Patents

Literature

94results about How to "Guaranteed peeling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

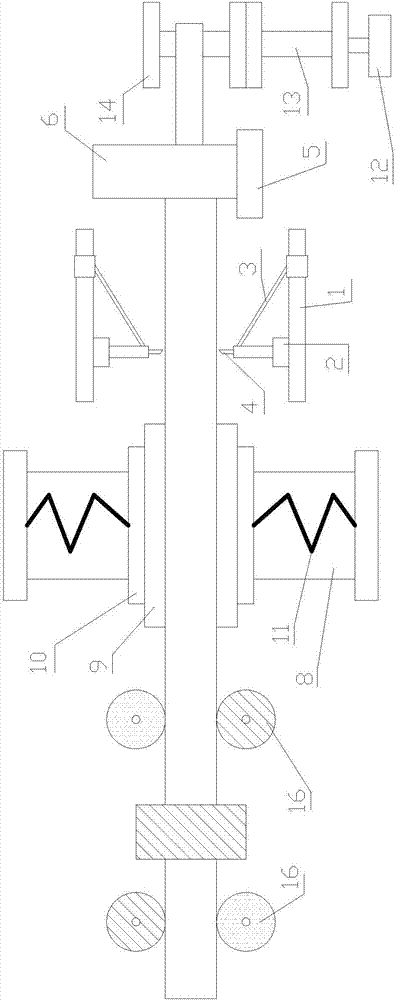

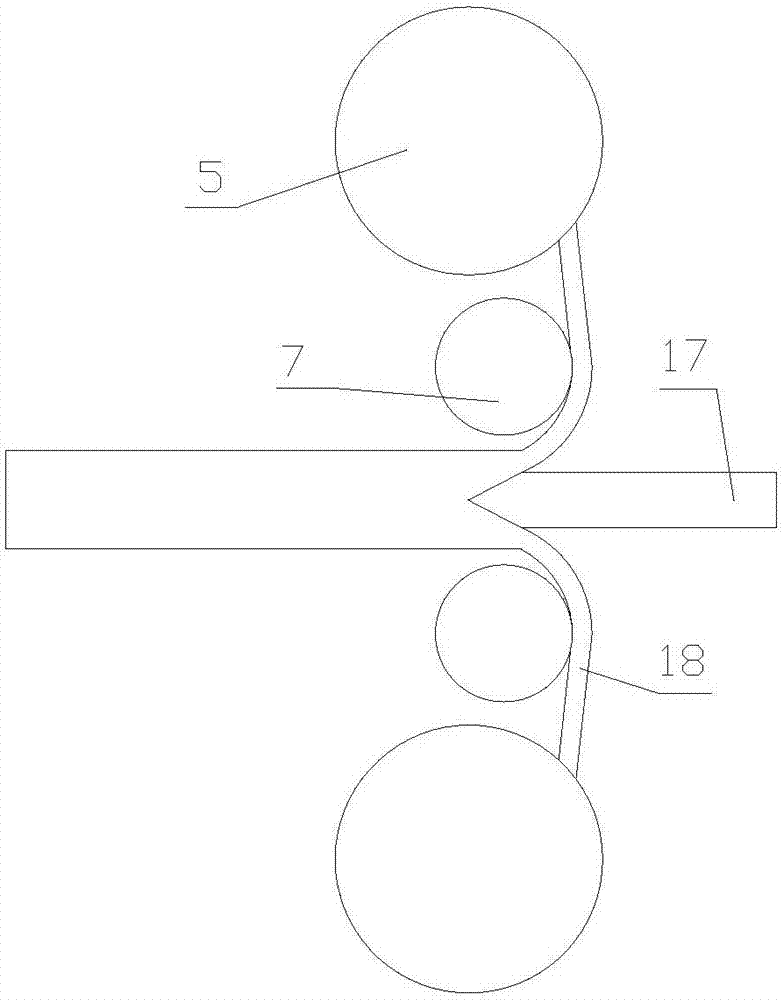

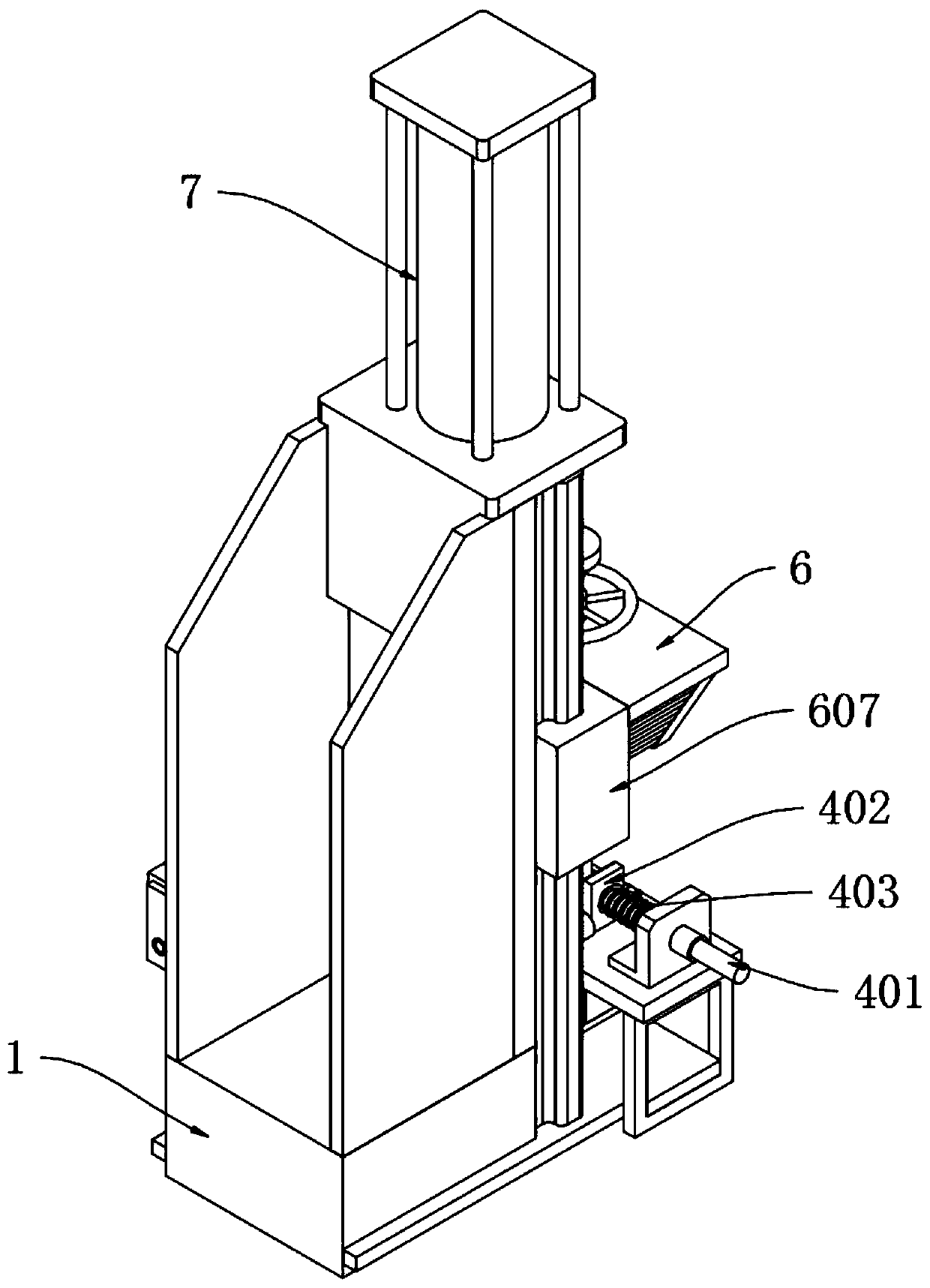

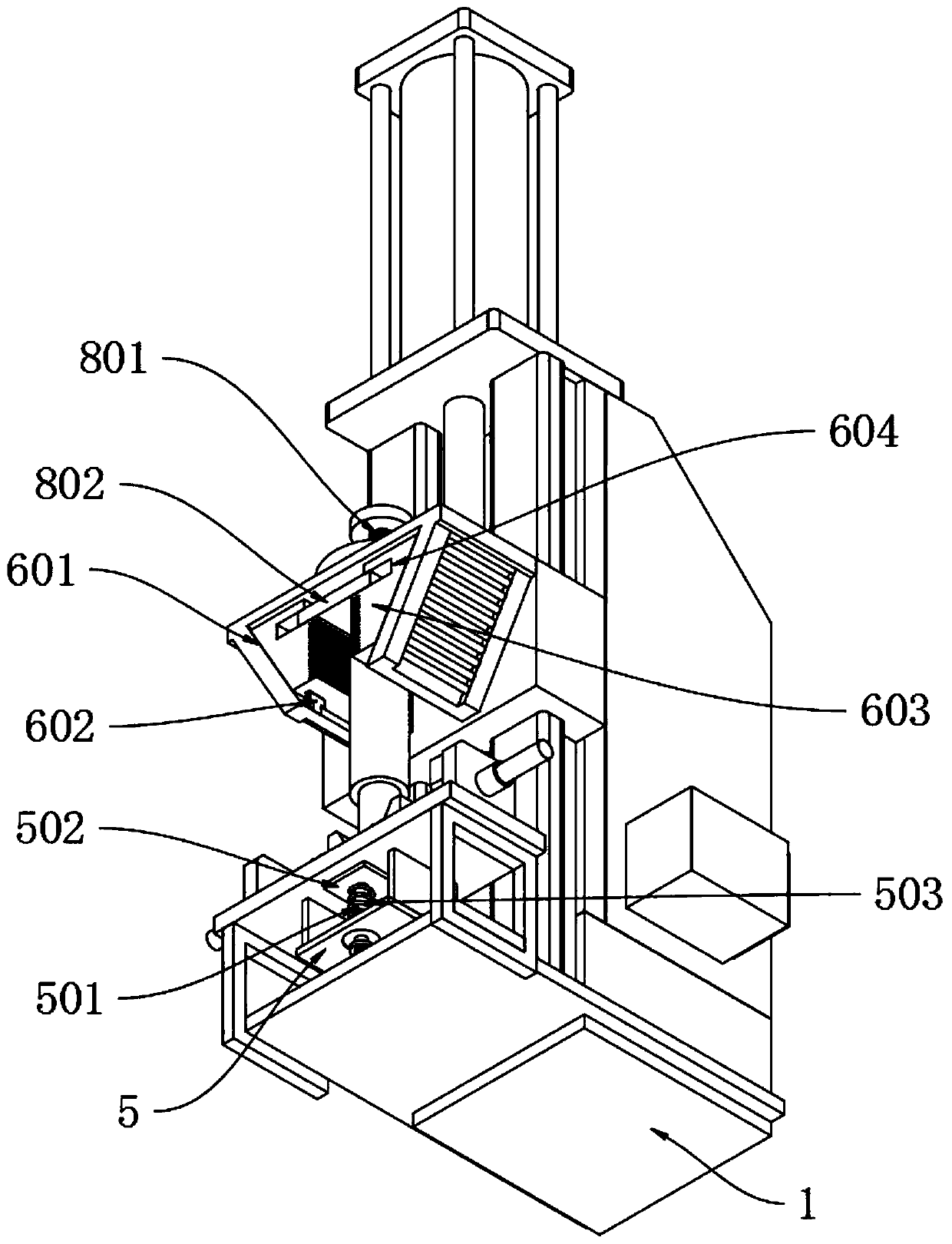

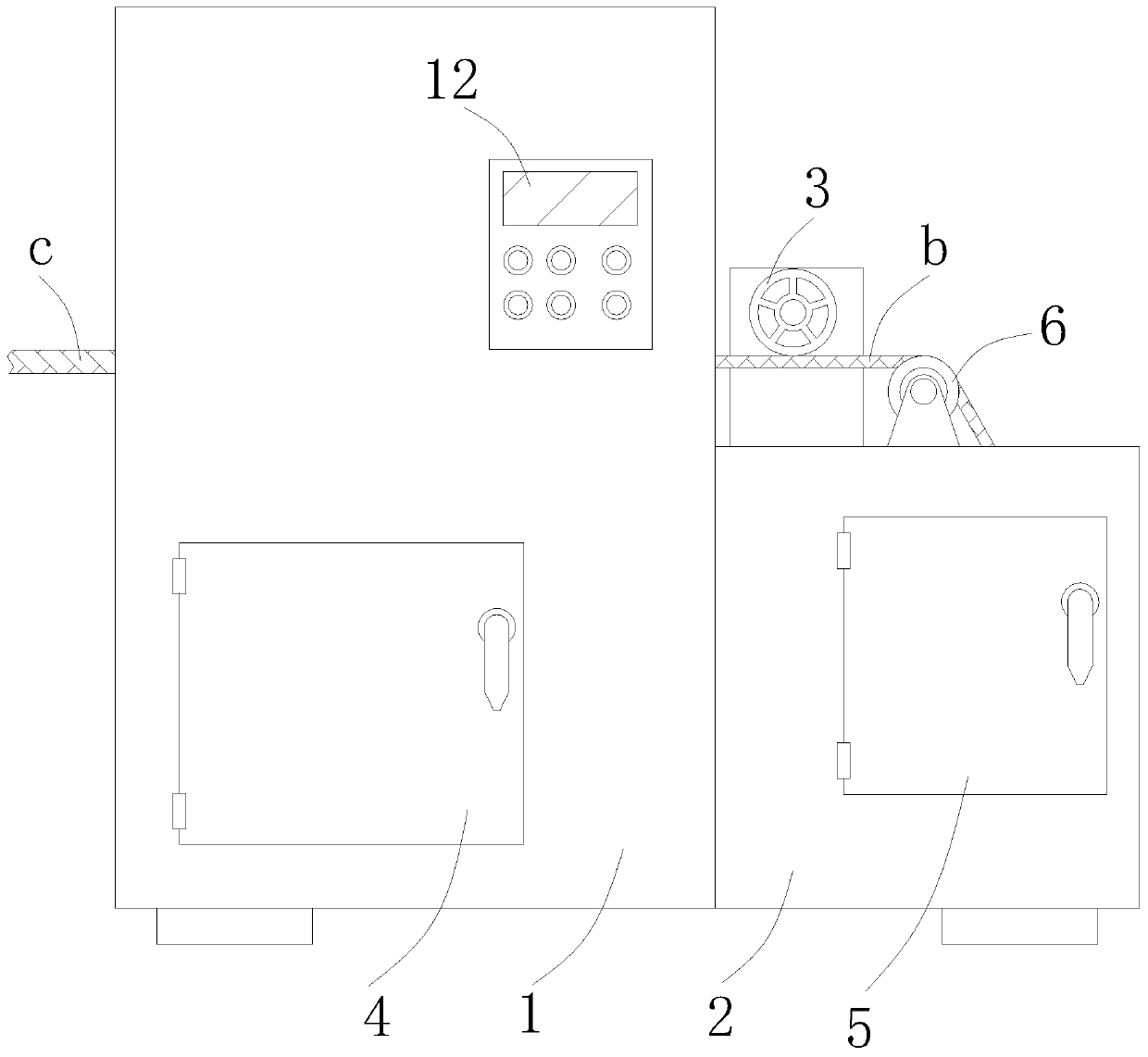

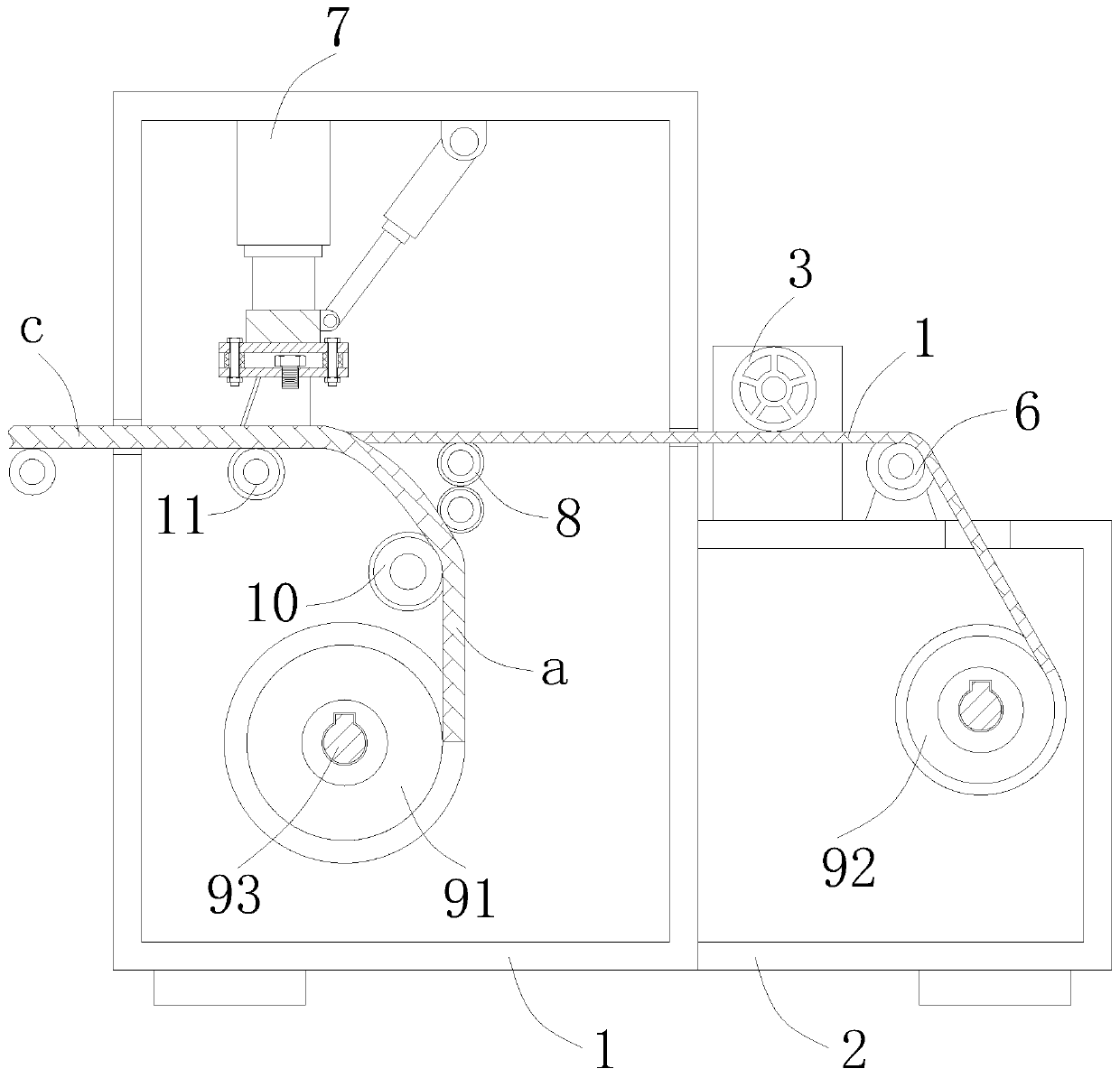

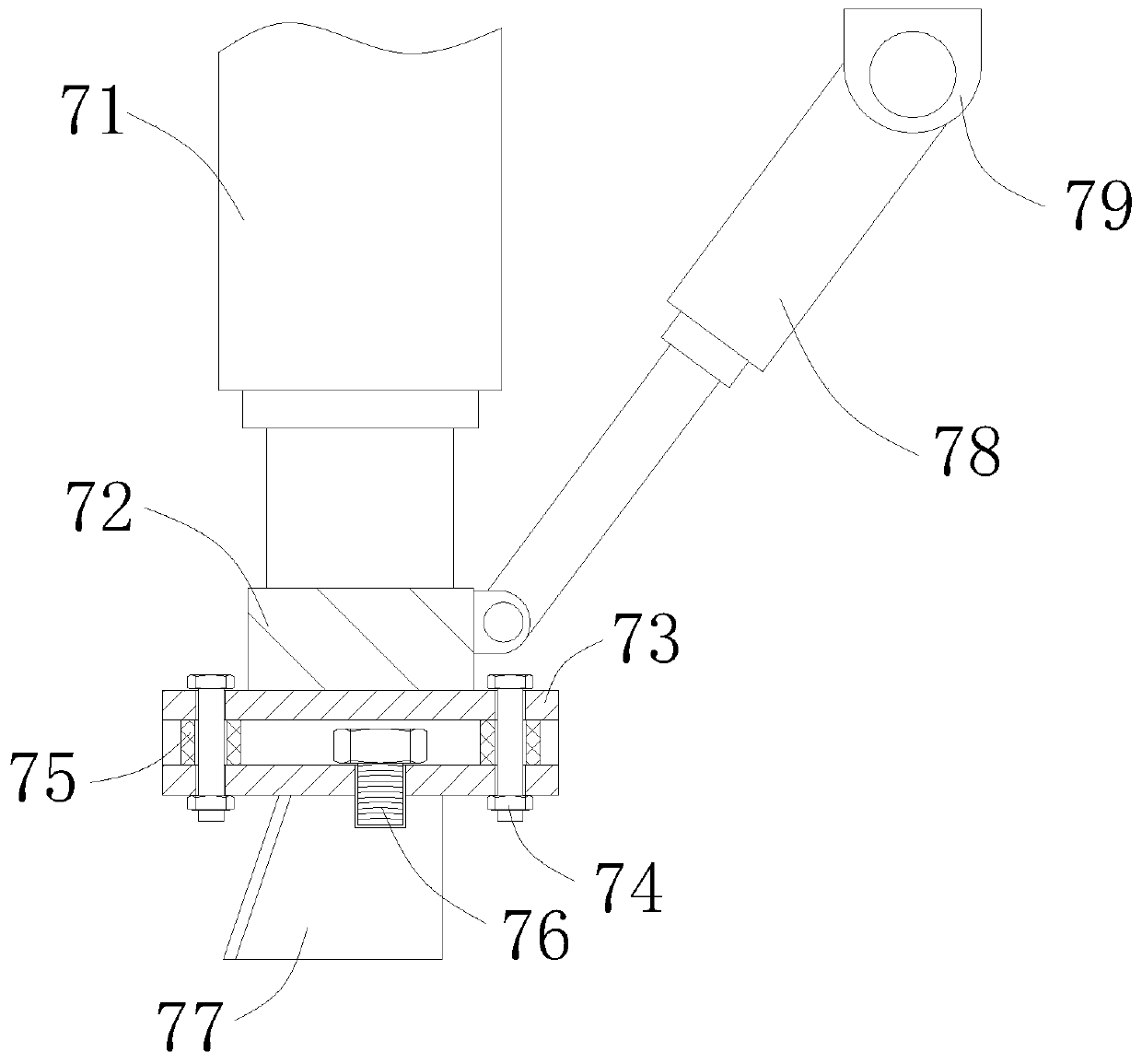

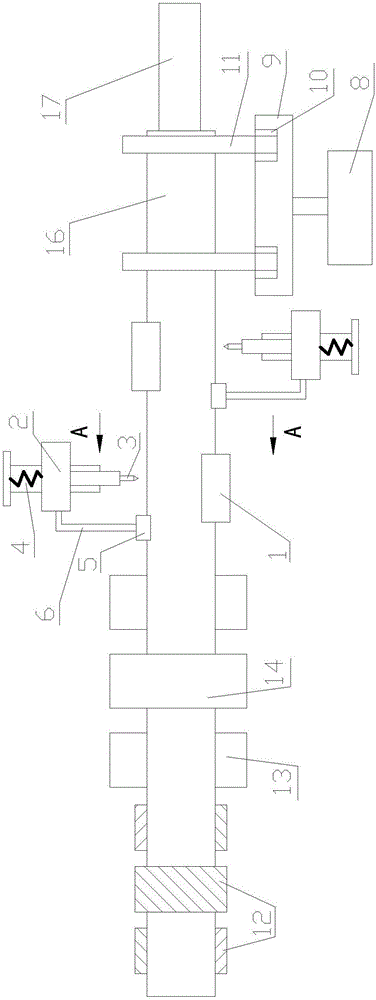

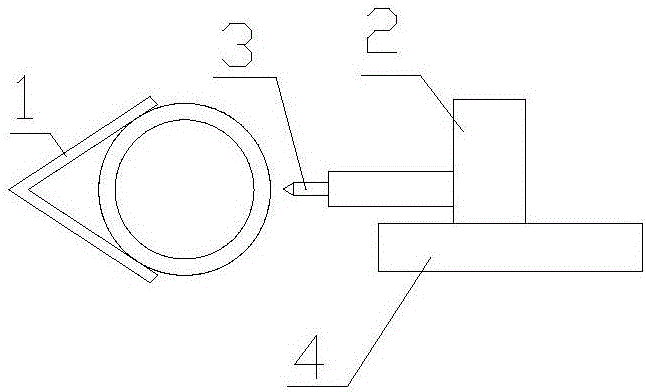

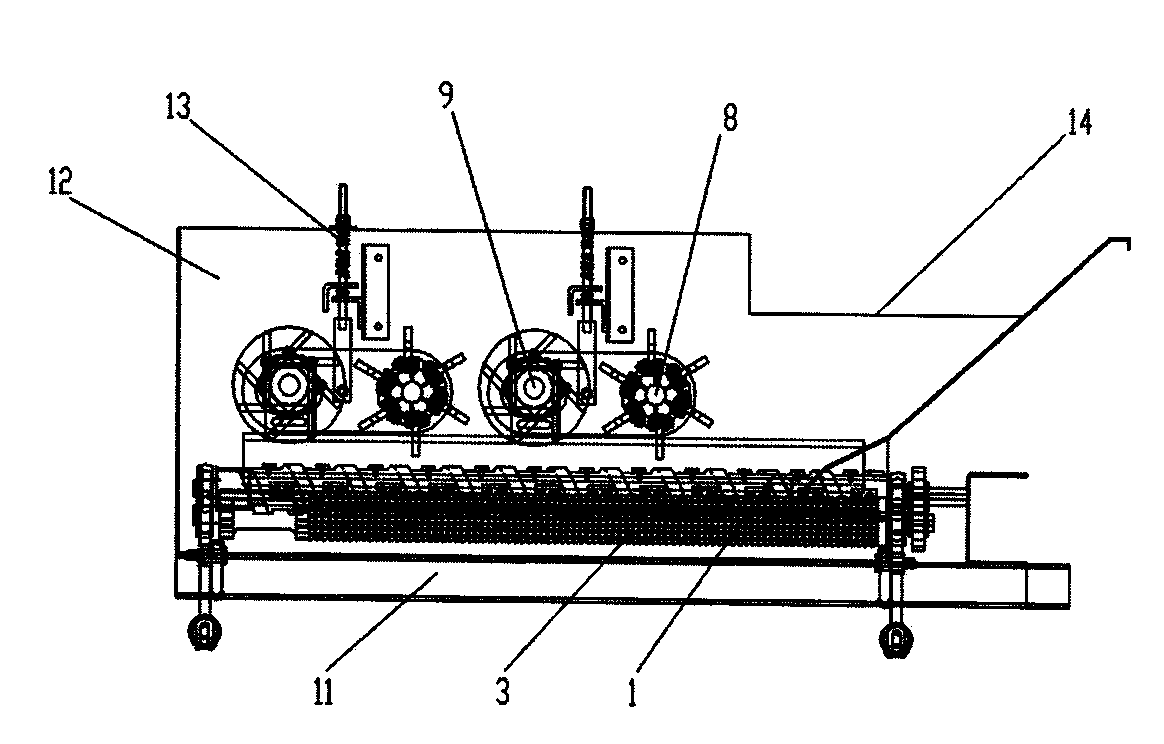

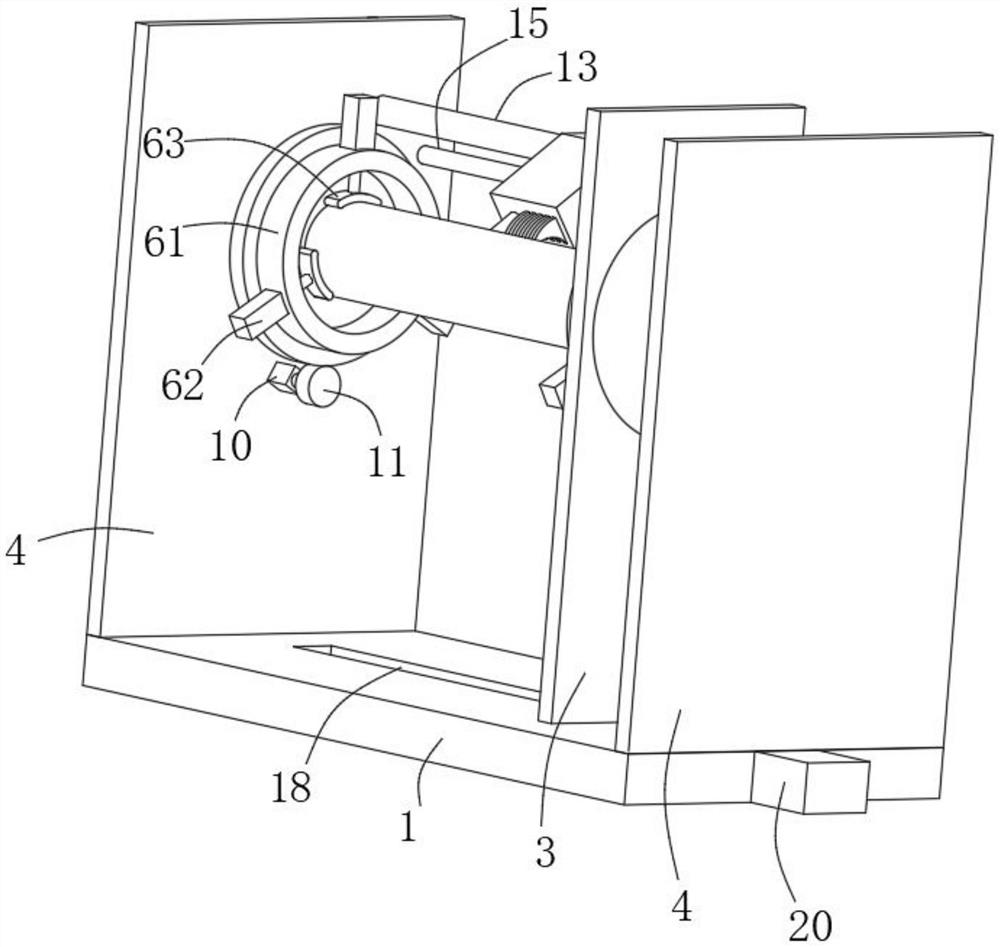

Waste wire stripping device

ActiveCN103259221AGuaranteed peeling effectExtended service lifeApparatus for removing/armouring cablesEngineeringWheel and axle

