Patents

Literature

100 results about "Deep diving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deep diving is underwater diving to a depth beyond the norm accepted by the associated community. In some cases this is a prescribed limit established by an authority, and in others it is associated with a level of certification or training, and it may vary depending on whether the diving is recreational, technical or commercial. Nitrogen narcosis becomes a hazard below 30 metres (98 ft) and hypoxic breathing gas is required below 60 metres (200 ft) to lessen the risk of oxygen toxicity.

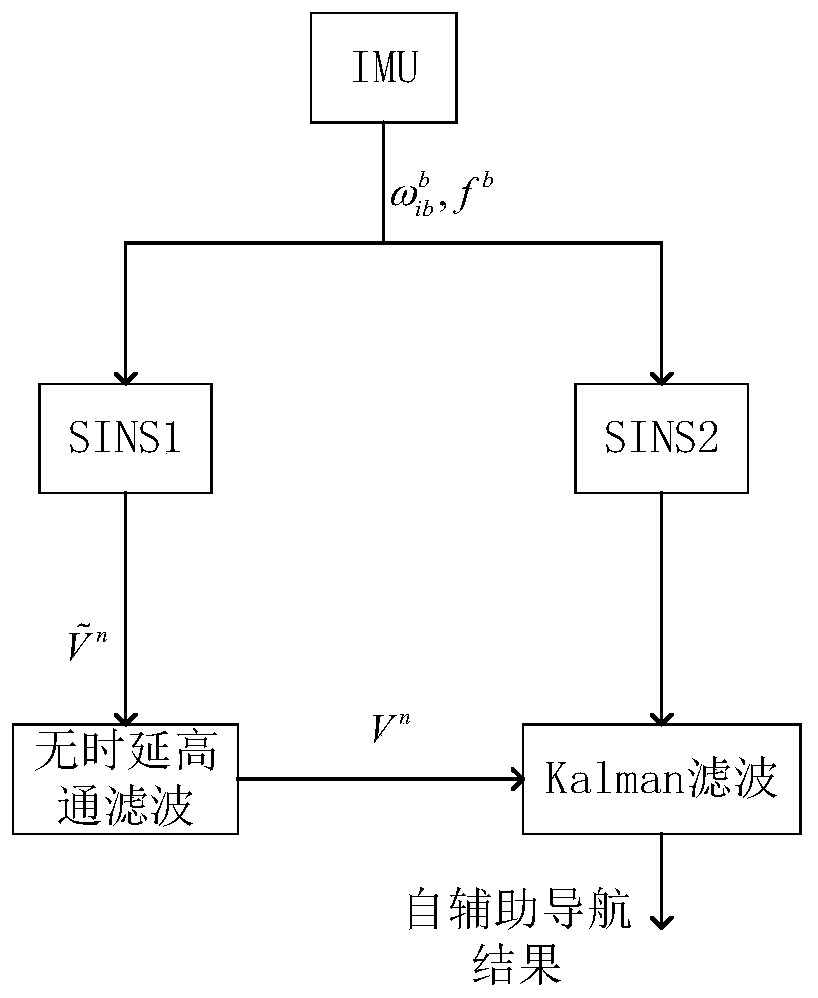

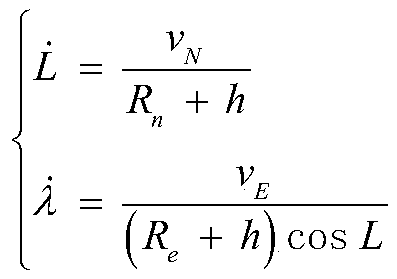

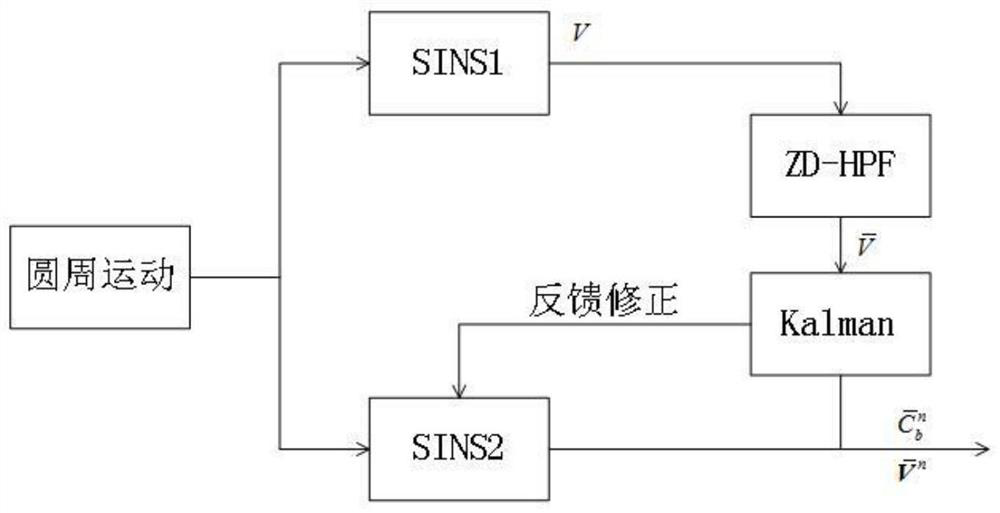

SINS self-aided navigation method for deep diving manned submersible

ActiveCN110345941AError propagation suppressionReduce phase lagNavigation by speed/acceleration measurementsWater resource assessmentInertial measurement unitTime delays

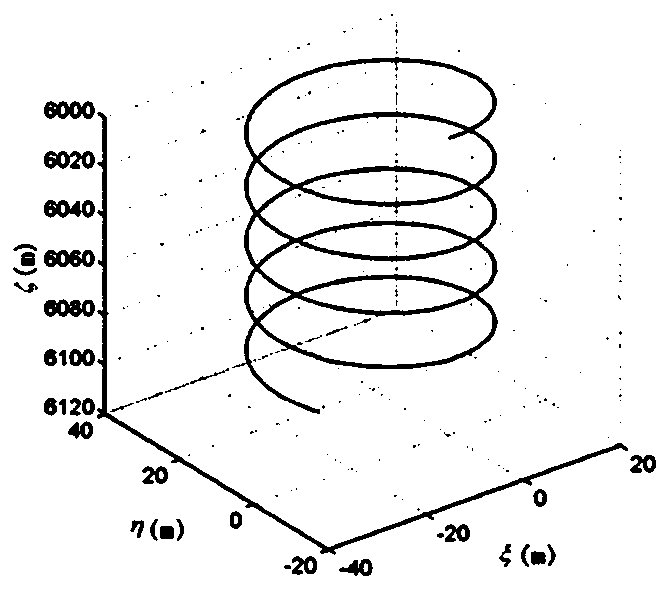

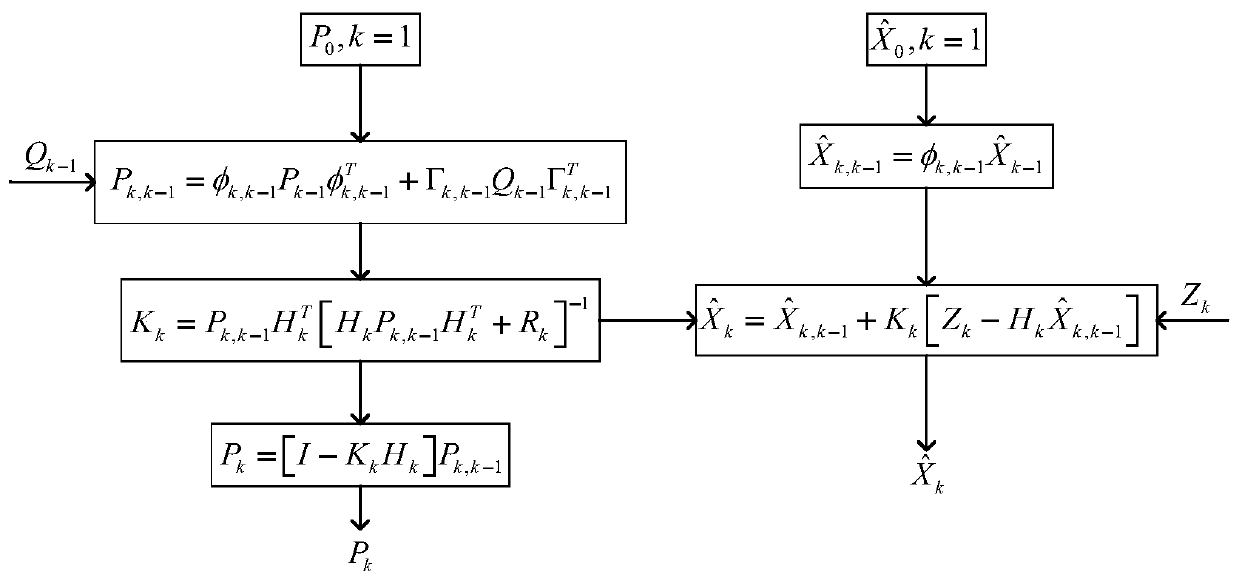

The invention discloses a SINS self-aided navigation method for a deep diving manned submersible. The method comprises the following steps: 1, taking angular motion and linear motion measurement provided by an inertial measurement unit (IMU) on the manned submersible as input of a strapdown inertial navigation system (SINS), executing two navigation calculation algorithms in parallel, and outputting two groups of identical navigation parameters, thus obtaining two sets of identical strapdown inertial navigation systems SINS1 and SINS2; 2, performing frequency difference characteristic analysison a horizontal speed output by the SINS1 in the step 1; 3, designing a high-pass time-delay-free digital filter, and filtering out a low-frequency speed error component contained in the horizontal speed output by the SINS1, thereby obtaining the real horizontal speed of the manned submersible; and 4, commonly constructing speed matching integrated navigation through Kalman filtering and the SINS2 by utilizing the real horizontal speed obtained in the step 3, thus obtaining an integrated navigation result of which the positioning error is not accumulated along with time. According to the method, auxiliary speed information under a navigation system can be obtained, and the positioning errors are not accumulated along with time.

Owner:SOUTHEAST UNIV

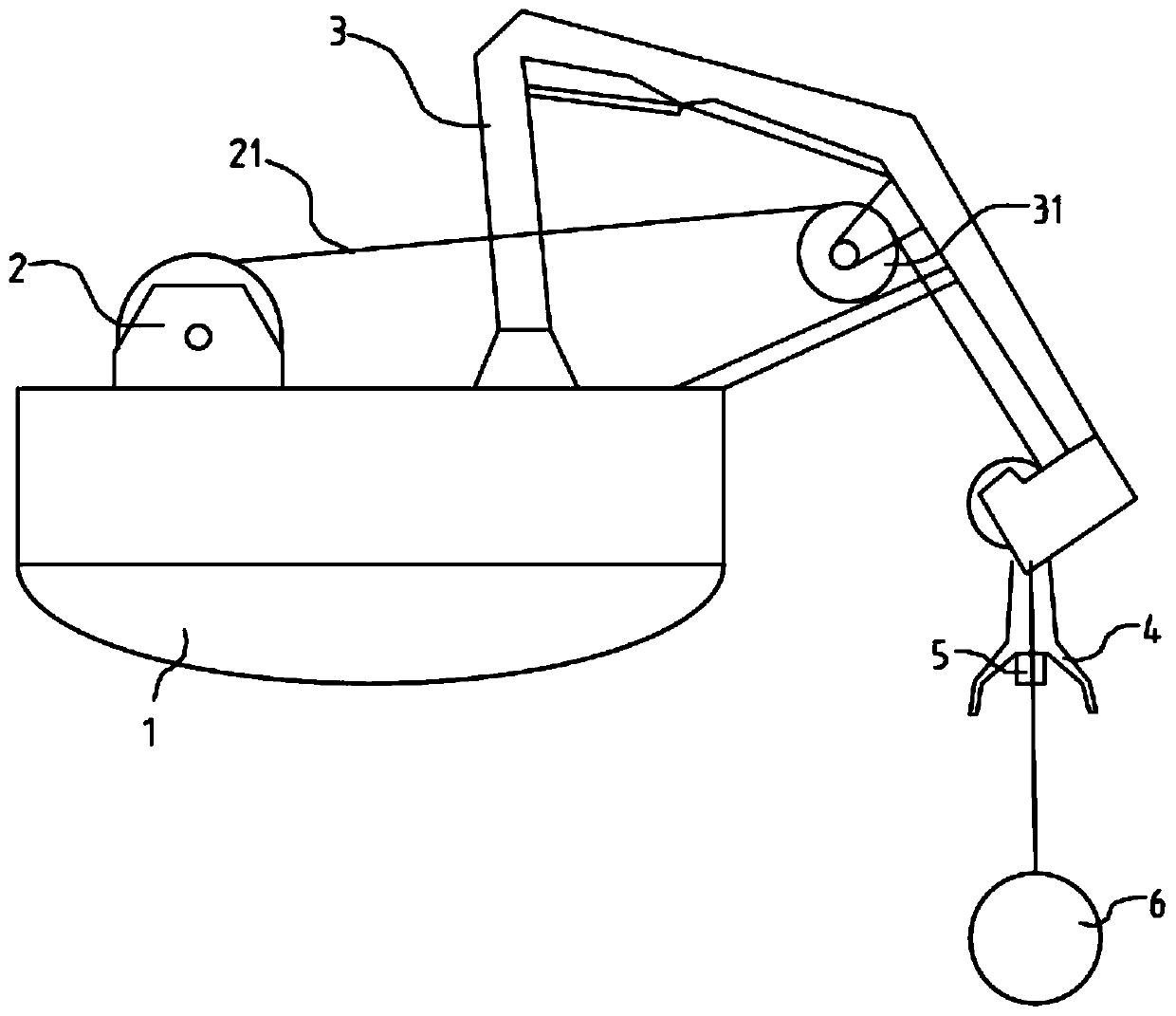

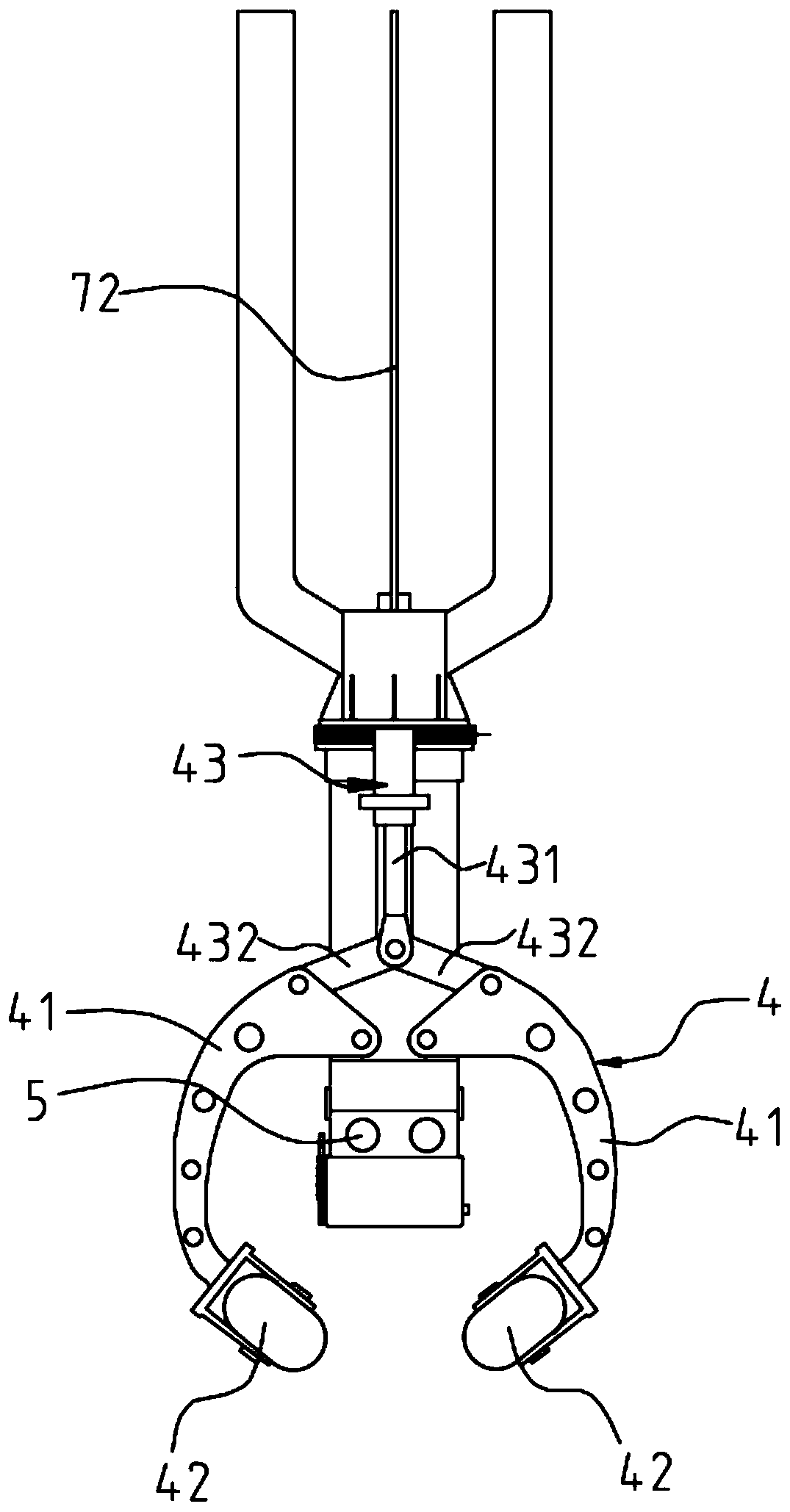

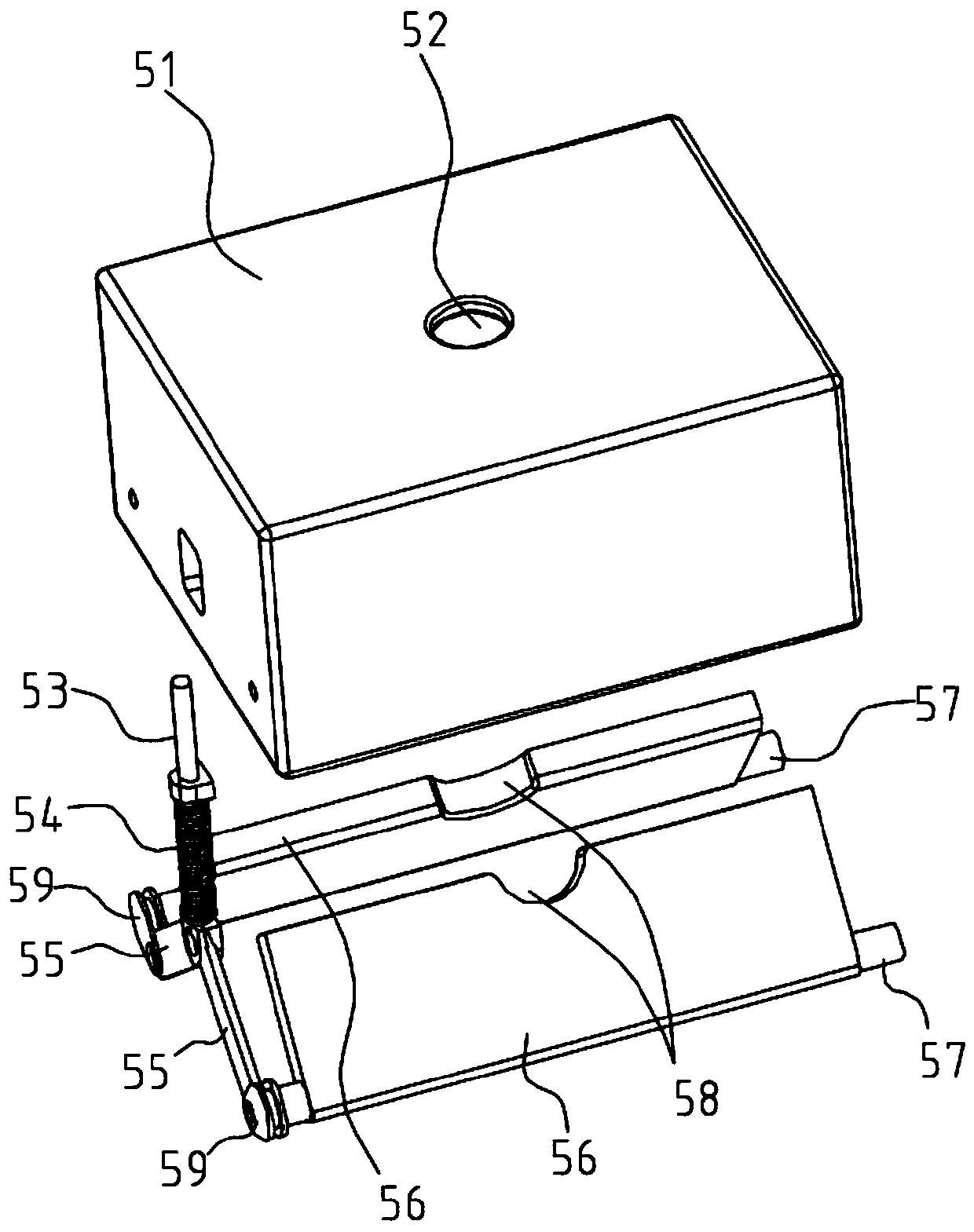

Single-rope recovery method of unarmored cable deep diving submersible

ActiveCN110816788AAvoid water operationReduce riskHoisting/lowering gearUnderwater equipmentFisheryDeep diving

The invention provides a single-rope recovery method of an unarmored cable deep diving submersible. The method comprises following steps: (1), an emitter is mounted on a deep diving submersible; (2),one end of a throwing rope is fixed on the deep diving submersible, and the other end of the throwing rope winds around a bullet; (3), after the deep diving submersible returns to water surface near amother ship, an operator on the mother ship controls the emitter to start by a remote-control unit; (4), the bullet carrying the throwing rope flies and lands on the mother ship; (5), the operator onthe mother ship takes down the throwing rope from the bullet, and then one end of the throwing rope is fixed on a mushroom head; (6), a winch rolls up and hoists the mushroom head and the deep divingsubmersible through the throwing rope; and (7), a lifting arm is started to lift the deep diving submersible connected with the mushroom head onto the mother ship, and recovery is finished. A cable is thrown on the mother ship by the aid of the emitter, so that the operator is not required to perform underwater operation, risks of the operator are reduced, and working efficiency is increased.

