Patents

Literature

51results about How to "Will not damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

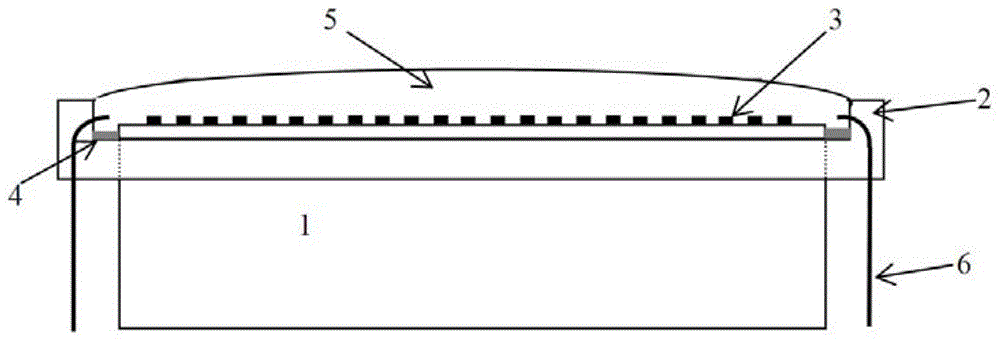

LED (Light Emitting Diode) lamp filament and manufacturing method thereof

ActiveCN104600174AImprove thermal reliabilityMaximum Thermal ReliabilitySemiconductor devicesFluorescenceConductive coating

The invention provides an LED (Light Emitting Diode) lamp filament and a manufacturing method thereof. An LED chip is encapsulated on the edge top surface of a thin and long sheet metal support of the LED filament innovatively, meanwhile the sheet metal is inserted into a preformed transparent plastic model frame to produce a light source, and accordingly the automated continuous production of the LED lamp filament is implemented and the problem of the facing direction strength caused by the too thin and too long metal support is solved due to the transparent plastic model frame; meanwhile the lateral direction strength of the metal support is effectively utilized and accordingly the integral mechanical strength of the LED lamp filament is ensured; the heat dissipation characteristics of the metal is directly utilized, meanwhile the heat dissipation efficiency of the LED chip is maximized through the innovative encapsulation of thermal conductive coatings, and accordingly the problem of a heat dissipation bottleneck of the LED lamp filament is effectively solved, the LED lamp filament can work at the rated power for a long time, and the cost is reduced; the LED light extraction efficiency is improved, the light attenuation is reduced, the high lighting effect and ambient light of lamp filament light emission is implemented, and the market vacancy of the existing LED lamp filament is filled through innovative fluorescence encapsulation materials.

Owner:DONGGUAN RIWEI ELECTRONICS

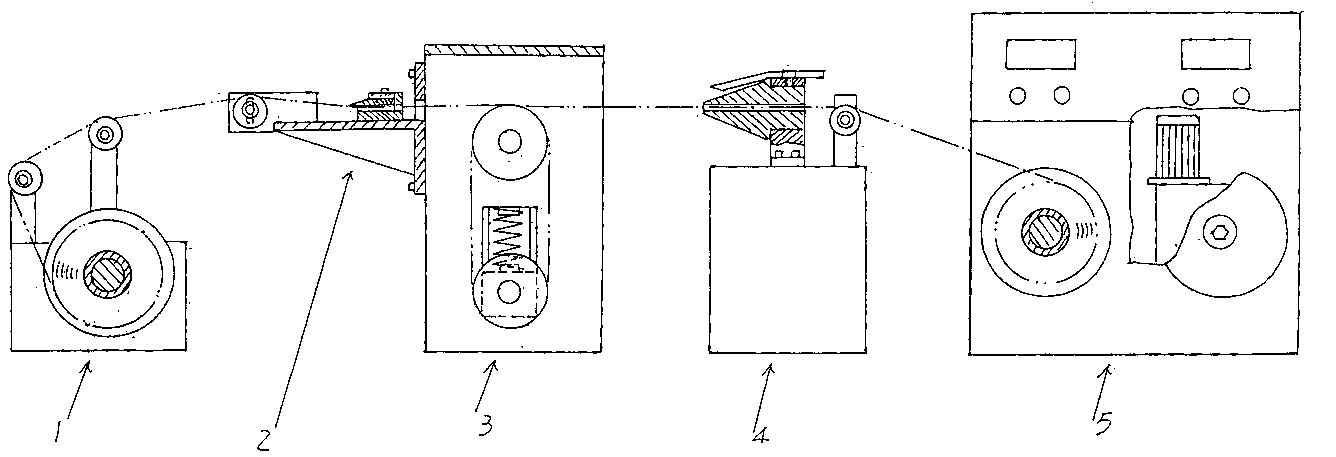

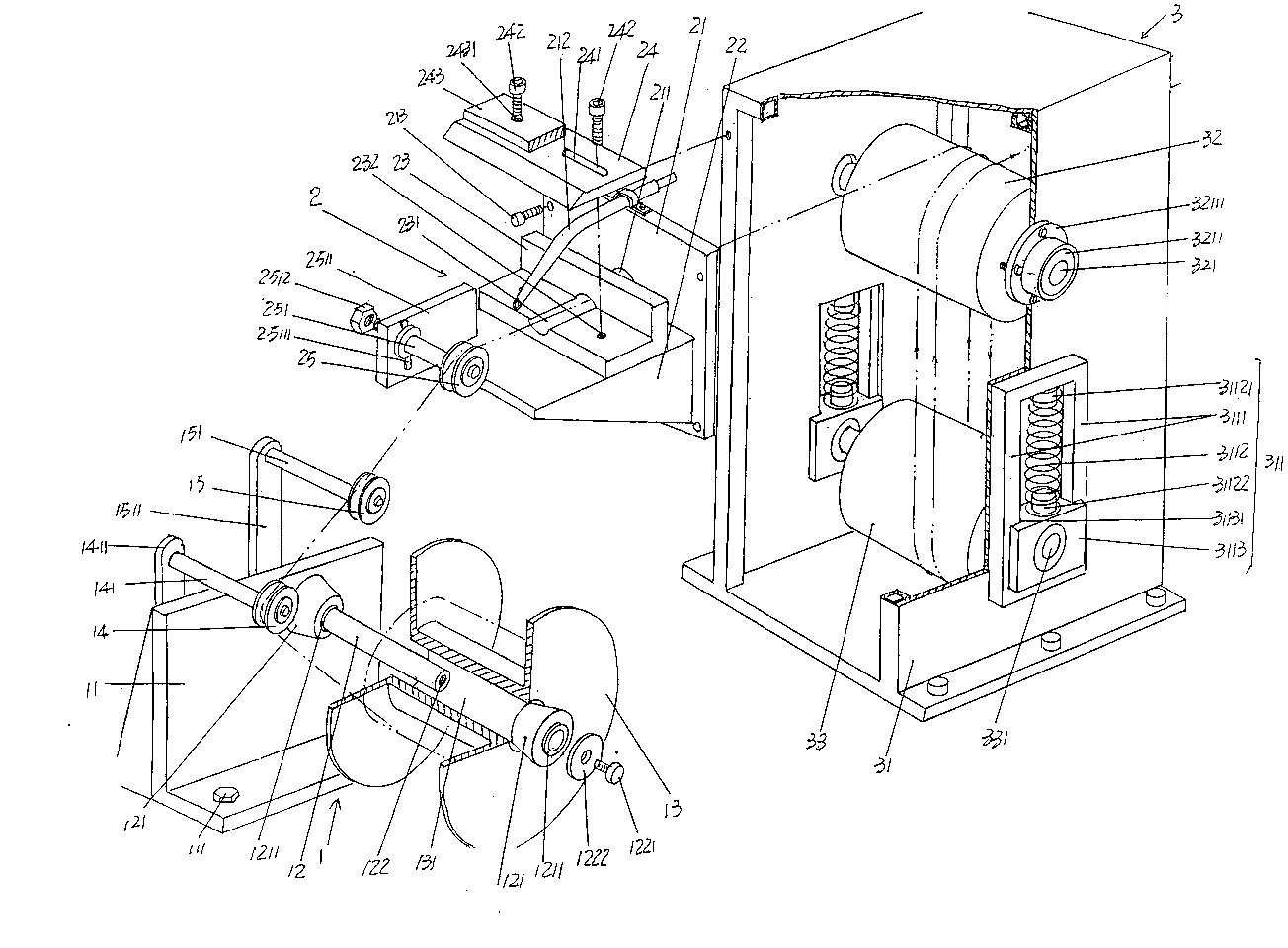

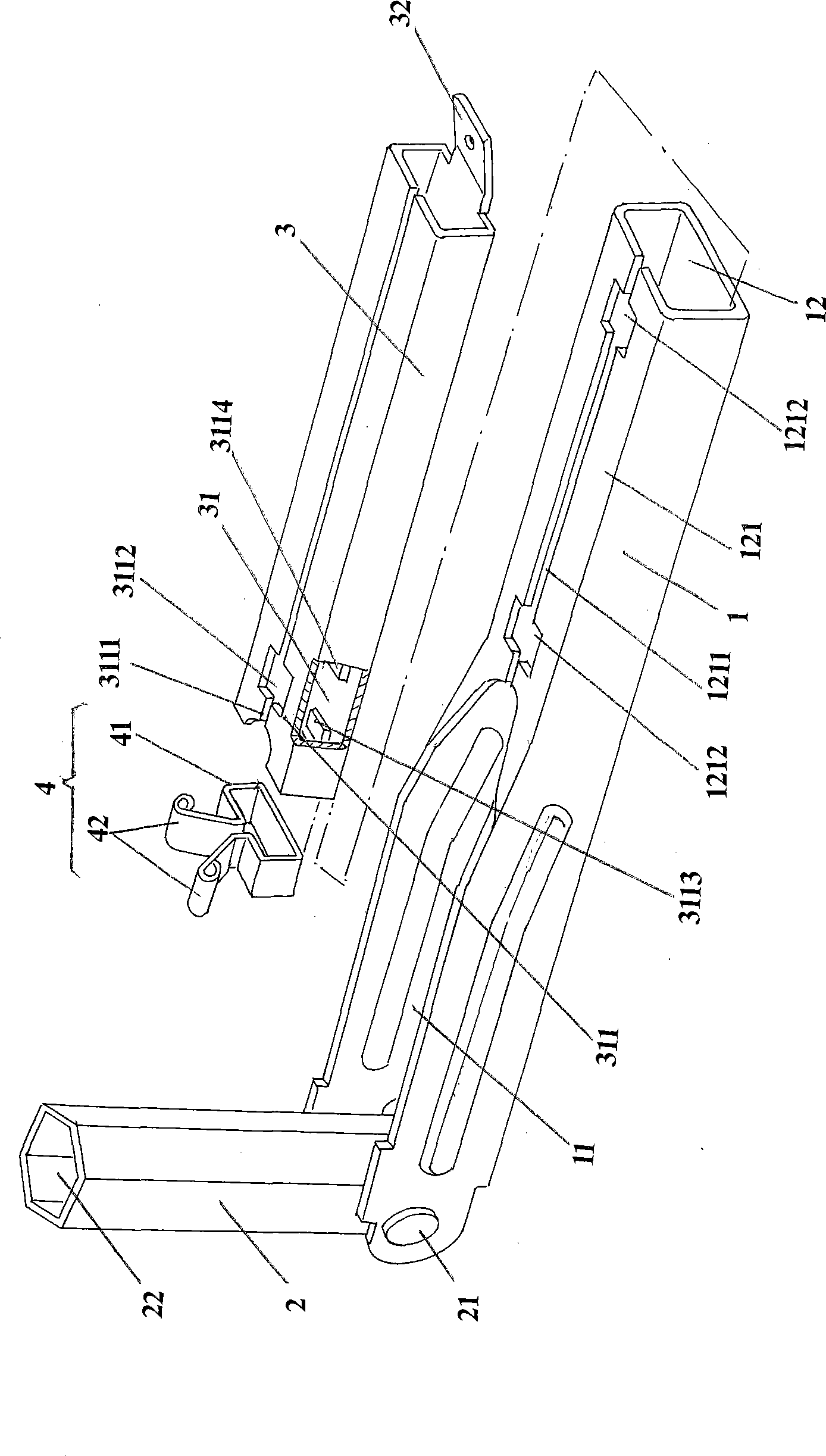

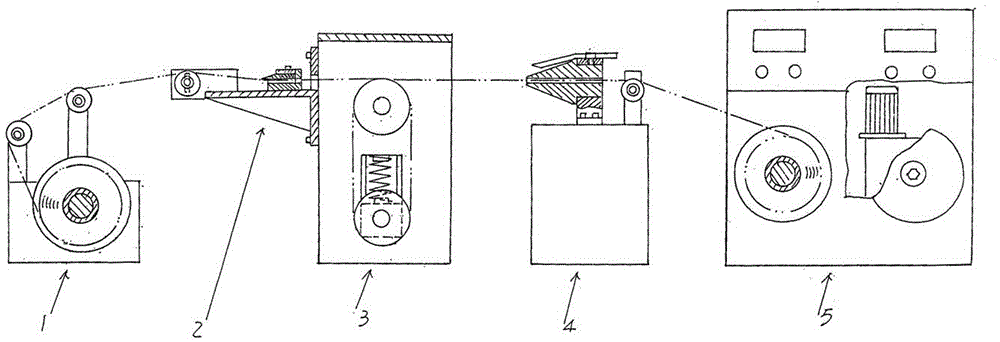

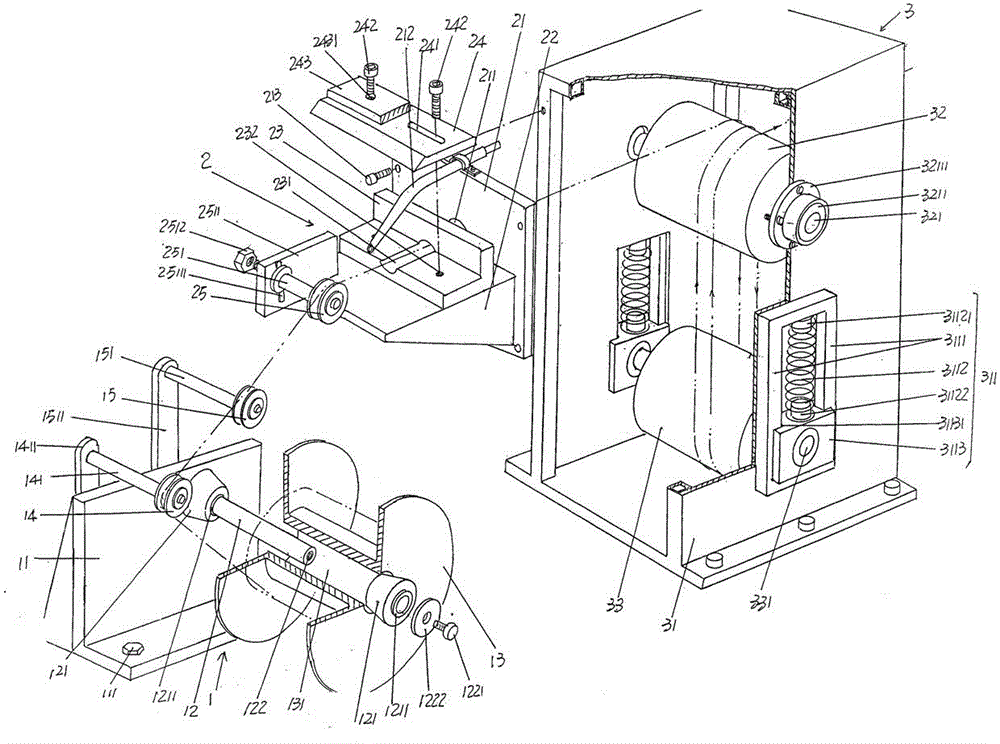

Waste wire stripping device

ActiveCN103259221AGuaranteed peeling effectExtended service lifeApparatus for removing/armouring cablesEngineeringWheel and axle

The invention discloses a waste wire stripping device, and belongs the technical field of recovery devices of waste materials. The waste wire stripping device comprises a paying-off mechanism, a paring mechanism, a tension automatic adjustment mechanism, a peeling mechanism and a wire core winding mechanism, wherein the paring mechanism is arranged on one side of the tension automatic adjustment mechanism, the peeling mechanism is located between the tension automatic adjustment mechanism and the wire core winding mechanism, the paring mechanism comprises a fixed plate, a paring knife fixing base supporting arm, a paring knife fixing base, a paring knife and a guiding wheel, the fixed plate is fixed with one side of the tension automatic adjustment mechanism, a wire passing hole is formed in the fixed plate, the paring knife fixing base supporting arm is fixed with one side of the fixed plate, a wire passing groove is formed in one side of the paring knife fixing base, two ends of the paring knife are respectively provided with a paring knife adjustment groove, the guiding wheel is arranged on a guiding wheel shaft, the guiding wheel shaft is fixed on a guiding wheel shaft base, and the guiding wheel shaft base is fixed on the paring knife fixing base supporting arm. The waste wire stripping device is ideal in stripping effect, free of damage to the guiding wheel caused by friction, long in service life and low in knife cost, and ensures a paring effect.

Owner:CHANGSHU HONGLIN WIRE & CABLE CO LTD

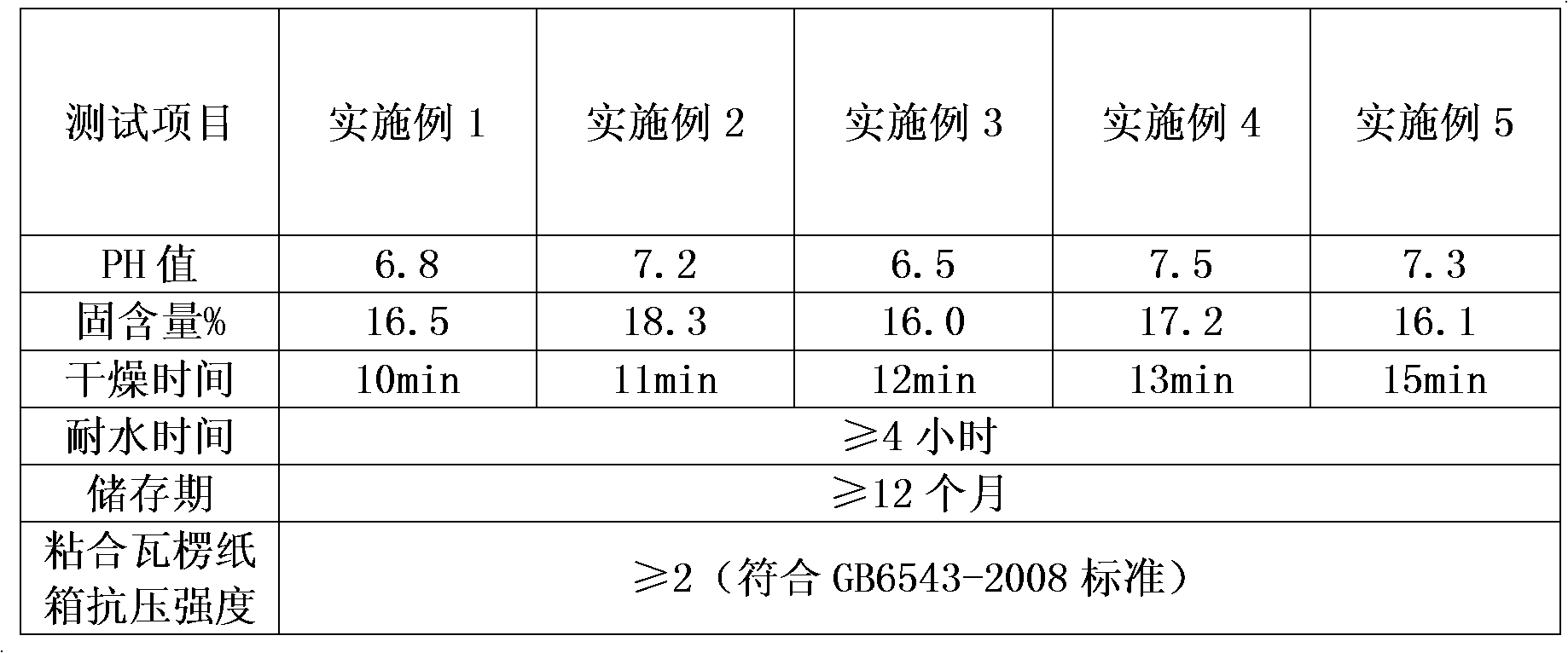

Preparation method of starch adhesive for adhering cartons

InactiveCN102433084AWill not damageStable storageNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveDrying time

The invention discloses a preparation method of a starch adhesive for adhering cartons, which belongs to the technical field of adhesive preparation, and comprises: adding 450 to 600 weight parts of water and 100 weight parts of starch into a reaction kettle; uniformly stirring, and adding 3 to 8 weight parts of hydrogen peroxide; reacting for 0.5 to 1 hour, and slowing adding 5 to 12 weight parts of aqueous solution of sodium hydroxide; stirring and reacting for 110 to 130 minutes, adding 0.2 to 0.8 weight part of crosslinking agent, 0.01 to 0.05 weight part of ferrous sulfate, 9 to 16 weight parts of water-proof agent, 10 to 20 weight parts of catalyst, 0.2 to 1.2 weight parts of tackifier, 0.05 to 0. 1 weight part of preservative, 15 to 18 weight parts of quick drying agent, and 0.5 to 1 weight part of tributyl phosphate in turn; stirring and reacting for 55 to 65 minutes; and obtaining the starch adhesive for adhering cartons. The method has the advantages that: the starch adhesive is stable in storage and is environment-friendly; the drying time is short, and the water-proof time is long; and the starch adhesive meets national standards.

