Patents

Literature

54results about How to "Uniform crystallinity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of manufacturing a semiconductor device

InactiveUS6872607B2Uniform crystallinityEasy to useRadiation applicationsSolid-state devicesLaser annealingAmorphous semiconductors

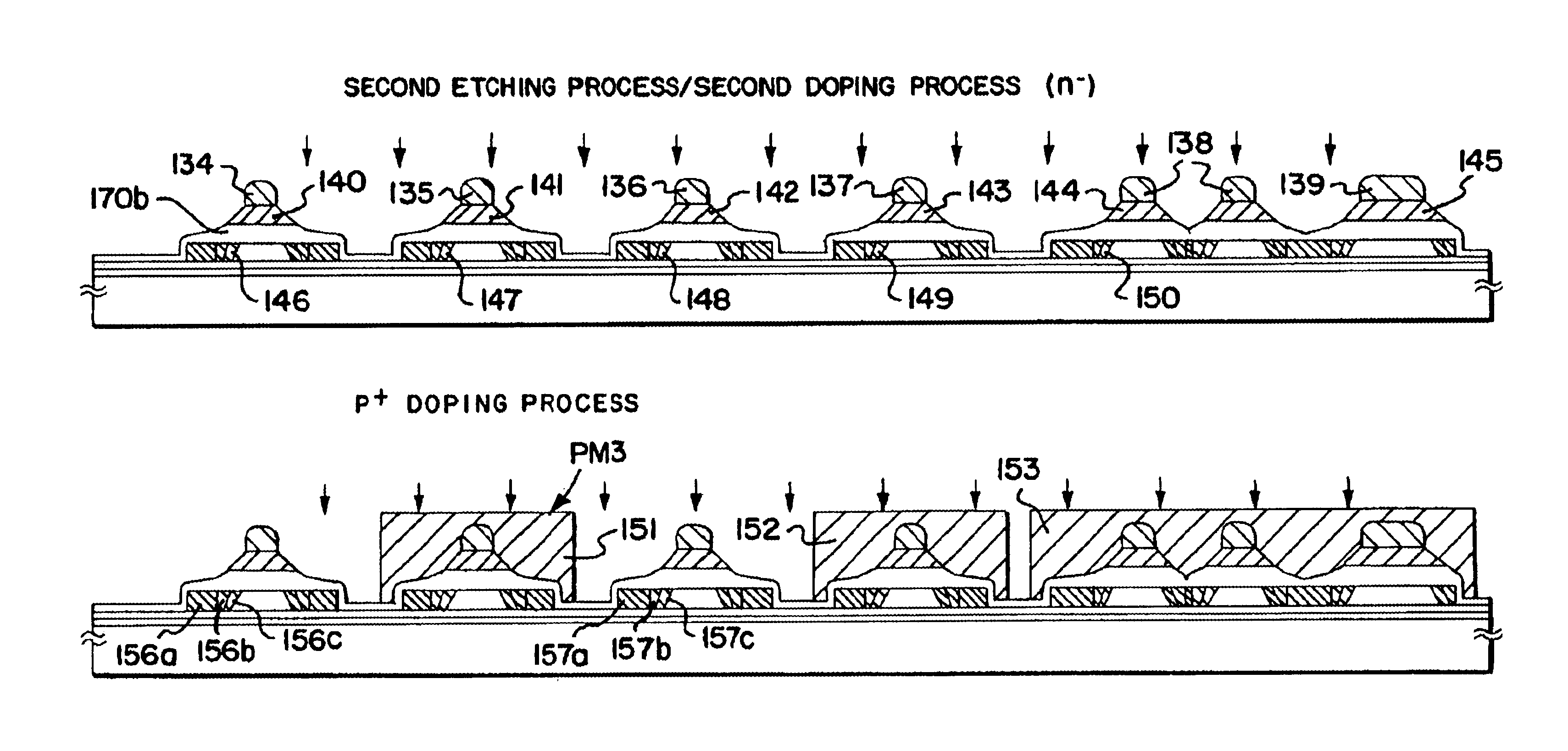

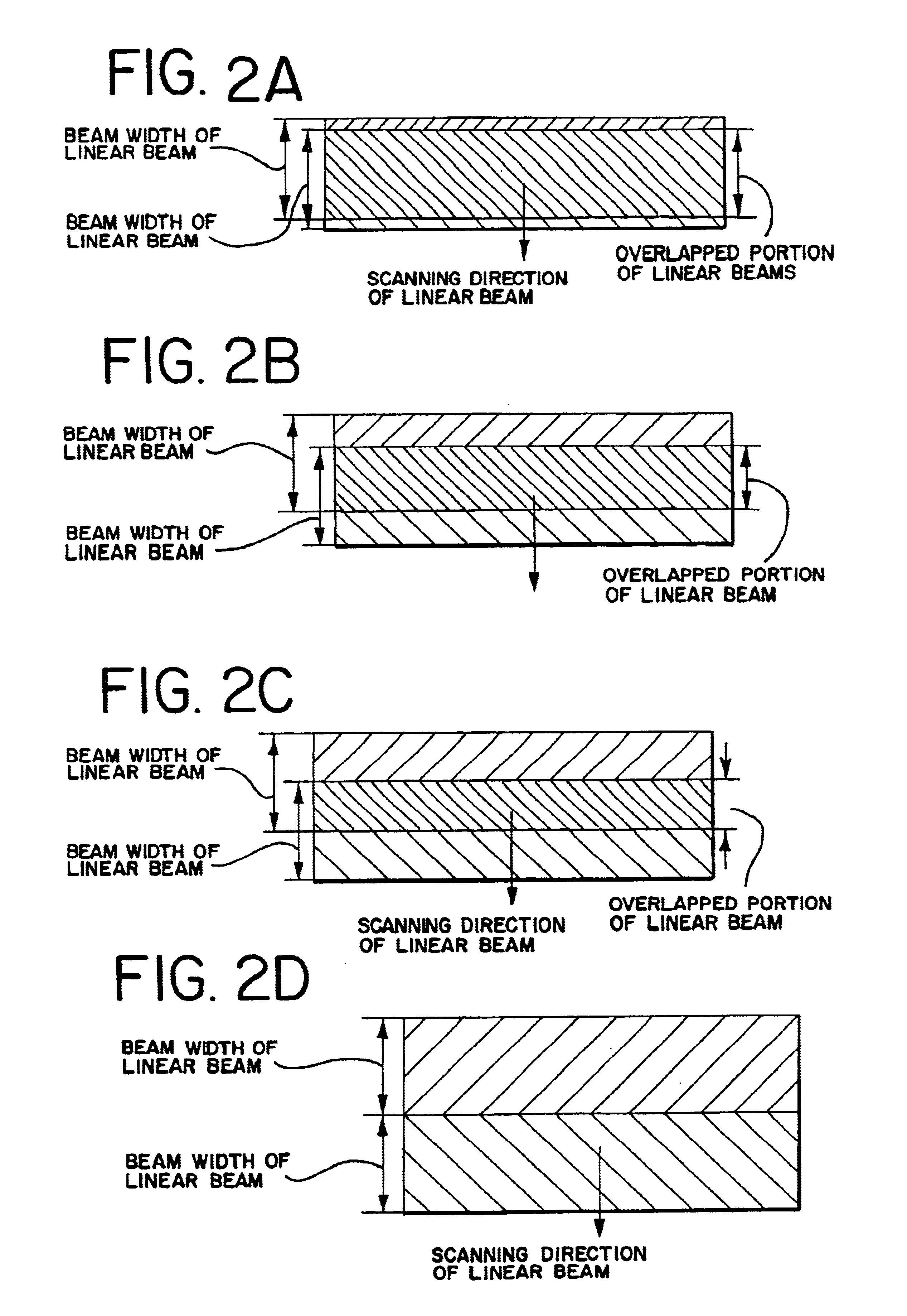

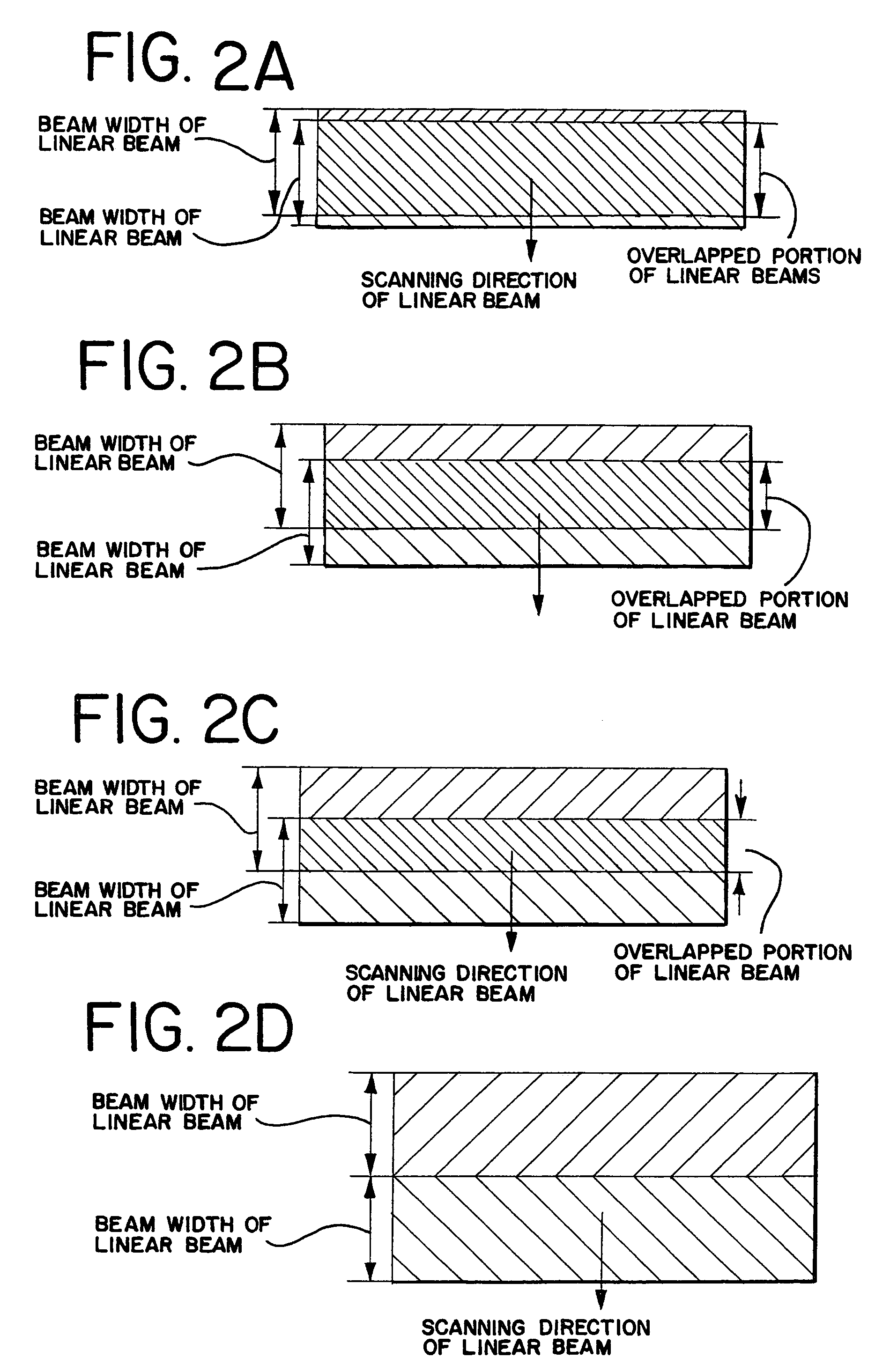

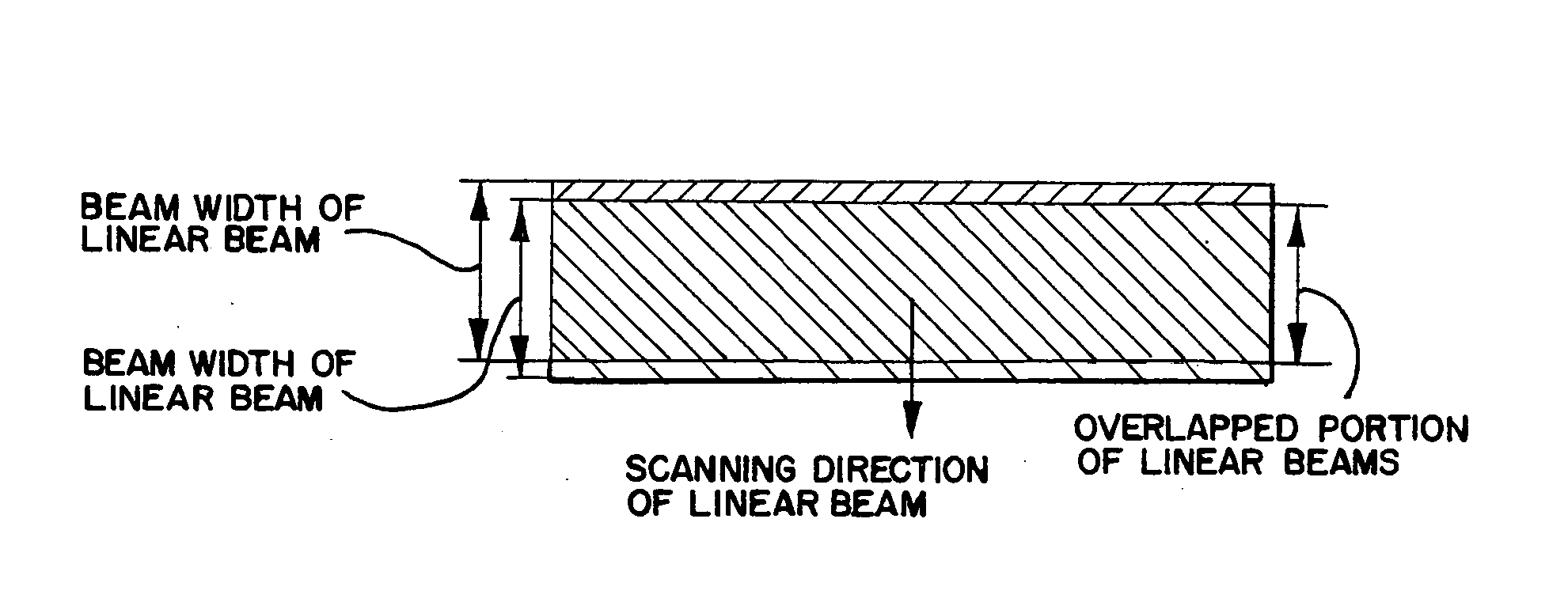

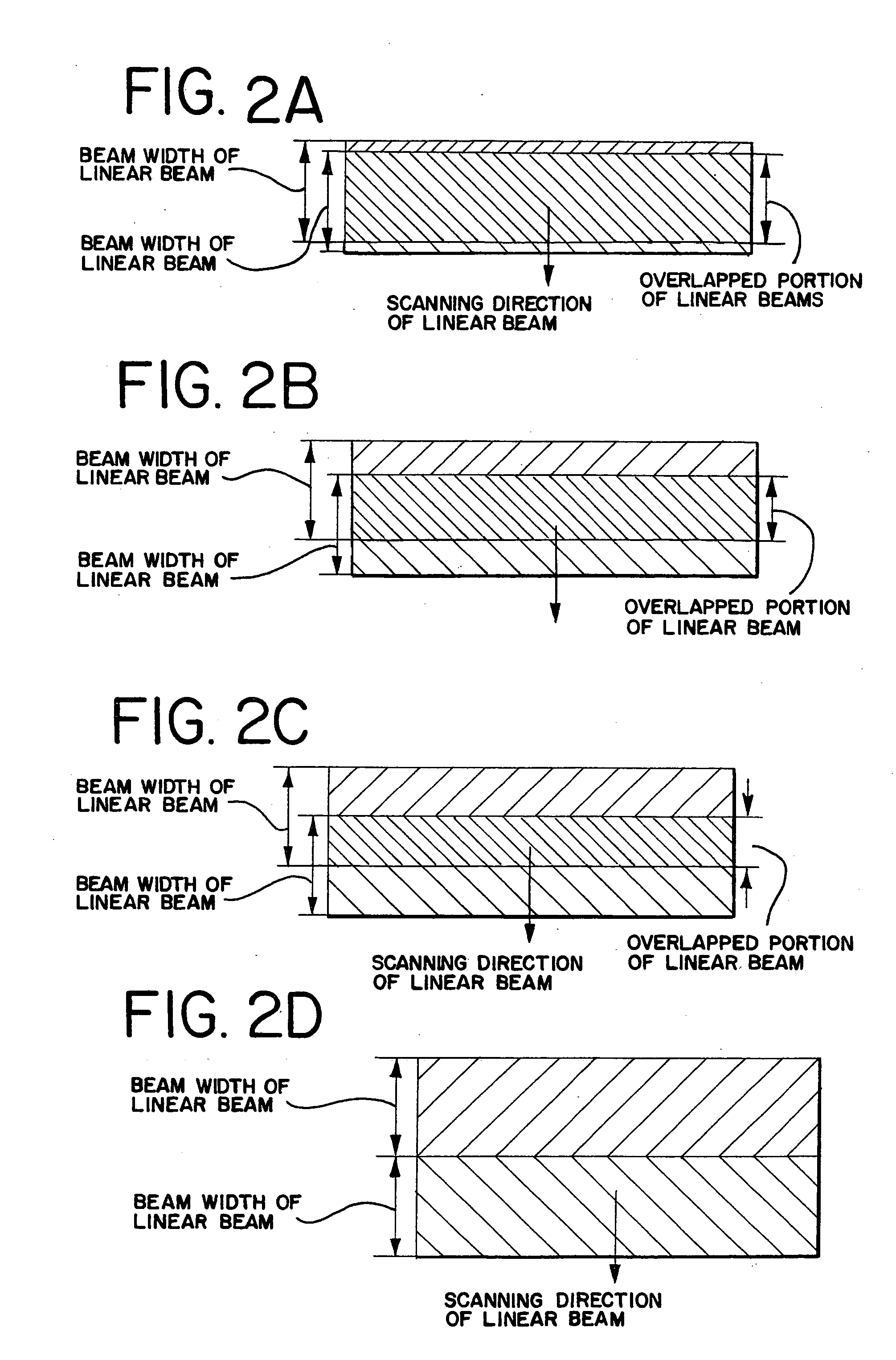

By using lasers having different wavelengths in laser annealing of an amorphous semiconductor film, the amorphous semiconductor film can be crystallized and the crystallinity of the crystallized film is improved. A laser 126 to 370 nm in wavelength is used first to subject an amorphous semiconductor film to laser annealing, thereby obtaining a crystalline semiconductor film. In desirable laser annealing, a subject surface is irradiated with a laser beam processed by an optical system into a linear laser beam that is linear in section on the subject surface. Next, a laser 370 to 650 nm in wavelength is used to irradiate the above crystalline semiconductor film by again processing the laser beam into a linear beam through an optical system. A crystalline semiconductor film thus obtained has an excellent crystallinity. If this crystalline semiconductor film is used to form an active layer of a TFT, an electric characteristic of the TFT can be improved.