Owner:SOUTH CHINA MARINE MACHINERY

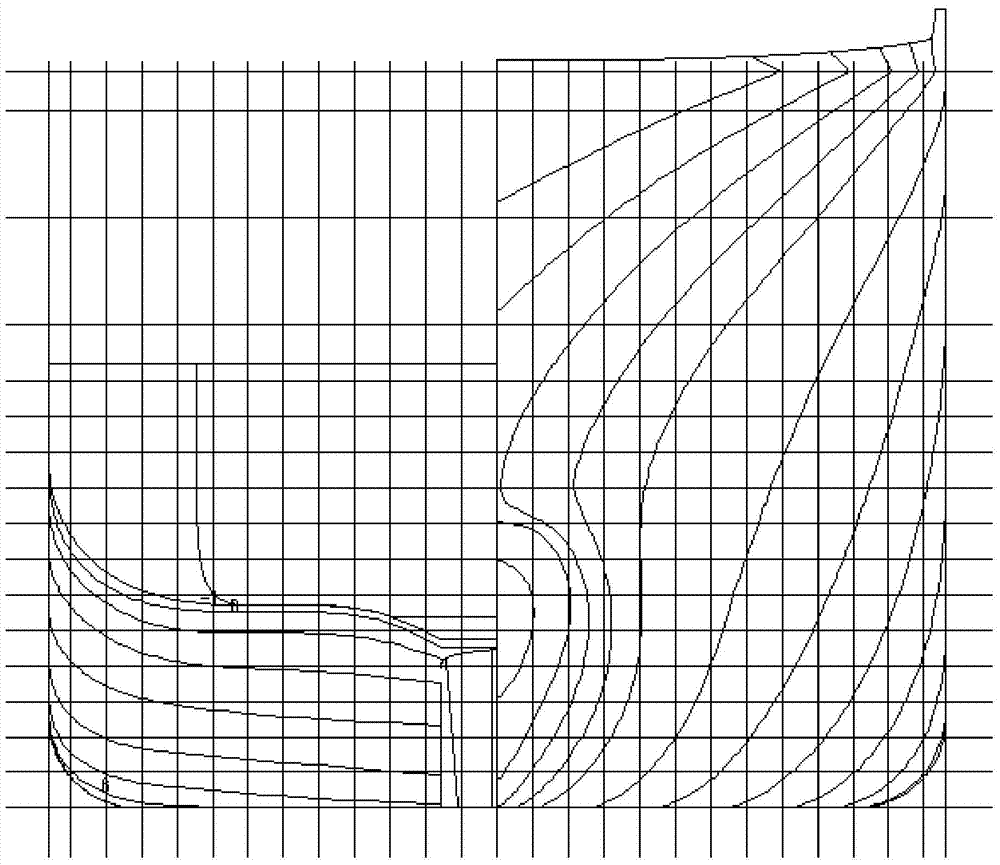

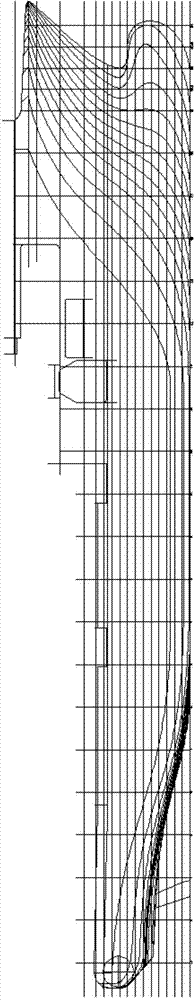

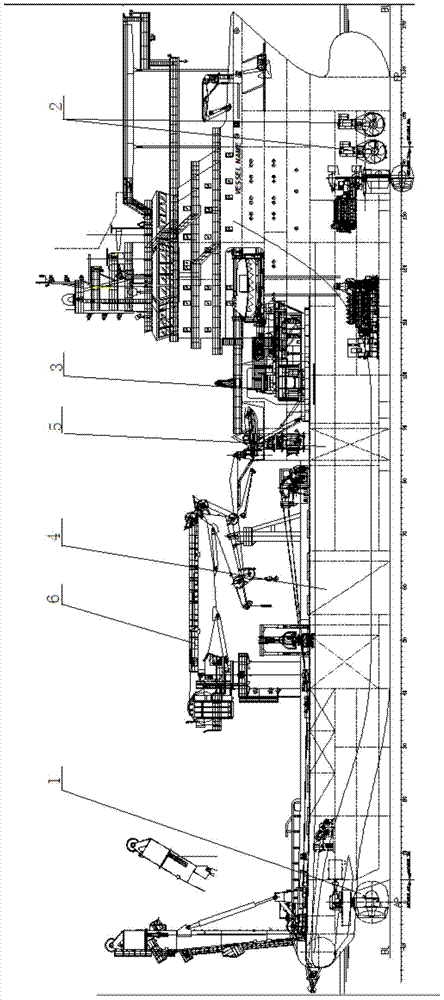

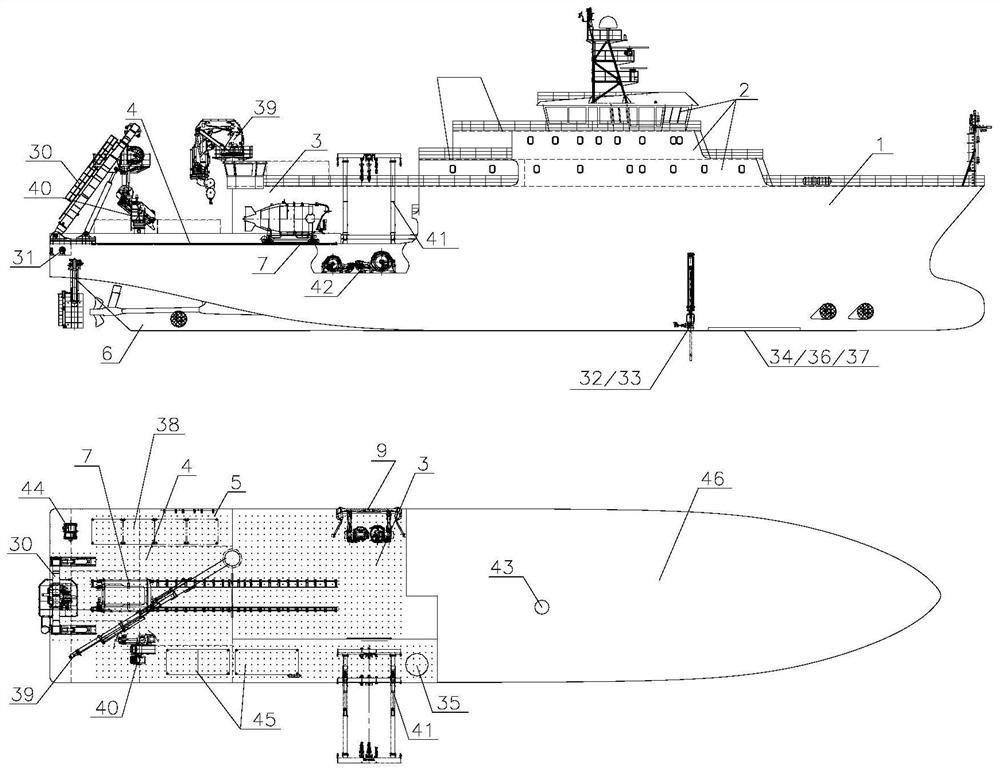

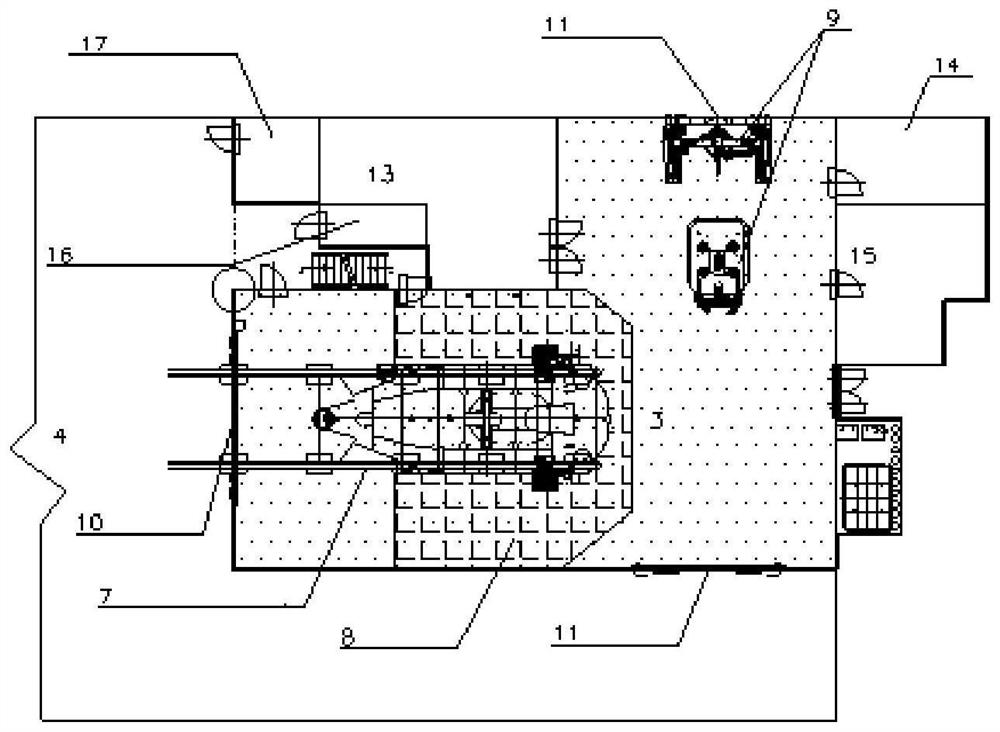

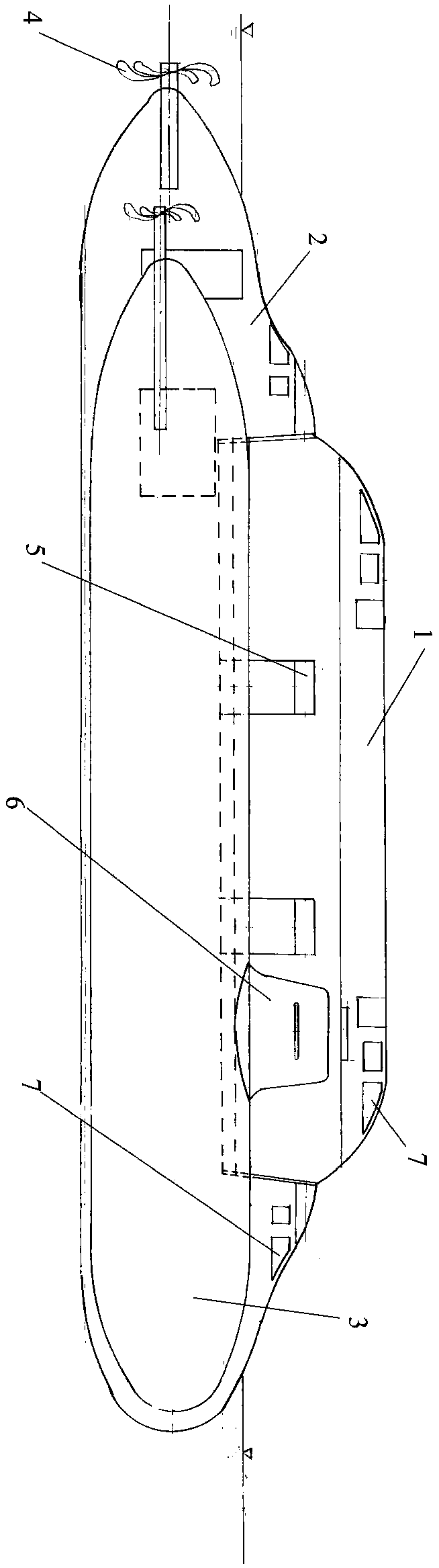

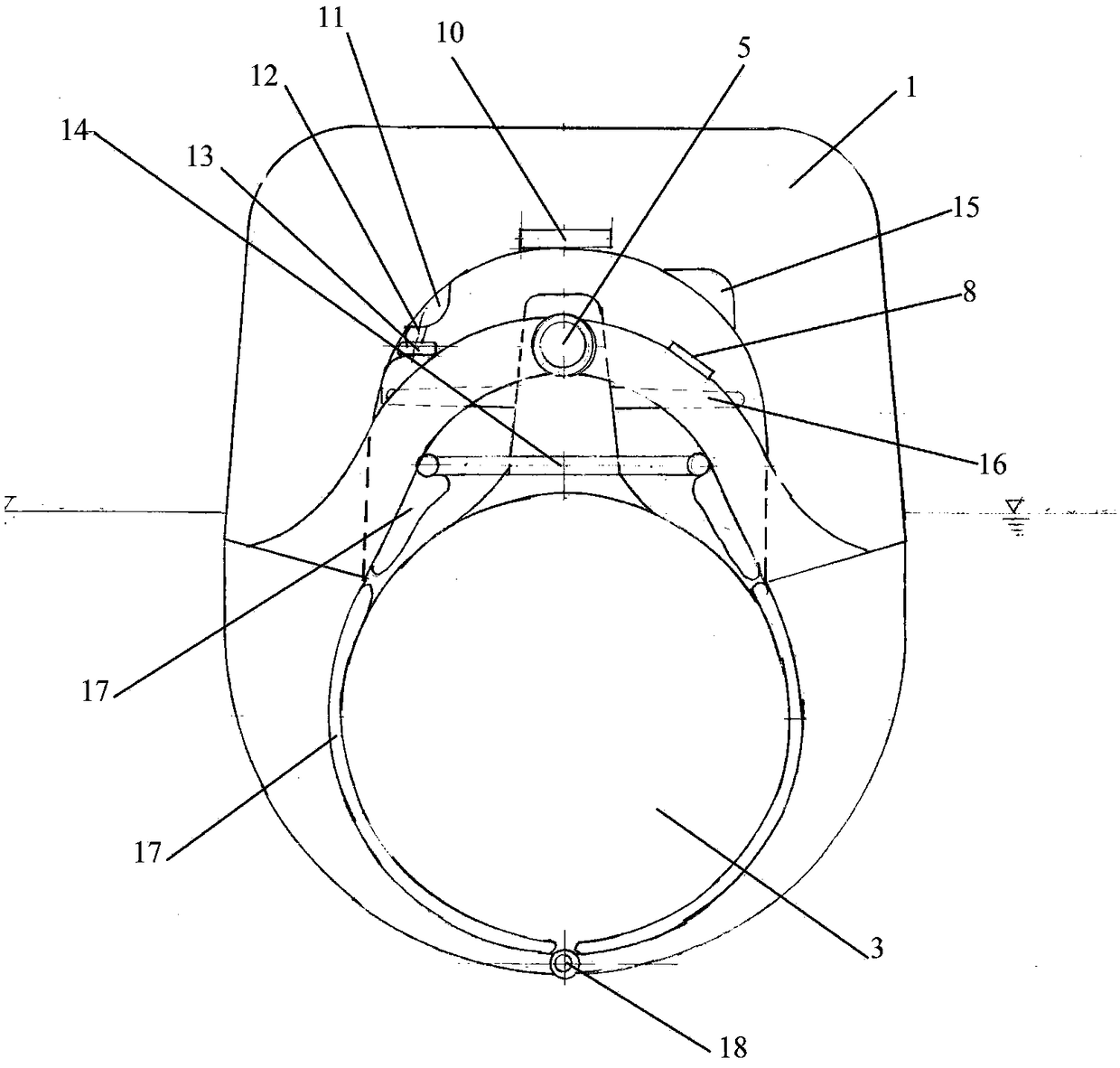

Deep diving operation supporting ship

InactiveCN104229082AReasonable arrangementCompact structureHull reinforcementsSpecial purpose vesselsMarine engineeringRemote control

The invention discloses a deep diving operation supporting ship which comprises a bulbous bow, a working deck, a fully-rotating propelling plant, a lifting system, a saturation diving system, an air diving system and a remote control detection working system, wherein the bulbous bow is arranged on a ship foremost region, the working deck is arranged on a ship midship region and a ship tail region, the fully-rotating propelling plant is arranged on the ship tail region, the lifting system is arranged on the ship midship region through stand columns, the saturation diving system is arranged between the ship foremost region and the ship midship region, the air diving system is arranged on a ship side region, and the remote control detection working system is arranged on the ship side region. According to the deep diving operation supporting ship, the fully-rotating propelling plant can be arranged reasonably through the tail shaped line design, and the deep diving operation supporting ship has the advantages that all function regions are compact in structural layout and high in integration level.

