Patents

Literature

67results about How to "Reduce the risk of stripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

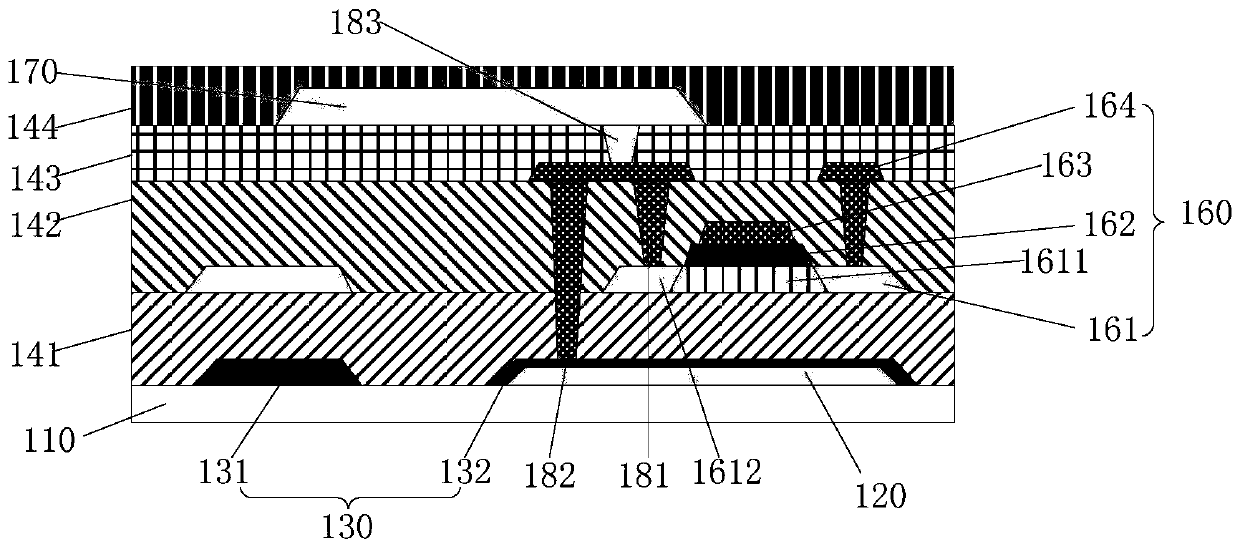

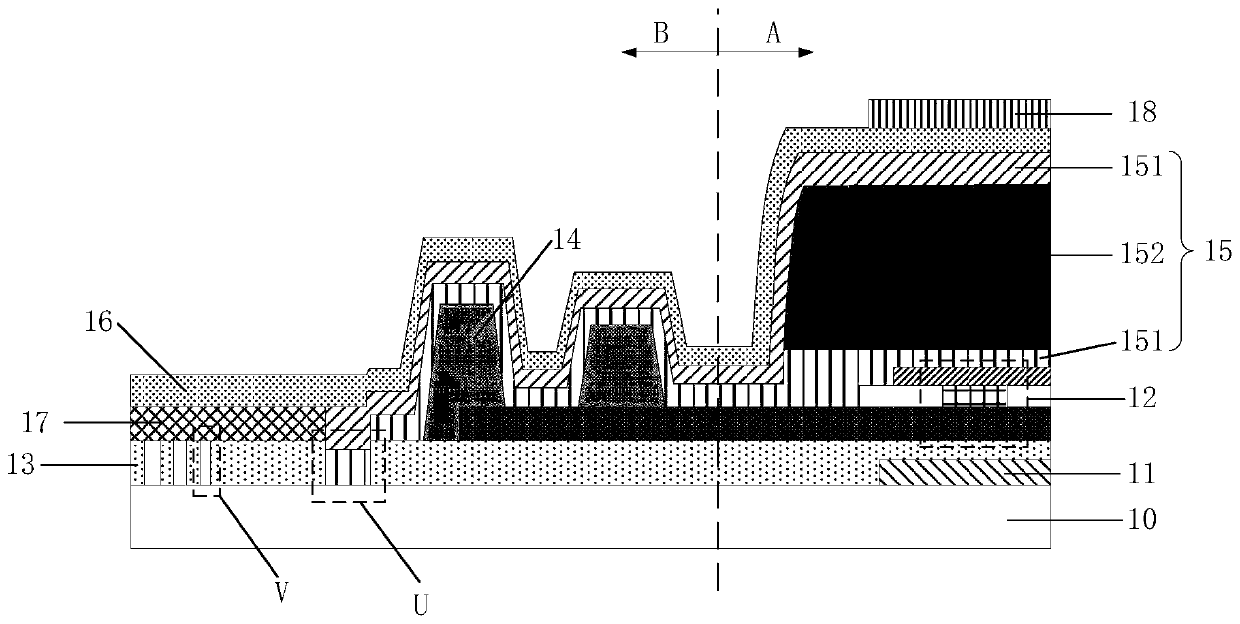

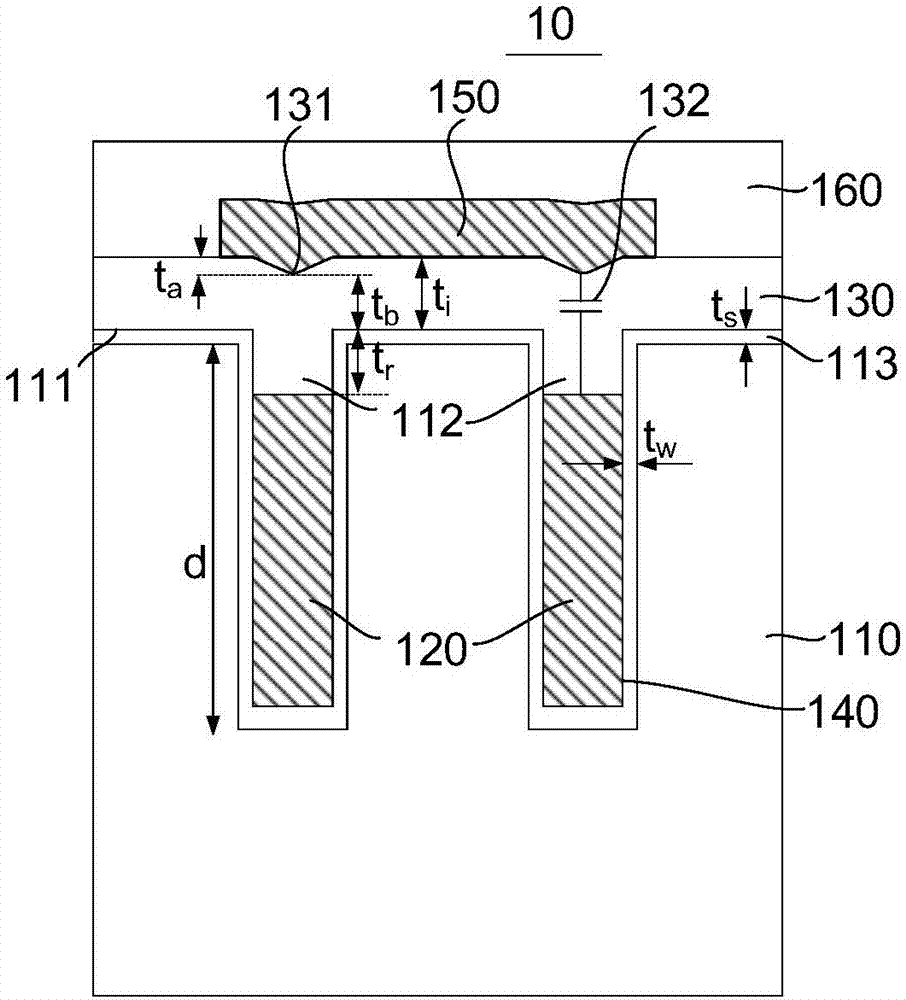

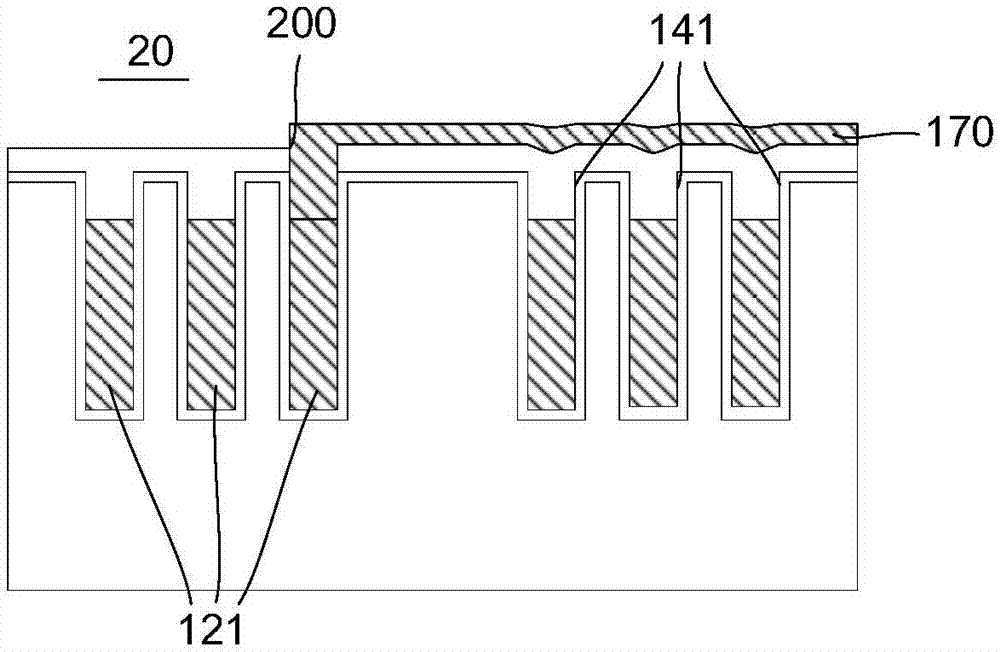

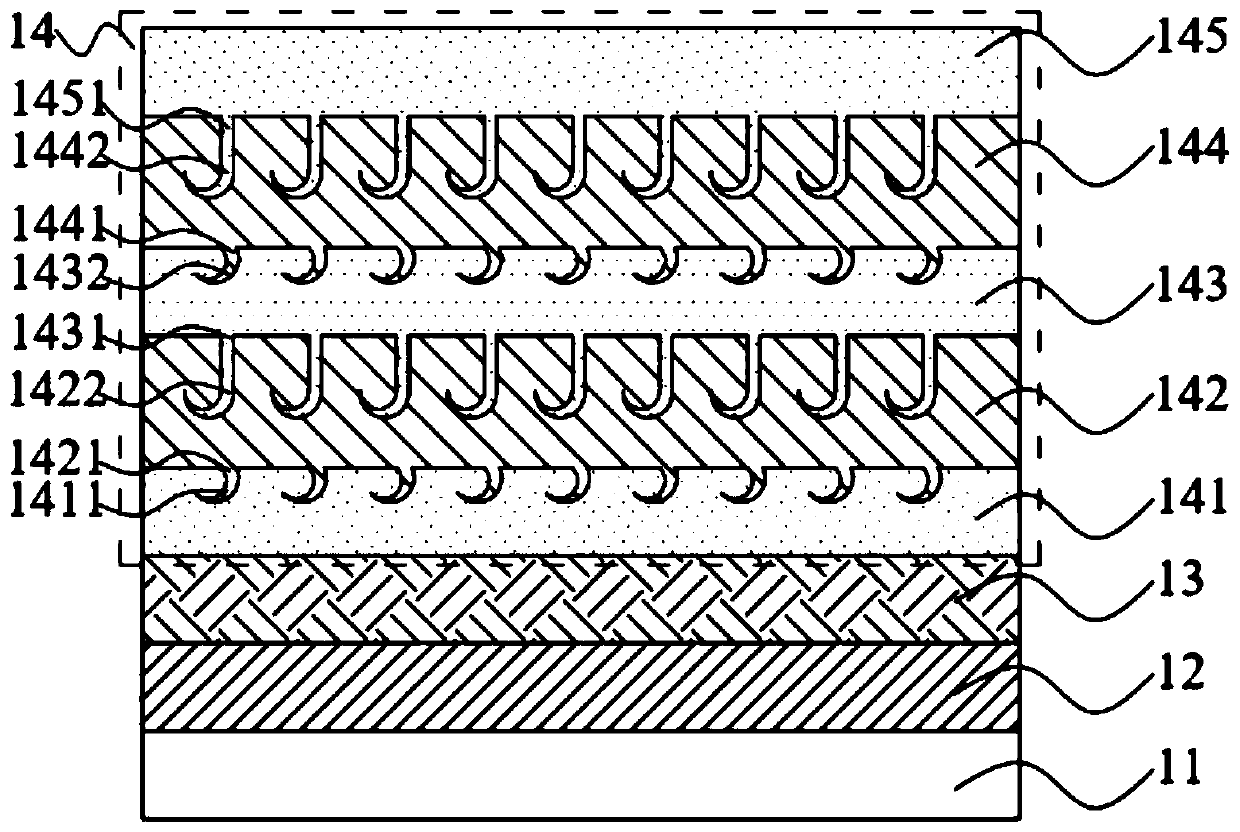

Organic light-emitting display panel, organic light-emitting display device, and method for preparing organic light-emitting display panel

ActiveCN107068715AImprove bindingPrevent extensionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceDisplay device

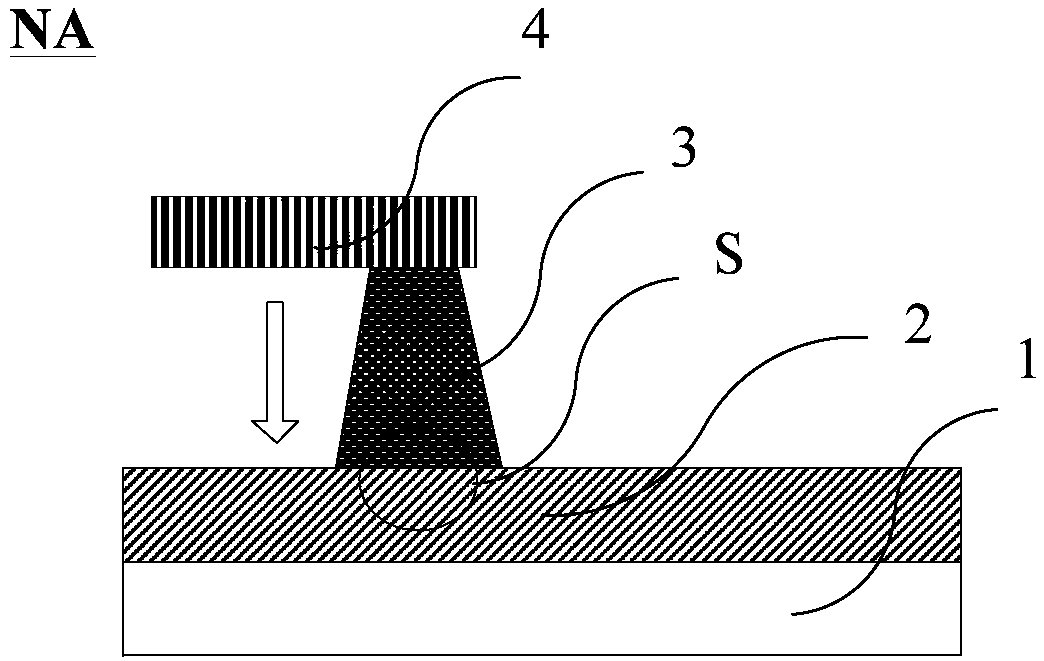

The invention provides an organic light-emitting display panel comprising a substrate including a display region and a non-display region, wherein the non-display region comprises: an insulating layer disposed on the same side of a array layer and provided with at least one groove exposing the substrate; a metal layer comprising a first portion covering the groove and in contact with the substrate, and a second portion covering the outer side of the groove and in contact with the insulating layer; at least one shielding wall disposed on a side, away from the substrate, of the second portion and in contact with the second portion, wherein the material of the shielding wall comprises an organic substance. The organic light-emitting display panel can increase the bonding ability of the shielding wall and the substrate, reduce a peeling risk when being in contact with a mask plate, and prevent the expansion of cracks, increases a side wrapping effect in order that little water enters to corrode an organic light emitting device from the side.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

