Radiation device for reducing indoor air humidity

An indoor air humidity and radiation device technology, applied in the field of radiation devices, can solve the problems of increasing the investment cost of special dehumidification equipment, the failure of the air conditioning system to operate normally, and increasing the energy consumption of the dehumidification system, so as to ensure indoor comfort and cooling effect Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

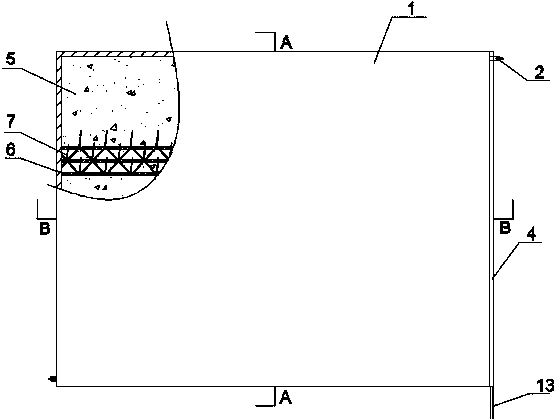

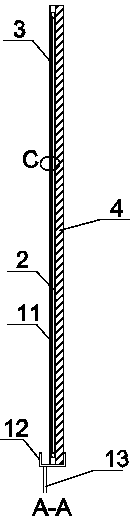

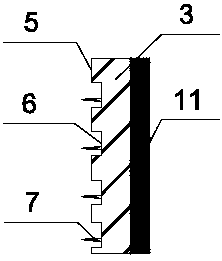

[0015] Such as Figure 1-4 As shown, the radiation device body 1 includes a cold water circulation system 2, a radiation plate 3 and an insulation layer 4. The radiation plate 3 made of copper or aluminum is a rectangular flat plate with a thickness of 1-2 mm. The radiation plate 3 is different from the cold water circulation system 2. There is a superhydrophobic substrate 5 on one side of the superhydrophobic substrate 5, and a number of hydrophobic microgrooves 6 with a width of 0.1~10mm and a depth of 0.1~5mm are evenly distributed on the superhydrophobic substrate 5, and the direction of the hydrophobic microgrooves 6 is 0~90° There are 0.1-30mm long needle-like hydrophilic biomimetic structures 7 arranged in random disorder or equidistant manner, the hydrophilic regions and super-hydrophobic regions are organically combined, and the needle-like hydrophilic biomimetic structures 7 can quickly capture airborne pollutants. Molecules of water vapor reduce the humidity of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com