Patents

Literature

201results about How to "Increase the effective use area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multiscreen portable terminal and touch control method thereof

InactiveCN103793093ASmall sizeIncrease the effective use areaInput/output processes for data processingHuman–computer interactionSenses touch

Owner:SHANGHAI WINGTECH ELECTRONICS TECH

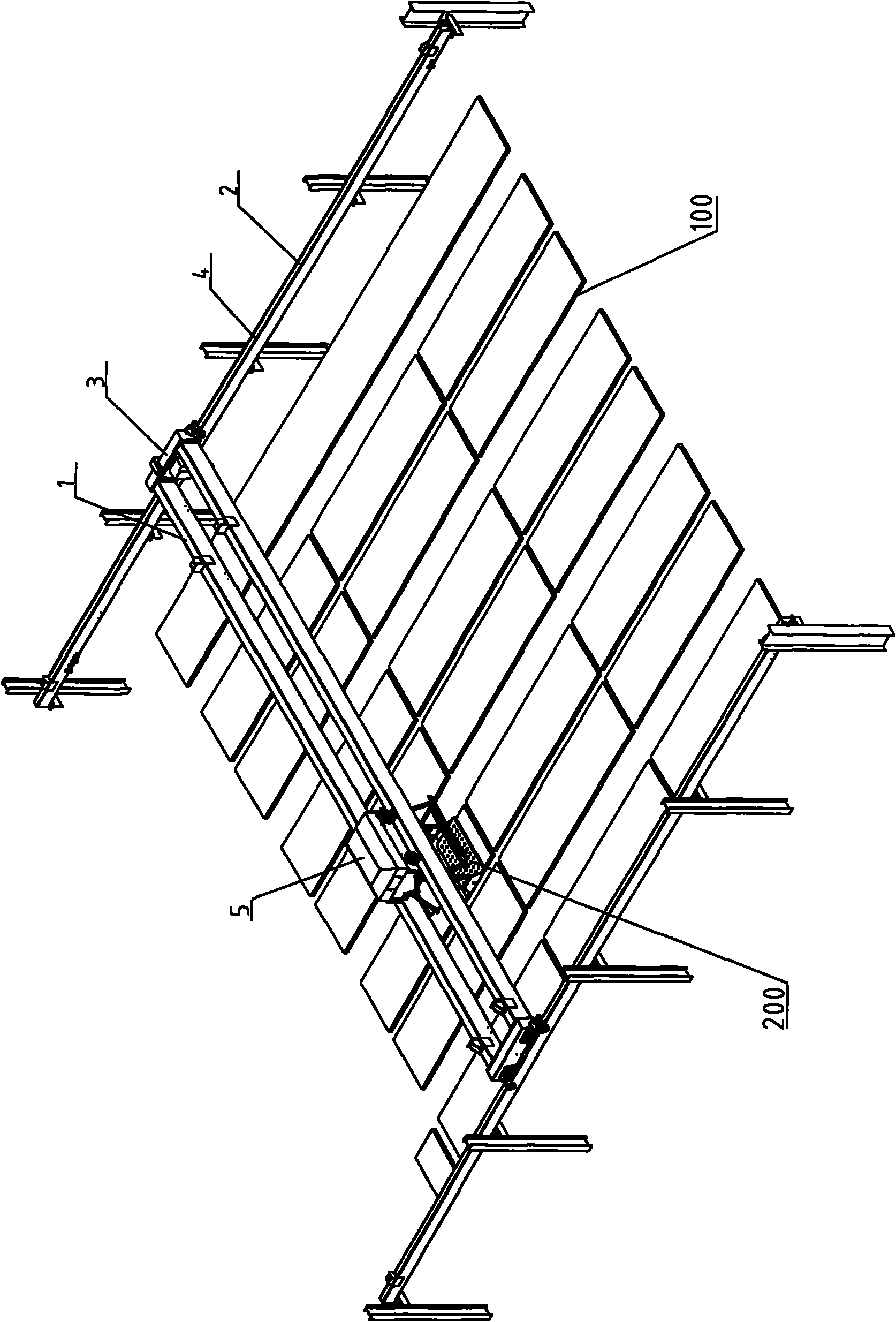

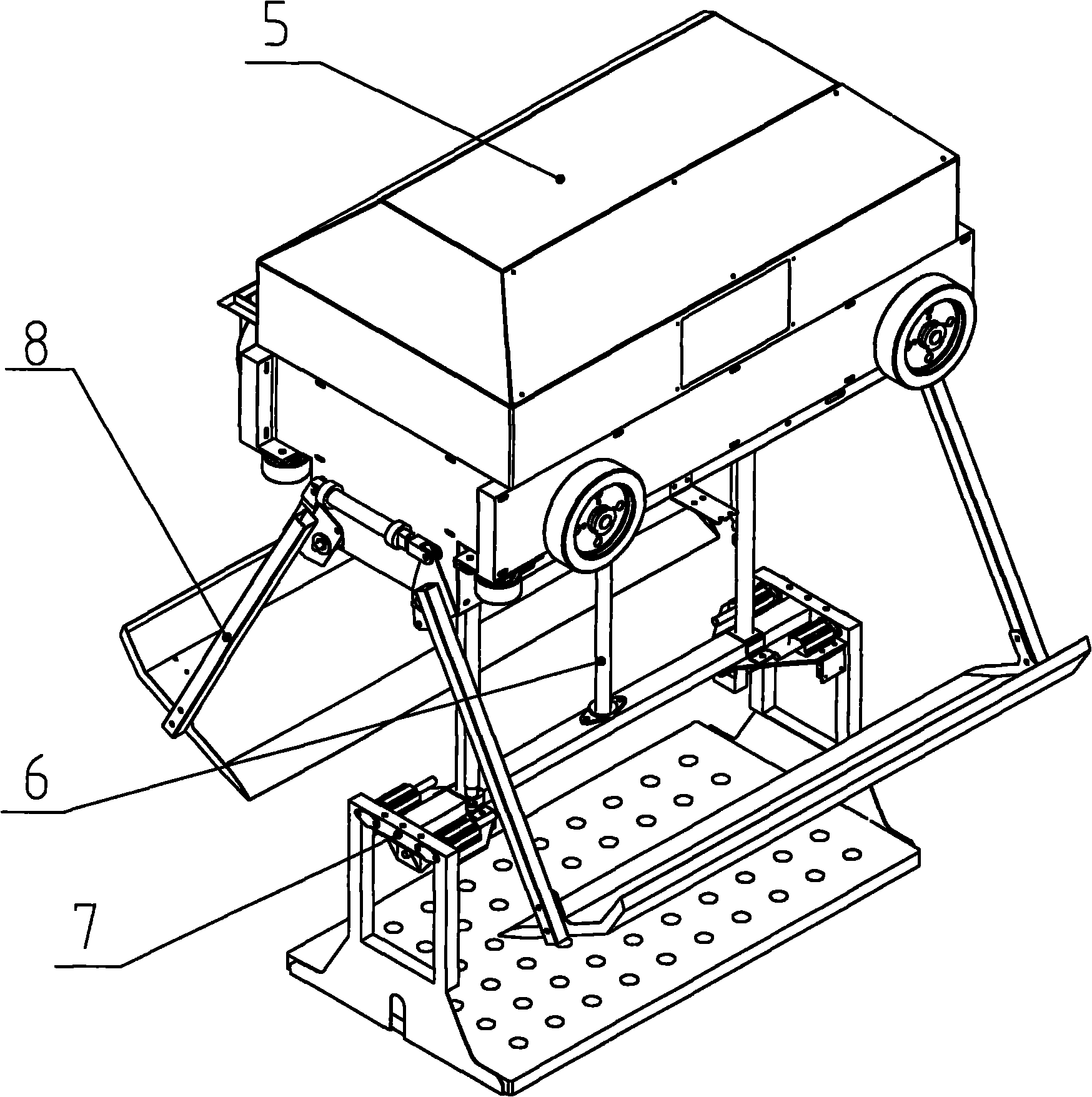

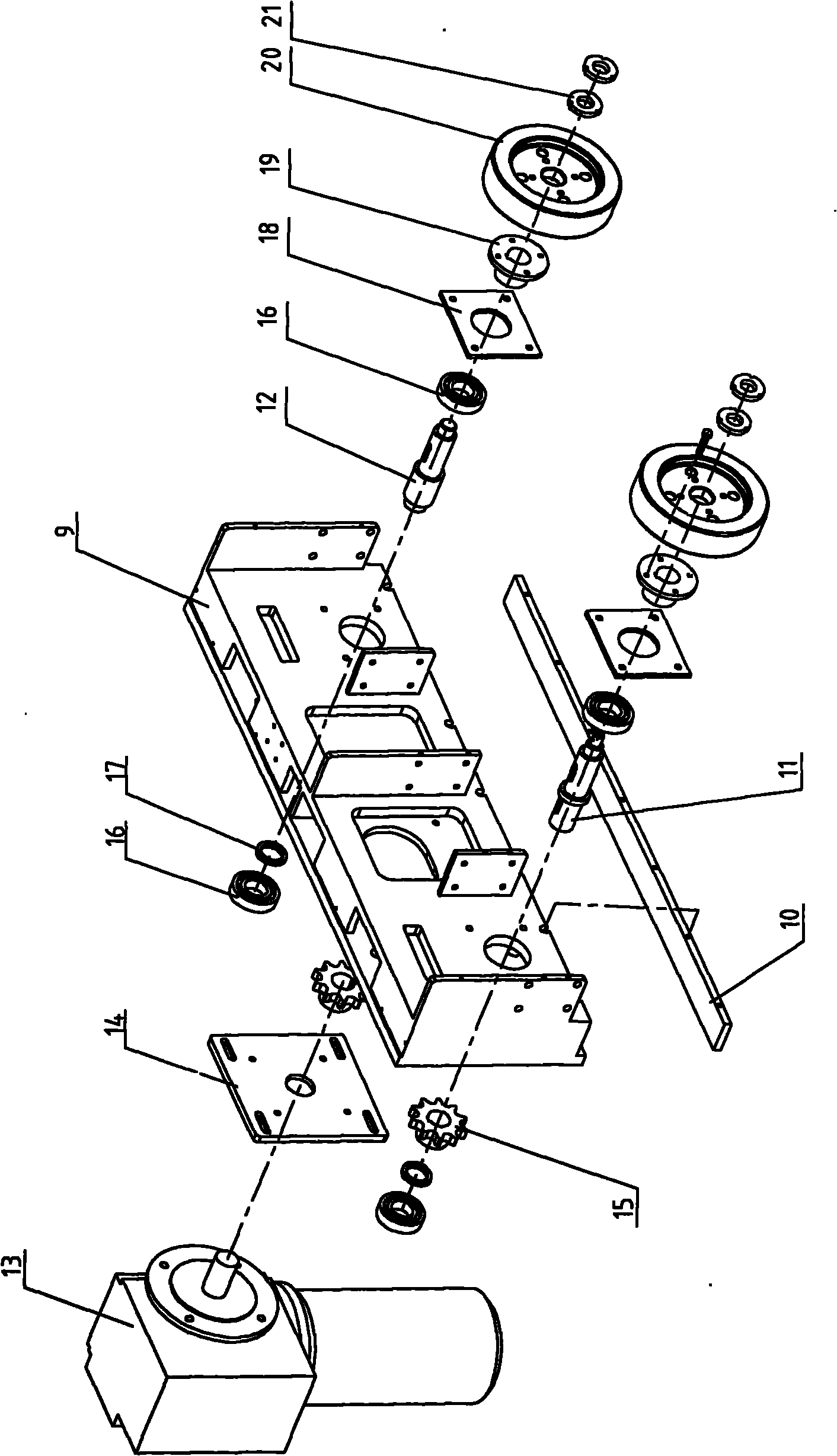

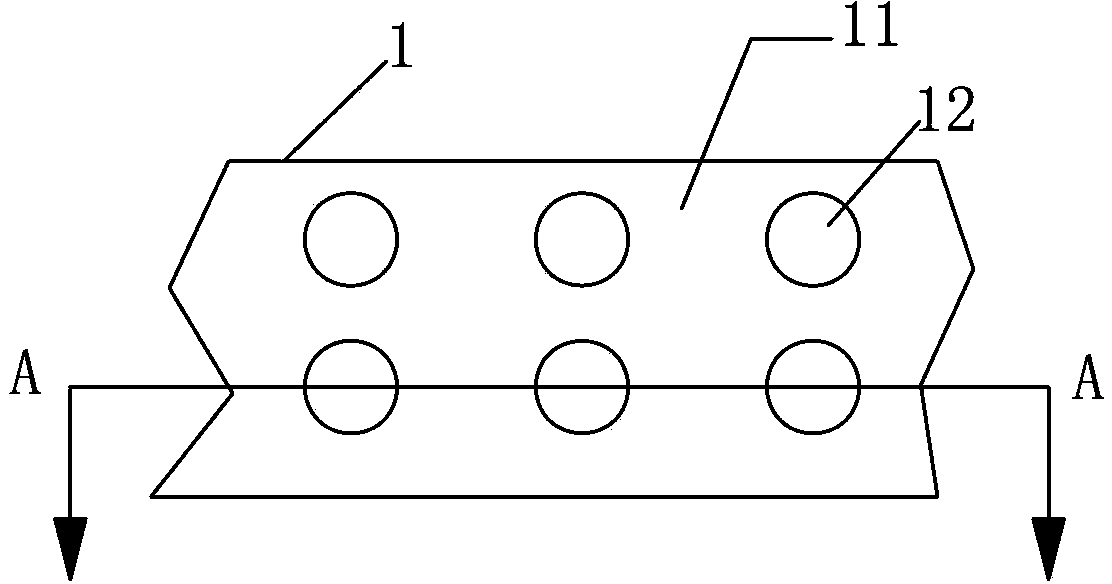

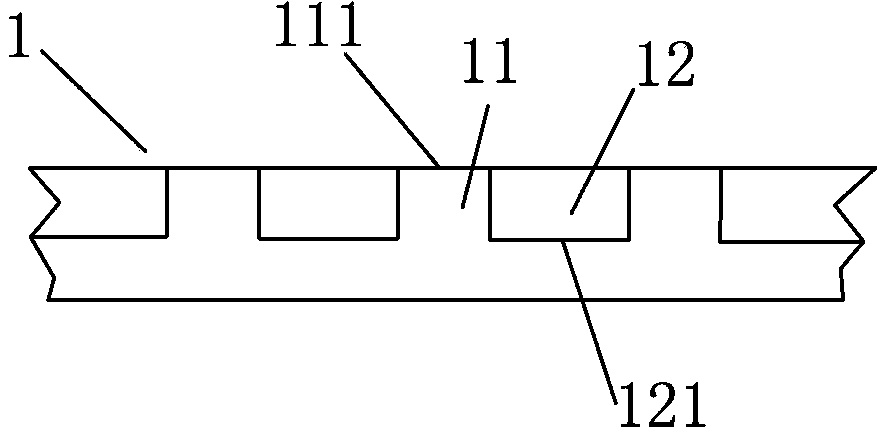

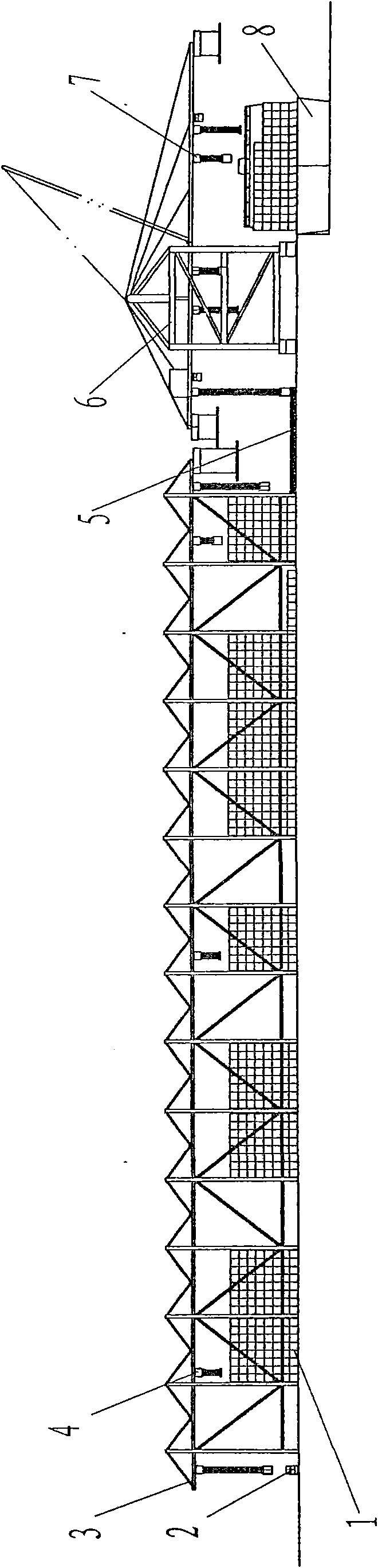

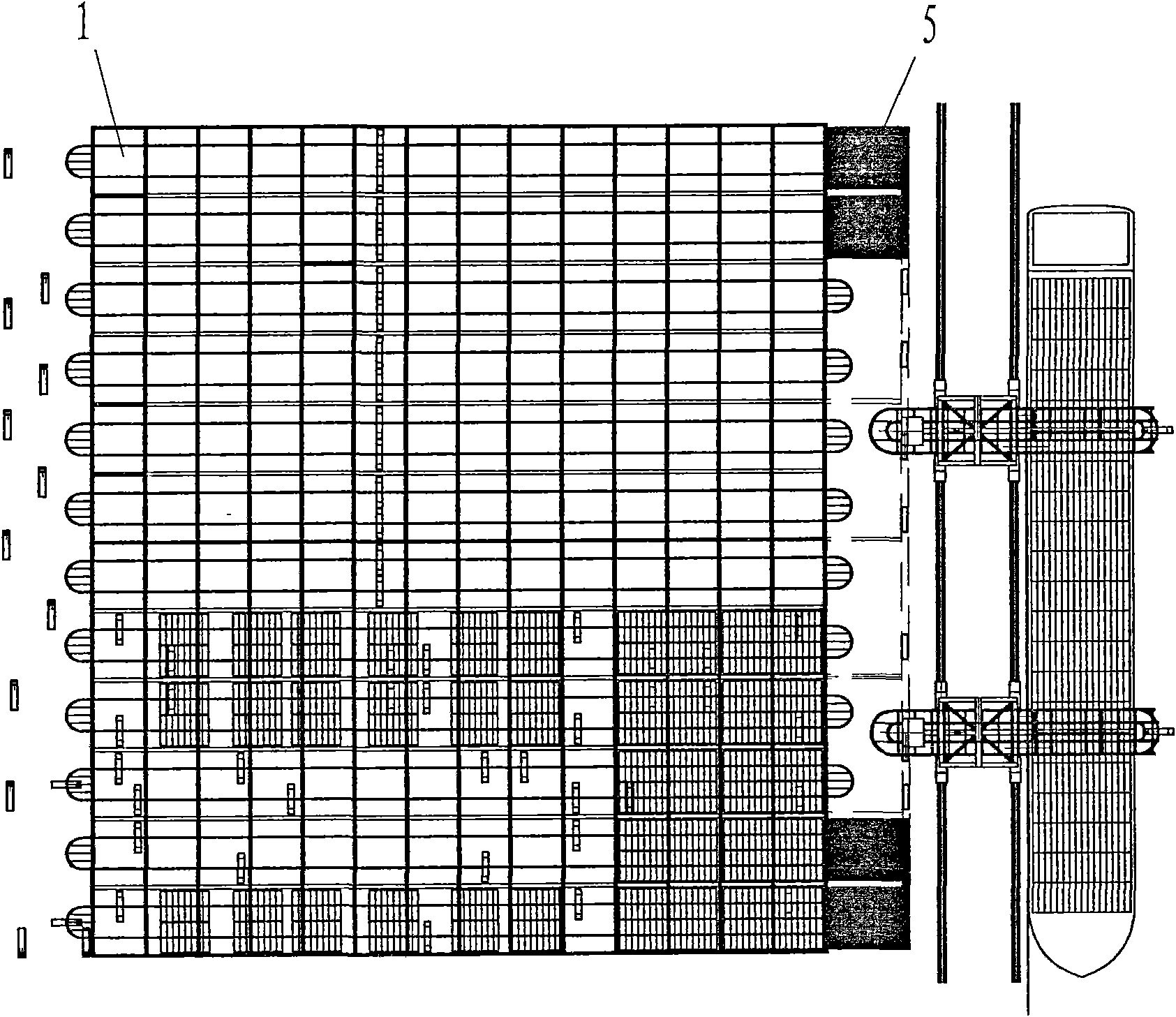

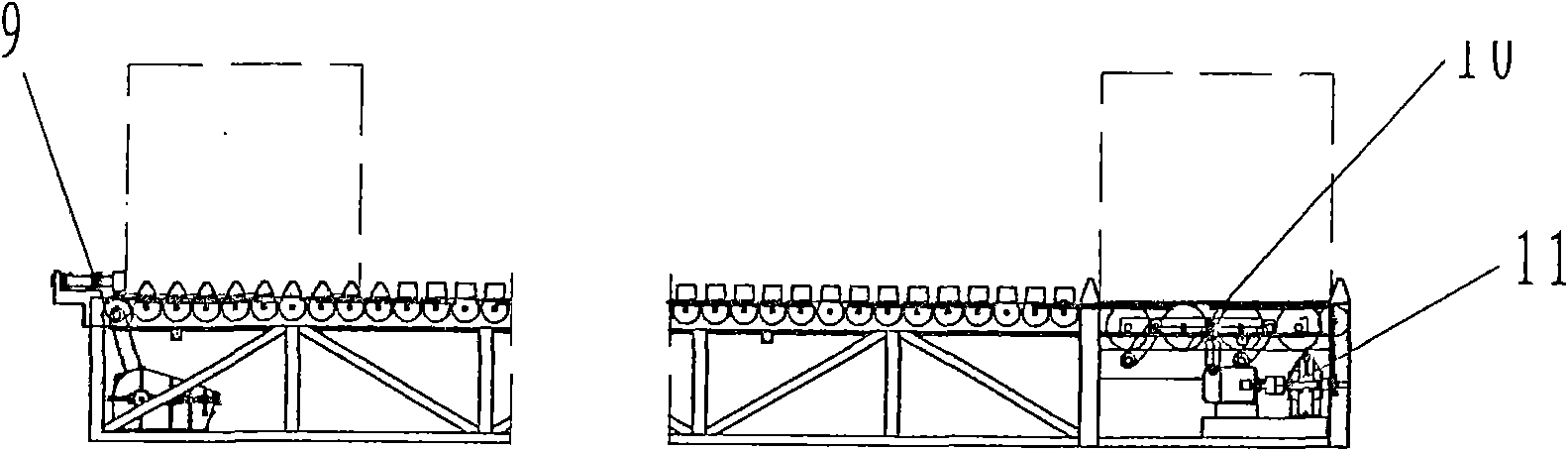

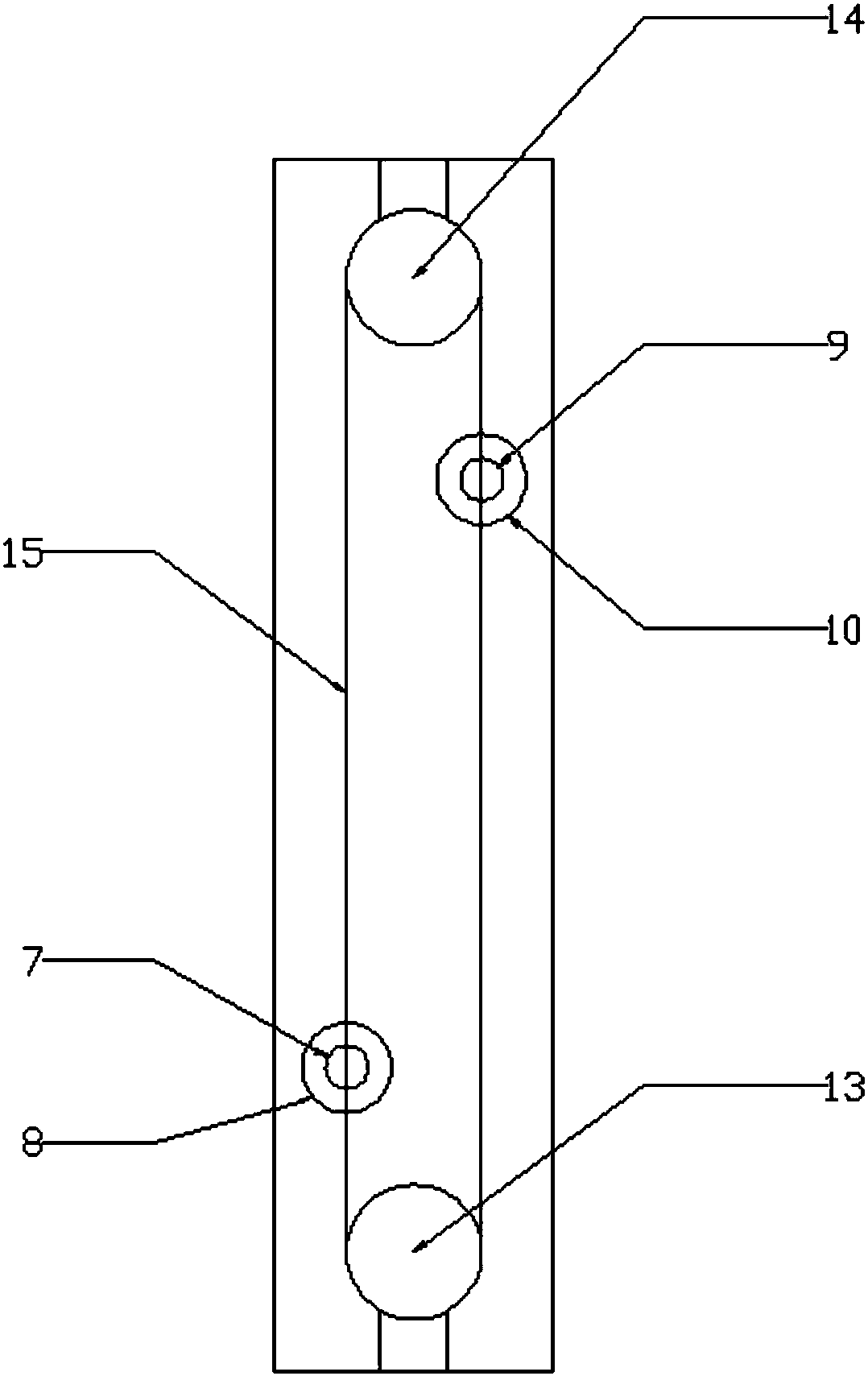

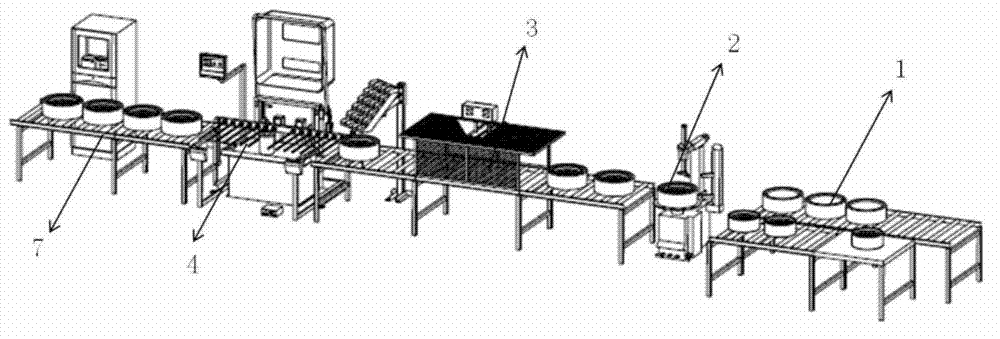

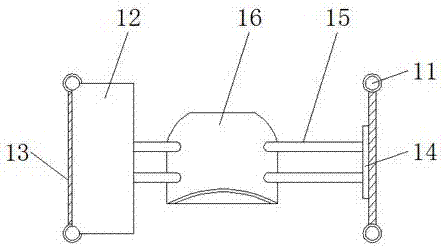

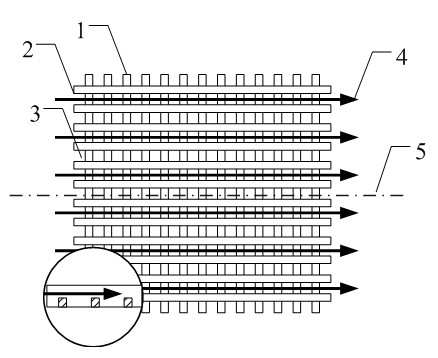

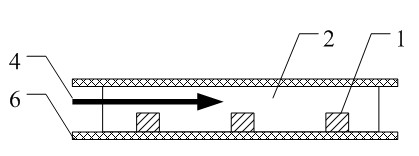

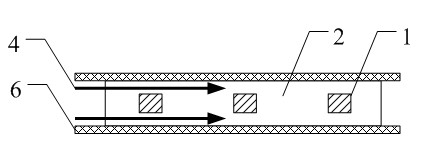

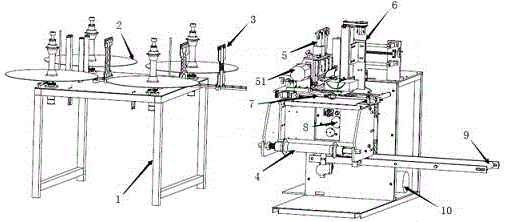

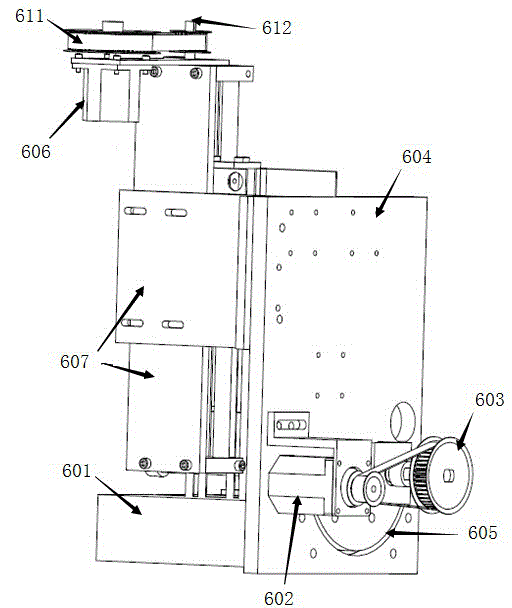

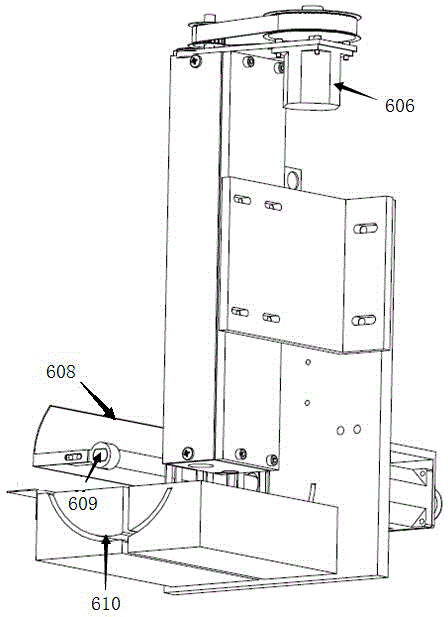

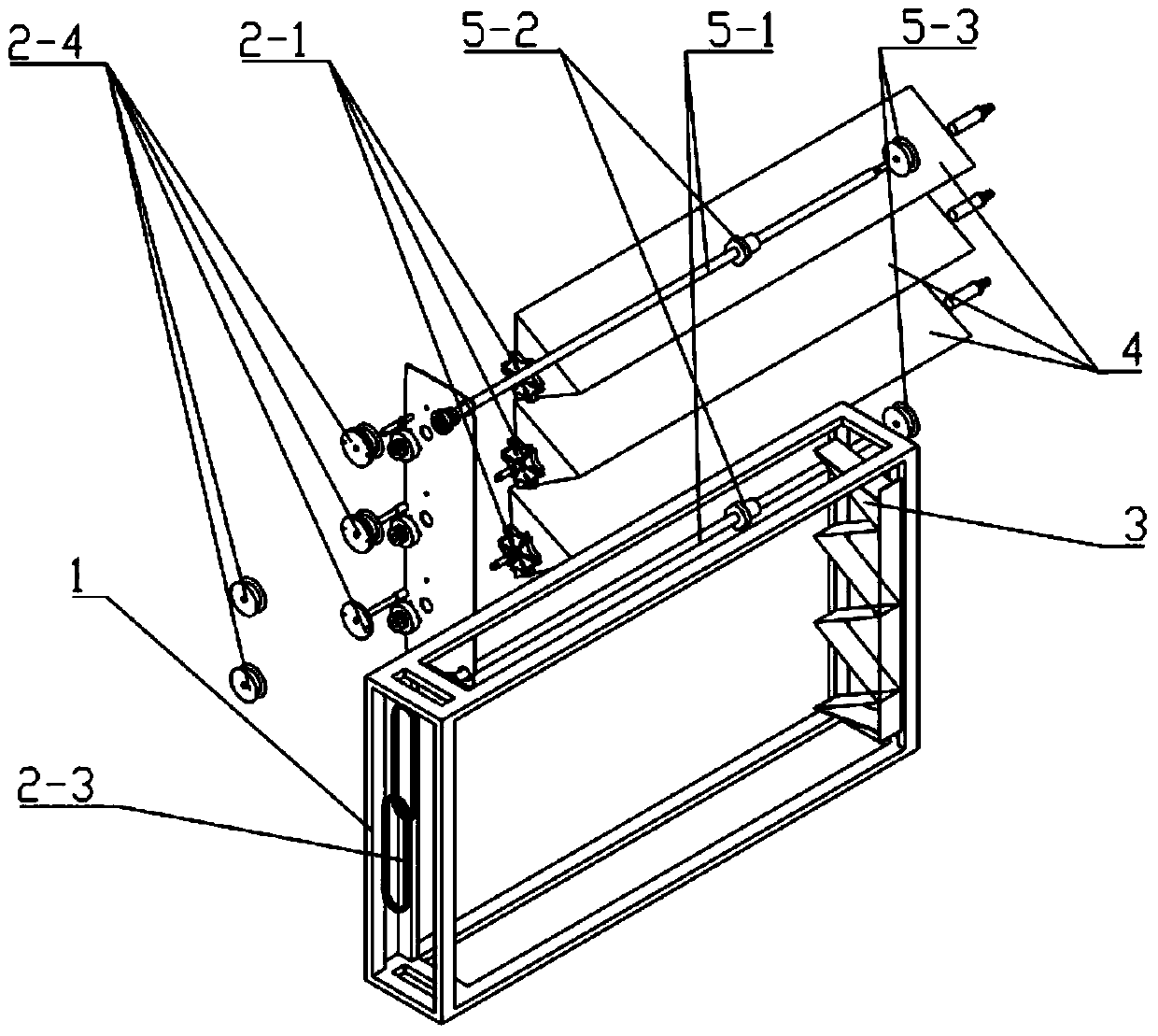

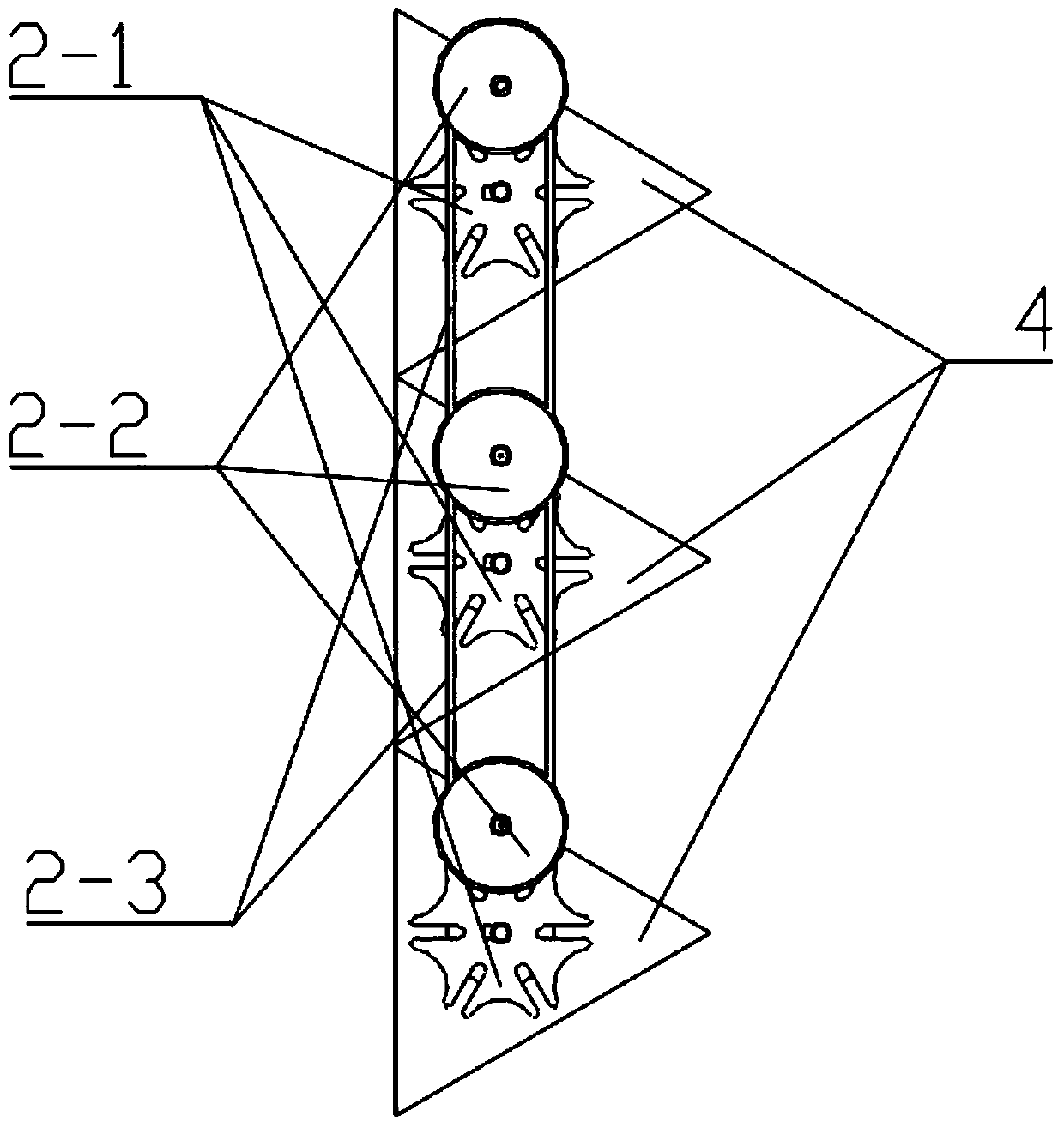

Conveying device for plug transplantation

ActiveCN101792064AIncrease the effective use areaIncrease profitCultivating equipmentsConveyor partsWheel driveSprocket

The invention relates to a conveying device for plug transplantation, which comprises stationary rails, two movable rails and a mobile car device, wherein the stationary rail is respectively erected at the two sides of a whole seedling bed in a greenhouse, and the two movable rails bestride the two stationary rails; the movable rail consists of two sprocket wheel driving devices, and the same sides of the two movable rails are respectively fixed on a pair of movable rail moving devices; the movable rail moving devices are erected on the stationary rails and can move along the stationary rails, and the mobile car device is arranged on sprocket wheels of the two movable rails; the lower part of the mobile car device is connected with a pneumatic lifting device, and the output end of the pneumatic lifting device is connected with a pneumatic gripping device; a pneumatic protecting device is arranged below the mobile car device, and at least one of a movable rail movement detecting deviceand a mobile car detecting device is assembled; and sensors for detecting and positioning are assembled on the pneumatic lifting device, the pneumatic gripping device and the pneumatic protecting device. The invention aims to reduce the labor intensity of workers, reduce the number of the workers, improve the utilization rate of greenhouse space, and increase the number of plugs in the existing greenhouse area to increase yield.