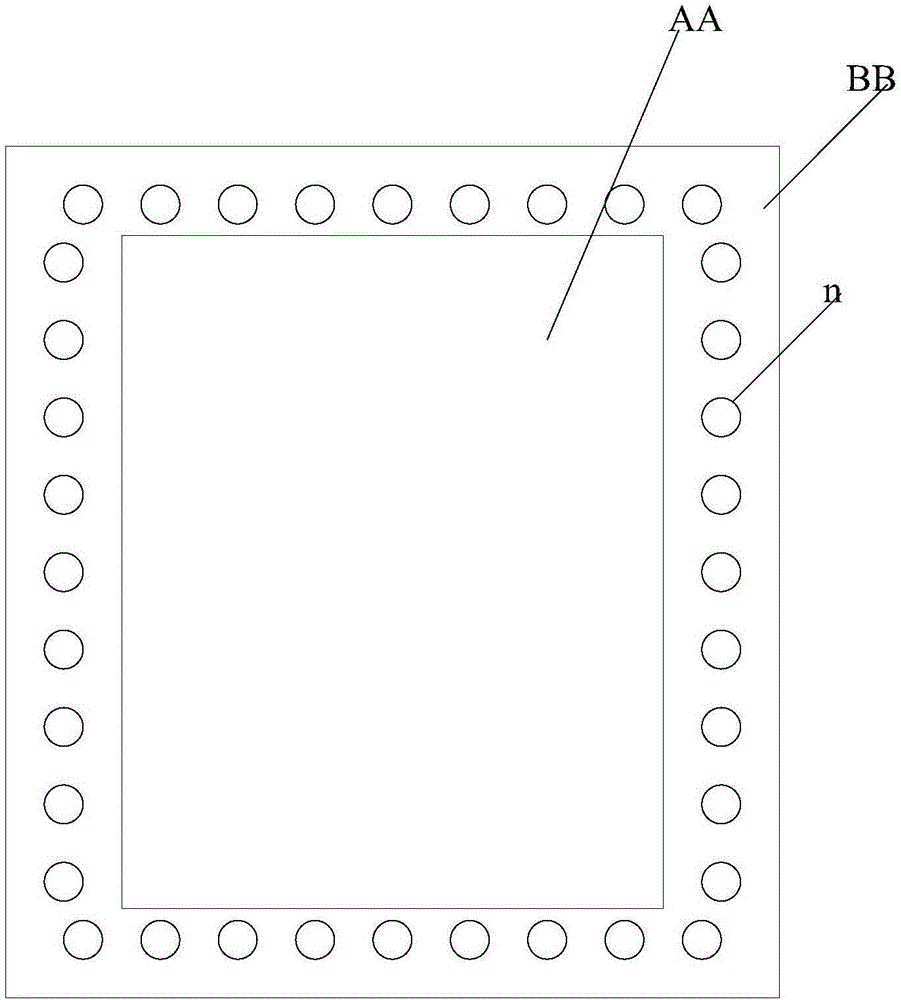

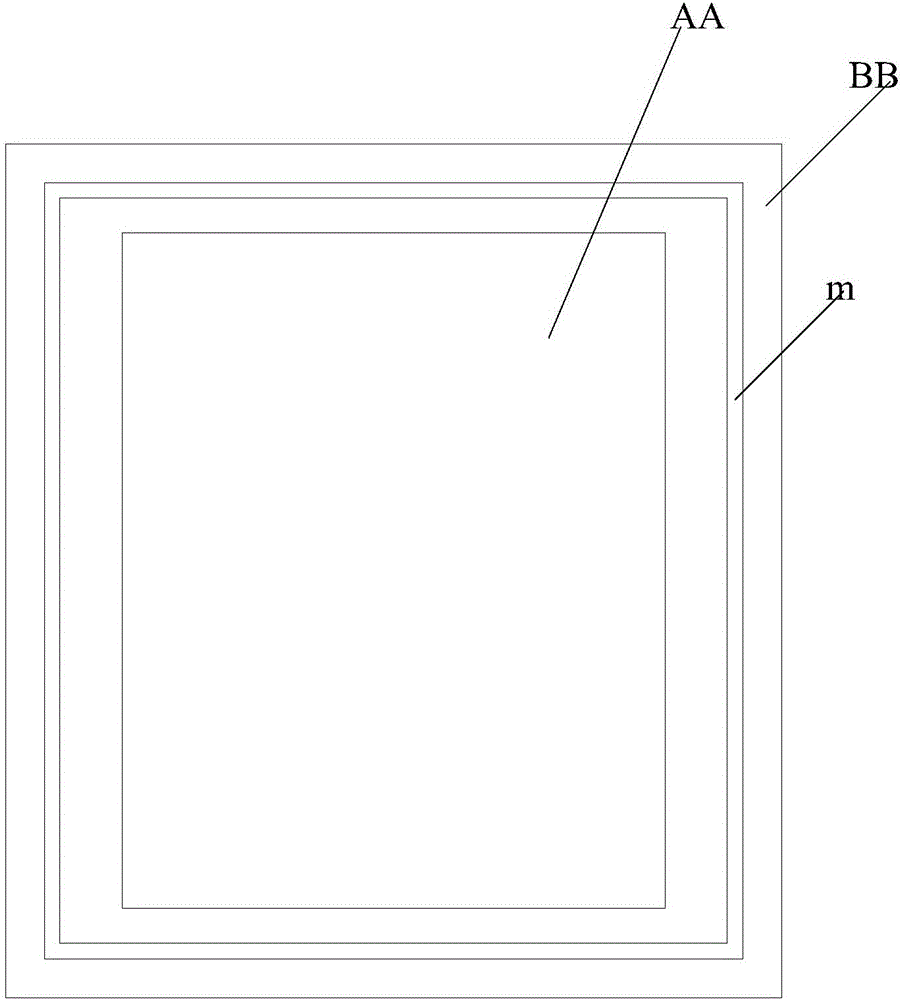

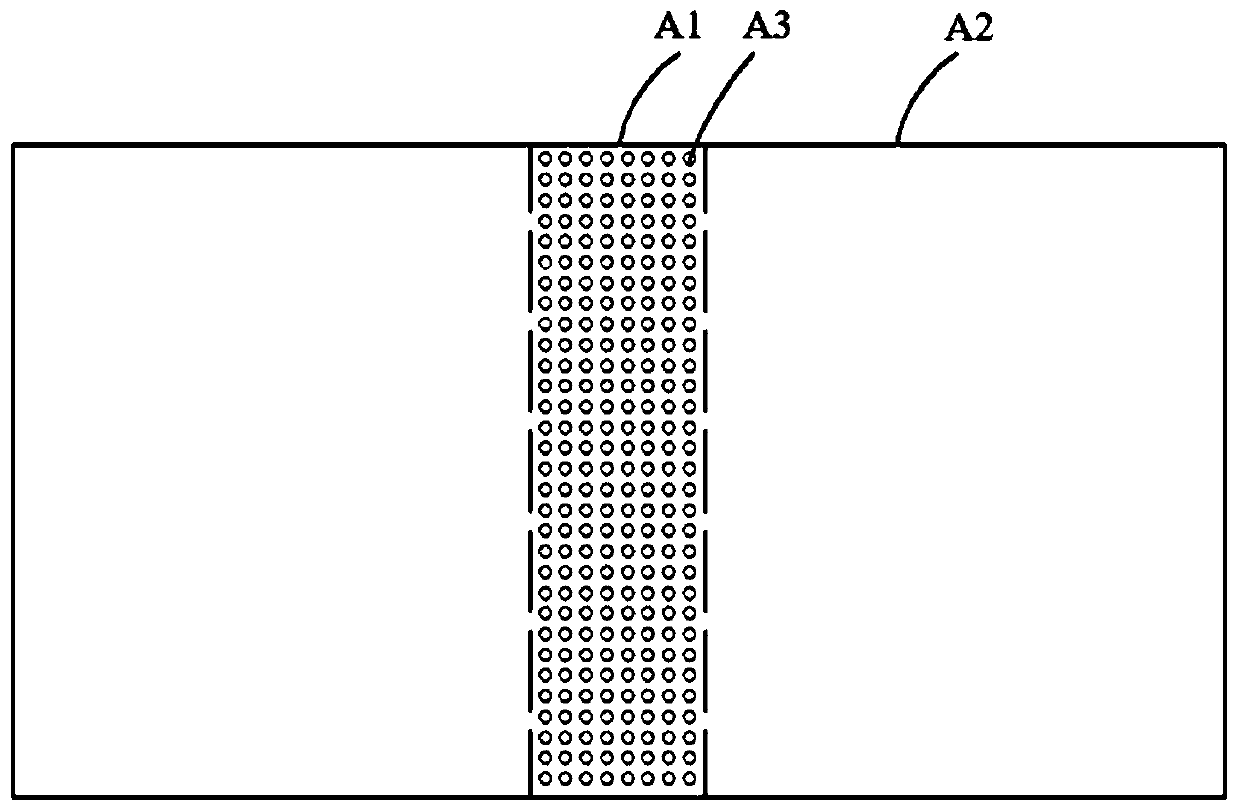

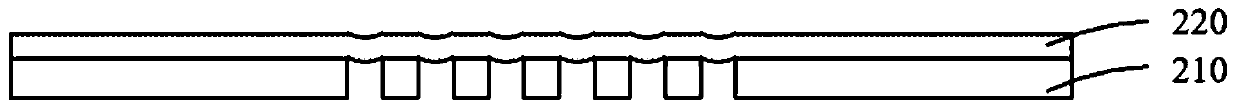

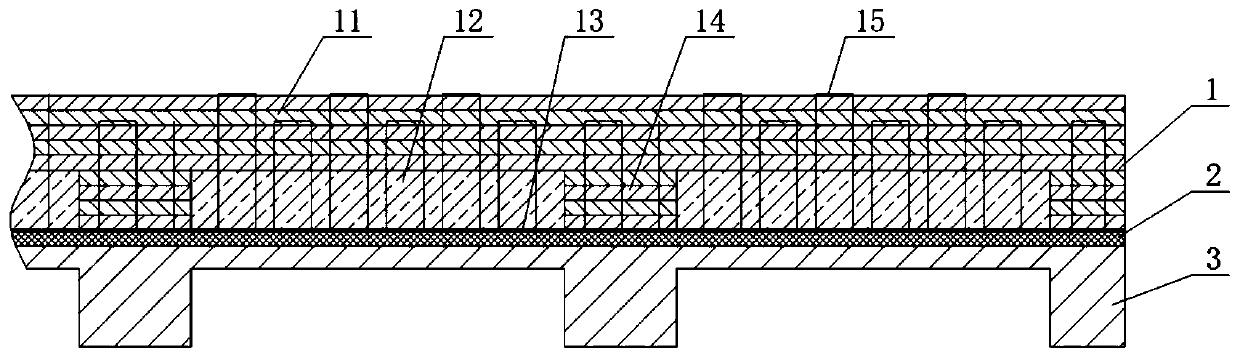

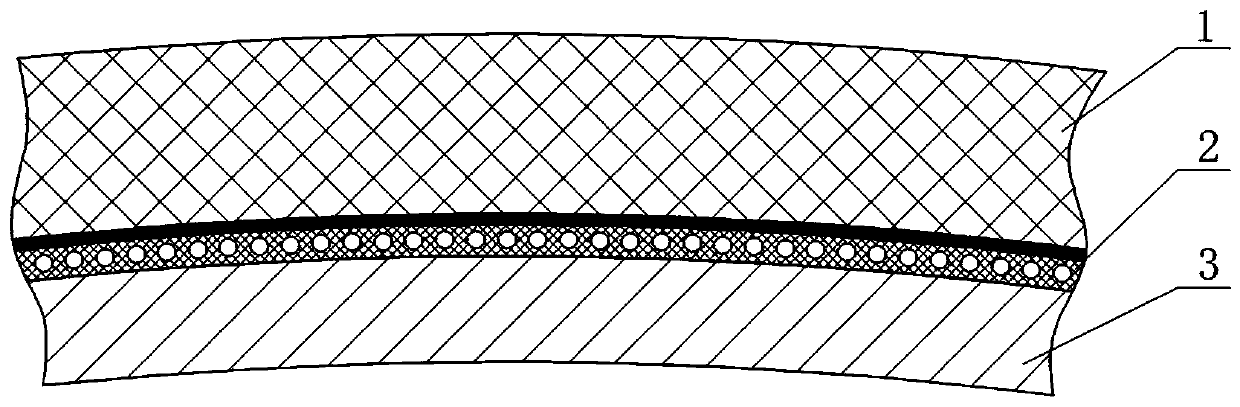

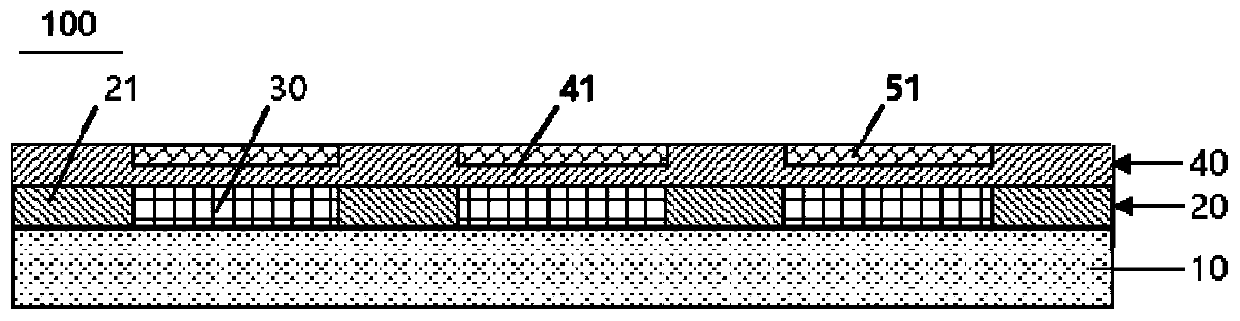

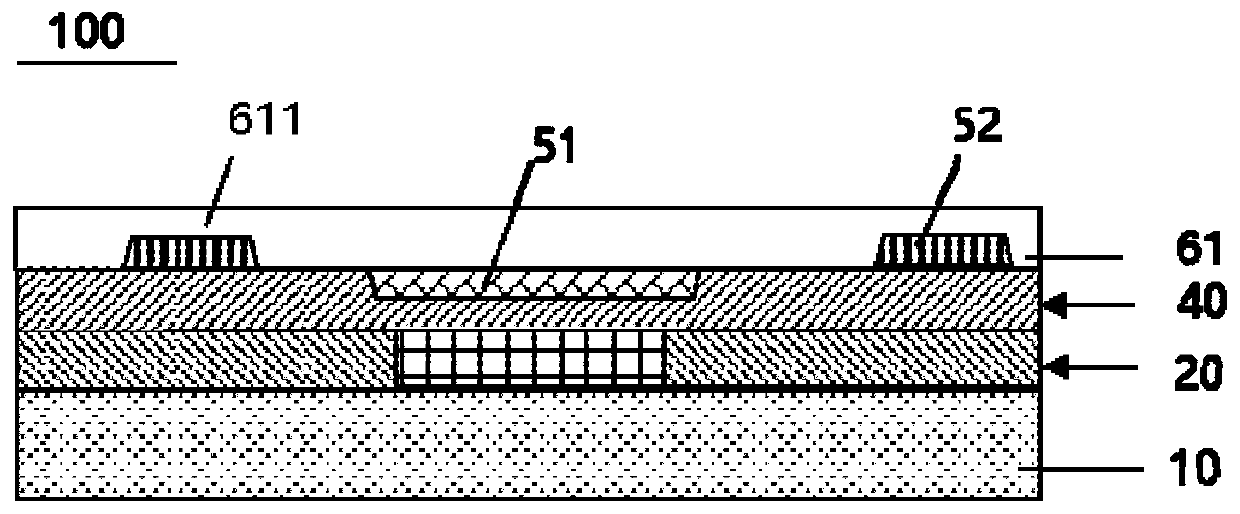

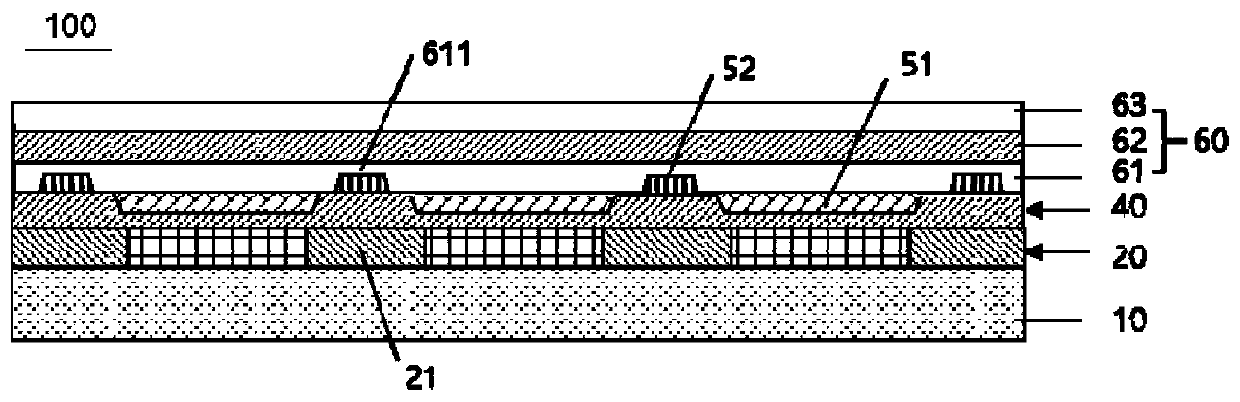

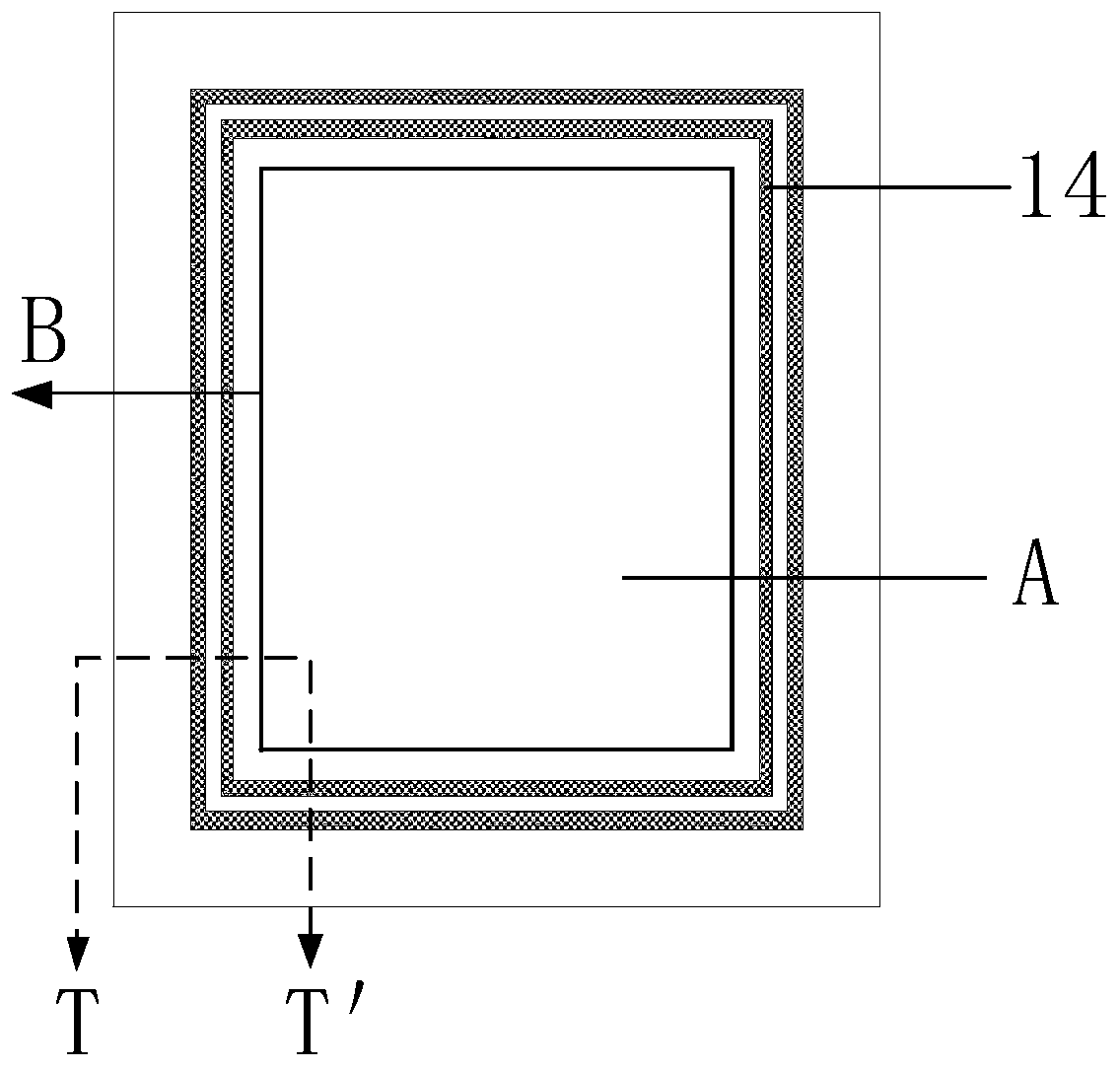

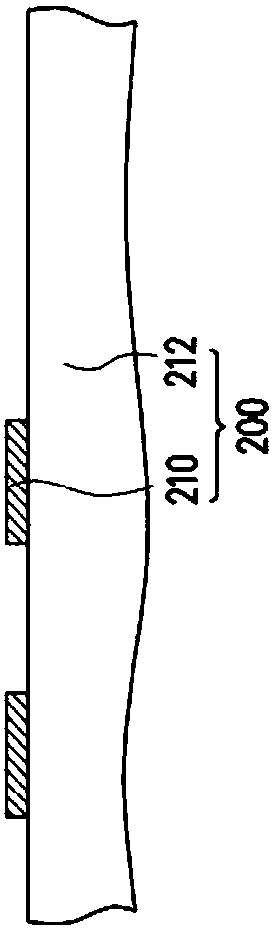

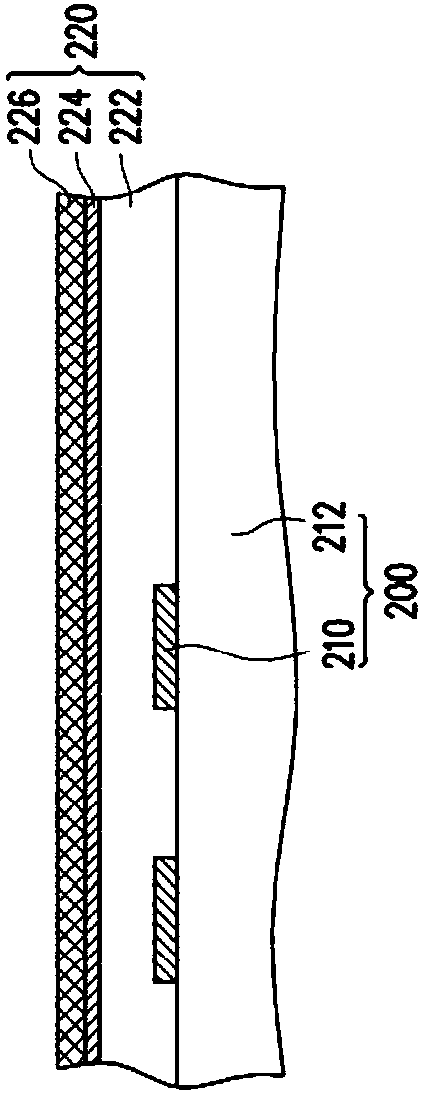

Flexible display panel and display device

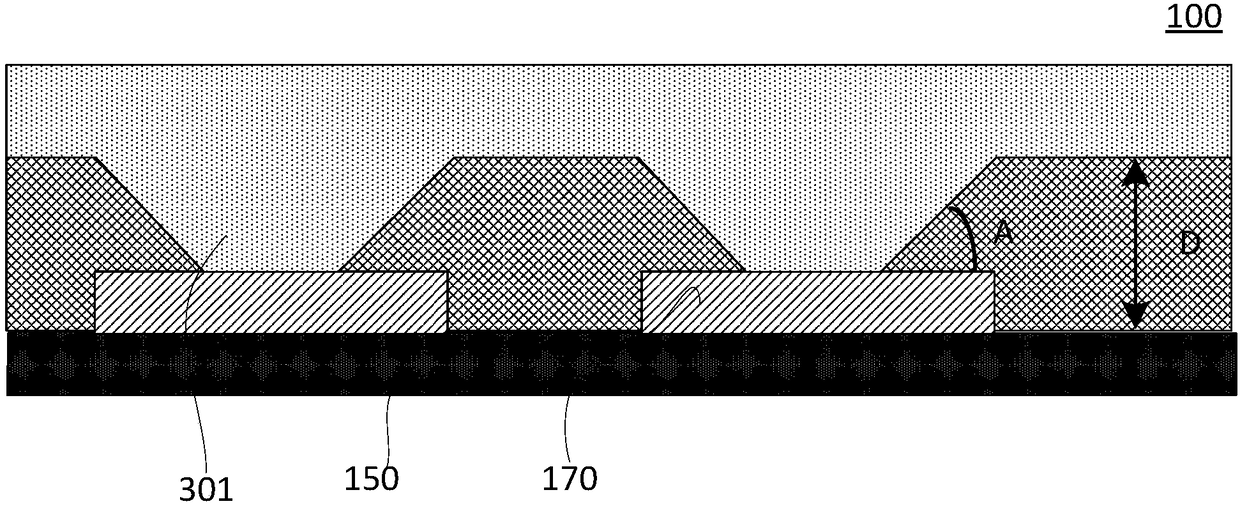

ActiveCN106684243AImprove adhesionIncrease contact areaSynthetic resin layered productsSolid-state devicesDisplay deviceEngineering

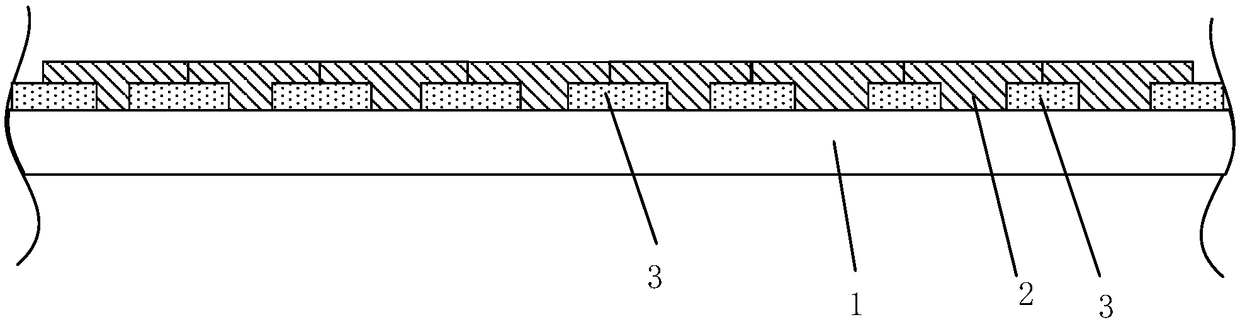

The invention discloses a flexible display panel and a display device. The flexible display panel comprises a first flexible substrate, a second flexible substrate and an inorganic layer located between the first flexible substrate and the second flexible substrate, wherein the inorganic layer is provided with a plurality of grooves and / or via holes; and the first flexible substrate is in contact with the second flexible substrate through the grooves and / or via holes. The inorganic layer is provided with the plurality of grooves and / or via holes, the first flexible substrate is in contact with the second flexible substrate through the grooves and / or via holes and the contact area of the second flexible substrate and the inorganic layer can be increased, so that the adhesive force of the first flexible substrate and the second flexible substrate is improved and the stripping risk of an organic layer and the inorganic layer of the flexible display panel in the bending deformation process is reduced.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

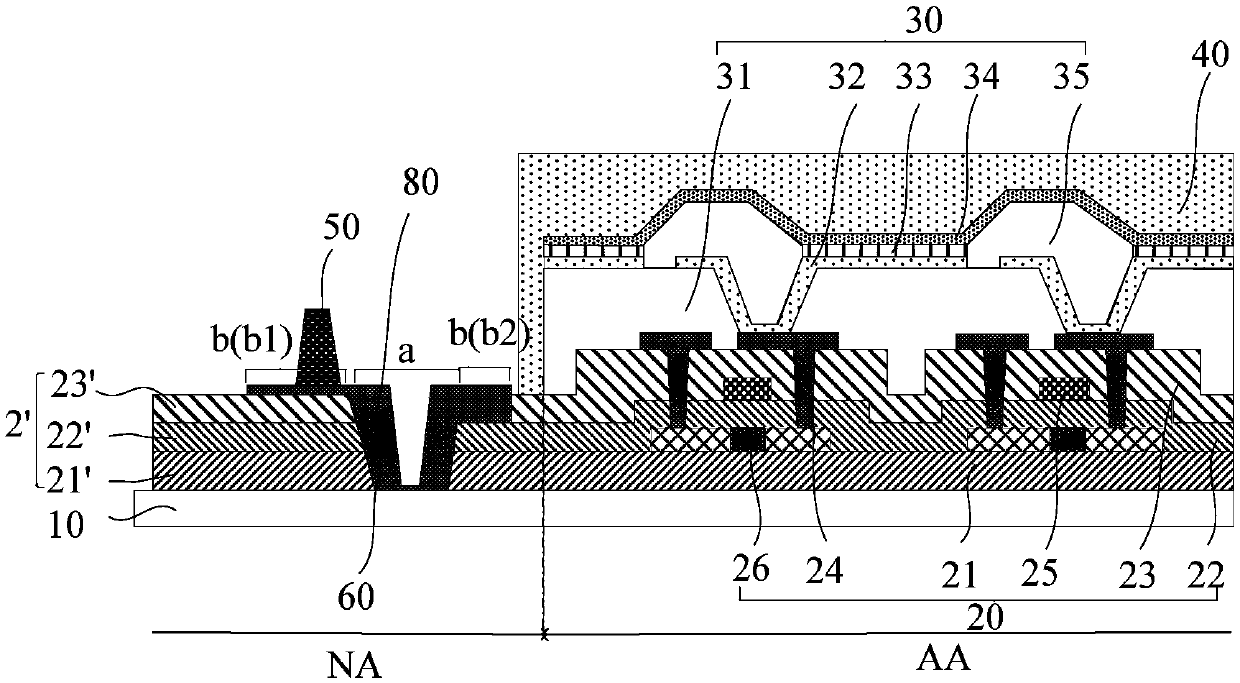

Display panel and display device

ActiveCN108550617AReduce the risk of strippingIncrease contact forceSolid-state devicesPhotovoltaic energy generationDisplay deviceContact layer

The embodiment of the invention provides a display panel and a display device. The display panel comprises a substrate base plate and a flexible packaging layer arranged on the substrate base plate, wherein the flexible packaging layer comprises a first inorganic layer; and a power signal line, a signal connection layer and a first electrode sequentially arranged on the substrate base plate, wherein the signal connection layer is connected with the power signal line and the first electrode. The display panel also comprises an inorganic contact layer arranged between the signal connection layerand the power signal line, wherein the signal connection layer comprises a plurality of via holes, and the first inorganic layer contacts the inorganic contact layer by the via holes. According to the display panel and the display device provided by the invention, through the arrangement of the inorganic contact layer and the via holes formed in the signal connection layer, the first inorganic layer used for packaging contacts the inorganic contact layer by the via holes, and thus the contact force between the first inorganic layer and the display panel is increased, the packaging effect is enhanced, and the risk that the first inorganic layer is peeled off during a flexible bending process is reduced.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

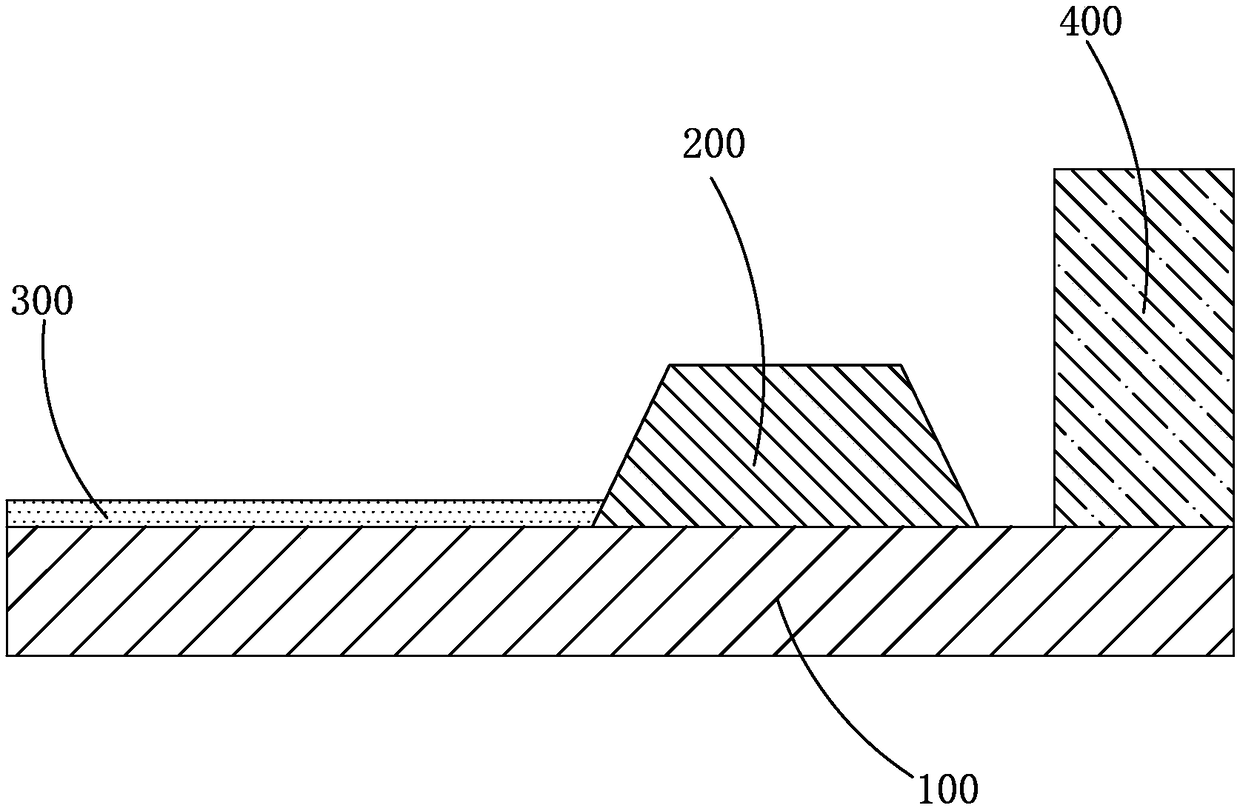

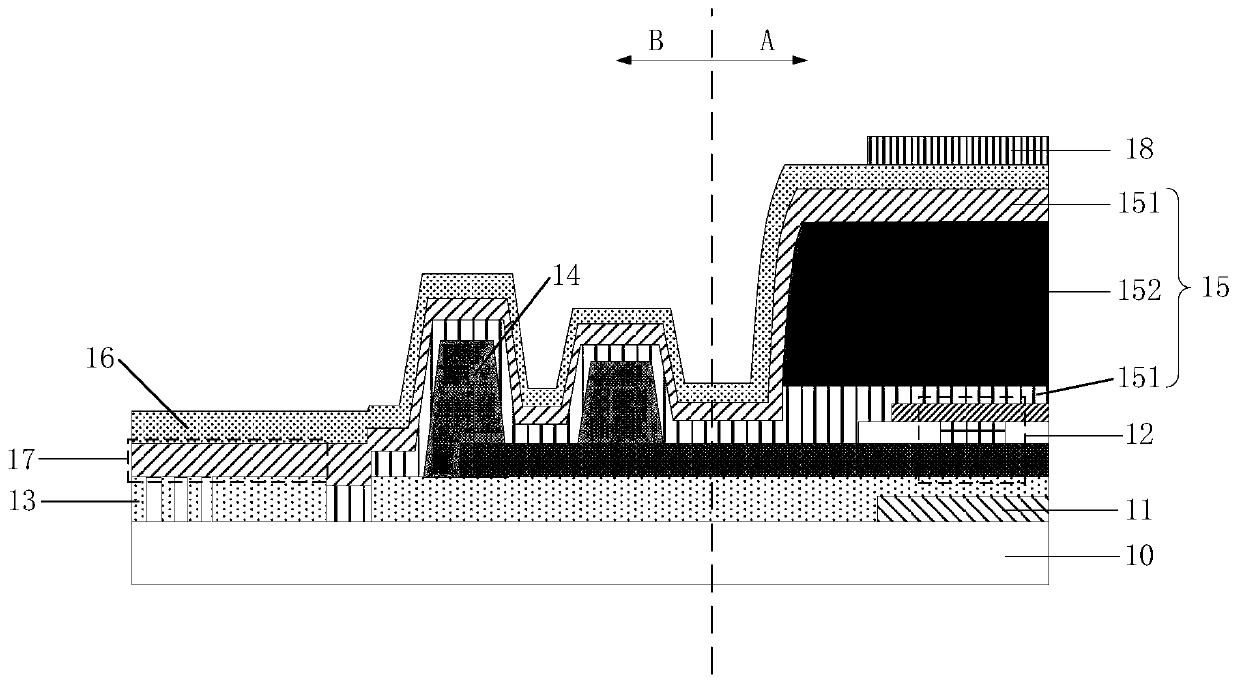

Liquid crystal display panel and manufacturing method thereof

InactiveCN109143689AReduce the risk of strippingSolve weak adhesionNon-linear opticsLiquid-crystal displayEngineering