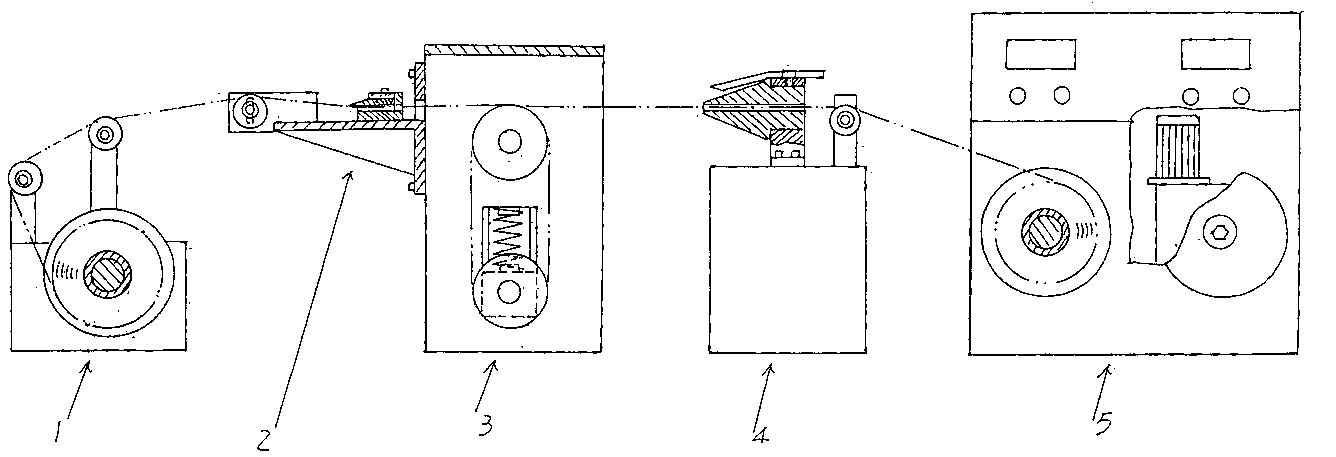

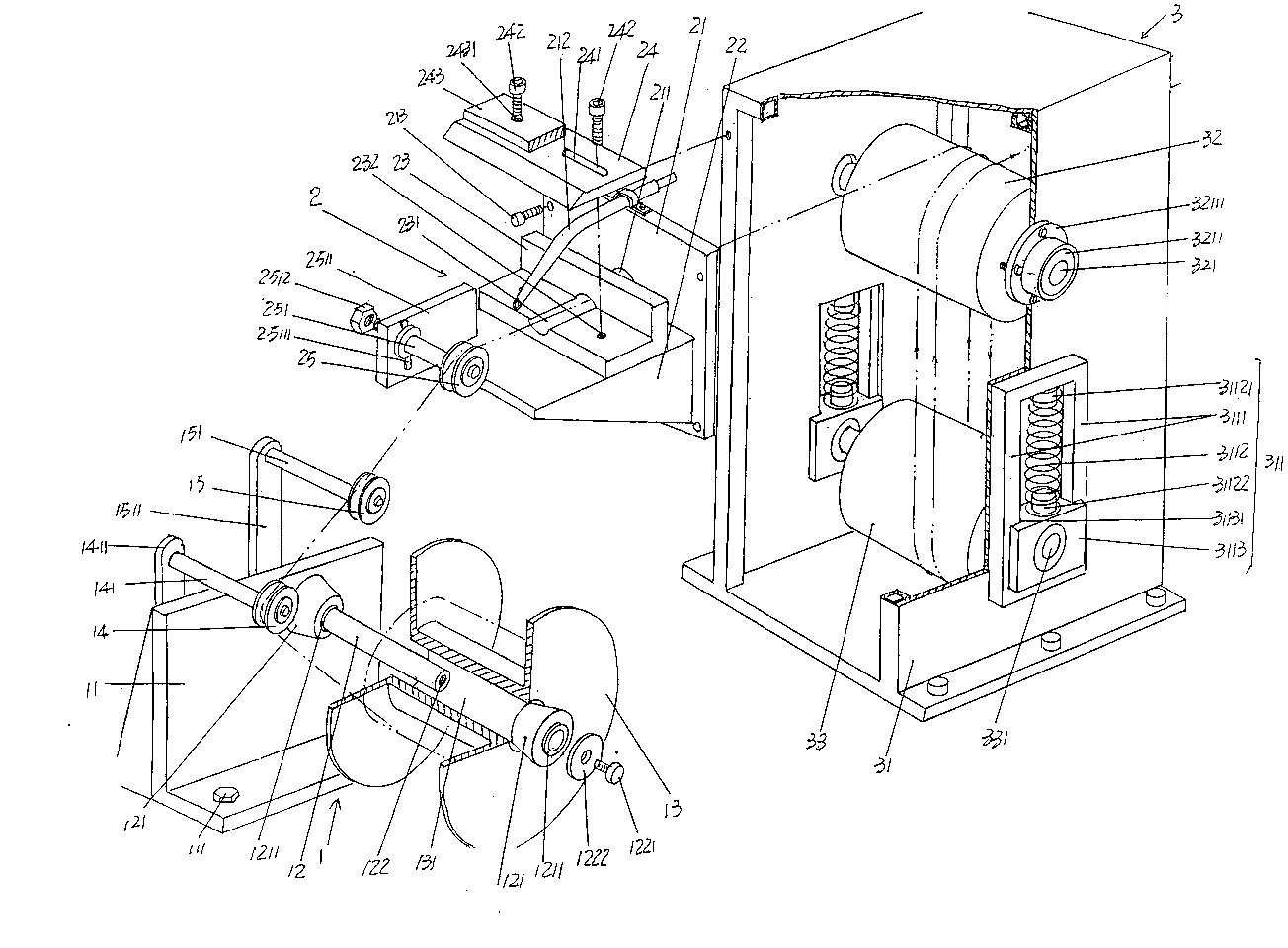

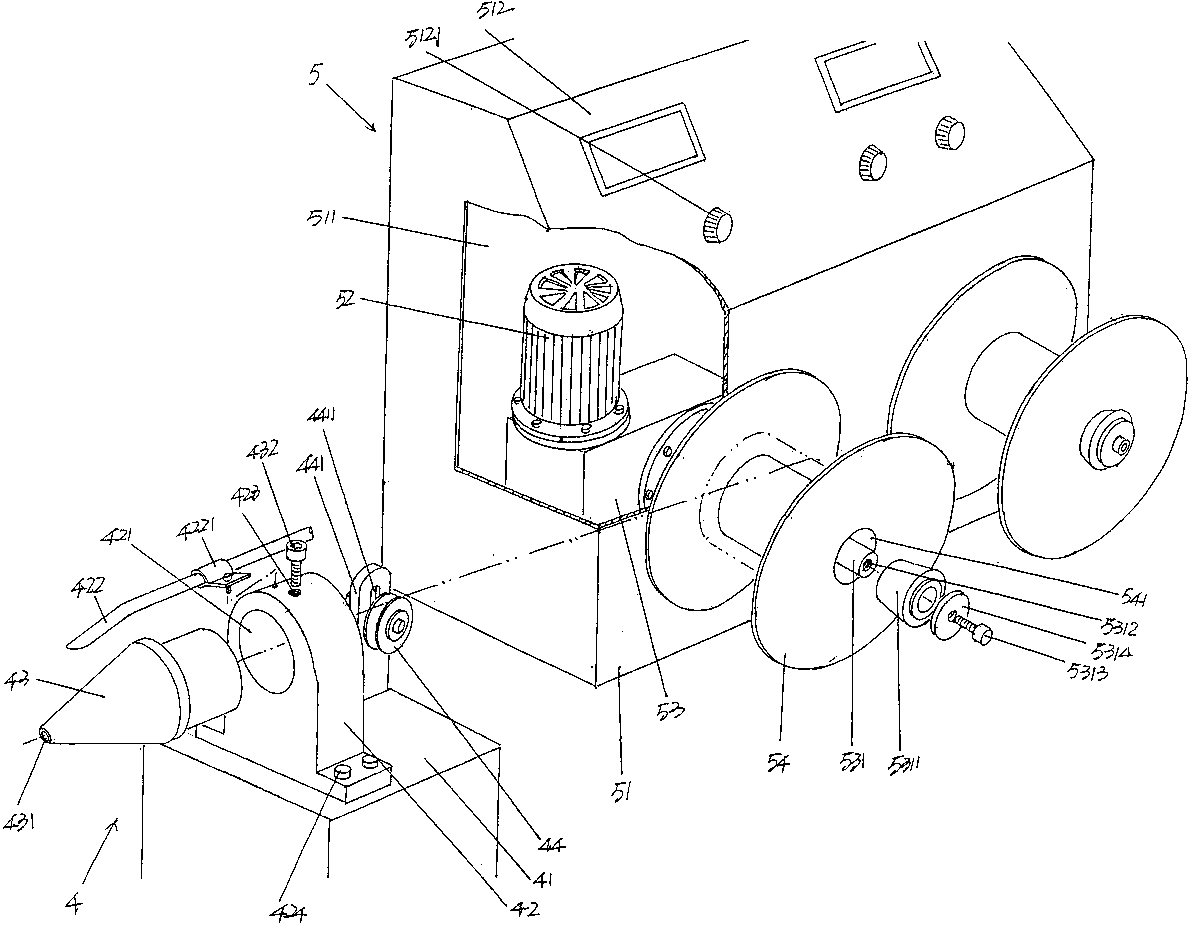

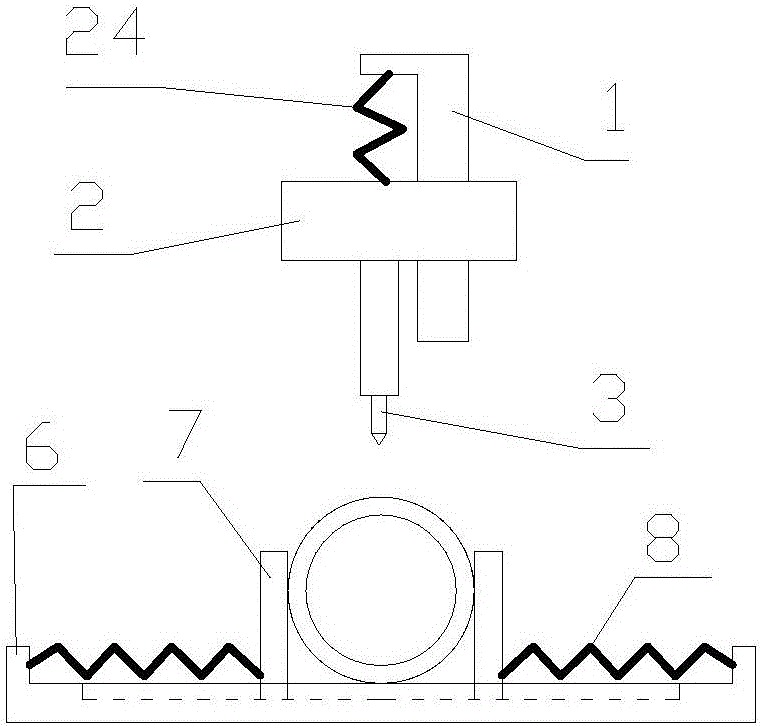

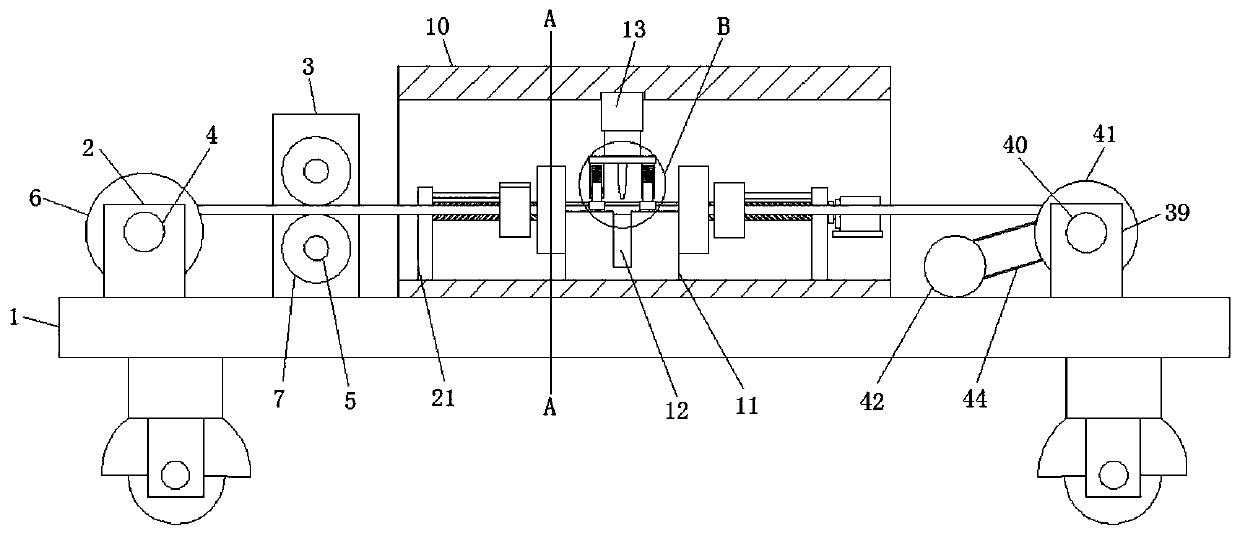

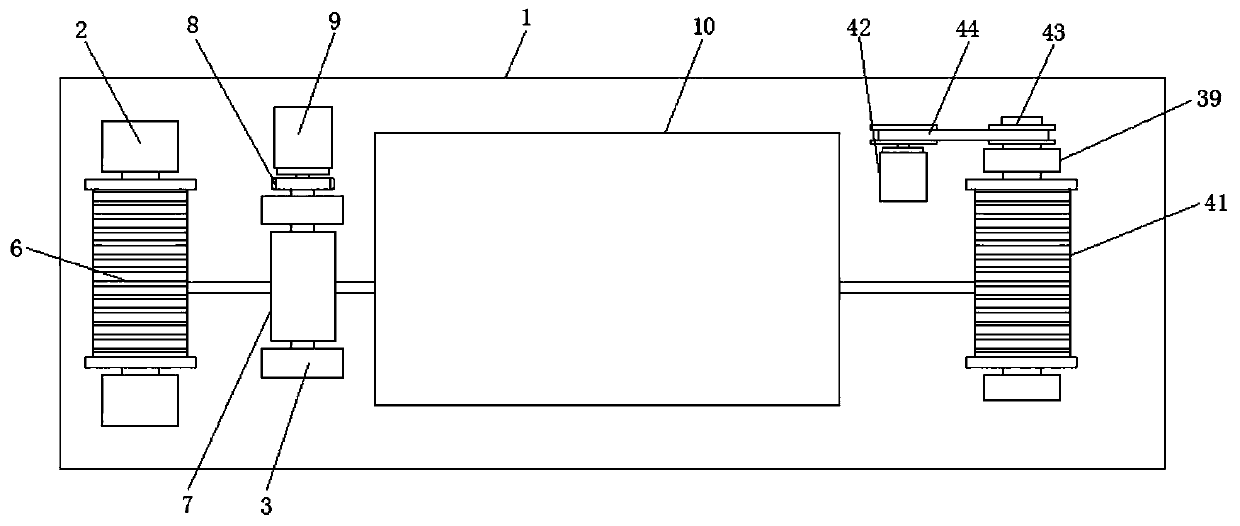

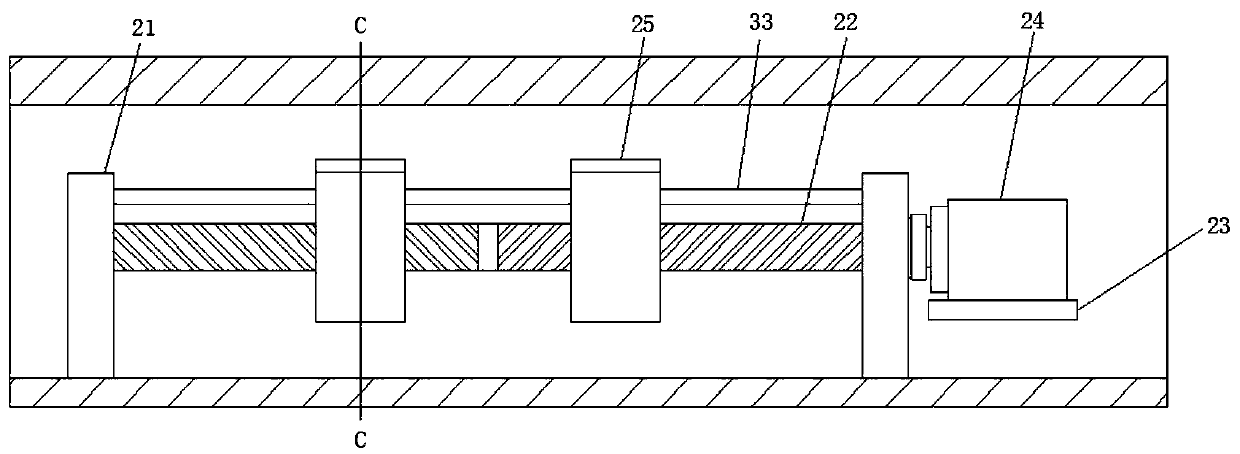

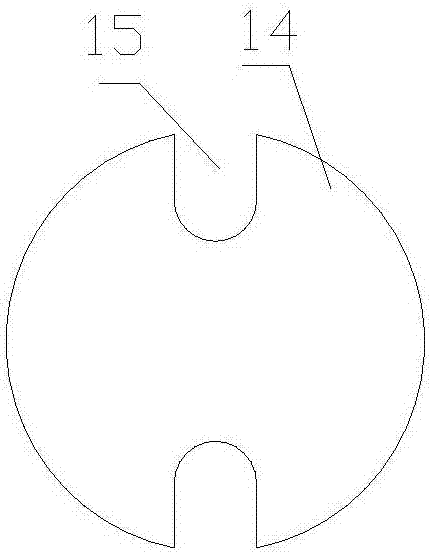

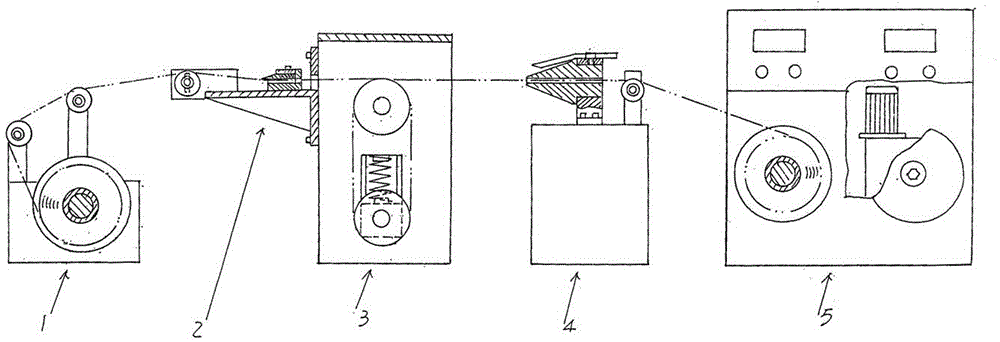

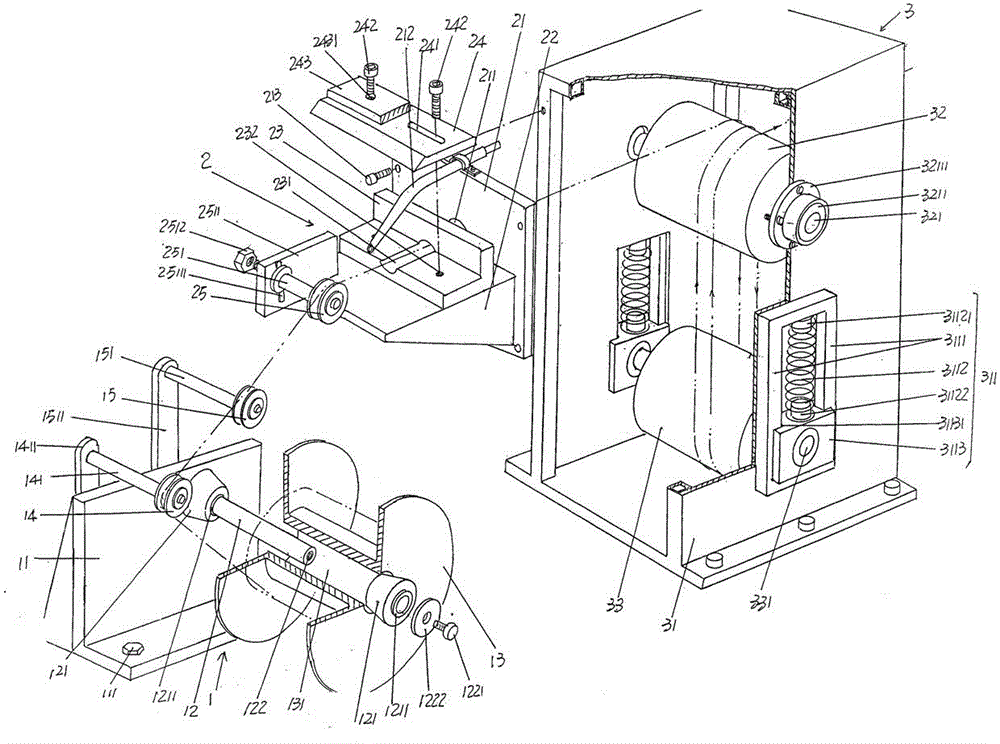

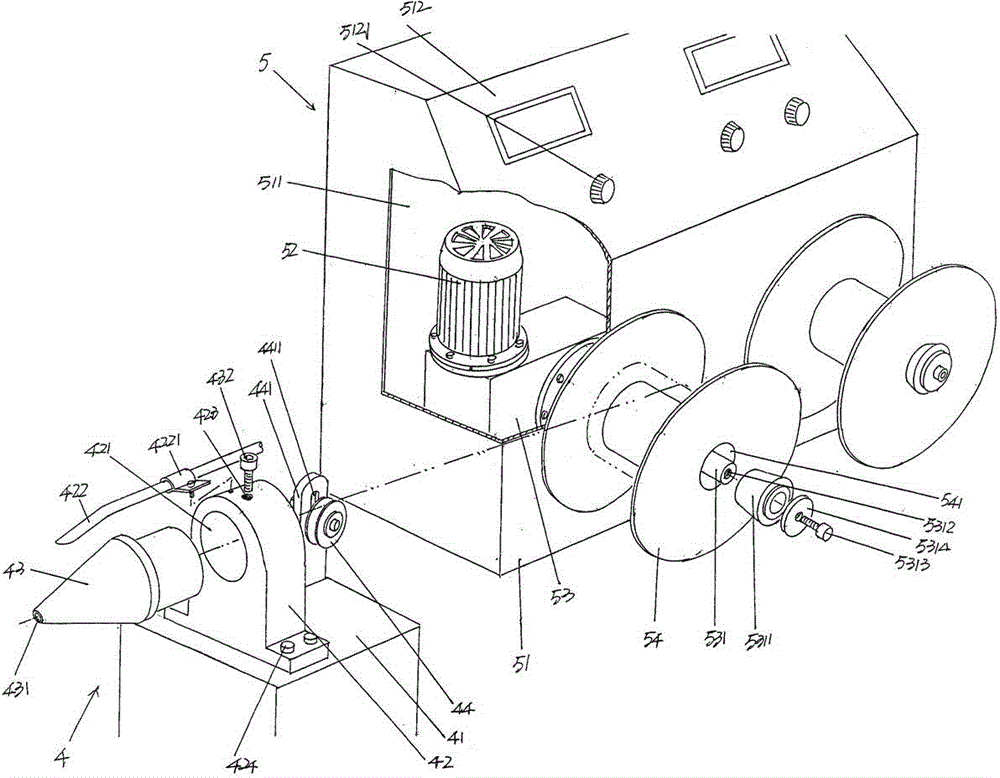

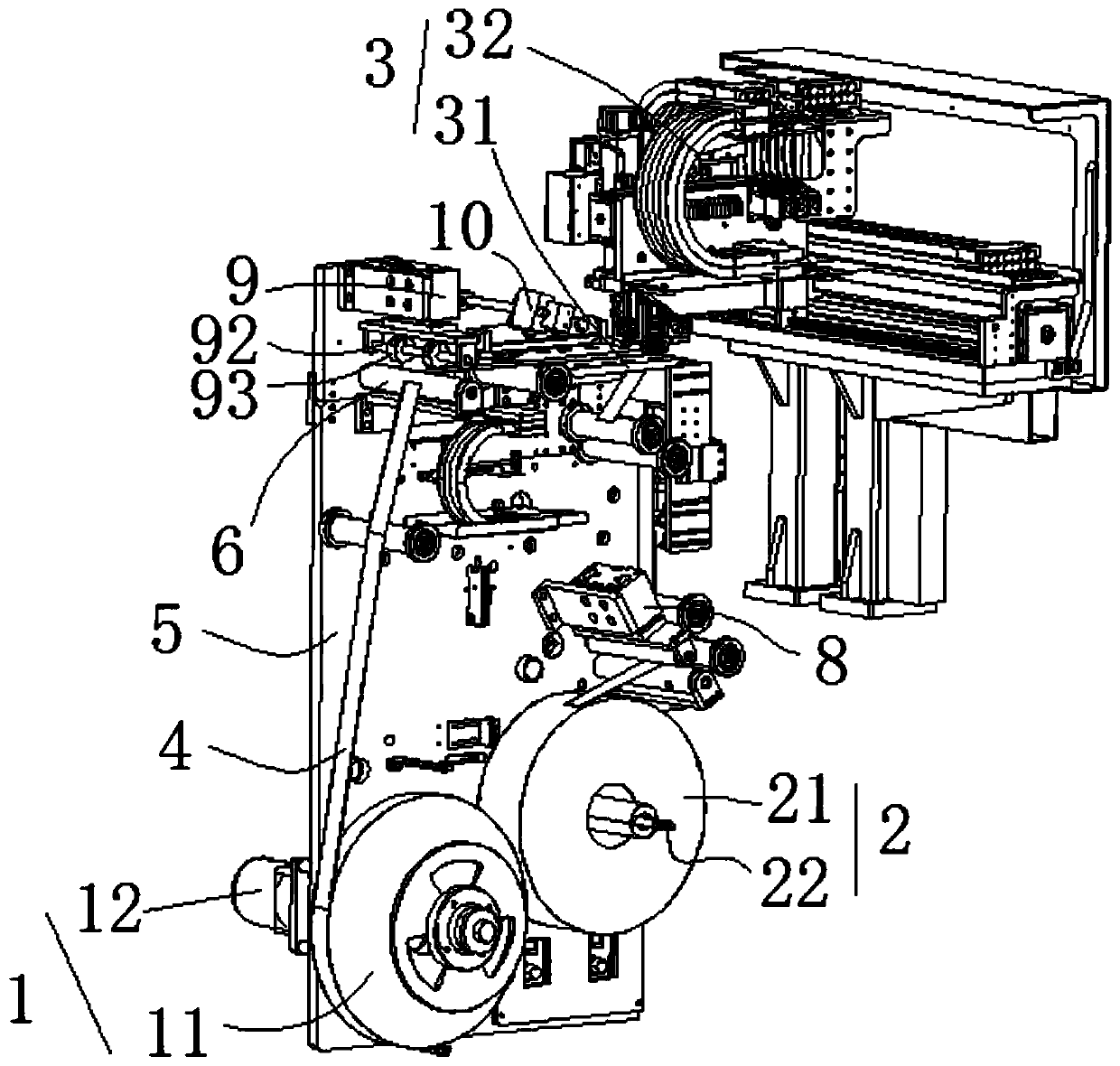

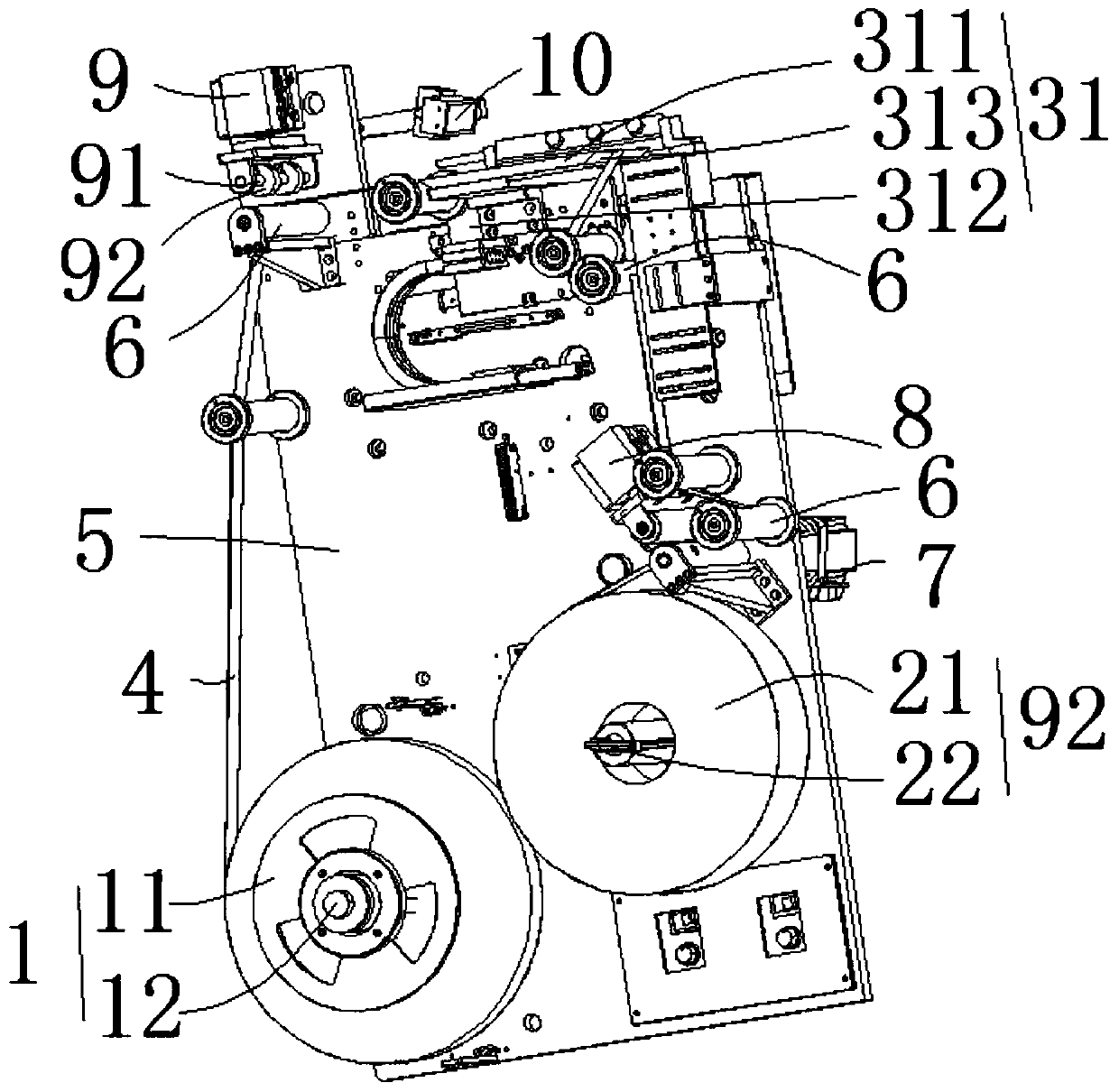

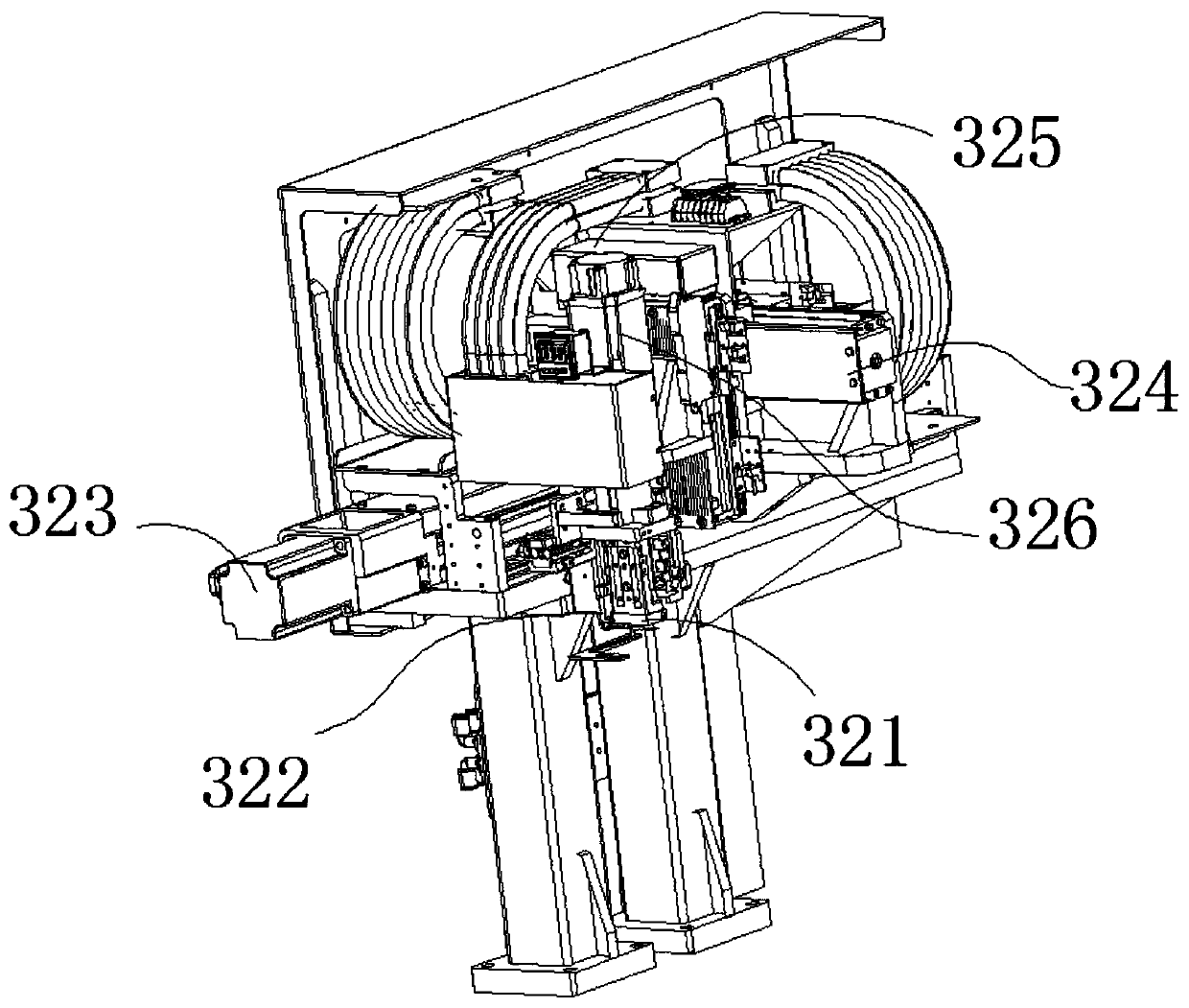

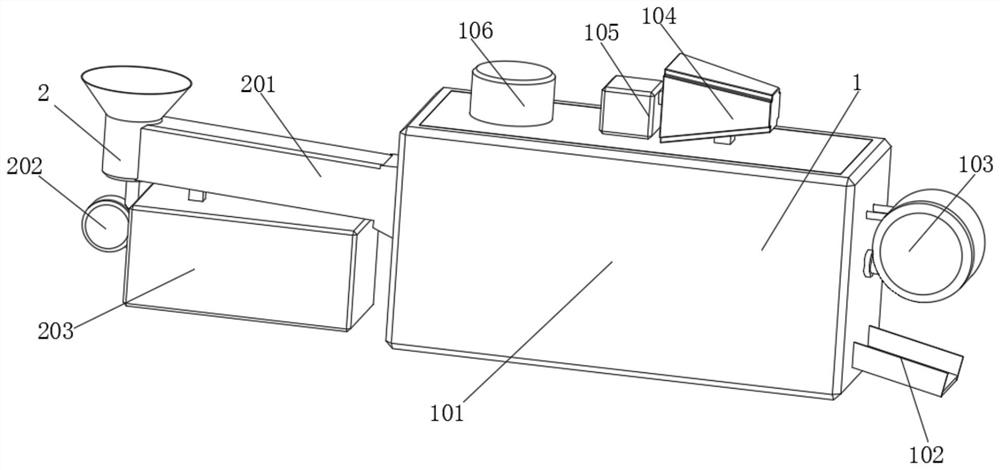

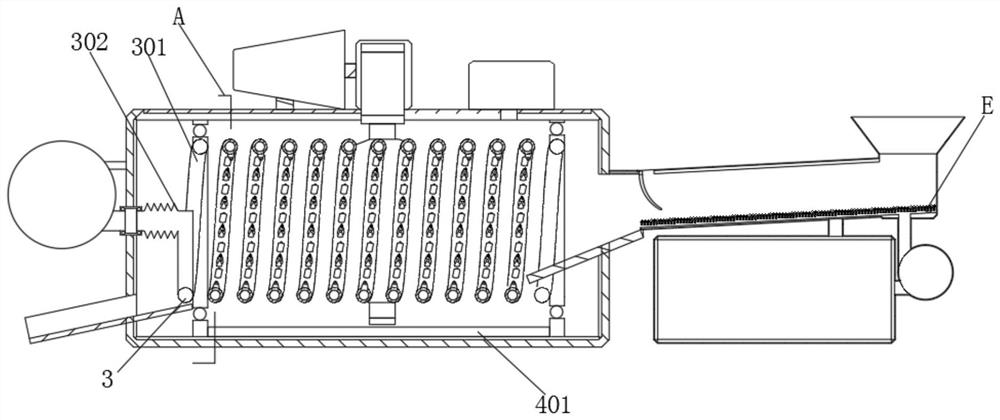

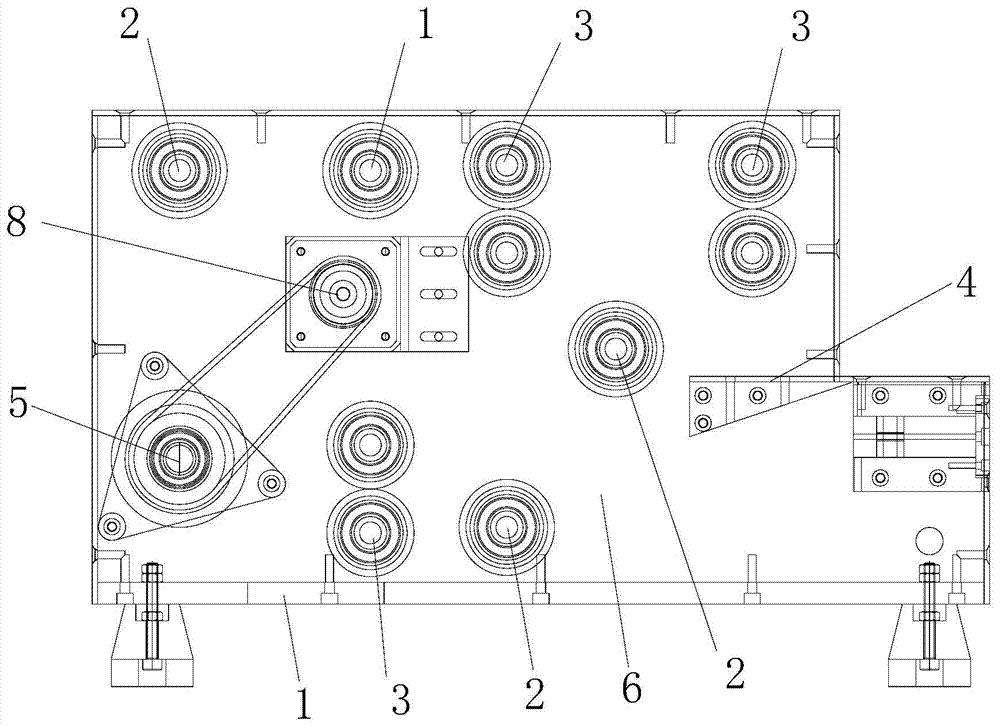

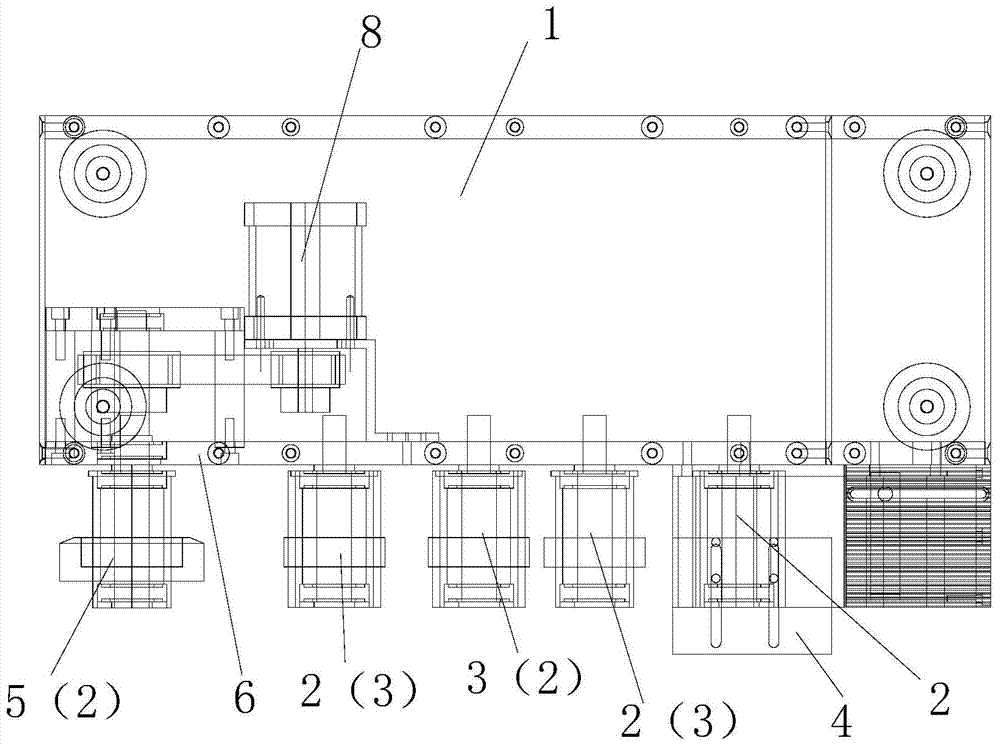

The invention discloses a waste wire stripping device, and belongs the technical field of recovery devices of waste materials. The waste wire stripping device comprises a paying-off mechanism, a paring mechanism, a tension automatic adjustment mechanism, a peeling mechanism and a wire core winding mechanism, wherein the paring mechanism is arranged on one side of the tension automatic adjustment mechanism, the peeling mechanism is located between the tension automatic adjustment mechanism and the wire core winding mechanism, the paring mechanism comprises a fixed plate, a paring knife fixing base supporting arm, a paring knife fixing base, a paring knife and a guiding wheel, the fixed plate is fixed with one side of the tension automatic adjustment mechanism, a wire passing hole is formed in the fixed plate, the paring knife fixing base supporting arm is fixed with one side of the fixed plate, a wire passing groove is formed in one side of the paring knife fixing base, two ends of the paring knife are respectively provided with a paring knife adjustment groove, the guiding wheel is arranged on a guiding wheel shaft, the guiding wheel shaft is fixed on a guiding wheel shaft base, and the guiding wheel shaft base is fixed on the paring knife fixing base supporting arm. The waste wire stripping device is ideal in stripping effect, free of damage to the guiding wheel caused by friction, long in service life and low in knife cost, and ensures a paring effect.

