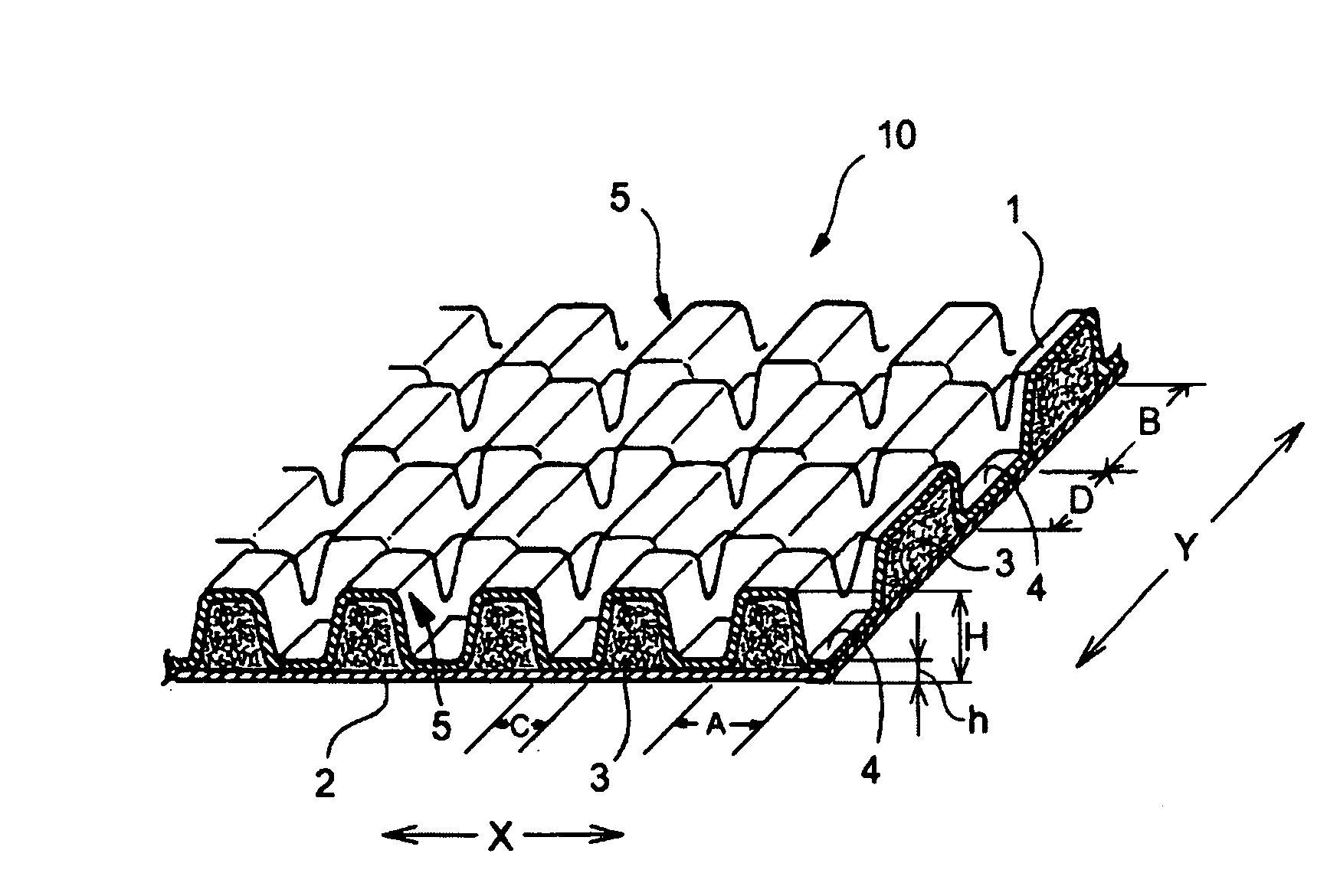

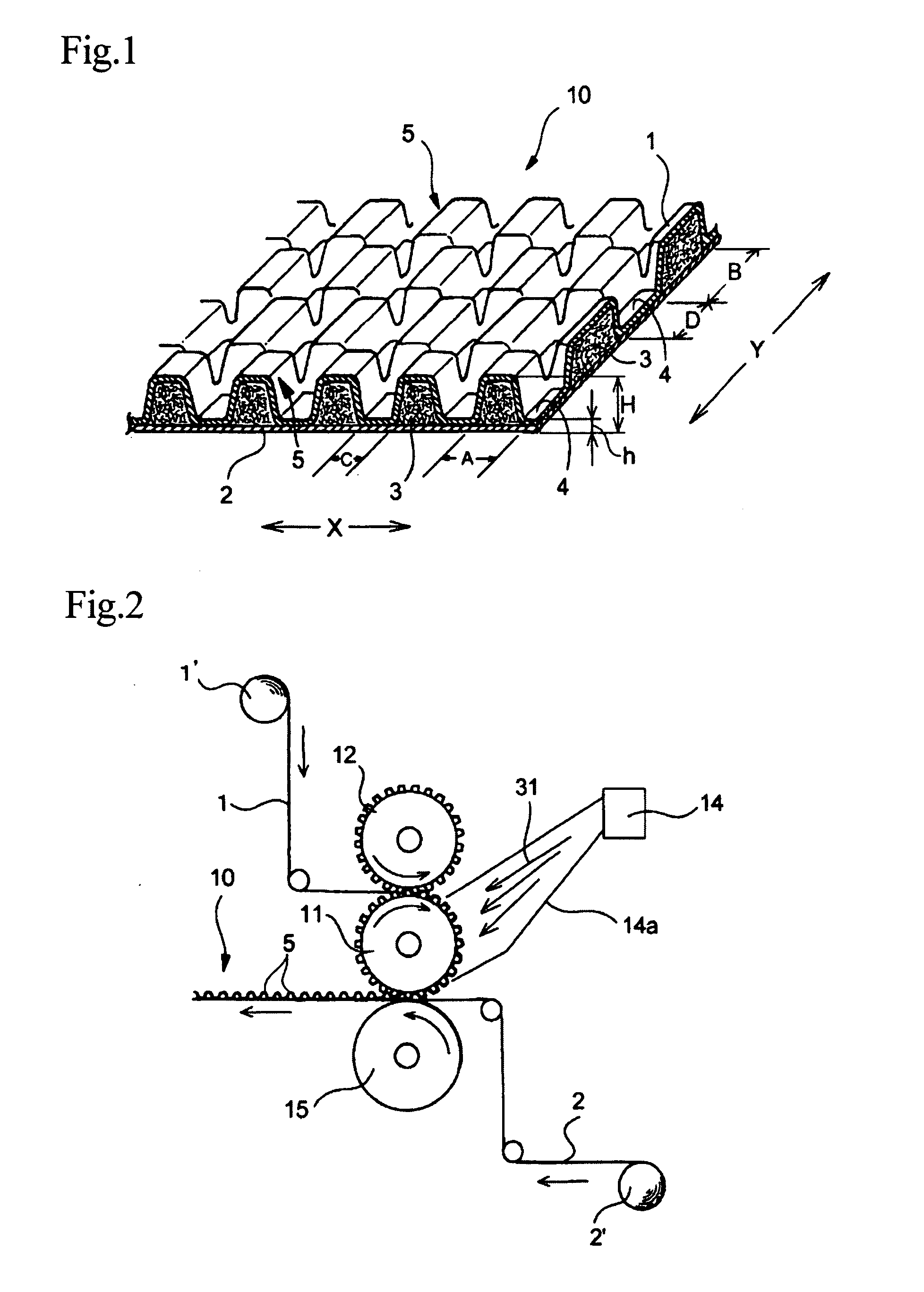

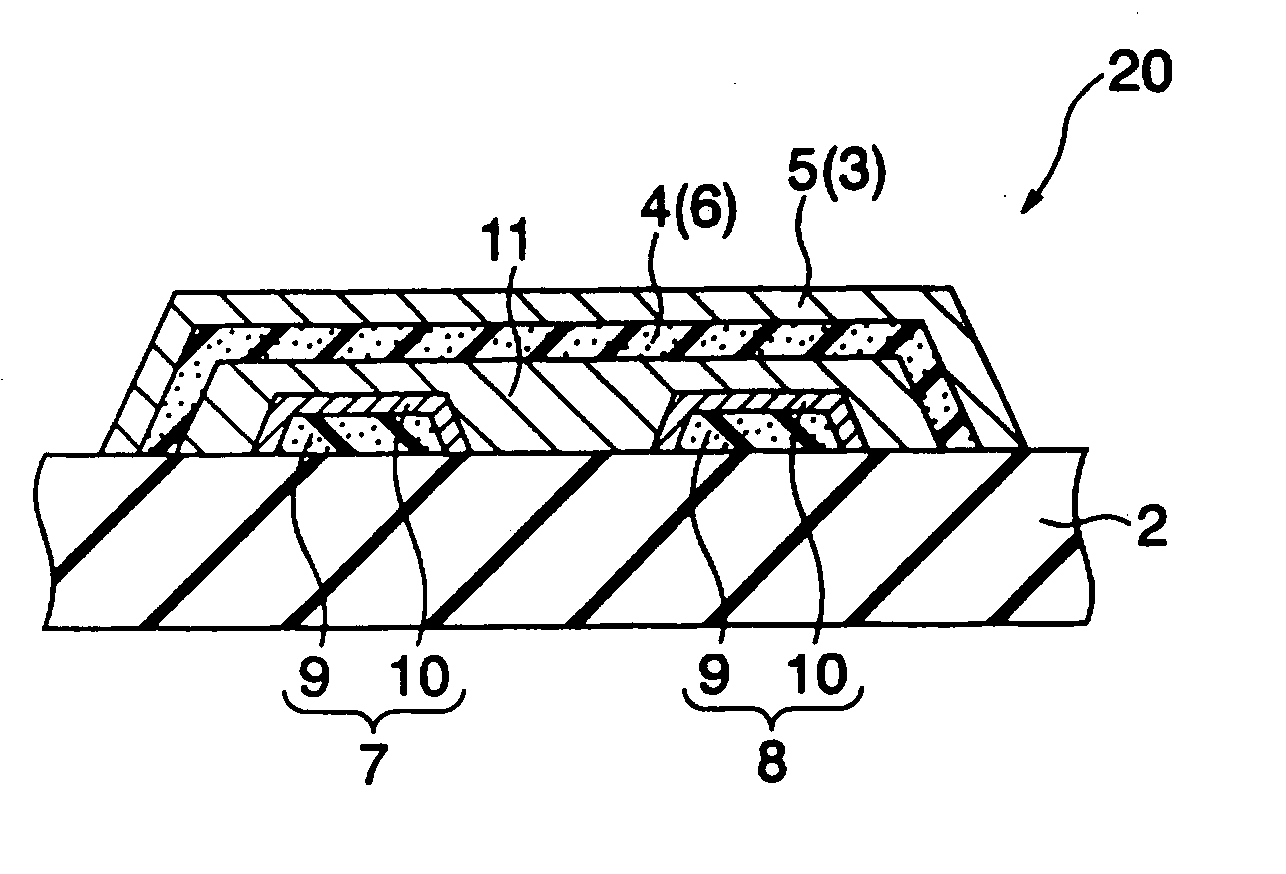

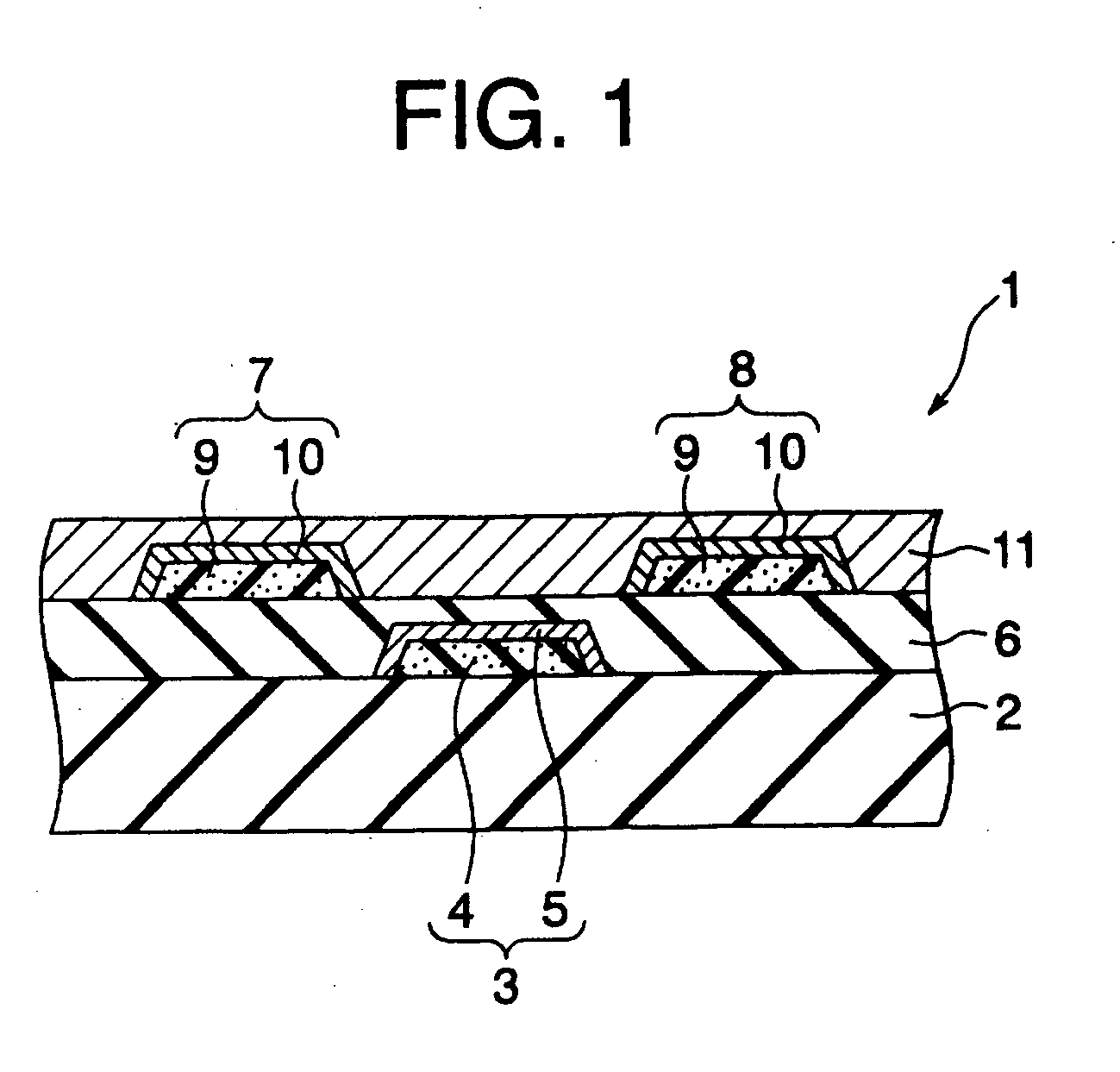

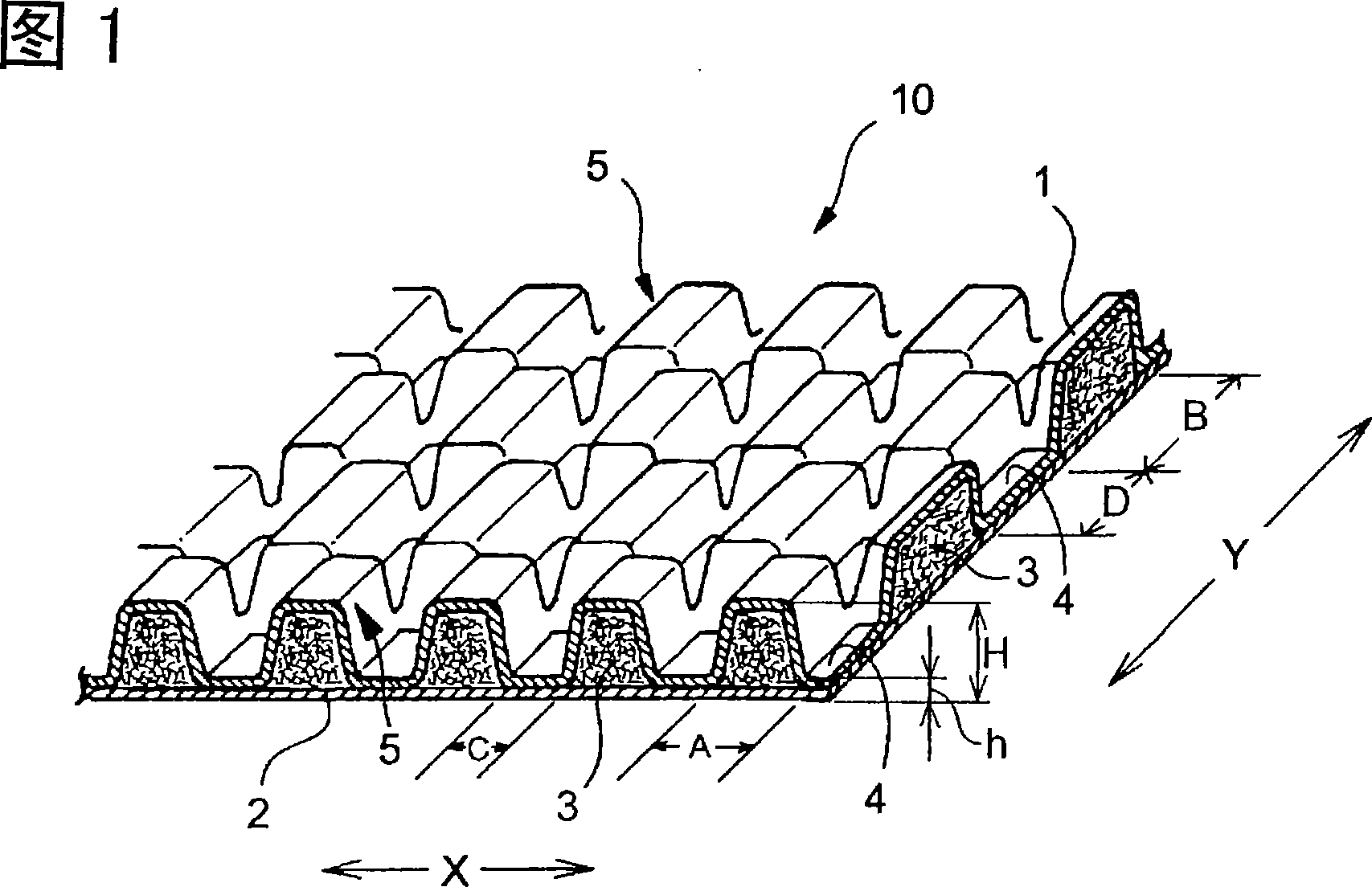

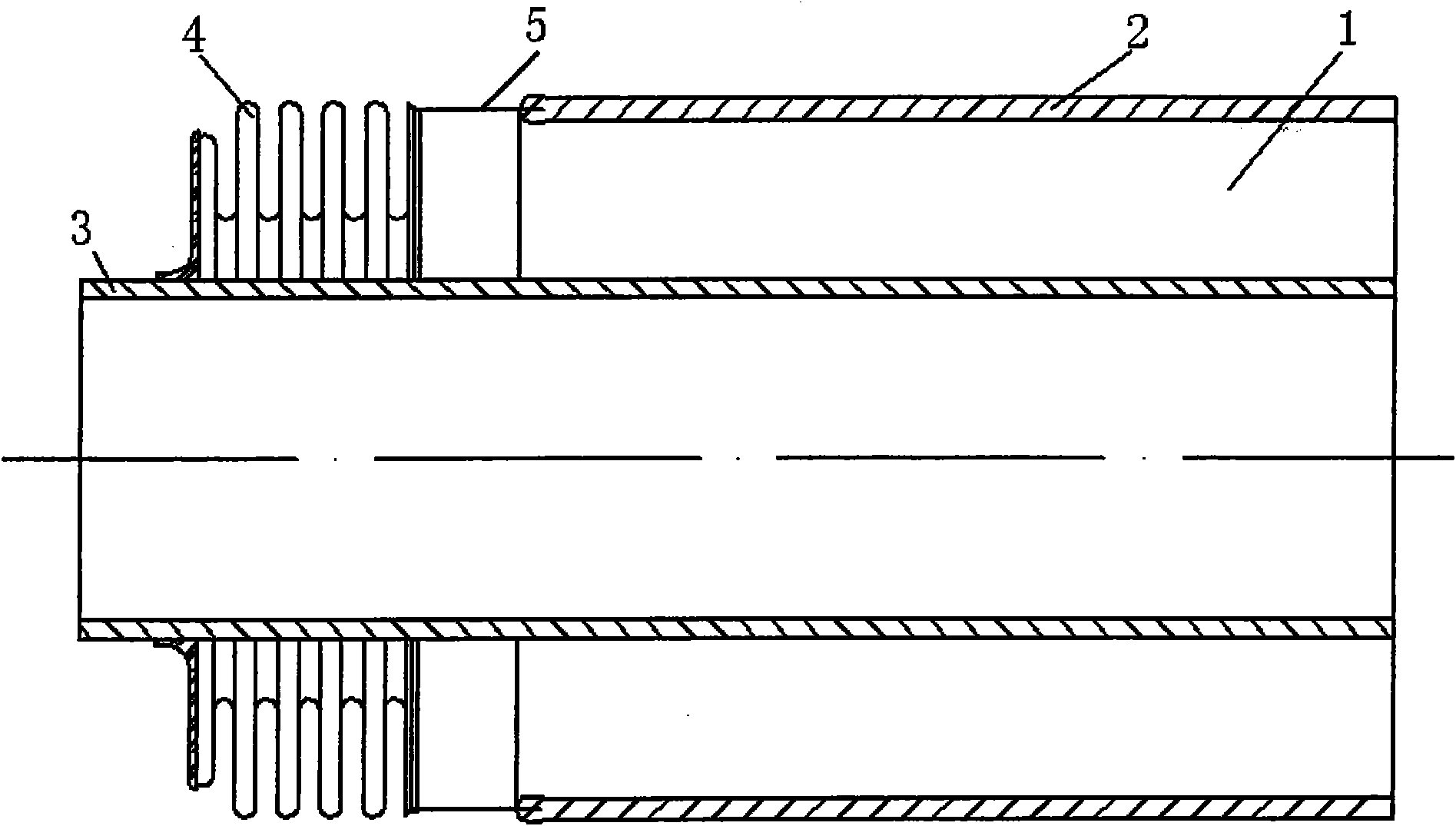

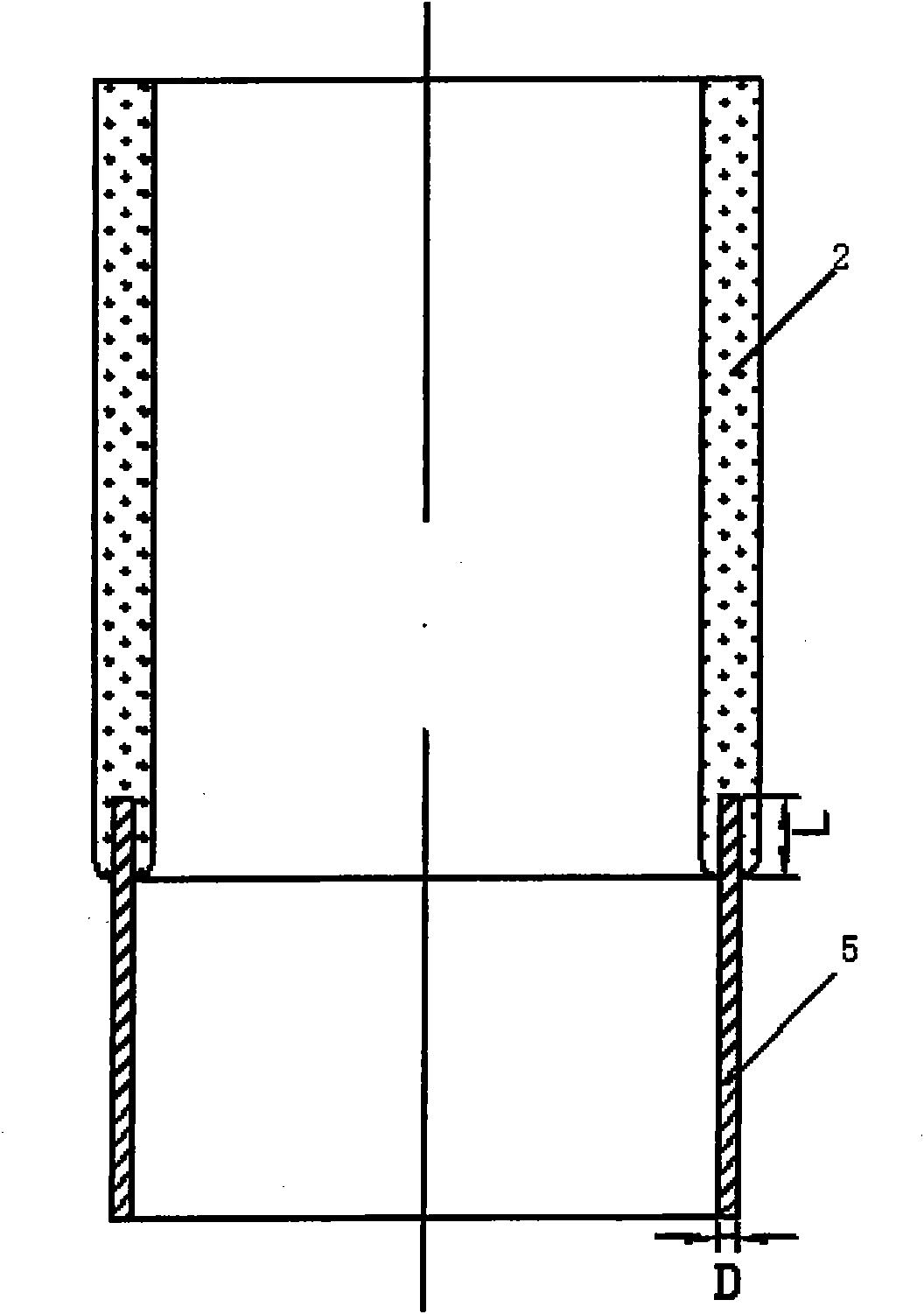

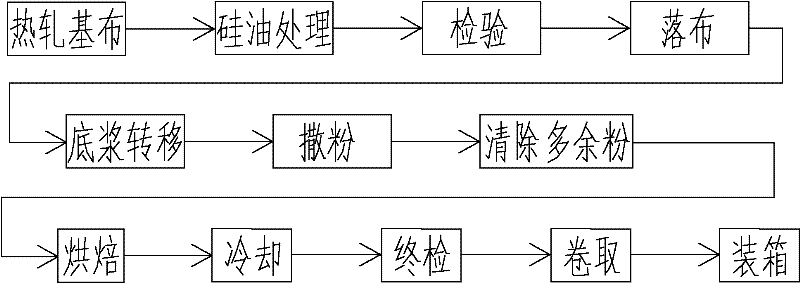

Topsheet For Absorbent Articles

A topsheet for use on the skin facing side of an absorbent article. The topsheet includes a first nonwoven fabric layer 1 and a second nonwoven fabric layer 2 laminated and partly joined together by heat fusion bonding, forming fusion bonds 4. The first nonwoven fabric layer 1 forms a large number of projections 5 projecting toward the skin of a wearer in portions other than the fusion bonds 4. The projections 5 are arranged discretely in both a first planar direction (direction X) and a second planar direction perpendicular to the first planar direction (direction Y). The individual projections 5 are filled with staple fiber 3. The staple fiber 3 is substantially absent in the fusion bonds 4. The individual projections 5 of the topsheet have fiber densities in the following relationship: first nonwoven fabric layer 1<the staple fiber 3<the second nonwoven fabric layer 2.