The invention provides a liquid crystal display panel and a manufacturing method thereof. The liquid crystal display panel comprises a first substrate, a baffle wall, an alignment film and frame glue,wherein the baffle wall, the alignment film and the frame glue are arranged on the first substrate, the baffle wall is in an annular shape, the alignment film is arranged at an inner side of the baffle wall, the frame glue is arranged at an outer side of the baffle film, the baffle film comprises at least two layers of sub baffle walls which are sequentially arranged from bottom to top, each subbaffle wall is in an annular shape, in two adjacent layers of baffle walls, the projection of an inner side wall of the sub baffle wall at an upper layer is arranged between an inner side wall and anouter side wall of the sub baffle wall at a lower layer, so that the inner side wall of the baffle wall is in a step shape, the climbing resistance of a solution for forming the alignment film at theinner side wall of the baffle wall is greatly improved during preparation of the alignment film at the inner side of the baffle wall by a solution film formation mode, the alignment film is preventedfrom being expanded out of the baffle plate and overlapped with the frame glue, and the stripping risk of the frame glue is reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Flexible display module, preparation method thereof and flexible display device

The application discloses a flexible display module, a preparation method thereof and a flexible display device. The flexible display module comprises a metal sheet, a first adhesive layer, a back plate, a second adhesive layer, and a display panel. A plurality of through holes are formed in the metal sheet at least in a bending area; the first adhesive layer is arranged on the metal sheet and completely fills the holes in the metal sheet; the back plate is arranged on the first adhesive layer; the second adhesive layer is arranged on the back plate; and the display panel is arranged on the second adhesive layer. The lower part of the first adhesive layer is designed into the special shape which completely fills the holes in the metal sheet, so that the risk that the upper display panel wrinkles and the display module layer is stripped can be effectively reduced, and the reliability of the folding function of the display module is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

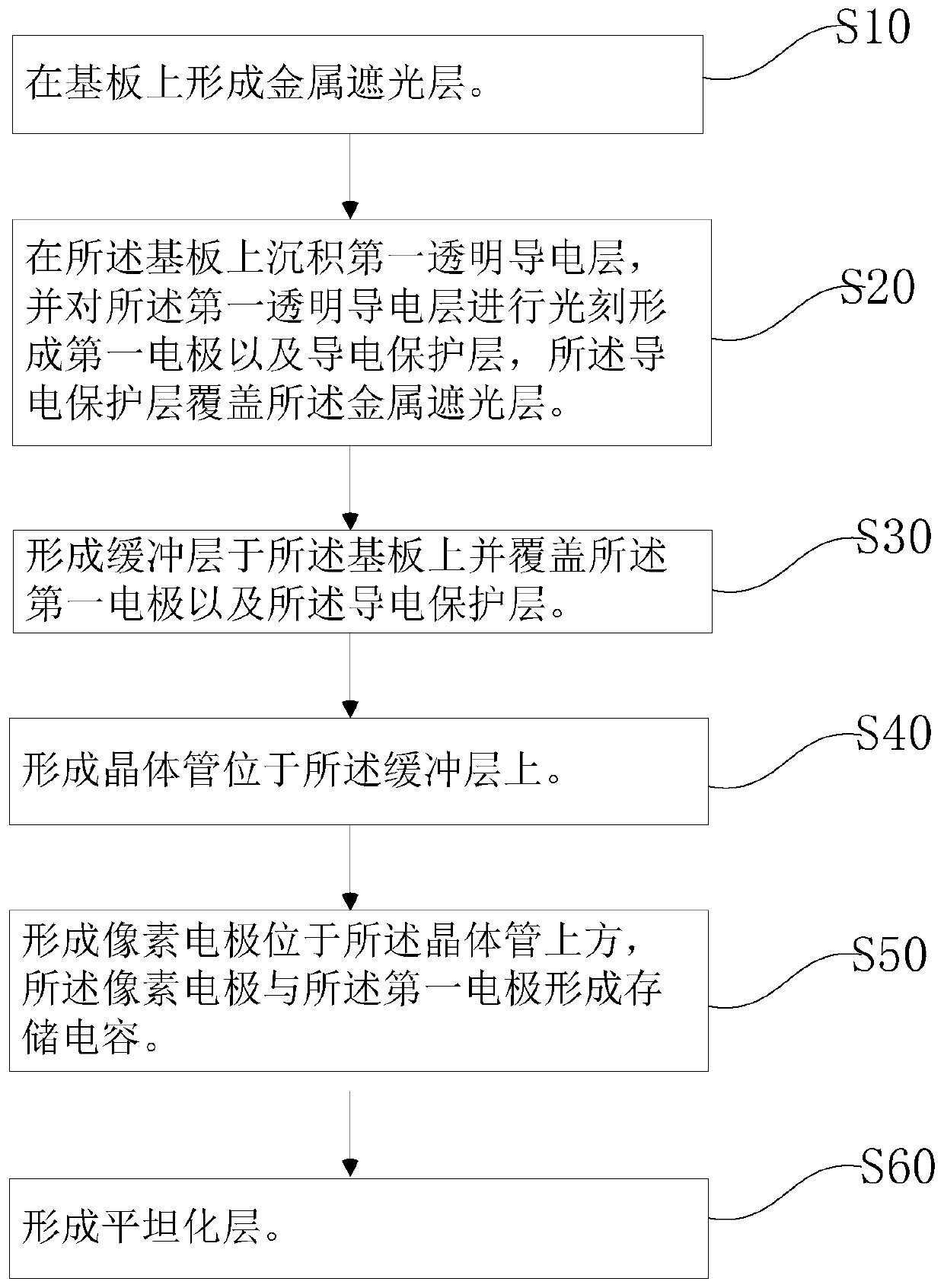

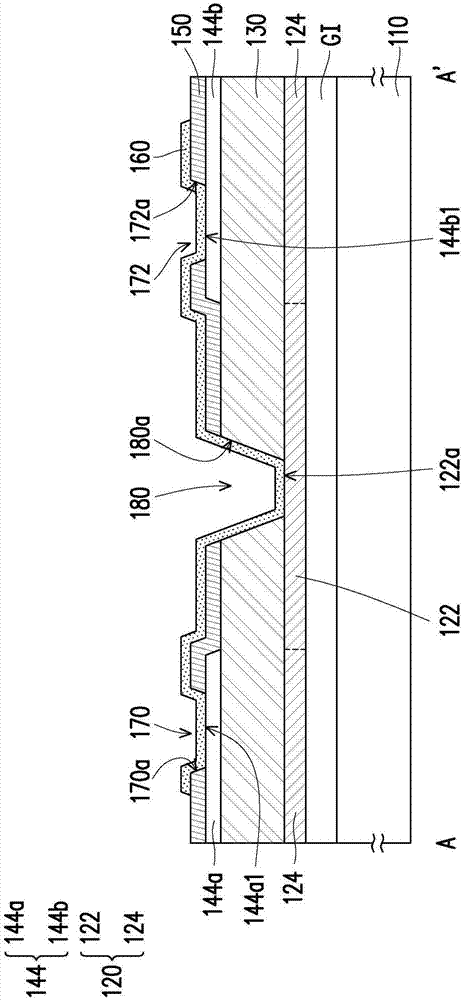

Array substrate and manufacturing method thereof

InactiveCN110518018APrevent oxidationPrevent proliferationSolid-state devicesSemiconductor/solid-state device manufacturingCopperProtection layer

An array substrate comprises a substrate body, a metal shading layer, a conductive protection layer, a buffer layer, a transistor and a pixel electrode. The conductive protection layer covers the metal shading layer. The buffer layer is located on the substrate and covers the conductive protective layer. The transistor is located on the buffer layer and connected with the conductive protective layer. The pixel electrode is connected with the transistor. The problem of copper oxidation of the metal oxide thin film transistor driving backboard is effectively solved, and the transparent conductive layer covers the surface of the shading layer copper to form protection for copper, thereby preventing copper oxidation, avoiding copper diffusion, reducing damage of etching to copper and reducingthe risk of copper stripping of the shading layer.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Heat preventing and insulating integrated thermal protection structure suitable for negative curvature shape

ActiveCN110524974AImprove resistance to damageSolve problems prone to separationSynthetic resin layered productsFuselage insulationAdhesiveNear space vehicle

The invention discloses a heat preventing and insulating integrated thermal protection structure suitable for a negative curvature shape, and belongs to the technical field of thermal protection of hypersonic-speed near space aircrafts. The thermal protection structure includes a force bearing shell and a thermal protection layer; the thermal protection layer includes a heat insulating layer and aheat preventing layer, the inner wall of the heat preventing layer is provided with grid-like heat-preventing layer reinforcement ribs, the heat insulating layer is arranged in the grids of the heat-preventing layer reinforcement ribs, and the surface of the heat insulating layer is provided with a heat insulating layer covering skin; the heat preventing layer, the heat insulating layer coveringskin, and the heat-preventing layer reinforcing ribs are sewed together with the heat insulating layer through a sewing line in a prepreg state, and the whole is subjected to high-temperature curing to form the heat preventing and insulating integrated structure; and an adhesive layer is located between the force bearing shell and the thermal protection layer, and the adhesive layer is an adhesivewith high-temperature resistance and heat matching performance. The thermal protection structure provided by the invention adopts the heat preventing and insulating integrated thermal protection layer, and the thermal protection layer is bonded to the force bearing shell by using the high-temperature-resistant adhesive, so that interface separation at the negative curvature part of the thermal protection structure of an aircraft can be avoided.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

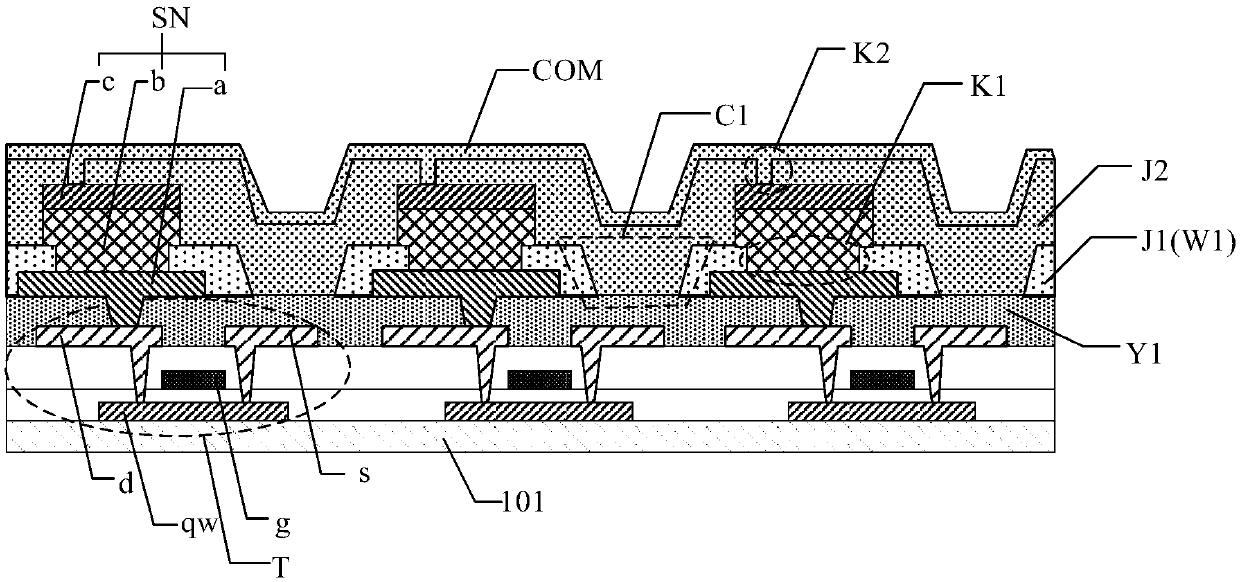

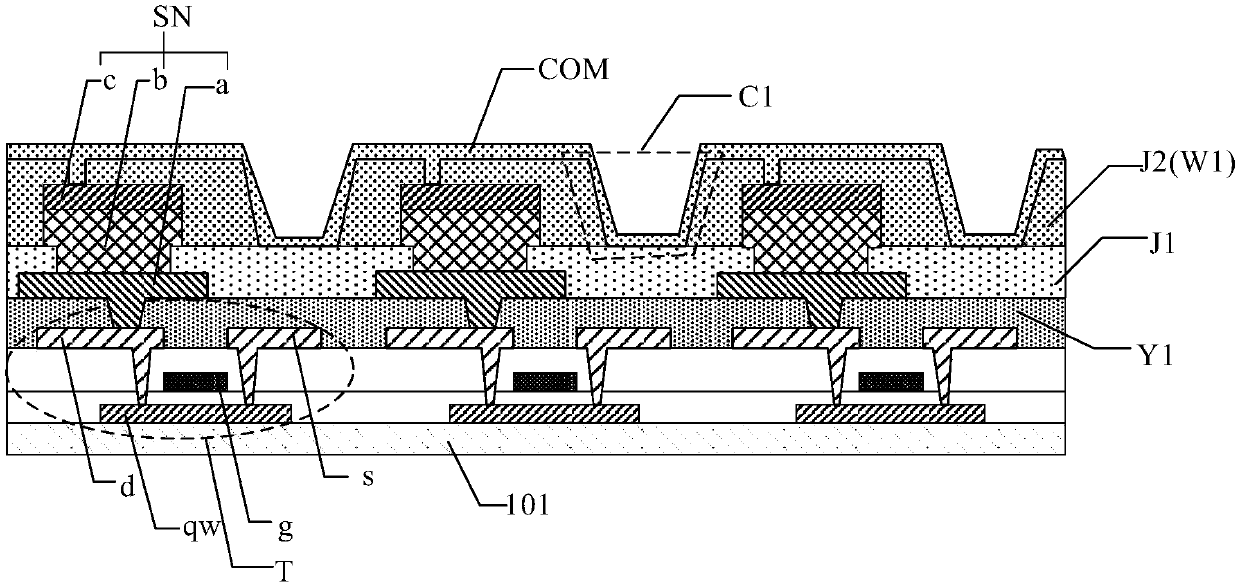

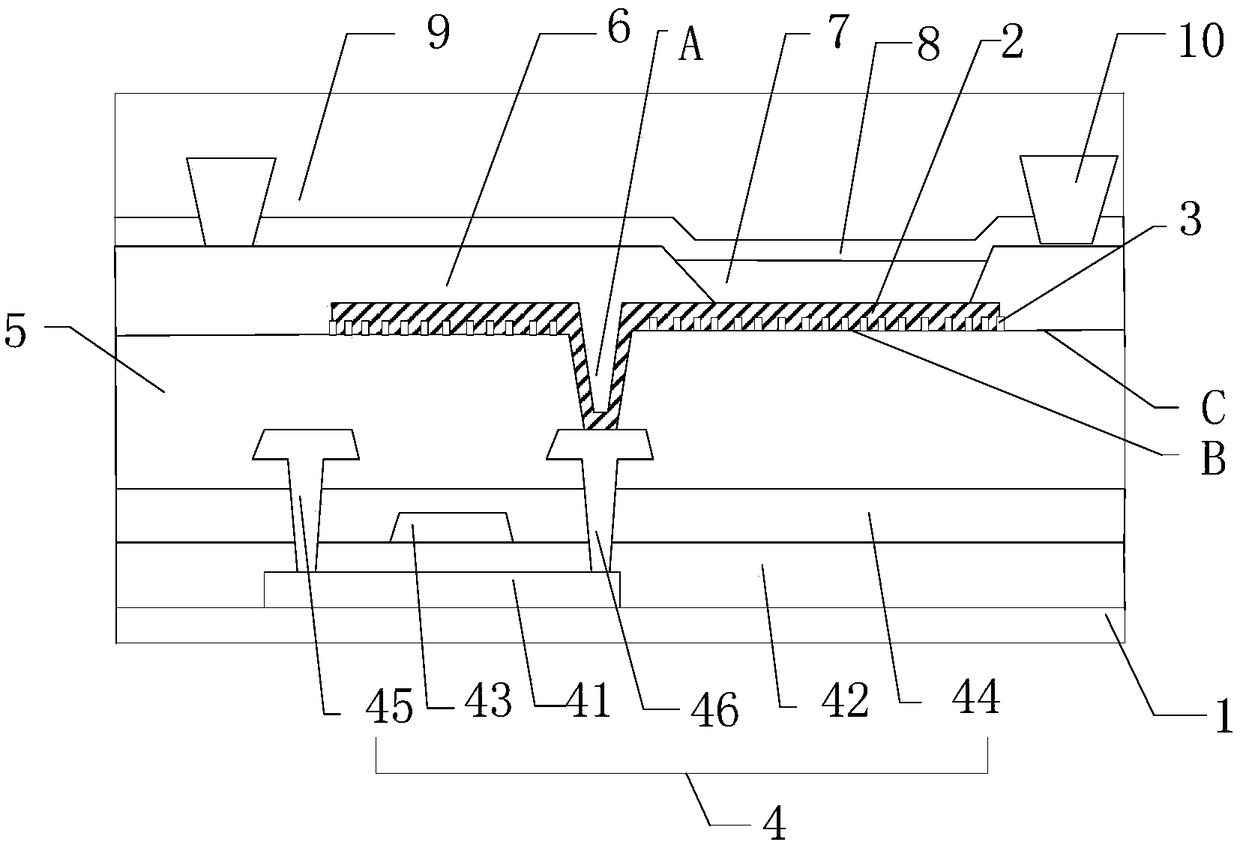

Light sensation module and display panel

ActiveCN109670475ADoes not affect protectionReduce stressSolid-state devicesPrint image acquisitionLight sensingEngineering

The invention discloses a light sensation module and a display panel. The light sensing module comprises a substrate; a plurality of light sensing unit switch tubes located on the substrate; a first organic flat layer which is positioned on one side, far away from the substrate, of the light sensing unit switch tube; a plurality of light sensing units which are positioned on one side, far away from the light sensing unit switch tube, of the first organic flat layer; a common electrode which is located on the side, away from the first organic flat layer, of the light sensing unit; a first inorganic layer which is located between the first organic flat layer and the common electrode, and is provided with a first groove, wherein the first groove is located between every two adjacent light sensing units. According to the present invention, the risk of film stripping of the first organic flat layer can be reduced, and the performance reliability of the light sensing module is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

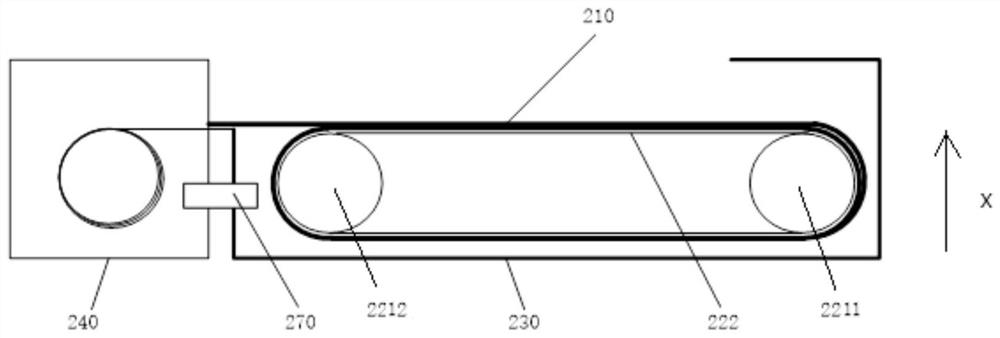

Display device

ActiveCN112466213AReduced number of curlsSmall amount of lateral slipIdentification meansDisplay deviceFlexible display

The invention provides a display device which comprises a rotating shaft assembly, the rotating shaft assembly comprises a plurality of display screen storage rotating shafts arranged at intervals anda winding supporting belt, and the winding supporting belt surrounds the display screen storage rotating shafts and makes contact with the display screen storage rotating shafts; the flexible displayscreen surrounds the rotating shaft assembly, the back face of the flexible display screen faces the rotating shaft assembly, and when the flexible display screen is completely wound, the flexible display screen is located on the surface of the side, back on to the rotating shaft assembly, of the winding supporting belt; the rotating shaft assembly is suitable for driving the flexible display screen to rotate around the center shafts of the multiple spaced display screen storage rotating shafts, so that the flexible display screen is rolled up or unfolded. Compared with single-shaft rolling,the lateral sliding amount of each film layer in the flexible display screen is smaller, stripping between the film layers is not likely to happen, and the possibility of screen body breakage can be reduced.