Owner:BEIJING KINGPENG INT HI TECH CORP

Three-dimensional non-woven fabric

ActiveCN103417338AIncrease the effective use areaPromotes rapid absorptionNon-woven fabricsBandagesWoven fabricEngineering

The invention discloses three-dimensional non-woven fabric. The surface of the three-dimensional non-woven fabric comprises a plurality of convex parts and a plurality of concave parts. The convex parts and the concave parts are arranged at intervals and are made of the same material. The contact angle of 20% to 100% area of each convex part and water is larger than 70 degrees, and the contact angle of 20% to 100% area of each concave part and the water is smaller than 70 degrees. The three-dimensional non-woven fabric has the advantages of being dry and comfortable.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

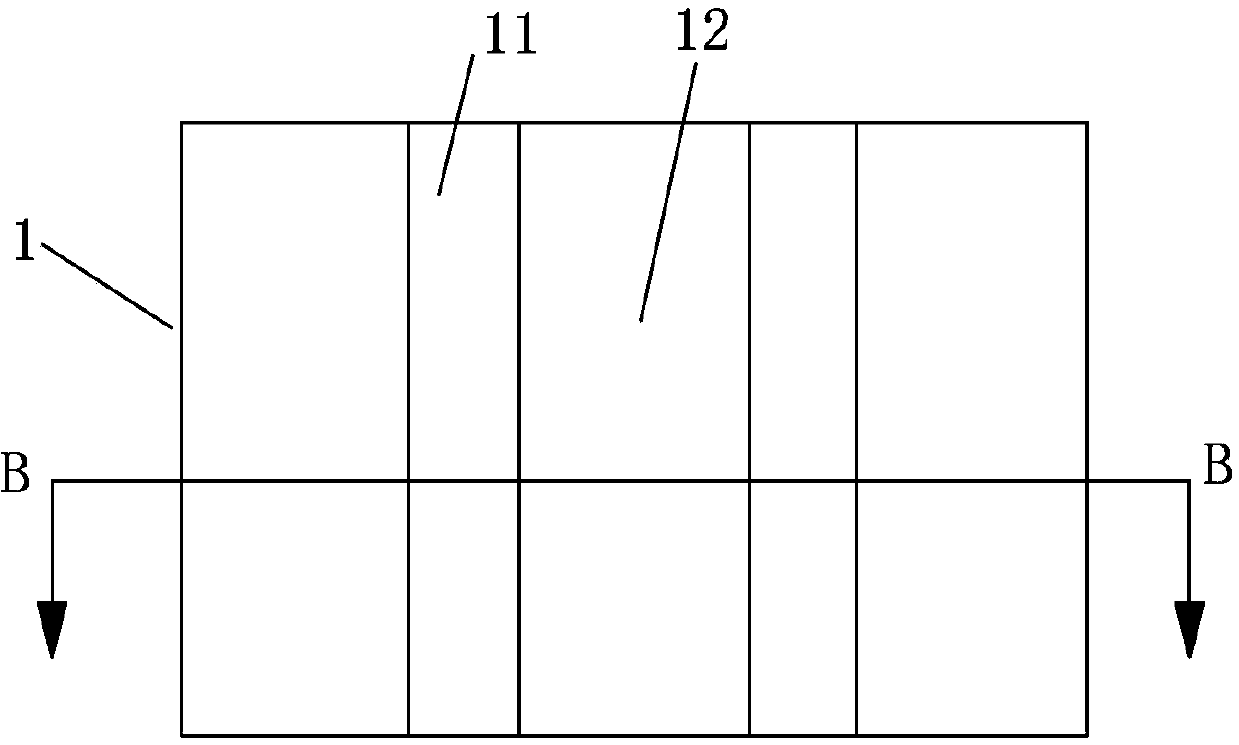

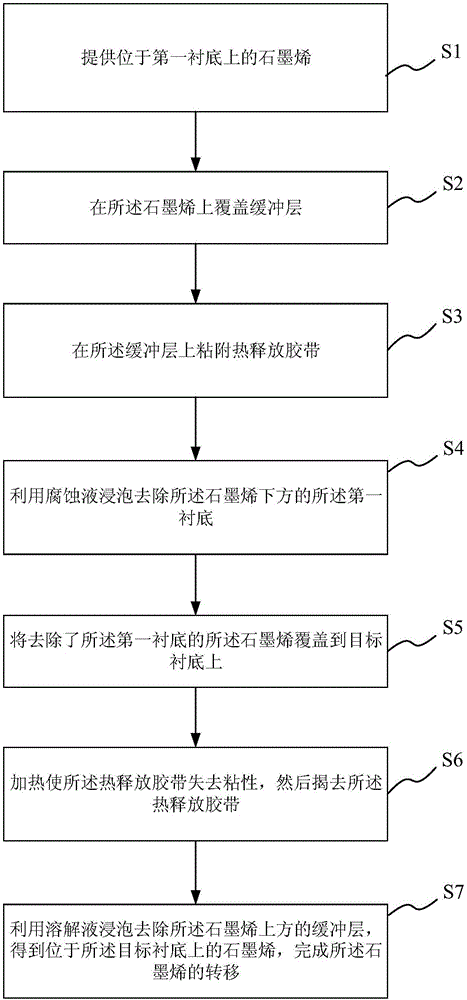

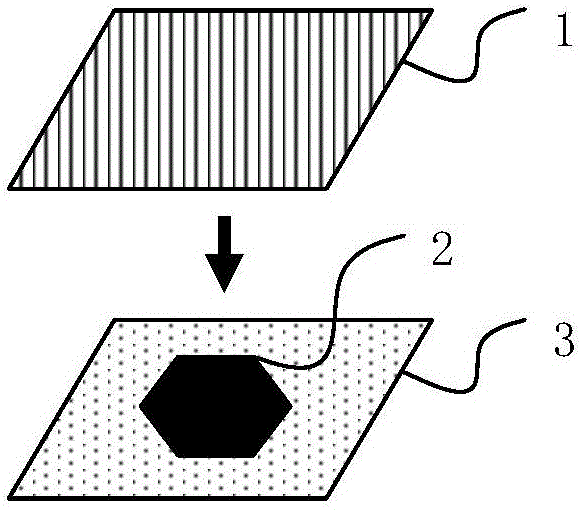

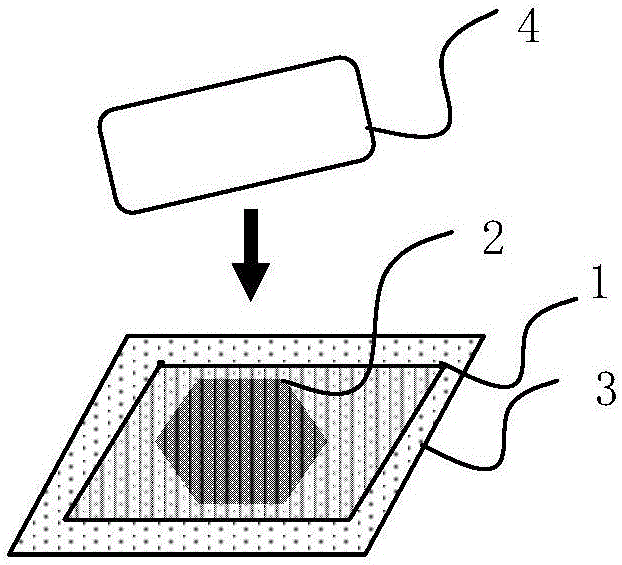

Method for transferring graphene

The invention provides a method for transferring graphene. The method comprises the following steps: providing graphene on a first substrate; covering a buffer layer on the graphene; adhering a heat release adhesive tape on the buffer layer; soaking the first substrate in a corrosive solution to remove the first substrate under the graphene; covering the graphene without the first substrate on a target substrate; heating to make the heat release adhesive belt become non-sticky, removing the heat release adhesive belt; and soaking the buffer layer in a dissolving solution to remove the buffer layer on the graphene to obtain graphene on a target substrate to finish the transferring of graphene. According to the method, a buffer layer is used to assist the transferring of graphene, the required steps are few, the process is fast and convenient, the upper and lower surfaces of graphene are clean, no substance is adhered on the upper and lower surfaces of the graphene, the wrinkles in the microscopic level are reduced, thus the effective usable area of graphene is enlarged, and the graphene can be more suitable for being used to prepare electronic devices.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

