Patents

Literature

640results about How to "Uniform irradiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

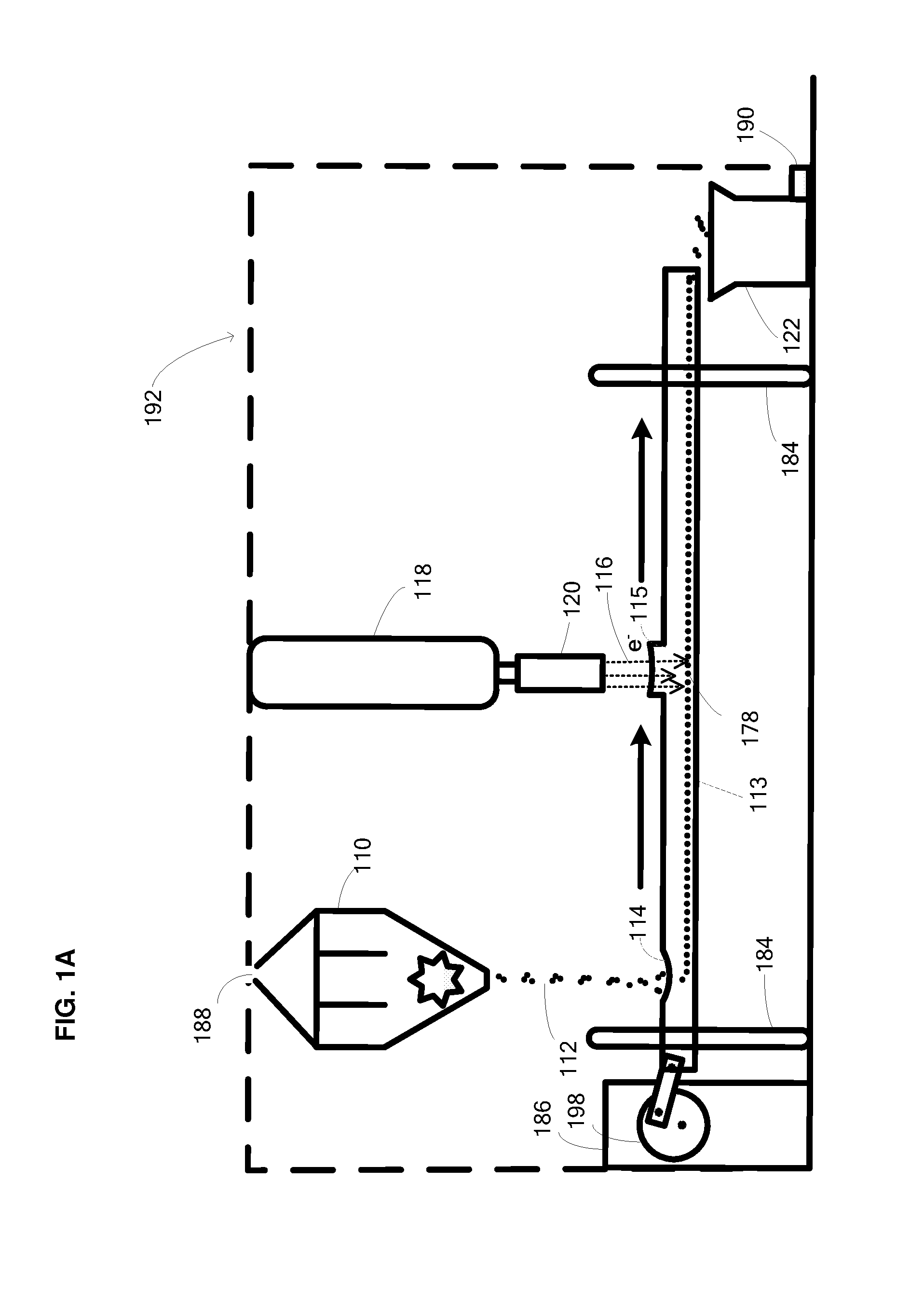

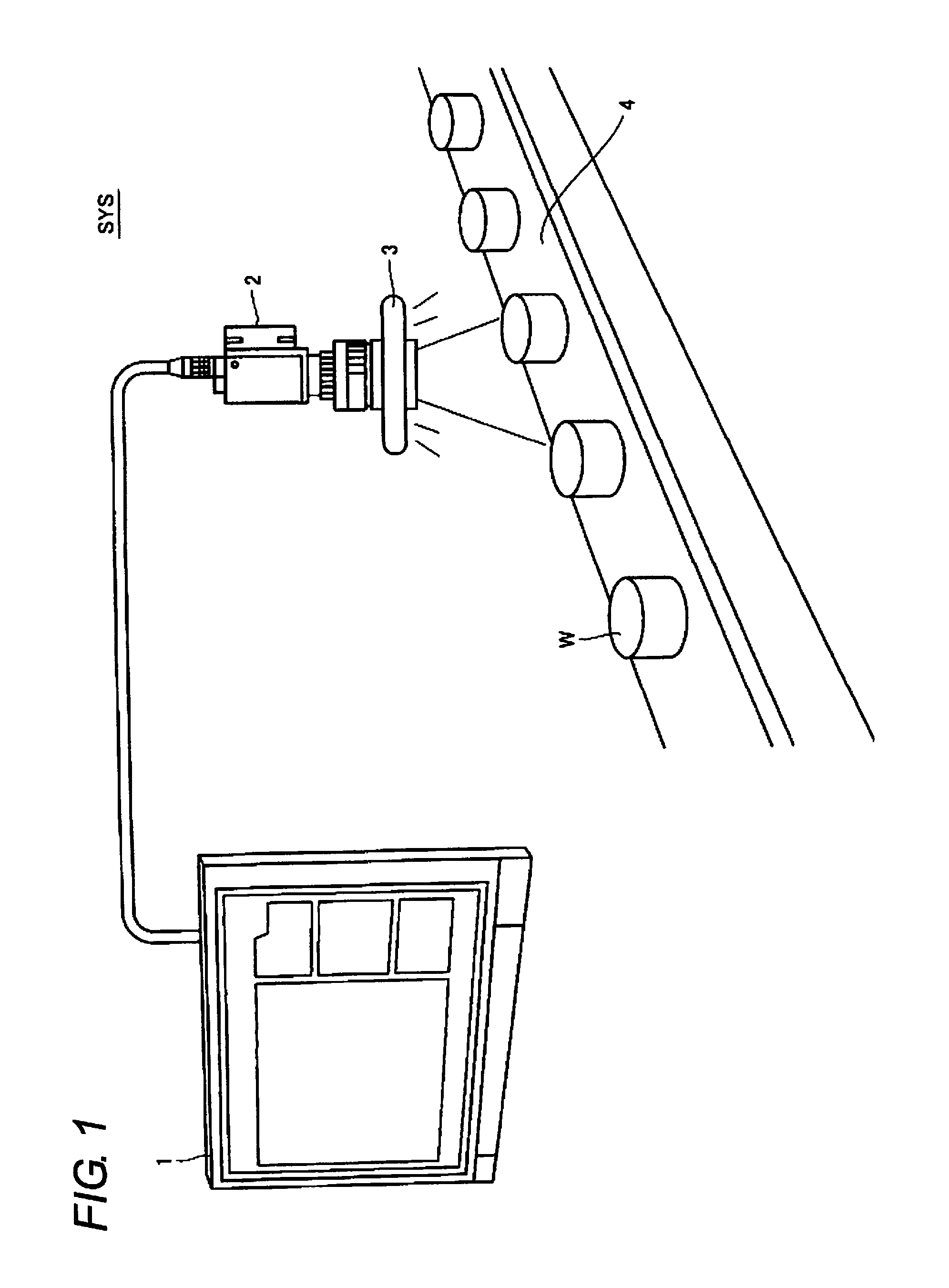

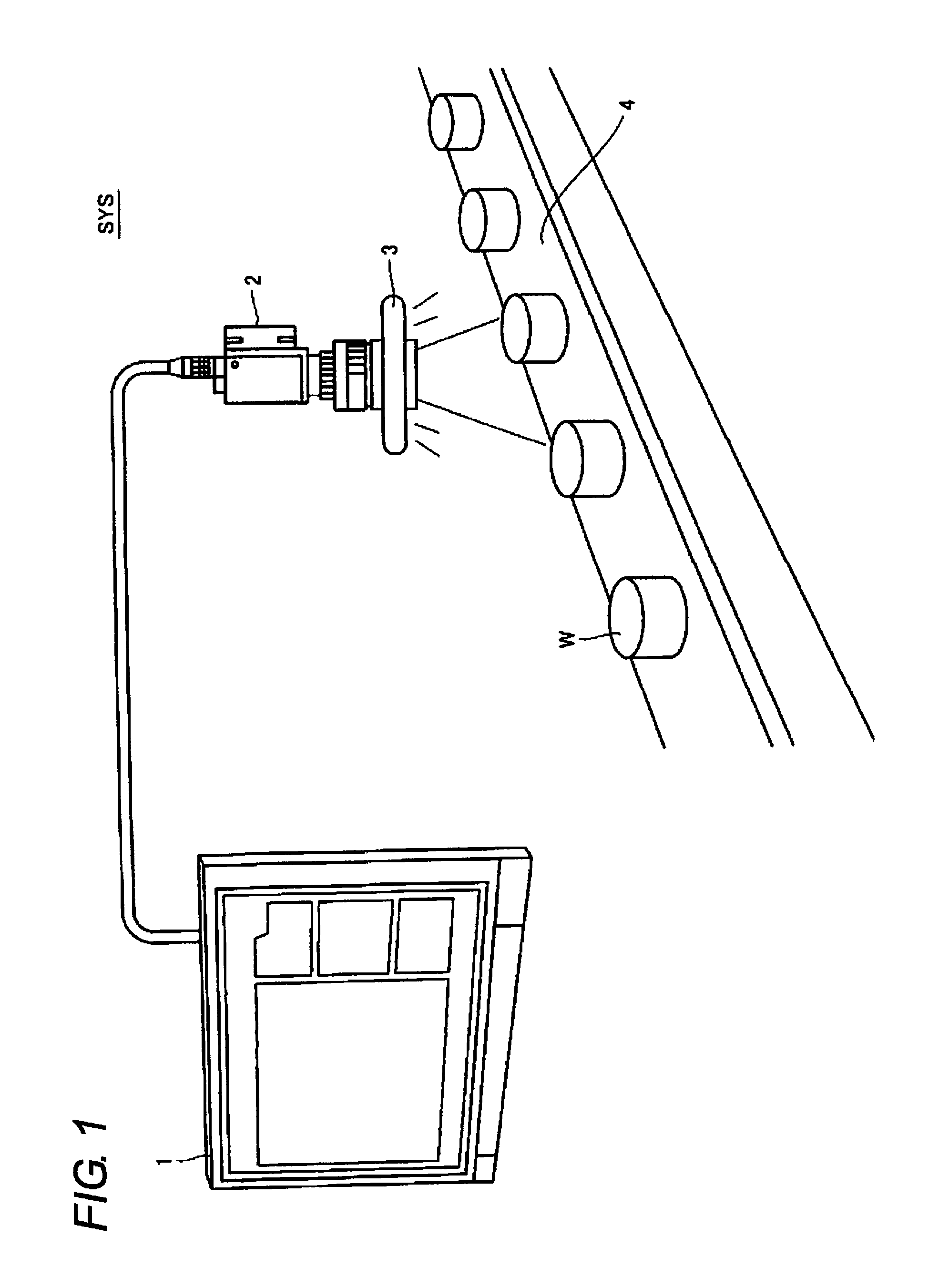

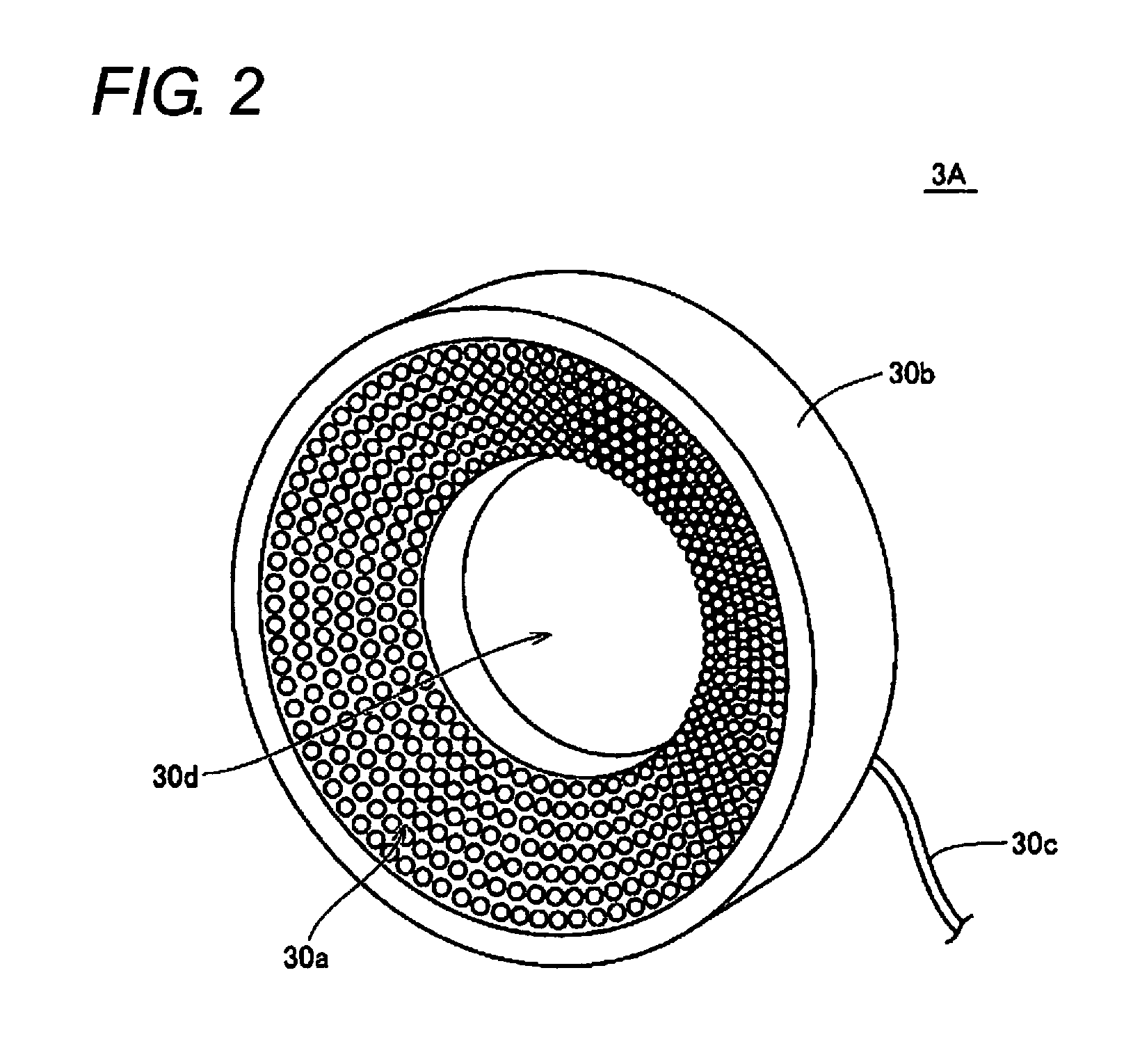

Gas-target neutron generation and applications

InactiveUS6922455B2Improve performanceMaximize productionNuclear energy generationX-ray tube electrodesHigh resistanceNeutron emission