Owner:CHANGSHU KAILIDA HONEYCOMB PACKING MATERIALS

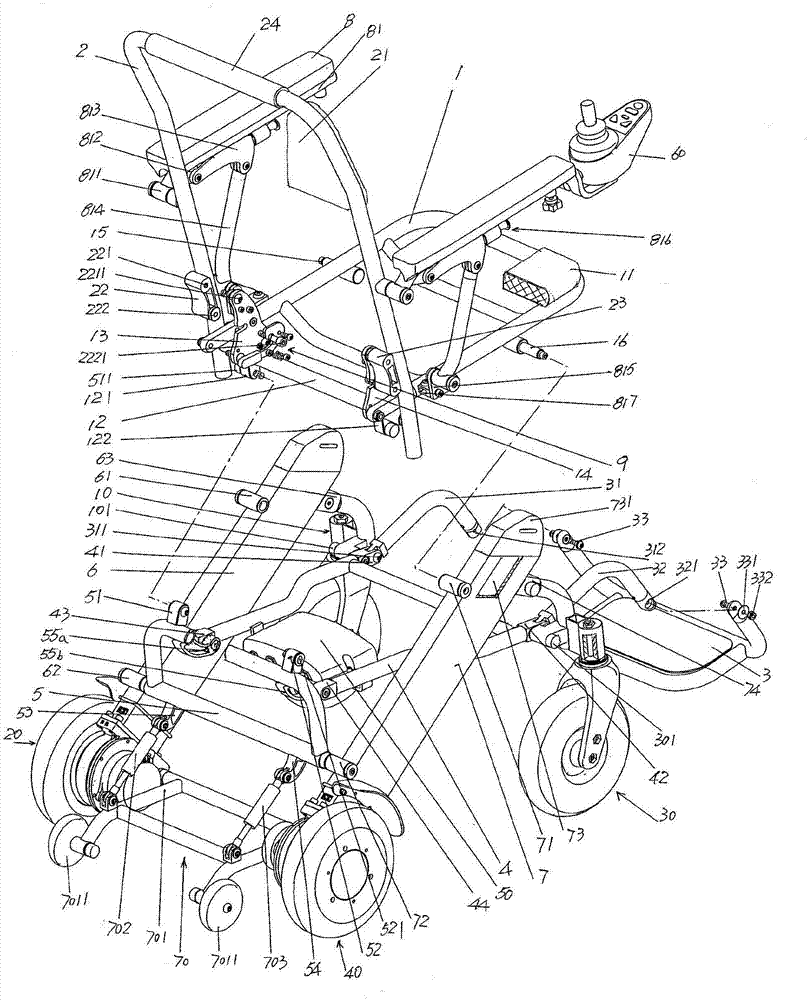

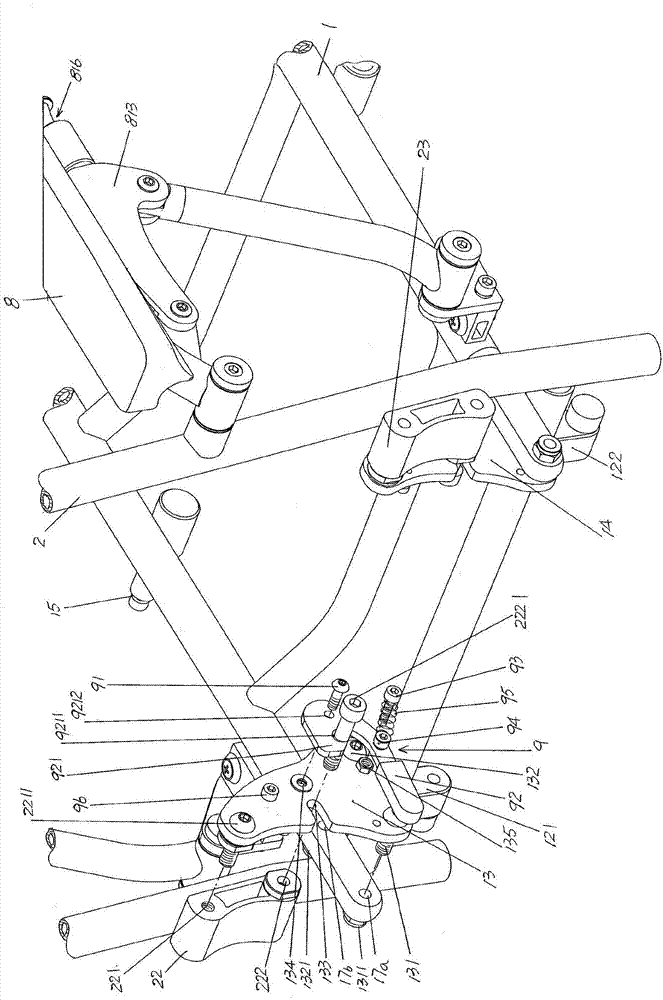

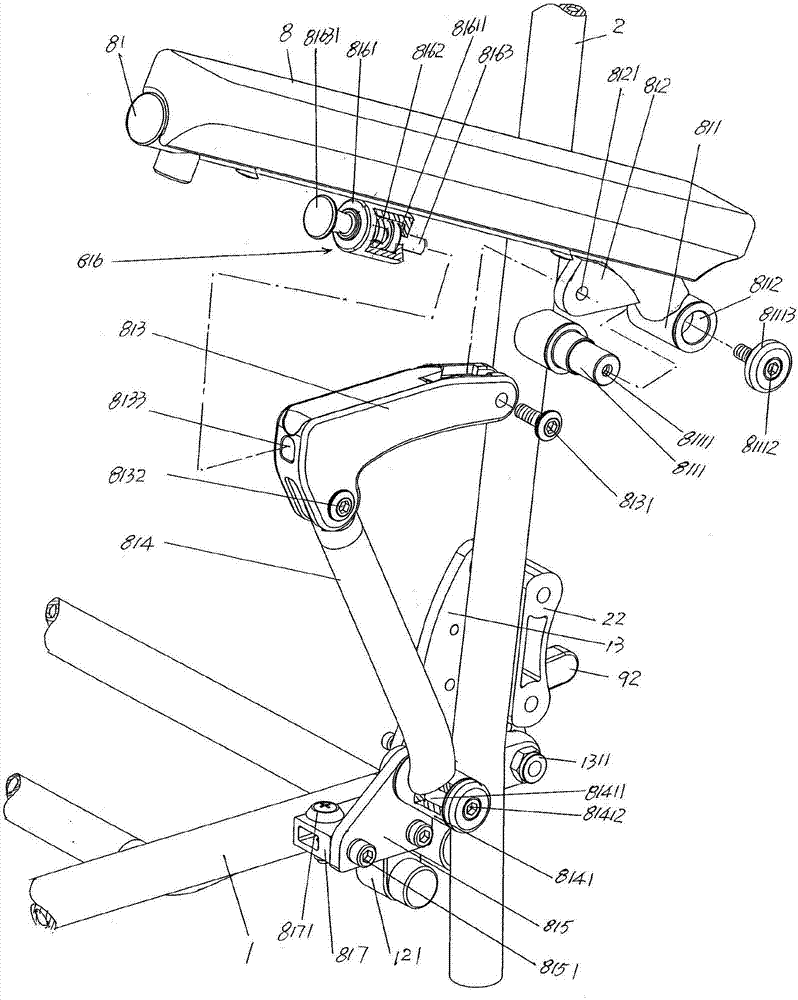

Folding electric wheelchair vehicle

ActiveCN107468438AReasonable lockReliable lockingWheelchairs/patient conveyanceWheelchairVehicle frame

Provided is a folding electric wheelchair vehicle. The folding electric wheelchair vehicle comprises a chair seat frame, a chair back frame and a pair of armrests, wherein a pedal is hinged to the rear end of a vehicle frame, the front end of the vehicle frame is hinged to a reversing frame, and one side of the upper end of a left battery box is provided with a first walking wheel assembly; the lower end of the left battery box is provided with a first driving wheel assembly, one side of the upper end of a right battery box is provided with a second walking wheel assembly, and the lower end of the right battery box is provided with a second driving wheel assembly; one of the armrests is provided with a remote controller. The folding electric wheelchair is characterized in that the front end of the chair seat frame is provided with a front horizontal pipe of the chair seat frame, and the chair seat frame is provided with a left hook plate seat and a right hook plate seat; the lower parts of the left and right side of the chair back frame are provided with a left hinge seat and a right hinge seat of the chair back frame, and one side of the left or right hook plate seat is provide with a snap mechanism; the side, facing upward, of the left battery box is supported through the middle of the left side of the chair seat frame, and the side, facing upward, of the right battery box is supported through the middle of the right side of the chair seat frame; the upper part of the reversing frame is hinged to the front horizontal pipe of the chair seat frame, and the lower part of the reversing frame is hinged to the sides, facing upward, of the lower parts of the left and right battery boxes. According to the folding electric wheelchair vehicle, the structure is simplified, the security is ensured, and unlocking and storing are convenient; no damage is caused to the left and right battery boxes, feet are comfortable on the wheelchair, and tipping is avoided.

Owner:CHANGSHU PINGFANG WHEELCHAIR CO LTD

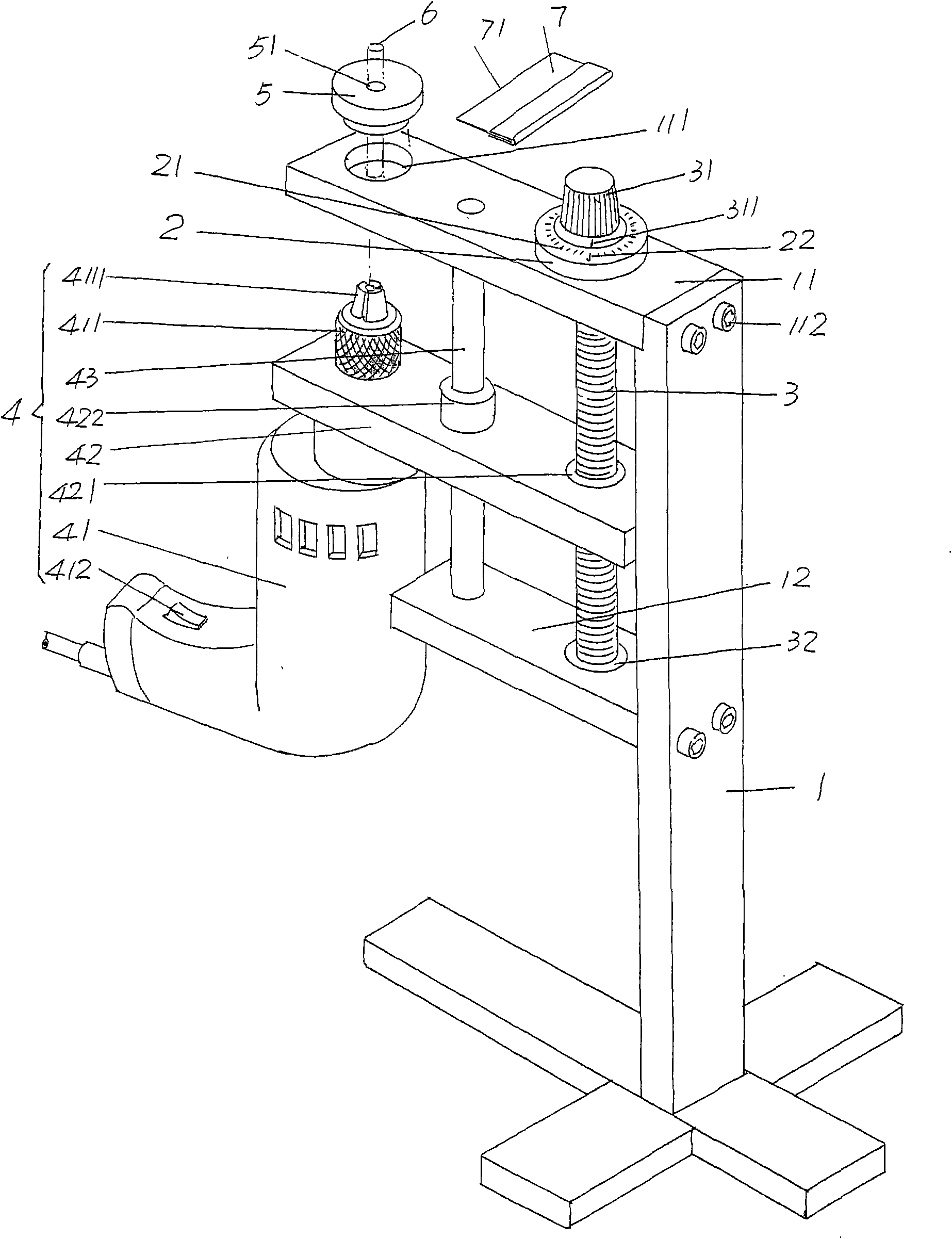

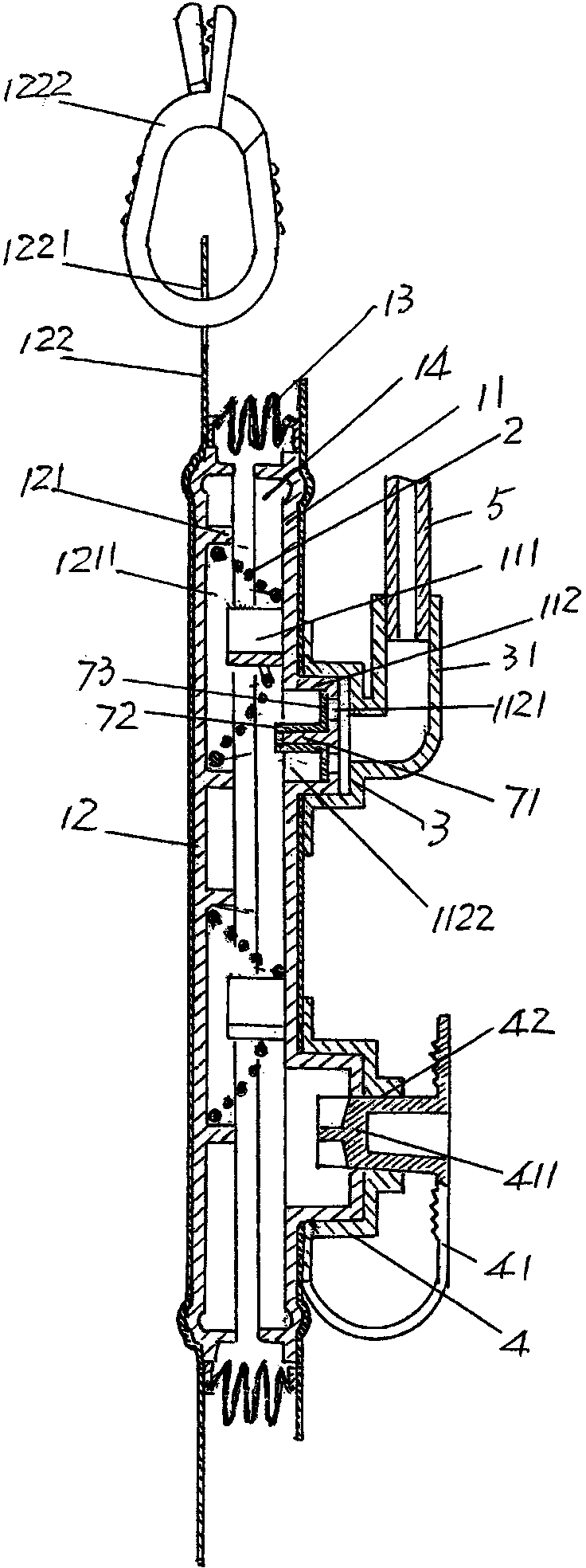

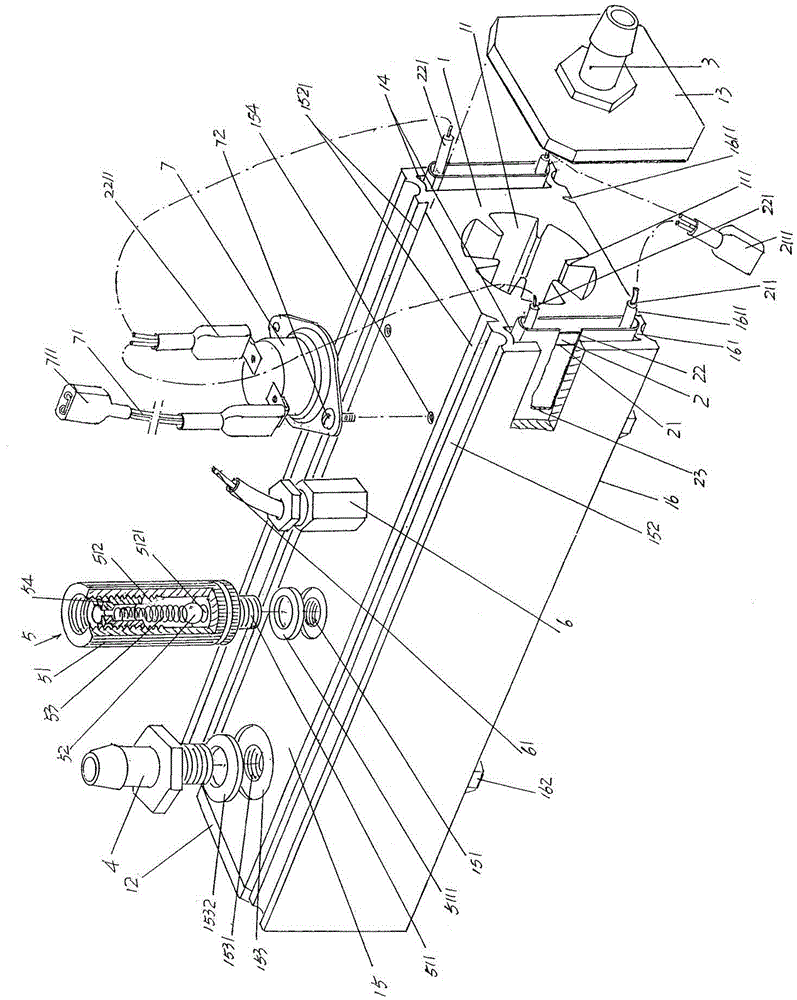

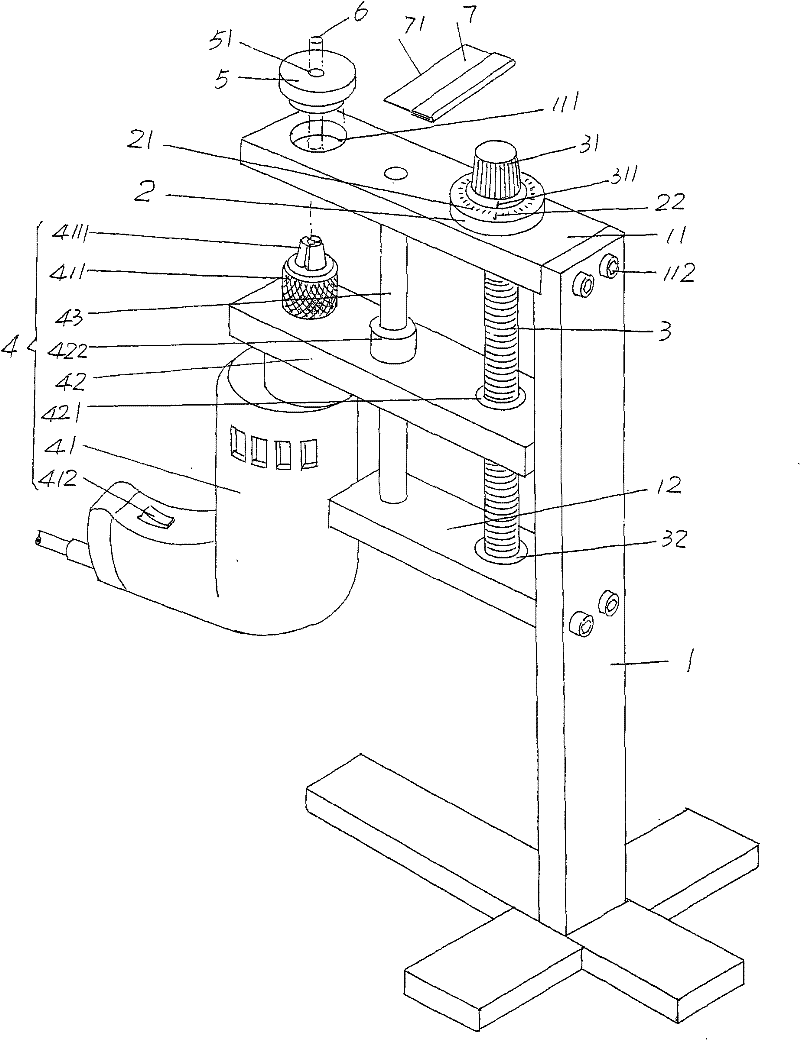

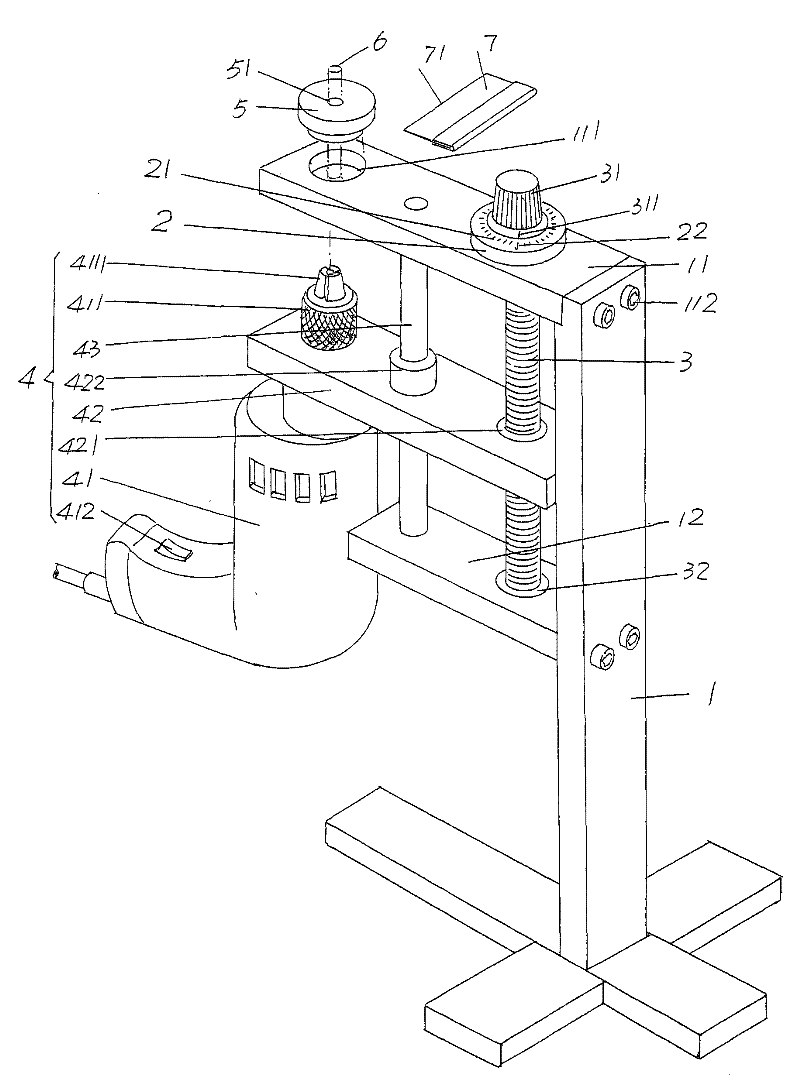

Cable foaming insulation layer sampling device

ActiveCN101598636AWill not damageConsistent and flat thicknessWithdrawing sample devicesInsulation layerEngineering

The invention relates to a cable foaming insulation layer sampling device, and belongs to the technical field of special devices for sampling wires and cables, which comprises a bracket, a dial, a screw, a cable catching mechanism and a cable die sleeve, wherein a first suspension plate and a second suspension plate are fixed on the bracket, the first suspension plate is positioned on the upper part of the bracket, while the second suspension plate is correspondingly arranged below the first suspension plate; the dial is provided with scale reticules and fixed at one end of the first suspension plate, and the other end of the first suspension is provided with a die sleeve positioning hole; the upper end of the screw passes through the center of the dial and fixed with a knob, the lower end of the screw is supported on the second suspension plate, and the knob is provided with an indicating mark; the cable catching mechanism is connected to the screw; and the cable die sleeve is arranged in the die sleeve positioning hole. The device has the advantages that: the whole sampling process does not damage a foaming insulation layer and a wire core; the device can ensure consistency and smoothness of the thicknesses of the measured foaming insulation layer; and the device provides guarantee for the correct detection of detecting devices.

