Air film roof fixing device and using method

A technology of fixing devices and air film, which is applied to roofs, roof coverings, and roofs using flexible materials, etc., can solve problems such as increased investment costs, low construction efficiency, and easy deformation of aluminum alloy fixtures, so as to reduce maintenance during use, Improve the quality of engineering construction and the effect of simple processing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but it is not intended as a limitation of the present invention.

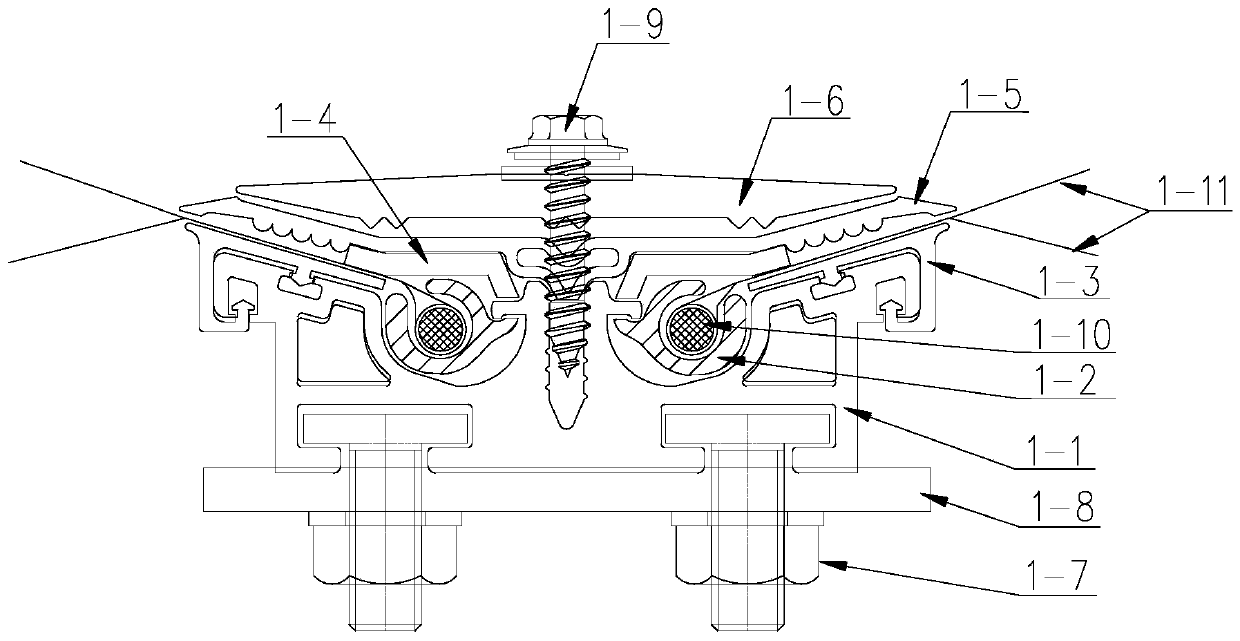

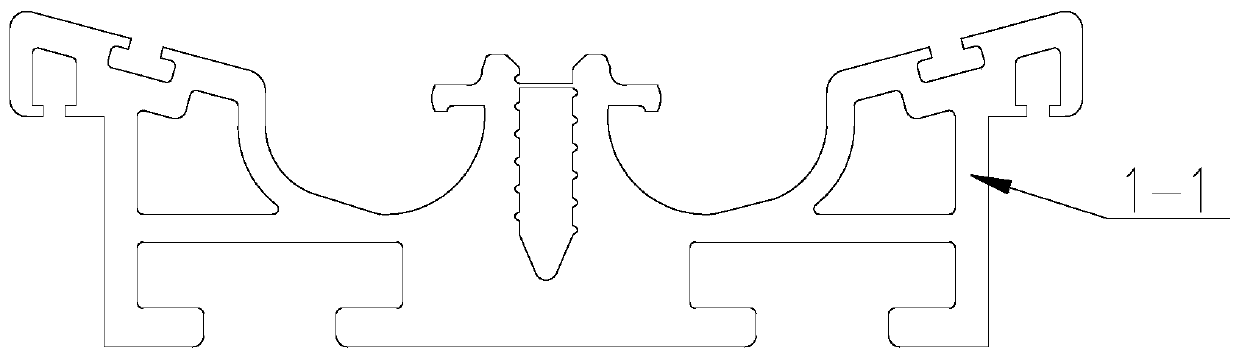

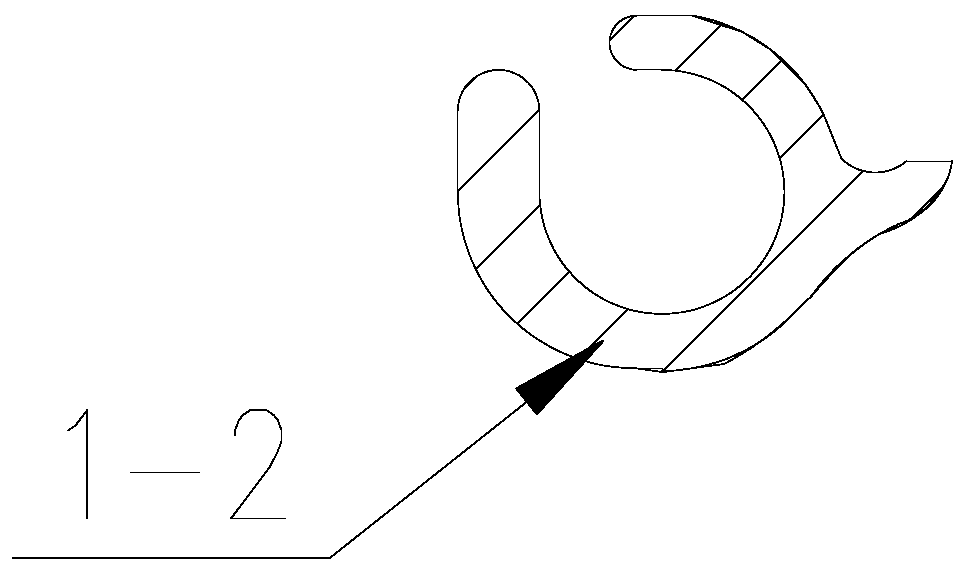

[0049] Such as Figure 1 to Figure 10 As shown, the embodiment of the present invention discloses an air film roof fixing device, including a base 1-1, a buckle 1-2, a rubber pad 1-3, an isolation rubber pad 1-5, a cover plate 1-6, and bolts 1-7, connecting plate 1-8, self-tapping screw one 1-9, anti-shedding rubber rod 1-10, cover plate two 2-1 and self-tapping screw two 2-2, the lower part of the base 1-1 and the building Fixed, the rubber pad 1-3 is installed on both sides of the upper end of the base 1-1, the buckle 1-2 is buckled on the upper end of the base 1-1 and is positioned at the inner side of the rubber pad 1-3, and a ring is arranged in the middle of the buckle 1-2 to prevent The shedding rubber rod 1-10 is installed in the ring, the middle part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com