Owner:CHANGSHU HONGLIN WIRE & CABLE CO LTD

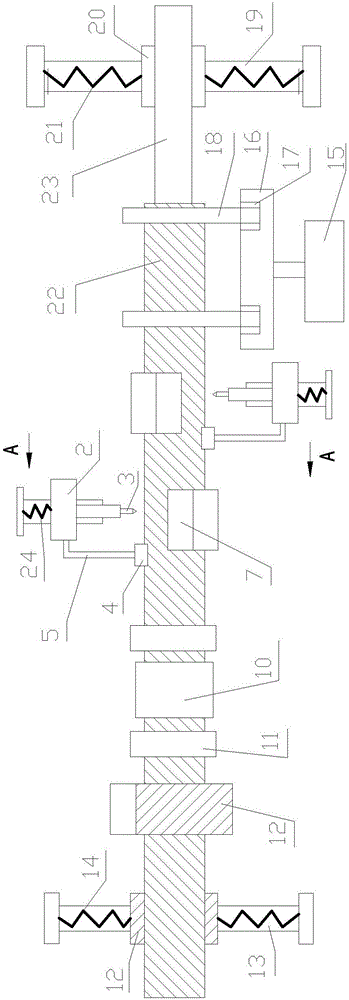

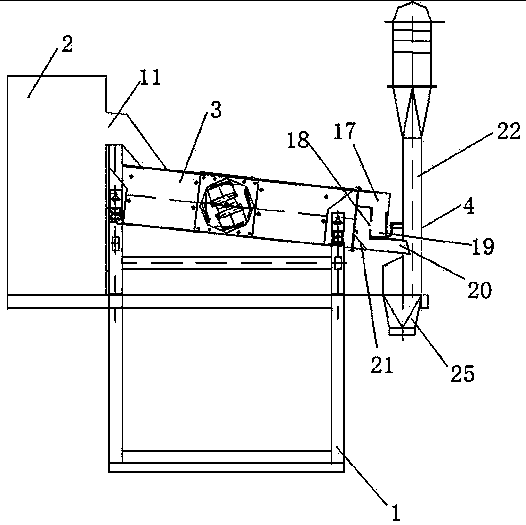

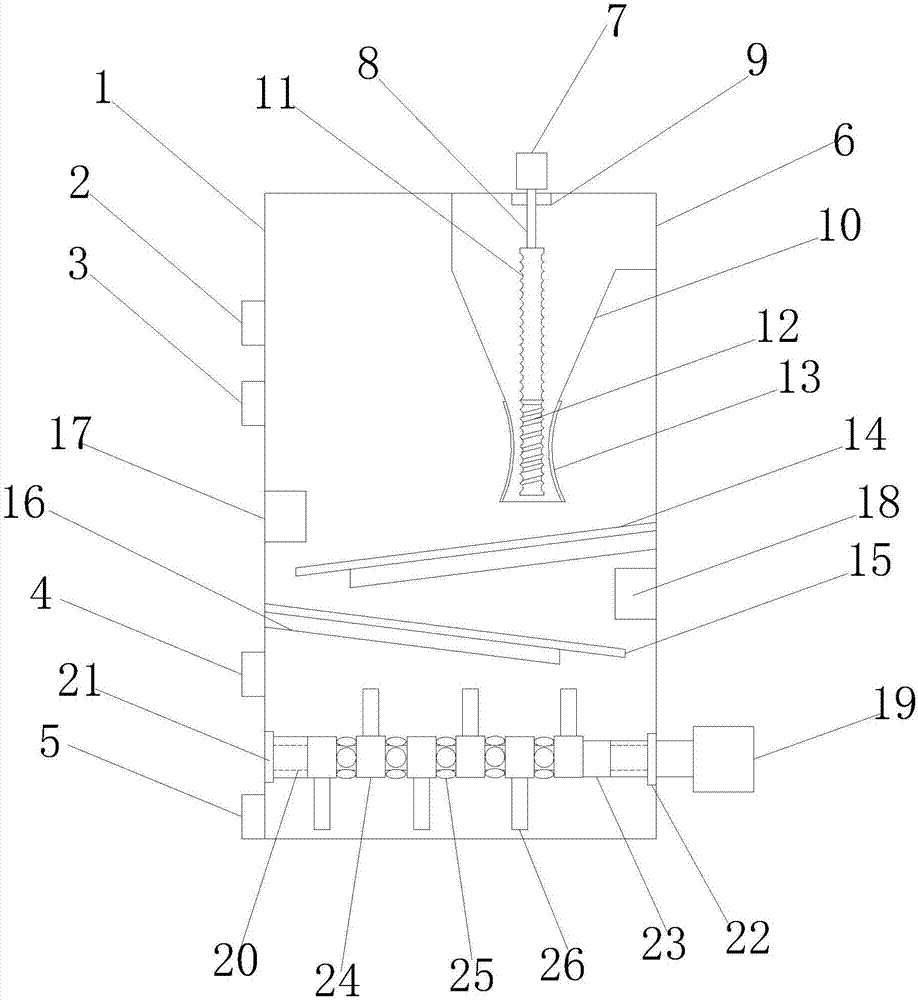

Device for processing waste cables

InactiveCN106655018AAutomatic peeling operationGuaranteed peeling effectApparatus for removing/armouring cablesHydraulic cylinderIndustrial engineering

The invention discloses a device for processing waste cables. The device for processing waste cables comprises a skinning mechanism used for destroying the insulating layer on the cable; the skinning mechanism comprises X skinning units; the skinning units are distributed along the direction of the movement of the cable; and the skinning unit comprises a first sliding rod, a hydraulic cylinder, a blade, and a detecting plate used for attaching to the surface of the cable; wherein the first sliding rod is inclined or perpendicular to the direction of movement of the cable; the hydraulic cylinder is slidably coupled to the first sliding rod, and the hydraulic cylinder drives the blade move along the radial direction of the cable; a first spring is arranged on the hydraulic cylinder, and the first spring is distributed along the extending direction of the first sliding rod; the first spring is fixedly connected with the end of the first sliding rod away from the cable, and the distance between the two ends of the first spring is smaller than the natural length of the first spring; and the detecting plate and the blade are successively arranged according to the direction of the movement of the cable, and the detecting plate drives the hydraulic cylinder move along the direction of the first sliding rod through the connecting rod. By means of the device for processing waste cables, the separation effect of the insulating layer and the cable core is good, and the use is convenient.

