Frame bridge jacking construction method

A construction method and technology for frame bridges, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of prolonged construction period, high construction cost, impact, etc., and achieve the goal of reducing engineering cost, shortening construction period, and reducing investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

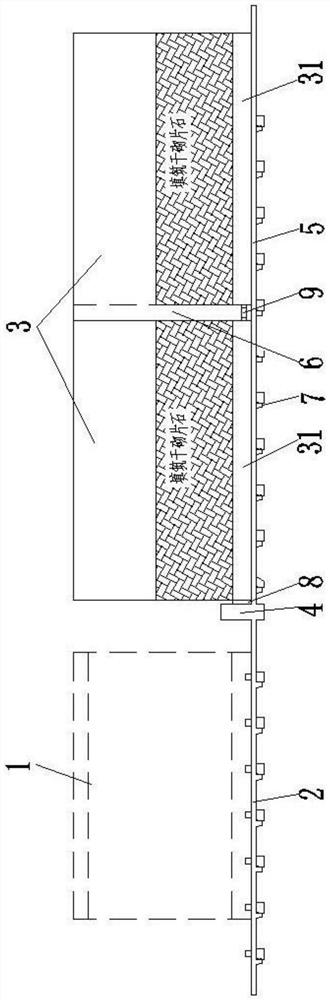

[0013] As shown in the accompanying drawings, a jacking construction method of a frame bridge uses the U-shaped groove of the approach adjacent to the jacking frame section to replace the back of the traditional bored pile for jacking construction. It is characterized in that: the U-shaped groove of the approach road and the prefabricated jacking frame are constructed in parallel construction procedures, and the U-shaped groove 3 of the approach road adjacent to the jacking frame 1 is used as the back of the jacking construction, which is obtained through theoretical calculation The required number of sections of the U-shaped groove 3 of the approach, and fill the U-shaped groove 3 of the approach with rubble or earthwork as a counterweight to provide the purpose of jacking reaction force. In order to prevent the U-shaped groove 3 of the approach ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com