Rotary booster energy-absorbing cylinder fixing device

The technology of a fixing device and an energy-absorbing cylinder is applied in the field of machinery, which can solve the problems of large workload and low work efficiency, and achieve the effects of firm fixing, simple structure and preventing forward movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

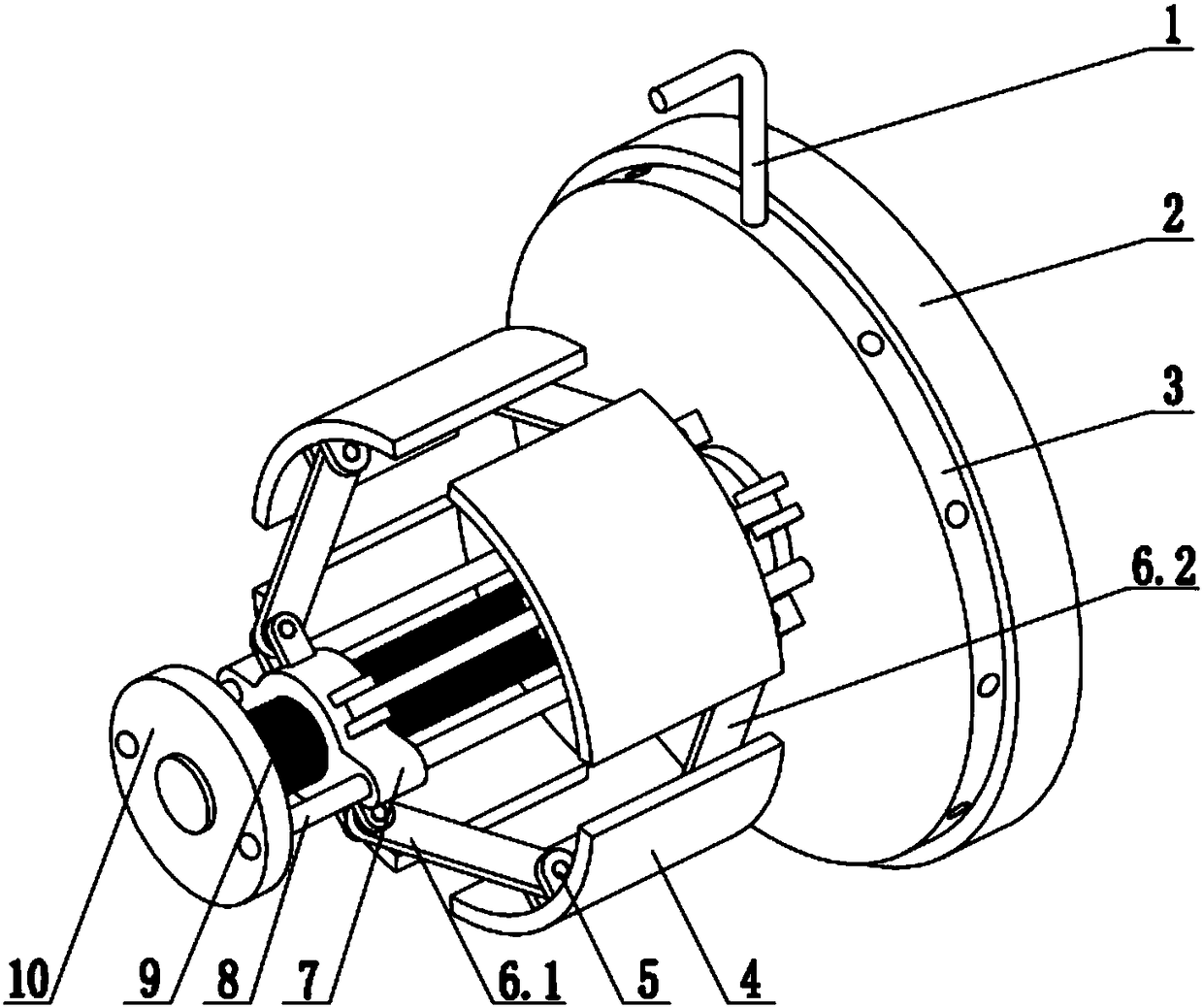

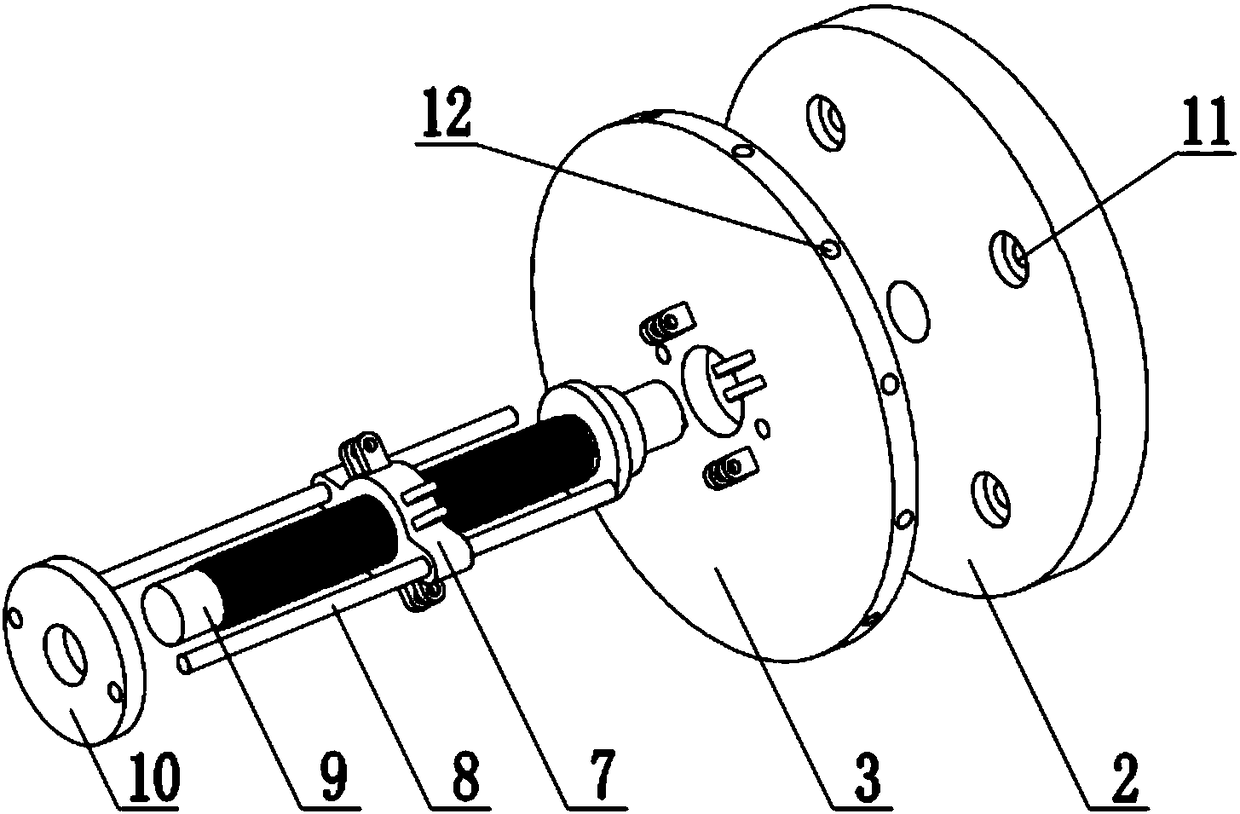

[0021] Such as figure 1 and figure 2 The shown rotating power-boosting type energy-absorbing cylinder fixing device mainly includes a rotating rod 1, a fixed chassis 2, a rotating disk 3, a tension piece 4, a rotating pin 5, a first connecting rod 6.1, and a second connecting rod 6.2 , sliding block 7, guide rod 8, screw mandrel shaft 9, rotating piece 10.

[0022] The fixed chassis 2 is fixed on the front end of the trolley through screw holes 11 or directly welded to the front end of the trolley. Welding together, the rotating disk 3 can rotate between the screw shaft 9 and the fixed chassis 2 at this time, the rotating piece 10 is sleeved on the screw shaft 9, the guide rod 8 passes through the two holes of the sliding block 7, and inserts In the two holes corresponding to the rotating disk 3, they are connected by welding. The other end of the guide rod 8 is inserted in the hole of the rotating piece 10 and connected by welding. The rotating piece 10 and the sliding bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com