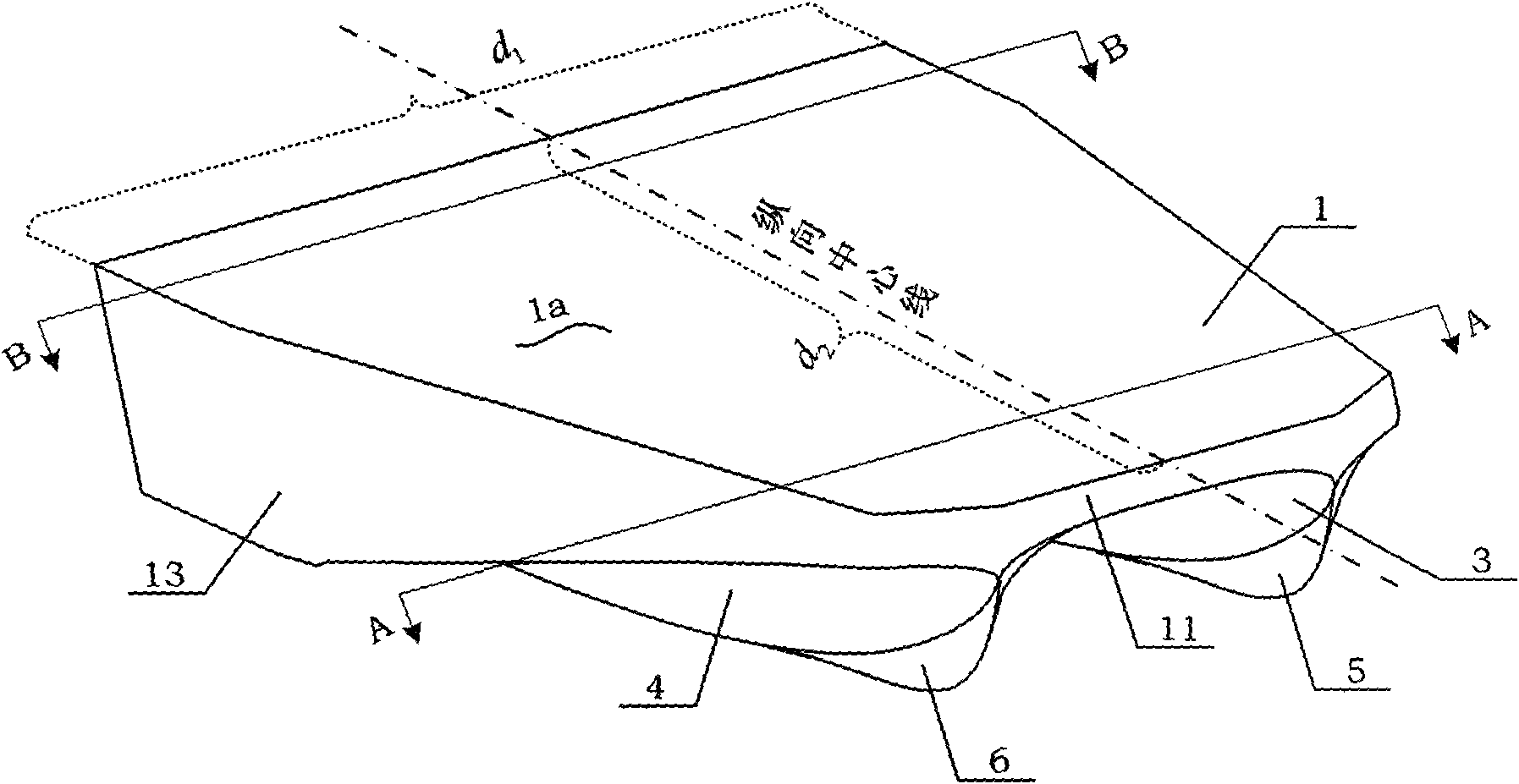

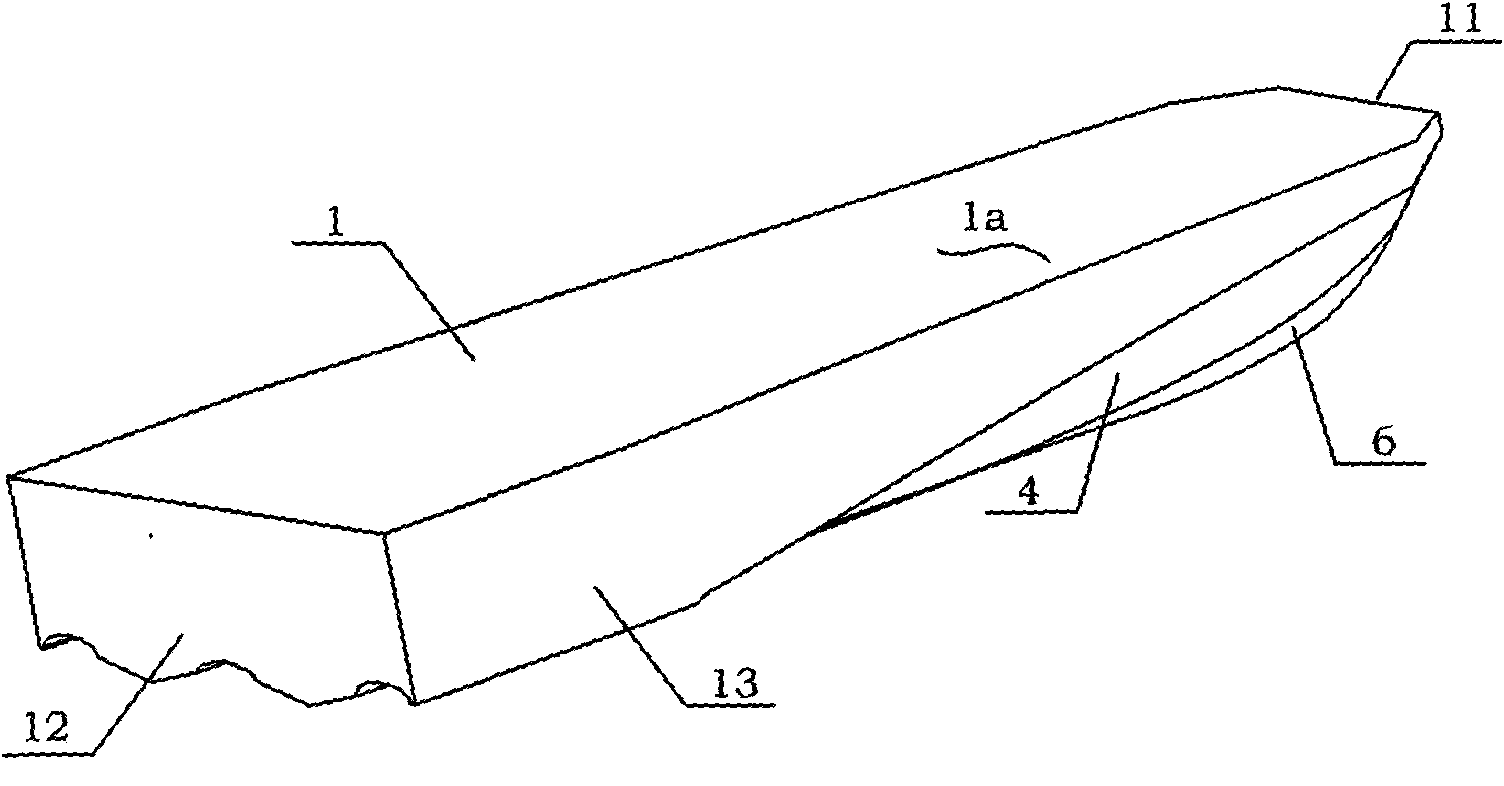

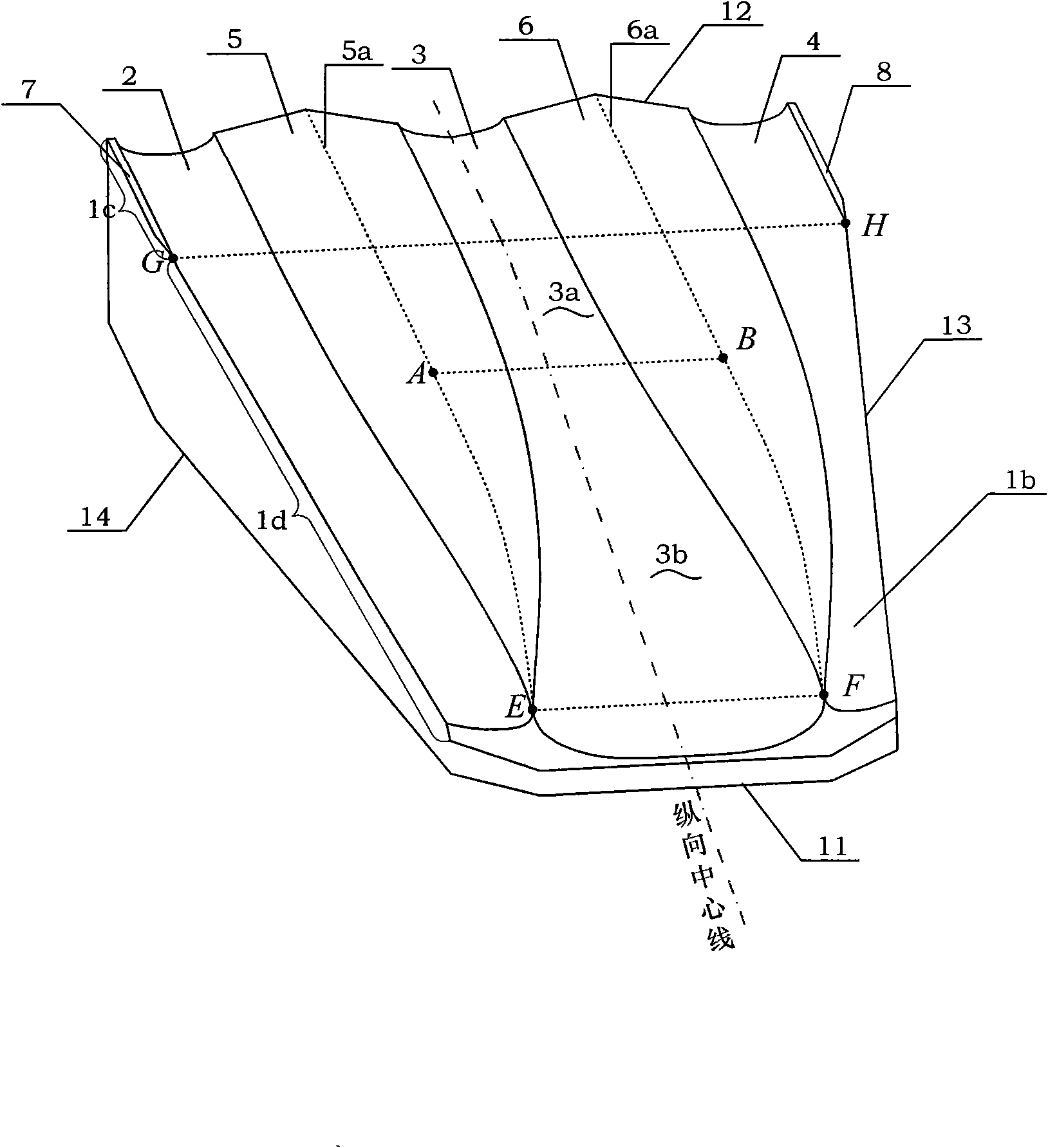

Planing boat with catamaran three-channel hull

InactiveCN101554918AReduced sailing draftSuppressing wavesHull stemsHydrodynamic/hydrostatic featuresStress concentrationStress Problem

The invention discloses a planing boat with a catamaran three-channel hull. The planing boat is provided with a hull and a board at least. The bottom of the hull is provided with an A trunk bulkhead end surface, a B trunk bulkhead end surface, an A slideway, a B slideway, a C slideway, an A planing surface and a B planing surface; the B slideway is arranged along a central line and is a sector structure; the A planing surface and the B planing surface are arranged at two sides of the B slideway; the A slideway is arranged between the A planing surface and a right trunk bulkhead which is provided with the A trunk bulkhead end surface at the stern; and the C slideway is arranged between the B planing surface and a left trunk bulkhead which is provided with the B trunk bulkhead end surface at the stern. The catamaran three-channel hull adopts oval channel section conformation to solve the concentrative stress problem of the hull effectively.simultaneously, on the basis of common channel planing boats, the invention adds two outer side channels at two sides of the stern and changes single channel type into three-channel type, thus greatly increasing the width of the stern, not only improving the effective use area of the board, but also enhancing the transversal stability of the planing boat and being capable of reducing the wave making of the boat.

Owner:BEIHANG UNIV

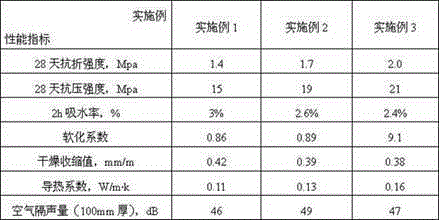

Waterproof phase-change heat storing plaster wallboard formed by reinforcing straw fibers

ActiveCN105060830AHigh strengthImprove waterproof performanceSolid waste managementCement boardPhase change

The invention discloses a waterproof type phase-change heat storing plaster wallboard formed by reinforcing straw fibers. The plaster wallboard is compounded from the following raw materials in percentage by weight: 20-60% of plaster gelate materials, 10-25% of phase-change heat storing microcapsules, 1-7% of a composite water repellent, 25-55% of mineral micro powder, 0.1-0.6% of straw fibers, 0.8-1.5% of a binder, 1-5% of an exciting agent and 0.2-1.5% of a water reducing agent. The preparation method comprises the following steps of: 1) firstly, adding the plaster gelate materials, the mineral micro powder, the straw fibers and the exciting agent into a reaction kettle, adding water, and uniformly stirring the plaster gelate materials, the mineral micro powder, the straw fibers, the exciting agent and the water so as to obtain a material A; 2) sequentially adding the phase-change heat storing microcapsules, the composite water repellent, the binder and the water reducing agent into the reaction kettle, and stirring the material A, the phase-change heat storing microcapsules, the composite water repellent, the binder and the water reducing agent once again so as to obtain a material B; and 3) directly pouring the material B in the reaction kettle into a mold through a grouting pump so as to obtain the phase-change heat storing plaster wallboard, wherein a fiber cement board is arranged on the inner surface of the mold. The waterproof type phase-change heat storing plaster wallboard disclosed by the invention has the advantages of being suitable for operation under humid environment, simple in production technology and environment-friendly.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

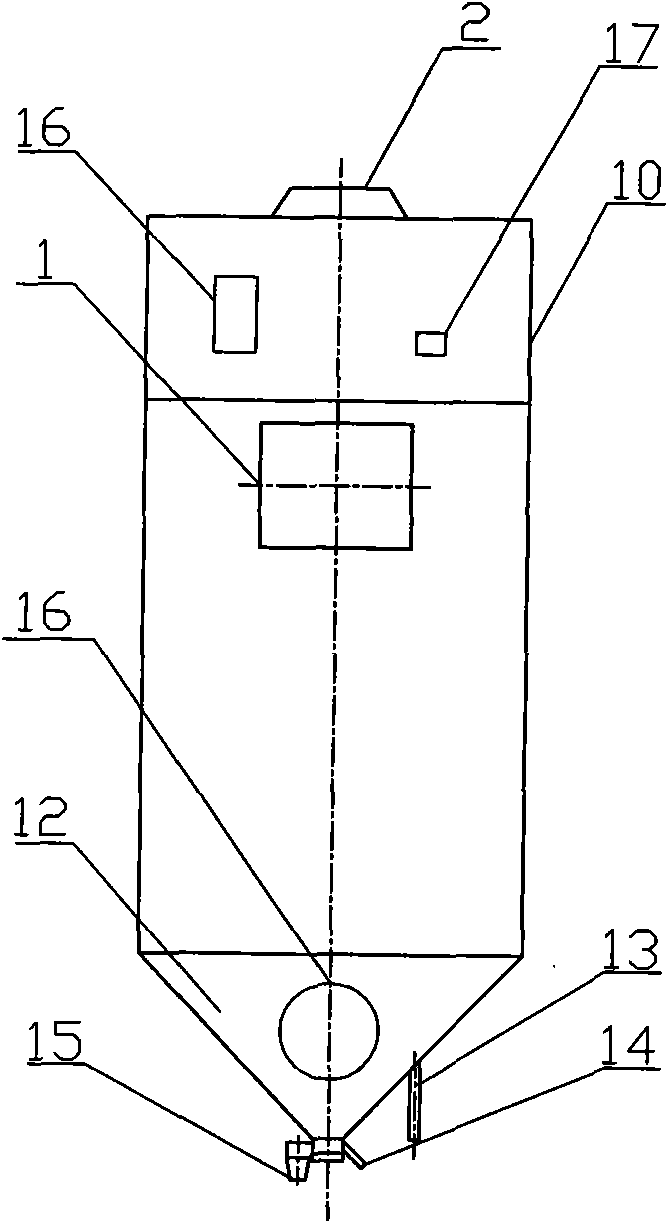

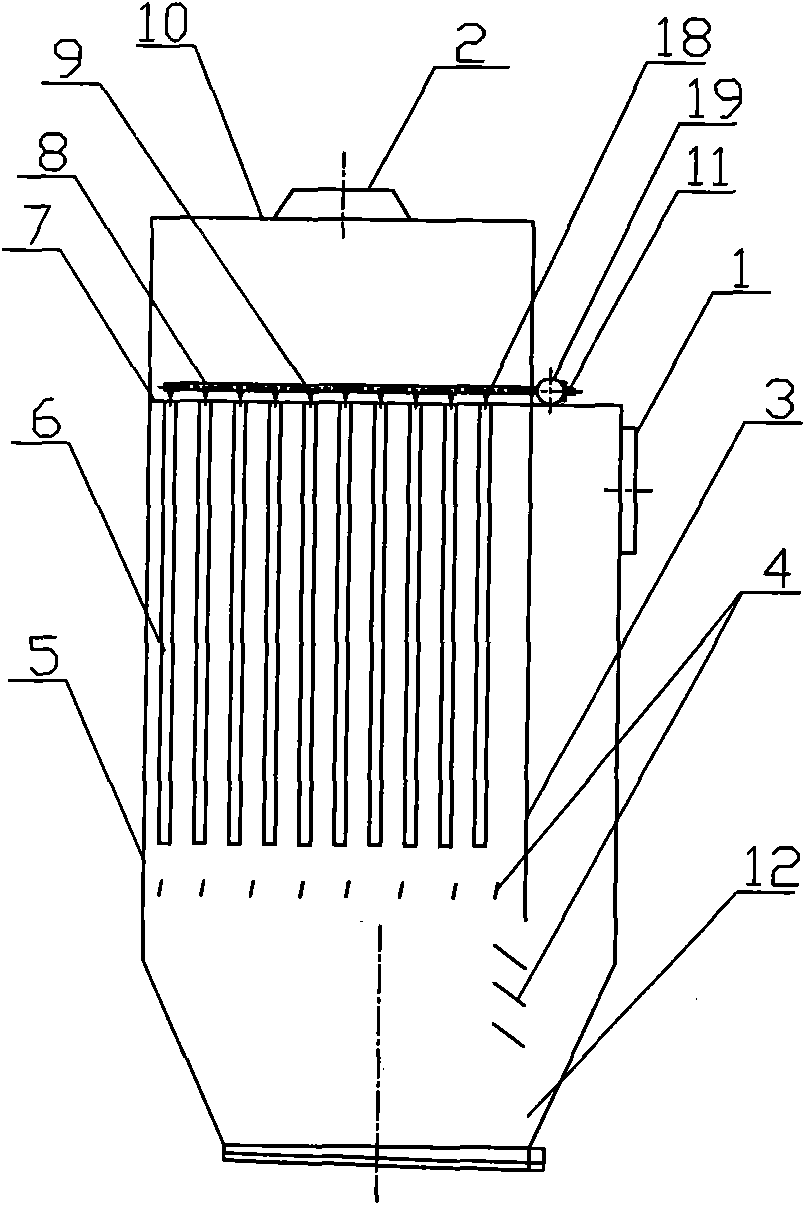

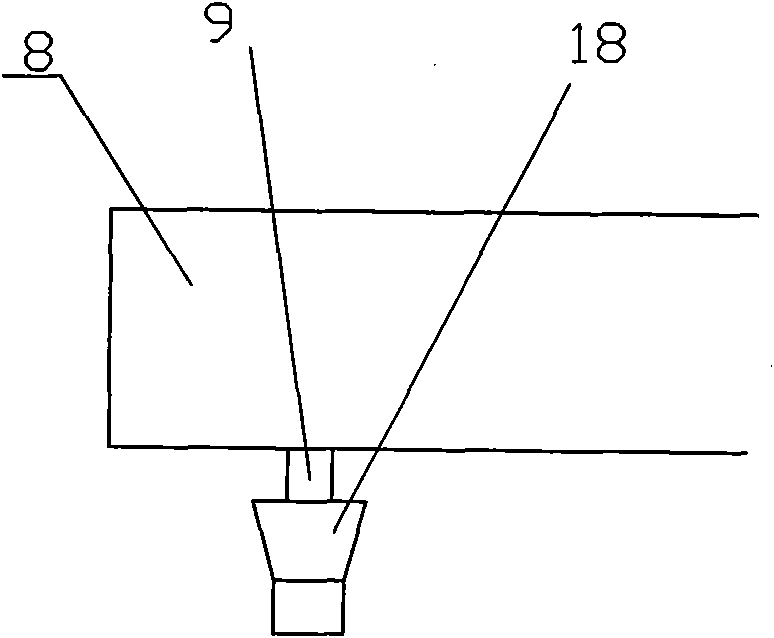

High-efficiency pre-separation pulse bag-type dust collector

InactiveCN102059026AIncrease distanceImprove adsorption efficiencyDispersed particle filtrationElectrolysisBaghouse

The invention relates to a high-efficiency pre-separation pulse bag-type dust collector. The high-efficiency pre-separation pulse bag-type dust collector comprises a dust collector air outlet formed on an upper box body, and a dust collector air inlet formed on the lower part of a middle box body; a blowpipe, a nozzle, a framework and a cloth bag are arranged in the middle box body; the dust collector air inlet is formed on the upper part of the middle box body, and a separator is arranged between the dust collector air inlet and the framework; the cloth bag is arranged on the framework; and a guide plate is arranged below the separator. The high-efficiency pre-separation pulse bag-type dust collector has the advantages that: the motion distance of flue gas and particles inside the dust collector is increased, the adsorption efficiency of alumina particles is improved, the adsorption effect in the whole purification process is improved, gas-solid separation is realized before dust reaches a filter bag, the compressed air consumption is reduced, the load of the filter bag is reduced, and the service life of the filter bag is prolonged. The dust collector is limited to an electrolysis flue gas purification system, and can be applied to other industries of dust removal and flue gas purification.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

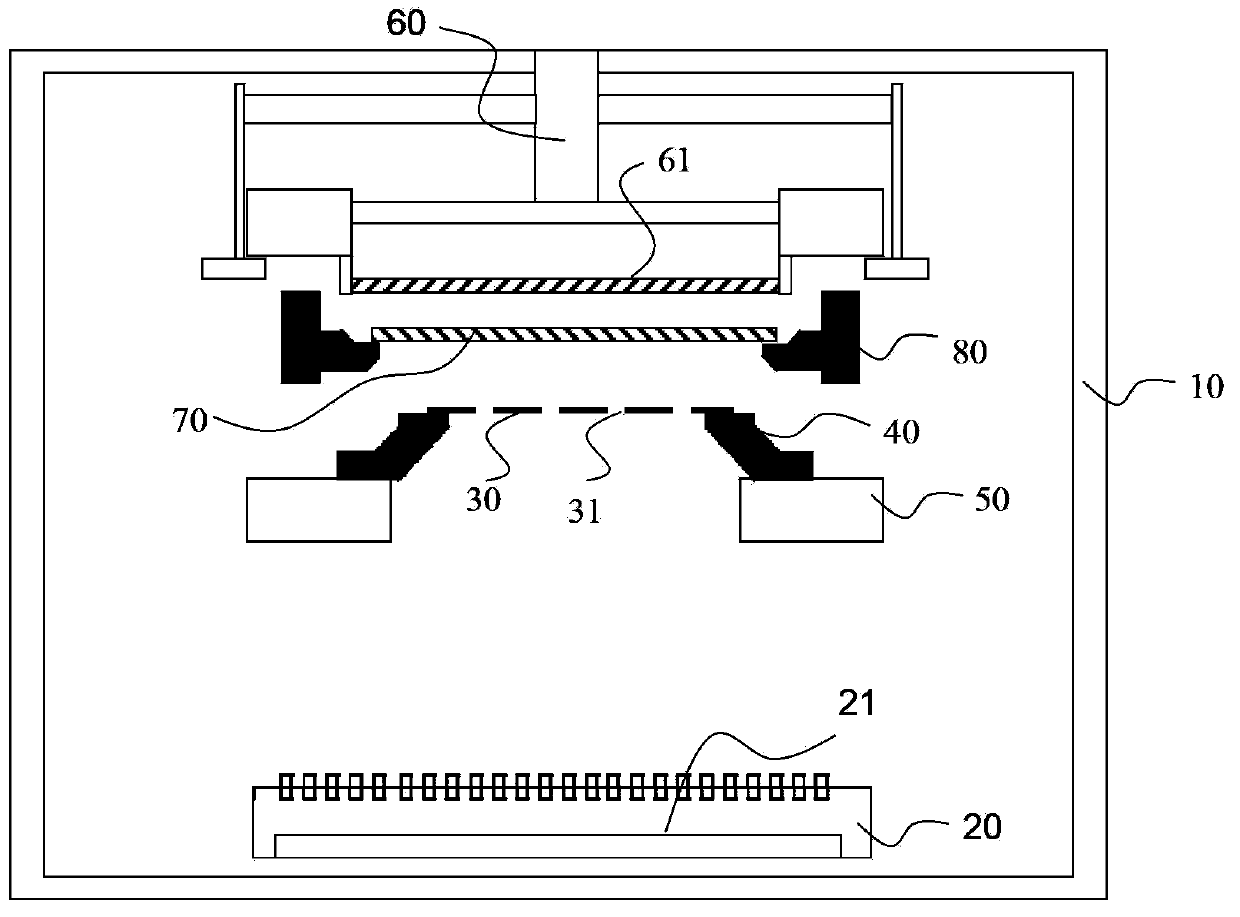

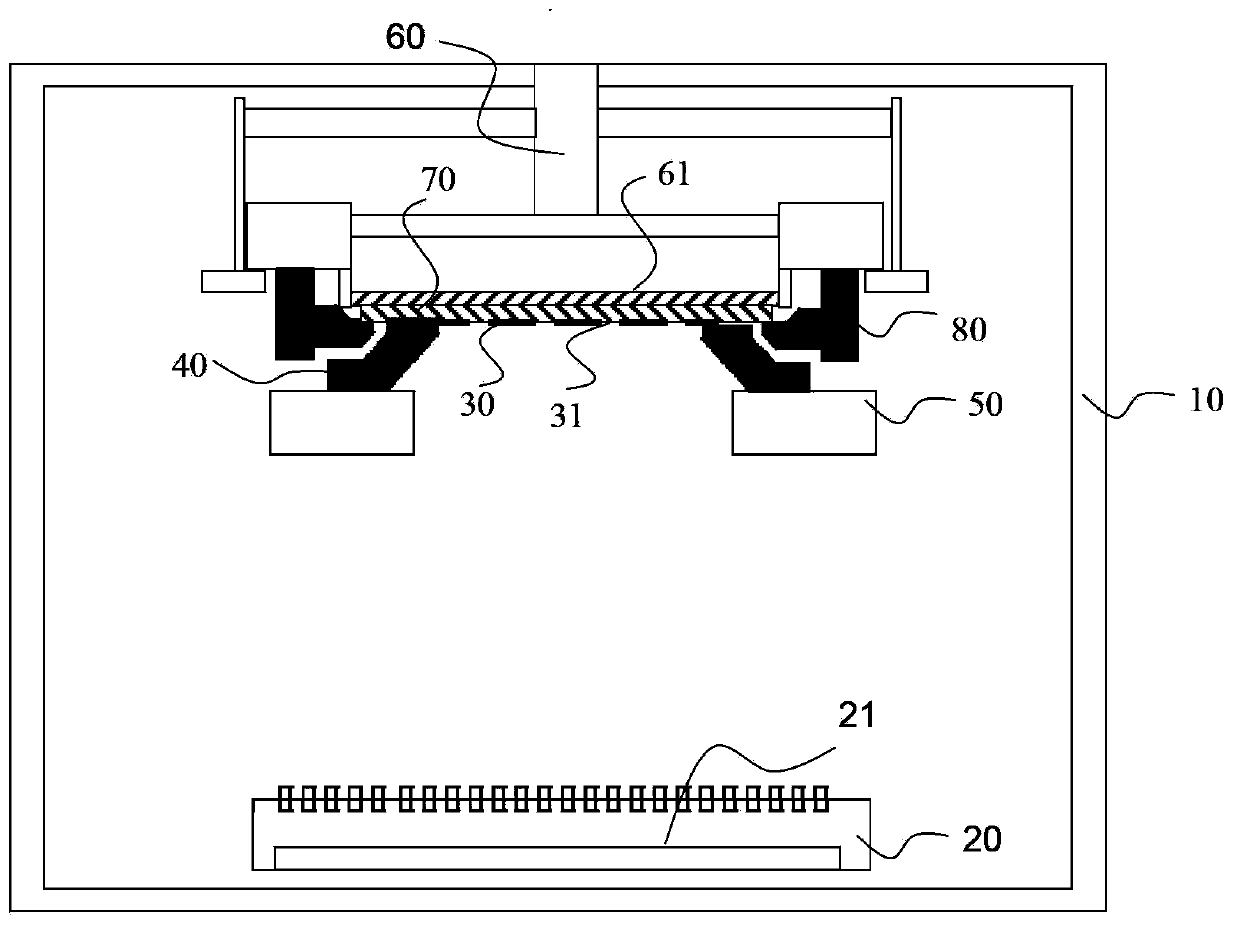

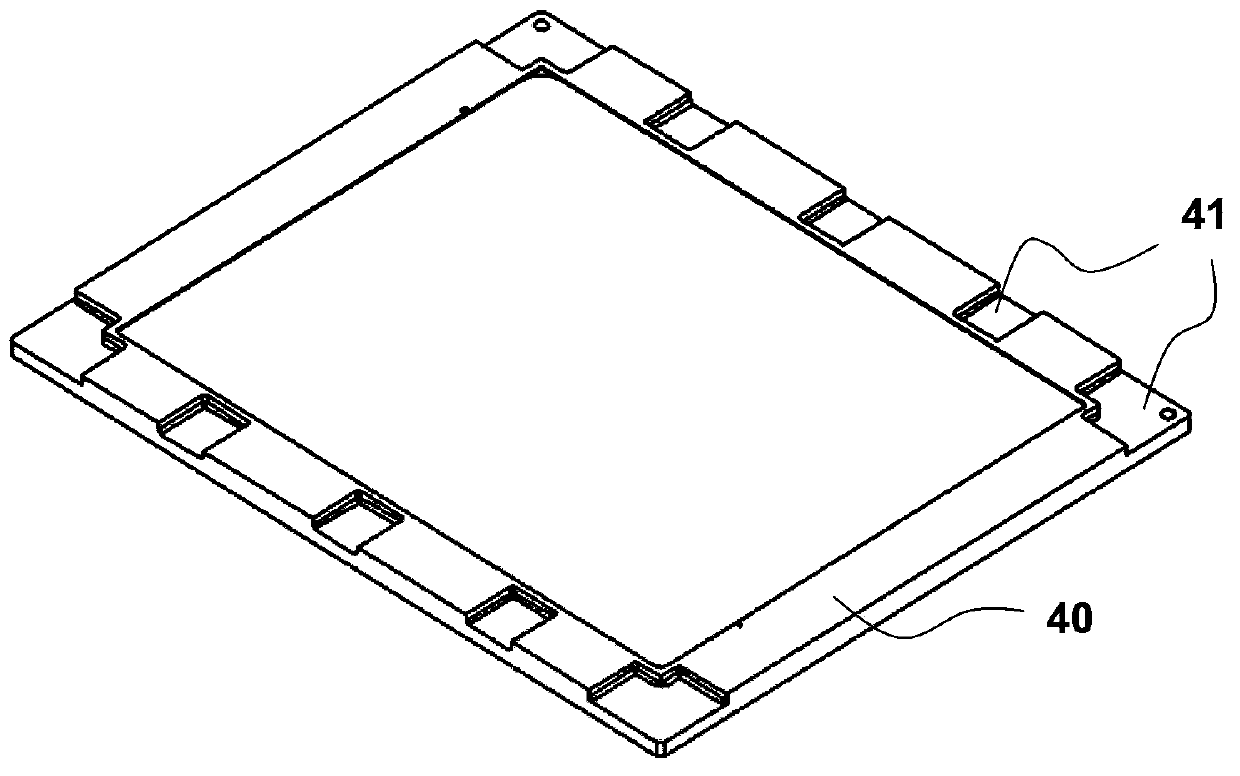

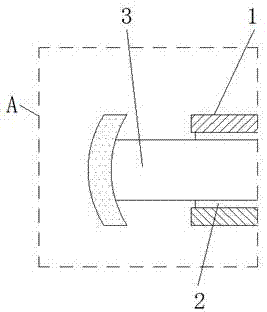

Thin film evaporation coating apparatus, and method for making OLED display device

