Patents

Literature

112results about How to "Clear all" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

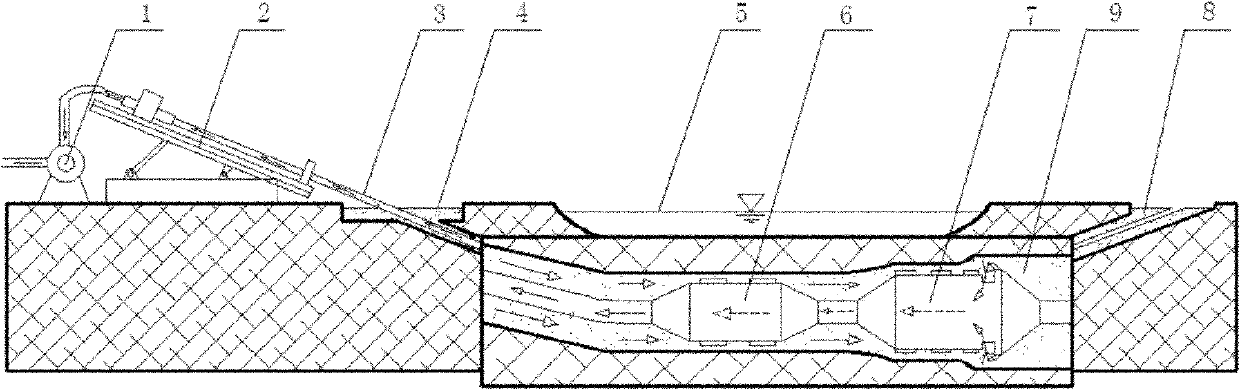

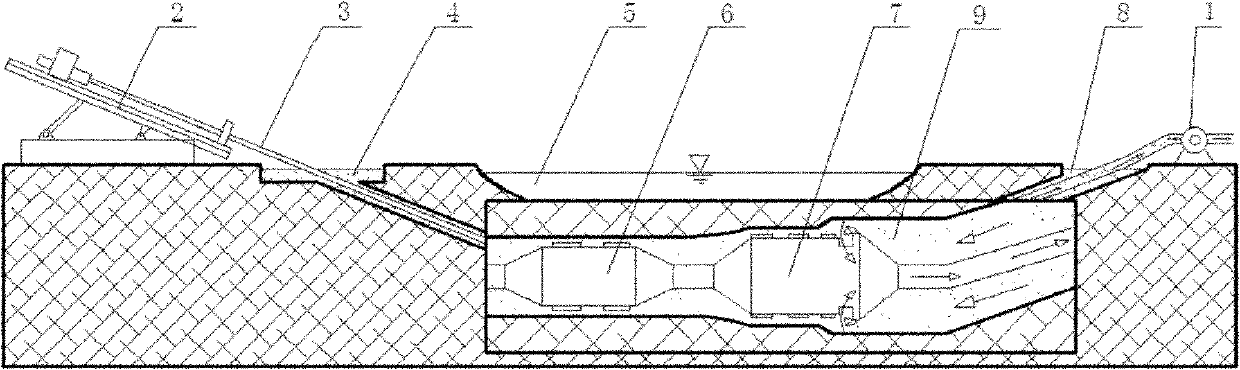

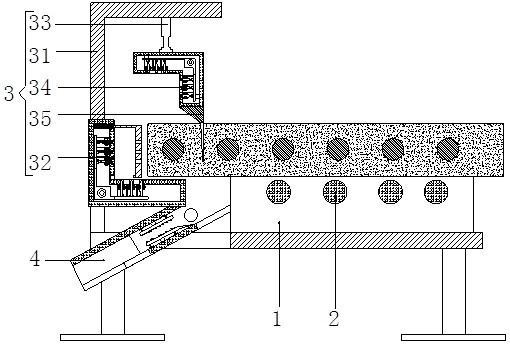

