Patents

Literature

390 results about "BCN nanotube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

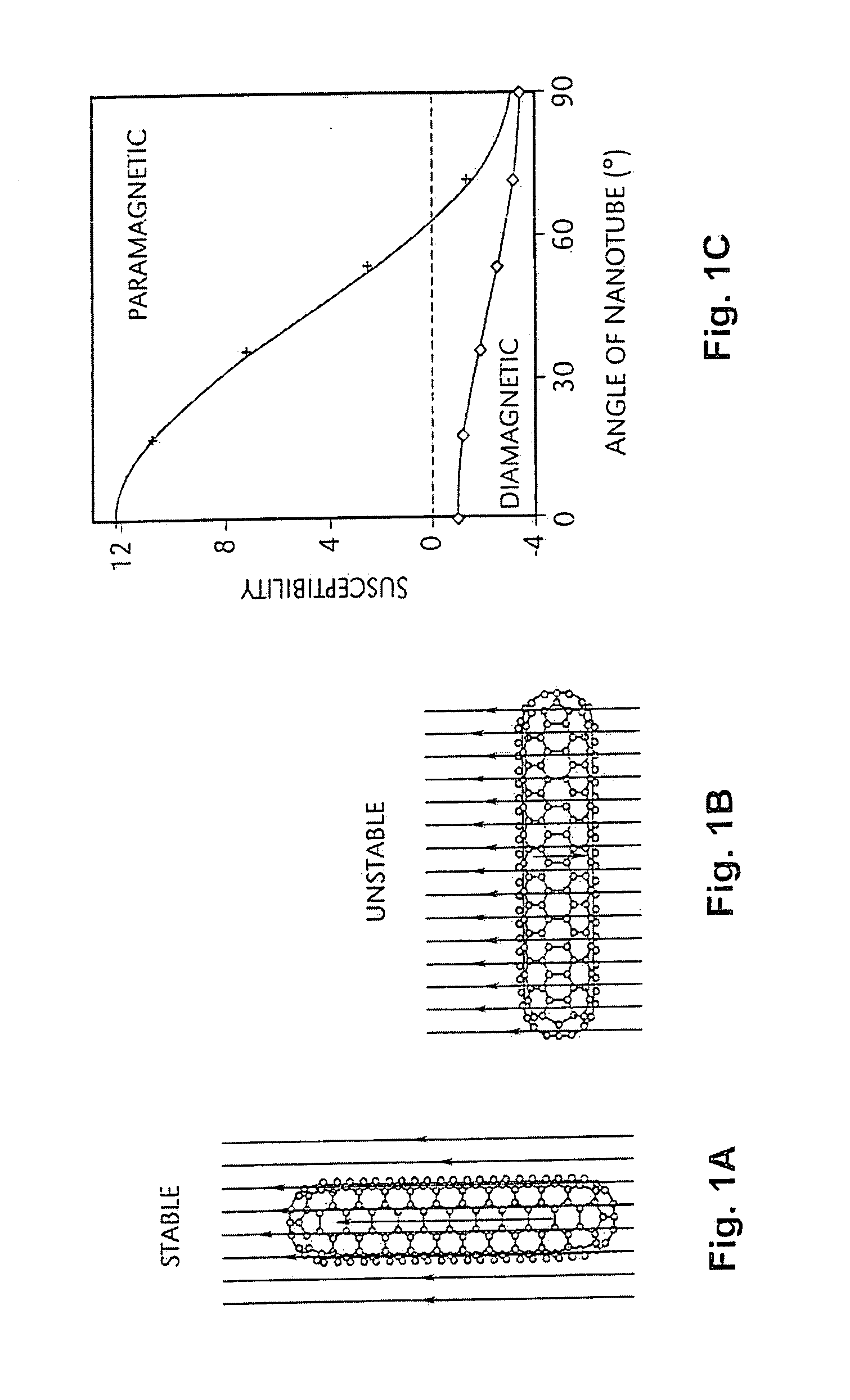

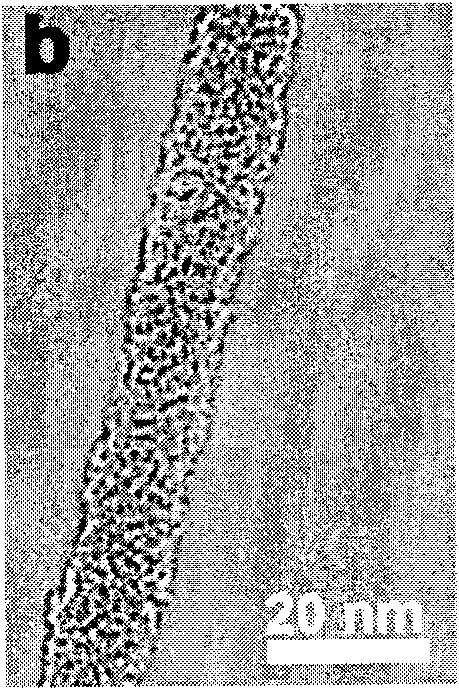

BCN nanotubes are tubular structures with a sub-micrometer diameter and a length much longer than diameter. They are composed of comparable amounts of boron, carbon and nitrogen atoms. First made in 1994, synthesis methods have included: arc-discharge, laser ablation, chemical vapor deposition (CVD), template route, and pyrolysis techniques. Single-walled B–C–N nanotubes have been made with a hot-filament method.

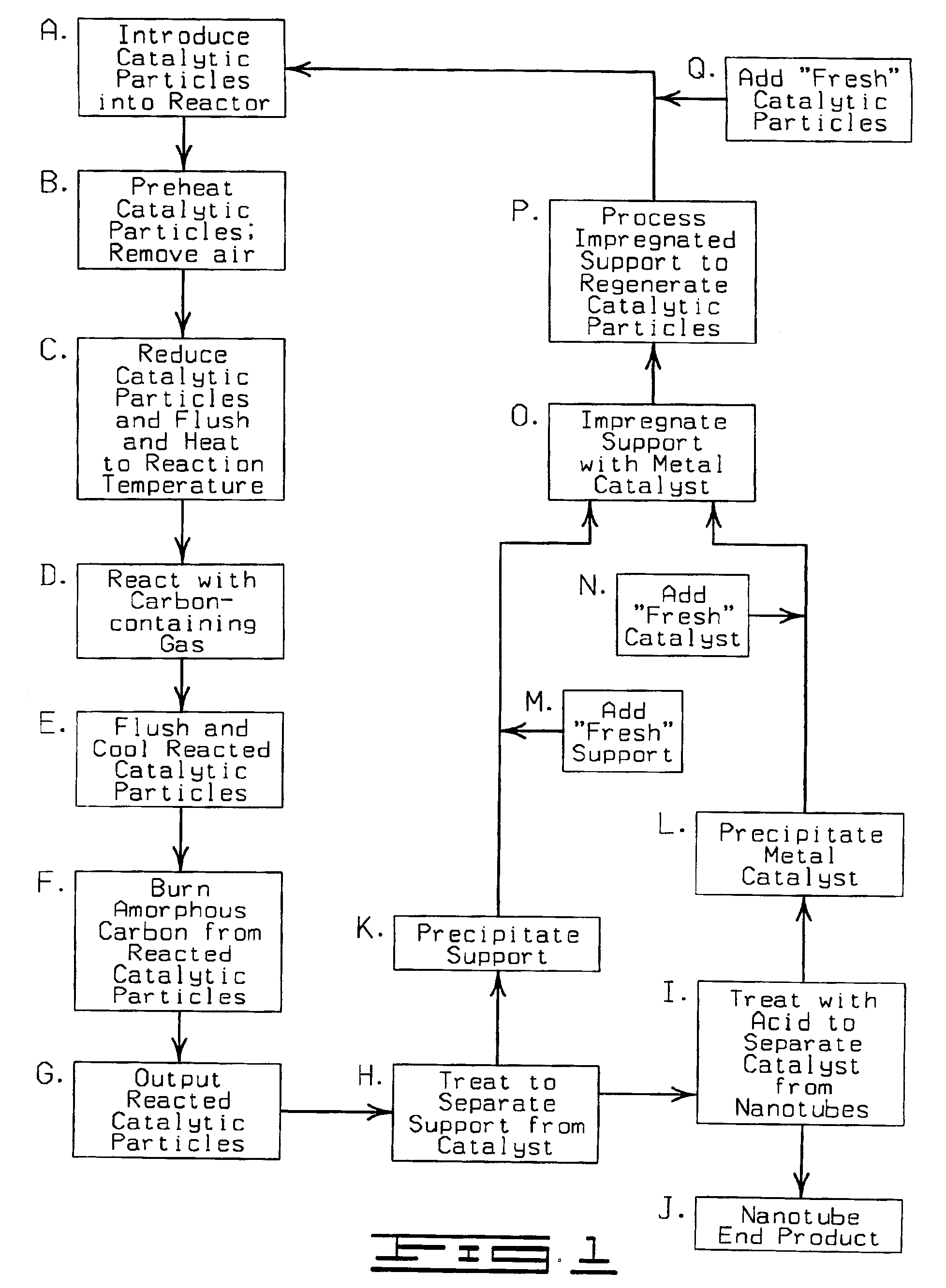

Method and apparatus for producing carbon nanotubes

InactiveUS6955800B2Avoid disadvantagesAvoid defectsMaterial nanotechnologyCatalyst regeneration/reactivationParticulatesCarbon nanotube

A method and apparatus for catalytic production of carbon nanotubes. Catalytic particles are exposed to different process conditions at successive stages wherein the catalytic particles do not come in contact with reactive (catalytic) gases until preferred process conditions have been attained, thereby controlling the quantity and form of carbon nanotubes produced. The method also contemplates methods and apparatus which recycle and reuse the gases and catalytic particulate materials, thereby maximizing cost efficiency, reducing wastes, reducing the need for additional raw materials, and producing the carbon nanotubes, especially SWNTs, in greater quantities and for lower costs.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

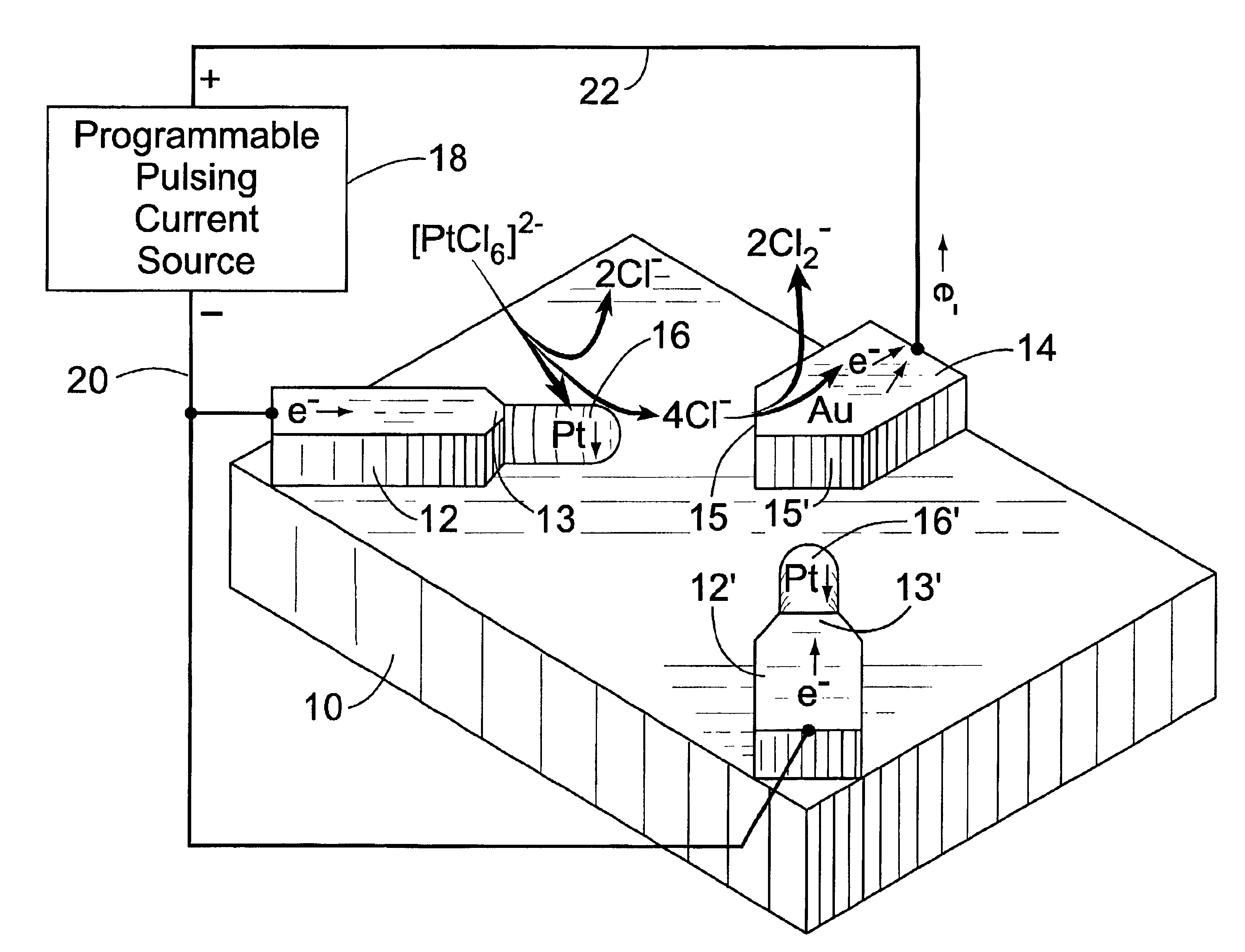

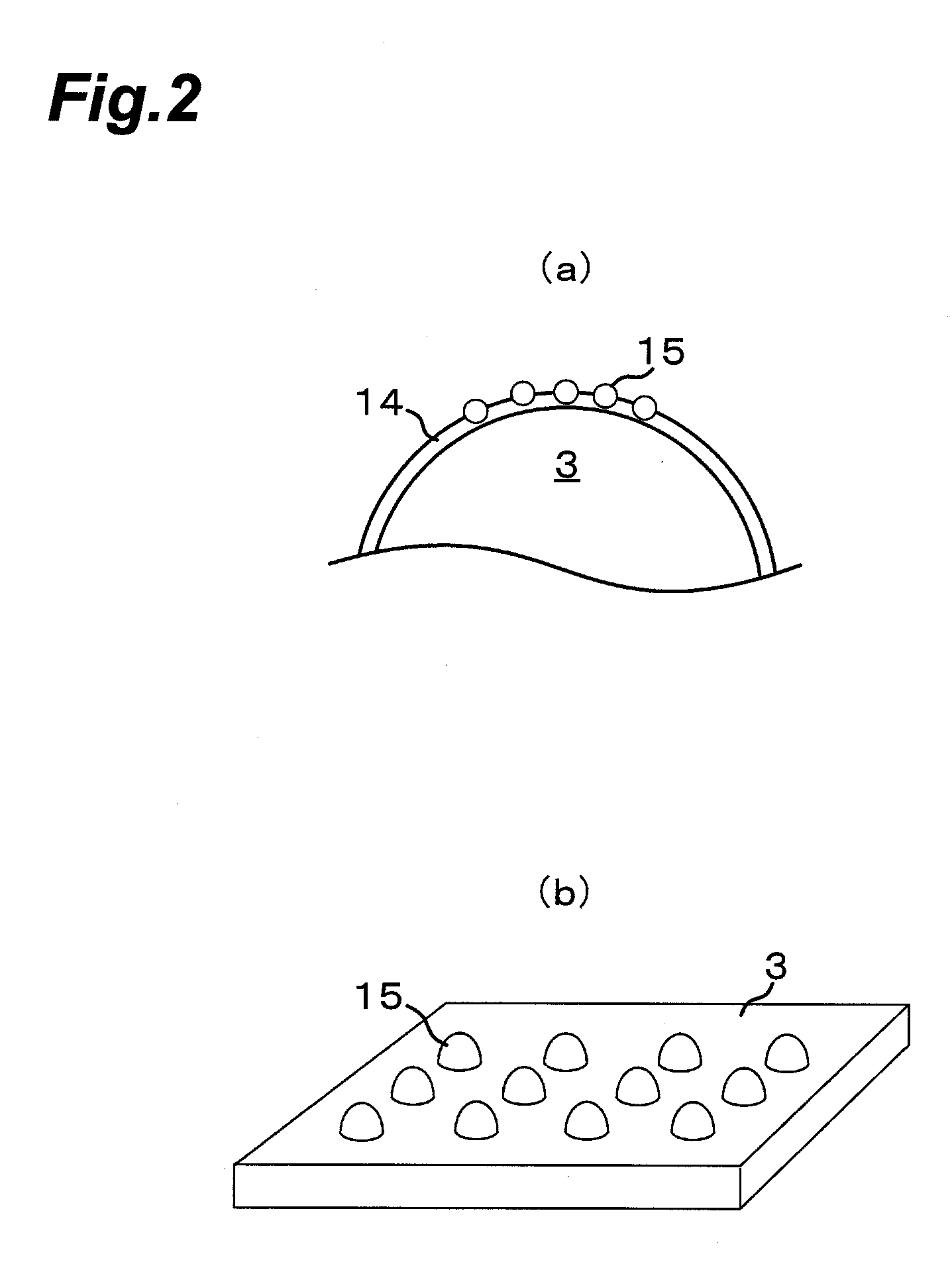

Catalyst-induced growth of carbon nanotubes on tips of cantilevers and nanowires

InactiveUS6755956B2Improve performanceEasy to controlMaterial nanotechnologyCarbon compoundsFiberNanowire

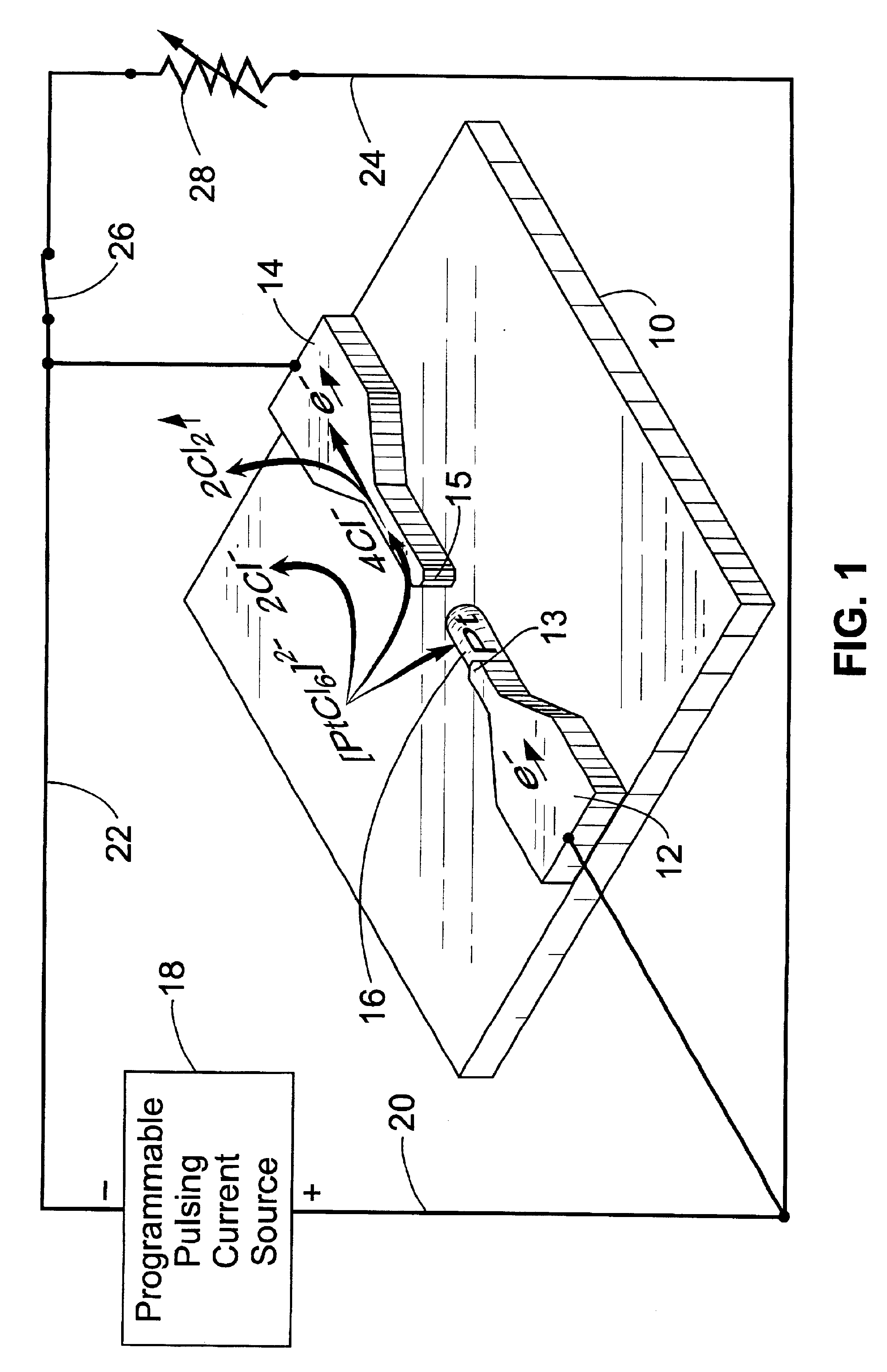

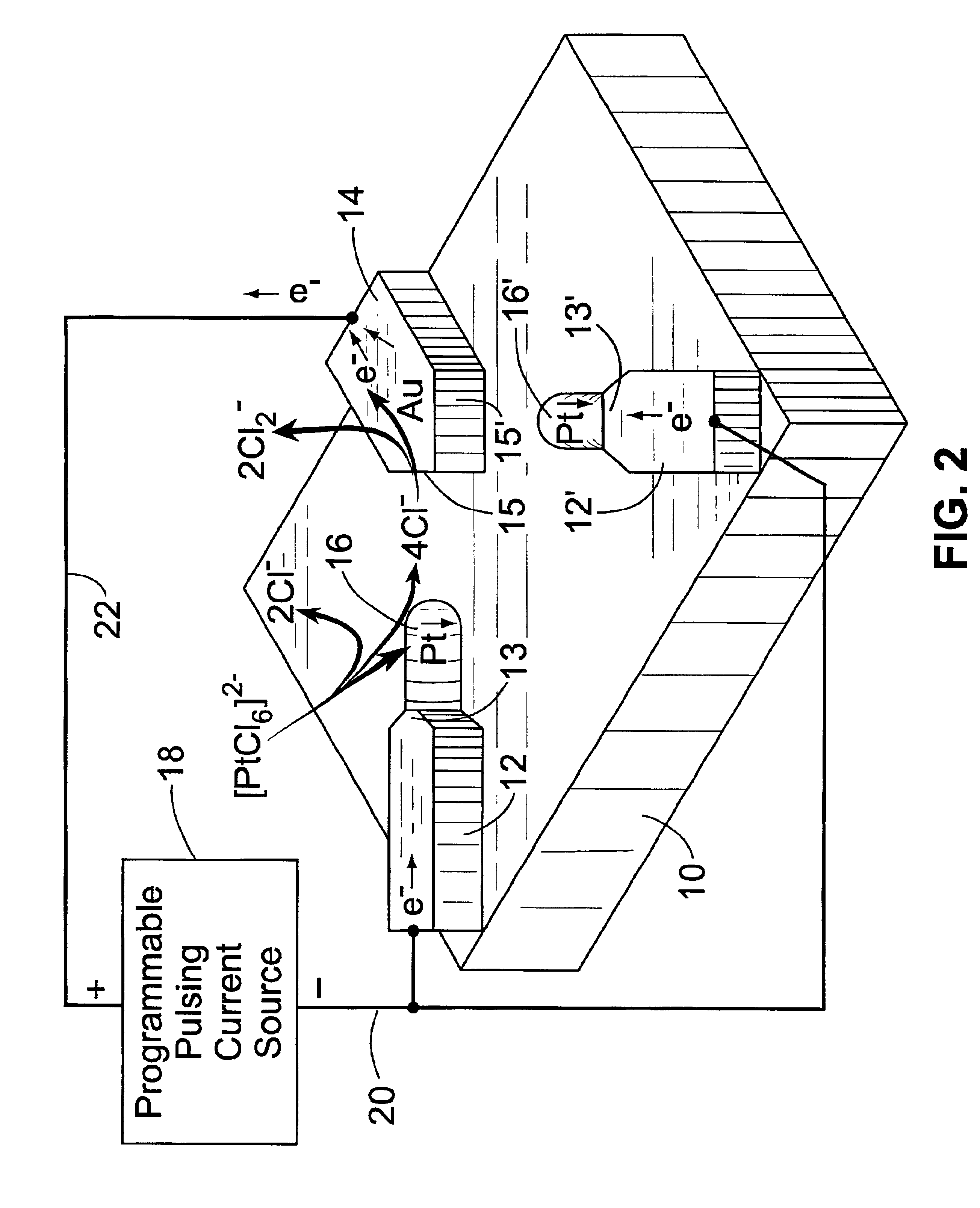

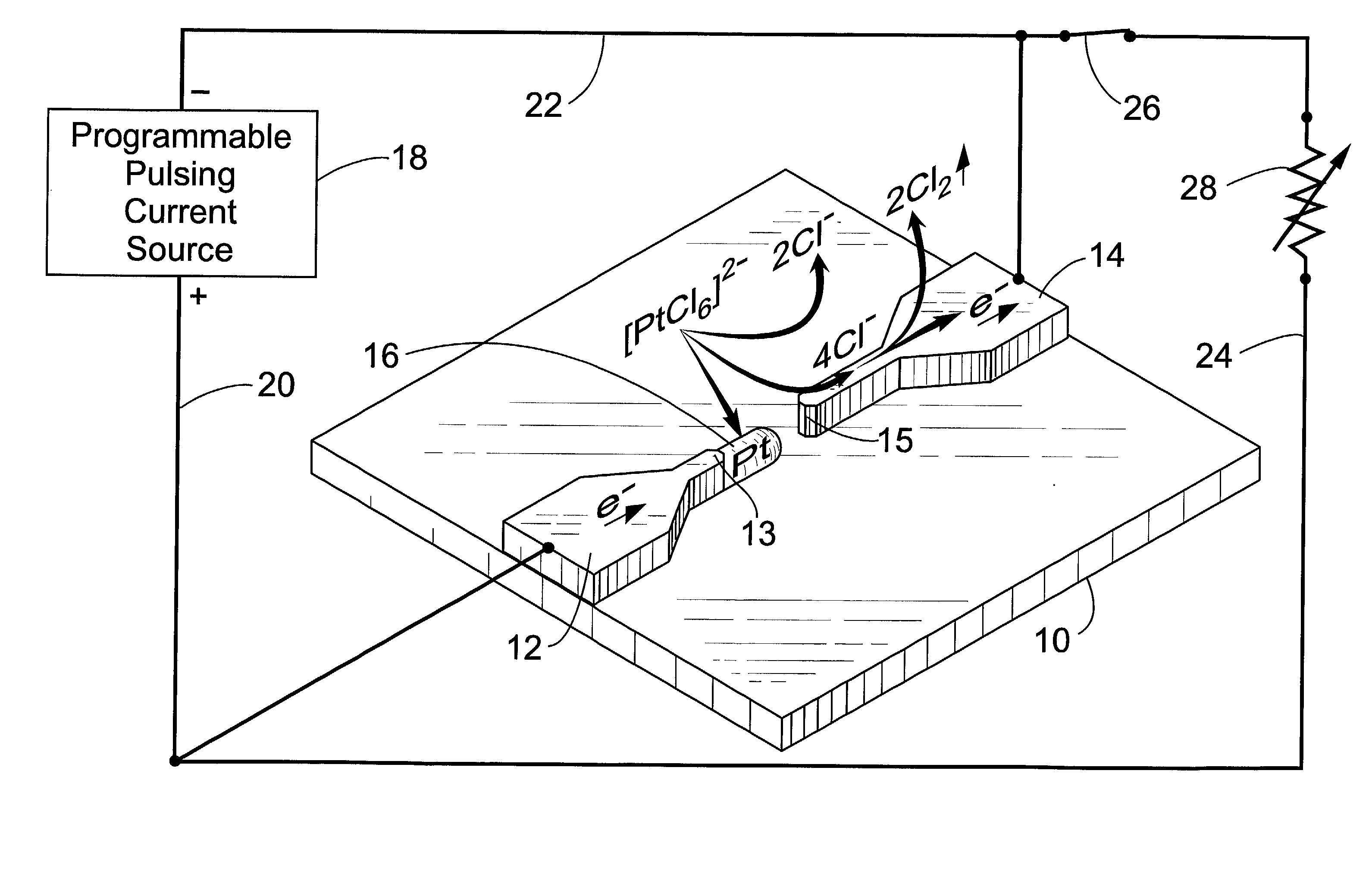

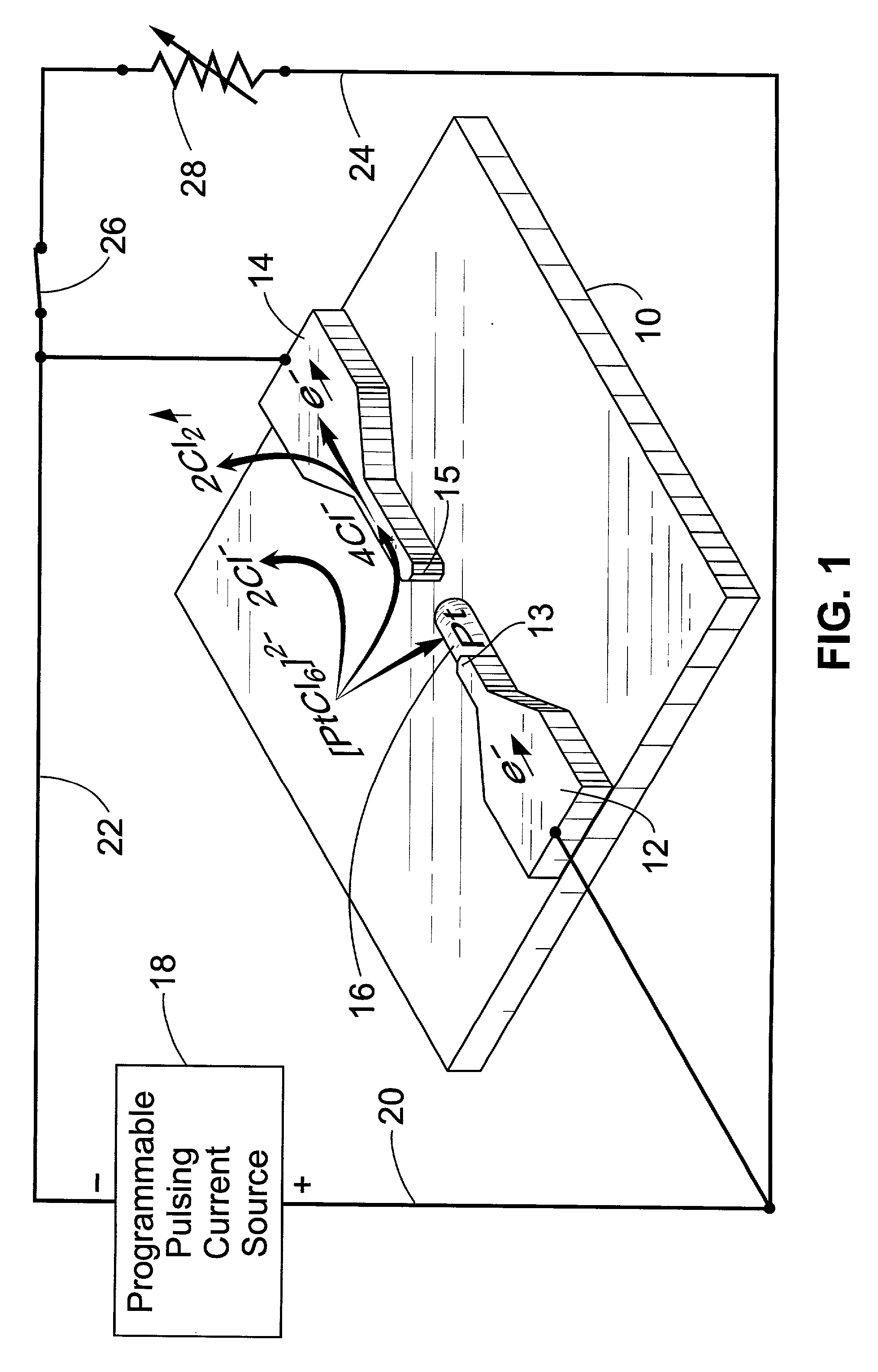

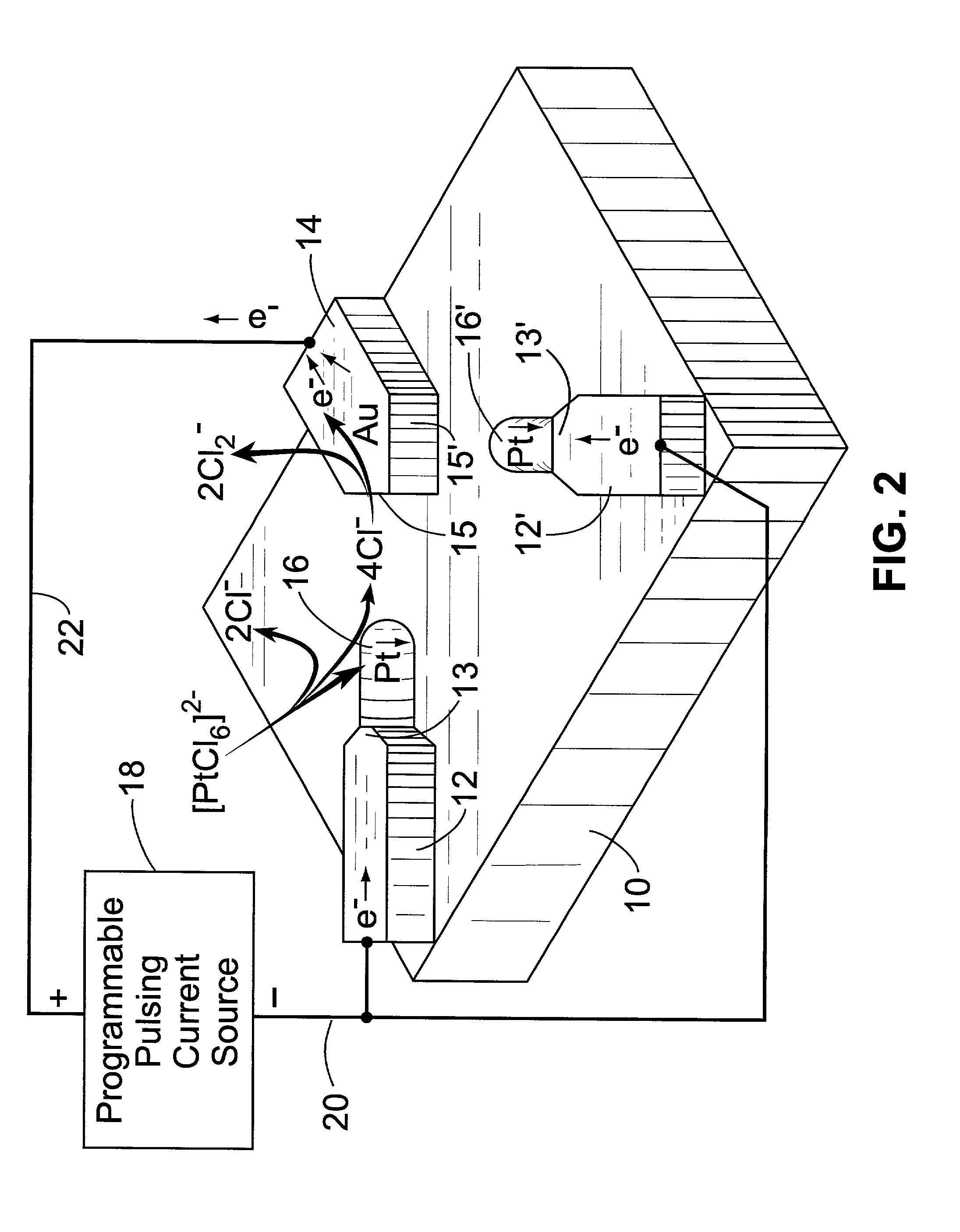

A method is described for catalyst-induced growth of carbon nanotubes, nanofibers, and other nanostructures on the tips of nanowires, cantilevers, conductive micro / nanometer structures, wafers and the like. The method can be used for production of carbon nanotube-anchored cantilevers that can significantly improve the performance of scaning probe microscopy (AFM, EFM etc). The invention can also be used in many other processes of micro and / or nanofabrication with carbon nanotubes / fibers. Key elements of this invention include: (1) Proper selection of a metal catalyst and programmable pulsed electrolytic deposition of the desired specific catalyst precisely at the tip of a substrate, (2) Catalyst-induced growth of carbon nanotubes / fibers at the catalyst-deposited tips, (3) Control of carbon nanotube / fiber growth pattern by manipulation of tip shape and growth conditions, and (4) Automation for mass production.

