A concrete crack-resistant construction method for the main structure of an open-cut and cast-in-place tunnel

A technology of the main structure and construction method, which is applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of shrinkage cracking of concrete that have not been completely solved, achieve the suppression of penetrating shrinkage cracks, improve the quality of engineering construction, and solve the problem of Effects of Leakage Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The first is the performance requirements of crack-resistant concrete.

[0043]

[0047] The performance design of the above-mentioned three types of crack-resistant concrete is shown in Table 2 below.

[0049]

[0051] Then there are the requirements for the entry temperature of crack-resistant concrete.

[0066] The above-mentioned anti-cracking construction method of the present invention will be described below through specific construction cases.

Embodiment 1

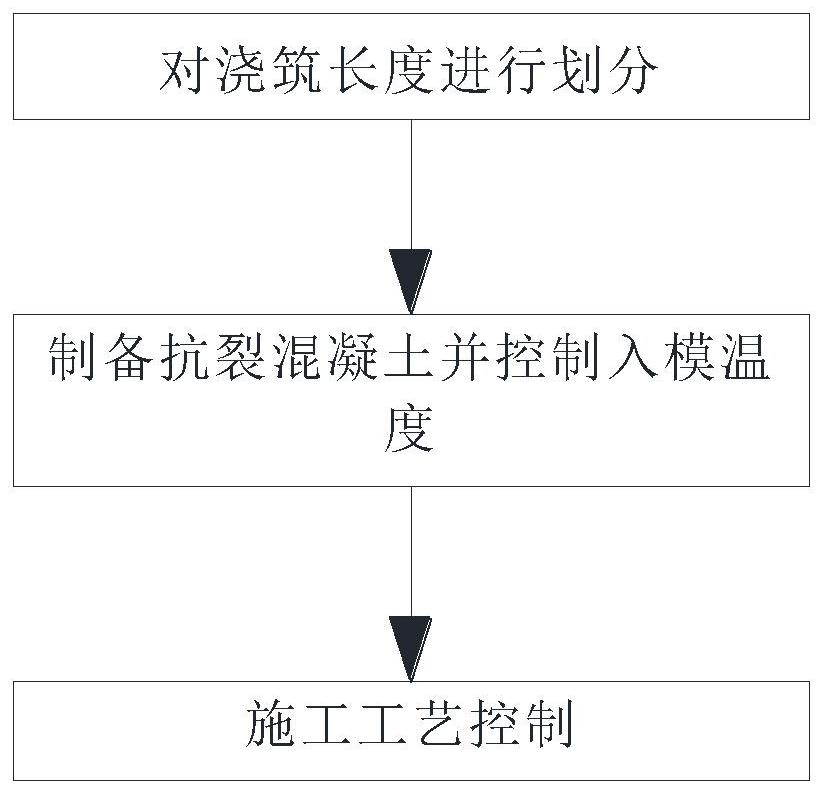

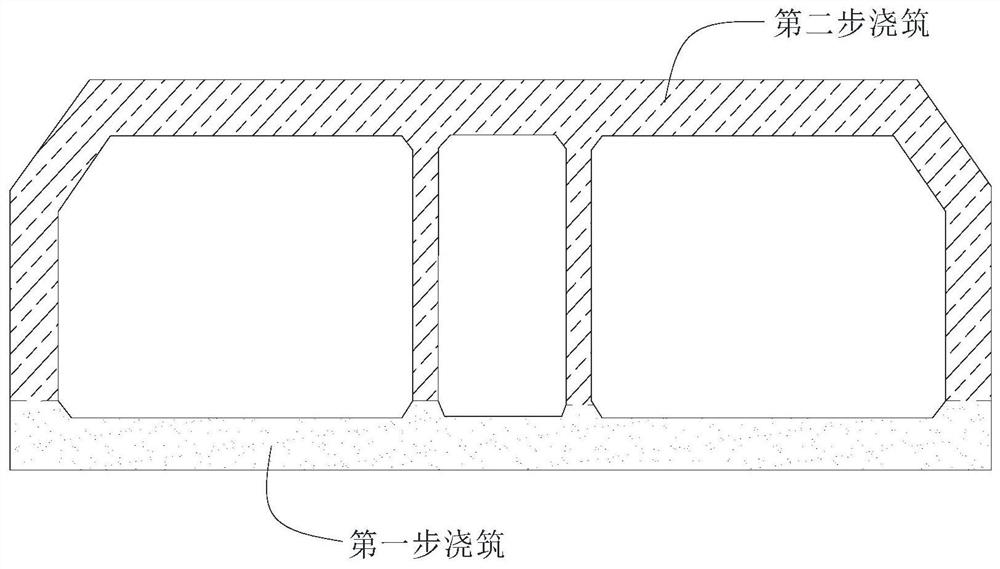

[0069] First, the pouring length is divided.

[0072] Then, the crack-resistant concrete is prepared and the temperature of the mold is controlled.

[0074] Specifically, one is the performance requirements of crack-resistant concrete.

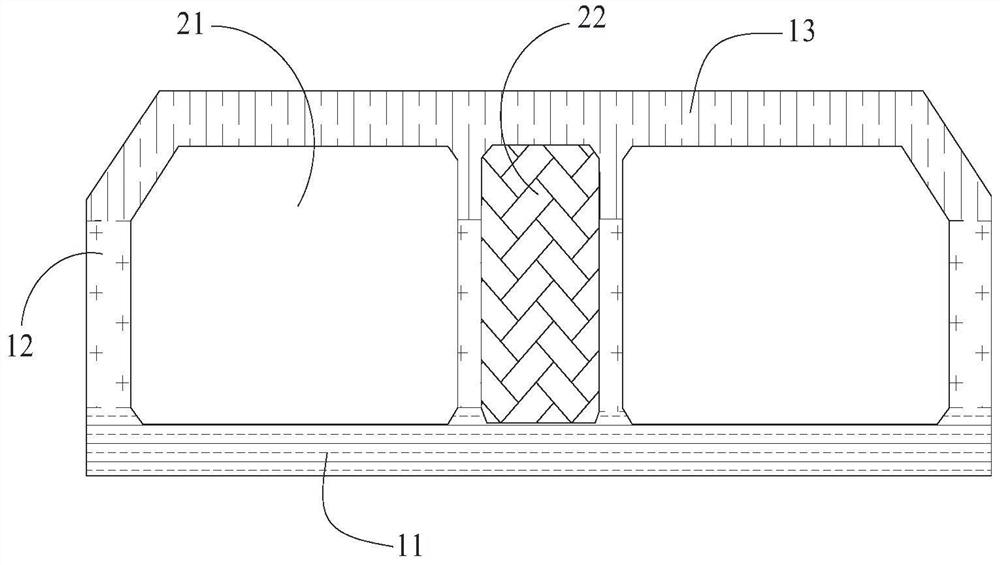

[0076] According to the consumption shown in the following table 3, the floor concrete, the side wall concrete and the roof concrete are formed by mixing respectively.

[0079]

[0082]

[0083] The second is the requirement for the temperature control of the mold entry of the above-mentioned three types of crack-resistant concrete.

[0087] Finally, the construction technology is controlled from the two aspects of temperature parameter control after the pouring age difference and the anti-cracking concrete pouring.

[0092]

Embodiment 2

[0097] First, the pouring length is divided. This embodiment only involves the pouring project of the tunnel side wall, which is divided into single

[0098] Then, the sidewall concrete was prepared.

[0100] Specifically, one is the performance requirements of the side wall concrete.

[0102] According to the consumption shown in the following table 6, the side wall concrete is formed by mixing respectively.

[0104] Unit: kg / m

[0105]

[0106] The performance of the aforementioned sidewall concrete was tested, and the results are shown in Table 7.

[0108]

[0109] The second is the requirement to control the mold temperature of the above-mentioned sidewall concrete.

[0110] In the specific construction of this embodiment, the construction period from March to April is involved. Average daily air during construction

[0111] Finally, control the construction process.

[0113] The inventor evaluates according to Ruan Zhu Deng Zi No. 1470077 "Analysis Software for Early Crack R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com