Patents

Literature

33results about How to "Improve the quality of engineering construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

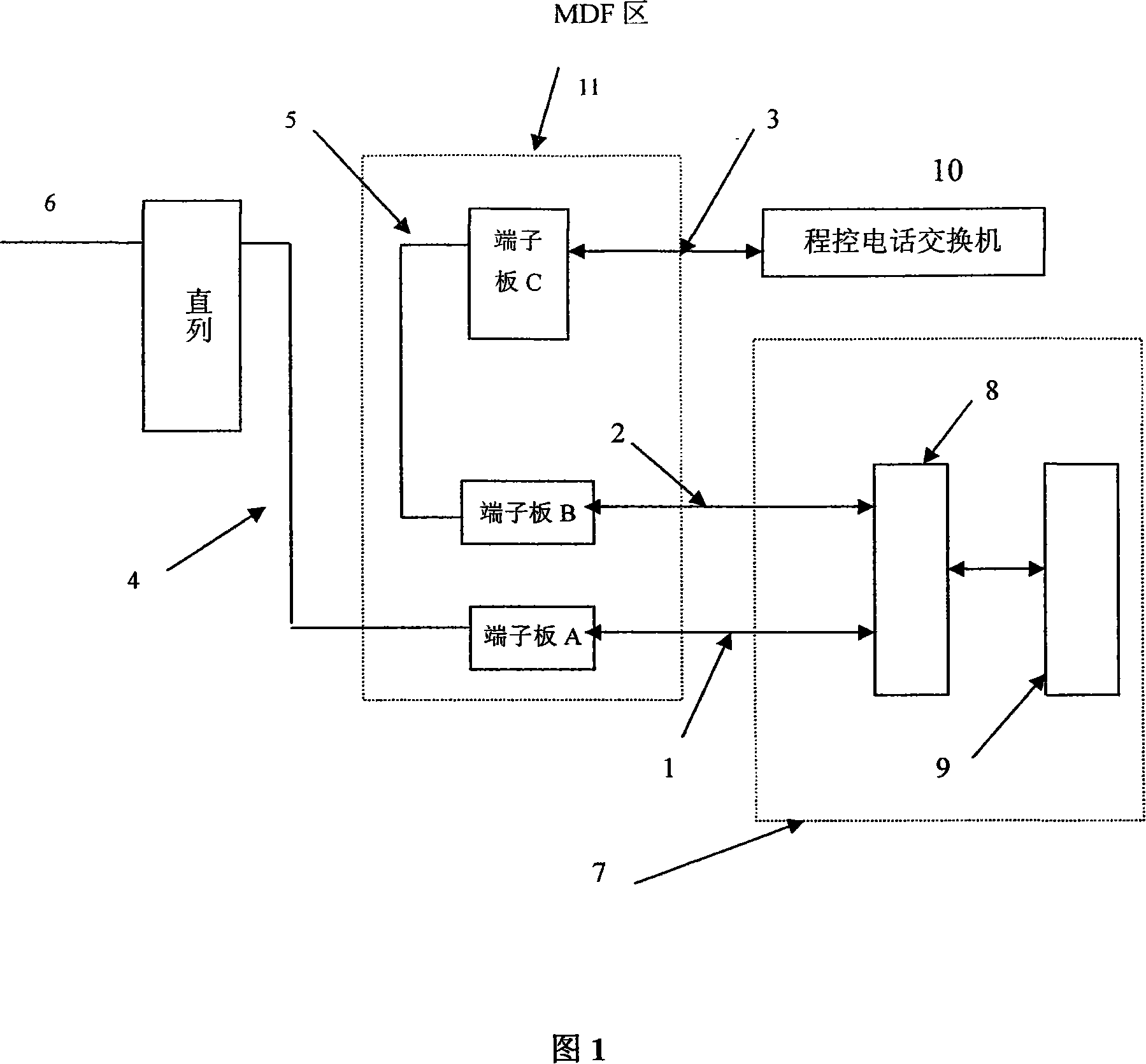

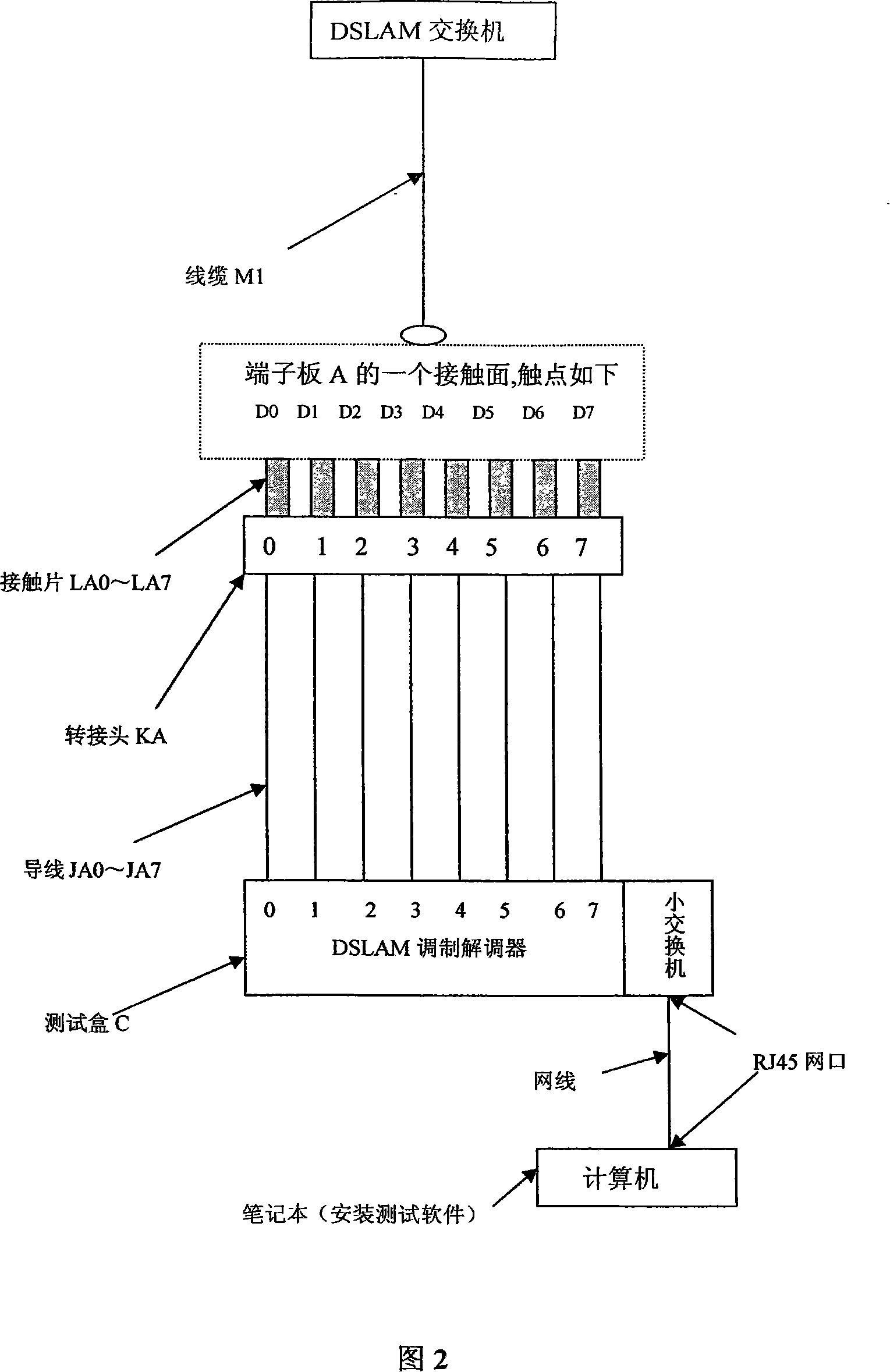

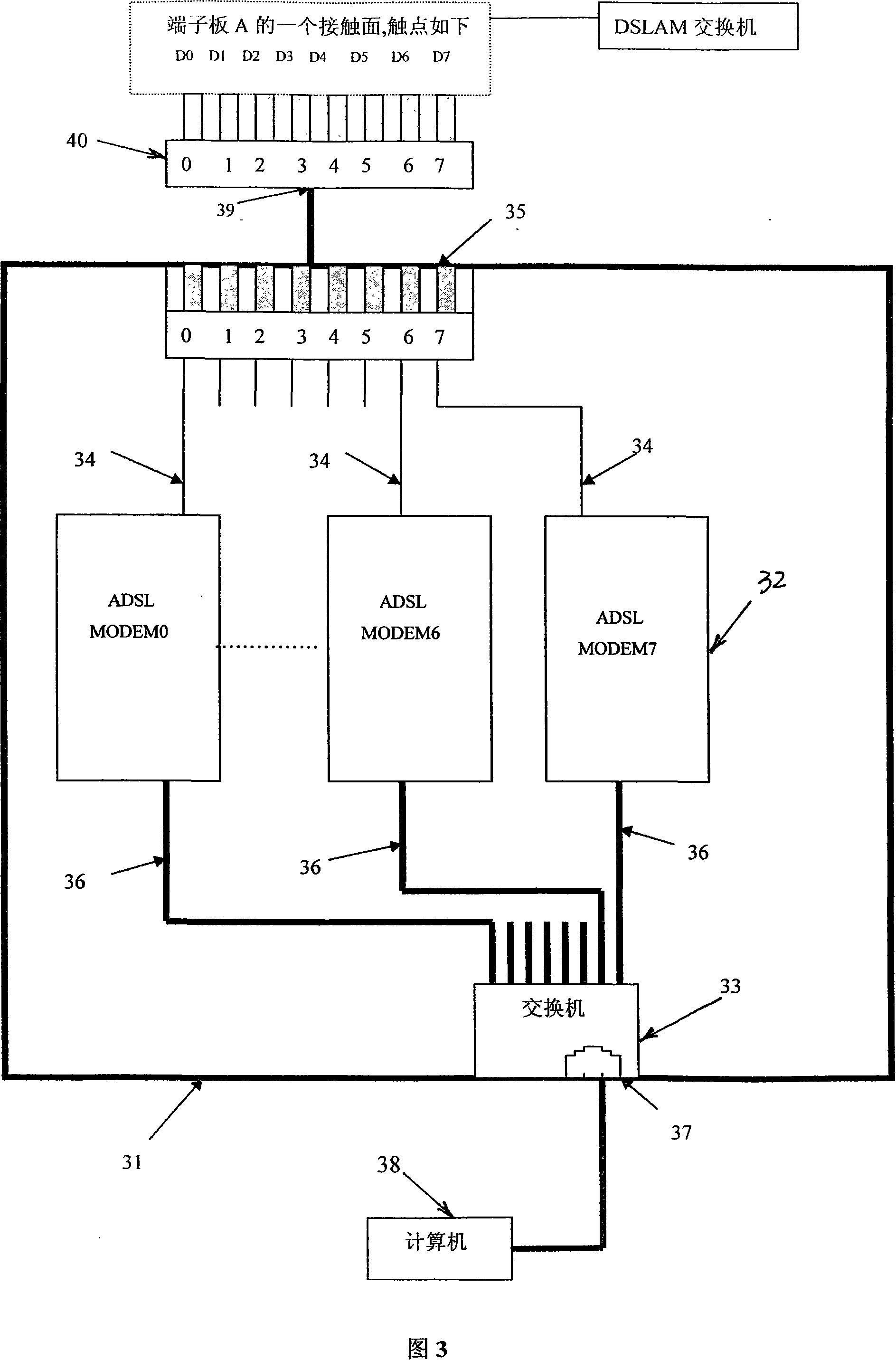

DSLAN port fast detecting device and its detecting method

ActiveCN101072047AScalableQuick connectionSupervisory/monitoring/testing arrangementsLine-transmission monitoring/testingTest efficiencyDistribution frame

The quick detection device for DSLAM ports includes N pieces of 8 routes testing plugs (N8TP), testing cable, notebook computer (NC), and testing case. 8XN pieces of xDSL MODEM circuit board, and one switching exchange with multiple ports are setup inside the case. Through testing cables, phone lines of the said board are connected to N8TP respectively, and data lines of the said board are connected to 8XN pieces of data ports on the switching exchange. The other one data port on the switching exchange is connected to network port of NC. Using 8 routes testing plugs can accomplish quick connecting to 8 pieces of DSLAM ports in high efficiency. Then, using program stored in NC accomplishes testing in batch. When N is 1, the device can test 8 pieces of DSLAM ports within 1 minute. Thus, comparing current method, the invention raises testing speed for 8 times; moreover, N can be selected as 2 or 3 etc. The invention is suitable for telecom company to check, accept and maintain work.

Owner:CHINA TELECOM CORP LTD

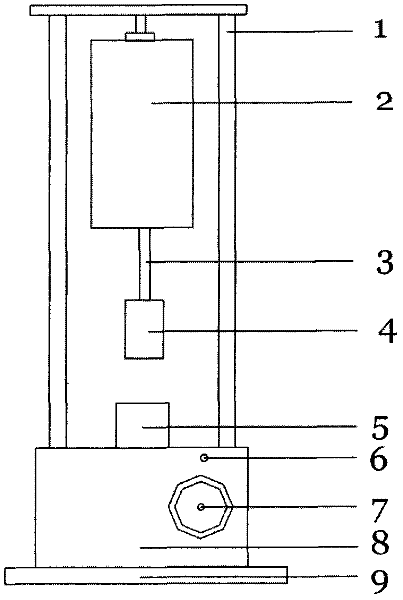

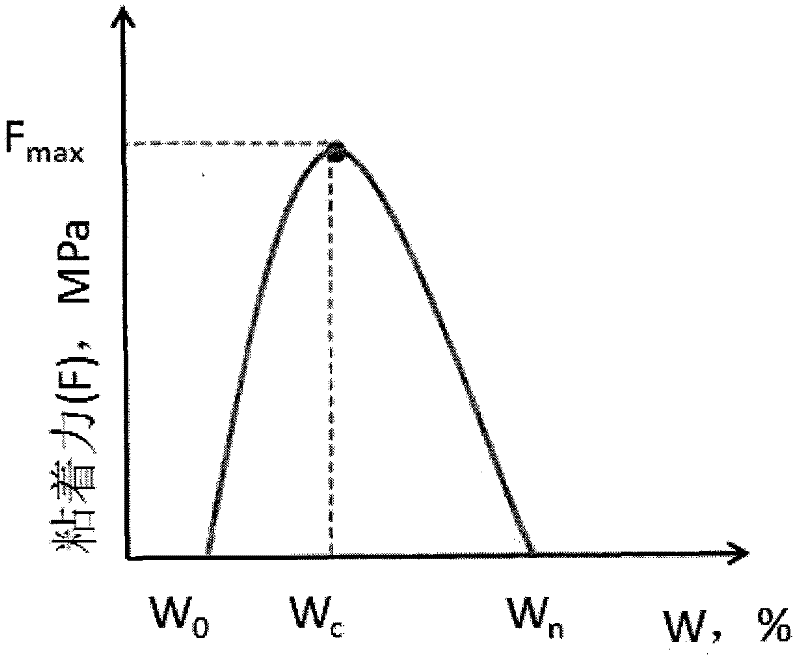

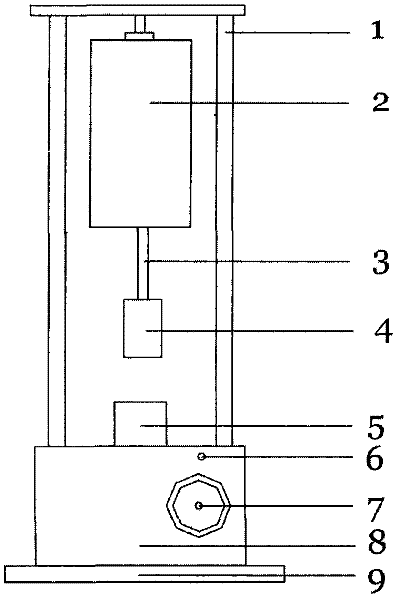

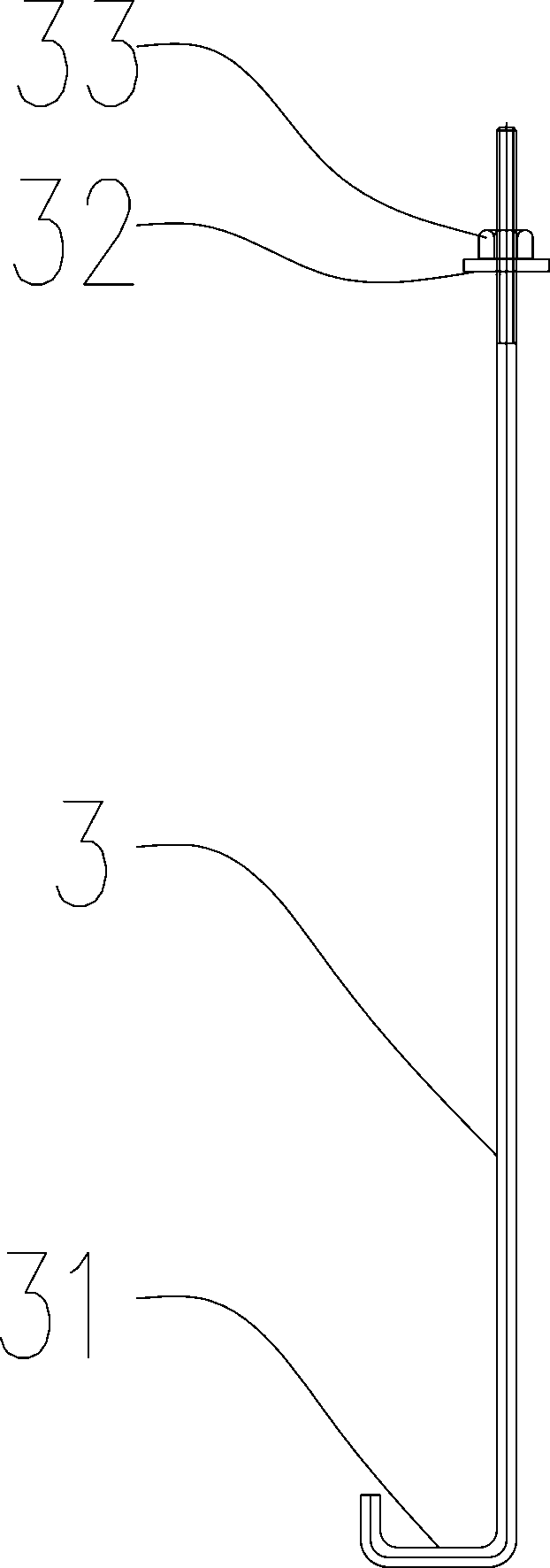

Instrument for measuring soil adherence force

InactiveCN102494994AMeet the testing needs of adhesionMeasuring AdhesionUsing mechanical meansMaterial analysisPull forceEngineering

The invention relates to an instrument for measuring soil adherence force, which is structurally characterized in that the top part of a steel frame is connected with a hydraulic dynamometric system; the lower end of the hydraulic dynamometric system is connected with a different material replaceable testing head through a telescopic rod; a pressure regulating system and the hydraulic dynamometric system are connected through a copper pipeline in the steel frame; a detachable sample box is fixed above a housing of the pressure regulating system; an oil pressure valve and a handwheel are arranged on one side of the housing; and the pressure regulating system is fixed on a base plate. The different material replaceable testing head is driven by the hydraulic dynamometric system through the telescopic rod to transmit pull force and pressure in different directions, so as to measure the adherence force between different materials and soil of different types and states. The instrument for measuring soil adherence force provides test data and technical guidance in reducing energy consumption and improving engineering building quality for civil and military transportation.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

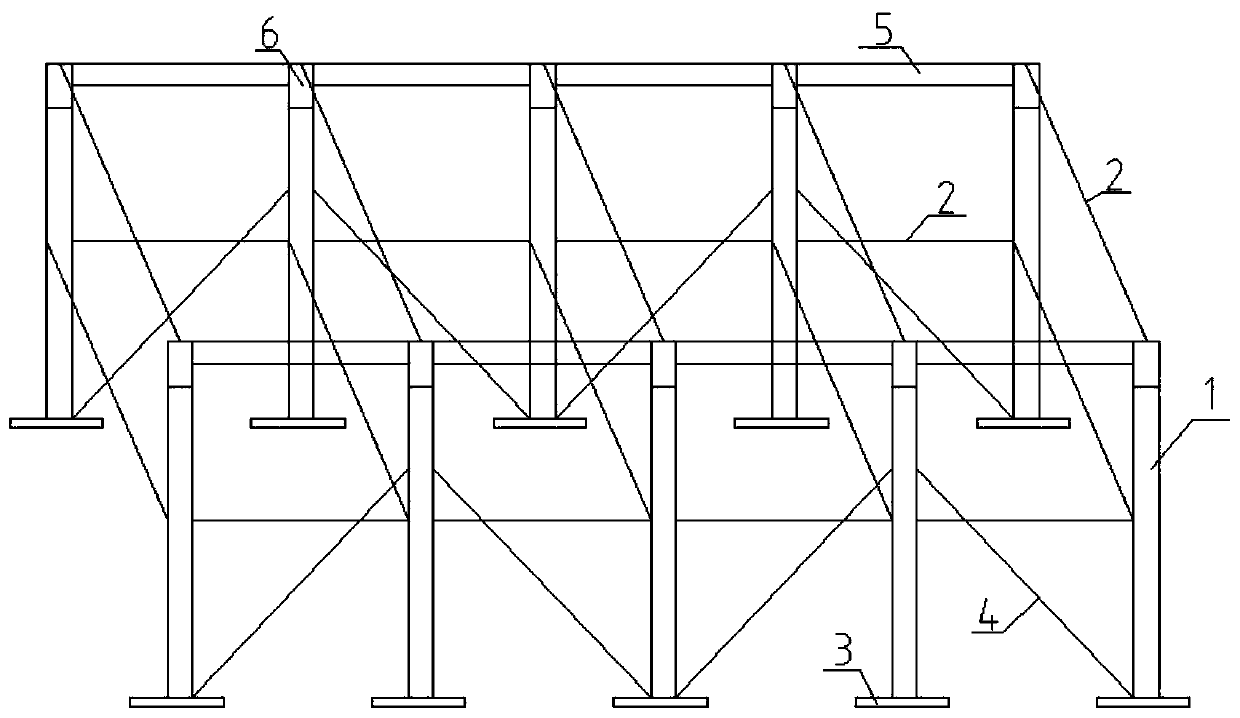

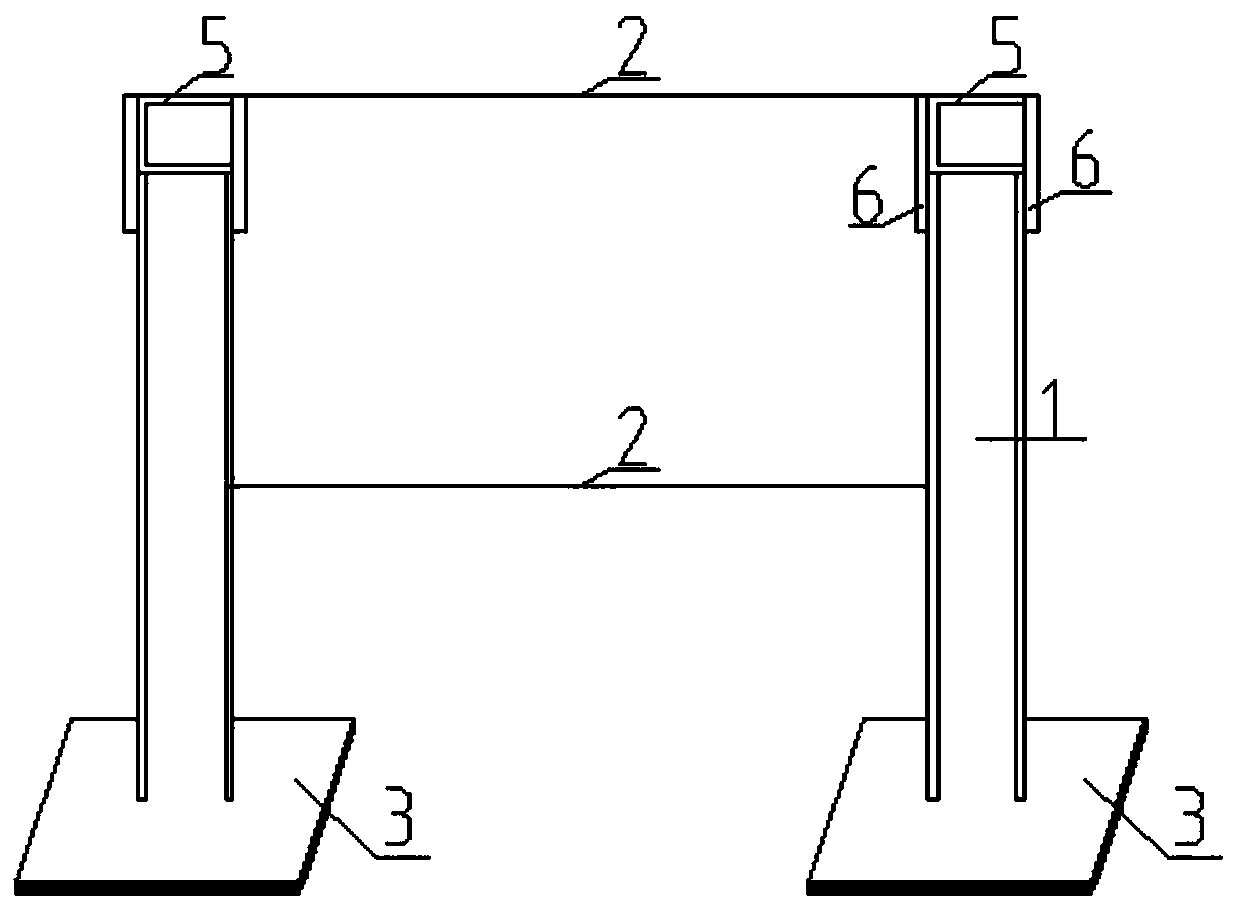

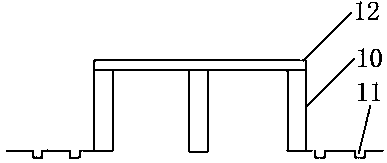

Manufacturing method for large-size concrete raft reinforcing steel bar bracket

InactiveCN110984205AShorten the construction periodReduce construction costsFoundation engineeringConstruction engineeringMesh reinforcement

The invention discloses a manufacturing method for a large-size concrete raft reinforcing steel bar bracket, and relates to the technical field of architectural engineering construction methods. The manufacturing method comprises the following steps: A, making construction preparation; B, performing stand column, cushion plate and welding plate construction; C, performing reinforcing steel bar reticulate frame construction; and D, mounting the whole reinforcing steel bar bracket. The manufacturing method can process a certain number of stand column, cushion plate and welding plate assemblies outside a site by calculating the section dimension of a raft structure according to a construction drawing, shortens the construction period of welding a horse stool on the site and improves engineering construction quality.

