Patents

Literature

97results about "Hull frames" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

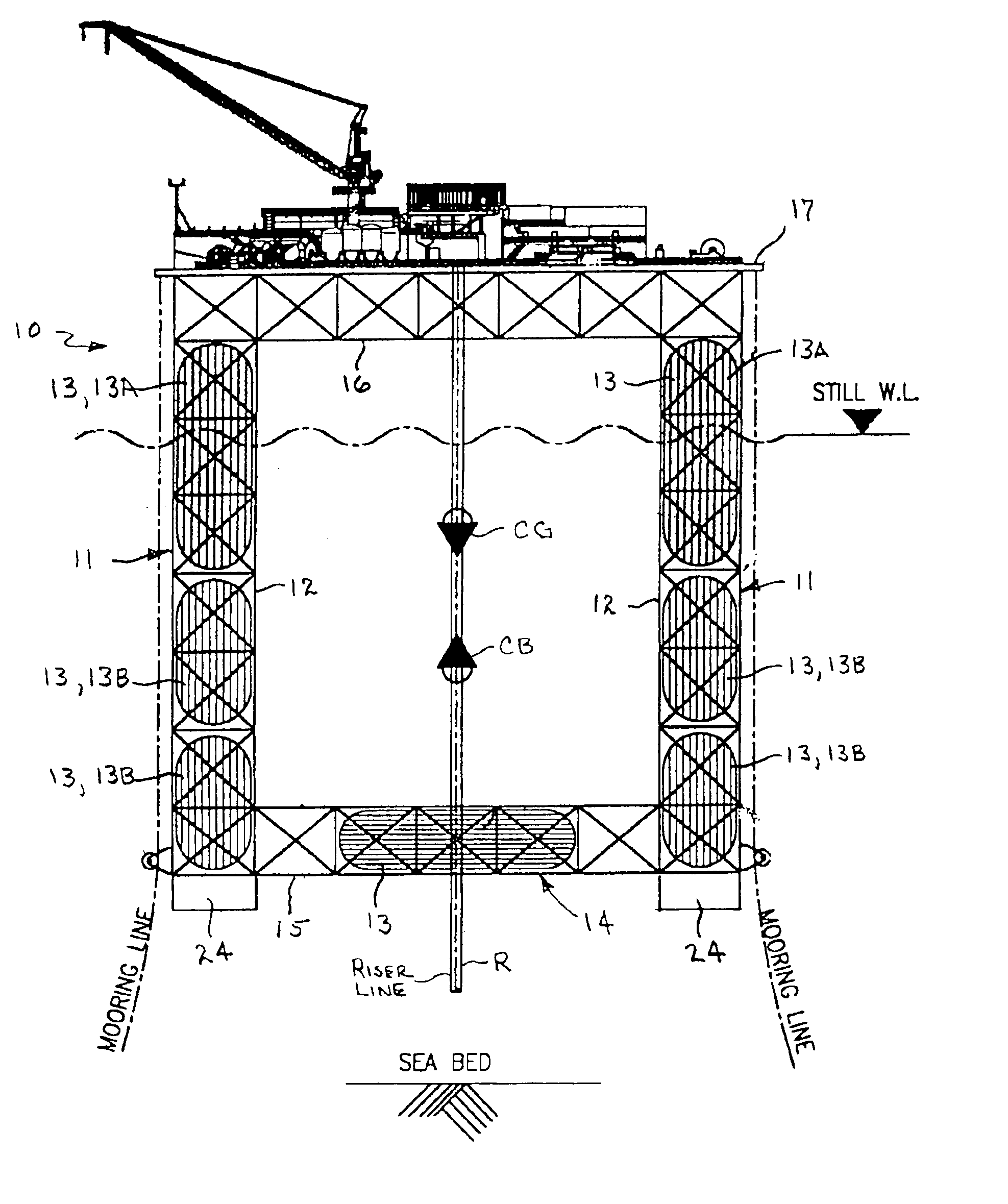

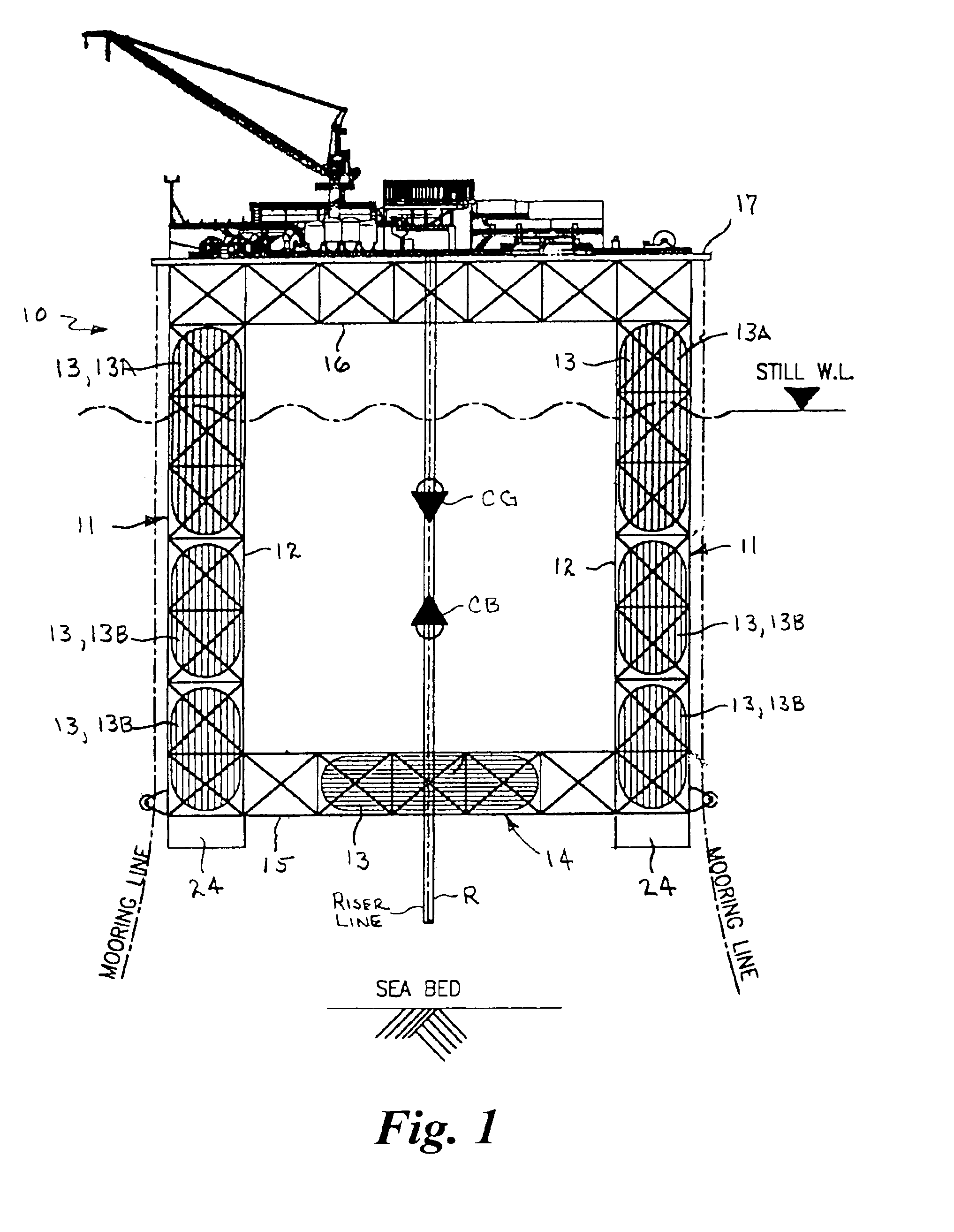

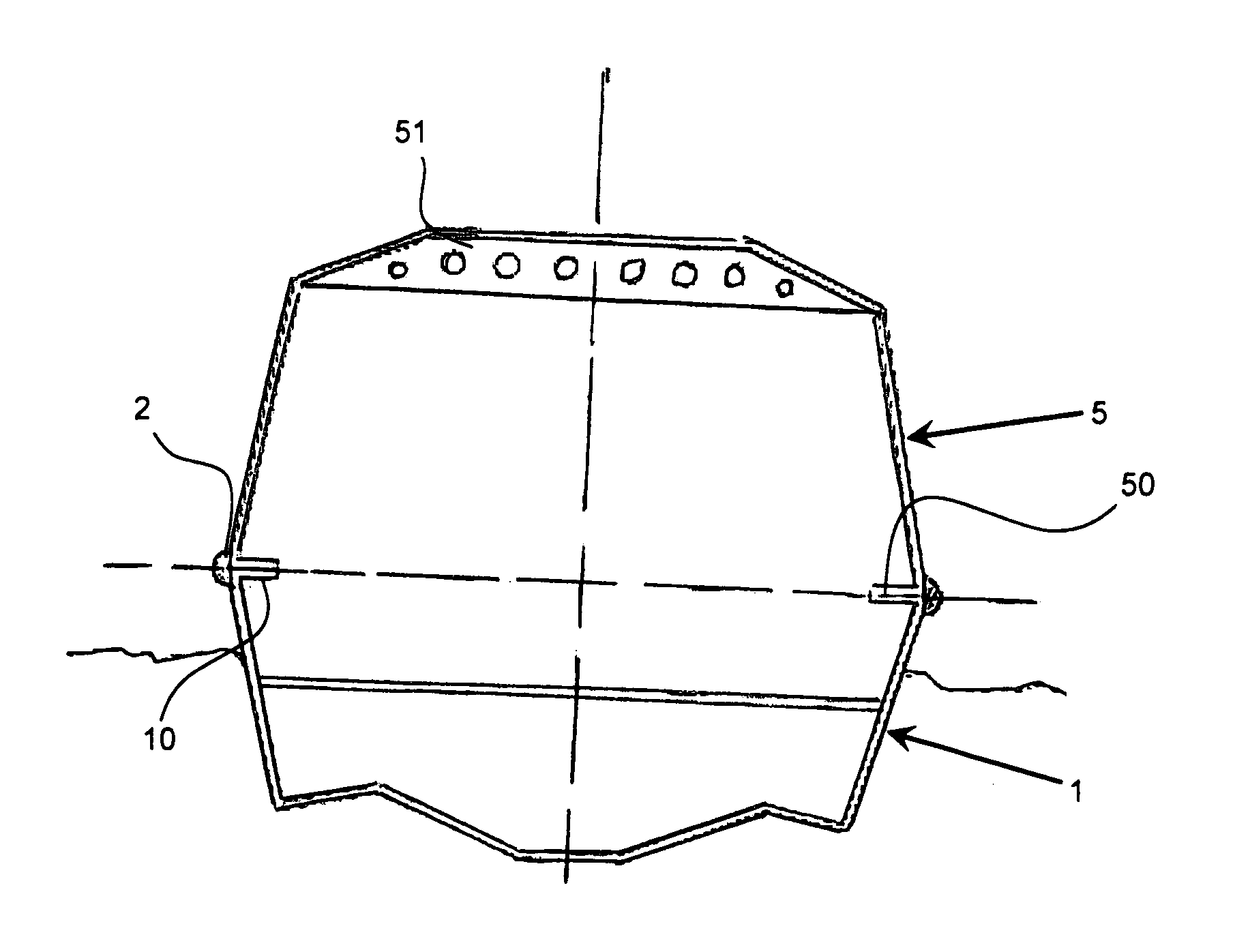

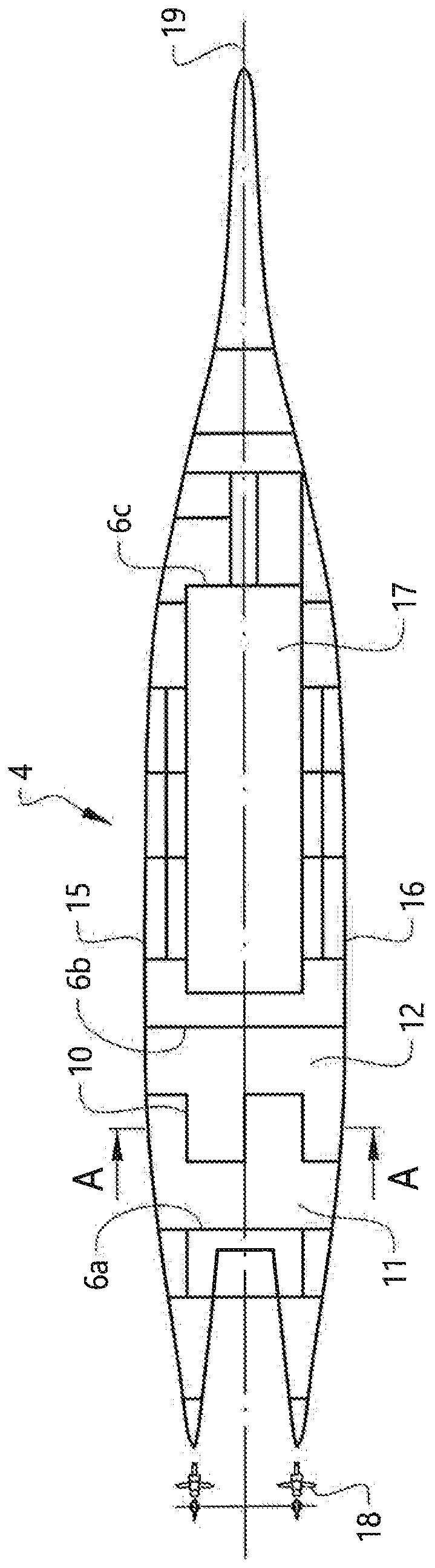

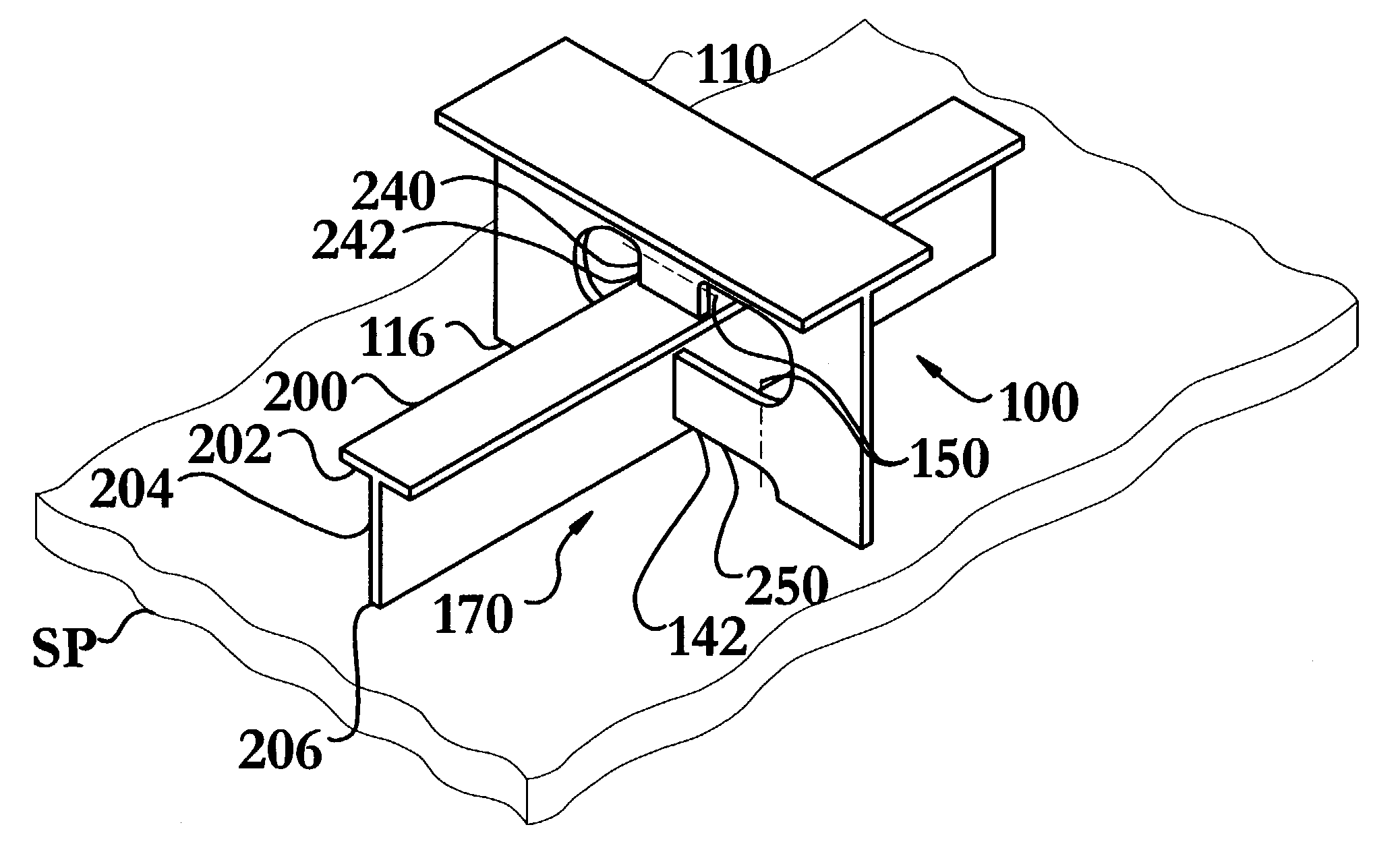

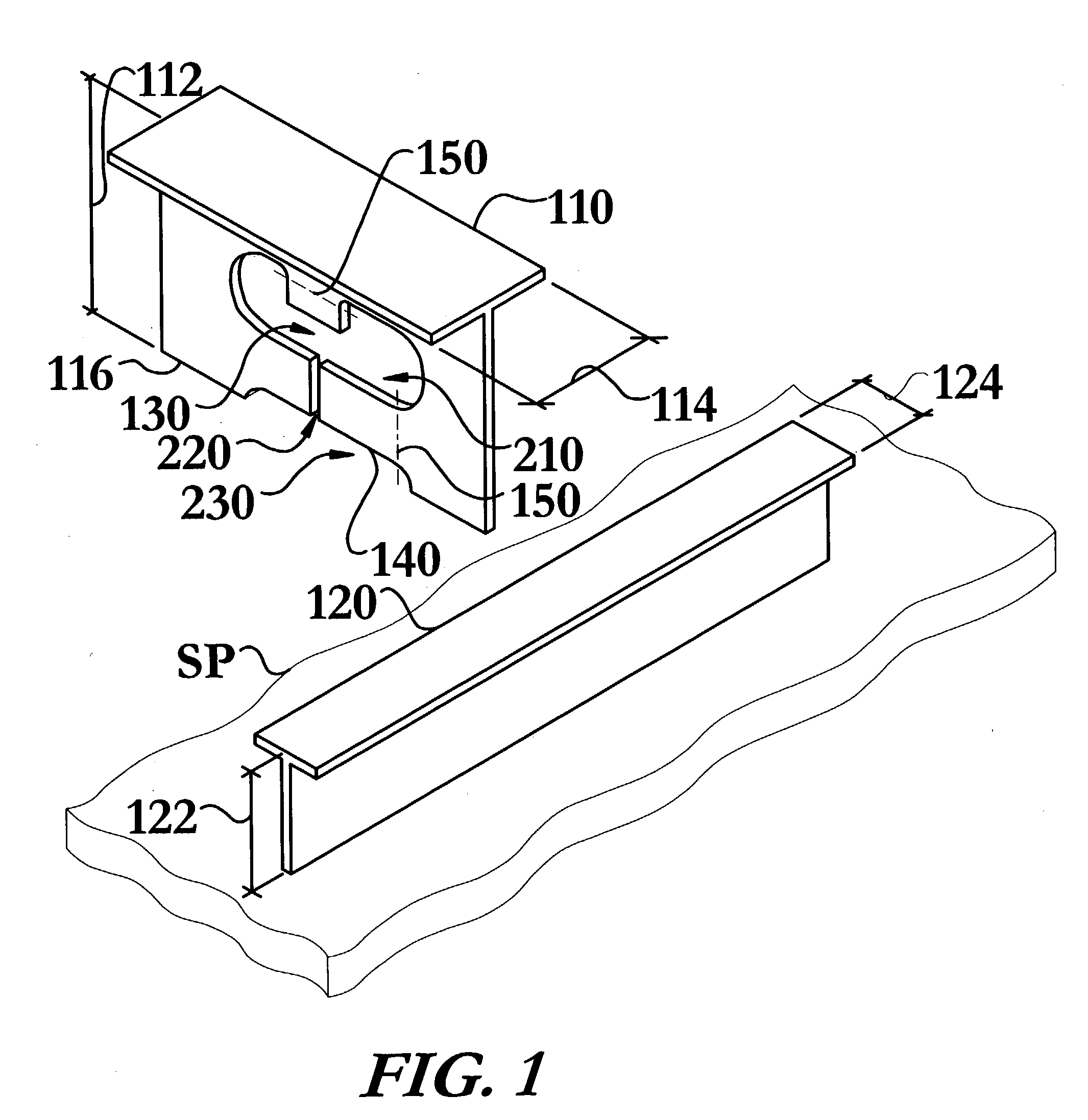

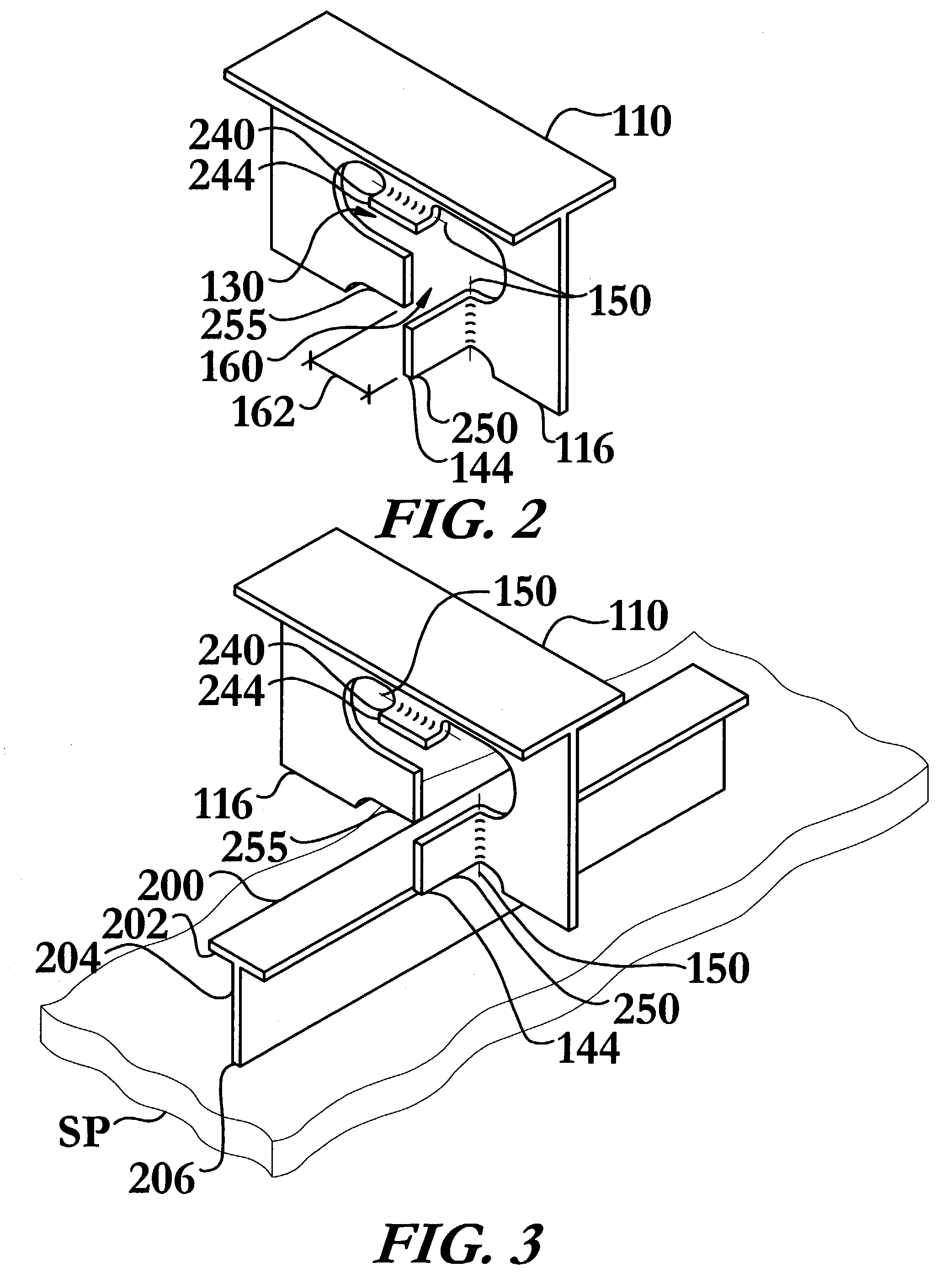

Jacket frame floating structures with buoyancy capsules

InactiveUS6899492B1Increase the areaEffectively respondsArtificial islandsDrilling rodsKeelOpen framework

Jacket frame floating structures comprise one or more elongate vertical support columns formed of an open cross-braced jacket formwork of tubular members interconnected together and at least one cylindrical buoyancy capsule disposed in the open framework near an upper end and at least one cylindrical second buoyancy capsule near a lower end in vertically spaced relation. The buoyancy capsule(s) may be a single, or a plurality of upper and lower capsules bundled in circumferentially spaced relation with a central opening therethrough. Alternatively, a keel tank may replace the lower capsule. The buoyancy of the upper buoyancy capsule(s) is adjustably tuned to provide a buoyant force and a sufficient water plane area and moment of inertia required for stability of the floating structure, and the water mass and weight of the lower buoyancy capsule(s) or keel tank(s) is adjustably tuned to raise or lower the center of gravity of the entire mass of the floating structure with respect to its center of buoyancy according to ballast and variable or fixed loads including deck payloads to stabilize the structure. Alternatively, a keel tank may replace the lower capsule. The buoyancy of the upper buoyancy capsule(s) is adjustably tuned to provide a buoyant force and a sufficient water plane area and moment of inertia required for stability of the floating structure, and the water mass and weight of the lower buoyancy capsule(s) or keel tanks(s) is adjustably tuned to raise or lower the center of gravity of the entire mass of the floating structure with respect to its center of buoyancy according to ballast and variable or fixed loads including deck payloads, to stabilize the structure, and to compensate for different operational, environmental, survival and installation stages of the structure. The length of the upper buoyancy capsule(s) is sufficient so as to be partially submerged and allow oscillation of the trough and crest of waves within its top and bottom ends.