Owner:HEFEI VISIONOX TECH CO LTD

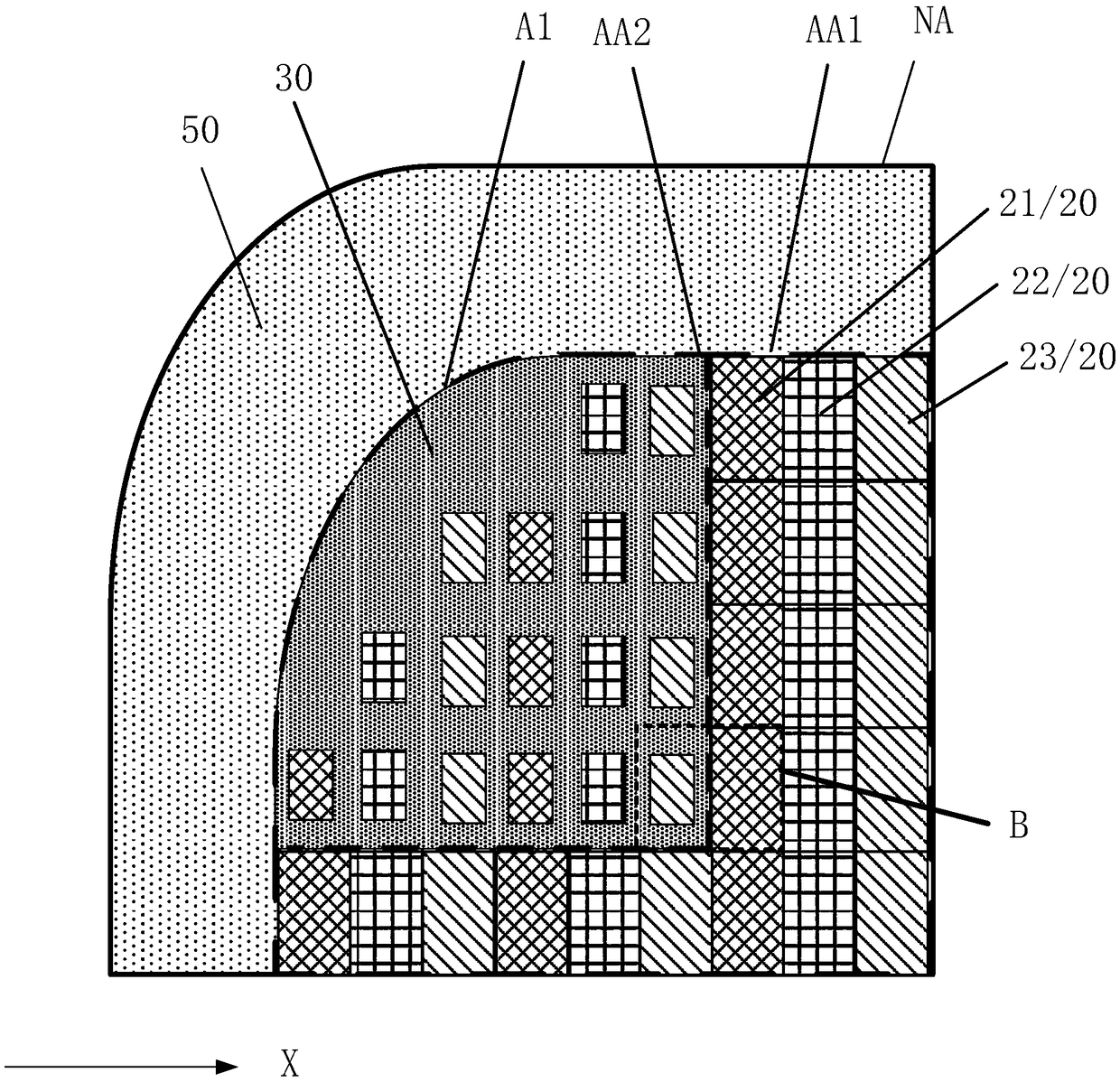

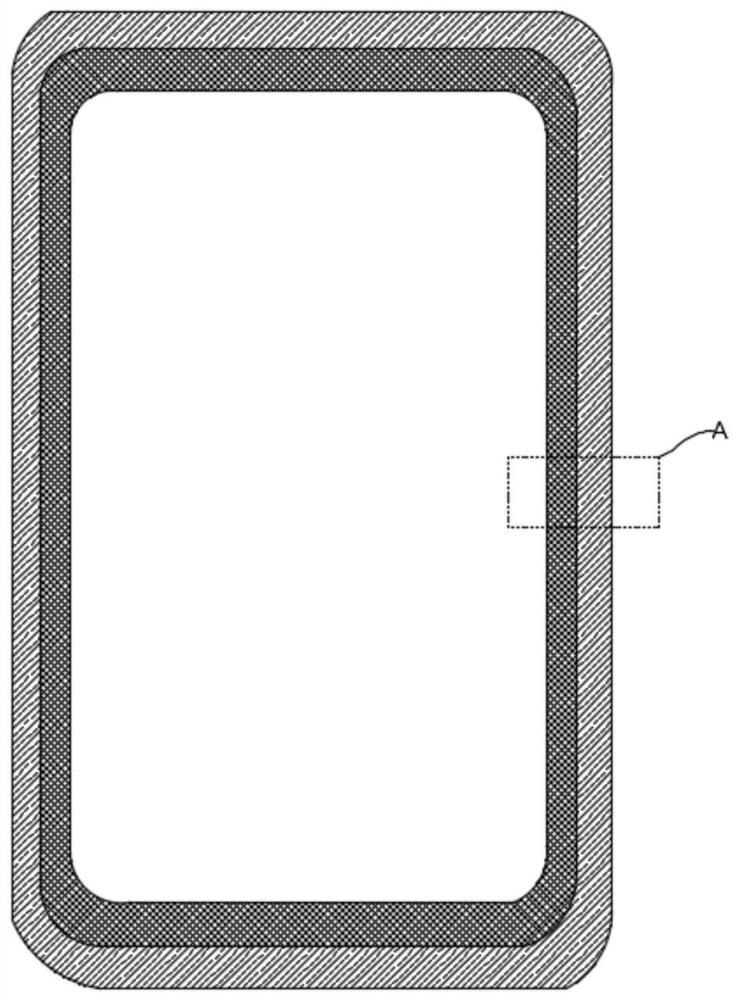

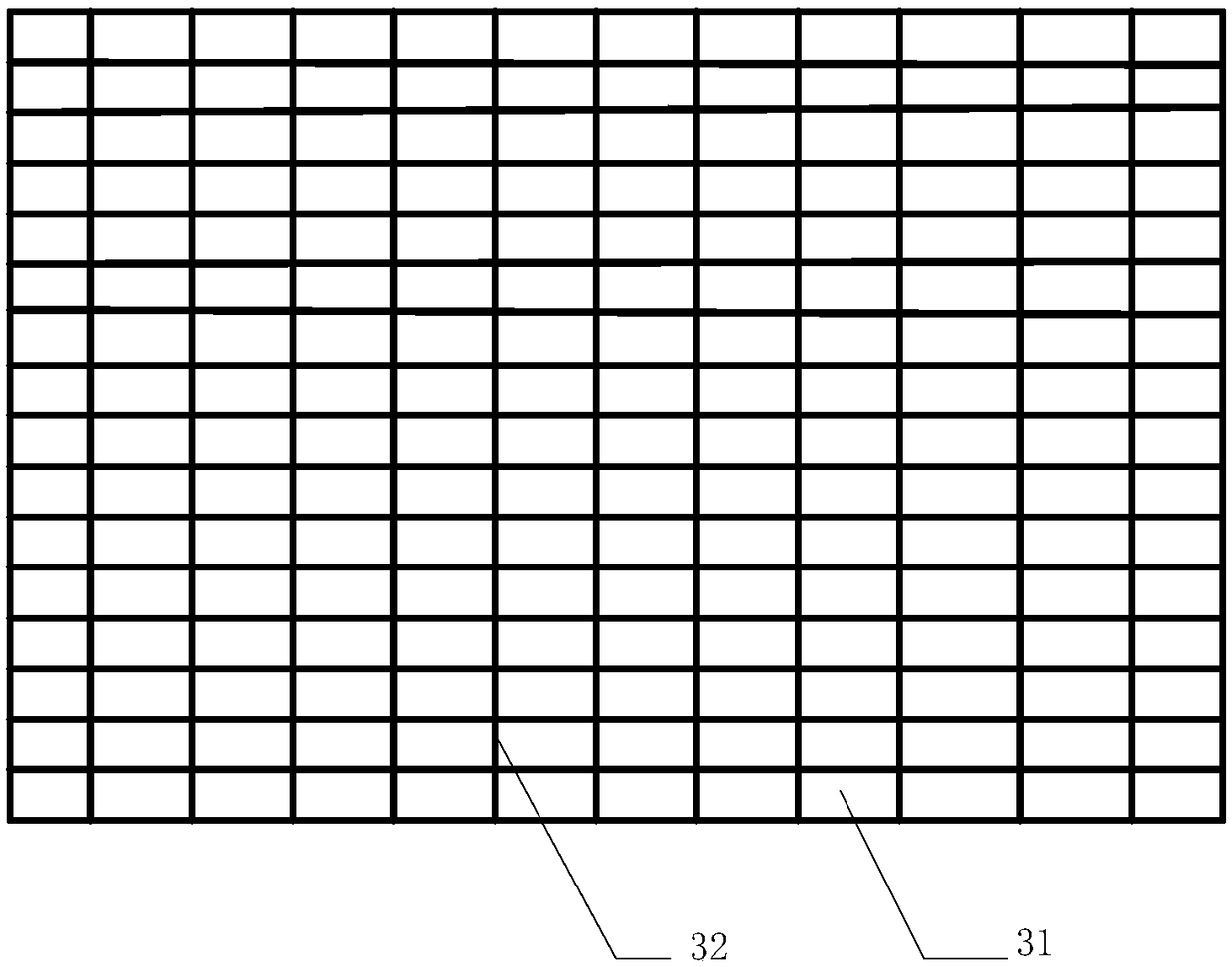

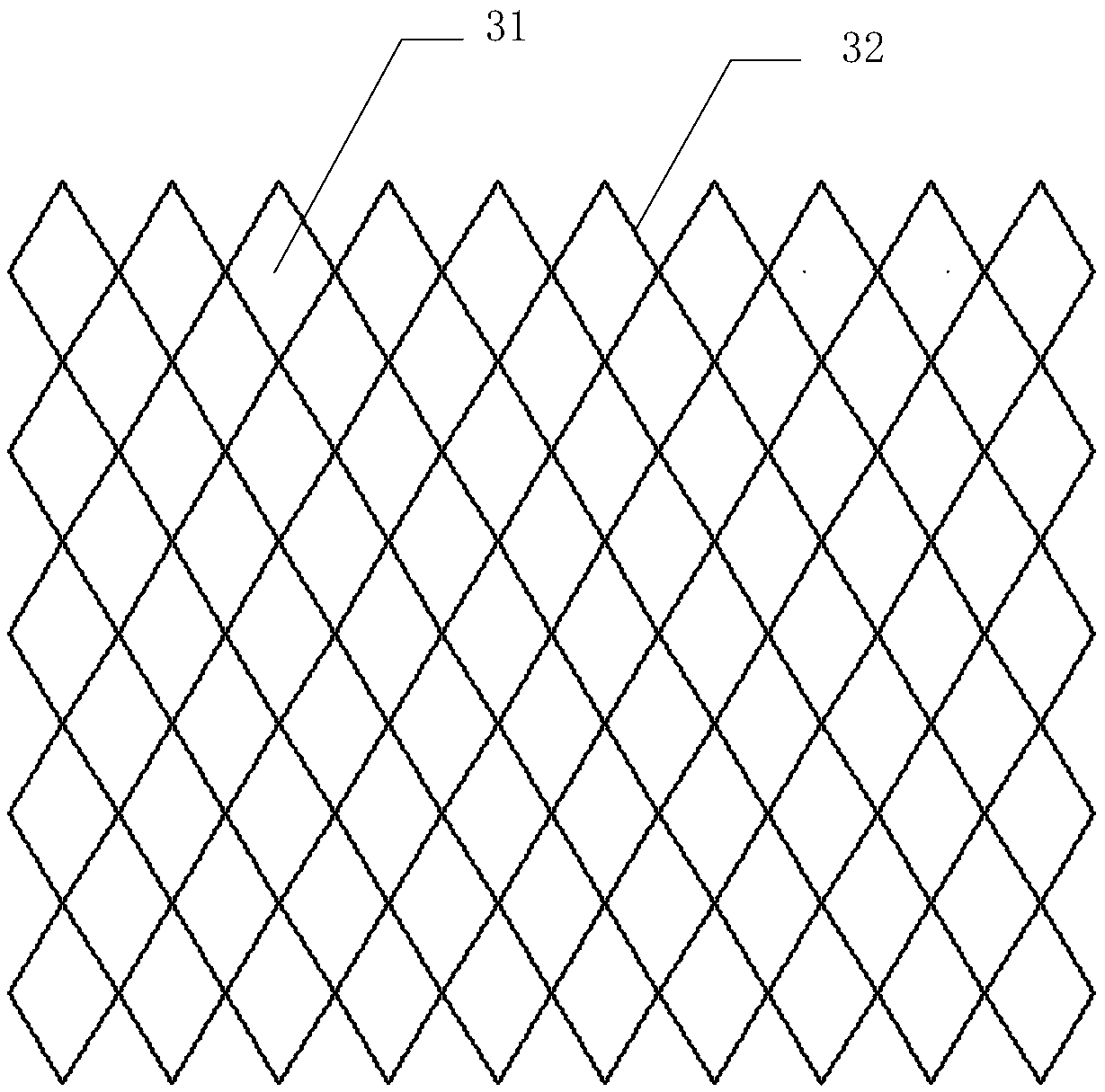

Color film substrate, display panel and display device

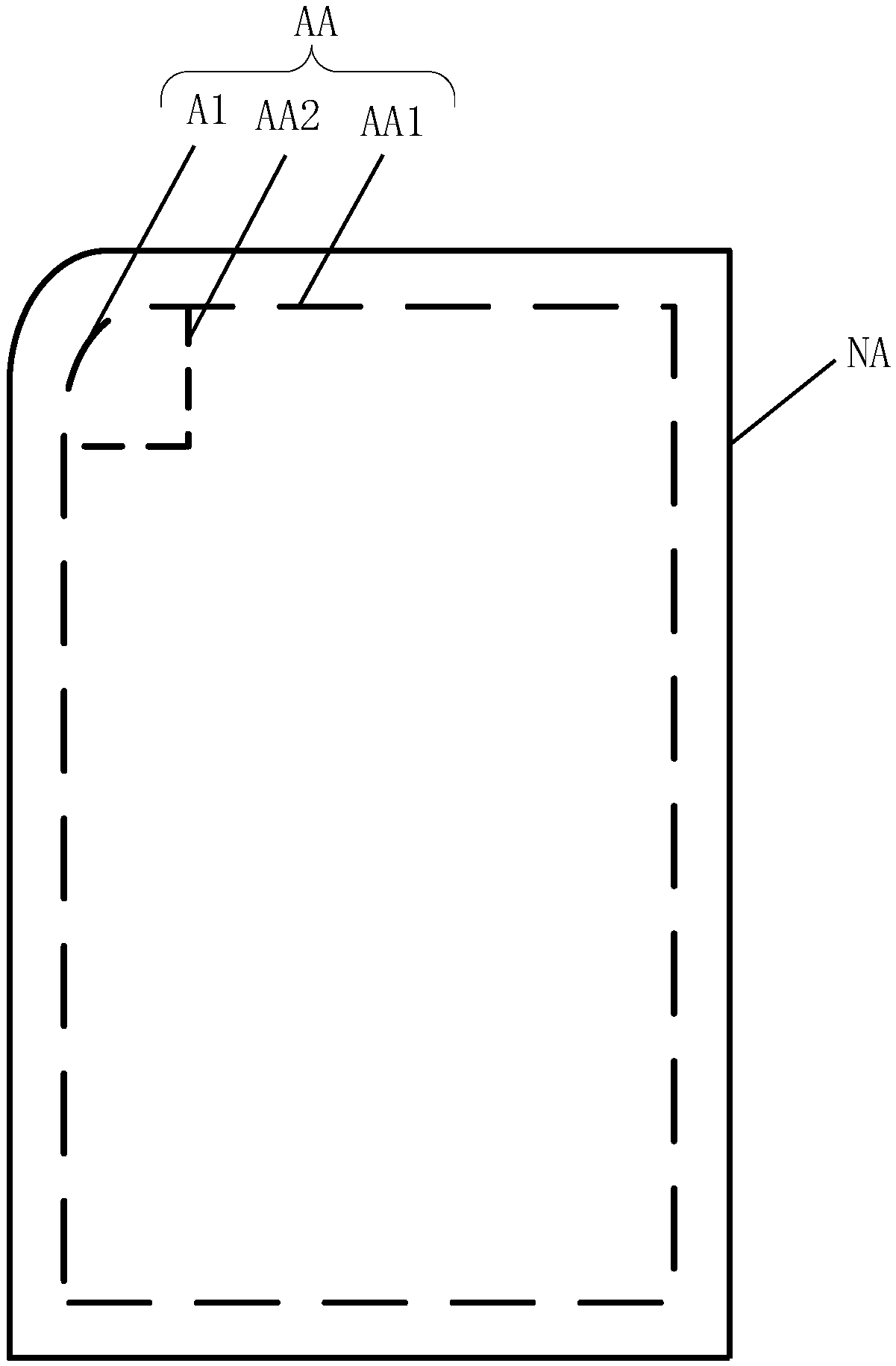

ActiveCN109445168AReduce the risk of strippingReduce penetrationNon-linear opticsDisplay deviceColor film

The invention discloses a color film substrate, a display panel and a display device. The color film substrate includes a substrate and a display region. The display region includes a special-shaped boundary, a main region, and an edge transition region between the main region and the special-shaped region; the display region also includes a color resistor arranged on one side of the substrate; the color resistor at least includes a first color resistor, a second color resistor and a third resistor; the edge transition region includes a first blue resistor arranged on one side, far away from the substrate, of the color resistor; the first blue resistor includes a grid structure having multiple meshes; the part, in the edge transition region, of the color resistor is exposed by the meshes.The color resistor in the edge transition region can completely cover the substrate, so that the risk that the color resistor in the edge transition region is stripped from the substrate is decreased.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

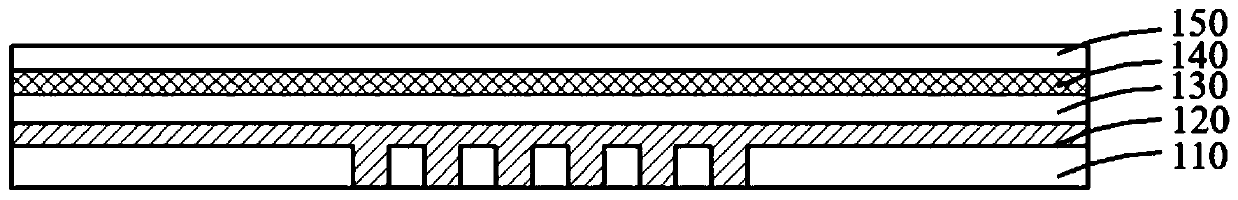

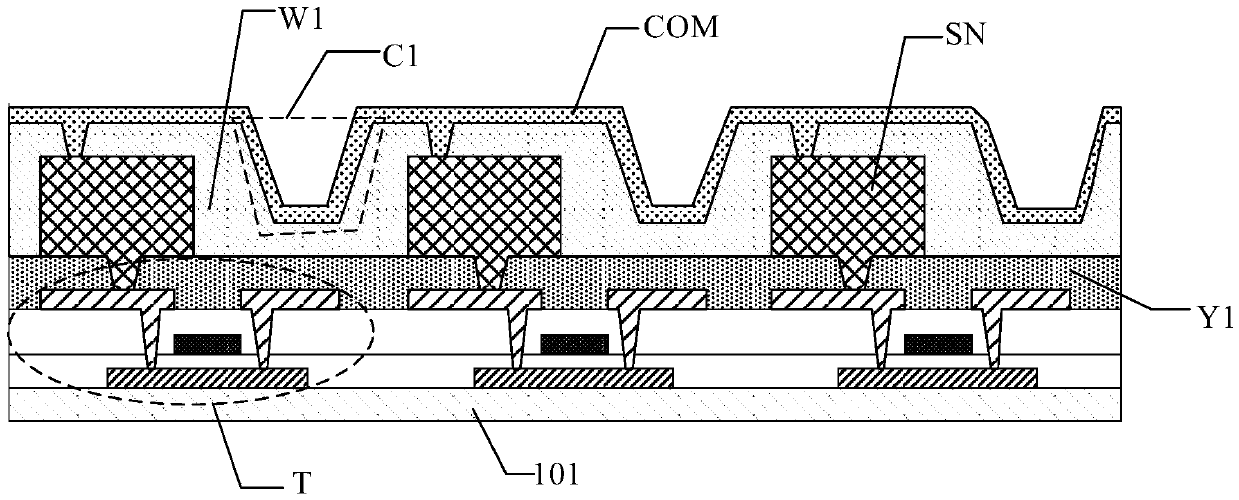

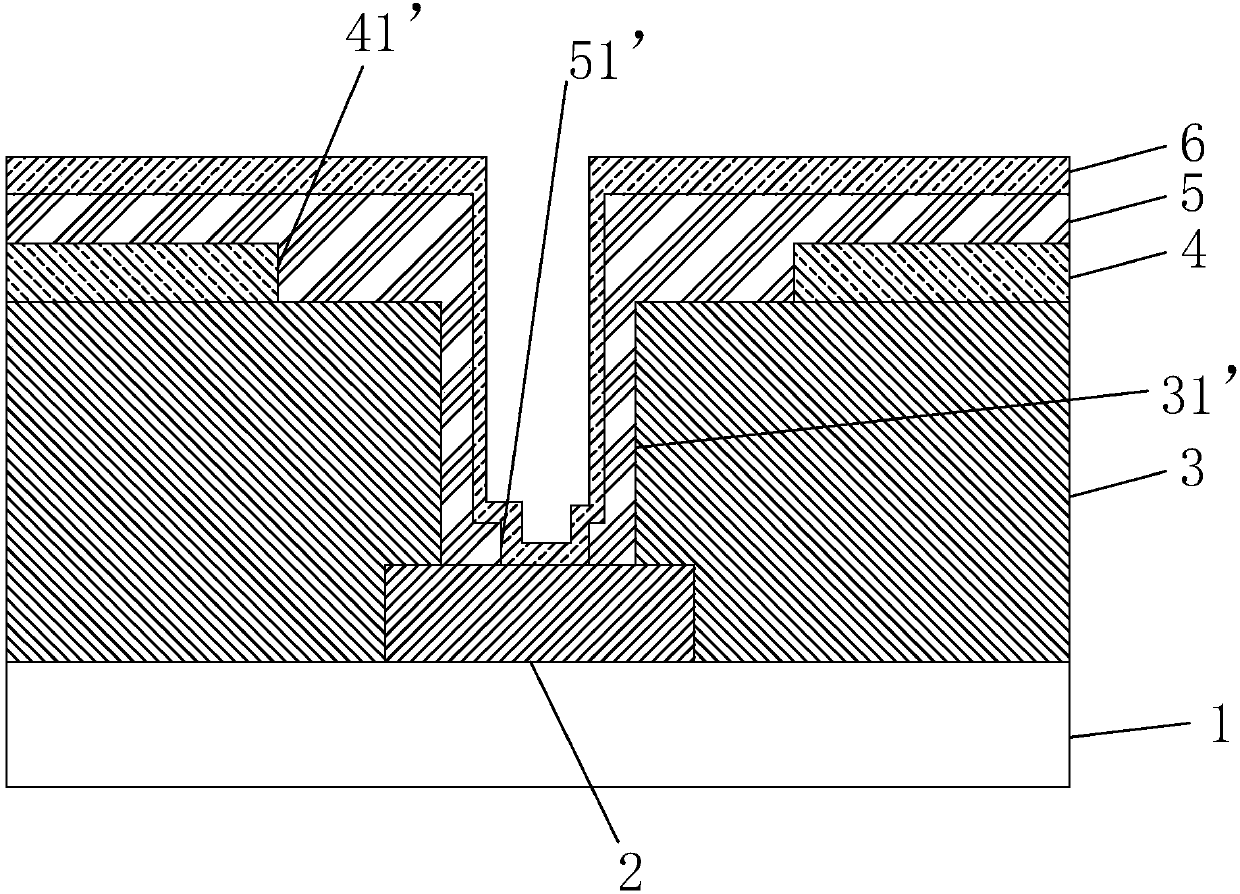

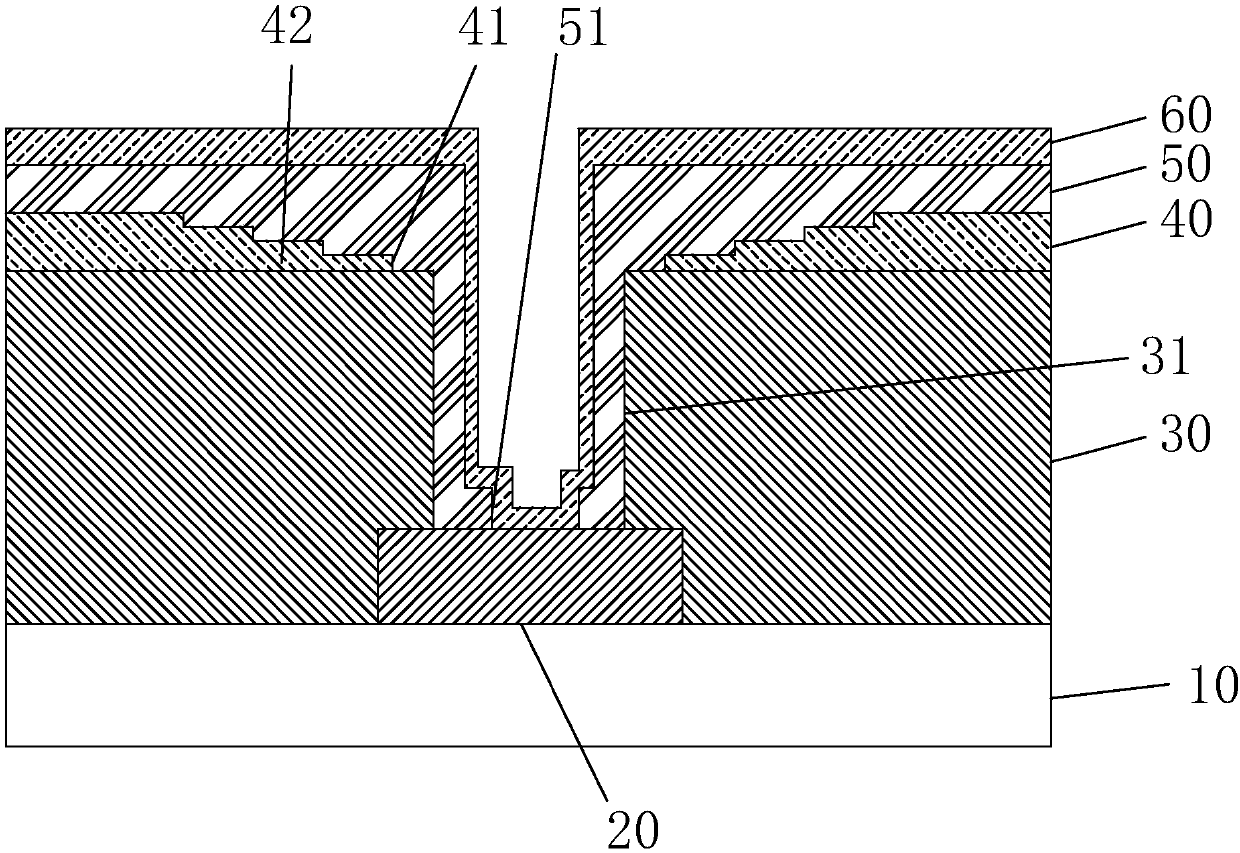

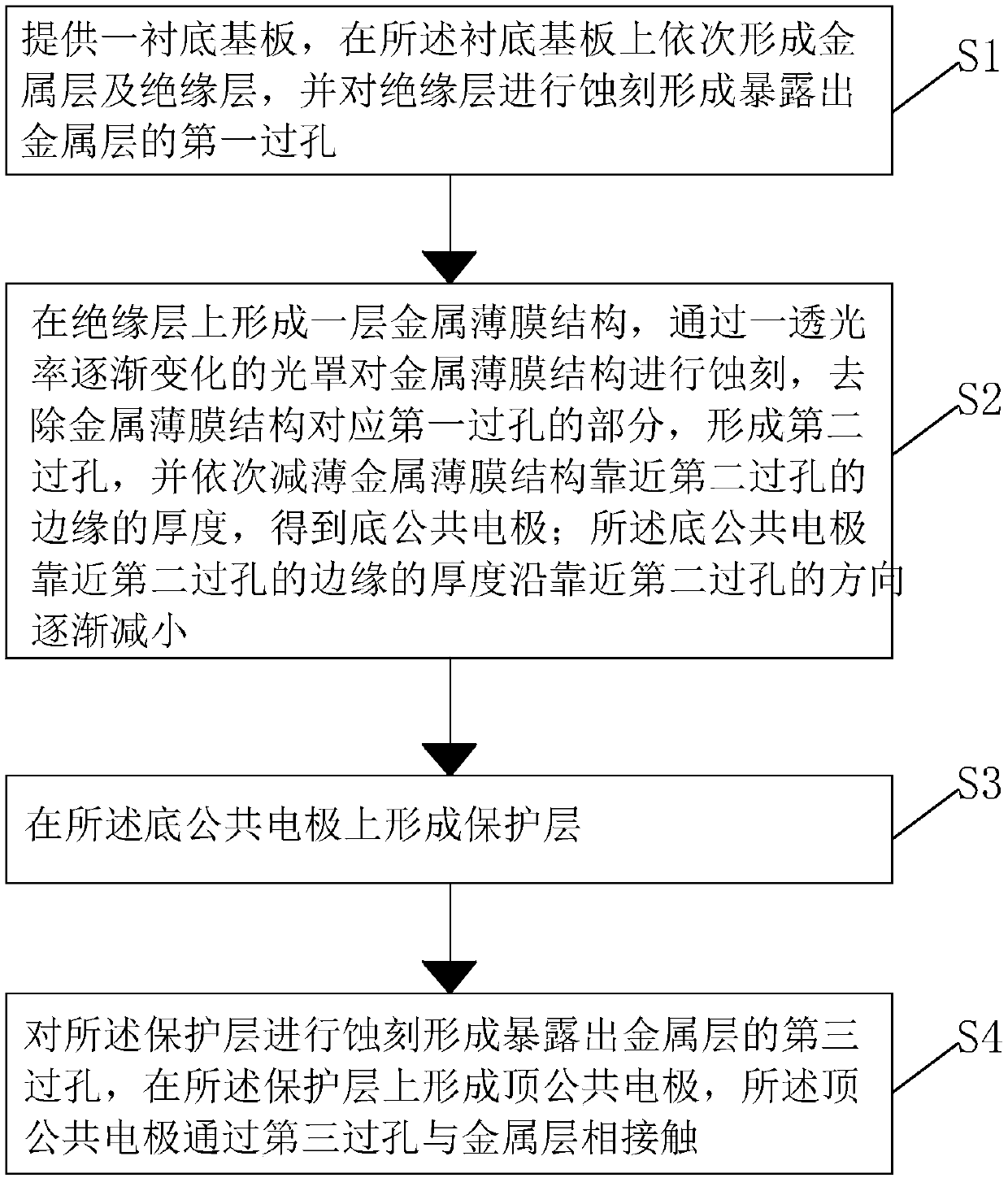

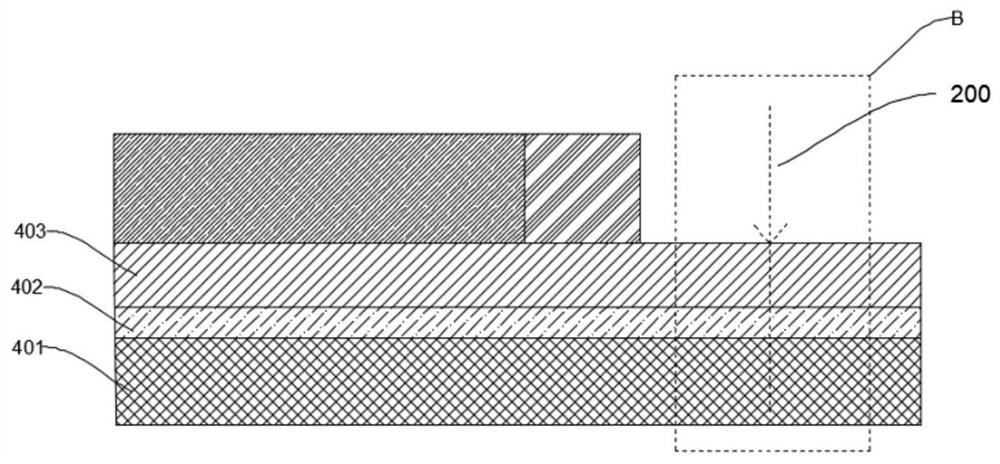

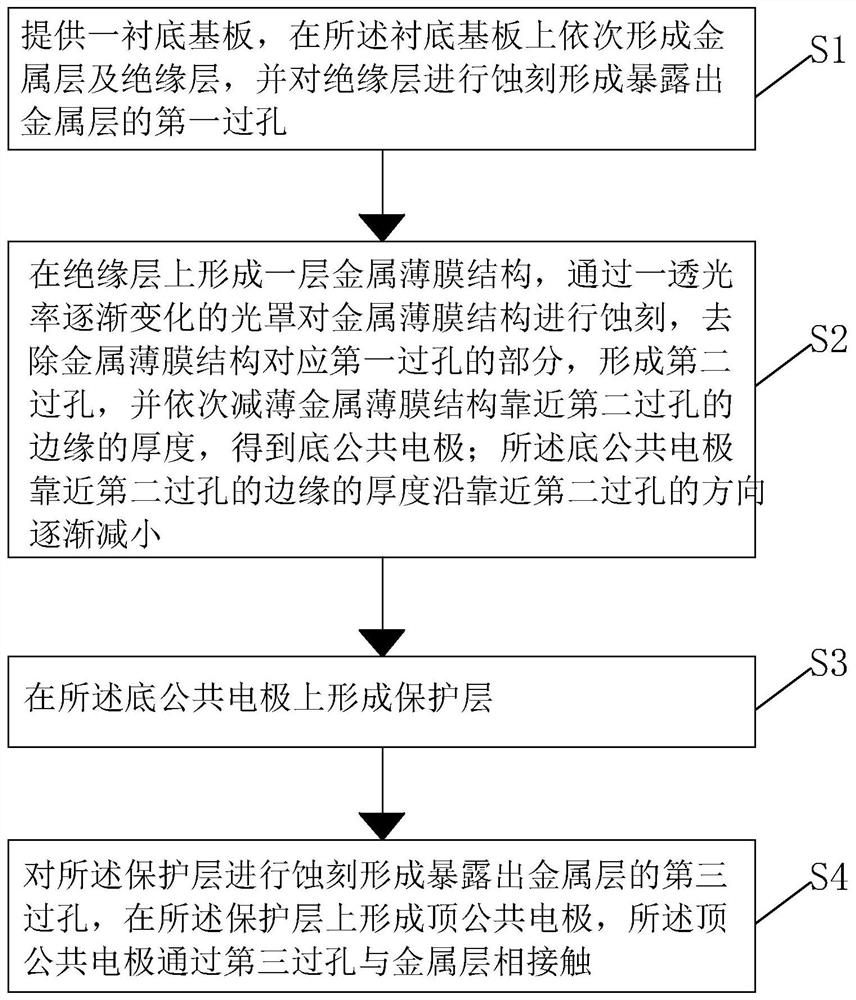

TFT substrate and manufacturing method thereof

ActiveCN108257976AImprove yieldReduce tilt angleSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLiquid crystal