Owner:UT BATTELLE LLC +1

Catalyst-induced growth of carbon nanotubes on tips of cantilevers and nanowires

InactiveUS20020046953A1Easy to controlImprove performanceAnodisationMaterial nanotechnologyFiberNanowire

A method is described for catalyst-induced growth of carbon nanotubes, nanofibers, and other nanostructures on the tips of nanowires, cantilevers, conductive micro / nanometer structures, wafers and the like. The method can be used for production of carbon nanotube-anchored cantilevers that can significantly improve the performance of scaning probe microscopy (AFM, EFM etc). The invention can also be used in many other processes of micro and / or nanofabrication with carbon nanotubes / fibers. Key elements of this invention include: (1) Proper selection of a metal catalyst and programmable pulsed electrolytic deposition of the desired specific catalyst precisely at the tip of a substrate, (2) Catalyst-induced growth of carbon nanotubes / fibers at the catalyst-deposited tips, (3) Control of carbon nanotube / fiber growth pattern by manipulation of tip shape and growth conditions, and (4) Automation for mass production.

Owner:UT BATTELLE LLC +1

Aggregate of carbon nanotubes, dispersion thereof and conductive film using the same

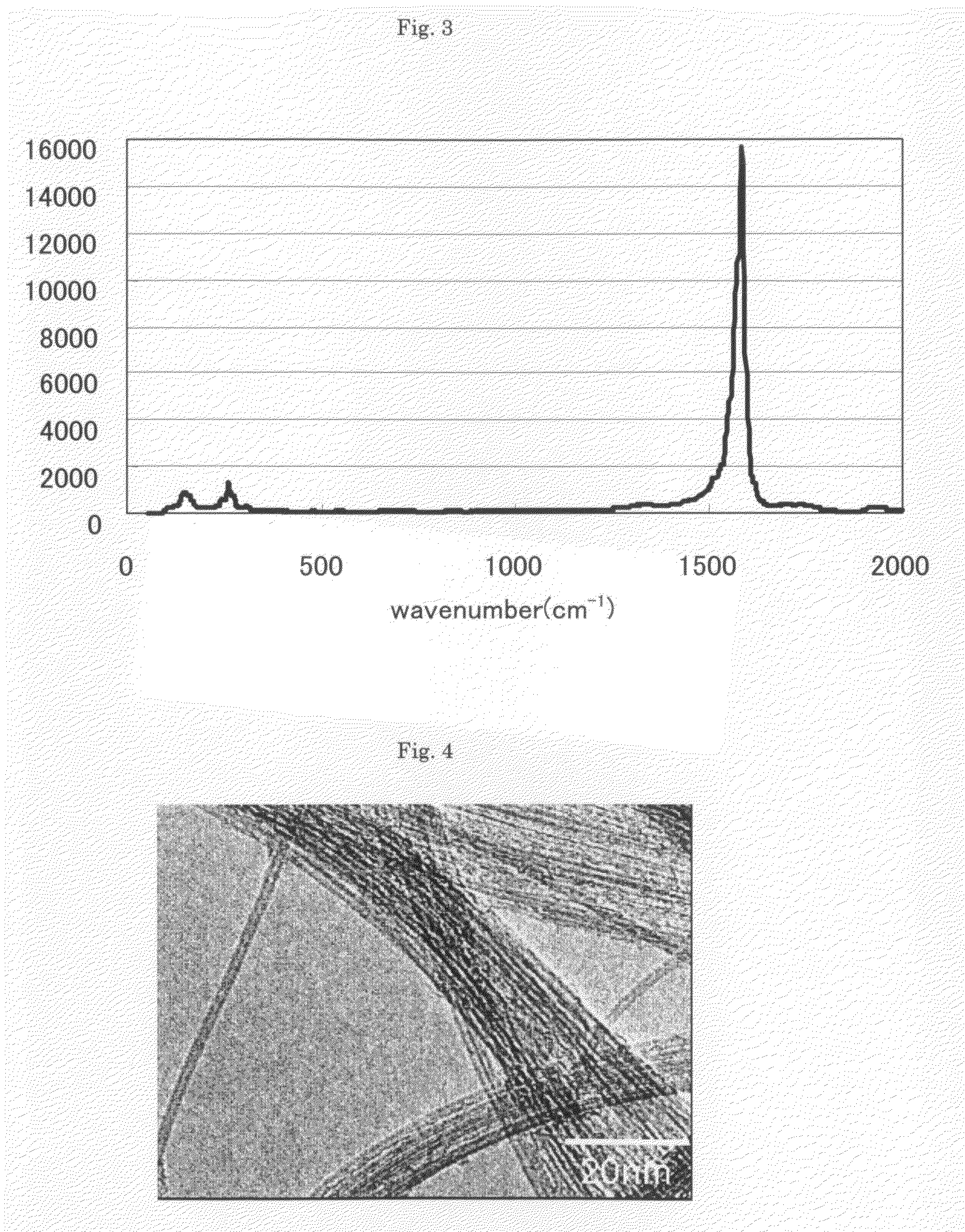

InactiveUS20090001326A1Good dispersionQuality improvementMaterial nanotechnologyNon-metal conductorsCombustionX-ray

Provided is an aggregate of carbon nanotubes satisfying (1) there is a 2θ peak at 24°±2° by X-ray powder diffraction analysis; (2) a height ratio (G / D ratio) of G band to D band by Raman spectroscopic analysis of wavelength 532 nm is 30 or more; and (3) a combustion peak temperature is 550° C. or more, and 700° C. or less. The present invention provides an aggregate of carbon nanotubes excellent in dispersibility while high quality, giving a film, molded article, membrane or the like having excellent characteristics

Owner:TORAY IND INC

Polymethylmethacrylate augmented with carbon nanotubes

InactiveUS6872403B2Improve mechanical propertiesGood load transferBiocidePowder deliveryCarbon nanotubeSynthetic resin

An augmented synthetic resin is provided. That resin includes carbon nanotubes dispersed in a polymethylmethacrylate matrix. The method of preparing this synthetic resin includes the mixing and disaggregating of the carbon nanotubes.

Owner:UNIV OF KENTUCKY RES FOUND

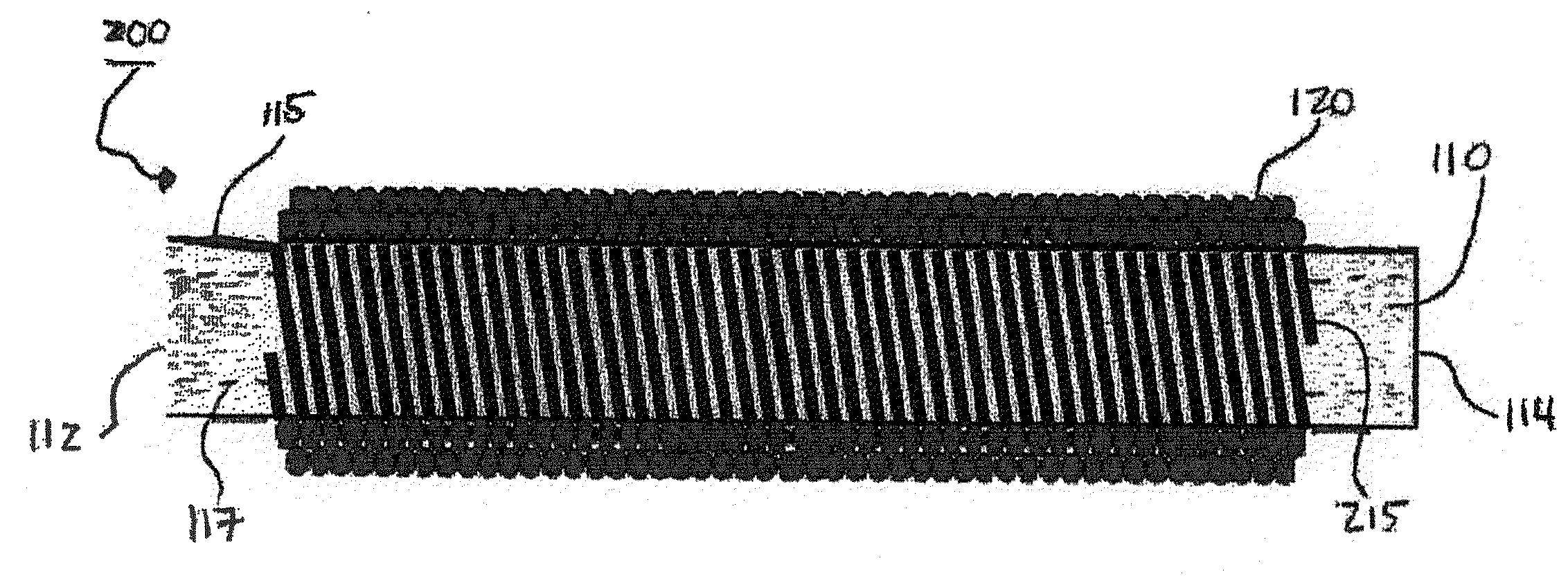

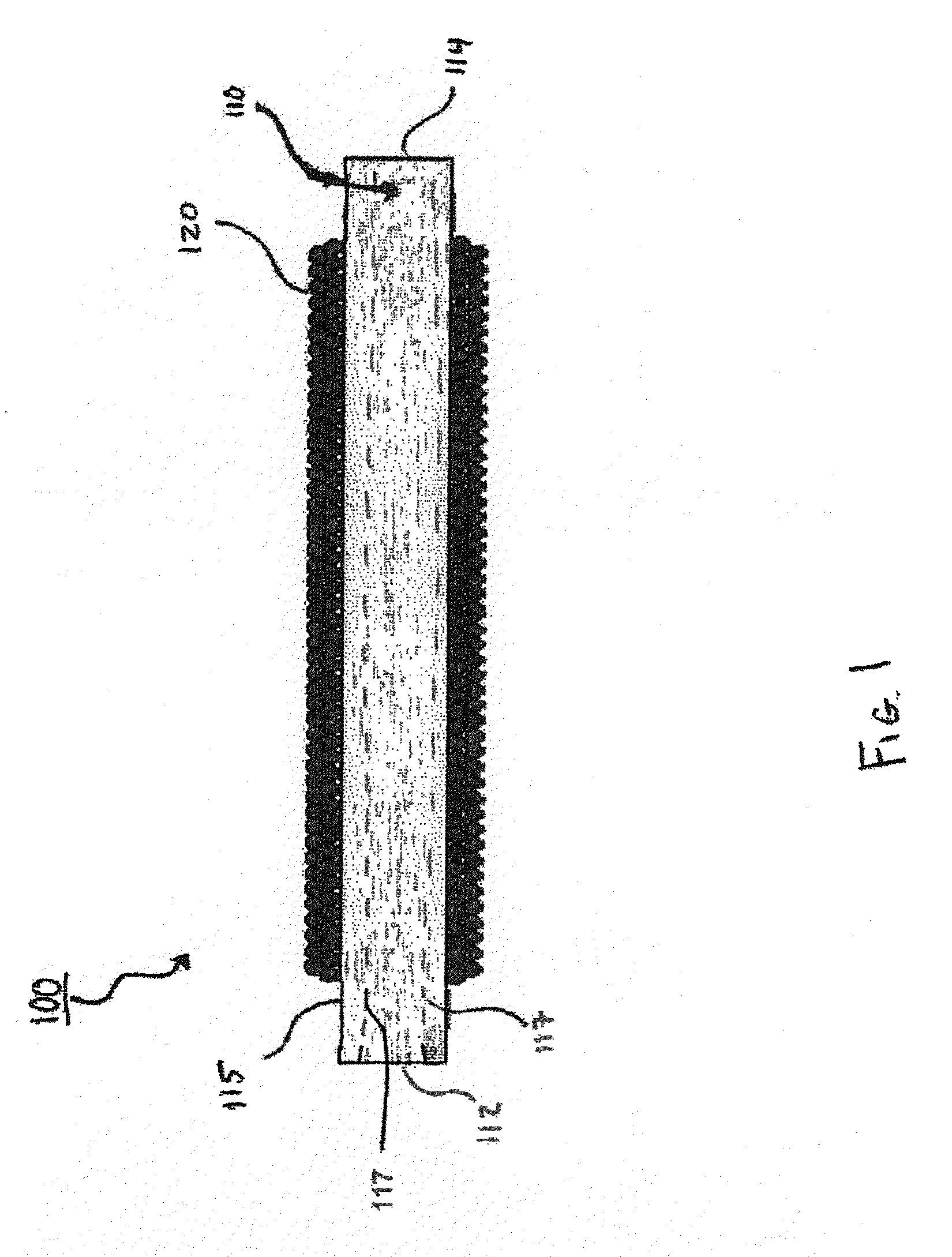

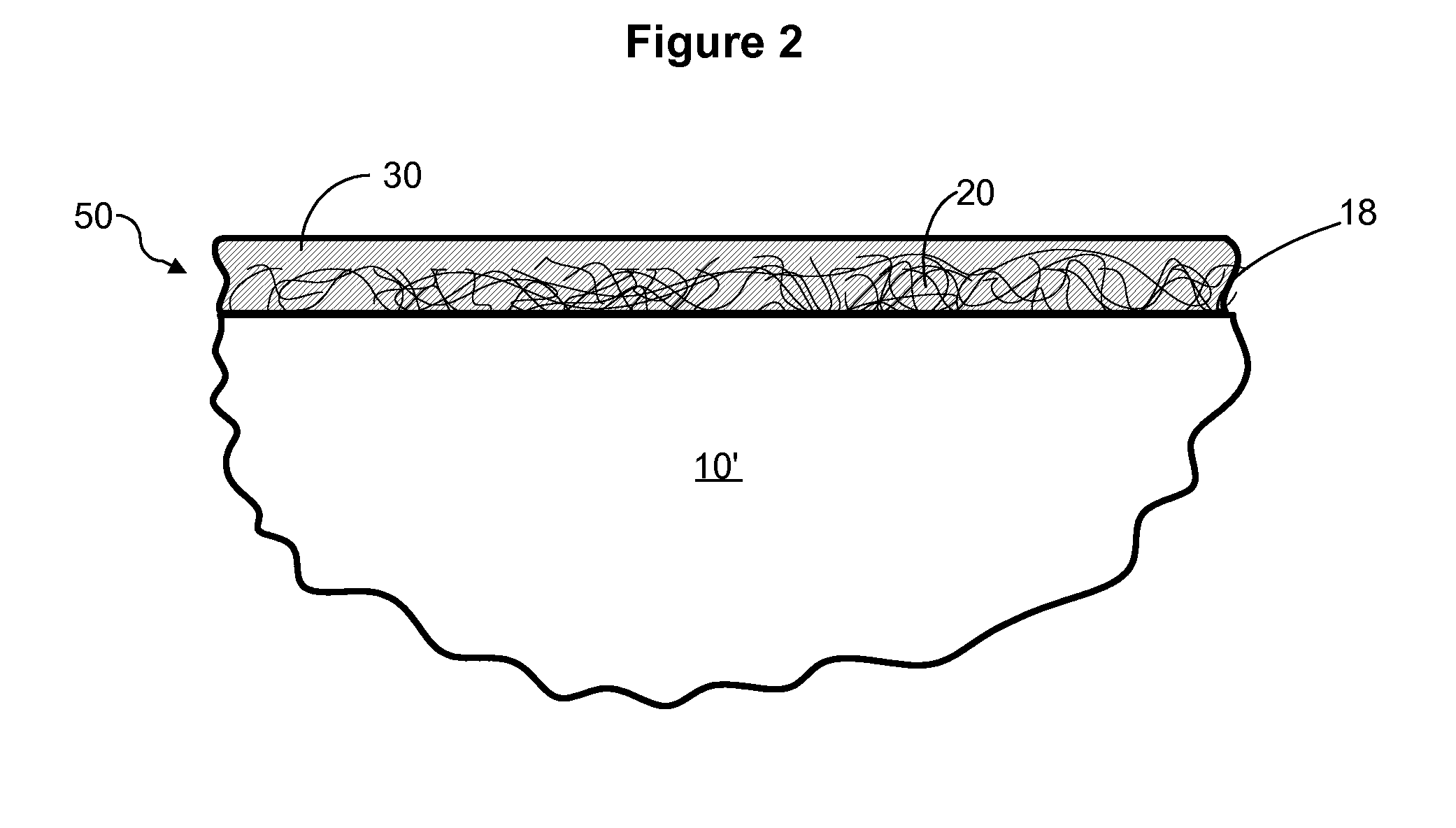

Solar receiver utilizing carbon nanotube infused coatings

A solar receiver includes a heat absorbing element having an outer surface and an inner surface opposite the outer surface and a first coating including a carbon nanotube-infused fiber material in surface engagement with and at least partially covering the outer surface of the heat absorbing element. Solar radiation incident onto the first coating is received, absorbed, and converted to heat energy, and the heat energy is transferred from the first coating to the heat absorbing element. A multilayer coating for a solar receiver device includes a first coating that includes a CNT-infused fiber material and an environmental coating disposed on the first coating.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

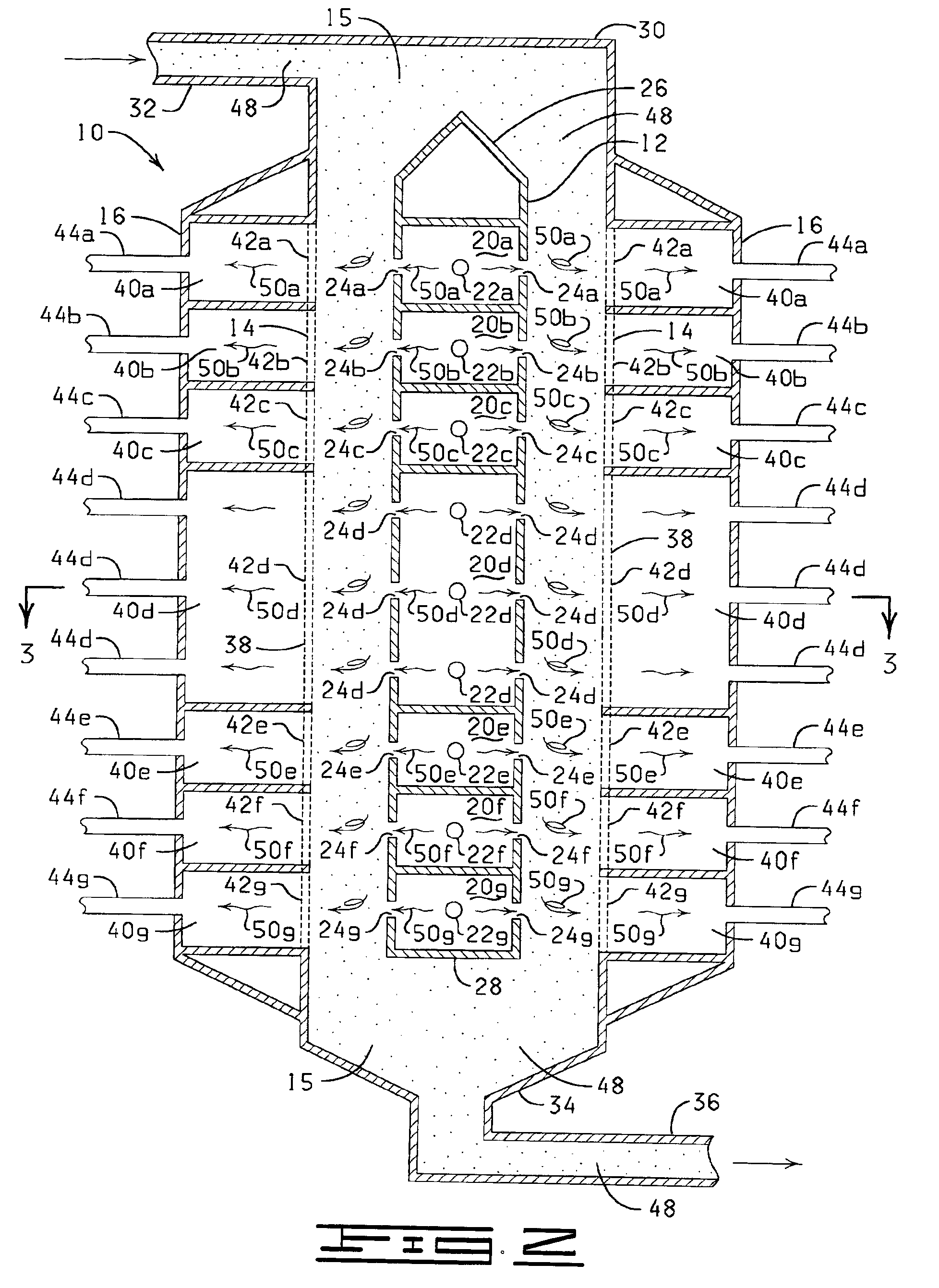

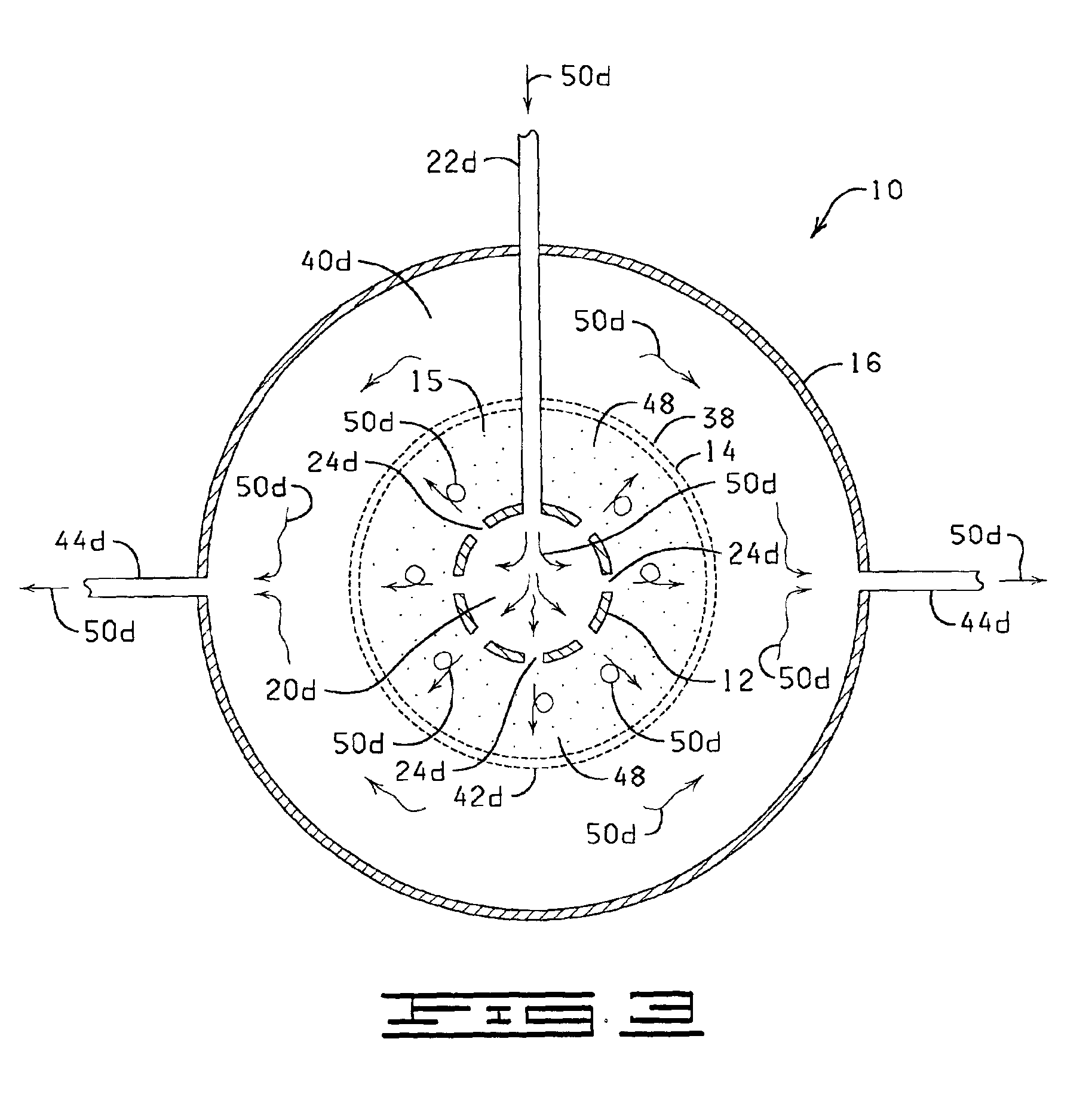

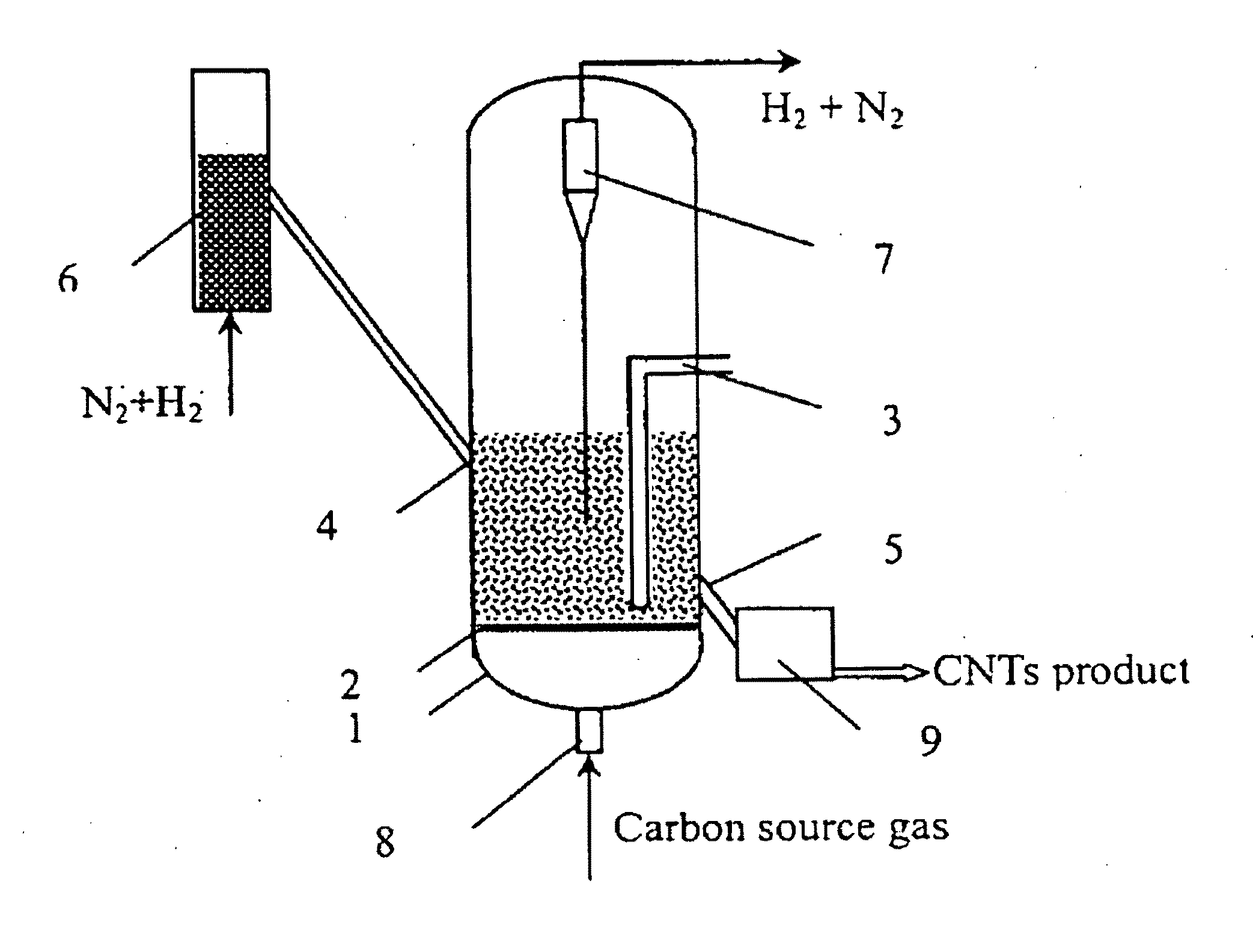

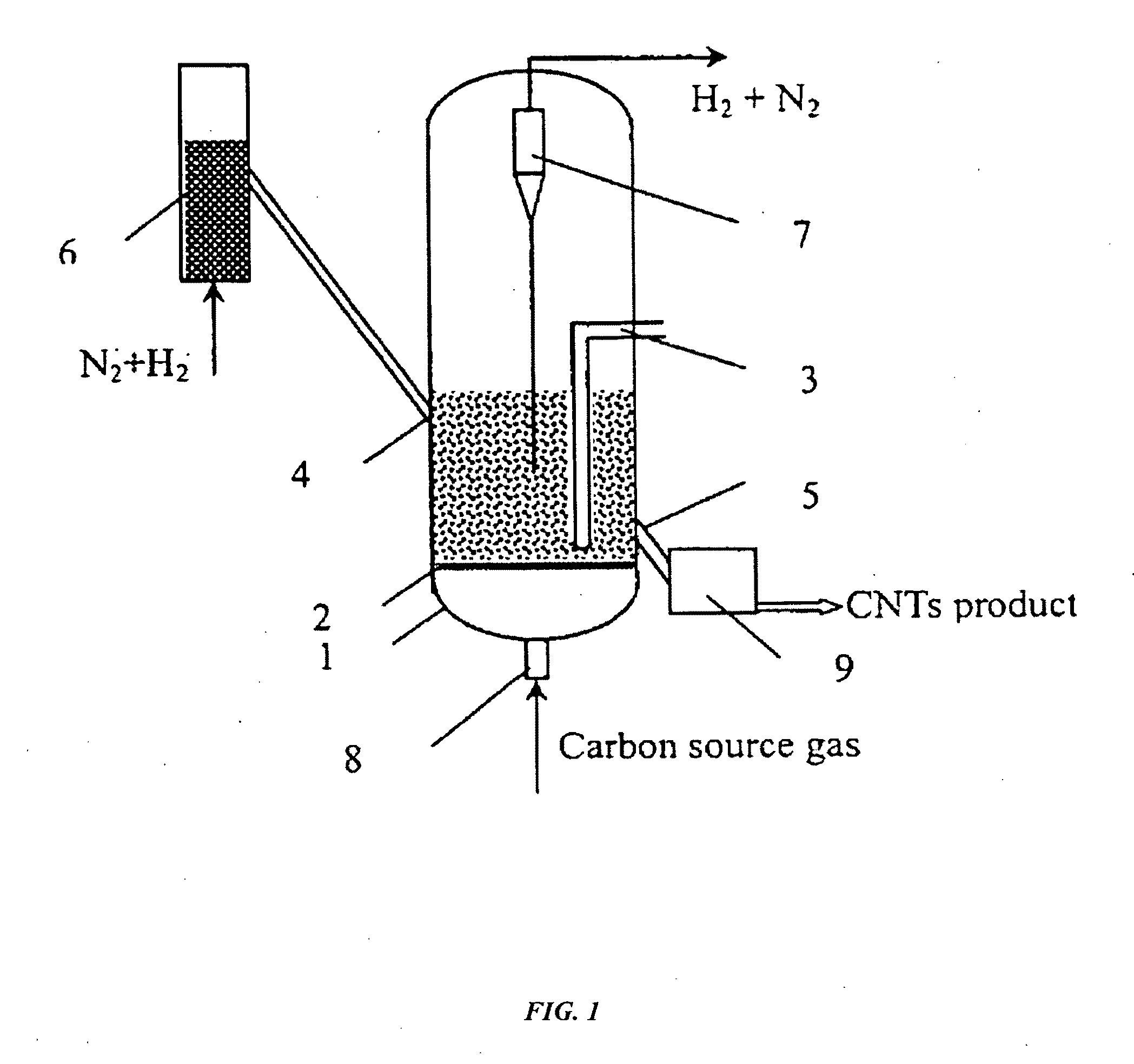

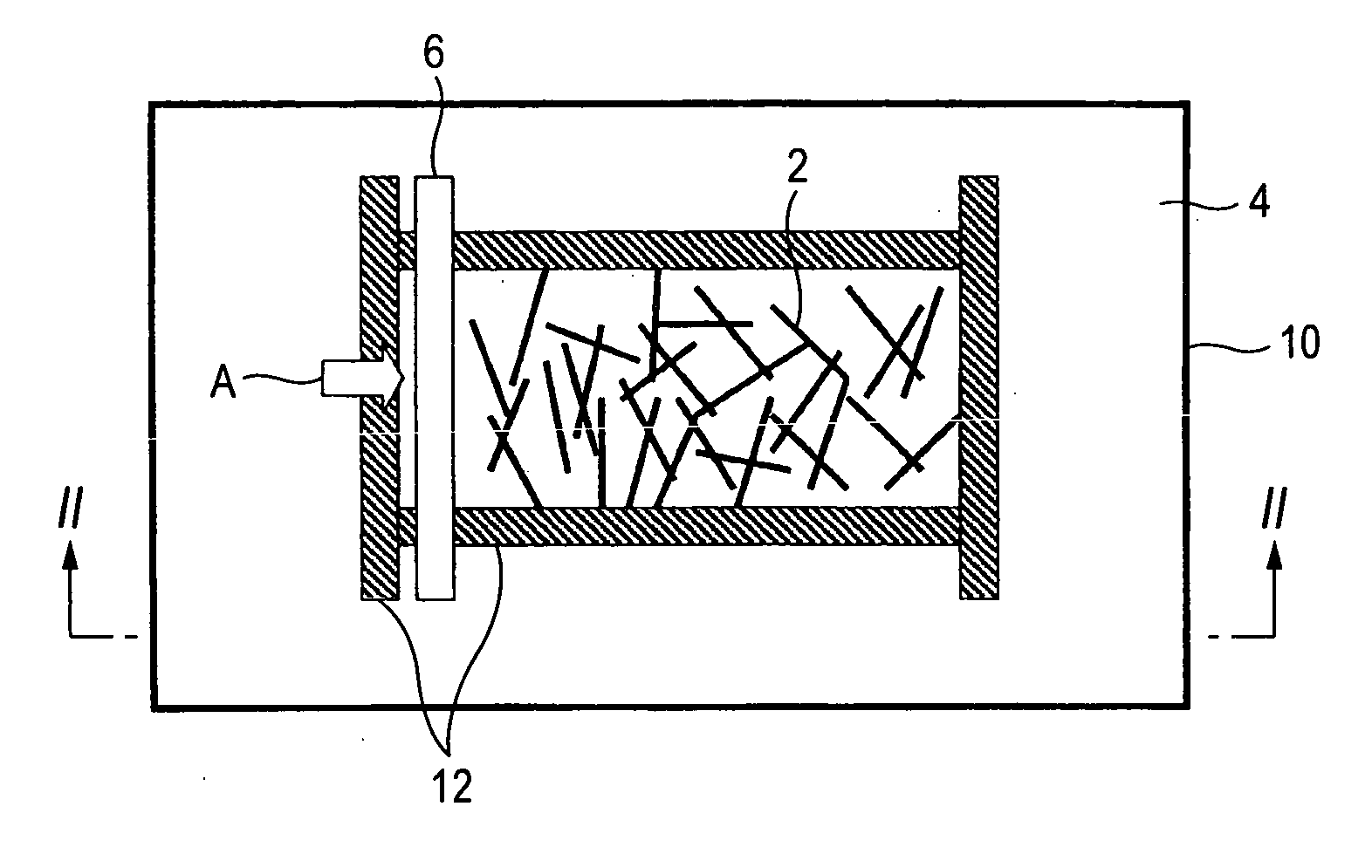

Continuous mass production of carbon nanotubes in a nano-agglomerate fluidized-bed and the reactor

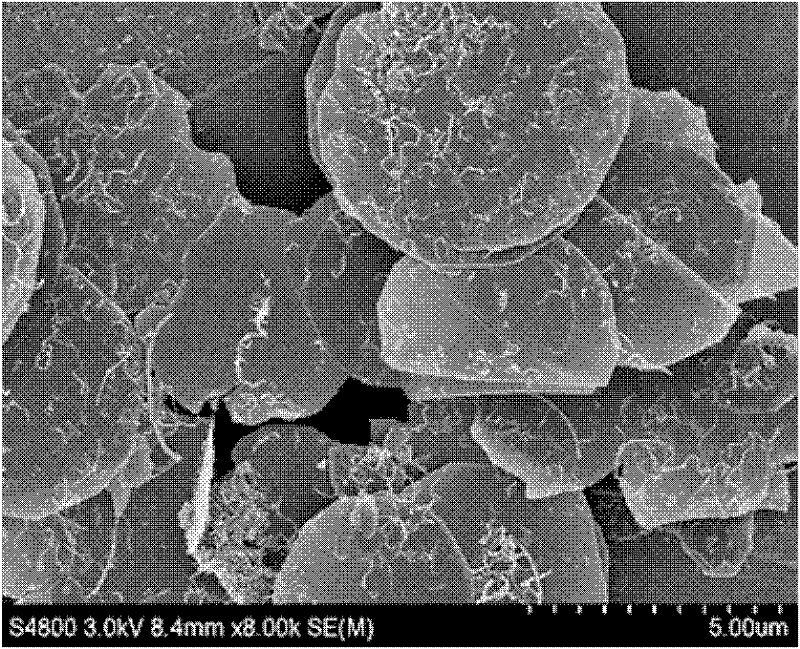

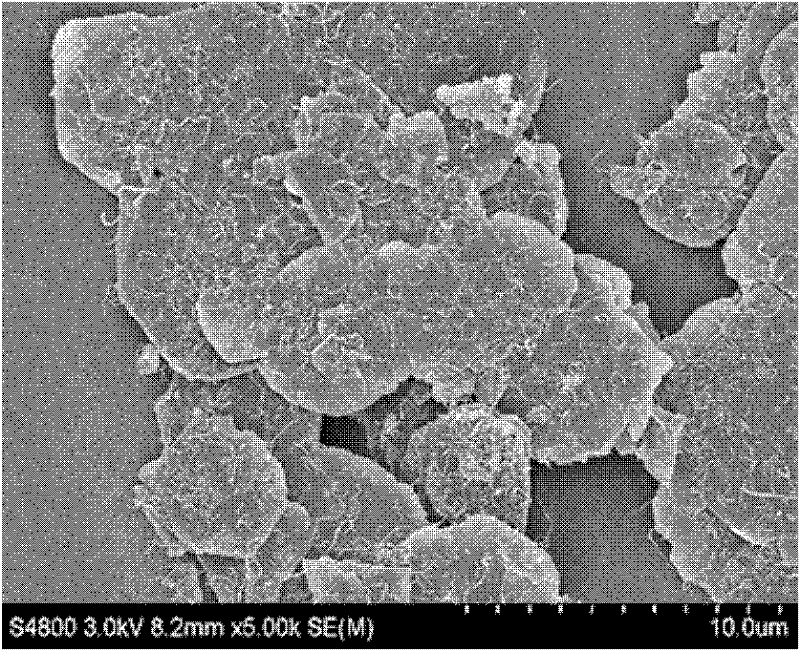

InactiveUS20090286675A1Improve adaptabilityHigh crystallinityMaterial nanotechnologyIndividual molecule manipulationReaction rateCarbon nanotube

The present invention relates to a method for continuous production of carbon nanotubes in a nano-agglomerate fluidized bed, which comprises the following steps: loading transition metal compounds on a support, obtaining supported nanosized metal catalysts by reducing or dissociating, catalytically decomposing a carbon-source gas, and growing carbon nanotubes on the catalyst support by chemical vapor deposition of carbon atoms. The carbon nanotubes are 4˜100 nm in diameter and 0.5˜1000 μm in length. The carbon nanotube agglomerates, ranged between 1˜1000 μm, are smoothly fluidized under 0.005 to 2 m / s superficial gas velocity and 20-800 kg / m3 bed density in the fluidized-bed reactor. The apparatus is simple and easy to operate, has a high reaction rate, and it can be used to produce carbon nanotubes with high degree of crystallization, high purity, and high yield.

