Patents

Literature

187results about How to "High space-time yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ethanol by hydrogenation of acetic ester

ActiveCN102093162AHigh activityImprove stabilityOrganic compound preparationHydroxy compound preparationReaction temperatureBULK ACTIVE INGREDIENT

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

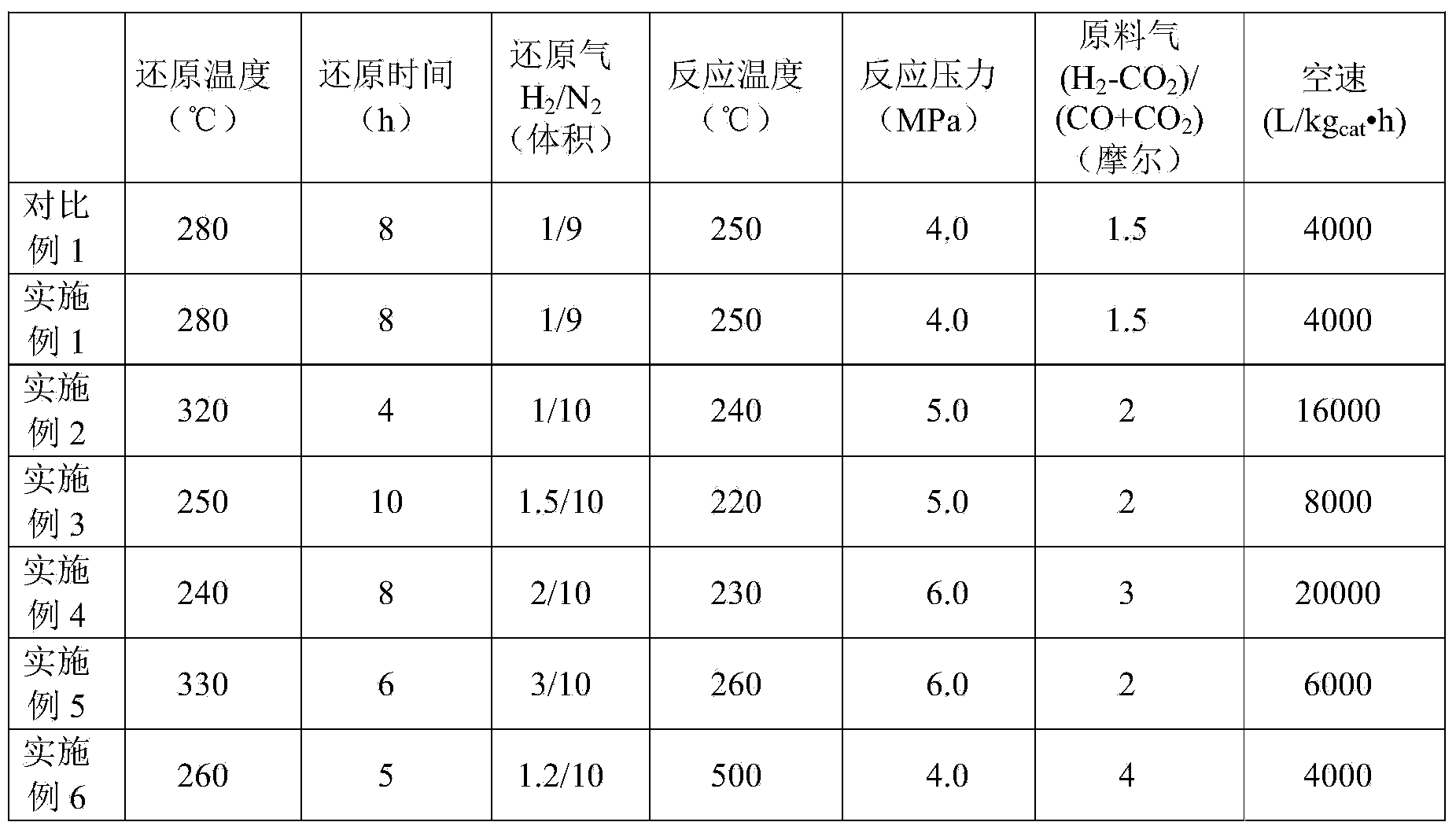

Co-Zr catalyst for Fischer-Tropsch synthesis and its prepn and application

InactiveCN1398669AImprove stabilityReduced inactivation rateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetalChemistry

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Alkene polymerization system and method

