Patents

Literature

1404results about How to "Excellent peelability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

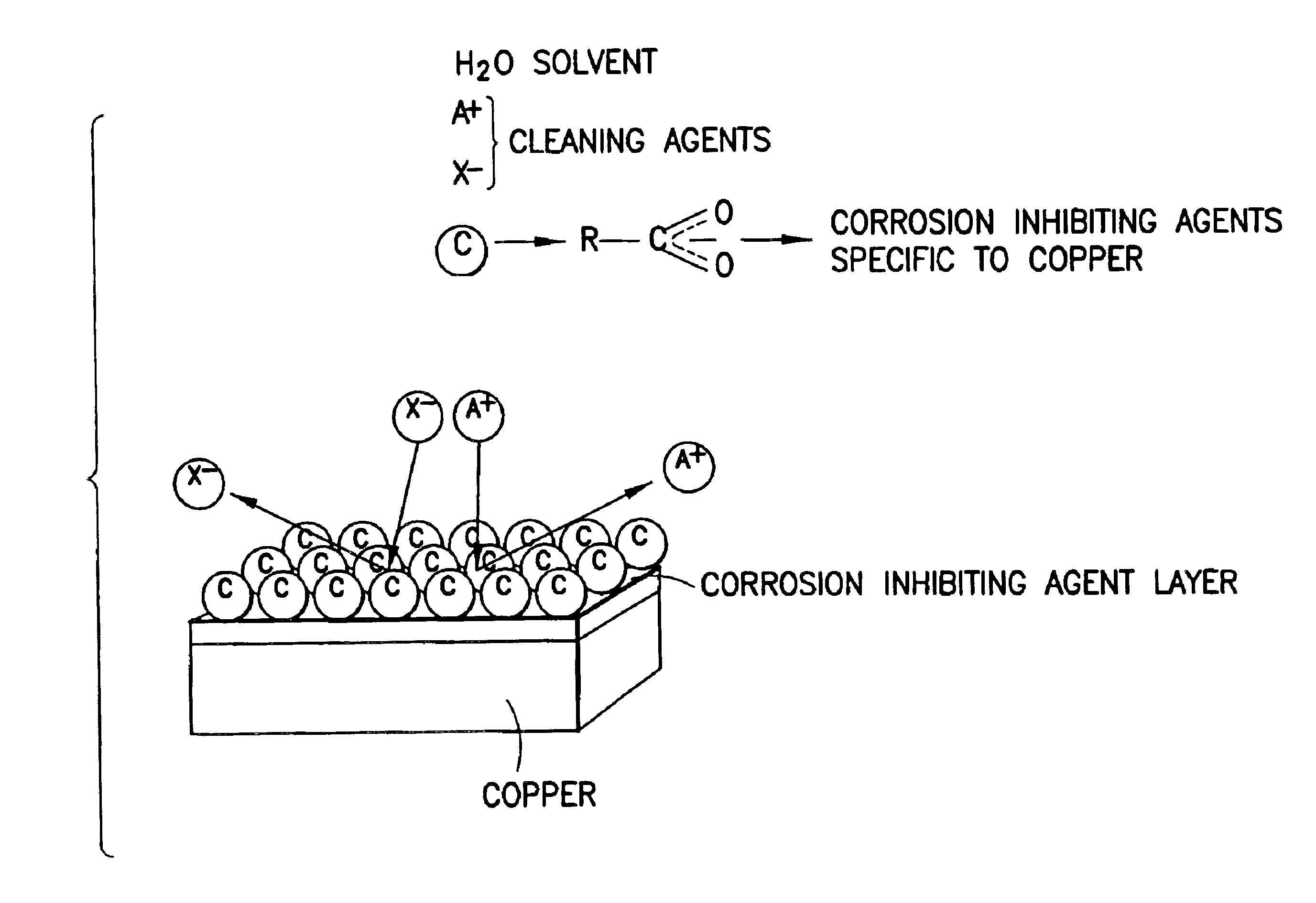

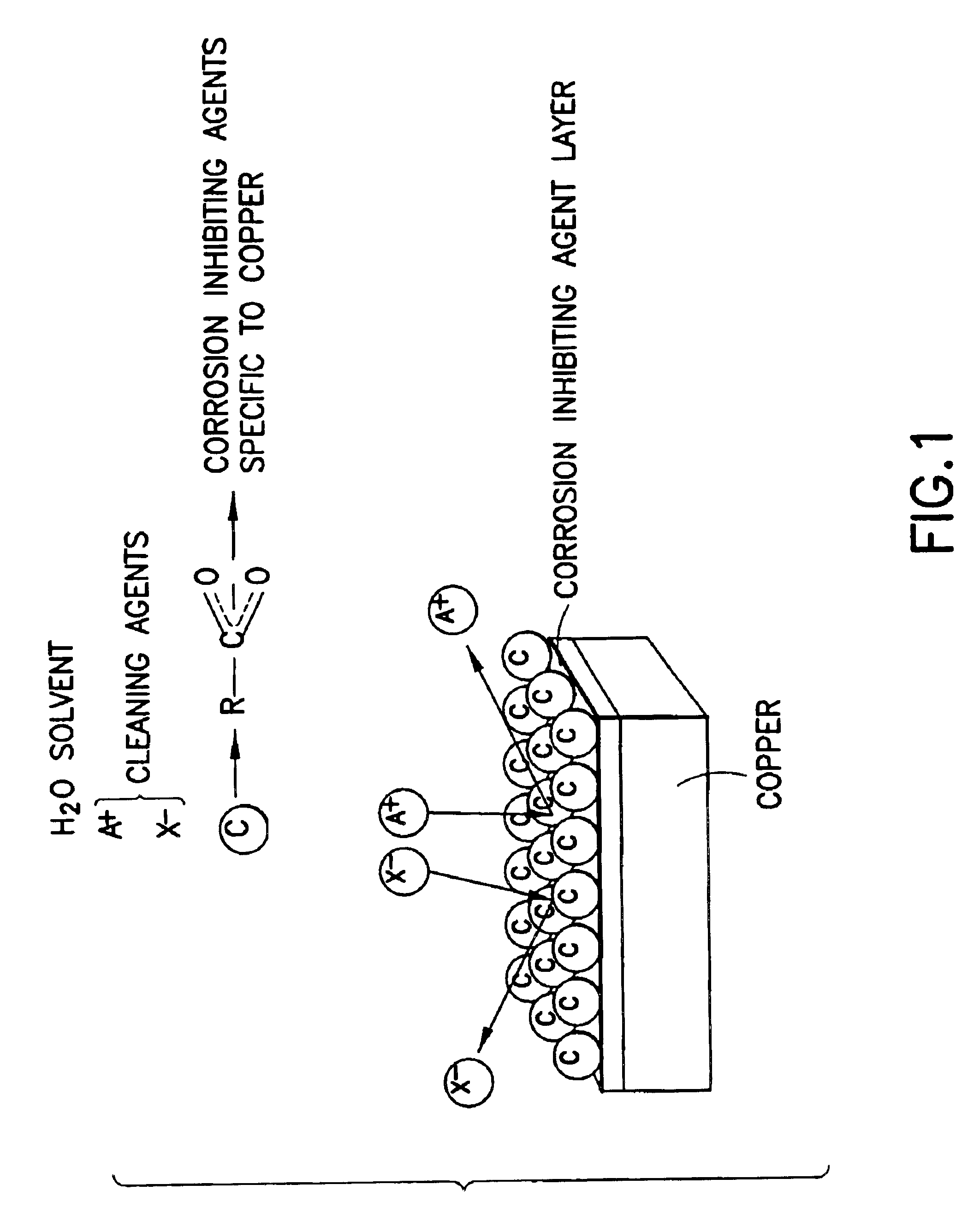

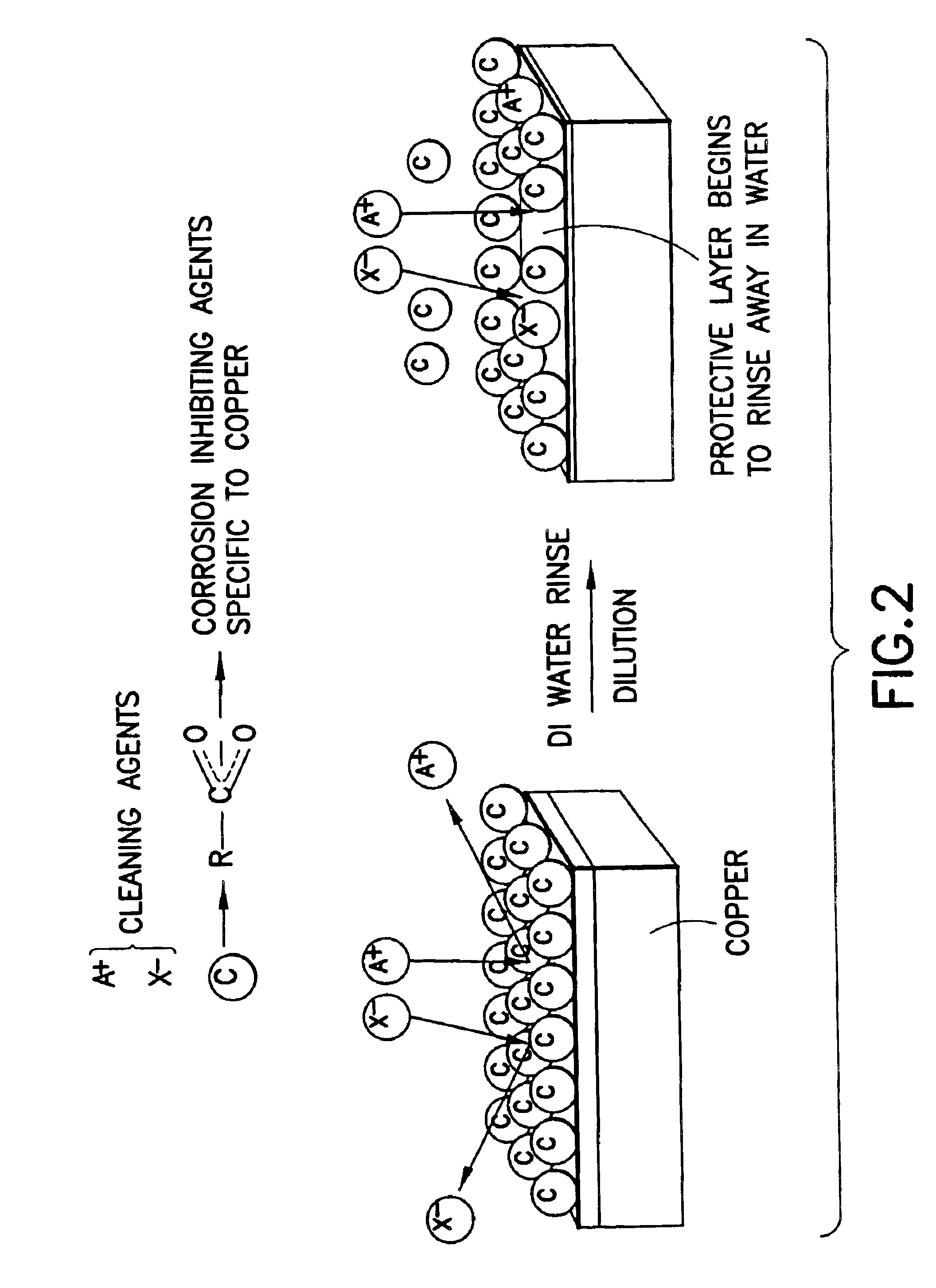

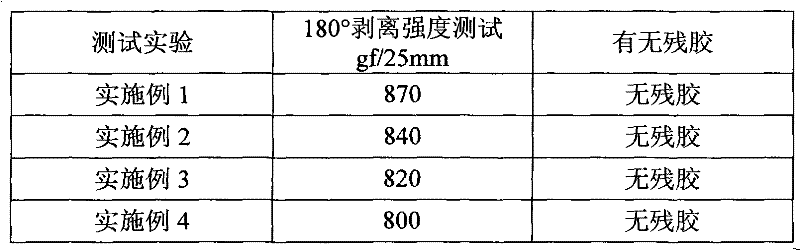

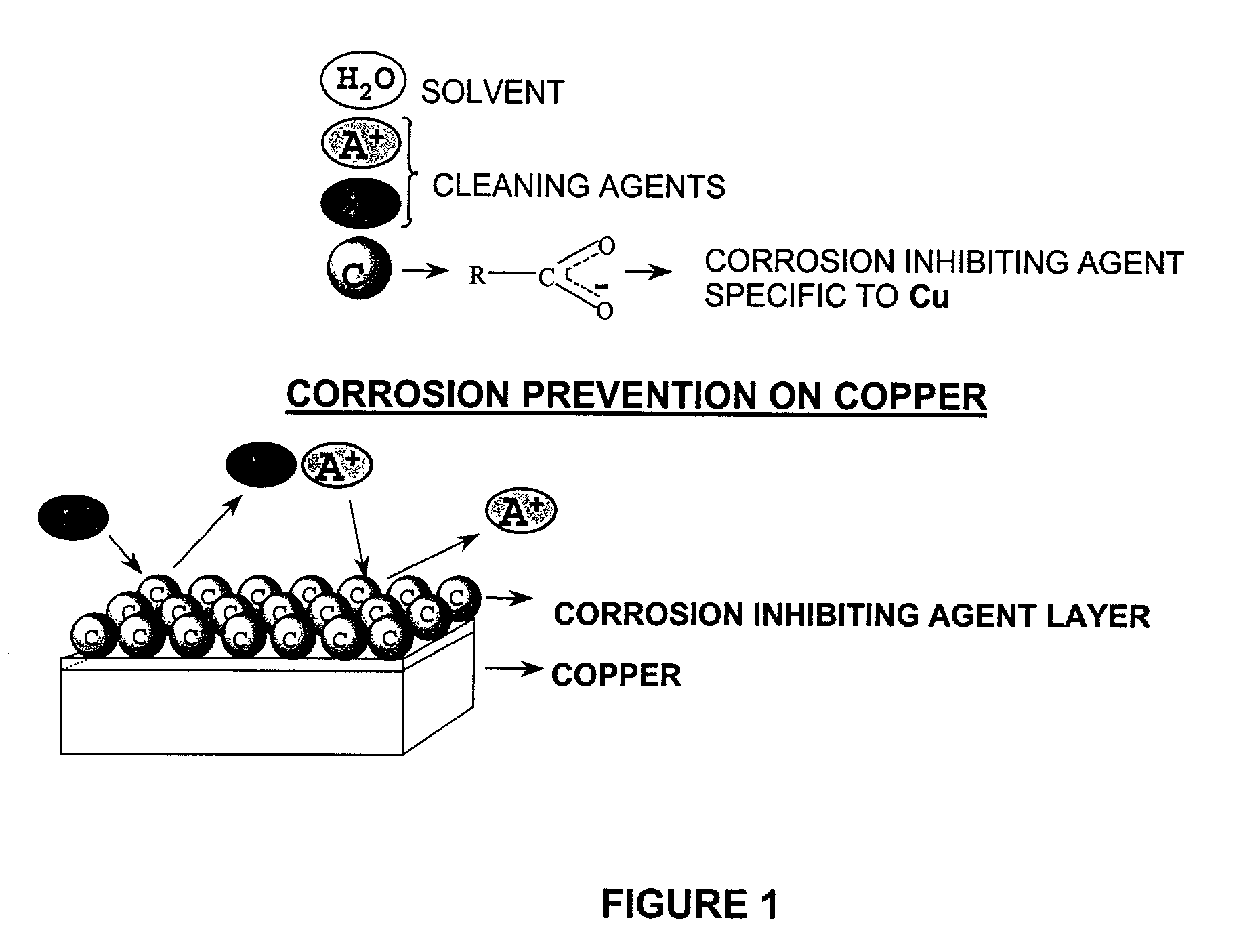

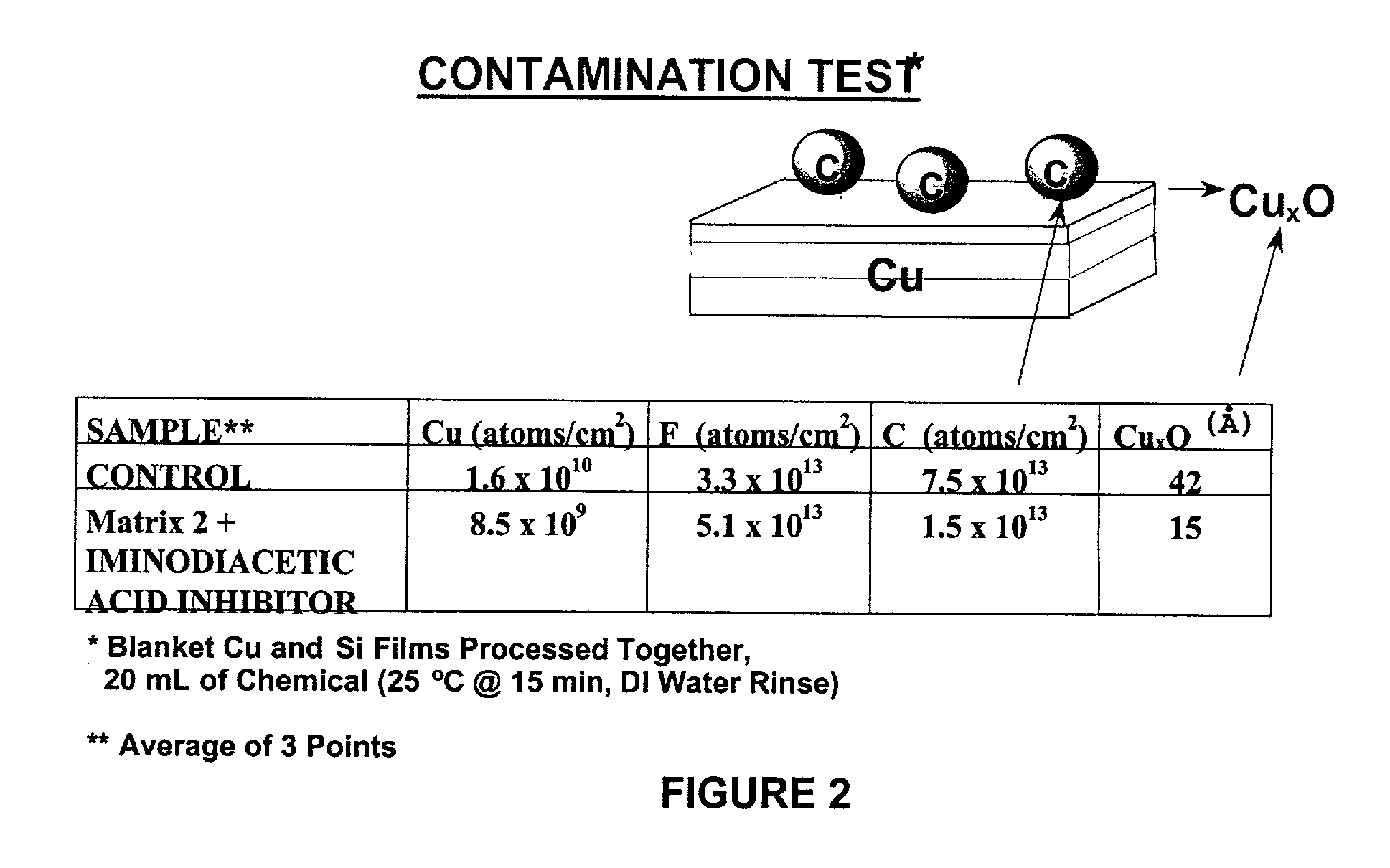

Aqueous cleaning composition containing copper-specific corrosion inhibitor for cleaning inorganic residues on semiconductor substrate

InactiveUS6896826B2Efficient removalExcellent peelabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsResistNitrogen

Owner:ENTEGRIS INC

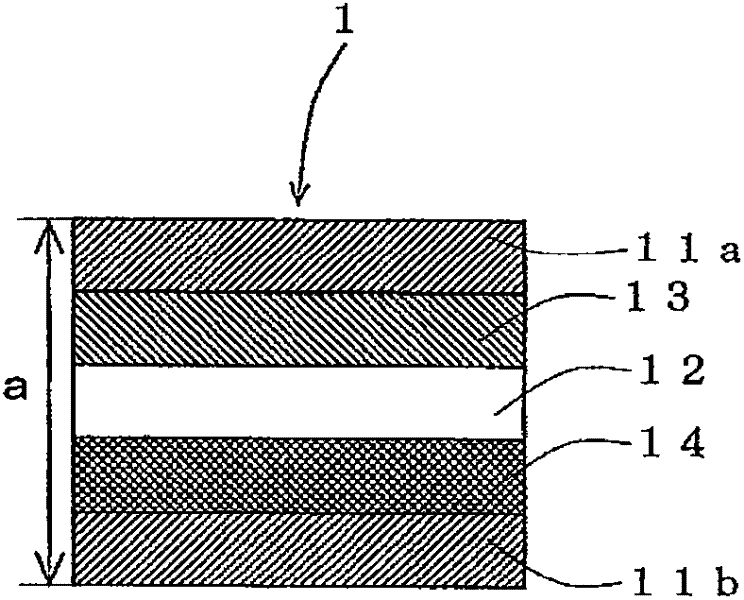

Cellulose acylate, cellulose acylate film, and method for production and use thereof

InactiveUS20060222786A1Good optical performanceImprove thermal stability performanceLiquid crystal compositionsThin material handlingCelluloseSulfur

A cellulose acylate solution containing a cellulose acylate which satisfies 2.5≦A+B≦3, 0≦A≦2.5, 0.3≦B≦3 (wherein A is the substitution degree of an acetyl group, and B is the sum of the substitution degrees of an acyl group having 3 to 7 carbon atoms) and whose content of sulfur atoms of residual sulfate moiety S is such that 50 ppm<S<500 ppm. When solution casting is carried out using this solution, a cellulose acylate film having good surface state and low peel-off load can be produced.