InactiveCN103866235AIncrease the effective use areaHigh strengthVacuum evaporation coatingSputtering coatingDisplay deviceEvaporation

The invention provides a thin film evaporation coating apparatus, and a method for making an OLED display device by utilizing the apparatus. The apparatus comprises: a cavity, wherein an evaporation source accommodation part used for accommodating an evaporation source is arranged in the cavity; a press plate and a movable mechanism driving the press plate to move up and down; a substrate carrying clamp used for carrying a substrate; a frame used for bearing a mask plate; and an electrostatic thin film layer arranged on the lower surface of the press plate. The electrostatic thin film layer enables the substrate to be evenly adsorbed on the press plate in an electrostatic adsorption manner and to be separated from the support of the substrate carrying clamp, and the substrate is applied to the mask plate in order to carry out thin film evaporation coating. The apparatus can improve the effective use area of the substrate, and the morphological structure of a frame is not restricted by the morphological structure of the substrate carrying clamp, so the morphological structure having a high strength can be adopted to avoid the easy deformation problem of the frame.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

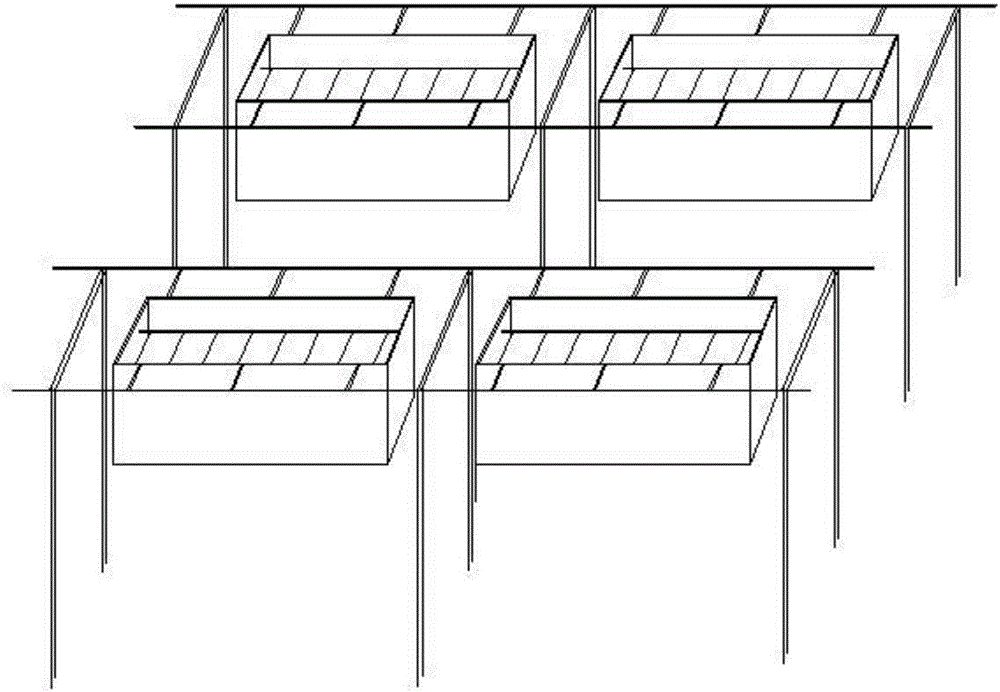

Container automatic yard

InactiveCN101920852AReduce the number of handoversIncrease the effective use areaStorage devicesAutomatic controlContinuous operation

The invention discloses a container automatic yard. An elevated circular rail is erected on each container stacking line; a plurality of automatic control travelling jacks run on each rail, thus the circulatory continuous stacking and reclaiming operation can be carried out; and a container automatic plane conveyor is arranged between a yard seaside end and a container continuous loading and unloading shore bridge to finish bidirectional automatic continuous conveying of the container between the container continuous loading and unloading shore bridge and the container yard. The container automatic yard of the invention is characterized by capability of eliminating the loading and unloading of all internal combustion engine drivers and the transportation equipment in the yard, environmental protection and high automaticity; as a container shore bridge loading and unloading ship and the container yard stacking and reclaiming form a continuous operation manner, the loading and unloading efficiency of a container terminal and the trafficability of the container can be greatly improved, so as to satisfy the loading and unloading requirement of very large container ships.

Owner:张铁忠 +1

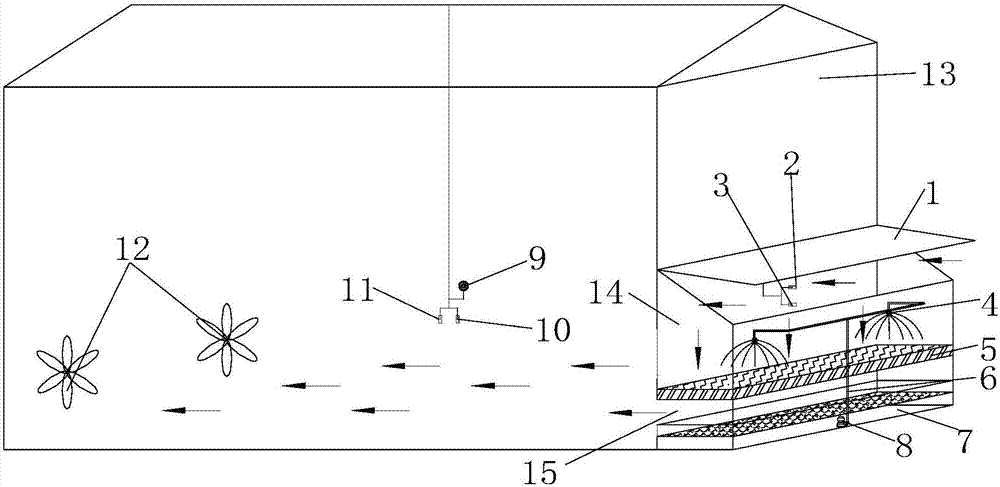

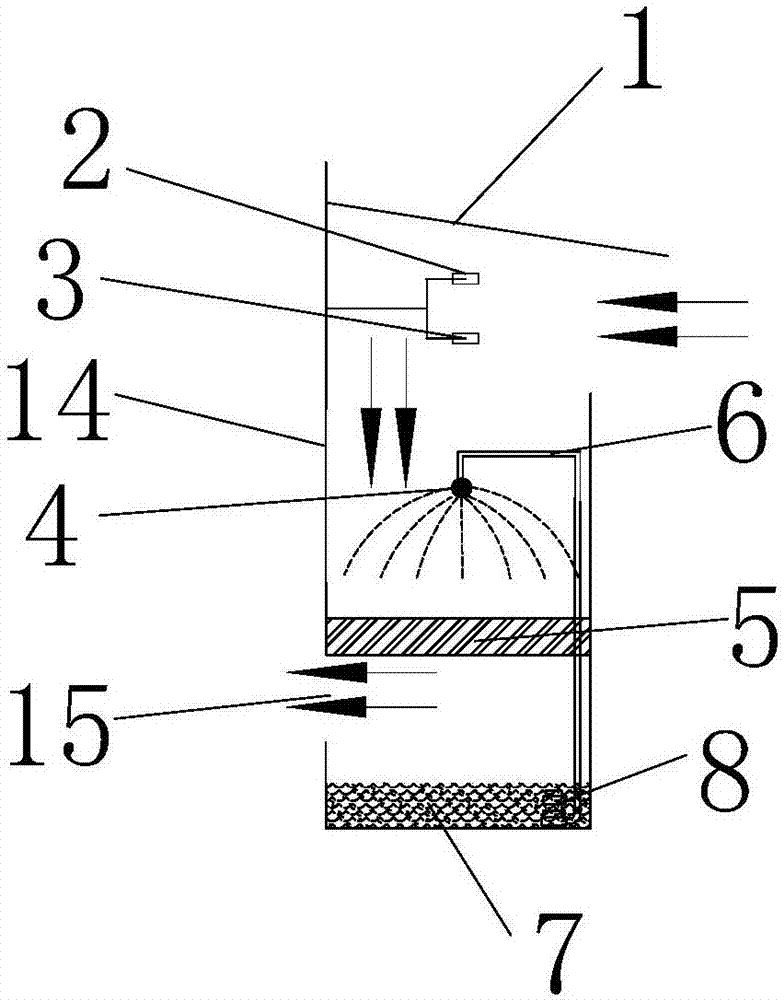

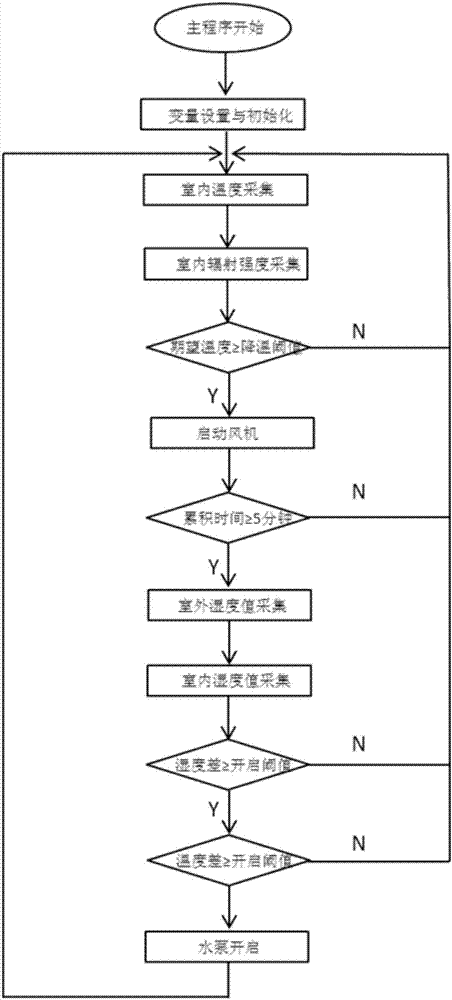

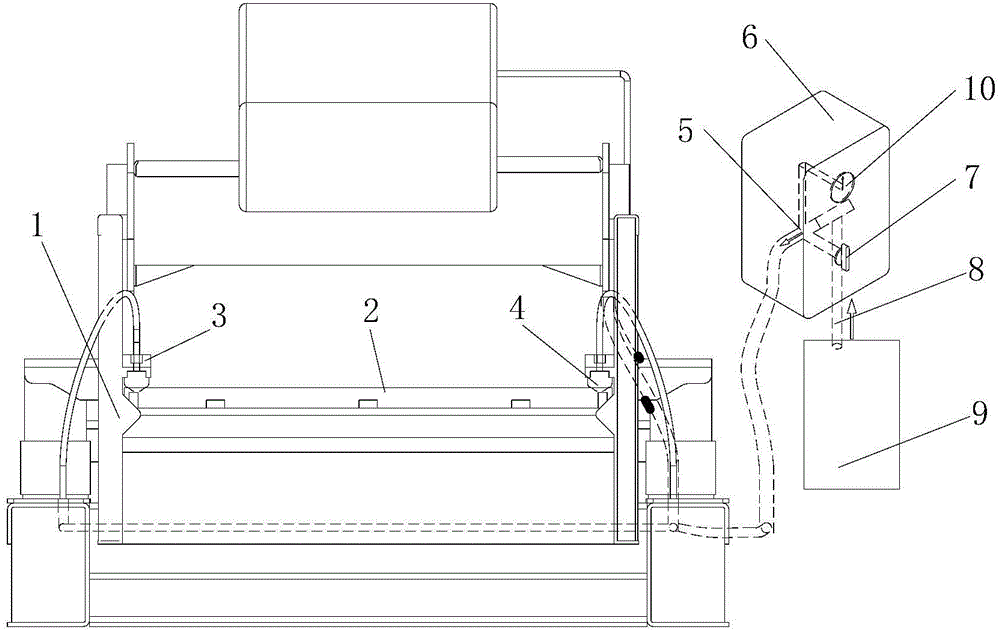

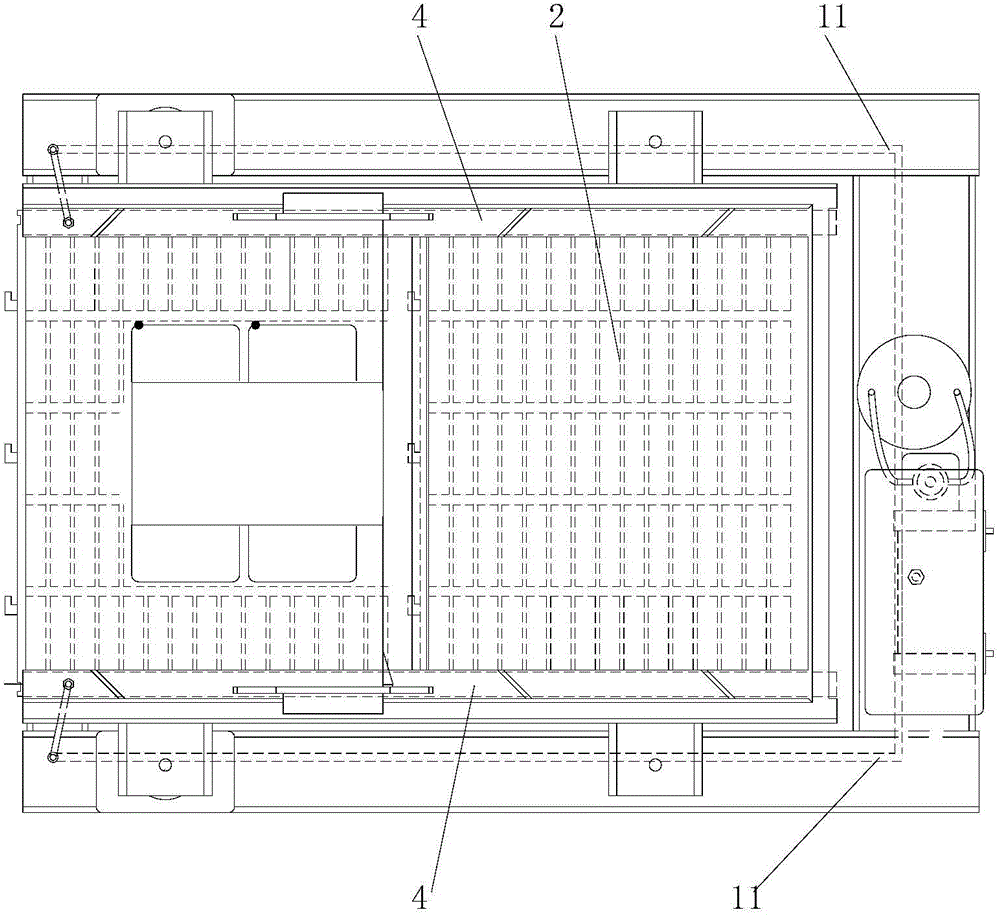

Cooling device with fan and wet curtain and control method thereof

ActiveCN107223495AIncrease the effective use areaImprove cooling effectClimate change adaptationGreenhouse cultivationTemperature controlGreenhouse

The invention discloses a cooling device with a fan and a wet curtain and a control method thereof. The device comprises a water pump, a wet curtain, a water supply pipe, a sprayer, a water recycling pond, a vent fan, a side window, a controller, a temperature sensor, a humidity sensor and an illuminance sensor, wherein one side of a greenhouse of the device is provided with the fan, the other side of the greenhouse is provided with the horizontally arranged wet curtain, and the wet curtain is provided with water through the water pump and the sprayer; since an included angle is formed by the wet curtain and the vertical surface of the device, the sun-shielding effect of the wet curtain on the wet curtain side in the greenhouse is reduced, and the effective utilization area of the greenhouse is improved; since the wet curtain is provided with water through the sprayer in an atomized mode, the threshold of the outer air humidity is improved when the wet curtain achieves the cooling effect because the wet curtain needs absorbing heat for gasification, and the cooling performance and efficiency of the wet curtain cooling device is improved; since the control method adopts fore-feedback type control, the precision of the temperature control and the cooling efficiency of energy are improved. The device can be widely used in the greenhouse which requires high environment control precision, high illuminance conditions and a good cooling effect.

Owner:ZHEJIANG UNIV

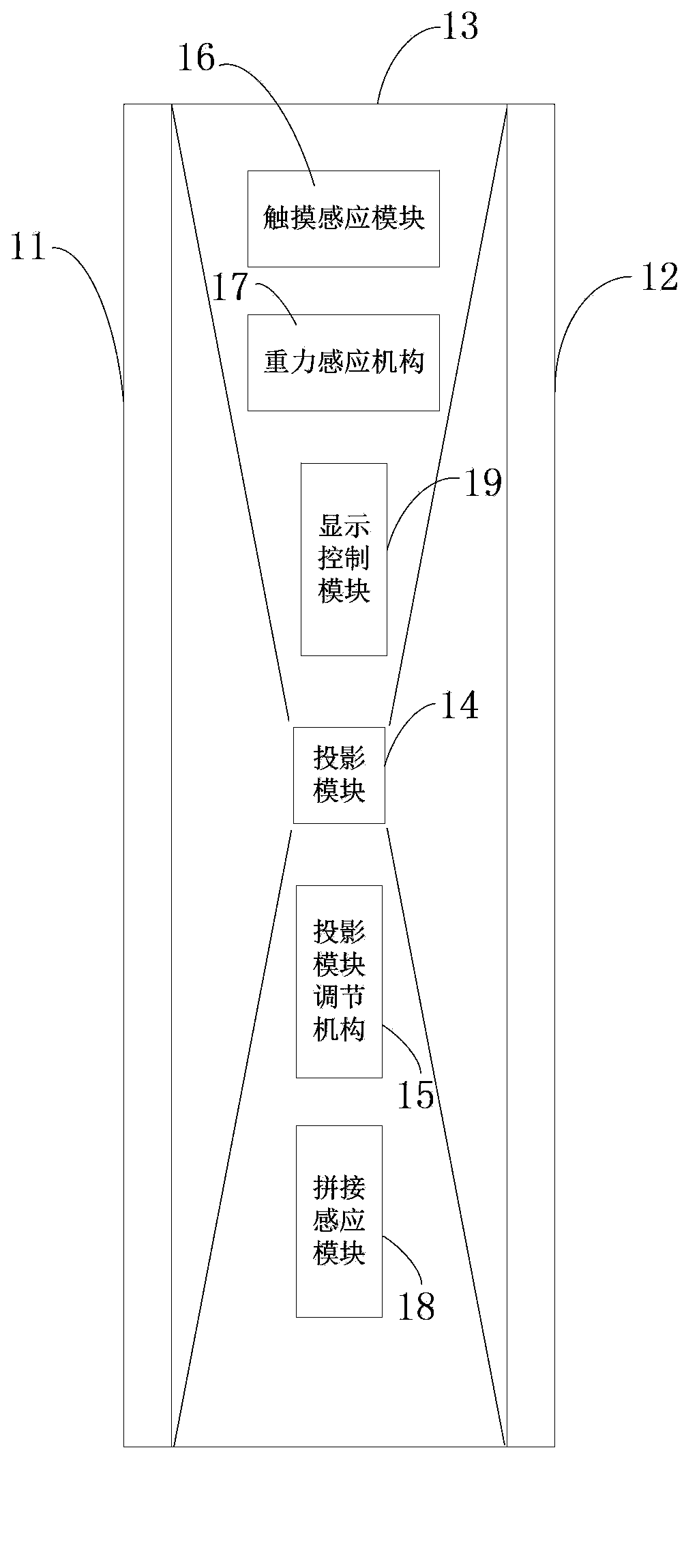

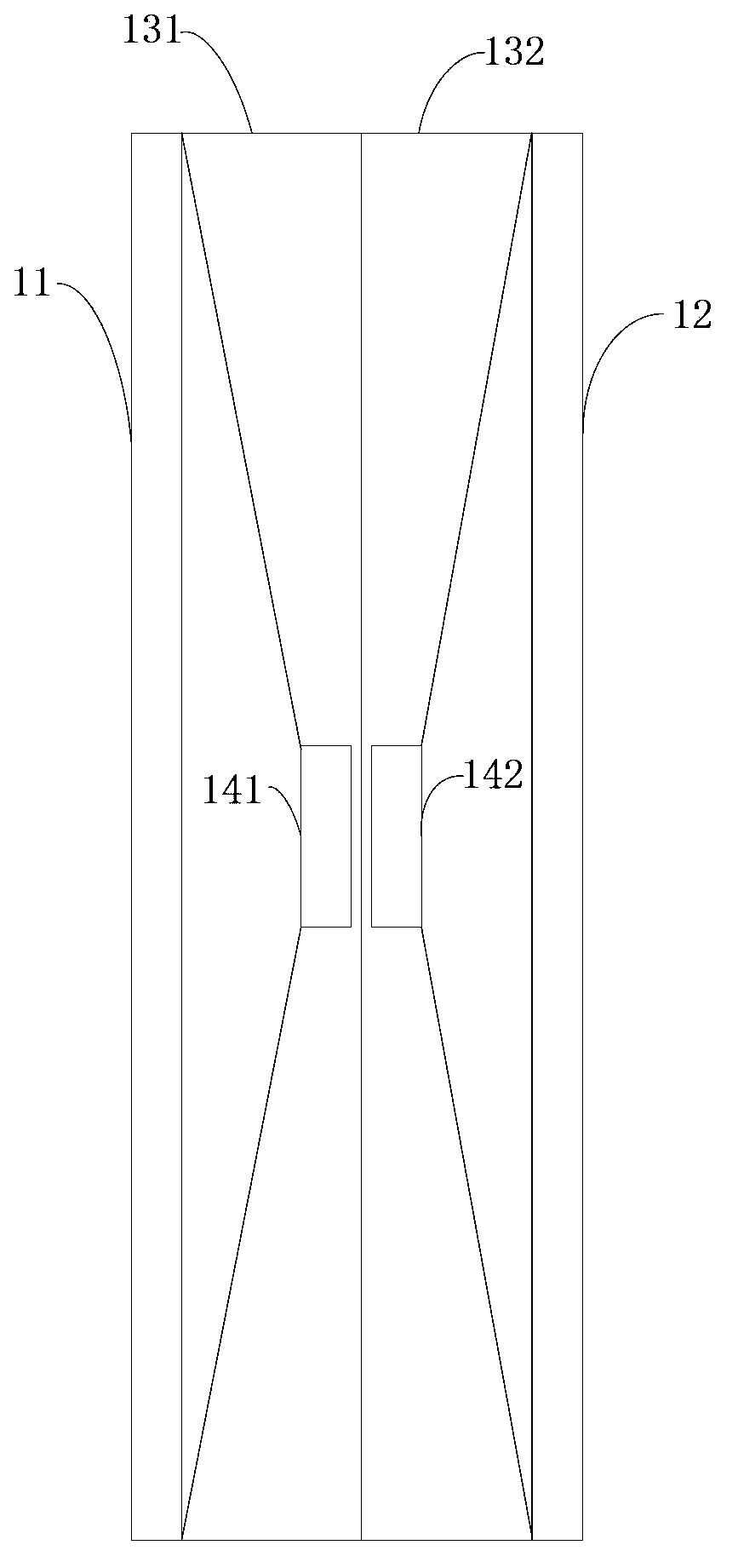

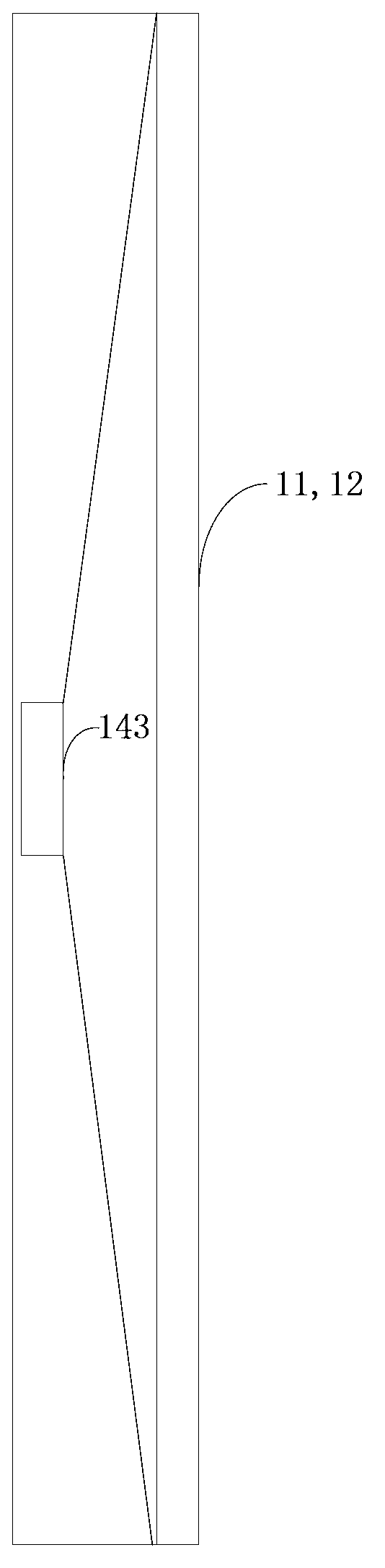

Multi-screen projection display control system and method of handheld electronic device

ActiveCN103853510AEasy to controlIncrease the effective use areaDigital output to display deviceControl systemProjection display

The invention discloses a multi-screen projection display control system and method of a handheld electronic device. The system comprises multiple screens, a projection module, a sensing module, a projection module adjusting mechanism and a display control module. The multiple screens can be spliced into a spliced screen; the projection module is used for projecting display pictures to the multiple screens respectively, or projecting the display pictures to one screen, or projecting the display pictures to the spliced screen formed by splicing of the multiple screens; the sensing module is used for sensing changes, including position changes and splicing and separation changes, of the screens in real time; the projection module adjusting mechanism is used for adjusting the position, projection angle and focal length of each projection unit in the projection module; the display control module is used for controlling actions of the projection module adjusting mechanism according to sensing of the sensing module so as to control actions of each projection unit in the projection module. Images can be displayed in the multiple display screens through a projection mode.