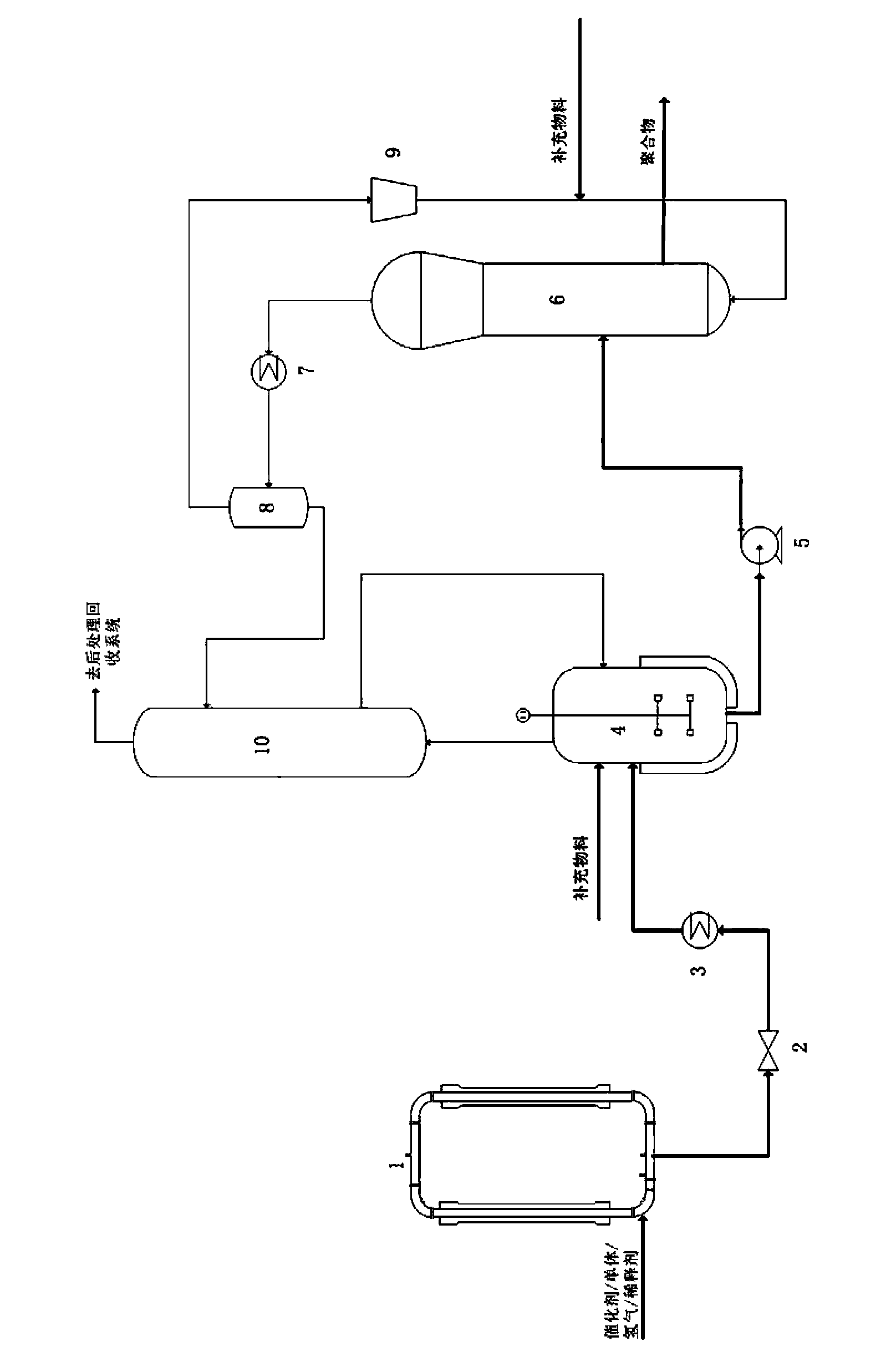

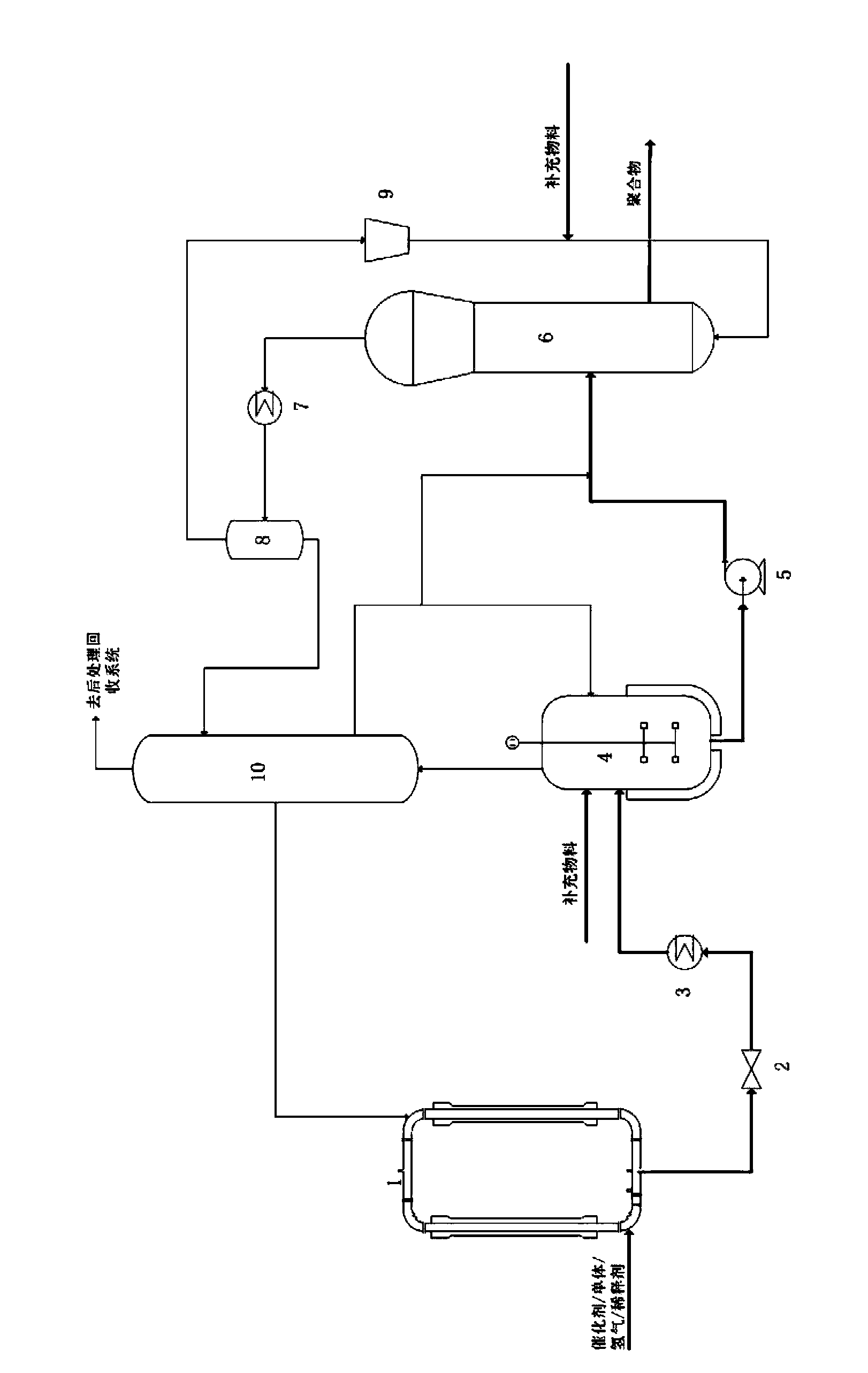

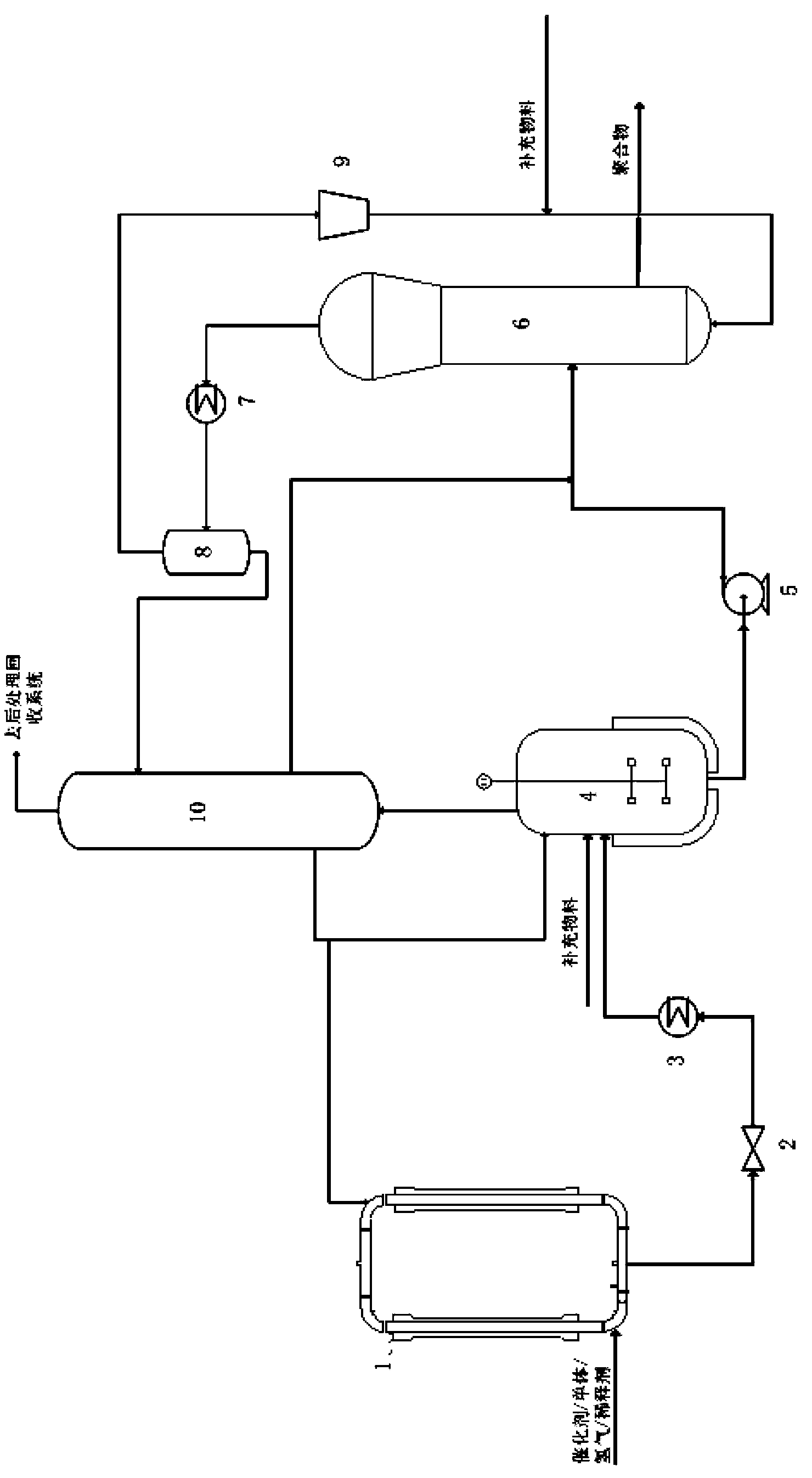

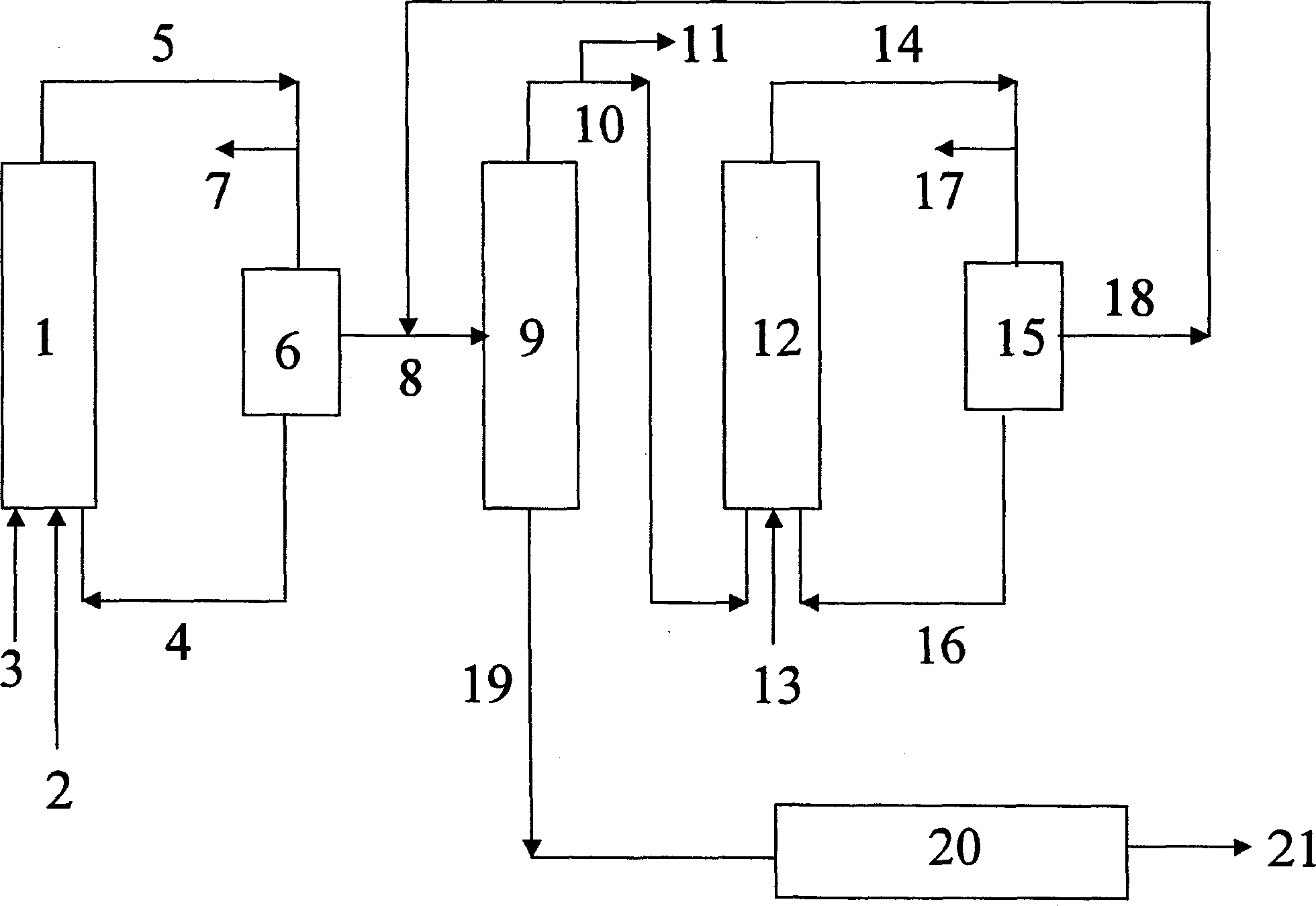

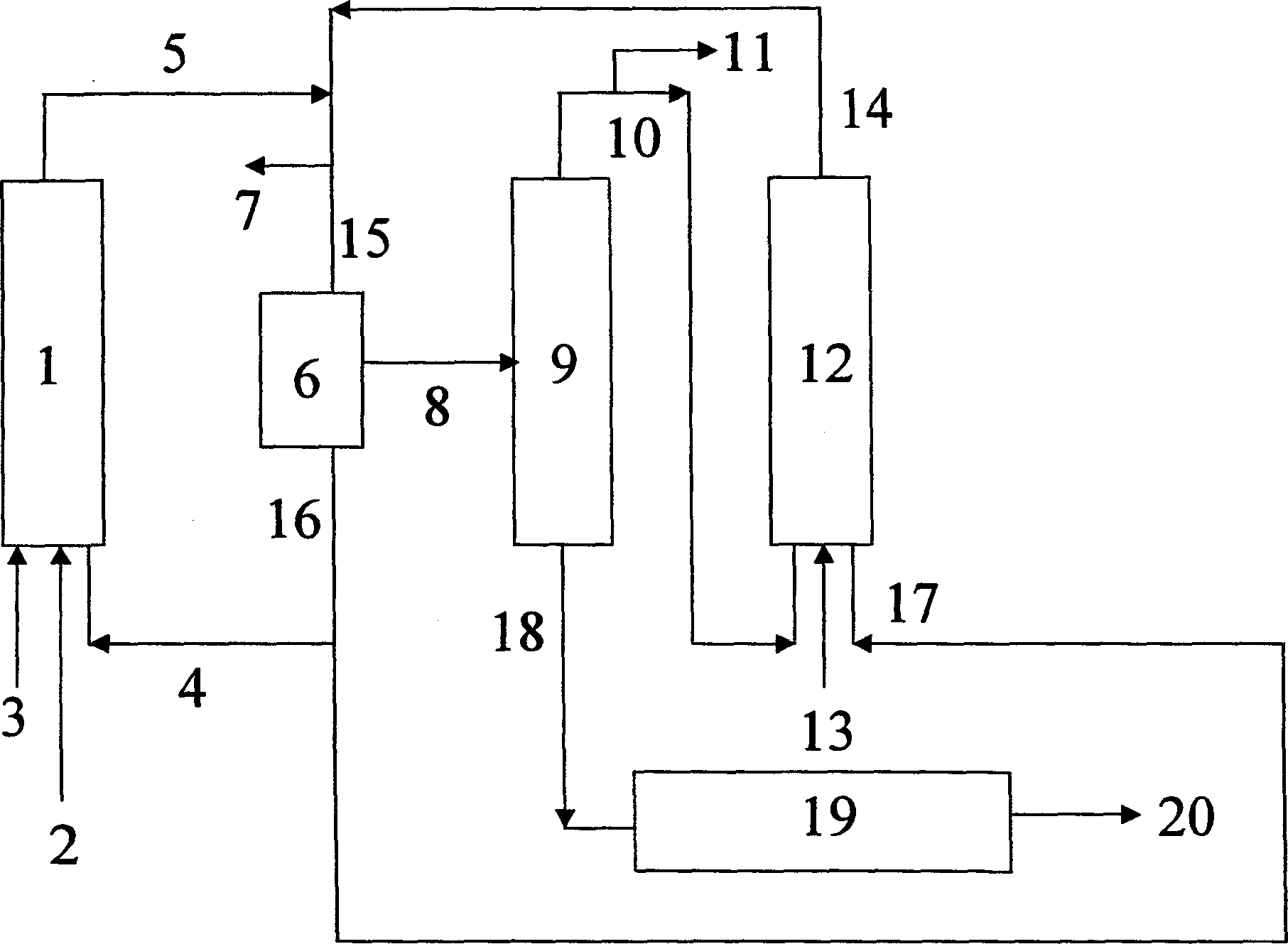

The invention provides an alkene polymerization system and method. The system comprises more than three reactors connected in series. The first reactor is one or more than two annular pipe reactors; the second reactor is one or more than two stirring kettle reactors; and the third reactor is one or more than two gas-phase fluidized-bed reactors. A catalyst and a reaction material enter a first reactor and is subjected to a polymerization reaction; the reaction product with the catalyst enters the second reactor, the material is supplemented into the second reactor, and a reaction is carried out; the product from the outlet of the second reactor enters the third reactor, the material is supplemented into the third reactor, and a reaction is carried out; and a final product is obtained in the third reactor. The system and method provided by the invention is used for producing ultra-wide-molecular-weight-distribution polyolefin with excellent mechanism performances and processing performances.

Owner:CHINA PETROLEUM & CHEM CORP +2

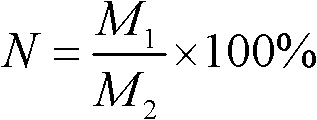

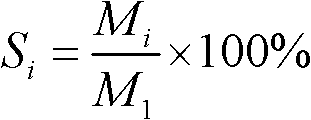

Catalyst used in preparation of ethanol through hydrogenation of acetate and preparation method thereof

ActiveCN102423710AHigh space-time yieldHigh ethanol selectivityOrganic compound preparationHydroxy compound preparationActive componentCopper

The invention discloses a catalyst used in the preparation of ethanol through hydrogenation of acetate and a preparation method thereof. The catalyst uses Cu as an active component, SiO2 as a carrier and at least one selected from the group consisting of transition metal and alkali metal as an auxiliary agent. The copper-based catalyst provided in the invention has good stability and high activity, and has a low requirement for the content of the active component Cu, which only needs to be more than 15%. The preparation method provided in the invention has the advantages of simple operation, low cost and environment-friendliness and is benefit for industrial production.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Catalyst for hydrogenating cis-butenedioic anhydride to prepare butanedioic anhydride and its prepn and application

InactiveCN1453066AHigh surface areaImprove thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsCarboxylic acid anhydrides preparationButanedioic acidPtru catalyst

The catalyst has active component Ni and carrier SiO2 and Al2O3 in the molar ratio of 1 to 1.47-5.98 to 0-3.3. The catalyst is prepared with Ni(NO3)2, ethyl metasilicate with or without aluminum nitrate and ethanol, and through pH regulation to 3-5 or 7-9 with acetic acid, ammonia water or urea, heating at 80-120 deg.c to form gel, roasting at 400-550 deg.c and reduction at 400-580 deg.c. One technological process of catalytically hydrogenating cis-butenedioic anhydride to prepare butasnedioic anhydride in the state with or without solvent is provided. The catalyst has the features of highspecific surface area, high dispersion of metal in carrier, high heat stability, high catalytic activity, high selectivity, capacity of being reused, easy separation from the product, low cost, low consumption and mild reaction condition.

Owner:SHANXI UNIV

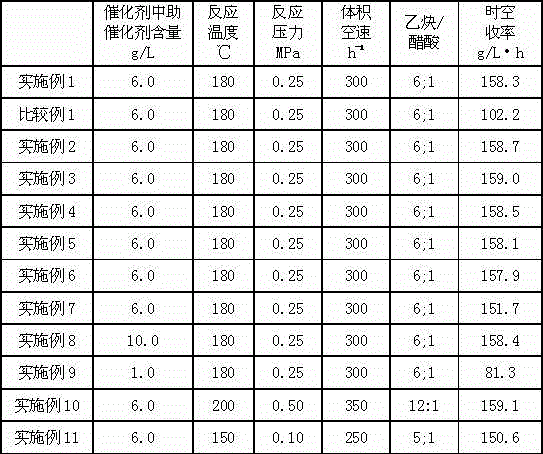

Acetylene method vinyl acetate catalyst and preparation method thereof

InactiveCN104437627AUniform load carrierStable load carrierOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonPtru catalyst

The invention relates to a vinyl acetate catalyst, a preparation method and a vinyl acetate synthesis method which are mainly used for solving the problem of low catalyst activity in the prior art. In order to better solve the problem, the technical scheme adopted by the invention is as follows: the vinyl acetate catalyst provided by the invention comprises a carrier, 50-200 g / L zinc acetate and 0-10 g / L potassium acetate; the preparation method comprises the following steps: (a) performing microwave treating on activated carbon under a non-oxidizing atmosphere relative to the activated carbon to obtain the carrier; (b) loading the necessary dosage of zinc acetate and a cocatalyst by an impregnation method; (c) drying to obtain the catalyst. The vinyl acetate catalyst can be used in the industrial production of acetylene method vinyl acetate synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

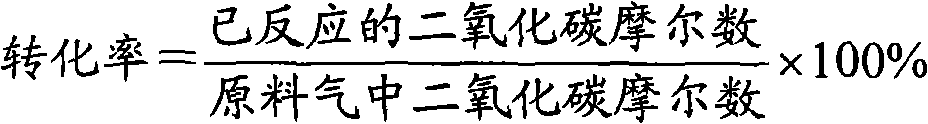

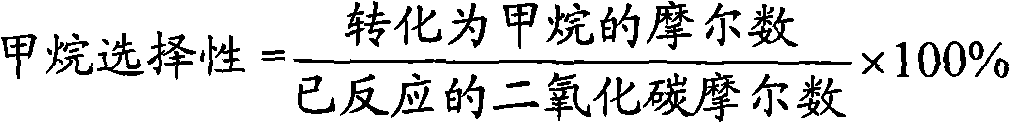

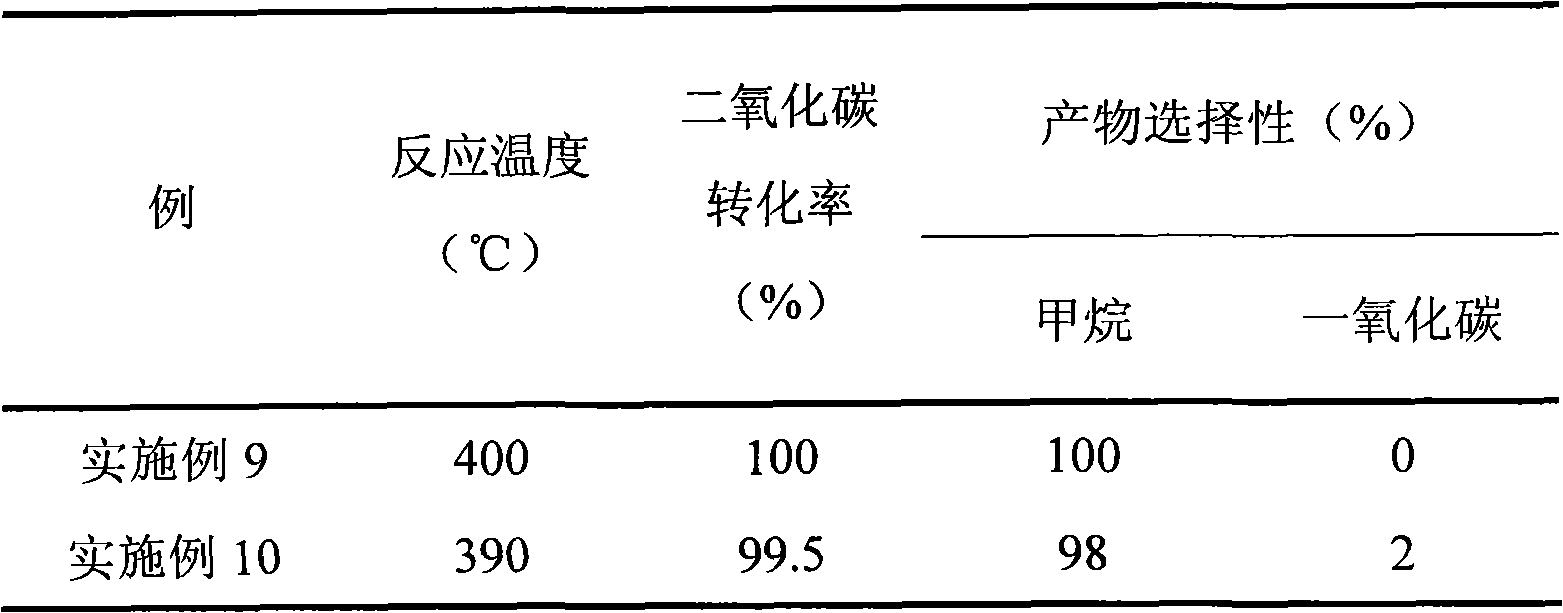

Catalyst for methanation of carbon dioxide

InactiveCN102091629AImprove structural stabilityImprove heat stabilityHydrocarbon from carbon oxidesHydrogen separation using solid contactMethanationActive component

The invention discloses a catalyst for the methanation of carbon dioxide. The carrier of the catalyst is composite oxide of rare earth and other metals, and the composition of the catalyst is represented by a general formula of AxByOz, wherein in the formula, A is a rare metal, B is one or two metals from groups IIB, IIIA, VIA, IVB, VB and VIB, x is 0 to 1, y is 0 to 2, and z is 2 to 4; and the active component of the catalyst is nickel, and the nickel loaded on the carrier accounts for 1 to 15 percent of the total weight of the catalyst. Compared with the conventional carbon dioxide methanation technique, the catalyst technique disclosed by the invention, under the similar reaction conditions, can achieve a carbon dioxide conversion rate of 100 percent, a methane selectivity of 100 percent and a methane time space yield of more than 1,000g / kg.h.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