Owner:CHINA MCC17 GRP

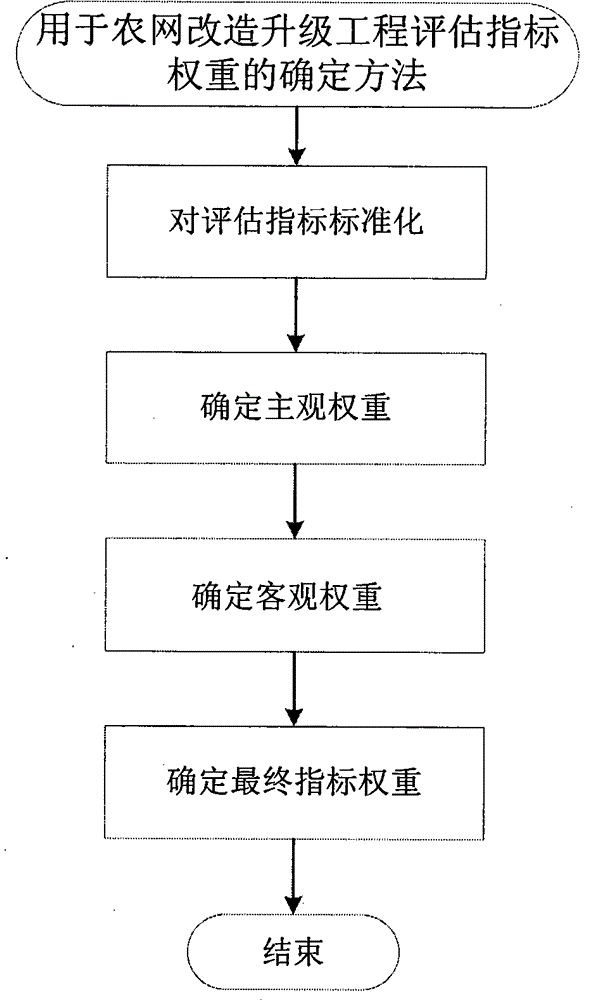

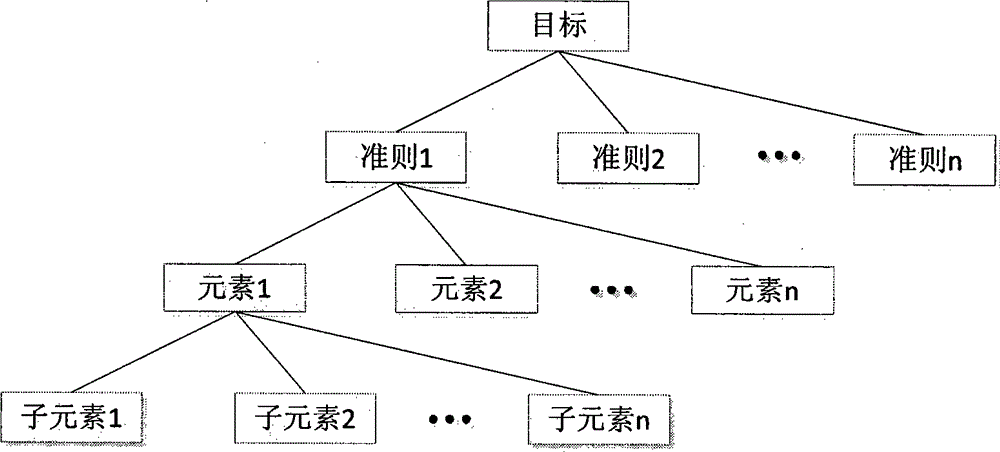

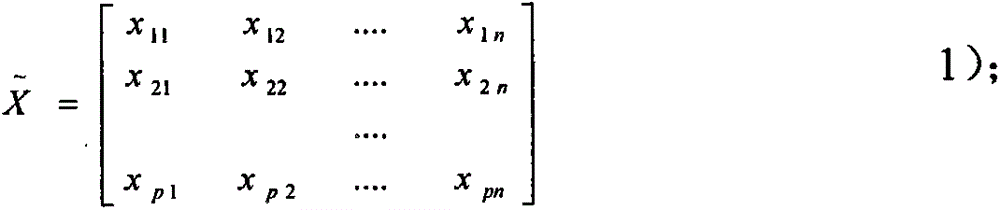

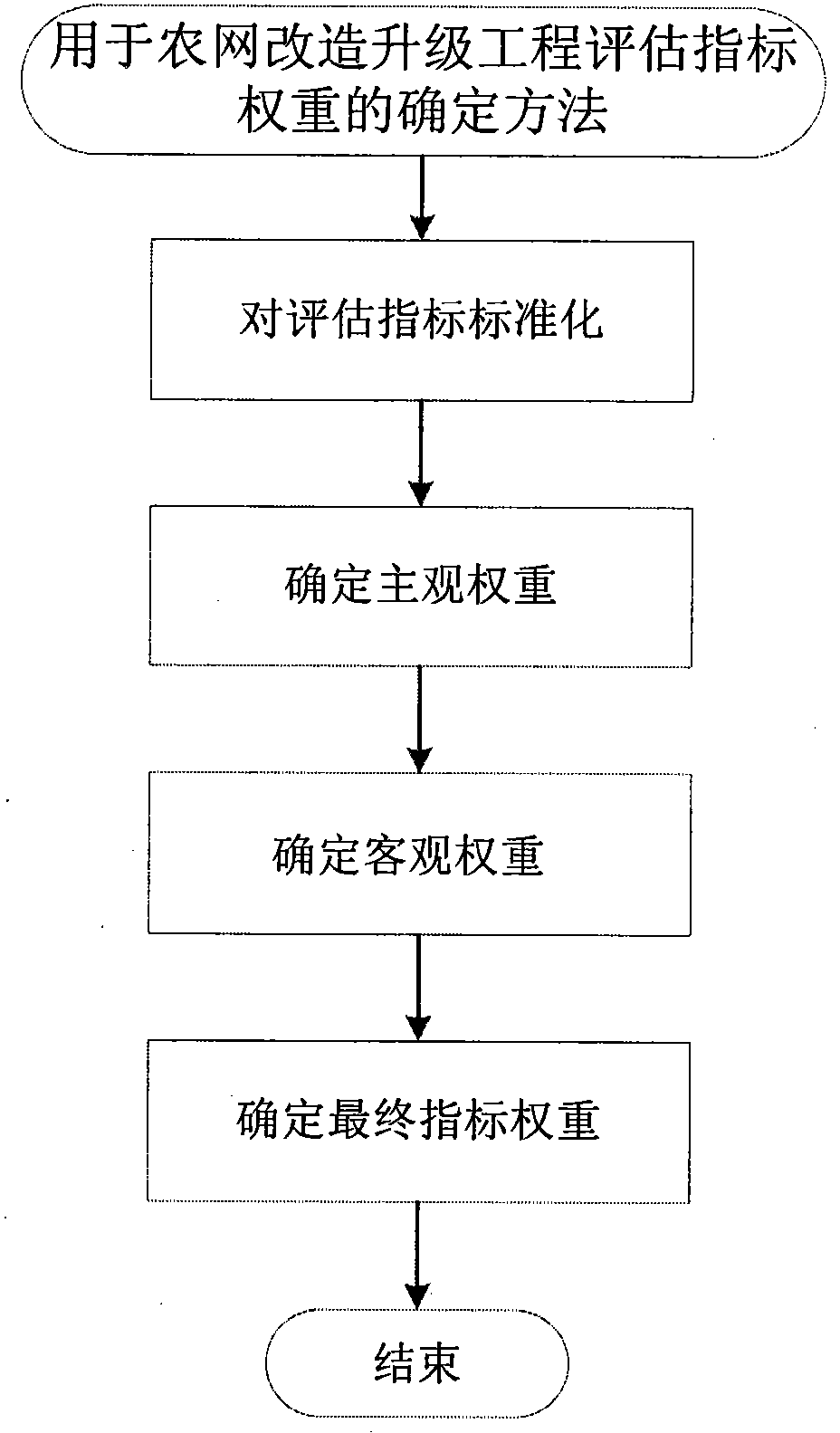

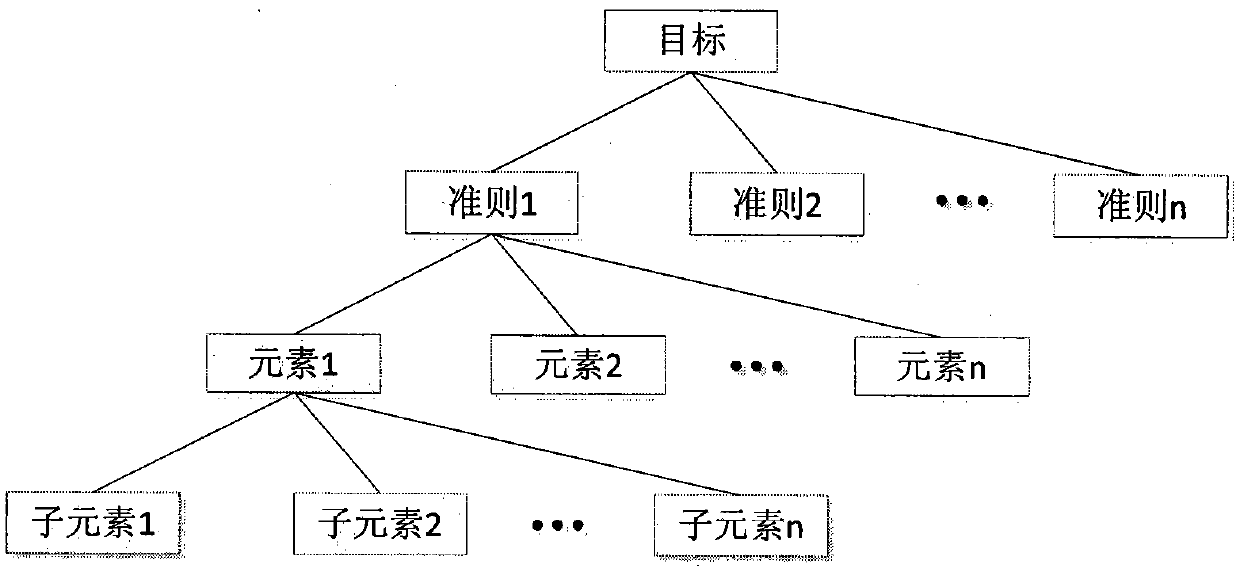

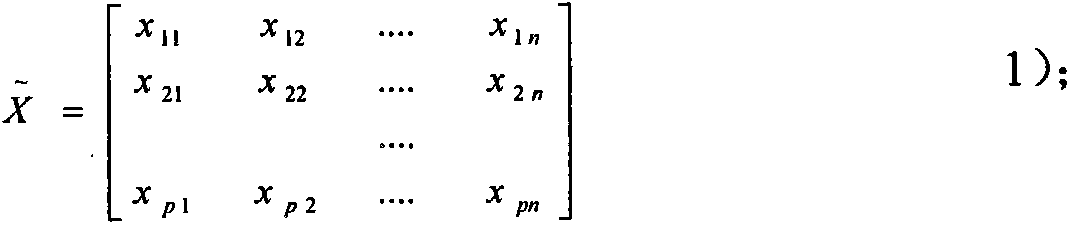

Method for determining weight of evaluation index of rural power grid renovation and upgrading project

ActiveCN104156878AImprove scienceImprove accuracyData processing applicationsStatistical analysisPower grid

The invention relates to a method for determining the weight of an evaluation index of a rural power grid renovation and upgrading project. According to the method, first, the subjective weight is determined with an analytic hierarchy method; secondly, statistic analysis is performed on historical data of a rural power grid, and the objective weight is determined with a mean-variance method; finally, the subjective weight and the objective weight are integrated through multiplication, and the final index weight is determined. Not only are influences caused by subjective deviation avoided, but also the objective actual conditions can be fully reflected, and scientificity and accuracy of index weight assignment can be effectively improved.