Owner:SHANGHAI WINGTECH ELECTRONICS TECH

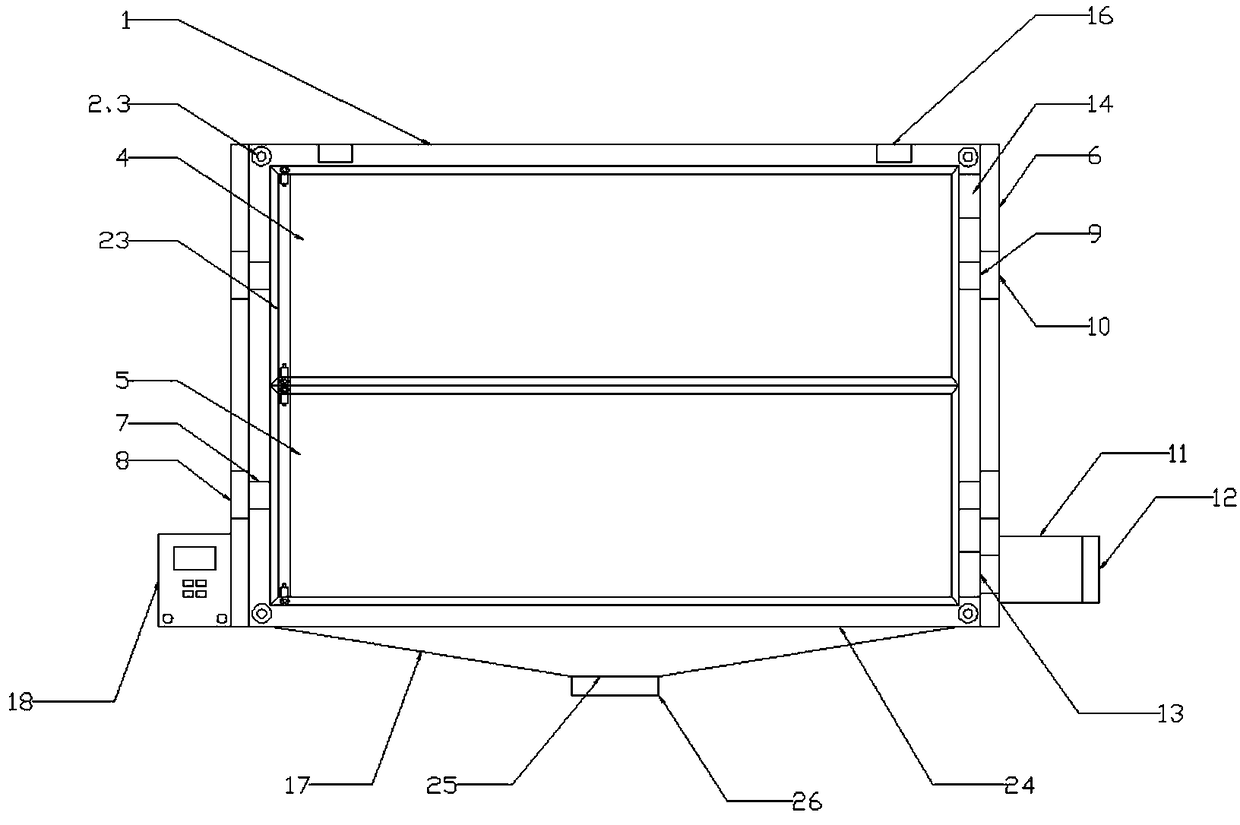

Teaching blackboard capable of automatically rising and falling

InactiveCN108081823ATake advantage ofReduce the number of timesBoard cleaning devicesWriting boardsEngineeringLimit switch

Owner:沈艳

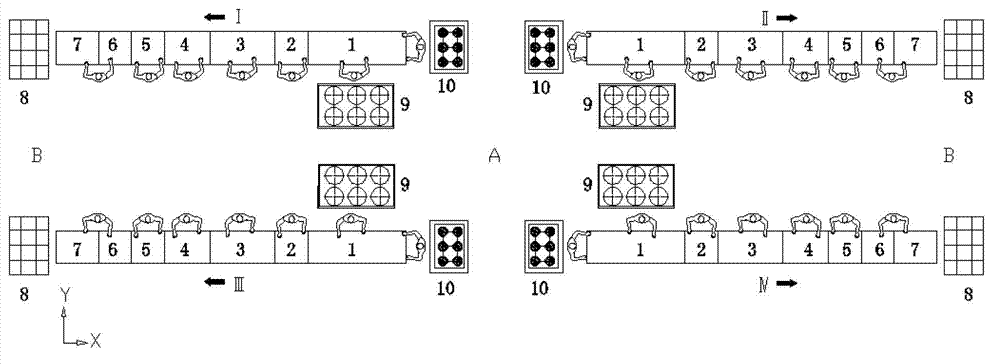

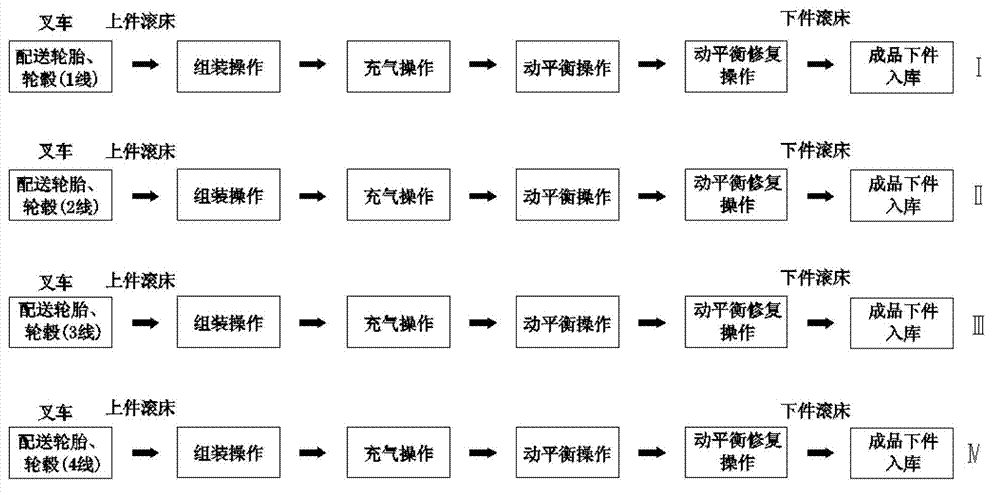

Manual assembly line layout for automobile tires

ActiveCN102756614AIncrease productivityLess investmentWheel assembling toolsBalancing machineAssembly line

The invention discloses a manual assembly line layout for automobile tires, belonging to the field of automobile tire assembly. The manual assembly line for the tires comprises more than two assembly lines, wherein each assembly line comprises a dismantling and assembling machine, an aerator, a balancing machine, a correction roller machine which are arranged in parallel along the Y-axis direction, and each assembly line is perpendicular to an assembly type part loading roller machine and an assembly type part unloading roller machine which are arranged along the X-axis direction. The manual assembly line layout has the advantages that the scattered part loading roller machines in the prior art are assembled into the part loading roller machine, the scattered part unloading roller machines in the prior art are assembled into the part unloading roller, the assembly type part loading roller machine and the assembly type part unloading roller machine are driven through a motor for transmission, the transmission spacing is carried out through an optoelectronic switch, and therefore, the convenience of manual assembly is increased, the production efficiency of the assembly line is improved, the operation region of a forklift is reduced, operating personnel are not needed in the production process, the cross operation of the forklift in the production process is eliminated, and the fluency of tire line physical distribution and the operation safety are increased. The length of equipment stations is shortened; and the effective usable areas of plants are increased.

Owner:CHERY AUTOMOBILE CO LTD

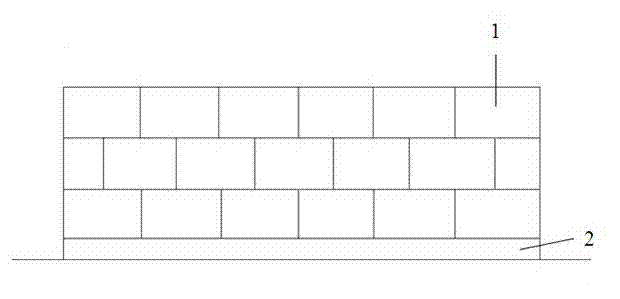

Gypsum block masonry and construction method thereof

InactiveCN102352660AUnique structureHas breathing functionWallsBuilding material handlingLap jointSlurry

The invention discloses a construction technology for gypsum block masonry. The gypsum block masonry has a simple structure and attractive appearance, is convenient to construct, environment-friendly, fire-resistant and quake-proof, and saves manufacturing cost. The construction technology comprises masonry of the gypsum block masonry and construction of decorative layers. The invention has the technical key point that: a wall cushion is arranged on the lower part of the gypsum block masonry; gypsum blocks of the gypsum block masonry are in lap joint with one another in an up-and-down staggered mode and are constructed by using binding slurry; the gypsum block masonry is provided with tie bars equidistantly on each gypsum block along a main body structural column or a wall height direction; and the tie bars extend into the masonry. By the construction technology for the gypsum block masonry, the technical problems of low efficiency, long construction period, large pollution, large occupied space of heavy walls and non-low-carbon and non-environment-friendly building materials in the traditional partition wall construction technology are solved.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

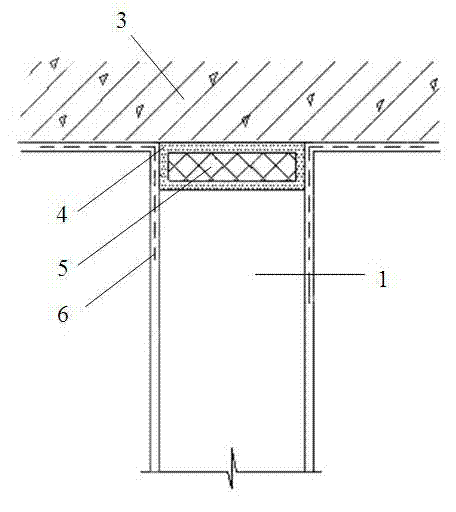

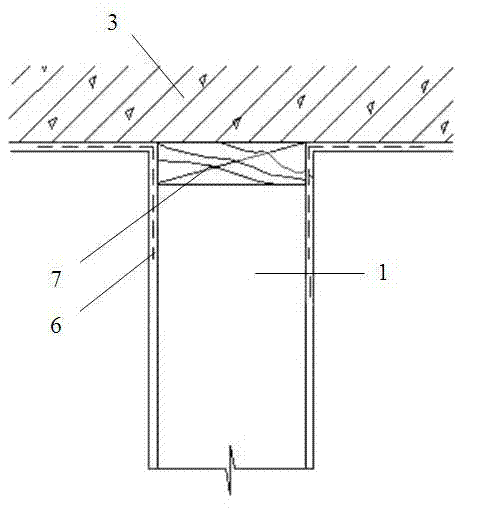

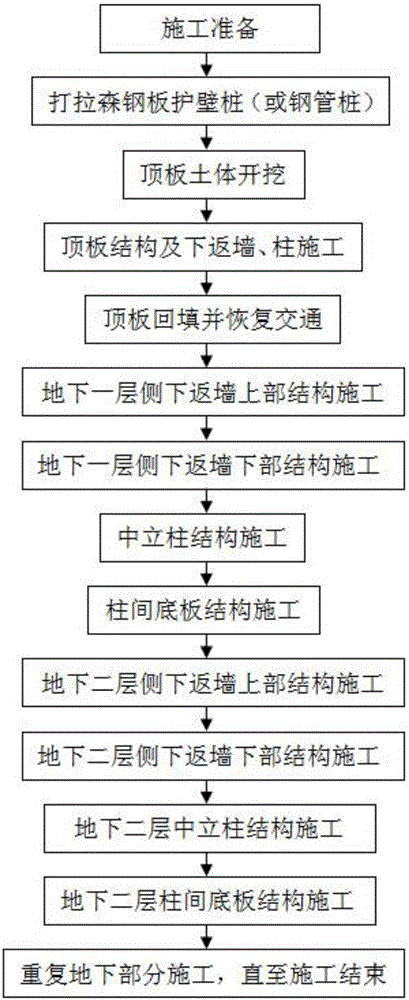

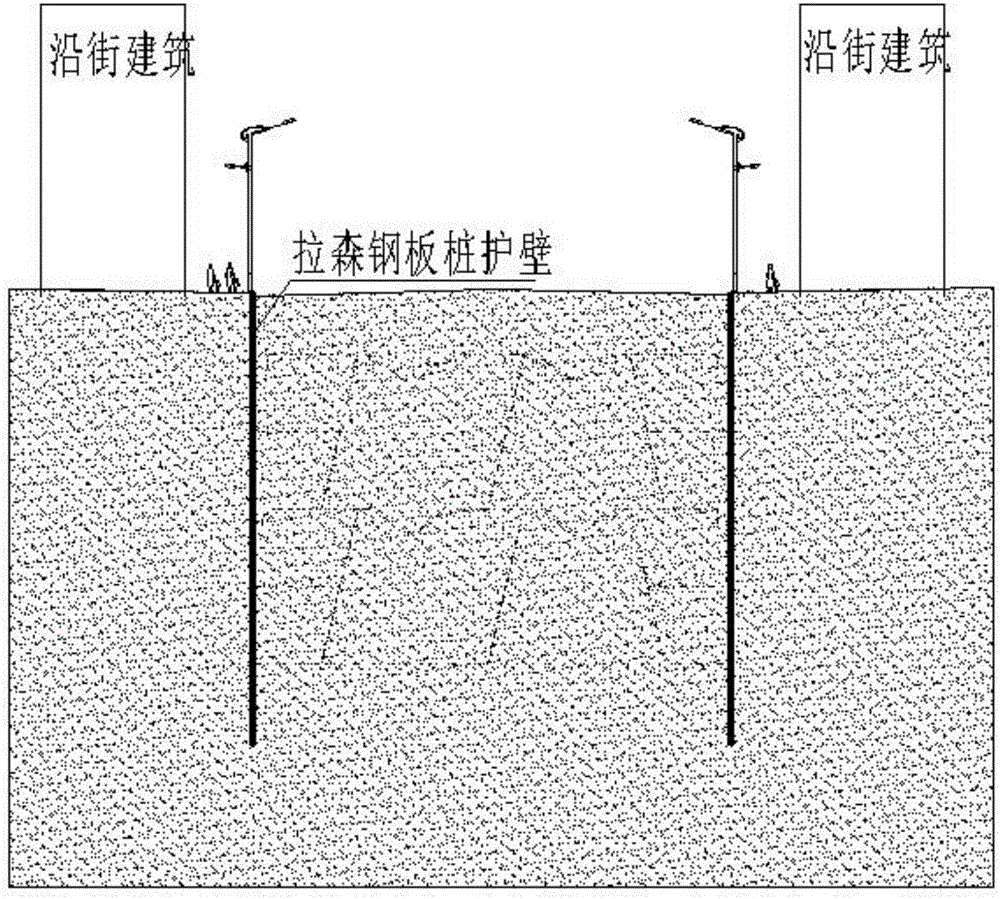

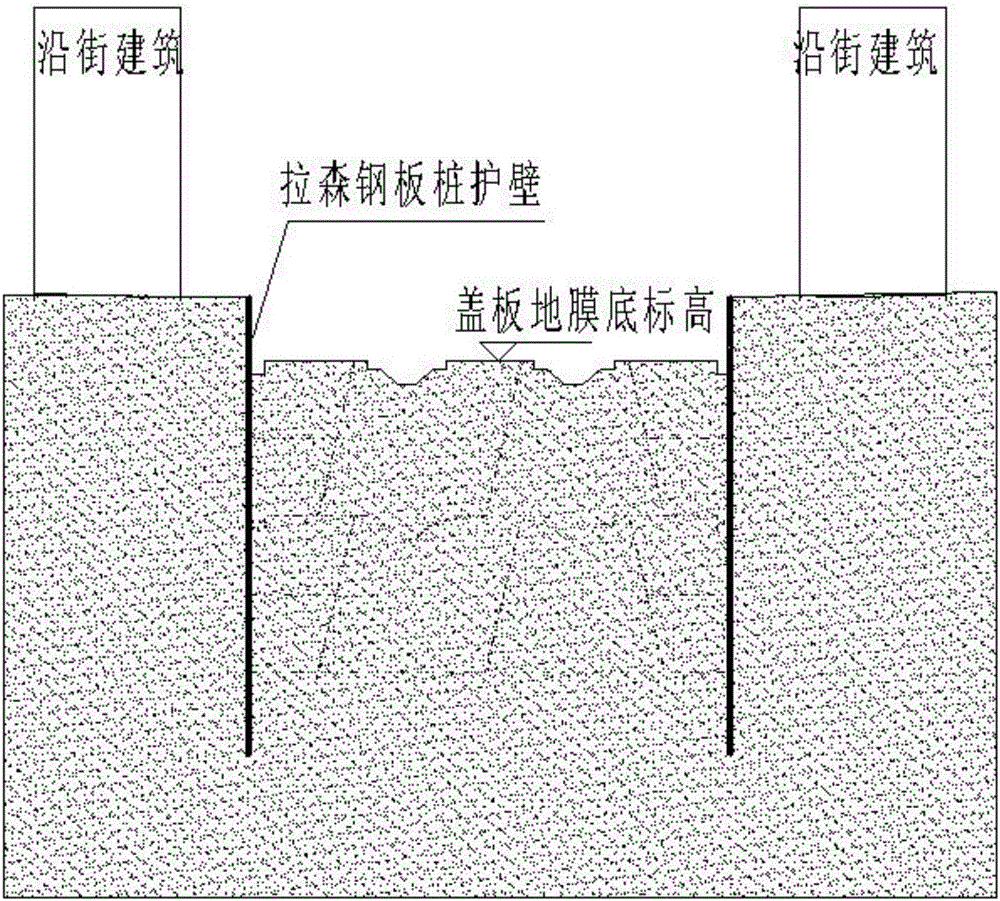

Covered-excavation full-top-down construction method of municipal underground engineering

ActiveCN105735354AShort construction periodIncrease the areaArtificial islandsUnderwater structuresEngineeringRoad surface

The invention discloses a covered-excavation full-top-down construction method of municipal underground engineering. The method comprises the following steps: carrying out construction preparation, performing supporting by using steel plates, excavating top plate soil, constructing lower returning walls, constructing lower returning pillars, constructing top plate structures, carrying out back filling of top plates, constructing upper structures of the lower returning walls on the side of an underground floor I, constructing lower structures of the lower returning walls on the side of the underground floor I; constructing middle standing pillar structures, constructing inter-pillar bottom plate structures, constructing an underground floor II, and repeating the construction of the underground part till the whole engineering is ended. The covered-excavation full-top-down construction method of municipal underground engineering can effectively solve the problems such as severe road traffic influence, high noise, severe pollution, long engineering period, high cost and investment and a large number of invoked staff during construction of the conventional municipal underground engineering.

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

Extension type intelligent computer desk with foot drying function

InactiveCN107951170AVersatileImprove scalabilityOffice tablesExtensible tablesHorizontal axisSoftware engineering

The invention discloses an extended intelligent computer desk with the function of drying feet, which comprises a desktop board, a base board, a supporting board, a foot drying box and a massage cylinder. The bottom end of the board is connected to the desktop board, the supporting board is located inside the extension groove, the lower end surface of the table board is fixed with table leg rods, and the table leg rods are connected to each other through the horizontal plate of the device, and the device Slide rails are installed on the horizontal plate, and the two sides of the foot drying box are connected to each other through connecting rods and slide rails. A heating element is installed inside the foot drying box, and a horizontal shaft is arranged above the heating element. The cylinder is installed on the horizontal axis, and massage protrusions are arranged on the massage cylinder. The stretchable intelligent computer desk with the function of drying feet can conveniently expand the overall volume of the desktop board, and has a wider scope of application. , the design is more reasonable.

Owner:南京市雨花台区创新创业法治宣传与法律服务中心

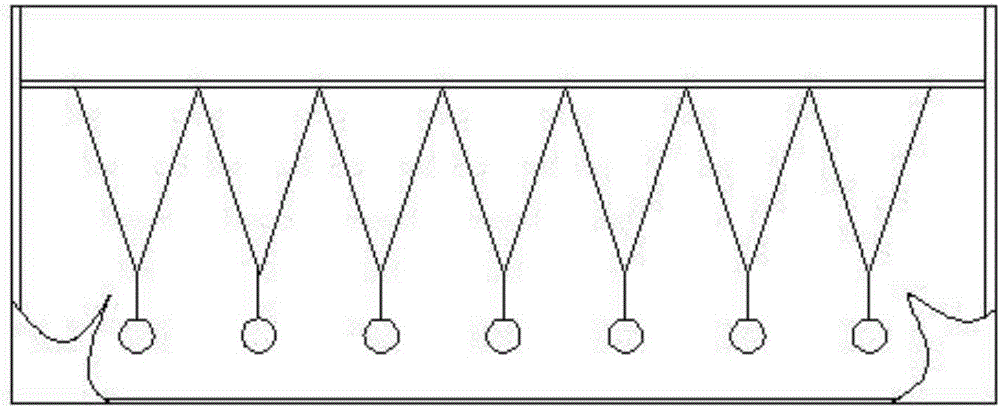

A winter pond net cage intermediate culture method for stichopus japonicus larvae

InactiveCN106386596AExpand the breeding spaceReduce resistanceClimate change adaptationPisciculture and aquariaStichopusProduction rate

The invention provides a winter pond net cage intermediate culture method for stichopus japonicus larvae. The method comprises the steps of selecting a culture pond with a water depth of 1.8m-2m; erecting net cages, with the top surfaces of the net cages being 5cm-10cm lower than a water surface; making W-type adhering substances with 6 mesh-10 mesh polyethylene nets and distributing the adhering substances in the net cages uniformly; performing daily management of adjusting the water quality of pond water, and putting larvae in the pond at the end of October or at the beginning of November, with the stocking density being 0.5Kg per net cage to 0.7Kg per net cage; increasing light illumination in an icebound period in winter and monitoring under-ice water quality indexes; after ice melts, starting an oxygenation apparatus to promote vertical flow of water and improve the water quality environment; when larvae in the cages reach 250 / kg-300 / kg at the end of April, selling the larvae as commercial larvae for culture. The method can increase the culture space after the water is icebound, create the optimal environment for overwintering of sea cucumbers, greatly increase the effective usage area of adhering substances, reduce the production cost of larvae, basically guarantee all-weather production all year round, increase the culture survival rate and body wall production rate, and guarantee the quality of adult sea cucumbers.