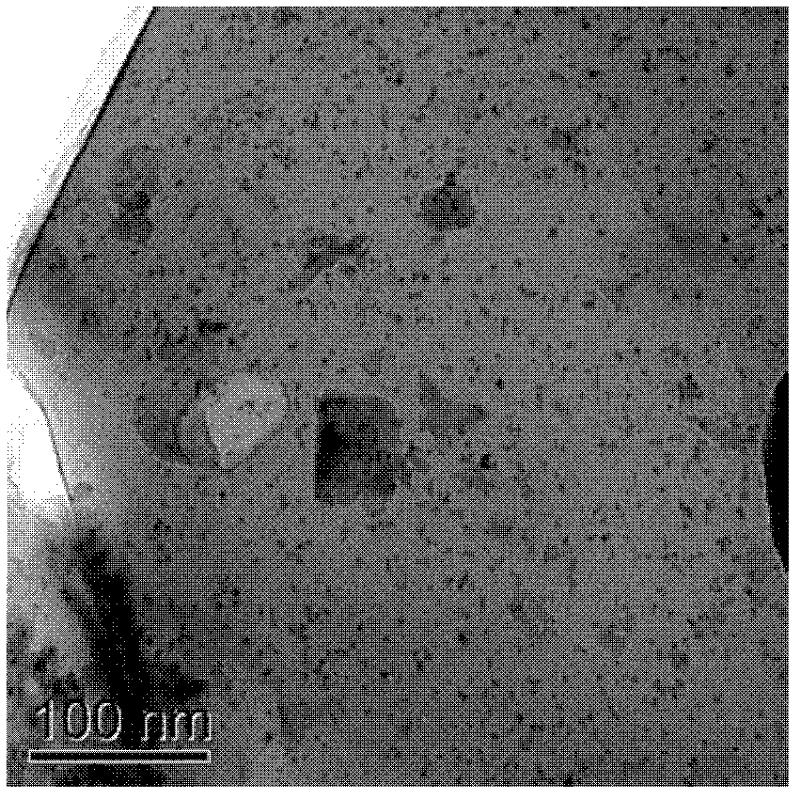

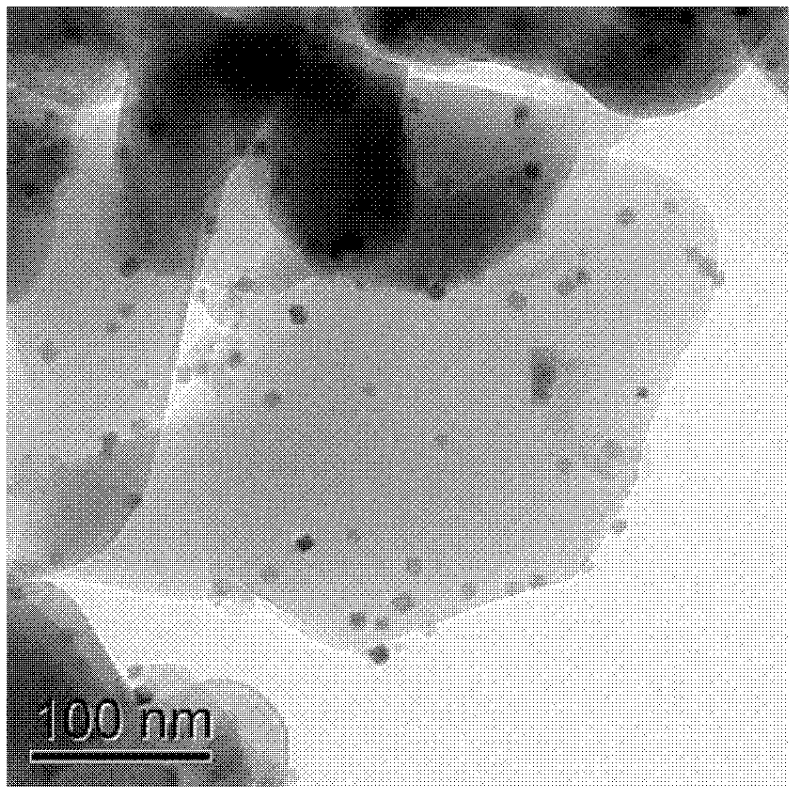

Nano Pd catalyst used for preparing oxalic ester by CO gas phase oxidation coupling and its preparation method

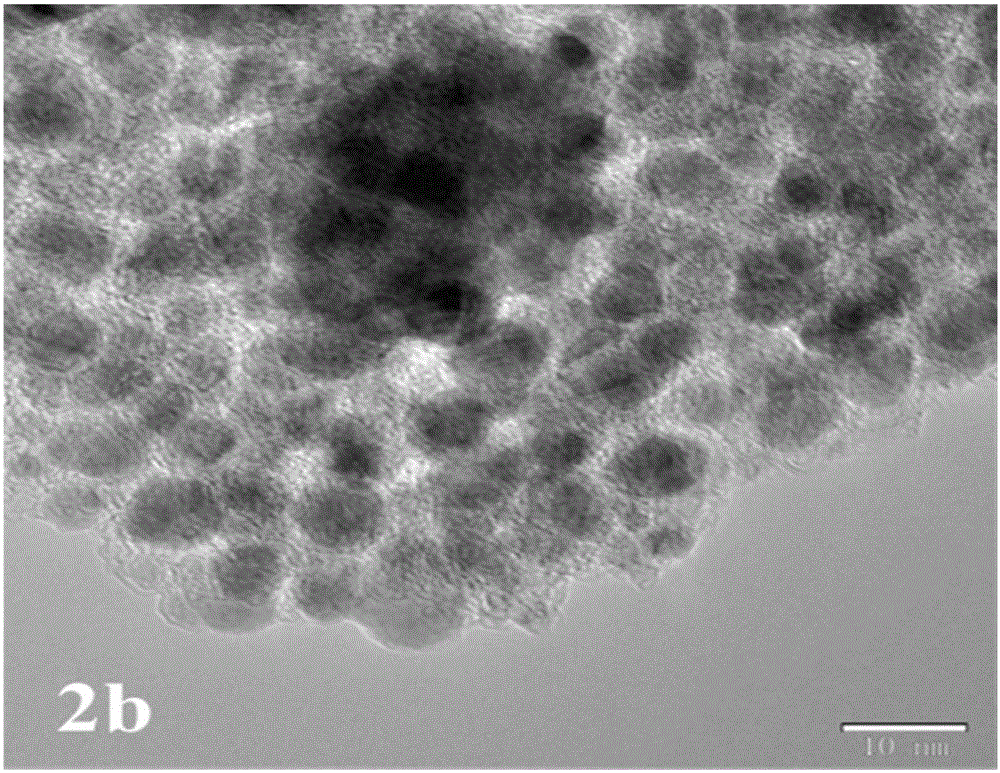

ActiveCN102513101AHigh selectivityHigh space-time yieldPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsGas phaseOxidative coupling of methane

The invention belongs to the oxalic ester preparation technical field, and provides a nano Pd catalyst used for preparing oxalic ester by CO gas phase oxidation coupling in coal glycol, its preparation method and its purpose. According to the invention, the catalyst takes alpha-alumina as a carrier, precious metal Pd nano particles are taken as an active component, by referring the weight of the catalyst carrier, the weight percentage content of the active ingredient Pd is 0.05-2%. The catalyst is prepared by using a nano metal in-situ loading method. The preparation method has the advantages of simple process and low energy consumption, and enables accurate regulation and control on the size and bare crystal face of the Pd nano particles. The catalyst with the bare crystal face of (lll) surface has the advantages of high Pd dispersiveness of active components, small size and narrow distribution, and can catalyze CO gas phase oxidation coupling to oxalic ester with high efficiency under low precious metal load capacity.

Owner:贵州鑫醇科技发展有限公司

Method for preparing catalyst for hydrogenation reaction of dimethyl oxalate and product

ActiveCN102125843APracticalSimple process conditionsOrganic compound preparationHydroxy compound preparationHydrogenation reactionCopper nitrate

The invention discloses a method for preparing a catalyst for a hydrogenation reaction of dimethyl oxalate, which comprises the following steps of: dissolving copper nitrate in water at room temperature to prepare aqueous solution of copper nitrate, wherein the concentration of the aqueous solution is between 0.04 and 1.0 mol / L; adding urea to dissolve a solid completely, adding silica sol with stirring, and continuing to stir for over 4 hours; adding a reaction mixture into a hydrothermal kettle, and keeping the temperature between 50 and 250 DEG C until the pH value is between 6 and 7; and filtering, and washing, drying, roasting and reducing the obtained solid to obtain a catalyst with 0.5 to 50 percent of the capacity of copper, wherein a ratio of the amount of substance of the coppernitrate to the urea is 1: (2-10). The invention also discloses a catalyst prepared by the method. In the preparation method, the catalyst is prepared from the low-cost silica sol serving as a siliconsource and the urea serving as a precipitant by a method of uniform precipitation, so the method has a simple process condition and is favorable for industrial production.

Owner:ZHEJIANG UNIV

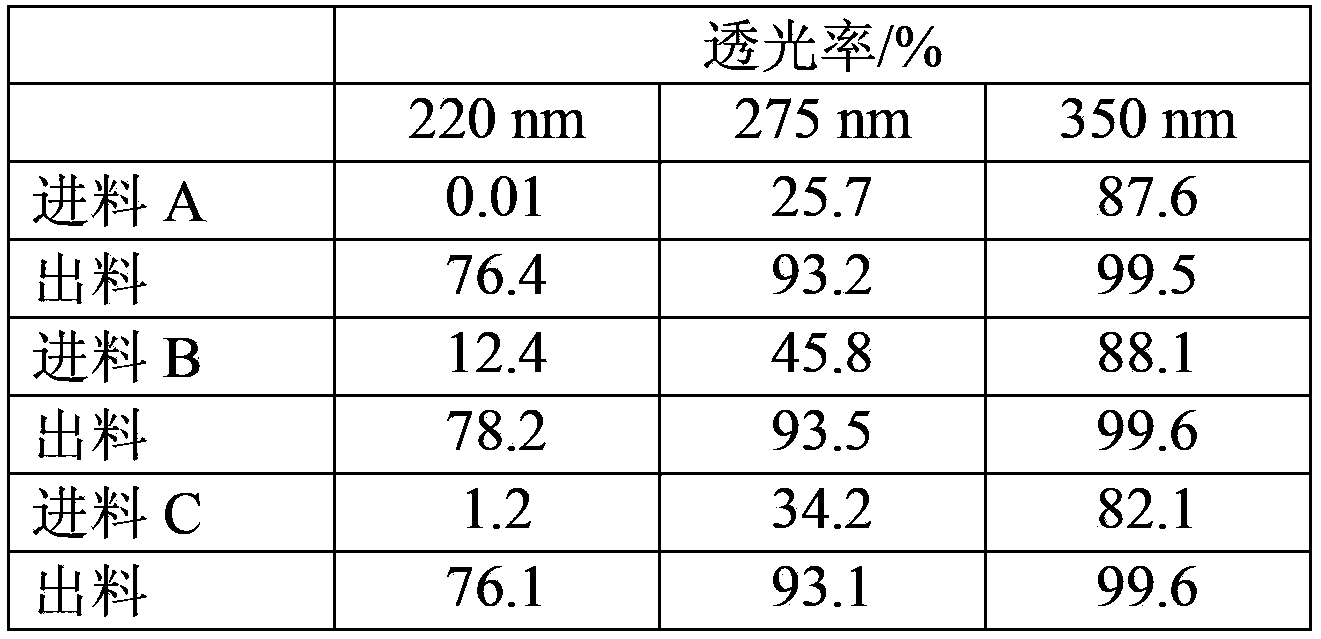

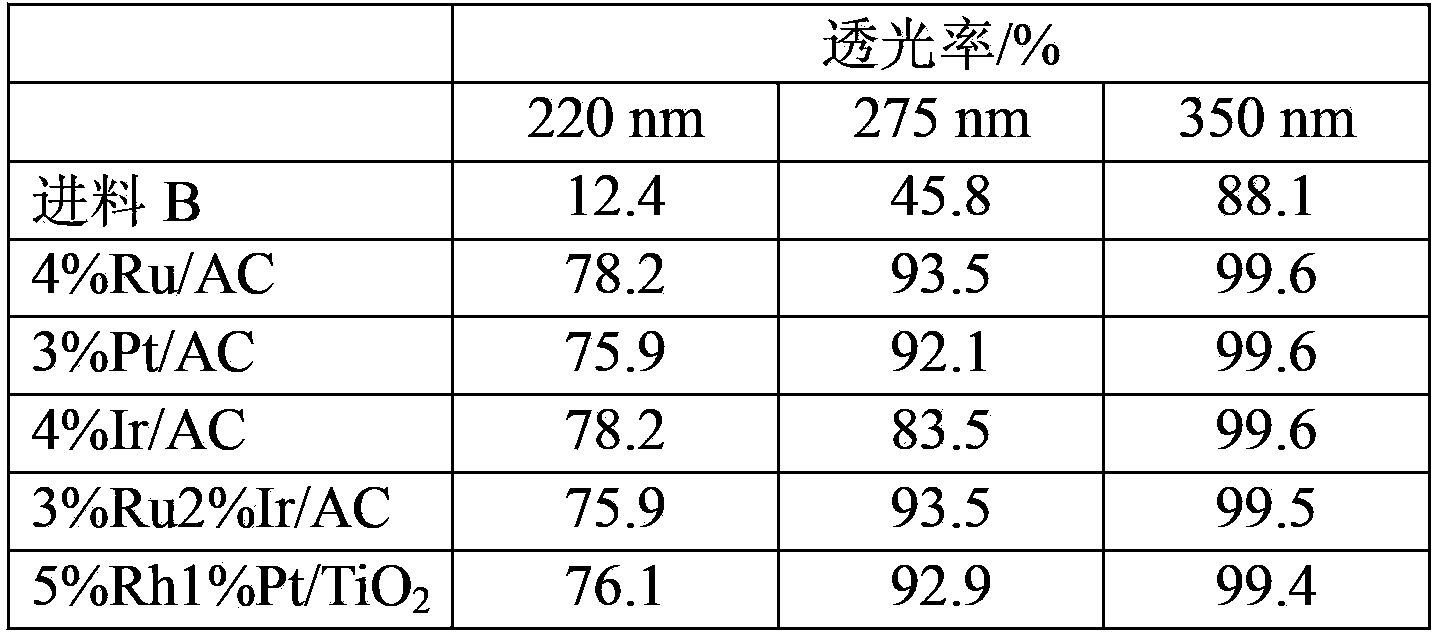

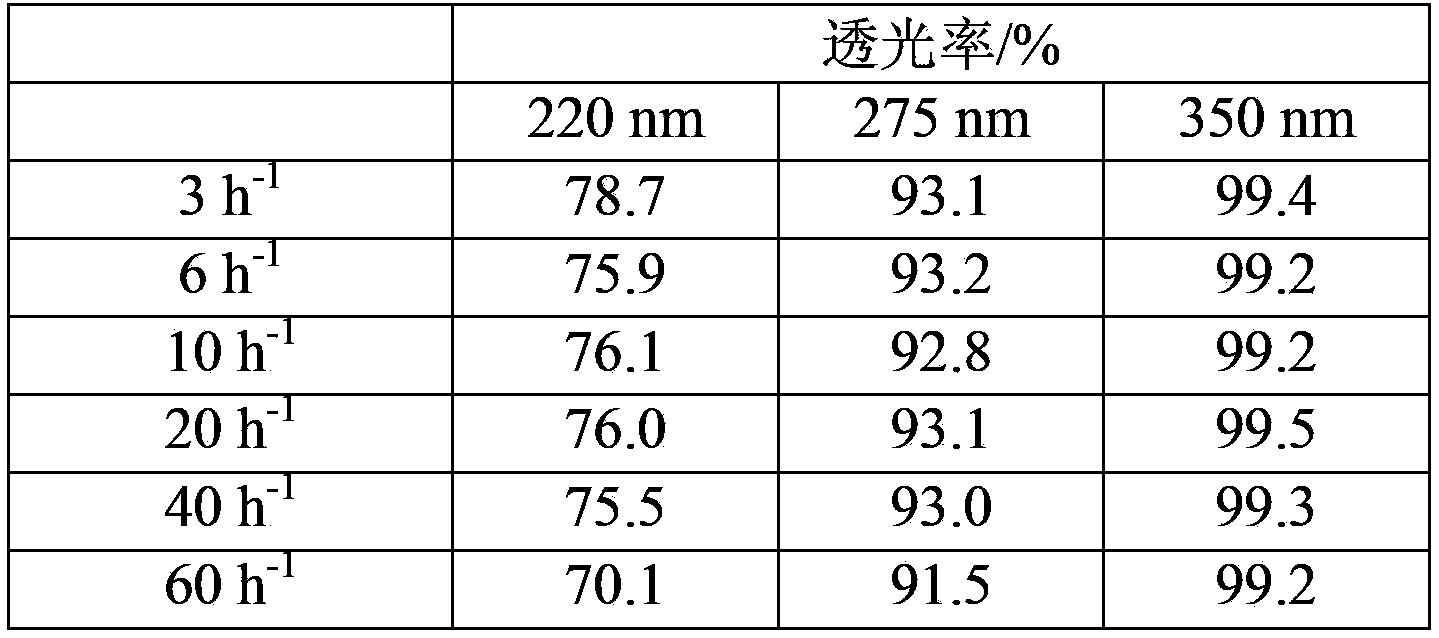

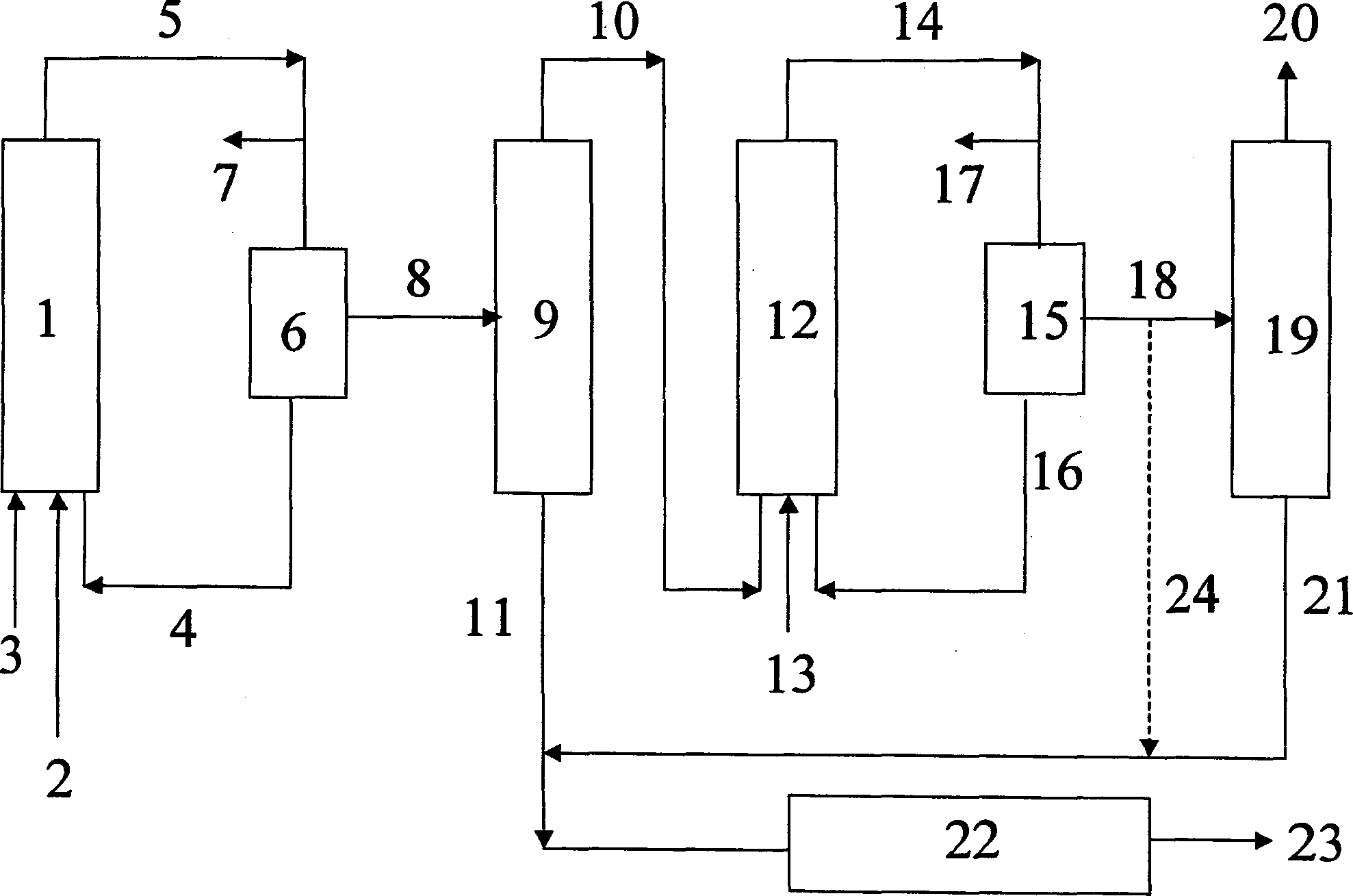

Biomass glycol refining method

InactiveCN104098439AHigh space-time yieldEase of industrial productionOrganic compound preparationHeterogenous catalyst chemical elementsIridiumHydrogen pressure