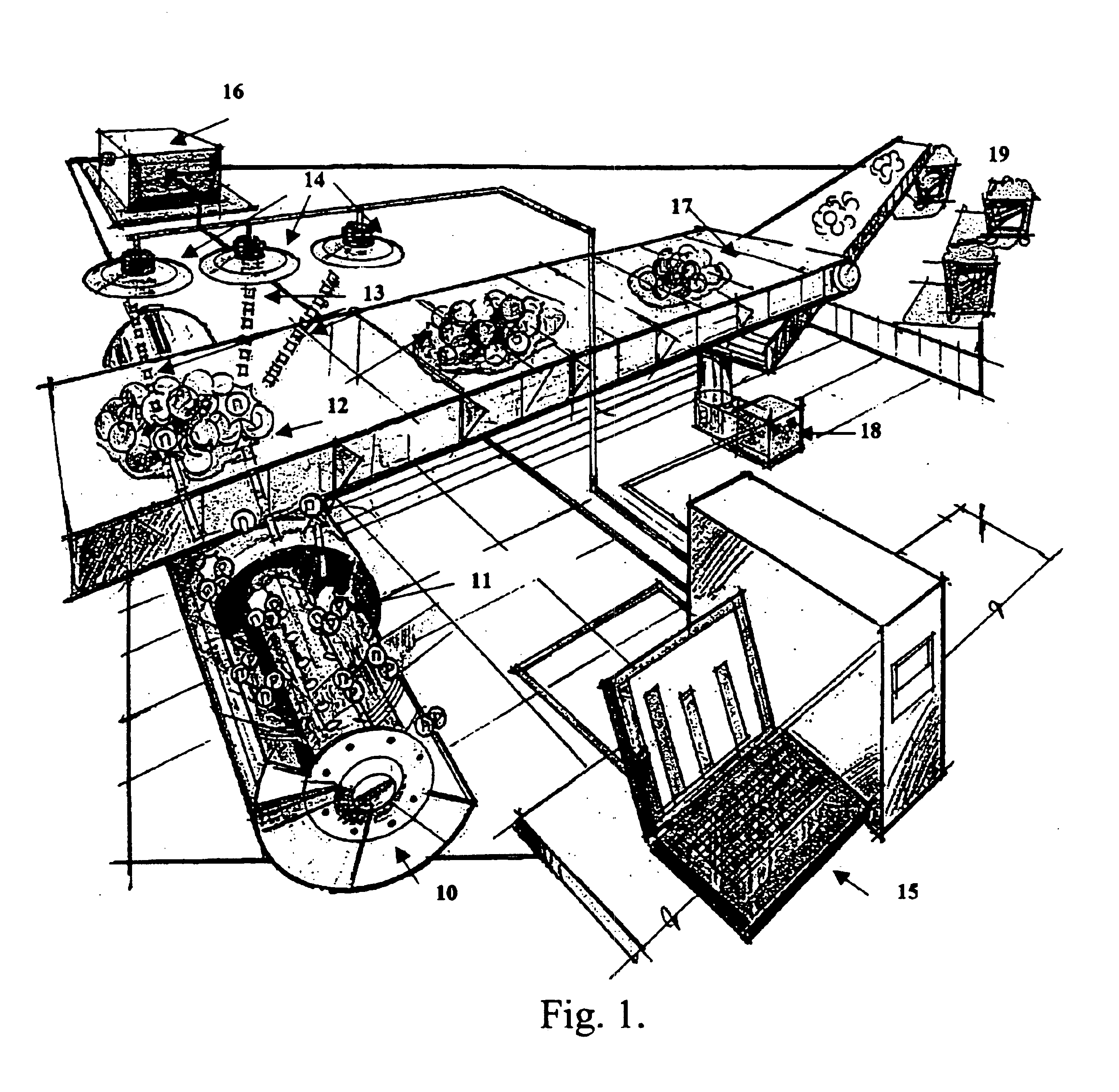

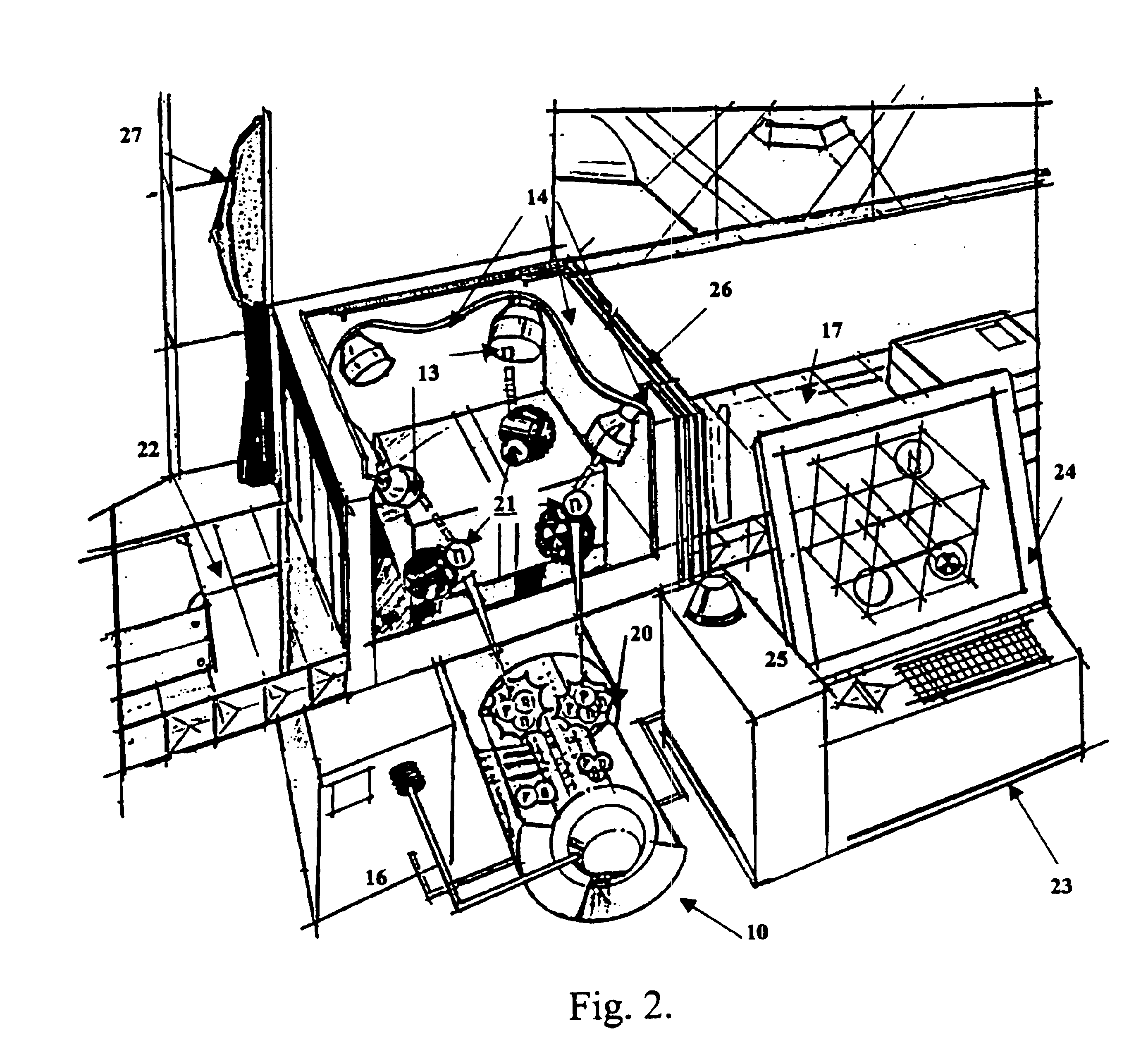

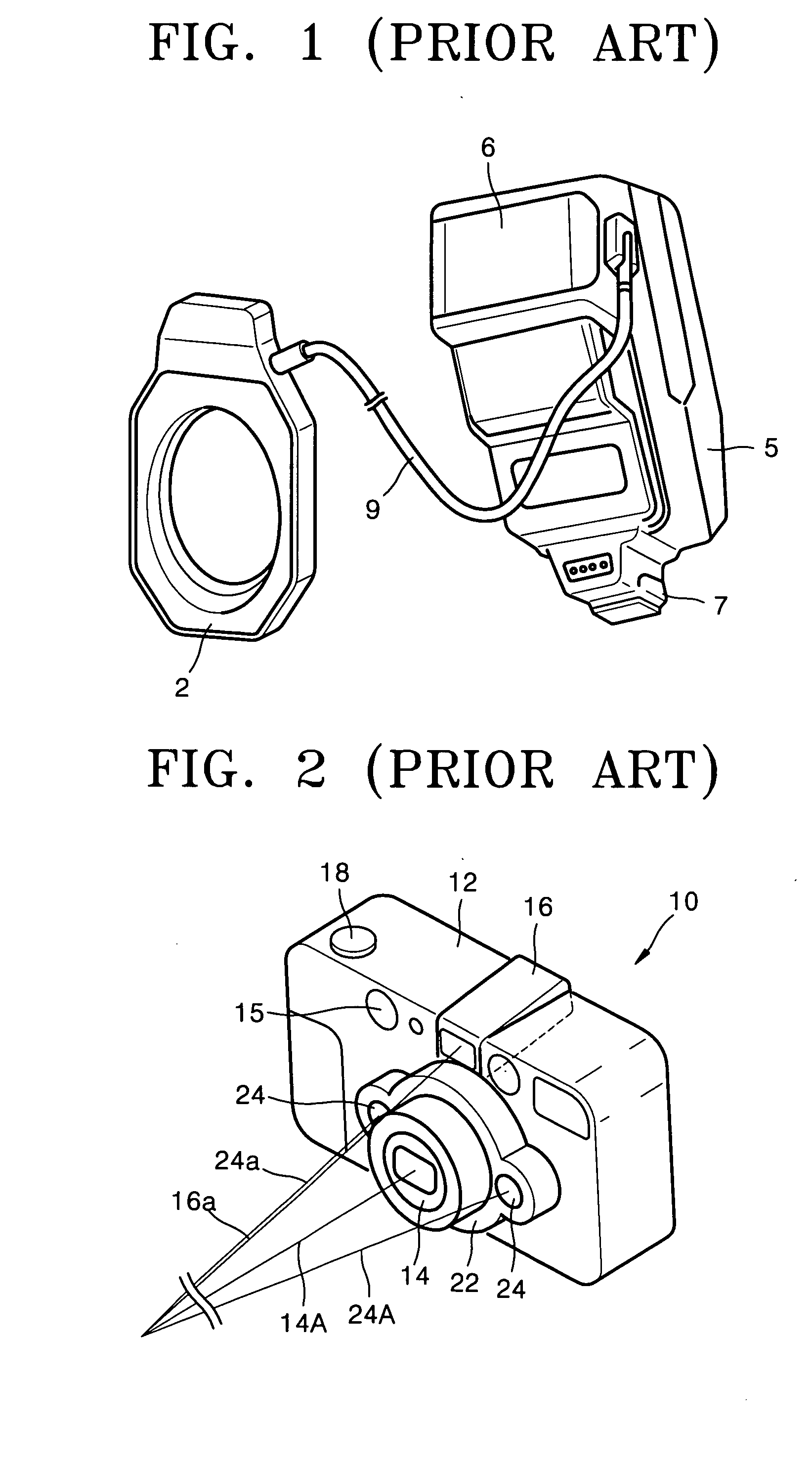

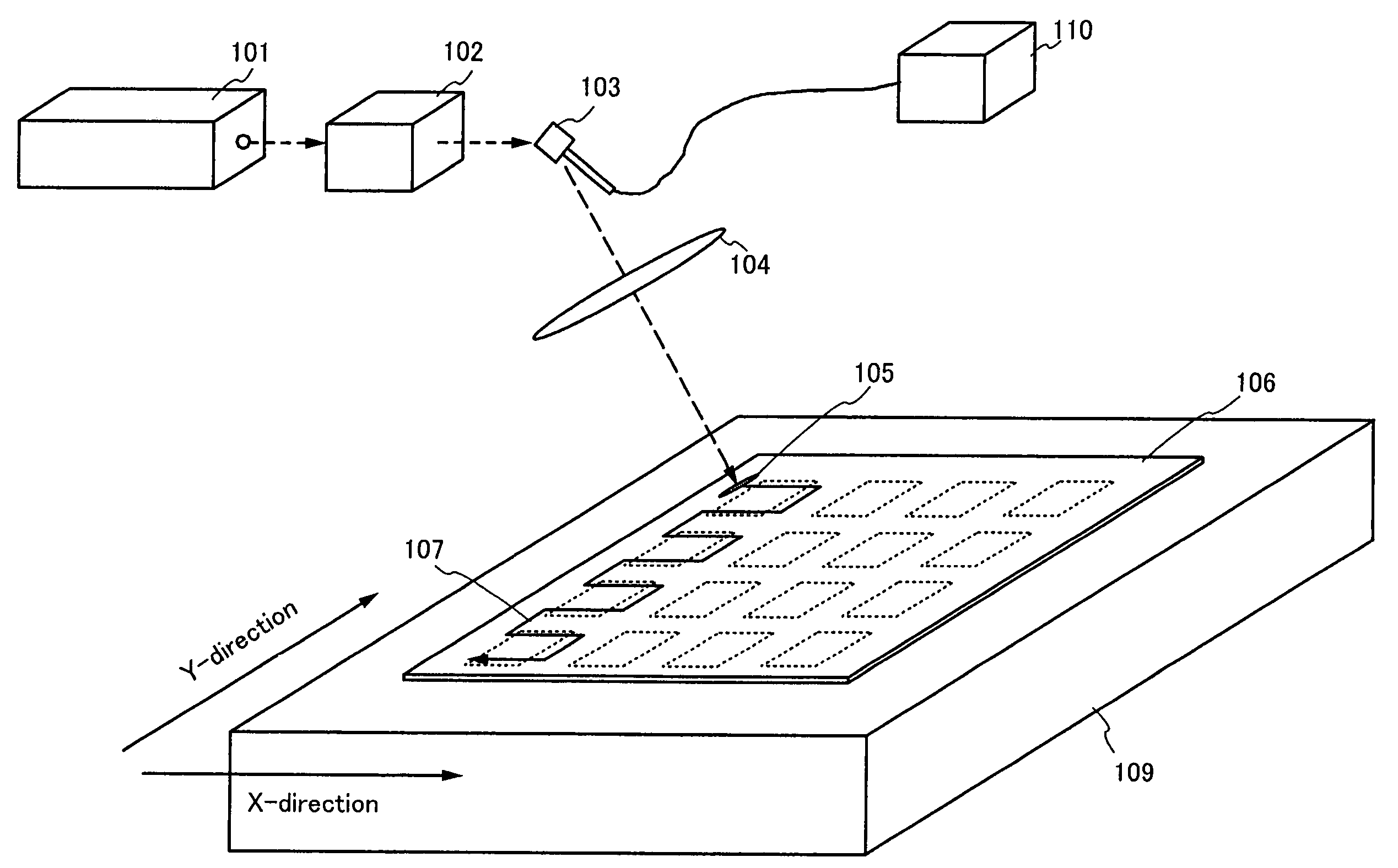

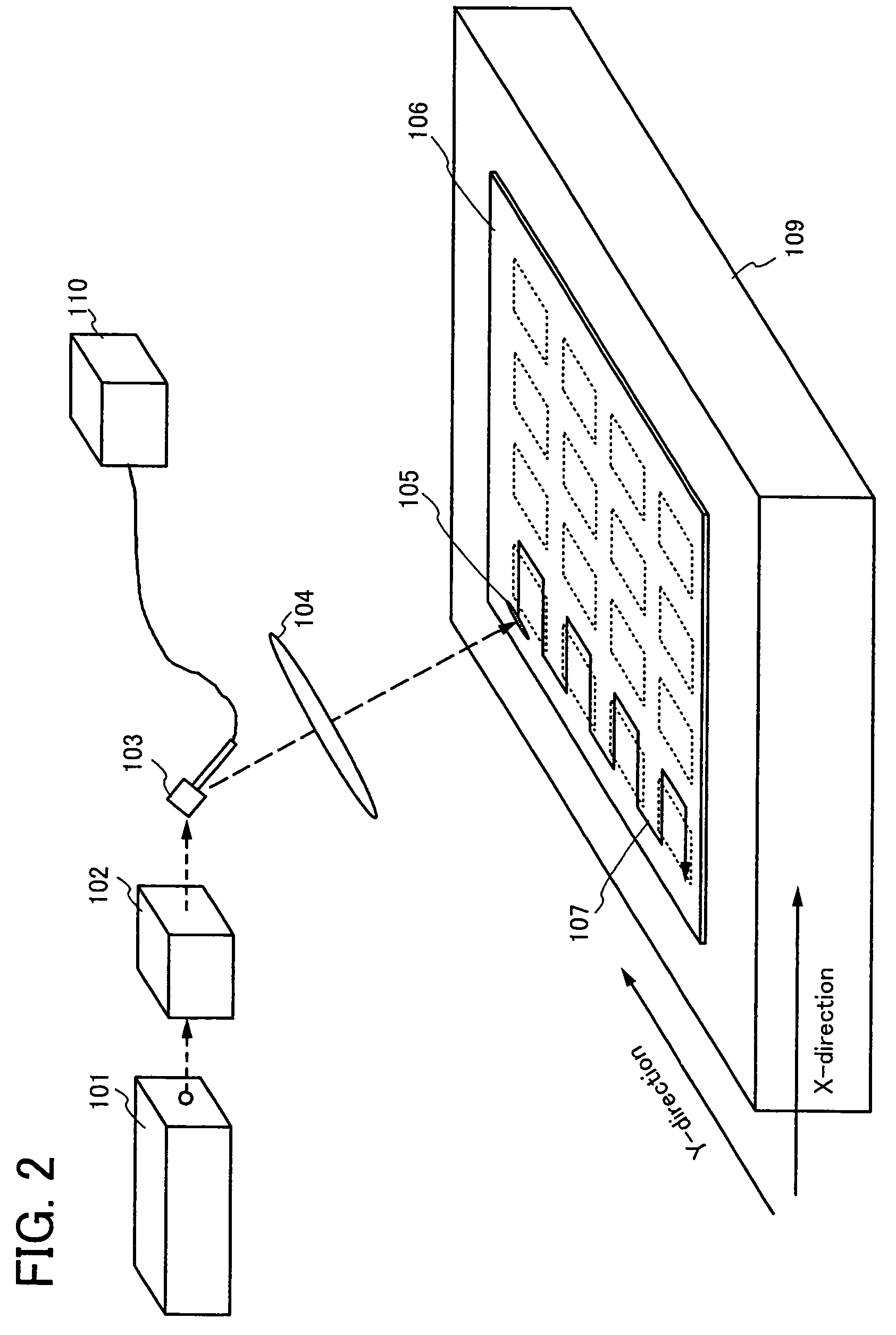

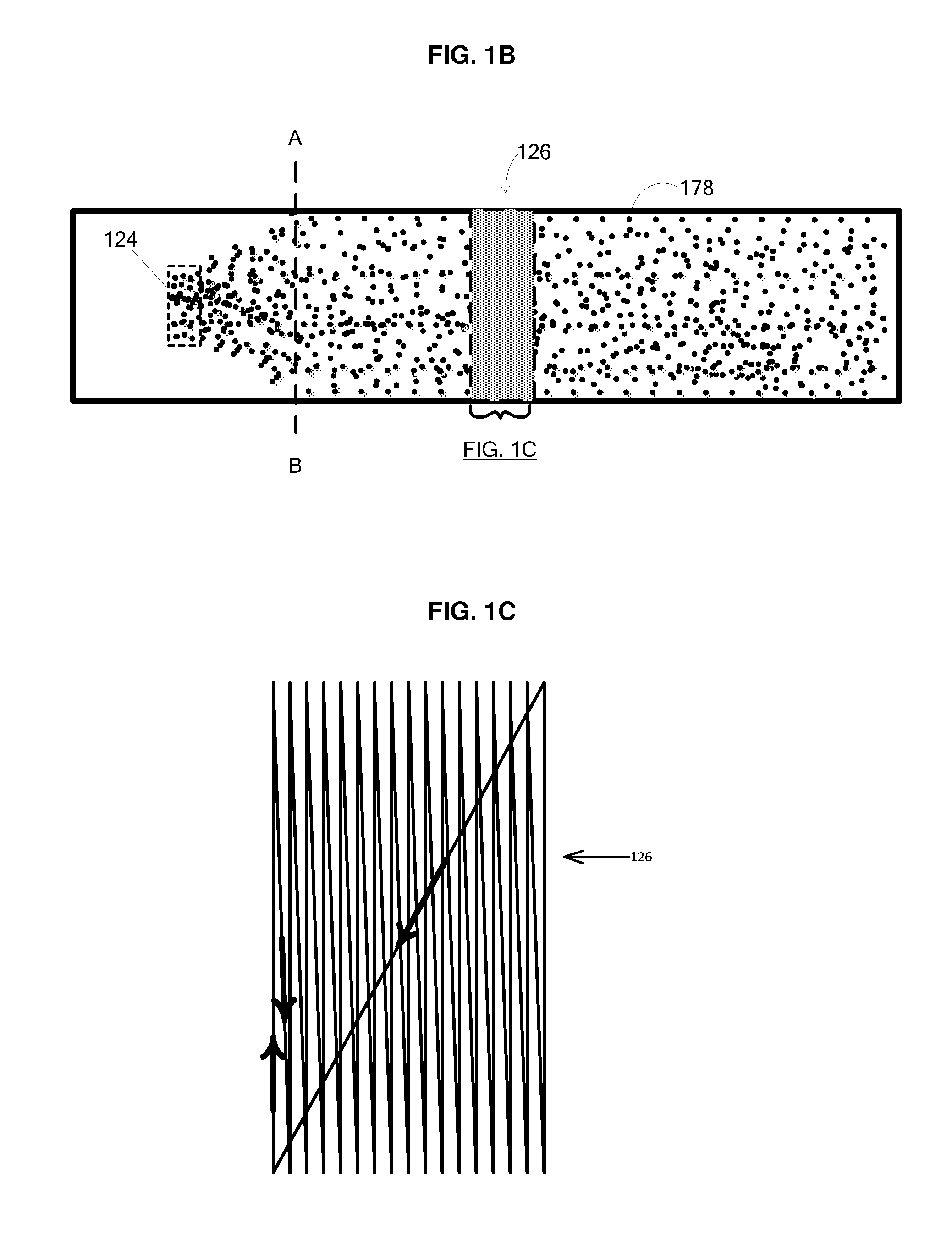

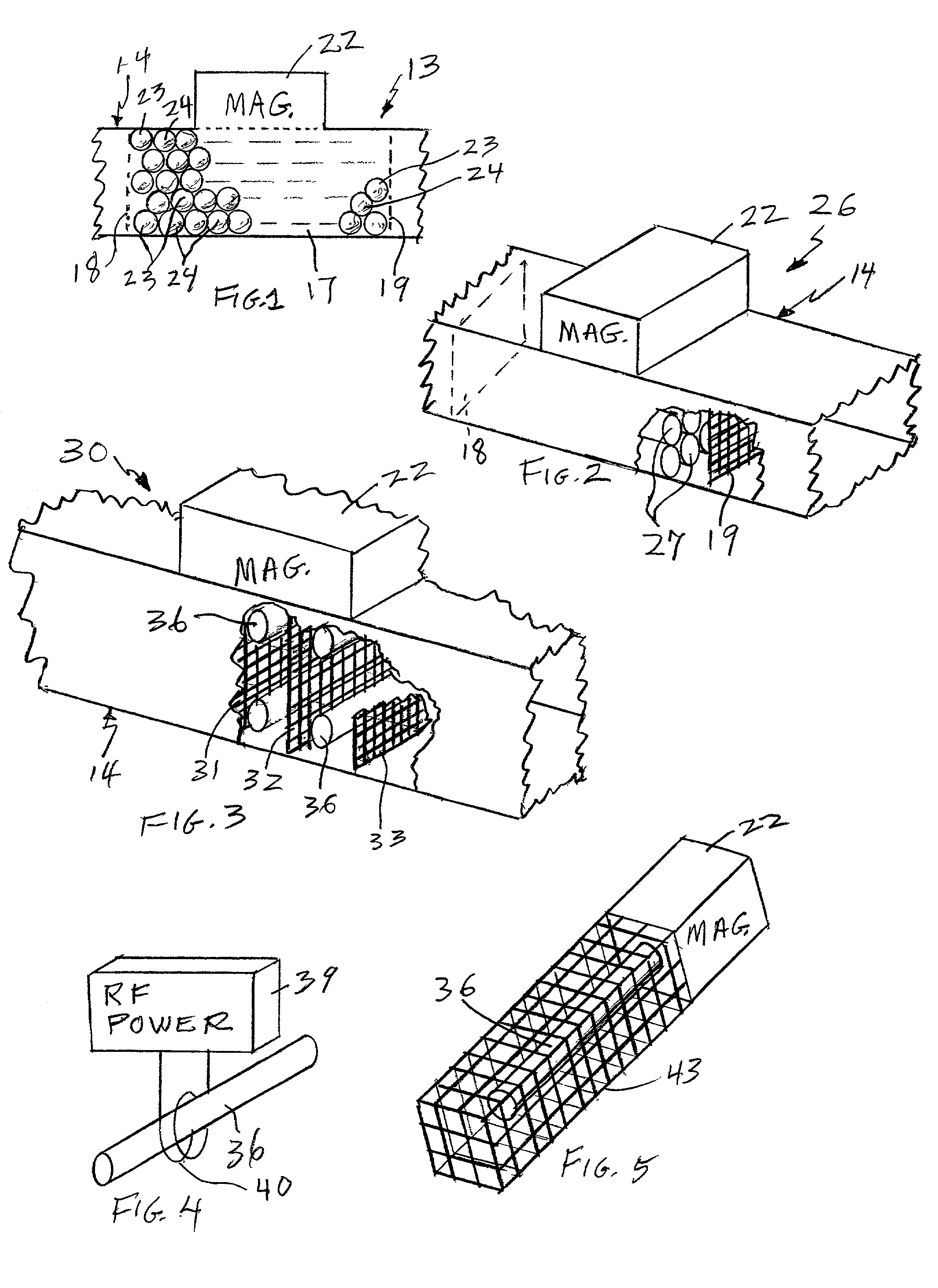

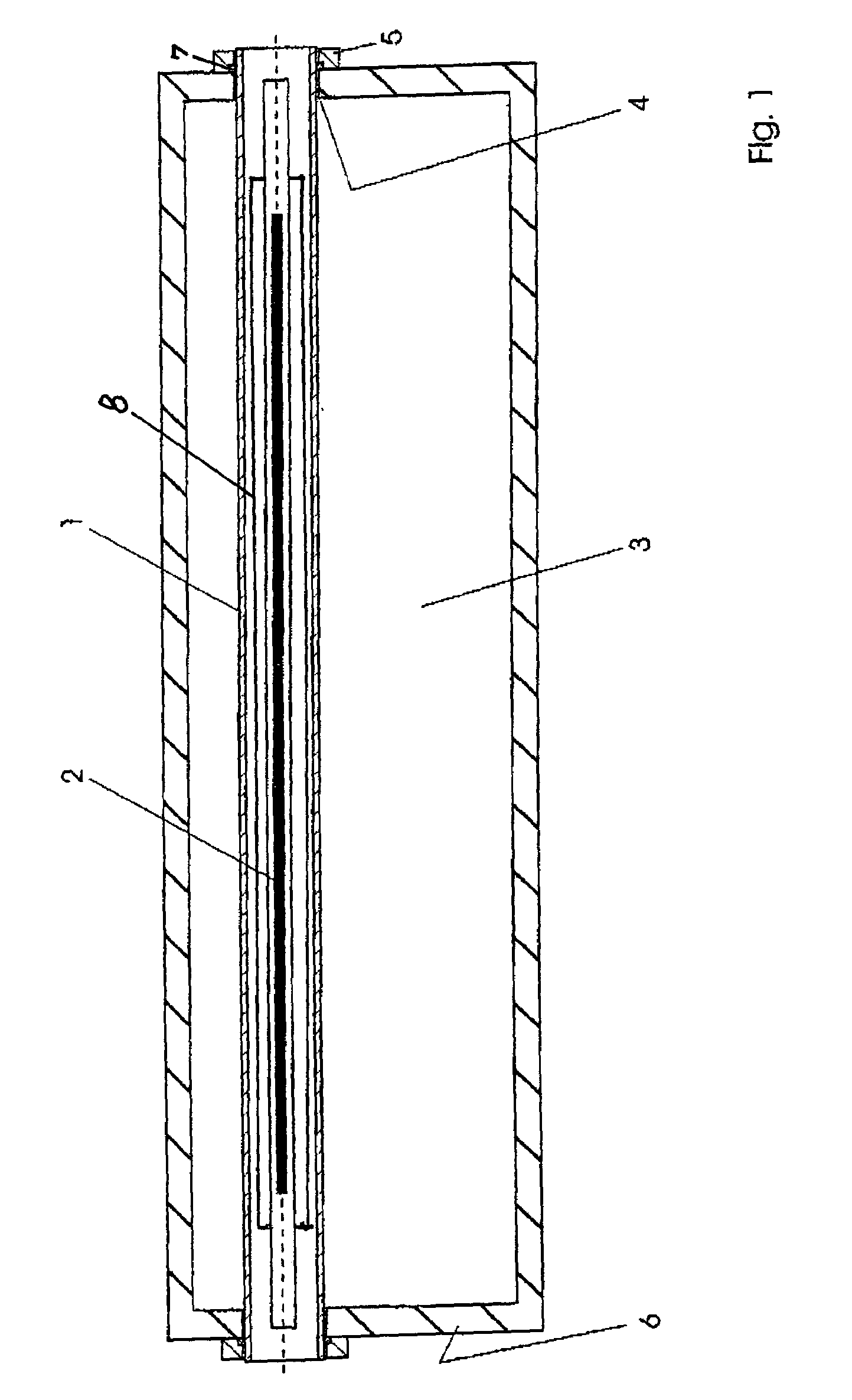

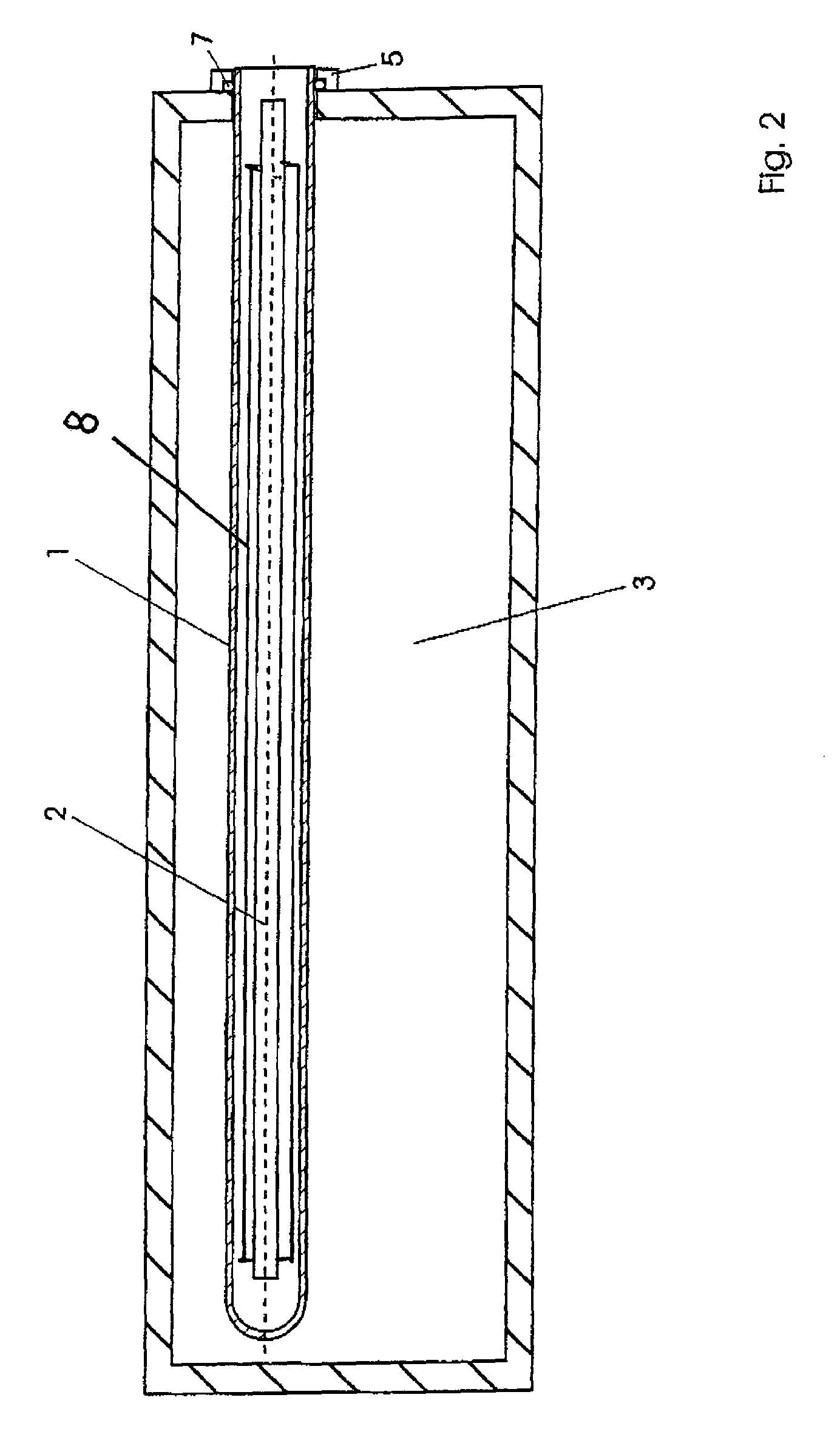

Described herein are integrated systems for generating neutrons to perform a variety of tasks including: on-line analysis of bulk material and industrial process control (as shown in FIG. 1), security interrogation (as shown in FIG. 2), soil and environmental analysis, and medical diagnostic treatment. These systems are based on novel gas-target neutron generation which embodies the beneficial characteristics of replenishable fusible gas targets for very long lifetime, stability and continuous operation, combined with the advantageous features common to conventional accelerator neutron tubes including: on / off operation, hermetically sealed operation, and safe storage and transport. Innovative electron management techniques provide gas-target neutron production efficiencies that are comparable or surpass existing sources. The high-pressure high-resistance gaseous discharge is presented as a favorable gas-target neutron generator embodiment, combining ion source regions, accelerator regions, gas-target regions and electron management components within a single simple cost-effective device that is adaptable to various geometric configurations that provide specific neutron emission profiles for greater analysis capacity.

Owner:STARFIRE INDS MANAGEMENT

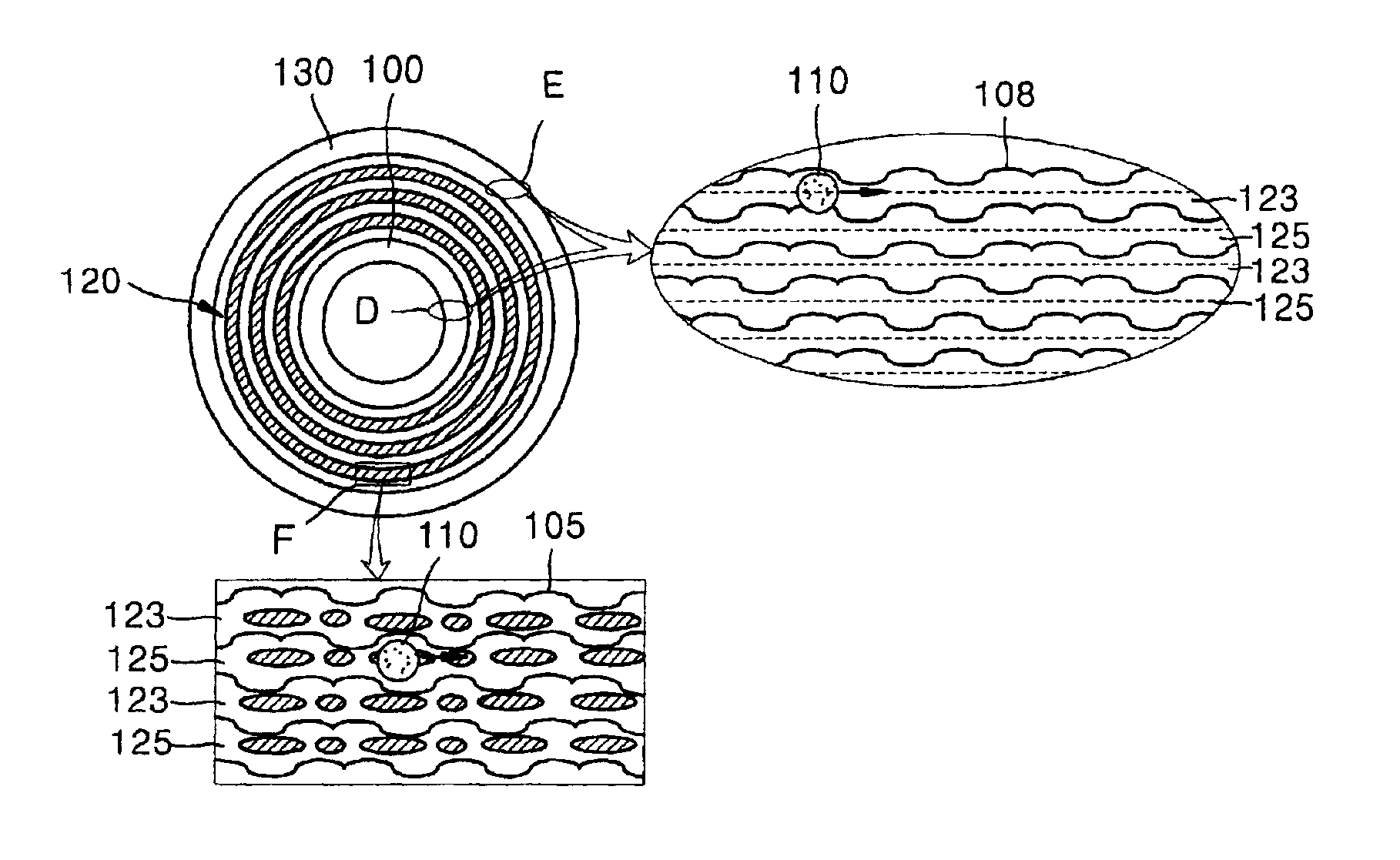

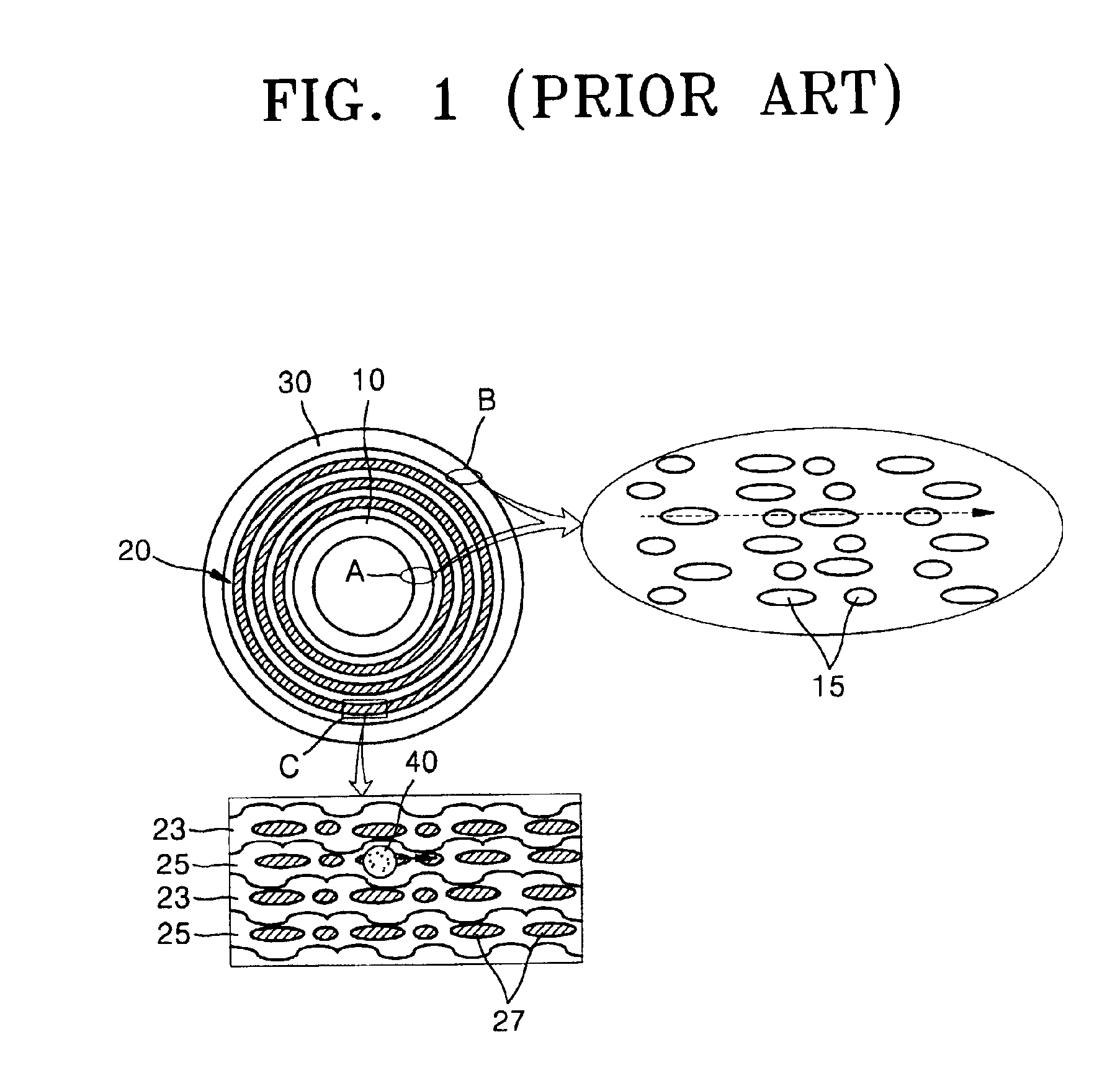

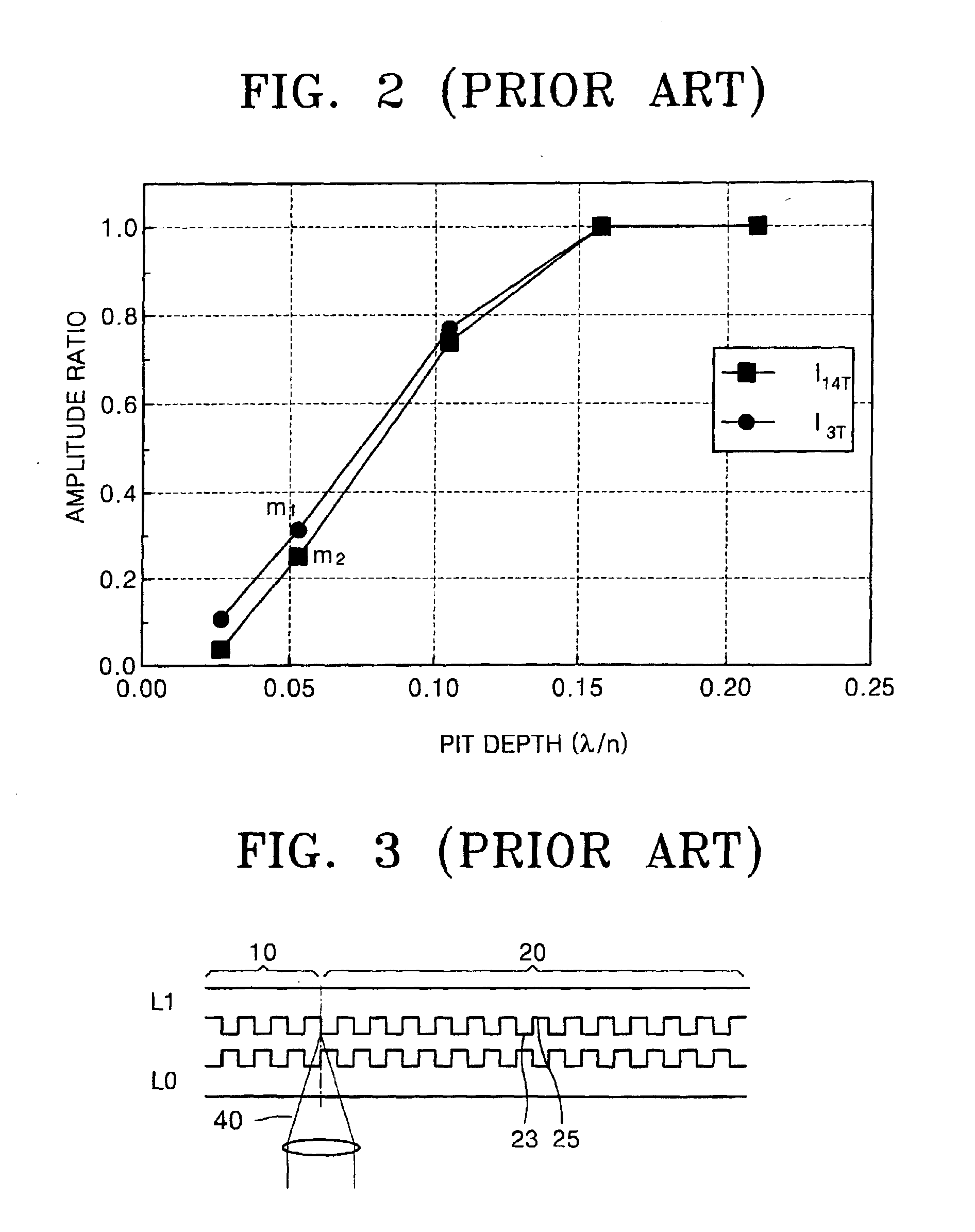

Optical disc having uniform structure

InactiveUS7065015B2Increase productionReduce manufacturing costFilamentary/web record carriersRecord information storageManufacturing cost reductionEngineering

An optical disc is manufactured under a uniform condition by forming grooves and lands on the entire surface of the disc. The optical disc is configured to obtain a reliable reproduction signal, and the grooves and lands are formed on a lead-in area, a user data area and a lead-out area of the optical disc. Since the same manufacturing condition can be adopted in mastering discs, the yield can be enhanced and the manufacturing cost can be reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

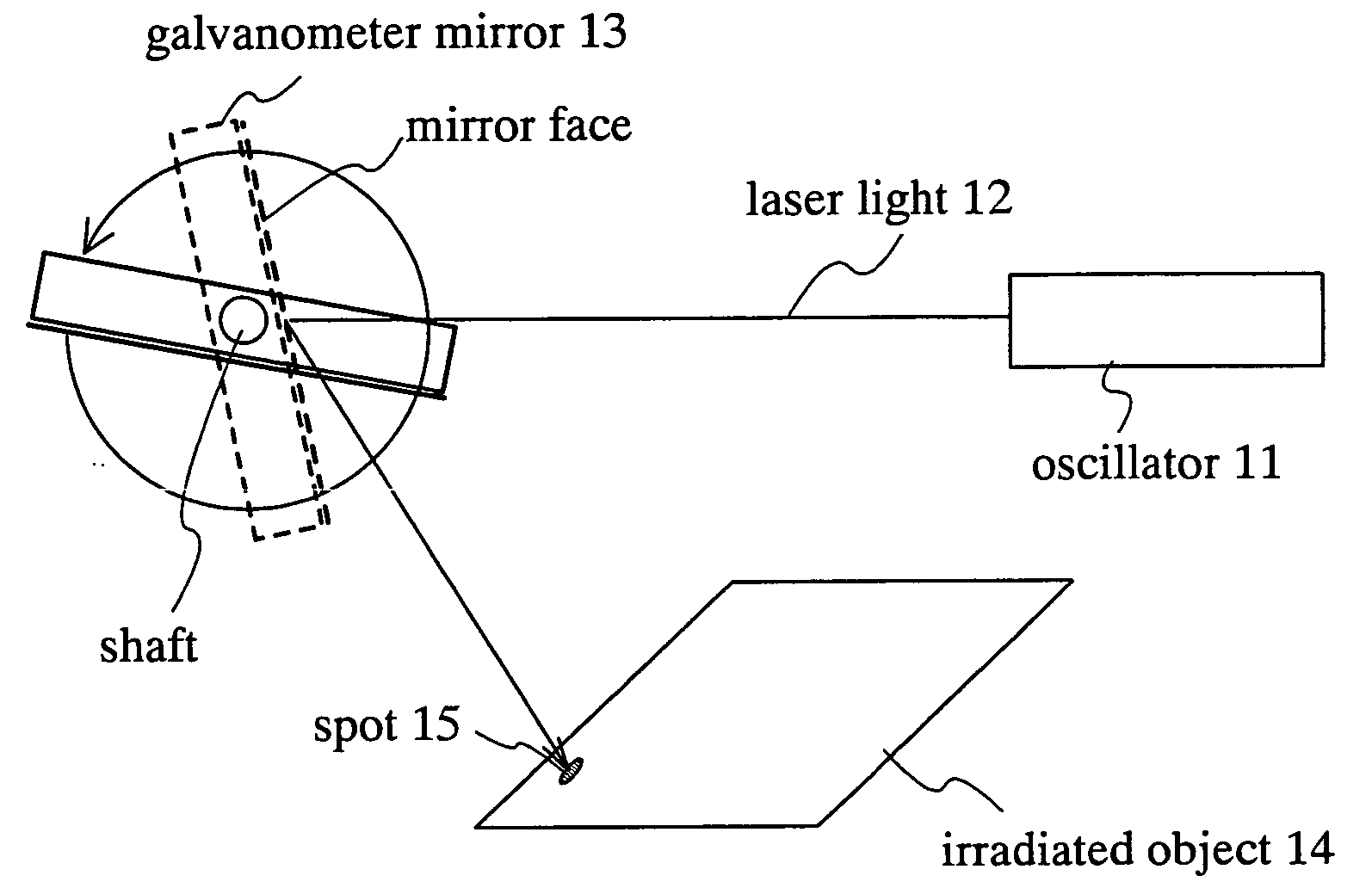

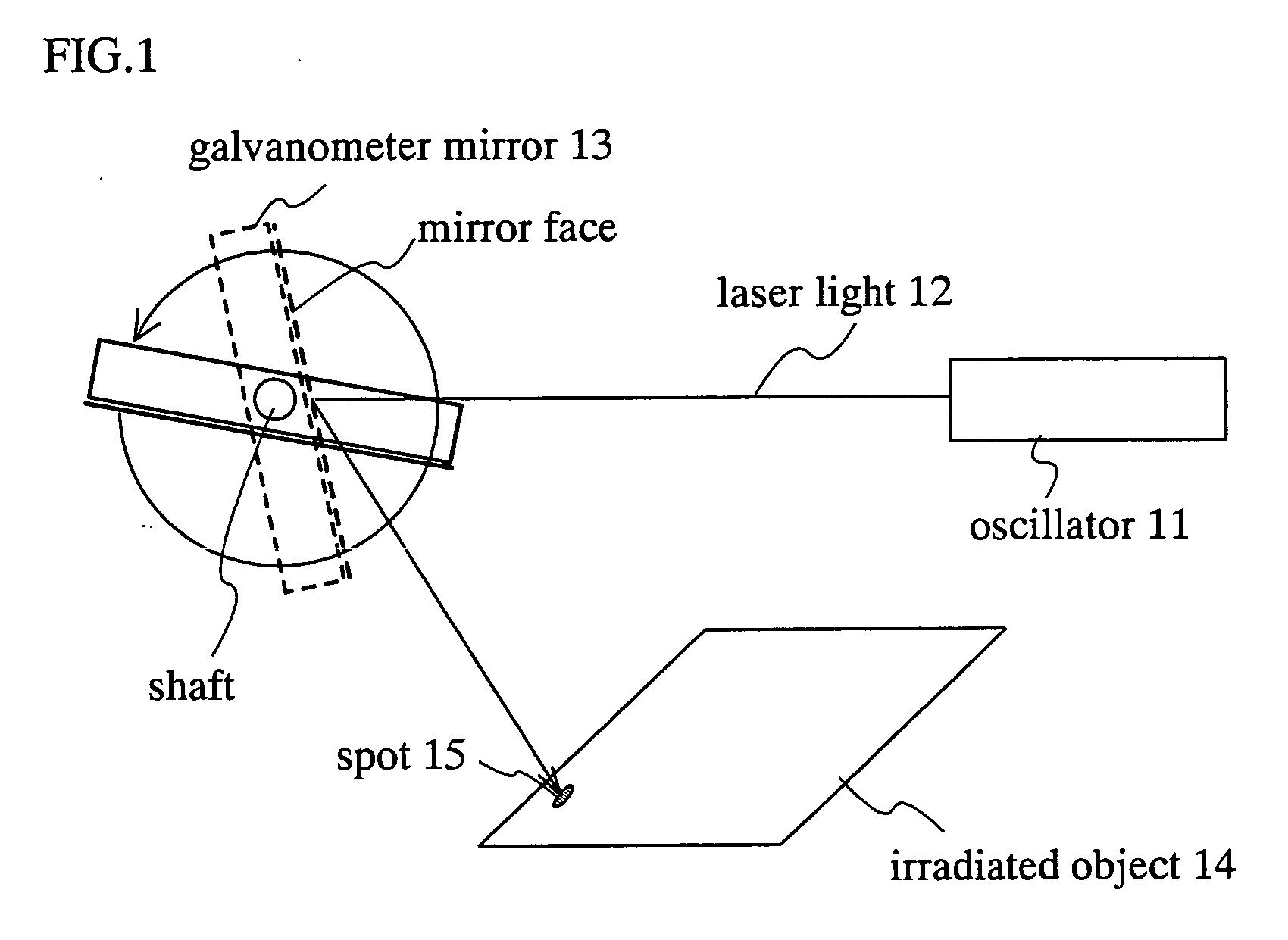

Beam irradiation apparatus, beam irradiation method, and method for manufacturing a thin film transistor

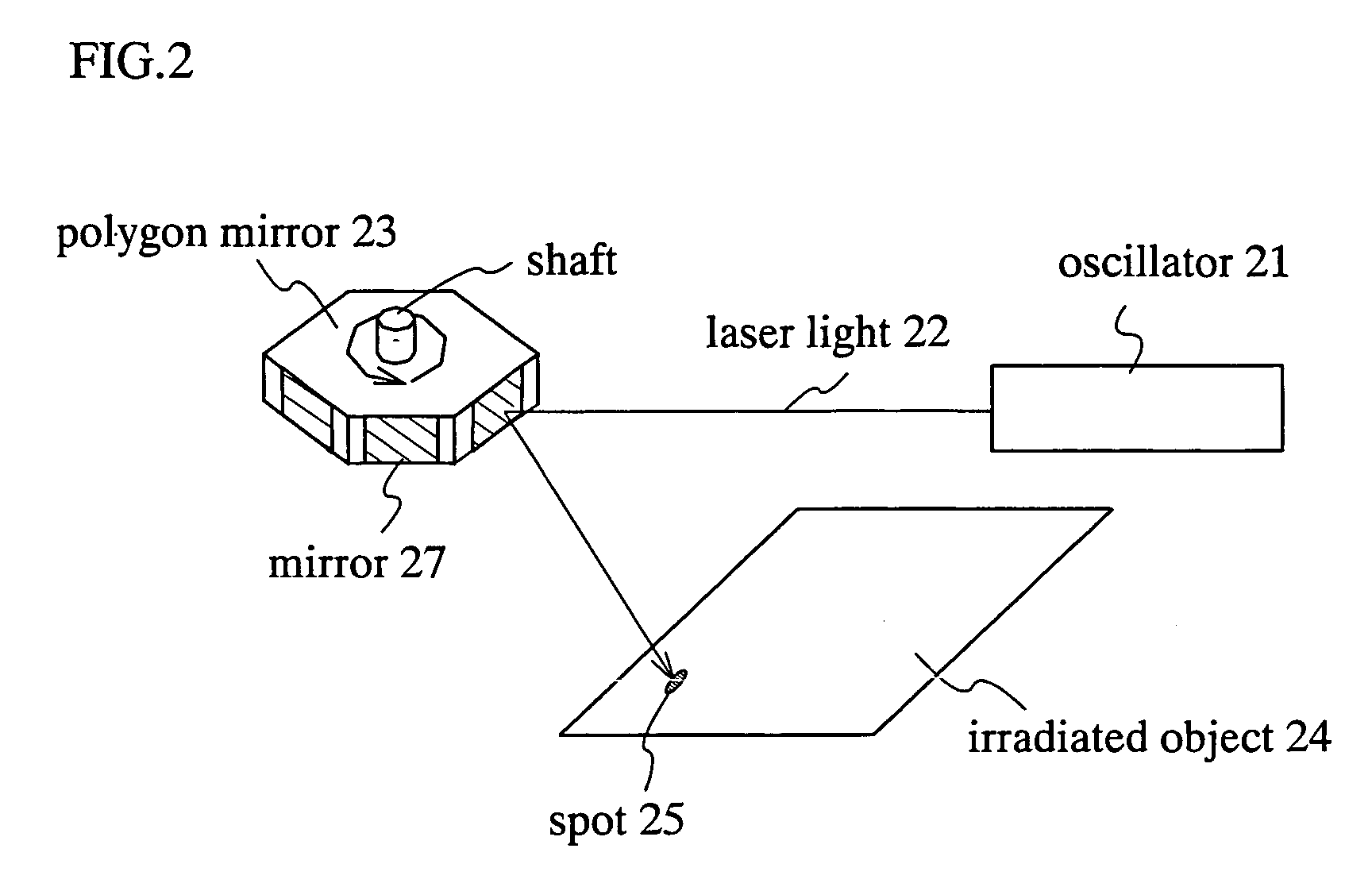

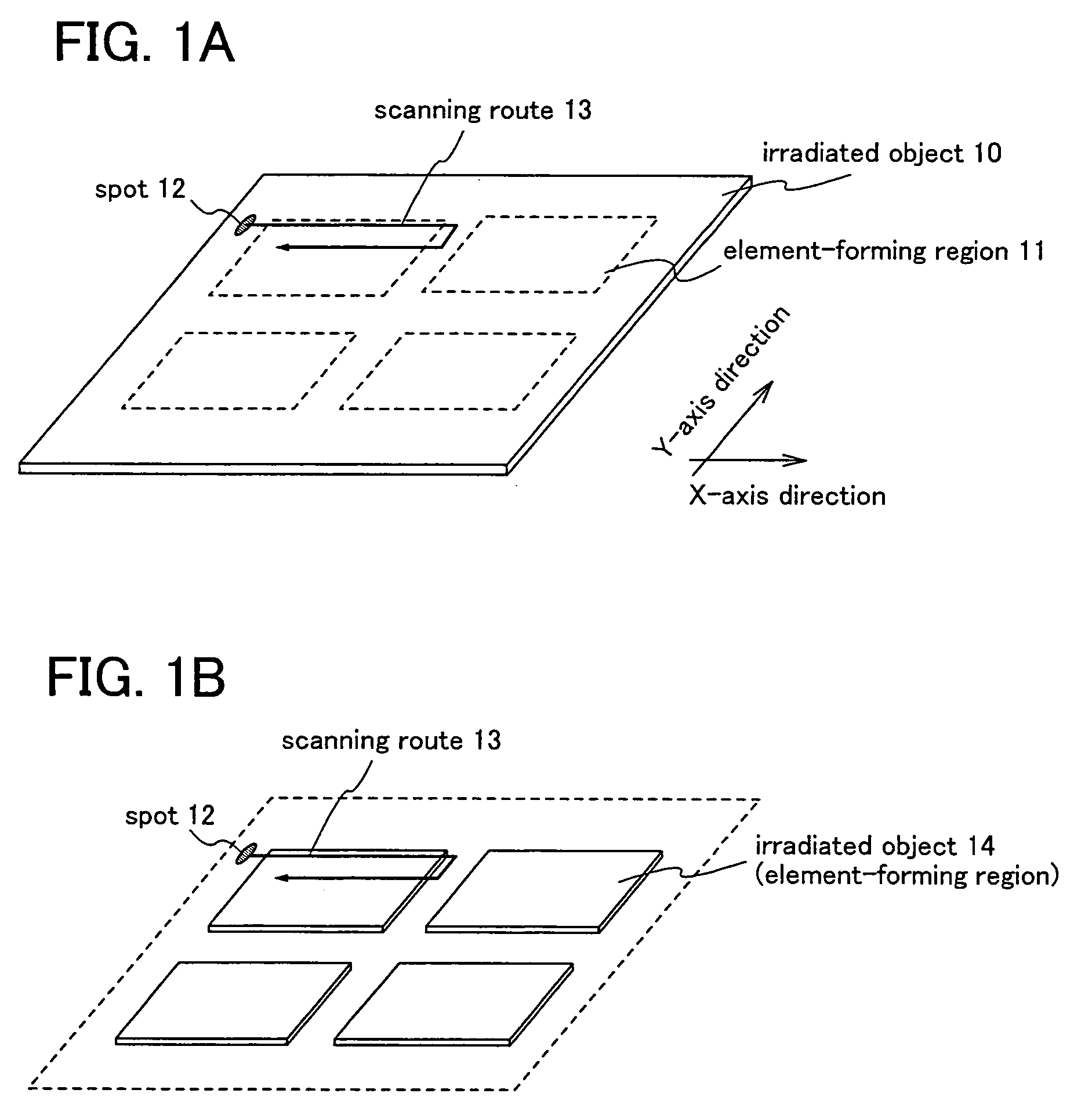

InactiveUS20050036190A1Uniform crystallinityUniform characteristicsLaser beam welding apparatusOptical elementsGalvanometerLight beam

A galvanometer mirror rotates in one direction when the galvanometer mirror is used. A spot can be scanned on an irradiated surface at a more constant speed by rotating the galvanometer mirror and by using the inertia. Moreover, it is preferable to make the galvanometer mirror heavy because the inertia becomes higher so that the spot is scanned at a more constant speed. In addition, in a polygon mirror of this invention, mirrors are arranged so as not to contact each other because a change time of the scanning position between the mirrors is provided. By moving the irradiated object with timing together when the laser light is not irradiated, the laser process can be performed efficiently.