Owner:CSIC WUHAN SHIP & MARINE ENG EQUIP DESIGN

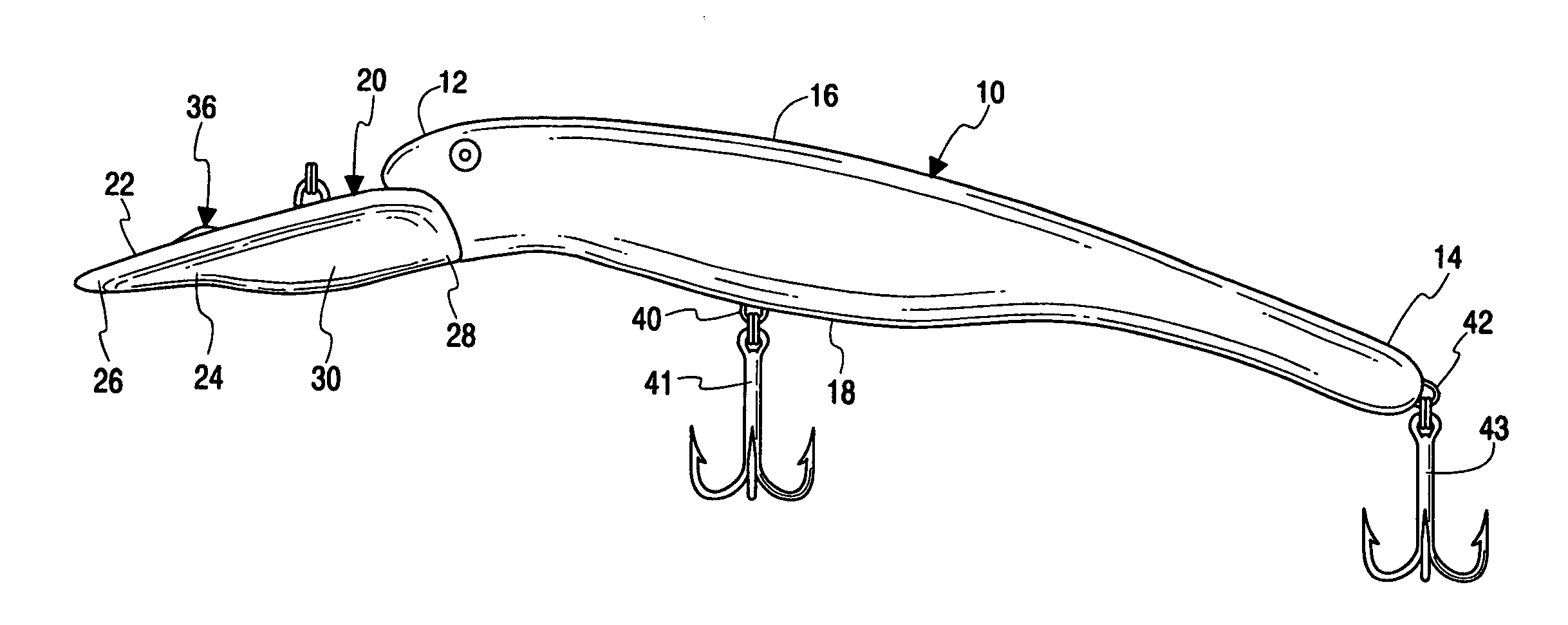

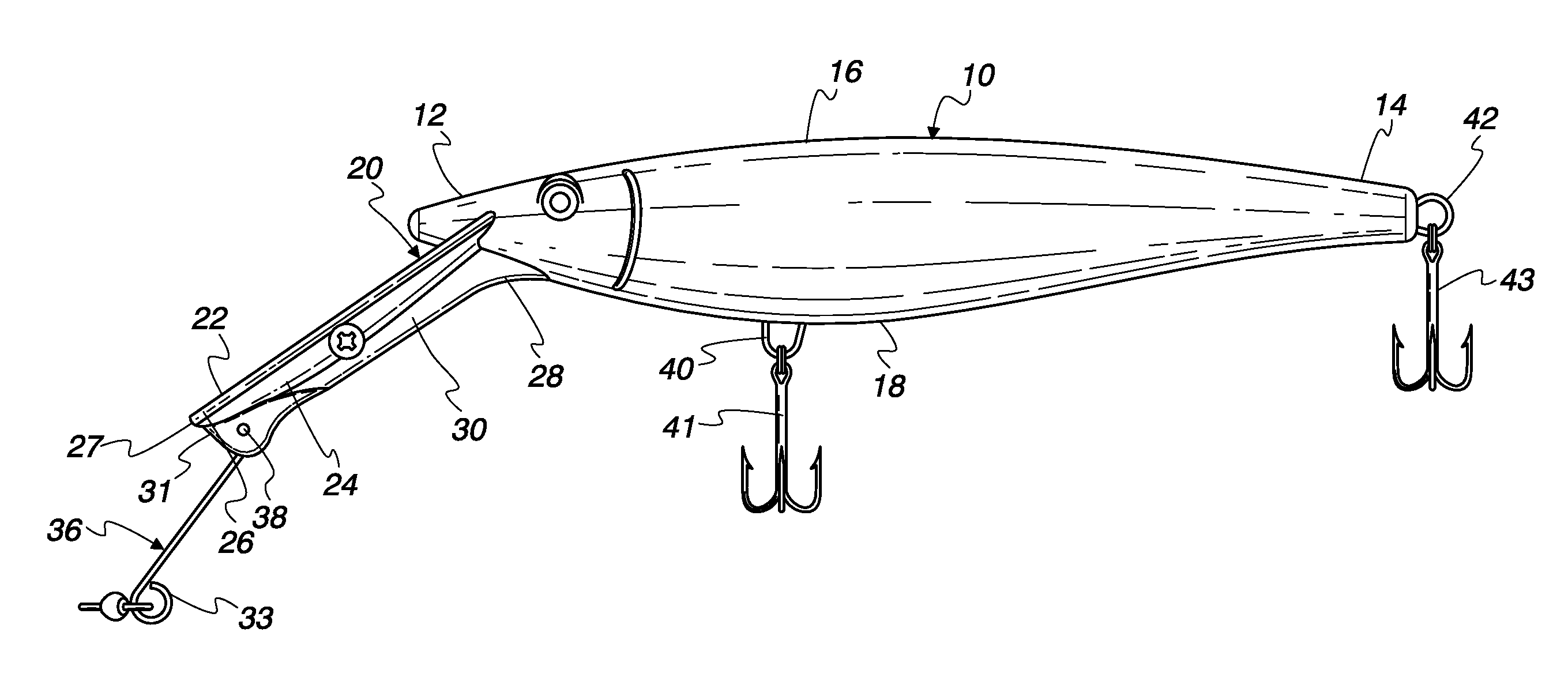

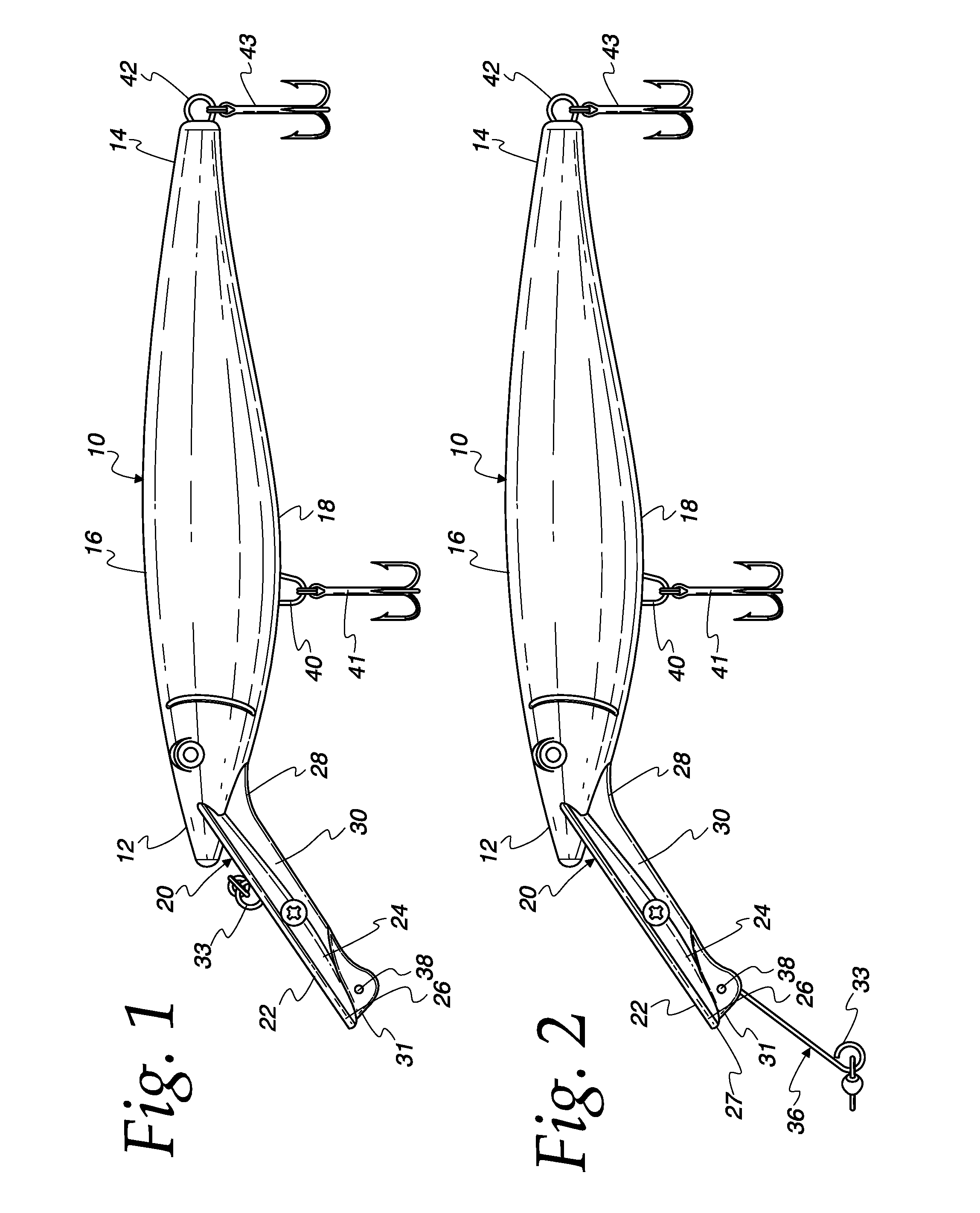

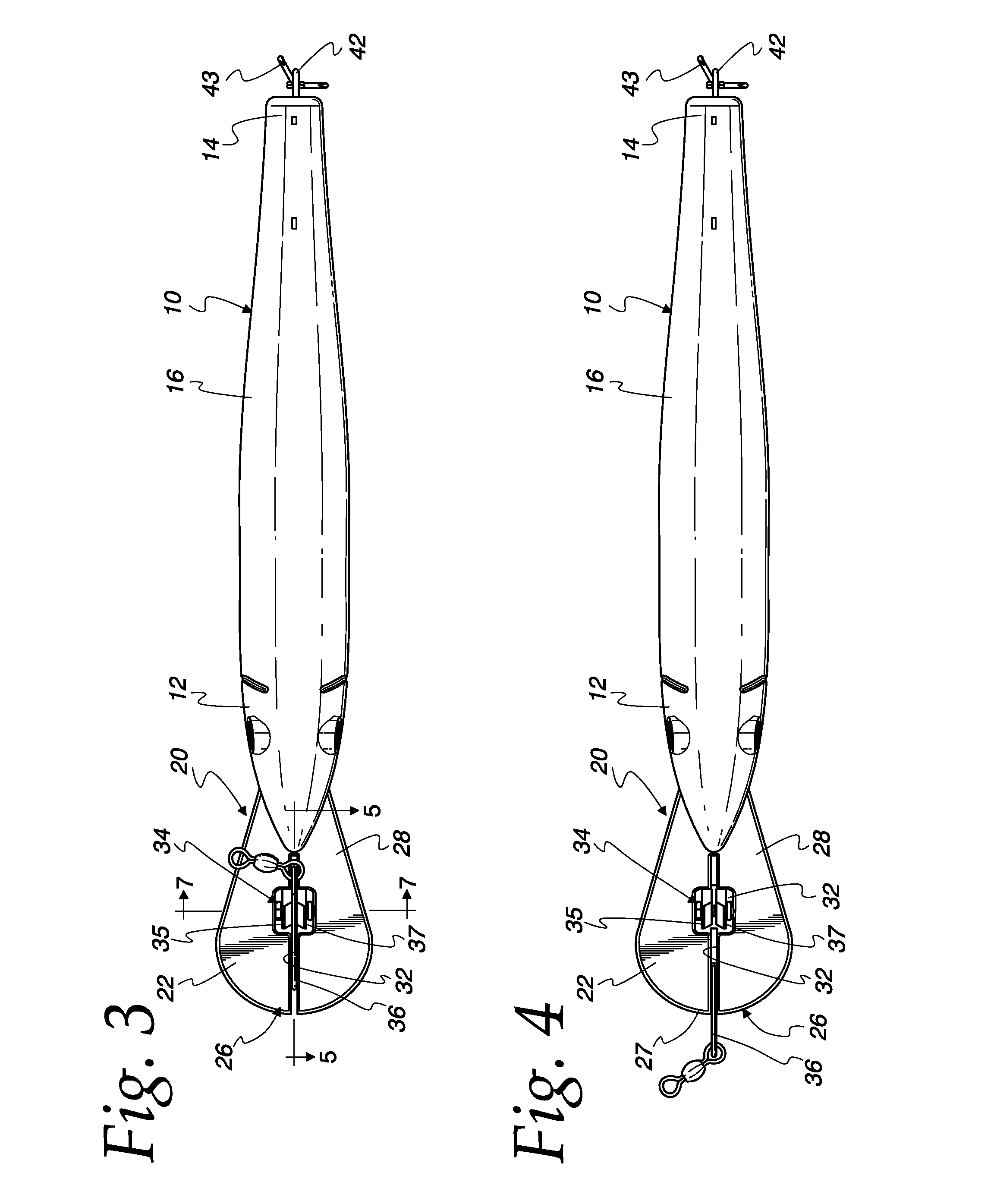

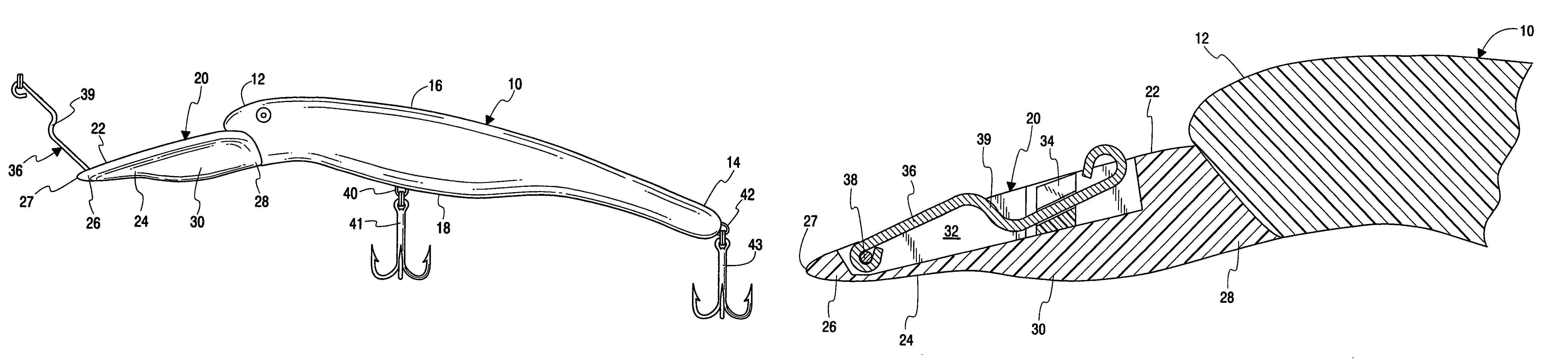

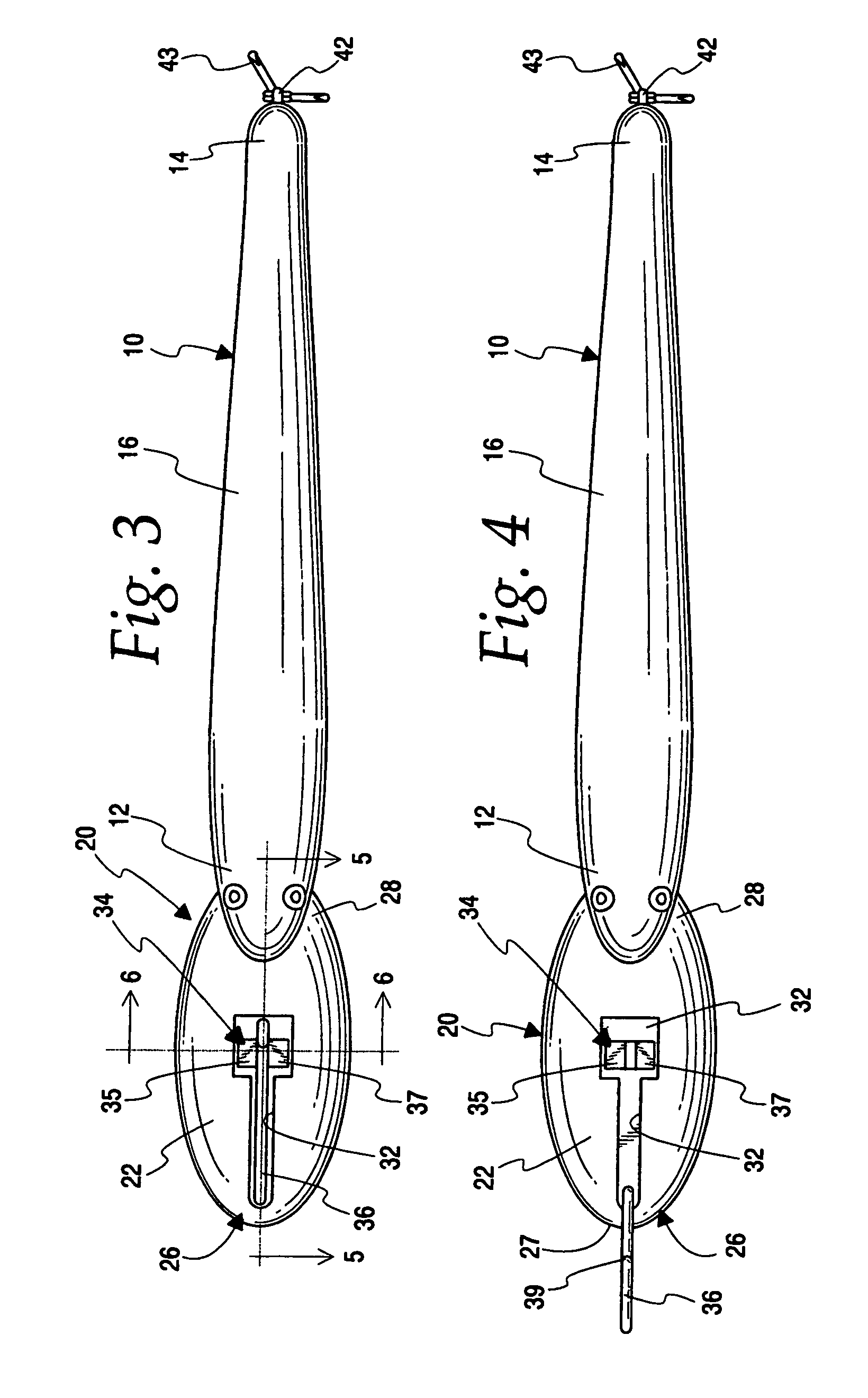

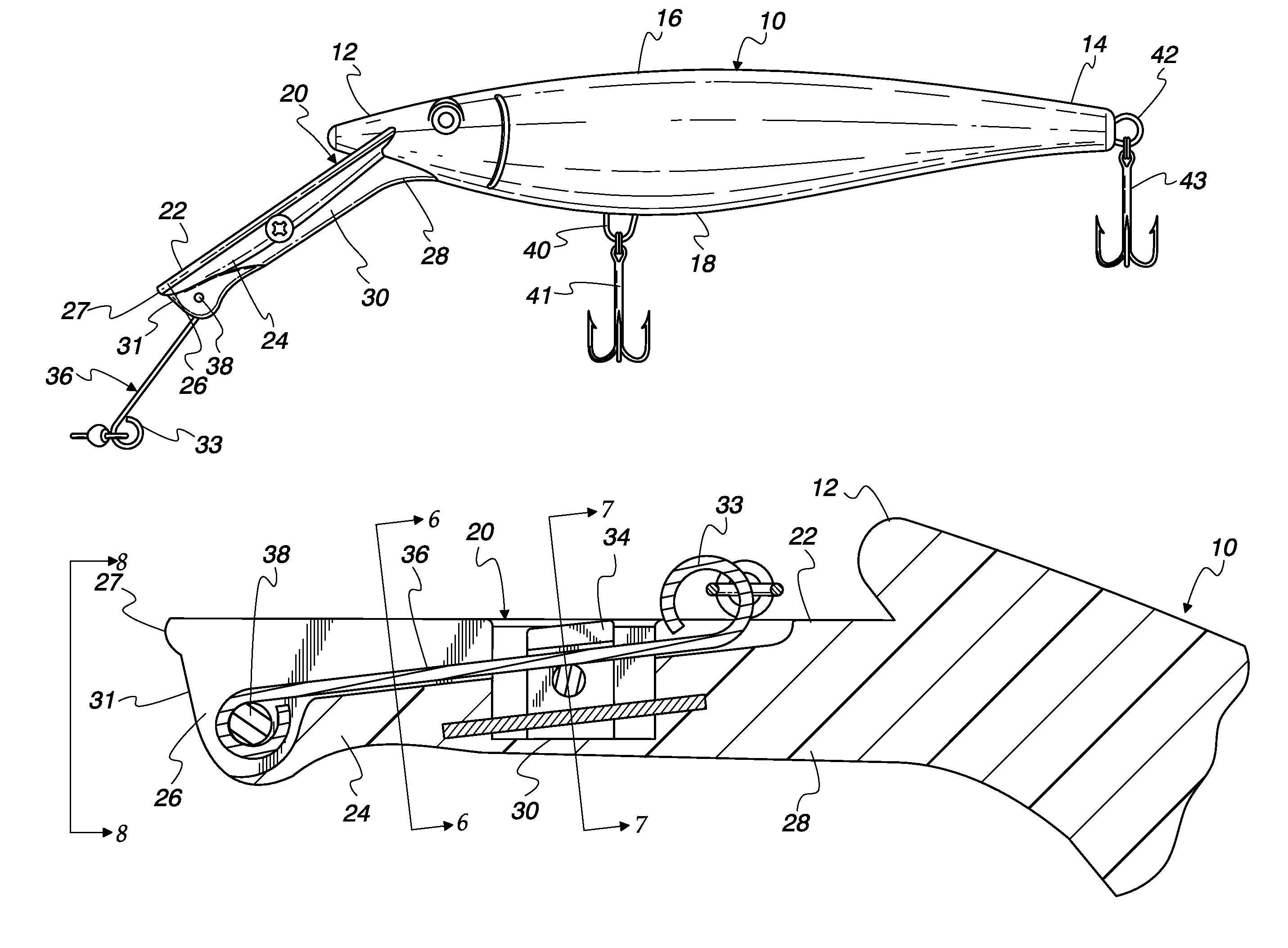

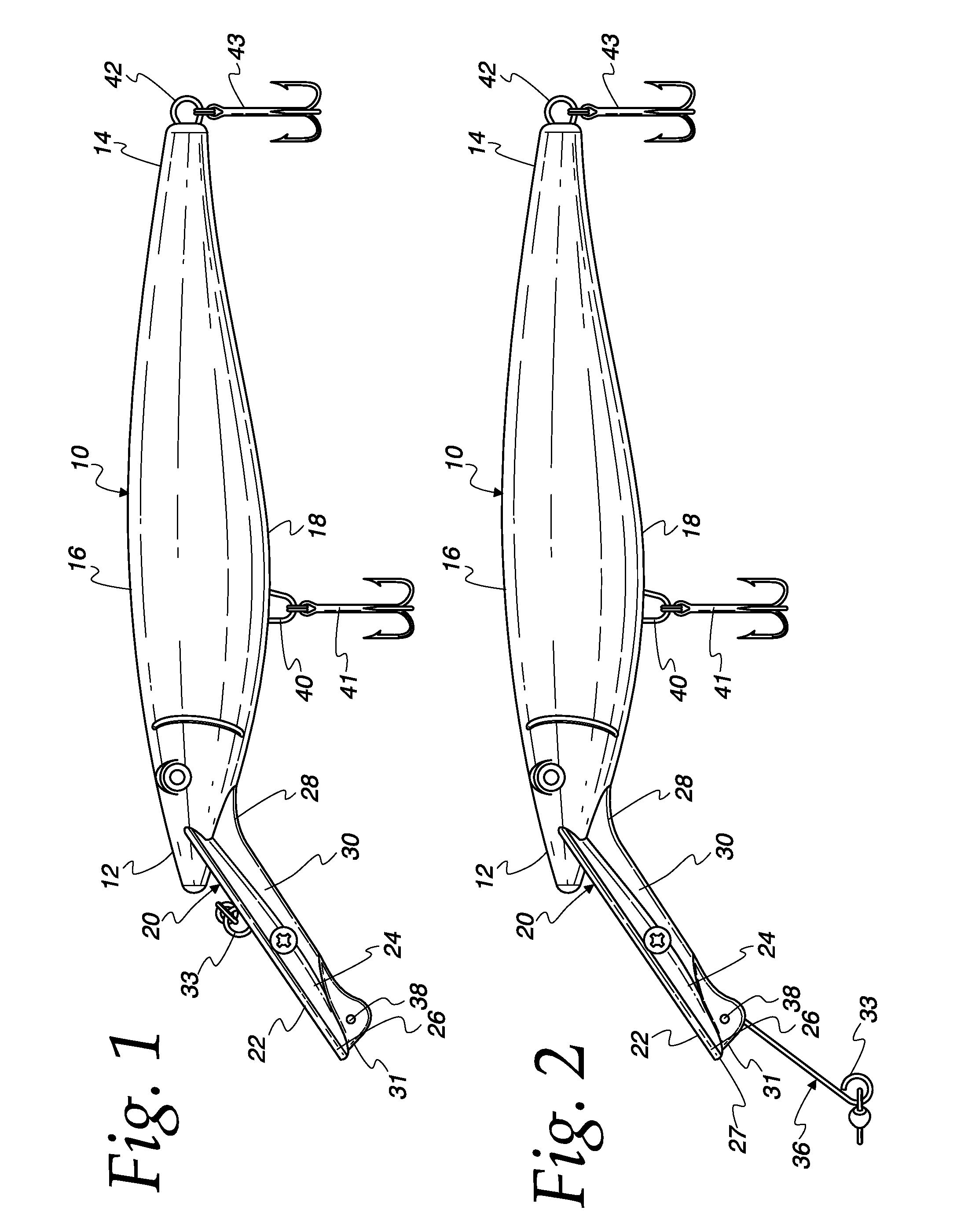

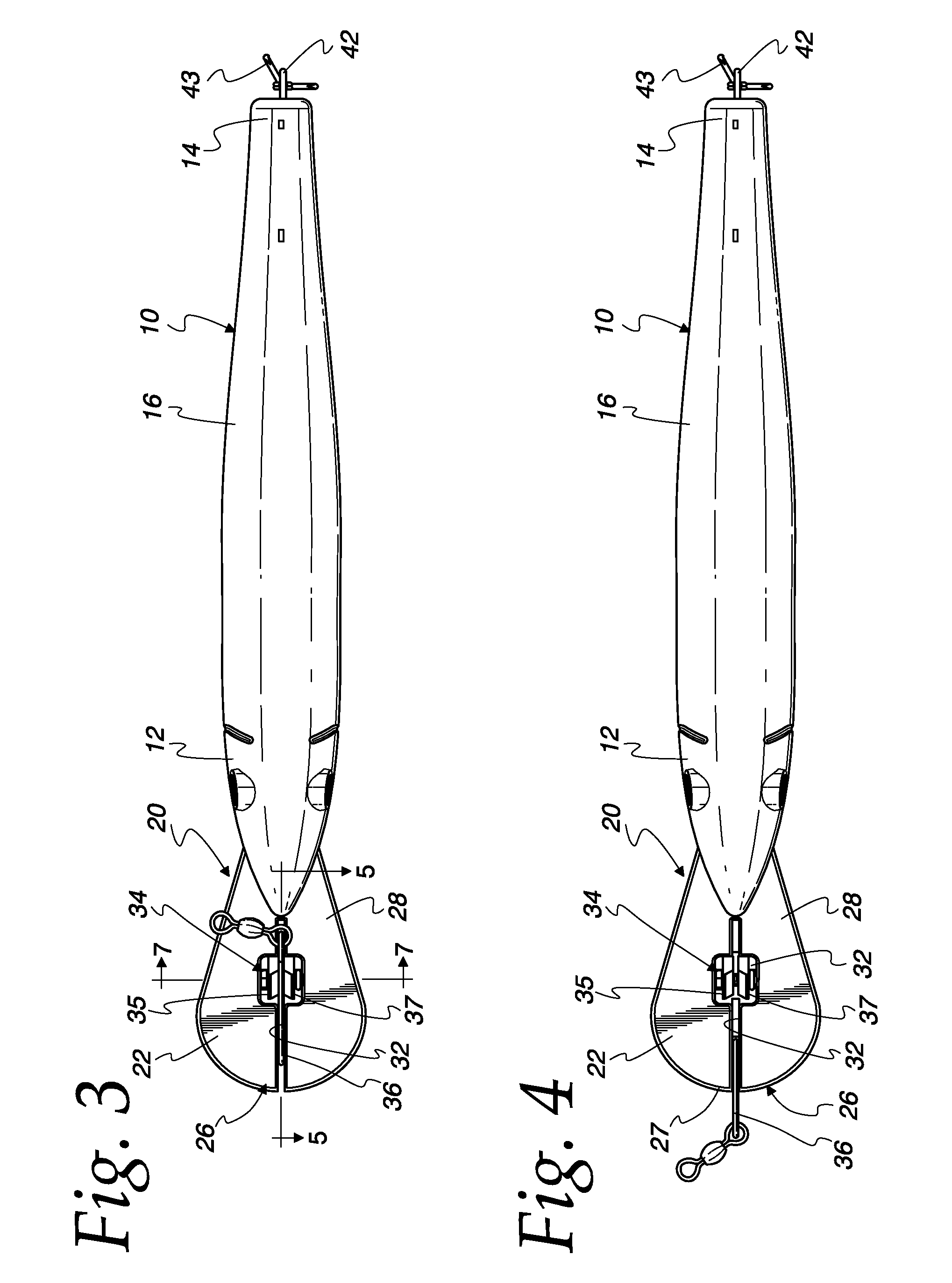

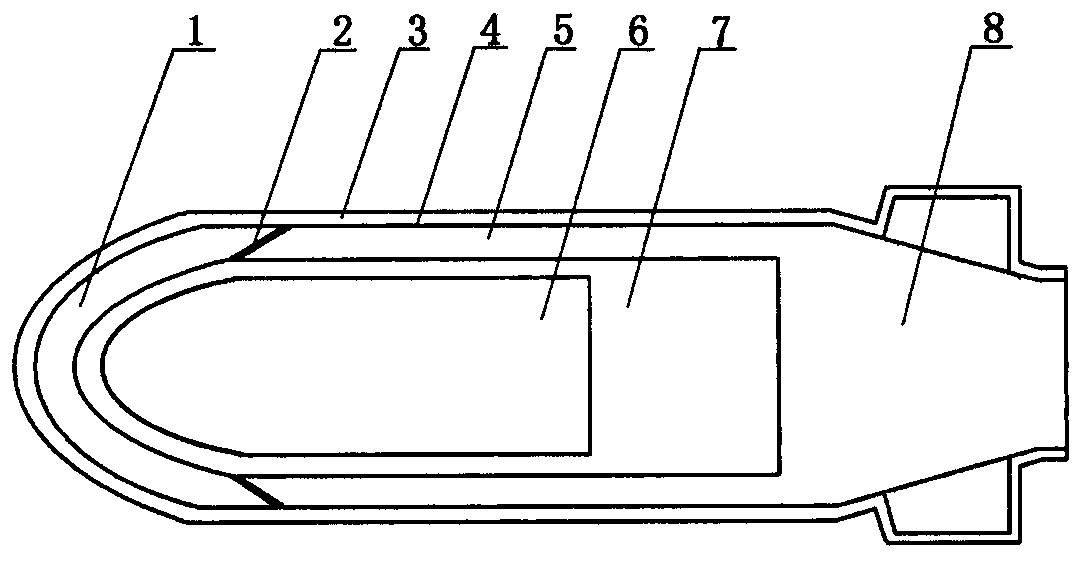

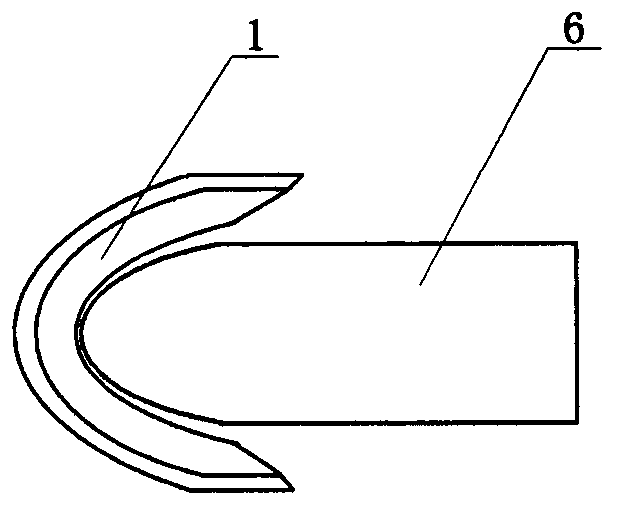

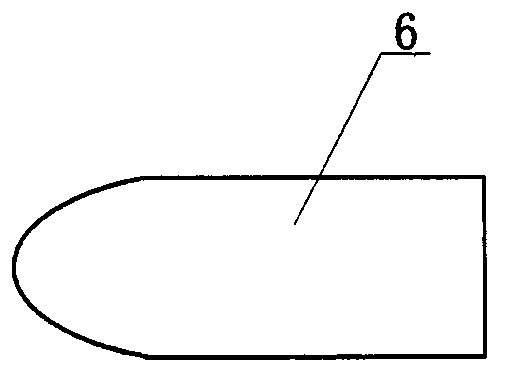

Deep diving fishing lure

A deep diving fishing lure having a forwardly-extending diving lip is provided with a fore-and-aft pivotable lure positioning arm mounted to the diving lip. The lure positioning arm, when locked in aft position, maintains the lure in a diving position when pulled through a body of water but negates the lure's tendency to dive when released from the aft position.

Owner:2327086 ONTARIO

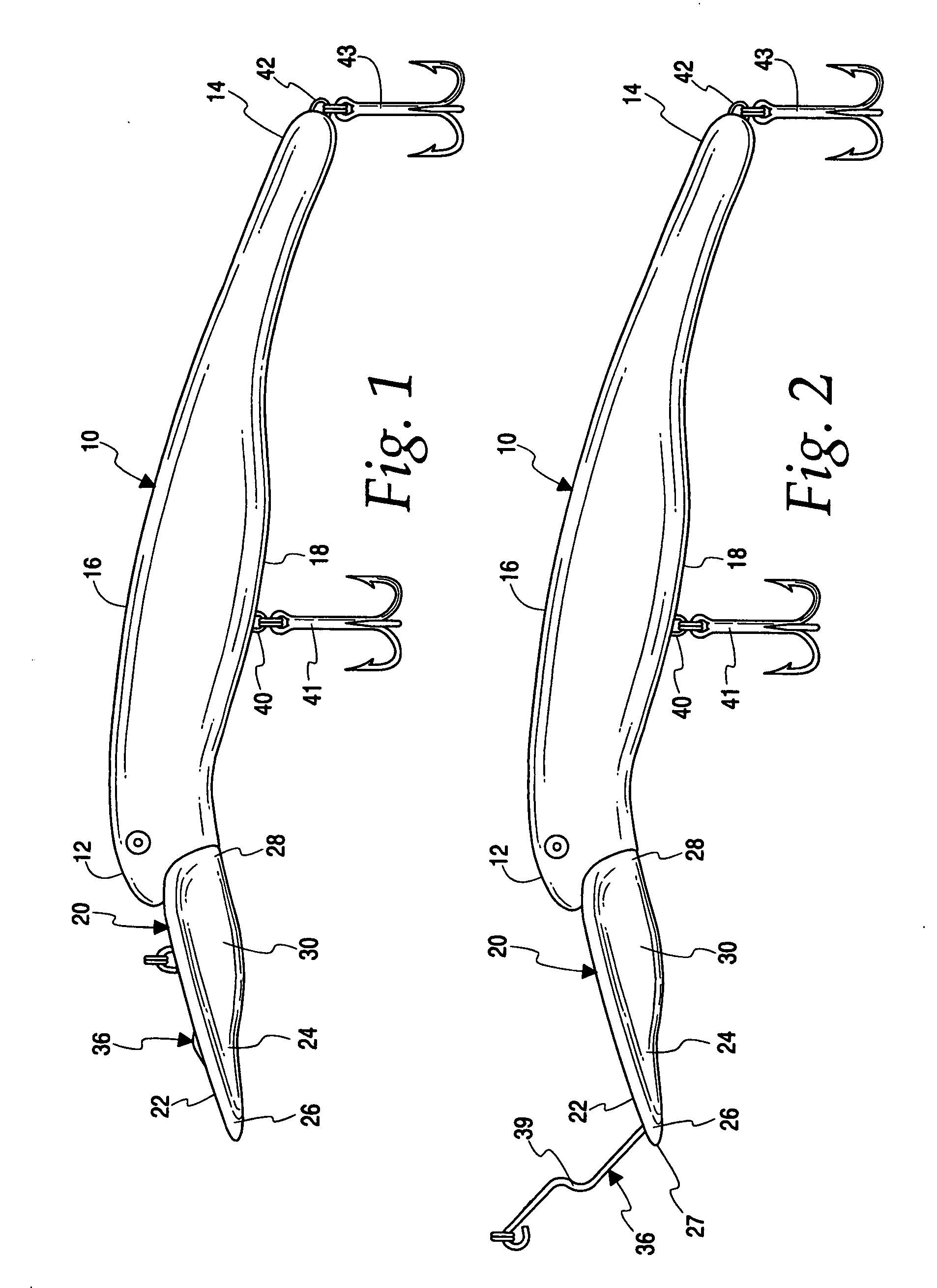

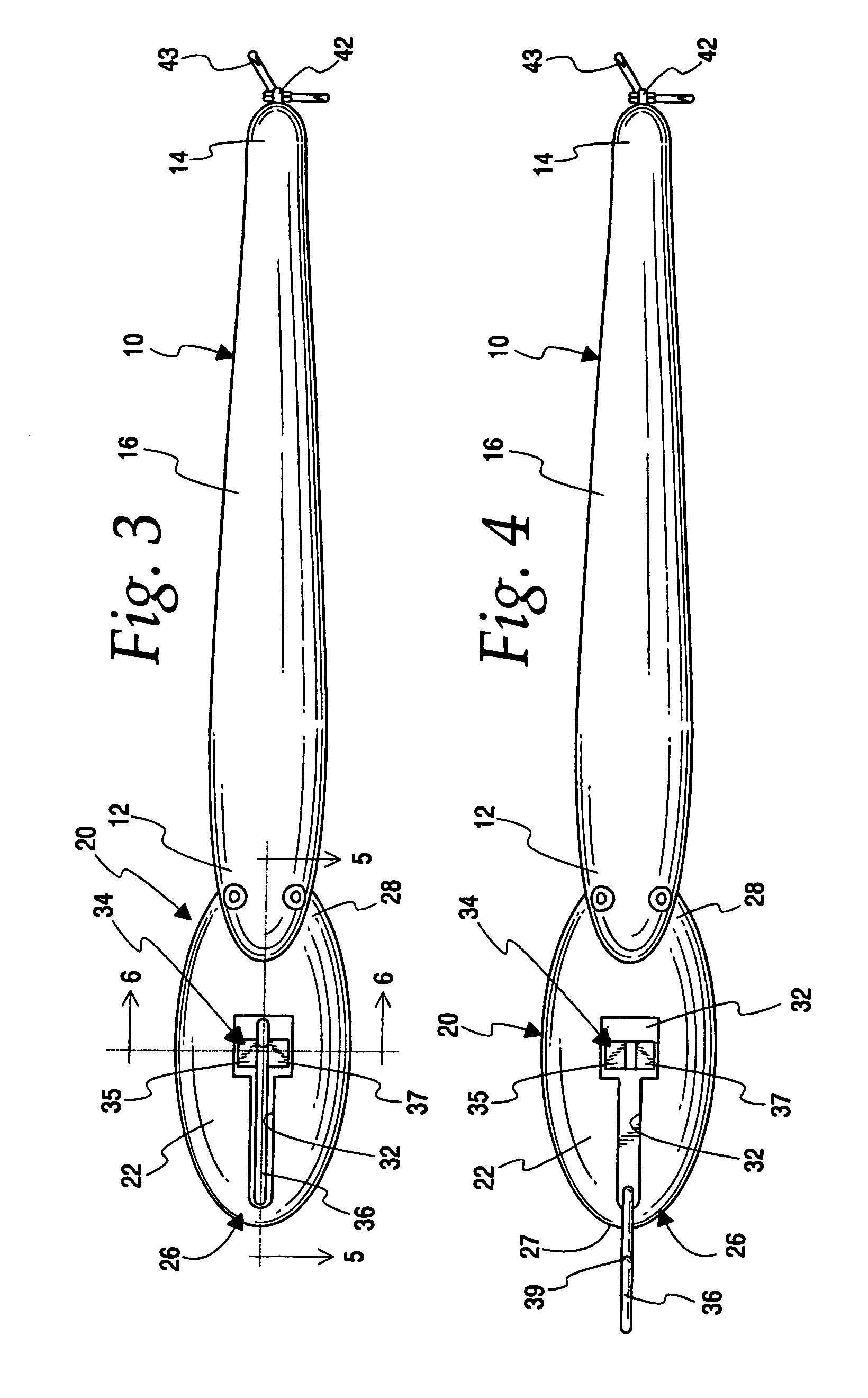

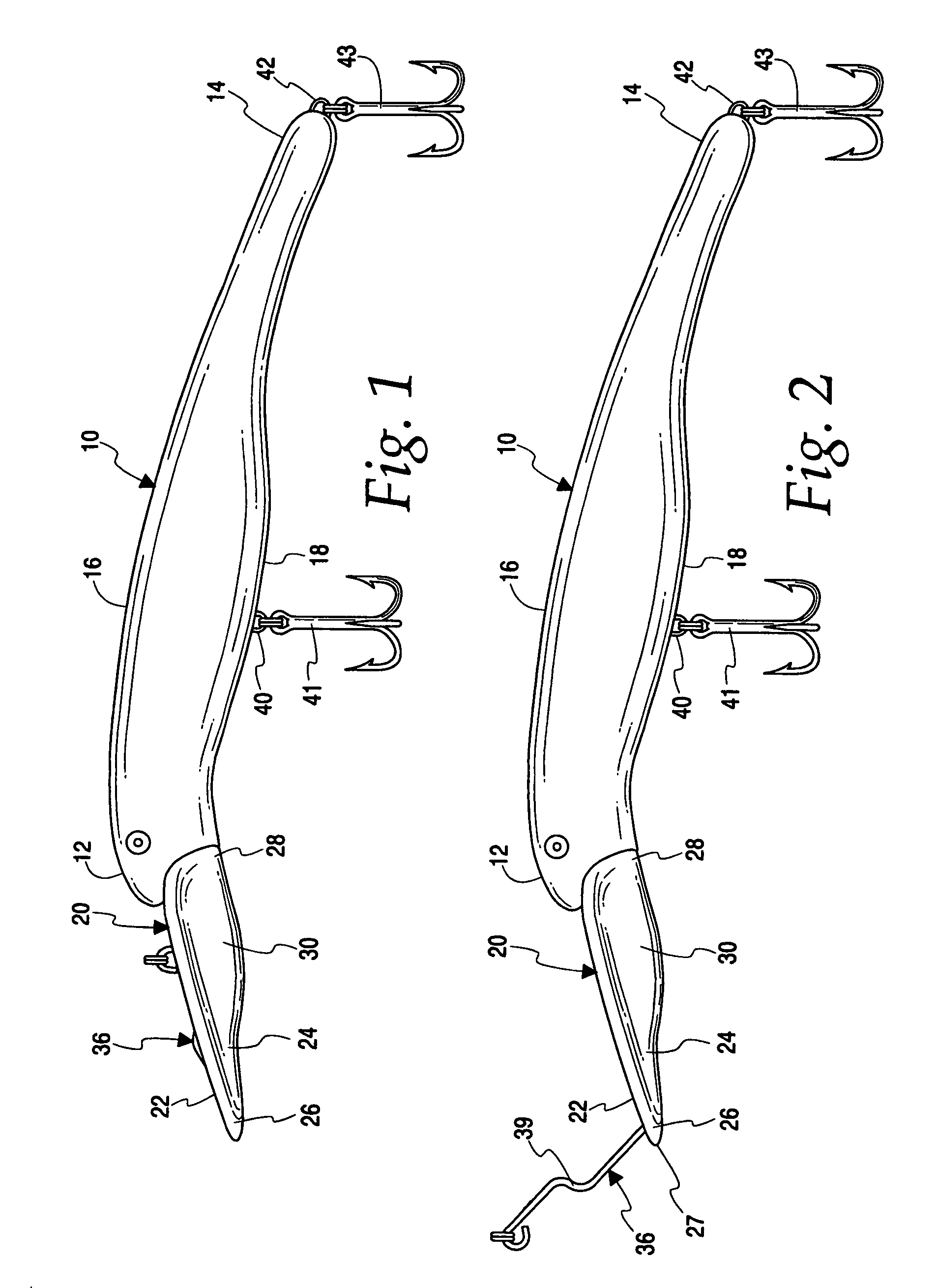

Deep Diving Fishing Lure

A deep diving fishing lure having a forwardly-extending diving lip is provided with a fore-and-aft pivotable lure positioning arm pivotably mounted about a pivot axis within the diving lip near the lower portion of the forward face. The lure positioning arm, when fixed in an aft position relative to the pivot axis rests within a longitudinally extending groove located in the diving lip. The lure positioning arm, when in the fixed aft position maintains the lure in a diving position when pulled through a body of water but negates the lure's tendency to dive when released from the aft position.

Owner:2327086 ONTARIO

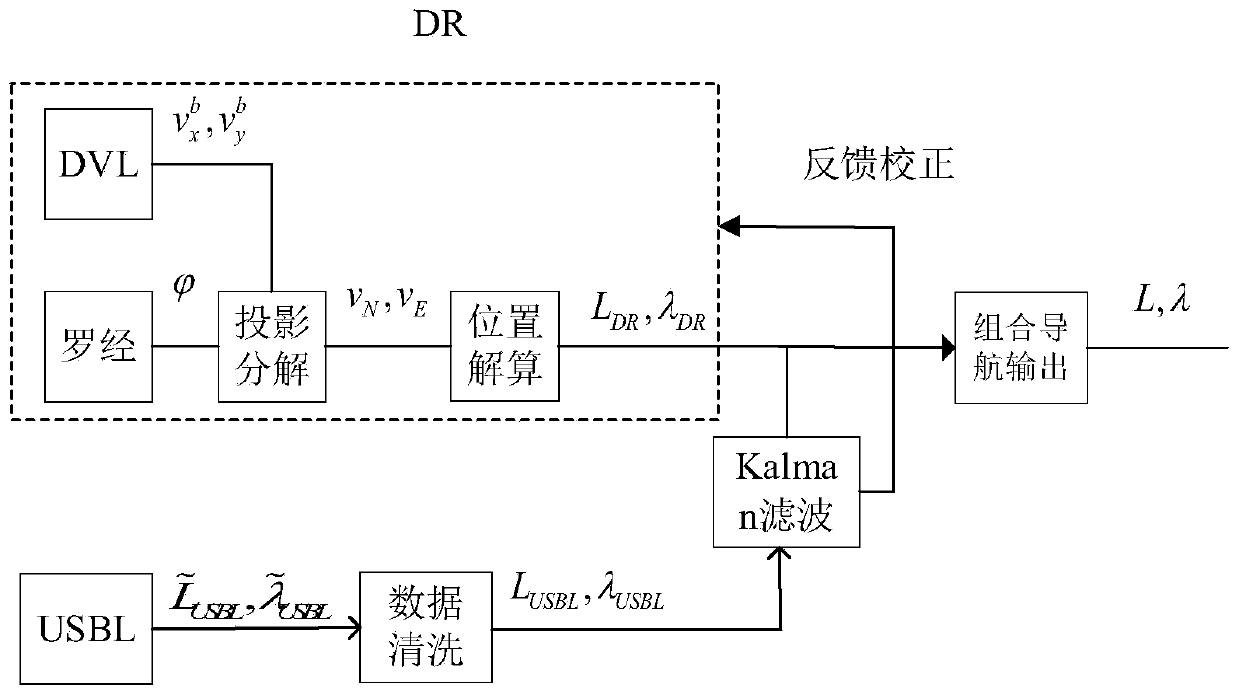

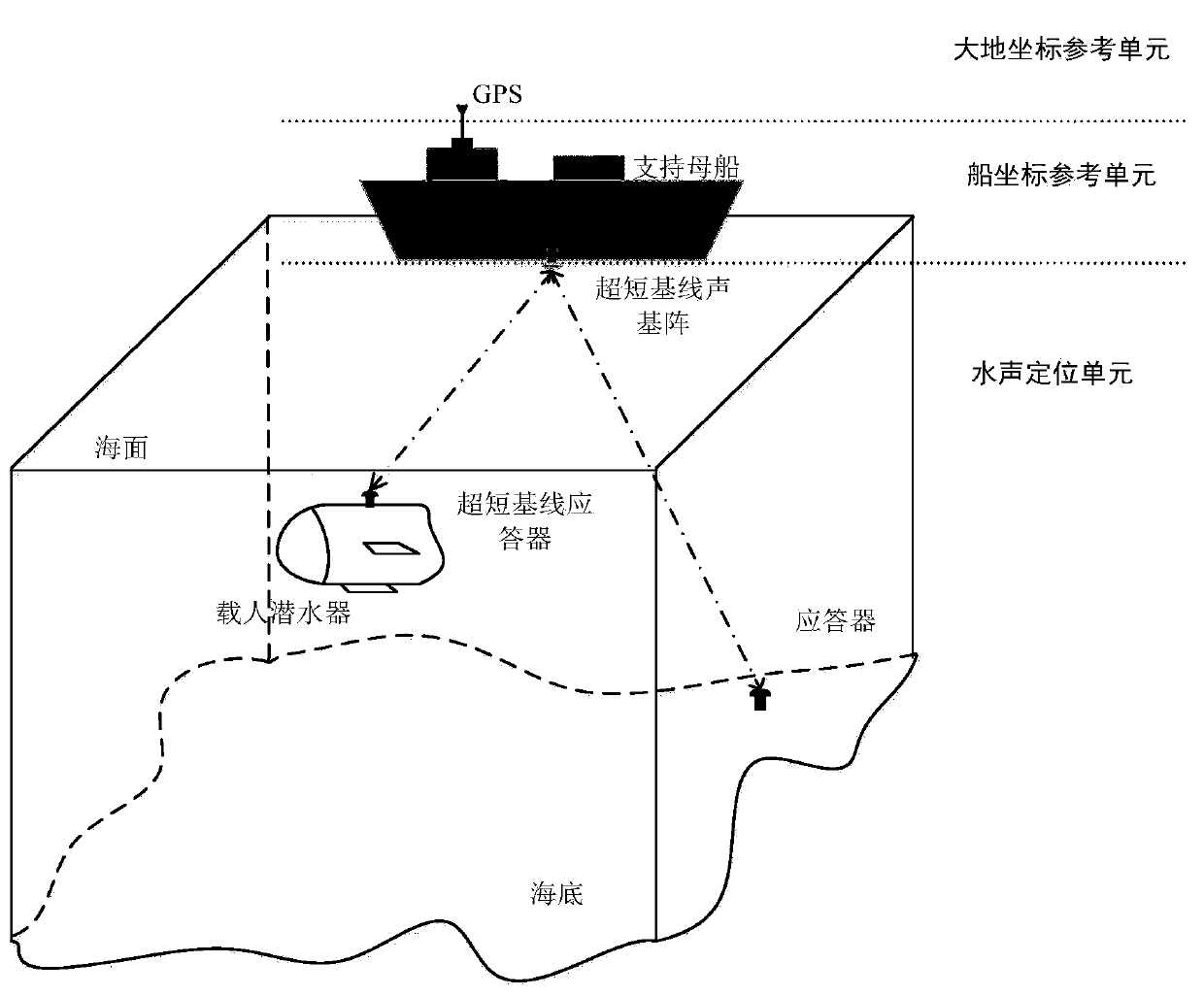

Deep diving manned submersible integrated navigation method based on DR/USBL

InactiveCN111076728AThe method is simple and fastImprove reliabilityNavigational calculation instrumentsDeep divingNavigation system

The invention discloses a deep diving manned submersible integrated navigation method based on DR / USBL. The method comprises the following steps: (1) performing real-time recursive calculation by utilizing attitude angle information provided by an attitude sensor carried on a manned submersible and ground speed information provided by a Doppler log to obtain position information, thereby forming aset of autonomous dead reckoning system DR; (2) positioning the manned submersible by using an ultra-short baseline USBL array mounted at the bottom of a water surface support mother ship, and designing an online data cleaning scheme to process outliers and missing values in USBL source data so as to obtain continuous and consistent position data; and (3) designing a Kalman filter, effectively fusing the dead reckoning system DR and the ultra-short baseline underwater acoustic positioning system USBL, and constructing a DR / USBL integrated navigation system, thereby obtaining a near-seabed integrated navigation result of which the positioning error is not accumulated along with time. According to the method, the problems of USBL positioning data loss and jump point and DR positioning erroraccumulation along with time are solved, and near-seabed high-precision navigation positioning of the deep diving manned submersible can be realized.

