Patents

Literature

69results about How to "Reduce stress concentration factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

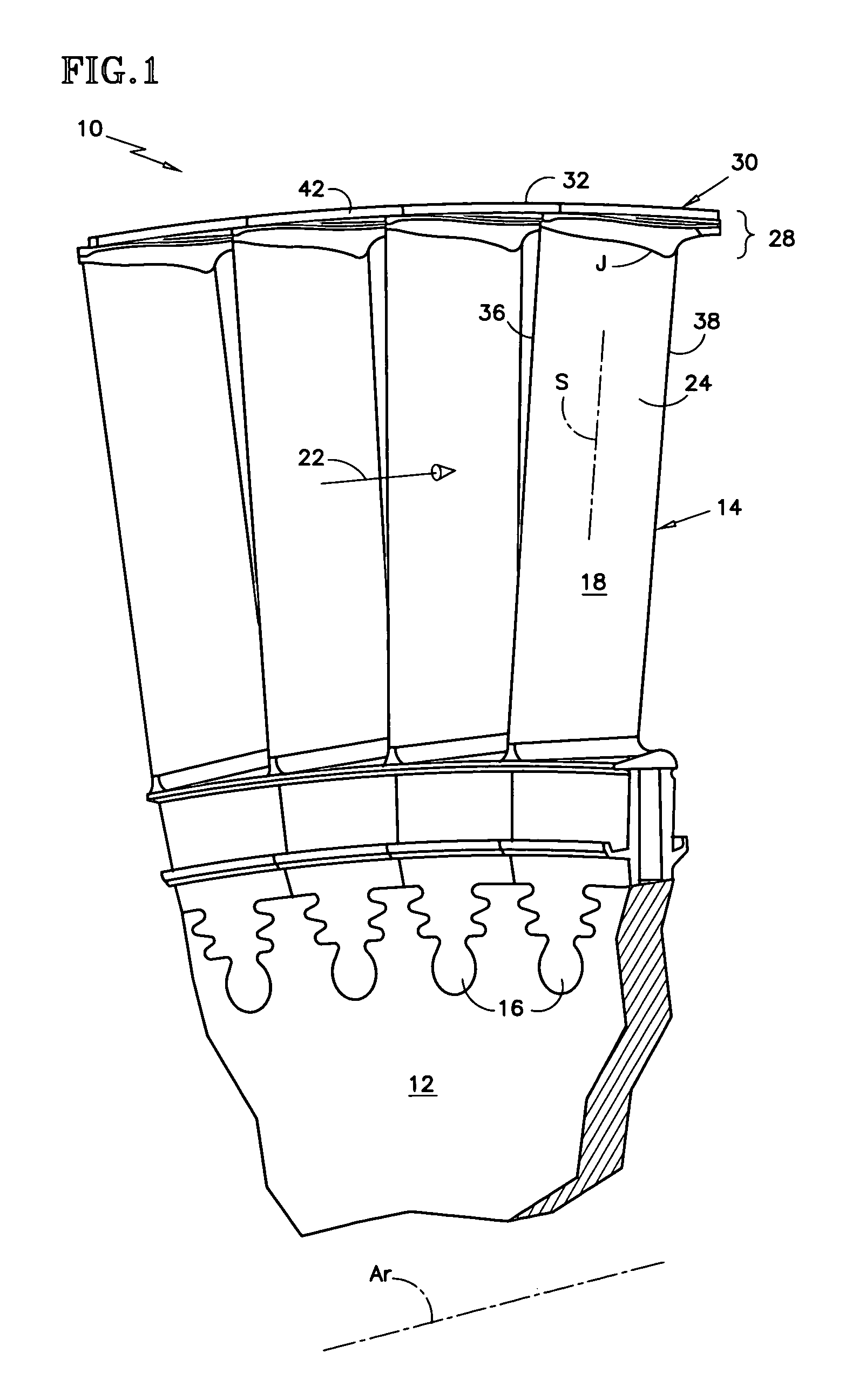

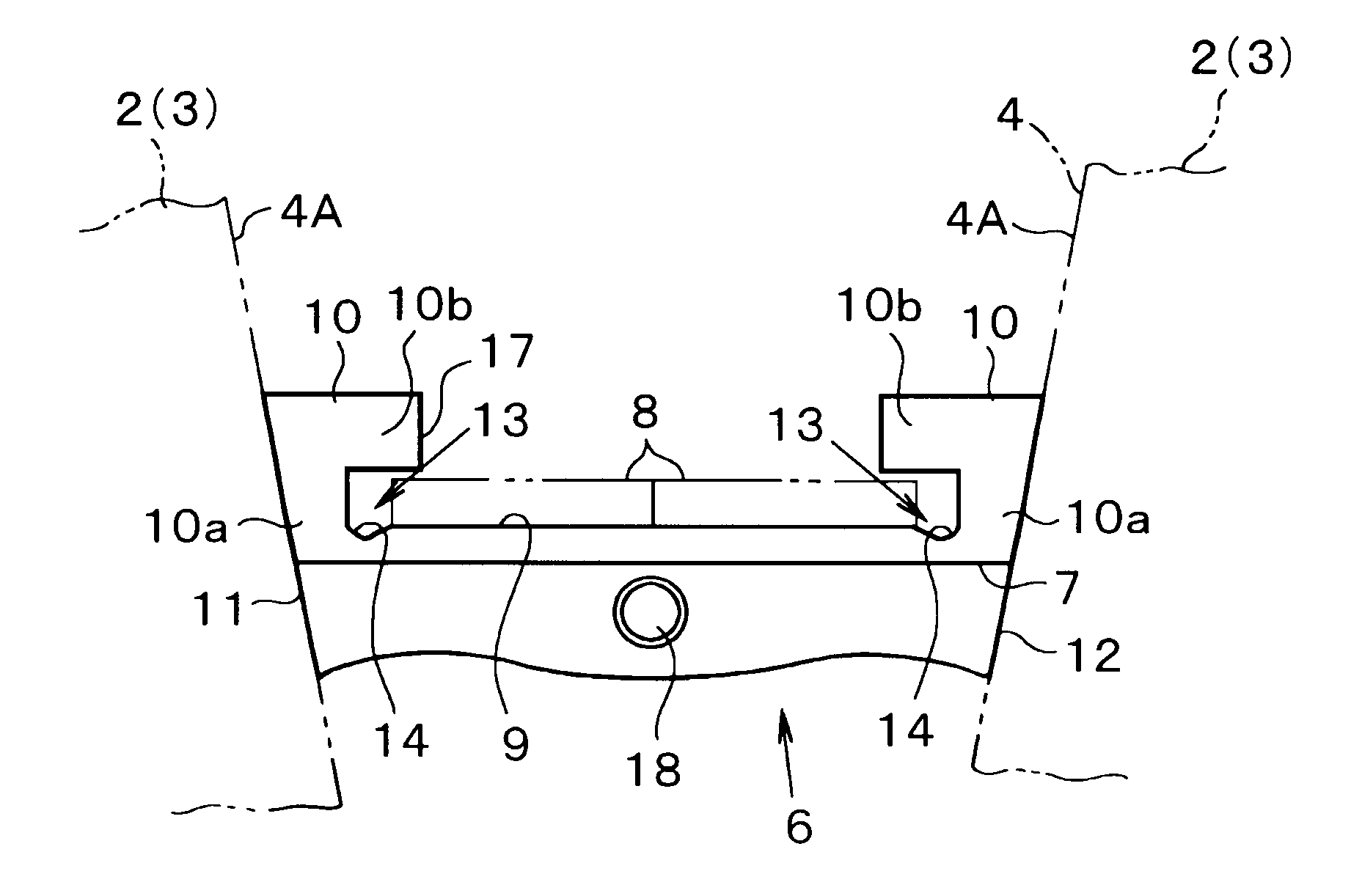

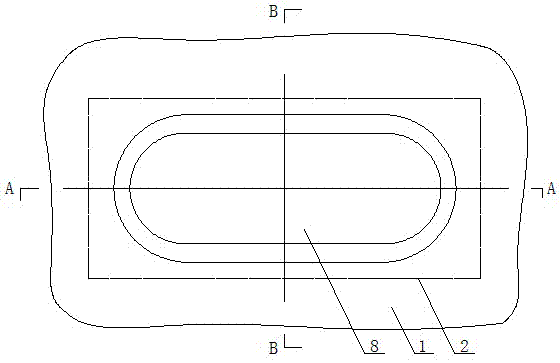

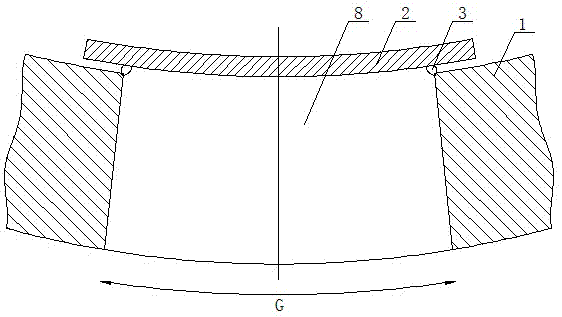

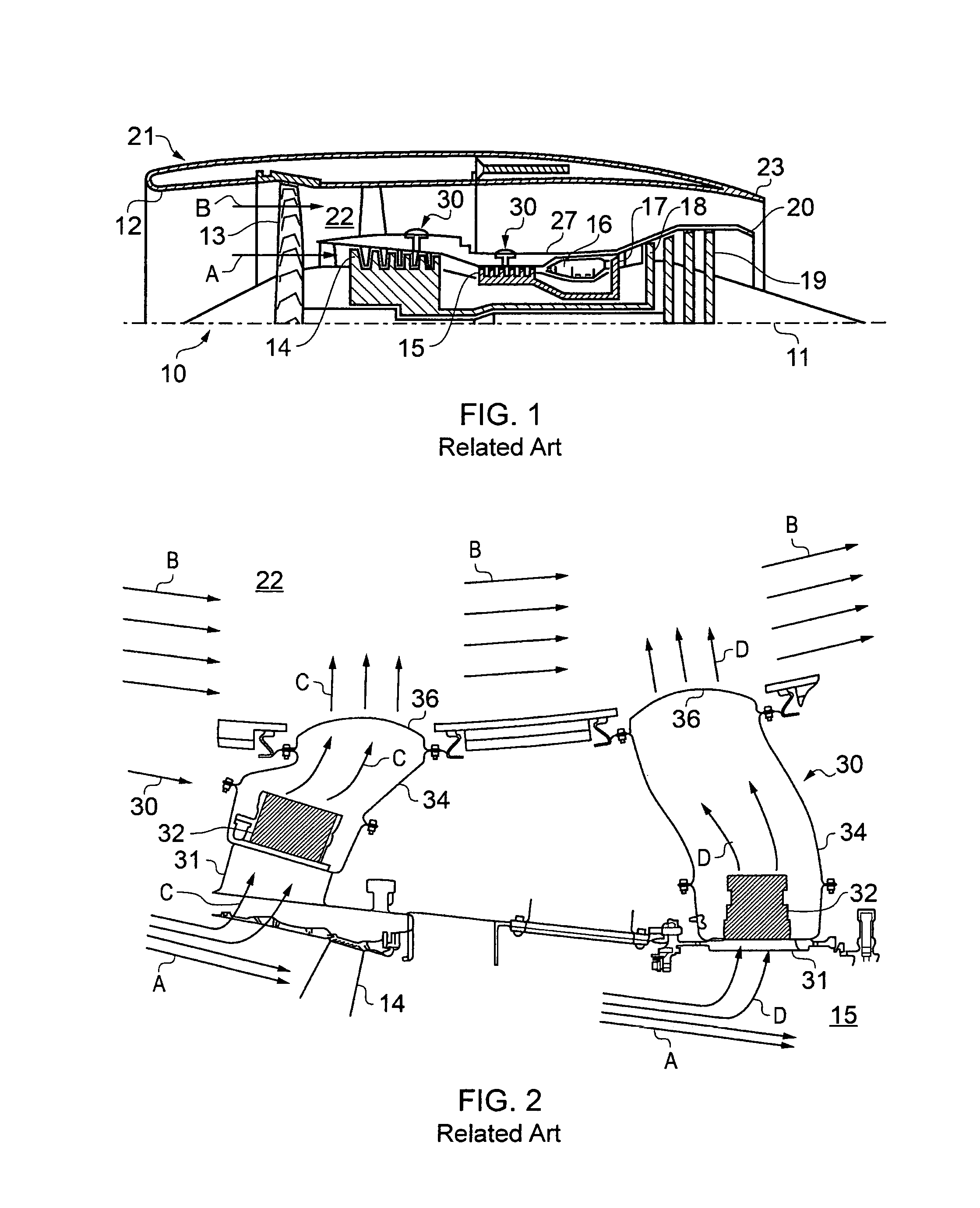

Wind turbine blade shear web connection assembly

ActiveUS20120027613A1Reduce the amount requiredReduce weightFinal product manufactureBlade accessoriesTurbine bladeEngineering

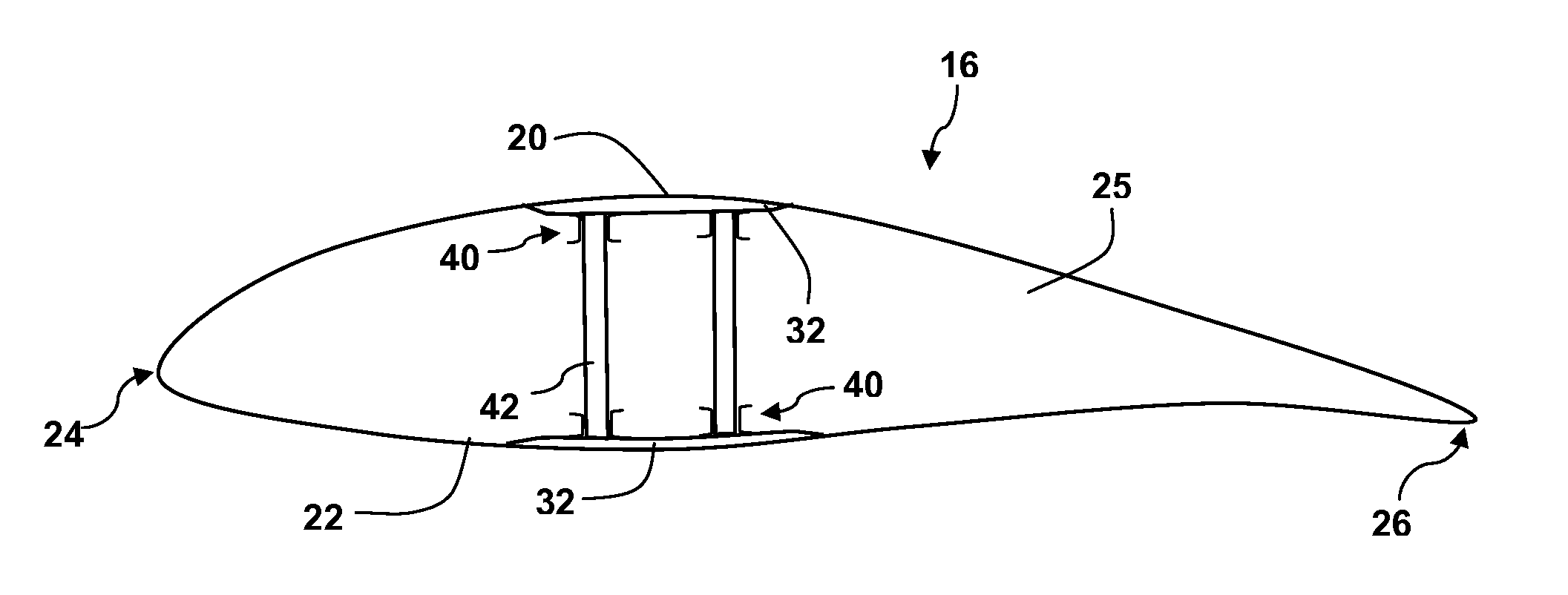

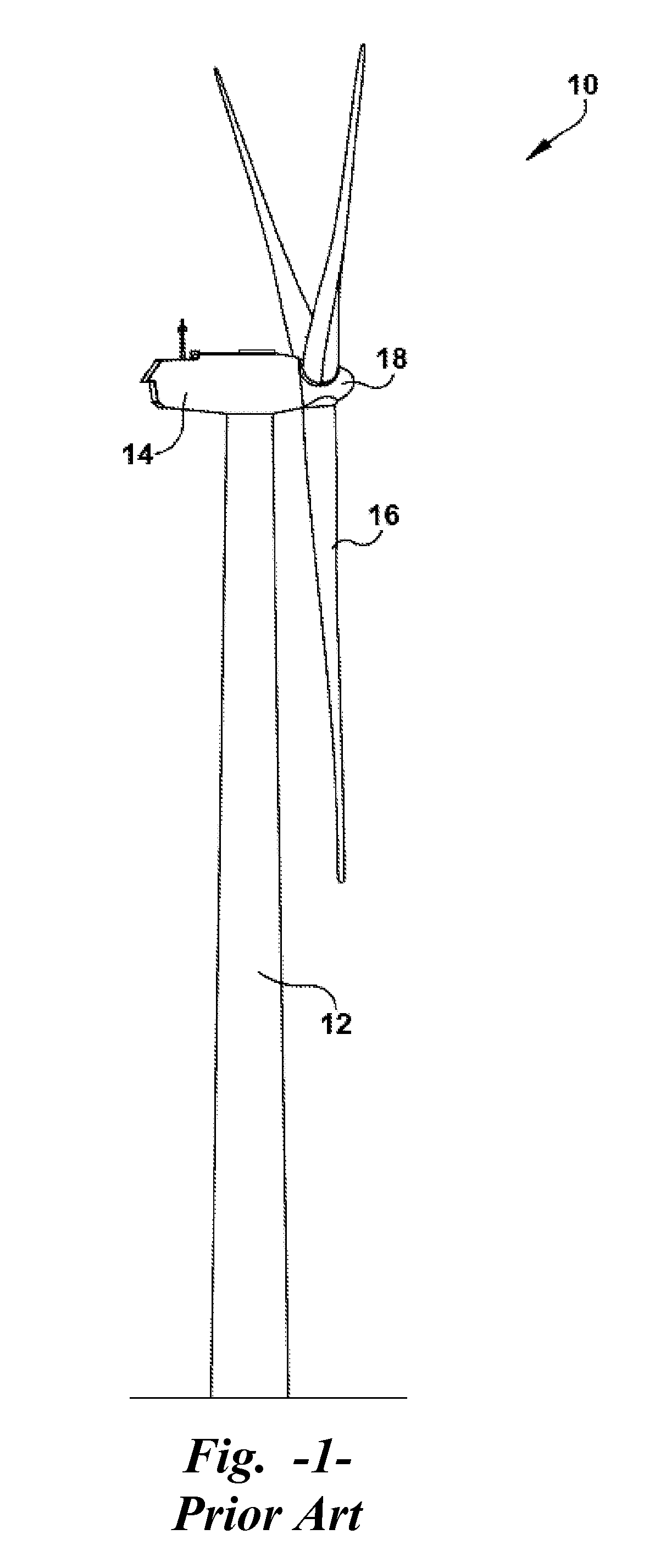

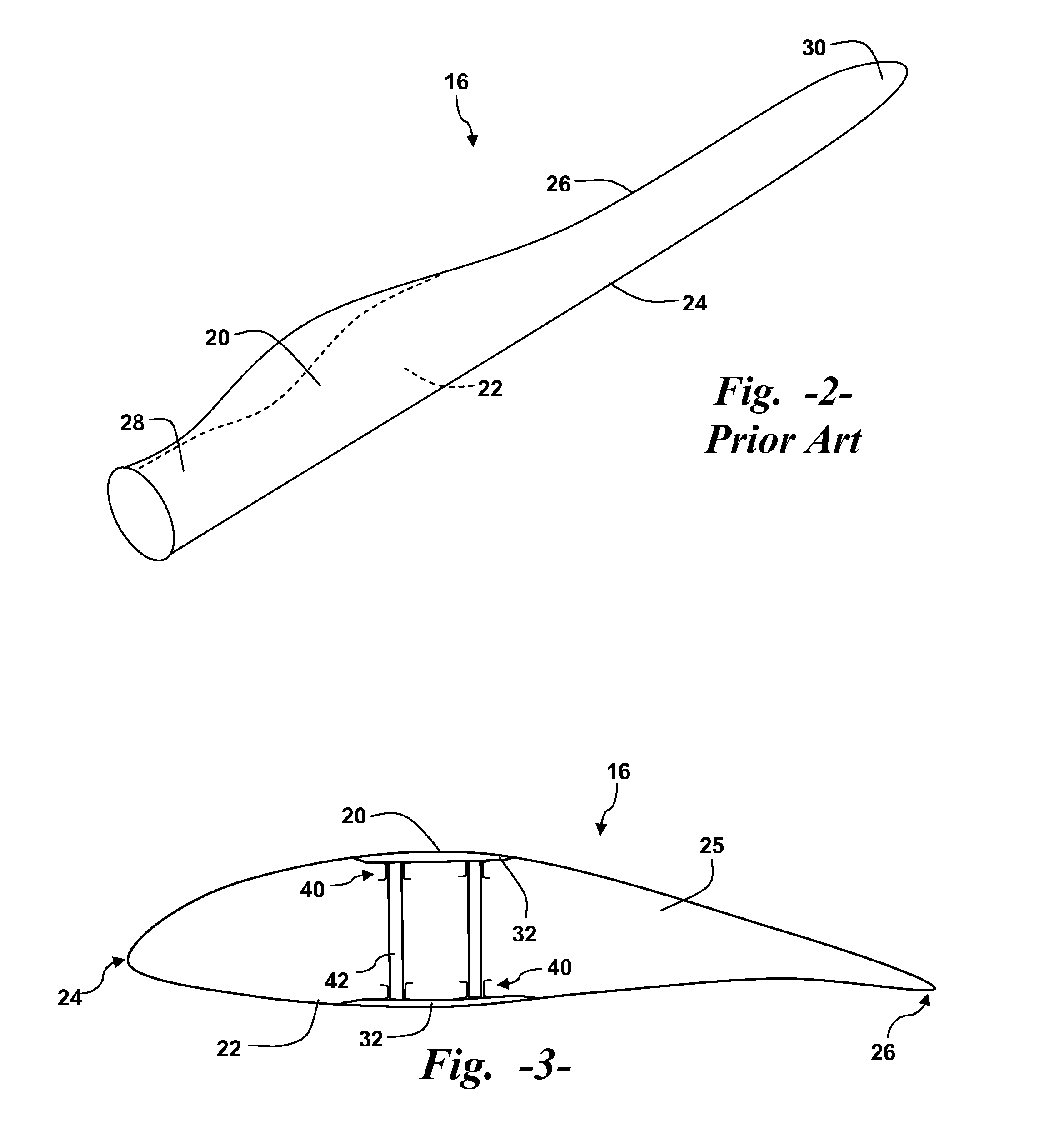

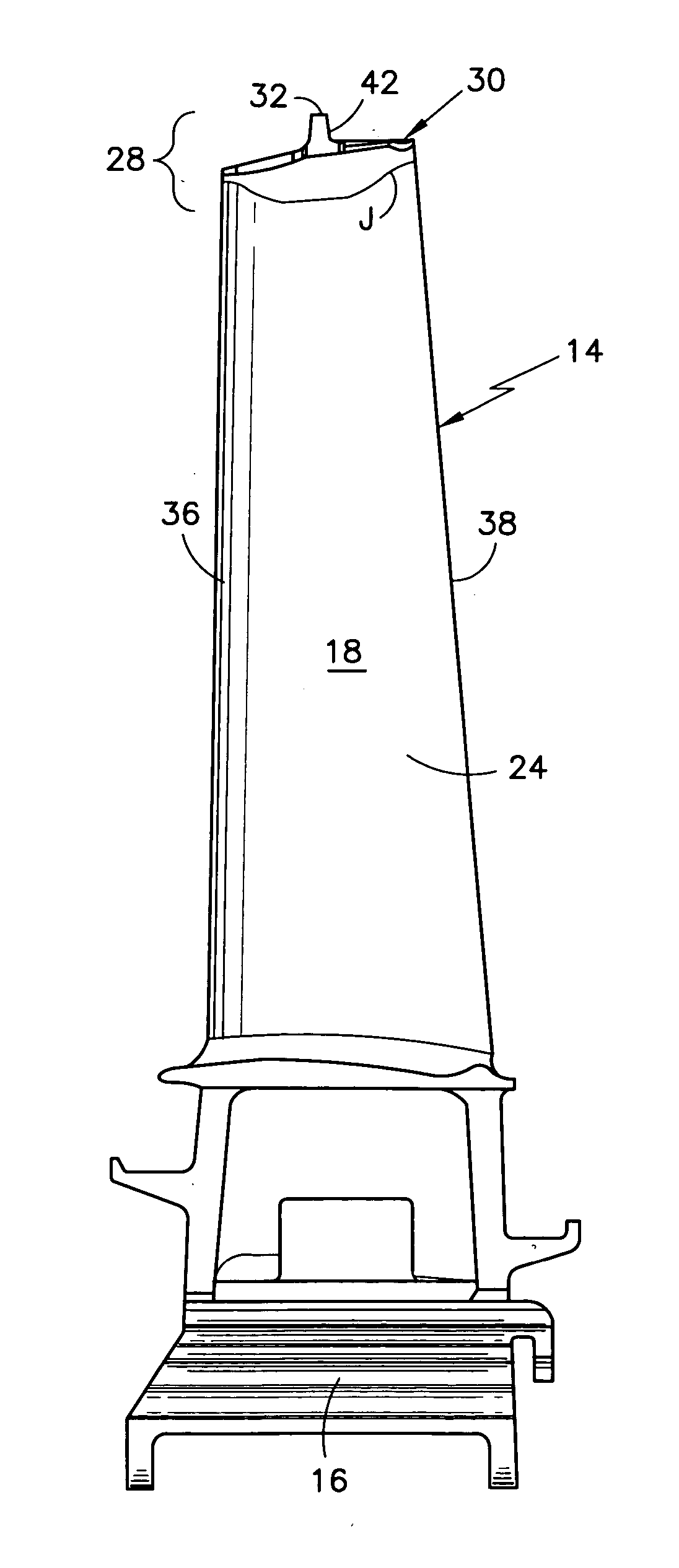

A wind turbine blade has upper and lower shell members with a respective spar cap configured on an internal face of the shell members. A shear web extends between the spar caps along a longitudinal length of the blade. A connection assembly is configured between the transverse ends of the shear web and the spar caps and includes a channel structure configured on the spar cap. The channel structure includes rigid side walls that extend from the spar cap along the longitudinal sides of the shear web. Bond paste is disposed between the channel structure side walls and the longitudinal sides of the shear web.

Owner:GENERAL ELECTRIC CO

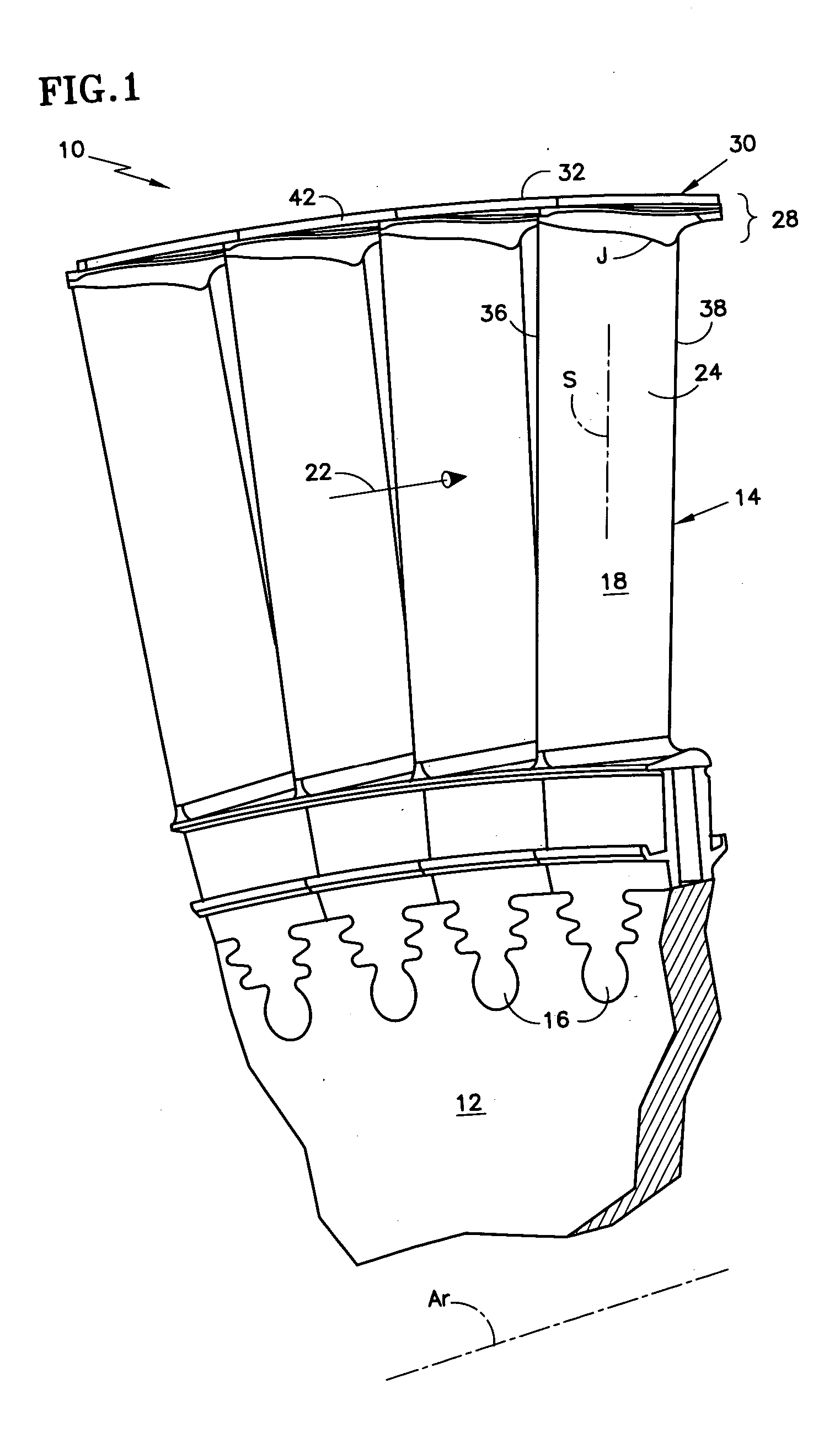

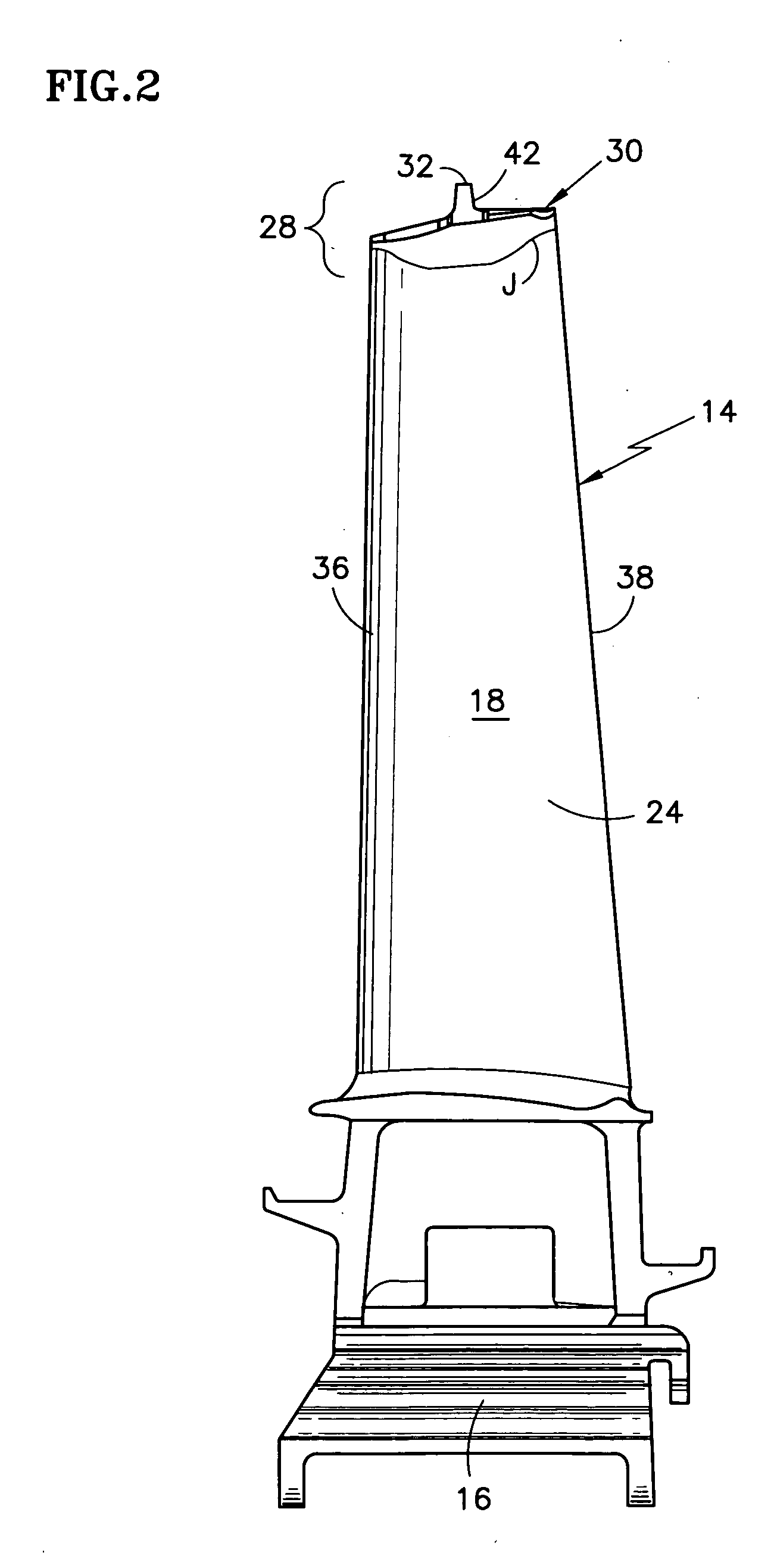

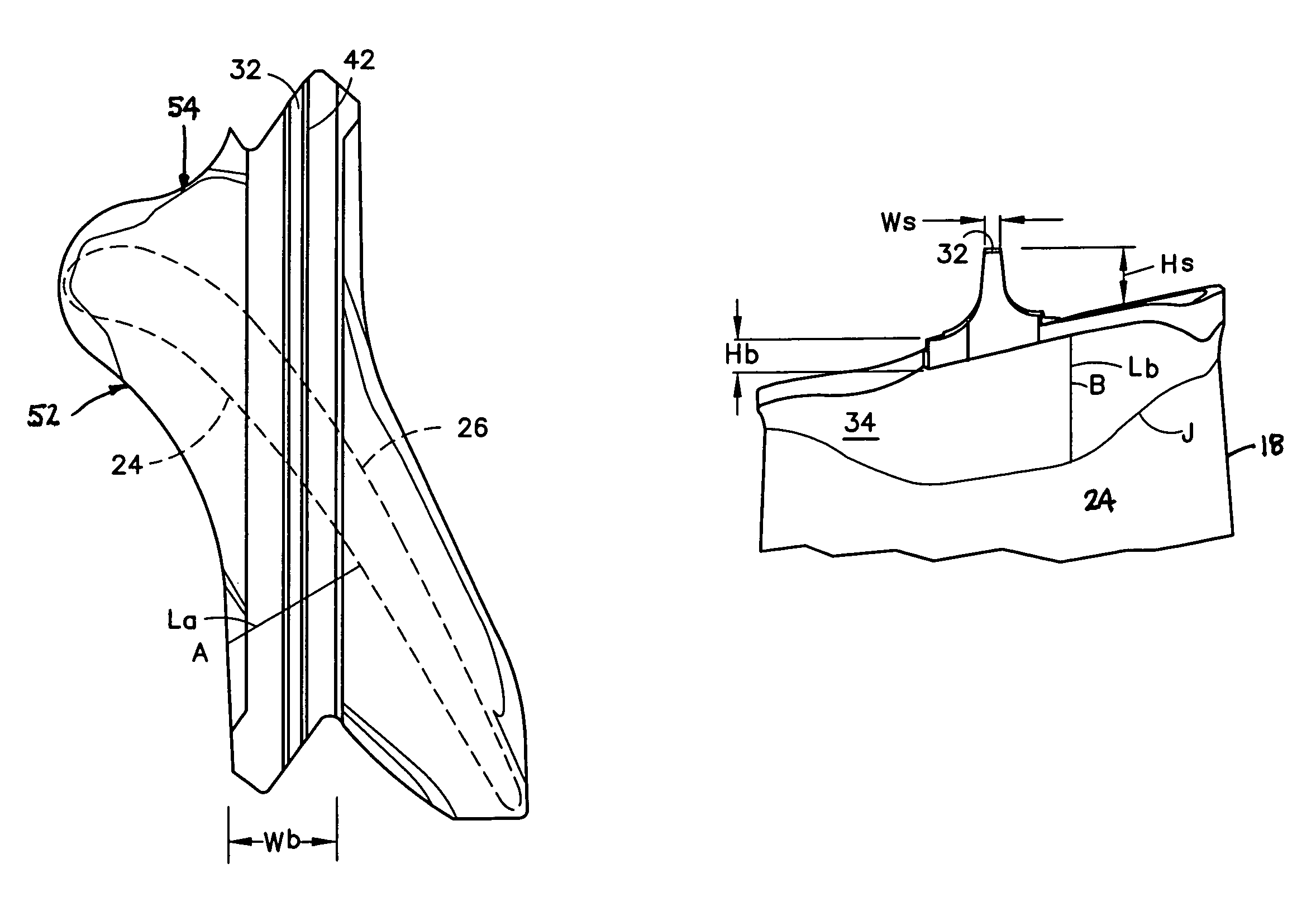

Rotor blade for a rotary machine

ActiveUS20050169761A1Reduce stress concentration factorReduce surface stressPropellersEngine manufactureLeading edgeTrailing edge

A rotor blade having a wing and beam construction for a tip shroud is disclosed. Various construction details are developed for providing a transition zone that extends from the suction side and pressure side of the airfoil to provide a flow path surface of the shroud. In one detailed embodiment, the transition zone over substantially all of its extent between the leading edge region and the trailing edge region is contoured to extend to the sides of the wings to provide a spanwise taper that extends to the side of the wing.