The invention provides a biomass glycol refining method. According to the method, a glycol crude product obtained by a biomass route is used as a raw material, 8th, 9th and10th group transition metal iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium and platinum are uses as catalyst active components, one step catalytic hydrogenation is performed in a fixed bed reactor at 40-160 DEG C under the hydrogen pressure of 0.2-10MPa to realize efficient refining of the crude glycol, the aldehyde content of the refined glycol product is less than 3ug / g, and the UV transmittance at 220nm, 275nm and 350nm are respectively more than 75%, 92% and 99%. The crude glycol raw material comes from renewable resources, and has the advantages of being environmental friendly, green and renewable. In addition, the process has the advantages of short reaction time, good catalyst stability, good glycol UV transmittance, high space-time yield and the like, and has potential application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst for hydrogenation, preparation method thereof and use thereof

InactiveCN101733108AGreat operating flexibilityImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionGas phaseReaction temperature

The invention provides a catalyst for hydrogenation, a preparation method thereof and use thereof. The chemical formula of the catalyst is CuOx-ROy / SiO2. The catalyst of the invention is used for hydrogenation in a gas-phase method for preparing glycol and is prepared from the raw materials including but not limited to oxalate or ethyl glycolate and hydrogen. The catalyst of the invention requires low reaction temperature and allows for a wide temperature range. The catalyst of the invention has extremely high operation elasticity, high activity and selectivity within a temperature range of 160 to 260 DEG C and a pressure range of 1 to 10 MPa, high time space yield, over 99 percent raw material conversion rate, over 96 percent target product selectivity, less than 0.1 percent by-product yield, high stability and a one-pass service life of up to 3,500 hours. The catalyst can greatly reduce energy consumption, save follow-up product separation equipment and procedures reduce production cost and avoid equipment corrosion and environmental pollution.

Owner:SHANGHAI HUAYI ENERGY CHEM

Multi-stage preparation process of carbonyl synthesizing aldehyde and/or alcohol

InactiveCN1333201AImprove conversion rateHigh selectivityPreparation by oxo-reaction and reductionOrganic compound preparationCarbonyl groupBoiling point

A multistage cobalt- or rhodium catalyzed hydroformylation of 6-24C olefins to alcohols and aldehydes comprises: (a) hydroformylation of the olefin to a conversion of 20-98%; (b) removal of the catalyst from the resulting reaction mixture; (c) separation of the resulting reaction mixture into a low boiling fraction containing olefins and paraffins and a sump fraction containing aldehyde and alcohol; and (d) reaction of the low boiling fraction containing olefin in further process stages comprising steps (a), (b) and (c) and combining all sump fractions from step (c) of all process stages.

Owner:EVONIK DEGUSSA GMBH

Method for producing alcohols by hydrogenating carbong/compounds

InactiveCN1487911ALow bulk densityReduce dosageSugar derivativesOrganic compound preparationPlatinumAlcohol

A method for preparation of alcohols by catalytic hydrogenation of carbonyl compounds with hydrogen or hydrogen-containing gases in the presence of a hydrogenation catalyst of Raney type, where the catalyst is used in the form of hollow bodies, Preferred as catalytically active components are nickel, cobalt, copper, iron, platinum, palladium or ruthenium.

Owner:DEGUSSA AG

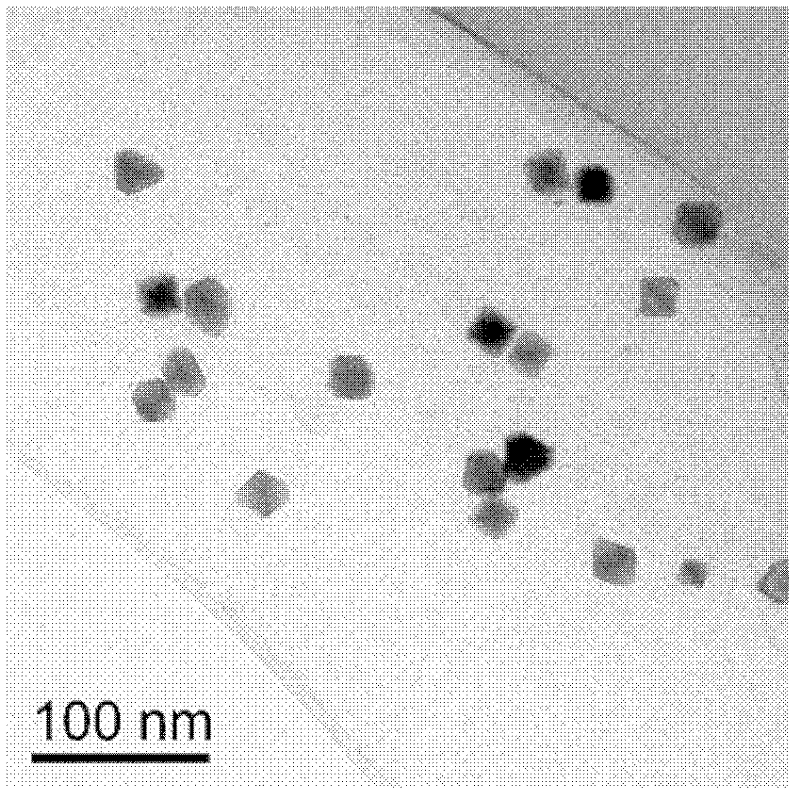

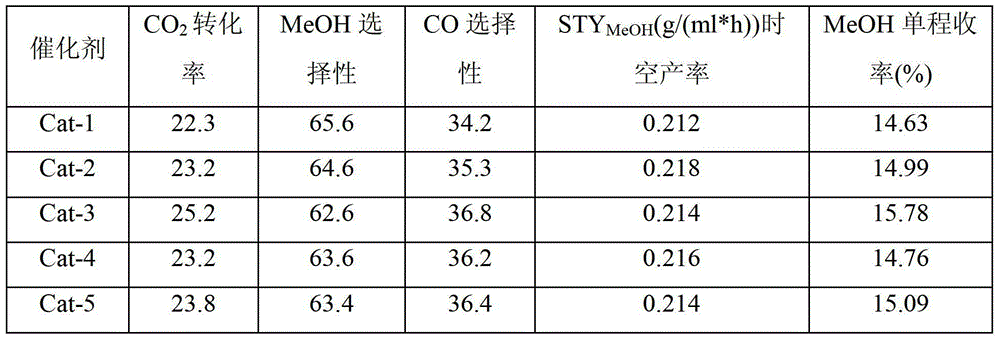

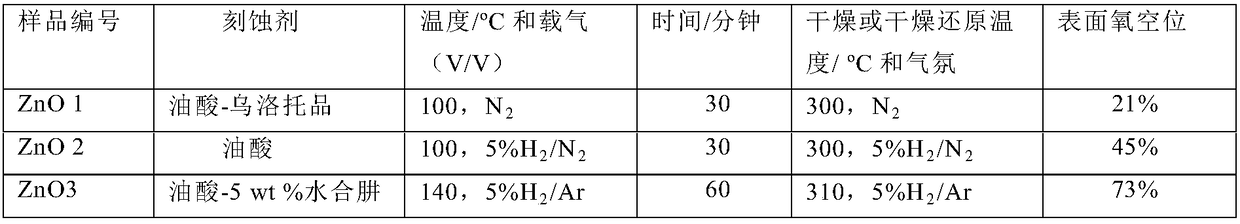

Copper based catalyst used for hydrogenating carbon dioxide to synthesize methanol, and preparation method and application thereof

ActiveCN103272607BEvenly dispersedSmall particle sizeOrganic compound preparationHydroxy compound preparationZinc saltsCarbonate

The invention discloses a copper based catalyst used for hydrogenating carbon dioxide to synthesize methanol, and a preparation method and an application thereof. The preparation method of the catalyst comprises the following steps: 1, processing a zinc salt, an aluminum salt, a zirconium salt and a stabilizer to prepare a first solution, or processing the zinc salt, the aluminum salt and the zirconium salt to prepare a second solution; 2, processing carbonate and hydroxide to prepare a third solution; 3, processing a copper salt to prepare a fourth solution; 4, processing the first solution and the third solution to form a first precipitation solution, or processing the second solution and the third solution to form a second precipitation solution; 5, adding the fourth solution to the first precipitation solution to form a third precipitation solution or adding the fourth solution to the second precipitation solution to form a fourth precipitation solution, ageing after Cu in the precipitation solution precipitates, and washing; and 6, drying, and calcining. The catalyst contains 30-50% of Cu, 20-40% of Zn, 10-20% of Al, and 5-20% of Zr. The catalyst is used for a reaction for hydrogenating carbon dioxide to synthesize methanol.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