Owner:SOUTHEAST UNIV

Deep diving fishing lure

A deep diving fishing lure having a forwardly-extending diving lip is provided with a fore-and-aft pivotable lure positioning arm mounted to the diving lip. The lure positioning arm, when locked in aft position, maintains the lure in a diving position when pulled through a body of water but negates the lure's tendency to dive when released from the aft position.

Owner:2327086 ONTARIO

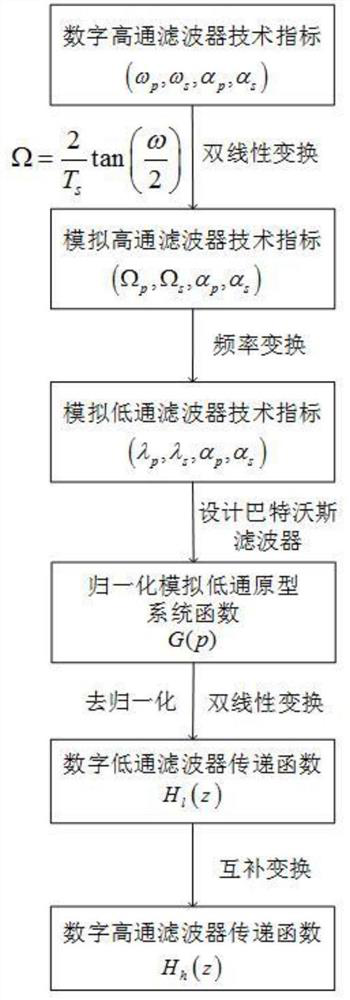

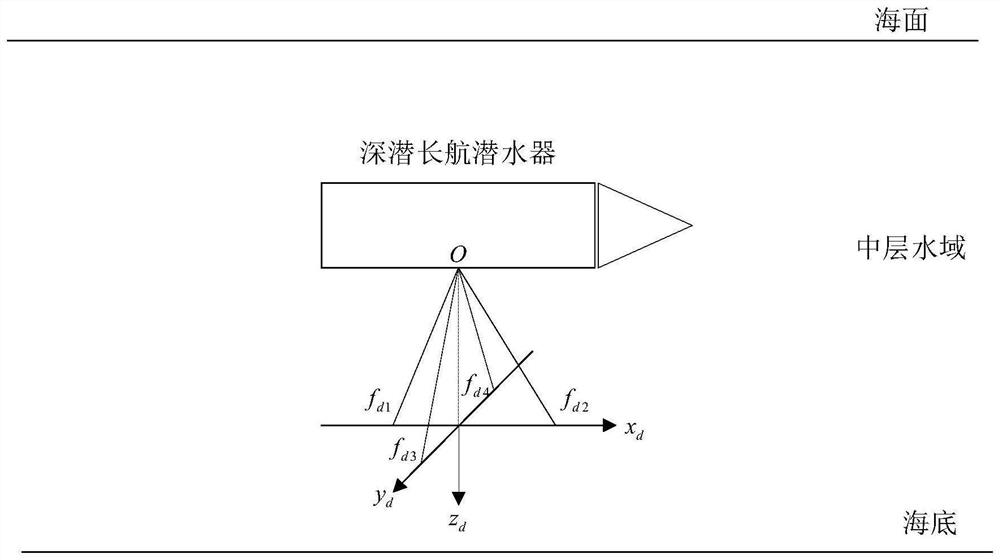

Deep-diving long-endurance submersible SINS/DVL ocean current speed estimation method

ActiveCN112729291ANavigational calculation instrumentsNavigation by speed/acceleration measurementsMarine engineeringClassical mechanics

The invention discloses a deep-diving long-endurance submersible SINS / DVL ocean current speed estimation method which comprises the following steps: 1, performing navigation calculation output twice on the basis of a strapdown inertial navigation system SINS under specific trajectory motion, namely SINS1 and SINS2, designing a high-pass filter to obtain the real horizontal speed of the SINS1, and combining the real horizontal speed with the SINS2 to realize SINS self-aided navigation; 2, according to the Doppler effect principle, the deep diving long-endurance submersible working in the middle-layer water area uses a water tracking mode of a Doppler log DVL to measure the convection velocity; and 3, estimating the ocean current speed by using a least squares estimation algorithm RLS in combination with high-precision navigation parameters provided by SINS self-aided navigation and the convection speed obtained by using DVL. According to the method, the ocean current speed information of the middle-layer water area can be estimated through the SINS / DVL under the conditions that a navigation information source is lacked and the ocean current speed is difficult to obtain in real time.

Owner:SOUTHEAST UNIV

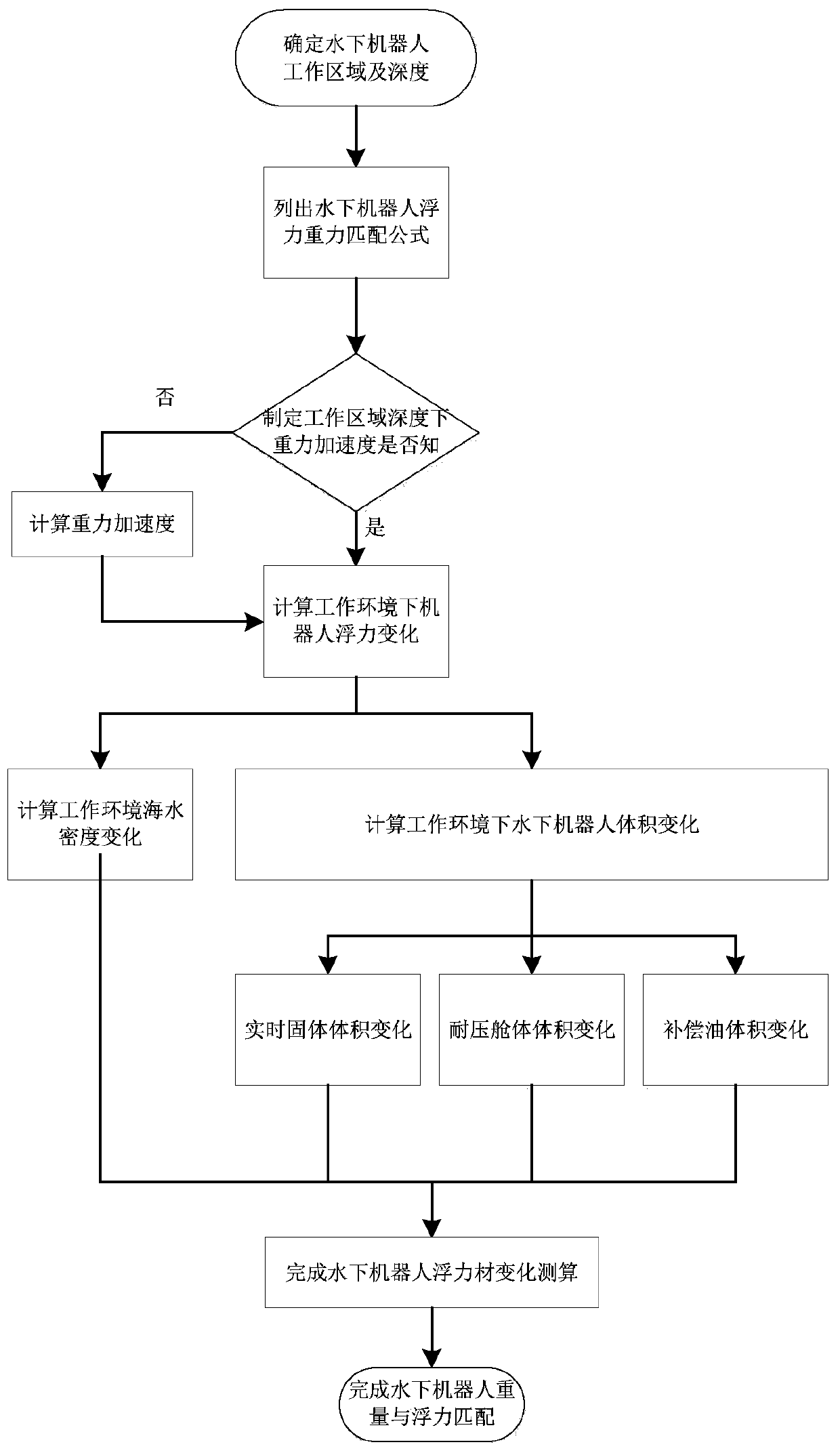

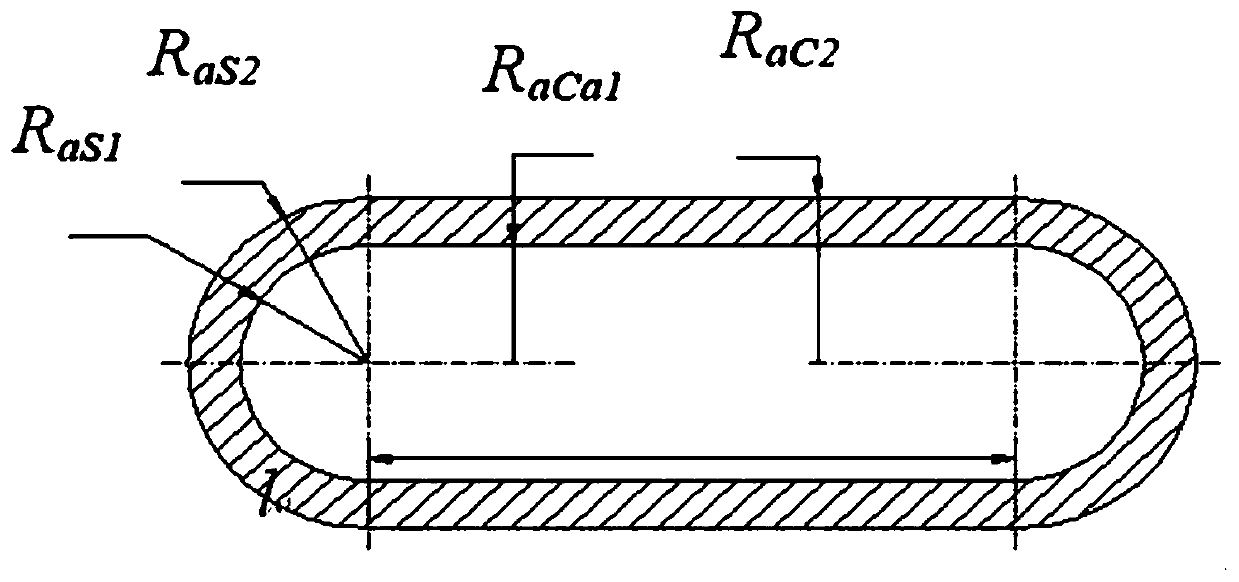

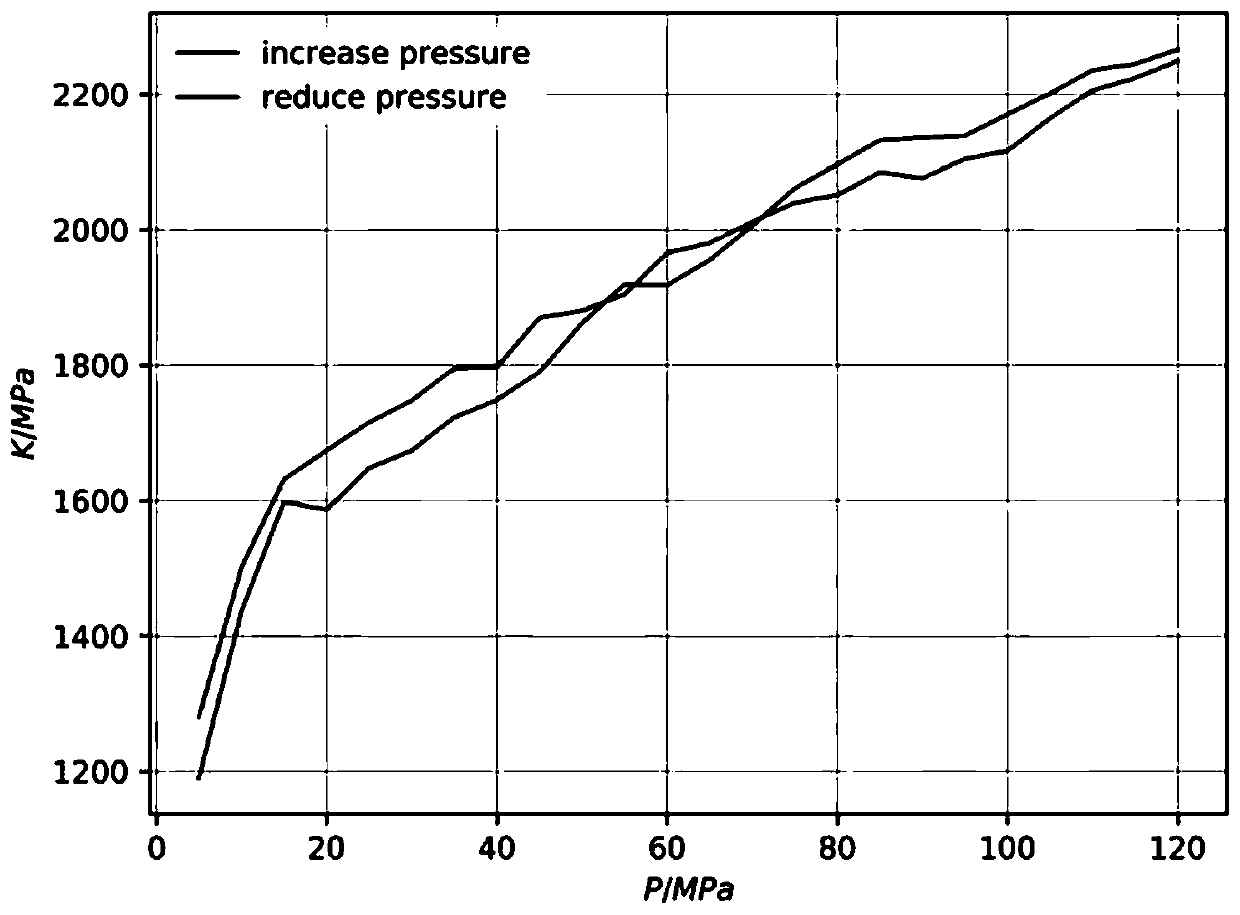

Buoyancy matching calculation method for large-depth underwater robot

InactiveCN111348160ADesign optimisation/simulationUnderwater vesselsMarine engineeringClassical mechanics

The invention relates to a buoyancy matching calculation method for a large-depth underwater robot, and aims to solve the problem that after a full-sea-depth ARV dives into a Marilona sea ditch, the seawater pressure of a working environment is increased, and the temperature is reduced, so that the volume change of a carrier structure and supplementary electric appliance insulating oil is influenced. The buoyancy state of the robot can be changed by increasing the seawater density and changing the weight acceleration. The full-sea-depth ARV buoyancy balancing calculation method is obtained through formula derivation in combination with 'sea bucket number' deep diving data and compensation oil laboratory data. The method mainly comprises seawater density measurement and calculation, Maridena sea ditch gravitational acceleration measurement and calculation and robot structure and compensation oil drainage volume change measurement and calculation. On the basis of buoyancy balancing, multiple times of deep submergence of the marinade sea ditch are completed through the sea bucket number, and matching of buoyancy and gravity in the working environment of the robot is guaranteed. The balancing method provides a theoretical calculation basis for buoyancy balancing of the full-sea-depth and large-depth underwater robot.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

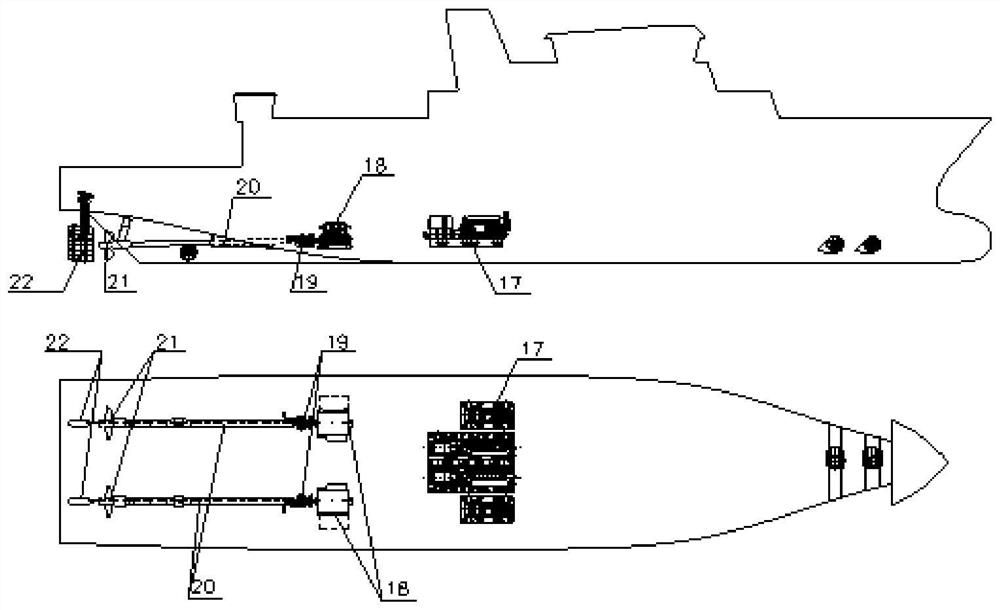

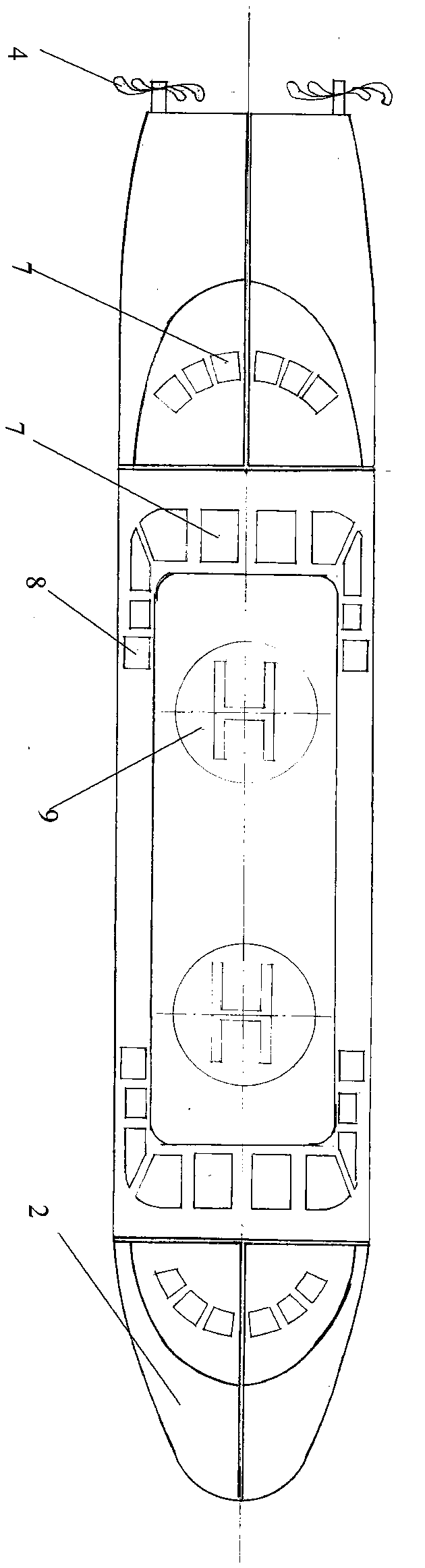

Manned submersible supporting mother ship

InactiveCN111791993AAdd supportEfficient supportWaterborne vesselsSpecial purpose vesselsInformation sharingDynamic positioning

The invention discloses a manned submersible supporting mother ship. The ship comprises a main ship body, a propelling system, a dynamic positioning system, a scientific investigation system and an informatization system. The main ship body advances through the propelling system; the dynamic positioning system provides support for fixed-point operation of the ship; the scientific investigation system can provide the functions of towing in place, water surface support, operation environment investigation, scientific research and the like for the manned submersible, and the informatization system can provide reliable and advanced means for information sharing and data fusion among equipment of a ship during diving operation of the submersible and conventional investigation operation. The efficiency of the manned submersible can be brought into full play, the manned deep diving exploration capacity is effectively formed, comprehensive, efficient and reliable land, sea and air support is provided for operation and maintenance of the manned submersible, and the unique advantages of the manned submersible in the field of deep sea scientific investigation are brought into full play.

Owner:708TH RES INST OF CSSC

Artificial gills for deep diving without incurring the bends and for scavenging O2 from and dispelling CO2 into water or thin air

InactiveUS20080295828A1Prolonged underwater breathingLower resistanceFire rescueRespiratory apparatusFiberHemolysis

The invention provides a system whereby oxygen can be derived from seawater or from thin air at higher altitudes while simultaneously eliminating carbon dioxide from the blood. This allows prolonged underwater liquid breathing at greater depths without suffering from the bends or, alternatively, the ability of workers to breathe underwater or at high altitudes without having to rely upon air tanks or the like. The artificial gill comprises a plurality of concatenated modules each containing a semi-permeable membrane operative to transfer oxygen in a first direction and carbon dioxide in a second direction across the membrane. By providing multiple concatenated interconnected modules, oxygen becomes concentrated to allow breathing thereof. Because the system is connected in series with a person's blood supply, CO2 produced in the body is extracted and disposed of via the artificial gill. The semipermeable membrane preferably comprises a plurality of tubular fibers, each with a relatively large lumen when compared to present day blood oxygenators arranged as a bundle in a housing such that seawater or rarefied air passes over the exterior surfaces of the fibers while blood or Hgb flows through the lumens. The larger diameter fibers reduce hemolysis and clotting.

Owner:LANDE ARNOLD J

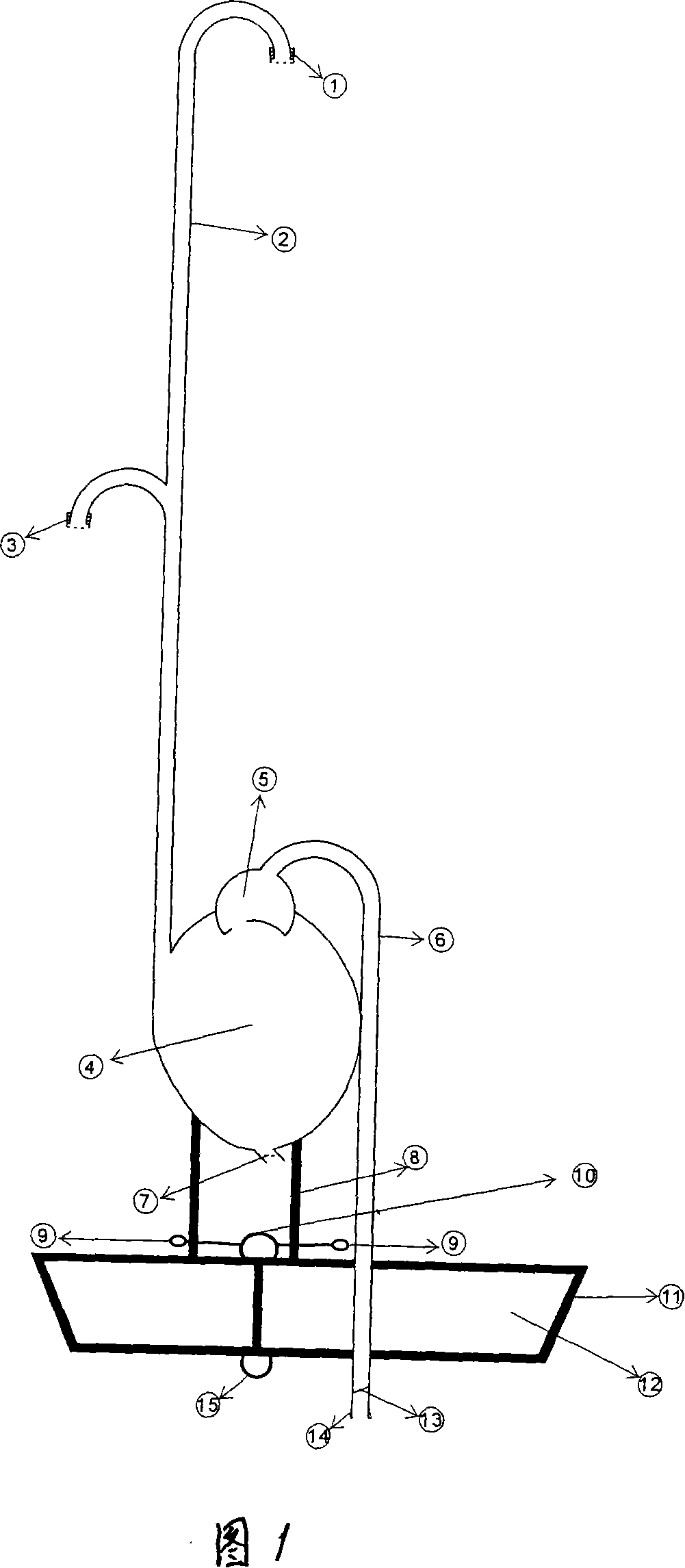

Safety diving breathing apparatus

InactiveCN101112911ASwimming is easy to learnIncreased dive depthUnderwater equipmentWater diversionBuoy

A safe aqualung belongs to the diving apparatus technical field. The invention is characterized in that an air plastic pipe is connected to a calabash-shaped plastic water diversion air chamber and an upper air chamber and is connected with a respiration head of a face mirror through an air pipe, a movable joint and an air pipe of a stainless steel pipe. The other movable joint of the air pipe is connected with a buoy which can be inflated. The bottom part of the calabash-shaped air chamber is provided with a check valve; two frames are connected with horizontal EVC foam. The middle part of the EVC foam is provided with a knob and two living-knot ropes; a lower fixing card of the EVC foam is provided with a fixing head of a deep diving part. The invention has the beneficial effects that the calabash-shaped air chamber is adopted, and if a small quantity of water enters, the water is discharged by the check valve at the bottom part of the air chamber. The floating force of the EVC foam exposed at the exterior of the stainless steel can be used as the buoy; when people feel tired, the knob and the two living-knot ropes can be adopted to fix both hands, which is safe and reliable. The deep diving part can increase the diving depth; the invention is more convenient and practical in economy and application.