The invention provides a TFT substrate and a manufacturing method thereof. The TFT substrate comprises a base substrate, a metal layer arranged on the base substrate, an insulating layer arranged on the base substrate and the metal layer, a bottom common electrode arranged on the insulating layer, and a protective layer arranged on the insulating layer and the bottom common electrode. The insulating layer has first via holes exposing the metal layer. The bottom common electrode has second via holes formed in areas corresponding to the first via holes. The thickness of the edge of the bottom common electrode near the second via holes gradually decreases along the direction near the second via holes, so that the upwarp angle of the edge of the bottom common electrode near the second via holes is reduced, and the probability of bottom cutting is reduced. Therefore, the risk of peeling of the film formed on the bottom common electrode is reduced, the yield of the TFT substrate is improved,and the display effect of the LCD panel is good.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

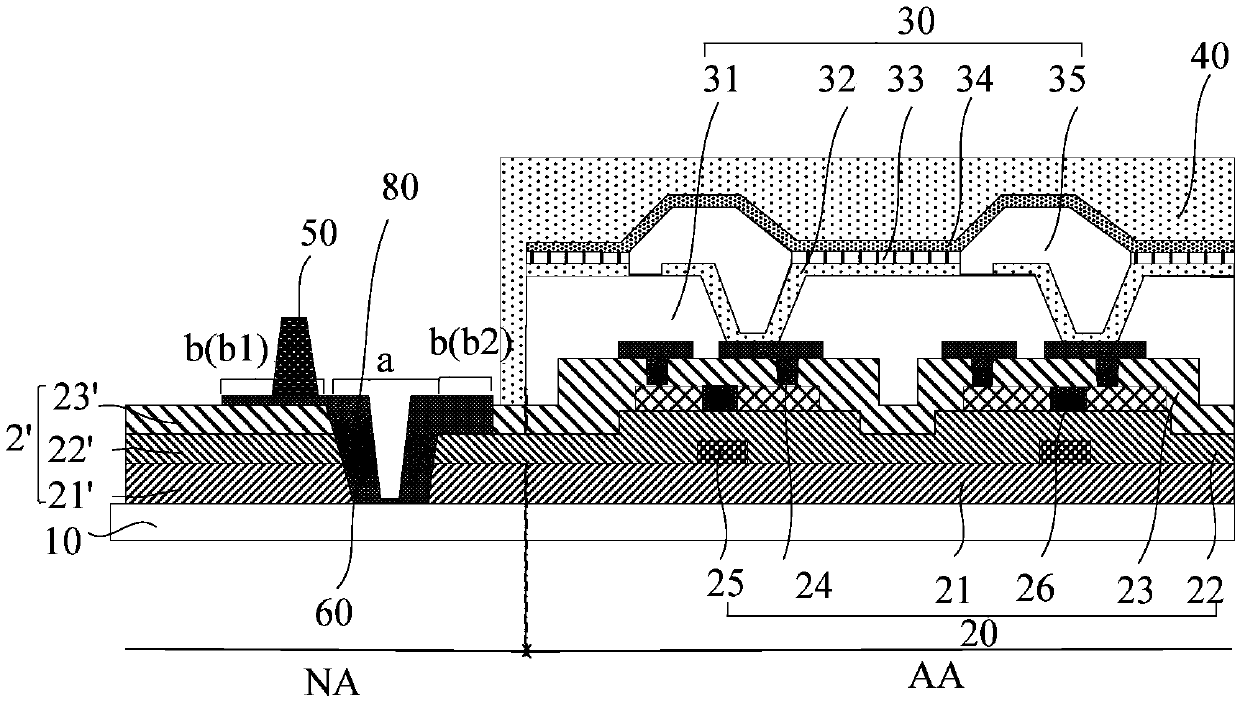

Display panel, display device and preparation method of display panel

ActiveCN110581229AImprove bending performanceImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

The invention discloses a display panel, a display device and a preparation method of the display panel. The display panel comprises an array substrate, a pixel definition layer, a light emitting layer and a first electrode, wherein the pixel defining layer is located on the array substrate and comprises an opening area and a pixel defining area surrounding the opening area, the light emitting layer is located in the opening area, and the first electrode is located on the side of the light emitting layer away from the array substrate and comprises a first thinning area corresponding to the opening area. The display panel is advantaged in that adhesiveness between the first electrode and the light emitting layer can be increased, a film stripping phenomenon caused by bending is avoided, andbending performance of the display panel is improved.

Owner:YUNGU GUAN TECH CO LTD

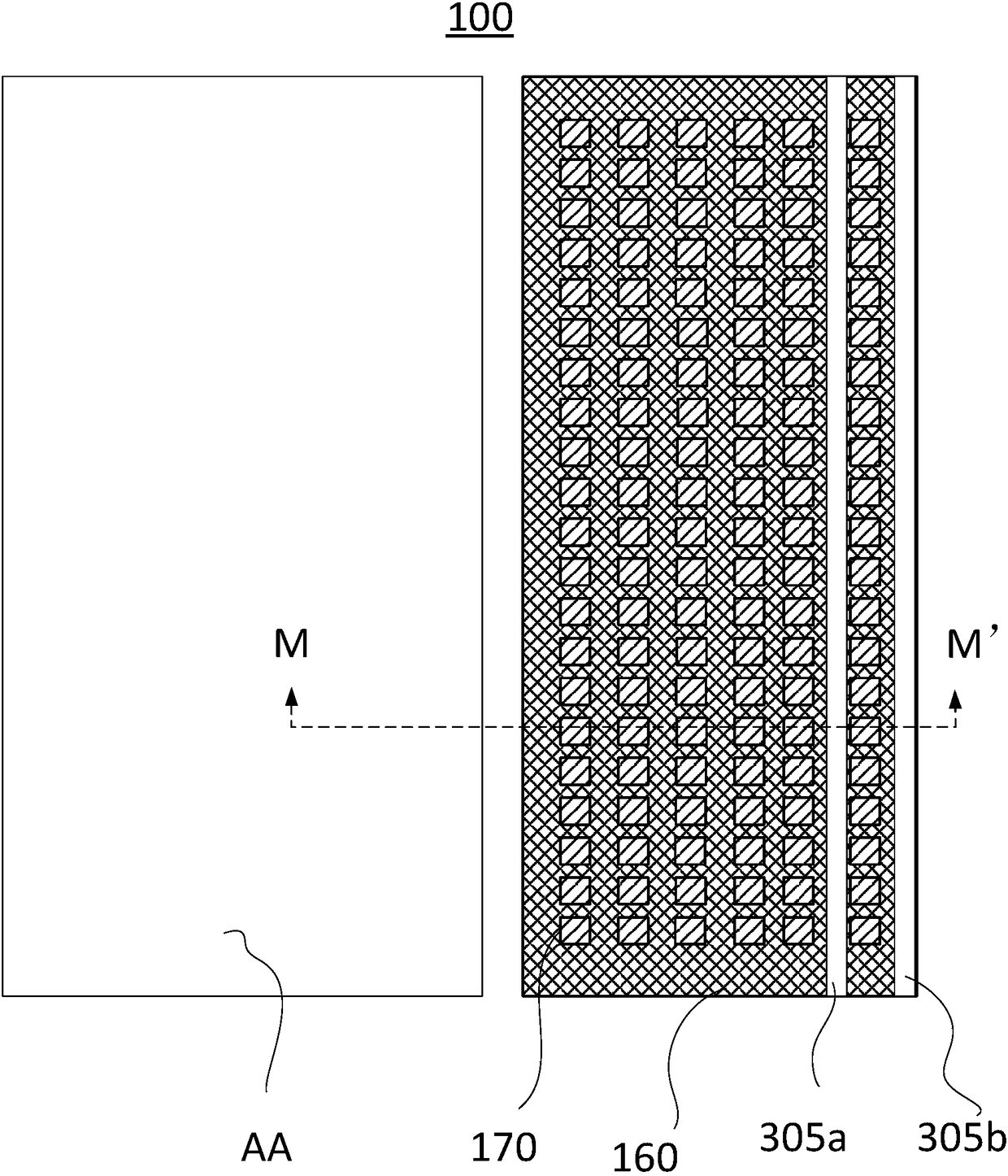

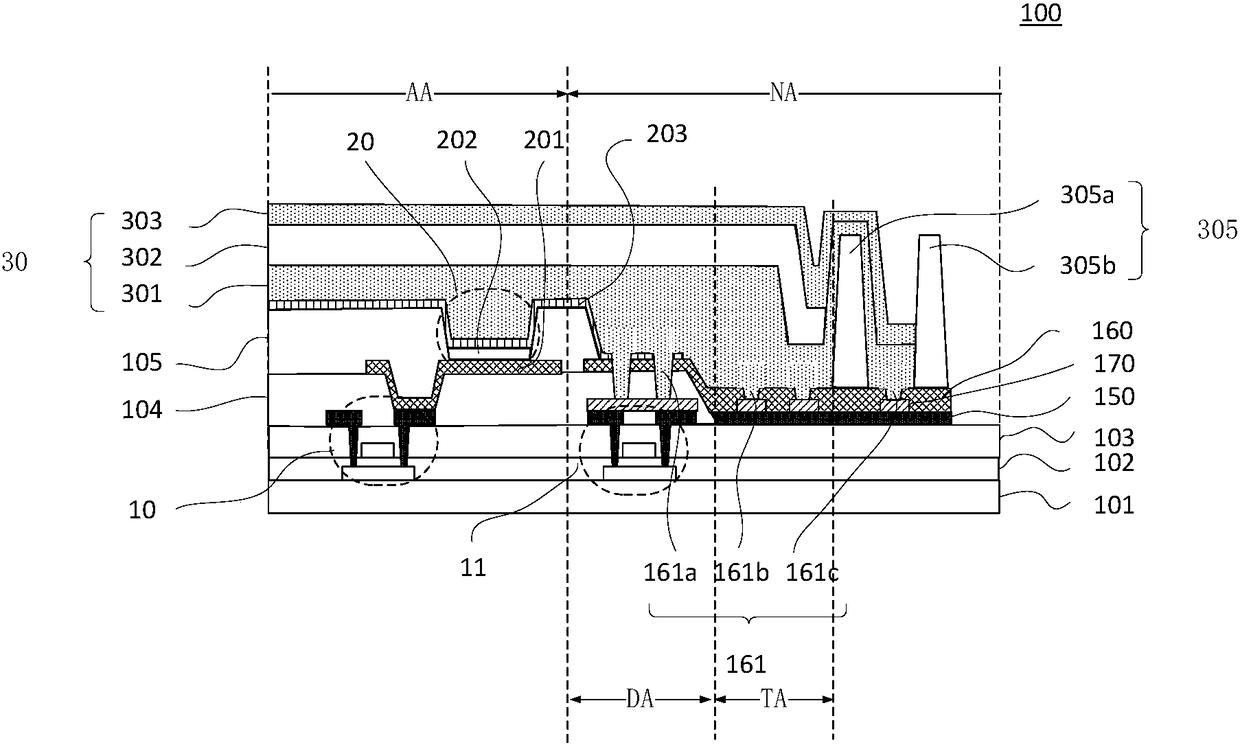

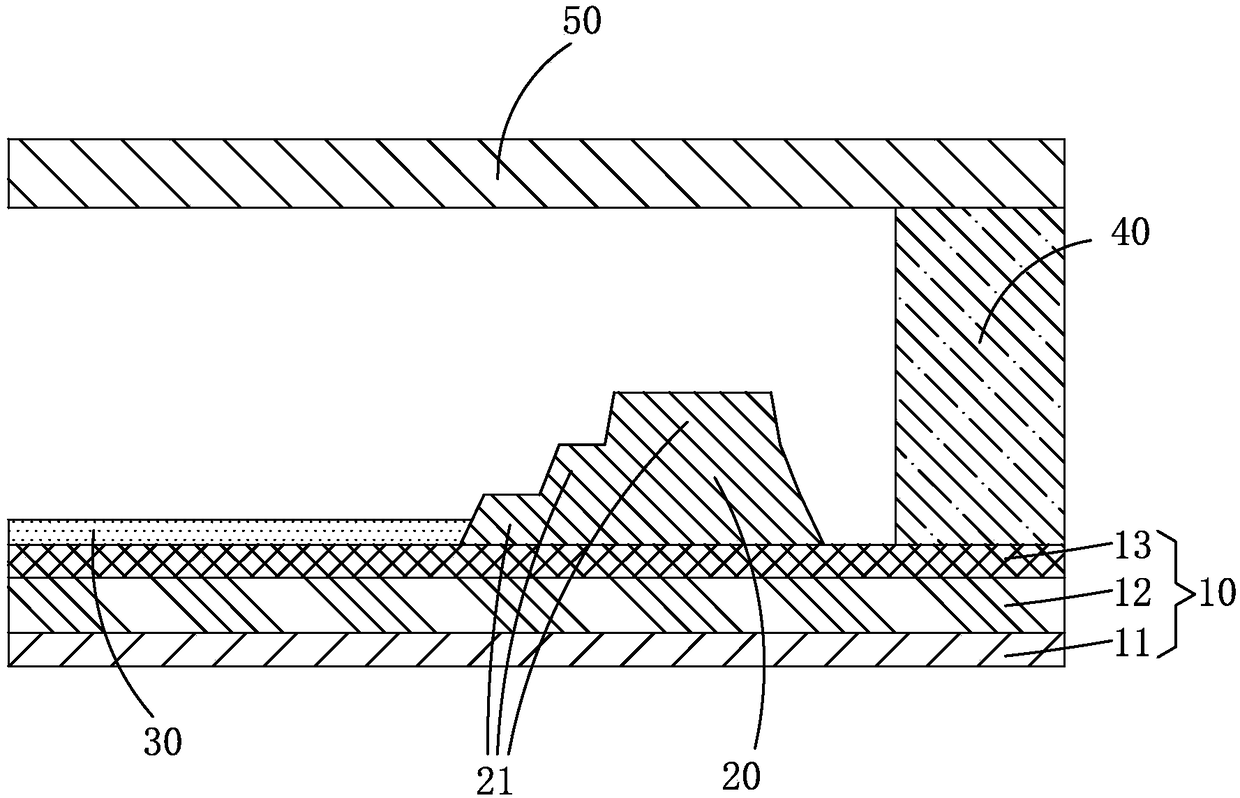

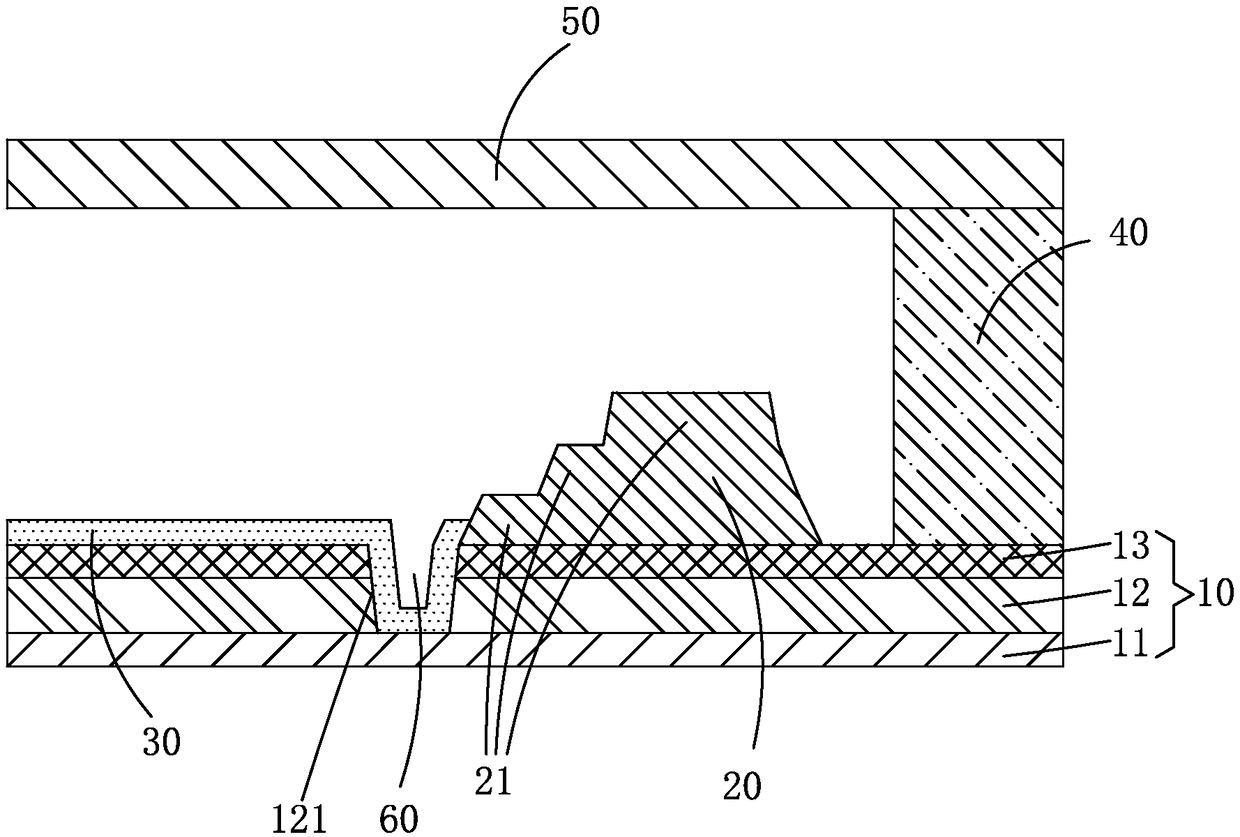

Display panel and manufacturing method thereof and display device

ActiveCN111524949ARelieves moisture absorptionReduce the risk of strippingSolid-state devicesSemiconductor devicesDisplay deviceStructural engineering

The invention discloses a display panel and a manufacturing method thereof and a display device. The display panel comprises: a substrate; a flat layer which is arranged at one side of the substrate;a retaining wall which is positioned in a peripheral area, wherein the retaining wall is positioned on one side, deviating from the substrate, of the flat layer and is of an annular structure surrounding a display area; a packaging layer which covers the display area and at least part of the peripheral area; a touch barrier layer which is located on the side, deviating from the substrate, of the packaging layer; and a water blocking layer which is located in the peripheral area, wherein the water blocking layer is located between the flat layer and the touch barrier layer, the flat layer and the touch barrier layer extend to the side, away from the display area, of the retaining wall. The water blocking layer located between the flat layer and the touch barrier layer is arranged in the peripheral area, in the wet cleaning process before the touch barrier layer is formed, due to the fact that the water blocking layer covers the flat layer located in the peripheral area, the phenomenon that the flat layer absorbs water can be relieved, and the risk of stripping between the touch barrier layer and the flat layer is effectively reduced.

Owner:BOE TECH GRP CO LTD +1

Display panel cutting and trimming method, display panel and display device

ActiveCN113471394AAvoid influenceSolve associativitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention relates to the technical field of display, and particularly relates to a display panel cutting and trimming method, a display panel and a display device. The cutting and trimming method comprises the following steps that a flexible substrate comprises a first organic layer, an inorganic layer and a second organic layer which are arranged in a stacked mode, and the first organic layer is located on the side, away from the light emitting surface of the display panel, of the inorganic layer; a barrier layer is formed on at least one side, far away from the first organic layer, of the second organic layer, and the barrier layer is patterned by taking the cutting channel as a center; the flexible substrate is etched by taking the barrier layer as a mask pattern to at least expose the first organic layer so as to form a groove taking the cutting channel as the center on the flexible substrate; and laser cutting and trimming are performed on the cutting area along the cutting channel. The grooves can avoid the influence of residual heat in the laser cutting process on interfaces of the second organic layer and the inorganic layer, the problems of interface bonding force weakening, dislocation and warping separation of the second organic layer and the inorganic layer are solved, and then the risk of film layer stripping caused by multiple times of bending is reduced.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

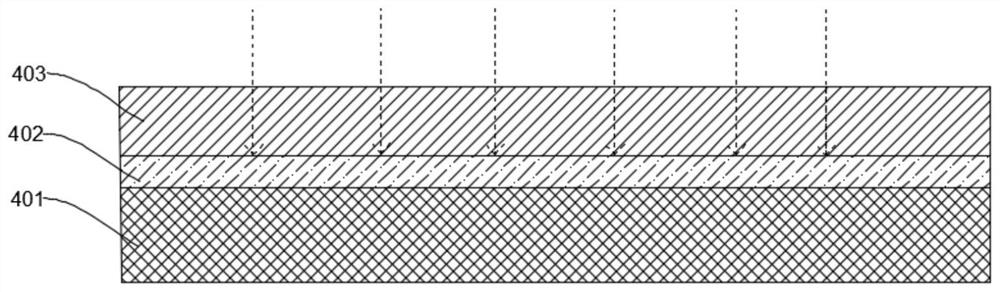

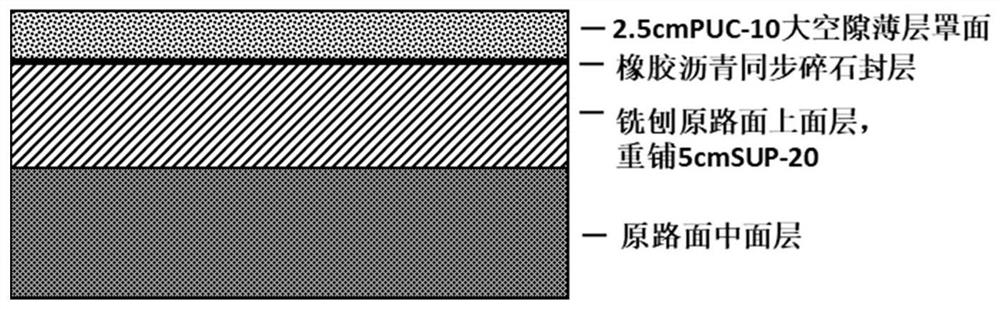

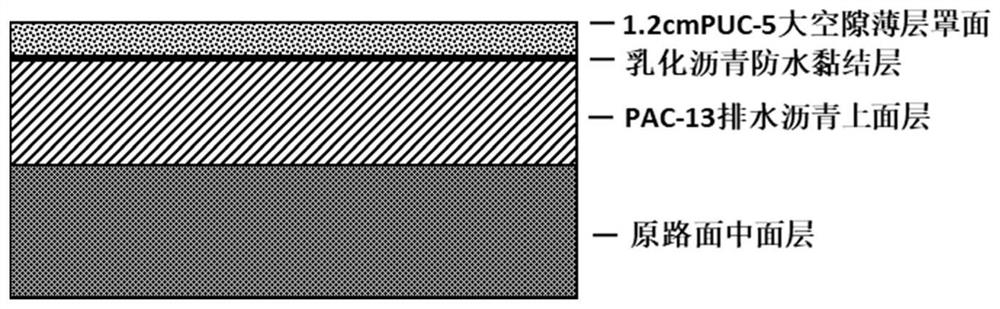

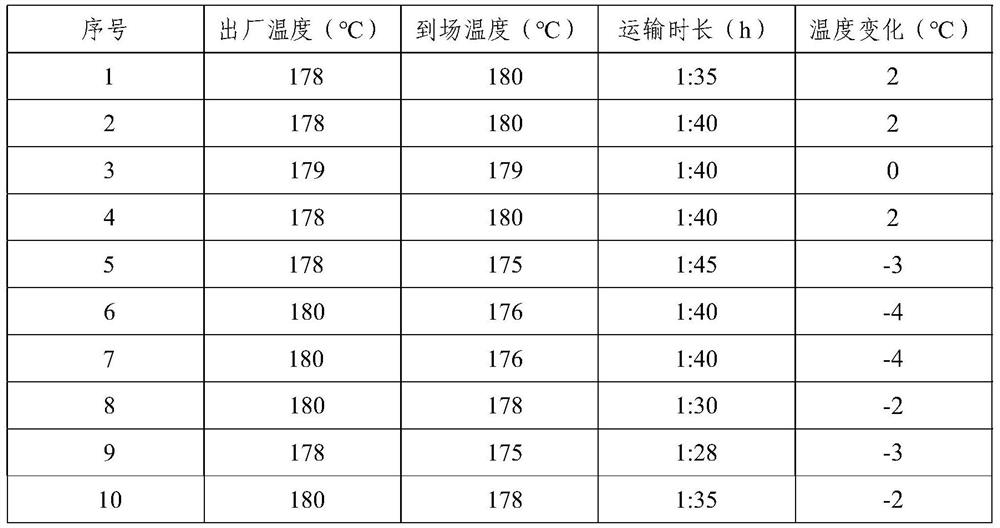

Construction method of large-gap thin overlay

PendingCN111764222AIncrease temperatureHigh bonding strengthIn situ pavingsRoad engineeringStructural engineering