Owner:TSINGHUA UNIV

Carbon nanotube heater

An apparatus includes a hollow heater. The hollow heater includes a hollow supporter, a heating element and at least two electrodes. The least two electrodes electrically connected to the heating element. The hollow supporter defines a hollow space, and the hollow supporter has an inner surface and an outer surface. The heating element is located on the inner surface or the outer surface of the hollow supporter. The heating element comprises at least one carbon nanotube film comprising a plurality of carbon nanotubes, and an angle between a primary alignment direction of the carbon nanotubes and a surface of the carbon nanotube film is 0 degrees to 15 degrees.

Owner:TSINGHUA UNIV +1

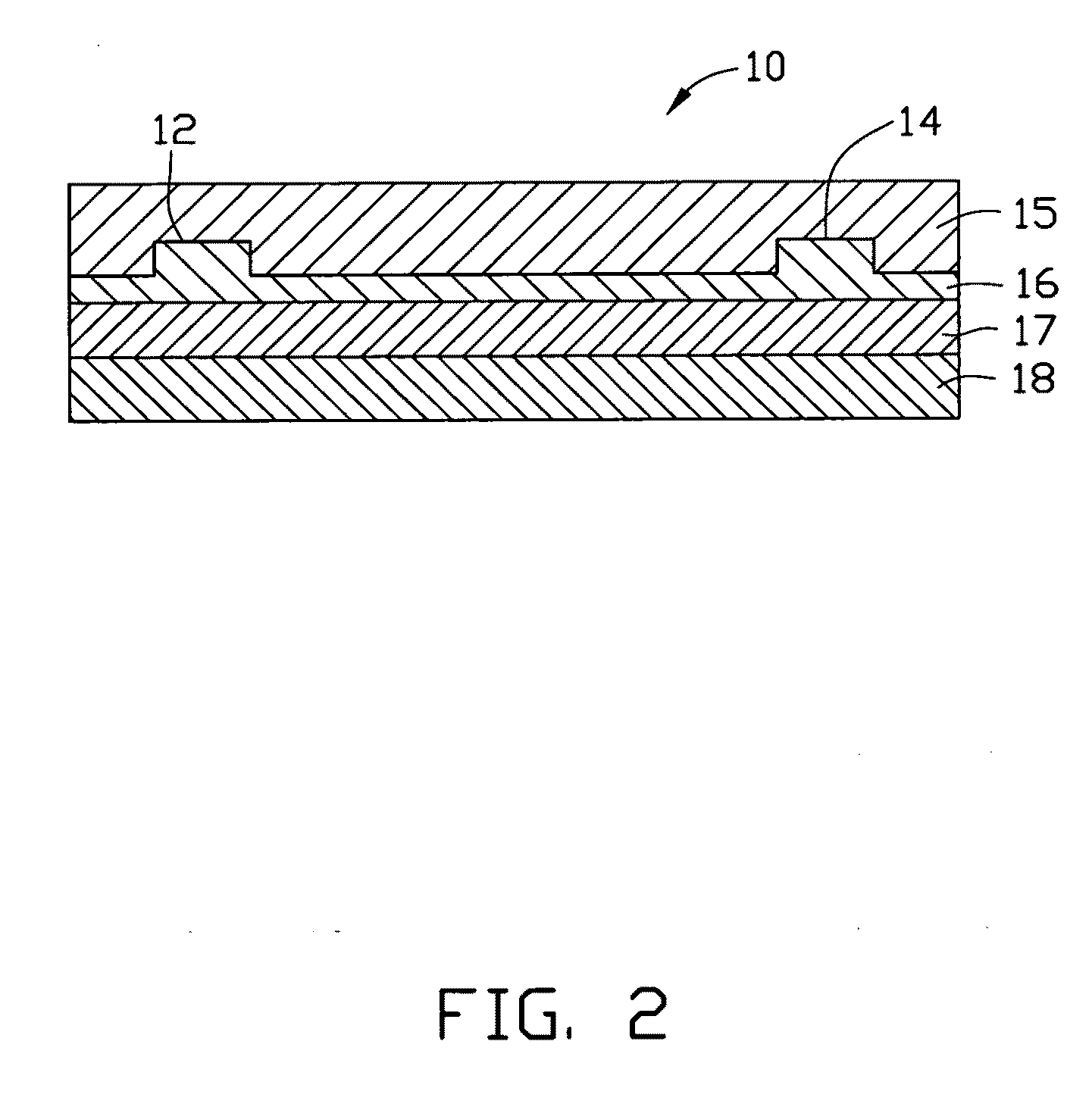

Fe, Ni and N three-doped carbon nanotube coated type FeNi@NCNT catalyst as well as preparation method and application thereof

InactiveCN108543545AIncrease the areaImprove conductivityPhysical/chemical process catalystsCell electrodesMetal particleOxygen

The invention discloses a Fe, Ni and N three-doped carbon nanotube coated type FeNi@NCNT catalyst as well as a preparation method and application thereof, and belongs to the fields of energy materialsand electrochemistry. The catalyst is prepared by using dicyandiamide as a C source and N source and ammonium ferric citrate and NiCl2.6H2O as metal sources, adopting one pot method and performing pyrolysis in two steps; and a plurality of Fe and Ni metal particles in the catalyst are uniformly wrapped in walls of ''bamboo-like'' N-doped carbon nanotubes, and a small number of the particles are distributed at the tip ends of the carbon nanotubes. Compared with a common metal alloy oxygen reduction reaction and oxygen evolution reaction bifunctional catalyst, the catalyst disclosed by the invention exhibits good oxygen evolution reaction activity and stability under alkaline conditions; the preparation method is simple, and raw materials used in the method have low costs and wide sources;and the catalyst can be widely used in the fields of proton exchange membrane fuel cells, electrolyzed water, metal-air batteries and the like, and has higher practical value.

Owner:DALIAN UNIV OF TECH

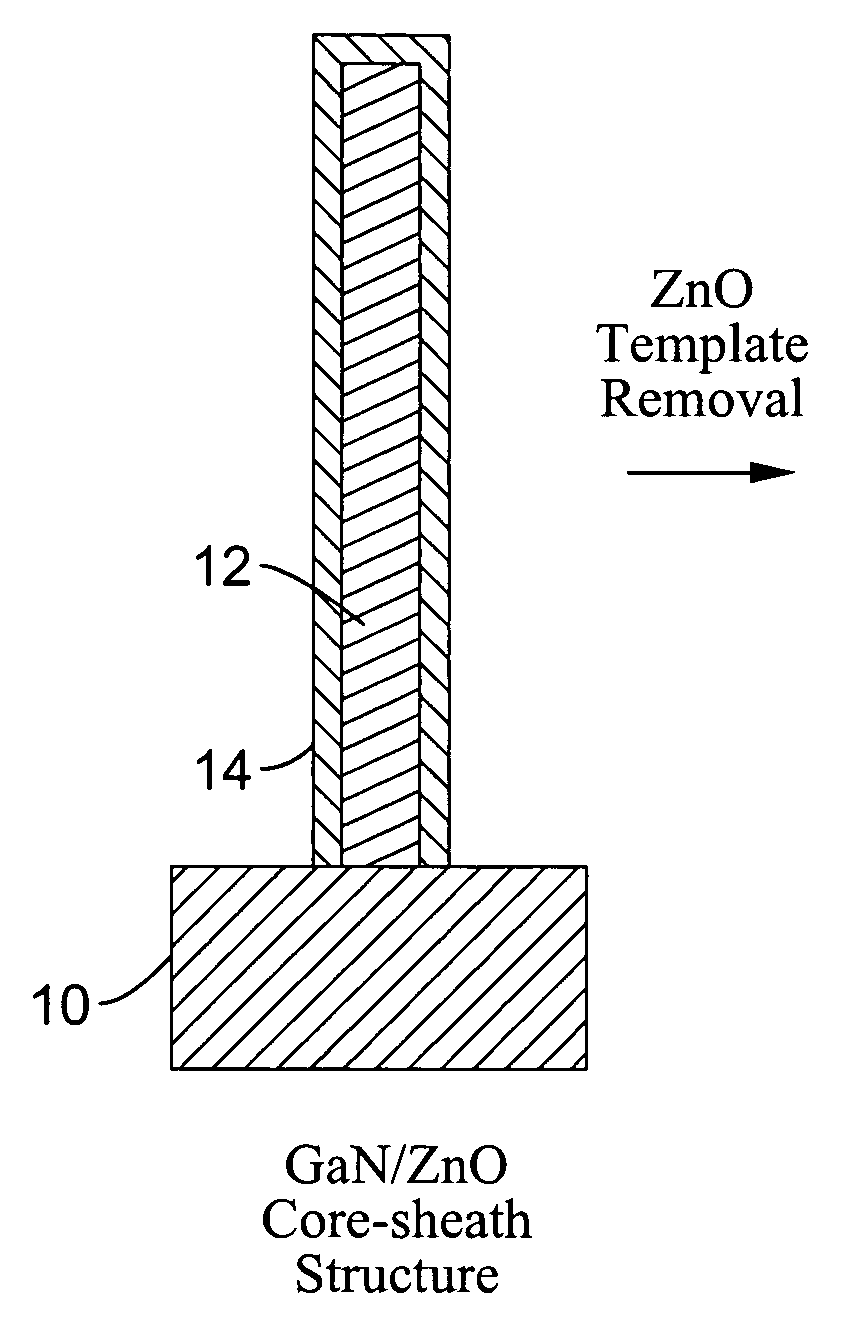

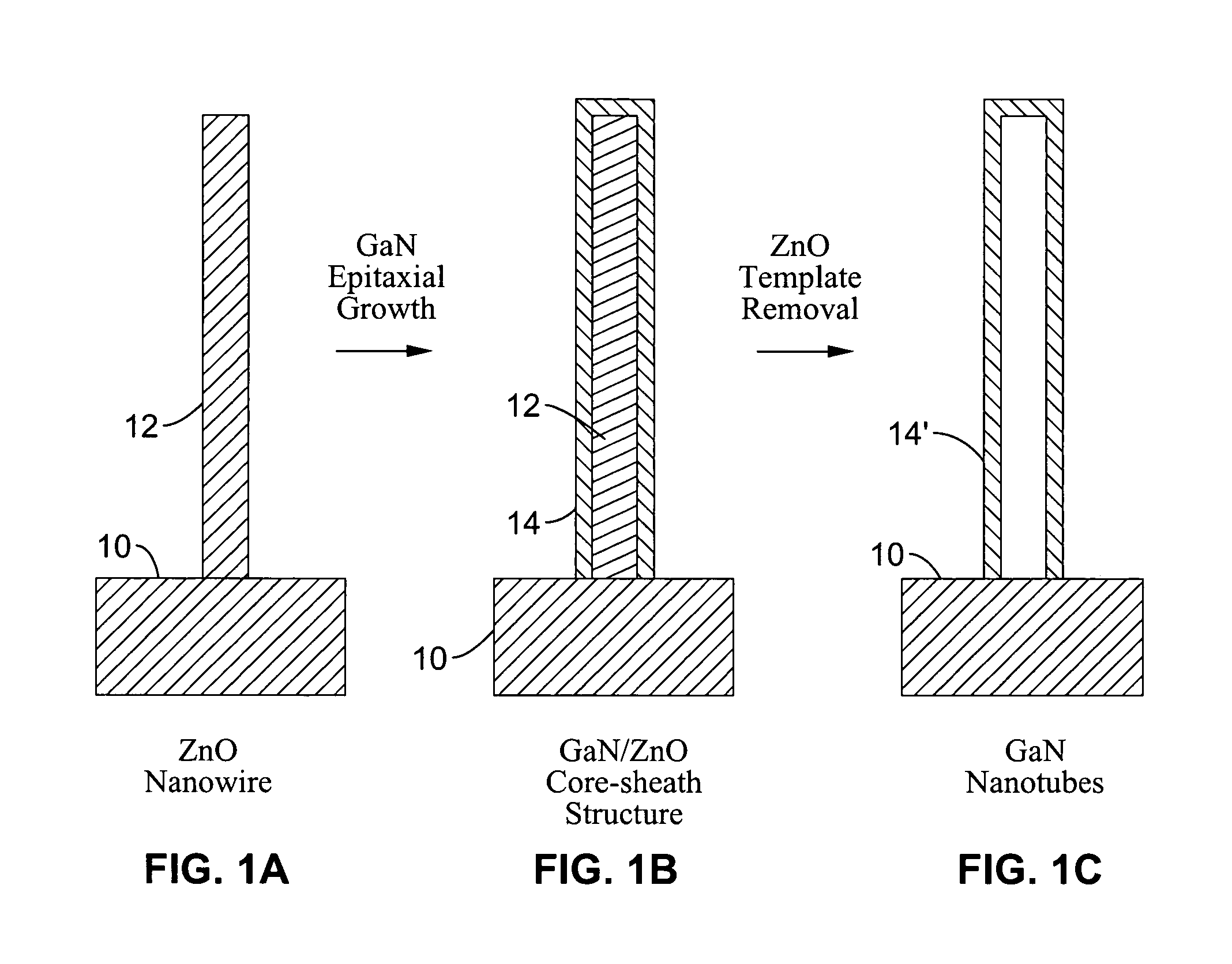

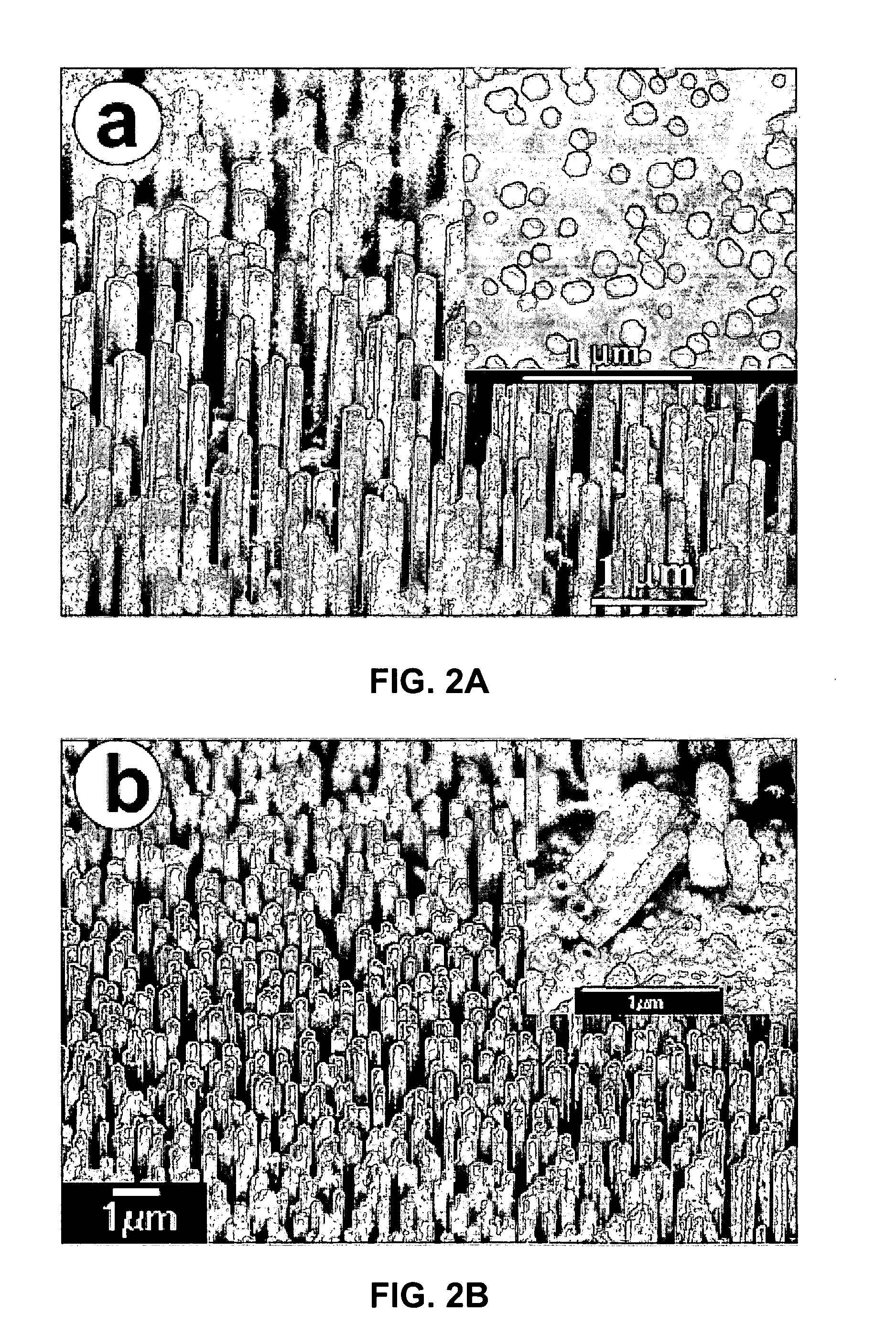

Sacrificial template method of fabricating a nanotube

Methods of fabricating uniform nanotubes are described in which nanotubes were synthesized as sheaths over nanowire templates, such as using a chemical vapor deposition process. For example, single-crystalline zinc oxide (ZnO) nanowires are utilized as templates over which gallium nitride (GaN) is epitaxially grown. The ZnO templates are then removed, such as by thermal reduction and evaporation. The completed single-crystalline GaN nanotubes preferably have inner diameters ranging from 30 nm to 200 nm, and wall thicknesses between 5 and 50 nm. Transmission electron microscopy studies show that the resultant nanotubes are single-crystalline with a wurtzite structure, and are oriented along the <001> direction. The present invention exemplifies single-crystalline nanotubes of materials with a non-layered crystal structure. Similar “epitaxial-casting” approaches could be used to produce arrays and single-crystalline nanotubes of other solid materials and semiconductors. Furthermore, the fabrication of multi-sheath nanotubes are described as well as nanotubes having multiple longitudinal segments.

Owner:RGT UNIV OF CALIFORNIA

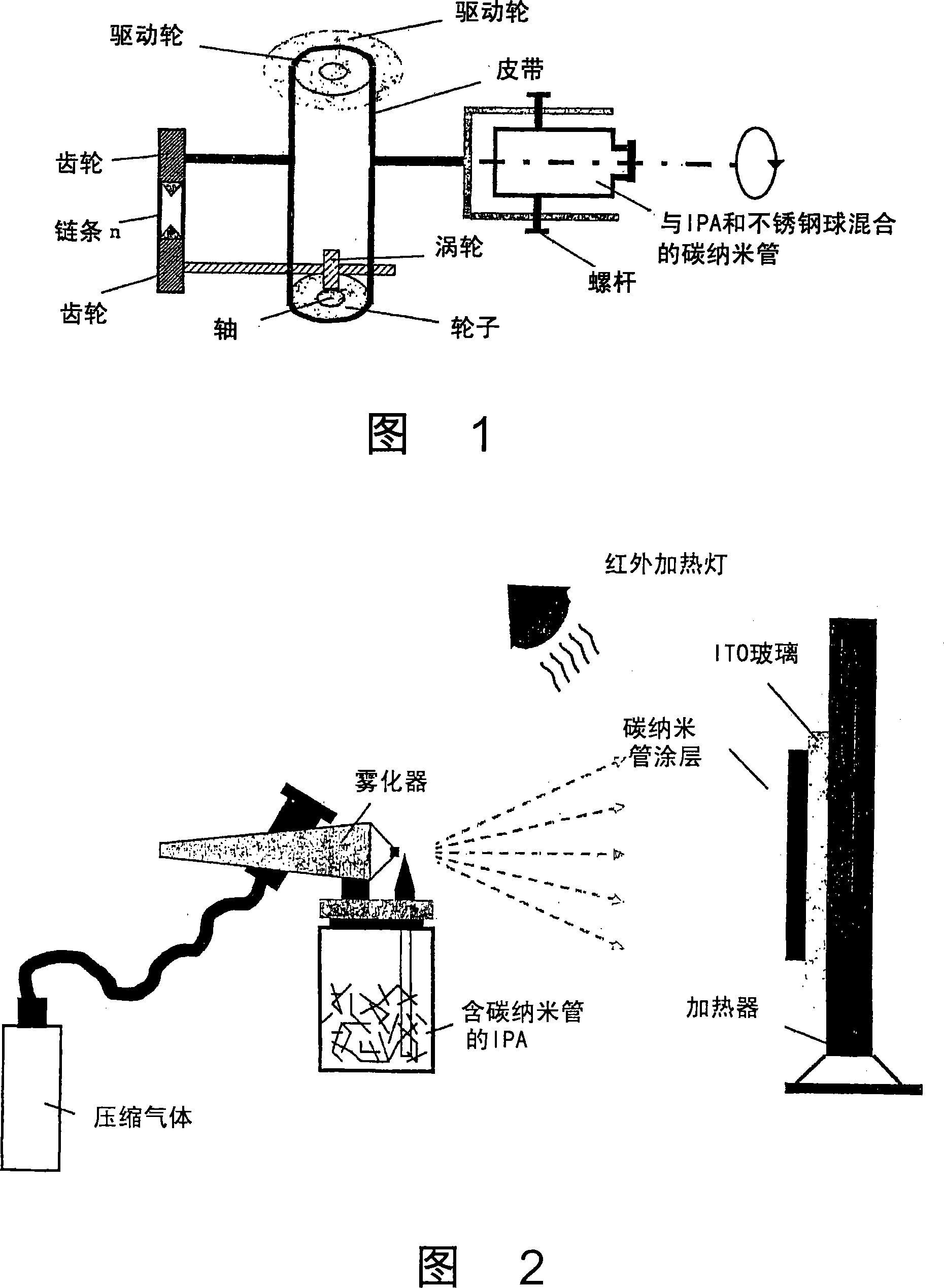

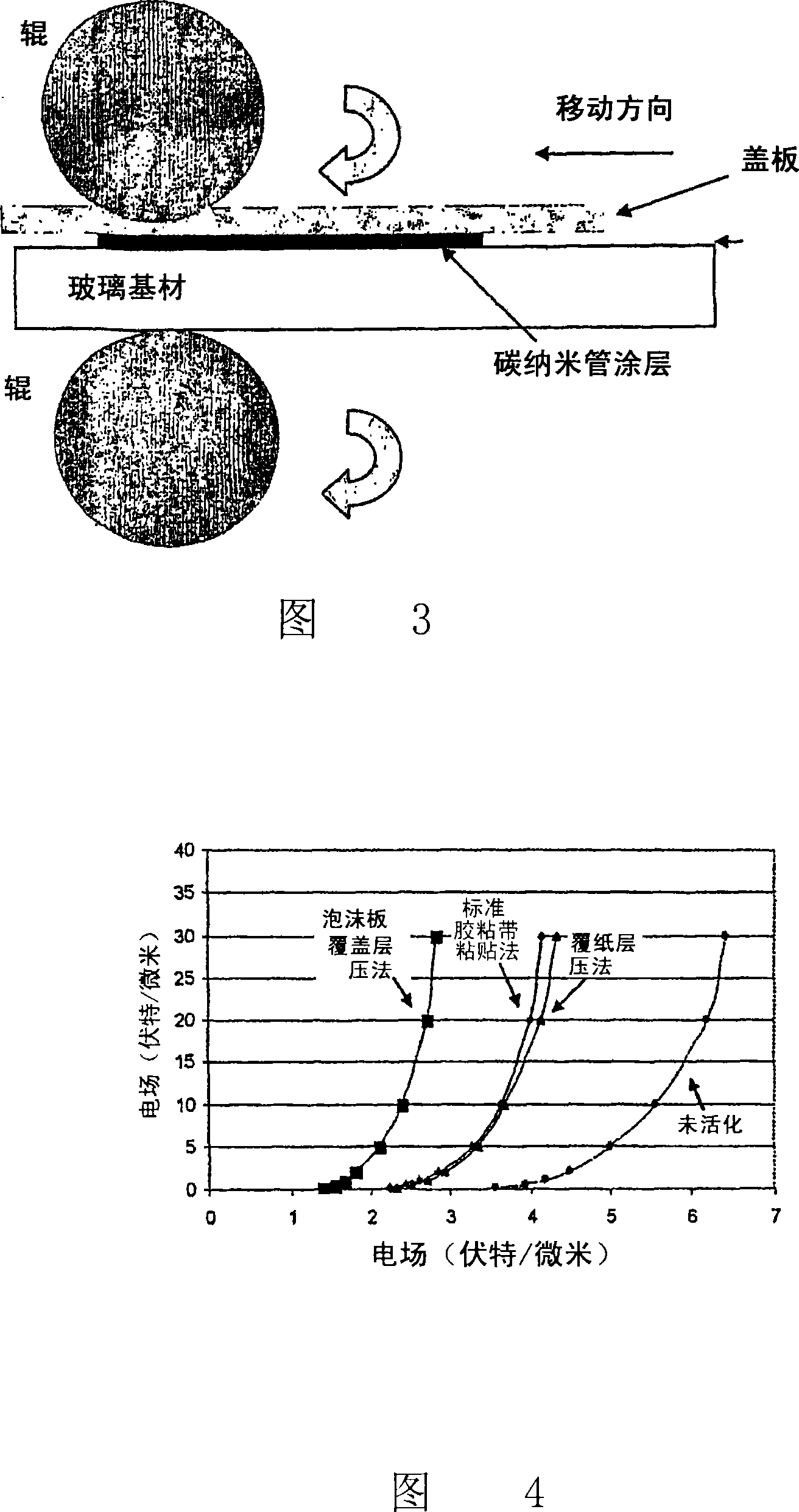

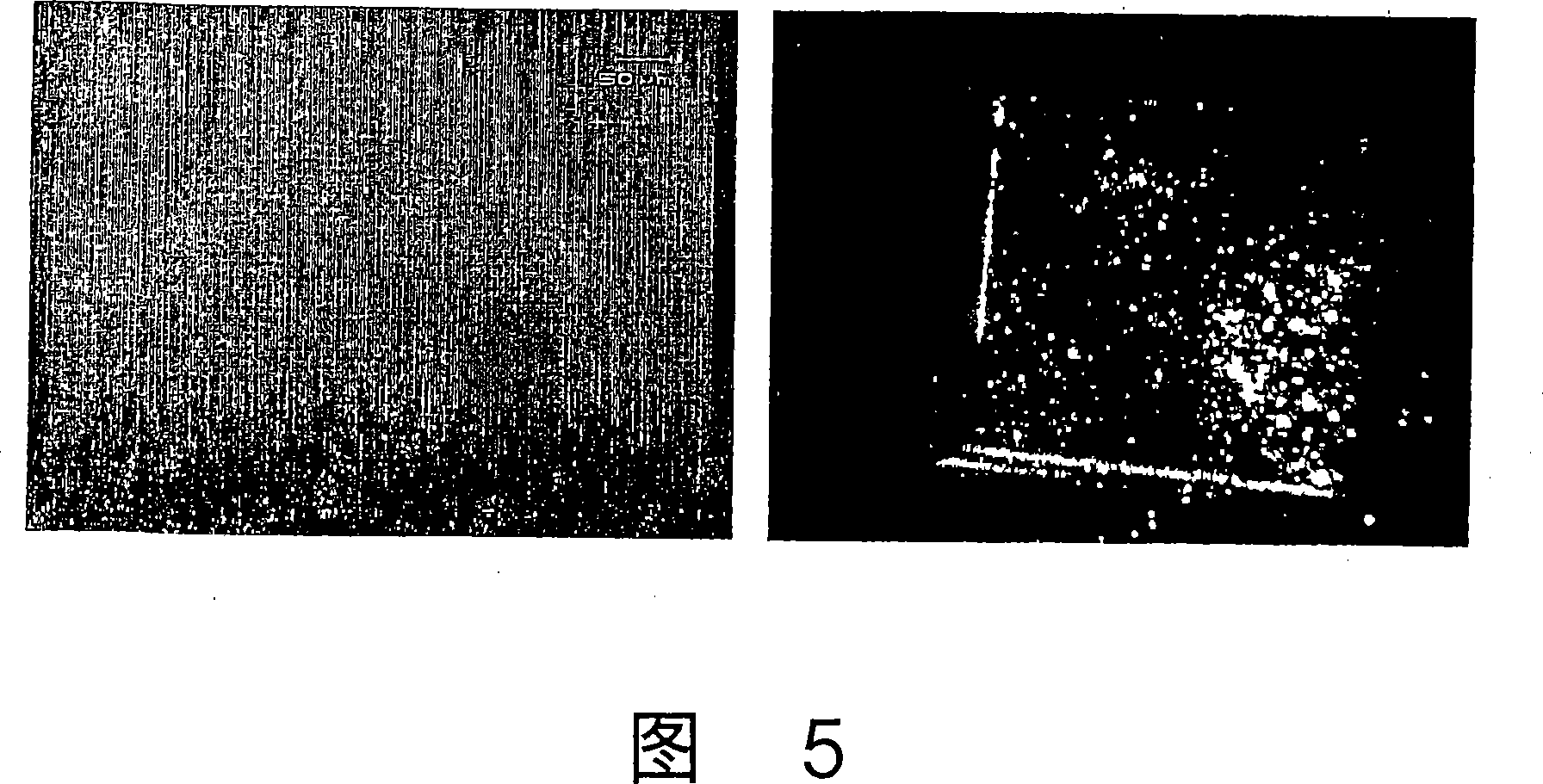

Activation of carbon nanotubes for field emission applications

InactiveCN1998067AEasy to handleLow costSemiconductor/solid-state device manufacturingCarbon nanotubeField electron emission

Substantially enhanced field emission properties are achieved by using a process of covering a non-adhesive material (for example, paper, foam sheet, or roller) over the surface of the CNTs, pressing the materiel using a certain force, and removing the material.