Owner:KAO CORP

Electrical stretch hose

InactiveUS20090050227A1Tight limitGreat stretch ratioSuction cleanersInsulated cablesHelical lineEngineering

The present invention is an electrical extensible hose that includes an outer shell, an inner core and at least one helical wire, which acts like a skeleton. In the present invention one implemented an additional wire that was conductive. The outer shell and inner core of the present invention may be bonded together via heat fusion. The helical wire is attached to the inner core via heat fusion. The helical wire supports the outer shell and inner core so as to form a tube. The outer shell and the inner core have a portion that forms an angular fold and have a portion that remains fixed. The second wire is attached at a point below the fixed portion of the electrical stretch hose so as to allow for maximum constriction caused by the shrinkable force created by the helical wire, thus increasing the stretch ratio of the hose.

Owner:FLEXIBLE TECH INC

Thermal-melting welding flux igniting material and its constructred heat generation melt welding flux

InactiveCN1559745ATo achieve the purpose of weldingQuick and easy welding operationWelding/cutting media/materialsSoldering mediaCopper wirePotassium

A thermo-melting solder for the thermo-melting welding between copper wire and structural member is composed of the thermo-melting welding stock which contains less Zn and Sn for generating CuZnSn alloy at welded point and excessive Al for removing surficial oxide from welded point, and the igniting agent containing potassium permanganate instead of potassium bichromate (or chloride).

Owner:成都桑莱特科技股份有限公司

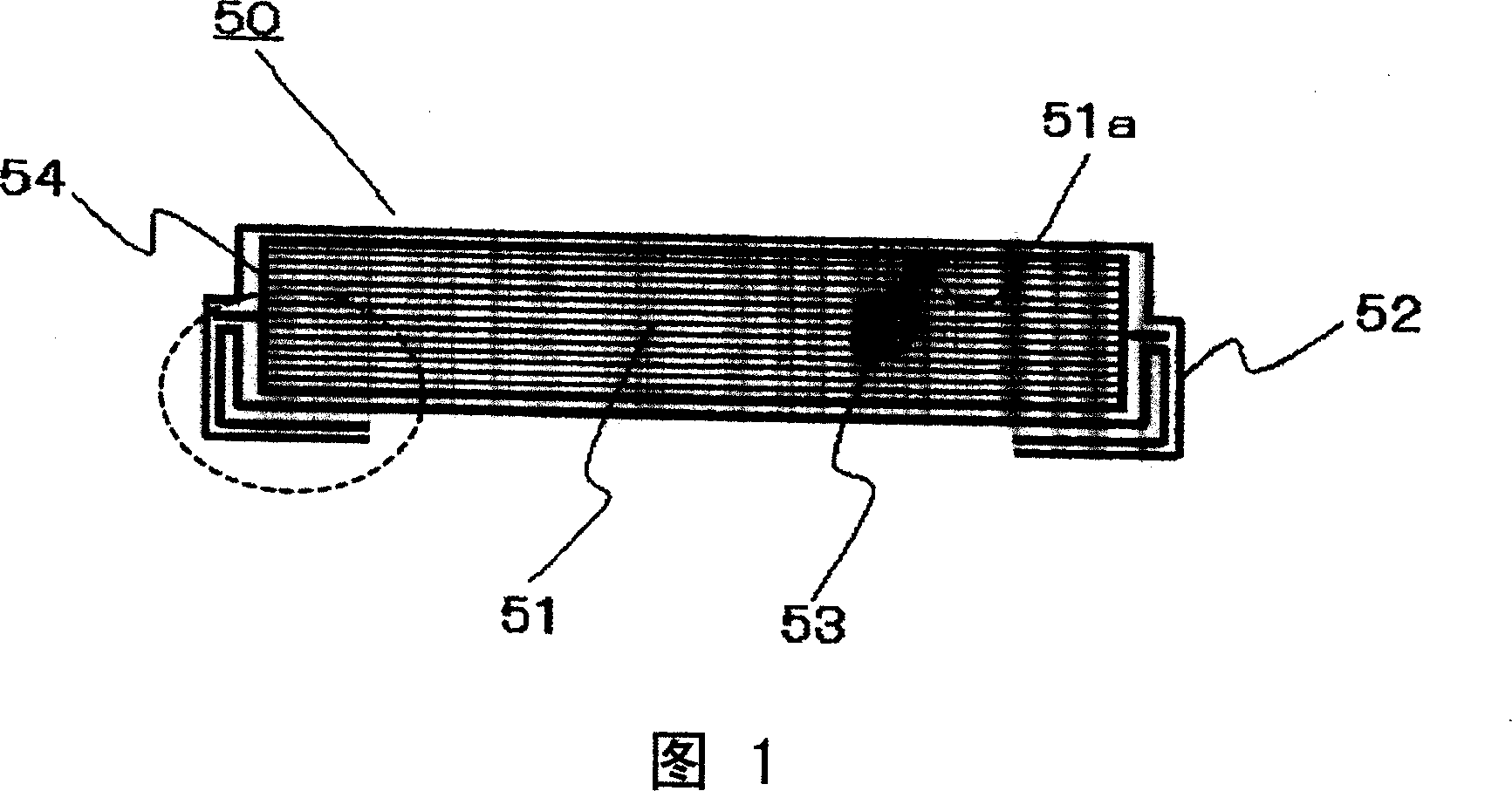

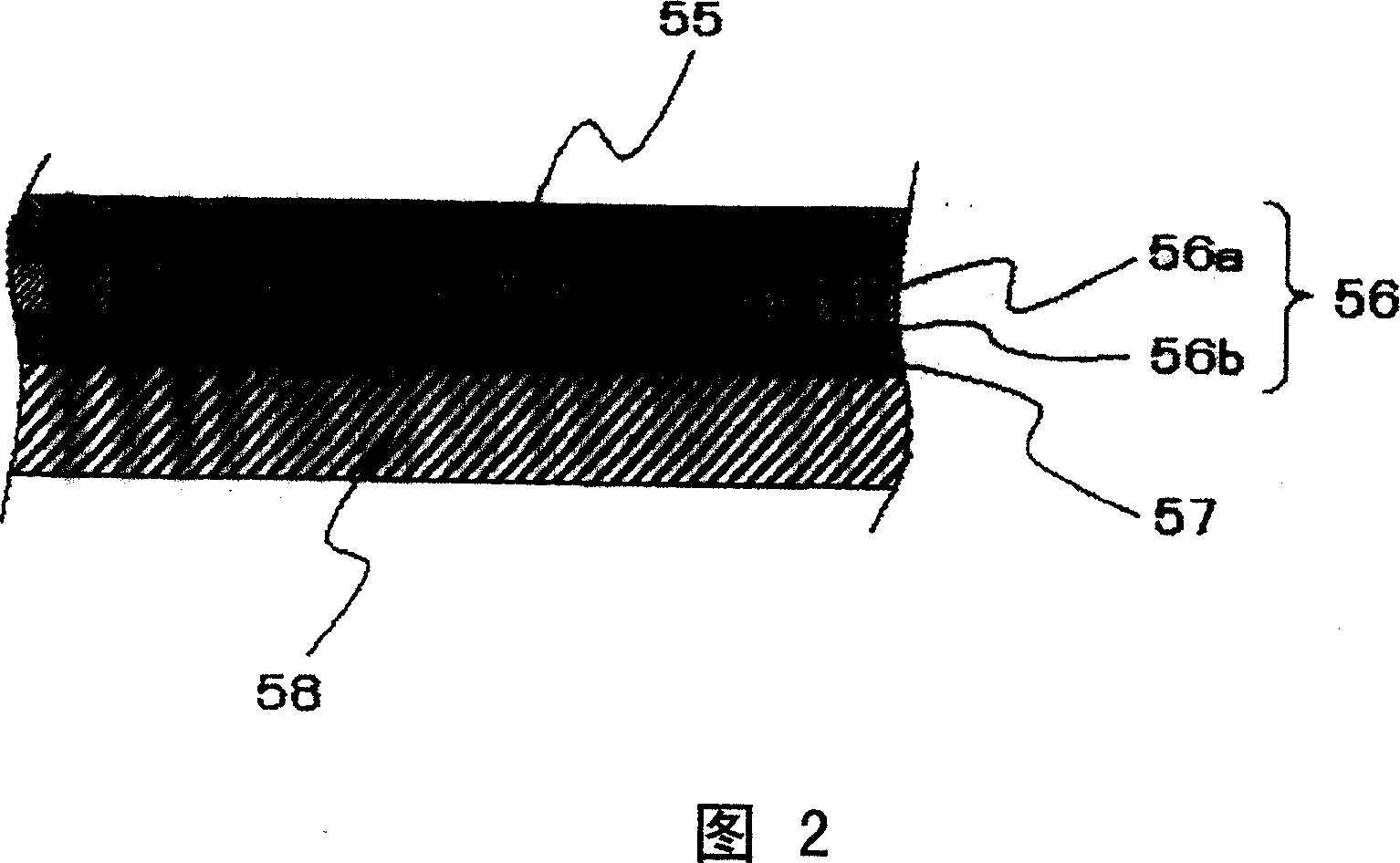

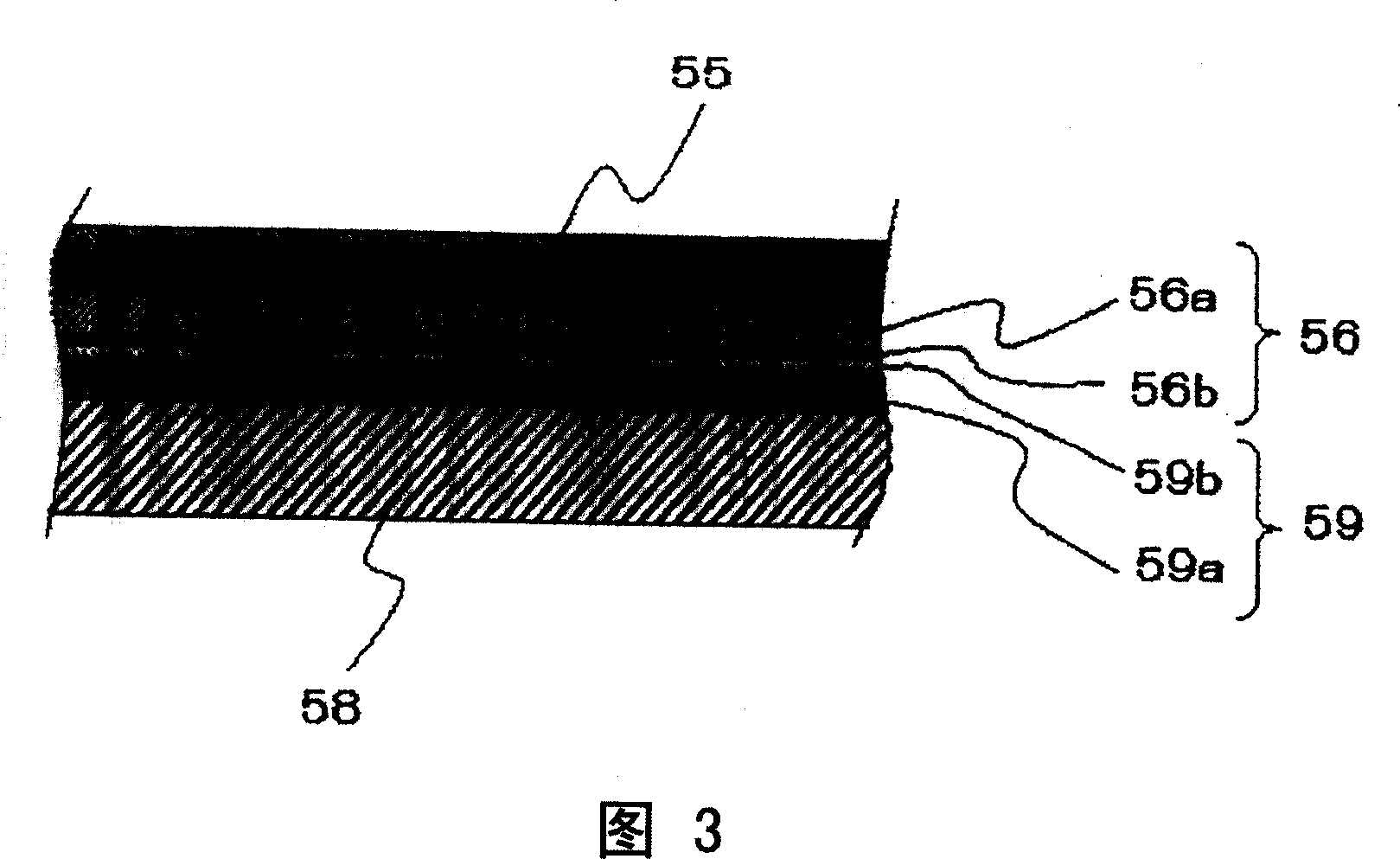

Vacuum insulating material, hot water supplying device using the same and electric drive type hot water device

InactiveCN101046271ASuppresses deterioration of thermal insulation performanceInhibit entryCooking-vessel materialsThermal insulationFiberSorbent

The present invention provides a vacuum heat insulation material capable of maintaining high heat insulation capacity even in high temperature circumstance, and provides a hot water supply device having high heat insulation capacity. In the vacuum heat insulation material comprising core material (51) composing of inorganic fiber polymer, a housing material (52) having surface protection layer and aerospace sealing layer and heat melting coating layer, and sorbent (53) absorbing the moisture and air component of core material (51) and the housing material (52), the heat insulation capacity can be maintained in long time in condition of high temperature by laminating the aerospace sealing layer of the housing material (52) with a first aerospace sealing layer and the second aerospace sealing layer in terms of opposite metal surface of at least tow layers of metal layer, and using resin film with melting point more than 150 DEG C as heat melting coating layer.