The invention belongs to the field of road engineering, and particularly relates to a construction method of a large-gap thin overlay. The method sequentially comprises the following steps of preparing raw materials of the large-gap thin overlay and a waterproof bonding layer, stirring the raw materials, preheating, paving and rolling, wherein a temperature of the materials is maintained at 140-195 DEG C in a process from completion of material mixing to paving. The construction process is an effective construction process of a large-gap thin mixture, main technical indexes and durability of the constructed overlay are equivalent to those of a densely-graded thin overlay, meanwhile, remarkable drainage, skid resistance and noise reduction functions are possessed, and the method has important significance in popularization and application of the structure.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

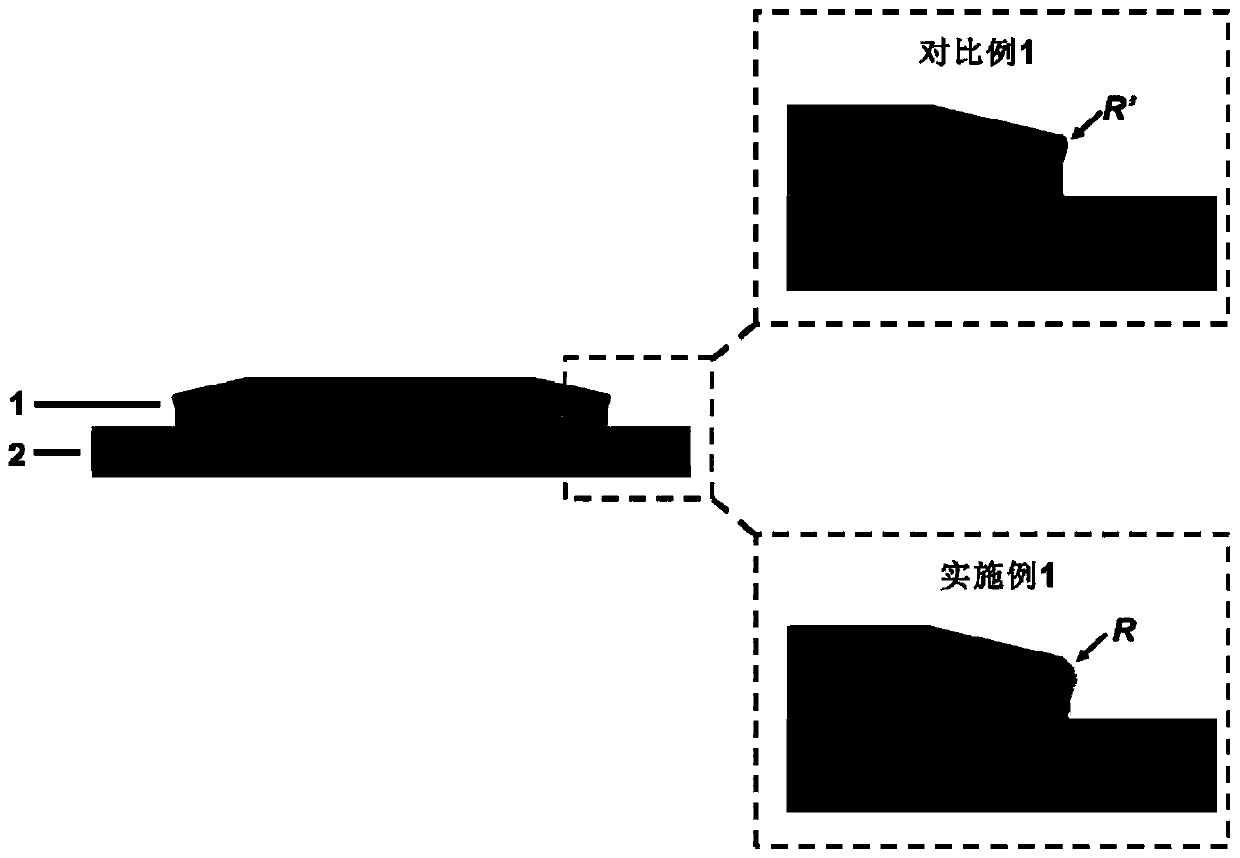

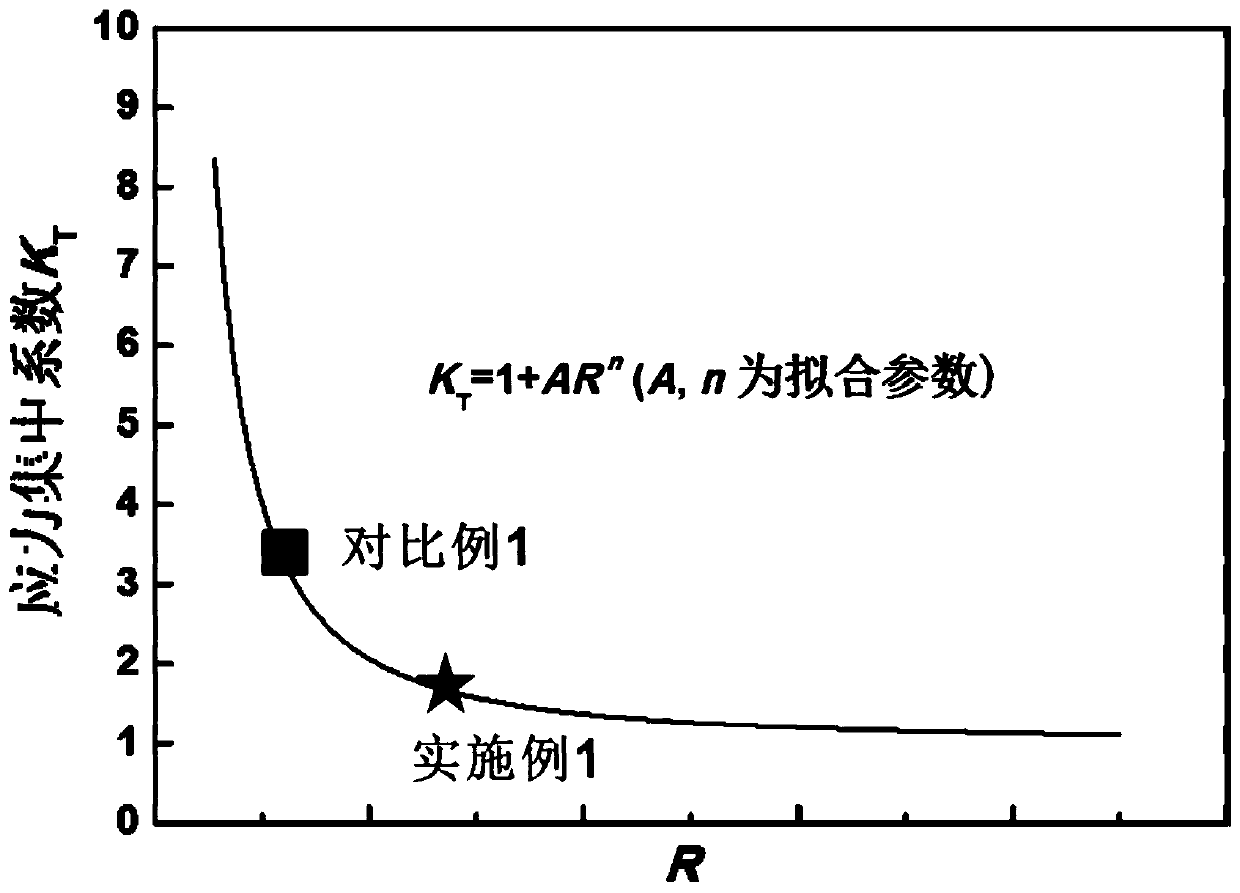

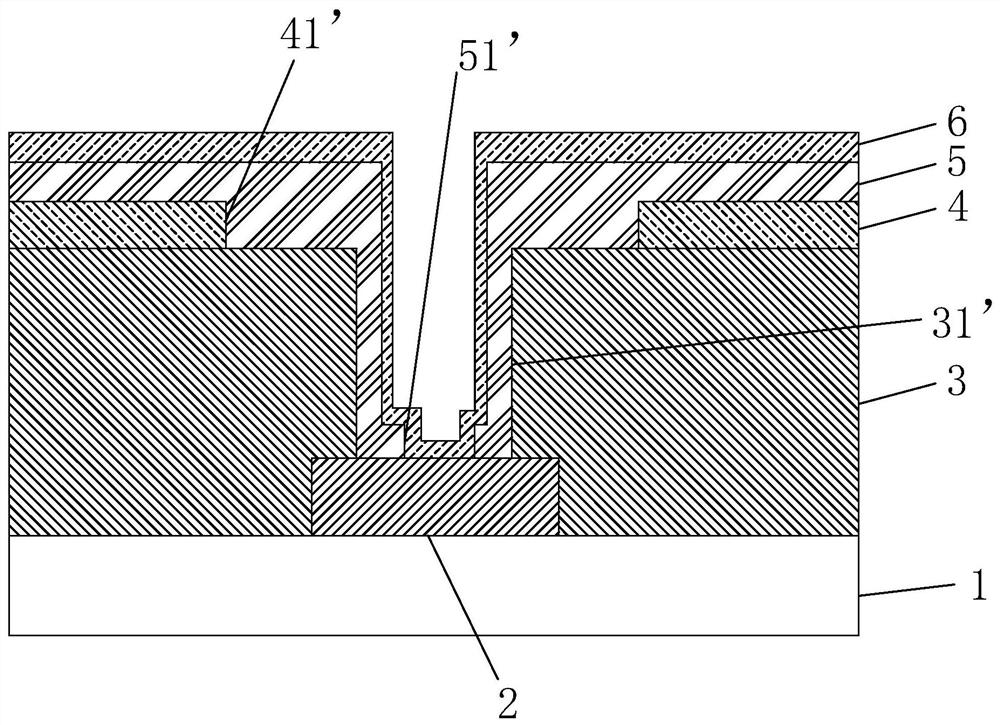

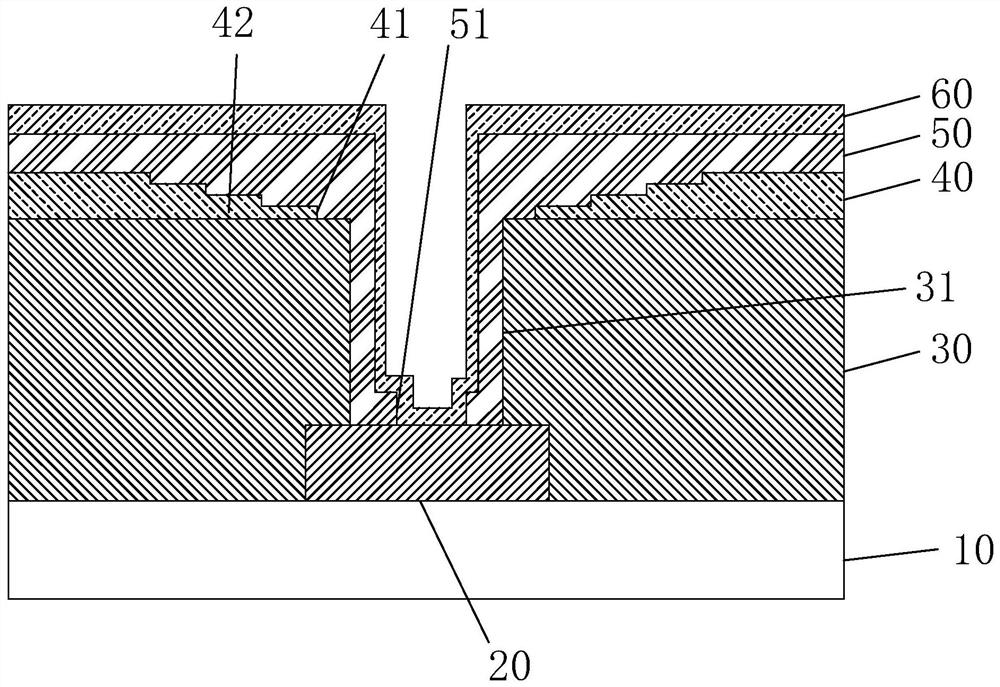

SIP series target material capable of avoiding stripping of anti-sputtering layer and application thereof

PendingCN111455328AReduce stress concentration factorReduce the risk of strippingVacuum evaporation coatingSputtering coatingPhysicsSilicon chip

The invention relates to an SIP series target material capable of avoiding stripping of an anti-sputtering layer and application thereof. The SIP series target material comprises a cathode metal, wherein the chamfer radius R of the edge of the cathode metal is larger than or equal to 4mm. In the prior art, according to a conventional SIP series target material, the interface design between the cathode metal and the anti-sputtering layer cannot well alleviate the problems of interface stress mismatch and stress concentration caused by the difference of thermal expansion coefficients, and the risk of stripping of the anti-sputtering layer exists; and an abnormal physical tip is generated due to stripping of the anti-sputtering layer, so that tip discharge is caused, and the problems of subsequent chip electrical test failure and silicon chip scrapping are caused. The SIP series target material can effectively alleviate the stress mismatch and stress concentration situations between the cathode metal and the anti-sputtering layer, and can avoid the problems of stripping of the anti-sputtering layer and tip discharging of a plasma.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

TFT substrate and manufacturing method thereof

ActiveCN108257976BImprove yieldReduce tilt angleSolid-state devicesSemiconductor/solid-state device manufacturingProtection layerElectrode pair

The invention provides a TFT substrate and a manufacturing method thereof. The TFT substrate comprises a base substrate, a metal layer arranged on the base substrate, an insulating layer arranged on the base substrate and the metal layer, a bottom common electrode arranged on the insulating layer, and a protective layer arranged on the insulating layer and the bottom common electrode. The insulating layer has first via holes exposing the metal layer. The bottom common electrode has second via holes formed in areas corresponding to the first via holes. The thickness of the edge of the bottom common electrode near the second via holes gradually decreases along the direction near the second via holes, so that the upwarp angle of the edge of the bottom common electrode near the second via holes is reduced, and the probability of bottom cutting is reduced. Therefore, the risk of peeling of the film formed on the bottom common electrode is reduced, the yield of the TFT substrate is improved,and the display effect of the LCD panel is good.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

