Patents

Literature

54results about "Hull reinforcements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

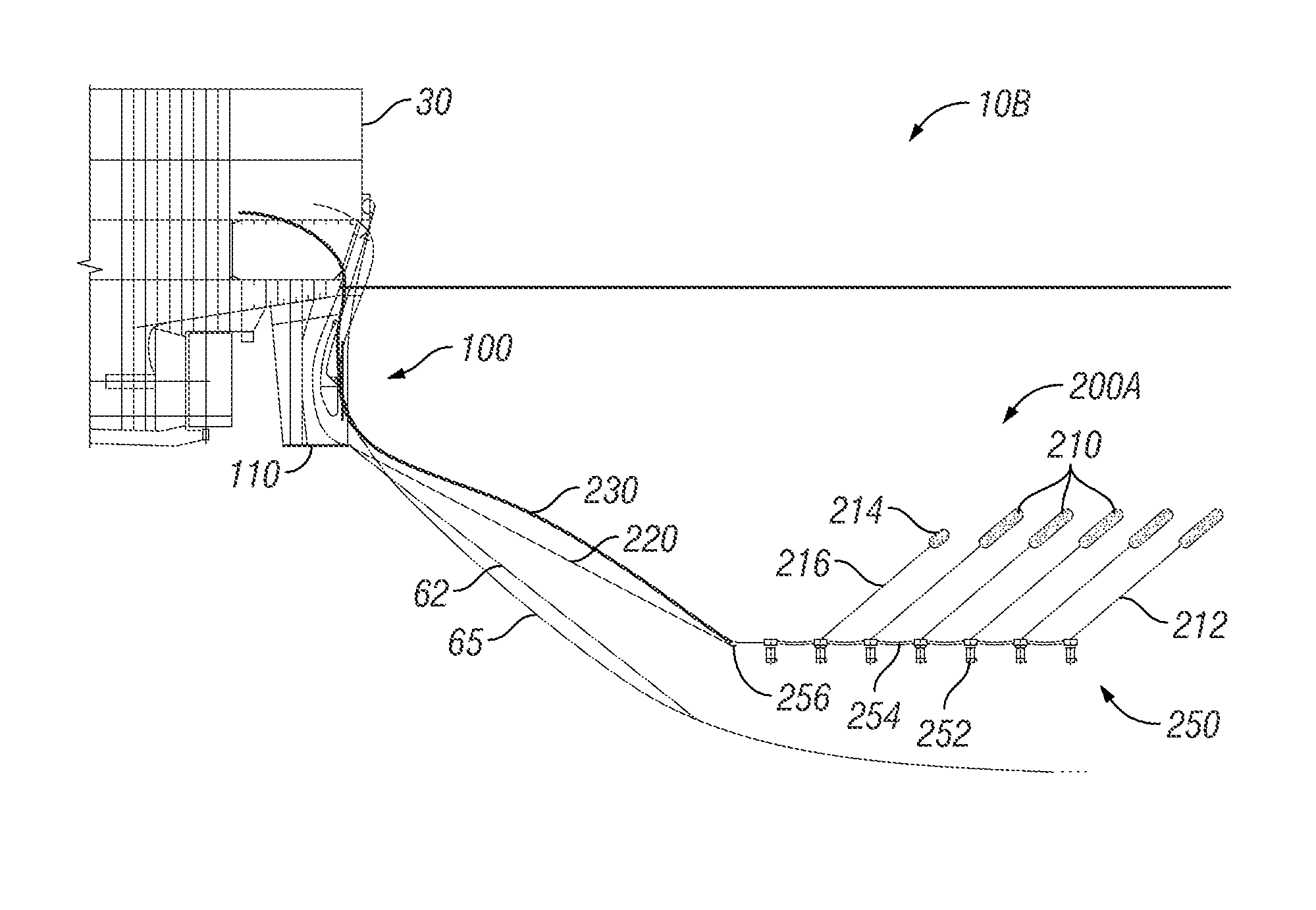

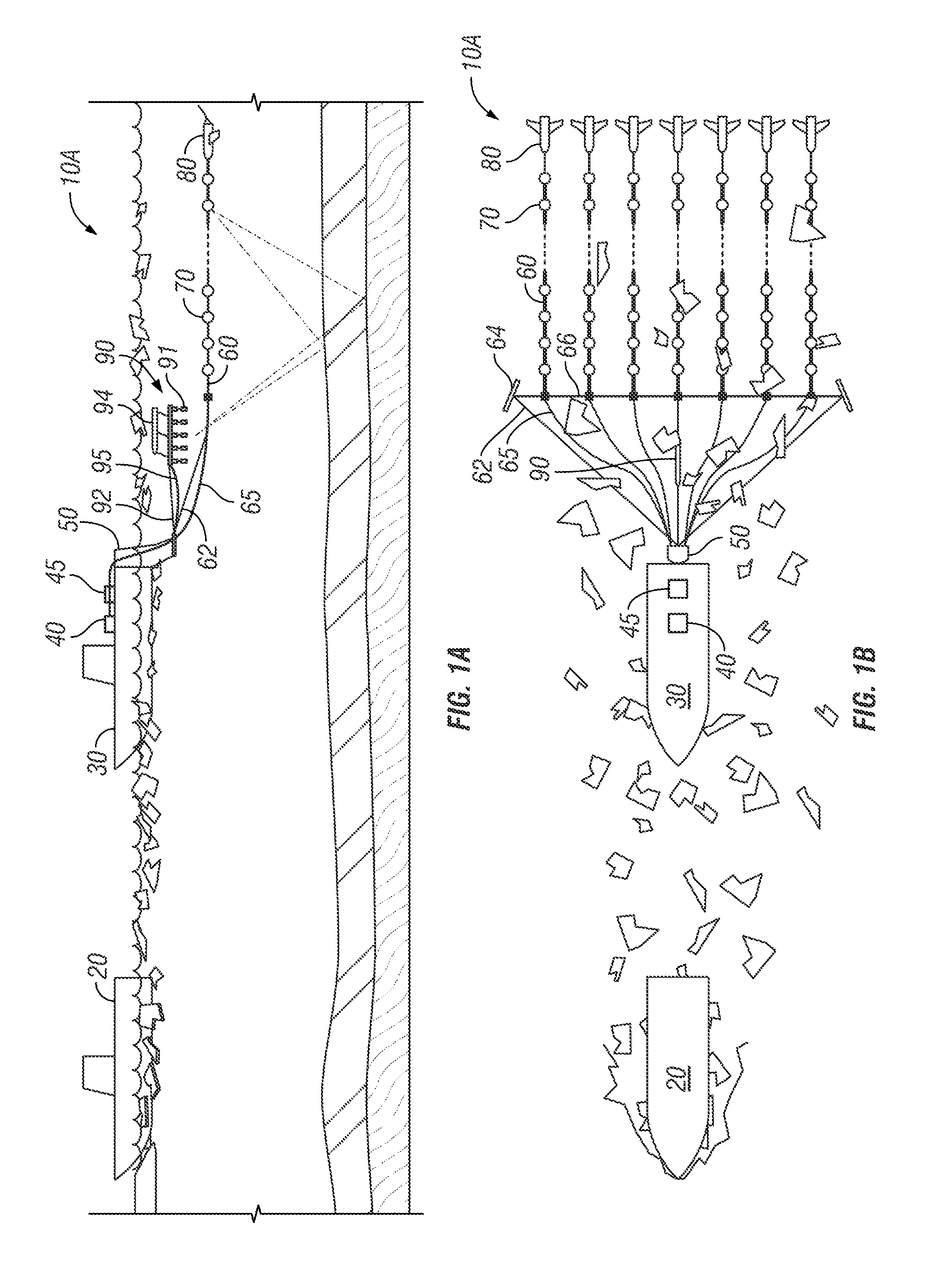

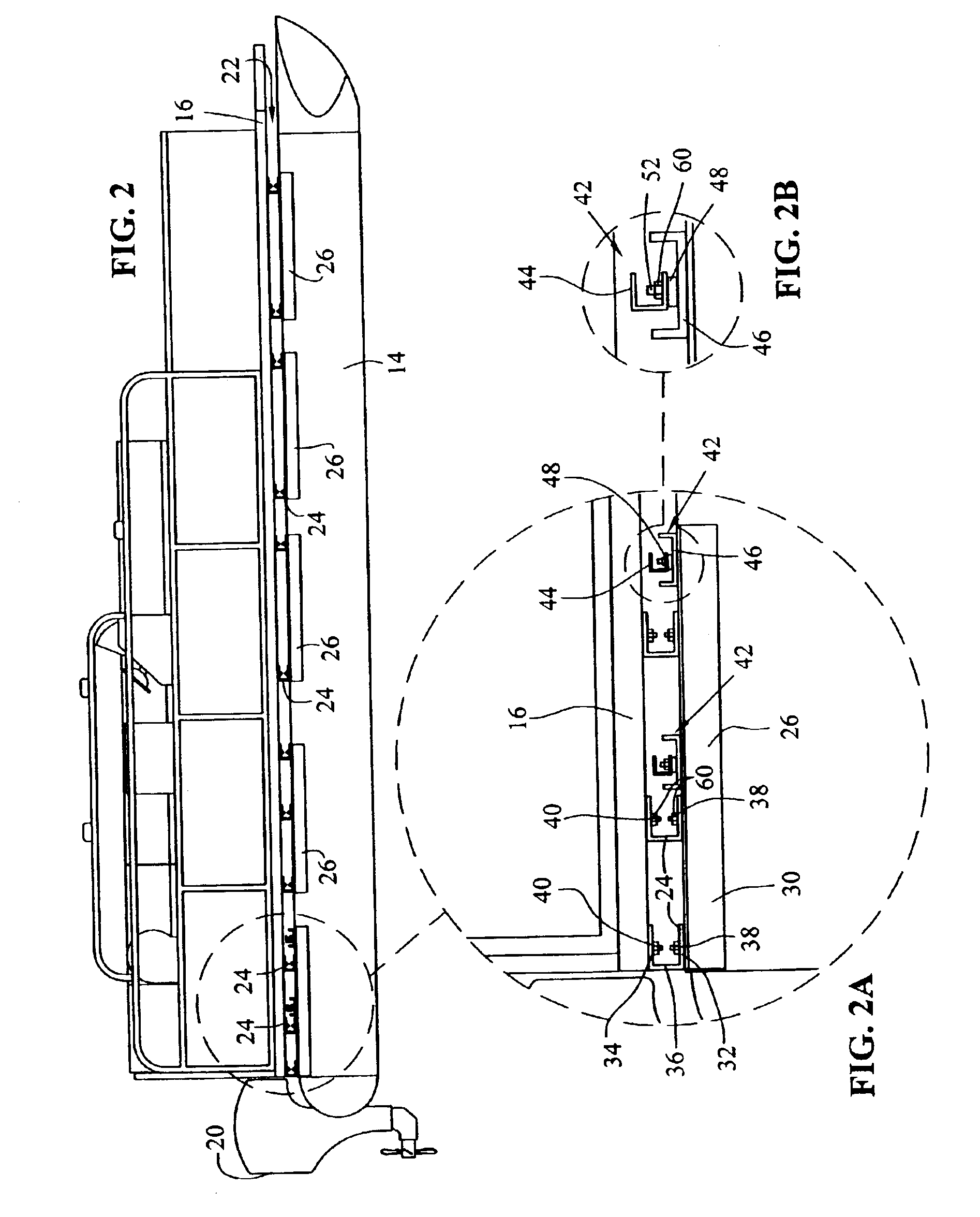

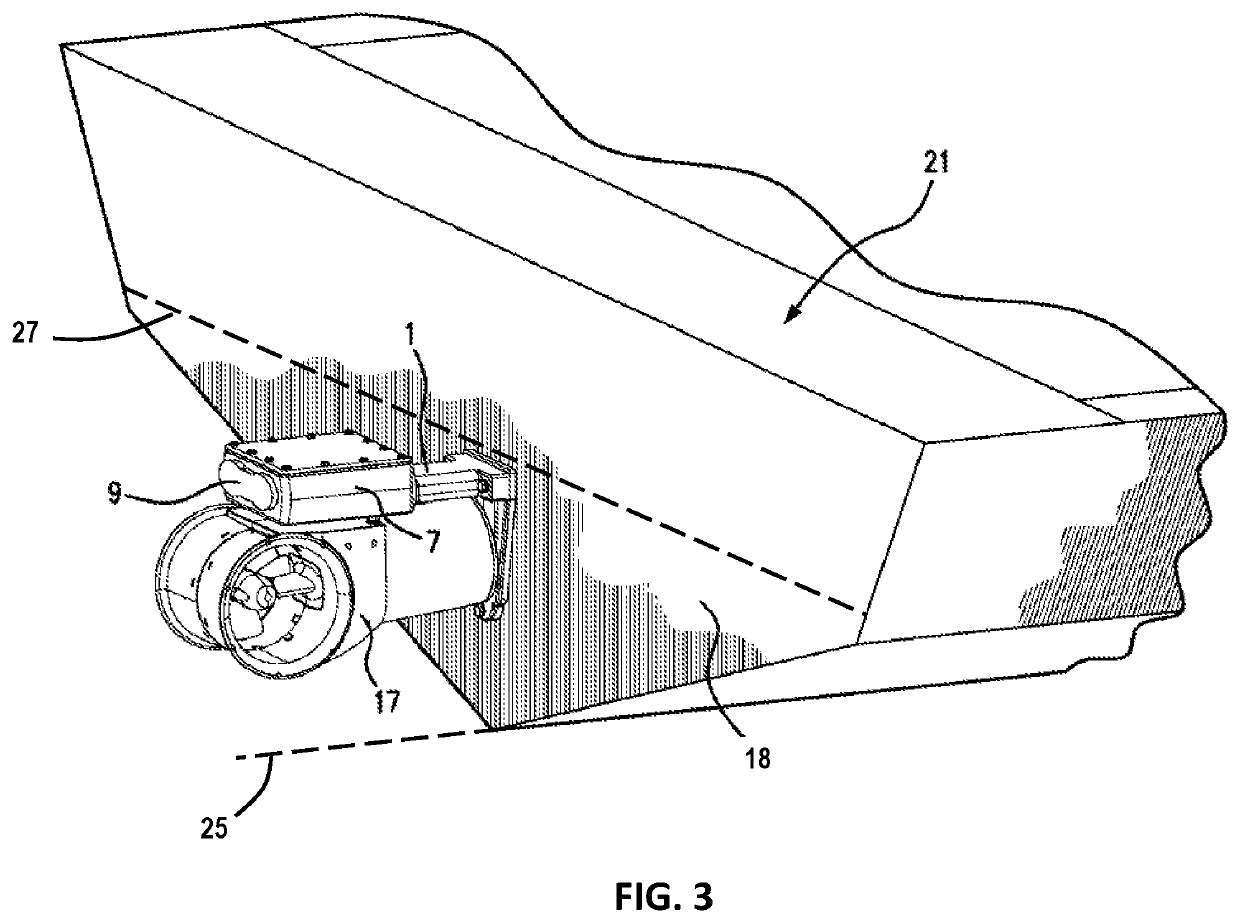

Marine seismic surveying in icy or obstructed waters

ActiveUS8593905B2Maintain fidelityPrecise positioningDefensive equipmentTowing/pushing equipmentSurface oceanSeismic survey

A skeg mounts from the stern of a towing vessel and extends below the waterline. A channel in the skeg protects cables for steamers and a source of a seismic system deployed from the vessel. Tow points on the skeg lie below the water's surface and connect to towlines to support the steamers and source. A floatation device supports the source and tows below the water's surface to avoid ice floes. The streamers can have vehicles deployed thereon for controlling a position on the streamer. To facilitate locating the streamers, these vehicles on the streamers can be brought to the surface when clear of ice floes so that GPS readings can be obtained and communicated to a control system. After obtaining readings, the vehicles can be floated back under the surface. Deploying, using, and retrieving the system accounts for ice at the surface in icy regions. In addition, handling the seismic record can account for noise generated by ice impact events.

Owner:NUTEC SCI

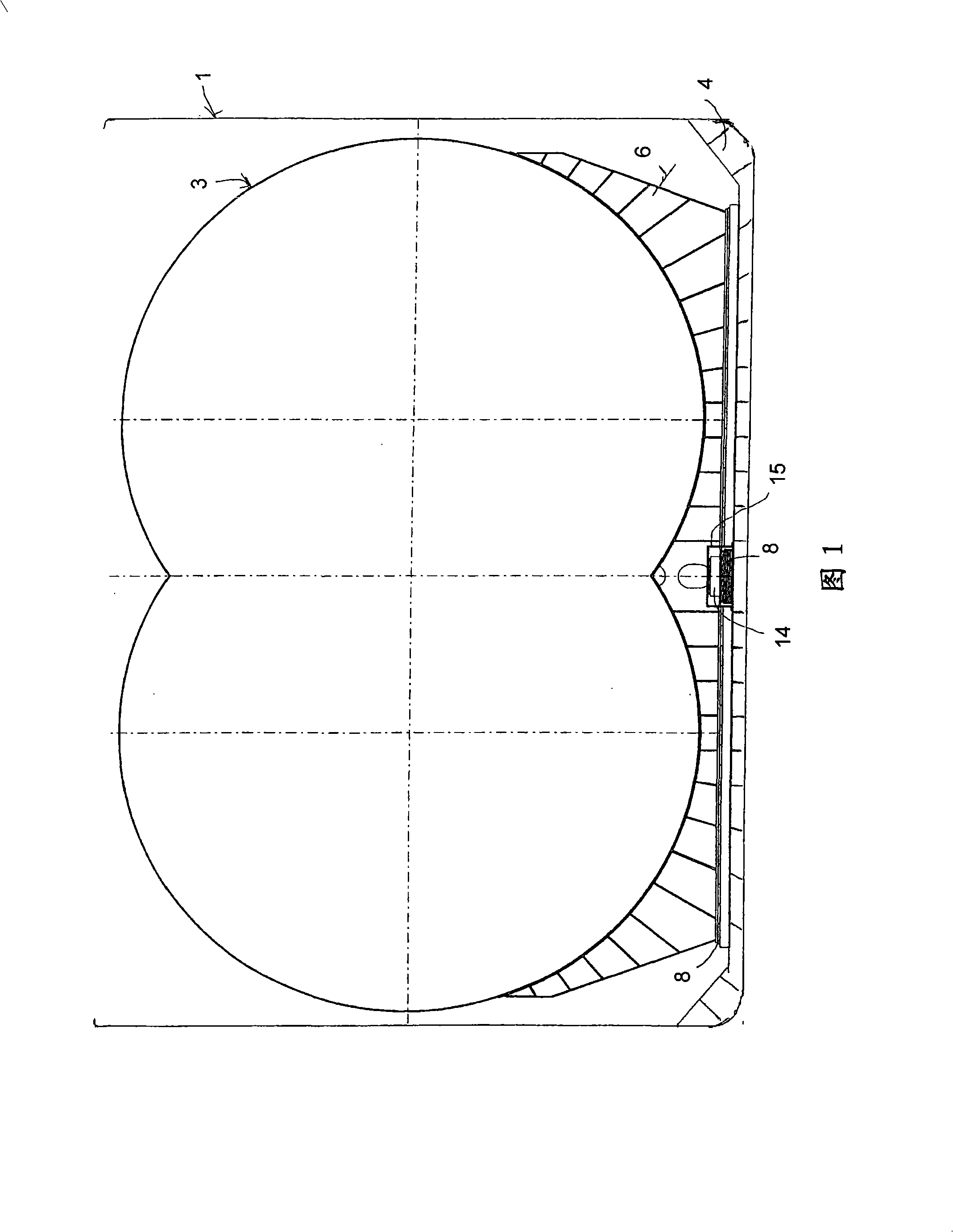

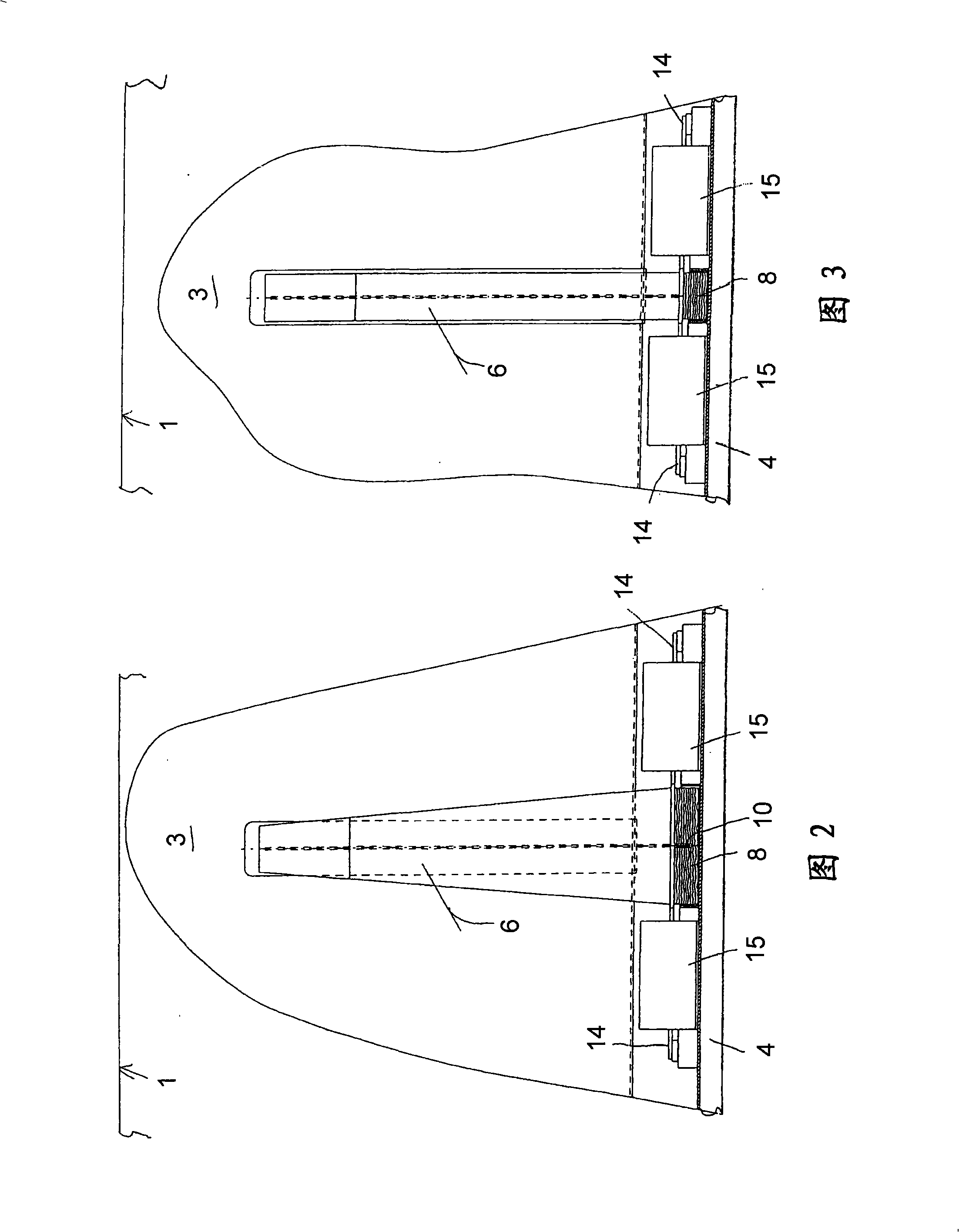

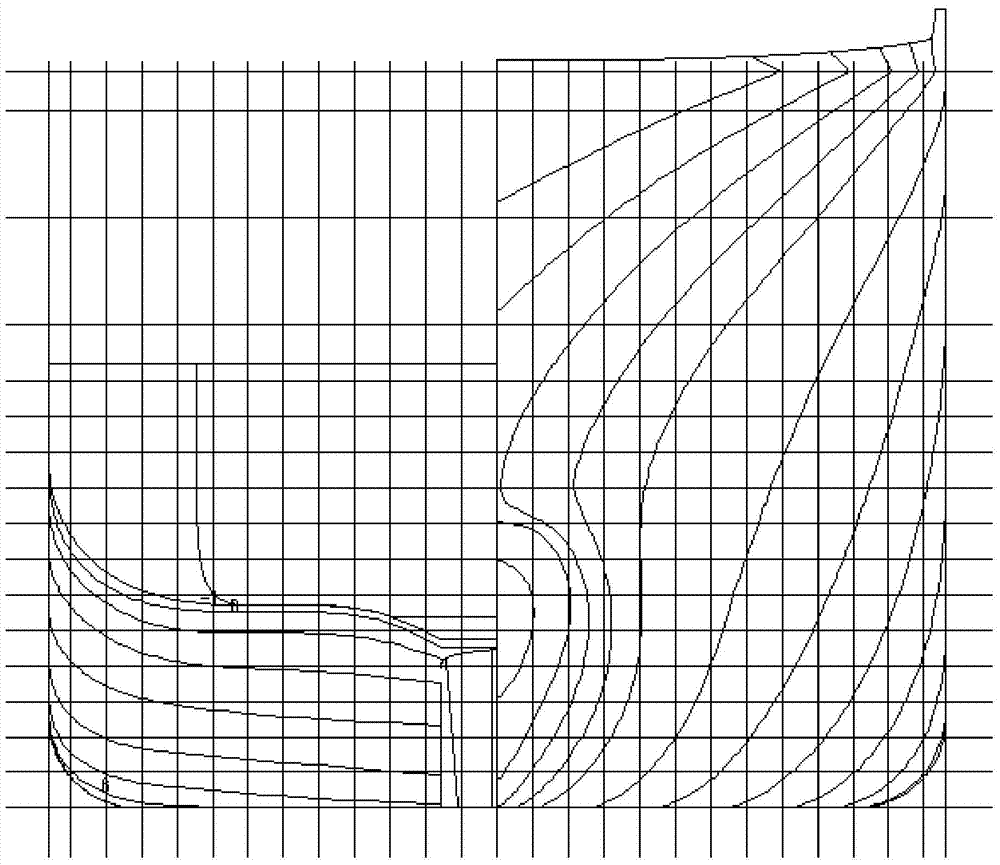

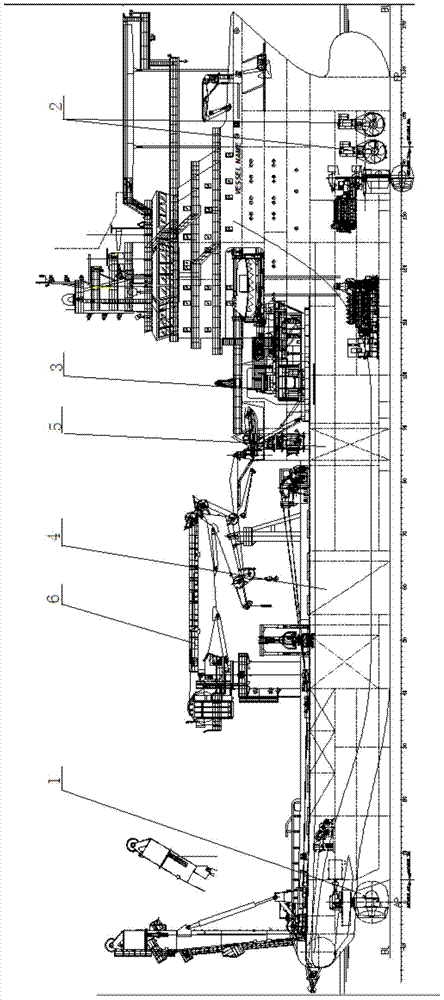

Device for mounting a tank in a ship

ActiveCN101321662APrevent longitudinal movementPrevent movementVessel mounting detailsVessel geometry/arrangement/sizeMarine engineeringThermal insulation

Disclosed is a device for mounting a tank in a ship (1). Said device comprises at least two foundations (4) which are fastened to the hull at a distance from each other in the longitudinal or transversal direction of the ship (1) and each of which supports one saddle (6) that is adapted to the shape of the tank (3) and is used for accommodating the tank (3). The inventive device further comprises an insulating layer (8) that is provided on each saddle (6) to thermally insulate the foundations (4) relative to the tank (3) as well as safety mechanisms (10; 12; 15) for mounting the tank (3) on the foundations (4), said safety mechanisms (10; 12; 15) allowing a relative movement between the tank (3) and at least one foundation (4) on the insulating layer (8) in the longitudinal direction of the tank. Each saddle (6) is fastened directly to the tank (3) and has a planar bottom face (7) while each foundation (4) has a planar top face (5), all bottom and top faces (7; 5) being parallel to one another. The insulating layer (8) is disposed between the bottom face (7) of the saddle (6) and the top face (5) of the associated foundation (4) while the safety mechanisms (10; 12; 15) allow a limited relative movement between each saddle (6) and the foundation (4) thereof on or in the insulating layer (8).

Owner:TGE MARINE GAS ENG GMBH

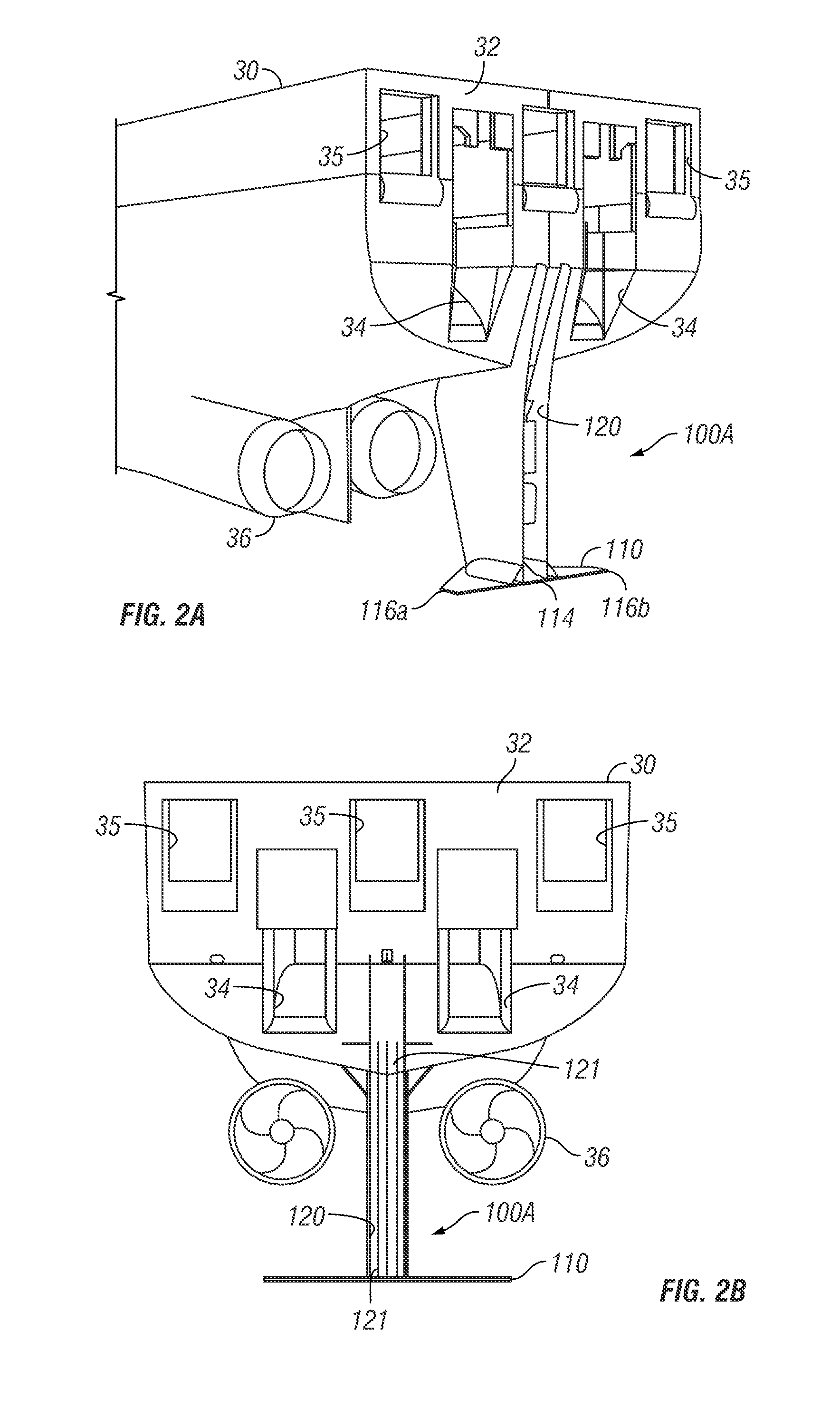

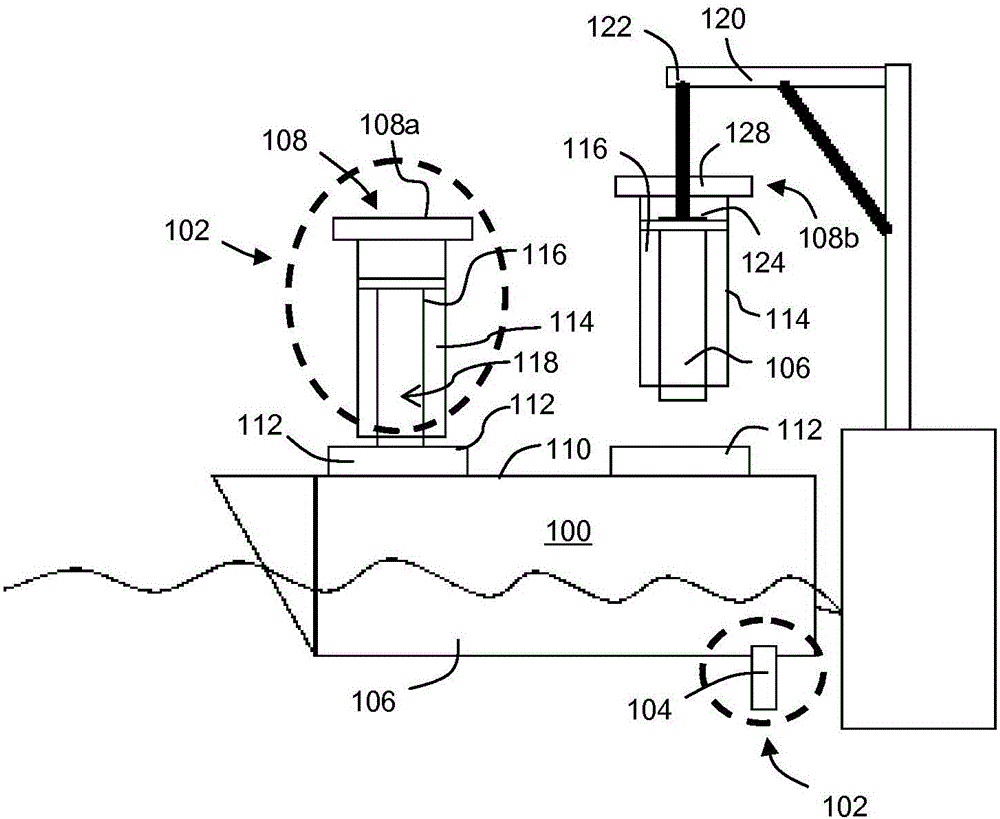

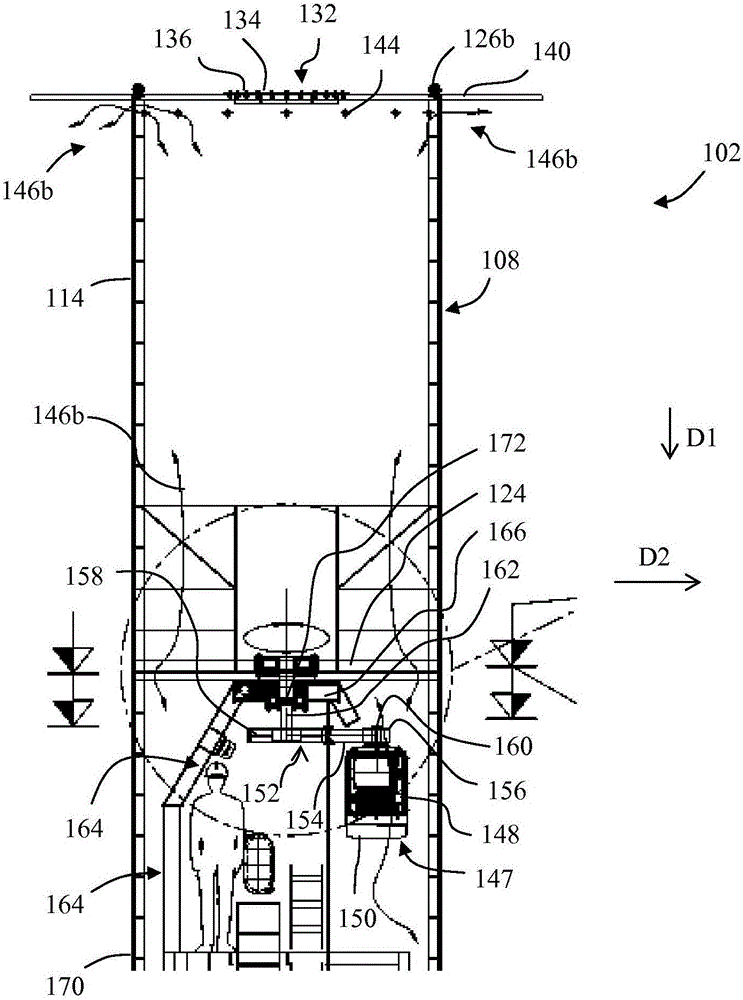

Propulsion systems for aquatic vessels

ActiveCN106255637AEasy to replaceEasy accessRoller bearingsPropulsion based emission reductionAerospace engineering