Owner:SEMICON ENERGY LAB CO LTD

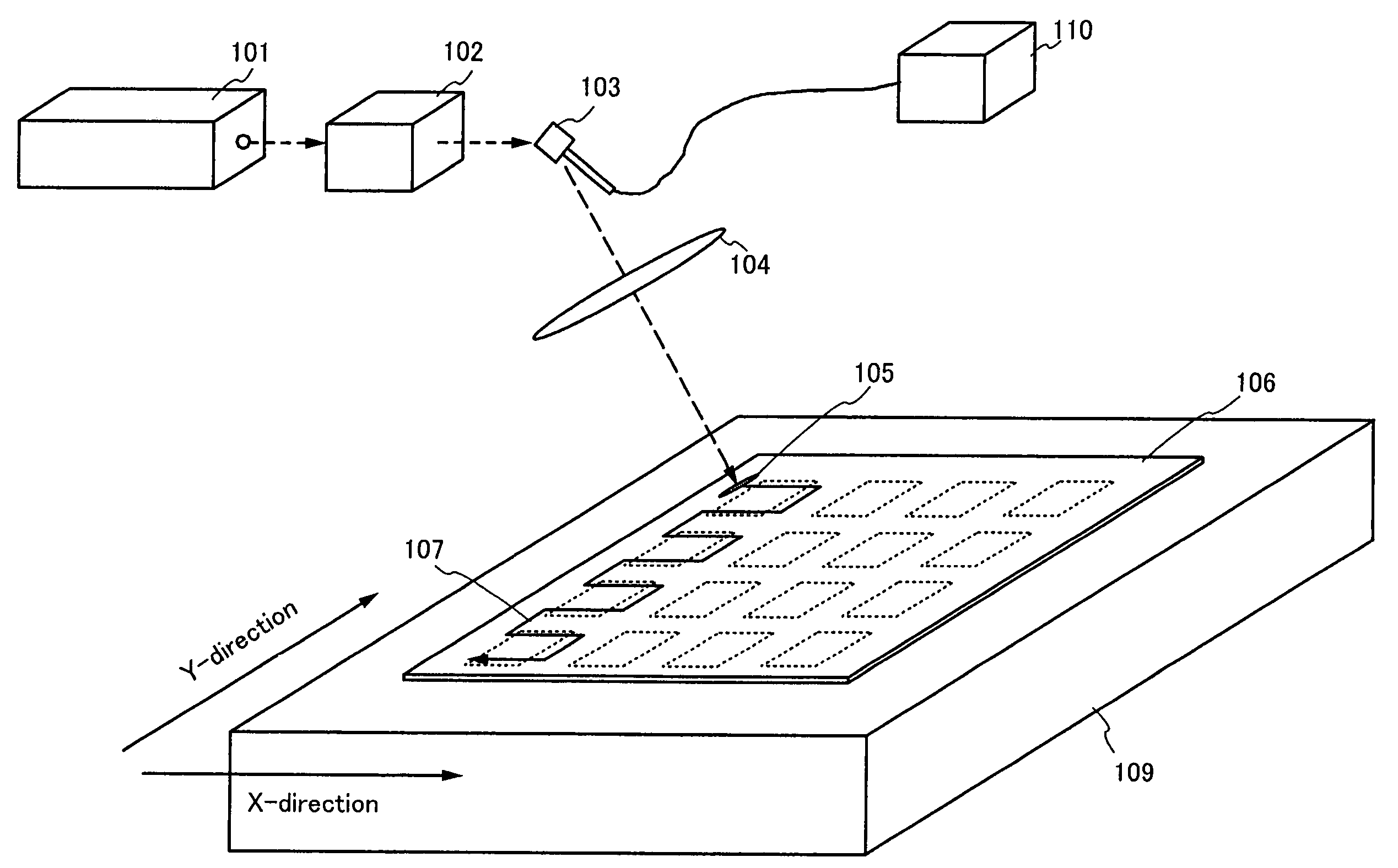

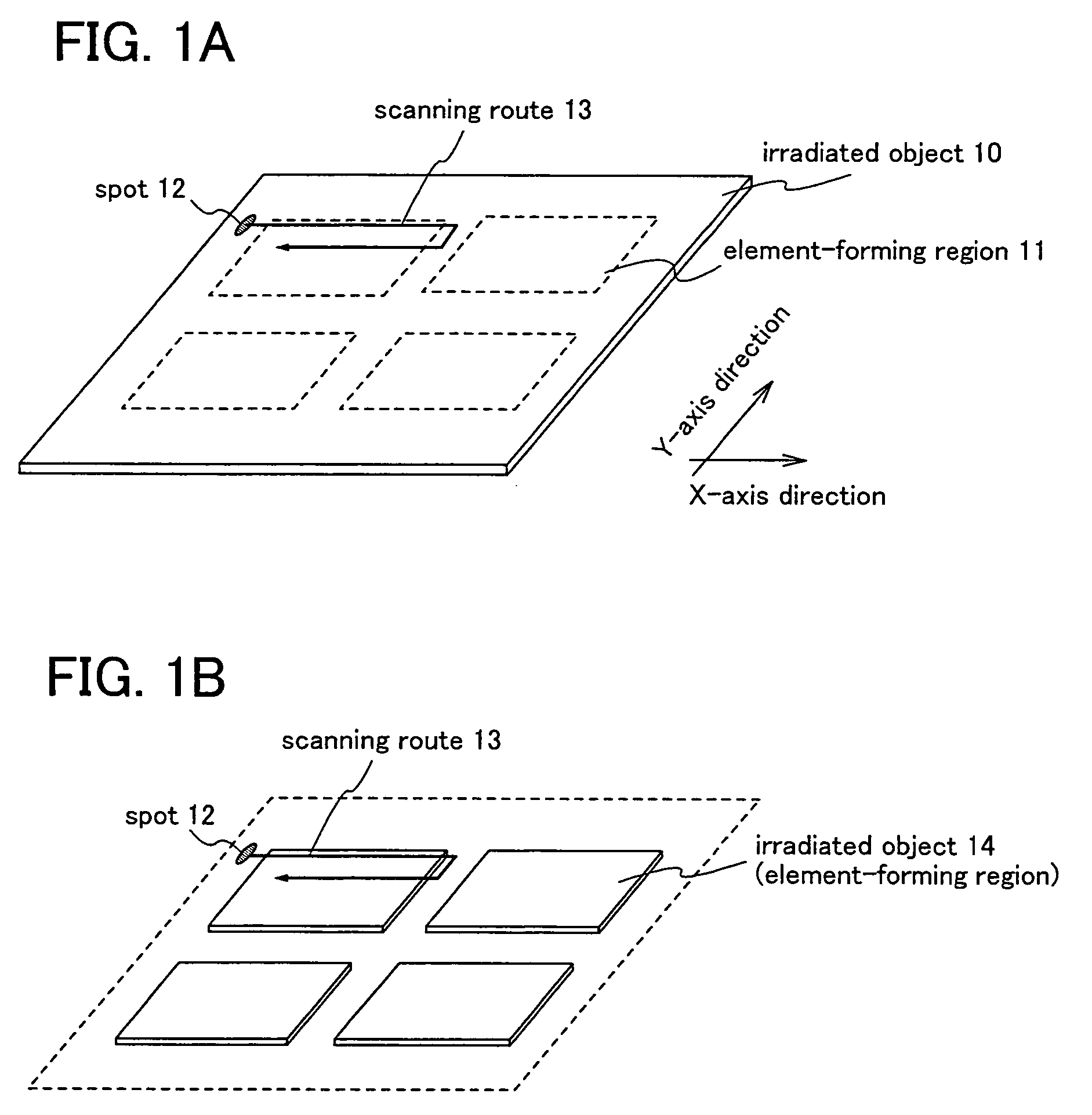

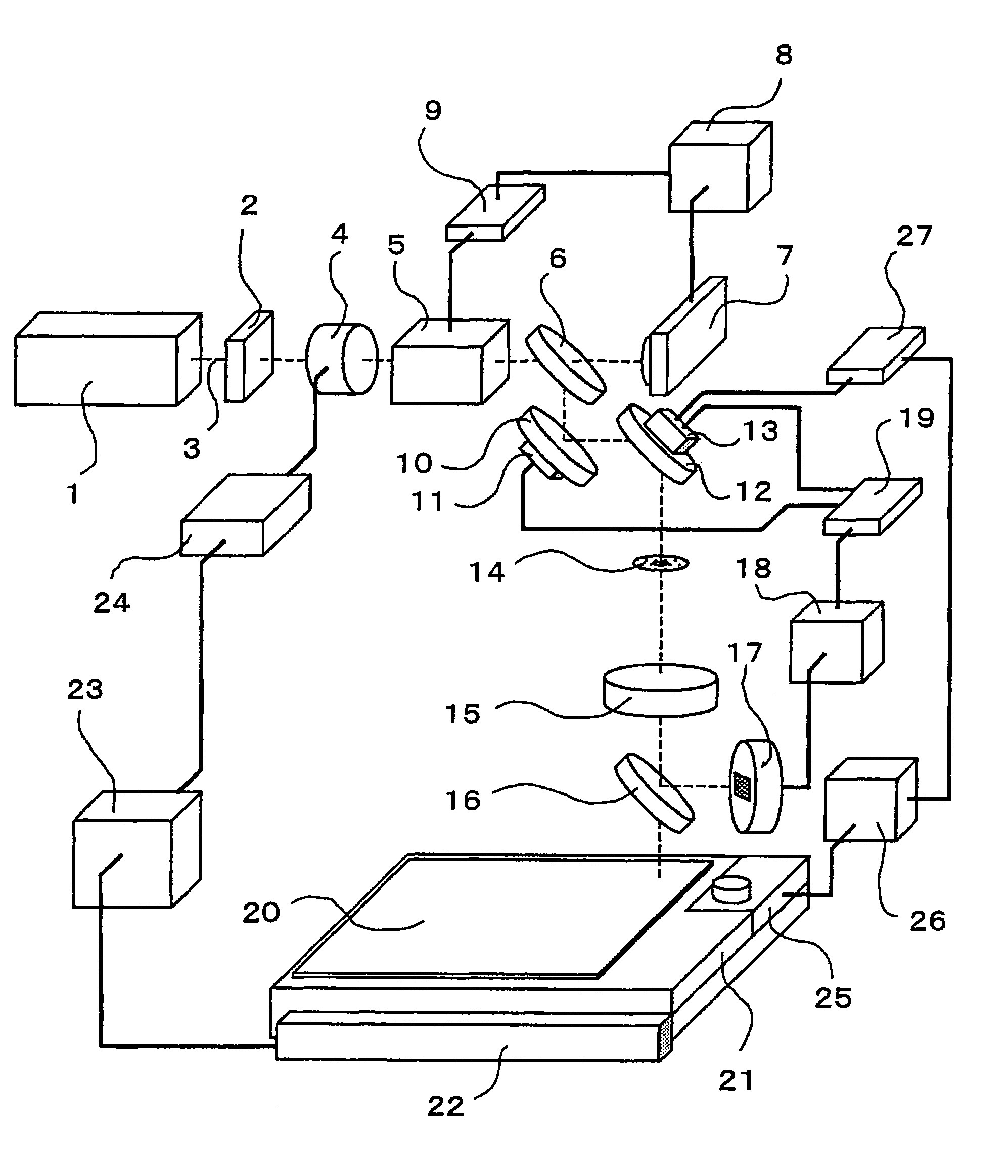

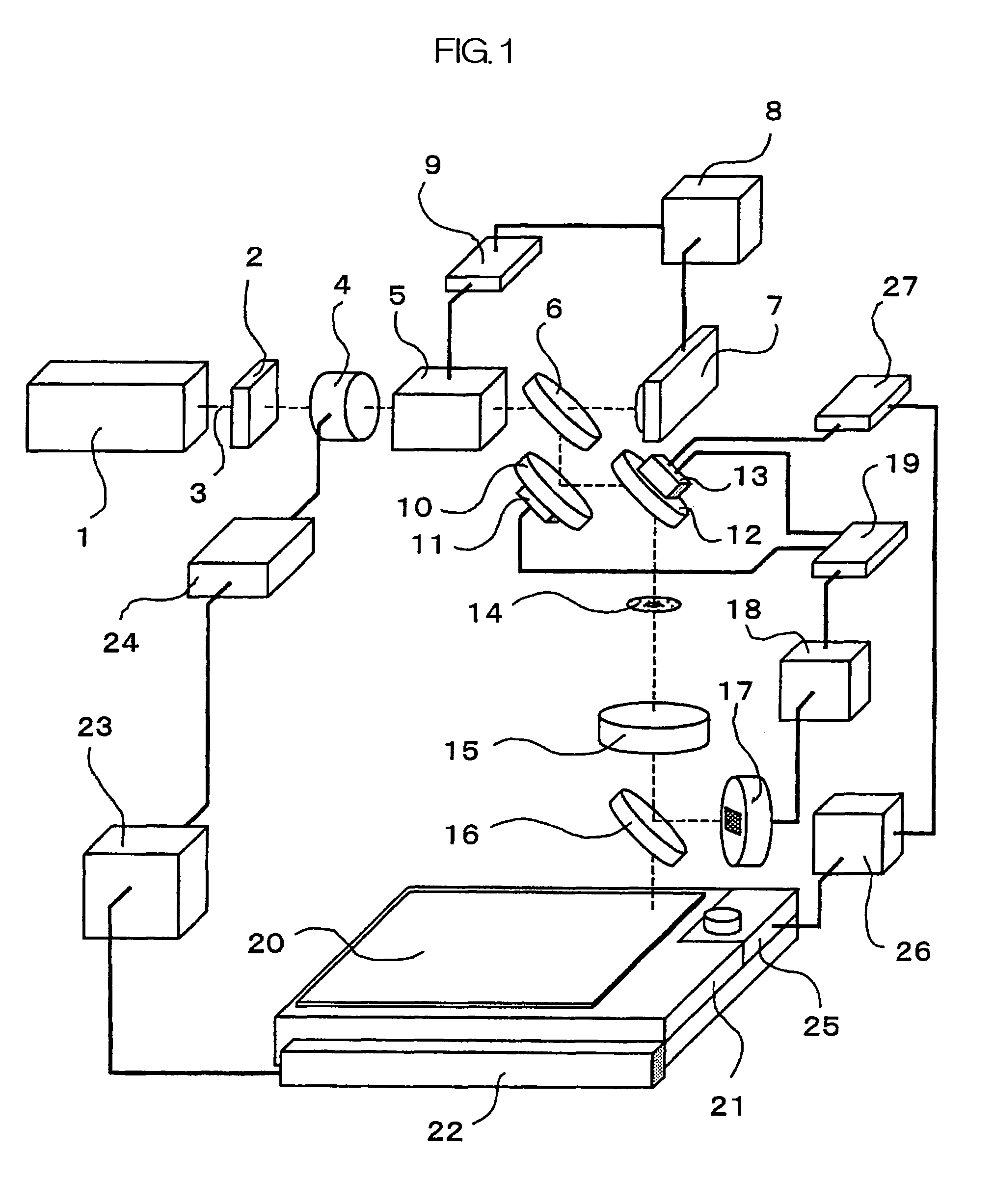

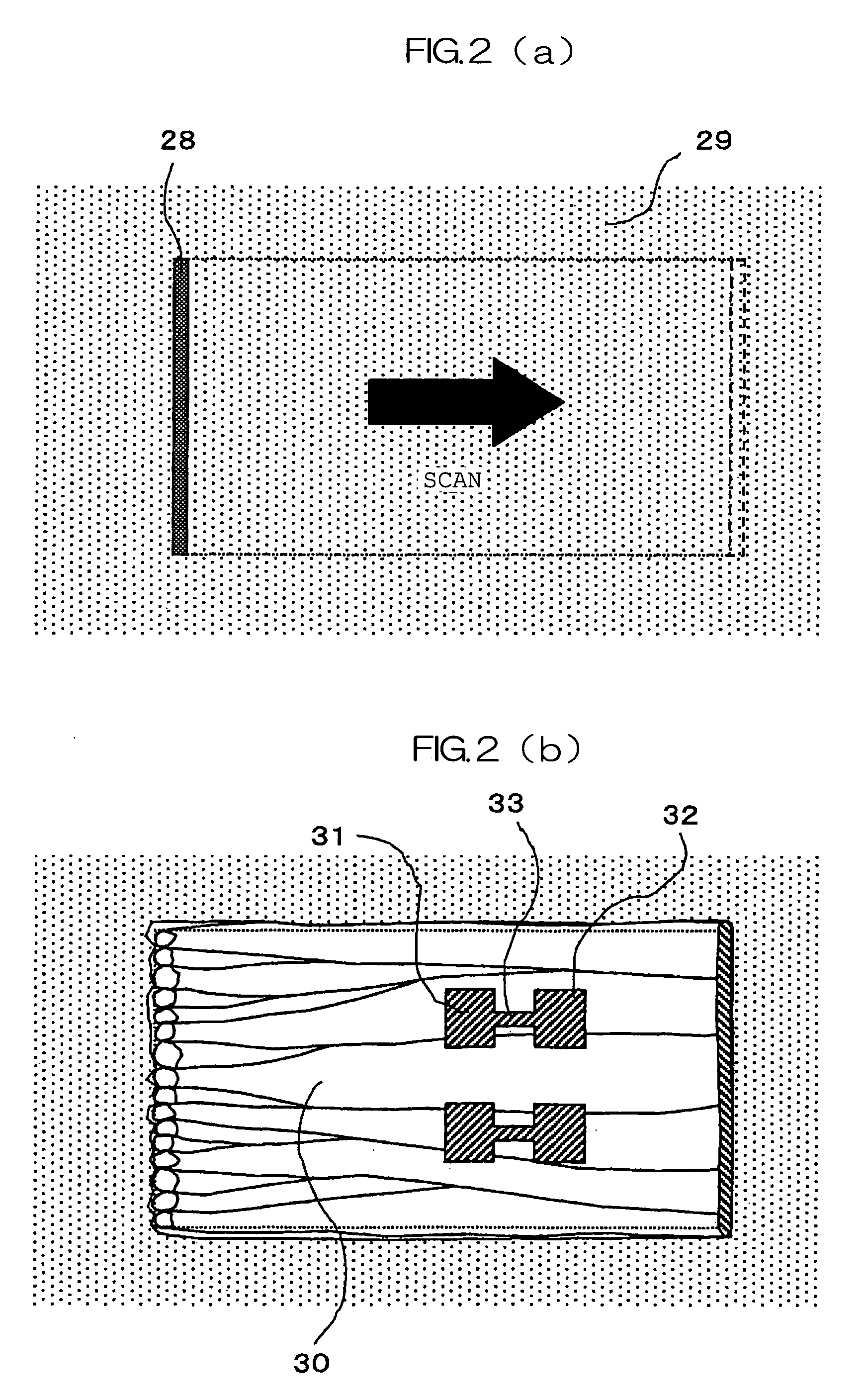

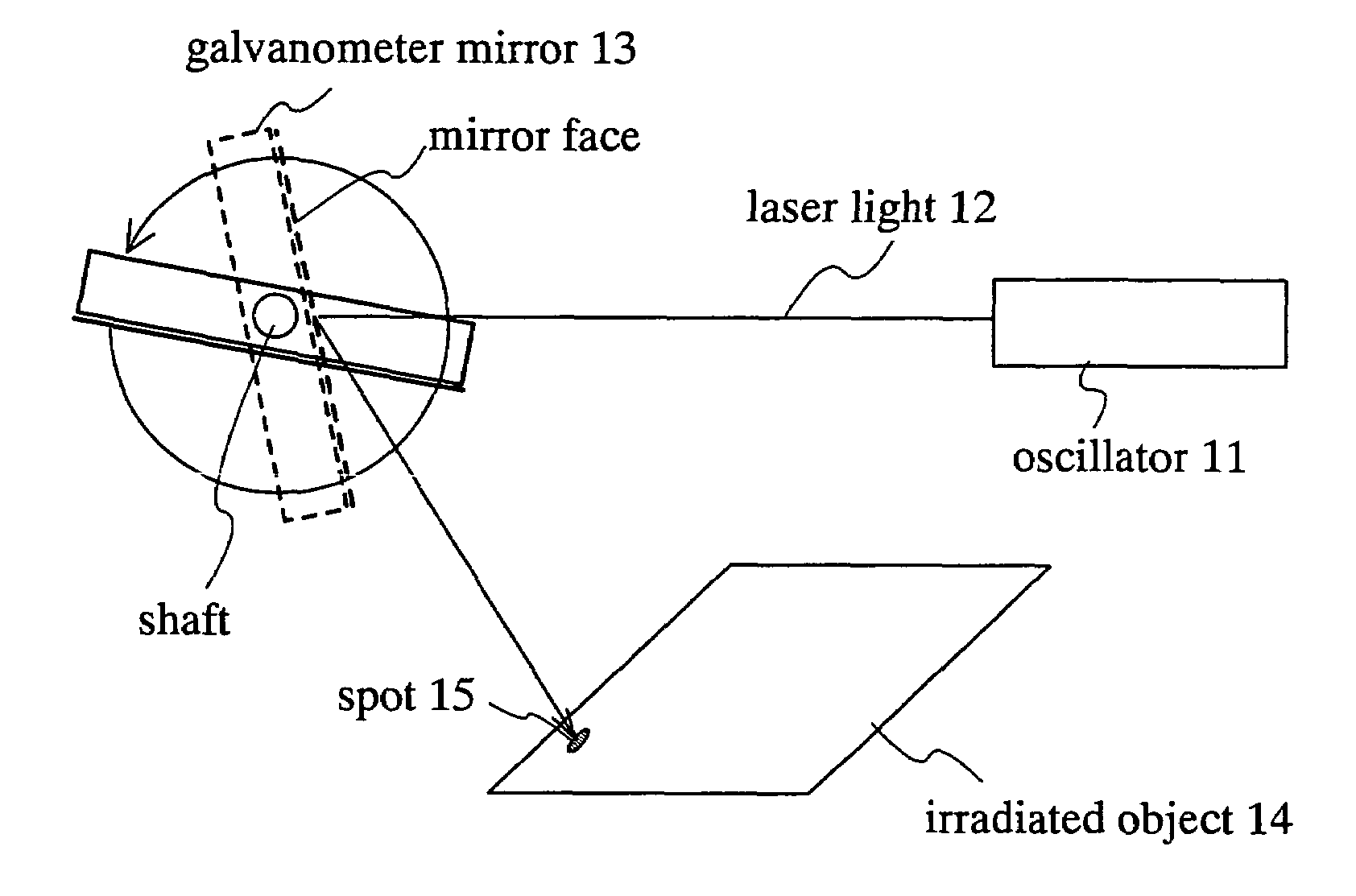

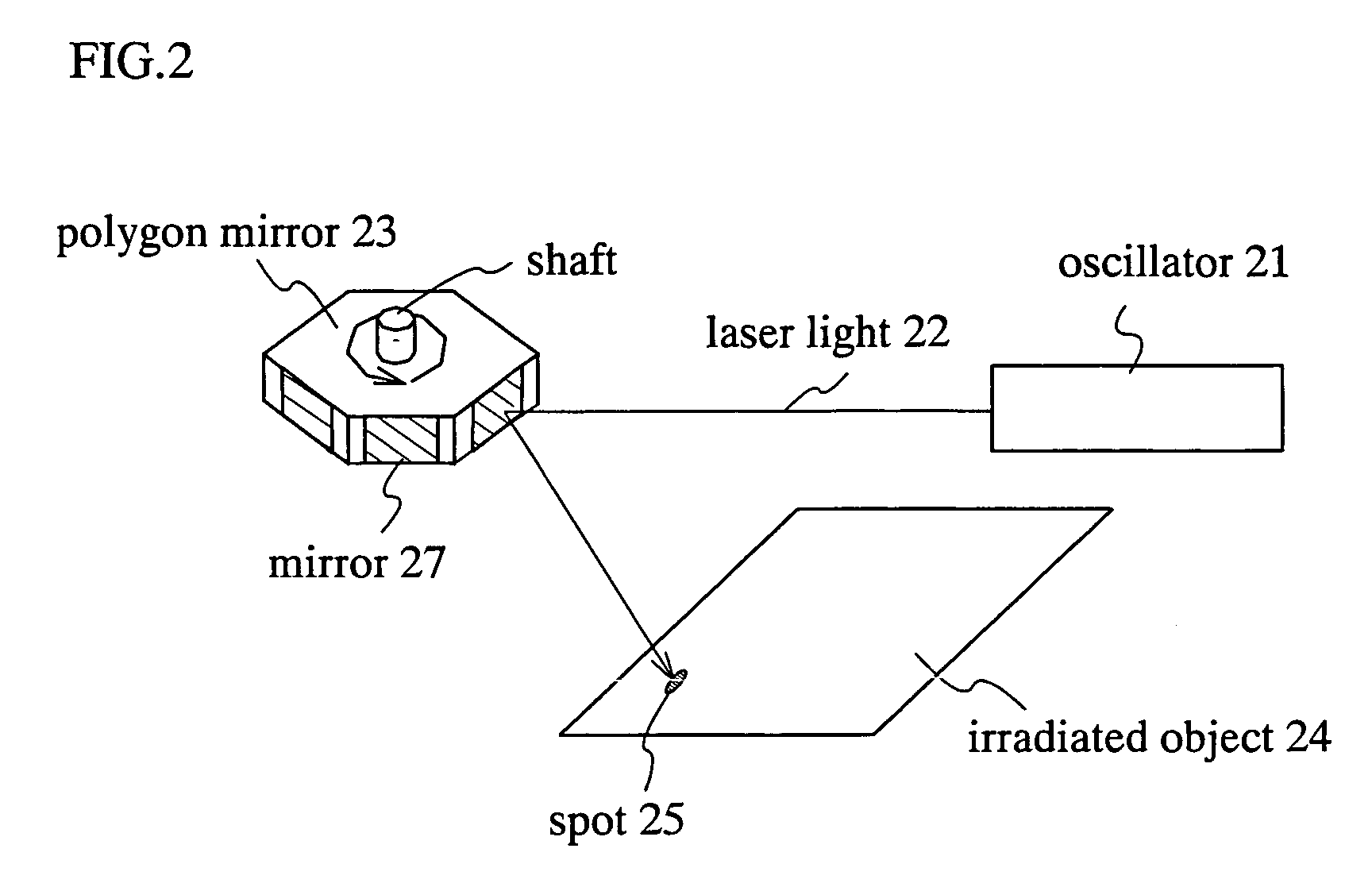

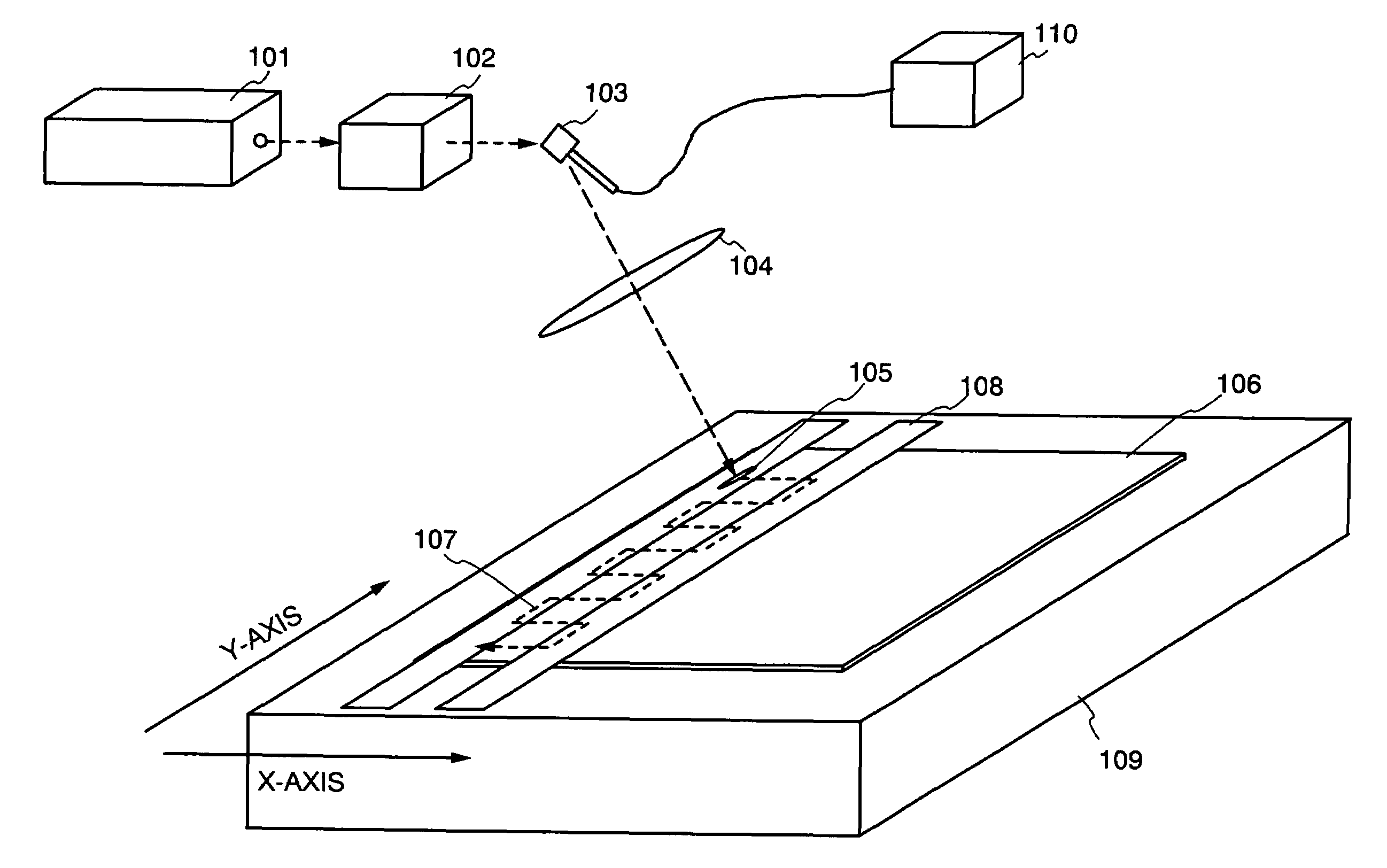

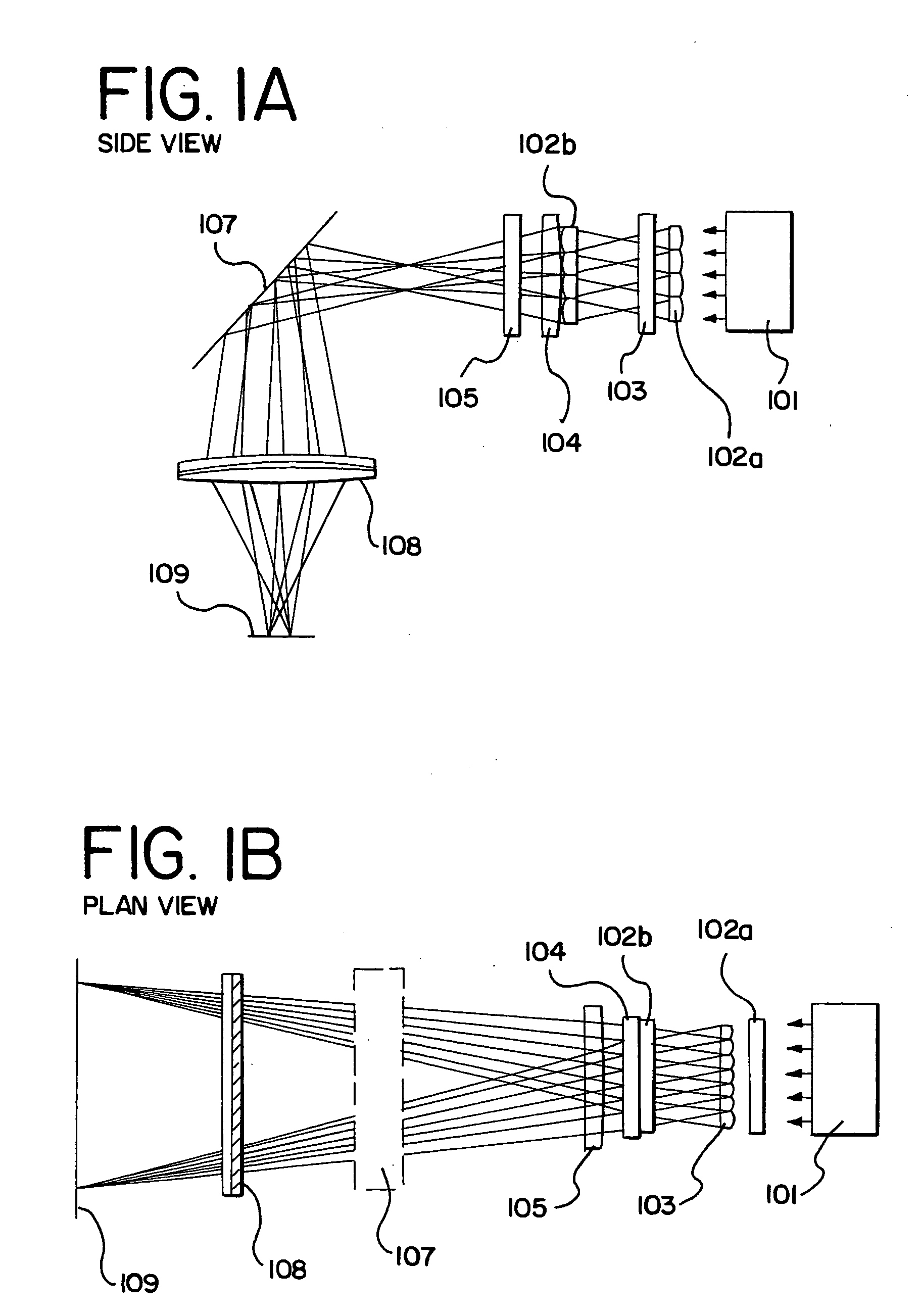

Beam irradiation apparatus, beam irradiation method, and method for manufacturing semiconductor device

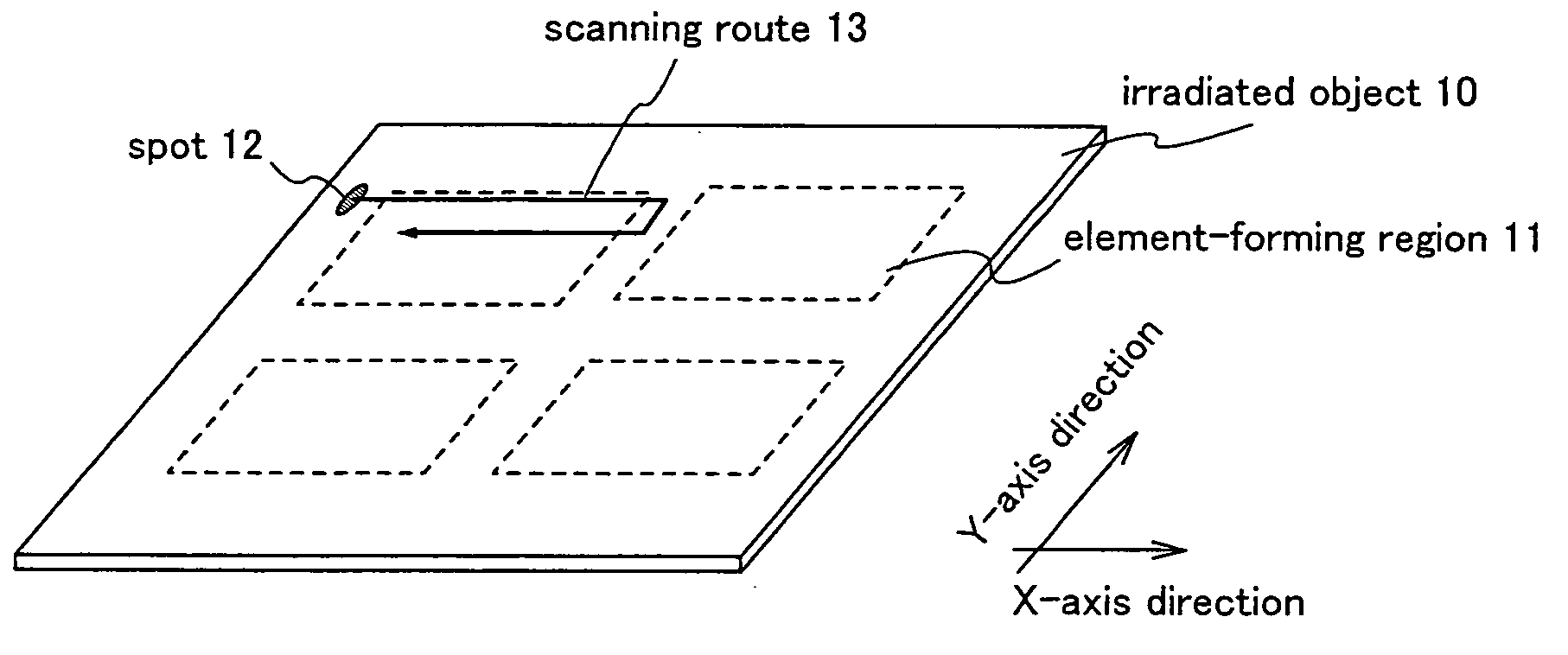

ActiveUS20050037552A1Reduce manufacturing costEase of mass productionSolid-state devicesSemiconductor/solid-state device manufacturingLight beamGalvanometer

