Process for constructing surface of wall body

A construction technology and wall technology, applied in covering/lining, construction, building structure, etc., can solve the problems of reducing the effective indoor area, increasing the construction cost, slow construction progress, etc., to improve the construction speed and save the construction cost. , to ensure the effect of project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

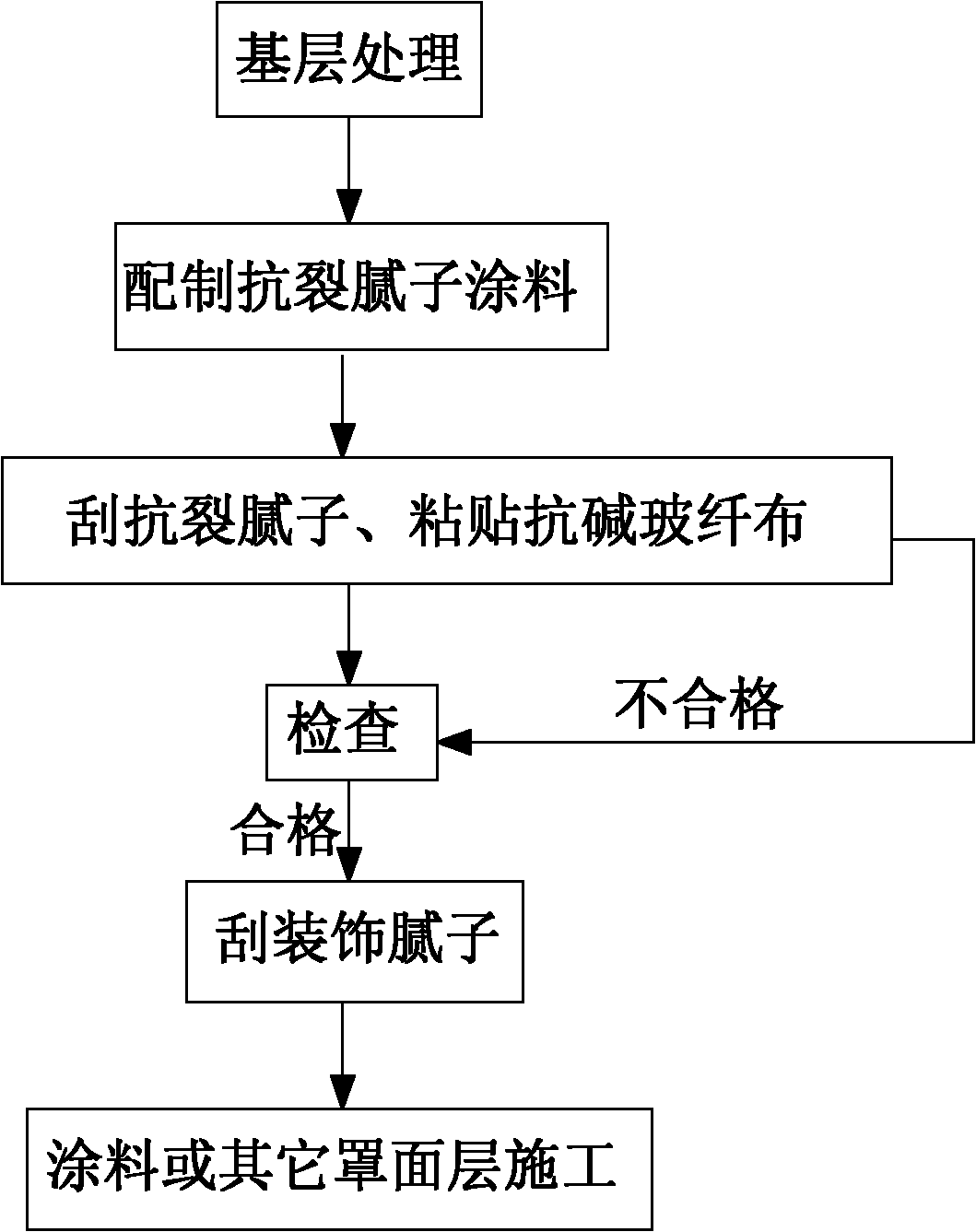

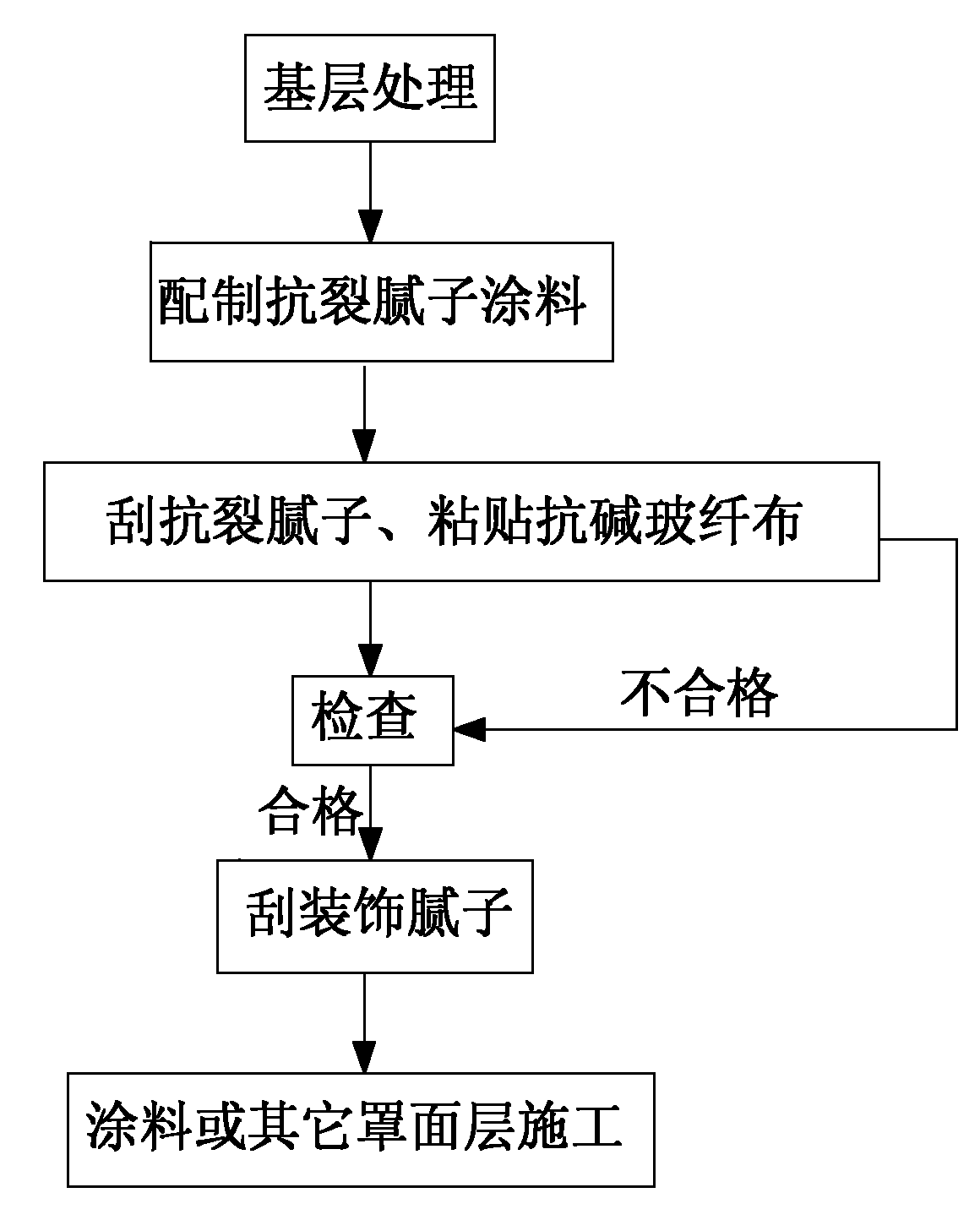

[0018] Such as figure 1 In the process flow shown, in order to make the deviation of the flatness of the wall surface ≤ 4mm and the deviation of verticality ≤ 4mm, before applying the anti-cracking putty paint, the wall should be treated with the base layer. If there is a local protrusion of more than 4mm from the wall, it can be eliminated by chiseling or smoothing with a grinding wheel. If the vertical deviation of part of the wall is greater than 4mm, it should be marked, and the cement mortar leveling should be carried out according to the conventional method during construction. After the treatment is completed, rinse off the dust and stains on the wall with water, and the anti-crack putty construction can be carried out one day later. The purpose of controlling the flatness deviation of the wall surface to ≤4mm and the verticality deviation to ≤4mm is to create conditions for the use of anti-cracking putty paint instead of cement mortar plastering.

[0019] Such as fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com