Owner:JIANGSU ZHONGLI GRP CO LTD +4

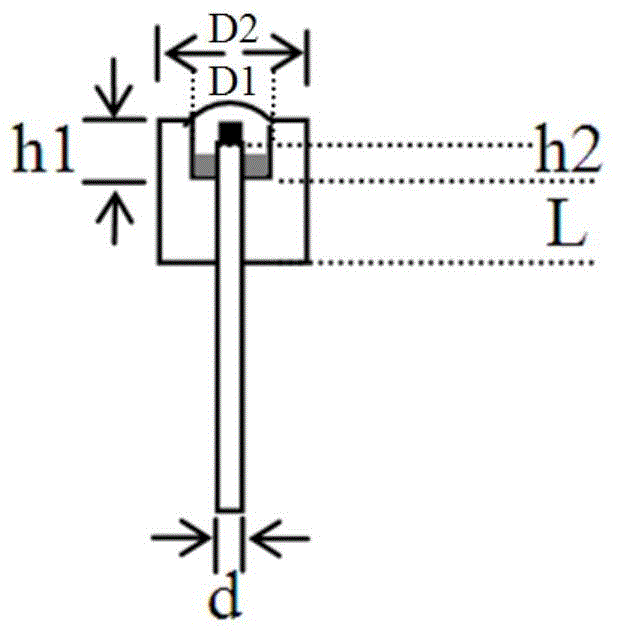

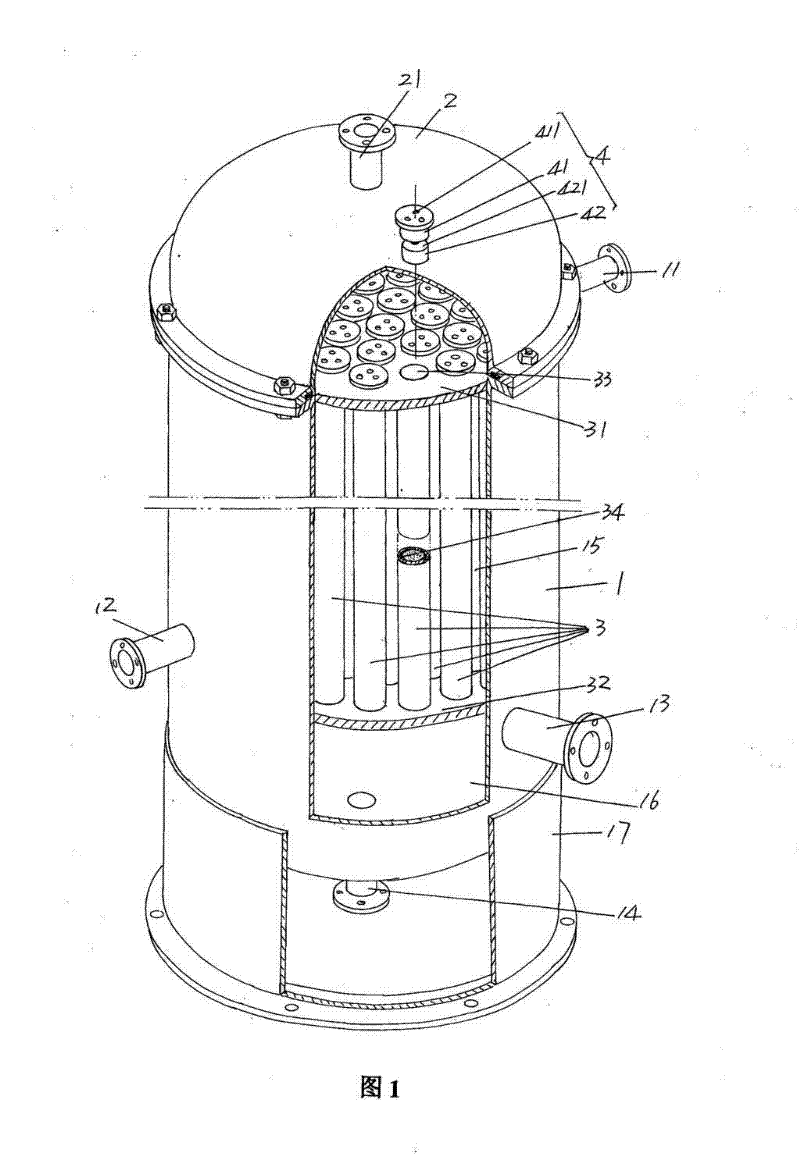

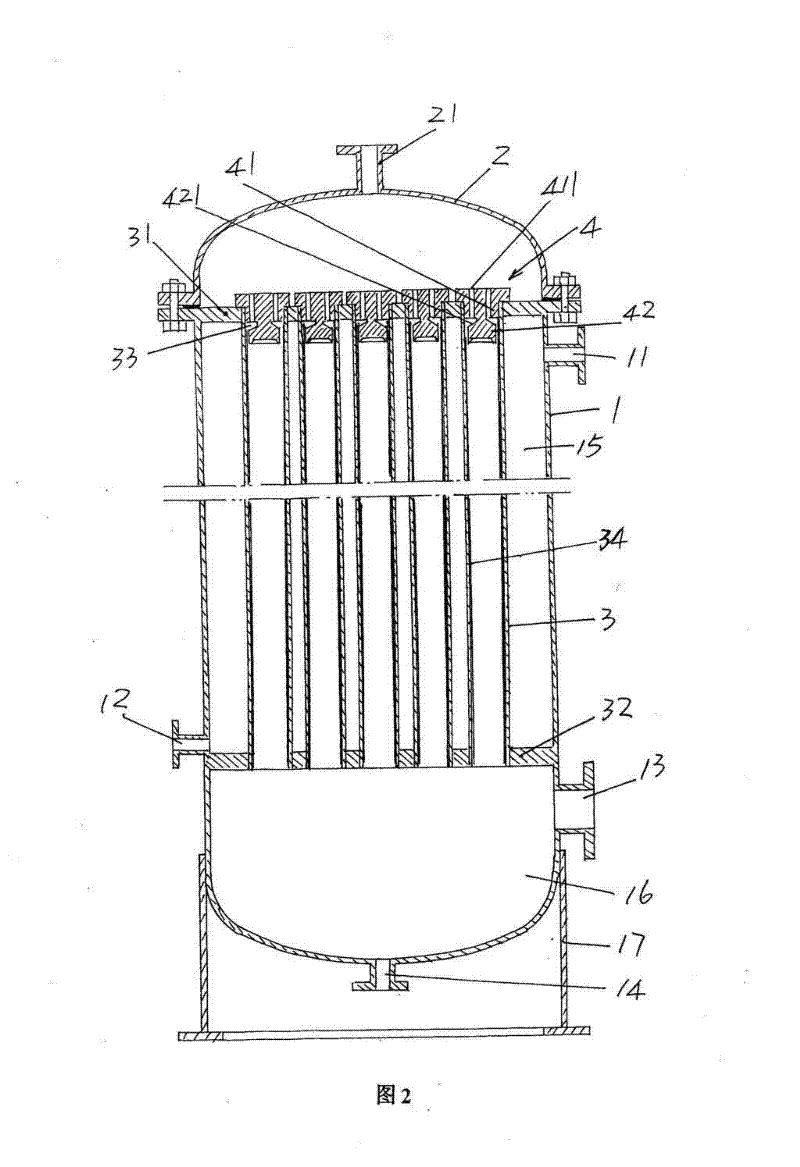

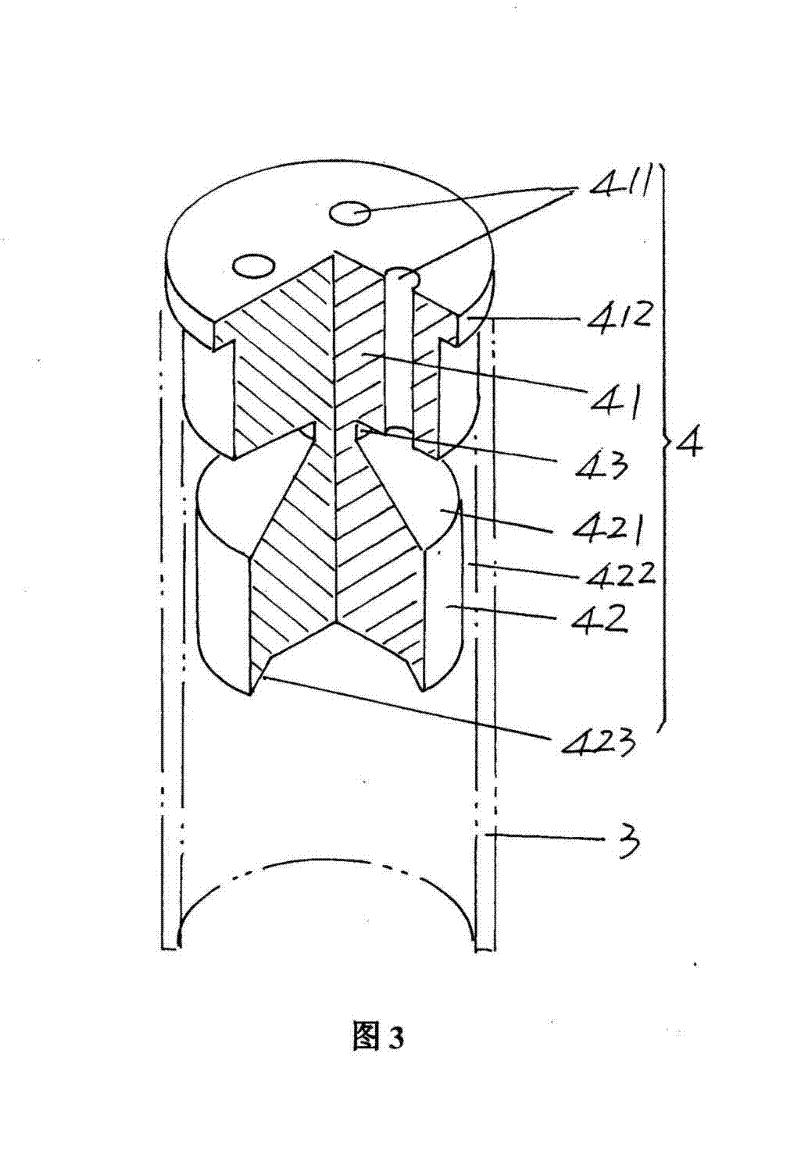

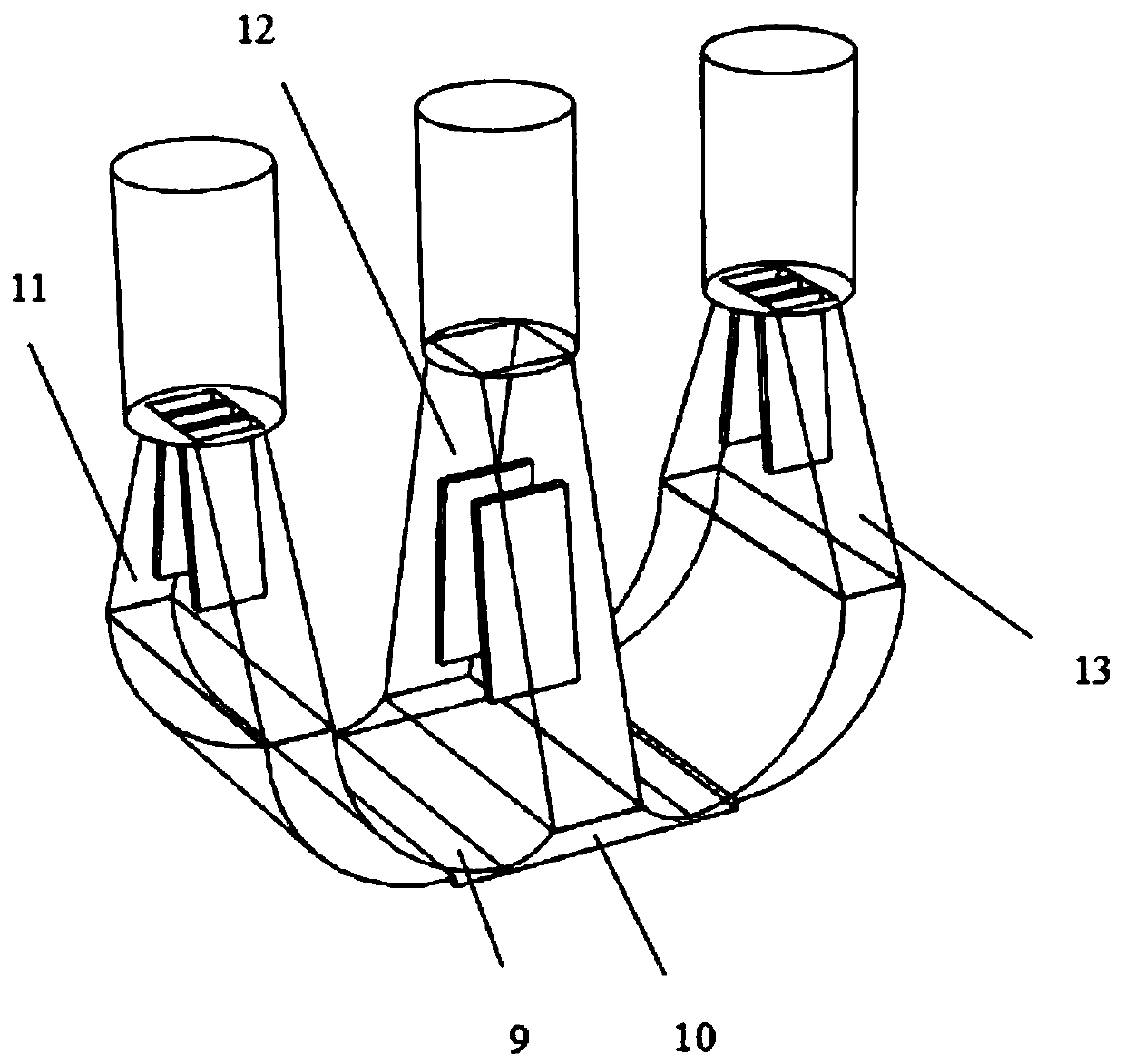

Shell and Tube Falling Film Evaporator

A shell-and-tube falling film evaporator belongs to the technical field of biomedicine and chemical equipment. It includes a tank body equipped with a steam inlet port, a steam condensate outlet port, a secondary steam outlet port and a concentrated liquid outlet port, a tank cover arranged on the upper part of the tank body, a set of falling film evaporation tubes arranged in the tank body and configuration The liquid distributor at the mouth of each falling film evaporation tube is characterized by: the liquid distributor includes the first and second column sections, a set of liquid distribution holes is opened on the first column section, and a set of liquid distribution holes is opened on the second column section. A liquid guide slope is formed on one end of the section, the diameter of the second column section is smaller than that of the first column section, and the flange edge of the liquid distributor is expanded on the edge of the top of the first column section, and the liquid distributor The flange edge is matched with the nozzle of the falling film evaporation tube, and there is a liquid gap between the second column section and the inner wall of the evaporation tube of the falling film evaporation tube. Advantages: It can ensure the uniformity of the liquid film to improve the evaporation effect of the evaporating tube; it will not damage the evaporating tube, and the connection between the entire liquid distributor and the evaporating tube is very convenient.