Owner:RTX CORP

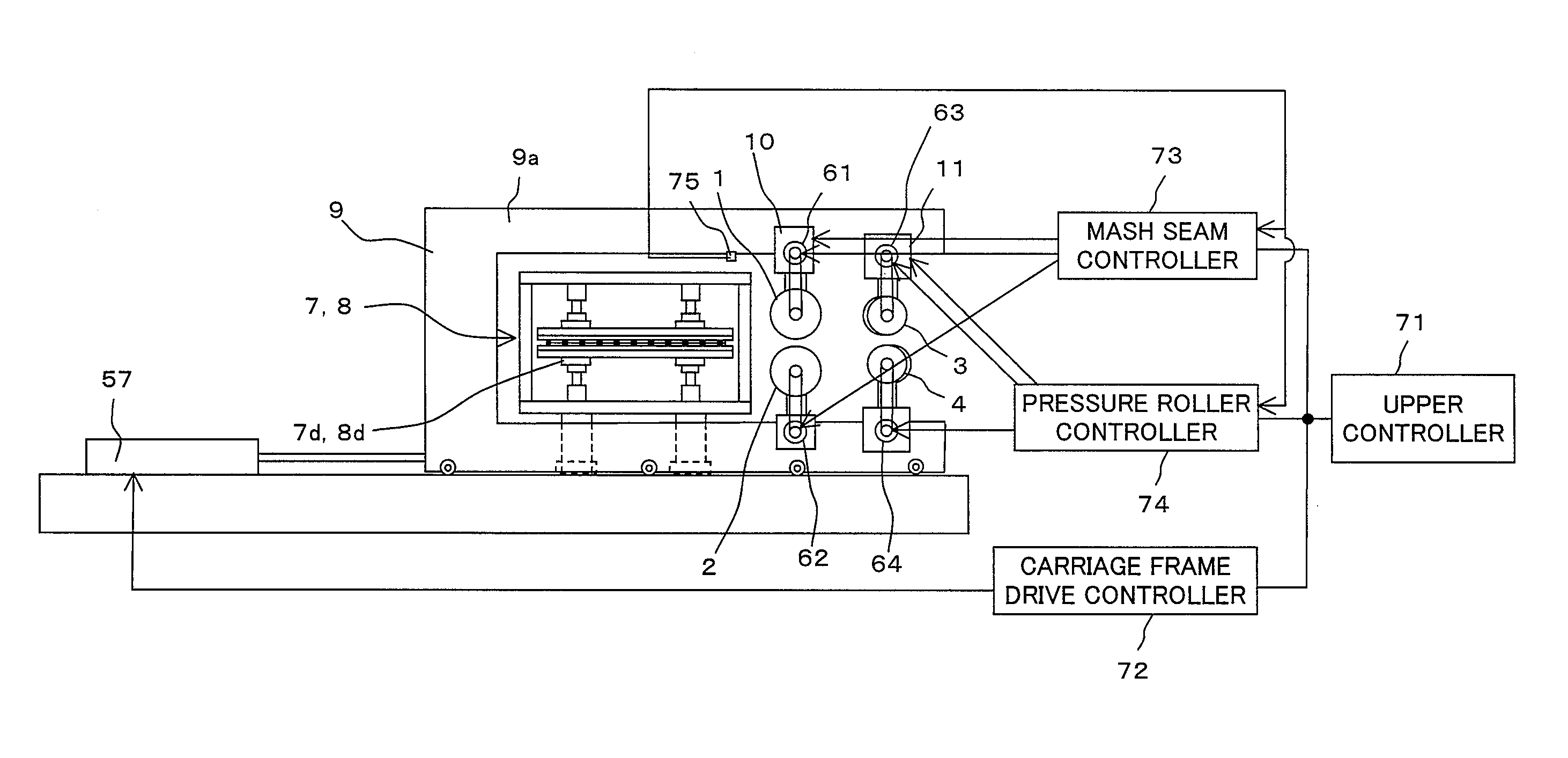

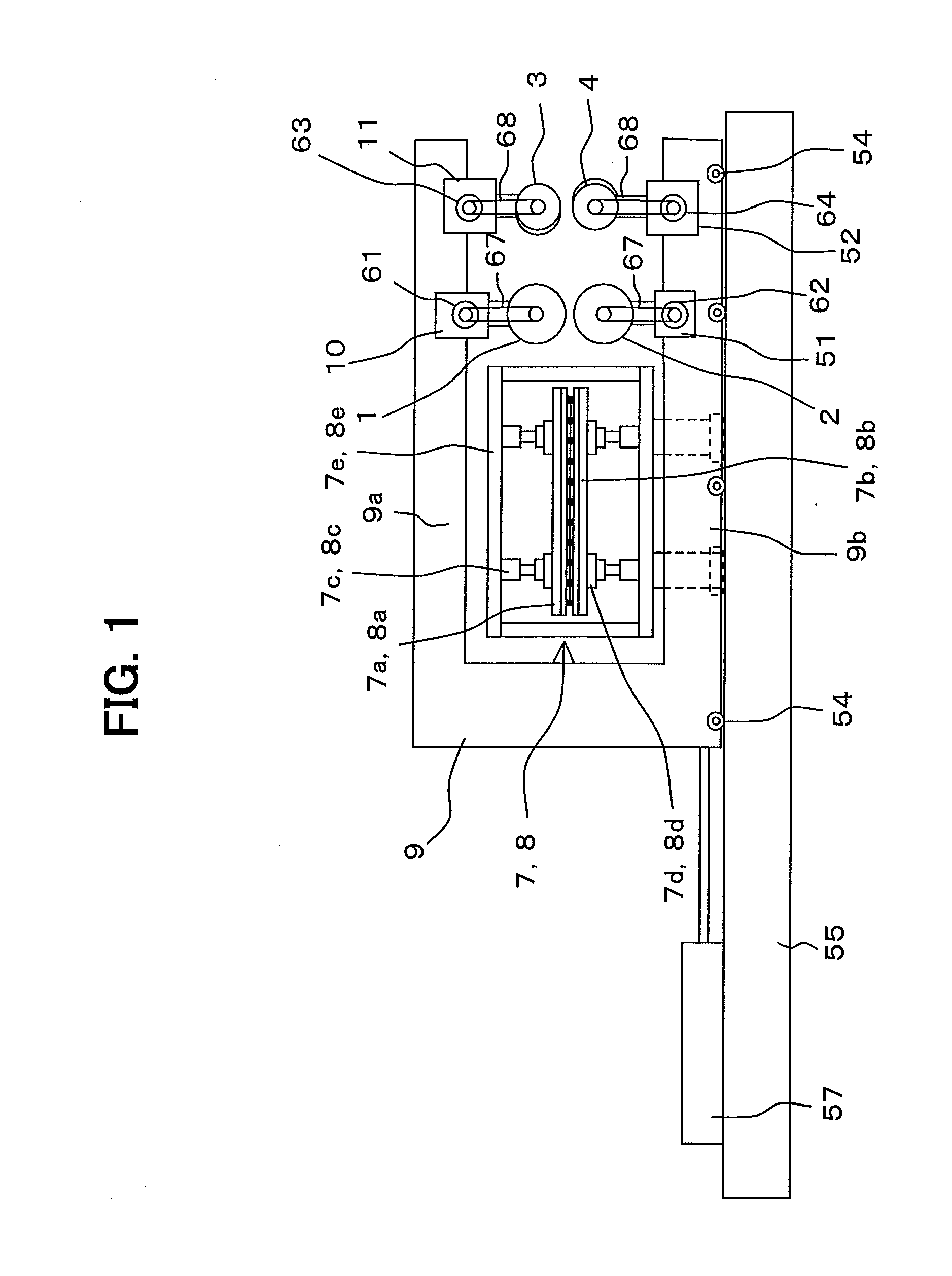

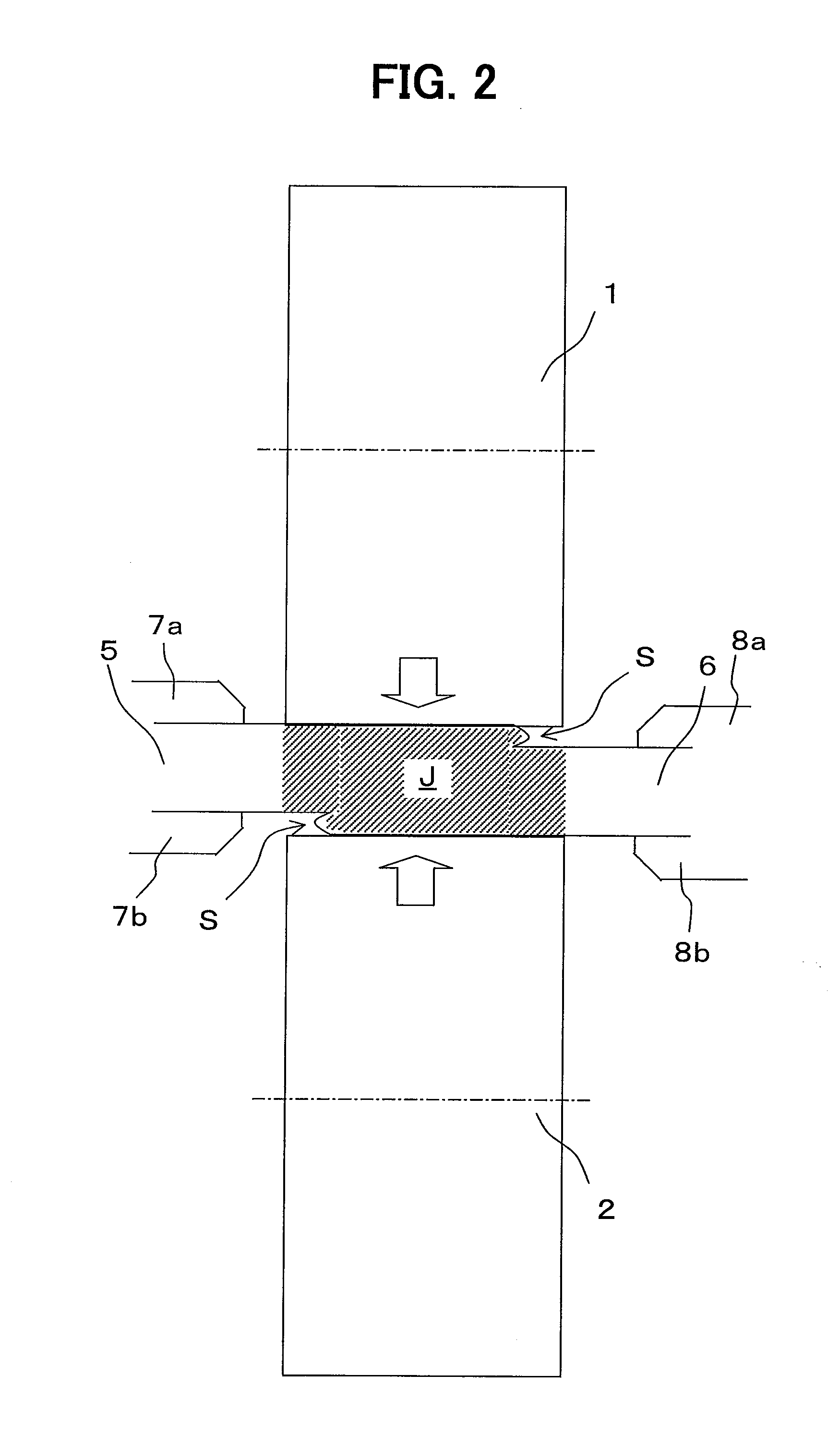

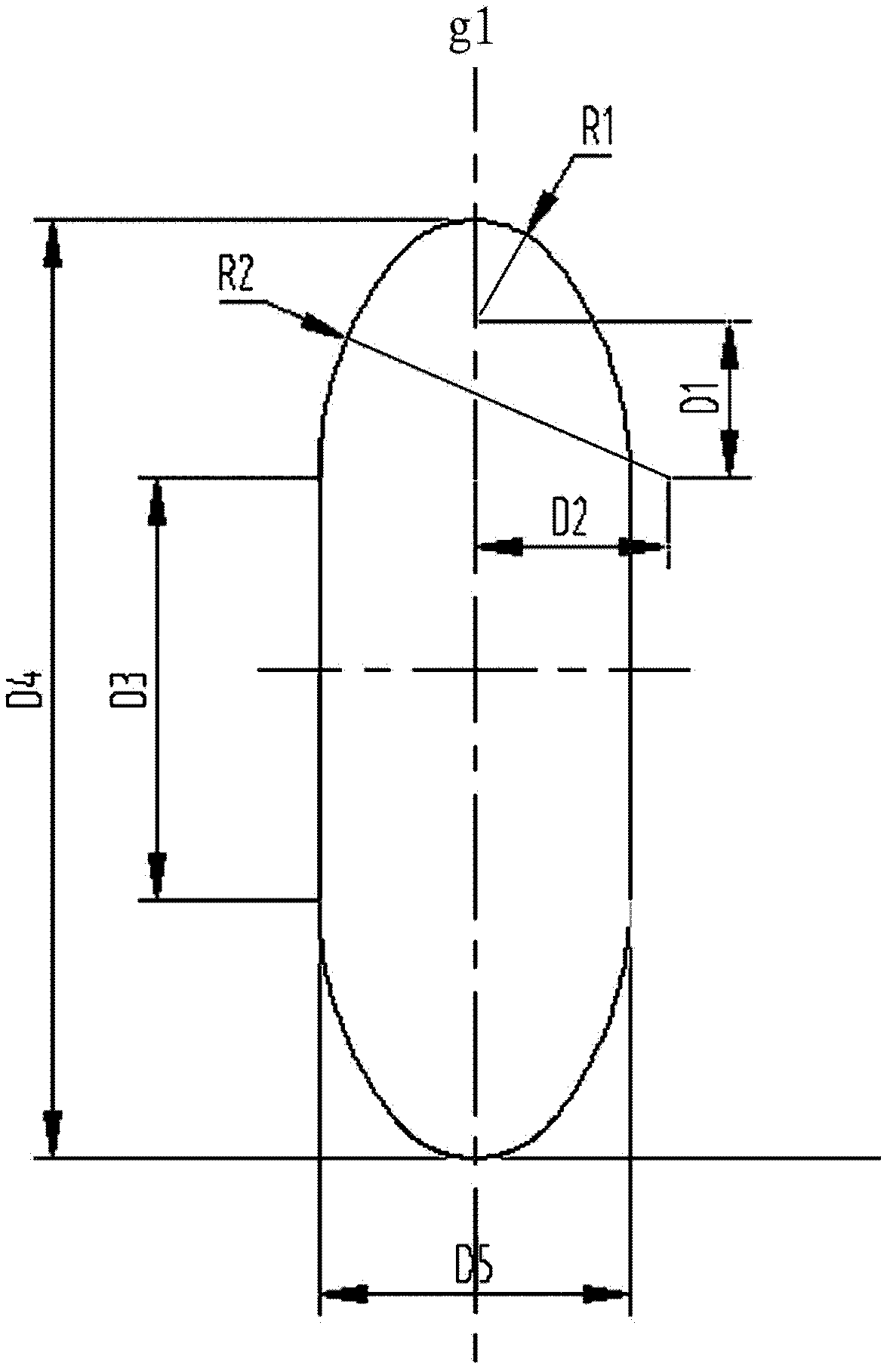

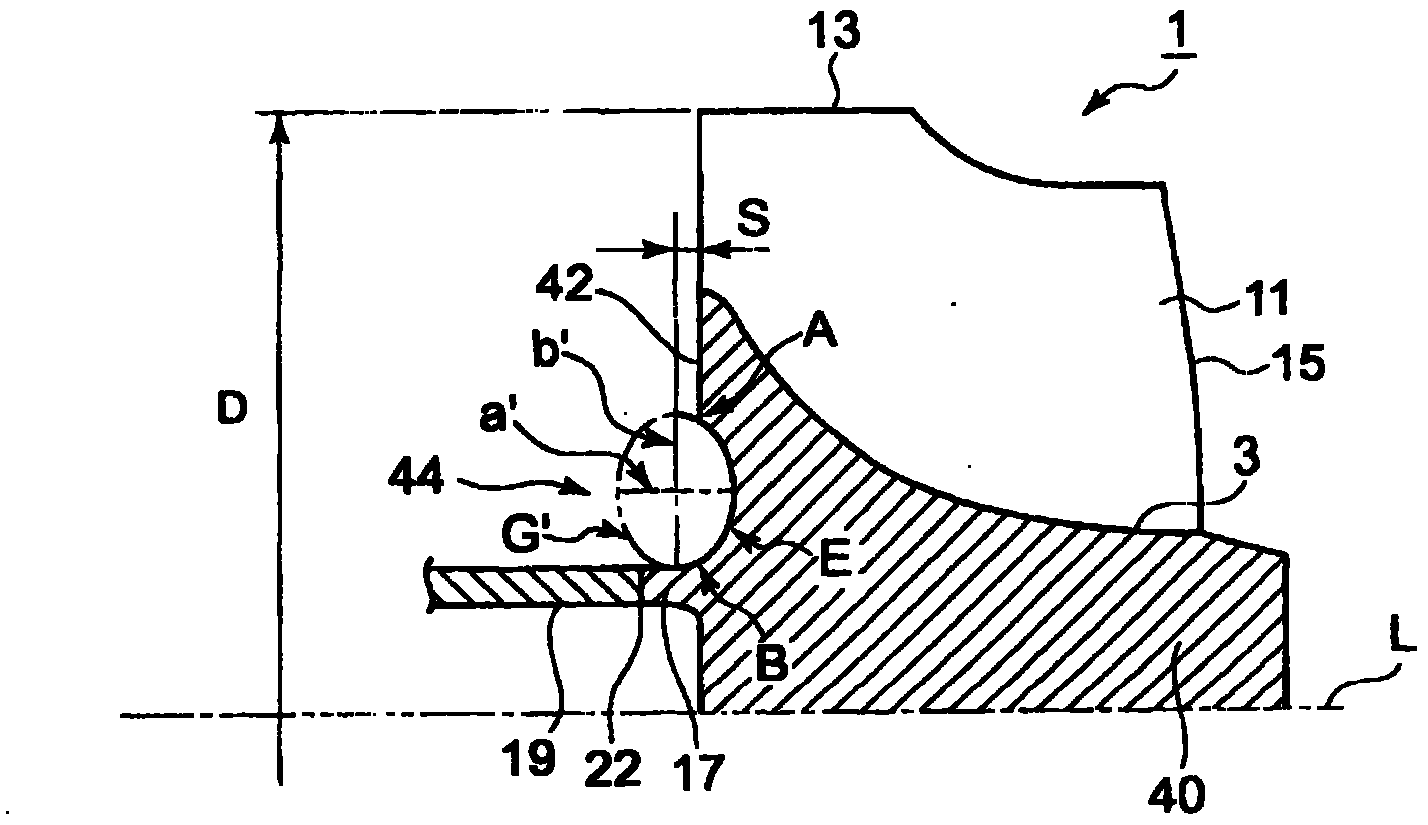

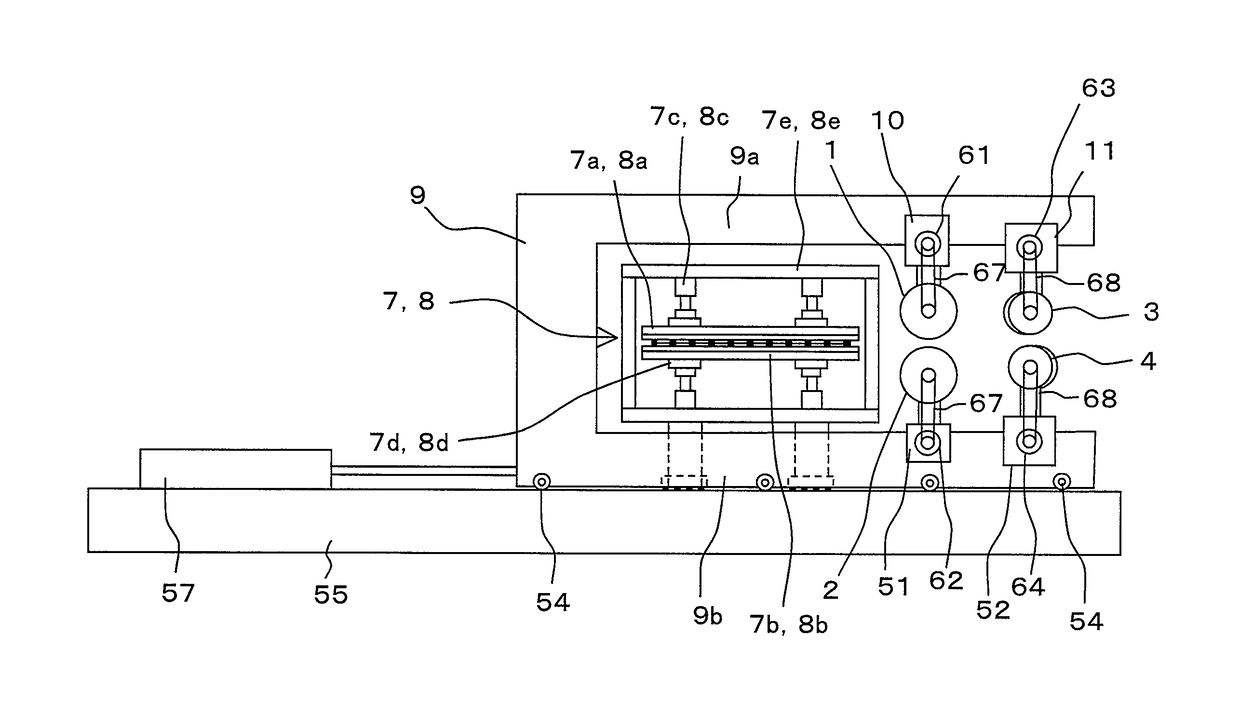

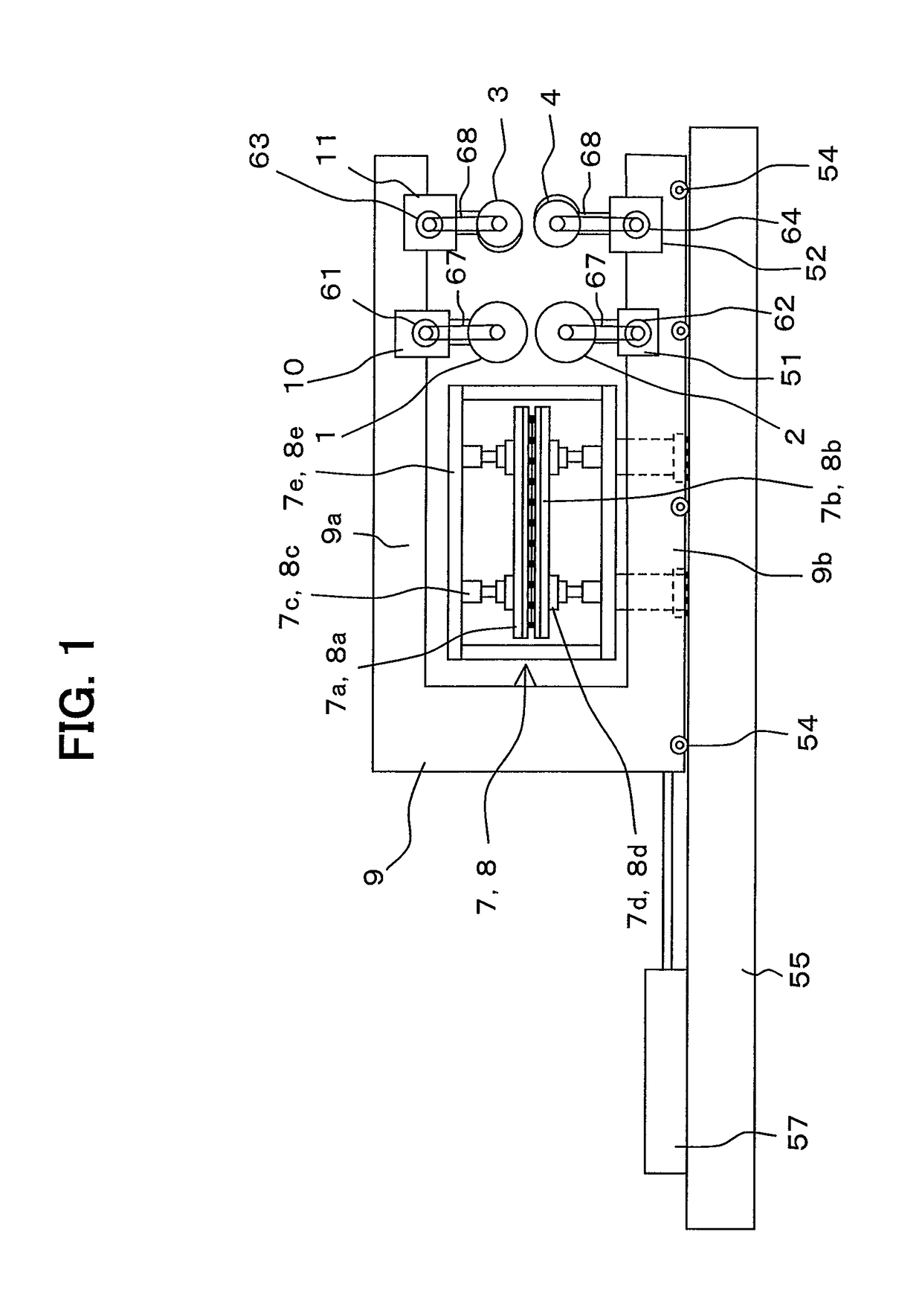

Metal plate joining method and apparatus

ActiveUS20110163074A1High degreeIncrease the amount of cuttingWelding/cutting auxillary devicesRectilinear seam weldingEngineeringMetal

A pair of upper and lower pressure rollers 3, 4 is disposed so that their axes 15, 16 are tilted in a horizontal plane in respective directions opposite to each other with respect to a straight line perpendicular to a welding line of a joint portion J. The pressure rollers 3, 4 are positively driven by corresponding electric motors 63, 64 to thereby roll the joint portion. Thus, steps defined at the joint portion can be smoothed and a step gradient can be reduced to ensure a high degree of joint strength.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