Owner:安徽万博电缆材料有限公司

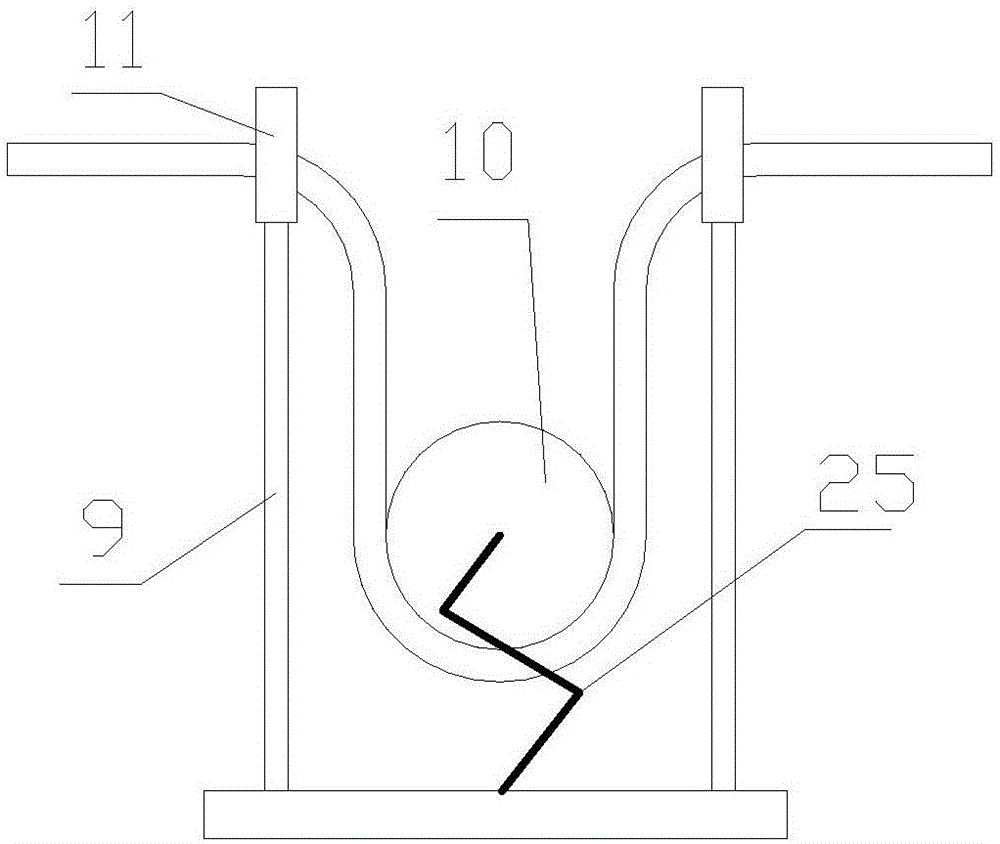

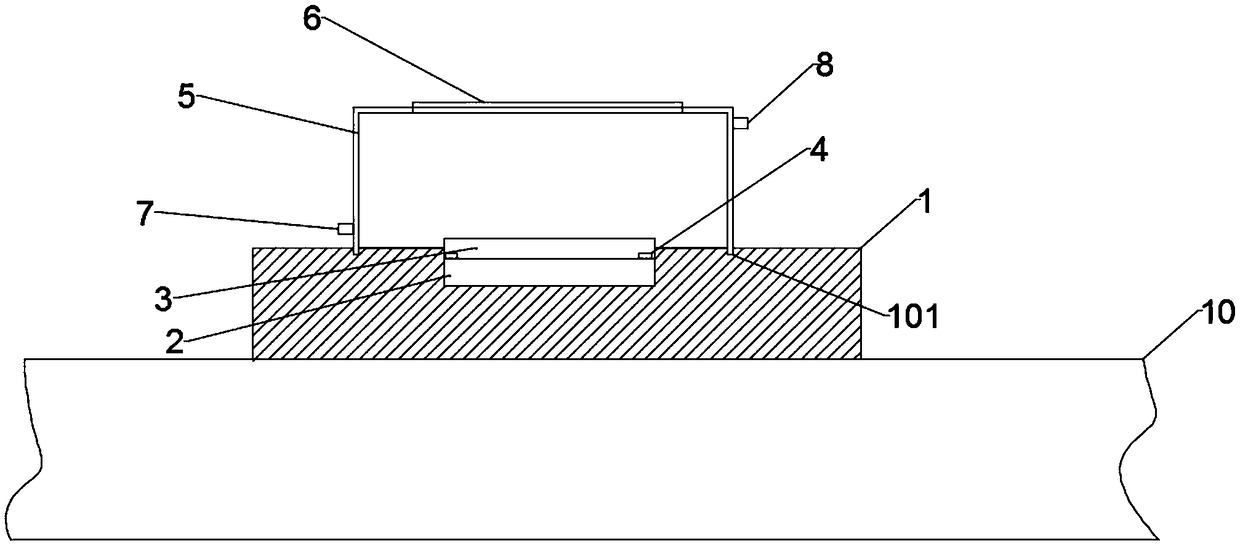

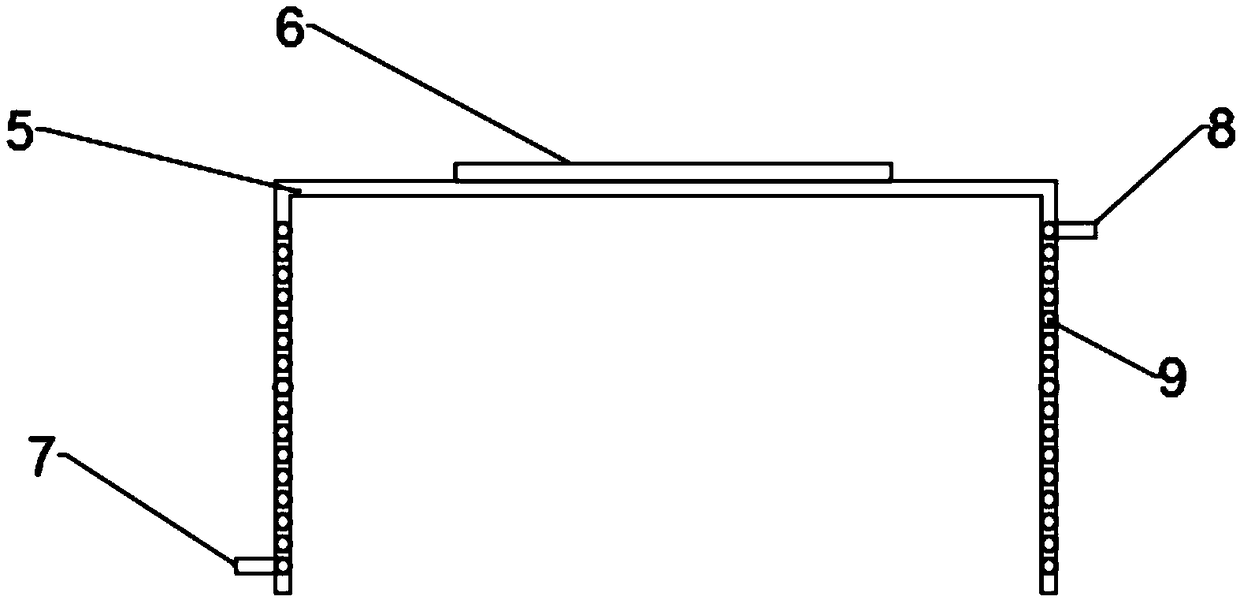

Automatic peeling machine for white gourd

The invention provides an automatic peeling machine for a white gourd. The automatic peeling machine comprises a frame. A clamping device capable driving the white gourd to rotate freely is disposed on the frame. A threaded rod and a guide column are vertically disposed on the frame one side of the clamping device. The threaded rod and the clamping device are driven to rotate by the driver device disposed at the bottom of the frame. Two cutter carriers are mounted on the threaded rod and the guide column through slide devices. A tool bit pointing at the clamping device is mounted at the outer end of each cutter carrier. The automatic peeling machine is characterized in that each cutter carrier corresponds to one set of the slide device, each slide device comprises a nut disposed on the threaded rod and a cutter carrier slider disposed on the guide column, the cutter carrier slider is connected with the nut through a transverse rod, the two slide devices and cutter carriers are distributed up and down, a torsion spring is disposed on the guide column between the two cutter carrier sliders, and two ends of the torsion spring respectively acts on the upper cutter carrier and the lower cutter carrier. The automatic peeling machine for the white gourd is reasonable in structure and convenient to operate, and white gourd machining efficiency can be increased evidently.

Owner:TAIXIANG GRP TECH DEV

Cable laying and installation cutting and peeling equipment

InactiveCN110265933ALine optimizationConveying works wellApparatus for removing/armouring cablesApparatus for laying cablesBiochemical engineering

The invention discloses cable laying and installation cutting and peeling equipment, which comprises a work bench. The four corners of the lower end surface of the work bench are respectively and fixedly connected with a supporting leg through a screw; the lower end of each supporting leg is equipped with a universal wheel; one side of the upper end surface of the work bench is fixedly connected with support bases 1 and support bases 2 through screws; the support bases 2 are located at the side, close to the center of the work bench, of the support bases 1; the number of the support bases 1 and the number of the support bases 2 are two; a fixation shaft 1 is rotatably connected between the two support bases 1 through a rolling bearing and fixation shafts 2 are rotatably connected between the two support bases 2 through rolling bearings; the rod body outer walls of the fixation shaft 1 and the fixation shafts 2 are fixedly connected with a pay-off roller and a conveying roller through screws respectively; the two fixation shafts 2 are symmetrically arranged at the upper and lower ends of the support base 2; the back sides of the two fixation shafts 2 pass through the support bases 2 and are rotatably connected through a gear set; and the back end of the rear support base 2 is provided with a servo motor 1.

Owner:ANHUI TIANMING CABLE

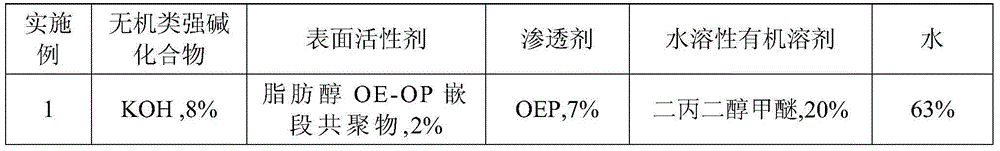

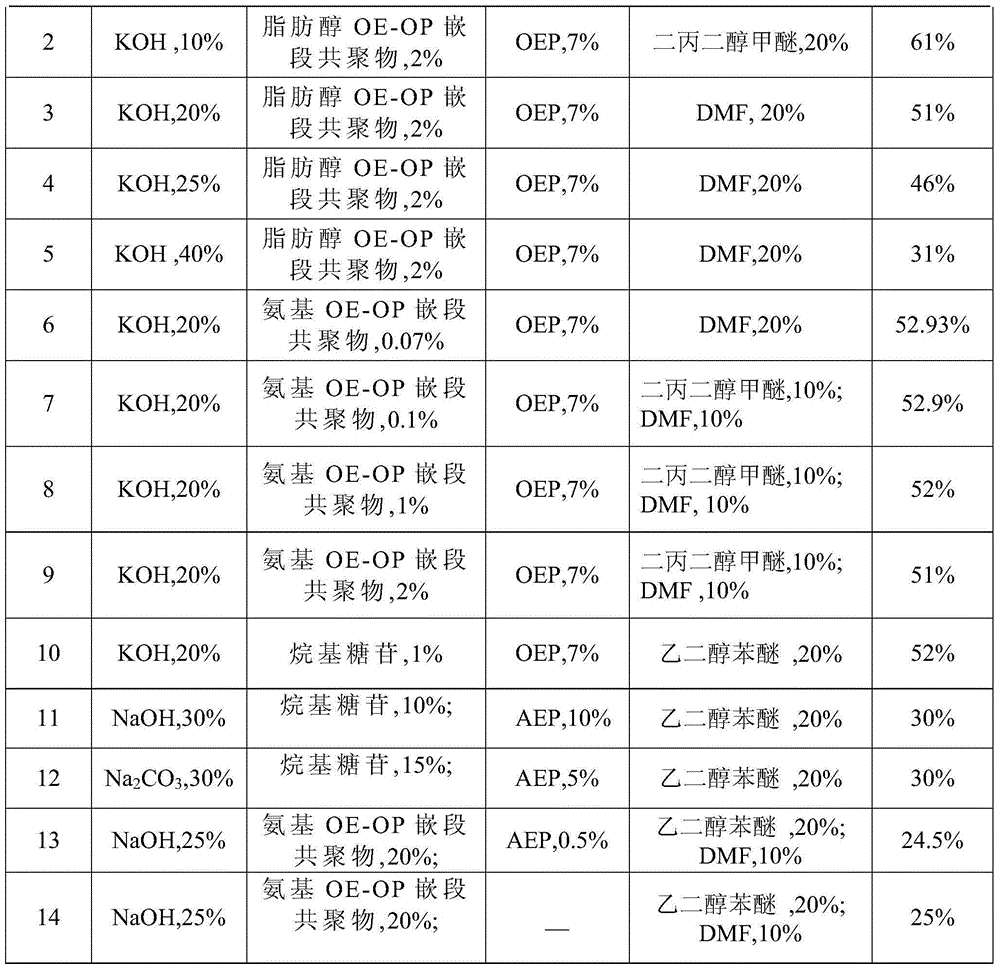

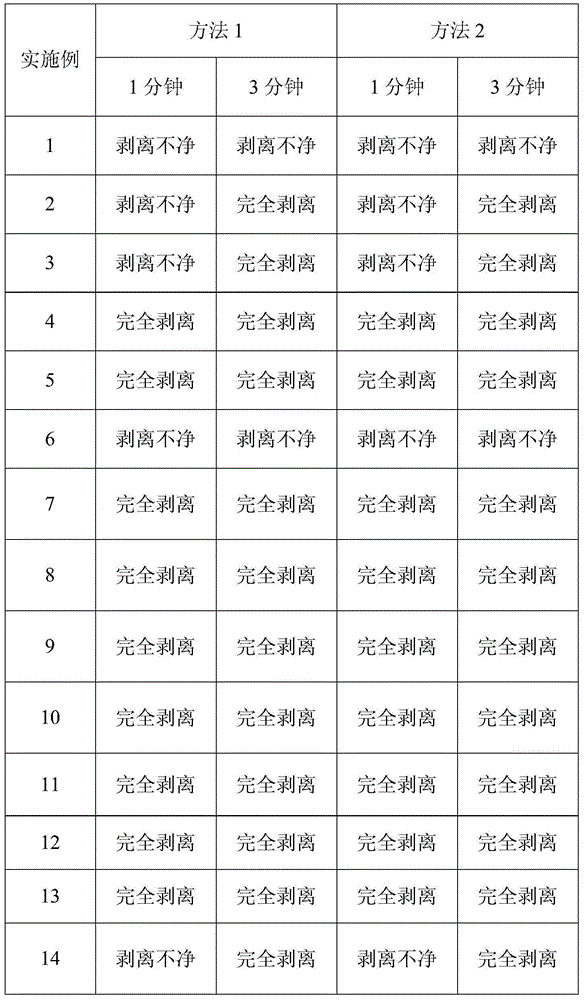

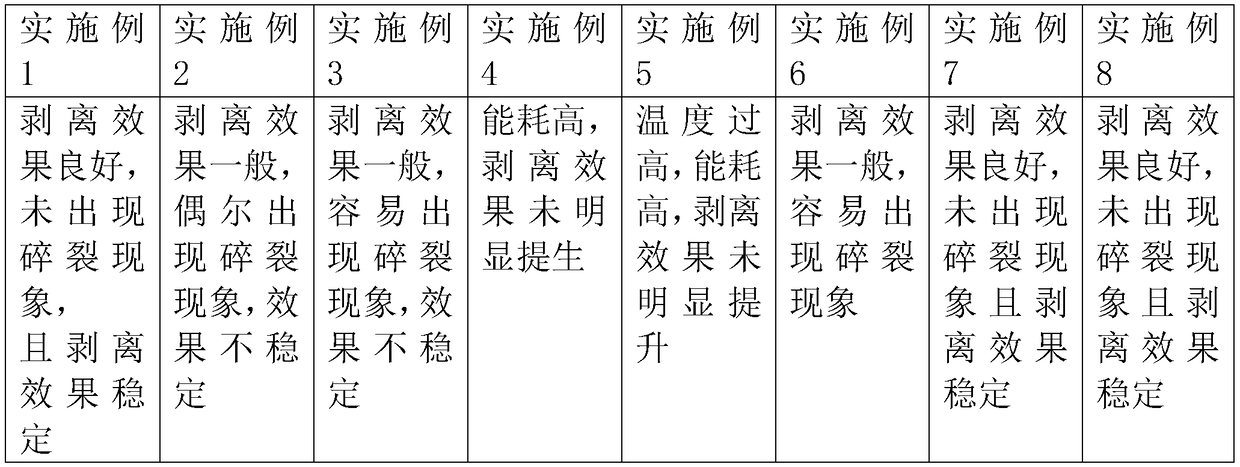

Low-temperature photoresist reworking stripping liquid and application thereof

ActiveCN104155854AAchieve strippingExcellent peelabilityPhotosensitive material processingGlycosideAlcohol

The invention relates to low-temperature photoresist reworking stripping liquid and application thereof. The low-temperature photoresist reworking stripping liquid comprises 10-40% of inorganic strong base compound, 0.1-20% of a surfactant, 0.5-10% of a permeating agent, 10-60% of a water-soluble organic solvent and 20-65% of water, wherein the surfactant is selected from alkyl glycosides, fatty alcohol OE-OP block copolymer and amido OE-OP block copolymer; the water-soluble organic solvent is selected from water-soluble alcohol ether solvent and water-soluble amide solvent. By adopting the stripping liquid, various photoresist and the OC glue protective layer on the surface of a color filter can be completely stripped off within 1-3 minutes at the temperature of 50-60 DEG C, and after stripping, the solution can be recycled after being filtered, so that the cost is reduced, and in addition, the stripping liquid is stable in stability, lower in cost and less harmful to person and environment.

Owner:SUZHOU RUIHONG ELECTRONIC CHEM CO LTD

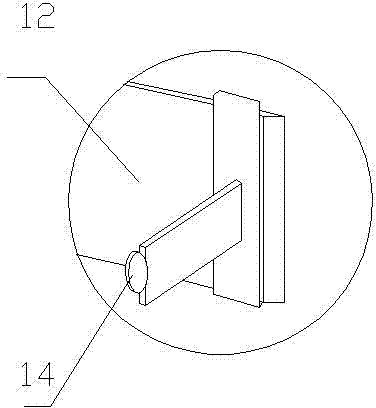

Cable processing equipment

InactiveCN107481814AImprove flexibilityGuaranteed peeling effectBasic electric elementsApparatus for removing/armouring cablesInsulation layerEngineering

The invention discloses cable processing equipment comprising a clamping mechanism used for clamping a cable, a processing mechanism used for removing an insulation layer on the cable, and a first recycling mechanism used for recycling the cable core; the processing mechanism is arranged between the clamping mechanism and the first retrieve mechanism, and comprises N processing units; the processing unit comprises a crossbar having a cylinder and a connecting rod; the cylinder output end is provided with a blade; the cylinder drives the blade to radially move along the cable; the cylinder is hinged to the crossbar; one end of the connecting rod is hinged to the cylinder, and the other end is connected with the crossbar in a slide manner. The cable processing equipment uses a flattening unit to properly extrude and flatten the cable, thus flattening the cable bending portions, and effectively removing the cable skin; the processing mechanism can flexibly enable the blade to destroy the cable insulation layer according to different angles, thus ensuring the peeling effect.

Owner:TONGLING CITY TONGDOU SPECIAL CABLE CO LTD

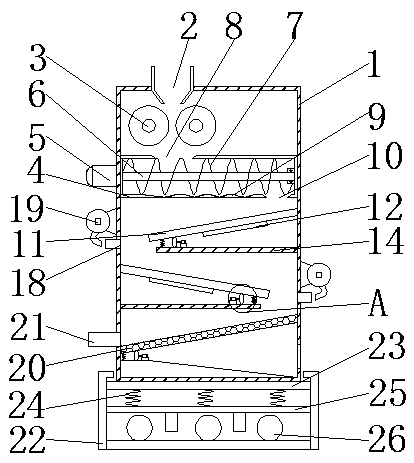

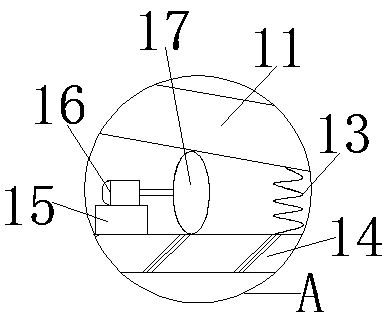

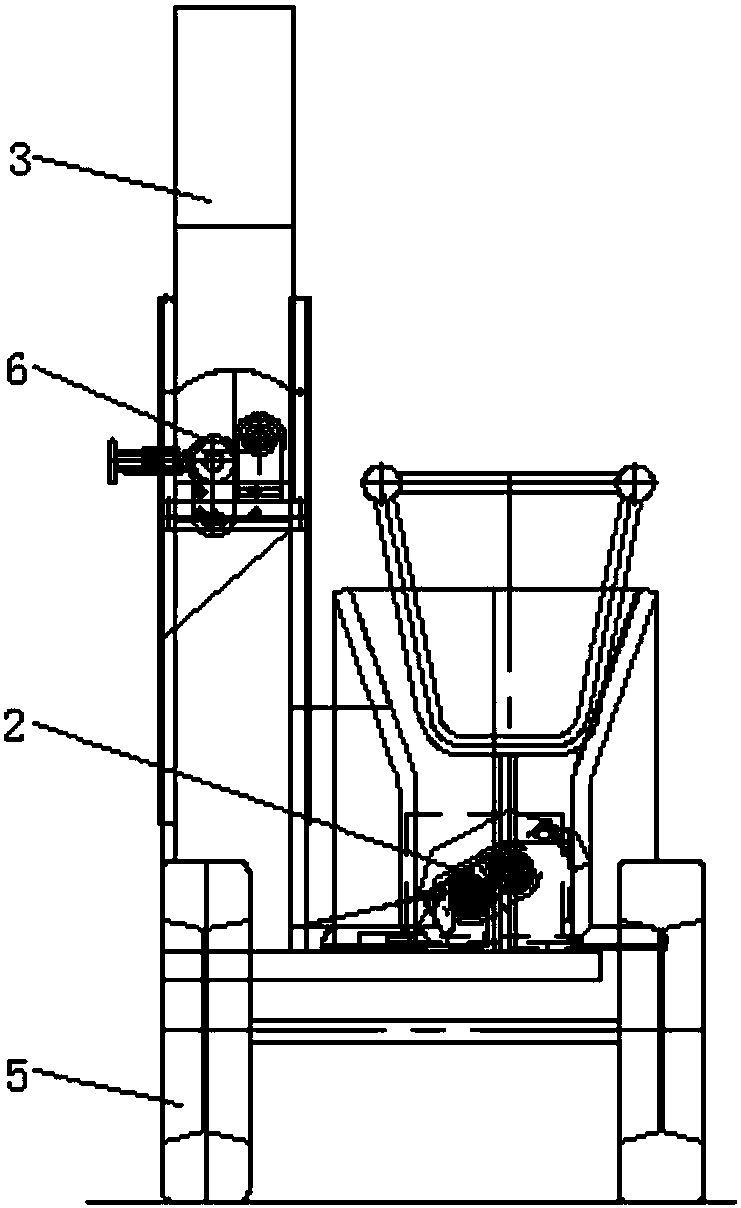

Nut huller

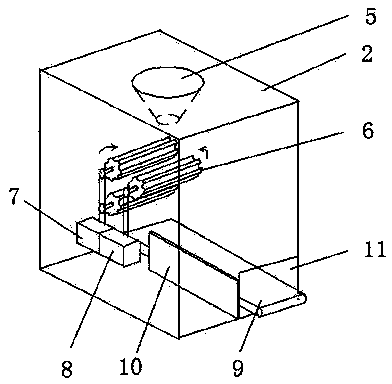

InactiveCN104705768APrevent crushingGuaranteed peeling effectHuskingHullingMechanical engineeringExtrusion

The invention relates to a nut huller. The nut huller comprises a box body, a charge device arranged on the box cover, a hulling device arranged in the box body, and a separation device connected with the hulling device, wherein a box cover is arranged at the top of the box body; a guide device communicated with a discharge port is arranged at the bottom of the charge device, and the guide device is adaptive to the shapes of nuts; the hulling device comprises an adjustment mechanism movably arranged at the bottom of the box body and an extrusion mechanism arranged opposite to the adjustment mechanism; a gap is reserved between the adjustment mechanism and the extrusion mechanism, and the gap is adjusted through the movement of the adjustment mechanism to be adapt to the sizes of the kernels of the nuts; the separation device is used for separating the kernels in the nuts subjected to extrusion hulling treatment from shells. A phenomenon that the kernels are crushed during a hulling process for the nuts can be avoided by forming the gap adaptive to the sizes of the kernels between the adjustment mechanism and the extrusion mechanism.

Owner:北京权进常光机电化科学研究院中原分院

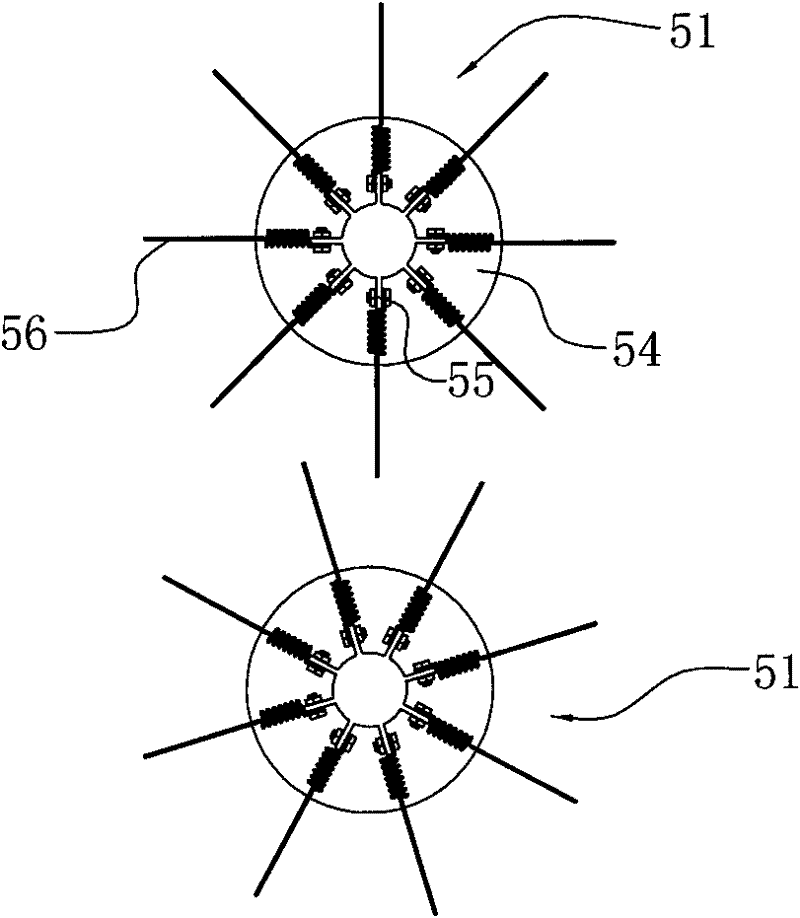

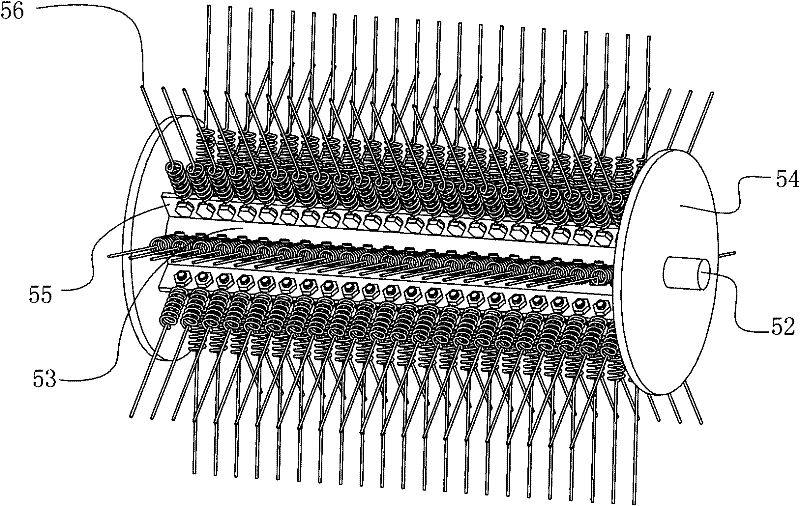

Sugarcane leaf grinding device

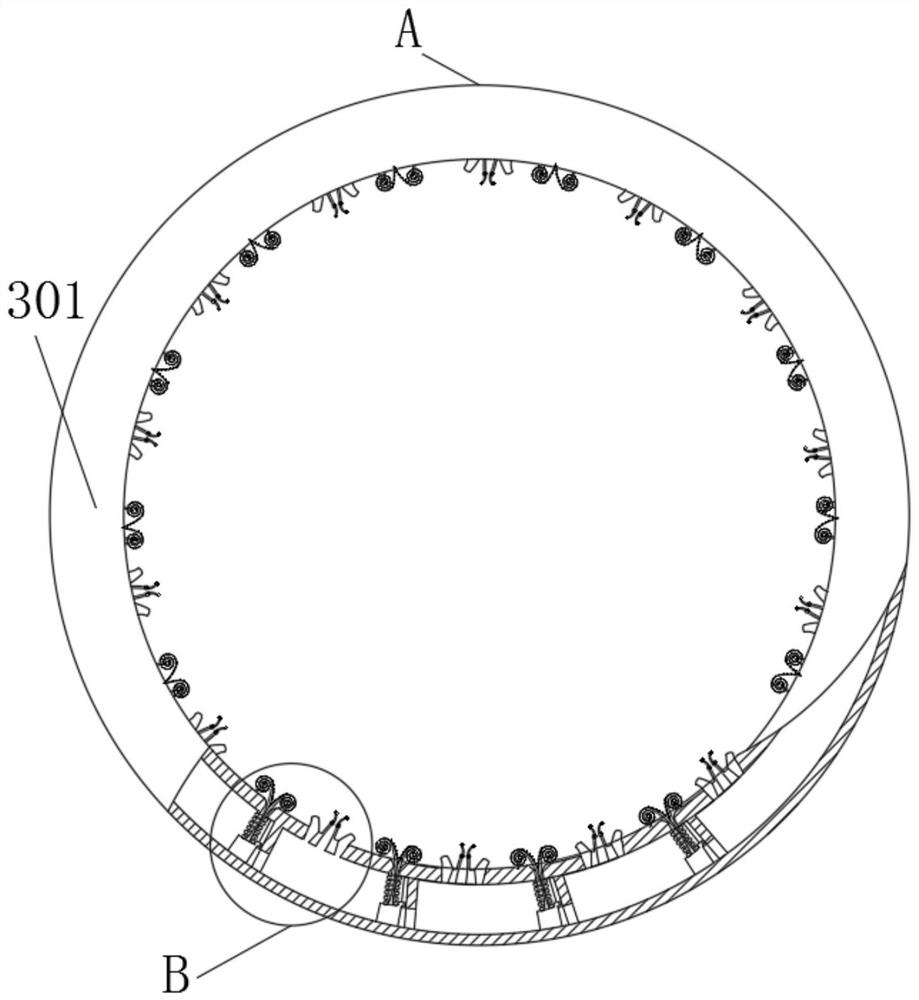

The invention relates to a sugarcane leaf grinding device. The device comprises at least one pair of leaf grinding wheels which are correspondingly arranged above and below a sugarcane conveying channel, wherein each leaf grinding wheel comprises a center shaft for installation and a roller which rotates by taking the center shaft as the axis; the outer peripheral surface of each roller is provided with a plurality of steel wires which are distributed in a matrix shape; and the steel wires extend along the radial directions of the rollers. The leaf grinding device can be used for ripping and grinding sugarcane leaves outside sugarcanes; after being processed by a leaf stripping brush device, the sugarcane leaves can be stripped cleanly; the bottom parts of the steel wires on the leaf grinding wheels are provided with helical springs, so that the steel wires can swing up and down and left and right, sugarcane skin is prevented from being scratched, the blockage of the sugarcane leaves is prevented and the leaf grinding effect and the leaf stripping effect of a combine harvester are further ensured.