Owner:常熟市龙宇化工设备有限公司

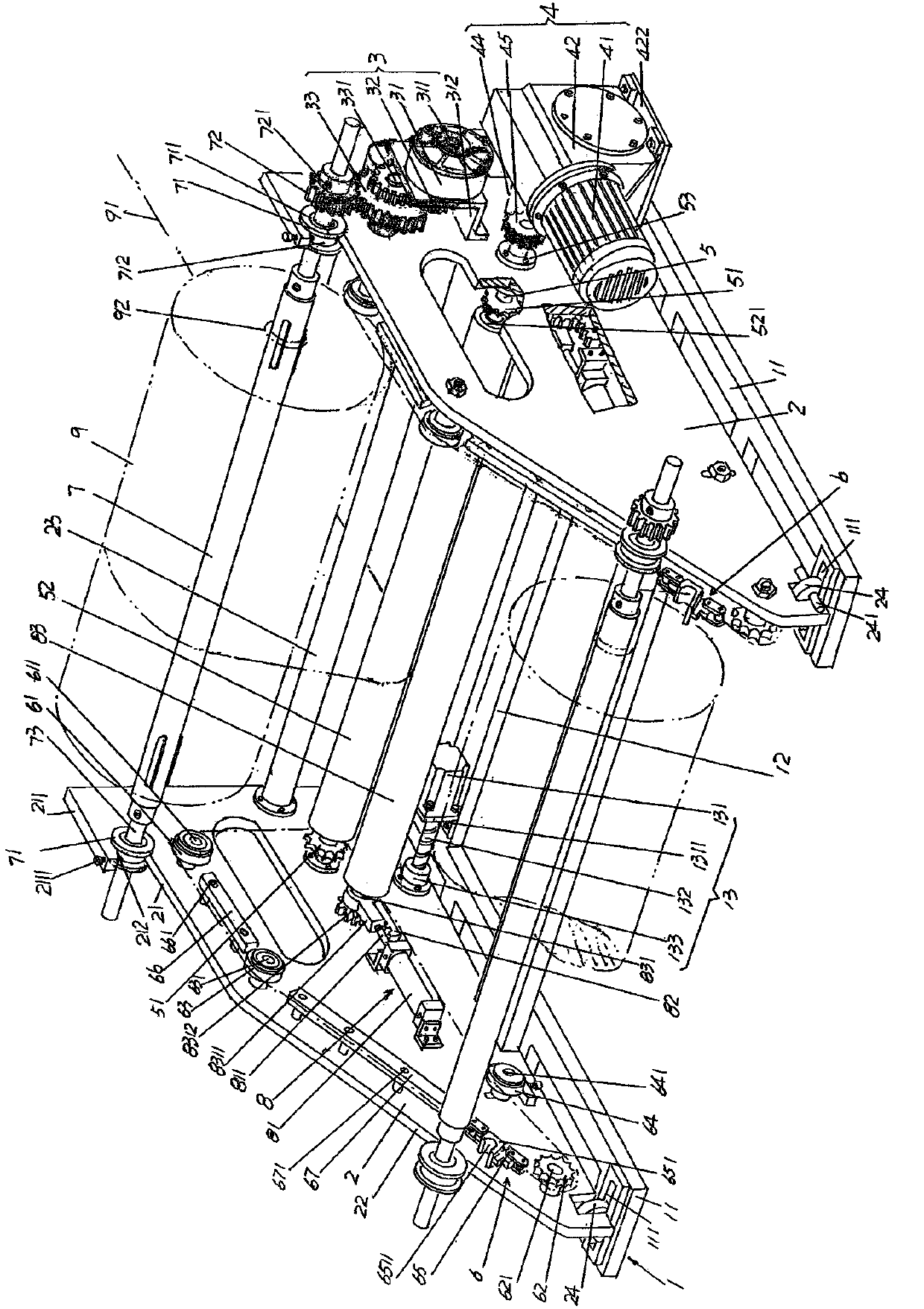

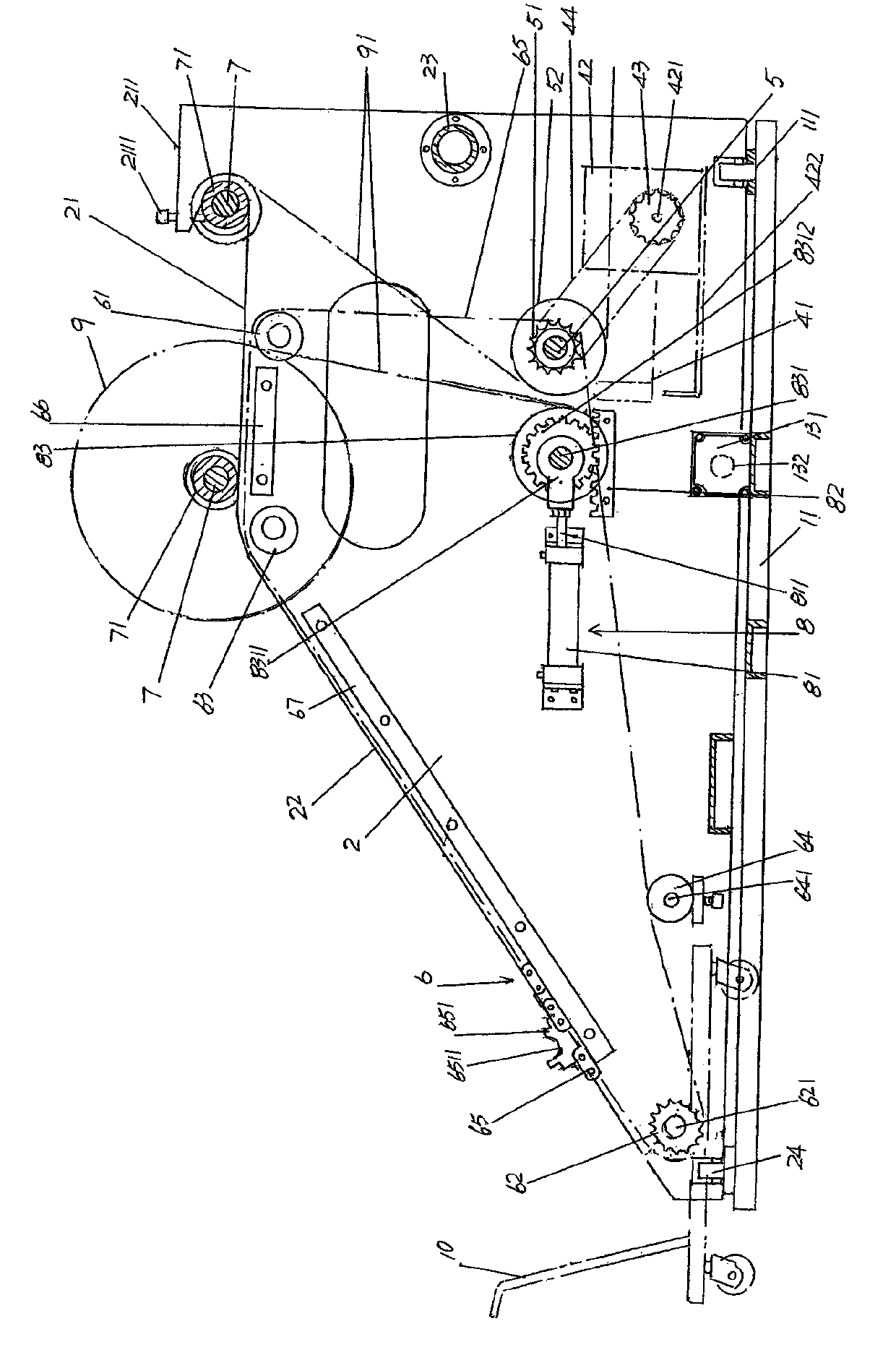

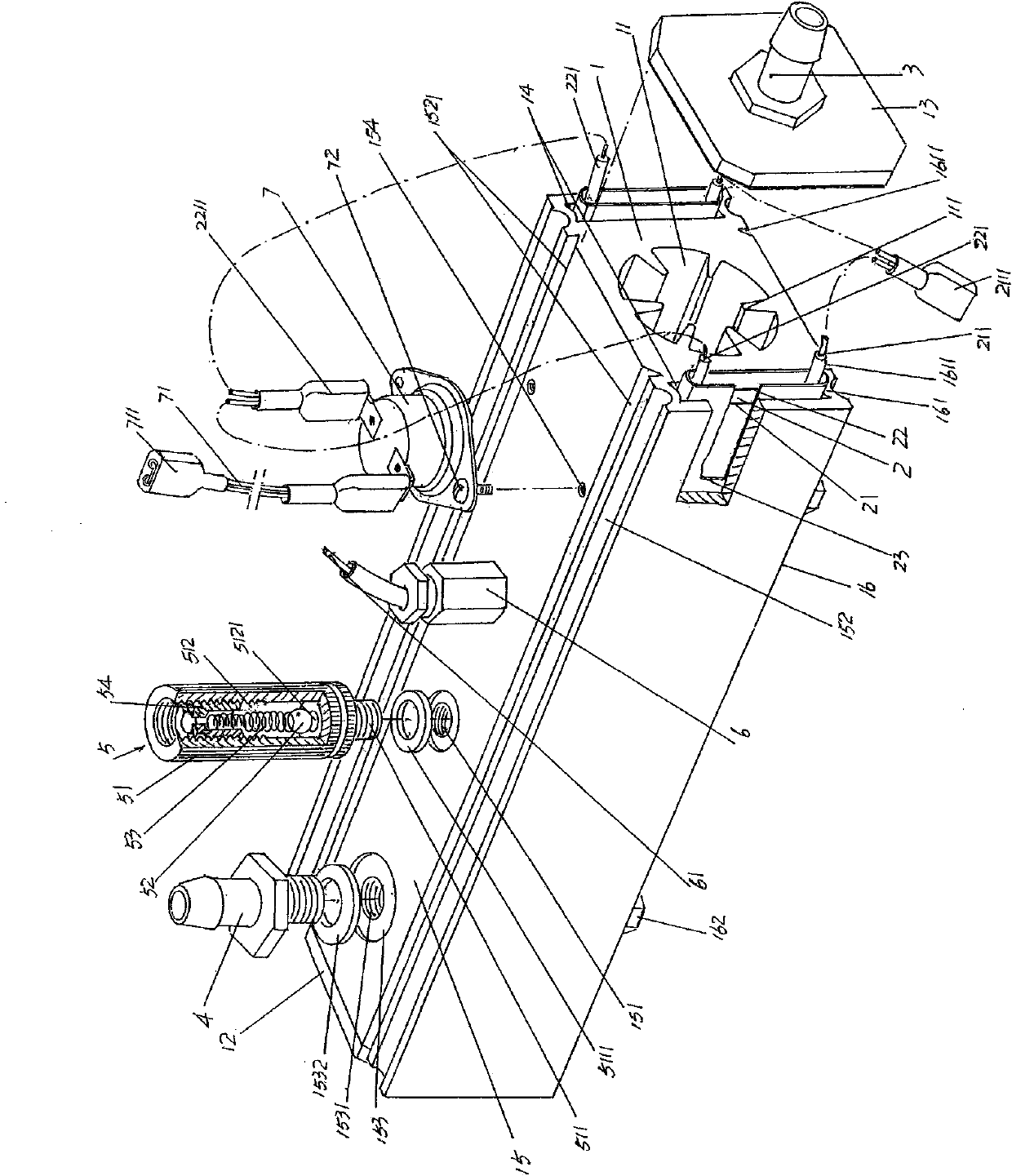

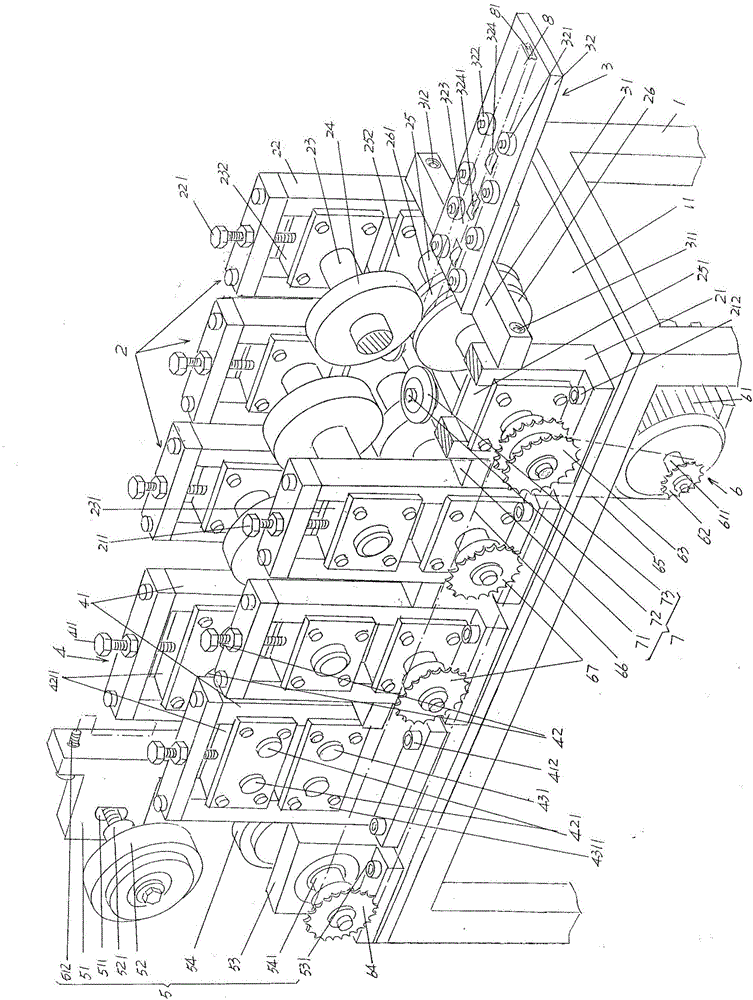

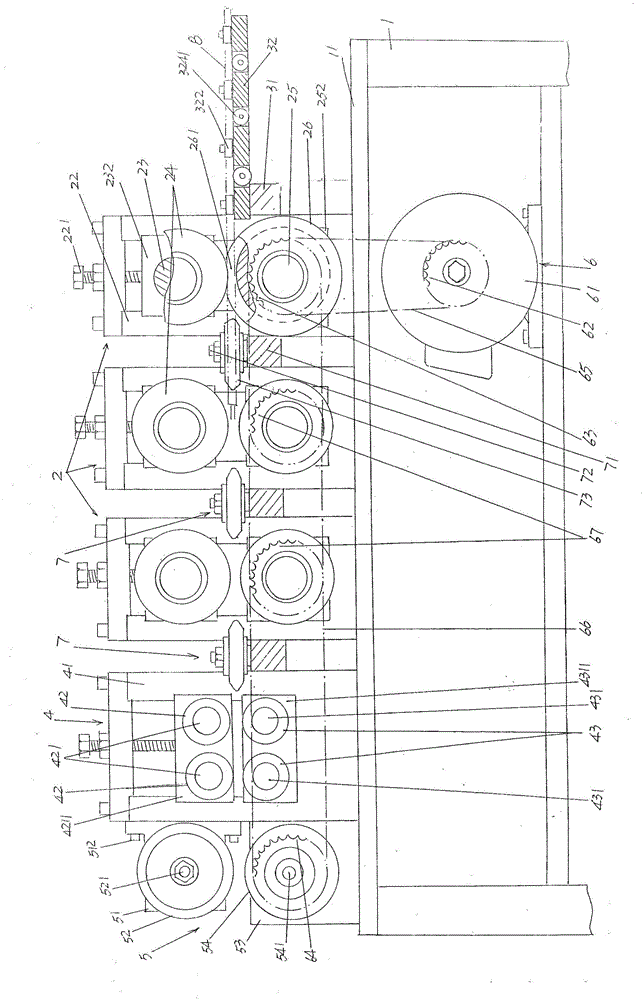

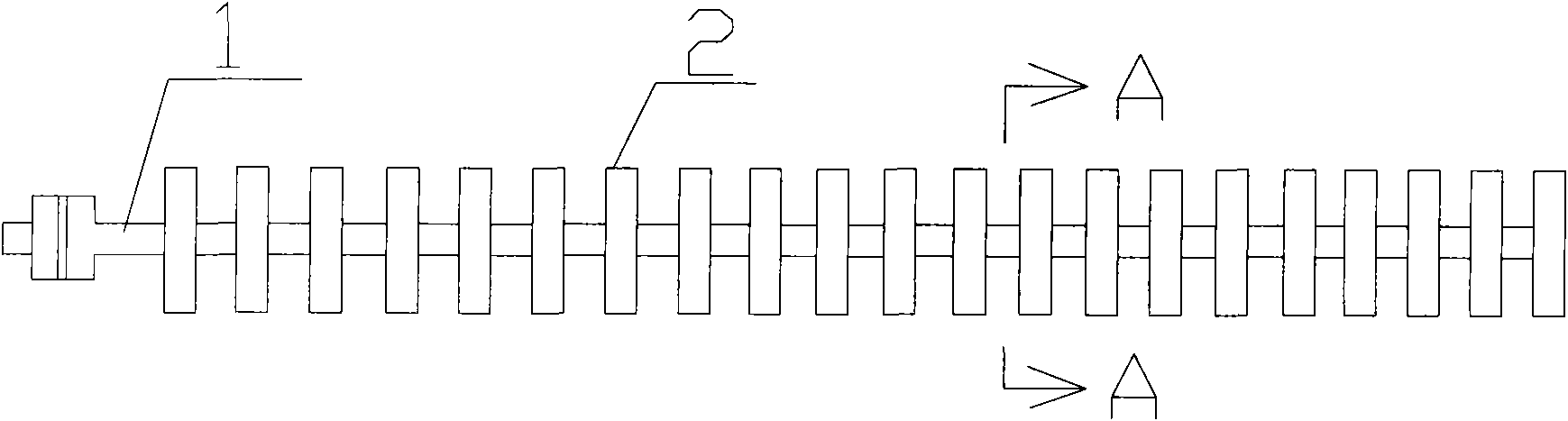

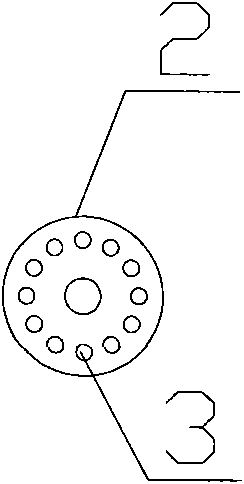

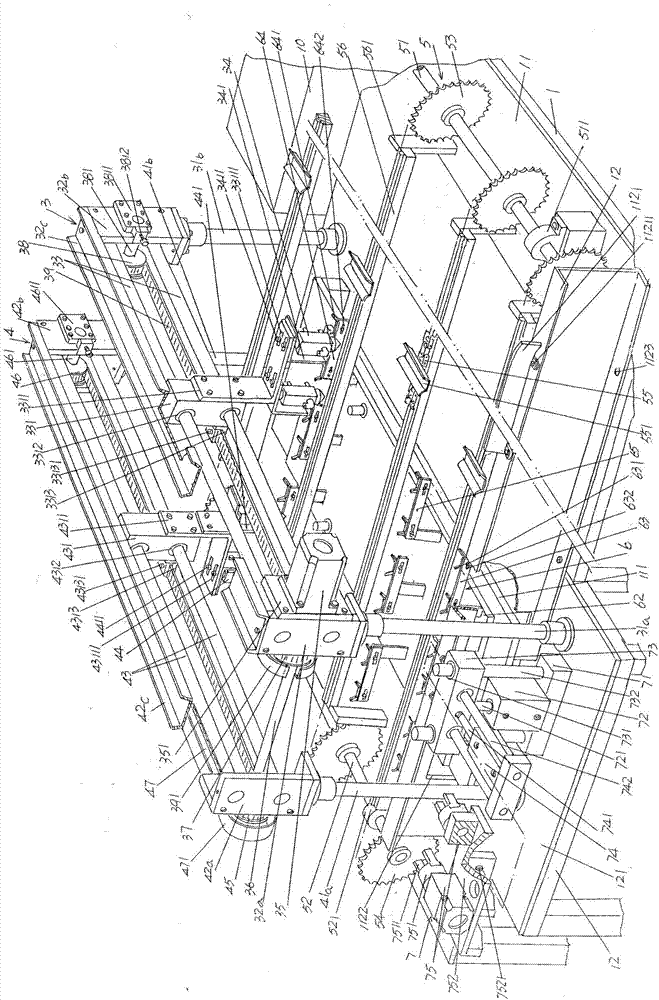

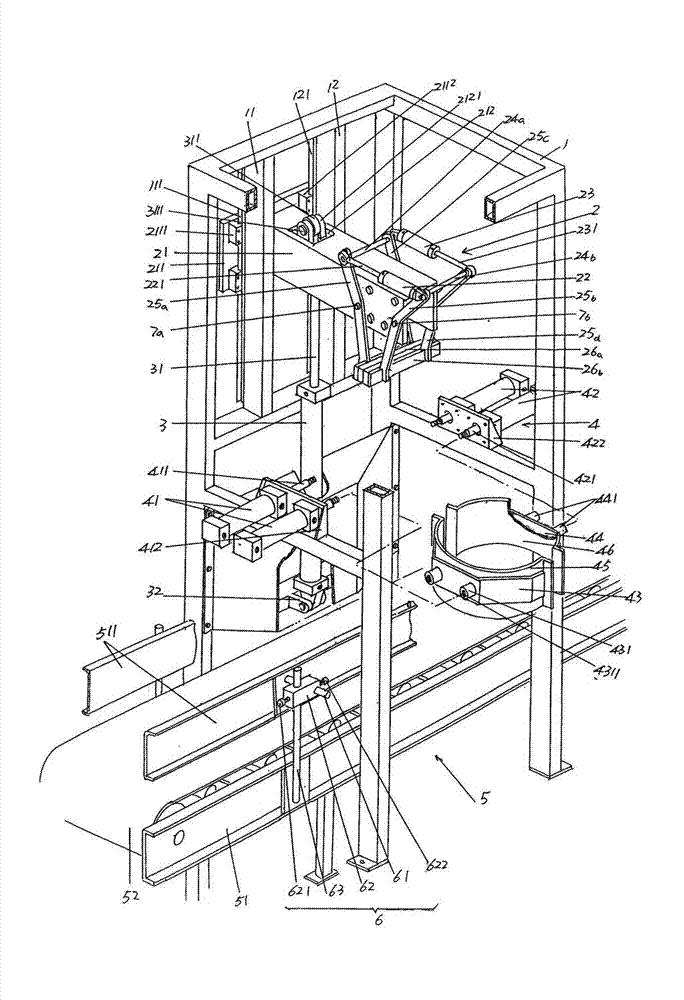

Feed lifting device of roll-dividing machine

The invention discloses a feed lifting device of a roll-dividing machine, and belongs to the field of devices special for thin film adhesive tape production. The roll-dividing machine comprises a machine base, a pair of wall plates and a carrier roller driving mechanism, wherein the wall plates form a carrier roller horizontal roller path and a carrier roller crawling roller path respectively, the end, away from the carrier roller crawling roller path, of the carrier roller horizontal roller path forms a wall plate blocking shoulder, the space between the wall plate blocking shoulder and the carrier roller horizontal roller path forms a carrier roller unrolling cavity, and the carrier roller driving mechanism is arranged on the side, facing outwards, of one wall plate. The feed lifting device comprises a carrier roller lifting power mechanism, a traction transmission shaft, a carrier roller traction mechanism and a carrier roller, wherein the traction transmission shaft is supported between the pair of wall plates, the carrier roller traction mechanism is connected with the traction transmission shaft, and the carrier roller is firstly matched with the carrier roller traction mechanism in the use state and dragged from the carrier roller crawling roller path to the carrier roller horizontal roller path through the carrier roller traction mechanism and is then matched with the carrier roller driving mechanism after entering the carrier roller unrolling cavity from the carrier roller horizontal roller path. Work intensity is lowered, the overall structure is simple, production space is saved, quality of thin film adhesive tape is ensured, and safety of online workers is protected.

Owner:SUZHOU BAIQI ELECTRONICS MATERIAL

Engine internal cleaning oil and preparation technology thereof

ActiveCN105199816AMeet the basic requirements of the functionWill not damageLubricant compositionMaterials preparationSludge

The invention discloses engine internal cleaning oil and a preparation technology thereof and relates to the field of lubricating oil. The cleaning oil is prepared from 64-66% of base oil, 12-16% of engine oil composite agent solution, 14-16% of cleaning agent and 5-7% of dispersing agent. The invention further discloses the preparation technology of the engine internal cleaning oil. The preparation technology includes the material preparation step and the blending step. According to the engine internal cleaning oil prepared through the technology, accumulated carbon, oily sludge and other impurities in an engine can be dispersed, filtered out and removed under the condition that the engine is not detached, internal cleanliness of the engine is restored, maintenance without detachment is achieved, power is improved, and oil consumption is reduced.

Owner:李云庆

Method for extracting construction engineering pile foundation

The invention discloses a method for extracting a construction engineering pile foundation and belongs to a civil engineering construction method. The method includes the steps: learning conditions of the pile foundation and formulating equipment for pile extracting; equipping a geological drilling rig, a high-pressure jet pump, an air compressor, a jack and lifting equipment; leveling terrace and sorting out pile heads, and transporting a complete set of facilities to a site; drilling, namely leading a high-pressure liquid injection tube to the bottom of a hole so as to form a semicolumn slurry-hole body at a position where the pile foundation corresponds to the drill hole; inserting a slurry-discharging tube into the hole body; inserting a slurry-pump slurry-discharging tube into the bottom of the slurry-discharging tube, and pumping slurry out from the slurry-discharging tube; fixing a counterforce device at the top of the pile foundation, jacking the counterforce device through the jack, lifting the pile foundation through the lifting equipment, after the whole pile foundation is extracted, pulling out the high-pressure liquid injection tube and the slurry-discharging tube prior to cleaning the same, detecting the extracted pile foundation, and finally refilling the pile foundation hole. The method is flexible to operate, and favorable for disintegrating binding force of the pile foundation and surrounding soil mass; resistance of the pile foundation when being extracted is enabled to be reduced, so that resources are saved, and an environment is protected.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

PTC liquid heater

ActiveCN103743093AImprove heating efficiencyReduce consumptionSteam generation heating methodsOhmic-resistance heatingEngineeringCavity wall

The invention relates to a PTC liquid heater and belongs to the technical field of liquid heating devices. The PTC liquid heater comprises a heater body, a liquid inlet interface and a liquid outlet interface, wherein a liquid heating cavity is formed at the center of the heater body, a left sealing cover and a right sealing cover are arranged at the left end and the right end of the heater body in a matched mode, PTC element mounting cavities are respectively formed on a front side wall and a rear side wall of the heater body, and PTC elements are arranged in the mounting cavities. The liquid inlet interface is arranged on the right sealing cover and communicated with the liquid heating cavity, the liquid outlet interface is arranged on one of the left sealing cover and a top wall of the heater body, and a bottom wall of the heater body forms a heater body mounting wall. The PTC liquid heater is characterized in that a group of heating cavity cooling fins protruded out of a cavity wall surface of the liquid heating cavity are formed on the cavity wall of the liquid heating cavity at intervals in the length direction along the length direction of the liquid heating cavity. The PTC liquid heater is good in heat dissipation effect and high in heating efficiency, saves energy and materials, prevents the heater body from bursting, is safe to use, does not damage the PTC elements when pressing a cavity top wall and a cavity bottom wall and is good in intelligence effect.

Owner:嘉善县魏塘资产管理有限公司

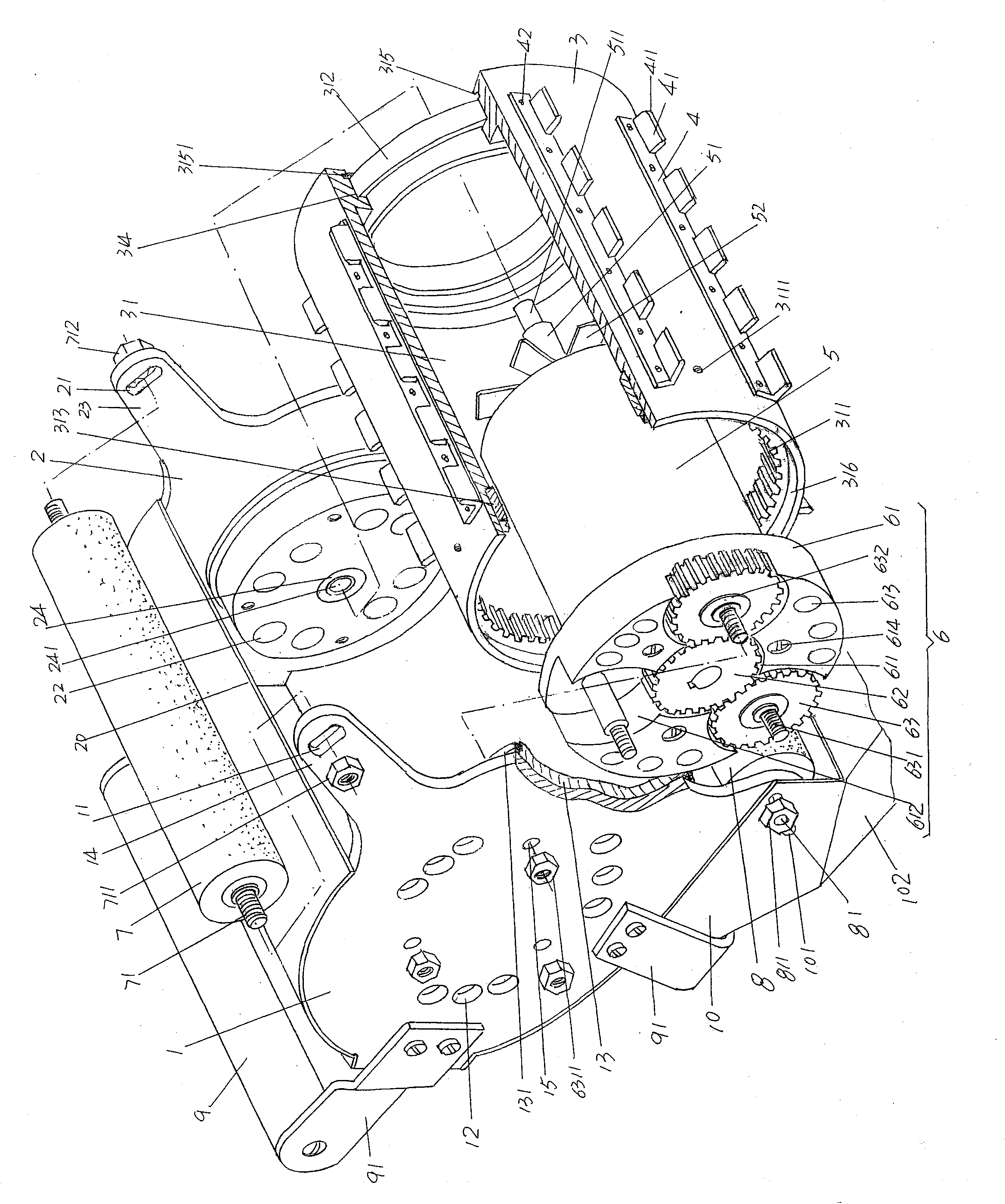

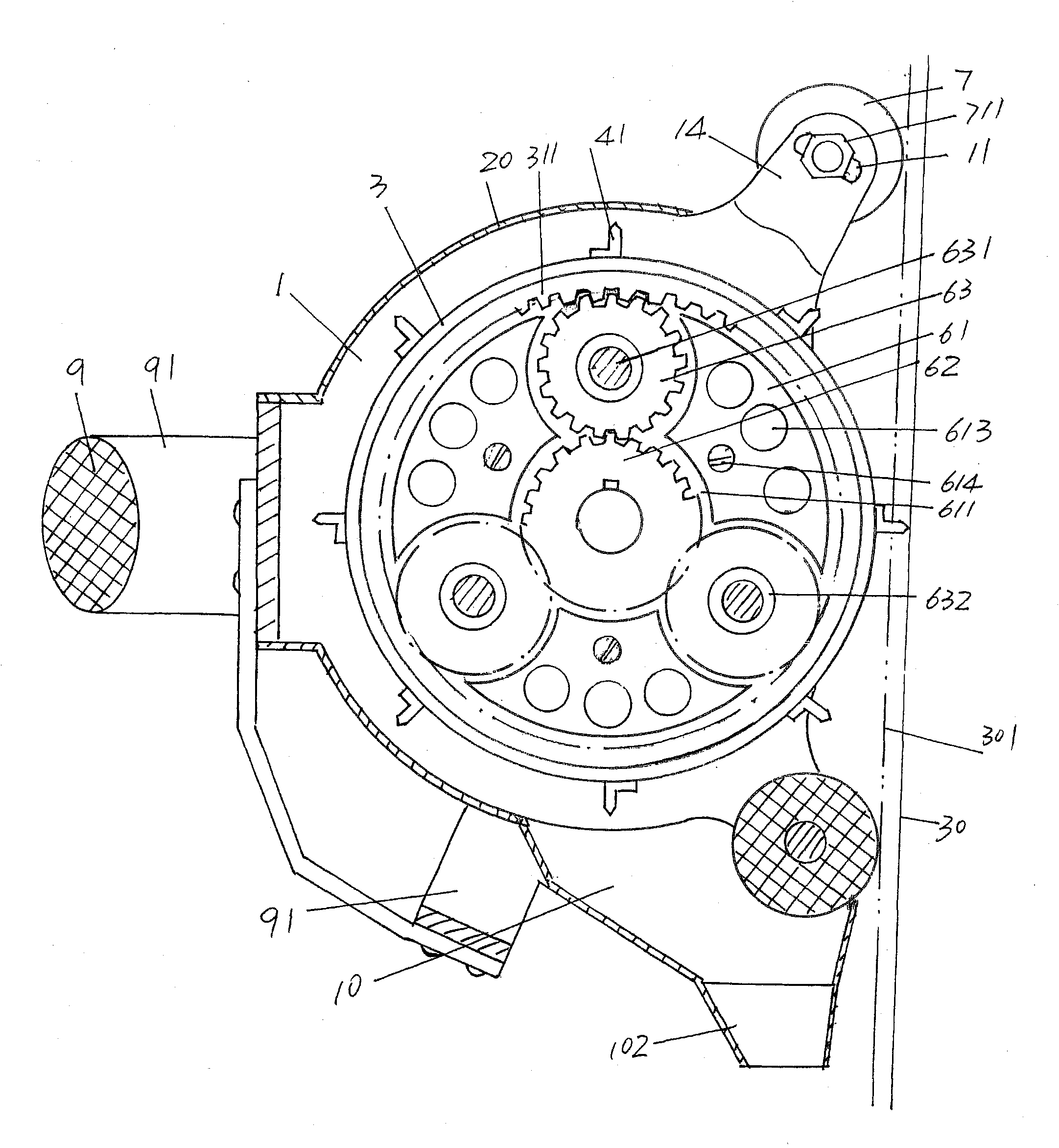

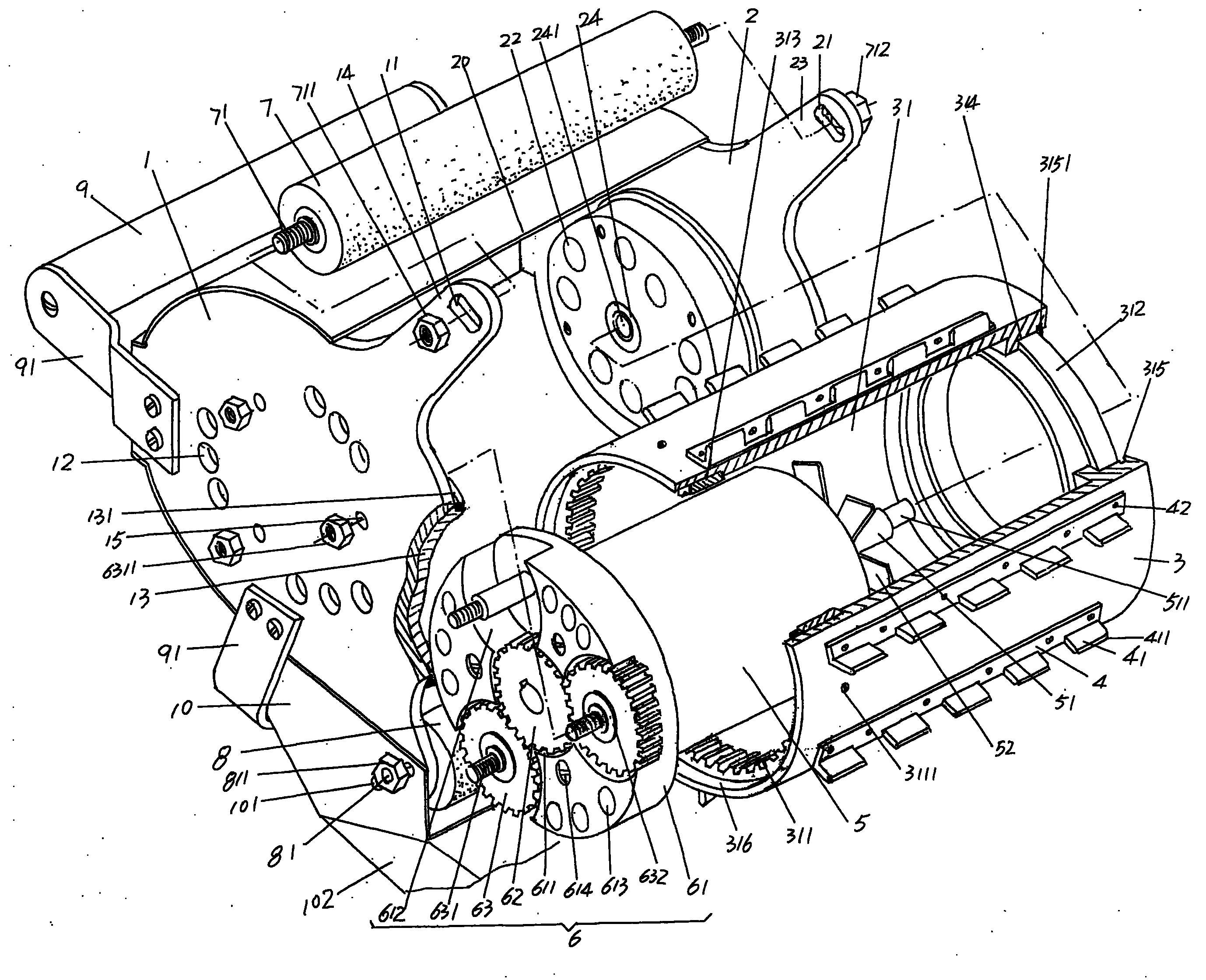

Device for eliminating wall surface coating

The invention relates to a device for eliminating a wall surface coating, which belongs to apparatus for decoration constructions of wall surface of buildings. The device comprises a first supporting plate, a second supporting plate, a roller, a group of planer tool posts, a motor, a transmission mechanism meshed with a gear ring, an upper guide roll, a lower guide roll and a pair of handles, wherein one end of the roller is fixedly provided with the gear ring while the other end is fixedly provided with a roller bearing, and the second supporting plate is fixed with the roller bearing; the planer tool posts are arranged on the outer wall of the roller at intervals, and planer tools are arranged at intervals on each planer tool post; the motor is arranged in a roller cavity, and the right end of a motor shaft is arranged on the second supporting plate; the transmission mechanism is arranged at one end of the motor, facing the first supporting plate and is connected with the left end of the motor shaft; the upper guide roll and the lower guide roll are fixed on the first supporting plate and the second supporting plate; and the two handles are fixed with the first supporting plate and the second supporting plate respectively. The device has the advantages that the device has a compact structure, a small volume and ideal equitability, is favorable for reducing the operating strength of constructors, is convenient to replace, is favorable for comprehensively and uniformly eliminating an obsolete mortar bed, a coating or an oil paint on a wall body without generating missed planing and white flying phenomena, and is helpful for combining a new decorative layer with the wall body reliably.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

