Preparation method and application of high-efficiency nitrogen-doped carbon nanotube

A technology of nitrogen-doped carbon and multi-walled carbon nanotubes, which is applied to the production method of high-efficiency nitrogen-doped carbon nanotubes and the application field of nitrogen-doped carbon nanotubes, and can solve the problem of affecting performance, low nitrogen doping amount, etc. problems, to achieve the effect of improved anti-agglomeration ability, high nitrogen doping amount, and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1, hydrothermal oxidation of carbon nanotubes

[0064] ①. Measure 0.23mL of nitric acid and 74.77mL of deionized water, add them into a beaker, stir for 10min, and make a 0.05mol / L nitric acid aqueous solution;

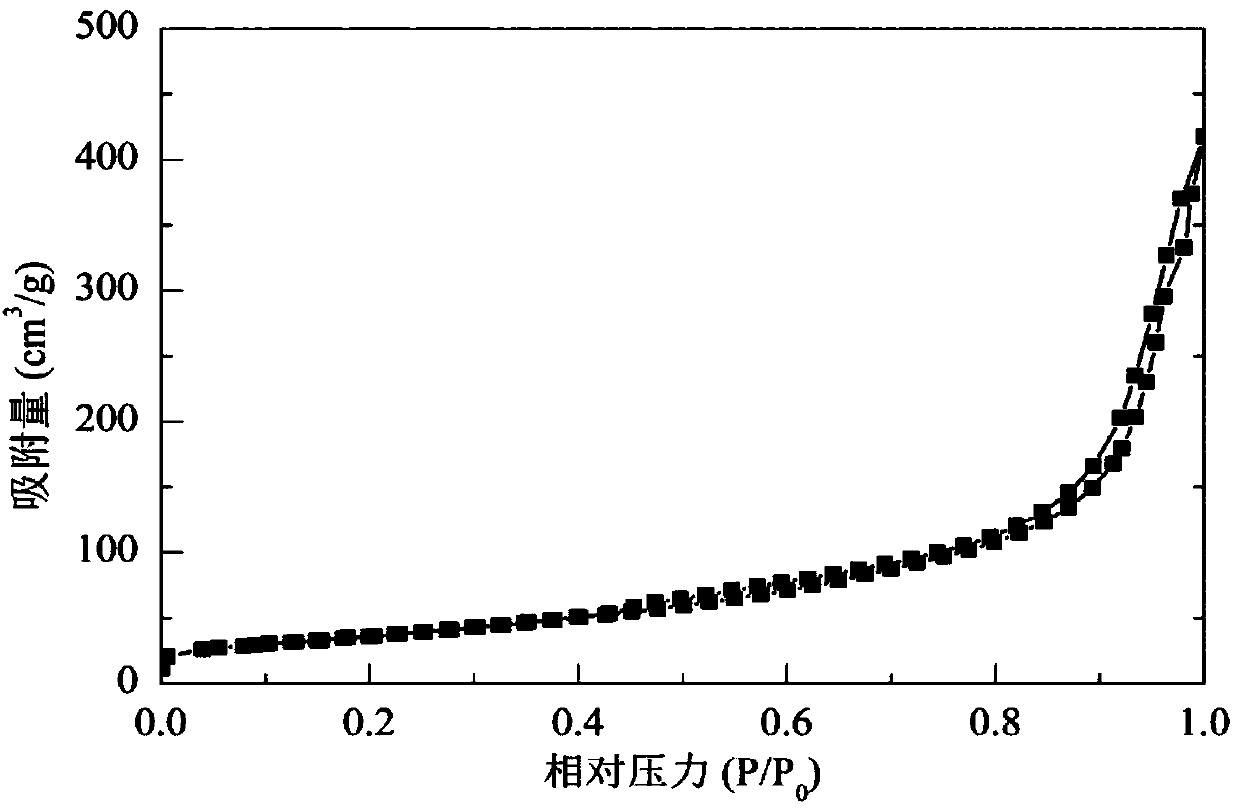

[0065] ②. Weigh the specific surface area to be 180m 2 / g, the pore volume is 0.90ml / g, and the average pore diameter is 2g of the original multi-walled carbon nanotubes of 12.8nm, add in the above-mentioned nitric acid aqueous solution;

[0066] ③. Transfer the above mixture to an autoclave equipped with a temperature controller and a propeller stirring system. The autoclave is sealed and flushed with nitrogen three times to exhaust the dissolved oxygen in the solution. Stir at a speed of 1 / min, then heat up to 120°C and keep for 1h, finally cool the autoclave to room temperature and release the pressure, wash with ionized water until neutral, filter with suction, and dry in an oven at a drying temperature of 90°C for a drying time of 12h .

