A method for improving the quality of Ganmaoling granule intermediate

A technology for Ganmaoling and intermediates, applied in the field of production of traditional Chinese medicine extracts, can solve the problems of easy loss of active ingredients, high concentration temperature, long concentration time, etc., to improve the quality of Ganmaoling granules intermediates, clear control indicators, and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of Ganmaoling traditional Chinese medicine extract: according to the prescription of Ganmaoling, weigh 982g of Sanchaku, 492g of wild chrysanthemum, 654g of calendula silver plate, 1472g of Gangmei, a total of 3600g, add 25000g of water as a solvent, heat to a slight boil, and decoct 3 times, 2 hours each time, combine the extracts three times, filter, take samples and determine the content of mongolin in them, and the extracts are used for concentration experiments.

Embodiment 2

[0024] Measure 3000 mL of the extract prepared in Example 1, put it in a rotary evaporator concentrator, evaporate and concentrate in a constant temperature water bath, heat to boil, concentrate and dehydrate. Different concentration temperatures and times are determined according to the experimental design. The set concentration temperatures are 70° C., 85° C. and 100° C. respectively, and the concentration time range is 1-10 hours, and the more preferred time range is 1-5 hours. When the extract is concentrated to the specified time, stop the rotary evaporator, transfer the concentrated solution to a 1000mL volumetric flask after cooling down on the rotary evaporator, and distill it to volume for later use.

[0025] The concentration temperature is determined by adjusting the vacuum degree of the system and the temperature of the heating water bath. The corresponding vacuum degree of 70°C is -90±5KPa, and the corresponding vacuum degree of 85°C is -55±5KPa. Sampling and analy...

Embodiment 3

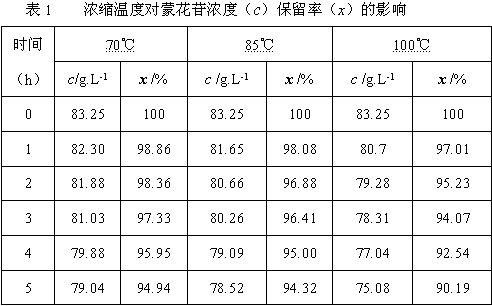

[0030] As in the evaporation concentration method in Example 2, three temperatures were set for fine-tuning concentration experiments, namely 70°C, 85°C and 100°C, and the concentrate was returned to the system to maintain material balance. The heating time of the material was extended to more than 5 hours, during which the concentrated solution was sampled and analyzed every hour to investigate the retention rate of mongoside. Three experiments were performed in parallel for each group.

[0031] The experimental results are listed in Table 1.

[0032]

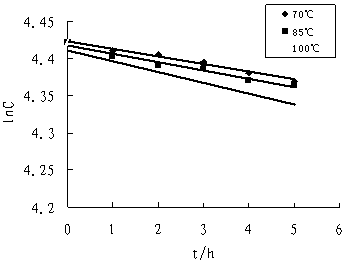

[0033] In order to determine the reaction order of thermal degradation of mongoside, the ln c plotted against time t, see appendix figure 1 .

[0034] attached figure 1 It was shown that the thermal degradation process of mongoside conformed to the typical first-order chemical reaction characteristics, that is, the concentration of mongoside changed with time as an exponential function. Where k is the reaction rate con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com