Owner:STATE GRID CORP OF CHINA +1

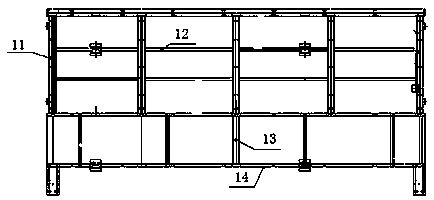

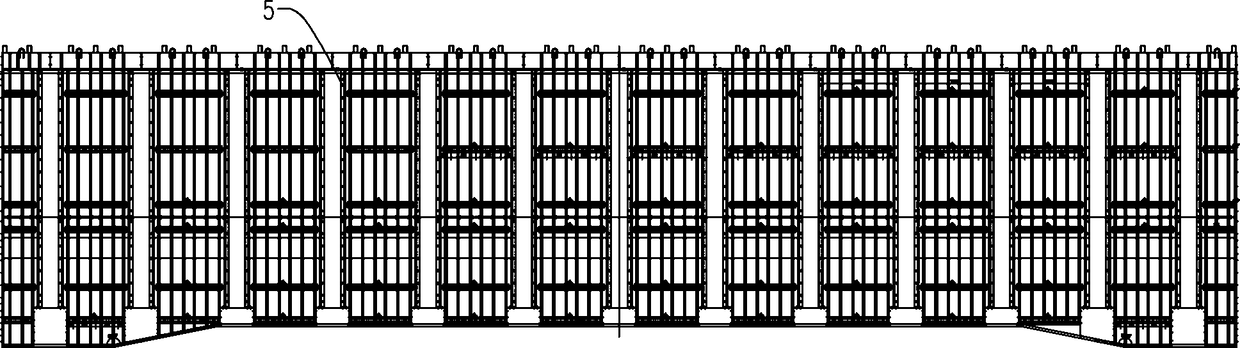

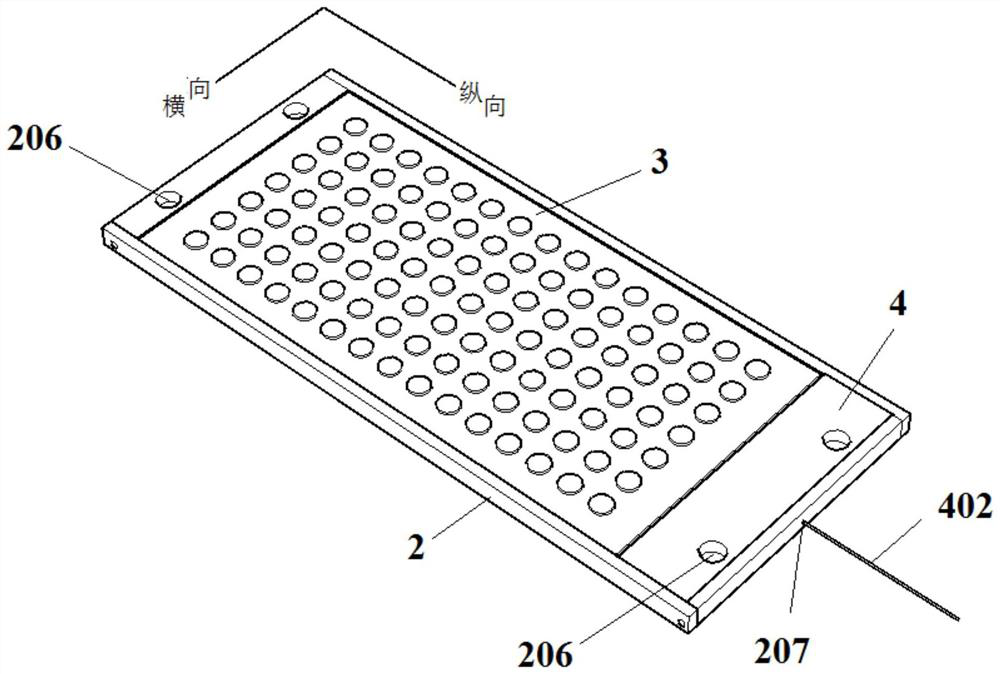

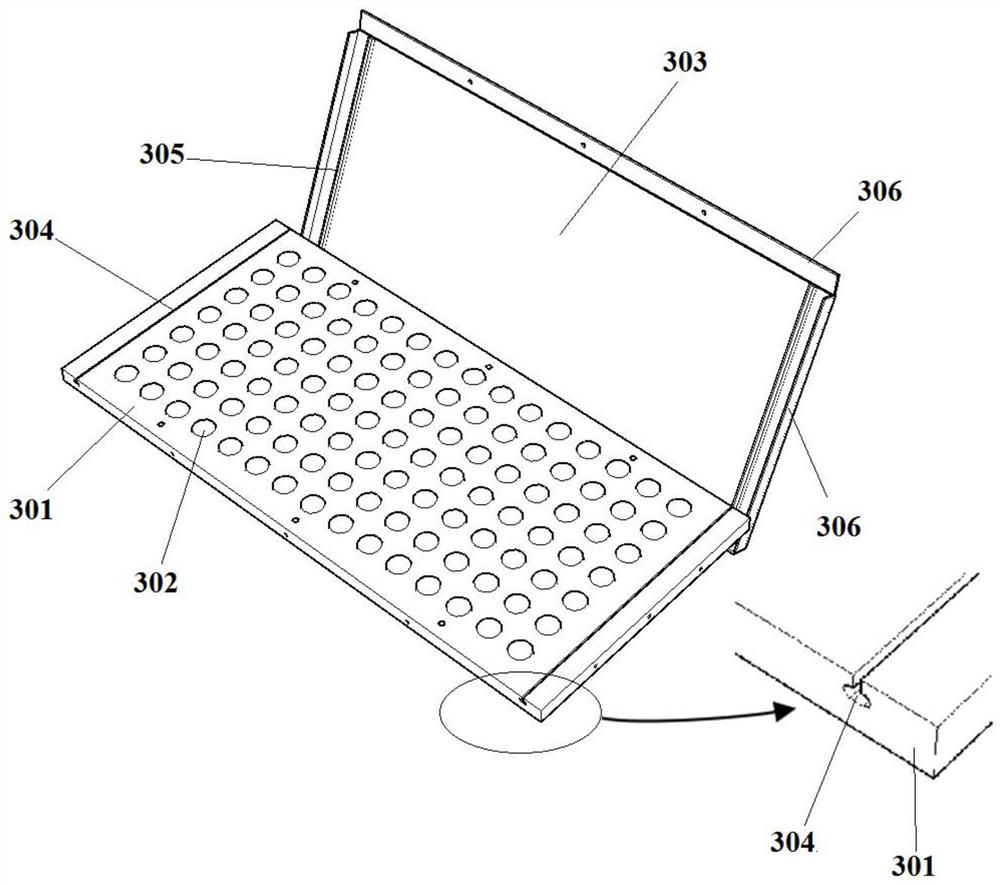

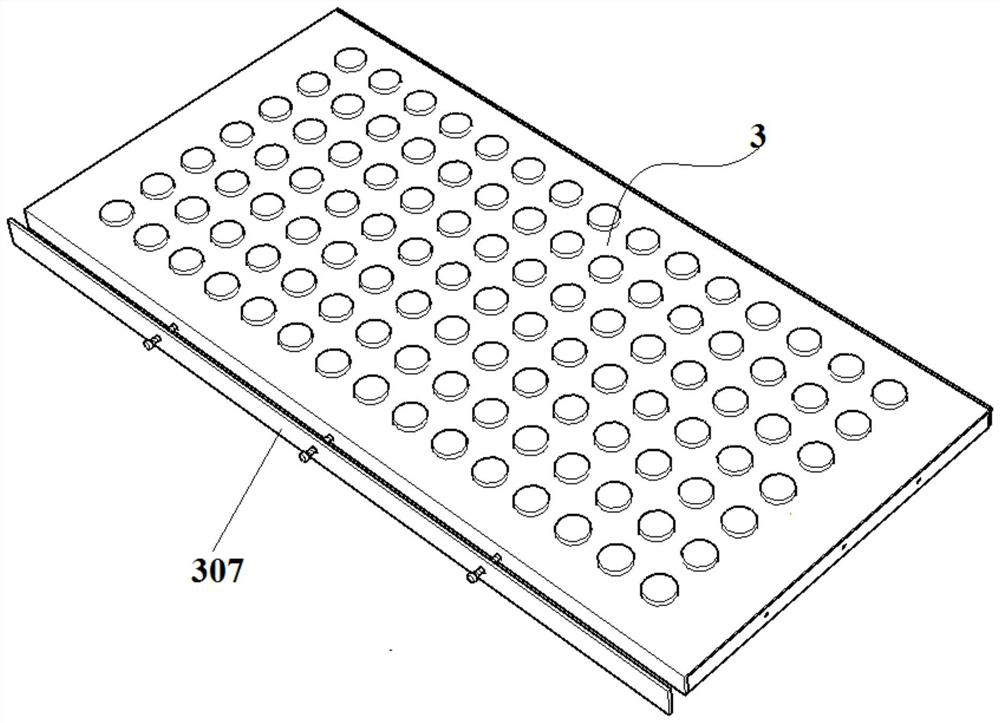

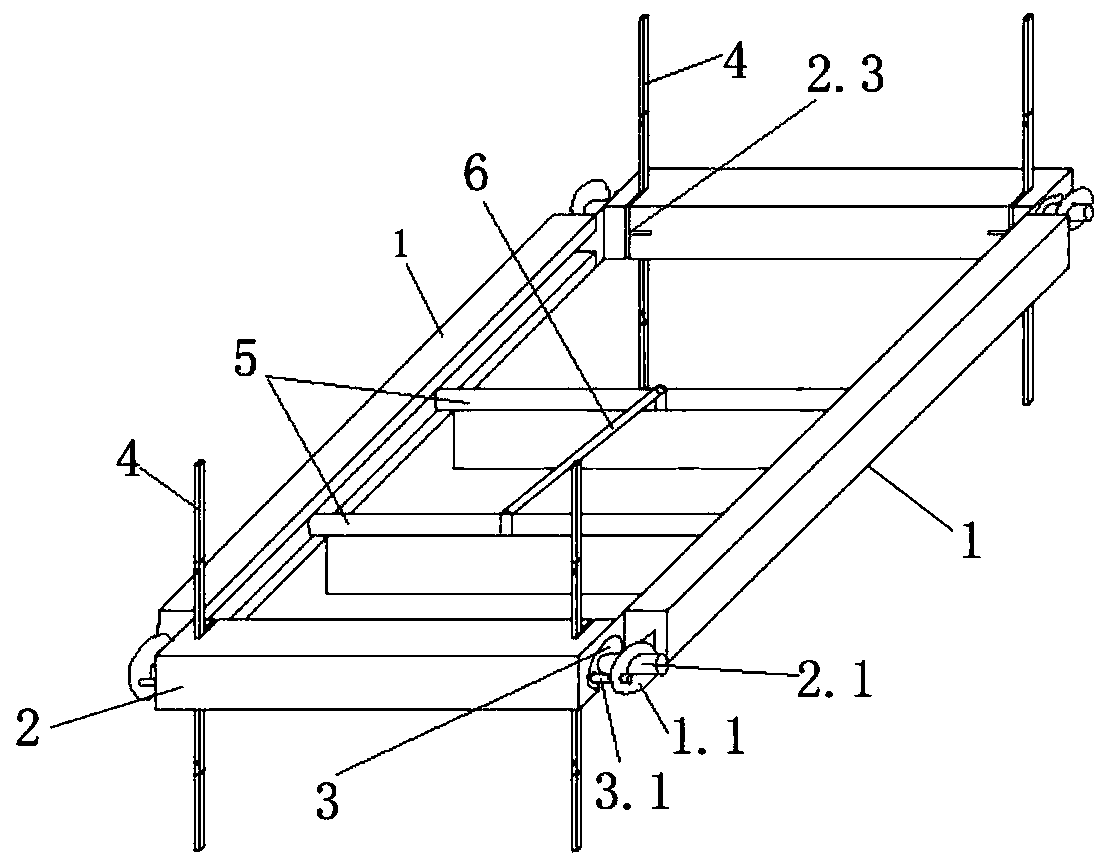

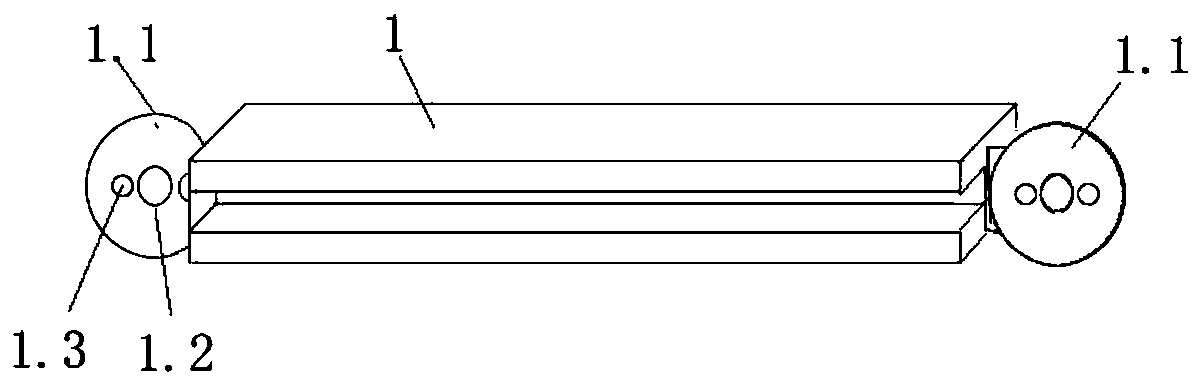

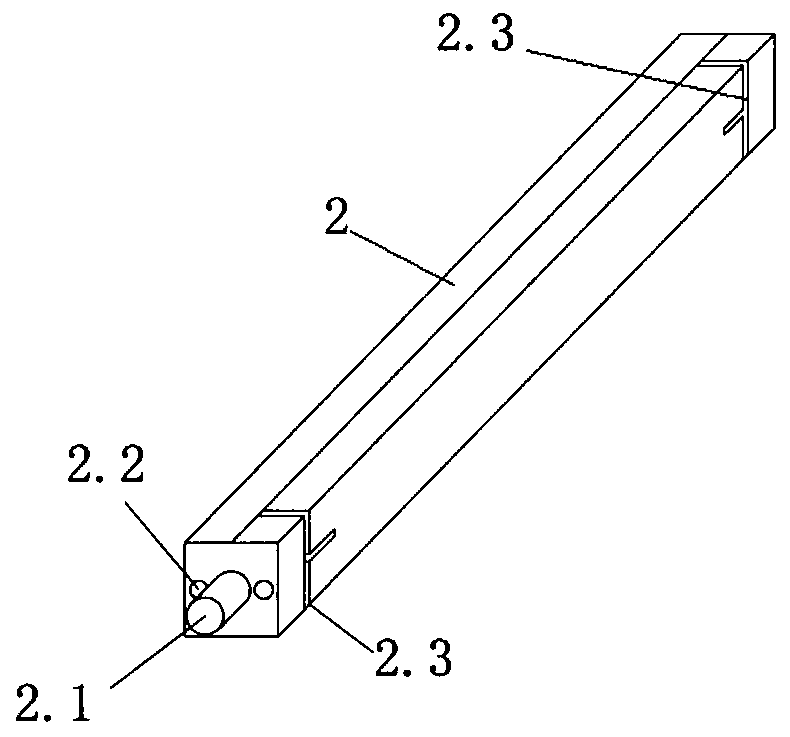

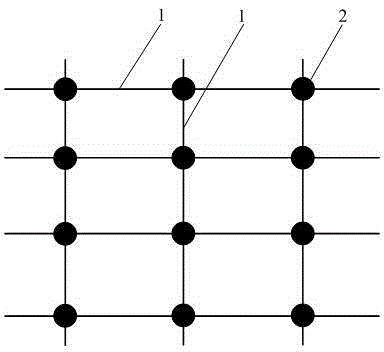

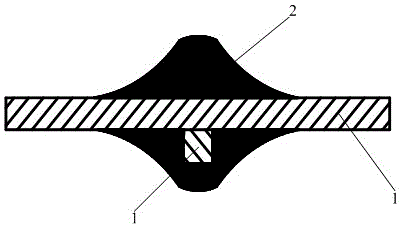

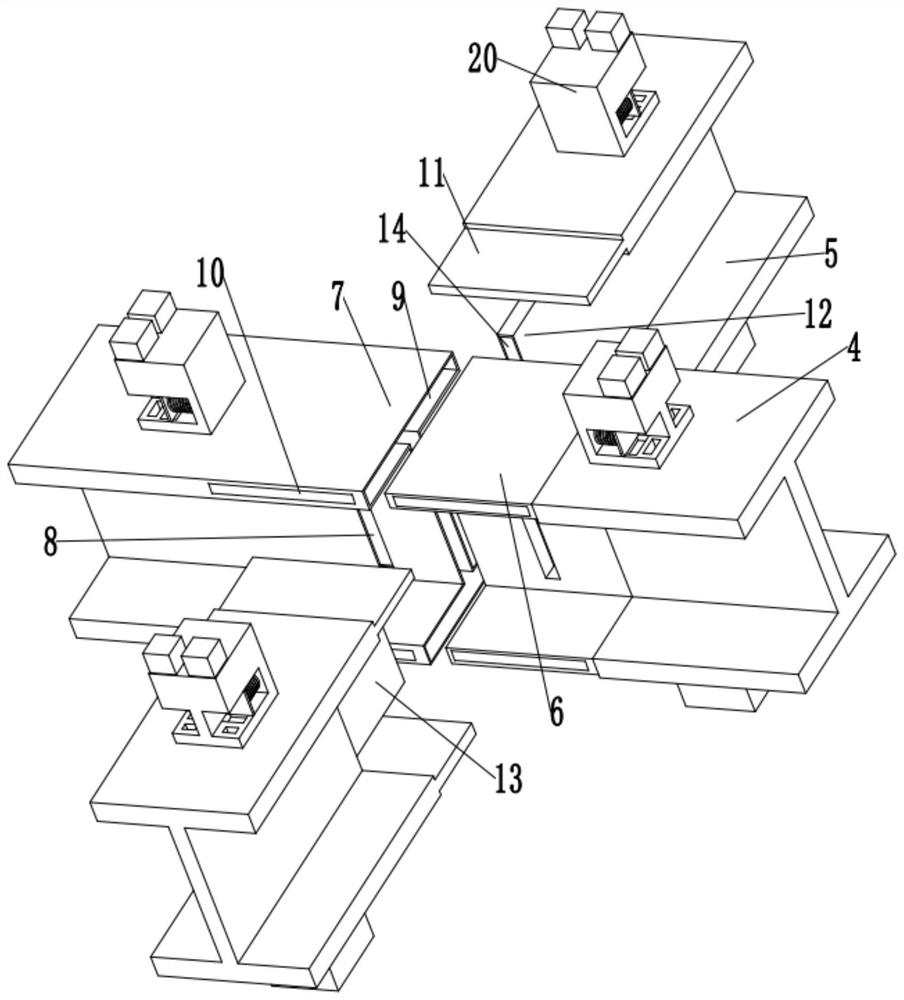

Pull-type reinforcement mesh braiding machine and method for braiding reinforcement mesh by pull-type reinforcement mesh braiding machine

The invention provides a pull-type reinforcement mesh braiding machine and a method for braiding a reinforcement mesh by the pull-type reinforcement mesh braiding machine. The pull-type reinforcementmesh braiding machine and the method can improve the reinforcement binding efficiency and project efficiency. The pull-type reinforcement mesh braiding machine comprises an underframe, a plurality ofcomb plates, a comb plate lifting mechanism, a longitudinal rib locating mechanism and a travelling traction mechanism; a plurality of travelling wheels are arranged at the bottom of the underframe; aplurality of rollers are arranged at the end of the underframe; the comb plates are arranged in parallel in a spaced manner in the width direction of the underframe; the comb plate lifting mechanismis arranged in the length direction of the underframe, is arranged below the comb plates and is connected with the comb plates; the longitudinal rib locating mechanism comprises a plurality of groupsof guide rolls and is arranged in the length direction of the underframe; each group of guide rolls comprises two guide rolls arranged up and down; the travelling traction mechanism comprises electrictractors; the electric tractors are arranged on the underframe; and steel wire ropes on the electric tractor are connected with guardrails of a to-be-constructed bridge.

Owner:SHANDONG LUQIAO GROUP

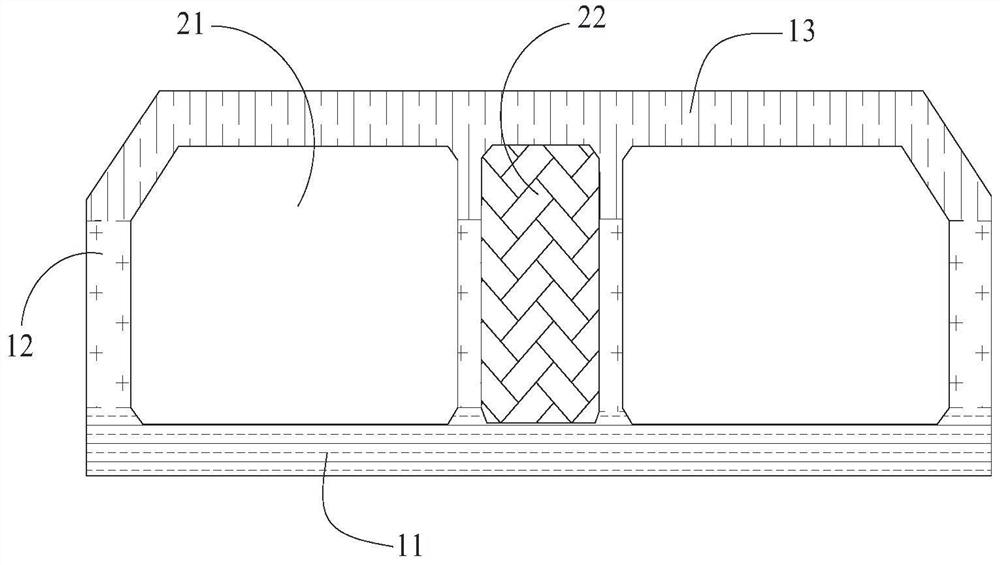

Formwork system of prefabricated comprehensive pipe gallery and construction method thereof

PendingCN110682416AShort exposure timeProcess loss is smallArtificial islandsMouldsArchitectural engineeringStructural engineering

The invention relates to a formwork system of a prefabricated comprehensive pipe gallery and a construction method thereof. The formwork system comprises a prefabricated pedestal, walking rails are arranged on two sides of the prefabricated pedestal in the longitudinal direction correspondingly, the walking rails are provided with outer mold hydraulic systems which are matched with the walking rails and are used for forming a comprehensive pipe gallery outer mold, a bottom plate is arranged on the upper side of the prefabricated pedestal, the bottom plate is provided with an inner mold hydraulic system capable of moving in the longitudinal direction and is used for forming a comprehensive pipe gallery inner mold, and the bottom plate is further provided with an end formwork of the comprehensive pipe gallery. The formwork system of the prefabricated comprehensive pipe gallery is beneficial to improving the engineering construction quality and improving the working efficiency.

Owner:HUNAN NO 6 ENG CO LTD

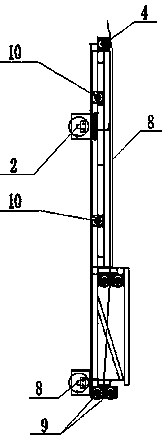

Lifting and sliding mounting technology for platform large equipment

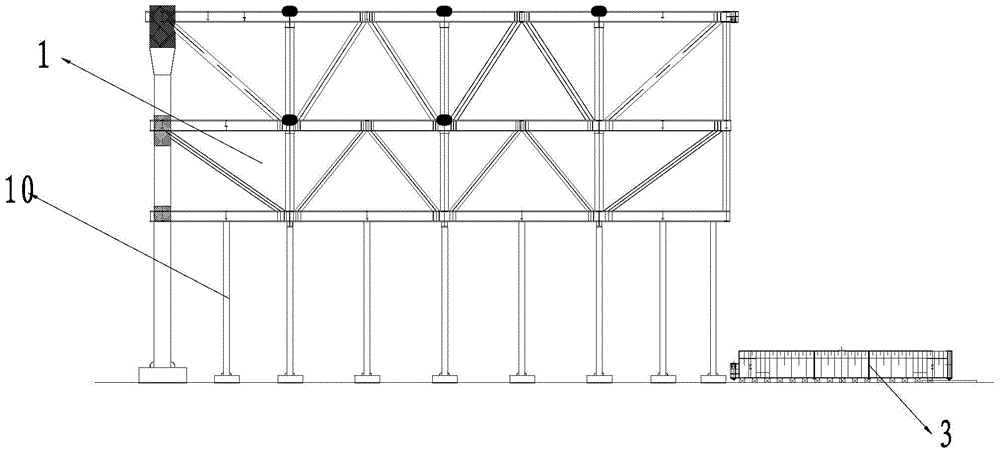

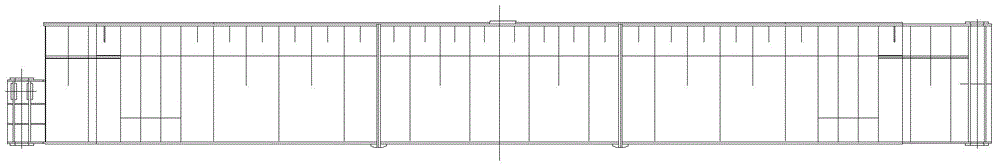

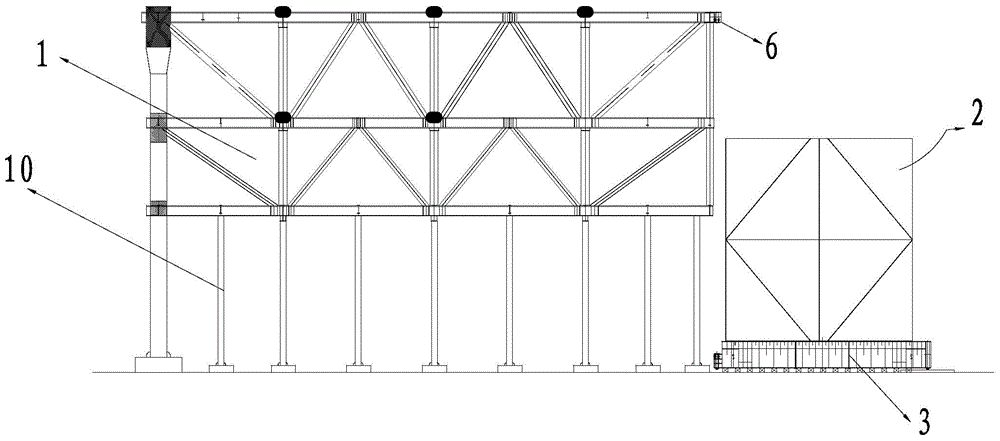

InactiveCN104555834AReduce operating costsImprove the quality of engineering constructionArtificial islandsLifting devicesTowerCorbel

The invention relates to a lifting and sliding mounting technology for platform large equipment. The lifting and sliding mounting technology comprises the following steps of 1, arranging a lifting transverse beam at one side of a large topside; fixing a sliding rail on the lifting transverse beam, and arranging the large equipment on the lifting transverse beam; arranging a lifting corbel; 3, arranging a lifting tower frame at one side of the lifting transverse beam, and arranging lifting jacks on the lifting tower frame and the lifting corbel; 4, arranging a tower frame oblique brace and a guy cable wind rope at one side of the lifting tower frame, and tightening; 5, lifting the lifting transverse beam to the setting height; 6, fixing the lifting corbel and the lifting transverse beam; 7, paving the sliding rail and a slide block on the large topside, arranging a sliding pull jack on the large topside, and sliding the large equipment to the proper position; 8, removing the slide block and the sliding rail, so as to complete the mounting operation. The lifting and sliding mounting technology has the advantages that the large equipment can be mounted on the platform topside without using large floating cranes and large crawler cranes, the operation cost is greatly reduced, and the quality of engineering construction is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

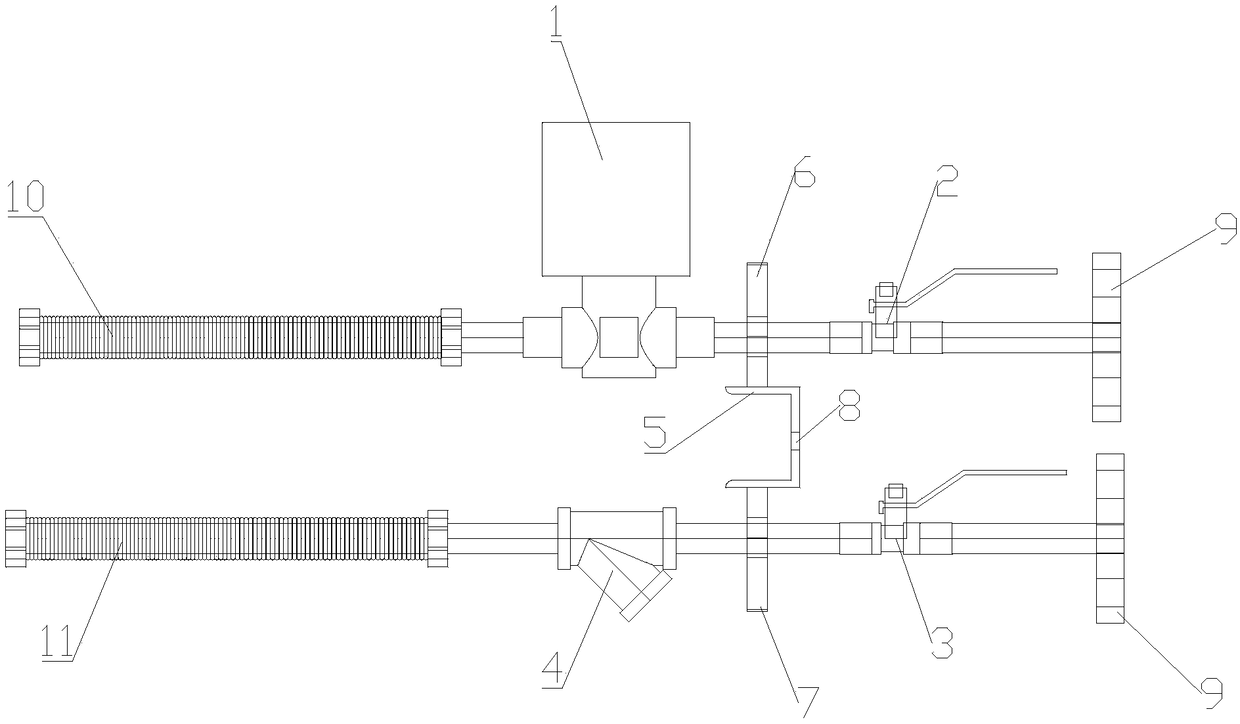

Prefabricated valve set for four-pipe fan coiler

InactiveCN108825839AImprove the quality of engineering constructionThe quality and appearance are neat and beautifulPipe supportsFlanged jointsEngineeringVALVE PORT

The invention provides a prefabricated valve set for a four-pipe fan coiler. The prefabricated valve set comprises a support, an electric two-way valve, a first ball valve, a second ball valve and a filter. The support comprises a steel channel, first supporting plates and second supporting plates. Multiple first supporting plates are fixedly connected to the outer side of the first side wall of the steel channel. Multiple second supporting plates are fixedly connected to the outer side of the second side wall of the steel channel. The first side wall and the second side wall are parallel. Thefirst end of the electric two-way valve is connected with the first end of the first ball valve through a first pipe section. The first end of the filter is connected with the first end of the secondball valve through a second pipe section. The first pipe section penetrates through holes in the first supporting plates, and the second pipe section penetrates through holes in the second supportingplates. According to the prefabricated valve set, the project construction quality is improved greatly, the prefabricated valve set has integrality and compactness, and is easy to install, and unnecessary potential safety hazards of high-altitude operation are avoided.

Owner:CHINA CONSTR THIRD ENG BUREAU INSTALLATION ENG CO LTD +1

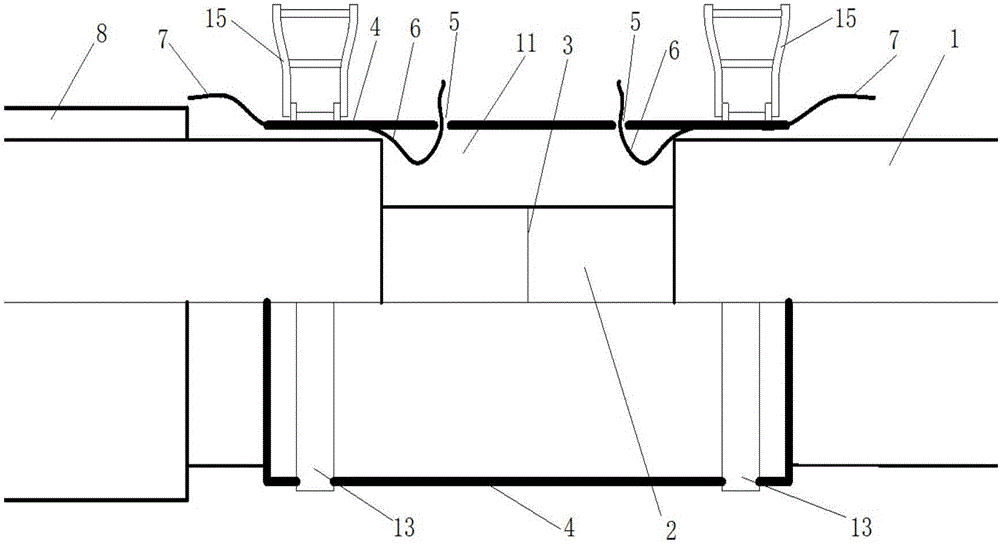

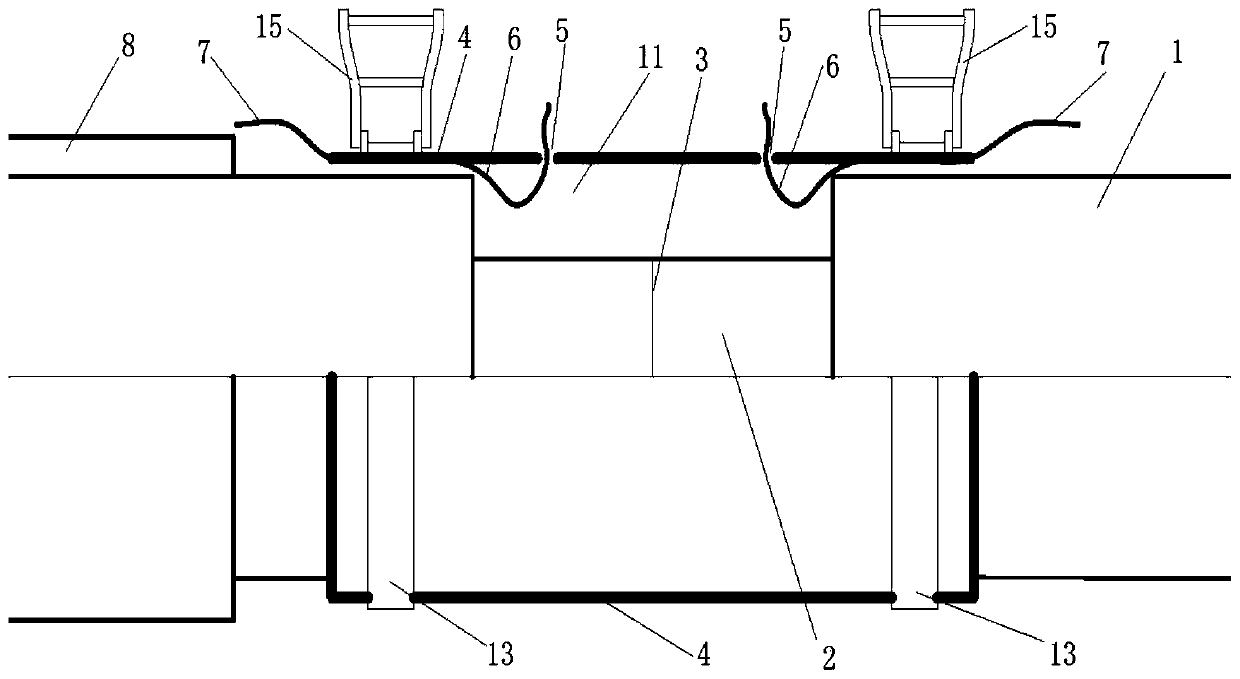

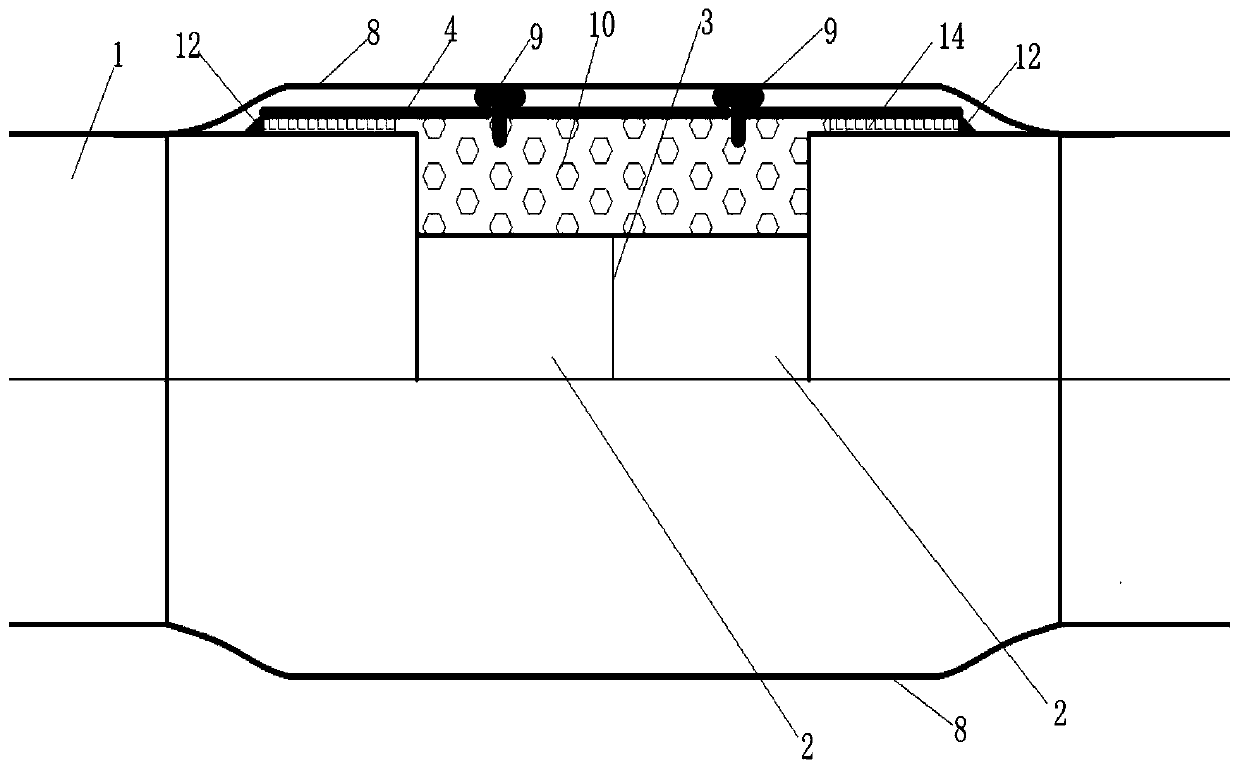

Installation method of waterproof-type electric-melting heat-preservation joint

ActiveCN105927803AImprove sealing and waterproof performanceImprove the quality of engineering constructionThermal insulationPipe protection by thermal insulationWater pipeMelting heat

The invention belongs to the field of heat preservation and relates to an installation method of a heat-preservation joint of a directly embedded high-temperature-hot-water pipe network used for heat-supply engineering, in particular to an installation method of a waterproof-type electric-melting heat-preservation joint. The method comprises following technical steps of: cleaning a working environment, installing an electric-melting sleevelet, welding gaps, foaming polyfoam, plugging a feeding port and sealing a seamless heat shrink sleeve. The installation method of the waterproof-type electric-melting heat-preservation joint has following beneficial effects: by utilizing the electric-melting sleevelet and the seamless heat shrink sleeve outside a pipeline, sealing and water-proof performance of the heat-preservation joint can be improved; through two-time heating and welding of the electric-melting sleevelet, especially transverse seam heating, engineering construction quality can be further improved, which is of great importance to improving construction quality of heat-preservation pipelines; the method is reliable in principle, easy and convenient in operation, mature in installation technology and is safe; and the waterproof-type electric-melting heat-preservation joint used in simple in structure, low in manufacture cost, user-friendly in application environment and broad in application scope.