Owner:NANO

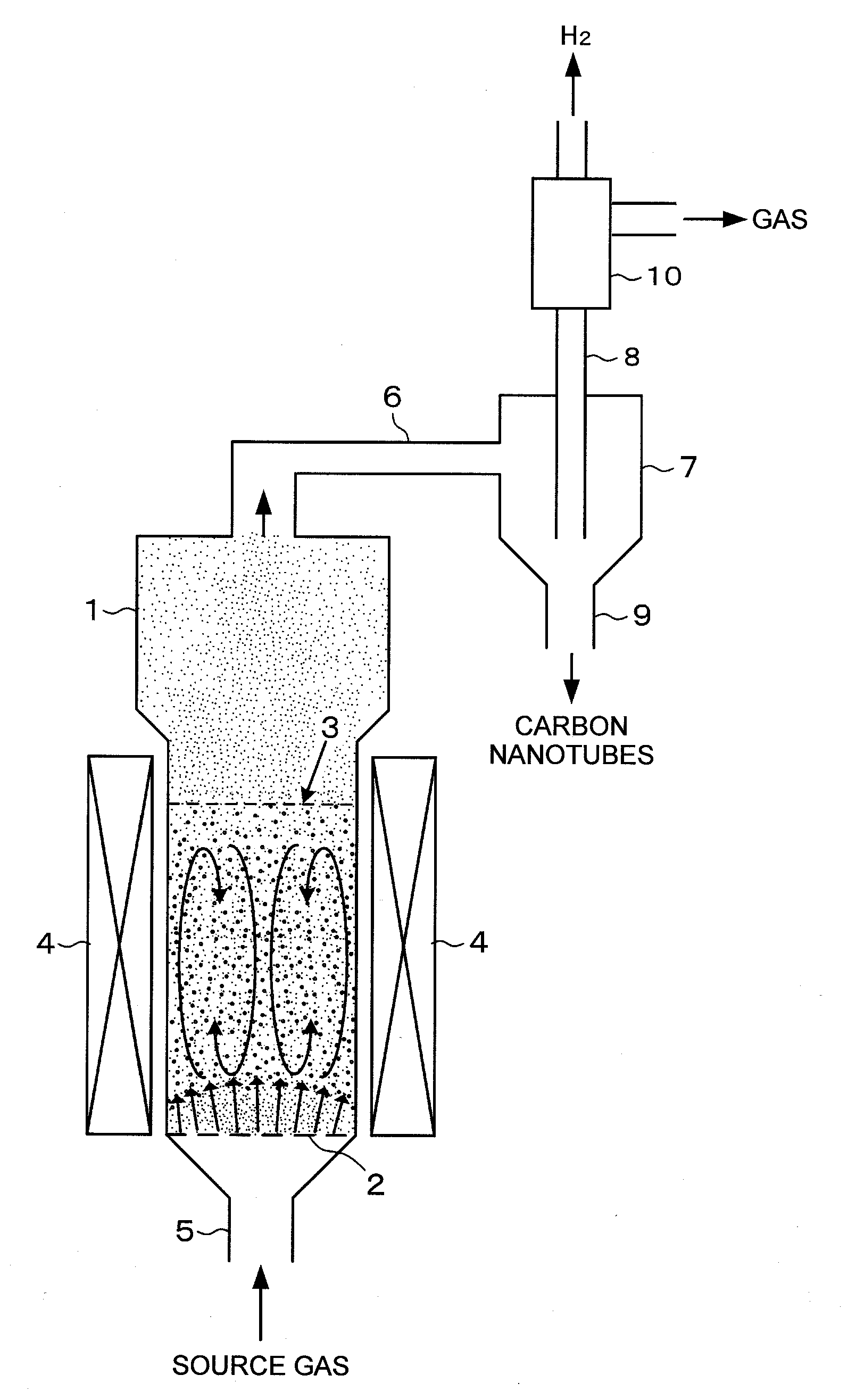

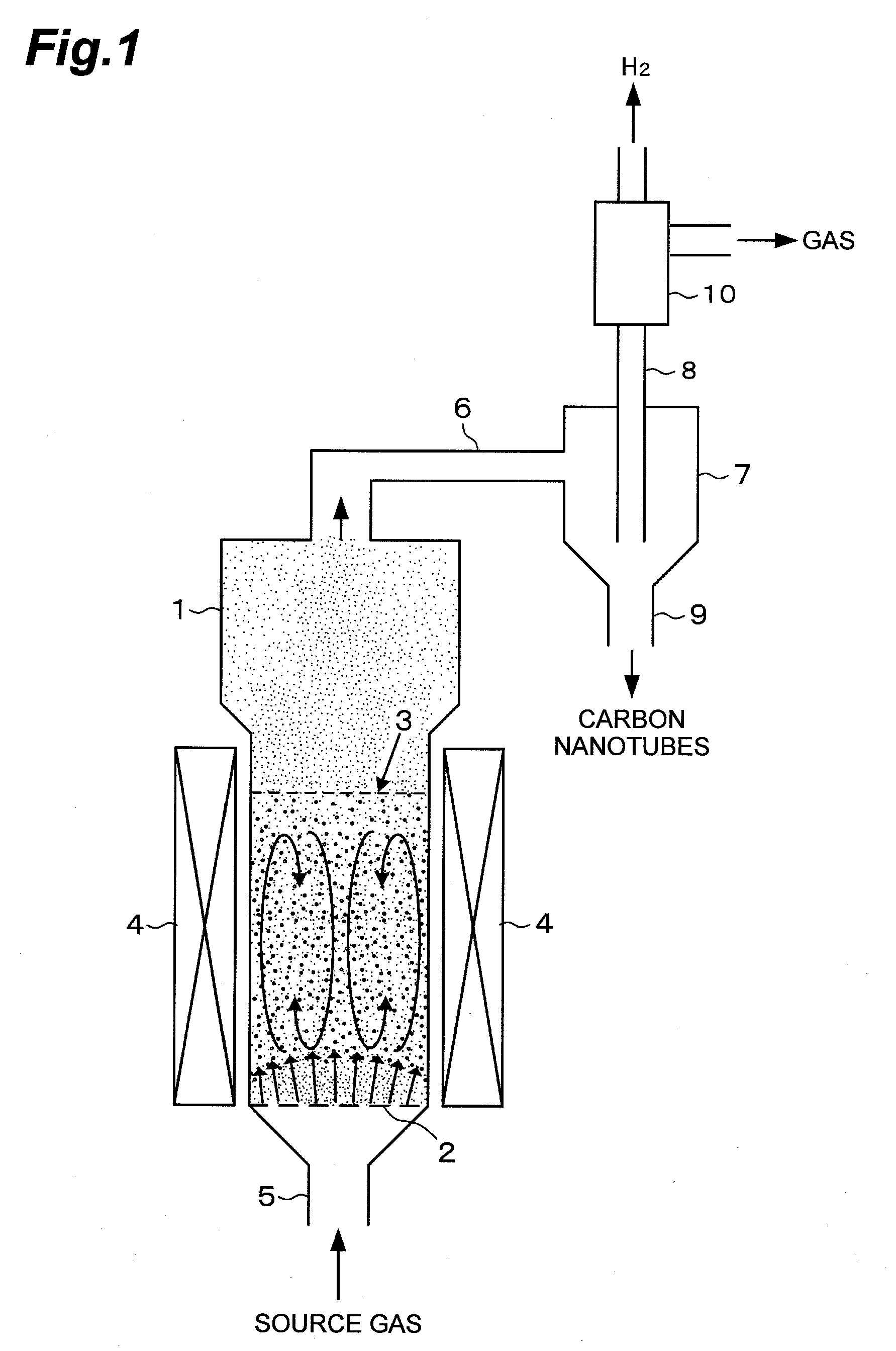

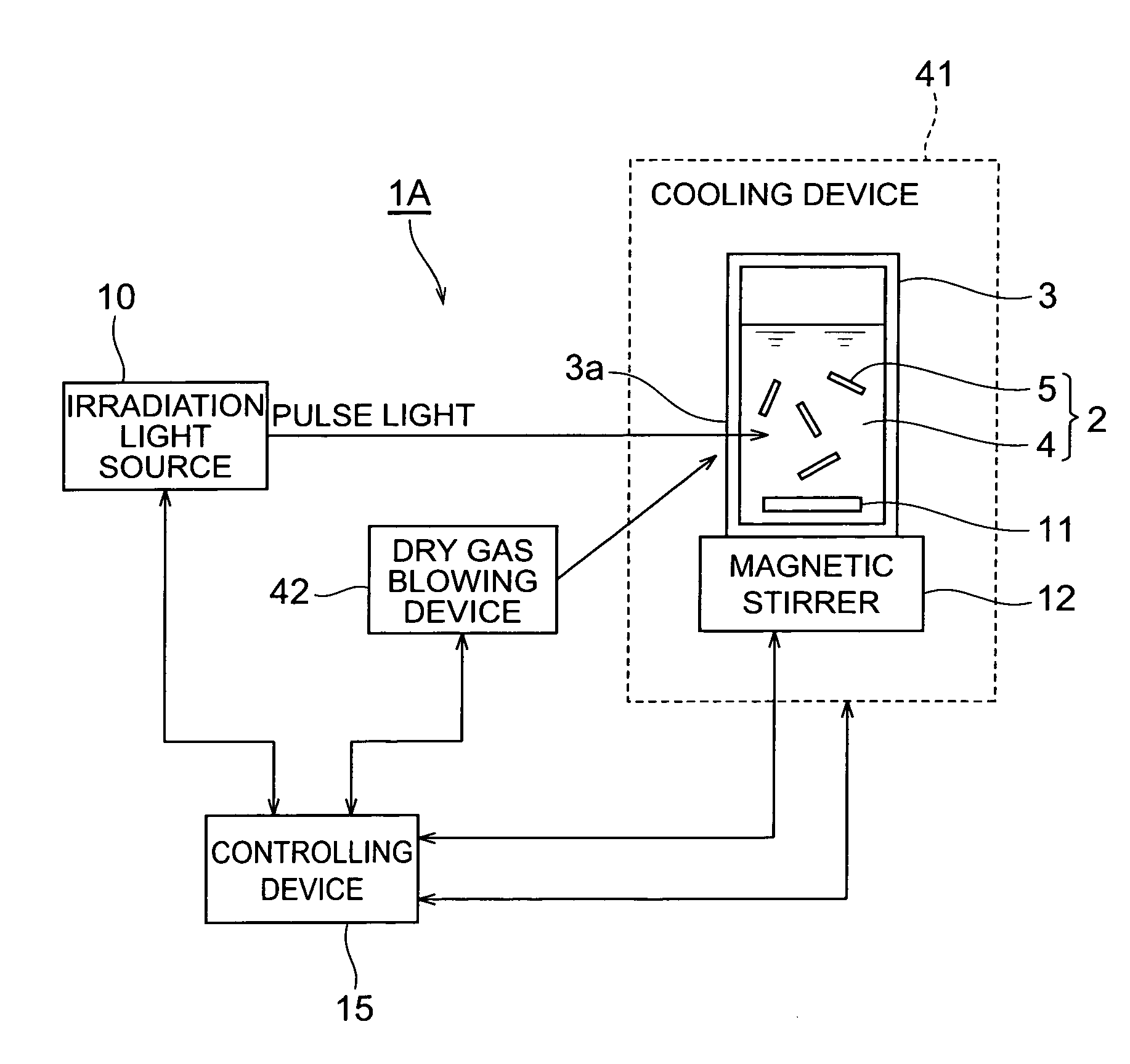

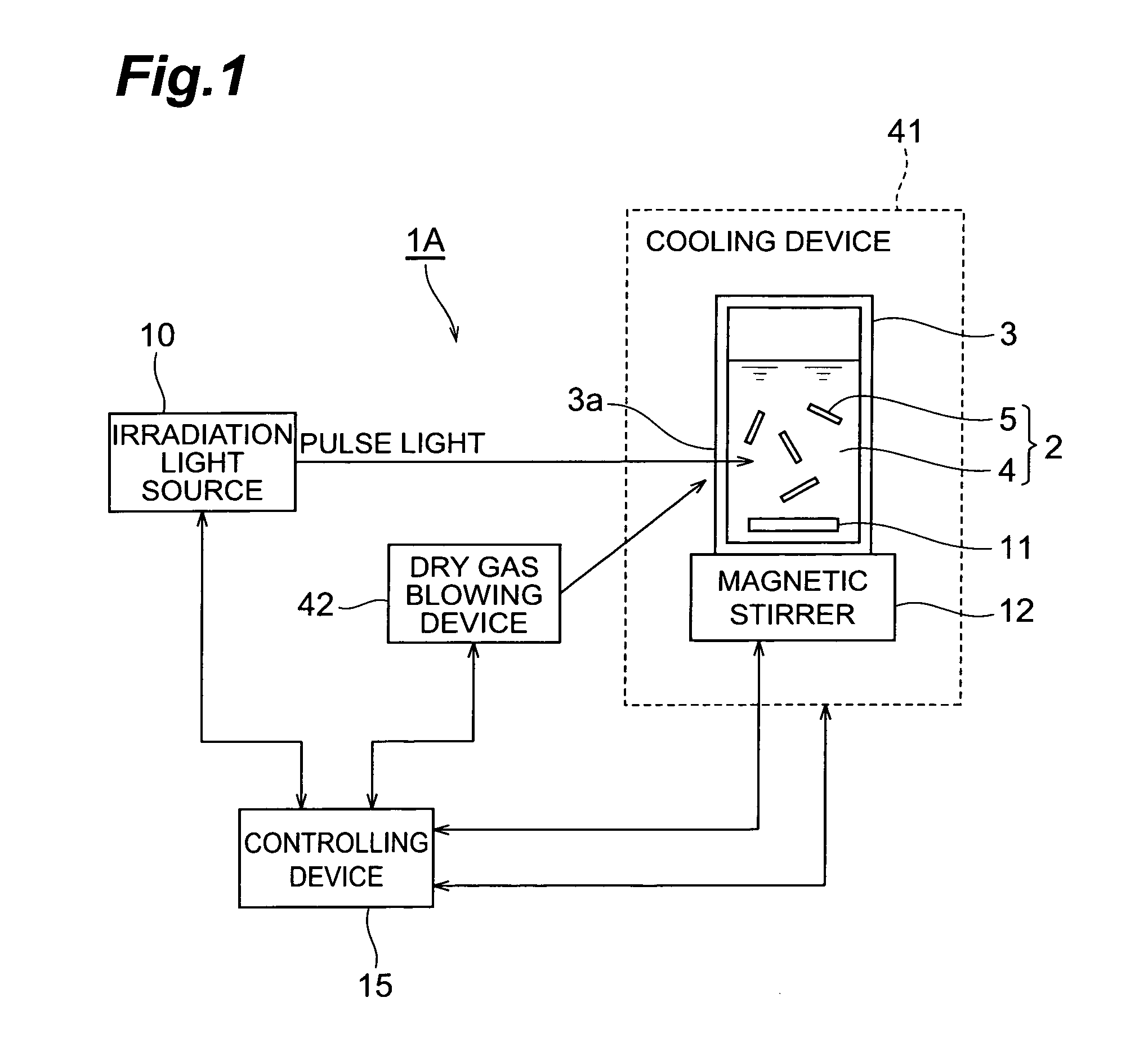

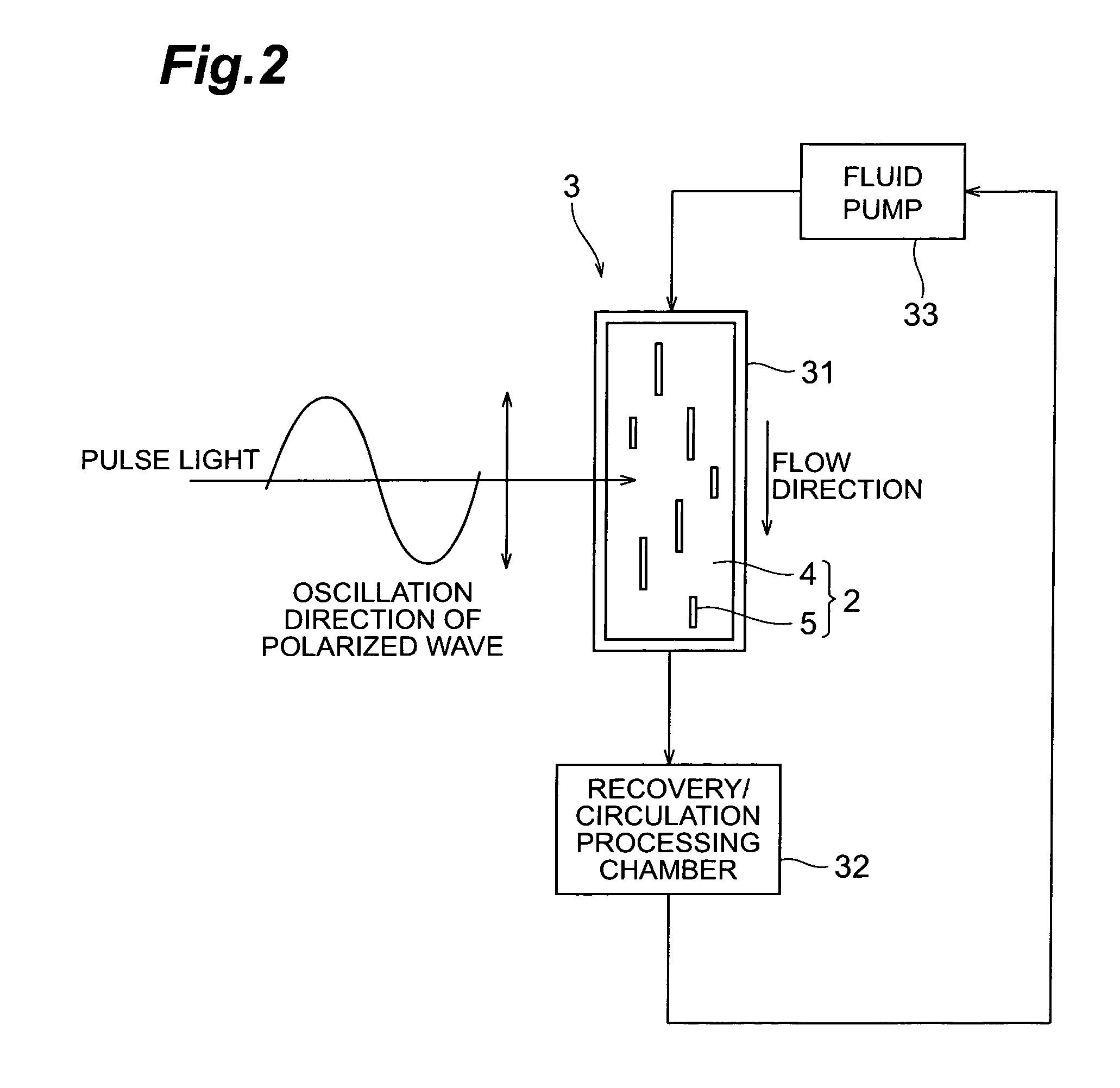

Method for simultaneously producing carbon nanotubes and hydrogen, and device for simultaneously producing carbon nanotubes and hydrogen

InactiveUS20120219490A1Produce significantEfficient productionMaterial nanotechnologyCell electrodesHydrogenHydrogen atom

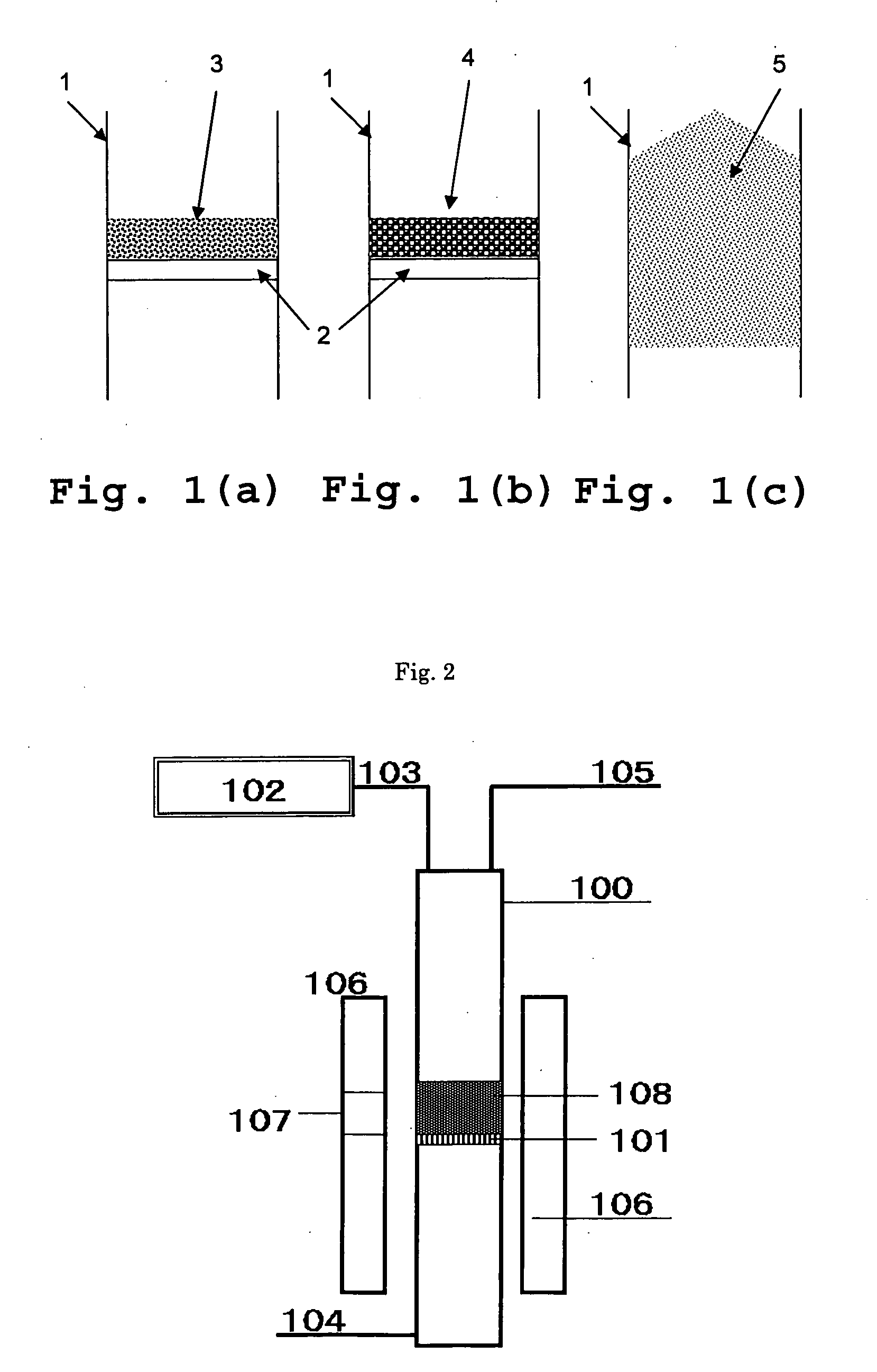

A method for simultaneously producing carbon nanotubes and hydrogen according to the present invention is a method for simultaneously producing carbon nanotubes and hydrogen, in which using a carbon source containing carbon atoms and hydrogen atoms and being decomposed in a heated state, and a catalyst for producing carbon nanotubes and H2 from the carbon source, the above carbon nanotubes are synthesized on a support in a heated state, placed in a reactor, and simultaneously, the above H2 is synthesized from the above carbon source, the method comprising a synthesis step of flowing a source gas comprising the above carbon source over the above support, on which the above catalyst is supported, to synthesize the above carbon nanotubes on the above support and simultaneously synthesize the above H2 in a gas flow.