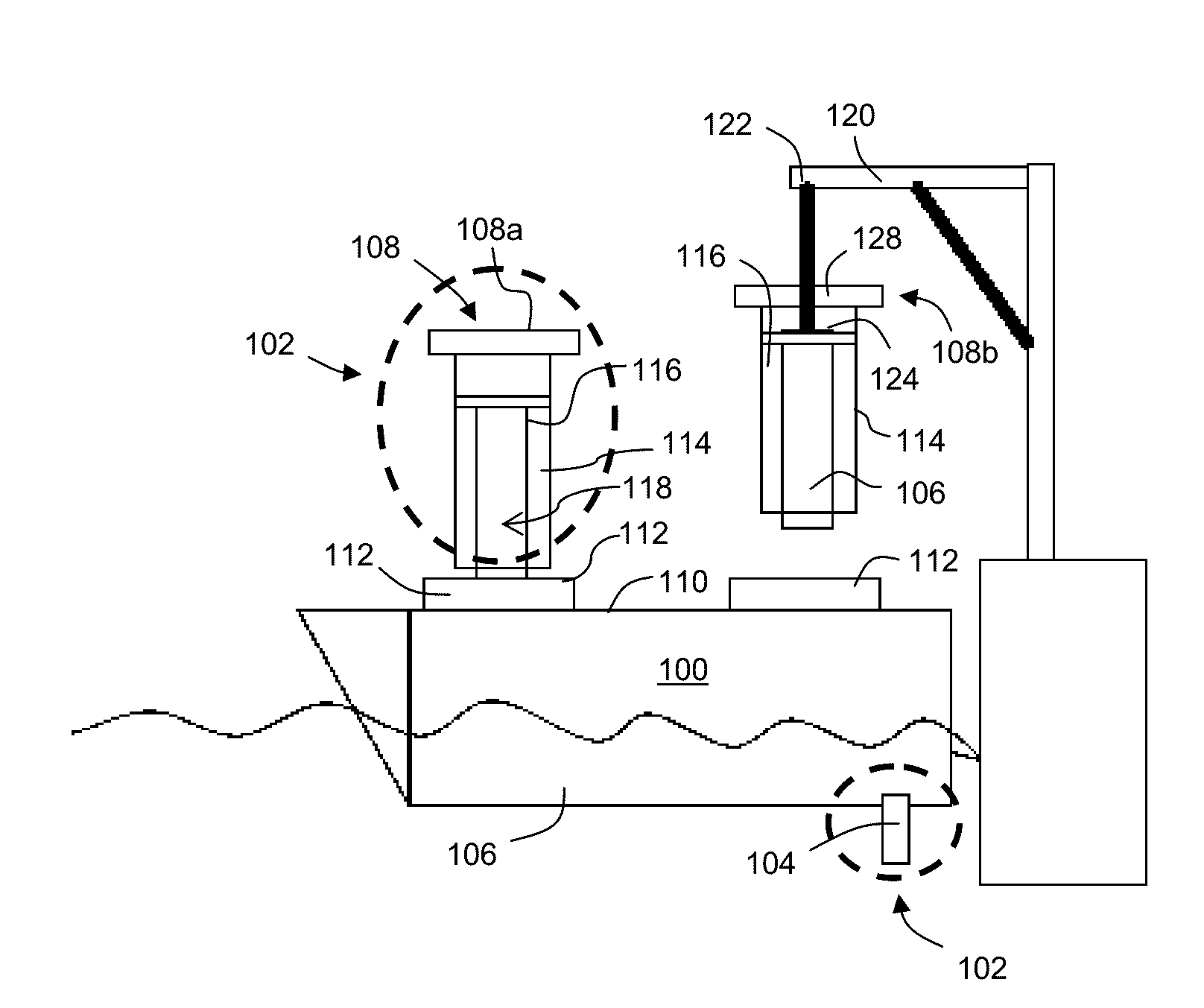

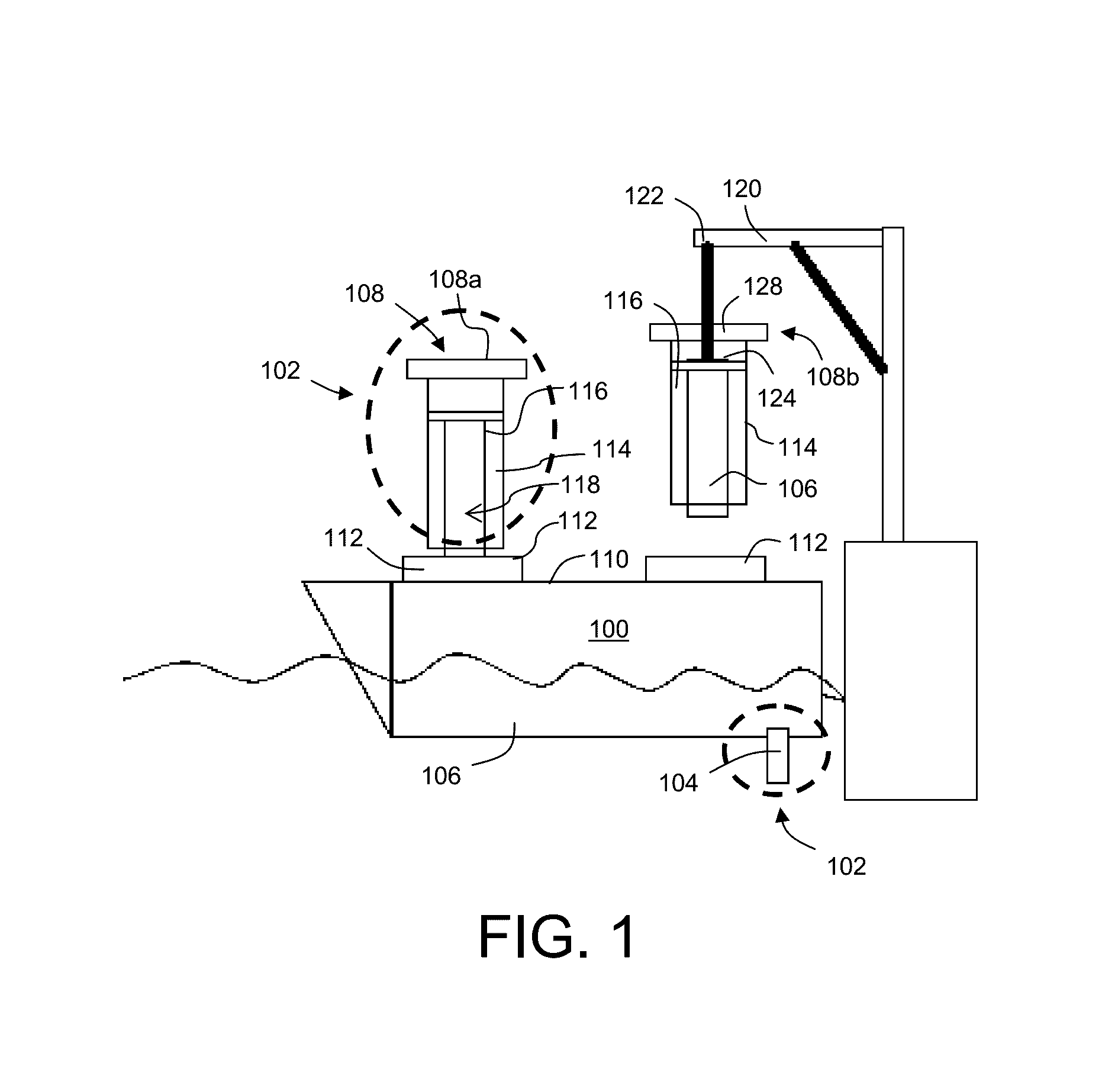

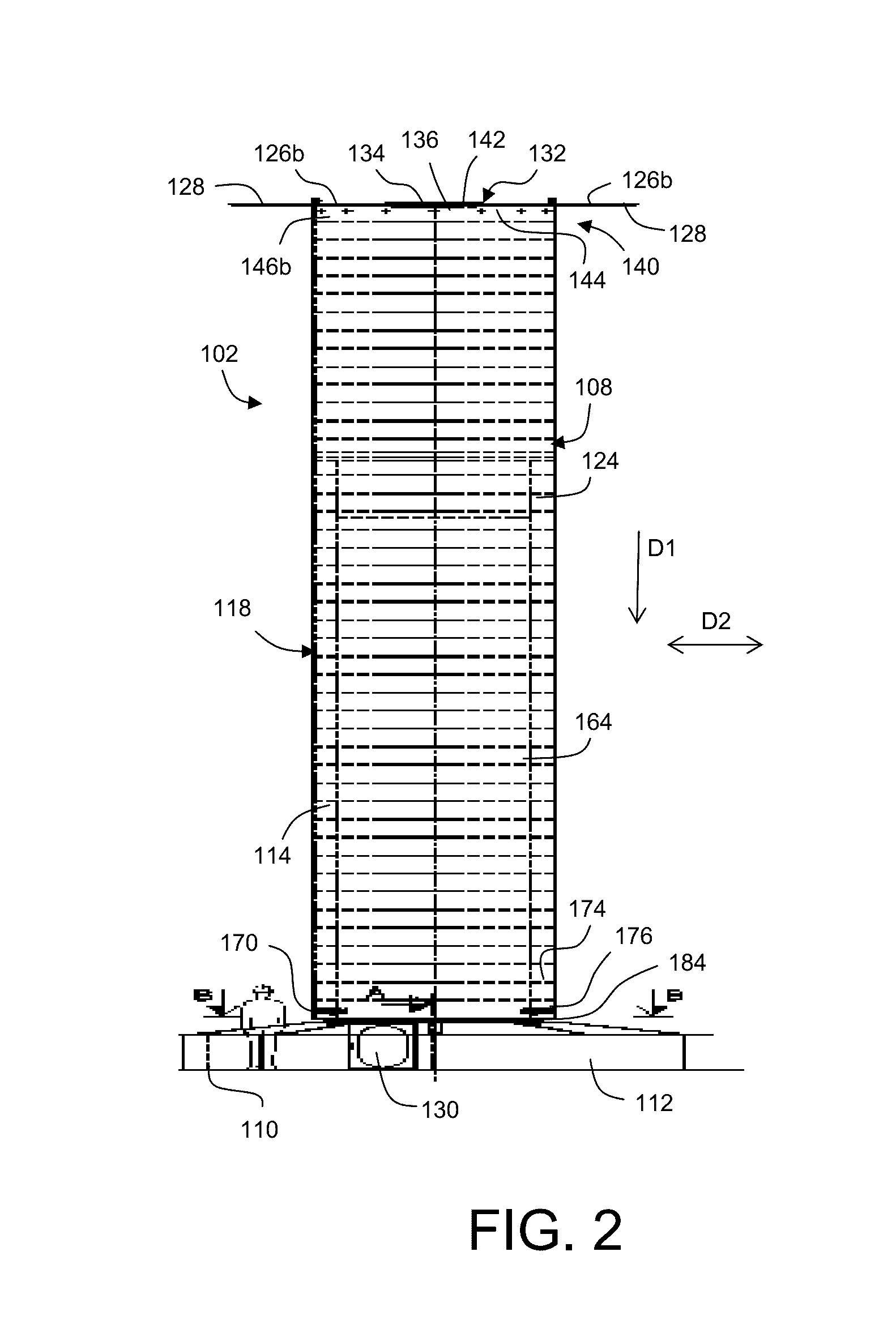

A propulsion system (102) for an aquatic vessel(100)is provided. The propulsion system includes a plurality of Magnus-type rotors(108)and a drive arrangement (147) for rotating the plurality of Magnus-type rotors. The plurality of Magnus-type rotors are operable to rotate about corresponding substantially upright axes. The propulsion system also includes a control arrangement(150)for controlling the drive arrangement to vary rates of rotations of the plurality of Magnus-type rotors. Each of the plurality of Magnus-type rotors includes a hollow region (116) therein. Each of the Magnus-type rotors is rotationally supported onto a support arrangement(118) which extends into the hollow region. The drive arrangement includes at least one motor(148) disposed in the hollow region and located outside the support arrangement such that the at least one motor is accessible for maintenance. Furthermore, the at least one Magnus-type rotor includes a ventilation aperture arrangement(132)for enabling an upward movement of air to occur in operation within the at least one Magnus-type rotor for ventilating and cooling the drive arrangement and / or other internal components.

Owner:挪世航力

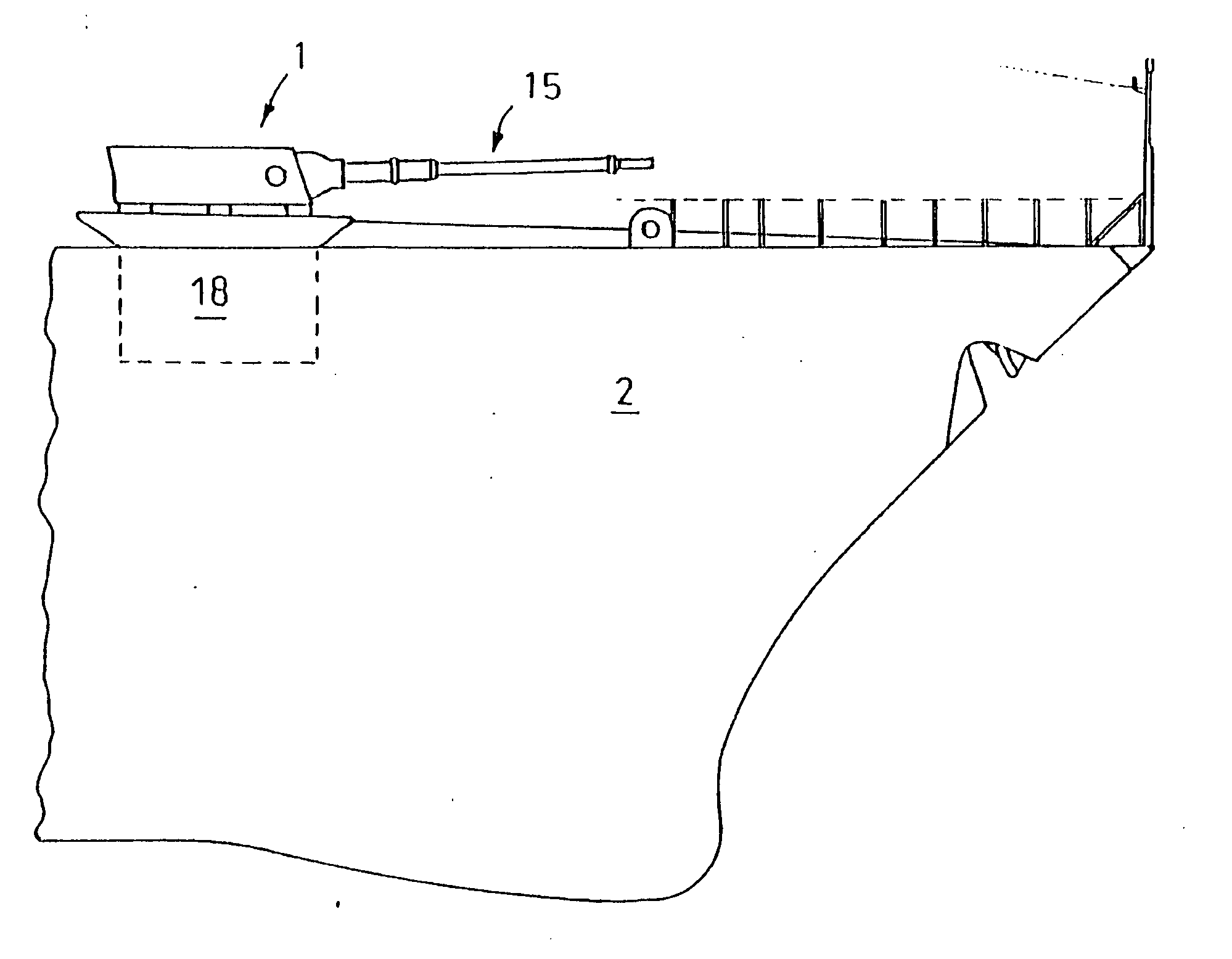

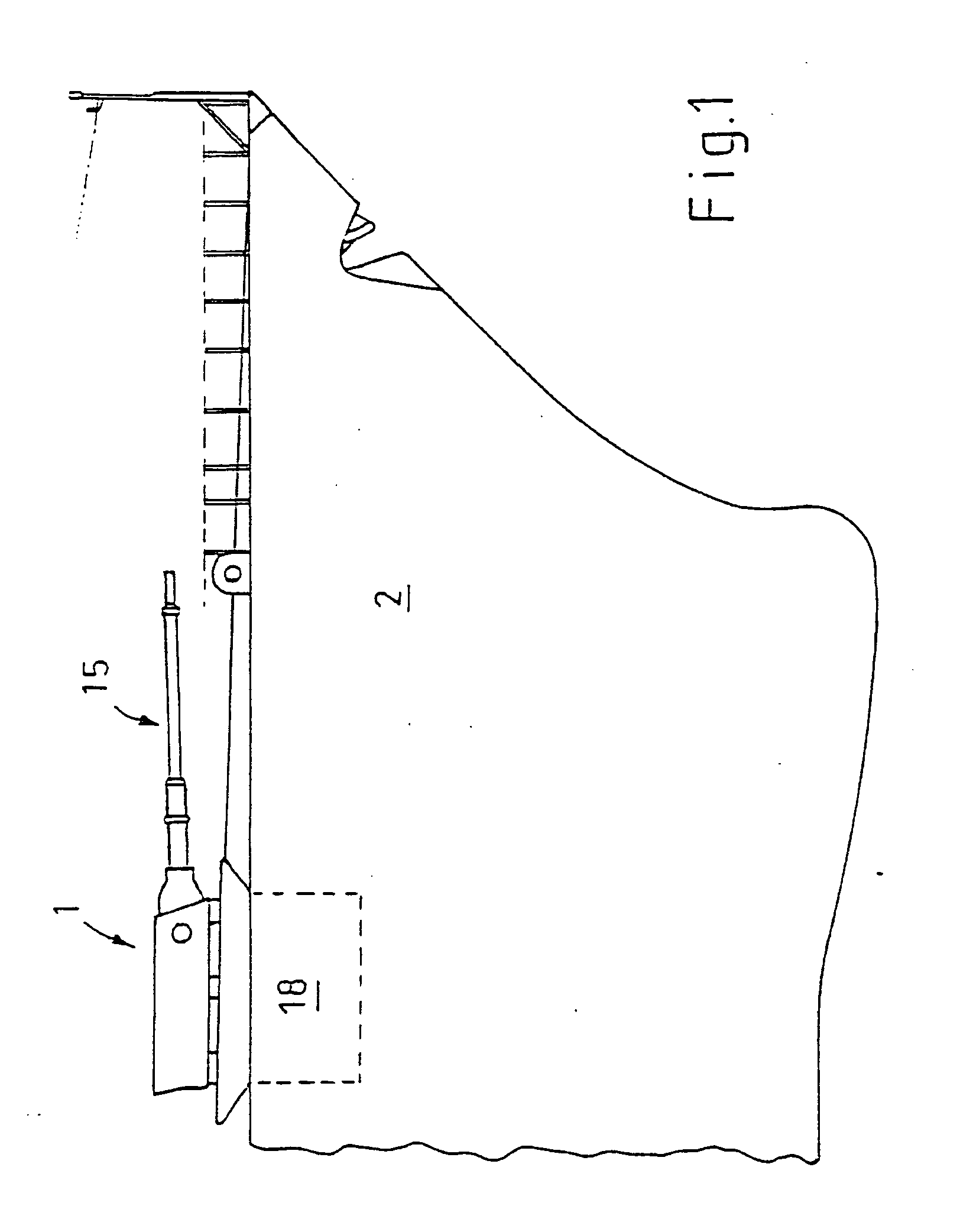

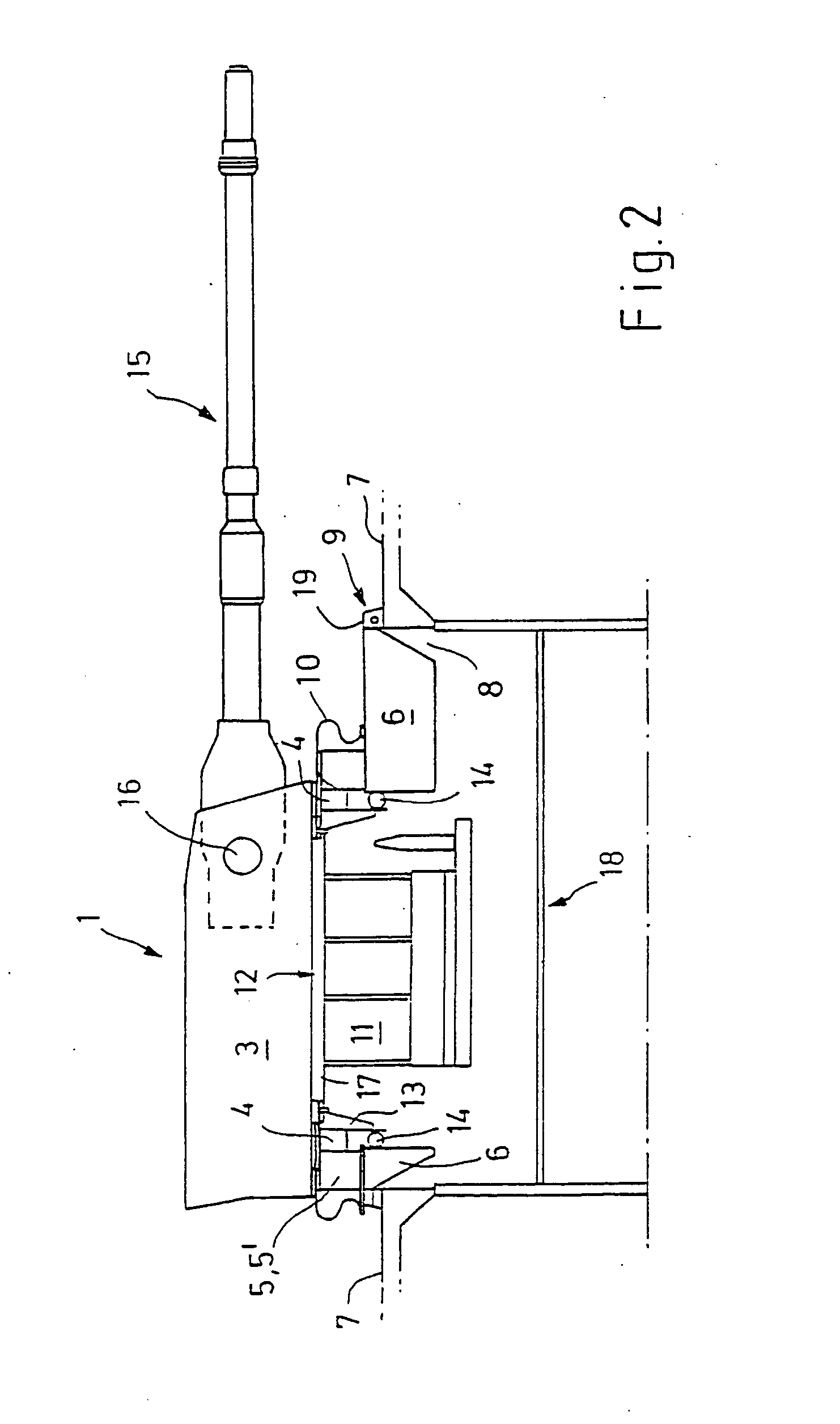

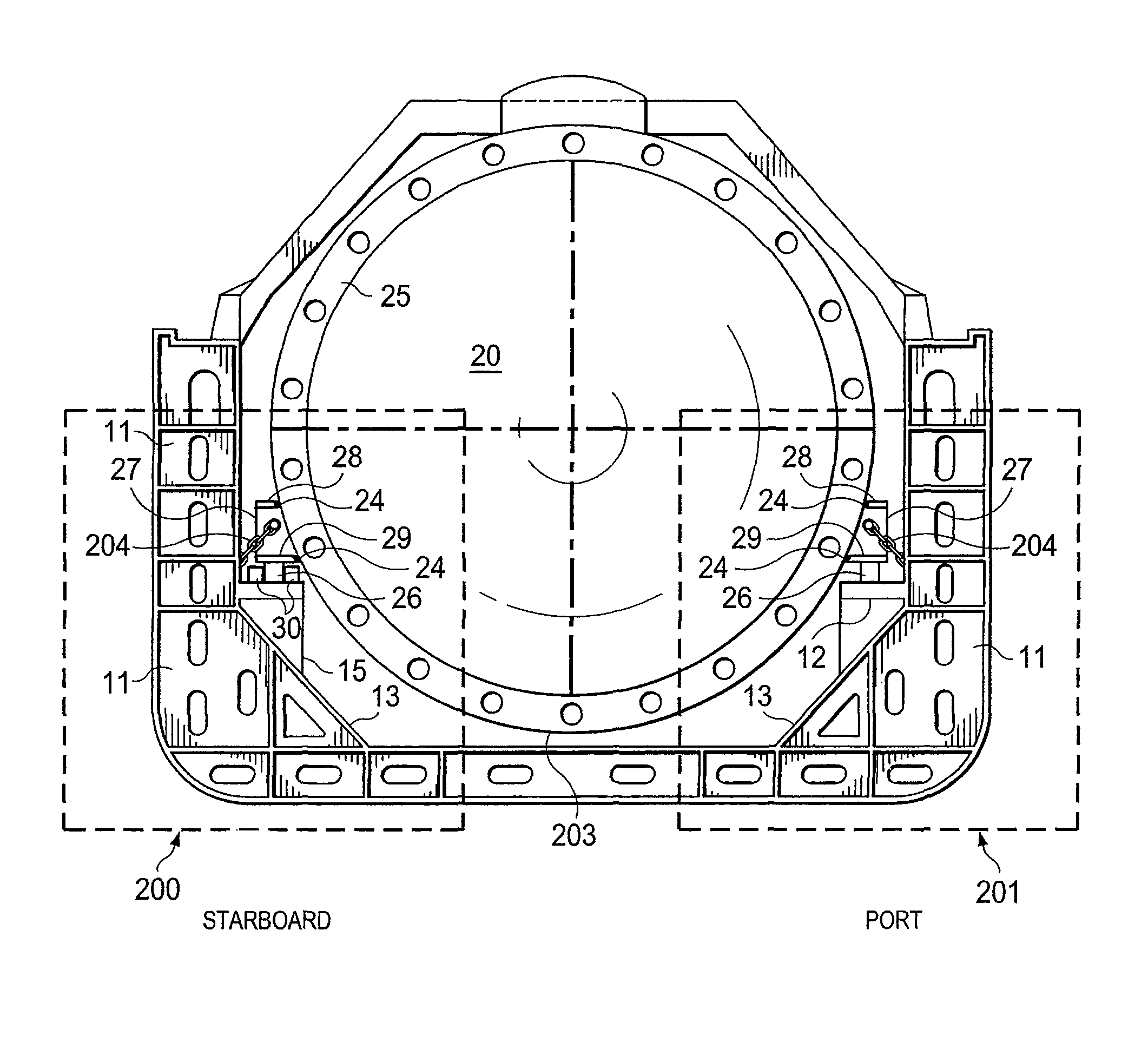

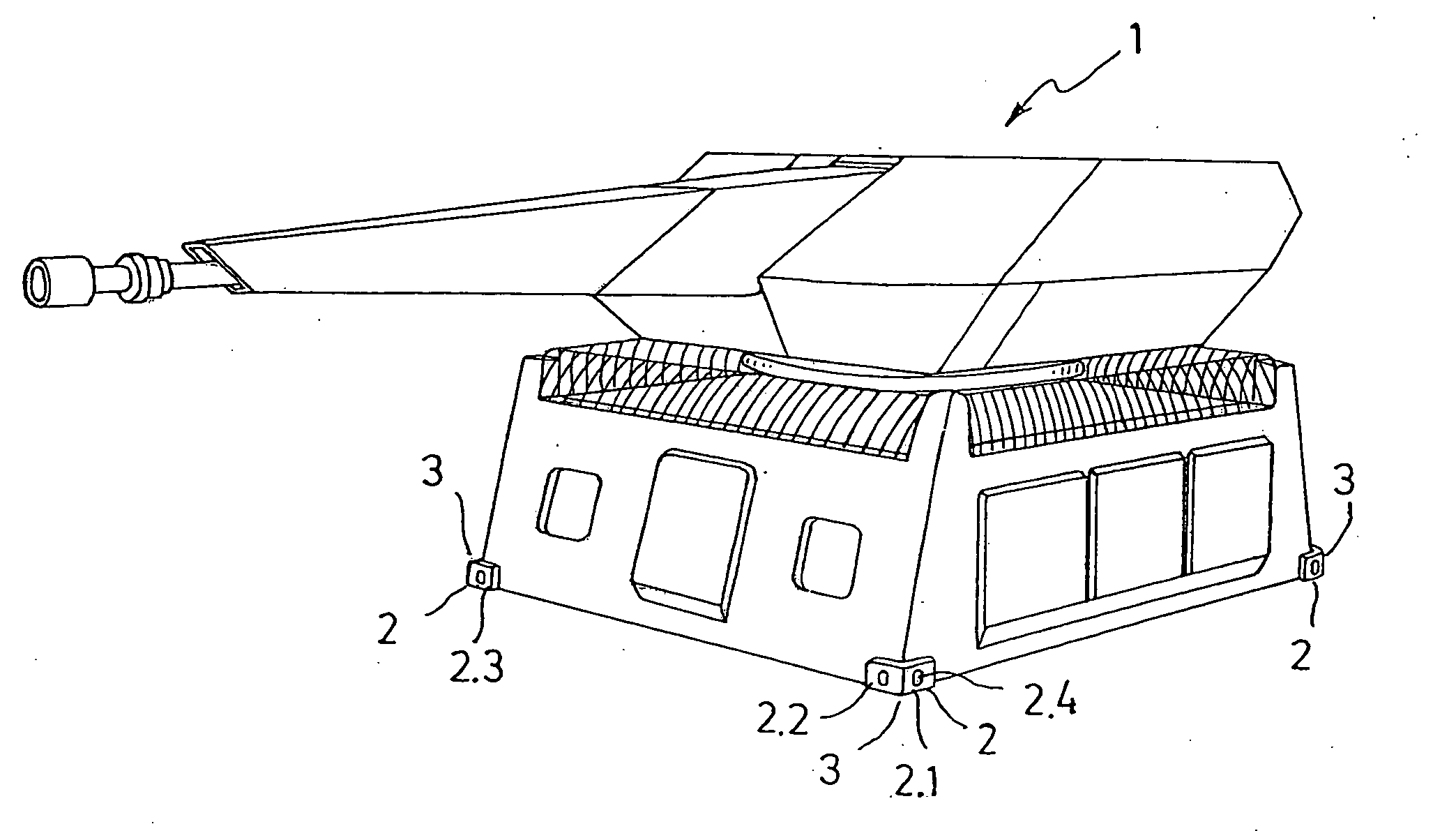

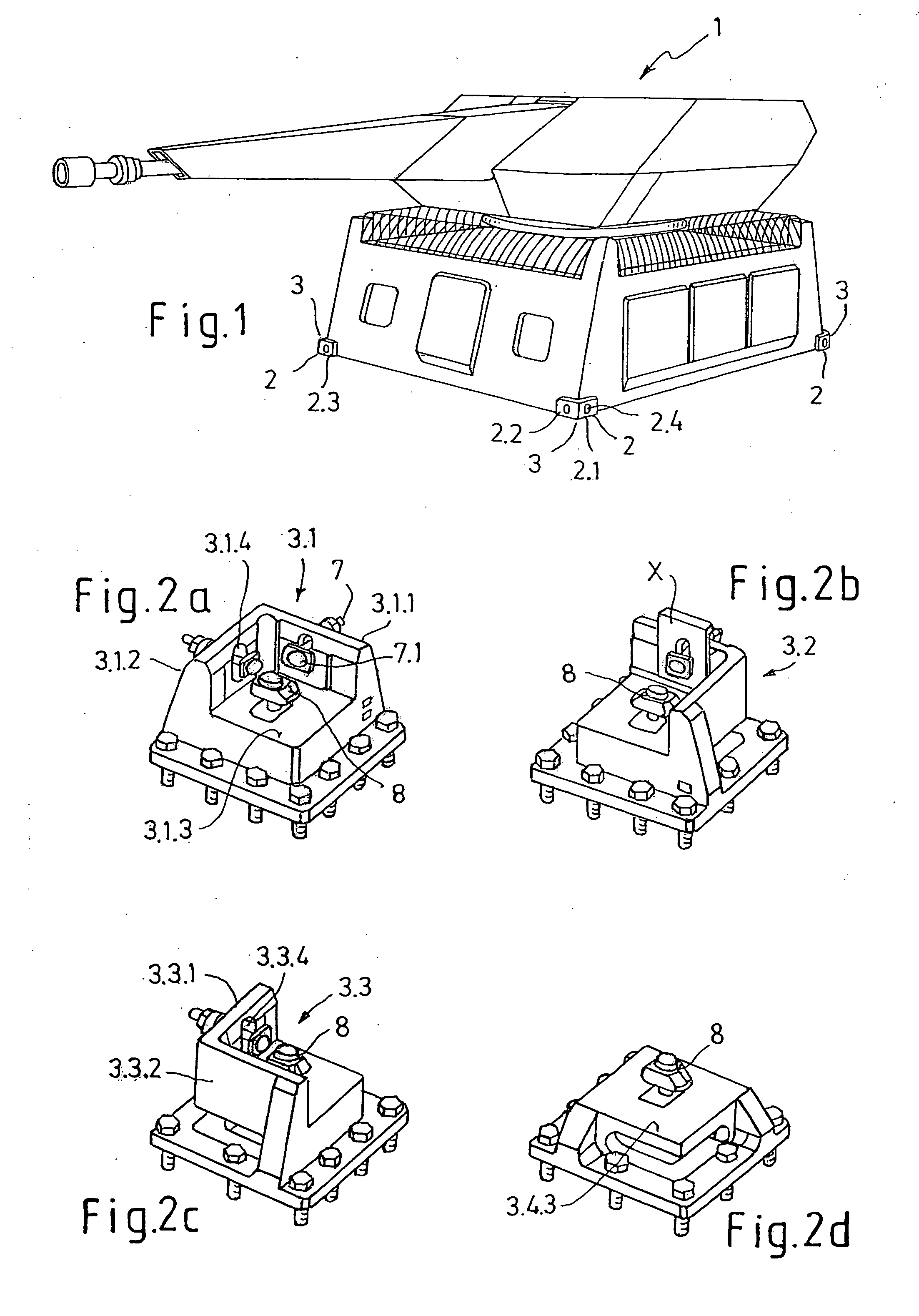

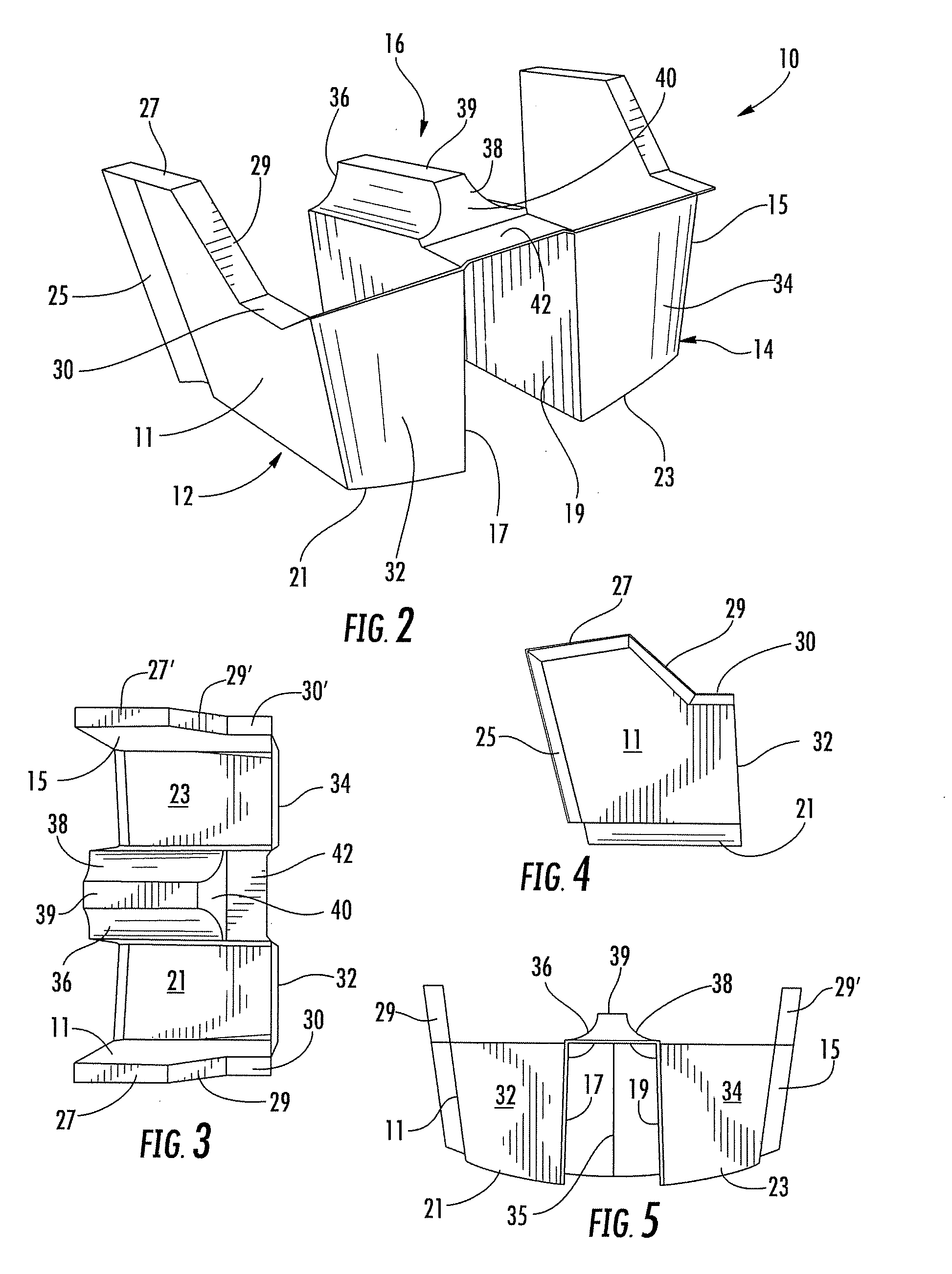

Integration of a large calibre gun on a ship

InactiveUS20070151493A1Short timeNew requirementMissile launchersVessel partsMarine engineeringModularity

A method for integrating a large-calibre gun on a ship, including connecting a turret having an armament of a lad gun with a calibre >127 mm in a modular configuration to an adaptor plate and a shock-absorbing mounting, and installing the turret on the ship so that an existing steel structure of the ship withstands increased recoil forces from the armament.

