Full-automatic wet wipe packaging device based on PLC and machine combination

A packaging equipment and a combined technology, applied in the field of automatic wet wipes packaging equipment, can solve the problems of reducing the operation speed and reliability of the equipment, difficult to meet the market demand, affecting the operating environment of the workshop, etc., to facilitate the operation of the control equipment, The effect of increasing the effective use area and reducing the maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

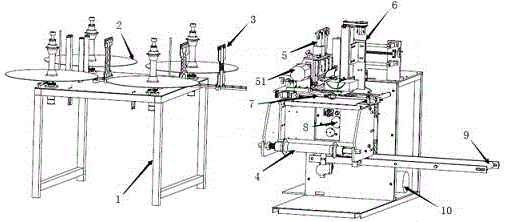

[0017] see Figure 1-4 , a fully automatic wet wipe packaging equipment based on the combination of PLC and machinery, including feeding equipment and main equipment; the feeding equipment includes a feeding frame 1, a feeding disc 2 and an inner core folding mechanism 3, and the feeding disc 2 is 4, and evenly arranged on the feeding frame 1, the inner core material is placed on the feeding disc 2, the inner core folding mechanism 3 is arranged along the transverse centerline of the feeding frame 1, and the front end of the inner core folding mechanism 3 extends to the main equipment , the inner core material on the feeding disc 2 is folded into the inner core folding mechanism 3, and is pulled to the main equipment under the drive of the driving device. The inner core material includes non-woven fabric or wet-strength paper, etc.;

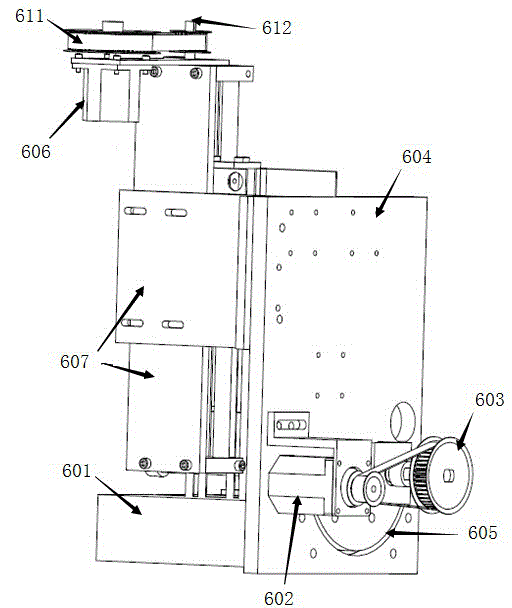

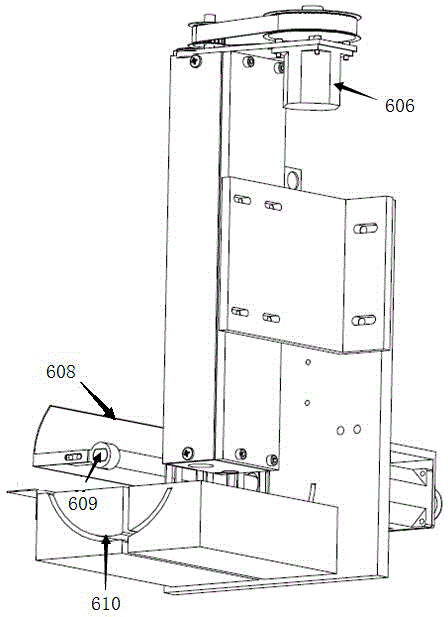

[0018] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com