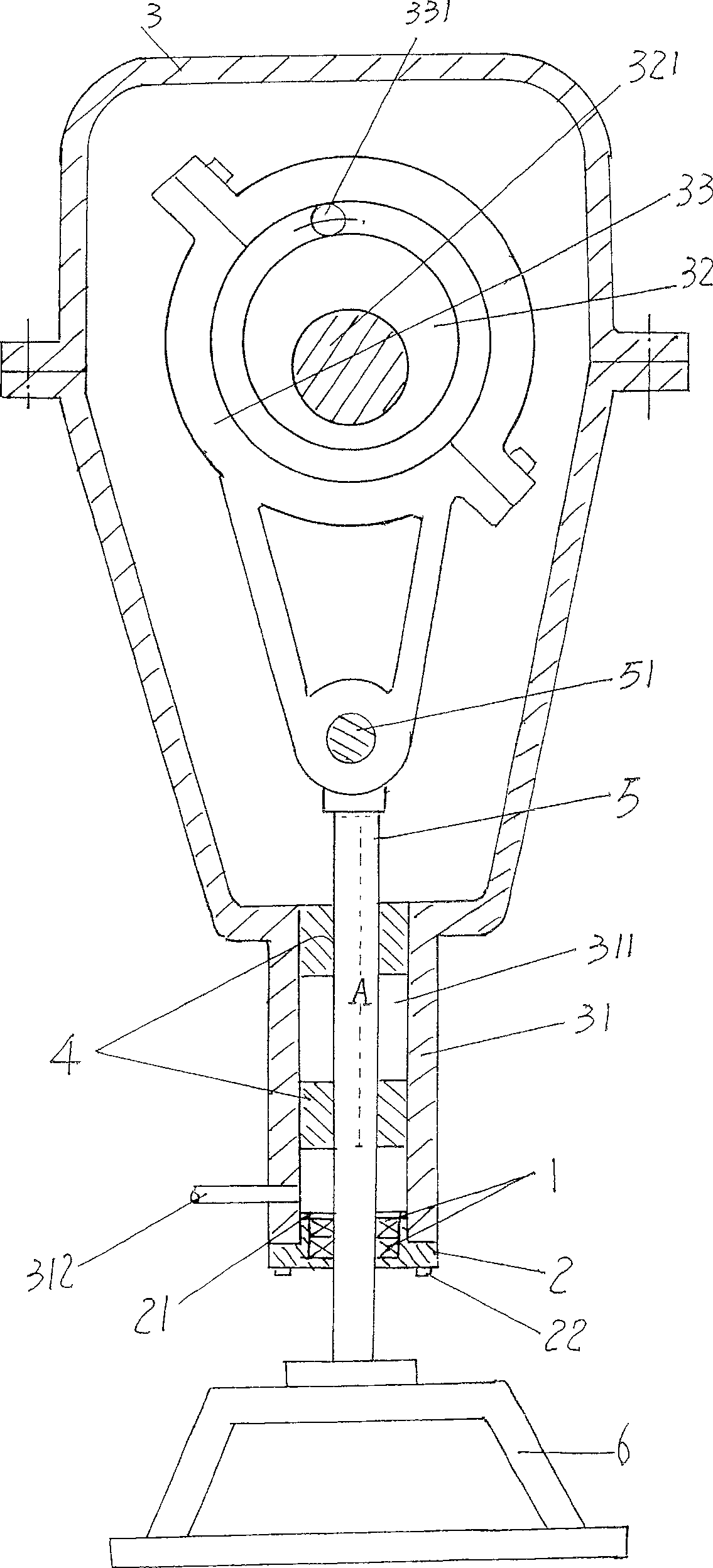

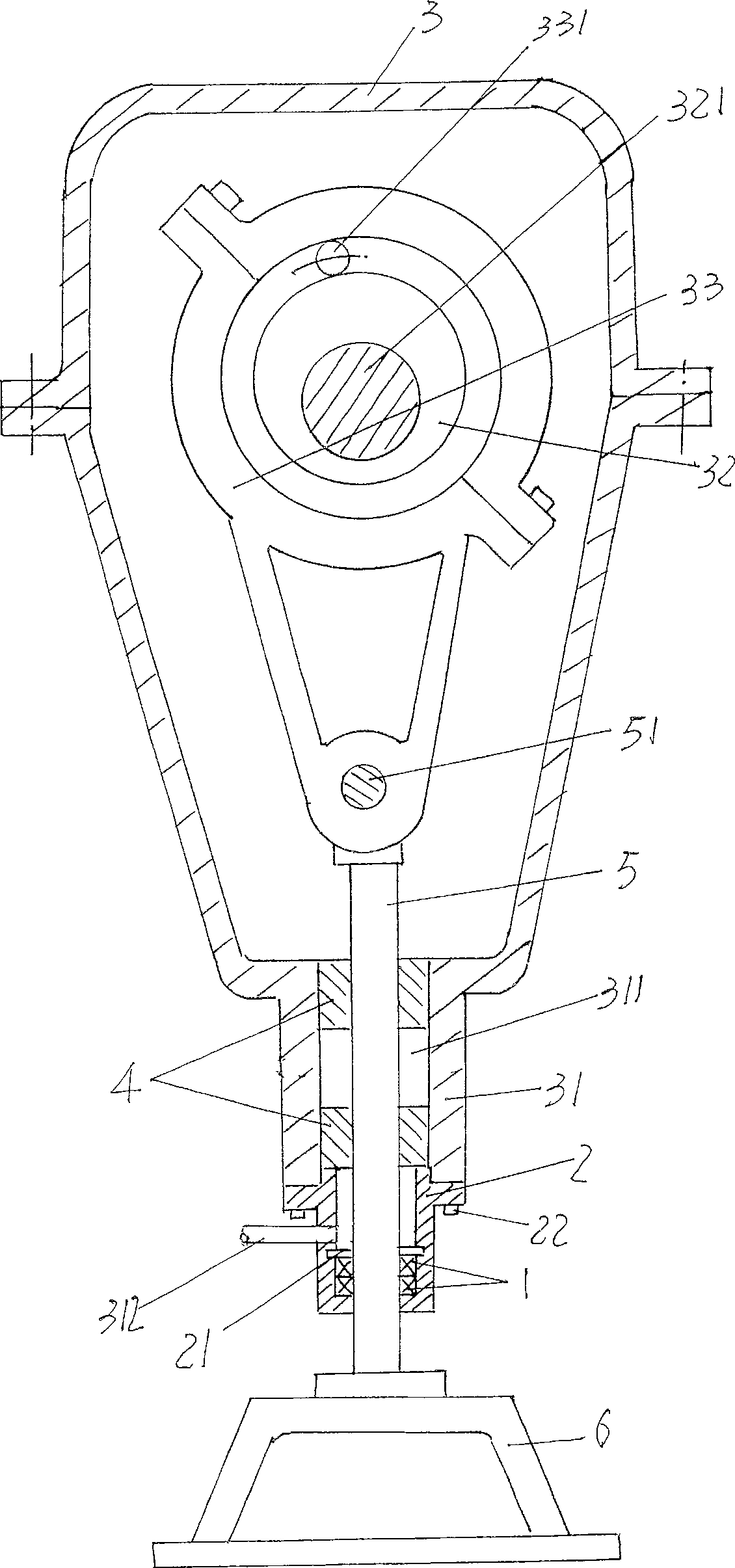

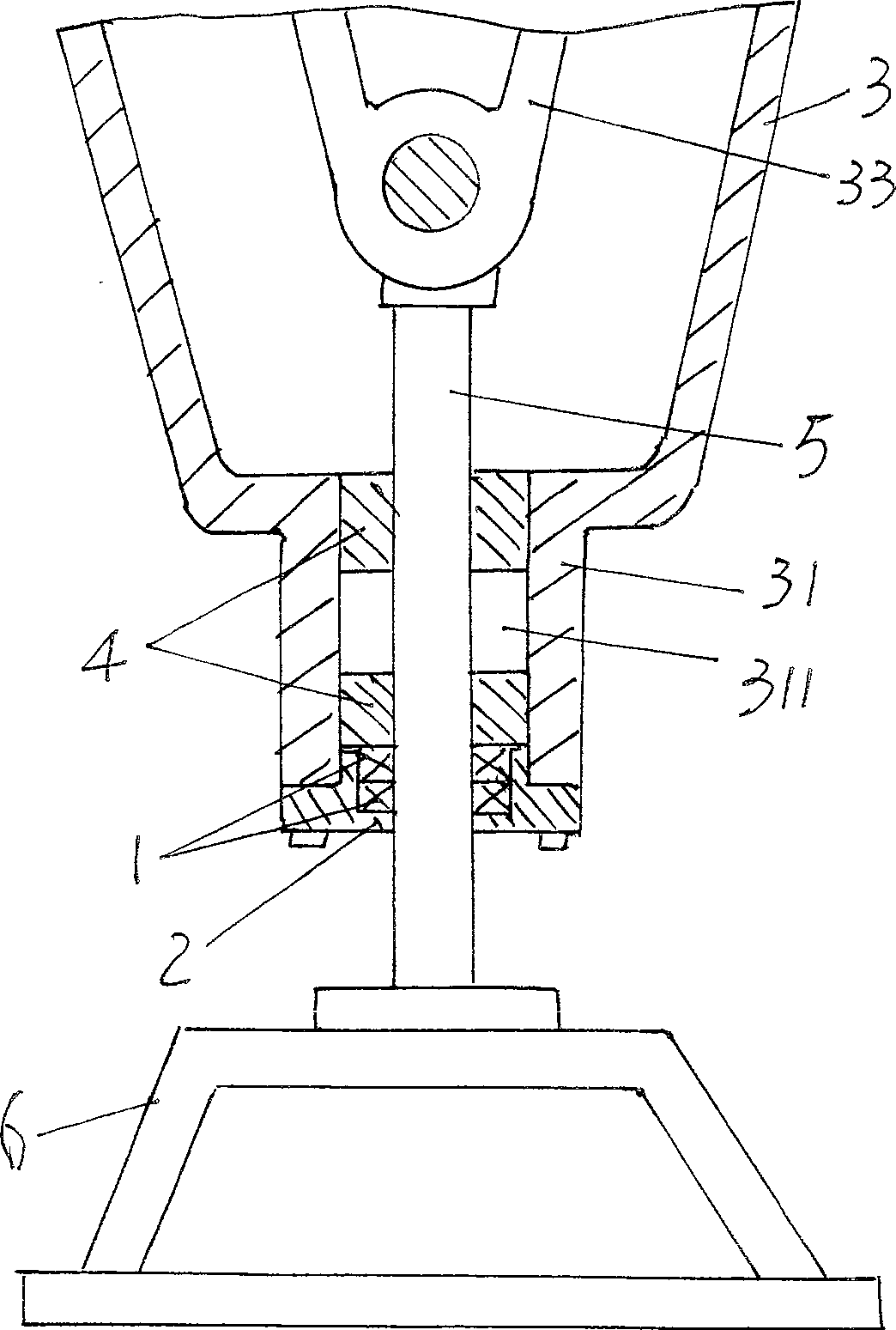

Guide pillar sealing mechanism for needle machine

InactiveCN100494547CPrevent leakageWill not damageNeedling machinesEngineeringMechanical engineering

A guide post sealing device of needing machine belongs to non-textile machinery applied technology fields. It includes sealing ring which is installed under guiding-sheathing, the guiding-sheathing and the sealing ring are both in the base cavity of guide post base which is equipped with eccentric cam and is contracted into tubular stage under the lower of main axle box body of connecting bars, and the sealing cover which is used for placing said sealing ring and maintaining the sealing ring is in covering phase, certain distance is retained between said sealing ring and guiding-sheathing. The advantages are: it can prevent the friction parts between the guide post and guiding-sheathing rub with the sealing ring, the movement of guide post will not damage the sealing ring, so the good effect of sealing ring for preventing lubricating oil leakage is ensured.

Owner:常熟市伟成非织造成套设备有限公司

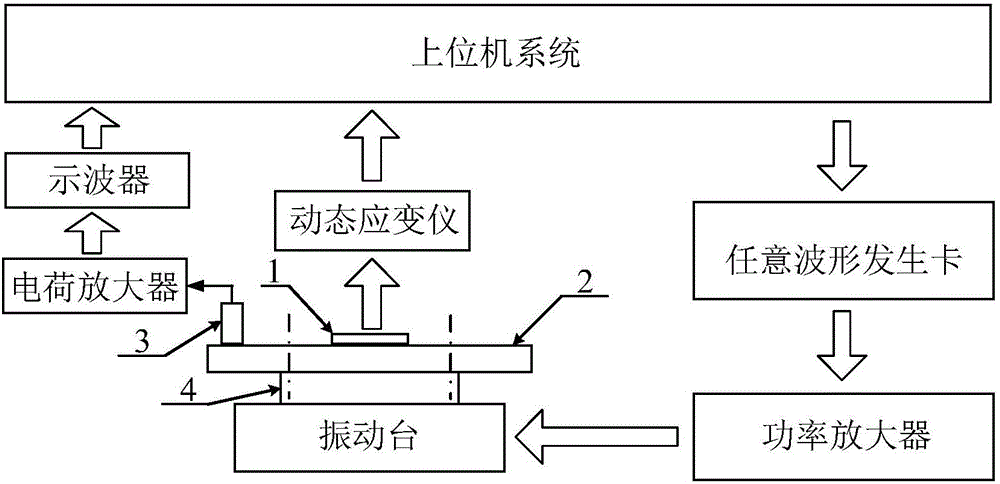

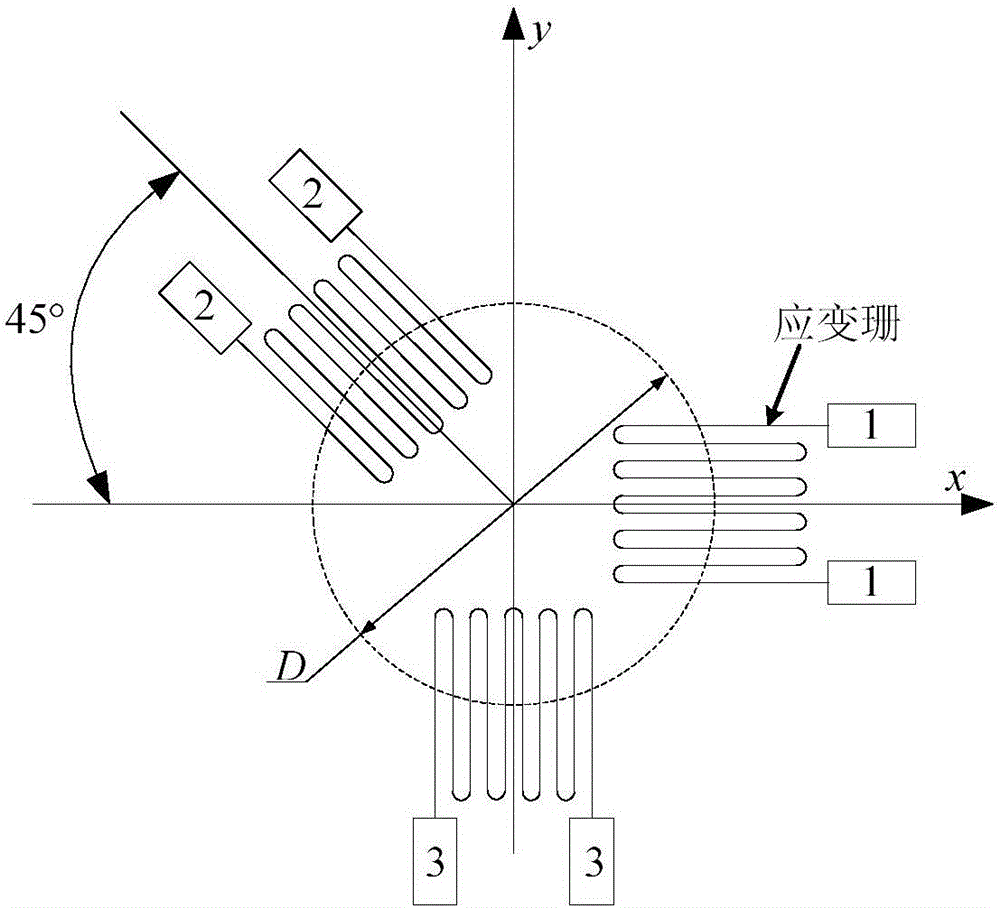

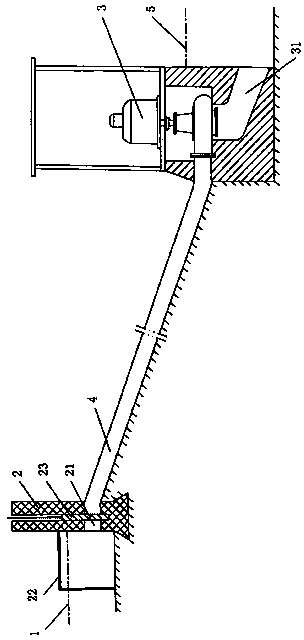

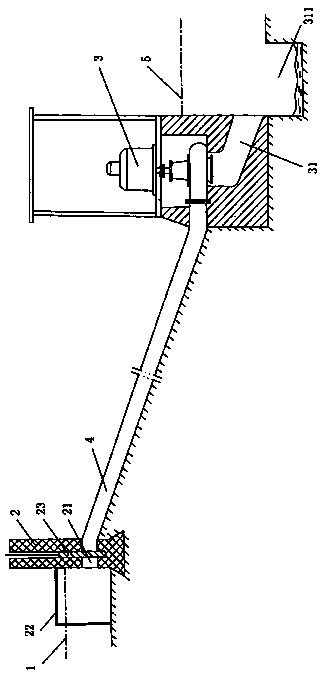

Nondestructive detection system and method for small-sized component surface layer micro-cracks

InactiveCN106198383ADetermination of microscopic cracksMicroscopic cracks determine whether the surface of small-sized components existsUsing mechanical meansMaterial analysisPeak valueEngineering

The invention discloses a nondestructive detection system for small-sized component surface layer micro-cracks. The nondestructive detection system comprises an upper computer system, a dynamic strain meter, a strain gauge, a vibrating table, a power amplifier, an arbitrary waveform generation card, a charge amplifier, an acceleration sensor and an oscilloscope, and the upper computer system comprises a strain waveform reading module, a strain identification module, a voltage waveform reading module, a voltage identification module and a vibration level conversion module. A nondestructive detection method for the small-sized component surface layer micro-cracks includes the steps: clamping a small-sized component onto an excitation vibration table top of a motion component of the vibrating table; firstly acquiring a modal peak value of an unmachined small-sized component by the upper computer system; secondly acquiring a modal peak value of a machined small-sized component by the upper computer system. If the acquired modal peak values are unequal under two conditions, namely, the surface layer of the small-sized component generates the micro-cracks. The nondestructive detection system has the advantage of capability of rapidly and accurately determining whether the micro-cracks are generated on the surface layer of the small-sized component or not.

Owner:SHANGHAI MARITIME UNIVERSITY

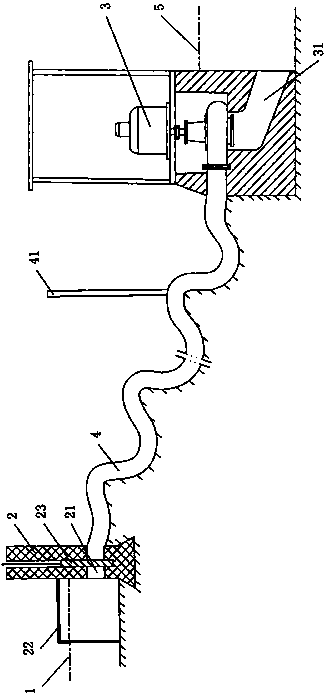

Hydroelectric power station

InactiveCN104234017AWill not damageImprove terrain adaptabilityWater-power plantsHydro energy generationPower stationSteam-electric power station

The invention provides a hydroelectric power station and belongs to the technical field of hydroelectric power facilities. The hydroelectric power station comprises a retaining dam, a hydraulic turbine generator and an energy concentration device, wherein the retaining dam is constructed on an upstream river and is used for intercepting and lifting the upstream river; the hydraulic turbine generator is mounted at the downstream; the energy concentration device is used for leading water of the upstream river, which is intercepted by the retaining dam, to the hydraulic turbine generator so that the hydraulic turbine generator generates power; a water outlet of the hydraulic turbine generator is communicated with the upstream river. The hydroelectric power station is characterized in that the energy concentration device is an energy collection pipe; one end of the energy collection pipe is connected and communicated with a water inlet of the retaining dam, and the other end of the energy collection pipe is connected with the hydraulic turbine generator. The hydroelectric power station has good landform adaptability and does not damage farmlands, mountain forests and villages and towns; the hydroelectric power station is suitable for natural river systems with great falls, is low in construction cost and can meet the requirements of nearby grid-connected generation; the investment and the resources can be saved; the energy collection pipe tends to be maintenance-free, and the good economical and cheap effects are reflected.