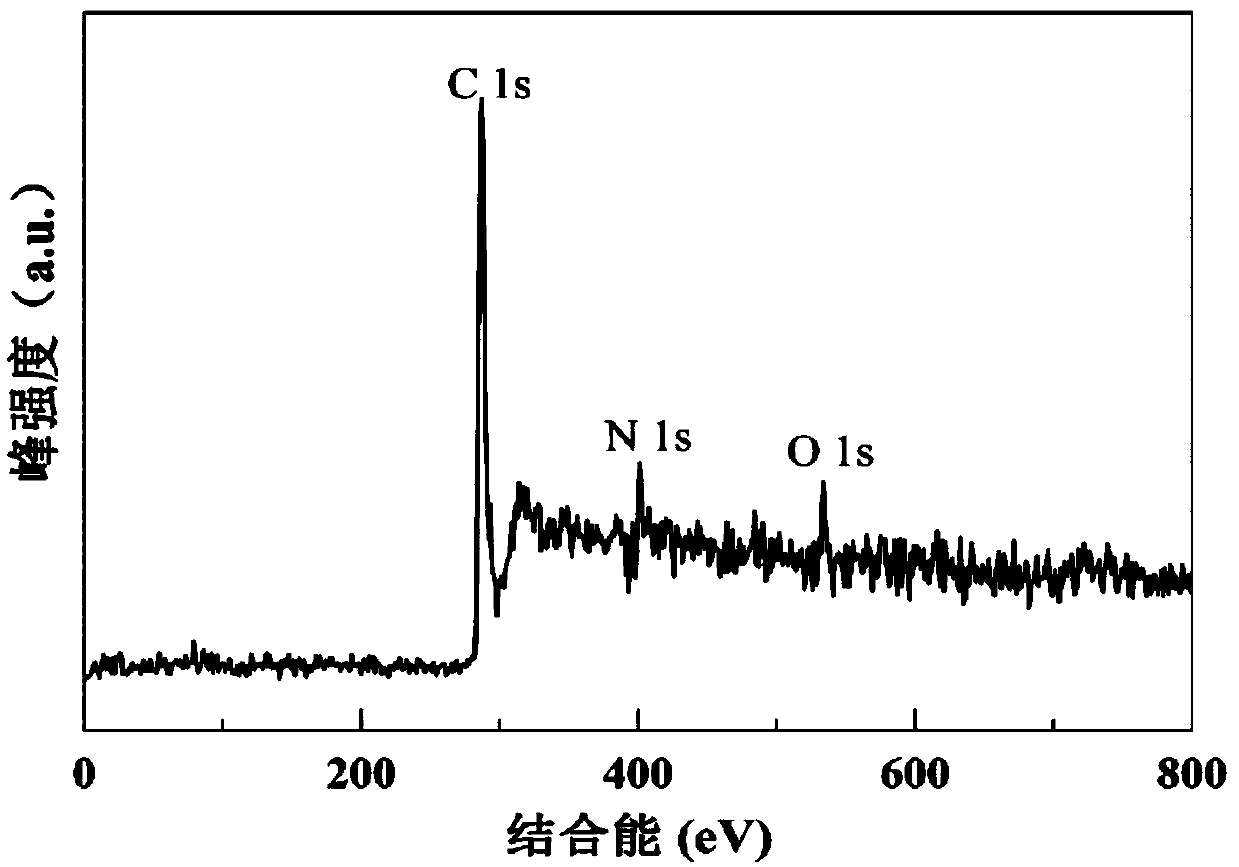

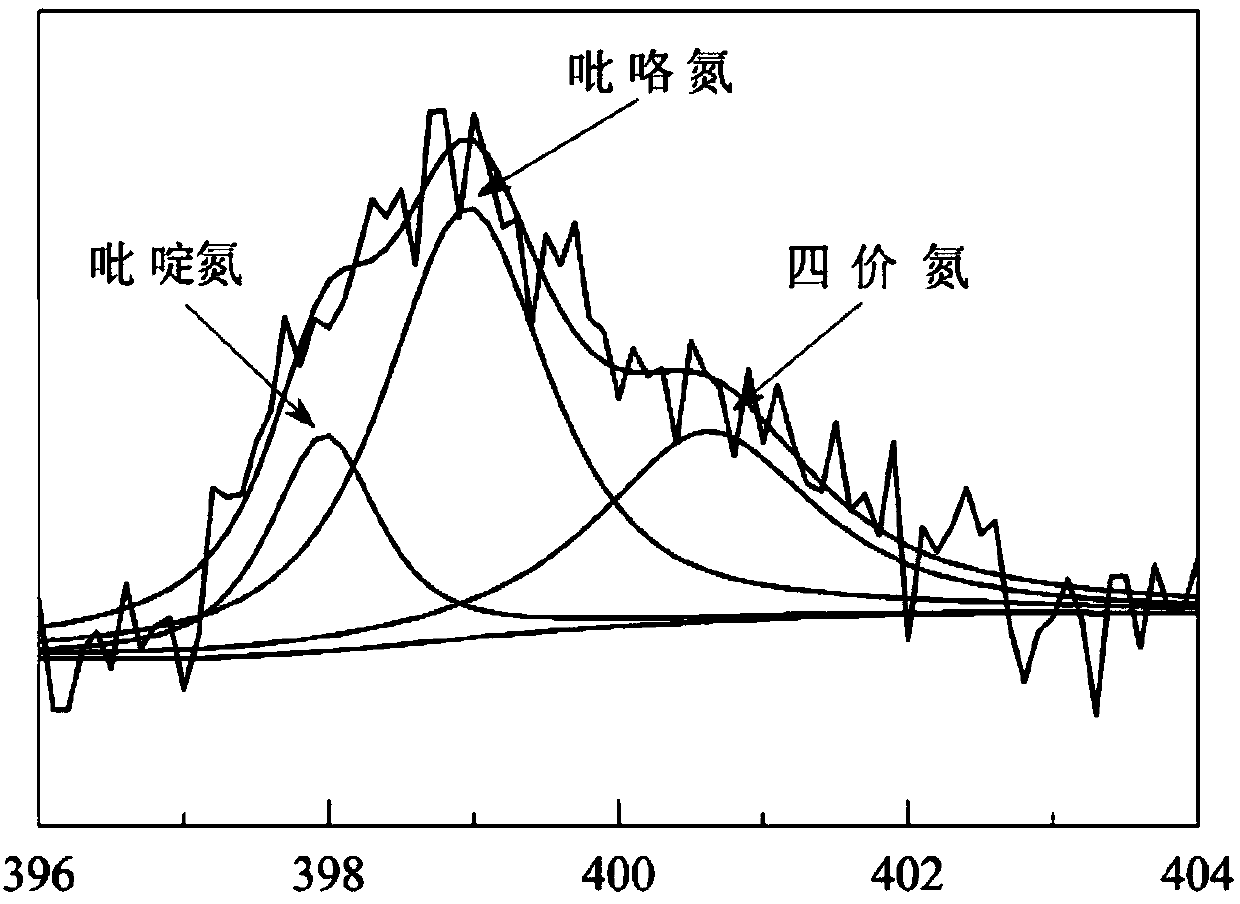

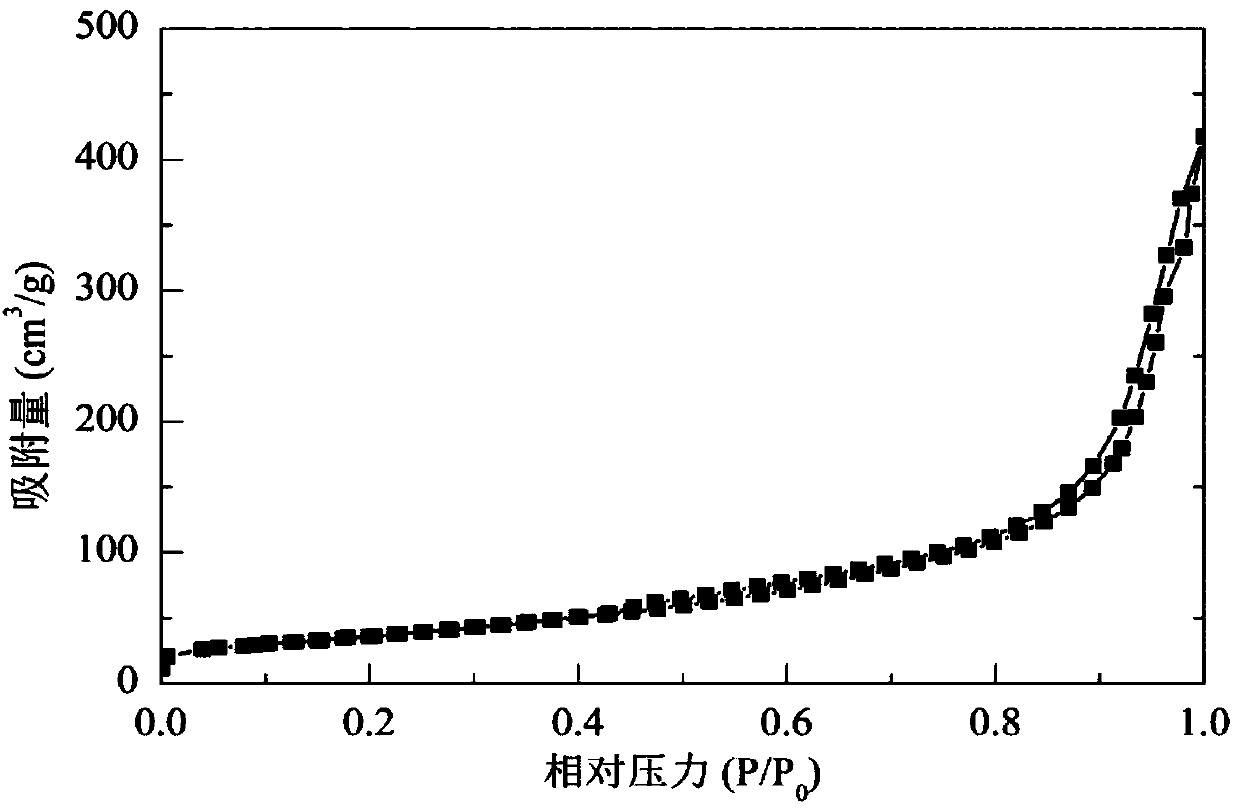

Preparation method and application of high-efficiency nitrogen-doped carbon nanotube

ActiveCN107686105ASmall particle sizeEvenly dispersedOrganic compound preparationCarbon compoundsMultiwalled carbonFiltration

The invention discloses a preparation method of a high-efficiency nitrogen-doped carbon nanotube. The preparation method comprises the following steps: adding a multiwalled carbon nanotube into a nitric acid solution; closing the solution in an autoclave; pressurizing to 0.4 to 1.0 MPa, and stirring; then heating to 120 to 200 DEG C and keeping for 1 to 4 hours; finally, cooling to room temperature by the autoclave; washing to neutral and carrying out suction filtration and drying; mixing the carbon nanotube with a melamine solid according to the mass ratio being 1 to (1 to 4), and uniformly grinding by using mortar; and carrying out high-temperature sintering in nitrogen, washing to neutral and then drying to obtain the nitrogen-doped carbon nanotube. The nitrogen doping amount of the high-efficiency nitrogen-doped carbon nanotube disclosed by the invention is 4.6 to 10.3 weight percent.

Owner:TAIYUAN UNIV OF TECH

Method for preparing olefin polymer by utilizing multiple temperature reaction areas

ActiveCN104628904AImprove cooling capacityHigh space-time yieldHeat transfer efficiencyFluidized bed

The invention discloses a method for preparing olefin polymer by utilizing multiple temperature reaction areas. The method provided by the invention comprises the following step of forming a plurality of olefin polymer reaction areas with different temperatures in a fluidized bed reactor by utilizing a circulating medium, wherein the circulating medium comprises an olefin monomer and a condensing agent. By utilizing the method, preparation of high-performance olefin polymer product by utilizing a single reactor is realized. The method is high in heat transfer efficiency. The olefin polymer prepared by utilizing the method is low in density, wide in distribution, uniform in degree of crystallinity and the like and can be widely applied to various fields of thin-film materials and the like.

Owner:ZHEJIANG UNIV

Catalyst for producing methyl-acrylate from methyl-acrolein and its production

InactiveCN101073776AImprove stabilityReduce manufacturing costPhysical/chemical process catalystsOrganic compound preparationPolymethyl methacrylateFixed bed

The invention is concerned with the activator of polymethyl methacrylate and the preparation method that makes by methyl propenal directly, which is heteropolyacids catalyst with Keggin structure character. The transforming rate of the activator MAL is over 95%, which can maintain the selection of MMA to be over 90%, the stability of the activator is good; the feedback rate is higher than the reaction that the activator is Pd, the activator is fit for fixing bed reactor, the touching time is 20 to 28second, but, the Pd activator is fit for batch reactor, the reacting time is several hours.

Owner:BEIJING UNIV OF CHEM TECH

Production method of high solid content melamine resin

The present invention relates to a formula of high solid content melamine resin and its preparation method. Said melamine resin is made up by using melamine, liquid formaldehyde (industrial product concentration is 37%) or paraformaldehyde and blending material through a synthesis process. The described material can be one of urea, monohydroxy-melamine, dihydroxy-melamine, alkyl-substituted melamine, polyvinyl alcohol, ethyl alcohol, ethylene glycol, methyl alcohol and others or their mixture. Said resin cam be used for producing melamine foamed plastics.

Owner:濮阳绿寰宇化工有限公司

Method for preparing liquid fuel coproduced low carbon olefin by directly converting catalyst and synthetic gas

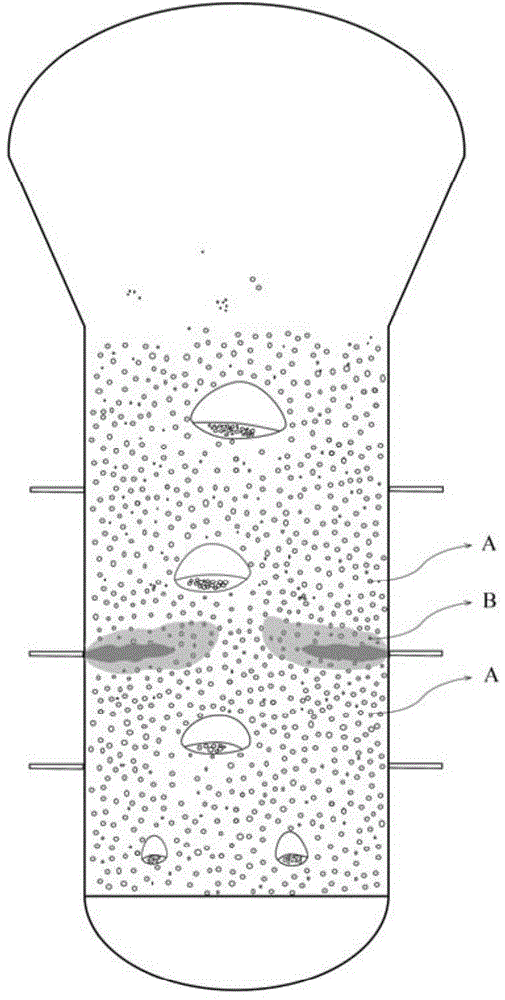

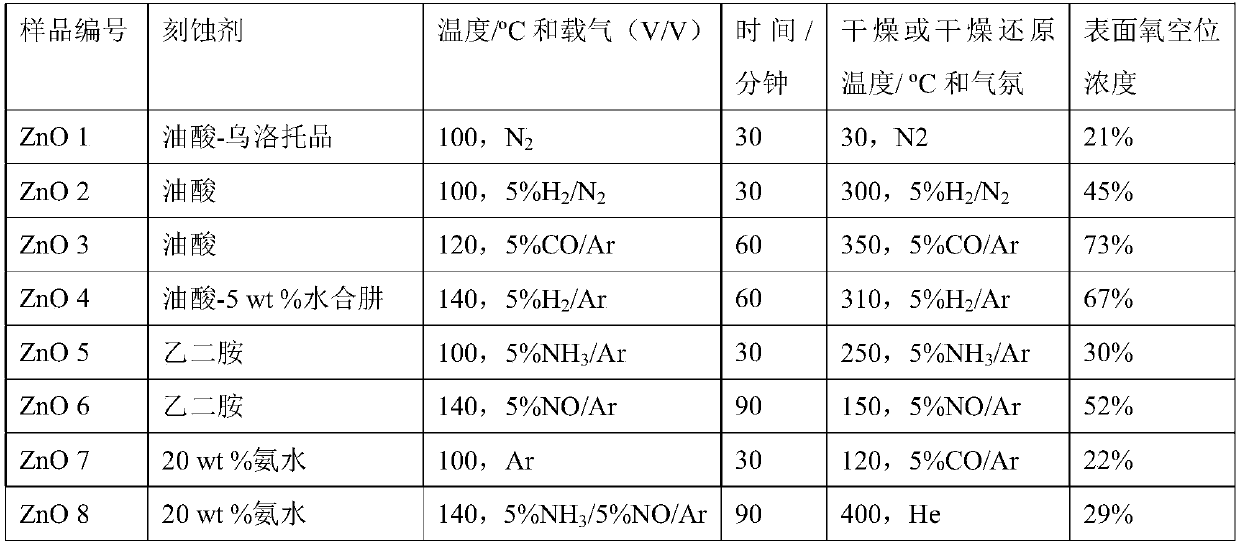

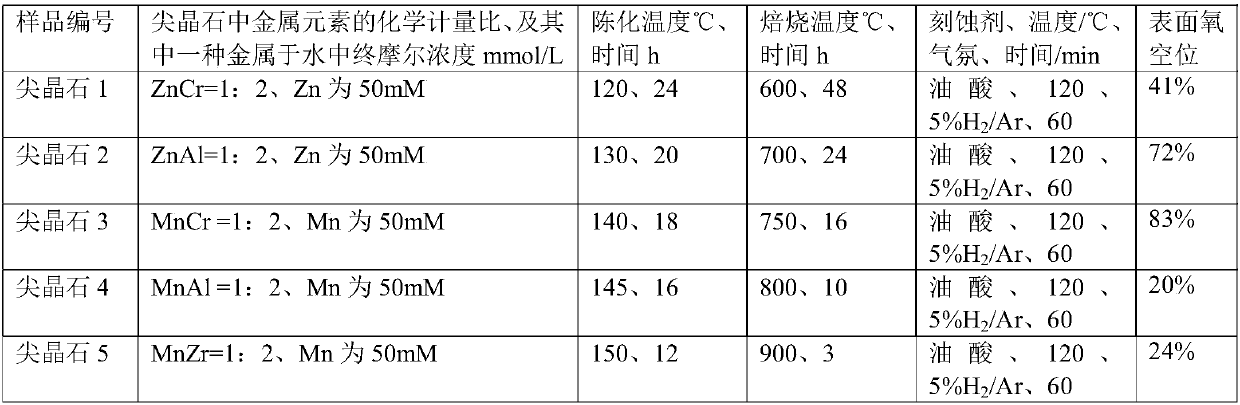

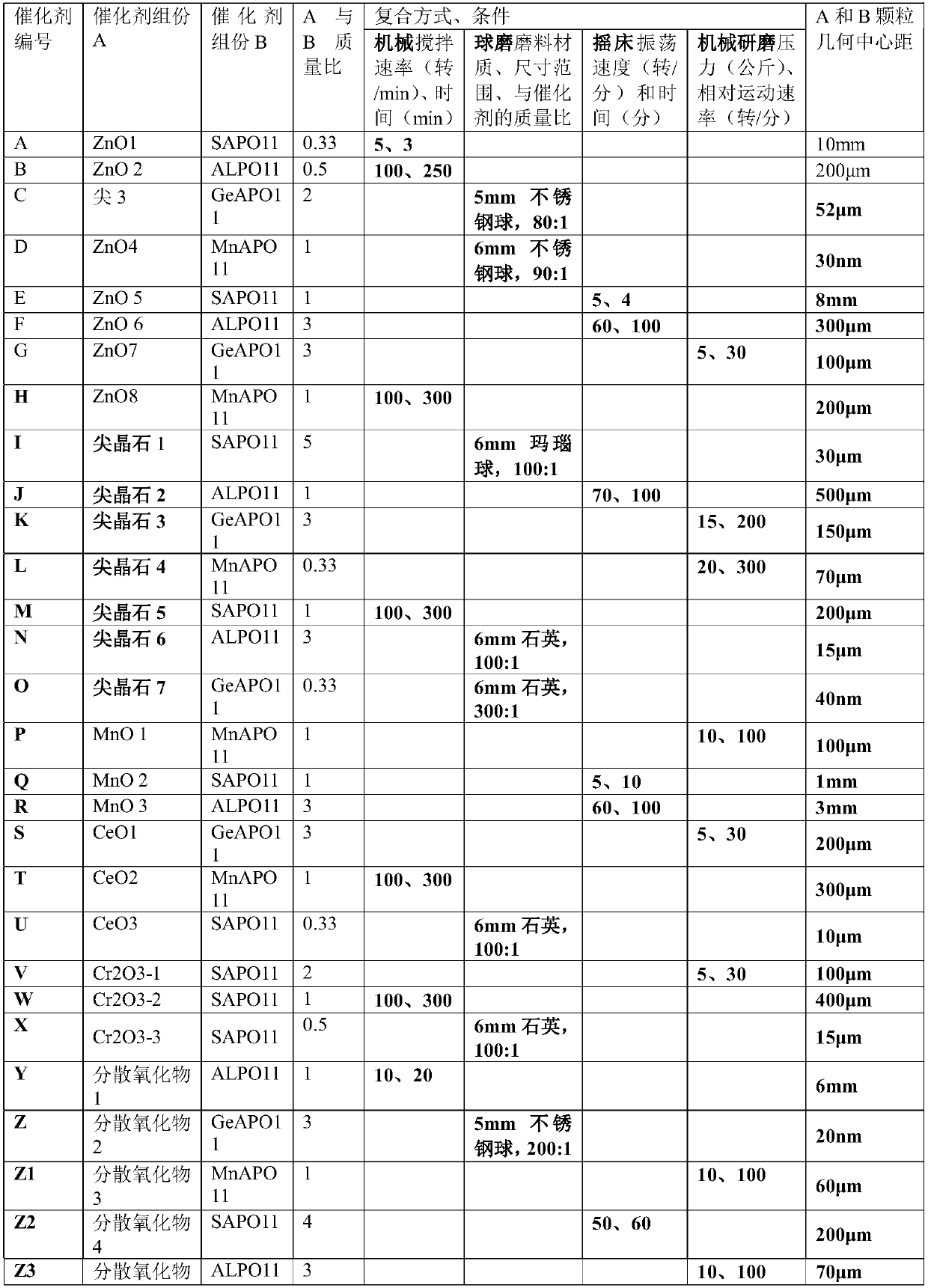

ActiveCN107774302AHigh selectivityHigh space-time yieldHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveReaction temperature