Owner:SRINIVASAN NAGAN

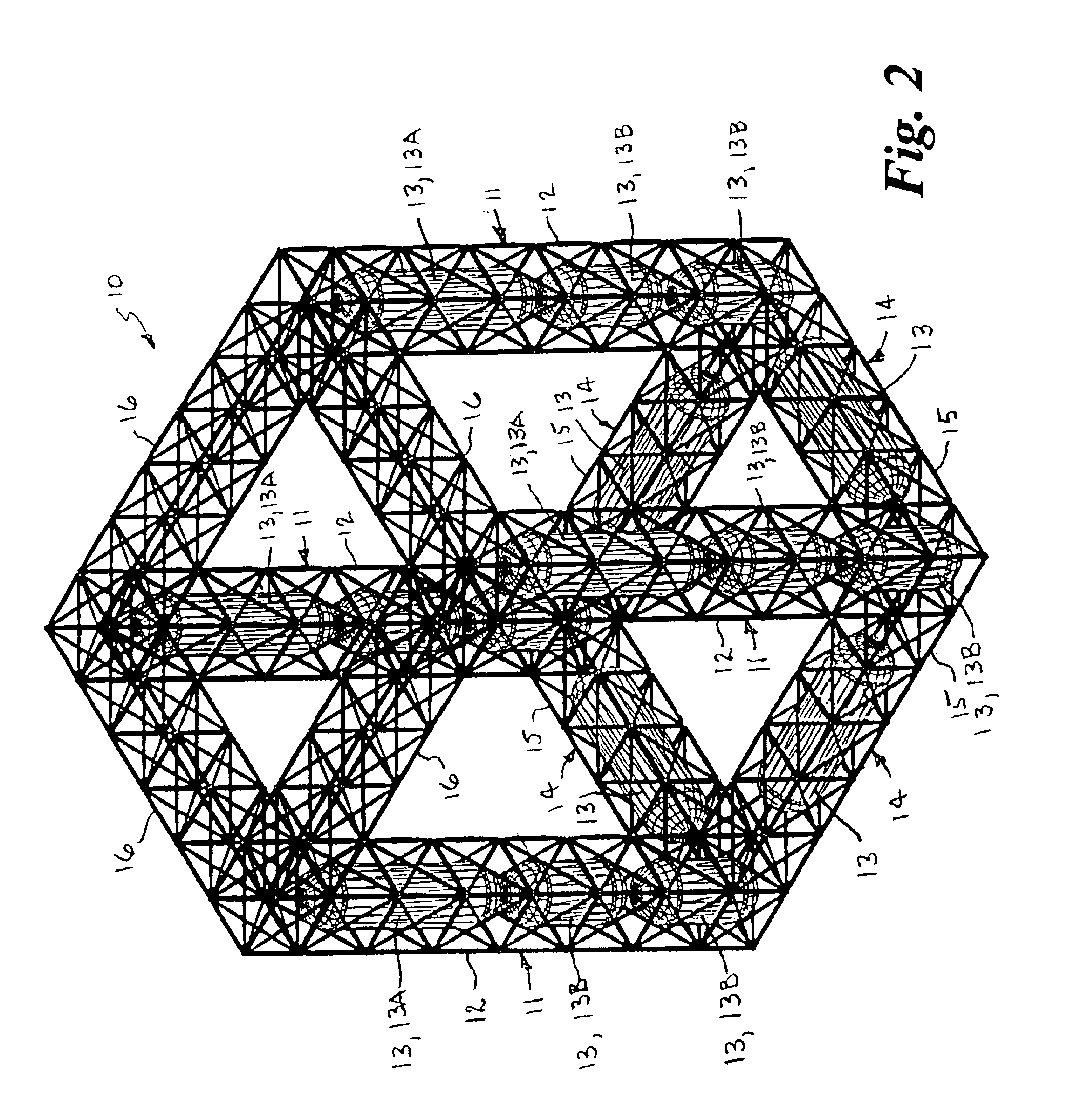

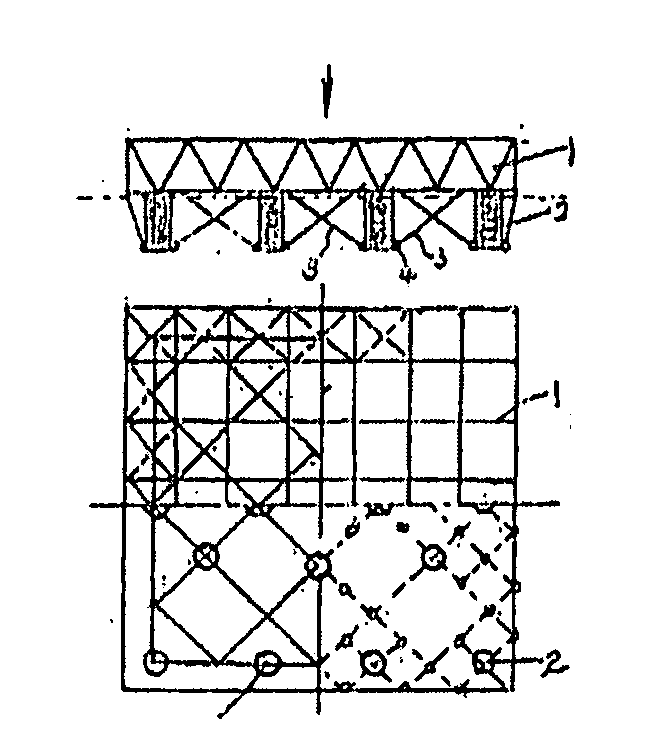

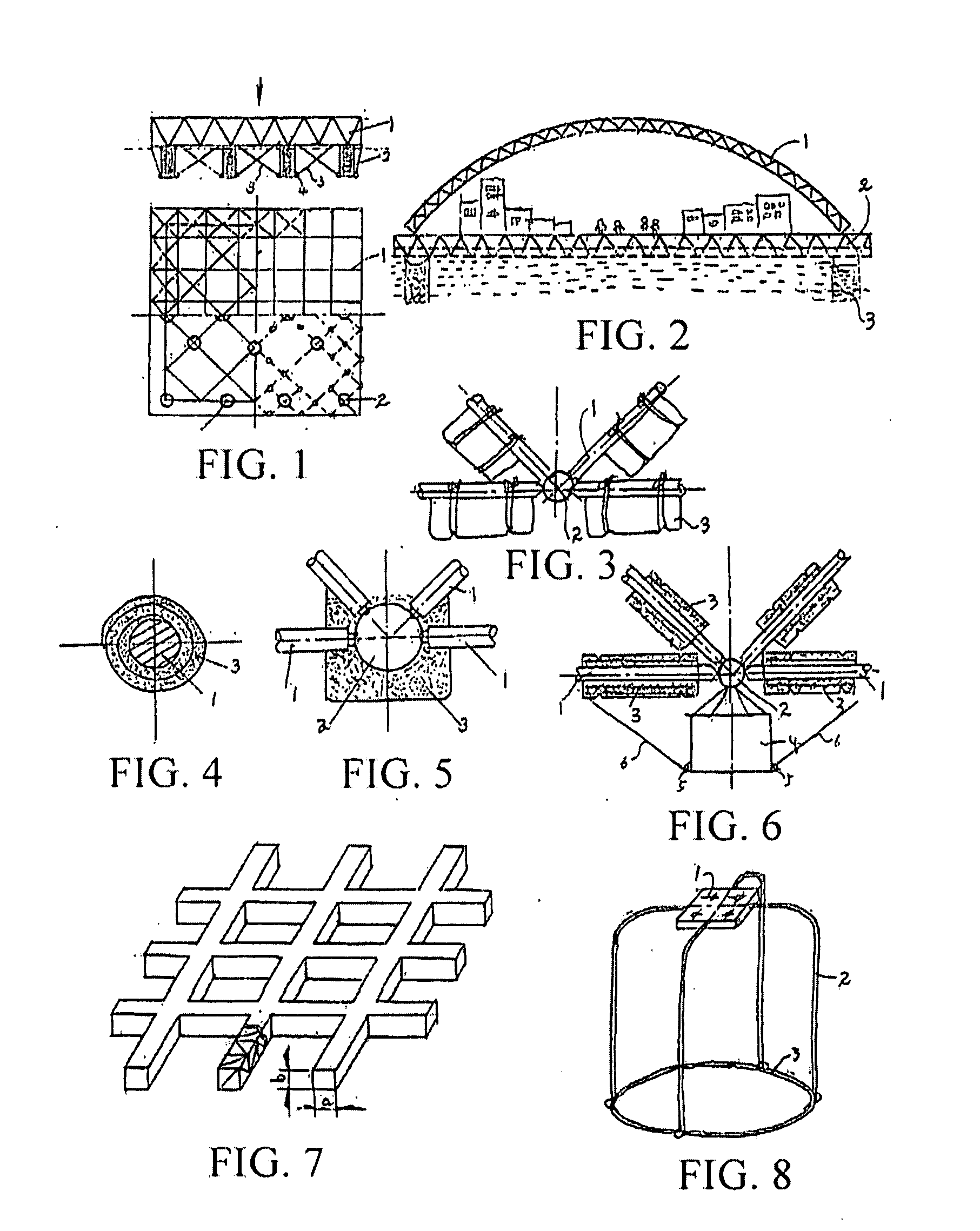

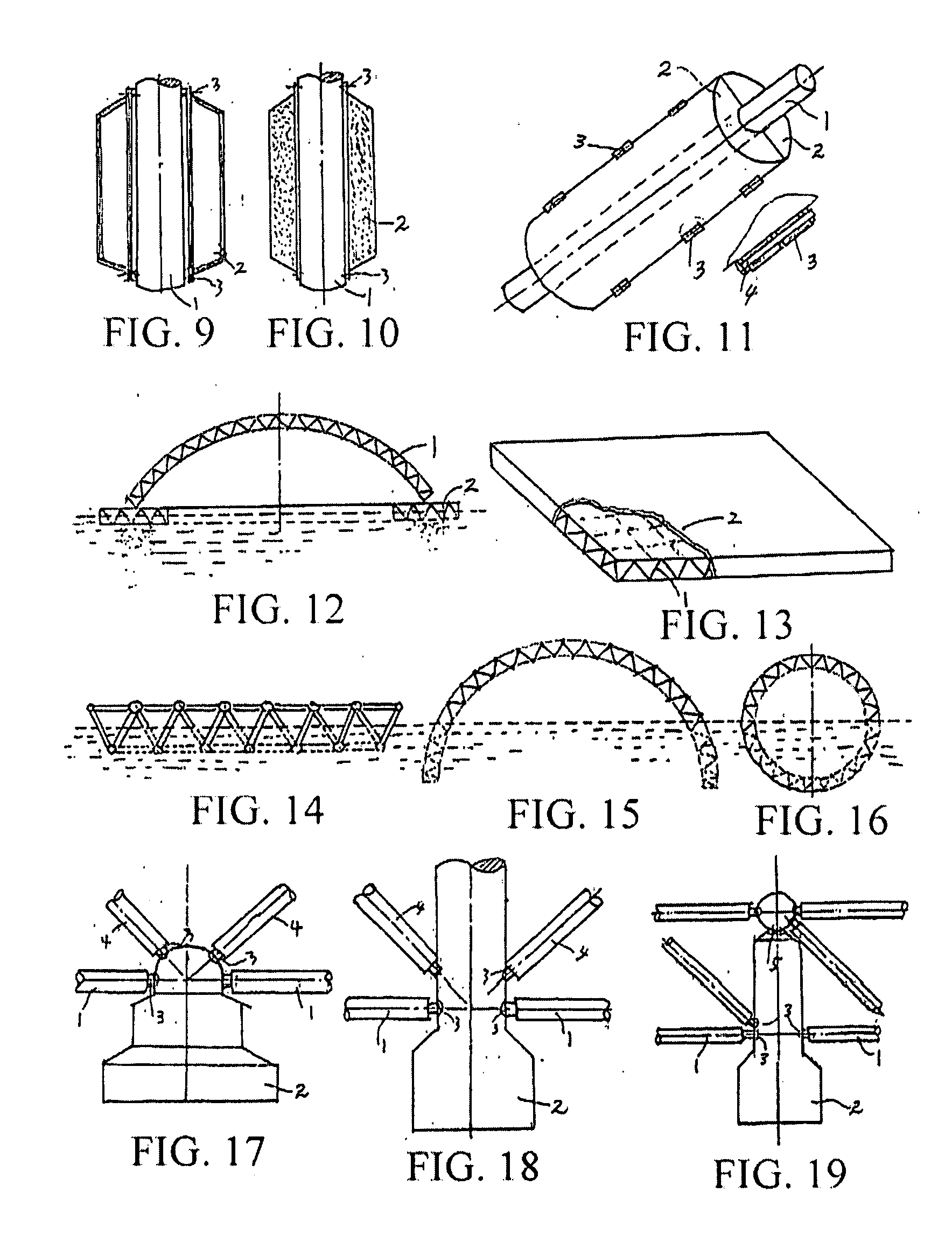

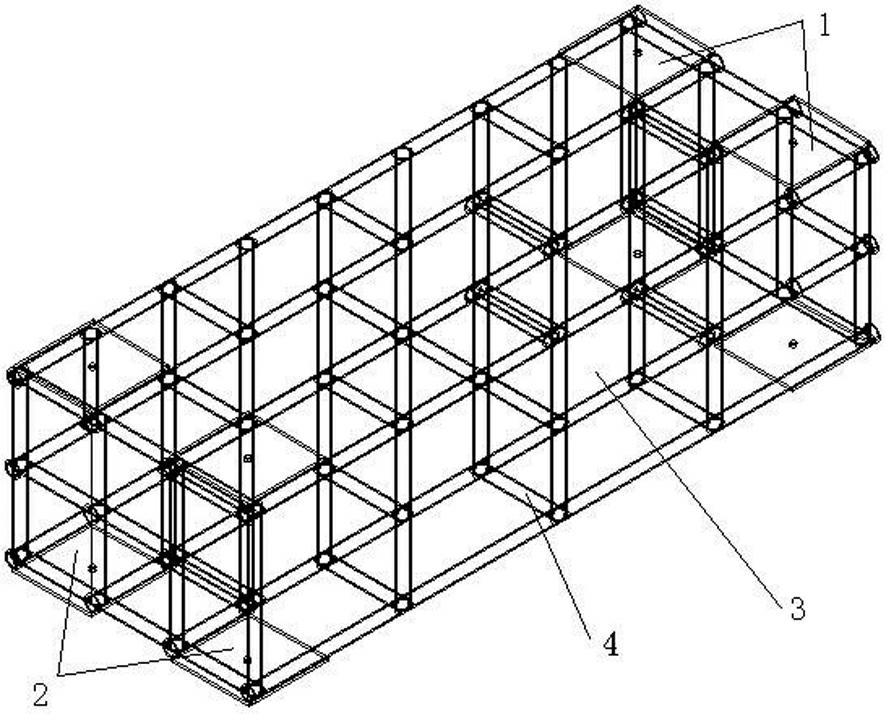

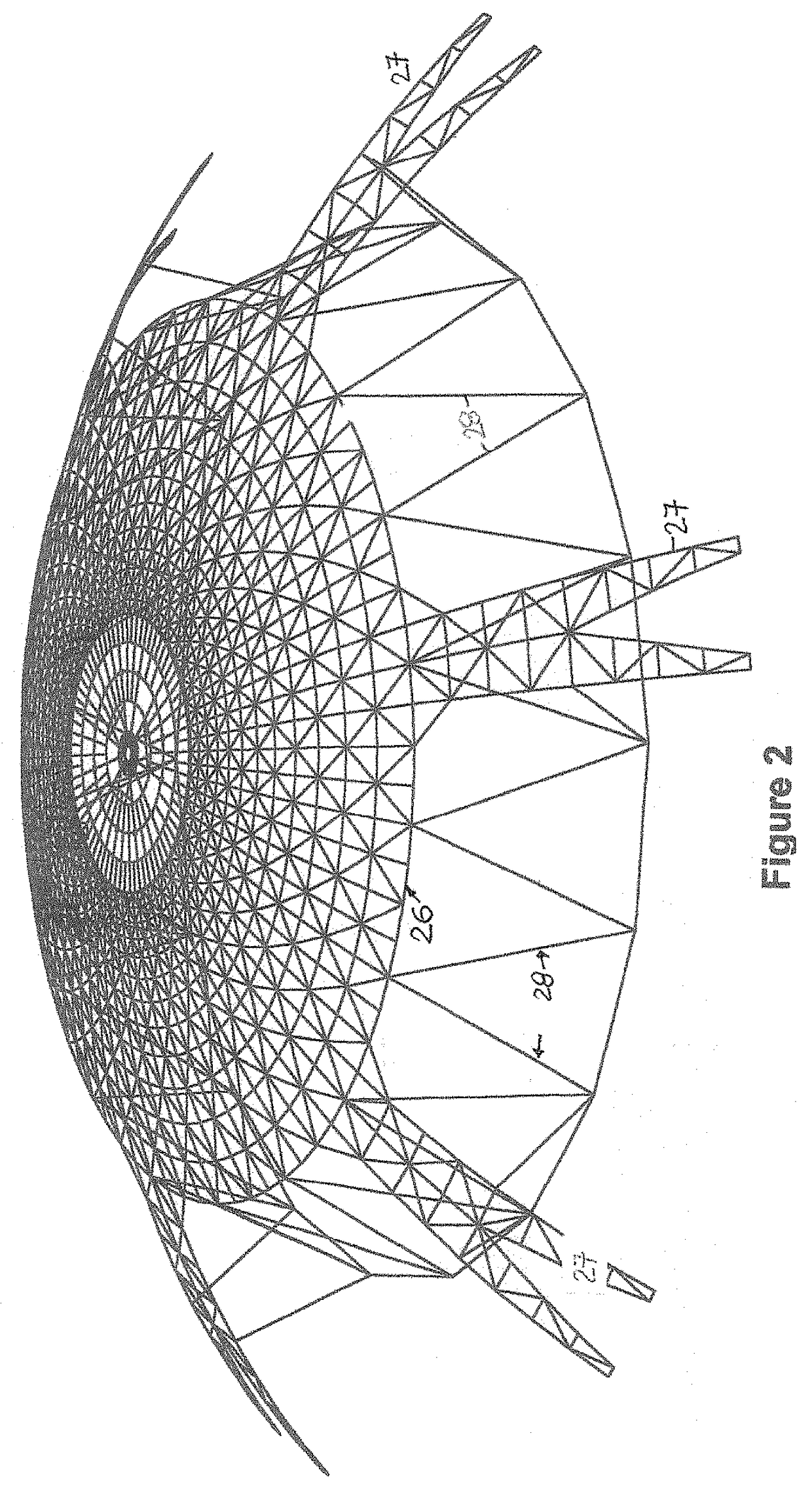

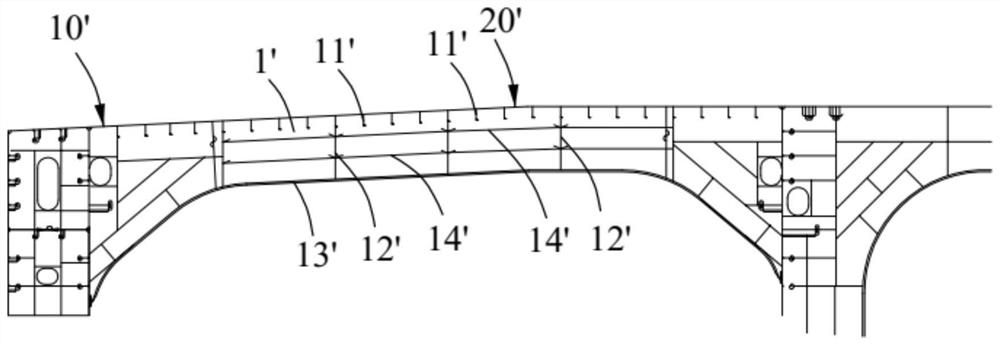

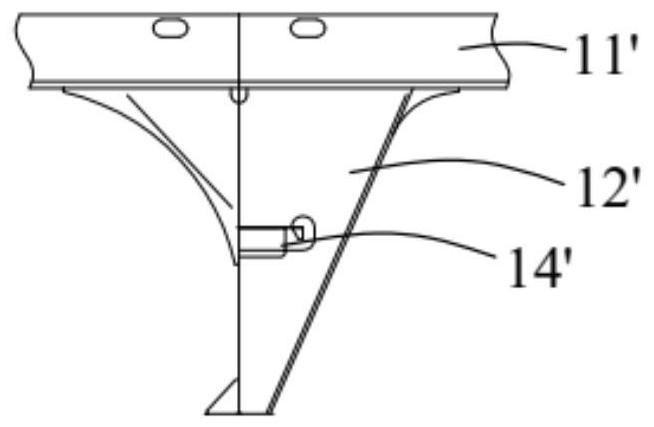

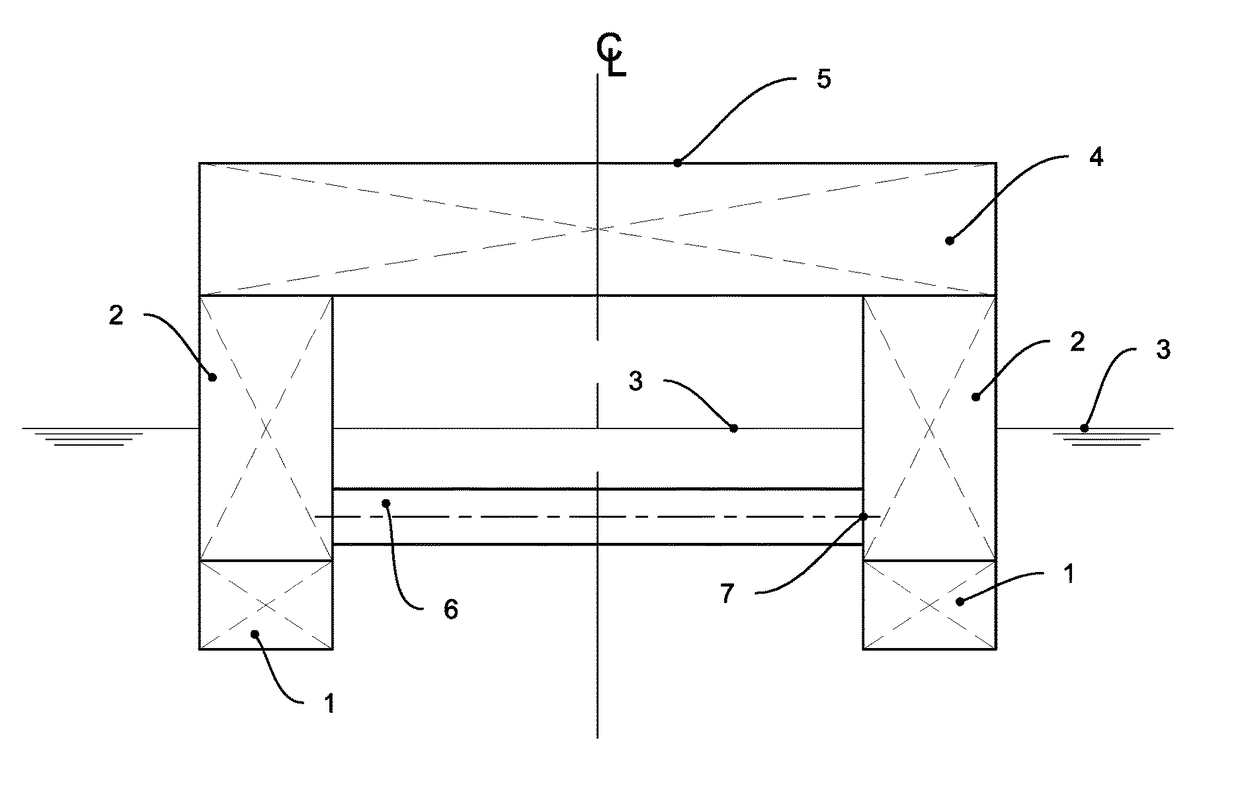

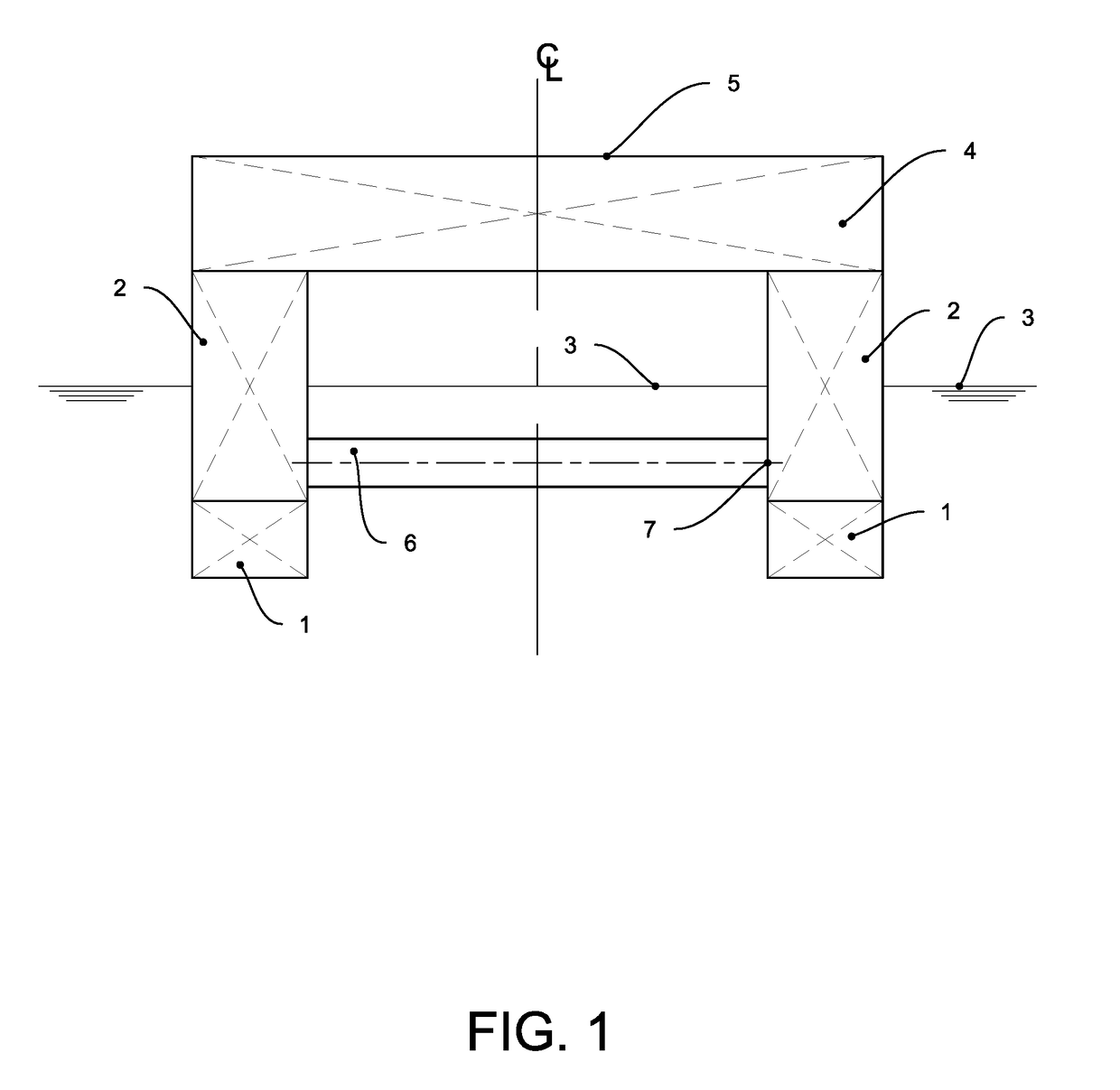

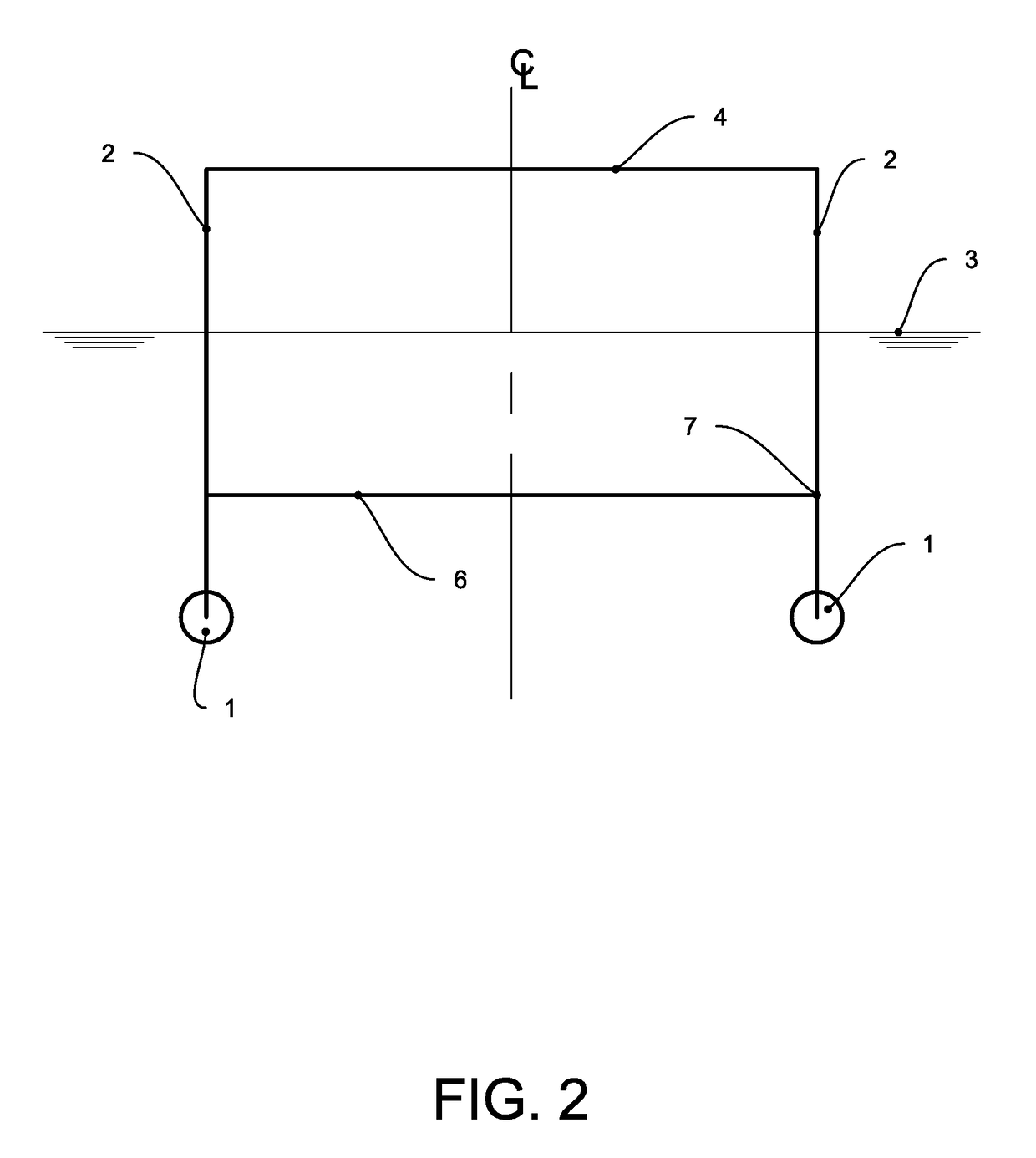

Floating Latticework

InactiveUS20100218712A1Improve rigidityHigh strengthBascule bridgesHull bulkheadsMarine engineeringSpatial structure

A floating latticework is suitable for a latticework, a truss-frame structure and a net-shell structure over water. The floating latticework is the combination of a latticework (1) and a floating structure (2), or members of the latticework (1) in themselves are able to float. The floating structure (2) makes the latticework (1) floated over water, the surface of upper chords of which is in form of a platy structure or covered and fixed with a platy structure, as a plane used for loading. There is an advantage that the space-structure floating body is less influenced by wind and wave, which go through its space. A ship structure and a cofferdam structure are parallel solutions with the above solution. Their skeletons are net-shell structure, wherein they are provided with high structural strength.

Owner:YAN JIANJUN

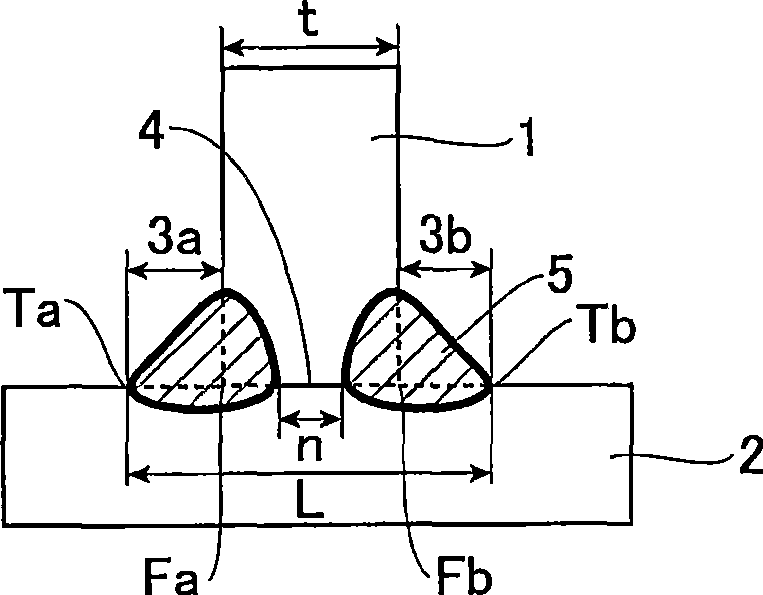

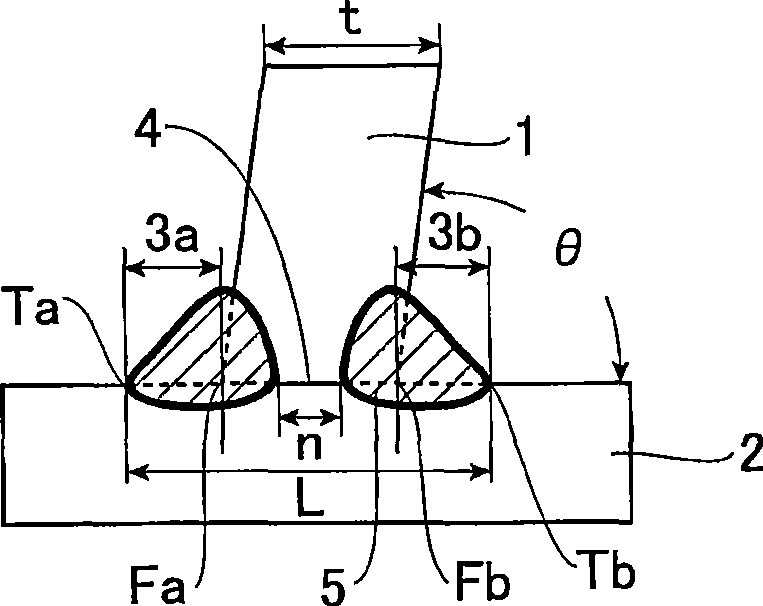

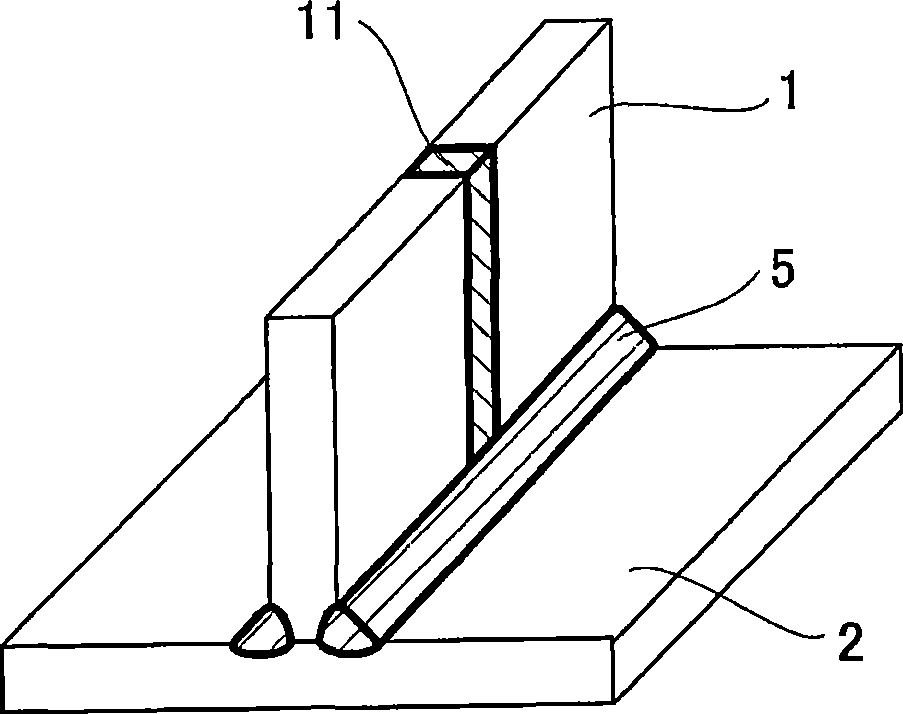

Welded structure excellent in brittle-cracking propagation stopping characteristics

ActiveCN101443150ATransmission stoppedEnsure safetyArc welding apparatusPipe protection against damage/wearFillet weldHull structure

Provided is a welded structure suitable for a hull structure and excellent in brittle-cracking propagation stopping characteristics. The welded structure is provided with a fillet welded joint having an unwelded portion (4) left on the abutting face of a web (1) against a flange (2). A percentage (X) (= 100 / L) (%) to the sum (L) of the width (n) of the unwelded portion (4) and the leg length (3 (3a and 3b)) of the left and right fillet welded joints in the joint section of the fillet welded joint, and the brittle-cracking propagation stopping toughness (Kca (N / mm3 / 2)) at the using temperature of the flange satisfy X (%) >= {5900 - Kca(N / mm3 / 2 / 85. The unwelded portion (4) in the fillet-welded joints is given a width of 15 to 90 % of the sum of the thickness (t) of the web (1) and the leg length (3 (3a and 3b)) of the left and right fillet welded joints. In case the web has the butt-welded joint portion of the thickness (t), the percentage (X) (%) and the brittle-cracking propagation stopping toughness (Kca)(N / mm3 / 2) satisfy the aforementioned formula.

Owner:JFE STEEL CORP +1

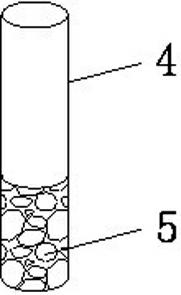

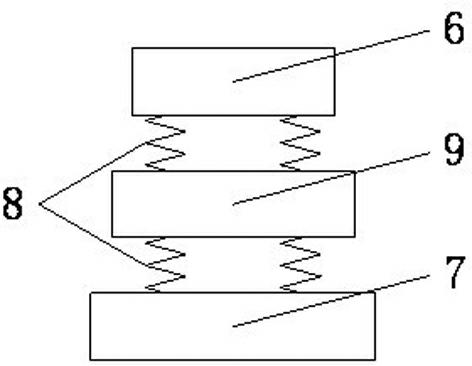

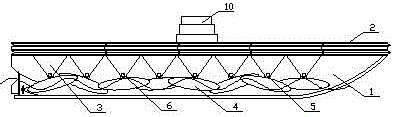

Vibration and noise reduction device

InactiveCN102673733AImprove vibration damping effectSimple structureVessel stability improvementHull framesEngineeringSolid particle

The invention discloses a vibration and noise reduction device which comprises an upper panel and a lower panel and further comprises a bar frame structure. The bar frame structure is fixedly connected between planes of the upper panel and the lower panel, the bar frame structure is constructed through hollow bars, and solid particles are filled in the hollow bars. The vibration and noise reduction device has the advantages that the solid particles are filled in the hollow bars to sufficiently use spaces of the hollow bars, so that the vibration and noise reduction device is simple in structure, effectively improves the vibration reduction effect, and needs no extra spaces; transmitted vibration waves are changed and scattered through the bar frame structure to improve the vibration reduction effect of the vibration and noise reduction device; and system vibration energy is further consumed through mutual friction and collision among the solid particles filled in the hollow bars to improve the vibration reduction effect.