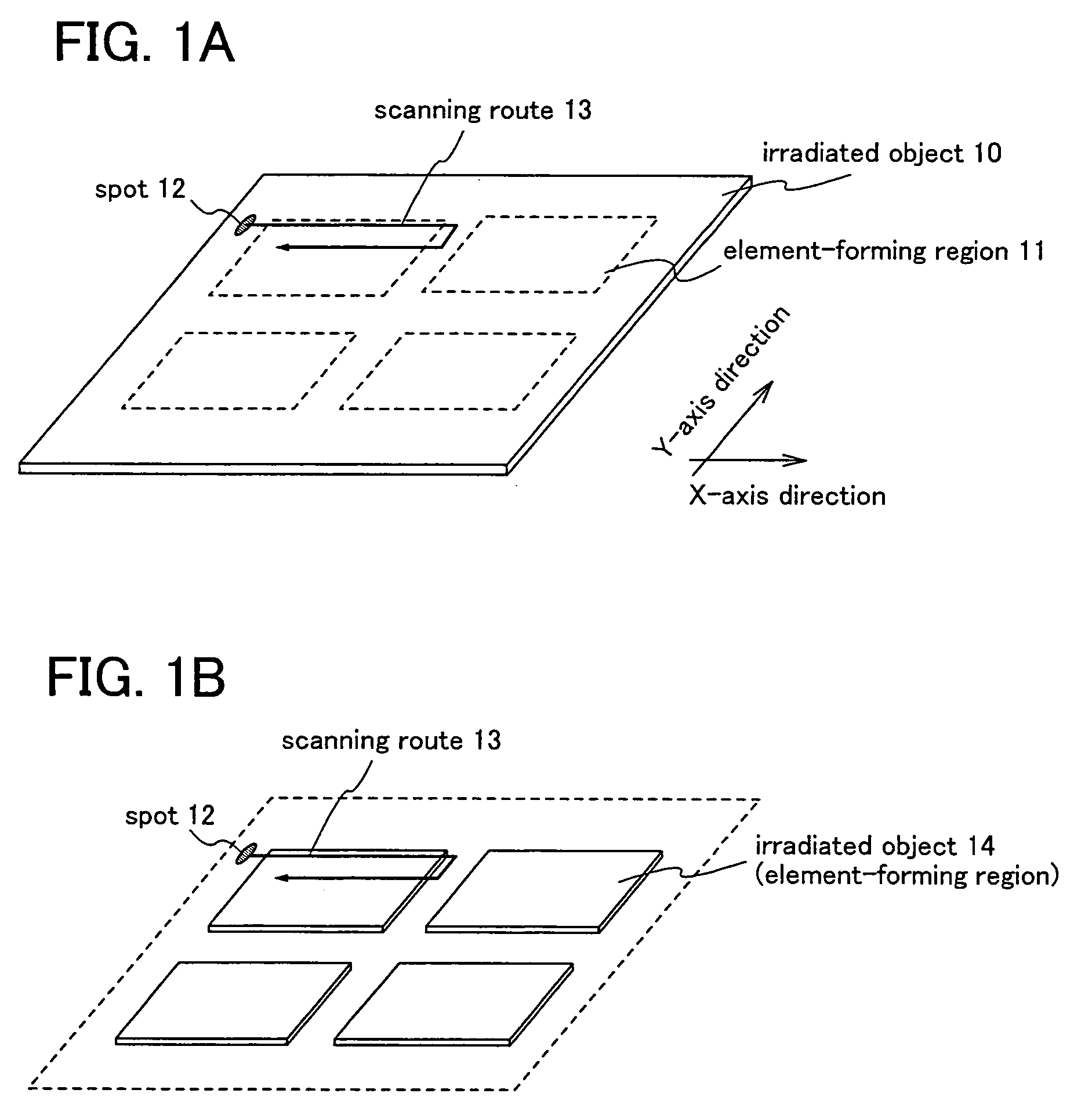

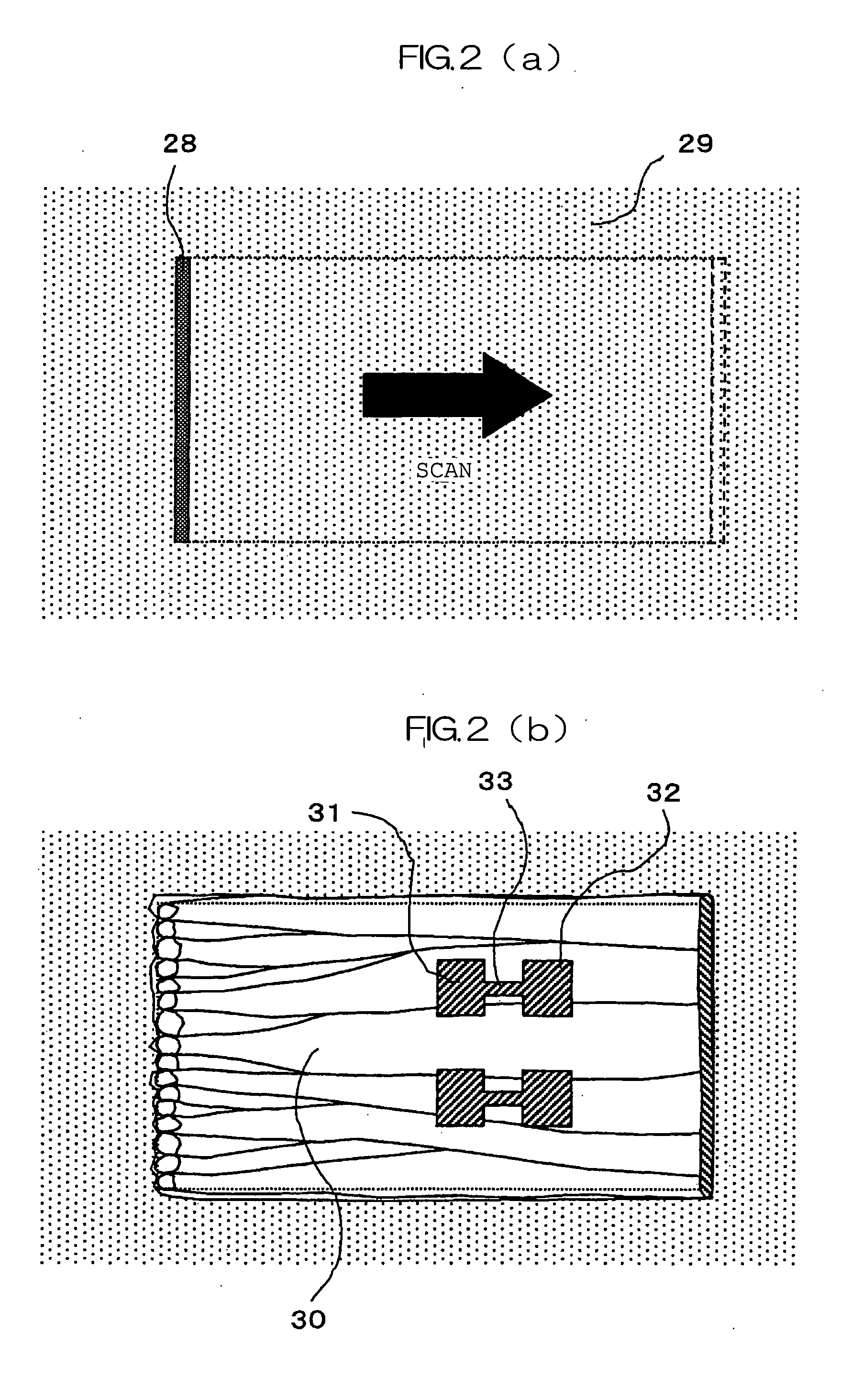

The speed of the laser scanned by the scanning means such as a galvanometer mirror or a polygon mirror is not constant in the center portion and in the end portion of the scanning width. As a result, the object, for example an amorphous semiconductor film, is irradiated with the excessive energy and therefore there is a risk that the amorphous semiconductor film is peeled. In the present invention, in the case where the laser spot of the energy beam output continuously on the irradiated object is scanned by moving it back and forth with the use of the scanning means or the like, the beam is irradiated to the outside of the element-forming region when the scanning speed of the spot is not the predetermined value, for example when the speed is not constant, and accelerates, decelerates, or is zero, for example in the positions where the scanning direction changes, or where the scanning starts or ends.

Owner:SEMICON ENERGY LAB CO LTD

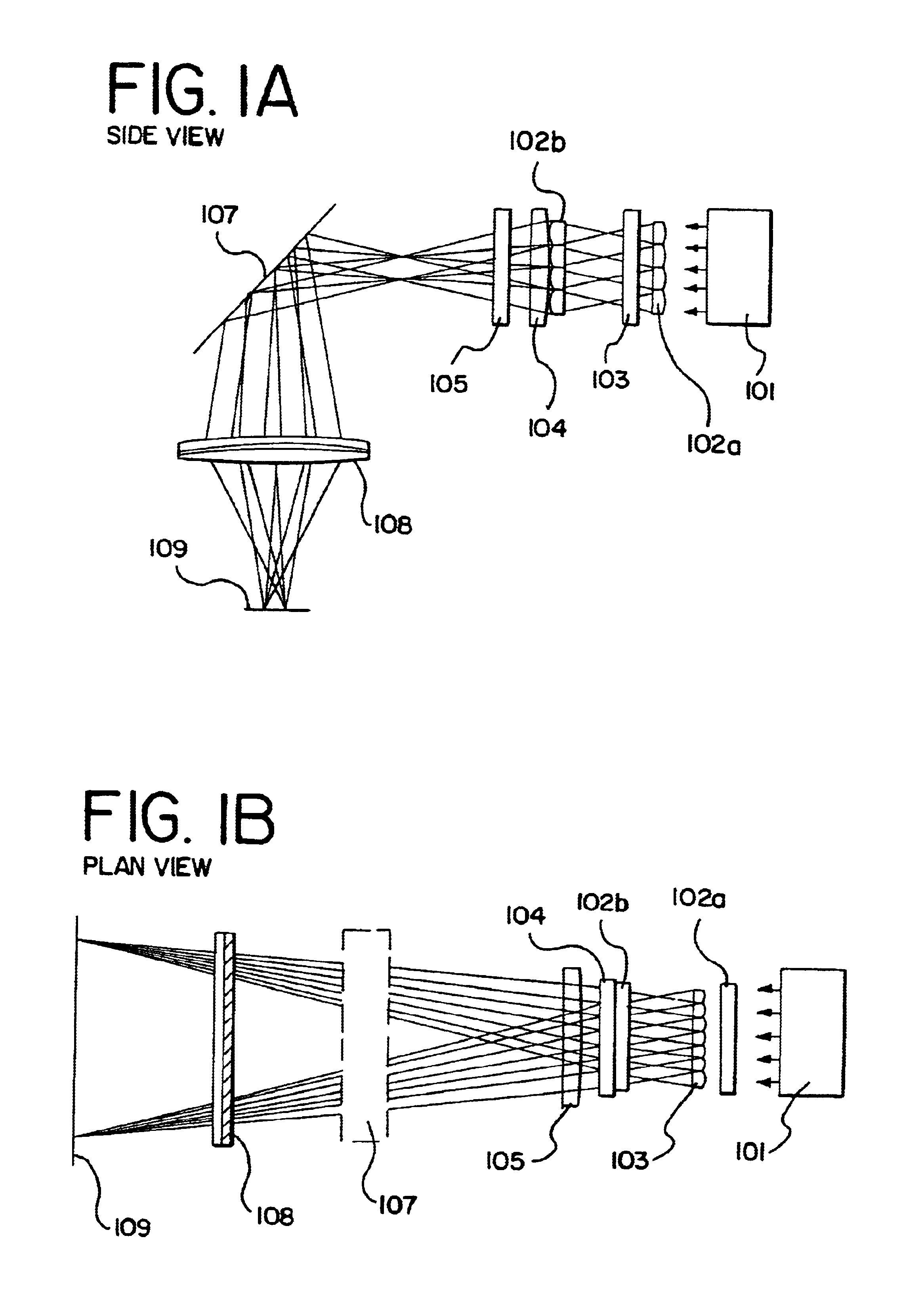

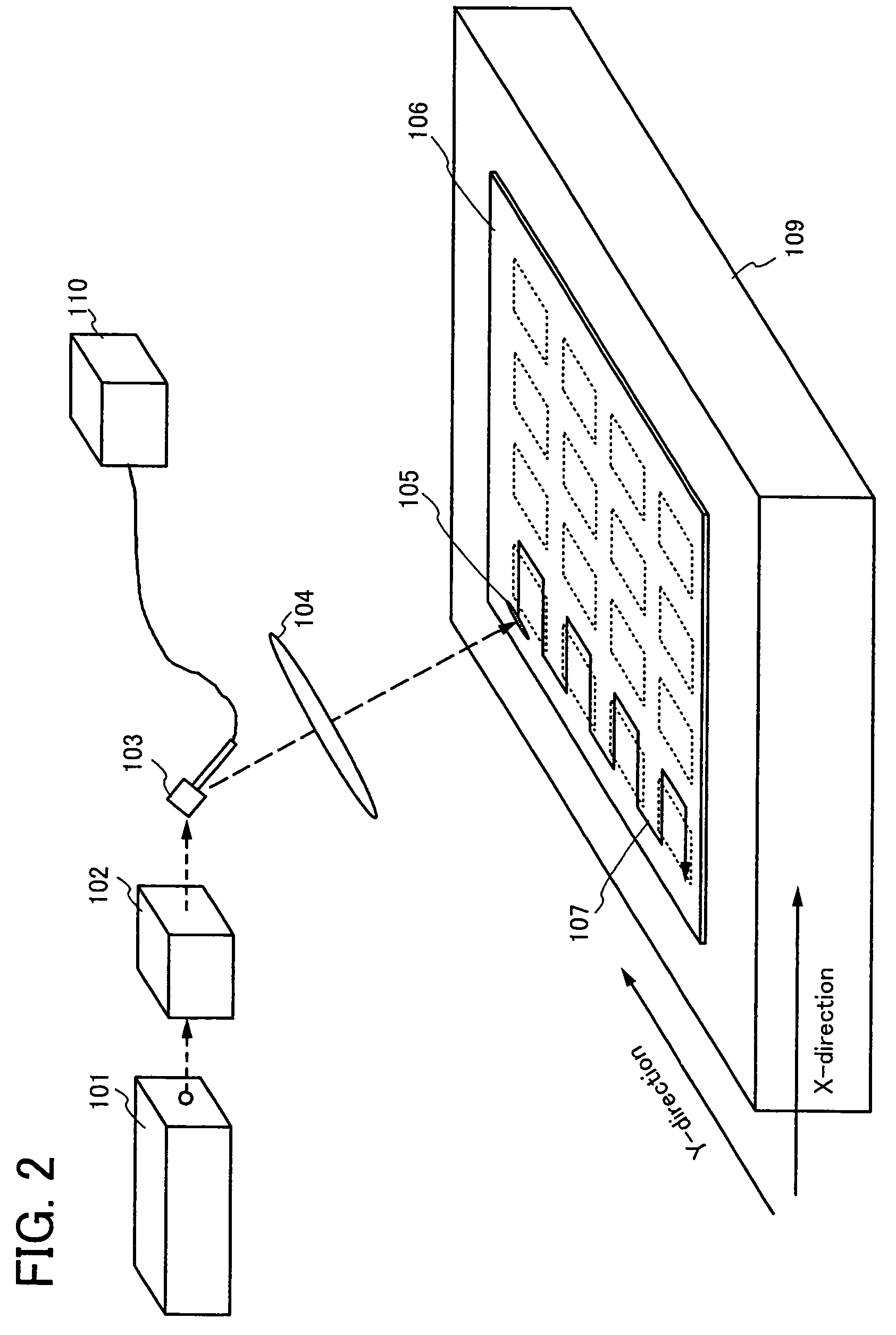

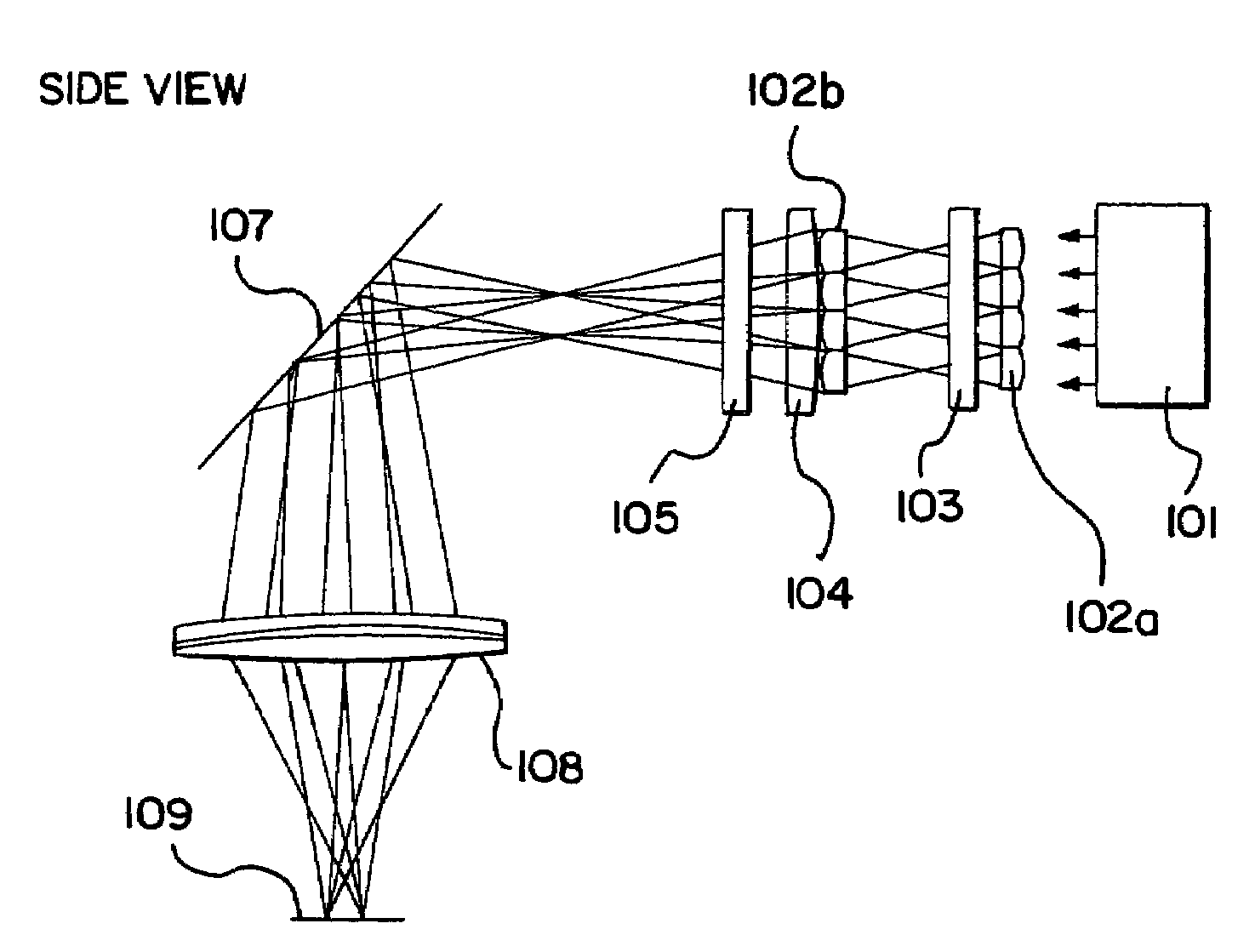

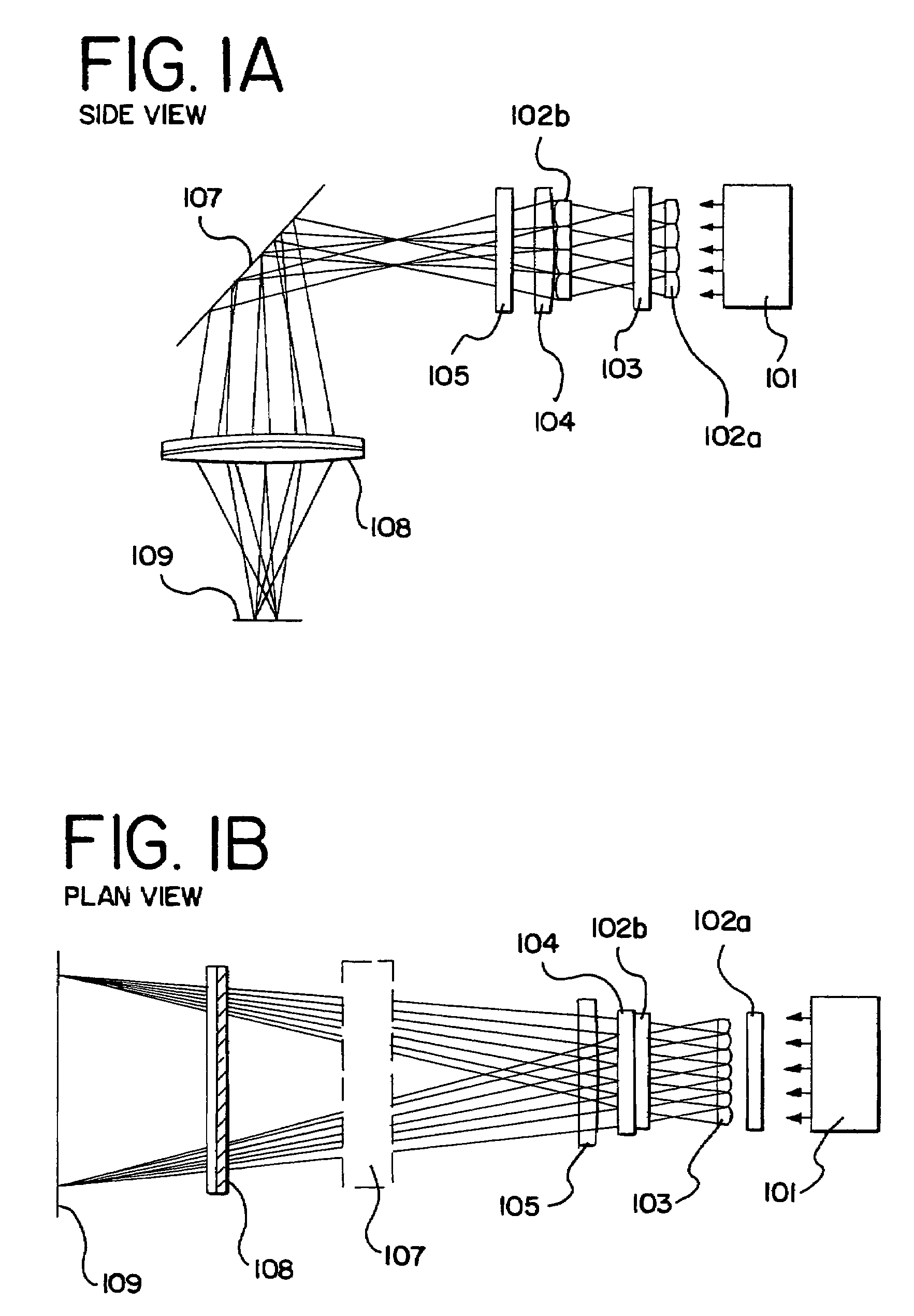

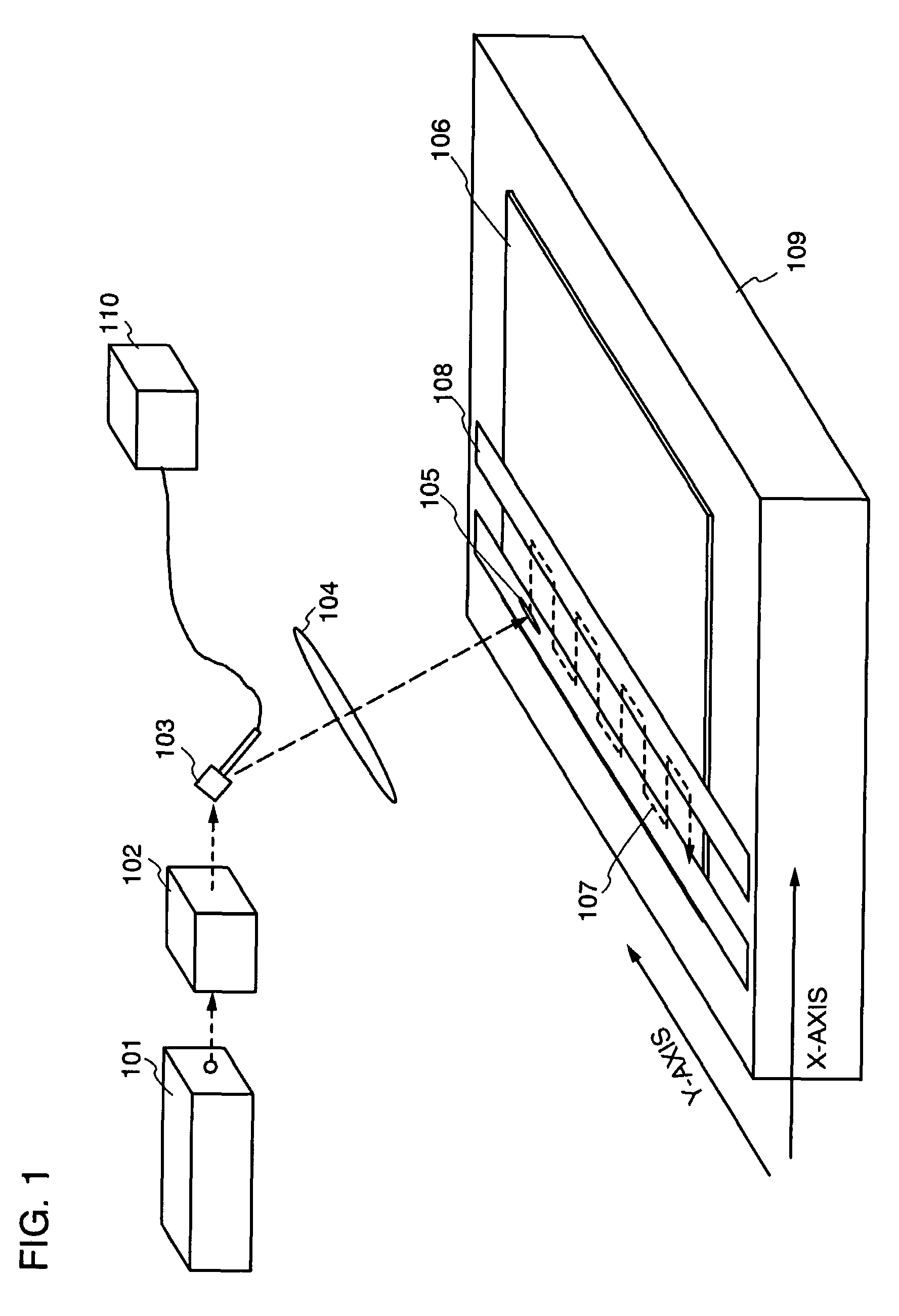

Apparatus for manufacturing flat panel display devices

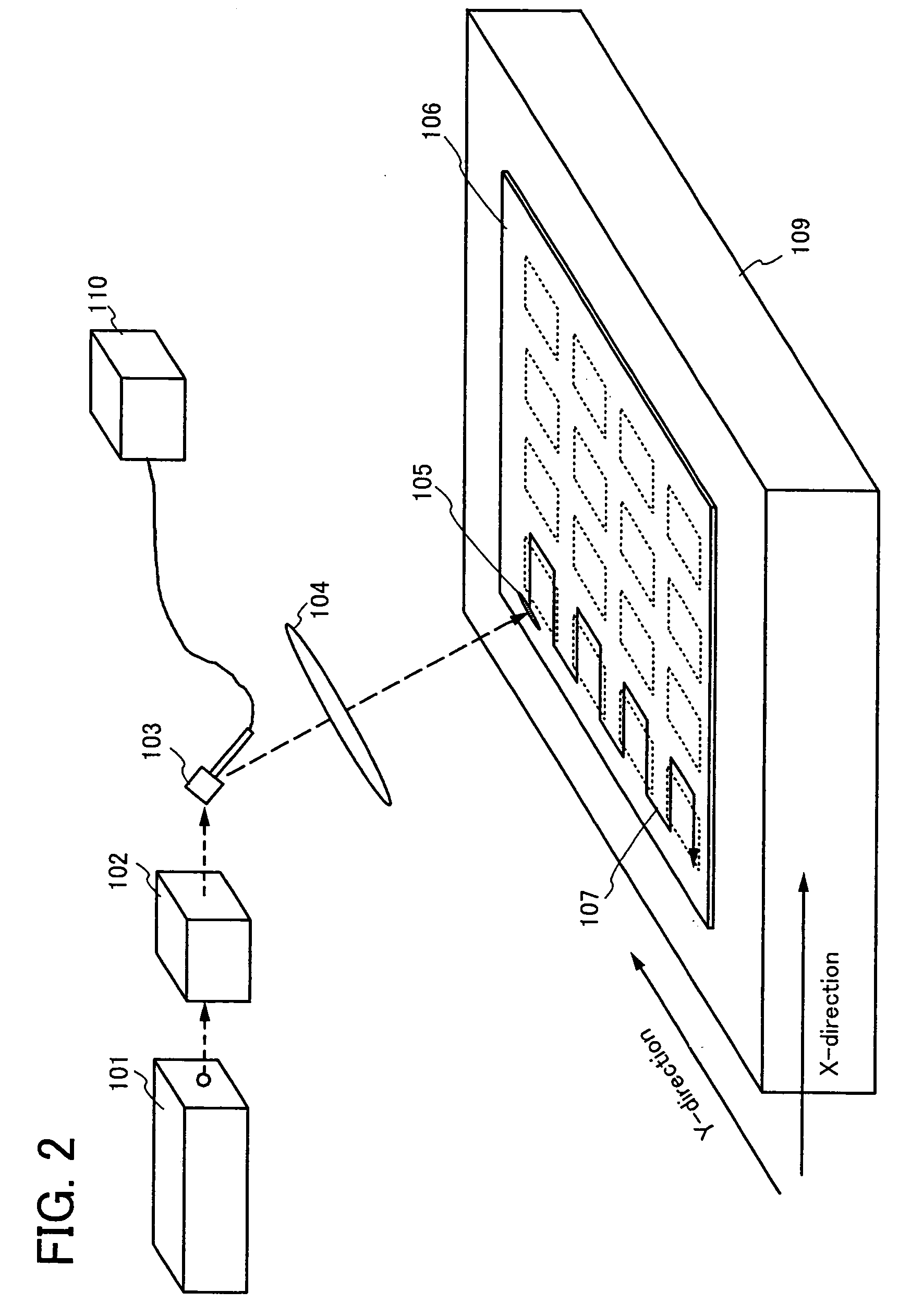

ActiveUS20050170569A1Uniform crystallinityHigh yieldTransistorStatic indicating devicesFlat panel displayFocal position

A mechanism for always measuring the spatial intensity distribution of a laser beam and displacement of the optical axis of the laser beam is provided so that a measured signal is processed when the laser beam incident on a laser beam shaping optical element is out of a predetermined condition. The shape, diameter and incidence position of the laser beam incident on the laser beam shaping optical element are always kept in the predetermined condition by a spatial filter disposed at the position of a focal point of lenses forming a beam expander disposed in the optical axis, on the basis of a result of the signal processing. In this manner, silicon thin films uniform in crystallinity can be formed stably with a high yield on an insulating substrate which forms display panels of flat panel display devices.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Method for manufacturing a semiconductor device where the scanning direction changes between regions during crystallization and process

ActiveUS7220627B2Uniform crystallinityImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingLight beamGalvanometer

The speed of the laser scanned by the scanning means such as a galvanometer mirror or a polygon mirror is not constant in the center portion and in the end portion of the scanning width. As a result, the object, for example an amorphous semiconductor film, is irradiated with the excessive energy and therefore there is a risk that the amorphous semiconductor film is peeled. In the present invention, in the case where the laser spot of the energy beam output continuously on the irradiated object is scanned by moving it back and forth with the use of the scanning means or the like, the beam is irradiated to the outside of the element-forming region when the scanning speed of the spot is not the predetermined value, for example when the speed is not constant, and accelerates, decelerates, or is zero, for example in the positions where the scanning direction changes, or where the scanning starts or ends.