Owner:陈福生

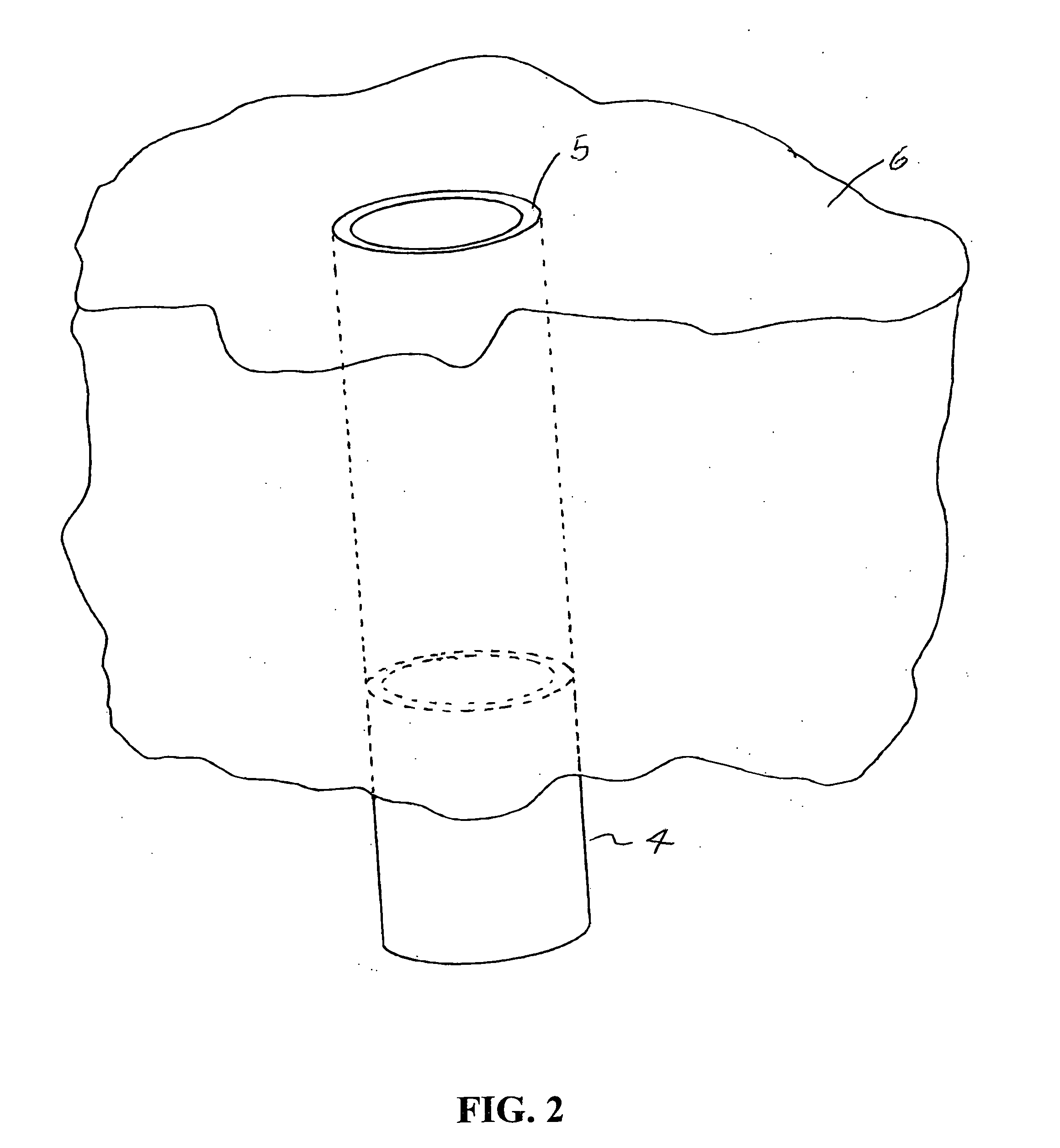

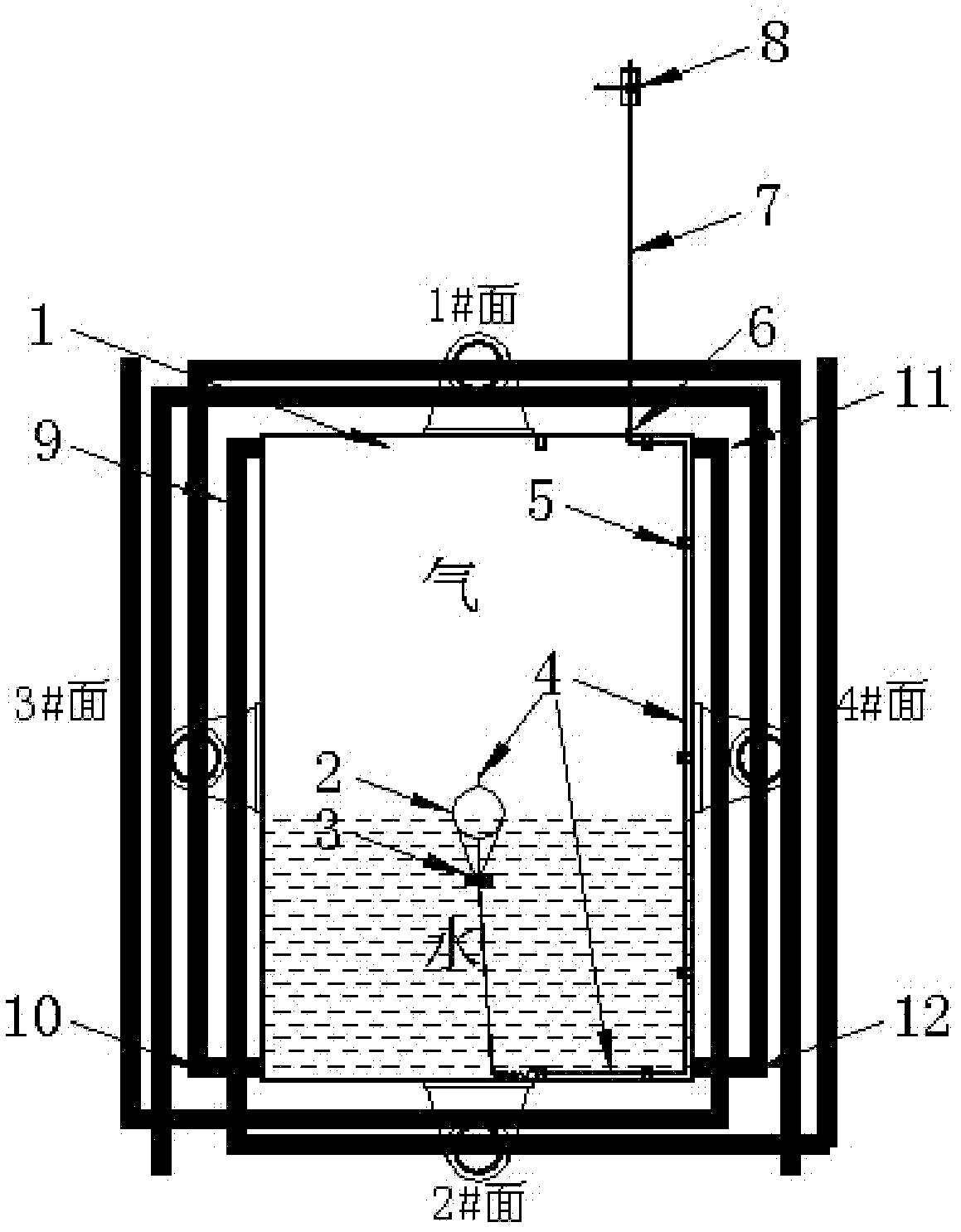

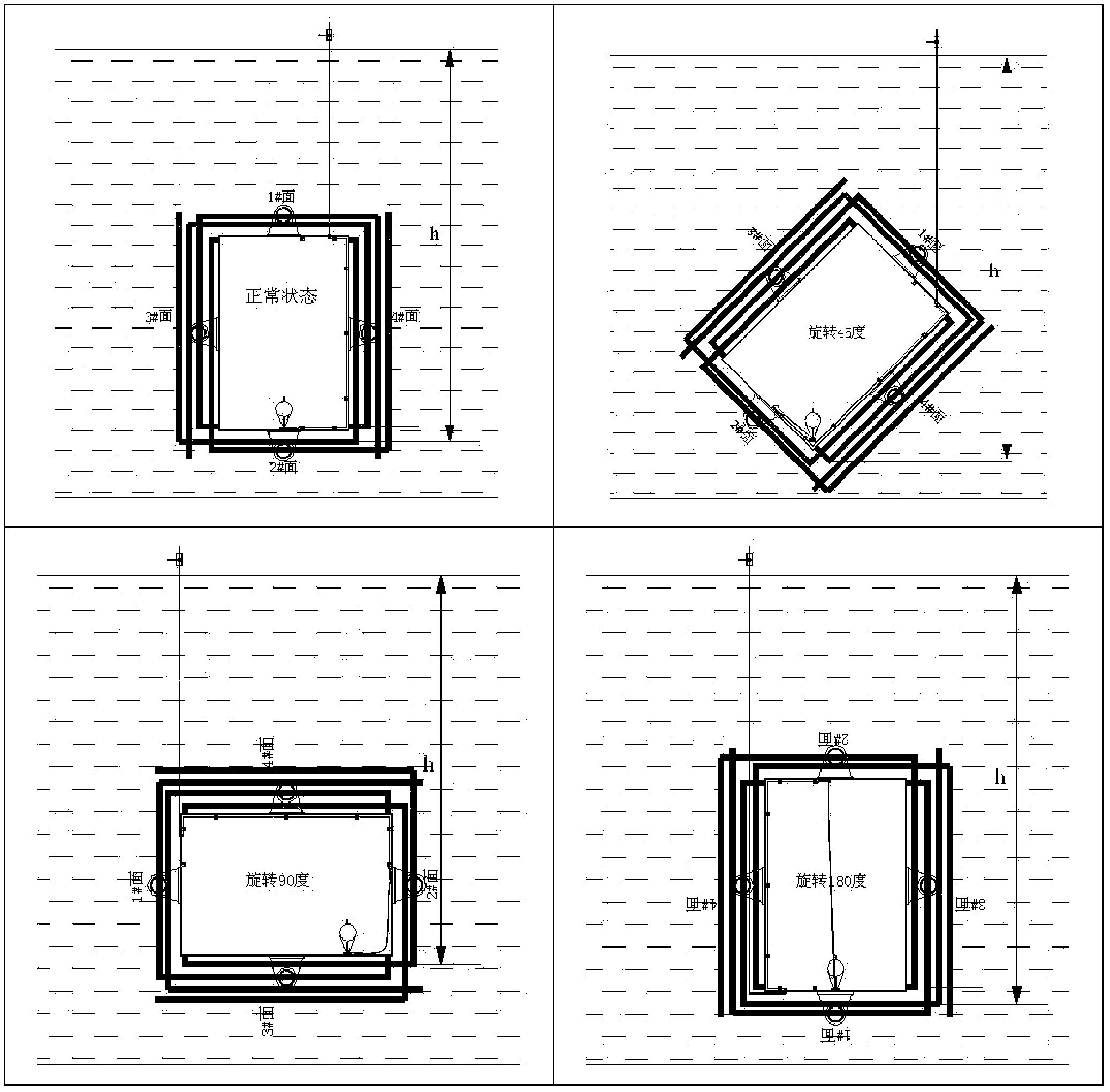

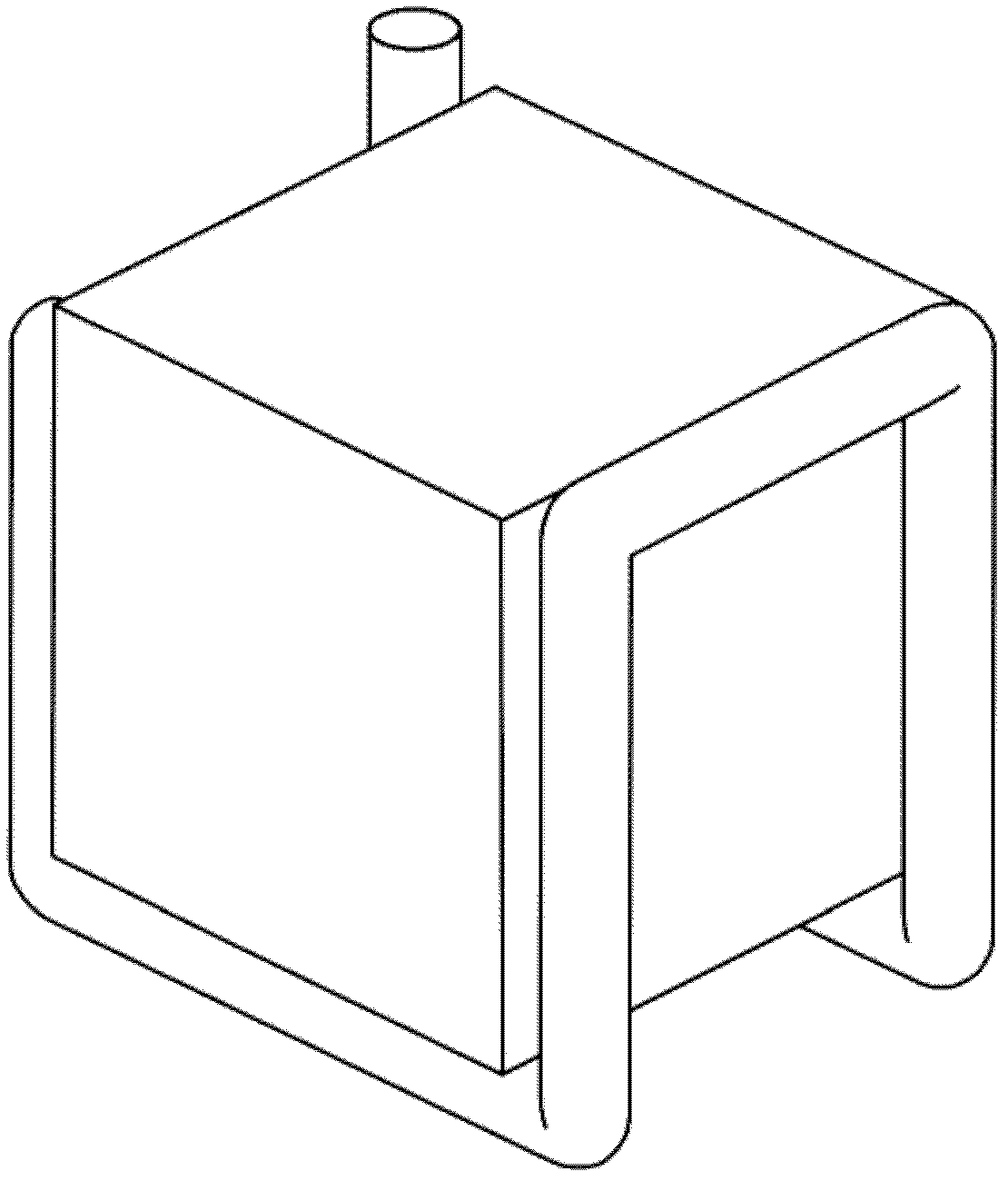

Thin-wall deep diving pontoon capable of automatically realizing internal and external pressure balance

The invention relates to a thin-wall deep diving pontoon capable of automatically realizing internal and external pressure balance. The pontoon comprises a pontoon main body, lifting lugs, external water pipes, a floating ball, a weight, an internal gas pipe, pipe clamps, a gas pipe joint, an external gas pipe and a ball valve, wherein the external water pipes are arranged on the outer walls of the four sides of the pontoon main body, are continuously arranged along the side lines of the outer walls of the pontoon and pass through all corners; the lifting lugs are arranged on the outer walls of the four sides of the pontoon main body; the weight is fixedly connected below the floating ball and arranged in the pontoon; the internal gas pipe is fixed between the upper end of the floating ball and the weight; the port of the gas pipe on the floating ball is open; the internal gas pipe with enough length is arranged in the pontoon, so that the floating ball and the weight can arrive in any place in the pontoon; the internal gas pipe extends to the inner port of the gas pipe joint along the inner wall of one side of the pontoon main body through the pipe clamps; the gas pipe joint crosses one side wall of the pontoon main body, and a junction is sealed by welding; one end of each external water pipe is connected to the outer port of the gas pipe joint; and the ball valve is arranged at the other end of each external gas pipe.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Deep diving fishing lure

A deep diving fishing lure having a forwardly-extending diving lip is provided with a fore-and-aft pivotable lure positioning arm pivotably mounted about a pivot axis within the diving lip near the lower portion of the forward face. The lure positioning arm, when fixed in an aft position relative to the pivot axis rests within a longitudinally extending groove located in the diving lip. The lure positioning arm, when in the fixed aft position maintains the lure in a diving position when pulled through a body of water but negates the lure's tendency to dive when released from the aft position.

Owner:2327086 ONTARIO

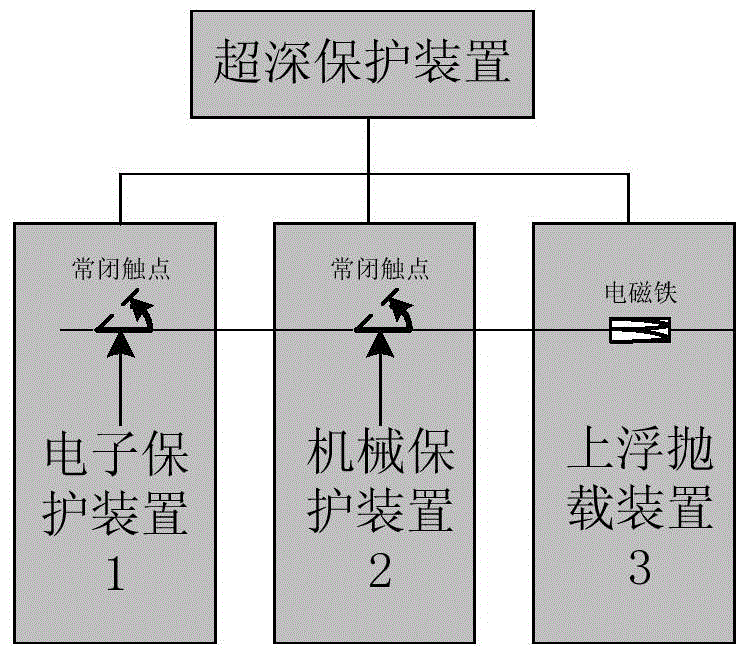

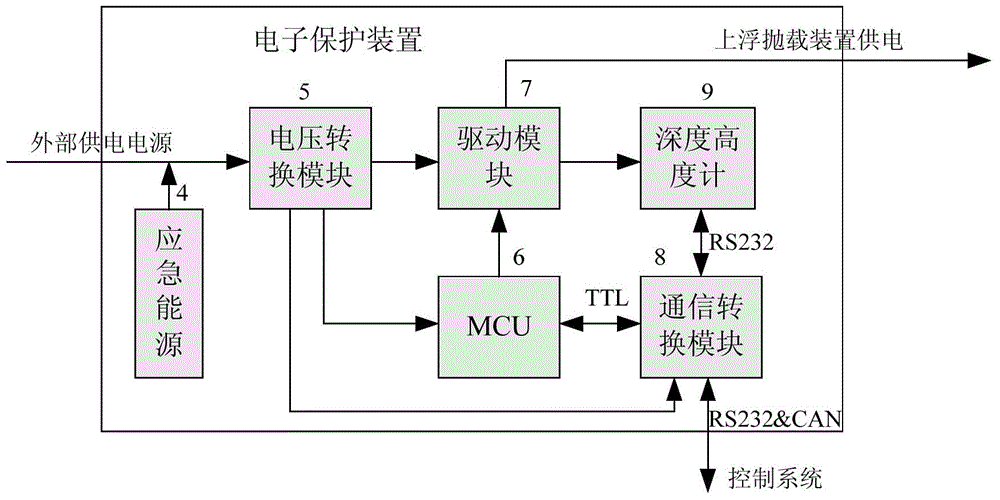

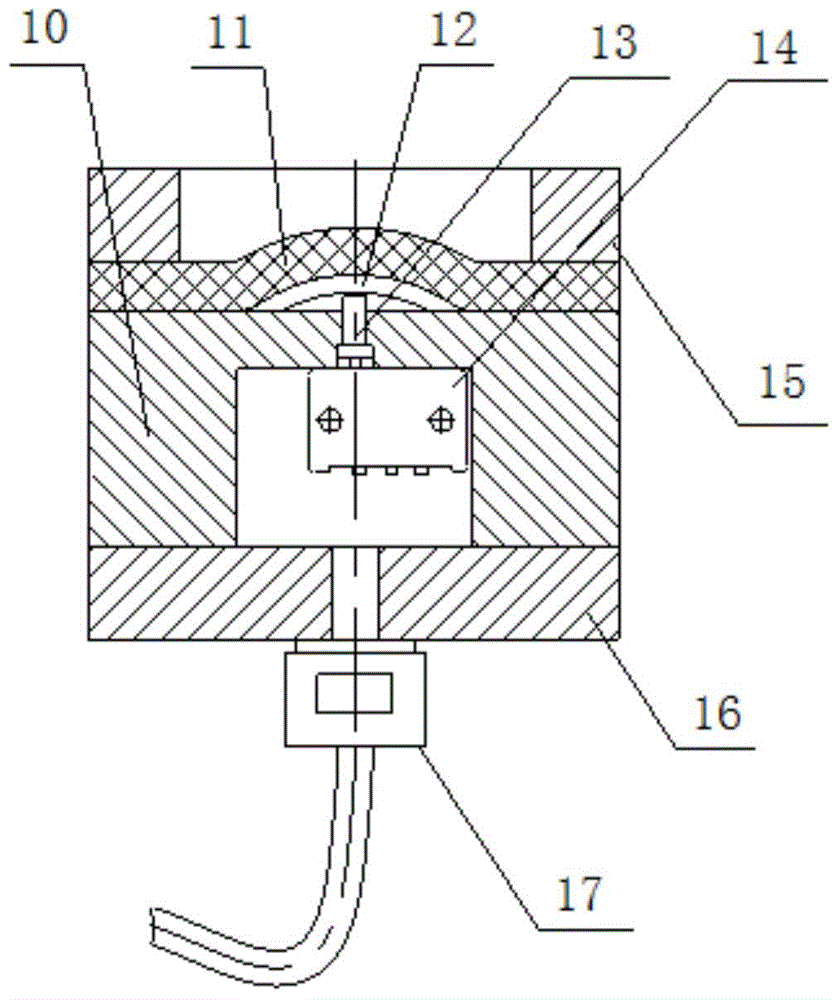

Submersible ultra-deep protective device and method

ActiveCN104670445ARealize emergency dumpUltra-deep protection function independentUnderwater vesselsUnderwater equipmentMarine engineeringDeep diving

The invention belongs to the technical field of submersible ultra-deep protection and relates to a submersible ultra-deep protective device. The submersible ultra-deep protective device comprises an electronic protection unit, a mechanical protection unit and a floating load throwing unit. A protection method includes the steps that an MCU (Microprogrammed Control Unit) of the electronic protection unit determines whether a submersible works at the safety depth or not according to the working depth and the height to the bottom of the submersible, which are obtained through a depth meter and a height meter, and the MCU controls the floating load throwing unit to throw away a floating load if the working depth of the submersible is too large or the height to the bottom of the submersible is too small; a rubber pad of the mechanical protection enables a reed to perform elastic deformation to push a push rod to move through the pressure in deep water, and when the working depth is too large, a micro switch is touched to act and a normally closed contact is disconnected to throw away the floating load. The electronic protection unit and the mechanical protection unit are connected in series and the floating load throwing unit can be triggered to throw away the floating load when either the electronic protection unit or the mechanical protection unit is activated, so that the safety of the submersible is protected maximally, wherein the safe working depth / height of the submersible can be set according to the actual situation. The submersible ultra-deep protective device has high applicability.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

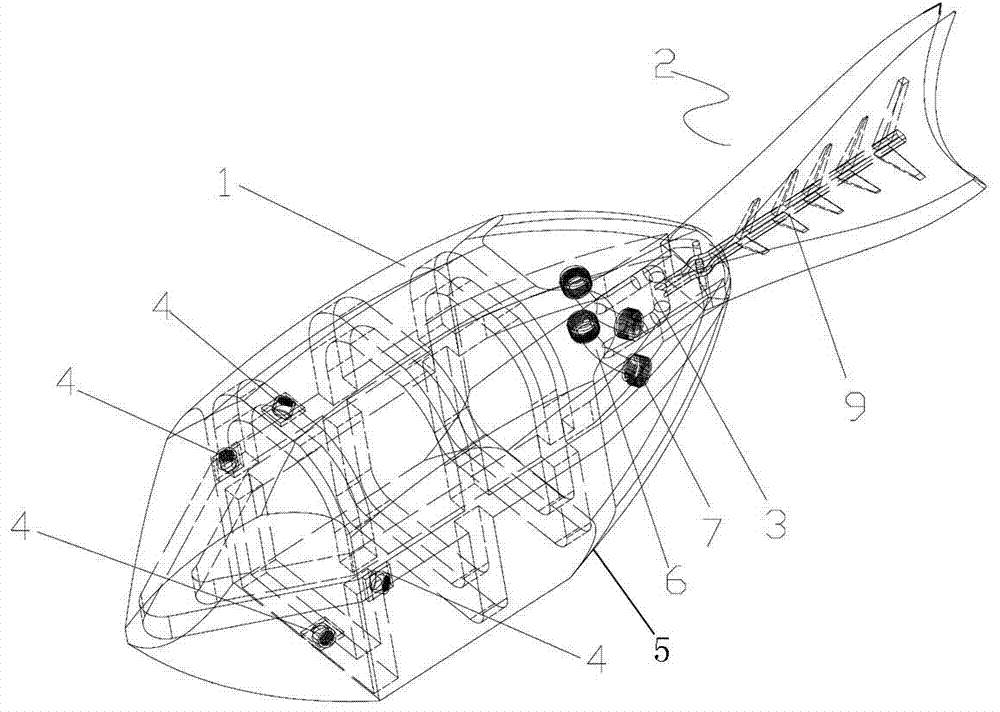

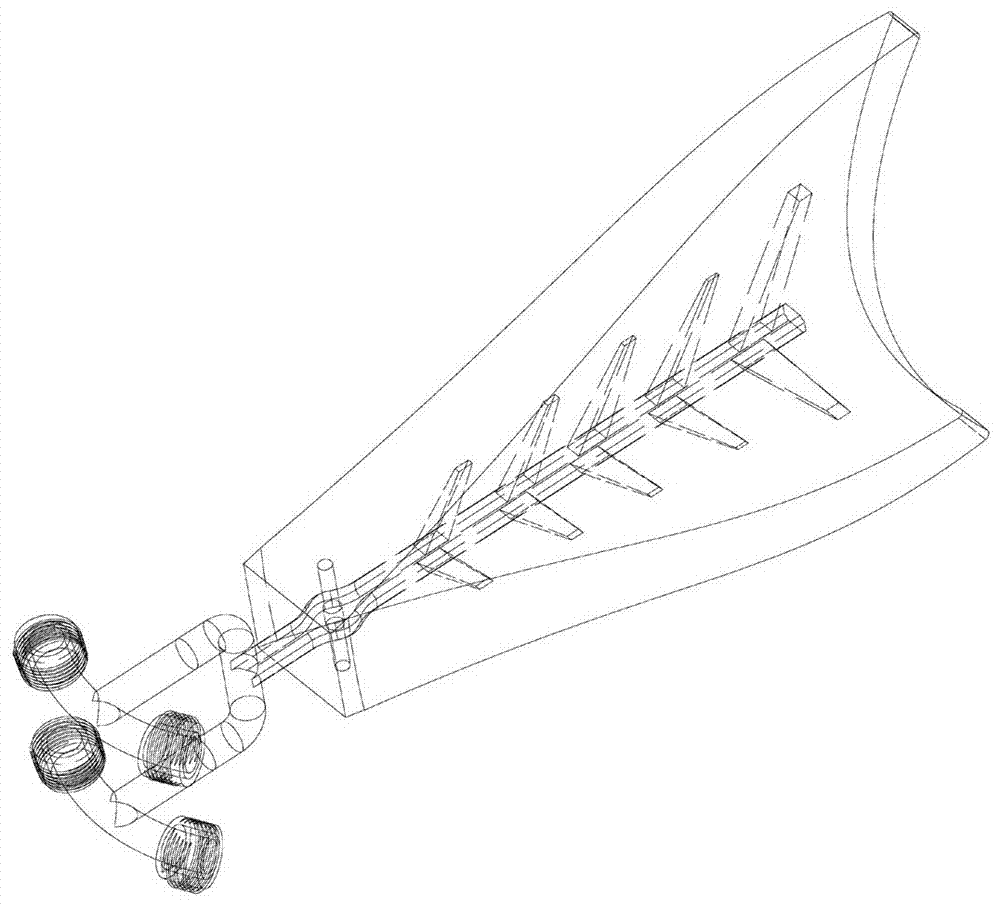

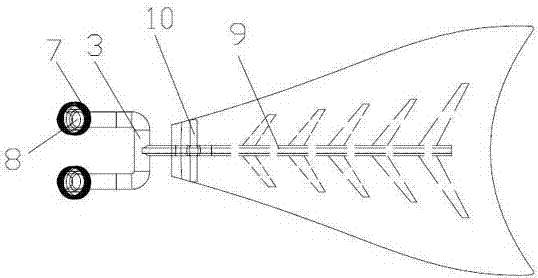

Underwater bathyscaphe

PendingCN107089311AImprove reliabilitySolve the speed problemPower plants being motor-drivenPropulsive elementsPermanent magnet rotorOcean exploration

The invention relates to an underwater deep diving device, and particularly relates to a tuna-imitative underwater bathyscaphe, and belongs to the technical field of ocean exploration. The underwater bathyscaphe comprises a main body, wherein the rear part of the main body is connected with a tail fin through a connecting piece; a coil is arranged in the rear part of the main body; the front end of the connecting piece is provided with a permanent-magnet rotor; the permanent-magnet rotor is inserted into the coil; the permanent-magnet rotor and the coil form an engine; the action of the permanent-magnet rotor is controlled through controlling the on-off time and the pulse period length of an electric current in the coil. The underwater bathyscaphe has the advantages and effects that the appearance of a tuna is imitated; the higher water pressure can be borne; the appearance is beneficial to quick navigation.

Owner:肖志东

Submarine support ship

ActiveCN109018272AAchieve salvageReduce volumeHull interior subdivisionSearch and rescue vesselsBuoyDeep diving

The invention discloses a submarine support ship, which is a trimaran and a deep-diving opposite-petal catamaran at the lower part, and uses its own form to pick up the submarine in deep sea and floatup as a whole. The upper part is a buoy, which can be supplied with air and lifted during deep diving, and it can also be used to support offshore submarines. The submarine support ship of the invention, Making use of the mature deep submersible technology, the submarine support ship is manufactured into a submarine-shaped deep submersible, which is quickly separated from the upper part of the submarine support ship to reach the position of the deep-sea submarine, and the submarine is held and floated up to the position of the water surface, so that the submarine outlet is butted with the special butt hatch of the submarine support ship, and the submarine is rescued and ensured. Mainly solve the current deep submergence lifeboat rescue water depth problem, but also solve the deep submergence lifeboat rescue links, slow speed, and can only save people cannot save the boat problem.