Owner:FUJIFILM CORP

Pressure sensitive adhesive composition for optical members, pressure sensitive adhesive layer for optical members, pressure sensitive adhesive optical member and image display

InactiveUS20050014879A1Improve adhesionExcellent in re-releasabilityFilm/foil adhesivesElectroluminescent light sourcesPolymer scienceMeth-

The present invention provides a pressure sensitive adhesive composition for optical members, which is excellent in durability, re-releasability and stress relaxation, as well as a pressure sensitive adhesive composition for optical members, which hardly increases adhesion after storage for a long time and does not leave a residual adhesive on glass upon disposal or repair. The pressure sensitive adhesive composition for optical members according to the present invention comprises 100 parts by weight of an acrylic polymer (A) having a weight-average molecular weight of 500,000 or more, containing at least 50 wt % alkyl (meth)acrylate having an alkyl group with 5 or more carbon atoms and 0.2 to 2 wt % unsaturated carboxylic acid as the monomer unit, 0.1 to 4 parts by weight of an acrylic polymer (B) having a weight-average molecular weight of 2,000 to 50,000, containing at least 70 wt % alkyl(meth)acrylate and 1 to 7 wt % unsaturated carboxylic acid as the monomer unit and having a higher carboxylic acid equivalent than that of the acrylic polymer (A), 0.01 to 1 part by weight of a silane coupling agent, and a crosslinking agent.

Owner:NITTO DENKO CORP

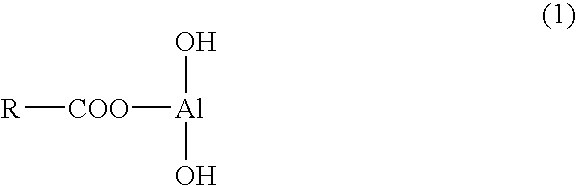

Latex composition comprising a cross-linking agent and molded product thereof

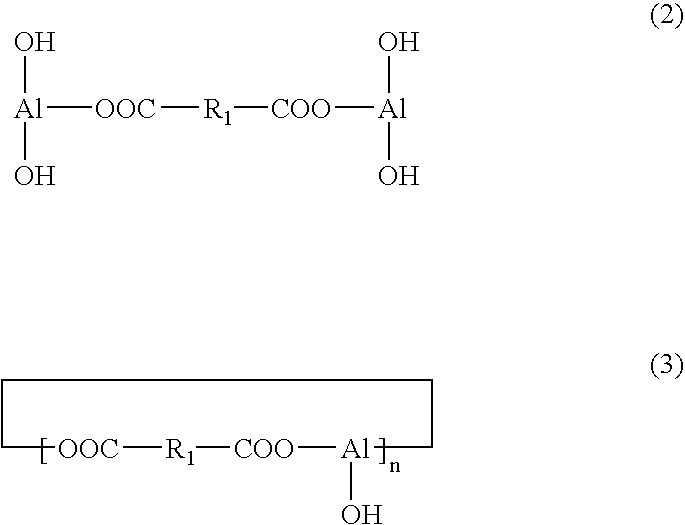

InactiveUS20080227913A1Easy to peelExcellent peelabilityGroup 3/13 element organic compoundsTitanium organic compoundsIonPolyamide

A carboxyl group-containing diene-based rubber latex composition comprising (a) a carboxyl group-containing diene-based rubber latex and one or more compounds selected from the following (b) to (e):(b) an organometallic crosslinking agent containing two or more hydroxyl groups each bonded to a metal atom;(c) a cationic property-deactivated, modified polyamine-based resin, a cationic property-deactivated polyamide-epichlorohydrin resin, a cationic property-deactivated polyamine-epichlorohydrin resin, a cationic property-deactivated amine group- or quaternary ammonium base-containing polyvinyl alcohol, a cationic property-deactivated amine group- or quaternary ammonium base-containing polyacrylamide, a cationic property-deactivated amine group- or quaternary ammonium base-containing carbohydrate, or a polyacrylamide, polyvinyl alcohol, or carbohydrate into which a crosslinkable functional group is introduced;(d) an anionic or nonionic polyvinyl alcohol, anionic or nonionic polyacrylamide, or anionic or nonionic carbohydrate to which a water resistant additive is added; and(e) a cationizing agent.

Owner:YUGENKAISHA FOUR ROAD RES

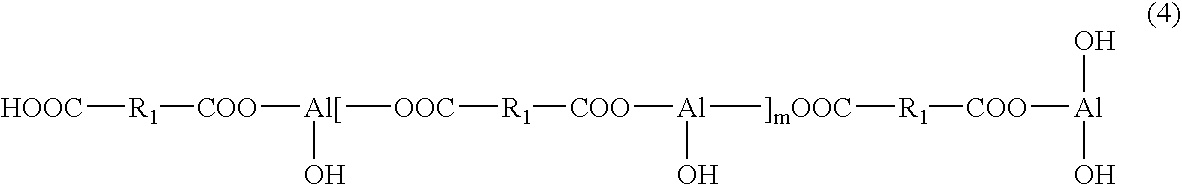

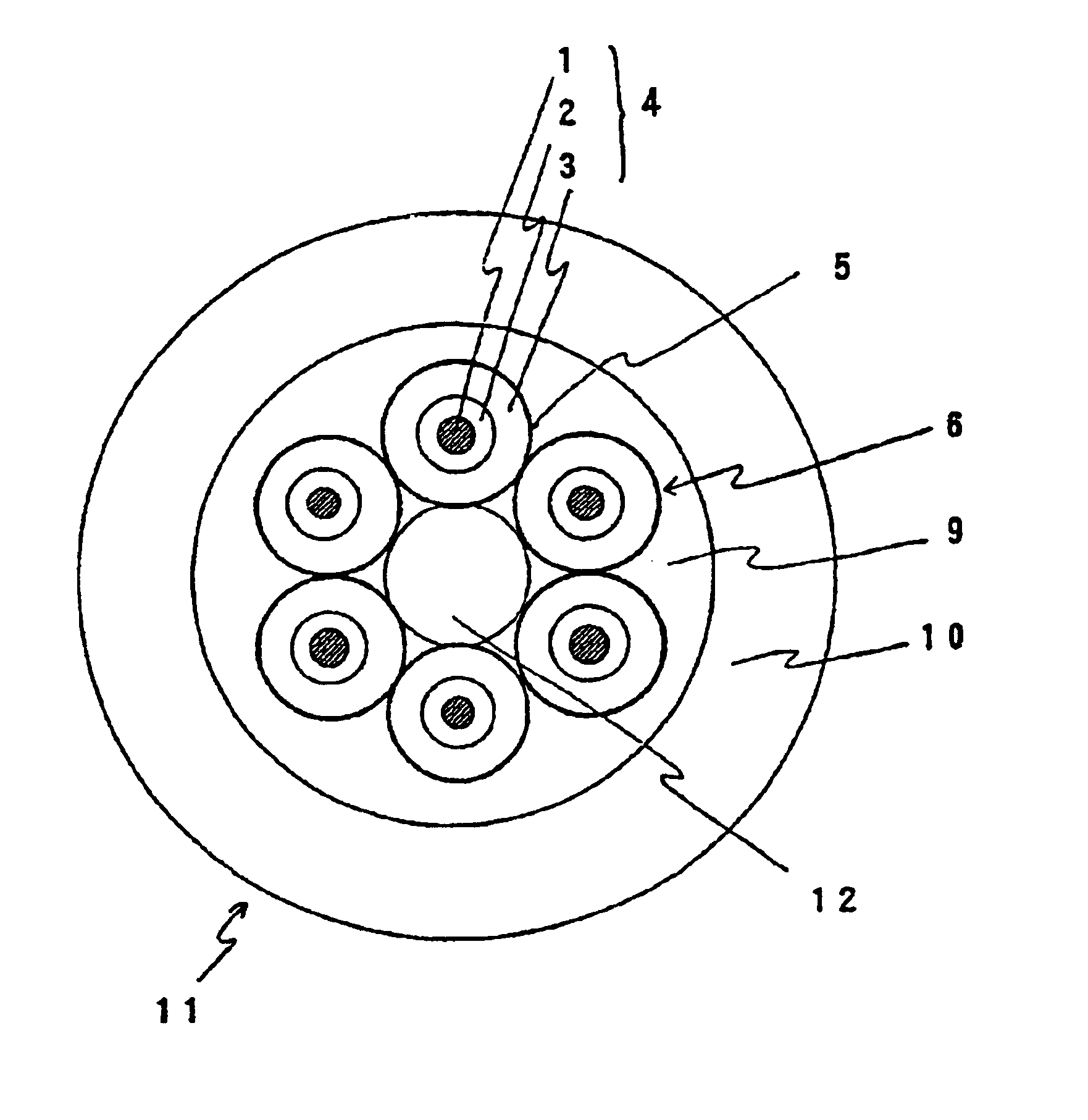

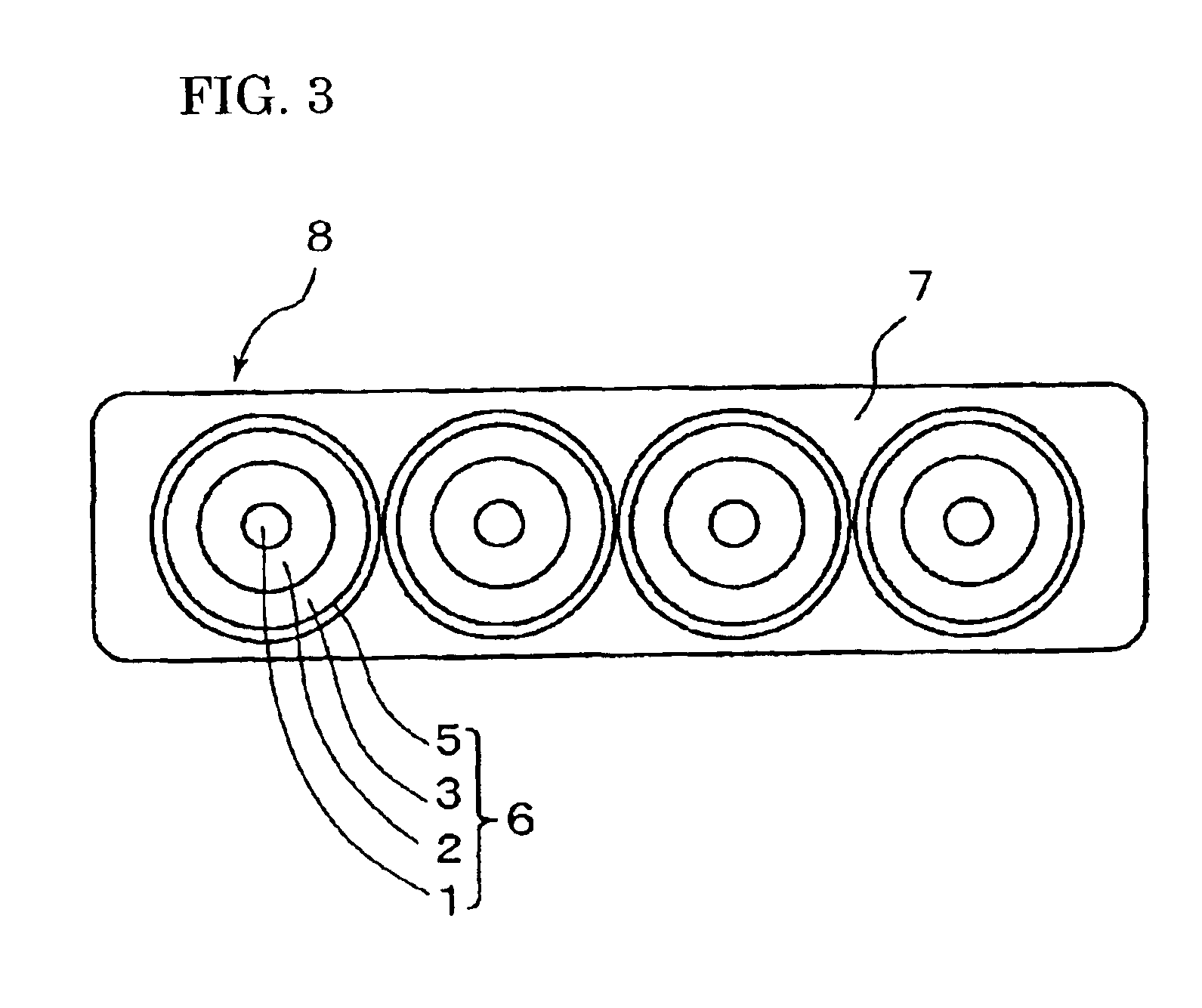

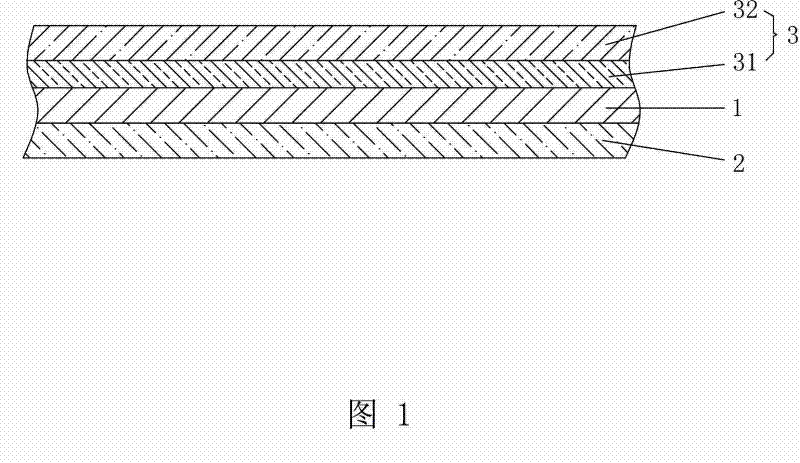

Coated optical fiber

InactiveUS6810188B1Shorten the production lineExcellent peelabilityGlass optical fibreOptical fibre with multilayer core/claddingOptoelectronicsPlastic optical fiber

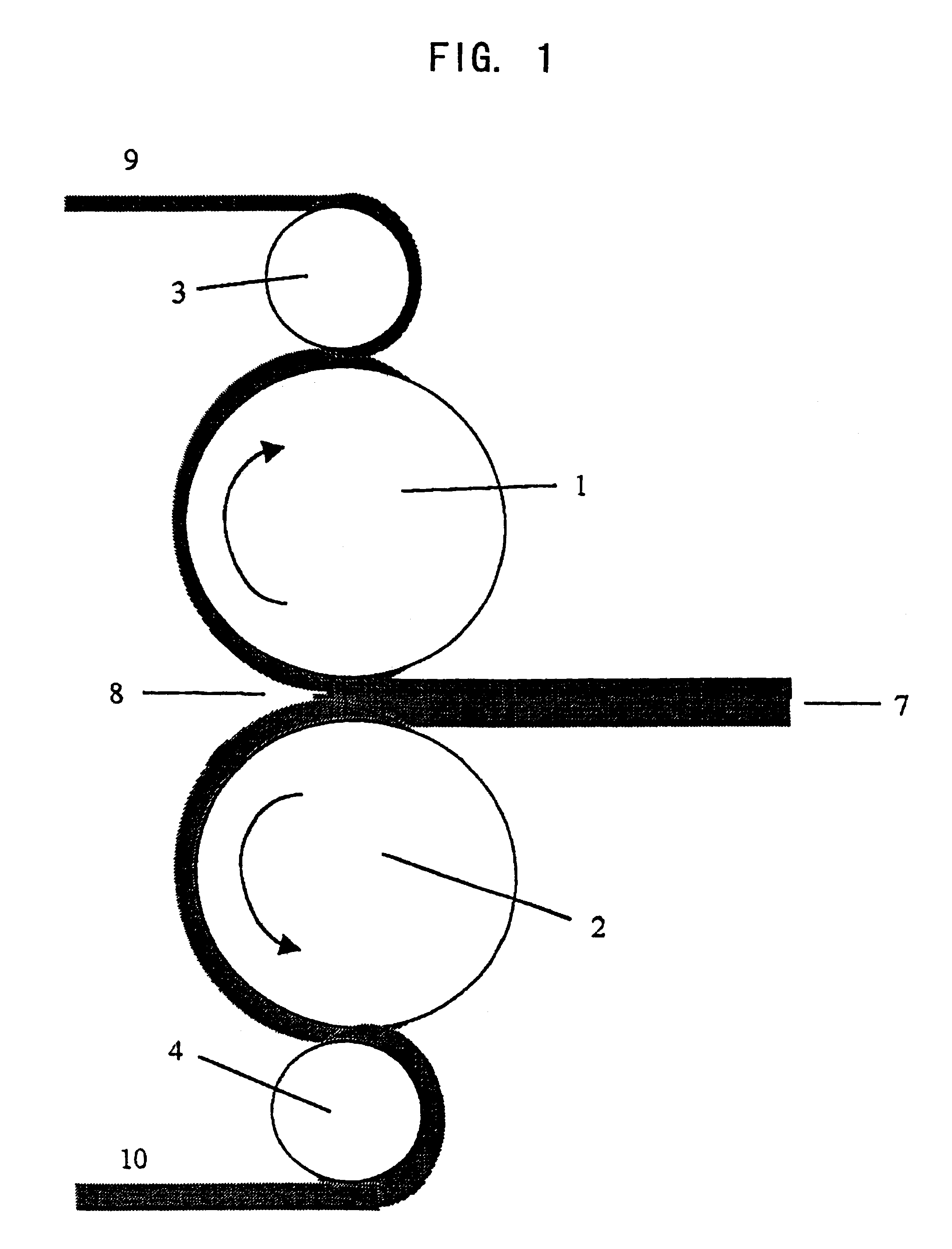

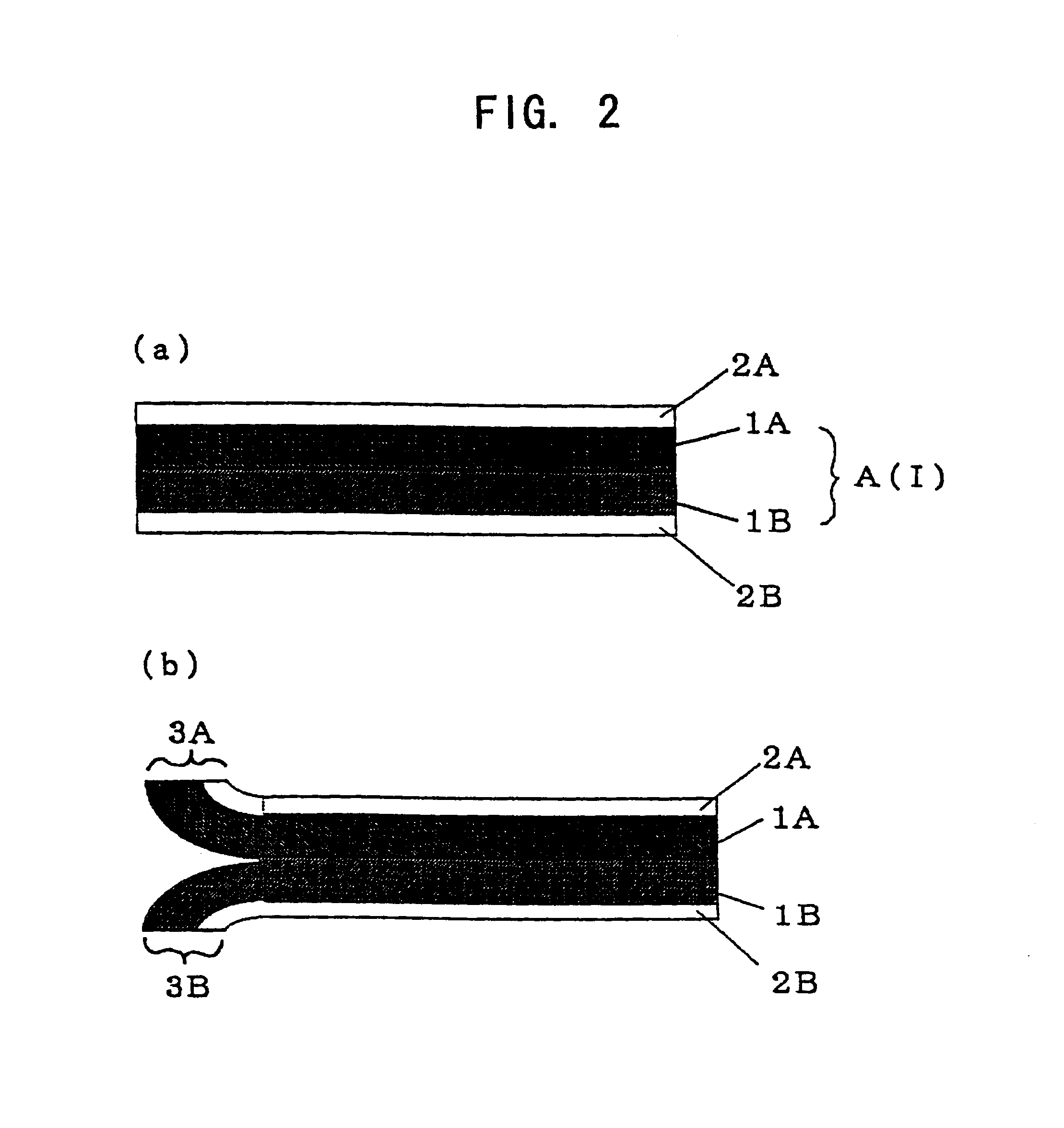

A coated optical fiber is shown in which, by coating a glass optical fiber with a primary coating having a storage modulus E' of 0.01 kg / mm<2 >to 2.0 kg / mm<2 >at 25° and 110 Hz and an adhesion of 10 g / cm to 200 g / cm to the glass optical fiber, delamination at the interface between the glass optical fiber and the primary coating, and voids are prevented during and after the production, for example, on the line during drawing and winding. An optical fiber ribbon of the present invention, which is formed by collectively coating the coated optical fibers each including a primary coating with a storage modulus E' of 0.01 kg / mm<2 >to 0.5 kg / mm<2 >and an adhesion of 10 g / cm to 100 g / m, has a high delamination resistance and a good collective strippability of coatings. In an optical fiber unit of the present invention which is formed by collectively coating the coated optical fibers having a storage modulus E' of 0.01 kg / mm<2 >to 0.5 kg / mm<2 >and an adhesion of 100 g / cm to 200 g / cm, delamination and voids will not occur.