Owner:SEMICON ENERGY LAB CO LTD

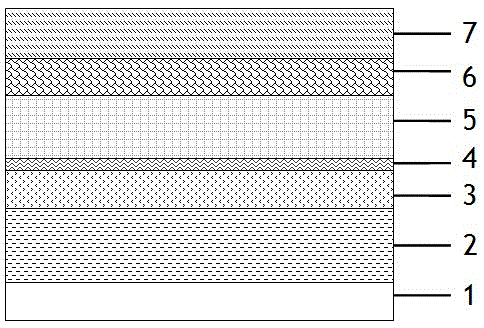

Perovskite solar cell and preparation method thereof

ActiveCN105609641AImprove film morphologyReduce surface defectsFinal product manufactureSolid-state devicesThin film morphologyLiquid-crystal display

The invention relates to a perovskite solar cell and a preparation method thereof. By arranging a liquid crystal layer on the surface of an electron transmission layer or a hole transmission layer, the thin film morphology of the electron transmission layer or the hole transmission layer is improved, the defect on the surface of the electron transmission layer or the hole transmission layer is passivated, the transmission of reverse current carriers is effectively blocked, the electric leakage generation is prevented, the combination probability of electrons and holes which are generated in a perovskite light absorption layer is reduced, and the photoelectric conversion efficiency and the stability of the cell are improved; and meanwhile, the liquid crystal layer is prepared by a low-temperature solution method, and the preparation method is suitably used for roll-to-roll industrial production of the perovskite photovoltaic cell, and is simple in process and low in fabrication cost.

Owner:CHINA LUCKY FILM CORP

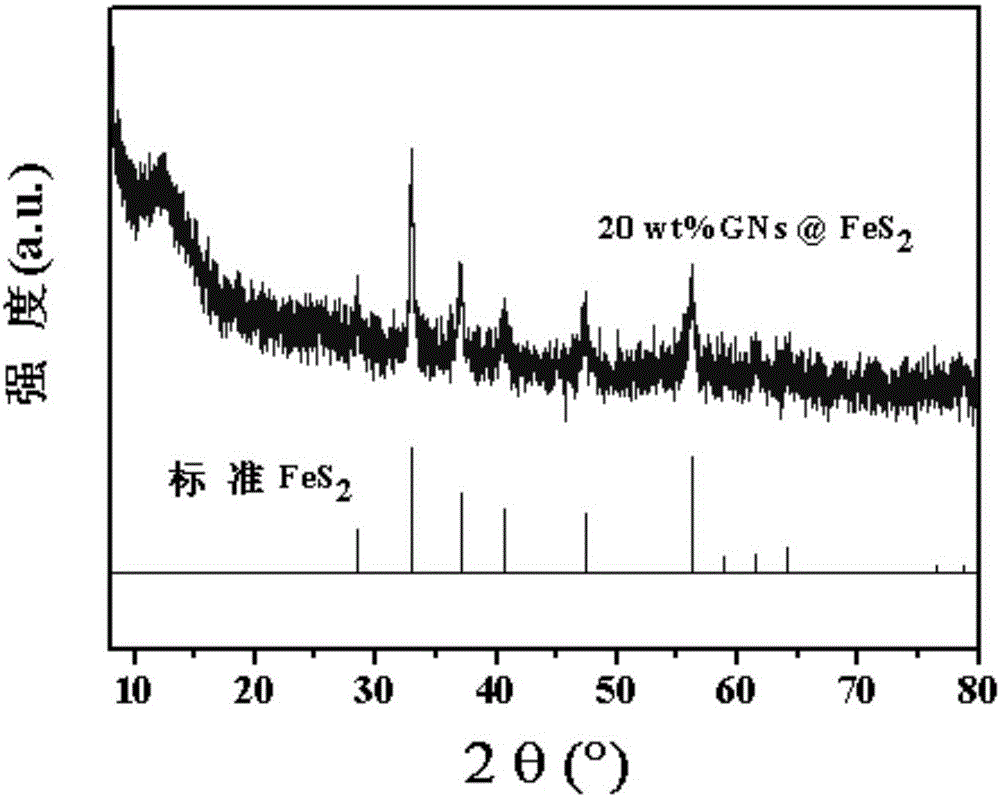

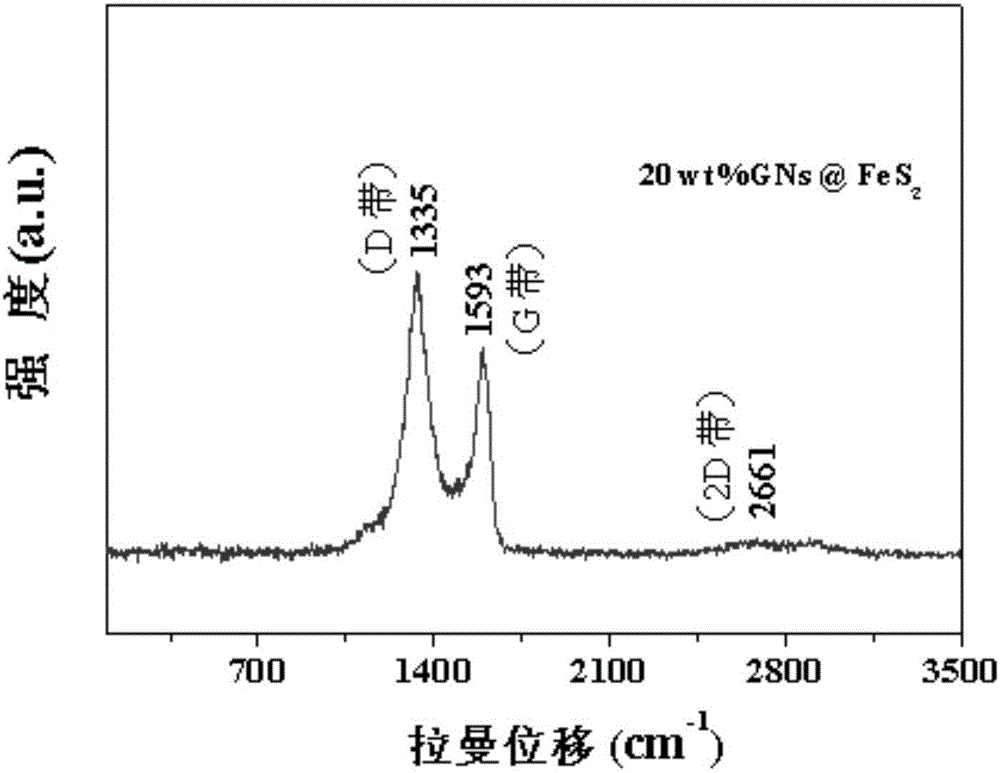

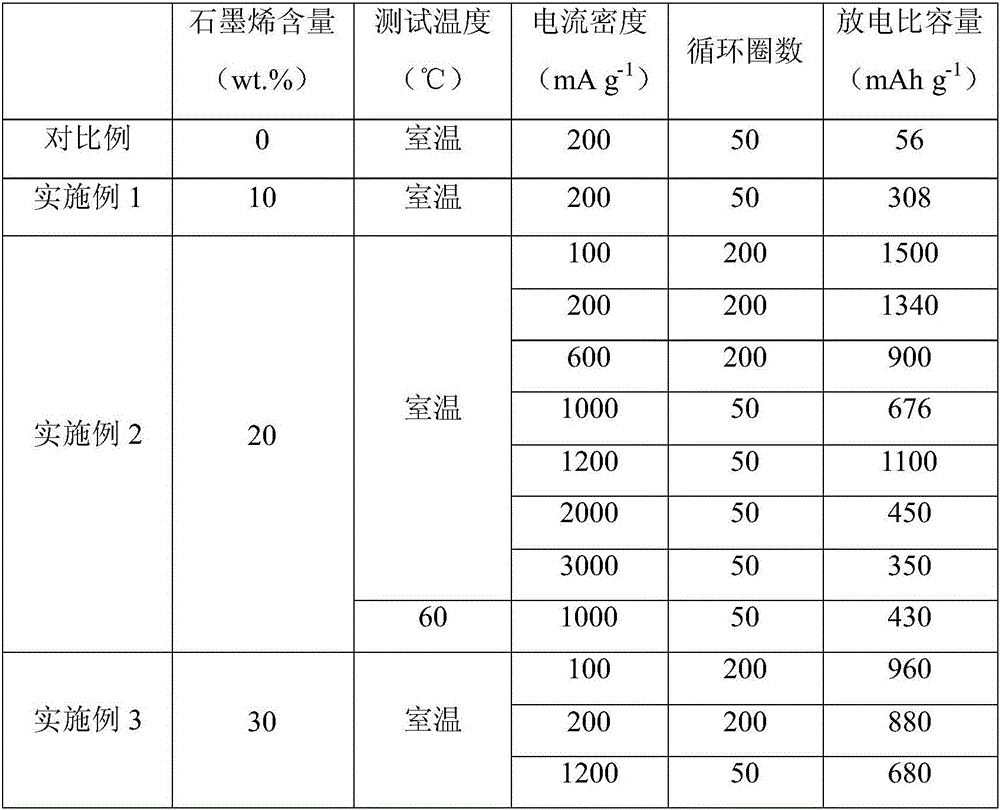

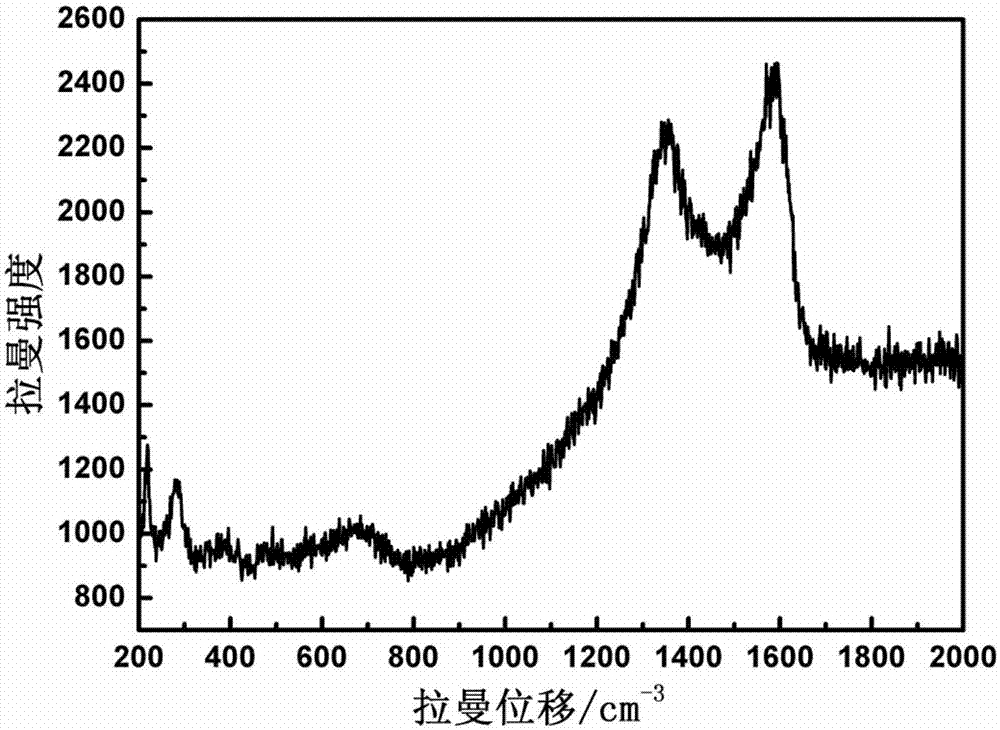

Graphene-based FeS2 nano-material and preparation and application thereof

ActiveCN105932256AImprove cycle stabilityImprove conductivityMaterial nanotechnologyNegative electrodesHigh rateReducing agent

The invention belongs to the technical field of lithium-ion battery materials, and discloses a graphene-based FeS2 nano-material and a preparation and an application thereof. The preparation method comprises the following steps: ultrasonically dispersing graphene oxide into water to obtain a graphene oxide suspension liquid, adding a reducing agent for ultrasonic treatment and then obtaining a graphene suspension liquid; adding Na2S and S to water, heating, stirring and dissolving the Na2S and the S evenly to obtain an Na2S2 solution; dissolving FeSO4 into water and mixing the solution with the graphene suspension liquid; and adding the Na2S2 solution, heating the Na2S2 solution to 100 DEG C, carrying out reflux reaction in an inert gas atmosphere for 0.5-3 hours, and centrifugally separating, drying and grinding a reaction product to obtain the graphene-based FeS2 nano-material. The obtained material can be applied to a negative electrode of the lithium-ion battery, and is relatively high in specific capacity and relatively good in performance under a high-rate condition.

Owner:GUANGDONG ORIENT RESIN

Method of manufacturing a semiconductor device

InactiveUS7229864B2Uniform crystallinityEasy to useTransistorSolid-state devicesLight beamCrystallinity

By using lasers having different wavelengths in laser annealing of an amorphous semiconductor film, the amorphous semiconductor film can be crystallized and the crystallinity of the crystallized film is improved. A laser 126 to 370 nm in wavelength is used first to subject an amorphous semiconductor film to laser annealing, thereby obtaining a crystalline semiconductor film. In desirable laser annealing, a subject surface is irradiated with a laser beam processed by an optical system into a linear laser beam that is linear in section on the subject surface. Next, a laser 370 to 650 nm in wavelength is used to irradiate the above crystalline semiconductor film by again processing the laser beam into a linear beam through an optical system. A crystalline semiconductor film thus obtained has an excellent crystallinity. If this crystalline semiconductor film is used to form an active layer of a TFT, an electric characteristic of the TFT can be improved.

Owner:SEMICON ENERGY LAB CO LTD

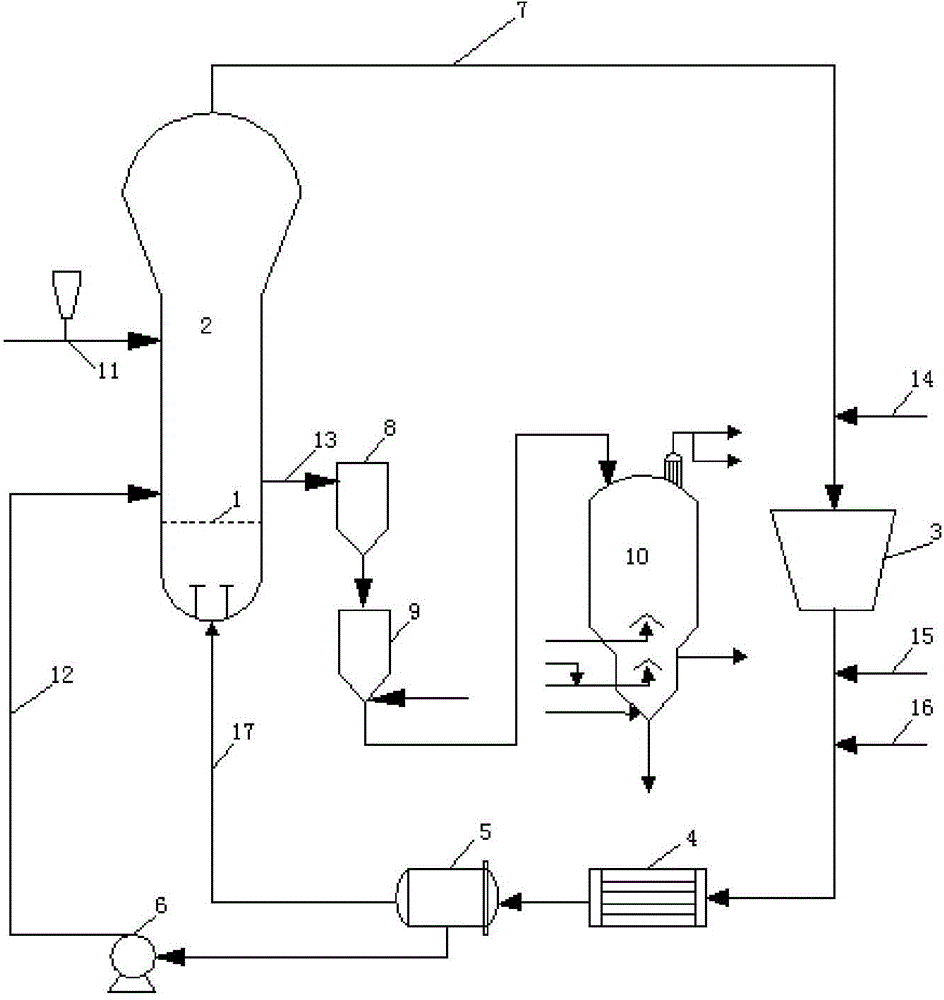

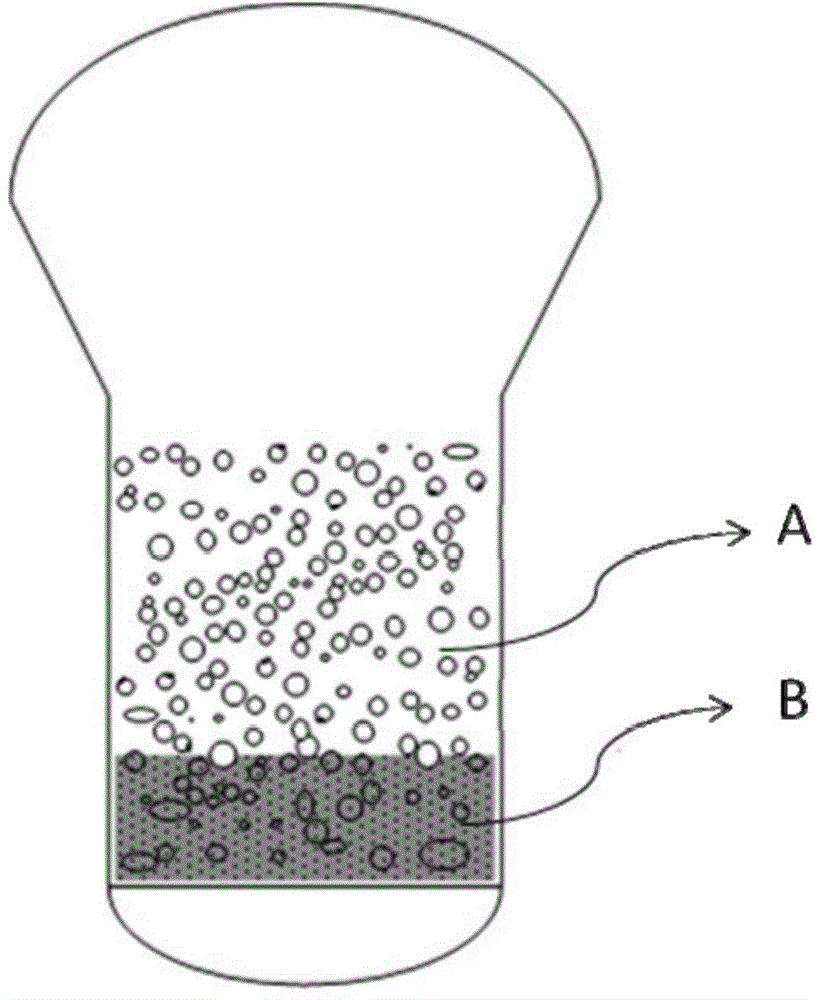

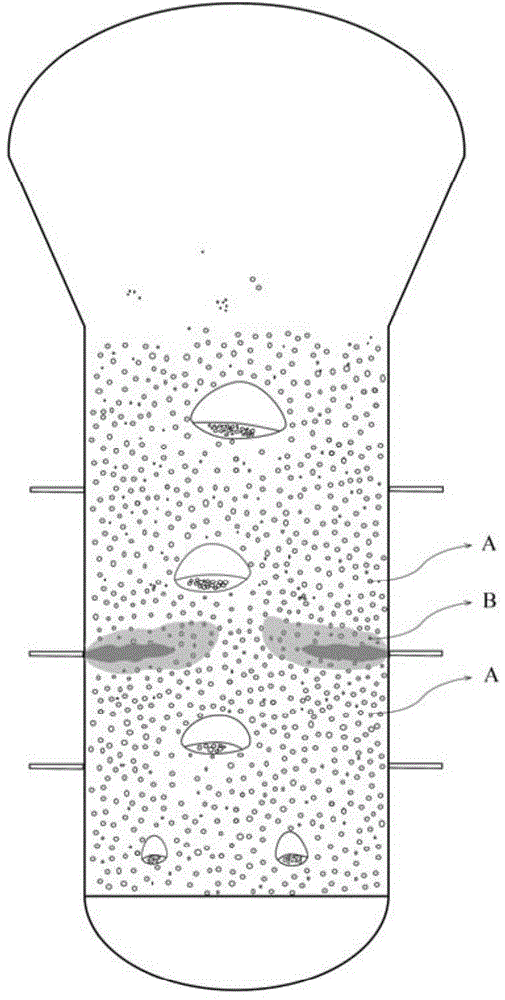

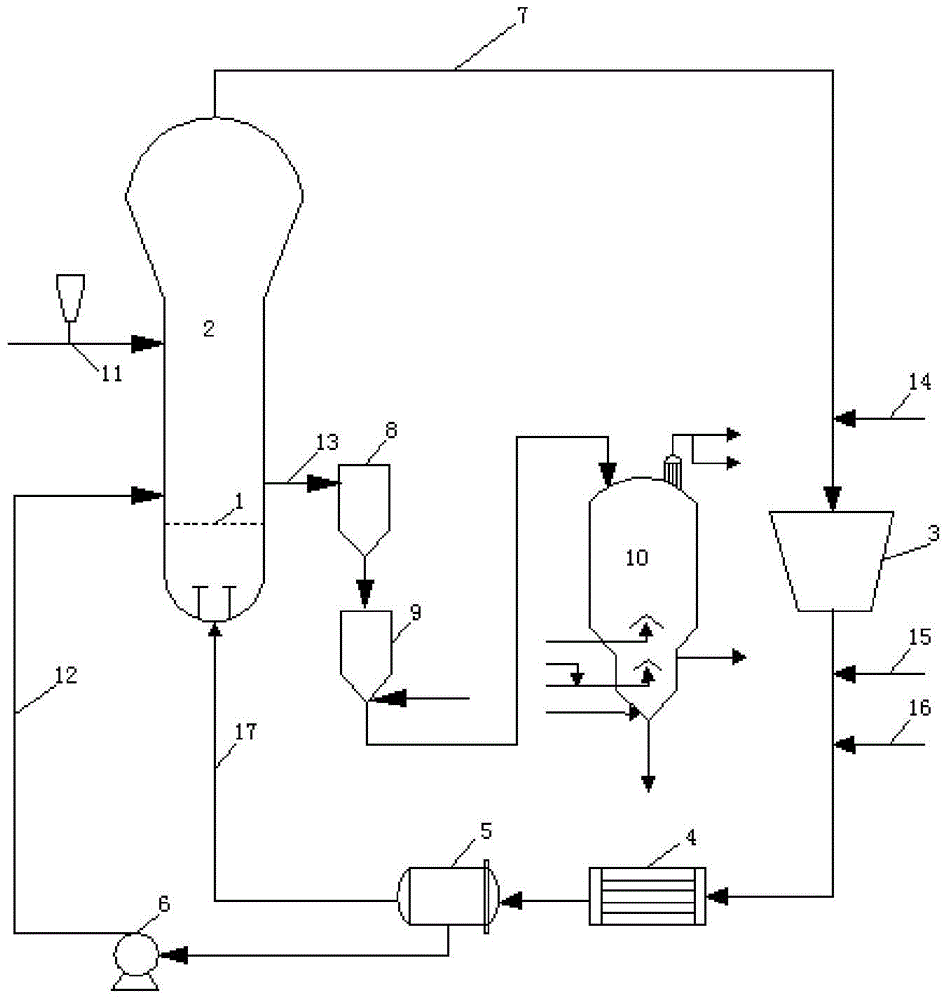

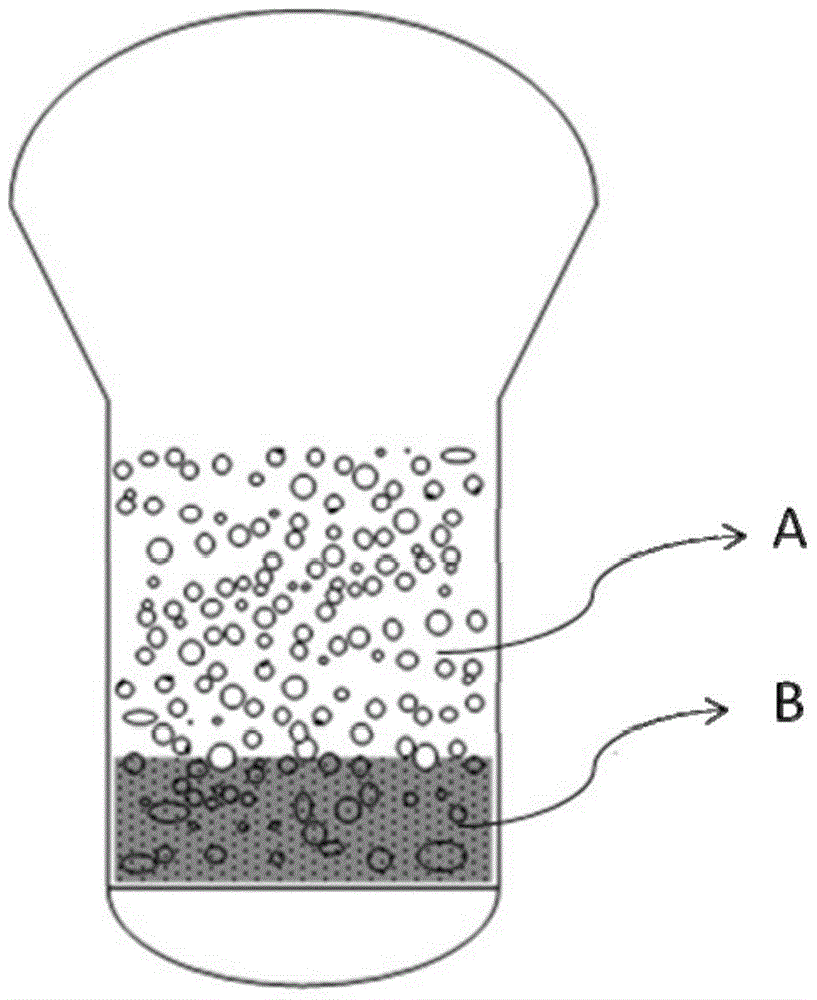

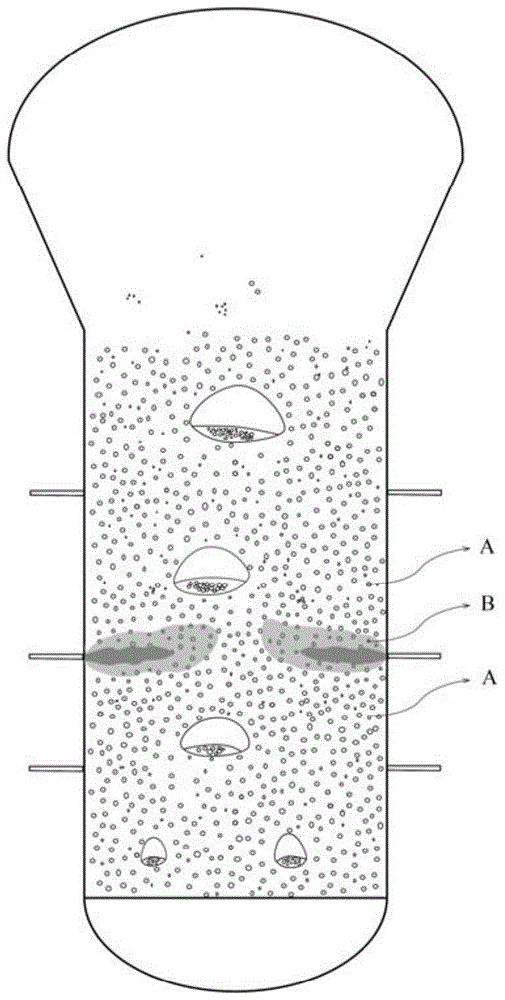

Method for preparing olefin polymer by utilizing multiple temperature reaction areas

ActiveCN104628904AImprove cooling capacityHigh space-time yieldHeat transfer efficiencyFluidized bed

The invention discloses a method for preparing olefin polymer by utilizing multiple temperature reaction areas. The method provided by the invention comprises the following step of forming a plurality of olefin polymer reaction areas with different temperatures in a fluidized bed reactor by utilizing a circulating medium, wherein the circulating medium comprises an olefin monomer and a condensing agent. By utilizing the method, preparation of high-performance olefin polymer product by utilizing a single reactor is realized. The method is high in heat transfer efficiency. The olefin polymer prepared by utilizing the method is low in density, wide in distribution, uniform in degree of crystallinity and the like and can be widely applied to various fields of thin-film materials and the like.