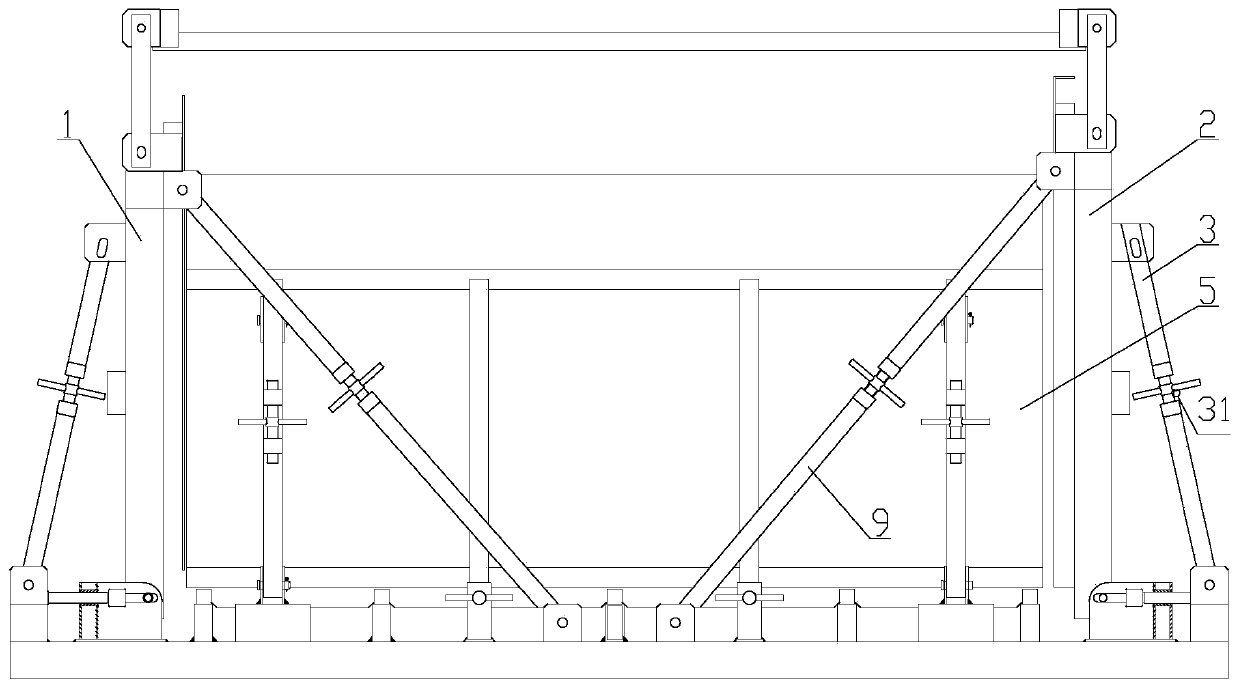

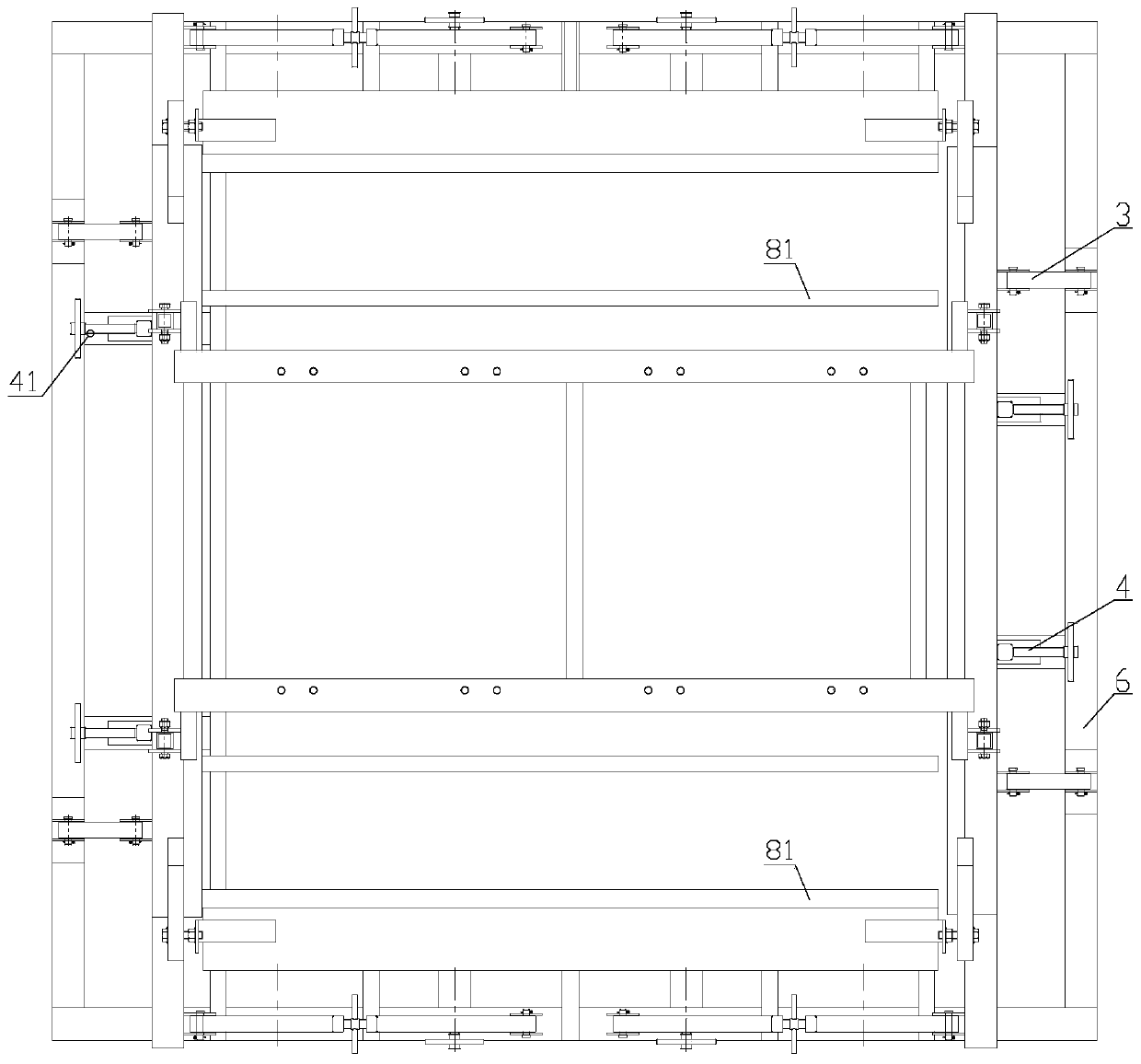

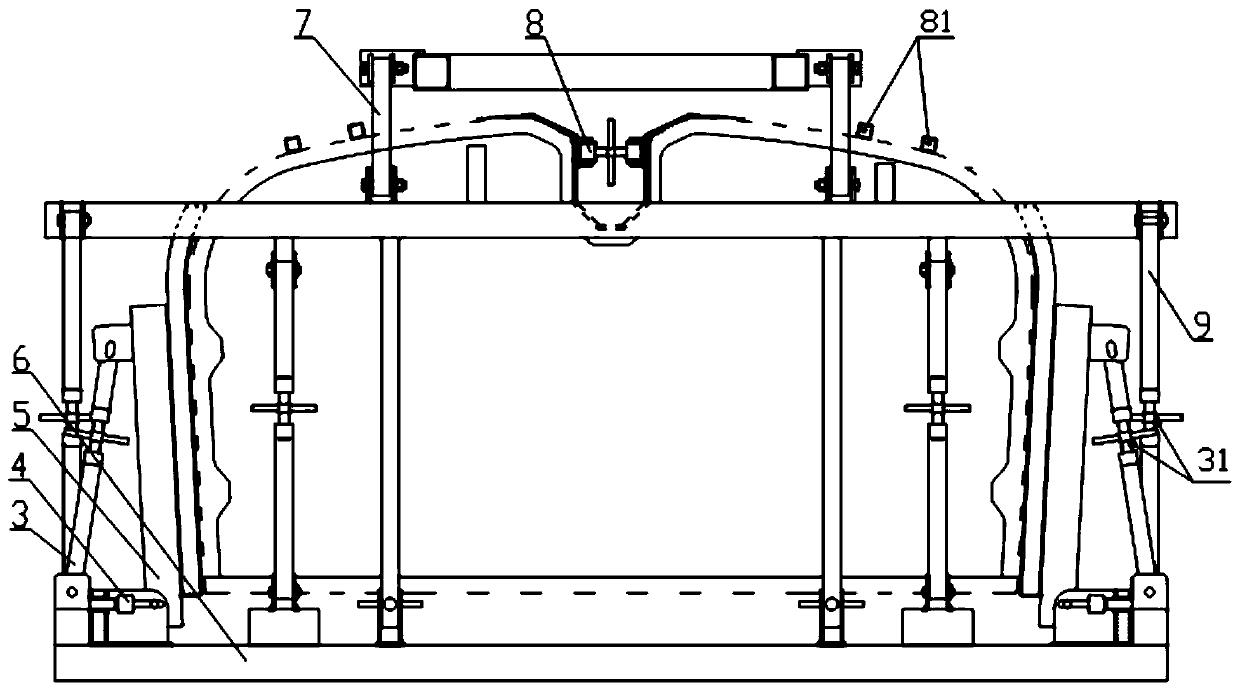

Quick overall foaming device and method for vehicle-mounted tank

Owner:滁州永强汽车制造有限公司

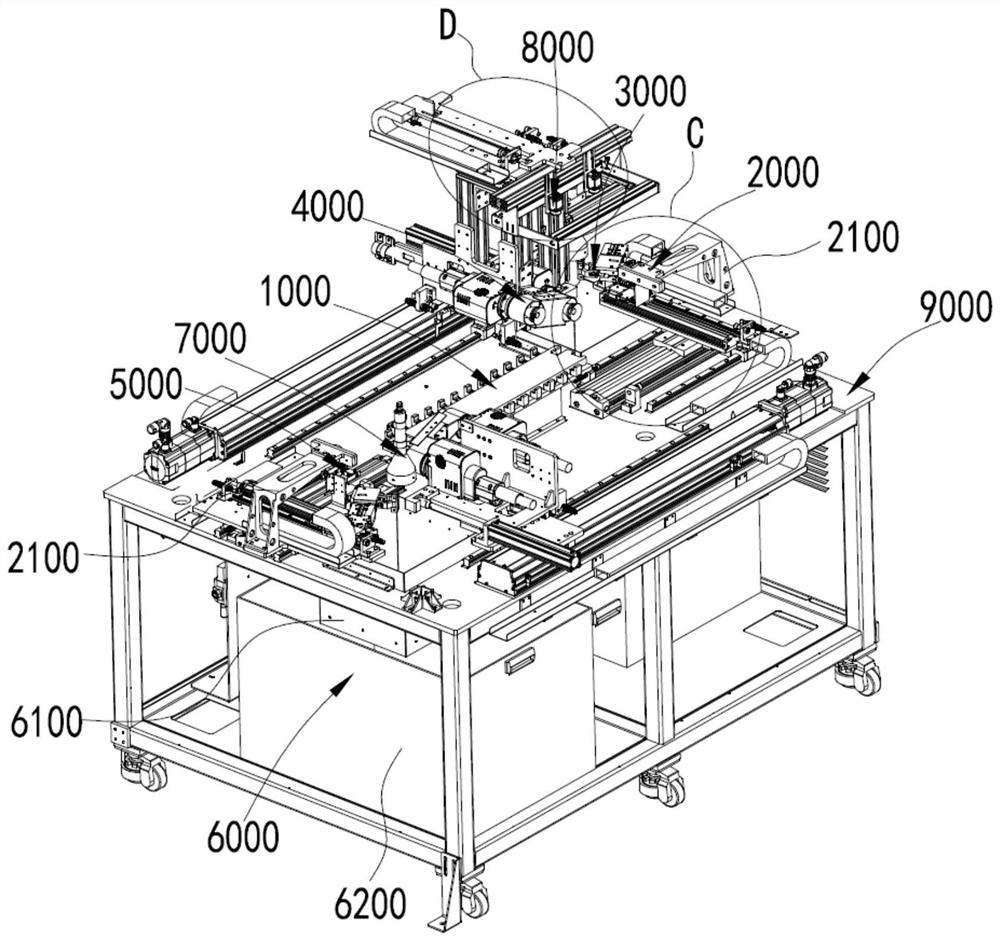

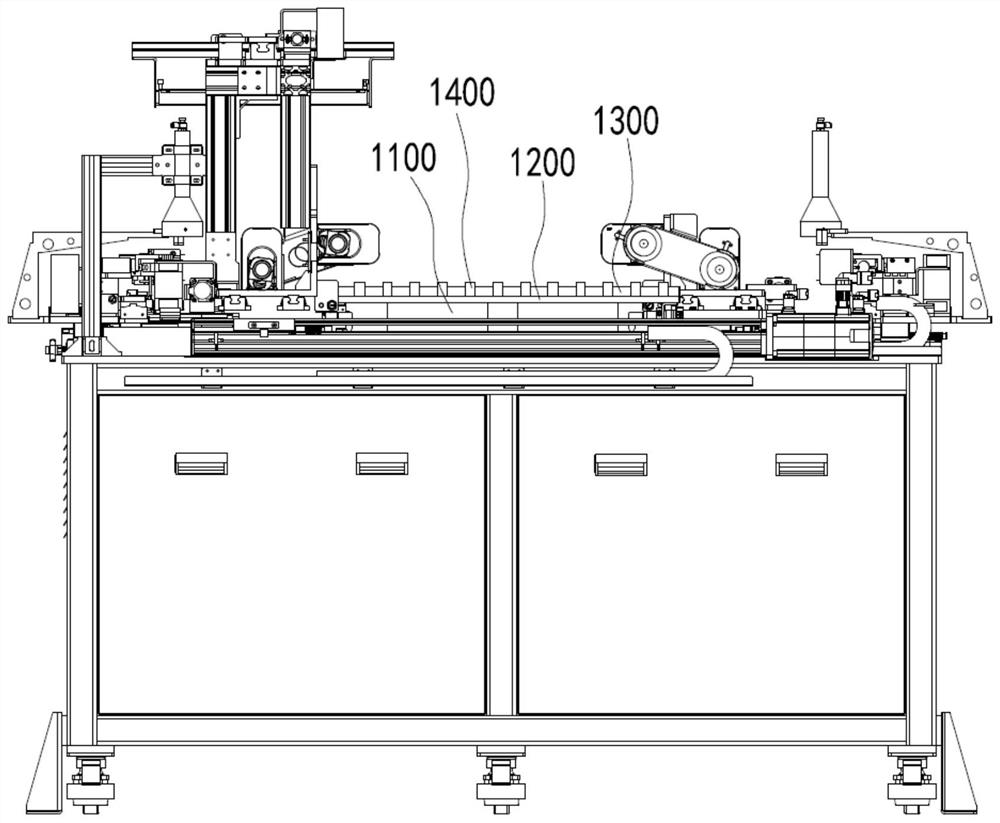

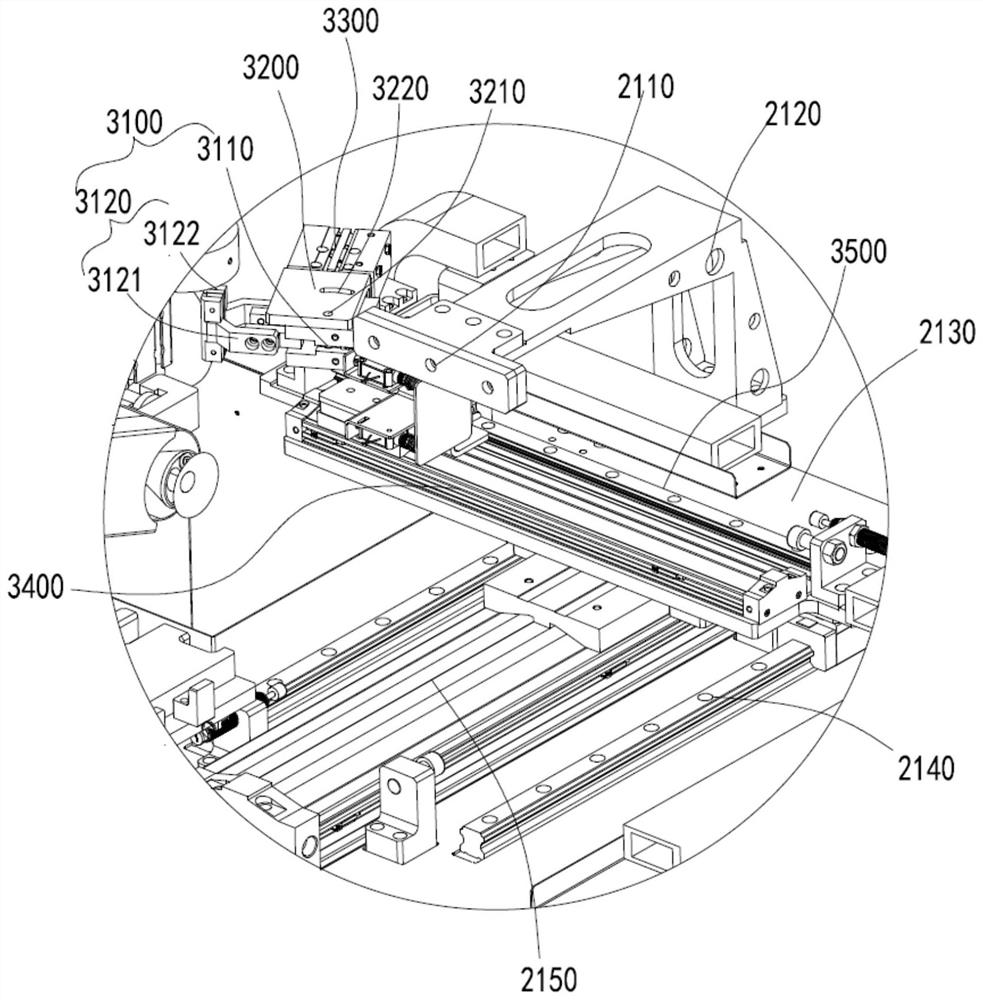

Battery cell module surface pretreatment device, battery cell module surface treatment method and battery pack assembly production line

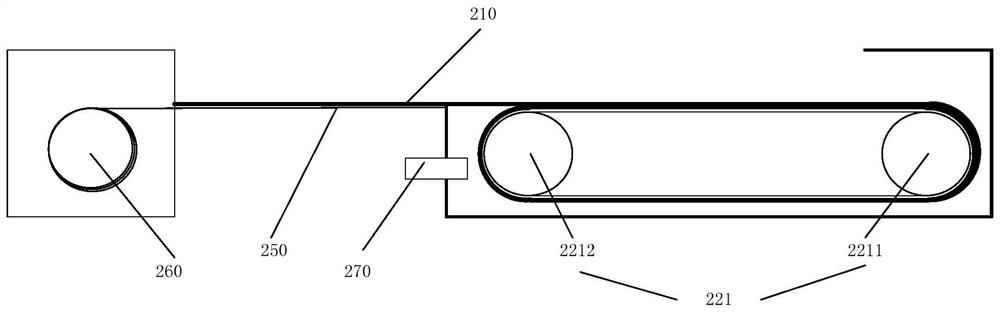

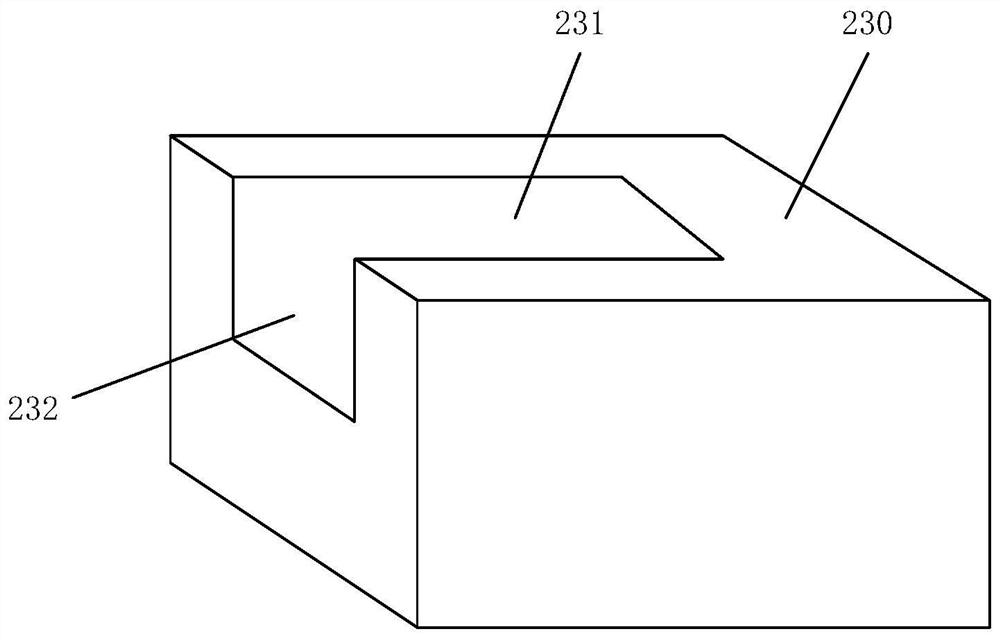

PendingCN111628204ARealize paper removalEasy to operateAssembling battery machinesFinal product manufactureProcess engineeringMechanical engineering

The invention discloses a battery cell module surface pretreatment device, a battery cell module surface treatment method and a battery pack assembly production line. The battery cell module surface pretreatment device comprises a battery cell module supporting table; a battery cell module locking mechanism used for fixing a workpiece on the battery cell module supporting table; a paper removing mechanism which is positioned in the outer side of the end part of the battery cell module supporting table and can reciprocate along the extending direction of the end part of the battery cell modulesupporting table; a cleaning mechanism which comprises a cleaning device located outside the side face of the battery cell module supporting table, and the cleaning device at least can reciprocate inthe extending direction of the side face of the battery cell module supporting table. According to the scheme, the battery cell module supporting table is arranged for supporting the battery cell module, the locking mechanism is arranged for positioning and fixing the battery cell, the paper removing mechanism and the cleaning mechanism are combined, paper removing and cleaning operation of the battery cell module can be achieved in one step, the automation degree is high, the efficiency is improved, cleaning and paper removing do not interfere with each other, and the treatment quality is guaranteed.

Owner:SUZHOU JEE INTELLIGENT EQUIP CO LTD

Method for reducing peeling risk of photoresist of ion implantation layer

ActiveCN106328506AReduce the risk of strippingSemiconductor/solid-state device manufacturingComputer sciencePhotoresist

The invention provides a method for reducing the peeling risk of photoresist of an ion implantation layer. The method includes: step 1, obtaining a design layout of an active region layer, a polycrystalline silicon layer, the ion implantation layer and all avoiding layers, and marking allowed adding regions which allow adding of polycrystalline silicon device auxiliary patterns in the design layout through logic operation; step 2, automatically searching long edges of the ion implantation layer, and generating original polycrystalline silicon device auxiliary patterns along the long edges; and step 3, marking and cleaning the original polycrystalline silicon device auxiliary patterns which are not in accordance with a design rule to obtain the expected polycrystalline silicon device auxiliary pattern.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Electronic component

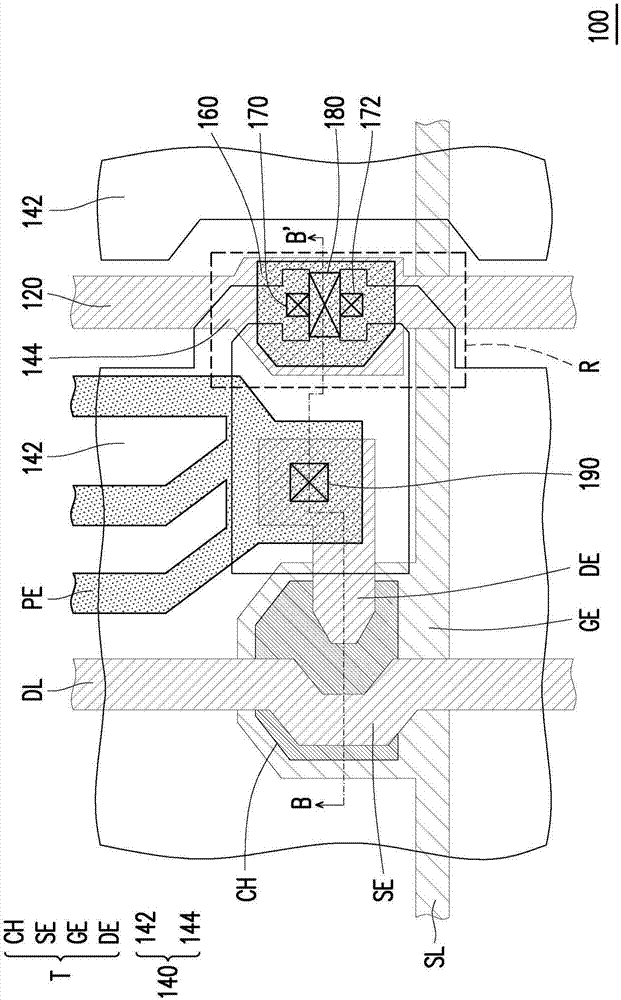

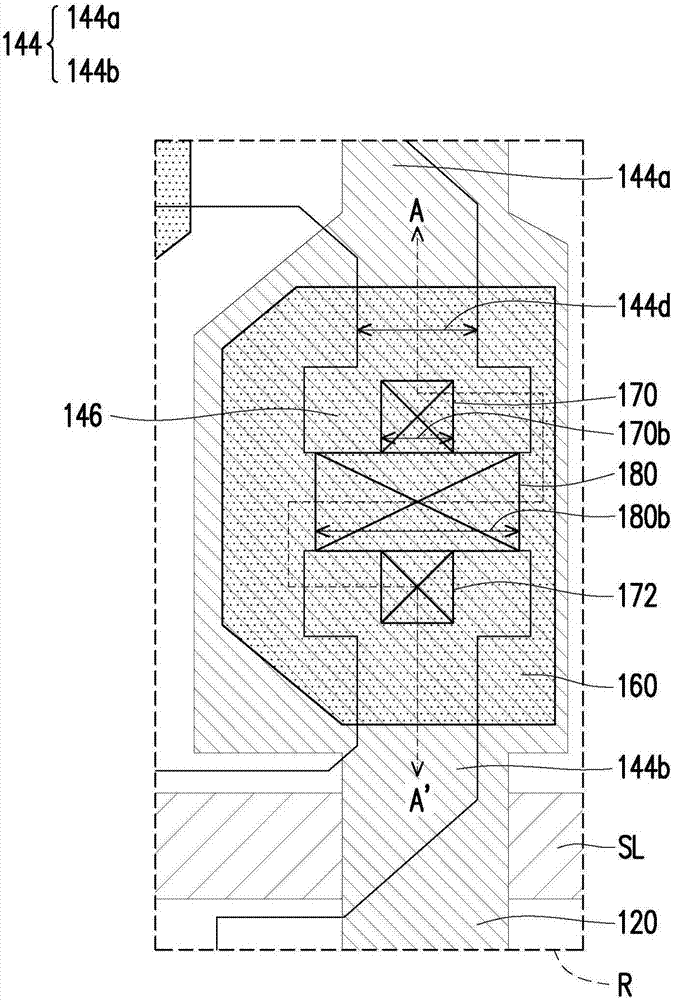

InactiveCN107368220AReduce the risk of strippingEasy dischargeSolid-state devicesInput/output processes for data processingEngineeringElectronic component

An electronic component comprises a substrate, a signal line, a first insulating layer, a first electrode, a second insulating layer and a second electrode. The signal line is arranged on the substrate. The first insulating layer is arranged on the signal line. The first electrode is arranged on the first insulating layer. The second insulating layer is arranged on the first electrode and the first insulating layer. The second electrode is arranged on the second insulating layer. The second insulating layer has a first through hole, and the first insulating layer and the second insulating layer share a second through hole. The signal line is electrically connected with the first electrode by means of the first through hole, the second through hole and the second electrode.

Owner:AU OPTRONICS CORP

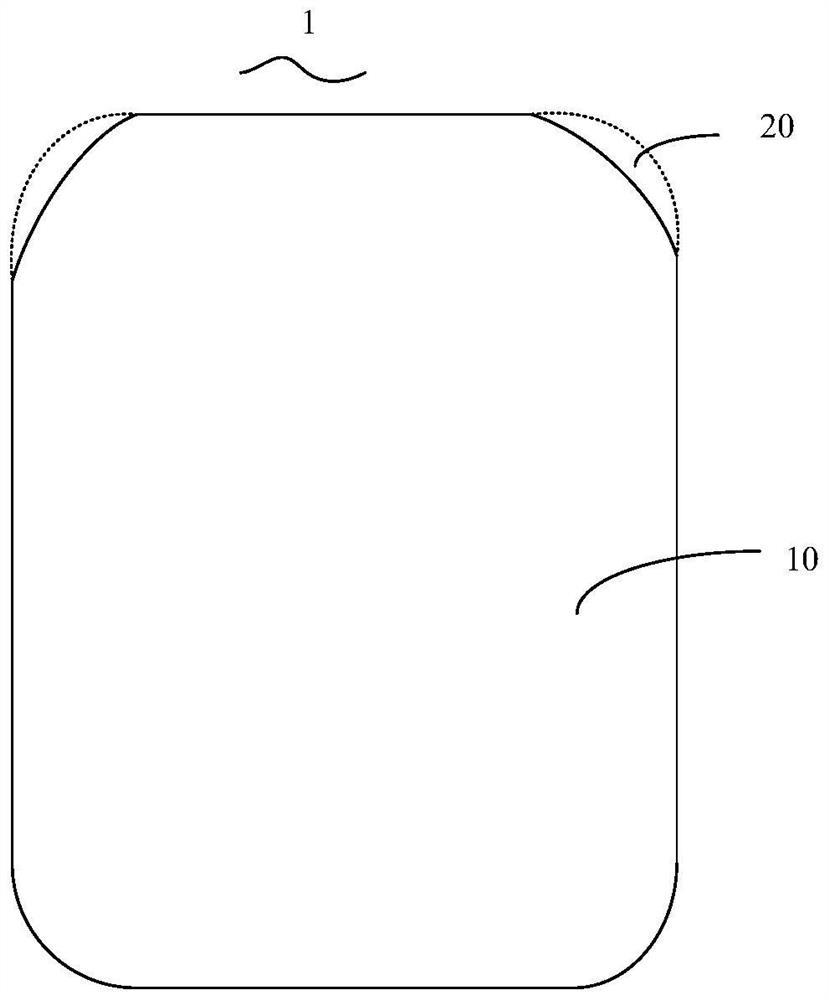

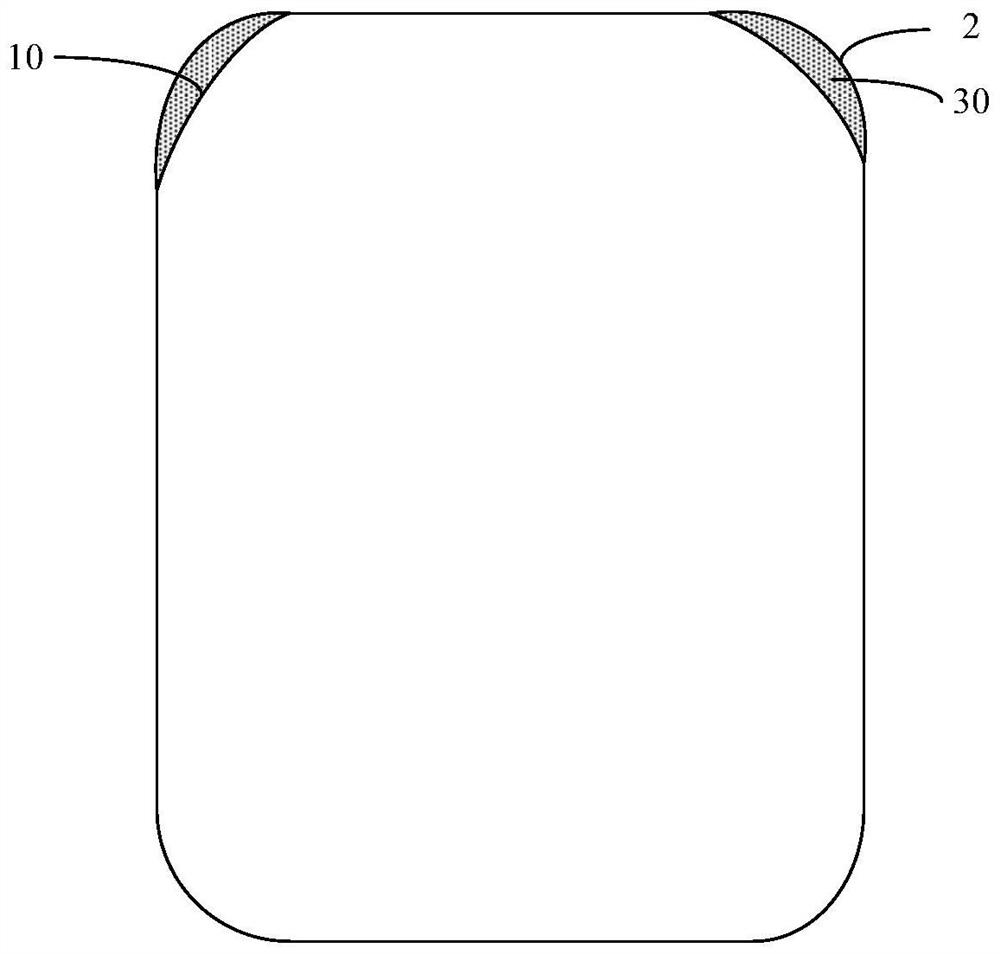

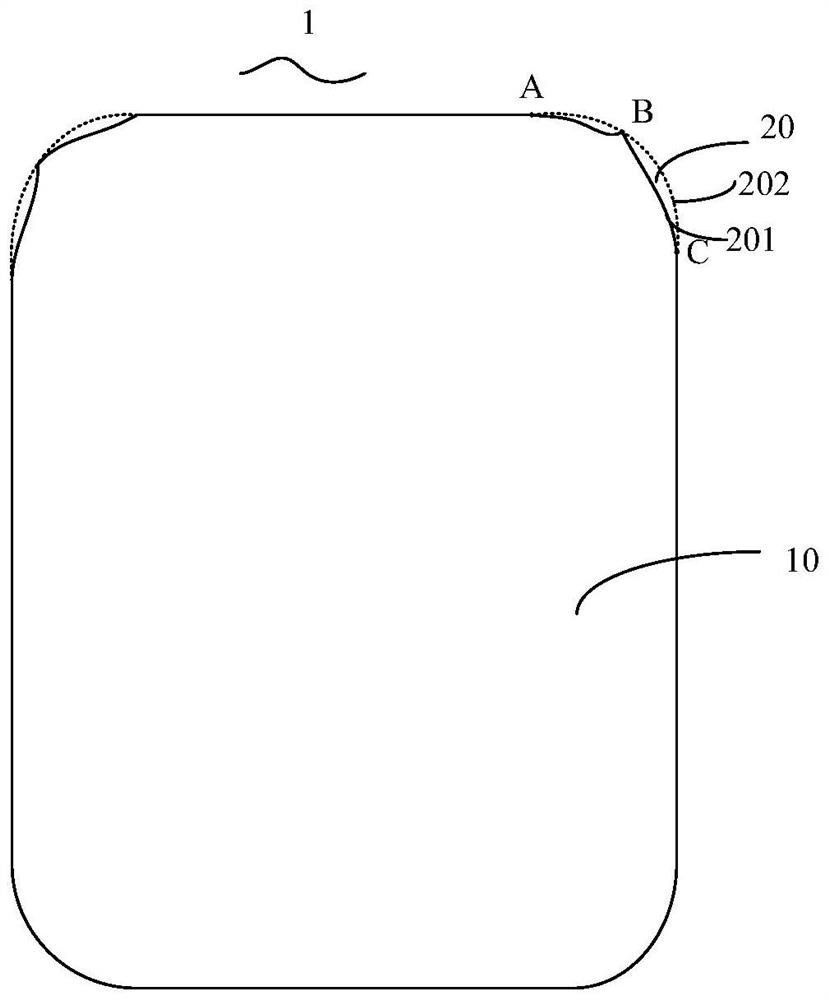

Polaroid, liquid crystal display panel, liquid crystal display device and assembling method thereof

InactiveCN113156566AImprove tearabilityIncrease the bonding areaPolarising elementsNon-linear opticsLiquid-crystal displayEngineering

The invention provides a polaroid which comprises a polaroid body, at least one corner of the polaroid body is provided with a notch, when the polaroid is attached to a substrate of a liquid crystal display panel, the substrate exposes an area corresponding to the at least one notch, the notch is provided with an inner side edge and an outer side edge which are opposite to each other, and the inner side edge and the outer side edge have at least three intersection points. According to the polaroid, under the condition that it is guaranteed that the protective film of the polaroid is easy to tear, the notch in the polaroid is designed to be the non-communication area, compared with a crescent-shaped notch in the prior art, the notch is smaller, and the area exposed out of the substrate is reduced. After the liquid crystal display panel is attached to the backlight module, the gap between the liquid crystal display panel and the backlight module is reduced, so that the attaching area between the polaroid and the backlight module can be enlarged, the adhesive force between the polaroid and the backlight module is increased, the stripping risk is reduced, and the yield of the liquid crystal display device is improved. The invention further provides a liquid crystal display panel, a liquid crystal display device and an assembling method thereof.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