Owner:THE UNIV OF TOKYO +1

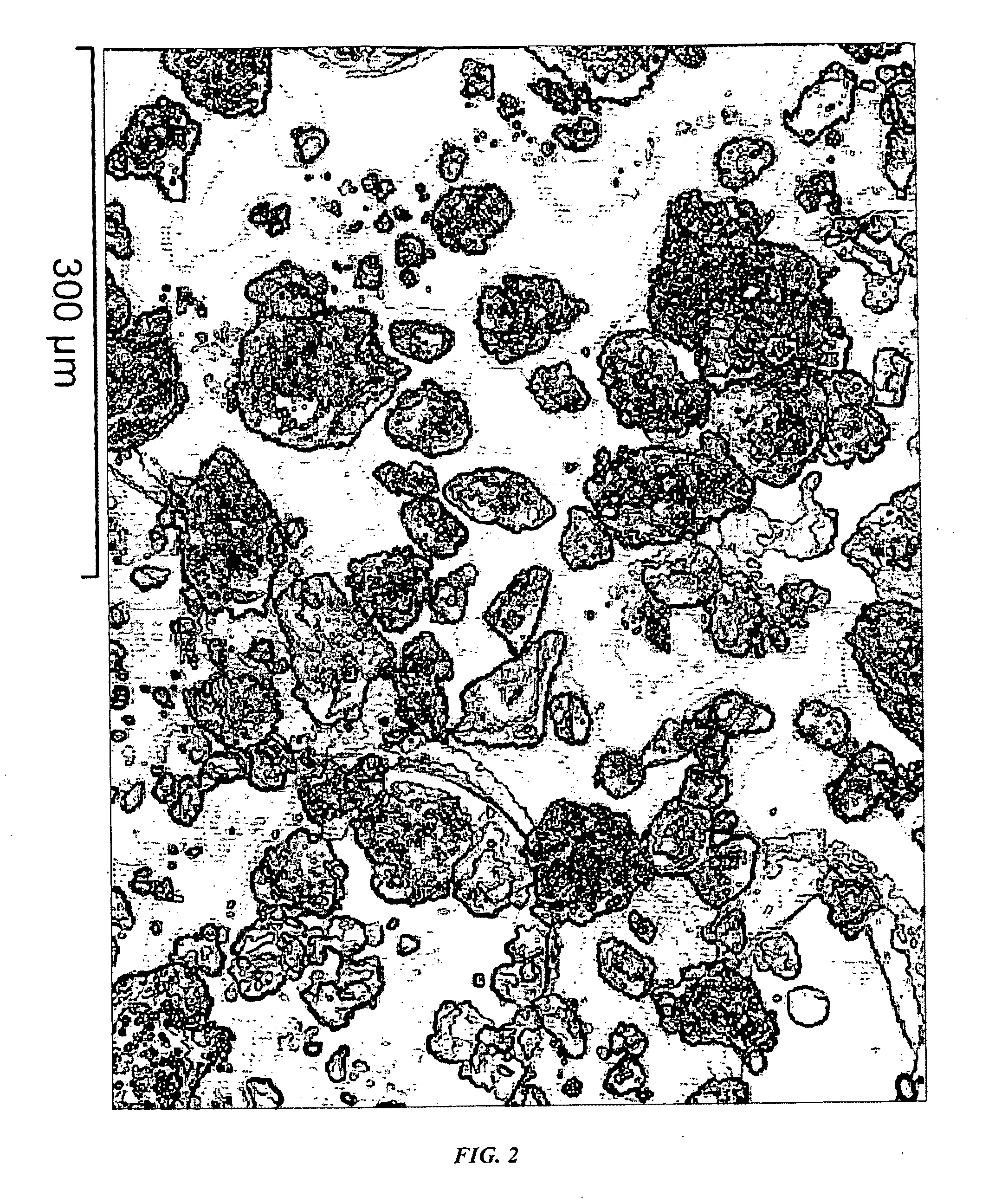

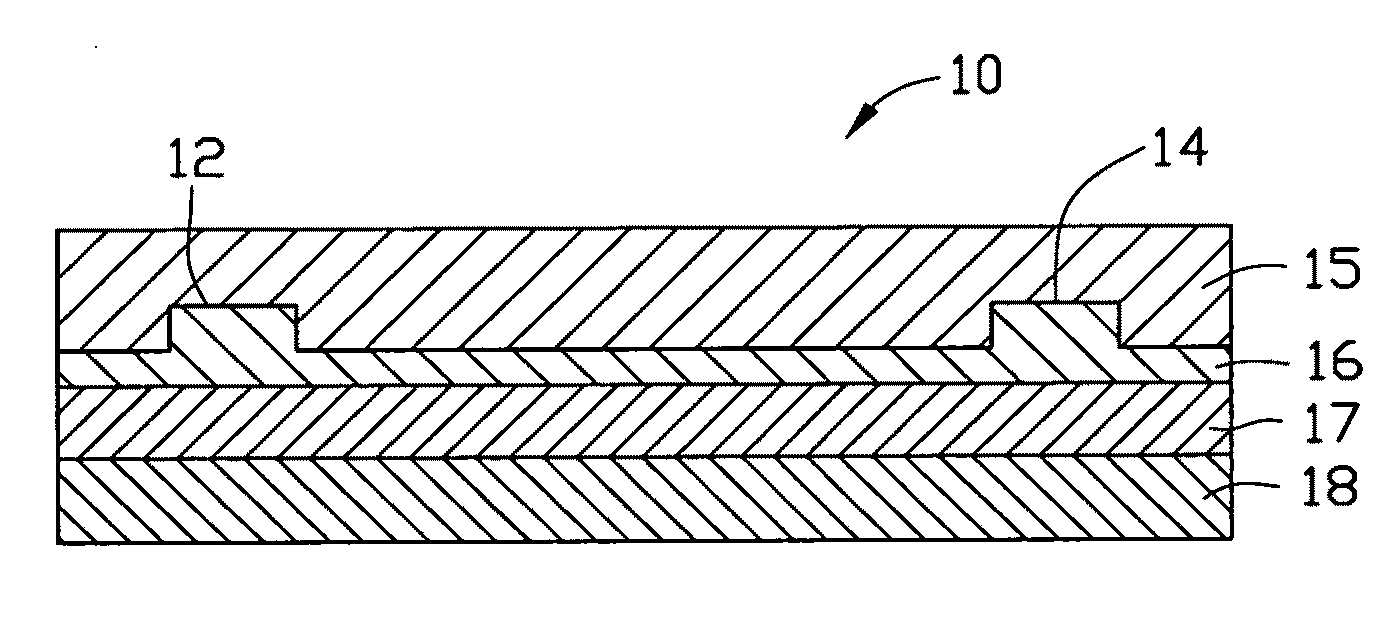

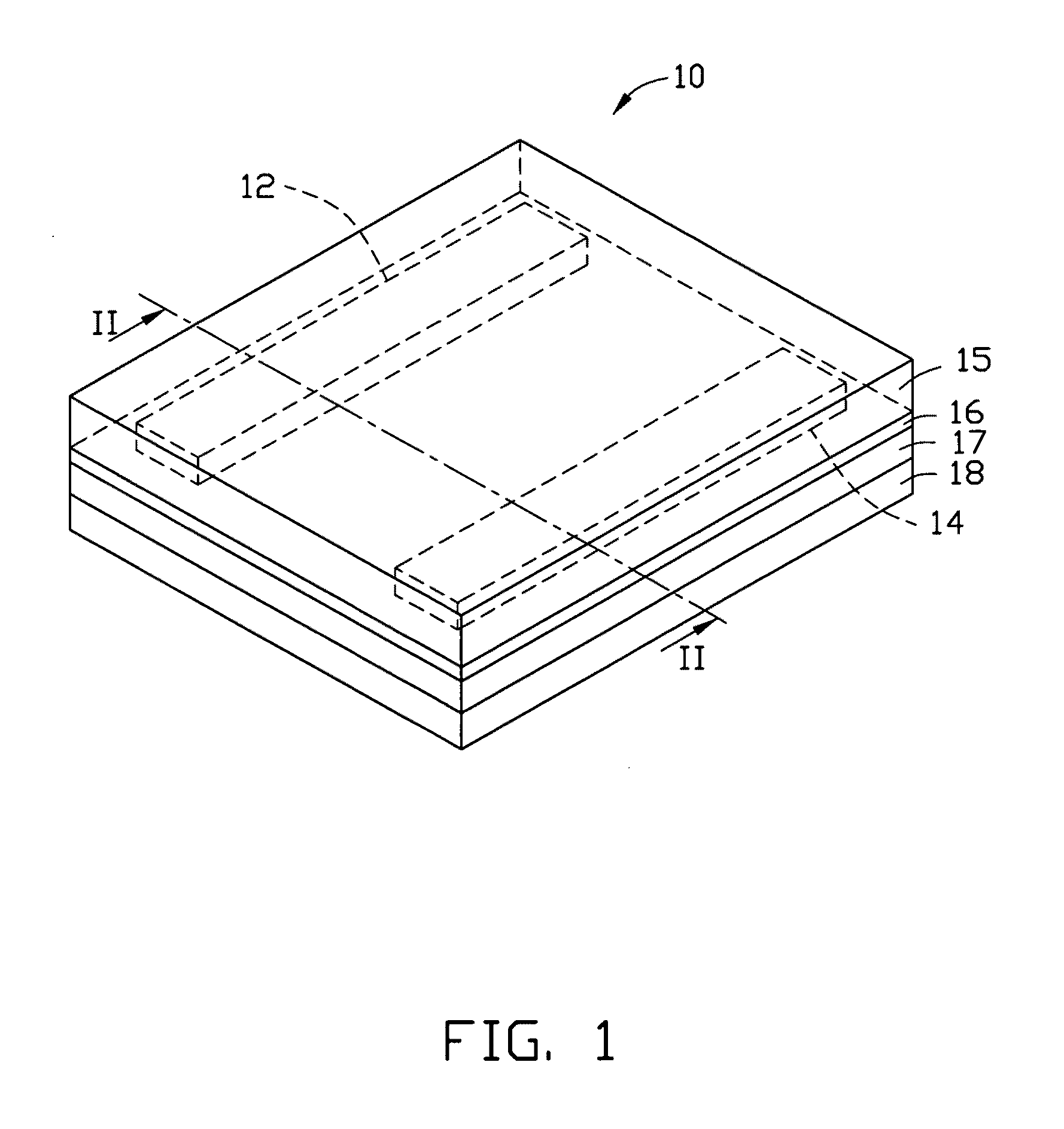

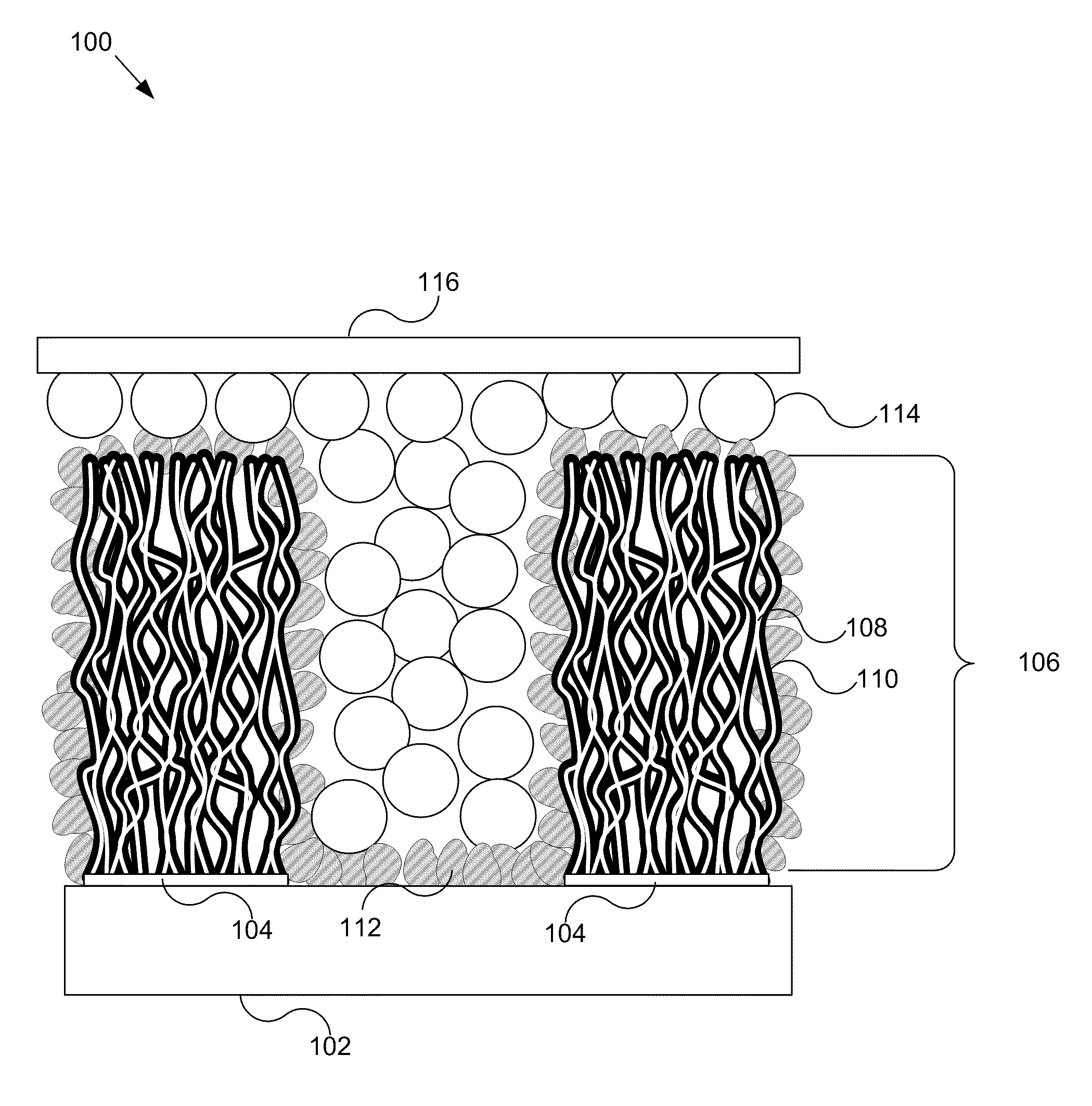

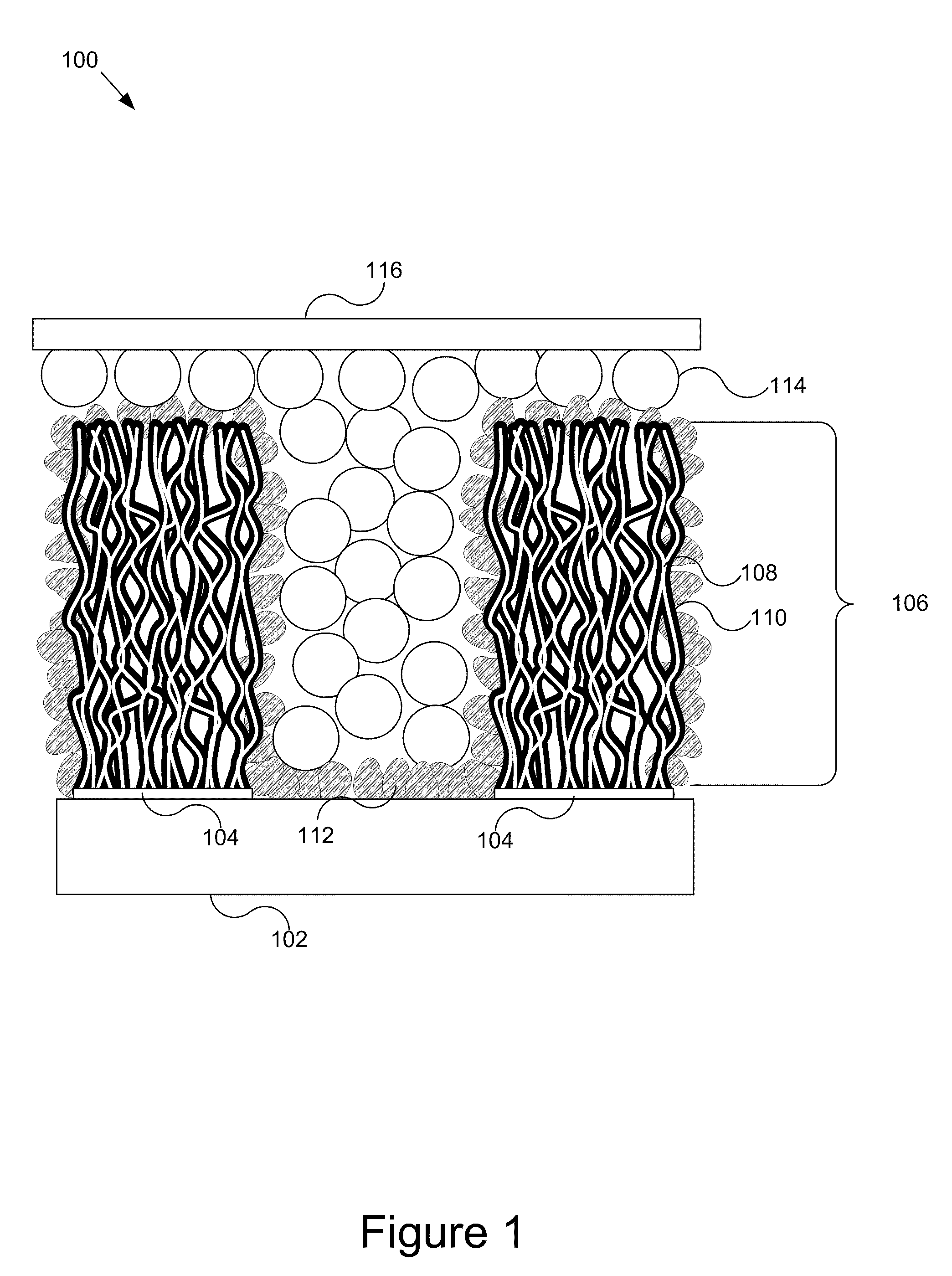

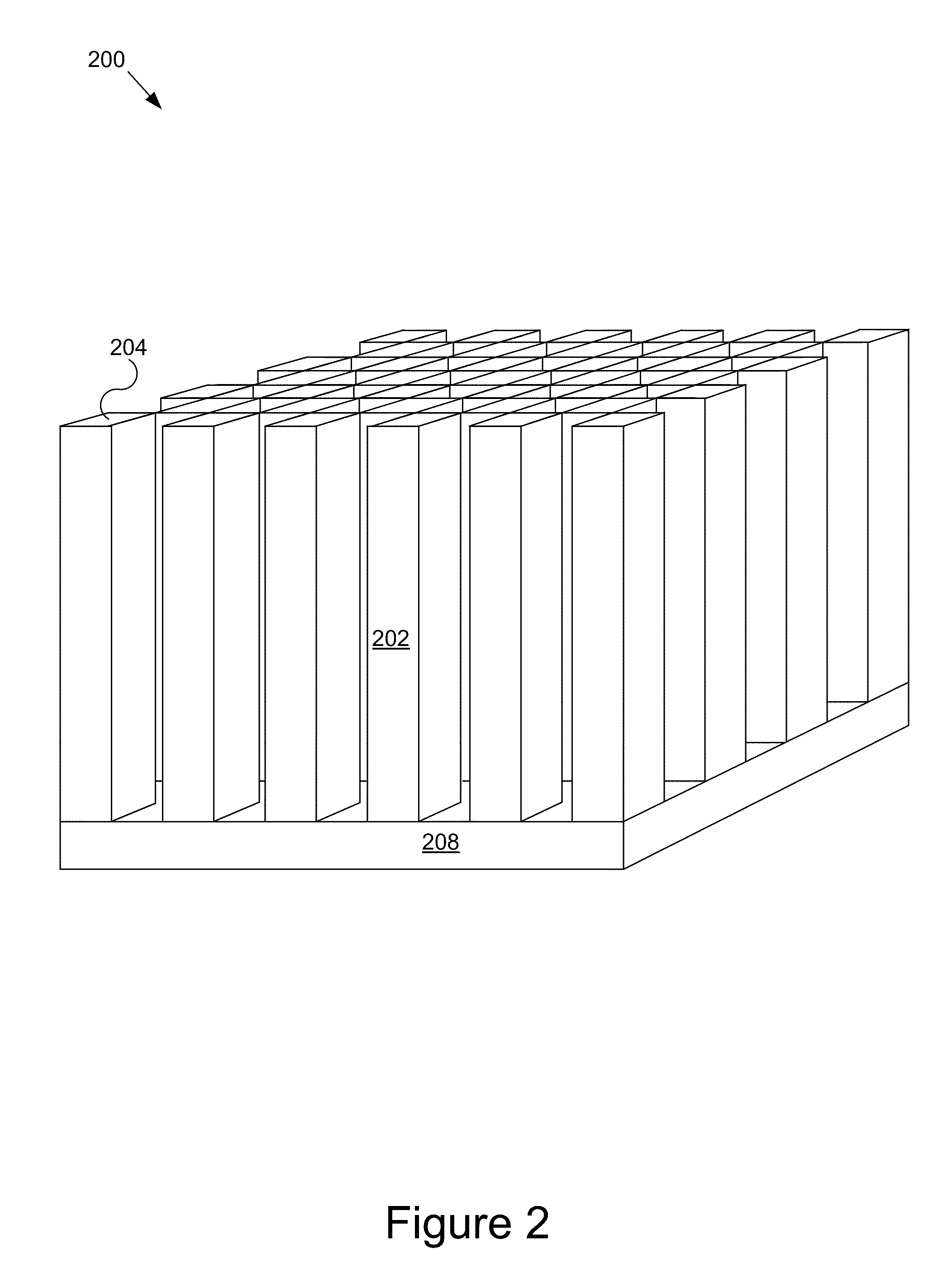

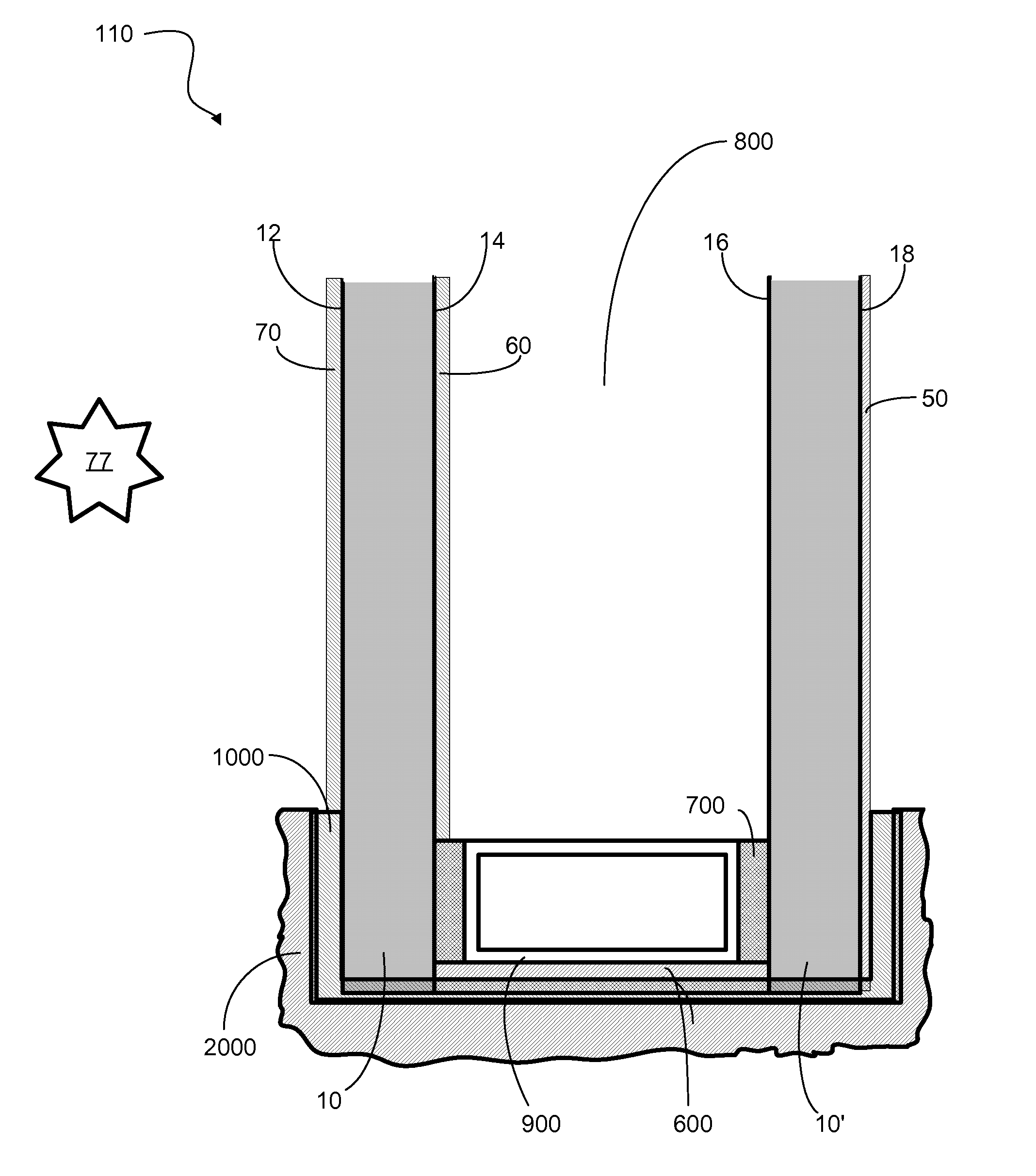

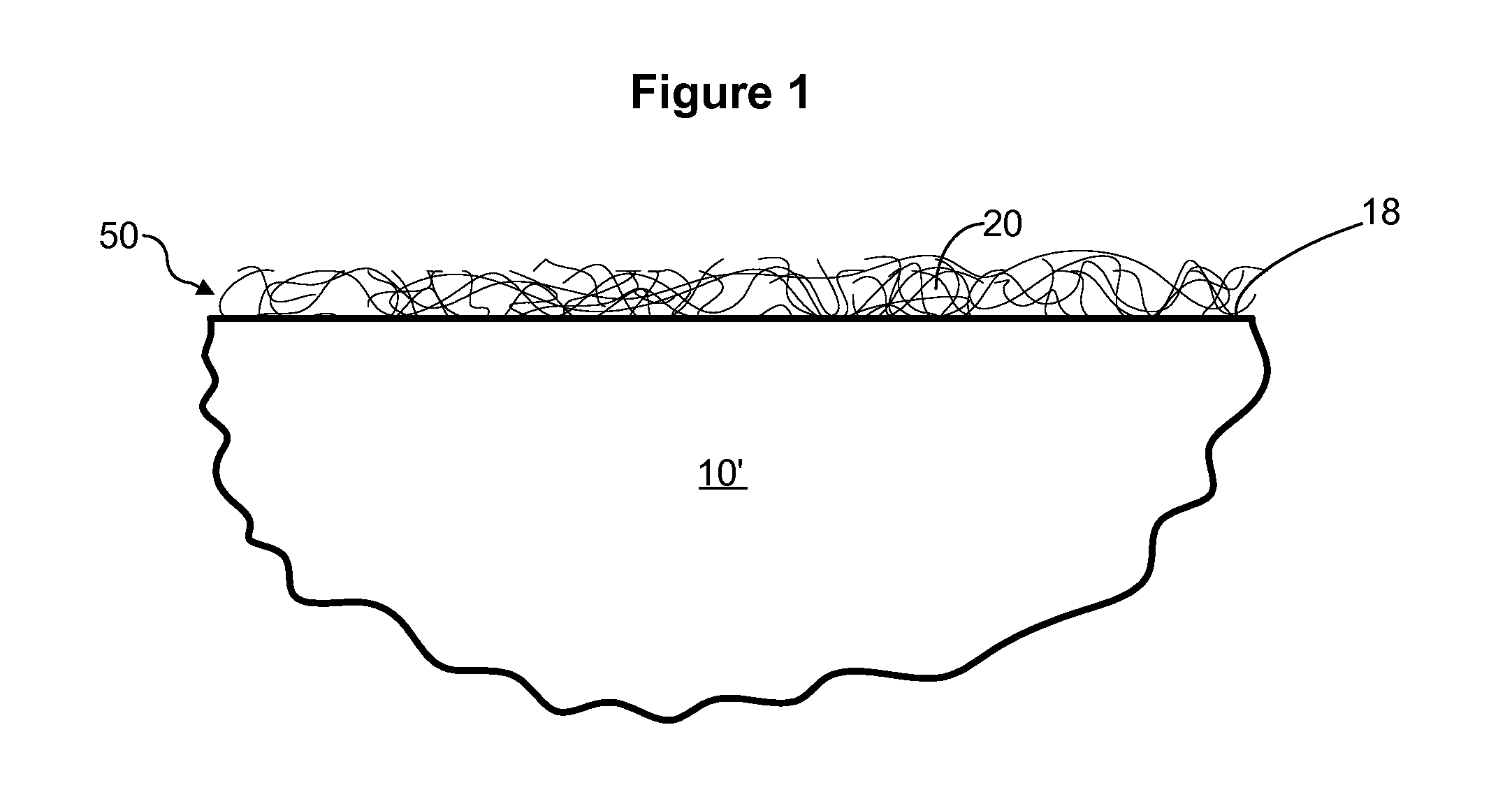

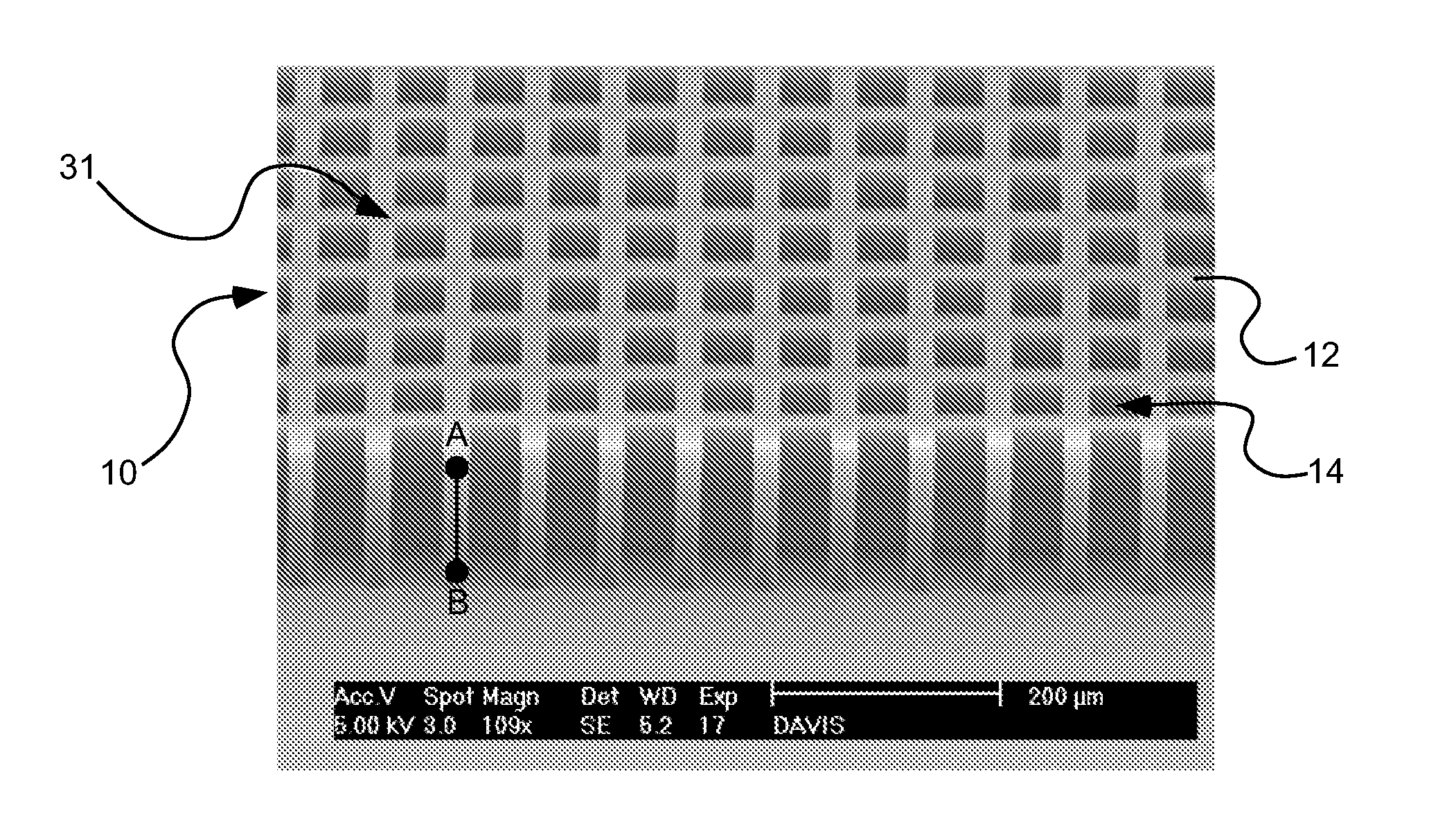

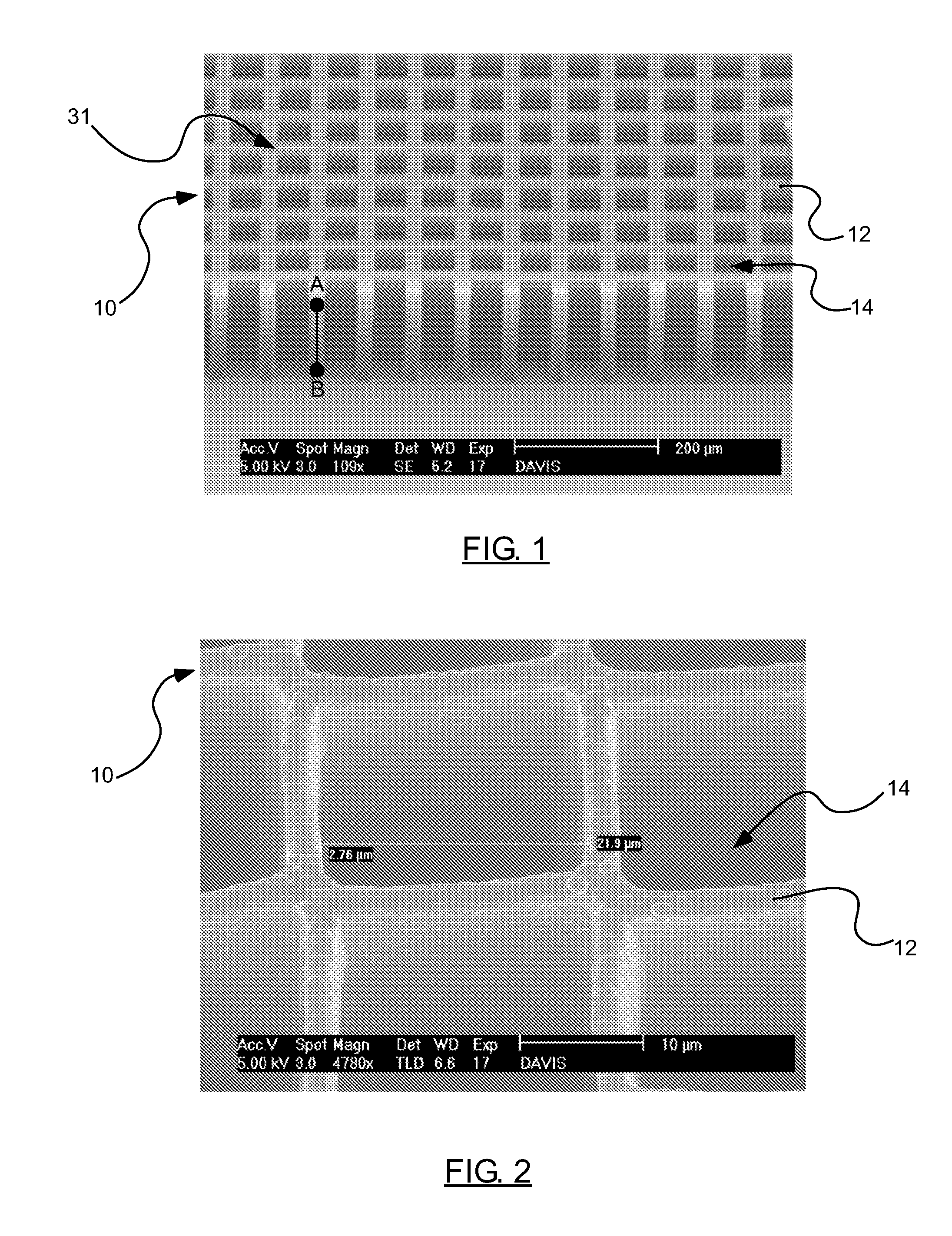

Apparatus, system, and method for carbon nanotube templated battery electrodes

InactiveUS20110183206A1Material nanotechnologyElectrode carriers/collectorsParticulatesCarbon nanotube

An apparatus, system, and method are disclosed for a carbon nanotube templated battery electrode. The apparatus includes a substrate, and a plurality of catalyst areas extending upward from the substrate, the plurality of catalyst areas forming a patterned frame. The apparatus also includes a carbon nanotube forest grown on each of the plurality of catalyst areas and extending upward therefrom such that a shape of the patterned frame is maintained, and a coating attached to each carbon nanotube in the carbon nanotube forest, the coating formed of an electrochemically active material. The system includes the apparatus, and a particulate cathode material distributed evenly across the apparatus such that the particulate cathode material fills the passages, a current collector film formed on top of the particulate cathode material, and a porous spacer disposed between the apparatus and the cathode.

Owner:BRIGHAM YOUNG UNIV

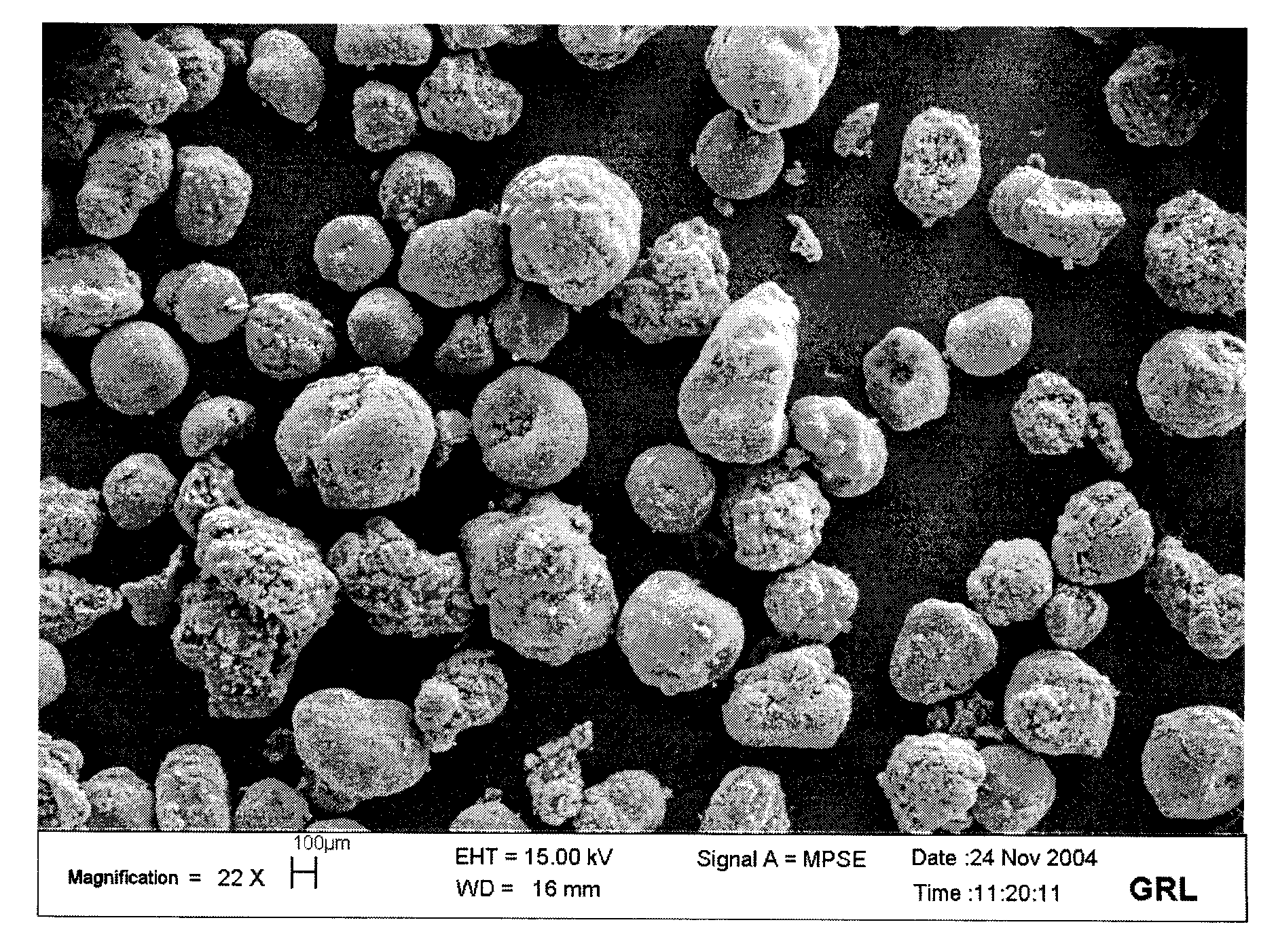

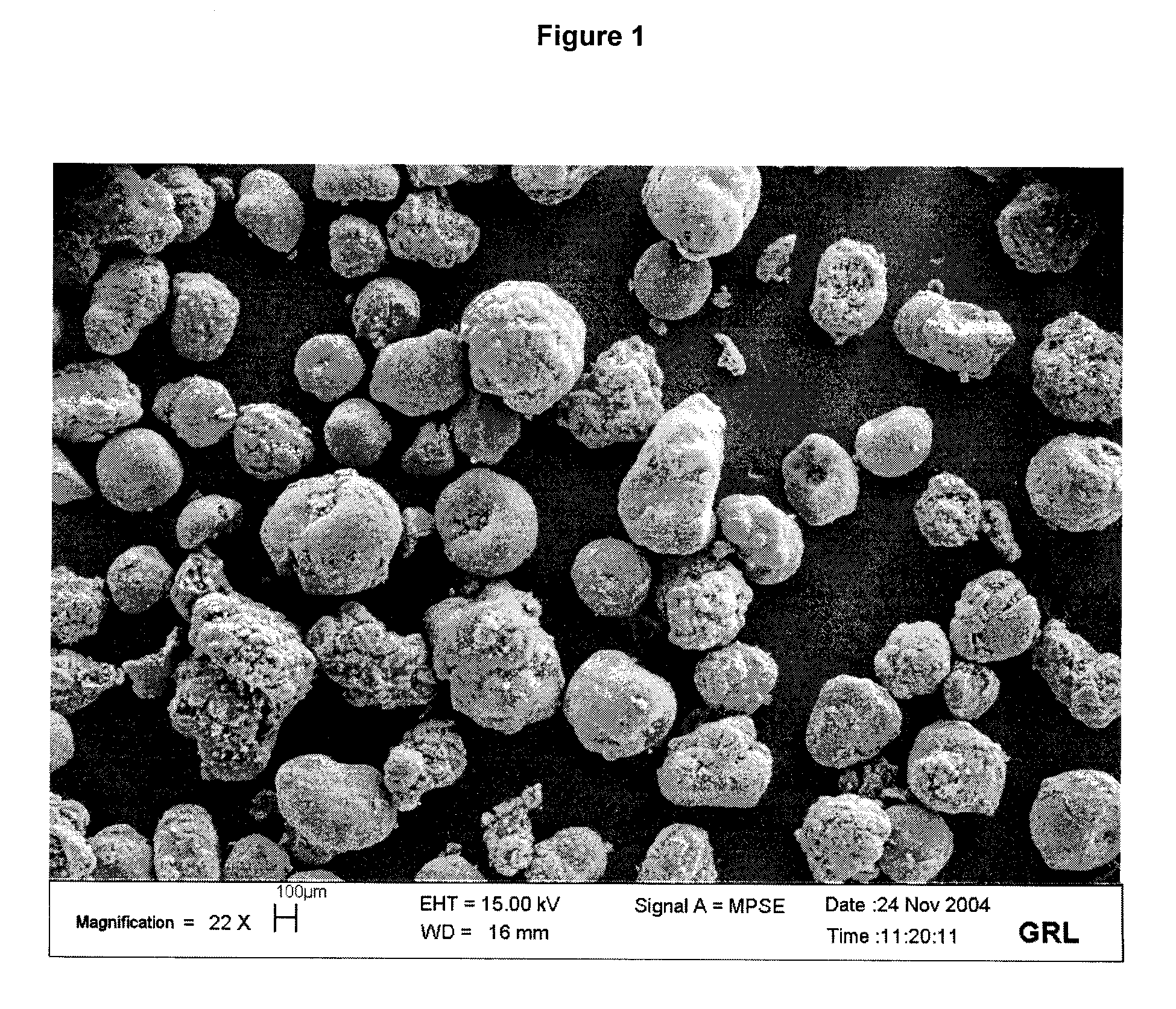

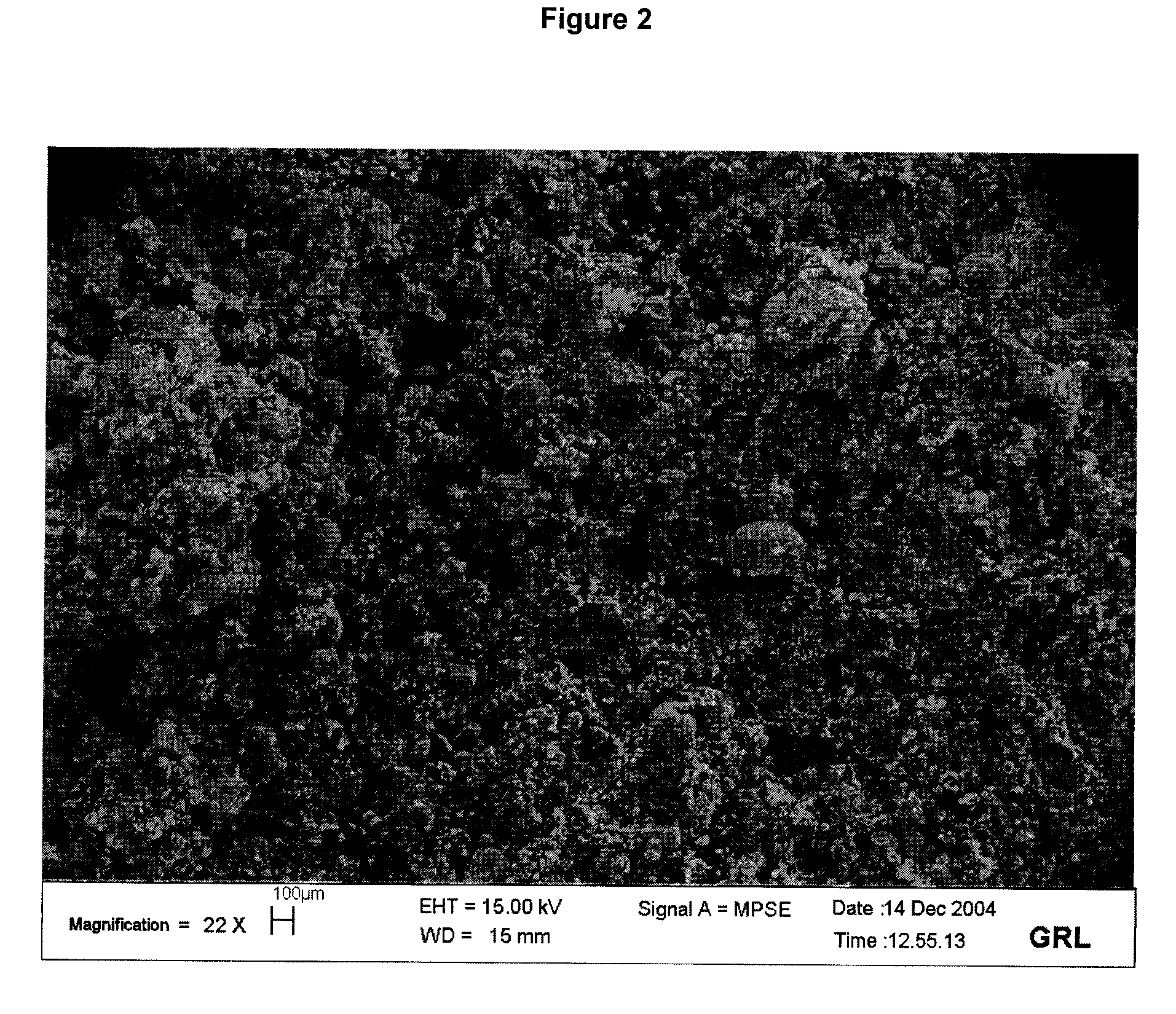

Method for synthesis of carbon nanotubes

InactiveUS20090134363A1Small particle sizeMaterial nanotechnologyPigmenting treatmentHigh carbonBCN nanotube

The invention relates to a method for synthesis of carbon nanotubes of the highest carbon purity by the process of vapour phase chemical deposition. The nanotubes produced can be used to advantage in all know applications of carbon nanotubes.