Owner:SUMITOMO ELECTRIC IND LTD

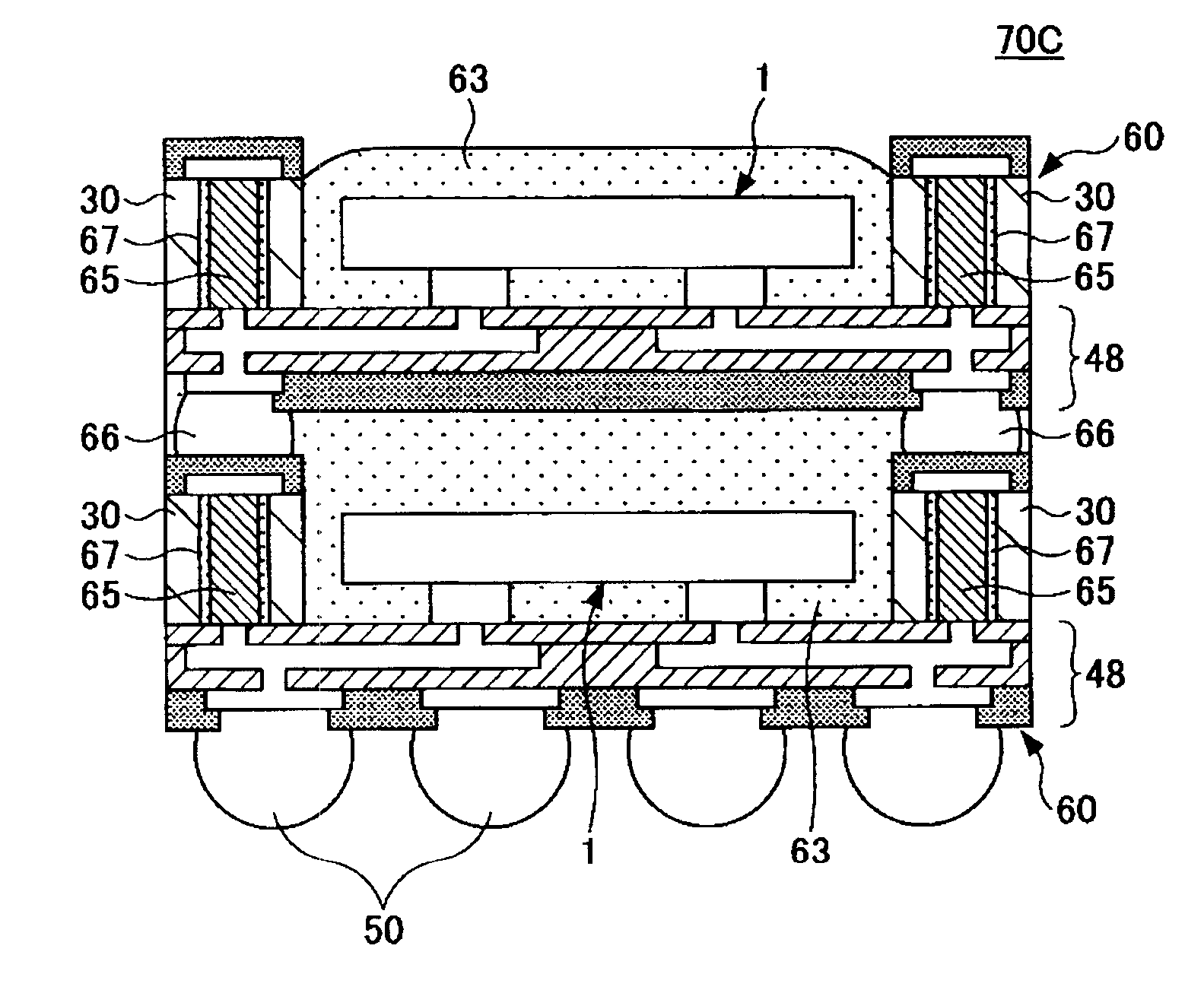

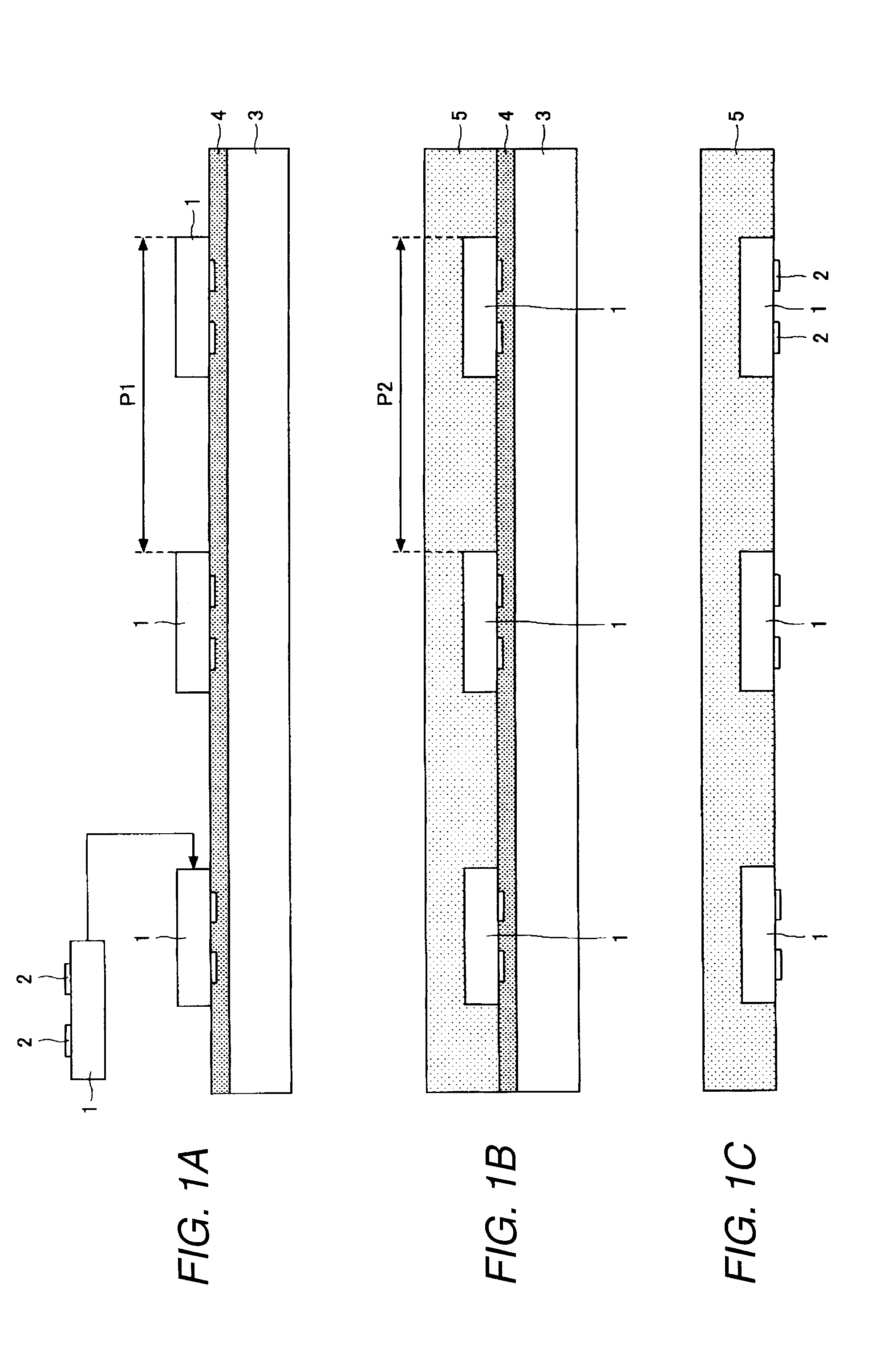

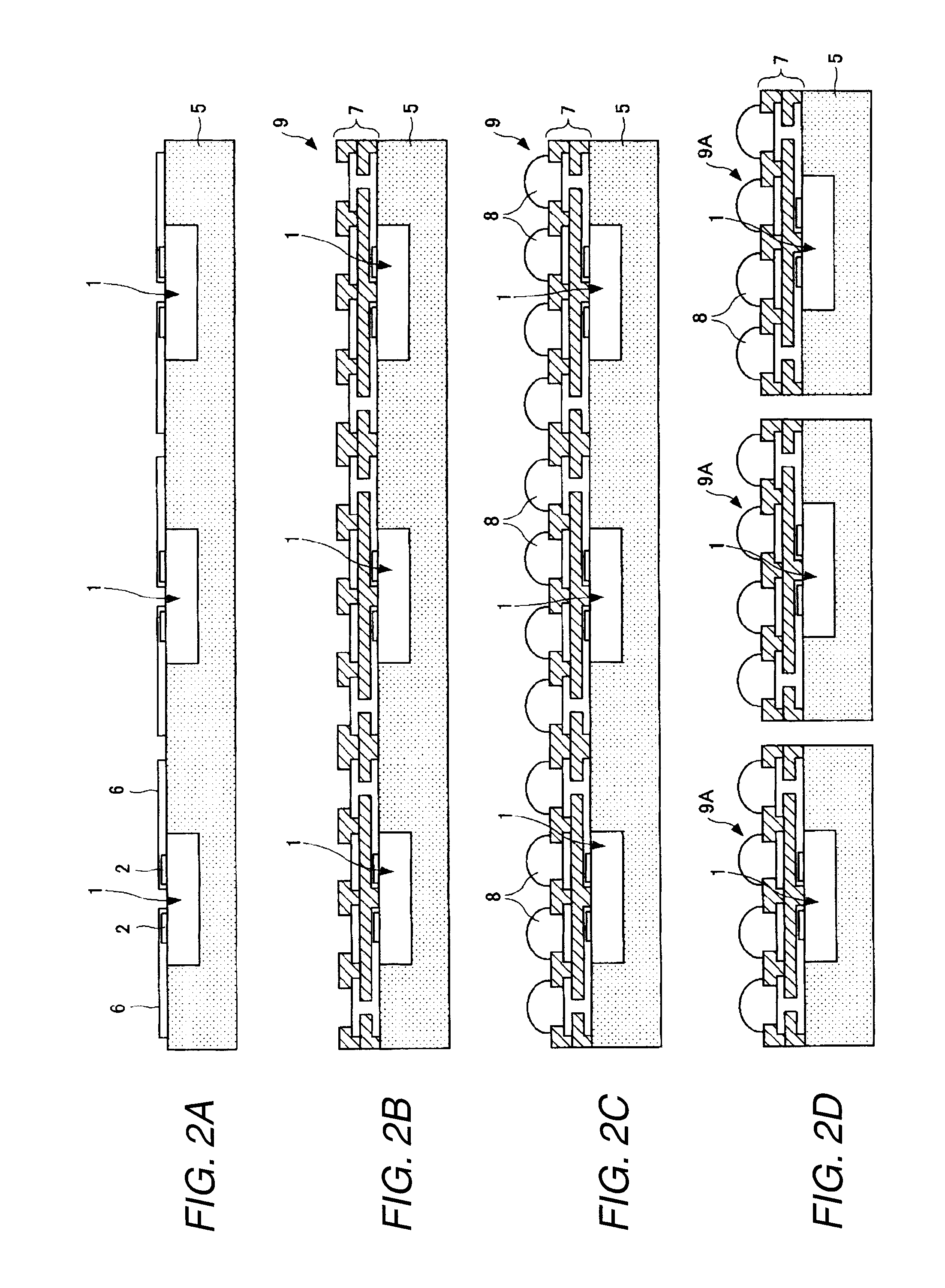

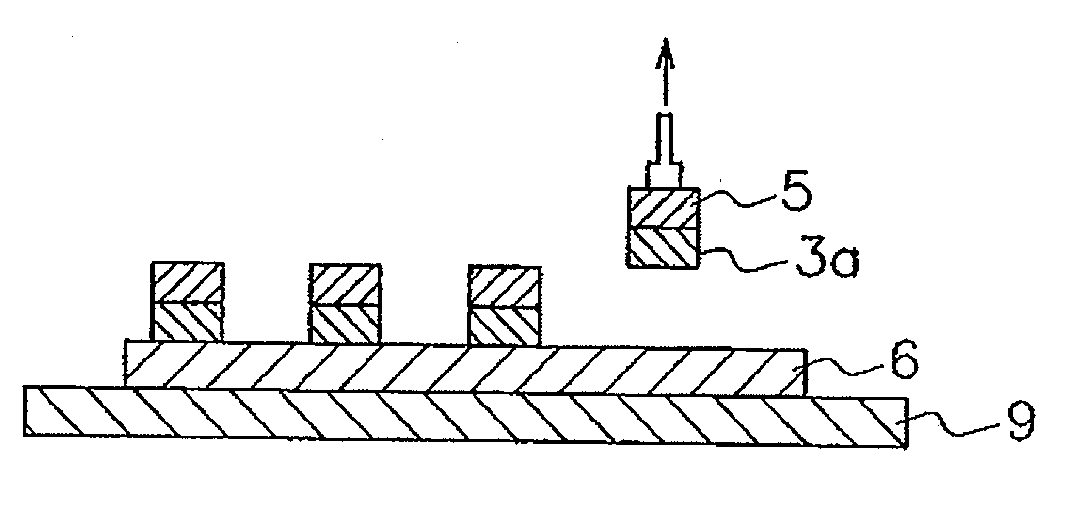

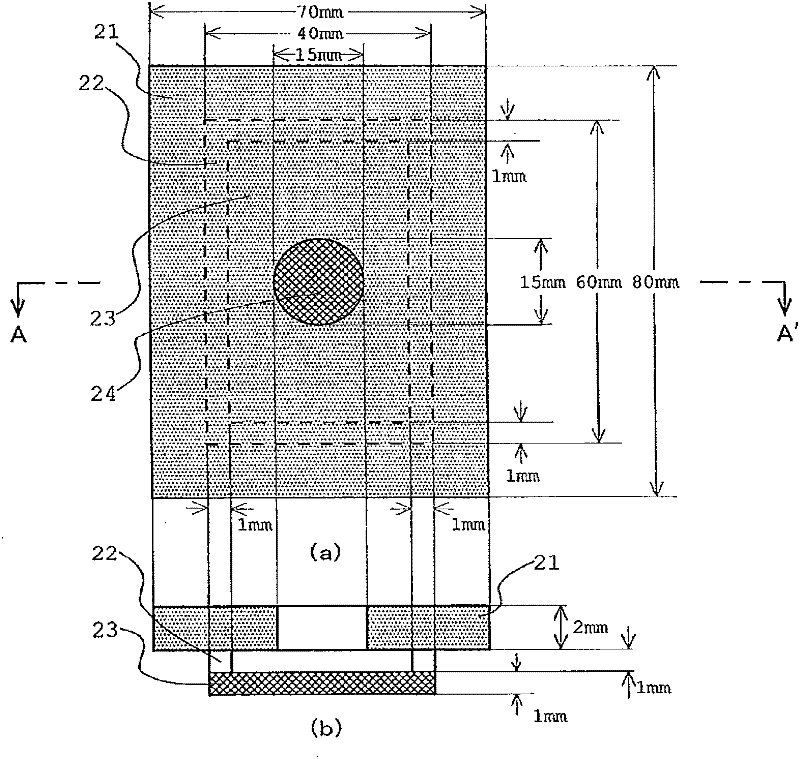

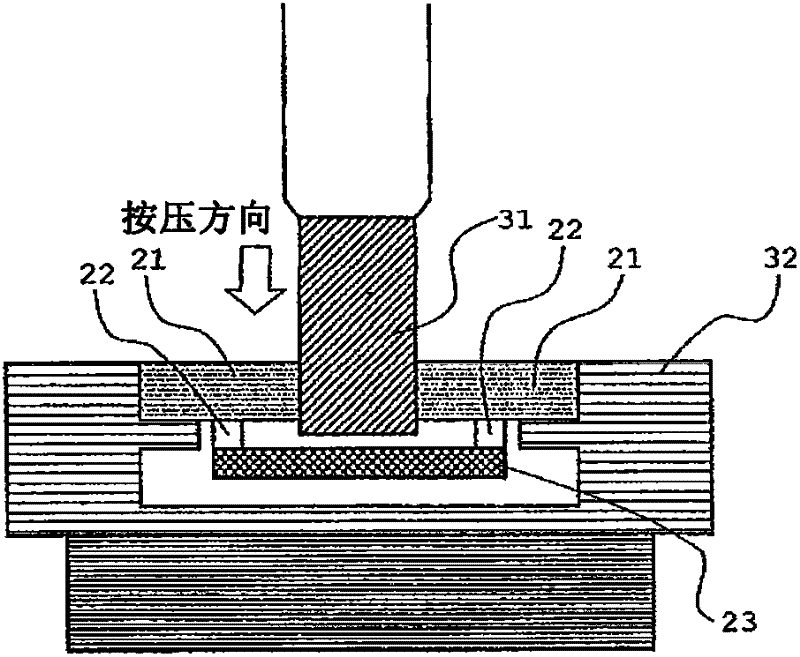

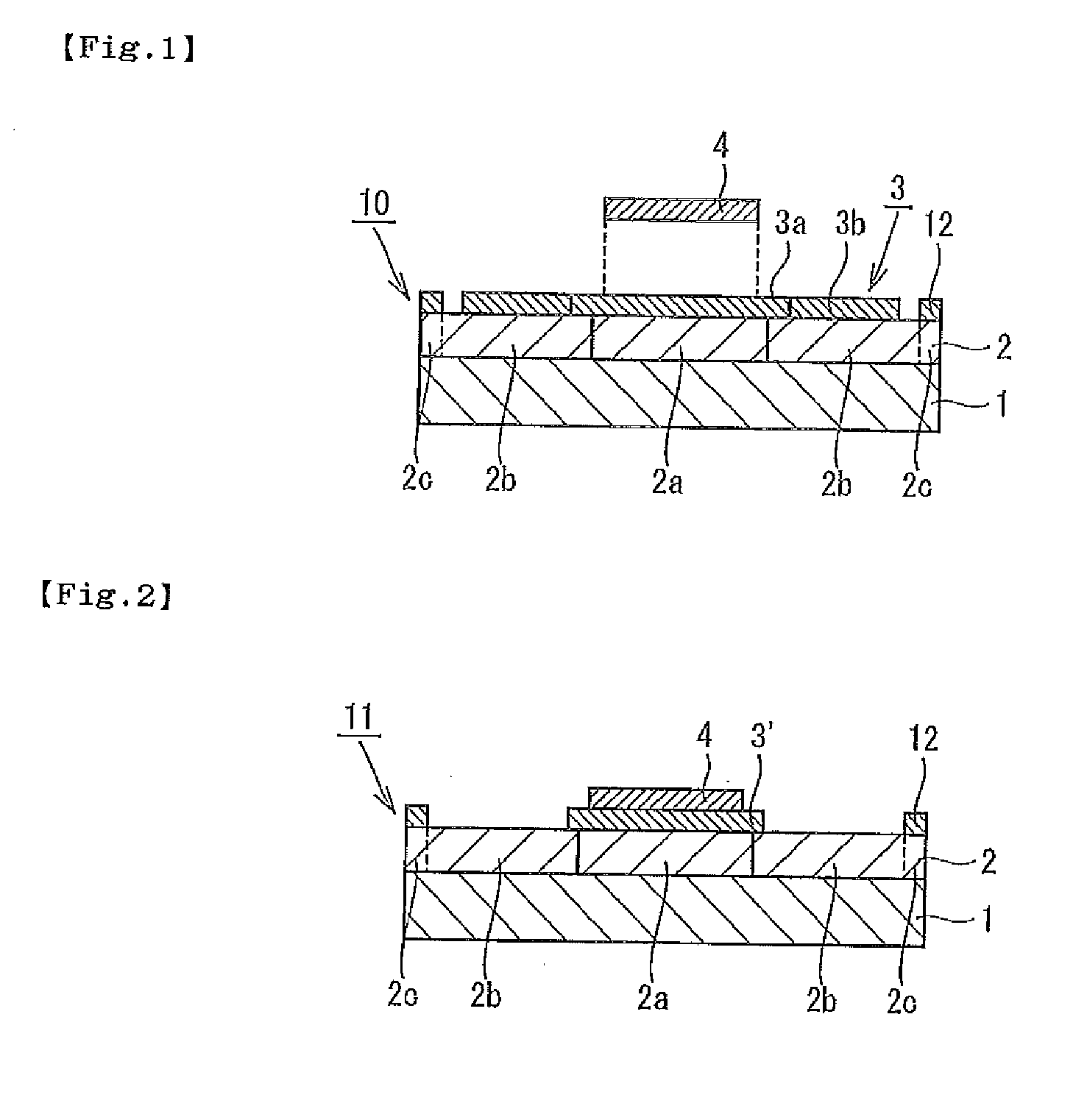

Method of manufacturing wiring substrate and method of manufacturing semiconductor device

ActiveUS20090236031A1Low costImprove efficiencyAdhesive processesLamination ancillary operationsSemiconductorSemiconductor device

There are provided a step of preparing a dummy chip, a step of forming a cavity in a stiffener substrate, a step of providing a second tape base member on one surface of the stiffener substrate, a step of inserting the dummy chip into the cavity to provide the dummy chip on the second tape base member, a step of sealing the stiffener substrate and the dummy chip with a sealing resin, a step of removing the second tape base member and forming a build-up wiring layer on a surface from which the second tape base member is removed, a step of removing the sealing resin; and a step of peeling the dummy chip from the build-up wiring layer.