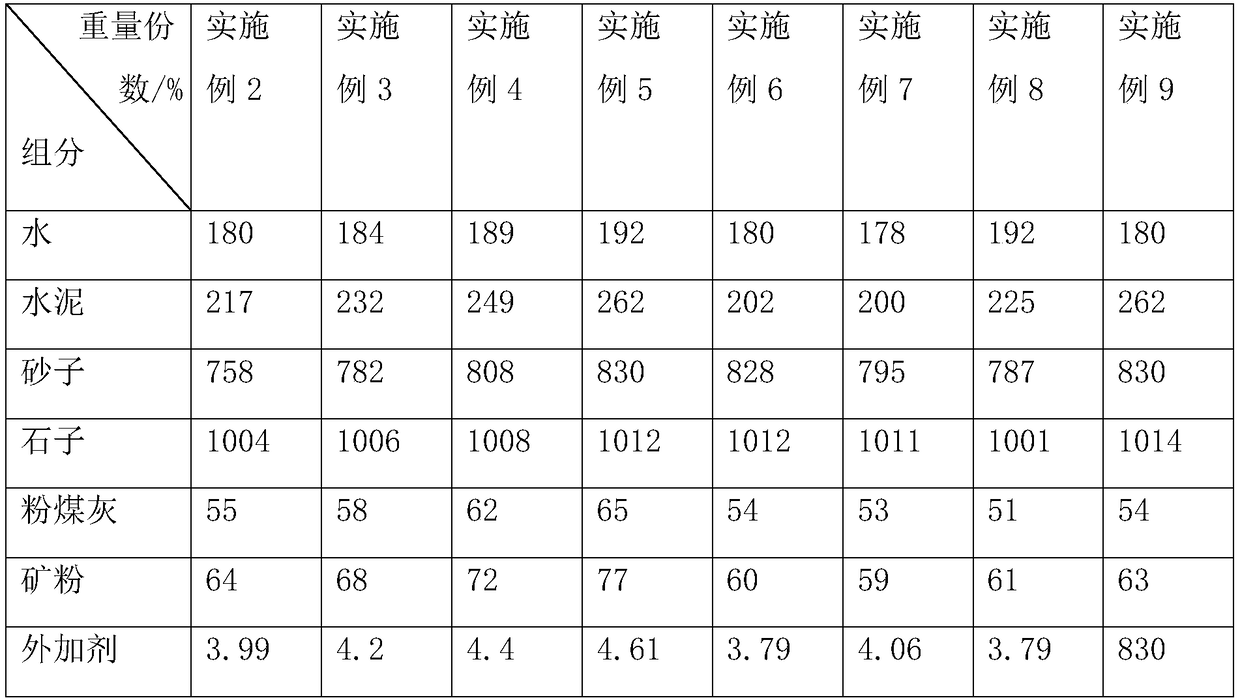

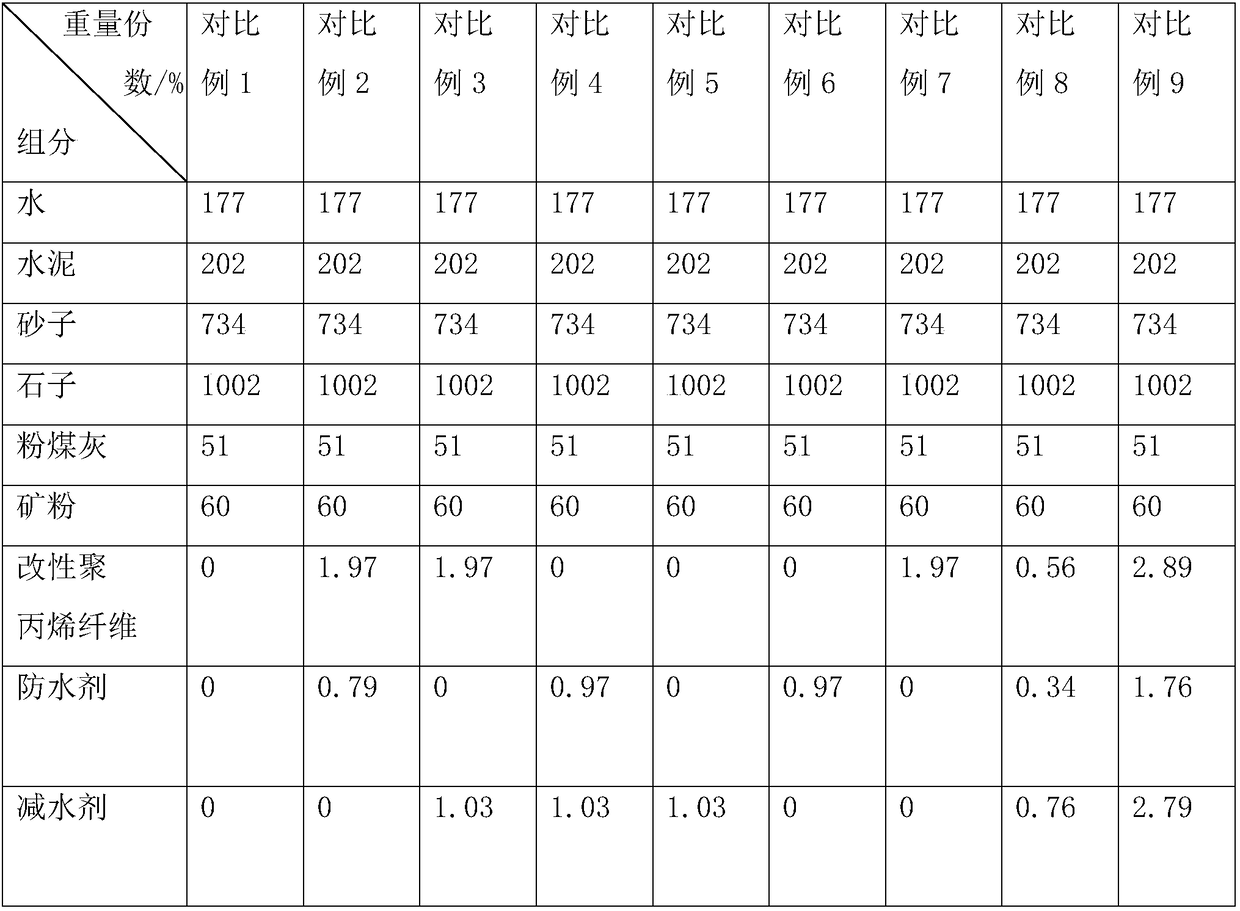

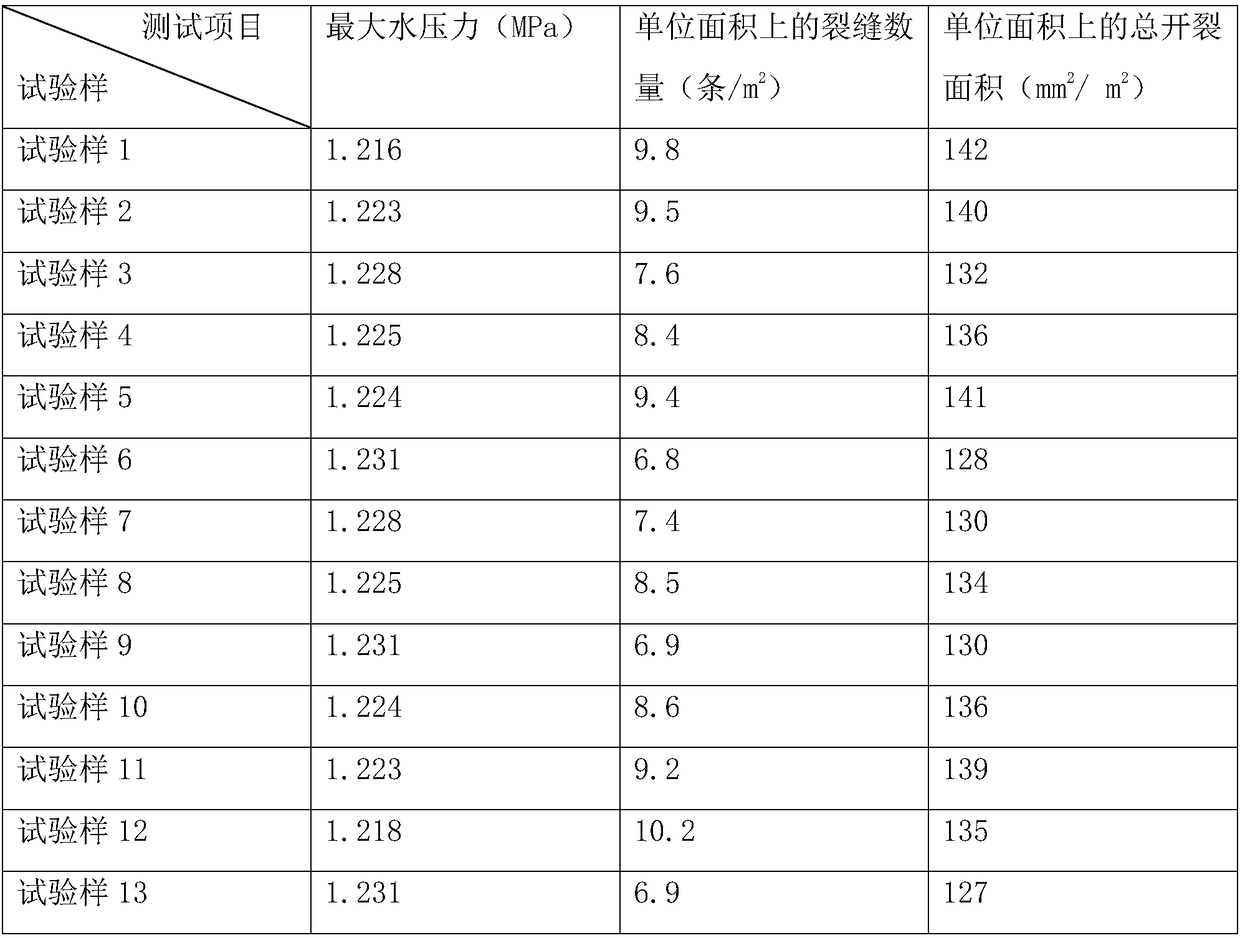

Anti-permeating and anti-cracking concrete and preparation method thereof

The invention discloses anti-permeating and anti-cracking concrete, which relates to the technical field of concrete. The technical scheme of the anti-permeating and anti-cracking concrete mainly comprises the following raw materials in parts by weight: 177-192 parts of water, 202-262 parts of portland cement, 734-830 parts of sand, 1,002-1,012 parts of stones, 51-65 parts of coal ash, 60-77 partsof mineral powder and 3.79-4.61 parts of an additive, wherein the additive comprises modified polypropylene fibers, a water-proofing agent and a water-reducing agent at a weight ratio of 3.2-4.7: 1.3-2.5: 1.7-2.3; the water-proofing agent comprises a triethanolamine water-proofing agent, an air-entraining water-reducing agent and a micro-expansion water-proofing agent at a weight ratio of 1.1-1.5: 1.3-1.7: 0.7-1.3. According to the anti-permeating and anti-cracking concrete, the problems that the concrete is cracked easily after hardening and is relatively poor in anti-permeating performanceare solved. By adding the modified polypropylene fibers and the water-proofing agent, the concrete can be prevented from being cracked when in hardening, so that the anti-permeating performance of theconcrete is improved.

Owner:上海石化安东混凝土有限公司

Rotor blade for a rotary machine

ActiveUS7066713B2Reduce stress concentration factorRatio is smallPropellersEngine manufactureRotary machineAerospace engineering

Owner:RTX CORP

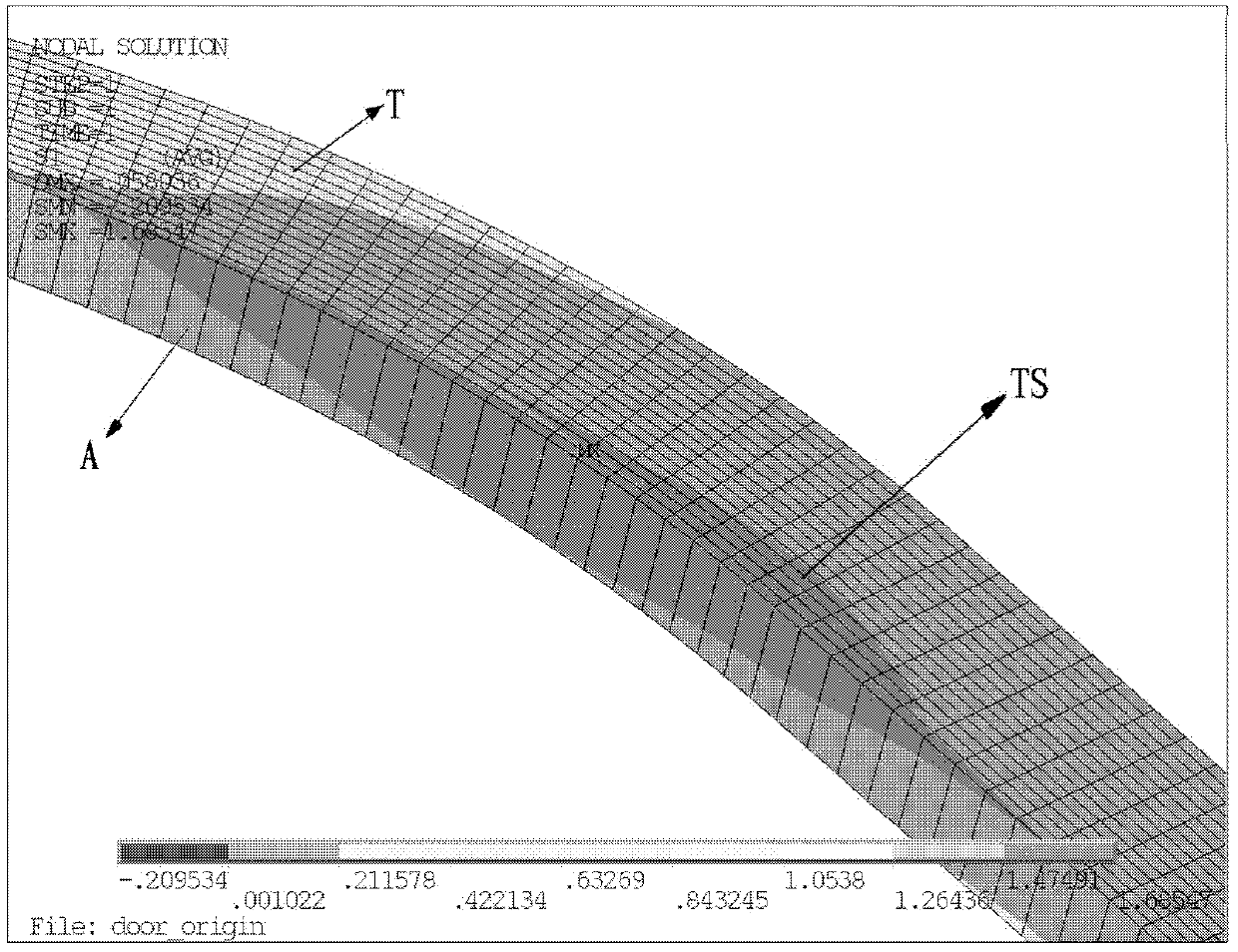

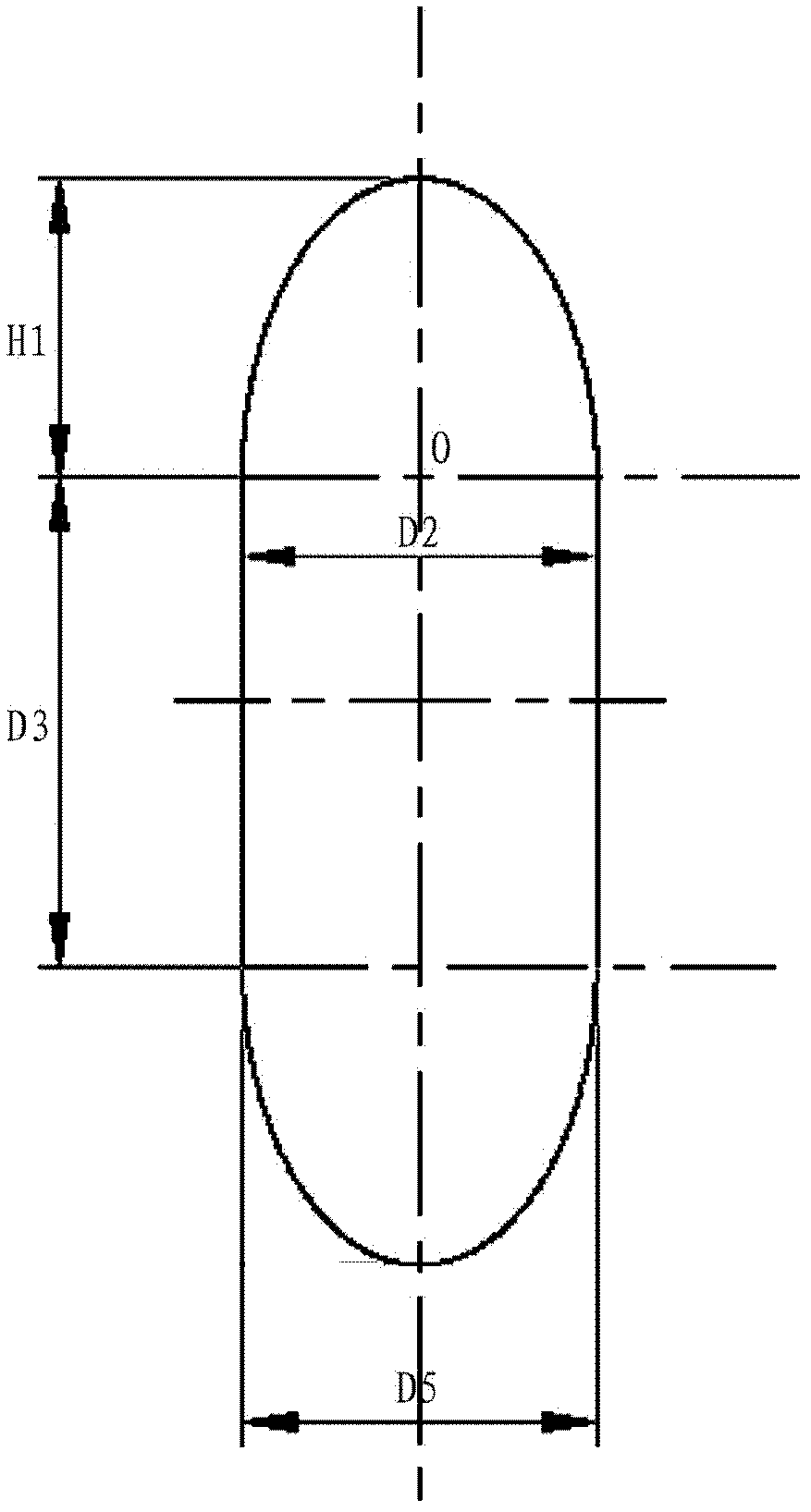

Tower frame door opening of wind generating set and design method of tower frame door opening

ActiveCN102434408AIncreasing the thicknessIncrease widthWind energy generationWind motor componentsLine segmentWind force

The invention discloses a tower frame door opening of a wind generating set and a design method of the tower frame door opening; the tower frame door opening consists of two straight line segments and a curve segment according to shape, and the curve segment consists of more than three circular arcs with different diameters. The thickness of a door frame of the tower frame door opening is 1.15 to 1.17 times of the thickness of a tower tube wall preferentially, the length of the door frame along the radial direction of a tower tube is 4.5 to 5.5 times of the thickness of the door frame preferentially, and the length of the door frame at the central height position of the door opening, which extends out of the tower tube wall, is about half of the length of the door frame along the radial direction of the tower tube. The actual design process of the tower frame door opening comprises an overall data design of a door frame section, a door frame section modeling, a stress concentration factor IIW (International Institute of Welding) interpolation calculation and the like. Firstly, obtain an optimized parameter of the shape of the curve segment at the door opening, secondly, based on the optimized parameter, perform a further optimization to a size parameter of the door frame. The tower frame door opening increases the mechanical property index and reduces the impact of the existing door opening on a tower tube structure.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

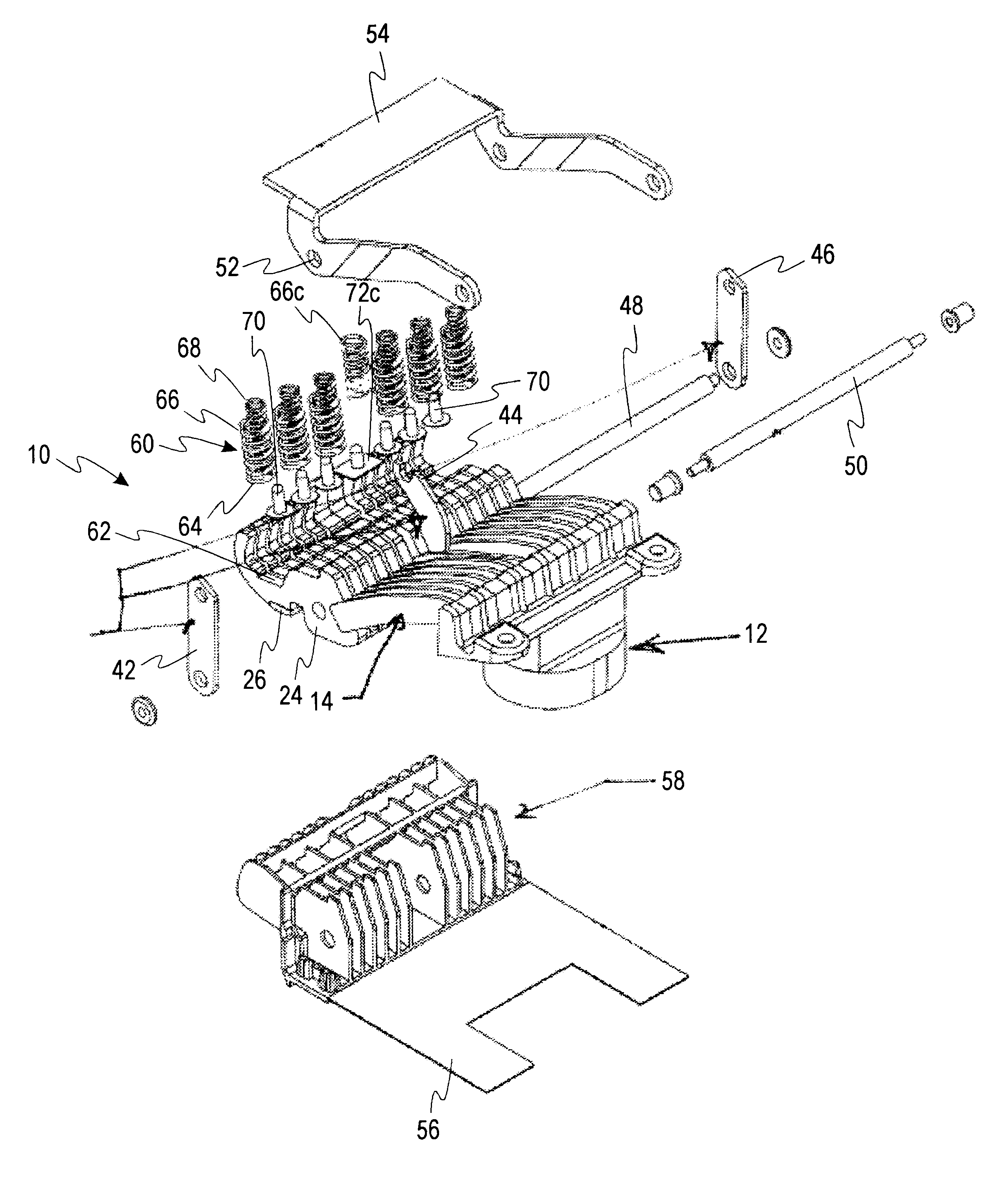

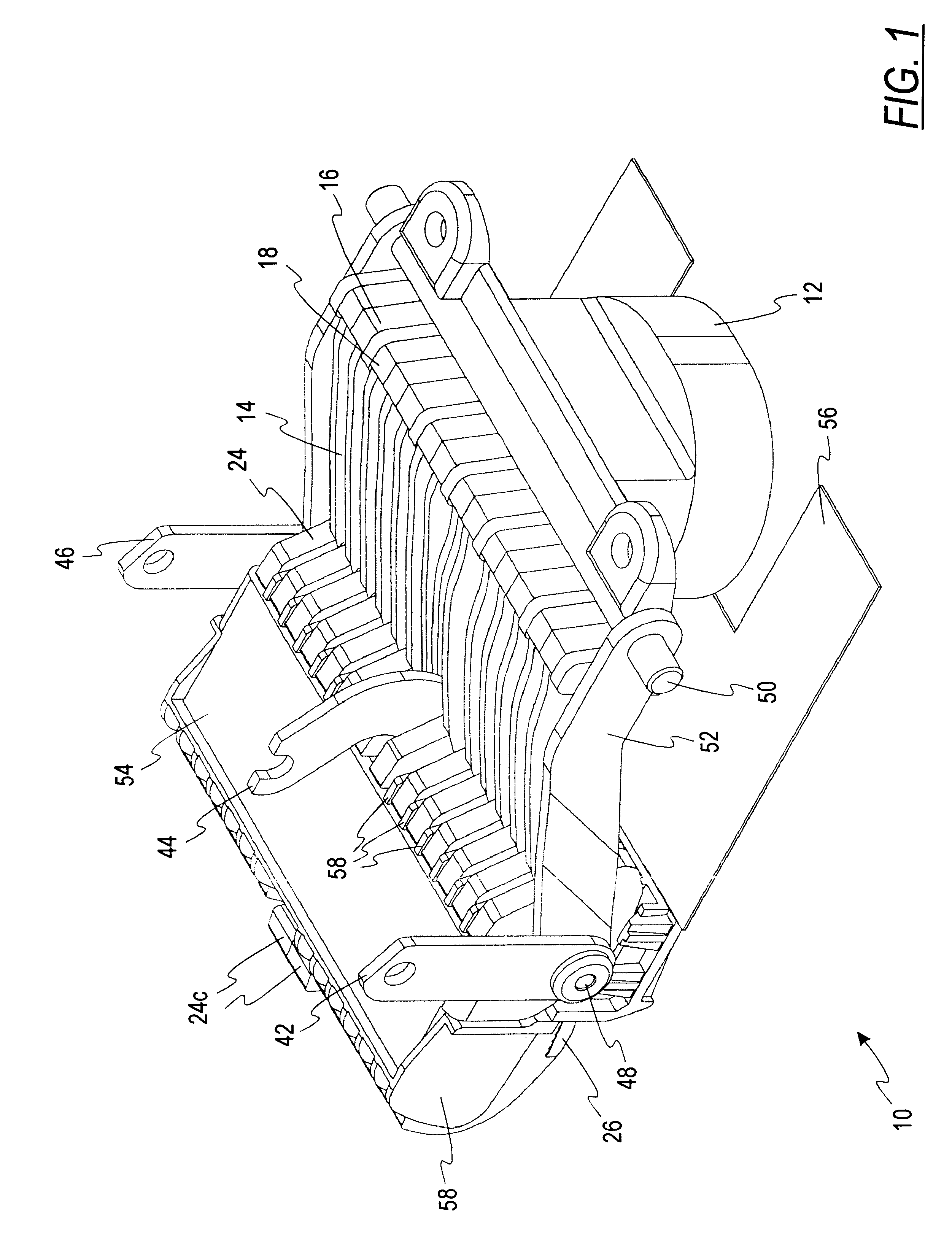

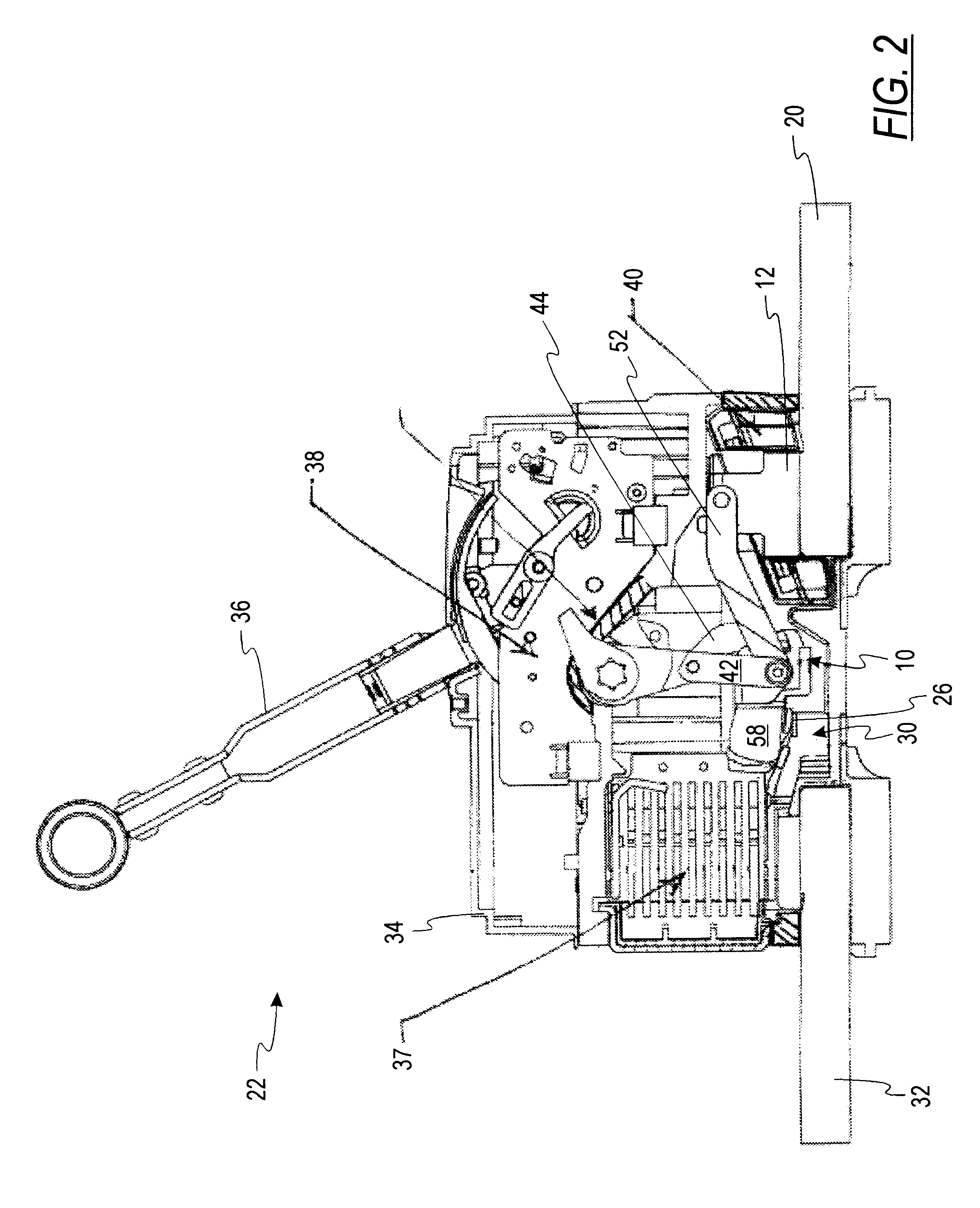

Current carrying assembly for a circuit breaker

InactiveUS6570116B2Good body shapeIncrease volumeCircuit-breaking switches for excess currentsProtective switchesEngineeringBearing surface

Owner:SQUARE D CO

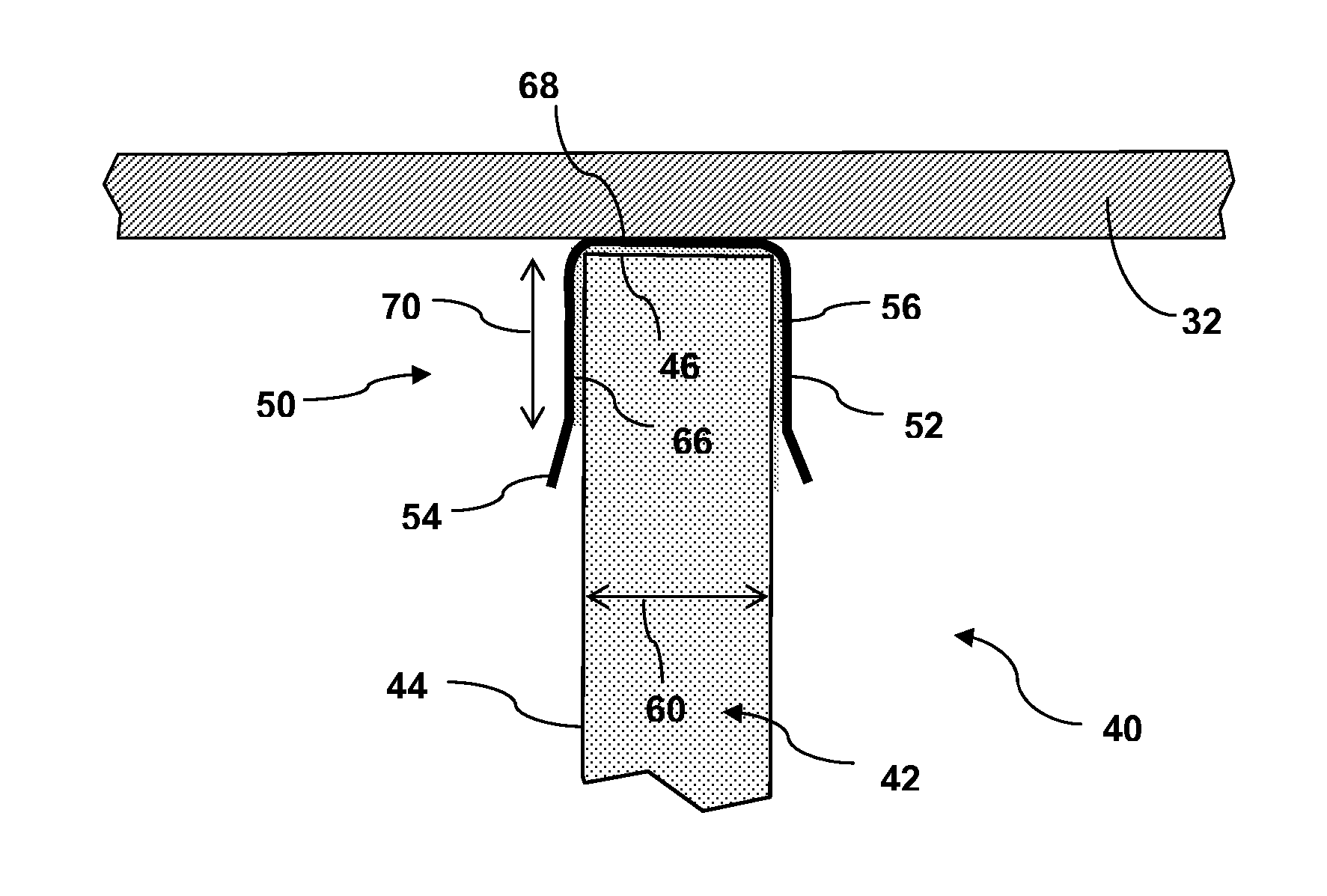

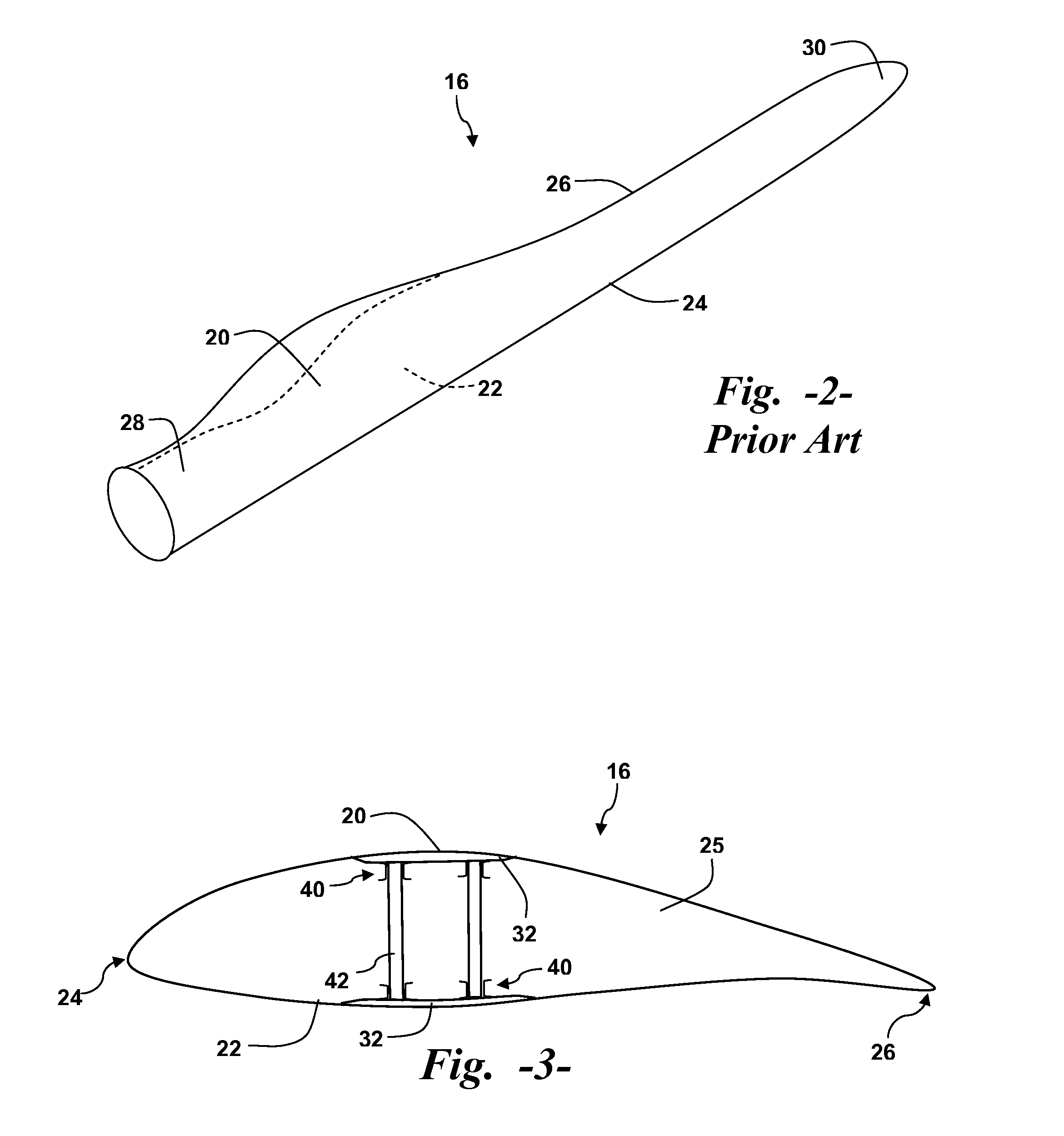

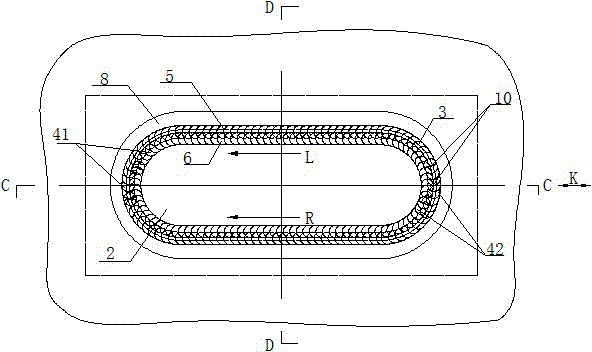

Wind turbine blade shear web connection assembly

ActiveUS8235671B2Reduce stress concentration factorDecrease overall amount and weightPropellersPump componentsTurbine bladeMechanical engineering

A wind turbine blade has upper and lower shell members with a respective spar cap configured on an internal face of the shell members. A shear web extends between the spar caps along a longitudinal length of the blade. A connection assembly is configured between the transverse ends of the shear web and the spar caps and includes a channel structure configured on the spar cap. The channel structure includes rigid side walls that extend from the spar cap along the longitudinal sides of the shear web. Bond paste is disposed between the channel structure side walls and the longitudinal sides of the shear web.