Owner:刘广

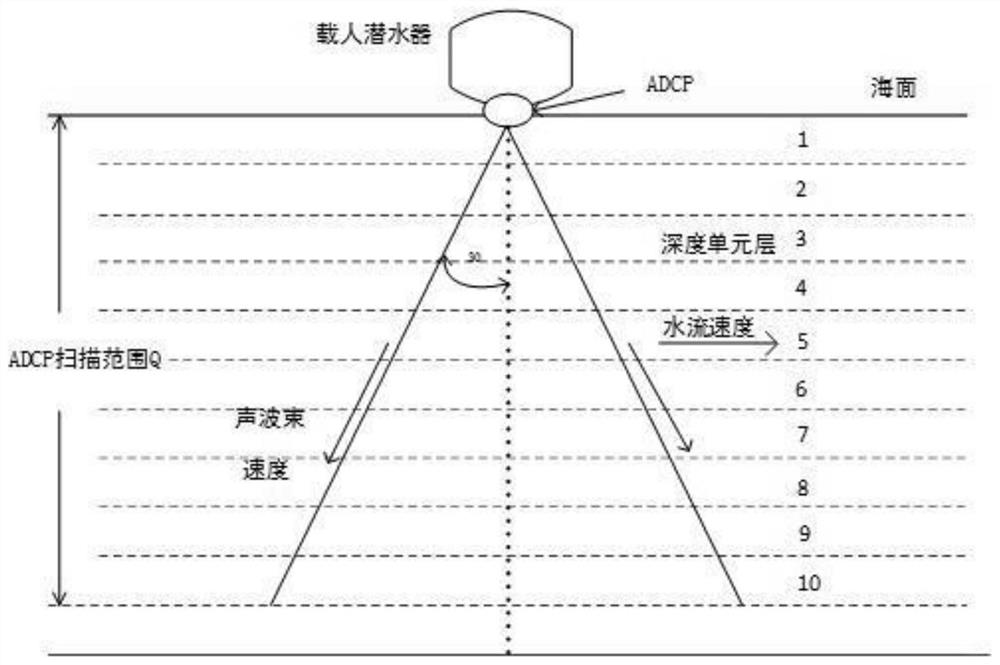

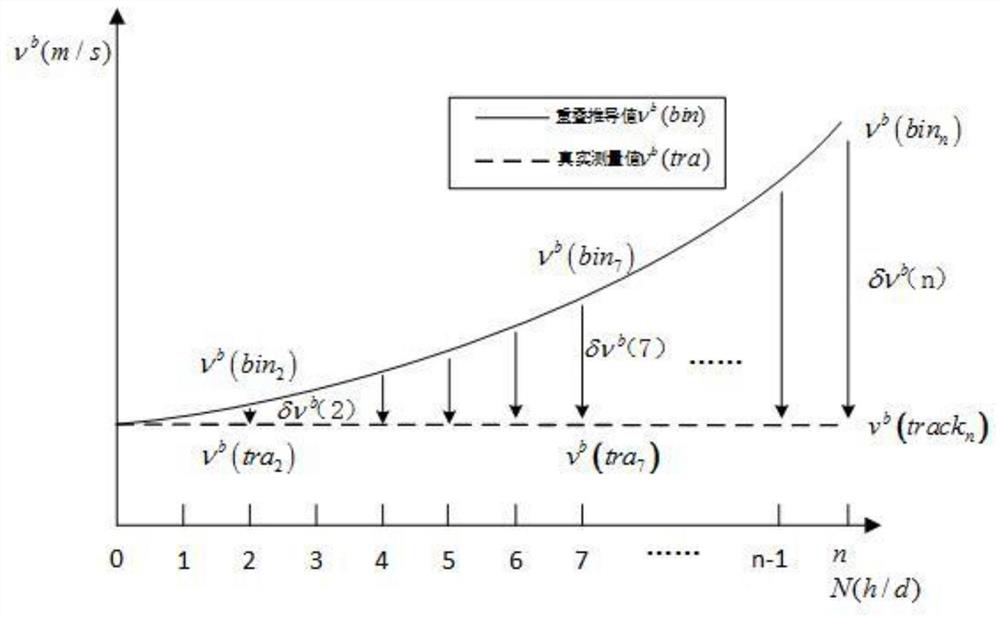

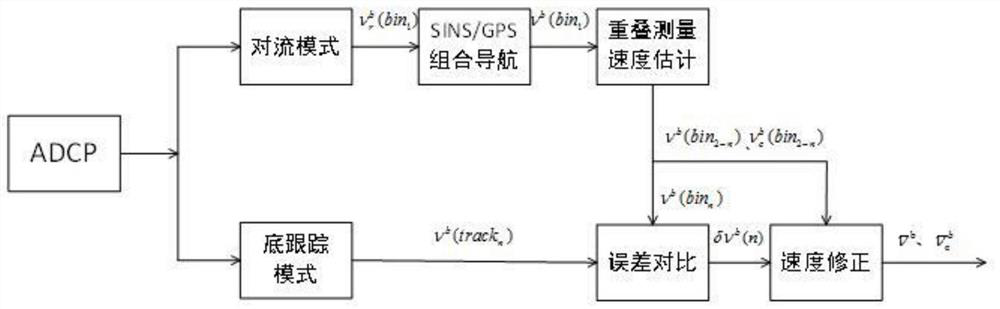

ADCP speed estimation and correction algorithm for deep diving manned submersible

ActiveCN112684207ARealize the speed measurement functionCompensation speedNavigation by speed/acceleration measurementsTesting/calibration of speed/acceleration/shock measurement devicesClassical mechanicsWater flow

An ADCP speed estimation and correction algorithm for a deep diving manned submersible comprises the following steps that 1, on the sea surface, SINS / GPS integrated navigation is used for providing the ground speed vb of the manned submersible at the initial moment; (2) the ADCP works in a convection mode, the relative water flow speed of the manned submersible is measured, and the ground speed vb and the water flow speed of the manned submersible are deduced through repeated measurement of ADCP scanning for multiple times; (3) the manned submersible dives to the position close to the seabed, the error of the ground speed of the manned submersible is derived by utilizing the ground speed of the manned submersible obtained by an ADCP bottom tracking function and overlapped ADCP measurement. A method for realizing error correction on the ground speed and the water flow speed of the manned submersible in each depth unit layer is provided. The problems that the ground speed and the ocean current speed of the manned submersible are difficult to estimate in the diving process and the speed error is accumulated along with time are solved, the ground speed and the ocean current speed can be obtained in the diving / floating process of the deep diving manned submersible, and reliable and accurate speed information can be obtained after error correction is completed.

Owner:SOUTHEAST UNIV

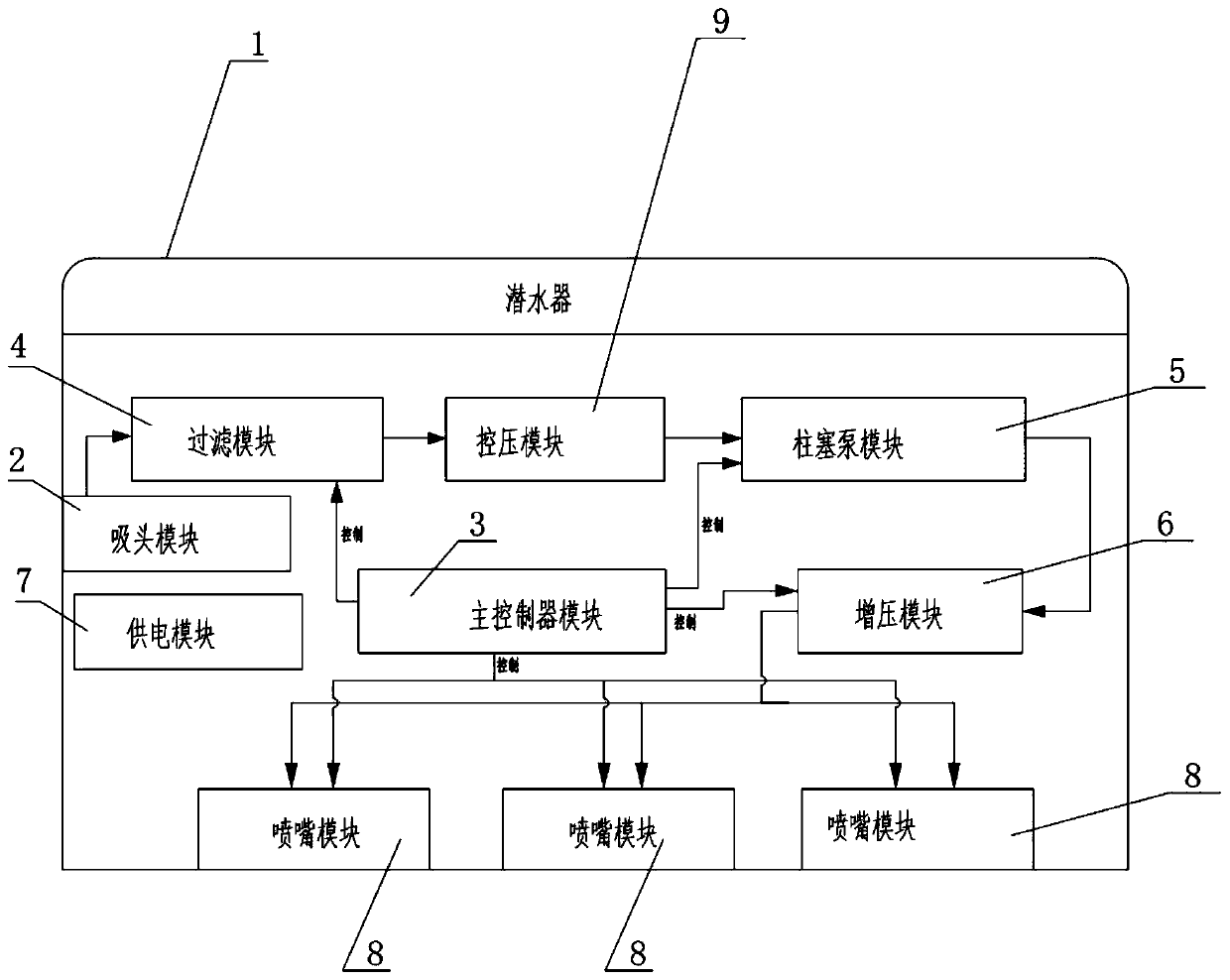

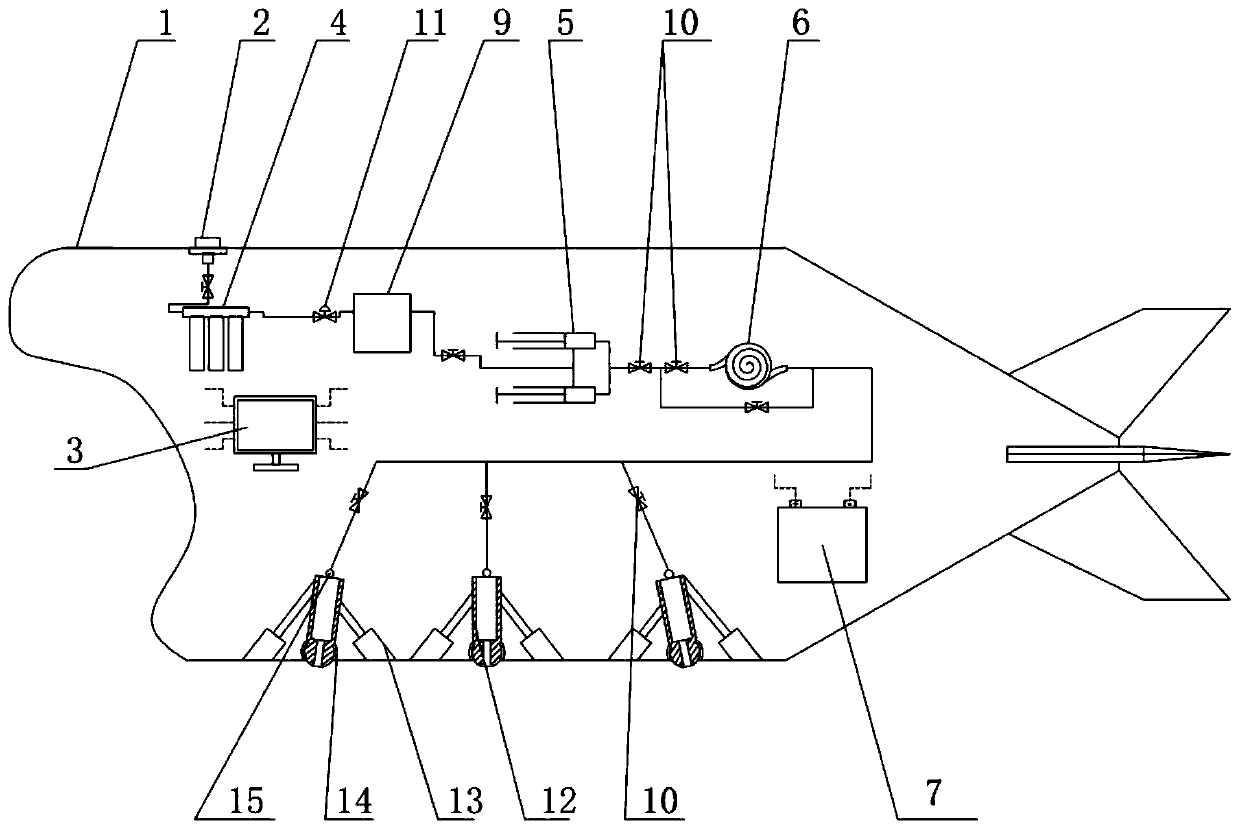

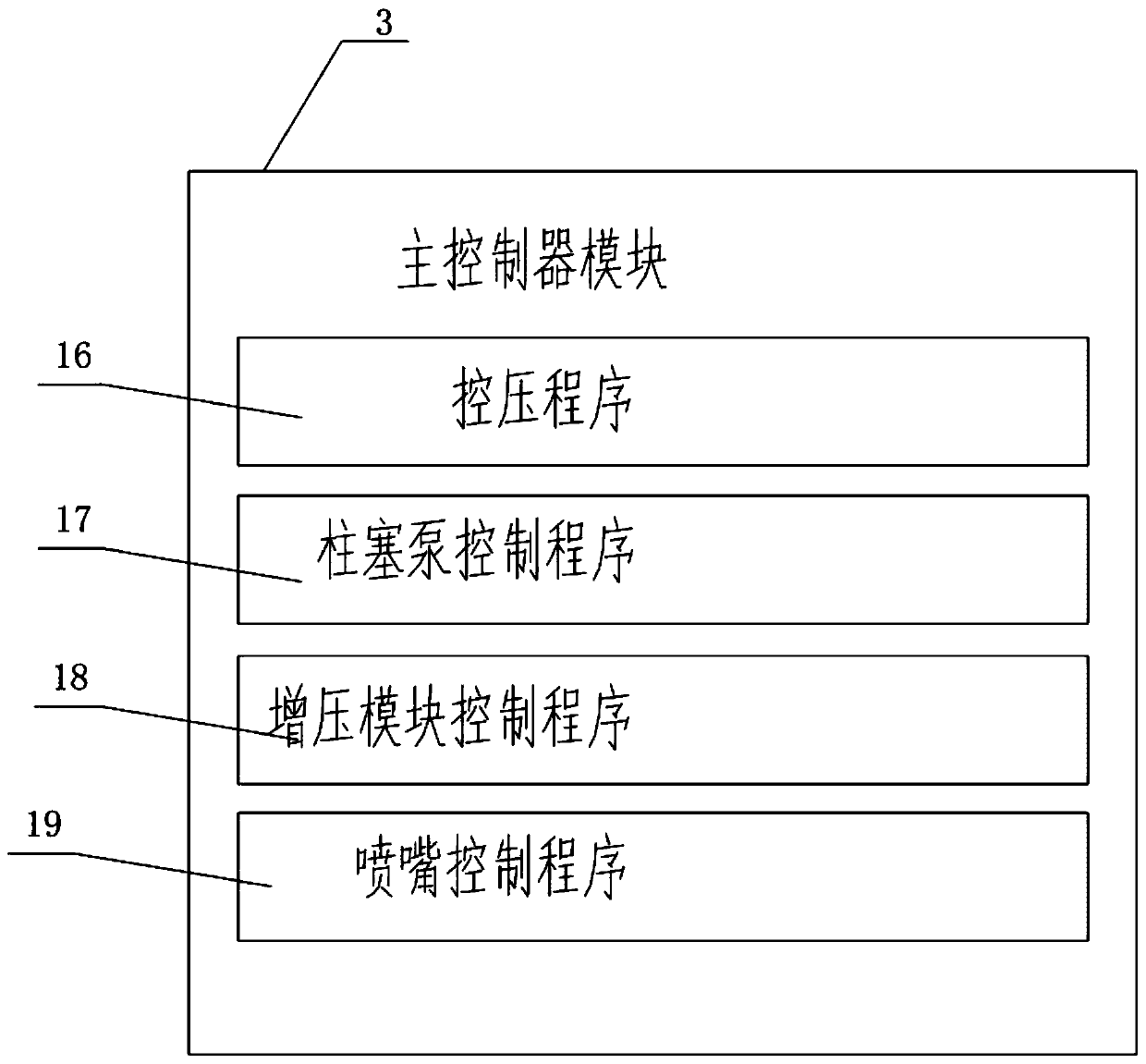

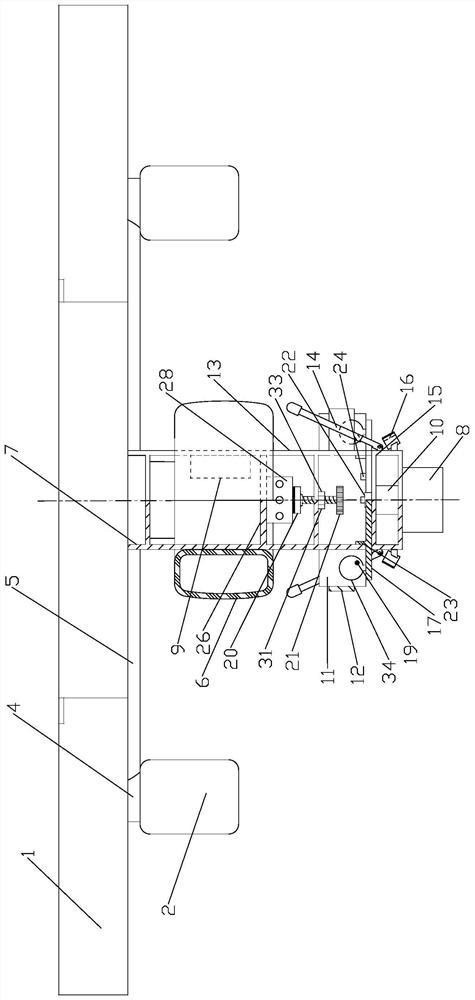

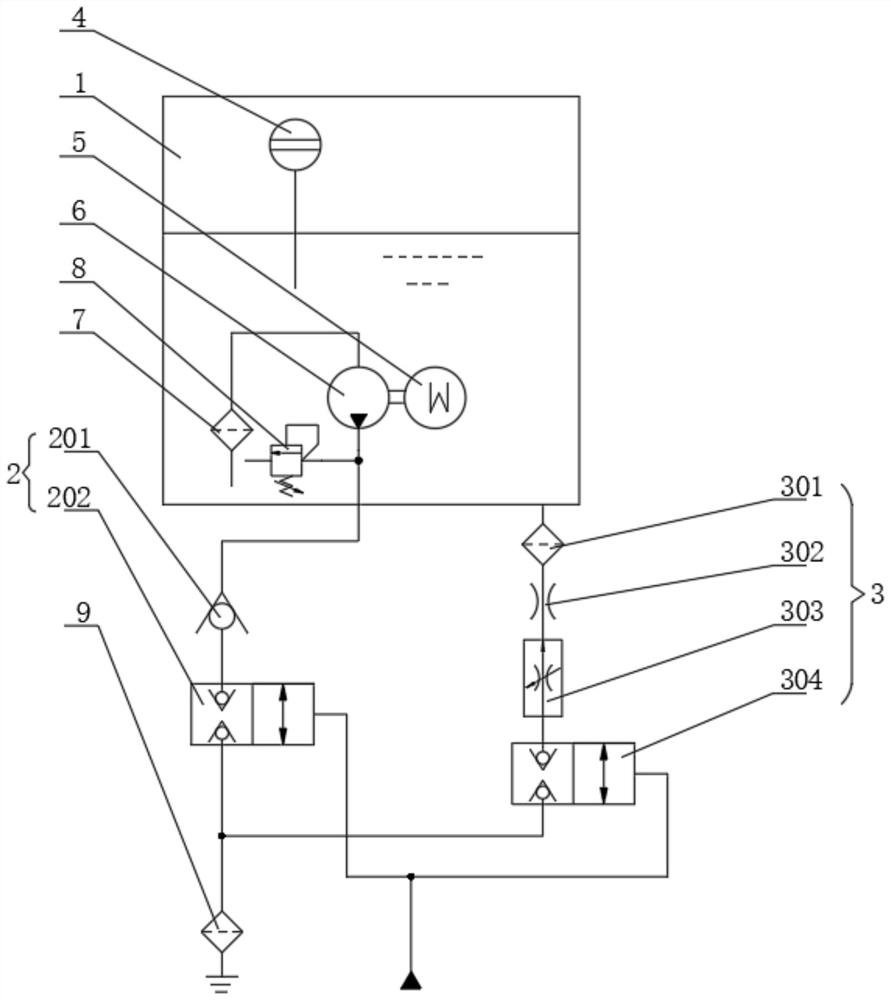

Hydraulic power jet system for eliminating bottom sitting adsorption effect of submersible

InactiveCN110104153AEnhancing Deep Diving CapabilitiesEnsure safetyUnderwater vesselsUnderwater equipmentEngineeringDeep diving

The invention relates to a hydraulic power jet system for eliminating a bottom sitting adsorption effect of a submersible. The hydraulic power jet system includes a main controller module, a sucker module, a pressure control module, a plunger pump module, a pressure boosting module and a plurality of nozzle modules which are located inside the submersible, wherein the signal output end of the maincontroller module is connected with the signal input ends of the plunger pump module, the pressure boosting module and the nozzle modules; and the pressure control module, the plunger pump module andpressure boosting module are connected in series with one another through pipelines, and a water outlet of the pressure boosting module is further connected in parallel with the nozzle modules through multiple pipelines. According to the hydraulic power jet system for eliminating the bottom sitting adsorption effect of the submersible, the existing adsorption effect after traditional submersiblebottom sitting can be alleviated or eliminated, safety of underwater operators is ensured, deep diving ability of the submersible is strengthened, and the hydraulic power jet system for eliminating the bottom sitting adsorption effect of the submersible is of great engineering significance for development of deep sea diving exploration.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

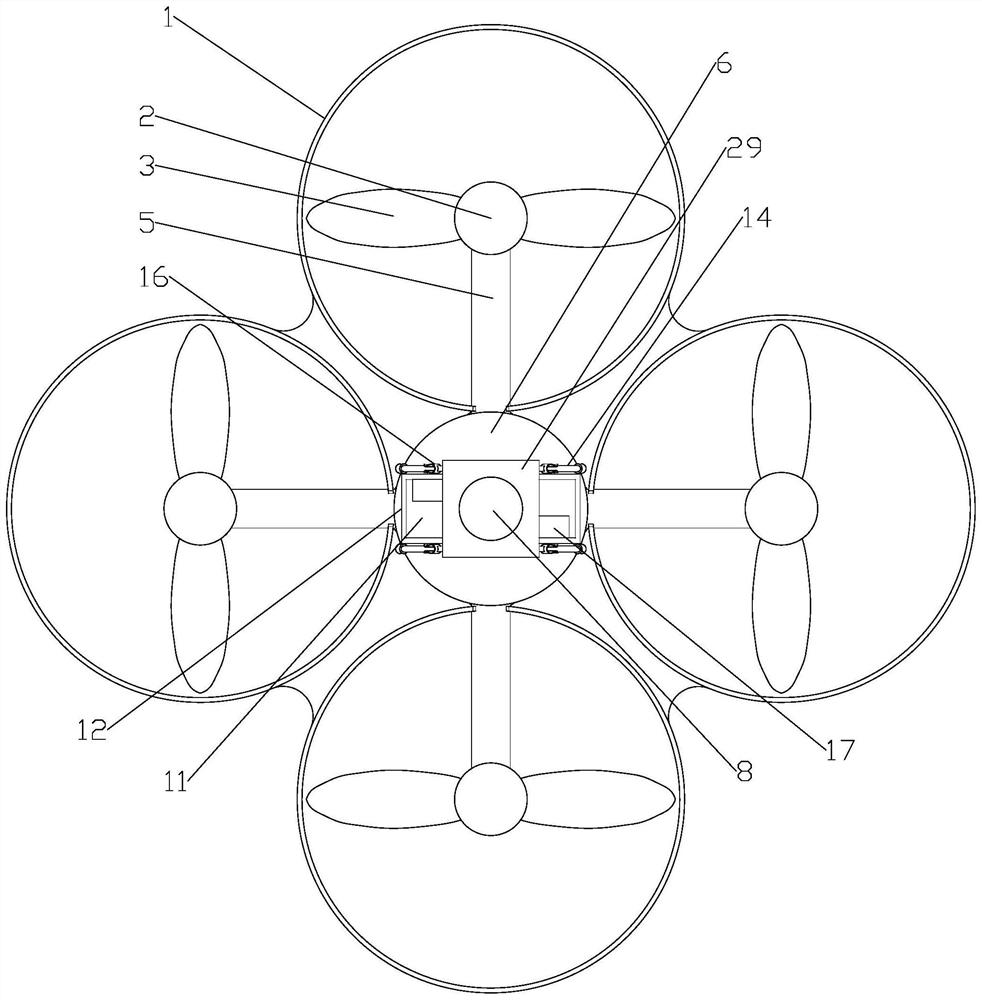

Marine environment detection platform with deep diving function and detection method of marine environment detection platform

ActiveCN113085461AEasy to replaceAvoid bumpingAircraft convertible vehiclesAcoustic wave reradiationMarine engineeringAir pump

The invention discloses a marine environment detection platform with a deep diving function and a detection method of the marine environment detection platform. The marine environment detection platform with the deep diving function comprises a control bin, four groups of rotor mechanisms, a floating air bag, an equipment mounting frame, a sensing mechanism mounting box, a centering clamping mechanism, a landing supporting mechanism and a counterweight adjusting mechanism. According to the marine environment detection platform with the deep diving function, an air pump is utilized to inflate and deflate the floating air bag, the size of the floating air bag is reduced in the diving process, the buoyancy of the floating air bag is larger than gravity, and diving is achieved; the counterweight adjusting mechanism is used for releasing a counterweight after data acquisition is completed, so that the gravity is greater than the buoyancy, and floating is realized; and the sensing mechanism mounting box is convenient to mount by utilizing the centering clamping mechanism, and the sensing mechanism mounting box carrying different sensors is convenient to replace; the landing supporting mechanism is linked with the counterweight adjusting mechanism, so that the landing supporting mechanism does not influence each sensor before data acquisition is completed, and meanwhile, instruments are prevented from colliding with one another during recovery and landing.

Owner:NAT UNIV OF DEFENSE TECH

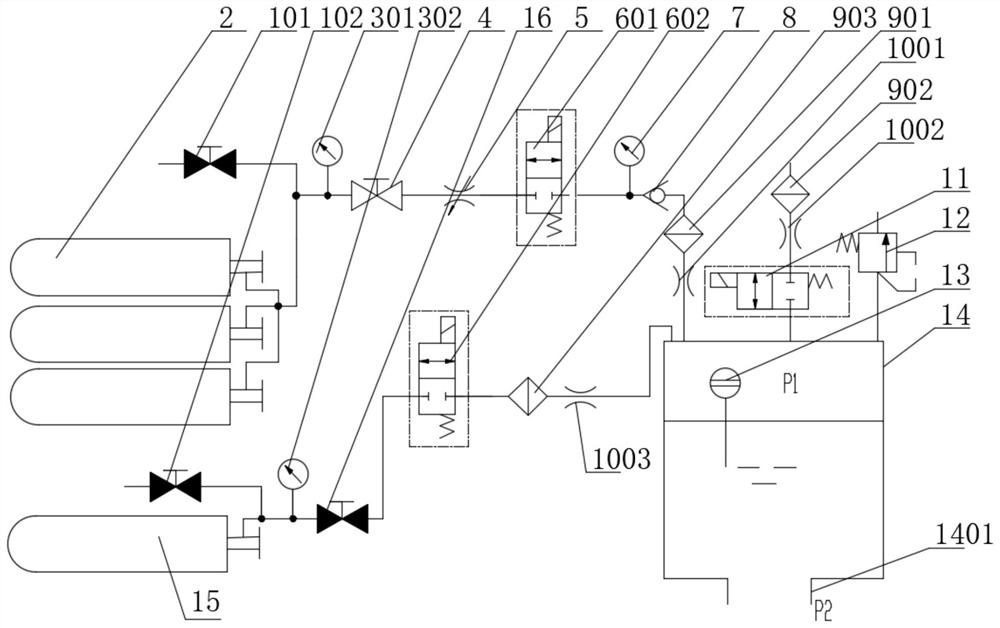

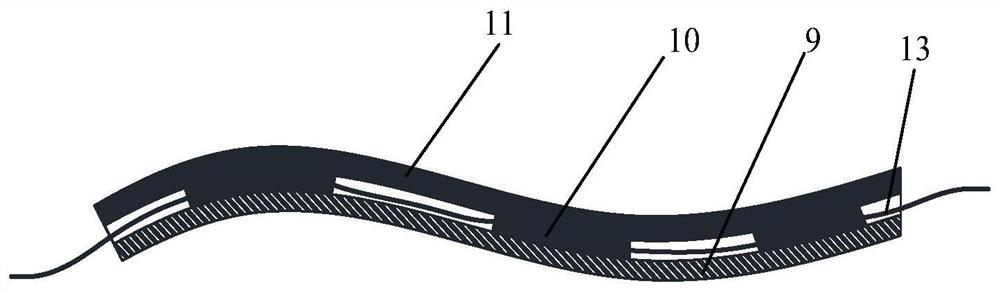

Buoyancy adjusting system and method for medium-shallow depth submersible

ActiveCN113184151ARealize the function of floating and divingAchieve buoyancy fine-tuningUnderwater vesselsUnderwater equipmentBuoyancy regulationGas cylinder

The invention provides a buoyancy adjusting system and method for a medium-shallow depth submersible. The system comprises a water tank assembly, a drainage branch and an emergency drainage branch, the water tank assembly structurally comprises a water tank, the water tank is a low-pressure-resistant component, and a sea opening is formed in the bottom of the water tank; the drainage branch structurally comprises a gas cylinder set, and the output end of the gas cylinder set is sequentially connected with a manual switching valve, a throttling valve, a first gas inlet valve, a check valve, a first seawater filter and a first fixed throttling hole in series through a pipeline; the emergency drainage branch structurally comprises an emergency gas cylinder, and the output end of the emergency gas cylinder is sequentially connected with an emergency switch valve, a second gas inlet valve, a third seawater filter and a third fixed throttling hole in series through a pipeline; a deflation valve, a second fixed throttling hole and a second seawater filter are further connected to the top face of the water tank in series, an output port of the second seawater filter is communicated with the external seawater environment, the floating and diving functions of the submersible can be achieved, buoyancy fine adjustment of the submersible can also be achieved, and the submersible has the advantages of being low in cost and high in reliability.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Underwater high-speed area-array camera

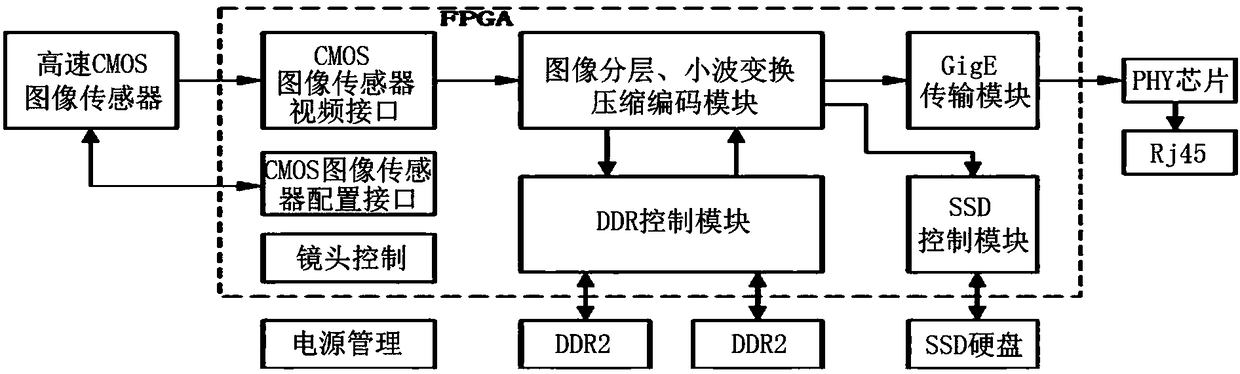

PendingCN108093163AUniform irradiationIncrease the scope of applicationTelevision system detailsColor television detailsStereo cameraEngineering

The invention provides an underwater high-speed area-array camera. The underwater high-speed area-array camera comprises a camera pressure-resistant shell, and a high-speed camera, an LED lamp circuitboard and a power management module which are placed in the camera pressure-resistant shell. Pressure-resistant glass is arranged on one side of the camera pressure-resistant shell. The high-speed camera is connected with a camera. LED lamps are evenly installed on the periphery of the camera and installed on the LED lamp circuit board. The LED lamps and the camera all face the pressure-resistantglass. An FPGA chip is adopted as a processing chip of the high-speed camera. The FPGA chip is connected with a DDR chip and used for improving the processing speed and data throughput of images. TheFPGA chip is connected with an SSD hard disk and used for storing parameter configurations of the images and the high-speed area-array camera at the camera end. Underwater photographing can be continuously carried out for ten workdays, deep diving can be realized, the application range can be increased, light illumination is uniform, and the photographing speed and processing speed are high.