Owner:SEMICON ENERGY LAB CO LTD

Methods for tissue irradiation with shielding

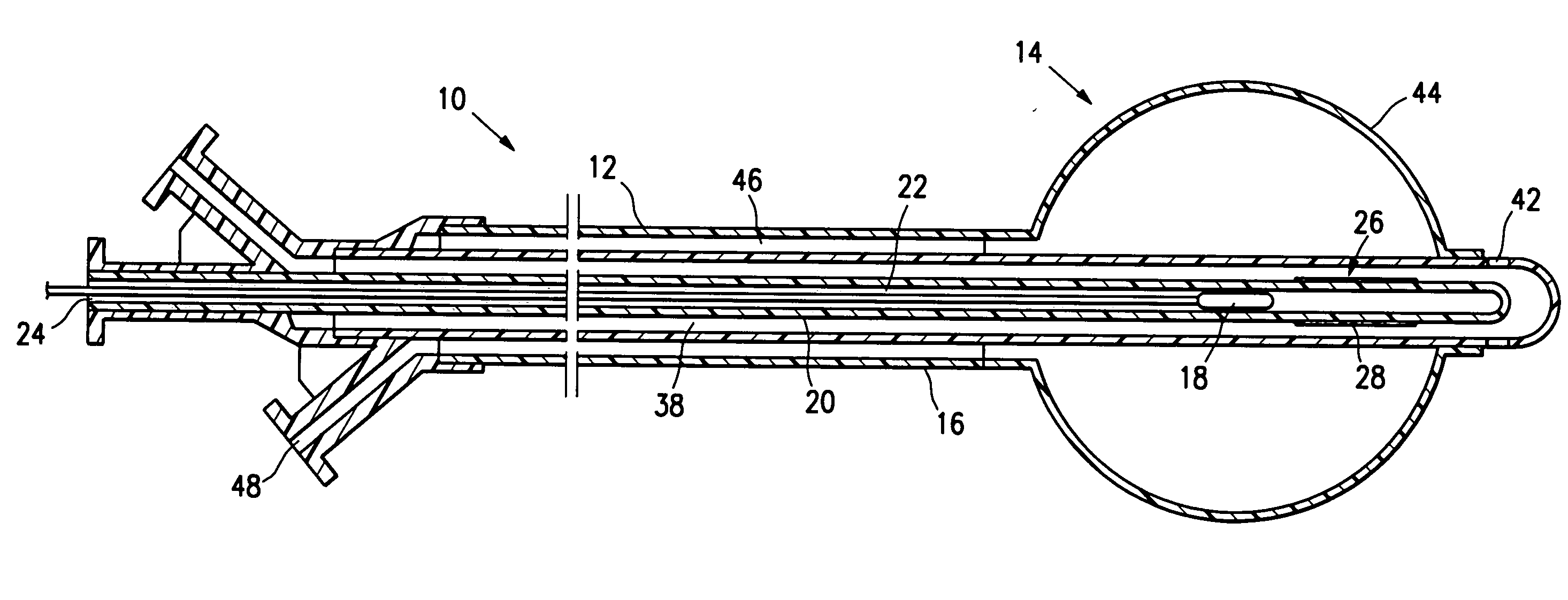

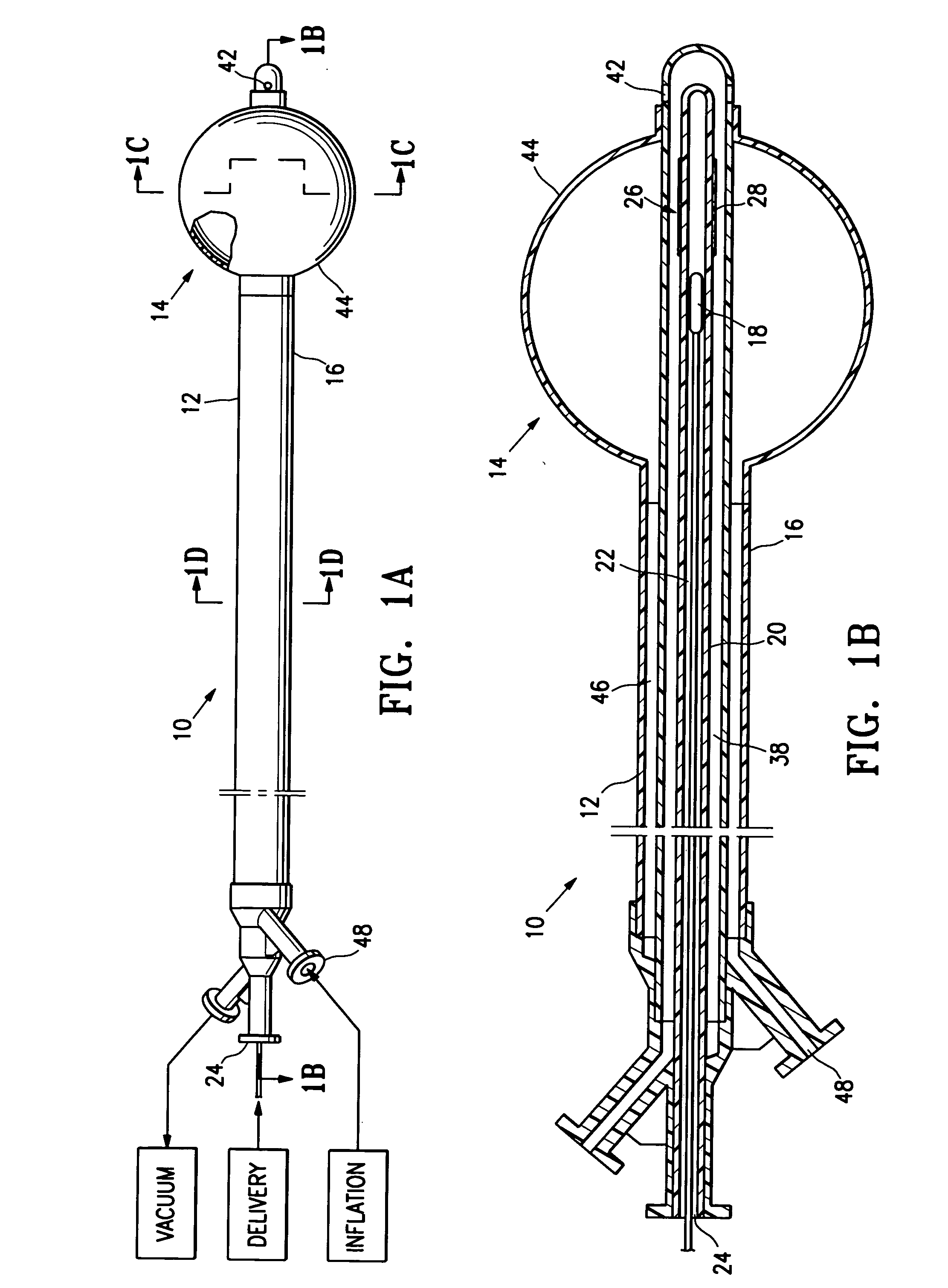

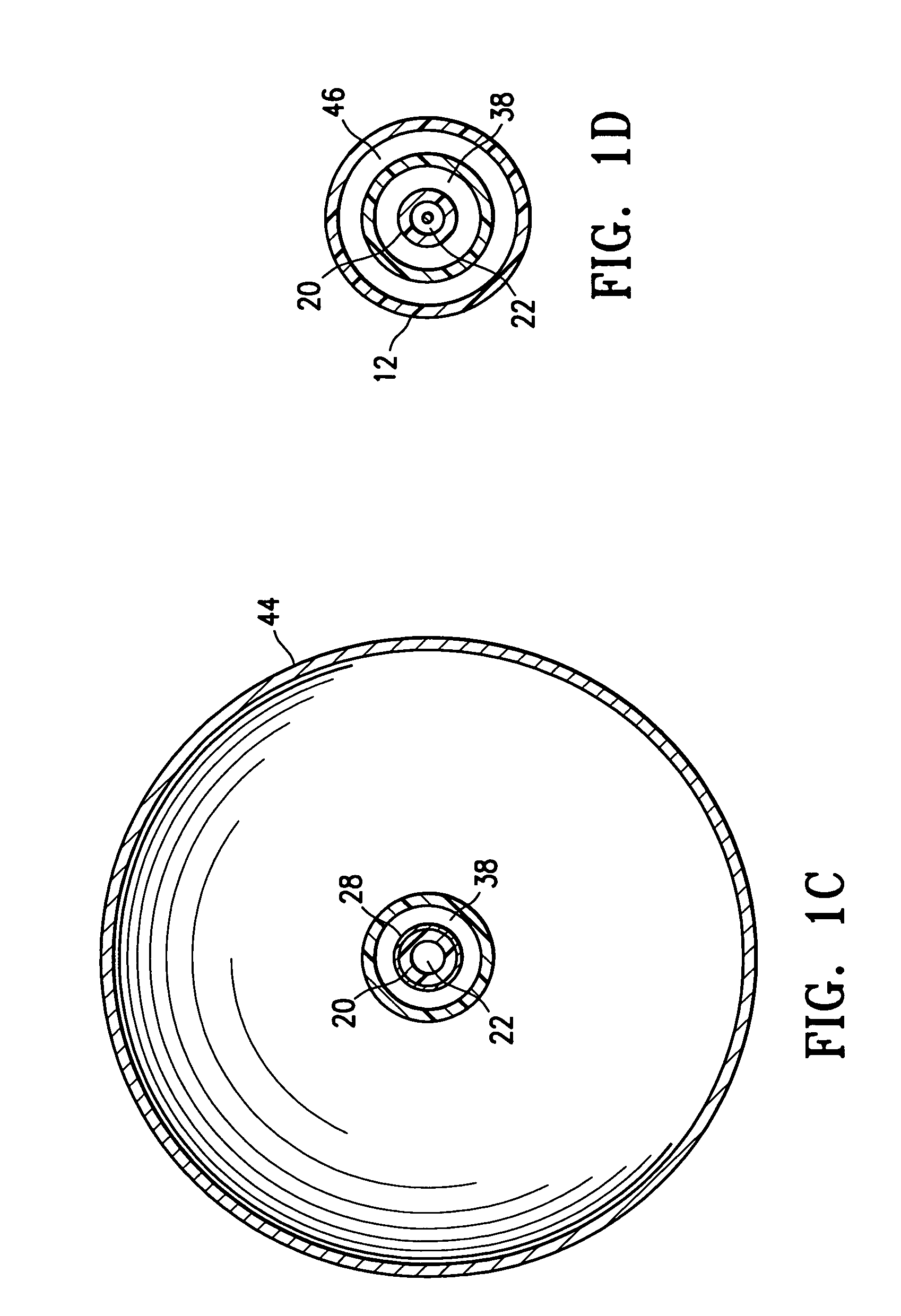

InactiveUS20070191667A1Reduce and minimize damaging irradiationUniform irradiationCannulasX-ray/gamma-ray/particle-irradiation therapyDistal portionRadiation damage

Devices and methods are disclosed for treatment to tissue surrounding a body cavity or other intracorporeal site, such as after removal of tissue, e.g. cancer. Such a device includes a treatment location on a distal portion of the device with one or more radiation shielding components that partially encircle a radiation source at the treatment location to control emitted radiation from the radiation source. The device minimizes radiation damage to healthy tissue surrounding the body cavity or other site while irradiating tissue not shielded by the radiation shielding components. A device embodying features of the invention can include a sealing member at a location on a shaft of the device proximal to a treatment location to seal the passageway leading to the body cavity.

Owner:HOLOGIC INC

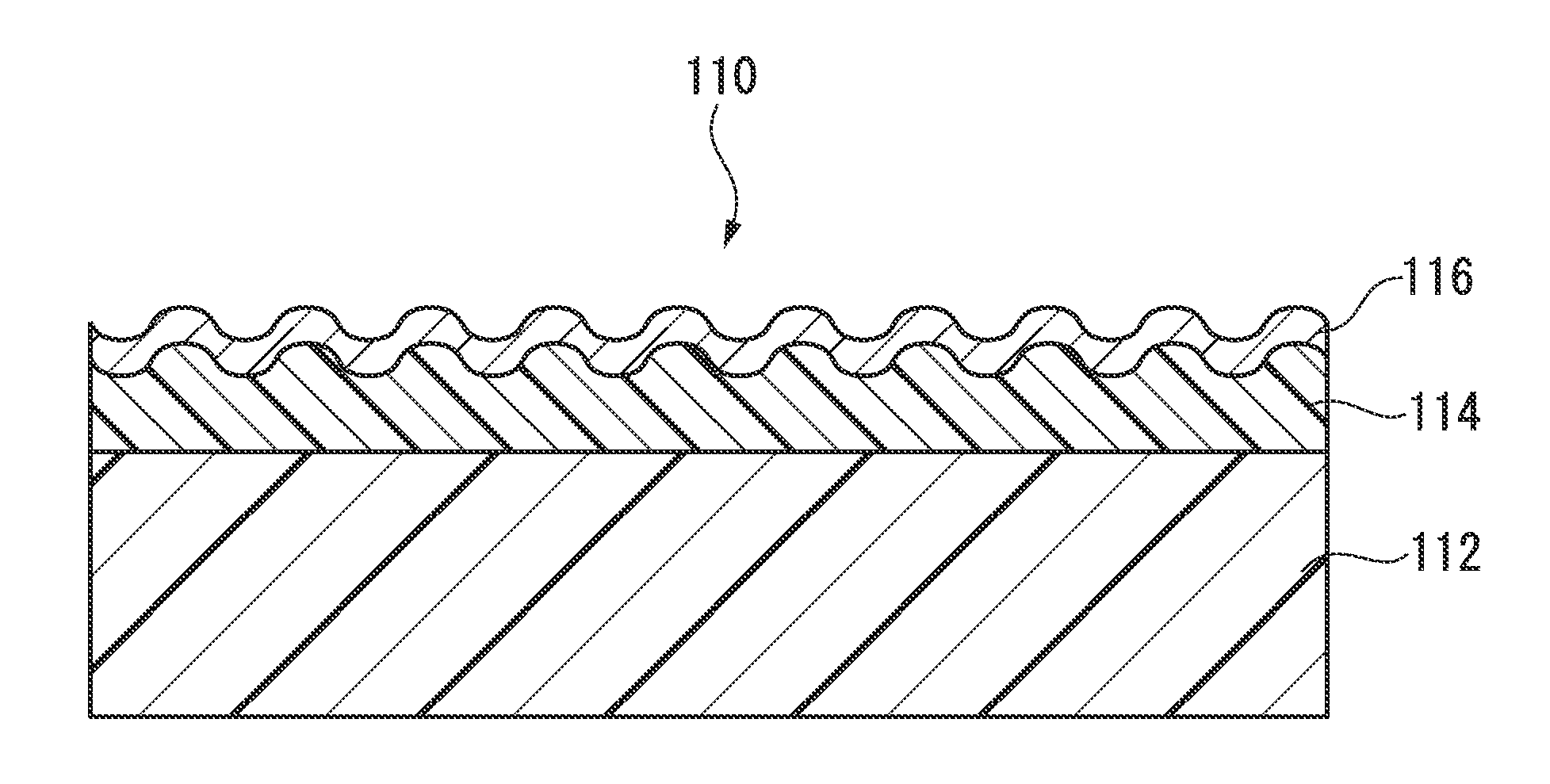

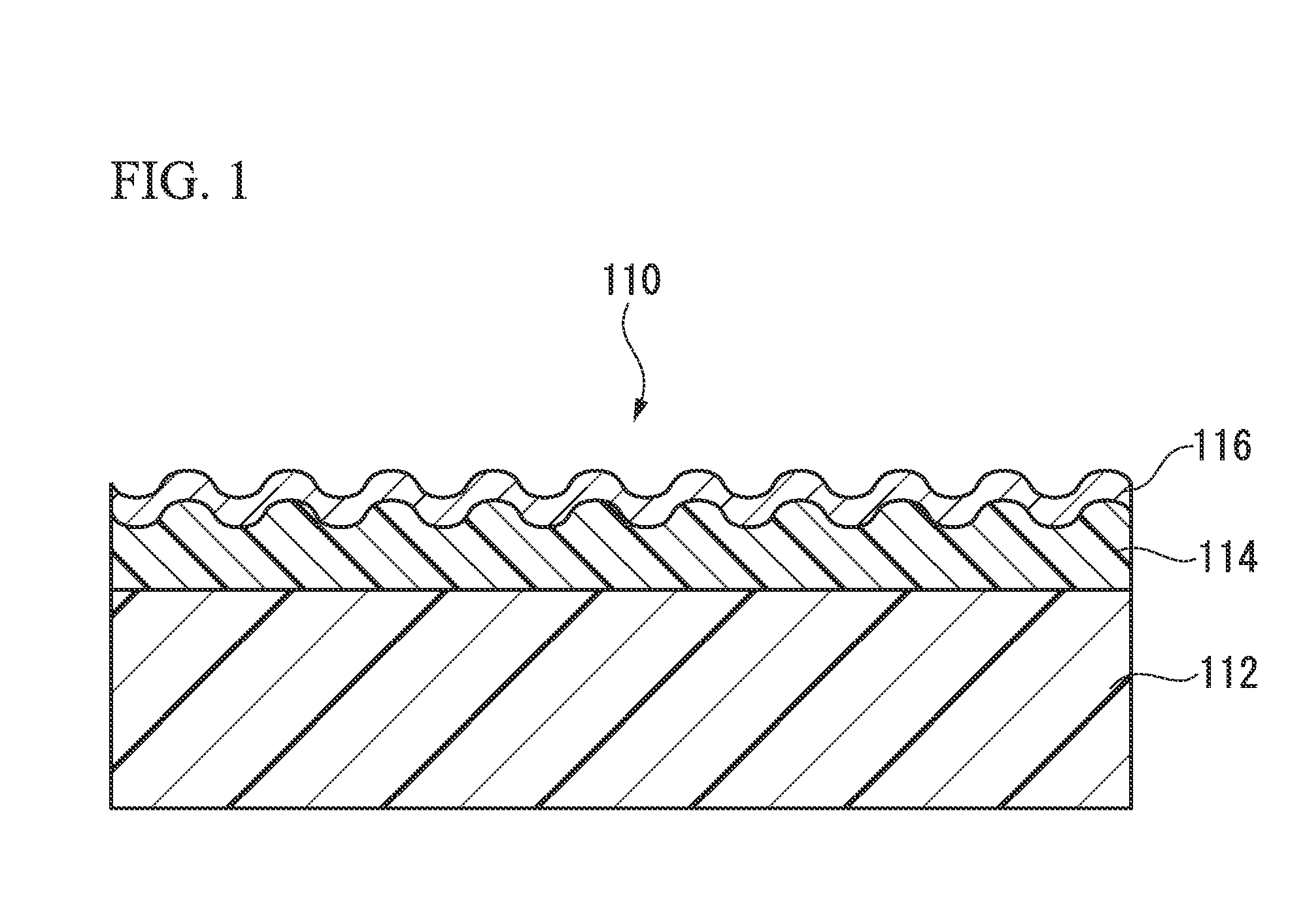

Mold having fine uneven structure in surface, method of manufacturing article having fine uneven structure in surface, use of article, laminated body expressing iris color, and surface-emitting body

InactiveUS20130186467A1Excellent adhesivenessStably manufacturedFinal product manufactureConfectioneryOptoelectronicsSurface roughness

A mold having an uneven structure is provided, wherein surface roughness Ra of the uneven structure, a maximum value Ra′(max) and a minimum value Ra′(min) of line roughness Ra′ satisfy the following Expression (1).0.13≦(Ra′(max)−Ra′(min)) / Ra≦0.82 (1)

Owner:MITSUBISHI RAYON CO LTD

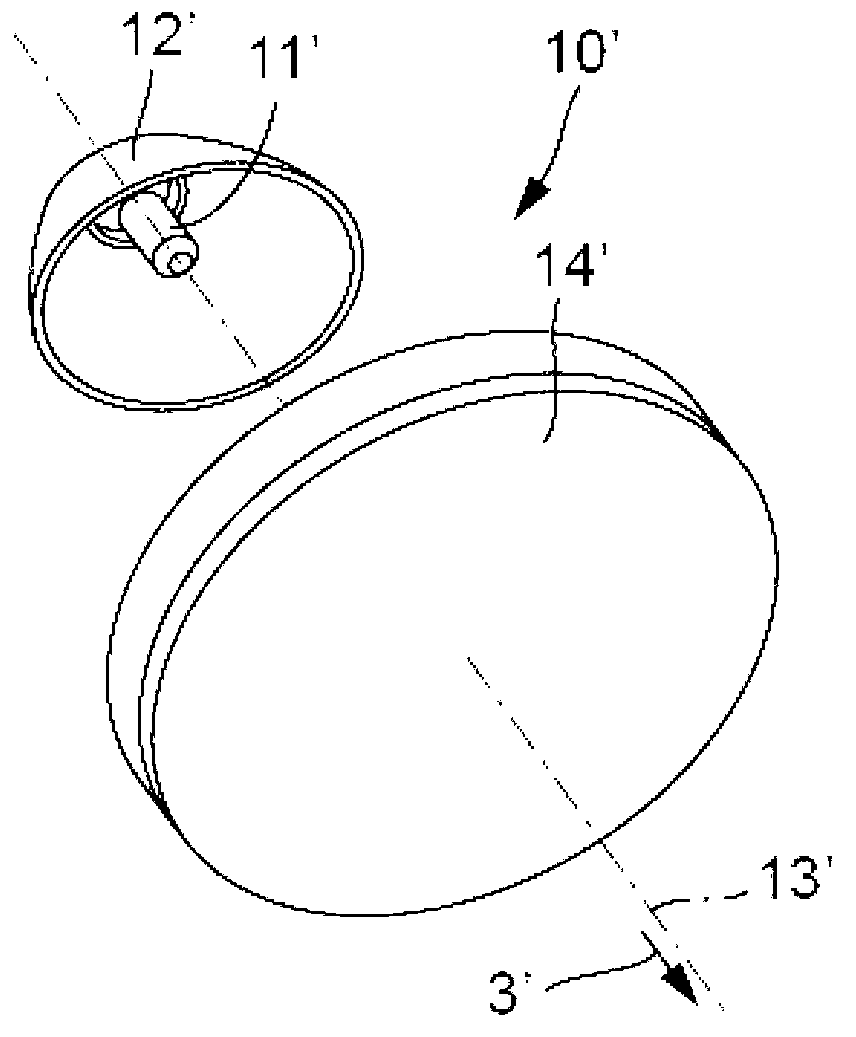

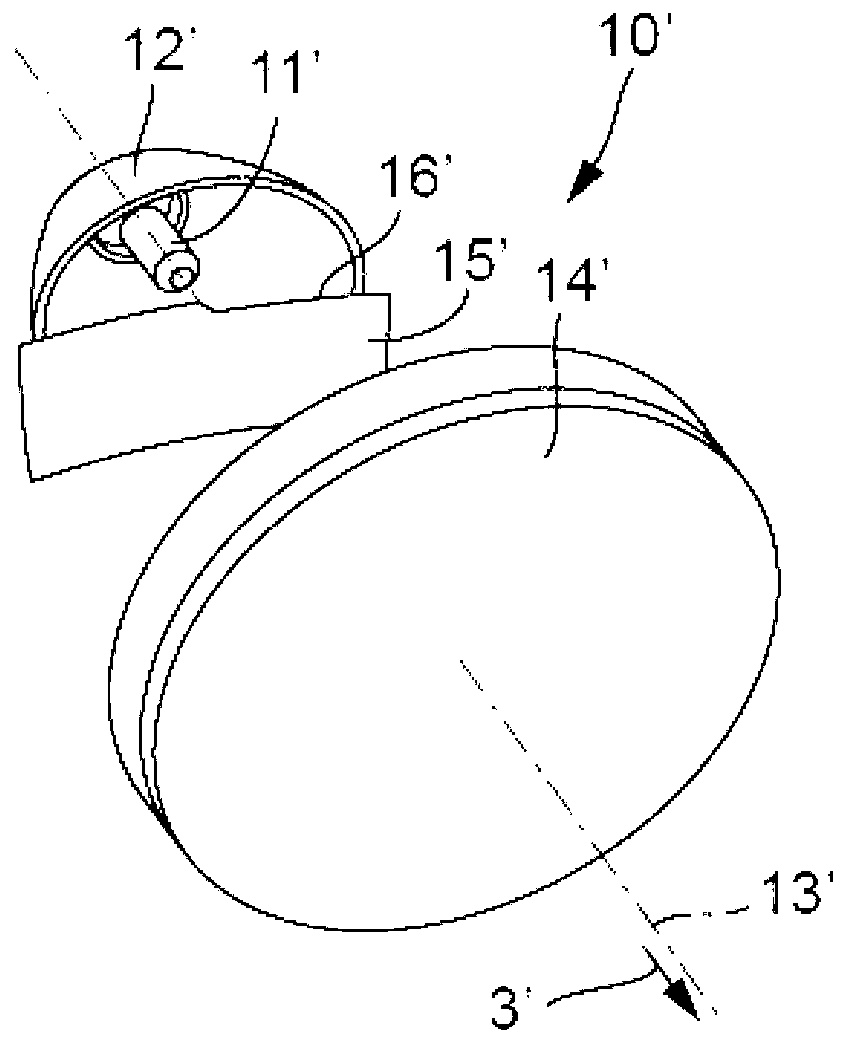

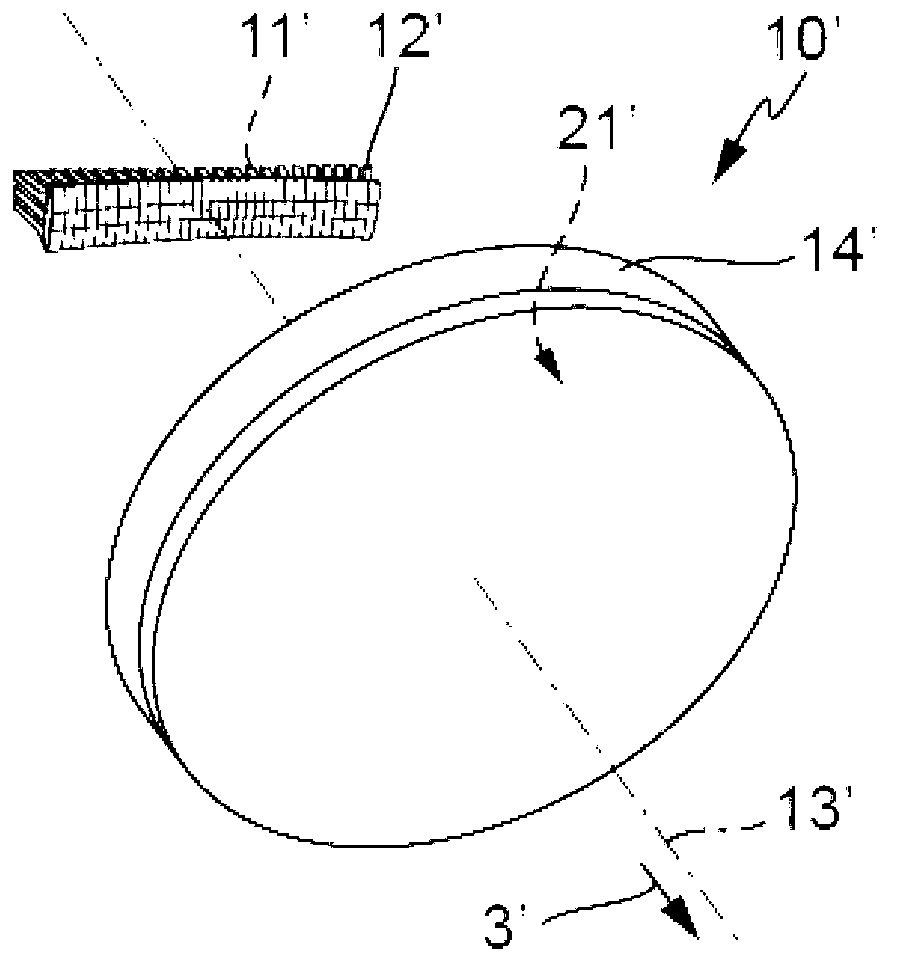

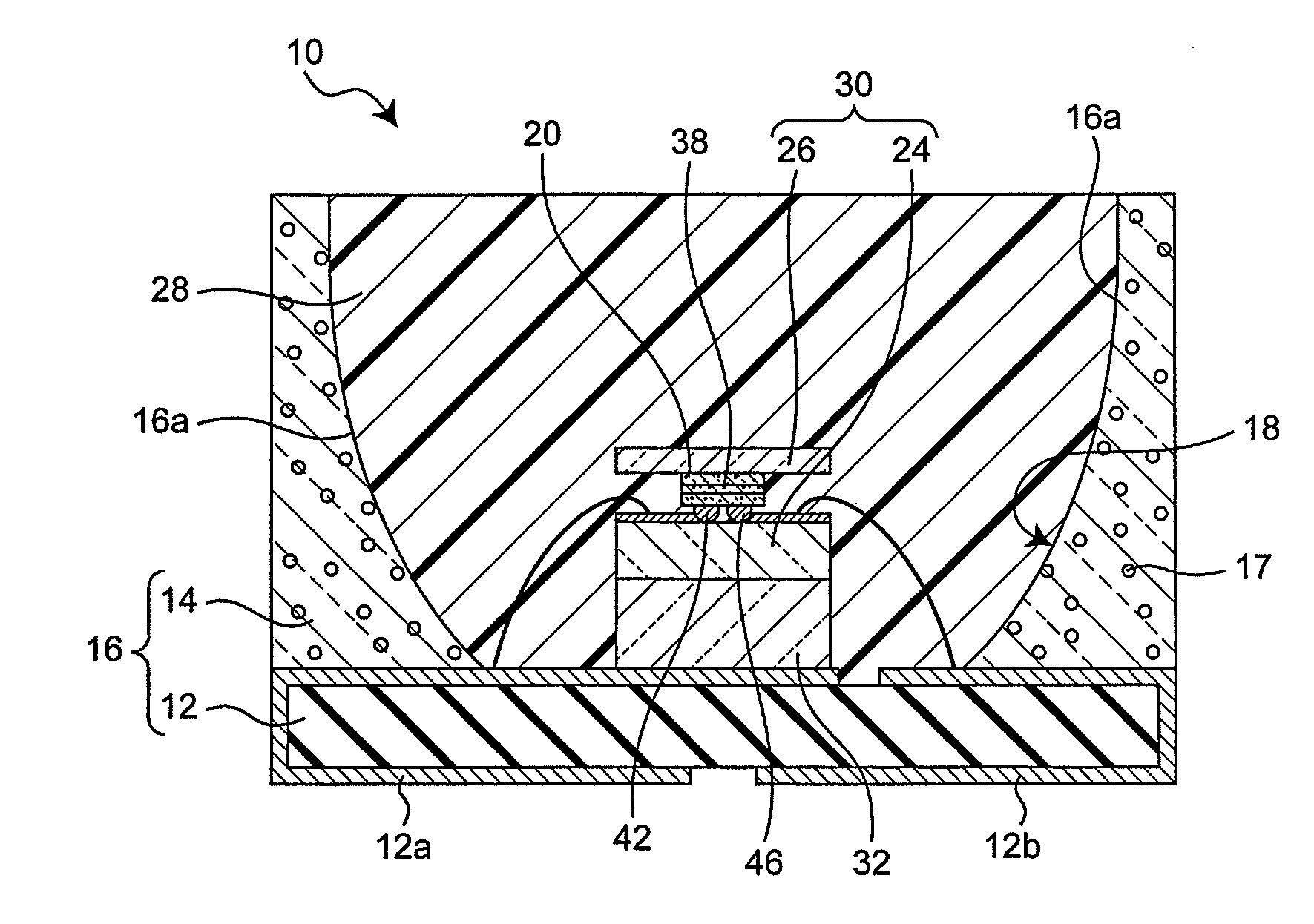

Headlight projection module for a motor vehicle

ActiveCN103090286AIncrease designEasy to illuminateVehicle headlampsPoint-like light sourceStructural elementOptical pathlength

The invention relates to a headlight projection module (10) for a vehicle, which is used for generating preset light distribution. The headlight projection module (10) has a light source (11) for emitting light, a primary lens (12) for concentrating a part of the emitted light, and a secondary lens (14) for projecting a part of the concentrated light in a light emitting direction (3) of the projection module. In order to enable the headlight projection module (10) to realize maximally effective structure and to illuminate a non-circular secondary optical unit (14) as uniform as possible with the whole surface, it is suggested that an optically active micro-structure (24) that refracts light be arranged in the beam path of the concentrated light in a virtual object position of the secondary optical unit (14). The micro-structure (24) has dimensions of the function-determining structural elements (26, 27) in the micrometer range, especially a height difference of the single structural elements (26, 27).