Owner:GENERAL ELECTRIC CO

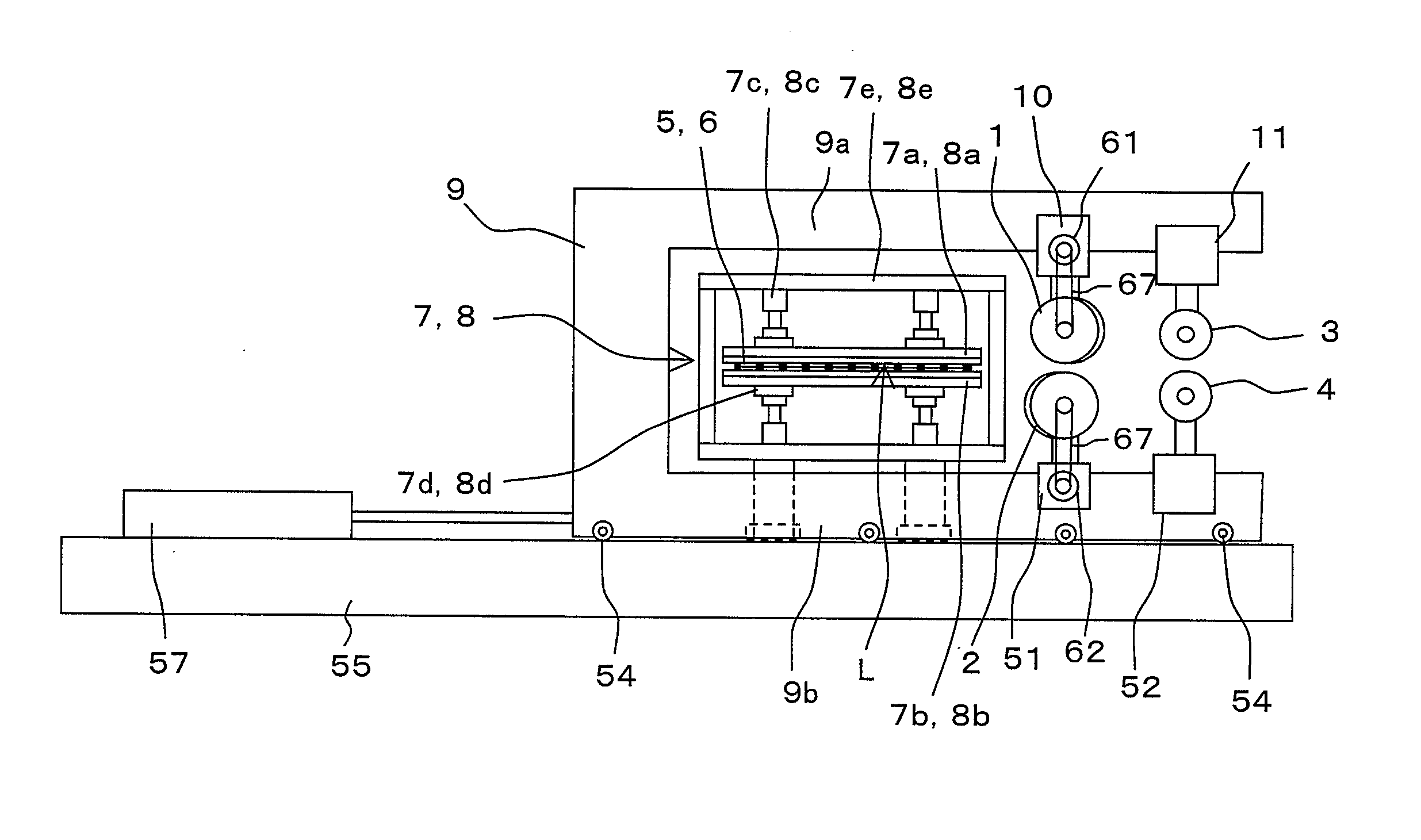

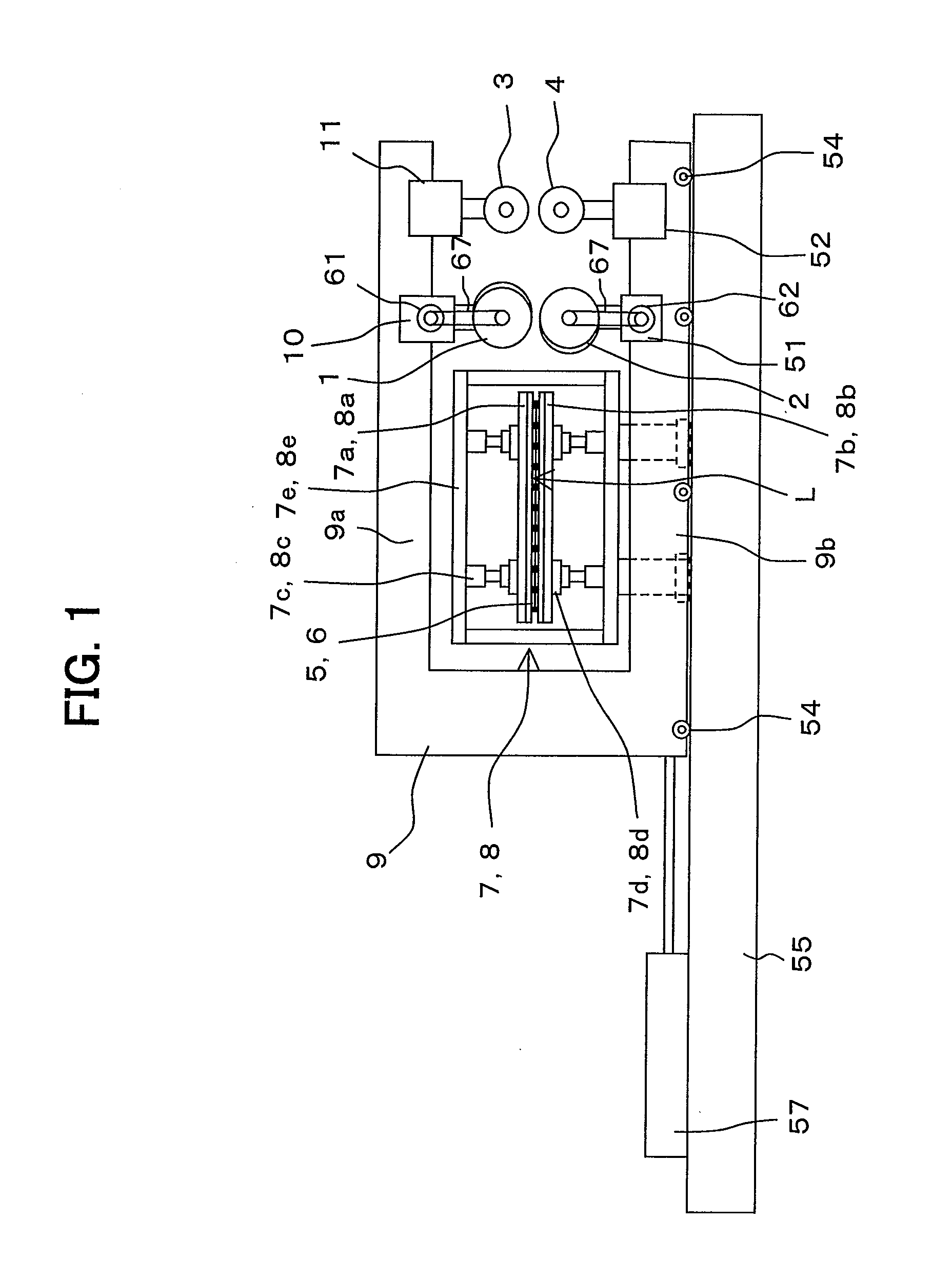

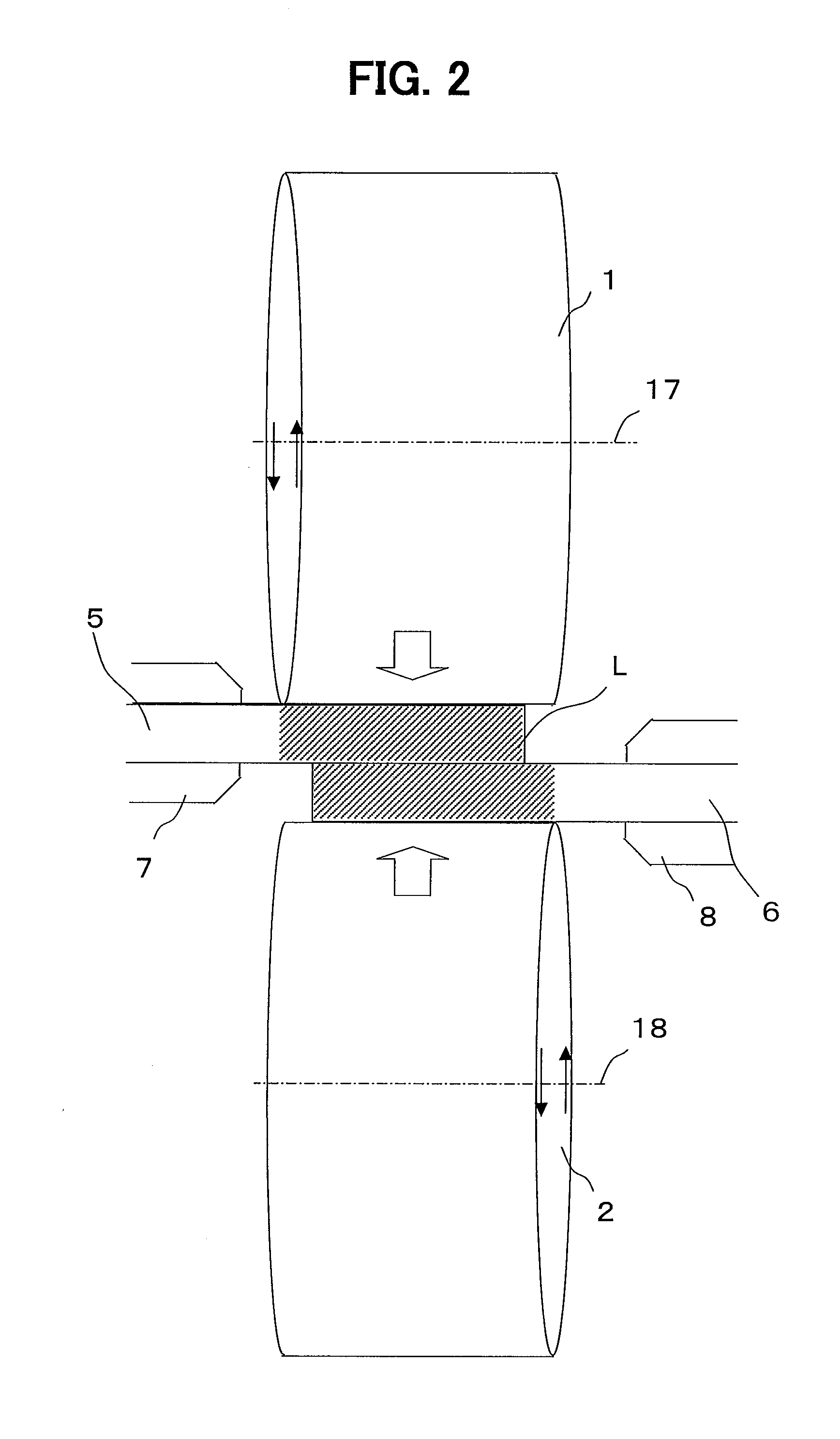

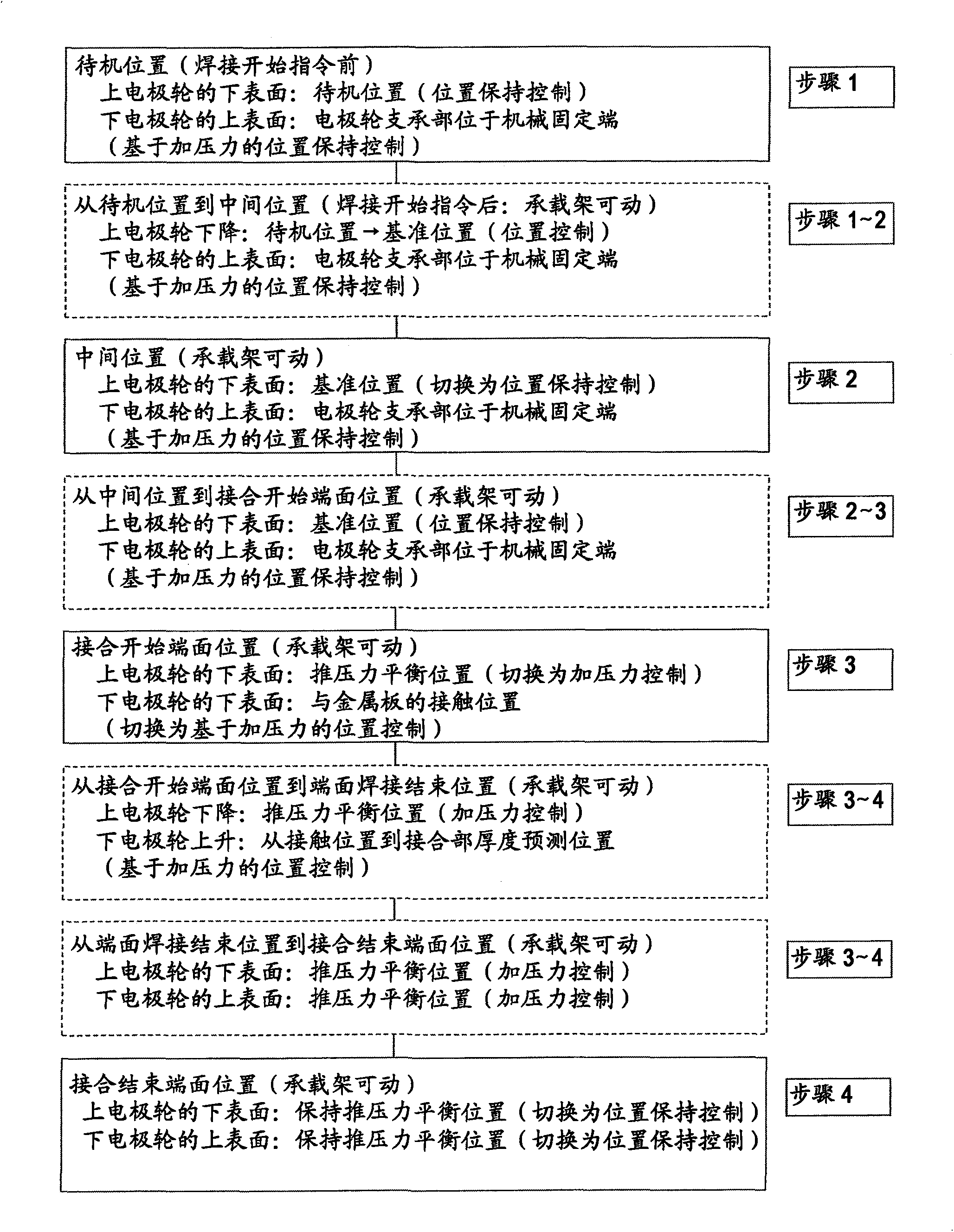

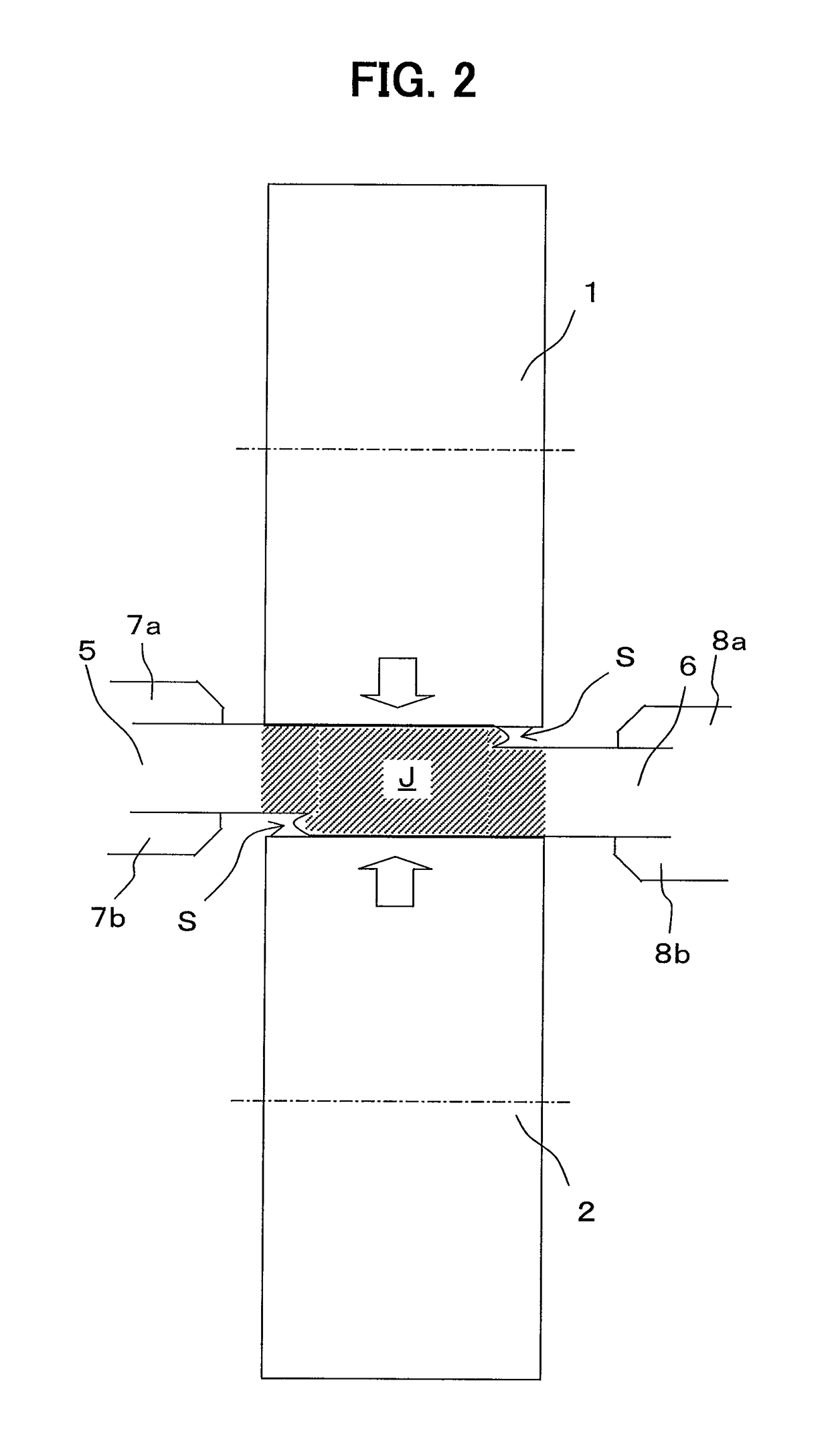

Mash seam welding method and apparatus

InactiveUS20110120979A1Reduce thicknessHigh degreeWelding/cutting auxillary devicesRectilinear seam weldingStress concentrationSeam welding

A pair of upper and lower electrode wheels 1, 2 are disposed so that their axes 17, 18 are tilted in a horizontal plane in respective directions opposite to each other with respect to a straight line Y perpendicular to a welding line X defined on overlapping portions (L) of two metal plates 5, 6, and mash seam welding is performed while positively driving electric motors 61, 62. This can reduce the increased amount of thickness and step gradient of a joint portion to reduce a stress concentration factor and ensure joint strength. The metal plates are joined to each other such that a nugget N is not deviated from a joint interface. Therefore, it is possible to prevent respective ends of the metal plates at the overlapping portions L from biting into and scratching the corresponding electrode wheels 1, 2 and to prevent spattering during the welding.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

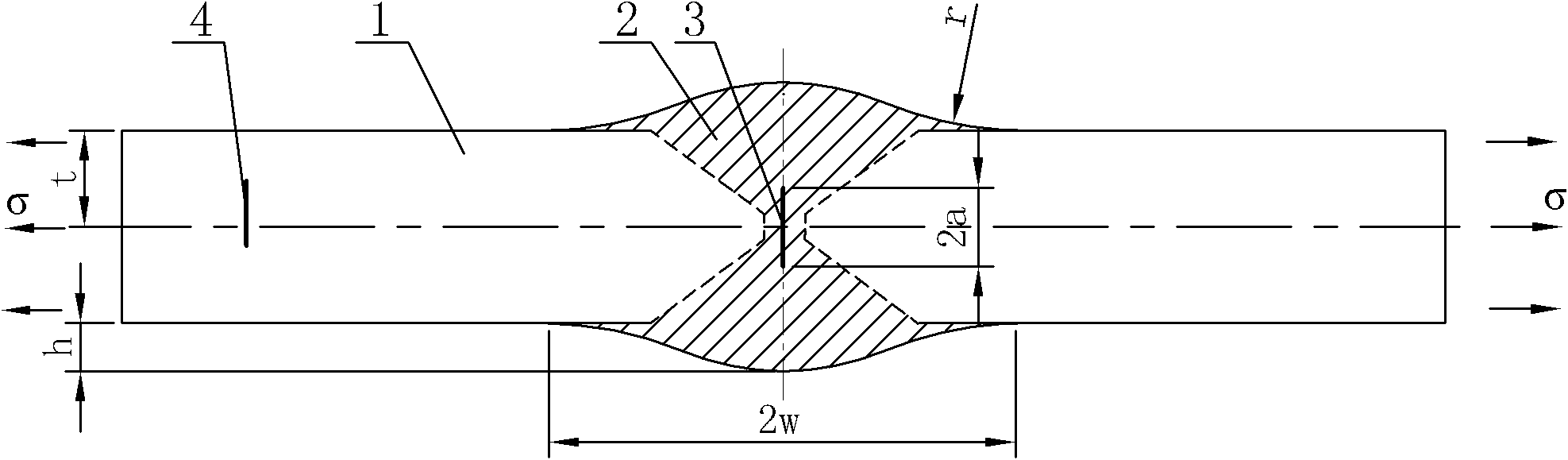

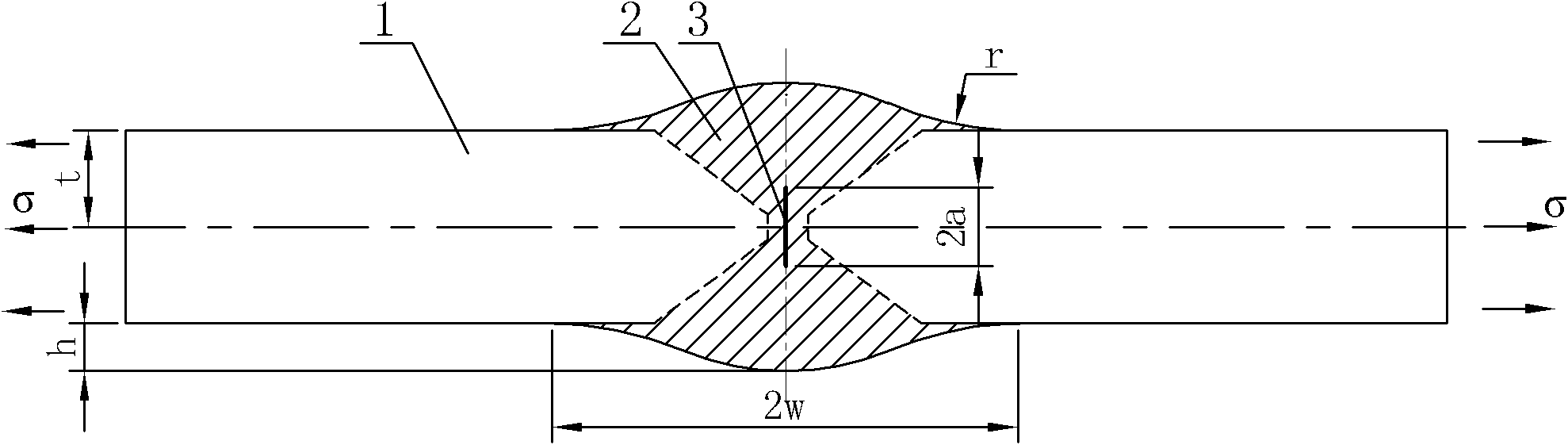

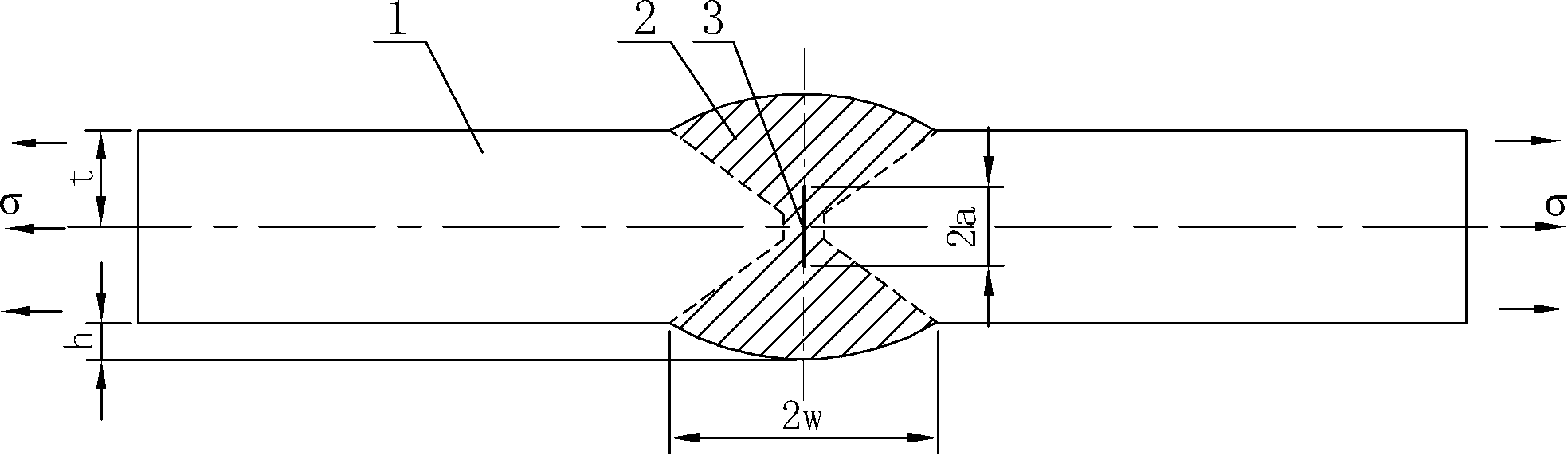

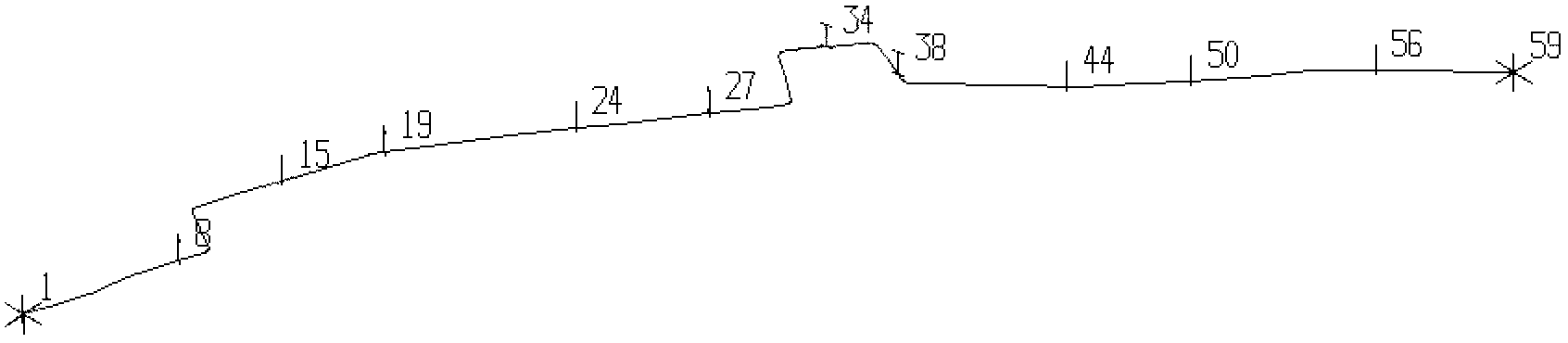

Designing method for realizing equal load-carrying of tension-loaded butt joint with central crack on welding line, and application of K factor

InactiveCN102136018AImprove carrying capacityImprove fatigue strengthSpecial data processing applicationsLoad carryingCarrying capacity

The invention discloses a designing method for realizing the equal load-carrying of a tension-loaded butt joint with a central crack on a welding line, and the application of a K factor, which belong to the field of welding and aim to solve the problem that the load-carrying capacity of the tension-loaded butt joint with the central crack is lower than that of a parent metal. If the parent metal of the tension-loaded joint with the central crack on the welding line also has a crack, the designing method comprises the following steps of: determining equal load-carrying conditions, and the fracture toughness of a weld metal and the parent metal; calculating a stress intensity factor of a parent metal area and the stress intensity factor of a welding line area meeting equal load-carrying; calculating a stress intensity factor formula; and obtaining geometrical parameter values of the welding line. If the parent metal of the tension-loaded joint with the central crack on the welding line is free from defect, the designing method comprises the following steps of: determining the equal load-carrying conditions, and the tensile strength of the parent metal; calculating the stress intensity factor formula; determining a critical stress relational expression, and the fracture toughness of the weld metal; and obtaining the geometrical parameter values of the welding line. The stress intensity factor of the welding line area is applied to the calculation of critical crack size, critical stress and remaining service life of the tension-loaded joint with the central crack. The method and the application are applied to plate butt joints welded on both sides.