Owner:JIANGSU UNIV OF SCI & TECH

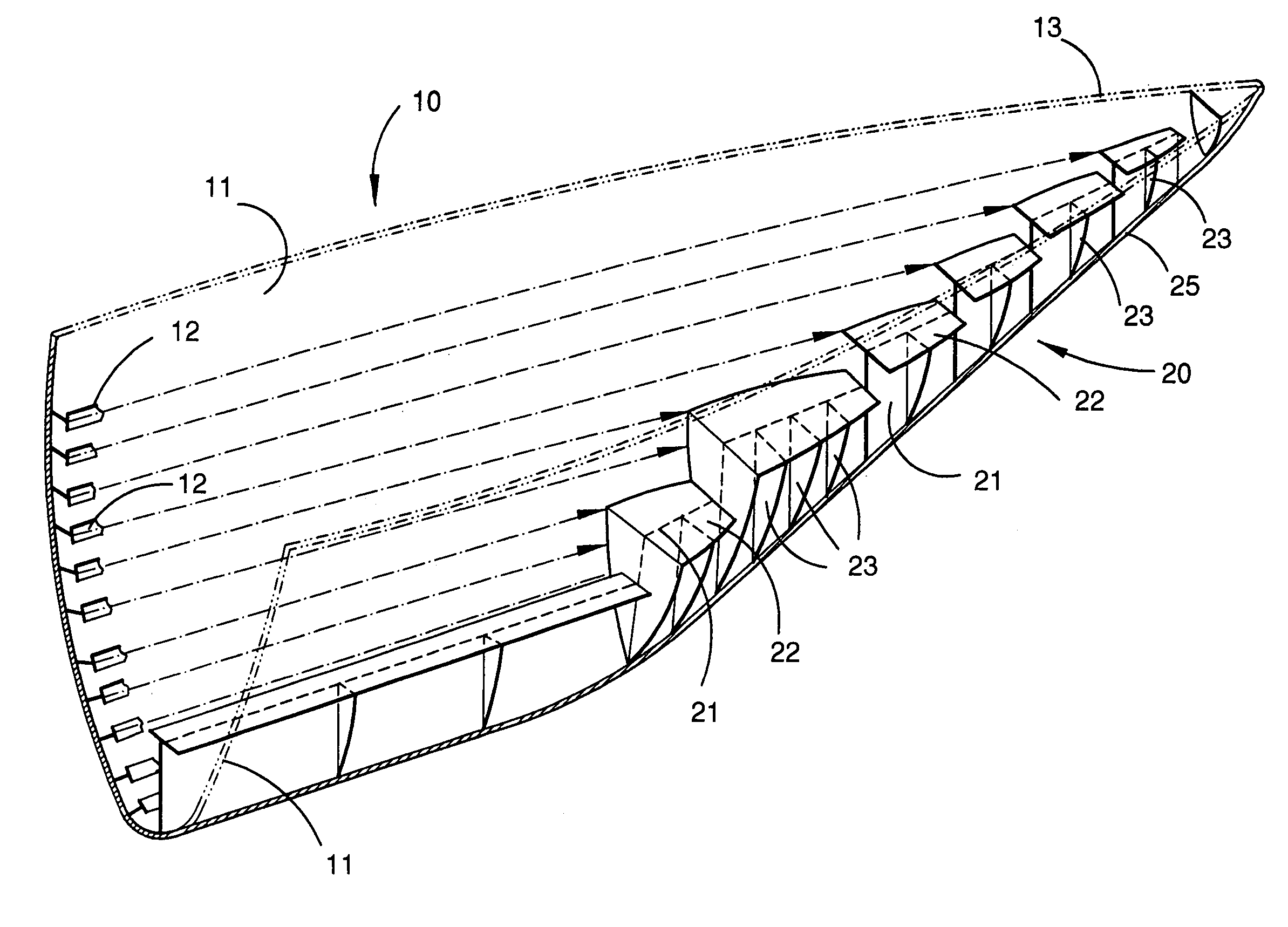

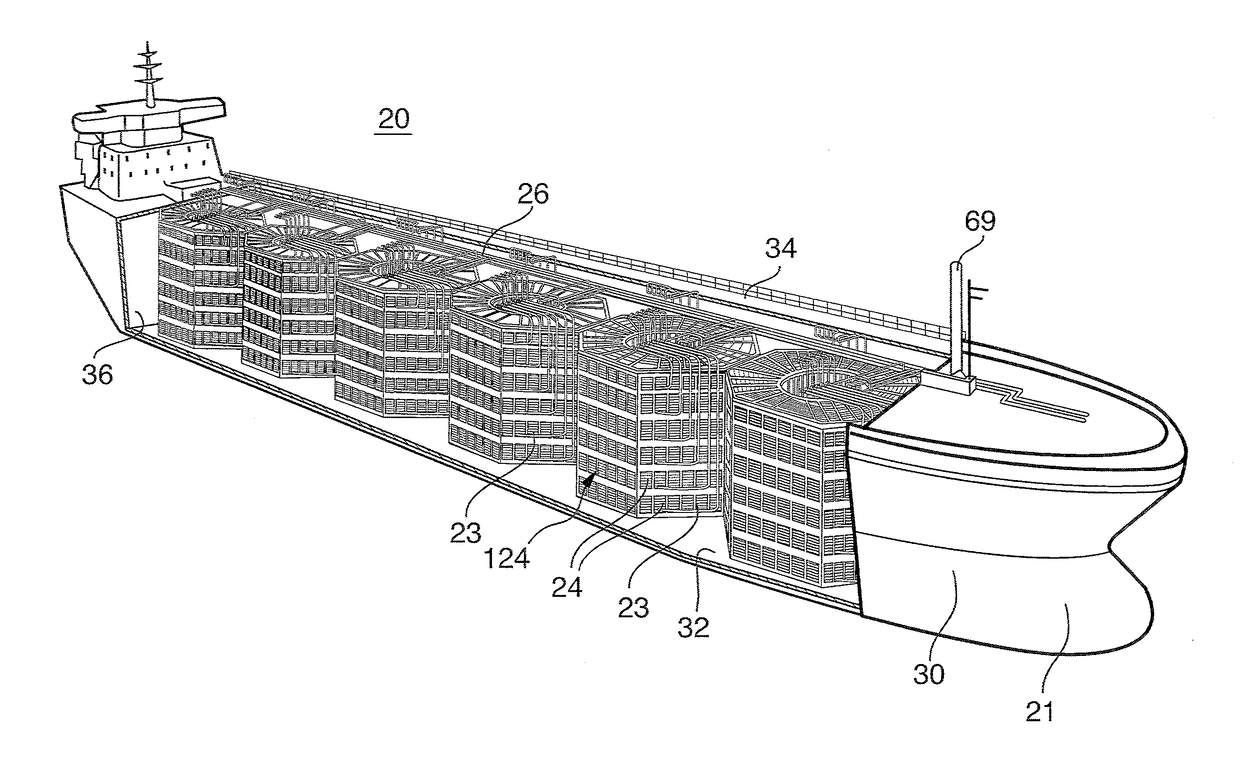

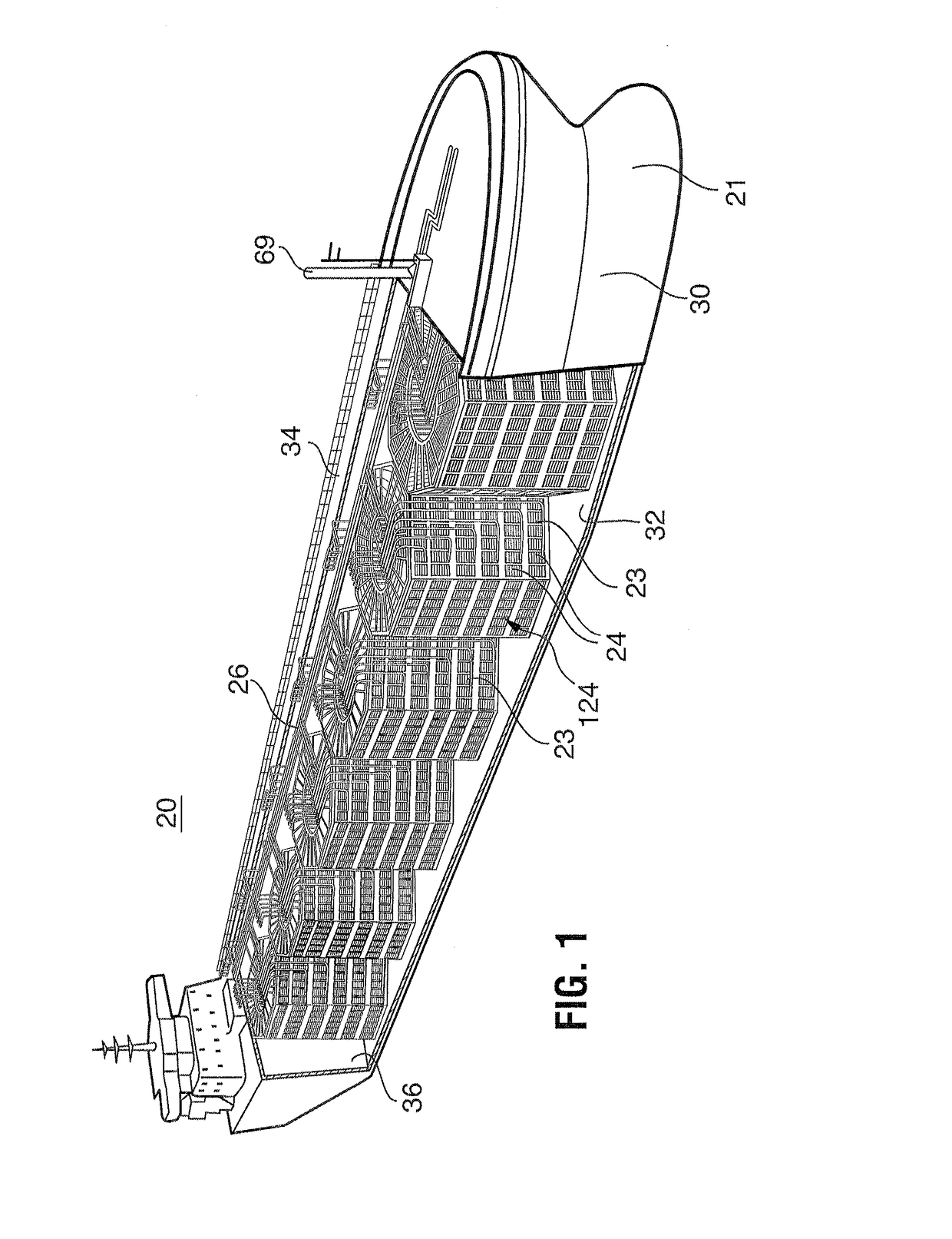

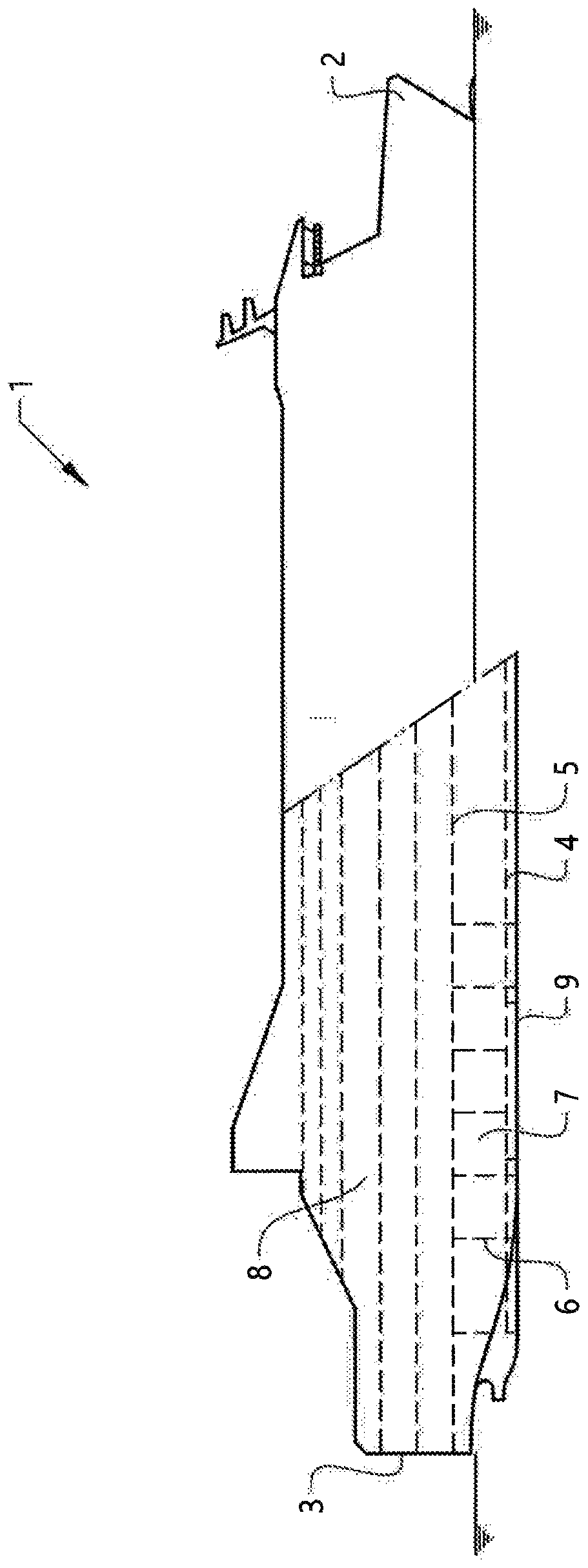

Method for enlarging a ship and enlarged ship

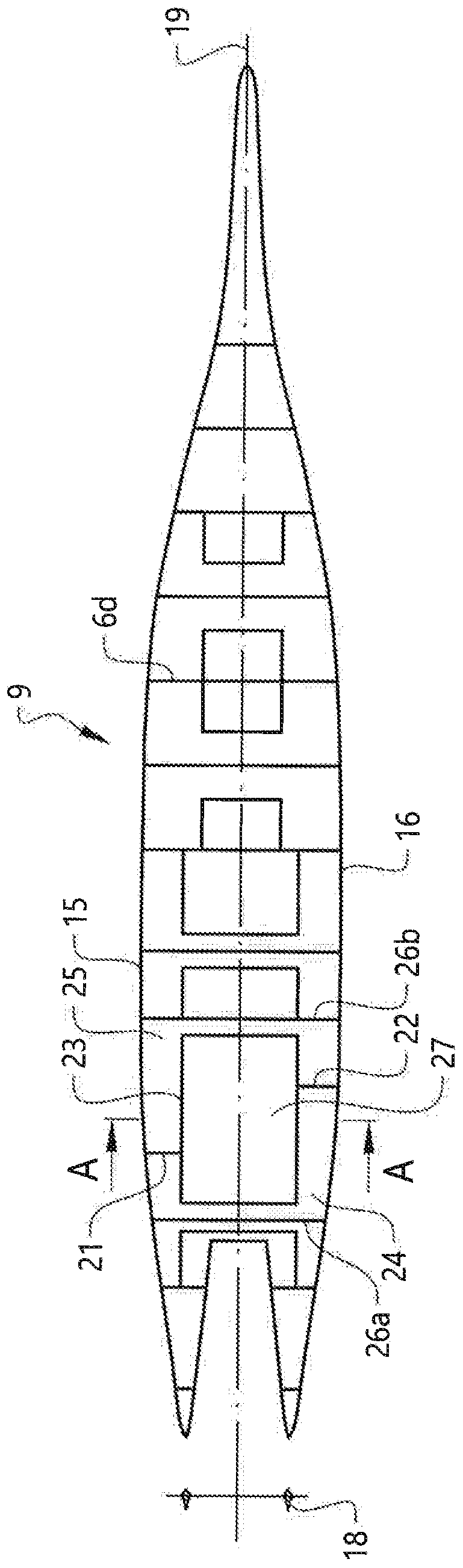

InactiveCN105658513AImprove lateral stabilityReduced steady ballast loadHull interior subdivisionHull decksStern

The invention relates to a method for enlarging a ship, in which method a container ship, conbulker, multi-purpose ship, LASH ship, or other ship having a high degree of deck opening is widened, wherein a front ship segment (23) comprising the bow (22) and a rear ship segment (25) comprising the stern (24) are separated from a middle ship segment (16) comprising at least part of the cargo hold, the middle ship segment (16) is divided into at least two middle ship parts (30, 31) in a longitudinal direction, the middle ship parts (30, 31) are moved apart in a transverse direction of the ship, an additional middle part (34) is installed between the middle ship parts (30, 31) that have been moved apart and thereby a widened middle ship segment is formed, a widened front ship segment (23) is attached to the front of the widened middle ship segment (16), and the rear ship segment (25) is attached directly to the rear of the widened middle ship segment (16).

Owner:NSB NIEDERELBE SCHIFFAHRTSGMBH

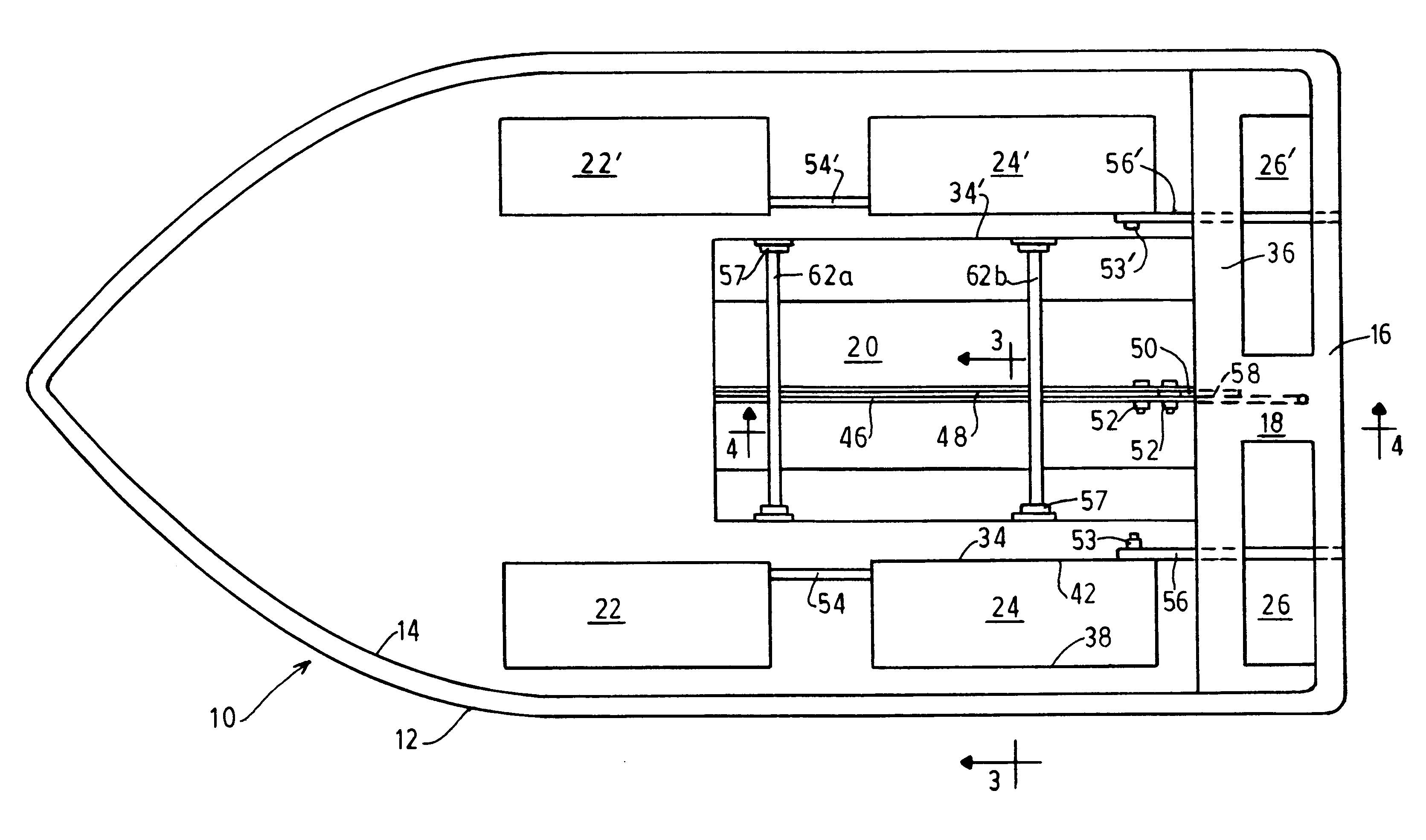

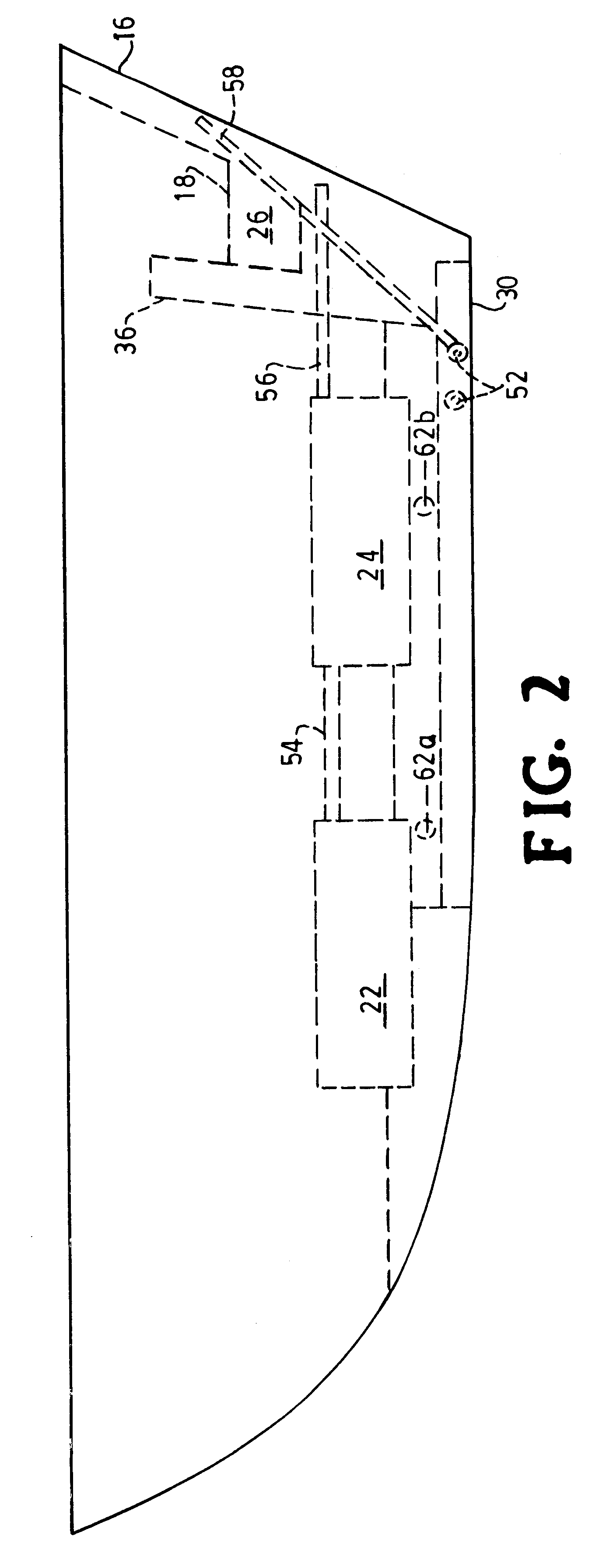

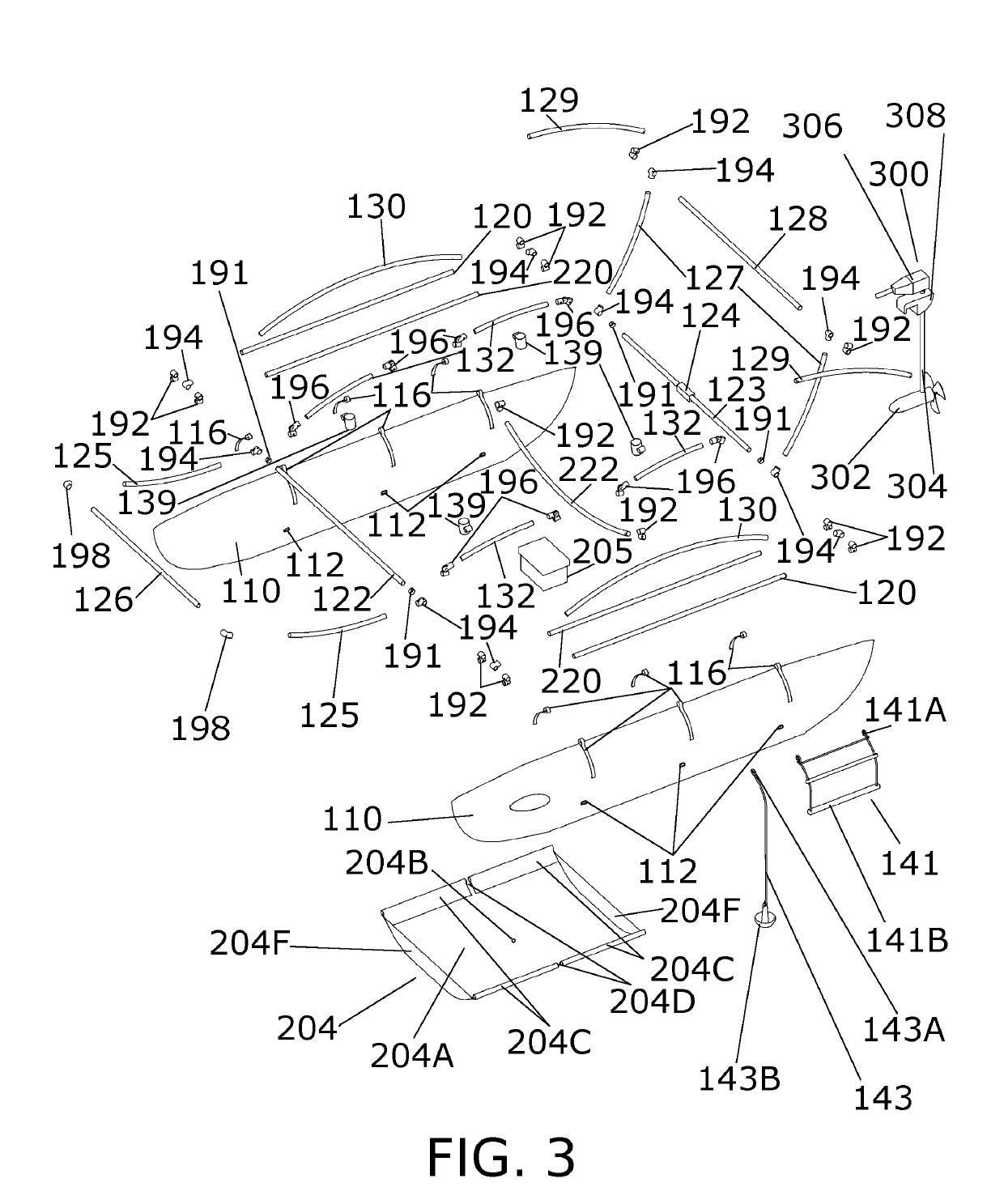

Structural system for a molded boat hull

The present invention provides a molded boat hull with a novel structural stiffening system. The boat hull has a number of laterally positioned compartments molded into the inner shell with vertical partitions that are integrally welded to the outer shell and are interconnected to each other and to the transom. A keel plate and a transom support are molded into the transom, the inner wall, and a bridge along the longitudinal center line of the boat. A keel support beam is placed along the keel, connected to the keel plate, and adhered into a channel in the boat hull inner shell. A pair of stringer braces is assembled between the integral stringers to provide transverse stiffness of the boat hull.