Owner:RHEINMETALL WAFFE MUNITION GMBH +2

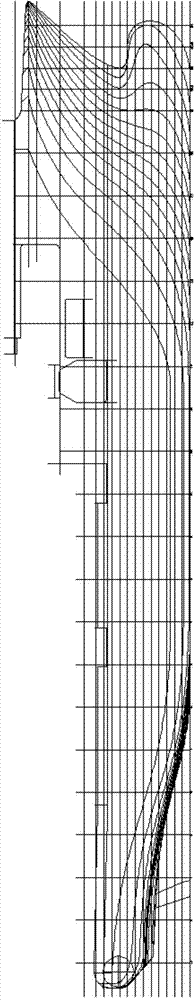

Deep diving operation supporting ship

InactiveCN104229082AReasonable arrangementCompact structureHull reinforcementsSpecial purpose vesselsMarine engineeringRemote control

The invention discloses a deep diving operation supporting ship which comprises a bulbous bow, a working deck, a fully-rotating propelling plant, a lifting system, a saturation diving system, an air diving system and a remote control detection working system, wherein the bulbous bow is arranged on a ship foremost region, the working deck is arranged on a ship midship region and a ship tail region, the fully-rotating propelling plant is arranged on the ship tail region, the lifting system is arranged on the ship midship region through stand columns, the saturation diving system is arranged between the ship foremost region and the ship midship region, the air diving system is arranged on a ship side region, and the remote control detection working system is arranged on the ship side region. According to the deep diving operation supporting ship, the fully-rotating propelling plant can be arranged reasonably through the tail shaped line design, and the deep diving operation supporting ship has the advantages that all function regions are compact in structural layout and high in integration level.

Owner:CSIC WUHAN SHIP & MARINE ENG EQUIP DESIGN

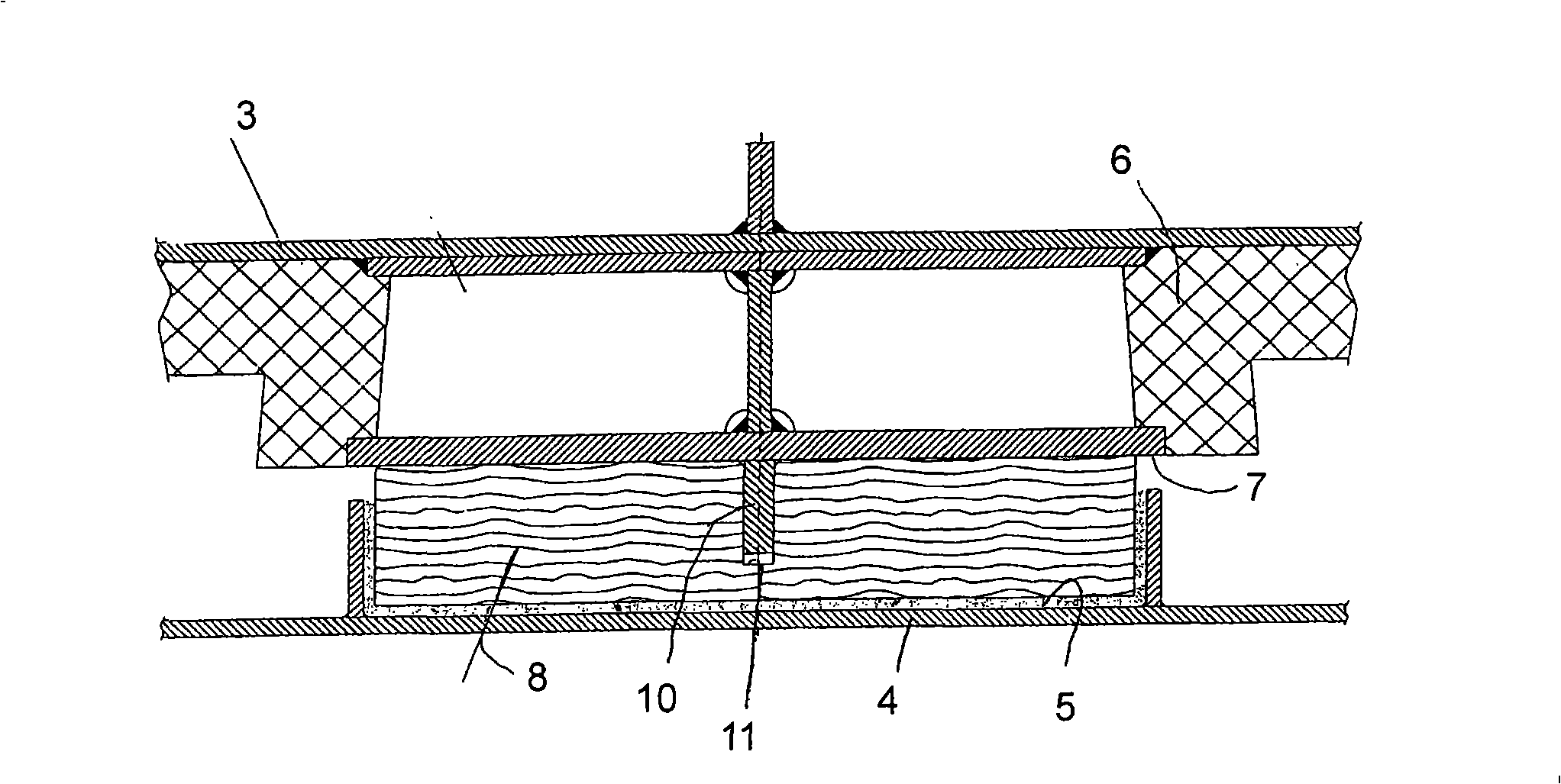

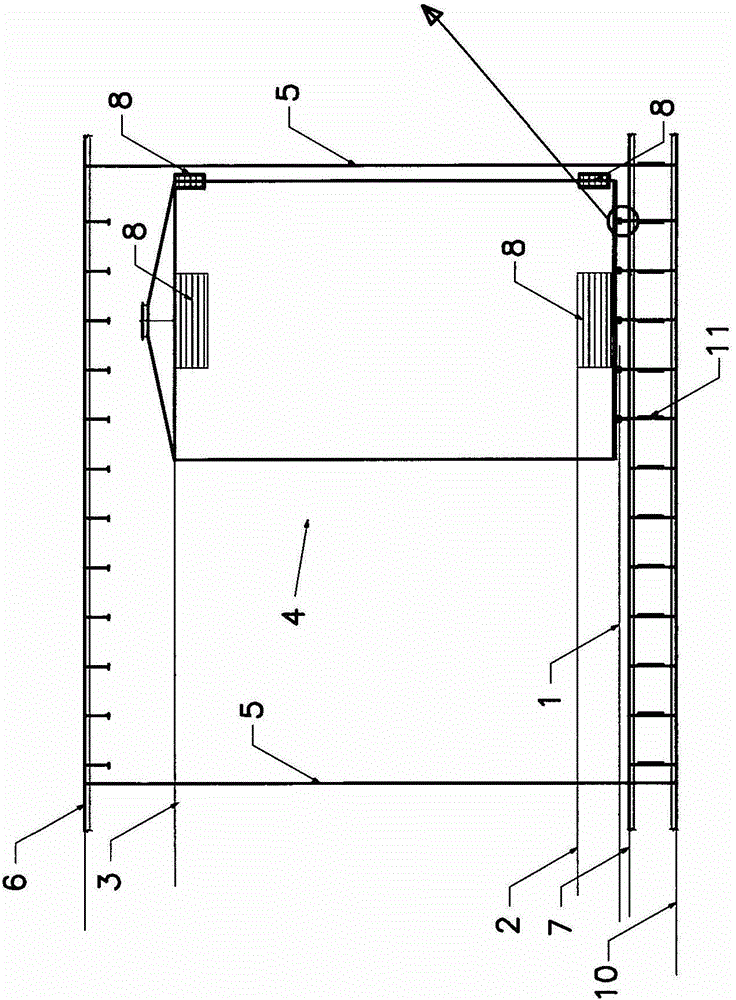

Support of tanks in vessels

ActiveCN102947638ASolve bearSolve supportiveVessel mounting detailsHull interior subdivisionHorizontal forceInsulation layer

The invention regards a system for support of a vertical cargo tank (4, 40) resting on an insulation layer (15) against the hull of a vessel (41). Vertical forces are supported through the base of the tank. Horizontal forces are supported by support point pairs (8). These pairs are designed to direct applied forces generally through the middle of the shell (23) of the tank in order not to apply bending moment to the shell of the tank. The base of the tank is flexible to generally distributed transferring forces from the tank directly to the bottom (7)of the vessel in order not to apply bending moment to the shell of the tank nor to the bottom of the vessel.

Owner:BREVIK TECH

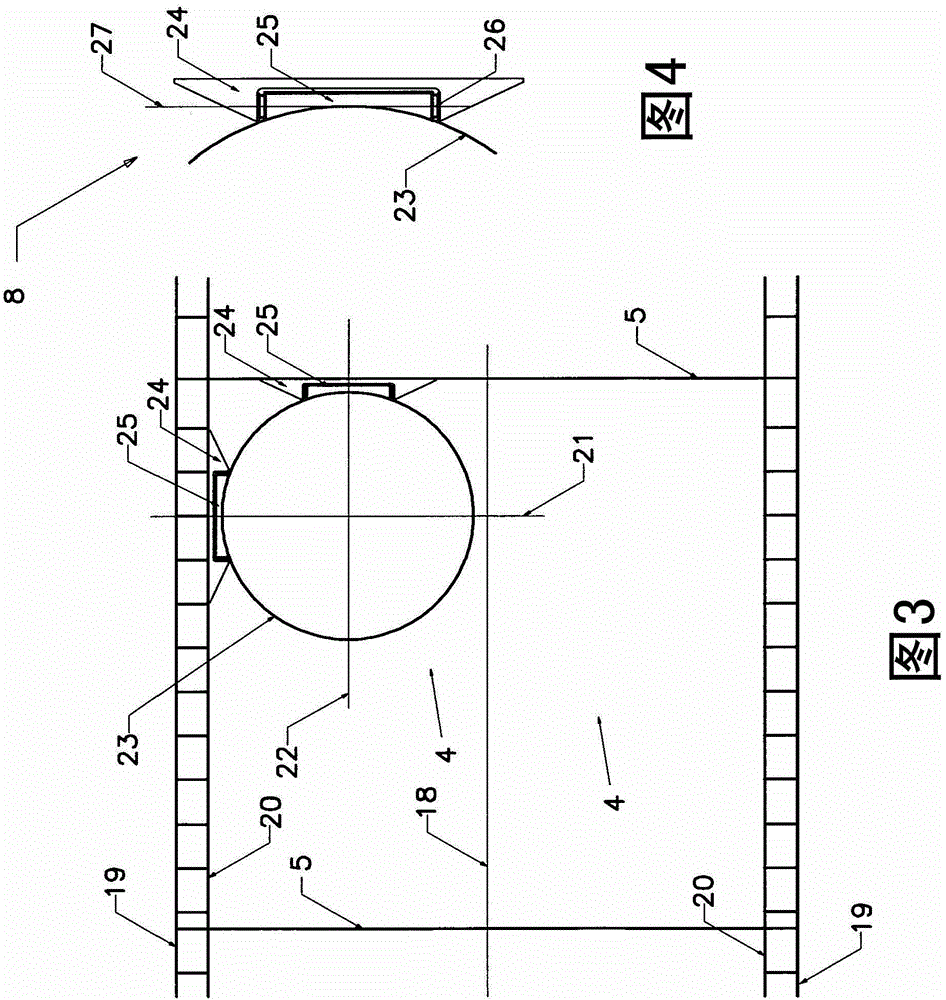

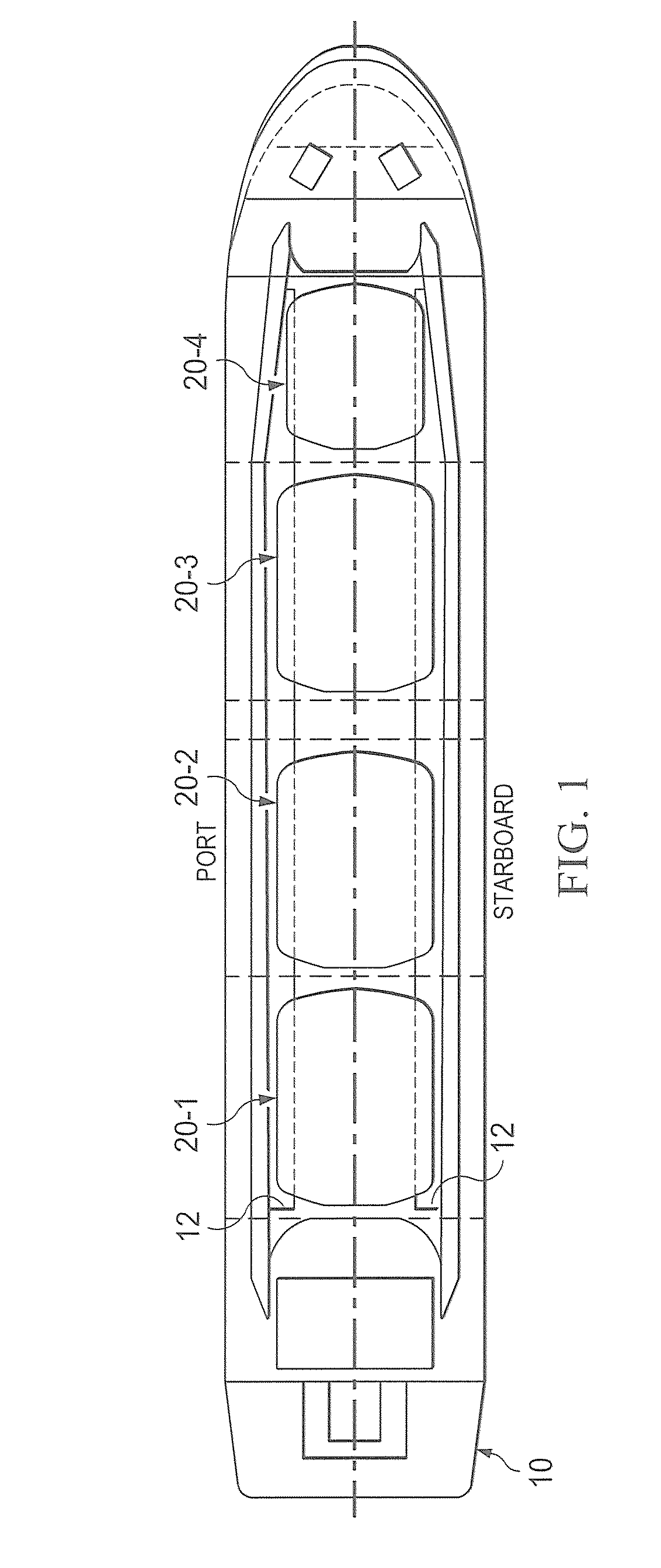

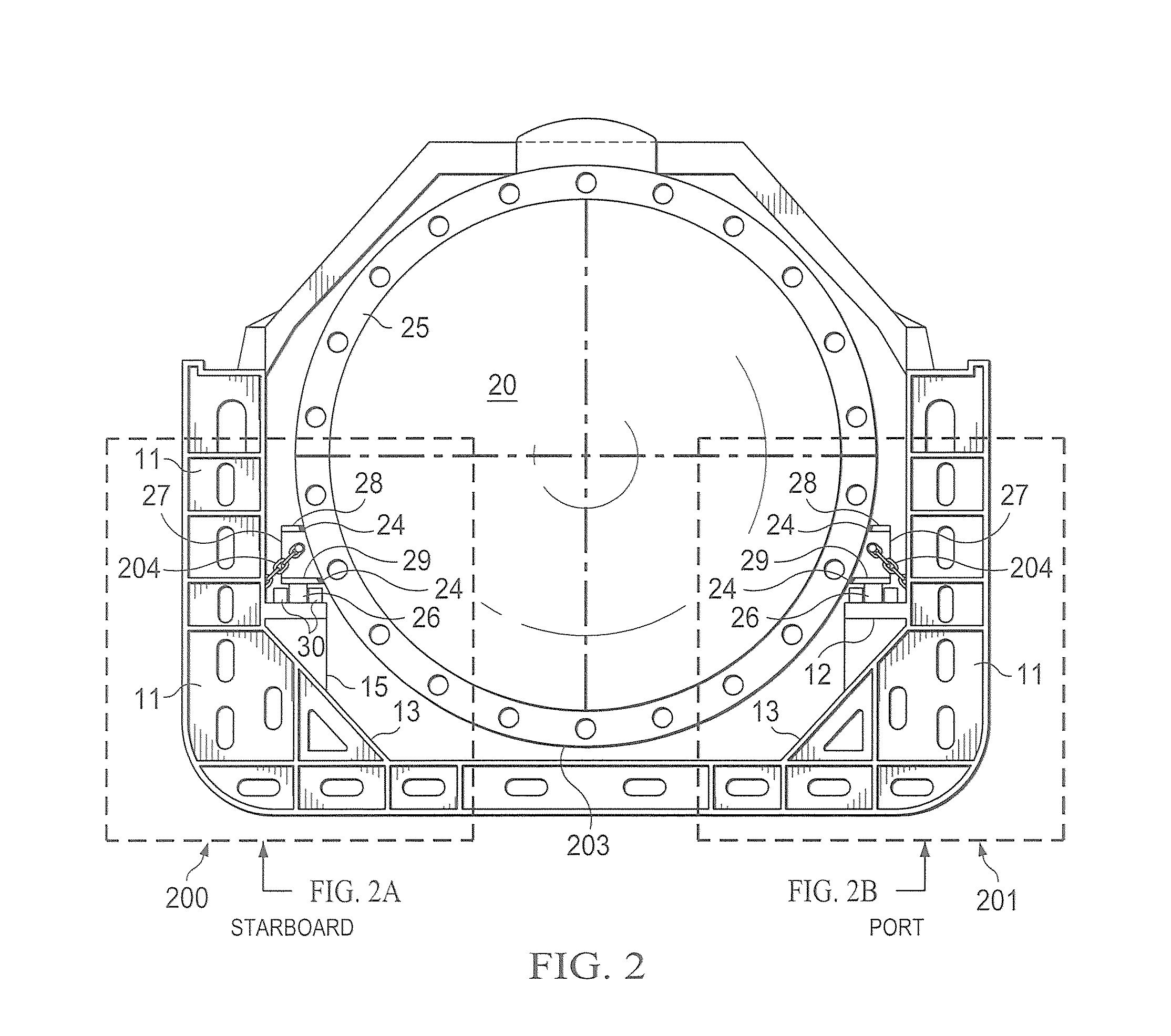

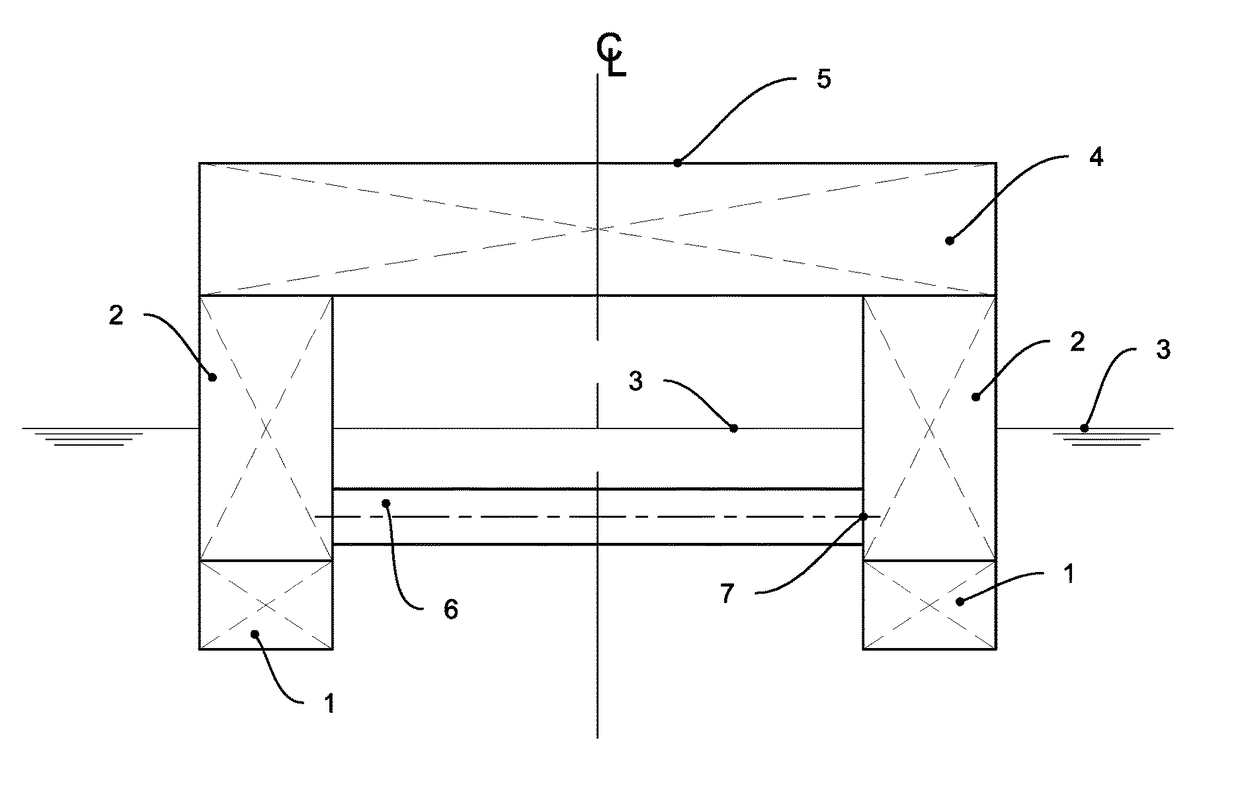

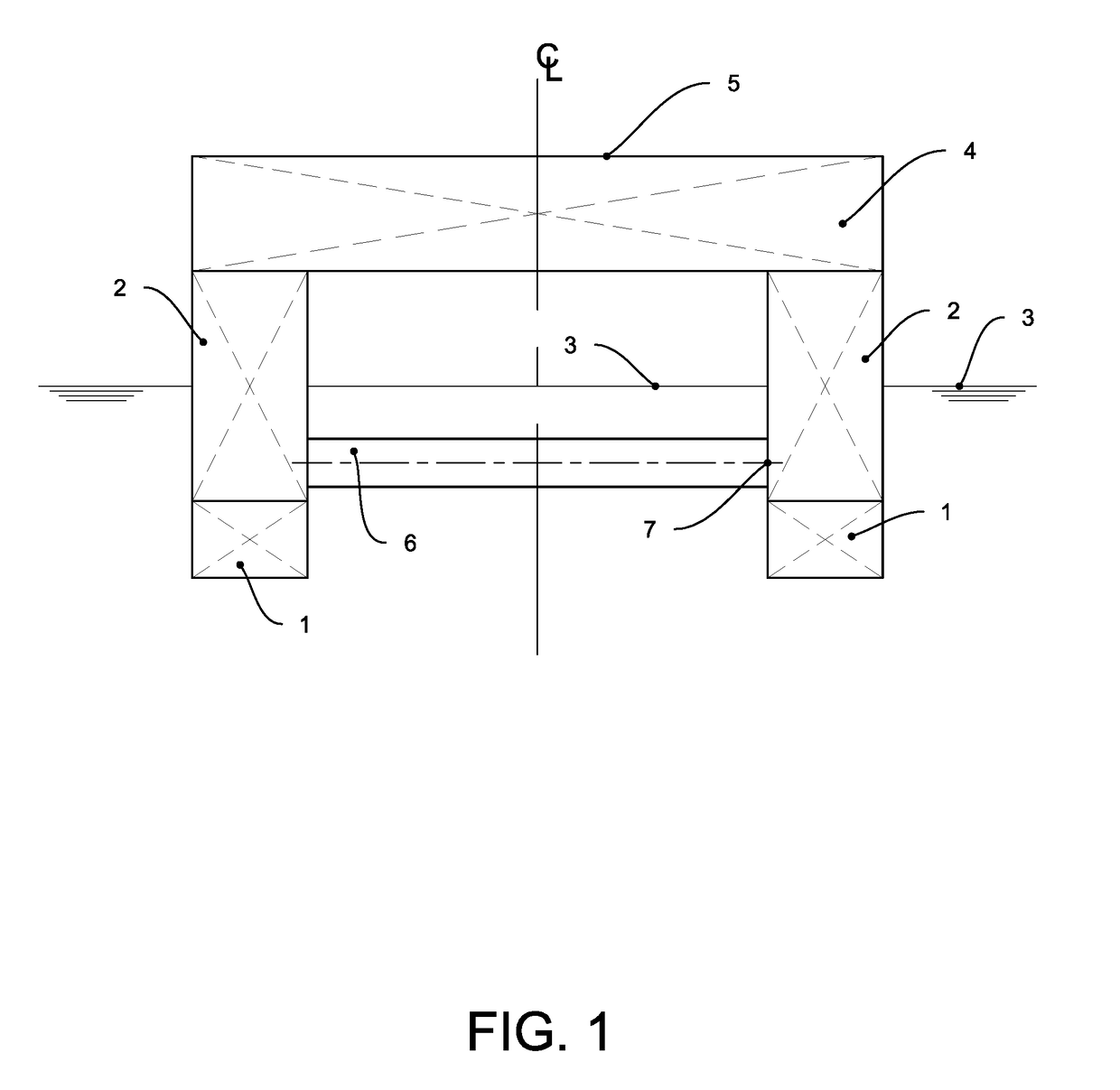

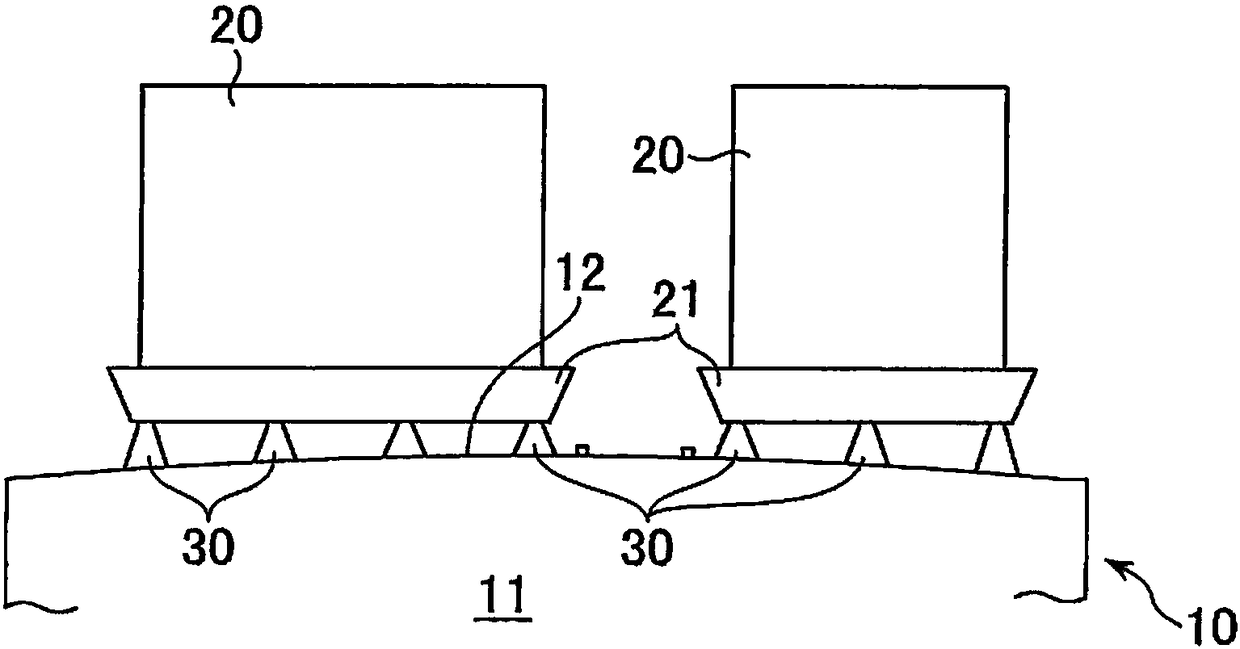

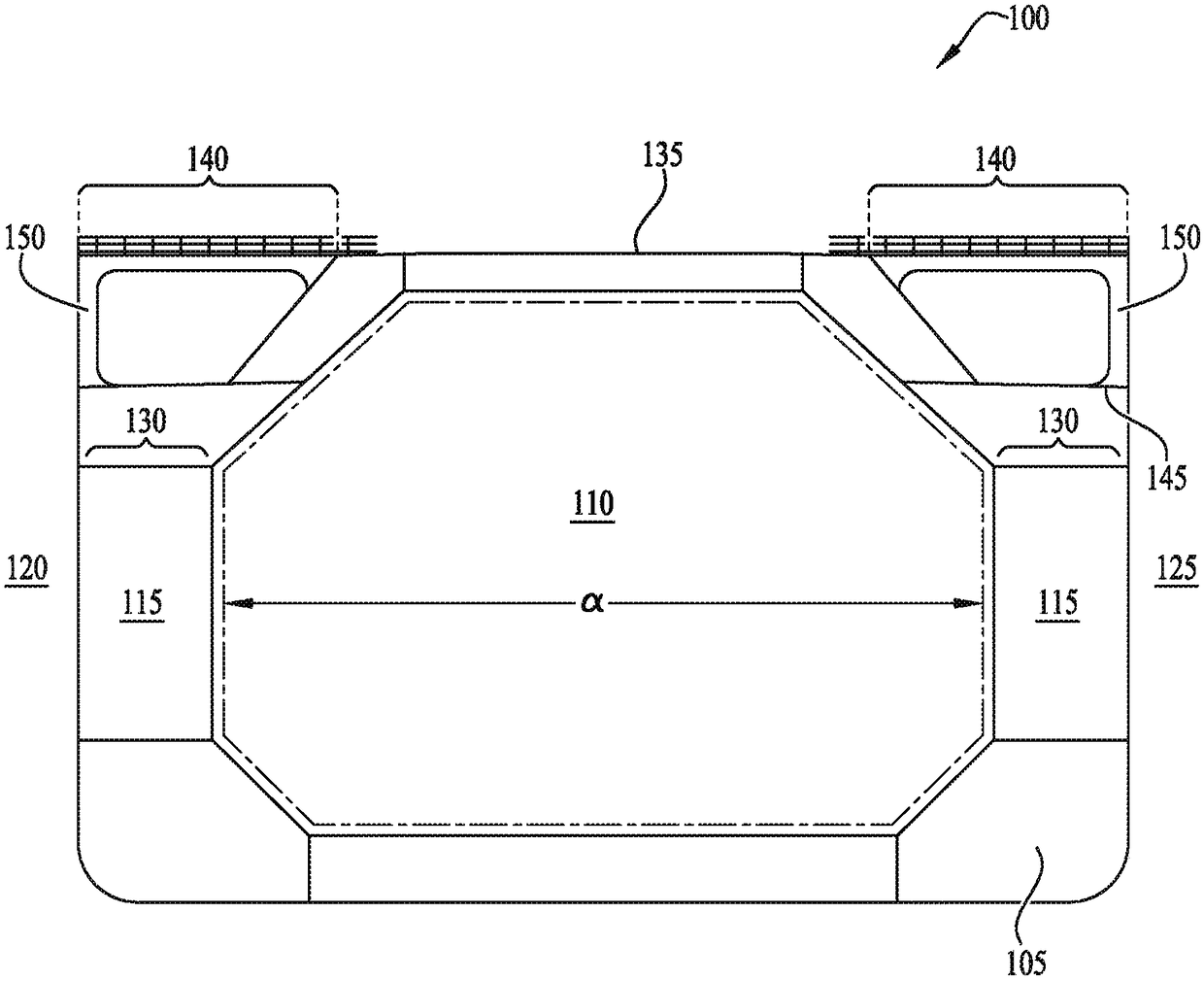

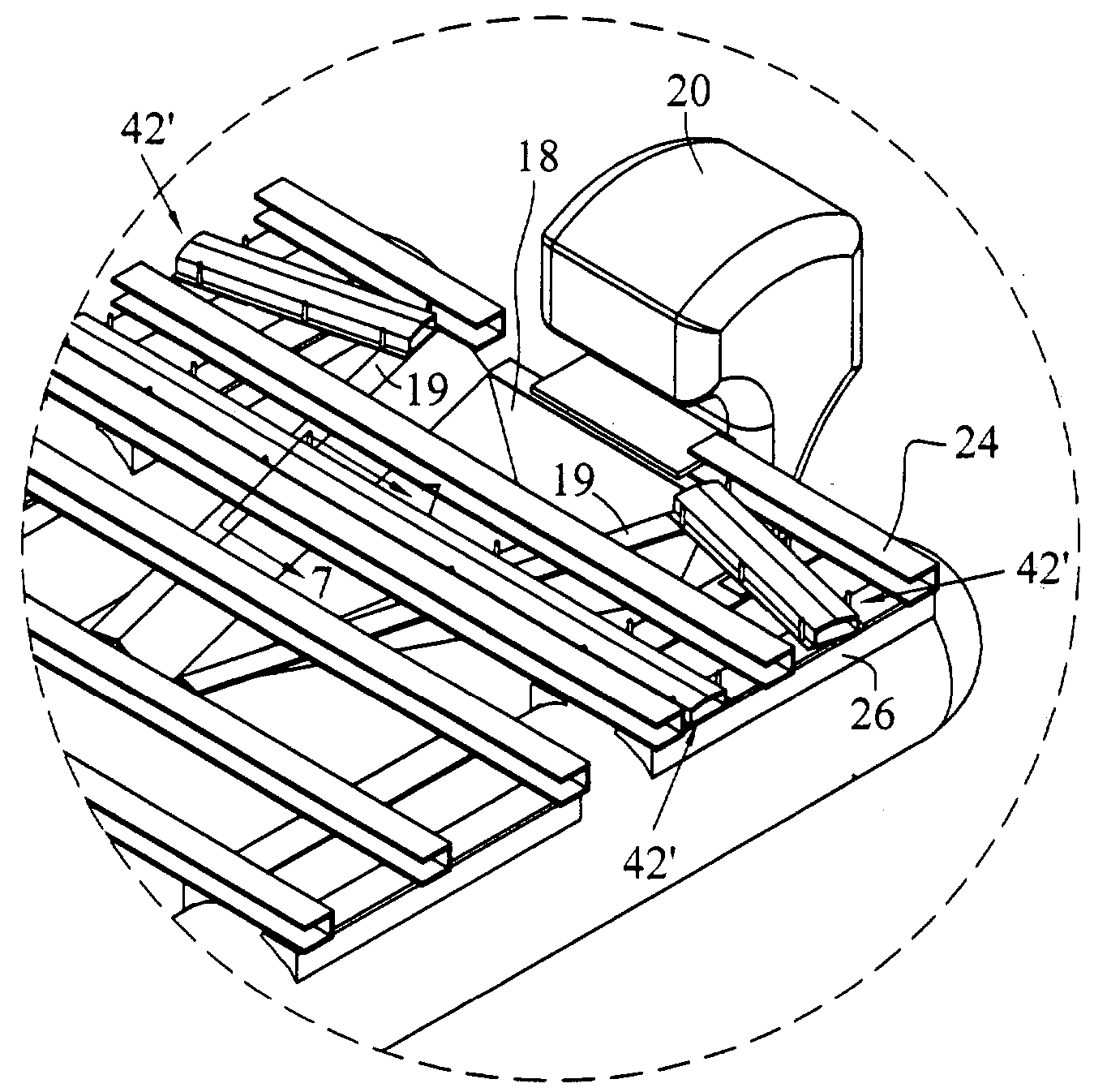

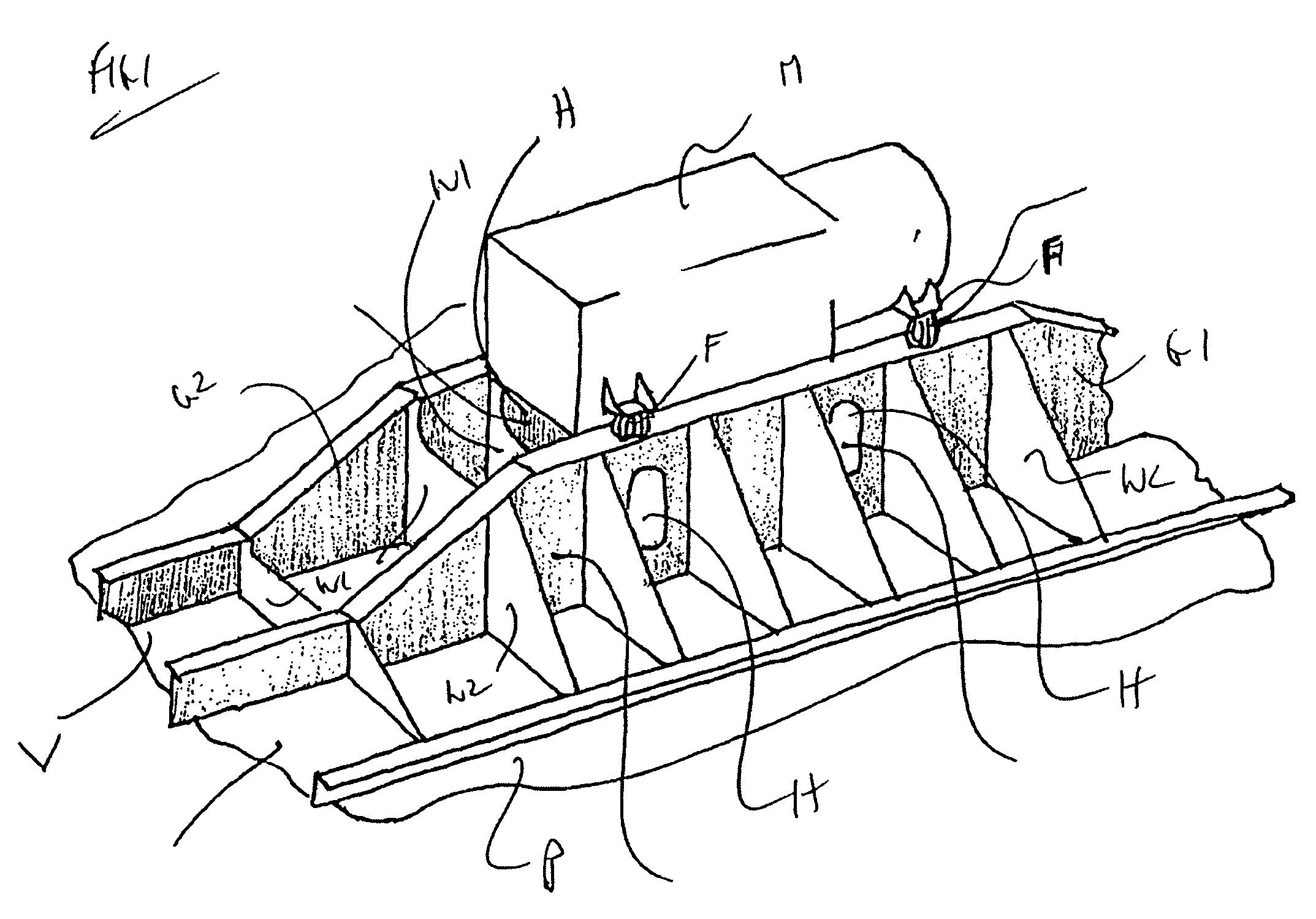

Systems and methods for supporting tanks in a cargo ship

ActiveUS8245658B2Reduce frictionImprove overall utilizationContainer filling methodsVessel partsHull structureCargo vessel

There are disclosed systems and methods for supporting cargo tanks within the hold of a liquefied gas carrier by establishing a series of spaced-apart pedestals along the longitudinal axis of a tank, said pedestals positioned in conjunction with the ship's structural components. These pedestals are of wood or other suitable thermal insulating and load bearing material fixed to the tank below its circumferential diameter along both the starboard and port tank sides. The pedestals rest on structural longitudinal stringers laying port and starboard in the horizontal plane and fixed and supported by the ship's hull structure. Longitudinal and transverse pedestal movement is controlled by stops attached to the stringers at one or more of the pedestals. The stops contact the pedestals via bearing pads which constrain the pedestal in one direction but permit its movement in another.