Owner:华电青岛热力有限公司 +1

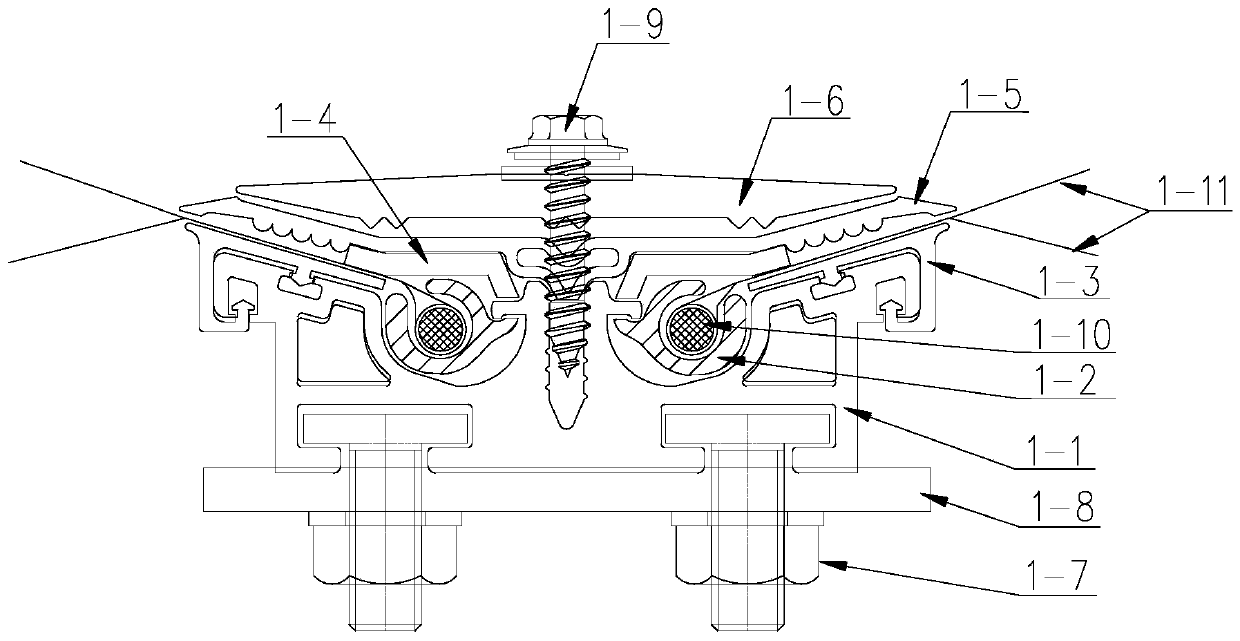

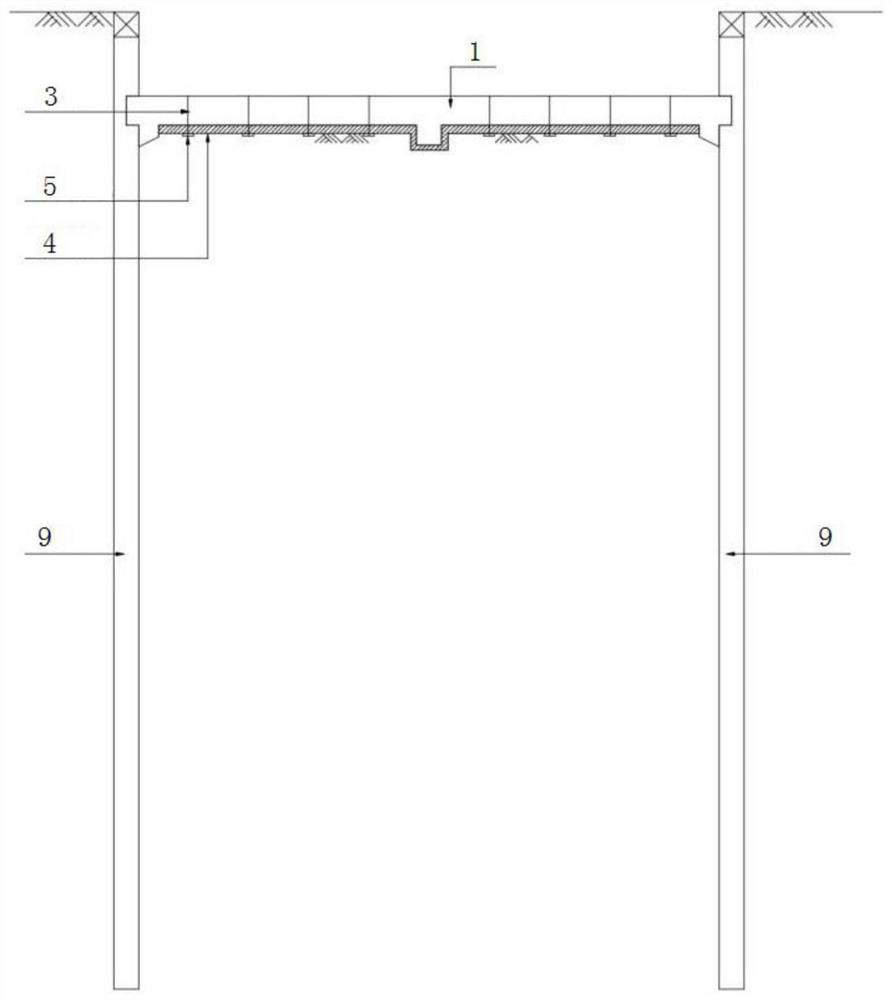

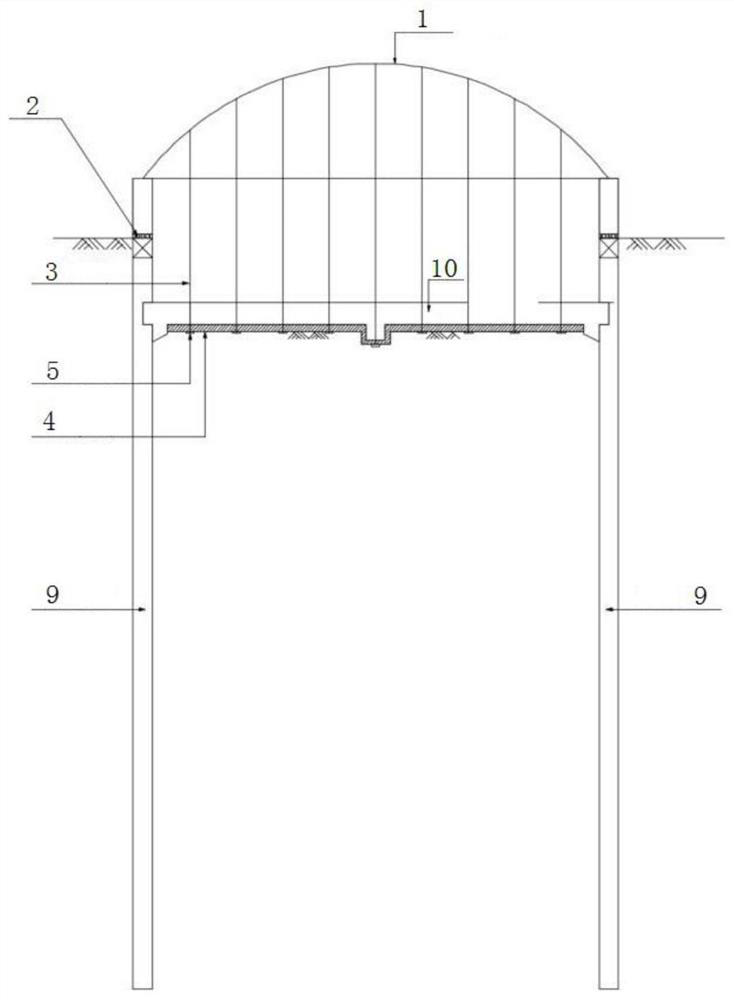

Air film roof fixing device and using method

PendingCN110158866AApplicable fixedProcessing materials are simpleBuilding roofsRoof covering using flexible materialsAgricultural engineeringSelf-tapping screw

The invention discloses an air film roof fixing device and a using method. The air film roof fixing device comprises a base, buckling strips, rubber blankets, isolating rubber blankets, a first coverplate, bolts, a connecting plate, a first self-tapping screw, an anti-falling rubber rod, a second cover plate and a second self-tapping screw, wherein the lower part of the base is fixed with a building; the rubber blankets are mounted on the two sides of the upper end of the base; the buckling strips buckle the upper end of the base and are positioned on the inner sides of the rubber blankets; aring is arranged between the buckling strips; the anti-falling rubber rod is mounted in the ring; the middle parts of the isolating rubber blankets are connected with the middle part of the base through the first self-tapping screw and are arranged at the upper end of the base; the first cover plate is mounted above the isolating rubber blankets through the first self-tapping screw; one end of anair film is fixed on the anti-falling rubber rod; one side of the air film is positioned between the rubber blankets and the isolating rubber blankets; the second cover plate is connected with the air film through the second self-tapping screw; and the connecting plate is fixed at the bottom of a bottom plate through the bolts. The air film roof fixing device is simple in structure, simple and convenient in processing and manufacturing, fast in mounting, lower in maintaining cost and long in durable years.

Owner:CHINA MCC5 GROUP CORP

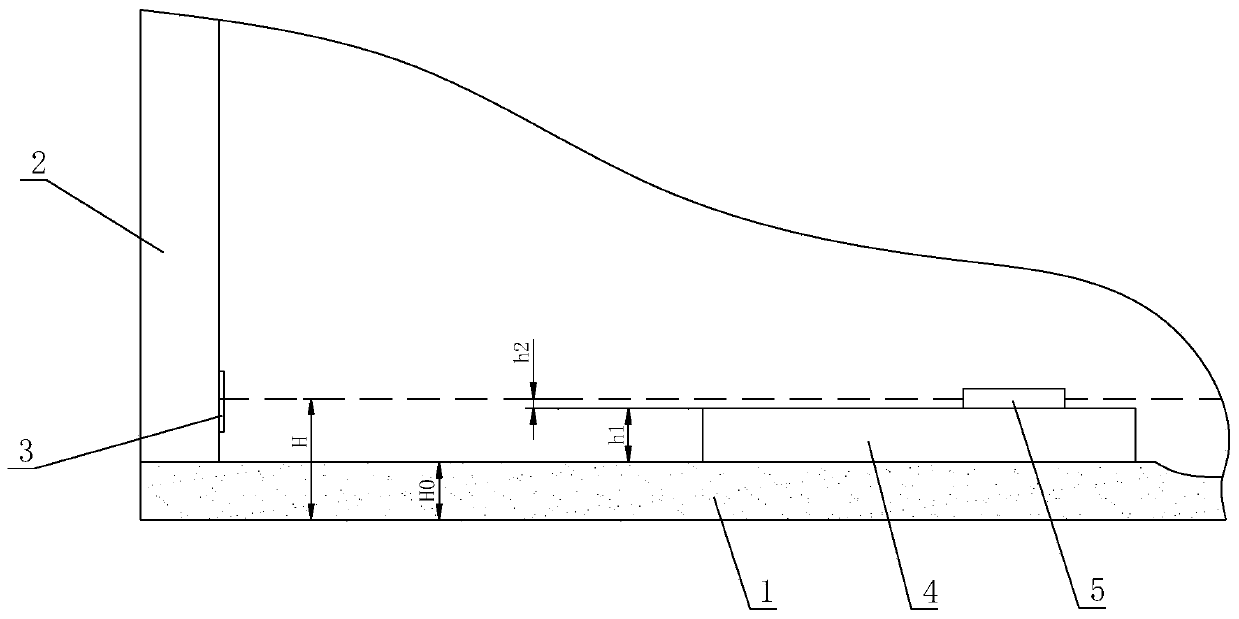

Method for controlling thickness and flatness of concrete floor

The invention relates to a method for controlling thickness and flatness of a concrete floor. The method comprises the following steps that a floor elevation reference control line and an auxiliary control line are marked on a white positioning plate, the white positioning plate is bound on a frame column or a shear wall reinforcing steel bar, and the floor elevation reference control line on thebound white positioning plate is consistent with a pre-marked positioning elevation corresponding to the vertical direction of the floor; a laser digital display horizontal ruler is fixed at the top of a horizontal darby slicker; when the concrete floor is subjected to last accurate flattening, the horizontal darby slicker is placed at the top of the concrete floor; and when laser light emitted bythe laser digital display horizontal ruler coincides with the elevation reference control line on the white positioning plate, the height of the bottom surface of the horizontal darby slicker is consistent with the design elevation of the upper surface of the concrete floor. The method can achieve the purposes of the economy, the convenience, the effective control of the thickness and the flatness of concrete, so that the thickness and the flatness of the poured concrete floor meet the quality standard requirements.

Owner:REAL ESTATE CONSTR ANGANG GROUP

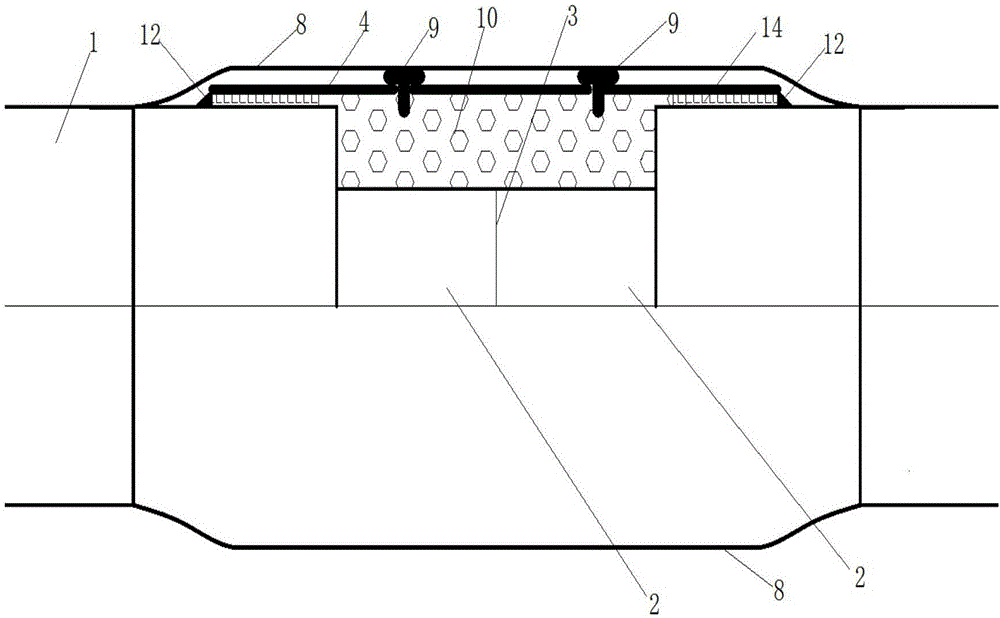

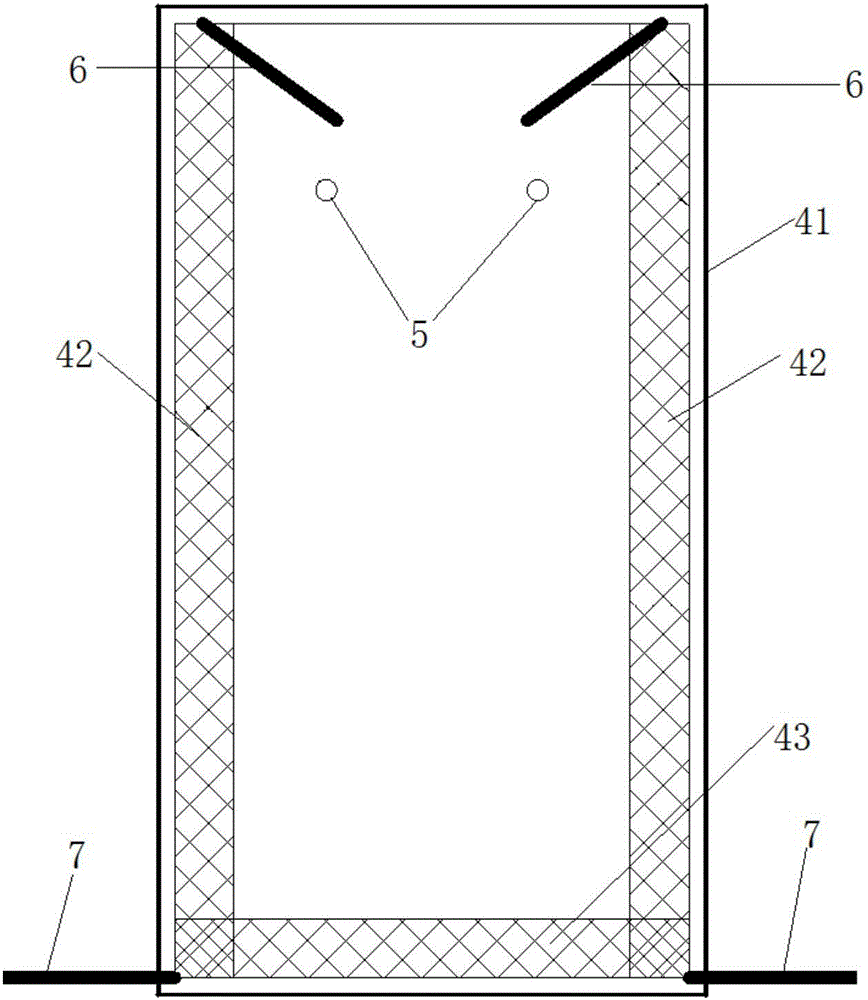

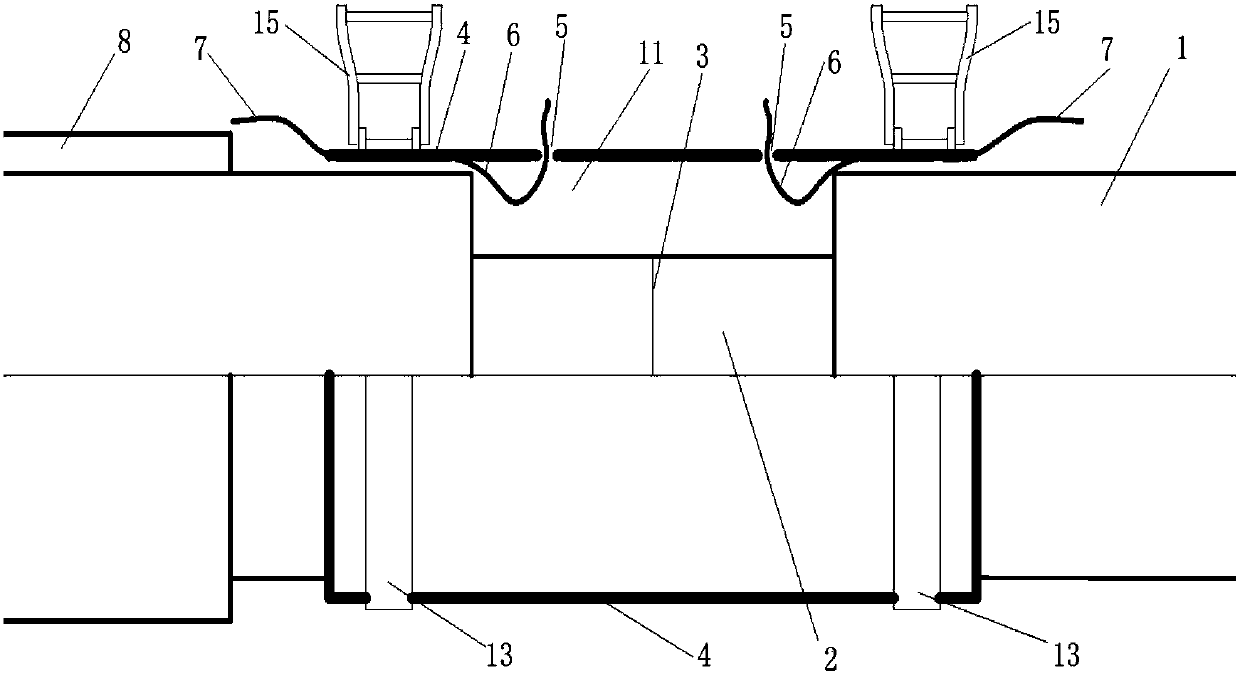

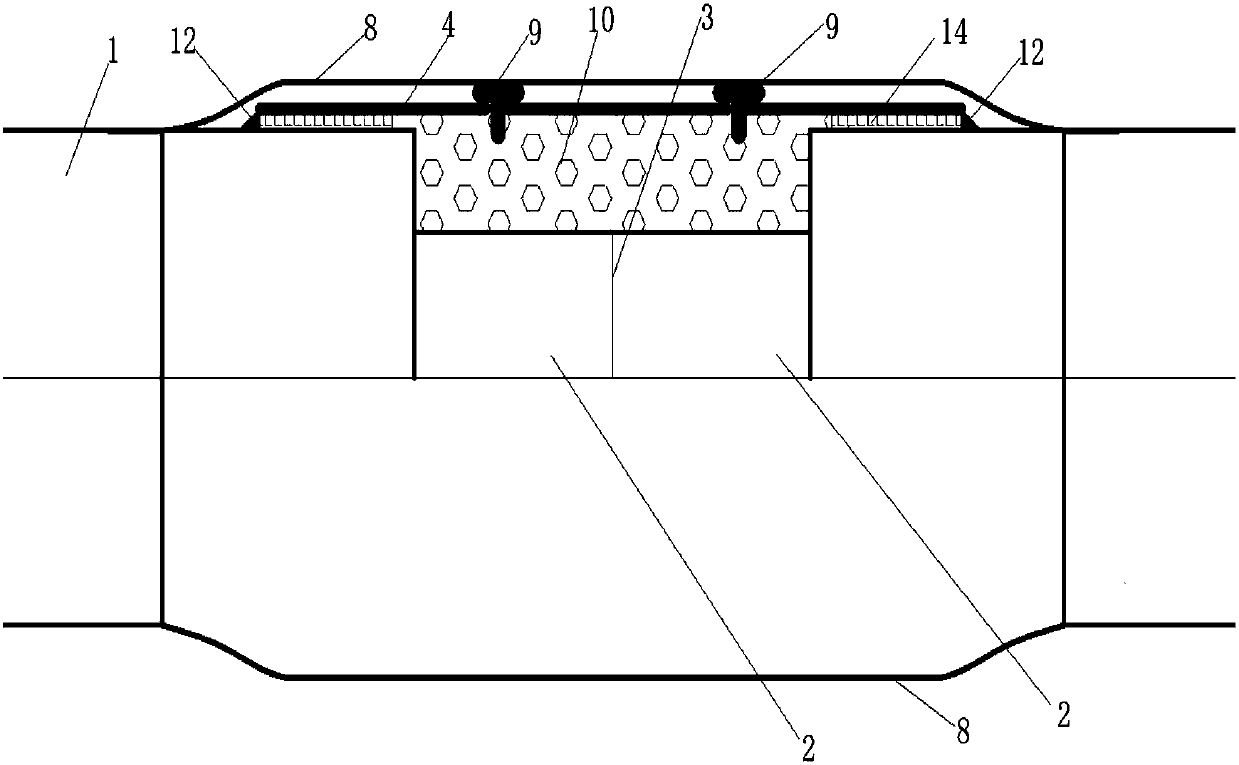

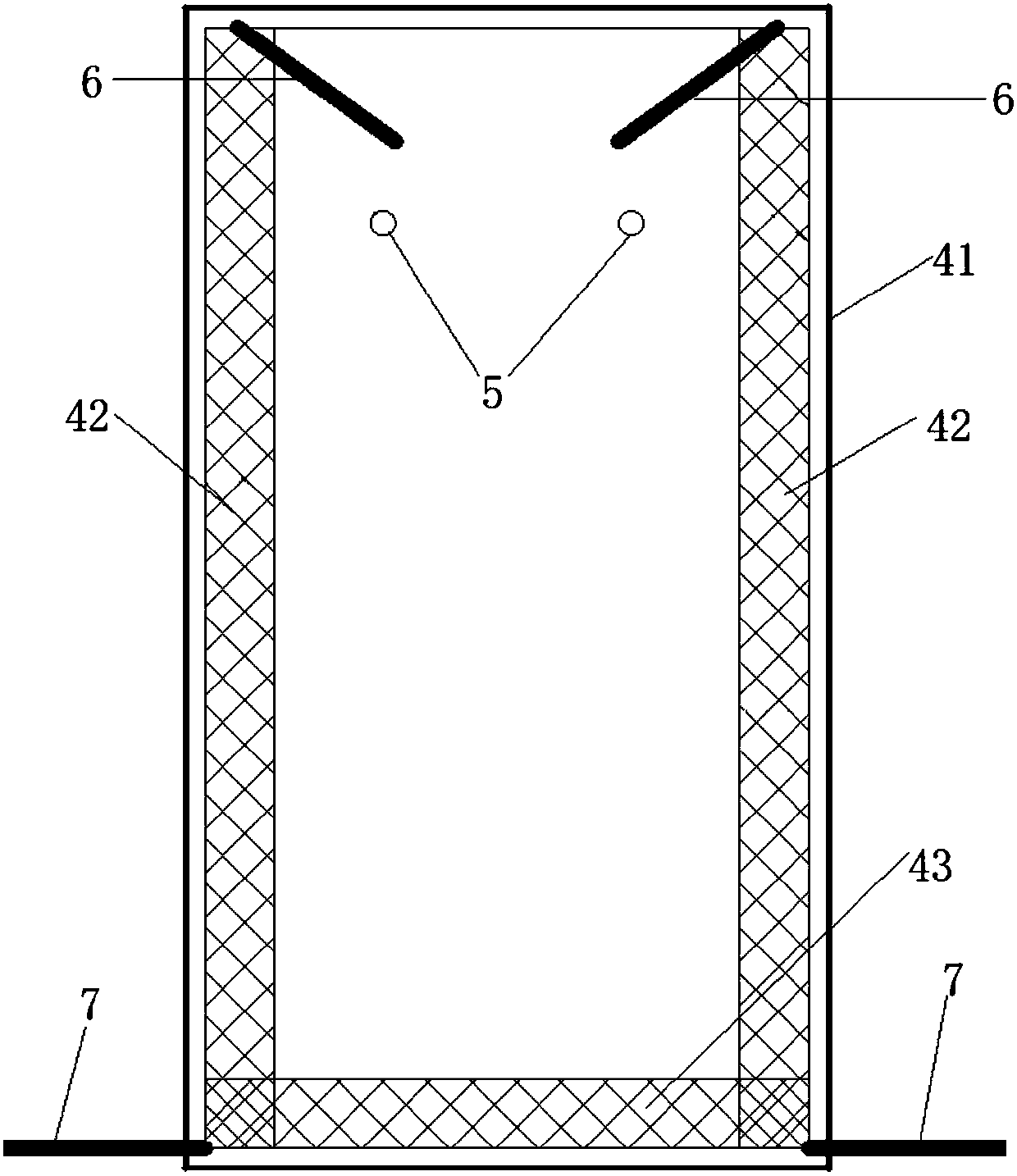

Waterproof type electric hot-melting insulation joint

ActiveCN105953015AImprove sealing and waterproof performanceImprove construction qualityPipe connection arrangementsNon-disconnectible pipe-jointsArchitectural engineeringPlastic welding