Owner:GENMAR LOGIC +1

Hull construction for side hulls of trimaran and the like

Owner:AUSTAL SHIPS

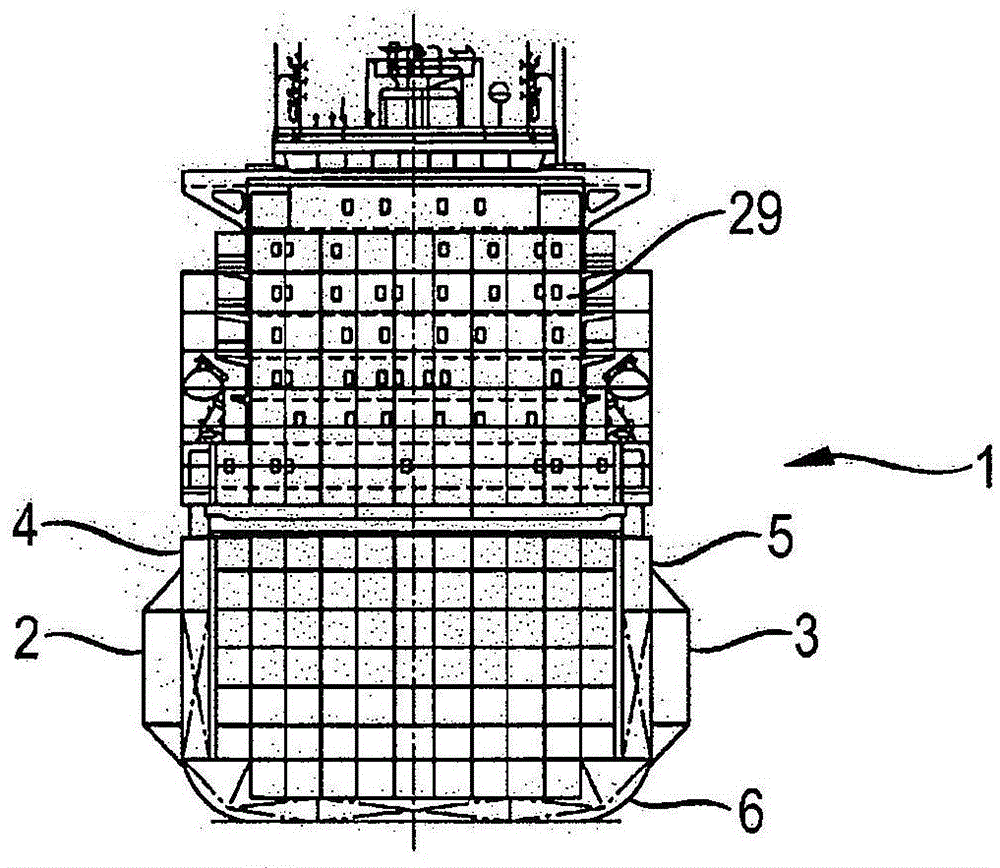

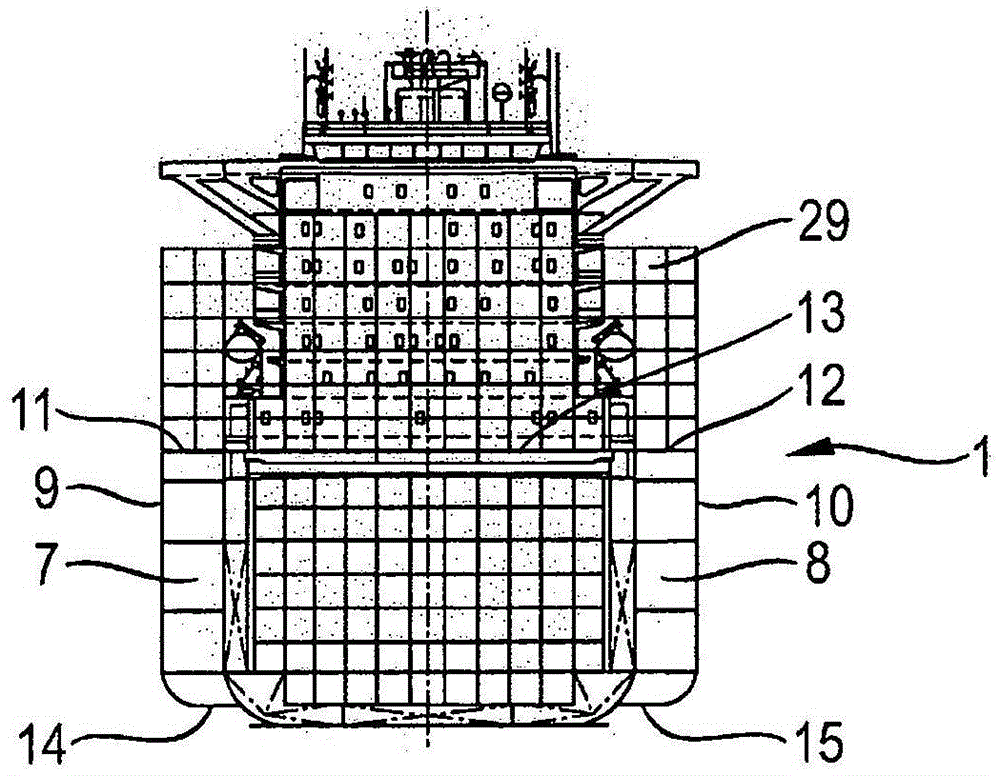

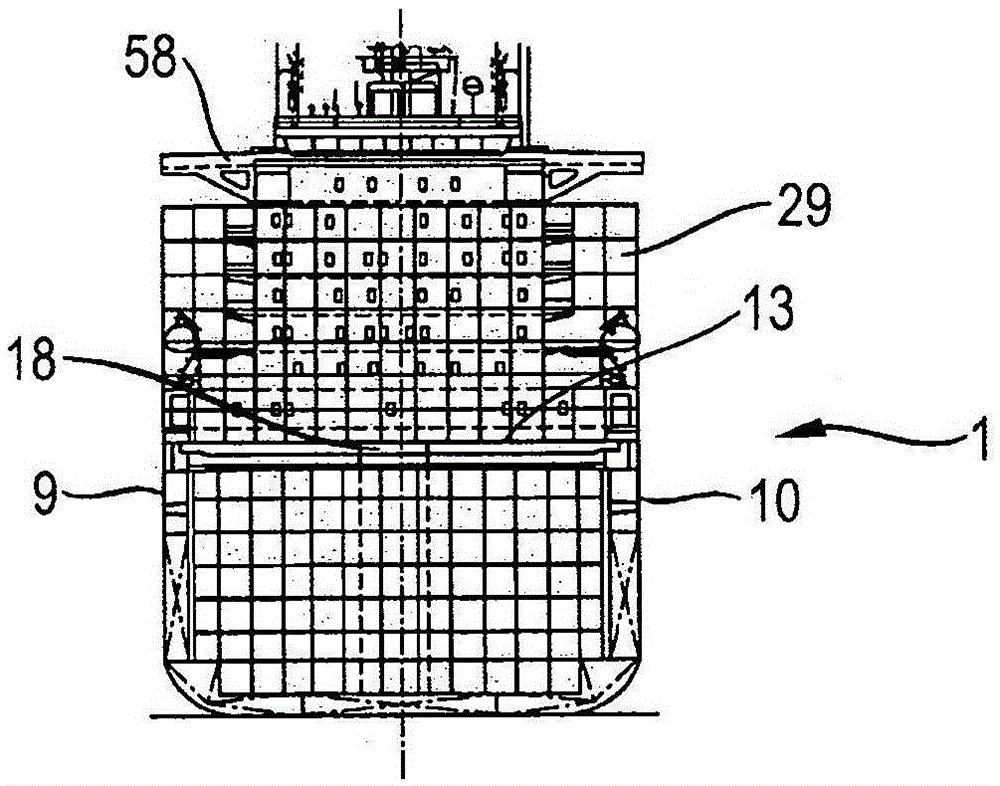

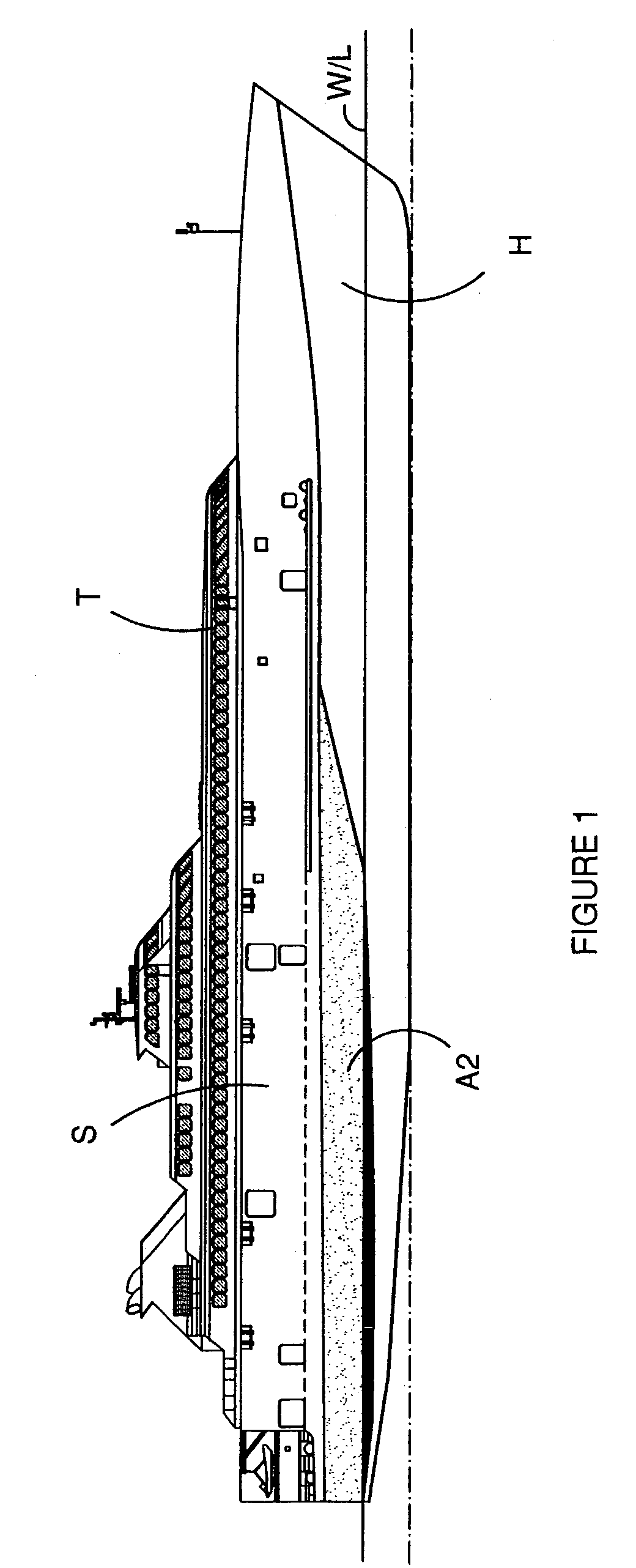

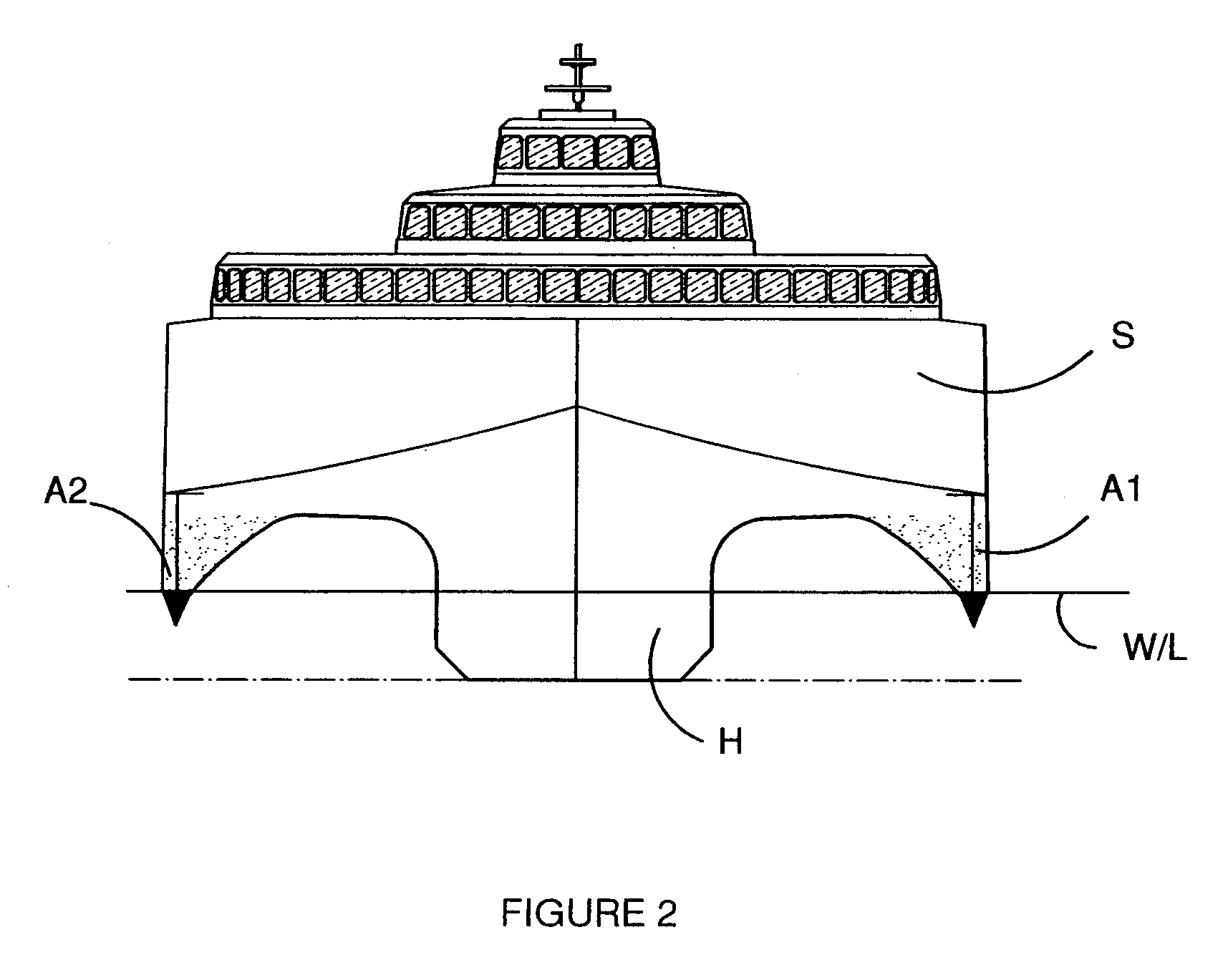

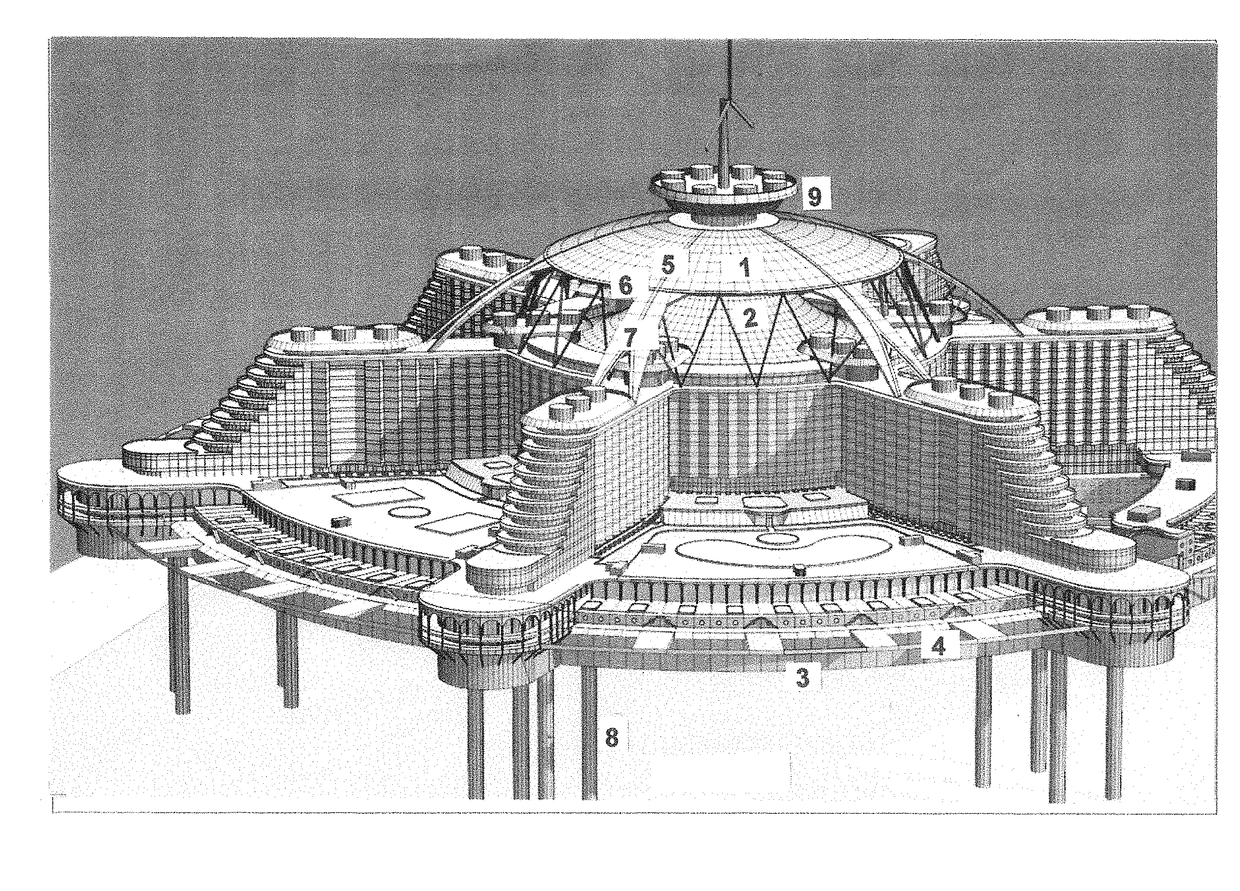

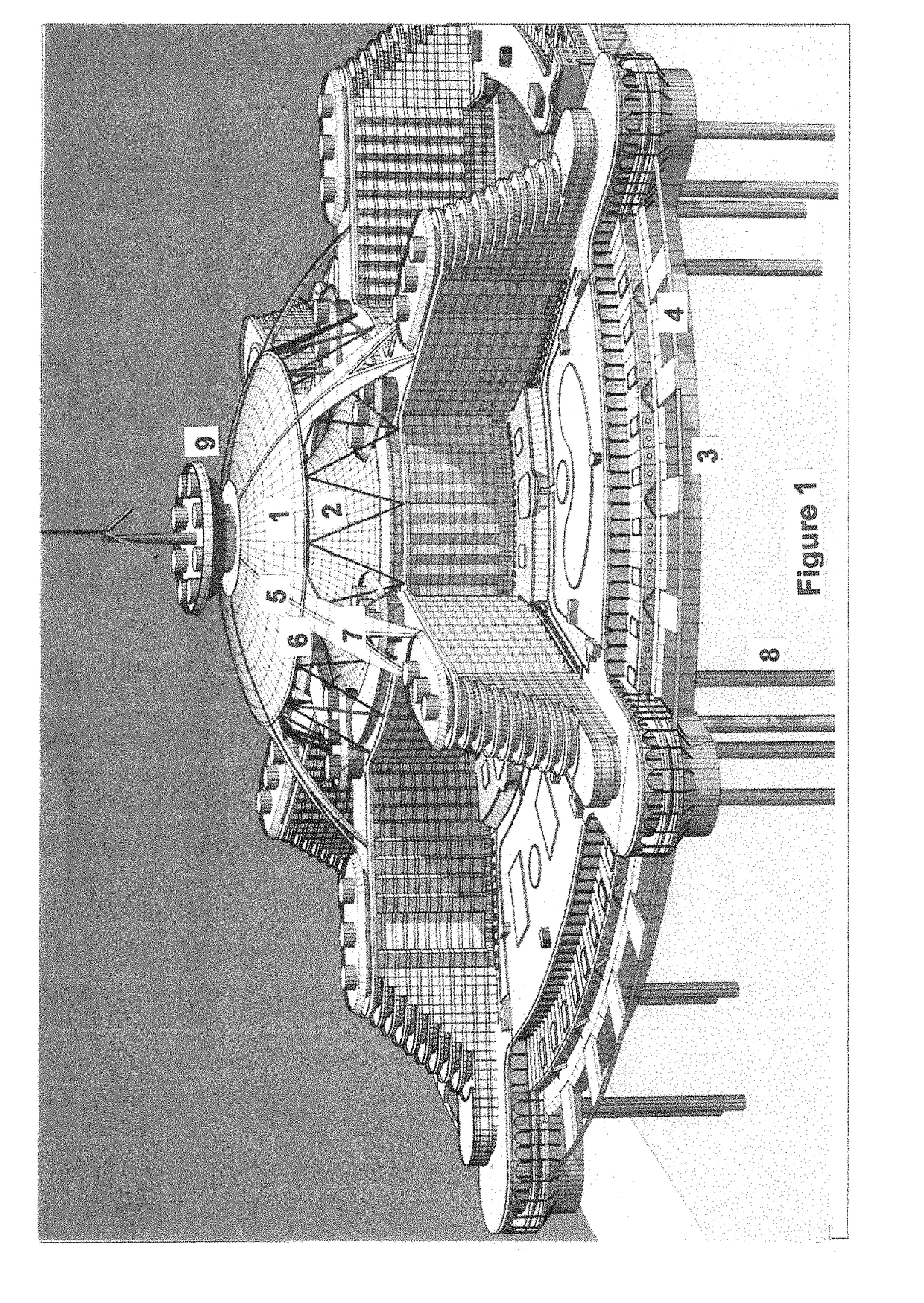

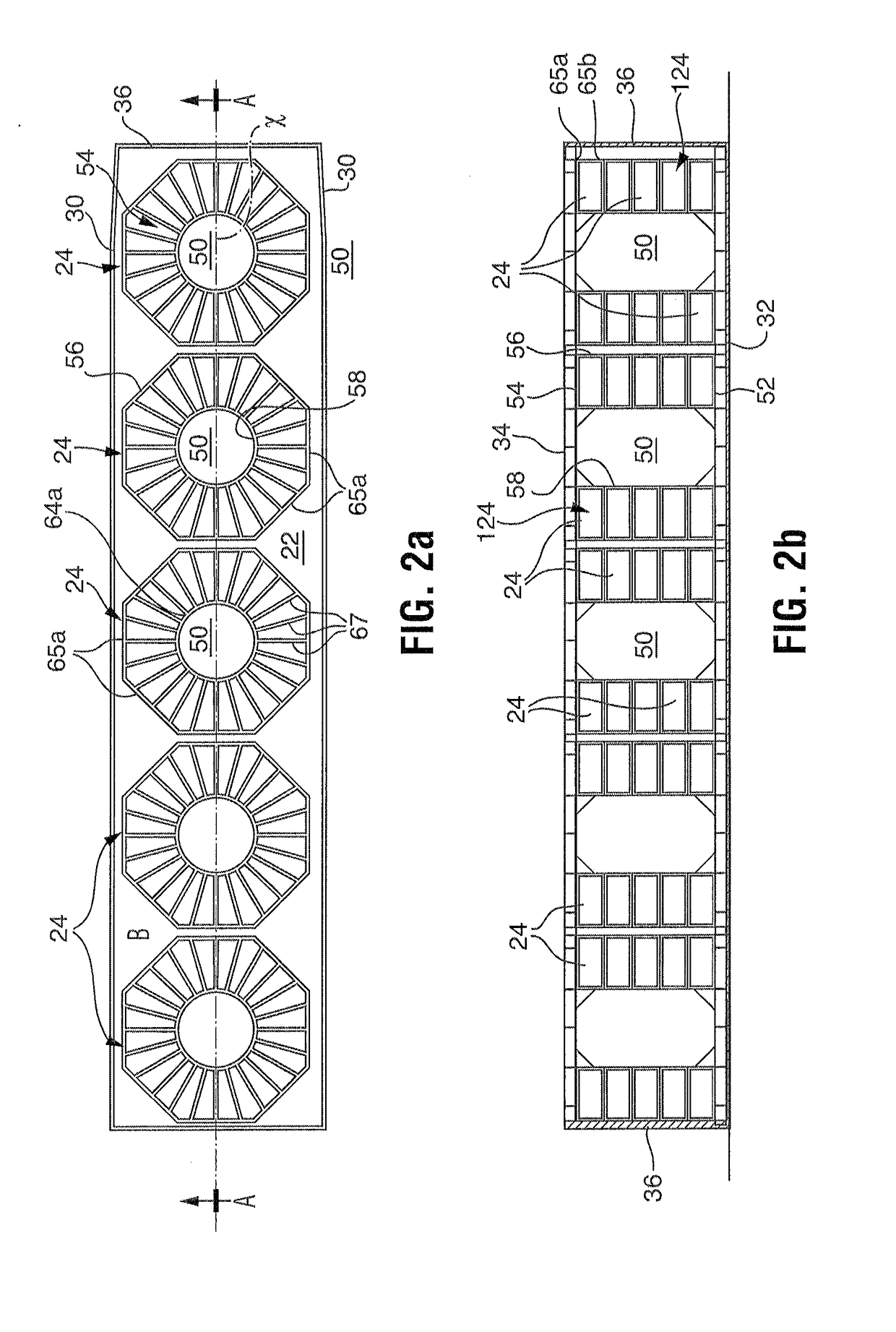

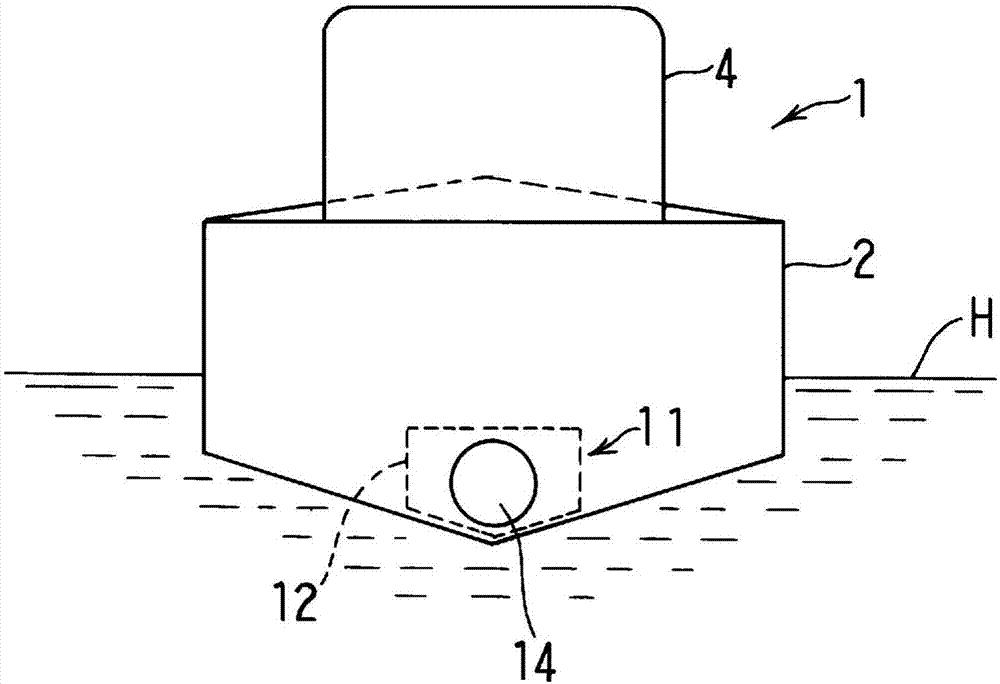

Devices and methods for producing a large-size floating structure

InactiveUS20180170489A1Low costHigh strengthArtificial islandsClimate change adaptationEngineeringLarge size

A large-size floating structure which meets the needs for extending the activities of coastal towns is provided. The architectural and technical design can accommodate several thousand inhabitants, while attracting many visitors and customers to live, work and enjoy varied leisure facilities. This energy-autonomous marine district, which is non-polluting and environmentally friendly, constitutes an example of sustainable development. Each component of the structure of the barge provides a maximum of functions: structural, functional, ecological and architectural. By concentrating all of the activities of a town in a single complex, it is easier and more economical to resolve all the problems of sustainable development and safety than in the habitant next to the coast.

Owner:DZIEWOLSKI RICHARD

Watercraft hull

A watercraft hull has a hull body defining a bow, a transom, and a longitudinal centerline extending from the bow to the transom along a center of the hull body. The hull body has an inner surface and an outer surface. A plurality of ribs extends at an angle to the longitudinal centerline on the inner surface.

Owner:BOMBARDIER RECREATIONAL PROD INC

Anti-impact protection structure for box type beams of hull

InactiveCN102407920AGood strength propertiesTotal strength has no effectHull framesResidual strengthUltimate tensile strength

The invention aims at providing an anti-impact protection structure for box type beams of a hull. The anti-impact protection structure comprises box type beams, an upper deck, a lower deck and ship planking, wherein the box type beams are respectively arranged on the upper deck, the lower deck and the ship planking; the section of each box type beam is of a quadrilateral structure formed by an inner plate of the box type beam, an outer plant of the box type beam and two box type beam supporting plates, wherein the inner plate of the box type beam and the outer plate of the box type beam are opposite sides and the lengths of the opposite sides are a; the two box type beam supporting plates are opposite sides and the lengths of the opposite sides are b; the two box type beam supporting plates are respectively provided with connecting plates for connecting the upper deck, the lower deck and the ship planking; and the upper deck, the lower deck and the ship planking are made of composite materials. The anti-impact protection structure has the advantages of good intensity characteristic, good explosion-proof performance and high residual intensity, and is beneficial for reducing the weight of the hull, protecting important pipelines and cables, and improving construction speed, quality control and maintenance.

Owner:HARBIN ENG UNIV

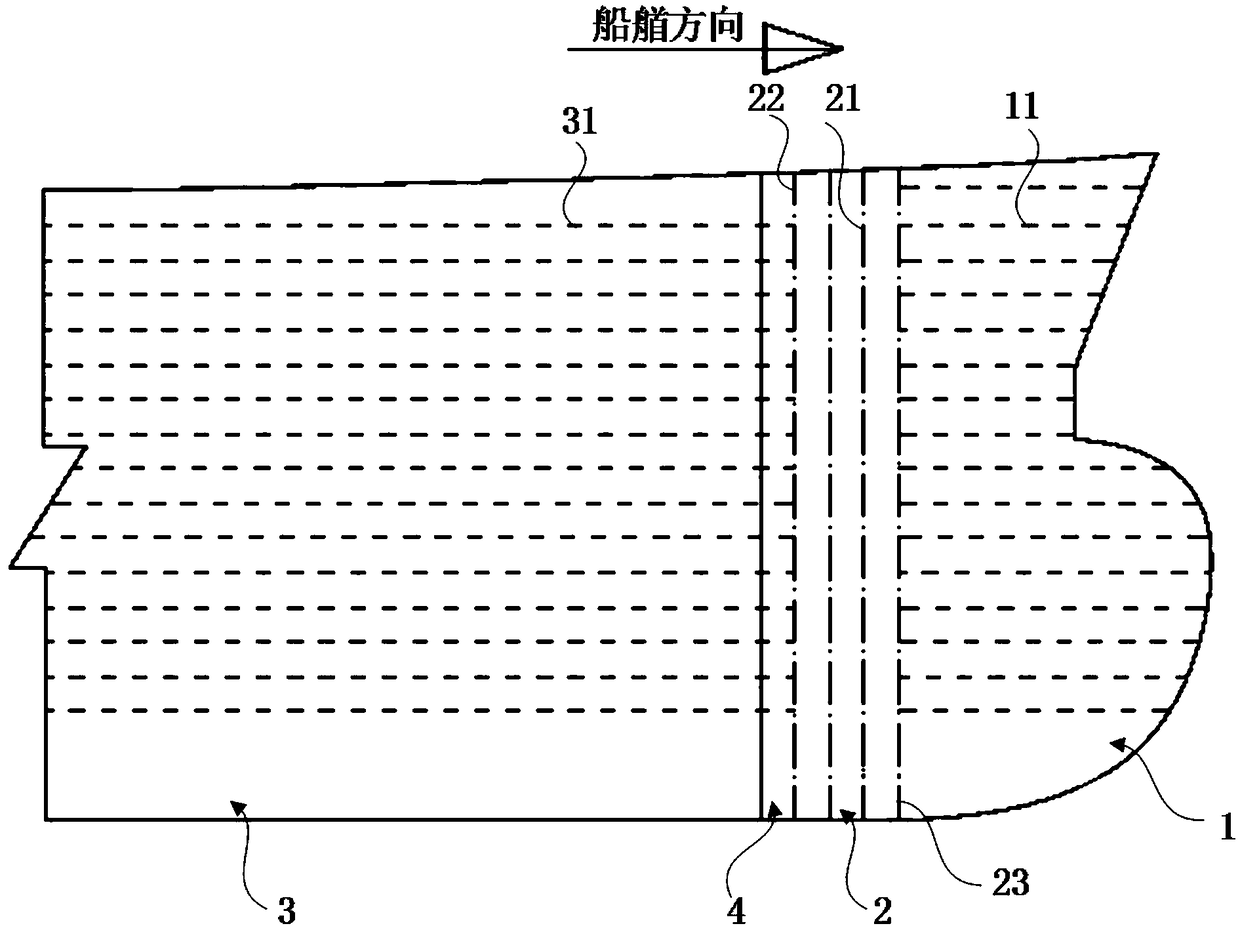

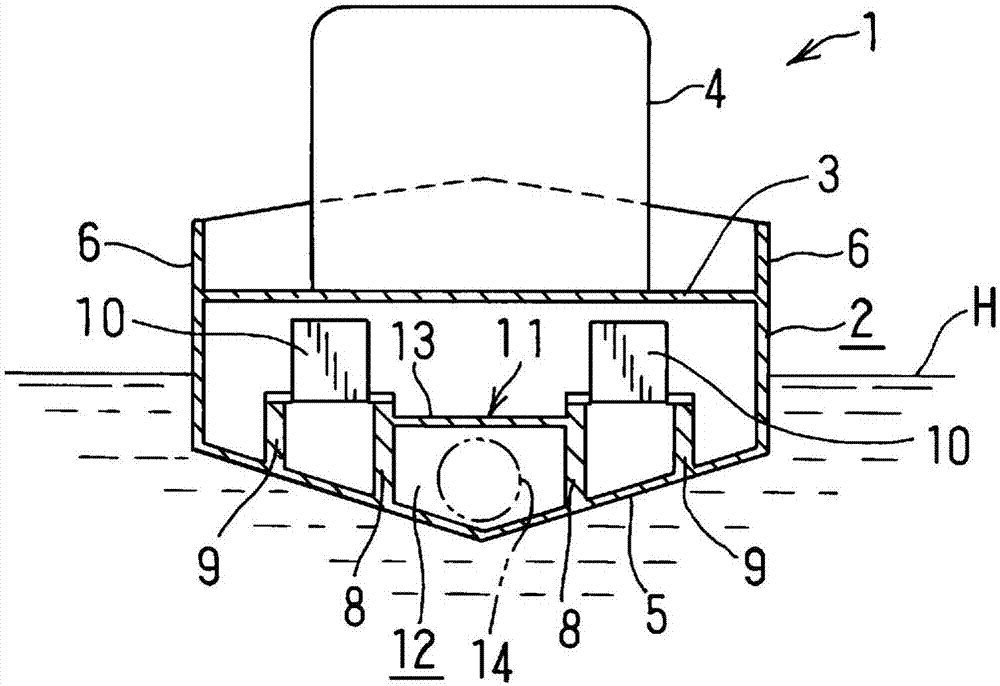

Combined type wind-wave-resistant ship

ActiveCN106697216AIncrease widthImprove lateral stabilityHull decksVessel movement reduction by wave dampingWind waveBuoy

A combined type wind-wave-resistant ship comprises a hull and is characterized in that a deck of the hull extends towards two sides; a plurality of support bodies are arranged under the parts, extending towards the two sides, of the deck and are all provided with support points; and buoys are in coupling connection to all the support points. The deck extends towards the two sides, so that the width of the deck is increased. The multiple support bodies are arranged under the deck and are all provided with the support points, the buoys are in coupling connection to all the support points, in this way, the parts, extending towards the two sides, of the deck are supported, and the transverse stability of the hull is improved. Transverse connection rods are arranged between the hull and the support points, and thus the transverse firmness of the support bodies is enhanced. Through the design, wind-wave resistance of the hull is improved, meanwhile, the structure is relatively simple, the manufacturing cost is low, most domestic shipyards can produce the combined type wind-wave-resistant ship, the technical requirements and site requirements of manufacturing are lowered greatly, and the manufacturing cost is lowered more.

