Method for preparing carbon nanotube (CNT)/layered double-metal hydroxide (LDH) compound

A layered bimetallic and carbon nanotube technology, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of low uniformity of carbon nanotube dispersion and cumbersome steps, and achieve good ion exchange and stripping performance, phase Capacitance is improved and the preparation steps are simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Put the carbon nanotubes into a muffle furnace, calcinate at 450°C for 30 minutes, add deionized water after cooling, ultrasonicate for 30 minutes, then treat with 9mol / L concentrated nitric acid at 80°C for 5 hours, filter with suction, and use excess Rinse with deionized water several times until the filtrate is neutral, and then dry to obtain acidified carbon nanotubes.

[0031] Add 0.05 g of the above-mentioned acidified carbon nanotubes into 200 ml of deionized water and sonicate for 15 minutes, and let stand to obtain a dispersion of acidified carbon nanotubes.

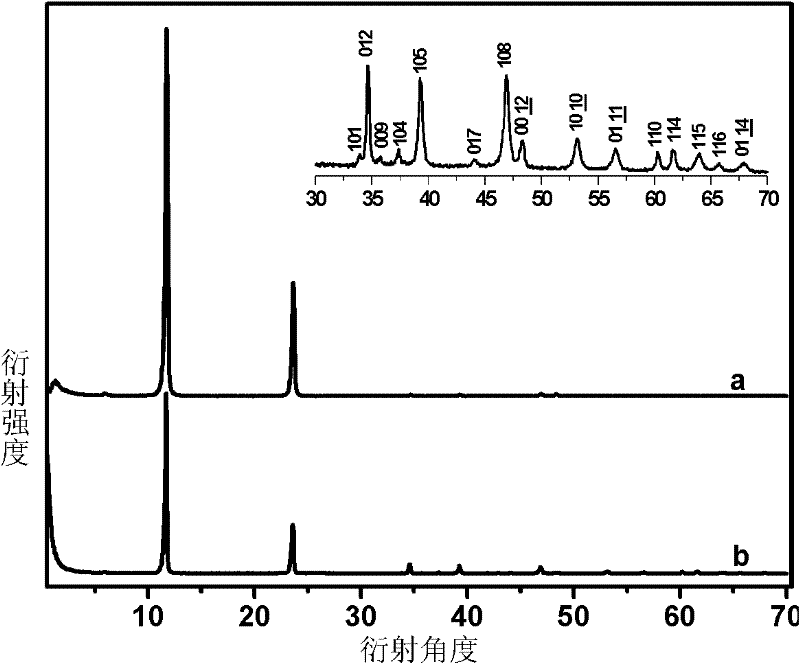

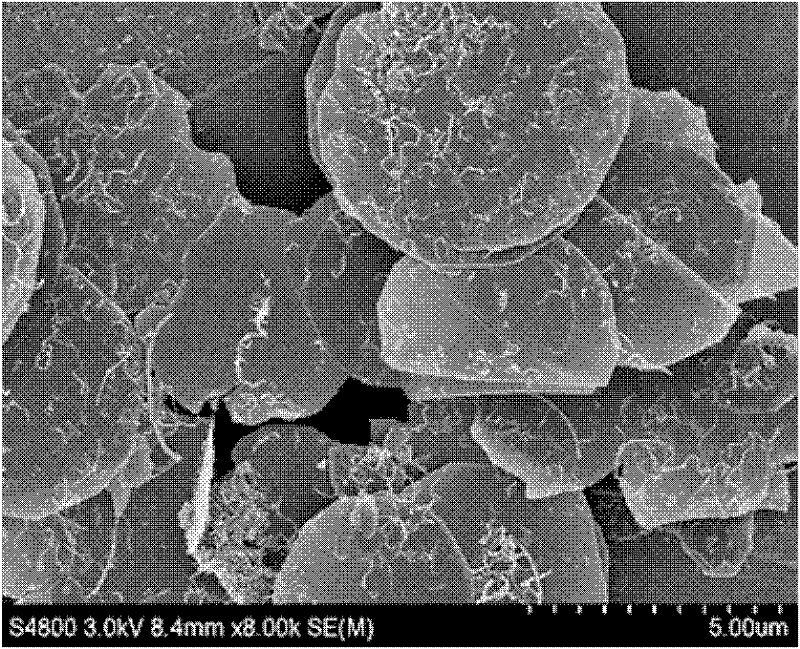

[0032]0.87g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 0.56g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and 0.63g urea (CH 4 N 2 O) be dissolved in 100ml deionized water, after stirring evenly, then mix with the dispersion liquid of above-mentioned acidified carbon nanotubes in a flask to obtain a reaction solution, wherein the concentration of acidified carbon nanotubes is 0.17mg / ml, cobalt nitrate, aluminu...

