Macroscopic ordered assembly of carbon nanotubes

a carbon nanotube and ordered assembly technology, applied in the manufacture of electrical systems, magnetic materials, energy-based chemical/physical/physicochemical processes, etc., can solve the problems of difficult separation of individual carbon nanotubes from the other reaction products, low nanotube yield, and significant variation in structure and siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0138]In order to facilitate a more complete understanding of the invention, a number of Examples are provided below. However, the scope of the invention is not limited to specific embodiments disclosed in the Examples, which are for purposes of illustration only.

1. Filter Apparatus

[0139]Referring to FIG. 12(a), materials of substantially aligned SWNT were formed with the following device. Container 1202 contained isopropyl alcohol (IPA). Container 1204 contained a 0.05% solution of Triton X. Container 1206 contained a solution of purified, well-sonicated SWNT in 0.05% Triton X. A 20 PSI air source was provided, keeping the contents of containers 1202, 1204, and 1206 under pressure. Two valves 1210 and 1214 controlled the flow of fluids from containers 1202, 1204, and 1206.

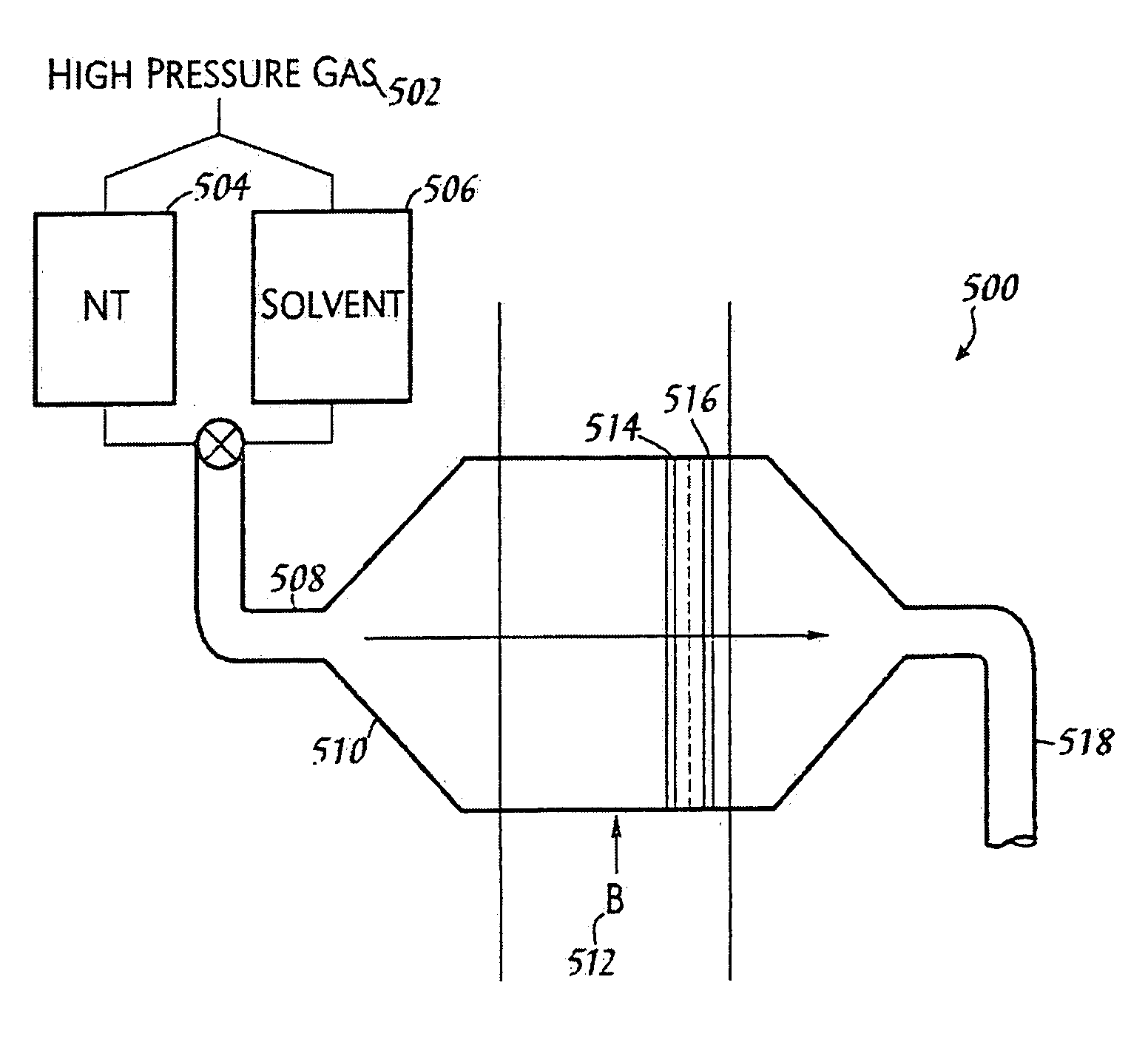

[0140]Referring to FIG. 12(b), the SWNT solution flowed through a 25 T magnetic field generated by a high-current coil. In the magnetic field, two Millipore Millex-GN syringe filters 1216, having 25 mm diameter ny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com