Owner:AUTOMOTIVE LIGHTING REUTLINGEN GMBH

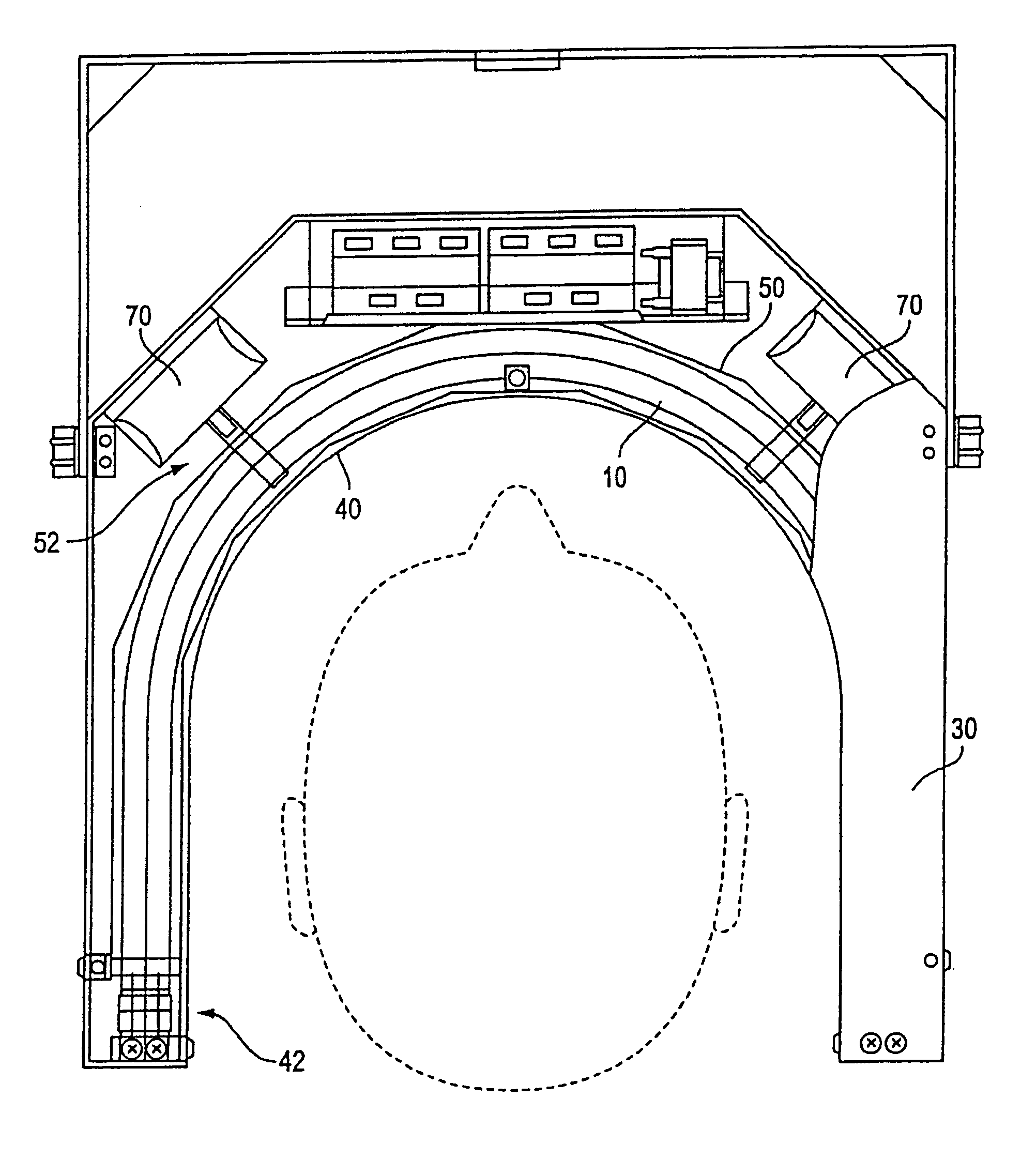

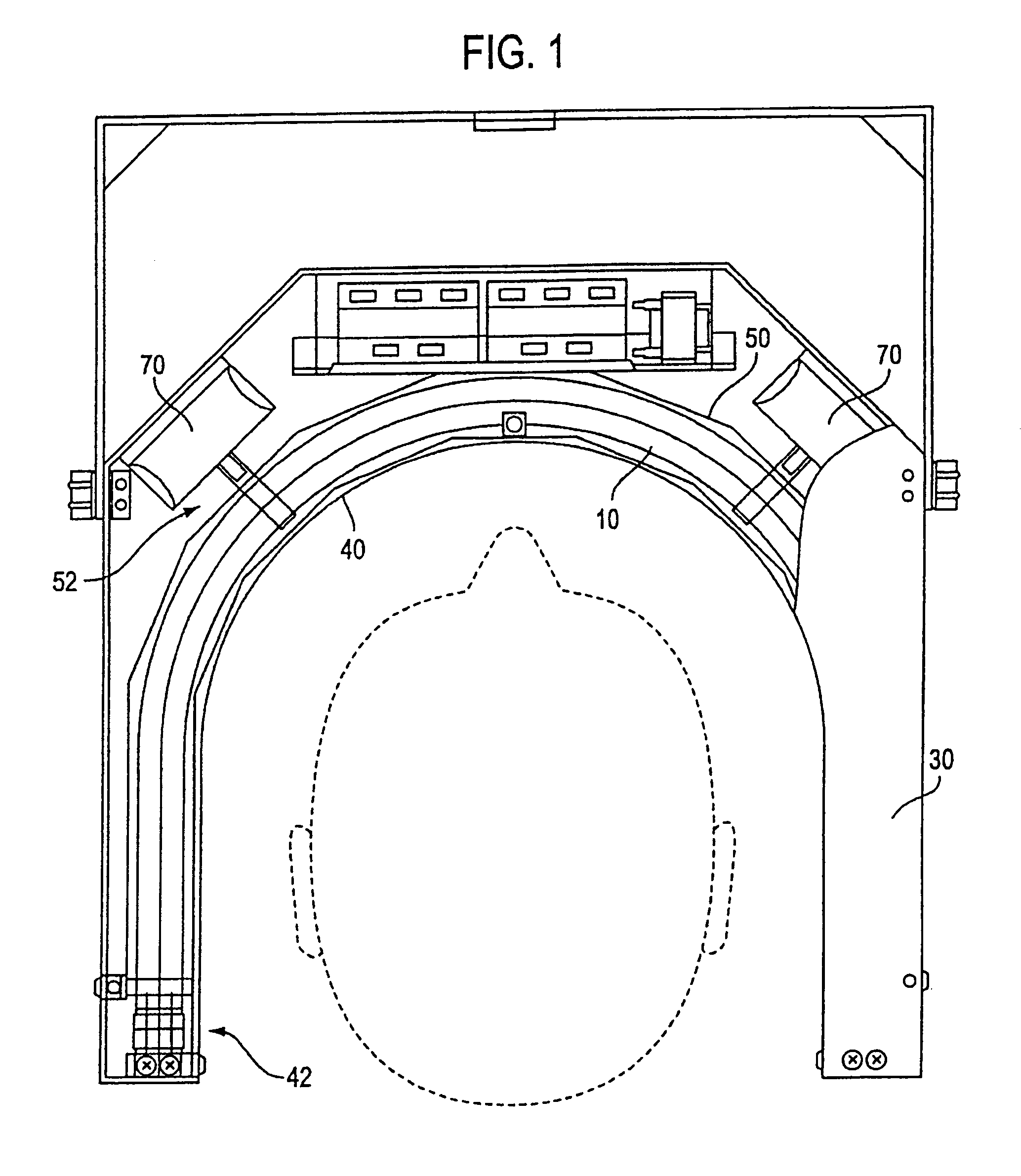

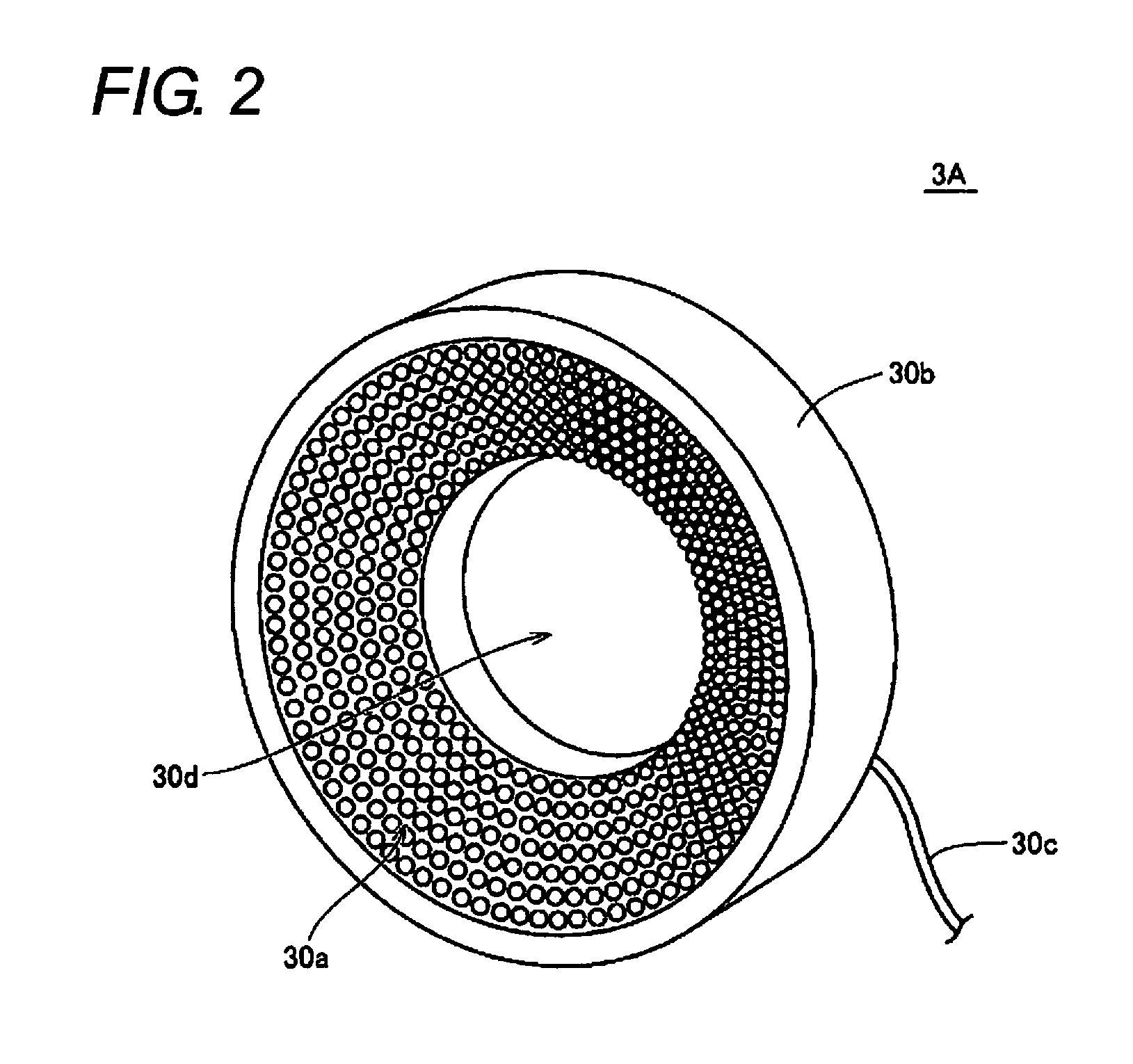

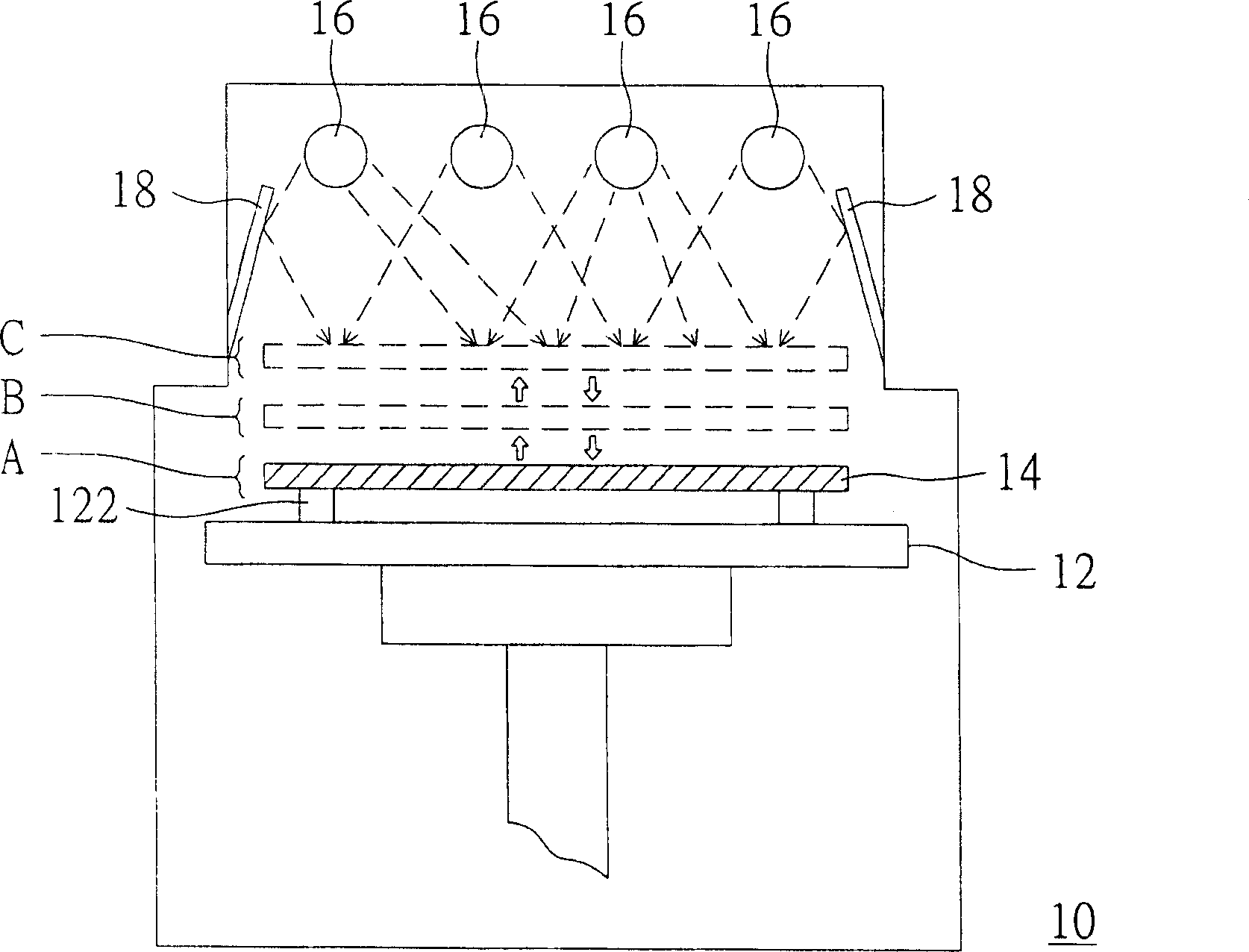

Illuminator for photodynamic therapy

InactiveUS7190109B2Improve cooling effectImproved irradiance uniformityElectrotherapyDischarge tube luminescnet screensAluminiumLight source

An apparatus and method for photodynamic therapy or photodynamic diagnosis using an illuminator comprising a plurality of light sources generally conforming to a contoured surface and irradiating the contoured surface with substantially uniform intensity visible light. The light sources may comprise generally U-shaped fluorescent tubes that are driven by electronic ballasts. Adjustment of the ballast voltage controls the output power of the tubes. The tubes are supported by a sheet-metal or plastic housing and are covered by a polycarbonate shield which directs cooling airflow within the unit and prevents glass-patient contact in the event of tube breakage. An aluminum reflector located behind the tubes increases both the output irradiance and the uniformity of the output distribution. The spacing of the U-shaped tubes is varied to increase the output at the edges of the illuminator to make the output more uniform. Also, different portions of the tubes are cooled at different amounts, to improve uniformity. A light sensor monitors output from the U-shaped tubes to provide a signal for adjusting the output from the tubes.

Owner:DUSA PHARMA INC

Beam irradiation apparatus, beam irradiation method, and method for manufacturing semiconductor device

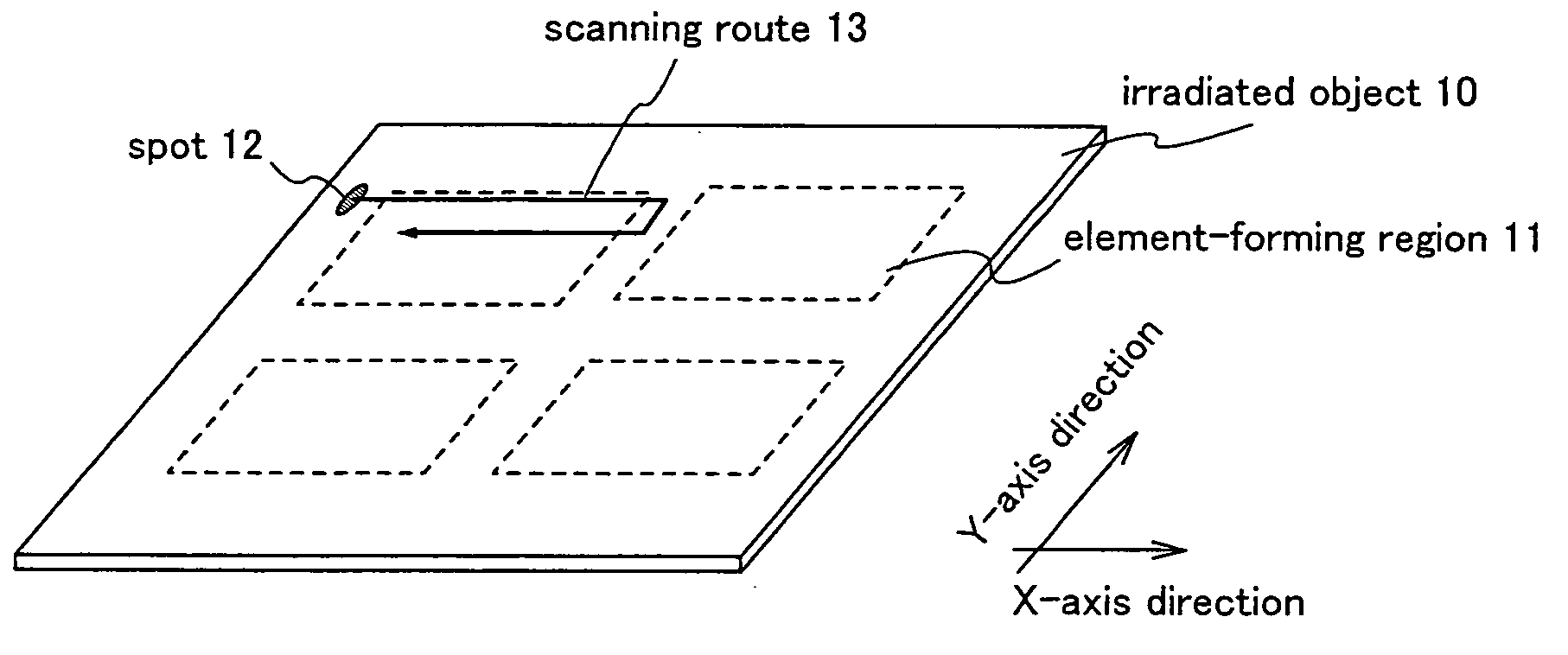

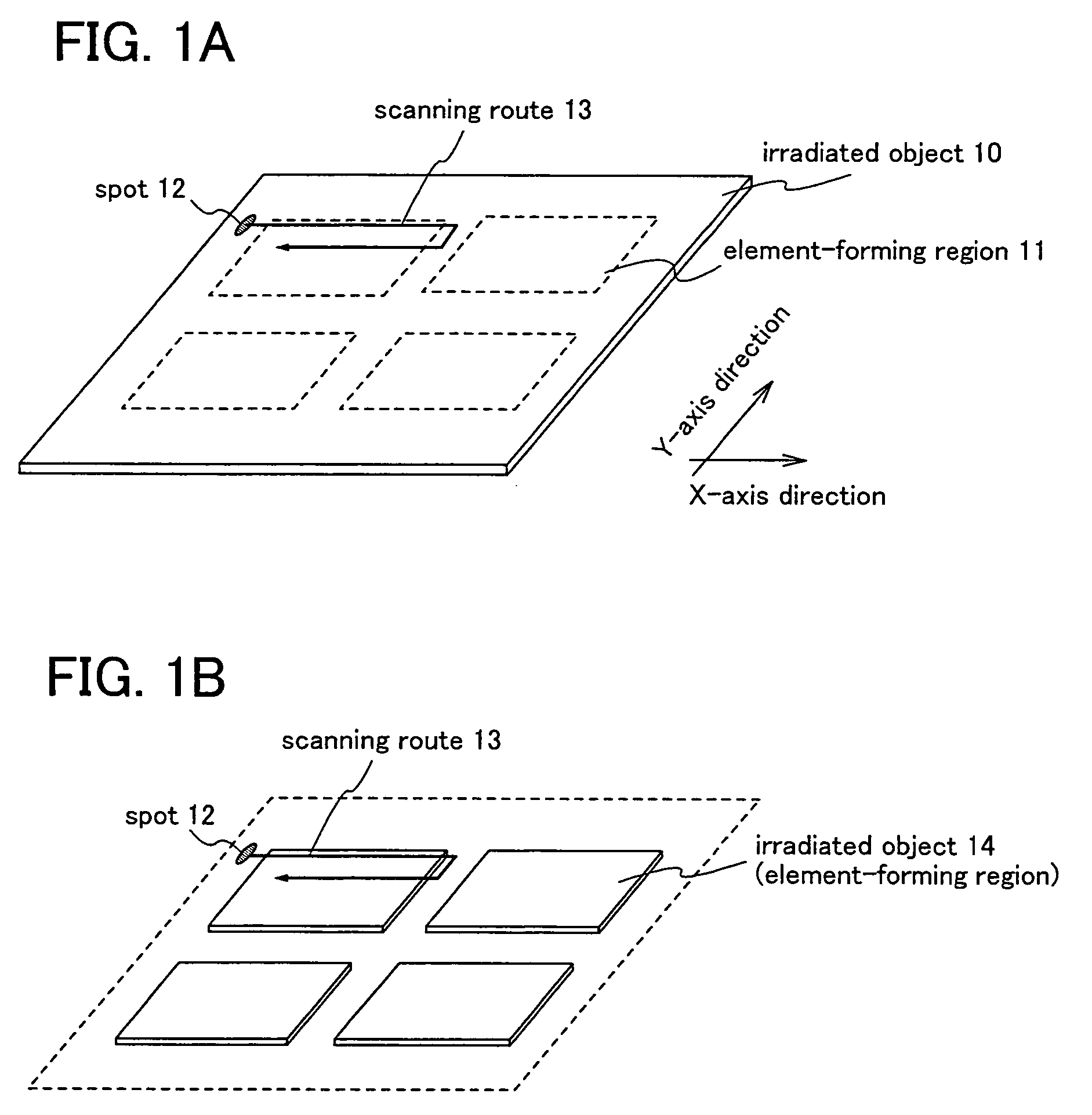

ActiveUS20050037552A1Reduce manufacturing costEase of mass productionSolid-state devicesSemiconductor/solid-state device manufacturingLight beamGalvanometer

The speed of the laser scanned by the scanning means such as a galvanometer mirror or a polygon mirror is not constant in the center portion and in the end portion of the scanning width. As a result, the object, for example an amorphous semiconductor film, is irradiated with the excessive energy and therefore there is a risk that the amorphous semiconductor film is peeled. In the present invention, in the case where the laser spot of the energy beam output continuously on the irradiated object is scanned by moving it back and forth with the use of the scanning means or the like, the beam is irradiated to the outside of the element-forming region when the scanning speed of the spot is not the predetermined value, for example when the speed is not constant, and accelerates, decelerates, or is zero, for example in the positions where the scanning direction changes, or where the scanning starts or ends.

Owner:SEMICON ENERGY LAB CO LTD

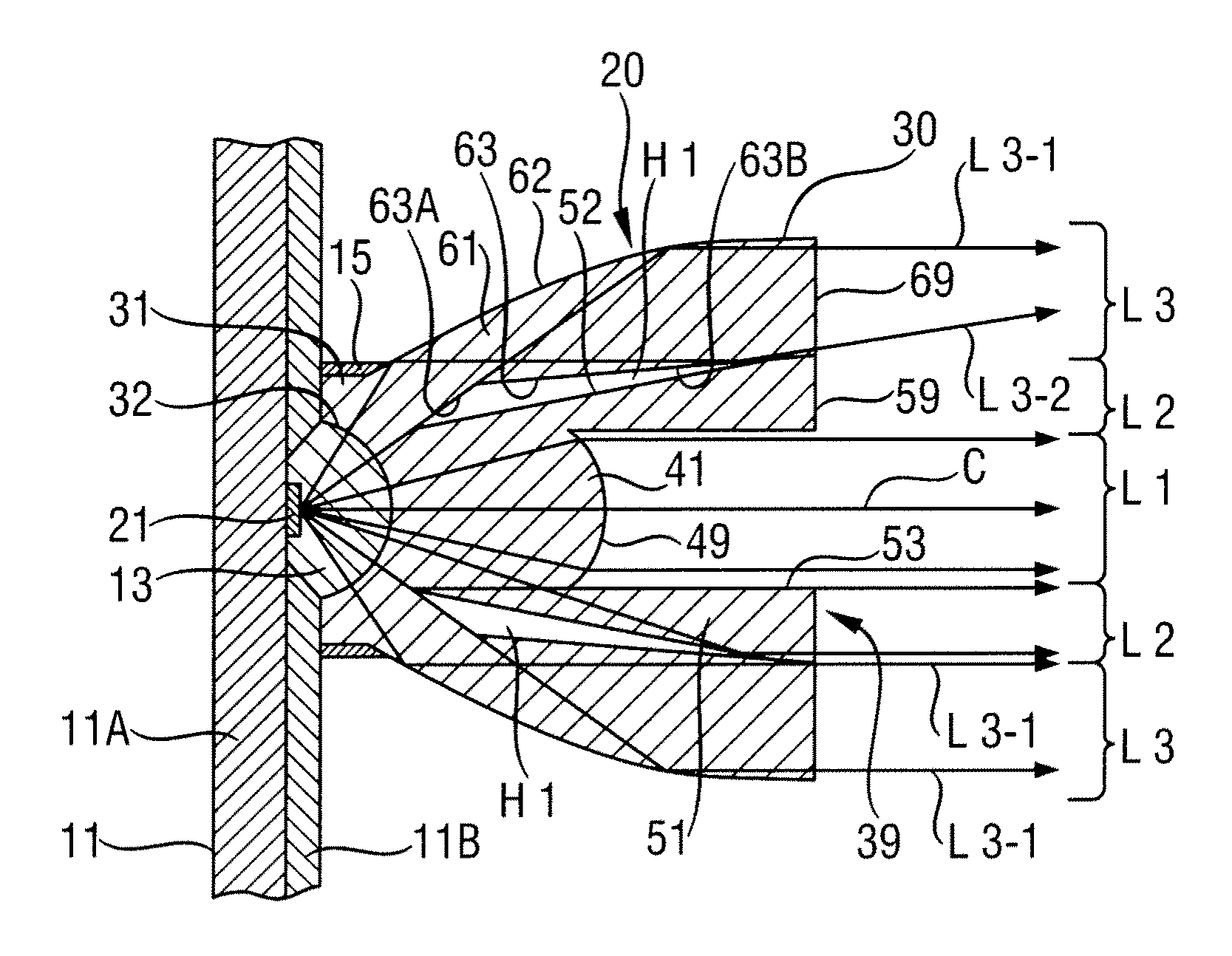

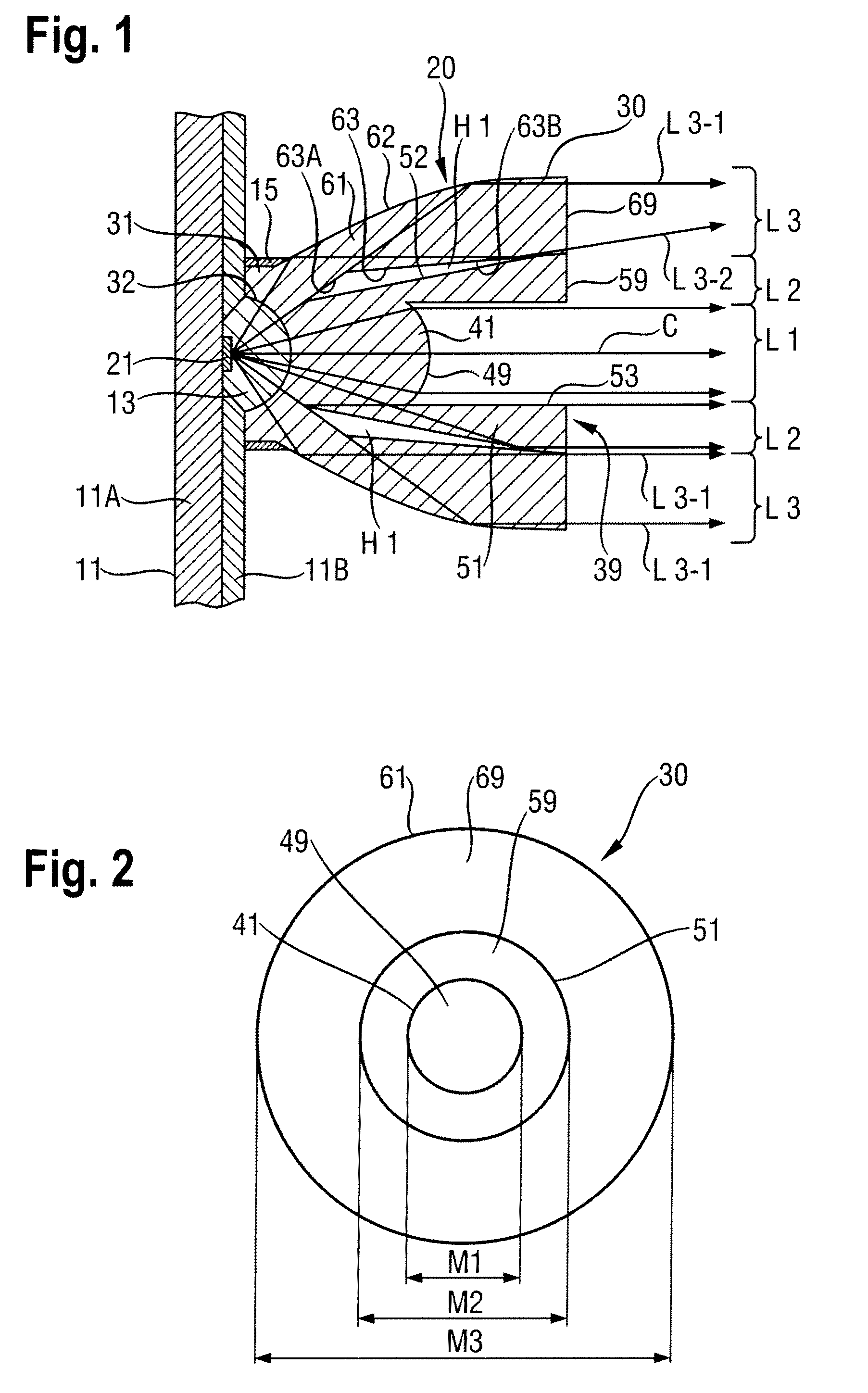

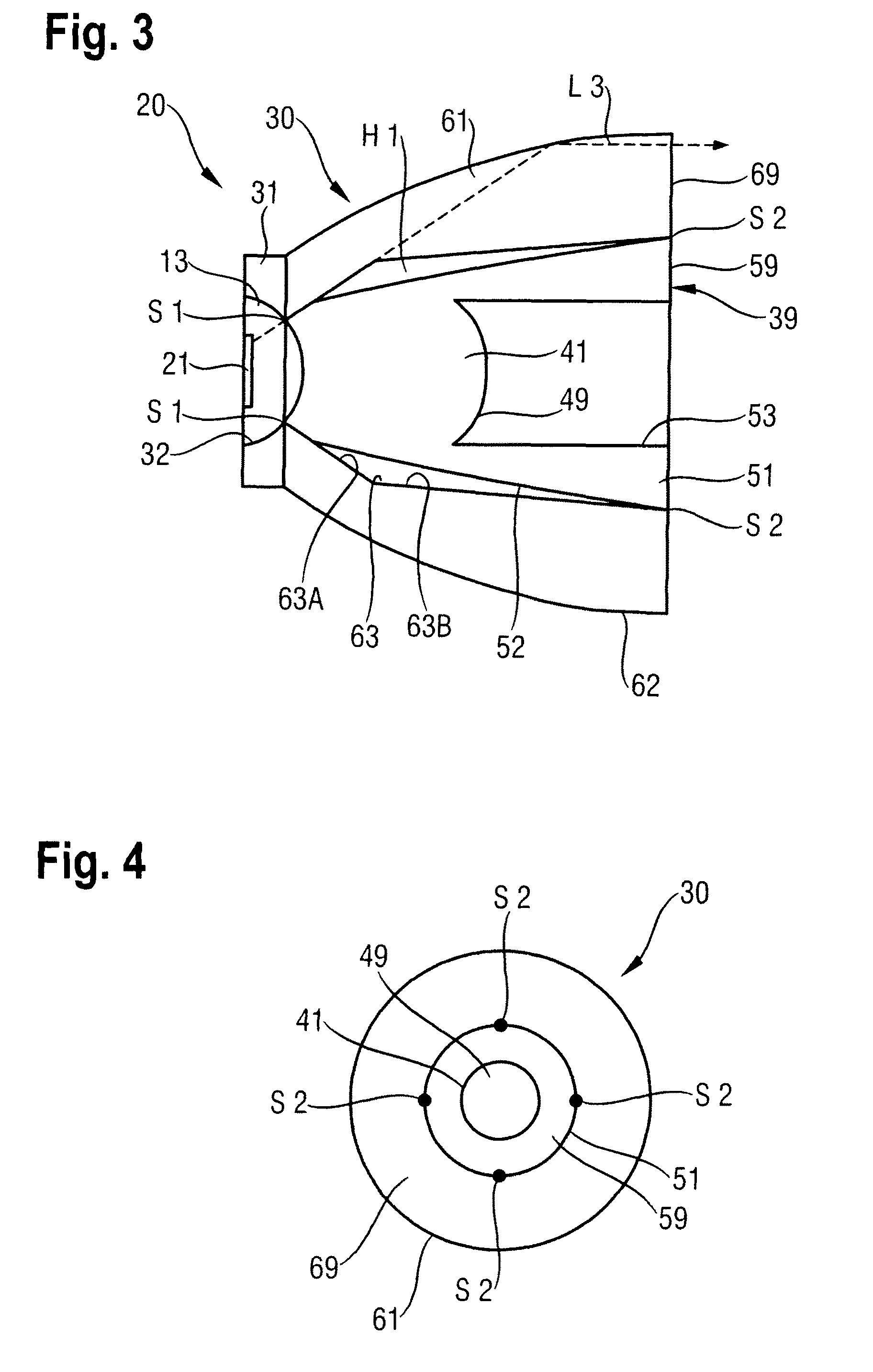

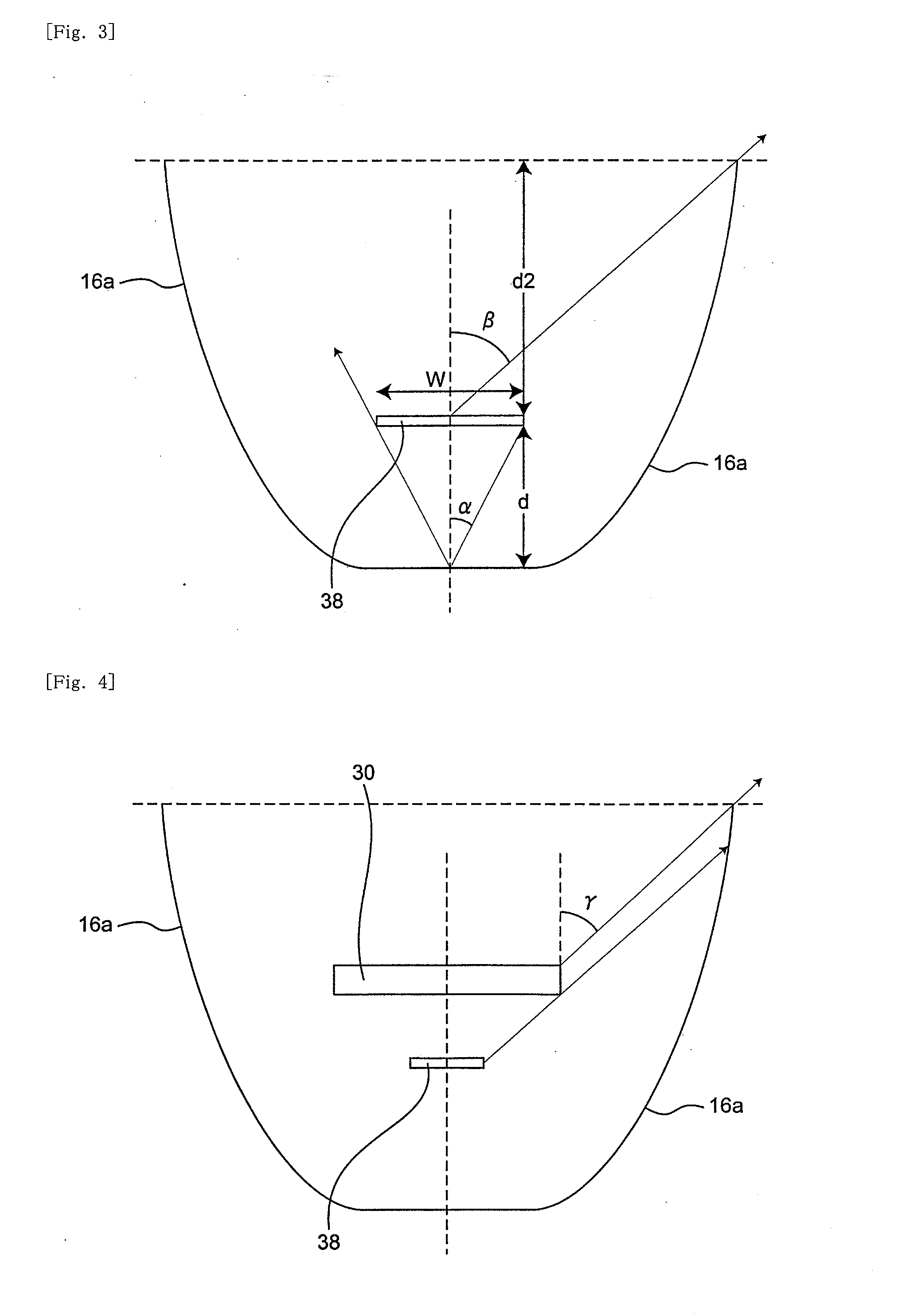

LED light source device

ActiveUS7901108B2Improve efficiencyImprove the level ofNon-electric lightingPoint-like light sourceLight guideOptoelectronics

An LED light source device using light from luminescent elements at a high level of uniformity and efficiency, and to conduct irradiation with a high level of design freedom an LED light source device is equipped with luminescent elements and a translucent light-guiding member. The translucent light-guiding member has a central convex lens with a first cylindrical light-guiding part formed on the outer periphery of the central convex lens and a second cylindrical light-guiding part formed on the outer periphery of the first cylindrical light-guiding part, such that an air layer is formed between the outer peripheral surface of the first cylindrical light-guiding part and the inner peripheral surface of the second cylindrical light-guiding part, the outer peripheral surface of the first cylindrical light-guiding part and the outer peripheral surface of the second cylindrical light-guiding part being rotated quadratic surfaces with the same focal point.