Owner:SSRC TECH AS

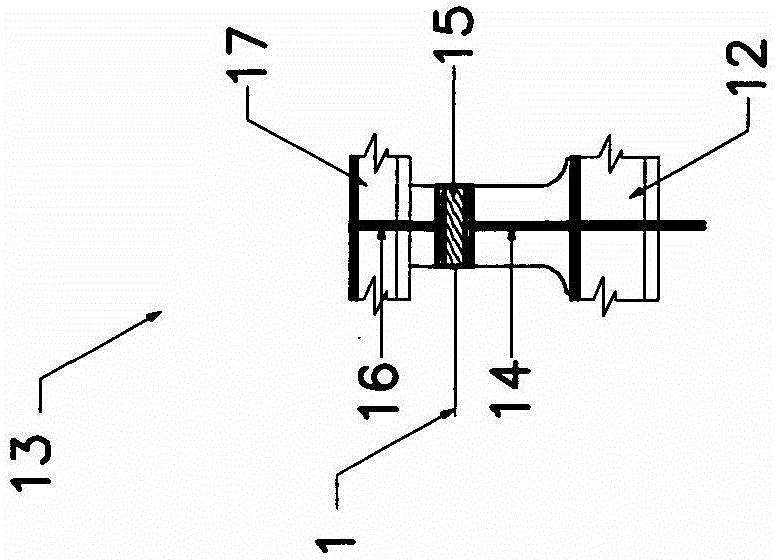

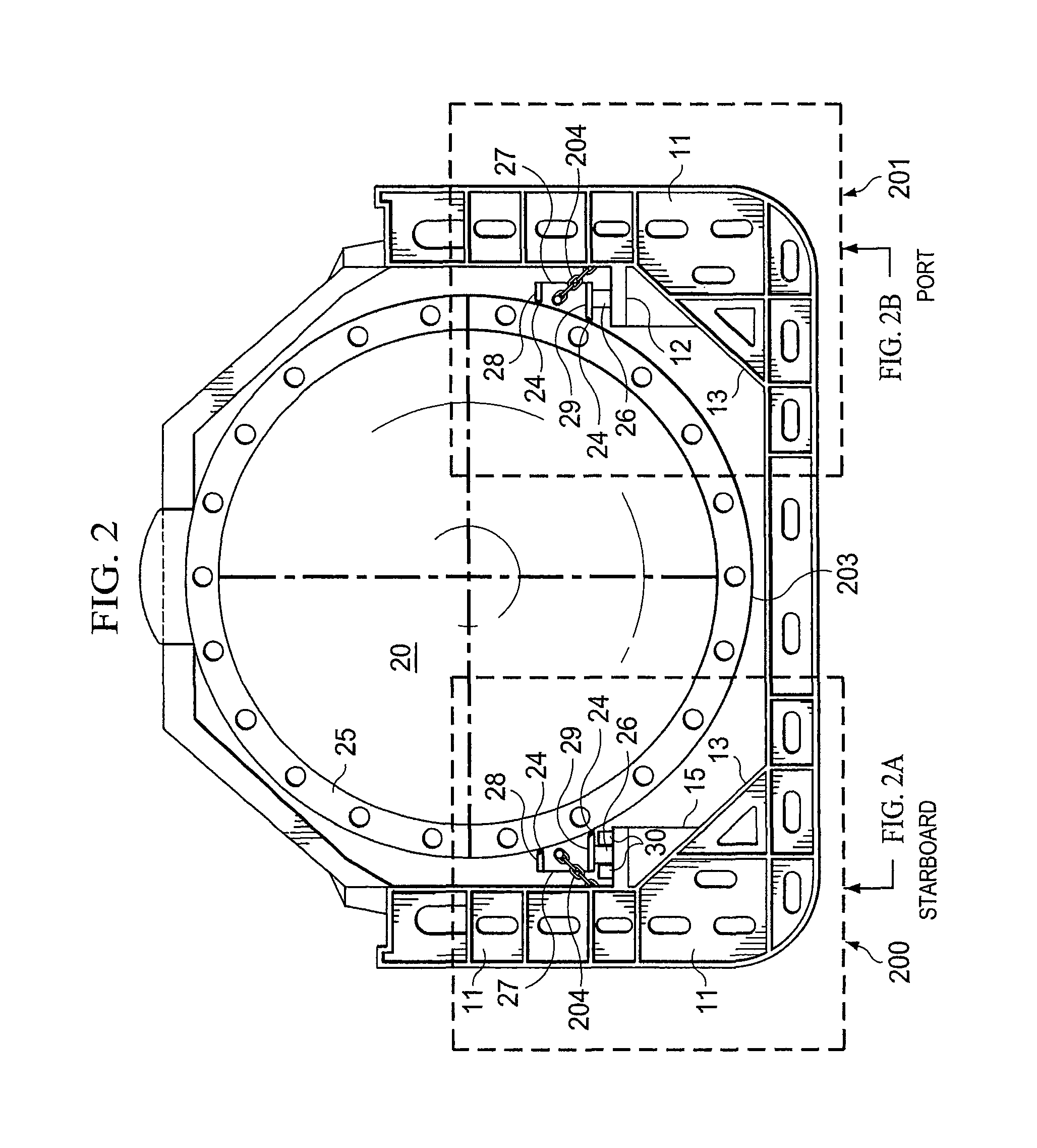

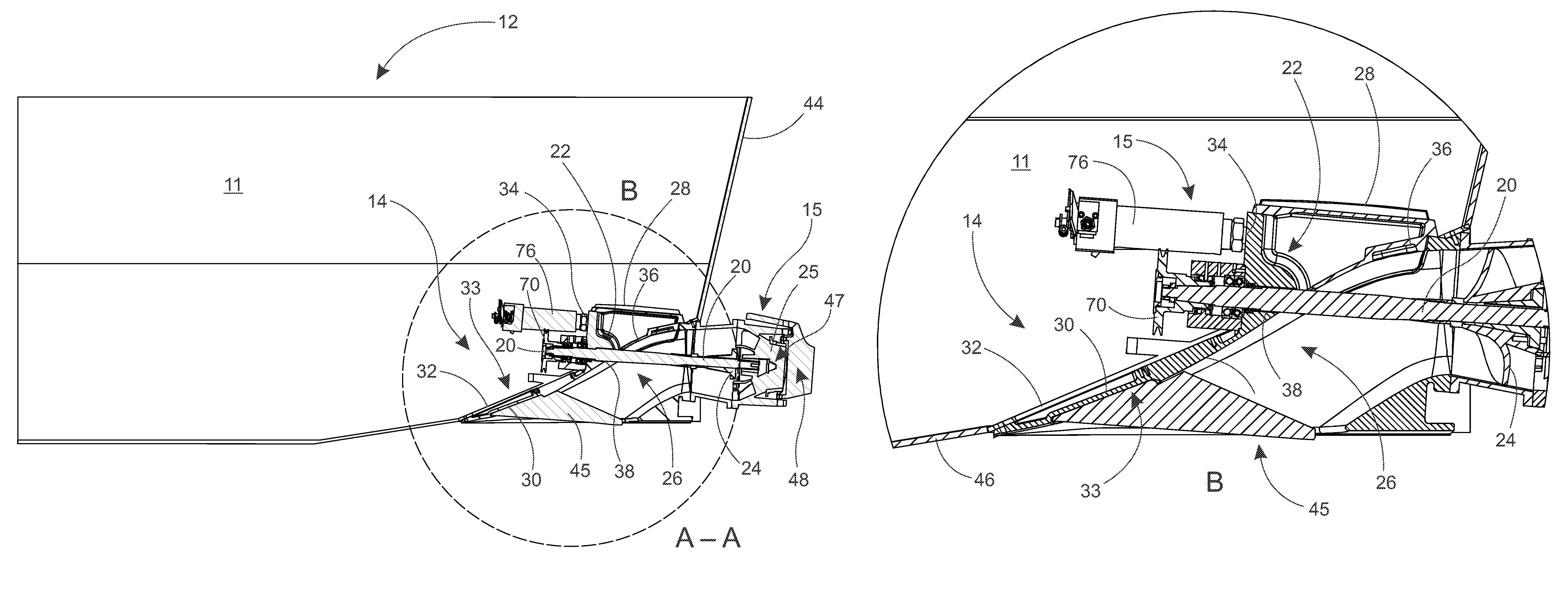

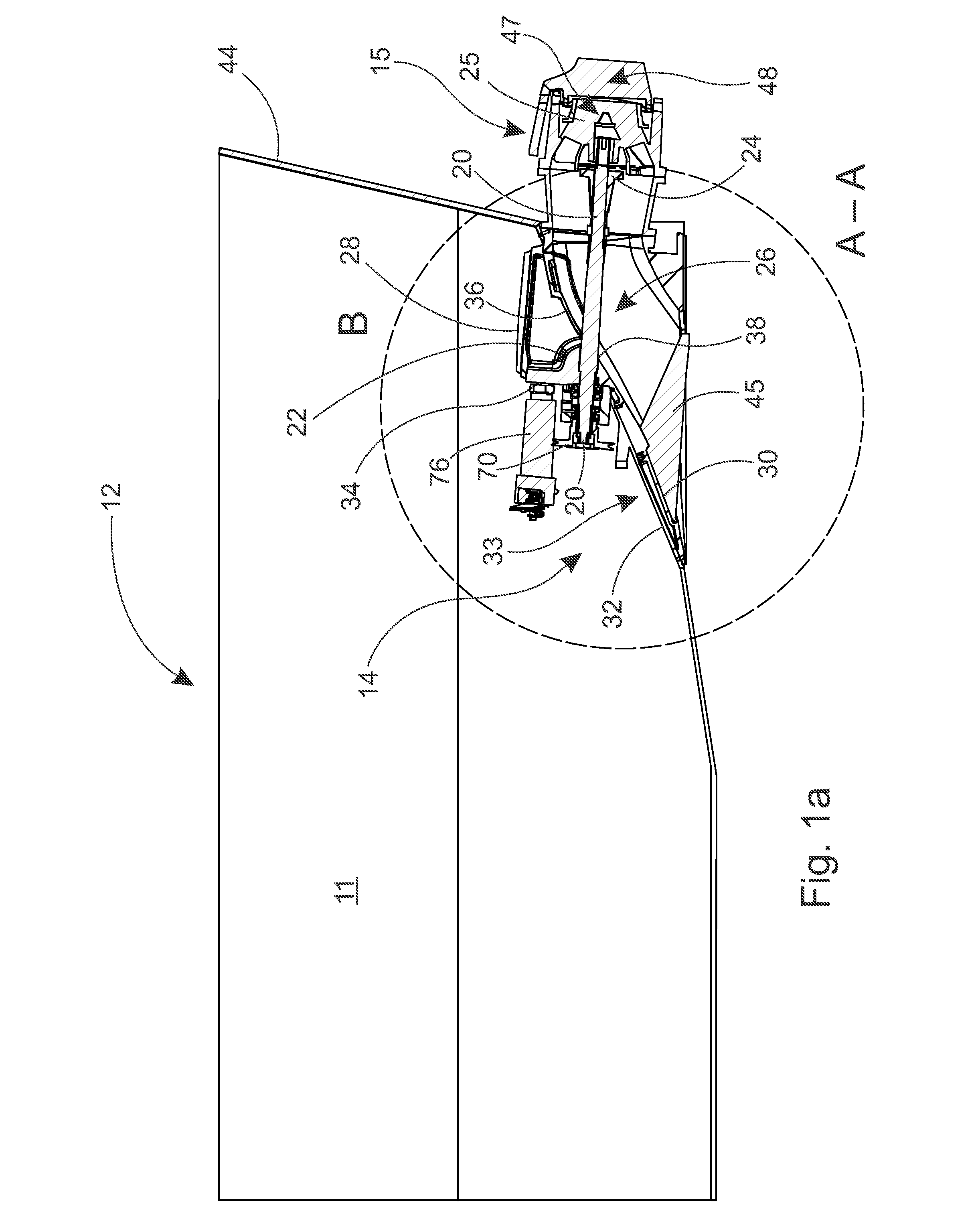

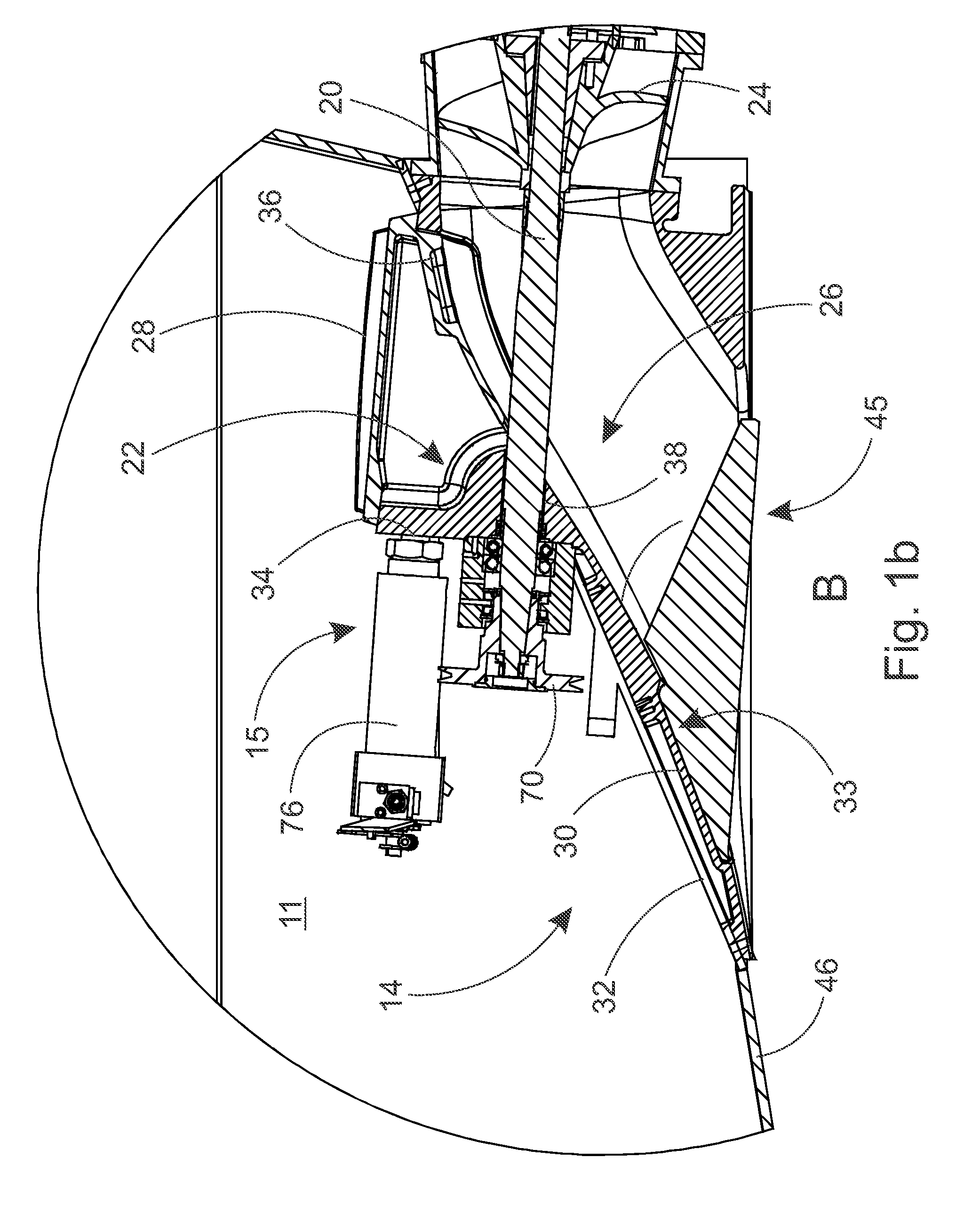

Frame of a water-jet propulsion unit for a boat, a water jet propulsion unit and an arrangement in a boat

ActiveUS9346522B2Easy to installImprove sealingPropulsion power plantsPropulsive elementsImpellerClosed loop

Owner:ALAMARIN JET

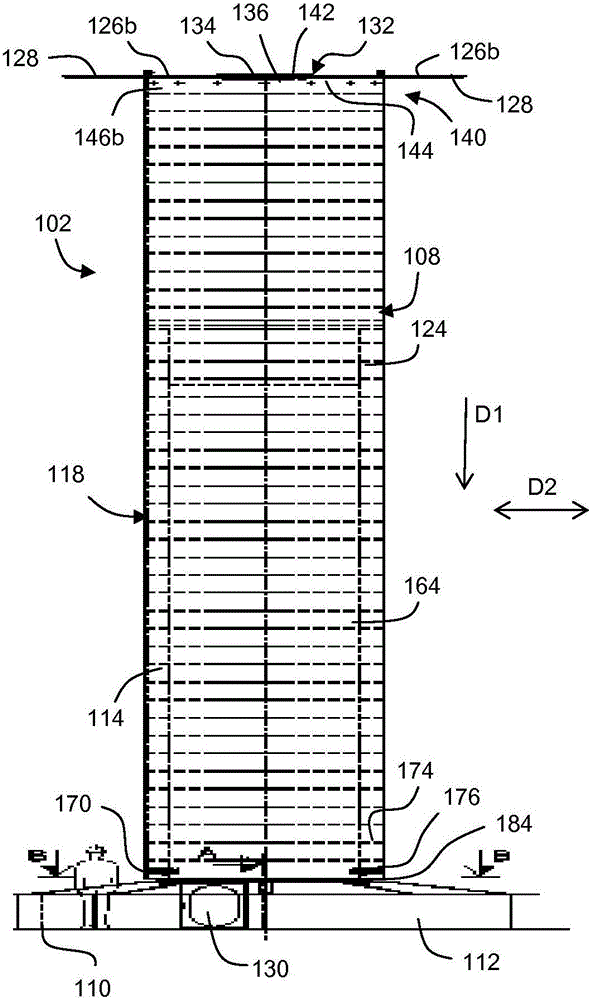

Propulsion system for aquatic vessels

ActiveUS20160280347A1Simple systemEasy maintenancePropulsion based emission reductionRoller bearingsBreathingElectric motor

A propulsion system (102) for an aquatic vessel (100) is provided. The propulsion system includes a plurality of Magnus-type rotors (108) and a drive arrangement (147) for rotating the plurality of Magnus-type rotors. The plurality of Magnus-type rotors are operable to rotate about corresponding substantially upright axes. The propulsion system also includes a control arrangement (150) for controlling the drive arrangement to vary rates of rotations of the plurality of Magnus-type rotors. Each of the plurality of Magnus-type rotors includes a hollow region (116) therein. Each of the Magnus-type rotors is rotationally supported onto a support arrangement (118) which extends into the hollow region. The drive arrangement includes at least one motor (148) disposed in the hollow region and located outside the support arrangement such that the at least one motor is accessible for maintenance. Furthermore, the at least one Magnus-type rotor includes a ventilation aperture arrangement (132) for enabling an upward movement of air to occur in operation within the at least one Magnus-type rotor for ventilating and cooling the drive arrangement and / or other internal components.

Owner:NORSEPOWER OY

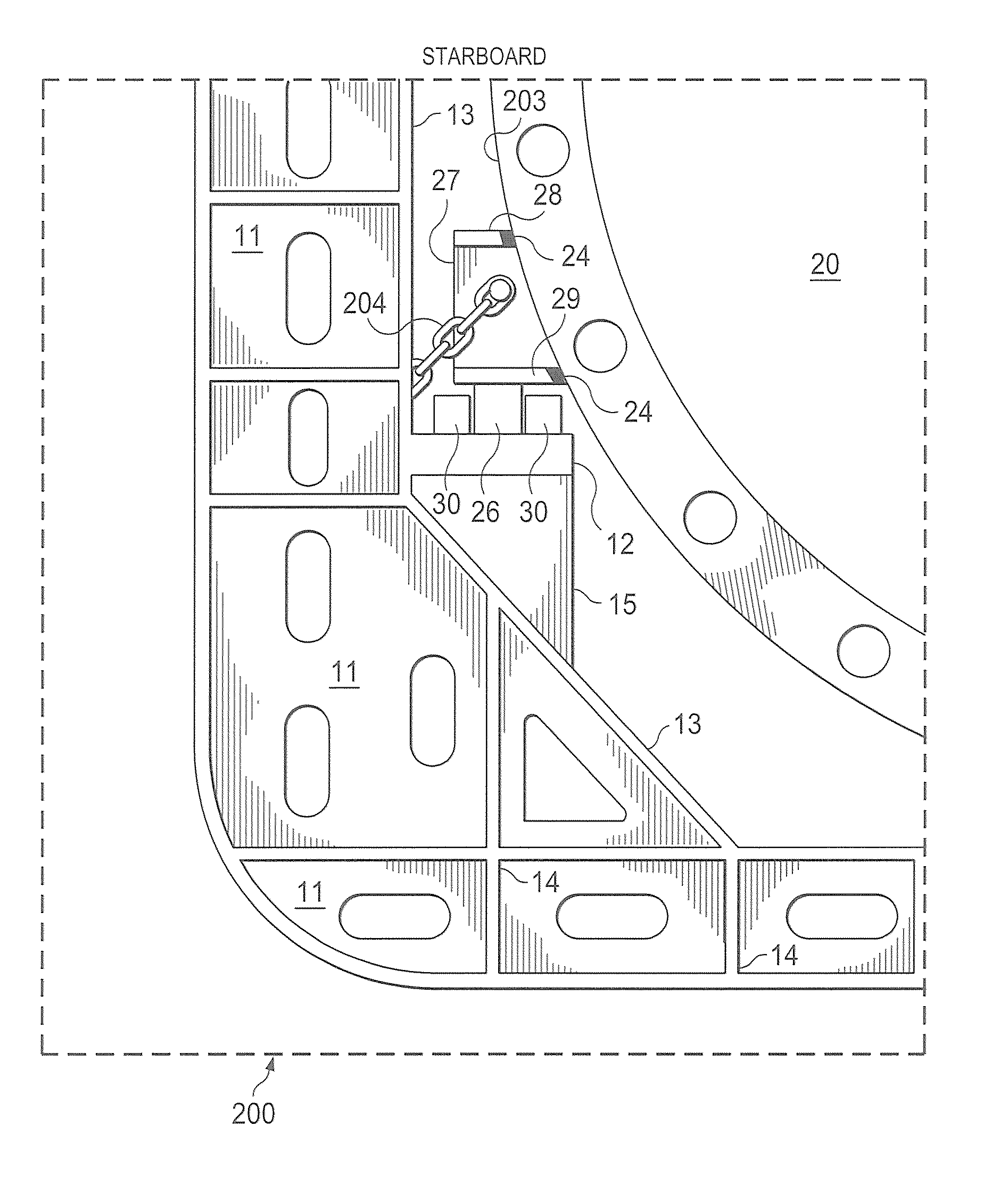

Systems and methods for supporting tanks in a cargo ship

ActiveUS20100012014A1Reduce frictionFreedom of movementPreventing unwanted cargo movementContainer filling methodsHull structureCargo vessel

There are disclosed systems and methods for supporting cargo tanks within the hold of a liquefied gas carrier by establishing a series of spaced-apart pedestals along the longitudinal axis of a tank, said pedestals positioned in conjunction with the ship's structural components. These pedestals are of wood or other suitable thermal insulating and load bearing material fixed to the tank below its circumferential diameter along both the starboard and port tank sides. The pedestals rest on structural longitudinal stringers laying port and starboard in the horizontal plane and fixed and supported by the ship's hull structure. Longitudinal and transverse pedestal movement is controlled by stops attached to the stringers at one or more of the pedestals. The stops contact the pedestals via bearing pads which constrain the pedestal in one direction but permit its movement in another.