Owner:锦州市水产技术推广站

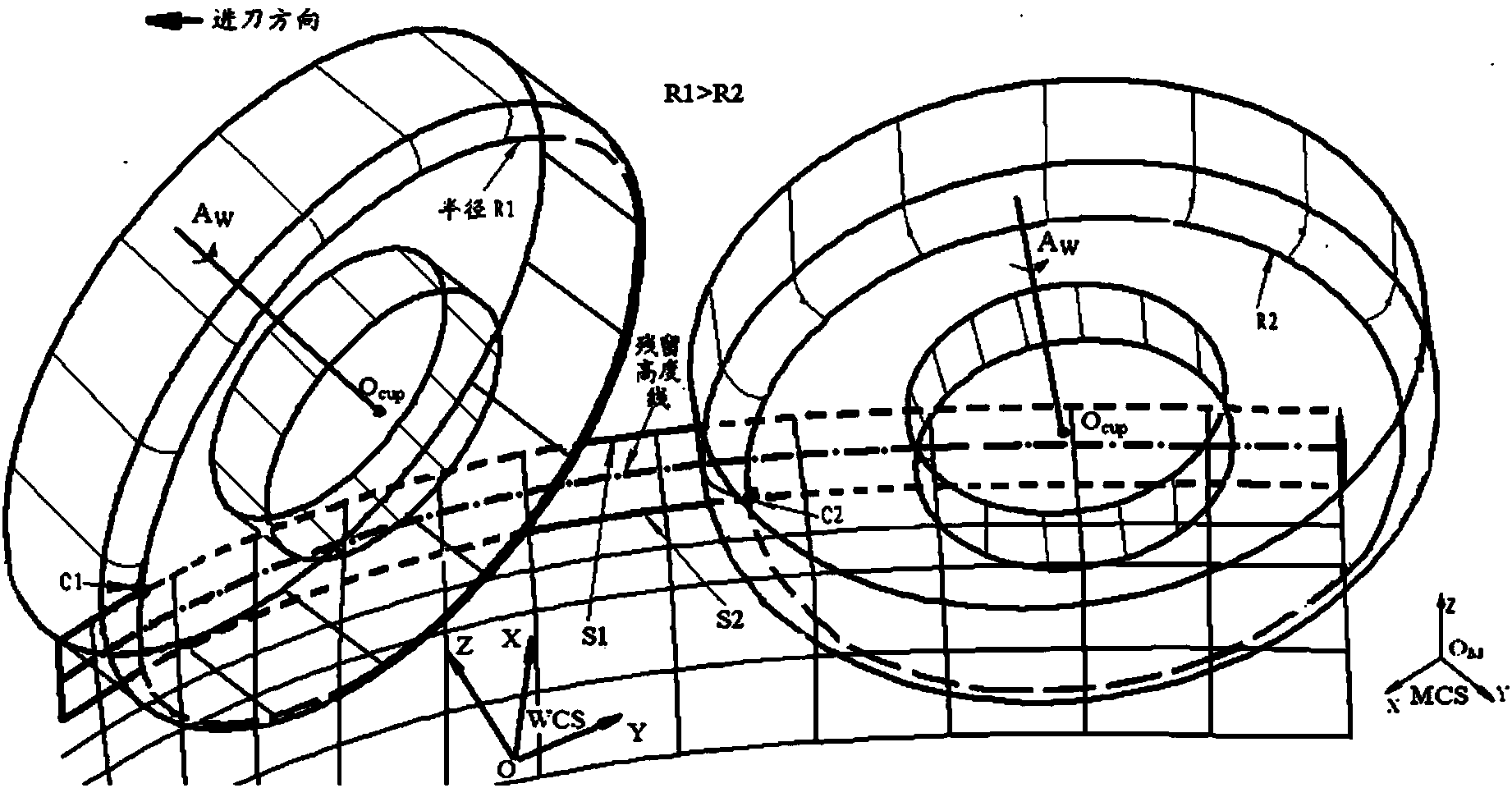

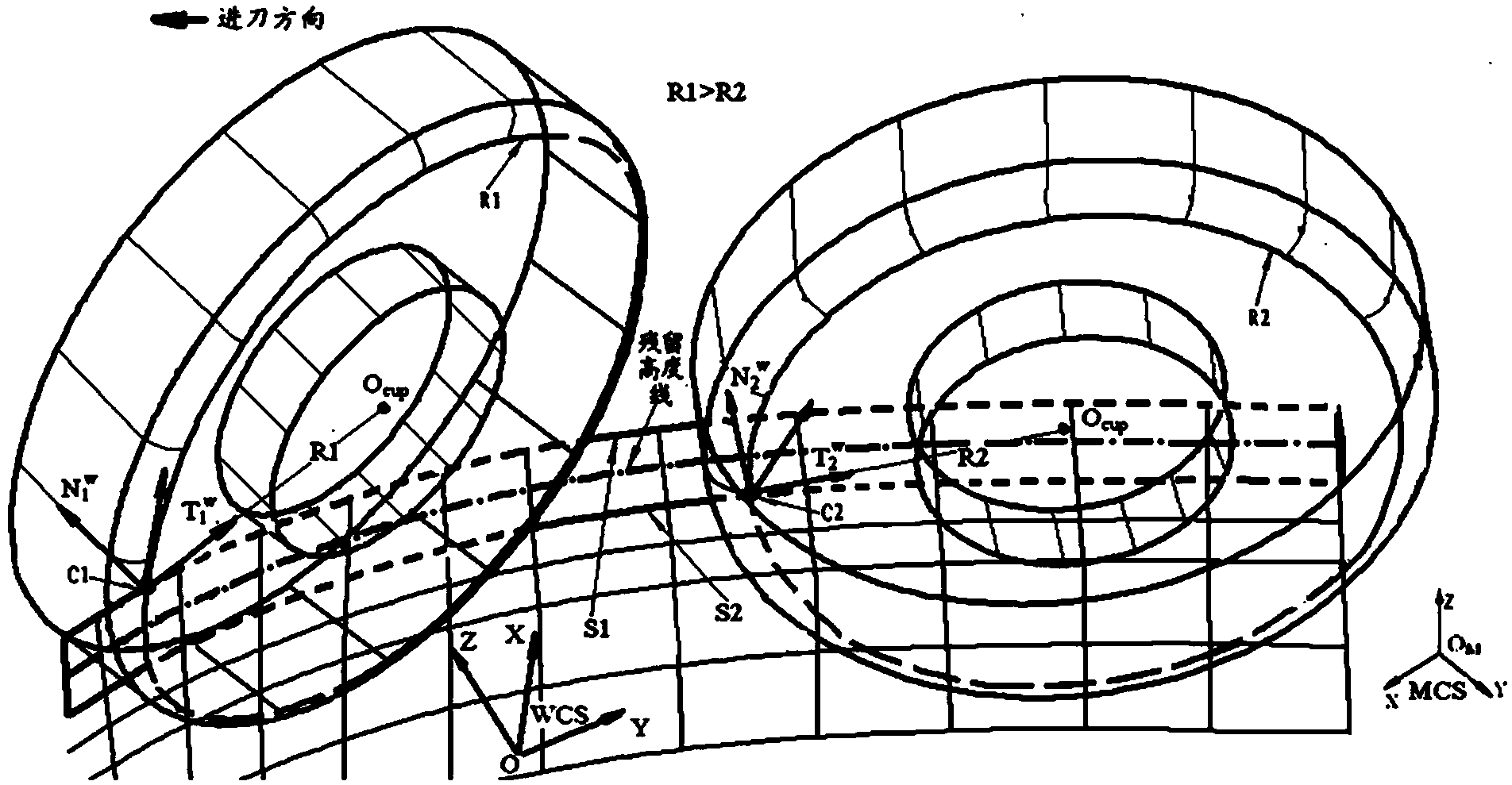

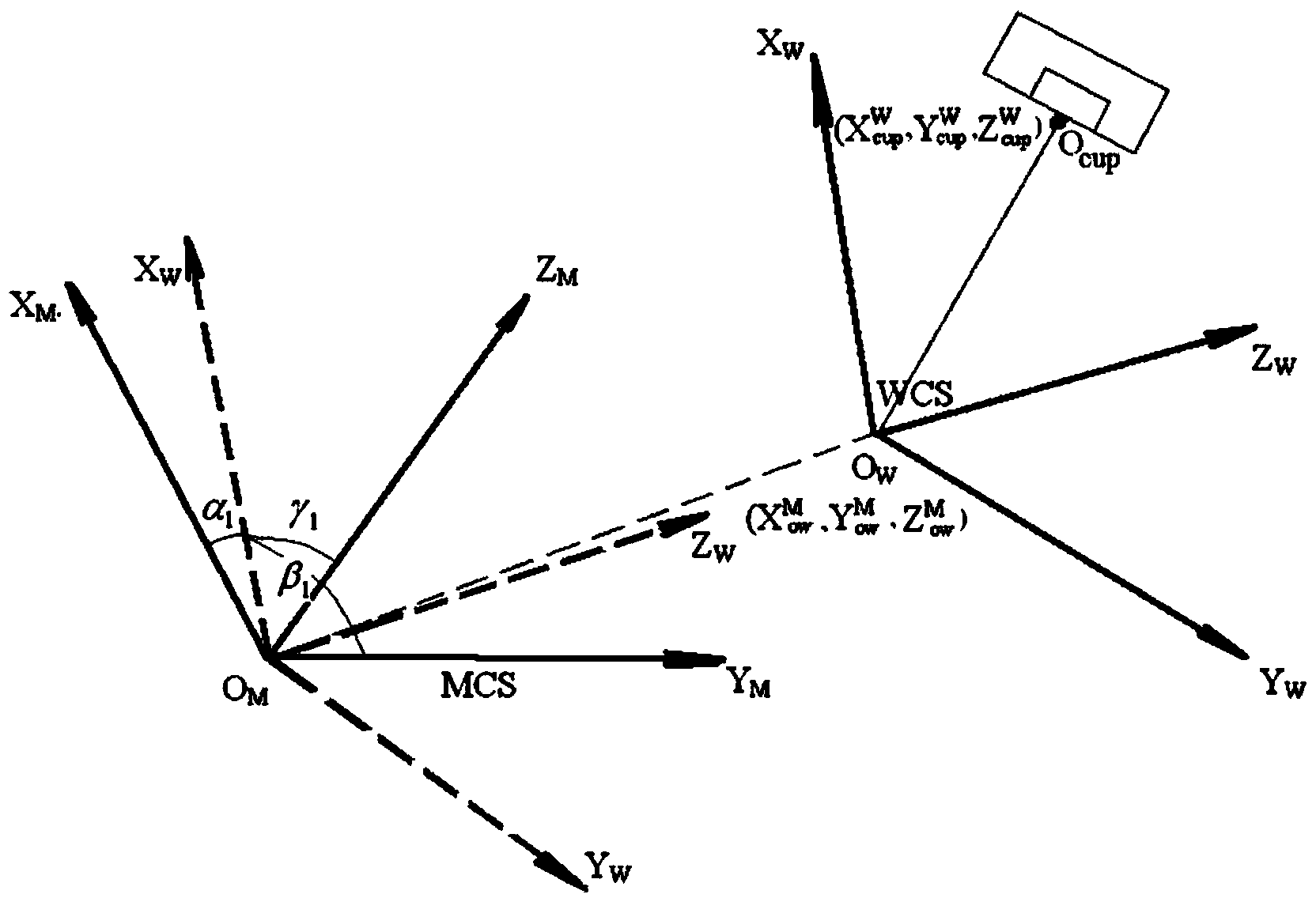

Cup grinding wheel variable-positioning-base-circle convex surface workpiece grinding method

ActiveCN104385083AAvoid loweringGuaranteed accuracyGrinding feed controlAutomatic grinding controlNumerical controlControl system

The invention discloses a method for machining a convex surface workpiece by using a cup grinding wheel installed on a five-axis linkage numerical control machine, a control system of the numerical control machine outputs a control signal during machining to control the cup grinding wheel to machine along a grinding trajectory, and the control system further outputs a center point running trajectory control signal to control the moving trajectory of the center point of the end surface of the cup grinding wheel such that the radius of a positioning base circle using the center point of the end surface of the cup grinding wheel as a circle center and a connecting line with a contact point as a radius is gradually reduced with change of machining time and cutting amount and the contact point is always guaranteed to be an unworn point on the end surface of the grinding wheel; the control system simultaneously outputs an angle control signal such that the end surface of the grinding wheel is always in tangent contact with the machined convex surface by adjusting the angle of the axis of revolution of the grinding wheel, the contact point is located on the grinding trajectory and the angle of the axis of revolution of the grinding wheel is consistent with the normal vector of the machined convex surface at the tangent contact point. By adopting the method, not only can the machining efficiency be improved, but also the machining accuracy is improved.

Owner:TIANJIN UNIV

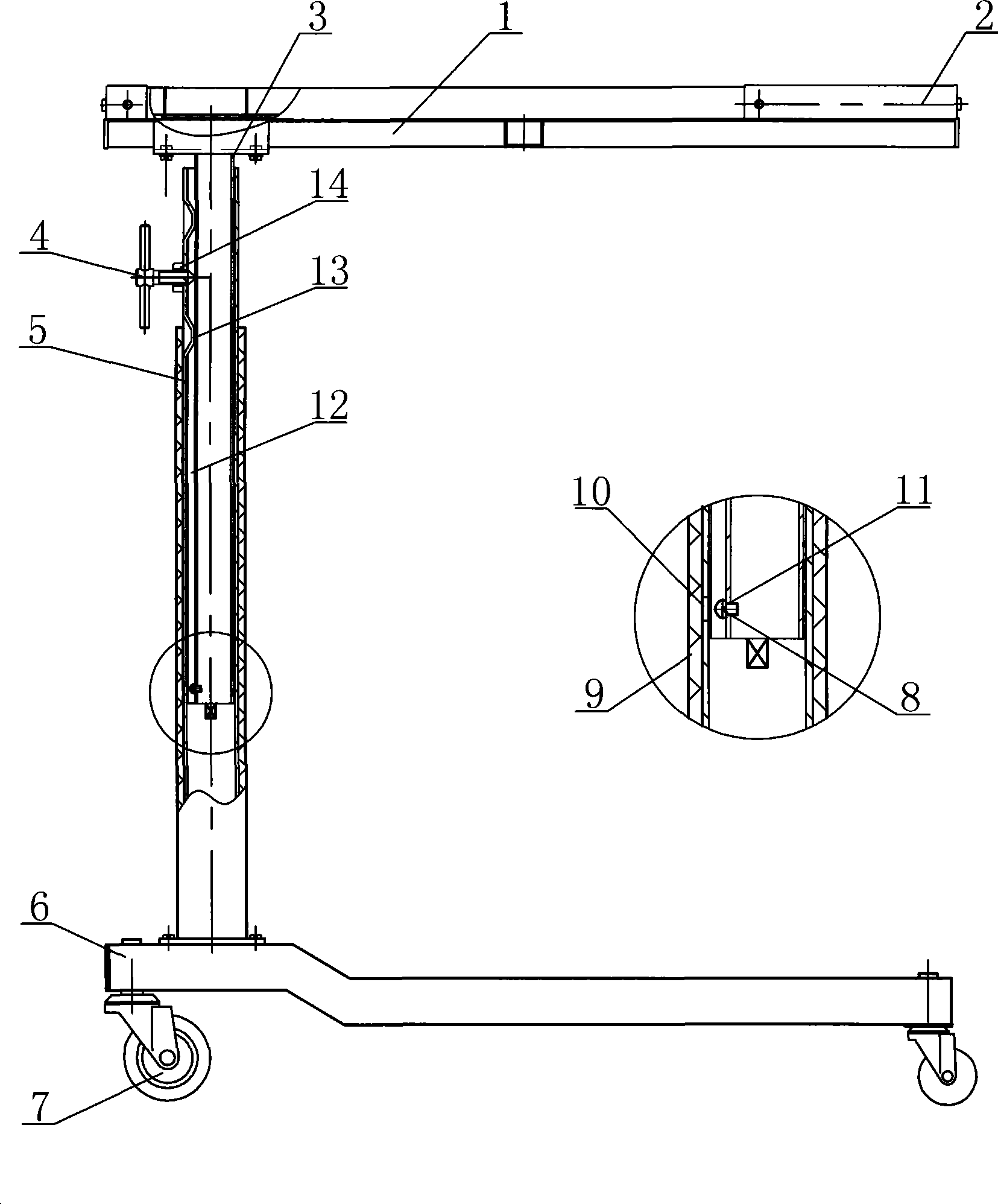

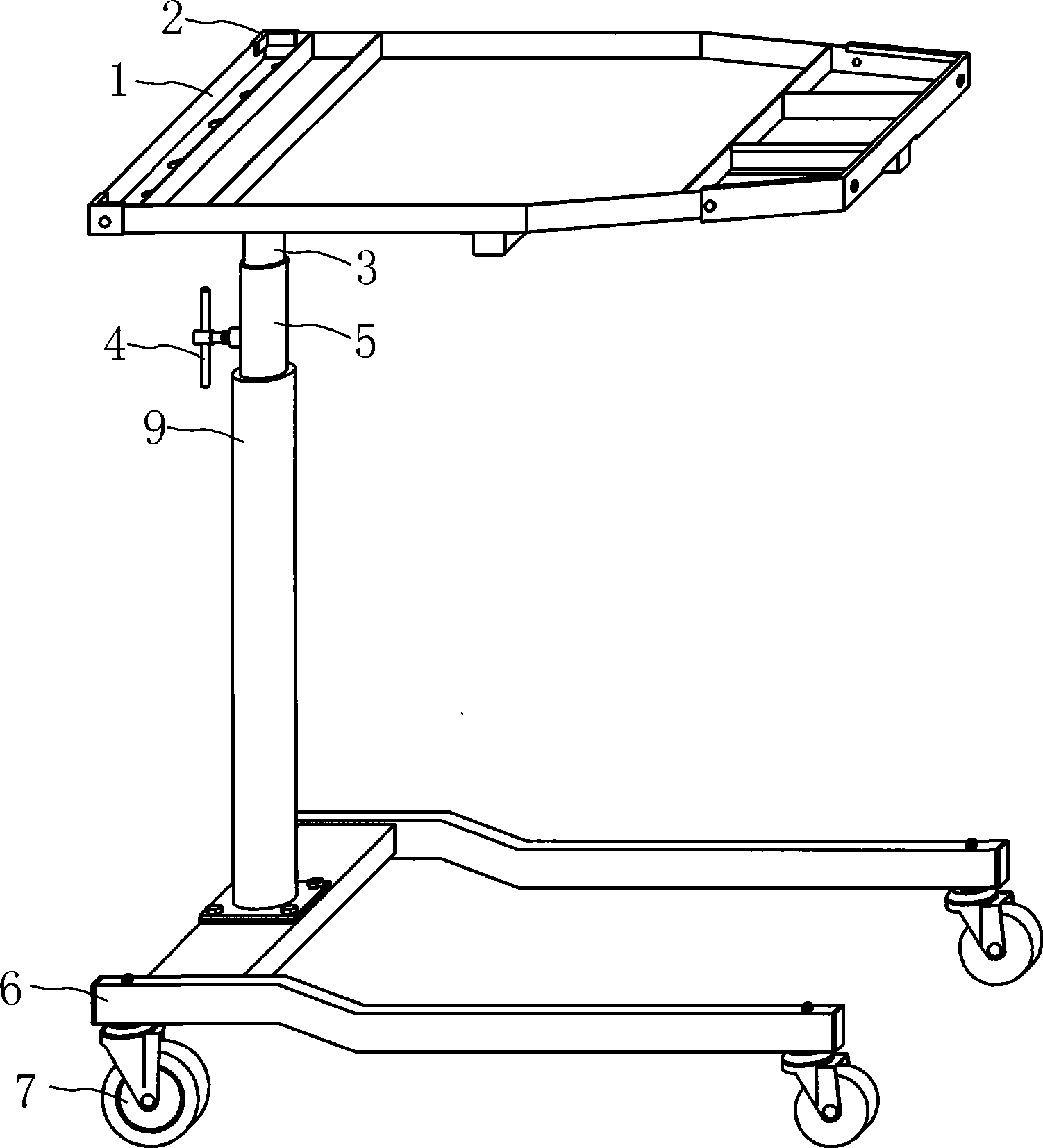

Elevated bench

The invention relates to a lifting working platform, comprising a working plate, a bottom frame, an upright post and a lifting tube; wherein, the lifting tube is arranged at the lower end of the working plate; the upright post is arranged on the bottom frame; the lifting tube is sleeved into the upright post; the bottom frame is provided with a universal wheel; two flutes are vertically positioned on the upper part of the outer wall of the upright post and a through hole is arranged at the lower part of the upright post; a guide groove is positioned on the outer wall of the lifting tube from top to bottom; a screw thread hole which is corresponding to the through hole is arranged at the lower part of the guide groove; and a stop nut goes through the through hole and is locked to the screw thread hole. The working table of the invention is safe and stable in sharp rising and falling, fixed and simple in operation, and convenient for the classification placement of tools, can be inserted deep into bottoms of cars and is suitable for a plurality of occasions.