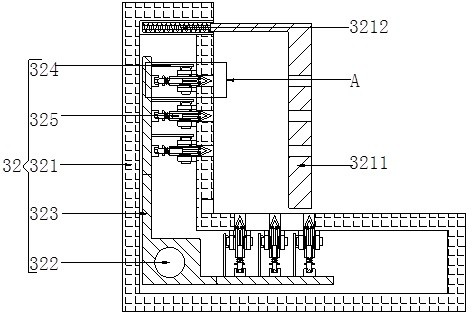

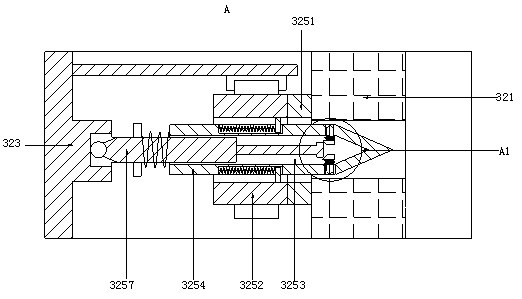

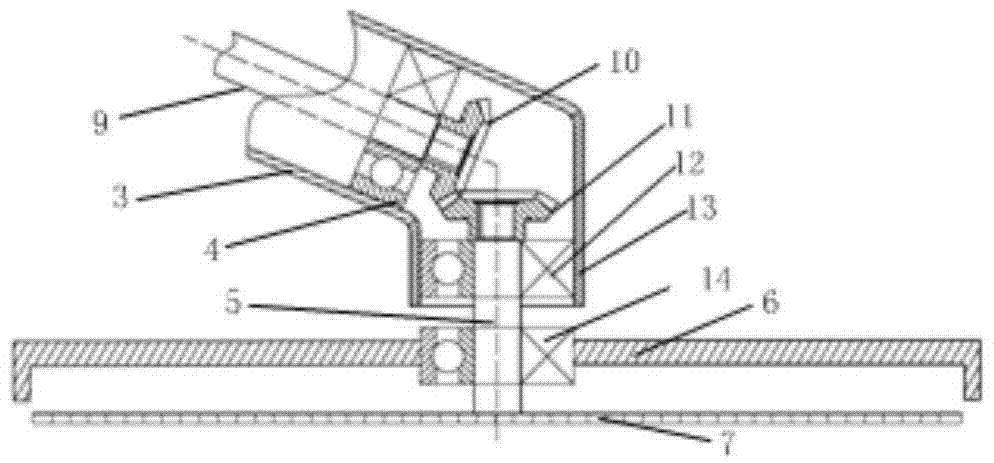

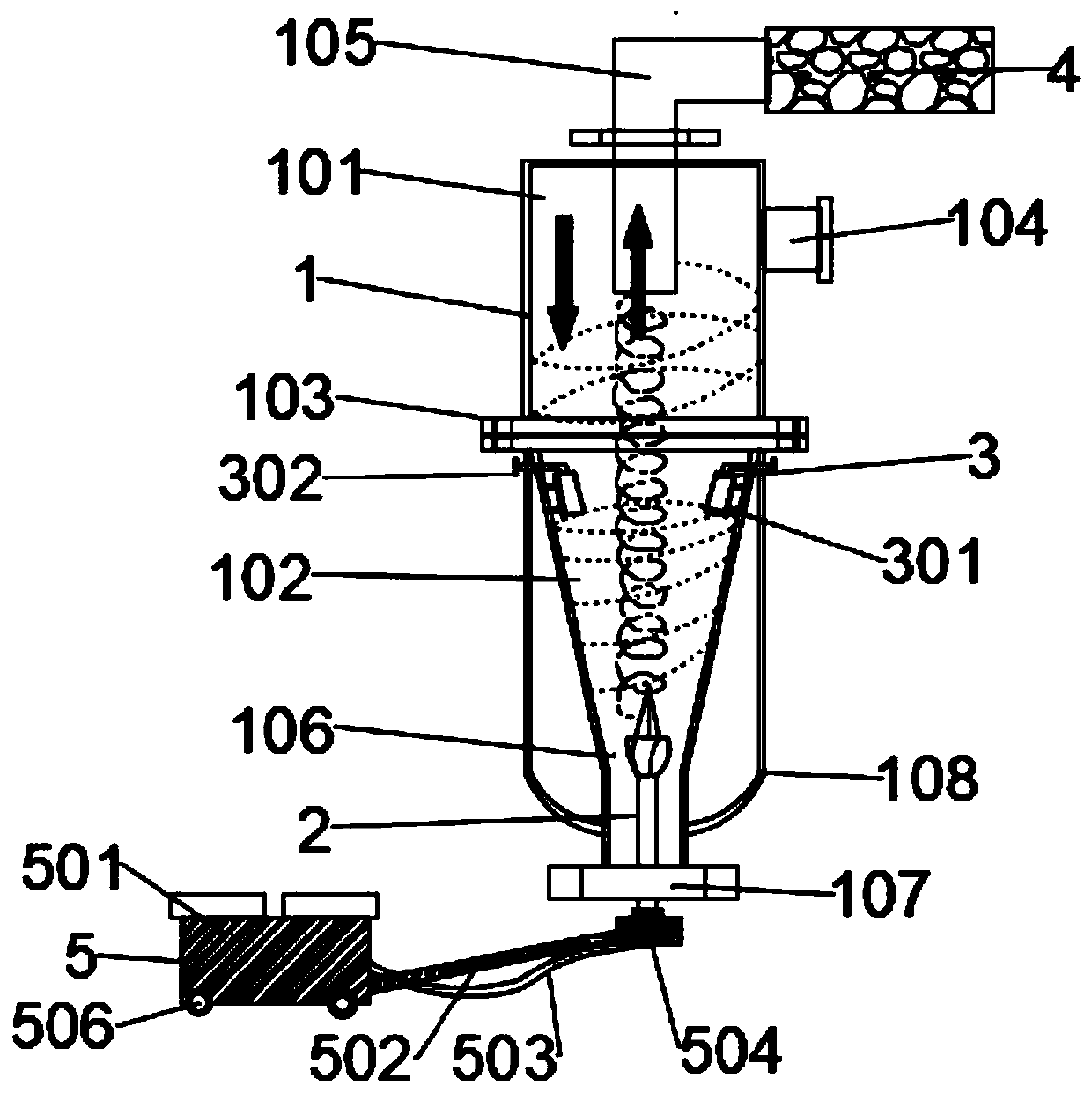

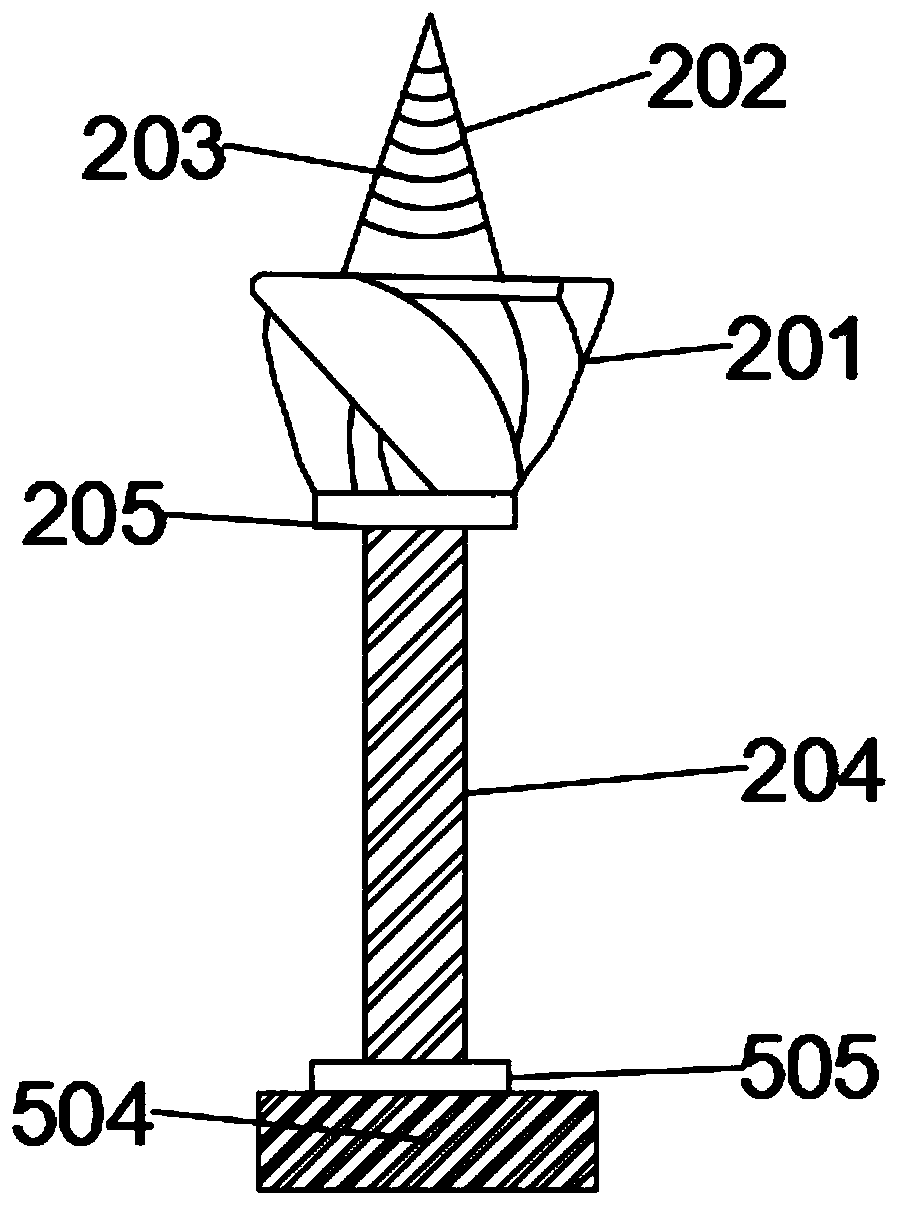

