Flat oxygen-enriched membrane component

An oxygen-enriched membrane, flat-plate technology, applied in membrane technology, oxygen preparation, semi-permeable membrane separation, etc., can solve the problem of affecting the service life of oxygen-enriched membrane components, affecting the effective use area of oxygen-enriched membrane, and low utilization rate of oxygen-enriched membrane And other problems, to achieve the effect of ensuring service life, improving utilization rate and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

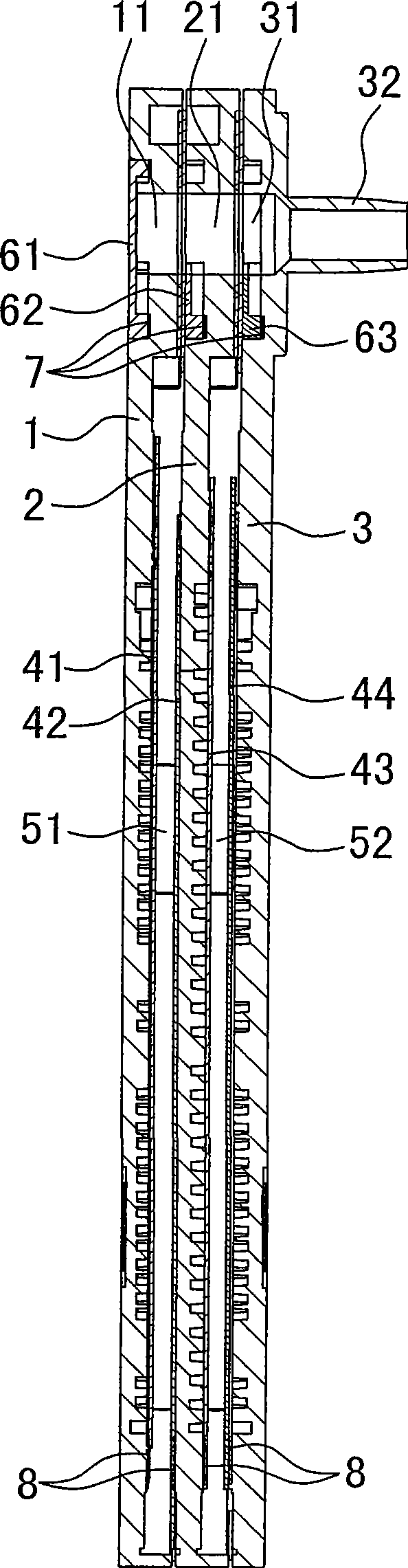

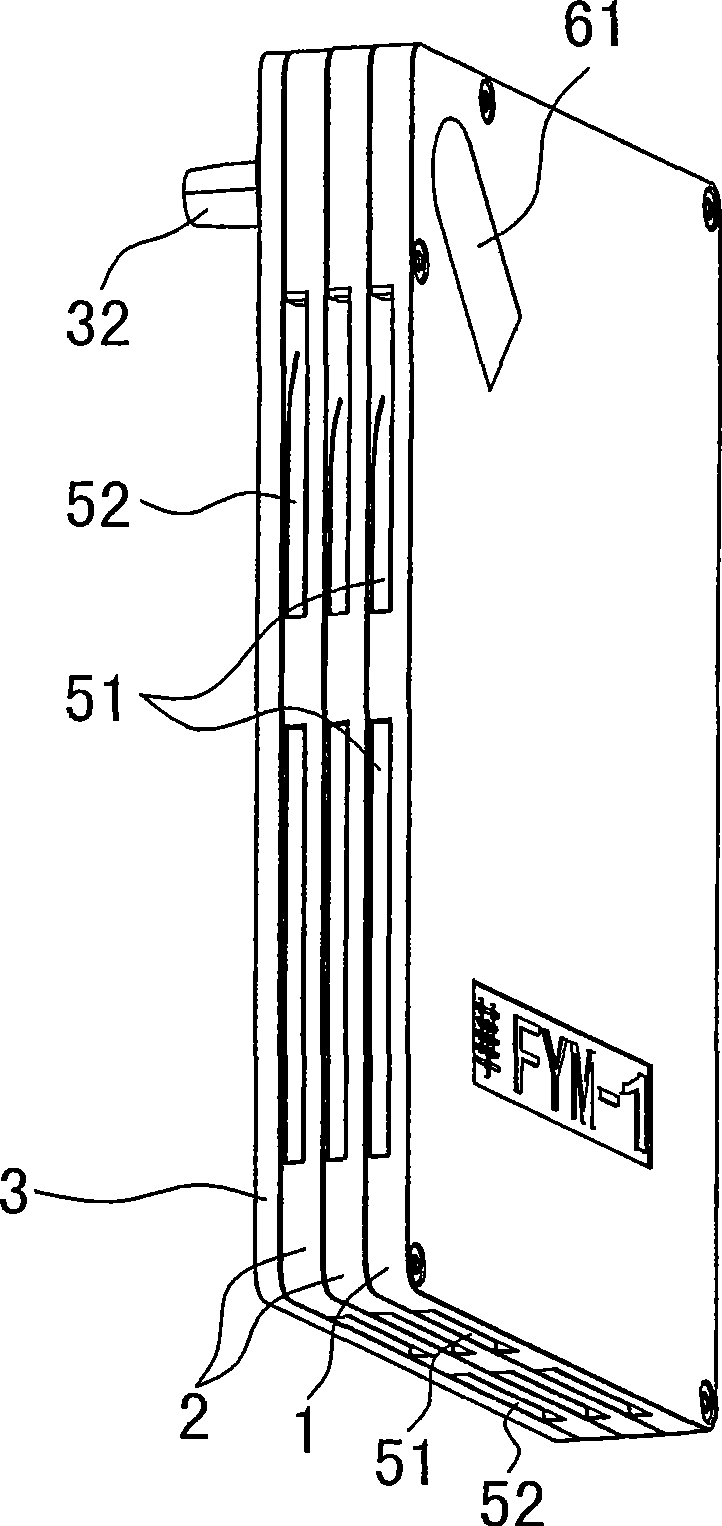

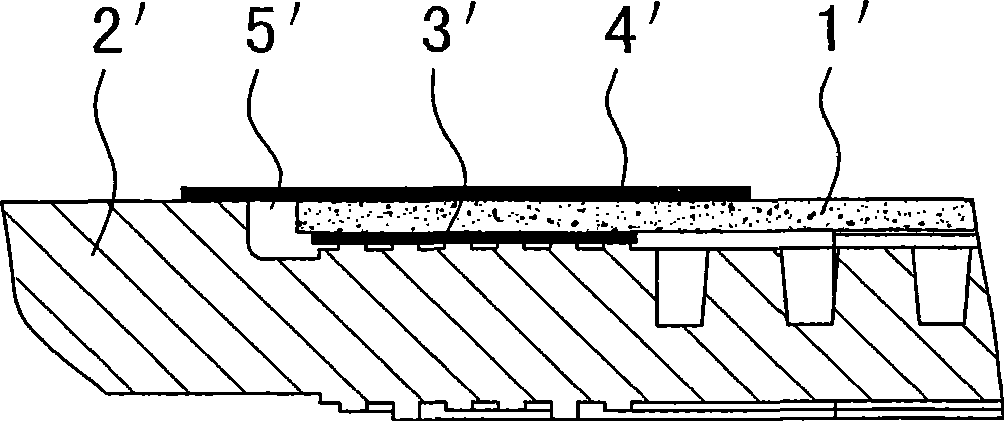

[0013] The invention discloses a flat oxygen-enriched membrane module, such as figure 1 As shown, it consists of an upper membrane plate 1, a middle membrane plate 2 and a lower membrane plate 3 fastened by screws, and one end of the upper, middle and lower membrane plates 1, 2, and 3 is formed with communicating oxygen outlets A, B, C 11, 21, 31, the inner sides of the upper and lower membrane plates 1, 3 are equipped with oxygen-enriched membranes A, D 41, 44 respectively, and the two sides of the middle membrane plate 2 are respectively equipped with oxygen-enriched membranes B, C 42, 43, There are air passages A and B 51, 52 between adjacent two oxygen-enriched membranes, and one end of the air passages A and B communicates with the atmosphere, such as figure 2 As shown, the upper, lower, left and right sides of the diaphragm are provided with a plurality of air passages, the other ends of the air passages A and B communicate with the oxygen outlets A, B and C 11, 21, 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com