Nondestructive detection system and method for small-sized component surface layer micro-cracks

A micro-crack, non-destructive testing technology, applied in measuring devices, instruments, mechanical devices, etc., can solve problems such as being easily interfered by external factors, reducing detection accuracy, and reducing detection accuracy, to ensure reliability and improve detection. Efficiency, reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] With reference to accompanying drawing, further illustrate the present invention:

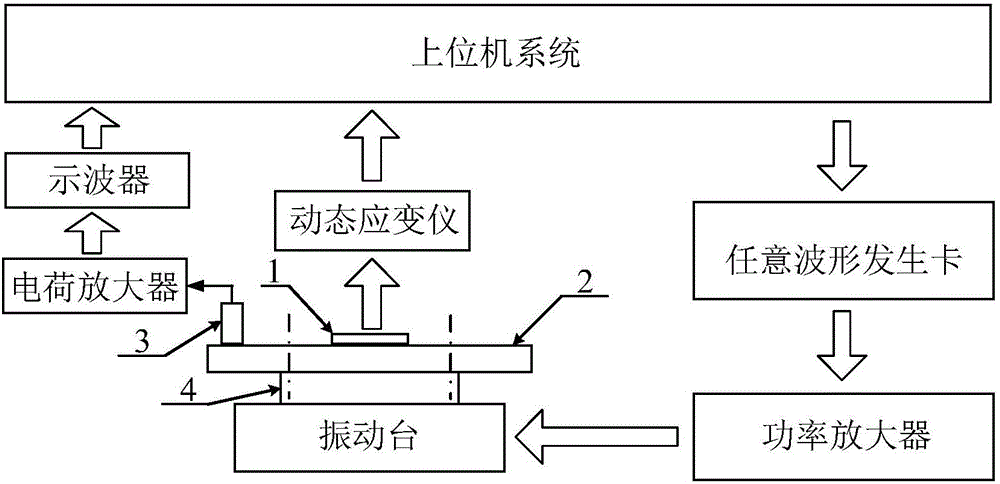

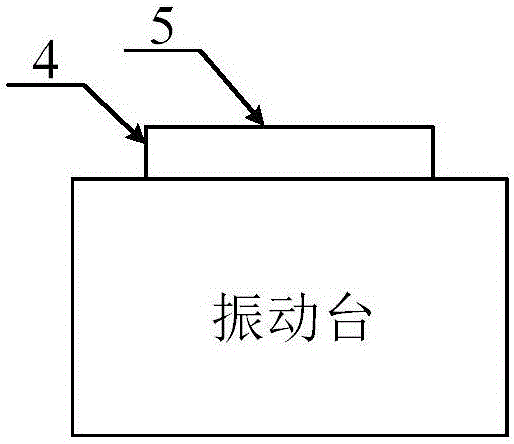

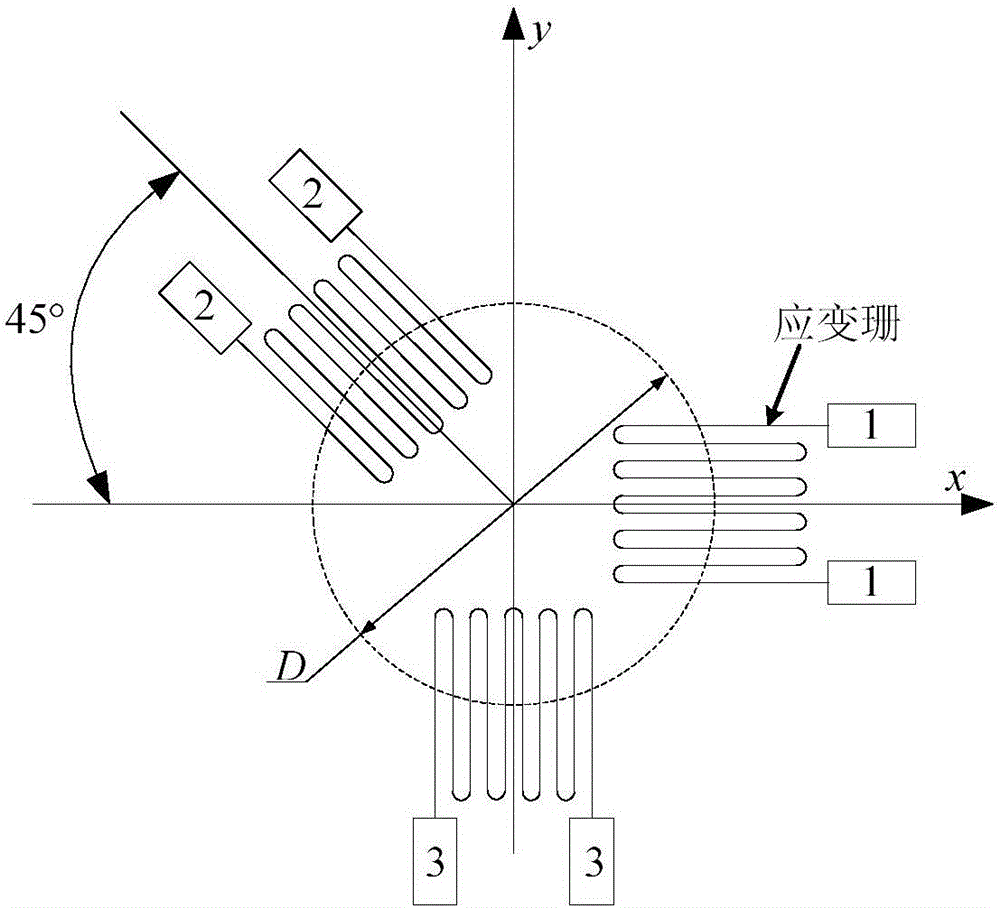

[0041] Non-destructive testing system for surface micro cracks of small-sized components 2, including host computer system, dynamic strain gauge, strain gauge 1, vibration table, power amplifier, arbitrary waveform generator card, charge amplifier, acceleration sensor 3, and oscilloscope.

[0042] The upper computer system controls the arbitrary waveform generation card to output a sinusoidal excitation signal with independent and continuously adjustable amplitude and frequency; the sinusoidal excitation signal output by the arbitrary waveform generation card is input to the vibration table through the power amplifier, thereby driving the vibration table to vibrate; The sensor 3 is installed on the small-sized component 2, the output terminal of the acceleration sensor 3 is connected to the input channel of the charge amplifier, the output channel of the charge amplifier is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com