Owner:HITACHI APPLIANCES INC

Automobile inner decorative board made of composite materials of natural fibers/thermoplastic resin, and mixing method of composite materials of natural fiber/thermoplastic resin

The invention discloses an automobile inner decorative board made of composite materials of natural fibers / thermoplastic resin, and a mixing method of the composite materials of the natural fiber / the thermoplastic resin. The automobile inner decorative board is composed of at least a core layer and a surface layer. The surface layer is composed of the following main raw materials, by weight, 5-35 parts of spandex fibers, 25-45 parts of polyester fibers, 15-25 parts of low-melting-point and skin-core type composite fibers, and 15-35 parts of high-melting-point hot melting fibers, wherein the difference between the melting point of the high-melting-point hot melting fiber and the melting point of the low-melting-point and skin-core type composite fibers is larger than 20 DEG C. The core layer is composed of the following main raw materials, by weight, 5-35 parts of basalt fibers and / or glass fibers, 5-35 parts of the natural plant fibers with modified surfaces, 15-35 parts of polyester fibers, 15-25 parts of low-melting-point and skin-core type composite fibers, and 15-25 parts of high-melting-point fibers. The automobile inner decorative board and the mixing method achieve integration of manufacturing and forming of the composite materials, and the material manufacturing stage can assist the material forming stage directly and effectively.

Owner:SHANDONG UNIV

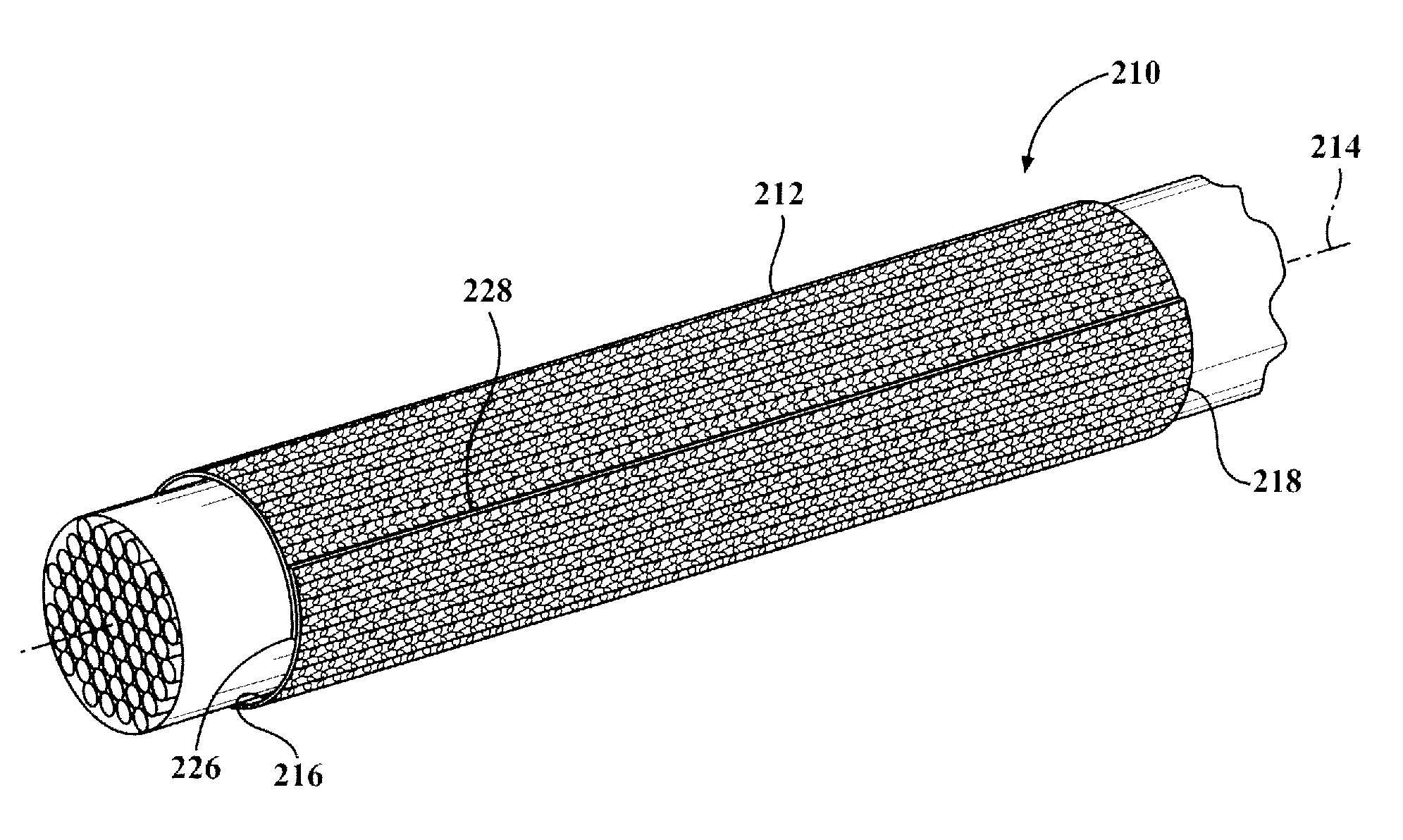

Protective Sleeve With Bonded Wire Filaments and Methods of Construction Thereof

ActiveUS20160021799A1Shielding materialsElectrostatic discharge protectionArchitectural engineeringHeat fusion

