Open-cut cast-in-place tunnel main body structure concrete anti-crack construction method

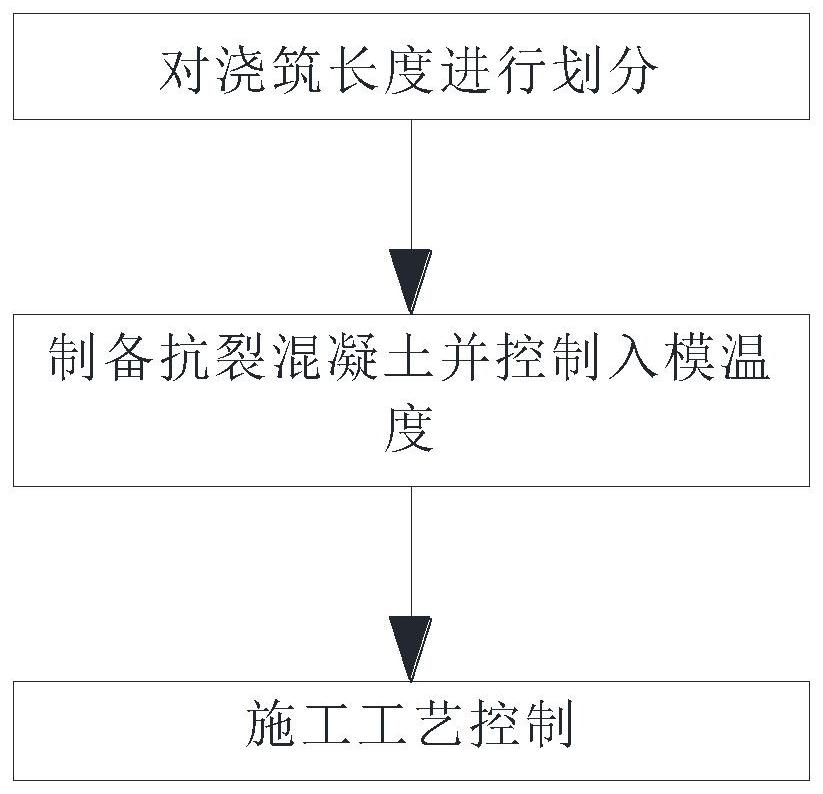

A technology for the main structure and construction method, which is applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of shrinkage and cracking of concrete that have not been completely solved, and achieve the purpose of suppressing penetrating shrinkage cracks, solving leakage problems, and improving construction efficiency. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] This step includes the limitation of the preparation material and performance of the anti-cracking concrete, and the control of its mold temperature.

[0039] The first is the performance requirements of crack-resistant concrete.

[0040] Specifically, considering that the performance requirements of the above-mentioned floor area, side wall area and roof area are not the same for crack-resistant concrete, the preparation of crack-resistant concrete involved in the present invention is divided into three types: floor concrete, side wall concrete and roof concrete. Refer to Table 1 below for the composition ratio design of the three types of crack-resistant concrete.

[0041] Table 1 Composition ratio of three types of crack-resistant concrete

[0042] Unit: kg / m 3

[0043]

[0044] As a choice of raw materials, the performance of cement should meet the requirements of "General Portland Cement" GB 175 and the requirements of CCES01 in "Guidelines for Durability Des...