Owner:SHINKO ELECTRIC IND CO LTD

Austenitic stainless steel

ActiveCN101194037APrevent peelingIncreased durabilityHeat exchange apparatusRare-earth elementSS - Stainless steel

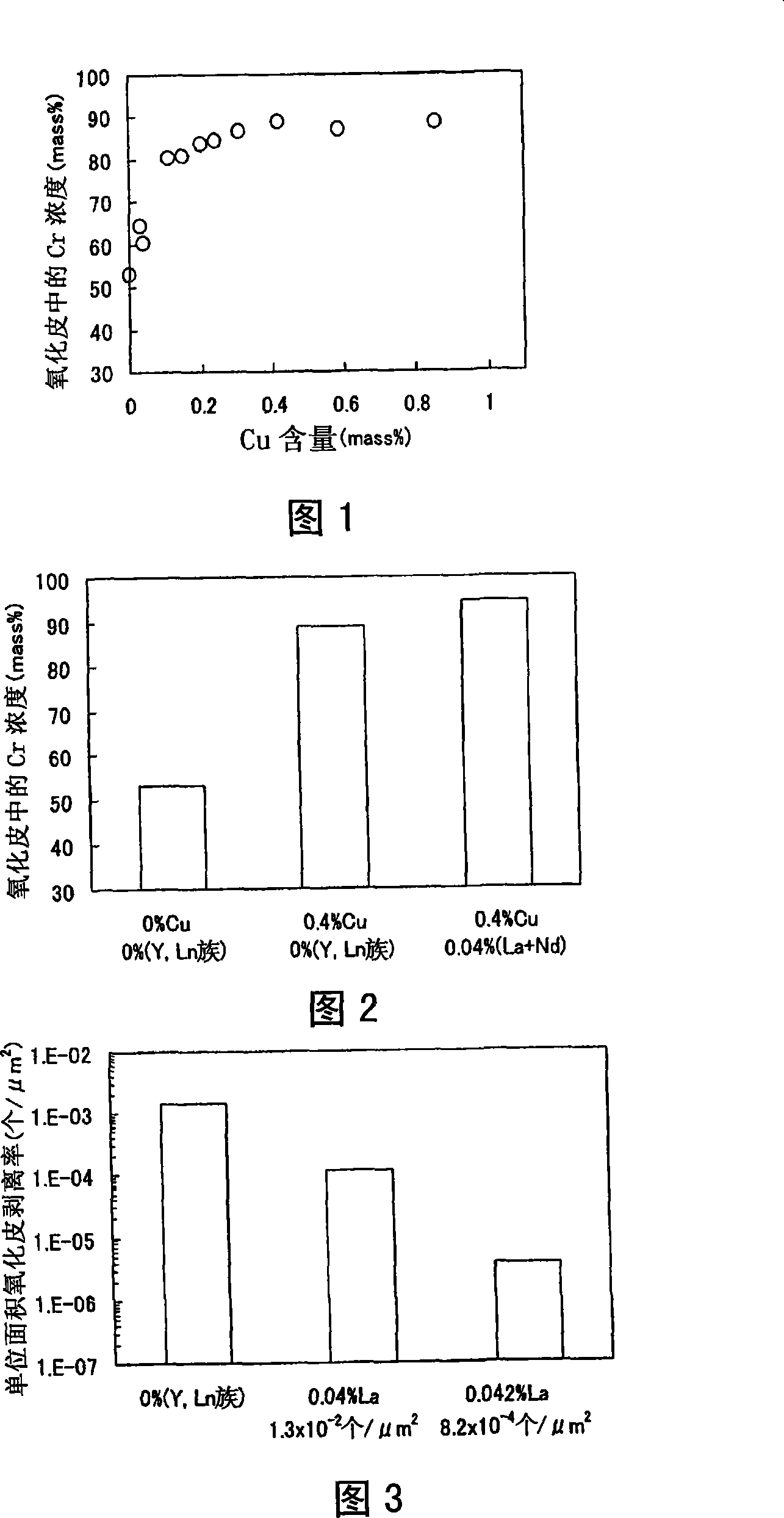

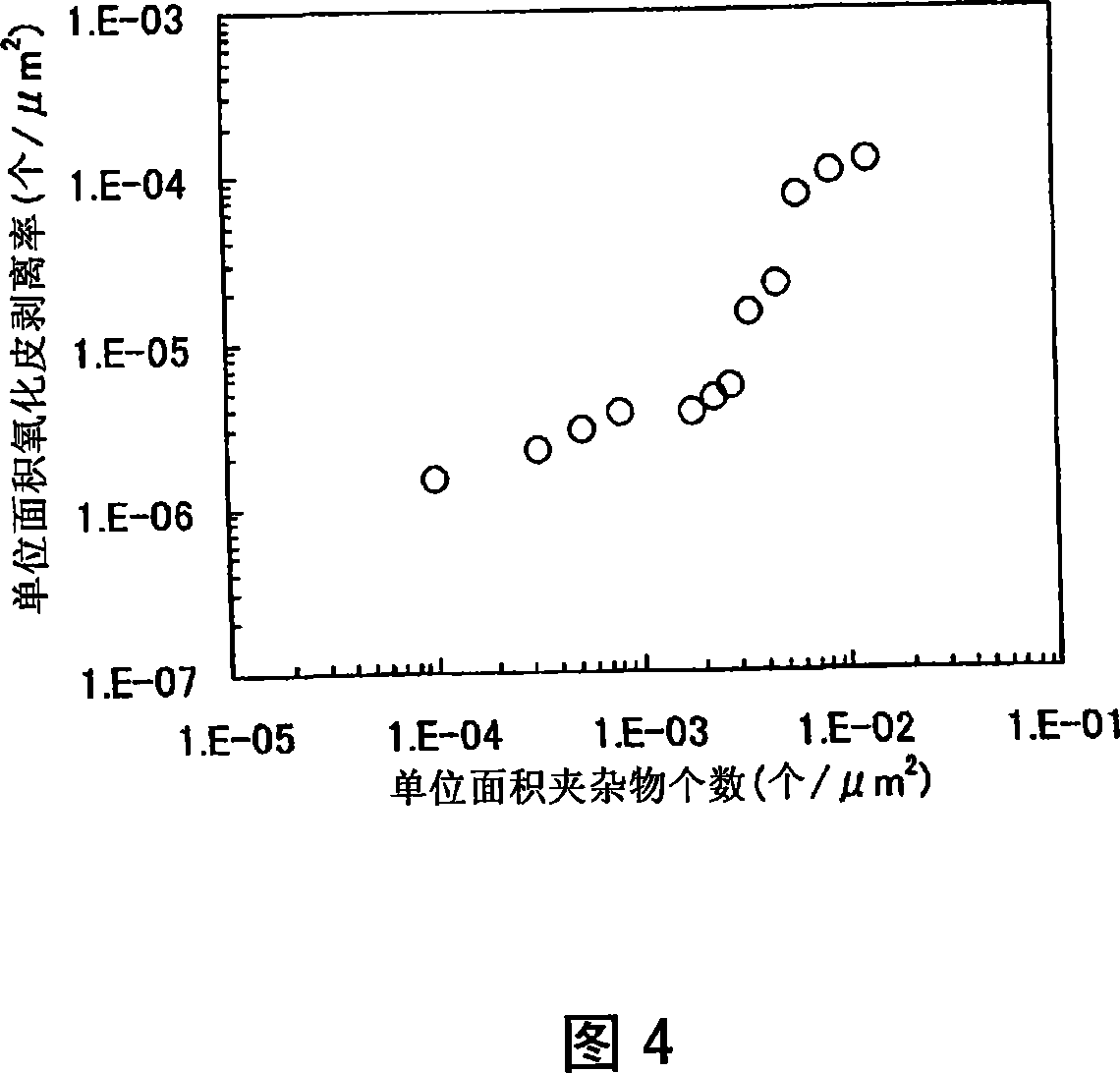

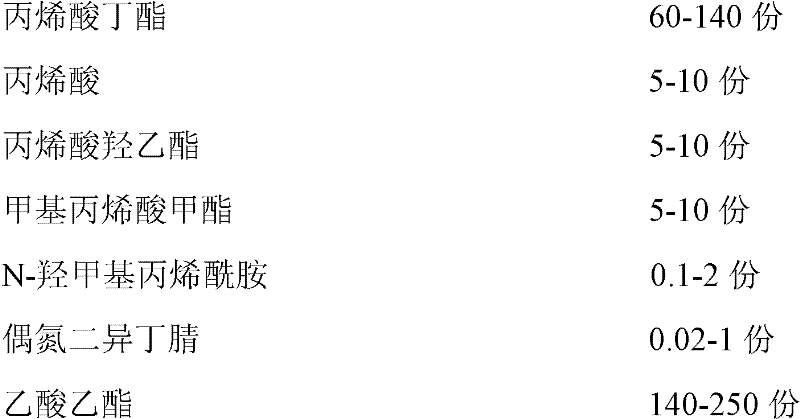

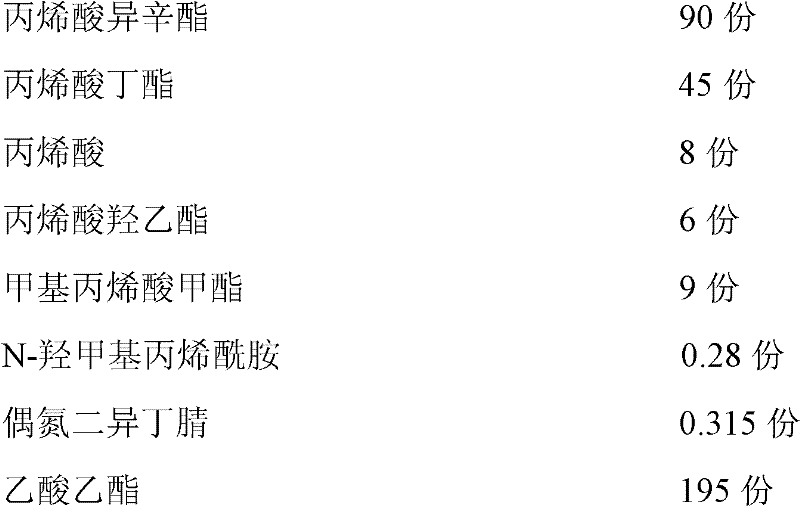

Even after repeated high-temperature heating-cooling cycles, it still has excellent scale peeling resistance that can inhibit the peeling of protective oxide scales formed on the steel surface, and can be used in high temperature, especially high temperature humidified gas environments above 1023K. System stainless steel with the following steel composition: C: 0.01-0.15%, Si: 0.01-3%, Mn: 0.01-2%, Cu: 0.1-2.5%, Cr: 23-30%, Ni: 16-25% , Al: 0.005 to 0.20%, N: 0.001 to 0.40%, P: 0.04% or less, S: 0.01% or less, and one or more rare earth elements selected from the Y and Ln groups: total 0.005 to 0.1%, the balance is substantially composed of Fe and unavoidable impurities, and the inclusions containing Y and Ln group elements on the steel surface are 5×10-3 / μm2 or less.

Owner:NIPPON STEEL CORP

Environment-friendly holography aluminising transfer paint, preparation and uses thereof

InactiveCN101402817ASimple processIncrease productivityCoatings with pigmentsCoatingsSolventChemistry

The invention relates to an environment protective type holographical aluminized transferring coating as well as a preparation method and an application thereof. The coating is prepared by adopting the following components and contents (weight percent): 0 to 16 percent of cellulose rein, 0 to 6 percent of chloroacetic resin, 4 to 20 percent of acrylics, 0 to 3 percent of accessory ingredient and 70 to 87 percent of solvent. Compared with the prior art, the invention has the advantages of: (1) peeling performance is excellent and holographical aluminized layer transferring is very sufficient; (2) single channel coating only has simple working procedure, high production efficiency and less energy consumption, but also has less coating amount and relative lower cost of the needed coating; (3) the coating layer has good flexibility, is hard to be chapped and the color of the coating is hard to be faded; moreover, the adhesion between the coating and the aluminum layer is quite good; the printing suitability of oil ink is high; (4) a PET basic film peeled off can be recoated and used for a plurality of times, thus reducing the product cost; and (5) the holographical aluminized transferring coating belongs to product of universal grade and has broad application range.

Owner:SHANGHAI WEIKAI CHEM

Thermal-spalling acrylic ester pressure-sensitive adhesive, adhesive tape and preparation method thereof

InactiveCN102559101AGood adhesion and thermal peelabilityGood application prospectNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryOCTYL ACRYLATE

The invention relates to a thermal-spalling acrylic ester pressure-sensitive adhesive, an adhesive tape and a preparation method of the adhesive. The thermal-spalling acrylic ester pressure-sensitive adhesive provided by the invention prepared by the following components by weight via radical polymerization: 60-140 parts of iso-octyl acrylate, 60-140 parts of butyl acrylate, 5-10 parts of acrylic acid, 5-10 parts of hydroxyethyl acrylate, 5-10 parts of methyl methacrylate, 0.1-2 parts of N-hydroxymethyl acrylamide, 0.02-1 part of azodiisobutyronitrile, and 140-250 parts of ethyl acetate. The pressure-sensitive adhesive prepared by the invention has good viscosity at low temperatures and does not have viscosity at high temperatures. Expansible microspheres and a cross-linking agent are added into the pressure-sensitive adhesive and then solidification is carried out to obtain the pressure-sensitive adhesive tape; when the temperature is below 60 DEG C, the pressure-sensitive adhesive tape has good viscosity; and when the temperature is above 120 DEG C and baking is carried out for 5min, the pressure-sensitive adhesive tape loses the viscosity. The viscosity variation of the pressure-sensitive adhesive tape is varied through temperature variation intervals by the pressure-sensitive adhesive, so that terrific adhesiveness and thermal-spalling property are provided.

Owner:新丰杰力电工材料有限公司

Dicing die-bonding film

InactiveUS20100029059A1Increased yieldExcellent in pickup propertyLamination ancillary operationsFilm/foil adhesivesPressure sensitiveFree-radical reaction

The present invention is a dicing die-bonding film having a dicing film having a pressure-sensitive adhesive layer on an ultraviolet-ray transmitting base and a die-bonding film provided on the pressure-sensitive adhesive layer, wherein the pressure-sensitive adhesive layer is formed by laminating the die-bonding film onto a pressure-sensitive adhesive layer precursor formed from an acrylic polymer comprising an acrylic ester as a main monomer, a hydroxyl group-containing monomer at a ratio in the range of 10 to 40 mol % with respect to 100 mol % of the acrylic ester, and an isocyanate compound having a radical reactive carbon-carbon double bond within a molecular at a ratio in the range of 70 to 90 mol % with respect to 100 mol % of the hydroxyl group-containing monomer, and then curing by irradiating with an ultraviolet ray from the base side, and the die-bonding film is formed from an epoxy resin.

Owner:NITTO DENKO CORP

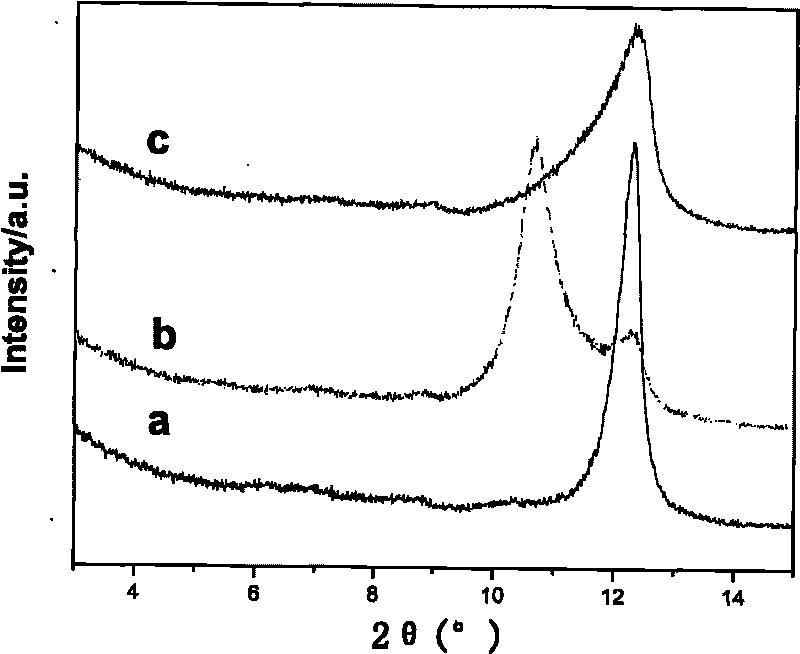

double sided adhesive tape

InactiveCN102268230AThe overall thickness is thinExcellent peelabilityEster polymer adhesivesFilm/foil adhesive release linersSurface layerAdhesive