The invention belongs to the technical field of heat supply and insulation and relates to an insulation joint for a directly-buried high-temperature hot-water pipe network in heat-supply engineering, in particular to a waterproof type electric hot-melting insulation joint. The waterproof type electric hot-melting insulation joint mainly comprises a PE casing, steel tubes, a steel tube weld seam, an electric hot-melting sleeve, charging ports, primary heating cables, secondary heating cables, a seamless thermal shrinkable sleeve, plugs, polyurethane foaming plastic, a foaming cavity, plastic welding, clamping straps, PE lap seams and clampers. The two sealing sleeves, namely the electric hot-melting sleeve and the seamless thermal shrinkable sleeve are arranged at the outer side of a pipeline, so that the sealing and water resisting properties of the insulation joint are enhanced; and by using two times of heating and welding for the electric hot-melting sleeve, in particular the secondary transverse joint heating, the construction quality of projects is further improved, and great significance for improving the construction quality of an insulation pipeline is realized. The waterproof type electric hot-melting insulation joint has the advantages of simple principle, reasonable structure, low preparation cost, mature and safe mounting process, good application environment and wide application range.

Owner:华电青岛热力有限公司 +1

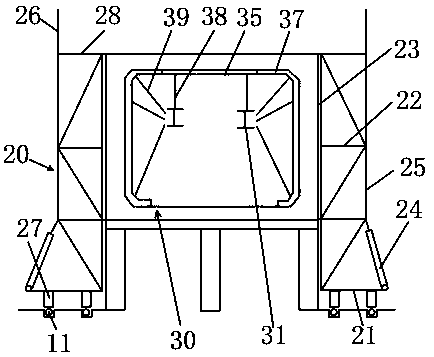

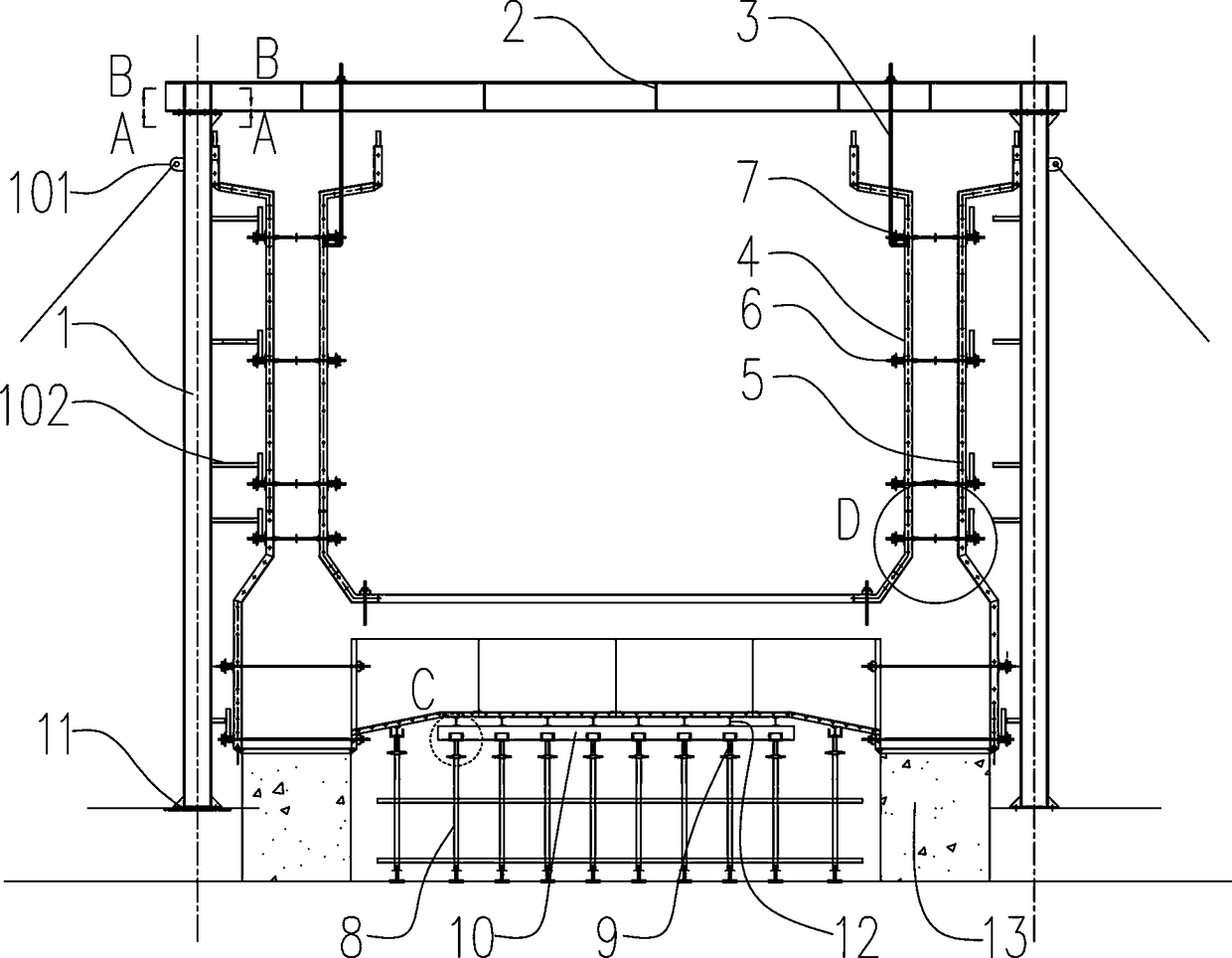

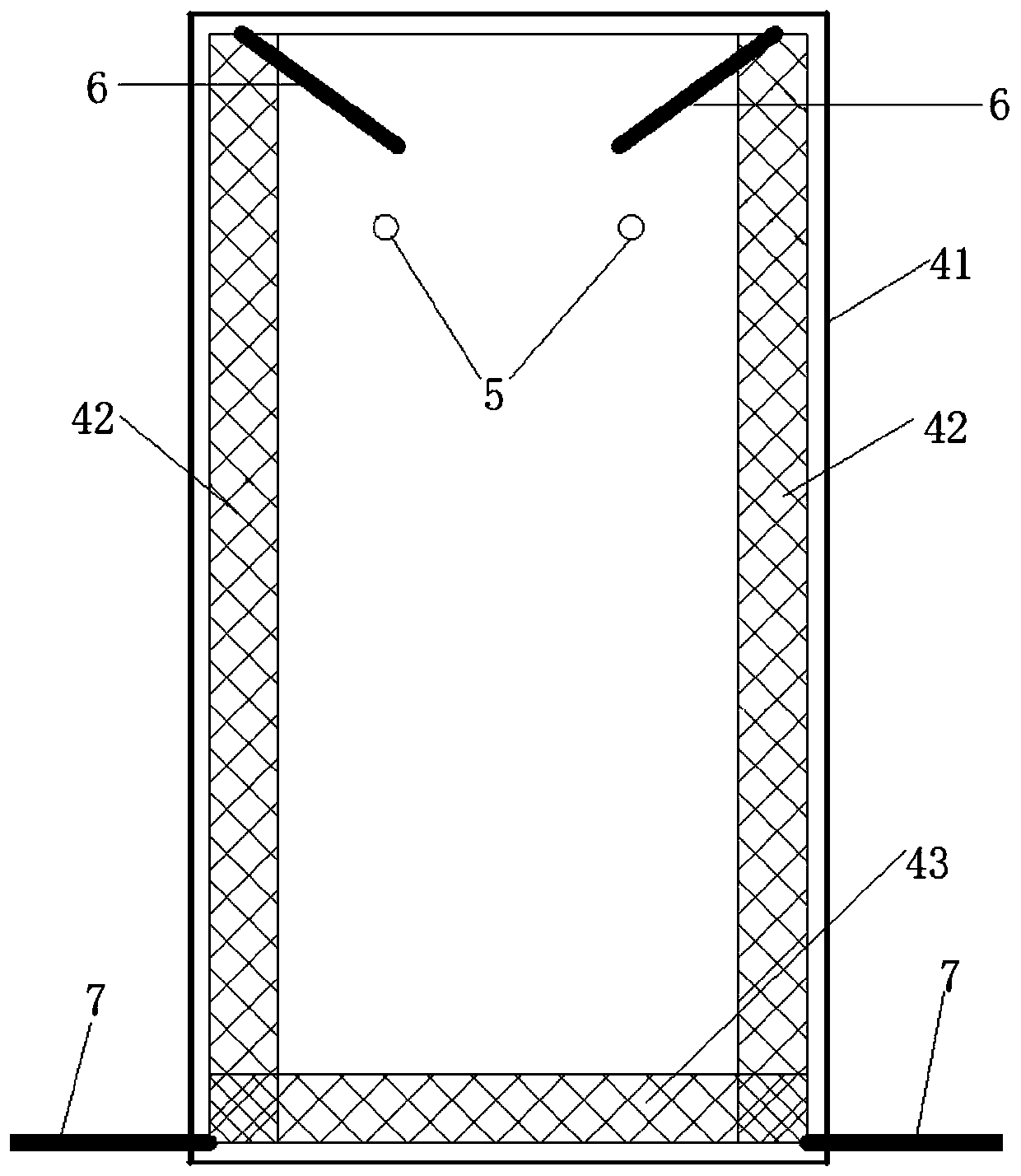

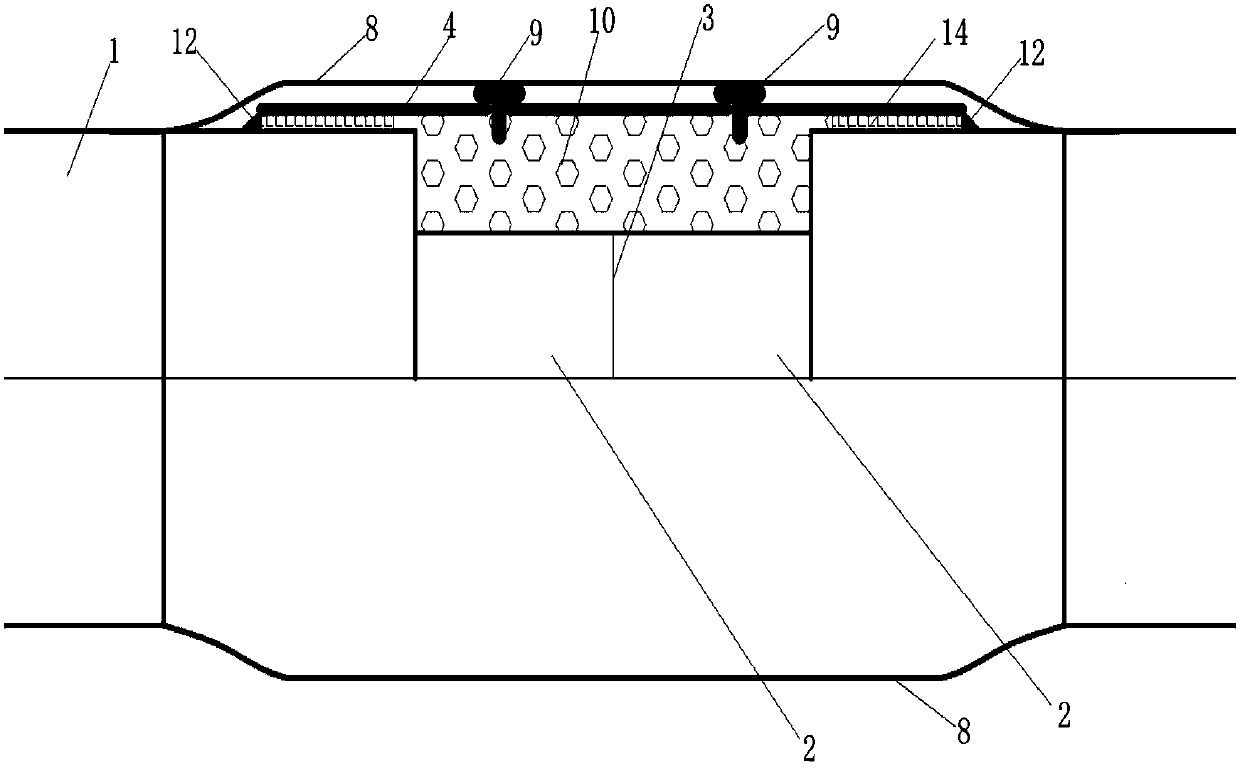

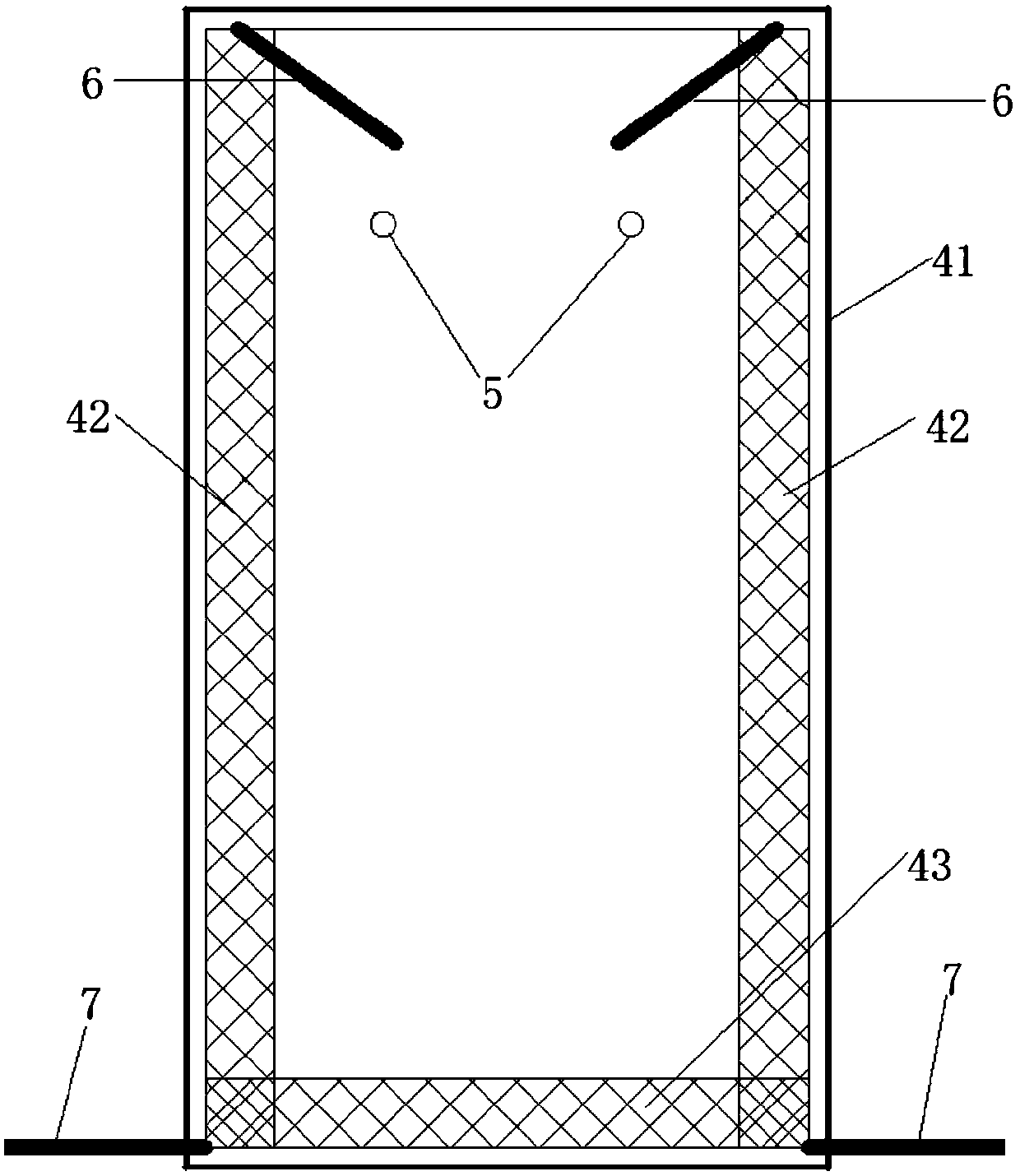

Large multi-rib prefabricated aqueduct formwork anti-deformation support device and construction method

The invention provides a large-scale multi-ribbed prefabricated aqueduct formwork anti-deformation support device and construction method. The portal frame is fixedly connected to the outer mold, the beam of the portal frame is fixedly connected to the inner mold through a plurality of inner mold pull rods, and the bottom of the outer mold is provided with a bottom Bracket; between the outer mold and the inner mold, there are multiple pre-embedded tie bar screws; the top of the inner mold is provided with an inwardly bent bending part; the bottom of the inner mold rod is provided with a hook, and the hook hooks the inner The horizontal fence on the inside of the mold is fixedly connected with the horizontal fence, the inner mold tie rod passes through the bending part of the inner mold, and the inner mold tie rod also passes through the crossbeam and pad and is fixedly connected with the nut. The construction method includes the following steps: processing the formwork support device in the factory; adjusting the position of the inner mold and the outer mold to the design size, installing the columns and beams; installing the tie rods of the inner mold, pouring the tank body, and realizing the large-span multi-ribbed prefabricated aqueduct through the above steps The pouring size is accurate and there is no deformation. It overcomes the deformation of the multi-rib prefabricated aqueduct in the pouring process in the prior art.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

Method for determining the weight of evaluation indicators for rural power grid upgrading projects

ActiveCN104156878BImprove scienceImprove accuracyData processing applicationsMean squareStatistical analysis

The present invention relates to a method for determining the weight of evaluation indicators for rural power grid transformation and upgrading projects. The method firstly uses the analytic hierarchy process to determine the subjective weight; The subjective and objective weights are multiplicatively integrated to establish the final index weight, which not only avoids the influence of subjective deviation but also fully reflects the objective actual situation, which can effectively improve the scientificity and accuracy of index weight assignment.

Owner:STATE GRID CORP OF CHINA +1

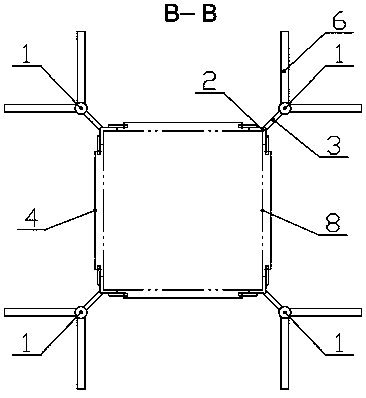

Reverse construction method of underground structure

ActiveCN112922025AHigh cost of settlementFast constructionArtificial islandsUnderwater structuresArchitectural engineeringMechanical engineering

The invention belongs to the field of underground engineering, and relates to a reverse construction method of an underground structure. The method comprises the following steps of 1) constructing an enclosure structure, excavating a foundation pit to the position of a structural top plate, constructing the structural top plate, and fixing a top plate suspension system on the structural top plate; 2) erecting a vertical bearing system, and connecting the top plate suspension system and the vertical bearing system; 3) continuously excavating to the position of a structural middle plate, constructing the structural middle plate, and fixing a middle plate suspension system on the structural middle plate; 4) connecting the middle plate suspension system and the top plate suspension system; 5) continuously excavating to the position of a structural bottom plate, constructing the structural bottom plate, and then constructing a structural side wall and a structural column below the structural middle plate; (6) dismantling the middle plate suspension system, and constructing a structural side wall and a structural column above the structural middle plate; and (7) dismantling the top plate suspension system. According to the method, the problem that a temporary vertical supporting framework in a traditional reverse building method is high in cost is solved, construction of structural components is not affected, the construction speed can be greatly increased, and the construction quality is improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