Owner:ARKEMA FRANCE SA

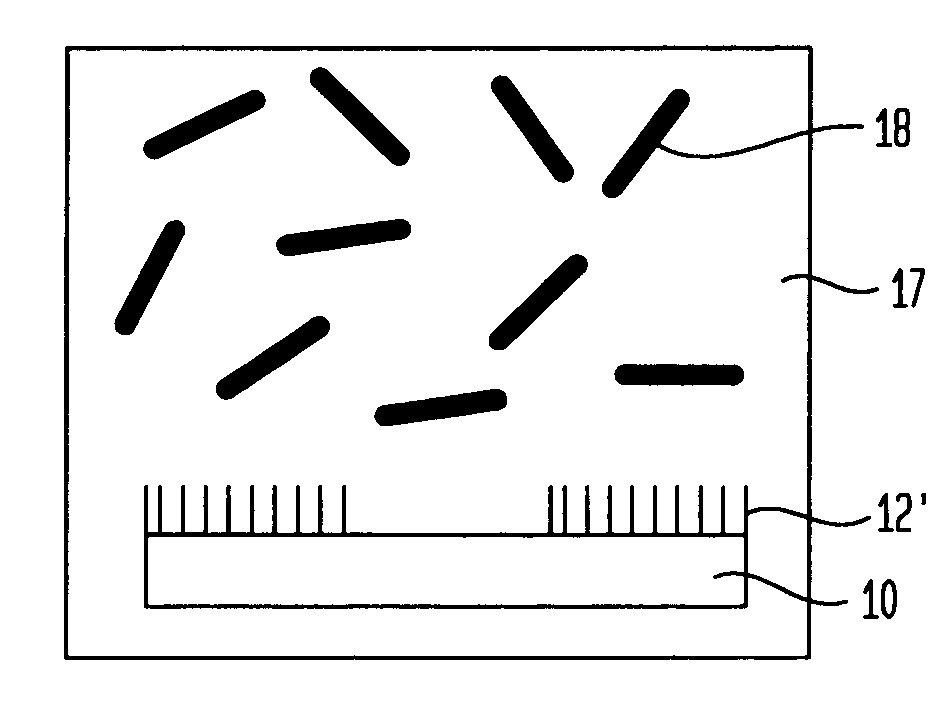

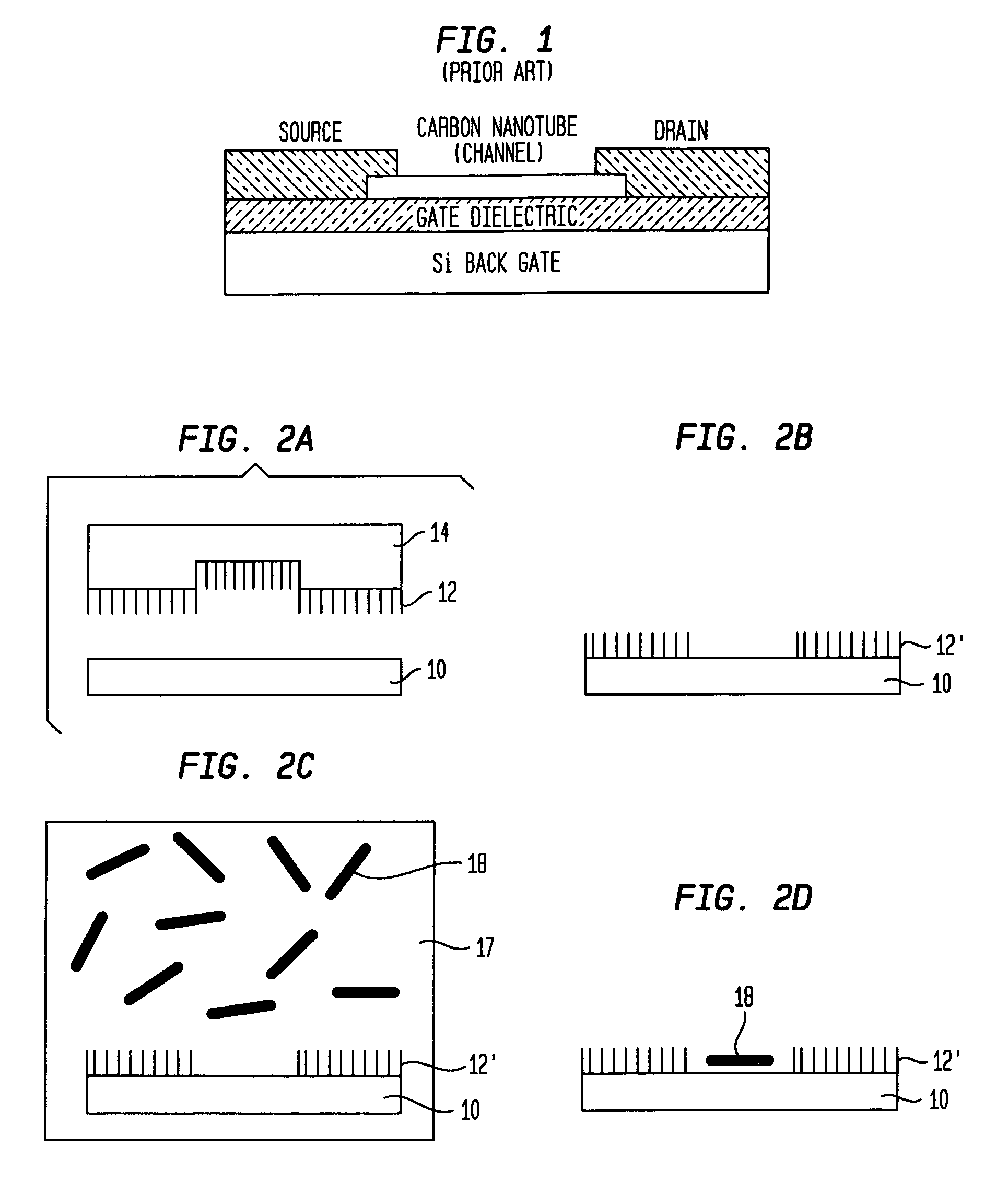

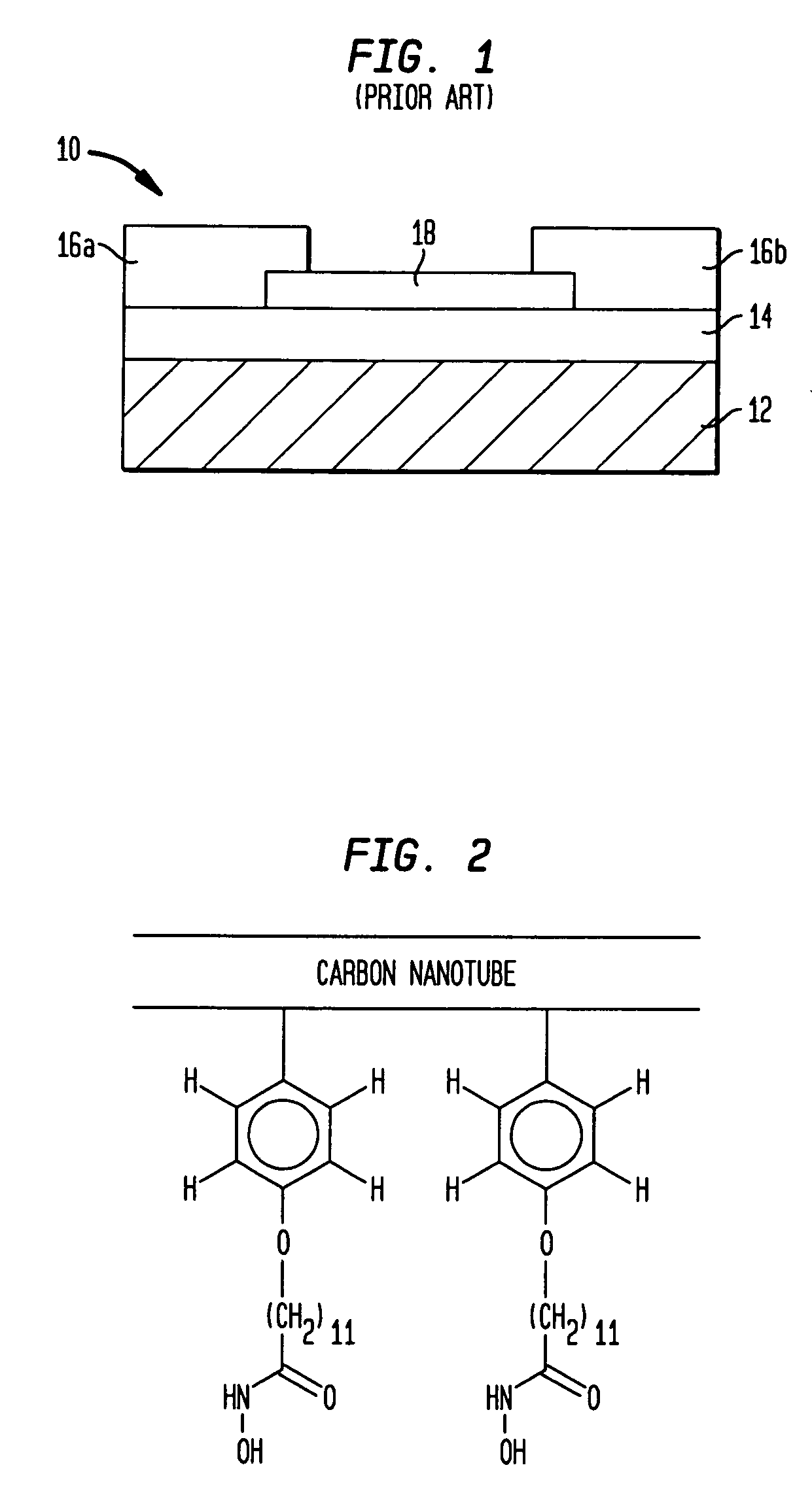

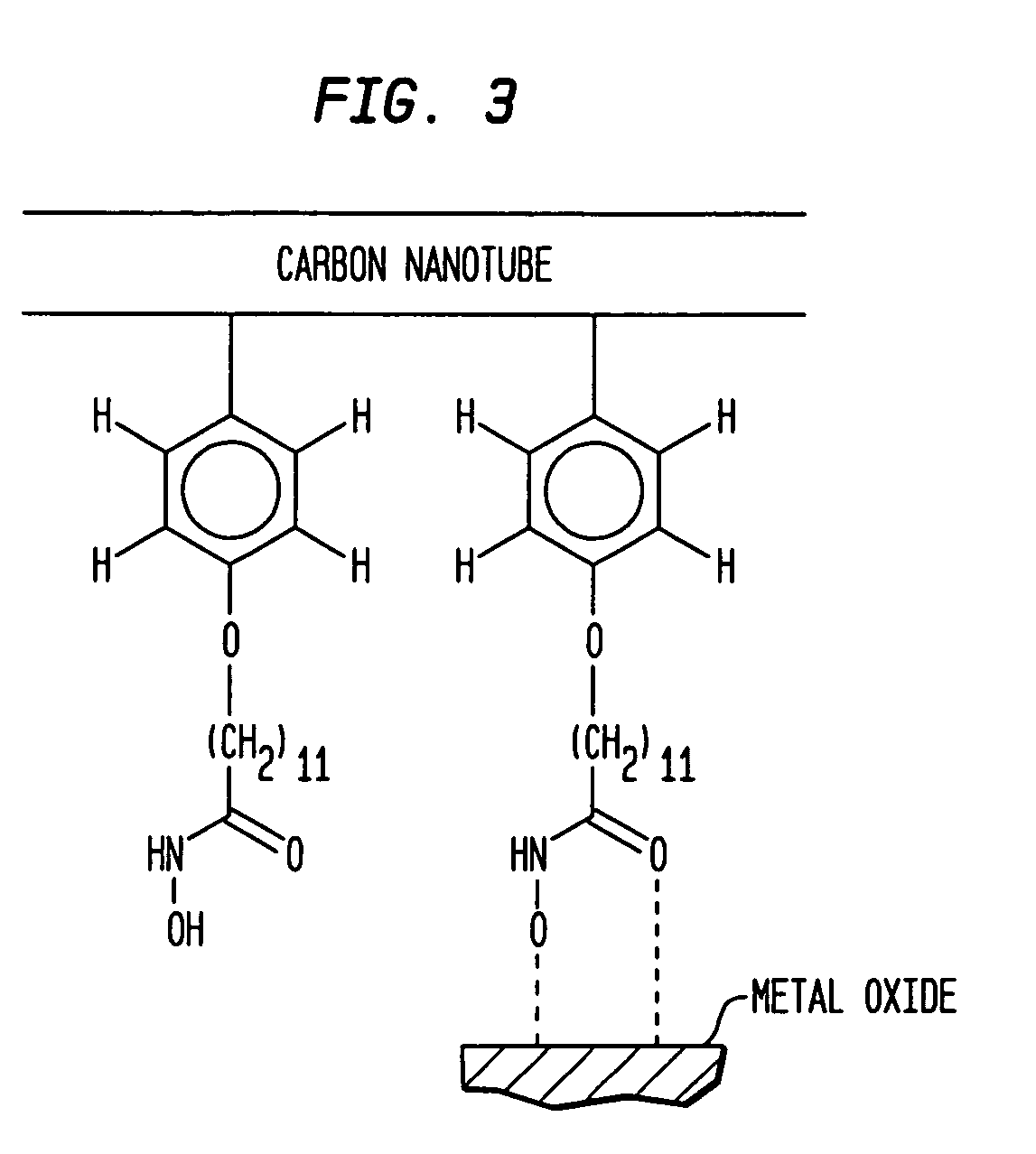

Selective placement of carbon nanotubes on oxide surfaces

The present invention provides a method for the selective placement of carbon nanotubes on a particular surface. In particular, the present invention provides a method in which self-assembled monolayers formed on an unpatterned or patterned metal oxide surface are used to attract or repel carbon nanotubes from a dispersion containing the same. In accordance with the present invention, the carbon nanotubes can be attracted to the self-assembled monolayers so as to be attached to the metal oxide surface, or they can be repelled by the self-assembled monolayers bonding to a predetermined surface other than the metal oxide surface containing the self-assembled monolayers.

Owner:GLOBALFOUNDRIES INC

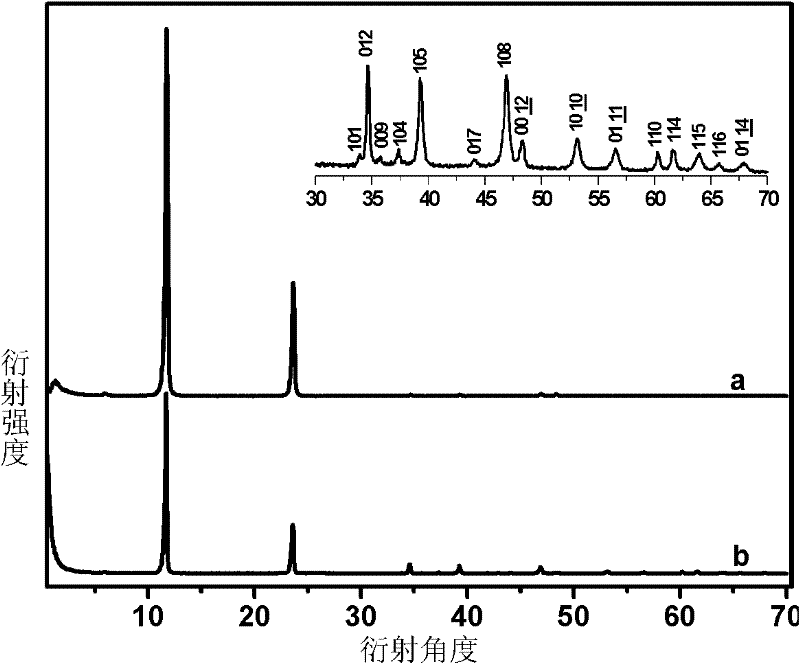

Method for preparing carbon nanotube (CNT)/layered double-metal hydroxide (LDH) compound

InactiveCN102350279AFacilitate ion exchangeExcellent peelabilityMicroballoon preparationMicrocapsule preparationCarbon nanotubeOxide composite

The invention discloses a method for preparing a CNT / LDH compound. The CNT / LDH compound is obtained through connecting hydroxy groups and carboxylic groups to the surface of CNTs through acidifying, adding metal salts and an alkaline substance to an aqueous dispersion of the CNTs, and forming an LDH in an in situ mode. The method of the invention has the advantages of simplicity, no need of a high temperature and low cost; and in the prepared CNT / LDH compound, the CNTs are uniformly dispersed in the LDH, and the composition and the structure are controllable. The prepared CNT / LDH compound which well preserves the layered structure of the LDH and effectively improves the dispersibility of the CNTs allows the sheet peeling of the LDH and the uniform dispersion of the CNTs to be easily realized when the CNT / LDH compound is applied to a polymer matrix.

Owner:ZHEJIANG UNIV

Carbon nanotube glazing technology

The invention provides a glazing that includes a substrate on which there is provided a coating comprising carbon nanotubes. The glazing can be an IG unit comprising two spaced-apart panes bounding a between-pane space, the IG unit having at least one exterior surface on which there is provided a transparent conductor coating comprising carbon nanotubes. The glazing can alternatively be a laminated glass assembly comprising two panes of glass and an interlayer comprising carbon nanotubes sandwiched therebetween. Monolithic substrate embodiments are also provided. In certain embodiments, the coating comprises both dielectric film and carbon nanotubes.

Owner:CARDINAL CG

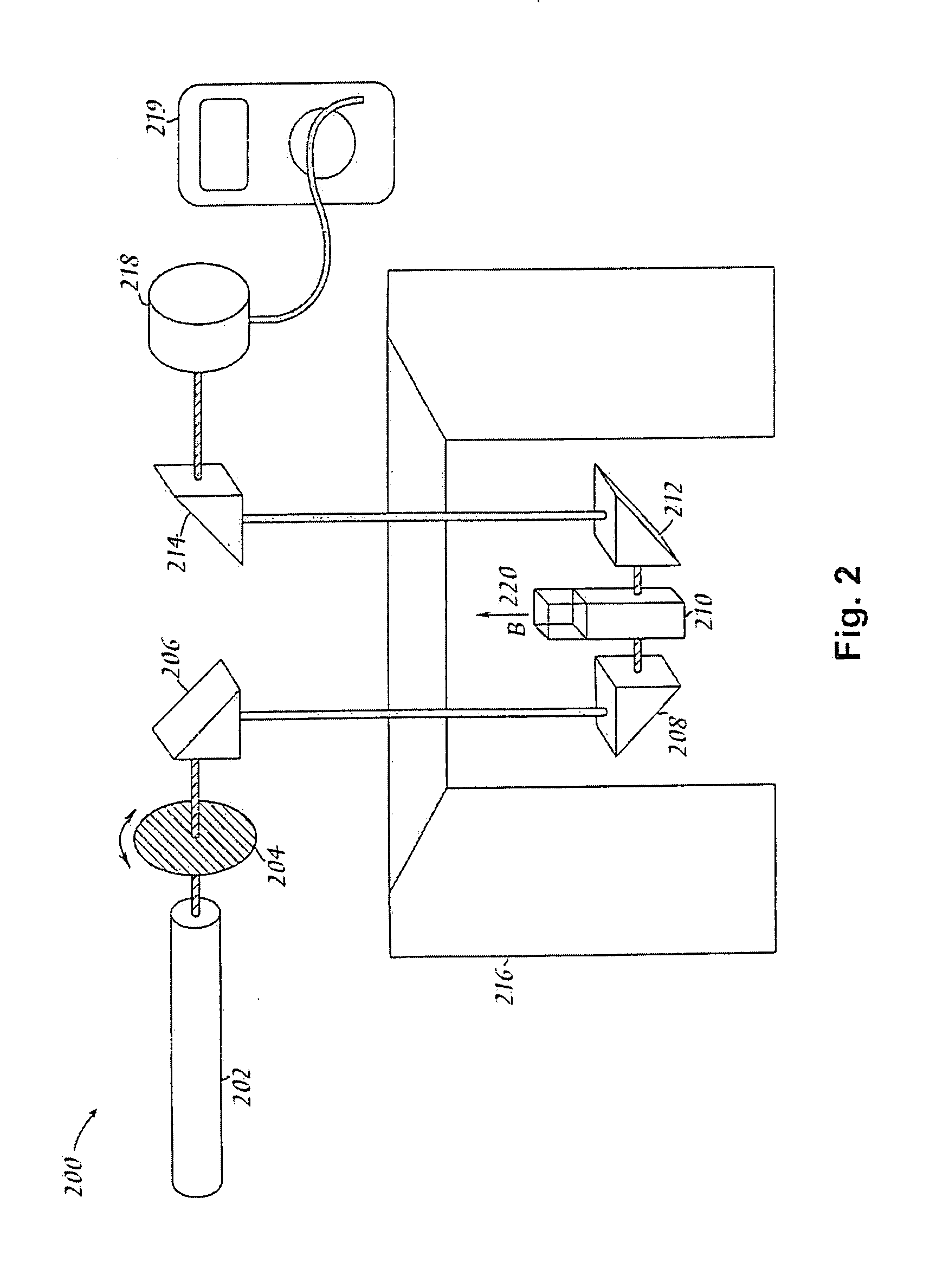

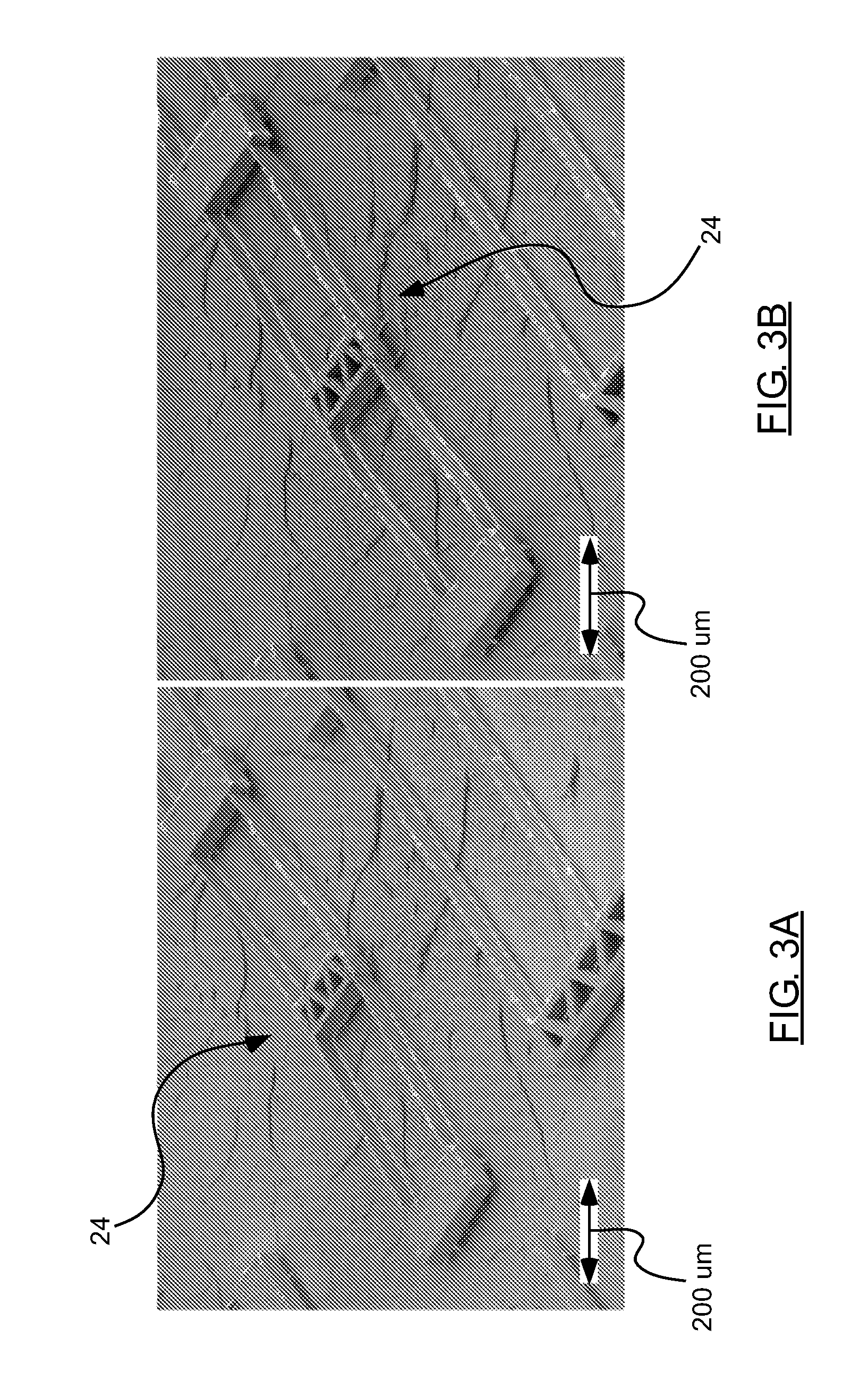

Macroscopic ordered assembly of carbon nanotubes

InactiveUS20080210370A1Firmly assembledMaterial nanotechnologyNanostructure manufactureNear neighborMicroscopic scale

The present invention is directed to the creation of macroscopic materials and objects comprising aligned nanotube segments. The invention entails aligning single-wall carbon nanotube (SWNT) segments that are suspended in a fluid medium and then removing the aligned segments from suspension in a way that macroscopic, ordered assemblies of SWNT are formed. The invention is further directed to controlling the natural proclivity or nanotube segments to self assemble into or ordered structures by modifying the environment of the nanotubes and the history of that environment prior to and during the process. The materials and objects are “macroscopic” in that they are large enough to be seen without the aid of a microscope or of the dimensions of such objects. These macroscopic ordered SWNT materials and objects have the remarkable physical, electrical, and chemical properties that SWNT exhibit on the microscopic scale because they are comprised of nanotubes, each of which is aligned in the same direction and in contact with its nearest neighbors. An ordered assembly of closest SWNT also serves as a template for growth of more and larger ordered assemblies. An ordered assembly further serves as a foundation for post processing treatments that modify the assembly internally to specifically enhance selected material properties such as shear strength, tensile strength, compressive strength, toughness, electrical conductivity, and thermal conductivity.

Owner:RICE UNIV

Carbon nanotube assembly

A carbon nanotube assembly comprises a plurality of carbon nanotubes arranged into a patterned frame and extending from a base of the patterned frame to a face of the patterned frame, the patterned frame having a height of at least about 10 μm or greater. At least one passage extends through or is defined in the patterned frame, the at least one passage extending from the base of the patterned frame to the face of the patterned frame. An interstitial material at least partially fills interstices between at least some of the carbon nanotubes.

Owner:BRIGHAM YOUNG UNIV

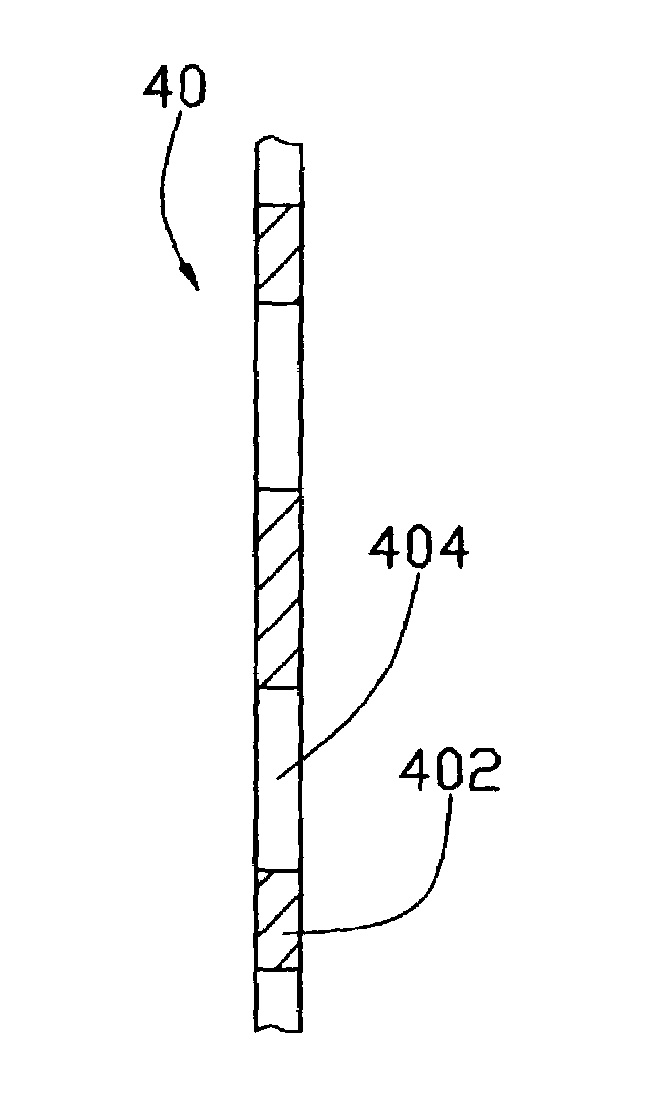

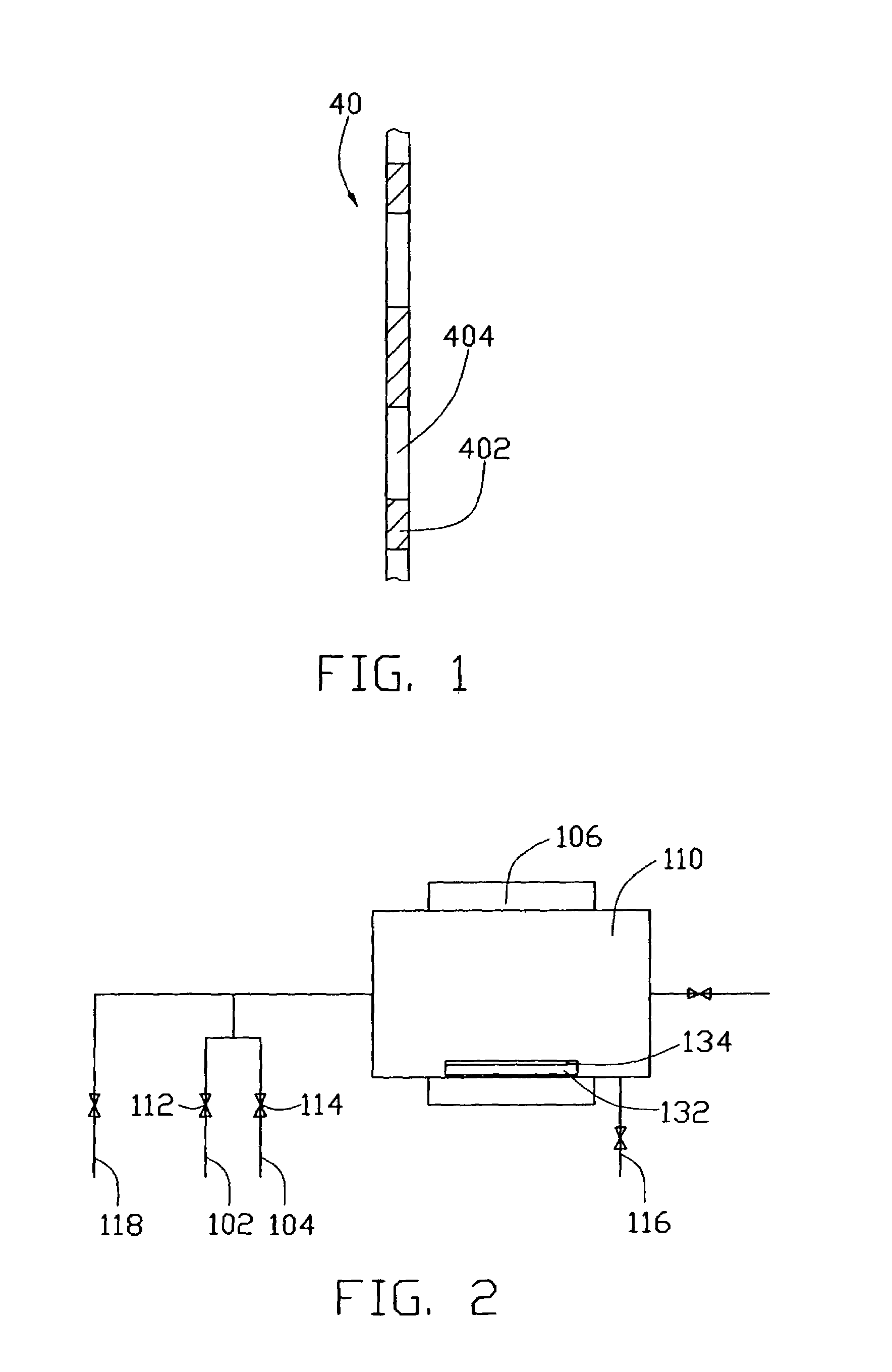

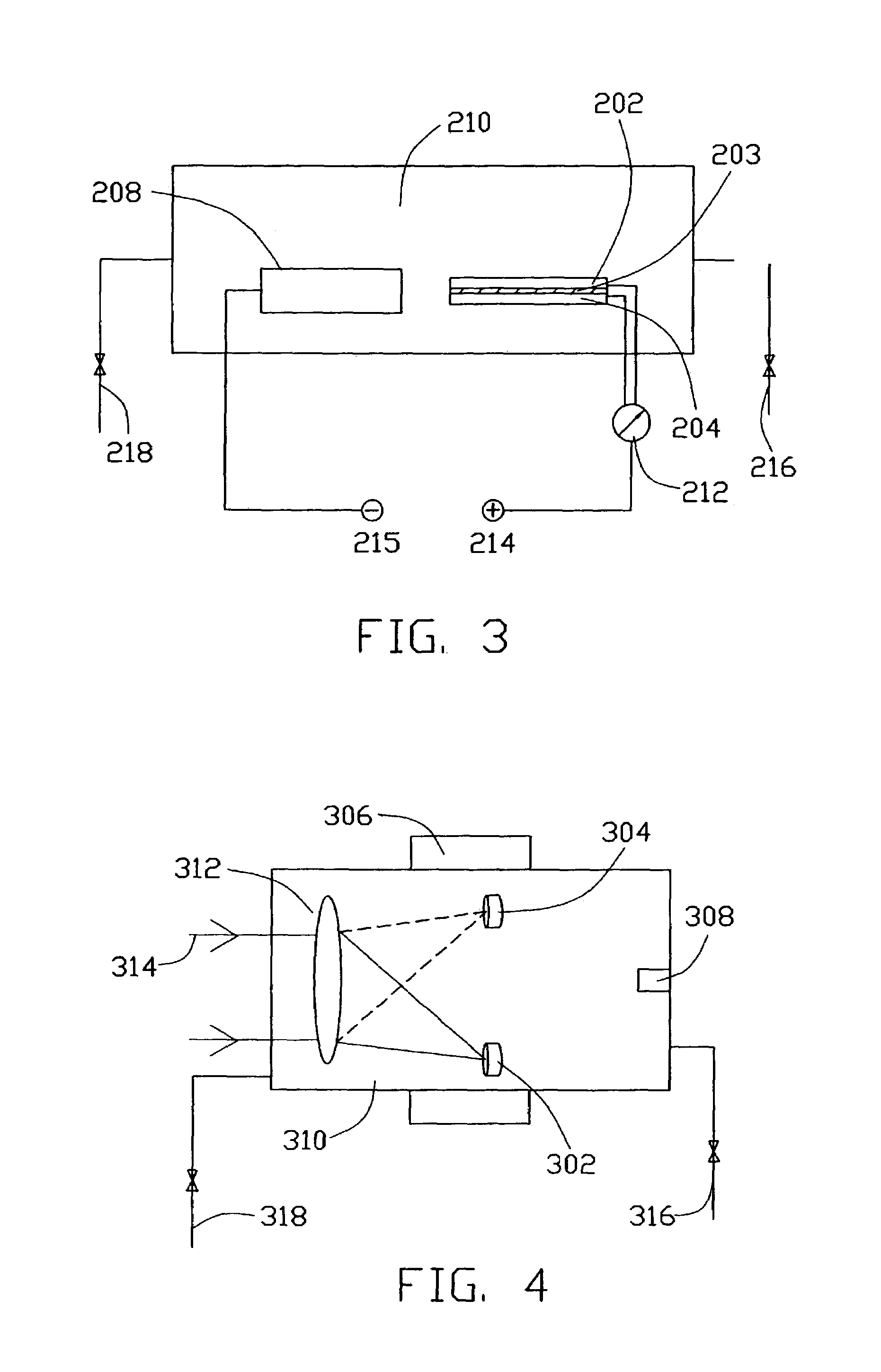

Isotope-doped carbon nanotube and method and apparatus for forming the same

An isotope-doped carbon nanotube (40) includes a plurality of first carbon nanotube segments (402) having carbon-12 isotopes and a plurality of second carbon nanotube segments (404) having carbon-13 isotopes. The first and second carbon nanotube segments are alternately arranged along a longitudinal direction of the carbon nanotube. Three preferred methods employ different isotope sources to form isotope-doped carbon nanotubes. In a chemical vapor deposition method, different isotope source gases are alternately introduced. In an arc discharge method, a power source is alternately switched between different isotope anodes. In a laser ablation method, a laser is alternately focused on different isotope targets. In addition, an apparatus for implementing the preferred methods is provided.