Owner:HARBIN INST OF TECH

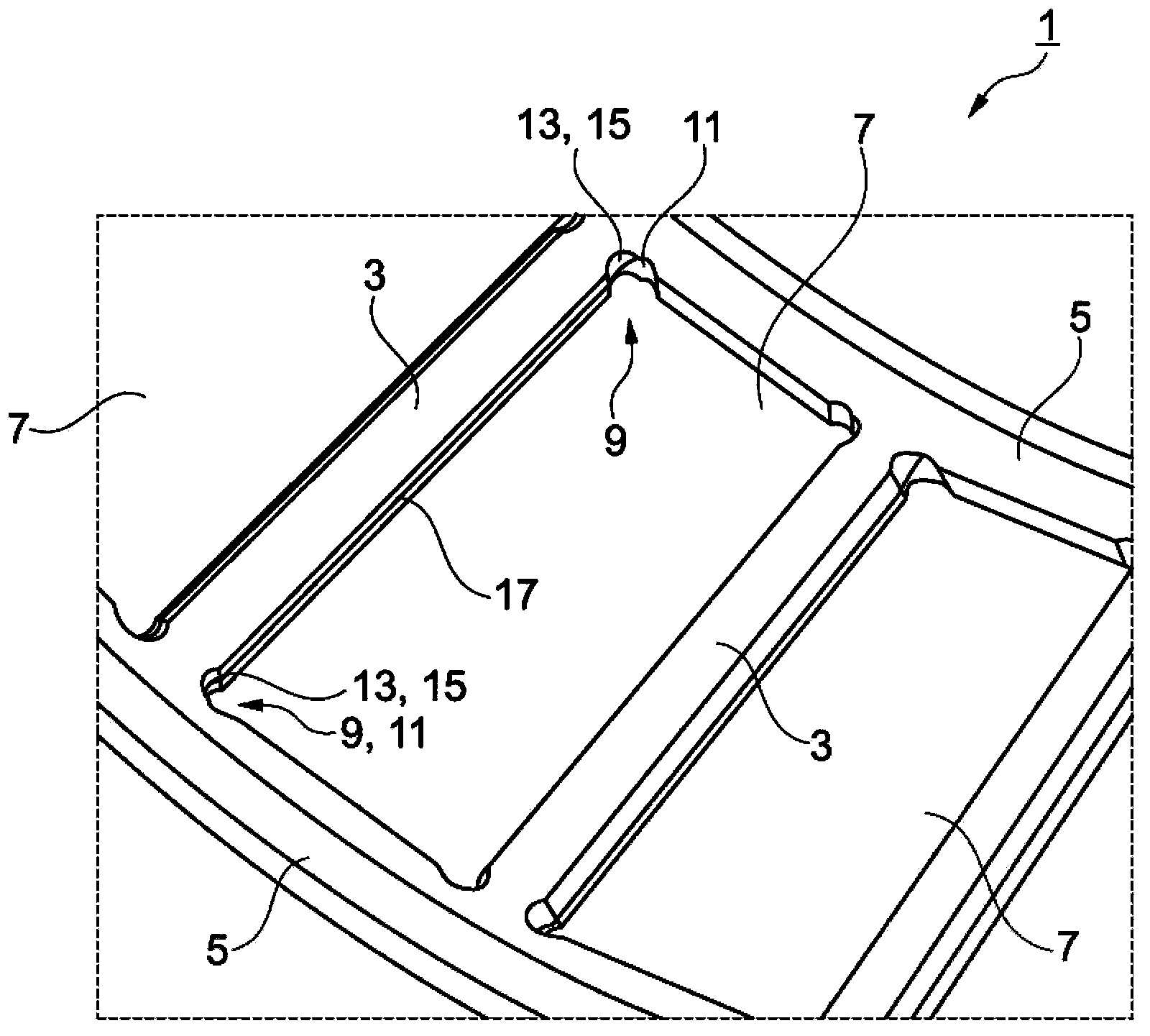

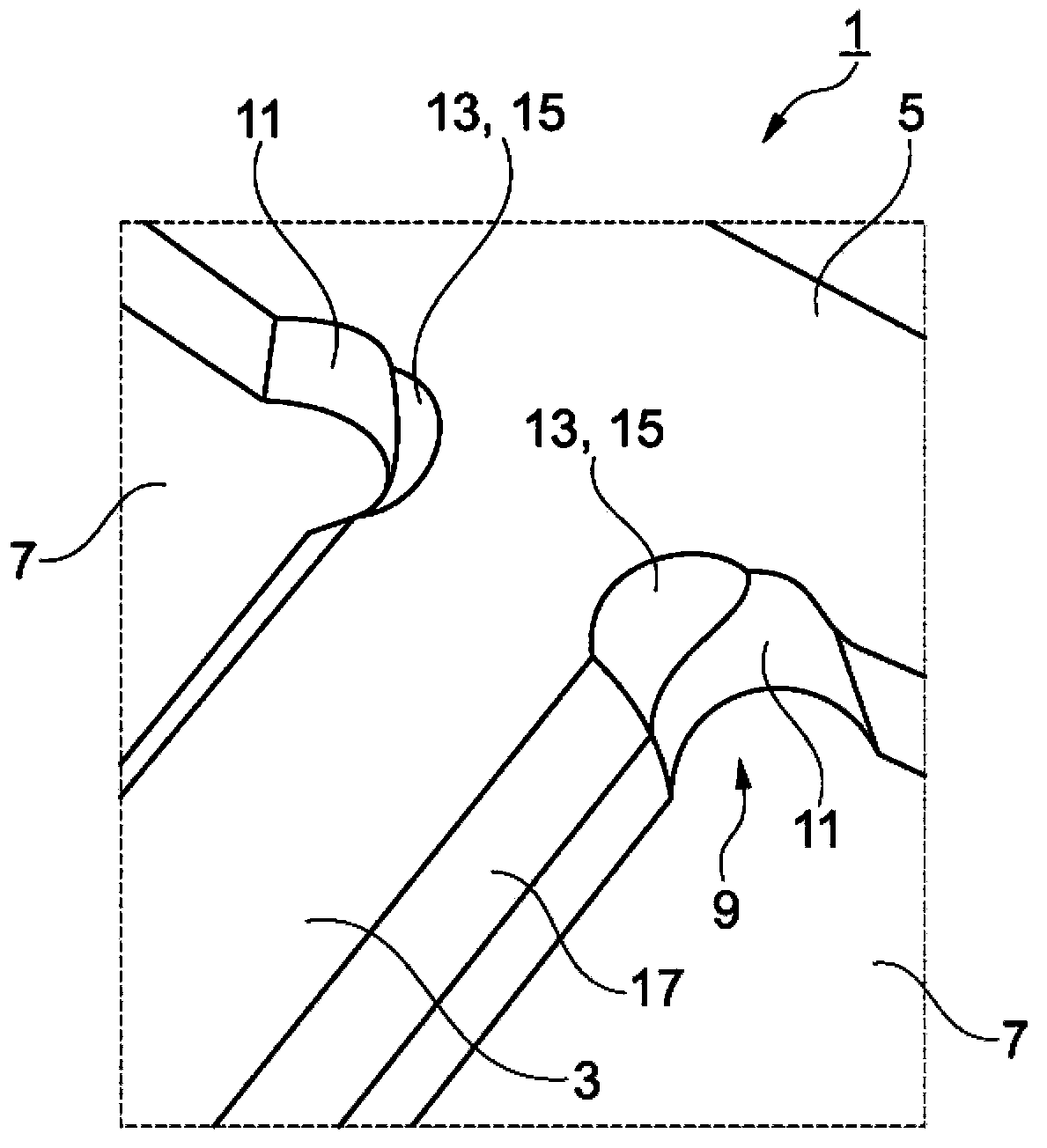

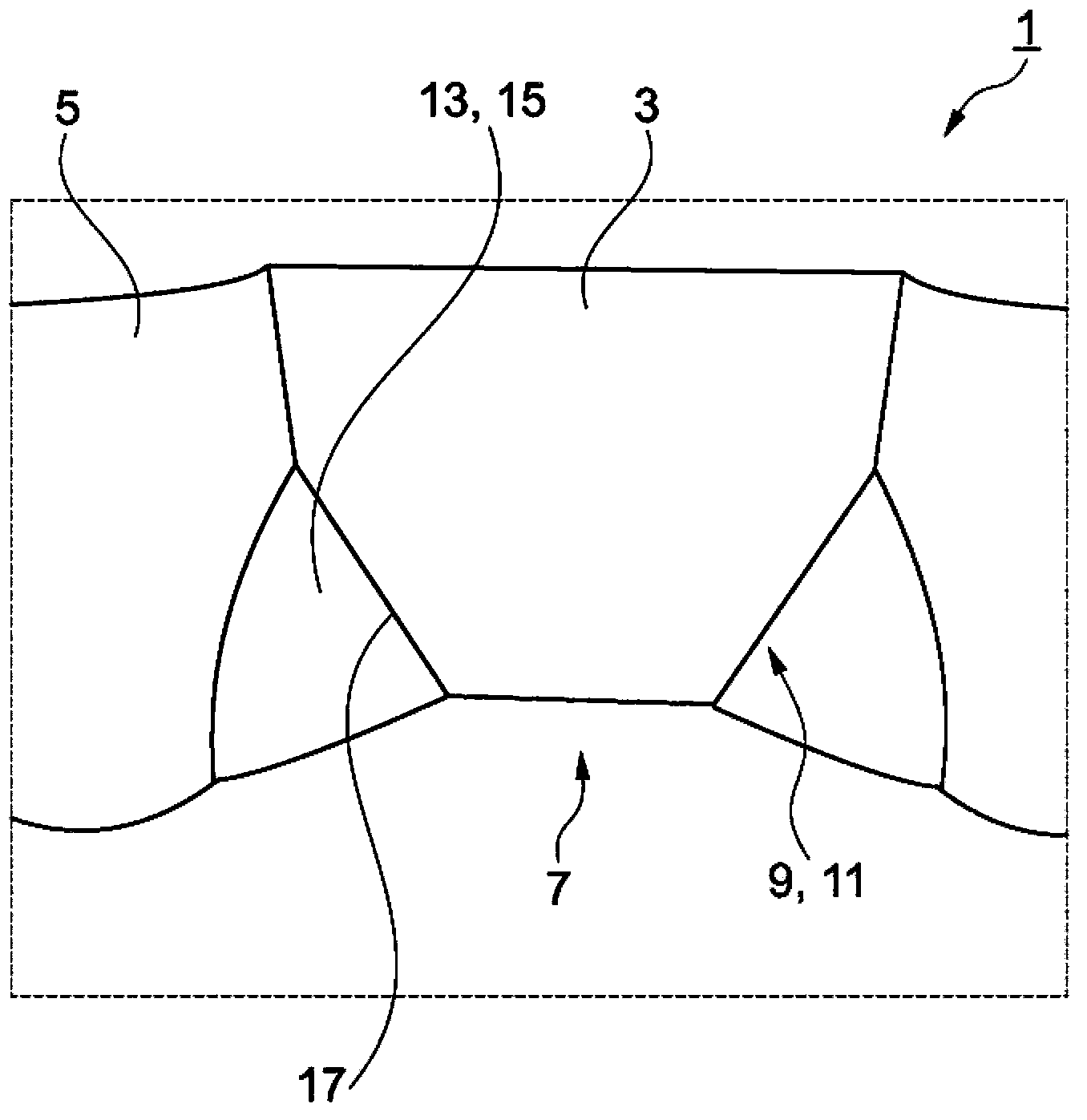

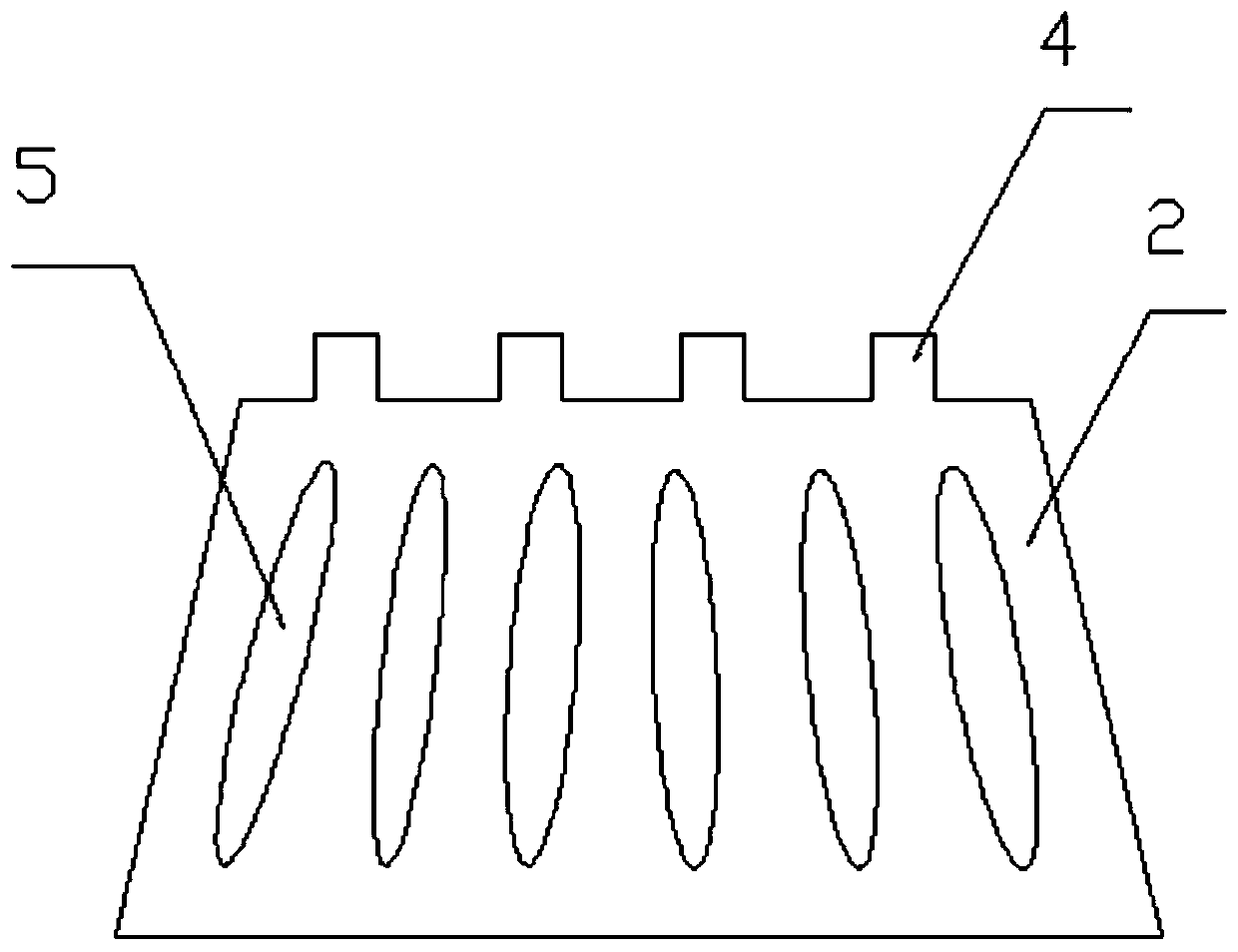

Sheet cage used for rolling bearing

The invention relates to a sheet cage (1) used for a rolling bearing. The sheet cage is used for a roller-shaped rolling element, and comprises a certain quantity of connecting pieces (3) axially extending between rings (5), wherein a cage hole (7) used for accommodating a rolling element (19) is formed between each two adjacent connecting pieces (3), and recesses (11) used for rounding corners (9) are introduced into the corners (9) of the cage hole (7) in all radial directions. On this occasion, the rounded recesses (11) inwardly widen in the radial directions through inclined plant portions (13). The invention also relates to a method for making the sheet cage (1). The sheet cage guarantees the strength required by the connecting pieces in the case of increasing the radius of each of the recesses.

Owner:SCHAEFFLER TECH AG & CO KG

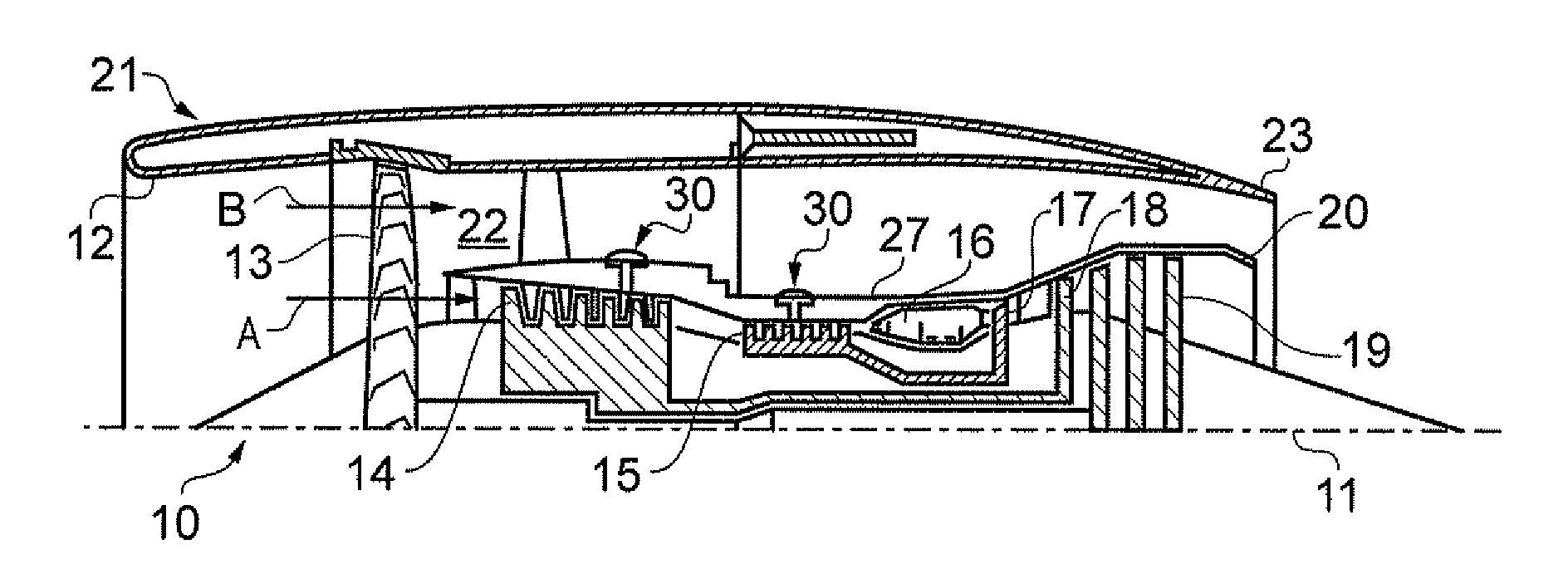

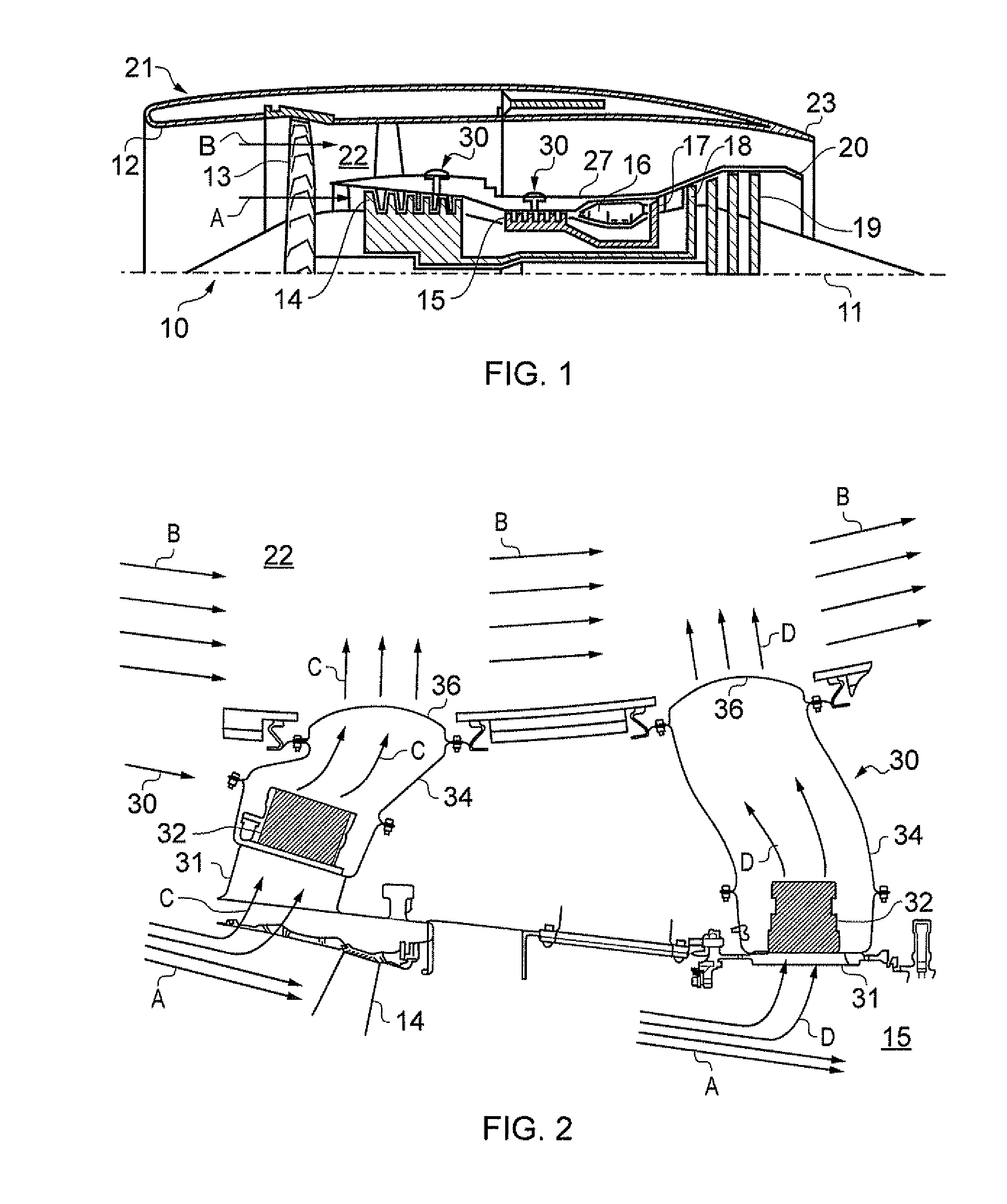

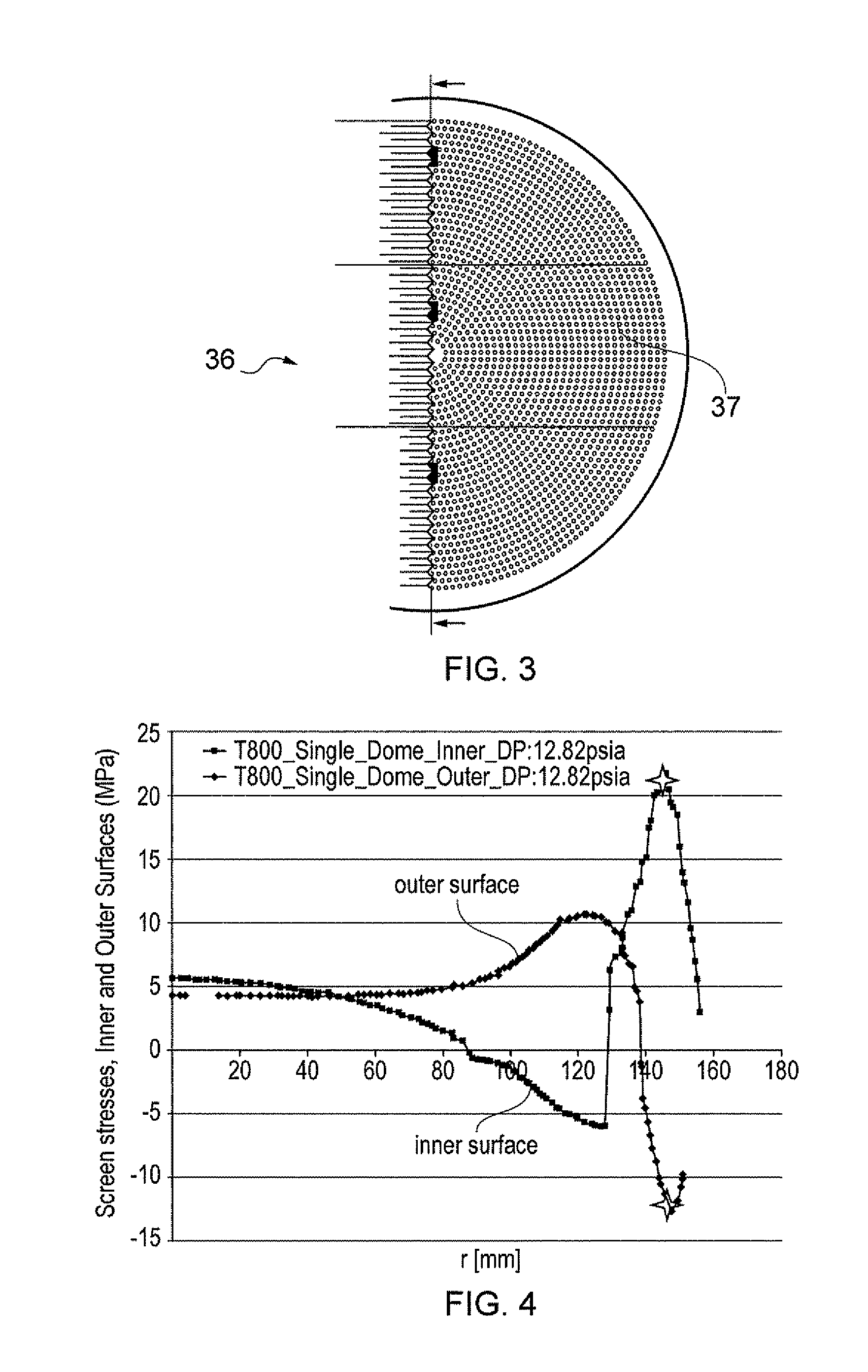

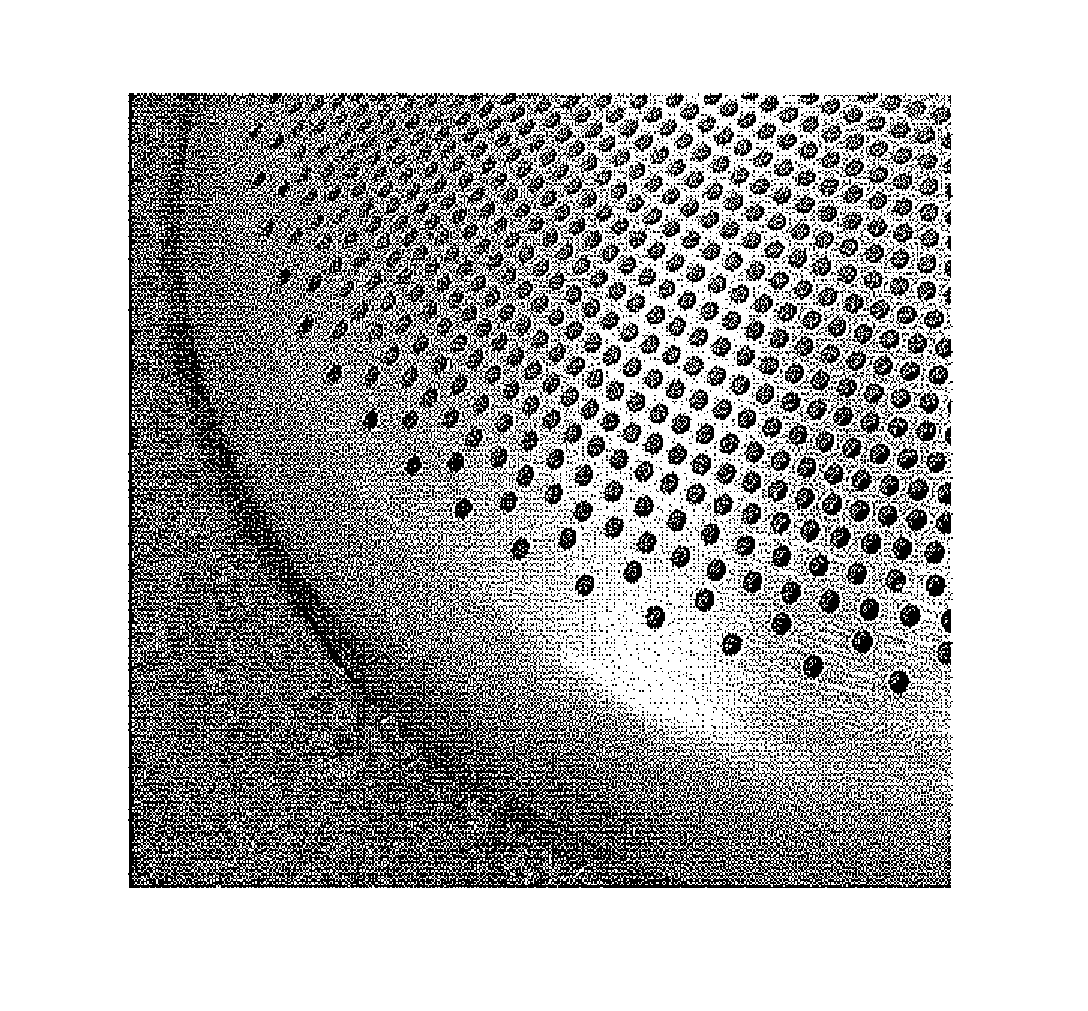

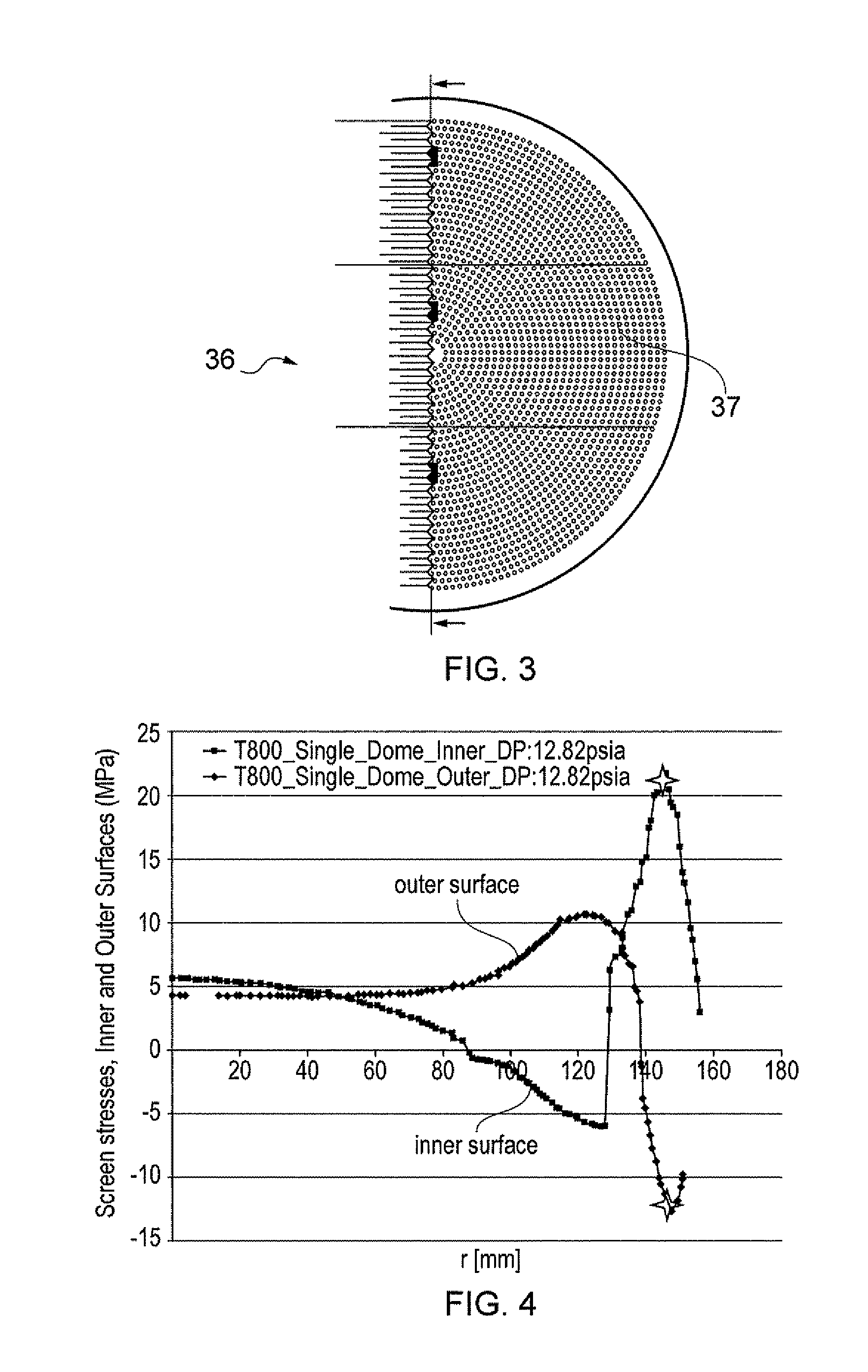

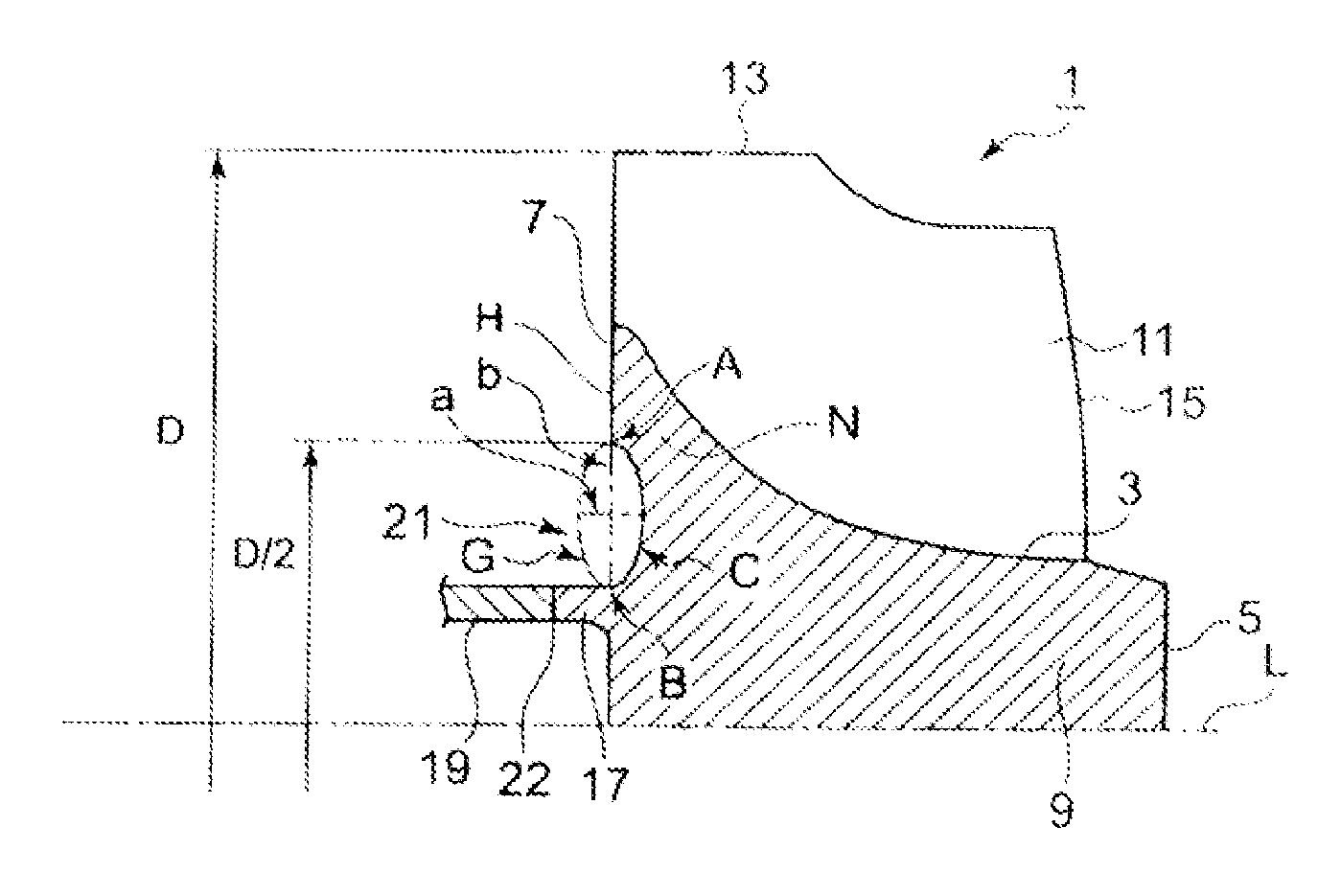

Bleed assembly for a gas turbine engine

ActiveUS20110146297A1Lower Level RequirementsReduce stress concentration factorEngine manufactureGas turbine plantsGas turbinesDome shape

A bleed assembly for a gas turbine engine is provided. The assembly includes: a duct having an inlet and an outlet; a bleed valve that controls the flow of bleed fluid into the inlet; and a dome-shaped diffuser screen which covers the outlet. The diffuser screen has a plurality of through-holes for passage of the bleed fluid. Each through-hole has one or more nearest-neighbour through-holes at a nearest-neighbour spacing. At the periphery of the diffuser screen, the average nearest-neighbour spacing of the through-holes at a given radial distance from the centre of the diffuser screen increases with increasing radial distance.

