Construction method for arch springing of arch cover type subway station

A technology for subway stations and construction methods, which is applied in underground chambers, earthwork drilling, wellbore lining, etc., and can solve problems such as poor line control of steel edge waterstops, ineffective connection of steel bars, offset of steel edge waterstops, etc. problems, to achieve the effect of improving the quality of engineering construction, facilitating multiple turnovers, and preventing offsets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

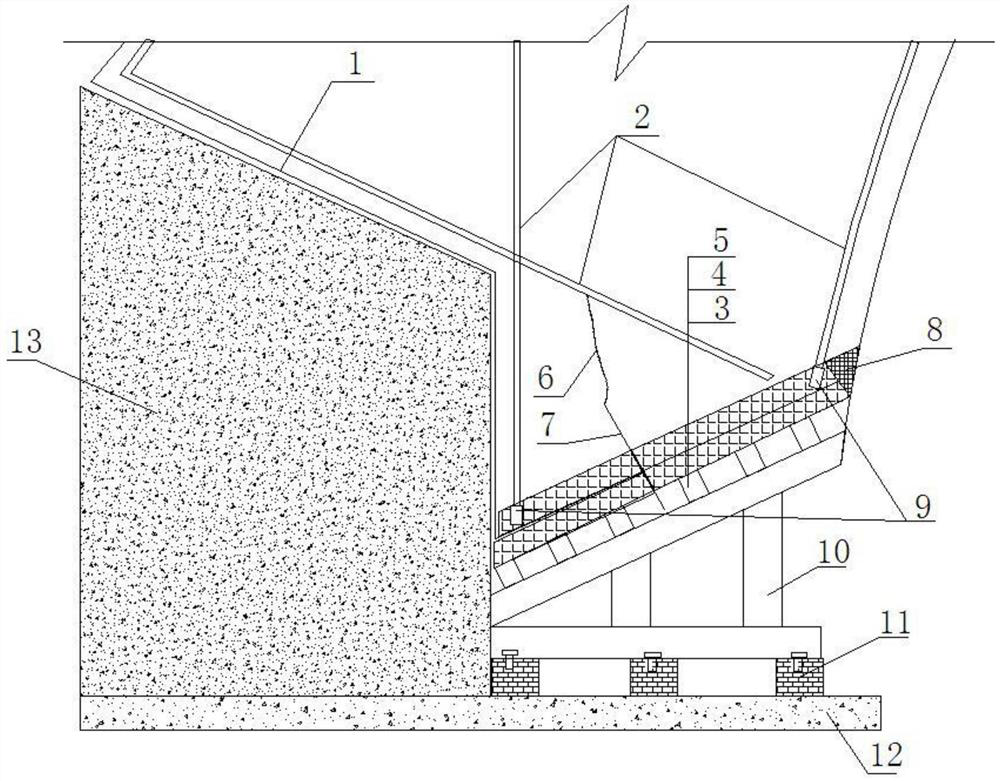

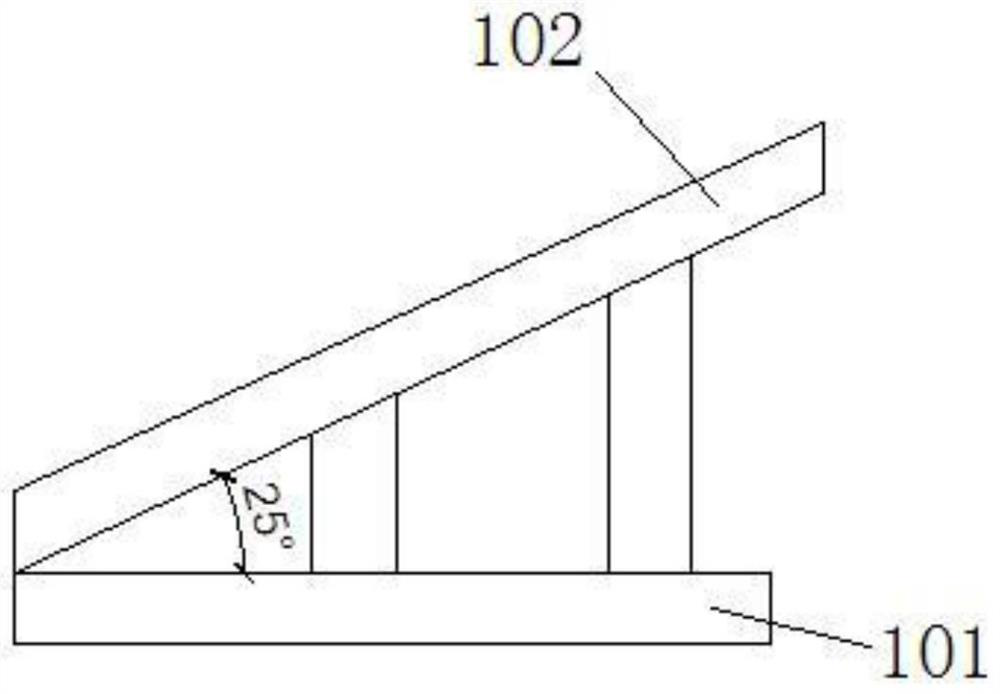

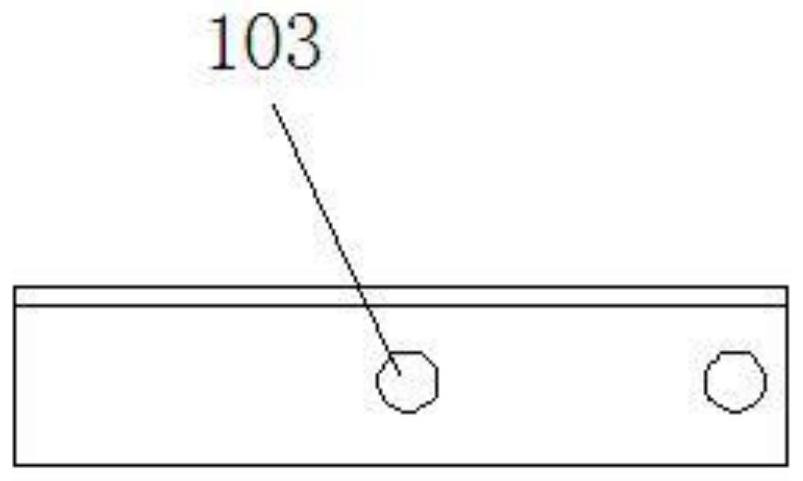

[0024] As shown in the accompanying drawings, a construction method for the arch foot of an arch-covered subway station adopts the arch foot support and the base formwork for construction. The arch foot support includes three square logs 11 arranged at the bottom and a plurality of triangular supports 10 arranged on the top of the three square logs 11 at intervals. Square timber 11 adopts 10*10cm square timber. The triangular support 10 includes a support beam 101, a support slant beam 102, and a support rod connected between the support beam 101 and the support slant beam 102. The triangular support 10 is processed by ∠10*10cm angle steel and welded to form a triangular structure. The design angle is 25°. A Φ26 mm bolt hole 103 is provided on the support beam 101 , and the support beam 101 of the triangular support 10 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com