Owner:FEDERAL MOGUL POWERTAIN LLC

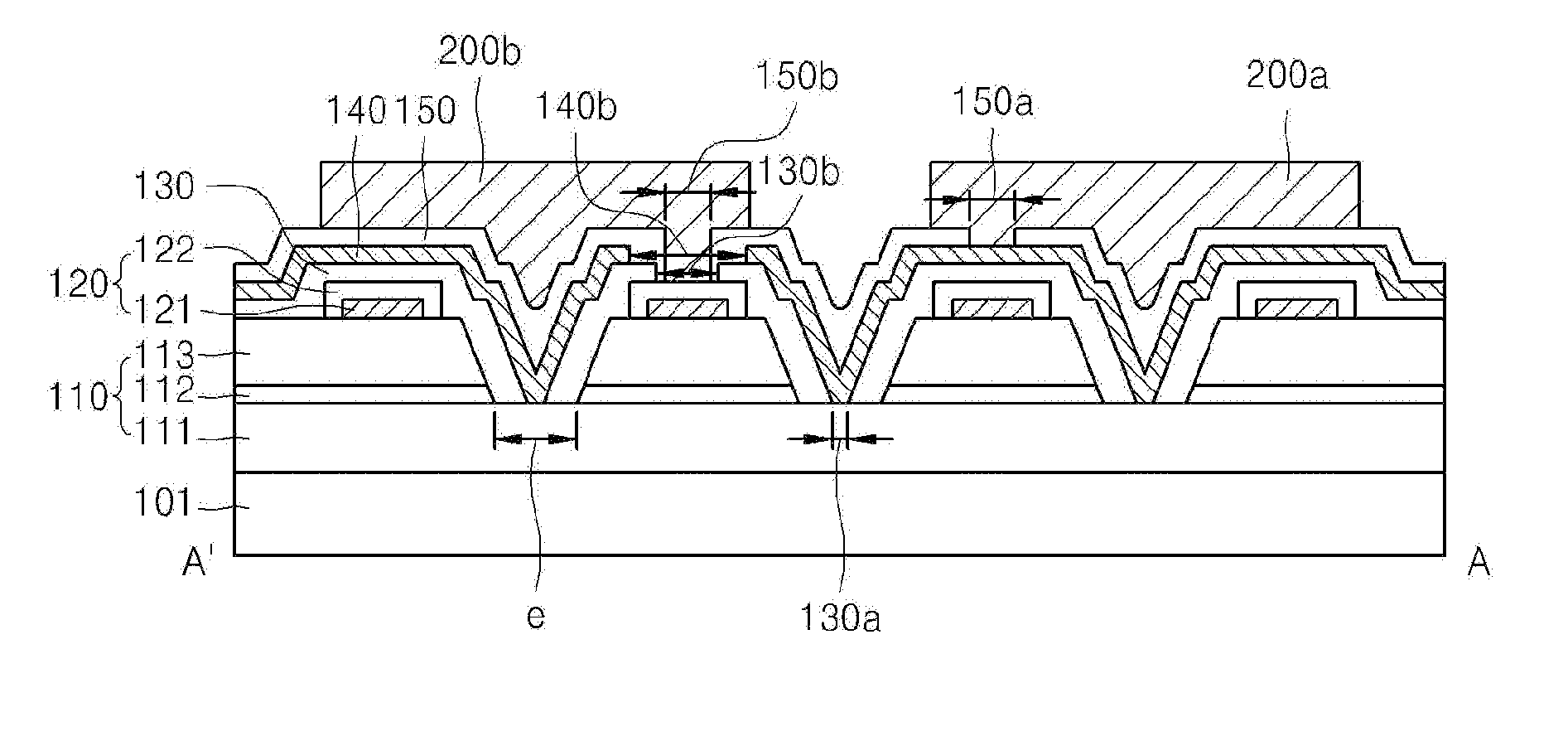

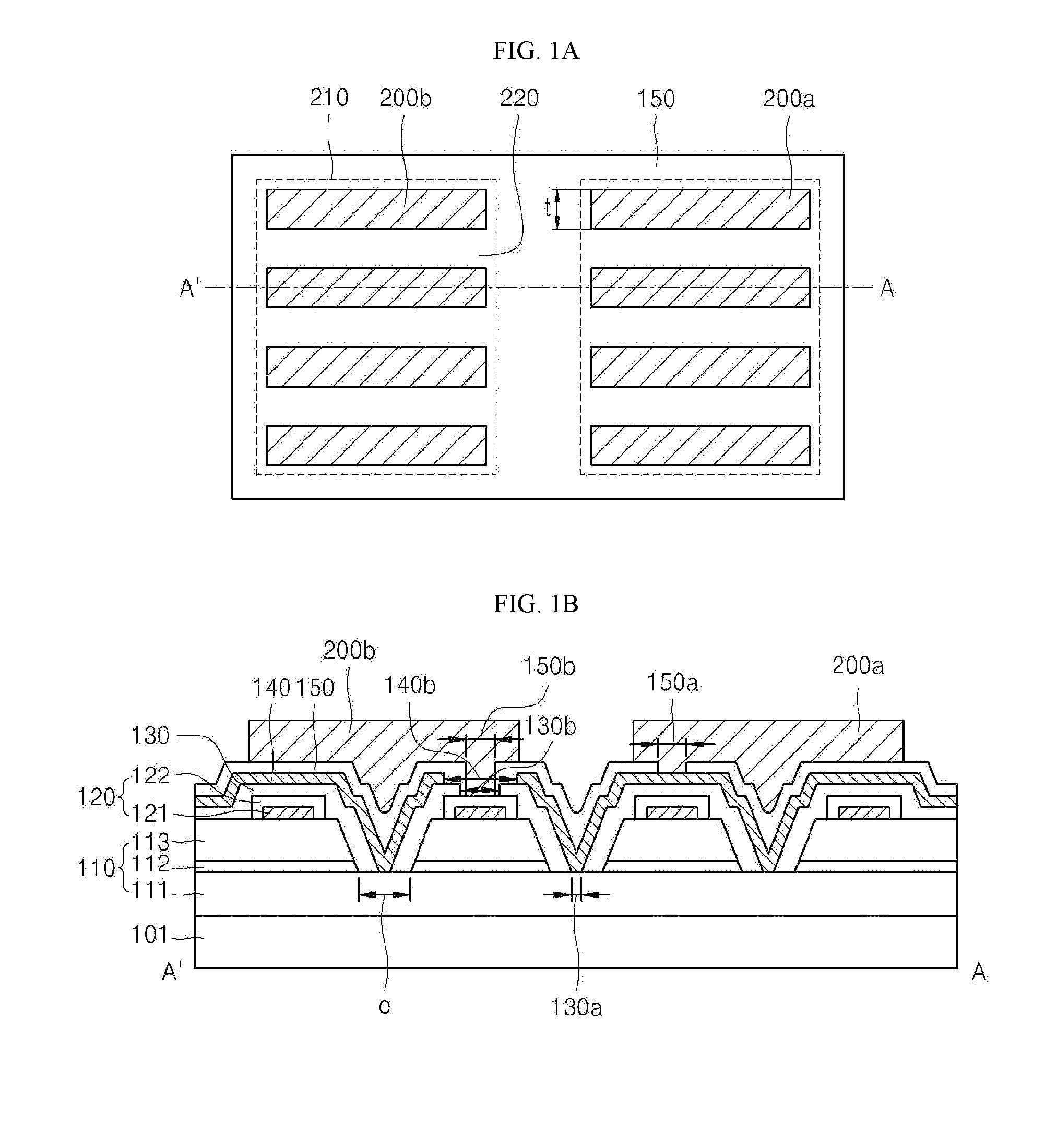

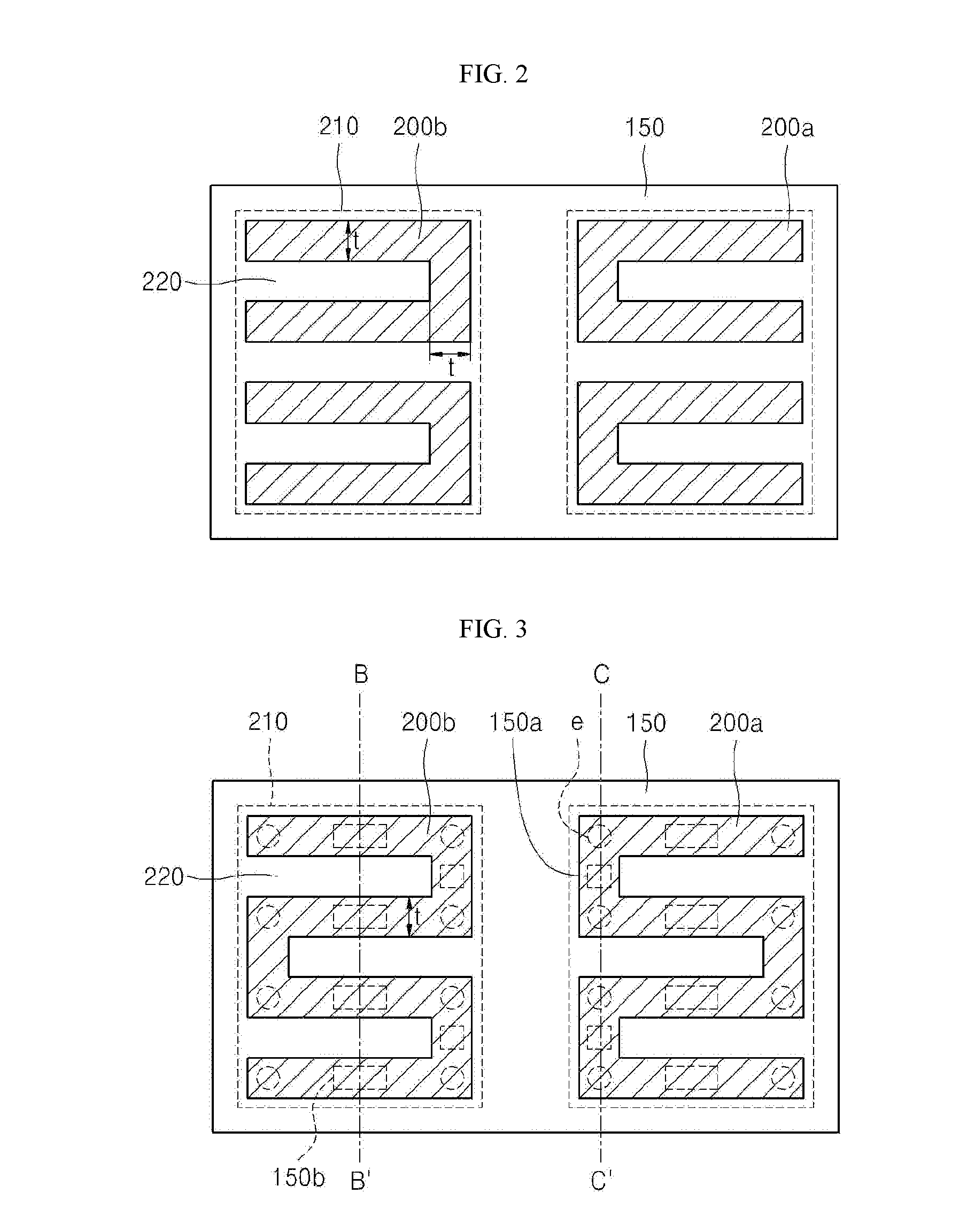

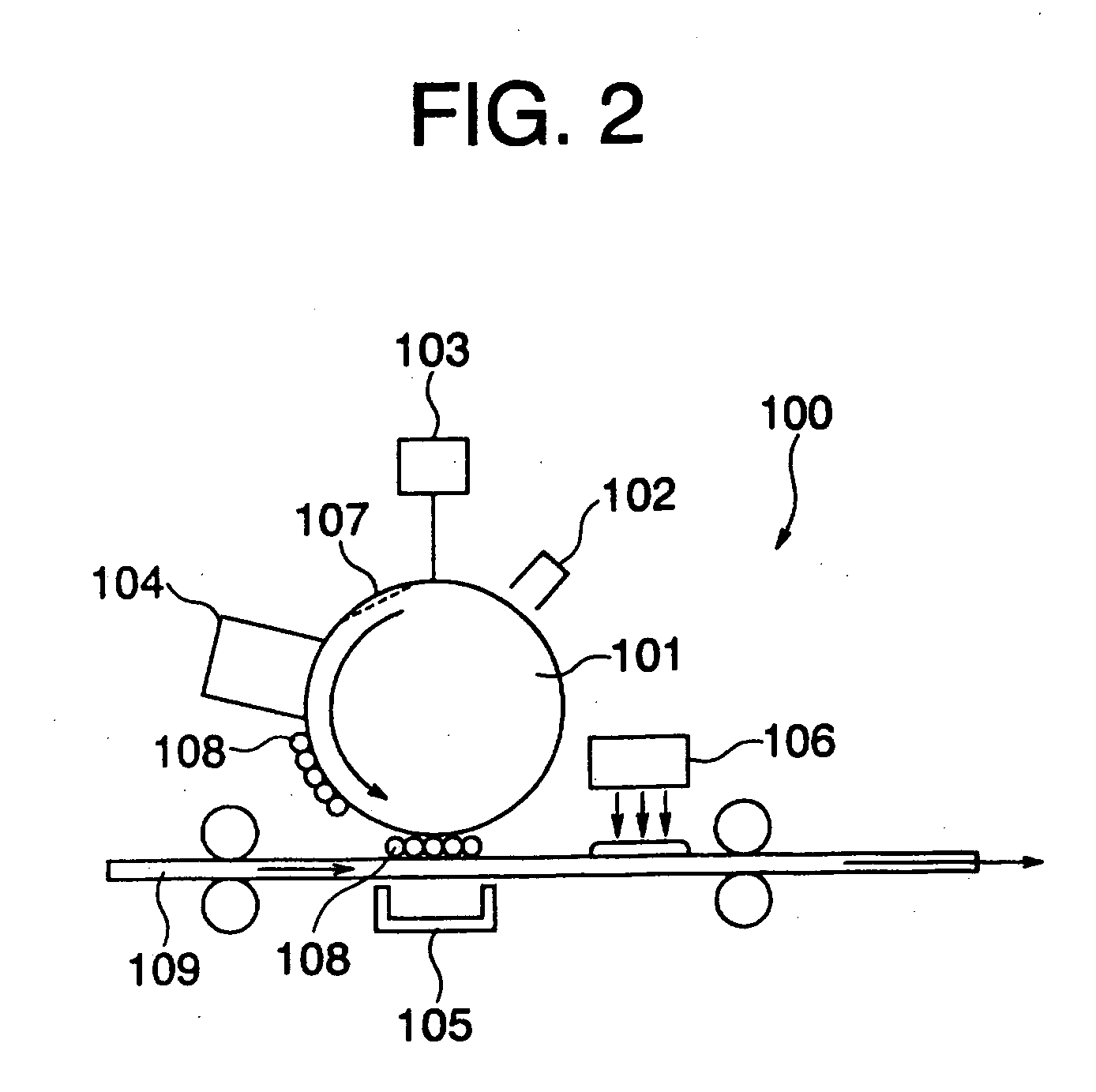

Organic semiconductor element and manufacturing method thereof

InactiveUS20050279996A1Solid-state devicesSemiconductor/solid-state device manufacturingMiniaturizationOrganic semiconductor

An organic semiconductor element comprises an organic semiconductor layer and an electrode supplying an electric current or an electric field to the organic semiconductor layer. The organic semiconductor layer includes a heat fusion layer of organic semiconductor particles. The heat fusion layer of the organic semiconductor particles is formed in such a manner that, for example, the organic semiconductor particles are made to adhere on a layer that is to be a base, by using an electrophotographic method, and thereafter, an adhesion layer of the organic semiconductor particles is heated to fusion bond the organic semiconductor particles. According to such an organic semiconductor element and a manufacturing method thereof, it is possible to enhance element manufacturing efficiency without an advantage of low cost and a miniaturization of an element structure.

Owner:KK TOSHIBA

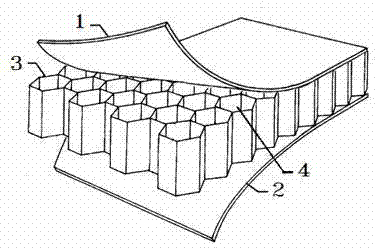

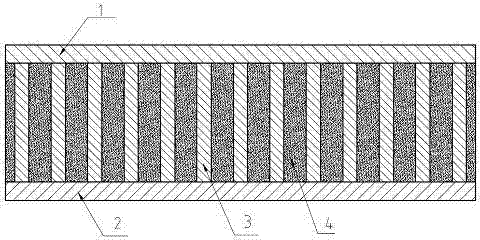

Continuous-fiber reinforced thermoplastic polymer temperature-adjusting plate

A continuous-fiber reinforced thermoplastic polymer temperature-adjusting plate comprises a surface plate, a bottom plate, a honeycomb core layer and a phase-change energy-storage material packed in the honeycomb core layer. The surface plate, the bottom plate and the honeycomb core layer are prepared from a sheet of a continuous-fiber reinforced thermoplastic polymer composite material filled with a modified heat-conduction filler, the honeycomb-core-layer phase-change energy-storage material is packed in multiple mutually-independent chambers in the honeycomb core layer, and the surface plate and the bottom plate are respectively combined with the upper surface and the lower surface of the honeycomb core layer through heat fusion. By blending a high-heat-conductivity substance with the polymer, the high-heat-conductivity continuous-fiber reinforced thermoplastic polymer plate, which is prepared by employing a double-face film coating method, has high specific modulus and specific strength. The honeycomb core layer employs a material same to that of the surface plate, and the honeycomb core layer and the surface plate are firmly bonded through fusion. Honeycomb holes are filled with the phase-change material, the addition amount is large and the problem that the phase-change material precipitates is effectively avoided. The continuous-fiber reinforced thermoplastic polymer temperature-adjusting plate has an expanded application field and is especially applicable to decoration of indoor decoration furred ceilings and wall surfaces.

Owner:BEIJING UNIV OF CHEM TECH

Surface sheet for absorbing article

A topsheet for use on the skin facing side of an absorbent article. The topsheet includes a first nonwoven fabric layer 1 and a second nonwoven fabric layer 2 laminated and partly joined together by heat fusion bonding, forming fusion bonds 4. The first nonwoven fabric layer 1 forms a large number of projections 5 projecting toward the skin of a wearer in portions other than the fusion bonds 4. The projections 5 are arranged discretely in both a first planar direction (direction X) and a second planar direction perpendicular to the first planar direction (direction Y). The individual projections 5 are filled with staple fiber 3. The staple fiber 3 is substantially absent in the fusion bonds 4. The individual projections 5 of the topsheet have fiber densities in the following relationship: first nonwoven fabric layer 1 < the staple fiber 3 < the second nonwoven fabric layer 2.

Owner:KAO CORP

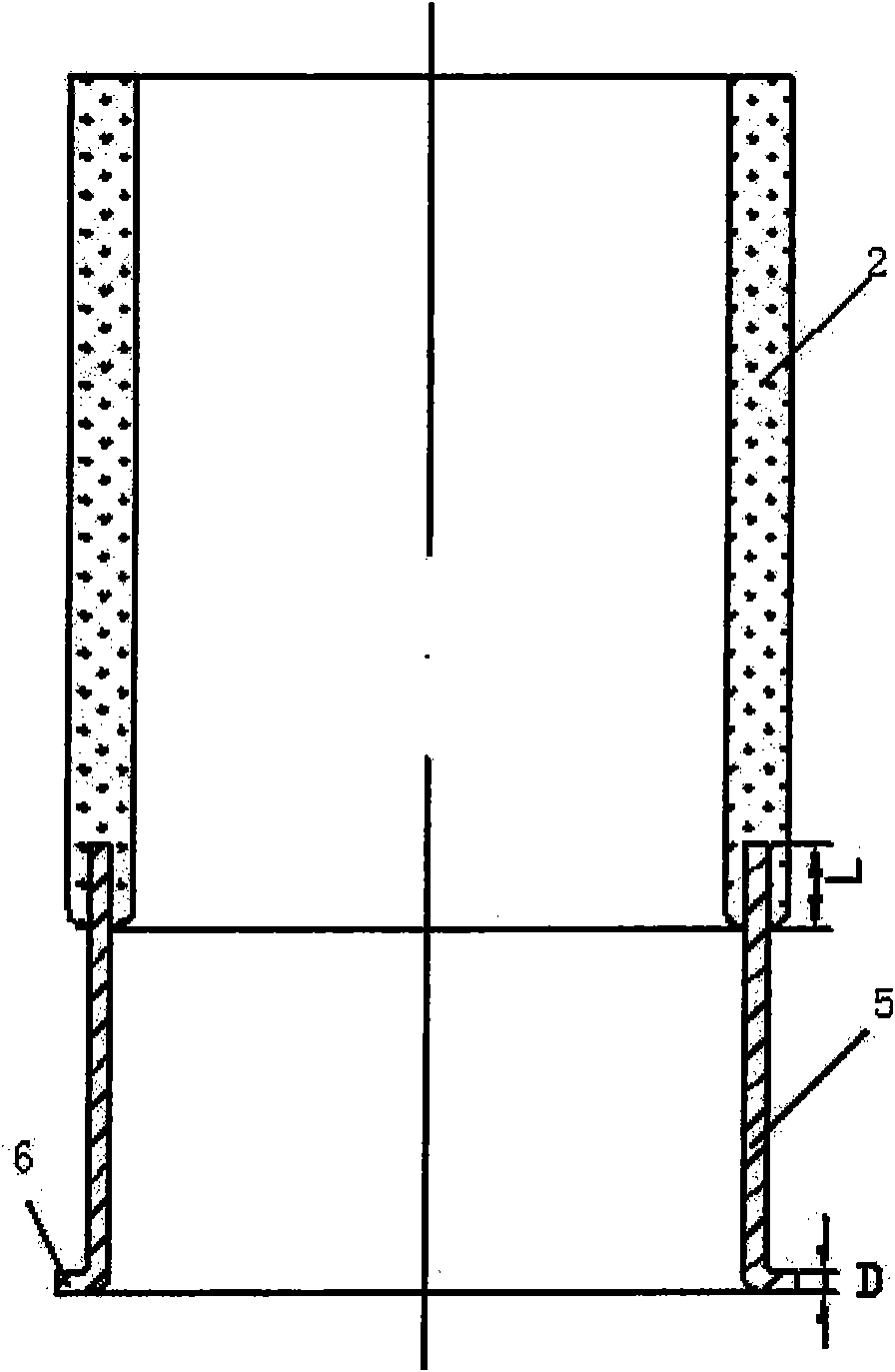

Thermal fusing sealing process of metal-glass solar heat-collecting tube

InactiveCN101602579AEasy to control temperatureConvenient time controlSolar heating energySolar heat devicesEngineeringHeat fusion