Owner:ROLLS ROYCE PLC

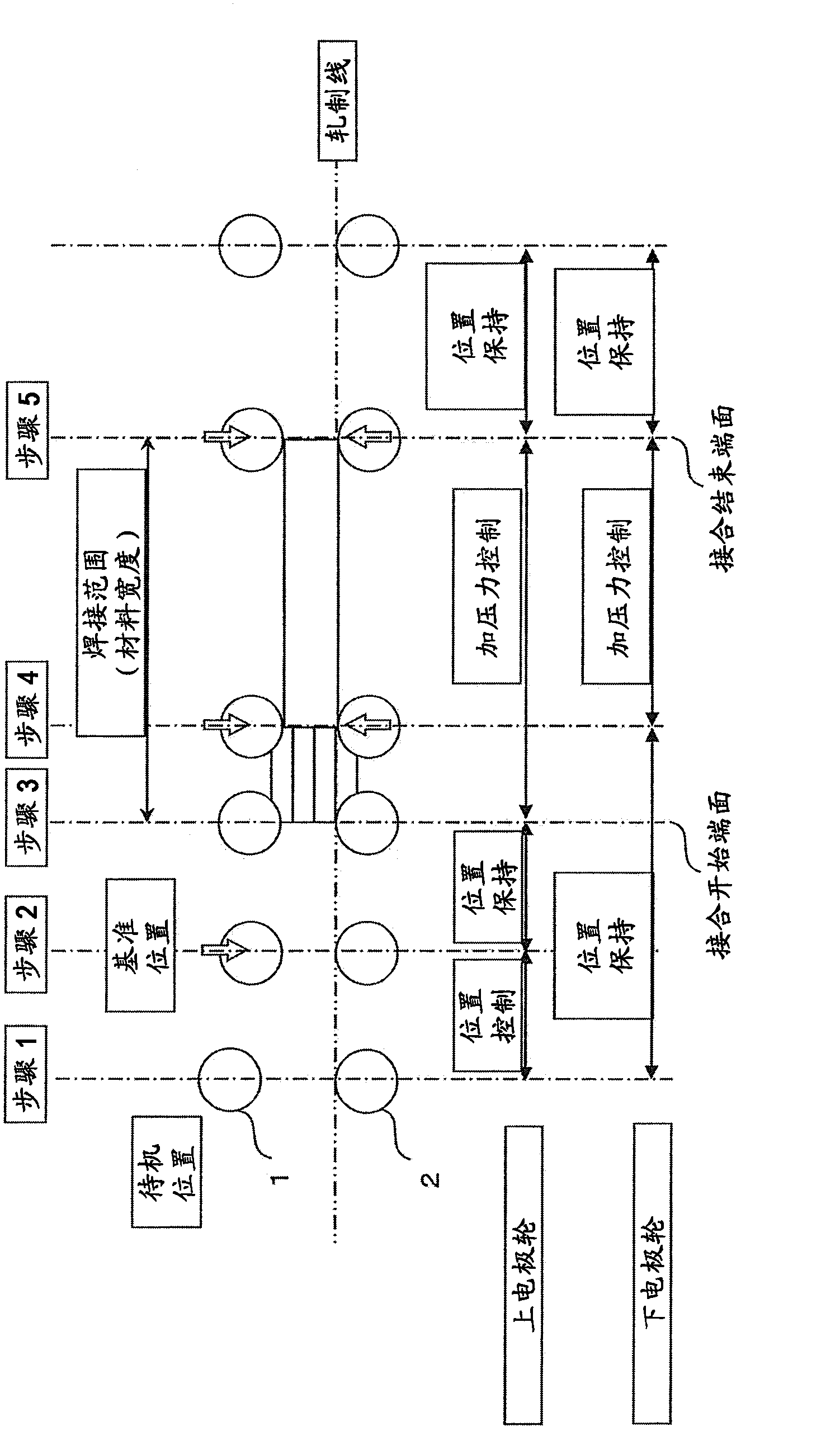

Mash seam welding method and device

ActiveCN103108719AIncreased pressure bearing shareIncrease the pressure differenceElectrode featuresWelding electric supplySeam weldingUltimate tensile strength

In order that in mash seam welding for metal plates with a thickness exceeding 2 mm, the joint strength is stabilized, the difference in the level of a joint part is reduced, high joint strength and reliability are ensured, and therefore metal plates with a thickness exceeding 4.5 mm can be also joined, two metal plates (5, 6) are grasped by first and second graspers (7, 8), respectively, ends of the two metal plates (5, 6) are overlapped , an overlap (L) therebetween is pressurized by a pair of upper and lower electrode wheels (1, 2) and continuously welded while a welding current is being passed to thereby join the two metal plates. While the overlap (L) is continuously welded while the welding current is being passed, welding pressure to be applied to the upper and lower electrode wheels (1, 2) is controlled such that upper and lower pressing forces acting on the overlap become equal.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

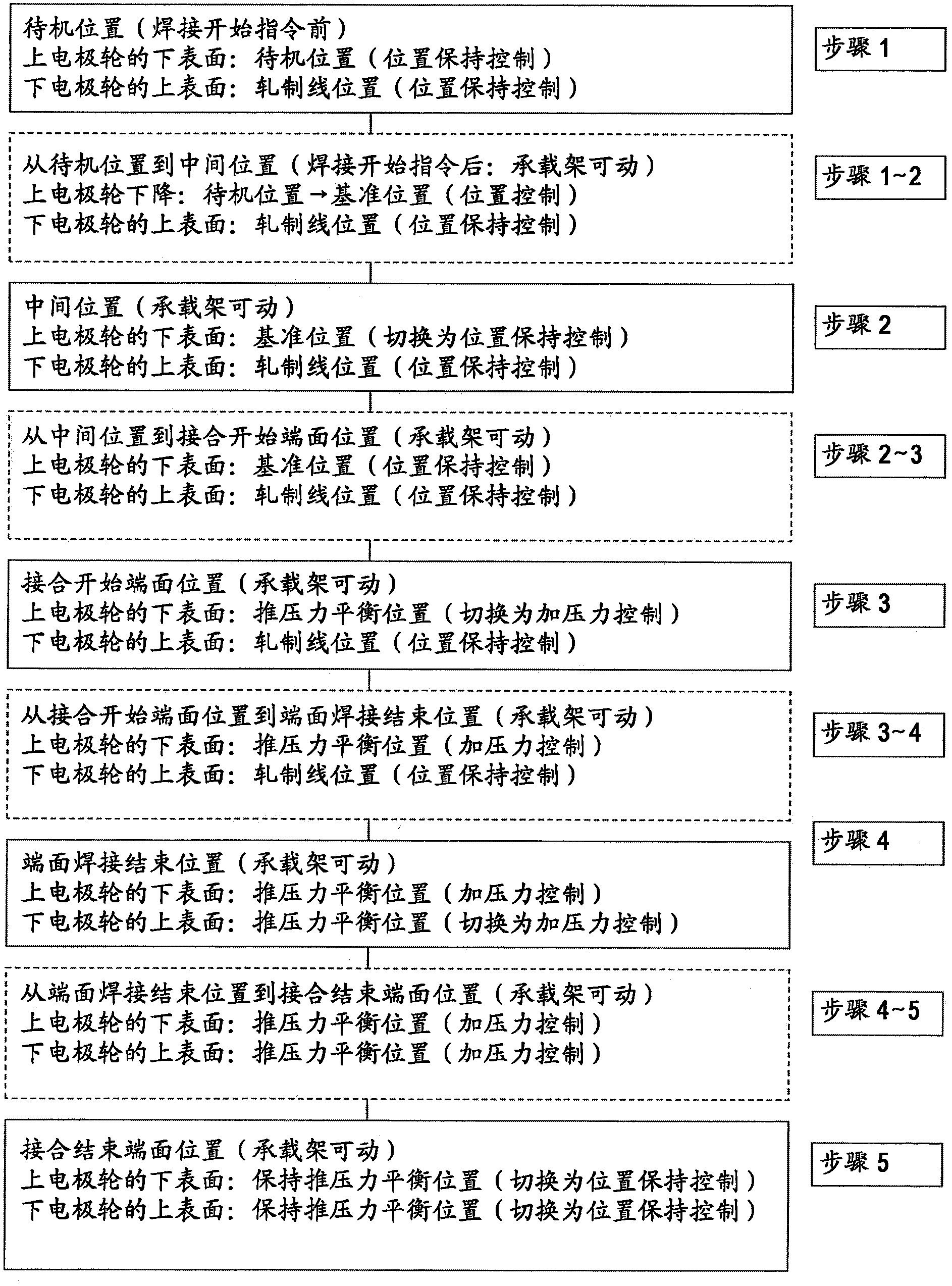

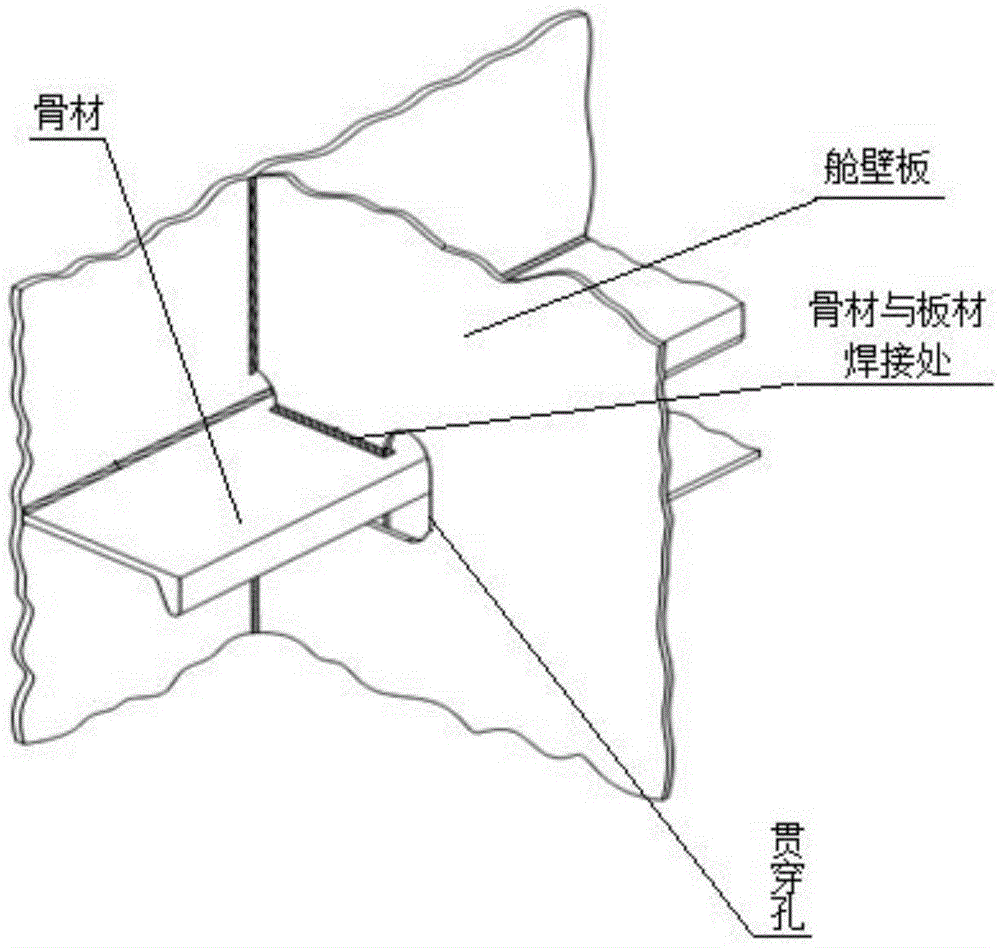

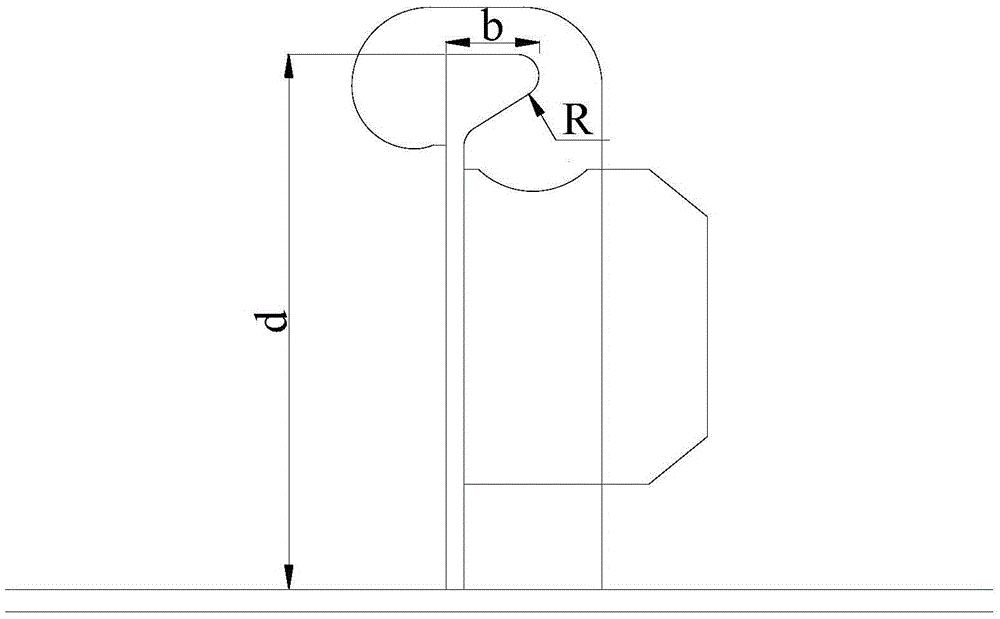

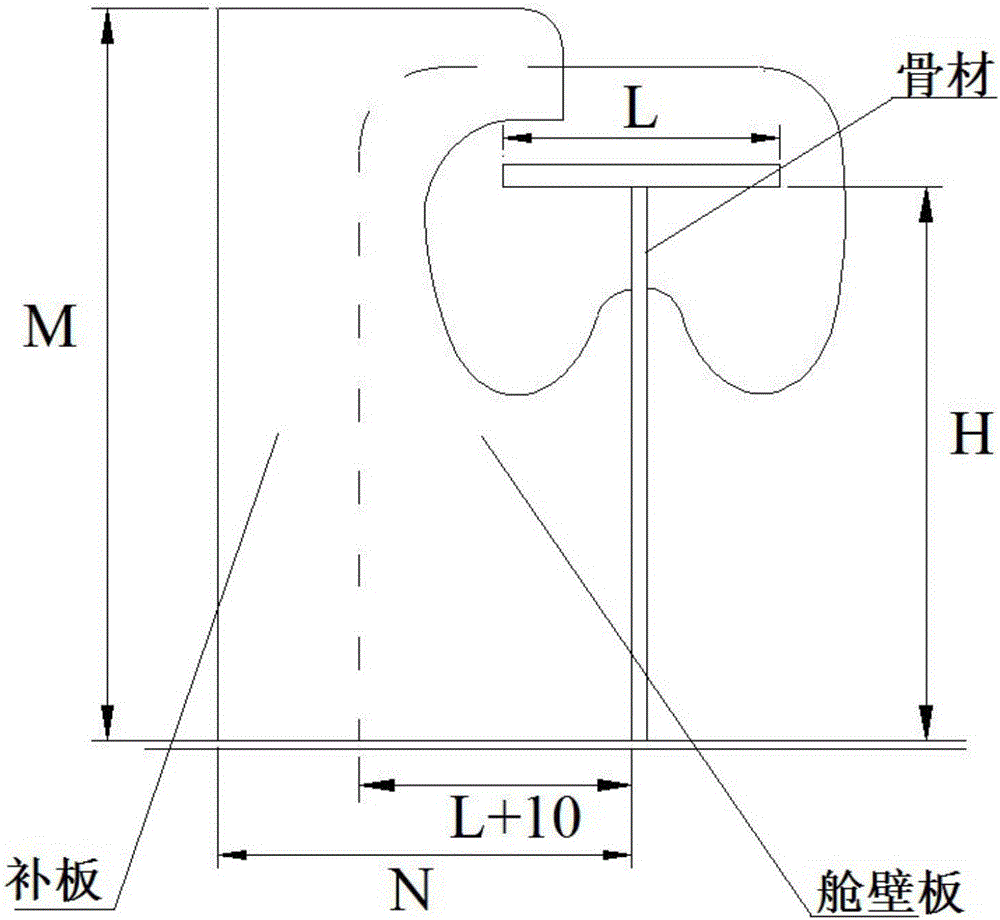

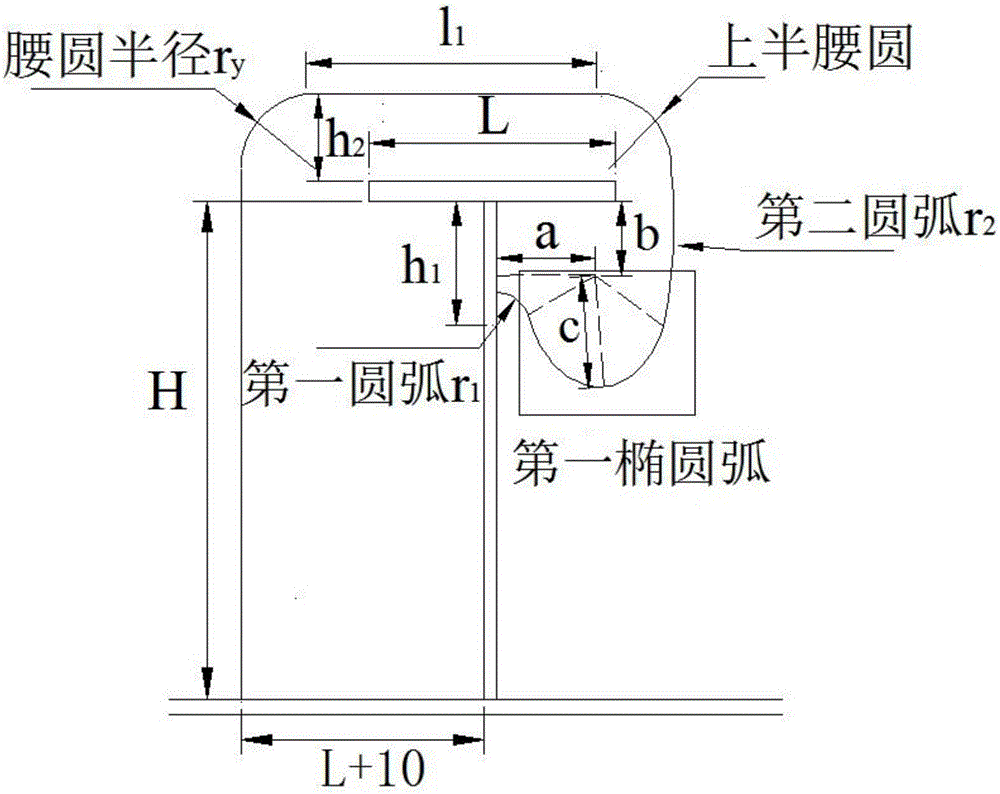

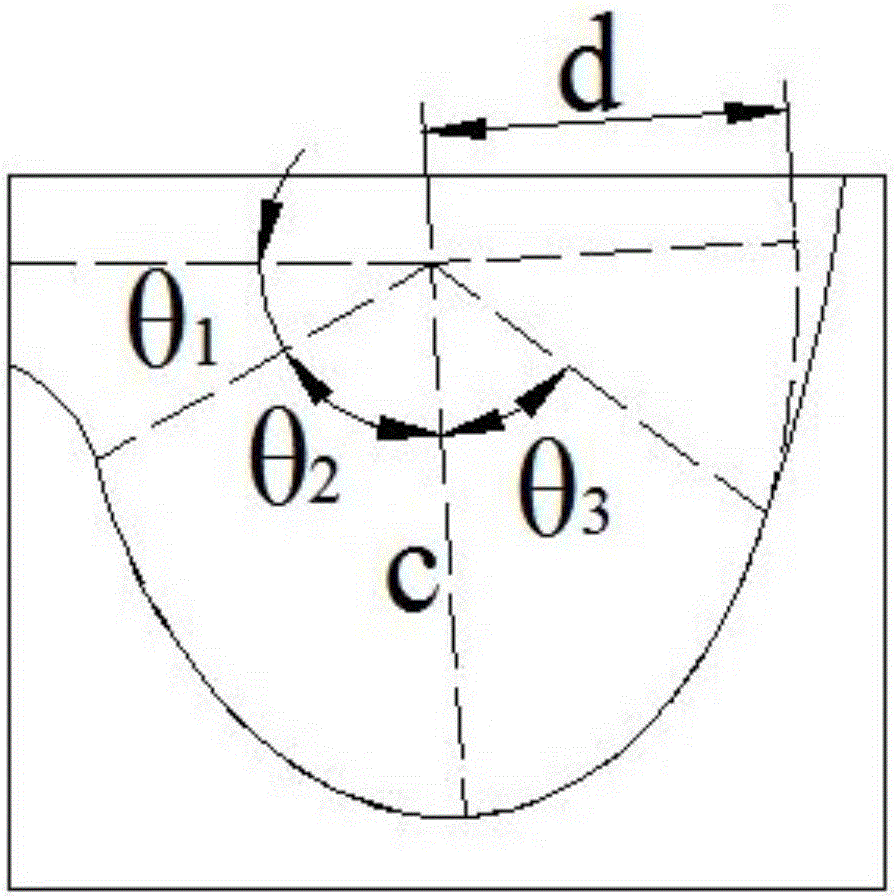

Aggregate through hole pattern structure of ship cabin wall plate

InactiveCN105620657AImprove fatigue strengthReduce stress concentration factorHull bulkheadsHull framesWall plateEngineering

The invention discloses an aggregate through hole pattern structure of a ship cabin wall plate. The structure comprises horizontal straight lines positioned on two sides of an opening of a through hole; the end part of the straight line on the left side is connected with a first arc line; the upper end of the first arc line is connected with a second arc line; the upper end of the second arc line is connected with an upper semicircle; the right lower end of the upper semicircle is connected with a third arc; the lower end of the third arc is connected with a fourth arc; the other end of the fourth arc is connected with the straight line on the right side of the opening of the through hole; and the through hole is an asymmetric hole. Aiming at an asymmetric aggregate for a ship, the hole edge stress concentration coefficient is reduced, and the ship fatigue strength is improved; and for frequent generation of cracks at a weld toe root part of a reinforcing material, the new design frequently adopts a reinforcing material removing method, but the rise of hole edge stress can be caused. The hole pattern can reduce stress concentration points when reducing the stress concentration coefficients to meetthe new design requirements so as to reduce fatigue sources; and compared with a novel hole pattern, the hole pattern is easily positioned, and is convenient for machining.

Owner:常熟市宝威机械设备有限公司

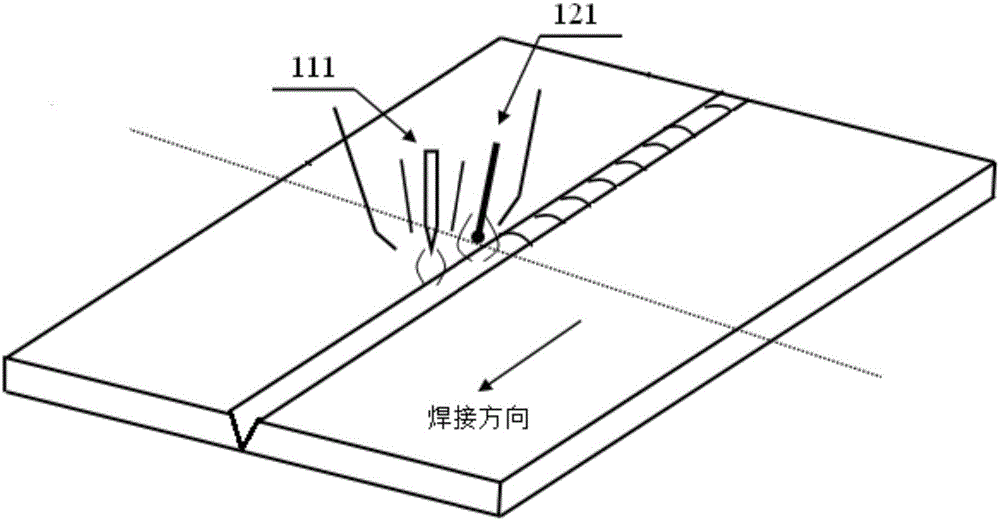

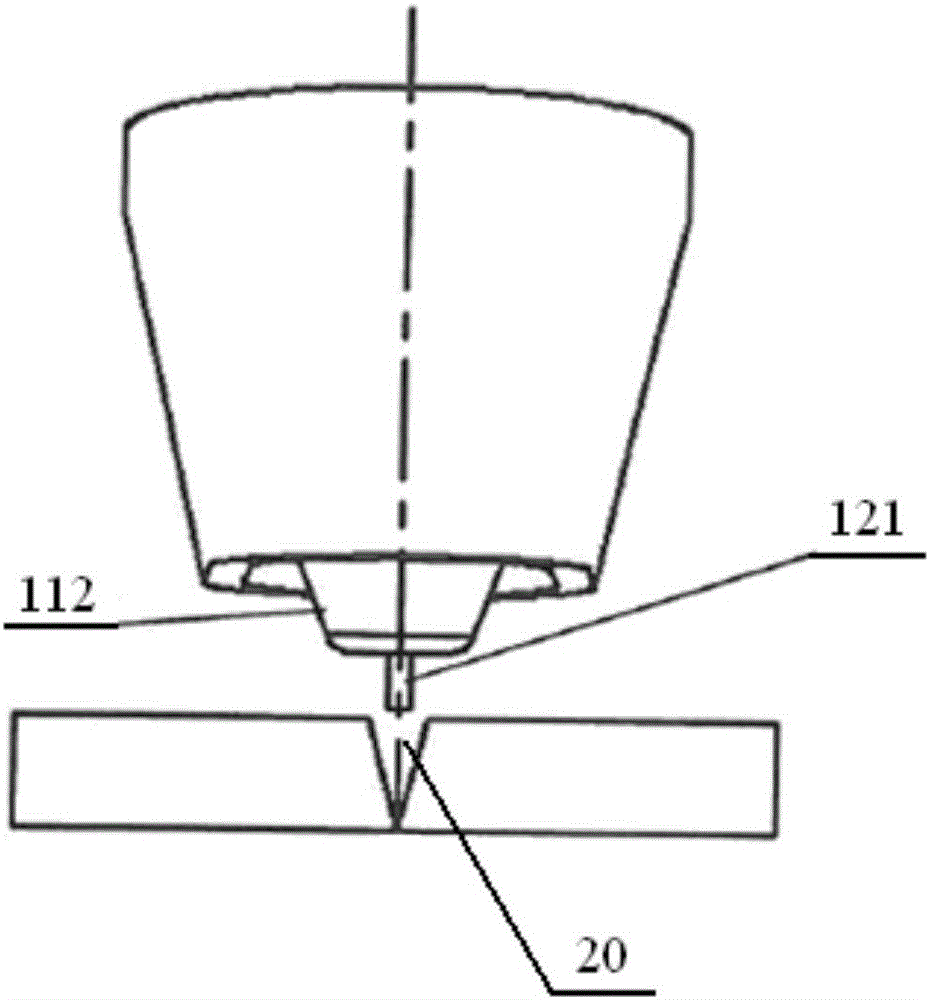

Plasma-MAG hybrid welding method

InactiveCN106271140AGuaranteed PenetrationImprove fatigue resistanceWelding apparatusHeat-affected zoneEngineering

The invention discloses a plasma-MAG hybrid welding method. According to the welding method, during welding, a plasma tungsten electrode is put front, and an MAG welding wire is put back, wherein a preset distance is kept between the tip of the tungsten electrode and the tip of the welding wire, and the height from the two tips to the surface of a weldment are equal; and moreover, the tungsten electrode is perpendicular to a welding bead, and a preset included angle is formed between the welding wire and the tungsten electrode. By means of the method, the welding process is completed through interaction of two independent heat sources and the action between the compound heat sources and the weldment; the welding method has the characteristics that the weld penetration is large; the welding speed is high; heat input is low; a heat affected zone is narrow, and the welding quality is high; and the welding quality of a framework can be improved, welding deformation of the framework can be reduced, and the basic requirements for welding of the framework are met.

Owner:CRRC QINGDAO SIFANG CO LTD

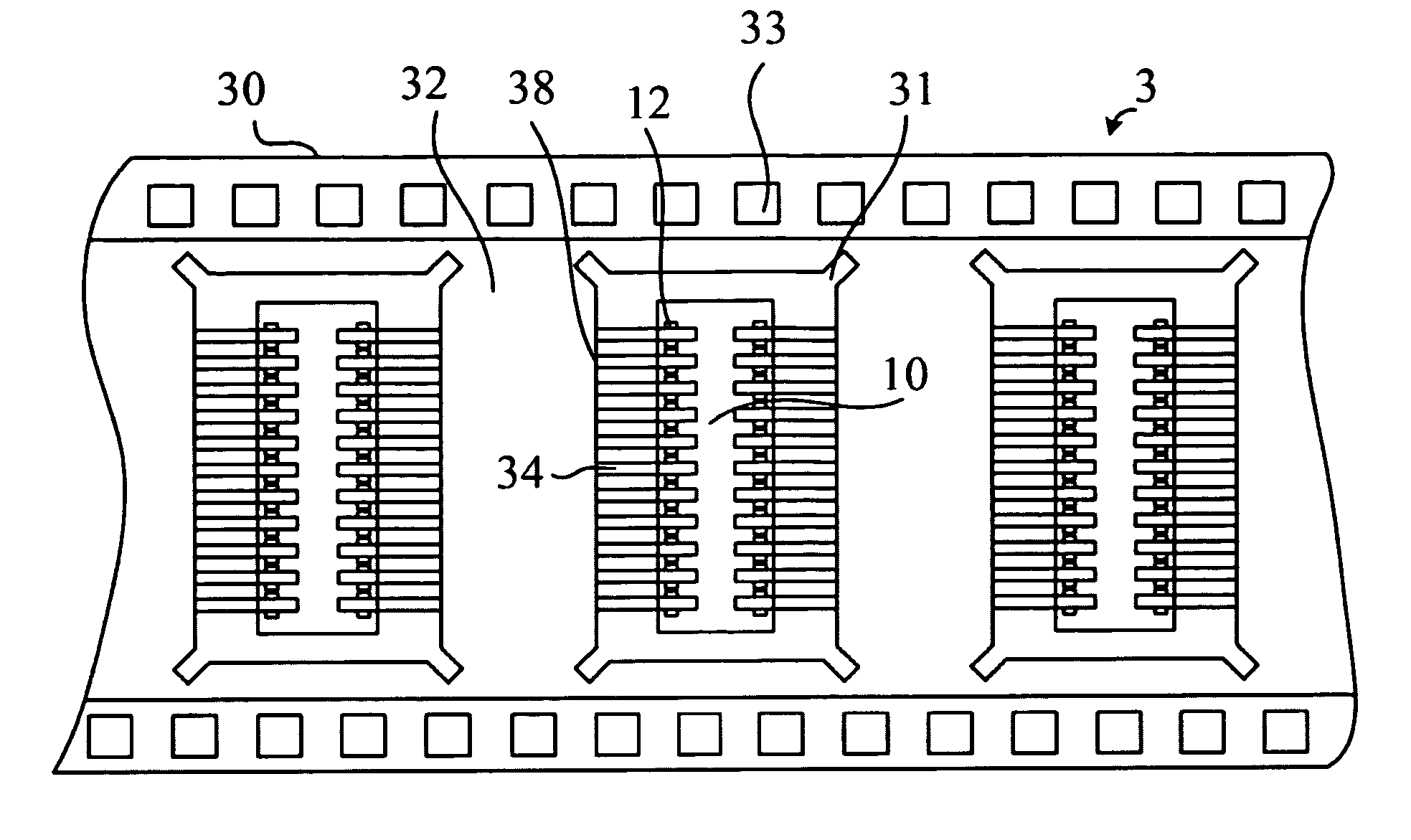

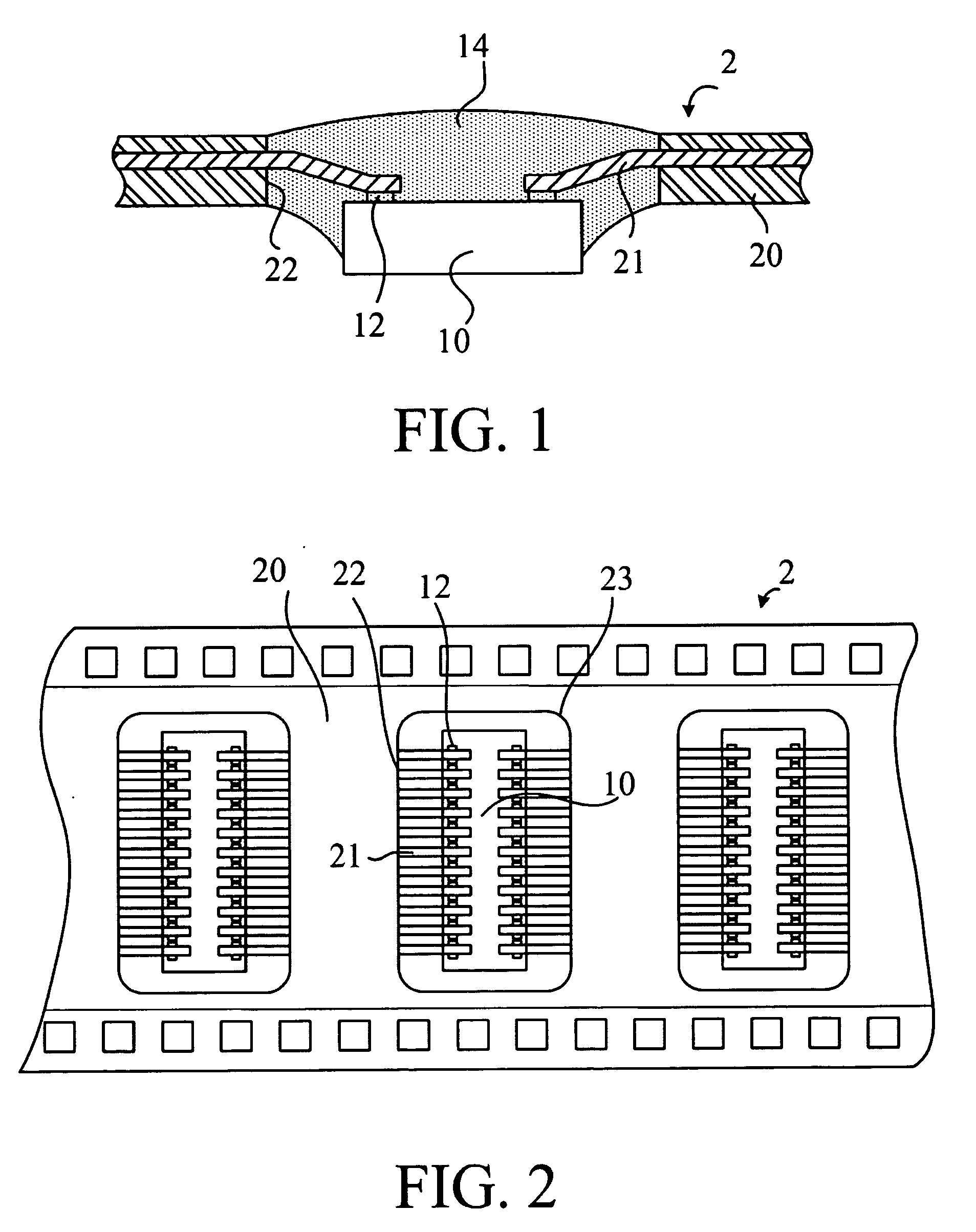

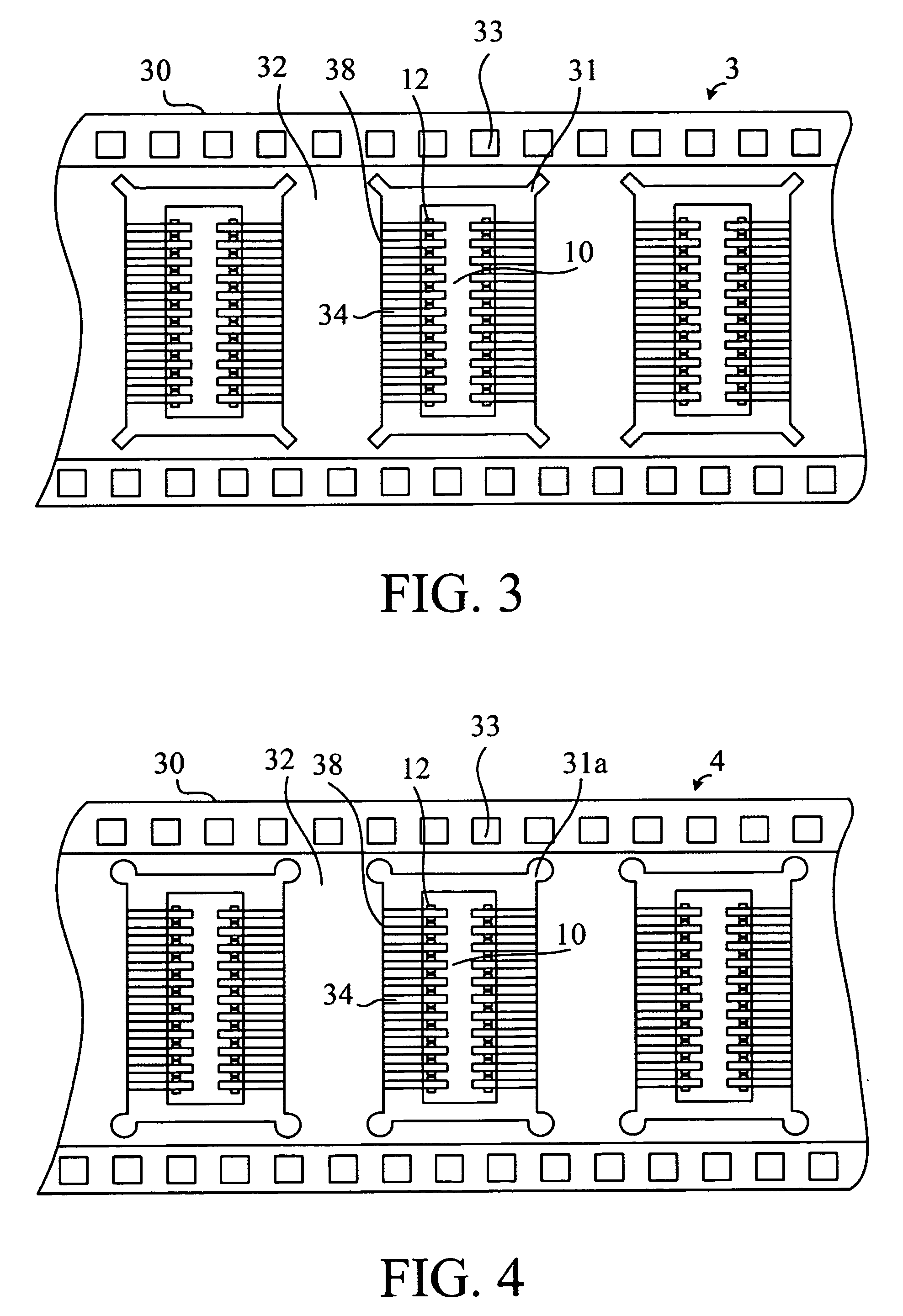

Tape for tape carrier package

InactiveUS20060145314A1Easy to shapeIncrease flexibilitySemiconductor/solid-state device detailsSolid-state devicesStress concentrationElectrical and Electronics engineering

The invention provides a tape for a tape carrier package. The tape includes a flexible insulating film. The flexible insulating film is divided into a plurality of units arranged successively, and each of the units has a device hole and a plurality of leads. The plurality of leads are formed on the flexible insulating film and protrude to the device hole. The device hole has a plurality of corners formed in a form of a notch for preventing the stress from concentrating on and breaking the leads.

