Node structures for lattice frames

A node structure and frame technology, applied in underwater structures, infrastructure engineering, building construction, etc., can solve the problems of unrealistic bottom structures, achieve weight and cost reduction, compact node structure, and reduce thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

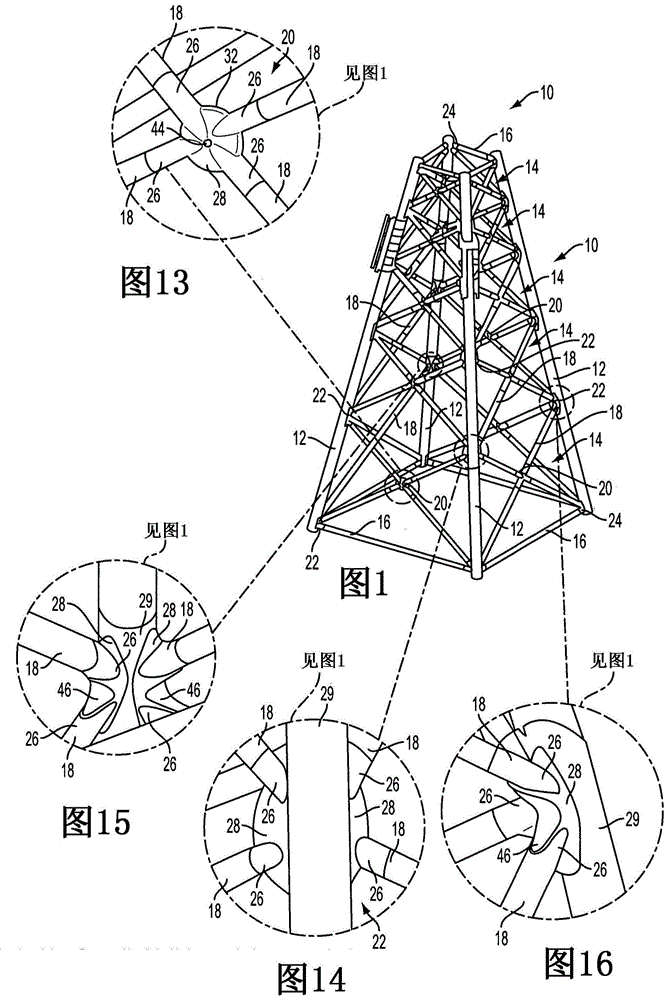

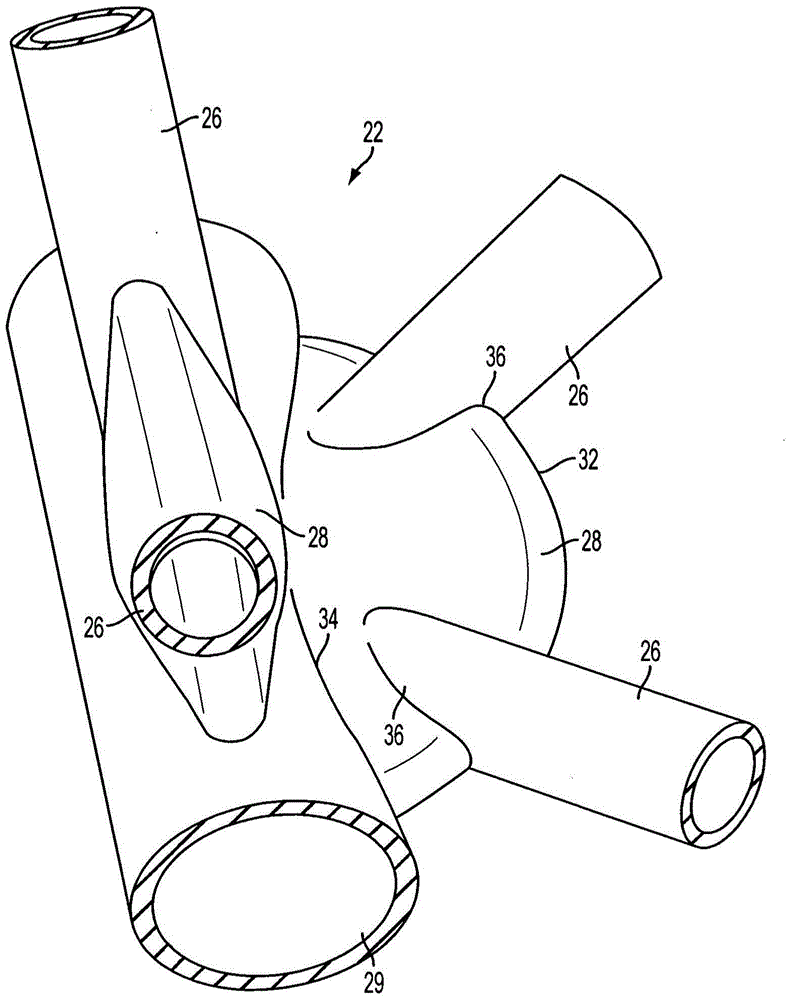

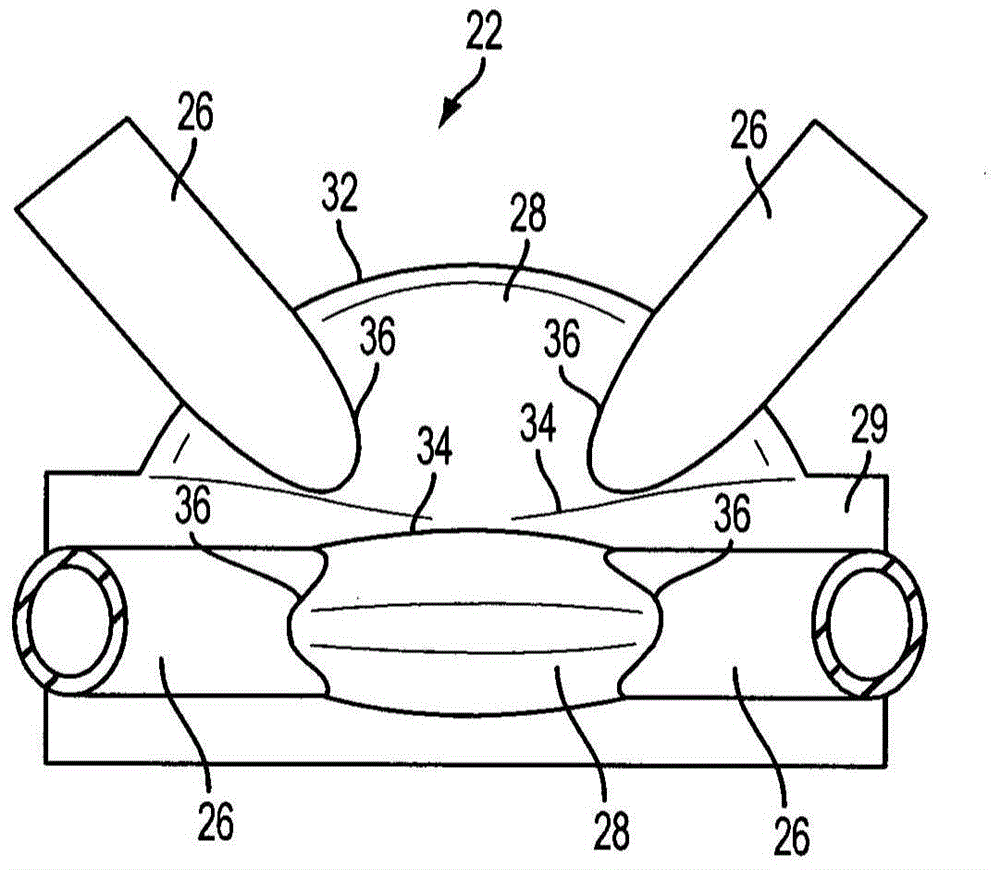

[0038] referenced figure 1 The invention is put in context. Then, next refer to the attached Figure 2 to Figure 6 , these figures show a double K-shaped node structure 22, which is used to figure 1 One member of the lattice frame jacket 10 shown in FIG. 10 (ie, the tubular leg 12 ) is connected to four other members of the jacket 10 (ie, the four tubular diagonal struts 18 ). The diagonal struts 18 are grouped in two pairs in mutually orthogonal planes about the central longitudinal axis of the leg 12 .

[0039] Each pair of diagonal struts 18 converges on a double K-shaped node structure 22 where each pair of diagonal struts is aligned and connected to a corresponding root 26 that converges at a corresponding hollow brace 28 and welded to the bracket. Each bracket 28 is welded to a leg 29 aligned with and connected to the other segments of leg 12 .

[0040] as in Figure 5 As best shown in , each bracket 28 includes opposing dish-shaped walls 30 that converge in cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com