Pull-type reinforcement mesh braiding machine and method for braiding reinforcement mesh by pull-type reinforcement mesh braiding machine

A mesh weaving machine and traction-type technology, which is applied in the field of steel mesh weaving machine, traction-type steel mesh weaving machine and its preparation of steel mesh, can solve the problems of difficult to meet the design requirements, insufficient thickness of protective layer, and increase of overlapping of steel mesh and other issues, to achieve the effect of saving resources and construction costs, improving the quality of project construction, and improving the quality of projects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

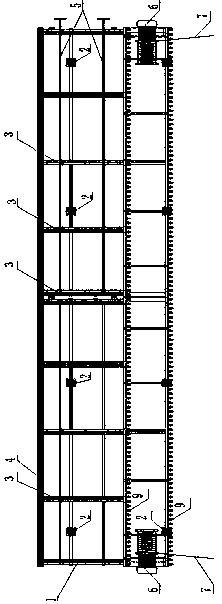

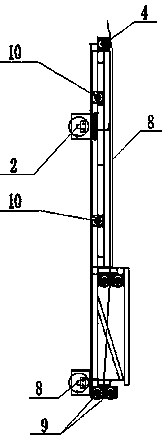

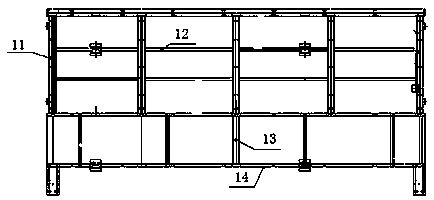

[0038] A traction type steel mesh weaving machine comprises a base frame 1, a plurality of comb plates 3, a comb lifting mechanism, a longitudinal rib positioning mechanism and a walking traction mechanism.

[0039] The underframe 1 is a frame structure composed of section steel welding and bolts and nuts. The underframe 1 includes a front frame and a rear frame. The front frame includes a guide roller fixing plate 14 and a front connecting channel steel 13. The guide roller fixing plate 14 is parallel to the front and rear. Setting, the front connecting channel steel 13 is arranged between the guide roller fixing plates 14, the comb tooth plate 3 and the comb tooth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com