Owner:CHIPMOS TECH INC

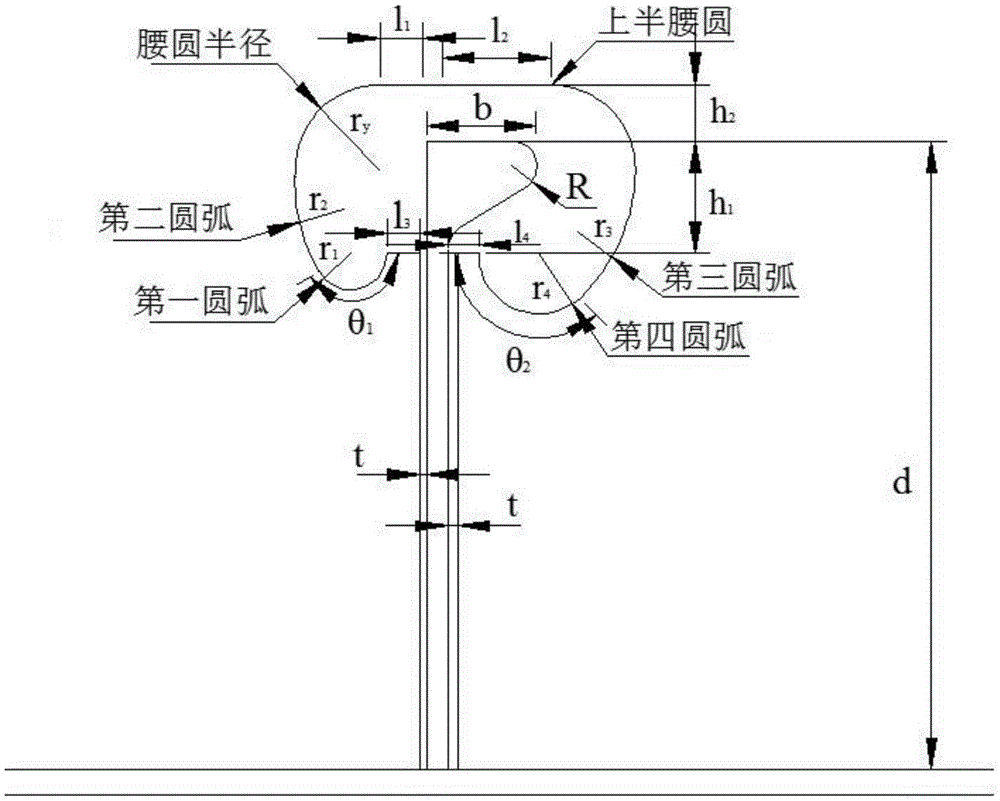

Welding structure for hole pattern of aggregate penetration hole in ship bulkhead plate and supplementary plate

ActiveCN106184608AReduce stress concentration factorExtend fatigue lifeHull bulkheadsVessel designingParent materialEngineering

The invention discloses a welding structure for a ship bulkhead plate aggregate hole and a matched supplementary plate. The welding structure for the ship bulkhead plate aggregate hole and the matched supplementary plate comprises a bulkhead plate and the supplementary plate. The aggregate penetration hole is formed in the bulkhead plate, the aggregate penetration hole and the supplementary plate are welded after an aggregate penetrates through the aggregate penetration hole to be assembled, a hole structure comprises a first arc, the first arc is connected with a first elliptic arc, the elliptic arc is connected with a second arc, the upper end of the second arc is connected with an upper semi-waist circle, the lower end of the upper semi-waist circle is connected with a straight line tangent to the upper semi-waist circle, the supplementary plate is provided with a third arc in the shape, the lower end of the third arc is connected with a second elliptic arc, the second elliptic arc is connected with a fourth arc, the other end of the fourth arc is connected with a fifth arc, the fifth arc is connected with a right angle, the other side of the right angle is connected with a sixth arc, and the sixth arc is tangent to the upper side of the supplementary plate. For the T-shaped aggregate for a ship, the operation requirement for improving the fatigue life of the ship is met through decreasing the stress concentration factor on the side of the hole; the stress concentration factor is decreased, so that the fatigue life of the connection of the supplementary plate and the hole parent material is prolonged; and the assembly is simple and the wide application is realized.

Owner:JIANGSU UNIV OF SCI & TECH

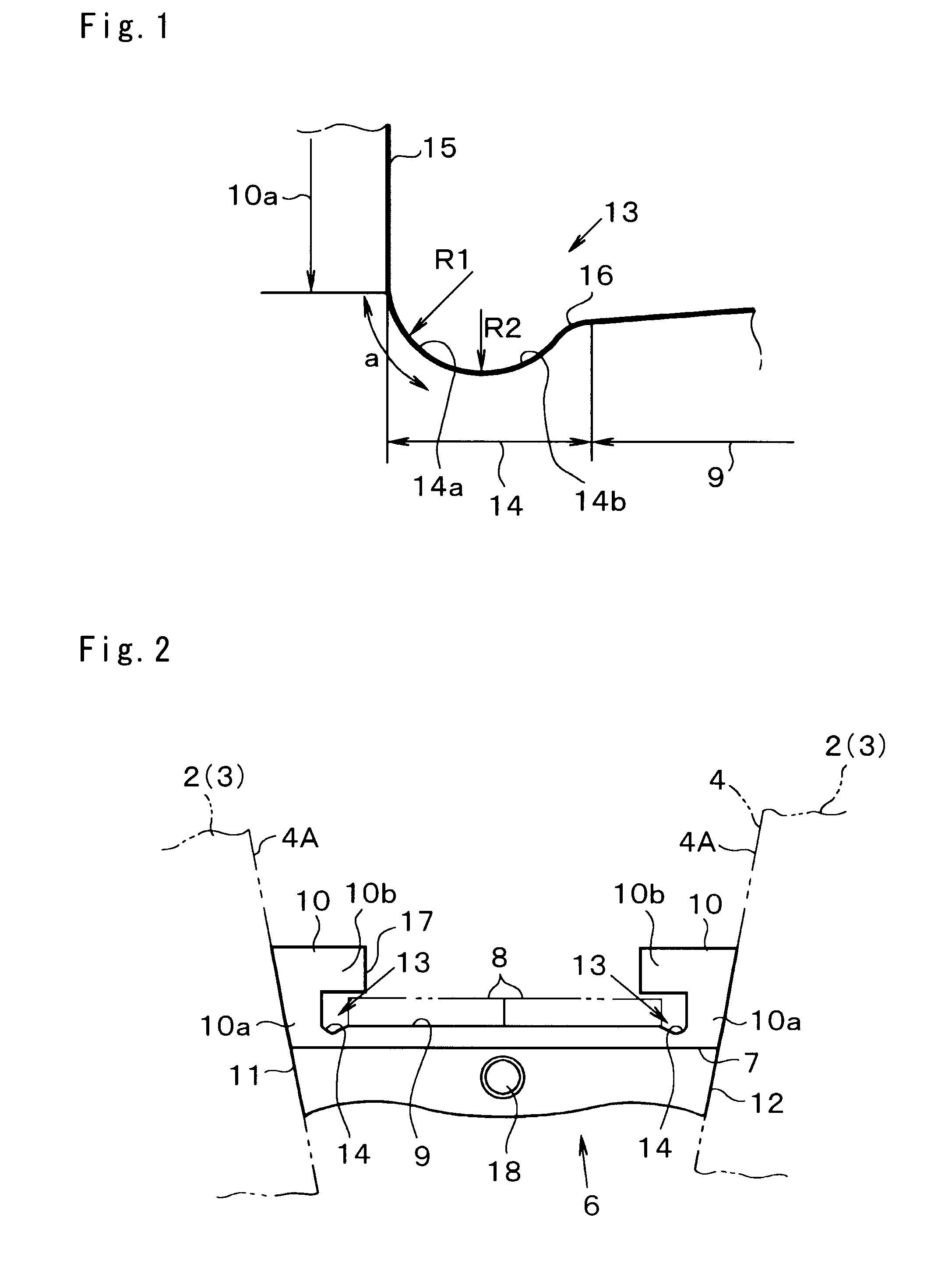

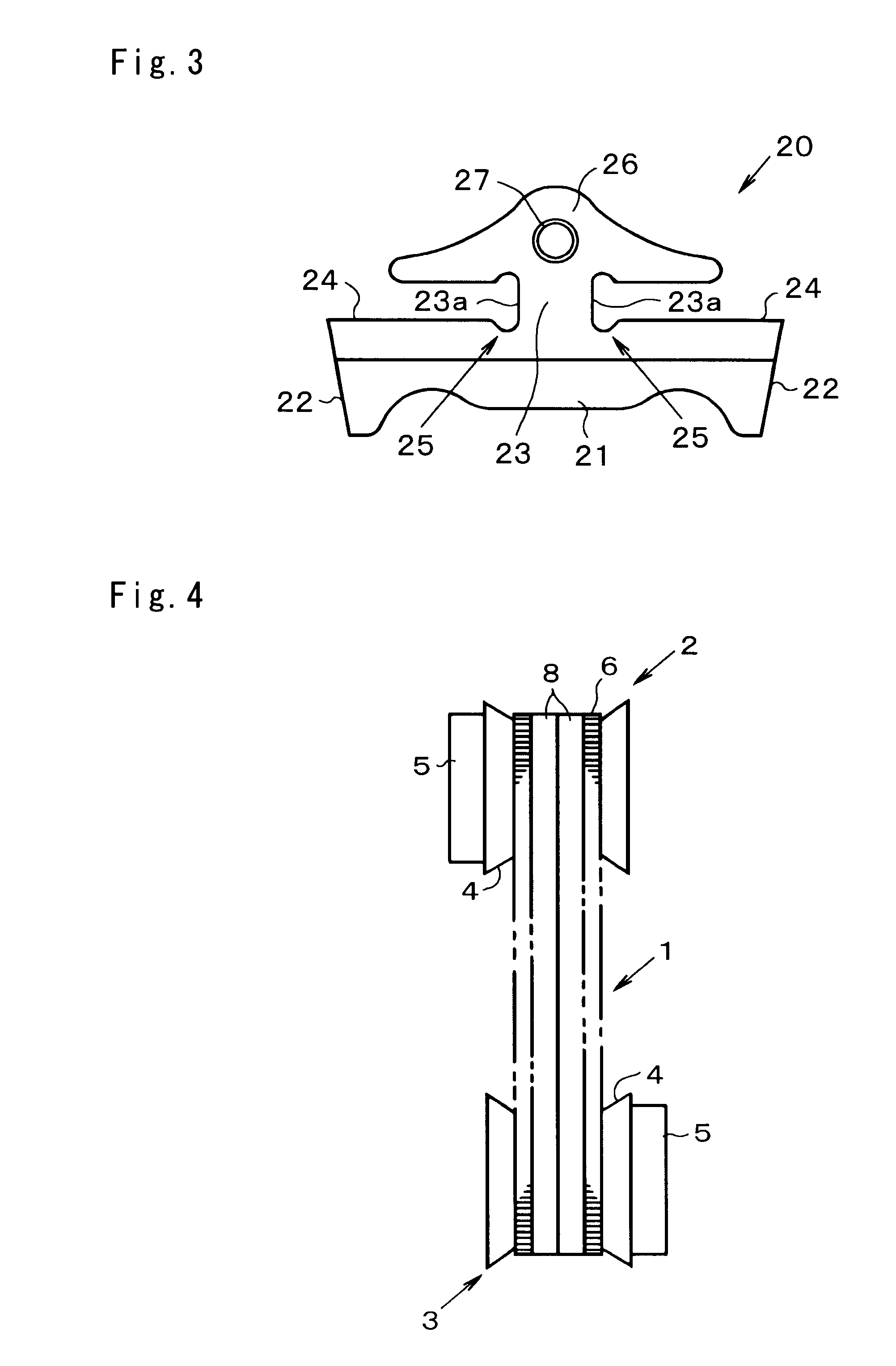

Element of belt for continuously variable transmission and belt for continuously variable transmission

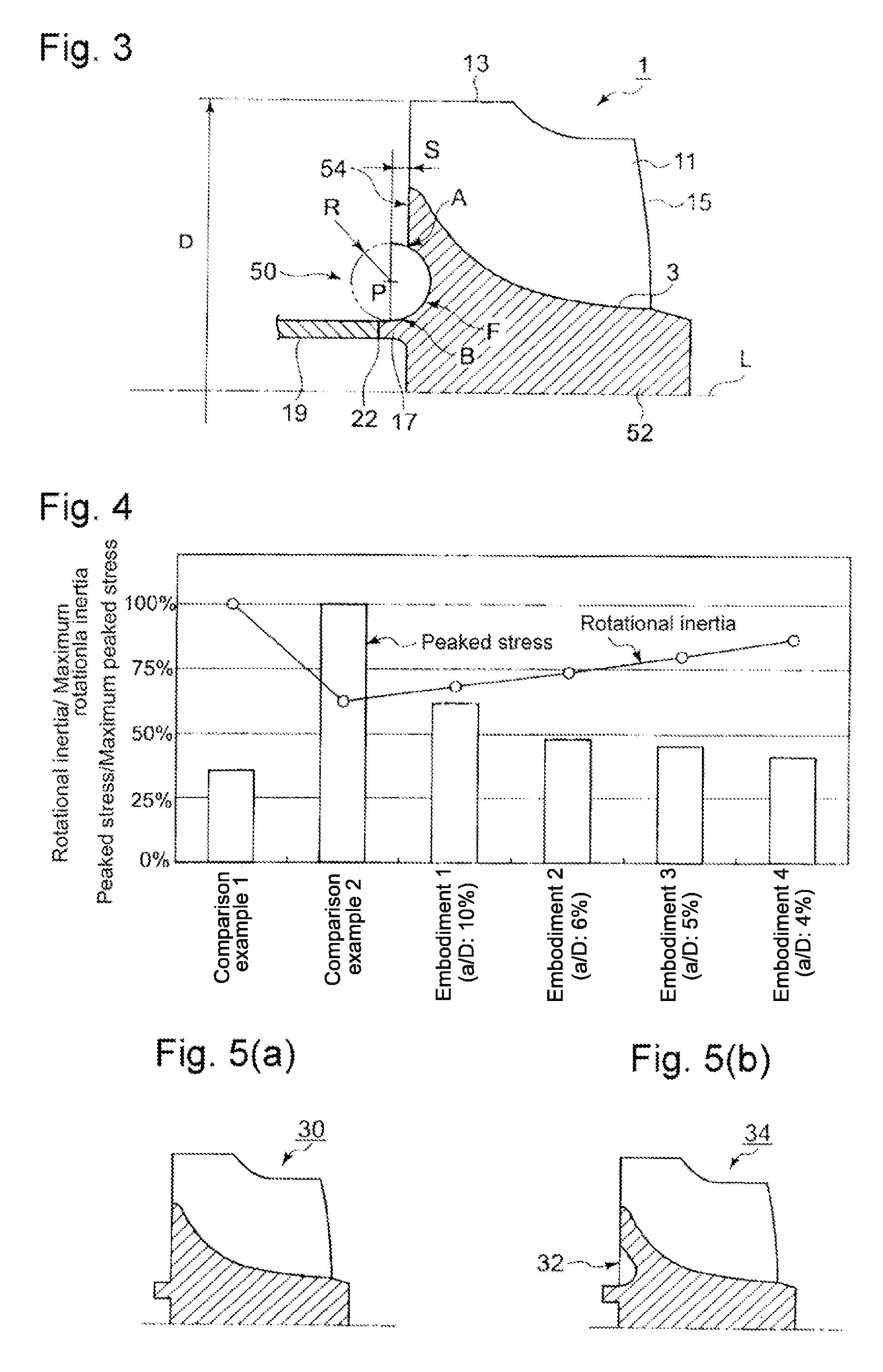

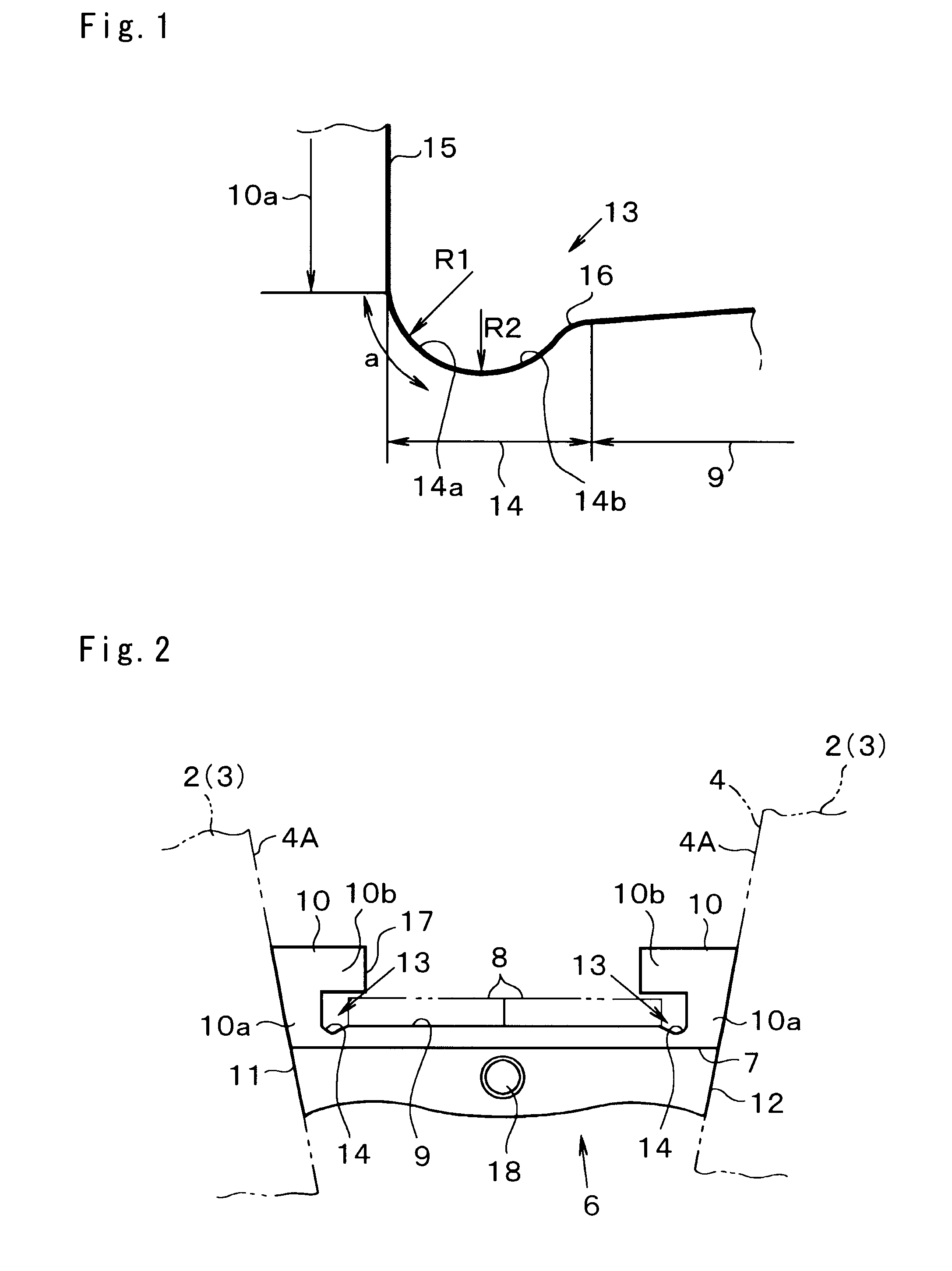

ActiveUS20100311531A1Reduce stress concentration factorEnhanced strength and durabilityV-beltsDriving beltsVariatorEngineering

A belt for a continuously variable transmission and elements used in the belt. The elements include a stopper portion formed integrally with a neck portion erected upwardly from a saddle face to hold a width end portion of the ring. The elements are juxtaposed annularly in a same orientation and fastened by rings disposed on a saddle face of the element thereby forming a belt for a continuously variable transmission. A recessed portion is formed by depressing the saddle face at a corner between a side face of the neck portion and the saddle face; and an inner face of the recessed portion includes a first inner face extending smoothly into the side face of the neck portion and having a relatively larger curvature radius, and a second inner face extending smoothly into the first inner face and having a relatively smaller curvature radius.

Owner:TOYOTA JIDOSHA KK

Preparation method of inorganic foam building thermal insulation material

InactiveCN103524101AImprove air tightnessUniform pore size distributionCeramicwareThermal insulationPulverized fuel ash

The invention provides a preparation method of an inorganic foam building thermal insulation material. The preparation method comprises the following steps: dispersing polypropylene fibers, pulverized fuel ash, sulphate aluminosilicate cement, calcium stearate, perlite, manganese dioxide and triethanolamine to water, and stirring, thus obtaining unfoamed slurry; and adding hydrogen peroxide with 30% of mass concentration to the unfoamed slurry, then molding the obtained pre-foamed slurry by casting, maintaining, demolding, and cutting, thus obtaining the inorganic foam building thermal insulation material. The preparation method has the advantages that the foaming process is controlled by controlling the mixing amount of the manganese dioxide catalyst so as to ensure the strength of the inorganic foam building thermal insulation material, simultaneously reduces the heat conductivity of the inorganic foam building thermal insulation material and enhances the heat preservation effect of the inorganic foam building thermal insulation material, the perlite is added so as to serve as an anti-collapse agent so as to reduce the rejection rate, and meanwhile, the triethanolamine is added so as to improve the property of the inorganic foam thermal insulation material. Compared with materials of the same kind, the inorganic foam building thermal insulation material has the characteristics of high strength, low heat conductivity, small volume weight, burning resistance, flame resistance and the like.

Owner:SHANGLUO UNIV

Barrel defect welding repair method

ActiveCN104722938AReduce stress concentration factorChange the direction of forceWelding/cutting auxillary devicesAuxillary welding devicesStress concentrationDefect repair

The invention discloses a barrel defect welding repair method which can improve the success rate of one-time repair welding and aims at avoiding inner wall repair welding. When repair welding is performed, the repair welding area of a barrel is regulated to the position of ten o'clock to eleven o'clock or the position of one o'clock to two o'clock, and then welding starts to be performed along the weld root near the inner side of the barrel to enable the projection area of the non-repair-welding-area on the barrel cross section to be roughly in the shape of a U; the U-shaped section is remained, and repair welding is completed layer by layer from inside to outside. When every a U-shaped section layer is welded, the welding bead must be overlapped from the thicker wall position to the center in the circumferential direction of the barrel in a symmetrical and circumferential mode, and each circumferential circle of the welding bead is divided into two half circles to complete welding in a climbing mode in the circumferential direction of the barrel. The stress concentration factors of the weld toe can be effectively reduced, welding shrinkage stress is reduced, the stress direction of the weld toe is changed, and therefore repeated cracking in the repair process and repair welding work after removing backing plates can be effectively avoided. The method is particularly suitable for defect repair of the barrel with the wall thickness more than 70 mm.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

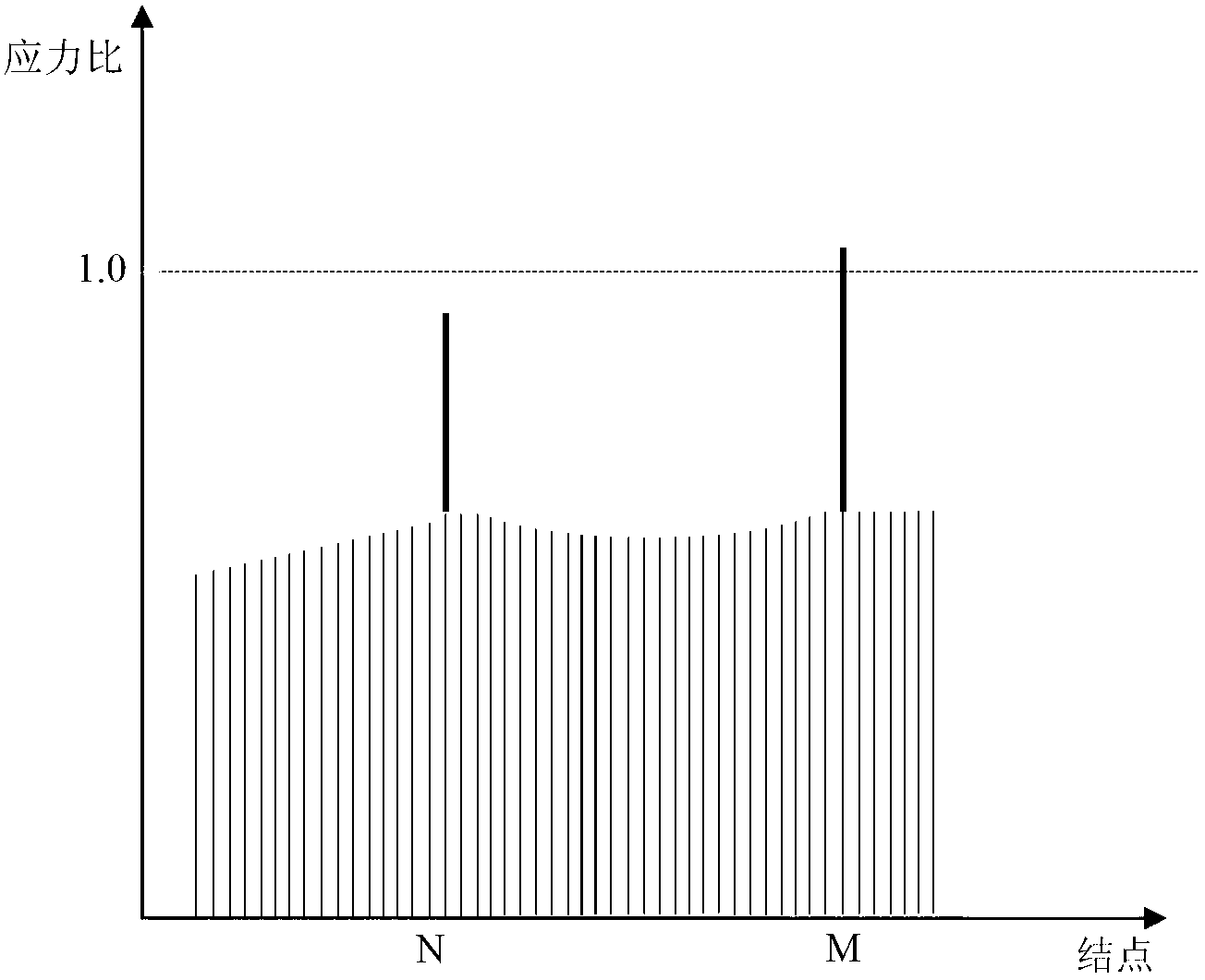

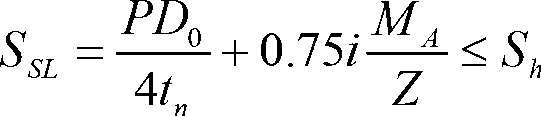

Auxiliary graphical method for rating pipeline stress for solving engineering practical problems

ActiveCN103020442ASolve engineering problemsReduce stress concentration factorSpecial data processing applicationsGraphicsProcess engineering

The invention relates to a pipeline stress analyzing and computing technology, in particular to an auxiliary graphical method for rating pipeline stress used for engineering practical problems. The method comprises the following steps of: outputting a quantity which is irrelevant to stress concentration in computed stress and a quantity which is relevant to stress concentration respectively; and partitioning the quantity which is relevant to stress concentration into a quantity before the consideration of stress concentration and a quantity after the consideration of stress concentration, and displaying by using graphics. According to the method, a user can obtain more information from graphics, methods for solving problems can be found more quickly by using graphics, and solving of engineering problems is greatly facilitated.