Owner:SSRC TECH AS

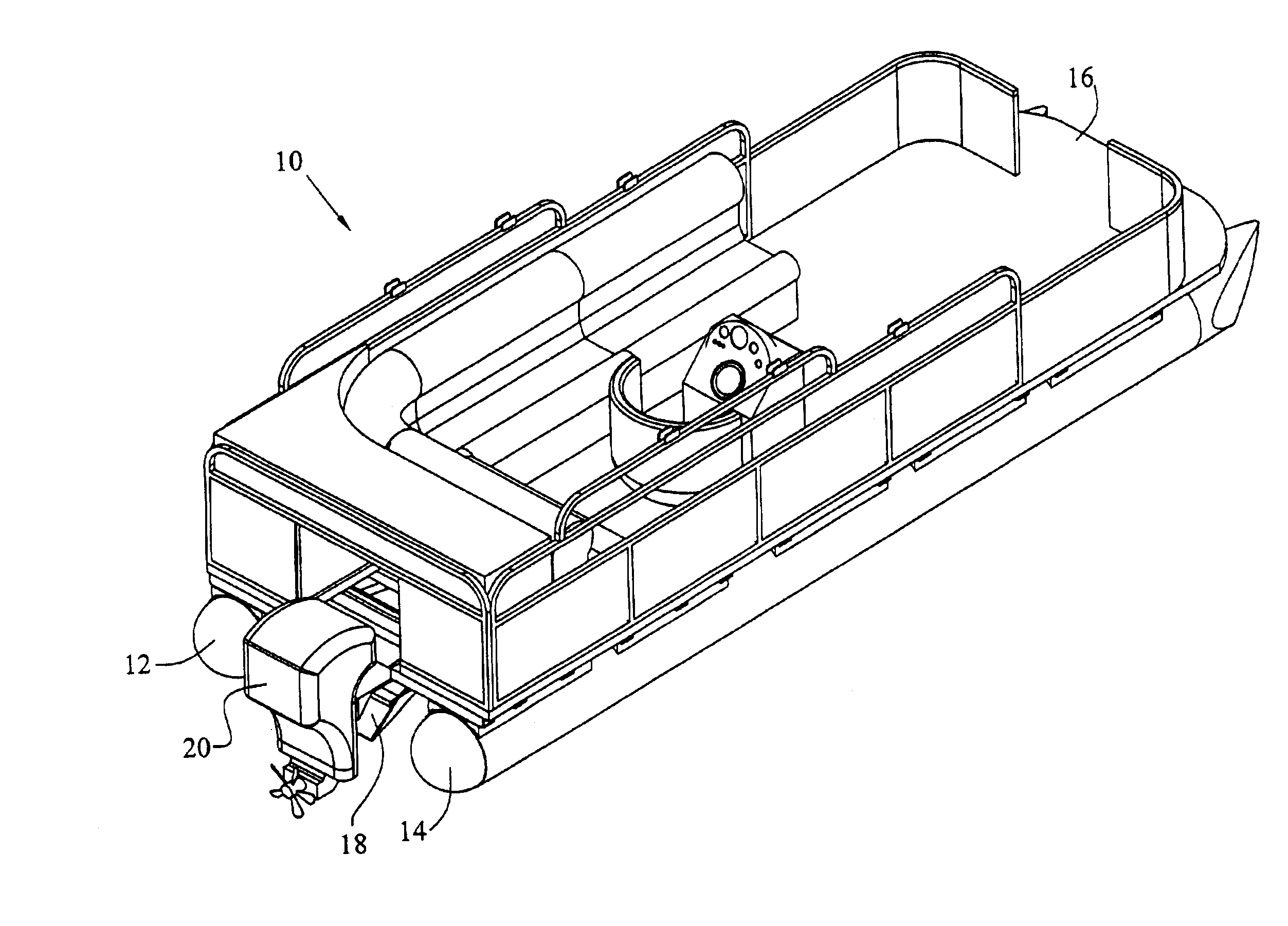

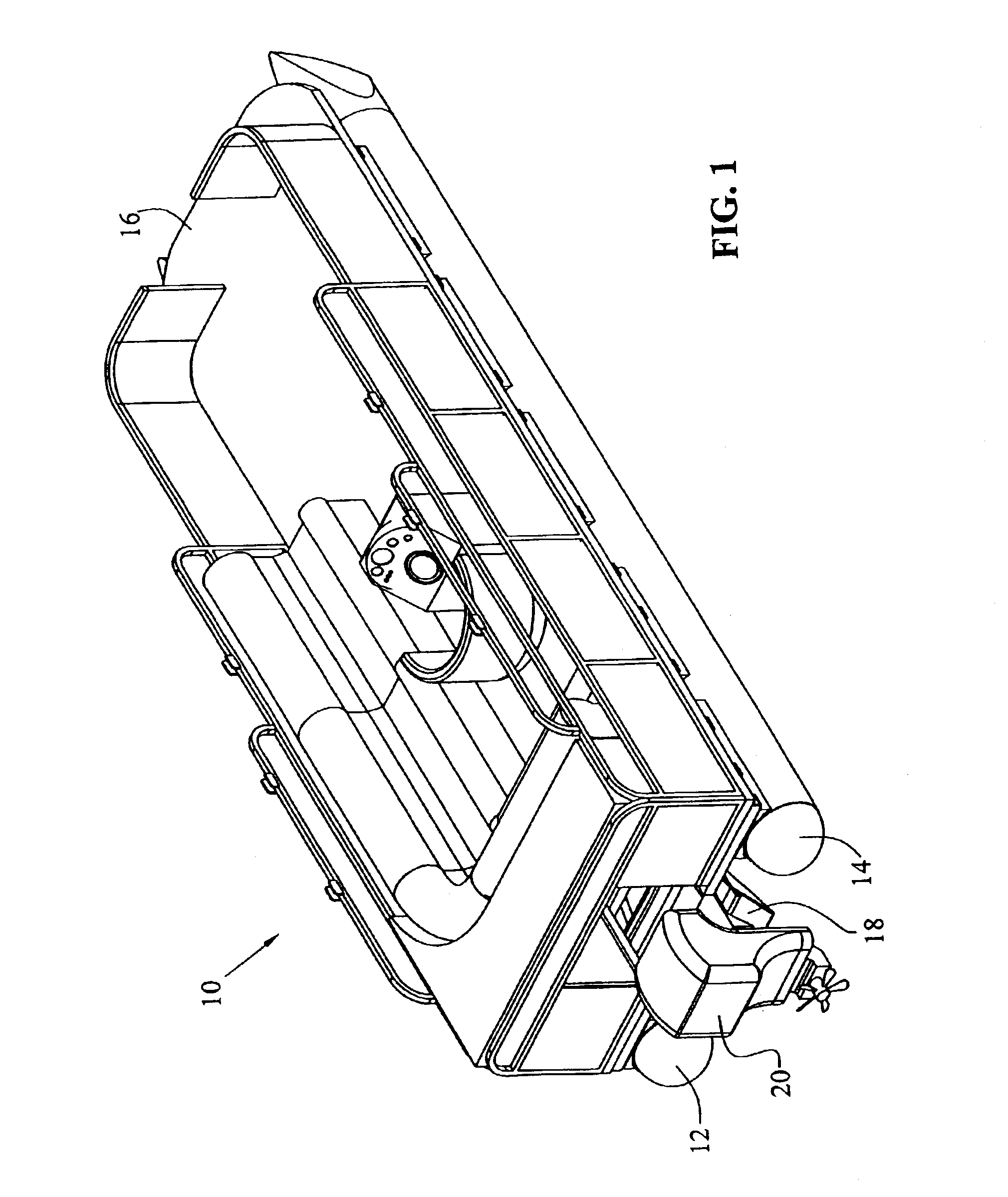

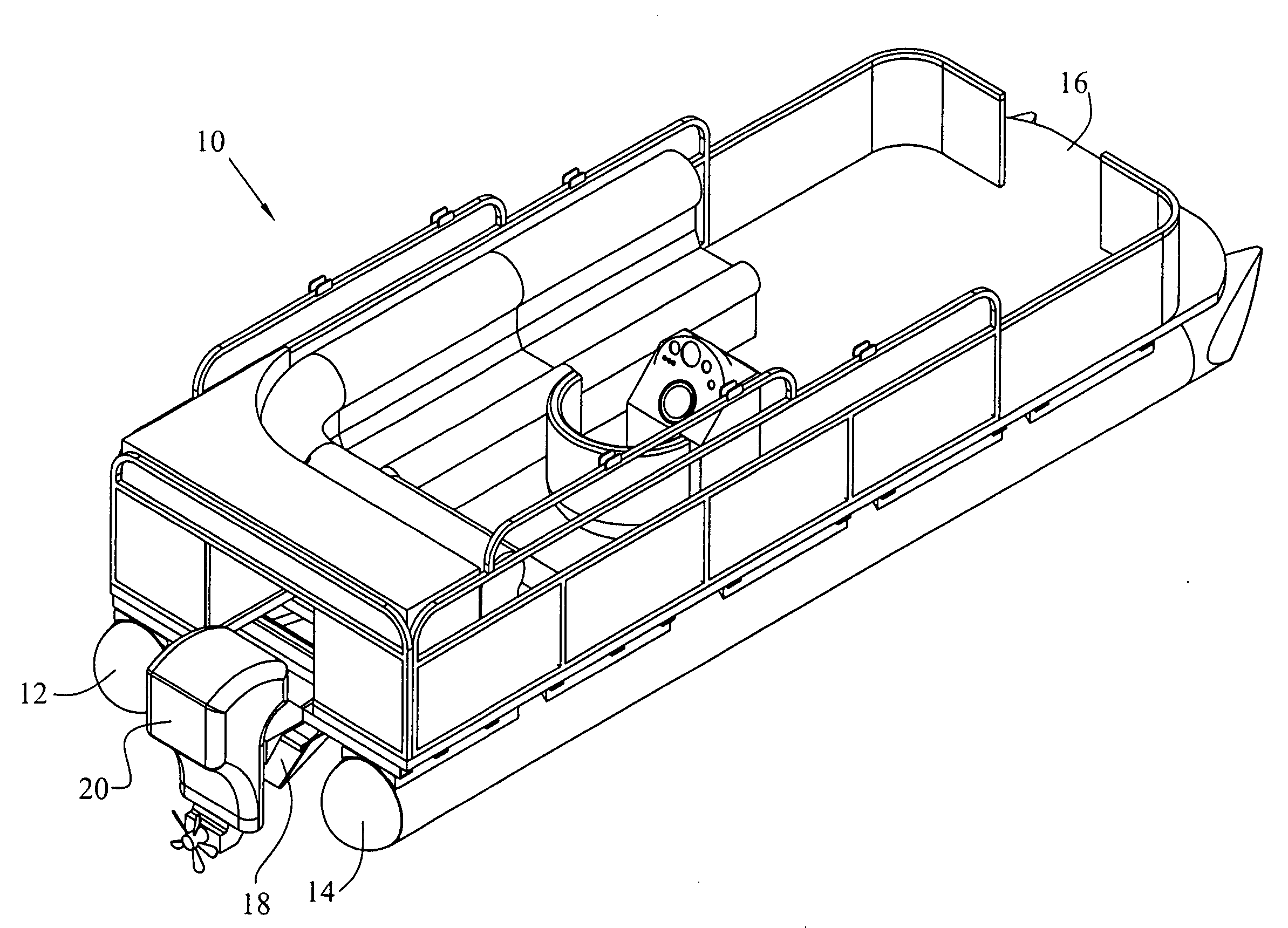

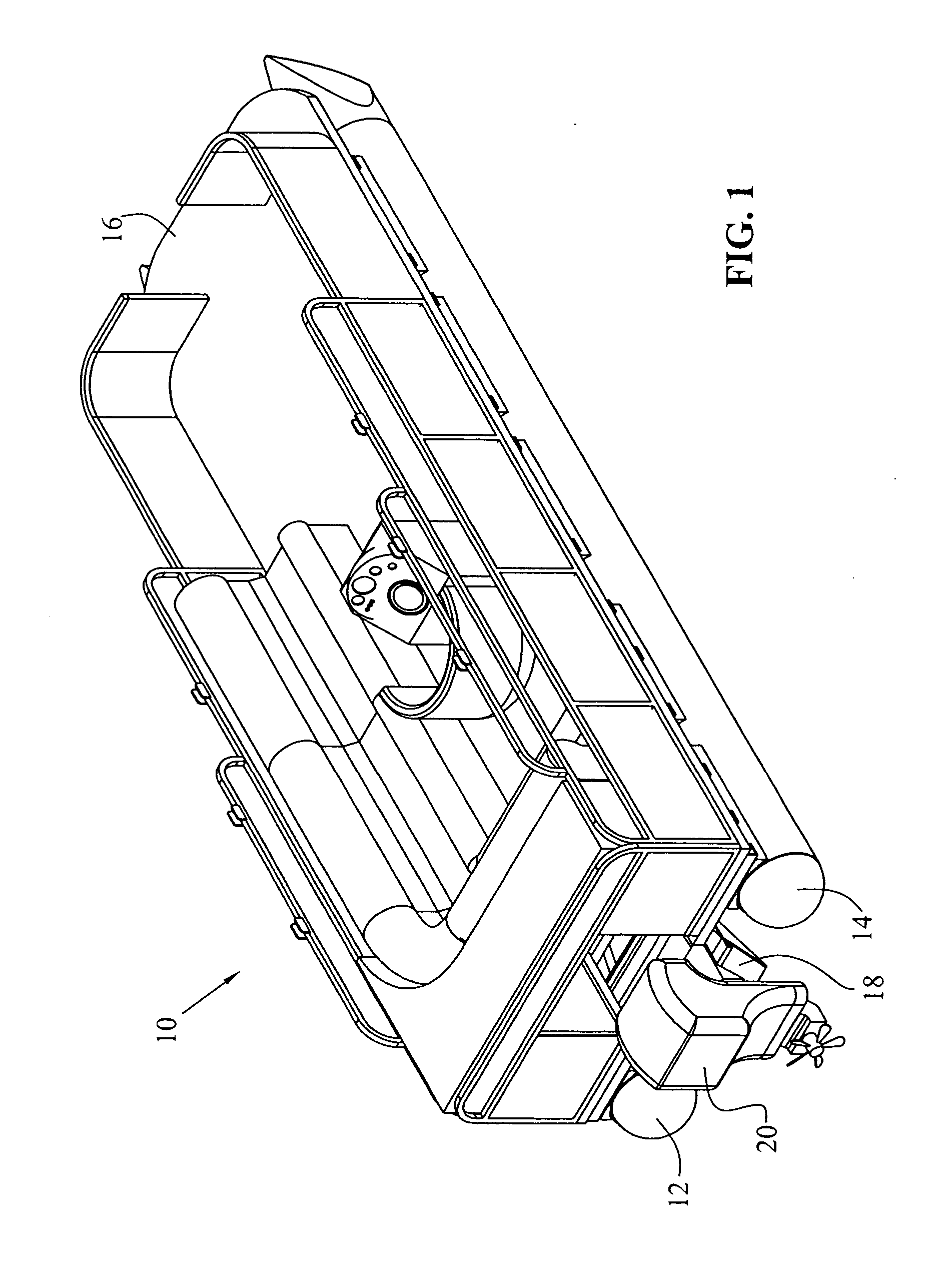

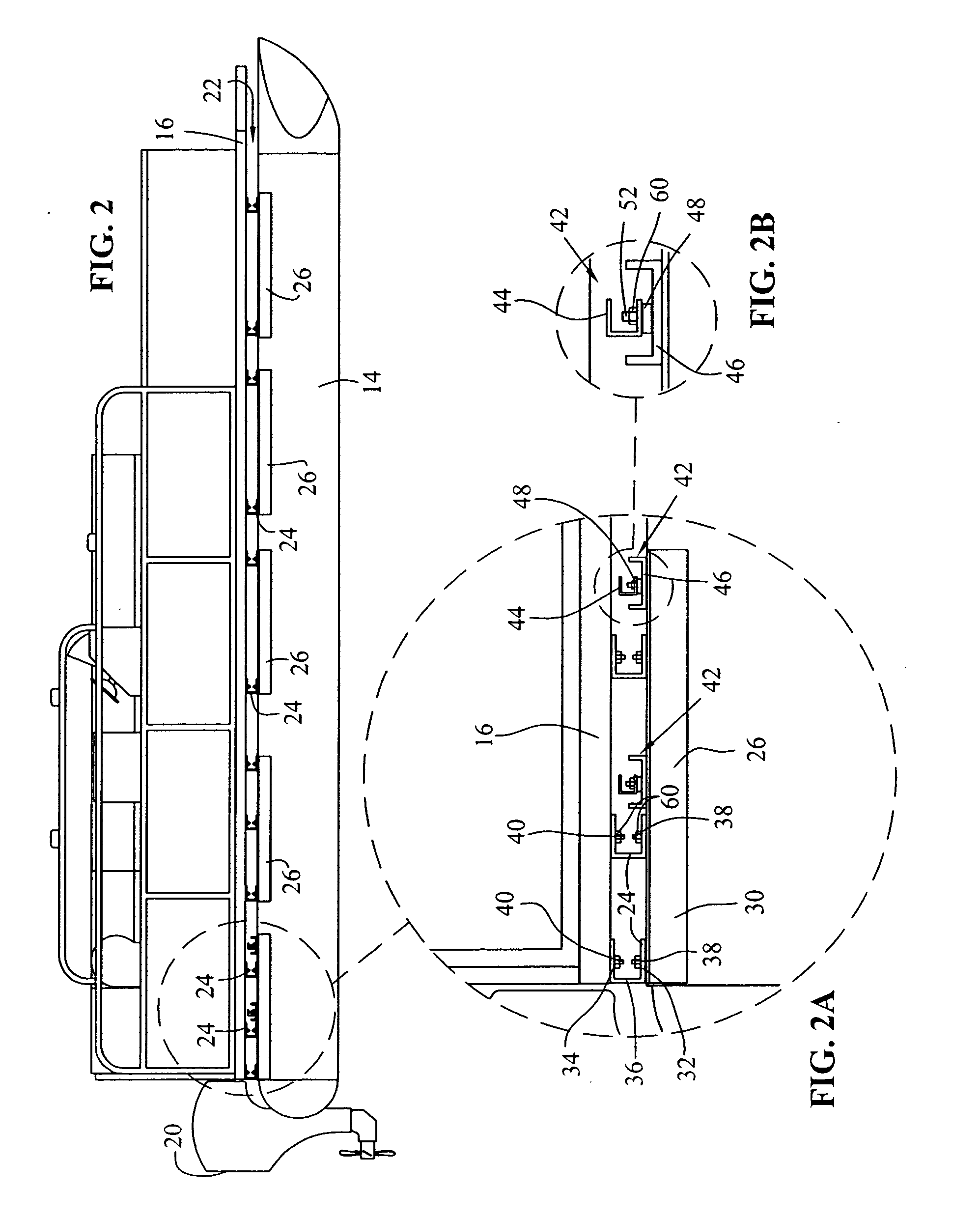

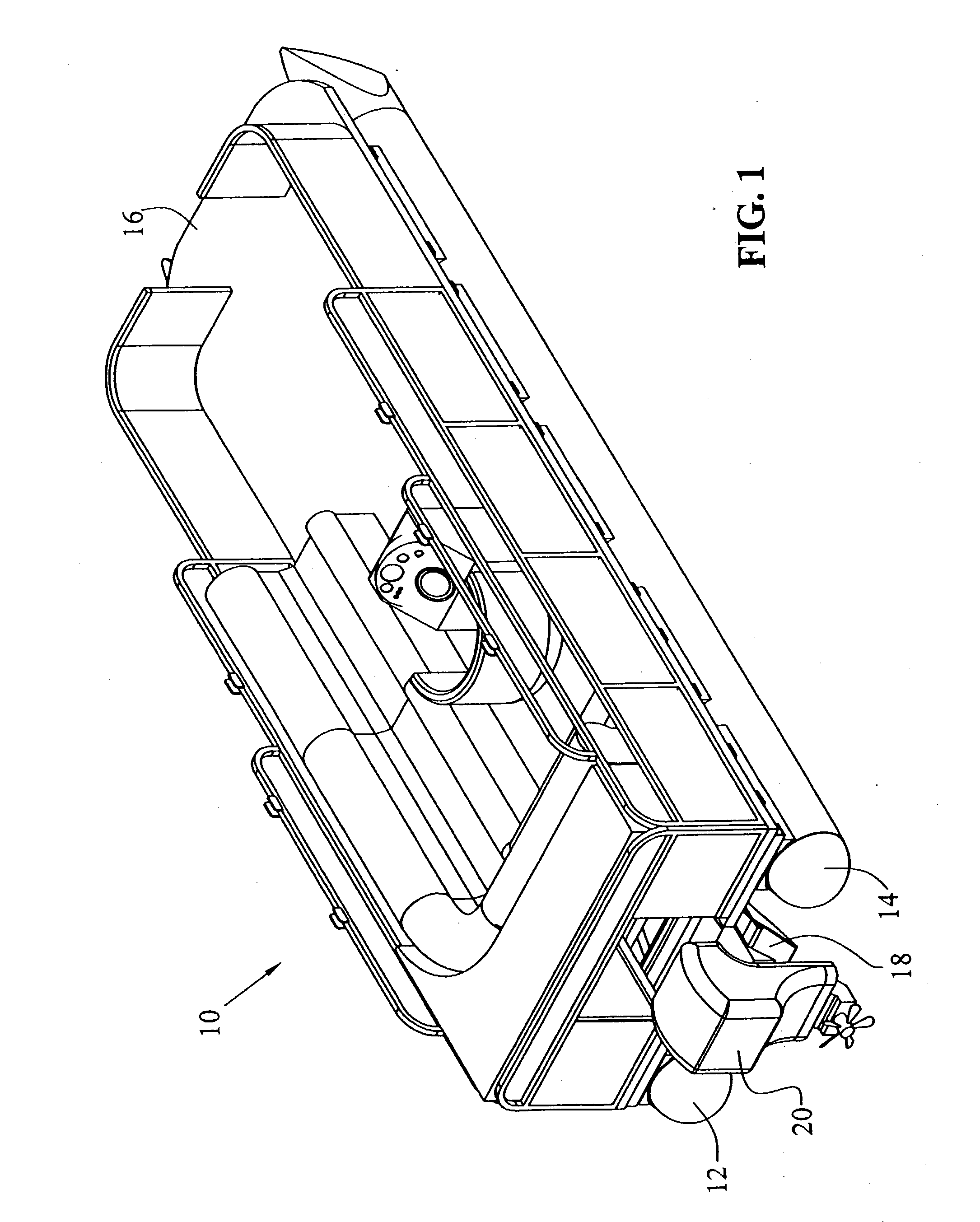

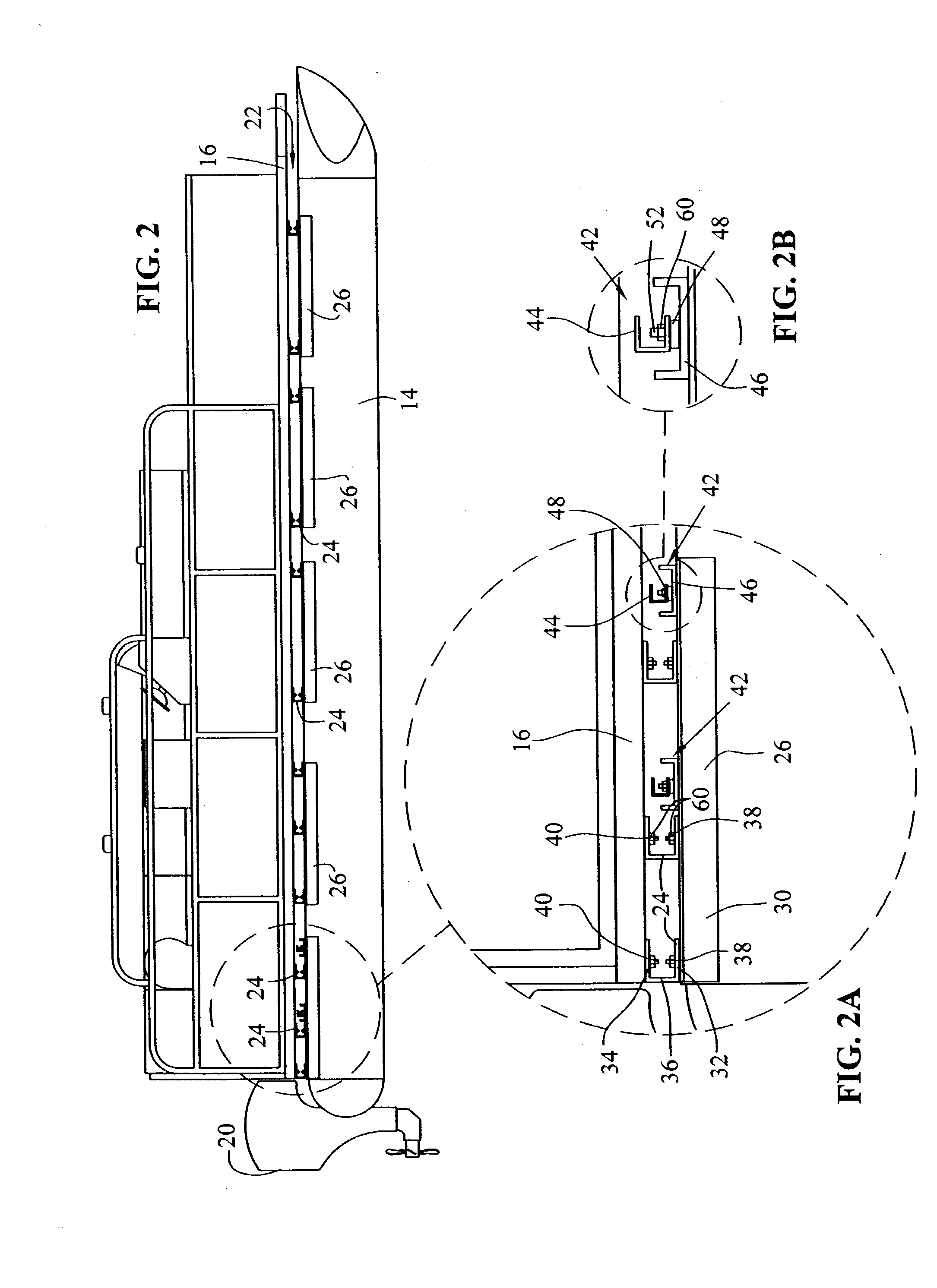

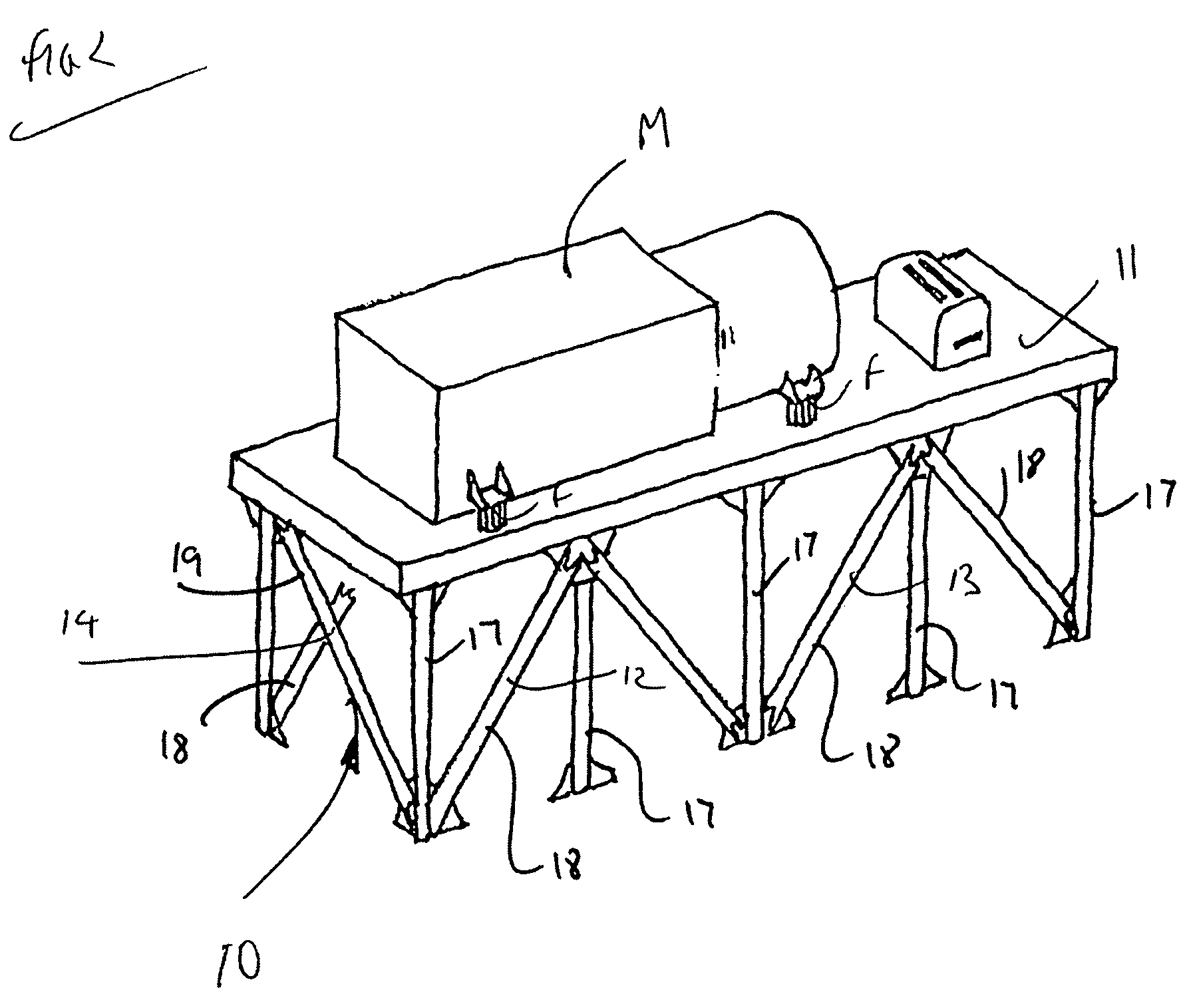

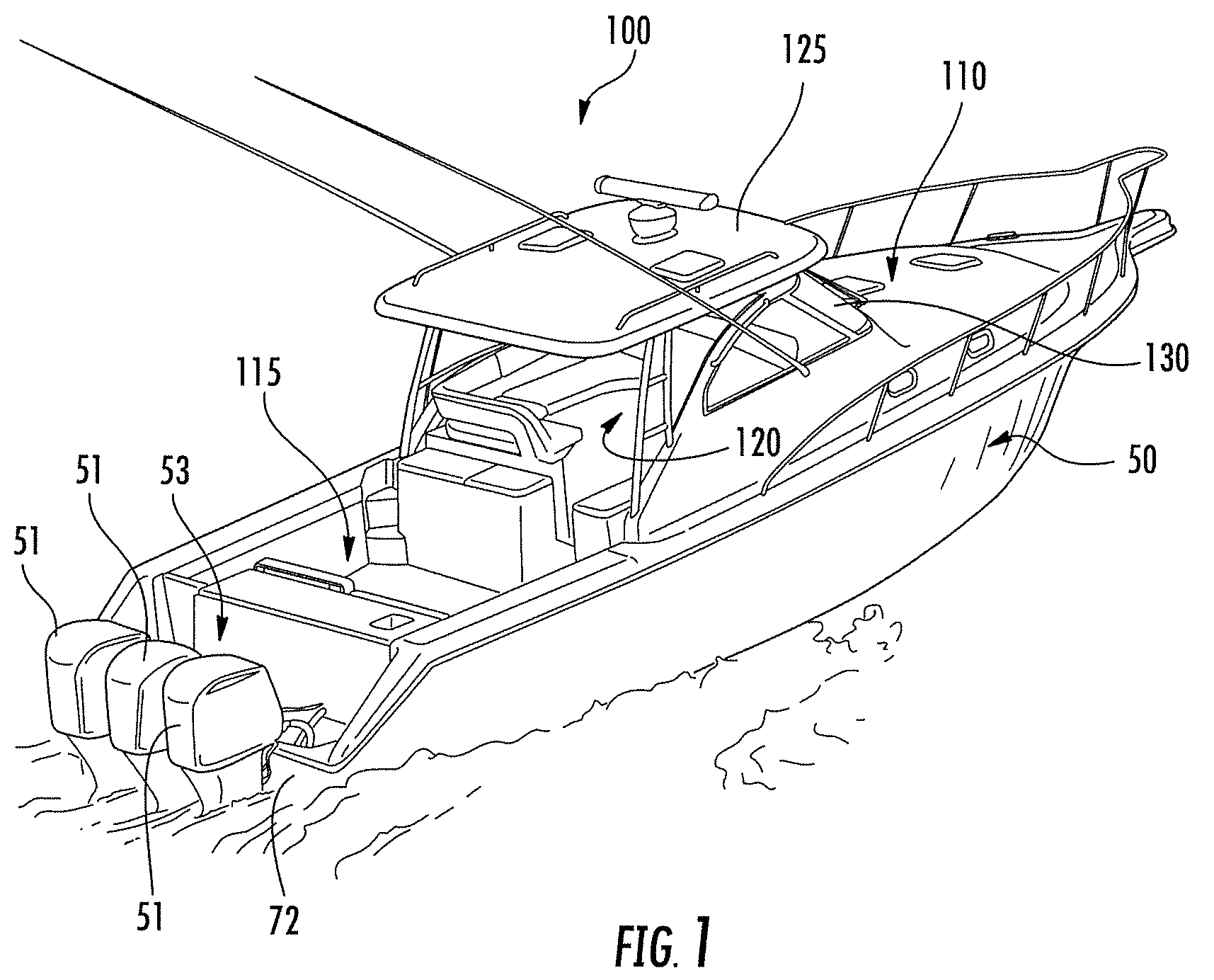

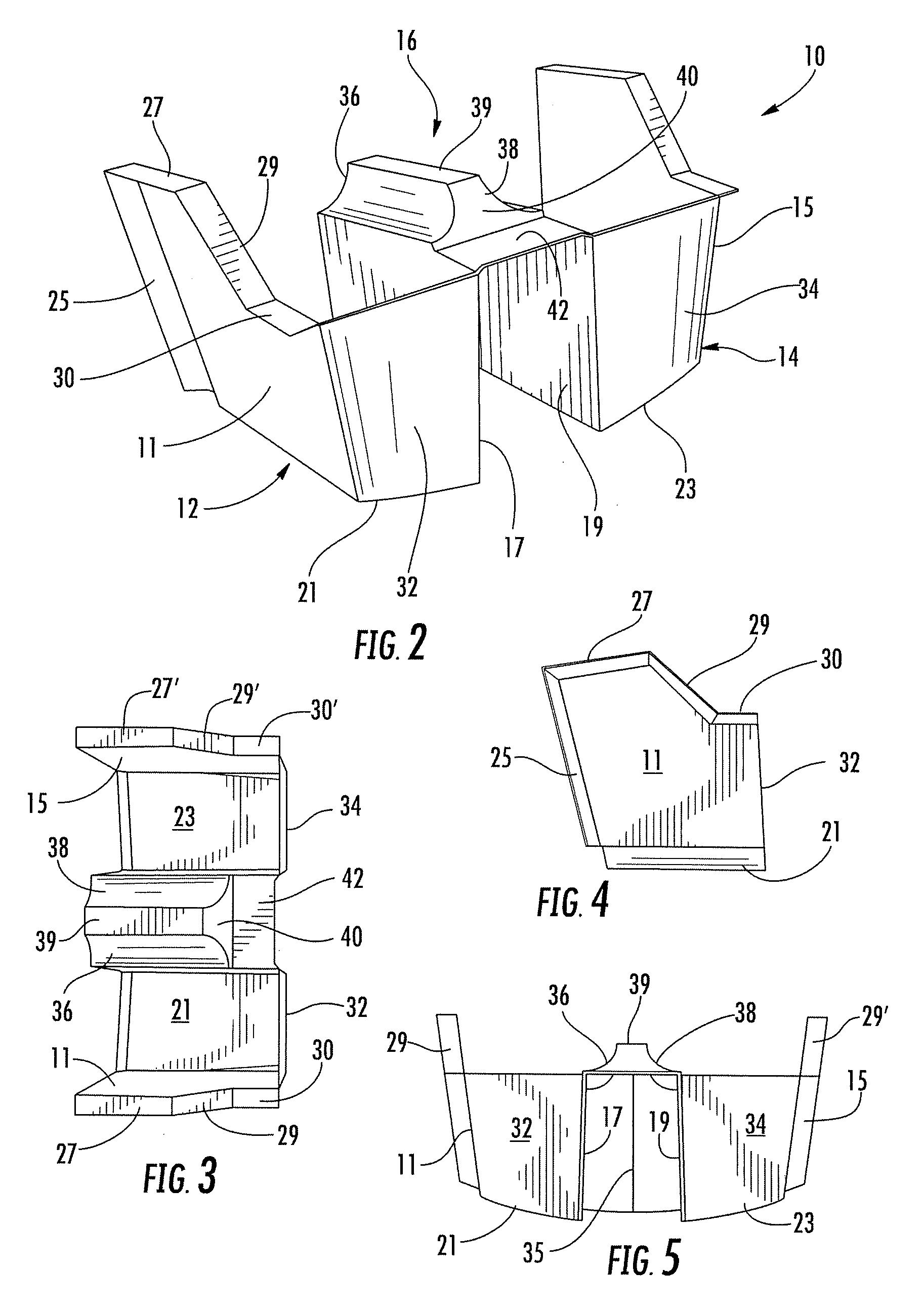

Isolated motor pan for watercraft

InactiveUS6939184B2Dampening energy transferredReduce vibration transmissionRotary propellersHull decksWatercraftControl theory

A dampening assembly used in watercraft to isolate the motor from the deck of the watercraft. In an embodiment of the invention, a frame including cross-members and a plurality of brackets supports the deck. The dampening assembly of the present invention extends from the brackets of the frame to the motor and retains the motor at a position ensuring the motor does not contact the frame. The only path available to the vibrations generated by the motor is represented by the dampening assemblies that direct the vibrations to the brackets and tubes, thereby eliminating the high amplitude, low frequency vibrations that readily transfer throughout the deck and frame structure. In this manner, the vibrations are prevented from traveling directly through the cross-members of the frame and into the deck of the watercraft.

Owner:PONTOON BOAT

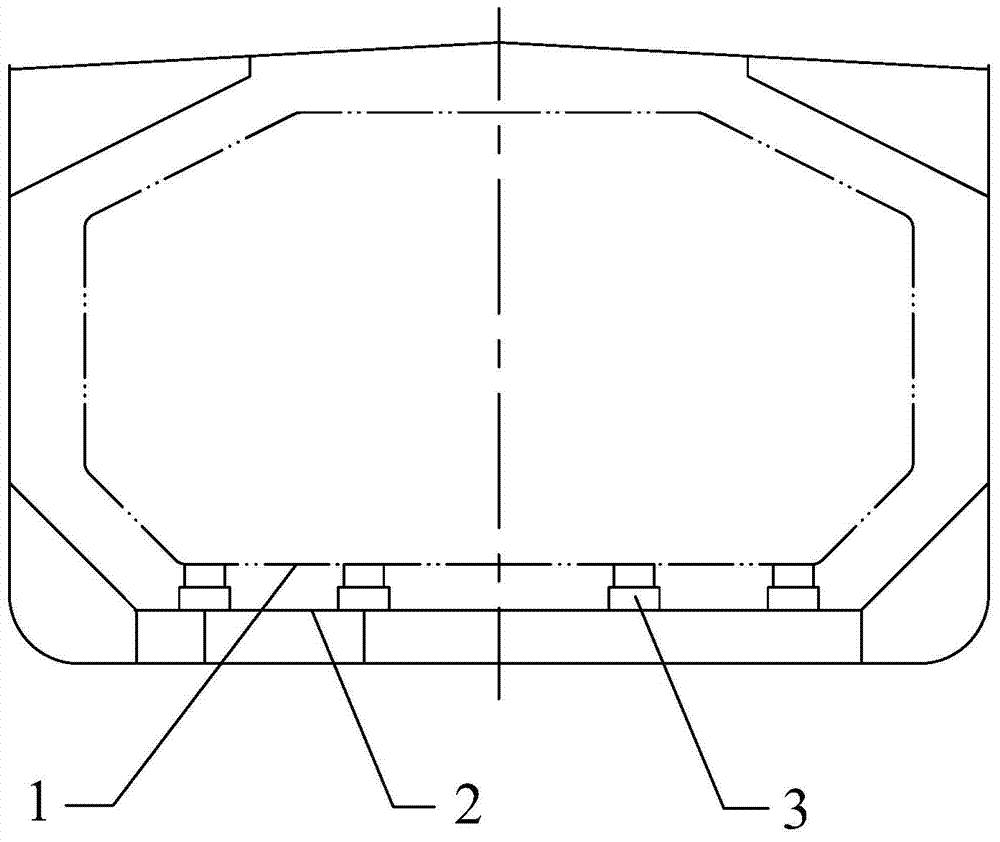

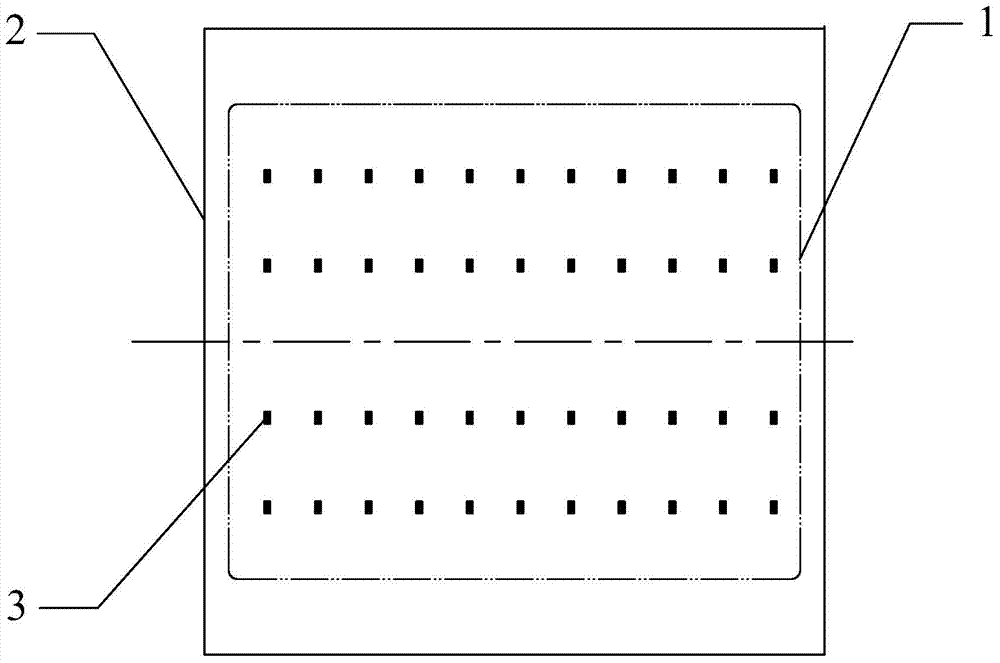

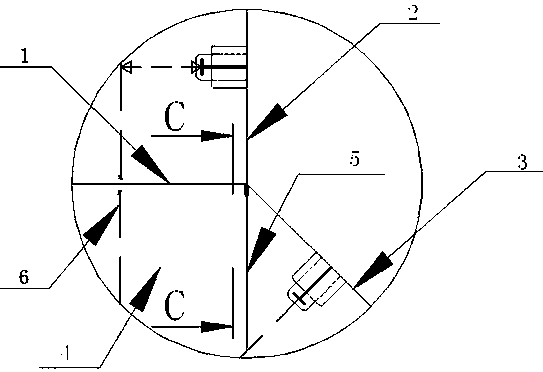

Independent liquid tank supporting structure

InactiveCN104709438AAvoid cold transferAvoid destructionHull reinforcementsFor bulk goodsHull structureEpoxy

The invention provides an independent liquid tank supporting structure, comprising an upper supporting part, a pressure-bearing insulating part and a lower supporting part. The upper supporting part comprises an upper web and an upper panel, the top end and the bottom end of the upper web are connected fixedly with a liquid tank floor board and the upper panel; the lower supporting part comprises a lower web and a lower panel, and the top end and the bottom end of the lower web are connected fixedly with the lower panel and the inner bottom of a hull; the pressure-bearing insulating part is installed between the upper panel and the lower panel and comprises laminated wood fixedly connected with the upper panel, an epoxy resin layer fixedly connected with the lower panel, and a stainless steel plate positioned between the laminated wood and the epoxy resin layer and capable of moving horizontally relative to the laminated wood; the stainless steel plate is fixedly connected with the epoxy resin layer. The independent liquid tank supporting structure can effectively bear static and dynamic loads generated by an independent liquid tank and low-temperature liquid cargoes loaded in the independent liquid tank, and has certain flexibility; relative displacements and deformation are allowed to exist between the independent liquid tank and the hull structure; the low temperature of the independent liquid tank can be effectively avoided being transmitted to the hull.