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

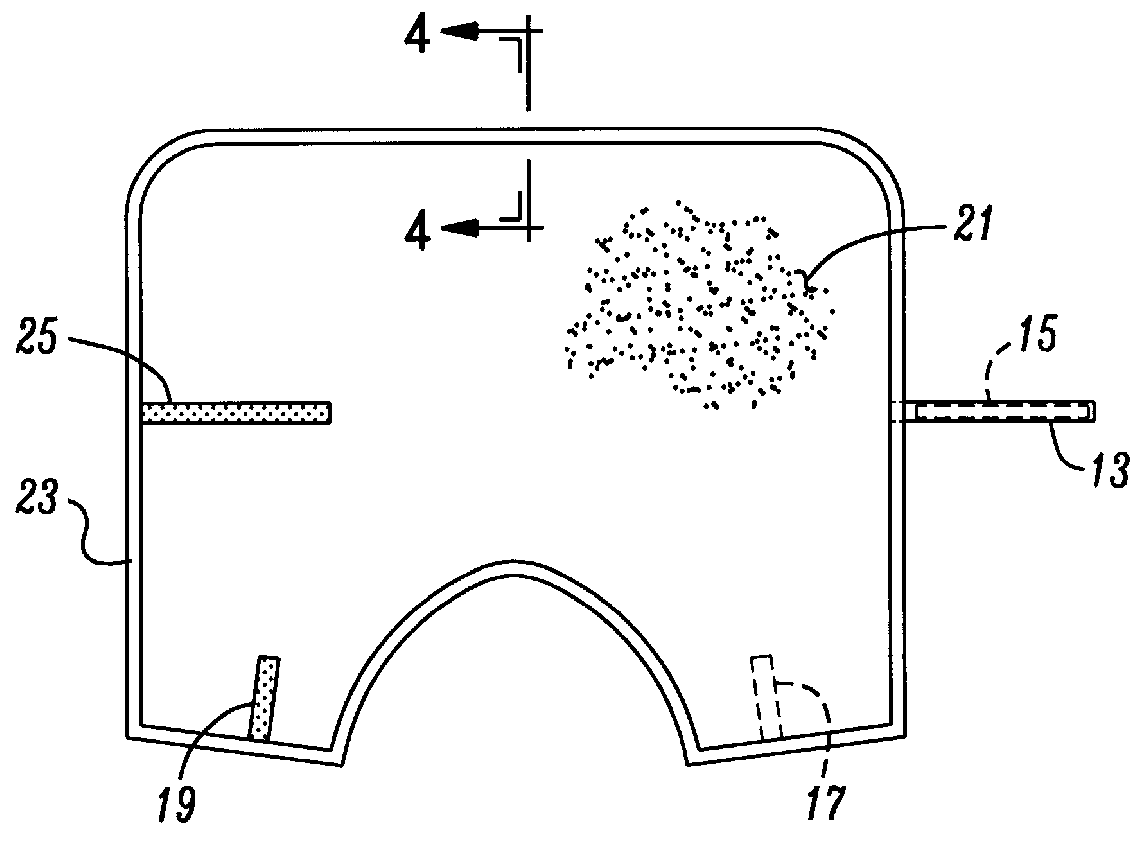

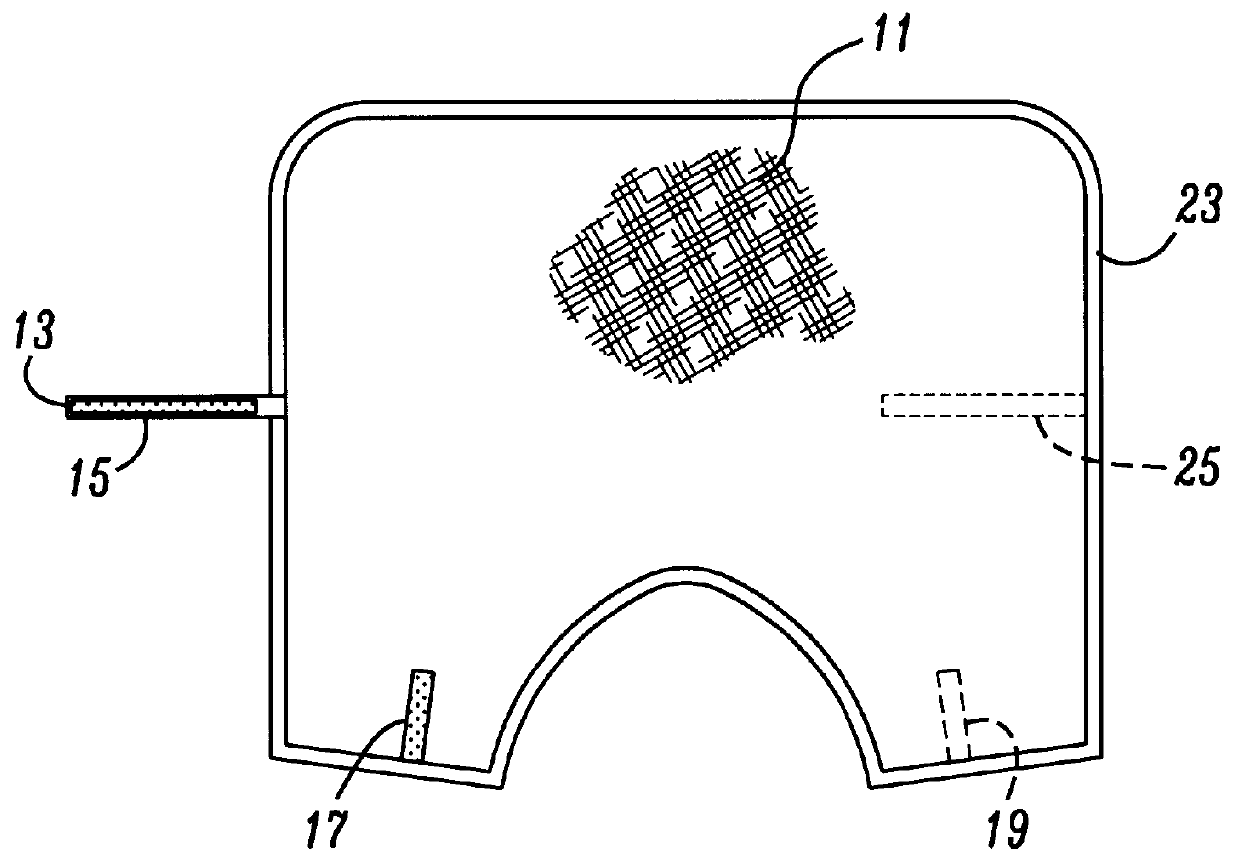

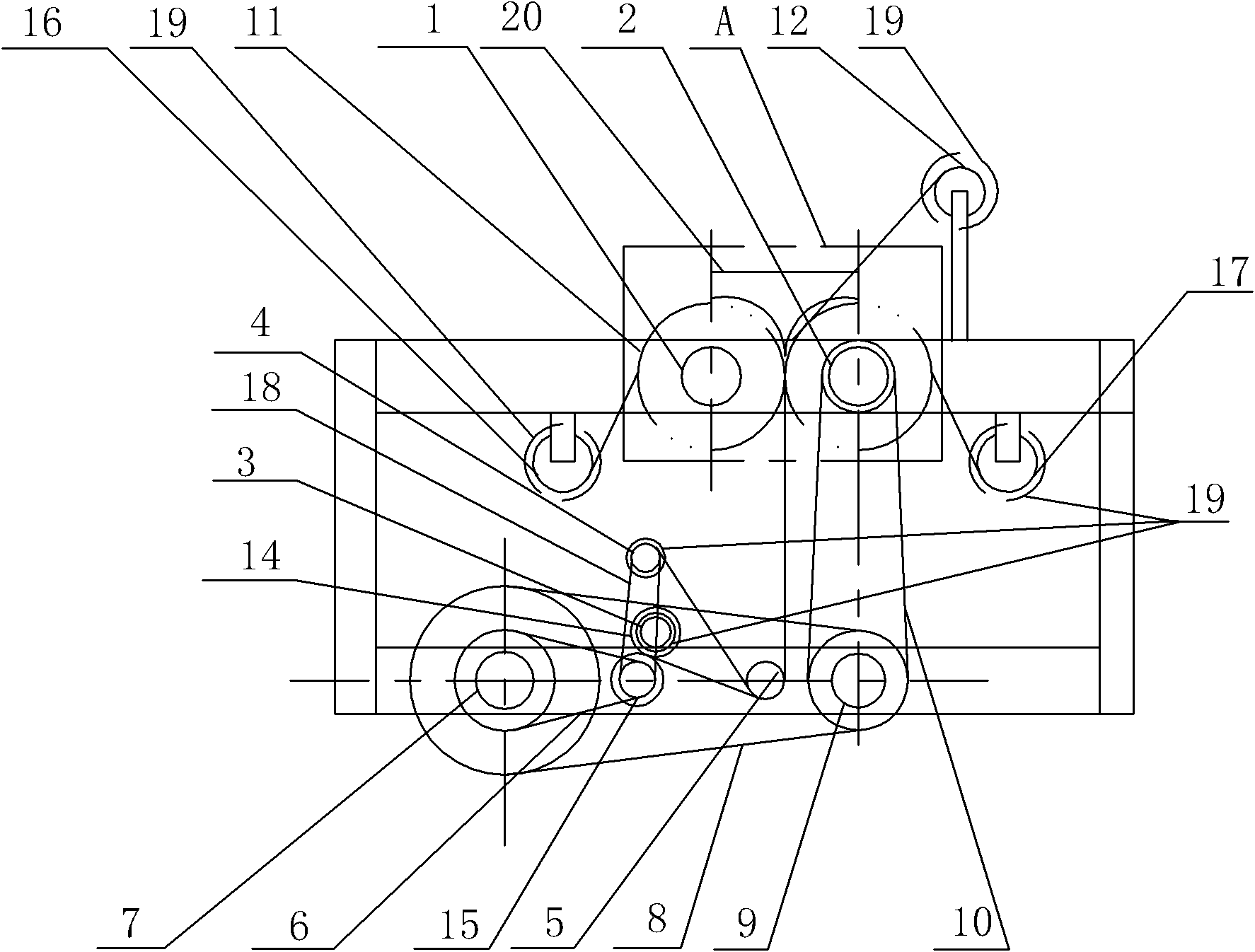

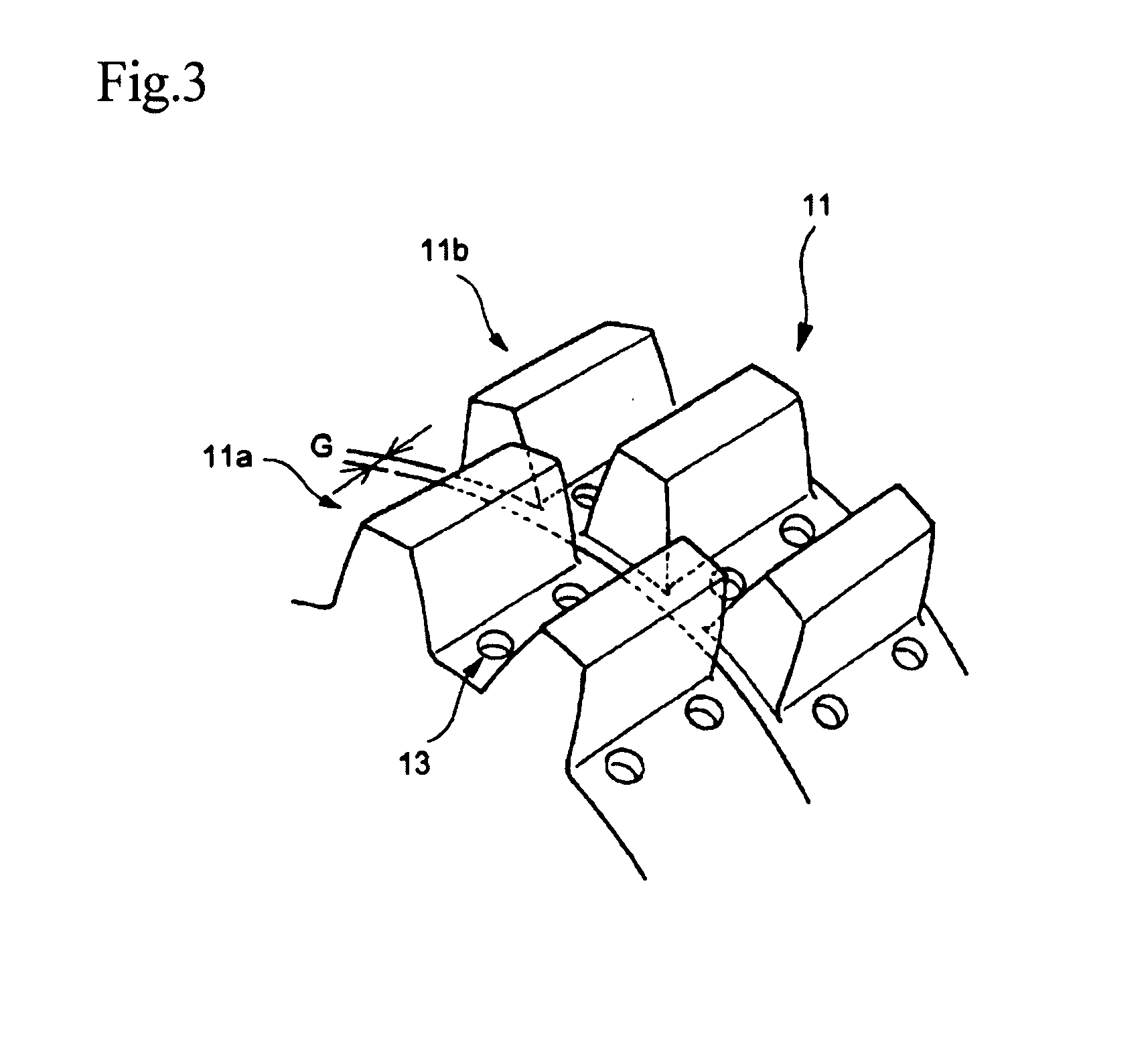

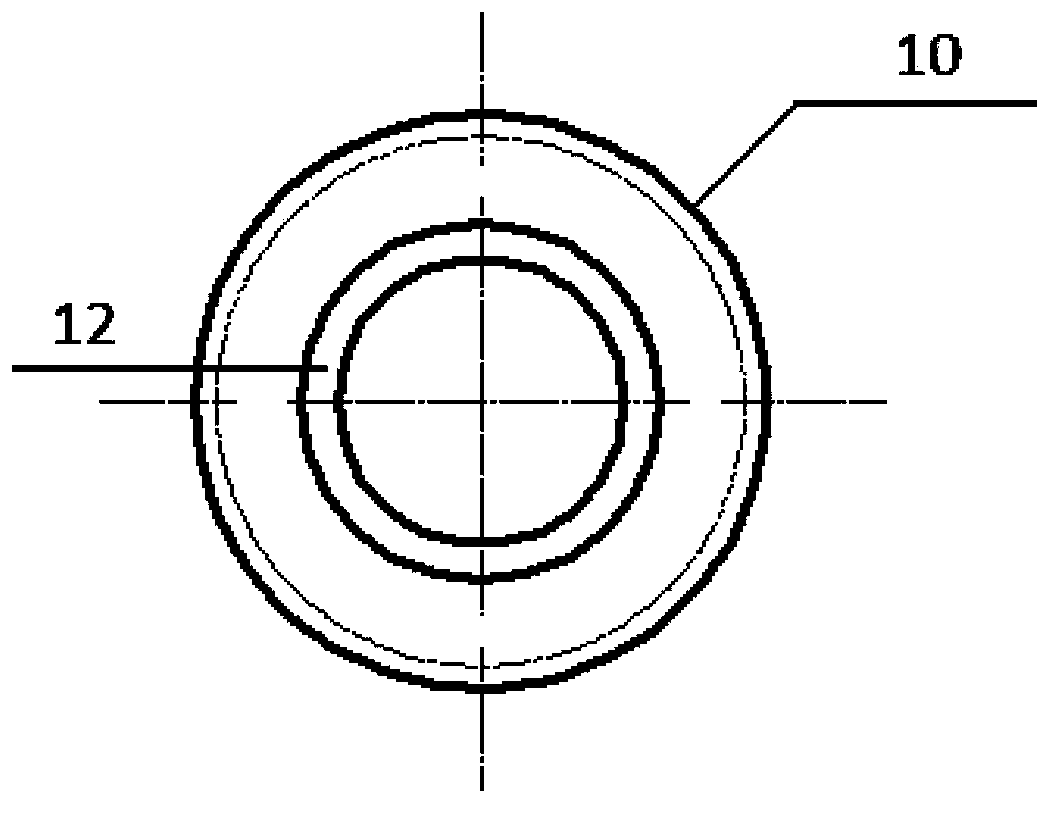

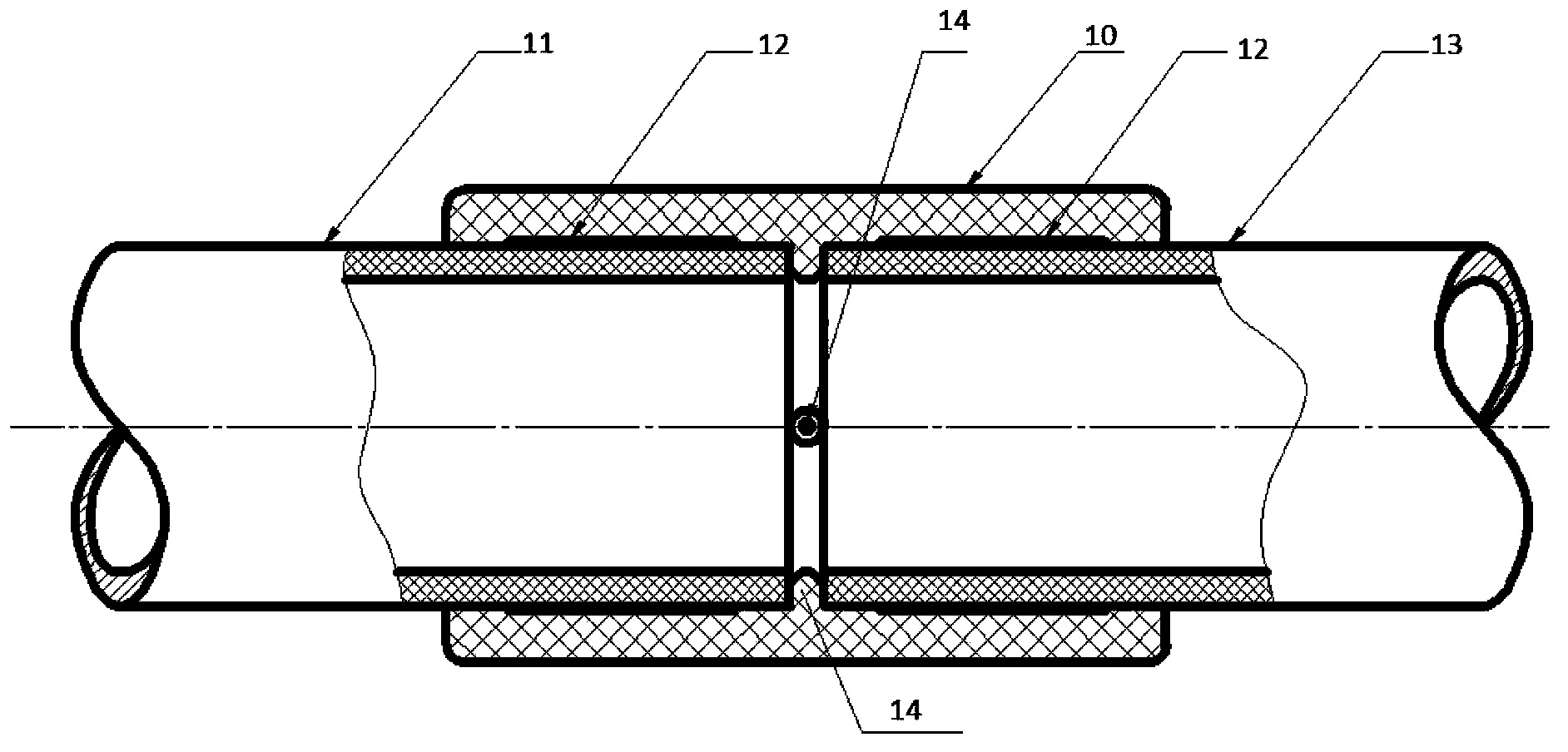

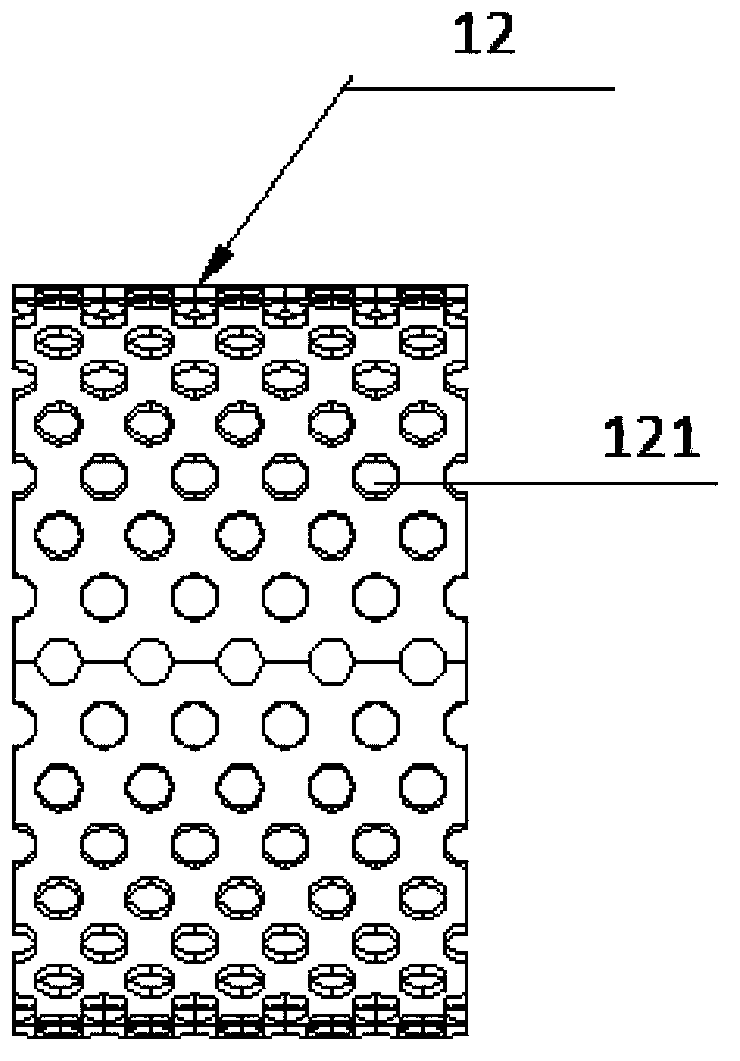

Electromagnetic heating welding method for thermoplastic pipes

InactiveCN103383044AImprove connection efficiencyReduce labor costsPipe connection arrangementsThermoplasticEngineering

The invention relates to a heating welding method for thermoplastic pipes. The method comprises the steps of Step 1, forming a metal mesh layer (12) on the inner wall of a plastic connecting piece (10); Step 2, performing inserting connection on the two thermoplastic pipes and the plastic connecting piece, and performing centering and positioning through positioning pins (14) in the plastic connecting piece; Step 3, sleeving an electromagnetic induction heating coil on the plastic connecting piece (10), and performing energization for heating; Step 4, performing heating till the two thermoplastic pipes and the plastic connecting piece are welded fully, and then performing deenergization; Step 5, performing cooling shaping. According to the method, the thermoplastic pipes or steel-plastic composites pipes are connected through the plastic connecting piece in advance and then fixed through electromagnetic heating hot melting, so that the traditional mode of heating before inserting connection is changed, the connection efficiency is improved, and meanwhile, the labor cost is reduced.