Owner:TSINGHUA UNIV +1

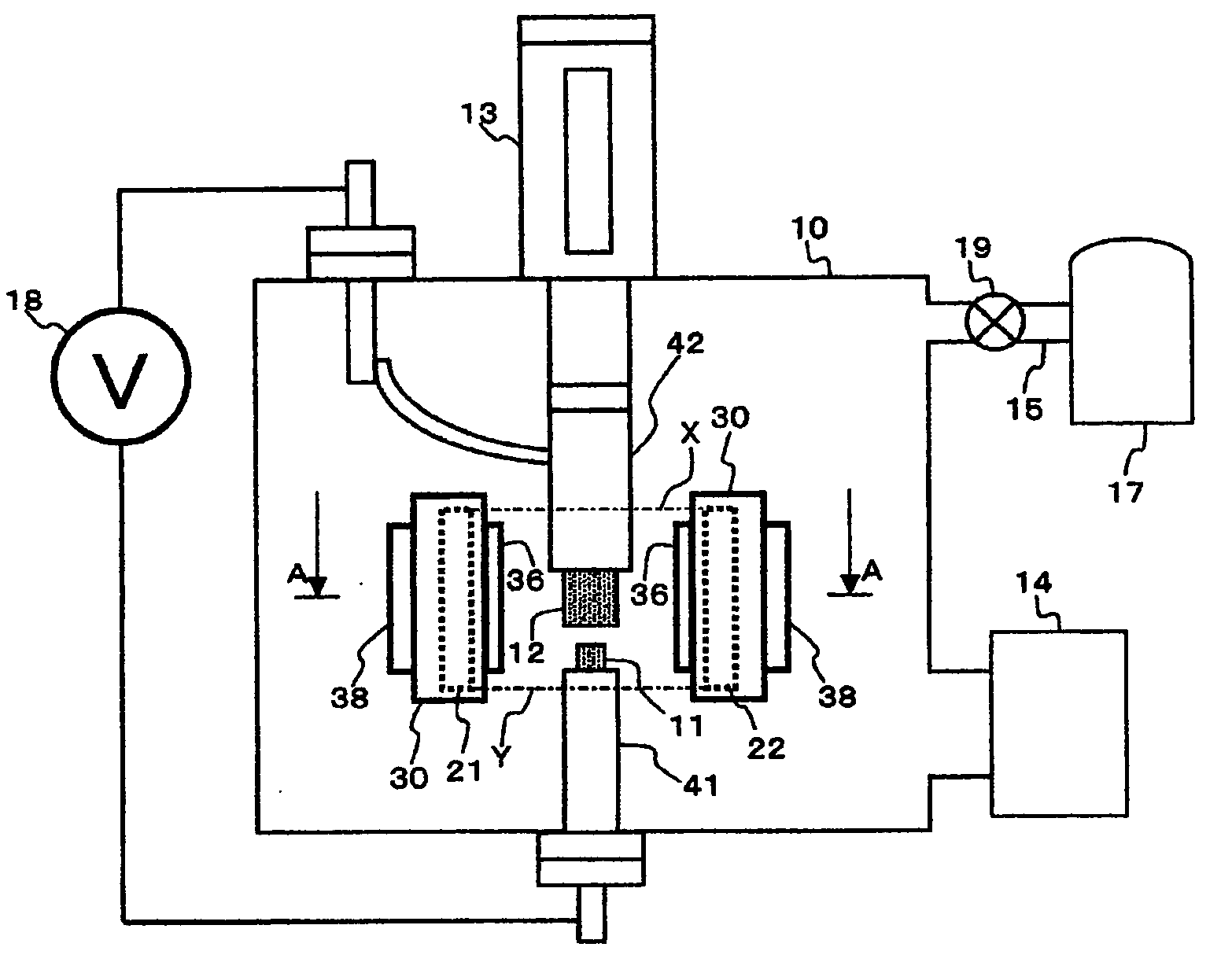

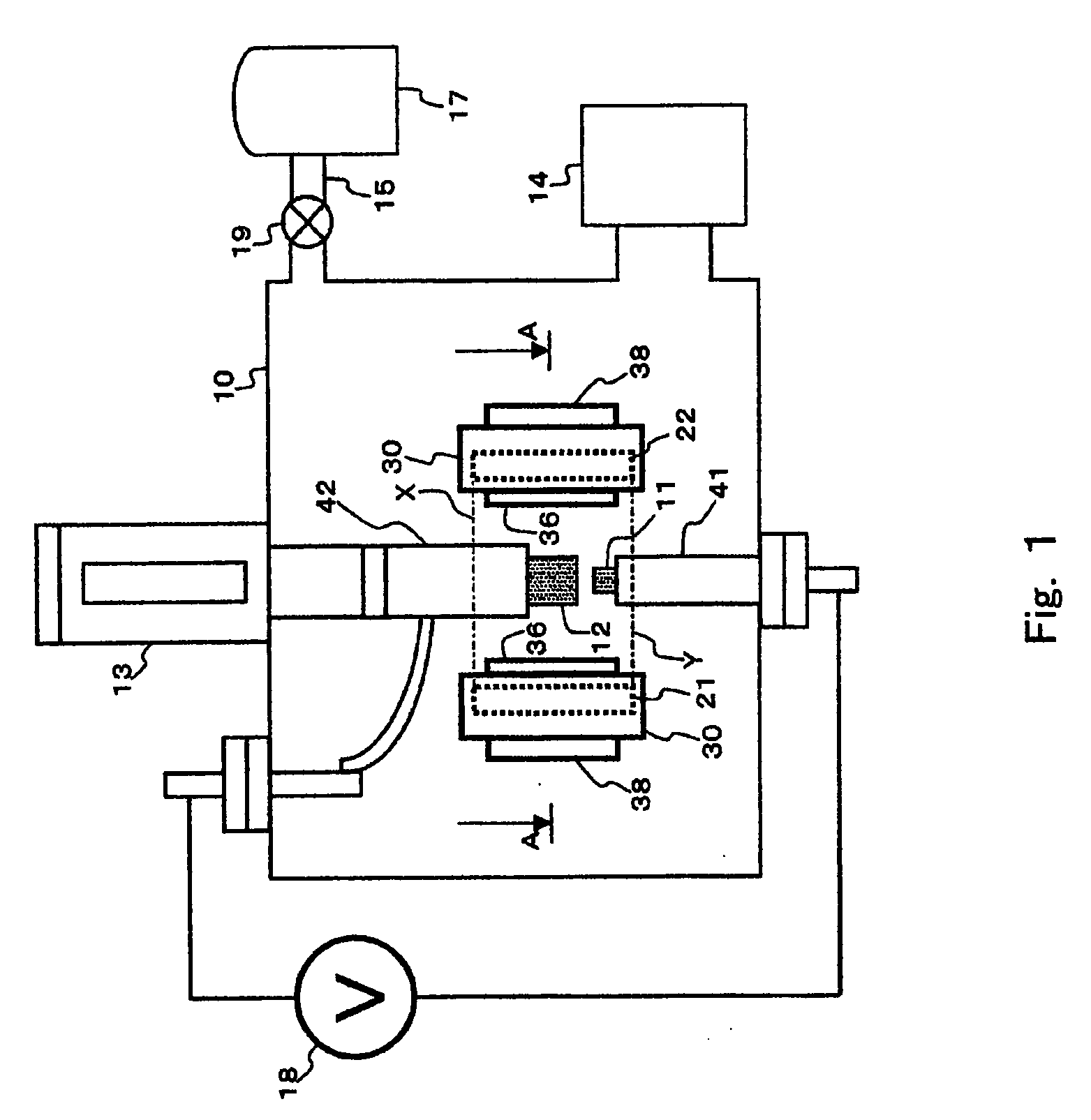

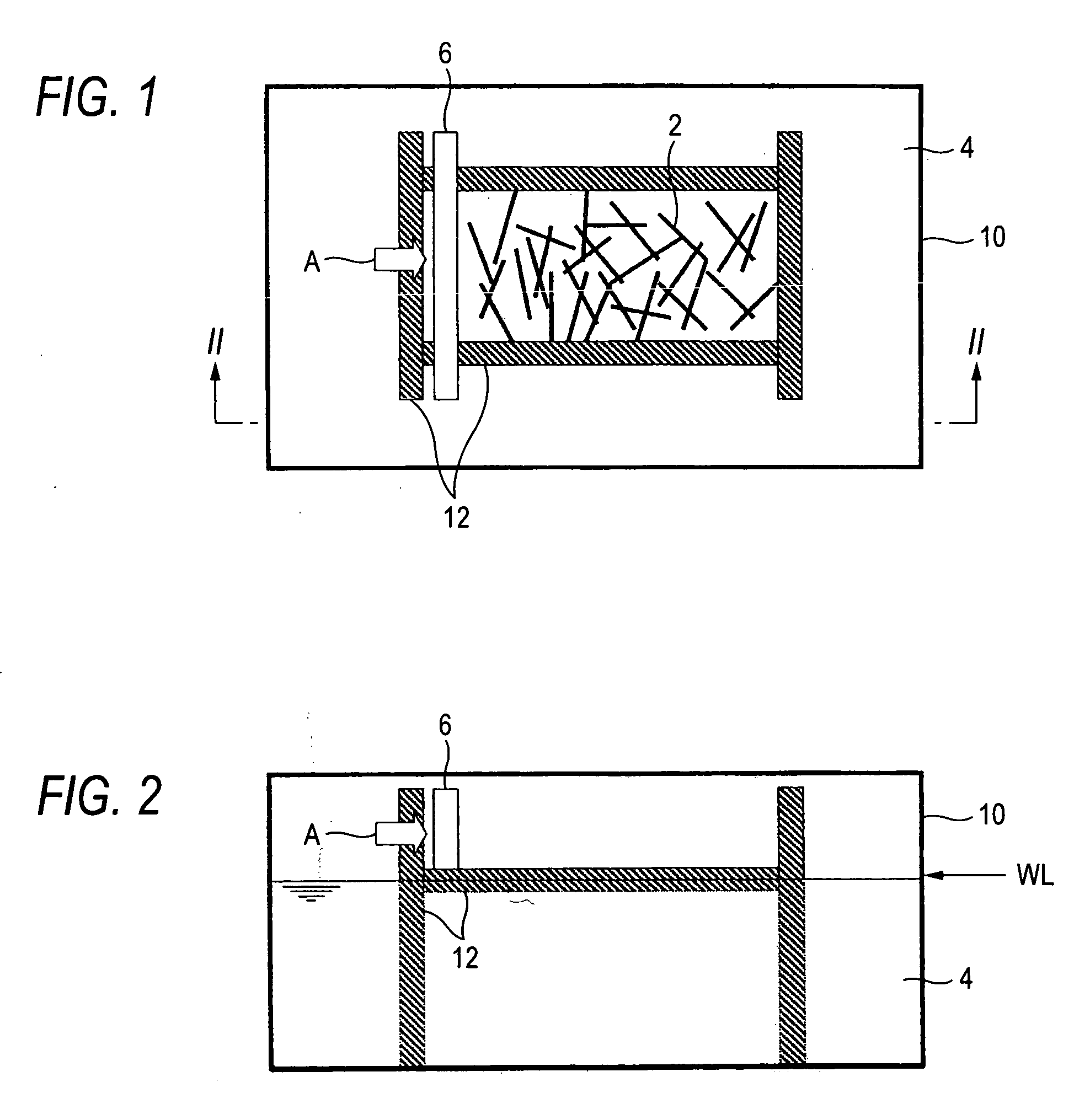

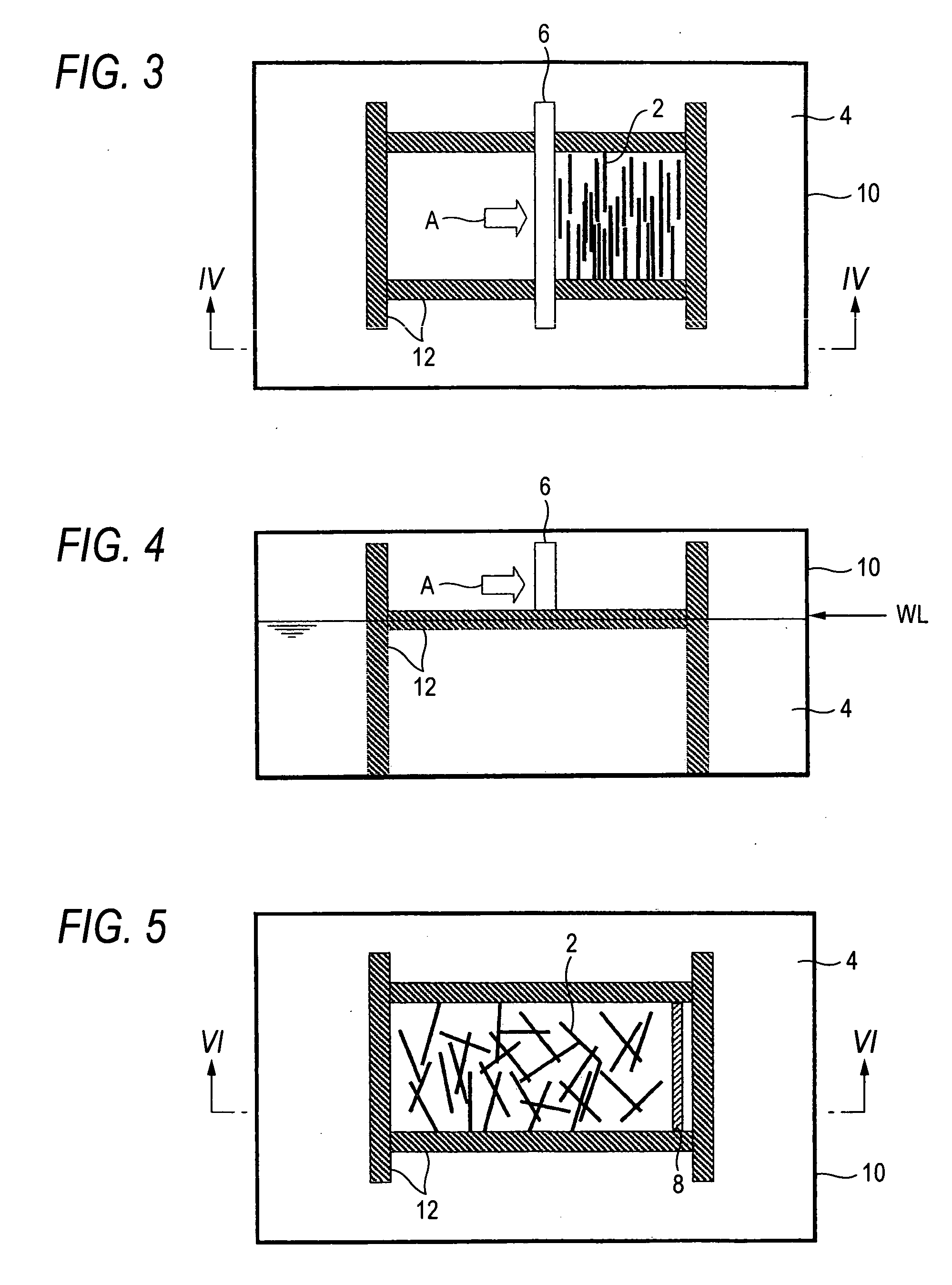

Manufacturing apparatus and method for carbon nanotube

InactiveUS20040168904A1Efficient synthesisHigh purityMaterial nanotechnologyCarbon nanotubesCarbon nanotubeBCN nanotube

Provided is a manufacturing apparatus for a carbon nanotube, including: at least two electrodes whose tips are opposed to each other, and a power supply that applies a voltage between the two electrodes to generate discharge plasma in a discharge area between the two electrodes. By using a porous carbonaceous material for at least one of the two electrodes, it is possible to provide a manufacturing apparatus and method for a carbon nanotube, which are capable of manufacturing at a low cost the carbon nanotube that is inexpensive and has a further higher purity.

Owner:FUJIFILM BUSINESS INNOVATION CORP

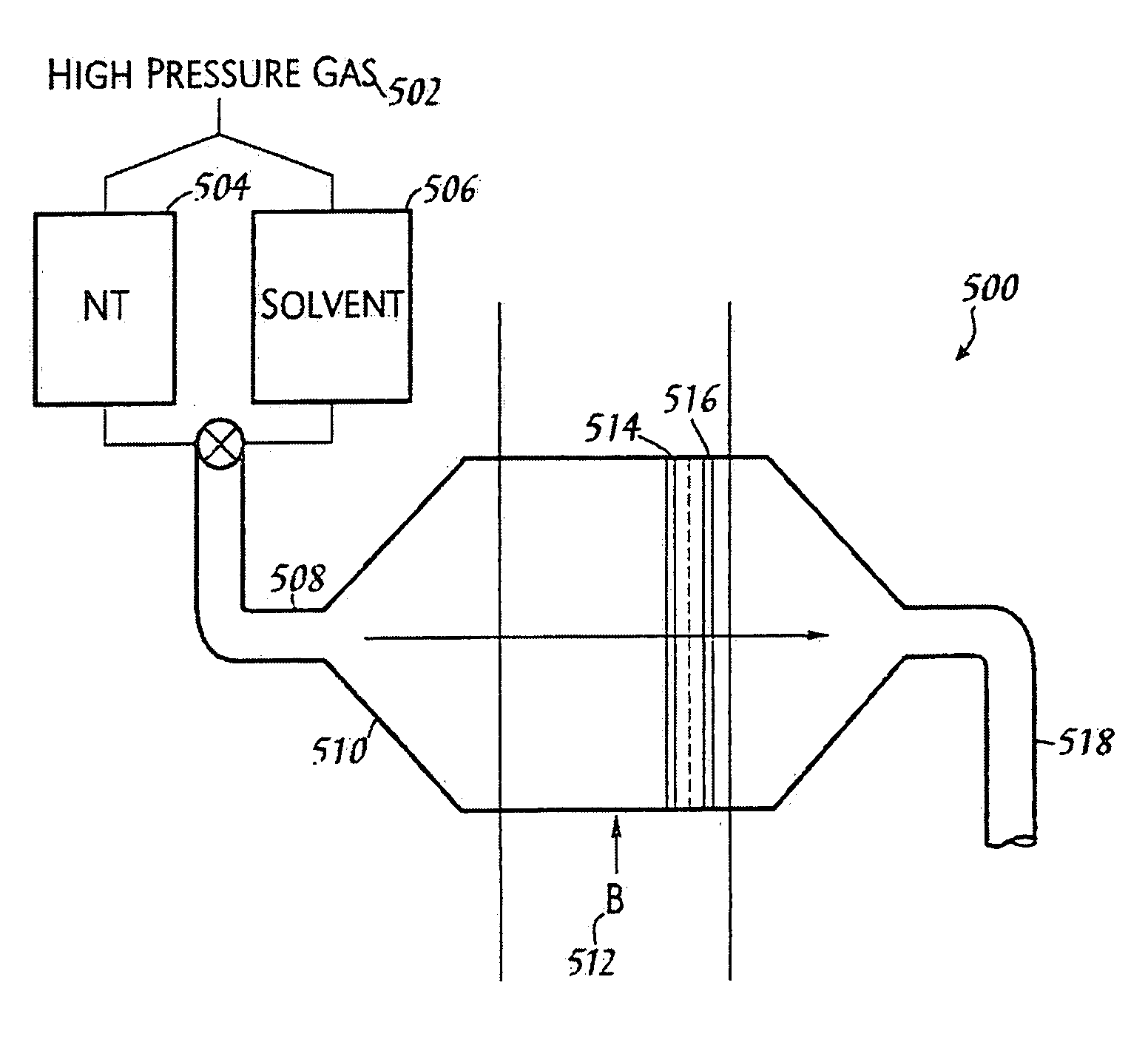

Carbon nano tube processing method, processing apparatus, and carbon nano tube dispersion liquid, carbon nano tube powder

InactiveUS7838843B2Low capability of cutting tubeImproving bundle stateMaterial nanotechnologyPigmenting treatmentCarbon nanotubeSolvent

Owner:HAMAMATSU PHOTONICS KK

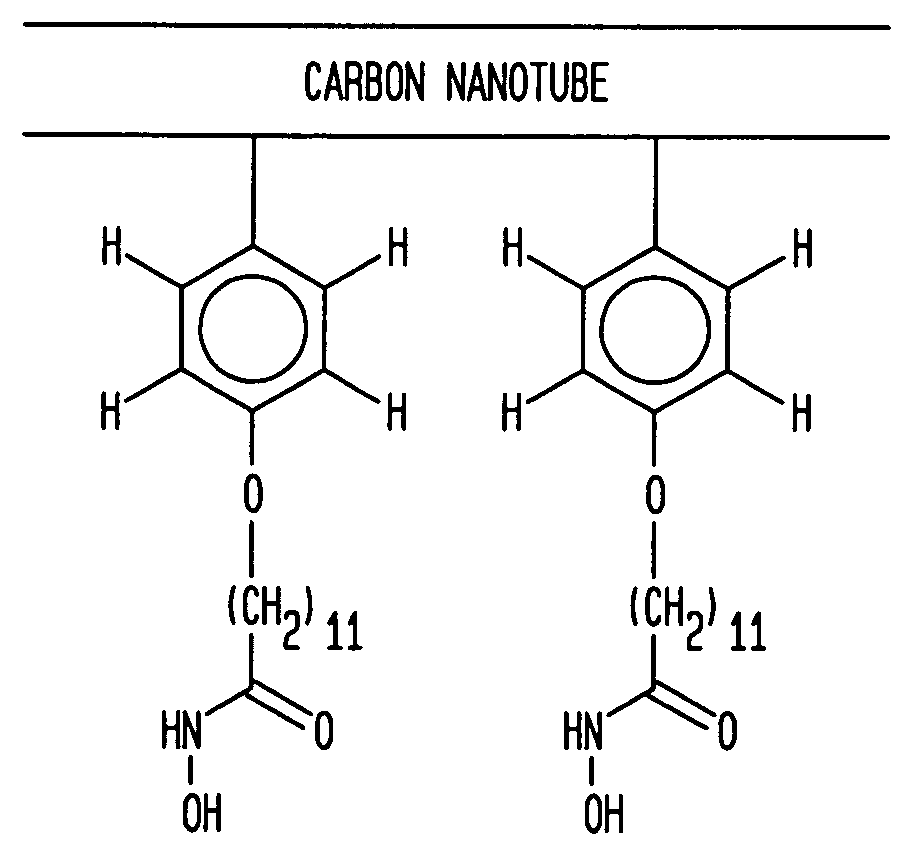

Selective placement of carbon nanotubes through functionalization

ActiveUS20080102213A1Little and no defectMaintain structural integrityMaterial nanotechnologyPretreated surfacesChemical compoundCarbon nanotube

The present invention provides a method for selectively placing carbon nanotubes on a substrate surface by using functionalized carbon nanotubes having an organic compound that is covalently bonded to such carbon nanotubes. The organic compound comprises at least two functional groups, the first of which is capable of forming covalent bonds with carbon nanotubes, and the second of which is capable of selectively bonding metal oxides. Such functionalized carbon nanotubes are contacted with a substrate surface that has at least one portion containing a metal oxide. The second functional group of the organic compound selectively bonds to the metal oxide, so as to selectively place the functionalized carbon nanotubes on the at least one portion of the substrate surface that comprises the metal oxide.

Owner:GLOBALFOUNDRIES US INC

Method for forming carbon nanotube thin film

InactiveUS20060134326A1Easy transferMaterial nanotechnologyLiquid surface applicatorsCarbon nanotubeThin membrane

A method for producing a carbon nanotube thin film comprises a step of dropping a mixed liquid containing carbon nanotubes and an ionic liquid onto a liquid surface of a film forming liquid to spread the carbon nanotubes on the liquid surface.

Owner:FUJIFILM BUSINESS INNOVATION CORP

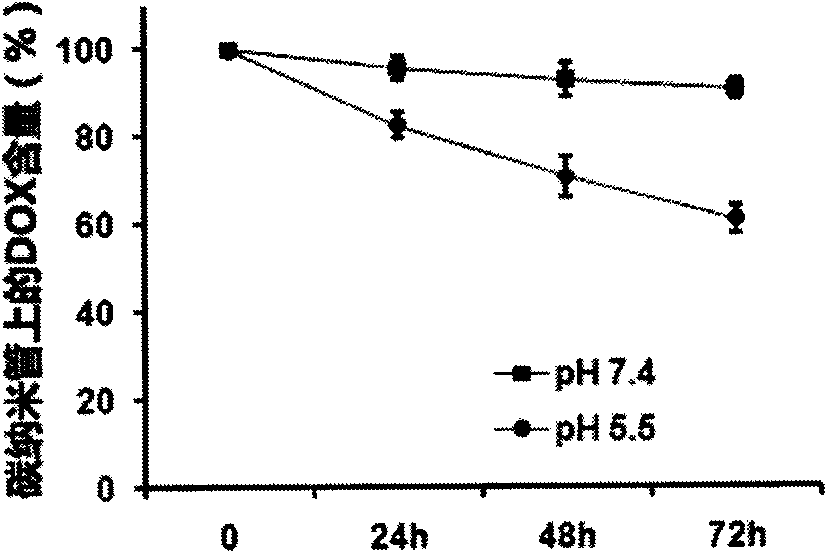

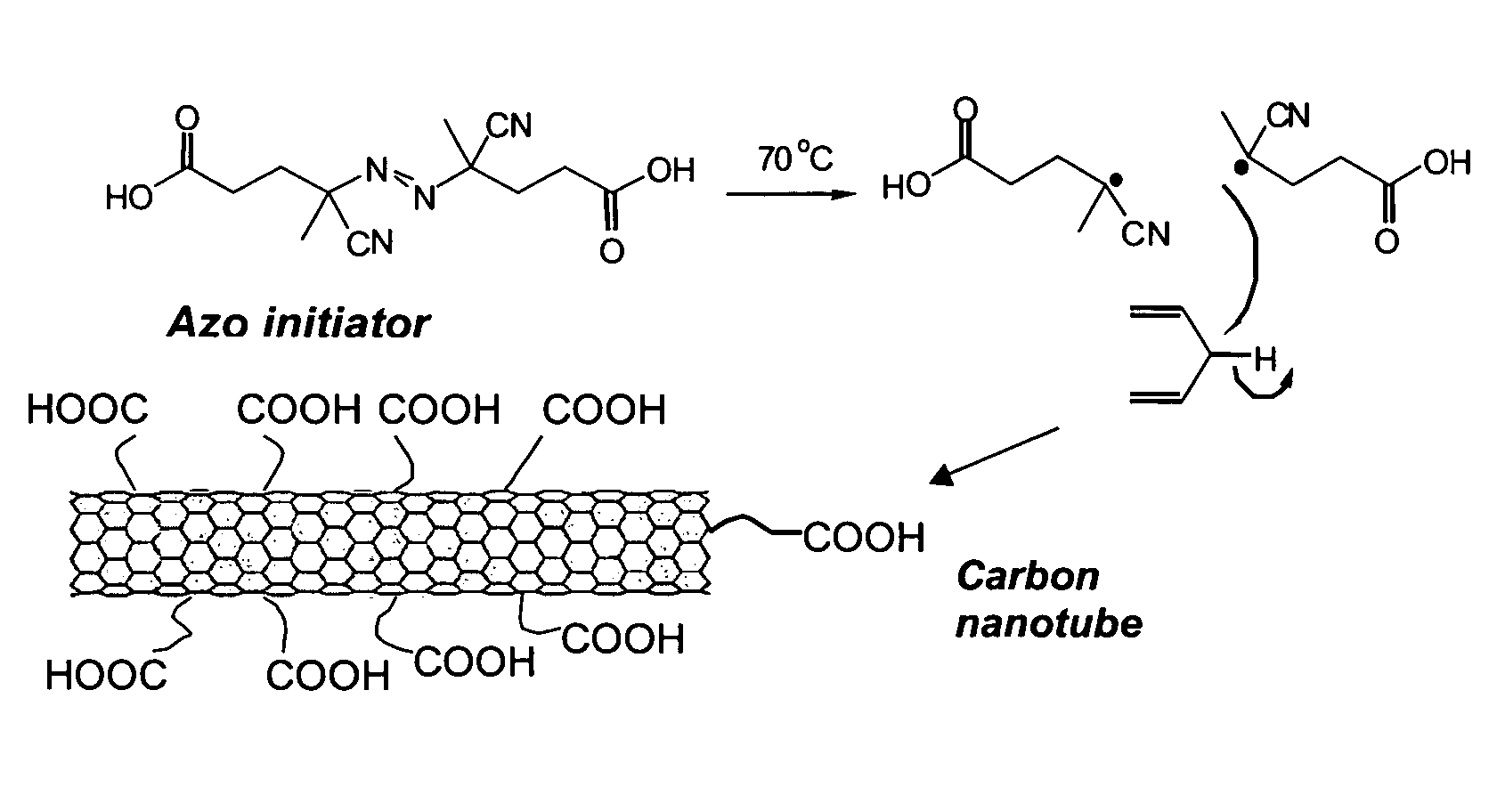

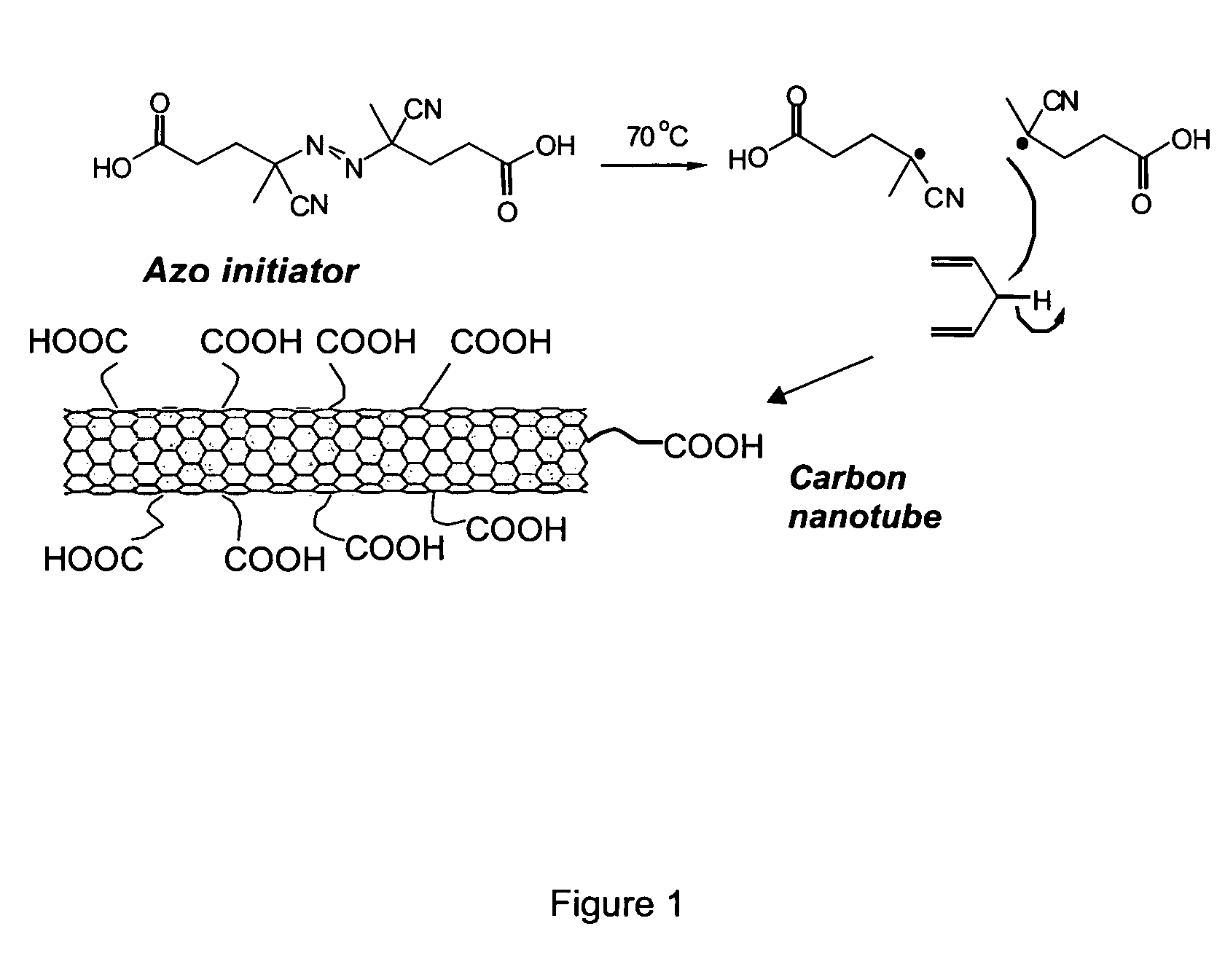

Method for preparing chitosan or sodium alginate-modified carbon nanotube-targeted slow release carrier

InactiveCN101590242AGood water solubilityAchieving sustained release at acidic pHPharmaceutical non-active ingredientsAntineoplastic agentsFiltrationModified carbon

The invention relates to a method for preparing a chitosan or sodium alginate-modified carbon nanotube-targeted slow release carrier in the technical field of nano materials, which comprises the following steps: preparing cut carbon nanotubes; preparing modified carbon nanotubes; preparing a modified carbon nanotube-targeted slow release carrier and adding aqueous solution of an anthracycline anticancer medicament; and subjecting the solution to supersonic treatment, stirring treatment and suction filtration, washing the product of the suction filtration, drying the product at room temperature under vacuum to obtain the chitosan or sodium alginate-modified carbon nanotube-targeted slow release carrier carrying the medicament. The method can realize an adriamycin carrying ratio of between 151 and 161 percent according to measurement.