Owner:ZHEJIANG UNIV

Apparatus for manufacturing flat panel display devices

ActiveUS7193693B2Increase productionUnified performanceTransistorStatic indicating devicesBeam expanderOptical axis

Owner:JAPAN DISPLAY INC +1

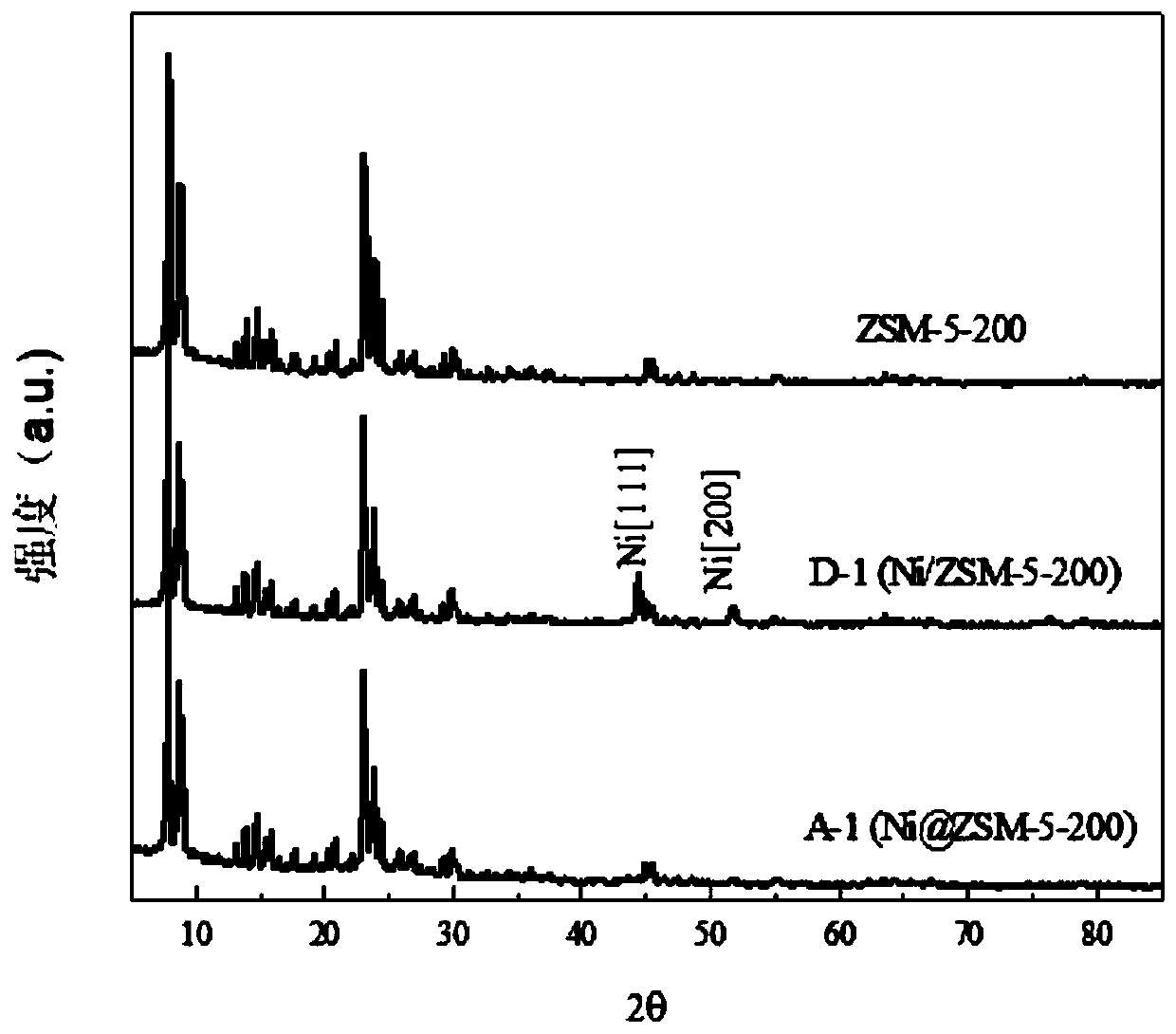

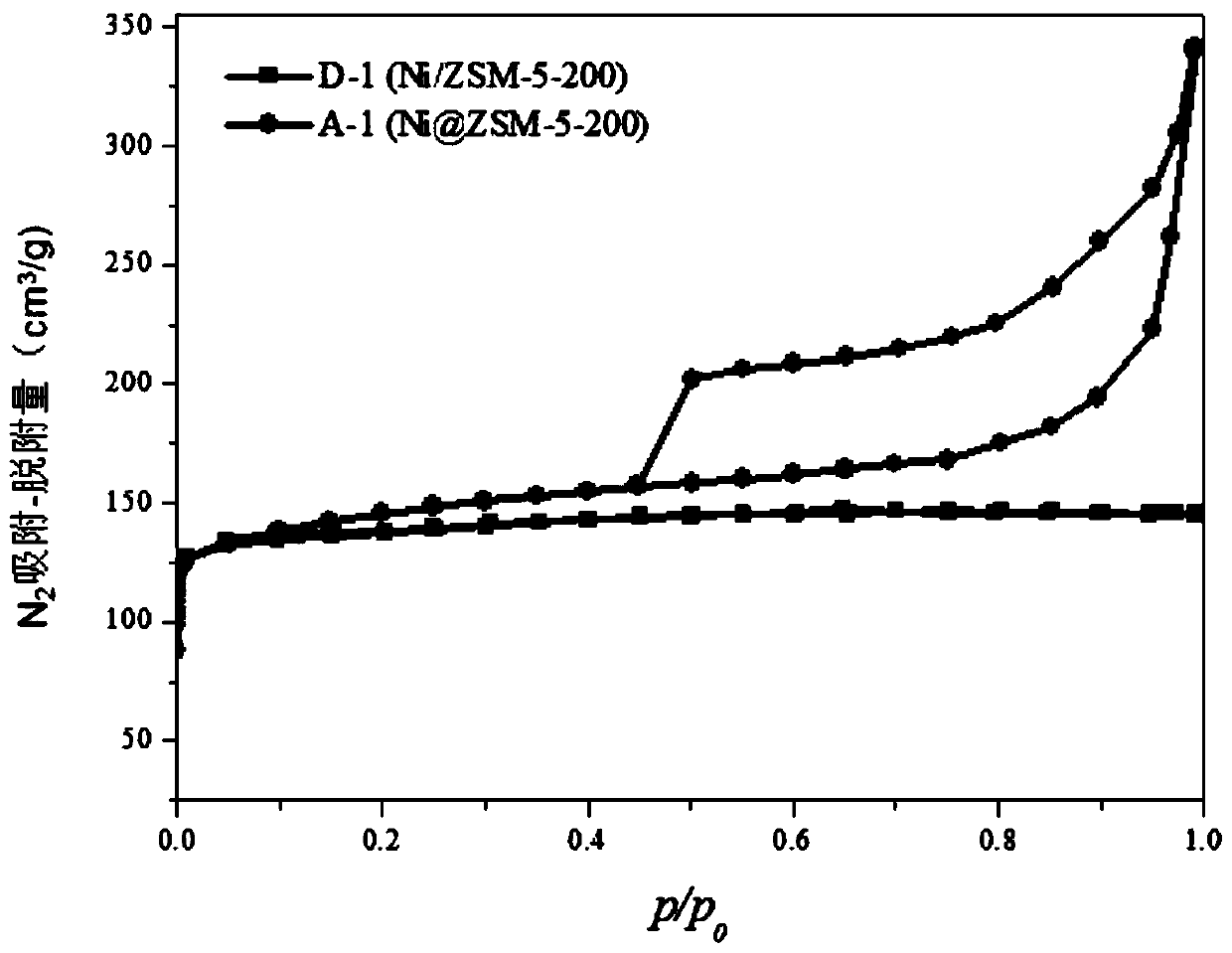

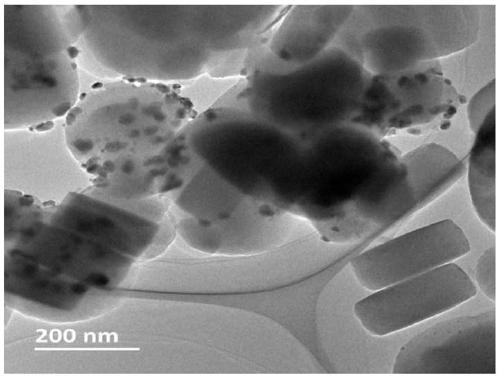

Metal-coated MFI hierarchical pore structure packaging catalyst and packaging method and application thereof

PendingCN111437870AEvenly distributedUniform particle sizeMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention relates to a metal-coated MFI hierarchical pore structure packaging catalyst and a packaging method and application thereof. Micropores and mesopores are contained in the pore channel structure of the packaging catalyst, the N2 adsorption-desorption curve of the packaging catalyst has an adsorption-desorption hysteresis loop under the condition that the relative pressure p / p0 is 0.1-1.0, and the particle size of metal nanoparticles in the packaging catalyst is 1-10 nm. In the preparation process of the packaging catalyst, the MFI structure molecular sieve is modified, the packaging of the metal nanoparticles and the reaming of the MFI structure molecular sieve are realized in one step, and the crystallinity of the molecular sieve parent is not reduced in the preparation process so that the problems of non-uniform distribution, non-uniform particle size, large particles and easiness in migration, agglomeration and loss of the metal nanoparticles in the catalyst prepared bythe traditional wet impregnation method are solved; meanwhile, high molecular sieve crystallinity is maintained through broaching treatment, and the diffusion performance is remarkably improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

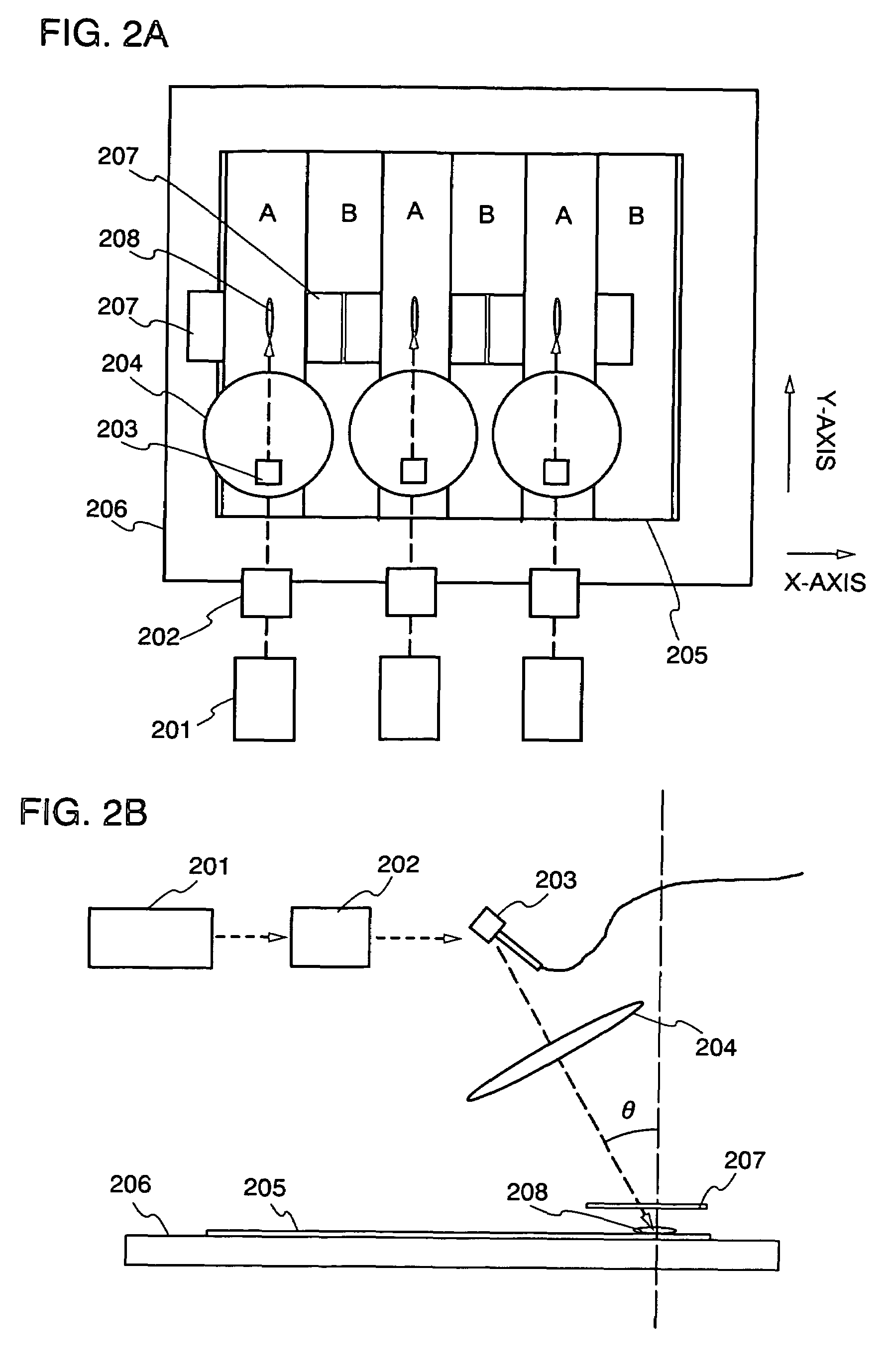

Beam irradiation apparatus, beam irradiation method, and method for manufacturing a thin film transistor

InactiveUS7397592B2Uniform crystallinityUniform characteristicsLaser beam welding apparatusOptical elementsGalvanometerLight beam

A galvanometer mirror rotates in one direction when the galvanometer mirror is used. A spot can be scanned on an irradiated surface at a more constant speed by rotating the galvanometer mirror and by using the inertia. Moreover, it is preferable to make the galvanometer mirror heavy because the inertia becomes higher so that the spot is scanned at a more constant speed. In addition, in a polygon mirror of this invention, mirrors are arranged so as not to contact each other because a change time of the scanning position between the mirrors is provided. By moving the irradiated object with timing together when the laser light is not irradiated, the laser process can be performed efficiently.

Owner:SEMICON ENERGY LAB CO LTD

Preparation method of large-grain perovskite thin film

InactiveCN108054284APromote growthReduce defectsSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellCrystallite

The invention relates to a preparation method of a large-grain perovskite thin film. The preparation method takes mixed anionic cationic perovskite as a main system, and adds Pb (SCN) 2 as an additiveto regulate and control the growth of the thin film. The method comprises a process of preparing a thin film with a mixed anion-cation type perovskite precursor solution and an additive, and calcium-titanium ore thin film which is flat and compact and has large-size crystal grains can be obtained by adjusting and controlling the Pb (SCN ) 2 additive. The preparation method is simple in process, convenient to operate and capable of effectively and rapidly forming the film. The mixed type anionic type perovskite is adopted as a main system, and the growth of the perovskite thin film is regulated and controlled by using an additive, the growth of the large-size perovskite crystal grains is realized, and the internal defects of the thin film are reduced. The service life of carriers is prolonged, the defect of grain boundaries is reduced, and the environmental stability of the perovskite thin film is greatly improved. The performance of the perovskite solar cell is enhanced, and the preparation of the highly-efficient and stable perovskite thin-film device with low hysteresis is realized.

Owner:TIANJIN UNIV

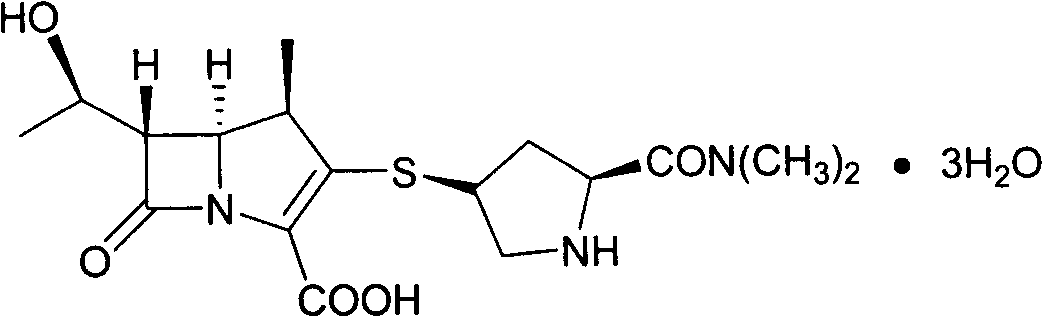

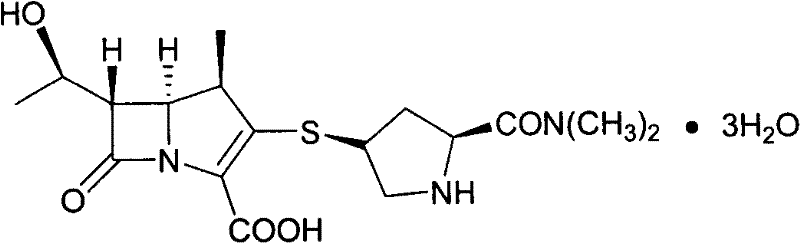

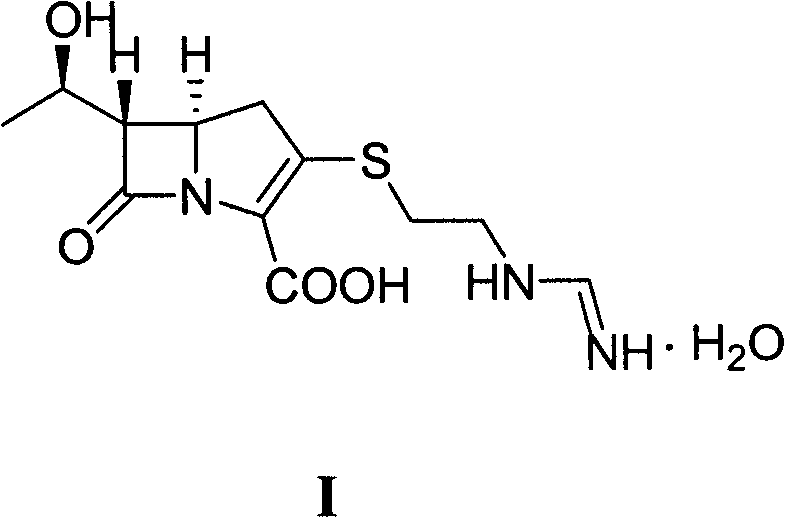

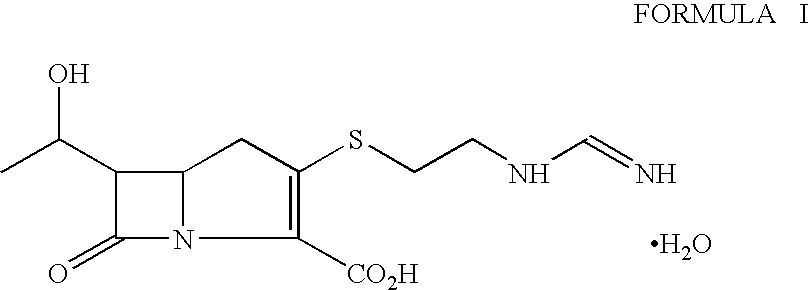

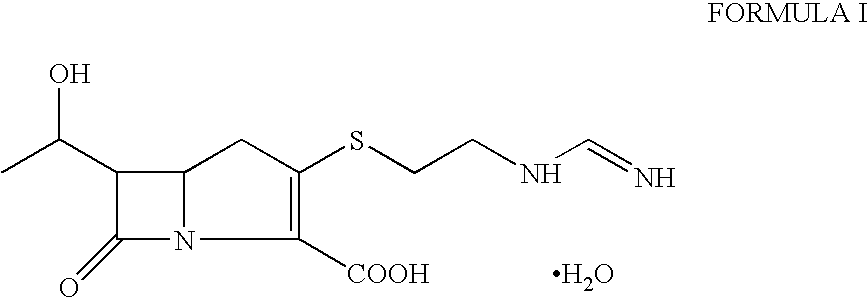

Preparation method of meropenem trihydrate crystal

The invention discloses a preparation method of a meropenem trihydrate crystal, comprising the following steps: dissolving a crude meropenem product in water at 30-70 DEG C to obtain solution I; treating the solution I with active carbon and then filtering the treated solution at 5-30 DEG C to obtain solution II; adding an organic solvent to the solution II and then cooling to -20-0 DEG C to form a crystal nucleus; and melting the crystal nucleus, adding an organic solvent, and then crystallizing to obtain the meropenem trihydrate crystal. The preparation method is simple and feasible; and the obtained meropenem trihydrate crystal has uniform crystallinity, high purity and fast dissolving performance, and the crystal can be used for preparing a meropenem medicinal preparation with good dissolubility.

Owner:JIANKANGYUAN PHARMA GROUP

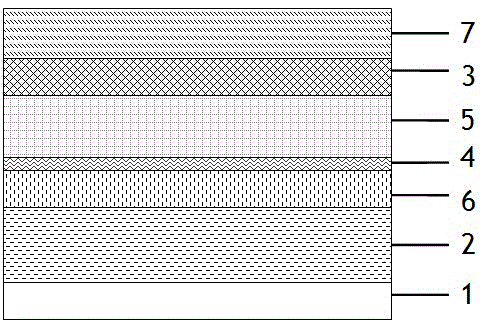

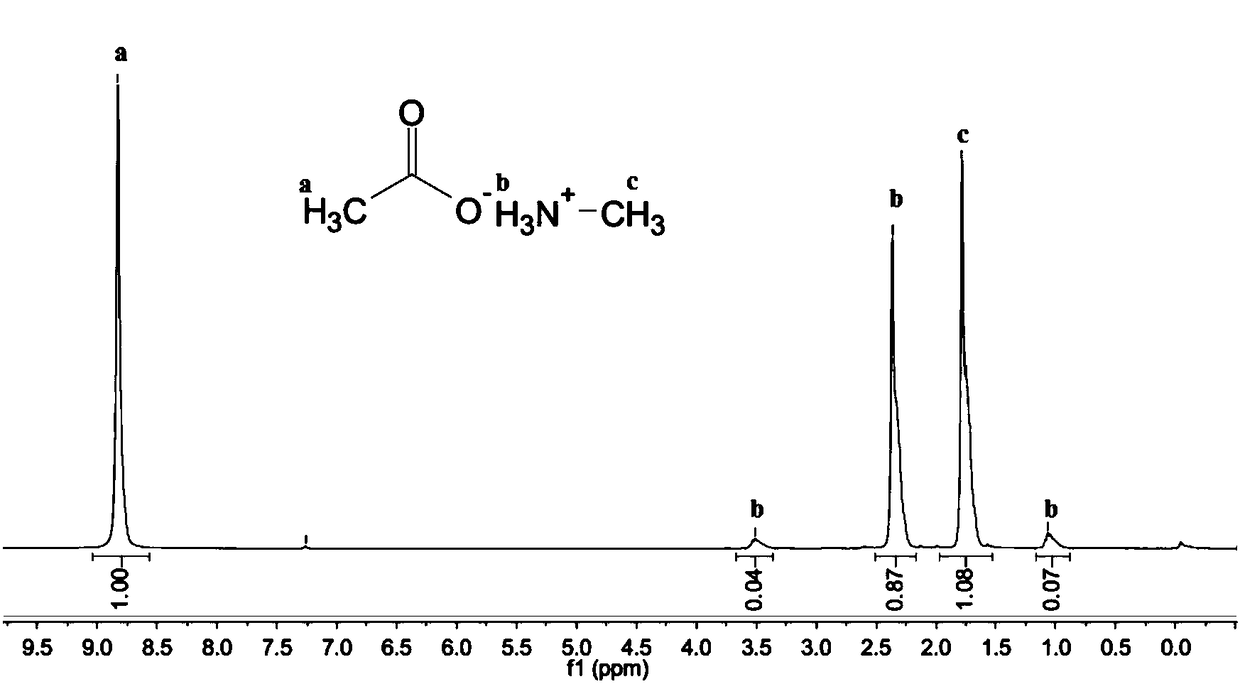

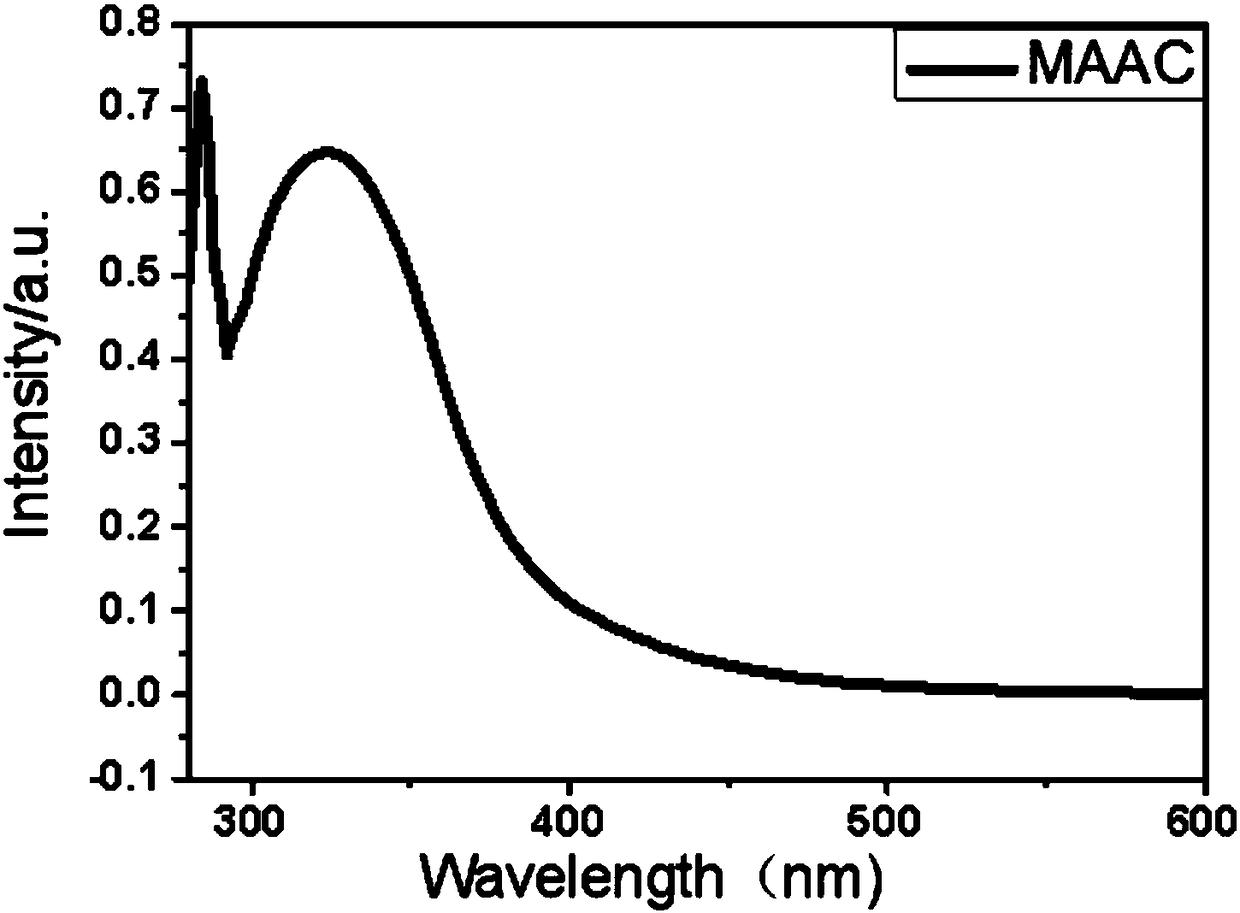

Perovskite solar cell prepared based on acetic acid-methylamine room-temperature molten salt as green solvent and method and application of perovskite solar cell

ActiveCN108666424AReduce pollutionLow toxicitySolid-state devicesSemiconductor/solid-state device manufacturingIce waterRotary evaporator

The invention relates to a perovskite solar cell prepared based on an acetic acid-methylamine room-temperature molten salt as a green solvent and a method and application of the perovskite solar celland belongs to the field of photoelectronic materials and devices. The method comprises the steps of stirring acetic acid and methylamine in an ice-water bath according to the stoichiometric ratio of1:1.5 for 2h and carrying out rotary evaporation on a rotary evaporator until no liquid drop drips to prepare an acetic acid-methylamine room-temperature molten salt; dissolving lead iodide and chlorine methylamine into an acetic acid-methylamine solution according to the stoichiometric ratio of 1:1 to prepare a perovskite precursor solution; carrying out spin-coating of the precursor solution onan ITO conductive substrate provided with a hole transport layer or an electron transport layer by using a thermal spin-coating technology separately and carrying out annealing to form a dense and uniform perovskite film with high stability, wherein the whole process is operated completely in the air; and then carrying out spin-coating on the electron transport layer or the hole transport layer onthe film and evaporating a modification layer and a metal Al electrode by using a vacuum evaporation technology.

Owner:NANJING UNIV OF TECH

Beam irradiation apparatus, beam irradiation method, and method for manufacturing thin film transistor

InactiveUS7476629B2Uniform crystallinityUniform characteristicsTransistorSolid-state devicesContinuous scanningGalvanometer

The speed of the laser scanned with the scanning means such as a galvanometer mirror or the polygon mirror is not constant in the center portion and in the end portion of the scanning width. As a result, the object to be irradiated is irradiated with the excessive energy and thereby there is a risk that the amorphous semiconductor film may be peeled.In the case of scanning the spot of the energy beam output continuously with the scanning means, the present invention is to block the CW beam irradiated to the regions in the object to be irradiated where the scanning speed of the spot accelerates, decelerates, and it becomes zero, that is to say, when the spot is in the position where the scanning starts and in the position where the scanning ends.

