Auxiliary mechanism for end socket pipeline inner wall cleaning device

A cleaning device and auxiliary mechanism technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of manpower consumption, inconvenient disassembly and assembly, and affect work efficiency, so as to reduce manual operations, Reduce the effect of fixing and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

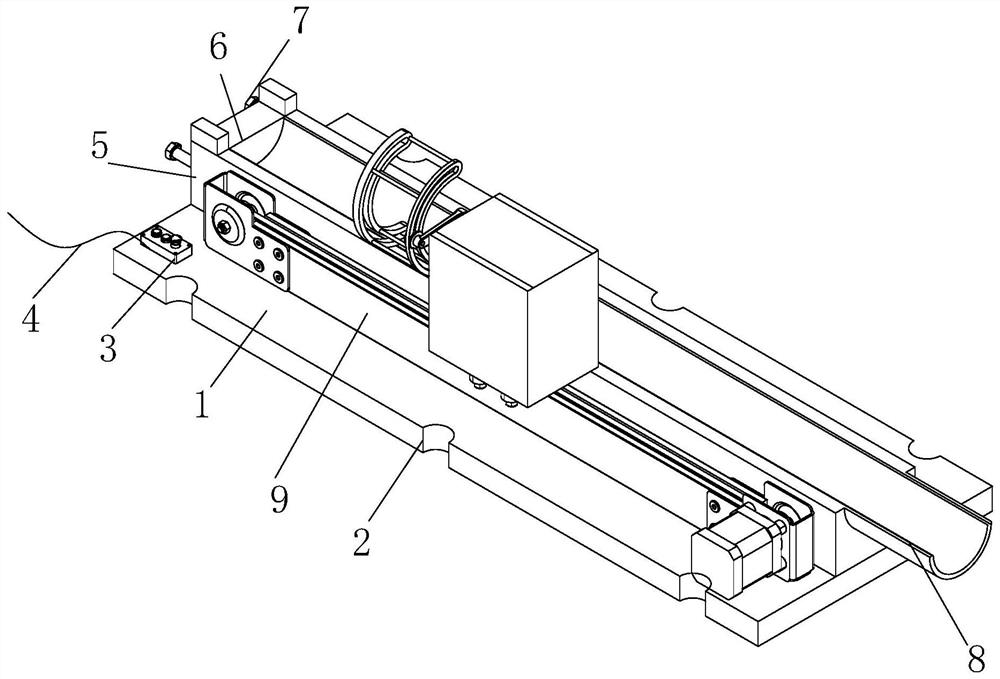

[0031] see figure 1 , the present invention provides an auxiliary mechanism for cleaning the inner wall of the head pipeline through improvement, including a base plate 1, lock grooves 2 are opened at the front and rear ends of the base plate 1, a controller 3 is installed on the left front end of the top of the base plate 1, and the controller 3 The left side is provided with a power cord 4, the top and rear end of the substrate 1 is welded with a placement slot 5, the left side of the placement slot 5 is embedded with a plugboard 6, and the front and rear ends of the right side of the plugboard 6 are fixed with the placement slot 5 by locking bolts 7. The right side of the groove 5 is connected with the extension pipe 8 , and a stabilizing device 9 is installed on the front end of the top of the base plate 1 .