Owner:CHINA INST OF SPORT SCI +2

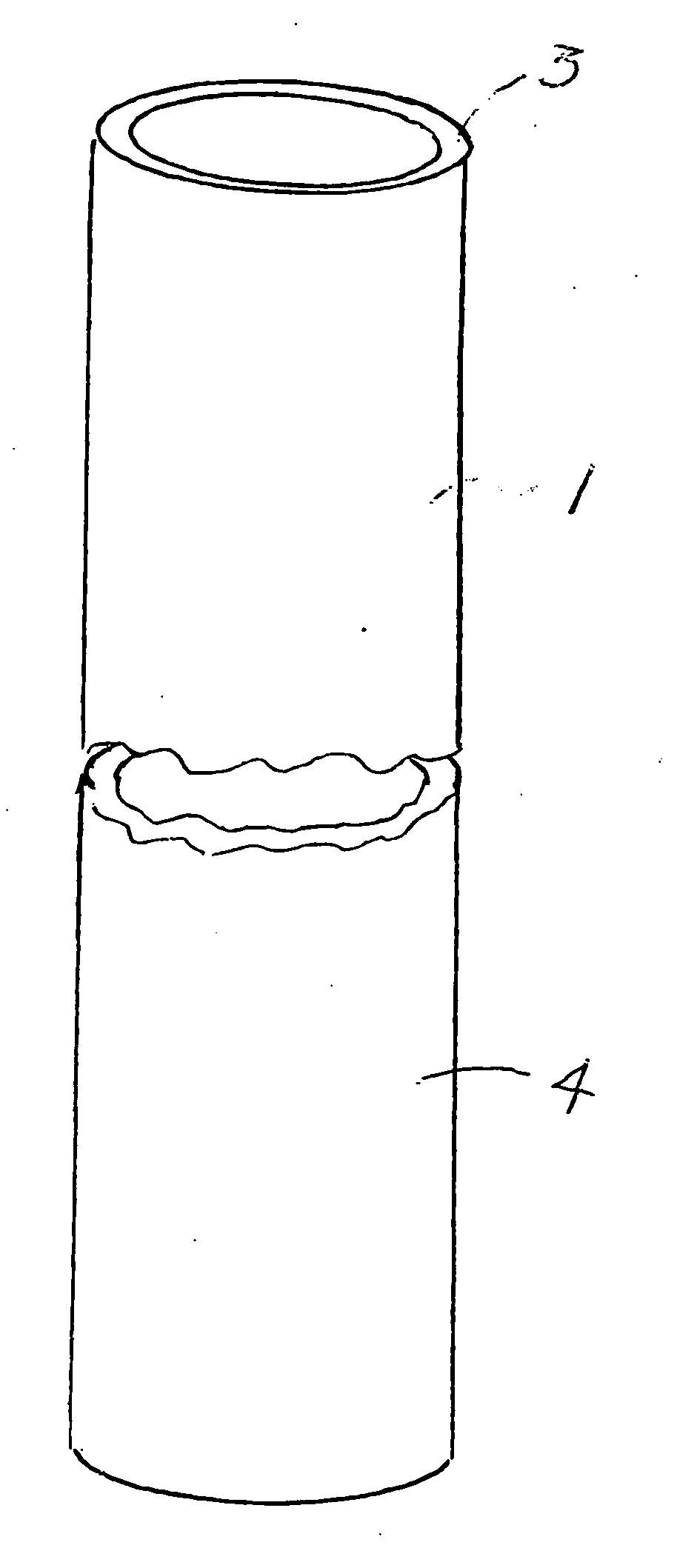

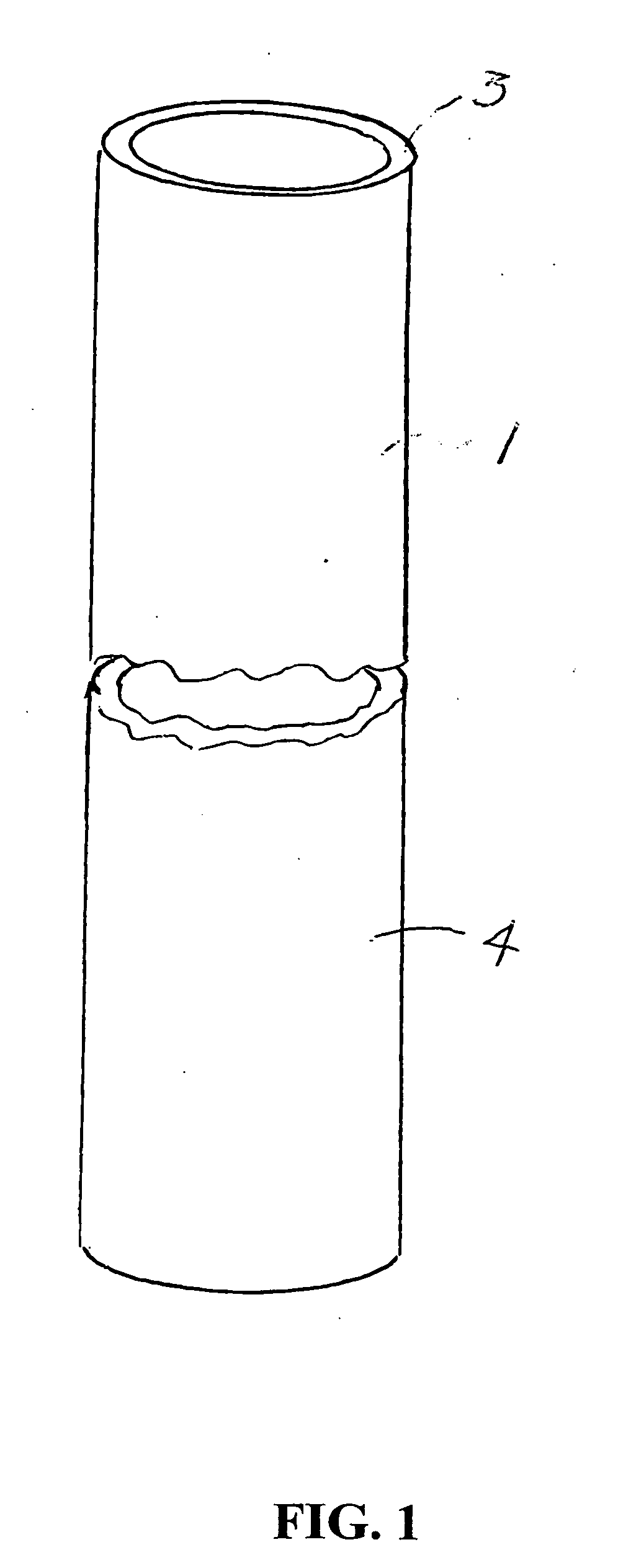

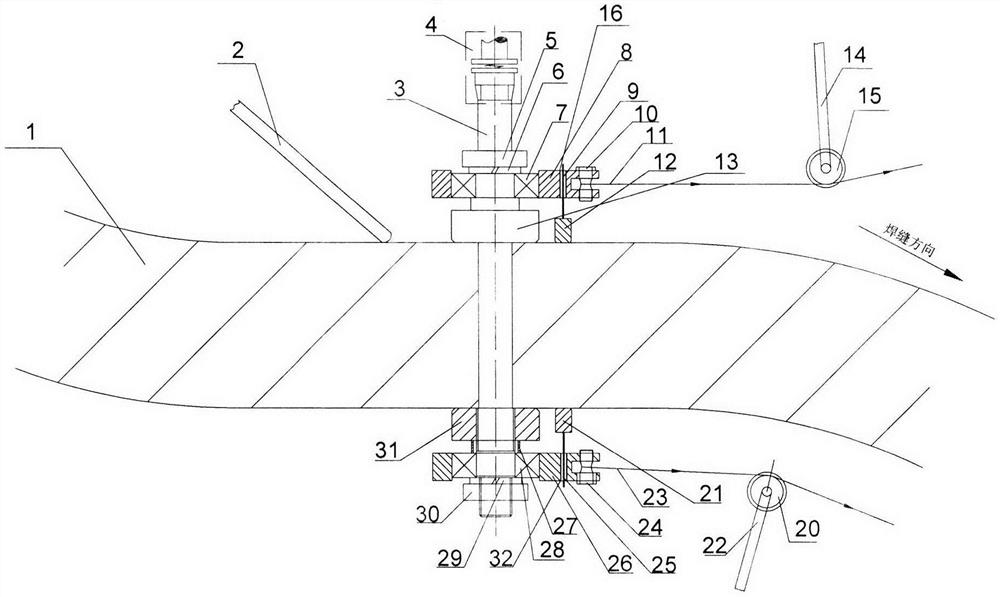

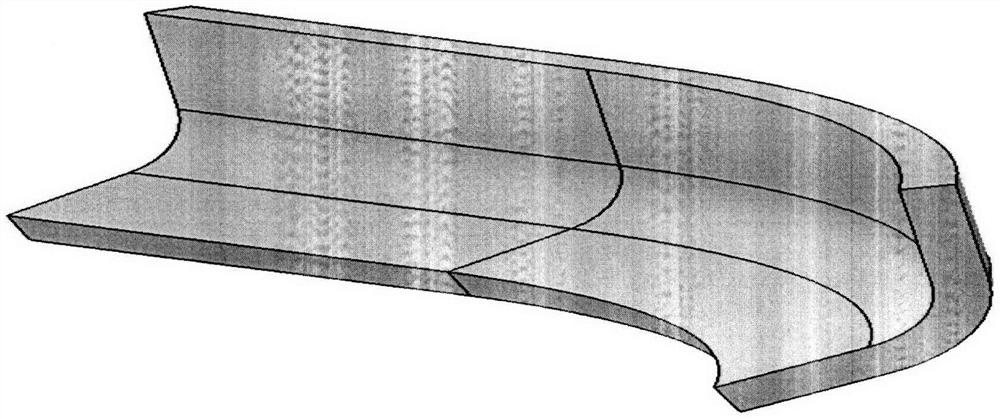

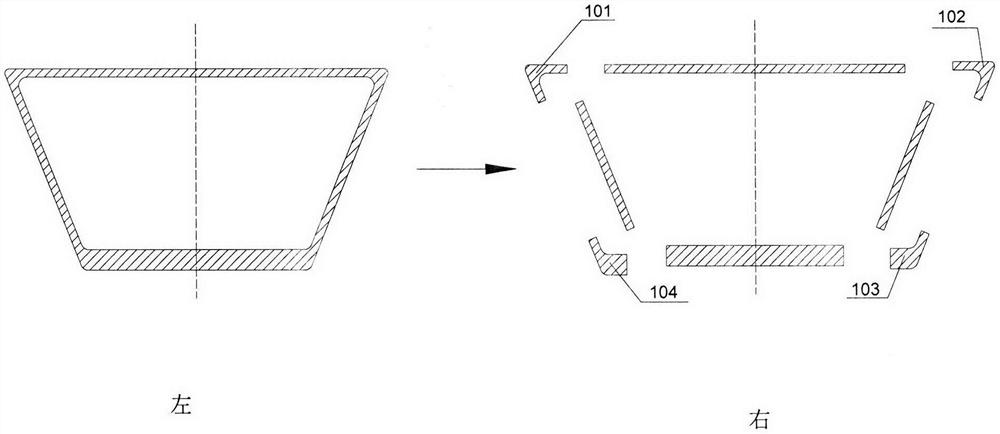

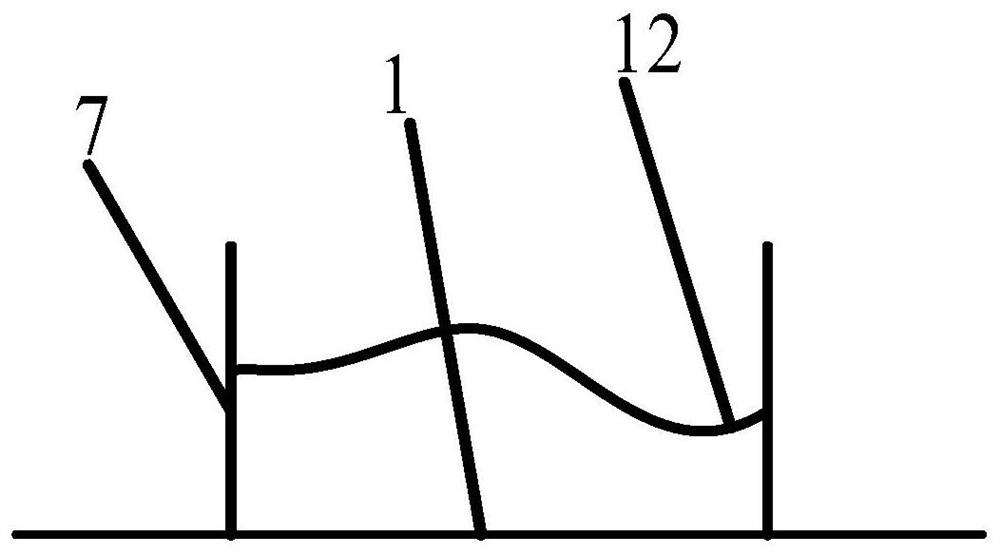

Double-shaft-shoulder friction stir welding stirring head with four sets of auxiliary devices and method for welding curve butt welds of medium-thickness steel parts through double-shaft-shoulder friction stir welding stirring head

ActiveCN112894120ARefine the weld grainImprove welding qualityProcess efficiency improvementNon-electric welding apparatusButt weldingCoupling

A double-shaft-shoulder friction stir welding stirring head with four sets of auxiliary devices comprises an auxiliary pull rope, a traction device, an auxiliary current heating device, a fixed pulley, an auxiliary multi-degree-of-freedom robot with a welding seam tracking device and a flexible coupler. With the four sets of auxiliary devices, the stress condition of the stirring head can be greatly improved, the service life of the stirring head is prolonged, and the welding length of the stirring head is increased. A slope is additionally arranged on an introduction plate, so that the reduction of the pre-tightening force between the two shaft shoulders after the pre-tightening force encounters softened metal in the working process is not reduced, and tunnel type welding defects can be reduced. Notches are formed in the corners and the positions with different thicknesses, so that the double-shaft-shoulder friction stir welding stirring head is particularly suitable for friction stir welding of plane and space curve butt welds, linear butt welds and segmented part transverse butt welds of medium-thickness steel parts and steel parts which are slightly staggered in height and are equal in thickness such as various ships, various warships including aircraft carriers, conventional submarines, nuclear submarines, deep diving submersibles, large cylinders, large platforms, large flat plates and large transporters. The invention also provides a corresponding welding method.

Owner:倪平涛

Deep diving bomb

The invention discloses a deep diving bomb which comprises a shell bomb and a core bomb. A core bomb cavity is contained inside the shell bomb, and the core bomb is stored in the core bomb cavity. The shell bomb can separate and release or be externally provided with the core bomb, so that attacks happen. The deep diving bomb can dive into the sea floor of any depth and lurk to wait for orders for a long time, meanwhile, the deep diving bomb cannot be destroyed after being intercepted by enemies, and therefore the deep diving bomb has enormous deterrent force and attack force.

Owner:刘威孝

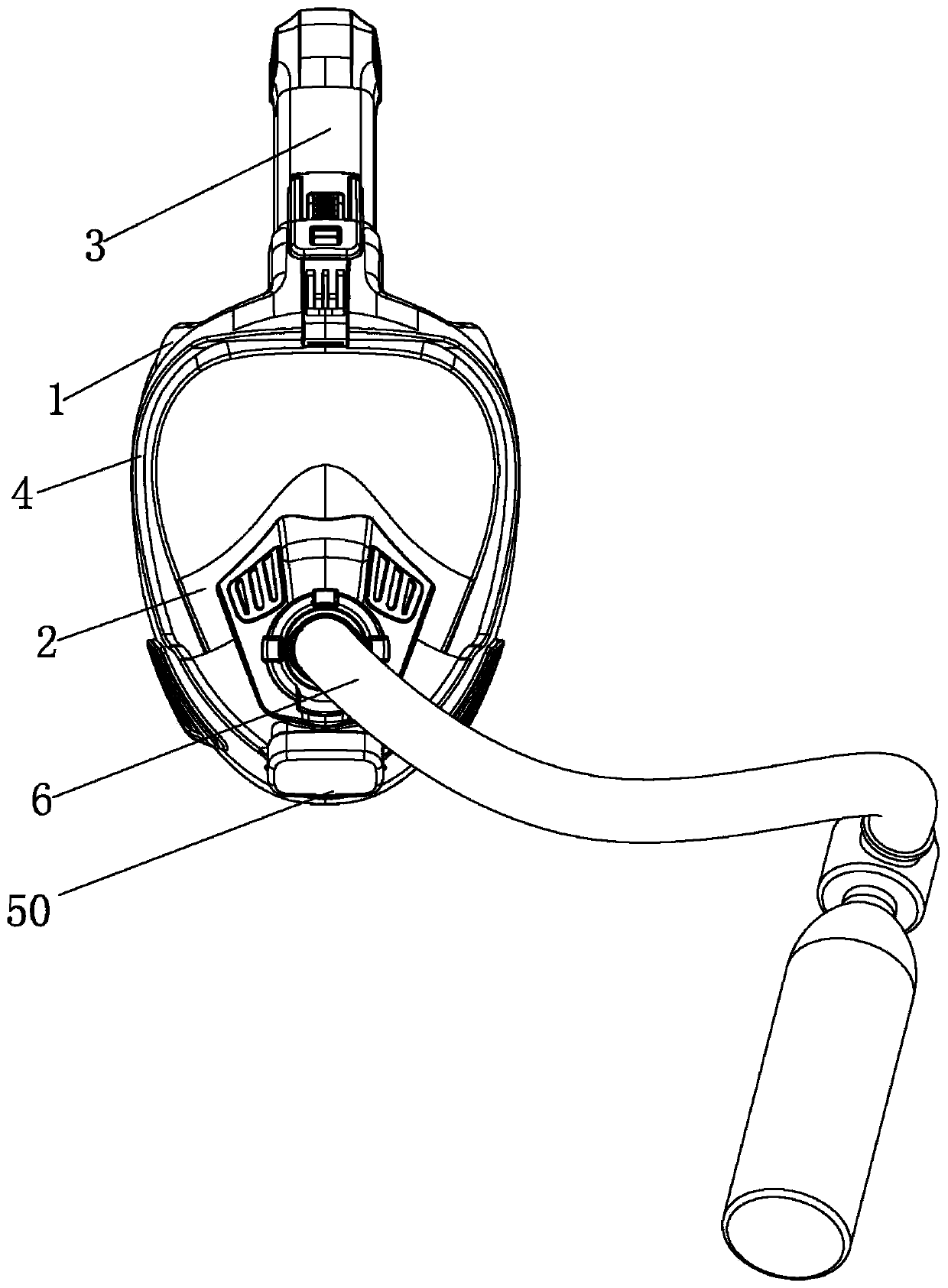

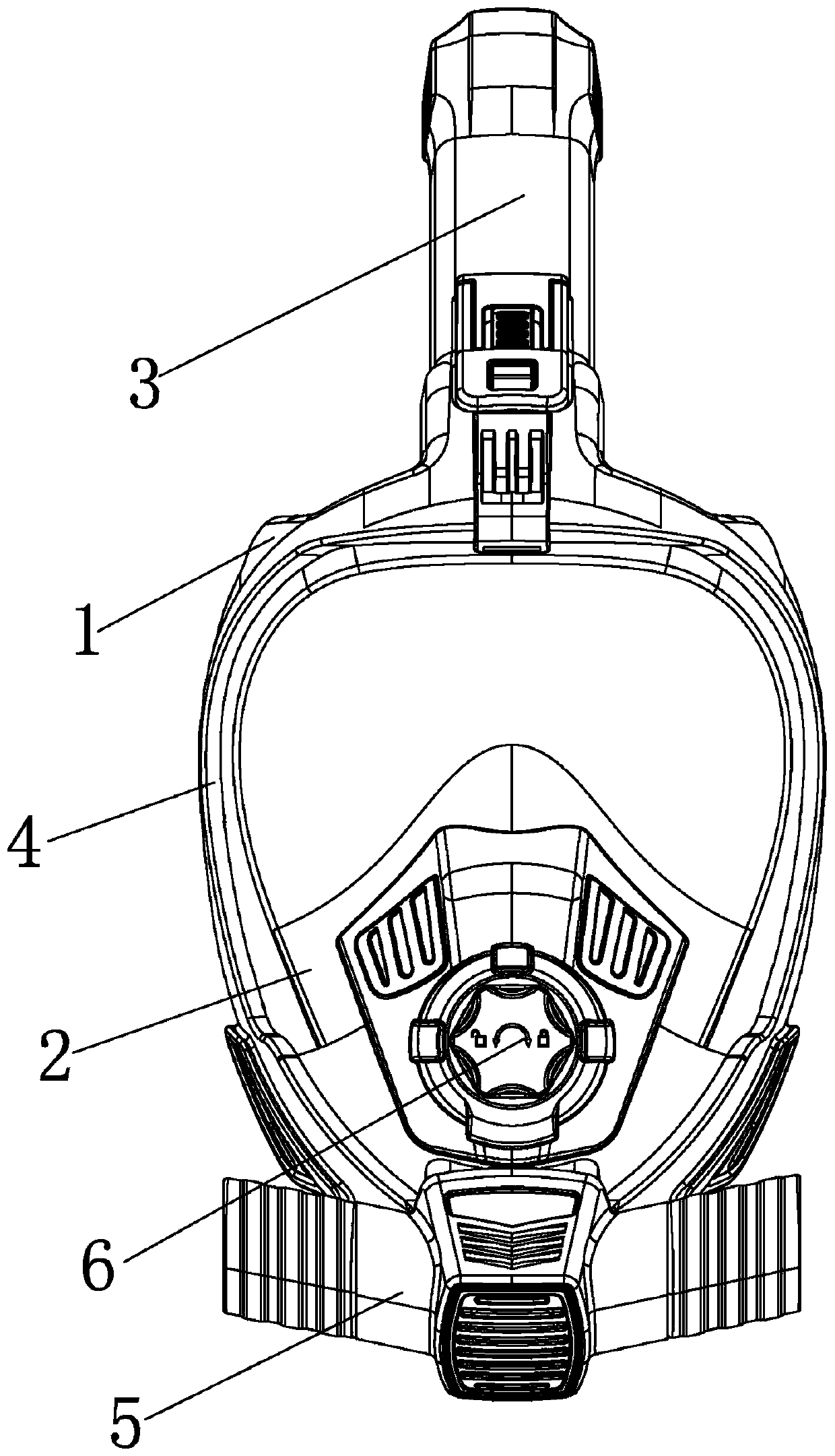

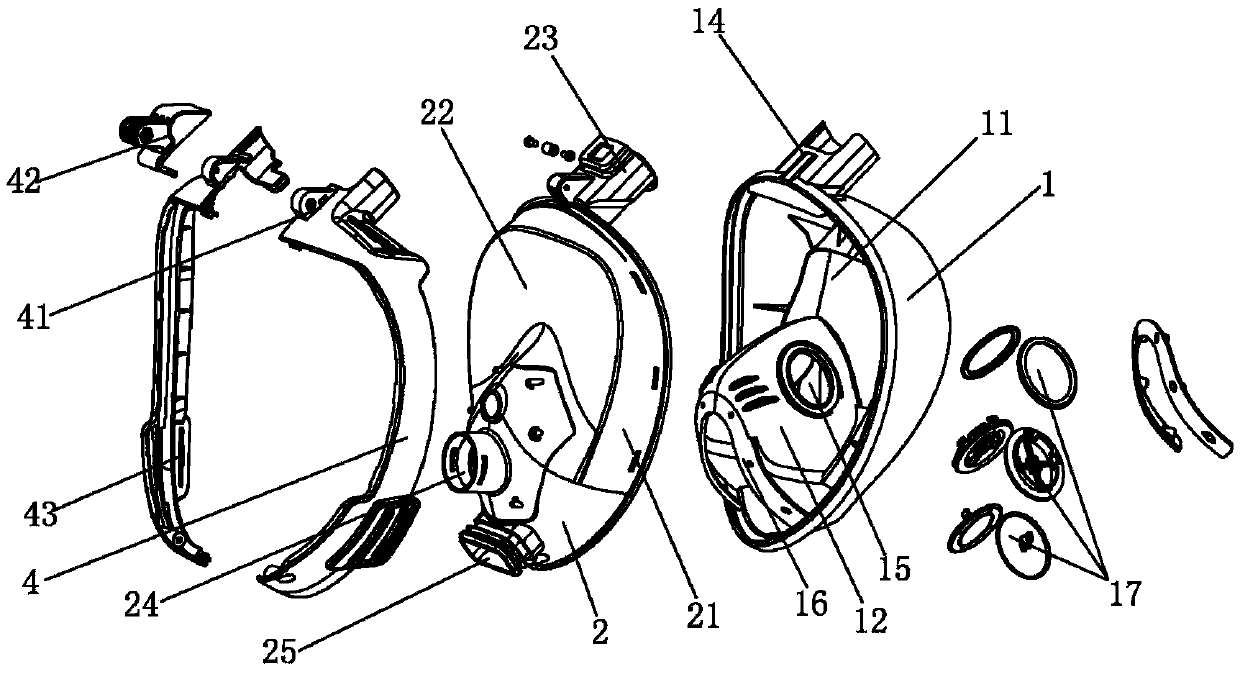

Diving mask with oxygen bottle

PendingCN110641656AReduce weightConvenient for free activitiesUnderwater equipmentOxygen tankDeep diving

The invention discloses a diving mask with an oxygen bottle. The dividing mask comprises a silica gel mask, a transparent mask, a pipeline, a frame, an exhaust device and an oxygen supply device. Thesilica gel mask comprises a flexible skirt and a baffle. The flexible skirt is divided into two parts of an upper chamber and a lower chamber through the baffle. The transparent mask is arranged at the front end of the silica gel mask. The outer side of the transparent mask is coated with the flexible skirt. The two sides of the flexible skirt are wrapped with the frame. The pipeline is arranged at the upper end of the transparent mask. The exhaust device is arranged at the lower end of the transparent mask. The oxygen supply device is arranged at the front end of the transparent mask. The diving mask is suitable for deep diving or shallow diving. The diving mask is suitable for deep diving or shallow diving, a wearer can select whether the oxygen bottle is worn or not according to the diving depth, the depth and shallow diving double-use is achieved, the mode switching is convenient and rapid, the smooth operation of the diving work is facilitated, and the diving mask with the oxygenbottle plays an innovation role in the underwater operation industry.