Owner:浙江三佳农业机械装备有限公司

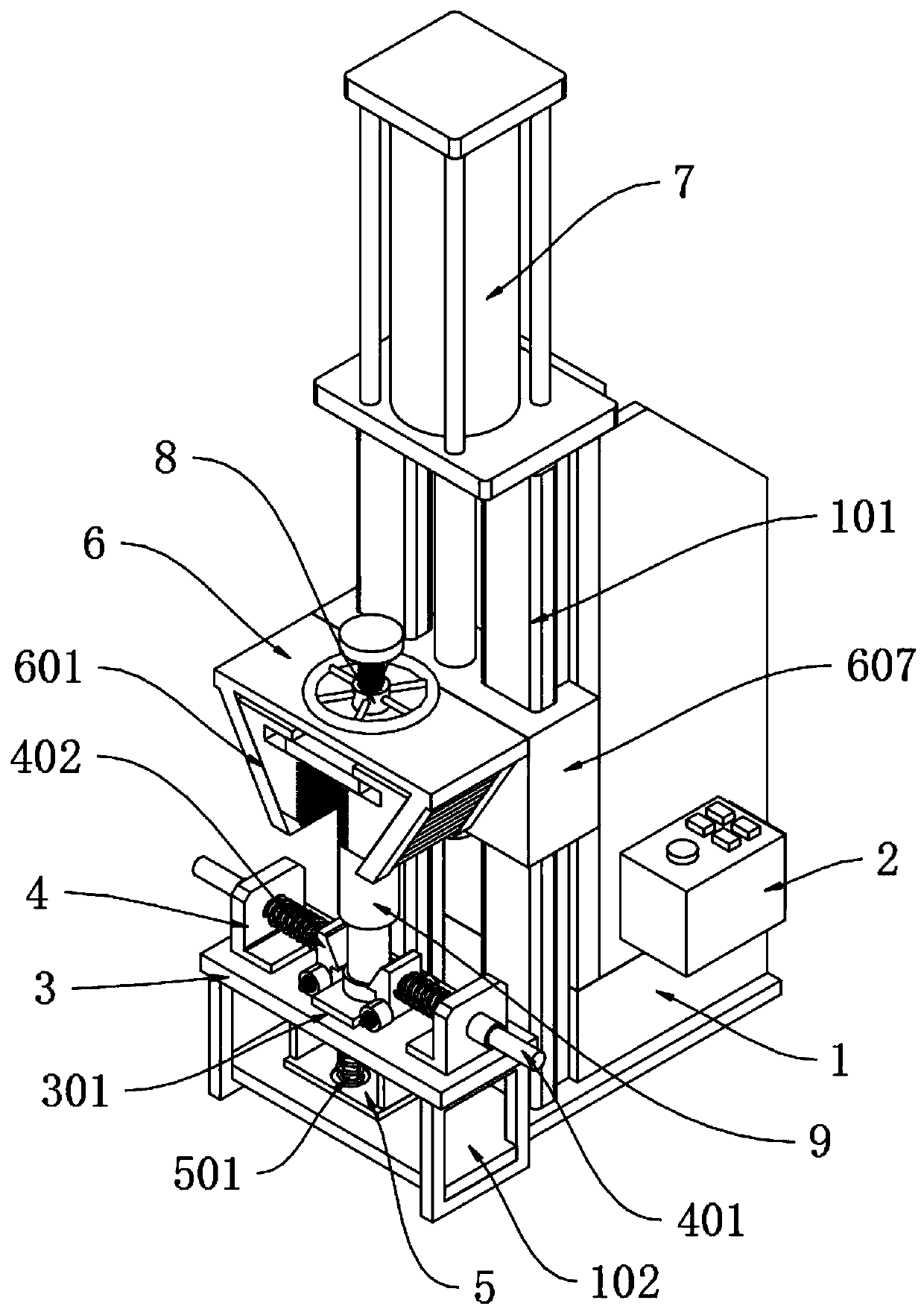

Tool equipment for stripping sleeve rod and sleeve based on machining

InactiveCN111408926AFacilitate strippingGuaranteed verticalityMetal working apparatusPhysicsMachining

The invention provides tool equipment for stripping a sleeve rod and a sleeve based on machining, and relates to the technical field of machining. The problems that in the separation process of the sleeve and the sleeve rod, the sleeve and the sleeve rod need to be clamped correspondingly, due to the uniform columnar structure of the sleeve and the sleeve rod, clamping and fixing are difficult, the length of the sleeve capable of being clamped is a fixed value due to limitation of a clamping table in the manner of clamping the sleeve through a fixed point, and universality is poor are solved;and in addition, in the clamping process of the sleeve rod, difficulties exist, the sleeve rod cannot be damaged by clamping due to the too large clamping force, and the sleeve rod needs to be clampedand fixed. The tool equipment comprises a tool machine body. An adaptation box is fixedly arranged on the side wall of the right end of the tool machine body. Due to the fact that a clamping rod is longitudinally and vertically inserted in the middle of a clamping mechanism in a sliding manner, the clamping mechanism can automatically complete the fastening and clamping actions after a clamping head is extruded under the joint action of a spring A and a guide wheel, and convenience and rapidness are achieved.

Owner:韩军伟

Heat laser strip device

PendingCN109148369AGuaranteed light transmissionSolve easy pollutionSemiconductor/solid-state device manufacturingLaser beam welding apparatusEngineeringLaser

A laser stripping apparatus is disclose, include a laser strip apparatus body, A laser stripping apparatus body include a mobile platform arranged at a lower end, the mobile platform is provided witha heating base, A sample table is arranged on the heating base, the heating base comprises an electric heating device arranged below the sample table and used for heating the sample table, A temperature sensor for detect that temperature of the sample table is also arranged at the low end of the sample table, and a heat insulating cover is cover above the sample table, and a heat insulating transparent window convenient for the laser to pass through is arranged at the position corresponding to the top end of the heat insulating cover and the sample table. The heating laser stripping apparatusof the present invention provides a suitable temperature environment for stripping GaN epitaxial wafers, solves the problem of residual stress of GaN epitaxial wafers grown on a sapphire substrate, and avoids the occurrence of easy fragmentation during stripping.

Owner:SINO INNOV SEMICON (PKU) CO LTD

Peeling device for grain processing

PendingCN108421585APlay peelingPlay the role of feedingGrain huskingGrain polishingSpiral bladeEngineering

The invention relates to the technical field of grain processing machines and discloses a peeling device for grain processing. The peeling device for grain processing comprises a shell. A feed hopperis arranged at the top of the shell, rotating rollers are arranged at the bottom of the feed hopper, the inner walls of both sides of the shell are fixedly connected with the outer surfaces of both sides of a conveying box, a motor is arranged at one side of the shell, and the output end of the motor is fixedly connected with a rotating shaft; and one end of the rotating shaft penetrates and extends into the conveying box, a spiral blade is fixedly connected to the outer surface of the rotating shaft, a feed inlet is formed in the top of the conveying box, and separating plates fixedly connected to the inner wall of the shell are arranged at the bottom of the conveying box. According to the peeling device, materials can be peeled and fed through the rotating rollers, the motor, the rotating shaft, the spiral blade and protrusions, so that the feeding is uniform while the peeling effect is ensured, the cleaning effect can be improved, and the materials can be peeled more fully; and thespiral blade can prevent excessive materials from accumulating on the separating plates and is beneficial to improving the cleaning effect.

Owner:刘丽娜

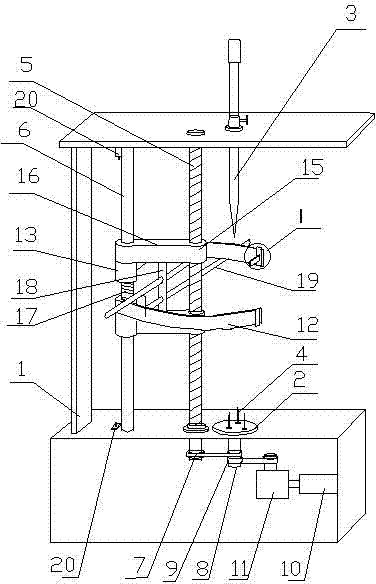

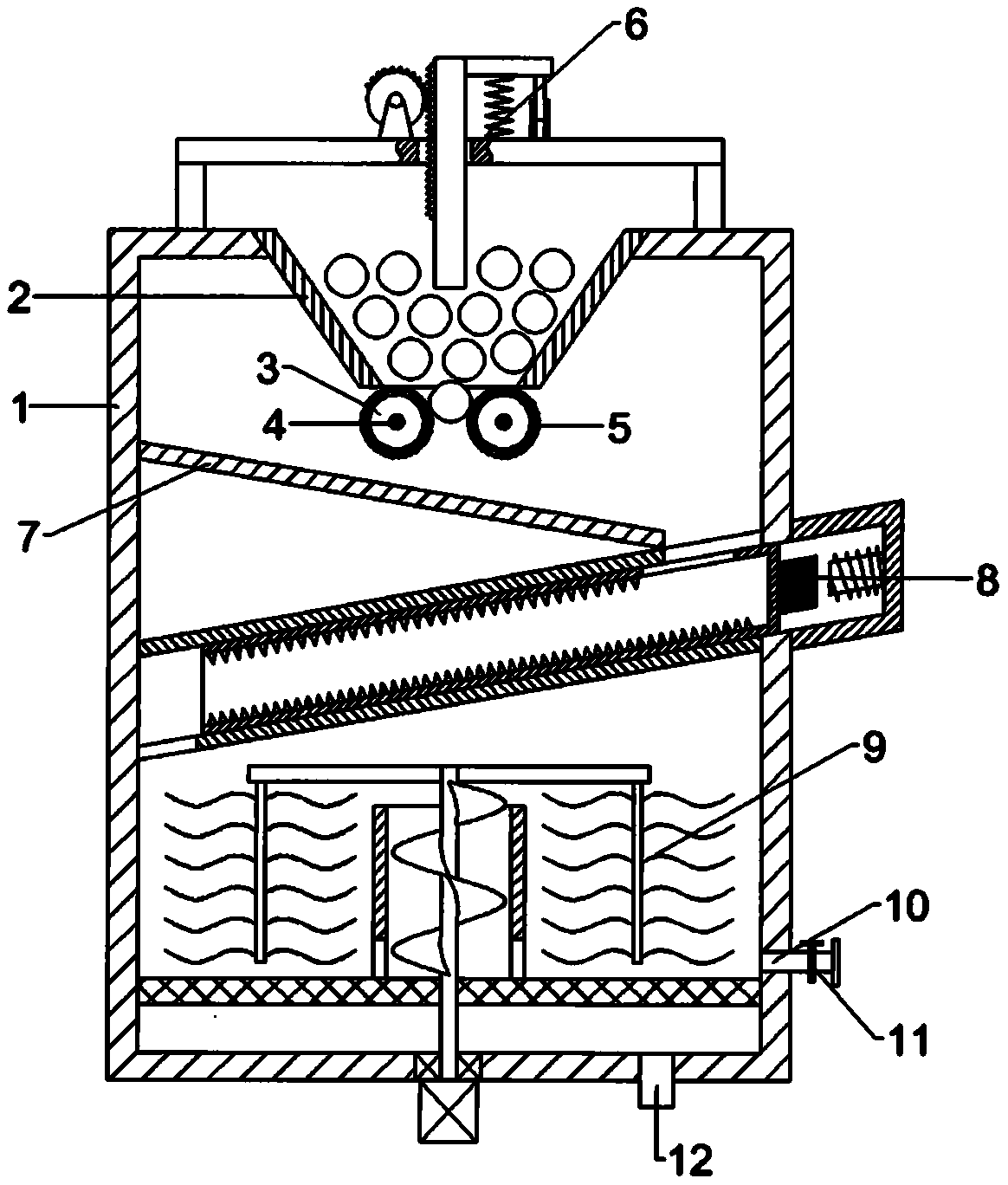

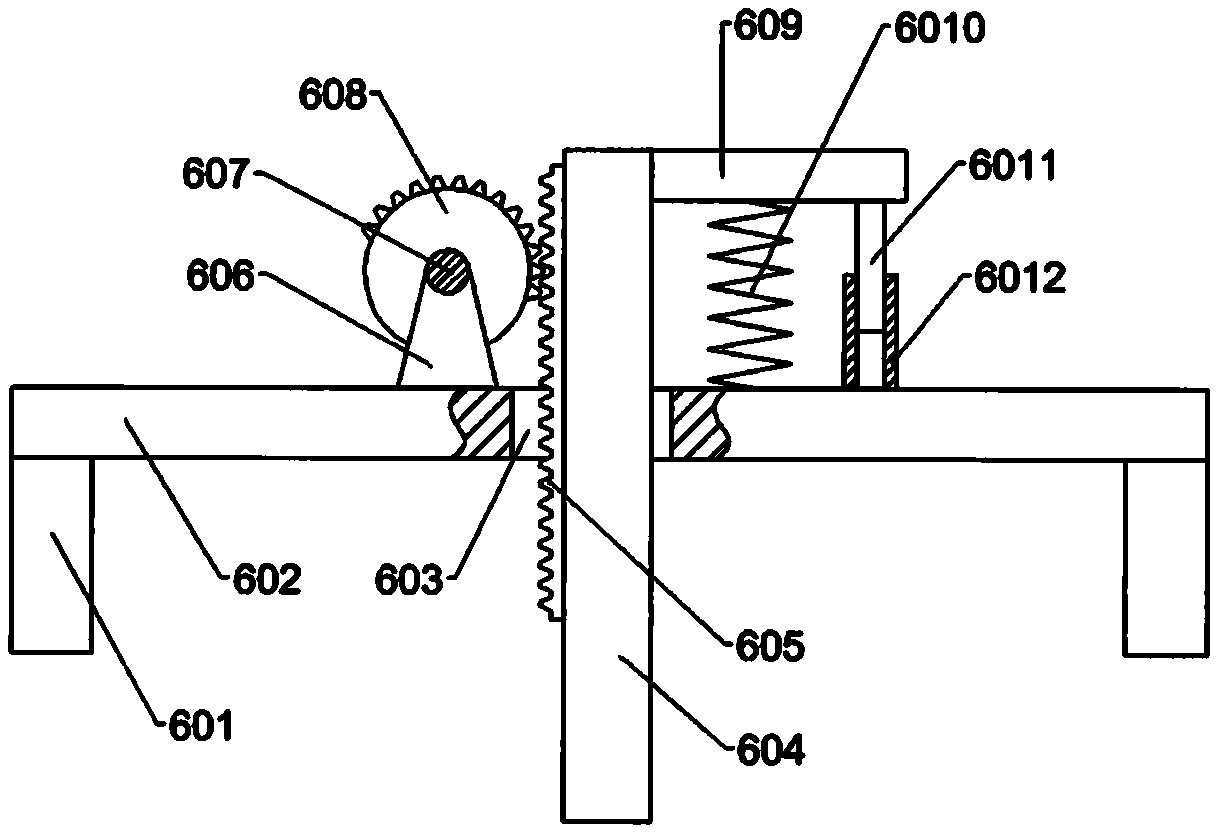

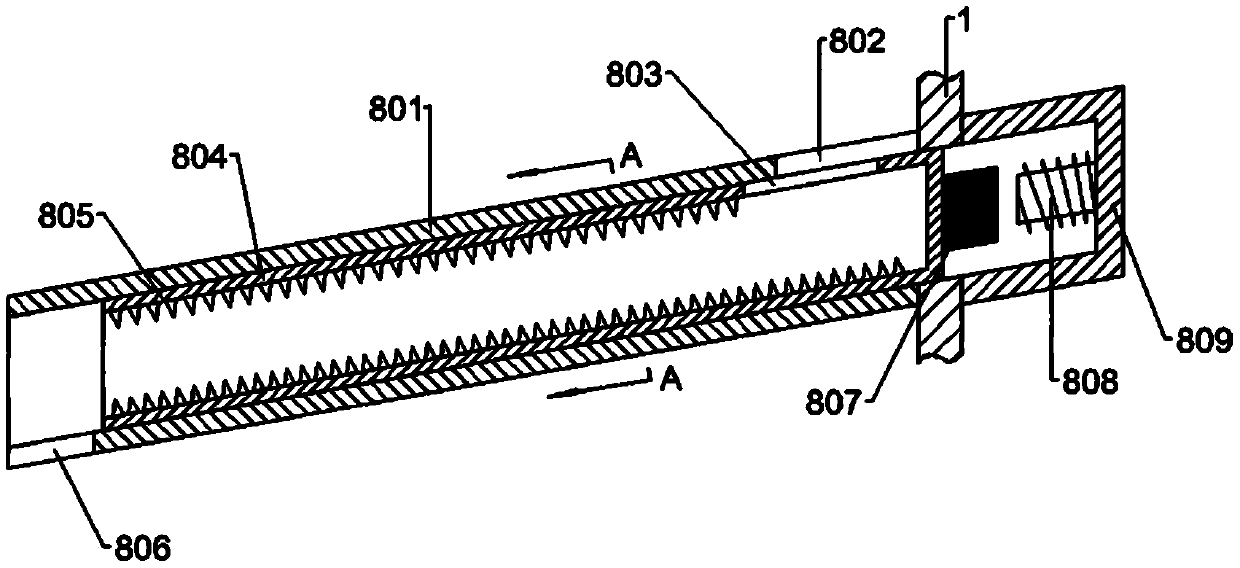

Fast stripping device for cable recovery

InactiveCN110310789ATimely and fast replacementGuaranteed peeling effectBasic electric elementsMechanical measuring arrangementsEngineering

The invention relates to the technical field of cable recovery equipment, in particular to a fast stripping device for cable recovery. The fast stripping device comprises a fixedly mounted recycle boxand a wire core box. Multiple support feet are mounted on the lower ends of the recycle box and the wire core box. The side wall of the recycle box is provided with a recycle cable in an insertion way. The recycle cable comprises a cable sheath and a wire core located in the middle of the cable sheath. The output end of the wire core penetrates through the side wall of the recycle box and extendsinto the inner cavity of the wire core box. A cable stripping device is arranged on the inner top wall of the recycle box at the position corresponding to the recycle cable, and a reeling assembly isinstalled at the lower part of the inner cavity of the recycle box. The shortcomings in the prior art are overcome, and the device has reasonable design and compact structure and effectively solves the problem of manual stripping which is poor in stability and liable to cause stripping personnel to be cut by a tool, and the stripping depth is uneven and the internal structure of the cable is liable to be damaged and the problem of low efficiency of manual stripping and thus has higher social use value and application prospect.

Owner:ANHUI TIANMING CABLE

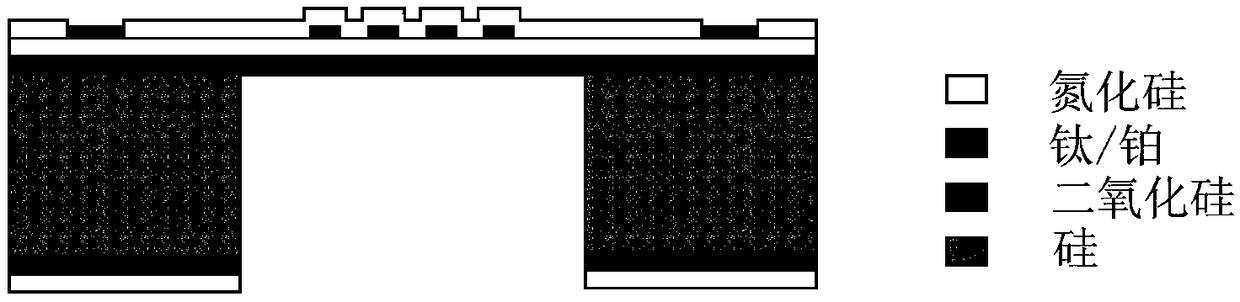

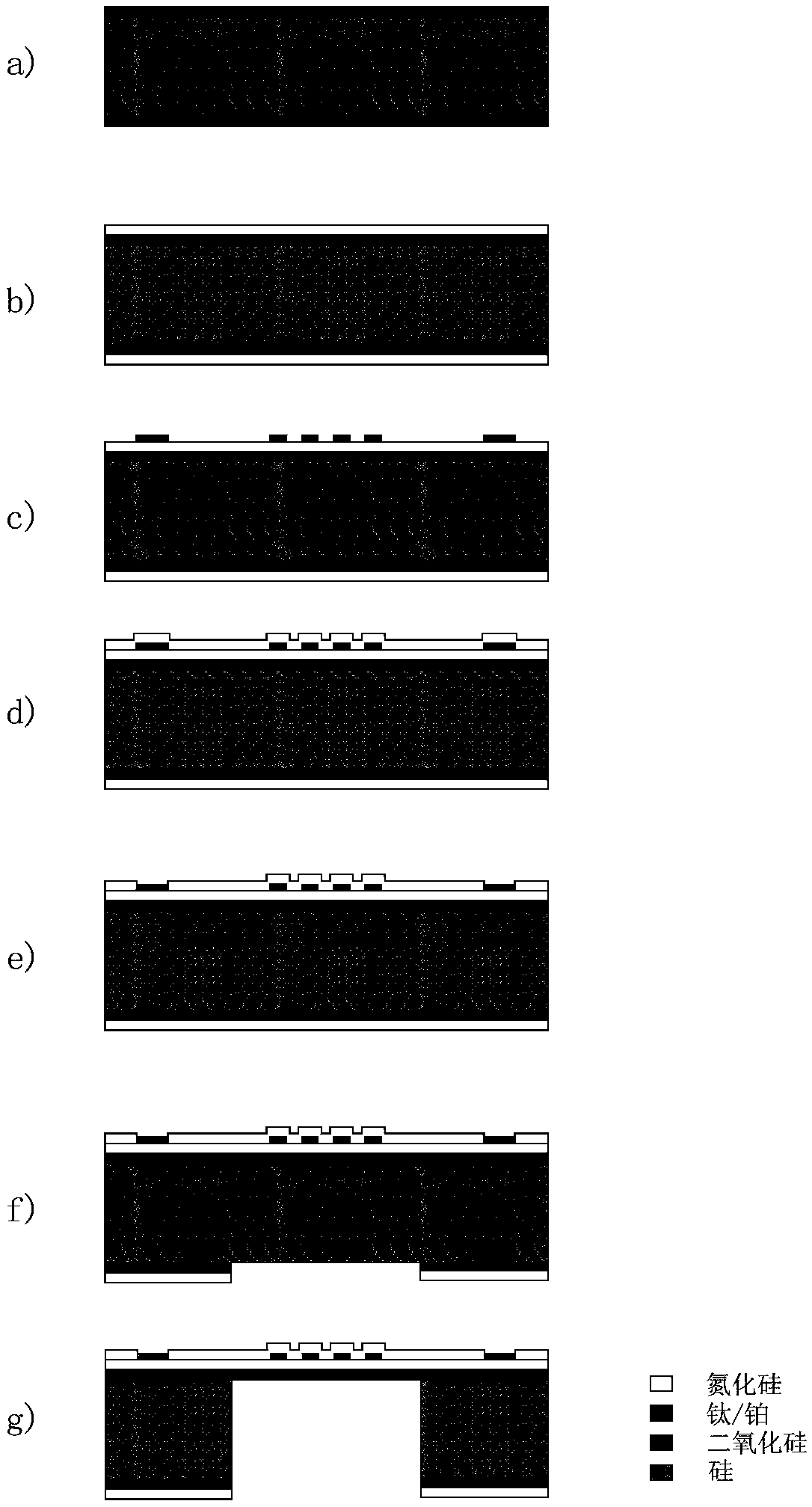

Production method for MEMS air mass flow meter with back-cavity structure

InactiveCN108658035AWon't breakGuaranteed accuracyTelevision system detailsImpedence networksThermistorProtection layer

The invention relates to a production method for an MEMS air mass flow meter with a back cavity structure. The method comprises the steps of forming composite dielectric film on a surface of a siliconwafer; preparing a metal thermistor thin film pattern through utilization of an exfoliation method; growing a protection layer on the surface of metal thermistor thin film; carrying out high temperature annealing; removing the protection layer on a bonding pad and exposing a metal layer of the bonding pad; carrying out photoetching on the back of the silicon wafer, and carrying out dry etching, thereby forming the back cavity structure; and cutting and splitting chips, thereby finishing processing the chips. According to the method, after photoetching, development and plasma glue extrusion steps are carried out, a deionized water washing step is imported, so residual impurities on the surface of the wafer can be effectively removed after the plasma washing is carried out, the adhesion ofthe metal film on the dielectric film is ensured, and the metal film is prevented from falling off. According to the method, through utilization of a back dry etching technology, a back cavity is realized, and a corrosive effect of corrosive liquid in wet etching for a front pattern structure can be effectively prevented.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Device for stripping waste cable

InactiveCN106786212ASo as not to damageIncrease flexibilityApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention discloses a device for stripping a waste cable. The device comprises a stripping mechanism for breaking an insulating layer on the cable, wherein the stripping mechanism comprises N stripping units, the stripping units are distributed along the movement direction of the cable, each stripping unit comprises a V-shaped clamping plate for clamping the cable, a cylinder and a blade, the blade is driven by the cylinder to be displaced along the radial direction of the cable, two clamping arms of the clamping plate are arranged symmetrically about the blade, and the blade and the clamping plate are distributed on two sides of the cable. According to the device, the stripping mechanism can be used for flexibly and automatically executing stripping operation on cables with different diameters; a correction unit is used for properly extruding and correcting the cable to effectively avoid the influence of sagging of the insulating rubber layer on stripping, and can also be used for correcting a bend of the cable to effectively ensure a stripping effect on the cable; an insulating layer recovery unit can be used for flexibly selecting the number of winding rods and the distances therebetween, and more convenience is brought to use.