Owner:SEMICON ENERGY LAB CO LTD

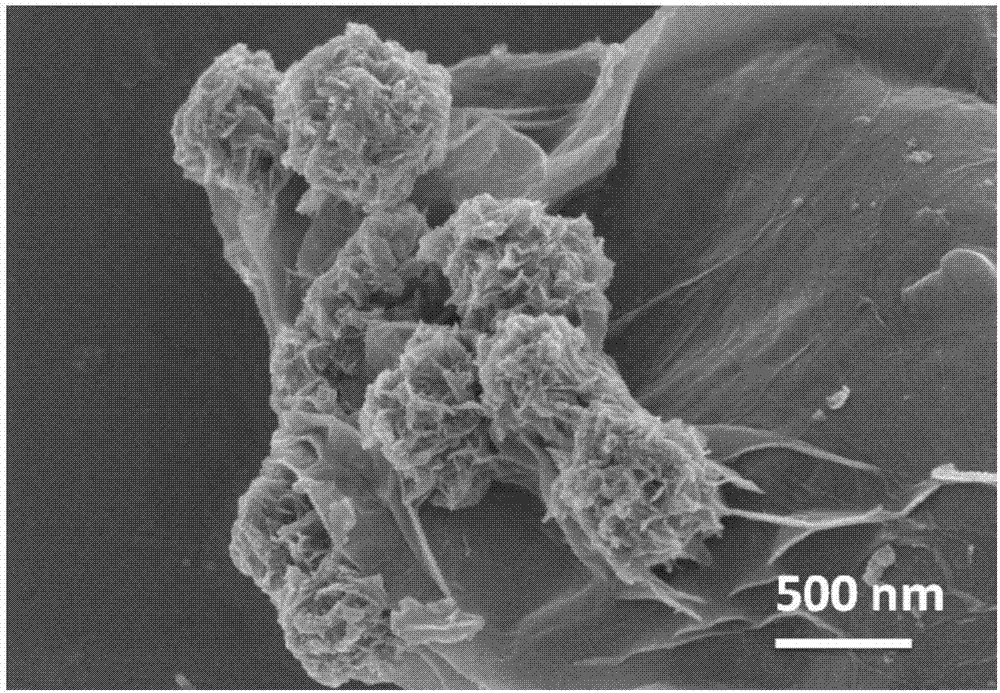

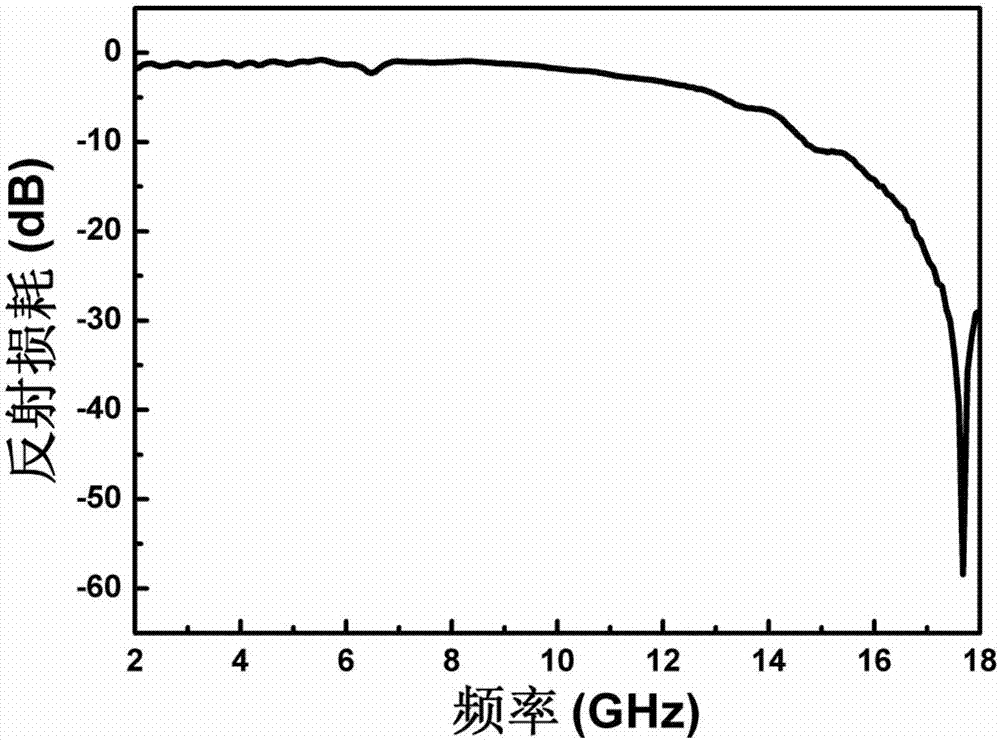

Preparation method for graphene/three-dimensional flower-shaped bismuth ferrite composite absorbing material

InactiveCN107960050AImprove absorbing performanceReduced operating requirementsOther chemical processesMagnetic/electric field screeningCorrosion reactionMass ratio

The invention discloses a preparation method for a graphene / three-dimensional flower-shaped bismuth ferrite composite absorbing material, and the method comprises the steps: mixing bismuth ferrite powder and oxidized graphene in corrosion solvent at the mass ratio of 25: (3-6), and obtaining mixed liquor A after supersonic processing; carrying out the heating and stirring of the mixed liquor A atthe protective atmosphere, adding a reducing agent and a complexing agent to the mixed liquor A in a dripping manner, carrying out the corrosion reaction for 40-50 min after dripping, and obtaining the three-dimensional flower-shaped bismuth ferrite powder through cooling. The method provided by the invention is novel, is uniform in particles, is low in requirements for the equipment operation, issimple in technology, is low in energy consumption, can achieve the continuous operation, and enables the process conditions to be controlled easily. Compared with a single phase, the composite material greatly improves the electromagnetic wave absorbing performances.

Owner:SHAANXI UNIV OF SCI & TECH

Melt/solid state polycondensation preparation method for polylactic acid

The invention relates to a melt / solid state polycondensation preparation method for polylactic acid, which mainly solves the problems of long reaction time, difficult continuous production or high cost in the prior art. The method comprises the following steps of: 1) performing a dehydration oligomerization reaction of lactic acid at the temperature of between 100 and 160 DEG C under the absolute pressure of between 6,000 and 25,000 Pa and under the action of a catalyst A for 0.5 to 5 hours first, and continuing the ehydration oligomerization reaction at the temperature of between of 120 and 180 DEG C under the absolute pressure of between 200 and 1,500 Pa and under the action of the catalyst A for 0.5 to 5 hours to generate a product I; 2) performing a melt polycondensation reaction of the product I at the reaction temperature of between 150 and 200 DEG C under the absolute pressure of between 30 and 600 Pa and under the action of a catalyst B for 0.5 to 15 hours to generate a polylactic acid prepolymer and lactide serving as a by-product, and refluxing the lactide to a reaction mixture at the reflux temperature of between 70 and 95 DEG C; 3) pelletizing the polylactic acid prepolymer obtained in the step 2), and crystallizing in an inertia airflow at the temperature of between 50 and 130 DEG C for 0.5 to 10 hours; and 4) performing a solid state polycondensation reaction of the polylactic acid prepolymer processed in the step 3) in the inertia airflow at the temperature of between 120 and 170 DEG C for 5 to 40 hours to obtain the polylactic acid. The technical scheme of the invention better solves the problem, and can be used for the industrial production of the polylactic acid.

Owner:CHINA PETROLEUM & CHEM CORP +2

A method for preparing olefin polymers using multi-temperature reaction zones

The invention discloses a method for preparing olefin polymer by utilizing multiple temperature reaction areas. The method provided by the invention comprises the following step of forming a plurality of olefin polymer reaction areas with different temperatures in a fluidized bed reactor by utilizing a circulating medium, wherein the circulating medium comprises an olefin monomer and a condensing agent. By utilizing the method, preparation of high-performance olefin polymer product by utilizing a single reactor is realized. The method is high in heat transfer efficiency. The olefin polymer prepared by utilizing the method is low in density, wide in distribution, uniform in degree of crystallinity and the like and can be widely applied to various fields of thin-film materials and the like.