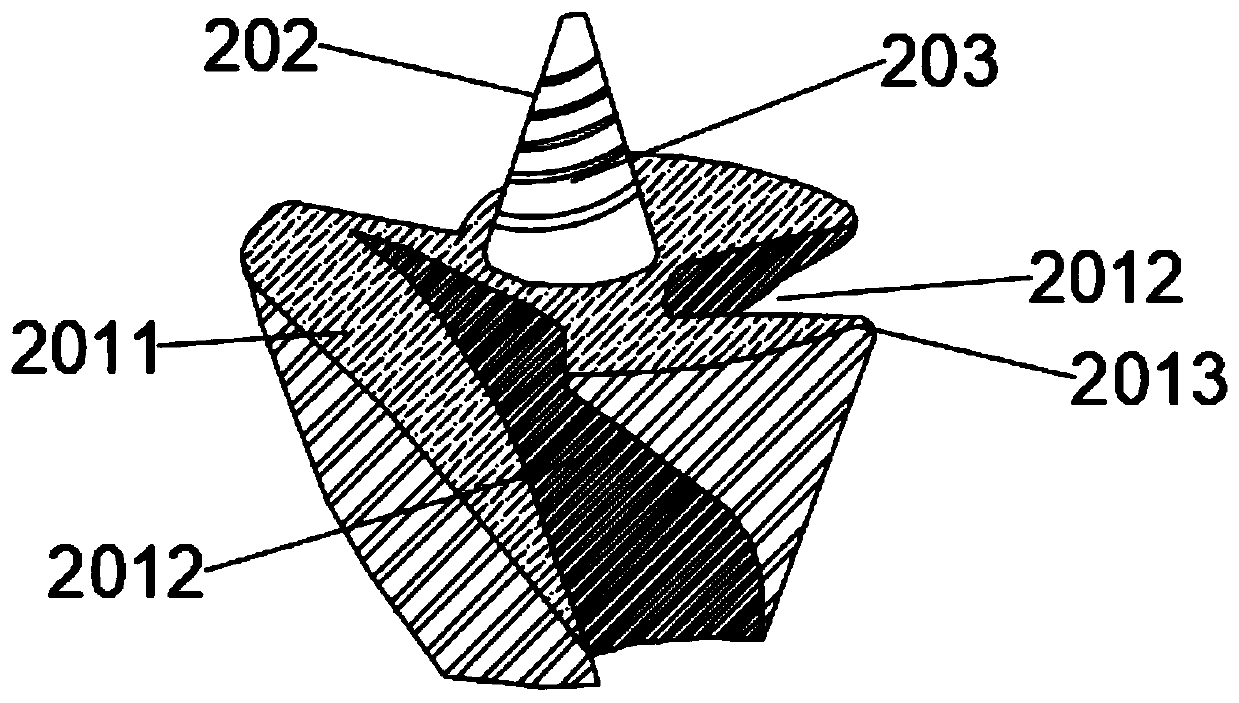

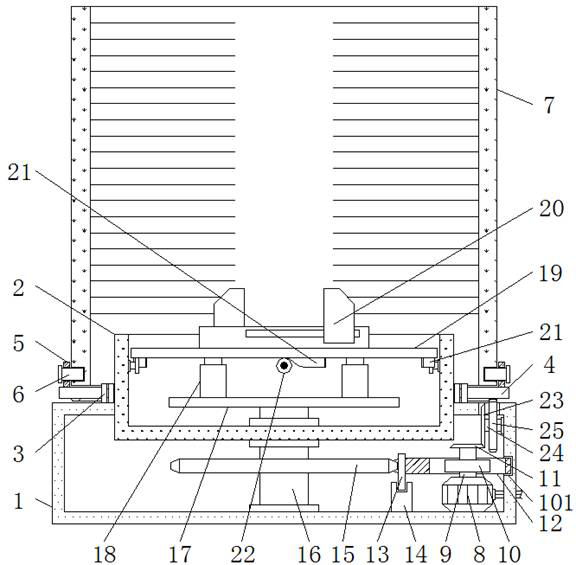