Owner:NITTO DENKO CORP

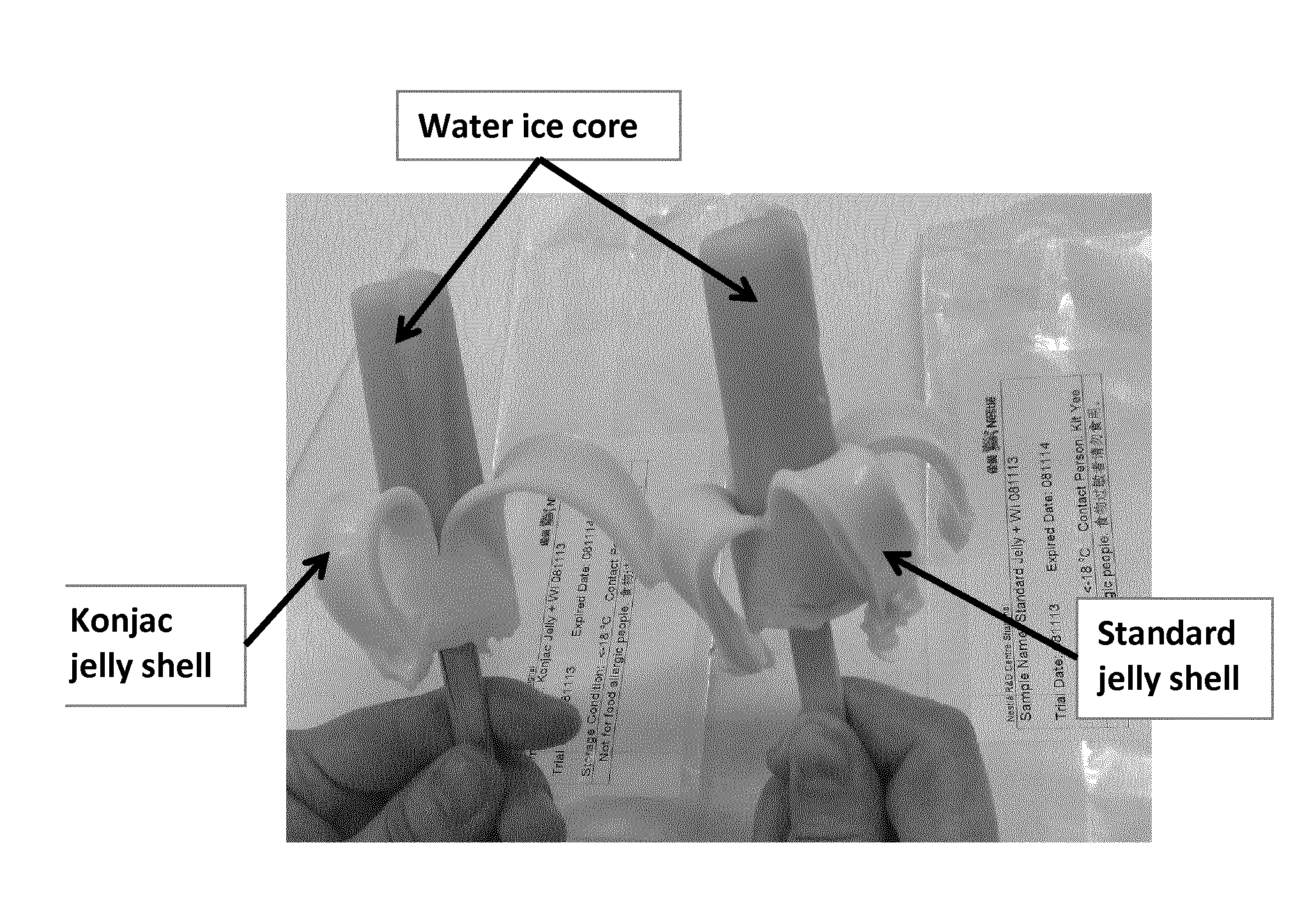

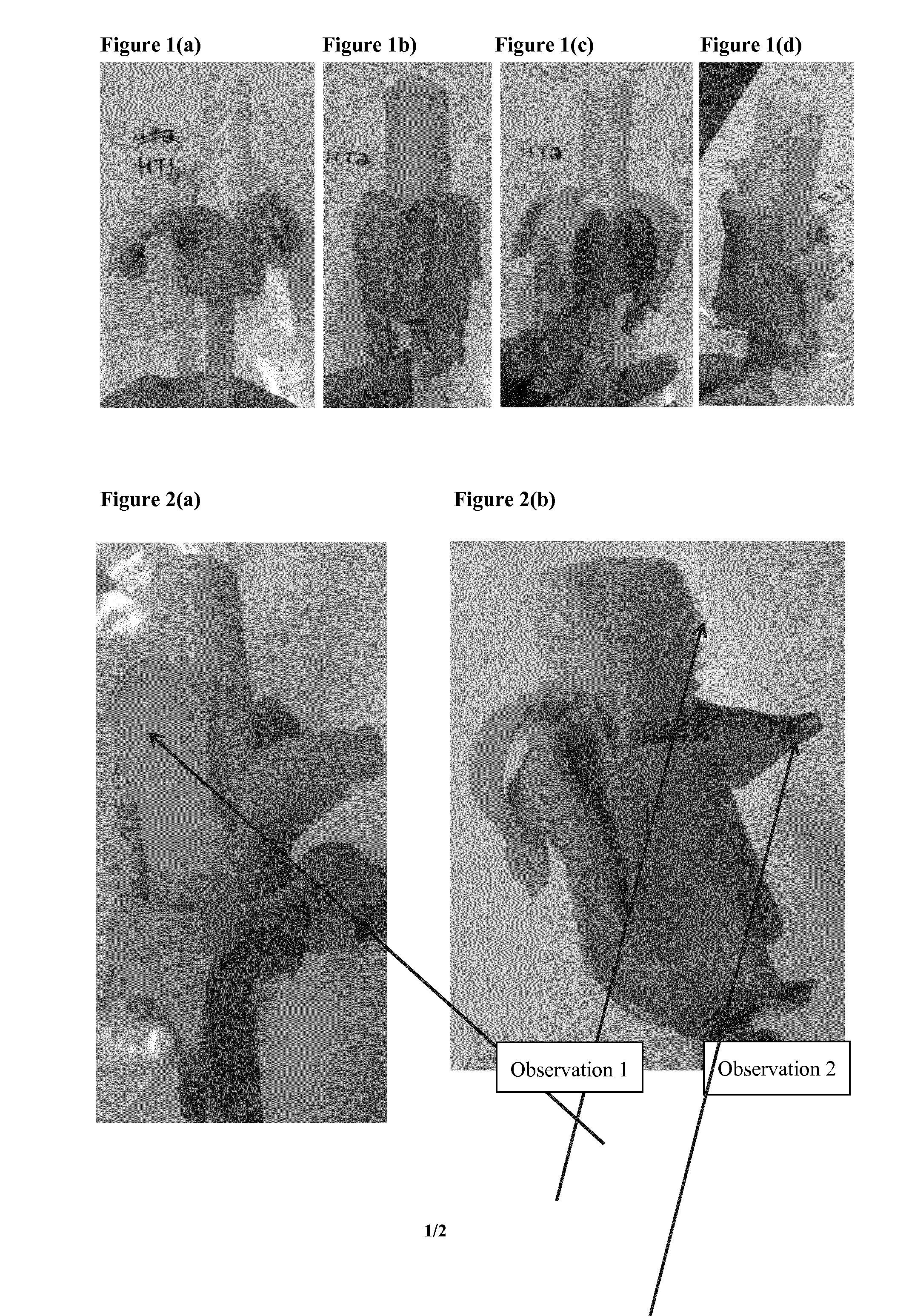

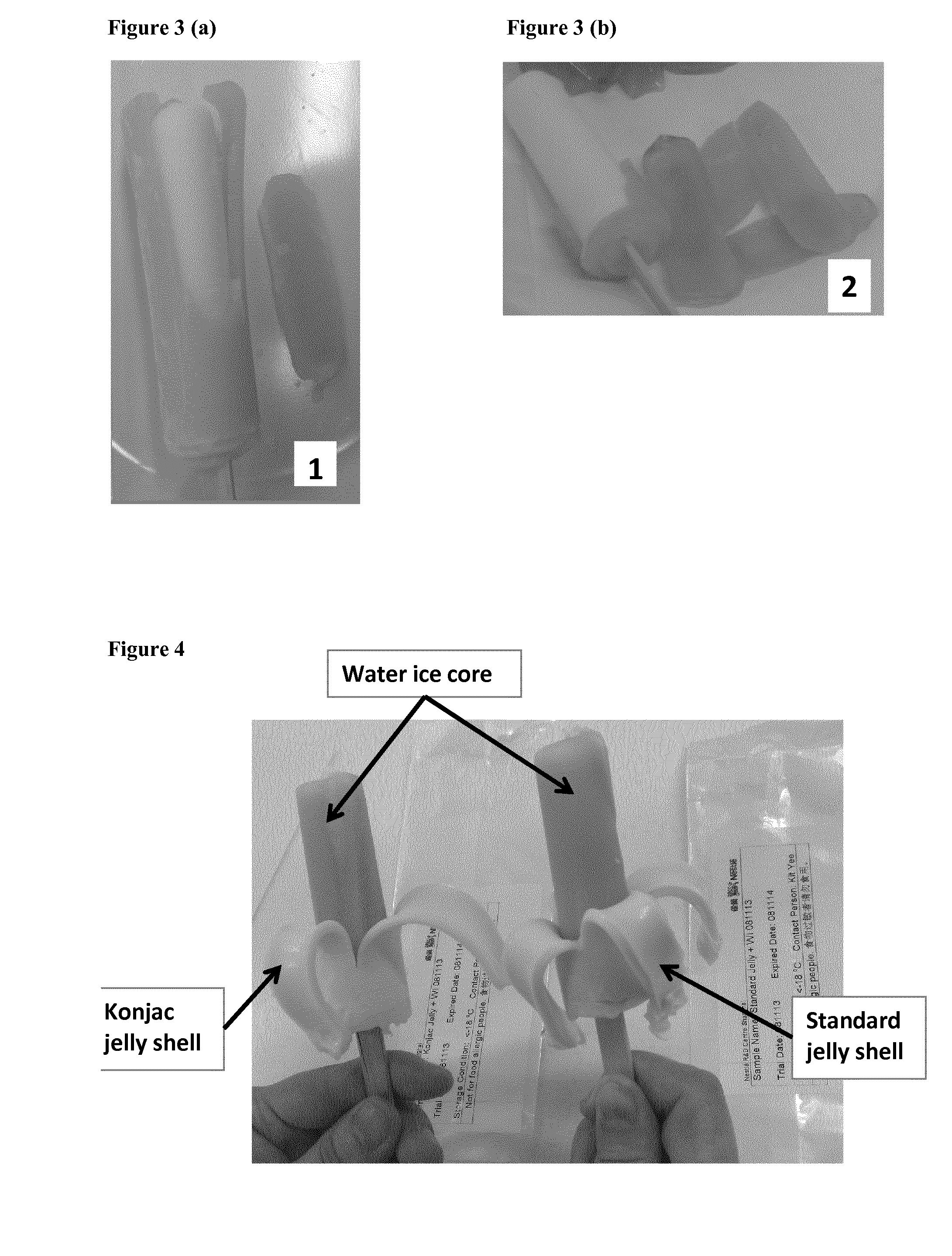

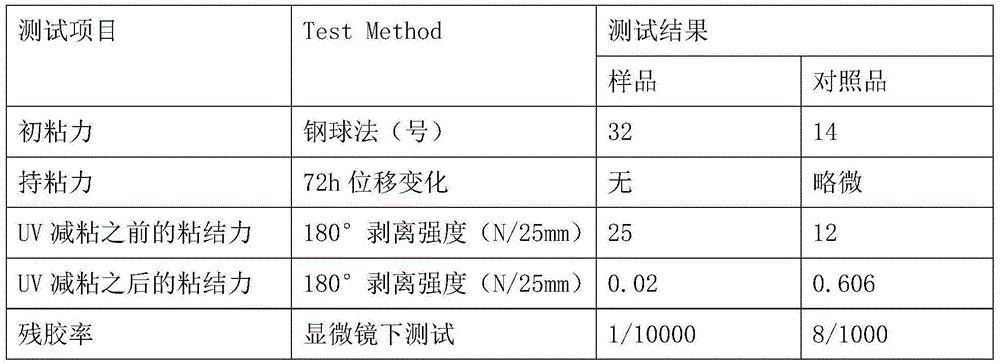

Frozen confectionery product with an easy peelable gel coating and a method for manufacturing same

The invention relates to a frozen confectionery product comprising a core of a frozen confection, which is at least partially coated with a gel coating, characterized in that the gel coating has a layer of frozen liquid on the surface of the gel coating that originates from syneresis of the gel. Furthermore, the invention relates to a method for making such a frozen confectionery product.

Owner:NESTEC SA

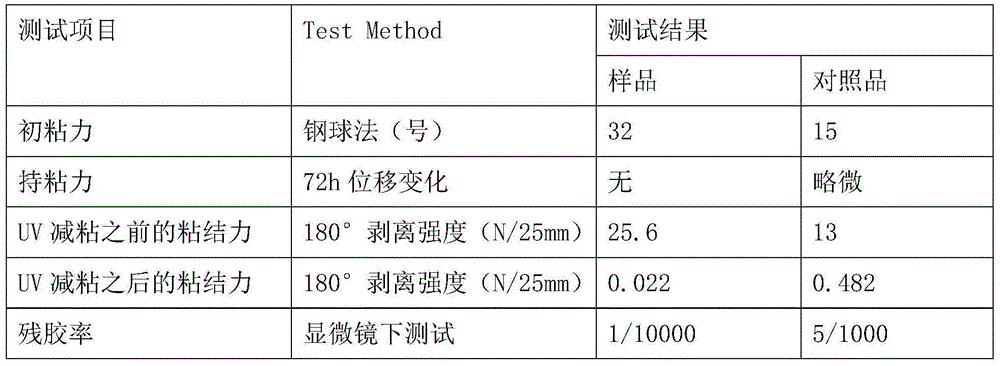

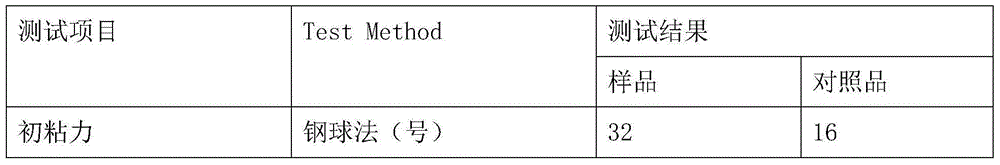

Bi-component cured UV viscosity-decreasing adhesive

ActiveCN105086730AImprove initial tack performanceImprove yield ratePolyurea/polyurethane coatingsAdhesiveDiluent

The invention relates to a bi-component cured UV viscosity-decreasing adhesive. The bi-component cured UV viscosity-decreasing adhesive comprises two components of the component A and the component B. The component A is composed of, by weight, 35-60 parts of cured resin, 22-45 parts of photosensitive monomers, 2-10 parts of photopolymerization initiators, 2-15 parts of diluents and 2-10 parts of auxiliaries, wherein the cured resin is resin containing hydroxyl or resin containing carboxyl; the component B is one of a curing agent containing NCO and a curing agent containing sulfydryl or a mixture of the curing agent containing NCO and the curing agent containing the sulfydryl, the curing agent containing NCO is isocyanate, the content of NCO of the isocyanate ranges from 12.5% to 23.5%, and the molecular weight ranges from 200 to 600; the curing agent containing the sulfydryl is polymercaptans, wherein the content of the sulfydryl ranges from 5% to 15%; the weight of the component B is 5%-20% of that of the component A. The bi-component cured UV viscosity-decreasing adhesive has the advantages that the initial viscous force is strong after curing forming is conducted at room temperature, after UV-irradiation is conducted for decreasing viscosity, the stripping effect is good, and adhesive residues do not exist.