Owner:谢翠斌

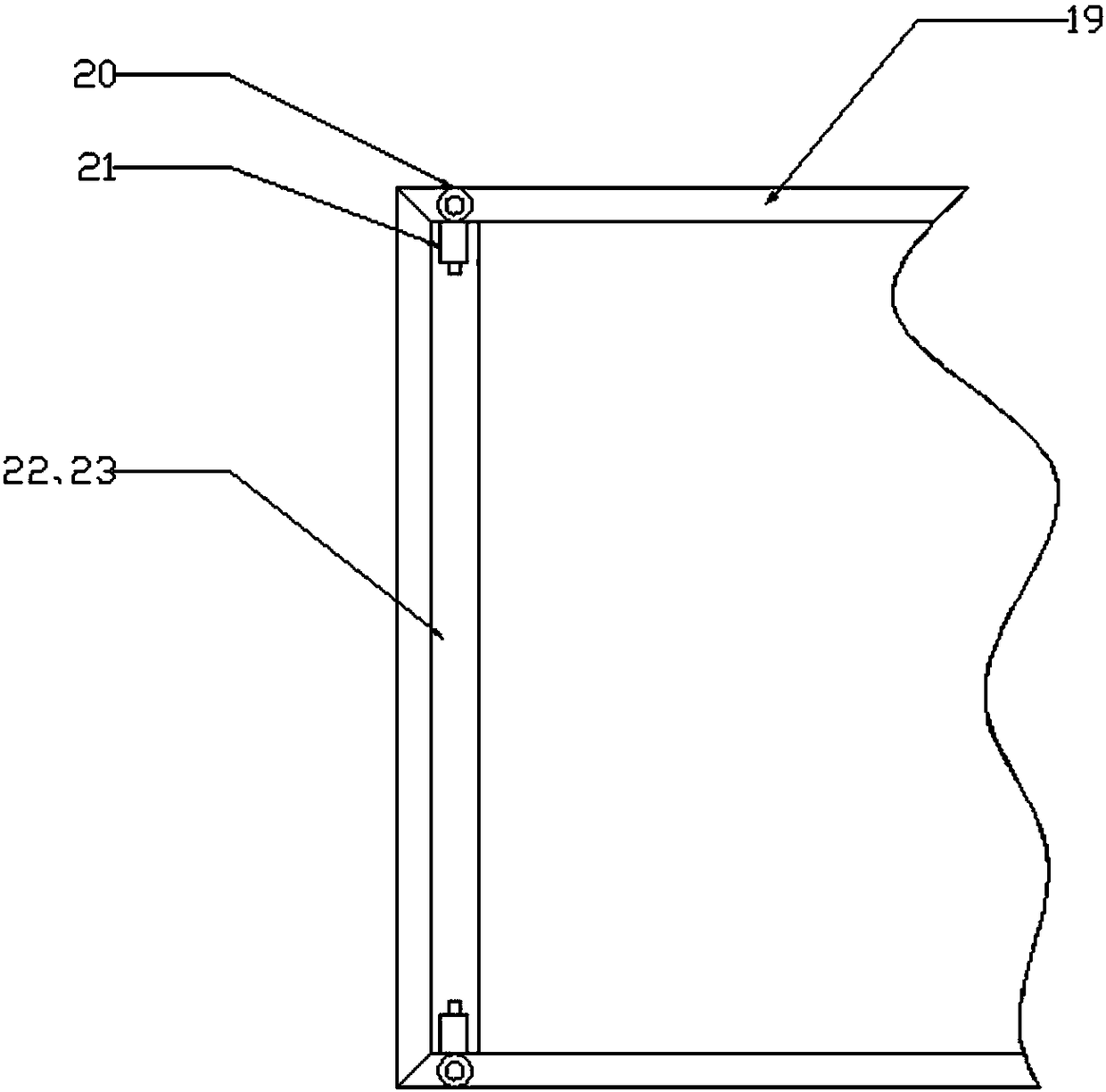

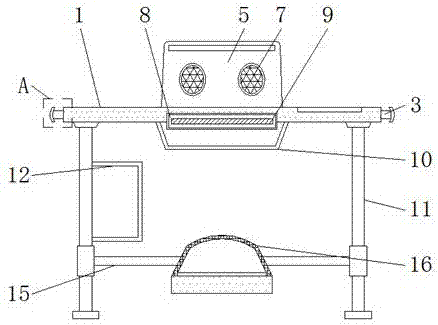

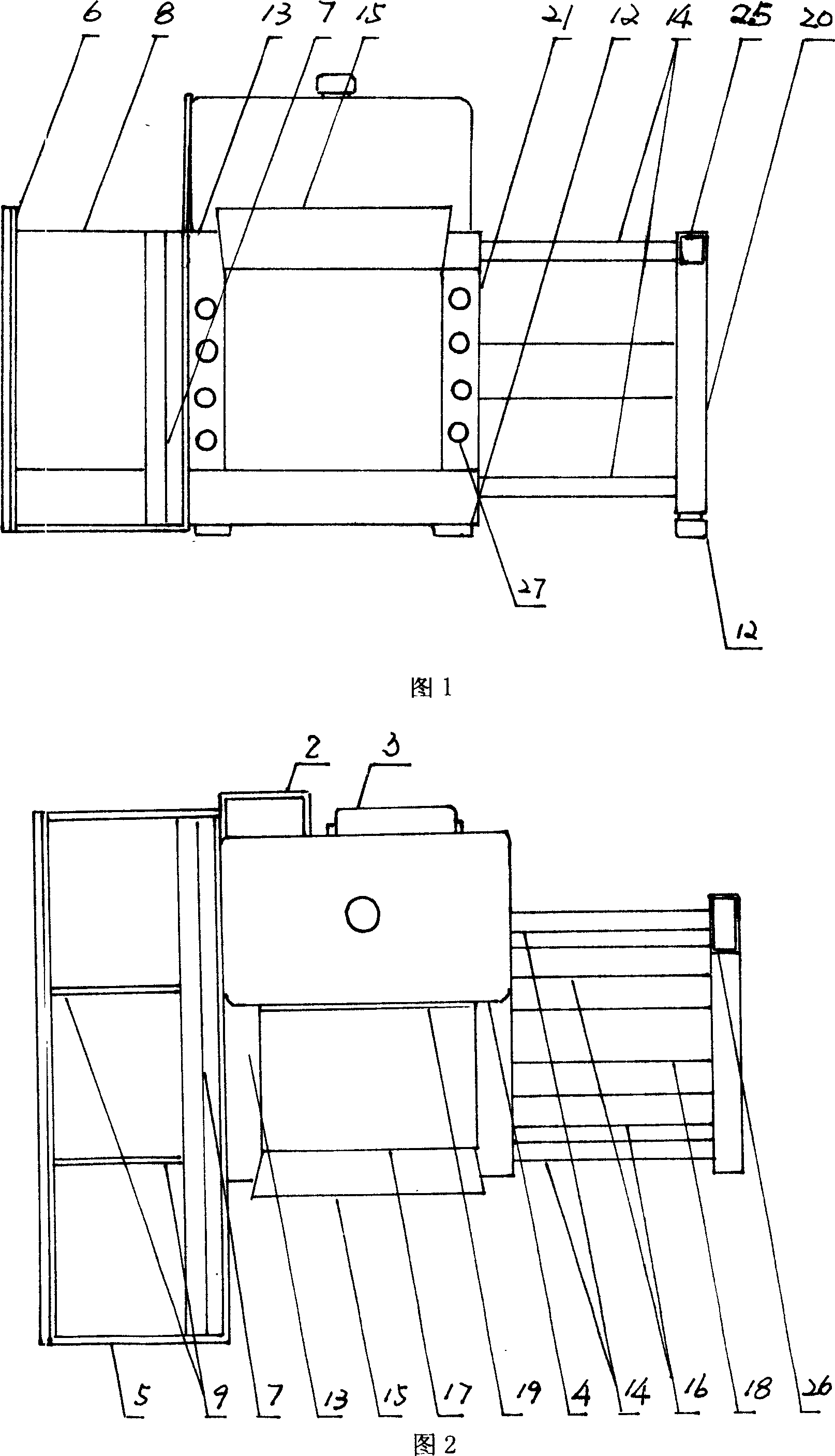

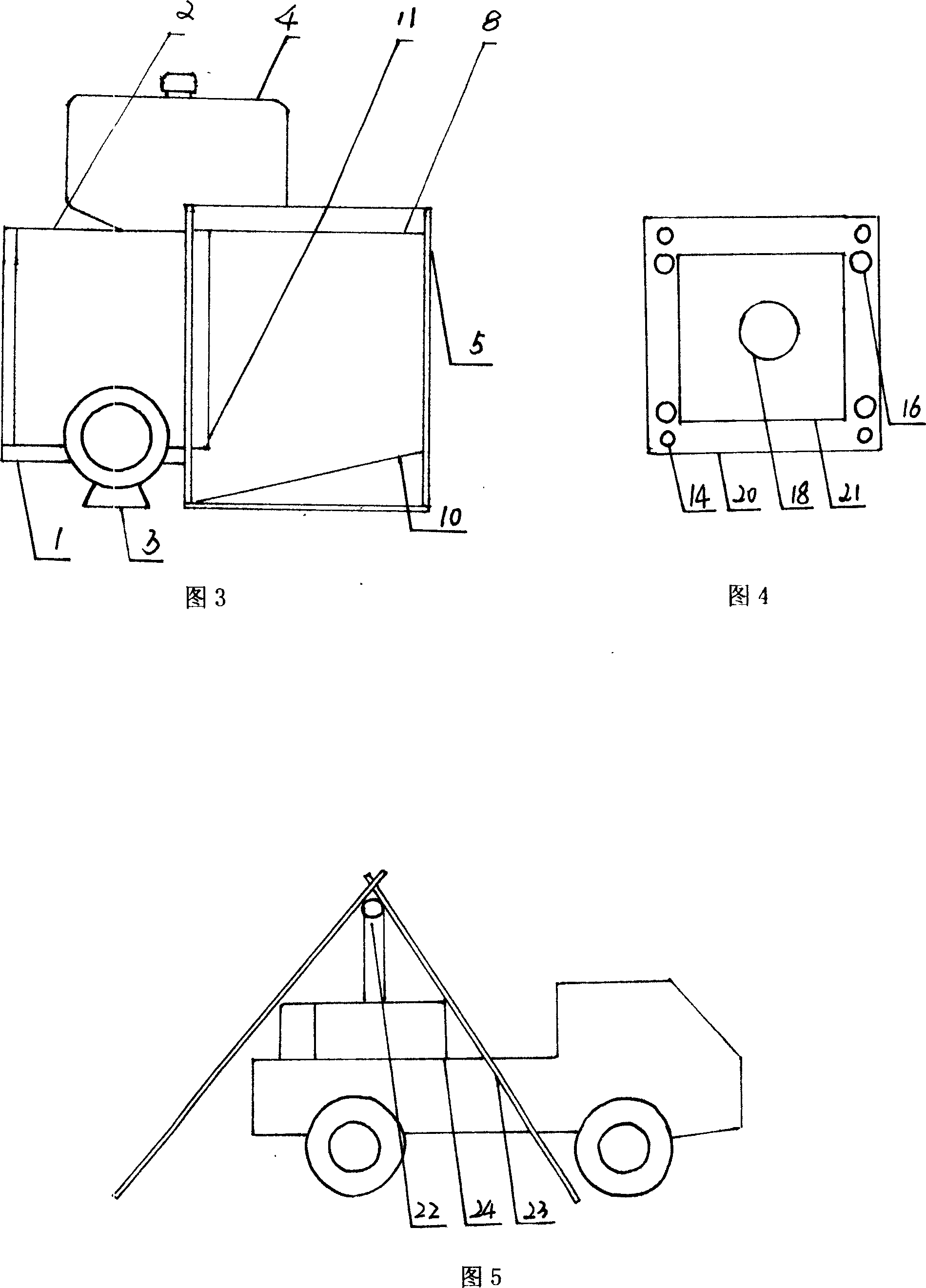

Flow type oil and electricity dual-purpose multifunctional plant stalk block making machine

The invention provides a flow petrol and electricity dual-purpose multifunctional plants straw block press. It includes plants straw shearing device, hydraulic forming device and power output device, the plants straw shearing device and connected with the hydraulic forming device, plants straw shearing device consists of storing materials basket 5, shearing machine cavity 8, adjustable shear cutter 7 installed on the storing materials basket 5 and fore guard board 6 installed on the side of storing materials basket 5; the hydraulic forming device consists of returning material ageing effect machine installed on the side of storing materials basket 5, material cavity, tanks, fore bearing plate 13, pressure plunger piston 18, mold cavity lateral roof 20 and lateral pressure plate 21. The invention can select production broad bean and equipments according to the resources condition of production raw materials; and decide the production power mode according to whether the production broad bean has electronic power. The block press can produce high-protein high-density tablet feed of corn straws and other plants directly, and produce architectural energy-saving, environment-friendly light brick and plants straw and grasses tablet fuels, and products of other aspects.

Owner:毛倜

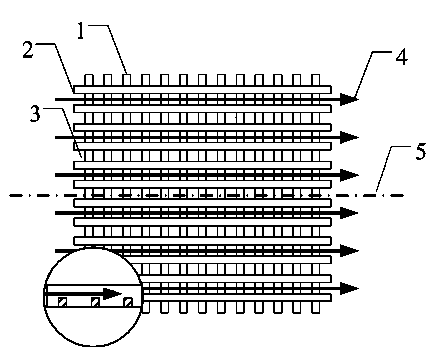

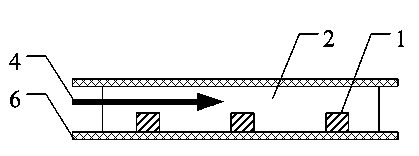

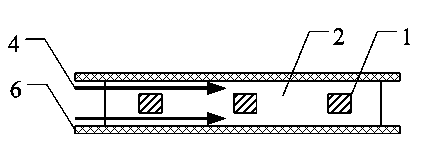

X-spiral-flow wound membrane diversion screen

InactiveCN102600728AIncrease the effective use areaImprove separation efficiencySemi-permeable membranesConcentration polarizationMembrane surface

The invention discloses an X-spiral-flow wound membrane diversion screen, which consists of a plurality of layers of flow passages which are overlapped together. Each layer of flow passages consists of longitudinal ribs. The layers of flow passages are in parallel with each other. Adjacent layers of flow passages are staggered in an X shape, i.e. the longitudinal ribs of the adjacent layers are connected in an X staggered and overlapped way to facilitate conversion from laminar flow to turbulent flow and eliminate influence caused by concentration polarization. Since the X-spiral-flow wound membrane diversion screen consists of a plurality of layers of flow passages consisting of longitudinal ribs, transverse ribs are not used and the scheme is different from the existing schemes, not only can the area of contact with a membrane surface be reduced and the effective available area of a separation membrane be increased, but also a dead corner is not produced, the disturbance of the laminar flow can be facilitated to convert the laminar flow to the turbulent flow under the secondary flow facilitating effect of an X spiral flow, the driving force and the mass transfer effect of solute diffusion are enhanced and the mass transfer capacity of primary liquid is greatly improved. The efficiency of membrane separation is improved, the volumetric percolate flux of the separation membrane is improved, the deposition of pollutants is avoided and the defects of the existing technical scheme are avoided.

Owner:王旭东

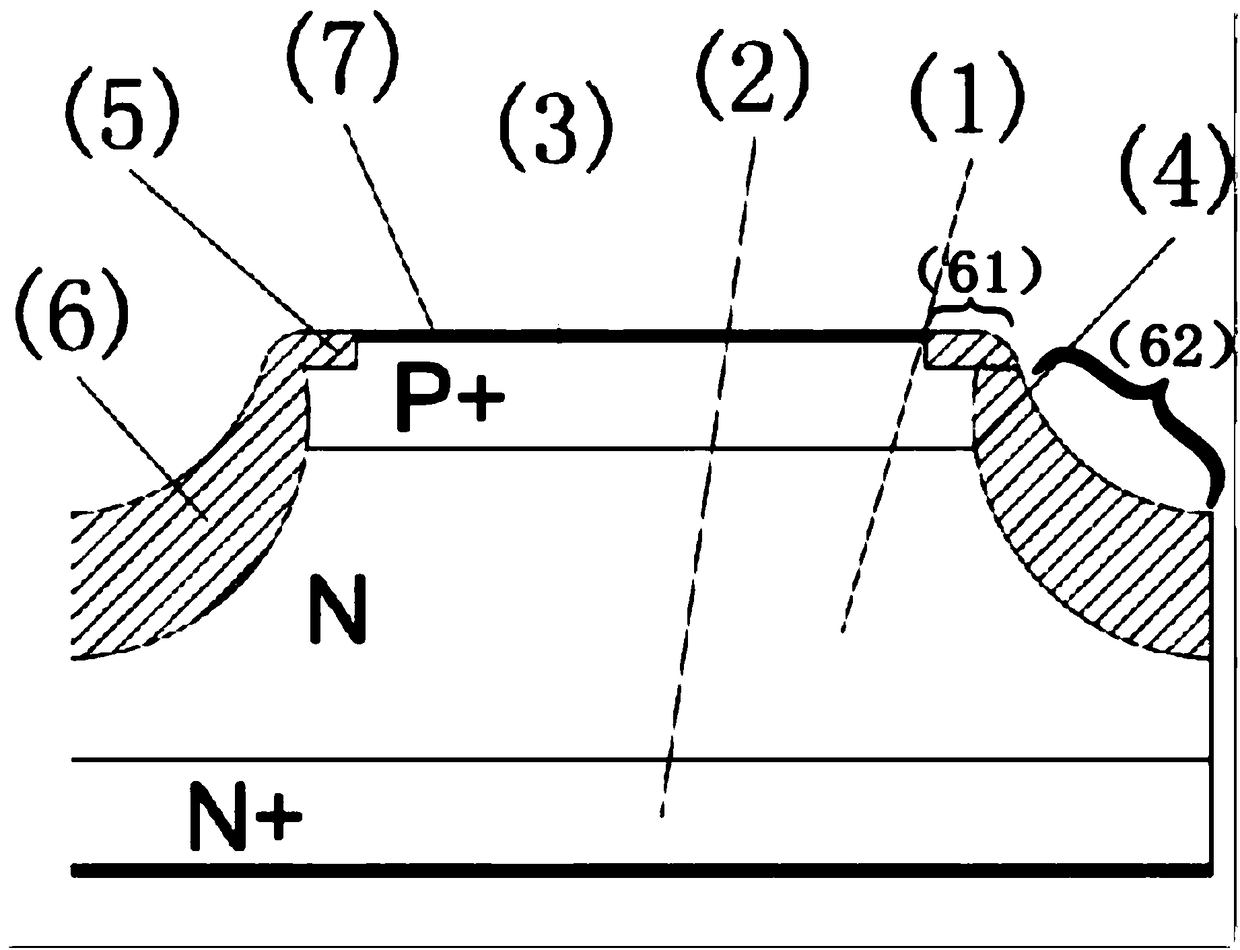

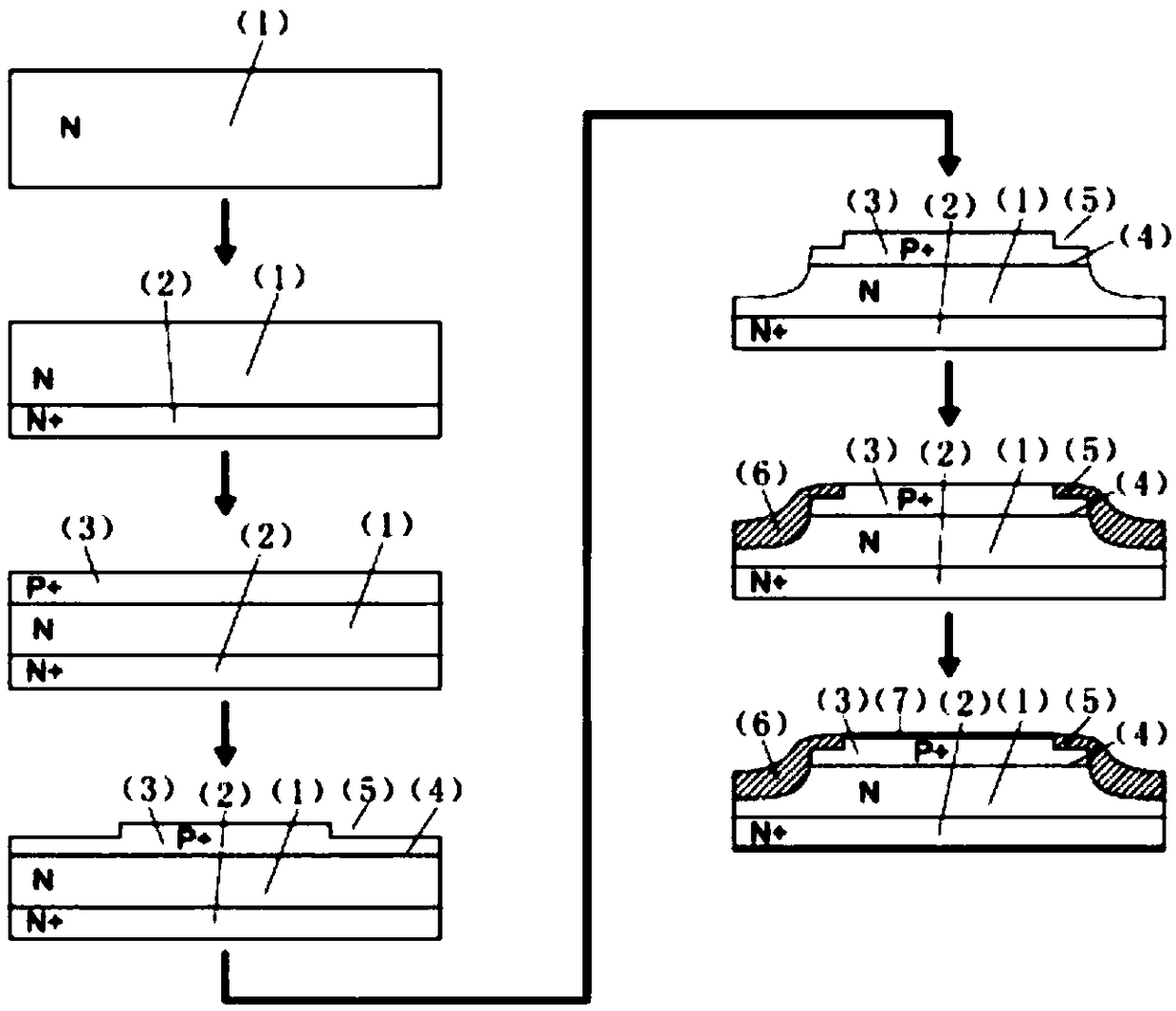

Semiconductor diode chip and manufacturing method thereof

InactiveCN108365015AIncreasing the thicknessIncrease the effective use areaSemiconductor/solid-state device detailsSolid-state devicesBeak shapeSand blasting

The invention belongs to the technical field of semiconductors, and relates to a diode chip, in particular to a semiconductor diode chip and a manufacturing method thereof. The semiconductor diode chip comprises a silicon chip substrate, wherein the bottom part of the silicon chip substrate is provided with a phosphorus diffusion layer, the upper part is provided with a boron diffusion layer, metal electrodes are arranged on the upper part of the boron diffusion layer and the bottom part of the phosphorus diffusion layer, a novel passivation layer is arranged at the outer side of the peripheryof the silicon chip substrate, and the novel passivation layer comprises a transition portion and a 'beak' portion. The manufacturing method comprises the steps of original sheet cleaning, diffusion,sand blasting, cleaning, primary photoetching, stepped corrosion, secondary photoetching, grooving corrosion, cleaning, passivation, third-time photoetching, metallization, electrical performance testing and scribing. The semiconductor diode chip has the advantages that the 'beak' portion of the semiconductor diode chip is protected by glass, the glass is not higher than the table board of the chip, ignition is not caused, the manufacturing cost is low (higher than that of a knife scraping manufacturing process, and lower than that of a photoresist manufacturing process), the effective use area of the chip is large, the VF is lower, the glass is thick, the pressure endurance capability is high, the service life is long, the high temperature reliability is high and the like.

Owner:济南兰星电子有限公司

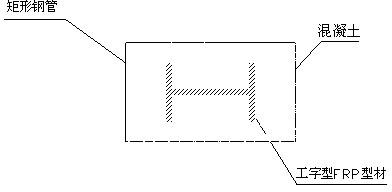

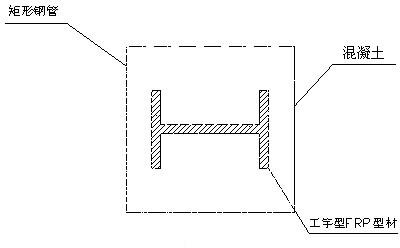

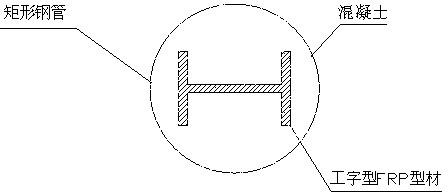

Steel pipe concrete column of I-shaped FRP section

InactiveCN101974958AImprove bearing capacityIncrease stiffnessStrutsPillarsFiberArchitectural engineering

The invention provides a steel pipe concrete column of an I-shaped fiber reinforce plastic (FRP) section and relates to a building member. The steel pipe concrete column consists of a rectangular, square or circular steel pipe, the I-shaped FRP section arranged in the steel pipe and concrete filled between the steep pipe and the I-shaped FRP section, wherein the steel pipe concrete column of the I-shaped FRP section is a coupled column consisting of three different materials of the FRP, the steel pipe and the concrete, namely the steel pipe concrete coupled column of the I-shaped FRP section; and the shape of the cross section of the steel pipe concrete column of the I-shaped FRP section has a rectangular structure, a square structure or a circular structure. Under the conditions of reasonable selection of steel ratio and distribution rate of the FRP, the cross section size of the column can be reduced; and a steel pipe framework can be temporarily supported during construction, so that the construction can be accelerated. The ductility of the column is improved because of the steel pipe so as to contribute to the aseismatic design of seismic areas. The characteristics of light weight and high strength of an FRP material is used to improve the bearing capacity of the column and increase the usable area.

Owner:SHENYANG JIANZHU UNIVERSITY

Full-automatic wet wipe packaging device based on PLC and machine combination

InactiveCN104890928AIncrease the effective use areaImprove the operating environmentPaper article packagingPackaging machinesWet wipeEngineering

The invention discloses a full-automatic wet wipe packaging device based on PLC and machine combination. The full-automatic wet wipe packaging device comprises a feeding device and a main body device. The feeding device comprises a feeding machine frame, a feeding disc and an inner core folding mechanism. An inner core material on the feeding disc is folded into the inner core folding mechanism and is pulled to the main body device under the driving of a driving device. The main body device comprises an outer packaging material roller, a paper cutting device, a folding insertion core device, a film sealing device, an outer packaging material slitting device, a finished product slitting device, a finished product discharging conveying belt and a main motor. The film sealing device is a film press sealing round roller, and the folding insertion core device is arranged on the upper portion of the main body device and located at the output end of the paper cutting device. The paper cutting device and the folding insertion core device are provided with motors serving as power mechanisms. According to the full-automatic wet wipe packaging device, stepping motors which are easier to control during the replacement of a traditional pneumatic element are omitted, the investment of auxiliary facilities can be reduced, and the effective use area of a factory building can be increased.

Owner:SHANGHAI YUCHEN MEDICAL TECH

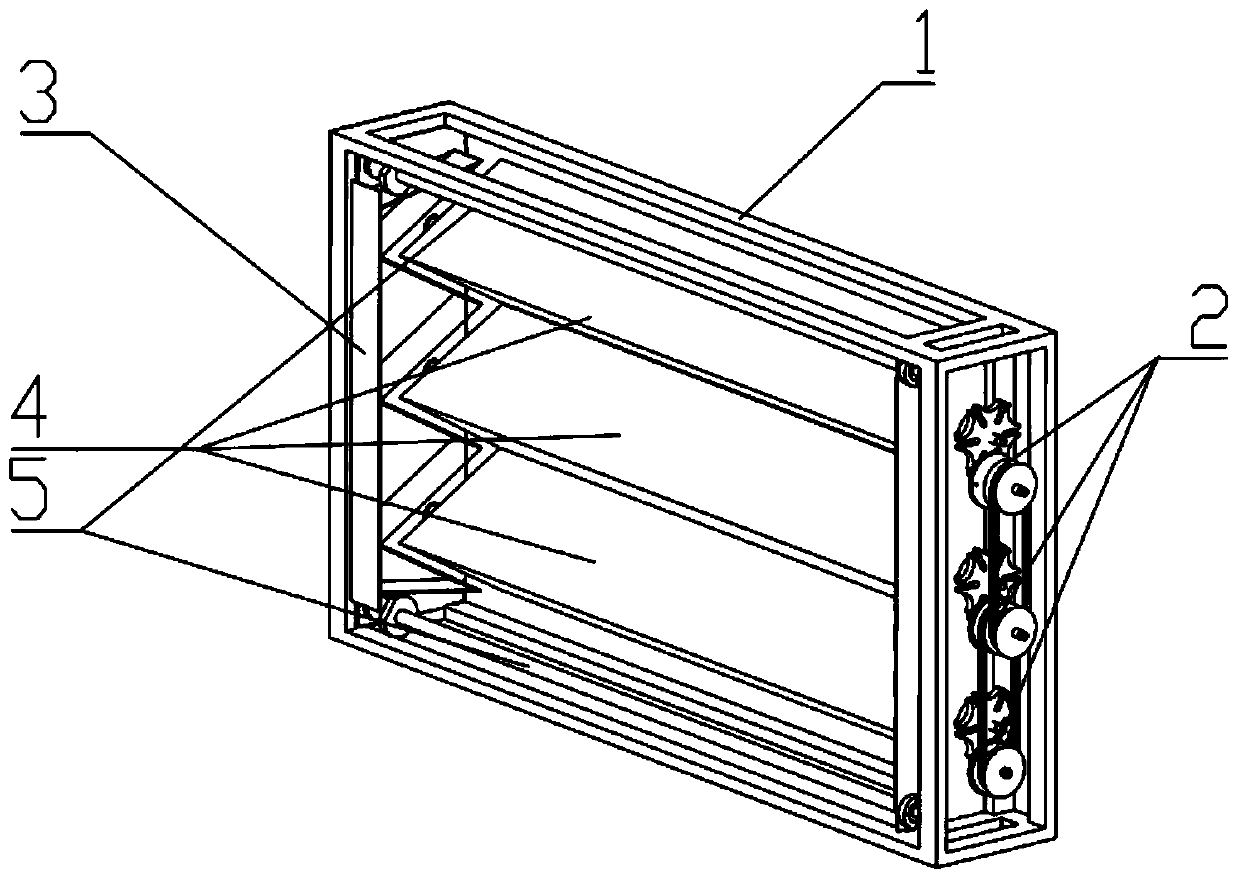

Stereoscopic overturning blackboard

InactiveCN104175763AIncrease the effective use areaIncrease the usable areaBoard cleaning devicesWriting boardsReciprocating motionEngineering

The invention discloses a stereoscopic overturning blackboard which comprises a blackboard framework, board overturning drive mechanisms, a W-shaped blackboard eraser, triangular prism boards and blackboard eraser drive mechanisms, wherein the blackboard eraser drive mechanisms are connected with the triangular prism boards to overturn the triangular prism boards; and the W-shaped blackboard eraser is arranged on the blackboard eraser drive mechanisms which drive the W-shaped blackboard eraser to reciprocate. With adoption of a spatial triangular prism structure, the use areas of the boards are increased, and meanwhile, the blackboard eraser drive mechanisms are matched, so that automatic cleaning is realized, and the class efficiency of a teacher is improved.

