Method for preparing olefin polymer by utilizing multiple temperature reaction areas

An olefin polymer and olefin polymerization technology, which is applied in the field of preparing olefin polymers using multi-temperature reaction zones, can solve the problems of unsuitable reaction exothermic polyethylene, low heat transfer efficiency in the descending section, and mutual interference of gases, etc., to achieve improved Heat removal ability, improved space-time yield, and less sticky or agglomerated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

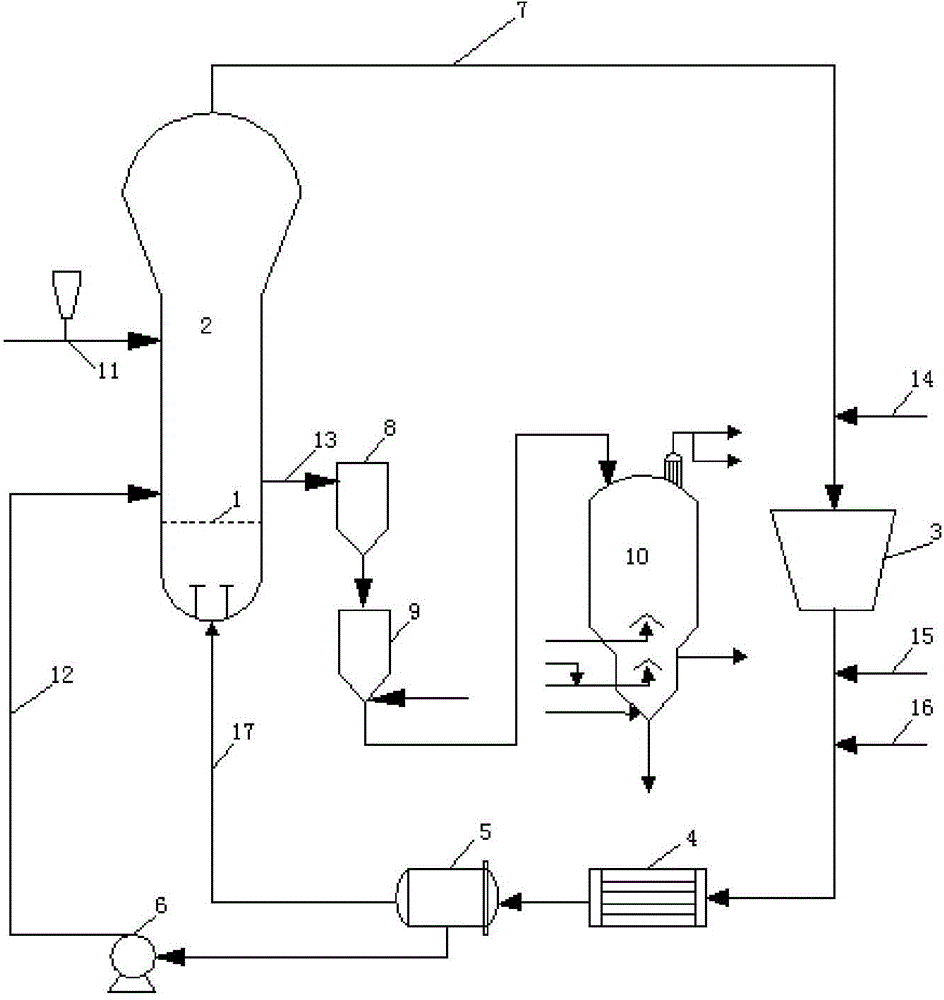

[0102] in such as figure 1 In the shown fluidized bed reactor 2 with nitrogen fluidization, at first, a small amount of catalyst and cocatalyst are continuously input in an amount of 0.1 kg / h through the pipeline 11, and ethylene is input through the pipeline 14, and 1 through the pipeline 15. -Butene raw material gas and pipeline 16 input a small amount of isopentane condensing agent to start the initial olefin polymerization reaction in the fluidized bed reactor to generate a small amount of polyethylene. Then gradually increase the consumption of catalyst and cocatalyst to 5kg / h, and gradually increase the consumption of isopentane, and keep the fluidization gas velocity constant. Along with the progress of reaction, continue to input ethylene through pipeline 14, pipeline 15 continues to input 1-butene raw material gas, thereby constitute circulating medium in fluidized bed reactor, described circulating medium comprises hydrogen, nitrogen, ethylene, 1 -Butene and isopent...

Embodiment 2

[0112] in such as figure 1 In the shown fluidized bed reactor 2 with nitrogen fluidization, at first, a small amount of catalyst and cocatalyst are continuously input in an amount of 0.1 kg / h through the pipeline 11, and ethylene is input through the pipeline 14, and 1 through the pipeline 15. - Hexene raw material gas and pipeline 16 input a small amount of isopentane condensing agent to start the initial olefin polymerization reaction in the fluidized bed reactor to generate a small amount of polyethylene. Then gradually increase the consumption of catalyst and cocatalyst to 5kg / h, and gradually increase the consumption of isopentane, and keep the fluidization gas velocity constant. Along with the progress of reaction, continue to input ethylene through pipeline 14, pipeline 15 continues to input 1-hexene raw material gas, thereby constitute circulating medium in fluidized bed reactor, described circulating medium comprises hydrogen, nitrogen, ethylene, 1 - Hexene and isope...

Embodiment 3

[0122] in such as figure 1 In the shown fluidized bed reactor 2 with nitrogen fluidization, at first, a small amount of catalyst and cocatalyst are continuously input in an amount of 0.1 kg / h through the pipeline 11, and ethylene is input through the pipeline 14, and 1 through the pipeline 15. -Butene and 1-hexene raw material gas and pipeline 16 input a small amount of isopentane condensing agent to start the initial olefin polymerization reaction in the fluidized bed reactor to generate a small amount of polyethylene. Then gradually increase the consumption of catalyst and cocatalyst to 5kg / h, and gradually increase the consumption of isopentane, and keep the fluidization gas velocity constant. Along with the progress of reaction, continue to input ethylene by pipeline 14, pipeline 15 continues to input 1-butene and 1-hexene raw material gas, thereby constitute circulating medium in fluidized bed reactor, described circulating medium comprises hydrogen, Nitrogen, Ethylene, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com