Embodiment 2

[0036] Put carbon nanotubes in a muffle furnace, calcinate at 400°C for 40min, add deionized water after cooling, ultrasonicate for 30min, then treat with 9mol / L concentrated nitric acid at 90°C for 5h, filter with suction, and use excess deionized water Rinse several times until the filtrate is neutral, and dry to obtain acidified carbon nanotubes.

[0037] Add 0.1 g of the above-mentioned acidified carbon nanotubes into 200 ml of deionized water and sonicate for 15 minutes, and let stand to obtain a dispersion of acidified carbon nanotubes.

[0038] 0.87g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 0.56g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and 0.63g urea (CH 4 N 2 O) be dissolved in 100ml deionized water, after stirring uniformly, then mix with the dispersion liquid of above-mentioned acidified carbon nanotubes in a flask to obtain a reaction solution, wherein, the concentration of acidified carbon nanotubes is 0.34mg / ml, cobalt nitrate, aluminum nitrate and urea concent...

Embodiment 3

[0042] Put the carbon nanotubes in a muffle furnace, calcinate at 500°C for 20min, add deionized water after cooling, ultrasonicate for 30min, then treat with 9mol / L concentrated nitric acid at 100°C for 5h, suction filter, and use excess deionized water Rinse several times until the filtrate is neutral, and dry to obtain acidified carbon nanotubes.

[0043] Add 0.2 g of the above-mentioned acidified carbon nanotubes into 200 ml of deionized water and sonicate for 15 minutes, and let stand to obtain a dispersion of acidified carbon nanotubes.

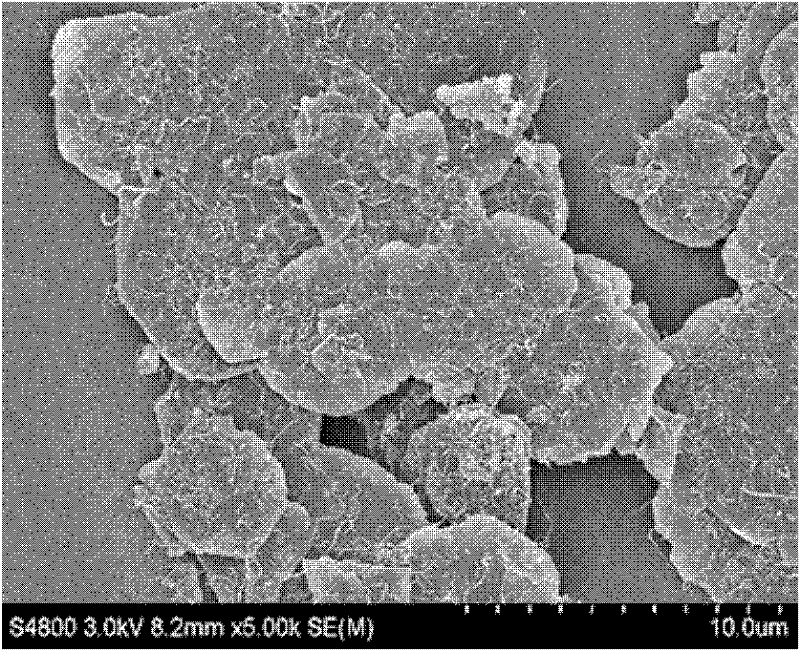

[0044] 0.87g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O), 0.56g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and 0.63g urea (CH 4 N 2 O) be dissolved in 100ml deionized water, after stirring uniformly, then mix with the dispersion liquid of above-mentioned acidified carbon nanotubes in a flask to obtain a reaction solution, wherein the concentration of acidified carbon nanotubes is 0.68mg / ml, cobalt nitrate, aluminum nitrate and urea concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com