Owner:东莞酷游运动用品有限公司

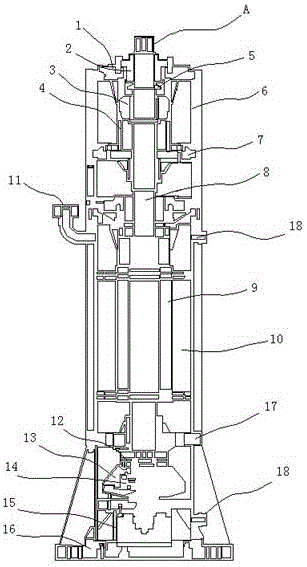

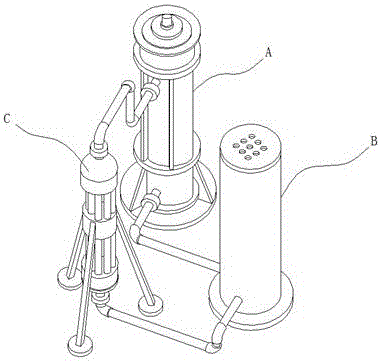

High-power oil-filled deep-diving underwater motor

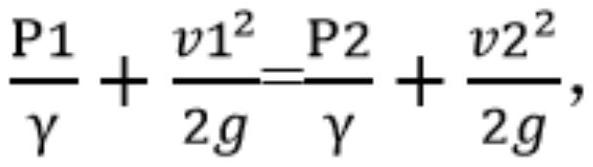

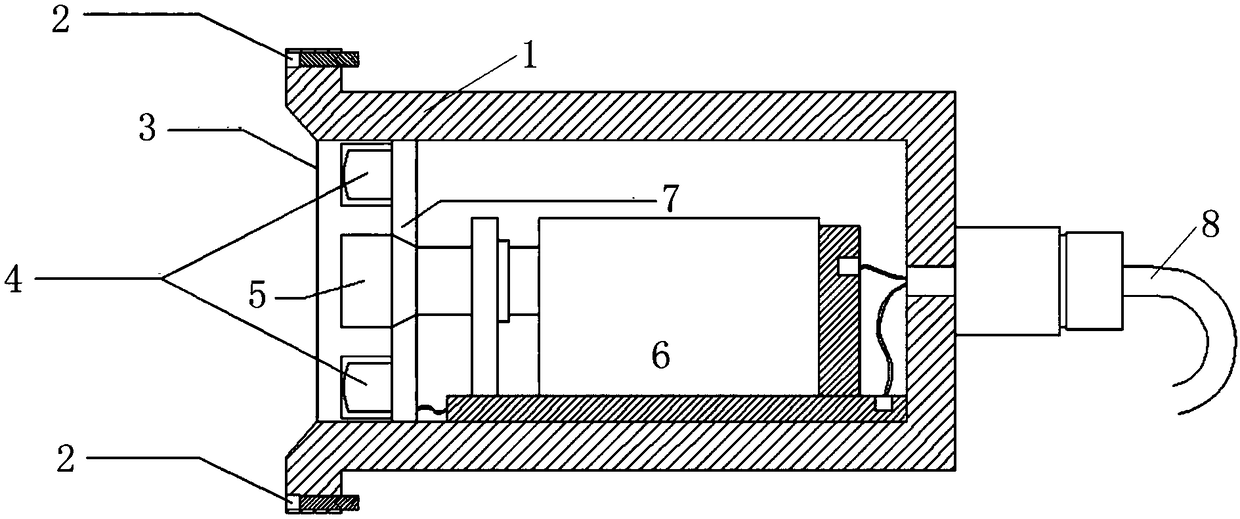

PendingCN106602778AWork reliablyReduce dependencySupports/enclosures/casingsWorking temperatureEngineering

The invention discloses a high-power oil-filled deep-diving underwater motor. The inside of the motor is separated from an external environment based on shaft driving sealing and static sealing of a motor housing. The inside of the motor is filled with mineral oil; and the mineral oil having high insulativity and lubricity is used as a medium for lubrication and cooling. The mineral oil plays a role in lubricating all parts inside the motor during the operation of the motor and taking away heat caused by the motor. The motor is used by matching a high-power oil-filled deep-diving underwater motor pressure compensator B and a heat-exchanging device C, thereby realizing internal and external pressure balancing of the system, maintaining the normal working temperature, and guaranteeing long-term, stable, and reliable work of the high-power oil-filled deep-diving underwater motor. The rated power of the motor can reach 1000 kW and the operating depth can reach 1500m. With the motor, the blank in domestic deep-water environment application can be filled and the purchasing cost can be lowered obviously; and the bottleneck constraint of the key technological resources in foreign companies can be avoided.

Owner:胜利油田胜利泵业有限责任公司

Buoyancy adjusting device and method for medium-shallow depth submersible

ActiveCN112918651ACompact structureReasonable structureUnderwater vesselsUnderwater equipmentBuoyancy regulationOutfall

The invention discloses a buoyancy adjusting device and method for medium-shallow depth submersible. The buoyancy adjusting device comprises a pressure-resistant water tank, a pump source is installed at the bottom of the pressure-resistant water tank, a drainage branch and a water injection branch which communicate with the pump source are arranged outside the pressure-resistant water tank, the pump source comprises a motor and a sea water pump, the sea water pump is connected with a water inlet filter, and an outlet is connected with a safety valve. One end, extending out of the safety valve, of a pipeline is open. The drainage branch comprises a one-way valve communicating with a water outlet of the sea water pump, the one-way valve communicates with a drainage switch valve, the drainage switch valve is connected with a sea filter, the sea filter communicates with outside seawater, the water injection branch comprises a water injection filter communicating with the bottom of the pressure-resistant water tank, and the water inlet end of the water injection filter communicates with a throttling hole. The water inlet end of the throttling hole communicates with a speed regulating valve, the water inlet end of the speed regulating valve communicates with a water injection switch valve, the water inlet end of the water injection switch valve communicates with the sea filter, the water injection switch valve communicates with the drainage switch valve, and the number of valves of the system is reduced.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

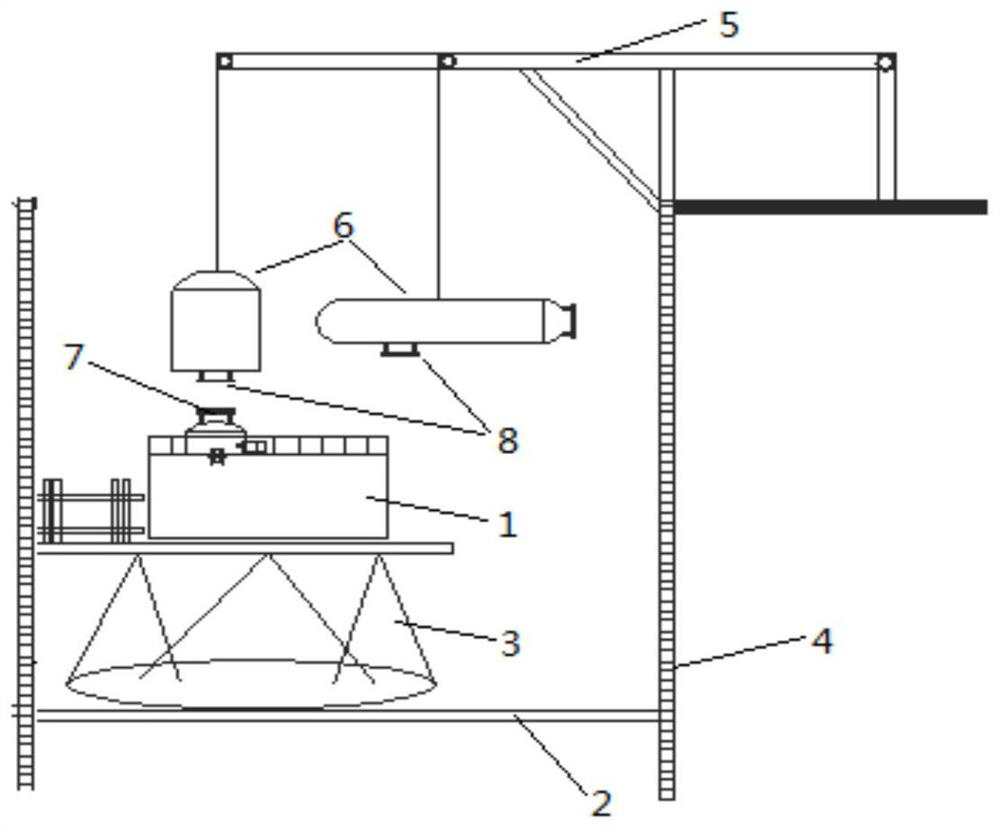

Hanging type test platform

ActiveCN111932978ALow costHigh simulationCosmonautic condition simulationsSimulatorsDeep divingFrequency modulation

The invention relates to the technical field of ship and ocean engineering underwater test devices, in particular to a hanging type test platform. The test platform can realize simulated butt joint rescue and material transfer of a lifesaving bell, a lifesaving submersible vehicle, a deep diving lifeboat and a submarine, can also realize butt joint of a shuttle submersible vehicle and a deep sea space station, realizes material transfer simulation, can carry out novel equipment development, test and test, and can carry out various trainings at the same time. By arranging the lifting device, different water depth environments can be simulated, and divers can simulate and train overwater and underwater operations under different sea conditions. Based on the irregular wave superposition theory, the characteristics of electric actuation and frequency modulation of a high-elastic dielectric material are adopted, waves are accurately simulated, a wave maker is not needed, and the cost is saved.

Owner:WUHAN TECHN COLLEGE OF COMM

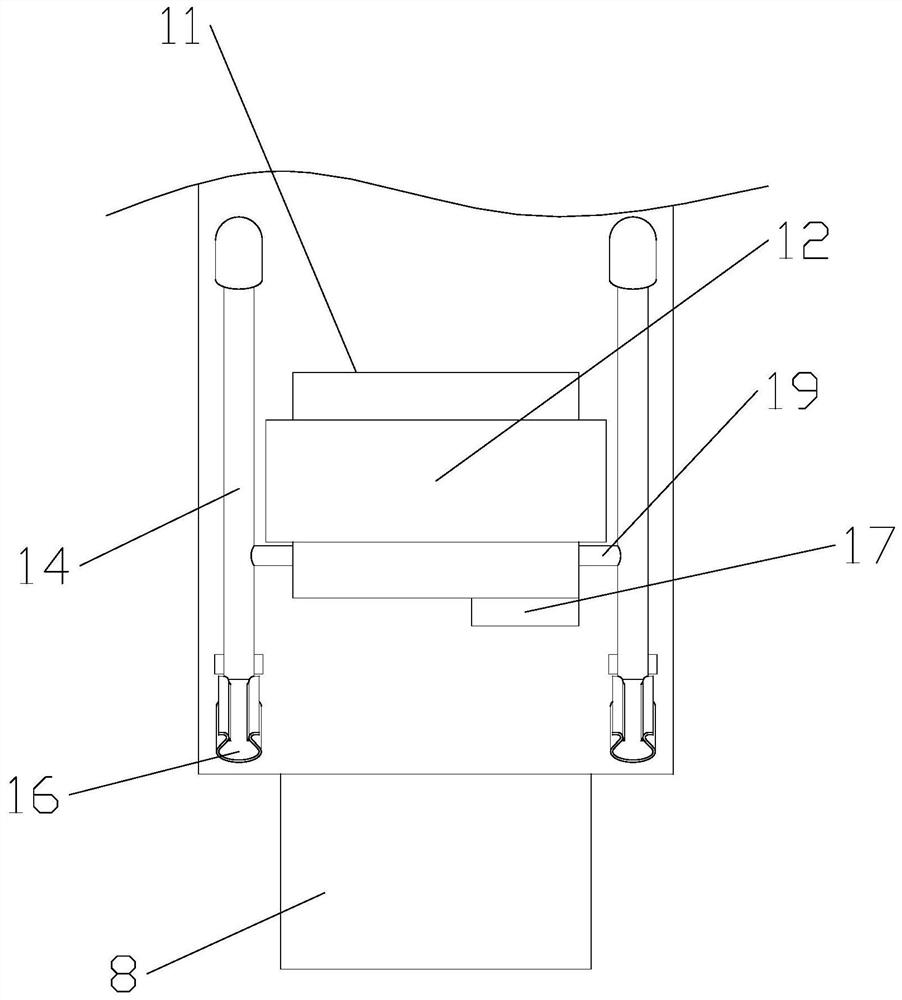

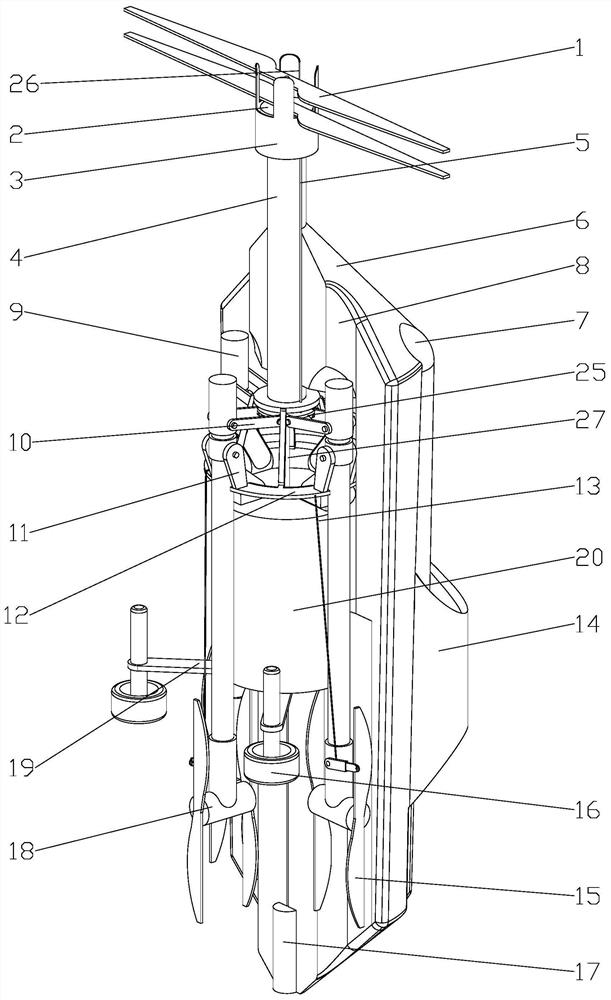

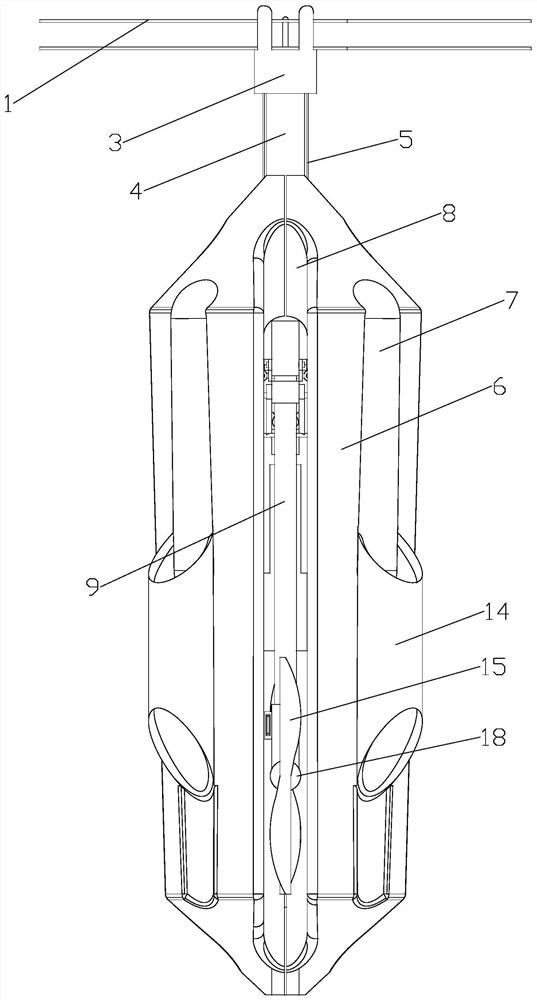

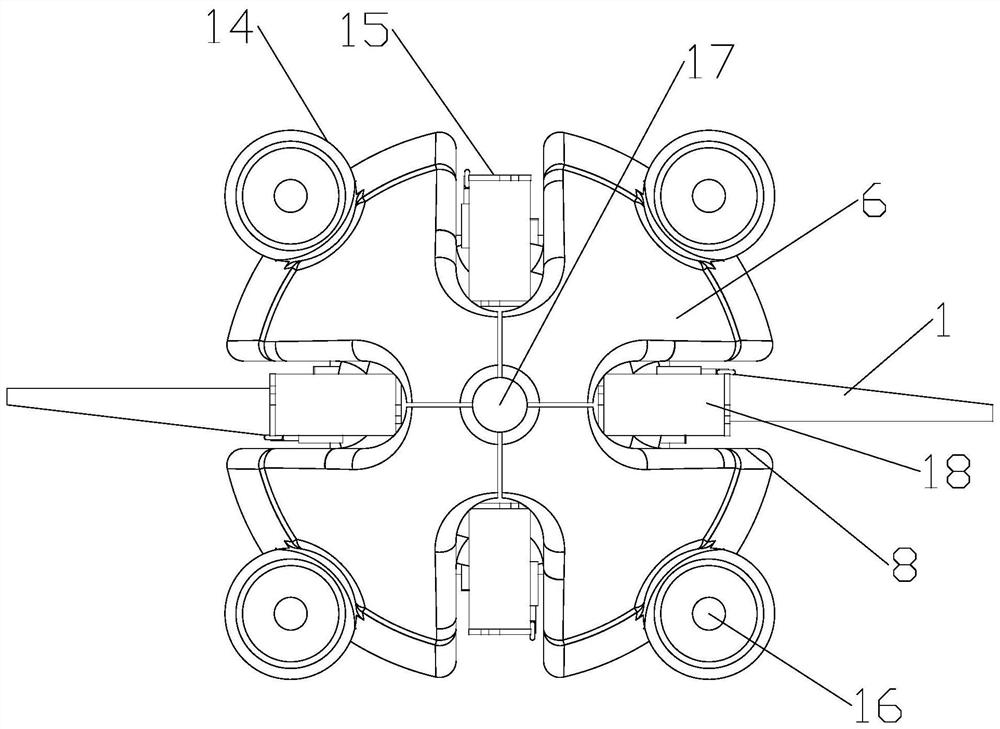

Detection device with deep diving function and detection method thereof

ActiveCN113511039AImprove stabilityAnti-bottomingMeasurement devicesTransmission systemsUnderwaterClassical mechanics

The invention discloses a detection device with a deep diving function and a detection method thereof. The detection device with the deep diving function comprises a main rotor mechanism, four groups of auxiliary rotor mechanisms, an auxiliary rotor folding and unfolding mechanism, four underwater propellers, a pressure-bearing cabin, a rotor mechanism fixing frame and a shell. According to the detection device with the deep diving function, the four underwater propellers are used for propelling underwater, the detection device can overcome the buoyancy effect to achieve diving and underwater maneuvering movement, and detection of a deep sea area environment is achieved; the four groups of auxiliary rotor mechanisms can swing downwards and retract, so that the resistance in the diving and floating processes is reduced, and meanwhile, the gravity center of the detection device moves downwards, and the stability of the detection device in water is facilitated; the four groups of auxiliary rotor mechanisms are controlled to swing to horizontal positions by using the auxiliary rotor folding and unfolding mechanism, so that the flight lift force and the air flight cruising ability of the detection device are improved; the height gauge is used to realize grounding prevention of the detection device.

Owner:JIANGSU MARINE RESOURCES DEV RES INST LIAN YUNGANG +1

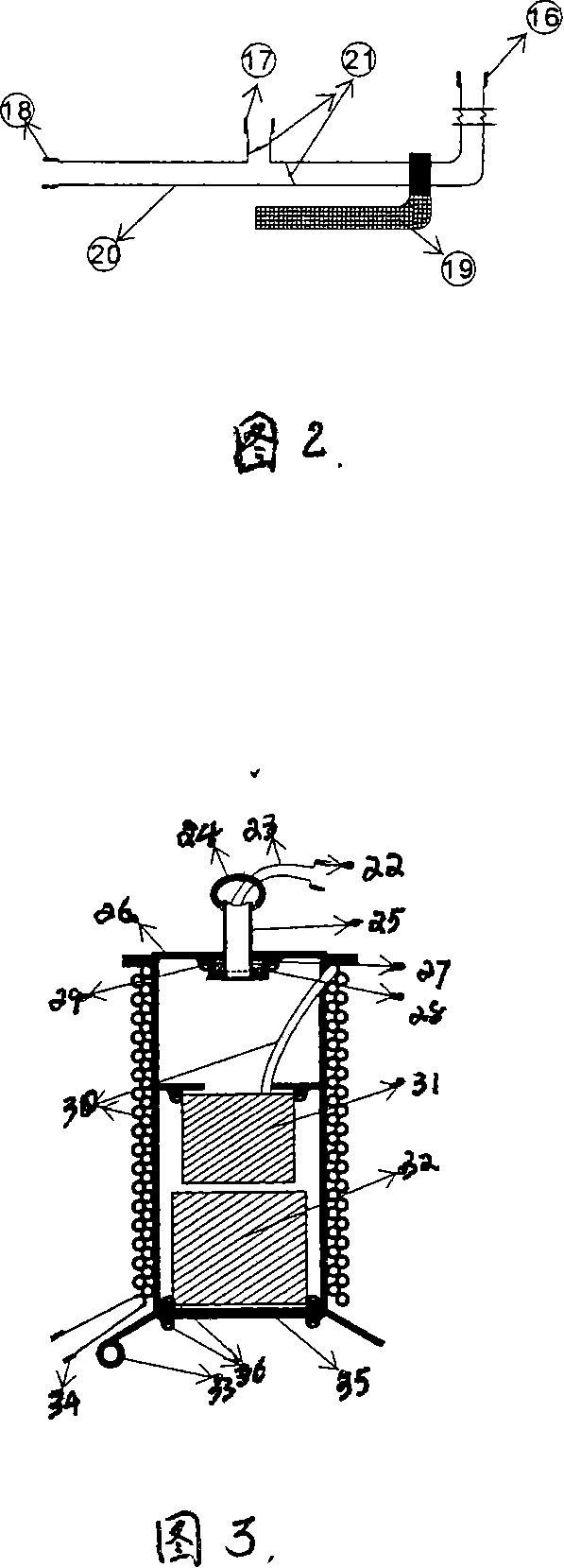

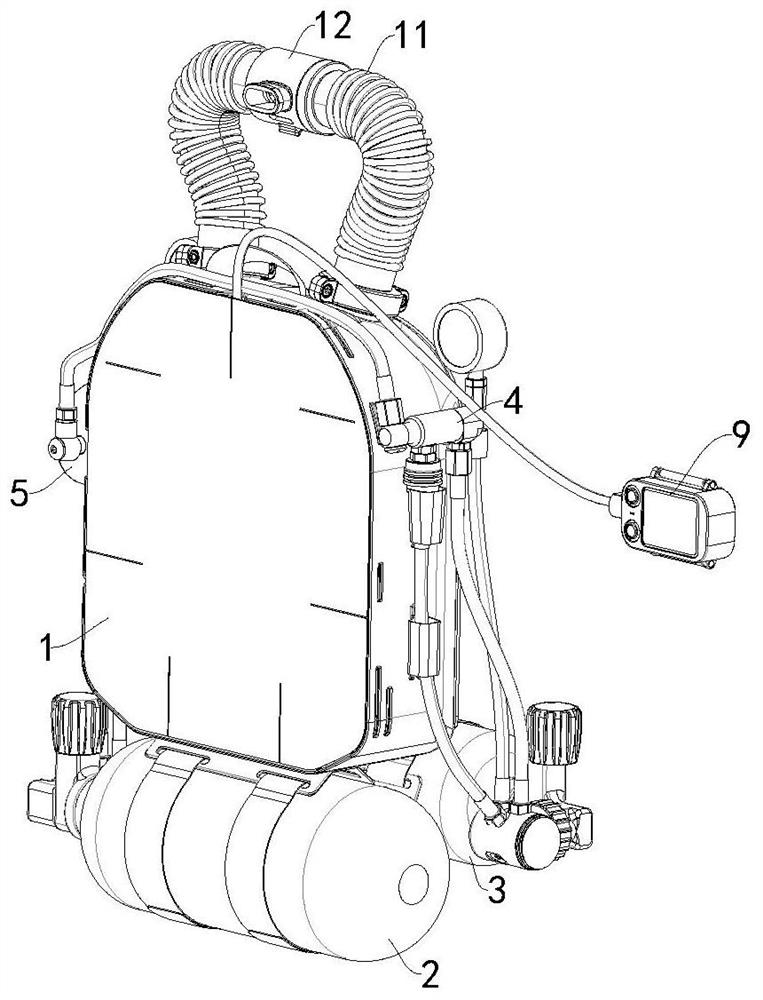

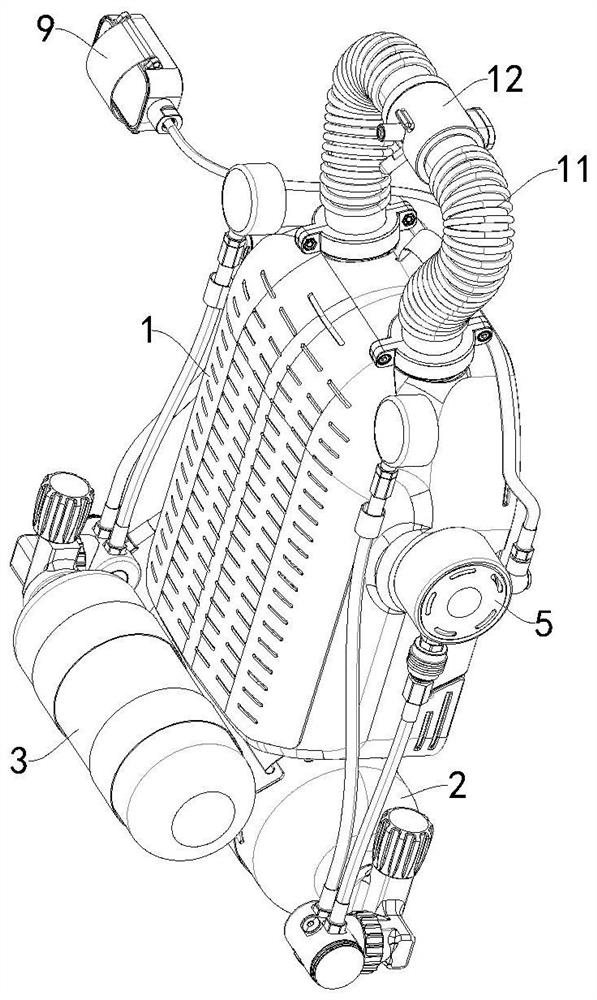

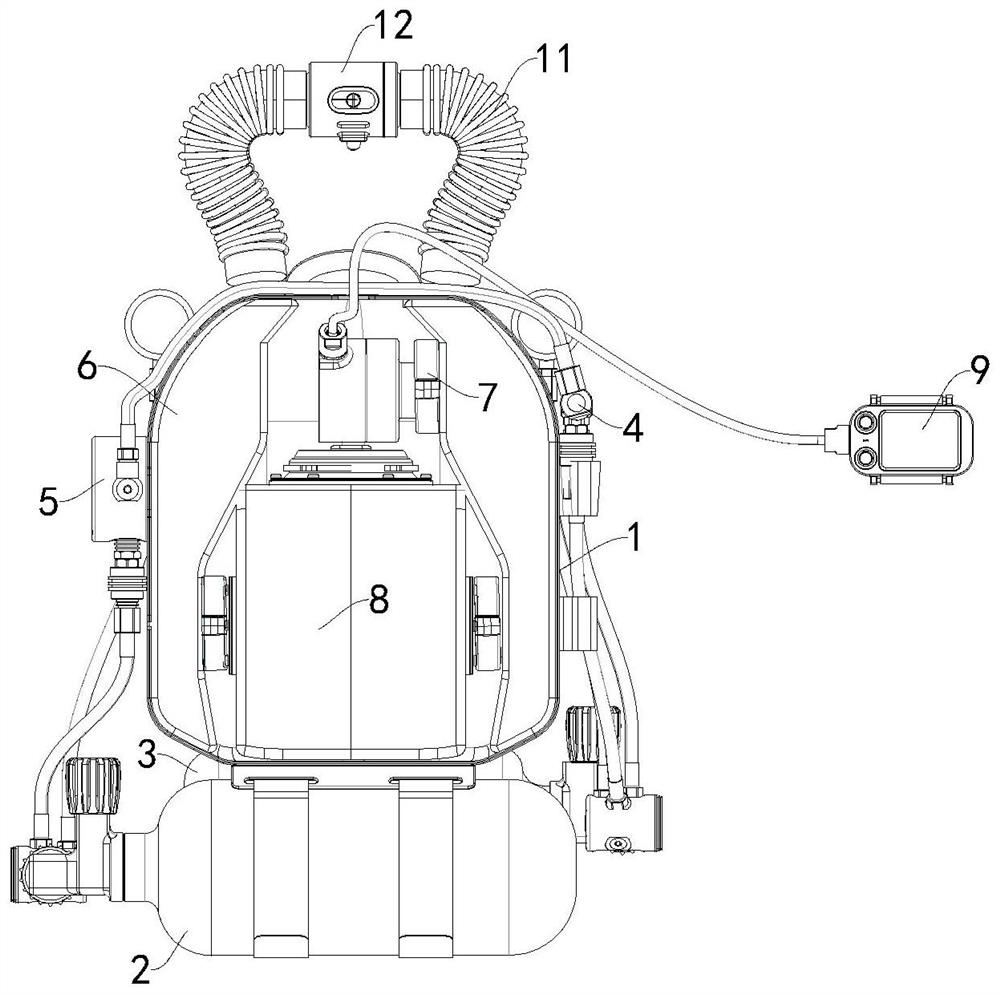

Mixed type closed circulating breathing system

The invention discloses a mixed type closed circulating breathing system, which comprises a box body provided with a breathing pipeline; a circulating breathing device is fixed in the box body and comprises a first lung bag connected with one end of the breathing pipeline, a second lung bag connected with the other end of the breathing pipeline and an adsorbent tank connected with the first lung bag and the second lung bag; and the adsorbent tank is used for adsorbing carbon dioxide in exhaled gas; a mixed oxygen supply device which comprises an oxygen tank filled with oxygen, a diluted gas tank filled with mixed gas and an automatic gas adding valve connected with the oxygen tank and the diluted gas tank respectively, and the automatic gas adding valve is connected with the first lung bag. By the adoption of the design, oxygen can be recycled, long-time deep diving can be achieved during use, and cost is saved.

Owner:深圳易如潜水装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com