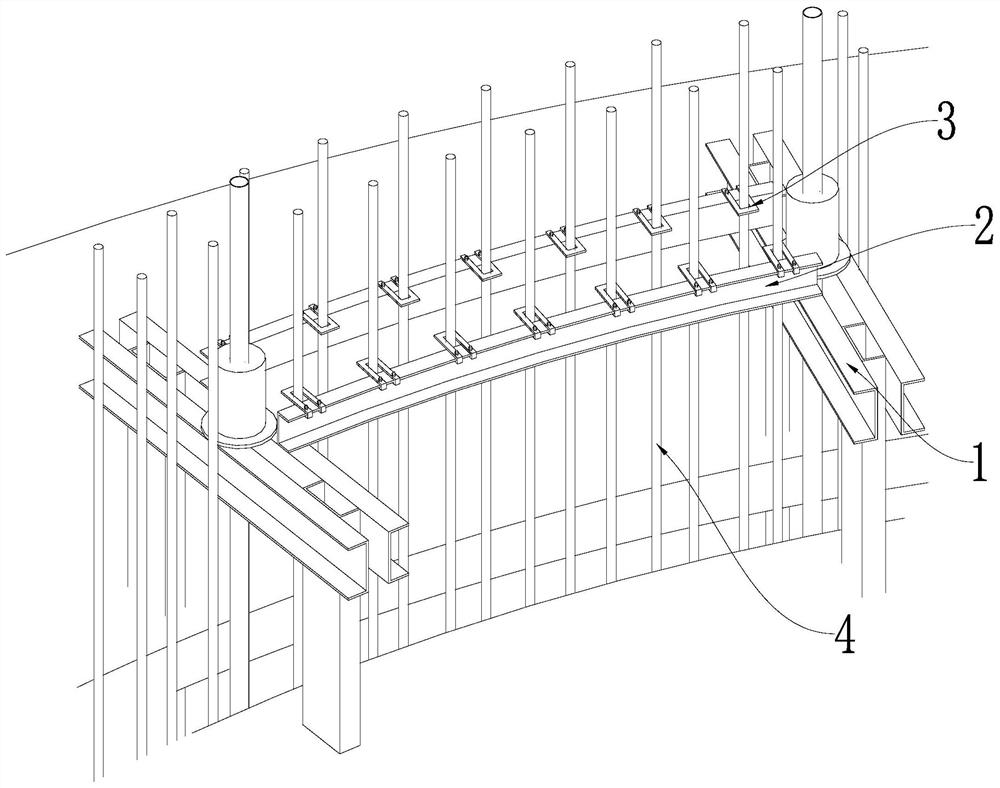

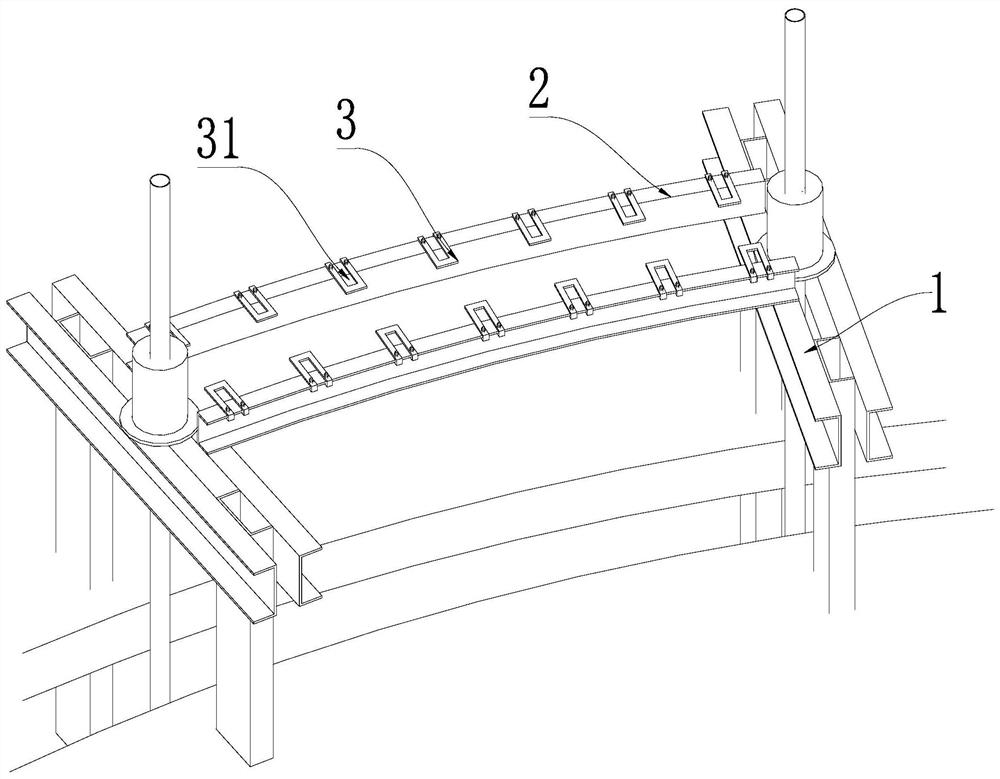

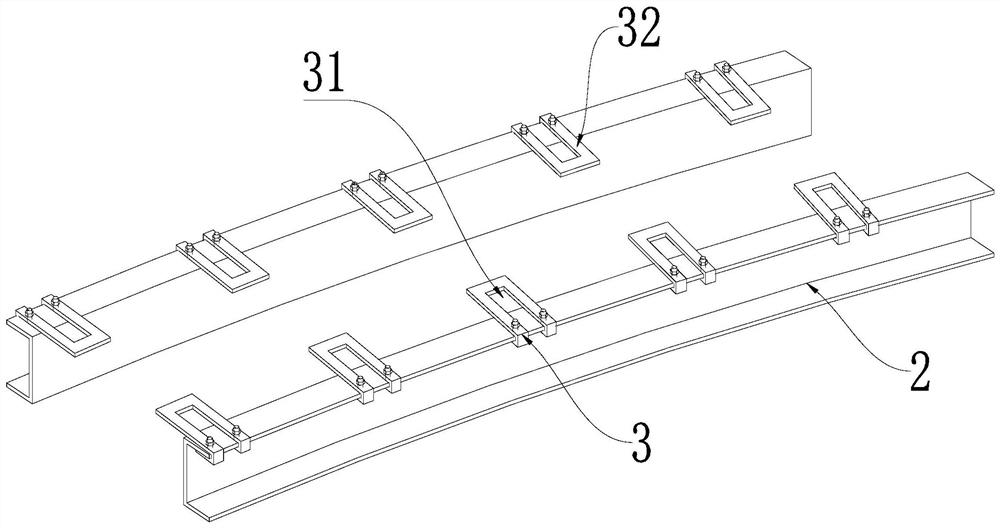

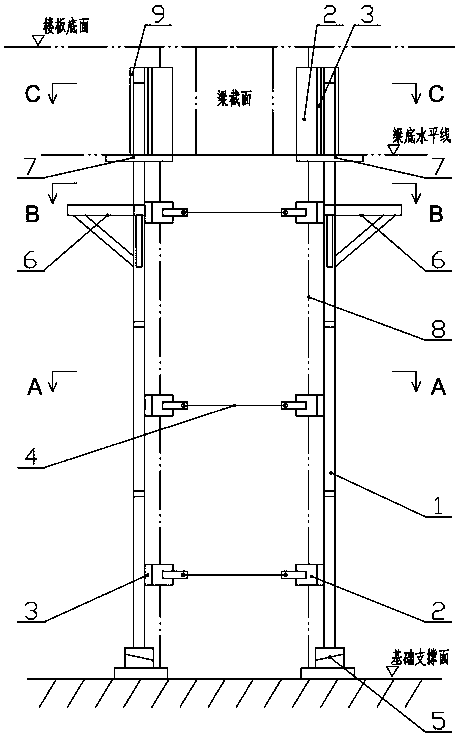

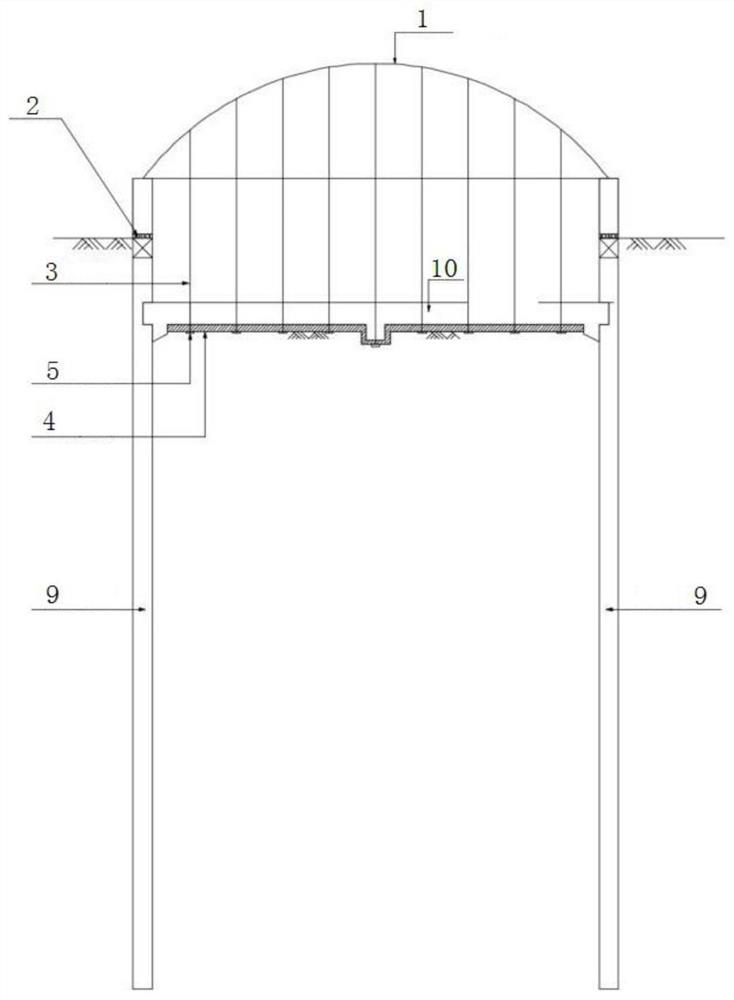

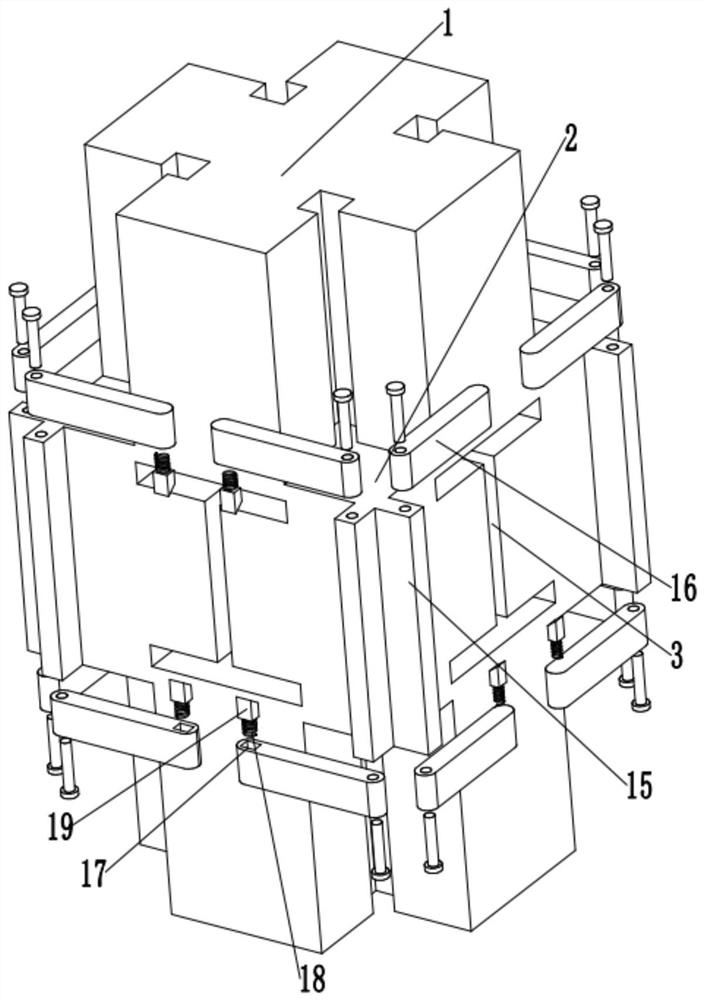

Turnover concrete silo structure steel bar accurate positioning device and method

PendingCN113323402AGuarantee the construction qualityImprove construction qualityForms/shuttering/falseworksBuilding material handlingArchitectural engineeringRebar

The invention discloses a turnover concrete silo structure steel bar accurate positioning device and method. Fixed channel steel is arranged on a slip form operation platform in a crossing mode, a plurality of detachable guide positioning steel plates are arranged on the fixed channel steel, fixing holes used for being connected with steel bars in a sleeved mode are formed in the guide positioning steel plates, and the perforating direction of the fixing holes is parallel to the lifting direction of the slip form operating platform; and a plurality of guide positioning steel plates are uniformly arranged on the fixed channel steel at intervals. Compared with a conventional construction method for positioning horizontal and vertical reinforcing steel bars during construction of a building structure main body, the construction method for accurately positioning the concrete silo structure reinforcing steel bars in a turnover manner is adopted in the sliding and lifting construction process of the silo wall of the concrete silo structure, installation is convenient, dismounting and changing are flexible, positioning is accurate, displacement is not prone to occurring, modular construction is achieved, labor is reduced, the construction cost is reduced, the engineering construction quality is improved, rework losses are reduced, and the management cost is reduced.

Owner:CHINA MCC5 GROUP CORP

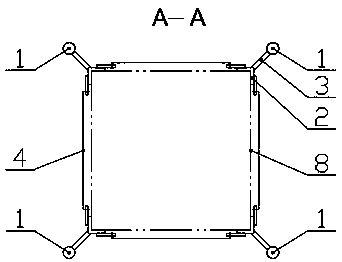

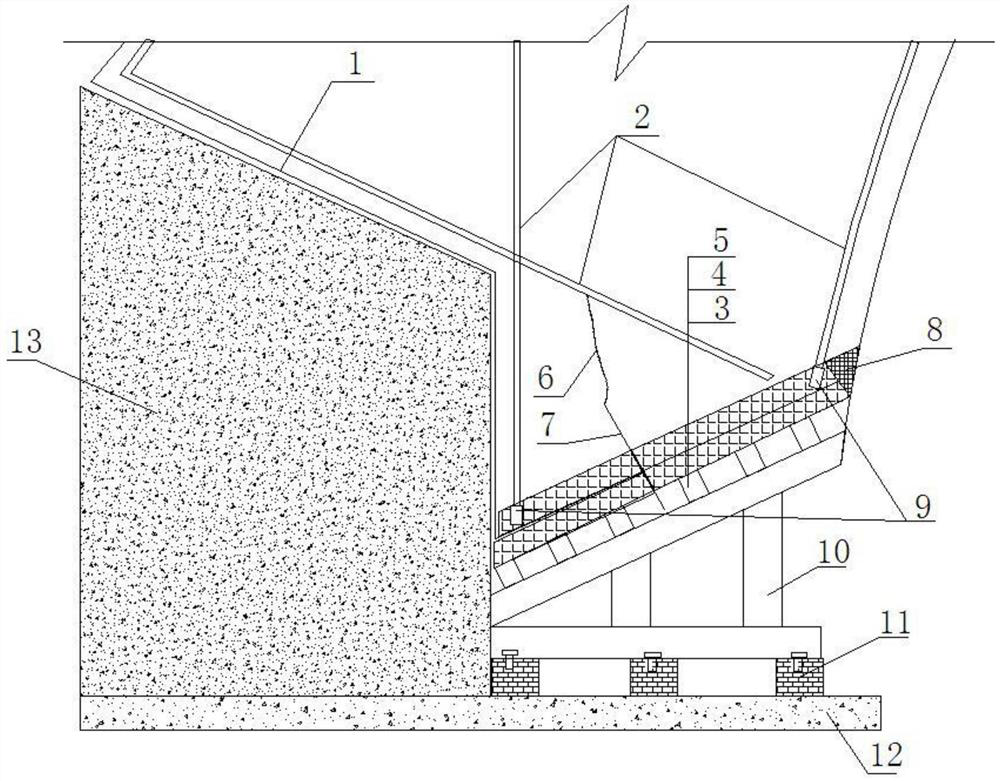

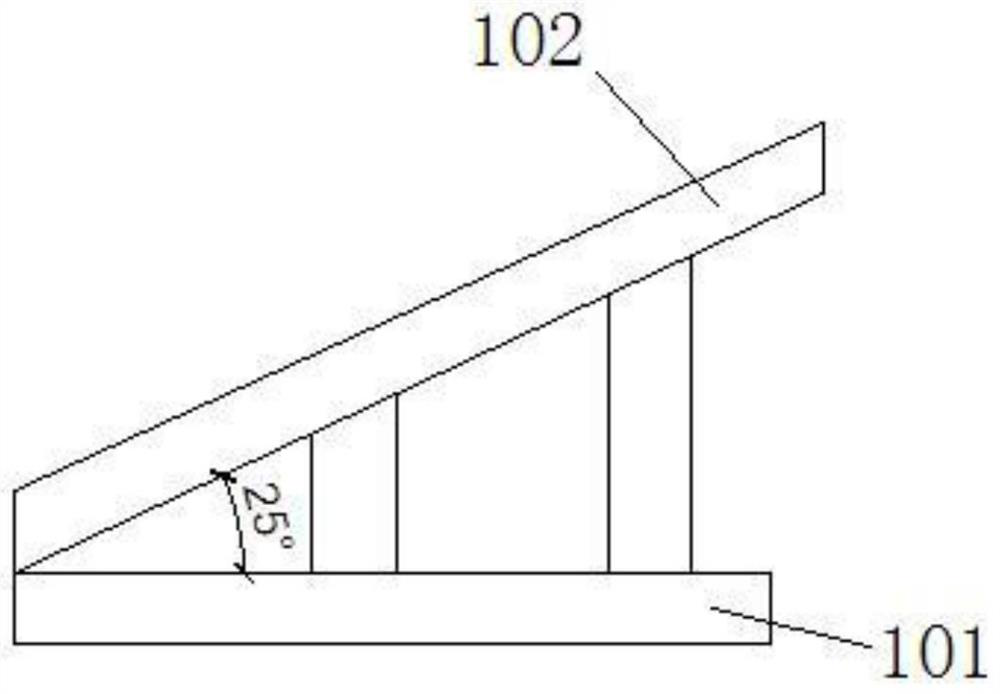

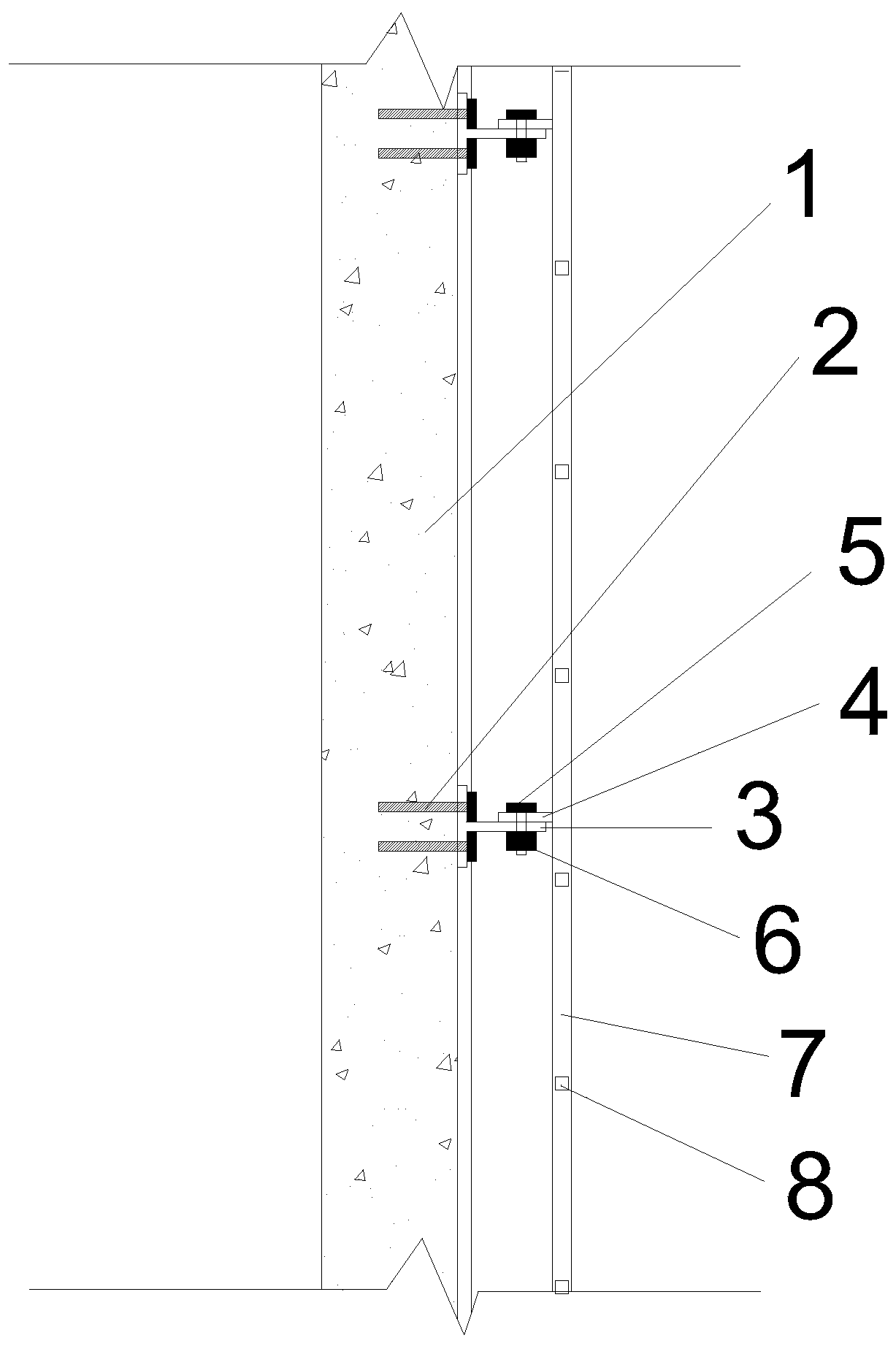

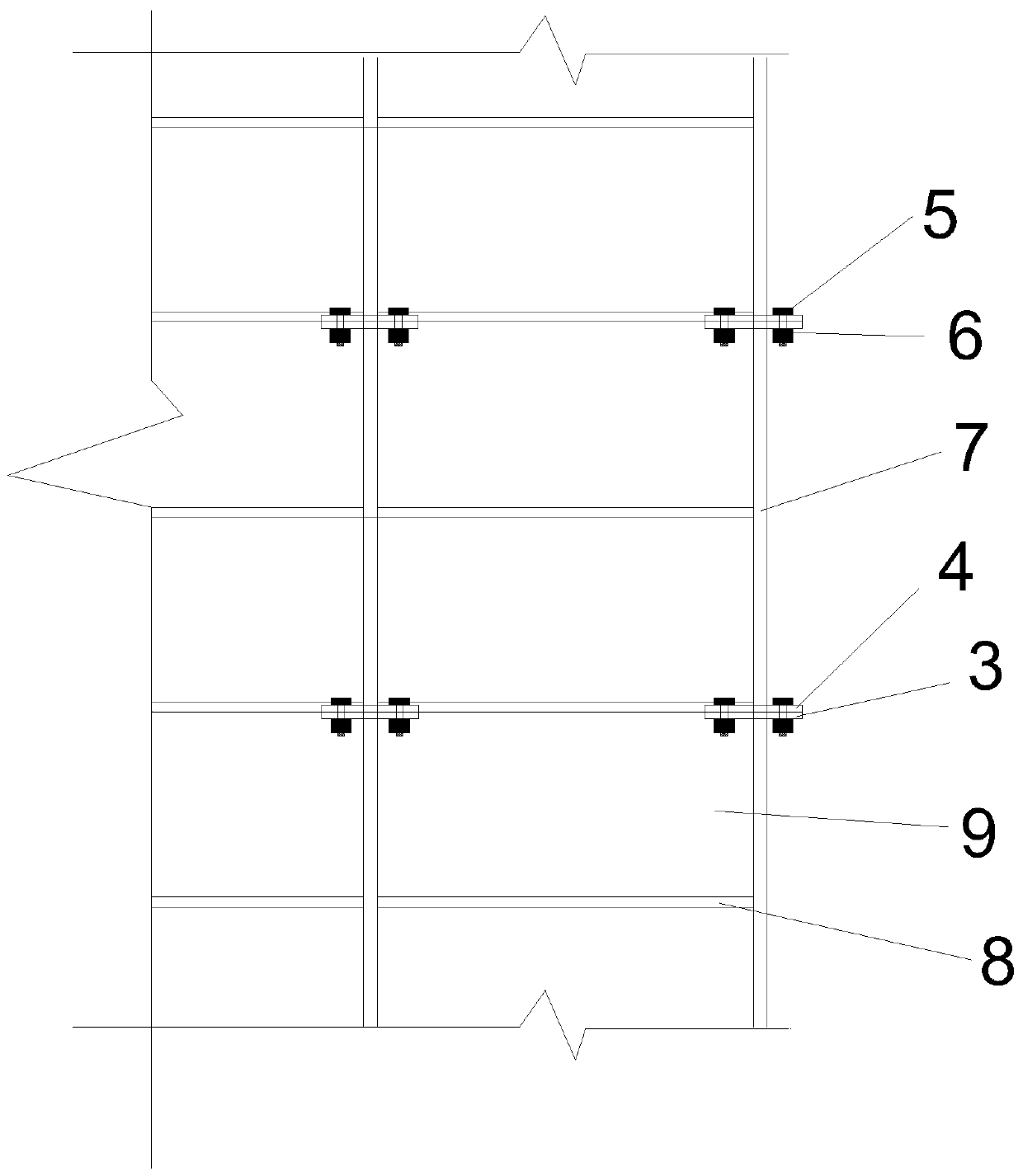

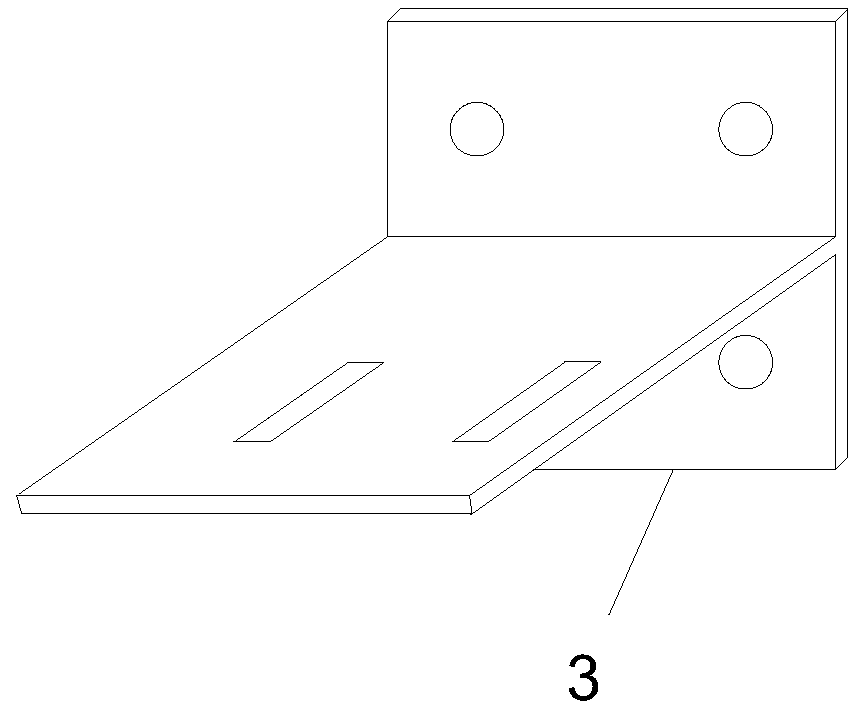

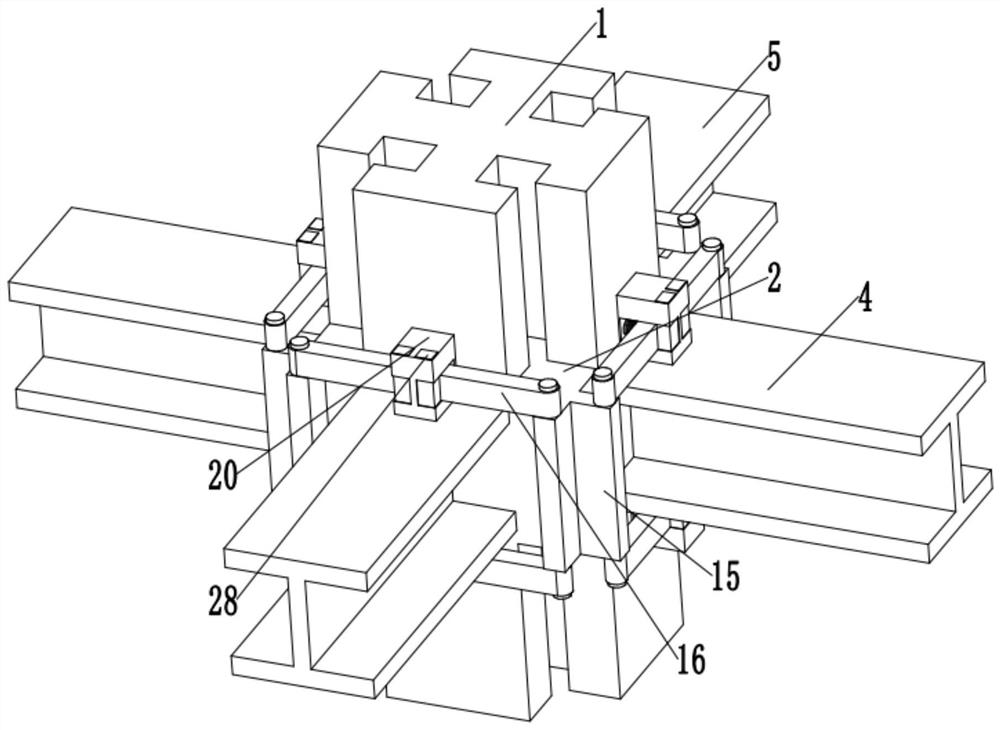

A column formwork support component

ActiveCN106245909BReliable supportEffective supportForms/shuttering/falseworksStructural engineering

The invention provides a column formwork surrounding bracket supporting assembly which comprises a plurality of surrounding bracket vertical rods. The surrounding bracket vertical rods are located on the column angle bisectors of the column formwork. Column angle sealing hoop plates are arranged on the surrounding bracket vertical rods at intervals, and the angles of the column angle sealing hoop plates adapt to the column angles of a column formwork so that the column angle sealing hoop plates can cover the column angles of the column formwork. The adjacent column angle sealing hoop plates located at the same height can be connected through telescopic pulling connectors, or the telescopic pulling connectors are connected between the adjacent surrounding bracket vertical rods located at the same height, so that a surrounding bracket supporting body hooping the outer side of the column formwork is formed. Certainly, due to a beam formwork, no telescopic pulling connector is arranged between the adjacent column angle sealing hoop plates located on the upper portion of the surrounding bracket vertical rod, or no telescopic pulling connector is arranged between the upper portions of the adjacent surrounding bracket vertical rods. According to the column formwork surrounding bracket supporting assembly, the modularly-assembling tool type surrounding bracket supporting body is formed on the periphery of the column formwork through the surrounding bracket vertical rods, the column angle sealing hoop plates and the telescopic pulling connectors, the structure is stable, supporting is firm, and reusing is achieved.