Owner:USHIO DENKI KK

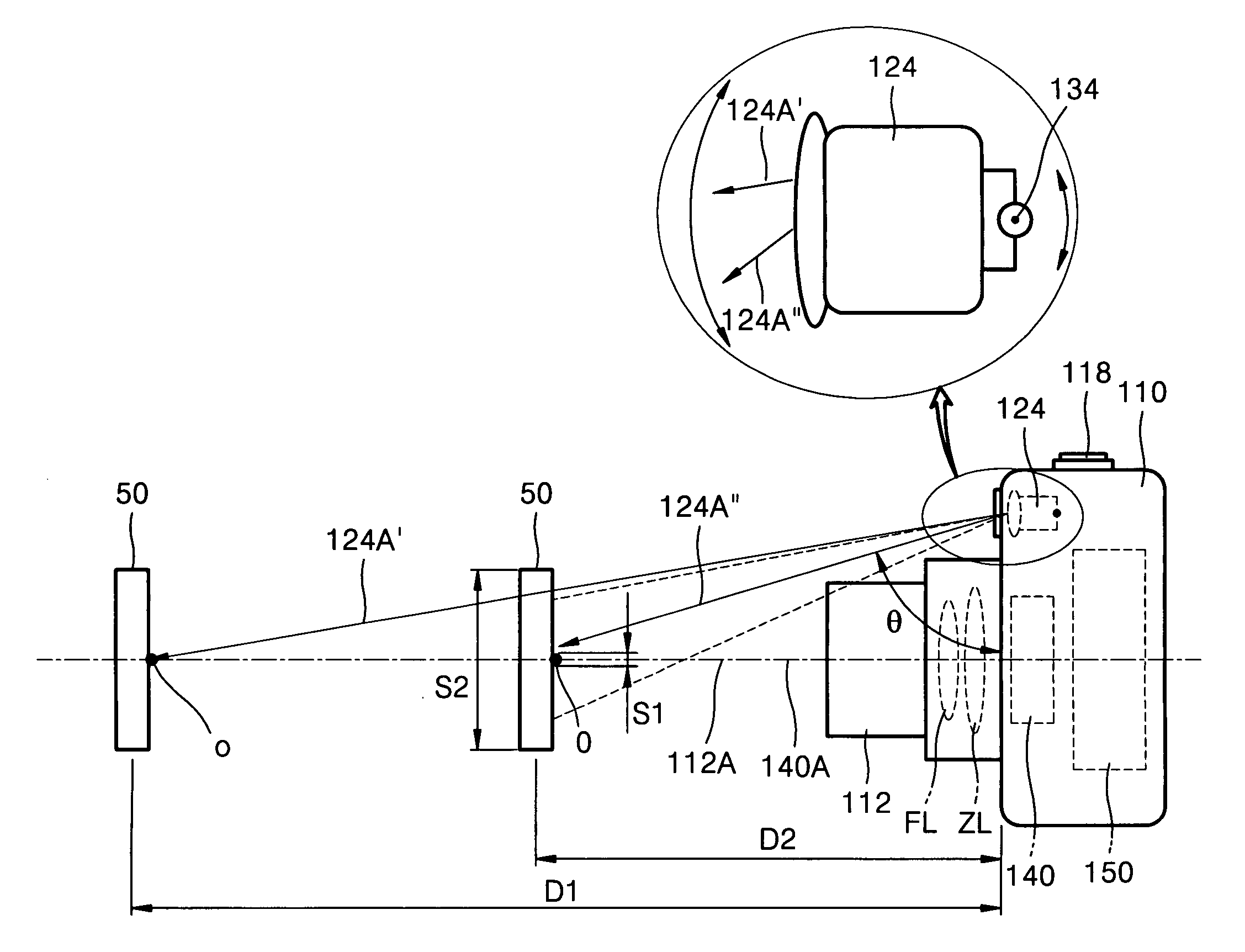

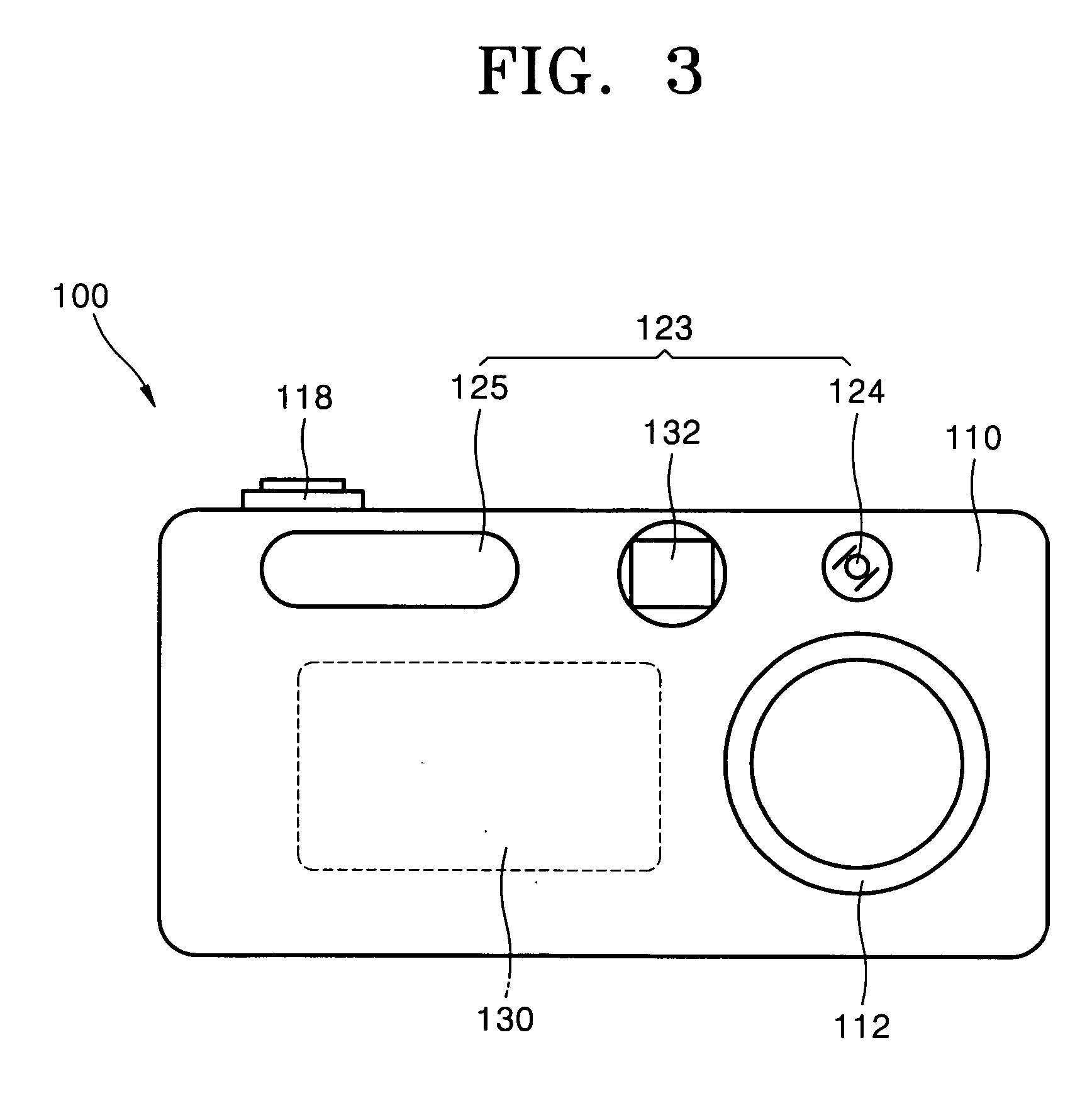

Method for close-range and general-range photographing by digital camera

InactiveUS20050157208A1Limit amount of lightUniform irradiationTelevision system detailsColor television detailsNormal modeLight exposure

A method for macro photographing with a digital camera without attaching a separate light source apparatus for macro photographing is provided. A method for macro photographing in automatic light emission mode of a digital camera with a two-stage shutter button, and capable of photographing an object in close range in automatic light emission mode by using built-in macro and normal flashes, in which the amount of light emission is automatically adjusted, includes: when the shutter button operates in stage 1, with the macro flash emitting light initially, and by performing auto focusing of an object, and setting light exposure automatically, determining a required light emission amount; and when the shutter button operates in stage 2, if the required light emission amount is equal to or less than the maximum light emission amount that the macro flash can emit, the macro flash emitting light, and if the required light emission amount is greater than the maximum light emission amount that the macro flash can emit, the normal flash which emits light in normal mode emitting light to photograph the object.

Owner:SAMSUNG ELECTRONICS CO LTD

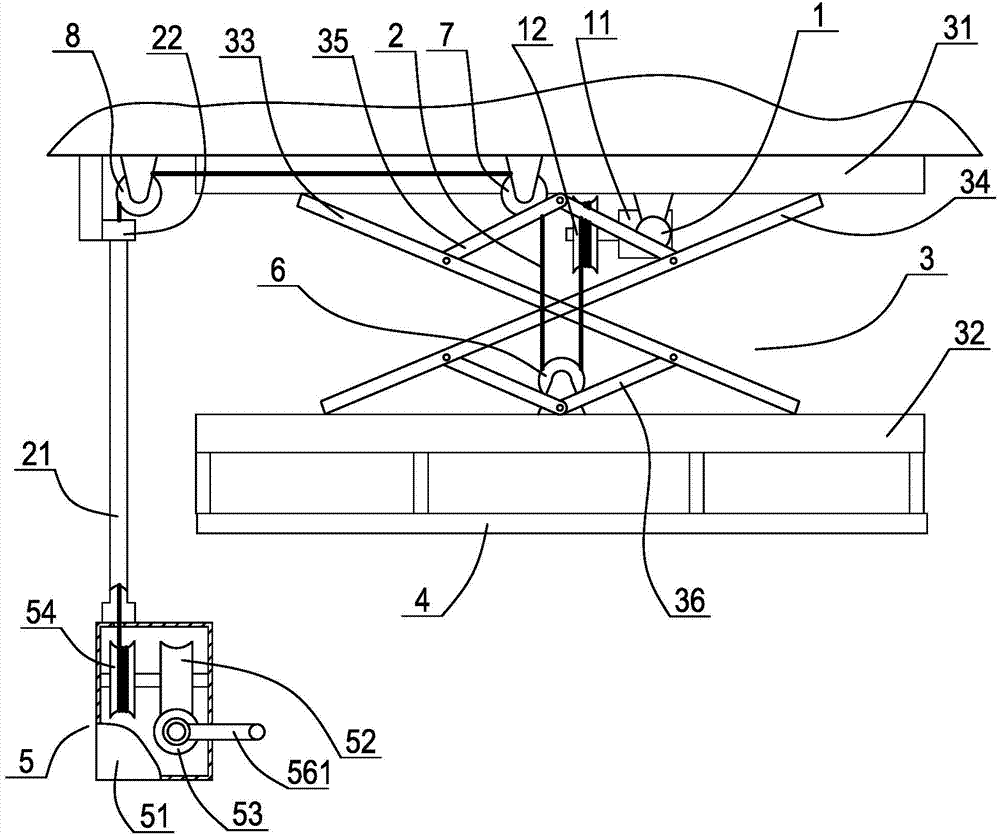

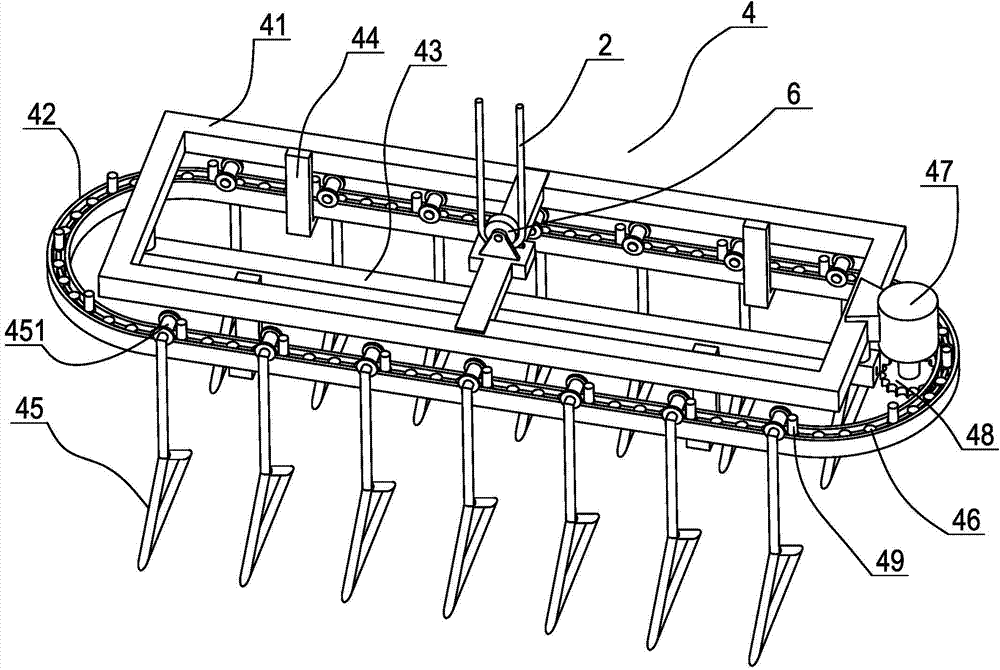

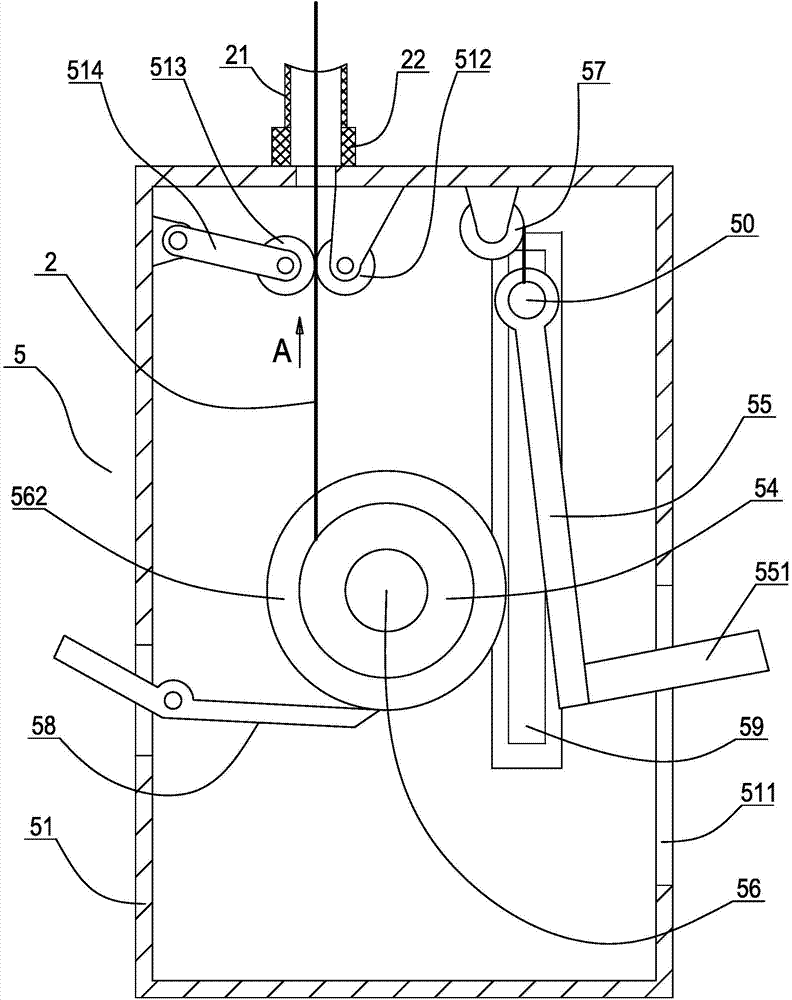

Lifting drying rack

ActiveCN103835104AImprove rigidityImprove stabilityOther drying apparatusWinding mechanismsIndustrial engineeringPulley

The invention discloses a lifting drying rack. The lifting drying rack comprises a lifting motor, a pull rope, a lifting rack and a drying rod, wherein the upper end of the stretchable lifting rack is fixed to a ceiling, and the drying rod is connected to the lower end of the lifting rack. The lifting drying rack further comprises a manual lifting mechanism provided with a rotatable second winding wheel, the lifting motor is arranged at the upper end of the lifting rack, an output shaft of the lifting motor is connected with a first winding wheel through a speed change mechanism, the lower end of the lifting rack is provided with a movable pulley, and the upper end of the lifting rack is provided with a fixed pulley; one end of the pull rope is fixedly wound on the first winding wheel in a stacked mode, the other end of the pull rope is sequentially wound around the movable pulley and the fixed pulley and then fixedly wound on the second winding wheel in a stacked mode. The lifting mechanism can be suitable for electrical operation and manual operation to ensure normal use of the drying rack in a power failure, saves labor for operation and is convenient to install.

Owner:浙江科秀五金有限公司

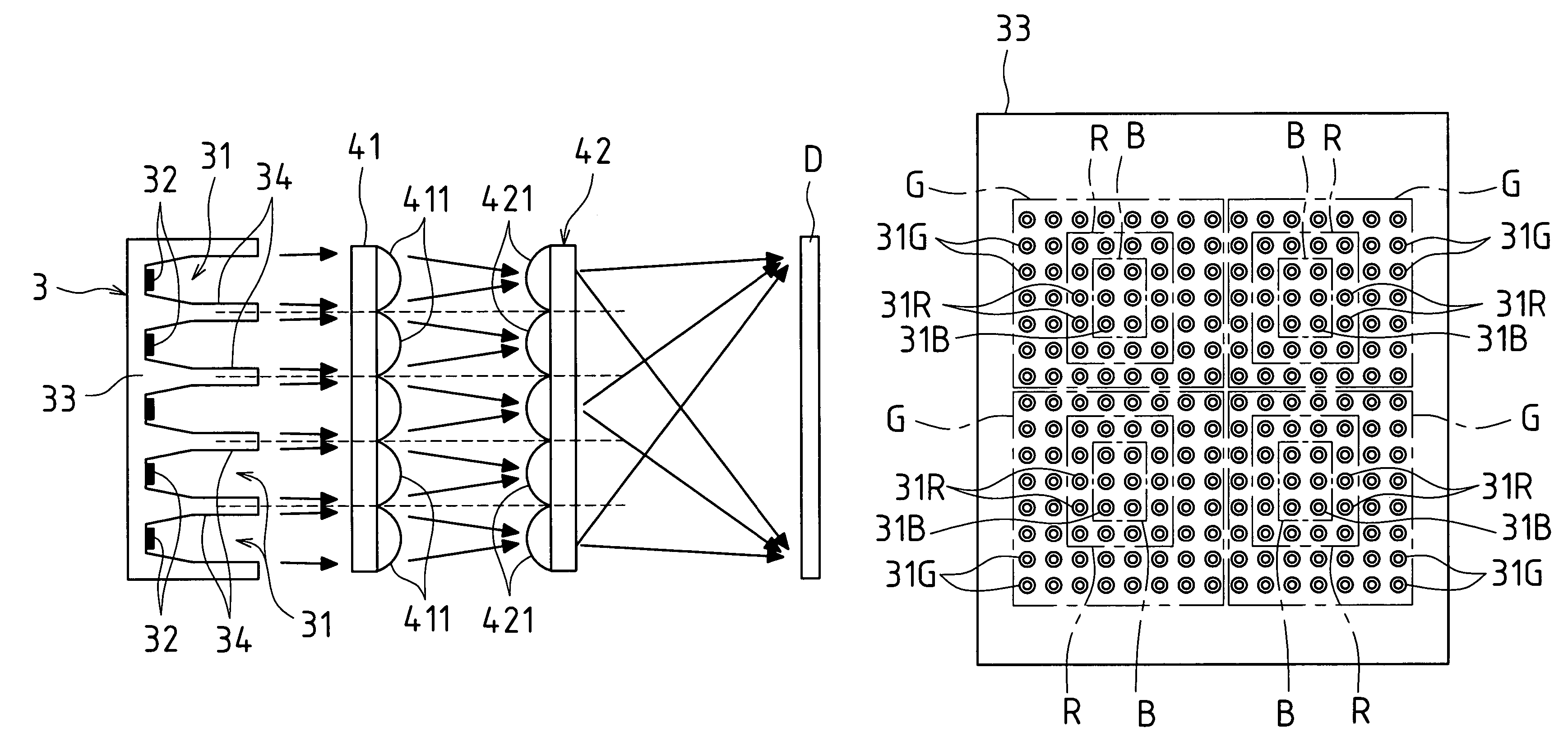

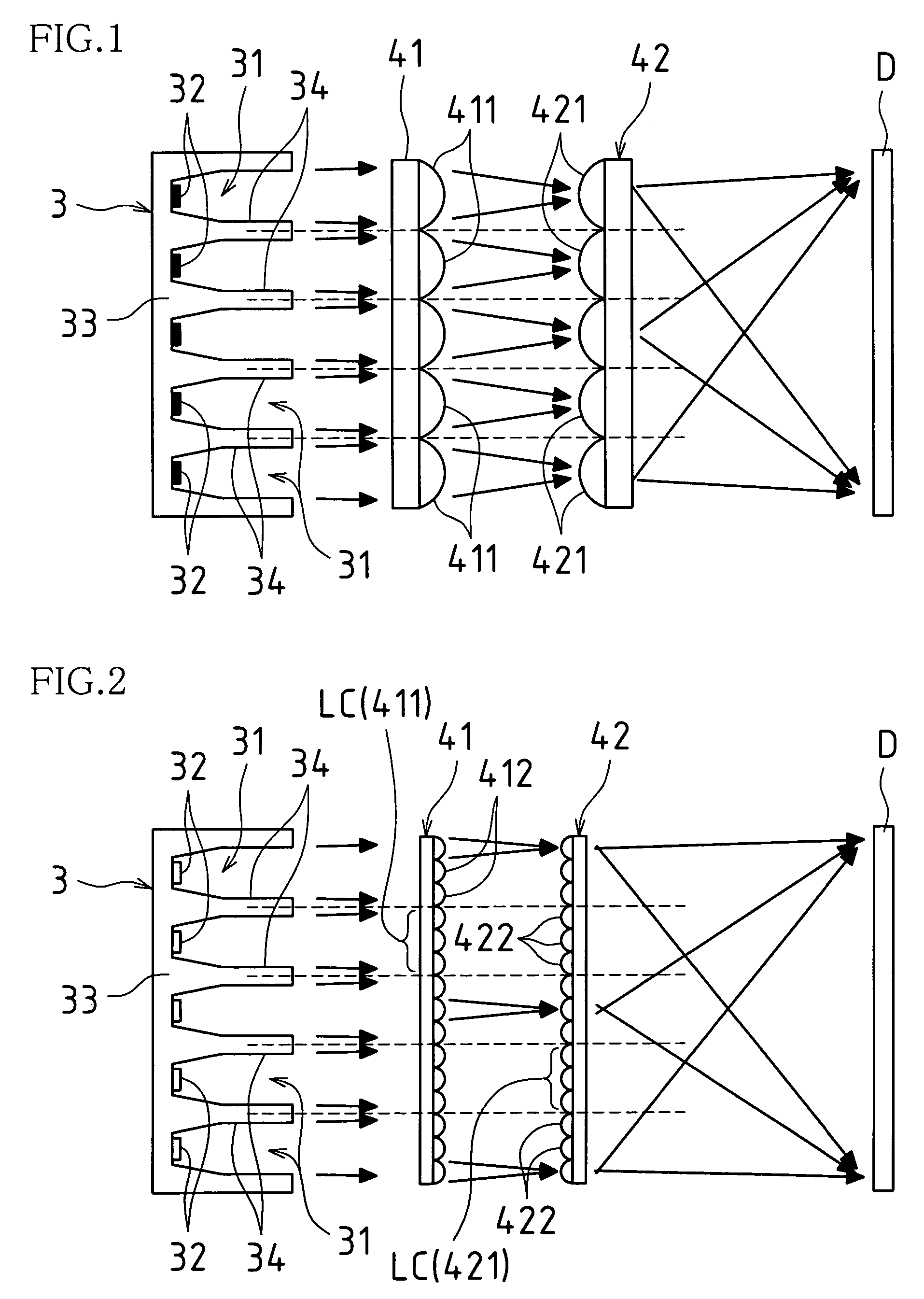

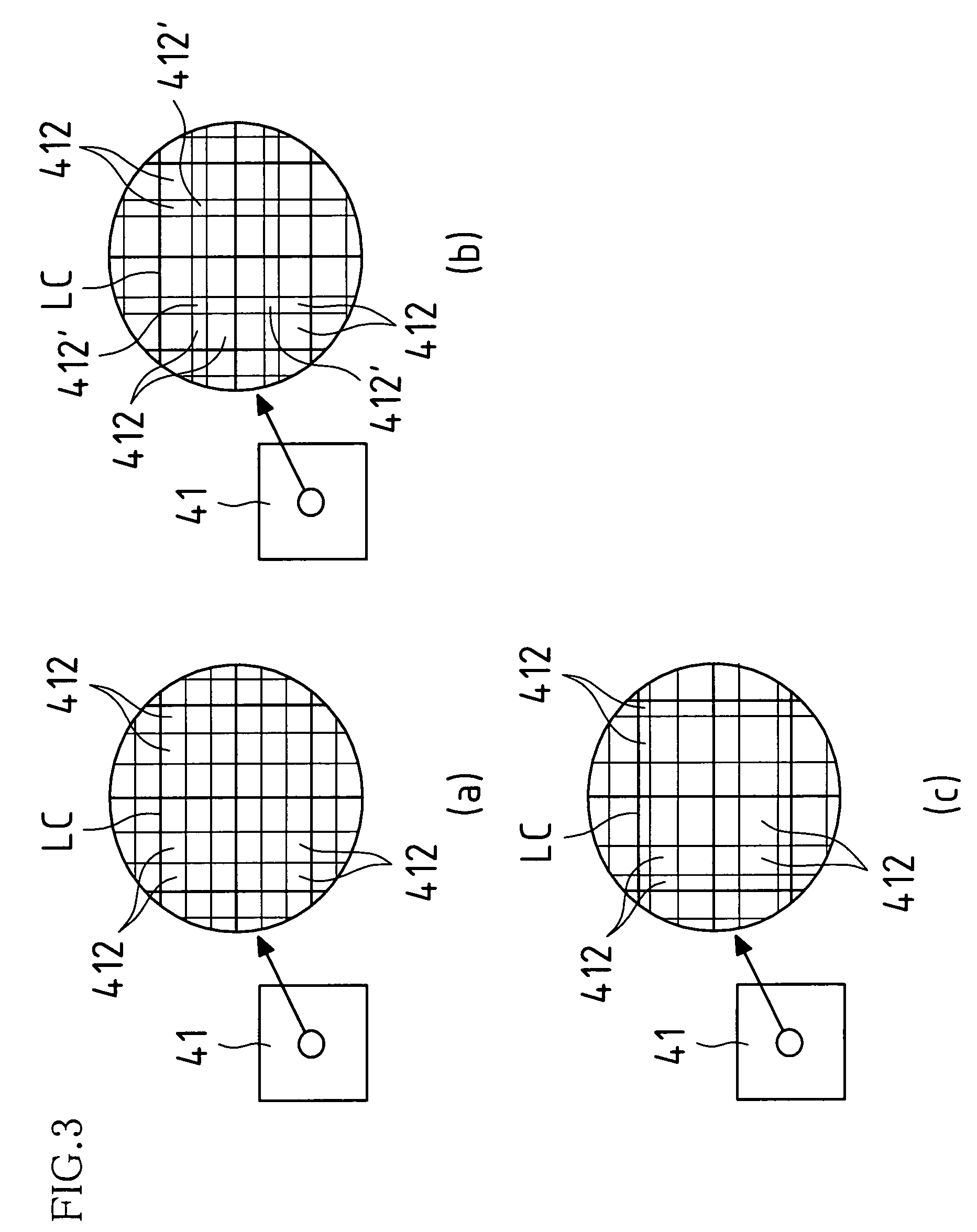

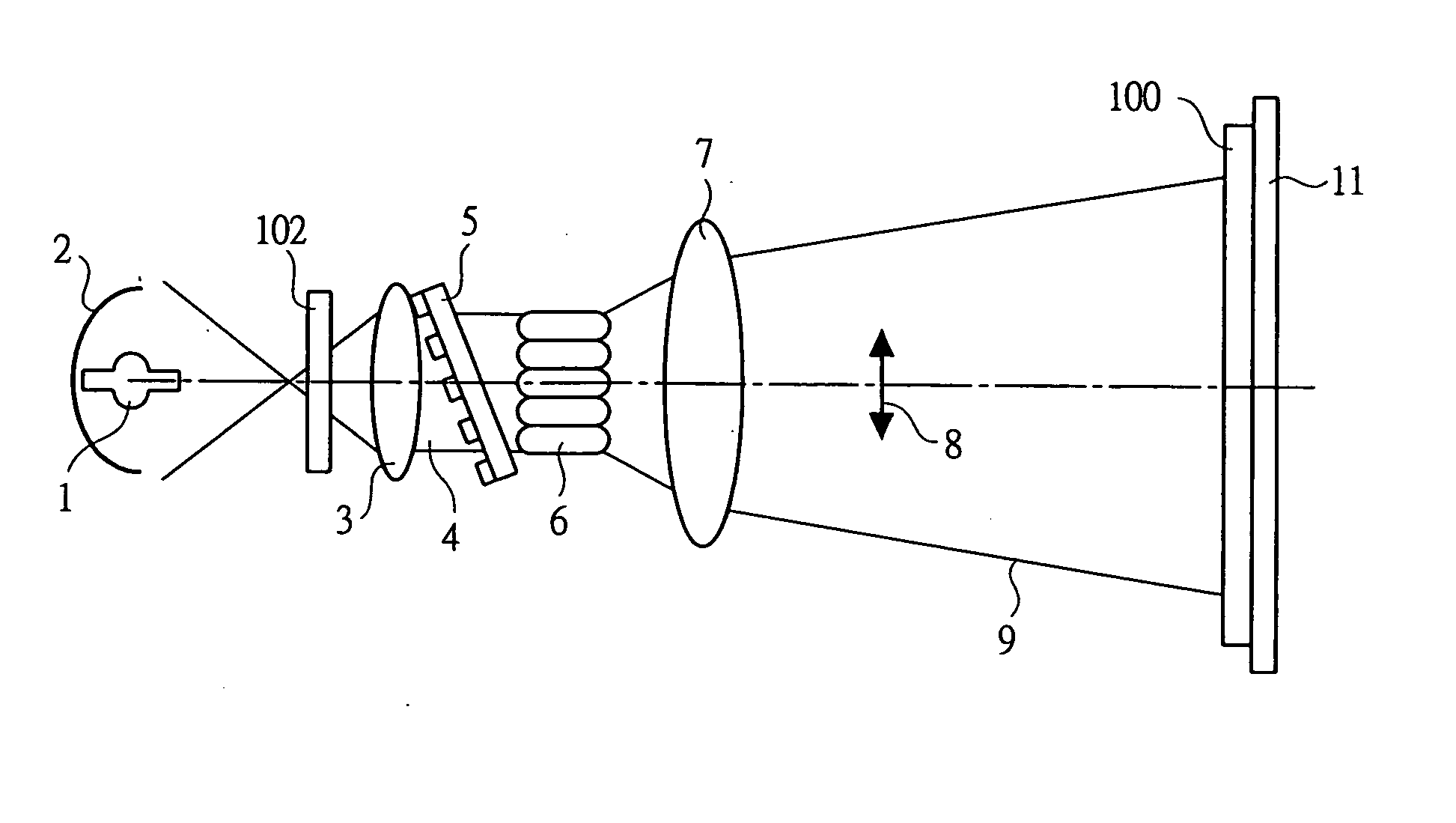

Projector optical system configuration, optical module, and projector, and also electronic equipment, vehicle, projection system, and showcase utilizing such projector

InactiveUS7258450B2Reduction in size/weightReduce the driving voltageShow cabinetsProjectorsOptical ModuleEffect light

Multiplicities of red LED cell(s), green LED cell(s), and blue LED cell(s) are arrayed in two dimensions on a single light source substrate so as to form LED plane light source(s). First lens array(s) and second lens array(s) are disposed on side(s) of the LED plane light source(s) from which light exits. Respective lens array(s) may be provided with plurality or pluralities of lenses opposing LED cell(s). Light irradiated from LED cell(s) is, by action of respective lens(es) of first lens array(s), separately collected and is thereafter, by action of respective lens(es) of second lens array(s), separately magnified; and light exiting therefrom is combined in mutually superposed fashion at irradiation surface(s). Furthermore, respective LED cell(s) is / are made to undergo timed lighting by color. Image(s) formed by reflective liquid crystal(s) and / or DMD(s) is / are switched in conformity to such timed lighting and such image(s) is / are projected onto screen(s).