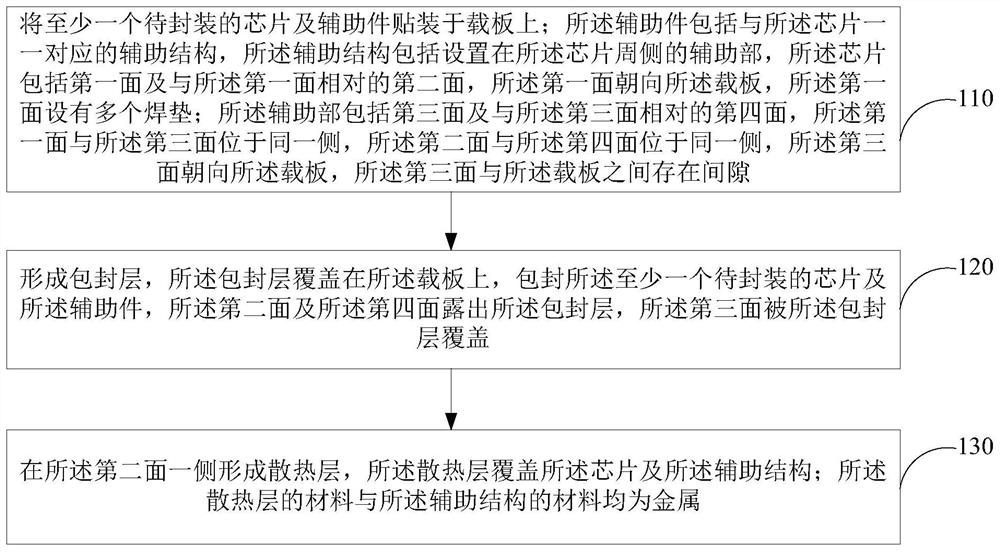

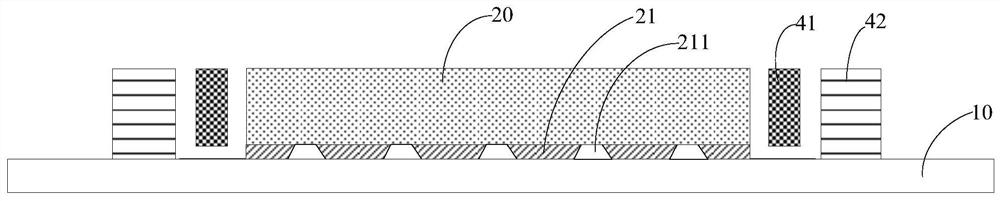

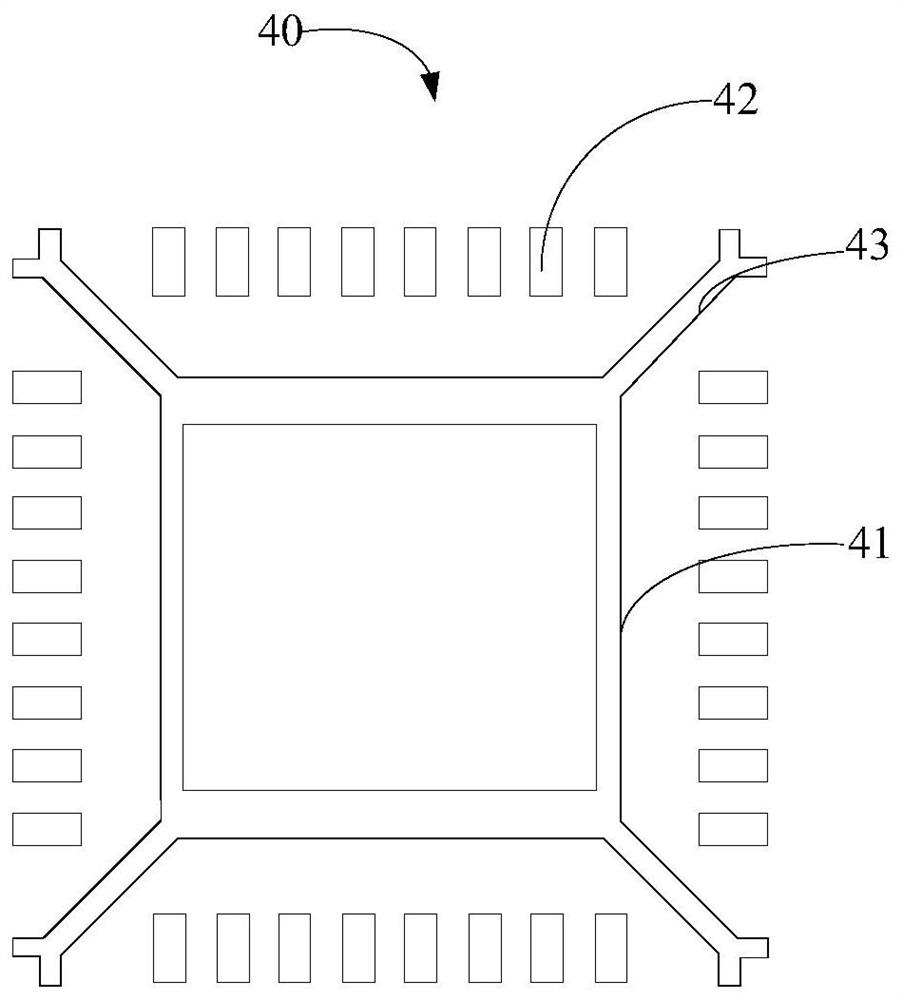

Semiconductor packaging method and semiconductor packaging structure

ActiveCN111739805APackage structure is simpleImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageMaterials science

The invention provides a semiconductor packaging method and a semiconductor packaging structure. The semiconductor packaging method comprises the steps that at least one to-be-packaged chip and an auxiliary member are mounted on a carrier plate, wherein the auxiliary member comprises auxiliary structures in one-to-one correspondence with the chips, the auxiliary structure comprises an auxiliary part arranged on the peripheral side of the chip, the chip comprises a first surface and a second surface opposite to the first surface, the first surface is provided with a plurality of welding pads, and the first surface of the chip faces the carrier plate, the auxiliary part comprises a third surface and a fourth surface opposite to the third surface, the third surface faces the carrier plate, and a gap exists between the third surface and the carrier plate; an encapsulation layer is formed, the encapsulation layer covers the carrier plate and encapsulates the at least one to-be-packaged chipand the auxiliary part, the second surface and the fourth surface are exposed out of the encapsulation layer, and the third surface is covered by the encapsulation layer; a heat dissipation layer isformed on one side of the first surface, wherein the heat dissipation layer covers the chip and the auxiliary structure; the material of the heat dissipation layer and the material of the auxiliary structure are both metal.

Owner:SIPLP MICROELECTRONICS CHONGQING CO LTD

Bipolar membrane based on pre-modified metal organic framework material and preparation method and application thereof

ActiveCN112473395AStable mechanical propertiesImprove film formationSemi-permeable membranesAdhesiveSolvent evaporation

The invention discloses a bipolar membrane based on a pre-modified metal organic framework material and a preparation method thereof. A commercial anion exchange membrane is used as a substrate, the surface of the anion exchange membrane is coated with an adhesive, a metal organic framework material and sulfonated polyethersulfone are blended and coated on an adhesive layer, and the bipolar membrane is prepared through a solvent evaporation method. By introducing the pre-modified metal organic framework material, the problems that the nano material is easy to agglomerate, the doping amount istoo low, the nano material is easy to leak and the like are better solved, the structure of the membrane is improved, an effective channel is provided for migration of ions in the cation exchange membrane side, the ion migration rate can be increased, the succinic acid yield is increased. The bipolar membrane has the advantages of stable membrane performance, simple preparation process, high separation efficiency, high doping amount and the like, and solves the problem that a cathode membrane and an anode membrane in the bipolar membrane are easy to layer and peel. The bipolar membrane has a wide application prospect in the field of preparation of succinic acid from the bipolar membrane.

Owner:OCEAN UNIV OF CHINA

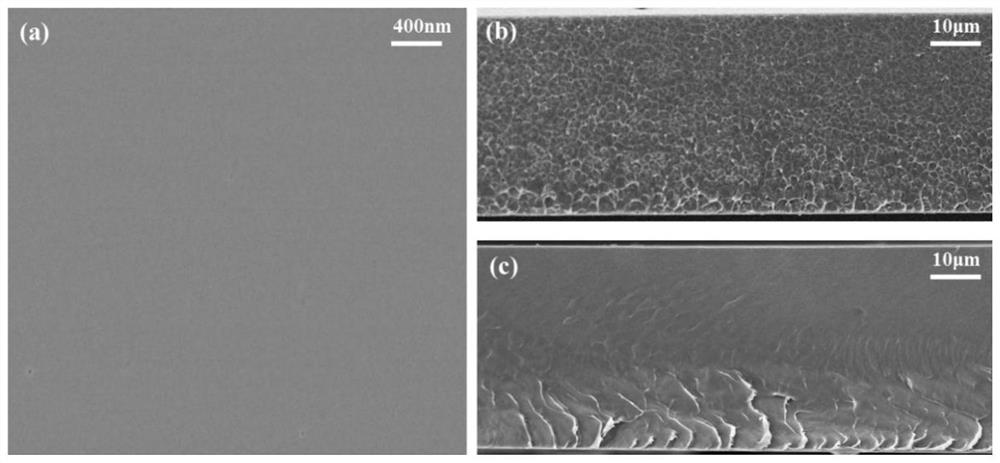

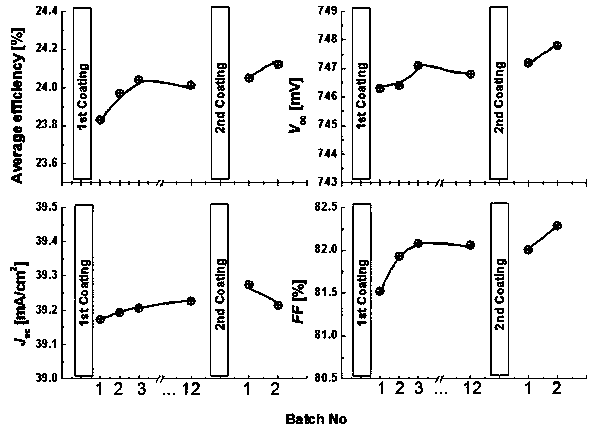

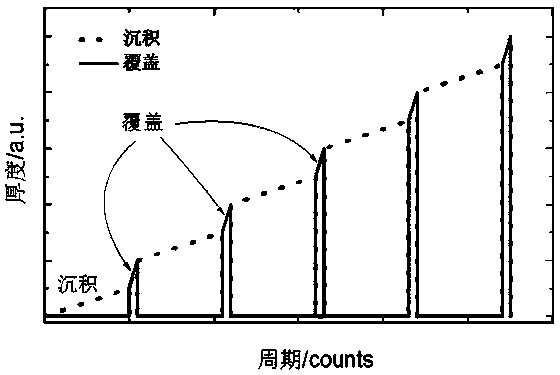

Preparation method of stable and high-efficiency silicon heterojunction solar cell

ActiveCN111599893AIncrease internal stressReduce consumptionFinal product manufacturePhotovoltaic energy generationHeterojunctionSolar cell

The invention discloses a preparation method of a stable and high-efficiency silicon heterojunction solar cell. The preparation method comprises the steps of depositing an intrinsic amorphous siliconthin film on the surface of an accumulation thin film, wherein the accumulation thin film comprises an accumulation thin film in a deposition chamber, the intrinsic amorphous silicon thin film deposited in the deposition chamber is an amorphous silicon thin film with high hydrogen content and high disorder degree, and the high hydrogen content refers to that the percentage content of hydrogen is 10%-25% relative to the number of silicon atoms of 5.22*10<22> by calculating the number of hydrogen atoms in unit volume; and the high disorder degree means that the microstructure factor R is 15-80%.The amorphous silicon thin film is deposited in the deposition chamber and on the surface of the tray, so that the internal stress of the accumulation thin film can be effectively reduced, the falling of the accumulation thin film in the deposition chamber is avoided, the stable output of the high-efficiency low-cost silicon heterojunction solar cell is facilitated, the accumulation thin film isquickly processed, and the stable high-efficiency silicon heterojunction solar cell is obtained.

Owner:ZHONGWEI NEW ENERGY CHENGDU CO LTD

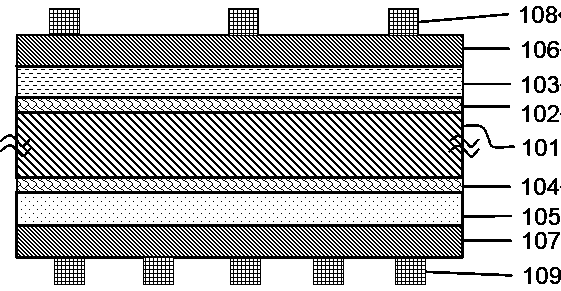

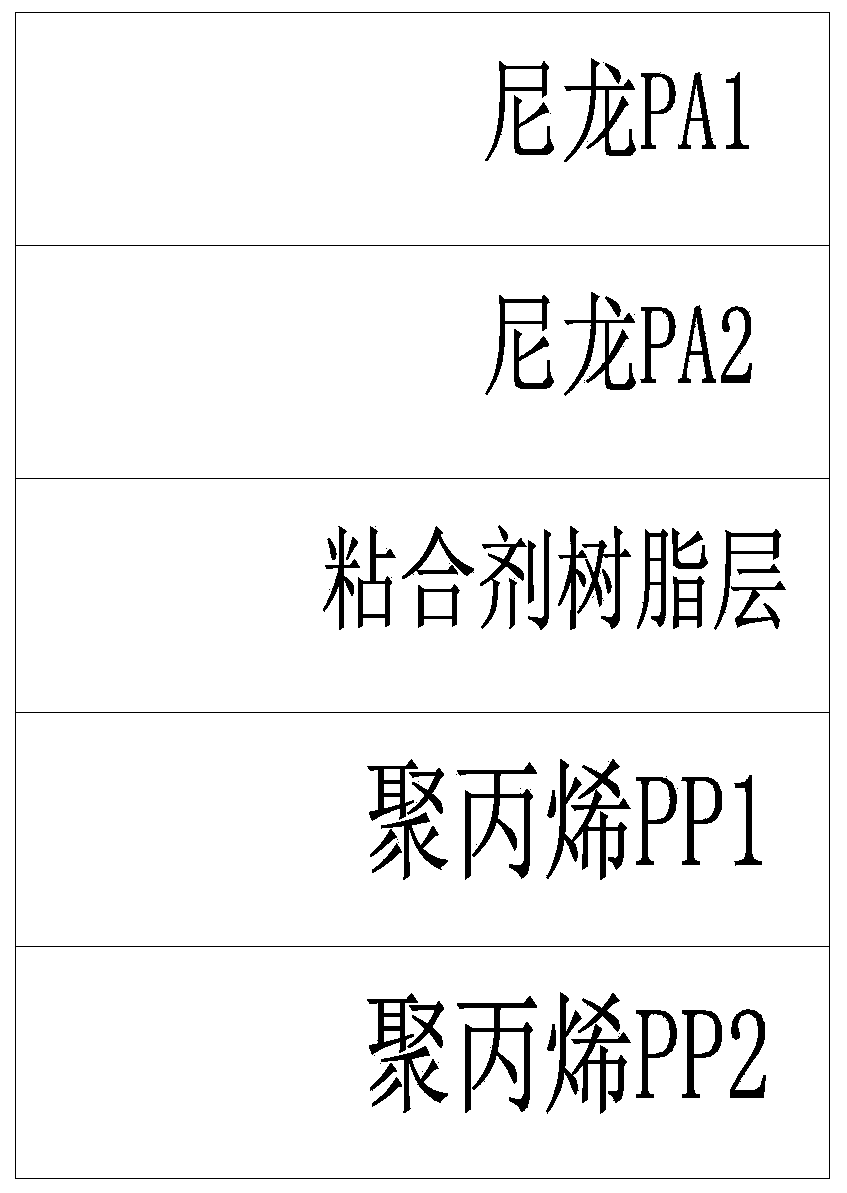

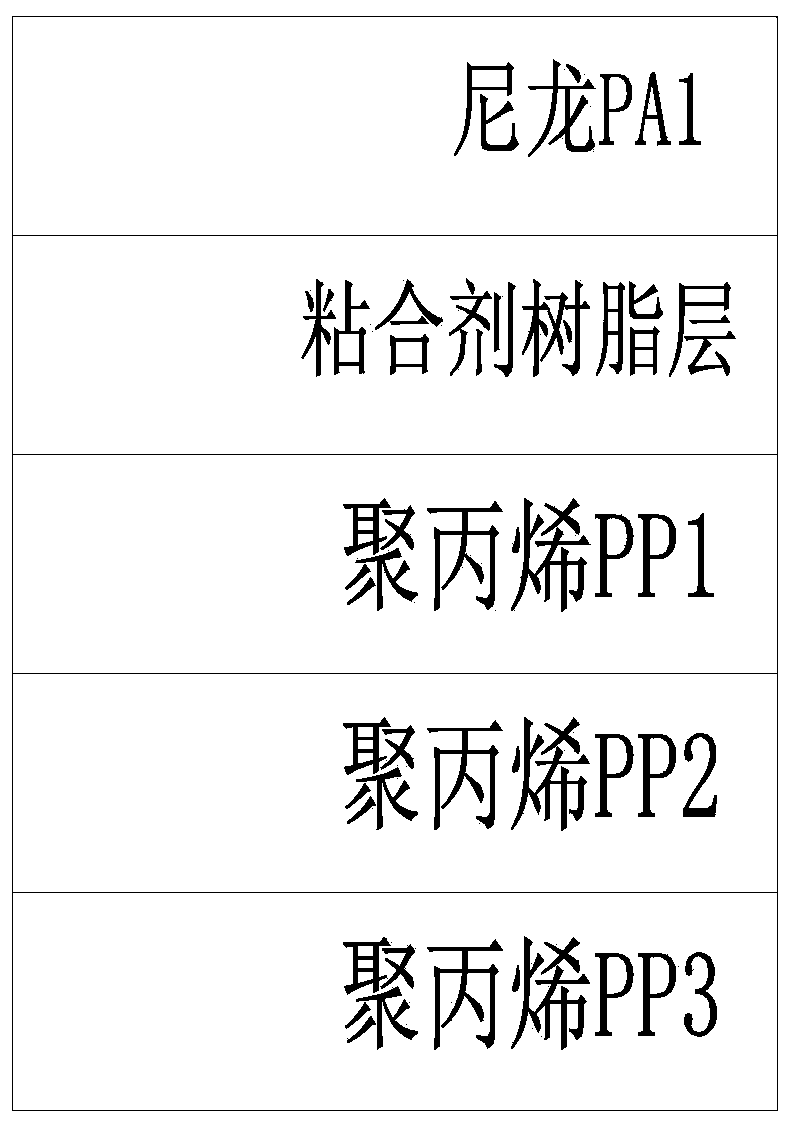

Anti-stripping sealing film for lithium battery and preparation method thereof and aluminum-plastic composite film thereof

PendingCN110065283AReduce the number of adhesive layersReduce the risk of strippingSynthetic resin layered productsCell component detailsAdhesiveLithium battery

The invention relates to an anti-stripping sealing film for a lithium battery and a preparation method thereof and an aluminum-plastic composite film thereof, wherein the anti-stripping sealing film comprises a sealing outer layer and a sealing inner layer; an adhesive resin layer is arranged between the sealing outer layer and the sealing inner layer. The composite film is subjected to twice foaming and once horizontal stretching; the aluminum-plastic composite film comprises a molding outer layer, an aluminum foil layer and an inner sealing layer, wherein the aluminum foil layer is bonded with the molding outer layer through a first bonding layer, the aluminum foil layer is bonded with the inner sealing layer through a second bonding layer, and the inner sealing layer adopts the sealingfilm. By changing the structure of the traditional sealing film (inner film) and connecting the sealing outer layer on the sealing inner film by adhesive resin, after the aluminum-plastic composite film is used, the sealing outer layer is used as an intermediate layer of the whole aluminum-plastic composite film, so that the problem that the prior intermediate layer needs to be coated with adhesive on two sides so as to increase the number of adhesive layers in the whole plastic composite film is avoided, and the peeling risk is reduced by reducing the number of adhesive layers.

Owner:江阴长庚高科技材料有限公司

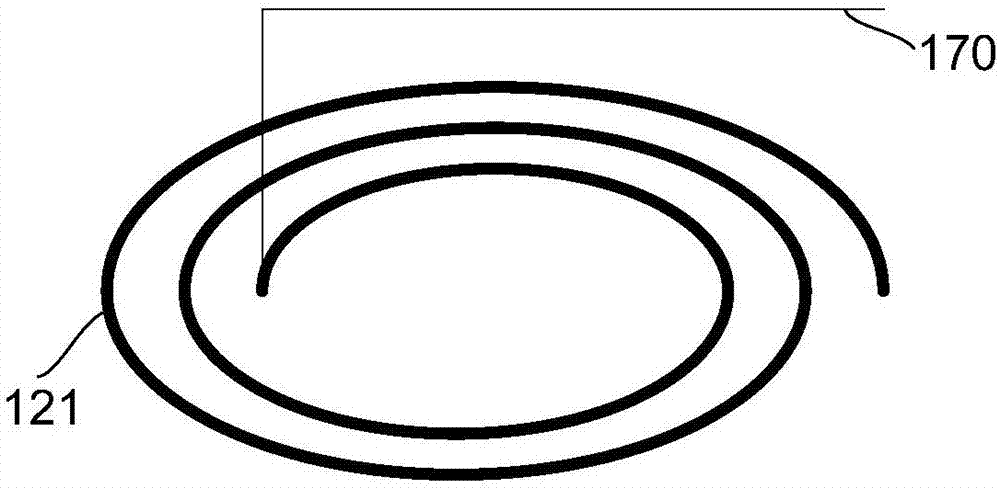

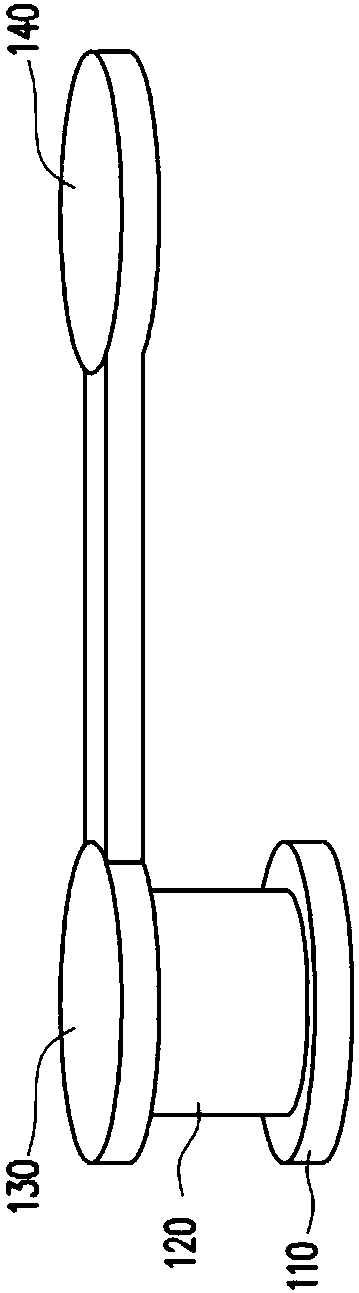

Magnetic induction device and manufacturing method therefor

ActiveCN107104120AReduce warpageReduce the risk of strippingSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceMetal

The invention provides a magnetic induction device. The magnetic induction device comprises a substrate, a first metal layer and a first dielectric layer; a groove is formed in the first surface of the substrate; the first metal layer is arranged in the groove; the surface of the first metal layer is lower than the first surface; the surface of the first metal layer and the first surface form a first concave part; and the first dielectric layer is arranged on the first surface of the substrate and the first concave part is filled with the first dielectric layer. According to the magnetic induction device and the manufacturing method therefor provided by the embodiments, the surface of the first metal layer is lower than the surface of the substrate to form the first concave part; in addition, the first dielectric layer is arranged on the surface of the substrate and the first concave part is filled with the first dielectric layer, so that the thickness of the dielectric between the first metal layer and the surface metal layer is increased while the thickness of the dielectric in other regions is unchanged; and therefore, stray capacitance can be lowered, breakdown voltage can be improved, and risk of substrate warping and dielectric layer stripping also can be lowered.

Owner:成都线易科技有限责任公司 +1

Flexible display screen and display device

InactiveCN109461759AAvoid gatheringImprove stress toleranceSolid-state devicesSemiconductor/solid-state device manufacturingState of artDisplay device

Embodiments of the invention relate to the technical field of display, and disclose a flexible display screen and a display device. The flexible display screen comprises a flexible substrate and lightemitting units arranged on the flexible substrate, wherein each light emitting unit comprises a first electrode and a grid layer used for absorbing stress; and the first electrode is integrally embedded into the grid layer. The display device comprises the flexible display screen. According to the embodiments of the invention, compared with the prior art, the grid layer used for absorbing stressis arranged in each light emitting unit, and the first electrode is integrally embedded into the grid layer, so that when the flexible display screen is bent, grids in the grid layer can release stress, and the stress is prevented from being gathered in the first electrode, and thus the stress bearing capacity of the first electrode is improved, and the risk that the first electrode is broken or stripped from other film layers is reduced.

Owner:YUNGU GUAN TECH CO LTD

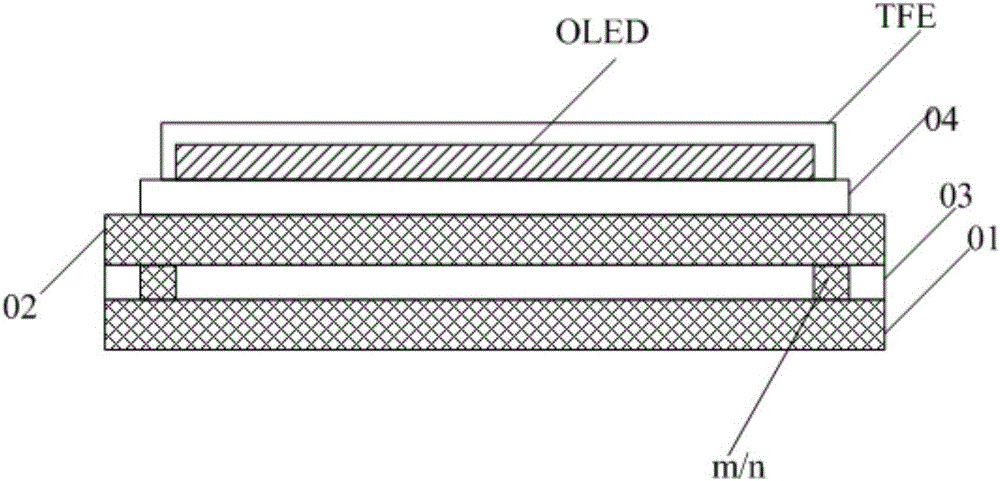

OLED display panel and manufacturing method thereof

InactiveCN110518143AQuality improvementImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingTransverse pressureEngineering

The invention discloses an OLED display panel and a manufacturing method thereof. The OLED display panel comprises a substrate, a thin film transistor layer, an OLED device layer and a packaging structure layer which are stacked in sequence, wherein the packaging structure layer comprises a first inorganic packaging layer, a first organic packaging layer and a second inorganic packaging layer which are stacked in sequence; the first inorganic packaging layer is provided with; and the first organic packaging layer is provided with a second groove. The display panel has the beneficial effects that firstly, the thin film packaging layer is provided with the groove structure, so that the adhesion and the stability of the inorganic packaging layer and the organic packaging layer are improved, the display panel is not easy to break away when being bent or subjected to transverse pressure, an internal film layer is better protected from being damaged by external water, oxygen, impurities andthe like, and the quality of the display panel is improved; and secondly, the grooves are divided into the first groove and the second groove according to different thicknesses of the inorganic packaging layer and the organic packaging layer, and the depths of the first groove and the second groove are different to a certain extent, so that the stability of the thin film packaging is further improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Circuit board manufacturing method

ActiveCN107734879AReduce widthEasy to limitMultilayer circuit manufactureFine lineConductive polymer

The invention provides a circuit board manufacturing method comprising the following steps: placing electronic elements configured with many receive pads into a contain groove formed by jointing a substrate with a bonding layer; forming a dielectric layer so as to cover the receive pads, the electronic elements, the bonding layer and the substrate, and etching the dielectric layer so as to exposethe receive pad top surfaces; forming a composite material layer so as to cover the receive pads and the dielectric layer, wherein the composite material layer comprises a platable dielectric layer, aconductive polymer layer and an anti-plating layer arranged from bottom to top in order; forming a plurality of open holes in the composite material layer so as to expose partial the receive pads andpartial the dielectric layer; forming a metal layer connected with the conductive polymer layer on the open hole bottoms and partial the side wall formed by the platable dielectric layer and the conductive polymer layer; forming a line layer in the open holes, and removing the conductive polymer layer and the anti-plating layer, wherein the line layer top surface is flush with the platable dielectric layer. The method can increase the circuit board area utilization rate and wiring density, and can improve the fine line peeling problems.

Owner:UNIMICRON TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com