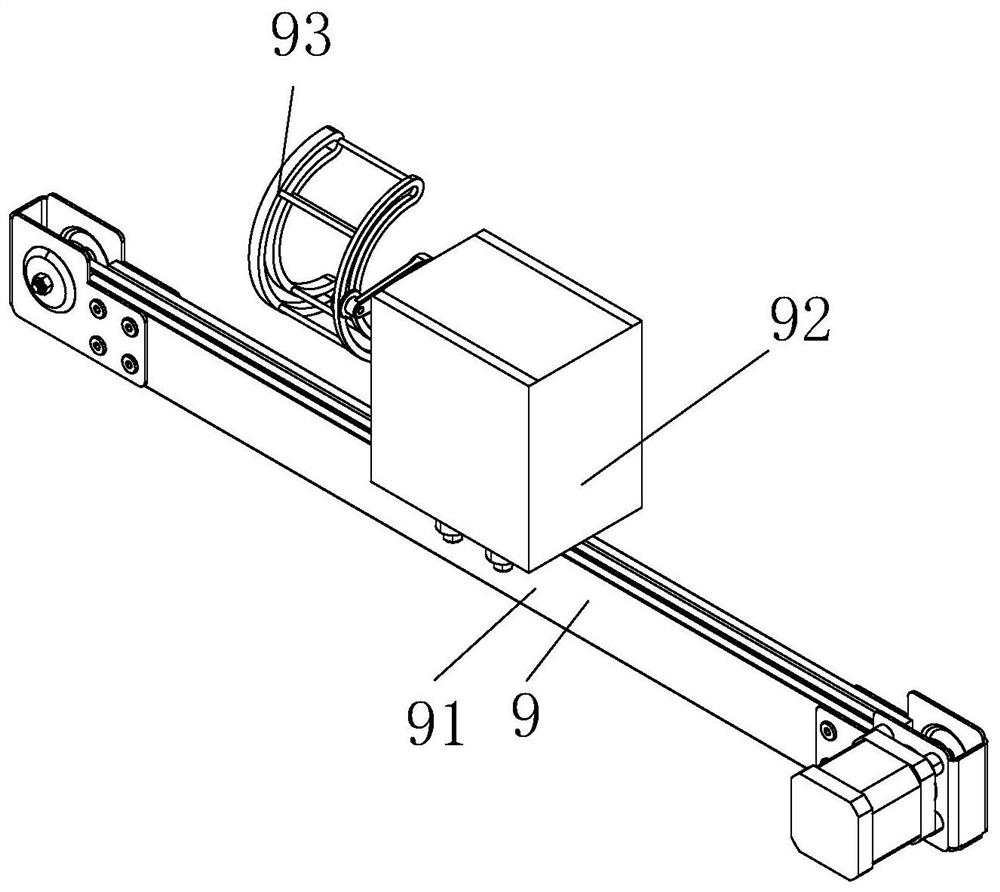

[0032] see figure 2 , the present invention provides an auxiliary mechanism for cleaning the inner wall of the head pipe through improvement. The stabilizing devic...

Embodiment 2

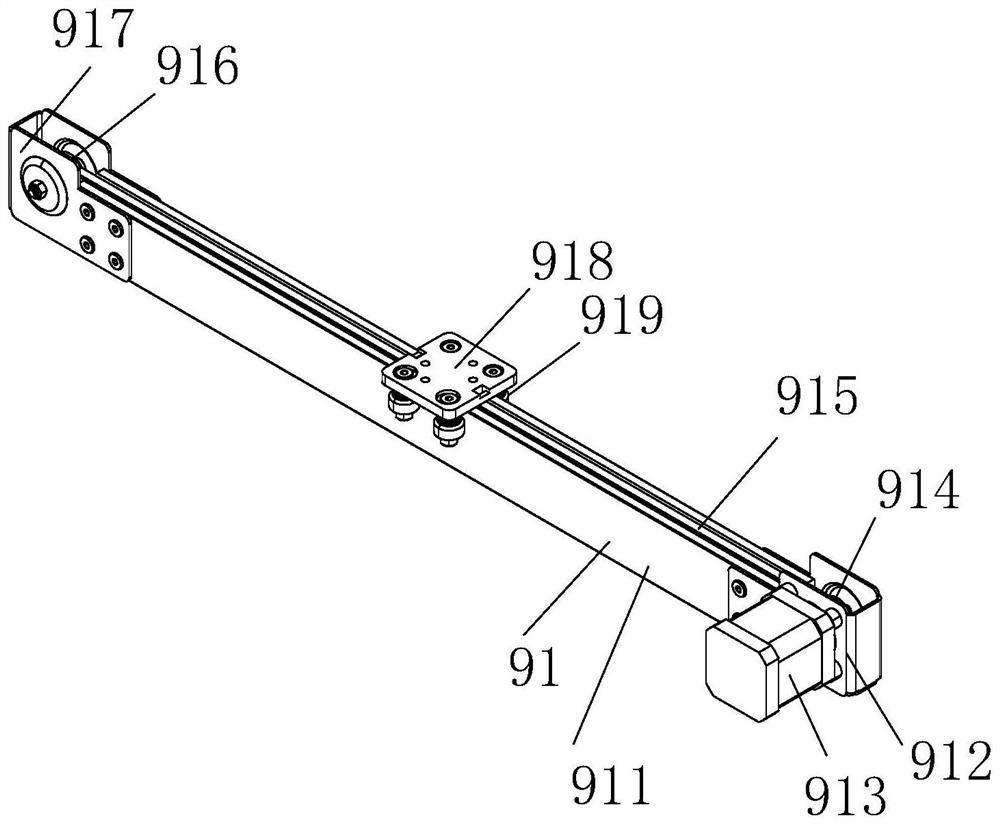

[0037] The present invention provides an auxiliary mechanism for cleaning the inner wall of the head pipe through improvement. The bottom of the connecting piece 918 is smooth, and the bottom of the connecting piece 918 is in contact with the top of the fixing piece 911, and the smoothness is good when sliding, and the sliding Stable; the limit plate is fixed on both sides of the left side of the pulley 933, and the outer diameter of the limit plate is larger than the thickness of the chute 932 to prevent the pulley 933 from falling off during the movement; the connecting rods 935 are provided with six groups, and the six groups of connecting rods 935 The same size, good fixation and strong durability.

[0038] The present invention provides an auxiliary mechanism of a head pipe inner wall cleaning device through improvement, and its working principle is as follows;

[0039] First, when it is necessary to use the equipment, first lock the base plate 1 through the lock grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com