Owner:TIANJIN JUNXING PIPE GRP CO LTD

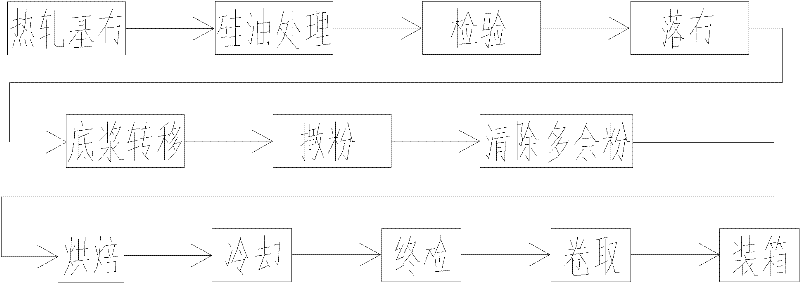

Production process of double-point non-woven fusible interlining

InactiveCN102389174AConsider softnessTaking into account the costFibre typesPolyureas/polyurethane adhesivesInterliningPolyester

Owner:温州鸿马科技有限公司

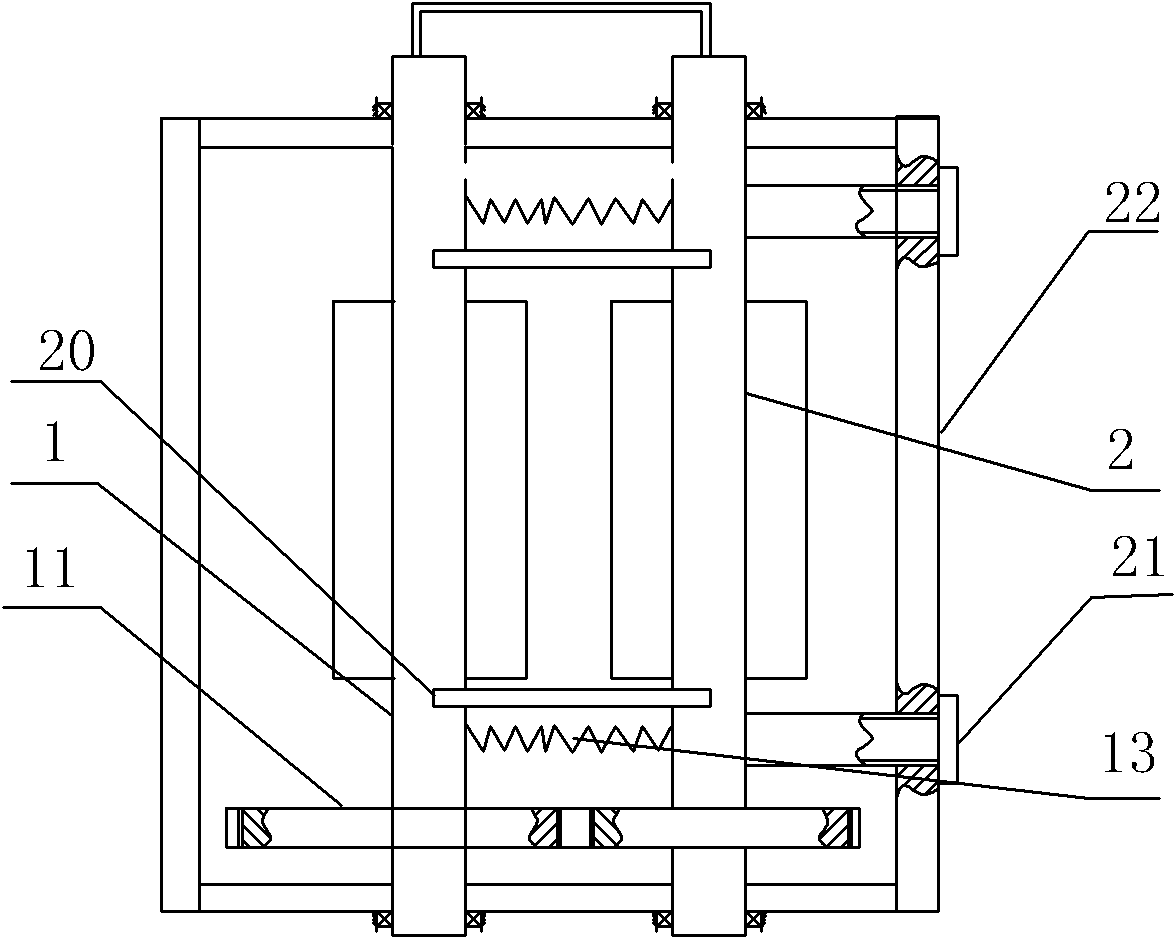

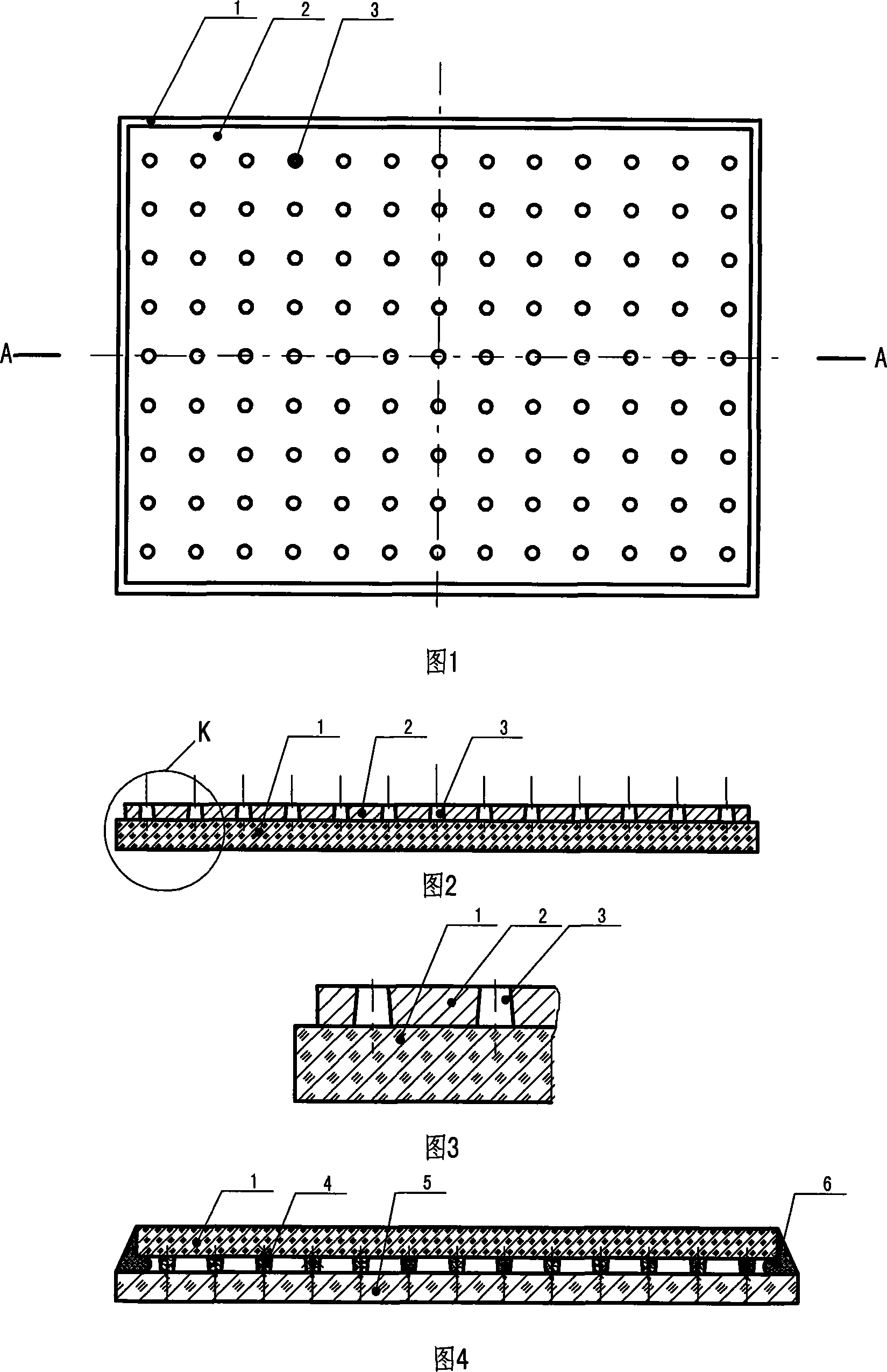

Method for preparing vacuum glass

ActiveCN101215076AImprove molding qualityImprove molding efficiencyGlass reforming apparatusPulp and paper industryHeating furnace

The invention relates to a process for preparing vacuum glass. The steps of the process are, (1) keeping a leaking plate mould flat on a glass substrate, on which die orifices are equispaced and compartmentally prepared, (2) coating the supporting pulp on the leaking plate mould to form backstops which are distributed compartmentally and have the same height, inverting the glass substrate on bottom glass, (3) preparing an opening which is inserted in a suction glass tube on the glass, and adopting supporting pulp to seal edges, (4) putting the glass into a heating furnace and treating, (5) connecting the suction glass with a vacuum device until vacuum degree in the vacuum glass reaches 10-2-10-4Pa, hot fusing and sealing the glass tube, thereby obtaining vacuum glass finished products. The invention has the advantages of simple preparation technology, easy operation, lower investment, lower rejection rate, perfect quality and higher production efficiency. Further, the invention adopts mechanical separator system to replace manual operation, which effectively reduces costs of vacuum glass and is applicable for industrial production.

Owner:天津沽上创新真空玻璃有限公司

Production method of vacuum glass

The present invention relates to a production method of vacuum glass. It is characterized by that said method includes the following steps: point-placing glass powder slurry with low-melting point on one glass sheet surface so as to form glass powder piles, coating a closed low-melting-point glass powder strip along four edges of the glass sheet, setting several anti-adhesive supports between upper and lower glass sheets, combining two glass sheets, placing them into sintering furnace to make hot-melting, at the same time of hot-melting and sealing edge the glass powder piles are molten so as to form glass supports, evacuating and sealing so as to obtain the invented vacuum glass.

Owner:刘元生

Gel electrolyte battery

InactiveUS20050000086A1Increase battery capacityPrevent voltageFinal product manufactureElectrode carriers/collectorsLithiumEngineering

A gel electrolyte battery in which adhesion between a layer of an active material of an electrode and a gel electrolyte is raised to provide for sufficient mobility of lithium ions, and a method for the preparation of the gel electrolyte battery. The gel electrolyte battery is comprised of a battery device accommodated in an exterior material of a laminated film and sealed in it on heat fusion. The method for the preparation of the gel electrolyte battery includes a battery device preparation step of layering a positive electrode and a negative electrode via a gel electrolyte to form the battery device, an accommodating step of accommodating the battery device from the battery device preparation step in the laminated film, and a heating step of heating the battery device, accommodated in the laminated film in the accommodating step, under a pressured state.

Owner:SONY CORP

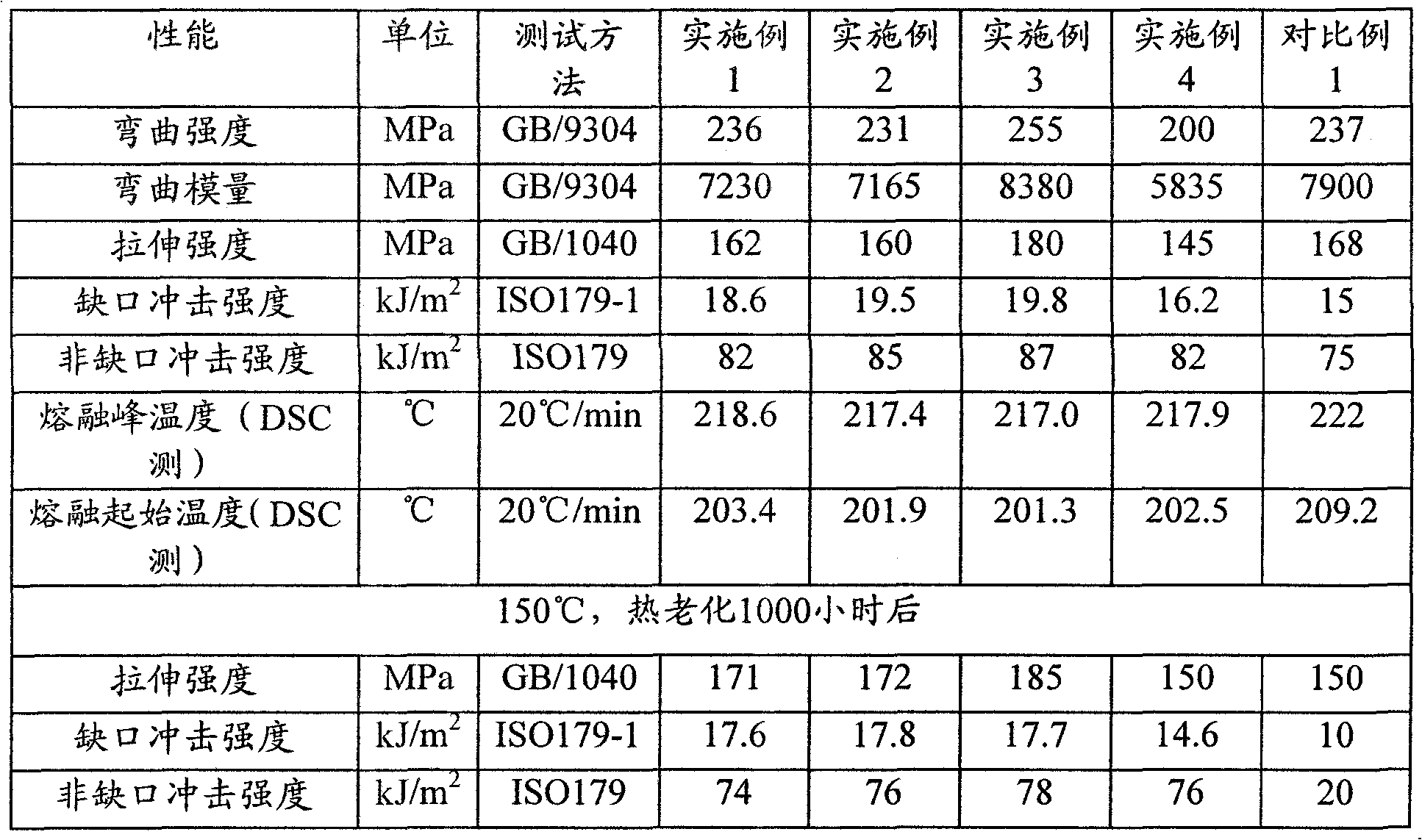

Polyamide composite material for vehicle induction manifold and preparation method thereof

InactiveCN101812230ASolve the problem of high temperature thermal oxygen agingImprove interface strengthCombustion-air/fuel-air treatmentMachines/enginesPolyamideHeat fusion

The invention discloses a polyamide composite material for a vehicle induction manifold. The polyamide composite material comprises the following raw materials in percentage by weight: 40-70 percent of polyamide 6, 1-10 percent of low-fusion point polyamide, 1-5 percent of compatilizer, 0.2-5 percent of composite heat stabilizer, 0.5-5 percent of lubricant and 20-40 percent of reinforcement component. Meanwhile, the invention discloses a preparation method of the polyamide composite material for the vehicle induction manifold. The composite material has good heat-resistant performance and heat fusion performance and is especially suitable for preparing workpieces of vehicle induction manifolds; moreover, the preparation method is simple, adopts traditional equipment, and is suitable for industrial production.

Owner:CGN JUNER NEW MATERIALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com