Owner:JIANGNAN SHIPYARD GRP CO LTD

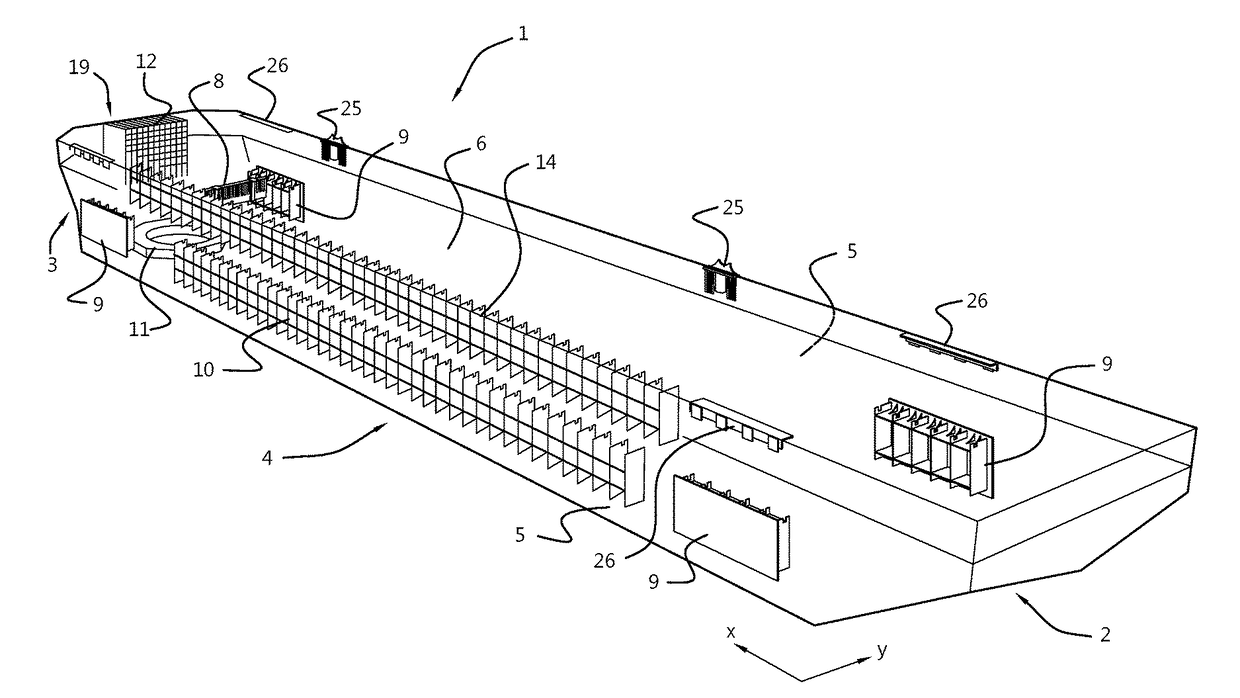

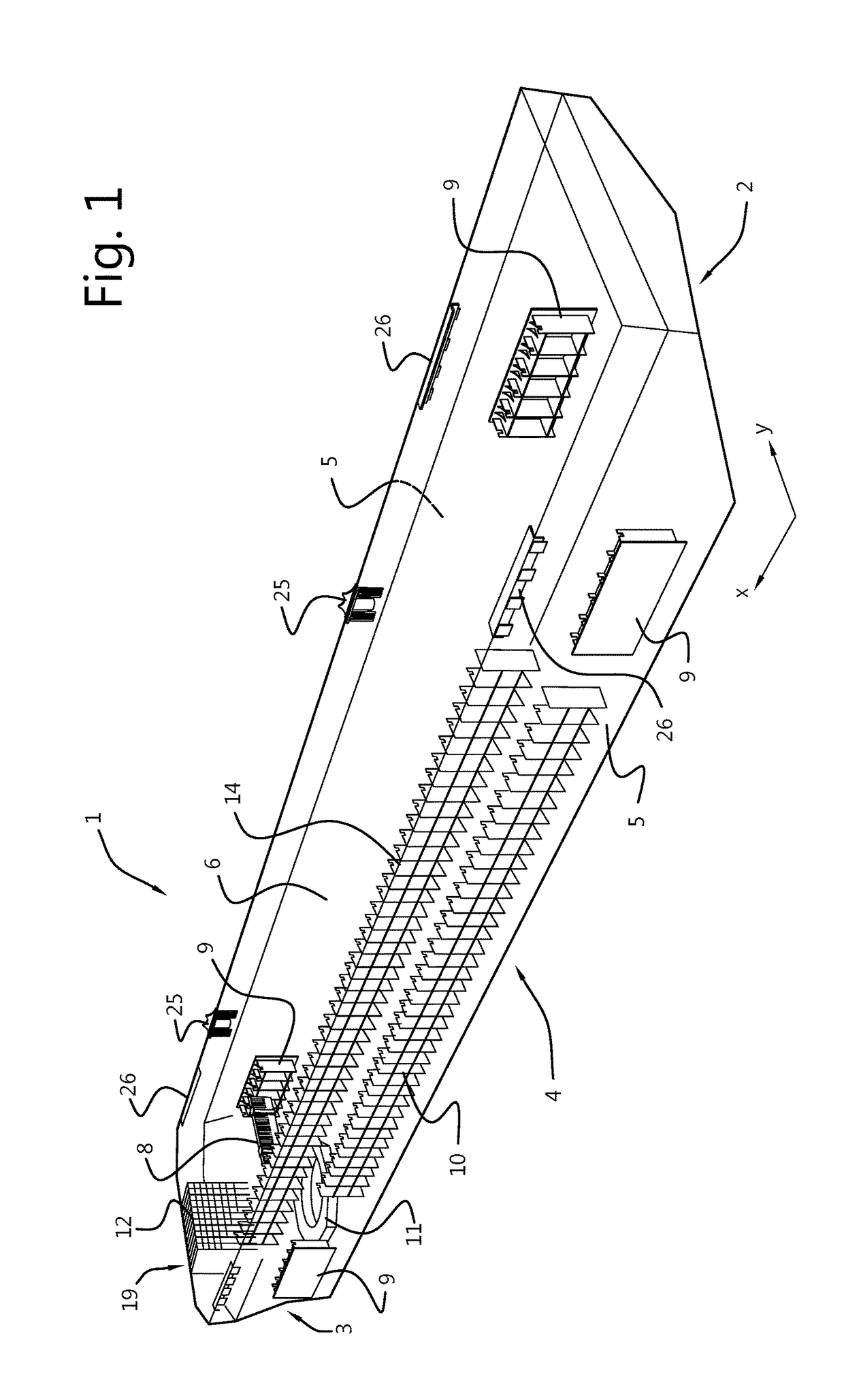

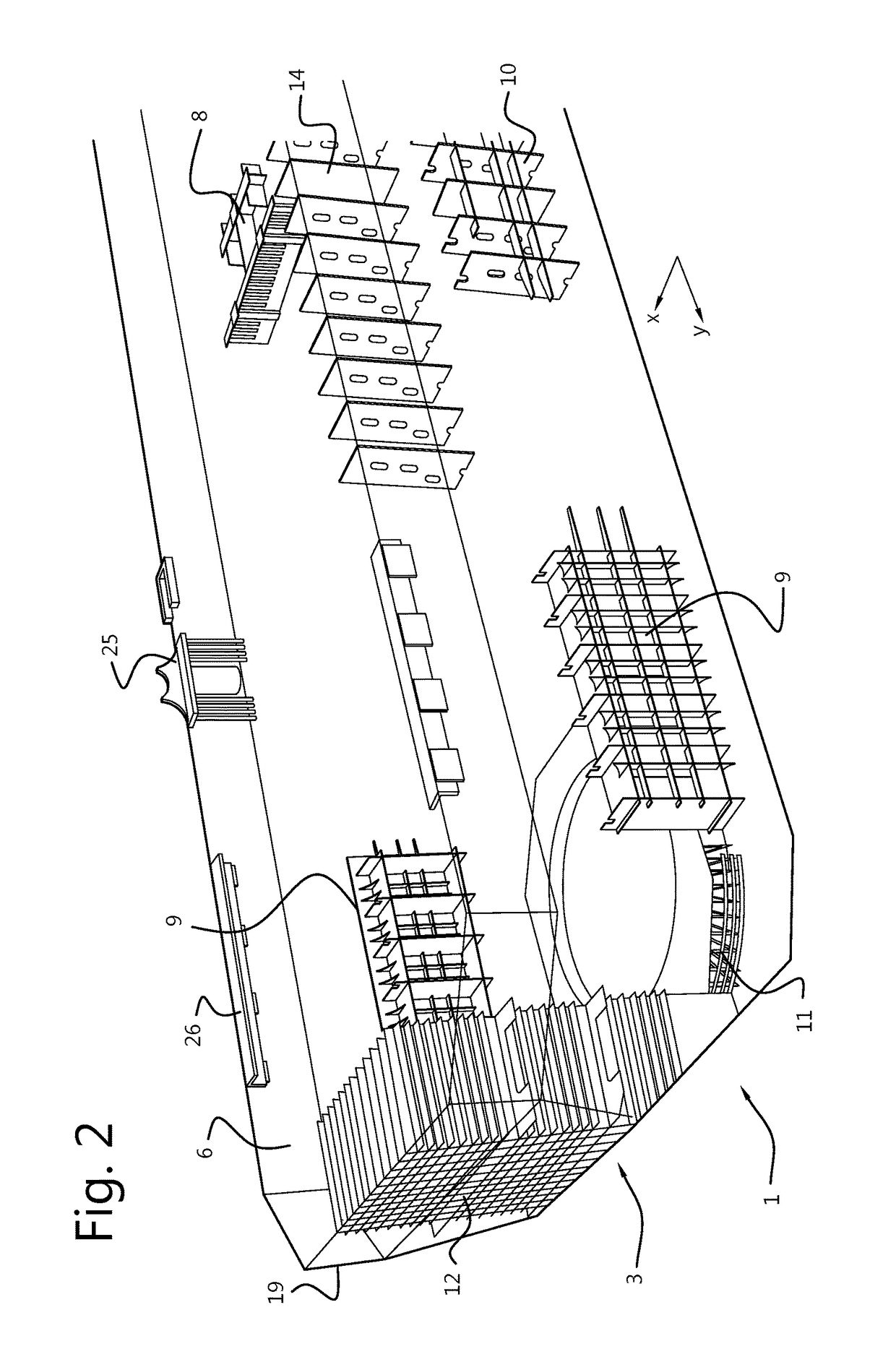

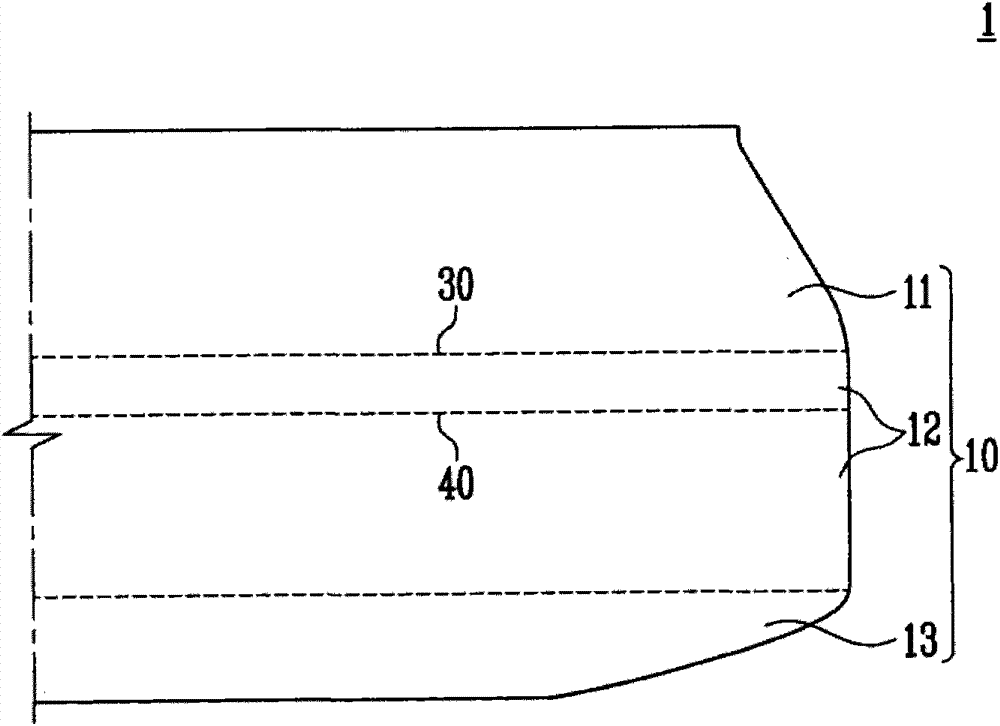

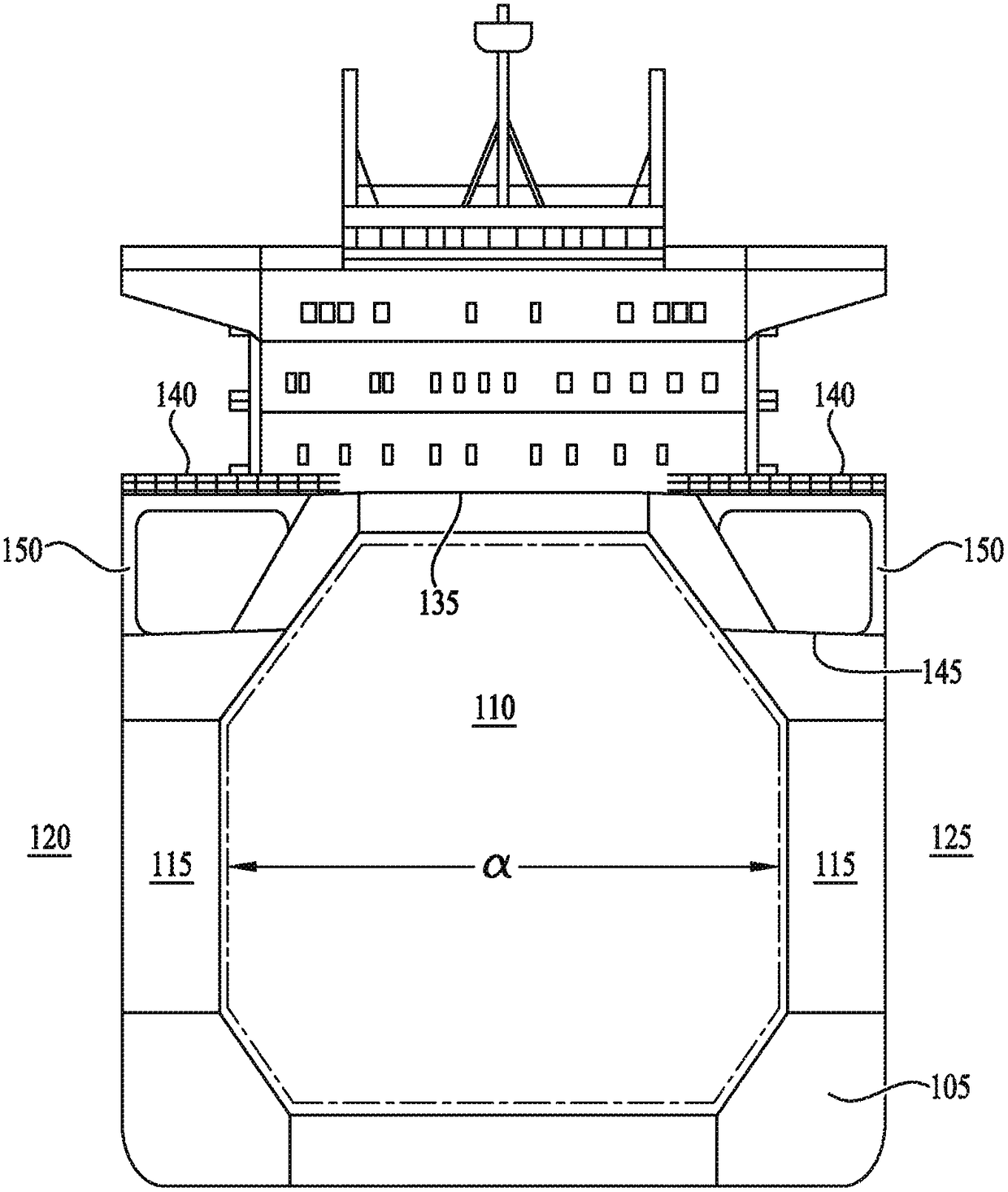

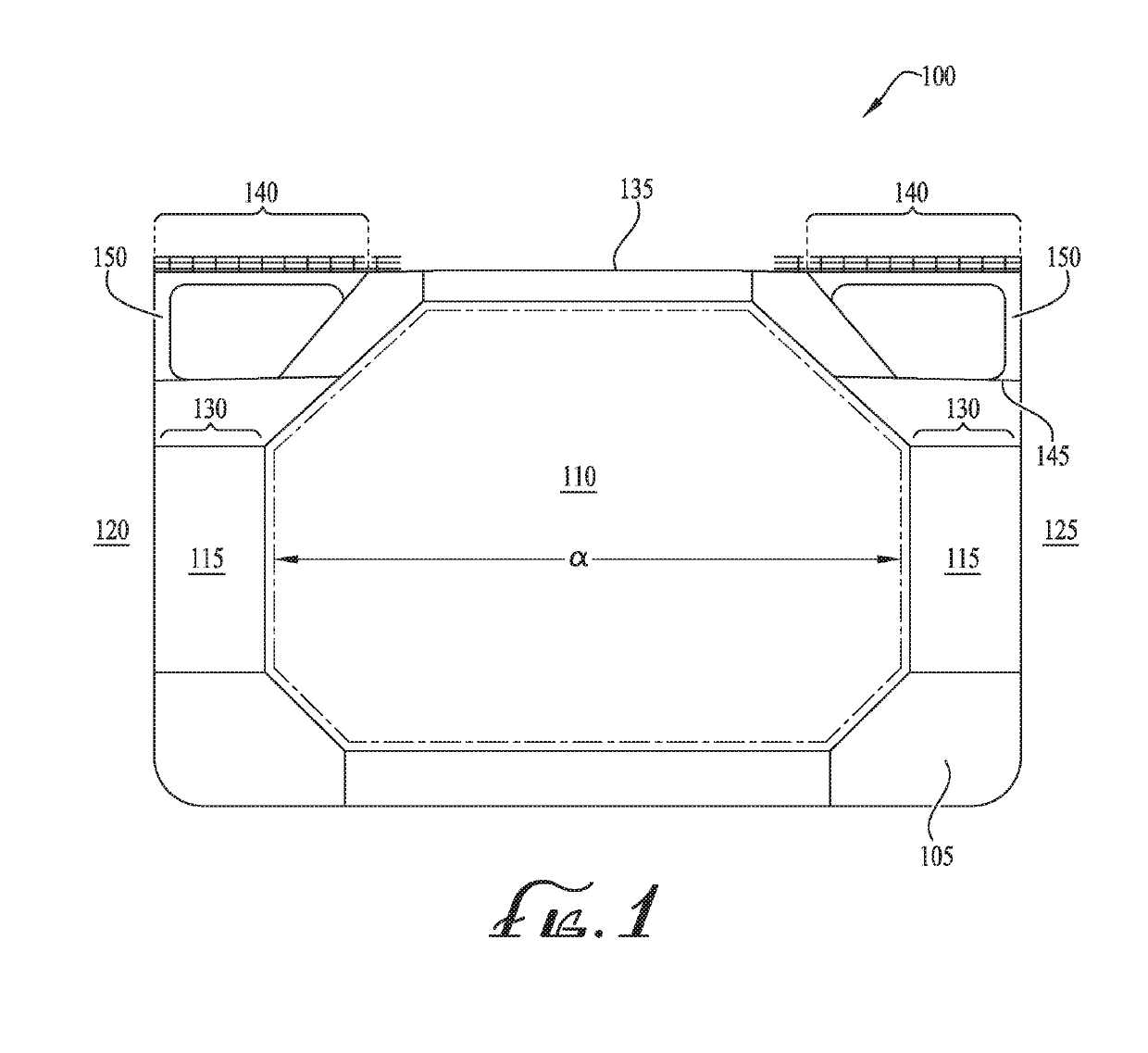

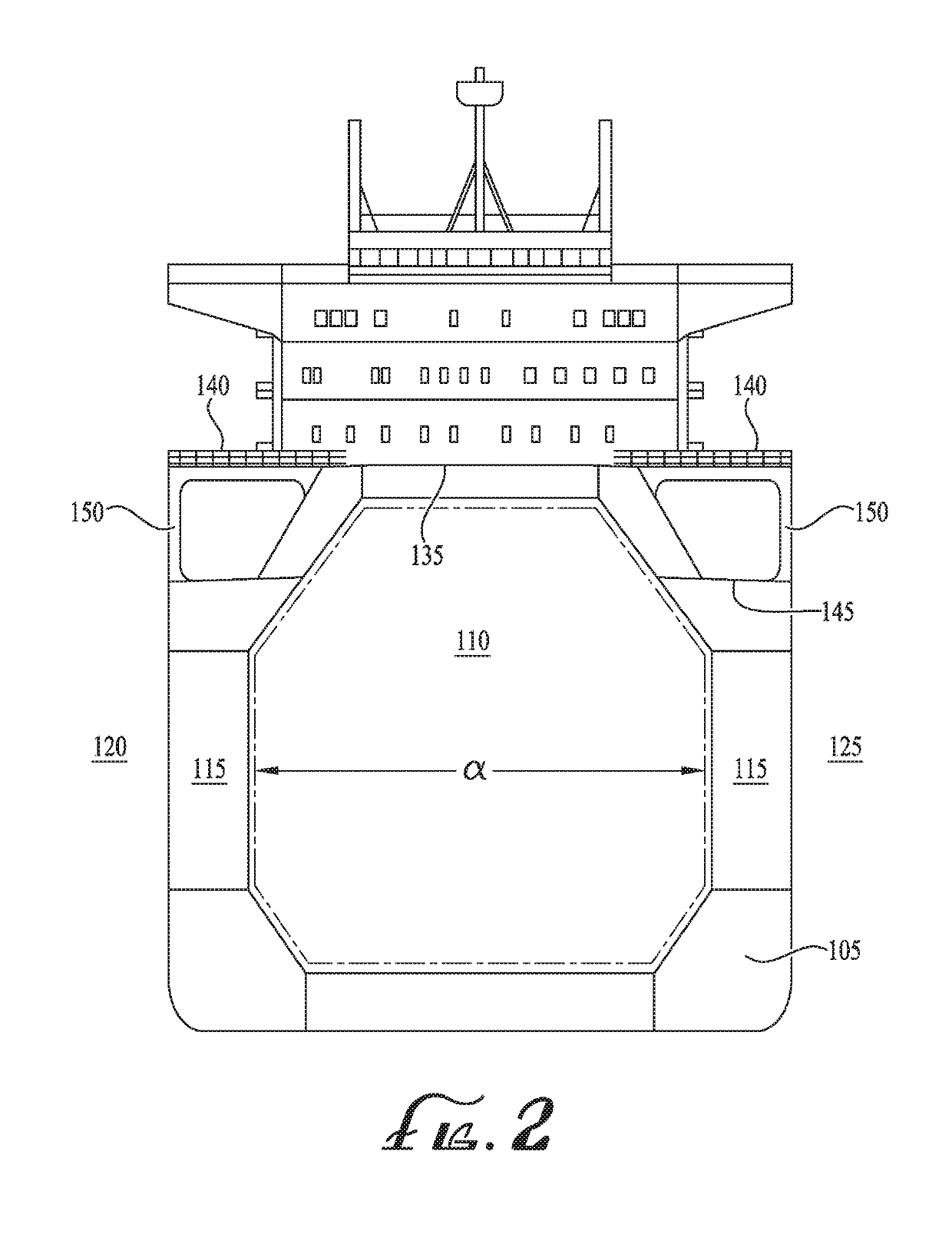

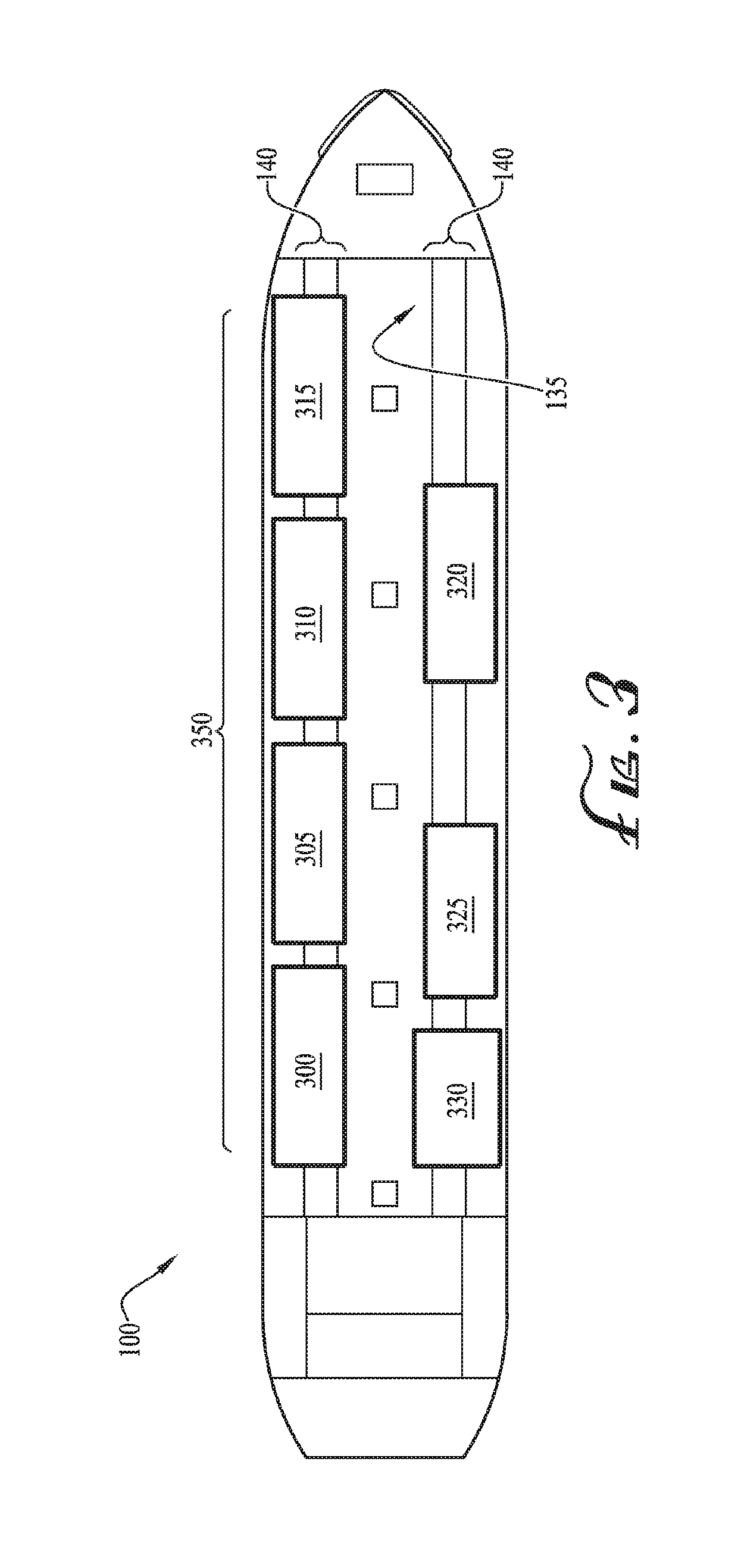

Vessel hull for use as a hull of a floating hydrocarbon storage and/or processing plant, method for producing such a vessel hull, vessel comprising such a vessel hull, as well method for producing such a vessel having such a vessel hull

ActiveUS20170327190A1Reduce conversionShorten the timeHull reinforcementsFloating buildingsProcess moduleMarine engineering

The invention relates to a method for producing a vessel hull (1) for use as a hull of an FPSO or FSO, comprising producing a vessel hull with a stern portion (2), a bow portion (3) and a central portion (4), arranging a deck (6) on the hull, for supporting processing modules, arranging hydrocarbon storage tanks inside the hull, providing the hull with an anchoring connection arrangement (7), characterized by arranging process module reinforcements (8) in the deck for supporting the hydrocarbon process modules, providing both longitudinal hull sides with mooring line connection reinforcements (9) at or near the bow portion, arranging riser connection reinforcements (10, 14) on one or more longitudinal hull sides, in between the mooring line connection reinforcements in longitudinal direction, for a riser balcony (28, 29), and providing the bow portion with turret reinforcements (11, 12).

Owner:SINGLE BUOY MOORINGS INC

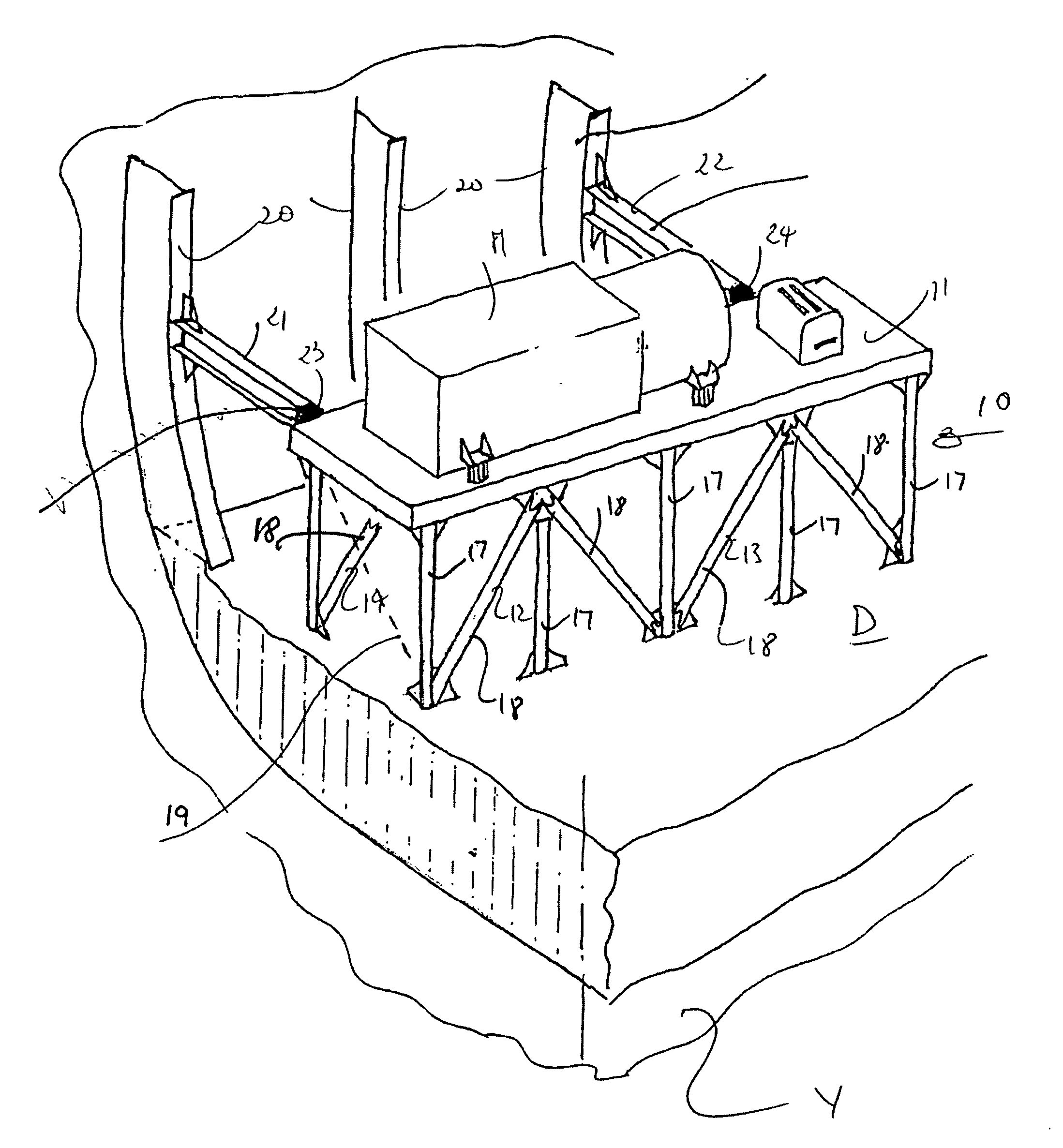

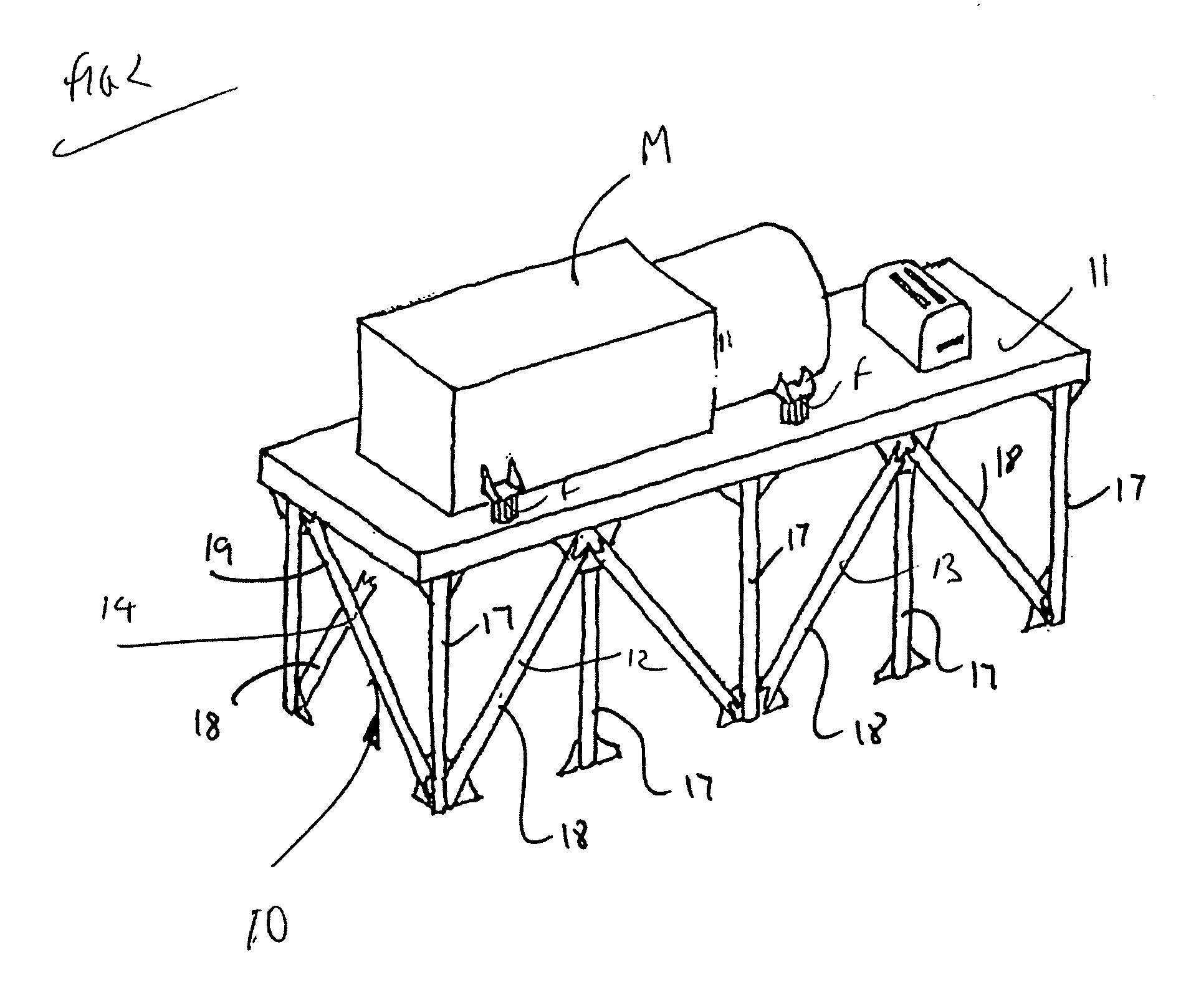

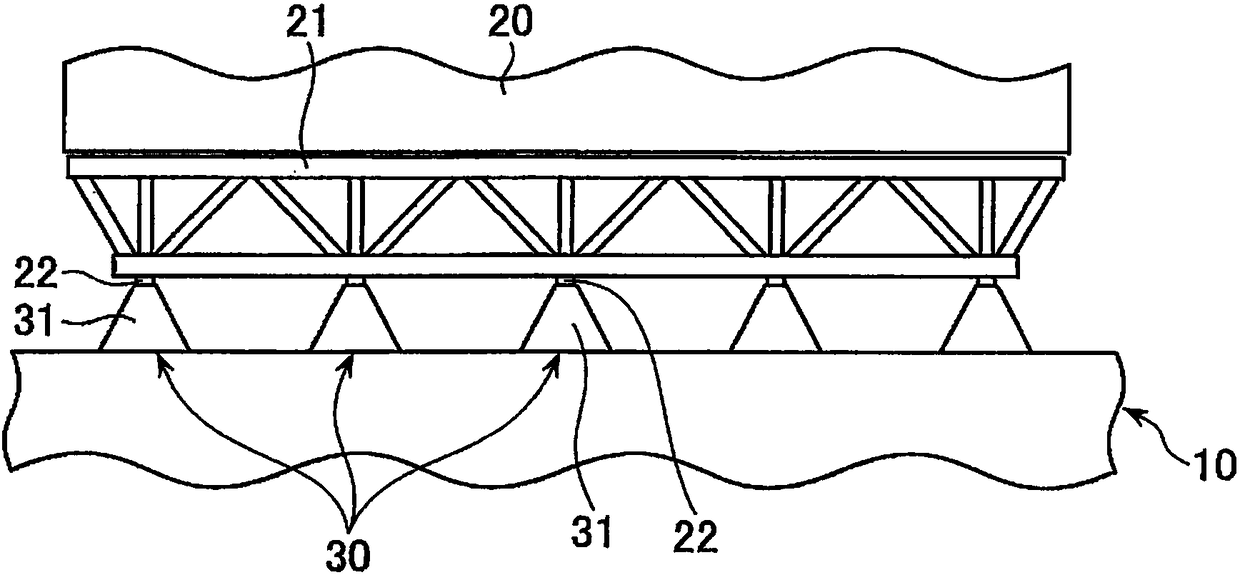

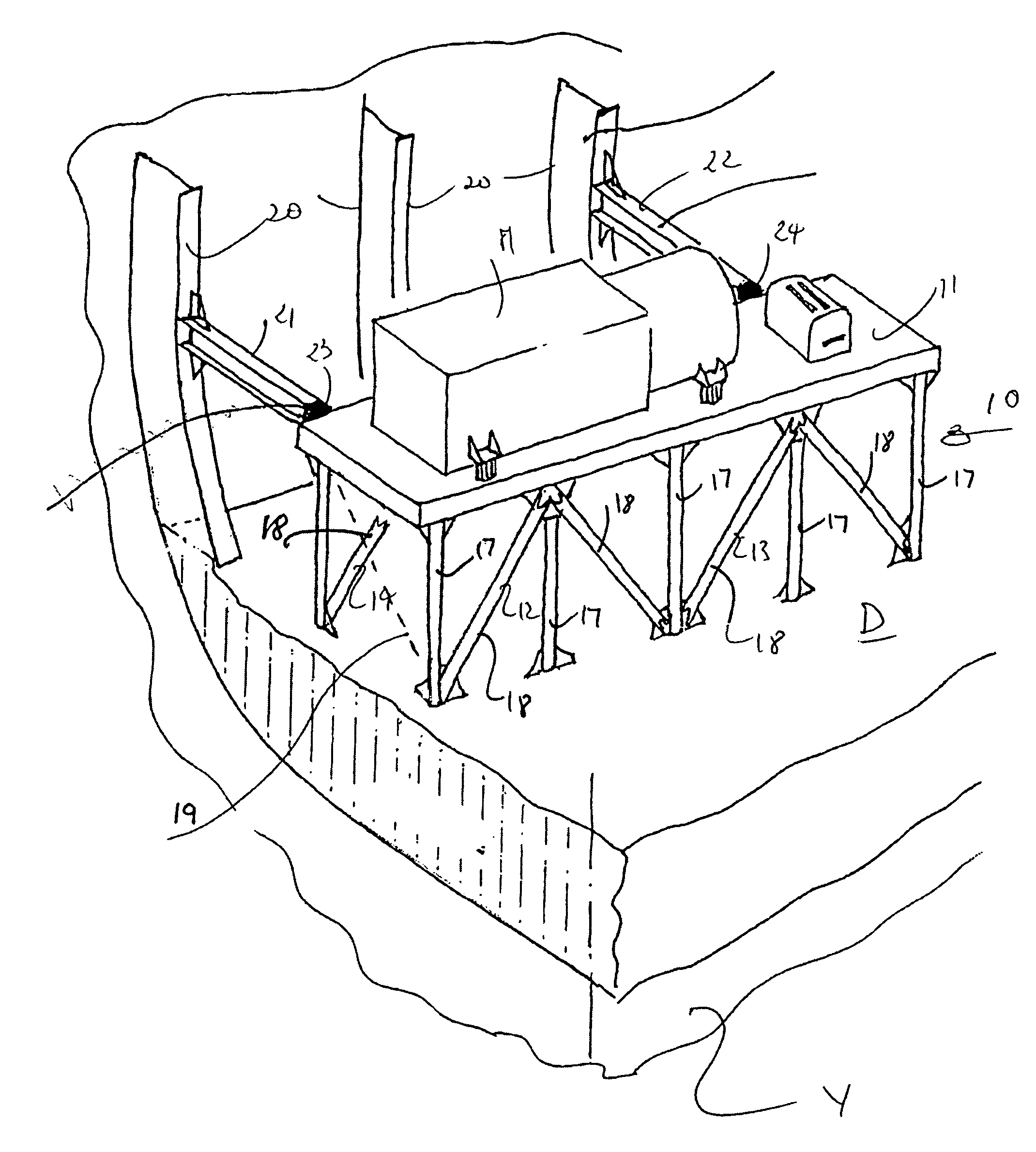

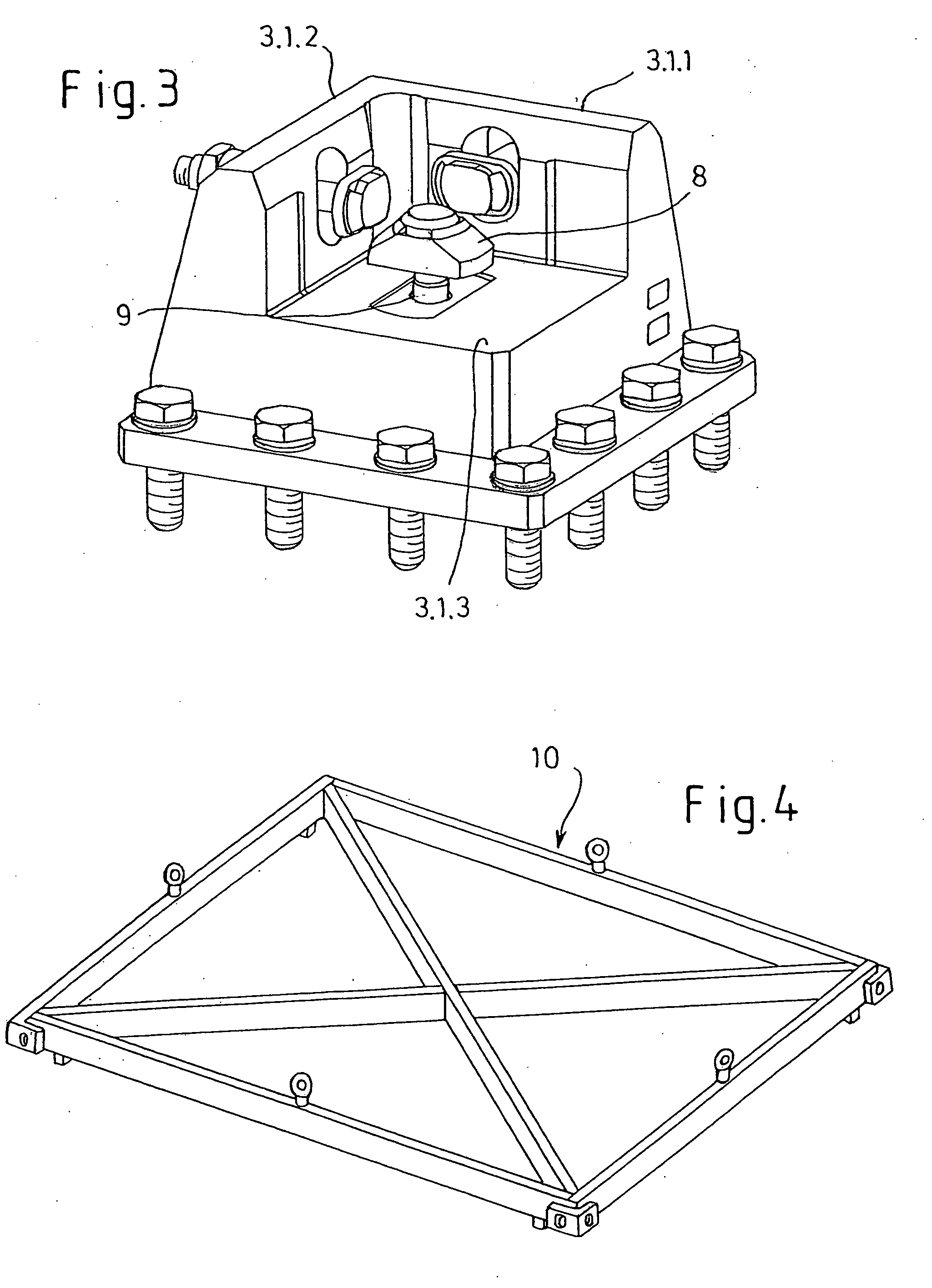

Support structure

InactiveUS20060243181A1Non-magnetic metal hullsPropulsion power plantsEngineeringMechanical engineering

A support structure for auxiliary machinery in a seagoing vessel, the support structure comprising a trussed frame supporting a mounting plate at an elevated height above the bottom or deck of the vessel, the mounting plate being adapted to support auxiliary machinery, the trussed frame comprising beams arranged in triangles along the sides and ends of the frame, whereby the frame elevates the machinery and provides ready access to the underside of the machinery.