Owner:福州鼓楼纹英建筑工程有限责任公司

A reverse construction method for underground structures

ActiveCN112922025BHigh cost of settlementFast constructionArtificial islandsUnderwater structuresArchitectural engineeringStructural element

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A kind of preconfigured piezoelectric generator circuit panel and preconfigured method

ActiveCN112211058BRealize environmental protection constructionImprove environmental applicabilityPiezoelectric/electrostriction/magnetostriction machinesTemporary pavingsStructural engineeringProcess engineering

Owner:CHANGAN UNIV

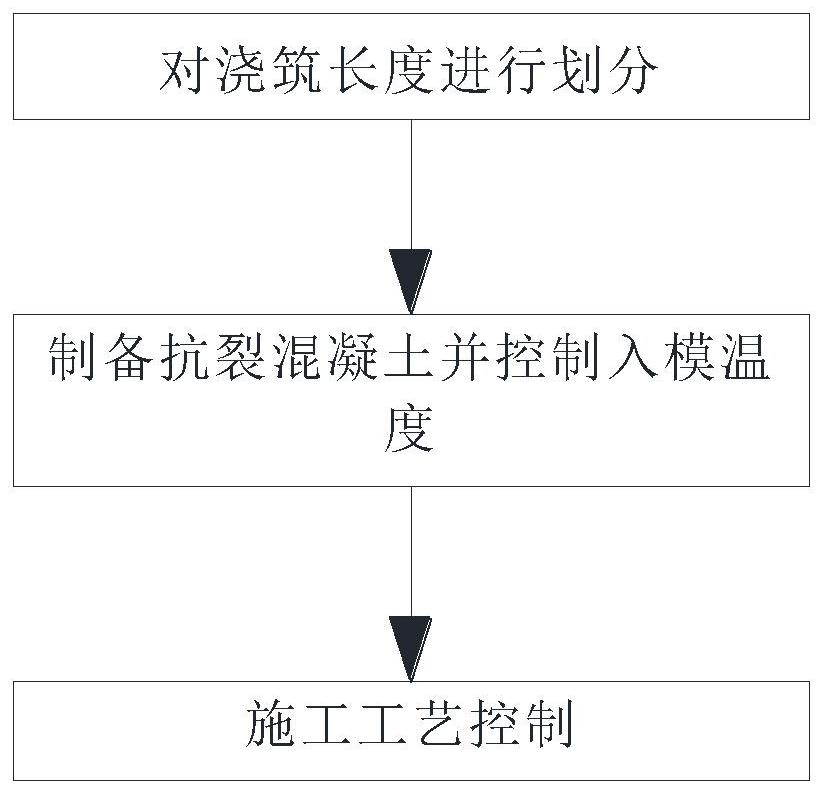

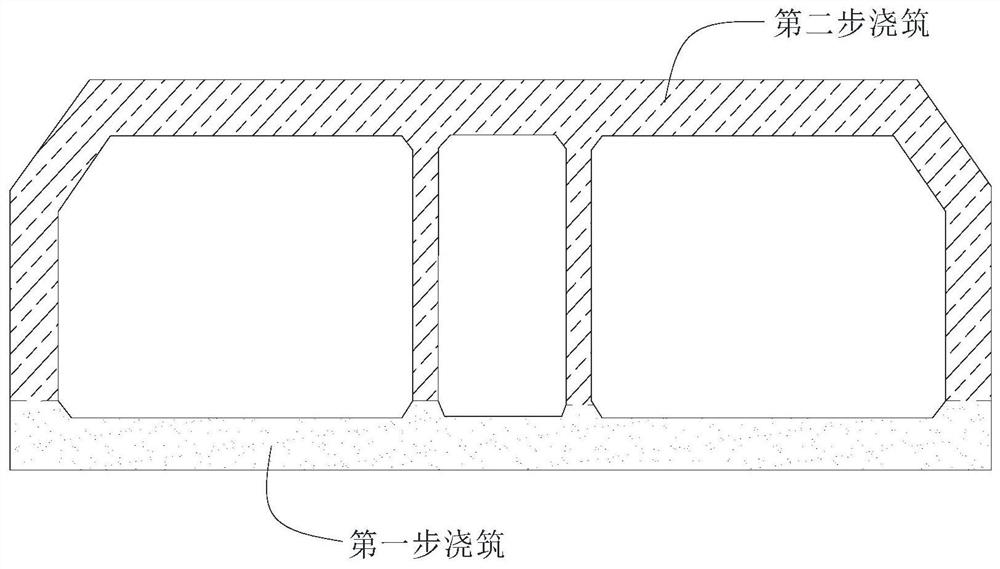

Open-cut cast-in-place tunnel main body structure concrete anti-crack construction method

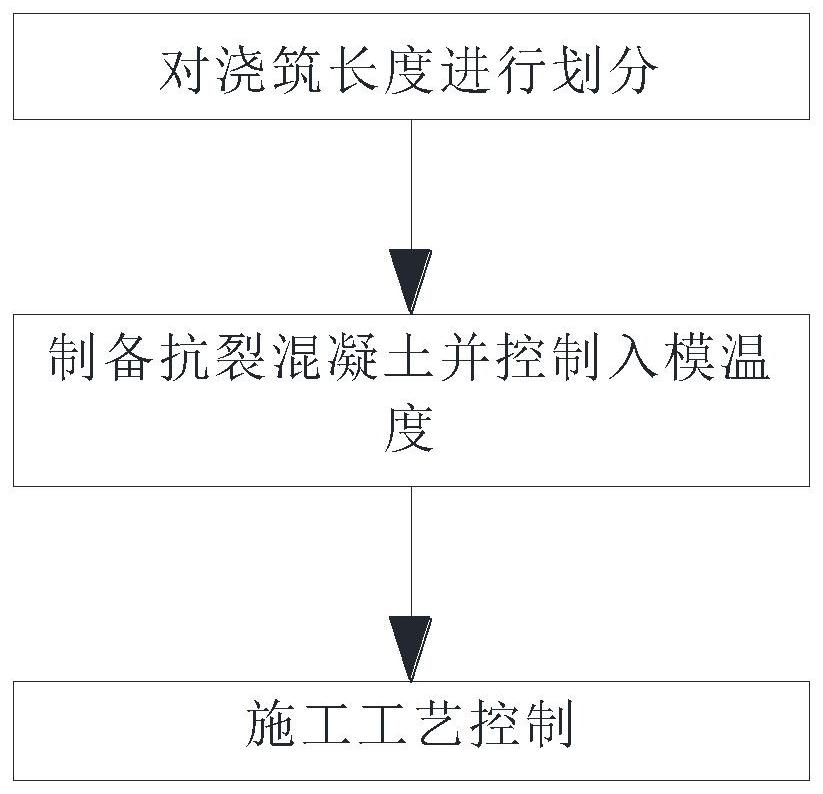

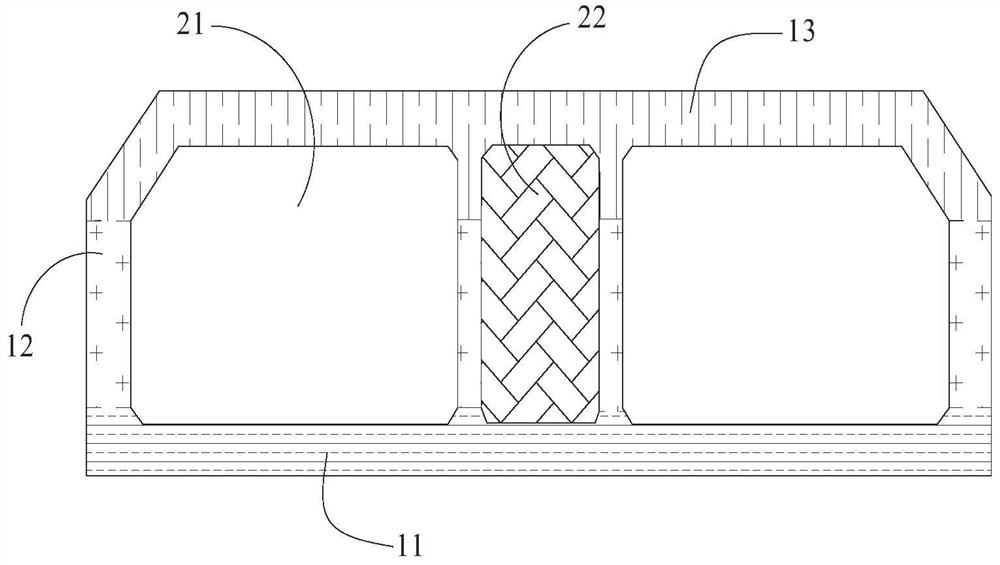

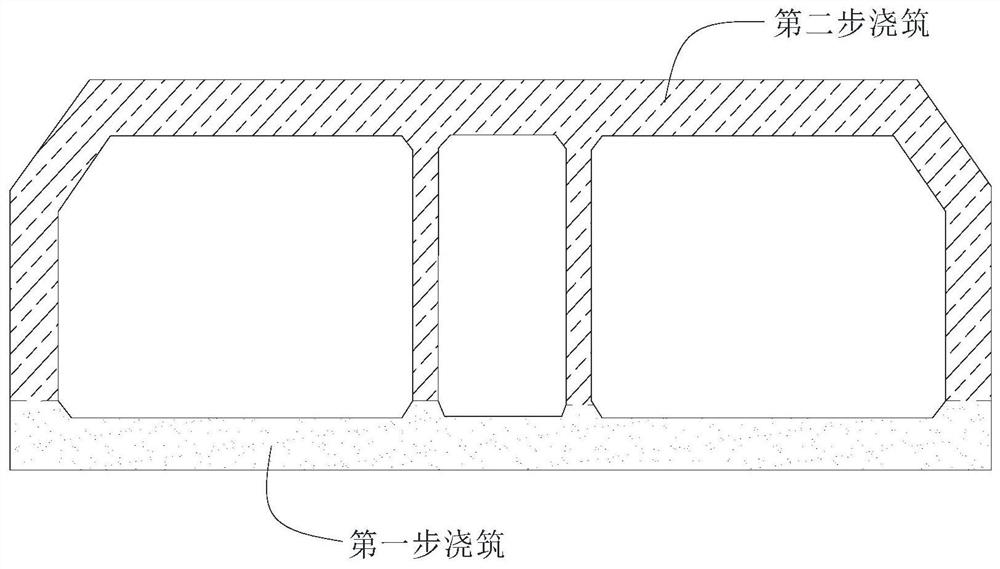

ActiveCN113774957AInhibition of penetrating shrinkage cracksControl indicators are clearArtificial islandsSolid waste managementShrinkage crackingTemperature control

The invention belongs to the technical field of tunnel construction, and particularly discloses an open-cut cast-in-place tunnel main body structure concrete anti-crack construction method. The method comprises a pouring length division step, an anti-crack concrete preparation and mold entering temperature control step and a construction process control step. The method aims at the main contradiction of shrinkage and cracking of open-cut cast-in-place tunnel main body structure concrete, an anti-cracking performance control index and an implementation scheme are provided from two aspects of controlling the temperature (adiabatic temperature rise of the anti-cracking concrete, mold entering temperature, maximum temperature rise, inner-surface temperature difference, center temperature drop rate and temperature difference of mold removal or external thermal insulation measure) of the anti-cracking concrete and shrinkage deformation (7d autogenous volume deformation and 28d deformation of the anti-cracking concrete), a customized complete technical scheme is formed for main structures of different parts, control indexes are clear, universality is high, construction is easy, penetrability shrinkage cracks can be effectively restrained, the leakage problem is solved, and the engineering construction quality is improved.

Owner:JIANGSU RES INST OF BUILDING SCI +3

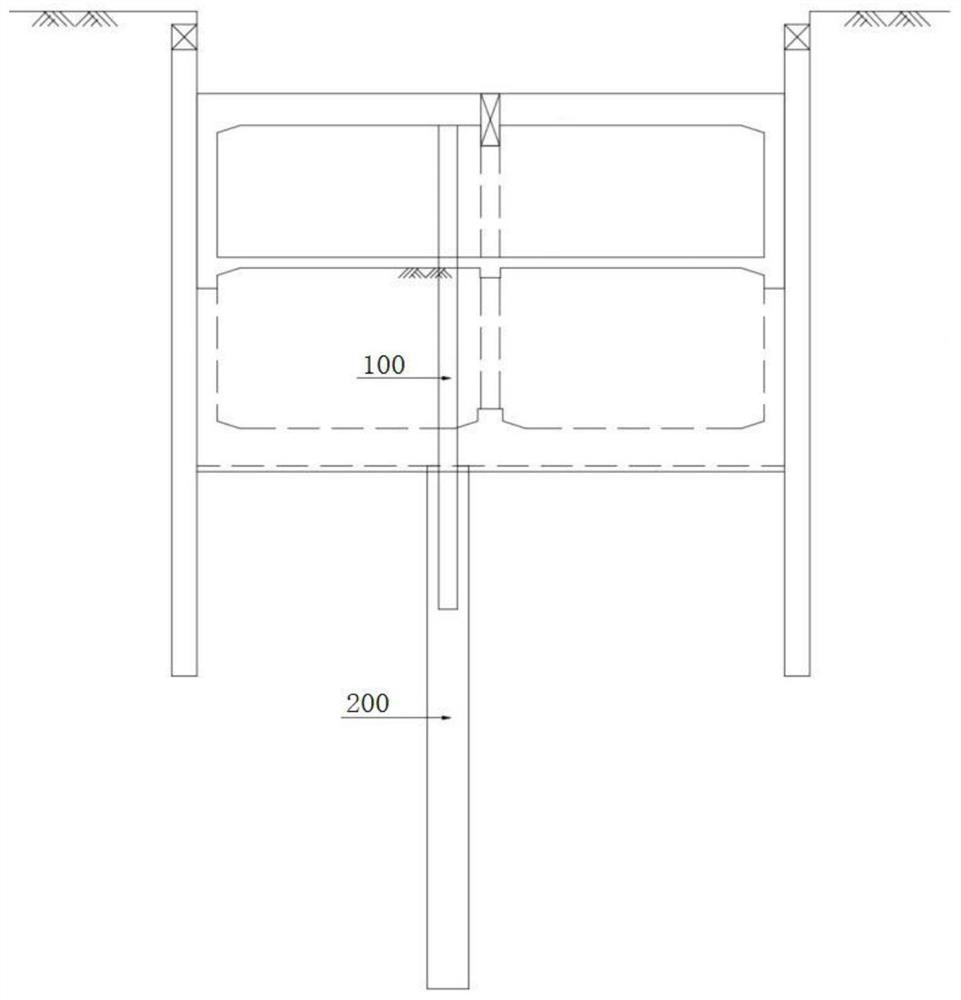

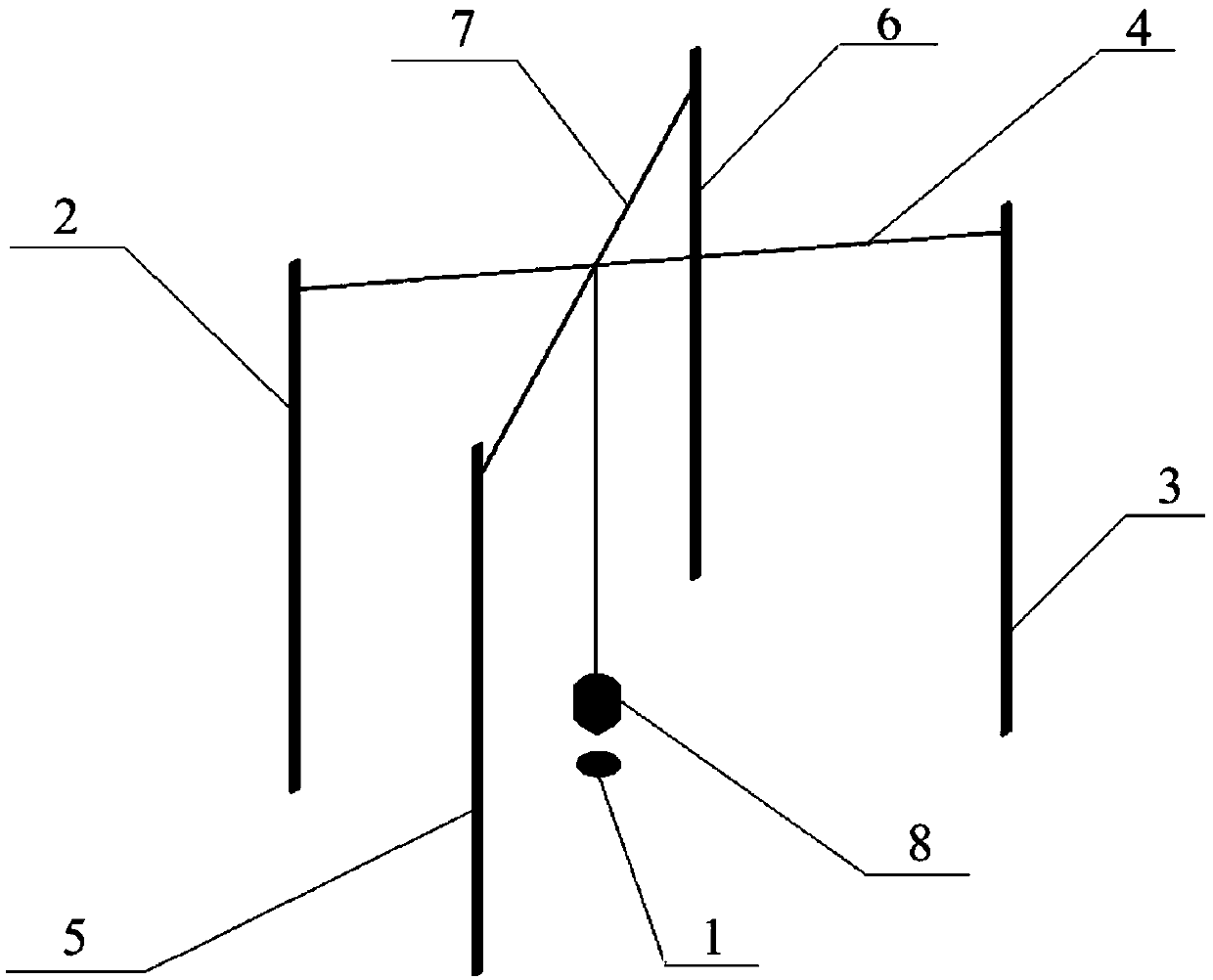

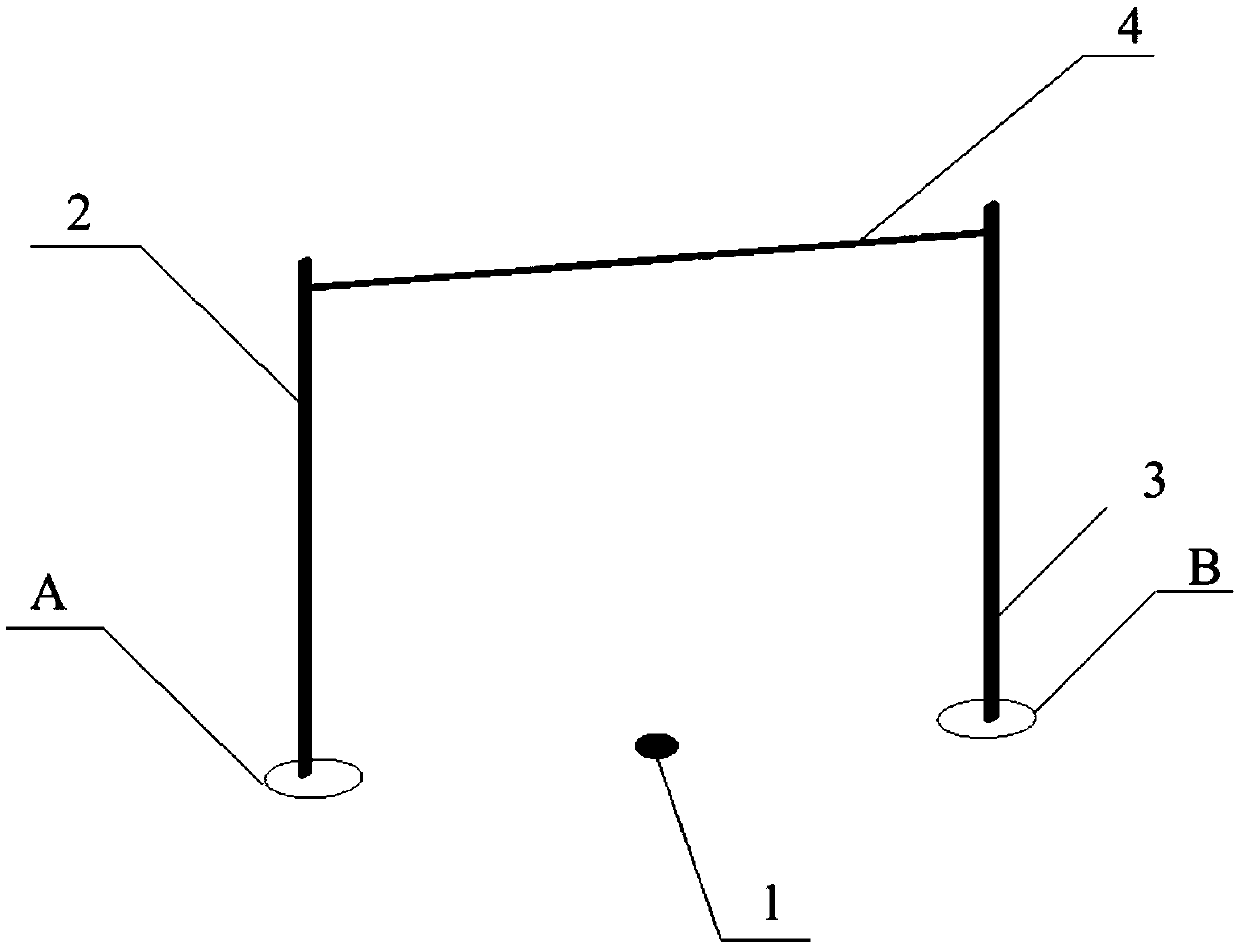

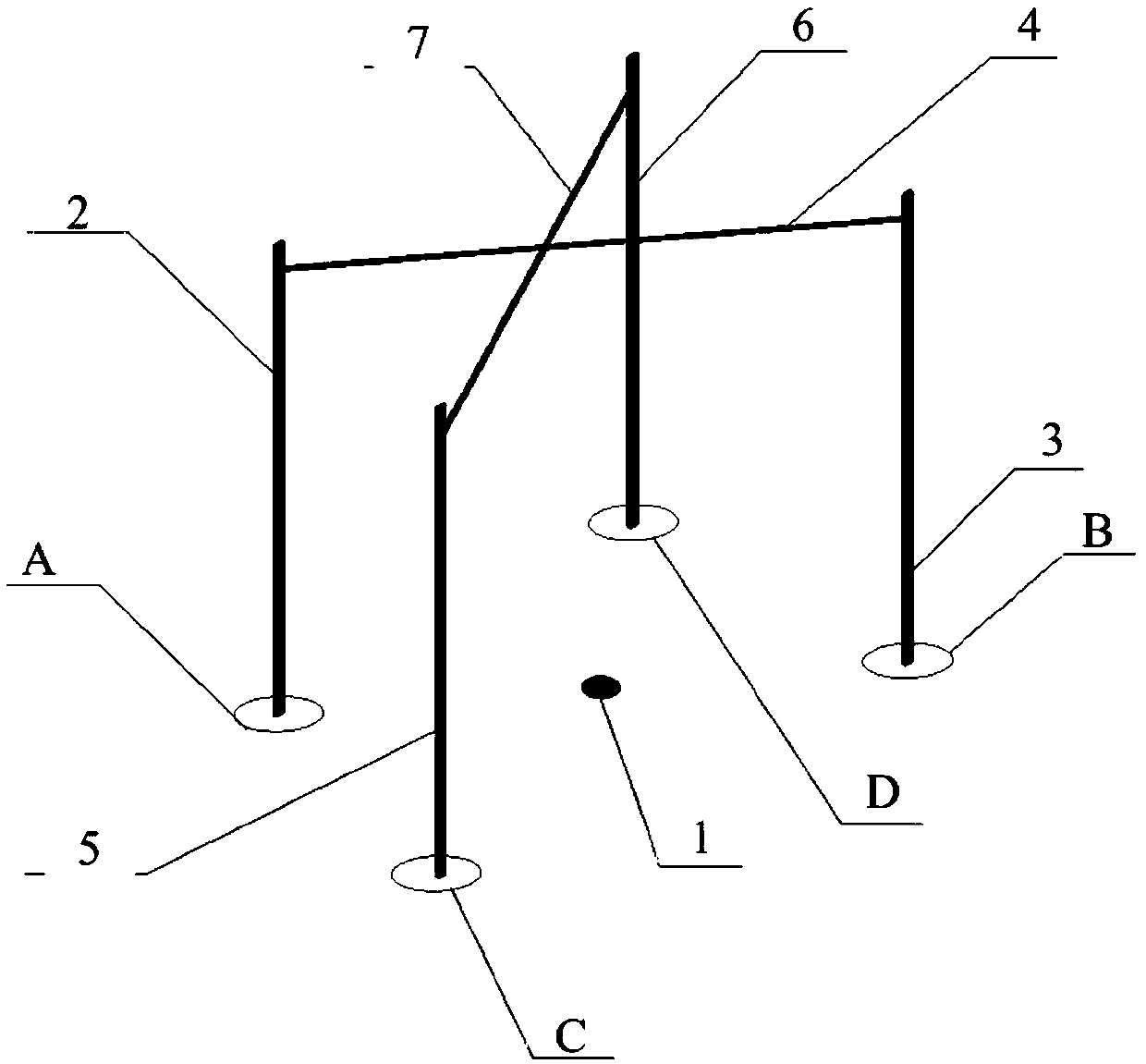

Pile centering method and pile centering device for cast-in-situ piles during construction