Owner:GUANGZHOU SHENWEI NEW MATERIAL TECH

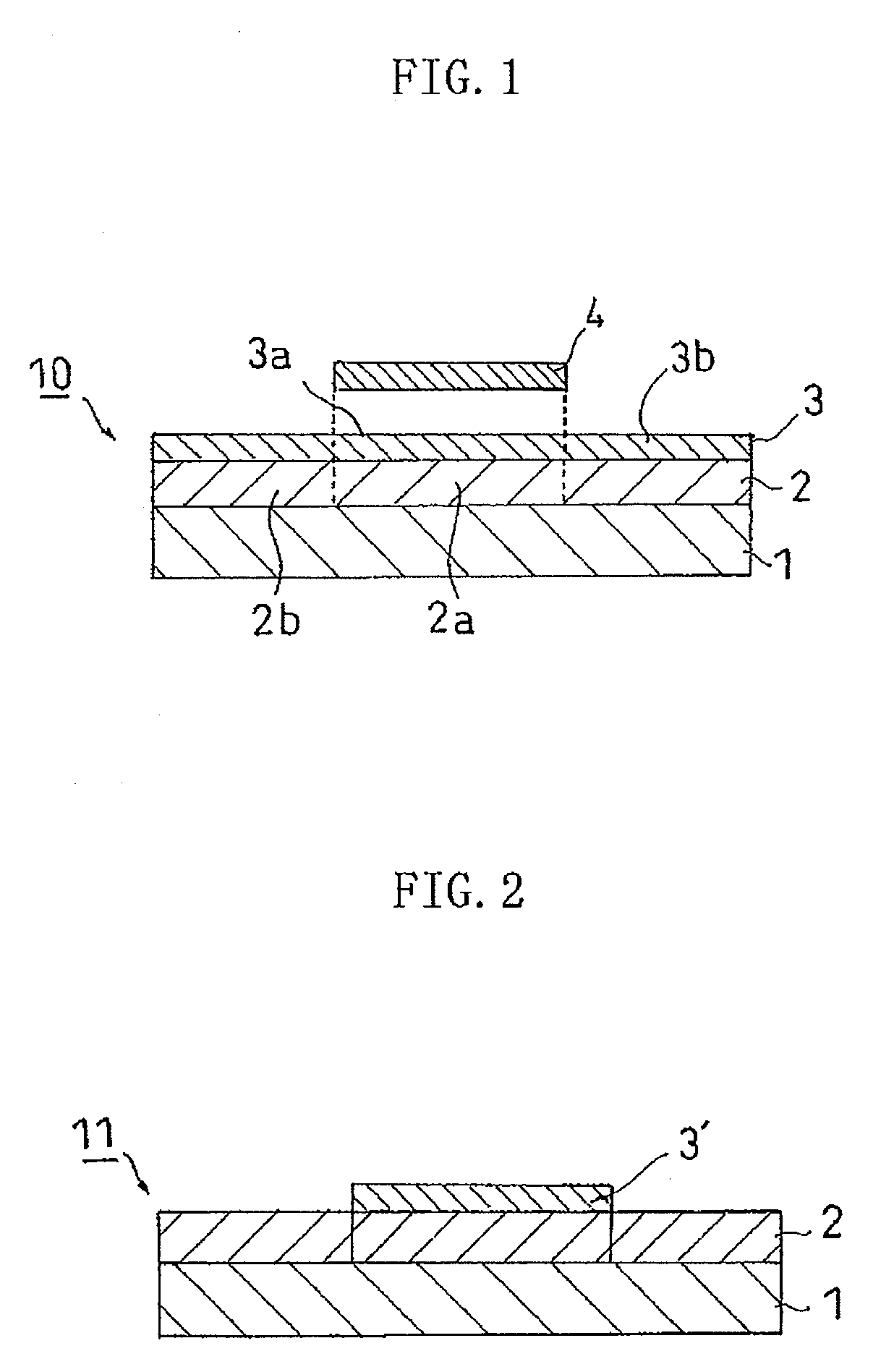

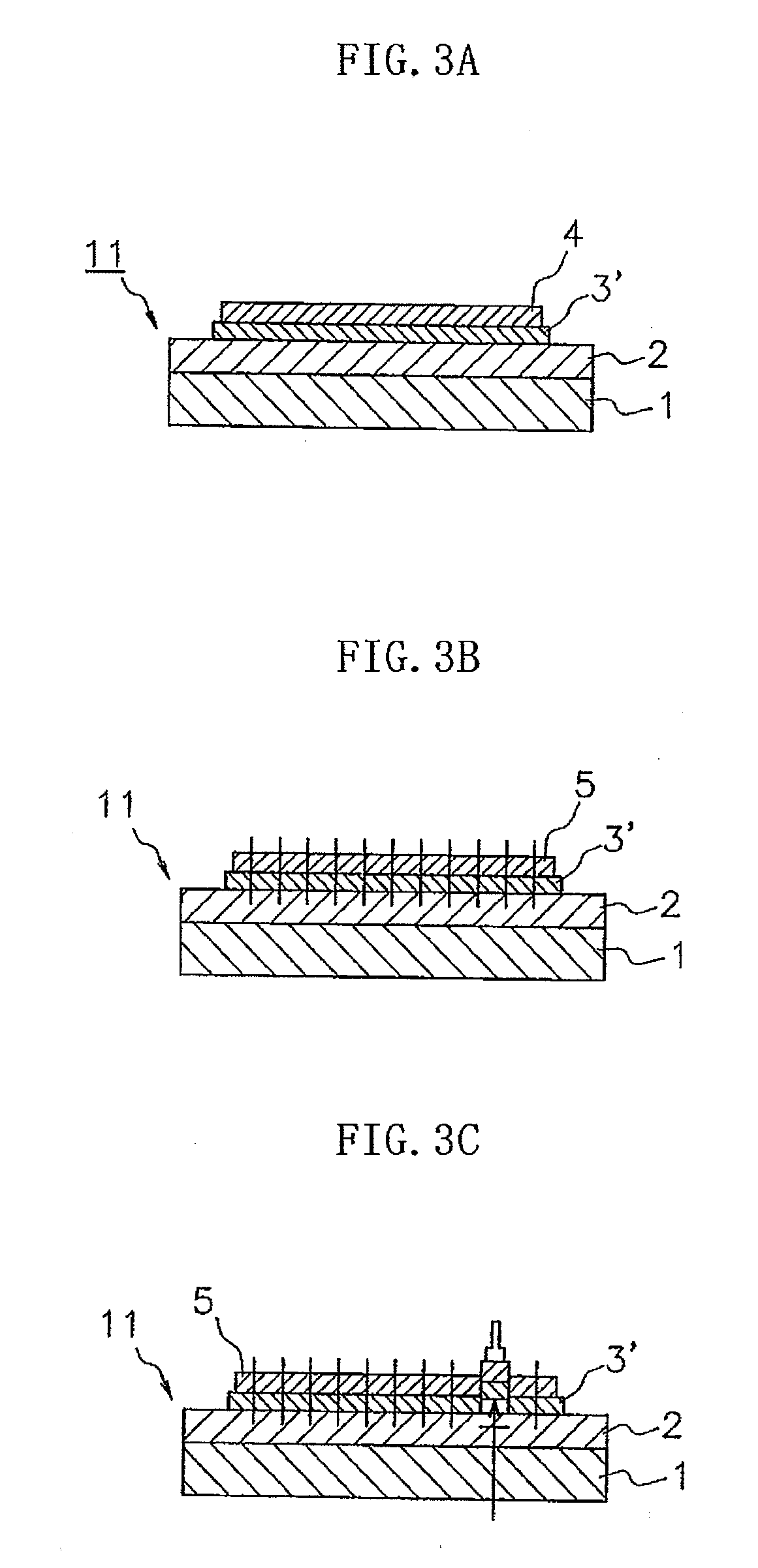

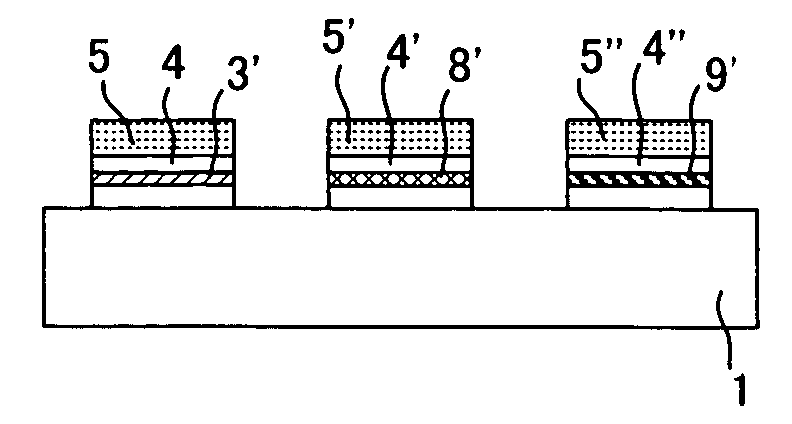

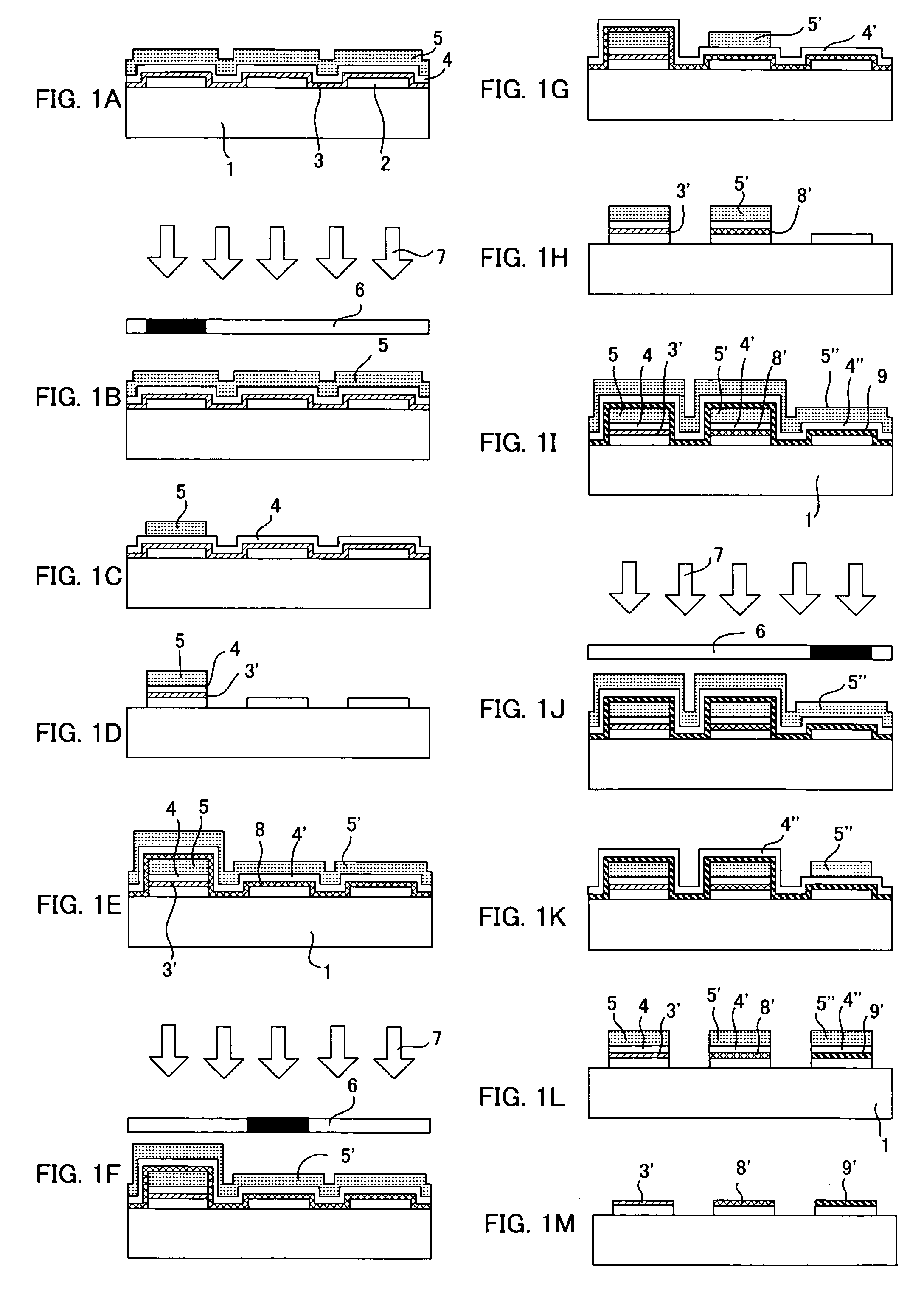

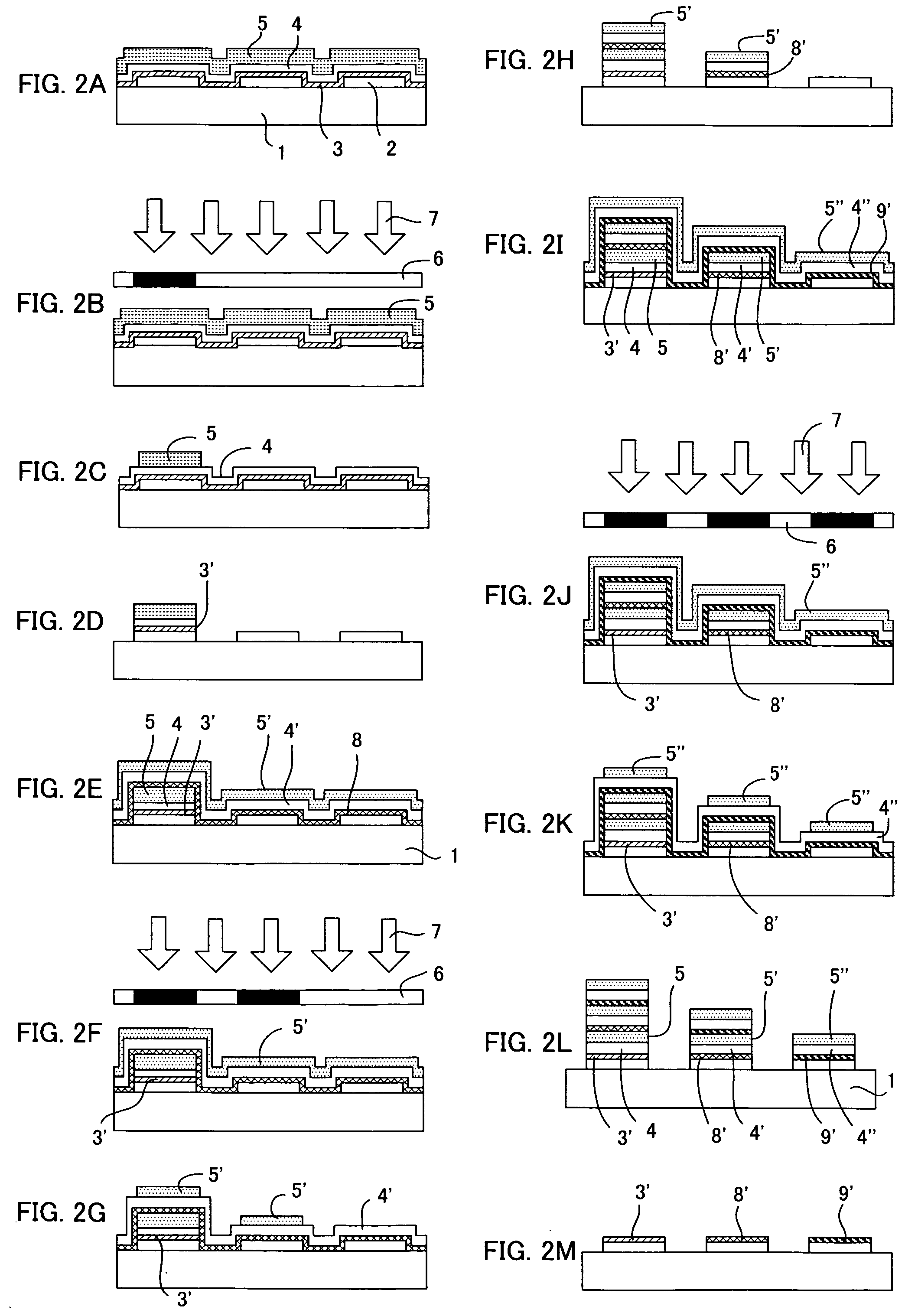

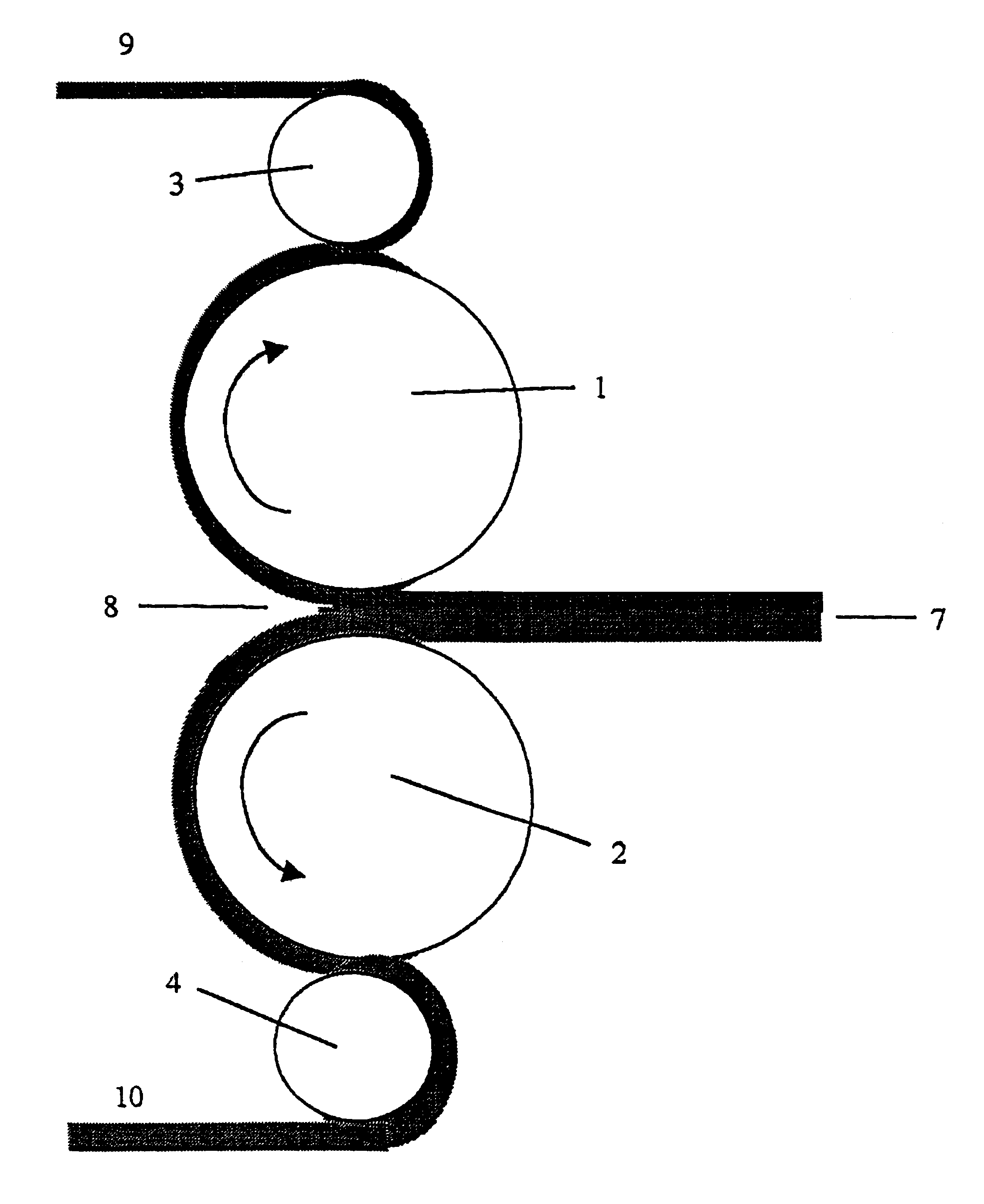

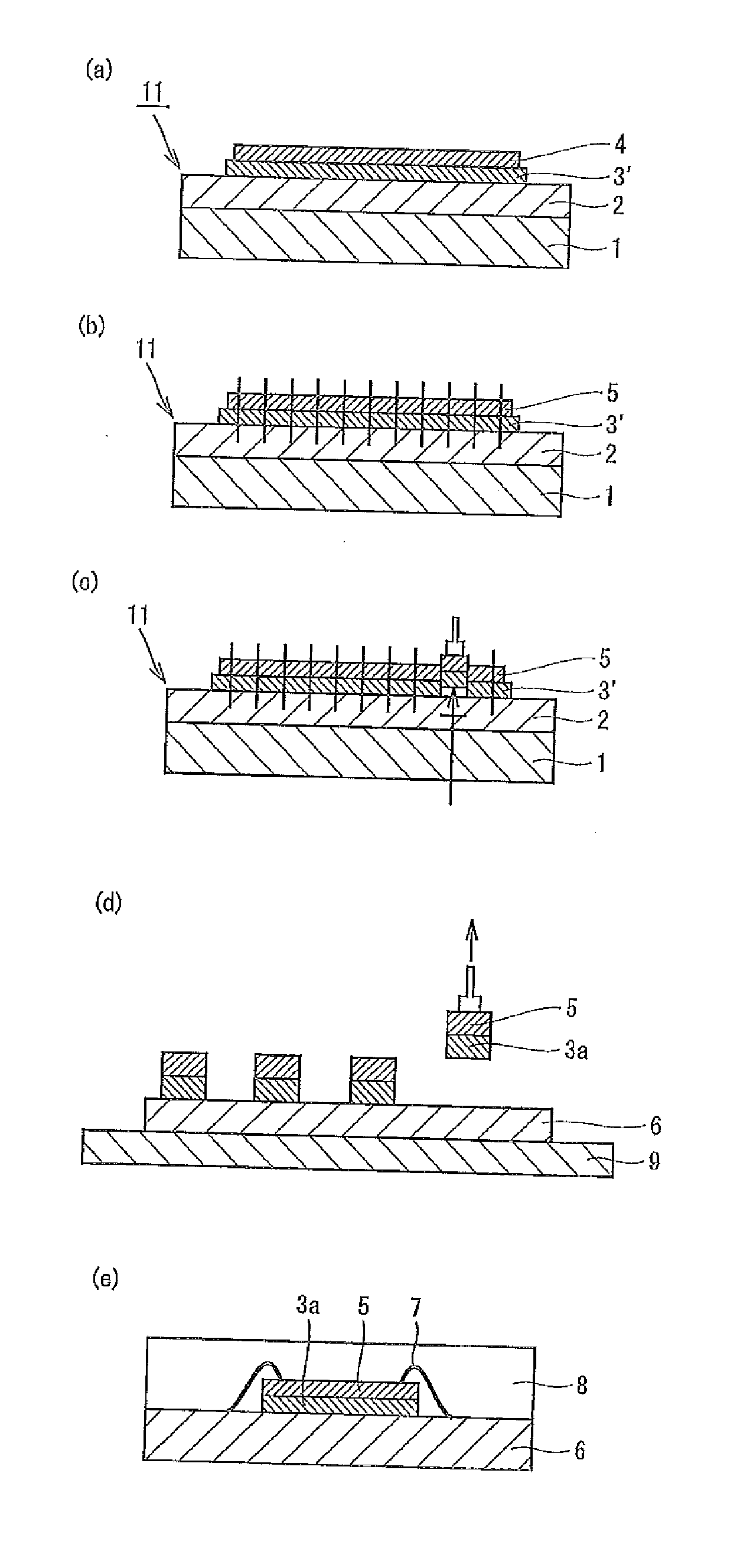

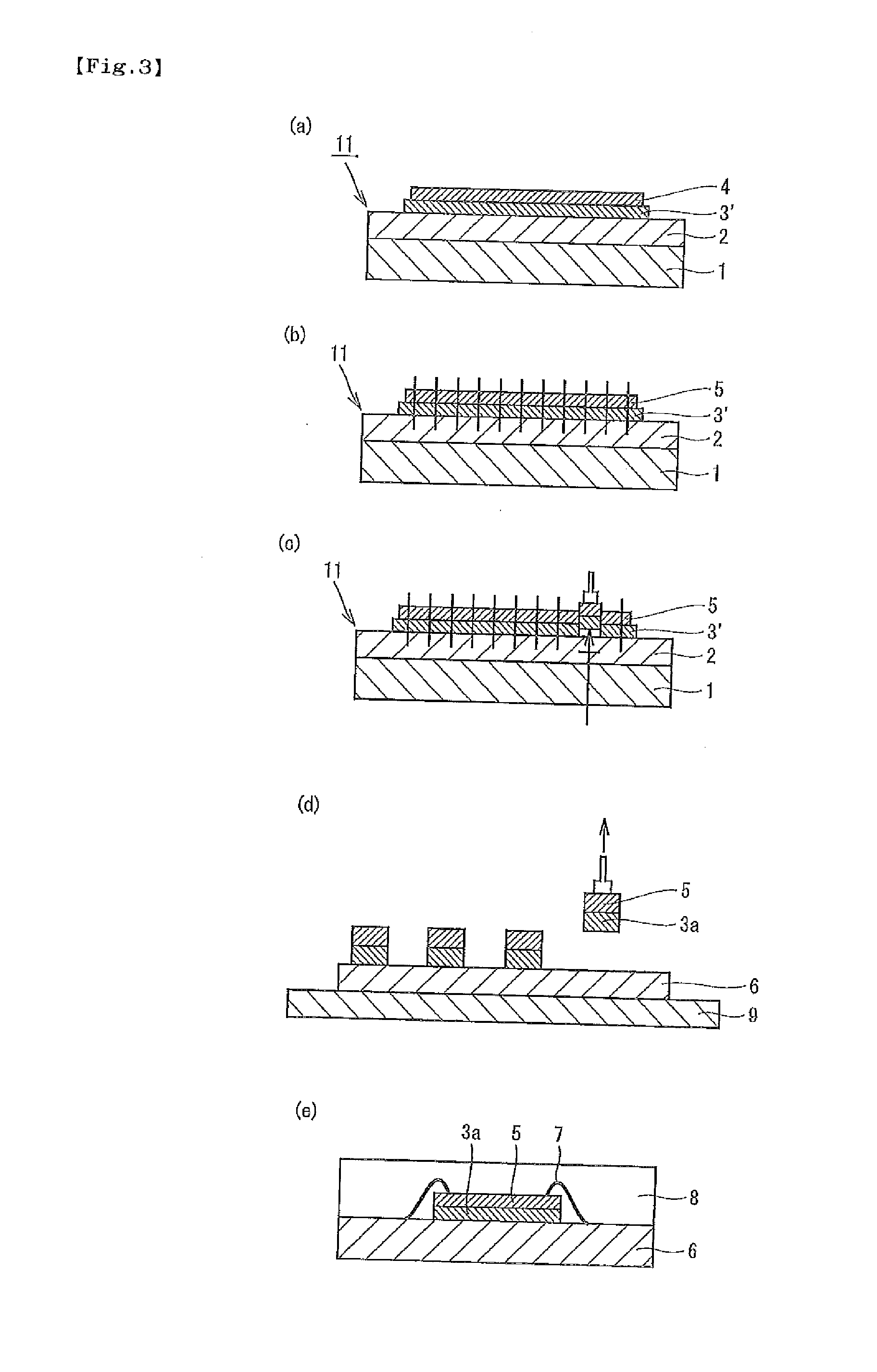

Production method for electroluminescent element

InactiveUS20050153058A1Avoid damageExcellent peelabilityElectroluminescent light sourcesSolid-state devicesPhotoresistEngineering

The main object of the present invention is to provide a method for manufacturing an EL element, capable of preferably carrying out the peeling operation at the time of peeling off an unnecessary layer such as a photoresist layer. In order to achieve the object, the present invention provides a method for manufacturing an EL element comprising: an organic EL layer forming process of forming an organic EL layer on a substrate, on which at least an electrode layer is formed; a peeling layer forming process of forming a peeling layer on the organic EL layer; a photoresist layer forming process of forming a photoresist layer on the peeling layer; a photoresist layer patterning process of patterning the photoresist layer by exposing and developing; an organic EL layer developing process of removing the organic EL layer of a part not covered with the photoresist layer; and a peeling layer peeling process of removing the photoresist layer laminated thereon by peeling off the peeling layer.