Owner:NANJING UNIV OF SCI & TECH

Device for compressing screen mesh pneumatically

InactiveCN104646282AAccurate and stable installationAchieve compactionSievingScreeningEngineeringAirbag

The invention relates to the technical field of drilling vibrating screen equipment, in particular to a device for compressing a screen mesh pneumatically. The device comprises a screen box and a screen mesh, and is characterized in that the screen mesh is movably arranged on the screen box; mounting grooves are formed in the two sides of the screen box; a sealing airbag is arranged between each mounting groove and the screen mesh; each sealing airbag is connected with an air source through an air delivery pipe; a control unit is arranged on the pipeline of the air delivery pipe. The air provided by the air source is introduced into the sealing airbags through the control unit, so that the sealing airbags are expanded to compress the screen mesh on the screen box; the screen mesh is compressed by the sealing airbags, and meanwhile, high sealing performance is guaranteed; the effective using area of the vibrating screen is improved; in addition, the screen mesh can be limited effectively in an inclined contact surface mode of the screen mesh and the screen box; the effects of compressing and positioning the screen mesh are achieved; according to the device, the screen mesh can be mounted or detached conveniently and quickly by only operating a switch; the device is easy to operate and convenient to assemble and disassemble; the work efficiency of the vibrating screen is effectively improved.

Owner:刘越浪

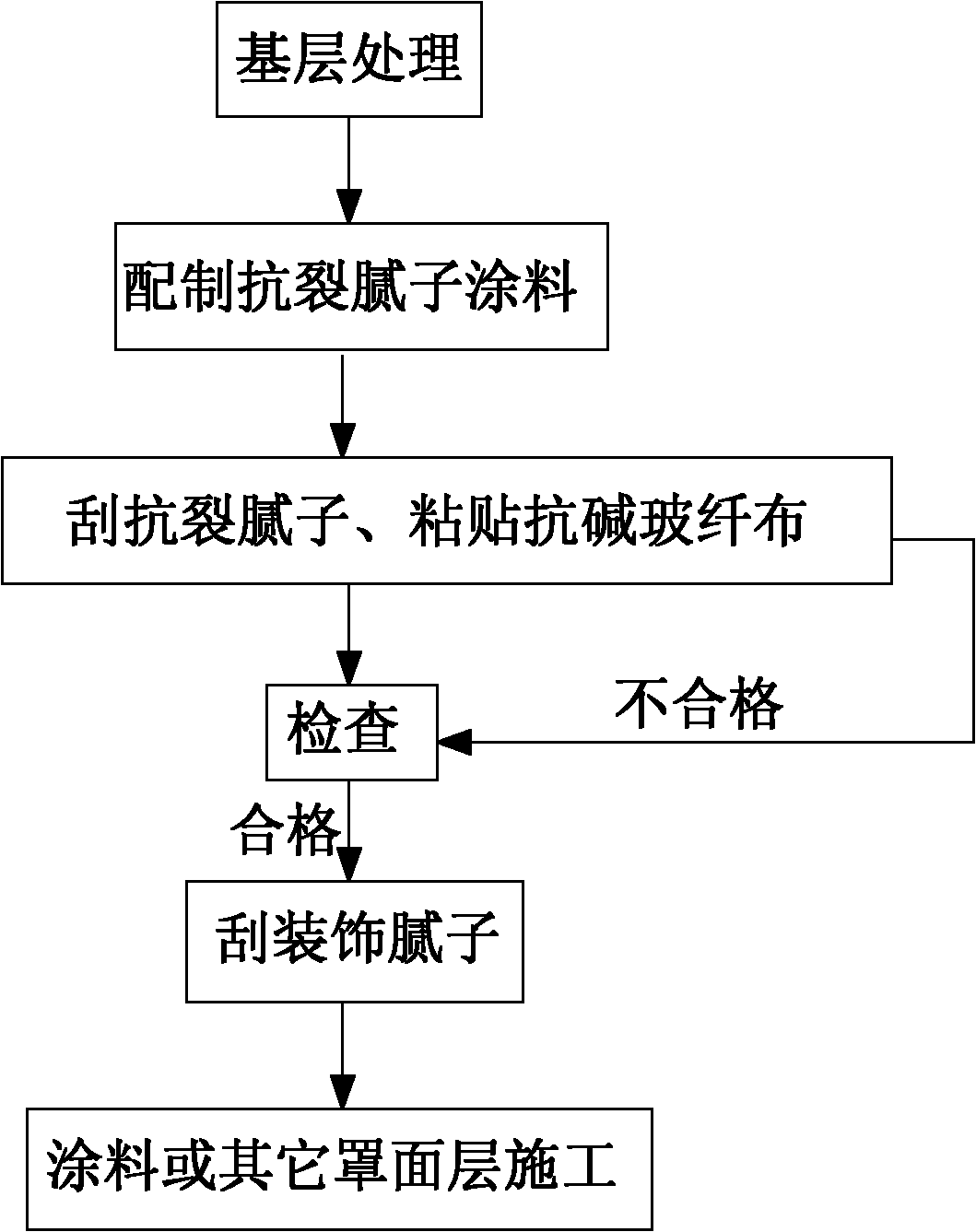

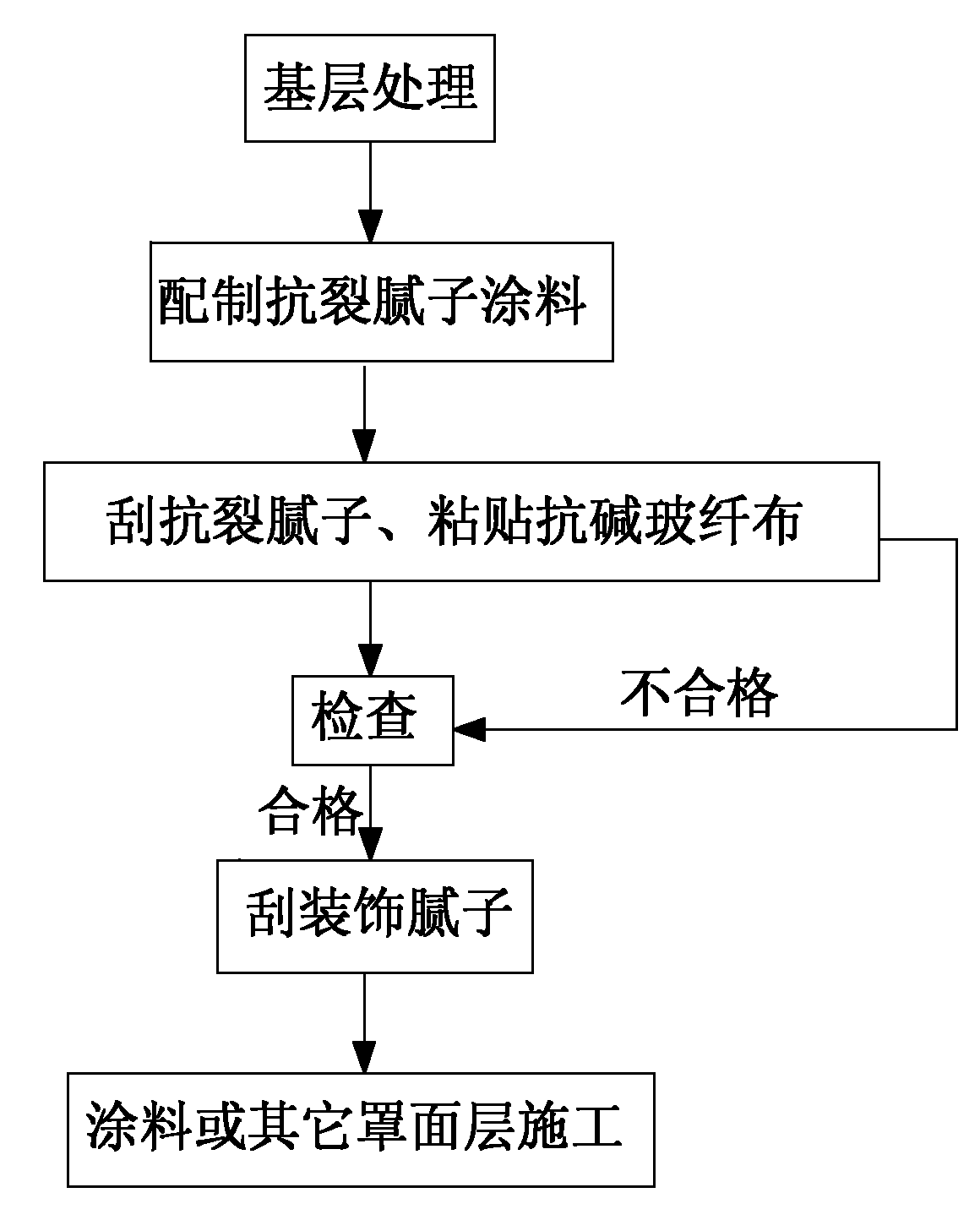

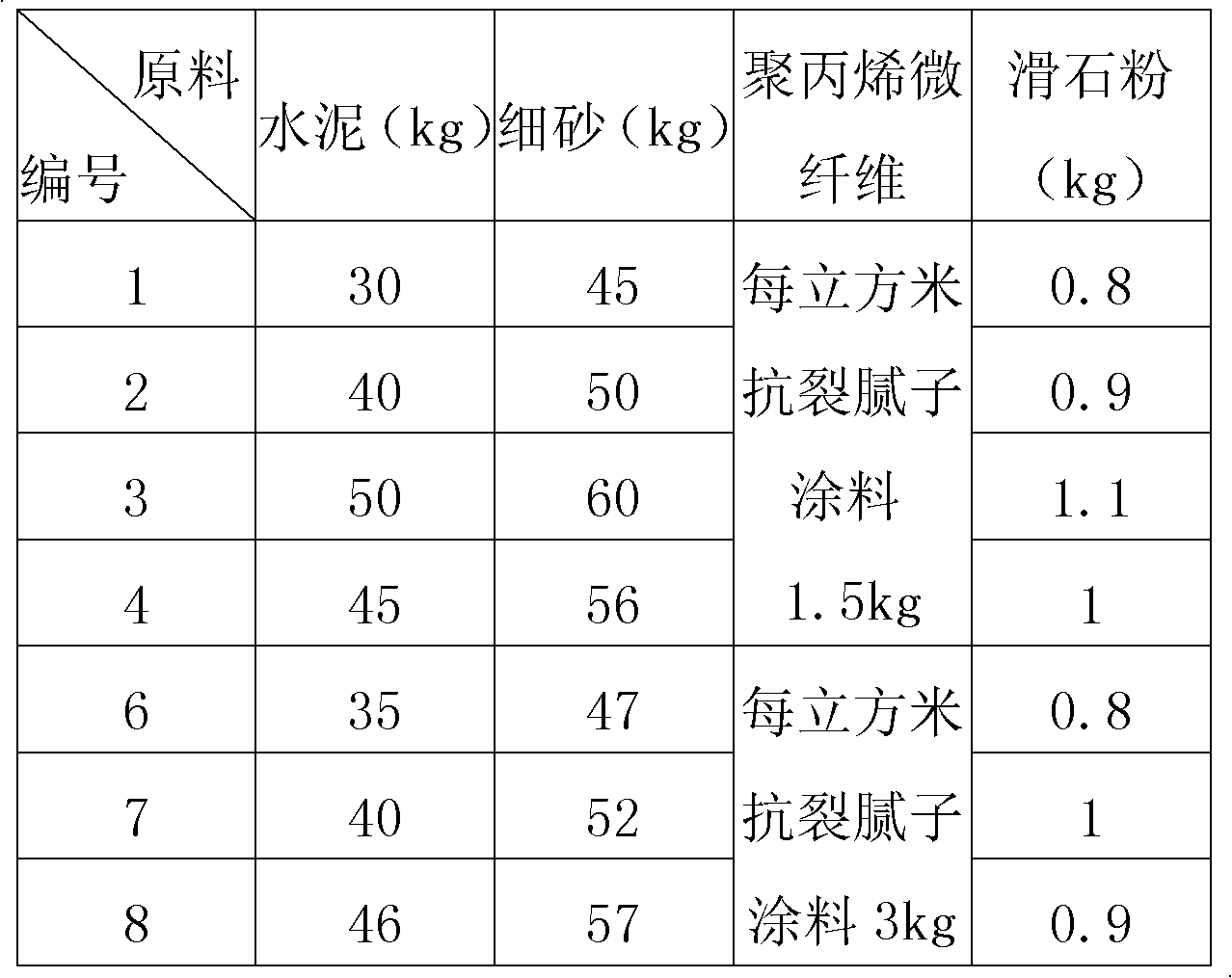

Process for constructing surface of wall body

ActiveCN101781921AEliminate common quality problemsReduce dosageCovering/liningsFineness modulusEngineering

The invention discloses a process for construction the surface of a wall body, which can significantly reduce the construction thickness on the surface of the wall body so as to improve the effective usable area of a house. The process is characterized by comprising the following steps of: firstly, directly daubing an anti-cracking putty coating with the thickness of 2 to 3 millimeters on the surface of the wall body of which the flatness deviation is less than or equal to 4 millimeters and the vertical deviation is less than or equal to 4 millimeters; secondly, daubing a decorative putty coating on the surface of the anti-cracking putty coating, wherein the anti-cracking putty coating is prepared from the following raw materials in part by weight: 3 to 5 parts of cement, 4 to 6 parts of fine sand and 0.8 to 1.2 parts of talcpowder; each cubic meter of the anti-cracking putty coating contains 1 to 4 kilograms of polypropene micro-fibers and a proper amount of water and glue water; and the fineness modulus of the fine sand is between 2.2 and 1.6, and the average particle diameter is 0.25 to 0.35 millimeter. By adopting the construction process of the invention, the bay and the depth of the house are increased for about 30 to 38 millimeters, the effective usable area can be increased by 1 to 1.5 percent, and the consumption of building materials is reduced, so the construction cost is saved and the energy consumption is reduced.

Owner:CHENGDU CONSTR ENG GROUP CORP

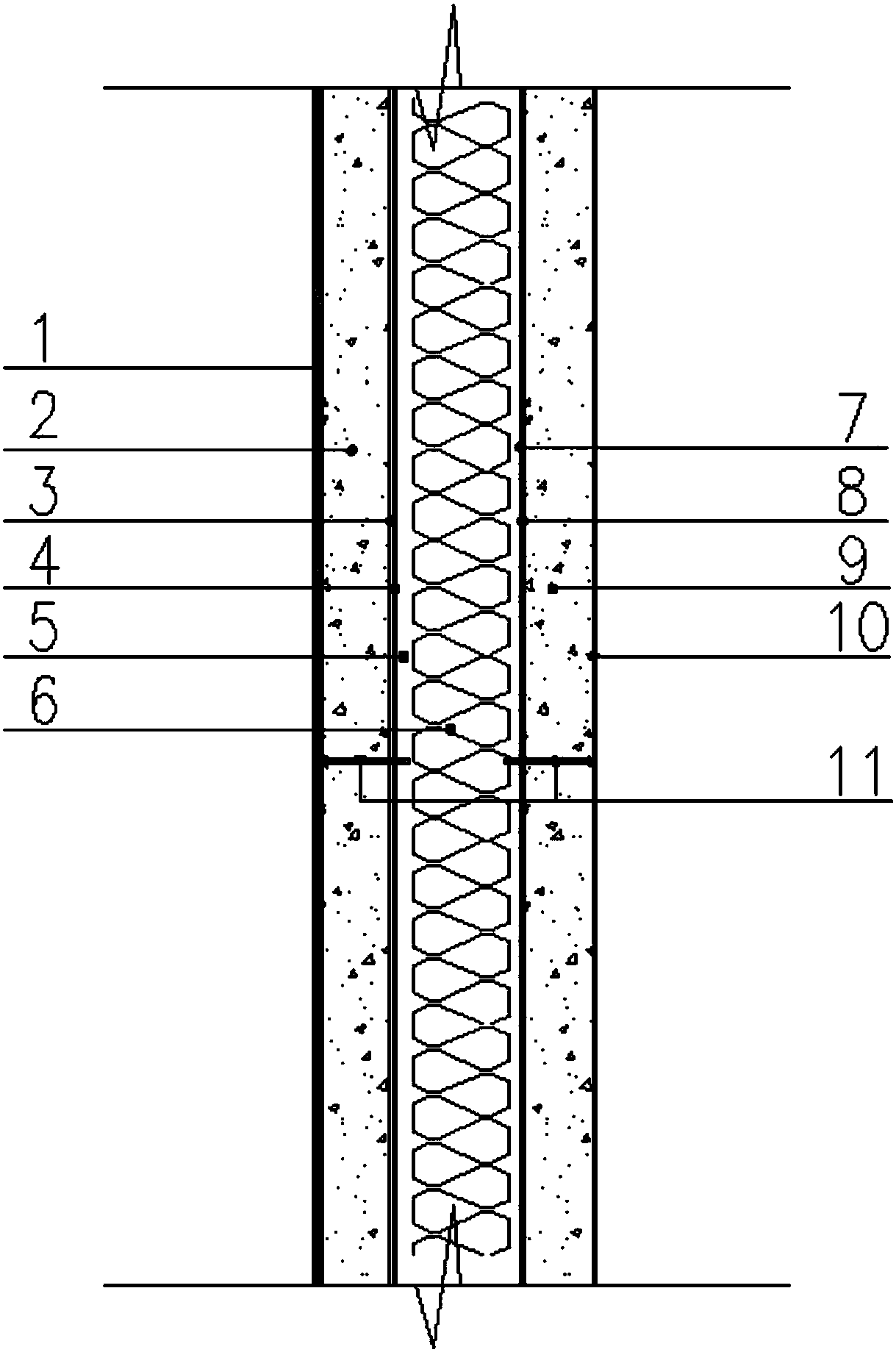

Fabricated light steel keel wall body suitable for building and construction technology

PendingCN107859213AImprove sound insulationImprove thermal insulation and energy savingWallsThick plateEngineering

The invention belongs to the technical field of fabricated light steel keel enclosure wall bodies of buildings and construction and discloses a fabricated light steel keel wall body suitable for a building and a construction technology. The fabricated light steel keel wall body suitable for the building comprises a wall surface anti-cracking and waterproof material composite layer and the like. AnALC board base layer with the thickness being 50-200 mm is arranged on the right side of the wall surface anti-cracking and waterproof material composite layer, and a damping and sound-insulating material layer with the thickness being 1.2-19 mm is arranged on the right side of the ALC board base layer with the thickness being 50-200 mm. A heat-insulating material layer with the thickness being 2-15 mm is arranged on the right side of the damping and sound-insulating material layer with the thickness being 1.2-19 mm, and a light steel keel wall frame is arranged on the right side of the heat-insulating material layer with the thickness being 2-15 mm. The light steel keel wall frame is filled with a heat-insulating material with the thickness being 30-140 mm, and a heat-insulating materialwith the thickness being 2-15 mm is arranged on the right side of the light steel keel wall frame. A sound-insulating material with the thickness being 1.2-19 mm is arranged on the right side of theheat-insulating material with the thickness being 2-15 mm, and an ALC board with the thickness being 50-200 mm is arranged on the right side of the sound-insulating material with the thickness being 1.2-19 mm. A facing layer is arranged on the right side of the ALC board with the thickness being 50-200 mm.

Owner:武汉麦特建筑科技有限公司

X-spiral-flow wound membrane diversion screen

InactiveCN102600728BIncrease the effective use areaImprove separation efficiencySemi-permeable membranesConcentration polarizationMembrane surface

The invention discloses an X-spiral-flow wound membrane diversion screen, which consists of a plurality of layers of flow passages which are overlapped together. Each layer of flow passages consists of longitudinal ribs. The layers of flow passages are in parallel with each other. Adjacent layers of flow passages are staggered in an X shape, i.e. the longitudinal ribs of the adjacent layers are connected in an X staggered and overlapped way to facilitate conversion from laminar flow to turbulent flow and eliminate influence caused by concentration polarization. Since the X-spiral-flow wound membrane diversion screen consists of a plurality of layers of flow passages consisting of longitudinal ribs, transverse ribs are not used and the scheme is different from the existing schemes, not only can the area of contact with a membrane surface be reduced and the effective available area of a separation membrane be increased, but also a dead corner is not produced, the disturbance of the laminar flow can be facilitated to convert the laminar flow to the turbulent flow under the secondary flow facilitating effect of an X spiral flow, the driving force and the mass transfer effect of solute diffusion are enhanced and the mass transfer capacity of primary liquid is greatly improved. The efficiency of membrane separation is improved, the volumetric percolate flux of the separation membrane is improved, the deposition of pollutants is avoided and the defects of the existing technical scheme are avoided.

Owner:王旭东

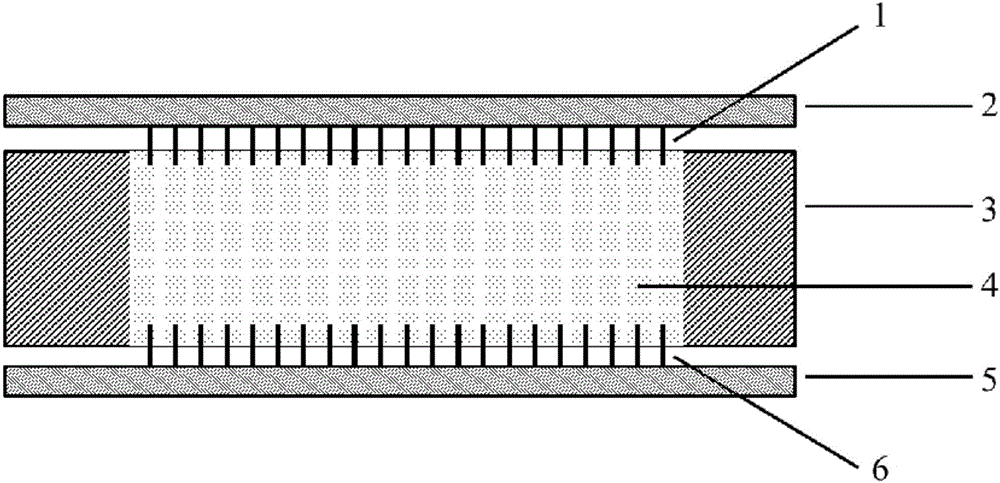

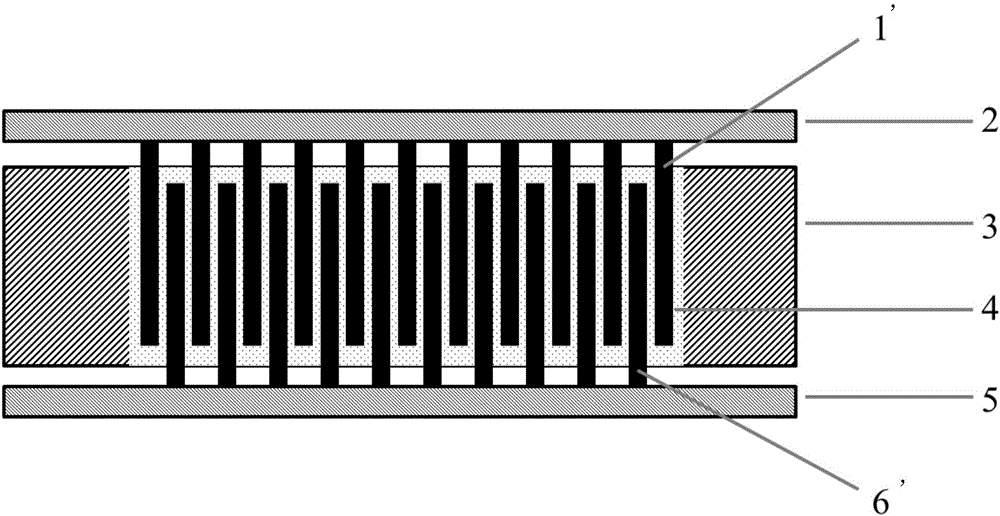

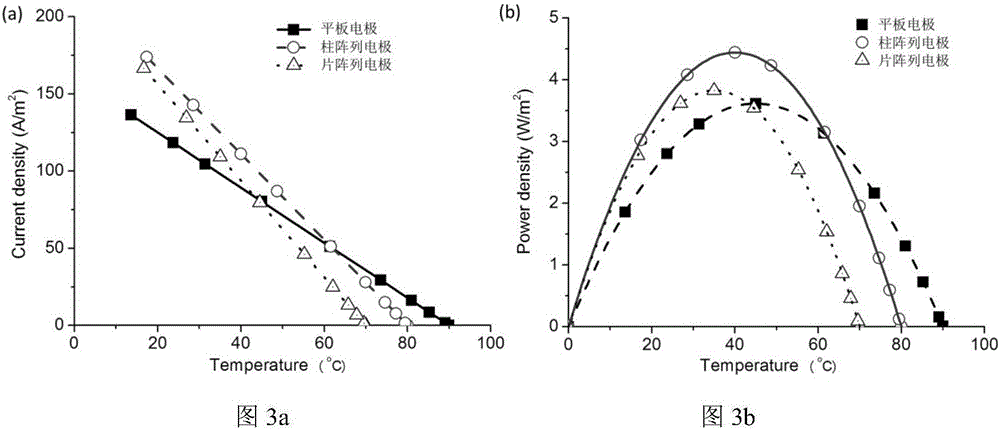

Electrode structure of electrolyte thermobattery and electrolyte thermobattery preparation method

ActiveCN106449961AIncrease the effective use areaImprove thermoelectric conversion efficiencyThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermal transitionOxidation-Reduction Agent

The invention discloses an electrode structure of an electrolyte thermobattery. The electrode structure comprises a battery hot-end electrode and a battery cold-end electrode which are positioned on two sides of an insulating partition with an electrolyte groove respectively, the electrolyte groove of the insulating partition is filled with a redox couple electrolyte, and the battery hot-end electrode comprises a battery hot-end current collector and array electrodes arranged on the battery hot-end current collector; the battery cold-end electrode comprises a battery cold-end current collector and array electrodes arranged on the battery cold-end current collector, and the array electrodes are divided column array electrodes and sheet array electrodes. Effective using area of the electrode structure is increased, and thermal transition efficiency of the electrolyte thermobattery is improved substantially.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com