Owner:ZHEJIANG UNIV

Preparation method of meropenem trihydrate crystal

Owner:JIANKANGYUAN PHARMA GROUP

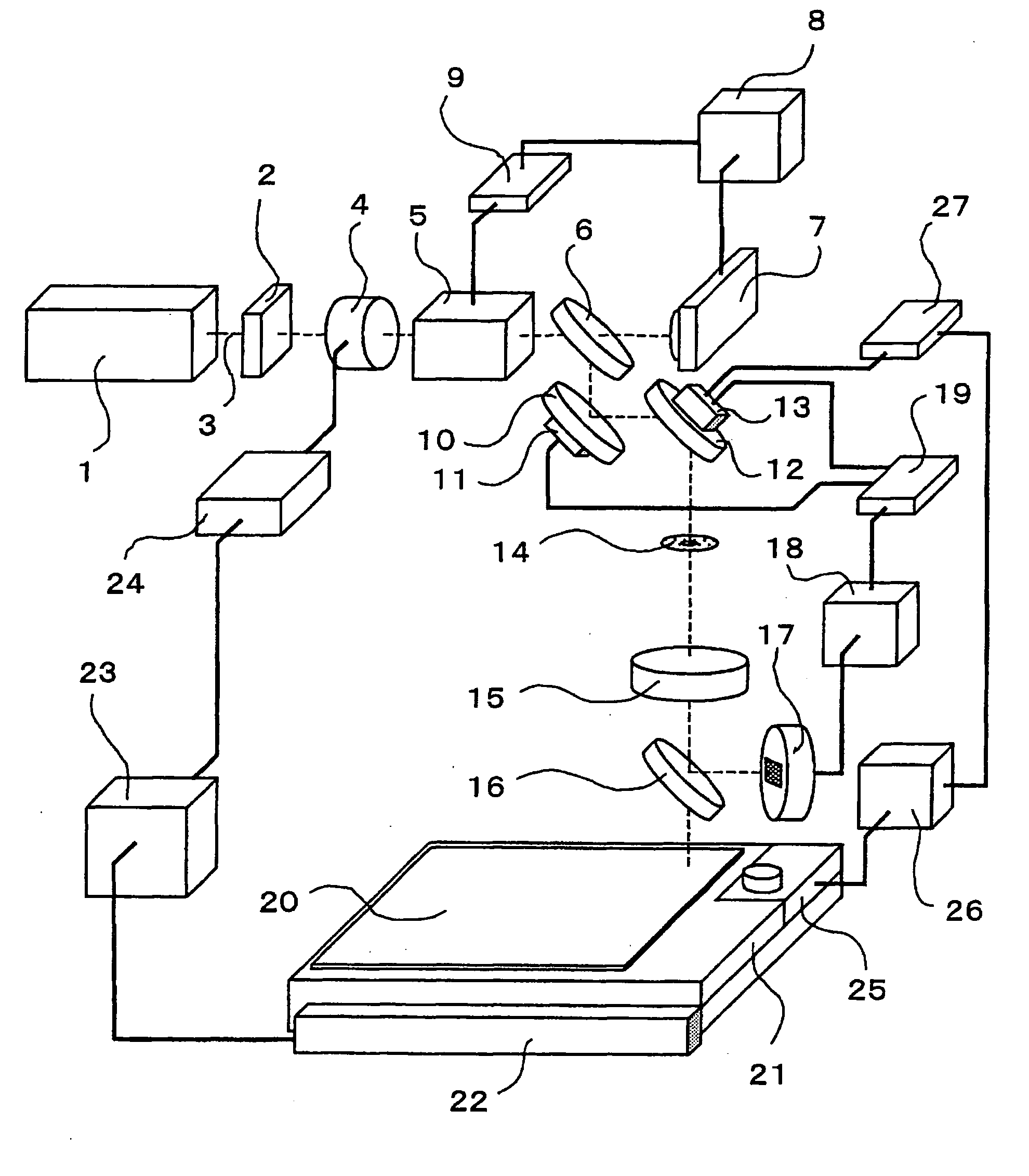

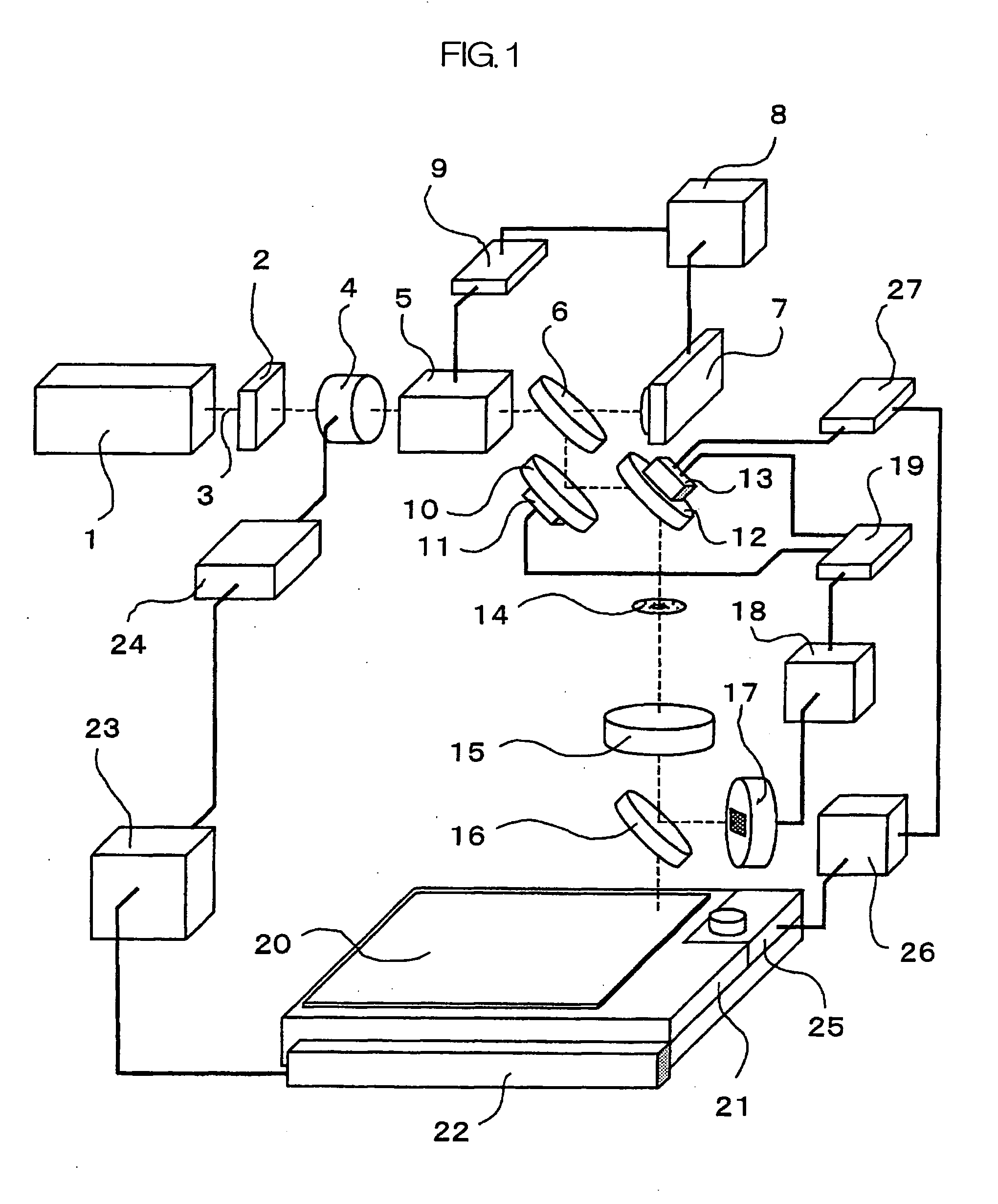

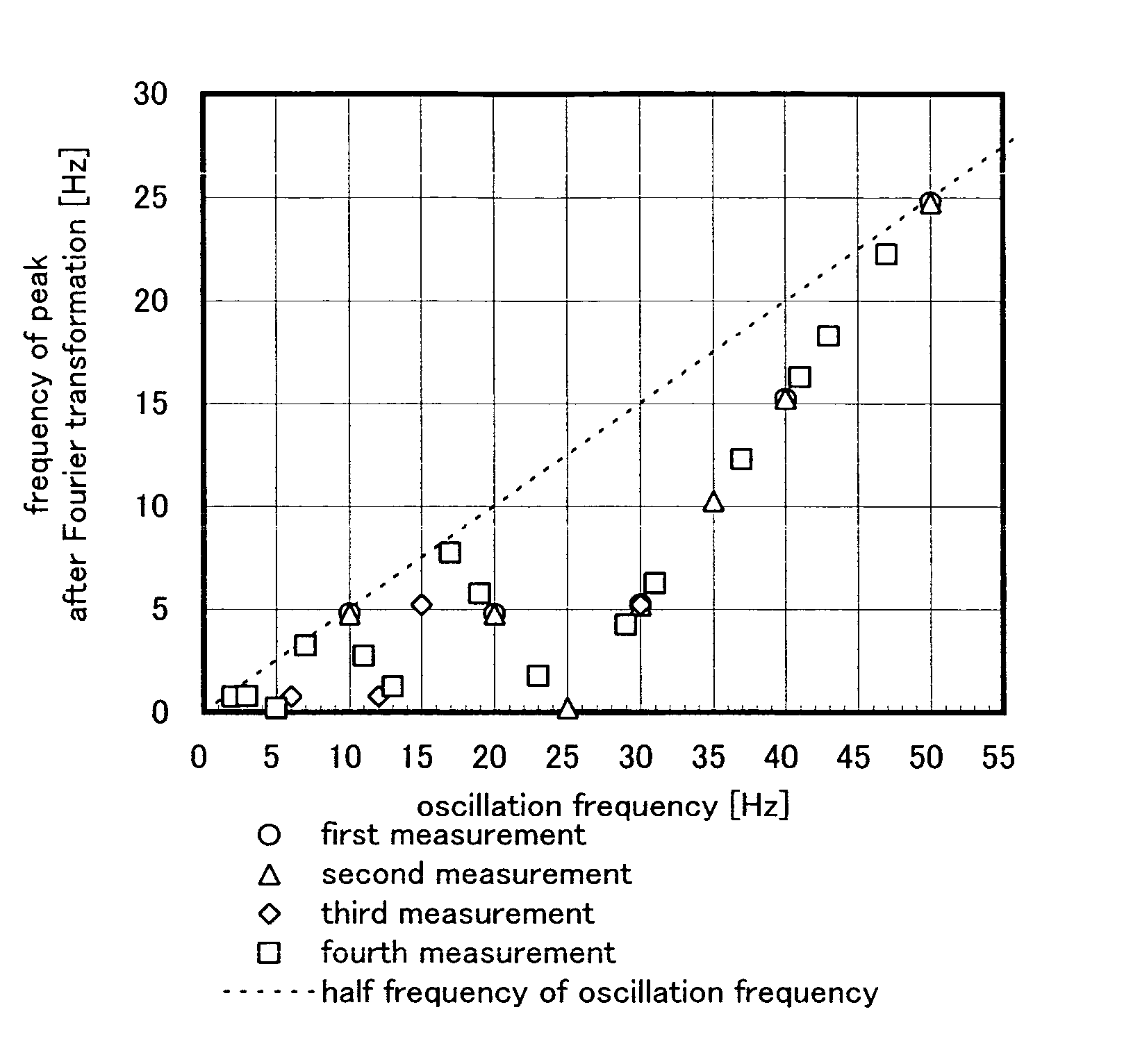

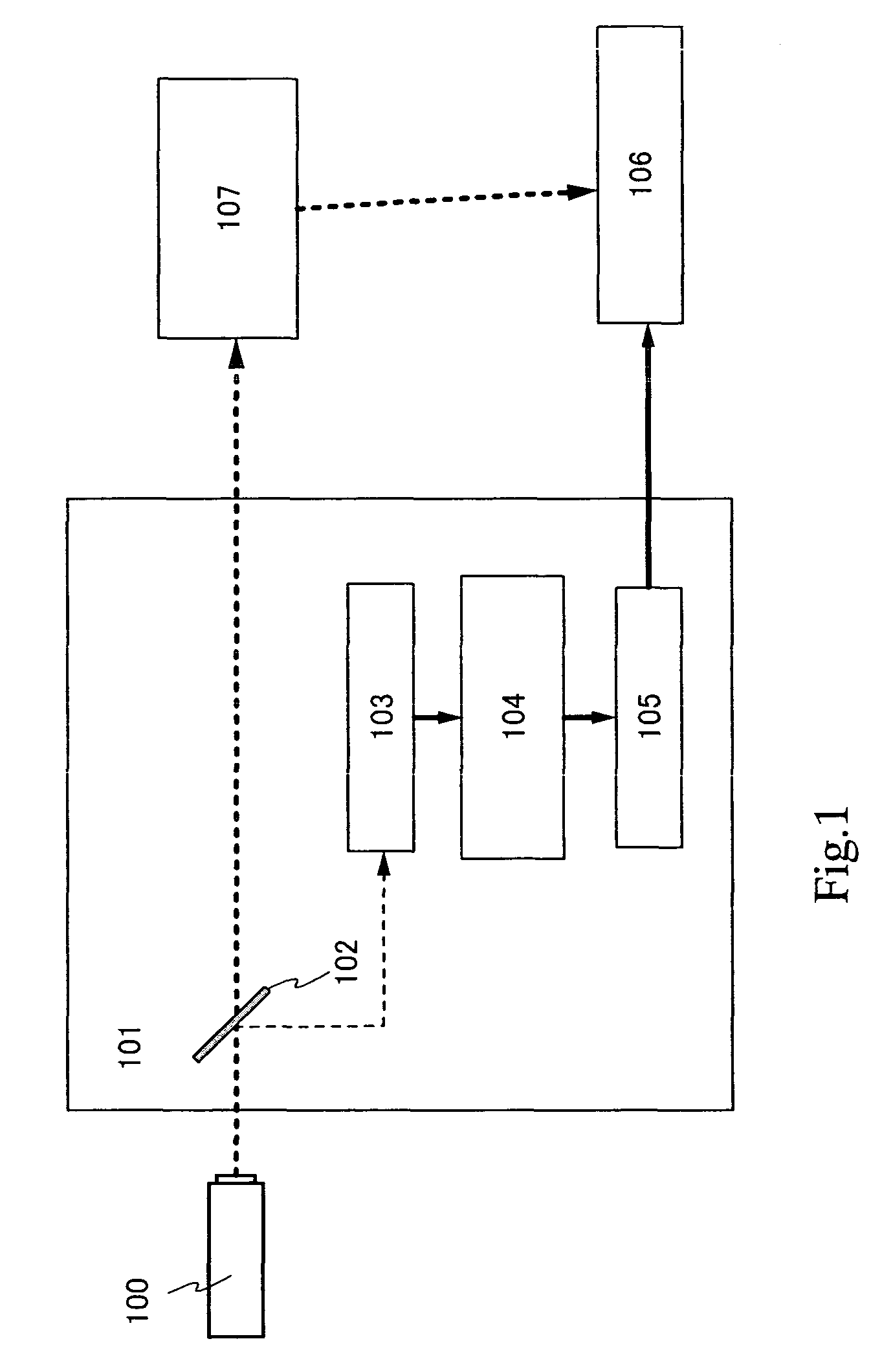

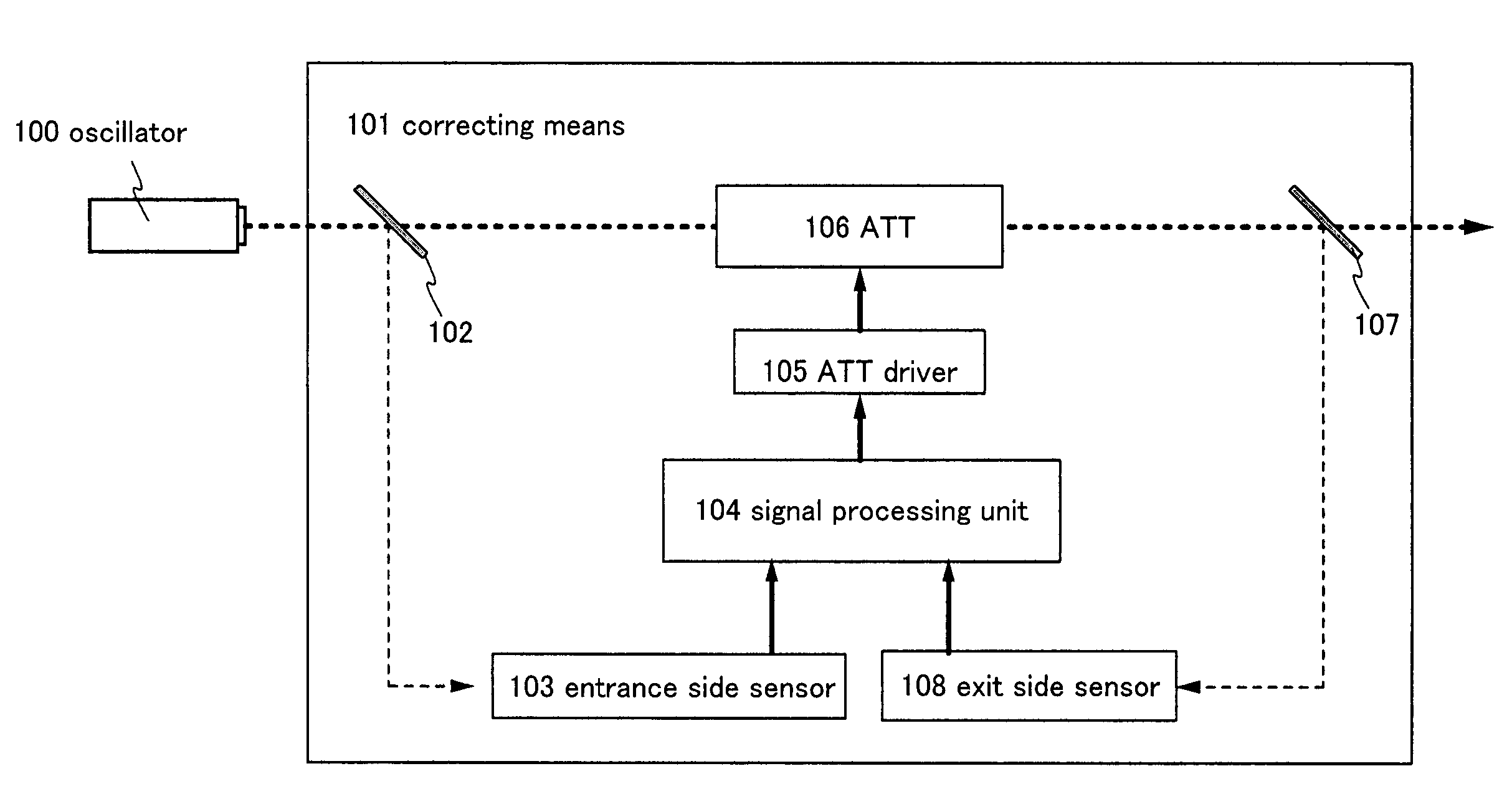

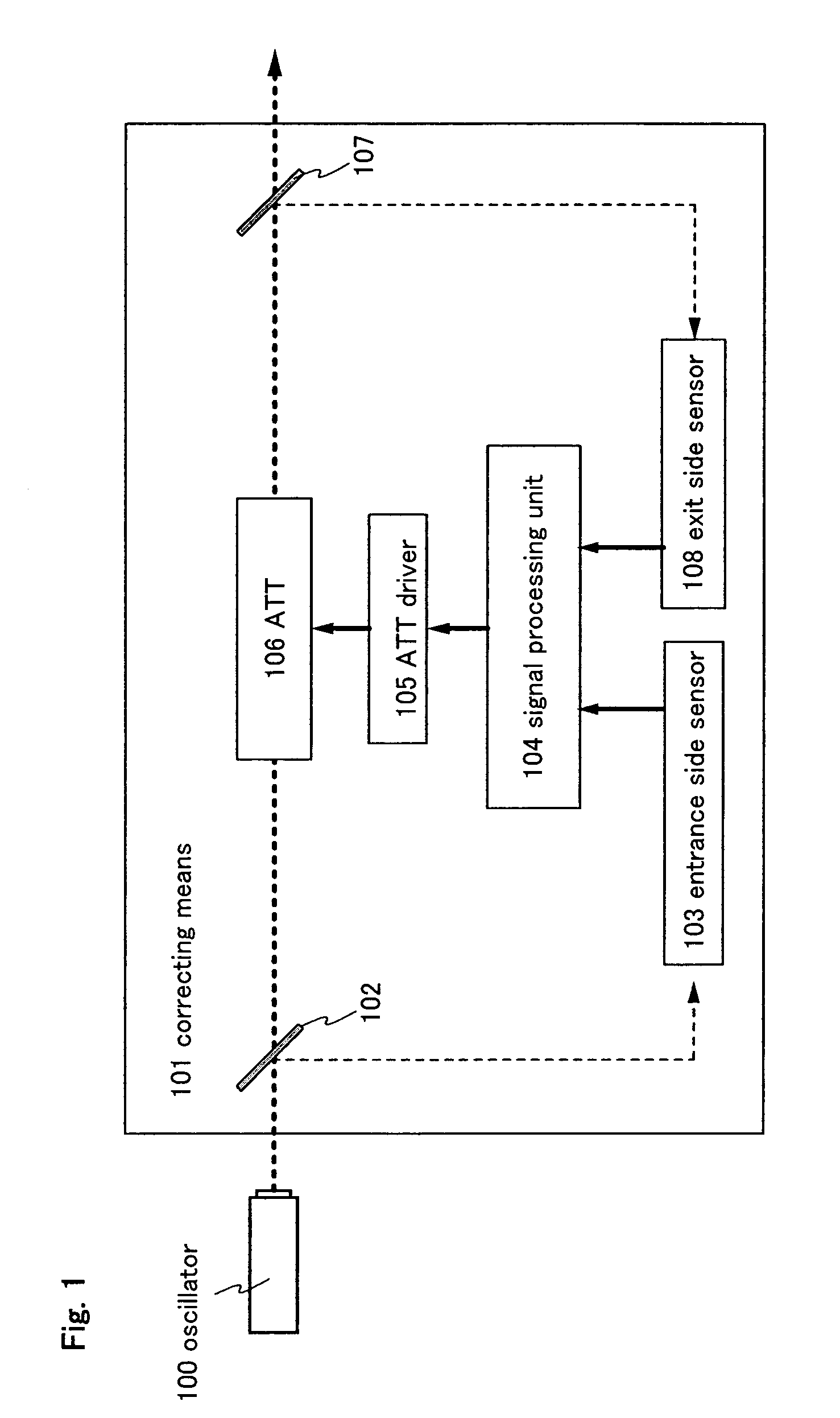

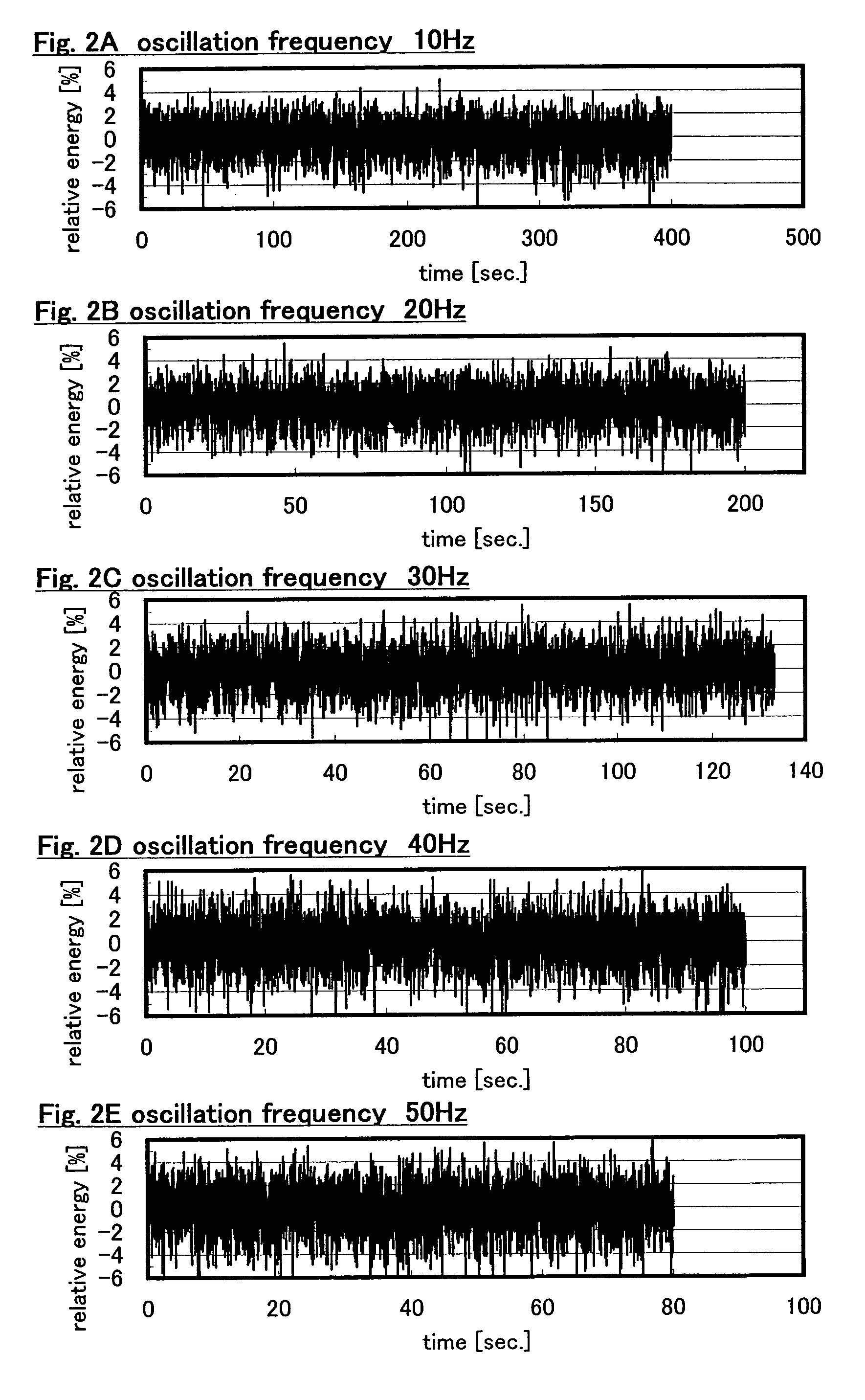

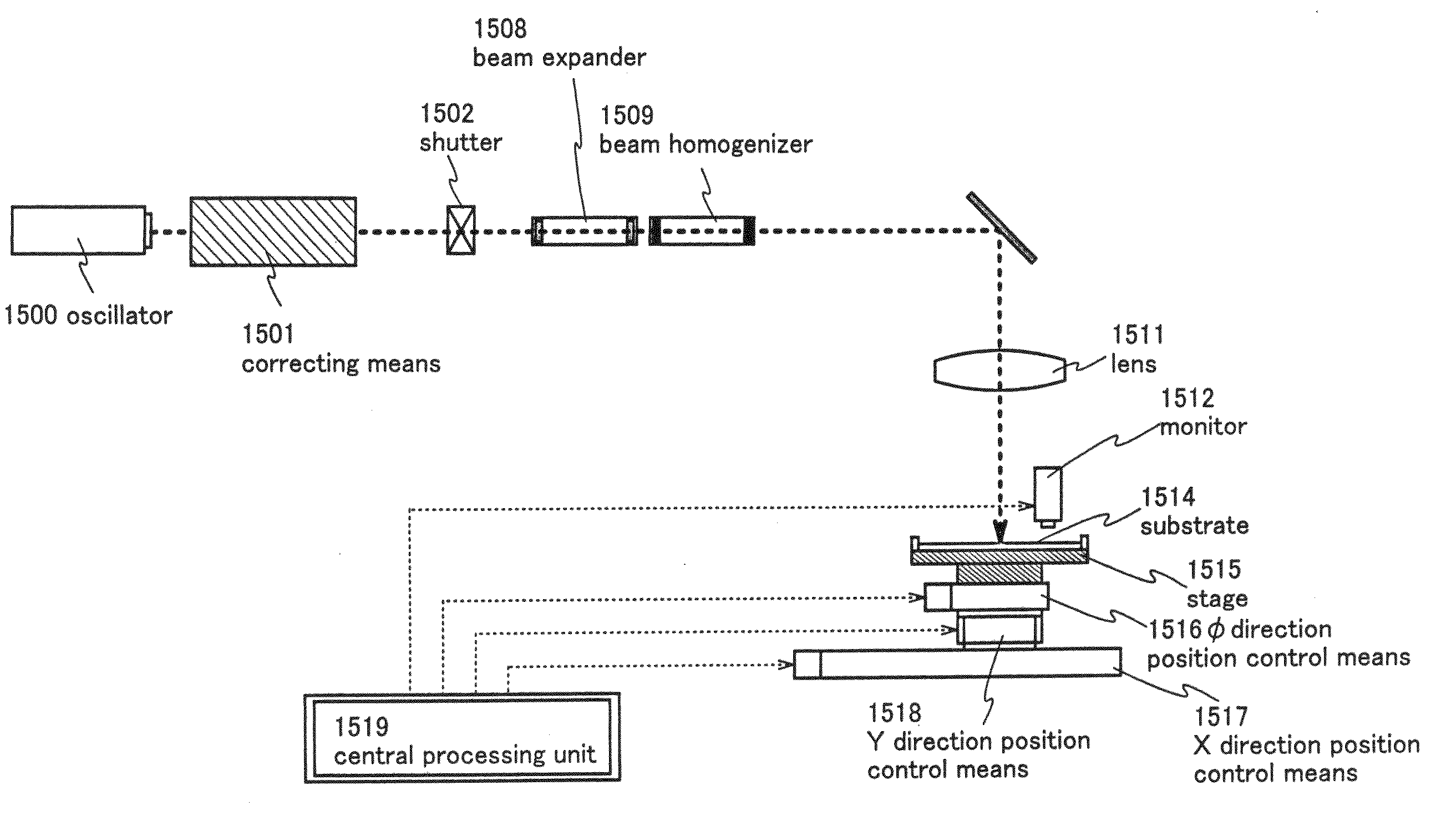

Laser apparatus, laser irradiation method, and manufacturing method of semiconductor device

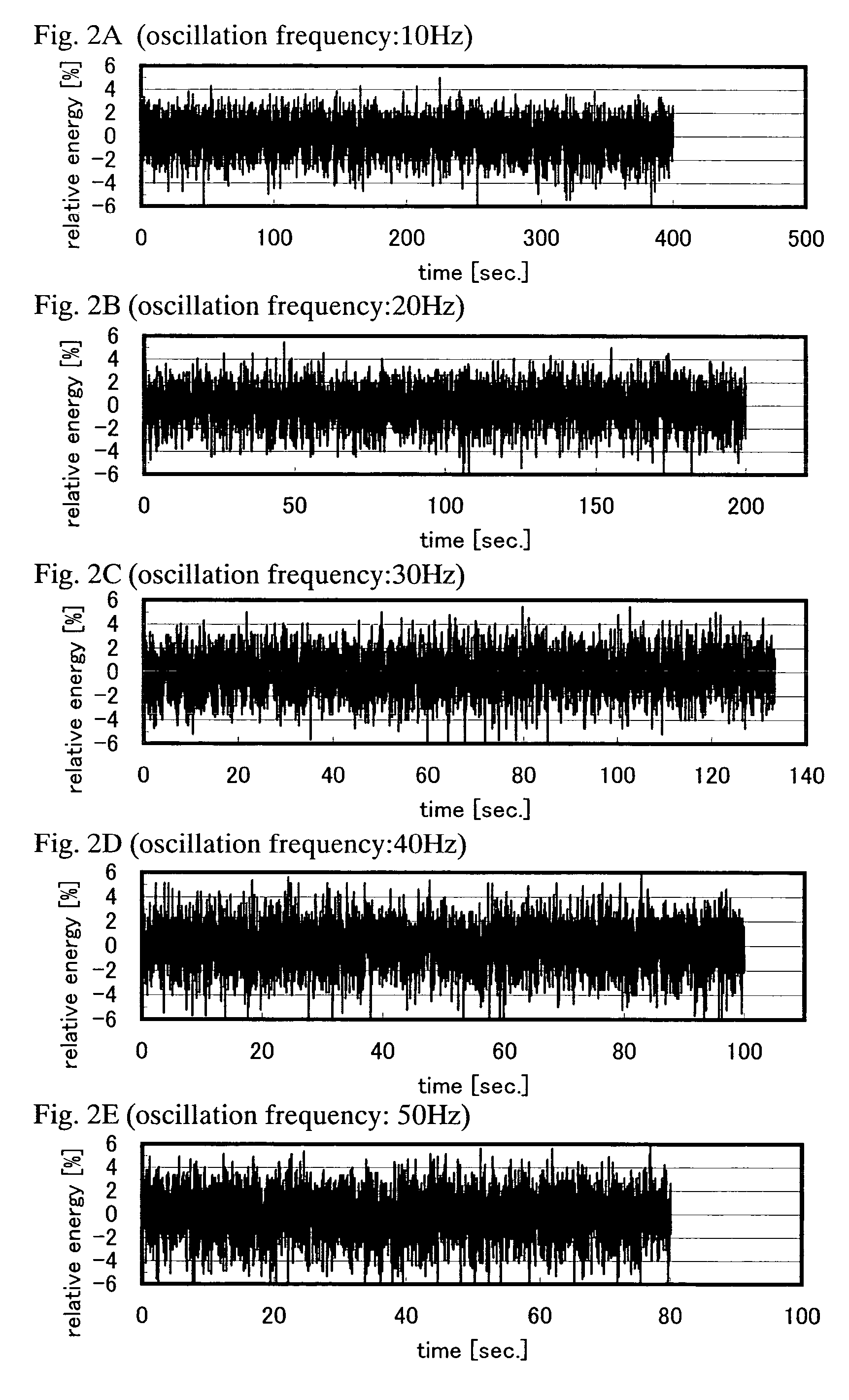

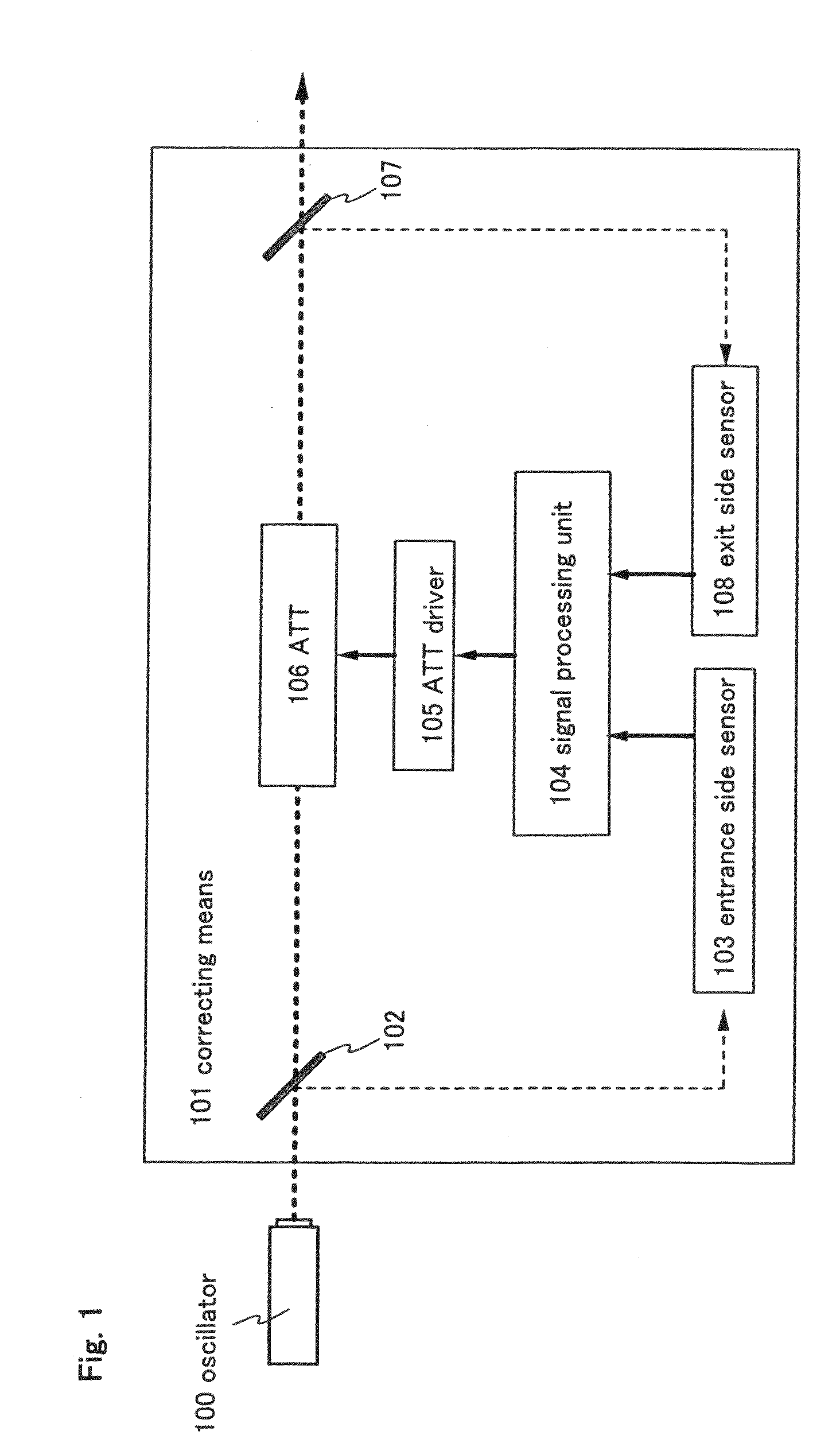

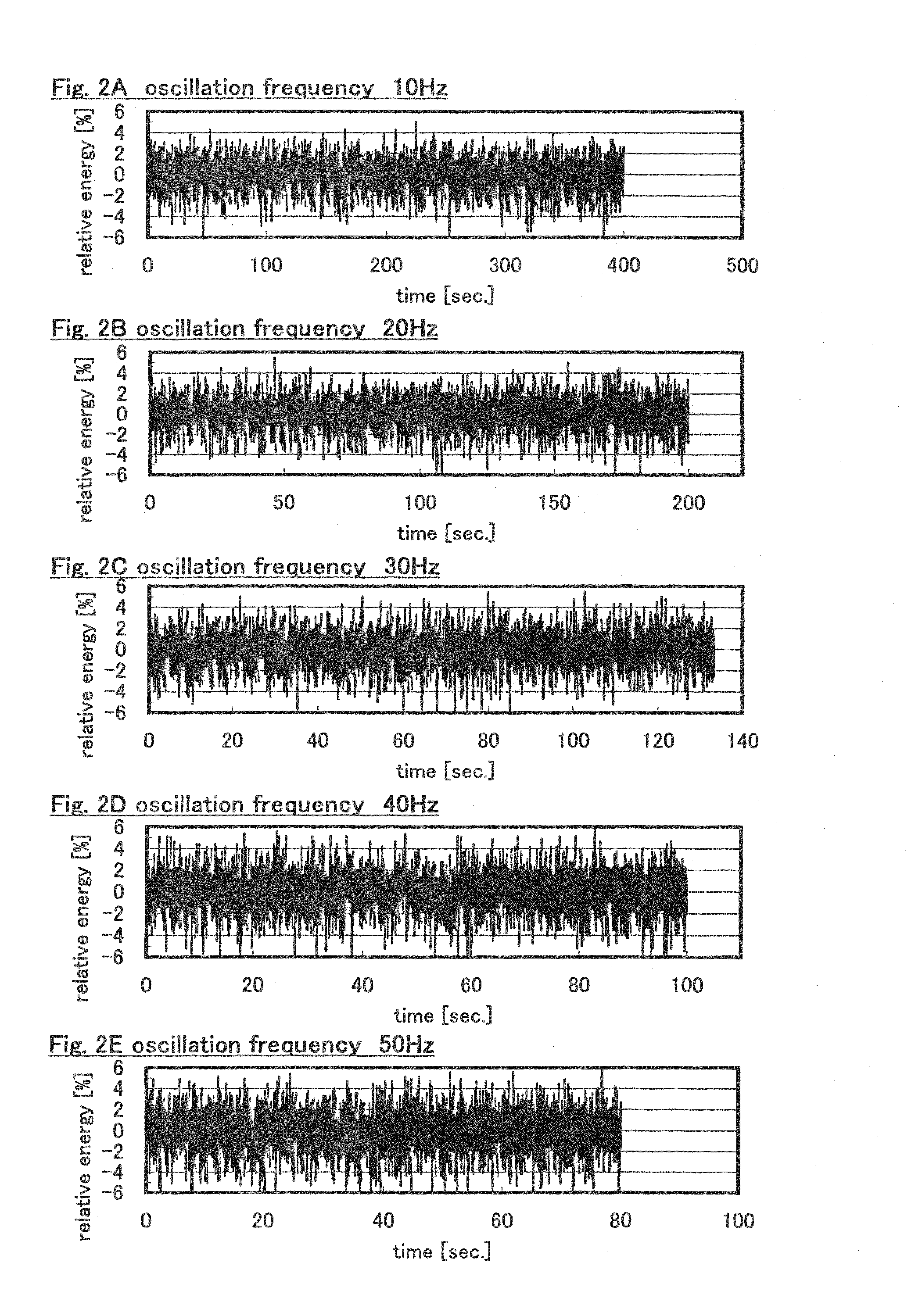

InactiveUS7223306B2Suppress pressure fluctuationsPressure fluctuationFrom gel statePolycrystalline material growthLight beamIrradiation

It is an object to provide a laser apparatus, a laser irradiating method and a manufacturing method of a semiconductor device that can perform uniform a process with a laser beam to an object uniformly. The present invention provides a laser apparatus comprising an optical system for sampling a part of a laser beam emitted from an oscillator, a sensor for generating an electric signal including fluctuation in energy of the laser beam as a data from the part of the laser beam, a means for performing signal processing to the electrical signal to grasp a state of the fluctuation in energy of the laser beam, and controlling a relative speed of an beam spot of the laser beam to an object in order to change in phase with the fluctuation in energy of the laser beam.

Owner:SEMICON ENERGY LAB CO LTD

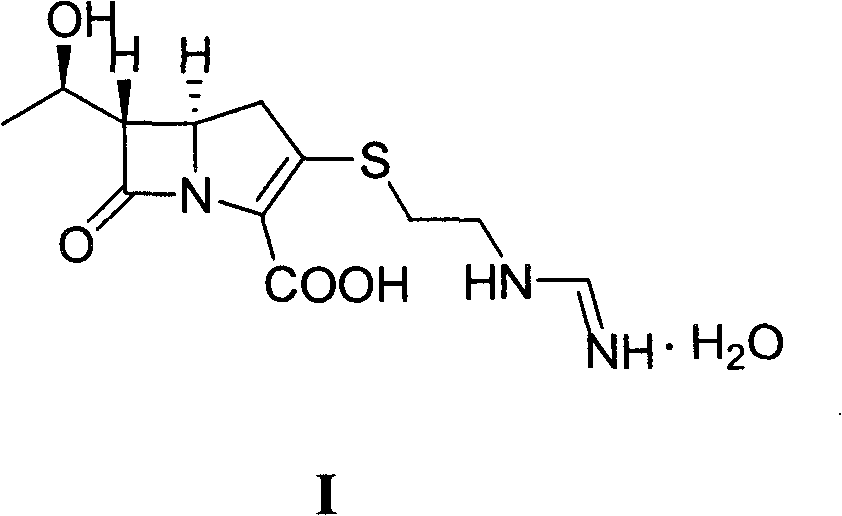

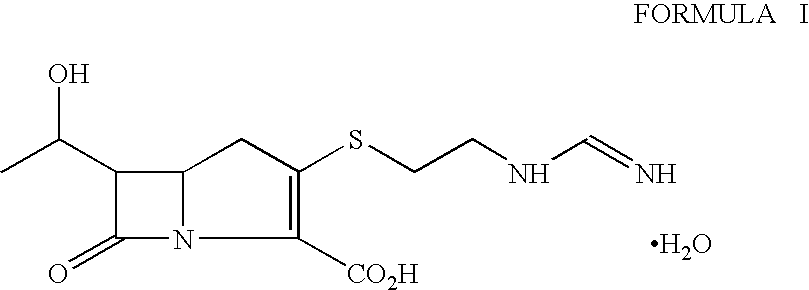

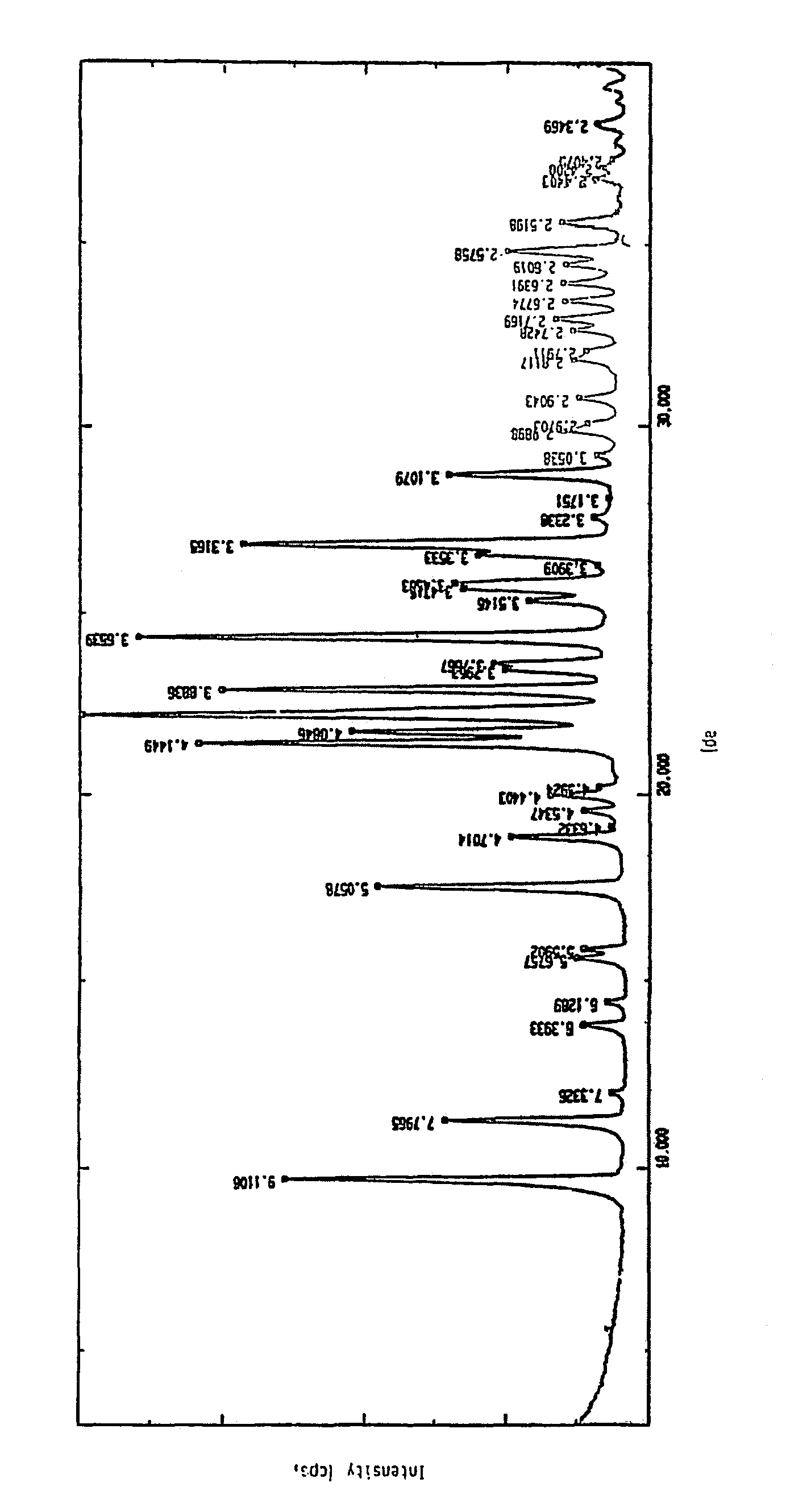

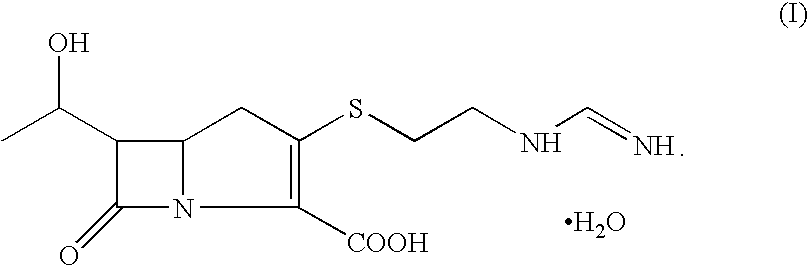

Method for preparing imipenem monohydrate crystal

The invention relates to a method for preparing an imipenem monohydrate crystal (I), which comprises the following steps of: 1) dissolving the crude product of imipenem in water in the nitrogen atmosphere to obtain solution; 2) performing activated carbon treatment on the solution; 3) adding an organic solvent into the solution and reducing the temperature to make the solution in a solid-liquid mixed state so as to form a crystal nucleus; and 4) raising the temperature to melt the crystal nucleus and adding the organic solvent to crystallize and precipitate imipenem monohydrate so as to obtain the imipenem monohydrate crystal. The method for preparing the imipenem monohydrate crystal does not comprise the step of thickening and dewatering or adding acid or alkali to adjust the pH value, so the method is simpler and effective and is easy to control; and the imipenem monohydrate crystal prepared by the method has the advantages of uniform crystallinity, high purity and quick solubility.

Owner:SHENZHEN HAIBIN PHARMA +1

Process for the isolation of crystalline imipenem

InactiveUS7241885B2Uniform crystallinityPractical and convenientPolycrystalline material growthFrom normal temperature solutionsOrganic solventAqueous solution

The present invention relates to a cost effective and industrially advantageous process for the preparation of imipenem of high purity comprising the steps of treating an aqueous solution containing imipenem with an organic solvent, wherein the imipenem is not lyophilized; and isolating the pure crystalline imipenem monohydrate from the reaction mixture thereof.

Owner:RANBAXY LAB LTD

Laser apparatus, laser irradiation method, and manufacturing method of semiconductor device

ActiveUS7359412B2Energy stabilityEasy to controlLaser detailsSemiconductor/solid-state device manufacturingPhase differenceTransmittance

It is an object to provide a laser apparatus, a laser irradiating method and a manufacturing method of a semiconductor device that make laser energy more stable. To attain the object, a part of laser beam emitted from an oscillator is sampled to generate an electric signal that contains as data energy fluctuation of a laser beam. The electric signal is subjected to signal processing to calculate the frequency, amplitude, and phase of the energy fluctuation of the laser beam. The transmittance of a light amount adjusting means is controlled in order that the transmittance changes in antiphase to the phase of the energy fluctuation of the laser beam and with an amplitude capable of reducing the amplitude of laser beam emitted from the oscillator, the control being made based on the phase difference between the phase of a signal that is in synchronization with oscillation of laser beam emitted from the oscillator and the phase calculated, on the energy ratio of the sampled laser beam to laser beam emitted from the oscillator, and on the frequency and amplitude calculated. In the light amount adjusting means, energy of the laser beam oscillated from the oscillator energy is adjusted.