Owner:SHARP KK

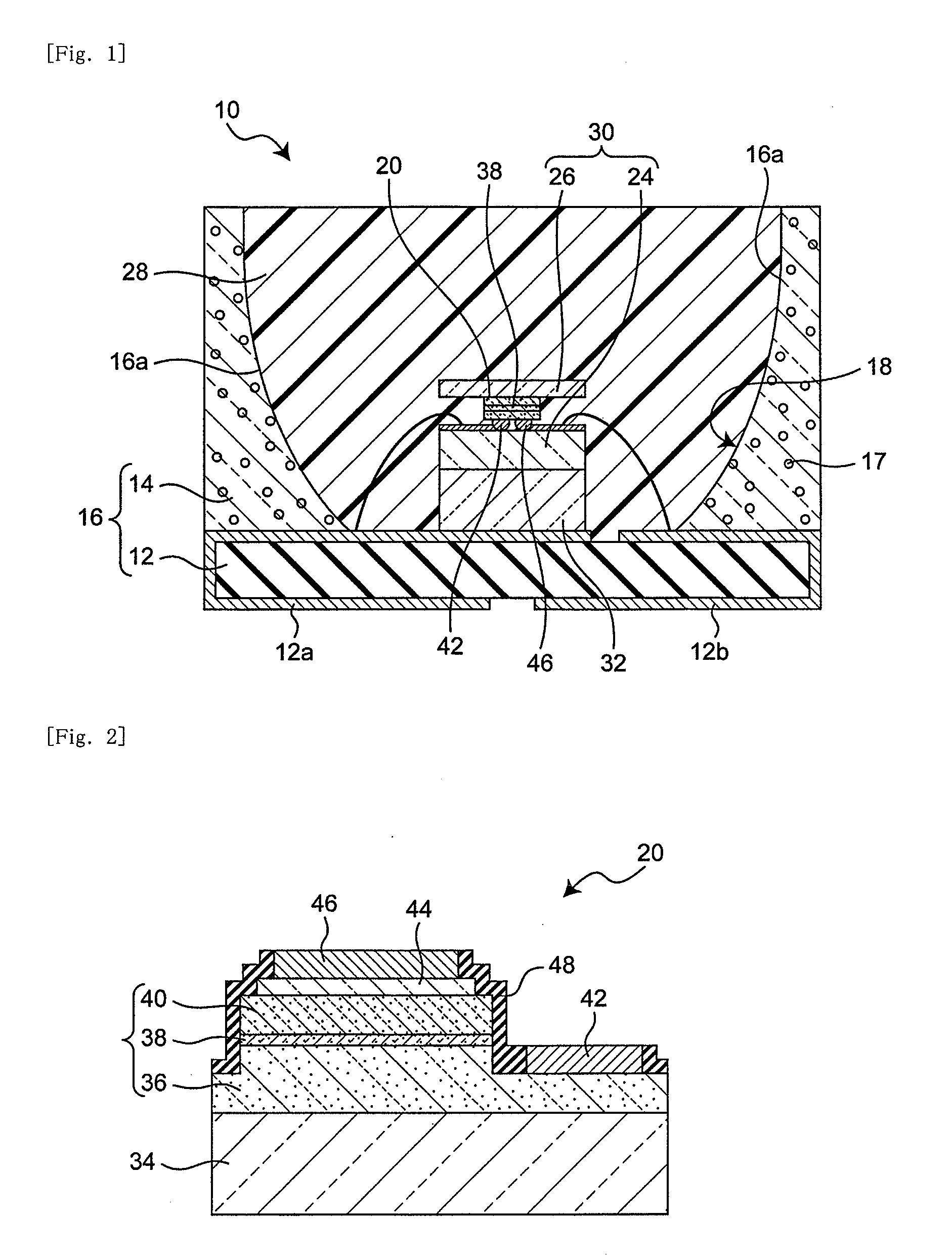

Light emitting device

ActiveUS20110248623A1Reduce probabilityReduce absorptionIncadescent screens/filtersDischarge tube luminescnet screensLength waveLight emitting device

A light emitting device includes a housing member having a recess open upward, a light emitting element arranged in the recess and having a light emitting layer of a semiconductor, and a wavelength converting member arranged in the recess and capable of absorbing a part of light emission from the light emitting element and emitting light of different wavelength. The light emitting device is capable of mixing the light emission from the light emitting element and the light emission from the wavelength converting member to emit light from the opening of the recess. A light scattering surface for scattering light emission from the light emitting element and wavelength converting member is formed on at least part of the side surface of the recess. The light emitting element and the wavelength converting member are spaced apart from the side and bottom surfaces of the recess, and the side surfaces of the light emitting element are exposed without being covered with the wavelength converting member.

Owner:NICHIA CORP

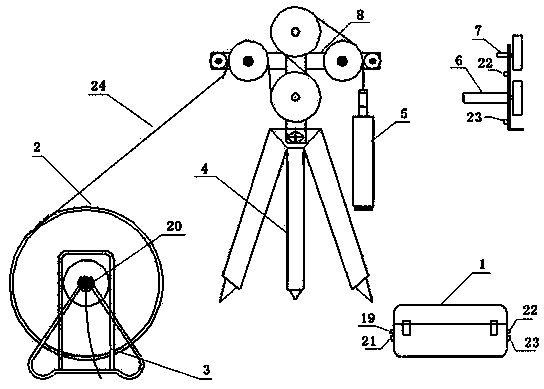

Intelligent drilling television imaging instrument

InactiveCN103628861ASolve foggingSolve the disadvantages of being easily scratched by the well wallConstructionsGlass coverEngineering

The invention relates to an intelligent drilling television imaging instrument, which mainly consists of a main controller, an underground probe, an underground cable, a windlass, a hub, a stepper motor, a depth counter and a tripod. The main controller is used for collecting and storing the information such as image splicing, video, depth and azimuth angle; the underground cable is used for supplying power to the probe and transmitting a control order, video, angle and the like; the underground probe is used for shooting a picture and video and recording the underground azimuth angle and transmitting the information to an industrial control computer through the cable; the depth counter is used for recording the underground depth of the underground probe; the stepper motor is used for controlling the probe to ascend and descend at a constant speed. An open-type lens is directly arranged in the water, and no glass cover is arranged in front of the lens, so that a shot image of a well wall is clearer, and the color retention is more authentic; a combined-type light source is adopted, so that the well wall and the underground situation can be directly observed; by adopting the unique stepper motor and the depth counting hub device, the probe can be lowered and lifted at a constant speed, and the images are completely spliced; by introducing electronic rock core library software, an electronic rock core file is established.

Owner:YUEYANG AOCHENG TECH

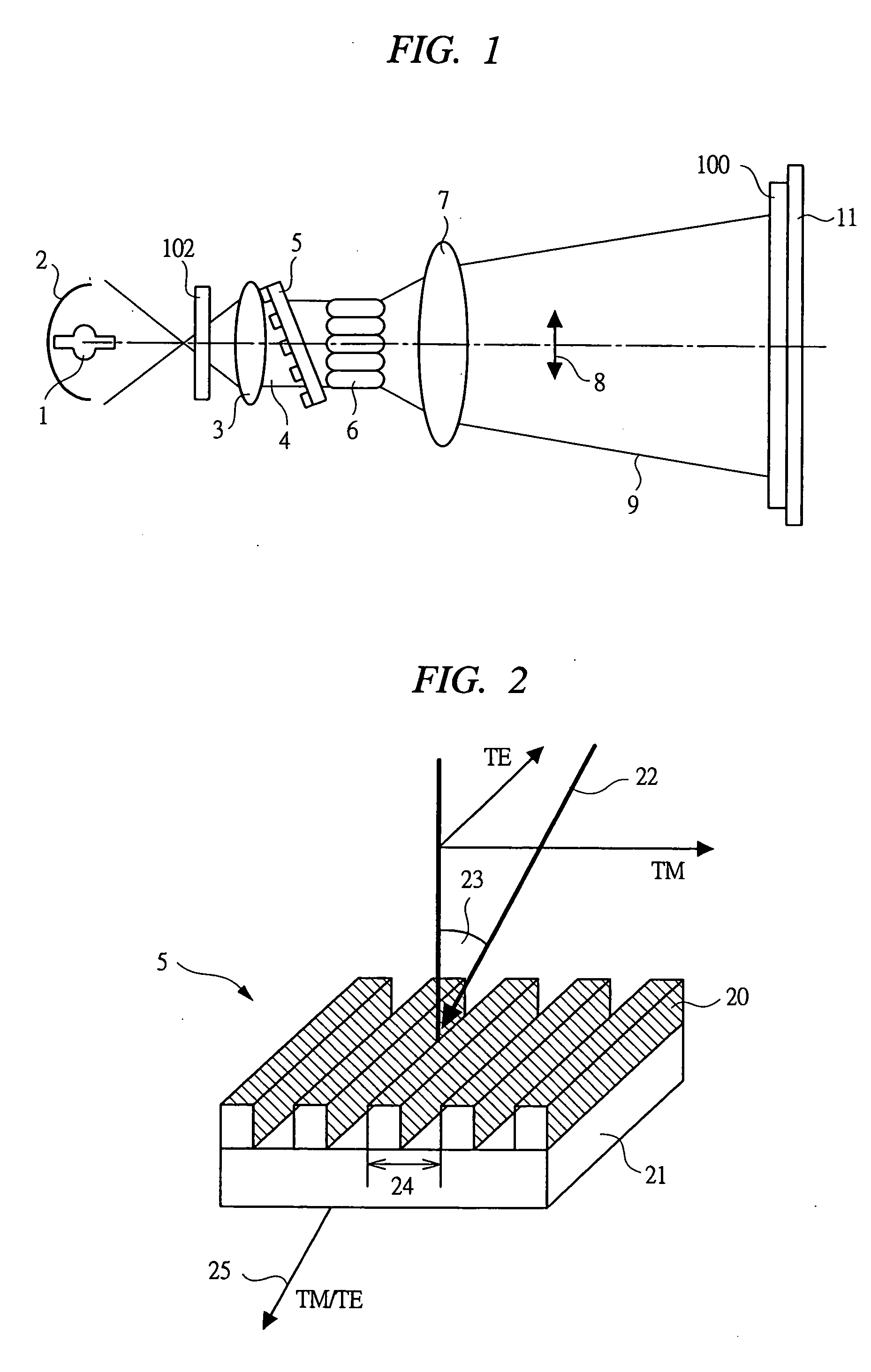

Apparatus for optically arranging surface of alignment film and method for manufacturing liquid crystal display device using the same

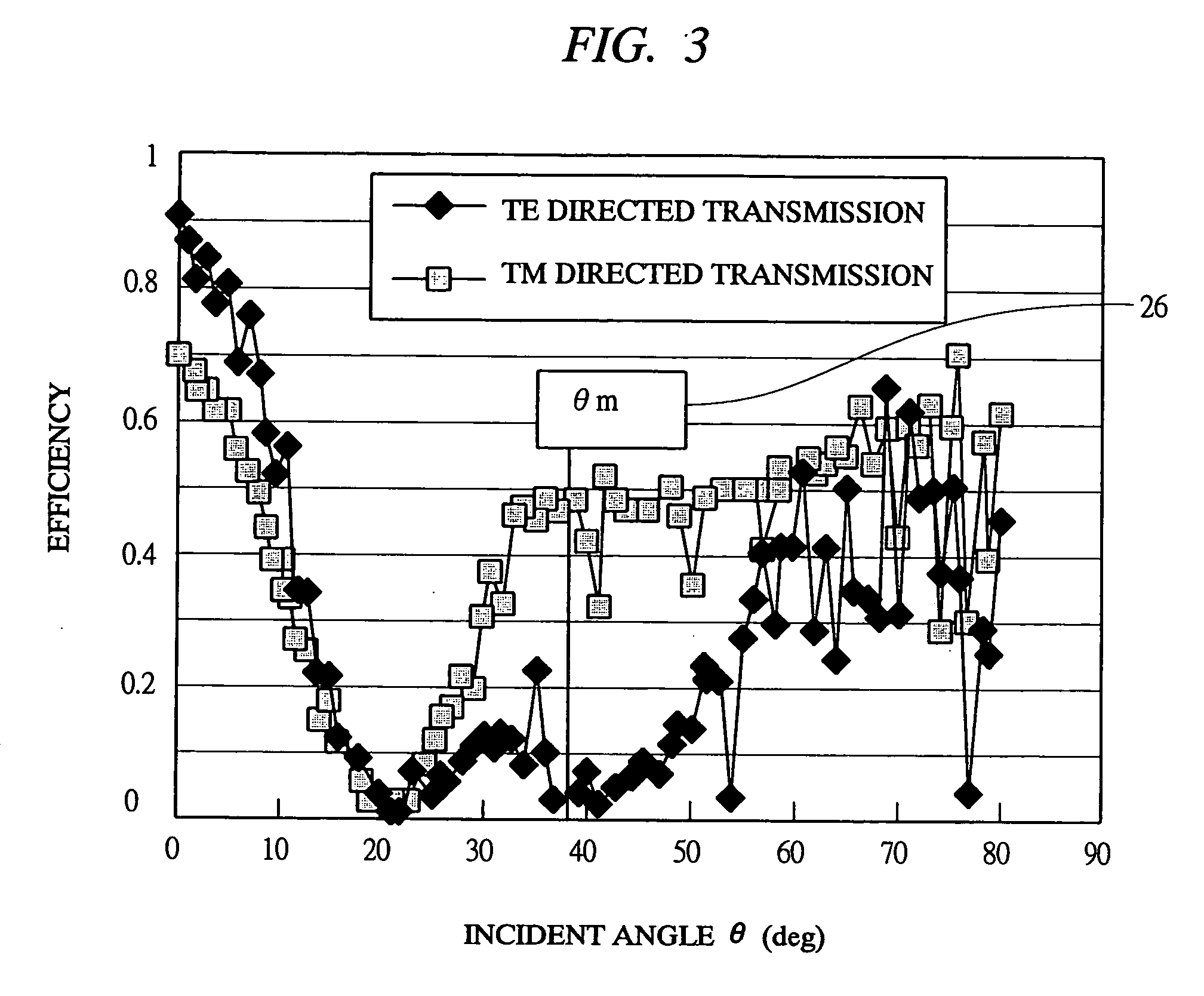

InactiveUS20050225695A1Amount of transmitted light decreaseReduce the amount of lightPolarising elementsNon-linear opticsIntegratorGrating

Work is irradiated with polarized light generated by configuring in such a manner as to have a polarizer using a grating that separates polarized light from non-polarized light, a lamp and a condenser mirror that allow light to fall on the polarizer, a collimator lens that converts the incoming light into parallel beams, an integrator lens that uniformizes intensity distribution of light radiated from the polarizer, and a diffusion lens with functions to enlarge or contract the irradiated range to the work size, and by forming protrusions and recesses of the shape, material, and size that fit to the desired wavelength on a substrate such as quartz, etc. that transmit ultraviolet light, and by providing the light-polarizing performance by appropriately providing an incident angle. By carrying out this processing, the alignment film in the liquid crystal display element can be photo-aligned at high accuracy and uniformly.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

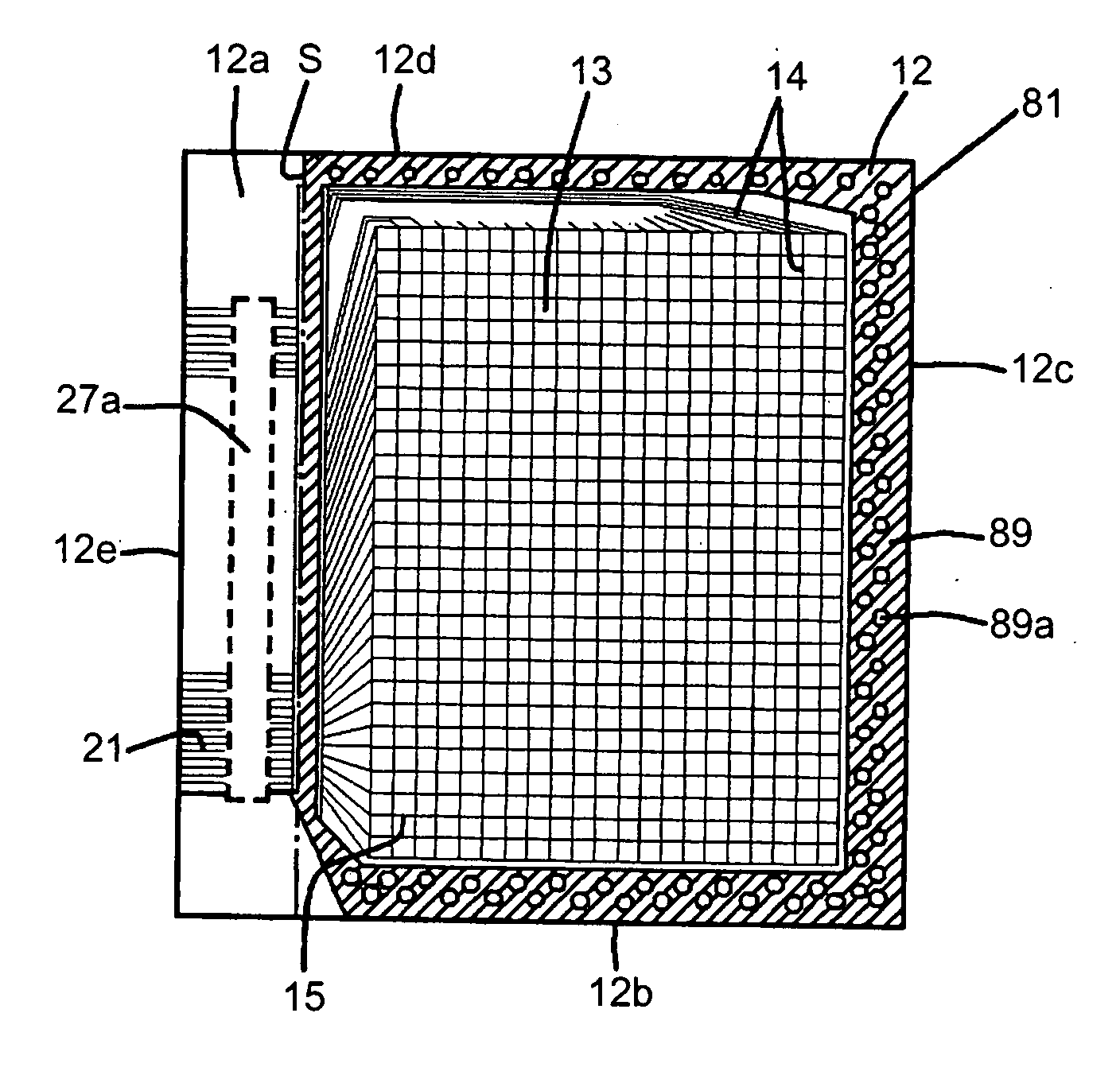

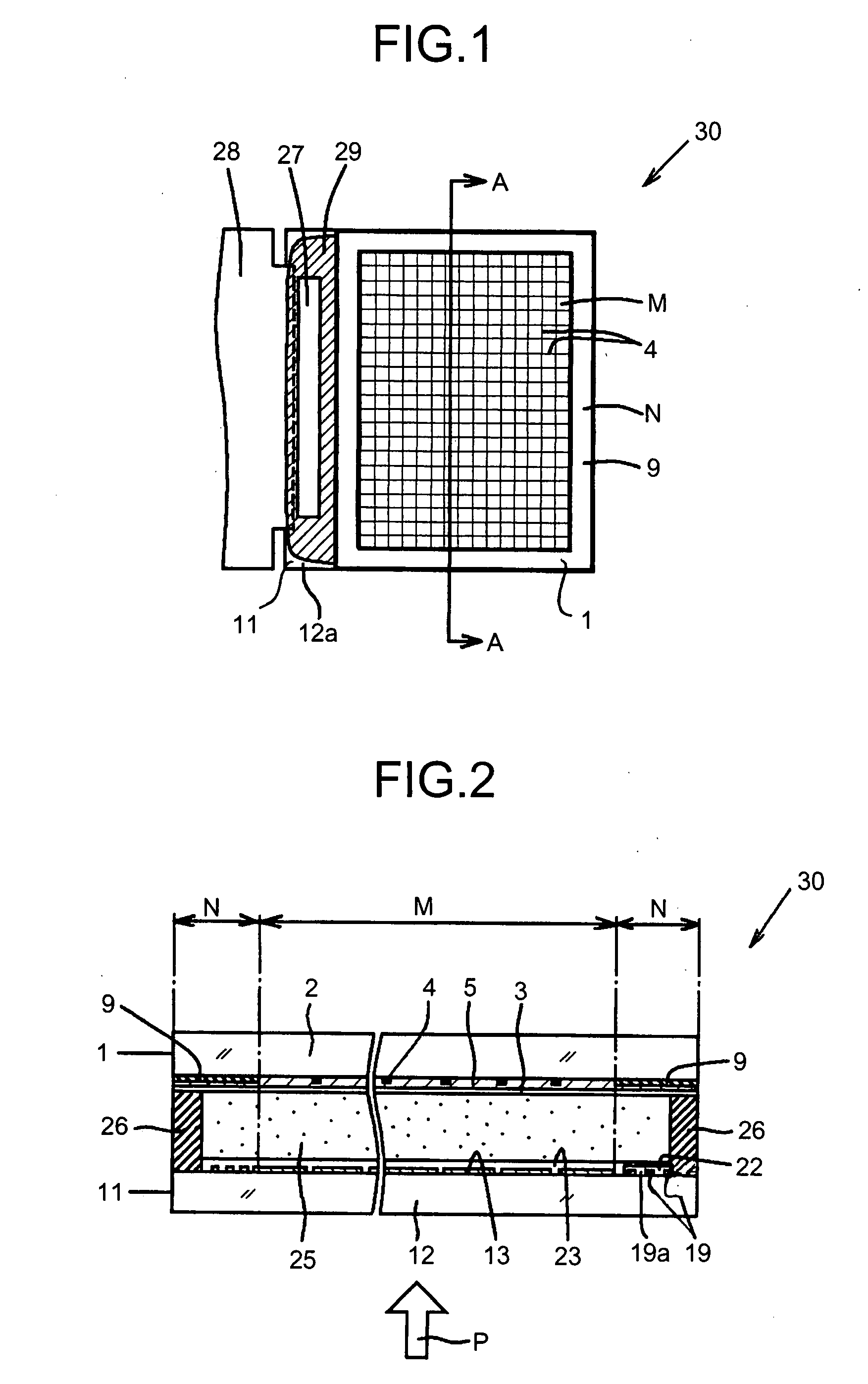

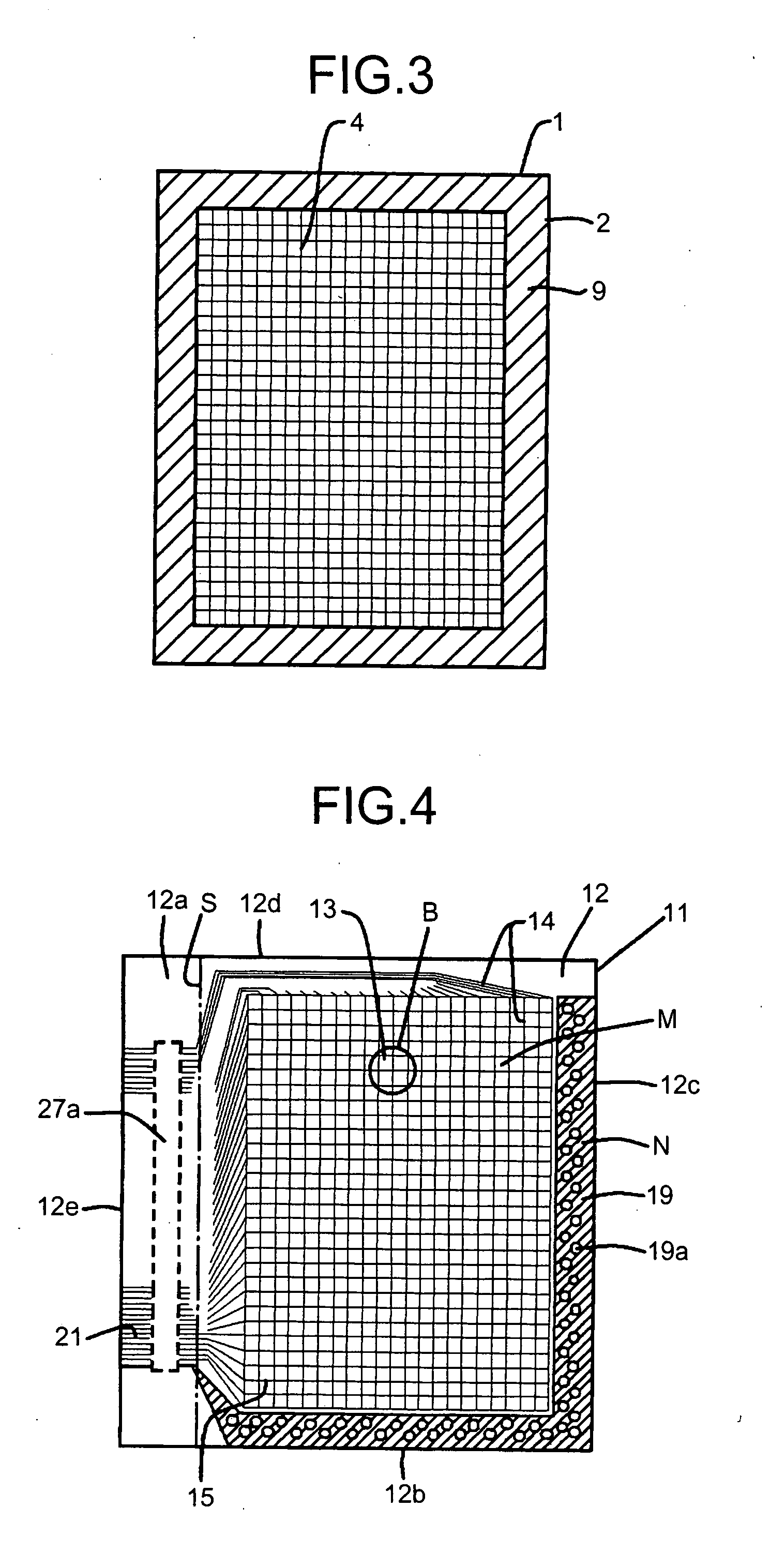

Display device and method of manufacturing display device

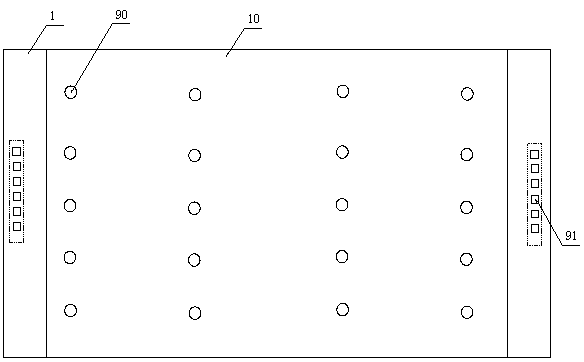

InactiveUS20070216830A1Uniform irradiationImprove connectivityNon-linear opticsUltravioletDisplay device

In a display apparatus that has a polymer dispersed liquid crystal material 25 encapsulated in a gap between a completed first substrate 1 and a completed second substrate 11 by using a sealing member 26 and has a display region M and a peripheral region N in a region where the polymer dispersed liquid crystal material 25 is encapsulated, a wiring electrode 19 having light shielding properties is provided in at least a part of the peripheral region N of the completed second substrate 11, and an ultraviolet ray transmitting portion 19a that transmits an ultraviolet ray therethrough is provided in the peripheral region where the wiring electrode 19 is provided. An ultraviolet ray is applied from the substrate side where the ultraviolet ray transmitting portion 19a is provided to polymerize a monomer in the peripheral region N. The ultraviolet ray transmitting portion is formed of, e.g., a plurality of small holes, and the small holes are dispersedly arranged at equal intervals.

Owner:CITIZEN WATCH CO LTD

Method for manufacturing a semiconductor device where the scanning direction changes between regions during crystallization and process

ActiveUS7220627B2Uniform crystallinityImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingLight beamGalvanometer

The speed of the laser scanned by the scanning means such as a galvanometer mirror or a polygon mirror is not constant in the center portion and in the end portion of the scanning width. As a result, the object, for example an amorphous semiconductor film, is irradiated with the excessive energy and therefore there is a risk that the amorphous semiconductor film is peeled. In the present invention, in the case where the laser spot of the energy beam output continuously on the irradiated object is scanned by moving it back and forth with the use of the scanning means or the like, the beam is irradiated to the outside of the element-forming region when the scanning speed of the spot is not the predetermined value, for example when the speed is not constant, and accelerates, decelerates, or is zero, for example in the positions where the scanning direction changes, or where the scanning starts or ends.