Owner:薛士成

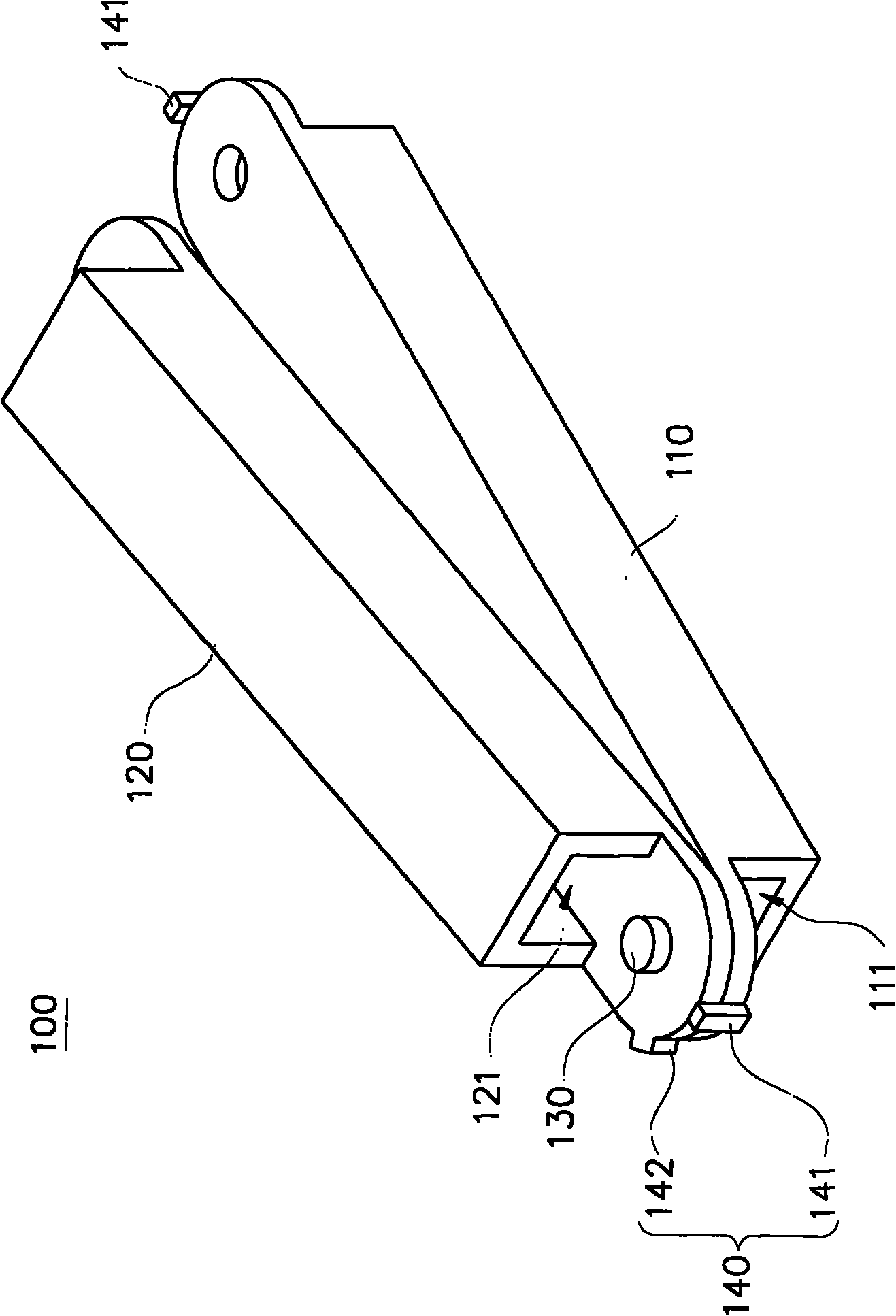

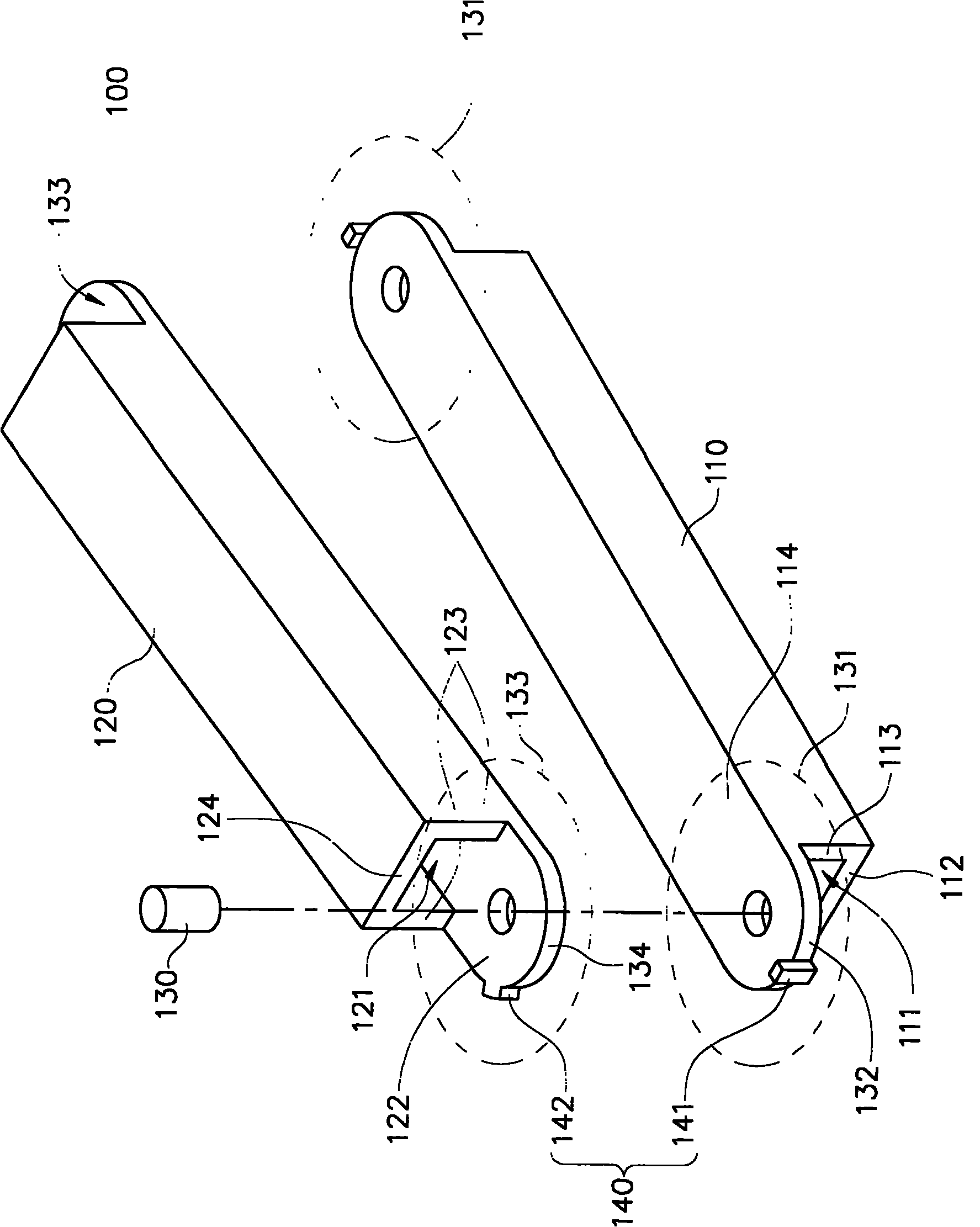

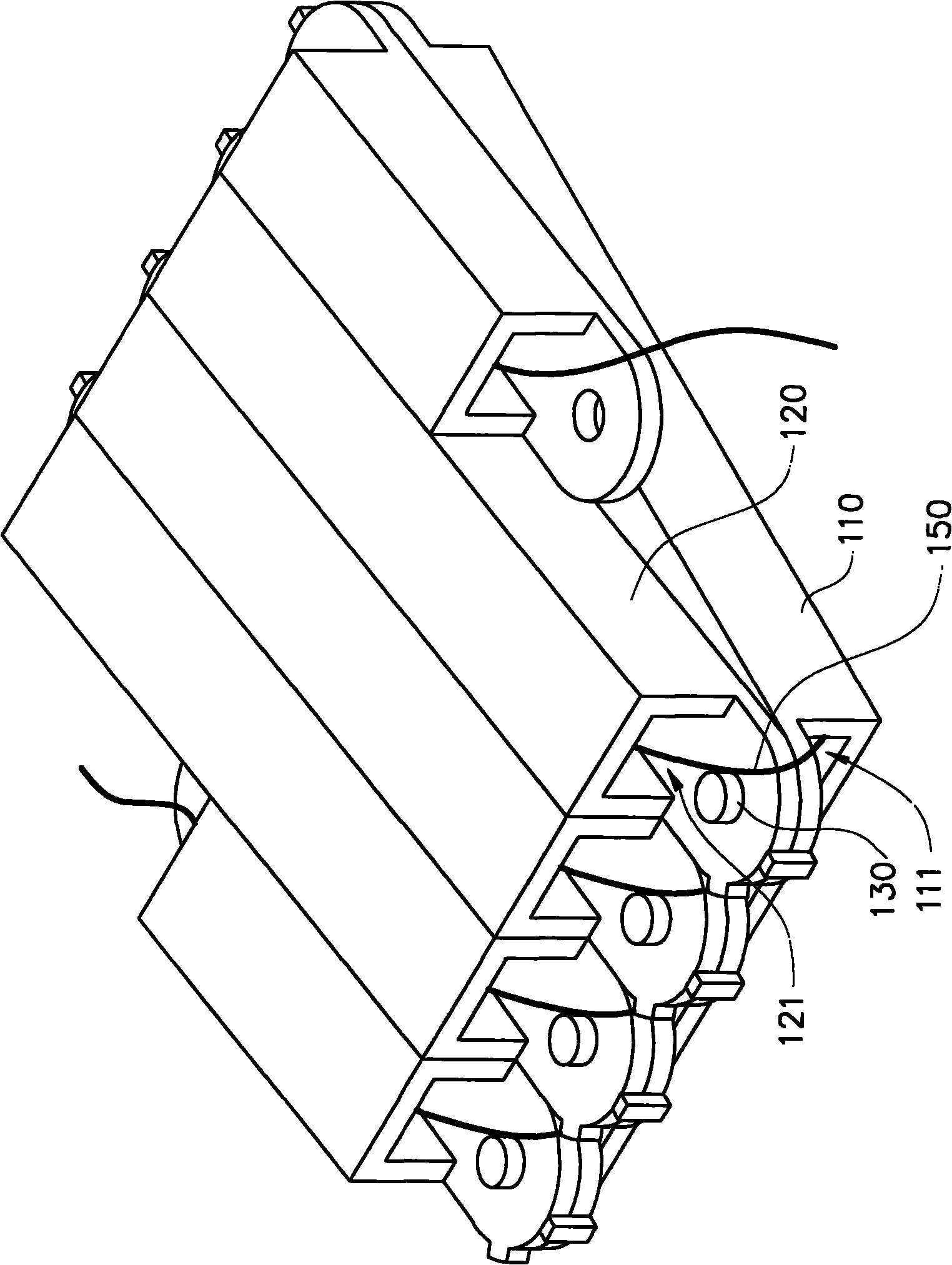

Lead guidance device

InactiveCN102055160ANot subject to collisionWill not damageCable arrangements between relatively-moving partsApparatus for laying cablesEngineering

The invention relates to a lead guidance device which is provided with a first protection pipe, a second protection pipe and a pivot, a pivot jointing part at one end of the second protection pipe is spliced to the pivot jointing part at one end of the first protection pipe and then the pivot penetrates through the pivot jointing parts, so that the second protection pipe can rotate pivotedly around the pivot relative to the first protection pipe; a lead penetrates through the first protection pipe and the second protection pipe to unfold or fold the lead through a relative pivoting rotation mode of the first protection pipe and the second protection pipe to protect the lead from being collided or broken.

Owner:INVENTEC CORP

Spanners for automobile tyre

An automobile tyre wrench belongs to the technical field of hardware tool. The automobile tyre wrench comprises a handle and a sleeve articulated on the handle. One end of the handle is configured with a sleeve accommodating cavity for accommodating the sleeve. The other end of the handle is configured with an adjusting handle cavity. A first top wall of adjusting handle cavity is provided with a sliding groove and at least one pair of first positioning opening. Each first positioning opening is communicated with the sliding groove. A height adjusting handle is accommodated in the adjusting handle cavity and is configured with a positioning cavity. A second top wall of the positioning cavity is configured with a guiding groove and a second positioning opening which is communicated with the guiding groove. A drawing clamp which is positioned in the positioning cavity and is projected from the second positioning opening, and furthermore the second positioning opening is matched with the first positioning opening. The automobile tyre wrench has the advantages of good handle selectivity for adjusting height; quick and power-saving operation without damage to the finger; simple integral structure and suitability for being processed and assembled.

Owner:NANTONG TONGRUN AUTO ACCESSORY

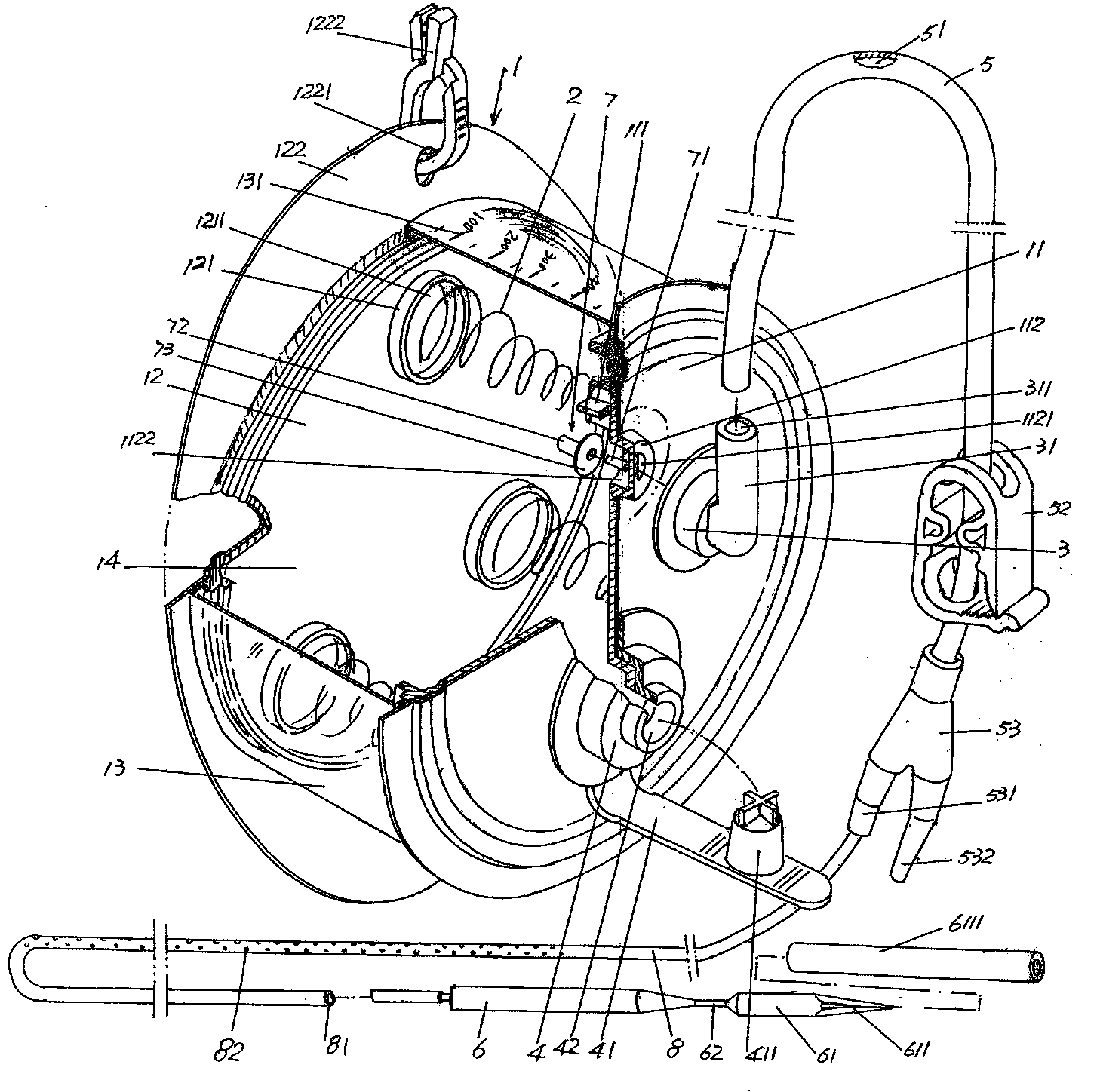

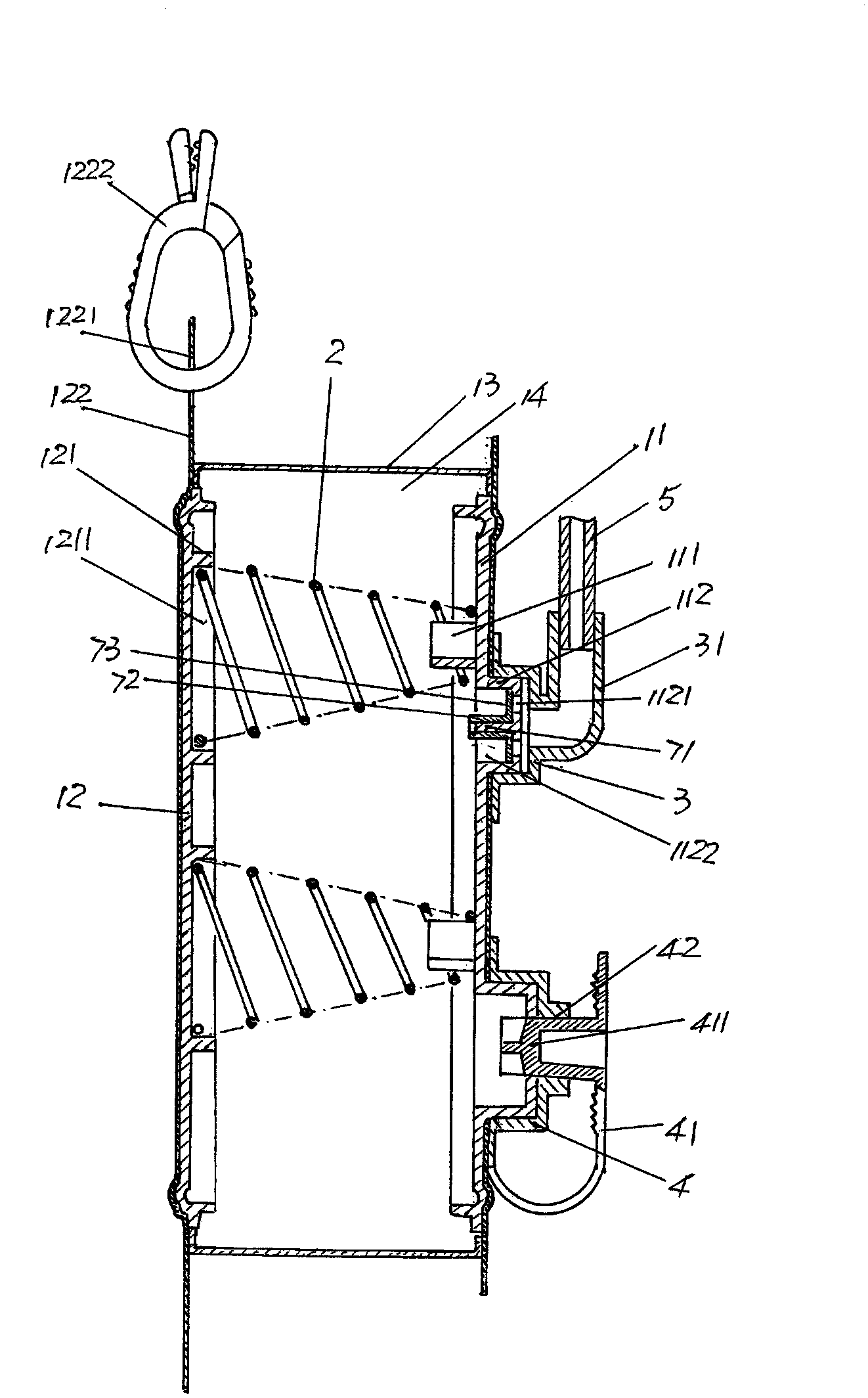

Disposable negative pressure drainage apparatus

InactiveCN104107463AAvoid reverse flowGuarantee drainage safetyIntravenous devicesSuction devicesInlet valveDrainage tubes

The invention discloses a disposable negative pressure drainage apparatus, and belongs to the technical field of medical apparatuses. The disposable negative pressure drainage apparatus comprises a negative pressure drainage container body including a top wall, a bottom wall and a seal sleeve; a group of springs, distributed in the cavity of the negative pressure drainage container body; a drainage tube seat, fixed to one side, with the back towards the cavity, of the top wall; a drain port, fixed to one side, with the back towards the cavity, of the top wall. One end of the drainage tube is matched and connected with the drainage tube seat while the other end is connected to one end of a collecting tube, the other end of the collecting tube is matched and connected with a puncture knife; the disposable negative pressure drainage apparatus is characterized in that a liquid inlet valve seat is formed on the top wall corresponding to the position of the drainage tube seat, a backflow-resistant liquid inlet check valve is arranged corresponding to the position of the liquid inlet valve seat, the seal sleeve is a transparent seal sleeve, and the seal sleeve is provided with scale marks in the height direction. According to disposable negative pressure drainage apparatus, hydrops which is drained from the body of a patient and enters into the cavity is prevented from flowing backwards, and medical staffs can correctly master the drainage volume of the patient; the middle part of the group of springs is prevented from bulging, and the springs are reliably matched with the top and bottom walls; drainage effect is excellent, and drainage time can be shortened.

Owner:CHANGSHU 3S MEDICAL DEVICE

Waste wire stripping device

ActiveCN103259221BExtended service lifeGuaranteed peeling effectApparatus for removing/armouring cablesEngineeringWheel and axle

The invention discloses a waste wire stripping device, and belongs the technical field of recovery devices of waste materials. The waste wire stripping device comprises a paying-off mechanism, a paring mechanism, a tension automatic adjustment mechanism, a peeling mechanism and a wire core winding mechanism, wherein the paring mechanism is arranged on one side of the tension automatic adjustment mechanism, the peeling mechanism is located between the tension automatic adjustment mechanism and the wire core winding mechanism, the paring mechanism comprises a fixed plate, a paring knife fixing base supporting arm, a paring knife fixing base, a paring knife and a guiding wheel, the fixed plate is fixed with one side of the tension automatic adjustment mechanism, a wire passing hole is formed in the fixed plate, the paring knife fixing base supporting arm is fixed with one side of the fixed plate, a wire passing groove is formed in one side of the paring knife fixing base, two ends of the paring knife are respectively provided with a paring knife adjustment groove, the guiding wheel is arranged on a guiding wheel shaft, the guiding wheel shaft is fixed on a guiding wheel shaft base, and the guiding wheel shaft base is fixed on the paring knife fixing base supporting arm. The waste wire stripping device is ideal in stripping effect, free of damage to the guiding wheel caused by friction, long in service life and low in knife cost, and ensures a paring effect.

Owner:CHANGSHU HONGLIN WIRE & CABLE CO LTD

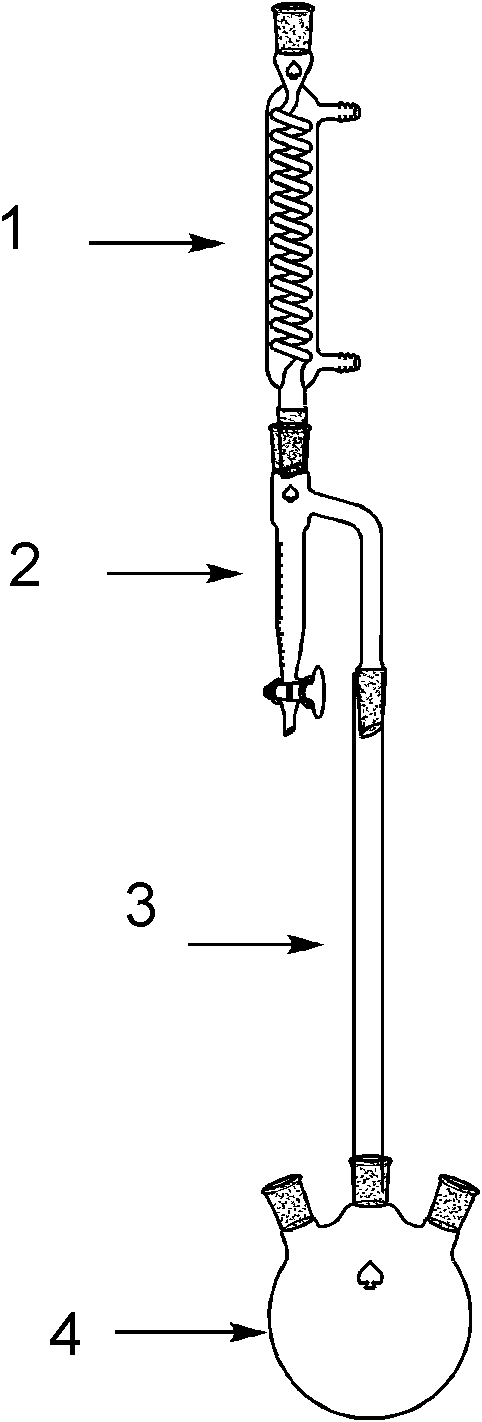

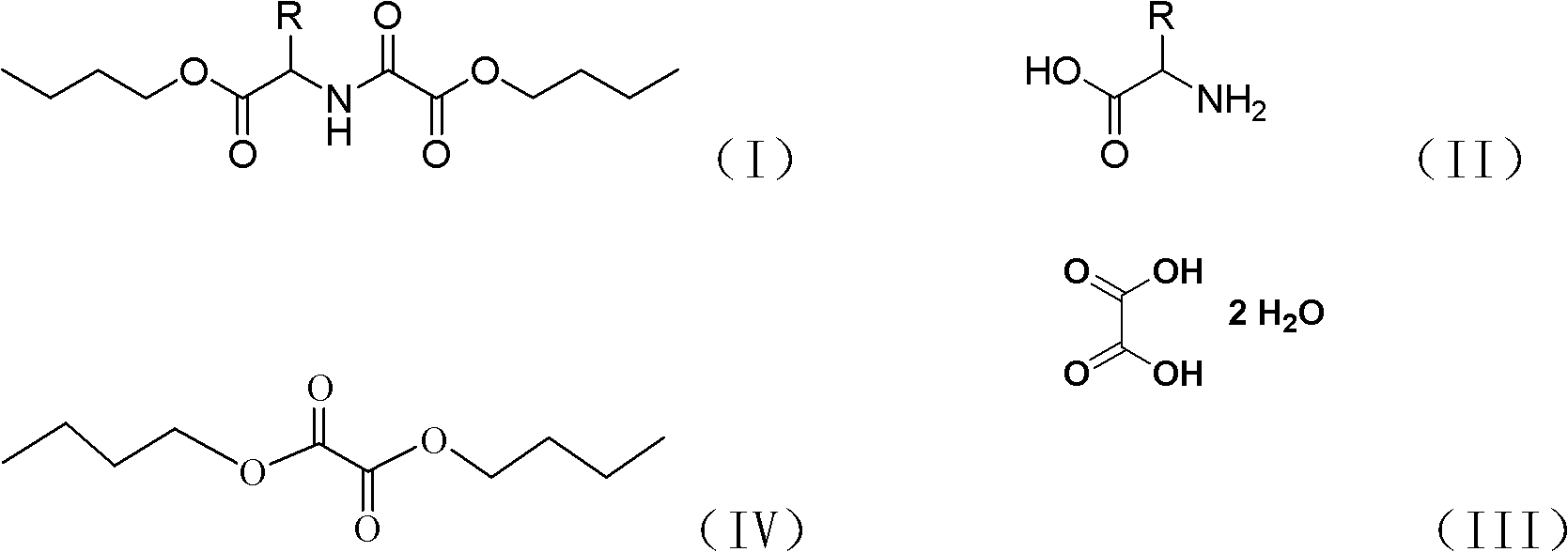

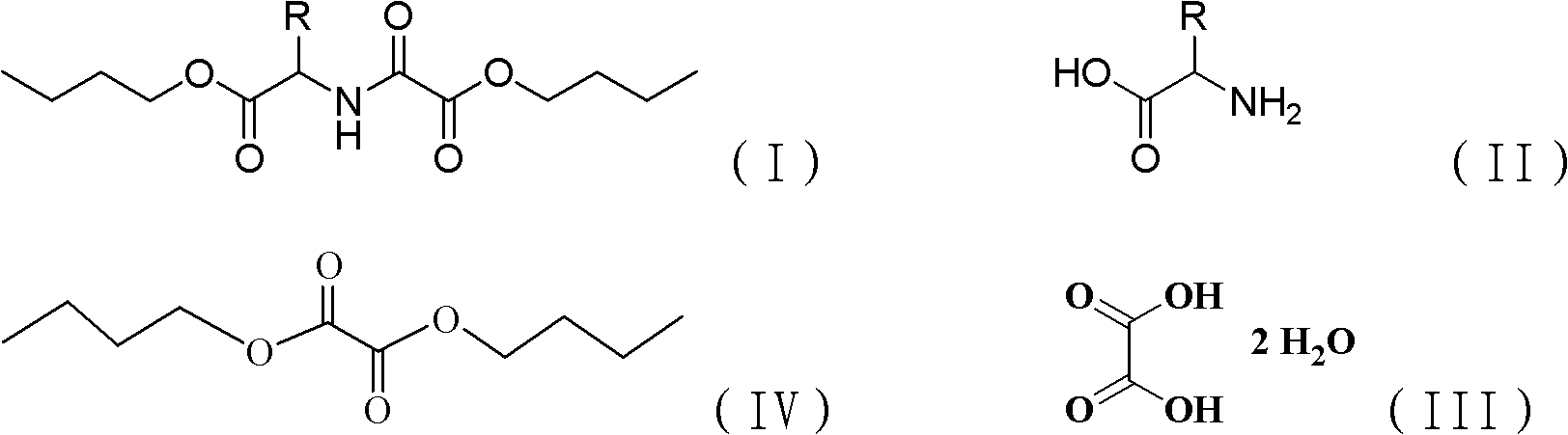

Chemical synthesis method of N-butoxyoxalyl amino acid butyl ester

InactiveCN101830823ASimple processReduce equipment and raw materialsOrganic compound preparationCarboxylic acid amides preparationChemical synthesisCorrosion