The invention belongs to preparation of liquid fuel coproduced low carbon olefin by synthetic gas and particularly relates to a method for preparing the liquid fuel coproduced low carbon olefin by directly converting a catalyst and the synthetic gas. The synthetic gas is used as a reaction raw material and reacts on a fixed bed or a movable bed, wherein the catalyst is prepared from a component Aand a component B; the component A is metal oxide; the component B is a molecular sieve with an AEL structure or one or more of molecular sieves which are modified by metal and have the AEL structures; the space between geometric centers of catalyst A particles and catalyst B particles is between 2nm and 20mm; the weight ratio of the catalyst A to the catalyst B is 0.1 to 20. The pressure of the synthetic gas is 0.1 to 6MPa, the reaction temperature is 300 to 600DEG C, and the air speed is 500 to 8000h<-1>. Gasoline with high octane number is mainly produced by reacting, and low carbon olefinis coproduced; methane as a byproduct has low selectivity (smaller than 10 percent); the method has a good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

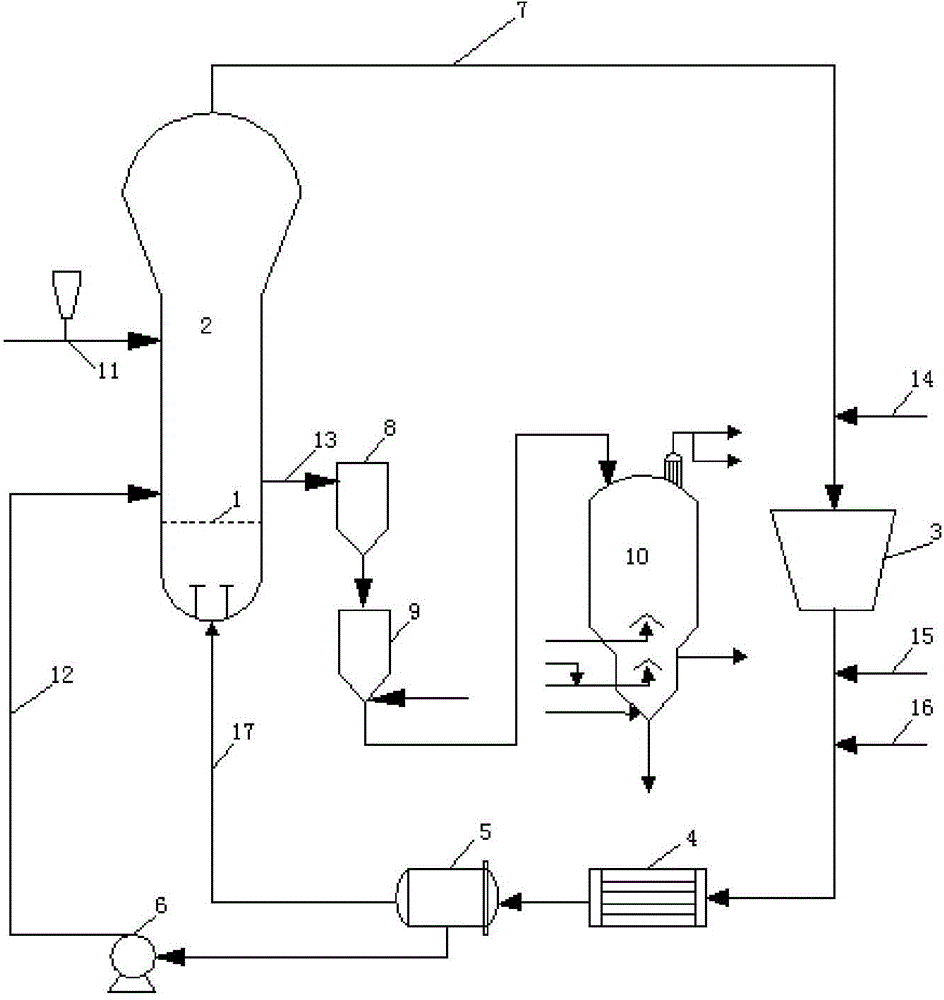

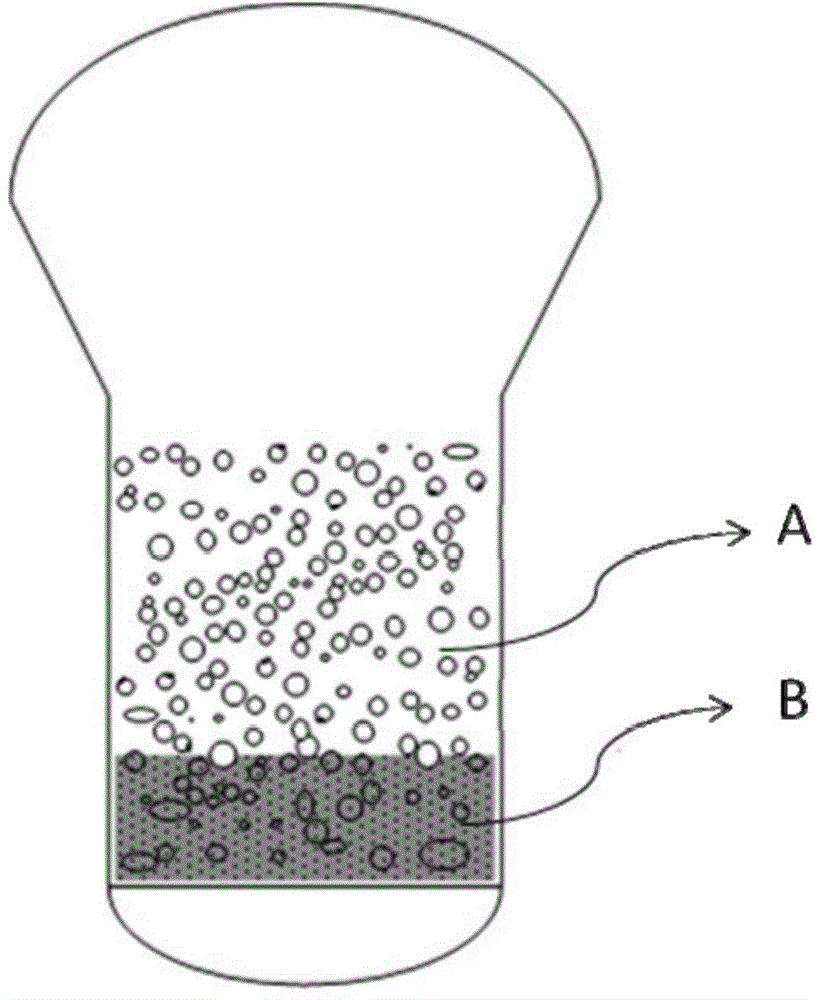

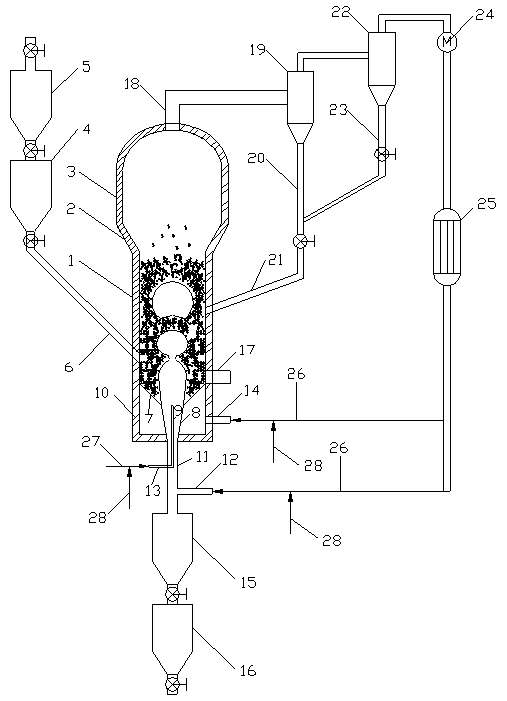

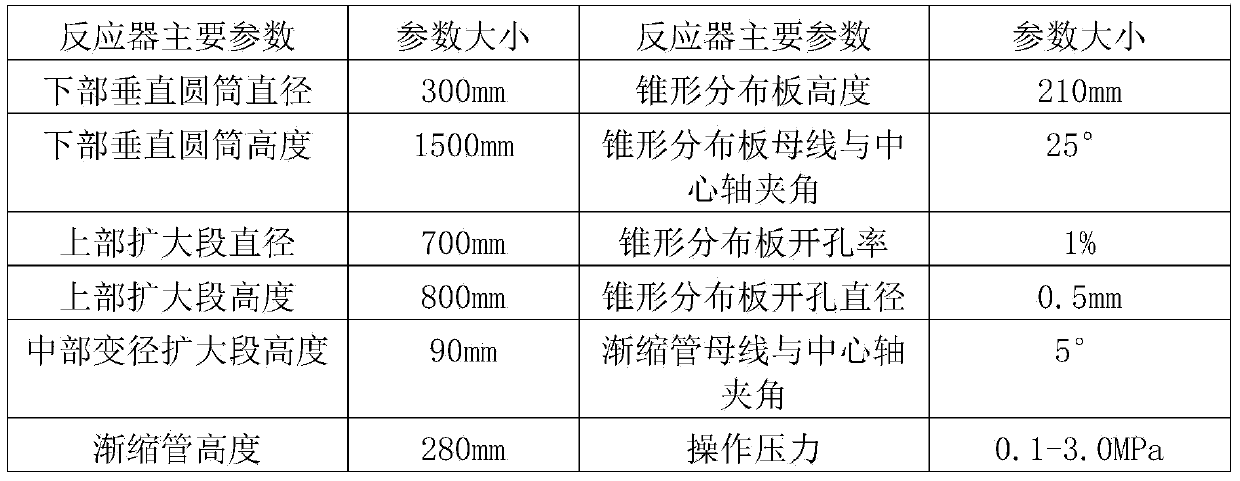

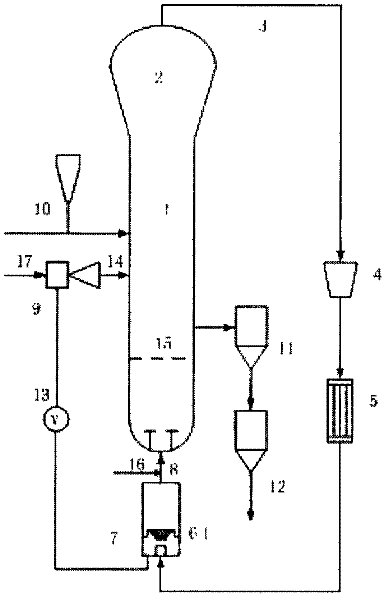

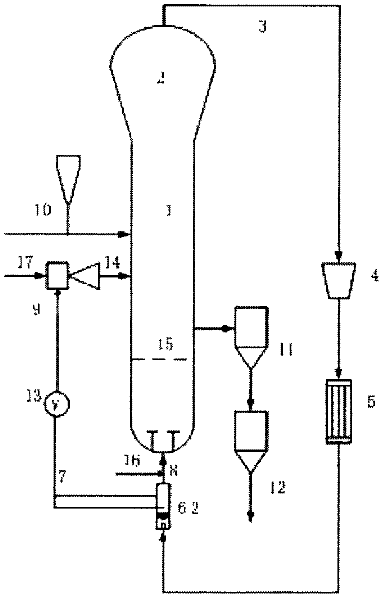

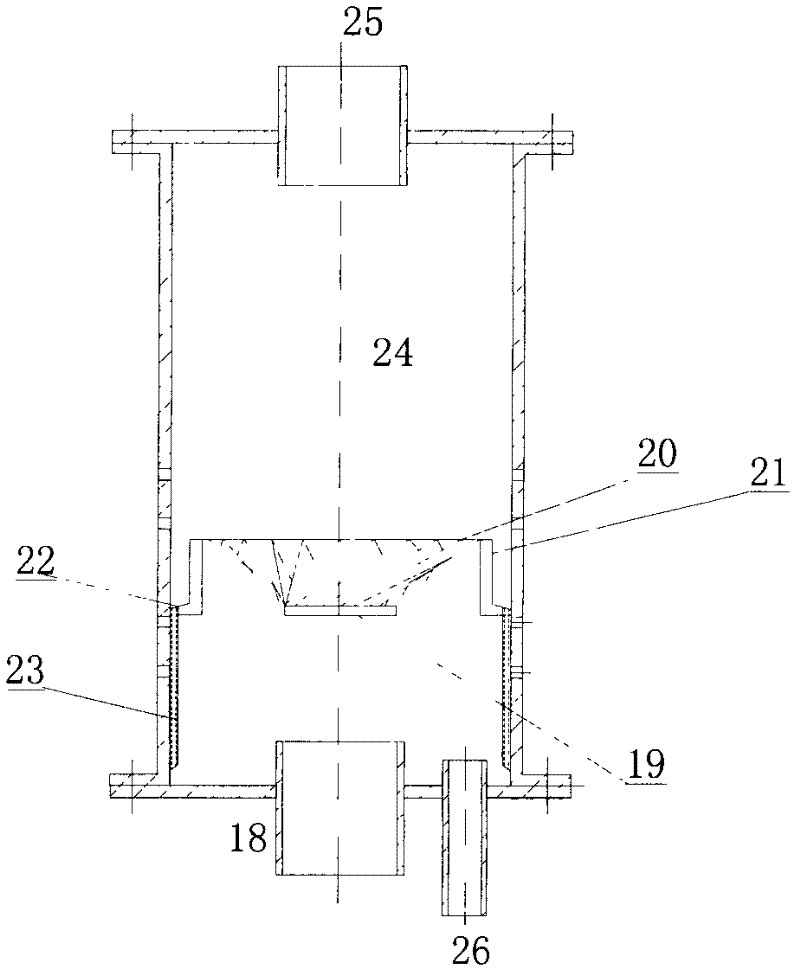

Jet flow fluidized bed reaction device and olefin polymerization method thereof

ActiveCN104190330AGuaranteed particle size distributionAvoid elevationChemical industryChemical/physical processesPolyolefinJet flow

The invention discloses a jet flow fluidized bed reaction device which comprises two units, namely a polymerization reactor unit and a particle gas cycle conveying unit, wherein the polymerization reactor unit comprises a lower vertical cylinder (1), a middle variable-diameter enlargement section (2) and an upper enlargement section (3); and the particle gas cycle conveying unit comprises a primary cyclone separator (19) and a secondary cyclone separator (22). By utilizing the device disclosed by the invention, C1-C6 olefin feed gas is subjected to an olefin polymerization reaction by using a known addition polymerization catalyst. The jet flow fluidized bed reaction device has the advantages of simple structure, low cost and capability of performing large-scale polyolefin production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