Owner:SEMICON ENERGY LAB CO LTD

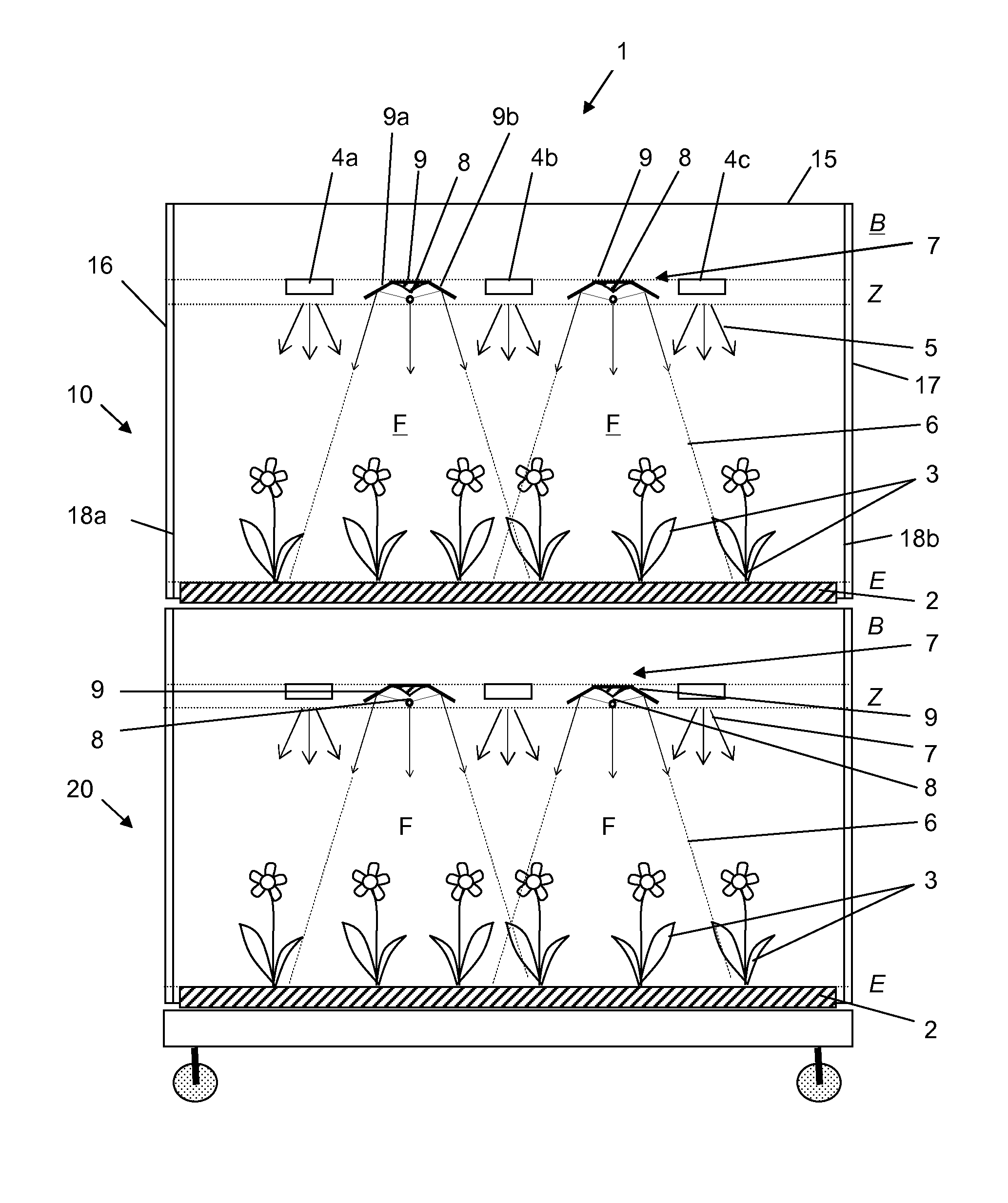

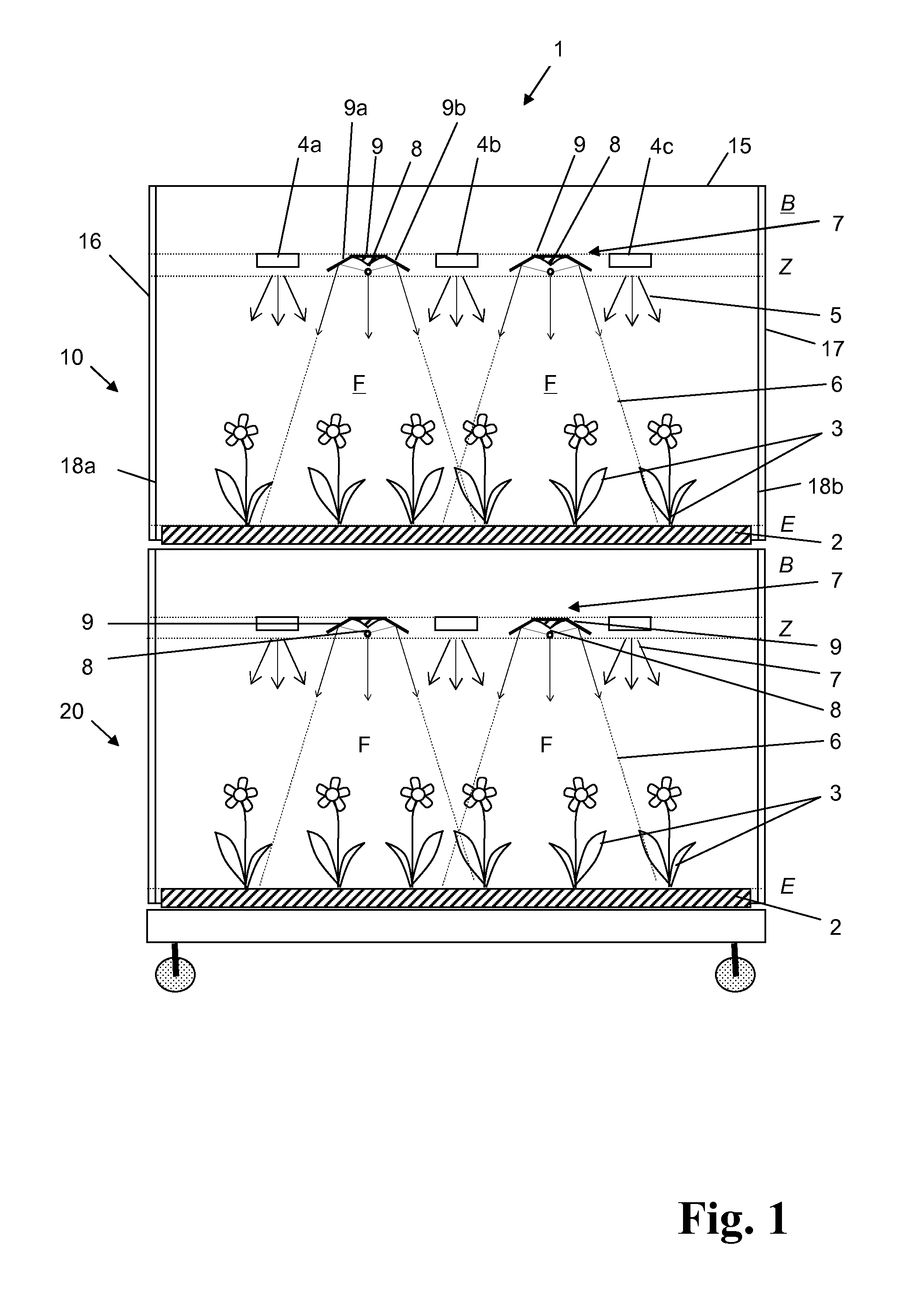

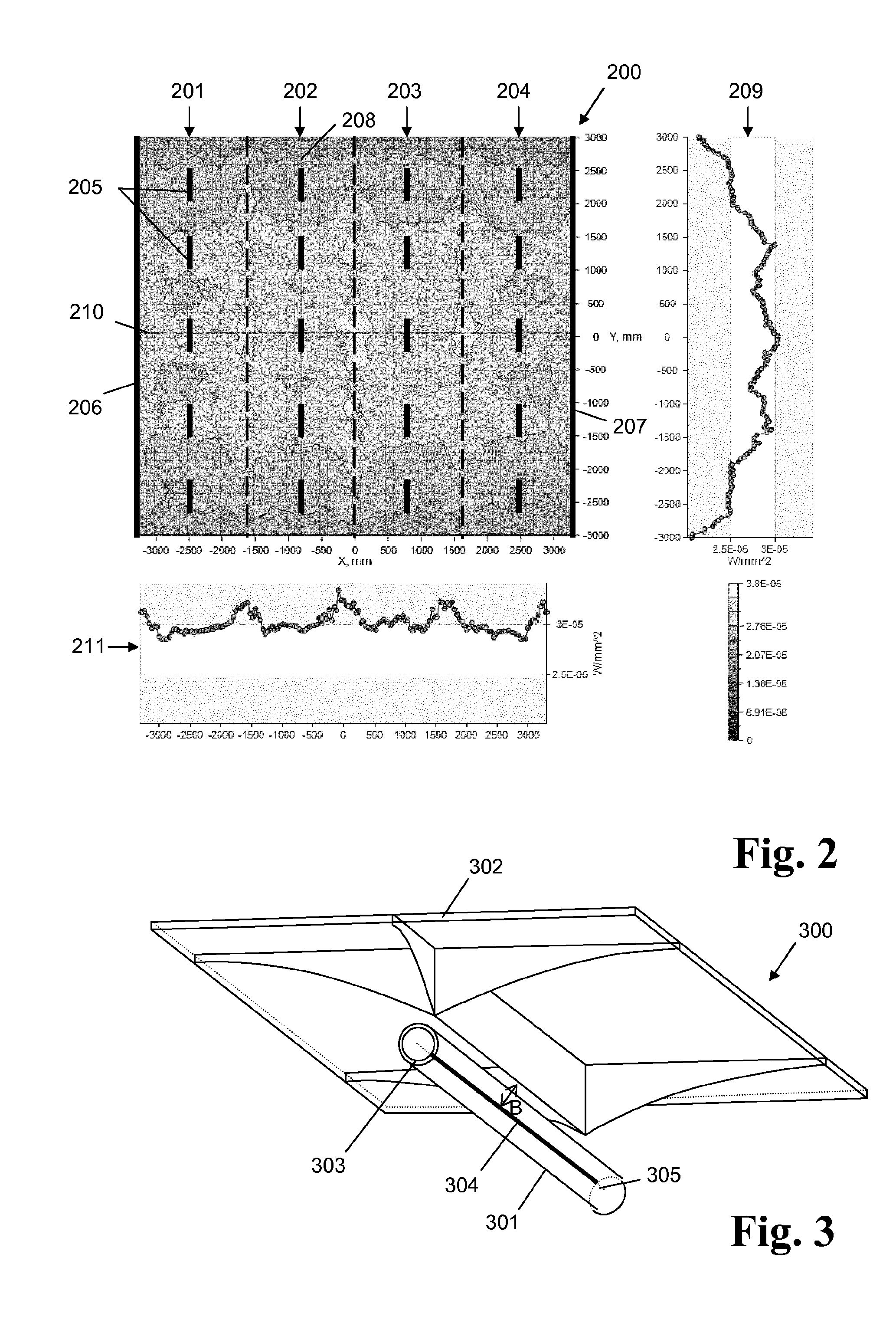

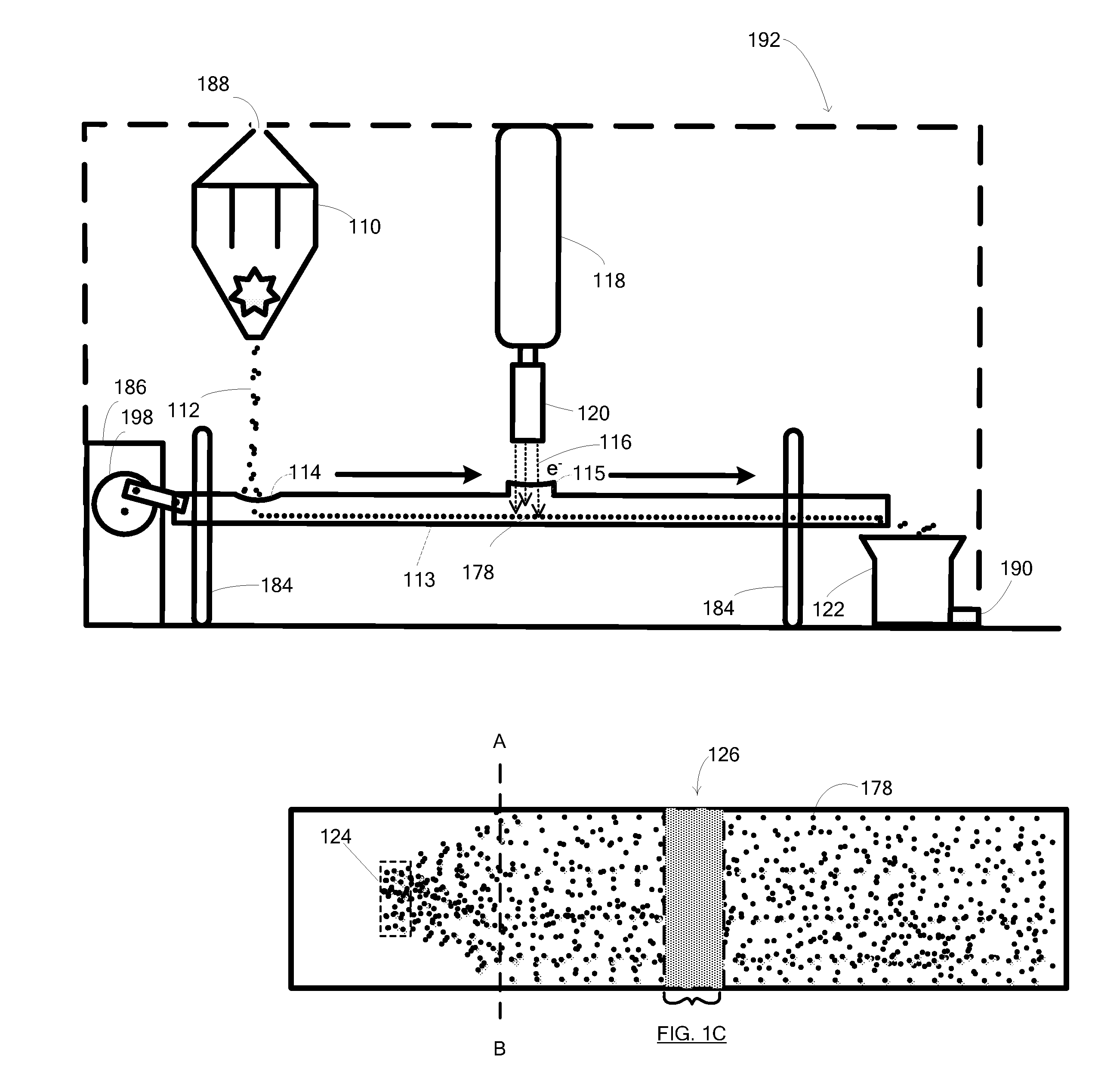

Irradiation device for irradiating plants

InactiveUS20150313090A1Easy to useUniform irradiationMaterial analysis by optical meansSaving energy measuresIrradiationInfrared emitter

A device is provided which ensures uniform irradiation of plants with infrared radiation along with ultraviolet and / or visible radiation and requires a small number of infrared emitters relative to the cultivation area. The infrared emitters are designed for temperatures of 800° C. to 1800° C. Each has a cylindrical emitter tube having a length of 50 mm to 500 mm. The emitter tubes extend parallel to one another in an emitter zone located above the culture plane. The infrared emitter occupation density relative to the area of the culture plane is between 0.2 m−2 and 1.0 m−2. Irradiation regions of adjacent infrared emitters on the culture plane overlap such that average irradiance on the culture plane is between 10 watt / m2 and 100 watt / m2 with a variation range of a maximum of 50%. A reflector facing a structural space is assigned to a top side of the emitter tube.

Owner:HERAEUS NOBLELIGHT GMBH

Processing biomass

Methods and systems are described for processing cellulosic and lignocellulosic materials into useful intermediates and products, such as energy and fuels. For example, conveying systems and methods, such as highly efficient vibratory conveyors, are described for the processing of the cellulosic and lignocellulosic materials.

Owner:XYLECO INC

Device and method for orientation of air floating type liquid crystal substrate

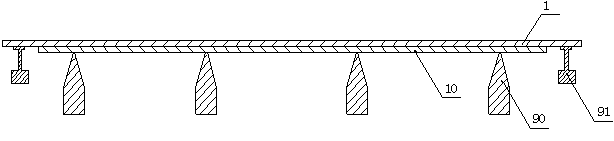

ActiveCN103529599AAvoid the phenomenon of non-uniform alignmentEvenly heatedNon-linear opticsUltraviolet lightsEngineering

The embodiment of the invention discloses a device for orientation of an air floating type liquid crystal substrate. The device comprises a heating platform, supports and supporting ejection needles, wherein a plurality of air holes are formed in the heating platform and used for delivering hot wind which is even in temperature and flows vertically upwards, the supports are arranged on the periphery of the heating platform and used for supporting and clamping the liquid crystal substrate to be oriented, the supporting ejection needles are evenly arranged in the heating platform, can move vertically with the supports in the same direction, and are used for supporting the bottom of the liquid crystal substrate for at least part time, and the air injection amount of the air holes is gradually reduced from the center of the heating platform to the edge of the heating platform. The embodiment of the invention further discloses a corresponding method for orientation. According to the device and method, the liquid crystal substrate is evenly heated and irradiated by ultraviolet light and the quality and the yield of the liquid crystal substrate can be improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Illuminating device and method for manufacturing thereof

ActiveUS20110222286A1Increase costAccurate imagingWave amplification devicesLighting support devicesEngineeringElectrical and Electronics engineering

To provide a method for manufacturing a plurality of types of illuminating devices having different specifications while reducing cost. A substrate includes a common flexible portion and a plurality of units bendable with respect to the common portion, where the common portion includes a pad that is extended in the horizontal direction in the plane of the drawing and that is arranged for every predefined interval. In the present manufacturing method, a substrate piece is created by cutting the substrate mounted with the light emitting element in a first direction, the common portion in the substrate piece is formed according to the illuminating device to be manufactured, the relative position of the individual portion with respect to the formed common portion is respectively positioned, and the wiring for supplying power to the pad in the substrate piece is formed.

Owner:ORMON CORP

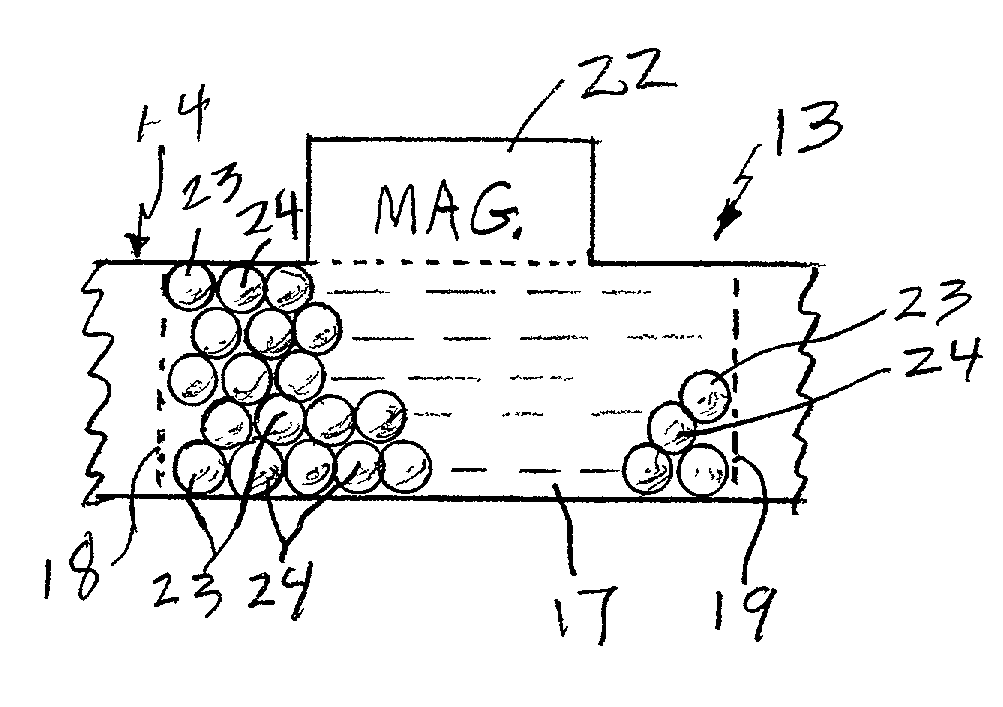

Electrodeless ultraviolet discharge fluid remediation

InactiveUS7112306B2Efficient use ofEfficient repairDeodrantsWater/sewage treatment apparatusMicrowaveUltraviolet

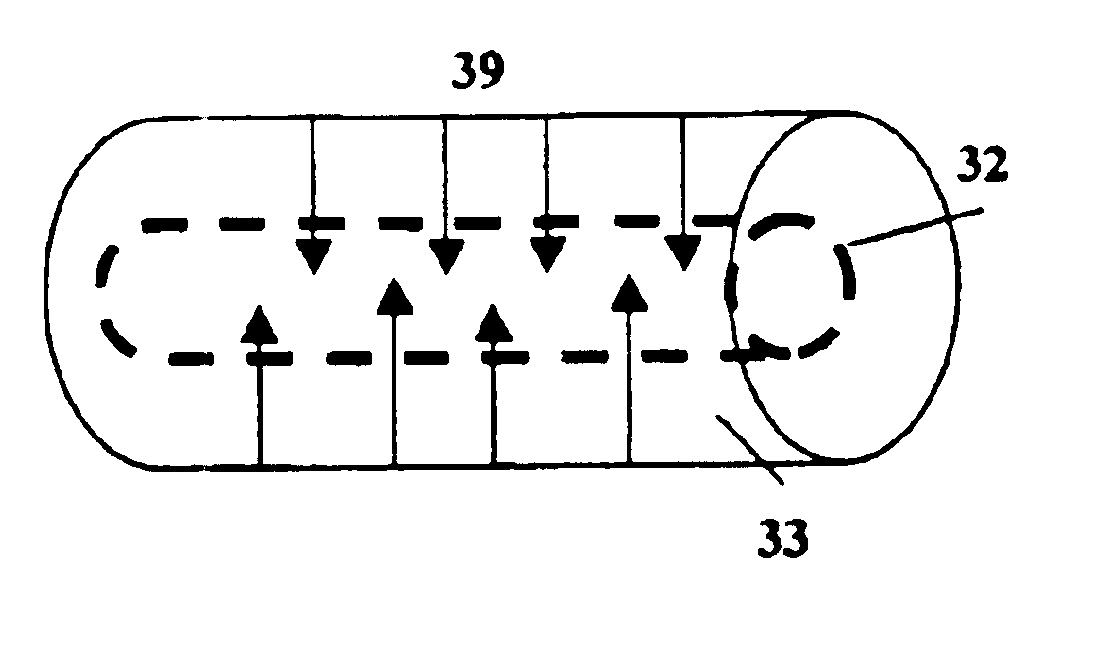

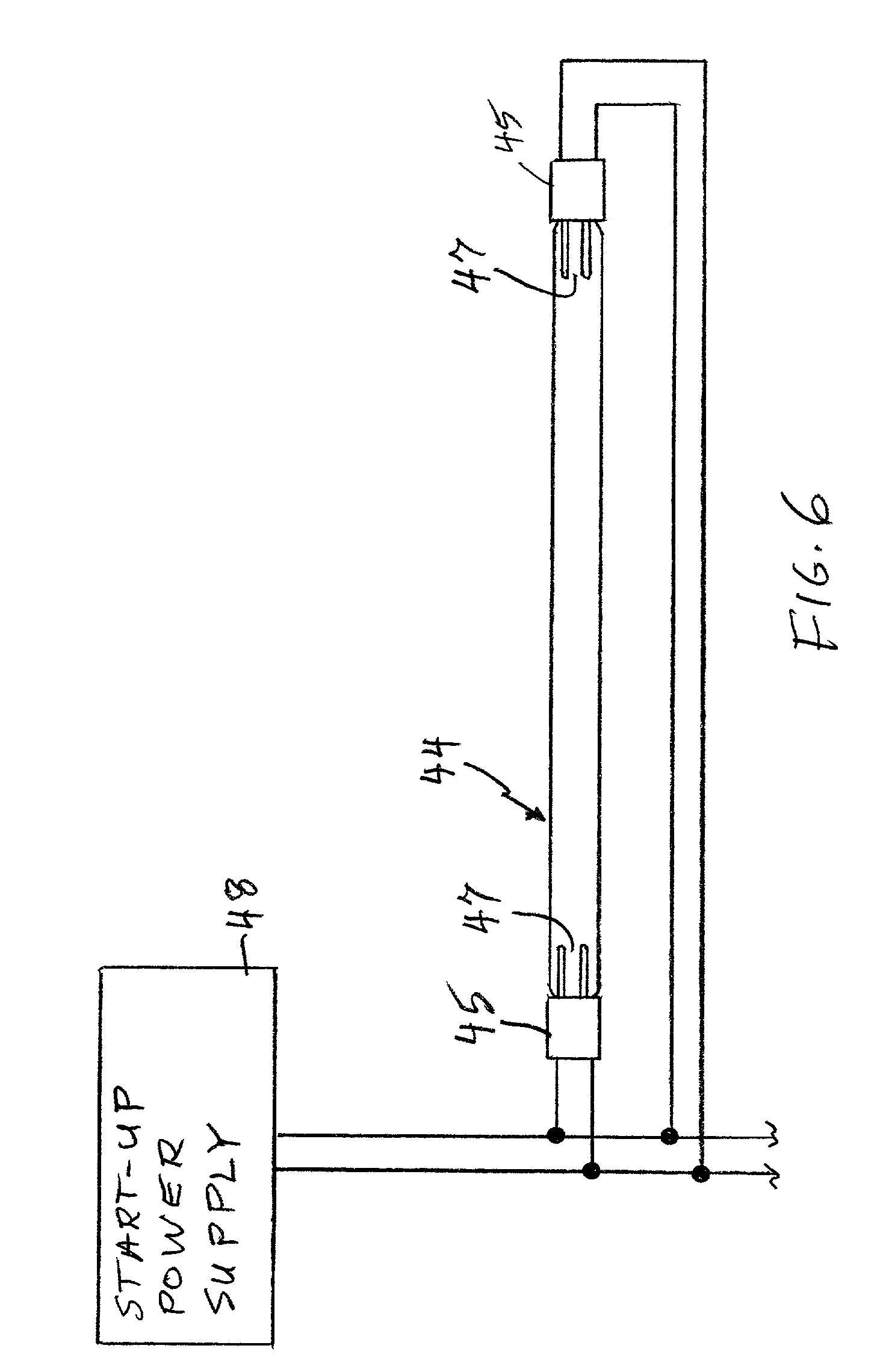

Spherical (23) or cylindrical (27, 36) electrodeless ultraviolet lamps are used to remediate fluid, directly or by excitation of ultraviolet-activated photocatalyst surfaces, which may be on the lamps themselves, or on structures which are permeable by the fluid. The lamps may be excited in cavities (18, 19; 43) by microwave energy from a magnetron (22), or by radio frequency power (39) inductively coupled (40) to the lamps. The lamps (44) may have start-up electrodes (47).

Owner:CARRIER CORP

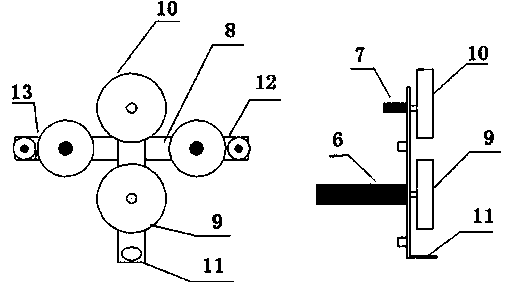

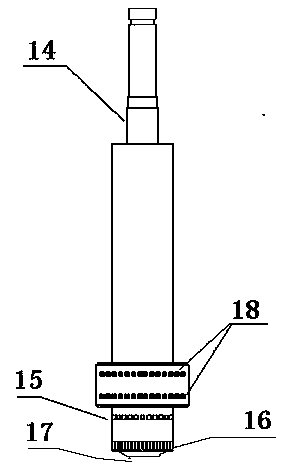

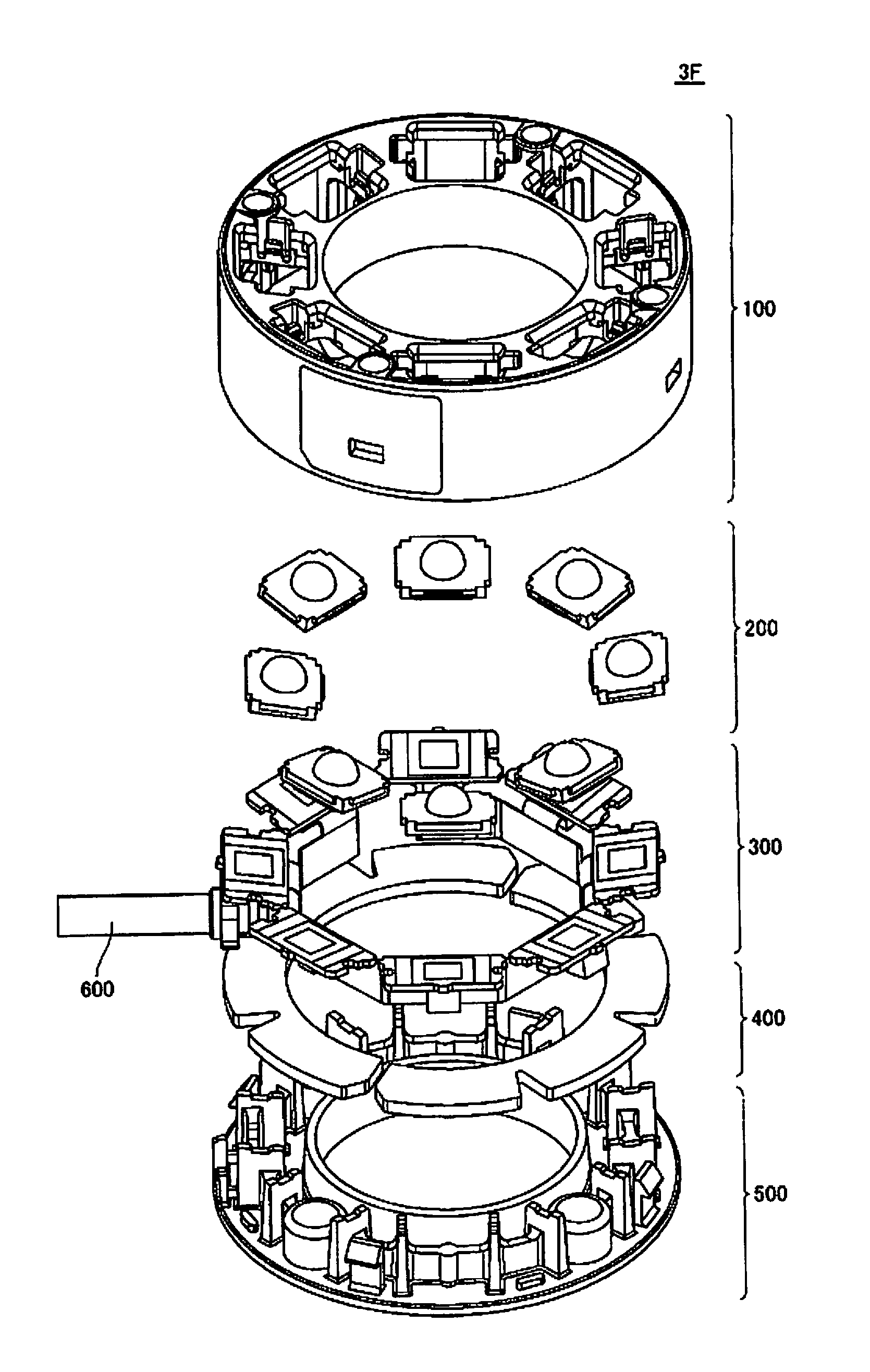

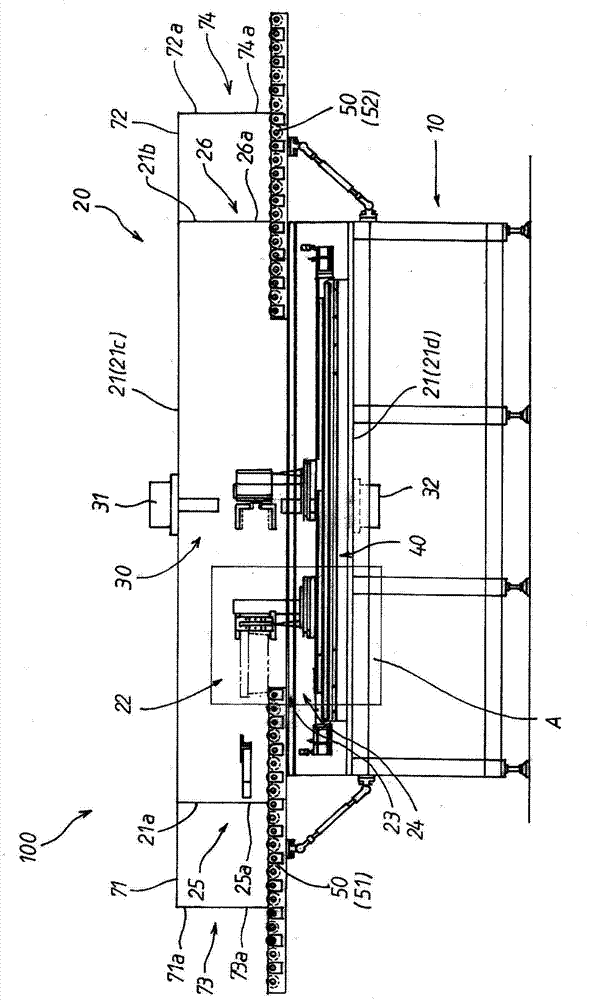

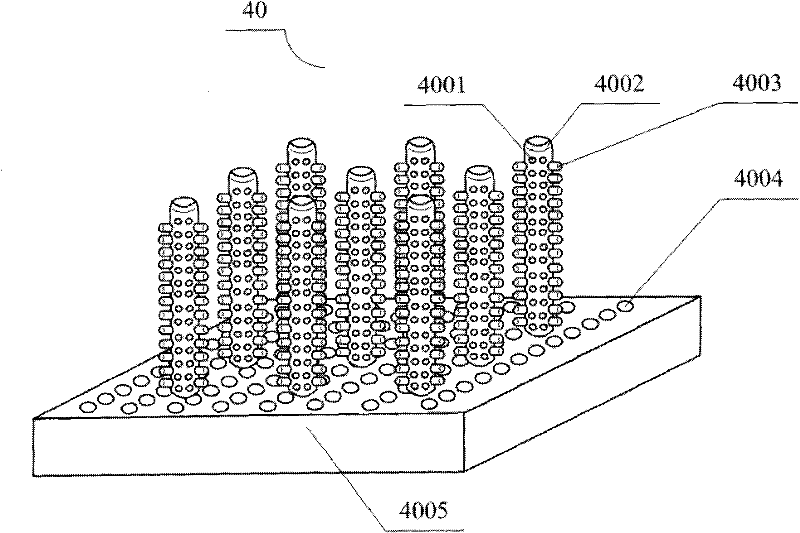

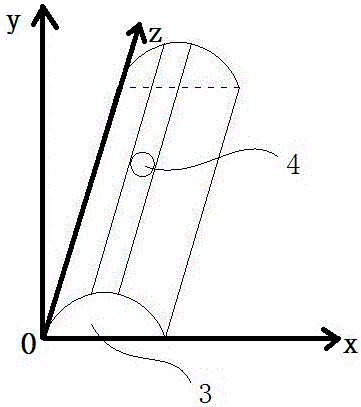

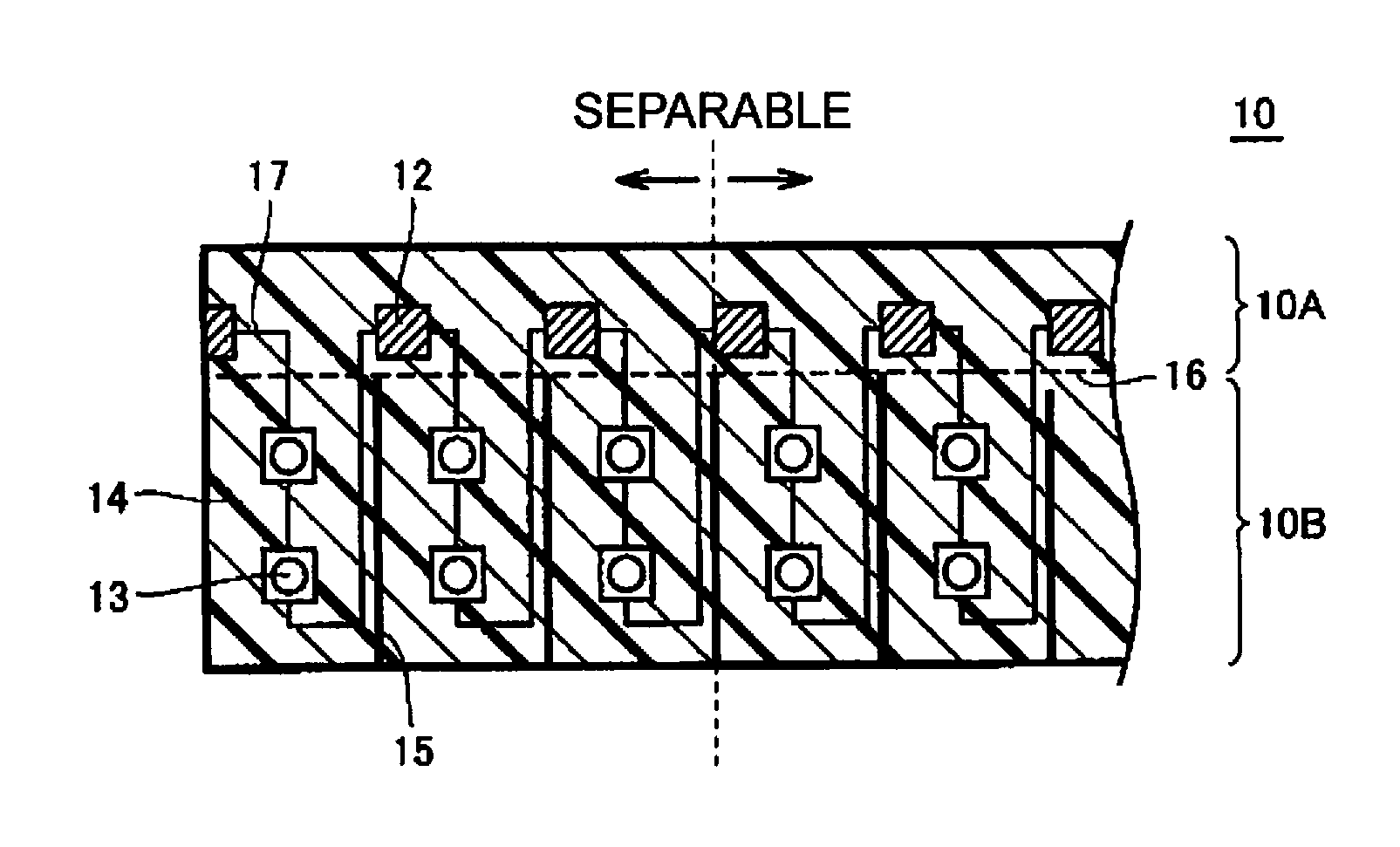

Electronic beam irradiation device

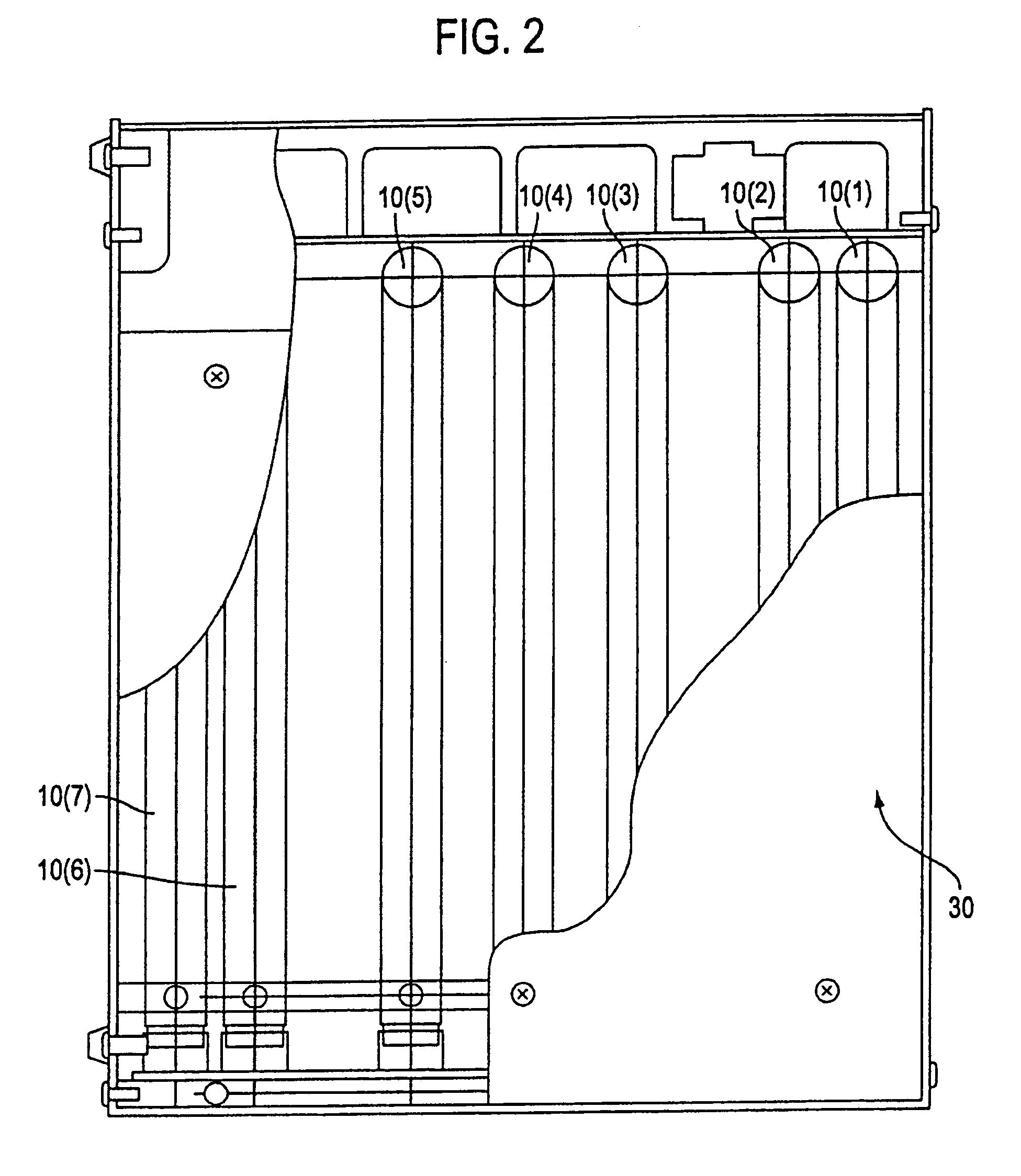

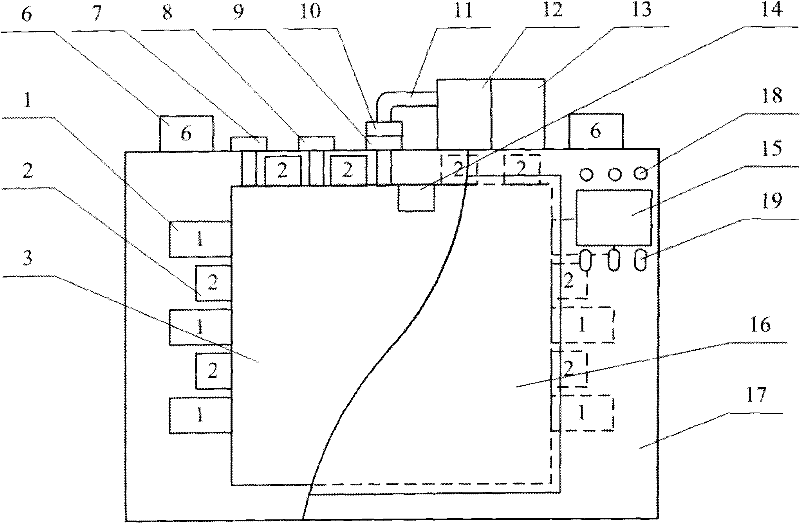

ActiveCN104335290AUniform irradiationDecrease the acceleration voltage actionIrradiation devicesRadiationEngineeringIrradiation

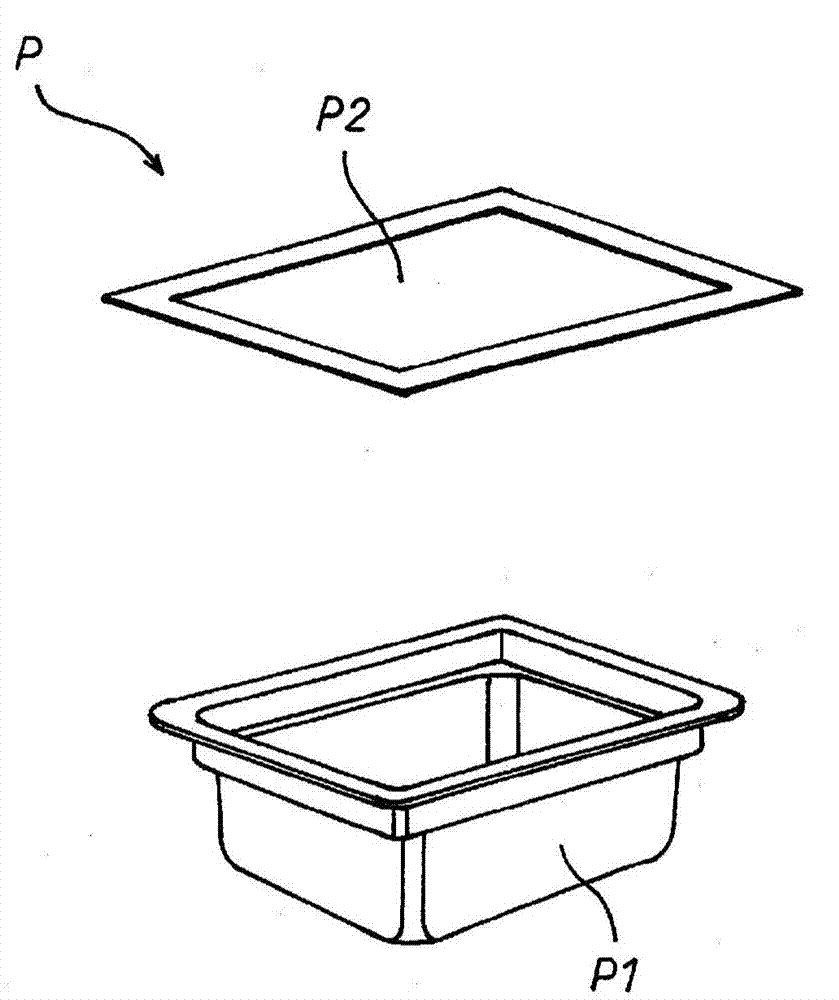

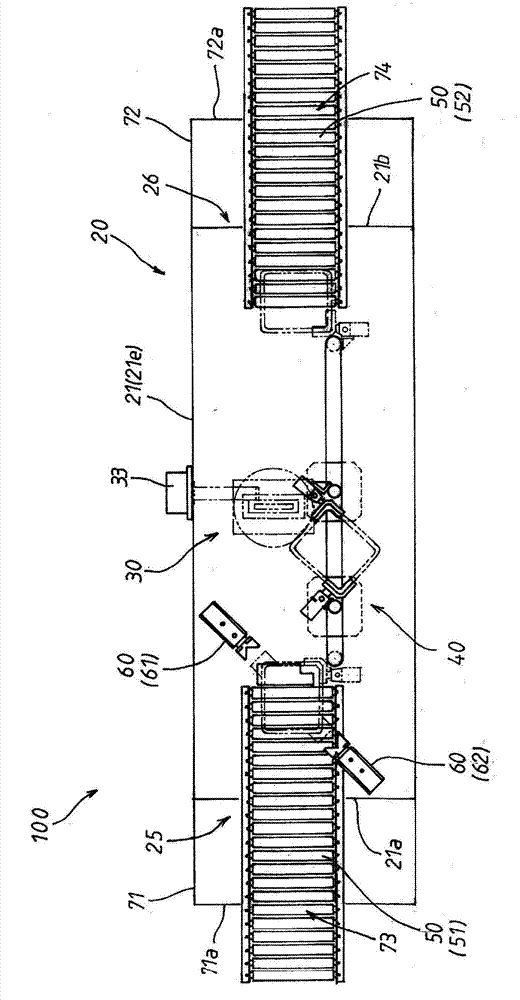

Provided is an electronic beam irradiation device that is able to: use a compact, low-energy electron accelerator with a narrow irradiation window to irradiate an electronic beam uniformly on the entire outer surface of an object for irradiation; keep the reliability and safety of sterilization performance high by making the sterilization level of each of multiple sites substantially the same; and reduce electron accelerator cost, and by extending usage limit (life), equipment initial cost and maintenance cost. The invention comprises an electron beam irradiation means forming an electron beam irradiation area, and a gripping / moving means that grips part of the object for irradiation, and passes said object through the inside of the electron beam irradiation area. The entire surface of the object for irradiation is capable of uniformly passing through the electron beam irradiation area by combining regripping of the object for irradiation by means of two gripping mechanisms that the gripping / moving means is provided with, rotating of the object for irradiation by means of two rotating mechanisms, and moving of the object for irradiation by means of two movement mechanisms.