The invention relates to a chemical synthesis method of N-butoxyoxalyl amino acid butyl ester. The synthesis method comprises the following steps of: reaching amino acid shown as a formula (II), oxalic acid shown as a formula (III) and dibutyl oxalate shown as a formula (IV) in n-butyl alcohol for 5-150 hours at 50-200 DEG C, wherein water generated in the reaction is removed through fine fraction in the reaction process; and then carrying out after-treatment on reaction liquid to obtain the N-butoxyoxalyl amino acid butyl ester shown as a formula (I), wherein the mass ratio of the amino acid to the oxalic acid to the dibutyl oxalate is 1:(1-10):(1-10); in the formula (I) and the formula (II), R is H and an alkyl group, a phenyl group, a benzyl group, a substituent phenyl group or a substituent benzyl group of C1-C6; and the substituent groups of the substituent phenyl group or the substituent benzyl group are respectively a methyl or a hydroxy. The invention has the advantages that a super acidic catalyst does not need to be used in the reaction process, and the reaction does not need to be carried out by steps, thereby simplifying the process and reducing equipment and raw materials; the corrosion to the equipment is reduced; and moreover, waste water polluting the environment cannot be generated in the production.

Owner:ZHEJIANG UNIV OF TECH +1

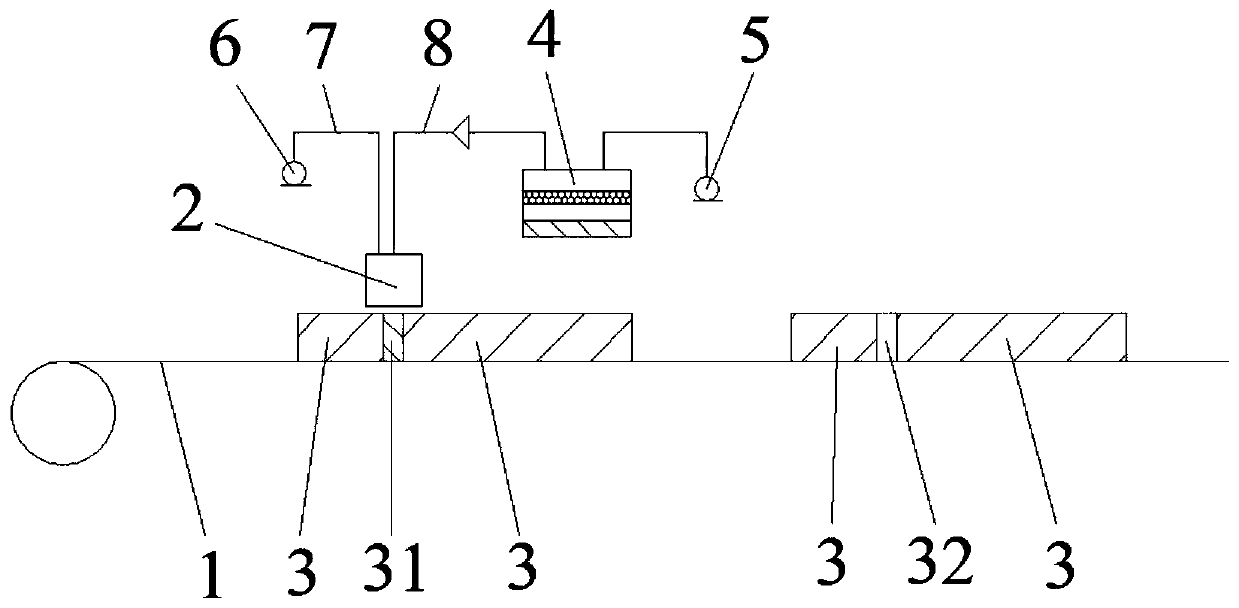

Slurry removing method and assembly and system for implementing method

PendingCN111081969AWill not damageImprove securityFinal product manufactureElectrode collector coatingMetallurgyElectrical battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a slurry removing method. The method comprises the steps of 1, arranging a probationary empty foil area on the surface of a current collector, and coating the current collector with slurry to obtain an active substance layer; 2, setting the upper part of the probationary empty foil area as positive pressure so as to enable the slurry on the surface of the probationary empty foil area to be gathered; and 3, setting the upper part of the probationary empty foil area as negative pressure so as to suck the slurry gathered on the surface of the probationary empty foil area to obtain the empty foil area. The method has the advantages of good mass production, no introduction of special consumables,low cost, no damage to the current collector compared with the current mode of scraping part of the active substance layer after drying, and more excellent safety performance of the electrical core.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

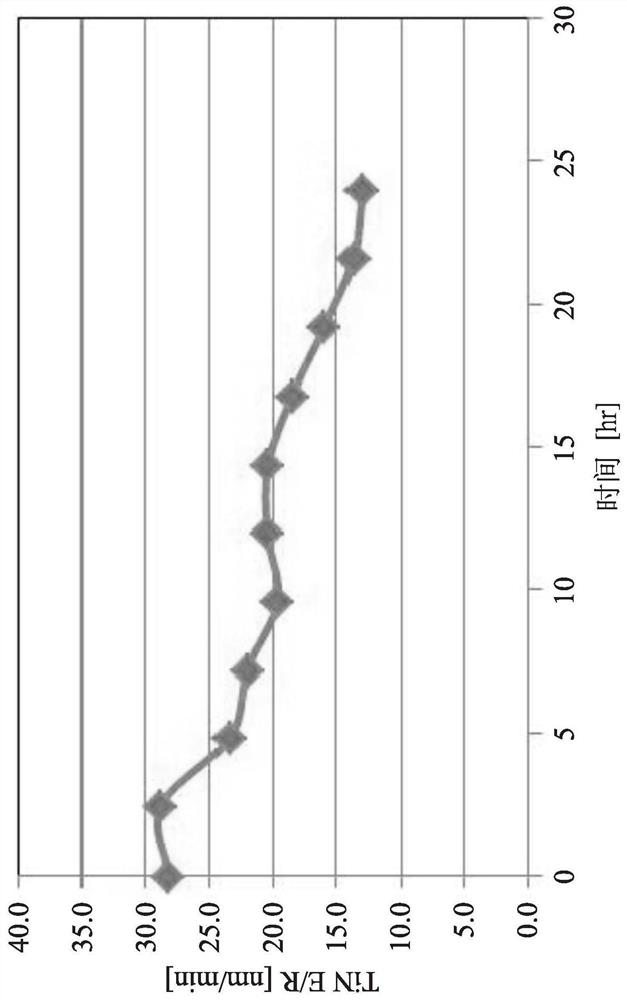

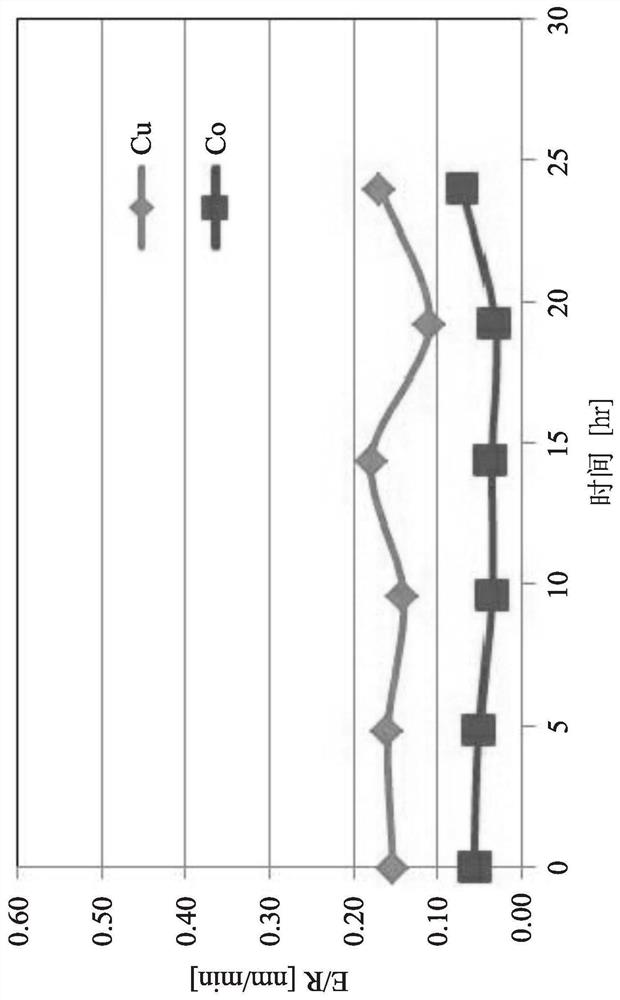

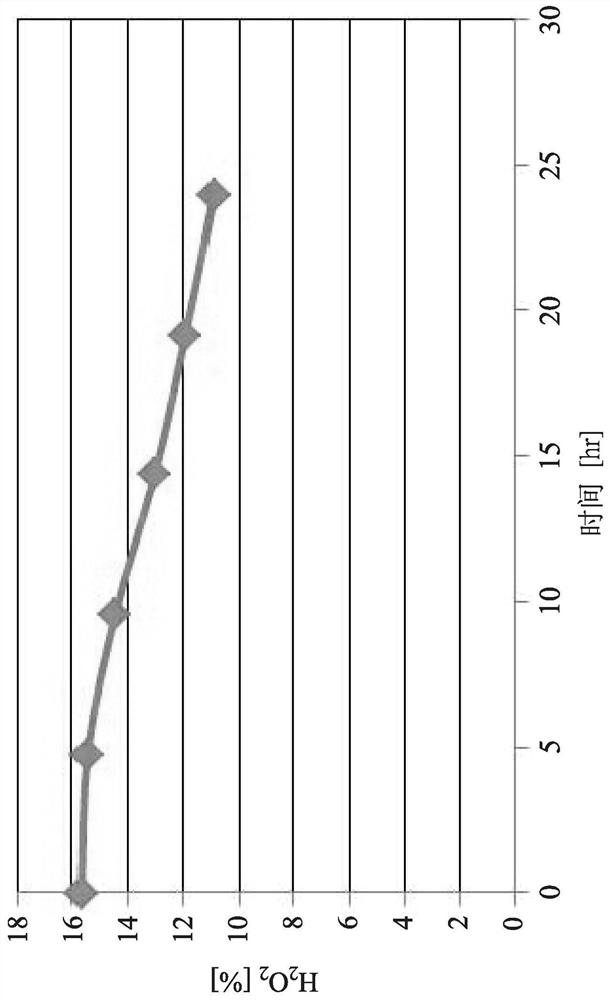

Etching composition

PendingCN112080279AImprove etch selectivityImprove stabilitySurface treatment compositionsElectrical conductorPhysical chemistry

The invention discloses an etching composition. Specifically, the invention relates to an etching composition for selectively etching a titanium nitride hard photomask, which comprises an alkaline compound, a chelating agent, a corrosion inhibitor and a solvent. The etching composition provided by the invention has excellent etching selectivity, can quickly remove titanium nitride (TiN) and dry etching residues, does not damage a lowk layer and a metal conductor layer, still has certain oxidation capacity, etching selectivity, pH value and other characteristics after being repeatedly used, andis suitable for being used in a recycling process.

Owner:KANTO PPC

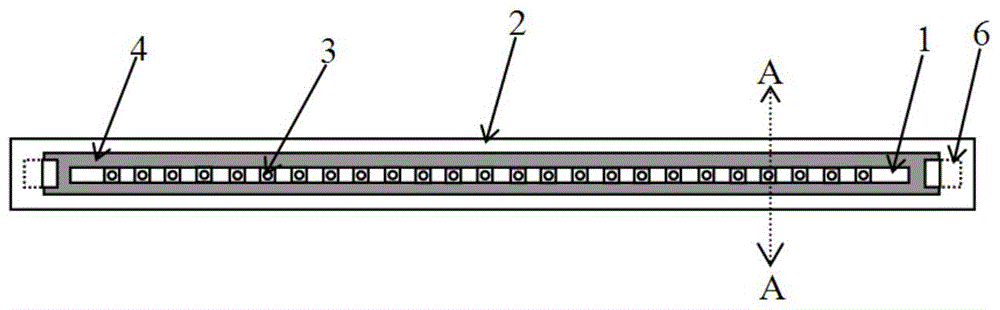

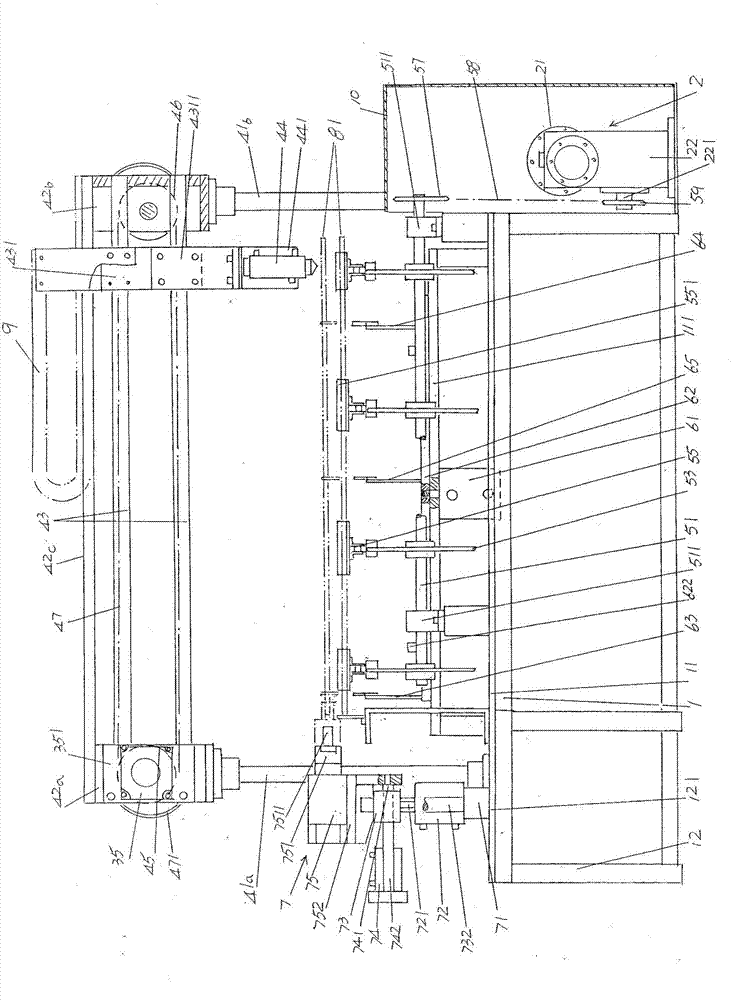

Roll compacting device of PTC heating core heat conduction pipe

ActiveCN104550387APrevent transition deformationReduce resistanceMetal-working feeding devicesPositioning devicesPositive temperatureEngineering

The invention discloses a roll compacting device of a PTC (positive temperature coefficient) heating core heat conduction pipe and belongs to the field of a special device for manufacturing a PTC heater. The roll compacting device comprises a rack on which a working table is arranged, one group of heat conduction pipe holding mechanisms, a heat conduction pipe leading-in mechanism, a heat conduction pipe transition leading-out mechanism, a heat conduction pipe leading-out mechanism, a power transmission mechanism, and one group of heat conduction pipe roll compacting mechanisms, wherein each heat conduction pipe holding mechanism respectively includes front and rear axle bases, an upper roller disc shaft, an upper roller disc, a lower roller disc shaft and a lower roller disc; the heat conduction pipe leading-in mechanism comprises a guide plate fixing cross rod and a guide plate, and one group of front and rear guide wheels of the guide plate is arranged on the guide plate; the heat conduction pipe leading-out mechanism comprises an upper leading-out axle base, an upper leading-out wheel, a lower leading-out axle base and a lower leading-out wheel; the power transmission mechanism comprises a motor, a main transmission wheel, a lower roller disc shaft transmission wheel, a lower leading-out axle transmission wheel, a main transmission belt and a transition transmission belt; one group of heat conduction pipe roll compacting mechanisms is distributed on the left side of each heat conduction pipe holding mechanism and corresponding to the left side of the passageway between upper and lower roller discs.

Owner:嘉善县魏塘资产管理有限公司

Ore crusher rotor disk hinge pin dismantling method

InactiveCN101683699AEasy to removeWill not damageGrain treatmentsGas flame welding apparatusCircular discEngineering

The invention discloses an ore crusher rotor disk hinge pin dismantling method. The method comprises the following steps: firstly using an oxygen lance with suitable length corresponding to a rotor, thick wall and small inside diameter to cut hinge pins on front row disks, cooling the cut hinge pins, then hammering the hinge pins into pieces with a hammer; for hinge pins on back row disks, placinga positioning sleeve between a disk of dismantled hinge pins and disk of hinge pins to be dismantled, passing the oxygen lance through a hinge pin bore of the disk of the dismantled hinge pins and apositioning bore of the positioning sleeve to cut hinge pins on back row disks which can not damage the rotor and disks after positioning the oxygen lance, using the oxygen lance to cut hinge pins from the tail end of the rotor after dismantling hinge pins on the front half section of rotor disks, and repeating the above steps to dismantle hinge pins on all the disks in turn. The method of the invention can conveniently dismantle hinge pins, increase the dismantling efficiency, reduce the labour intensity and not damage the disks and the rotor.

