Front support of fairing of wind generating set

A technology for wind turbines and shrouds, which is applied to wind turbines, wind power generation, installation/support configuration of wind turbines, etc., and can solve problems such as endangering the safe operation of wind turbines, easy cracking of front bracket welds, and small welding areas , to achieve the effect of overcoming cracking, reducing hidden troubles, and uniform stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

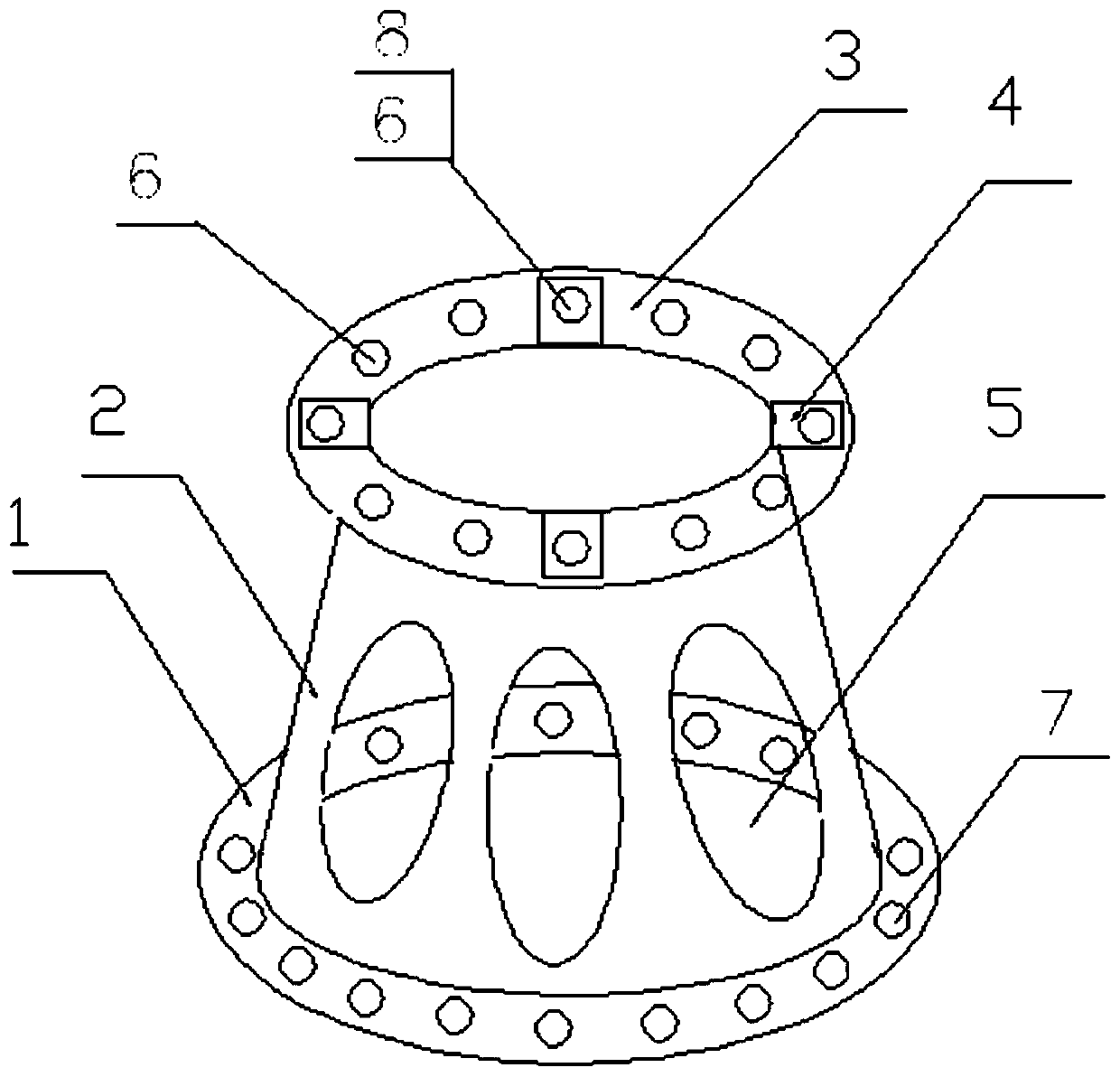

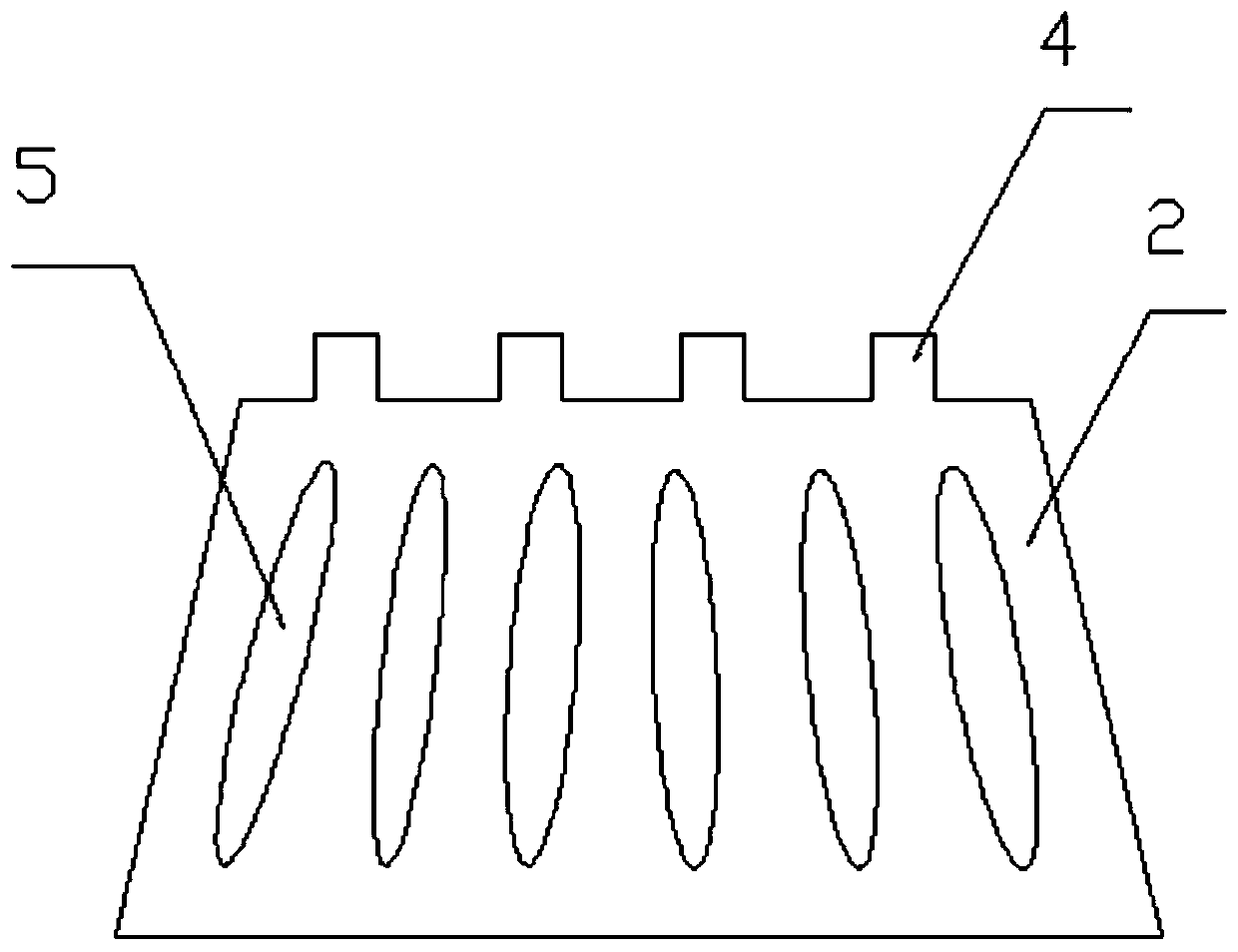

[0030] Such as figure 1 , the front bracket of the wind turbine wind turbine deflector of the present invention includes a conical cylinder 2 and a large annular plate 1 fixedly connected with the large end of the conical cylinder 2 and a small annular plate 3 fixedly connected with the small end of the conical cylinder 2 .

[0031] The small end of the conical cylinder 2 is connected with several lugs 4. In a preferred embodiment of the present invention, the number of the lugs 4 is 4, and the small end of the conical cylinder 2 is arranged at an interval of 90°. The conical cylinder 2 and the The hanging lug 4 adopts an integral structure; the hanging lug 4 is fixedly connected with the small annular plate 3 and the lower plane of the hanging lug 4 is closely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com