Owner:DAI NIPPON PRINTING CO LTD

Multi-layer paper peelable into at least two thin sheets

InactiveUS6977111B2Low densityLose weightNon-fibrous pulp additionSpecial paperWood veneerStencil printing

Disclosed is a multi-layer paper suitable as a material for preparing heat-sensitive stencil printing masters. The multi-layer paper is produced by combining a plurality of thin paper layers by paper making. The multi-layer paper has a peel strength of 10 N / m or less and may be delaminated into at least two tissue sheets.

Owner:RICOH KK +1

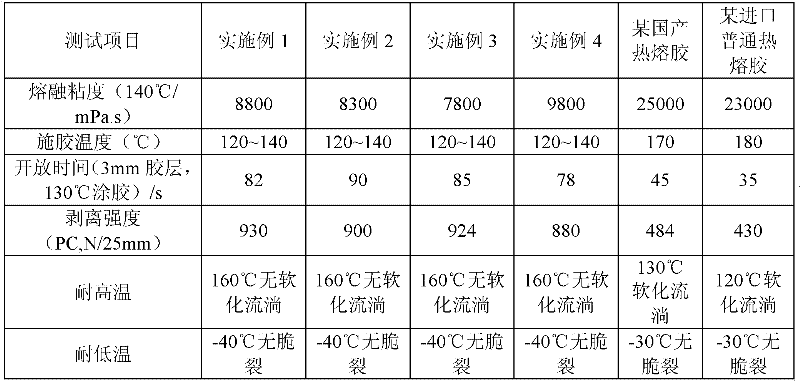

Polyurethane hot-melt adhesive for bonding and preparation method thereof

ActiveCN102585753AExcellent peelabilityEasy to apply glueNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to a polyurethane hot-melt adhesive for bonding and a preparation method thereof, belonging to the technical field of preparation of automobile hot-melt adhesives. The preparation method comprises the following steps of: firstly, feeding high-crystalline polyester glycol, polyester polyol and tackifying resin into a reactor, heating, dehydrating at vacuum while stirring, andthen cooling; secondly, preheating diisocyanate, adding the preheated diisocyanate to the reactor to uniformly stir and carrying out prepolymerization reaction; after the prepolymerization is finished, sequentially adding weighed catalyst, antioxidant, coupling agent, viscosity stabilizer and grey paste under nitrogen circulation, and stirring till being mixed uniformly; discharging in the nitrogen protection condition, sealing and packaging so as to obtain the product, that is, the polyurethane hot-melt adhesive for bonding automobile lights. The hot-melt adhesive prepared by adopting the preparation method disclosed by the invention can be used for bonding a plurality of base materials such as PP (Polypropylene), PBT (polybutylece terephthalate), ABS (Acrylonitrile Butadiene Styrene), PMMA (polymethyl methacrylate), PC (Poly Carbonate) and inorganic glass.

Owner:WUXI WANLI ADHESION MATERIALS

Composite bactericide containing dialkyl quaternary ammonium salt and its application

InactiveCN1426681AReduce use costExcellent peelabilityBiocideAnimal repellantsIsothiazolinoneDisinfectant

A composite disinfectant containing dialkyl quaternary ammonium salt for disinfecting the circulated cooling water contains at least one dialkyl quaternary ammonium salt disinfectant and at least one non-oxide disinfectant chosen from frequency used quaternary ammonium salt, isothiazolinone, glutaraldehyde, and bithiocyanomethane.

Owner:RES INST OF BEIJING YANSHAN PETROCHEM

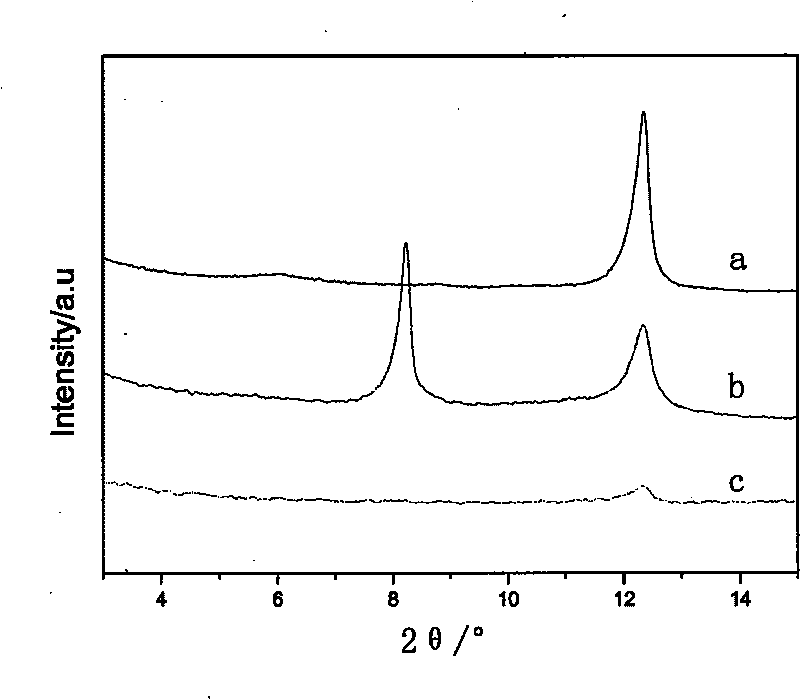

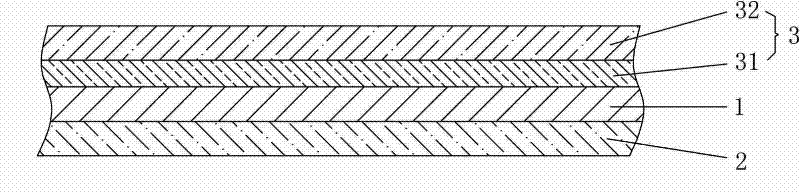

Method for stripping laminated inorganic material

The invention relates to a method for stripping a laminated inorganic material, which comprises the following steps of: firstly preparing a laminated inorganic material organic intercalation compound, then decomposing the organic substance at the interlayer of the solid of the laminated inorganic material organic intercalation compound or the laminated inorganic material organic intercalation compound added into a proper solution within short time under the condition of ultrasonic waves or microwaves, escaping from the interlayer of the laminated inorganic material so as to rapidly strip the laminated inorganic material, and finally separating, washing, drying and grinding to obtain a product. By using the method, not only the laminated inorganic material can be stripped within short time, but also the good crystal structure of the laminated inorganic material can be kept, so that the traditional application of the laminated inorganic material is qualitatively improved, and the value is doubled and redoubled.

Owner:BEIJING UNIV OF CHEM TECH

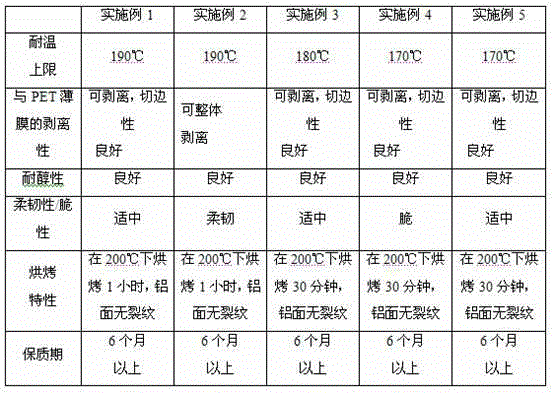

Water-based laser transfer coating for wine bottle glass baking paper, and preparation method thereof

The invention discloses a water-based laser transfer coating for wine bottle glass baking paper, and a preparation method thereof. The coating is prepared by mixing the following components in percentage by mass: 10-30% of water-based acrylic resin, 25-40% of water-based polyurethane resin, 0-8% of cosolvent, 20-45% of deionized water, 0-0.4% of water-based defoaming agent, 0.1-0.4% of base material wetting agent, and 0-0.2% of pH value regulating agent. The water-based laser transfer coating for the wine bottle glass baking paper is an environment-friendly laser transfer coating which meets national VOC detection standard by taking the water-based resin and deionized water as main raw materials. In addition, the composite water-based resin endows a curing film with good temperature resistance, aluminum adherence, strippability, alcohol resistance and the like, thus meeting the index requirement of the wine bottle glass baking paper.

Owner:三友(天津)高分子技术有限公司

Composition Containing Amphoteric Water-Soluble Polymer

InactiveUS20080230193A1Improve filtration rateExcellent peelabilityNatural cellulose pulp/paperSpecial paperFlocculationPolymer science

An object of the present invention is to provide a composition excellent in various flocculation performances for various sludge and papermaking systems, especially excellent as a polymer flocculant, and provide a sludge-dewatering agent excellent in dewatering performances for various sludge, especially excellent in flocculationability, as well as a retention aid which can realize a high retention and ensure excellent formation of paper and which is easy to use.A composition is provided, which comprises two or more amphoteric water-soluble polymers in combination shown below, the polymers being obtained by polymerizing a cationic radical-polymerizable monomer and an anionic radical-polymerizable monomer in a presence of a polysaccharide.1. A combination of a polymer satisfying the molar ratio of the cationic radical-polymerizable monomer to the anionic radical-polymerizable monomer (hereinafter referred to as Ca / An) of Ca / An≧1, and a polymer satisfying Ca / An<1, or2. a combination of two kinds of polymers satisfying Ca / An≧1.

Owner:TOAGOSEI CO LTD

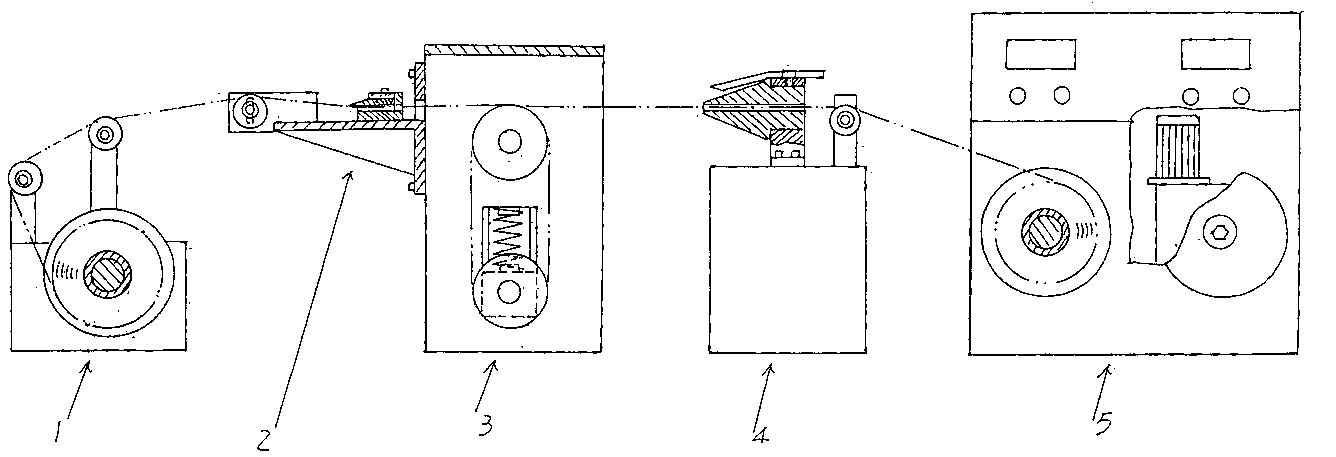

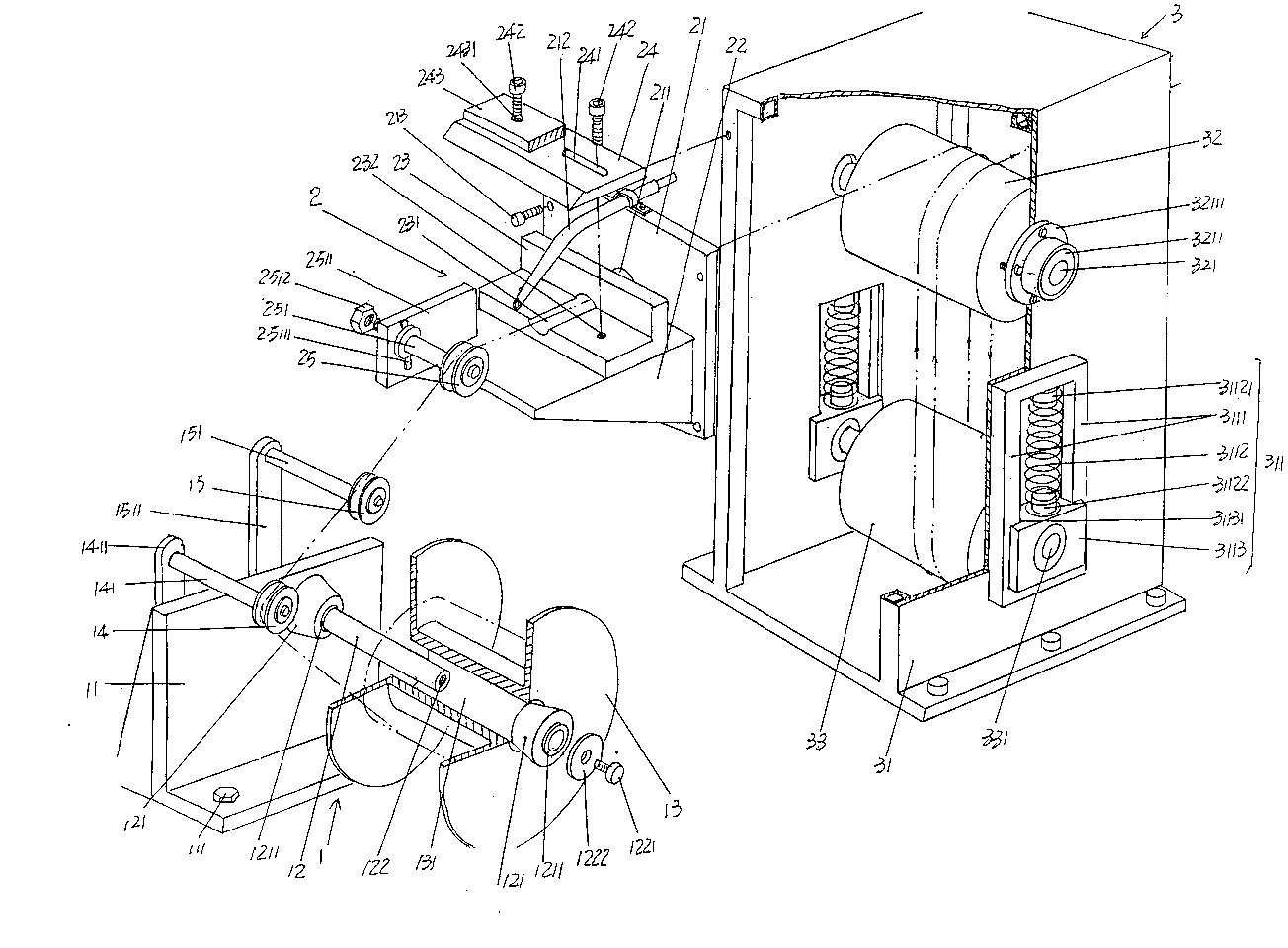

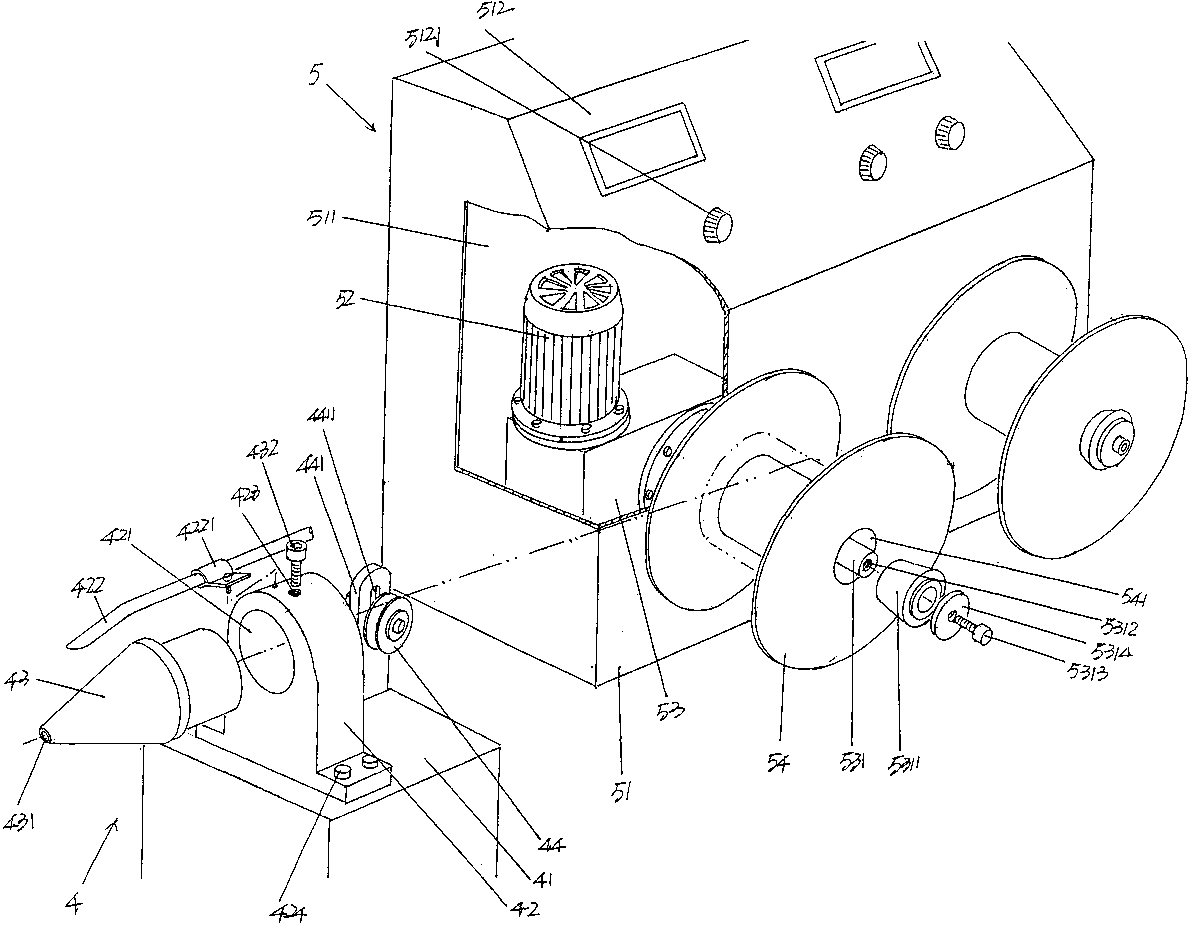

Waste wire stripping device

ActiveCN103259221AGuaranteed peeling effectExtended service lifeApparatus for removing/armouring cablesEngineeringWheel and axle

The invention discloses a waste wire stripping device, and belongs the technical field of recovery devices of waste materials. The waste wire stripping device comprises a paying-off mechanism, a paring mechanism, a tension automatic adjustment mechanism, a peeling mechanism and a wire core winding mechanism, wherein the paring mechanism is arranged on one side of the tension automatic adjustment mechanism, the peeling mechanism is located between the tension automatic adjustment mechanism and the wire core winding mechanism, the paring mechanism comprises a fixed plate, a paring knife fixing base supporting arm, a paring knife fixing base, a paring knife and a guiding wheel, the fixed plate is fixed with one side of the tension automatic adjustment mechanism, a wire passing hole is formed in the fixed plate, the paring knife fixing base supporting arm is fixed with one side of the fixed plate, a wire passing groove is formed in one side of the paring knife fixing base, two ends of the paring knife are respectively provided with a paring knife adjustment groove, the guiding wheel is arranged on a guiding wheel shaft, the guiding wheel shaft is fixed on a guiding wheel shaft base, and the guiding wheel shaft base is fixed on the paring knife fixing base supporting arm. The waste wire stripping device is ideal in stripping effect, free of damage to the guiding wheel caused by friction, long in service life and low in knife cost, and ensures a paring effect.