Owner:NINGBO ZHENHAI JIEDENG APPL TECH INST

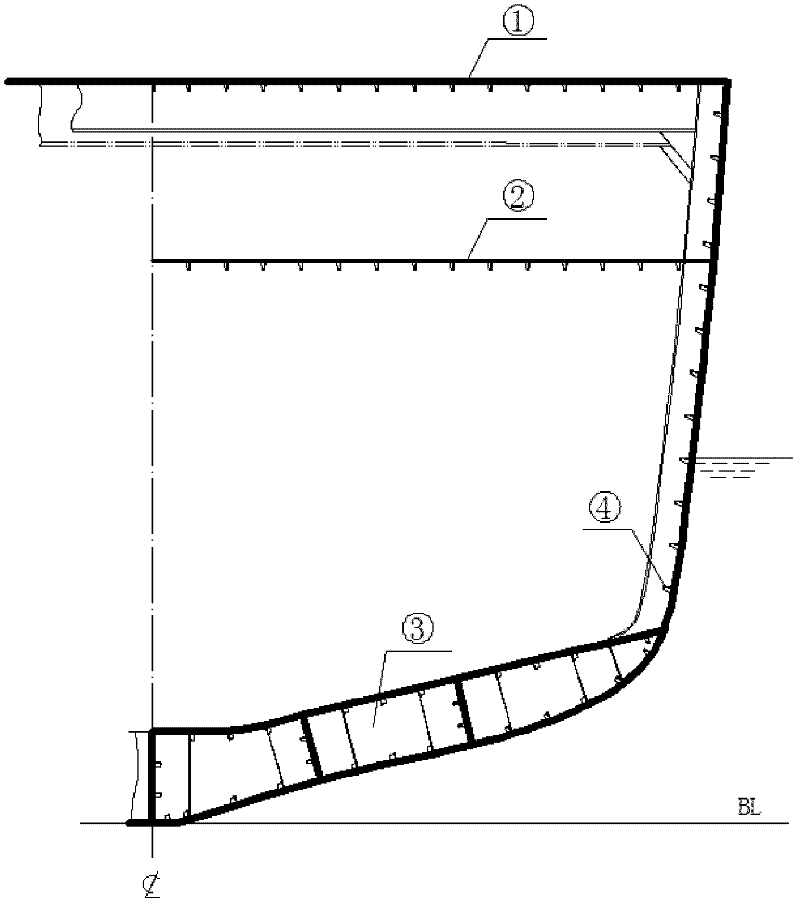

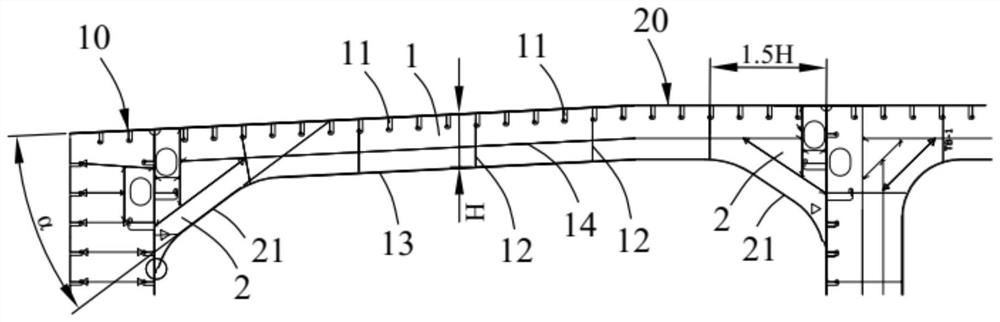

Structural strong frame, design method thereof and ship

ActiveCN113772010AReduce usageReduce weightHull decksVessel designingMarine engineeringStructural engineering

The invention relates to the technical field of ship construction, and discloses a structural strong frame, a design method thereof and a ship. The structural reinforced frame comprises a web plate, an end part and a stiffener, and the web plate has the minimum height value corresponding to the web plate in the HCSR specification. The two ends of the web plate are connected with end parts with inclined surfaces, and the length of each end part is 1.5 times of the minimum height value of the web plate. A stiffener is continuously welded on the web plate, and the distance between the stiffener and the bottom of the web plate is smaller than that between the stiffener and the top of the web plate. The design method of the structural strong frame comprises the following steps: calculating a minimum height value H of a web plate of the structural strong frame according to an HCSR specification and setting the length of the end part of the structural strong frameto be 1.5 H; and welding a continuous stiffener to the web, wherein the distance between the stiffener and the bottom of the web is smaller than that between the stiffener and the top of the web. The ship comprises the structural strong frame. According to the design method of the structural strong frame, the overall structure of the structural strong frame is simplified, and the construction efficiency of the structural strong frame is improved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

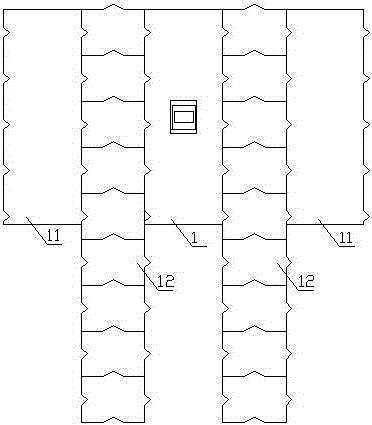

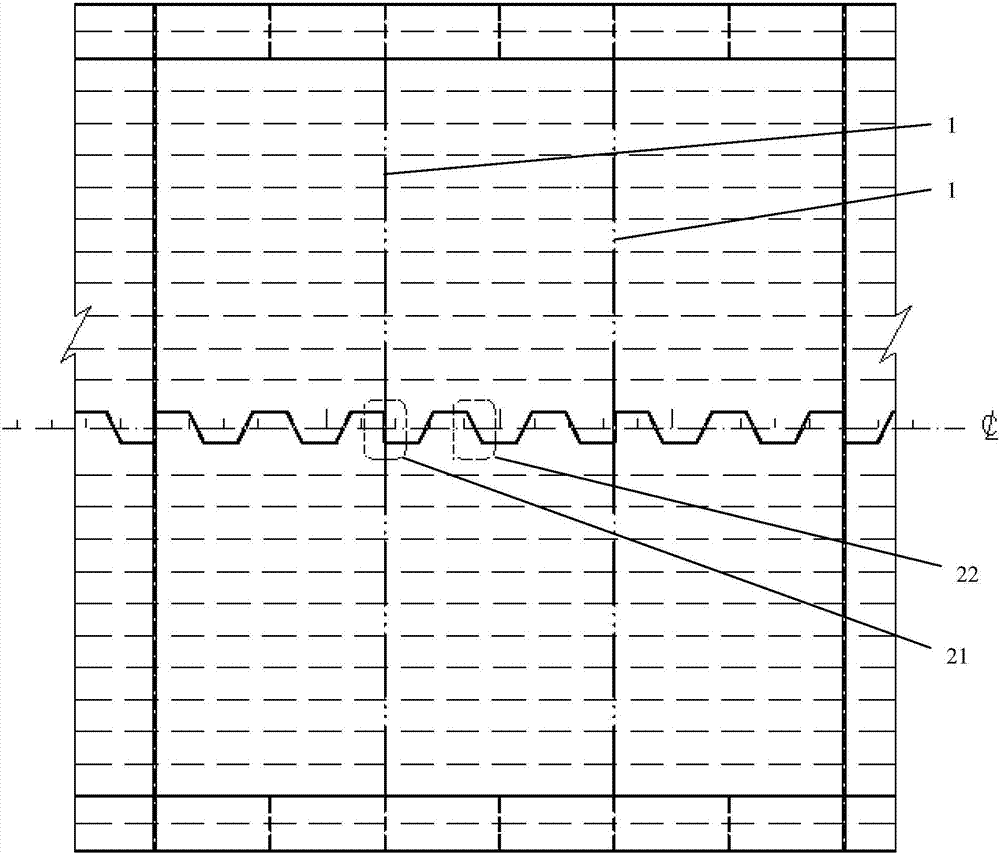

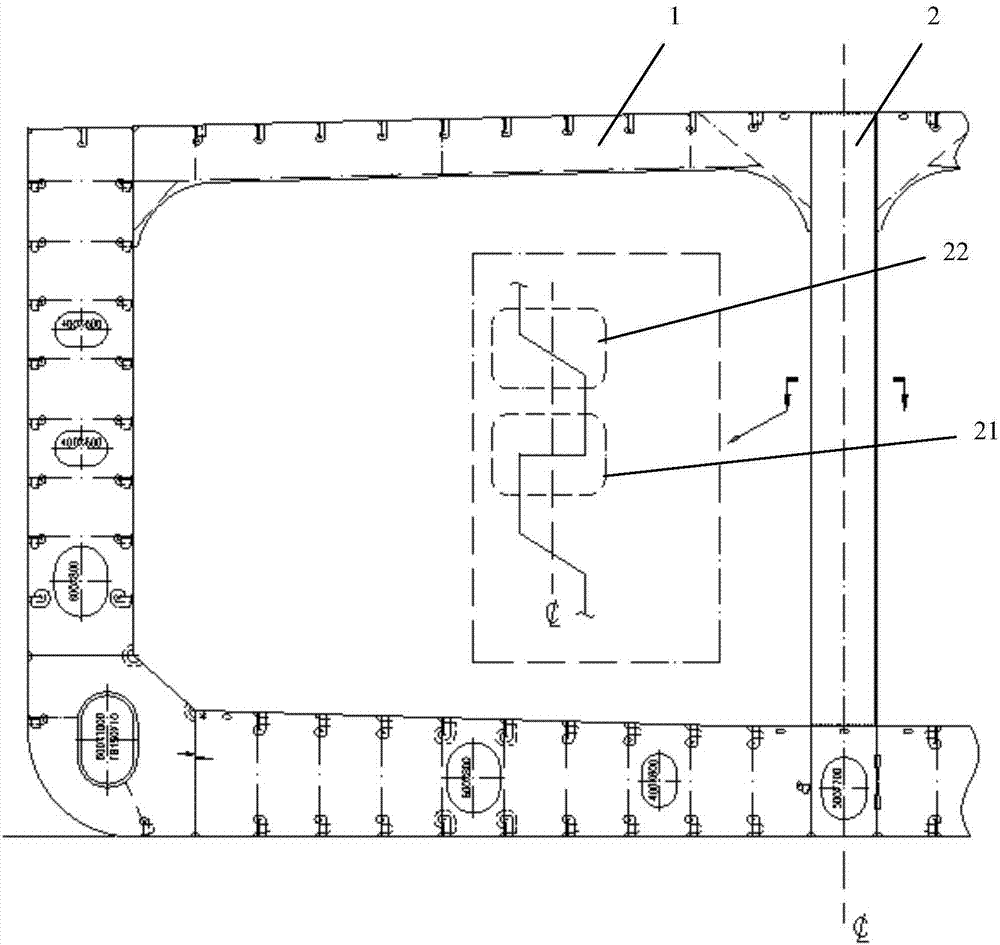

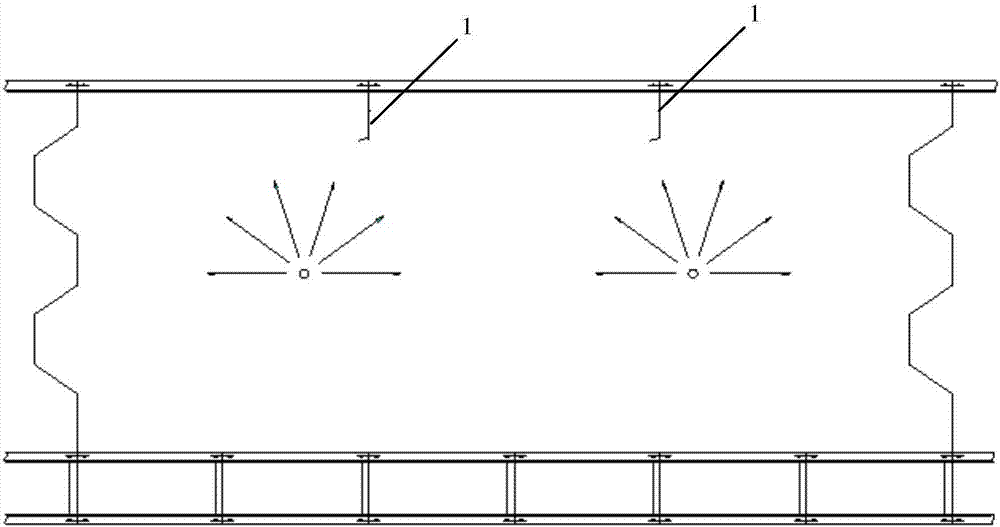

Large spacing deck web crossbeam and groove-type longitudinal bulkhead connecting structure

ActiveCN107539423AReduce in quantityReduce lossesHull decksHull framesMarine engineeringOblique angle

The invention discloses a large spacing deck web crossbeam and groove-type longitudinal bulkhead connecting structure. The large spacing deck web crossbeam and groove-type longitudinal bulkhead connecting structure comprises deck web crossbeams and groove-type bulkheads, wherein one deck web crossbeam is arranged between each two web frame spacing; each groove-type bulkhead comprises a right anglegroove and a bevel angle groove, a web of each right angle groove is aligned with a web of the corresponding deck web crossbeam, and the bevel angle grooves are located between the multiple deck webcrossbeams or between the deck web crossbeams and transverse bulkheads. According to the large spacing deck web crossbeam and a groove-type longitudinal bulkhead connecting structure, by arranging thelarge spacing deck web crossbeams, the number of the web crossbeams in a cabin is decreased, cabin washing shadows are reduced, the efficiency of a single tank washing machine is improved, and the investment cost is reduced; by arranging the groove-type bulkheads formed by combining the right angle grooves and the bevel angle grooves, the right angle groove webs are aligned with and welded to theweb crossbeam webs, effective connection between the web crossbeams and the groove-type longitudinal bulkheads is ensured, arranging of deck longitudinal pipe tunnels is avoided, the cabin capacity loss is reduced, and the structure weight is reduced.

Owner:708TH RES INST OF CSSC

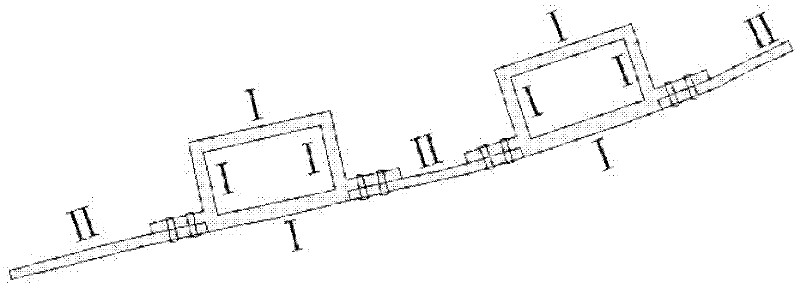

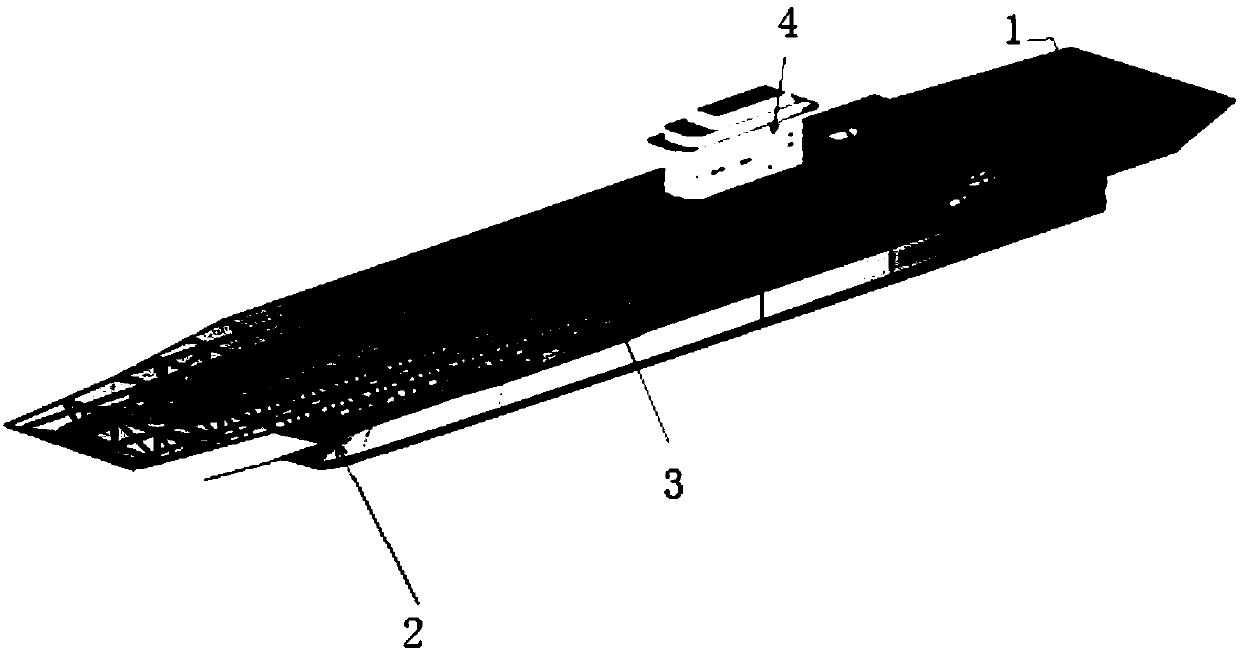

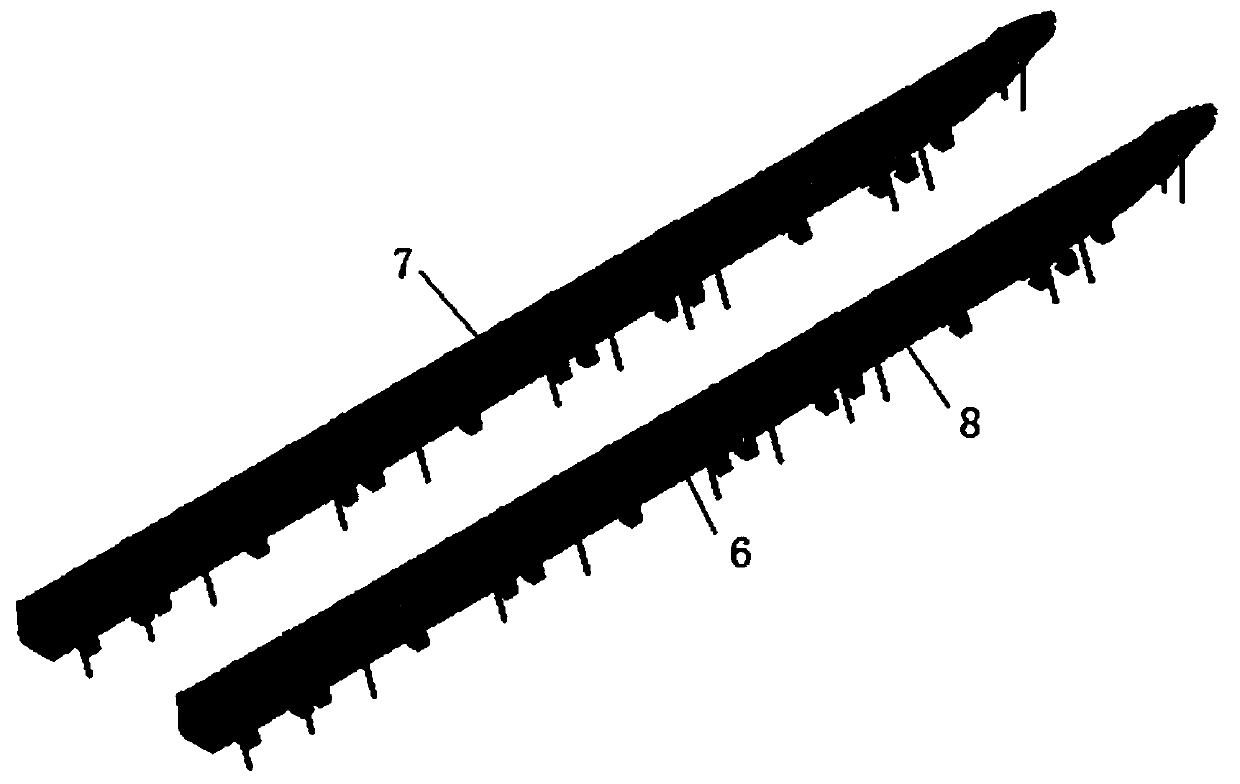

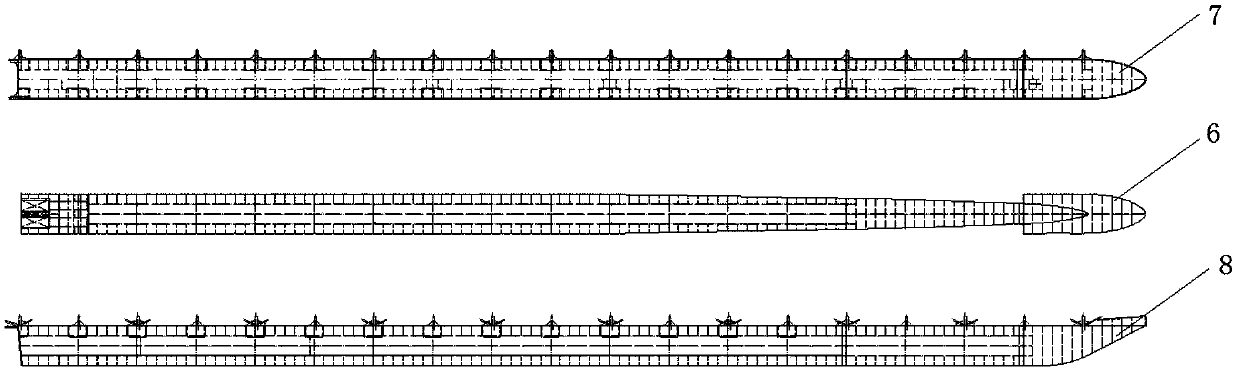

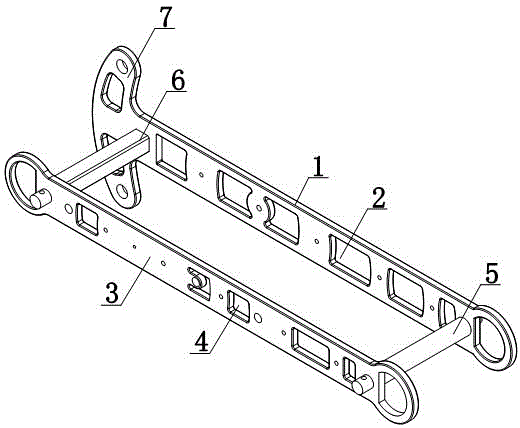

Aluminum alloy assembled twin-hull high-speed target vessel

InactiveCN107719592AQuality assuranceGuaranteed reliabilityHull framesHydrodynamic/hydrostatic featuresMarine engineeringYard

The invention relates to a target ship, in particular to an aluminum alloy assembleable double-body high-speed target ship, which mainly includes a target ship deck, a sheet body and a truss structure, the truss structure is placed between the target ship deck and the sheet body, and the sheet body It is assembled from a number of independent sealed cabins, which are filled with lightweight anti-sinking materials, and the shape of the pieces is streamlined. The sheet body in the present invention refers to the single hull of the high-speed target ship, which is spliced from the end to the end of partitioned sealed cabins of different specifications. Each sealed cabin is an independent module, and each cabin can be prefabricated in the shipyard. Rapid assembly on site at the desired location.

Owner:NANJING CHANGFENG AEROSPACE ELECTRONICS SCI & TECH

Ship for gas storage and transport

A ship for transporting cargo gas, such as natural gas, includes a ship structure and a middle transverse bulkhead constructed by gas storage containers. Each gas storage container includes an enclosure and a pipe coil within the enclosure that contains the cargo gas and it is the enclosures of the gas storage containers that are integrated into the ship structure to form the middle transverse bulk head.

Owner:GEV CANADA CORP

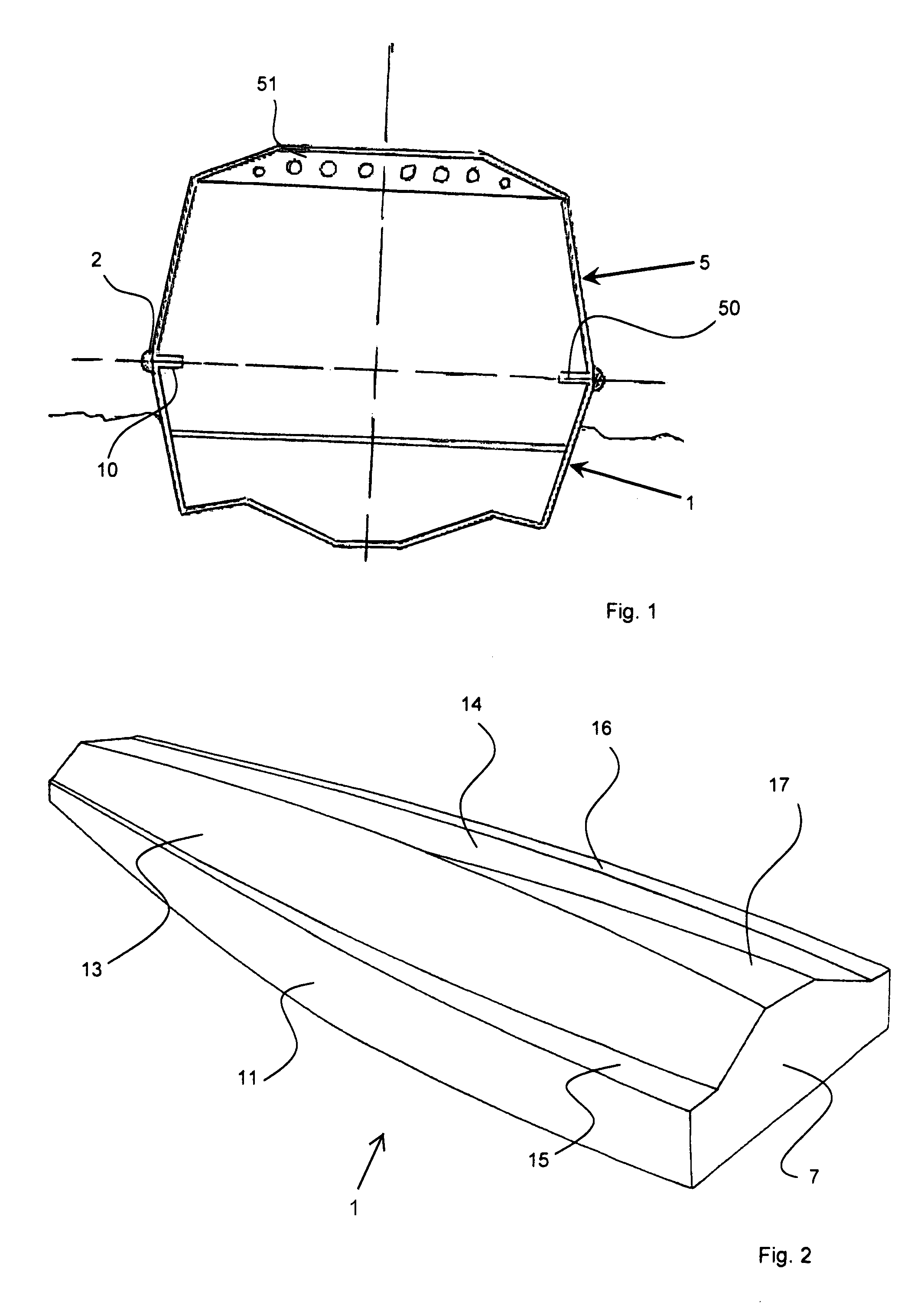

Boat or Ship Body of Aluminum-Based Material

ActiveUS20130068154A1Facilitate proper placementNecessary rigidityNon-magnetic metal hullsHull stemsGusset plateAdhesive

A watercraft body includes a hull made of an aluminum-based material and a separately fabricated superstructure that is mounted on the hull via adjoining flange plates. To fabricate the hull, frame elements are spot-welded onto the inner surface of initially-flat hull plates or plank elements, which are then curved according to the required hull contour and assembled onto the flange plate. The frame elements are screwed together via gusset plates and transverse beams to form transverse frames, and then longitudinal seams between plank elements are continuously welded from the outside. Additionally, the longitudinal seams may be welded from the inside, for example by temporarily removing gusset plates to allow continuous access to the longitudinal seams. Additionally, stand-offs may form a spacing gap between the frame elements and the plank elements, and an adhesive may fill this spacing gap to adhesively bond the framework to the hull plating.

Owner:OP MARITIM IP GMBH

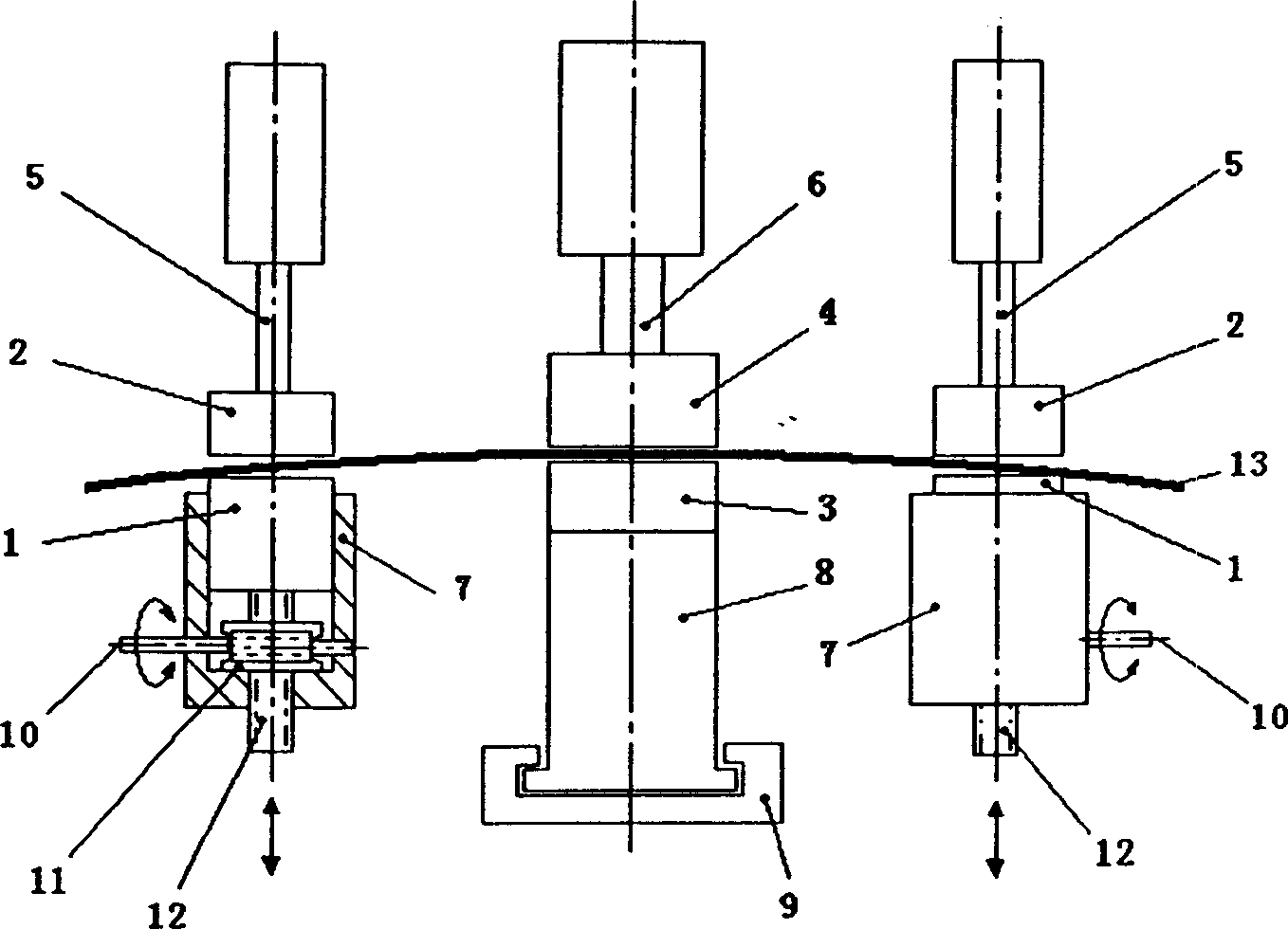

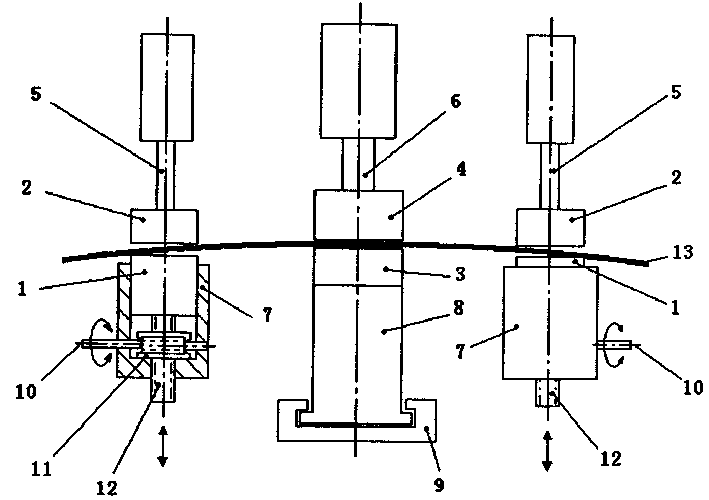

Vertical preflex device for rib cold bending unit

InactiveCN1425588AEliminate the phenomenon of "side bending"Simple organizationHull framesKeelHeight difference

The present invention relates to vertical preflex unit for rib cold bending machine. It has one combined driving mechanism comprising worm, worm gear and side lower chuck supporting screw to realize the vertical motion of the side lower chucks. There is some height difference between the clamping plane of the side lower chucks and the clamping plane of the middle lower chuck. When the rib shape is clamped, some vertical preflex is formed between each of the side chucks and the middle chuck, and this can eliminate the "side bending" phenomenon produced during bending rib. The present invention is used in ship yard for machining rib, cross beam, longitudinal keel and other curved members.