Owner:SHANGHAI JIAO TONG UNIV

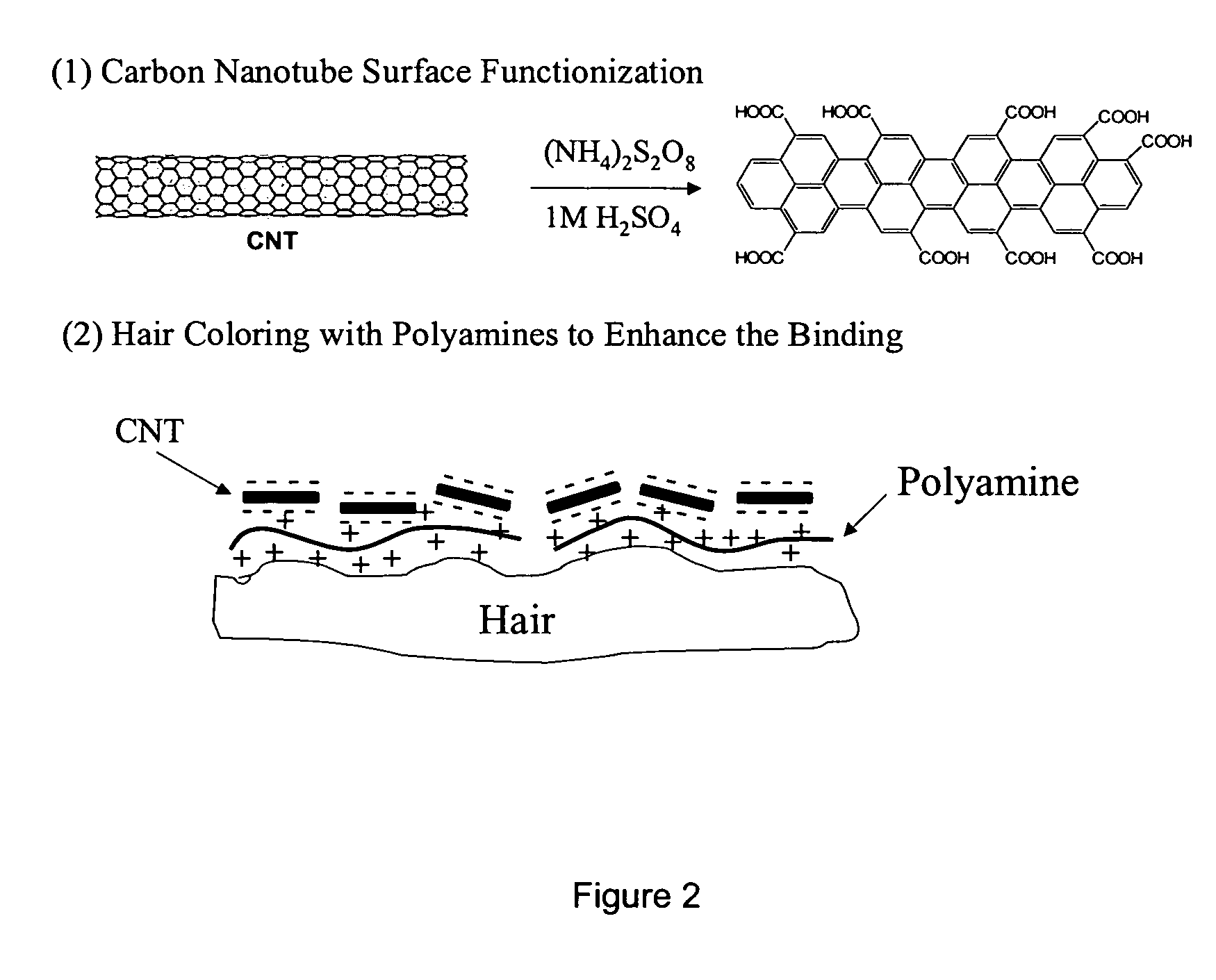

Hair coloring and cosmetic compositions comprising carbon nanotubes

Owner:EI DU PONT DE NEMOURS & CO

Composite hydroxyapatite/carbon nanotube material and its prepn process

InactiveCN1440948AImprove mechanical propertiesGood biocompatibilitySurgeryProsthesisApatiteCarbon nanotube

The present invention relates to a kind of composite hydroxyapatite / carbon nanotube material and its preparation process. The composite material consists of mainly two components including hydroxyapatite and carbon nanotube. The technological process includes chemical preciptiation to synthesize hydroxyapatite, and compounding directly with carbon nanotube to prepare compoiste hydroxapatite / carbon nanotube material. The composite material possesses excellent mechanical performance and biocompatibility and certain magnetism and wave absorbing performance, so that the composite material may be used in repairing and replacement of body bone and extracorporeal physical treatment of bone diseases, and may have latent application as body's bearing bone, magnetic and wave-absorbing material.

Owner:SHANDONG UNIV

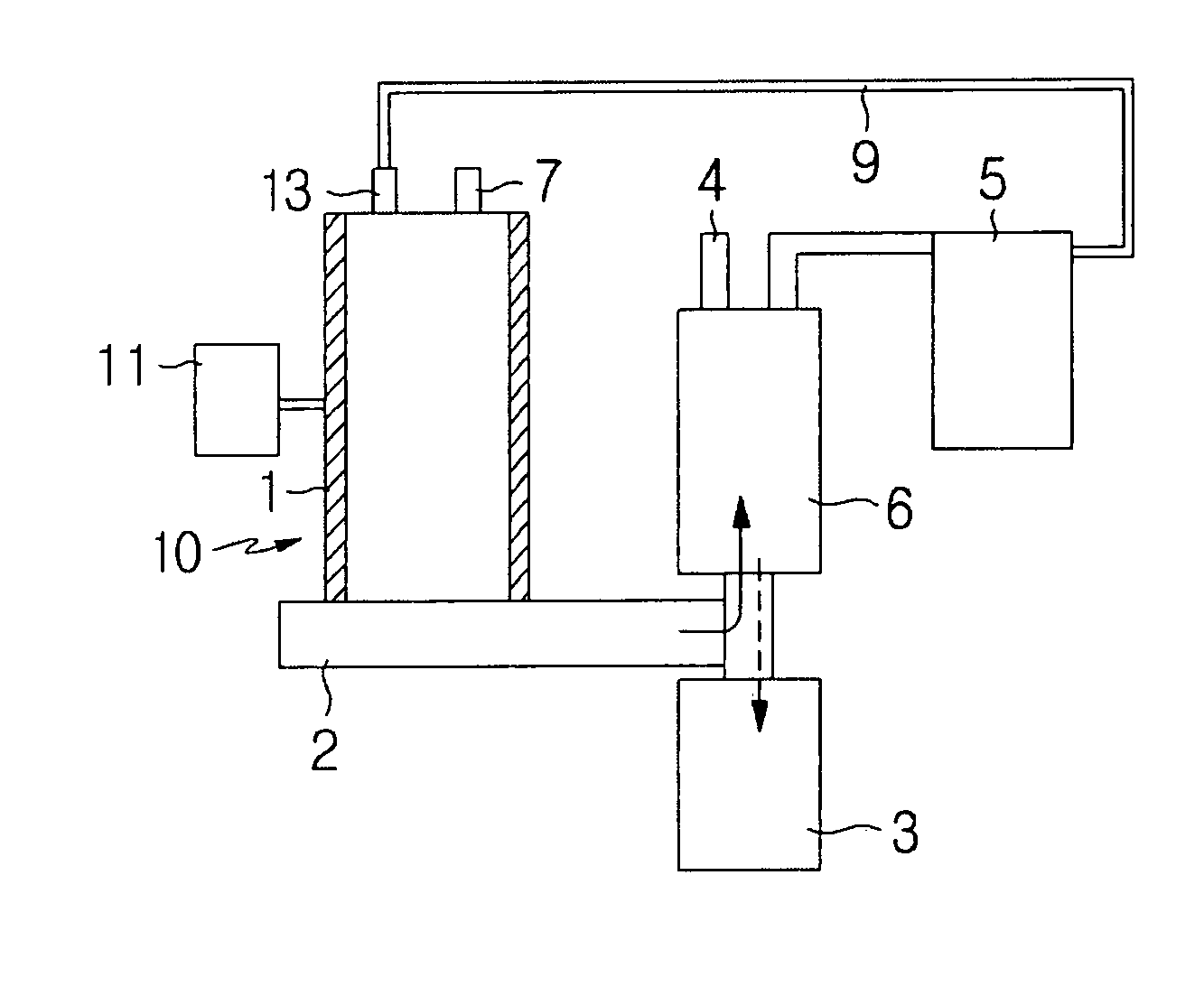

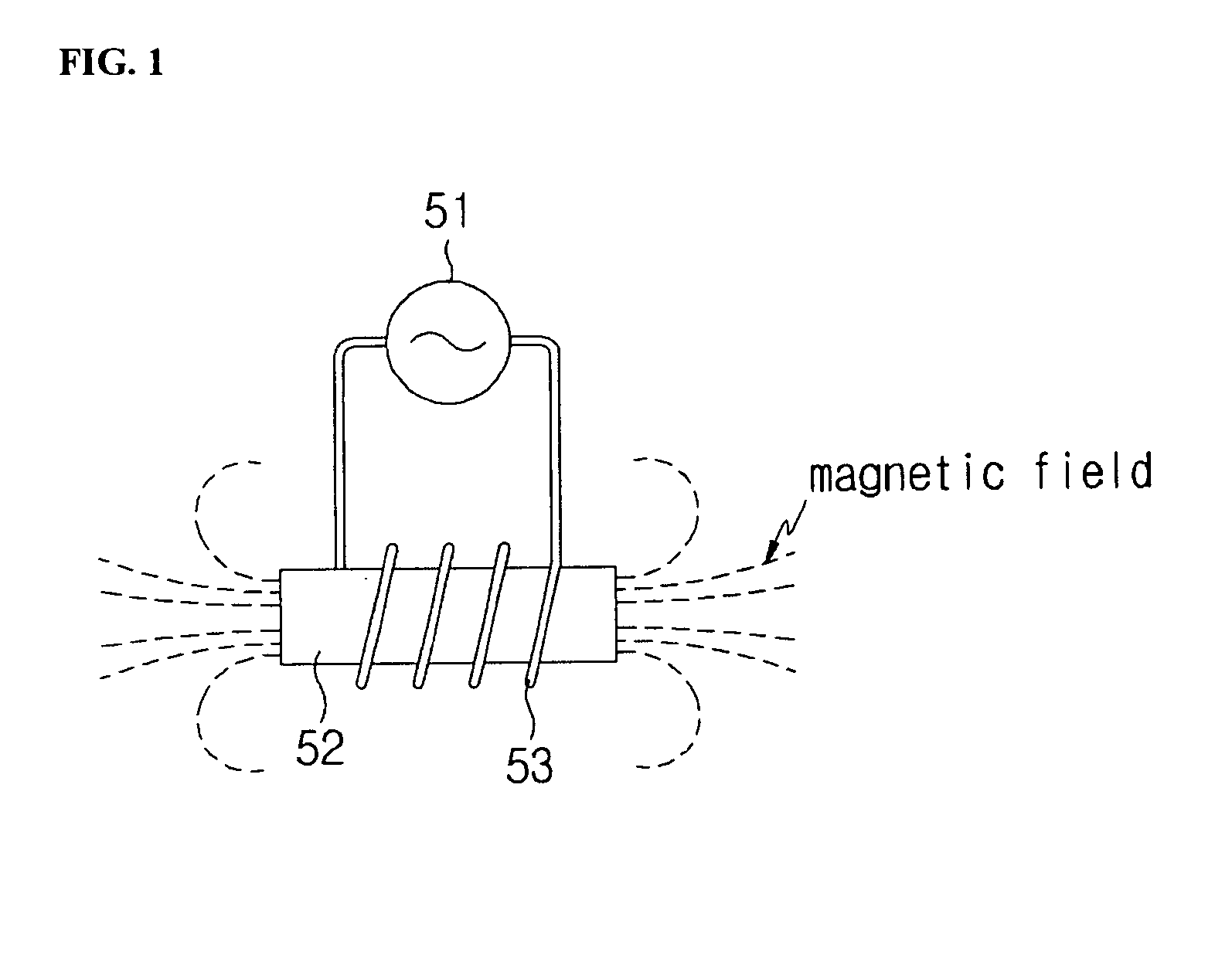

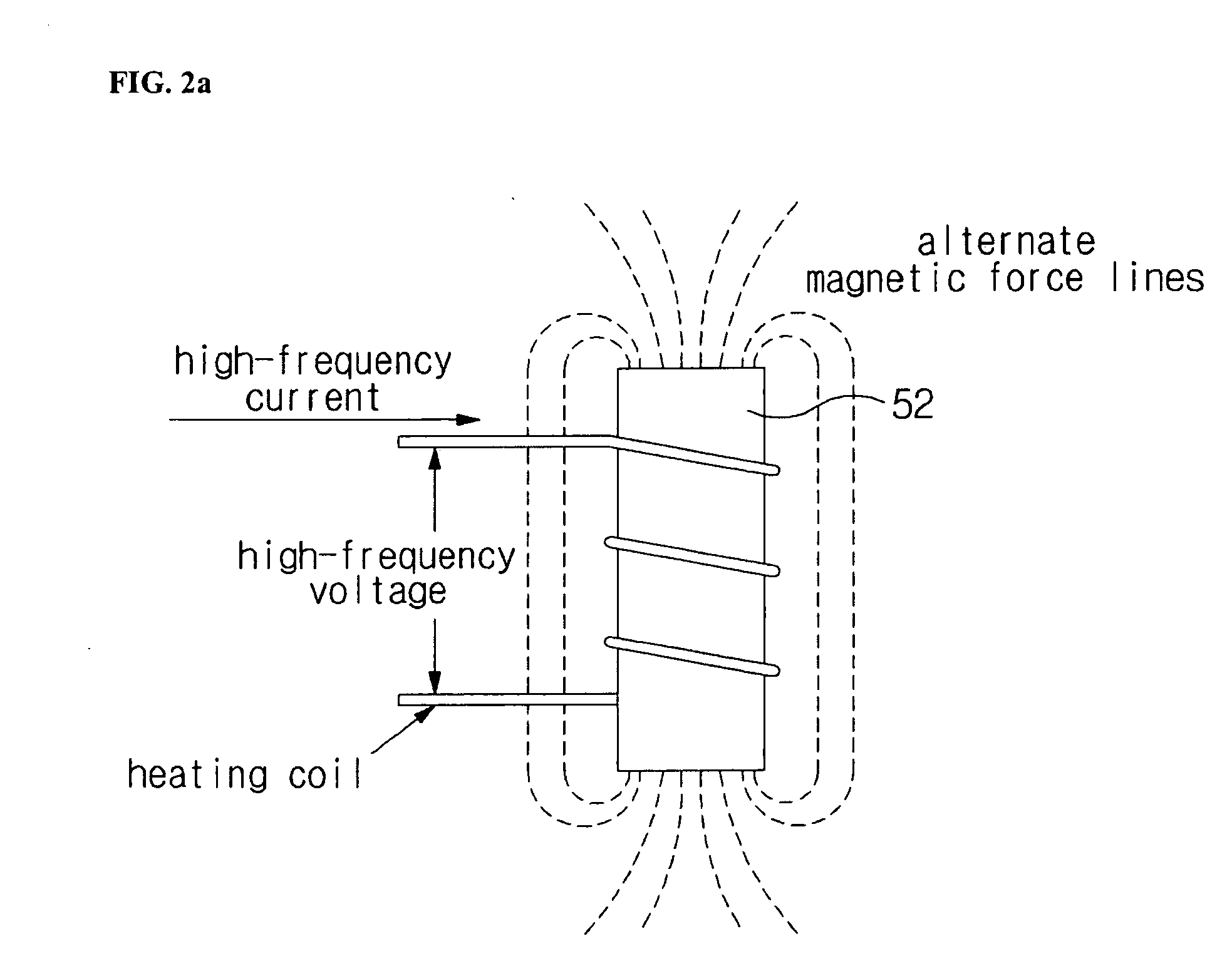

Apparatus for mass production of carbon nanotubes using high-frequency heating furnace

The apparatus for mass production of carbon nanotubes uses a high-frequency furnace and a fluid flow process. A metallic catalyst and a reaction gas are supplied into a reaction chamber so that the catalyst and the decomposed carbonization gas are reacted in a vapor phase in the chamber to produce the nanotubes. After the reaction, the carbonization gas and the carbon nanotubes are transferred to a filter via a heat exchanger in which they are separated from each other. Then, the carbon nanotubes are collected in a collector, hydrocarbon of the reacted gas burns in air and is discharged to the outside, and inert gas, such as nitrogen and argon, is collected and supplied again to the chamber. The apparatus produces the nanotubes in mass quantities under atmospheric pressure, and requires no separate vacuum device, minimizing the scale and cost of the equipment.

Owner:VIKO

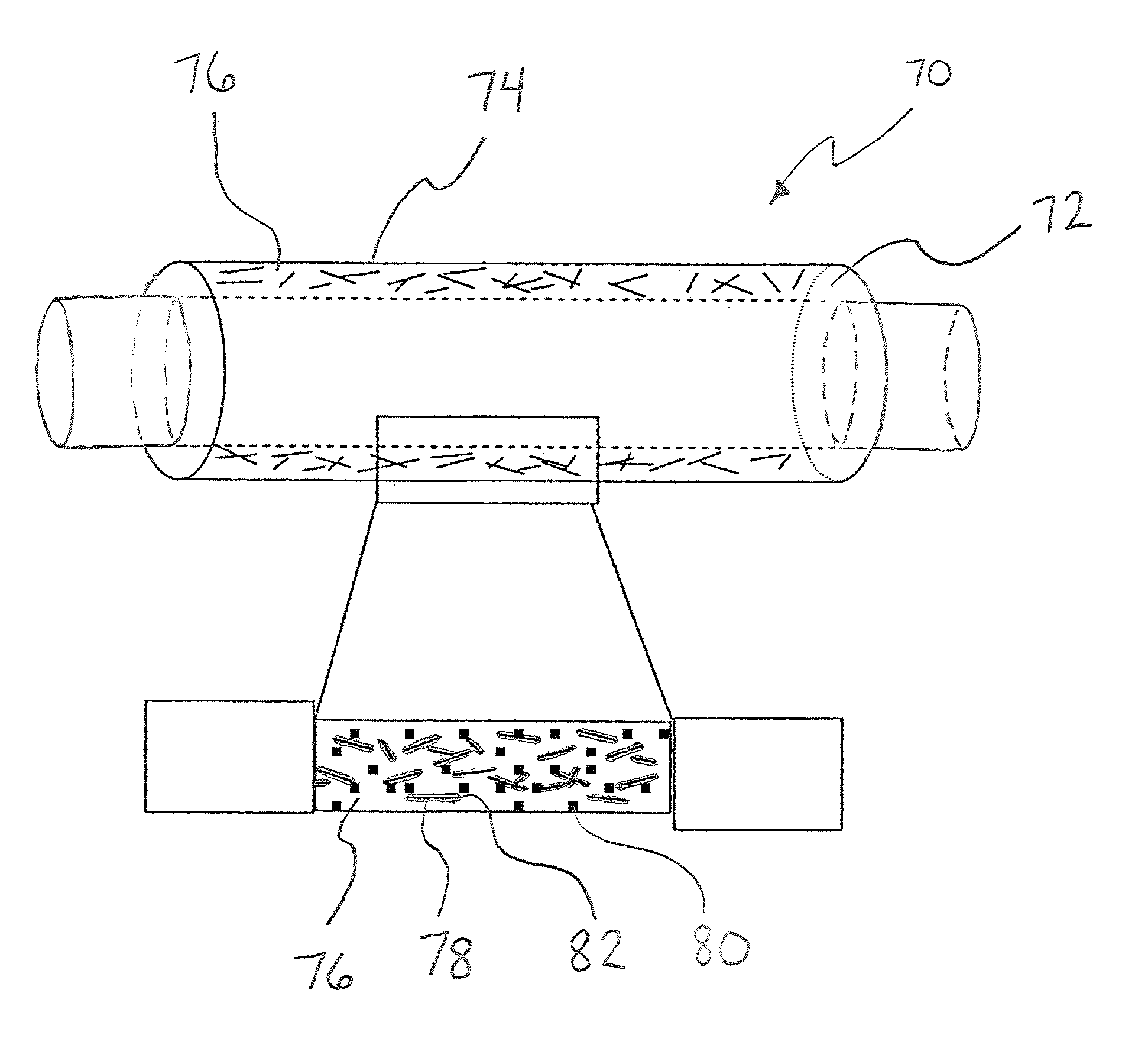

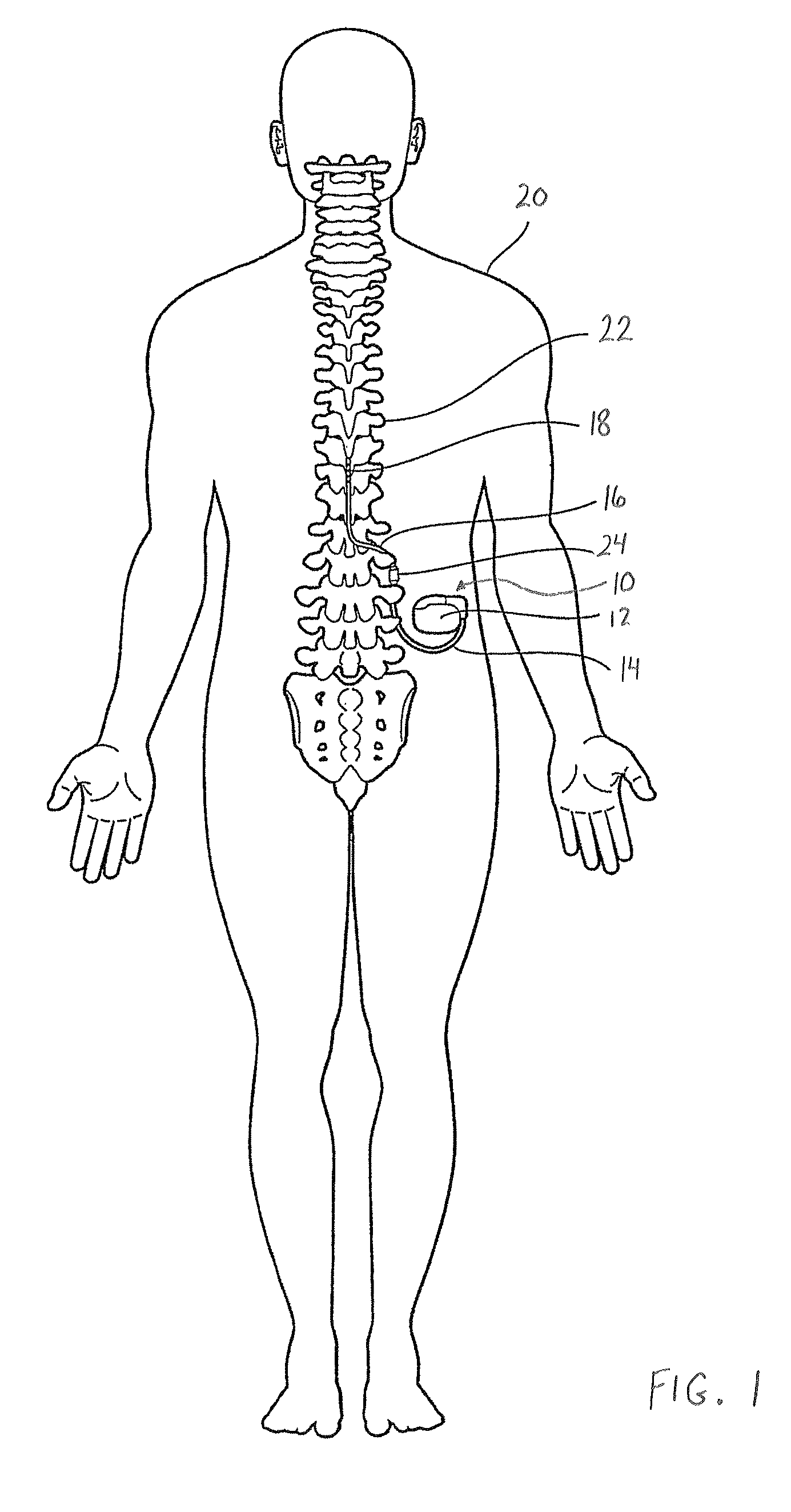

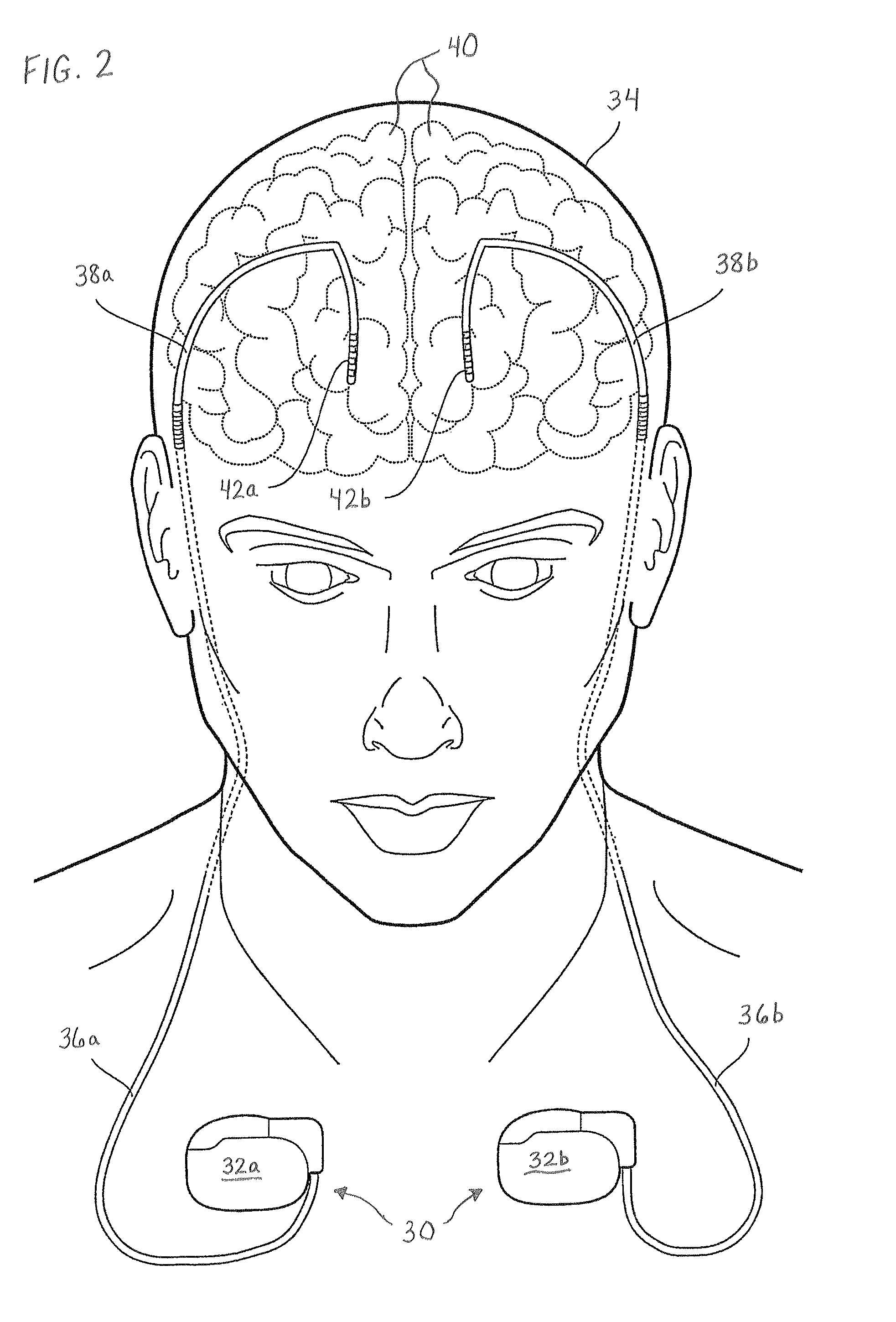

Discontinuous conductive filler polymer-matrix composites for electromagnetic shielding

ActiveUS9044593B2Internal electrodesDiagnostic recording/measuringElectrical conductorCarbon nanofiber

Owner:MEDTRONIC INC

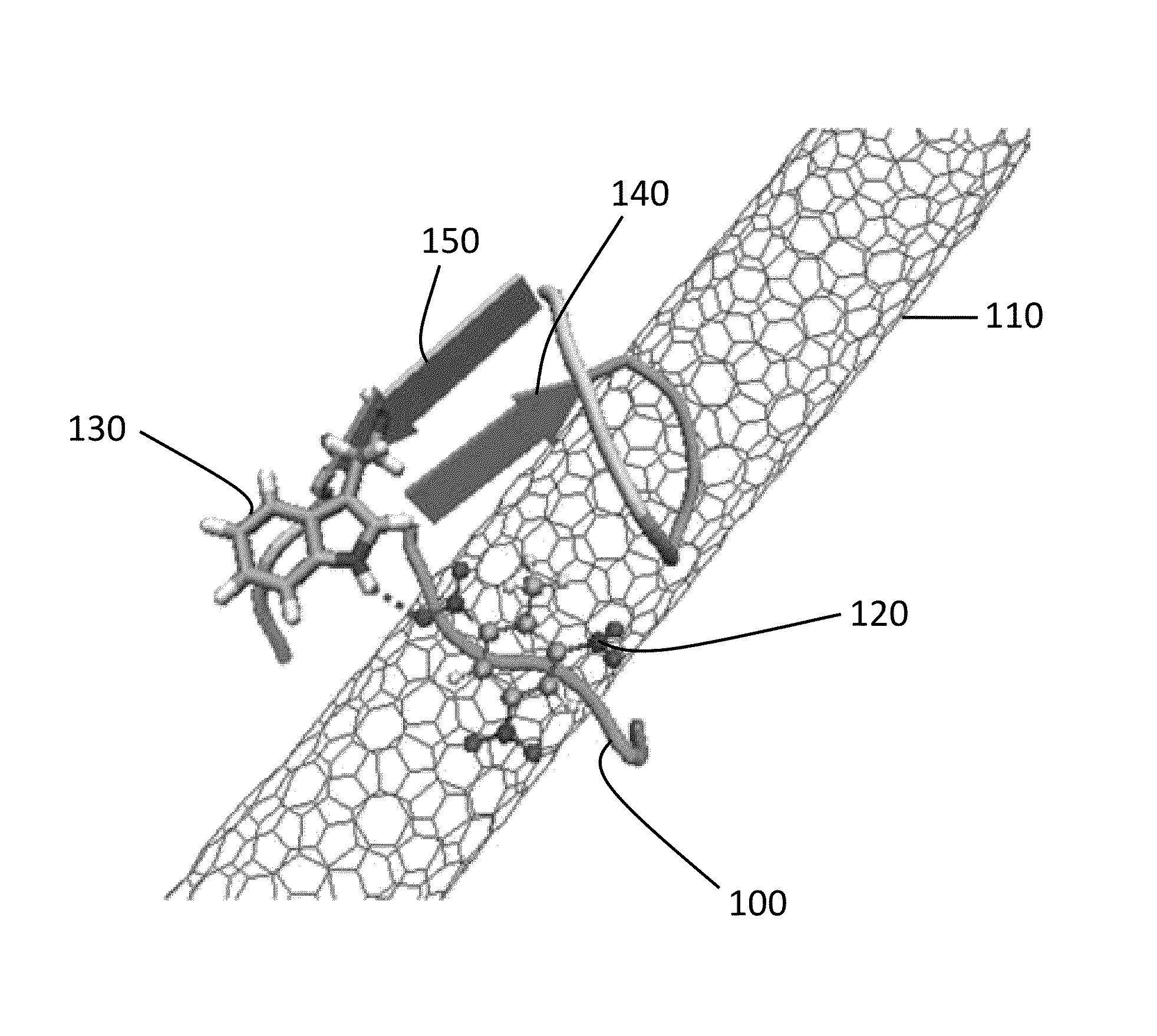

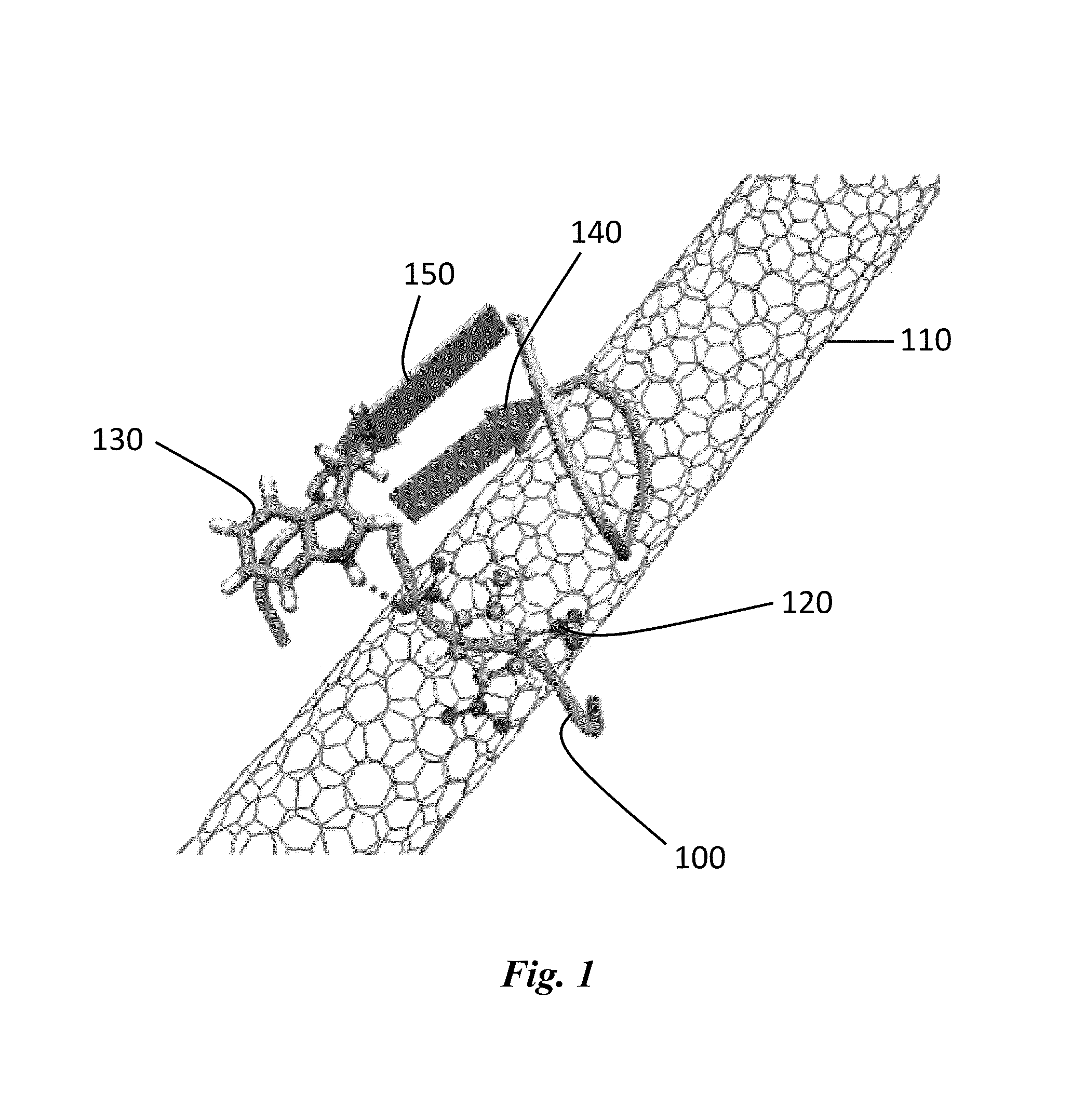

Carbon nanotube sensors employing synthetic multifunctional peptides for surface functionalization

ActiveUS8716029B1Bioreactor/fermenter combinationsBiological substance pretreatmentsCarbon nanotubePeptide sequence

A biosensor that utilizes carbon nanotubes functionalized with a protein sequence. One domain of the multifunctional peptide sequence noncovalently binds to the surface of single-walled carbon nanotubes (SWNTs), while a second domain of the sequence recognizes and binds to a target molecule. The sequence of the peptide may be tailored to allow it to recognize and bind to specific target molecules, such as chemicals, biological materials, and explosives. The binding of the target molecule to the peptide may alter a material property of the SWNTs.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com