Owner:CHINA NUCLEAR POWER ENG CO LTD

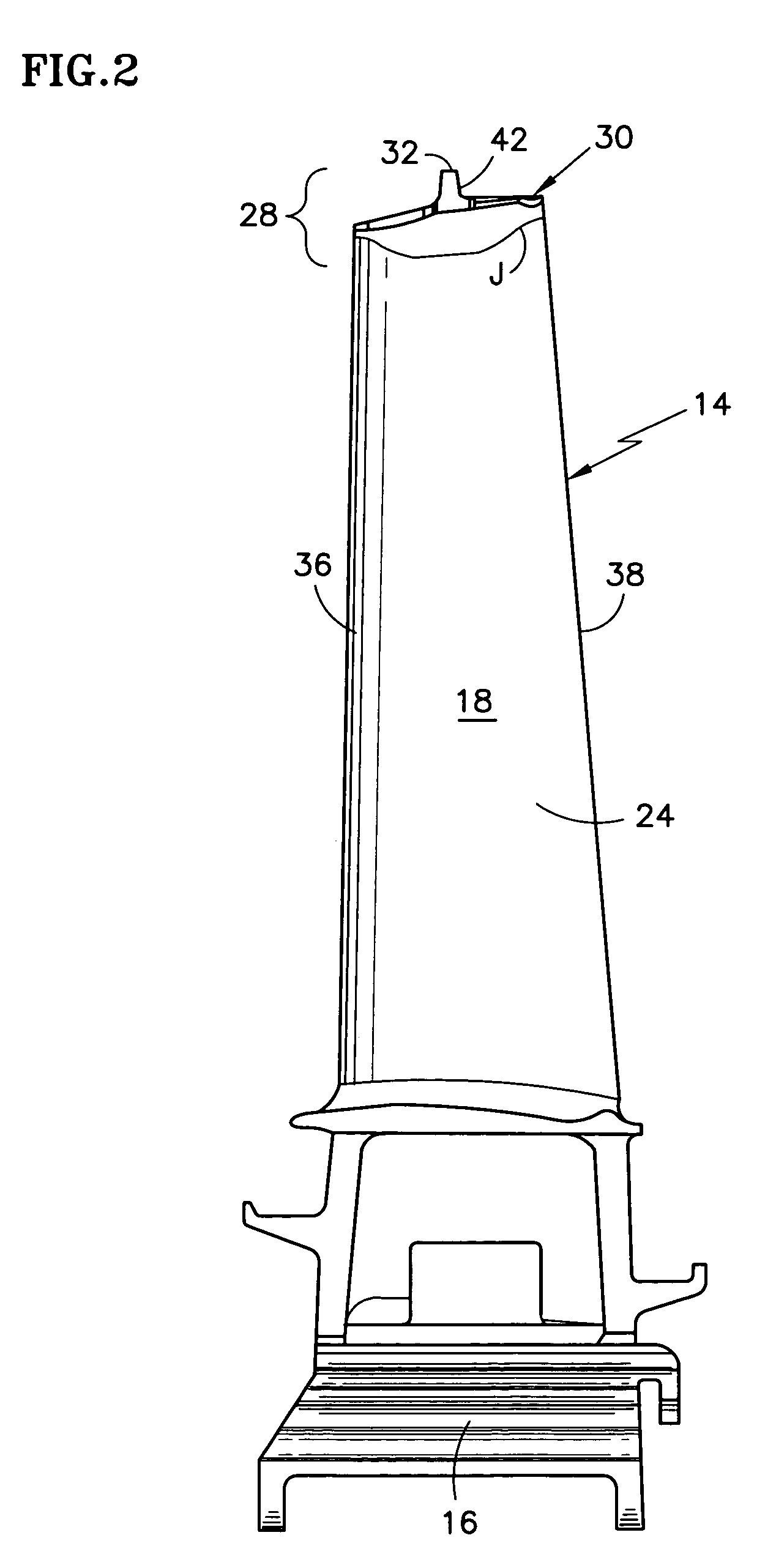

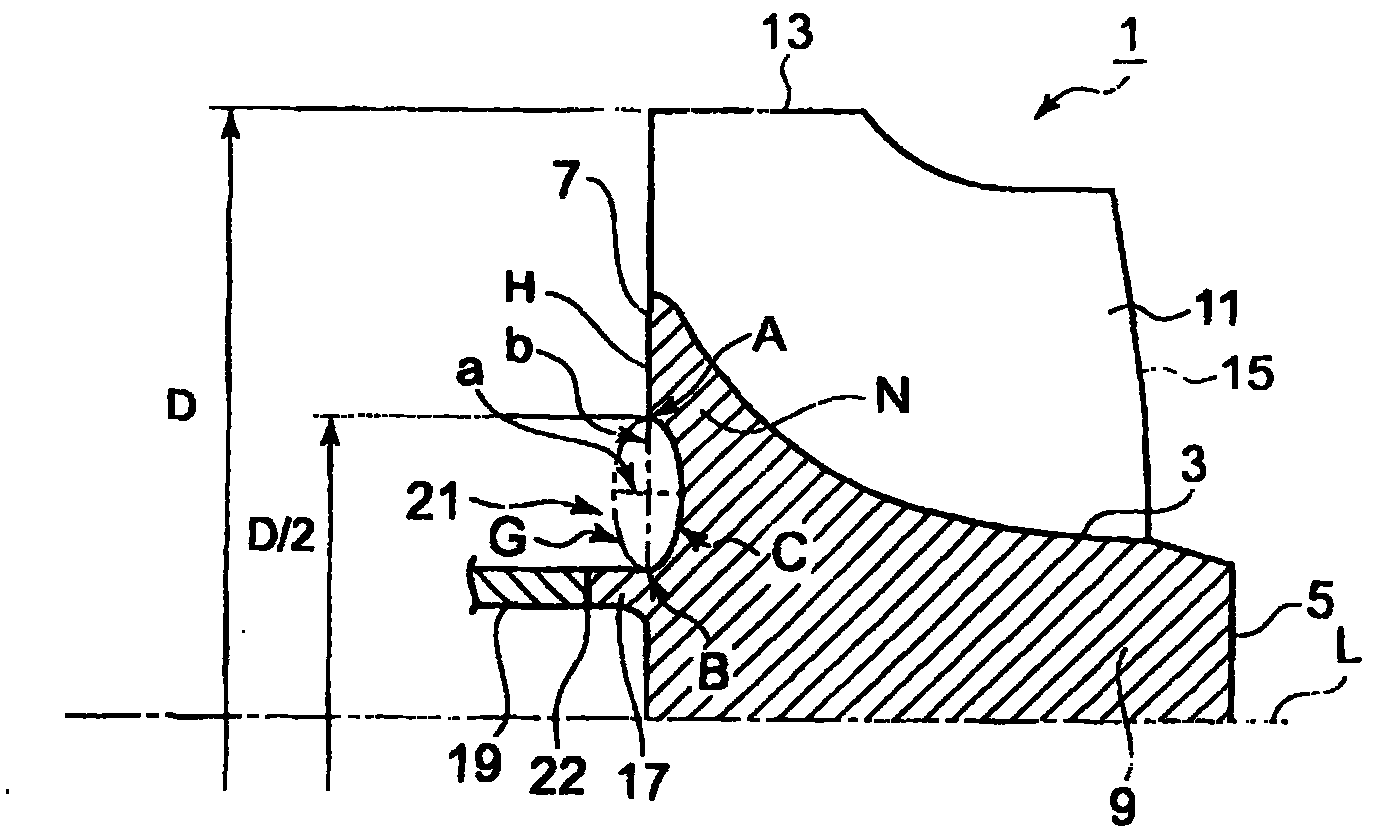

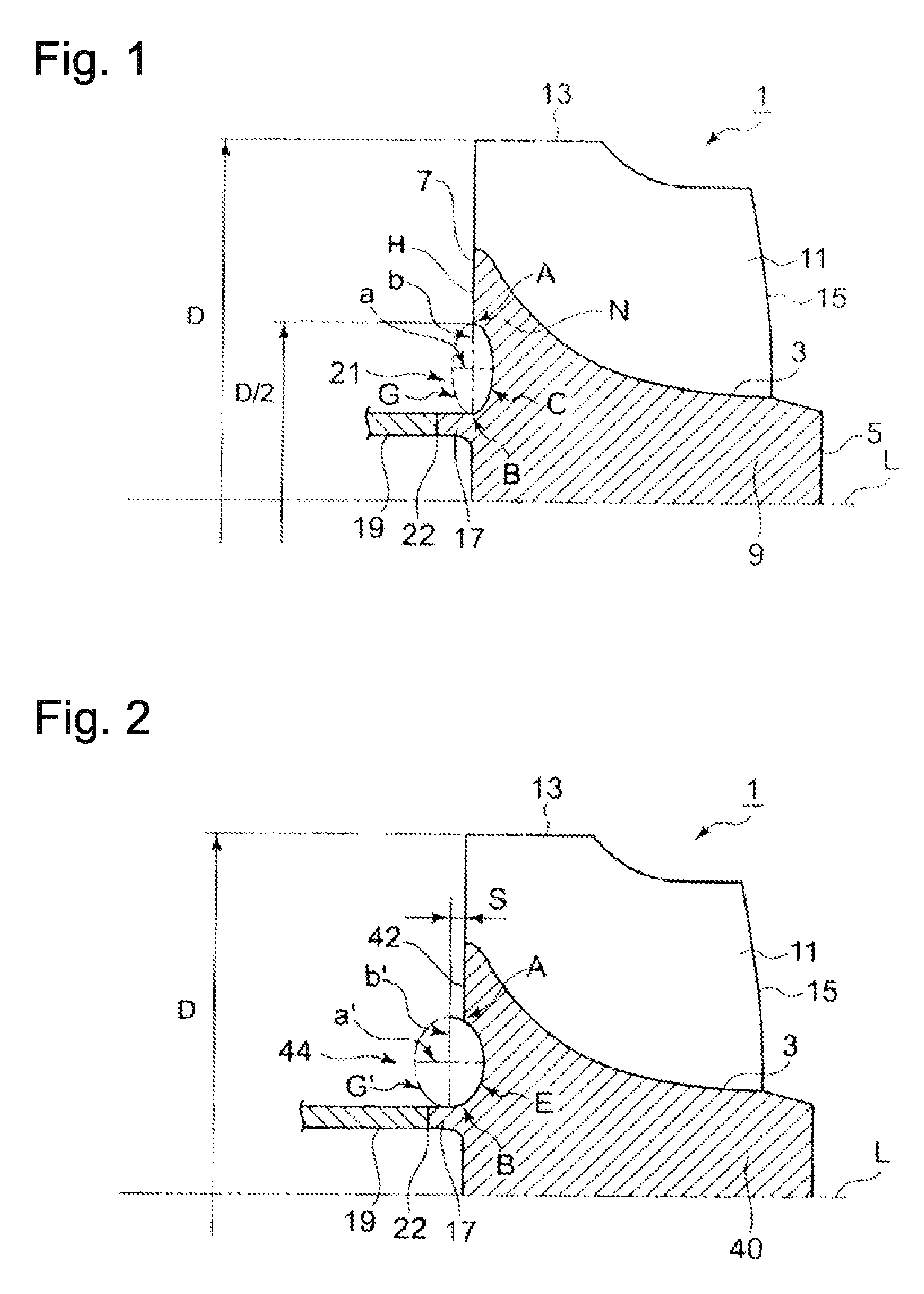

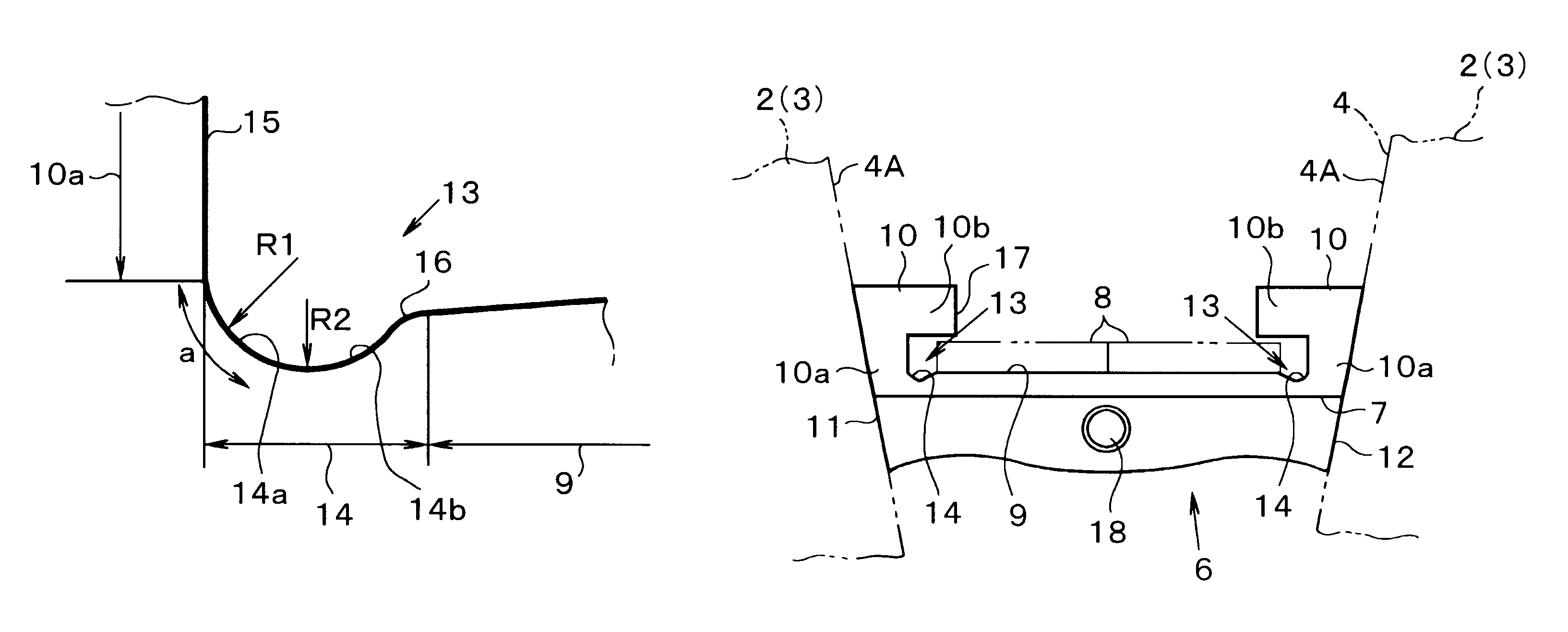

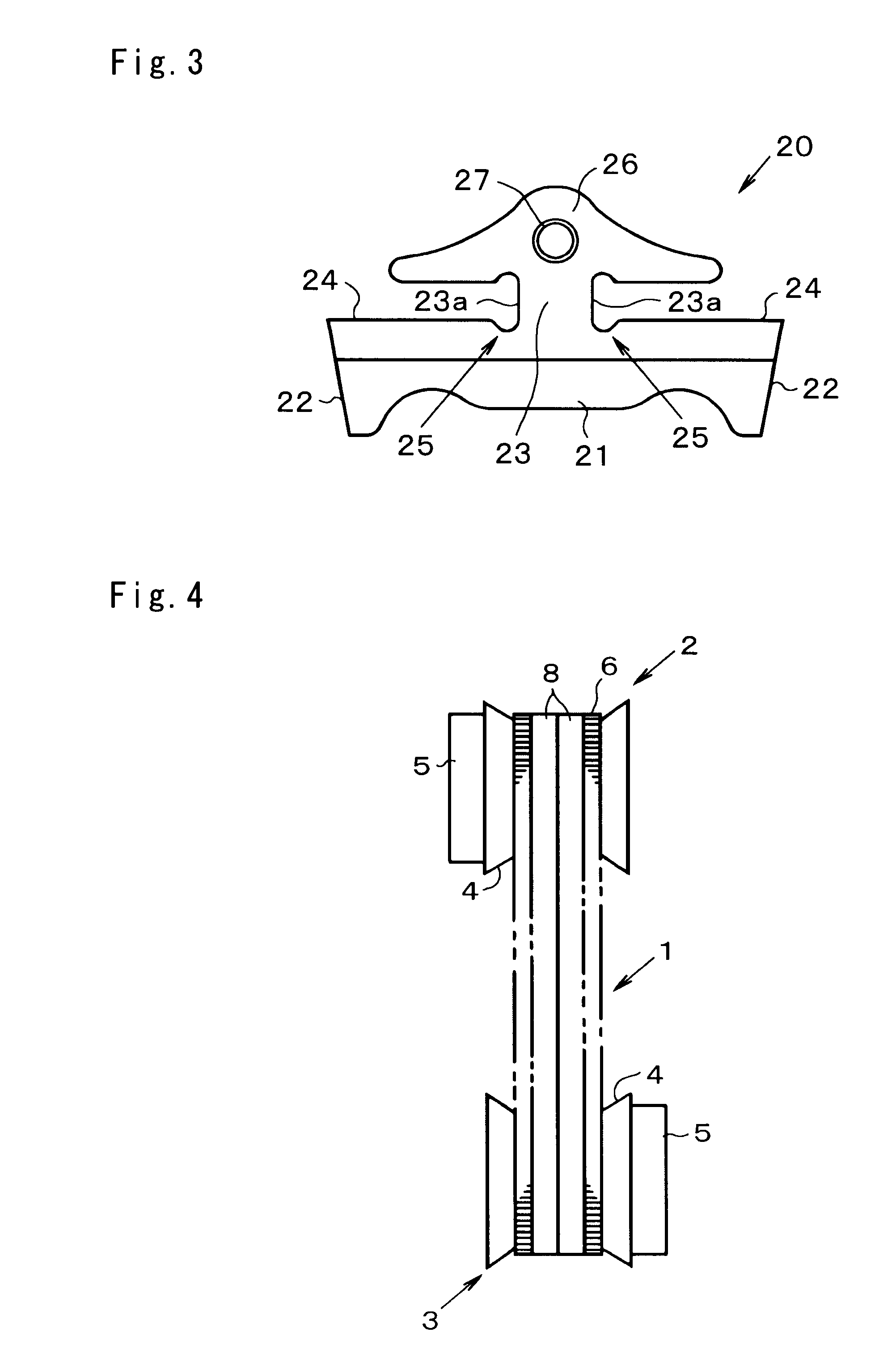

Turbine Rotor Blade

ActiveCN102341567ASmall moment of inertiaAvoid stress concentrationEngine manufactureEngine fuctionsStress concentrationCurve shape

Disclosed is a turbine rotor blade provided with the shape of the back surface of the rotor blade which while reducing the inertia moment of the rotor blade without changing the shapes of the blades, suppresses the occurrence of stress concentration at the root of the back surface of the rotor blade, thereby improving strength and durability. The turbine rotor blade (1) is obtained by integrally forming a shaft-shaped hub (9) connected with a rotary shaft (19) and the plurality of blades (11) formed in the periphery of the hub (9). The hub (9) has a shape gradually increasing in diameter toward the back surface (7) which is one end side thereof in the direction of the rotary shaft. In the back surface (7), an annular concave (21) is formed around the center line (L) of the rotary shaft (19). The cross-section shape of the concave (21) in the direction of the rotary shaft is formed of a long circular arc (C) of an ellipse obtained by dividing a curve shape symmetrical about the long axis such as an elliptical shape and an egg shape by the long axis, and formed such that the position of the long axis (b) matches with the back surface (7).

Owner:MITSUBISHI HEAVY IND LTD

Metal plate joining method and apparatus

ActiveUS9931718B2Increase the amount of cuttingSmooth stepWelding/cutting auxillary devicesRectilinear seam weldingEngineeringMetal

A pair of upper and lower pressure rollers 3, 4 is disposed so that their axes 15, 16 are tilted in a horizontal plane in respective directions opposite to each other with respect to a straight line perpendicular to a welding line of a joint portion J. The pressure rollers 3, 4 are positively driven by corresponding electric motors 63, 64 to thereby roll the joint portion. Thus, steps defined at the joint portion can be smoothed and a step gradient can be reduced to ensure a high degree of joint strength. Thus, it is possible to prevent a step portion from being interfolded into the base material of the meal plates 5, 6.

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

Powder injection molding turbine and structure optimization design method thereof

ActiveCN104915500AGood mechanical propertiesOptimized structural formSpecial data processing applicationsShrinkage porosityDesign methods

The invention discloses a structure optimization design method of a powder injection molding supercharger turbine. The structure optimization design method is characterized that the fact that turbine stress concentration factor is minimum under the condition that a turbine structure is lightest and the rotation speed is the highest is used, a target function is optimally designed under the premise that the turbine structure satisfies the strength requirement and the service life requirement, the maximum equivalent stress under the highest rotation speed work state of the turbine is used as the constraint condition, and the turbine structure weight reduction feature geometric size is used as the design variable to build the optimal mathematic model of the turbine structure. The method has the advantages that a powder injection molding process is used, and inherent defects such as heat cracks, shrinkage cavities and shrinkage porosities of precision casting are eliminated effectively; the constraint condition during optimization can be reduced, the existing turbine structure form can be changed, turbine structure can be optimized maximally, the sizes of parts of the turbine are determined by the method, turbine weight can be reduced maximally under the premise that the turbine structure strength requirement and the application requirement are satisfied, and turbine light weight is achieved.

Owner:PINGXIANG HUICHENG PRECISION MACHINERY & ELECTRONICS

Bleed assembly for a gas turbine engine

ActiveUS8915085B2Lower Level RequirementsReduce stress concentration factorEngine manufactureGas turbine plantsGas turbinesDome shape

A bleed assembly for a gas turbine engine is provided. The assembly includes: a duct having an inlet and an outlet; a bleed valve that controls the flow of bleed fluid into the inlet; and a dome-shaped diffuser screen which covers the outlet. The diffuser screen has a plurality of through-holes for passage of the bleed fluid. Each through-hole has one or more nearest-neighbour through-holes at a nearest-neighbour spacing. At the periphery of the diffuser screen, the average nearest-neighbour spacing of the through-holes at a given radial distance from the centre of the diffuser screen increases with increasing radial distance.

Owner:ROLLS ROYCE PLC

Turbine rotor

ActiveUS9260971B2Rotational inertia of the turbine rotor can be reducedIncreased durabilityEngine manufactureEngine fuctionsStress concentrationMoment of inertia

Providing a turbine rotor in which the rotational inertia of the turbine rotor can be reduced without changing the geometry of the blade part, whereas the turbine rotor is provided with the rear side surface so that the stress concentration appearing at the root part regarding the hub part on the rear surface side is constrained in order that the strength and the durability of the turbine rotor can be enhanced. A turbine rotor that comprises a hub part 9 connected to a rotor shaft 19 and a plurality of blade parts 11 formed around the outer periphery of the hub part 9, the hub part and the blade parts being integrated into one piece, wherein the diameter of the hub part 9 around the rotation axis L of the rotor shaft 19 gradually increases along the rotation axis direction toward a rear side surface 7 on an end side regarding the rotation axis direction; an annular recess 21 is formed annularly around the rotation axis as a rotation center line, on the side of the rear side surface 7 of the hub part 9; the cross-section of the annular recess whose plane includes the rotation axis is configured with a part of the major arc C of an oval shape or an egg shape, the major arc C being formed so that the oval shape or the egged shape is divided by the major axis b as a symmetrical axis of the oval shape or the egged shape; and, the major axis b is placed in the rear side surface 7.

Owner:MITSUBISHI HEAVY IND LTD

Element of belt for continuously variable transmission and belt for continuously variable transmission

ActiveUS8100798B2High strengthIncreased durabilityV-beltsDriving beltsEngineeringMechanical engineering

A belt for a continuously variable transmission and elements used in the belt. The elements include a stopper portion formed integrally with a neck portion erected upwardly from a saddle face to hold a width end portion of the ring. The elements are juxtaposed annularly in a same orientation and fastened by rings disposed on a saddle face of the element thereby forming a belt for a continuously variable transmission. A recessed portion is formed by depressing the saddle face at a corner between a side face of the neck portion and the saddle face; and an inner face of the recessed portion includes a first inner face extending smoothly into the side face of the neck portion and having a relatively larger curvature radius, and a second inner face extending smoothly into the first inner face and having a relatively smaller curvature radius.

Owner:TOYOTA JIDOSHA KK

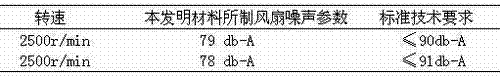

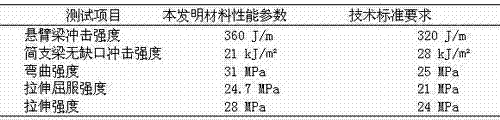

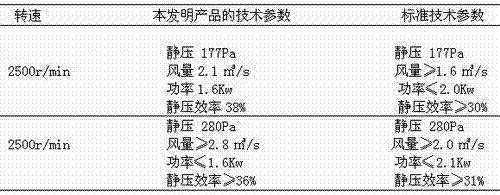

Cooling fan blade of diesel engine and manufacture method thereof

ActiveCN102212230AHigh mechanical strengthImprove toughnessPump componentsPumpsStress concentrationUltraviolet

The invention relates to a cooling fan blade of a diesel engine and a manufacture method thereof and belongs to the technical field of diesel engines. The cooling fan blade of the diesel engine comprises the following components in parts by weight: 70-90 parts of polypropylene, 15-20 parts of high-density polyethylene, 0.15-0.20 part of hydroisomerization dewax base oil 5CST, 0.13-0.18 part of hydroisomerization dewax base oil IOCST, 0.1-0.3 part of antioxidant CA (carbonic anhydrase), 0.5-1.0 part of ultraviolet absorbent and 0.1-0.3 part of dilauryl thiodipropionate; and the cooling fan blade is manufactured by virtue of extruding and injection molding. By using the manufacture process, the stress concentration factor is reduced, the impact resistance and fatigue resistance are improved, the flowing and mold-filling performance of the plastic melt is improved, the flowing resistance and local residual stress are reduced, the cracking and warping are prevented and the appearance of the cooling fan blade is beautiful, thus the cooling fan blade can be widely applied to medium trunks, especially to diesel engine trunks.

Owner:临海市四通制管有限公司

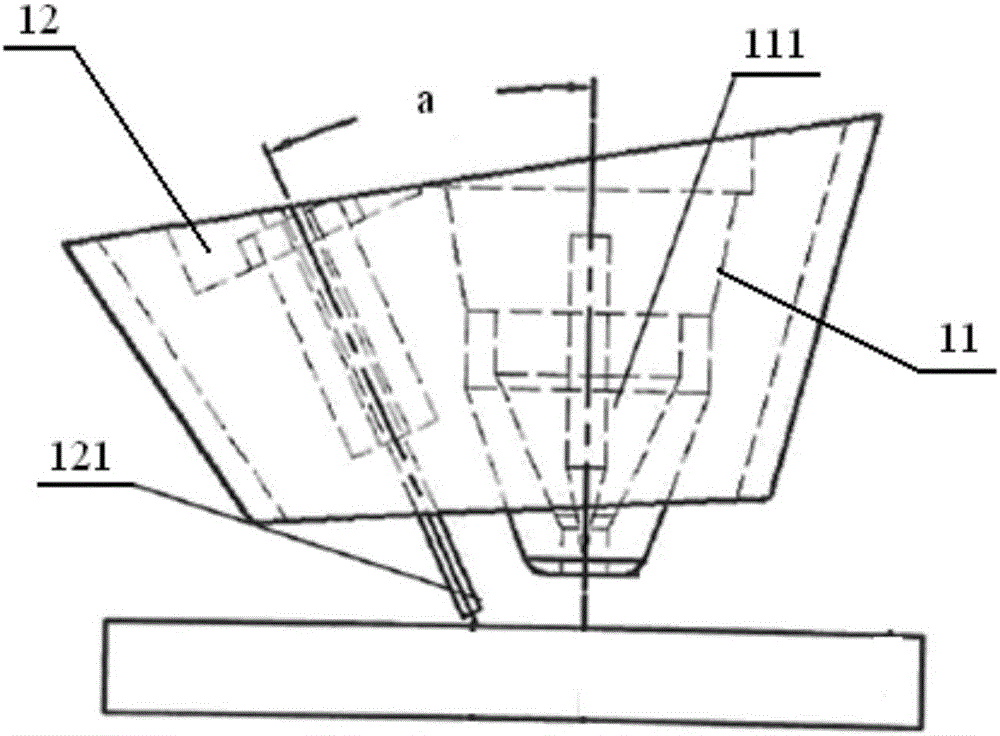

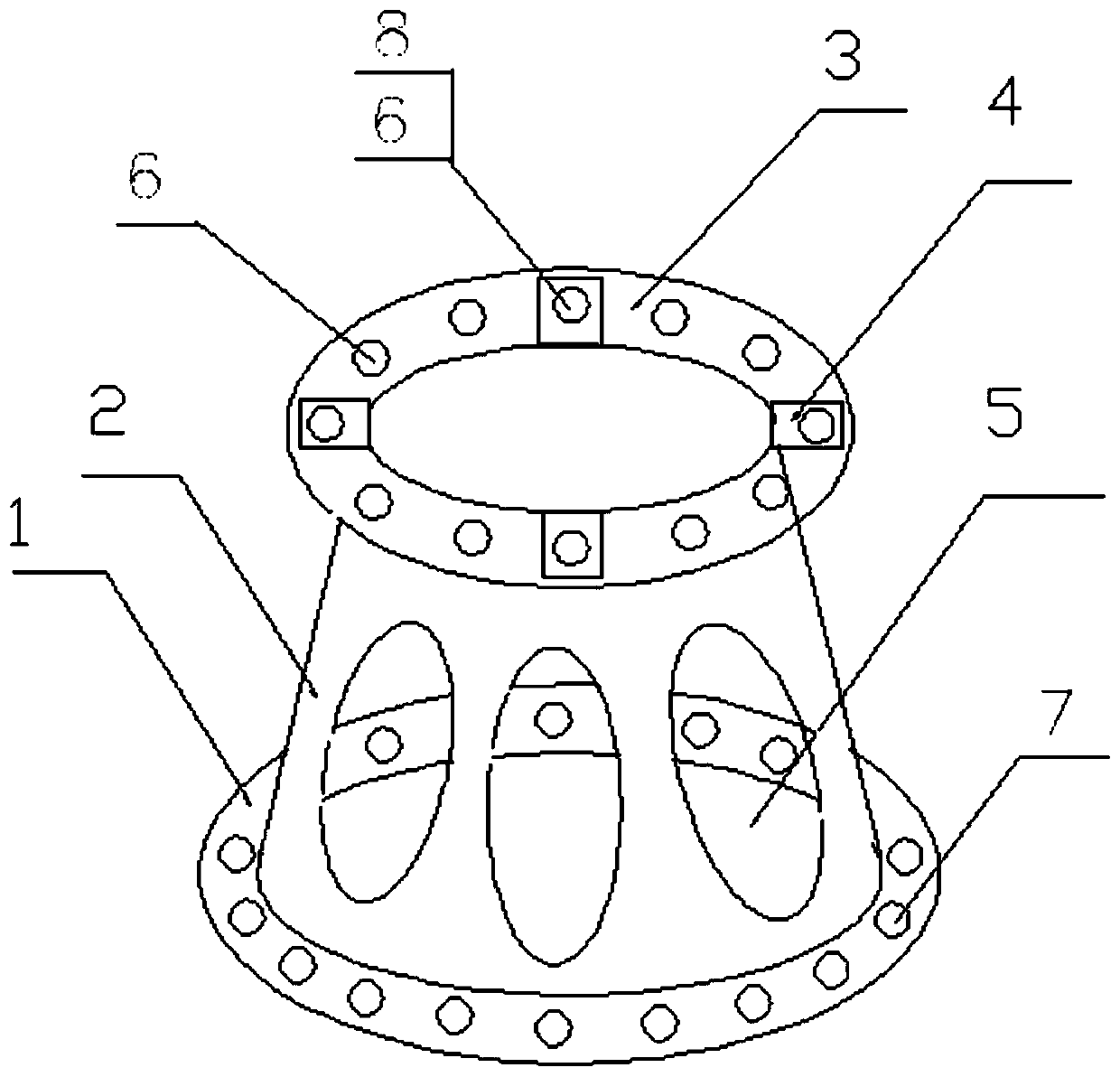

Front support of fairing of wind generating set

PendingCN111207045AGuaranteed safe operationImprove support strengthWind motor supports/mountsMachines/enginesEngineeringStructural engineering

The invention discloses a front support of a fairing of a wind generating set, and belongs to the technical field of wind power generation. The front support comprises a conical cylinder, a large annular plate fixedly connected with the large end of the conical cylinder and a small annular plate fixedly connected with the small end of the conical cylinder; and the small end of the conical cylinderis connected with a plurality of hanging lugs, the hanging lugs are fixedly connected with the small annular plate, and the lower planes of the hanging lugs are tightly attached to the upper plane ofthe small annular plate. Compared with an existing front support of a fairing of a wind generating set, an integrated conical cylinder structure is adopted, the large annular plate and the small annular plate are fixedly connected with the large end and the small end of the conical cylinder respectively, due to the fact that the stress of a hub connecting end is large, the connecting strength between the small annular plate and the conical cylinder is enhanced through the hanging lugs, the supporting strength of the front support is enhanced, stress is uniform, stress concentration is avoided, and the problem that a hub and the fairing front support crack due to stress concentration is solved. The structure design is reasonable, connection is reliable, and safe operation of a fan is guaranteed.

Owner:HUANENG CLEAN ENERGY RES INST

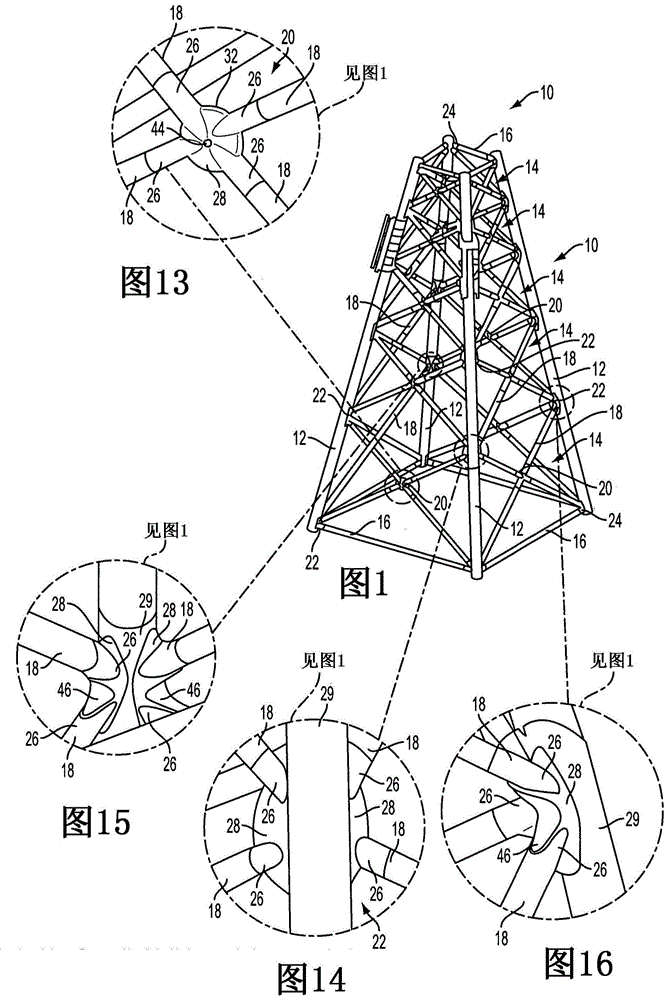

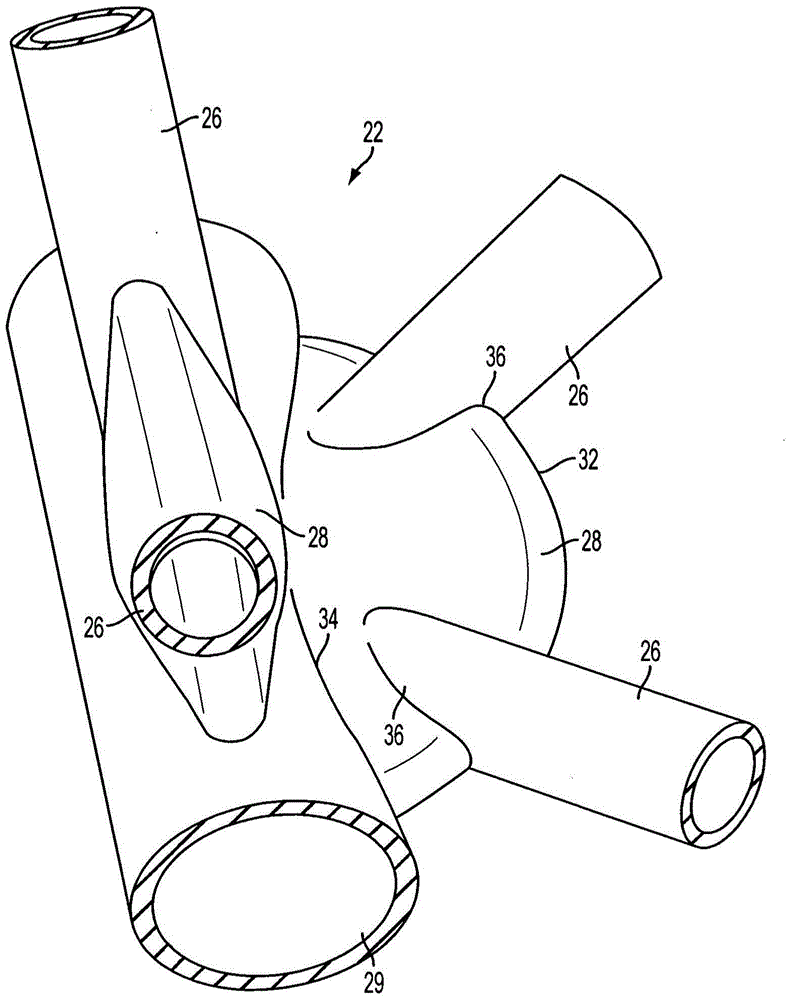

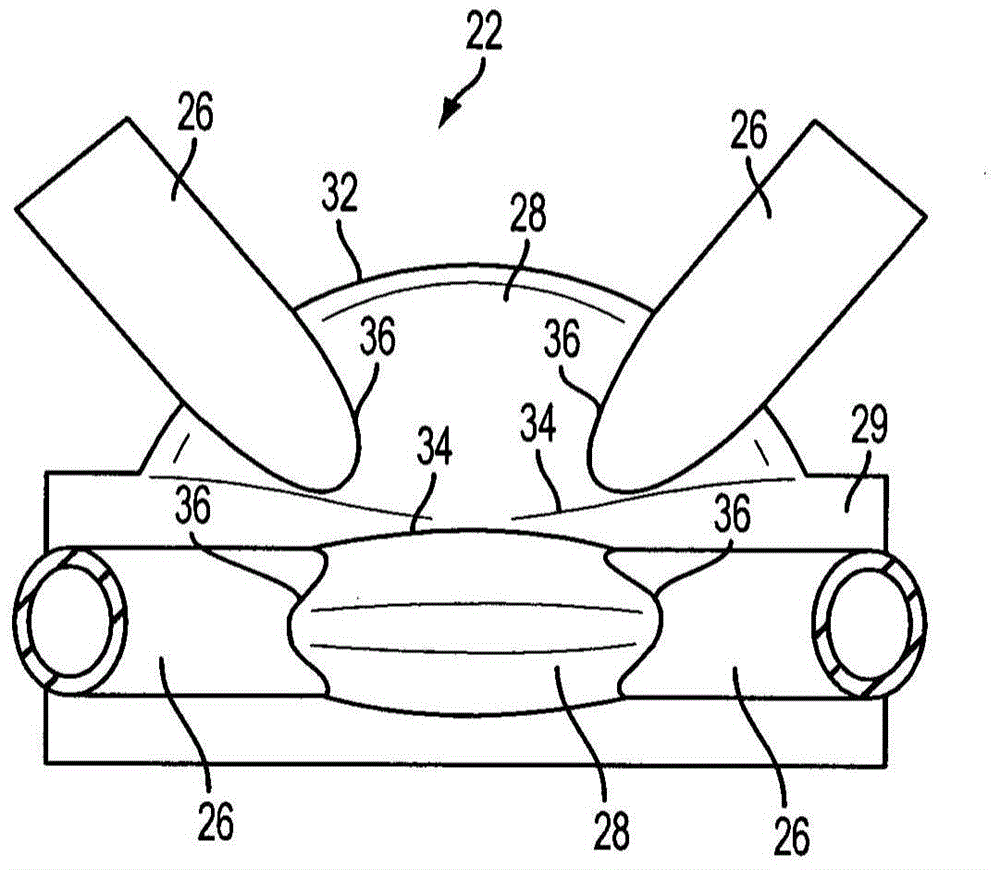

Node structures for lattice frames

InactiveCN104641049ALow water resistanceEasy to assembleArtificial islandsMetal-working apparatusAcute angleMechanical engineering

A node structure for connecting a member of a lattice frame to one or more other members of the frame comprises a hollow brace having opposed walls that converge outwardly at an acute angle in cross-section toward a central plane to connect at an outer edge. At least one root portion has a central longitudinal axis extending outwardly in the central plane of the brace for alignment with a member of the frame. The root portion has an inner end cut away at opposite sides around the central plane to leave a joining surface that intersects the converging walls of the brace while embracing an outer region of the brace extending inwardly from the outer edge.

Owner:MHI VESTAS OFFSHORE WIND AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com