Owner:WUHAN UNIV OF TECH

Portable Solar-Electric Watercraft

A watercraft includes a pair of inflatable pontoons. Releasably affixed atop each of the pontoons and aligned therewith are inner and outer lengthwise frame members. Forward and aft beamwise frame members are affixed to the inner and outer lengthwise frame members. Primary arch members are affixed to the forward and aft beamwise frame members. A main fabric panel is stretched between the pair of primary arch frame members, the forward beamwise frame member, and the aft beamwise frame member. A motor mount is affixed centrally to the aft beamwise frame member, the motor mount being configured to removably support a motor assembly. Aft panel side members are rotatably-lockably affixed to the aft beamwise frame member and joined by an aft panel top member. An aft fabric panel is stretched between the aft panel side members, the aft beamwise frame member, and the aft panel top member.

Owner:DESIGNER DIRECT INC

Anti-collision structure of ship

InactiveCN109263791AEnsure safetyGuaranteed stabilityHull stemsHull framesHull structureMarine engineering

The invention discloses a ship anti-collision structure, wherein the bow of the ship adopts a first longitudinal skeleton structure, a transverse skeleton structure is arranged between the bow and theship anti-collision bulkhead, and a second longitudinal skeleton structure is arranged on the side of the anti-collision bulkhead away from the bow. By providing a transverse skeleton structure between the bow of the ship and the collision bulkhead, the invention can effectively partition the stress transmission when the bow of the ship is collided, avoid the stress transmission when the bow of the ship is collided to the hull structure, cause the deformation or damage of the hull structure, ensure the safety and stability of the ship operation, reduce the damaged area and the damage area ofthe ship, and reduce the loss of the shipowner.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Ship with watertight wall

The invention concerns a ship, said ship comprising a lower deck, such as a tank top, and an upper deck, such as a bulkhead deck, arranged above the lower deck, said lower and upper decks extending ina longitudinal direction of the ship, wherein the lower deck is provided with watertight walls (bulkheads) that extend vertically between the lower and the upper deck and define a plurality of separated watertight compartments distributed between the upper and lower decks, and wherein a first of said watertight walls extends in a transversal manner from side to side of the ship so as to separatetwo longitudinally adjacent first and second compartments. The invention is characterized in that the first watertight wall does not extend only in a transversal direction but also in the longitudinaldirection so as to provide the first compartment with a first longitudinally extending portion that extends into the second compartment, wherein the first longitudinally extending portion is arrangedat a first distance from a first side of the ship, and wherein the first distance is greater than a width or depth of a theoretical damage according to standard requirements for the type of ship concerned.

Owner:BASSOE TECH

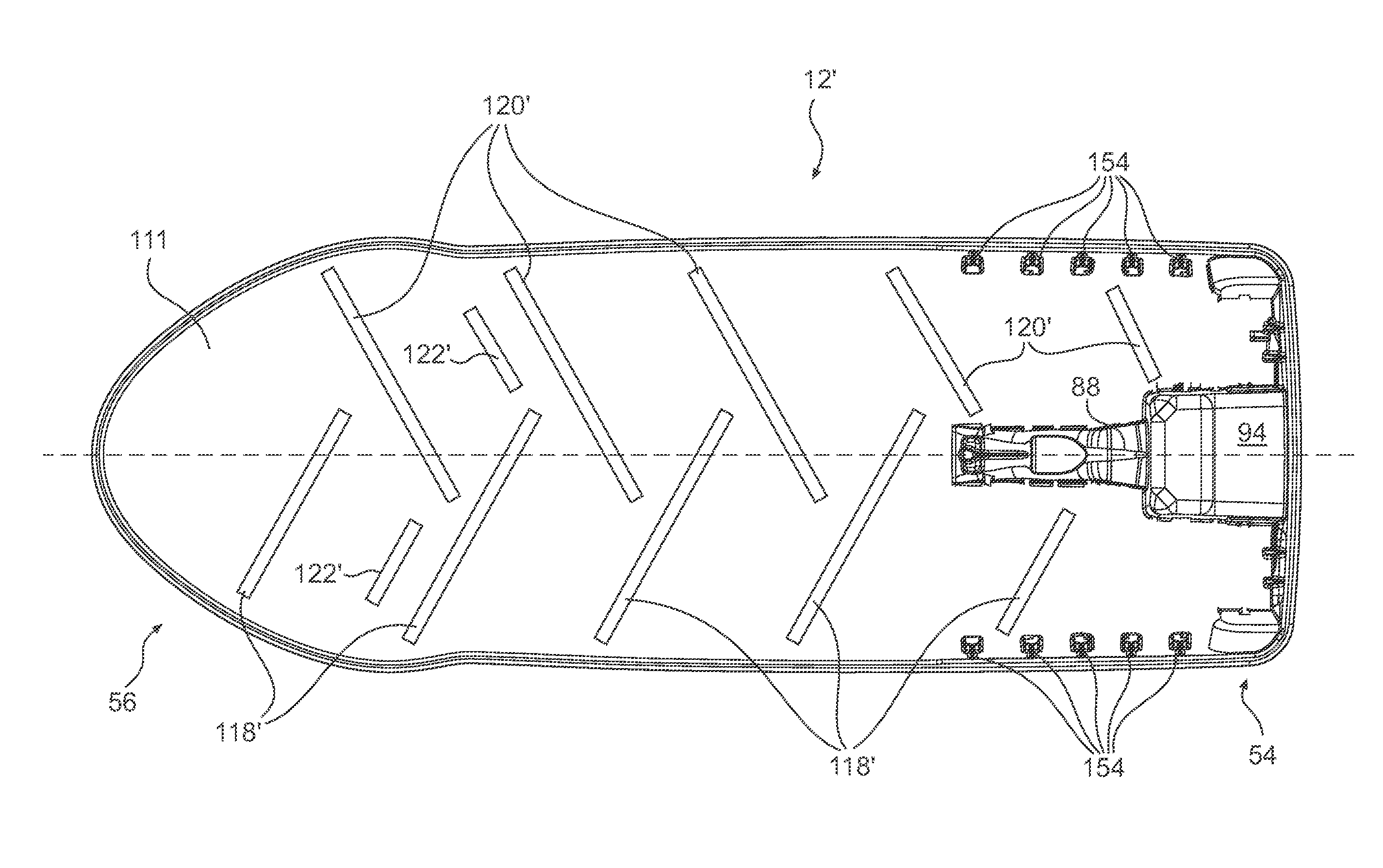

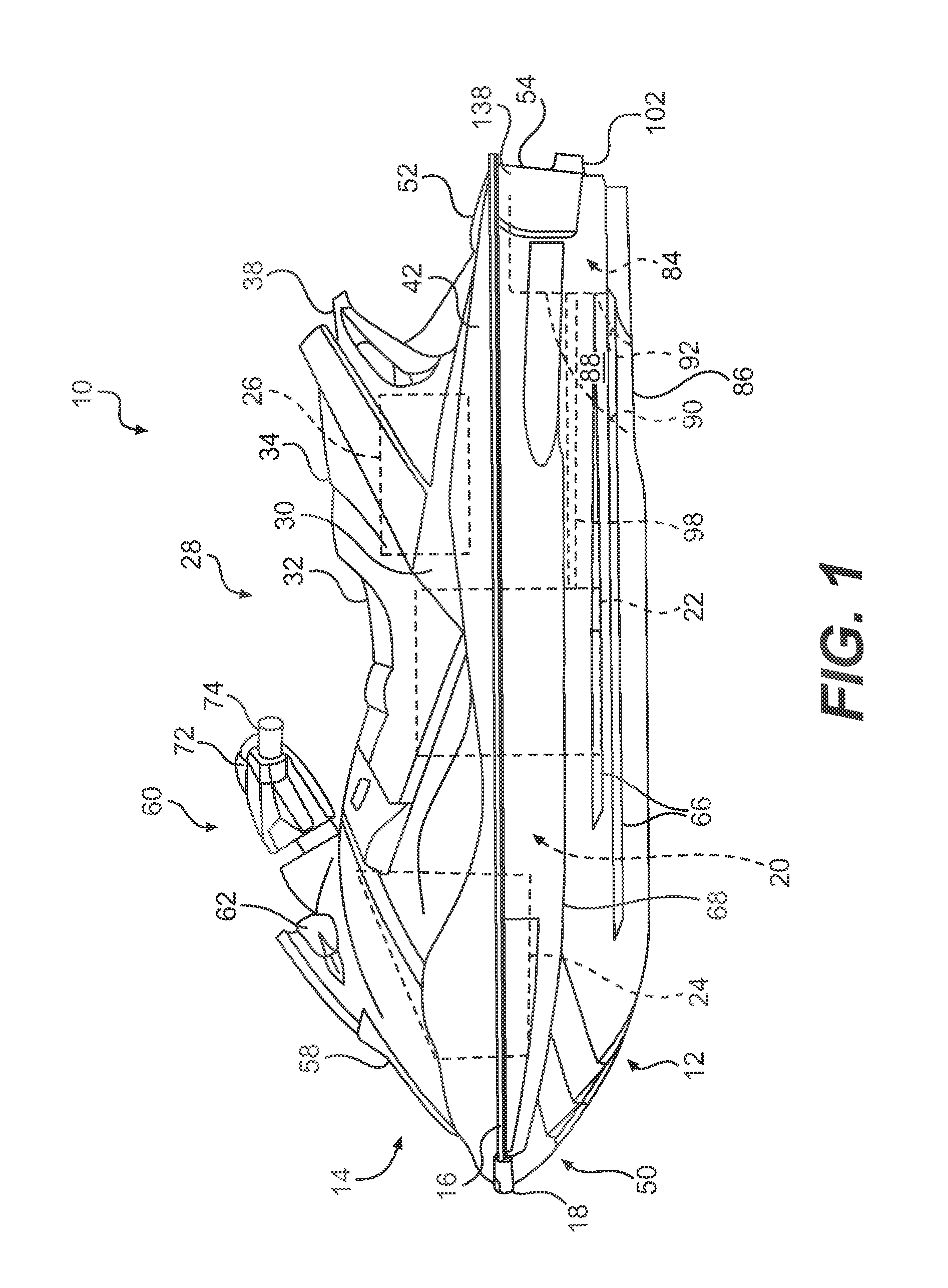

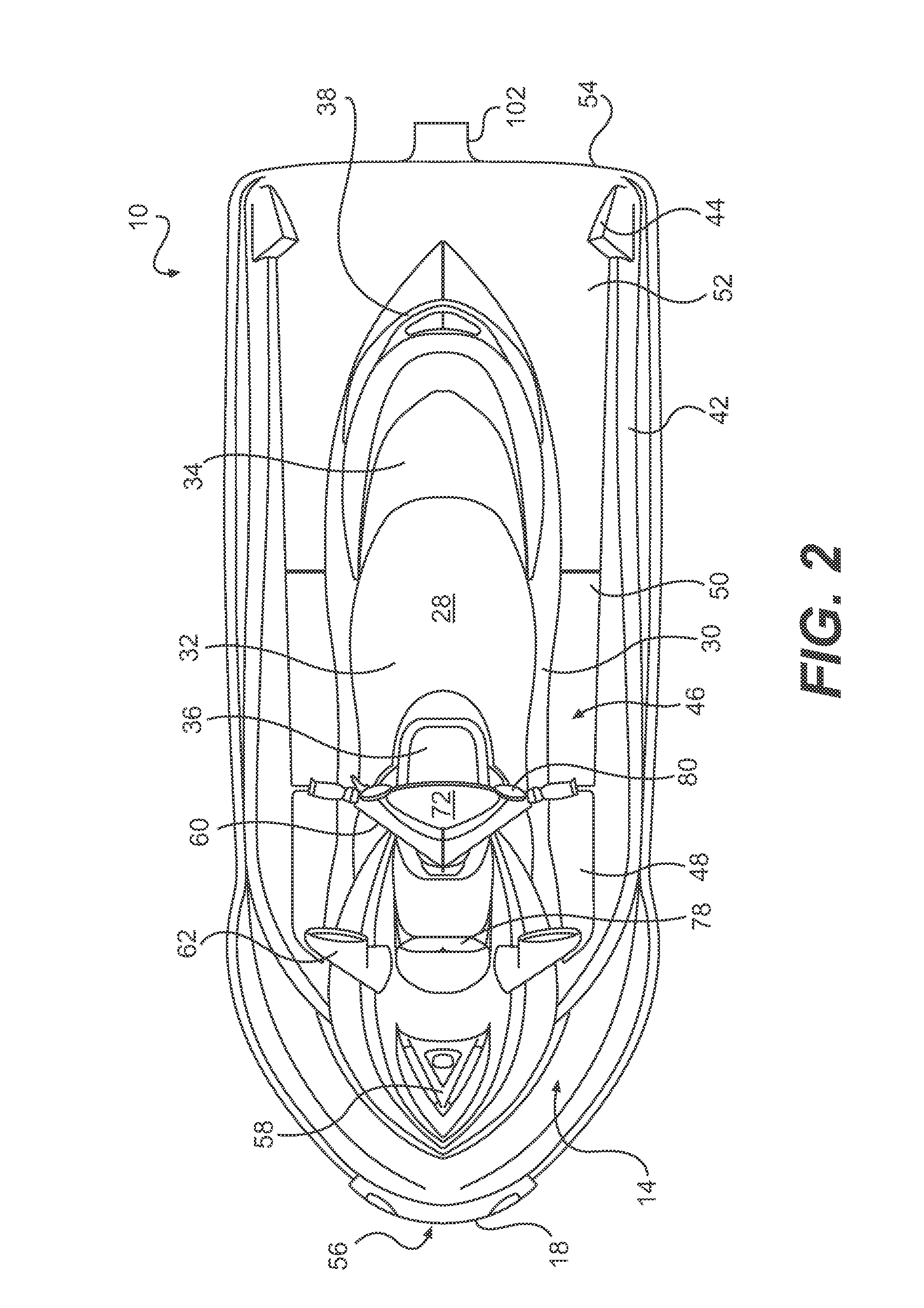

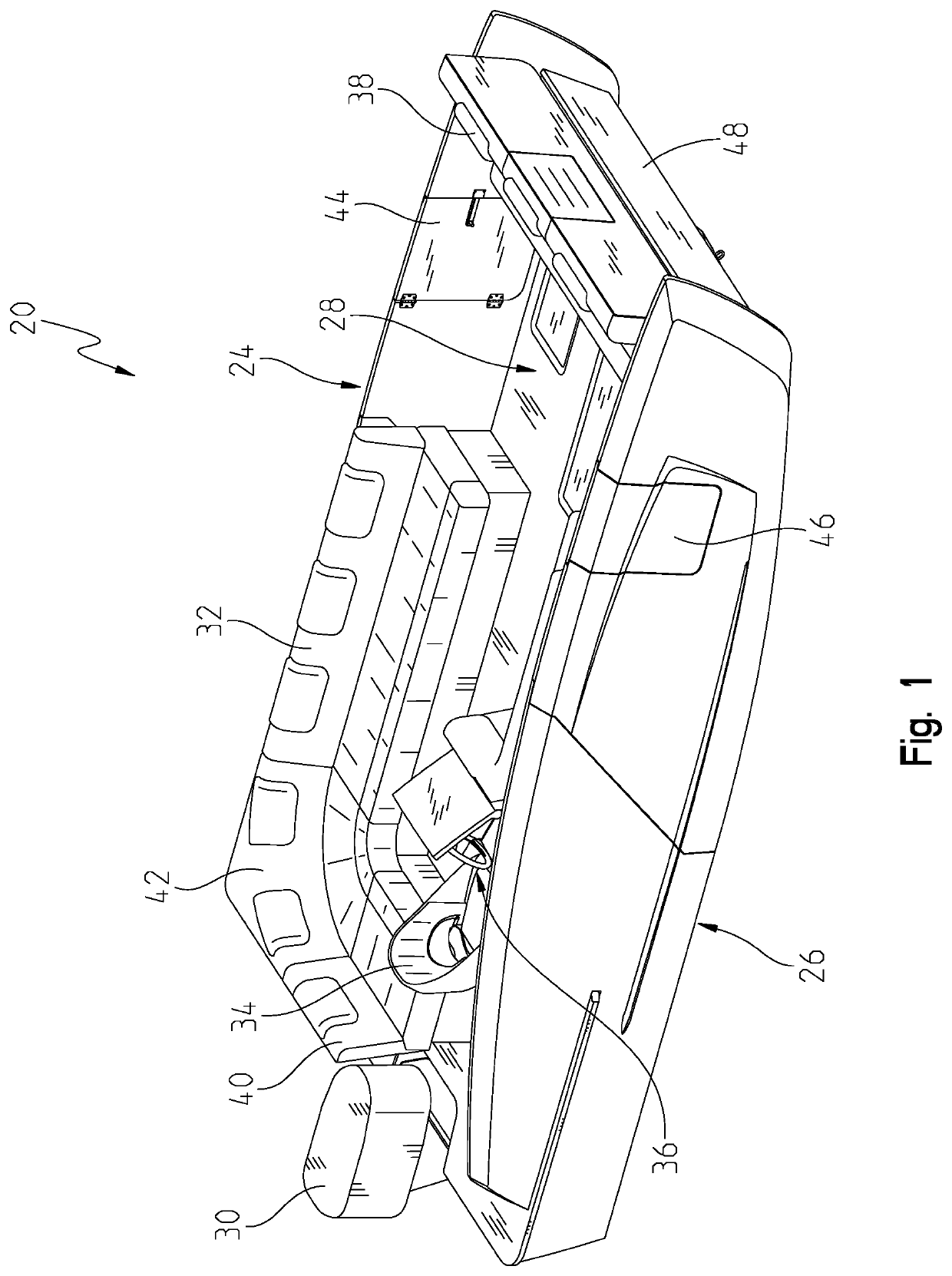

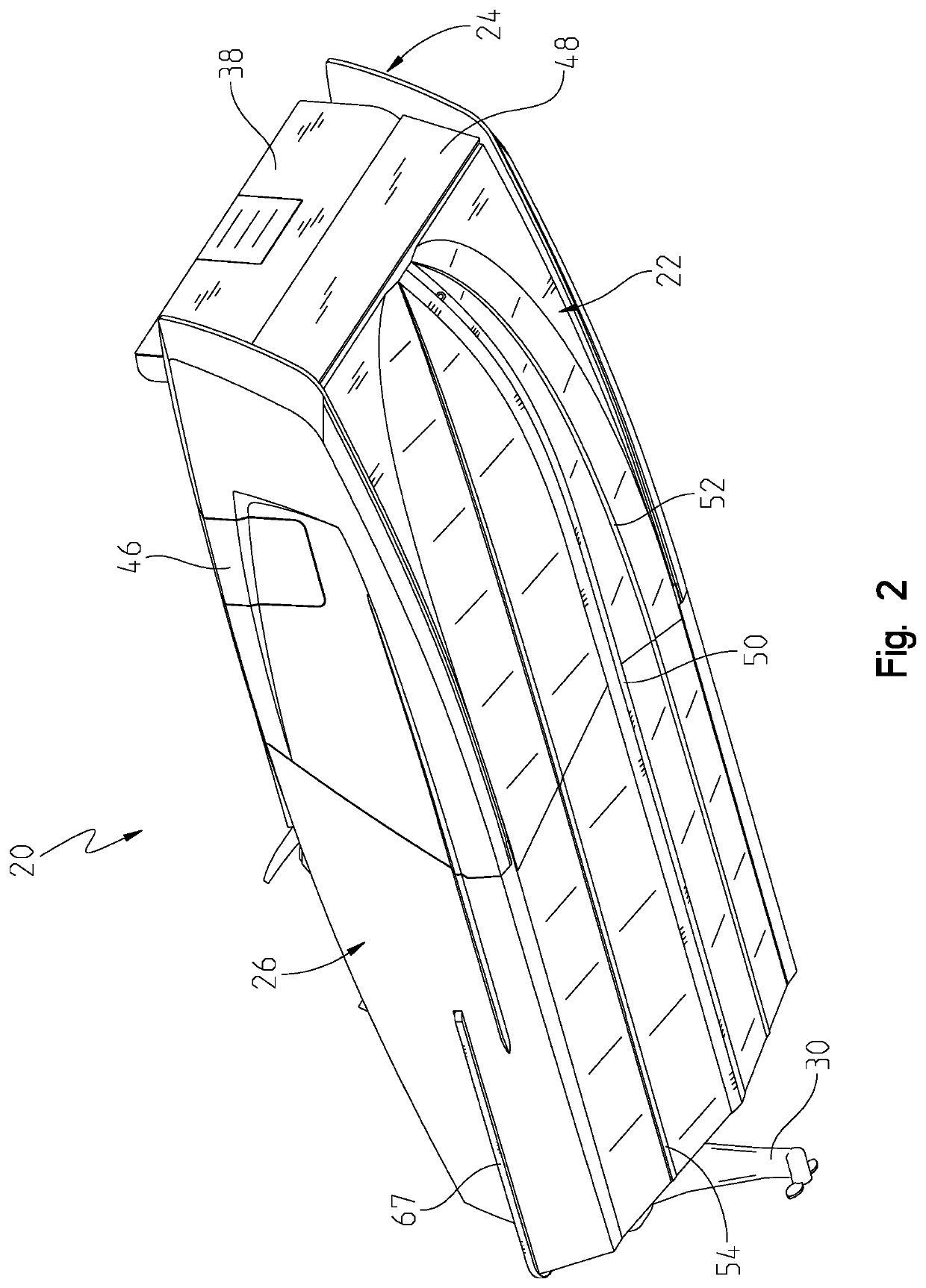

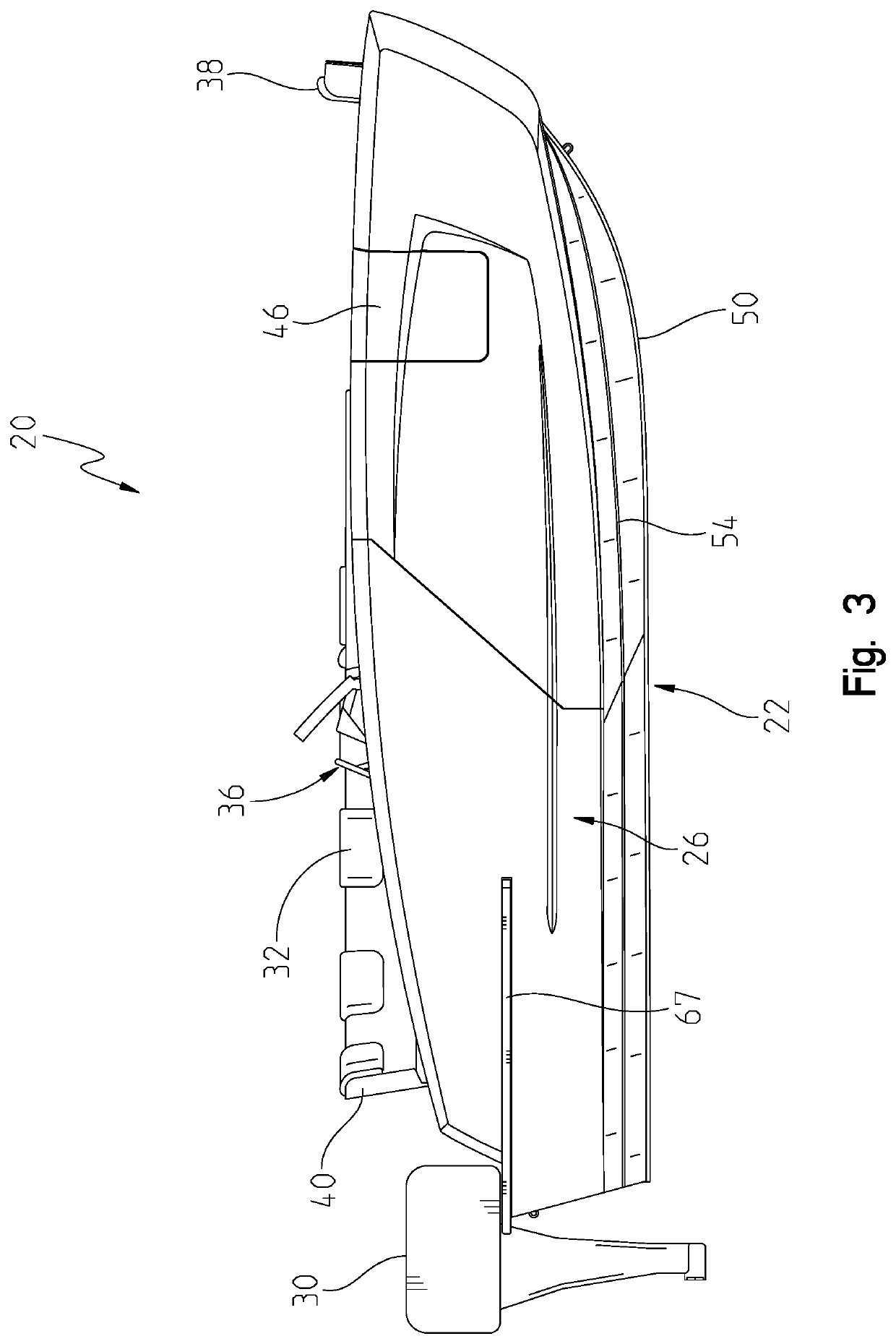

Personal watercraft

PendingUS20220266951A1Efficiently produced assembledCost-effectiveNon-magnetic metal hullsHull decksPolyolefinWatercraft

A hybrid personal watercraft combines features of pontoon boats and deck boats, in a cost-effective and versatile package. The watercraft includes port and starboard sponsons which combine a pair of outboard flotation cavities. A space below the deck and above the hull bottom creates at least one, and potentially up to three additional flotation cavities, which may also be used as storage areas accessible by an access door in the bow of the watercraft and / or a set of hatches in the deck. The watercraft may be efficiently produced assembled from polymer materials, such as thermoplastic polyolefin (TPO).

Owner:POLARIS IND INC

Intersecting structural member and a method for joining same

InactiveUS7062887B1Reduce the amount requiredLittle strengthVessel partsLoad-supporting elementsEngineeringStructural element

An intersecting structural member, and a method for assembling the same, allowing continuous structural members to intersect while also allowing one edge of each of the structural members to be bonded to a skin panel. A first structural member is provided with at least one bendable tab that allows an ingress area in the first member to be opened to permit the passage of a second structural member. The at least one bendable tab may optionally be designed in various shapes, with or without material reducing regions, may then be closed, interlocking the members and producing the intersecting structural member. This structure and method may be used to eliminate the need for welding collars around the member intersections, reducing labor, materials, weight, complexity of joining, and improving resistance to metal fatigue at the intersections.

Owner:EDISON WELDING INSTITUTE INC

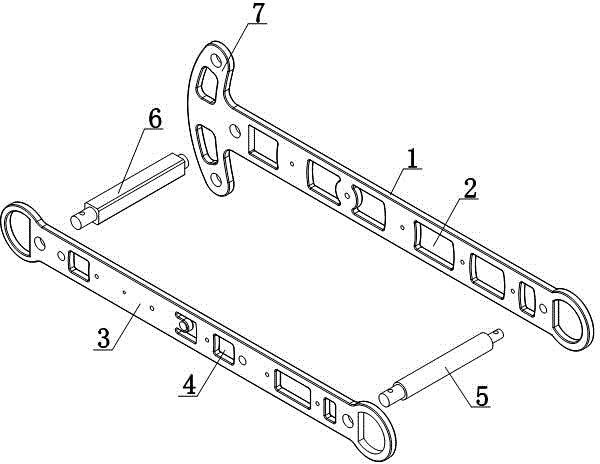

Portable hull skeleton

The invention discloses a portable hull skeleton, comprising a first support plate and a second support plate. The first support plate and the second support plate are arranged in parallel, the first support plate is provided with a plurality of first slots, the second support plate is provided with a plurality of second slots, the first support plate and the second support plate are connected through a connecting shaft, and the first support plate and the second support plate are connected through a connecting strip. According to the invention, the first support plate and the second support plate can achieve the effects of fixing and supporting, and form the skeleton, the first support plate and the second support plate are connected through the connecting shaft and the connecting strip, and thus installation is convenient.

