Machine-cabinet temperature controlling system, device and method

A technology of temperature control system and temperature control device, which is applied in the direction of control/regulation system, temperature control, non-electric variable control, etc. It can solve the problems of large power consumption, increased operating costs, and the inability to guarantee the internal temperature and humidity environment of the cabinet. Achieve the effect of saving energy and good high temperature heat dissipation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

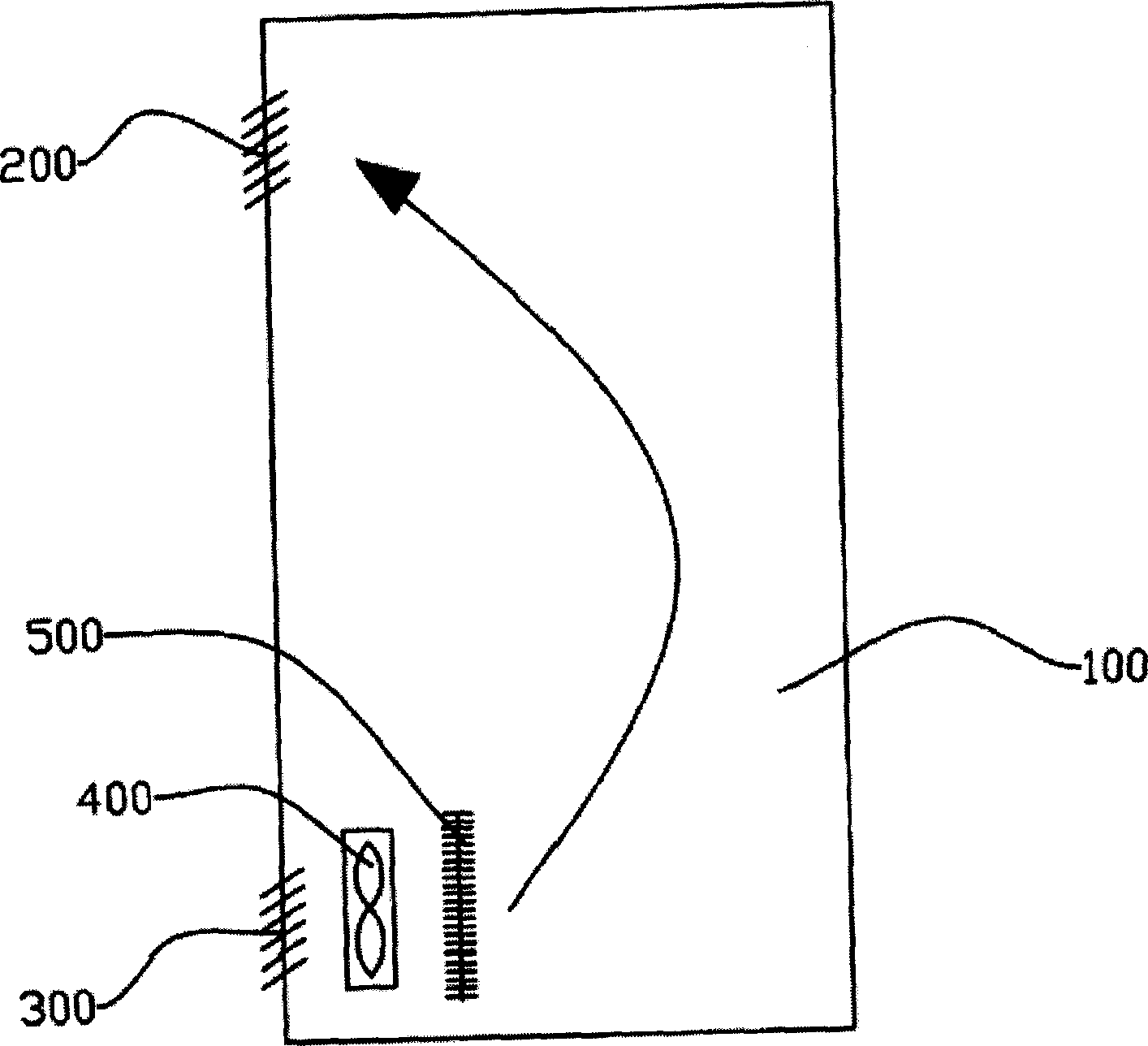

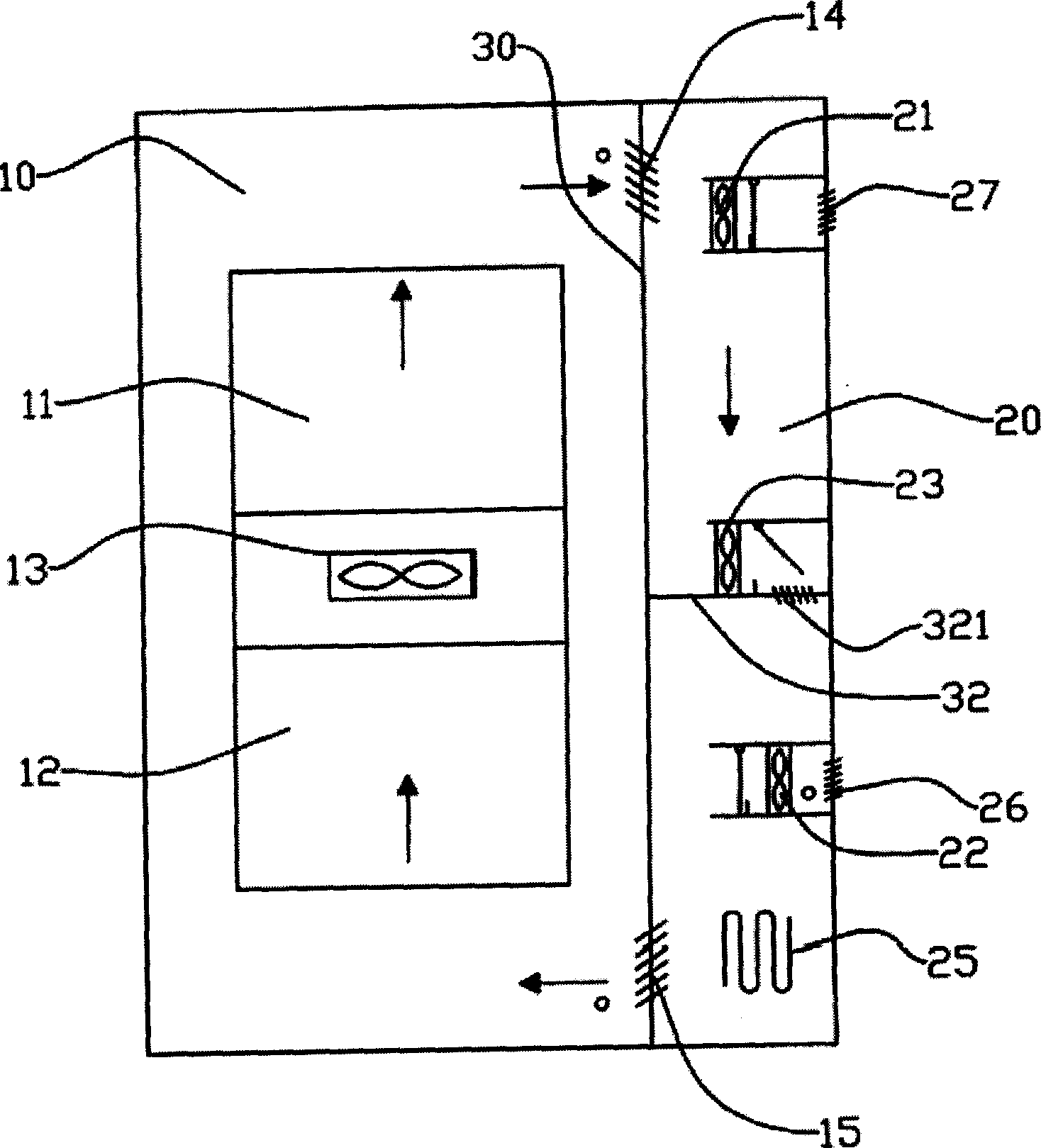

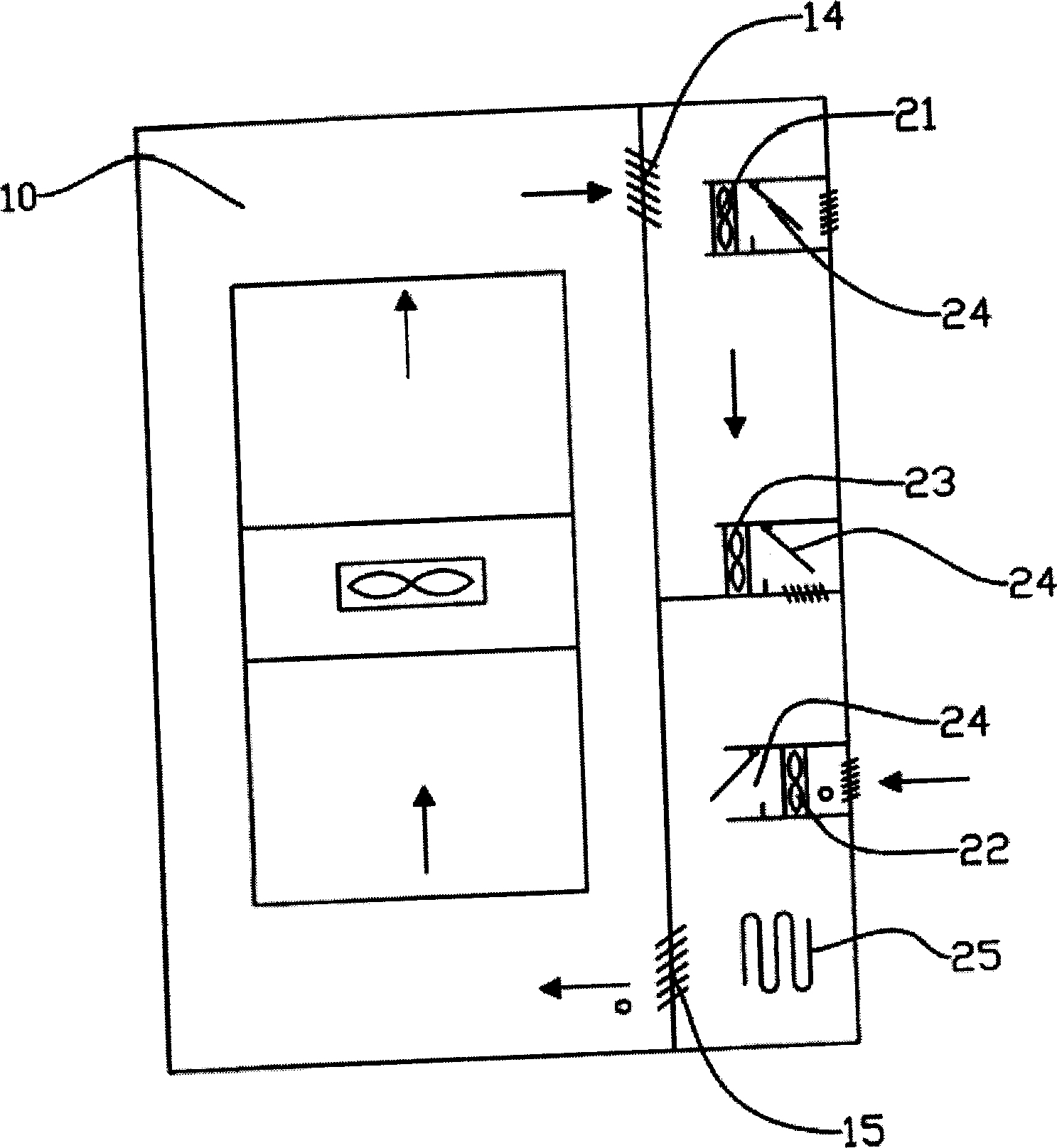

[0055] Figure 2 to Figure 4 It shows the cabinet temperature control system in a preferred embodiment of the present invention, which is used to maintain the temperature and humidity of the air in the cabinet within the normal operating temperature and humidity range of the equipment. Usually, the equipment in the cabinet can be the user unit of the access network Subracks, baseband single-board subracks of base stations, transceiver modules or power modules, etc. like figure 2 As shown, a vertical partition 30 is arranged in the cabinet, and the upper and lower ends of the vertical partition 30 are respectively fixed on the top plate and the bottom plate of the cabinet. The vertical partition 30 divides the interior of the cabinet into a heat dissipation air duct 10 for cooling the heating equipment in the cabinet and a return mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com