A kind of preconfigured piezoelectric generator circuit panel and preconfigured method

A pavement panel, pre-configured technology, applied in piezoelectric/electrostrictive or magnetostrictive motors, generators/motors, roads, etc. Efficiency, improved environmental suitability and the effect of mechanical vibration energy capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

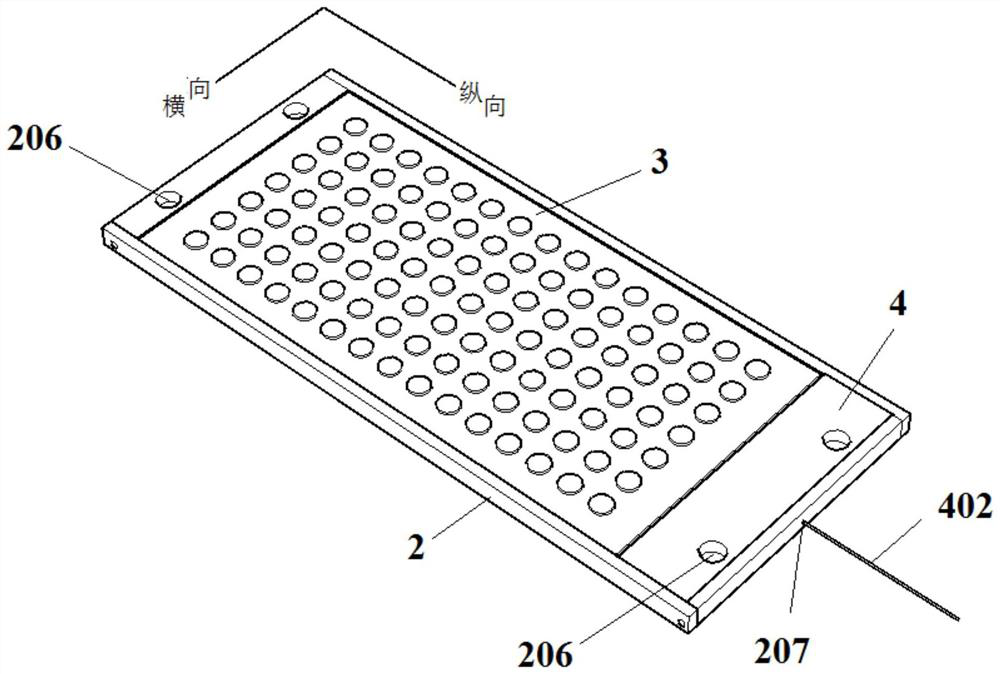

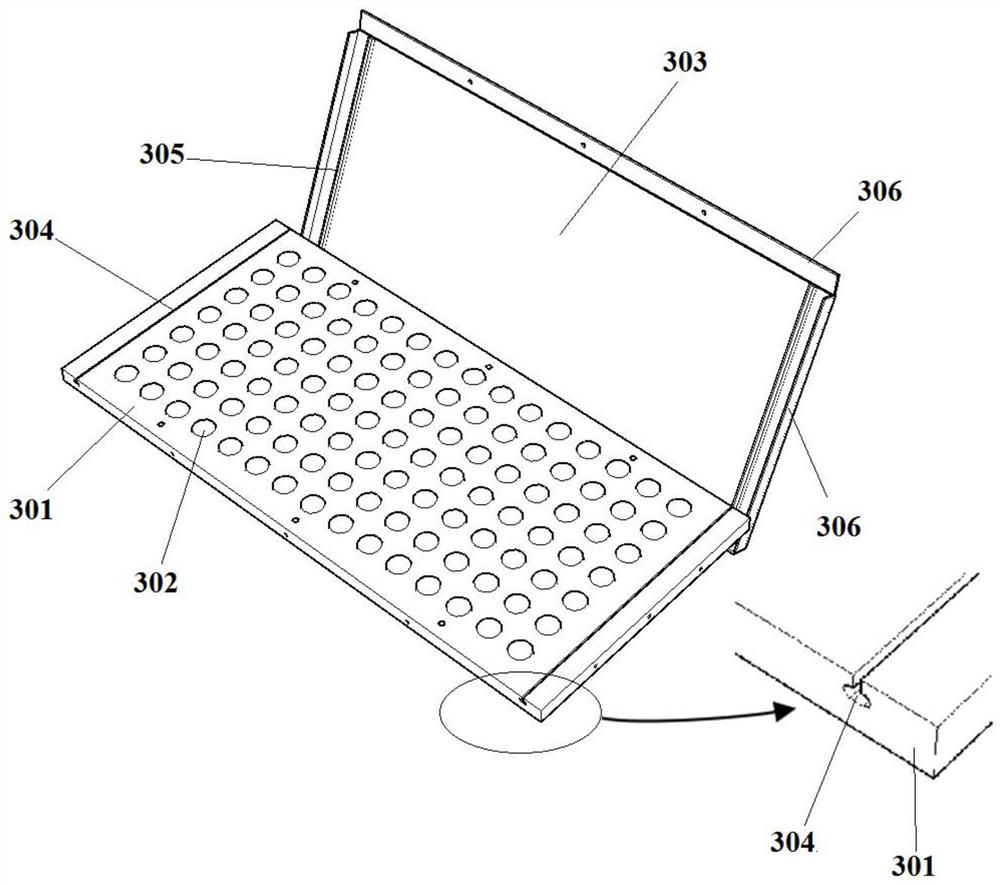

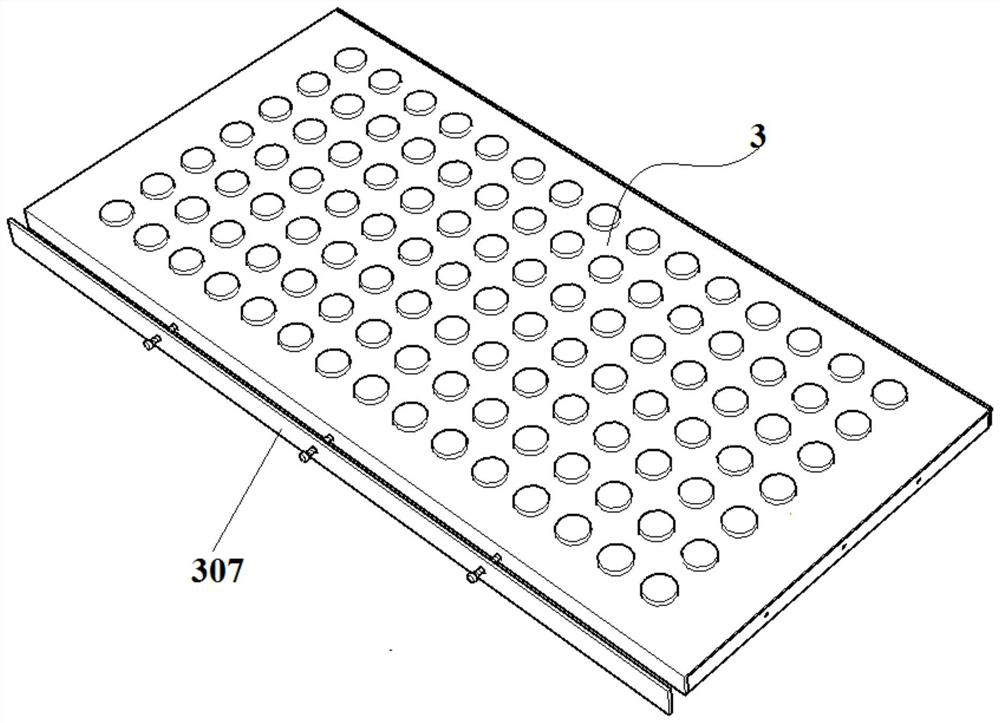

[0076] This embodiment provides a preconfigured piezoelectric generator circuit panel, such as Figure 1 to Figure 13 As shown, it includes a prefabricated concrete road slab 17, the prefabricated concrete road slab 17 includes a concrete layer 21, a steel mesh 11 laid inside the concrete layer 21, and a transduction module 1 is pre-equipped in the concrete layer 21;

[0077] The transduction module 1 includes a housing 2, and the housing 2 includes a bottom plate 205, and the longitudinal ends of the bottom plate 205 are fixed with a first transverse limiting strip 201 and a second transverse limiting strip 202, and the transverse limiting strip 202 on the bottom plate 2 There are detachable first longitudinal side panels 203 and second longitudinal side panels 204 on both sides, and the two ends of the first longitudinal side panels 203 and the second longitudinal side panels 204 are connected with the first transverse limiting strip 201 and the second transverse limiting str...

Embodiment 2

[0105] This embodiment provides a preconfiguration method for the preconfigured piezoelectric generator circuit panel. In this method, the method of step 1 is used to assemble the transduction module, and then the method of step 2 is used to realize the preconfiguration of the preconfigured piezoelectric generator circuit panel. match;