Owner:安徽万博电缆材料有限公司

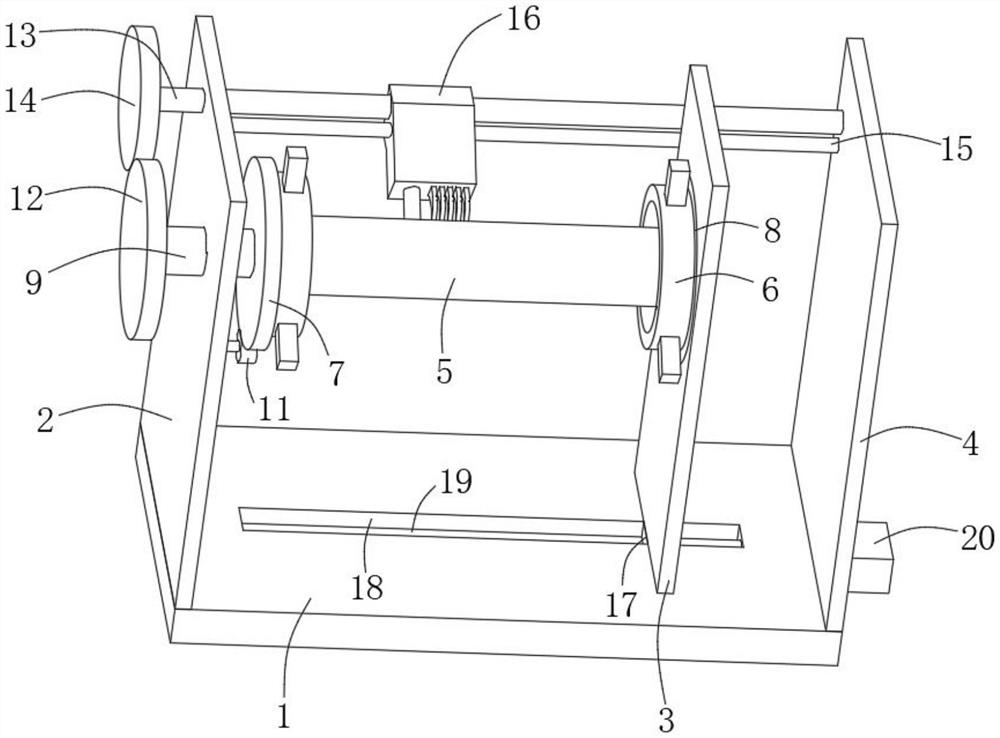

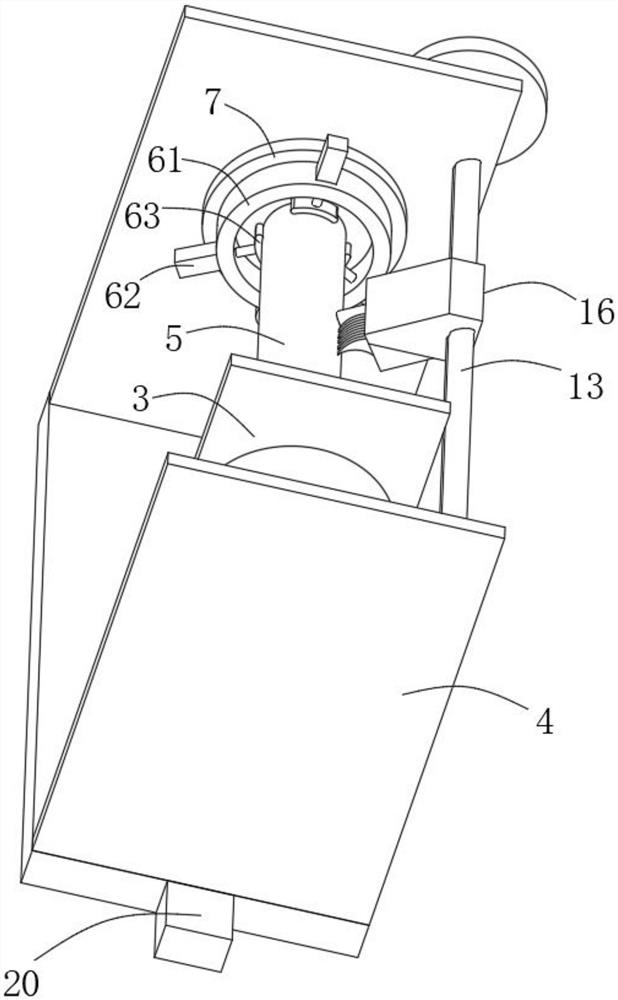

Waste wire stripping device

ActiveCN103259221BExtended service lifeGuaranteed peeling effectApparatus for removing/armouring cablesEngineeringWheel and axle

The invention discloses a waste wire stripping device, and belongs the technical field of recovery devices of waste materials. The waste wire stripping device comprises a paying-off mechanism, a paring mechanism, a tension automatic adjustment mechanism, a peeling mechanism and a wire core winding mechanism, wherein the paring mechanism is arranged on one side of the tension automatic adjustment mechanism, the peeling mechanism is located between the tension automatic adjustment mechanism and the wire core winding mechanism, the paring mechanism comprises a fixed plate, a paring knife fixing base supporting arm, a paring knife fixing base, a paring knife and a guiding wheel, the fixed plate is fixed with one side of the tension automatic adjustment mechanism, a wire passing hole is formed in the fixed plate, the paring knife fixing base supporting arm is fixed with one side of the fixed plate, a wire passing groove is formed in one side of the paring knife fixing base, two ends of the paring knife are respectively provided with a paring knife adjustment groove, the guiding wheel is arranged on a guiding wheel shaft, the guiding wheel shaft is fixed on a guiding wheel shaft base, and the guiding wheel shaft base is fixed on the paring knife fixing base supporting arm. The waste wire stripping device is ideal in stripping effect, free of damage to the guiding wheel caused by friction, long in service life and low in knife cost, and ensures a paring effect.

Owner:CHANGSHU HONGLIN WIRE & CABLE CO LTD

Garlic peeling device

InactiveCN104397843AQuality impactAvoid affecting product qualityVegetable peelingEngineeringAllium sativum

The invention relates to the field of garlic peeling, and in particular relates to a garlic peeling device. The garlic peeling device comprises a rack body, a sectioning box, a vibrating trough and a peel sucking machine, wherein the sectioning box, vibrating trough and peel sucking machine are fixed on a support. The garlic peeling device is characterized in that the sectioning box is connected to the upper end of the vibrating trough by virtue of a discharge opening; a garlic clove storage chamber is arranged at the rear end of the vibrating trough, and an opening is formed in the lower end of the garlic clove storage chamber; a garlic outlet pipe is connected with the lower end of the garlic clove storage chamber; the garlic outlet pipe is connected with a peel sucking air duct, and the upper end of the peel sucking air duct is connected with a drawing fan by virtue of a pipeline; the drawing fan is connected with a peel storage bag; and a garlic outlet is connected to the lower end of the peel sucking air duct. The garlic peeling device provided by the invention is convenient to use, is reasonable in design, ensures that garlic can be fully peeled, can finish peeling of garlic by virtue of mechanical operations and ensures the garlic peeling effect, and the entire peeling process has a relatively high efficiency and saves cost and human resources, so that the garlic peeling device has strong practicability and a wide application range.

Owner:SHANDONG SHUNBANG BIOTECH

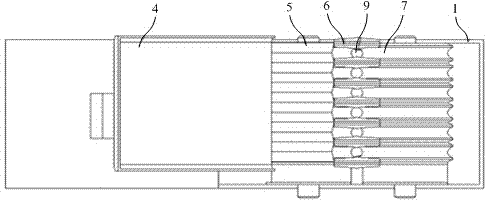

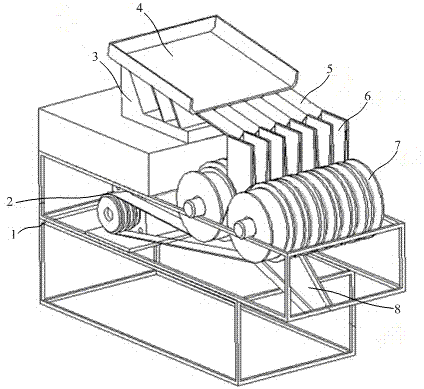

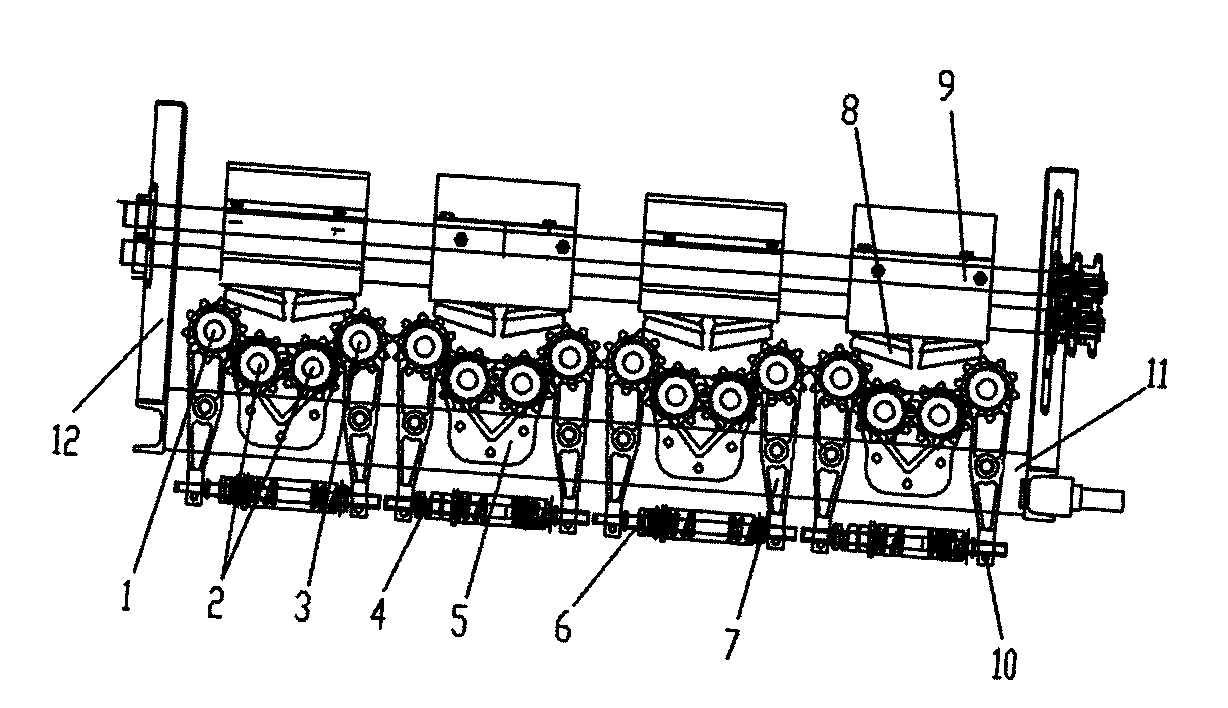

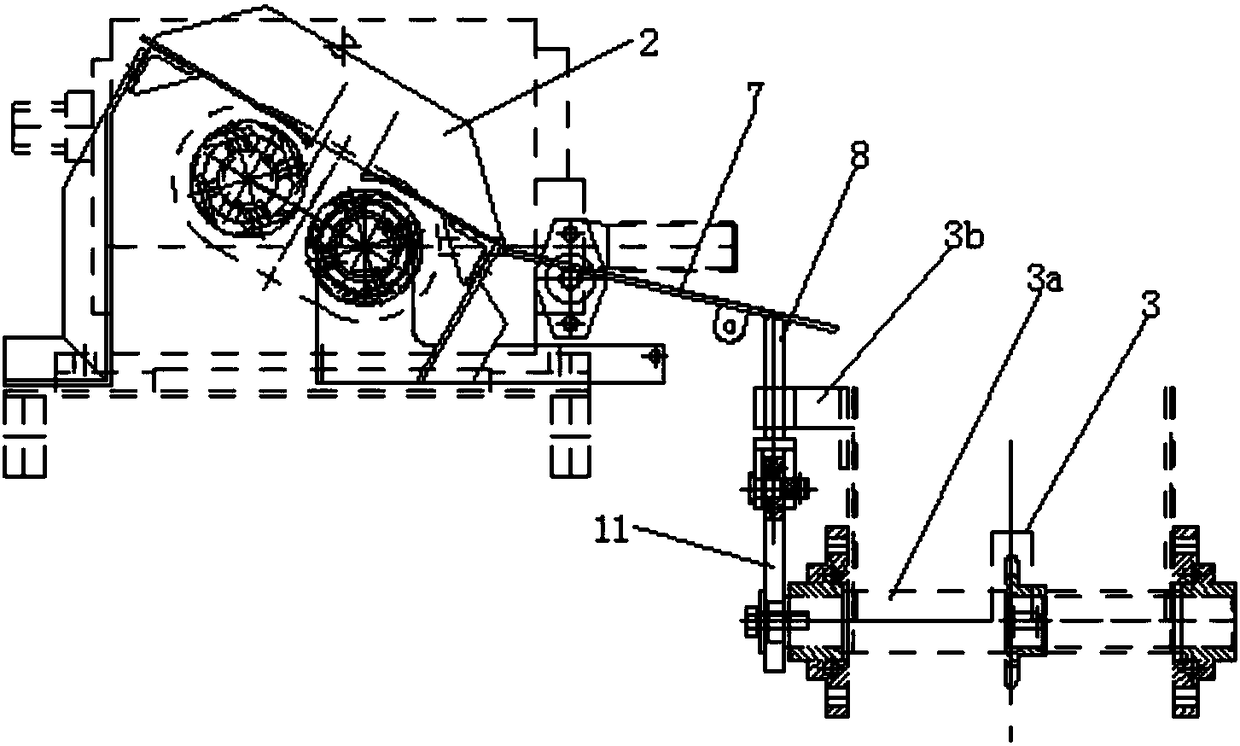

Four-unit corn husker

InactiveCN104412788ASimple structureEasy to implementThreshersAgricultural scienceAgricultural engineering

The invention belongs to the field of agricultural machinery and particularly relates to a four-unit corn husker. The four-unit corn husker comprises a frame, a husking mechanism, a feeding mechanism and a transmission mechanism. The husking mechanism is mounted at the bottom of the frame, the frame above the husking mechanism is provided with the feeding mechanism, and the husking mechanism is composed of four husking units arranged side by side; the husking units are composed of two fixed husking rollers in the middle and two swinging husking rollers on both sides of the fixed husking rollers, the center of the swinging husking rollers is higher than that of the fixed husking rollers, and the husking units are in a V shape. The four-unit corn husker is simple in structure and easy to implement; fixed pressure feeding rollers and floating pressure feeding rollers are arranged above the husking mechanism, wherein the floating pressure feeding rollers can float up and down according to the sizes of corncobs, so that the corncobs can be tightly attached to the husking rollers, cornhusks can be removed cleanly, and the husking effects can be ensured; by means of the four husking units, the husking speed can be increased, and the working efficiency can be improved; the two swinging husking rollers of the husking units are hinged to the frame through swinging arms, the lower ends of the swinging arms are connected through an extending spring, so that the width of the swinging husking rollers can be adjusted according to the sizes of the corncobs, and further jamming can be avoided.

Owner:蒋爱成

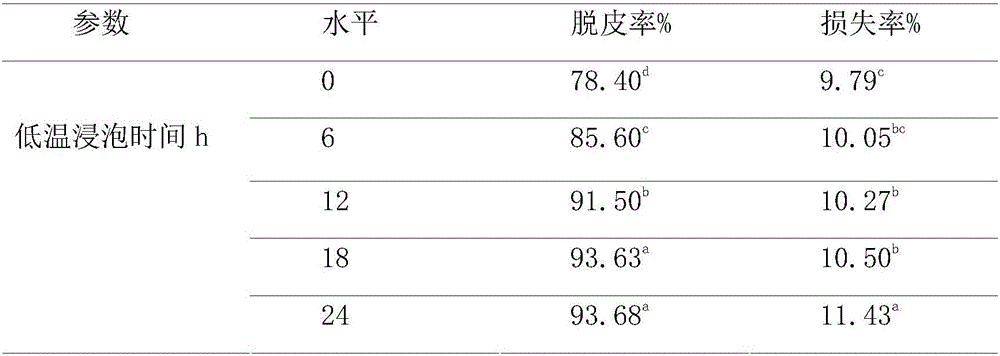

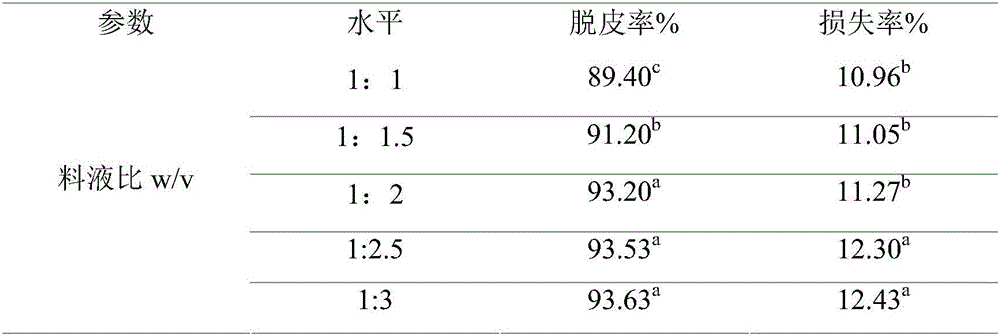

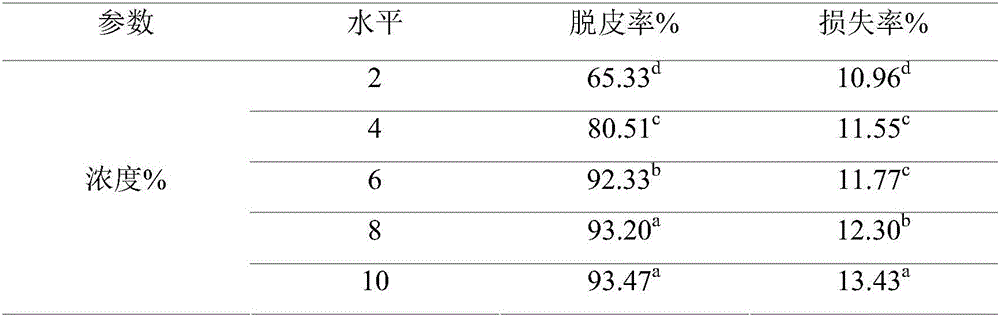

Sorghum dehulling method

InactiveCN106622451AIntegrity guaranteedGuaranteed hardnessGrain huskingGrain polishingFiltrationSorghum

The invention provides a sorghum dehulling method. The sorghum dehulling method comprises the steps of step I, adding water to soak sorghum to soften sorghum seed husks; step II, after soaking, filtering sorghum, and spin-drying filtered sorghum; step III, adding a soaking solution into the spin-dried sorghum; step IV, stirring a mixed solution of sorghum and the soaking solution, and carrying out ultrasonic treatment till the sorghum seed husks are separated; step V, removing the separated sorghum seed husks through filtration, and collecting sorghum grains; and step VI, spin-drying, cleaning and drying the collected sorghum grains, so as to obtain complete dehulled sorghum grains. The sorghum dehulling method has the beneficial effects that the sorghum dehulling efficiency is remarkably improved, the dehulling rate reaches 90% or above, the dehulled sorghum grains are complete, and loss of grains is reduced.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

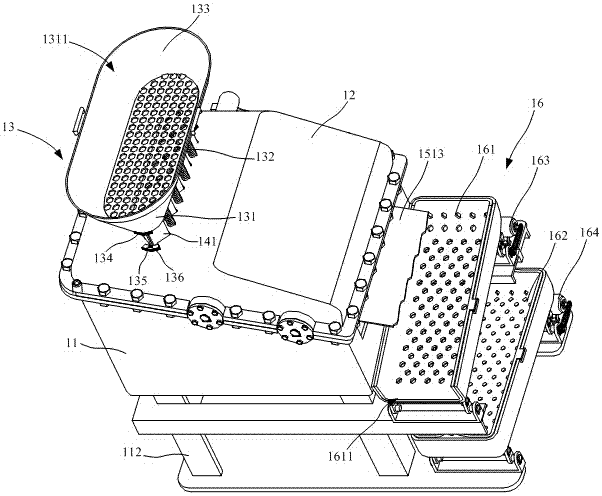

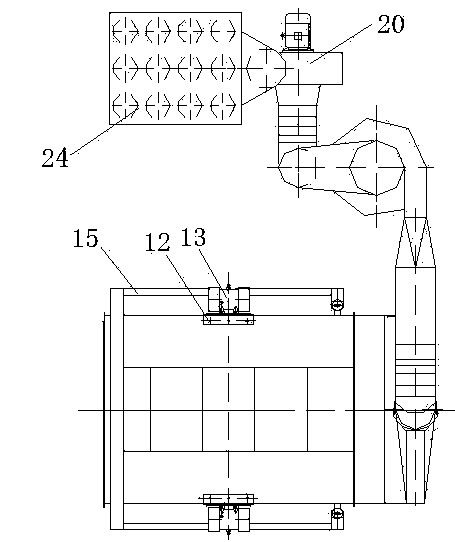

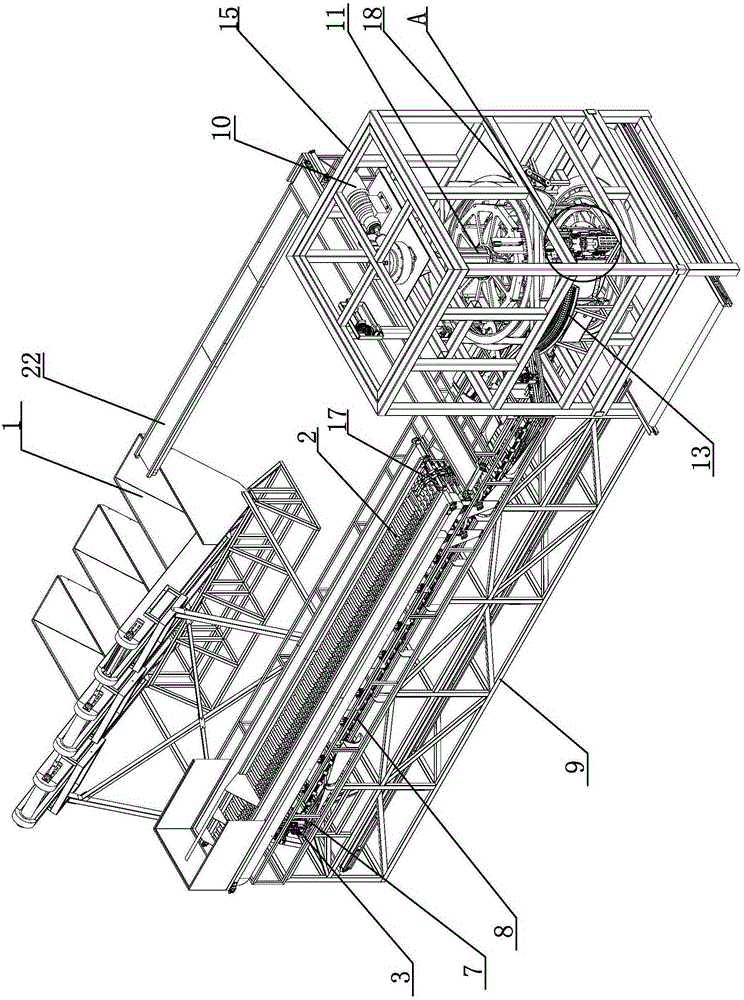

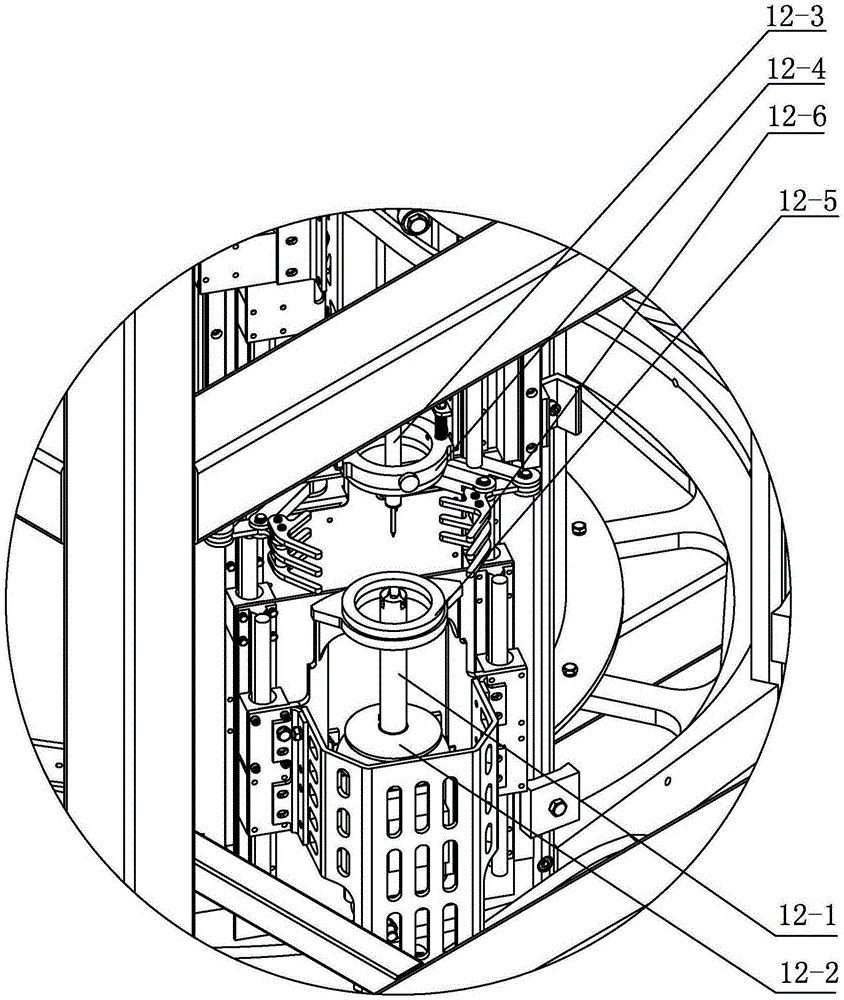

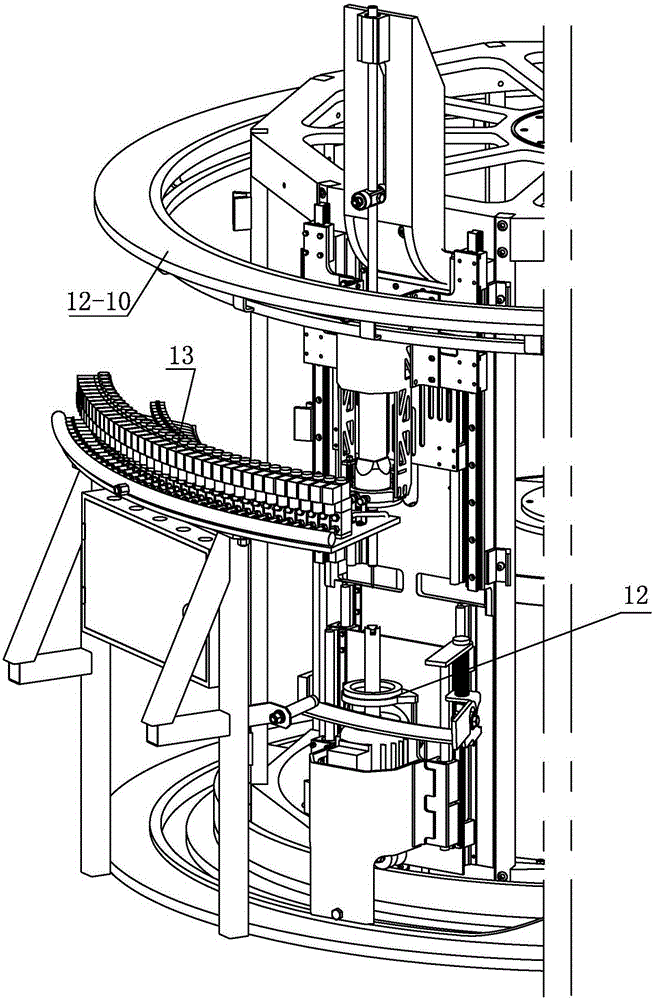

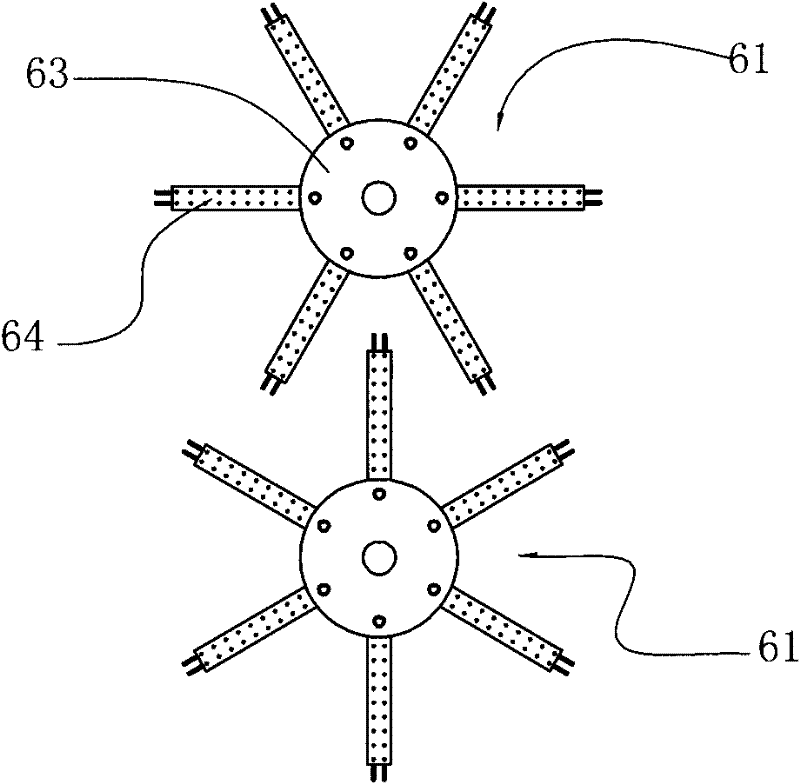

Fresh corn bract peeling apparatus

The invention discloses a fresh corn bract separation apparatus and relates to a bract separation apparatus. The apparatus aims at solving problems that a mode of peeling corn bracts manually wastes a large amount of manpower, and is relatively low in efficiency, and an existing peeling apparatus greatly increases a corn crushing rate. The apparatus comprises a main power motor, a main machine, an air blowing mechanism, a main machine frame, a corn residue bract removal mechanism, and a plurality of corn clamping units, wherein the main machine is mounted inside the main machine frame; the main power motor is mounted on the top of the main machine frame; the main machine motor is connected with the main machine; the air blowing mechanism is mounted on the main machine frame; the plurality of corn clamping units are mounted uniformly, in a circumferential direction, on a outer sidewall of the main machine, and the corn residue bract removal mechanism is mounted on the main machine frame. According to the present invention, the apparatus is used for removing the fresh corn bracts.