ActiveCN106869193BPrecise positioningEasy to operateFoundation testingBulkheads/pilesEngineeringBuilding construction

The invention provides a pile center centering method and a cast-in-place pile center centering device for the cast-in-place pile construction process. Four proper positions are found near the pile center of a cast-in-place pile, fixing rods are vertically arranged between every two opposite points and connected through opposite-pulling lines, and the two opposite-pulling lines are made to intersect above the pile center of the cast-in-place pile; and every two adjacent fixing rods are finely adjusted correspondingly, the two opposite-pulling lines are made to intersect at an intersecting point which is located over the pile center through a positioning tool, and then the first opposite-pulling line and the second opposite-pulling line are removed. During later cast-in-place pile construction, the first opposite-pulling line and the second opposite-pulling line can be arranged between the fixing rods to rapidly center the pile center of the cast-in-place pile. By means of the pile center centering method and the cast-in-place pile center centering device for the cast-in-place pile construction process, the problem that during pile center centering in the cast-in-place pile construction process, errors are large due to the fact that naked-eye observation is only adopted in traditional centering methods is solved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Installation method of a waterproof electric thermal insulation joint

ActiveCN105927803BImprove sealing and waterproof performanceImprove construction qualityThermal insulationPipe protection by thermal insulationThermal insulationWorking environment

The invention belongs to the field of heat preservation and relates to an installation method of a heat-preservation joint of a directly embedded high-temperature-hot-water pipe network used for heat-supply engineering, in particular to an installation method of a waterproof-type electric-melting heat-preservation joint. The method comprises following technical steps of: cleaning a working environment, installing an electric-melting sleevelet, welding gaps, foaming polyfoam, plugging a feeding port and sealing a seamless heat shrink sleeve. The installation method of the waterproof-type electric-melting heat-preservation joint has following beneficial effects: by utilizing the electric-melting sleevelet and the seamless heat shrink sleeve outside a pipeline, sealing and water-proof performance of the heat-preservation joint can be improved; through two-time heating and welding of the electric-melting sleevelet, especially transverse seam heating, engineering construction quality can be further improved, which is of great importance to improving construction quality of heat-preservation pipelines; the method is reliable in principle, easy and convenient in operation, mature in installation technology and is safe; and the waterproof-type electric-melting heat-preservation joint used in simple in structure, low in manufacture cost, user-friendly in application environment and broad in application scope.

Owner:华电青岛热力有限公司 +1

A concrete crack-resistant construction method for the main structure of an open-cut and cast-in-place tunnel

ActiveCN113774957BInhibition of penetrating shrinkage cracksControl indicators are clearArtificial islandsSolid waste managementShrinkage crackingTemperature control

The invention belongs to the technical field of tunnel construction, and in particular discloses an anti-cracking construction method for concrete of the main structure of an open-cut and cast-in-place tunnel, which includes the steps of dividing the pouring length, the preparation of crack-resistant concrete, the temperature control step of mold entry, and the construction process control step . The present invention aims at the main contradiction of shrinkage and cracking of the concrete of the main structure of the open-cut and cast-in-place tunnel, from the control of the temperature of the anti-crack concrete (the adiabatic temperature rise of the anti-crack concrete, the mold entry temperature, the maximum temperature rise, the temperature difference between the inside and the outside, the center temperature drop rate, Formwork removal or removal of external insulation measures (temperature difference) and shrinkage deformation (7d self-generated volume deformation and 28d deformation of crack-resistant concrete), put forward the crack resistance control index and implementation plan, and formed a customized package for the main structure of different parts The technical scheme has clear control indicators, strong universality, and simple construction, which can effectively suppress penetrating shrinkage cracks, solve leakage problems, and improve project construction quality.

Owner:JIANGSU RES INST OF BUILDING SCI +3

Construction method for arch springing of arch cover type subway station

ActiveCN114109450AEasy to fixAvoid offsetUnderground chambersTunnel liningWater stopReinforced concrete

The invention discloses a construction method of an arch springing of an arch cover type subway station. An arch foot support and a base formwork are adopted for construction, the arch foot support comprises three square timbers arranged at the bottom and a plurality of triangular supports fixedly connected to the upper portions of the three square timbers, the base formwork comprises a wood rubber plate and a plurality of back ridges connected to the bottom of the wood rubber plate, and the base formwork is fixedly arranged on the upper portions of support oblique beams of the triangular supports. The two base formworks are longitudinally symmetrical, a steel-edged water stop belt is clamped between the two base formworks, two layers of extruded sheets are laid on the upper portions of the base formworks, the lower end of the waterproof plate is folded outwards and then clamped between the two layers of extruded sheets, and the upper end of the steel-edged water stop belt is hung on an arch steel bar through an iron wire. And the reserved sleeve connected with the arch reinforcing steel bar is embedded in the extruded sheet. According to the method, the reinforced concrete secondary lining reserved sleeve can be protected against pollution and position deviation, the line type of the steel-edged water stop belt can be controlled, and the waterproof plate can be prevented from being damaged in follow-up procedure construction.

Owner:CHINA RAILWAY NO 10 ENG GRP NO 1 ENG CO LTD

Frame bridge jacking construction method

PendingCN113897872AReduce in quantityLess investmentBridge structural detailsBridge erection/assemblyRebarReinforced concrete

The invention discloses a frame bridge jacking construction method. The construction method is characterized in that the construction procedure of parallel construction is adopted for construction of an approach U-shaped groove and a prefabricated jacking frame, the approach U-shaped groove adjacent to the jacking frame serves as a back of jacking construction, and a reinforced concrete back is arranged at the front end of the approach U-shaped groove; the reinforced concrete back, the frame bridge working bottom plate and the concrete working bottom plate of the approach U-shaped groove form a whole during pouring, and the reinforced concrete back is anchored under a cushion layer; the number of sections of the U-shaped groove of the required approach way is obtained through theoretical calculation, and the objective of providing jacking counter force is achieved by adding a counter weight in the U-shaped groove of the approach way; and a post-cast strip with the width of 1 m is arranged between the two sections of approach U-shaped grooves in the rear portion, a water stop belt is embedded after jacking of the frame is completed, and construction of the post-cast strip and the settlement joint is completed. The U-shaped groove of the approach way is used as a jacking back, the number of temporary projects is greatly reduced, project investment is reduced, meanwhile, the U-shaped groove of the approach way and the prefabricated jacking frame are constructed in parallel, and the construction period is shortened.

Owner:中铁十局集团第一工程有限公司

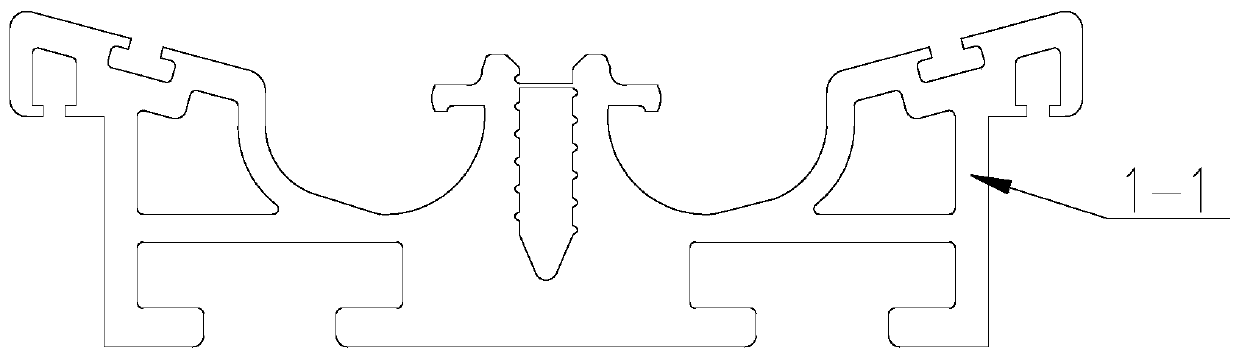

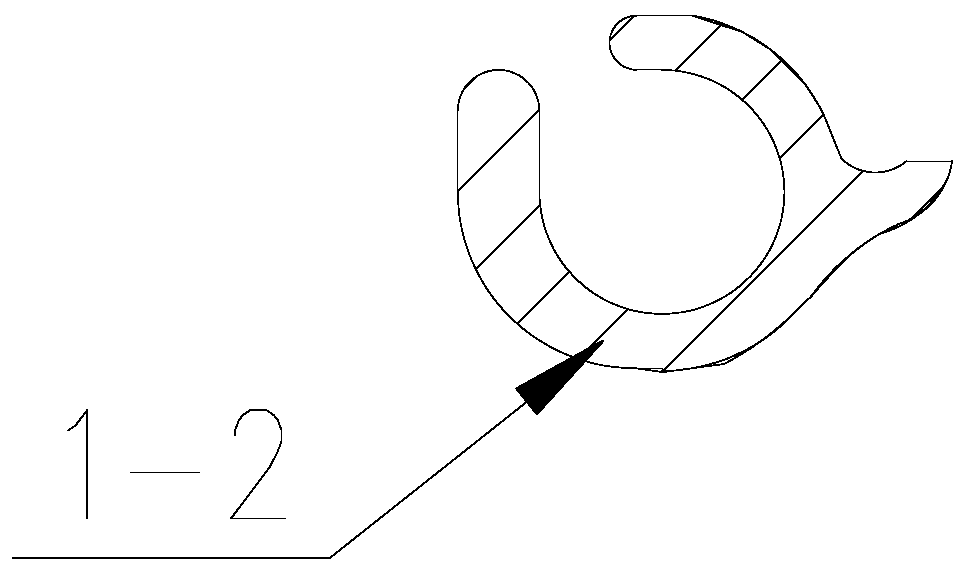

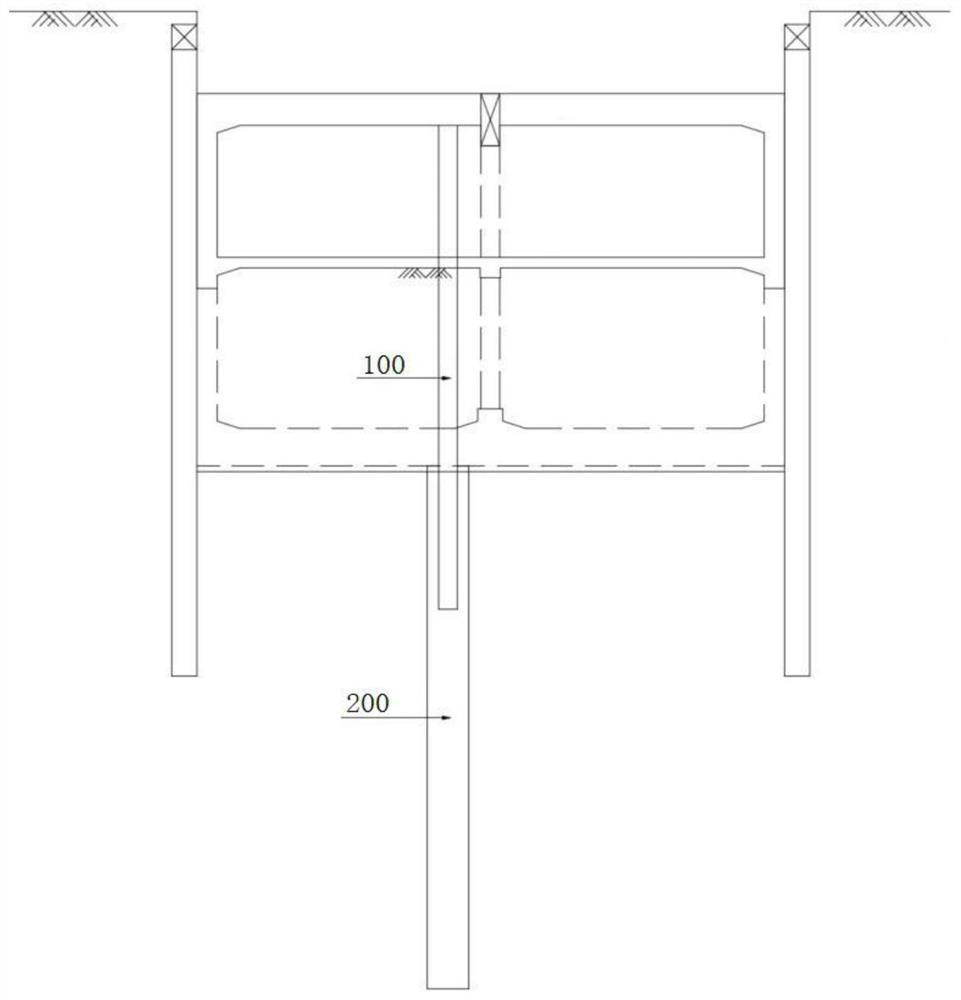

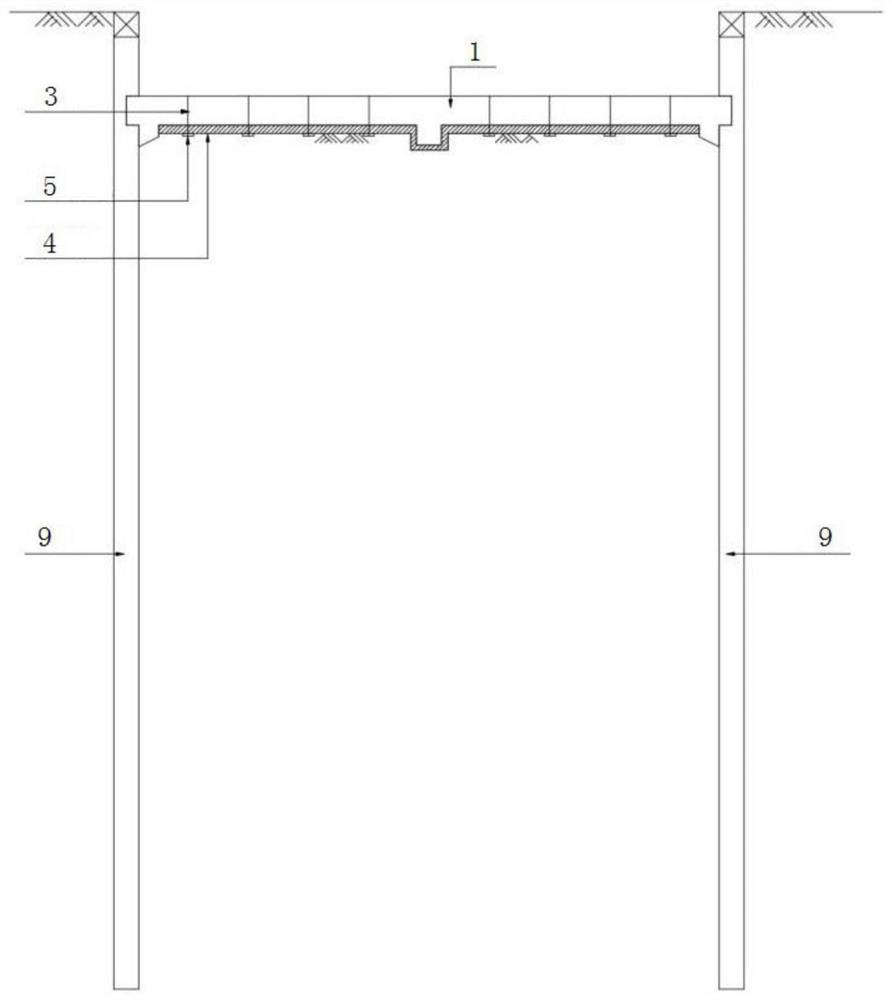

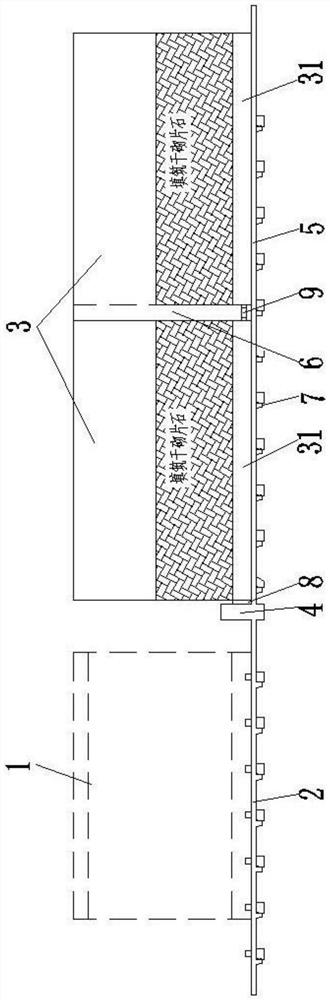

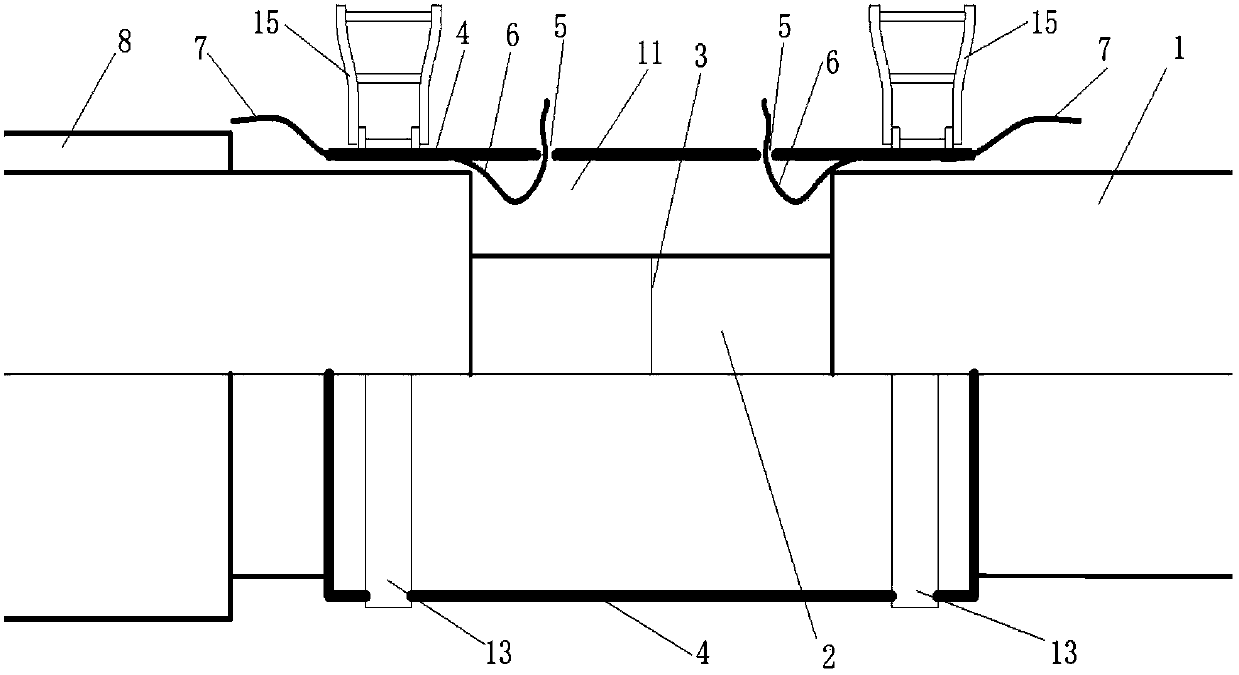

Overturn detachable floorslab concrete thickness control device

PendingCN110158966AControl thicknessSolve the problem of large area and large storage spaceBuilding material handlingDesign standardFloor slab

The invention relates to an overturn detachable floorslab concrete thickness control device which comprises two symmetrically arranged channeled guide rails (1), guide rail connecting rods (2) separately arranged at two ends of the two guide rails, bayonet lock fixing members (3) assembled at two ends of the guide rail connecting rods, four bidirectional measuring supporting legs (4) separately arranged at two ends of the guide rail connecting rods with scaleplates (4.1) and adjusting holes (4.2), two parallel floating rules (5) arranged between the two guide rails and located within the two guide rail connecting rods and floating rule push rods (6), two ends of which are clamped on the backs of the floating rules. The overturn detachable floorslab concrete thickness control device is simple in structure and high in universality, can control thickness of floorslab thickness well in a casting process of the floorslab concrete, and the thickness of the floorslab reaches the design standard and the surface of the floorslab is smooth, so that the quality of the engineering construction is improved favorably.

Owner:YUNNAN CONSTR ENG GENERAL CONTRACTING

A waterproof electric thermal insulation joint

ActiveCN105953015BImprove sealing and waterproof performanceImprove construction qualityPipe connection arrangementsNon-disconnectible pipe-jointsArchitectural engineeringHot melt

Owner:华电青岛热力有限公司 +1

Construction method for vertically penetrating lower hanging plate of external facade

InactiveCN111549998AEasy to installAvoid problems such as not in the design positionCovering/liningsKeelBolt connection

The invention discloses a construction method for vertically penetrating a lower hanging plate of an external facade. The construction method is characterized in that an expansion screw, a shaped flatsteel, a matched steel plate, a bolt, a nut, a main keel, a secondary keel, an external facade hanging plate and a wall body are used for matched construction; the shaped flat steel is a T-shaped structure and comprises a top surface steel plate and an elevation steel plate; a mounting hole is arranged on the top surface steel plate, and the the shaped flat steel is fixedly connected with the wall body through the expansion screw at the position of the mounting hole; the shaped flat steel is spliced up and down through the elevation steel plate and the matched steel plate, the elevation steelplate and the matched steel plate are provided with reserved holes, and the shaped flat steel and the matched steel plate are connected and fixed by bolts; one side of the matched steel plate is fixedly connected with the main keel, the main keel is a vertical keel, the secondary keel is a transverse keel, and the main keel and the secondary keel are staggered and fixedly arranged to form the external facade frame of a rectangular grid structure; and the external facade hanging plate is fixed to the external facade frame.

Owner:CHINA MCC17 GRP

A web-reinforced aluminum alloy plate joint structure

ActiveCN110924528BAchieve firmnessImprove the quality of node structureBuilding constructionsStructural engineeringMechanical engineering

The invention discloses a web-reinforced aluminum alloy plate-type node structure, which comprises a component, a first fixing block, a first bar and a second bar. The component is integrally formed with a first fixing block, and the first The four sides of the fixed block are symmetrically provided with first slots, one of the symmetrical two sides of the first slot is inserted with a first rod, and the other symmetrical two sides are inserted with a second rod, and One end of one of the first rods is integrally formed with a first plug, and the end of the other first rod is integrally formed with a second plug. The present invention can realize the firmness of the connection between the rod structures, thereby improving the joint Structural quality, improve the quality of engineering construction, it is more convenient and safe for the construction of node structure, improve the construction efficiency of structural mechanism, and then improve the efficiency of construction work.

Owner:湖南衡科铝材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com