Owner:AUSTAL SHIPS

Isolated motor pan for watercraft

A watercraft floating in water including a deck and a motor isolated from the deck. In an embodiment of the invention, the watercraft includes a frame comprising cross-members for supporting the deck. The watercraft further includes a dampening assembly connecting the motor to the components of the watercraft floating in the water while isolating the motor from the deck of the watercraft. The dampening assembly allows the vibrations generated by the motor to be transferred into the water in order to reduce the overall vibration in the deck.

Owner:BENNINGTON MARINE

Bending stiffness reducer for brace to hull connection

InactiveUS9902464B2Reduce stiffnessReducing the induced bending momentHull reinforcementsHull frameworksHull structureStress concentration

Semi-submersibles are subjected to loading from waves, causing racking, longitudinal shear and parallelogramming, or differential movement of the pontoons. The cyclic wave loading makes the various connections, where stress concentrations occur, susceptible to fatigue damage throughout the hull structure. This is most evident at the connections between the braces and the main hull structure. A revised brace to main hull connection with reduced bending stiffness is employed to reduce the moment being transferred from the brace to the hull, thereby reducing the bending stress and susceptibility to fatigue damage. This improved connection employs an internal member to transfer the loads between the brace and hull structure mainly as tension and compression. As a consequence of the improved fatigue performance, the structural weight of the connection can be greatly reduced, thus increasing the capacity with which the semi-submersible hull can operate.

Owner:COTTRELL ROY +3

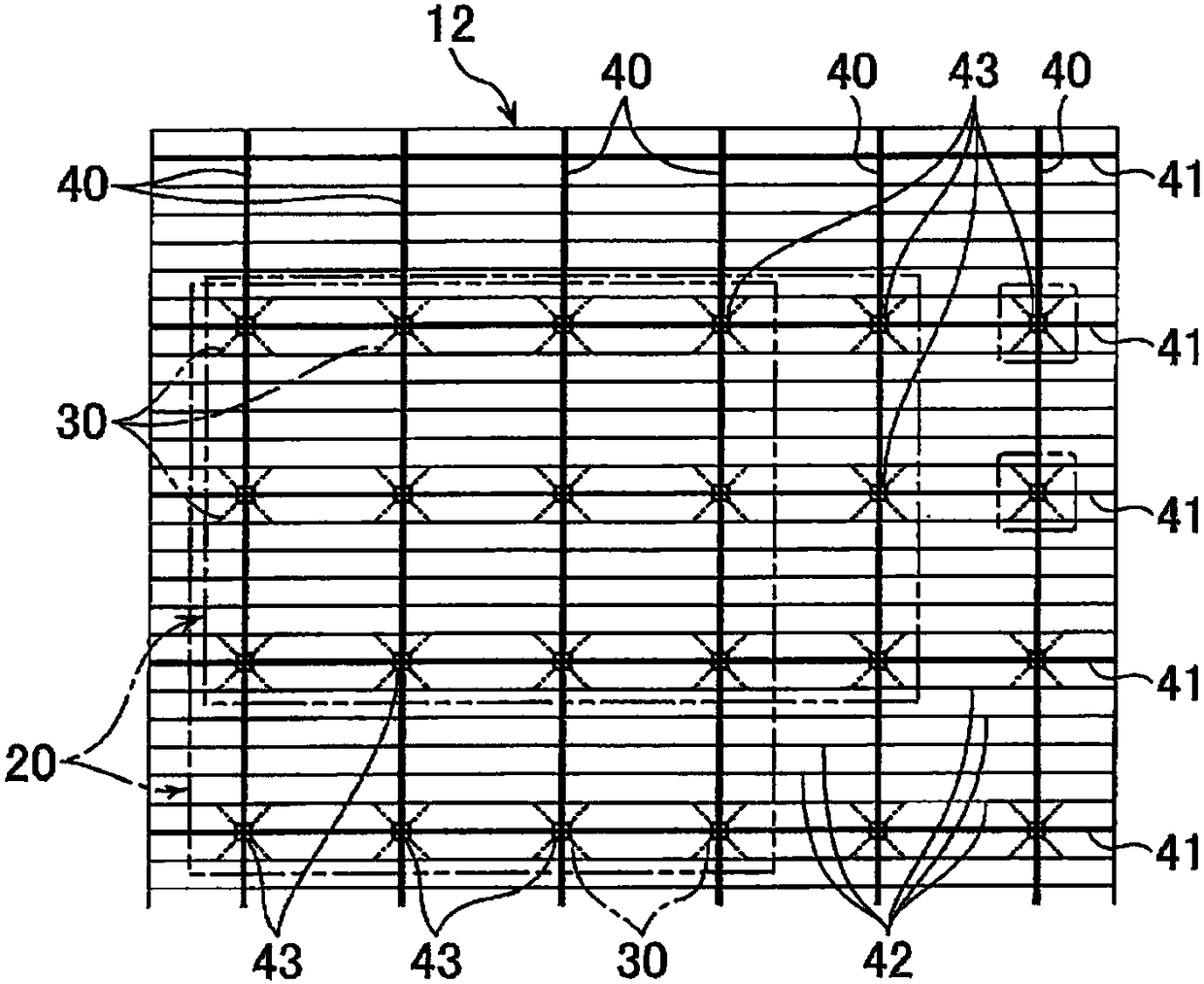

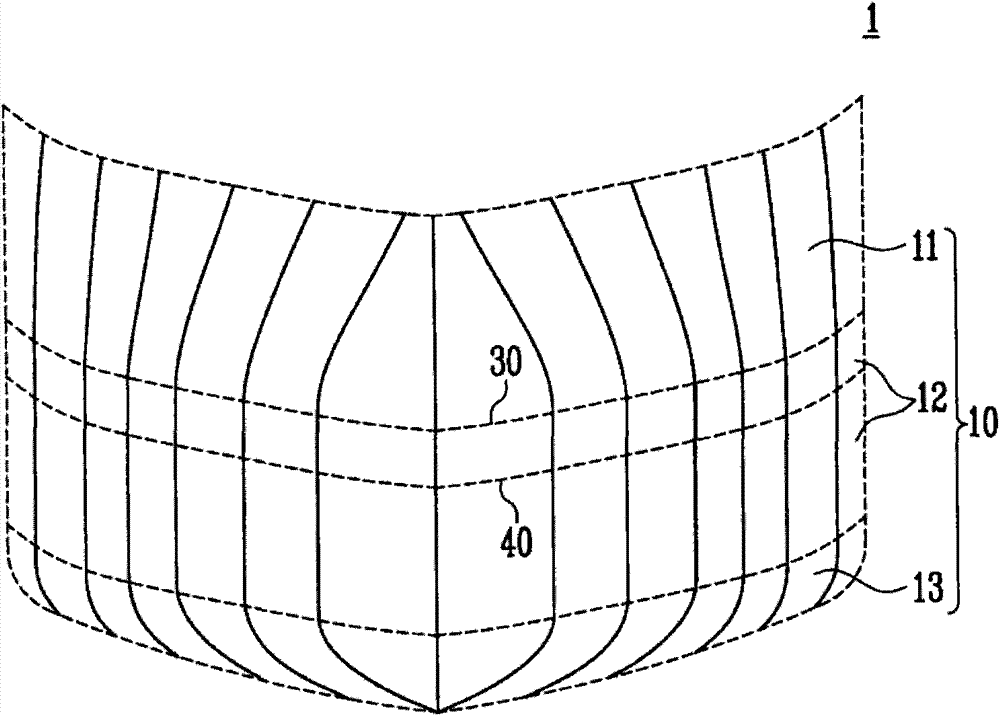

Ocean floating body structure

An ocean floating body structure, wherein production facilities can be mounted on an upper deck 12 of a floating body. The bottom surface of the upper deck 12 is provided with: transverse reinforcingmembers 40 extending in the width direction of the floating body 10; and vertical reinforcing members 41 extending in the longitudinal direction of the floating body 10. At least some of the pluralityof points on the top surface of the upper deck 12, where the transverse reinforcing members 40 and the vertical reinforcing members 41 intersect each other, are stool installation portions 43 on which stools 30 for supporting the production facilities 20 can be installed.

Owner:MITSUI ENG & SHIPBUILD CO LTD

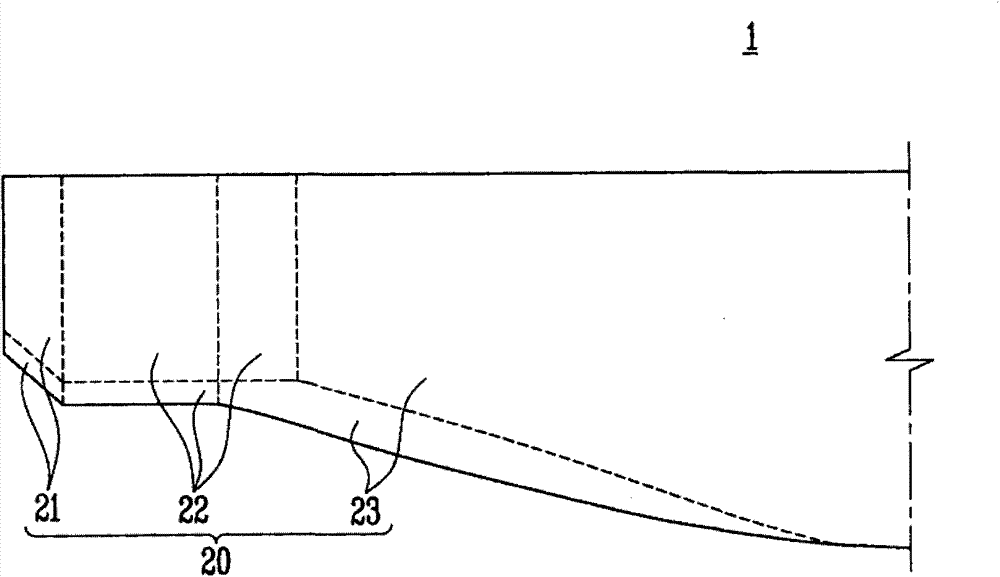

Ship

This invention discloses a ship comprising an inclined part, a plane part and a tail part of the streamline part, wherein the inclined part is arranged at the ship tail and the depth of the inclined part is deepening toward along the slop of the lower surface of the incline part; the plane part is coupled to the front part of the inclined part and extend a certain length horizontally and forward; the streamline part is coupled to the front part of the plane part and is coupled to the bottom of the ship when the streamline part is inclined is inclined along the lower surface of the streamline part and is deepened forward; and the middle part of the streamline part is extended forward and reaches upward to the predetermined range from the ship tail such that the ship tail is formed.

Owner:HYUNDAI HEAVY IND CO LTD

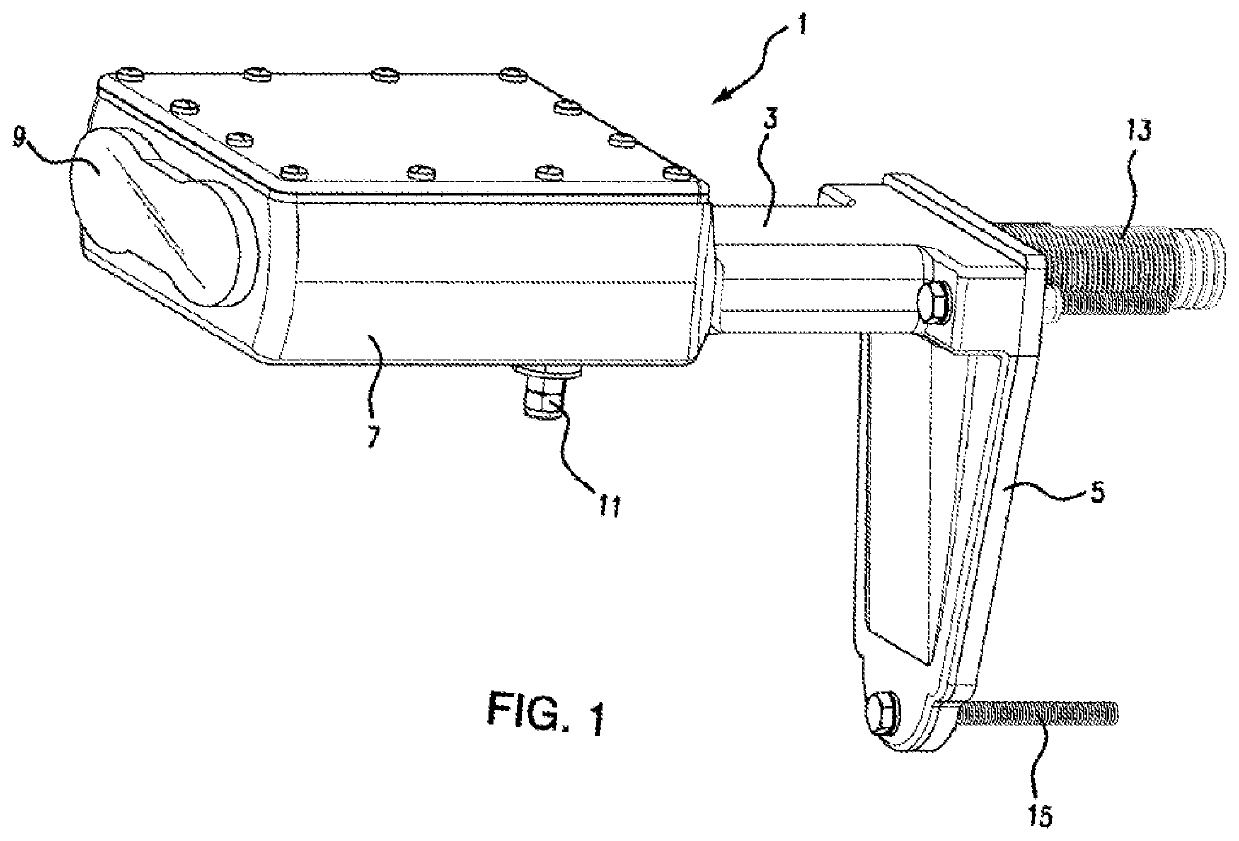

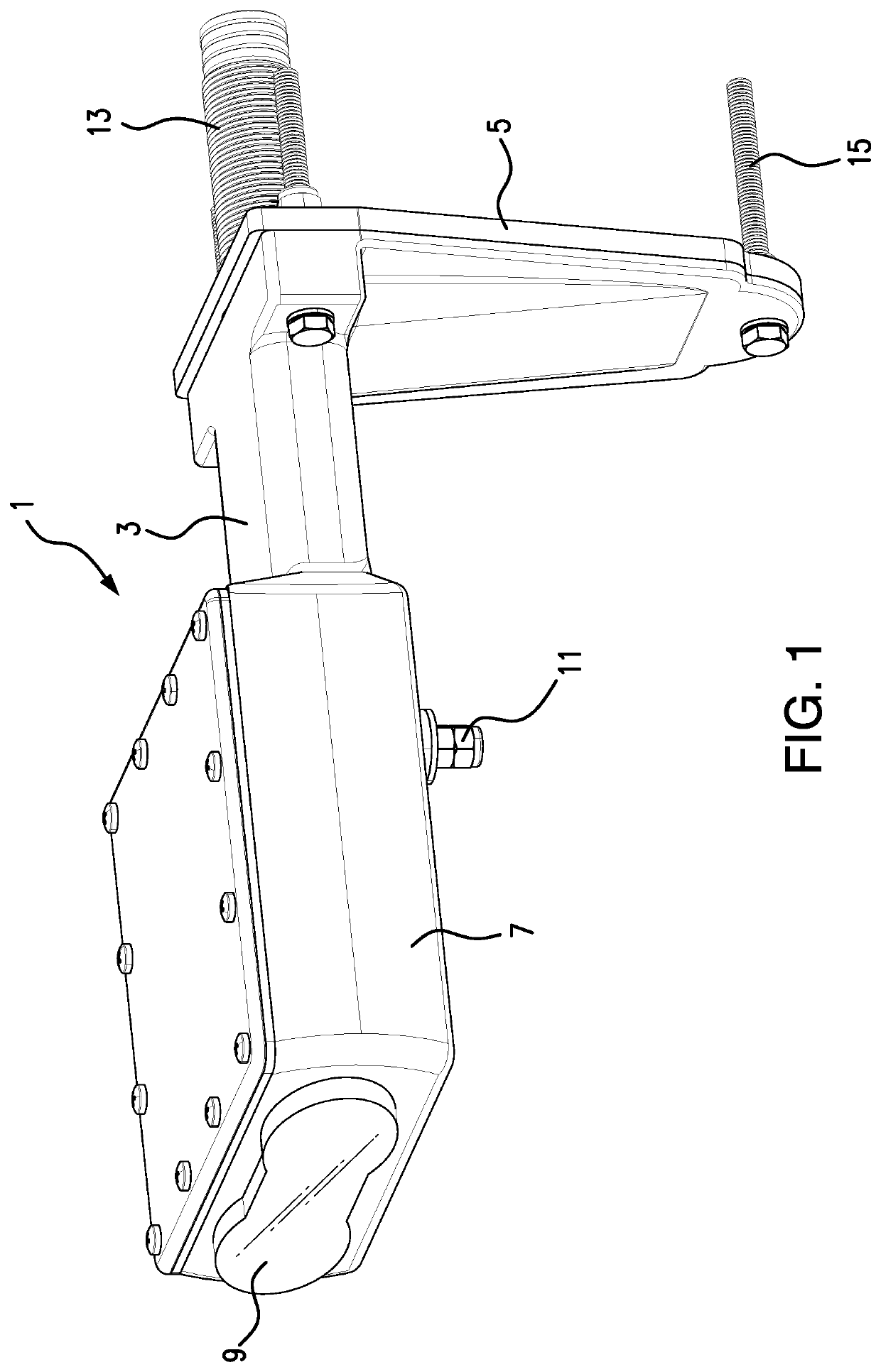

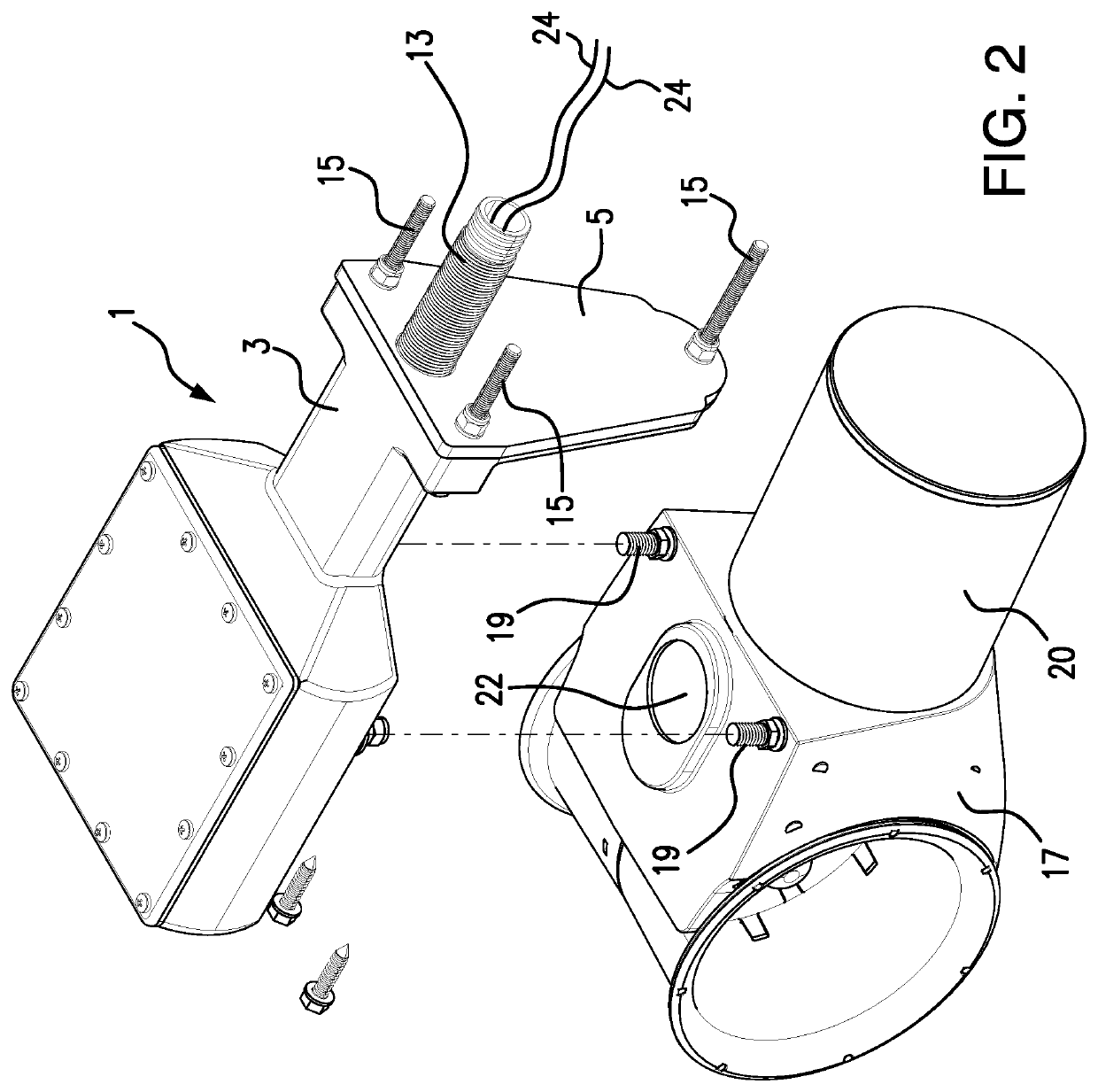

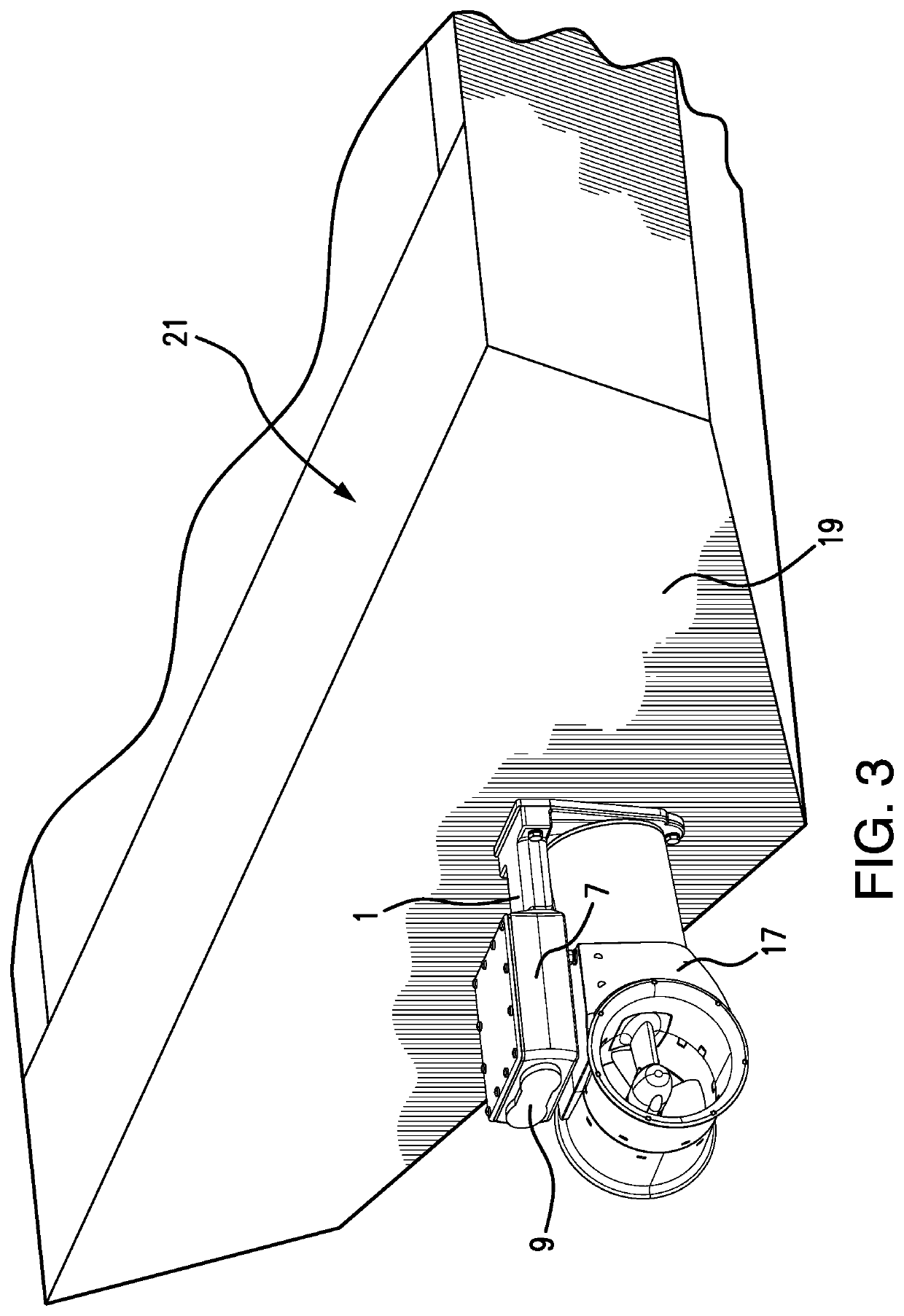

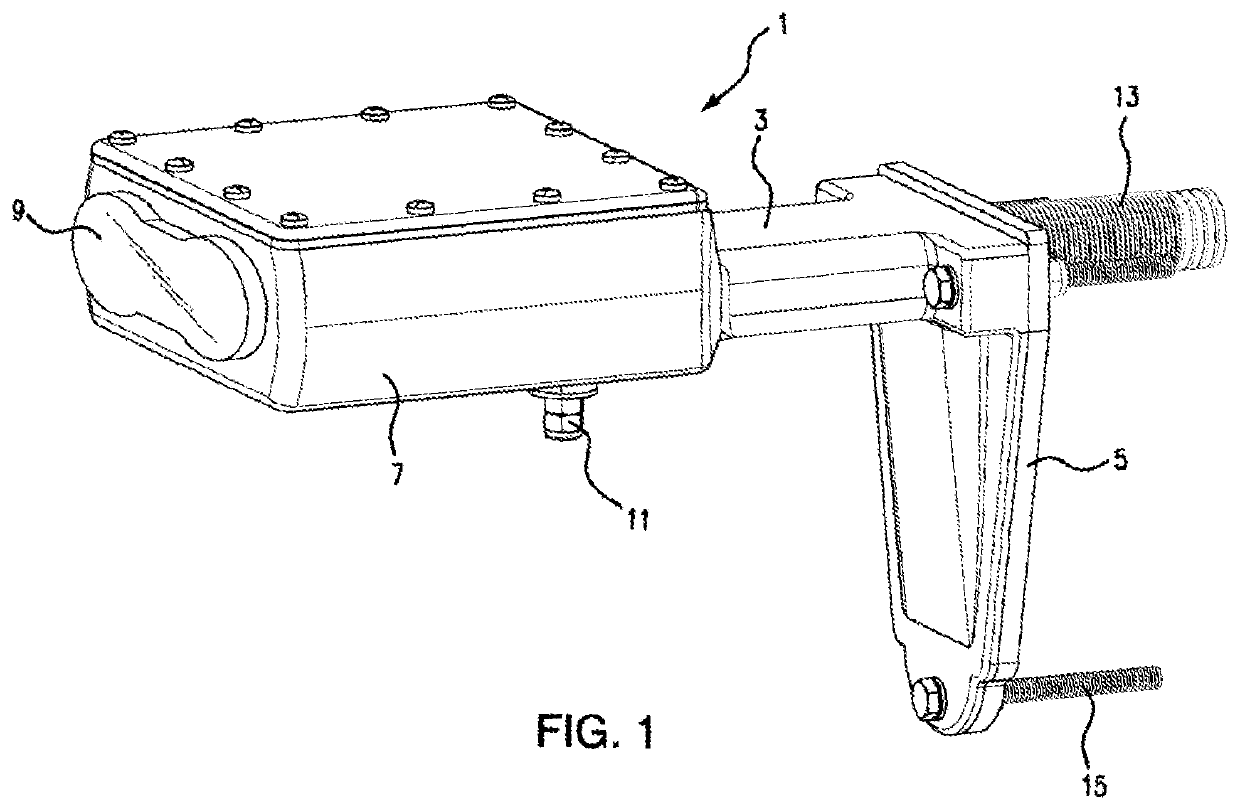

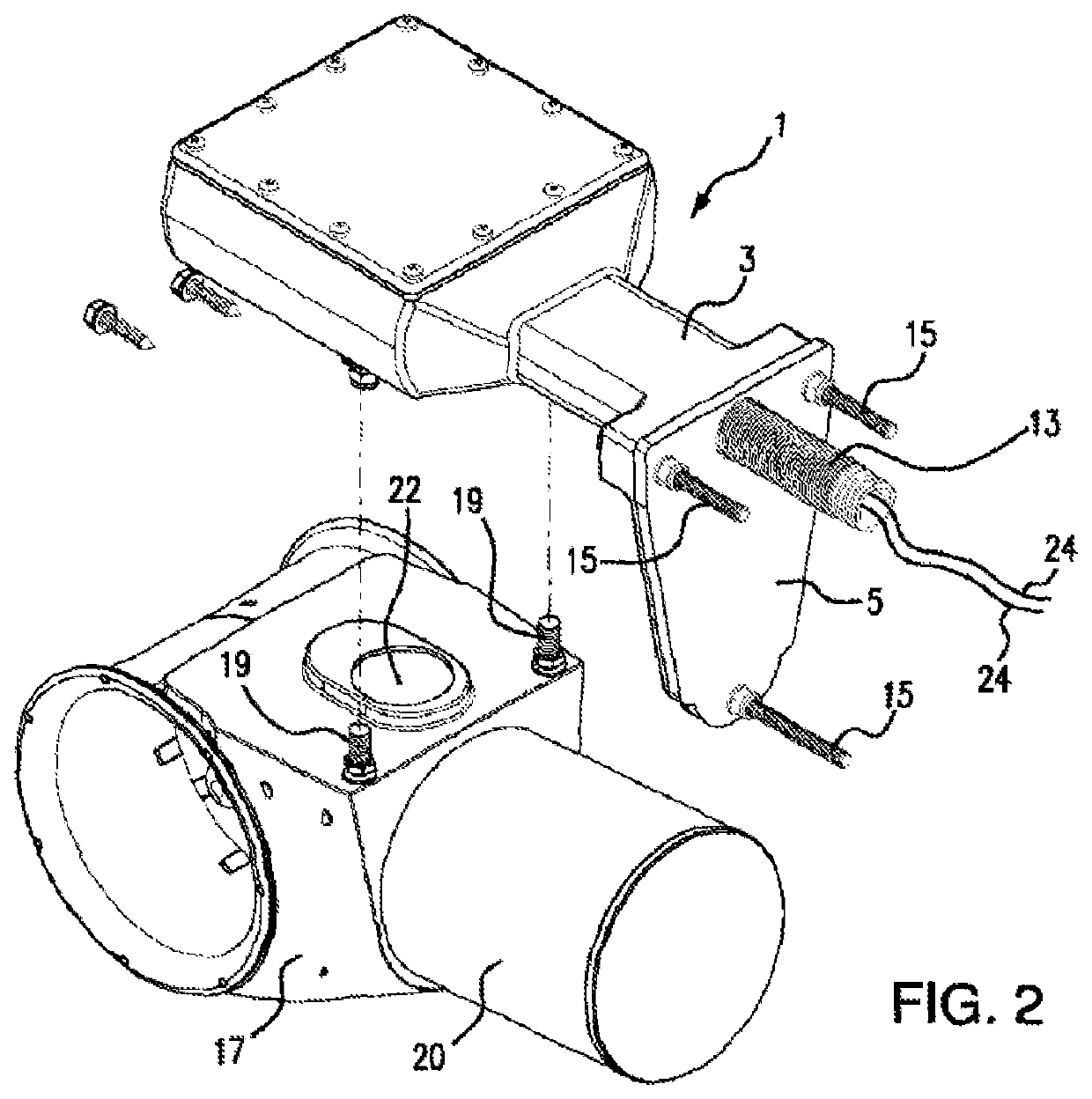

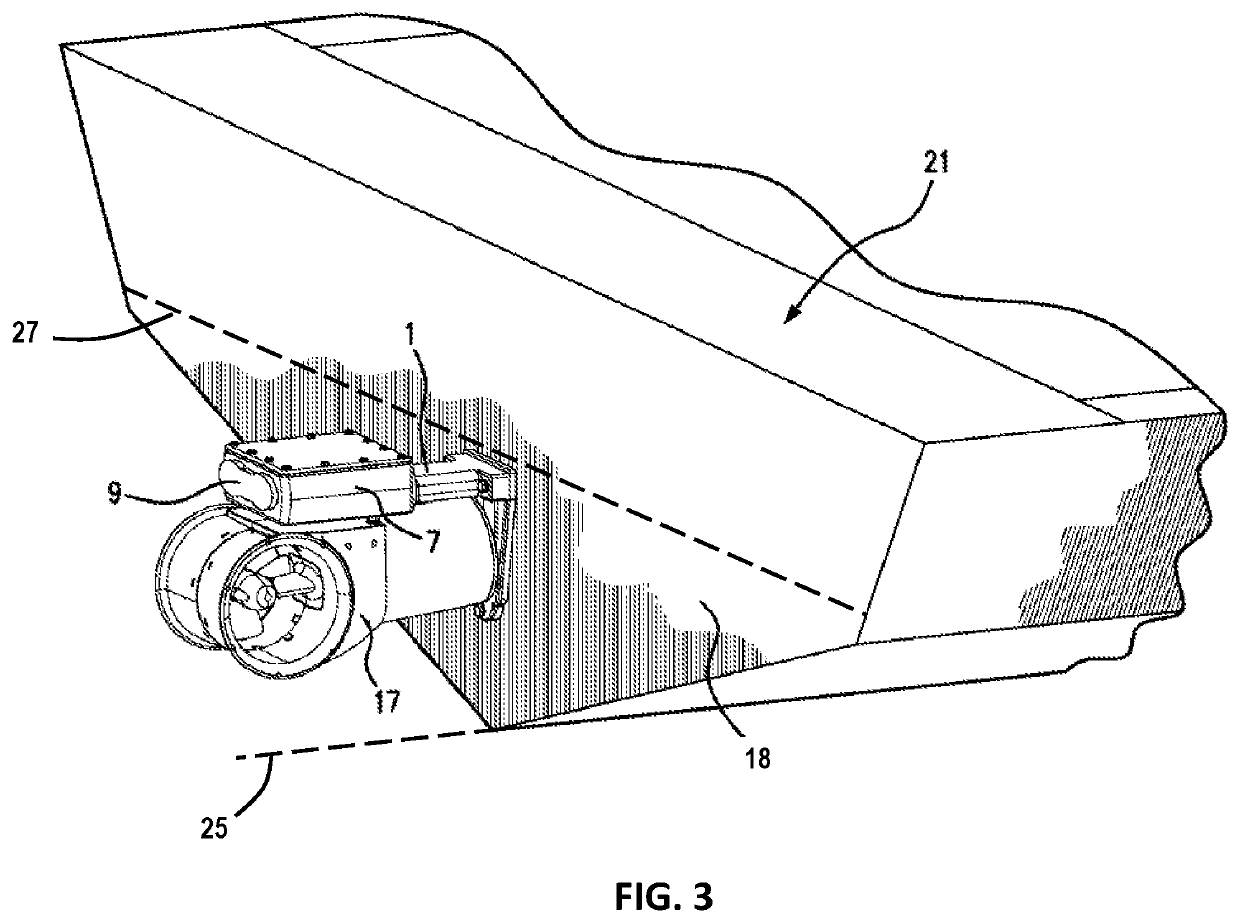

Bracket for mounting a thruster to a boat

A bracket for mounting a thruster to a boat includes a horizontal neck portion, an upper mounting support portion, a support plate portion that extends downward from the upper mounting support portion, and an enclosure portion. The support plate portion and the rear of the upper mounting support portion form a transom-facing surface in a plane that is generally at a right angle relative to a horizontal plane, within a small range of angles. The transom-facing surface can angled to match the angle of the transom of a boat to which the thruster bracket is mounted. A thruster can be mounted to the thruster bracket at a level where the thruster will be out of the water when the boat is moving fast and up on plane, and will be in the water when the boat is moving very slow.