[0106] Step 1, assemble the transducer module:

[0107] Such as Figure 1 to Figure 5 As shown, the transduction module 1 is assembled according to the structure of the transduction module 1 given in Embodiment 1;

[0108] Step 2, use unit cell slots to position and pour prefabricated concrete pavement slabs:

[0109] Step 201, pouring unit cell grooves:

[0110] Using the unit tank mold 5 to pour concrete to prepare the unit tank 6;

[0111] Such as Figure 6 As shown, the unit cell mold 5 includes a mold bottom plate 501 and a pair of lateral side walls 502 and a pair of longitudinal side walls 503 arranged on the mold bottom plate 501,...

Embodiment 3

[0123] This embodiment presents a preconfiguration method of the preconfigured piezoelectric generator circuit panel. In this method, the method of step 1 is used to assemble the transduction module, and then the method of step 3 is used to realize the preconfiguration of the preconfigured piezoelectric generator circuit panel. match;

[0124] Step 1, assemble the transducer module:

[0125] Such as Figure 1 to Figure 5 As shown, the transduction module 1 is assembled according to the structure of the transduction module 1 given in Embodiment 1;

[0126] Step 3, use the positioning board to position and pour the prefabricated concrete road slab:

[0127] Laying reinforcement mesh 11 in prefabricated road slab mold 10, such as Figure 9 and Figure 10 As shown, the transducer module 1 is respectively fixed on the bottom surface of a pair of positioning boards 14 through the connector 12 and the fixing coil 13. The positioning board 14 is provided with a wire groove reserve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com