Owner:刘波

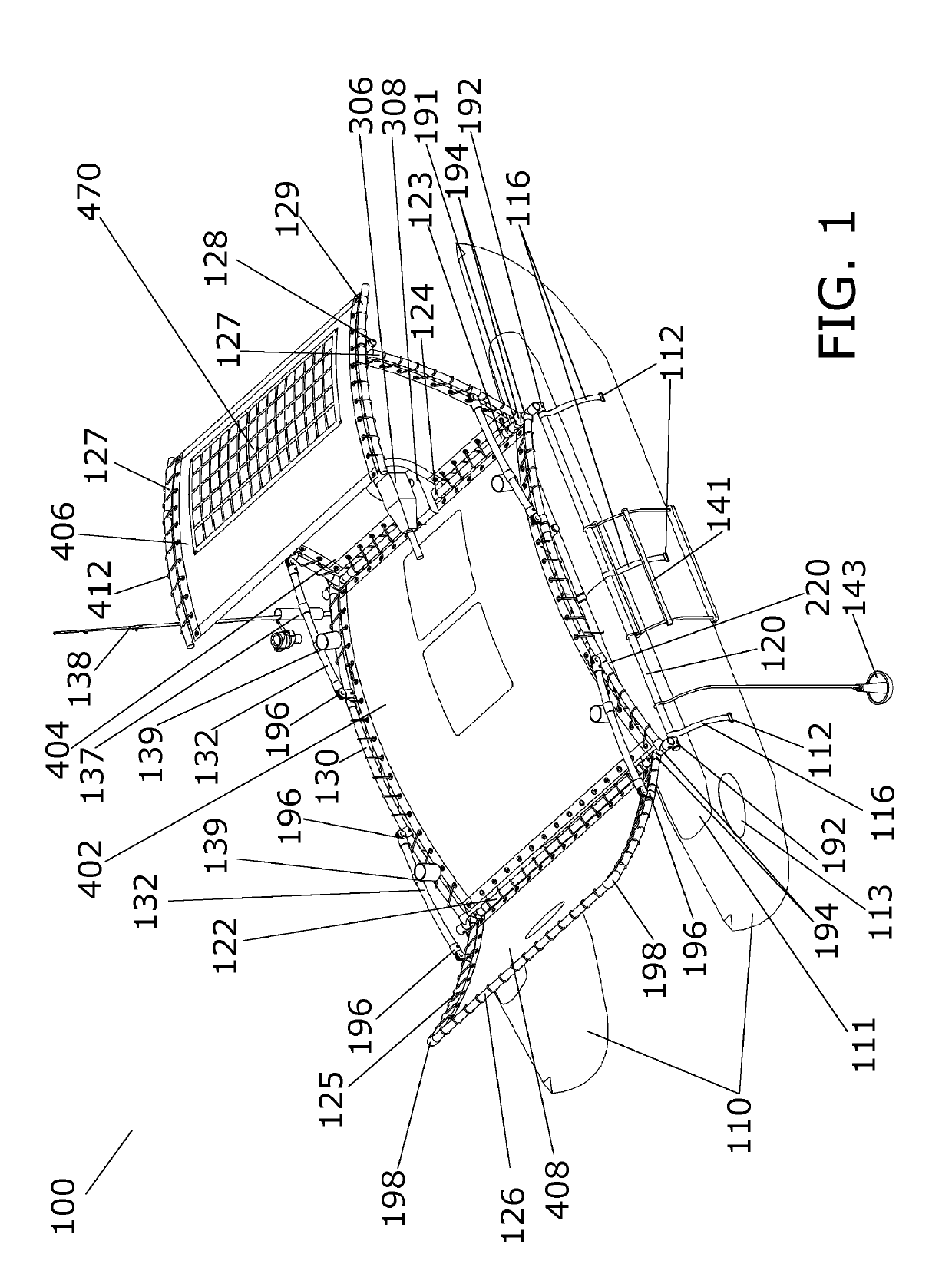

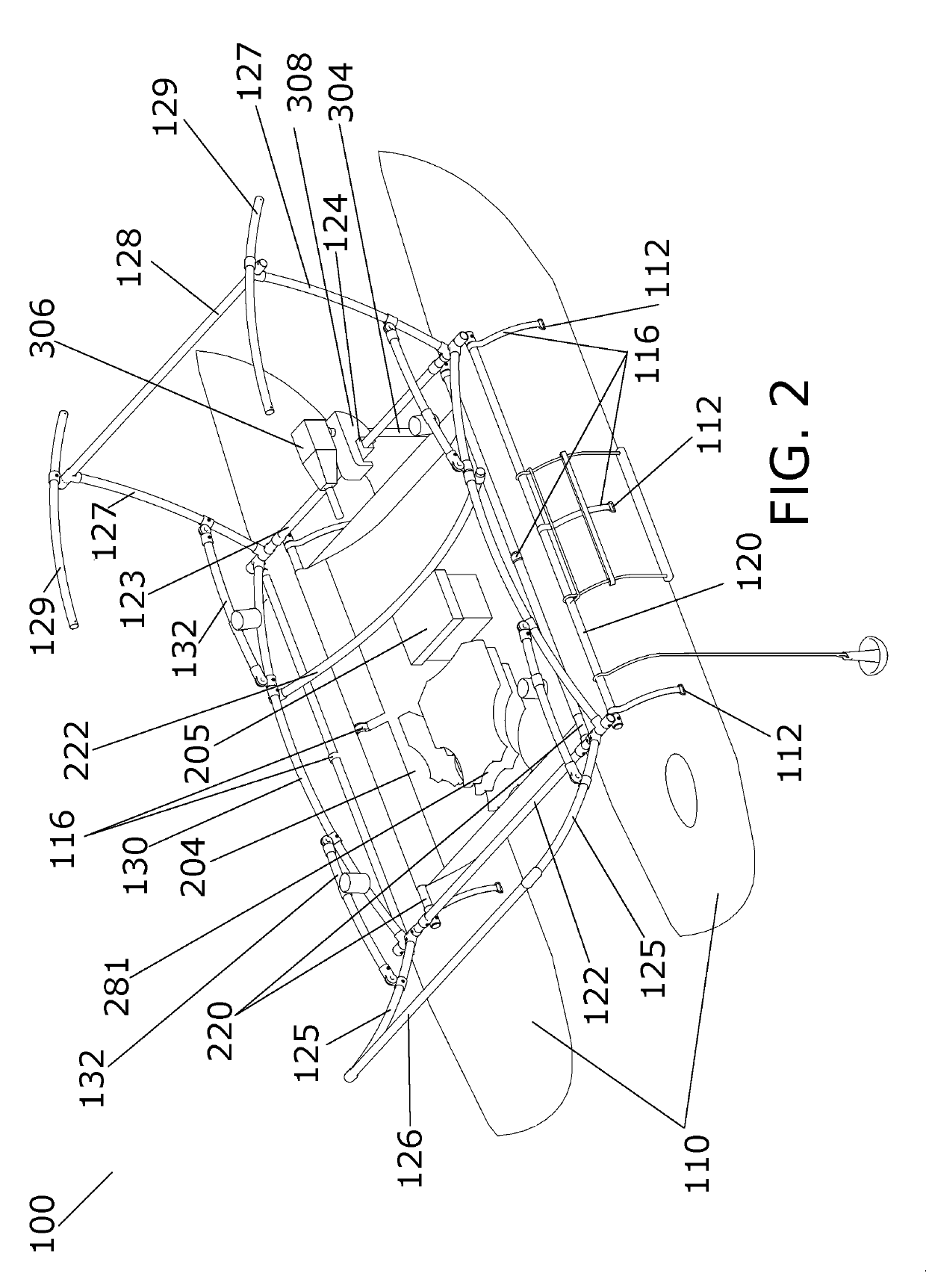

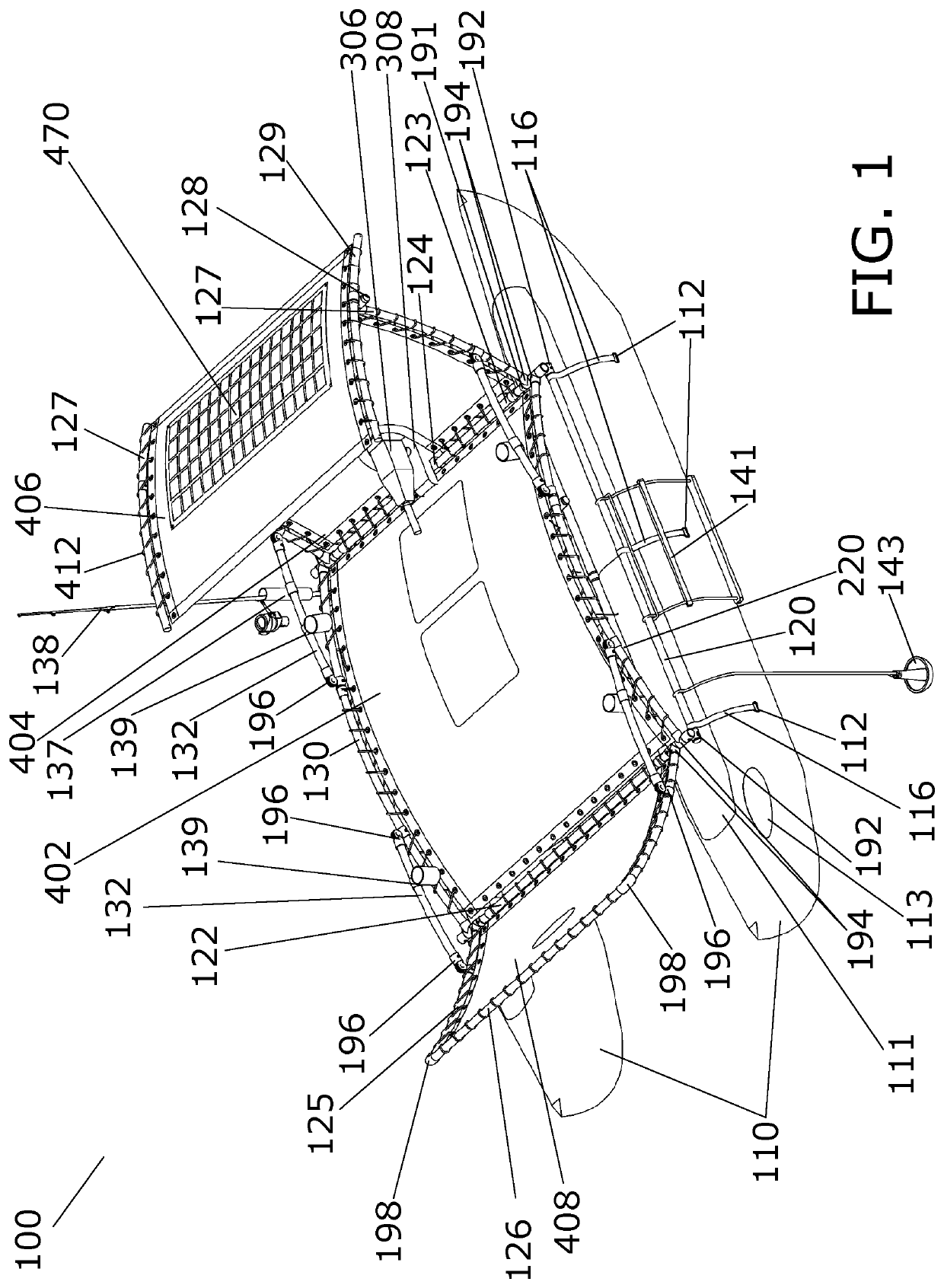

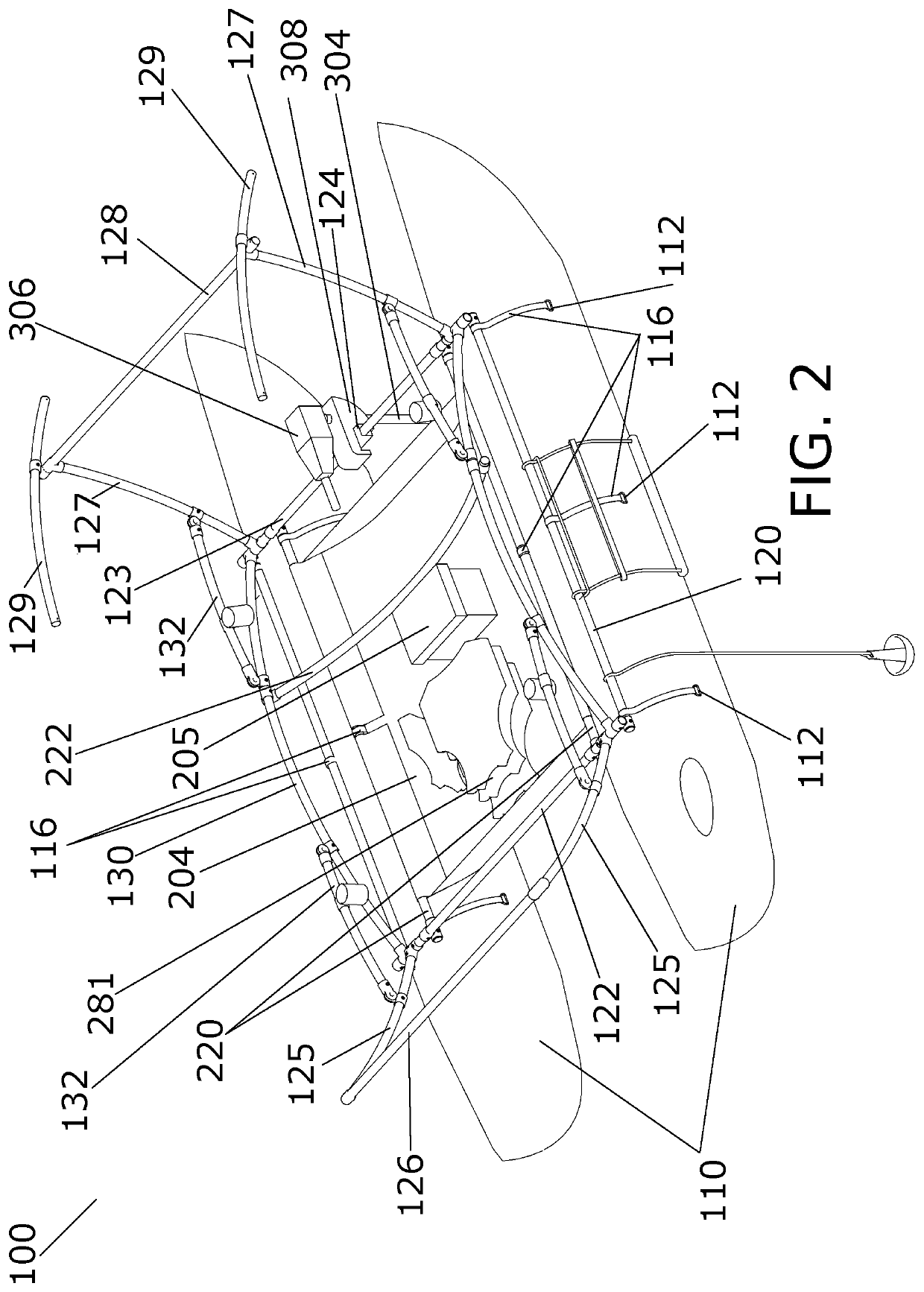

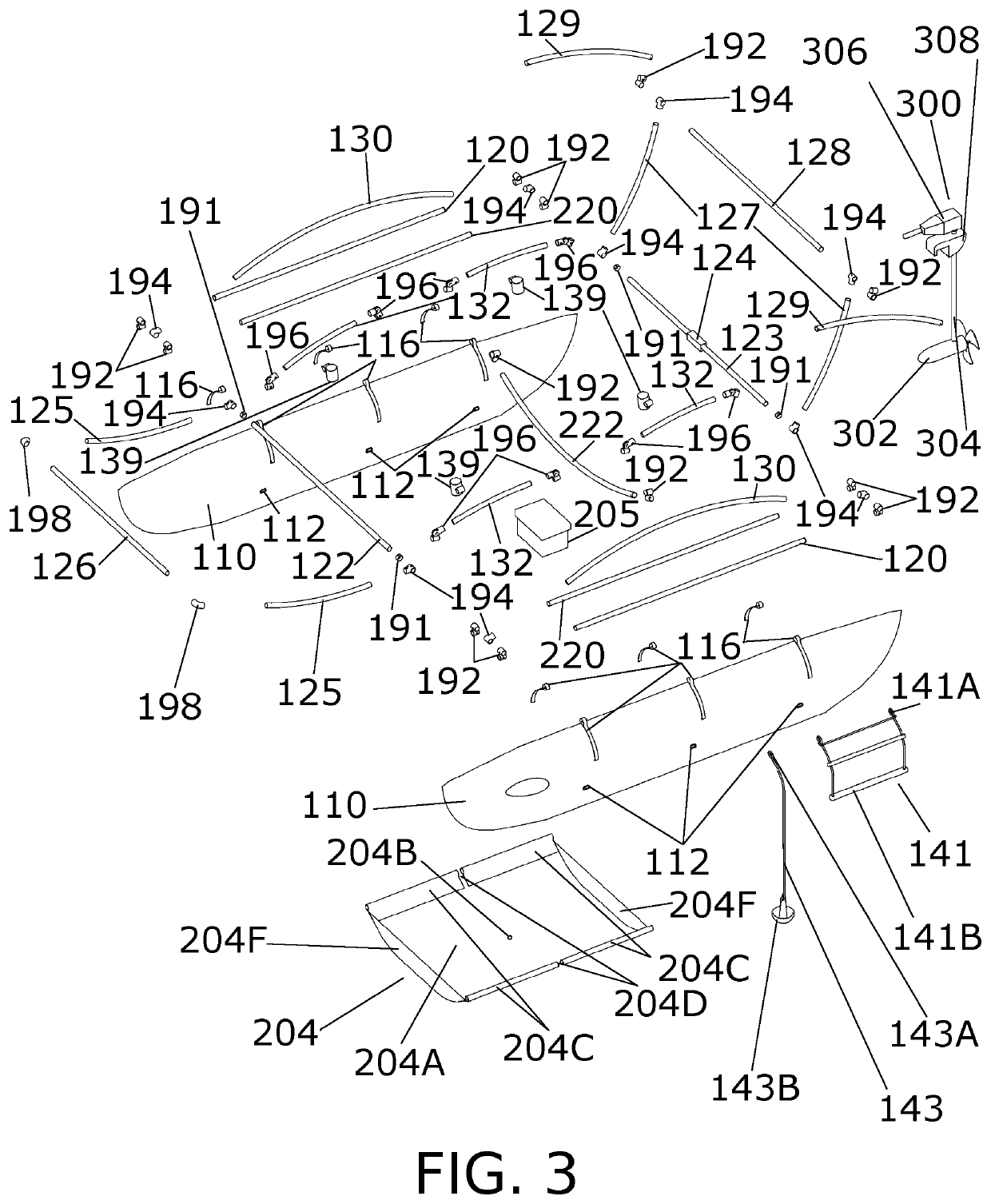

Portable solar-electric watercraft

A watercraft includes a pair of inflatable pontoons. Releasably affixed atop each of the pontoons and aligned therewith are inner and outer lengthwise frame members. Forward and aft beamwise frame members are affixed to the inner and outer lengthwise frame members. Primary arch members are affixed to the forward and aft beamwise frame members. A main fabric panel is stretched between the pair of primary arch frame members, the forward beamwise frame member, and the aft beamwise frame member. A motor mount is affixed centrally to the aft beamwise frame member, the motor mount being configured to removably support a motor assembly. Aft panel side members are rotatably-lockably affixed to the aft beamwise frame member and joined by an aft panel top member. An aft fabric panel is stretched between the aft panel side members, the aft beamwise frame member, and the aft panel top member.

Owner:DESIGNER DIRECT INC

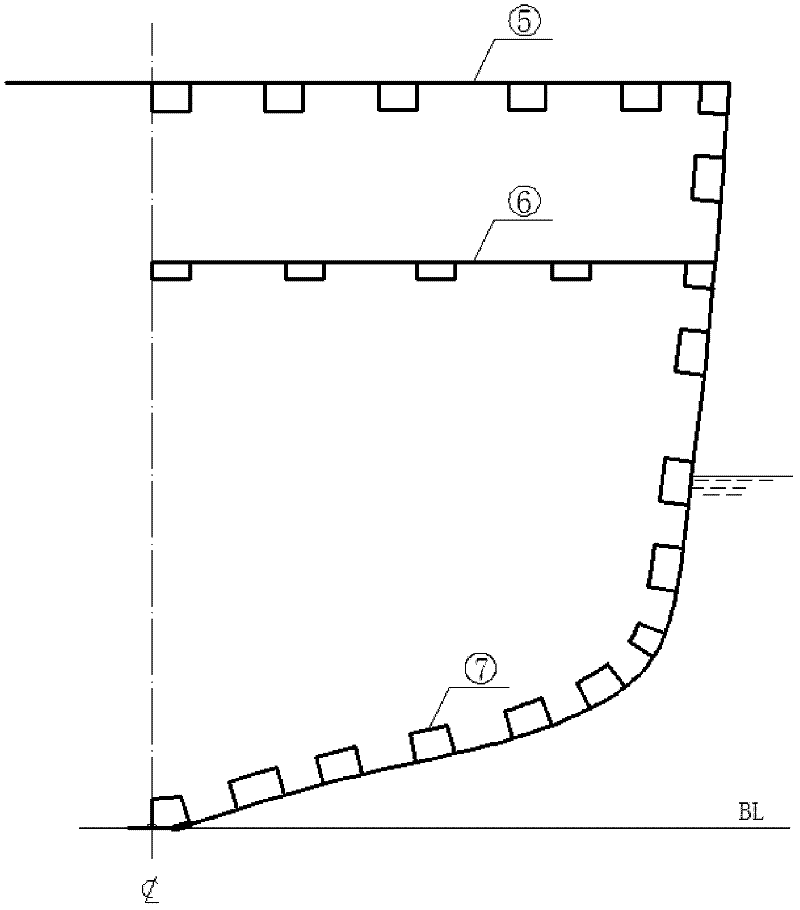

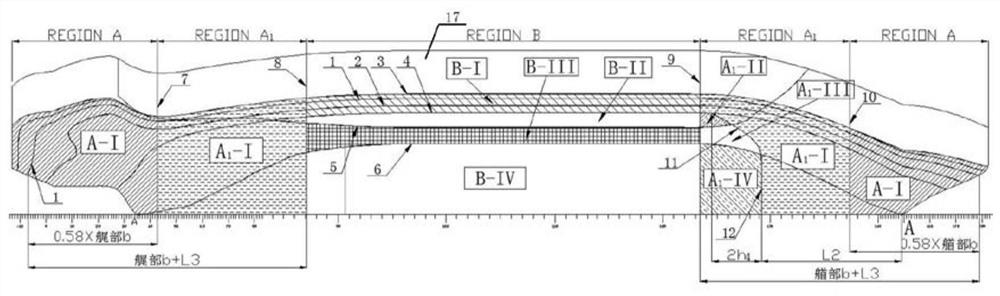

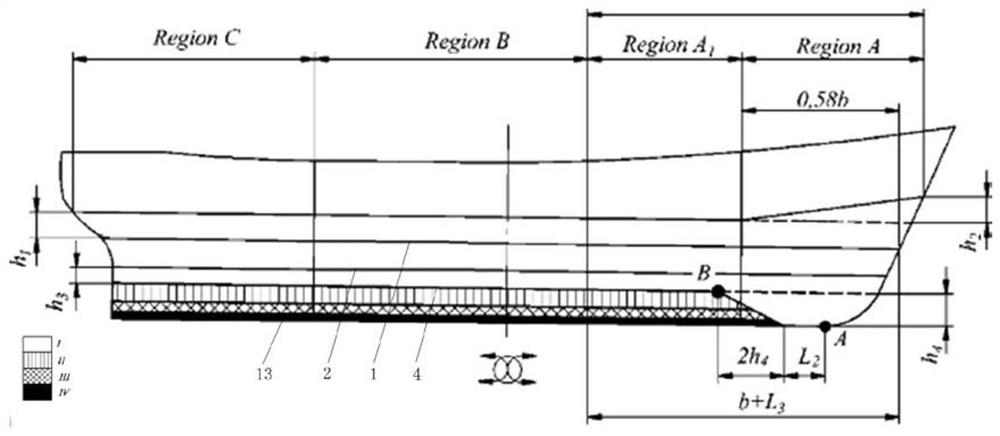

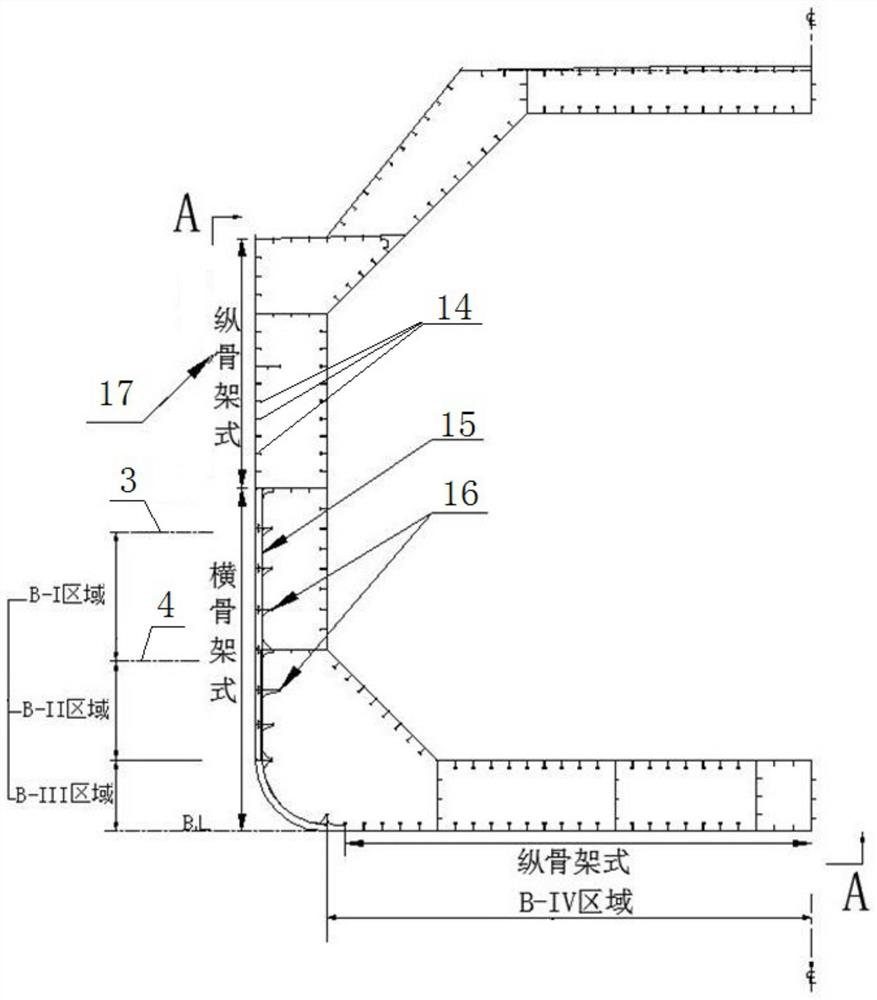

Whole ship skeleton structure of polar region icebreaking LNG ship

InactiveCN112550554AReasonable type distributionStable supportHull framesHull shellsClassical mechanicsStructural engineering

The invention discloses a whole ship framework structure of a polar region icebreaking LNG ship. A longitudinal framework type grillage structure is adopted in a non-ice area reinforcing area of the whole ship framework. An ice area reinforcing area of the whole ship framework is sequentially divided into a bow area A, a bow area A1, a midship area B, a stern area A and a stern area A1 according to borne ice loads from the bow to the stern, and the bow area A1 is divided into a bow first reinforcing area and a bow second reinforcing area. The midship area B is divided into a first midship reinforcing area and a second midship reinforcing area through a bottom horizontal line, the bow area A, the first bow reinforcing area, the first midship reinforcing area, the stern area A and the sternarea A1 are each of a transverse framework type grillage structure, and the second bow reinforcing area and the second midship reinforcing area are each of a longitudinal framework type grillage structure. The ice area reinforcing structure is more optimized in design, the ice resistance of the structure is brought into full play, and the ice area reinforcing structure has great practical value.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