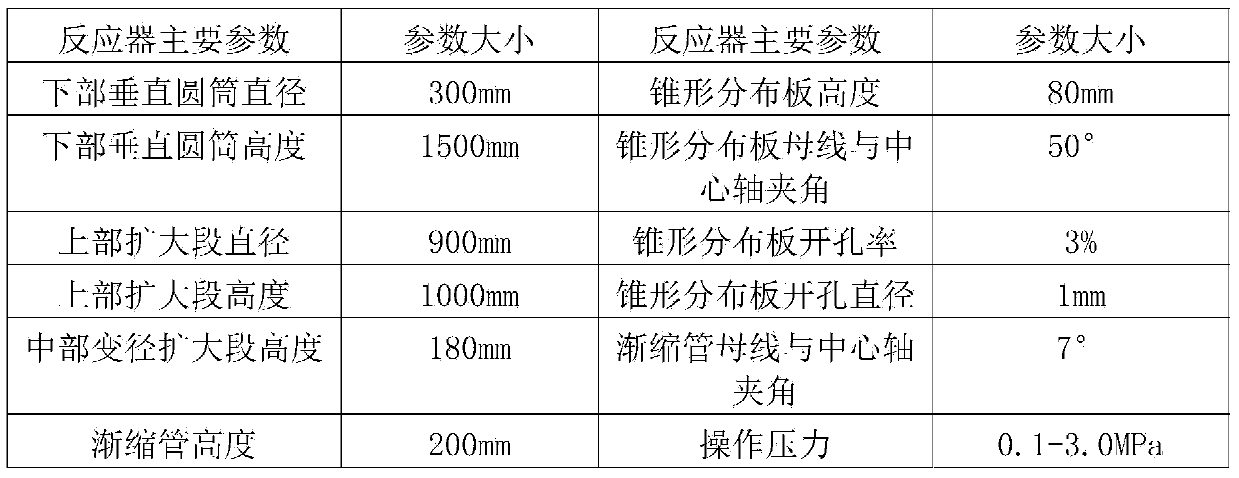

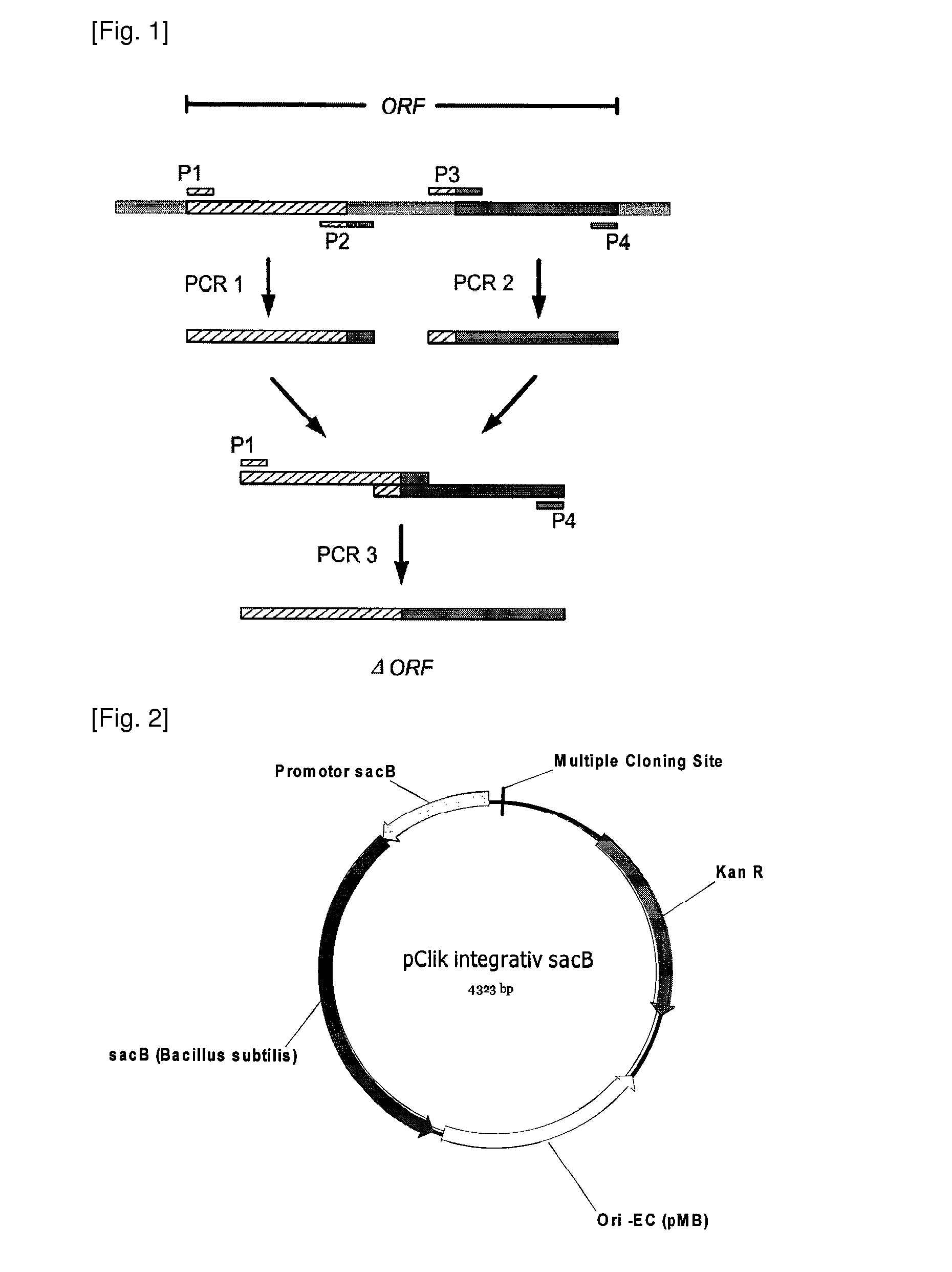

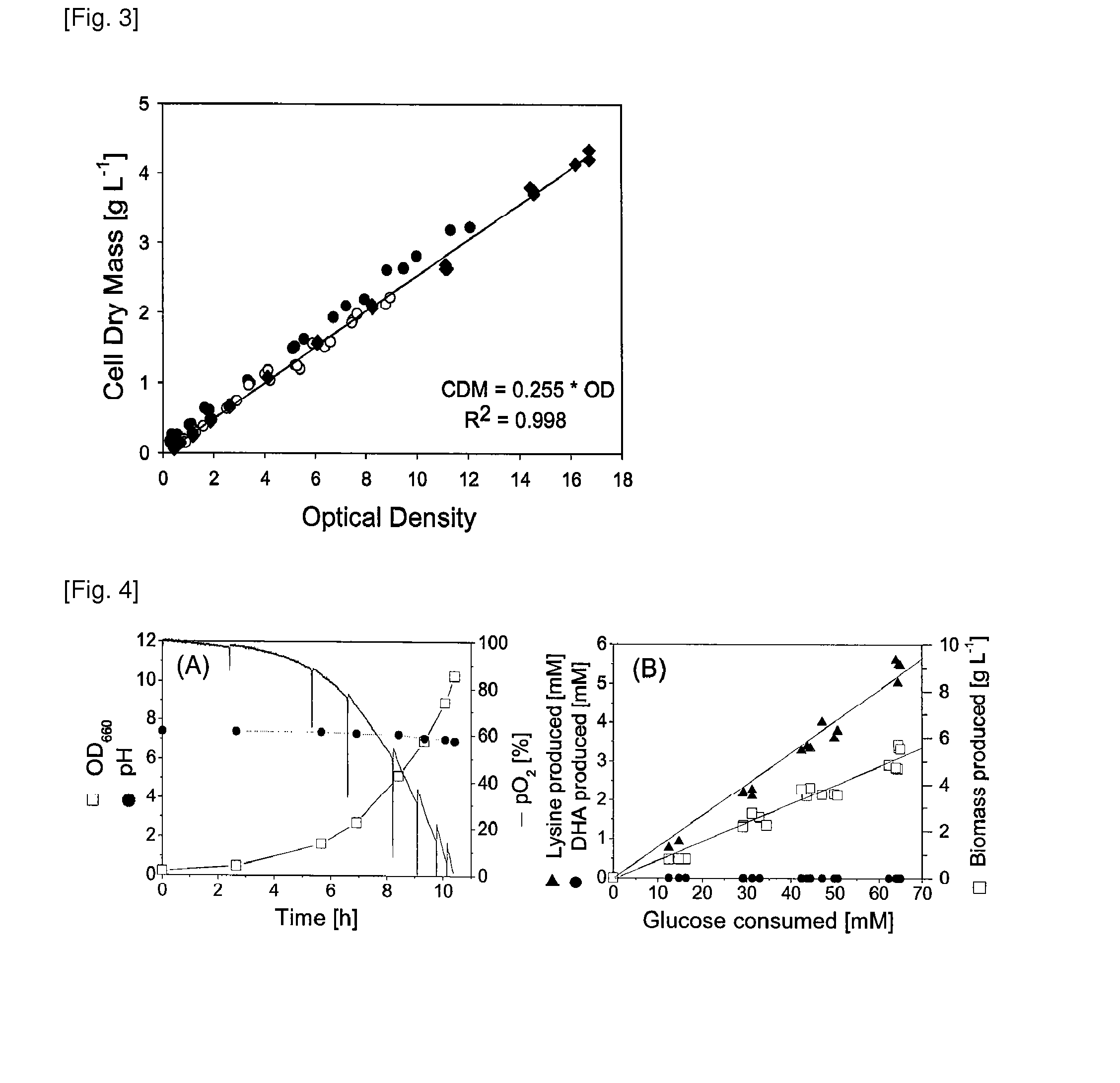

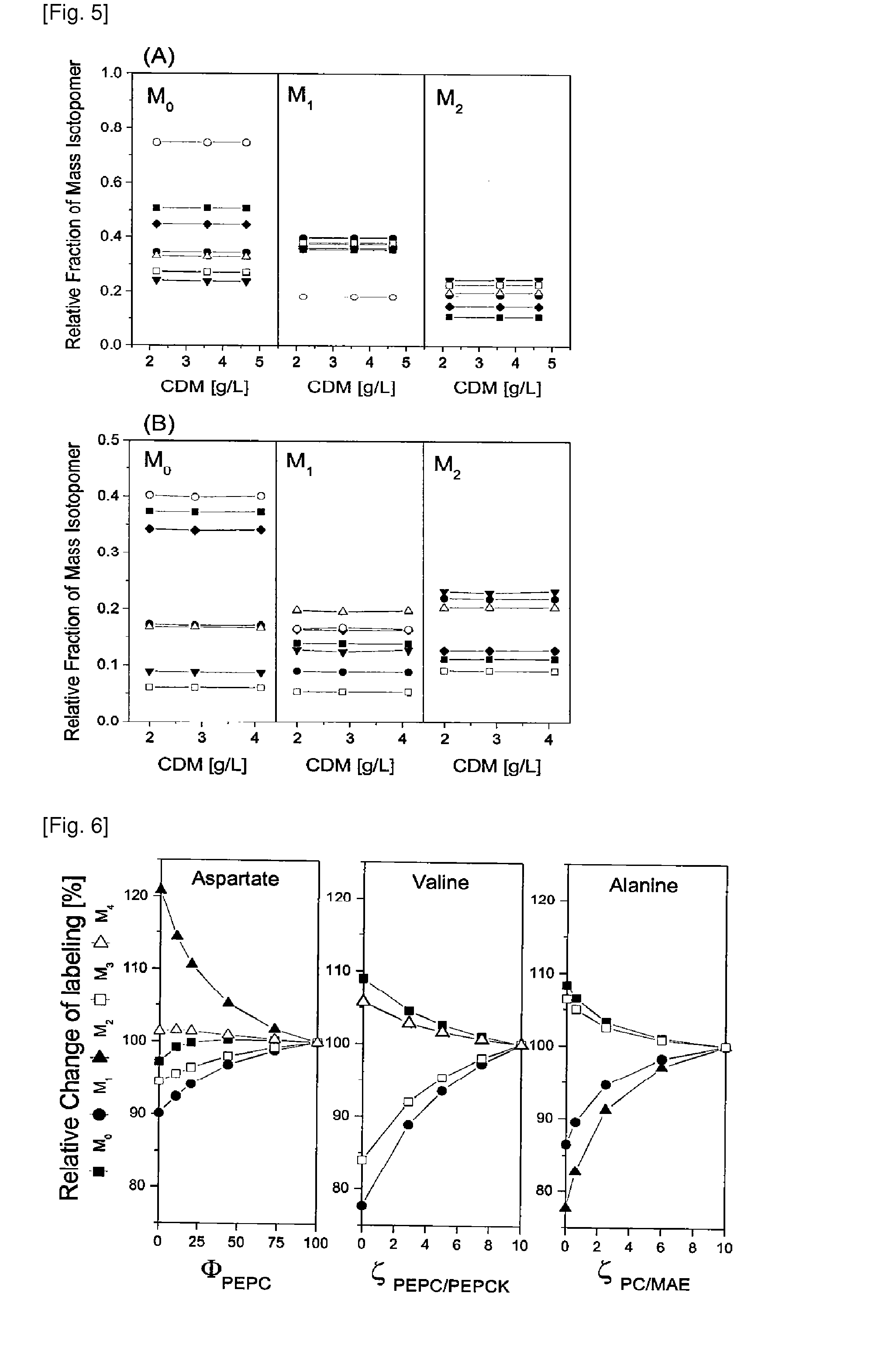

Production process for amino acids of the aspartate family using microorganisms

The present invention is directed to a method utilizing a recombinant microorganism for the production of aspartate derived amino acids and precursors thereof, in particular for the production of L-lysine. Furthermore, the present invention relates to a recombinant microorganism having improved aspartate-derived amino acid synthesis activity in comparison to the initial microorganism and the use of such microorganisms in producing said amino acids and precursors and derivatives, in particular in the synthesis of L-lysine.

Owner:DAESANG

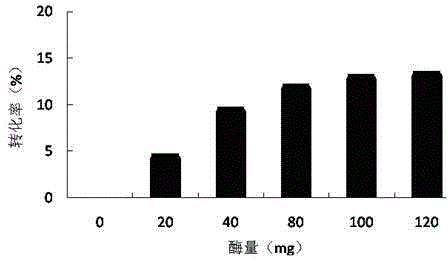

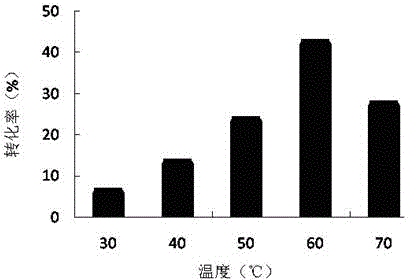

Method for synthesizing sucrose fatty acid ester

InactiveCN104593445AHigh space-time yieldSimple purification processFermentationBulk chemical productionSolubilitySucrose

The invention discloses a method for synthesizing sucrose fatty acid ester. The method comprises the following steps: by taking an ionic liquid or a double solvent of the ionic liquid and an organic solvent as a reaction medium, adding fatty acid or fatty acid ester and saccharides with hydroxyl to the reaction medium at a mole ratio of (1:3)-(4:1), and mixing for 3-7 minutes; and then adding lipase, and reacting for 4-48 hours to prepare the sucrose fatty acid ester. According to the method, an environment-friendly high-efficiency reaction system for synthesizing sugar ester through an enzymic method is established by designing and optimizing a reaction condition in a pure ionic liquid system and a double-solvent system; especially, the solubility of a matrix and a product is enhanced through the ionic liquid and tertiary amyl alcohol in the double-solvent system, so that the space time yield of the sugar ester is enhanced, a purifying process of the sugar ester is simplified, and the efficiency is improved.

Owner:SHENZHEN UNIV

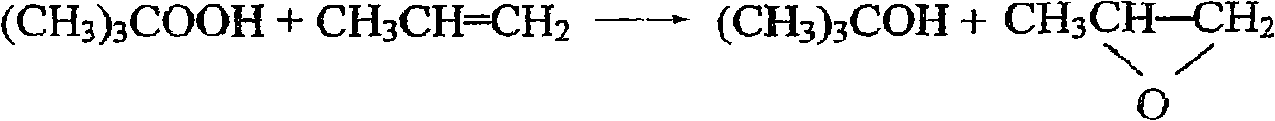

Method for preparing iso-butyl aldehyde by using isobutene or tert-butyl alcohol as raw material

ActiveCN101260028AHigh selectivityHigh space-time yieldOrganic compound preparationCarbonyl compound preparationMethacroleinBismuth

The invention aims to provide a method of using isobutylene or tert-butyl alcohol as raw material to prepare isobutyraldehyde. The method prepares isobutyraldehyde through two steps as follows: (1) under the action of molybdenum-bismuth base composite oxide catalyst, isobutylene or tert-butyl alcohol selects oxidation to prepare methacrolein; (2) under the action of supported hydrogenation catalyst, methacrolein selects hydrogenation to prepare isobutyraldehyde. The raw material in the method is cheap and easy to get, which breaks the dependence of the prior isobutyraldehyde production on expensive C3 propylene raw material and opens up a brand new process route for preparing isobutyraldehyde through C4 raw material low in chemical utilization ratio. The method is high in the yield coefficient of isobutyraldehyde, simple in process, low in production cost and convenient for mass production.

Owner:SHANGHAI HUAYI NEW MATERIAL

Catalyst for preparing methyl alcohol from syngas as well as preparation method and application of catalyst

ActiveCN104069870AEasy to makeHigh yieldOrganic compound preparationHydroxy compound preparationSyngasAlcohol

The invention relates to a catalyst for preparing methyl alcohol from syngas. The preparation method of the catalyst comprises the following steps: putting a CuO / ZnO / Al2O3 catalyst into a container, adding a rhodium salt solution with the same volume, immersing for 6-48 h, and then drying for 8-16 h at 80-120 DEG C; roasting the obtained product for 3-6 h at 300-400 DEG C to obtain the catalyst comprising 40-65 percent of Cu, 25-40 percent of Zn, 2-20 percent of Al and 0.1-0.2 percent of Rh in molar ratio. The catalyst has the advantages of high activity and good stability.

Owner:TAIYUAN UNIV OF TECH

Method for using rotating-stream tray in phase-phase polyethylene process and rotating-stream tray device

ActiveCN102532359AHigh precisionIncrease flexibilityDispersed particle separationFluid phaseFluidized bed

The invention discloses a method for using a rotating-stream tray in a phase-phase polyethylene process and a rotating-stream tray device. The method comprises the following steps of: arranging a rotating-stream tray separator on a circulating pipeline, leading circulating air current out of the top of a fluidized bed, compressing, condensing, and performing gas-liquid separation in the rotating-stream tray separator to form stream which is rich in liquid phases and stream which is rich in gas phases; and spraying the stream which is rich in liquid phases into the fluidized bed from the upper part of a distributing plate, and introducing the stream which is rich in gas phases into a reactor from the lower part of the distributing plate for fluidizing a material and participating in polymerization, wherein the content of a condensate in the stream which is rich in liquid phases is 60-100 percent by weight of the total content of a condensate in a circulating air current; and the pressure drop through the rotating-stream tray separator is 1,500-6,500 Pa. According to the method and the device, the quantity of the condensate entering a fluidized bed reactor from the upper part of the distributing plate can be increased greatly, the phenomenon of liquid accumulation is avoided, the pressure drop of a gas-liquid separating device is reduced, the adjusting and controlling accuracy and ranges of the condensate quantity are increased, and the energy consumption of a system is lowered; and moreover, the form of the rotating-stream tray separator is optional, and operation is flexible.