Owner:SHANGHAI BAOSTEEL EQUIP MAINTENANCE CO LTD

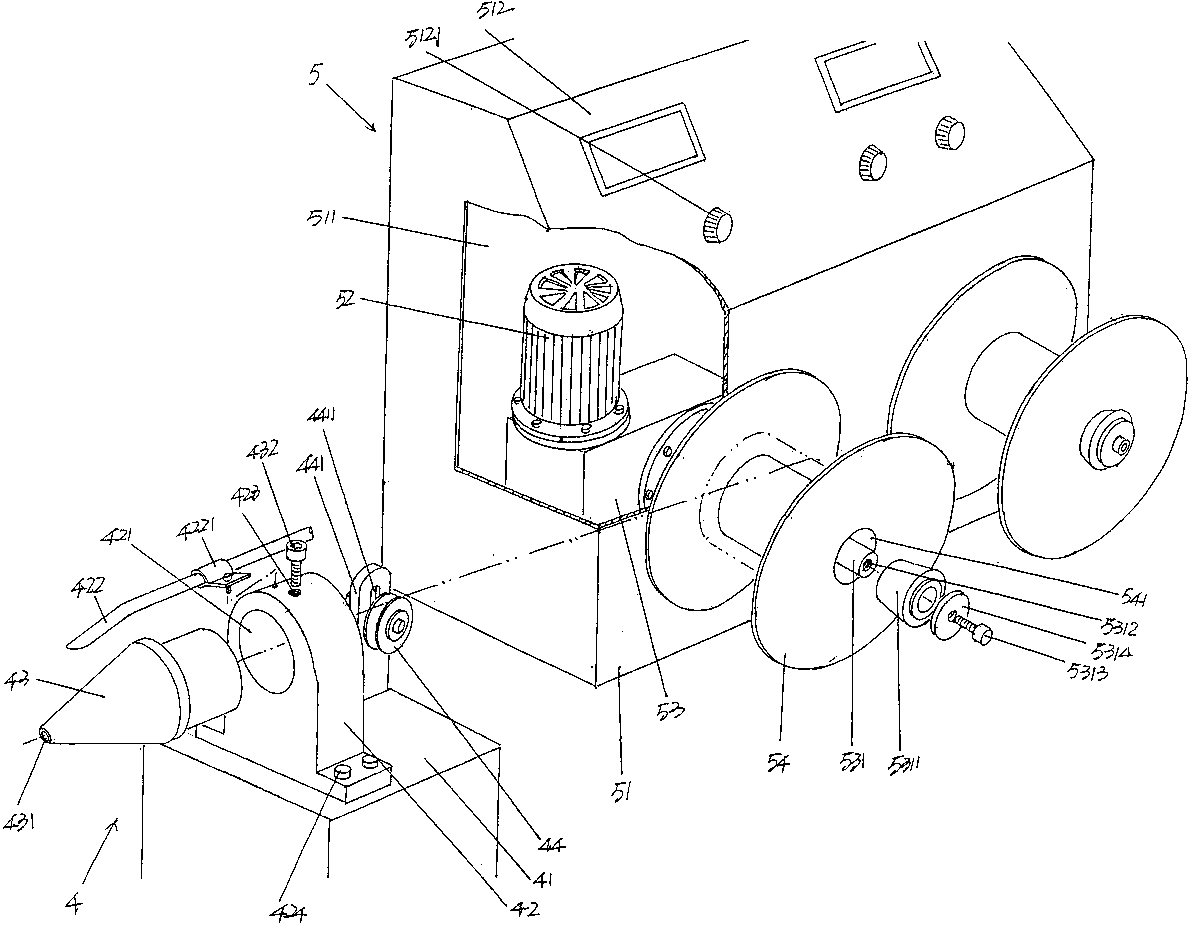

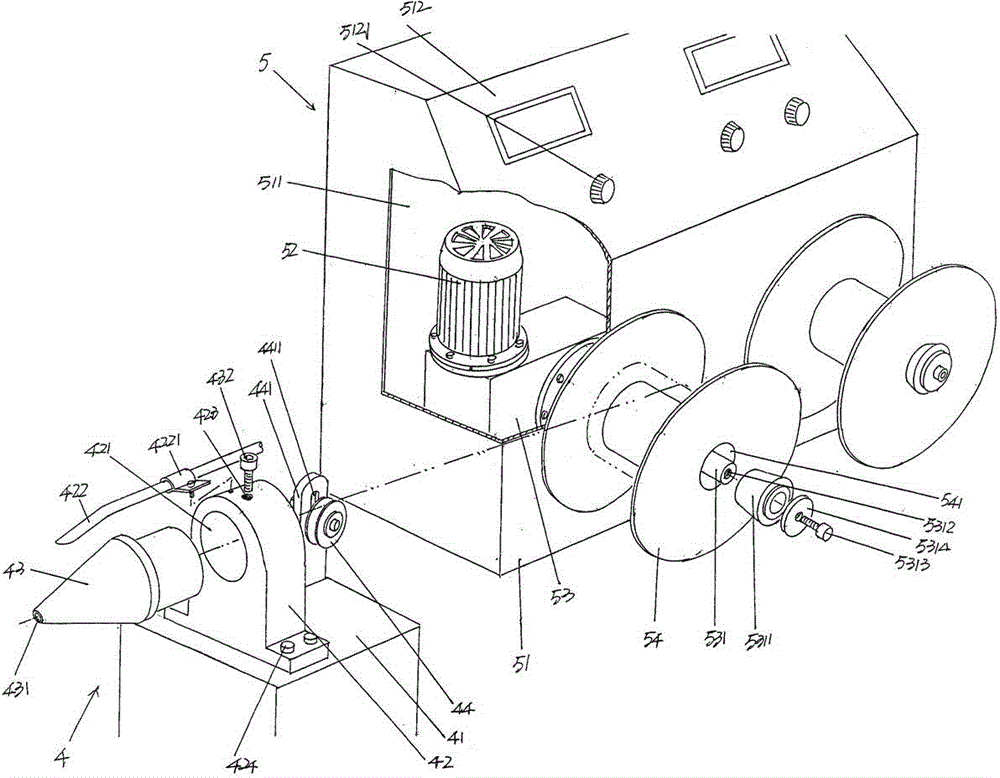

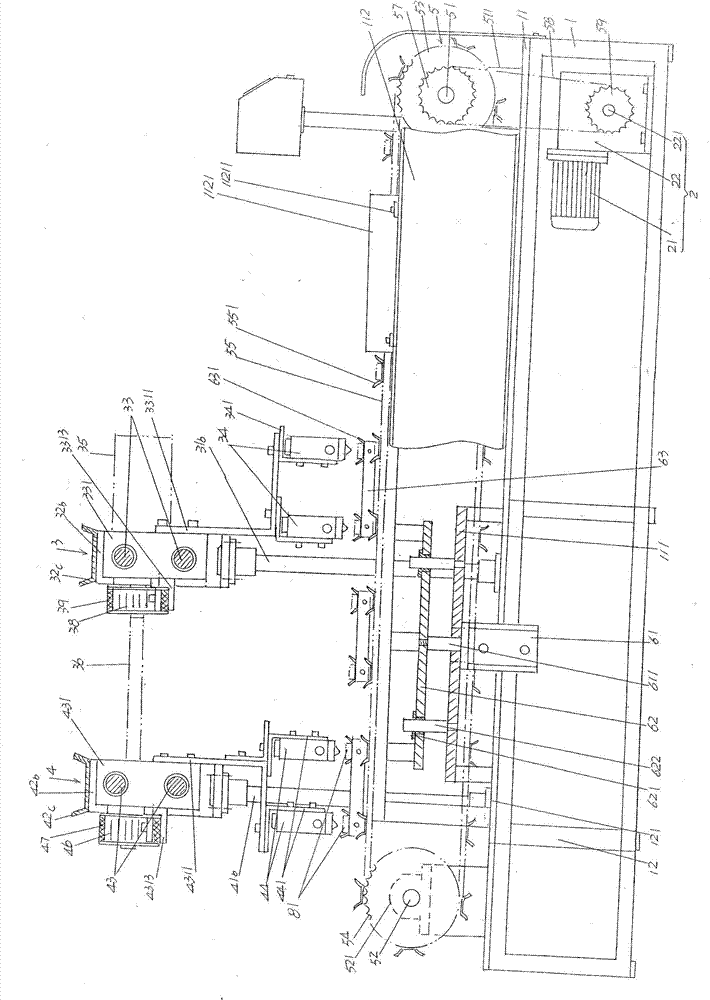

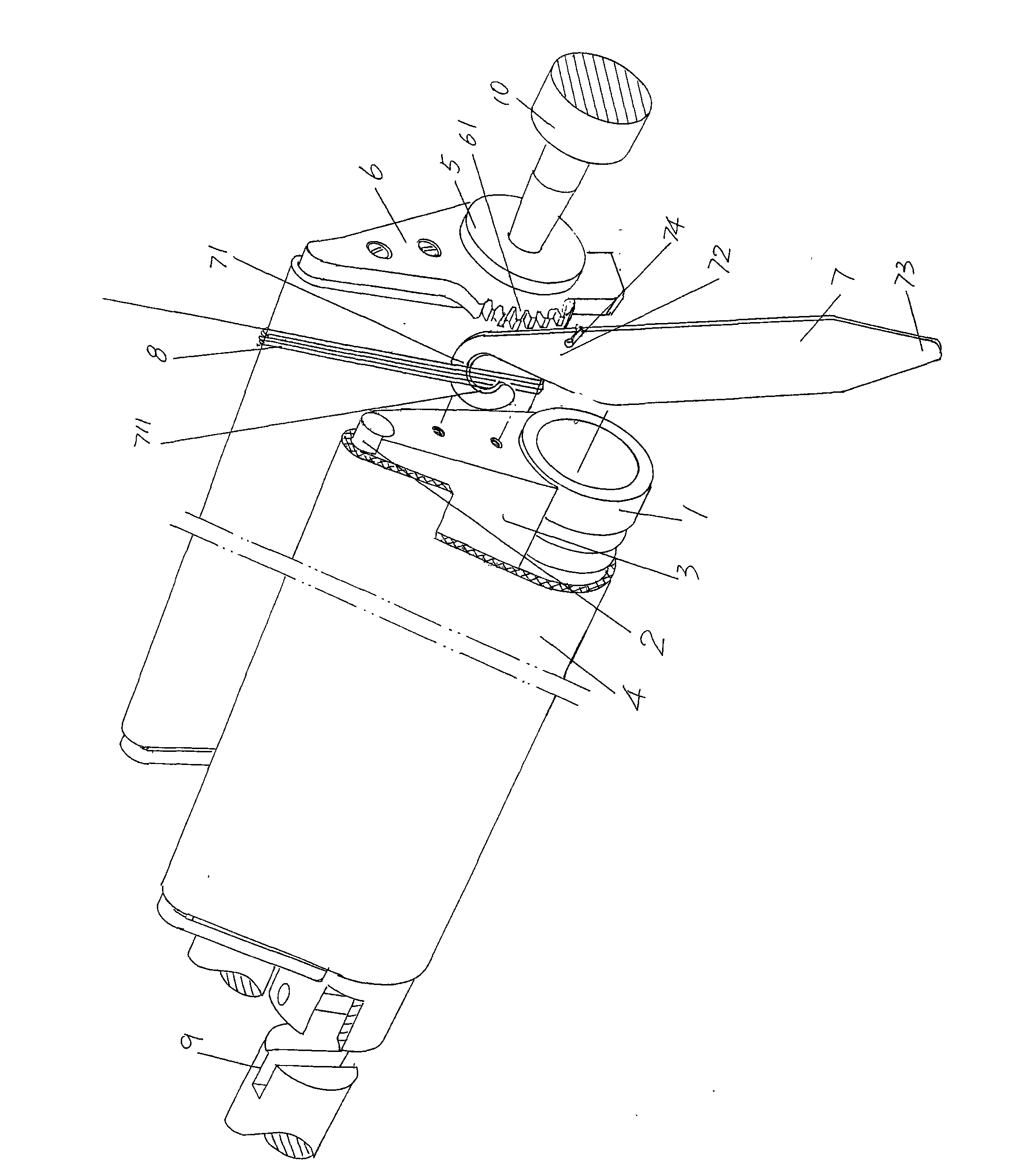

Automatic PTC heating tube glue spraying machine

ActiveCN104722430AMeet the requirements of non-contact glue sprayingWill not damageSpraying apparatusElectrical and Electronics engineering

The invention relates to an automatic PTC heating tube glue spraying machine, and belongs to the technical field of devices special for manufacturing PTC heaters. The automatic PTC heating tube glue spraying machine comprises a rack provided with a table board plate on the upper portion, a power mechanism arranged accompanying with the rack, a PTC heating tube front face glue spraying mechanism, a PTC heating tube back face glue spraying mechanism, a PTC heating tube conveying mechanism arranged on the table board plate and connected with the power mechanism, a PTC heating tube lifting mechanism arranged at the left end of the table board plate, and a PTC heating tube turnover mechanism arranged at the front side or rear side of the left end of the table board plate, wherein the PTC heating tube front face glue spraying mechanism and the PTC heating tube back face glue spraying mechanism are connected in a transmission mode and arranged at the left end of the table board plate in the state of rising high above the table board plate, and the PTC heating tube front face glue spraying mechanism is located at the right side of the PTC heating tube back face glue spraying mechanism. The requirement for spraying glue on PTC heating tubes in a non-contact mode of the PTC heating tube front face glue spraying mechanism and the PTC heating tube back face glue spraying mechanism are met, lack of glue is avoided, the manpower investment is reduced, the gluing efficiency is high, and the automatic PTC heating tube glue spraying machine is environmentally friendly and convenient to manufacture, use and maintain.

Owner:嘉善县魏塘资产管理有限公司

Semi-automatic barreling device of full-automatic filling machine

InactiveCN102923357AReduce labor intensityImprove work efficiencyPackagingStructural engineeringWaste material

The invention discloses a semi-automatic barreling device of a full-automatic filling machine, and belongs to the technical field of packing machinery. The semi-automatic barreling device of the full-automatic filling machine comprises a soft packing bag conveying mechanism, a bag opening clamping mechanism, a lifting action cylinder and a soft packing bag reshaping mechanism. The soft packing bag conveying mechanism comprises a conveying frame and a conveying belt. The semi-automatic barreling device comprises a machine frame, wherein a first guide rail stand column and a second guide rail stand column are fixed on one side of the upper portion of the machine frame. A first guide rail is fixed on the first guide rail stand column at the height direction of the first rail stand column, and a second guide rail is fixed on the second guide rail stand column at the height direction of the second rail stand column. The bag opening clamping mechanism is matched with the first guide rail and the second guide rail in a sliding mode. The lifting action cylinder is fixed on the machine frame and the tail end of the lifting action cylinder is connected with the bag opening clamping mechanism. The soft packing bag reshaping mechanism is arranged on the machine frame and corresponds to the lower portion of the bag opening clamping mechanism. The semi-automatic barreling device of the full-automatic filling machine has the advantages of obviously reducing labor intensity, improving working efficiency, completely eradicating damaged bags and wasted materials, and being simple in whole structure. The semi-automatic barreling device of the full-automatic filling machine can not damage soft packing bags.

Owner:常熟市贝普包装机械有限公司

Degradable cushioning packaging material and preparation method thereof

InactiveCN110771433AImprove protectionWill not damageCultivating equipmentsMushroom cultivationBiotechnologyCorn flour

The invention relates to a degradable cushioning packaging material and a preparation method thereof. The preparation method comprises the steps of acquiring the materials, including, by weight, 65-85% of hardwood sawdust, 13-33% of bran , 1% of corn flour, 0.5% of soybean flour and 0.5% of calcium carbonate powder, adding the materials into a container, adding water, and stirring to obtain a matrix; loading the matrix into a mold, punching holes in the matrix paved in the mold at intervals by using a conical rod, and sealing an opening of the mold by using a sealing device with air holes to obtain the matrix to be sterilized; sending the matrix to be sterilized to a high-temperature high-pressure sterilization device for high-temperature high-pressure sterilization, and transferring intoan aseptic chamber for cooling after sterilization is finished so as to obtain the matrix to be inoculated; inoculating a shiitake mushroom strain to the holes where an inoculation point is reserved,returning the sealing device with the air holes to the opening of the mold after inoculation is finished, sending the mold to a ventilated clean culture chamber for culture, and drying and removing from the mold after mycelia fully cover the matrix to obtain the finished product. The extreme cushioning performance is embodied; the environment is protected; the steps are simple and short.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Preparation method of environment-friendly halogen-free flame-retardant polyethylene glycol terephthalate molded plastic

The invention relates to a preparation method of environmental-friendly halogen-free flame-retardant polyethylene glycol terephthalate molded plastic, and belongs to the technical field of preparation of high molecular materials. The preparation method comprises the following steps: putting 63-75 parts of polyethylene glycol Terephthalate to a drying device to be dried to obtain a dried material which is put into a high speed mixer; then, putting 7-13 parts of polyolefin, 15-23 parts of amorphous polyester resin, 6-14 parts of a flexibilizer, 12-22 parts of phosphate, 18-27 parts of a filler, 0.7-1.2 parts of an antioxygen, 12-25 parts of a nanofiber and 1.3-1.9 parts of carbon black to the high speed mixer to be mixed with the dried material; and guiding the mixture in a twin-screw extruder to carry out melt extrusion, and cooling, granulating and drying to obtain a finished product, wherein the screw temperatures of zones I to X are controlled as follows: 210 DEG C, 215 DEG C, 225 DEG C, 235 DEG C, 245 DEG C, 255 DEG C, 265 DEG C, 265 DEG C, 265 DEG C and 265 DEG C. The tensile strength is 116-132 MPa, the bending strength is 205-226 MPa, the notch impact strength is 58-78 j / m, the fire resistance reaches V-0(UL-94-3.0mm), and the thermal distortion temperature is 220-240 DEG C. The wasted molded plastic does not damage the environment.

Owner:CHANGSHU YONGXIANG ELECTROMECHANICAL

ptc liquid heater

ActiveCN103743093BImprove heating efficiencyReduce consumptionSteam generation heating methodsOhmic-resistance heatingEngineeringCavity wall

The invention relates to a PTC liquid heater and belongs to the technical field of liquid heating devices. The PTC liquid heater comprises a heater body, a liquid inlet interface and a liquid outlet interface, wherein a liquid heating cavity is formed at the center of the heater body, a left sealing cover and a right sealing cover are arranged at the left end and the right end of the heater body in a matched mode, PTC element mounting cavities are respectively formed on a front side wall and a rear side wall of the heater body, and PTC elements are arranged in the mounting cavities. The liquid inlet interface is arranged on the right sealing cover and communicated with the liquid heating cavity, the liquid outlet interface is arranged on one of the left sealing cover and a top wall of the heater body, and a bottom wall of the heater body forms a heater body mounting wall. The PTC liquid heater is characterized in that a group of heating cavity cooling fins protruded out of a cavity wall surface of the liquid heating cavity are formed on the cavity wall of the liquid heating cavity at intervals in the length direction along the length direction of the liquid heating cavity. The PTC liquid heater is good in heat dissipation effect and high in heating efficiency, saves energy and materials, prevents the heater body from bursting, is safe to use, does not damage the PTC elements when pressing a cavity top wall and a cavity bottom wall and is good in intelligence effect.

Owner:嘉善县魏塘资产管理有限公司

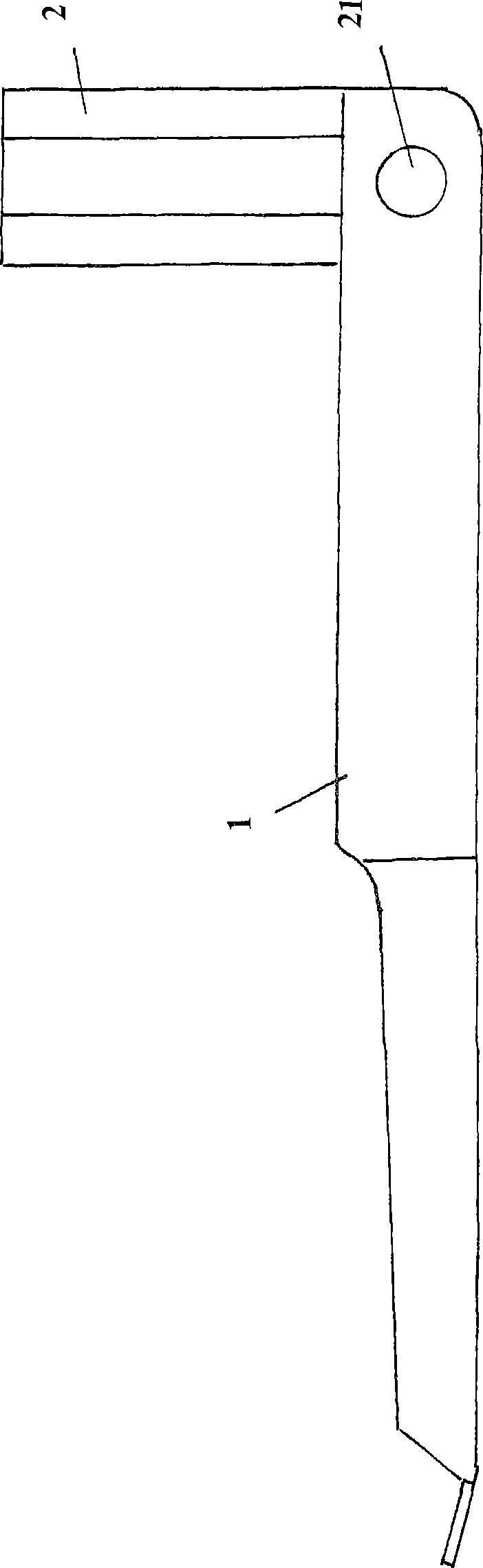

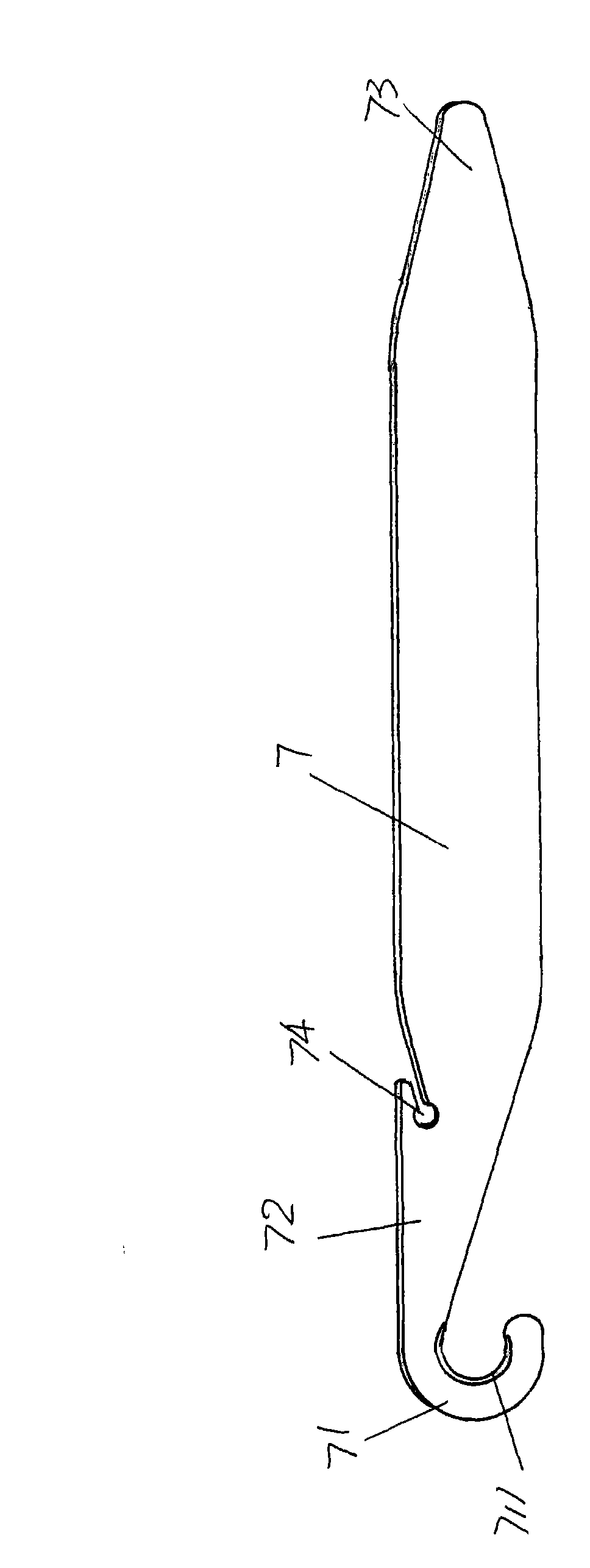

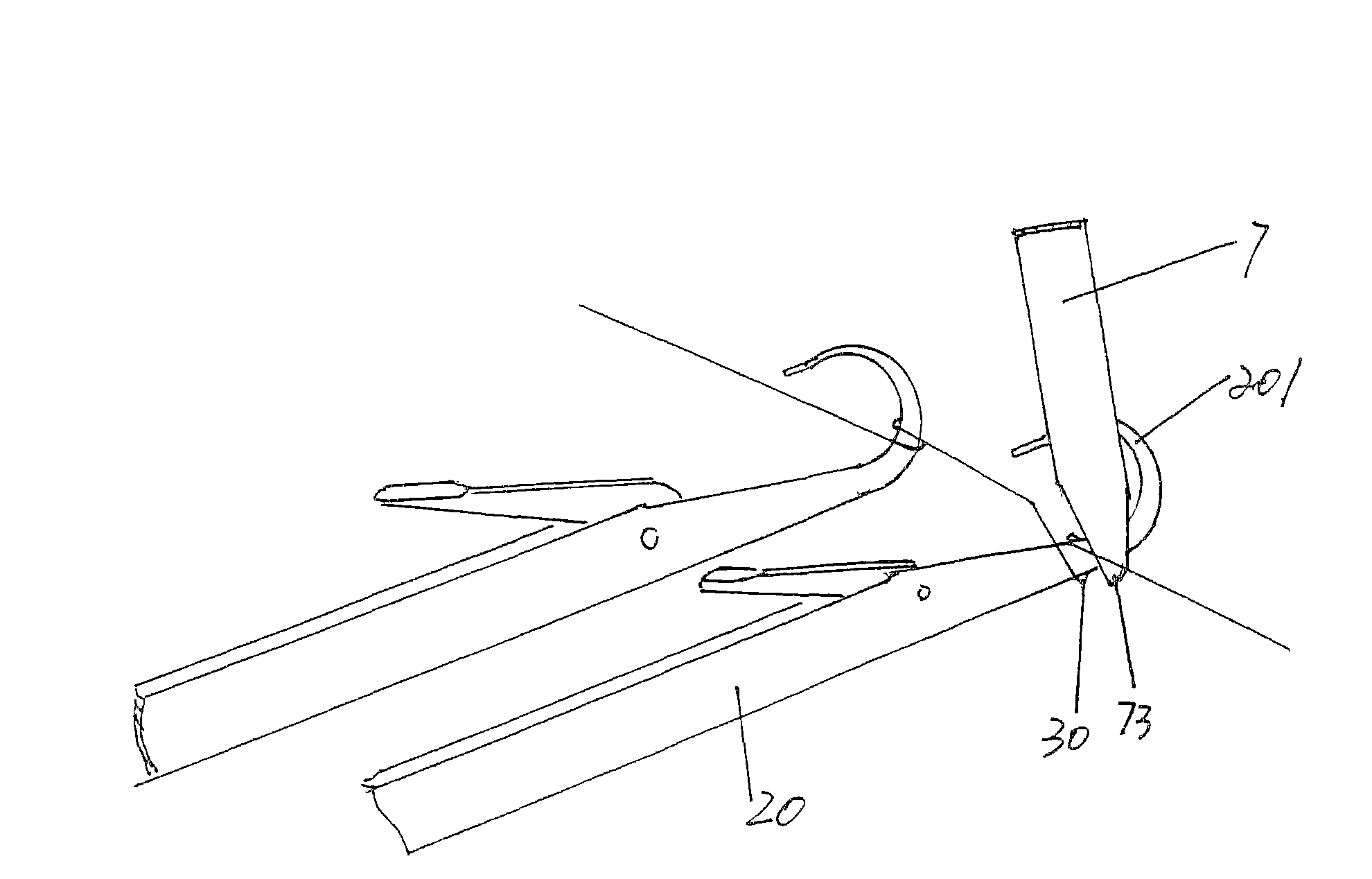

Yarn cutter for clearing winding yarn

The invention provides a yarn cutter for clearing winding yarn, and belongs to the technical field of auxiliary tools of knitting machines. The yarn cutter comprises a cutter rod; one end of the cutter rod forms a bended cutter head; and the cutter head is provided with a yarn cutting edge. The yarn cutter has the advantages that the yarn cutter can conveniently cut waste yarn wound on a cloth clamping sleeve, and the cloth clamping sleeve is not damaged when the waste yarn is cut.

Owner:JIANGSU JINLONG TECHNOLOGY CO LTD

Cable foaming insulation layer sampling device

ActiveCN101598636BWill not damageConsistent and flat thicknessWithdrawing sample devicesInsulation layerEngineering

Owner:JIANGSU ZHONGLI GRP CO LTD +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com