Owner:SEMICON ENERGY LAB CO LTD

Method of manufacturing a semiconductor device

InactiveUS20050095761A1Uniform crystallinityEasy to useTransistorSolid-state devicesDevice materialLaser beam machining

By using lasers having different wavelengths in laser annealing of an amorphous semiconductor film, the amorphous semiconductor film can be crystallized and the crystallinity of the crystallized film is improved. A laser 126 to 370 nm in wavelength is used first to subject an amorphous semiconductor film to laser annealing, thereby obtaining a crystalline semiconductor film. In desirable laser annealing, a subject surface is irradiated with a laser beam processed by an optical system into a linear laser beam that is linear in section on the subject surface. Next, a laser 370 to 650 nm in wavelength is used to irradiate the above crystalline semiconductor film by again processing the laser beam into a linear beam through an optical system. A crystalline semiconductor film thus obtained has an excellent crystallinity. If this crystalline semiconductor film is used to form an active layer of a TFT, an electric characteristic of the TFT can be improved.

Owner:SEMICON ENERGY LAB CO LTD

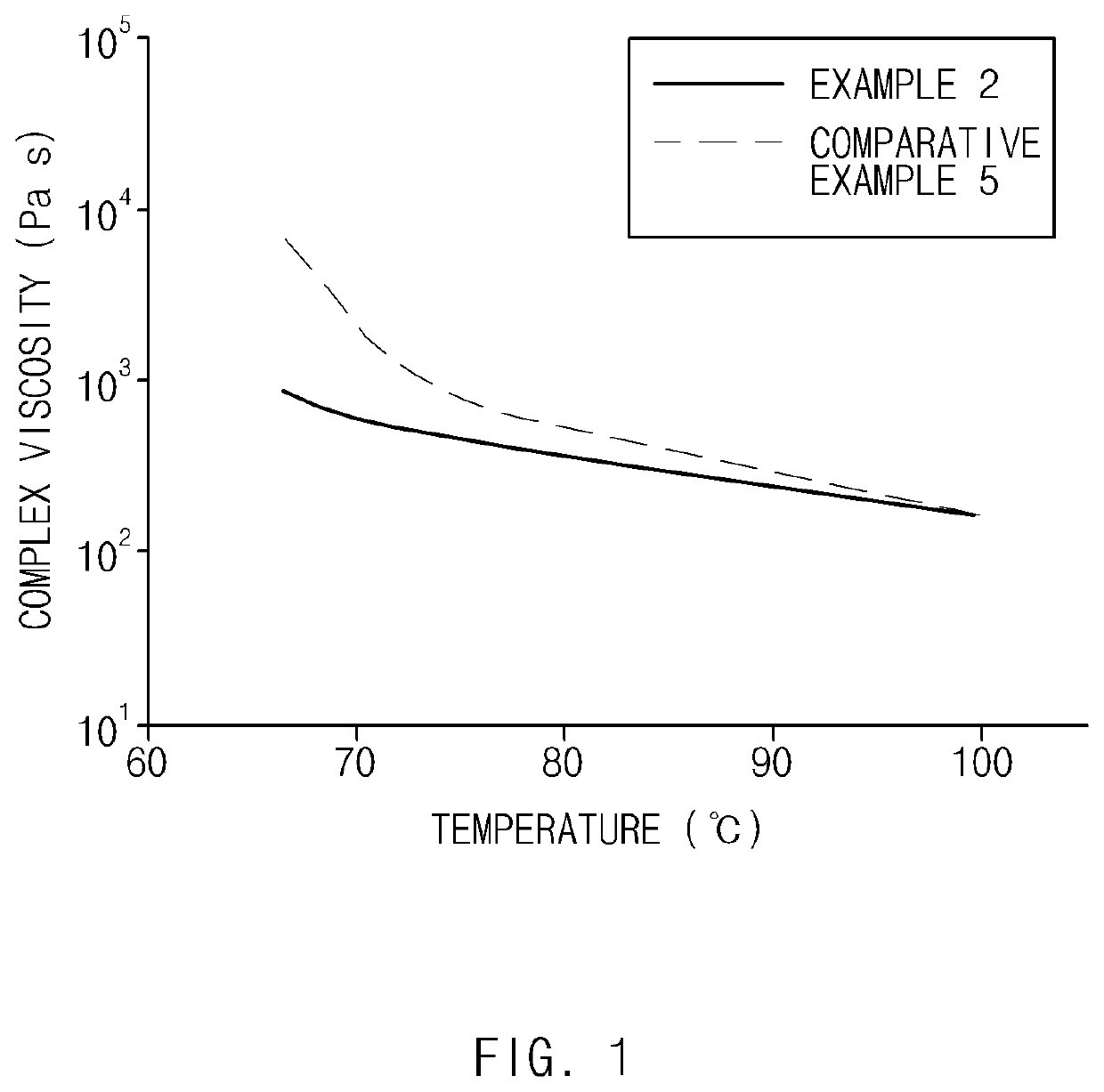

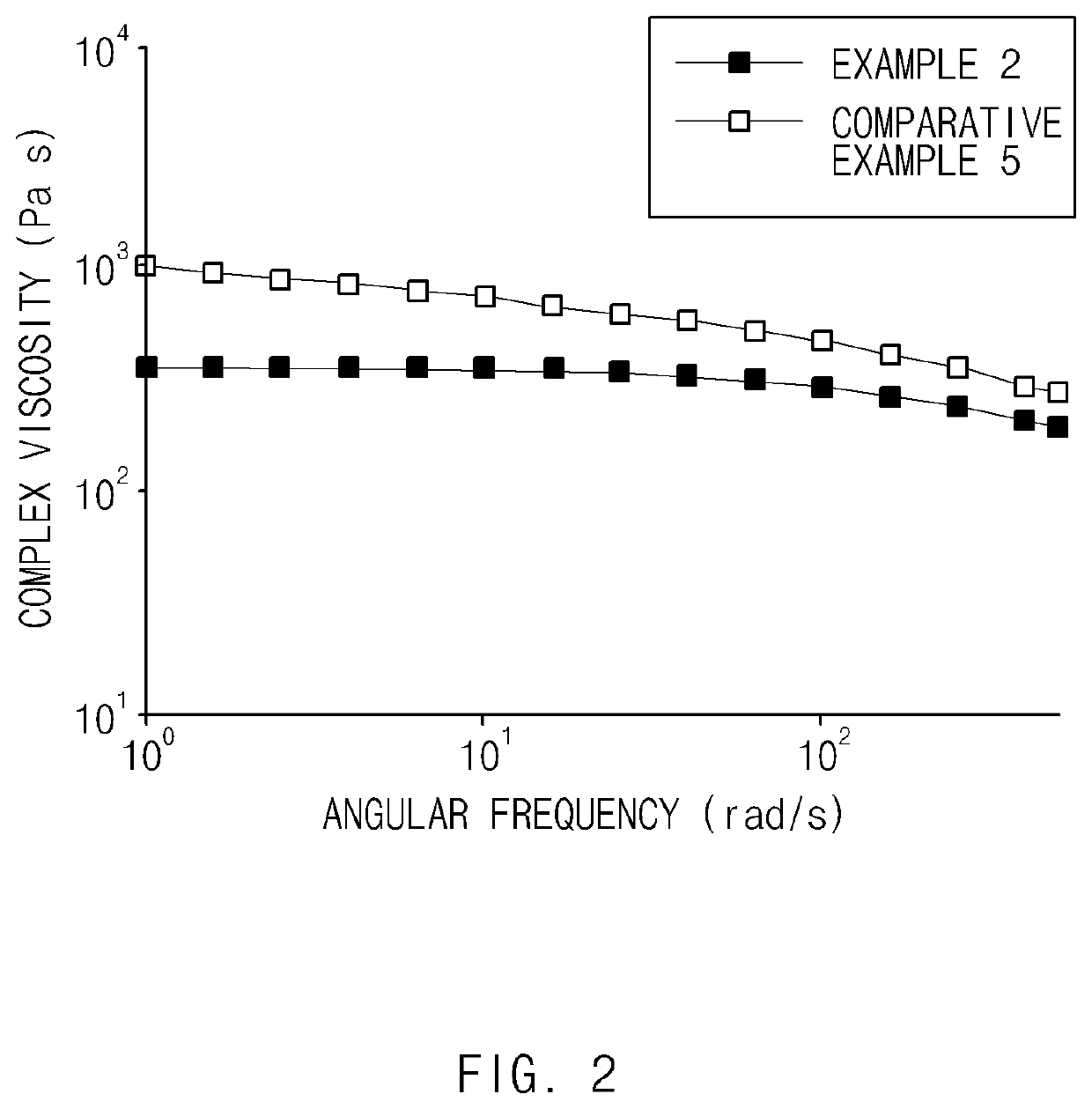

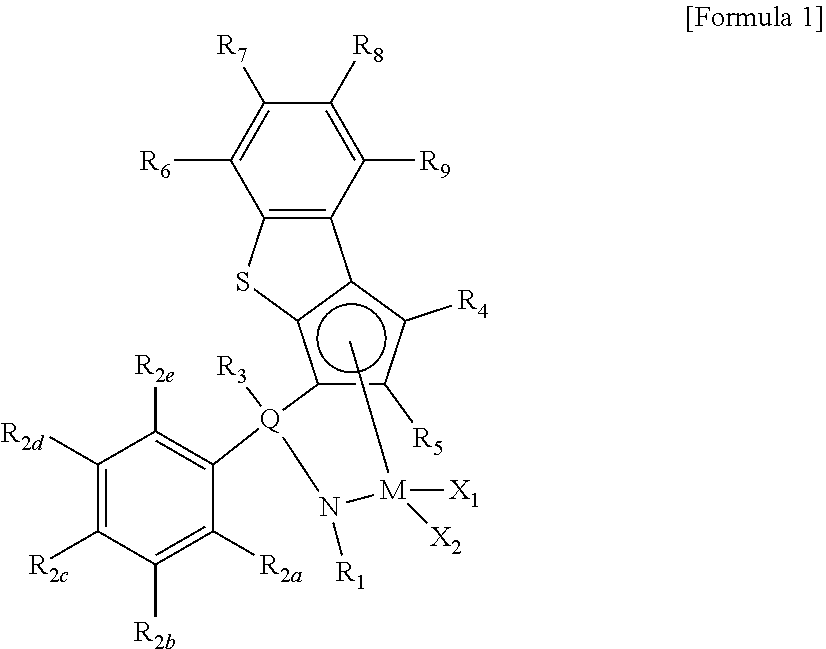

Ethylene/Alpha-Olefin Copolymer and Method for Preparing the Same

The present invention provides an ethylene / alpha-olefin copolymer having narrow molecular weight distribution together with a low density and an ultra low molecular weight, having minimized number of unsaturated functional groups, and having uniform crystallinity, thereby showing excellent physical properties, and a method for preparing the same.

Owner:LG CHEM LTD

Laser apparatus, laser irradiation method, and manufacturing method of semiconductor device

InactiveUS20090016393A1Laser energy is stableReduce flowSemiconductor/solid-state device manufacturingActive medium materialPhase differenceTransmittance

It is an object to provide a laser apparatus, a laser irradiating method and a manufacturing method of a semiconductor device that make laser energy more stable. To attain the object, a part of laser beam emitted from an oscillator is sampled to generate an electric signal that contains as data energy fluctuation of a laser beam. The electric signal is subjected to signal processing to calculate the frequency, amplitude, and phase of the energy fluctuation of the laser beam. The transmittance of a light amount adjusting means is controlled in order that the transmittance changes in antiphase to the phase of the energy fluctuation of the laser beam and with an amplitude capable of reducing the amplitude of laser beam emitted from the oscillator, the control being made based on the phase difference between the phase of a signal that is in synchronization with oscillation of laser beam emitted from the oscillator and the phase calculated, on the energy ratio of the sampled laser beam to laser beam emitted from the oscillator, and on the frequency and amplitude calculated. In the light amount adjusting means, energy of the laser beam oscillated from the oscillator energy is adjusted.

Owner:SEMICON ENERGY LAB CO LTD

Process for the preparation of crystalline N-formimidoyl thienamycin monohydrate (imipenem monohydrate)

InactiveUS7078534B2Cost effectiveUniform crystallinityOrganic active ingredientsAsymmetric synthesesCrystallographyThienamycins

The present invention relates to a cost effective and commercially viable process for the preparation of crystalline N-formimidoyl thienamycin monohydrate (Imipenem monohydrate) of Formula I.

Owner:RANBAXY LAB LTD

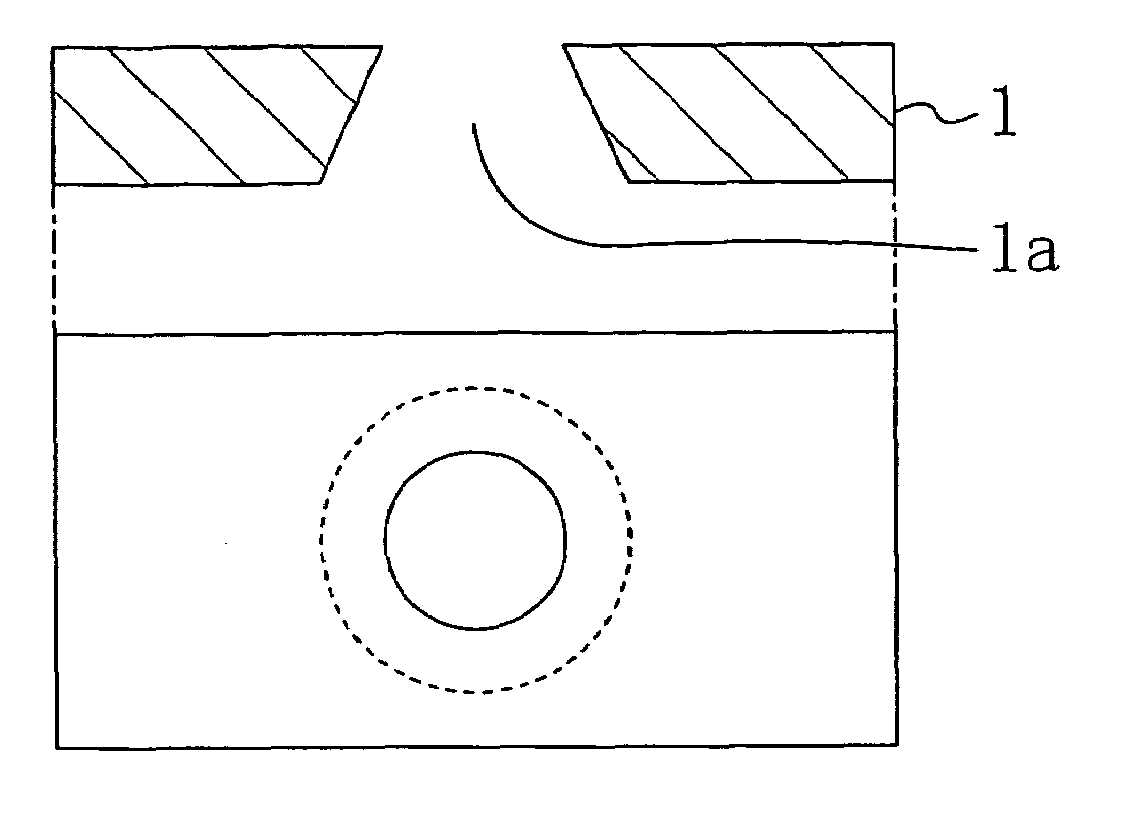

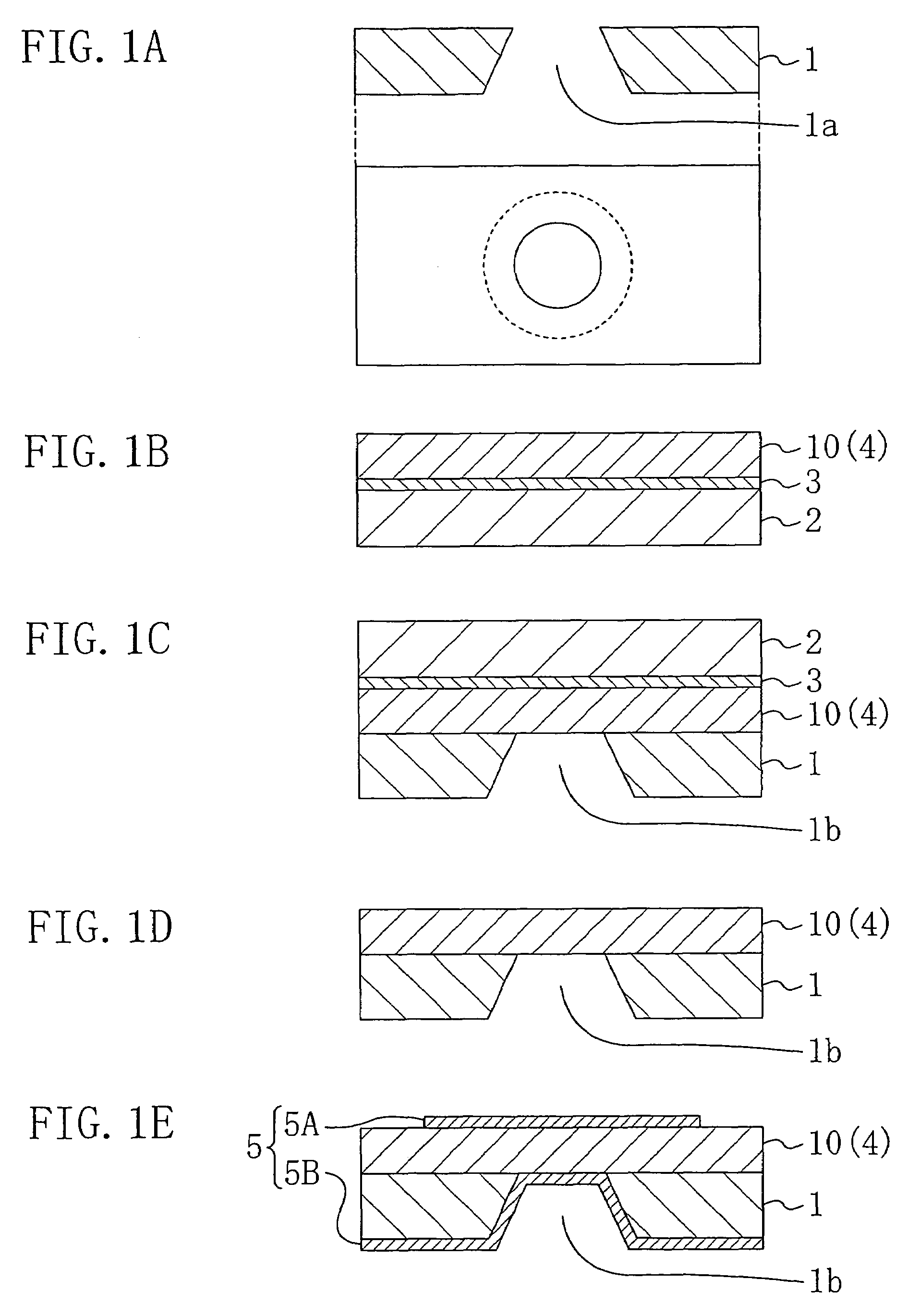

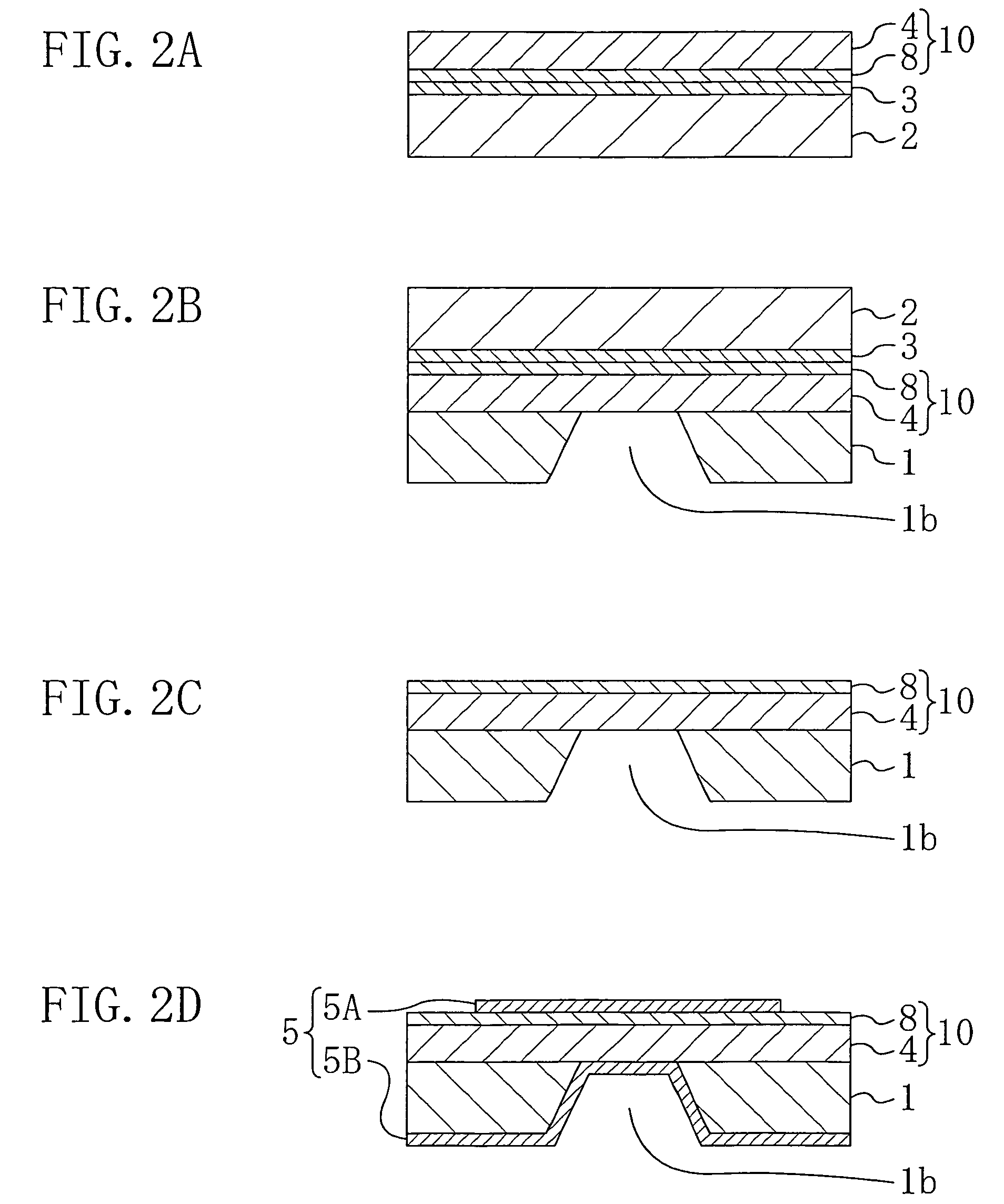

Method for manufacturing resonator

InactiveUS7501068B2Improve performanceHigh yieldPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksResonatorFilm making

A method for manufacturing a resonator of the present invention includes the steps of (a) forming a resonator film including a piezoelectric film made of piezoelectric material and (b) preparing a resonator substrate for supporting the resonator film. The method further comprises the step of (c) bonding the resonator film formed in the step (a) and the resonator substrate prepared in the step (b).

Owner:PANASONIC CORP

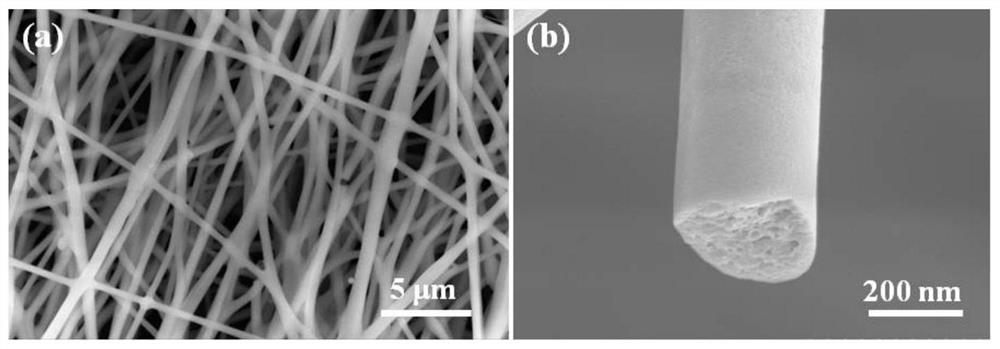

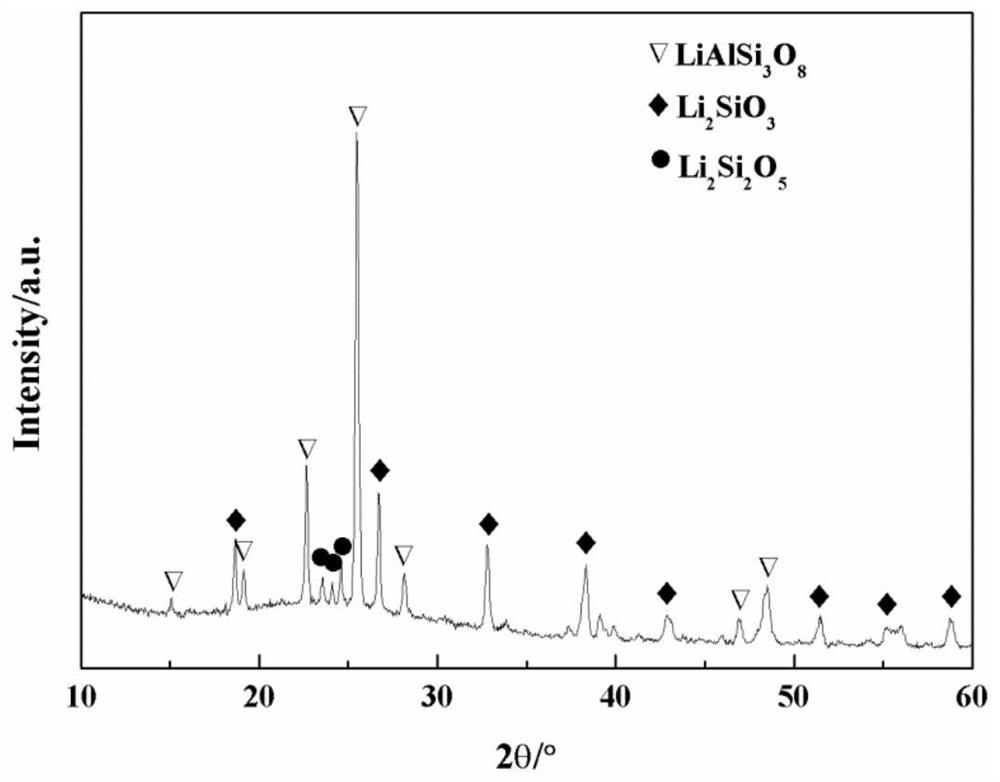

High-density LAS microcrystalline glass fiber and preparation method thereof

The invention provides a high-density LAS microcrystalline glass fiber and a preparation method thereof. The preparation method comprises the steps that lithium nitrate serves as a lithium source, aluminum nitrate serves as an aluminum source, tetraethyl orthosilicate and nano SiO2 particles serve as silicon sources, hydrochloric acid serves as a catalyst, a cosolvent absolute ethyl alcohol is added, an LAS precursor solution is prepared according to a certain proportion, then polymers such as PVP are added, a precursor solution with spinnability is obtained, electrostatic spinning parameters are set, and spinning is conducted; and then crystallization heat treatment is carried out on the collected fibers, grinding is carried out, and steps of ultrasonic crushing, volatilizing and drying are carried out to obtain nano LAS short fiber white powder. The material can be used as a reinforcing body to be added into LAS microcrystalline glass, crystals are induced to be separated out, and the mechanical property and the light transmittance performance of the microcrystalline glass are cooperatively improved.

Owner:SHAANXI UNIV OF SCI & TECH

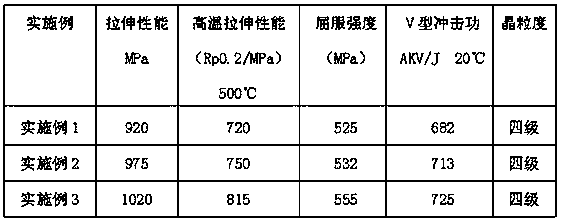

Manufacturing process of large pressurized vessel pipe plate forging

The invention provides a manufacturing process of a large pressurized vessel pipe plate forging, and belongs to the field of large forging heat treatment processes. The manufacturing process of the large pressurized vessel pipe plate forging comprises the concrete steps of carrying out forged heat treatment, forging, and carrying out heat treatment after forging. The process provided by the invention is mature, and conveniently solves the problems that during a production process, forging is easy to occur, the acceptability is lower, and the internal deformation is nonuniform. The steps of heat treatment after forging comprise pretreatment, isothermal bainite treatment for the first time, pre-heat treatment for the first time, normalizing treatment for the first time, bainite treatment forthe second time, pre-heat treatment for the second time, normalizing treatment for the second time, bainite treatment for the third time, and hydrogen relief treatment, so that white points in the forging can be effectively removed, grains are refined, and the strength of the forging is favorably improved.

Owner:WUXI HONGDA HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com