Embodiment 1

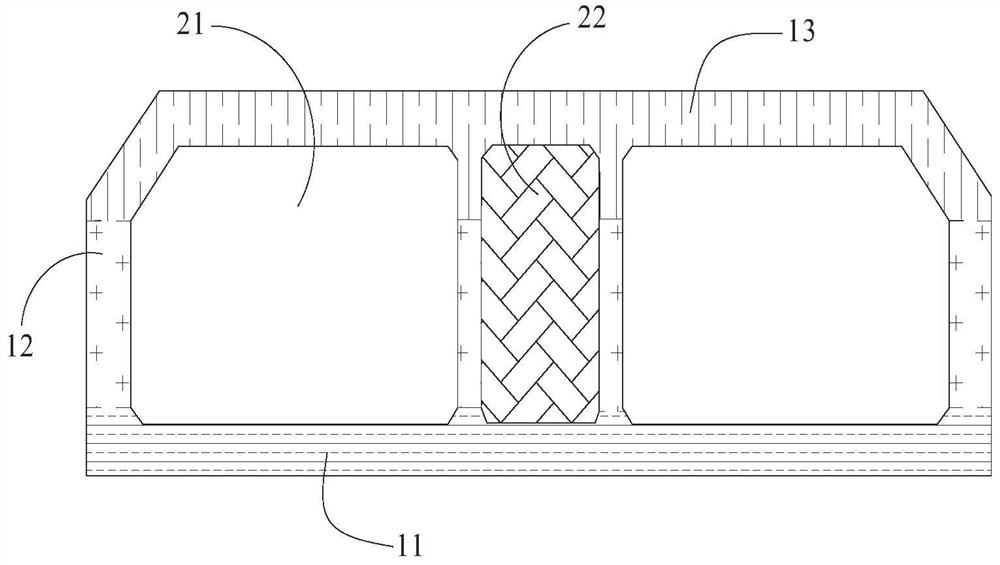

[0068] The anti-crack construction method described in the present invention is applied to the main structure of a certain expressway lake bottom tunnel, which has the following features: figure 2 The two-hole-one-pipe gallery structure shown is constructed using the cofferdam open-cut method. The thickness of the main structure of the buried section in the lake is 1.3m to 1.5m. The design grade of the crack-resistant concrete is C40P8. Very demanding.

[0069] First, divide the pour length.

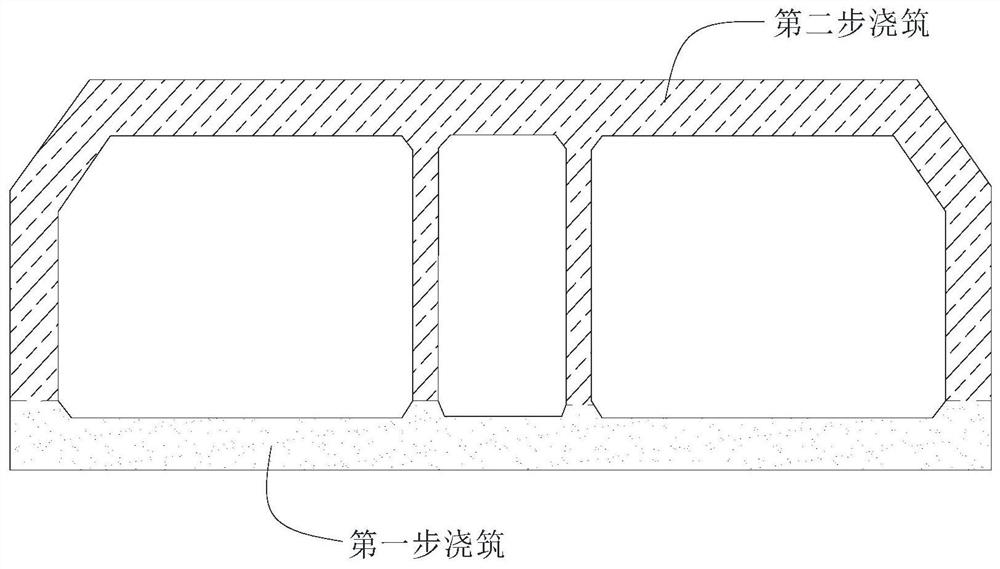

[0070] Specific reference figure 2 , it can be seen from the schematic diagram of the main structure of the cut-and-cast-in-place tunnel perpendicular to the tunnel length direction that the main structure of the tunnel is divided into successively connected floor areas, side wall areas, roof areas and side wall areas; The bottom plate area is used for subsequent pouring of crack-resistant concrete to form the tunnel floor 11, the side wall area is used for subsequent pouring of crac...

Embodiment 2

[0096] The anti-cracking construction method described in the present invention is applied to the side wall structure of a section of municipal engineering lake bottom tunnel, the concrete design grade is C35P8, and the thickness of the side wall concrete structure is 1.8m.

[0097] First, divide the pour length. In this embodiment, only the pouring project of the tunnel side wall is involved, and the single pouring length is divided into 20 m until the estimated construction length of the entire tunnel side wall is completed.

[0098] Next, prepare the side wall concrete.

[0099] This step includes the limitation of the preparation material and performance of the side wall concrete, as well as the control of its mold temperature.

[0100]Specifically, one is the performance requirements of the side wall concrete.

[0101] Concrete raw materials that meet the quality requirements include cement, fly ash, fine aggregate, coarse aggregate, water reducing agent, Concrete (te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com