Owner:AIREX

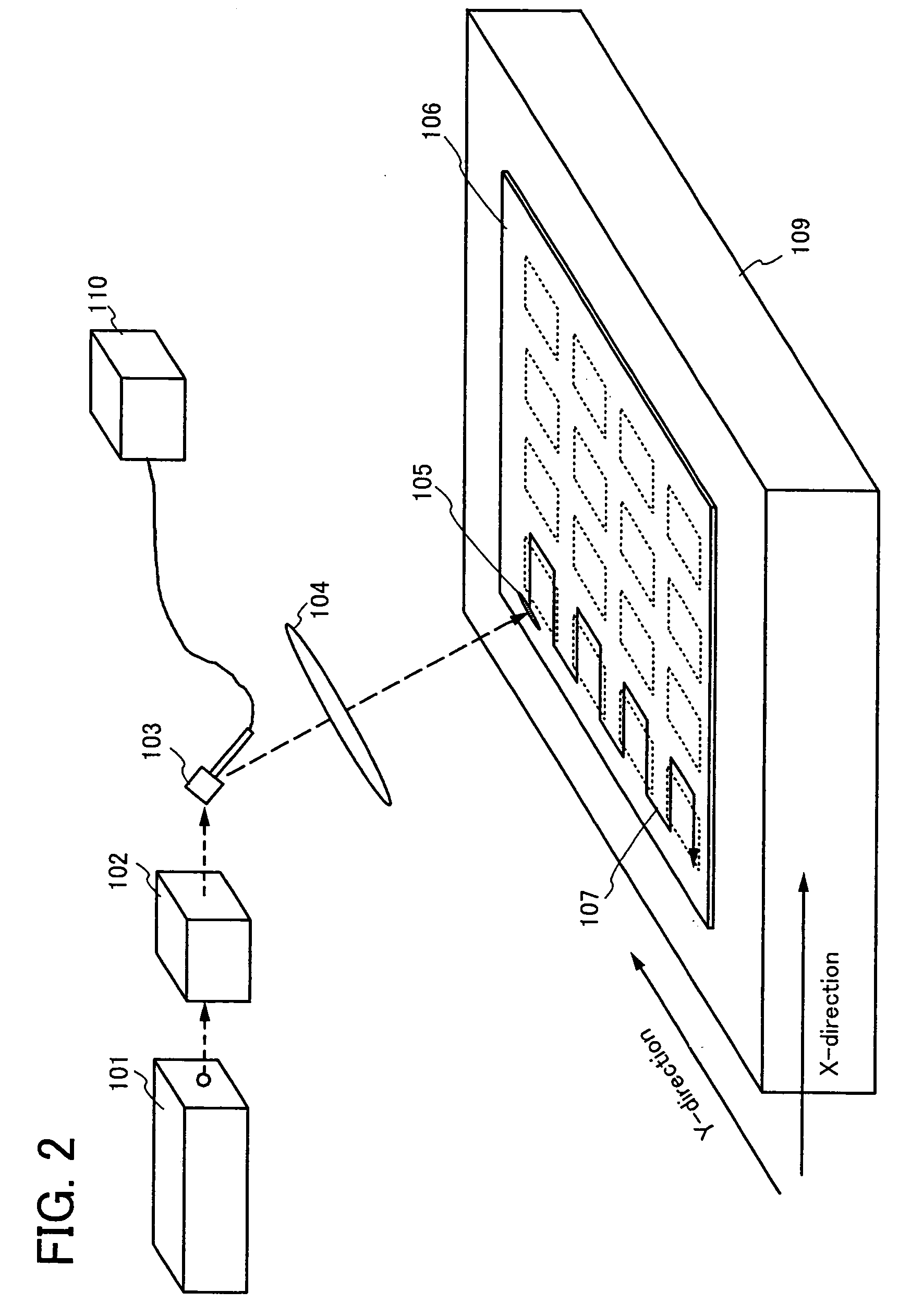

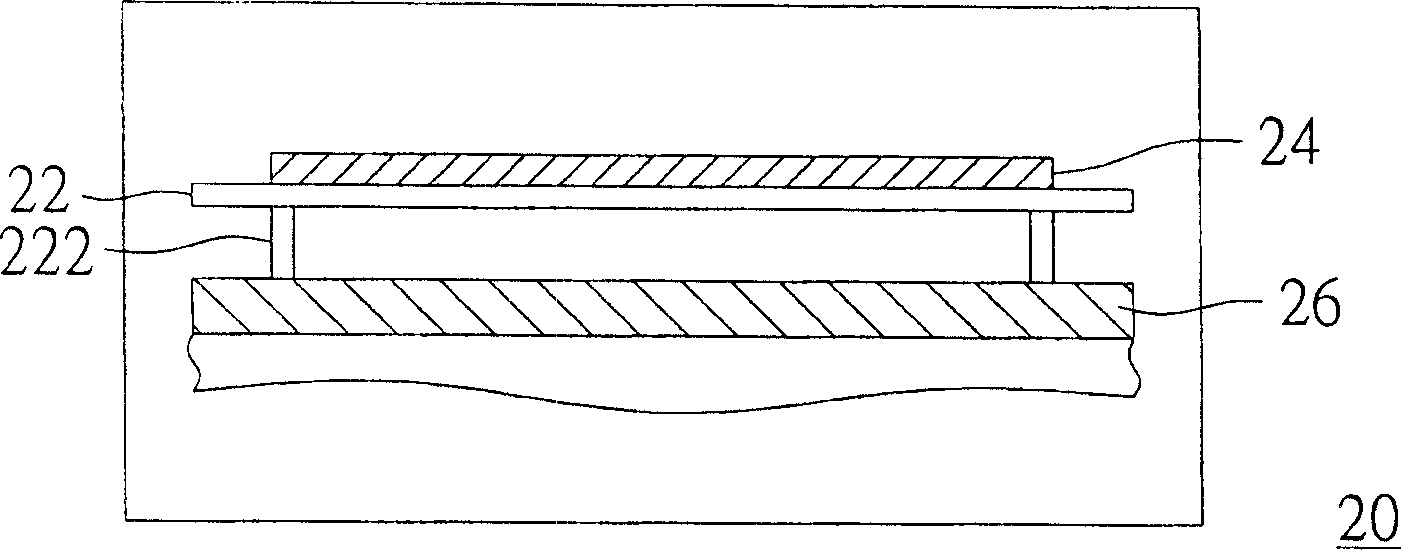

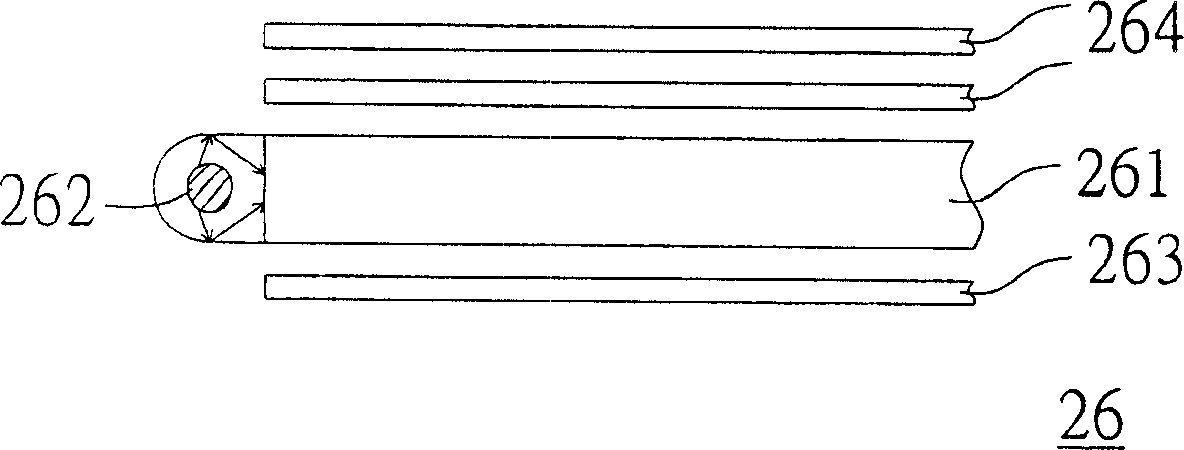

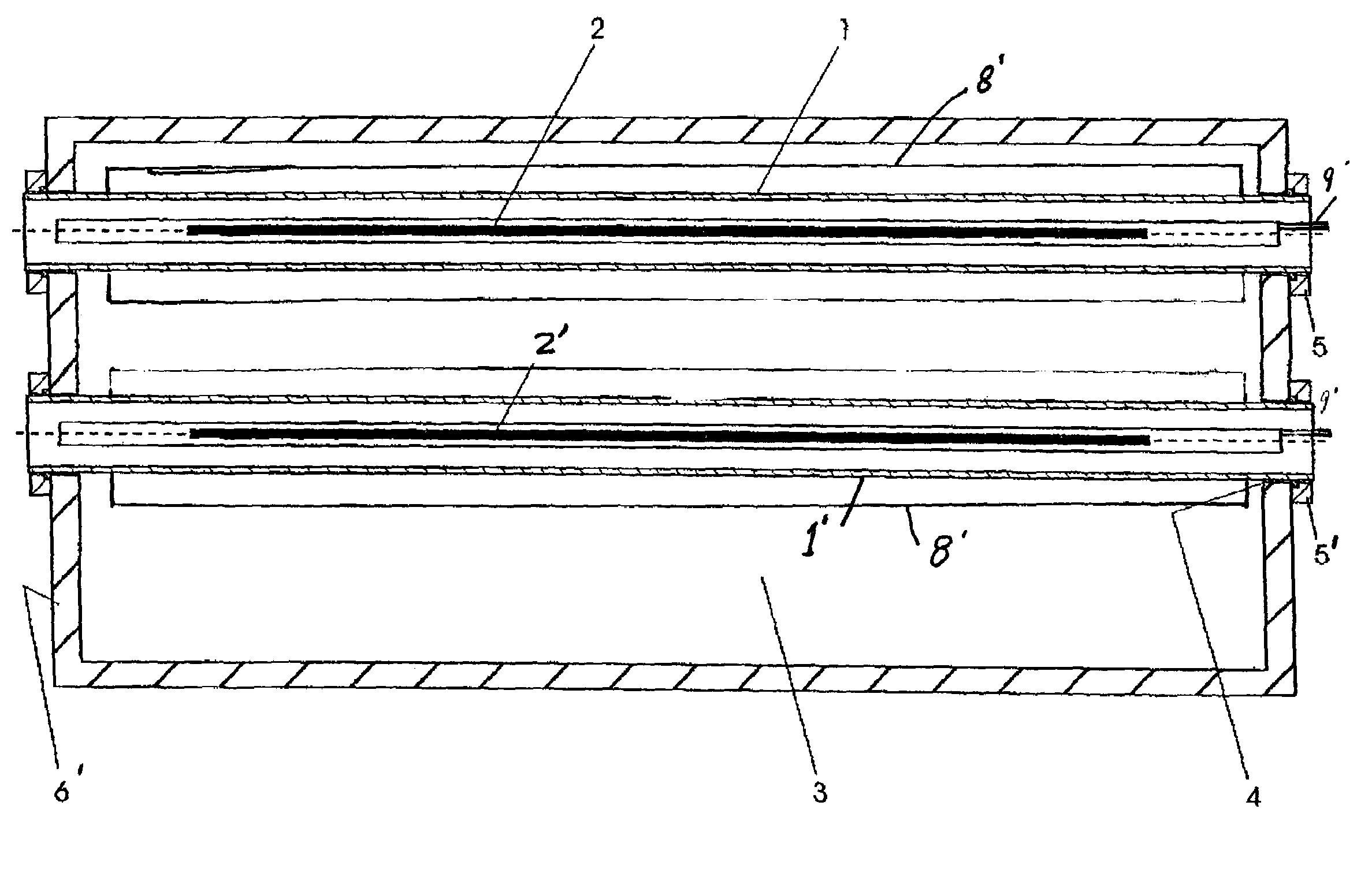

UV curing apparatus for group substrate

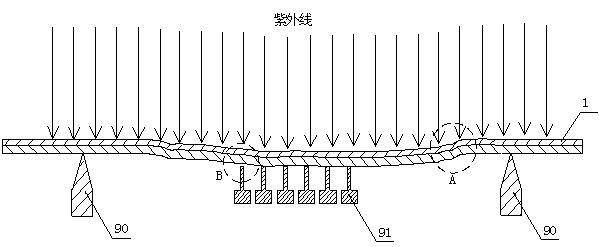

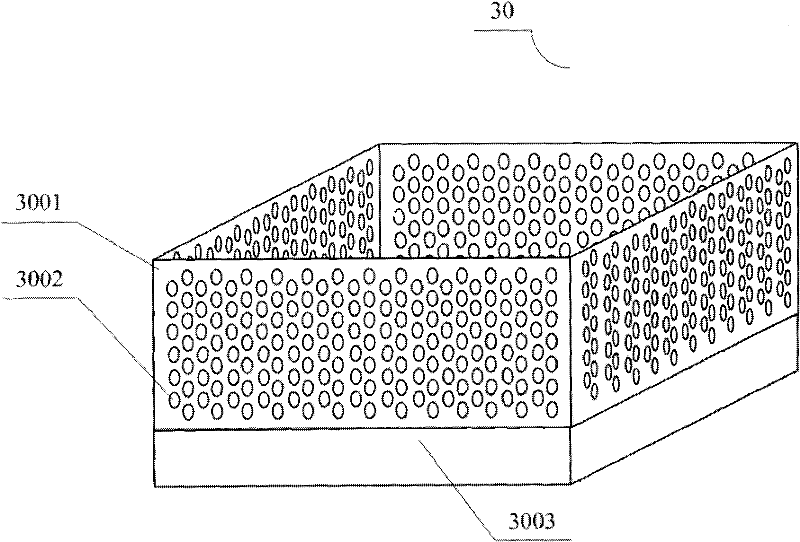

InactiveCN1869794AImprove uniformityIncrease illuminationNon-linear opticsIdentification meansIlluminanceUV curing

An ultraviolet curing apparetus consists of a bearing unit for bearing a pair of mother board and an optical unit for curing a pair of said mother board. It is featured as forming optical unit by a backlight unit set at one side of bearing unit and used to let light shine on pair of said mother board uniformly, forming said backlight unit by a light source and a substrate.

Owner:INNOLUX CORP

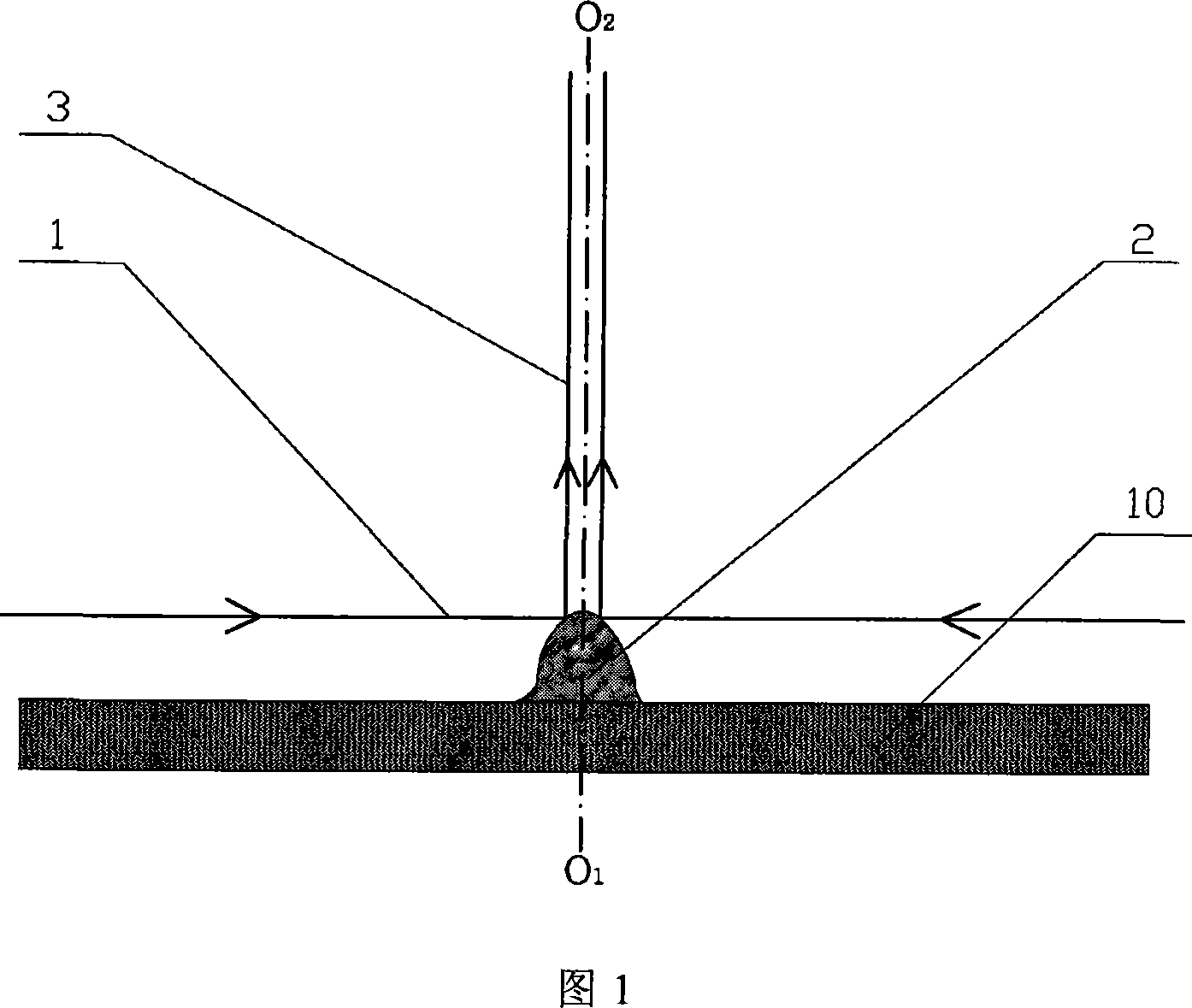

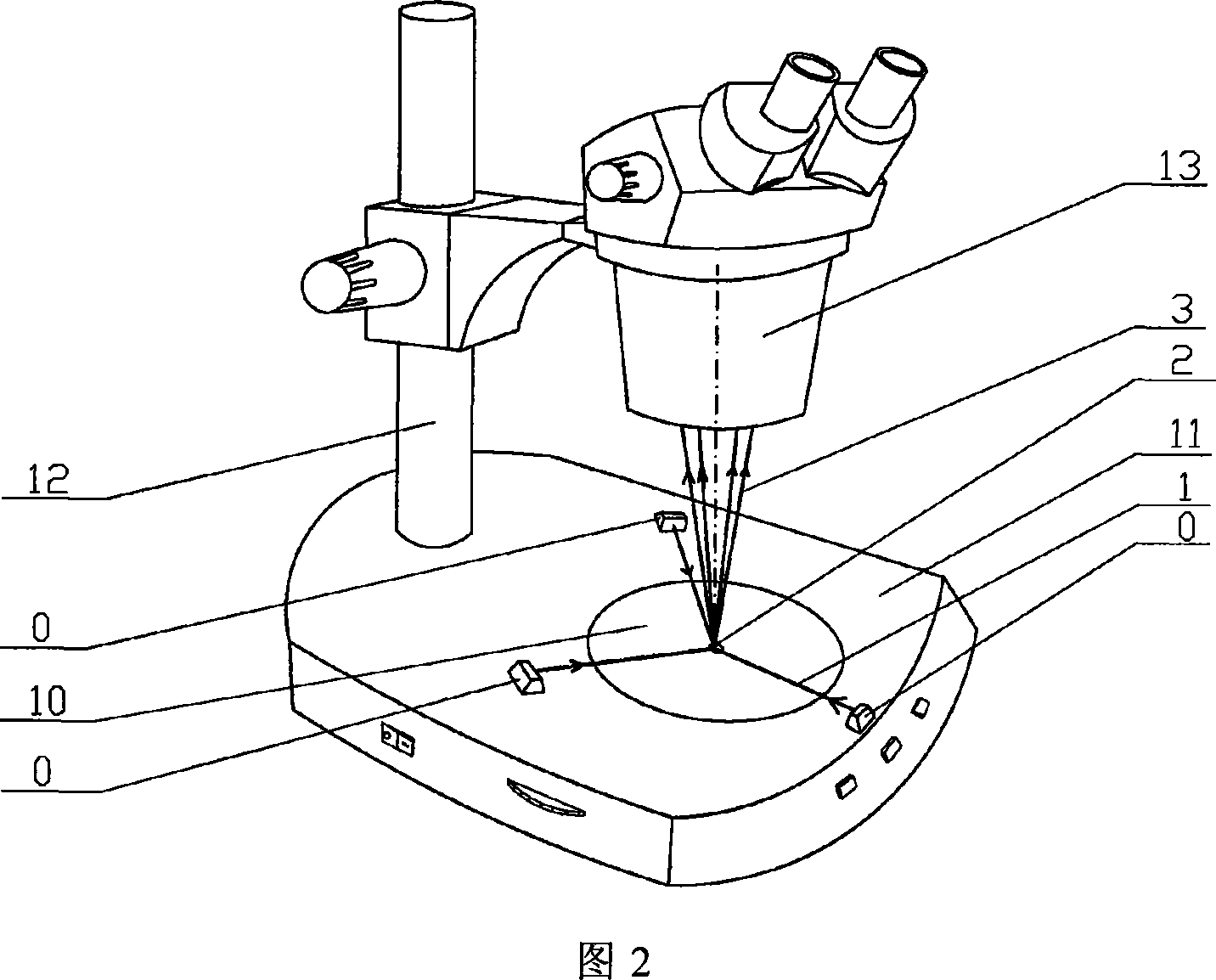

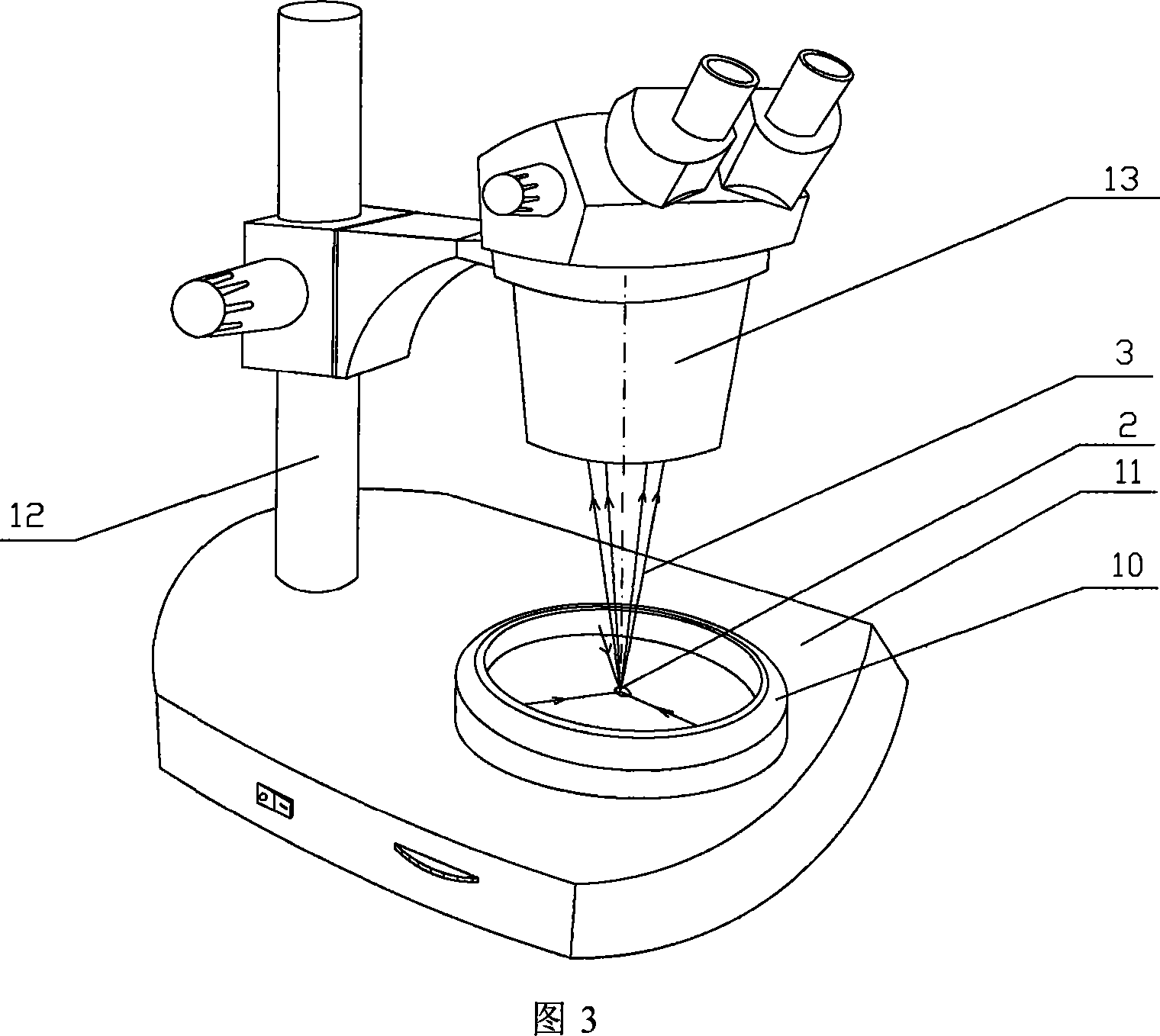

Stereomicroscope side-irradiation type lighting method and its dark view stereomicroscope

The invention relates to a stereomicroscope side lighting method and the dark-field stereomicroscope thereof. The method uses the beam emitted from the light source to lighting the observed sample from the side of the stereomicroscope stage, and the beam is satisfied the following characteristic: firstly,the beam and the observed sample are in a same plane spatial limit, secondly, the included angle between the beam and the symmetrical line O1O2 of the two object lens primary optic axis of the stereomicroscope is 80 to 100 degrees. The design consideration of the dark-field stereomicroscope which is an improvement for the traditional stereomicroscope, is enable the last light part directly emitted from the light source or through the optical instrument to change the direction to horizontally locate the observed sample stage, so that the symmetrical line O1O2 of the stage and the two object lens primary optic axis is arranged vertically. By using the method and the dark-field stereomicroscope thereof can effectively lighten the interference of the background light, greatly improve the contrast and the signal to noise ratio of the observed sample, especially fit for the liquid phase dissection observation.

Owner:TONGJI HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI TECH

Radiant heating system with a high infrared radiant heating capacity, for treatment chambers

InactiveUS7067770B1Simple adaptationUniform irradiationDrying solid materials with heatMuffle furnacesEngineeringRadiative heating

A radiant heating arrangement with a high infrared heating capacity for treatment chambers provides a vacuum-compatible radiant heating system with which it is possible to achieve considerable radiation levels reliably. The radiant heating arrangement includes a tube that is permeable to infrared radiation. The tube extends into the treatment chamber and penetrates the wall of the chamber with at least one end. A source of infrared radiation is situated inside the tube with the inside of the tube being isolated from the atmosphere inside the treatment chamber.

Owner:CENTROTHEM PHOTOVOLTAICS AG

Low-temperature negative pressure drying method and device for textile materials and textiles

InactiveCN102175071AOvercoming the bottleneck of the relatively long isokinetic drying phaseFast drying processDrying using combination processesDrying machines with local agitationResonant cavityMicrowave

The invention discloses a low-temperature negative pressure drying method and a low-temperature negative pressure drying device for textile materials and textiles. The device comprises a microwave source, a temperature sensor, a resonant cavity, an air-cooled or water-cooled device, a vacuum sensor, an air release valve, a humidity sensor, an air extraction valve, an air extraction pipeline, a vacuum pump, a vacuum pump motor, a stirrer, a panel, a controller, a shielding sealing door, a shell, an indicating lamp, a switch, a scattered article drying box and a cheese drying bracket; and the scattered textile materials or textiles are put into the scattered article drying box, or cheeses are stacked on the cheese drying bracket and then put into the resonant cavity, and the dried articles are heated and dried under the low-temperature negative pressure working condition. Relatively long bottleneck at the uniform velocity drying stage when single microwave is used for drying can be effectively overcome, over drying is avoided, and the whole drying process is quick and energy-saving; and the method and the device can particularly meet the drying requirements of special animal fibers, artificial fibers, synthetic fibers and like and the products thereof with special temperature requirements.

Owner:SHANGHAI ZHONGFANG BAODA TEXTILE INTELLIGENT INSTR +2

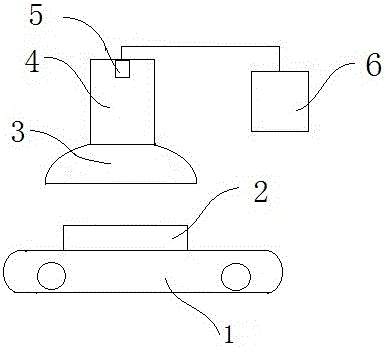

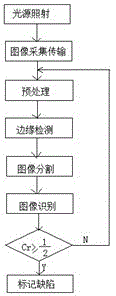

Device and method for detecting surface defects of perforated plate workpiece

PendingCN106442556AImprove interchangeabilityUniform irradiationOptically investigating flaws/contaminationImaging processingTransfer system

The invention discloses a device and method for detecting surface defects of a perforated plate workpiece. The system comprises a transfer system, a special-shaped illuminating light source, an industrial charge coupled device (CCD) image sensor, an image acquisition card and a processor. A to-be-detected perforated plate workpiece is horizontally arranged in the transfer system; the special-shaped illuminating light source adopts a shed-shaped structure light source of which the top is arc-shaped and the horizontal section is rectangular, and is arranged at the periphery of a lens of the industrial CCD image sensor; the industrial CCD image sensor comprises a camera main body, a lens and an interface C; the camera main body adopts an industrial CCD camera and is connected with the lens through the interface C; the lens is arranged on the inner side of the special-shaped illuminating light source and is perpendicular to the to-be-detected perforated plate workpiece; the image acquisition card serves as the connector of an image acquisition part and an image processing part; the processor is used for realizing the operation of corresponding codes in a programming environment, calculating and marking the defect positions and intuitively displaying the defect positions. According to the detection device disclosed by the invention, the surface defect positions can be accurately displayed, and the workpiece defect information is acquired instead of human eyes, therefore, the detection accuracy is high.

Owner:HARBIN UNIV OF SCI & TECH

Illuminating device and method for manufacturing thereof

ActiveUS8491157B2Accurate imagingUniform irradiationWave amplification devicesLighting support devicesEngineeringElectrical and Electronics engineering

To provide a method for manufacturing a plurality of types of illuminating devices having different specifications while reducing cost. A substrate includes a common flexible portion and a plurality of units bendable with respect to the common portion, where the common portion includes a pad that is extended in the horizontal direction in the plane of the drawing and that is arranged for every predefined interval. In the present manufacturing method, a substrate piece is created by cutting the substrate mounted with the light emitting element in a first direction, the common portion in the substrate piece is formed according to the illuminating device to be manufactured, the relative position of the individual portion with respect to the formed common portion is respectively positioned, and the wiring for supplying power to the pad in the substrate piece is formed.

Owner:ORMON CORP

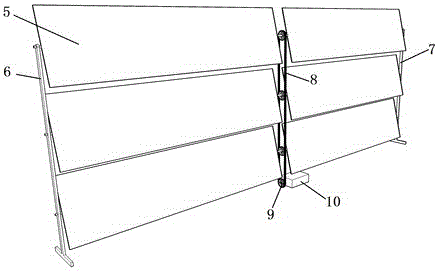

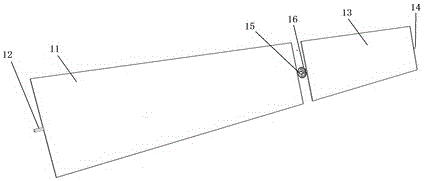

Greenhouse with adjustable light reflection device

InactiveCN106550798AUniform irradiationImprove strength utilizationClimate change adaptationRenewable energy machinesElectricityGreenhouse

The invention discloses a greenhouse with an adjustable light reflection device. The greenhouse comprises the adjustable light reflection device, a light-transmission layer, a heat preservation enclosing structure and a movable heat preservation quilt. The adjustable light reflection device is located in the greenhouse and close to the north face of the greenhouse. The movable heat preservation quilt is arranged on the light-transmission layer. The adjustable light reflection device comprises a plurality of reflector modules, a left supporting rod, a right supporting rod, a traction chain, driving gears and a motor cabinet. The reflector modules are parallelly placed in the vertical direction and connected with the traction chain through the gears. A motor in the motor cabinet drives the driving gears to rotate so as to adjust reflector angles. By adoption of the greenhouse, the solar energy utilization rate of the unit floor area is increased, meanwhile, the intensity of sunlight received by plants is improved, the heat preservation performance and the sunlight uniformity of the greenhouse are ensured, and the greenhouse is simple in structure, low in cost, attractive in appearance, and large in popularization potentiality.

Owner:NANJING SUOLEYOU ENERGY SAVING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com