Owner:CHINA PETROCHEMICAL CORP +2

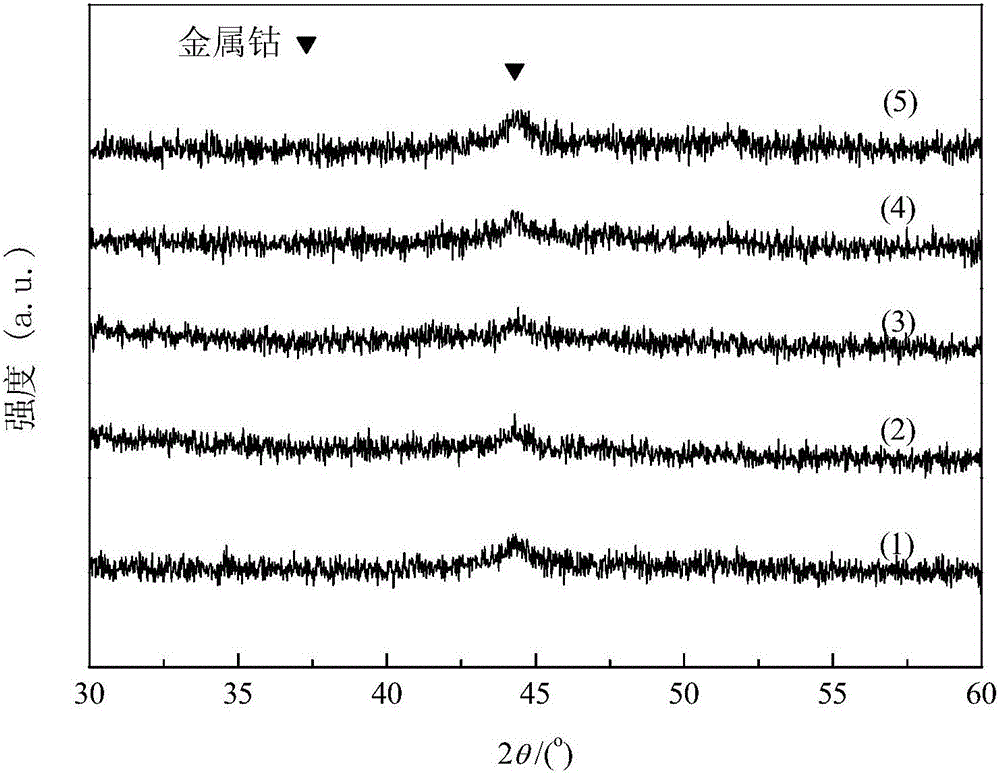

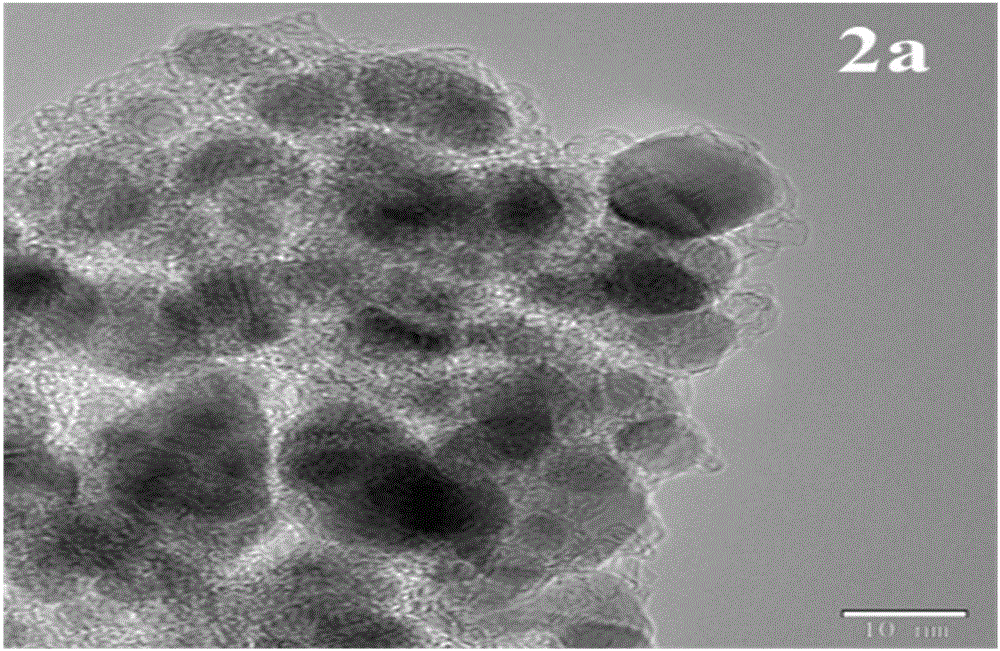

Porous carbon-loaded cobalt-based Fischer-Tropsch synthesis catalyst containing silicon dioxide auxiliary agent and preparation method thereof

ActiveCN106475101AHigher than active site densityComplete restorationLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsPorous carbonFixed bed

The invention discloses a porous carbon-loaded cobalt-based Fischer-Tropsch synthesis catalyst containing a silicon dioxide auxiliary agent and a preparation method thereof. The catalyst uses cobalt as an active component, silicon dioxide as the auxiliary agent and porous carbon as a carrier, and the mass percentages of cobalt and silicon dioxide are 25.8 to 30.6% and 6.2 to 21.0% respectively, with the balance being the porous carbon carrier. Metallic cobalt particles are uniformly distributed on the catalyst and densely arrayed; the diameters of the particles are in a range of 6 to 9 nm; and the silicon dioxide auxiliary agent exists on the surfaces of the particles. According to the invention, a CO-MOF-71 metal-organic framework is used as a sacrificial template, a silicon source is doped by using an impregnation method, and then the silicon dioxide-supported porous carbon-loaded cobalt-based catalyst is prepared on a fixed bed through one-step in-situ pyrolysis method. The catalyst prepared in the invention has high specific active site density; and when applied to Fischer-Tropsch synthesis, the catalyst has good C<5+> selectivity, especially high C<5+> space-time yield, on the basis of high activity.

Owner:SOUTH CHINA UNIV OF TECH

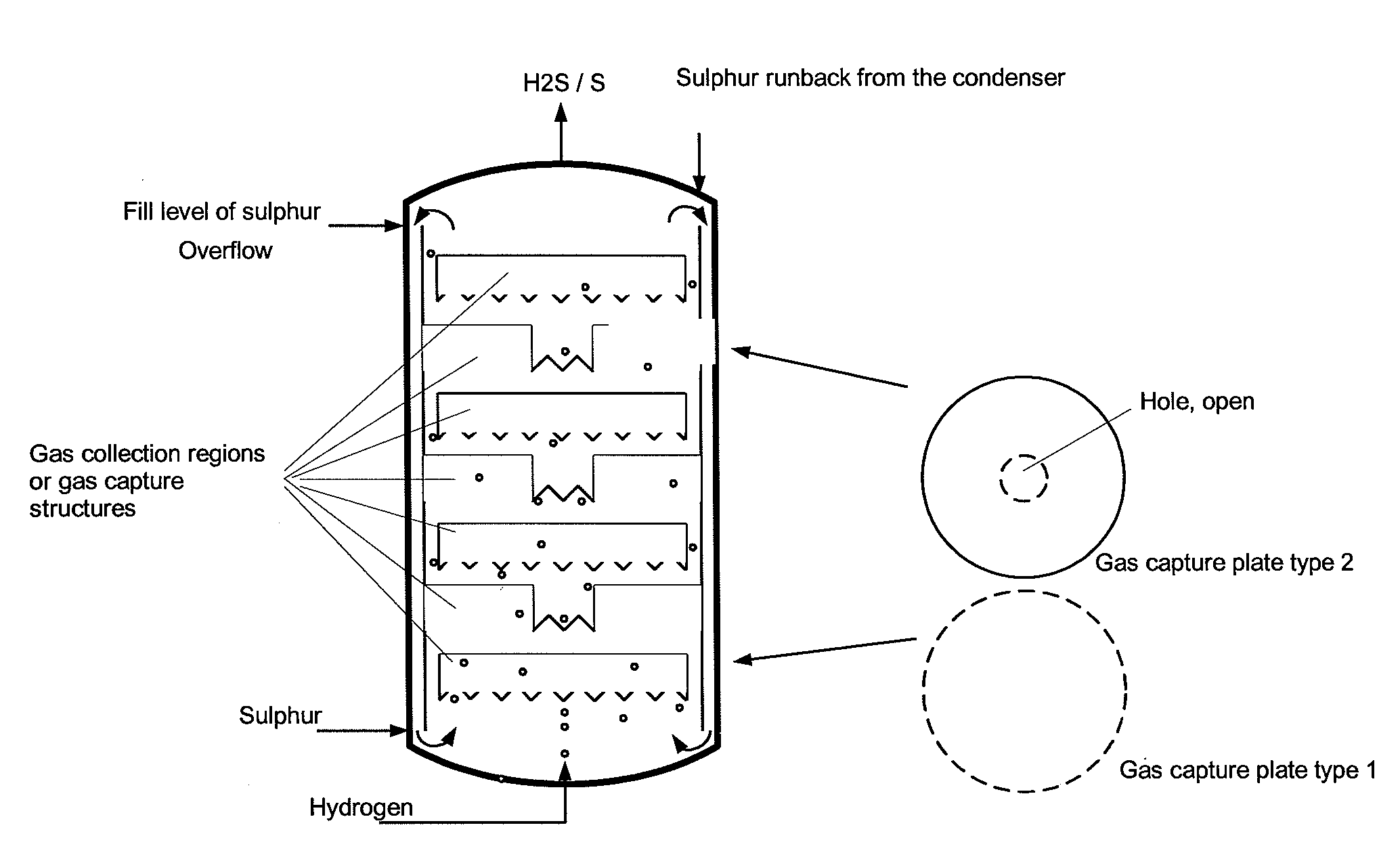

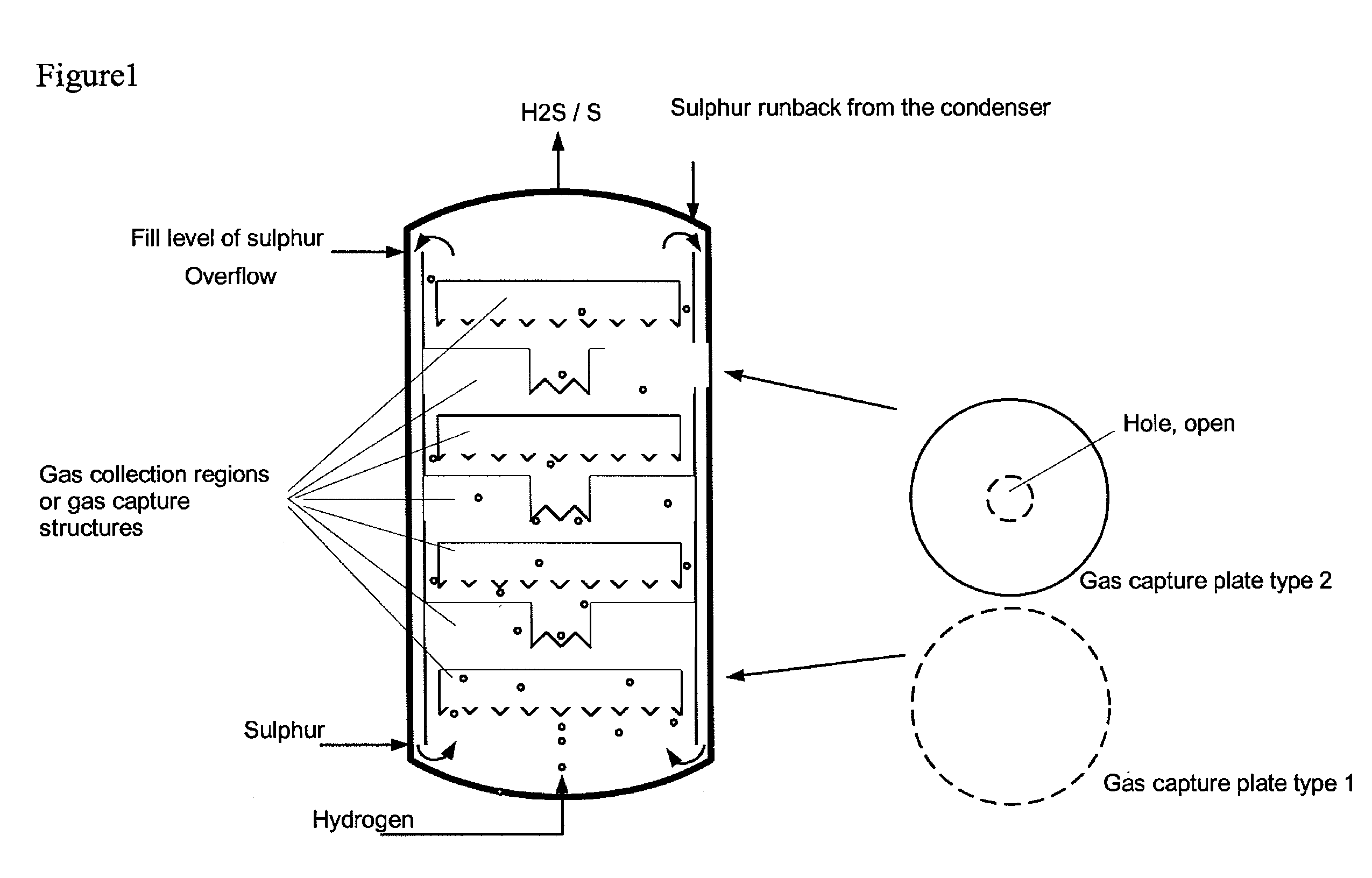

Reaction vessel and process for its use

InactiveUS7833508B2Severe corrosionExtended stayGaseous chemical processesSulfur-dioxide/sulfurous-acidHydrogenChemistry

The invention relates to a reaction vessel in which hydrogen sulphide is prepared from sulphur and hydrogen, wherein the reaction vessel consists partly or entirely of a material which is resistant to the reaction mixture, its compounds or elements and retains its resistance even at high temperatures.

Owner:EVONIK DEGUSSA GMBH

Method for producing biological ethylene by using solid-carrying dodecatungsten rare earth polyoxometallate

InactiveCN101125789AExcellent natureImprove stabilityHydrocarbon from oxygen organic compoundsMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureRare earth

The invention relates to a method for preparing biological ethylene by the use of catalytic action and dehydration of rare-earth lauryl heteropoly tungstic acid salt. The main technology process is that: the ethanol solution of rare-earth lauryl heteropoly tungstic acid salt is solid supported by the process of being leached and adsorbed by carriers such as active carbon or molecular sieve or Gamma-alumina, etc, being dried and baked, etc., and then is loaded in a tubular reactor and reacts under normal pressure, at 150 DEG C to 190 DEG C for 10 minutes with airspeed of the ethanol vapor being controlled from 30 to 50 per hour. The space time yield of ethylene is 88.3 percent and no aether is detected in the result. The invention provides the method for preparing biological ethylene, and reaction temperature is 150 DEG C to 250 DEG C lower than that of conventional oxide catalyst and 60 DEG C to 100 DEG C lower than that of molecular sieve catalyst. Furthermore, space time yield increases by 10 percent to 30 percent, reaction selectivity is greatly high and almost no aether is founded. The catalyst has excellent nature and stability.

Owner:CHINA THREE GORGES UNIV

Catalyst for use in preparation of 1,2-propanediol by low-temperature low-pressure hydrogenation of biological glycerol and preparation method thereof

InactiveCN102389800ALow reaction temperatureHigh activityPreparation by OH group eliminationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSilicic acid

The invention discloses a catalyst for use in the preparation of 1,2-propanediol by low-temperature low-pressure hydrogenation of biological glycerol and a preparation method thereof. The catalyst consists of an active main body, an assistant catalyst and a carrier, wherein the active main body is metal copper which is 15 to 35 mass percent; the carrier is silicon dioxide and is one or more than one of silicate, silica sol or silicate ester; and the assistant catalyst is one or more of transitional metal nickel, manganese and cobalt and is 1 to 5 mass percent. When the catalyst is used, aqueous solution of glycerol, which serves as a raw material, can react at a very mild reaction condition, the conversion rate of glycerol is up to 100 percent, and the selectivity for 1,2-propanediol reaches over 99 percent. The method has the advantages that: the reaction process is simple and convenient; the operation is easy; the controllability is high; the reaction temperature is low; the reaction pressure is low; the target product yield is high; and the like.

Owner:HAO HUA CHENGDU TECH

Bifunctional catalyst and method for preparing ethylene with carbon monoxide hydrogenation

ActiveCN108927132AHigh selectivityHigh space-time yieldHydrocarbon from carbon oxidesMolecular sieve catalystsChemistryMolecular sieve

The invention belongs to the direct preparation of ethylene by hydrogenation of carbon monoxide, concretely relates to a bifunctional catalyst and a method for preparing ethylene with carbon monoxidehydrogenation. Carbon monoxide and hydrogen are use as raw materials and are subjected to conversion reaction on a fixed bed or a moving bed; the catalyst is a composite catalyst formed by mixing component A and component B; the active ingredient of component A is a metal oxide, and component B is an aliphatic amine-modified molecular sieve of an MOR structure; and the weight ratio of the active ingredient of component A to component B is in the range of 0.1-20, preferably 0.3-8. The reaction process has higher product yield and selectivity, and the selectivity of C2-C3 olefins reaches up to 78-87%, wherein the selectivity of hydrocarbon products of more than four C atoms is lower than 10%, the selectivity of by-product methane is lower than 9%, and the selectivity of ethylene reaches 75-82%. Therefore, the bifunctional catalyst has good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com