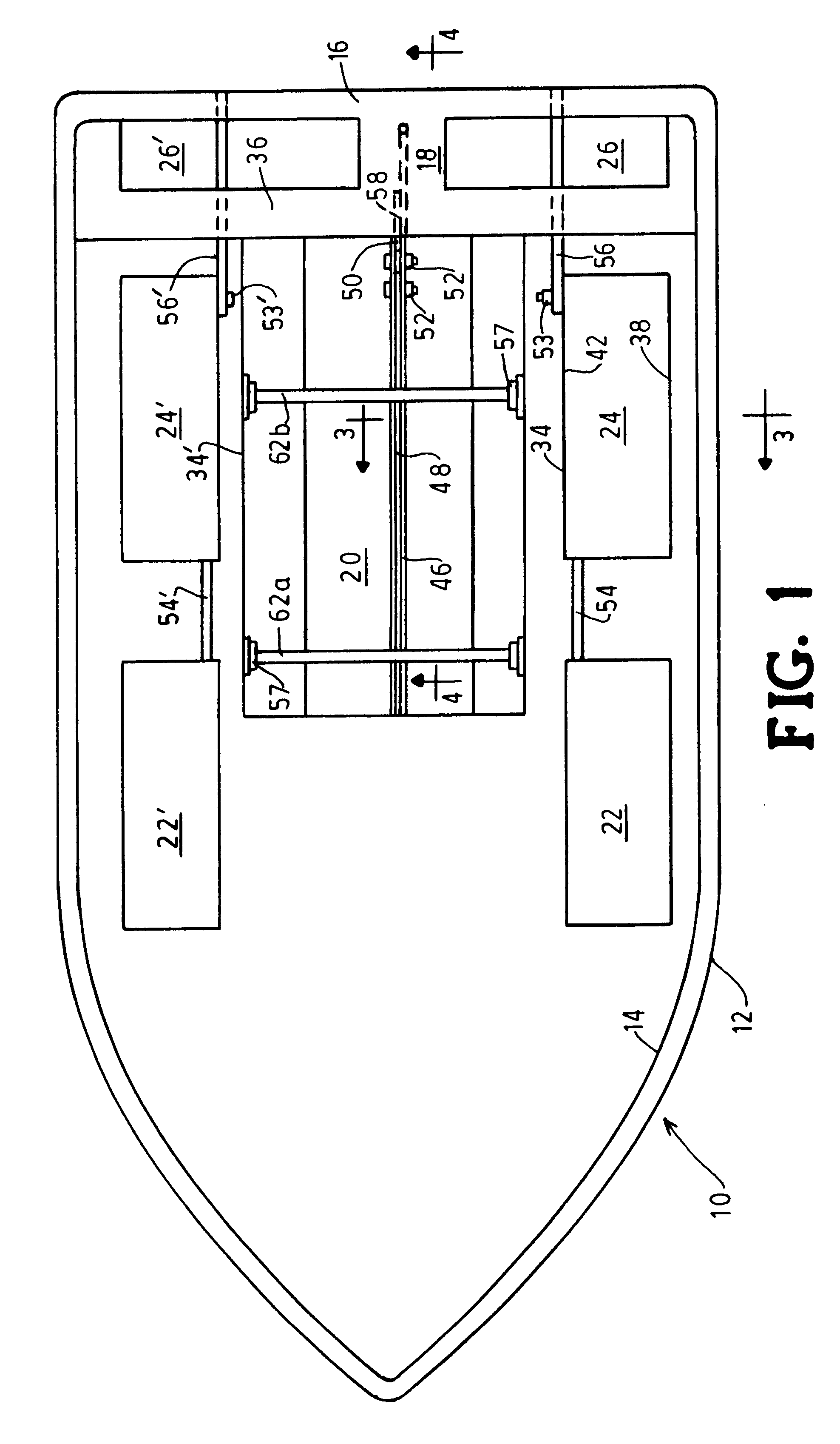

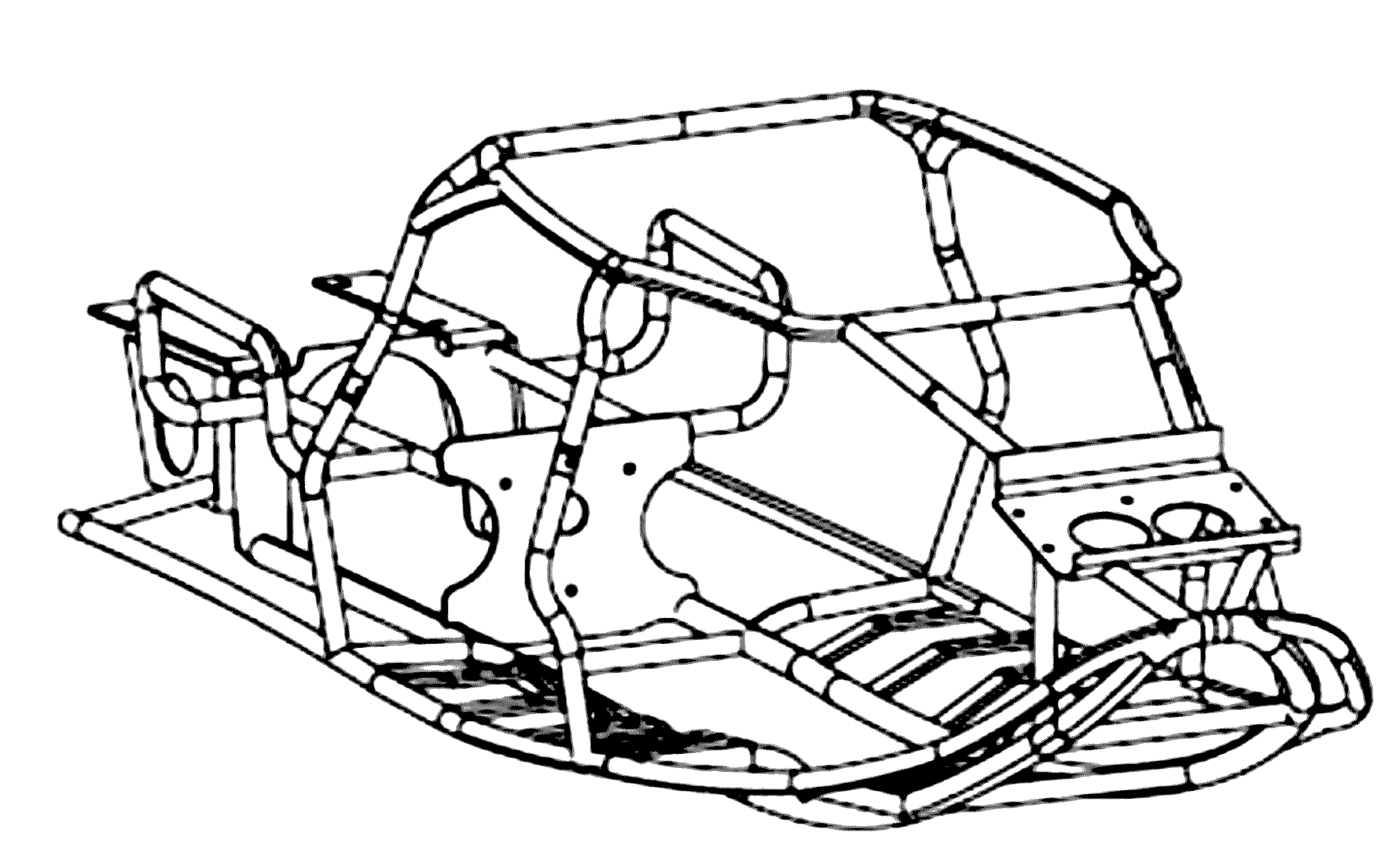

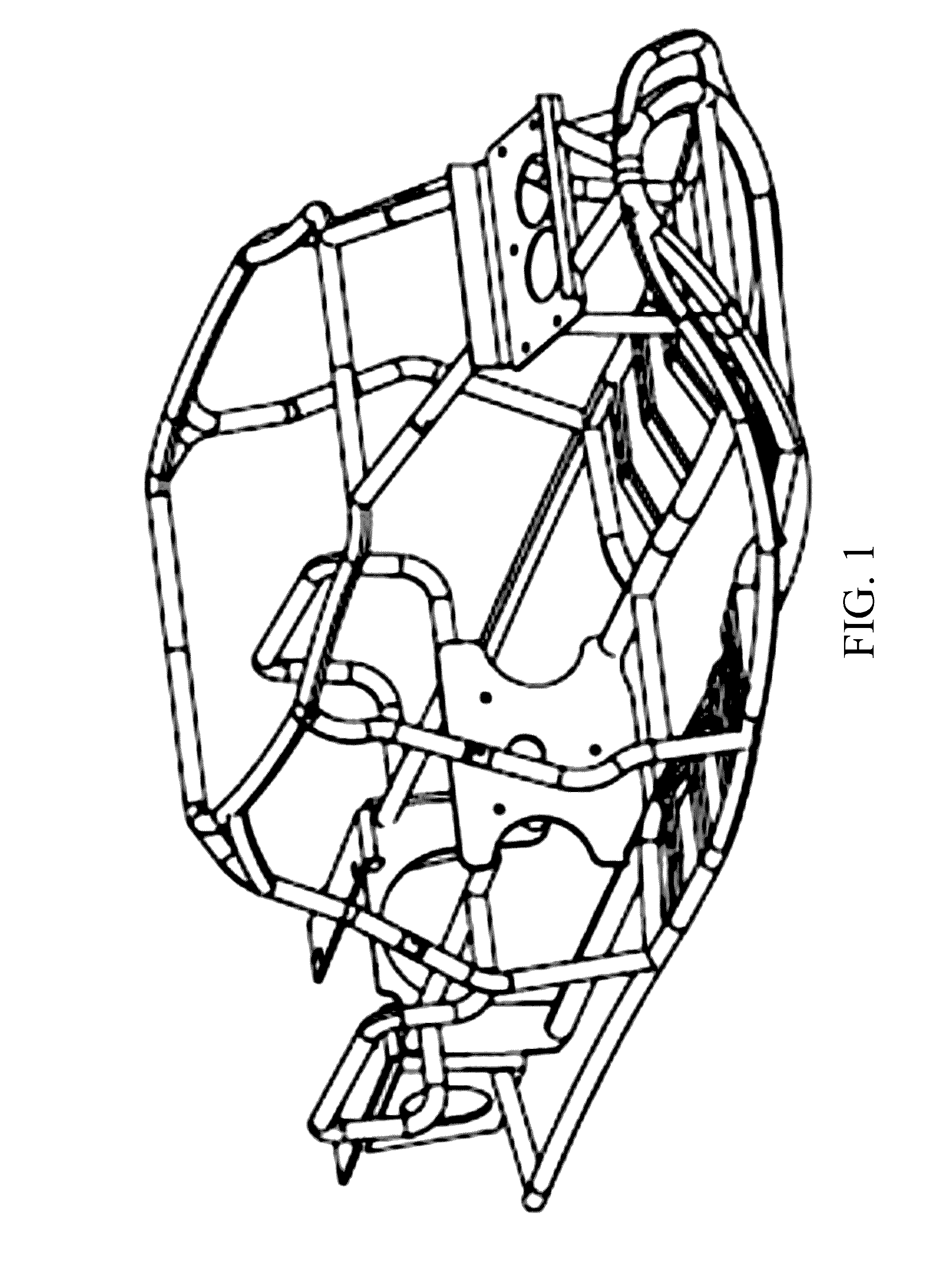

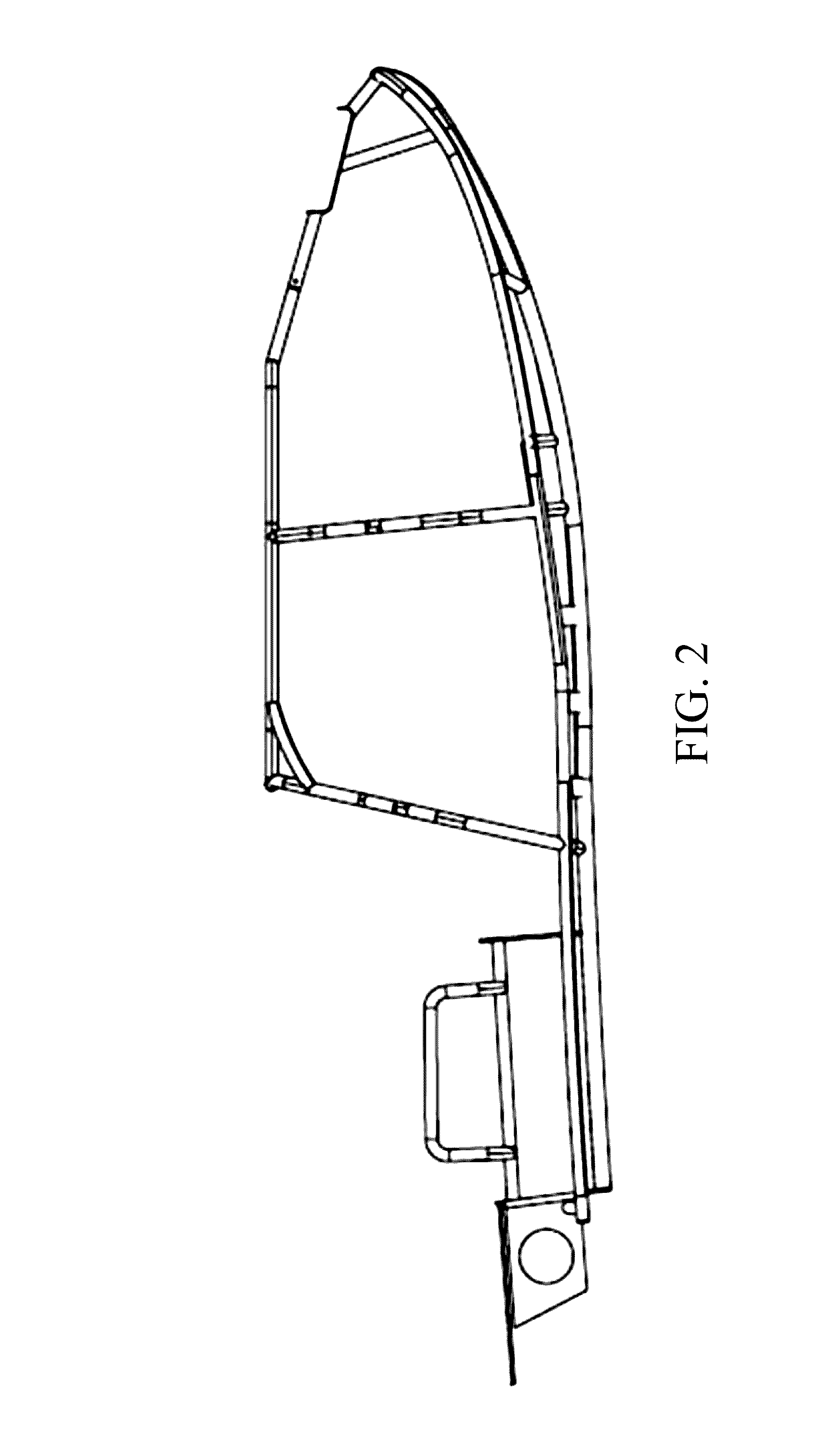

Personal watercraft chassis

ActiveUS20170029074A1Reliably buoyantReduce manufacturing costWater sport boardsPropulsion power plantsGlass fiberWatercraft

The various example embodiments disclosed herein pertain to an internal support structure in a watercraft that interfaces the motor to the hull and decreases the weight of the hull, by eliminating various components. The various example embodiments add structural stability to the overall structure of the hull or body, allowing for thinner hull and deck material. This chassis consists of a metal, composite, and or plastic bent or formed tubular structure that outlines the internal dimensions of the hull. The motor is able to mount to this structure so that the body is no longer the direct point of attachment. This furthers the structural stability and reliability of the hull as it disperses forces over a larger area and mounts to a means more suitable than direct hull mounts, which often shear and break loose from the traditional fiberglass hulls. By mounting the engine to this chassis, the hull can be completely removed without disassembling and other components. This allows easier access to the motor and ease of internal maintenance, and allows for replacement hulls and decks when damaged.

Owner:FREE FORM FACTORY INC

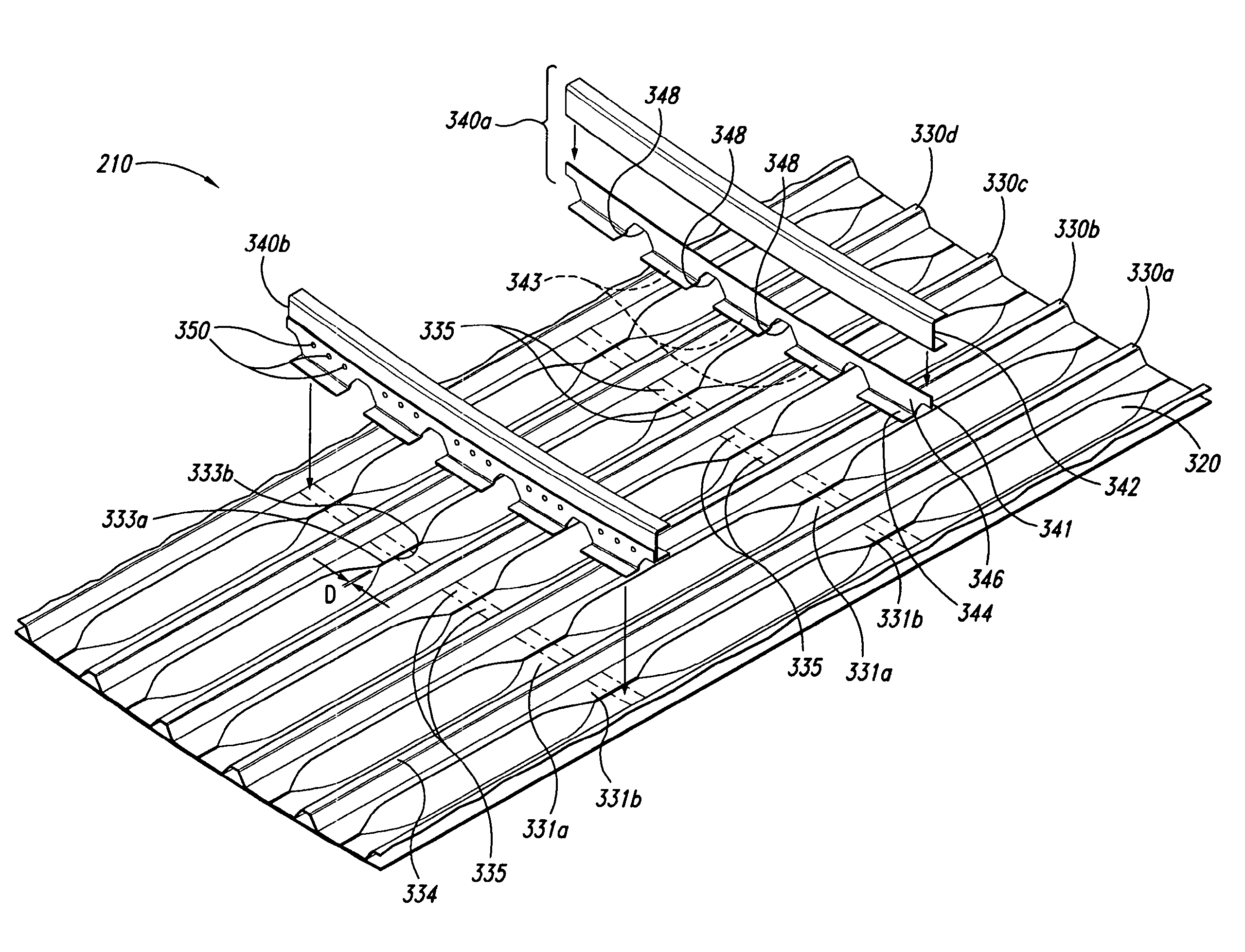

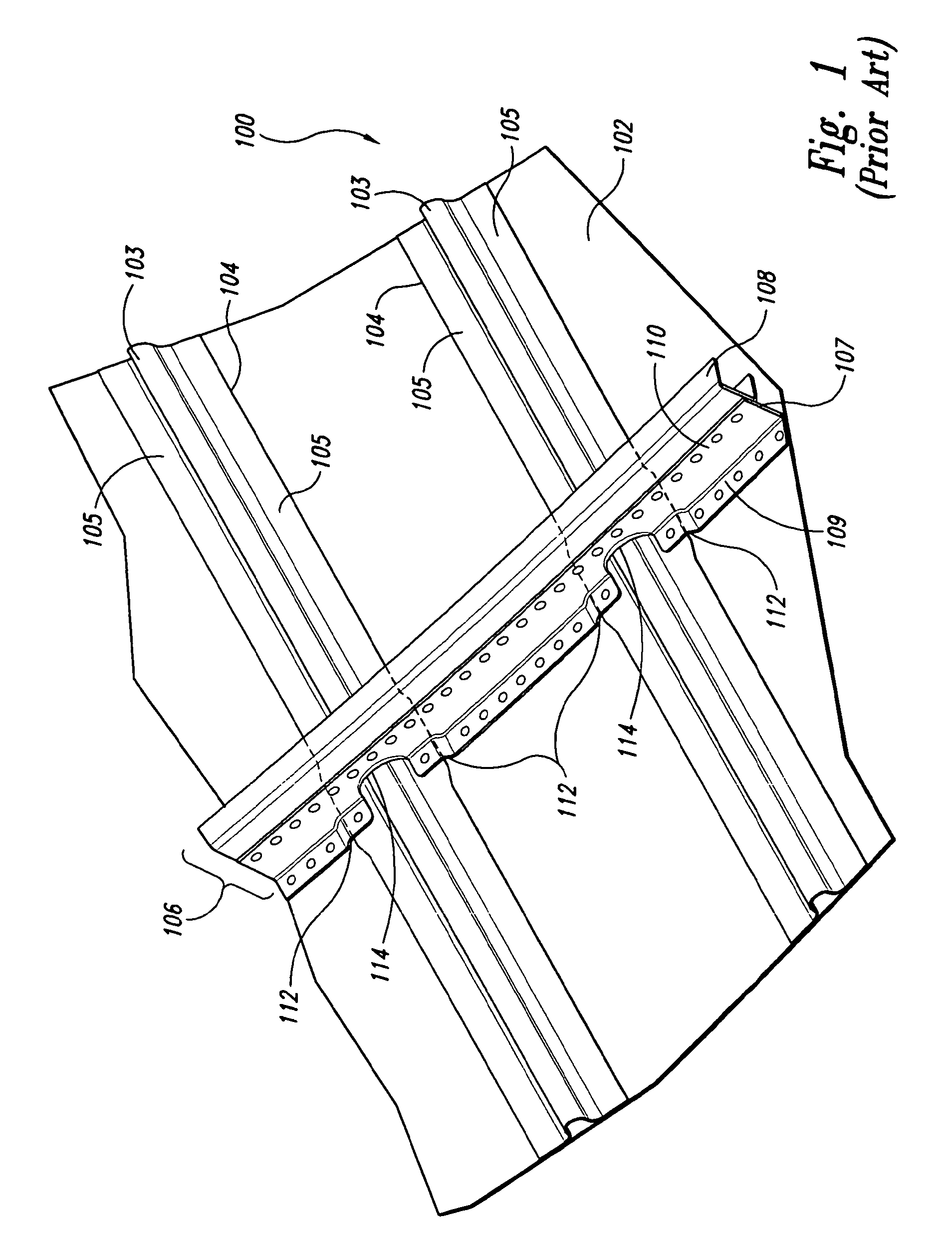

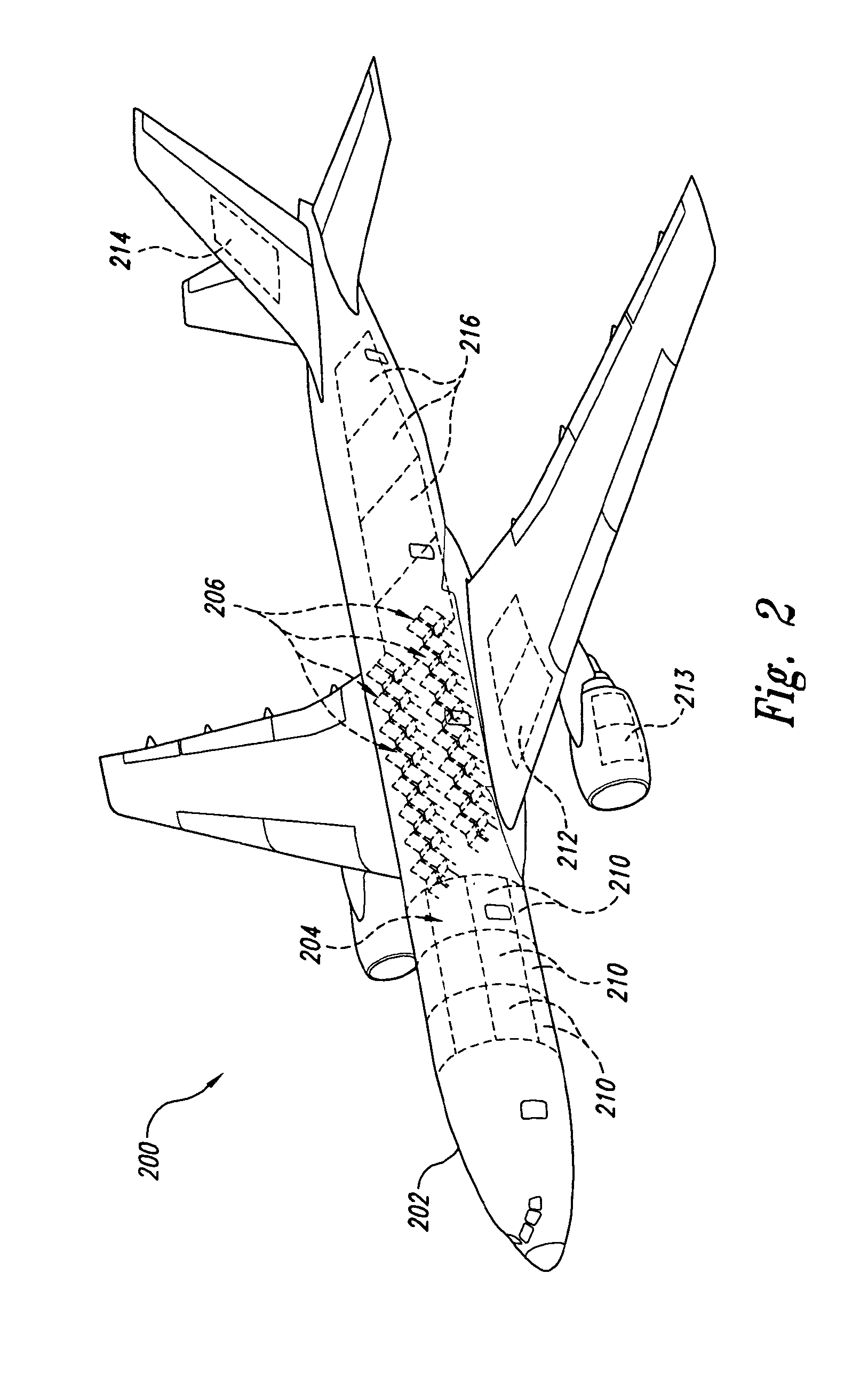

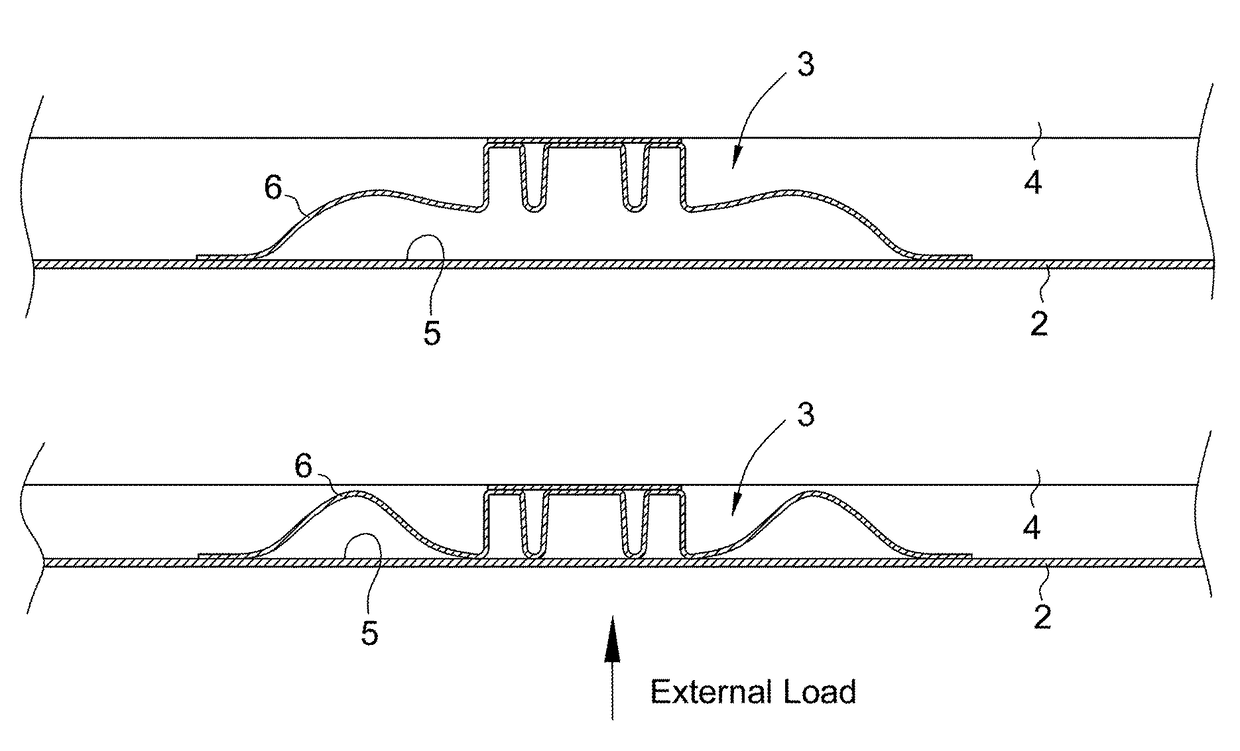

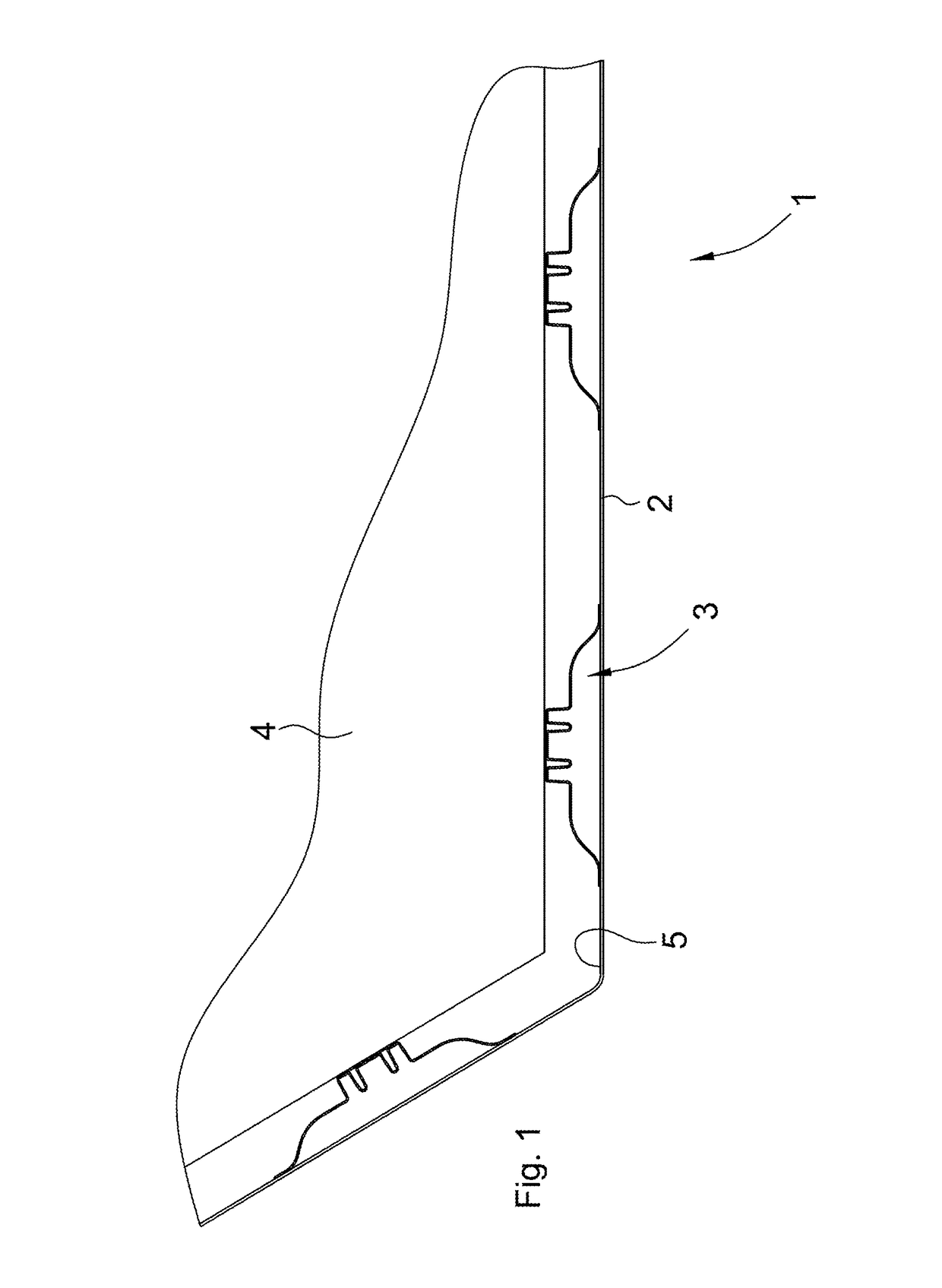

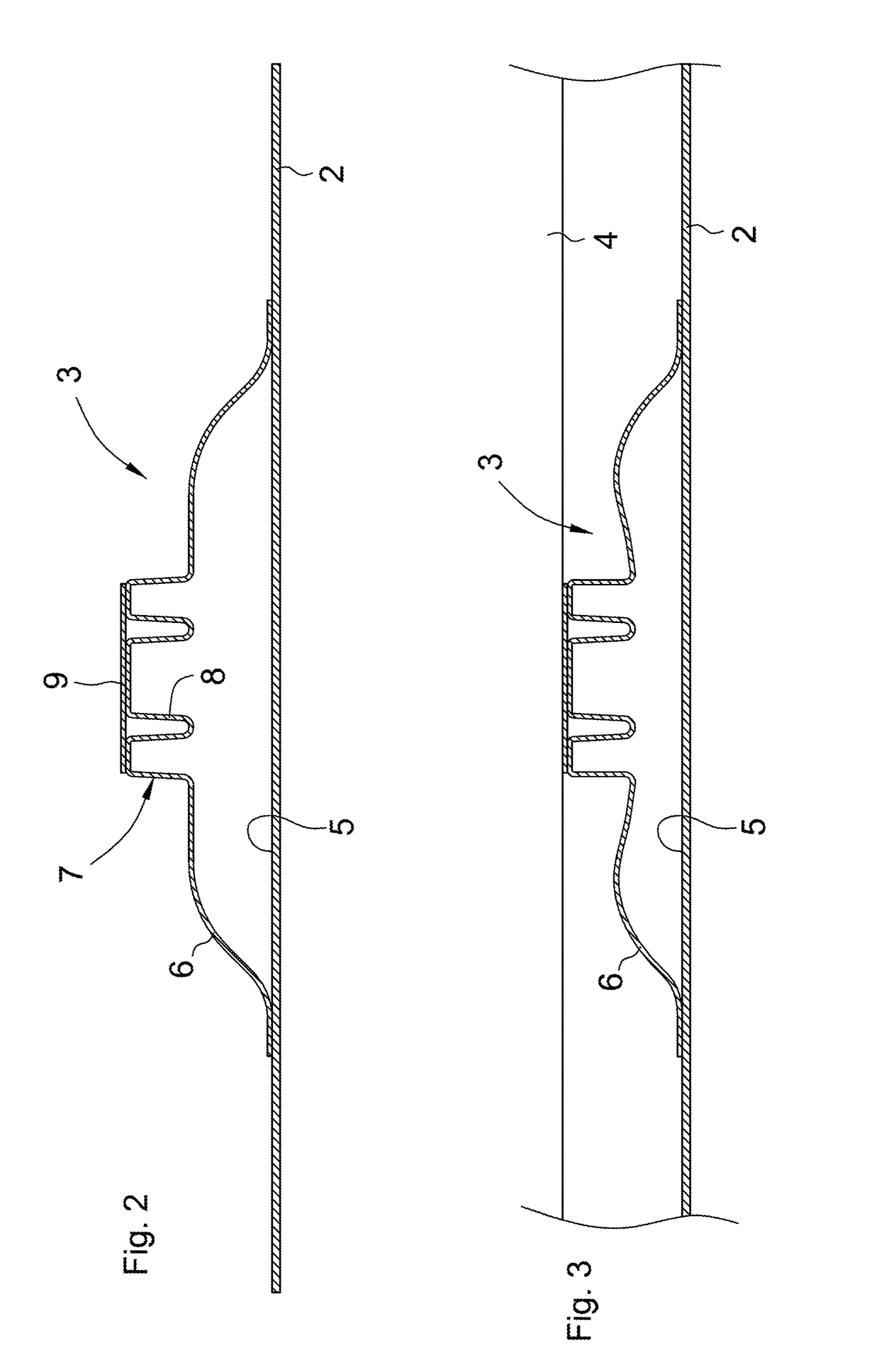

Structural panels for use in aircraft fuselages and other structures

Structural panels for use in manufacturing aircraft fuselages and other structures are disclosed herein. In one embodiment, a structural panel configured in accordance with the invention includes a skin and at least first and second stiffeners. The first stiffener can have a first flange portion mated to the skin and a first raised portion projecting away from the skin. The second stiffener can have a second flange portion mated to the skin and a second raised portion projecting away from the skin. At least one of the first flange portion of the first stiffener and the second flange portion of the second stiffener can extend toward the other of the first flange portion and the second flange portion to form an at least approximately continuous support surface to which a frame can be attached.

Owner:THE BOEING CO

Marine hull and marine vessel

Owner:SSY IP TECH LLC

Bending stiffness reducer for brace to hull connection

InactiveUS9902464B2Reduce stiffnessReducing the induced bending momentHull reinforcementsHull frameworksHull structureStress concentration

Semi-submersibles are subjected to loading from waves, causing racking, longitudinal shear and parallelogramming, or differential movement of the pontoons. The cyclic wave loading makes the various connections, where stress concentrations occur, susceptible to fatigue damage throughout the hull structure. This is most evident at the connections between the braces and the main hull structure. A revised brace to main hull connection with reduced bending stiffness is employed to reduce the moment being transferred from the brace to the hull, thereby reducing the bending stress and susceptibility to fatigue damage. This improved connection employs an internal member to transfer the loads between the brace and hull structure mainly as tension and compression. As a consequence of the improved fatigue performance, the structural weight of the connection can be greatly reduced, thus increasing the capacity with which the semi-submersible hull can operate.

Owner:COTTRELL ROY +3

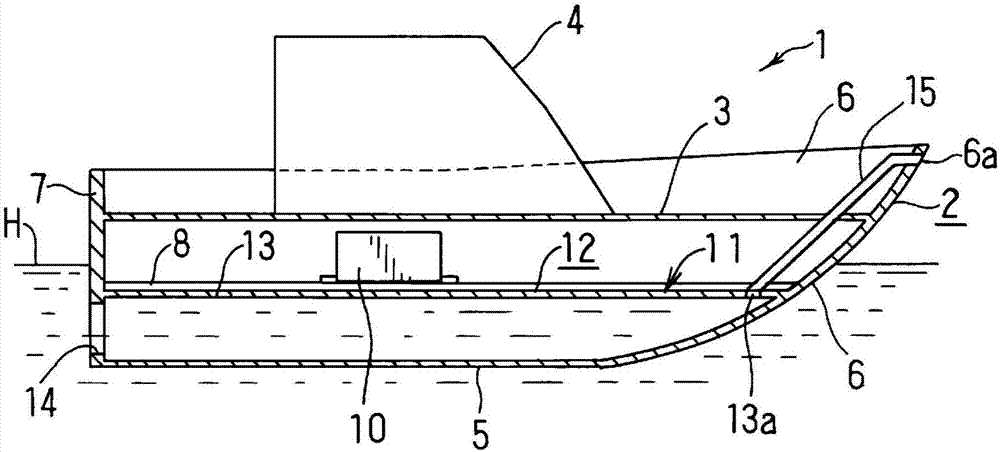

Planing ship and method for manufacturing same

InactiveCN107000823AAvoid swingingAvoid wasting timeVessel cleaningPropulsion power plantsRear quarterMarine engineering

Provided is a planing ship such that a rocking prevention device is prevented from interfering with the ship's navigation, and the work for preventing the interference with the navigation can be simplified. A top plate 13 is installed between upper portions of a pair of longitudinal plates (8), and a water tank (12) is formed by a ship bottom plate (5), a stern plate (7), front portions of ship side plates (6), the pair of longitudinal plates (8), and the top plate (13). A through hole (14) is provided in the stern plate (7). At the bow-side end of the top plate (13), there is installed a communication pipe (15) for providing communication between the inside of the water tank (12) and the outside of the water tank (12).

Owner:井爪雅幸

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com