SIP series target material capable of avoiding stripping of anti-sputtering layer and application thereof

A technology of layer peeling and reverse sputtering, which is applied in the field of SIP series targets, can solve the problems of tip discharge, abnormal physical tip, and can not well alleviate the interface stress mismatch and stress concentration problems, so as to reduce the stress concentration factor , Reduce the risk of stripping, increase the risk of discharge and wafer scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

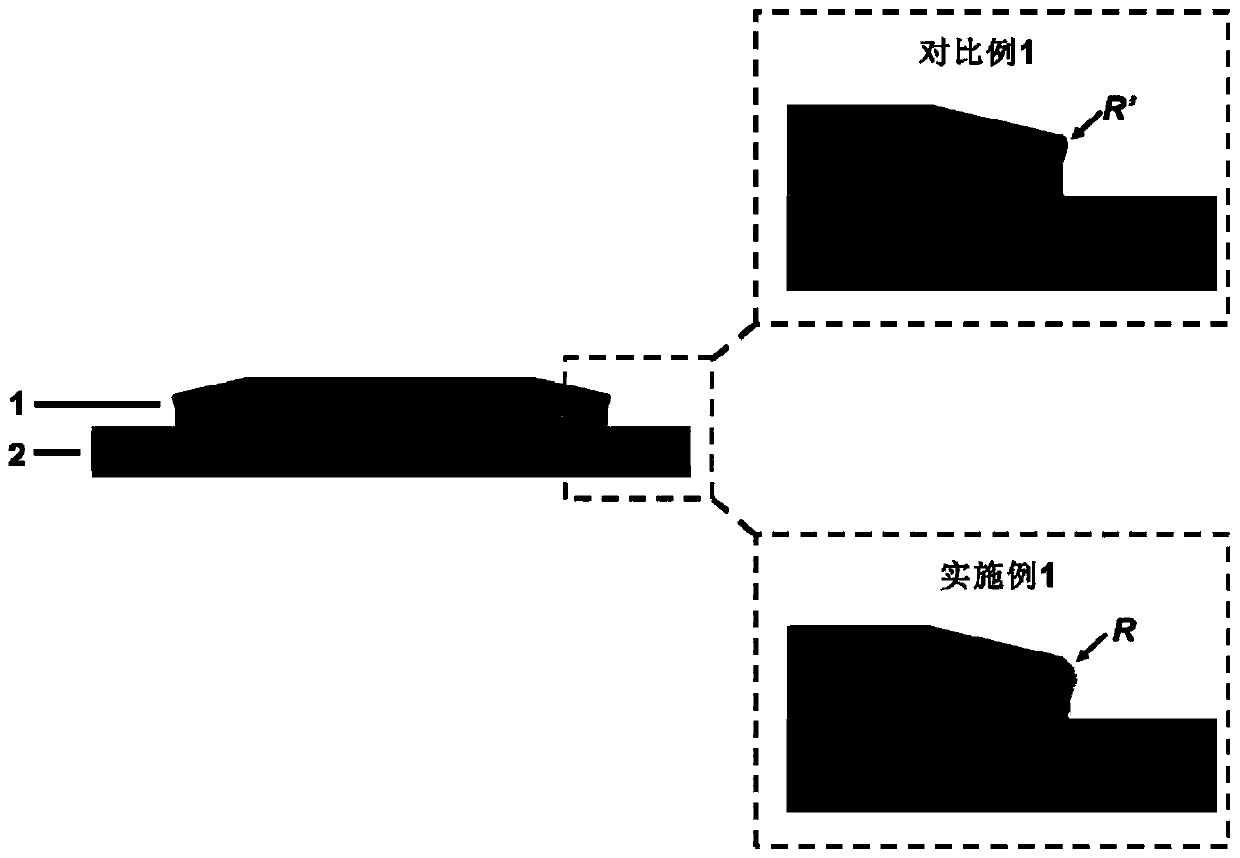

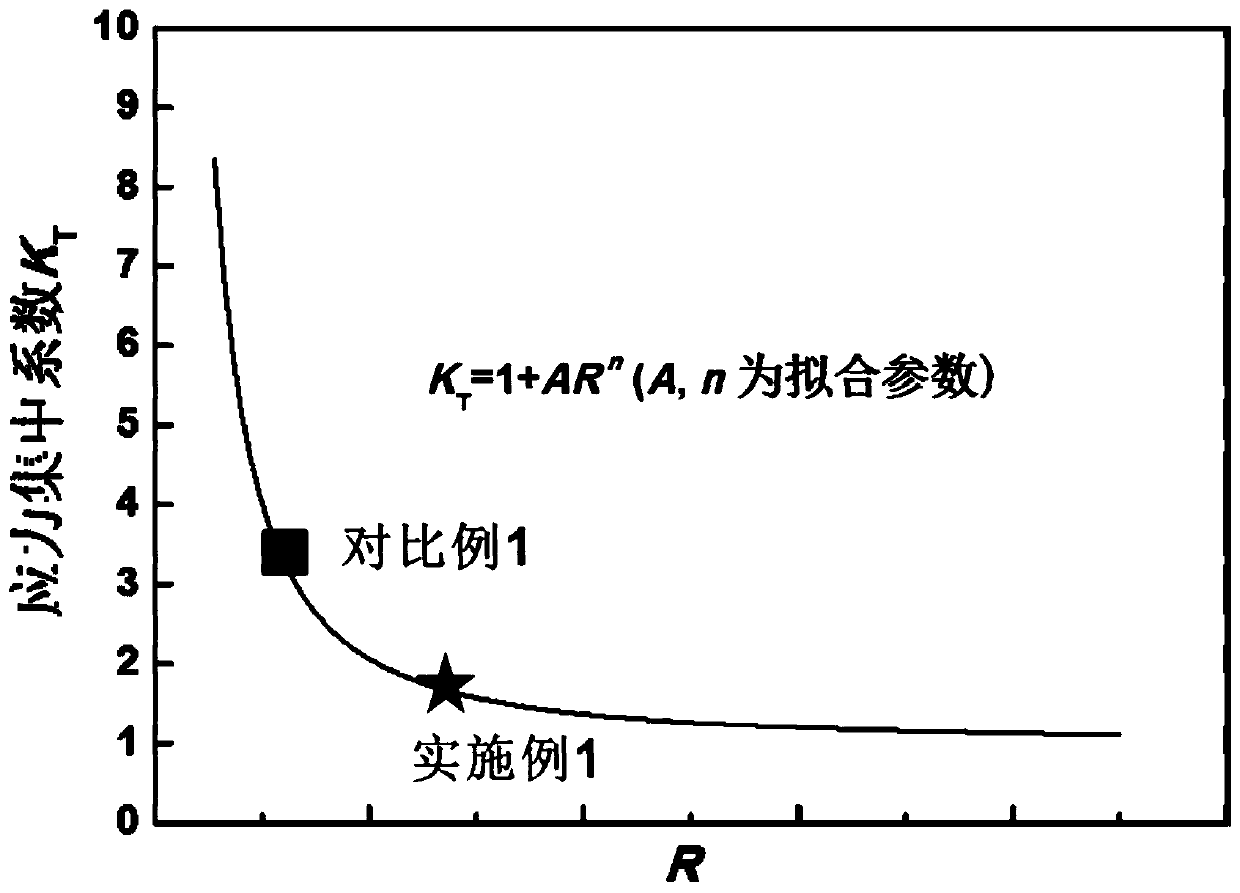

[0034] The schematic diagram of the structure of the SIP series target in this embodiment is as follows figure 1 As shown, where 1 is the cathode metal, 2 is the back plate, and the radius R=8mm;

[0035] The composition and preparation method of the cathode material and the back plate material in the SIP series target in this embodiment are as follows:

[0036]Cathode metal material: 4N5 Ti (purity ≥ 99.995%);

[0037] Cathode metal shape: disk-shaped, with hypotenuse and R angle on the edge;

[0038] Cathode metal size: the overall outer diameter is 425mm, and the total height is 12.7mm;

[0039] Backplane material: Cu alloy;

[0040] Preparation process: Machining (ordinary car, numerical control) is used to process a circular arc transition on the edge of the cathode metal, with a radius R=8mm.

Embodiment 2

[0042] The difference from Embodiment 1 is that the radius R=10mm.

Embodiment 3

[0044] The difference from Embodiment 1 is that the radius R=12mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com