Owner:HEILONGJIANG YANDING MACHINERY EQUIP MFG CO LTD

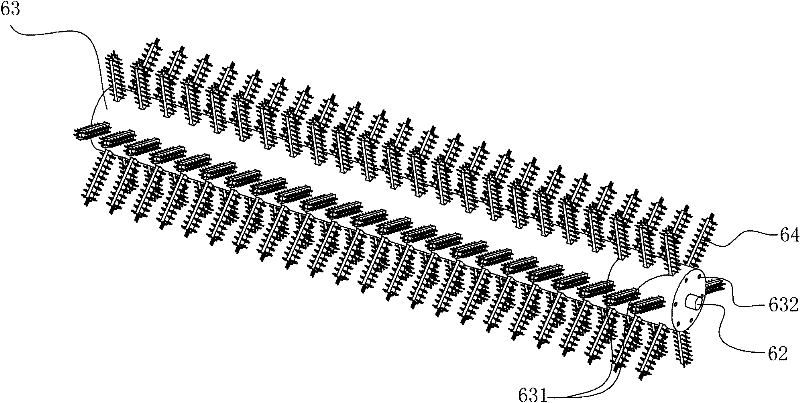

Sugarcane peeling brush

The invention discloses a sugarcane peeling brush which comprises at least one pair of peeling wheels, wherein each peeling wheel comprises a central shaft and a roller, and the roller rotates around the central shaft; and the sugarcane peeling brush is characterized in that a plurality of brushing blocks extending radially along the roller are distributed on the periphery of the roller in an array, and a plurality of steel wire clusters which are vertical to the external surfaces of the brushing blocks and distributed at intervals are arranged on the external surface of the brushing blocks. The steel wire clusters vertical to the peripheral surfaces of the brushing blocks are arranged on the peripheral surfaces of the brushing blocks of the peeling brush, therefore, the sugarcane peeling brush can peel the sugarcane tops off the external surface of sugarcanes all round from multiple planes.

Owner:浙江三佳农业机械装备有限公司

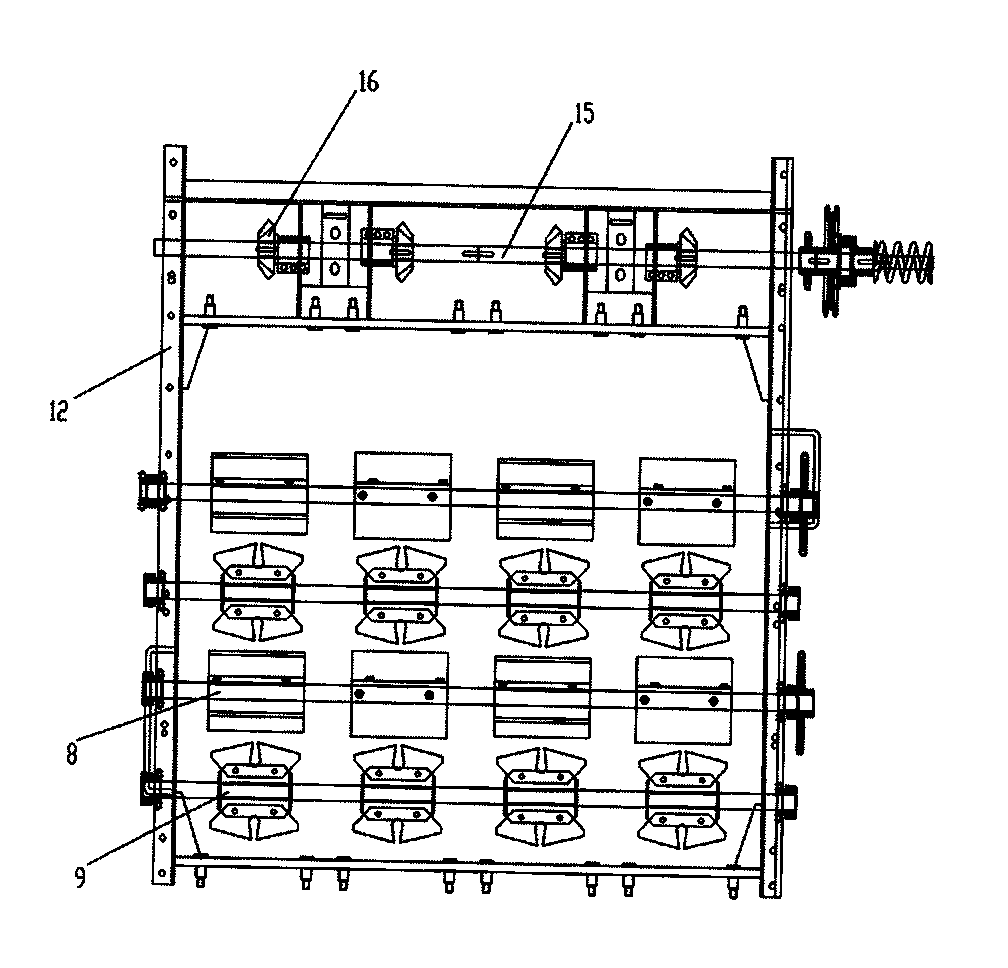

Integral machine for garlic clove separating, peeling and washing

InactiveCN107259614ATo achieve the purpose of peeling and peelingGuaranteed peeling effectFood treatmentHuskDrive shaft

The invention discloses an all-in-one garlic peeling and cleaning machine, which comprises a body, a control switch, a power interface, a water inlet, a material outlet, a material inlet, a motor 1, a driving shaft, a bearing 1, a conical bucket, and a peeling glue Sleeve, peeling rubber sleeve, elastic rubber cylinder, vibrating screen 1, vibrating screen 2, vibration mechanism, blower 1, blower 2, motor 2, support shaft, bearing 2, bearing 3, drum 1, drum 2, gears and blades . Beneficial effects: through the rotation of the peeling rubber sleeve, the garlic of different sizes can be peeled and peeled, so as to achieve the purpose of peeling and peeling the garlic; by setting the two-stage vibrating screen and the vibrating mechanism, the garlic can be washed in the vibrating screen and the blower. Under the combined action, the garlic rice is separated from the garlic skin, thereby ensuring the peeling effect of the garlic; by setting the stirring and washing structure under the vibrating screen, the peeled garlic rice can effectively clean the impurities produced during the peeling process, thereby improving the garlic peeling effect. quality.

Owner:宣永

Adhesive tape automatic peeling device

InactiveCN110589598AThe peeling process is stable and regularAffect aestheticsArticle deliveryAdhesive beltMobile phone

The invention discloses an adhesive tape automatic peeling device and relates to the field of mobile phone assembling. The adhesive tape automatic peeling device comprises a material discharging mechanism, a material collecting mechanism and an adhesive tape peeling mechanism; the material discharging mechanism discharges an adhesive tape and conveys the adhesive tape to the adhesive tape peelingmechanism; the adhesive tape peeling mechanism peels off an adhesive strip from a release paper of the adhesive tape conveyed to the adhesive tape peeling mechanism; the adhesive tape peeling mechanism comprises an adhesive tape peeling platform and an adhesive peeling platform; the adhesive tape peeling platform is used for placing the adhesive tape to finish the peeling work of the release paper; the adhesive peeling platform adsorbs a protective film and an adhesive strip of the adhesive tape to finish the peeling work of the adhesive strip; and the material collecting mechanism winds the peeled release paper. According to the adhesive tape automatic peeling device, as manual adhesive tape peeling action is simulated to automatically peel off the adhesive tape, manual operation can be replaced so that the production efficiency is enhanced; and moreover, the separated release paper can be recycled to prevent the release paper from being wound on a machine to affect the beauty and safety of equipment; through the adhesive tape peeling platform and the adhesive peeling platform which are separately arranged, the release paper and the adhesive strip are partitioned after being peeled off to guarantee the adhesive peeling effect.

Owner:SHENZHEN JIYIN TECH

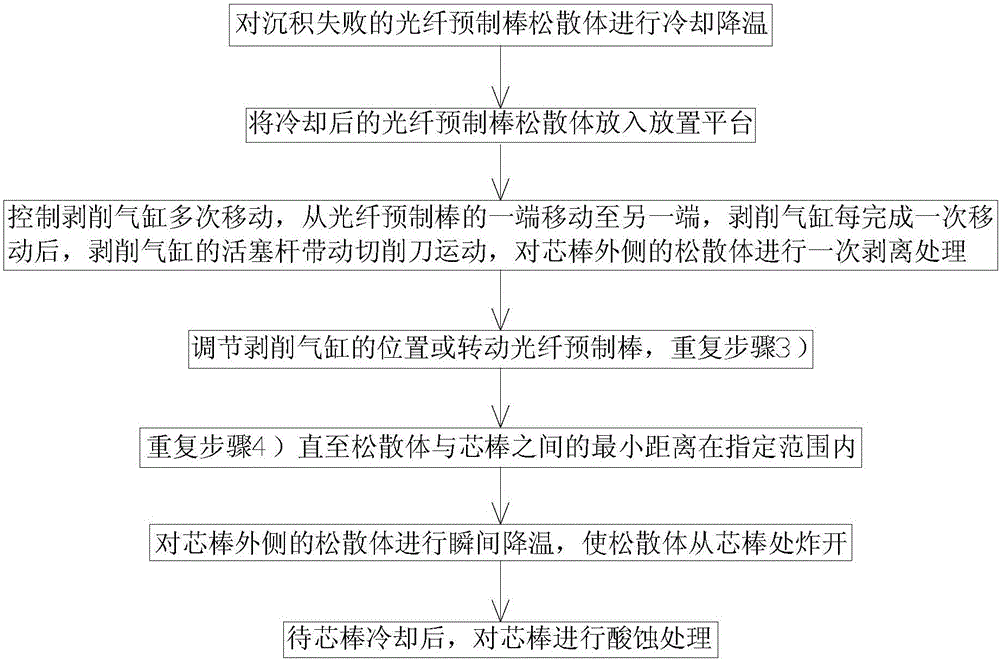

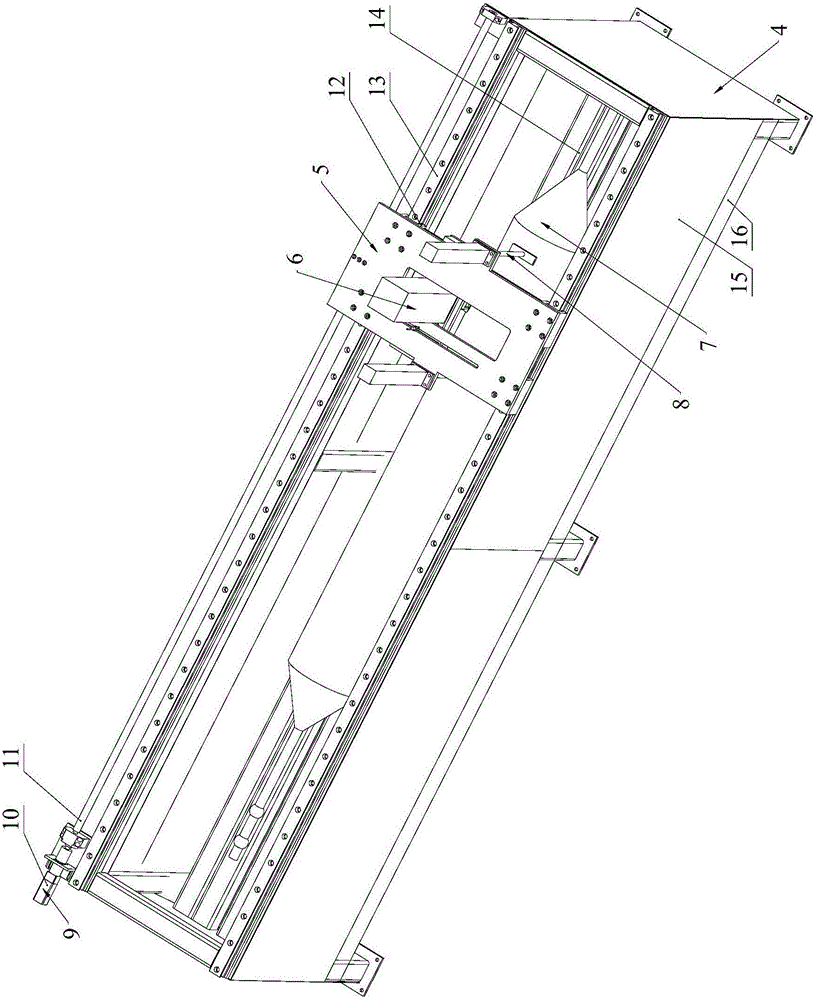

Method and device for stripping loose bodies of optical fiber preform rod

ActiveCN106186659AQuality improvementLarge amount of peelingGlass making apparatusAcid etchingMaterials science

The invention discloses a method and device for stripping loose bodies of an optical fiber preform rod. The method comprises the following steps: (1) cooling the loose bodies of the optical fiber preform rod; (2) putting the loose bodies of the optical fiber preform rod into a placement platform; (3) controlling a stripping air cylinder to move repeatedly, and carrying out stripping treatment once on the loose bodies at the outer side of a core rod; (4) repeating the step (3); (5) repeating the step (4) until the minimum distance between the loose bodies and the core rod is in a specific range; (6) carrying out instant cooling on the loose bodies at the outer side of the core rod so as to burst out the loose bodies; and (7) carrying out acid-etching on the core rod. According to the method and the device, cutting knifes are driven by the stripping air cylinder, so that the loose bodies can be stripped automatically and rapidly; the cutting knifes are driven by the stripping air cylinder, so that the cutting knifes can be adjusted through controlling the pressure of the stripping air cylinder; and the loose bodies of the optical fiber preform rod can be automatically cut, so that the labor intensity for laborers is lightened.

Owner:ZHEJIANG FUTONG OPTICAL FIBER TECH +1

Peeling device for peeling garlic by utilizing thermal expansion and cold contraction

InactiveCN112401272AGuaranteed separation effectAvoid enteringFood treatmentThermodynamicsEngineering

The invention discloses a peeling device for peeling garlic by utilizing thermal expansion and cold contraction. The peeling device comprises an external control mechanism for starting an external driving device, a steam heating mechanism for heating steam, an adsorption peeling mechanism for peeling by airflow adsorption, and a magnetic peeling mechanism for peeling by magnetic vibration, whereina shell is arranged in the external control mechanism, the external control mechanism is fixedly connected with the steam heating mechanism through the left side of the shell, the inner wall of the shell is fixedly connected with a bearing A, the inner wall of the shell is fixedly connected with the adsorption peeling mechanism through the bearing A, and the inner wall of the adsorption peeling mechanism is fixedly connected with the magnetic peeling mechanism. Rapid refrigeration is carried out after heating, separation is carried out according to different shrinkage degrees of garlic seedsand garlic peels, and a bent arc plate is arranged in a channel to guide middle steam to be sprayed outwards, so that the steam is prevented from entering the shell, and the effect of thermal expansion and cold contraction is not affected.

Owner:高增光

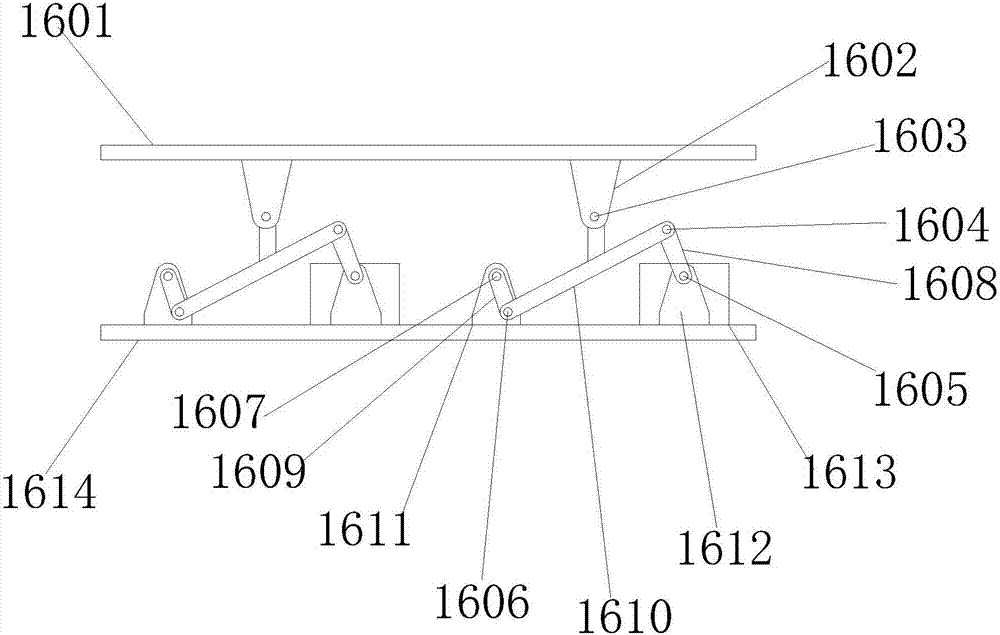

Progressive green walnut peeling equipment with auxiliary feeding function

PendingCN110250534AConvenience for later workGuaranteed normal feedingHuskingHullingWalnut NutEngineering

The invention provides progressive green walnut peeling equipment with an auxiliary feeding function. The equipment comprises a shell, a feeding hopper in a big-end-up inverted cone frustum shape is fixedly connected to the top of the shell, a pair of extrusion rollers are arranged at an opening of the lower side of the feeding hopper, horizontal rotating shafts are fixedly connected to middles of the extrusion rollers respectively, two ends of each horizontal rotating shaft are erected on side walls of the shell, and the outer end of each horizontal rotating shaft is connected with a driving device. The outer surface of each extrusion roller is provided with a rubber layer, and an auxiliary feeding device is arranged above the feeding hopper. The progressive green walnut peeling equipment has advantages that firstly, by relative rotation of the two extrusion roller, green peels on surfaces of green walnuts are extruded by the outer rubber layers of the extrusion rollers to be softened or cracked to facilitate subsequent operation; secondly, by virtue of the auxiliary feeding device, the green walnuts are enabled to pass through the extrusion rollers smoothly, so that feeding of the green walnuts is guaranteed.

Owner:诸暨市众创机械设备厂

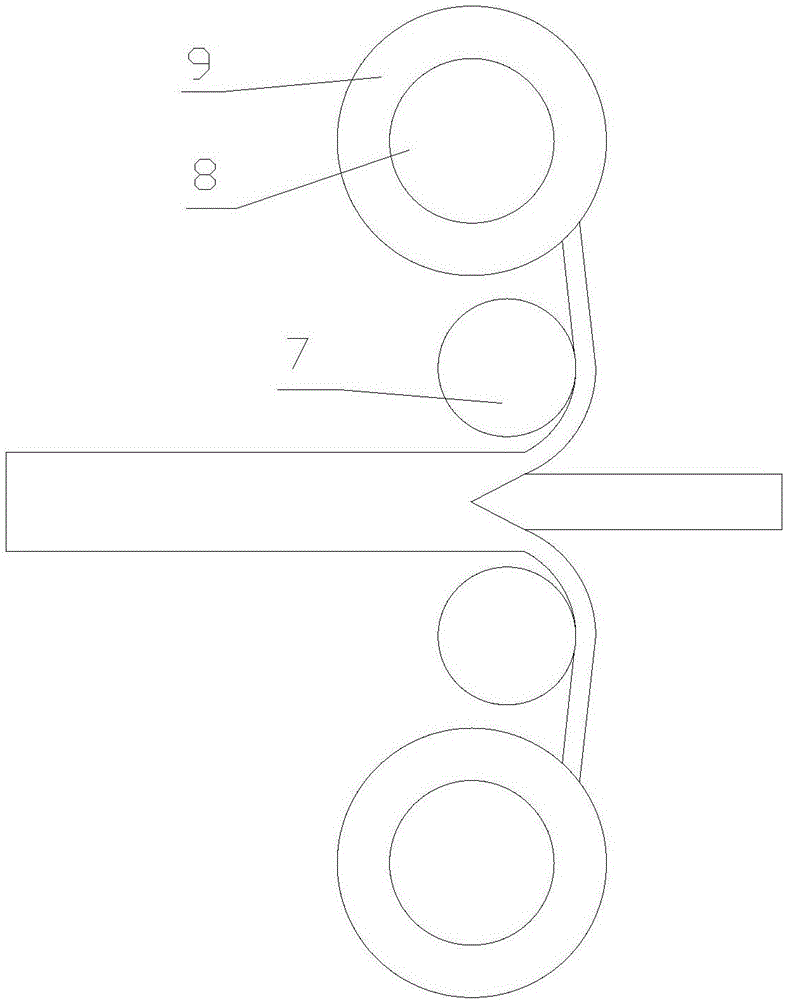

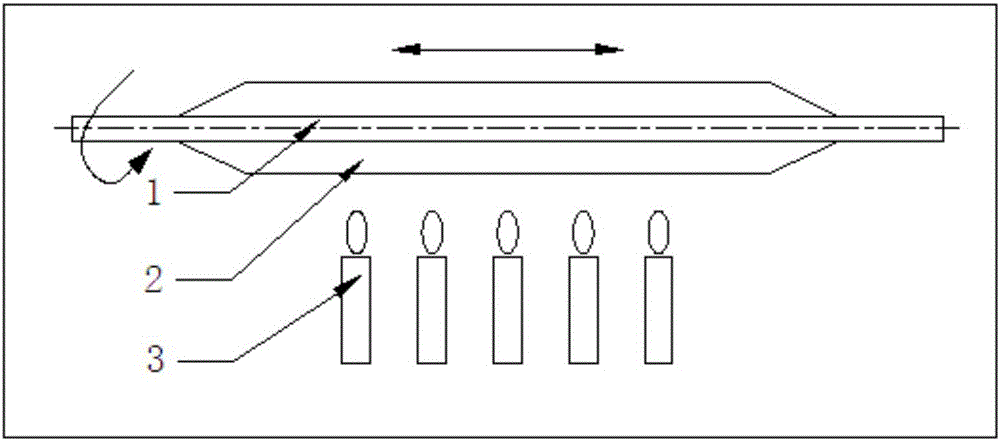

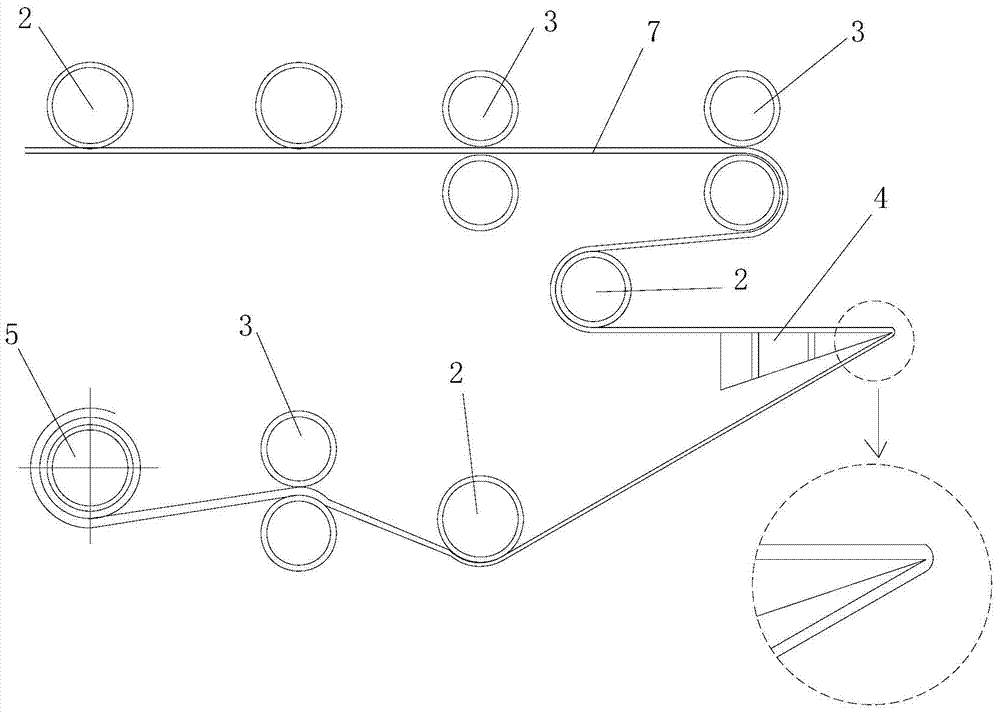

Label separating device of labeling machine

The invention discloses a label separating device of a labeling machine. The label separating device comprises a support, a plurality of material strap compression rollers, a plurality of guide roller groups, a label separating plate and a material strap recycling roll, wherein the support is provided with a fixed plate; the plurality of material strap compression rollers are arranged on the fixed plate at intervals; the plurality of guide roller groups are arranged on the fixed plate at intervals; the label separating plate is arranged on the end part at one side of the fixed plate; the longitudinal cross section of the label separating plate is a right triangle; the material strap recycling roll is arranged on the end part at the other side of the fixed plate opposite to the label separating plate. The label separating device is simple and compact in structure, and is small in size; a saltation corner is arranged at the conveying direction of a label trap at the front end of the label separation plate for label separation, so that labels and label straps are separated, the stripping speed of the labels and the label straps is improved greatly, and the stripping effect is ensured, thereby improving the labeling efficiency and quality of a non-dry sticker labeling machine.