Owner:THE YACHT GRP LLC

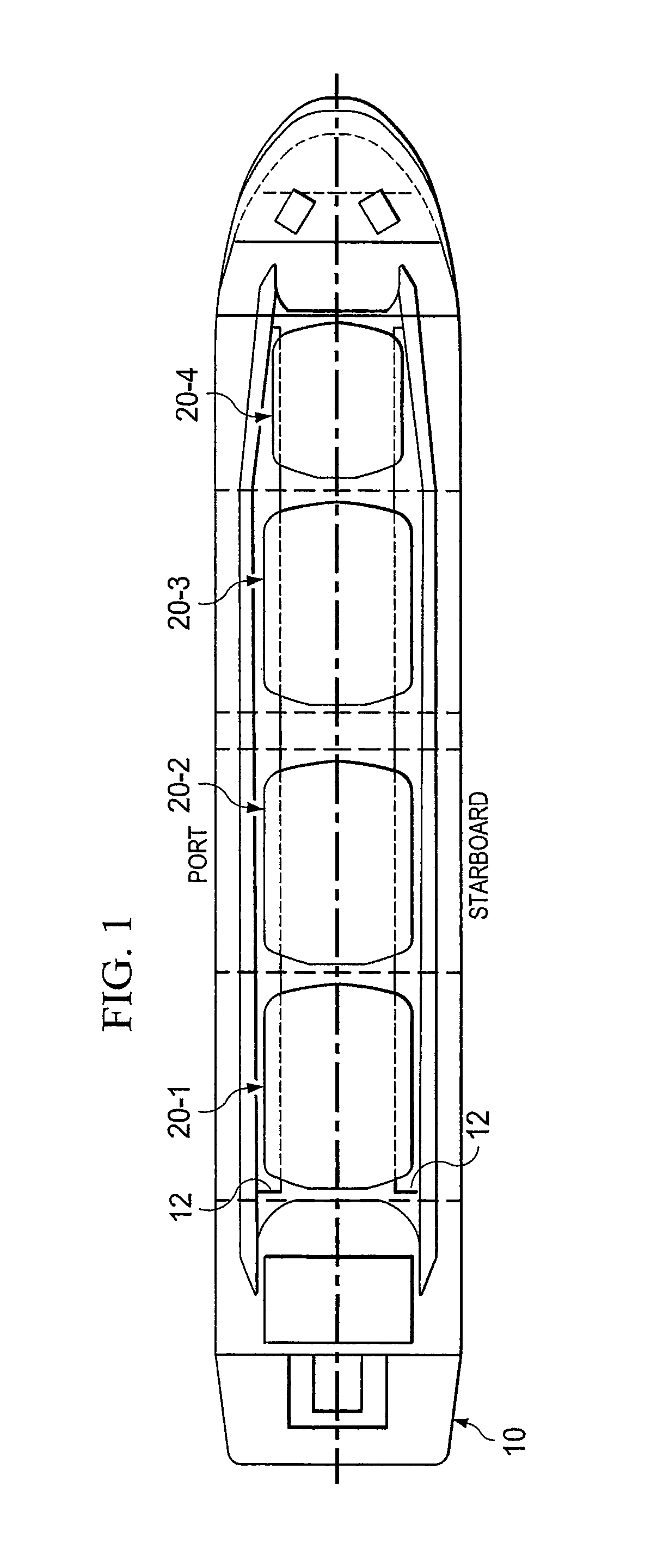

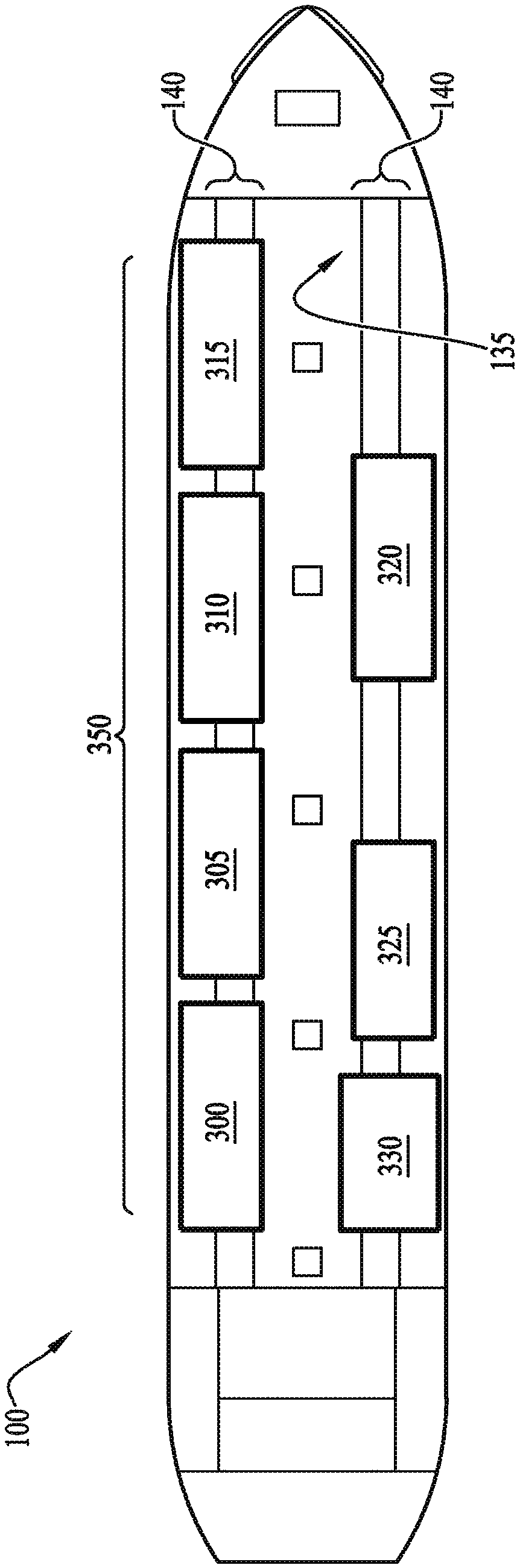

Natural gas liquefaction vessel

A natural gas liquefaction vessel including an increased deadweight tonnage, as compared to a liquefied natural gas carrier (LNGC) of a comparably-sized ship, is achieved by reducing the LNGC's cargocapacity. This difference creates room on the port and starboard sides of cargo tanks to increase the size of the adjacent wing tanks. The increased size of the wing tanks occupy the space created bythe reduced cargo tank size of the vessel and may- support a larger upper trunk deck. The ballast wing tanks and smaller cargo tanks increase the deadweight available. With this approach, the larger upper trunk deck of the vessel is able to support an efficient floating liquefaction plant that improves the LNG value chain because it is capable of producing 2.0 - 3.0 MTPA in the footprint of a standard vessel hull, such as for example a Q-Max hull

Owner:EXCELERATE LIQUEFACTION SOLUTIONS

Bracket for mounting a thruster to a boat

ActiveUS11173985B2Firmly connectedIncrease water flowPropulsion power plantsSteering by jetsClassical mechanicsWater flow

Owner:BERTON GERALD

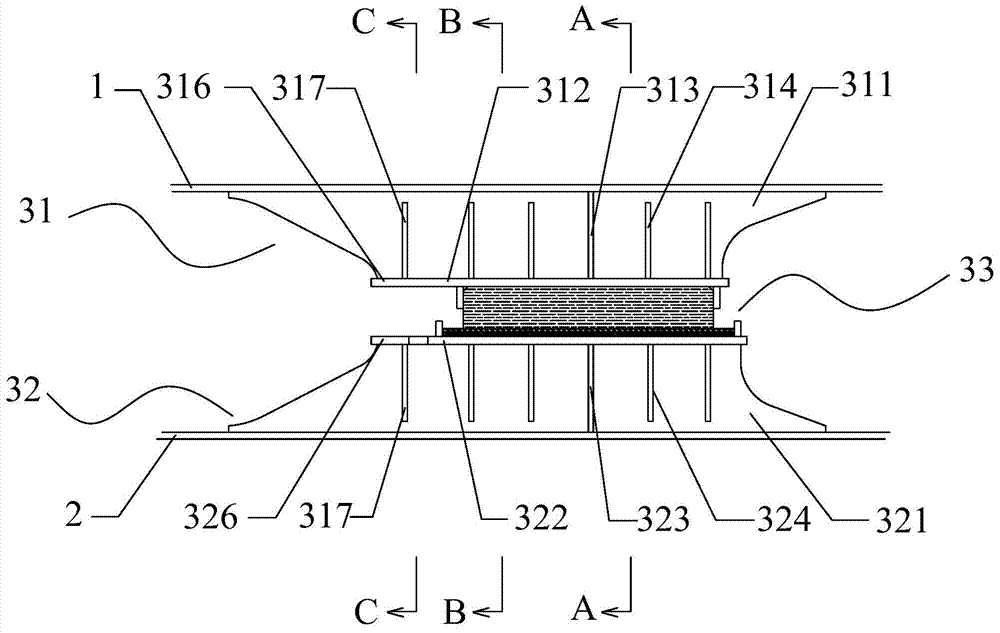

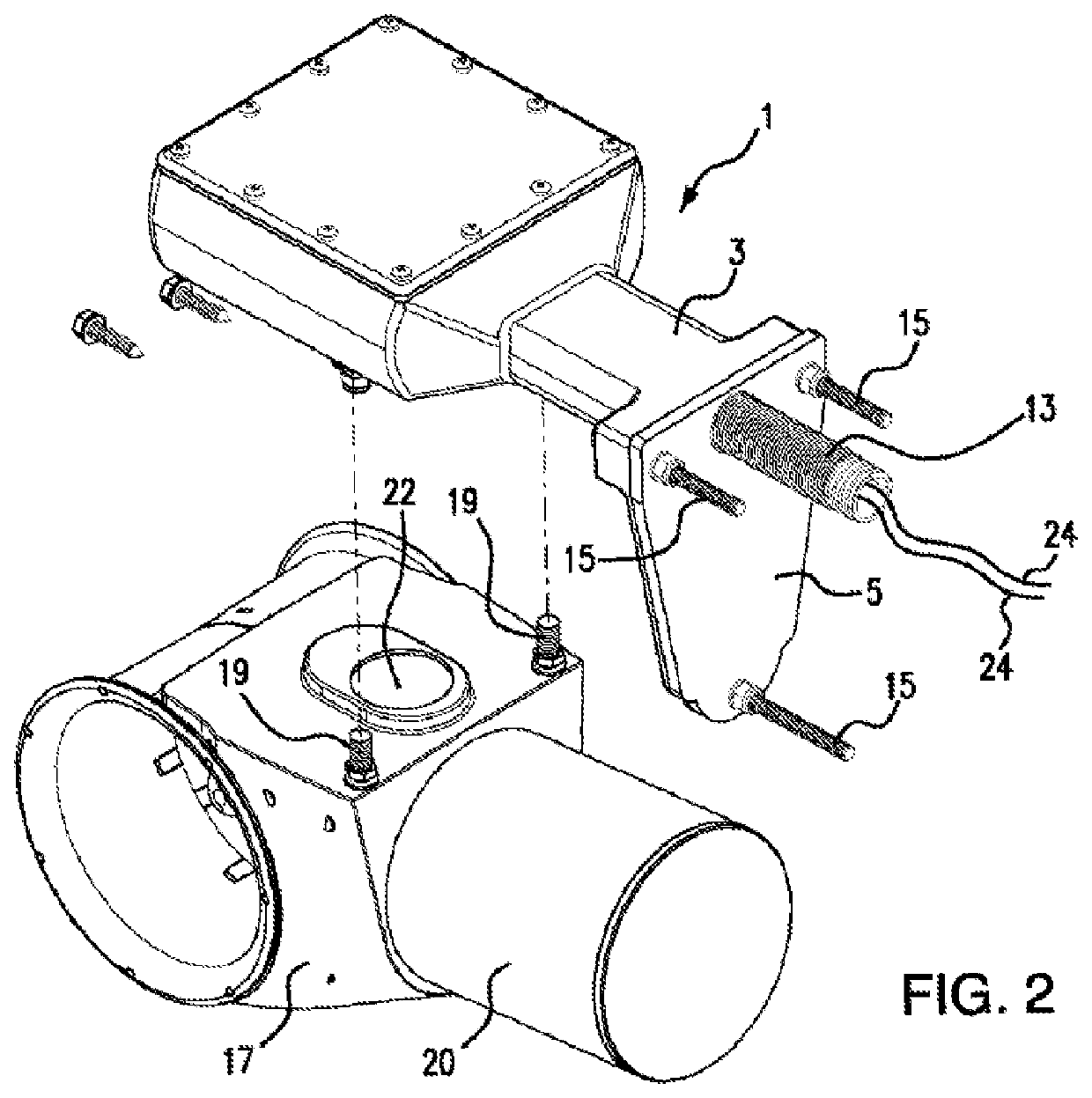

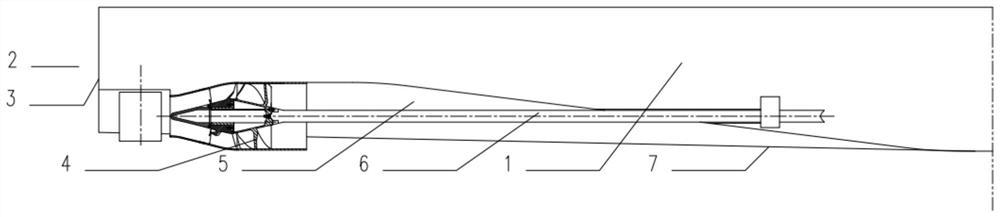

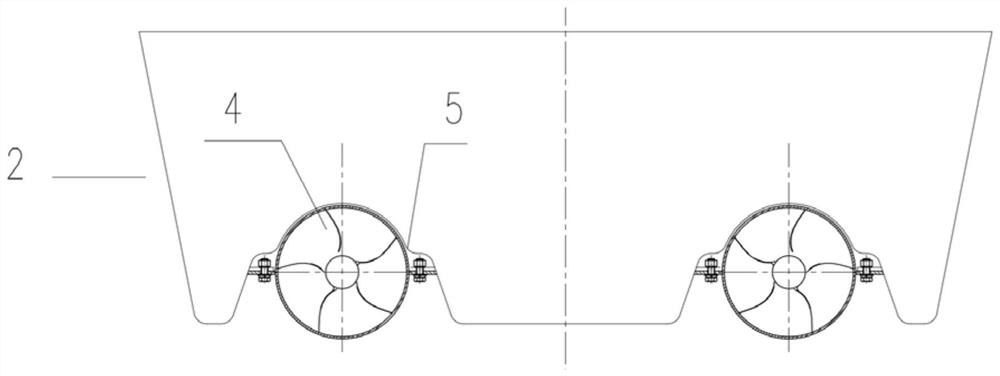

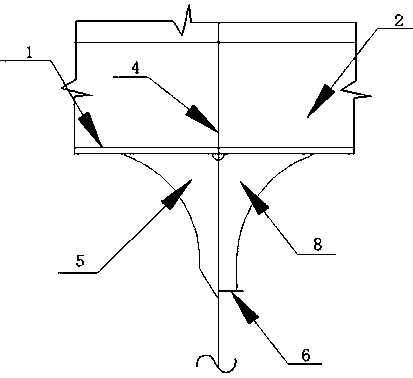

Ship body structure deeply coupled with water jet propulsion device

InactiveCN111824326AAvoid lostSolve the problem of low propulsion efficiencyPropulsive elementsHull reinforcementsHull structureDrive shaft

The invention relates to a ship body structure deeply coupled with a water jet propulsion device, which belongs to the technical field of ship design. The ship body structure comprises a ship body anda water jet propulsion device, wherein a tunnel for mounting the water jet propulsion device is arranged at the bottom of the tail of the ship body; and the water jet propulsion device is arranged inthe tunnel. The axis of the tunnel is located below the waterline, and the water jet propulsion device is integrally embedded into the tunnel and connected with the transmission shaft. According to the ship structure, the water jet propulsion device and the ship body structure are integrated and coupled with water power, the problem that the propulsion efficiency of a water jet propulsion ship within the navigation speed range of 18-30 kn is low can be solved, integration of the ship body and a propeller from the structure to the water power performance is achieved, and further development ofthe ship structure and the propulsion technology is promoted. The water jet propulsion ship disclosed by the invention has excellent rapidity, maneuverability and cavitation resistance of the propeller within a relatively wide navigation speed range.

Owner:708TH RES INST OF CSSC

Isolated motor pan for watercraft

A dampening assembly used in watercraft to isolate the motor from the deck of the watercraft. In an embodiment of the invention, a frame including cross-members and a plurality of brackets supports the deck. The dampening assembly of the present invention extends from the brackets of the frame to the motor and retains the motor at a position ensuring the motor does not contact the frame. The only path available to the vibrations generated by the motor is represented by the dampening assemblies that direct the vibrations to the brackets and tubes, thereby eliminating the high amplitude, low frequency vibrations that readily transfer throughout the deck and frame structure. In this manner, the vibrations are prevented from traveling directly through the cross-members of the frame and into the deck of the watercraft.

Owner:PONTOON BOAT

Support structure

A support structure for auxiliary machinery in a seagoing vessel, the support structure comprising a trussed frame supporting a mounting plate at an elevated height above the bottom or deck of the vessel, the mounting plate being adapted to support auxiliary machinery, the trussed frame comprising beams arranged in triangles along the sides and ends of the frame, whereby the frame elevates the machinery and provides ready access to the underside of the machinery.

Owner:AUSTAL SHIPS

ISO pallet concept for a gun

InactiveUS20090031890A1Quick installationMounted with minimal effort quicklyMissile launchersFiring/trigger mechanismsMarine engineeringPallet

A lower gun mount, which can be mounted in a standardized way on a ship or a permanent ground foundation, is used so that a gun can be mounted with minimal effort quickly, reproducibly and without slip, and later dismounted. This standardized lower gun mount is mounted geometrically correctly on a foundation or ship by so-called standardized ISO corners, which can be fixed in place on supports specially provided for this purpose and a mounting frame that assists the mounting. This makes it possible for the gun to be mounted rigidly and without play.

Owner:OERLIKON CONTRAVES BESCHRAENKTER HAFTUNG

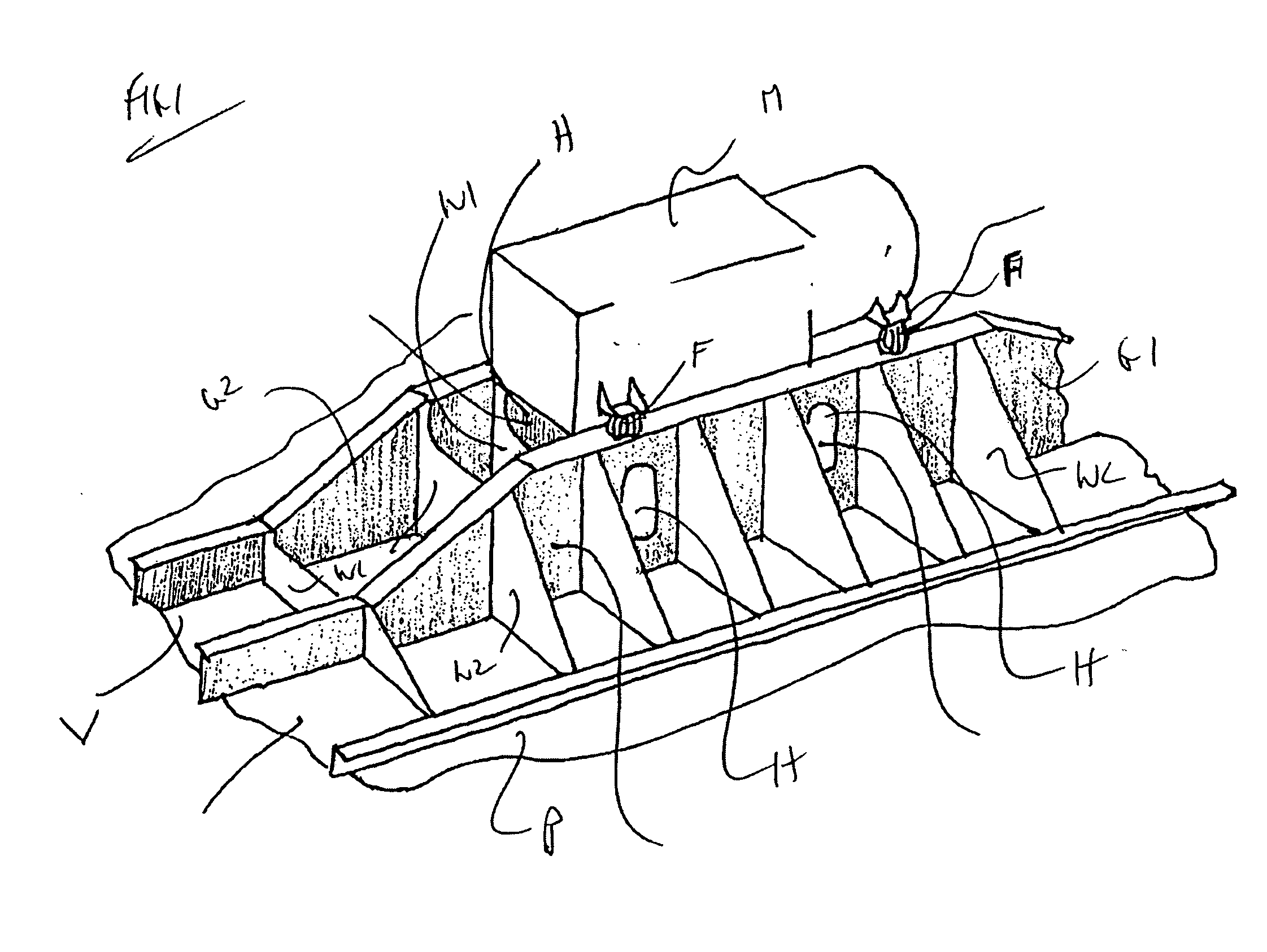

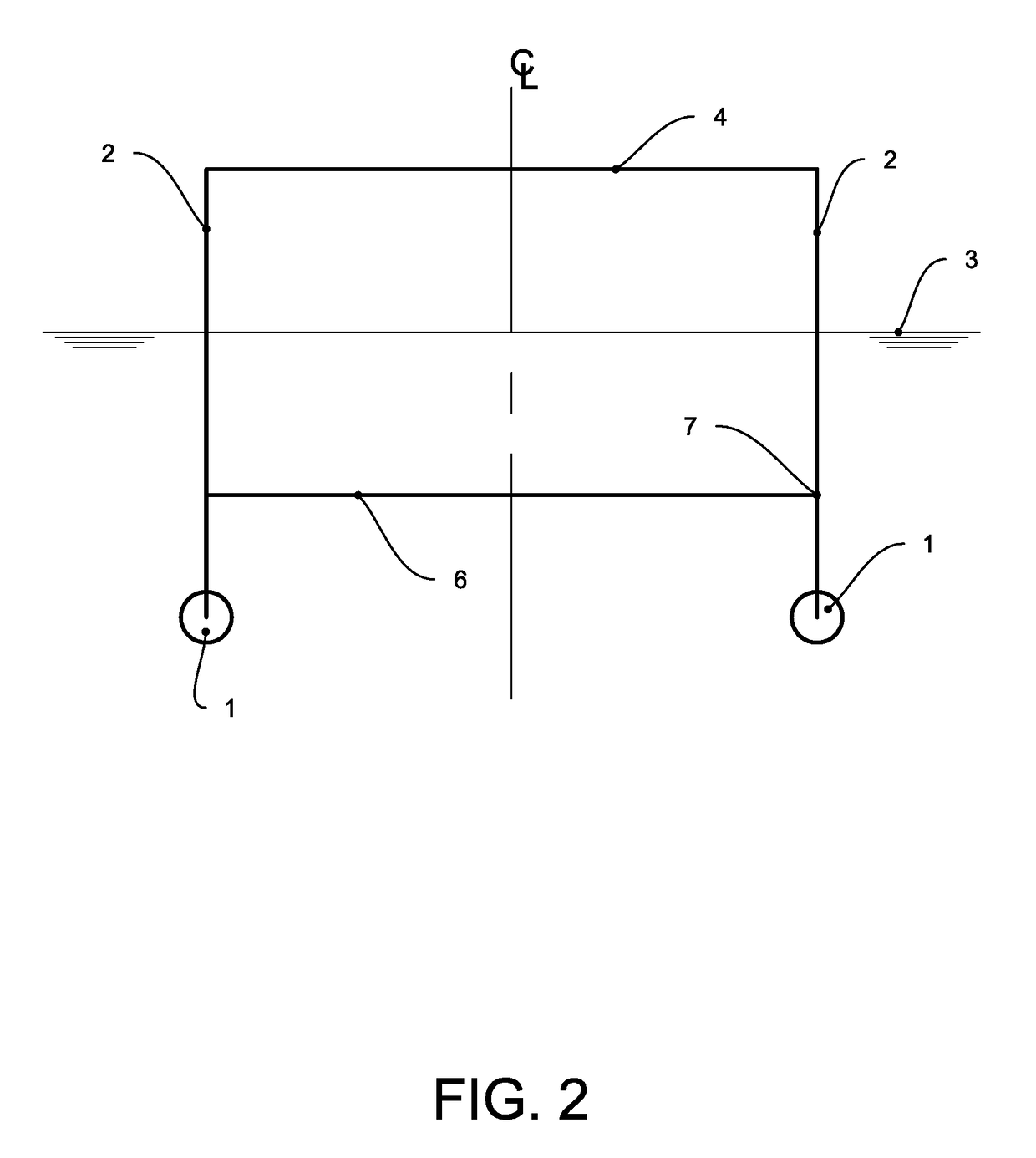

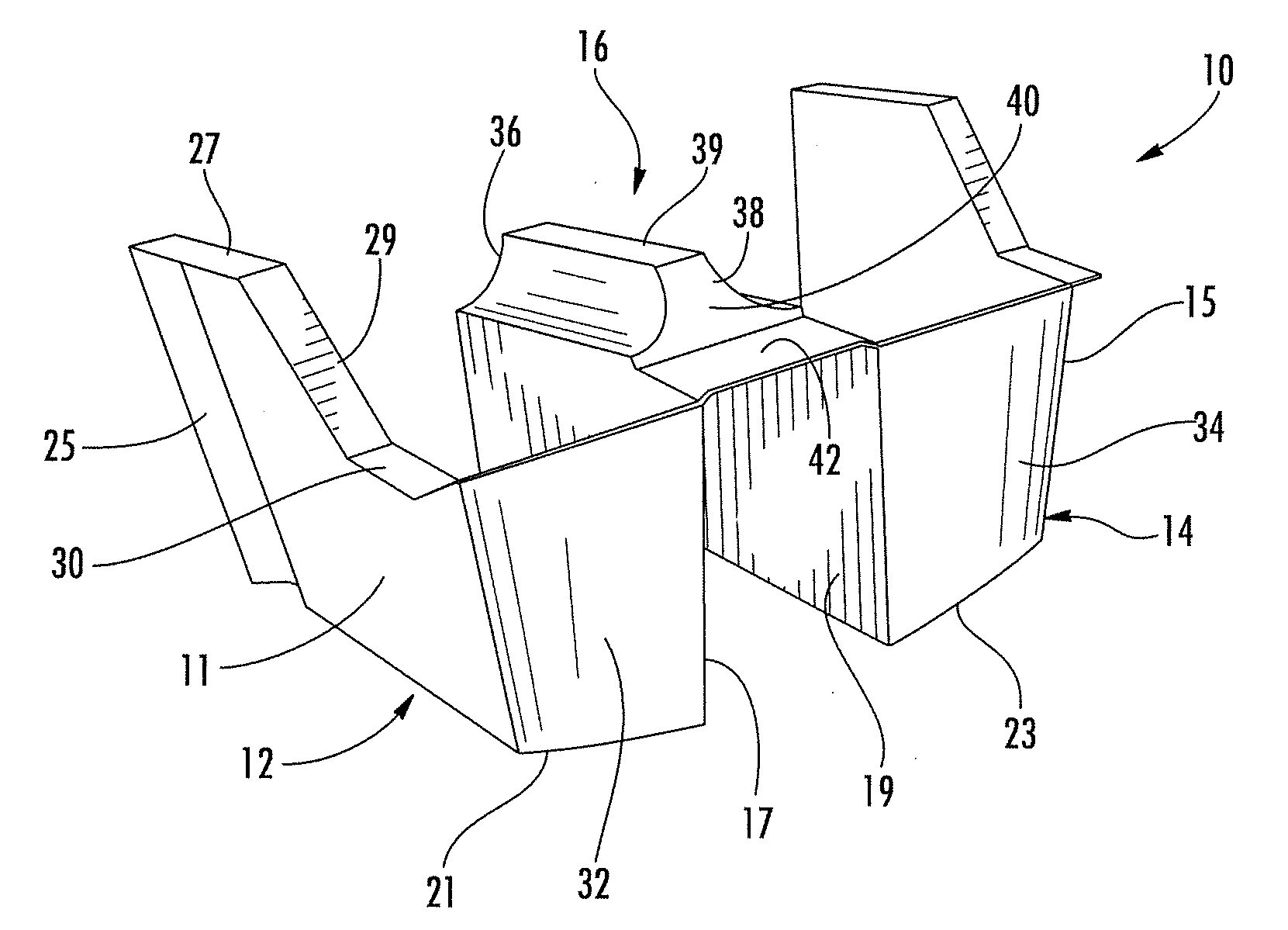

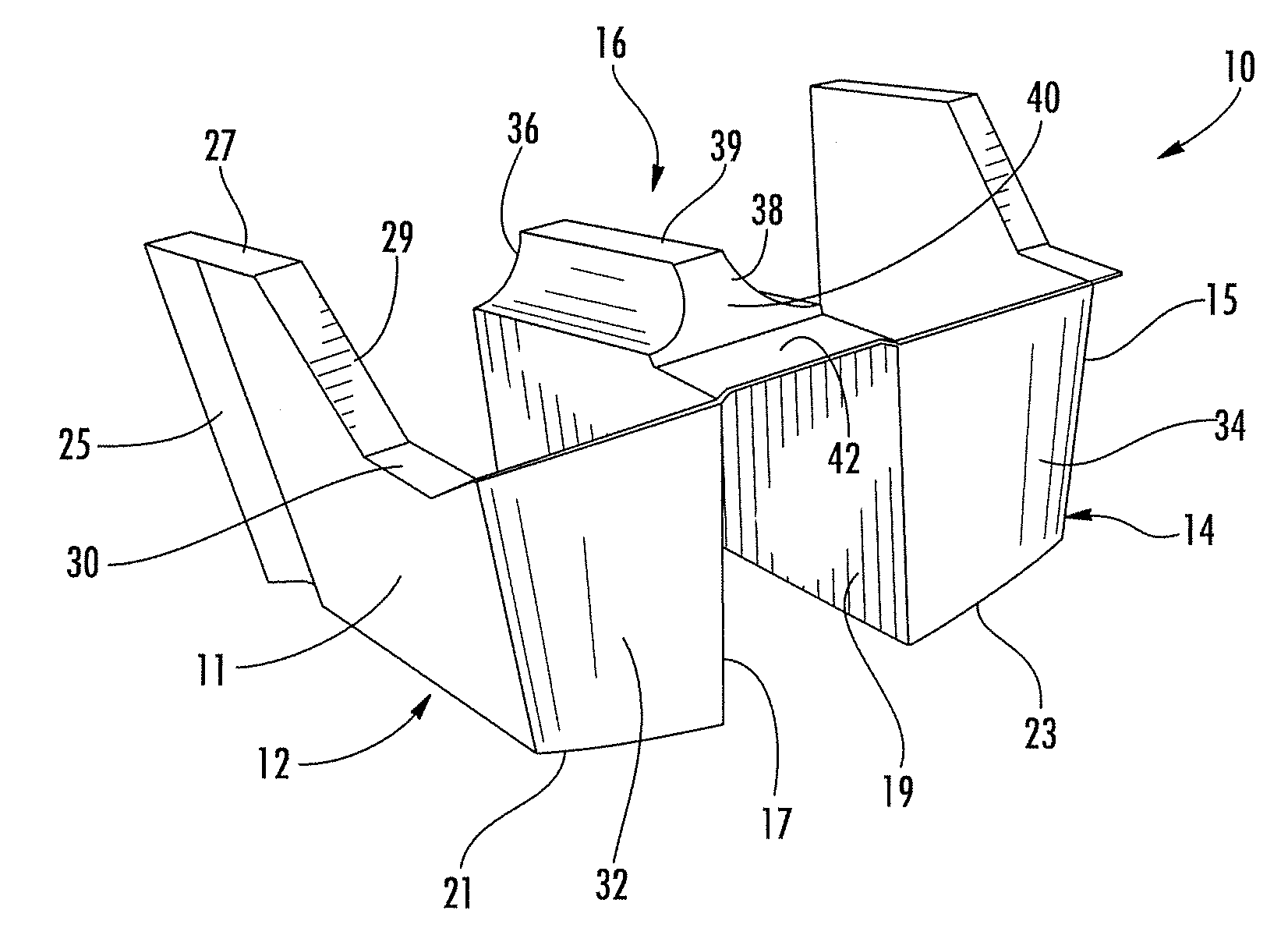

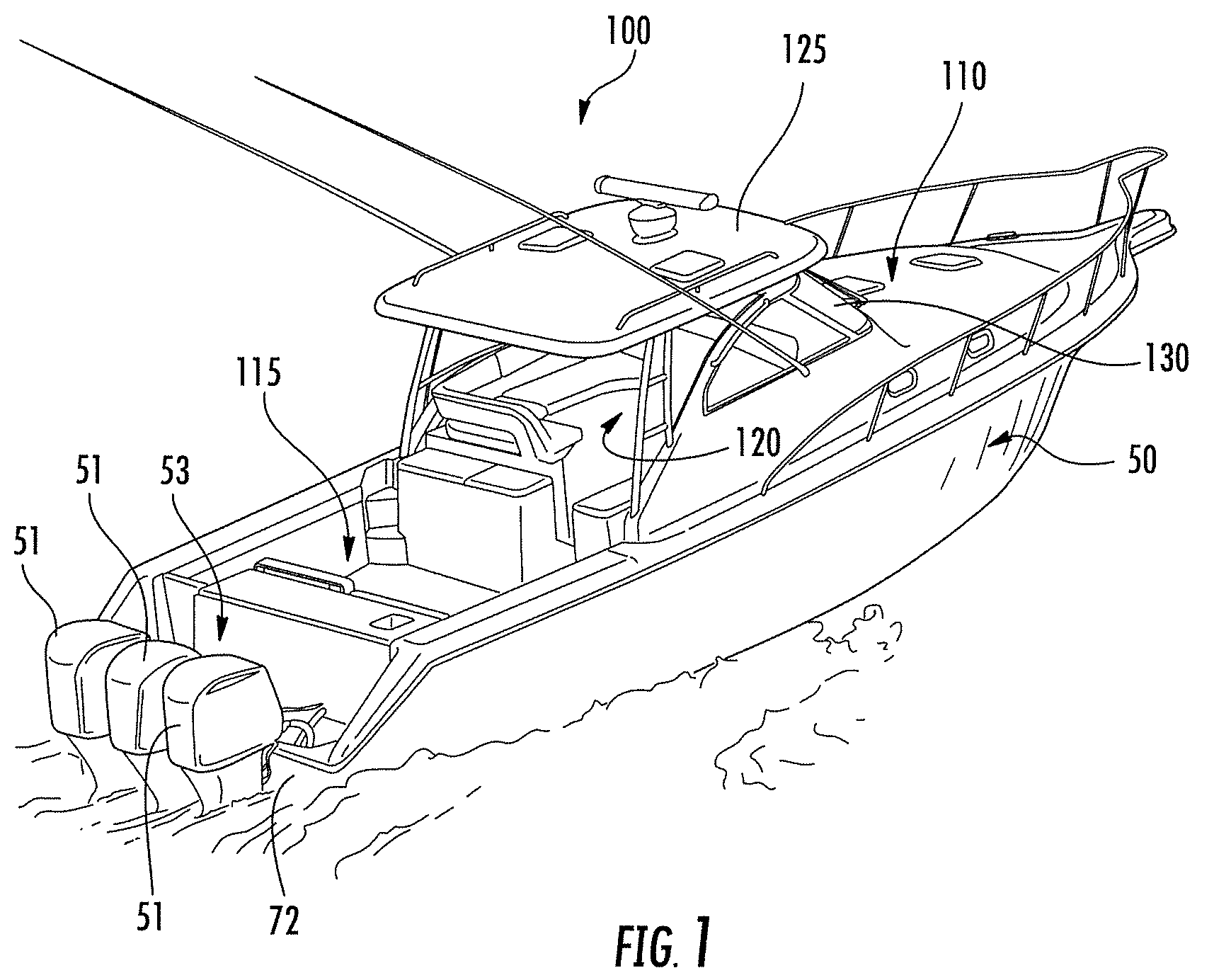

Transom reinforcement grid

ActiveUS20100006017A1Improve rigidityNon-magnetic metal hullsPropulsion power plantsMarine engineeringMesh grid

A reinforcement grid for a vessel includes a plurality of spaced-apart, generally vertically extending walls coupled by lateral floor sections and lateral walls which are coupled to stringers, the transom, and the bottom of the vessel hull to strengthen the transom, thereby allowing a greater number of higher horsepower engines to be mounted to the vessel.

Owner:PB HOLDCO LLC

Natural gas liquefaction vessel

A natural gas liquefaction vessel including an increased deadweight tonnage, as compared to a liquefied natural gas carrier (LNGC) of a comparably-sized ship, is achieved by reducing the LNGC's cargo capacity. This difference creates room on the port and starboard sides of cargo tanks to increase the size of the adjacent wing tanks. The increased size of the wing tanks occupy the space created by the reduced cargo tank size of the vessel and may support a larger upper trunk deck. The ballast wing tanks and smaller cargo tanks increase the deadweight available. With this approach, the larger upper trunk deck of the vessel is able to support an efficient floating liquefaction plant that improves the LNG value chain because it is capable of producing 2.0-3.0 MTPA in the footprint of a standard vessel hull, such as for example a Q-Max hull.

Owner:EXCELERATE LIQUEFACTION SOLUTIONS

Bracket for mounting a thruster to a boat

A bracket for mounting a thruster to a boat includes a horizontal neck portion, an upper mounting support portion, a support plate portion that extends downward from the upper mounting support portion, and an enclosure portion. The support plate portion and the rear of the upper mounting support portion form a transom-facing surface in a plane that is generally at a right angle relative to a horizontal plane, within a small range of angles. The transom-facing surface can angled to match the angle of the transom of a boat to which the thruster bracket is mounted. A thruster can be mounted to the thruster bracket at a level where the thruster will be out of the water when the boat is moving fast and up on plane, and will be in the water when the boat is moving very slow.

Owner:THE YACHT GRP LLC

Transom reinforcement grid

ActiveUS8191495B2Improve rigidityNon-magnetic metal hullsPropulsion power plantsMarine engineeringMesh grid

A reinforcement grid for a vessel includes a plurality of spaced-apart, generally vertically extending walls coupled by lateral floor sections and lateral walls which are coupled to stringers, the transom, and the bottom of the vessel hull to strengthen the transom, thereby allowing a greater number of higher horsepower engines to be mounted to the vessel.

Owner:PB HOLDCO LLC

Ship high-stress joint structure

ActiveCN108163136AReduce in quantityReduce structural weightHull reinforcementsStress concentrationMarine engineering

The invention discloses a ship high-stress joint structure which comprises a horizontally-arranged platform plate, longitudinal cabin wall plates vertically arranged on the platform plate in the longitudinal direction, oblique side plates obliquely arranged on the intersections of the platform plate and the longitudinal cabin wall plates, rib plates perpendicular to the platform plate and the longitudinal cabin wall plates, and wrist plates fixedly connected with the lower surfaces of the rib plates and the platform plate. The lower ends of the longitudinal cabin wall plates stretch out from the connecting positions of the longitudinal cabin wall plates and the platform plate, and cutting grooves used for enabling the longitudinal cabin wall plates to penetrate through are formed in the corners of the rib plates. According to the ship high-stress joint structure, the structure is simple, on-site manufacturing and mounting are convenient, the lower ends of the longitudinal cabin wall plates stretch out from the connecting positions of the longitudinal cabin wall plates and the platform plate by 30-50 mm, the rib plates and the wrist plates are arranged, thus joint stress can be downwards transmitted, the situation of stress concentration at a joint is remarkably reduced accordingly, the stress at the joint is greatly reduced, and the structural weight of a ship is effectively reduced.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com