[00...

Embodiment 2

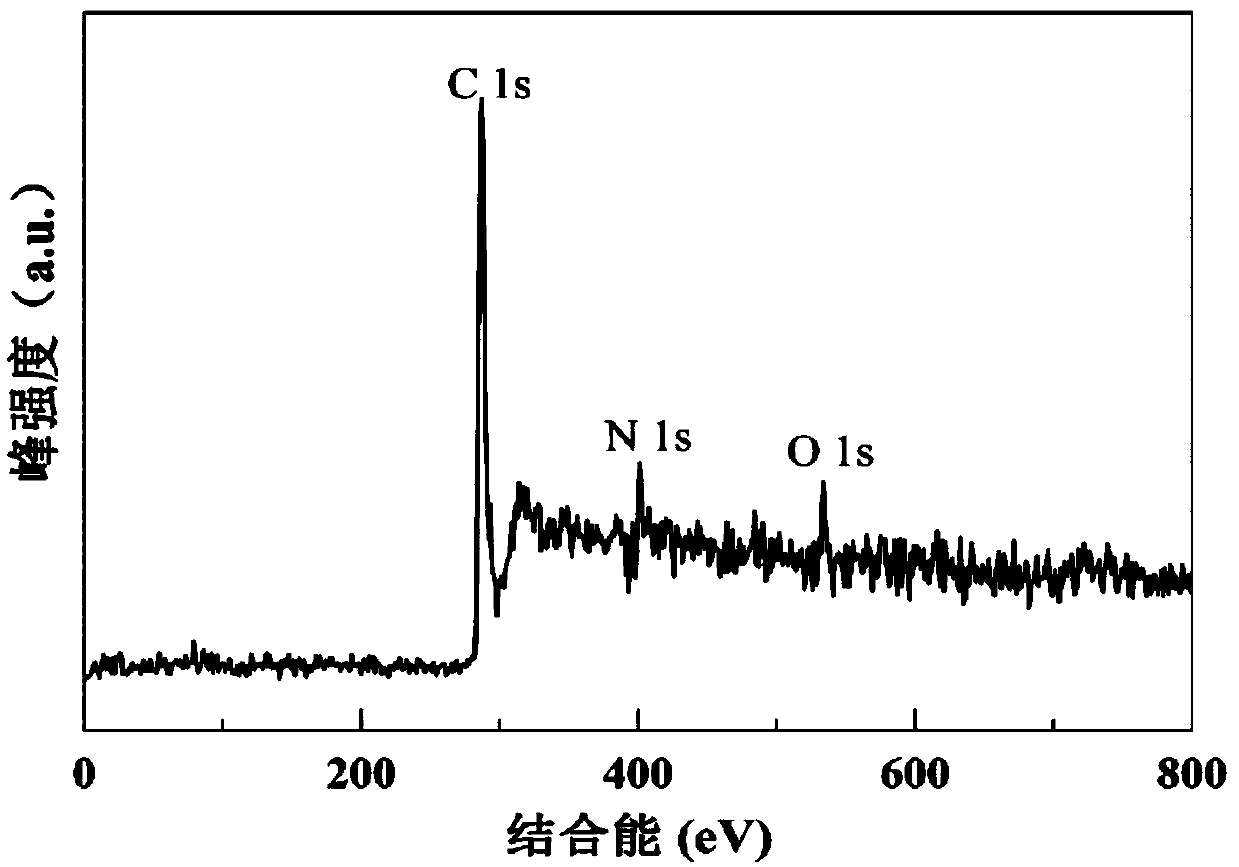

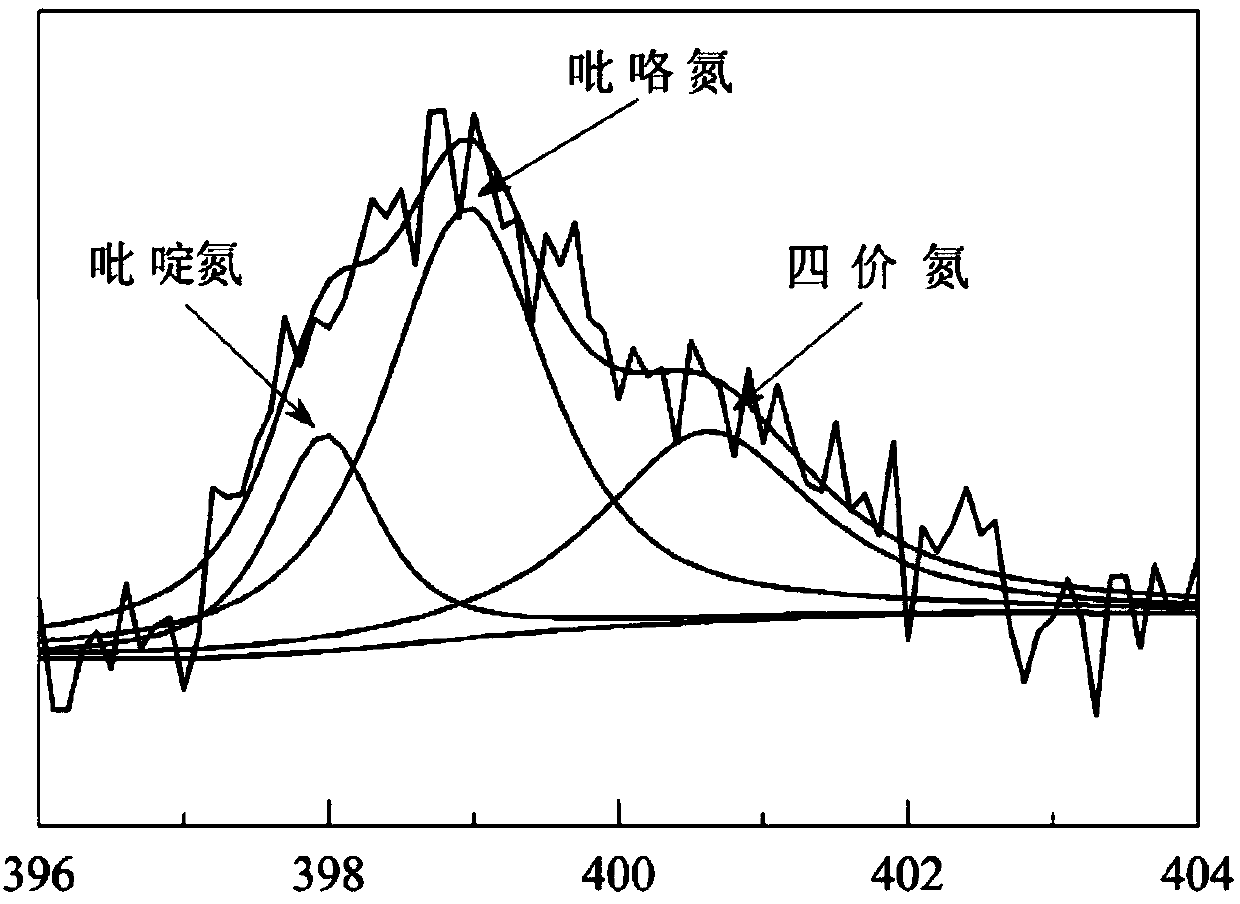

[0084] The operation and steps are the same as in Example 1, but the concentration of nitric acid used in the oxidation is changed to 0.5mol / L, the oxidation temperature is changed to 180°C, the oxidation pressure is changed to 0.8MPa, the stirring speed is changed to 200r / min, and the oxidation time becomes 2h; when high-temperature nitrogen doping, the quality of melamine becomes 4.5g, obtains high-temperature nitrogen-doped multi-walled carbon nanotubes, and the specific surface area of nitrogen-doped carbon nanotubes is 171m 2 / g, the pore volume is 0.87ml / g, the average pore diameter is 12.7nm, and the elemental analysis atomic percentage is that the carbon element content is 83.6%, the oxygen element content is 6.8%, and the nitrogen element content is 9.6%.

[0085] Preparation of nitrogen-doped carbon nanotube-confined copper catalyst

[0086] ①. Weigh 0.189g Cu(NO 3 ) 2 ·3H 2 O, measure 3 mL of deionized water, add it to a beaker, and stir it magnetically for 10 ...

Embodiment 3

[0095] The operation and steps are the same as in Example 1, but the concentration of the hydrothermal oxidation nitric acid aqueous solution is changed to 0.5mol / L, the oxidation temperature is changed to 200°C, the oxidation pressure is changed to 1.0MPa, the stirring speed is changed to 300r / min, and the oxidation The time becomes 3h; when high-temperature nitrogen doping, the mass of melamine becomes 6g, and high-temperature nitrogen-doped multi-walled carbon nanotubes are obtained, and the specific surface area of nitrogen-doped carbon nanotubes is 135m 2 / g, the pore volume is 0.76ml / g, the average pore diameter is 15.1nm, and the elemental analysis atomic percentage is that the carbon element content is 82.3%, the oxygen element content is 7.4%, and the nitrogen element content is 10.3%.

[0096] Preparation of nitrogen-doped carbon nanotube-confined copper catalyst

[0097] ①. Weigh 0.265g Cu(NO 3 ) 2 ·3H 2 O, measure 3 mL of deionized water, add it to a beaker, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com