Owner:苏州格林电子设备有限公司

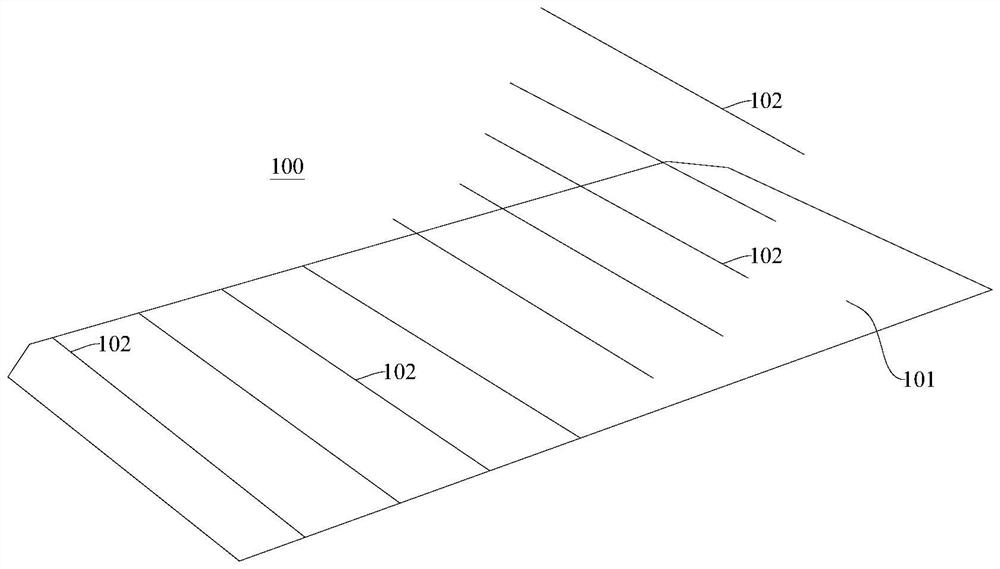

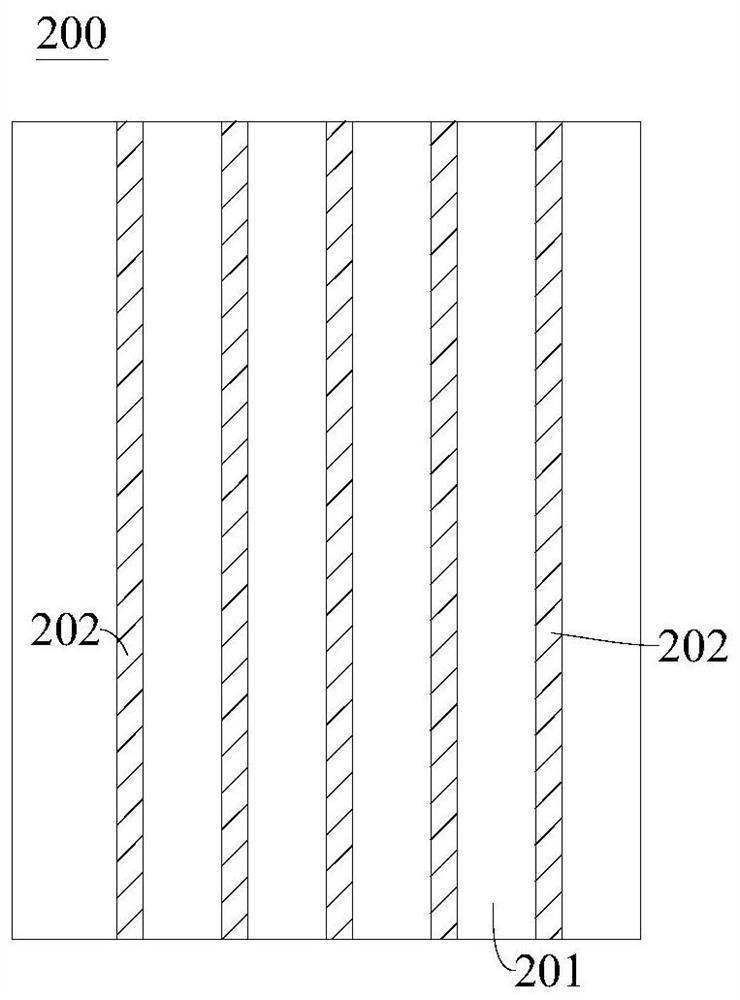

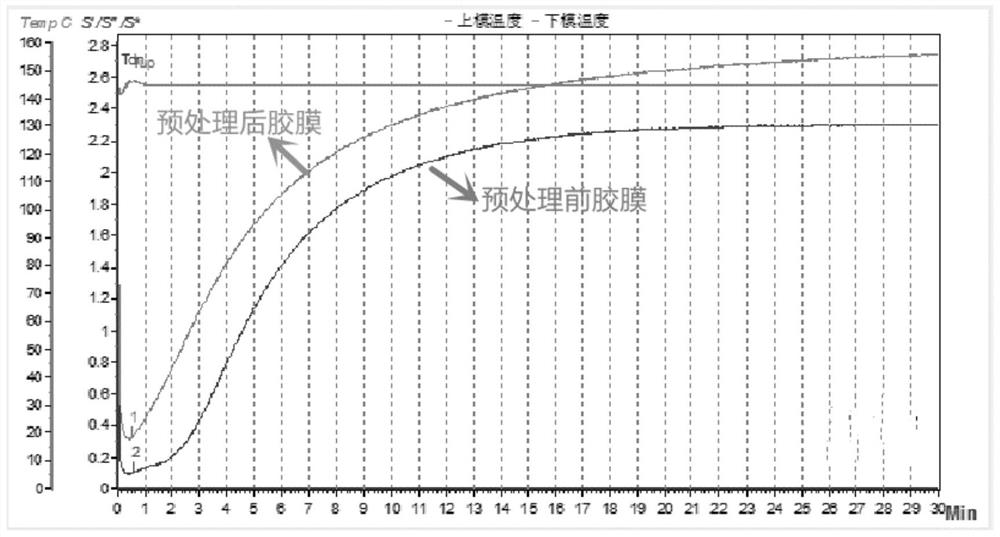

Monocell, packaging film, solar cell module and manufacturing method thereof

PendingCN113035986AStable electrical contactEliminates problems associated with welding operationsFinal product manufacturePhotovoltaic energy generationElectrical batteryPhysical chemistry

The invention discloses a single cell, a packaging film, a solar cell module and a manufacturing method thereof and belongs to the field of solar cells. The encapsulation film is a finished product of a hot melt material capable of cross-linking. The packaging film comprises a body part which is not crosslinked, and a pre-crosslinking part which is not completely crosslinked and is formed in a partial region in the body part. When the packaging film is heated, the fluidity of the pre-crosslinking part is smaller than that of the body part. By utilizing the packaging film, a problem caused by welding operation can be avoided, and meanwhile, a problem of deviation of metal wires on the surface of a battery in the assembly of the solar battery can also be avoided.

Owner:TONGWEI SOLAR HEFEI

Efficient wood peeling machine with cutting mechanism

InactiveCN113119260ASave equipment resourcesGuaranteed peeling effectTree debarkingElectric machineryIndustrial engineering

The invention discloses an efficient wood peeling machine with a cutting mechanism. The efficient wood peeling machine comprises a bottom plate, a first supporting plate and a second supporting plate are symmetrically and fixedly connected to the upper end of the bottom plate, a clamping plate is arranged between the first supporting plate and the second supporting plate in parallel, an axial displacement device is connected between the clamping plate and the bottom plate, the first supporting plate and the clamping plate are rotationally connected with a rotating rod and a circular plate correspondingly, the axis of the rotating rod coincides with the axis of the circular plate, the two ends of the rotating rod are coaxially and fixedly connected with a third gear and a first gear correspondingly, wood clamps are mounted on the opposite sides of the first gear and the circular plate correspondingly, to-be-peeled wood is jointly clamped between the two wood clamps, and a first motor is fixedly mounted on the side, facing the clamping plate, of the first supporting plate. Different types of to-be-peeled wood can be clamped, and the peeling quality is guaranteed under the condition that equipment resources are limited.

Owner:合创博远(北京)科技有限公司

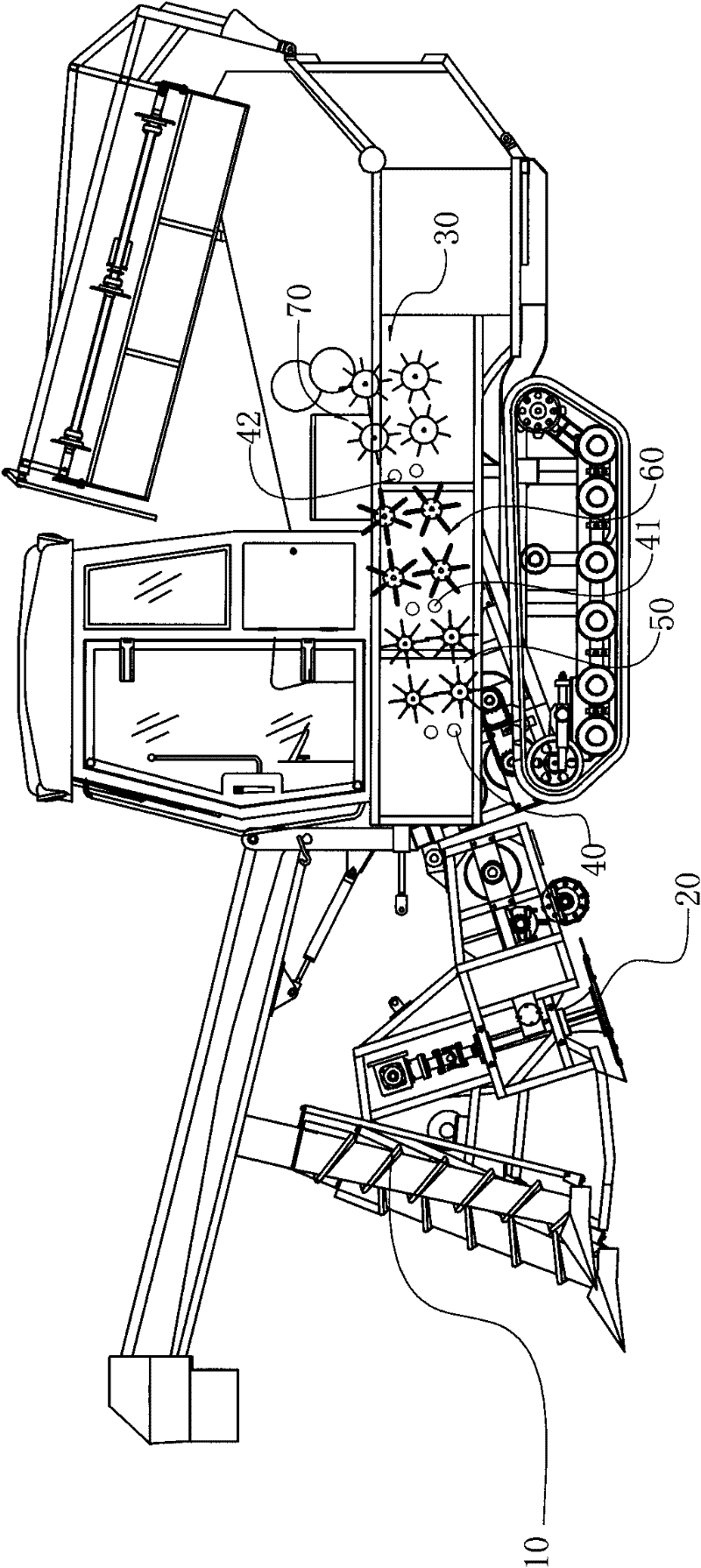

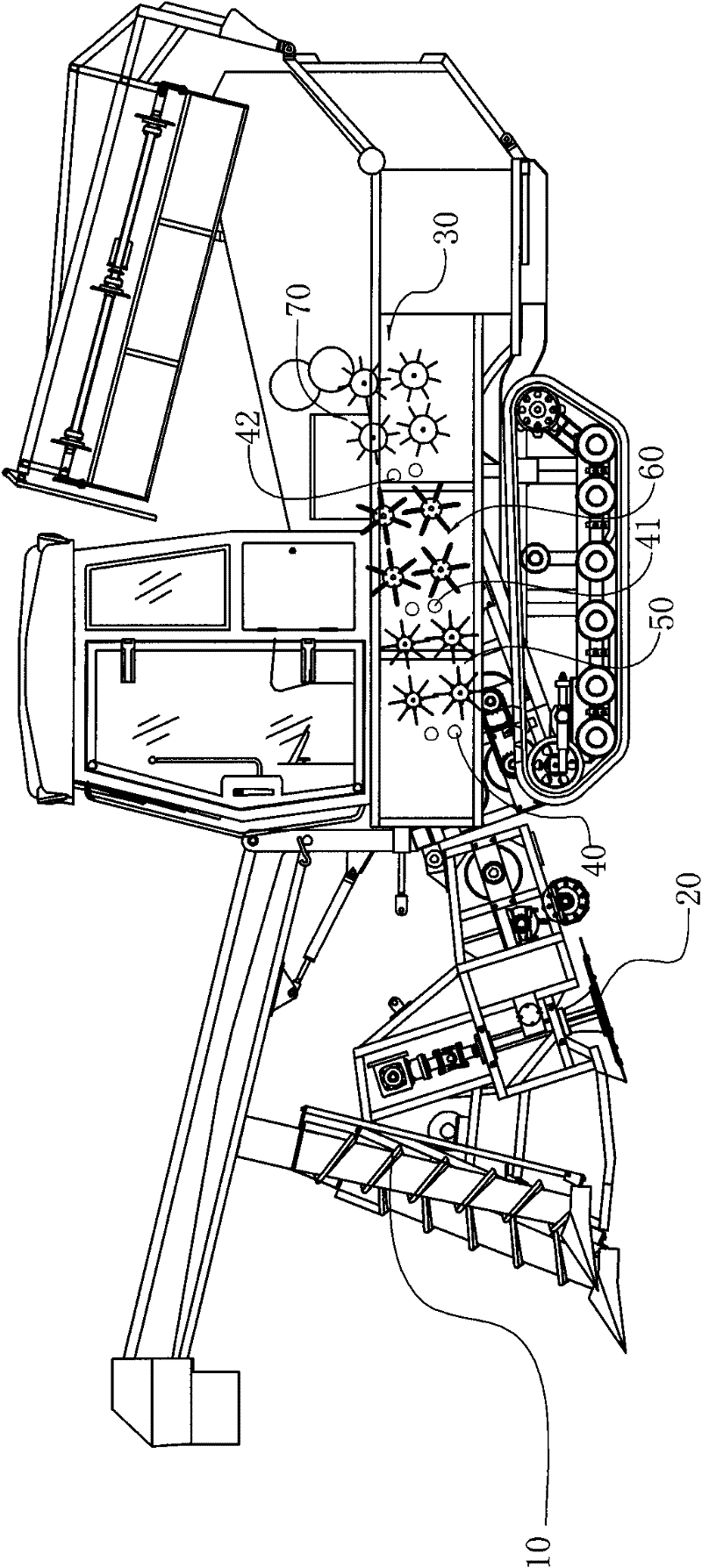

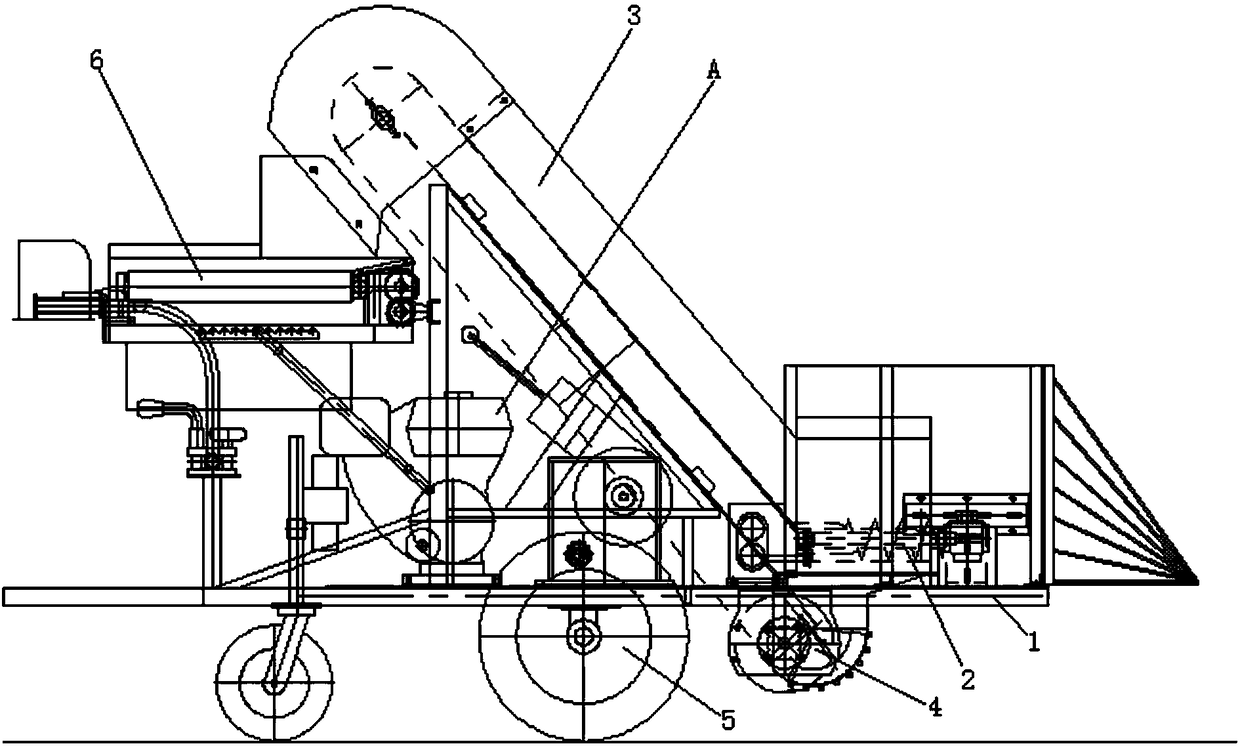

Corn harvesting machine

The invention discloses a corn harvesting machine. A spike picking mechanism is mounted at the front part of a stander, a straw crushing mechanism is arranged below the rear part of the spike pickingmechanism, a lifting mechanism is arranged on the left side of the rear part of the spike picking mechanism and is obliquely arranged in a front-low and rear-high manner, and a peeling mechanism is arranged below the rear part of a high end of the lifting mechanism; and a guiding plate is arranged between the spike picking mechanism and the lifting mechanism and is obliquely distributed in a left-low and right-high manner, a lower end of the guiding plate is supported by a top rod, and the top rod can alternately move up and down under the action of a driving mechanism. According to the corn harvesting machine, baby corns are guided into the lifting mechanism through an eccentric vibration device, so that a blocking phenomenon is effectively avoided; the corns are conveyed from a horizontal manner to a stereoscopic manner, so that the conveying is convenient and rapid; and meanwhile, the injury of the corns caused due to the contact with a spike picking roll can be prevented, and straws can be adequately and integrally crushed at a relatively low rotation speed. The corn harvesting machine is simple and compact in complete machine structure, occupies a small space and is beneficialto the development of a complete machine to the direction of miniaturization.

Owner:重庆市恒昌农具制造有限公司

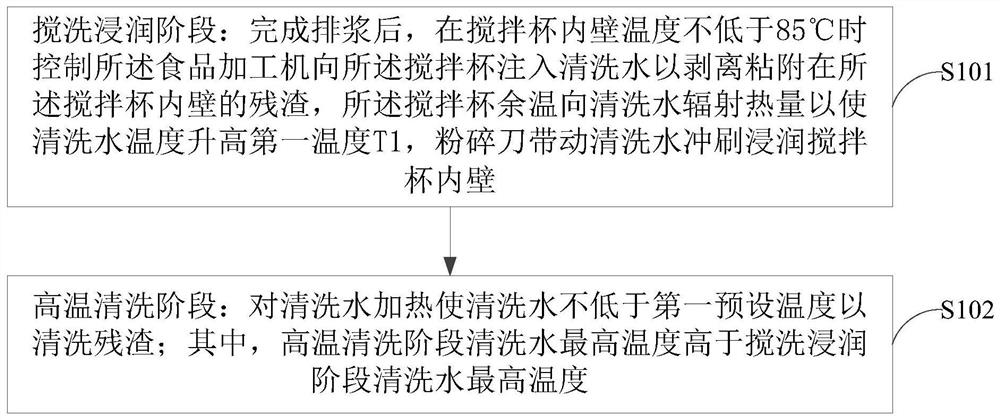

Self-cleaning method of food processor and food processor

PendingCN111802933AReduce impactPromote softeningKitchen equipmentElectric machineryProcess engineering

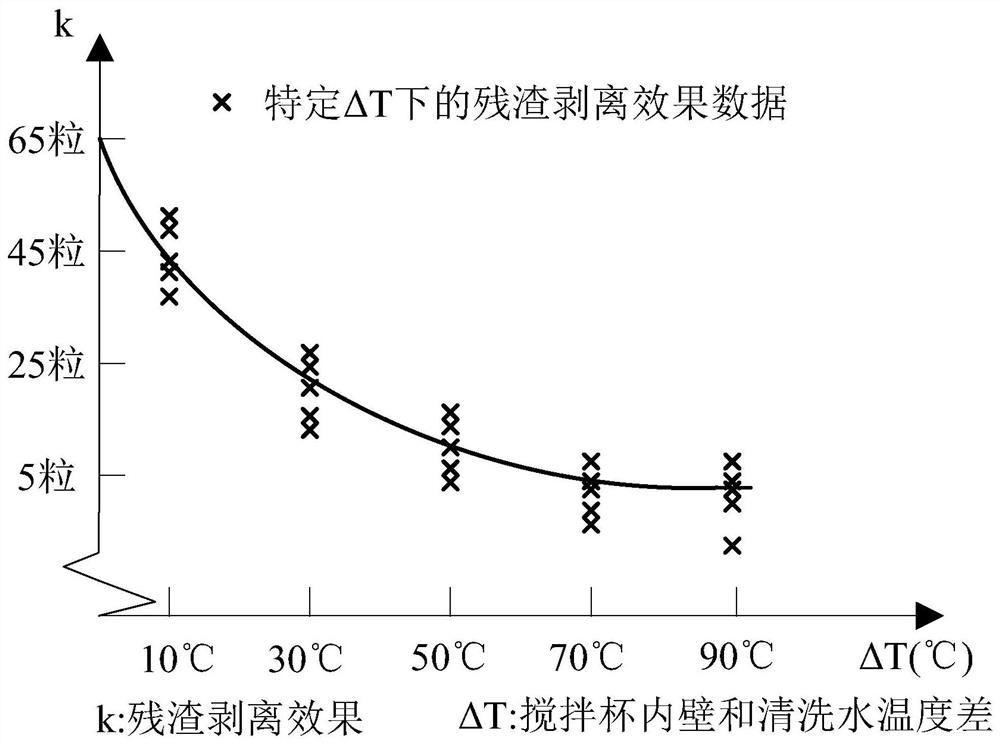

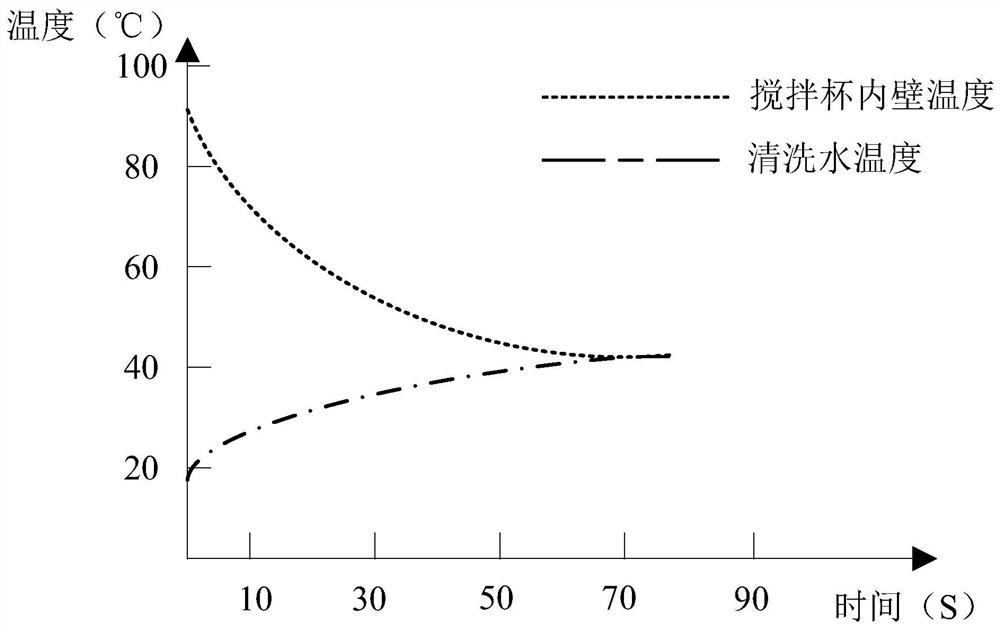

The invention provides a self-cleaning method of a food processor and the food processor. The food processor comprises a machine body, a stirring cup and a motor arranged on the machine body, the stirring cup comprises a cup body, a cup cover and a crushing knife driven by a motor, the self-cleaning method comprises the following steps: a stirring, washing and infiltrating stage: injecting cleaning water into a stirring cup to peel off residues adhered to the inner wall of the stirring cup when the temperature of the inner wall of the stirring cup is not lower than 85 DEG C after slurry discharge is completed, radiating heat to the cleaning water by the residual heat of the stirring cup to increase the temperature of the cleaning water by a first temperature, and driving the cleaning waterto wash and infiltrate the stirring cup, and a high-temperature cleaning stage: heating the cleaning water to enable the cleaning water to be not lower than a first preset temperature so as to cleanresidues. The highest temperature of cleaning water in the high-temperature cleaning stage is higher than that of cleaning water in the stirring-washing infiltration stage. According to the method, residues can be easily peeled off from the inner wall of the cup body or the inner wall of the cup cover, and therefore the good cleaning effect is achieved.

Owner:JOYOUNG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com