Owner:CHANGSHU HONGLIN WIRE & CABLE CO LTD

Multi-layer thermal transfer ribbon and manufacturing method thereof

The invention relates to a multi-layer thermal transfer ribbon and a manufacturing method thereof, and the multi-layer thermal transfer ribbon comprises a membranous base band, a heat-resistant printing ink layer and a heat transfer printing ink layer, wherein the heat-resistant printing ink layer is coated on one side of the base band, the heat transfer printing ink layer is coated on the other side of the base band, the heat transfer printing ink layer comprises a stripping printing ink layer and an adhesive printing ink layer, the stripping printing ink layer is directly coated on the surface of the base band, the adhesive printing ink layer is coated on the stripping printing ink layer, printing ink in the striping printing ink layer is hot-melting type printing ink, and the printing ink in the adhesive printing ink layer is the hot-melting type printing ink or solvent type printing ink. The heat transfer printing ink layer of the multi-layer mixed-based ribbon can be easily completely stripped off the base band, and the great adhesive ability is realized on a smooth medium; in addition, the multi-layer thermal transfer ribbon further has the advantages of high resolution, clear printing, anti-friction property, moisture resistance, chemical corrosion resistance, environment friendliness and the like.

Owner:泉州市山水电脑耗材有限公司

Microwave method for peeling laminar inorganic material quickly

The invention relates to a method for peeling a laminar inorganic material quickly. The method comprises the following steps of: firstly, preparing laminar inorganic intercalating composite of the laminar inorganic material; secondly, decomposing or evaporating the inter-laminar organic material of the organic intercalating composite solid of the laminar inorganic material in a short time in the presence of microwaves and allowing the inter-laminar organic material to escape from the space between the layers of the laminar inorganic material so as to quickly peal the laminar inorganic material; and finally, performing separation, washing, drying and grinding to obtain the products. The method not only can peal the laminar inorganic material in a short time but also keep a good crystal structure of the laminar inorganic material, so the application of the laminar inorganic material is substantially widened and the use value thereof is multiplied.

Owner:BEIJING UNIV OF CHEM TECH

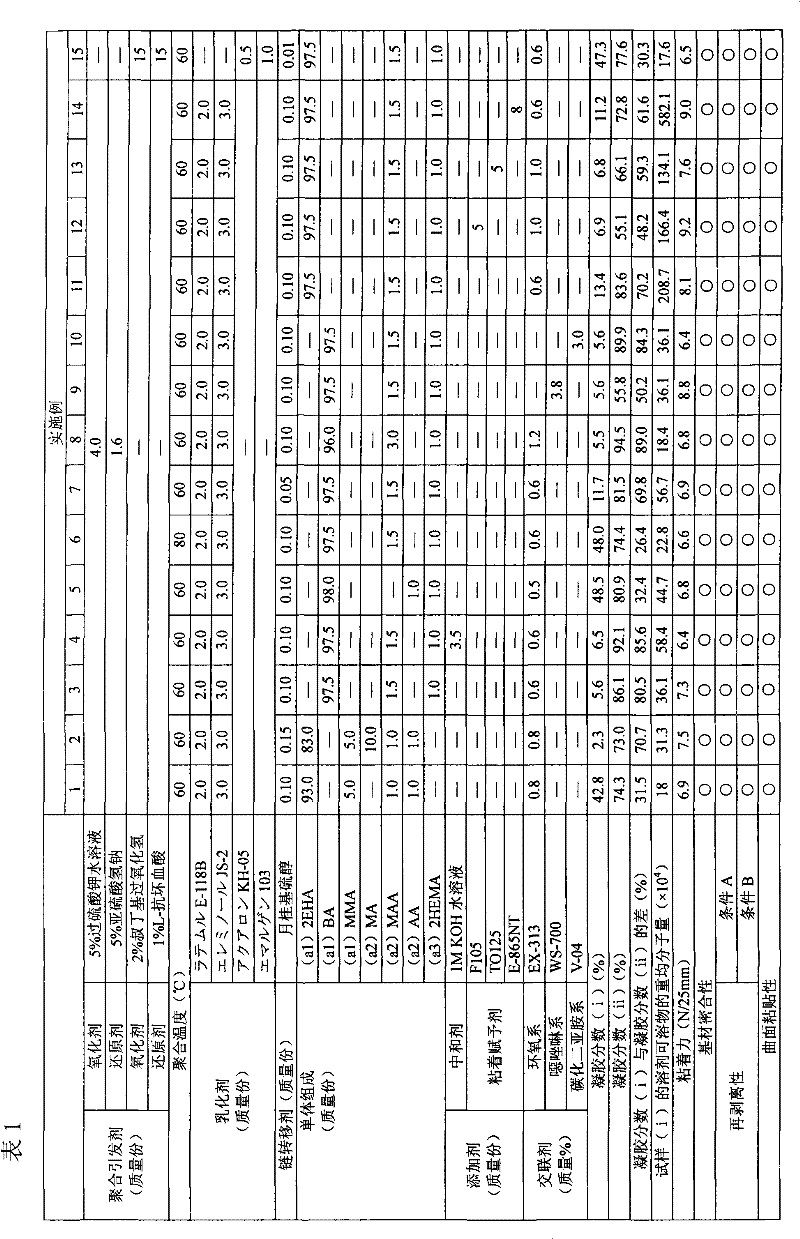

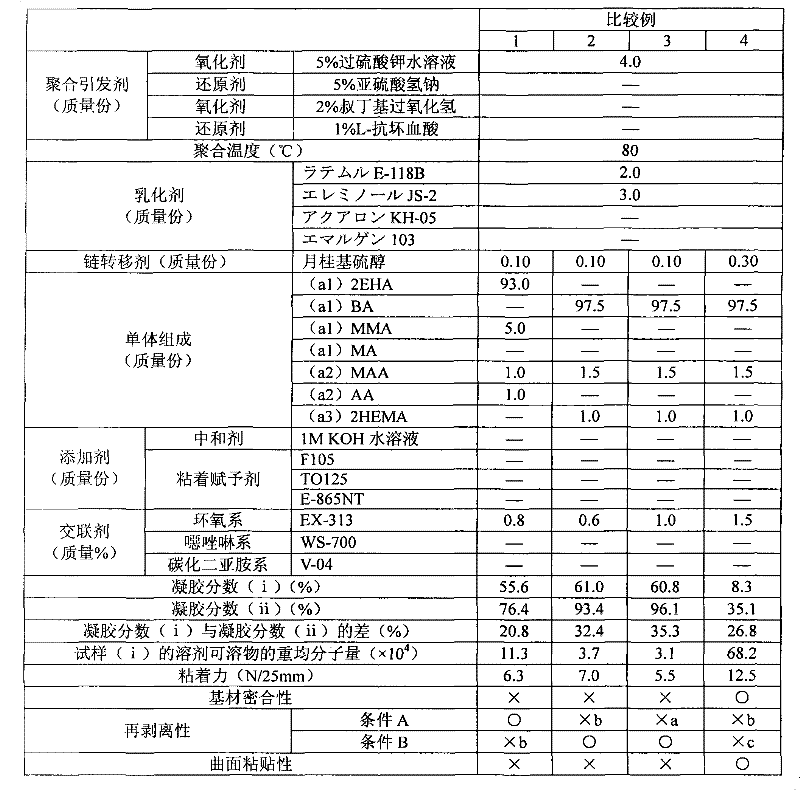

Water-dispersed acrylic acid series sticker composition and adhesion sheet and preparation method thereof

ActiveCN102051146AExcellent peelabilityExcellent adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkEmulsion

The invention provides a water-dispersed acrylic acid series sticker composition which has high adhesion property of substrate, good restripping property and good curved surface adhesion even when a transfer printing and coating method is adopted, and an adhesion sheet and a preparation method thereof. The composition comprises an acrylic acid series emulsion (A) and a cross-linking agent (B). The acrylic acid series emulsion (A) is obtained by conducting an emulsion polymerization on an unsaturated monomer mixture with the existence of a redox series polymerization initiator. The unsaturated monomer mixture comprises a (methyl) acrylic acid alkyl ester and an unsaturated monomer with a carboxyl. The composition is coated on the stripping sheet and is dried. The weight average molecular weight of a solvent soluble substance in the dried envelope just adhered to the substrate is over 150 thousand. The gel fraction (i) in the dried envelope is within 0-60%. The gel fraction (ii) in the dried envelope which has undergone slaking for seven days at the temperature of 40 DEG is within 50-99%. The difference between the gel fraction (i) and the gel fraction (ii) is over 20%.

Owner:LINTEC CORP

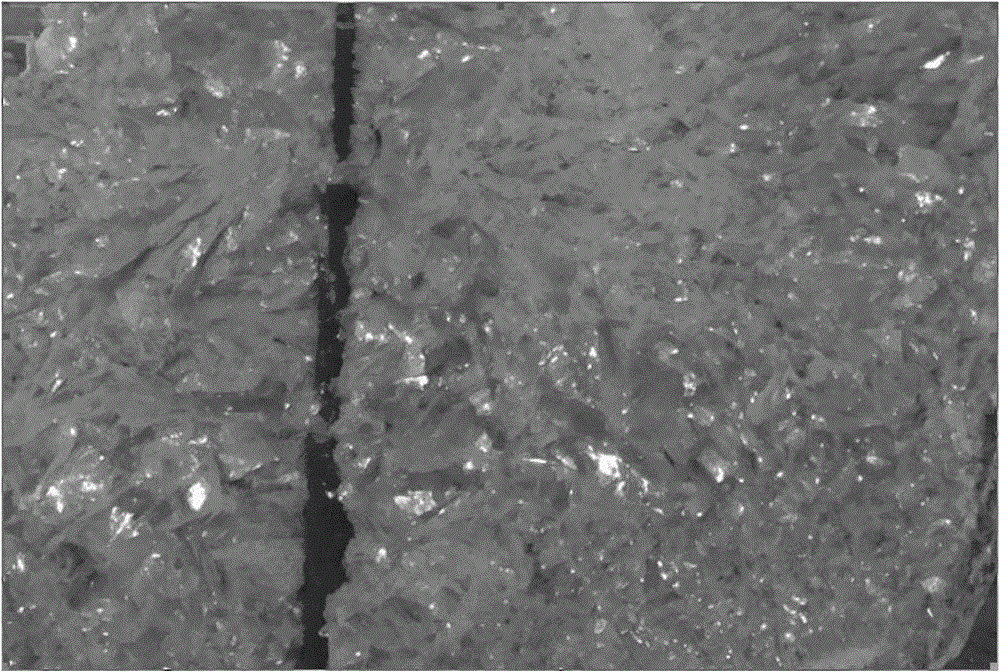

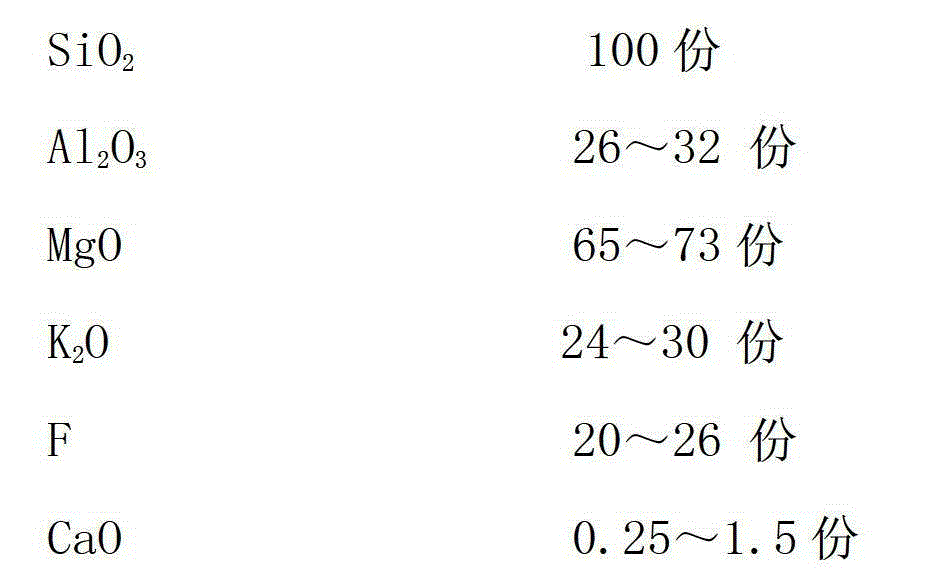

Synthesized mica crystal plate with high flexibility and high splitting performance as well as preparation method

The invention discloses a synthesized mica crystal plate with high flexibility and high splitting performance as well as a preparation method, the method is characterized in that in a formula for melting the synthesized mica, 0.1-0.6% of CaO (by referring calcium oxide, not specially referring calcium oxide) is introduced as an impurity enrichment agent, thereby the impurity can be enriched, and the flexibility and splitting performance of the synthesized mica can be enhanced, the flexibility of the obtained synthesized mica crystal plate can reach 38-50% (a winding method), 0.1-0.6% of CaO is contained, the thickness of the obtained powder plate is 0.05-0.8mum, especially 0.05-0.5mum. The synthesized mica crystal plate is used for preparing the ultrathin synthesized mica crystal powder, and can be used for industries of thermostability base materials, cosmetics, anticorrosive paints and engineering plastics.

Owner:杨修直

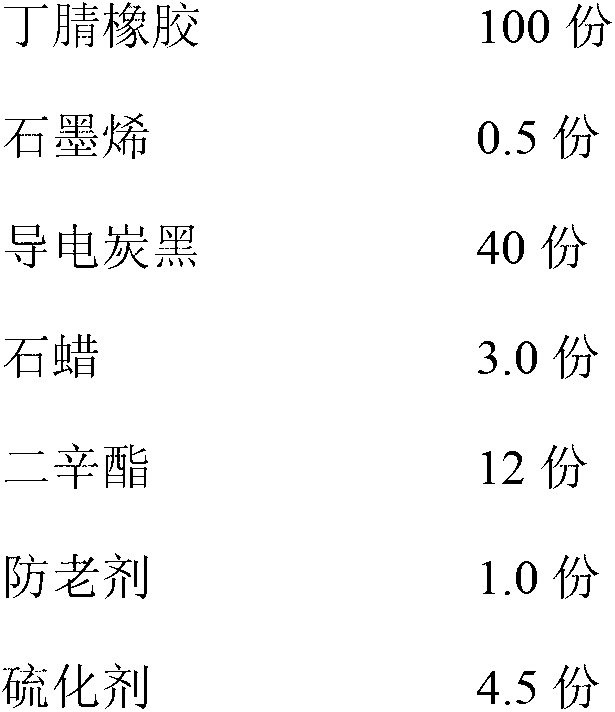

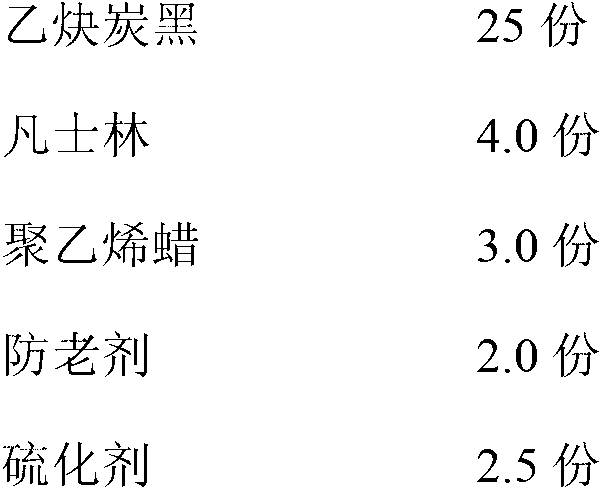

Strippable semiconductive shielding rubber for rubber insulation and preparation method thereof

ActiveCN103122085AHighly cleanAvoid performance biasPower cables with screens/conductive layersPlasticizerResidual carbon

The invention relates to a strippable semiconductive shielding rubber for rubber insulation and a preparation method thereof. The strippable semiconductive shielding rubber comprises the following components in parts by weight: 100 parts of nitrile-butadiene rubber, 0.5-8 parts of graphene, 10-40 parts of conductive carbon black, 7-15 parts of plasticizer, 1-2 parts of anti-aging agent and 2.5-4.5 parts of vulcanizing agent, wherein the nitrile-butadiene rubber is a solar one; the minimum surface-diameter ratio of the graphene is 1000; the plasticizer is one or a mixture of paraffin, dioctyl ester, stearic acid and the like; and the vulcanizing agent is a peroxide vulcanizing system. The preparation method comprises the following steps: plasticating the nitrile-butadiene rubber twice (10 minutes for each time), and standing at normal temperature for 12 hours; adding the graphene into the plasticated nitrile-butadiene rubber, evenly mixing, and adding 1 / 2 of the conductive carbon black or acetylene carbon black; 3 minutes later, adding the residual carbon black and the plasticizer, and compounding for 2 minutes; sequentially adding various assistants, finally adding the vulcanizing agent, compounding for 1 minute, and then discharging, wherein the compounding temperature is not higher than 120 DEG C; and after discharging, tabletting semiconductive shielding gum on a tabletting machine to prepare the semiconductive shielding rubber. The semiconductive shielding rubber provided by the invention is easy to process and strip and high in conductivity.

Owner:SHANGHAI LEVSON ENTERPRISE GRP

A kind of high-strength re-peelable pressure-sensitive adhesive for window film and preparation method thereof

ActiveCN102260472AHigh strengthExcellent peelabilityFilm/foil adhesivesEster polymer adhesivesVitrificationEthylene Homopolymers

The invention relates to a high-strength repeelable pressure-sensitive adhesive for a window film and a preparation method thereof. The high-strength repeelable pressure-sensitive adhesive for the window film consists of the following raw materials in part by weight: 35 to 94.9 parts of (methyl) acrylate monomer which has glass transition temperature of between -45 and 10 DEG C and is used for preparing homopolymers, 5 to 50 parts of (methyl) acrylate monomer which has glass transition temperature of between -90 and -50 DEG C and is used for preparing homopolymers, 5 to 20 parts of acrylic monomer with a functional group, 5 to 20 parts of vinyl monomers with functional groups, 0.01 to 10 parts of cross-linking agent, 0.01 to 10 parts of initiator, and 70 to 100 parts of solvent. The pressure-sensitive adhesive for the window film has the characteristics of high strength, good repeeling performance and the like. In the process of peeling the window film coated with the pressure-sensitive adhesive, the residual adhesive cannot be left on the protected surface, so the pressure-sensitive adhesive has better peelability. The invention also provides a preparation method for the pressure-sensitive adhesive.

Owner:上海绘兰材料科技有限公司

Pressure sensitive adhesive composition for optical members, pressure sensitive adhesive layer for optical members, pressure sensitive adhesive optical member and image display

InactiveUS7385007B2Improve adhesionExcellent peelabilityFilm/foil adhesivesElectroluminescent light sourcesMeth-Polymer science

Owner:NITTO DENKO CORP

Aqueous cleaning composition containing copper-specific corrosion inhibitor for cleaning inorganic residues on semiconductor substrate

InactiveUS20030078173A1Efficient removalExcellent peelabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCopper interconnectCarboxylic acid

A semiconductor wafer cleaning formulation, including 1-35% wt. fluoride source, 20-60% wt. organic amine(s), 0.140% wt. nitrogenous component, e.g., a nitrogen-containing carboxylic acid or an imine, 20-50% wt. water, and 0-21% wt. metal chelating agent(s). The formulations are useful to remove residue from wafers following a resist plasma ashing step, such as inorganic residue from semiconductor wafers containing delicate copper interconnecting structures.

Owner:ENTEGRIS INC

Dicing die bond film, method of manufacturing dicing die bond film, and method of manufacturing semiconductor device

InactiveUS20120070960A1Excellent peelabilityImprove adhesionLamination ancillary operationsFilm/foil adhesivesDevice materialUltraviolet

The present invention aims to provide a dicing die bond film that is capable of suppressing peeling of the dicing die bond film from a dicing ring. The present invention provides a dicing die bond film in which the pressure-sensitive adhesive layer contains a polymer formed by performing an addition reaction on a specific acrylic polymer with a specific isocyanate compound, and a specific crosslinking agent, and the specific peeling adhesive power of a portion of the pressure-sensitive adhesive layer where the dicing ring is pasted is 1.0 N / 20 mm tape width or more and 10.0 N / 20 mm tape width or less, the tensile storage modulus at 23° C. of the portion where the dicing ring is pasted is 0.05 MPa or more and less than 0.4 MPa, and the die bond film is pasted to the pressure-sensitive adhesive layer after irradiation with an ultraviolet ray.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com