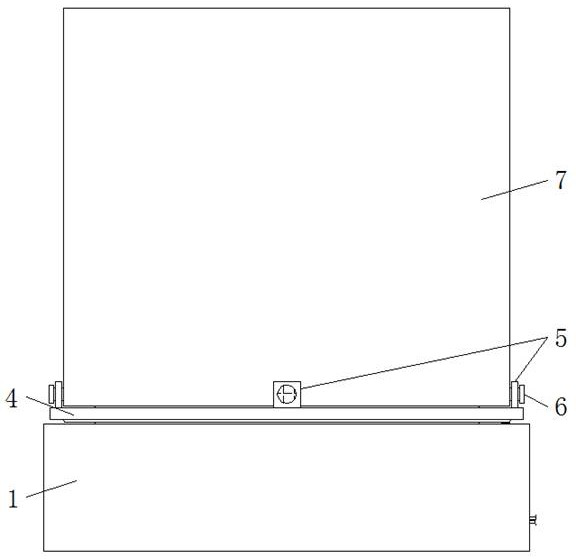

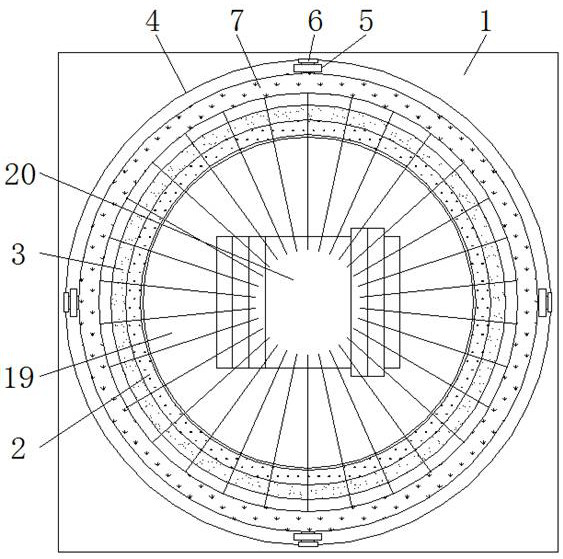

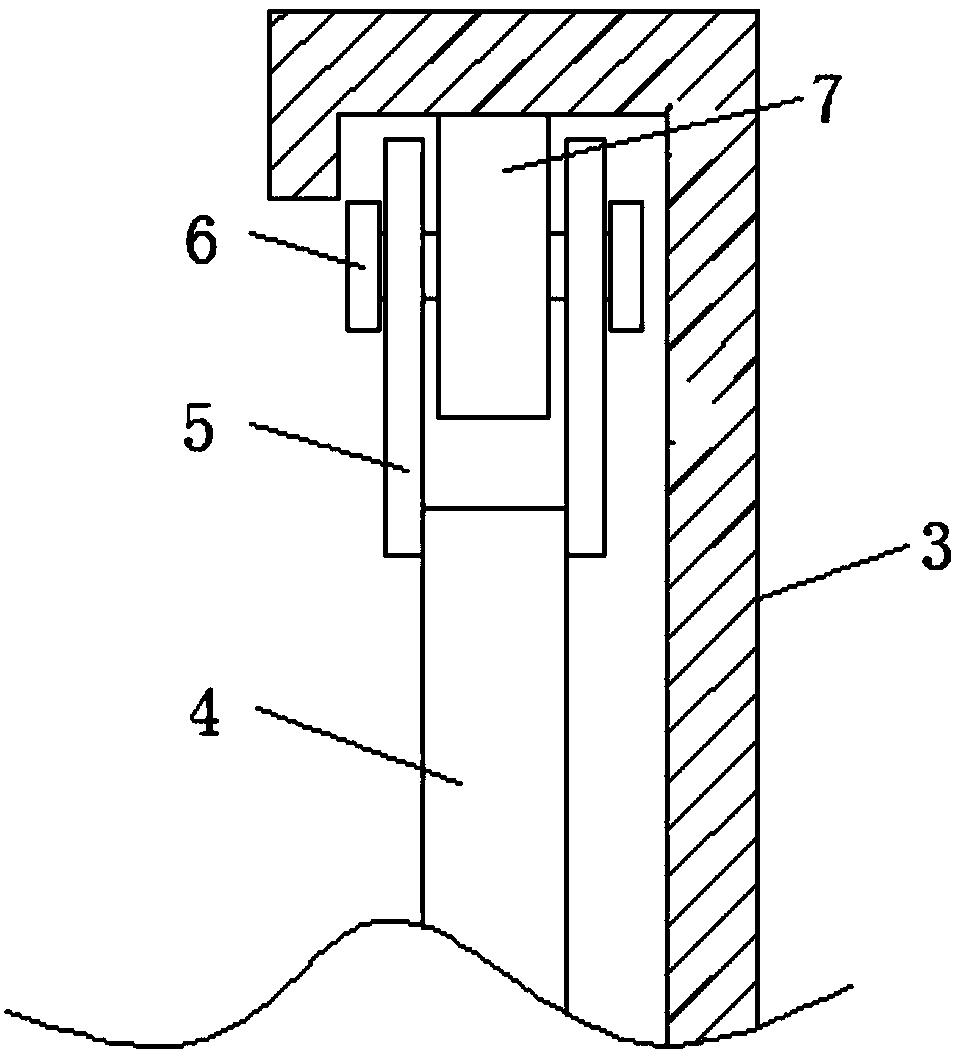

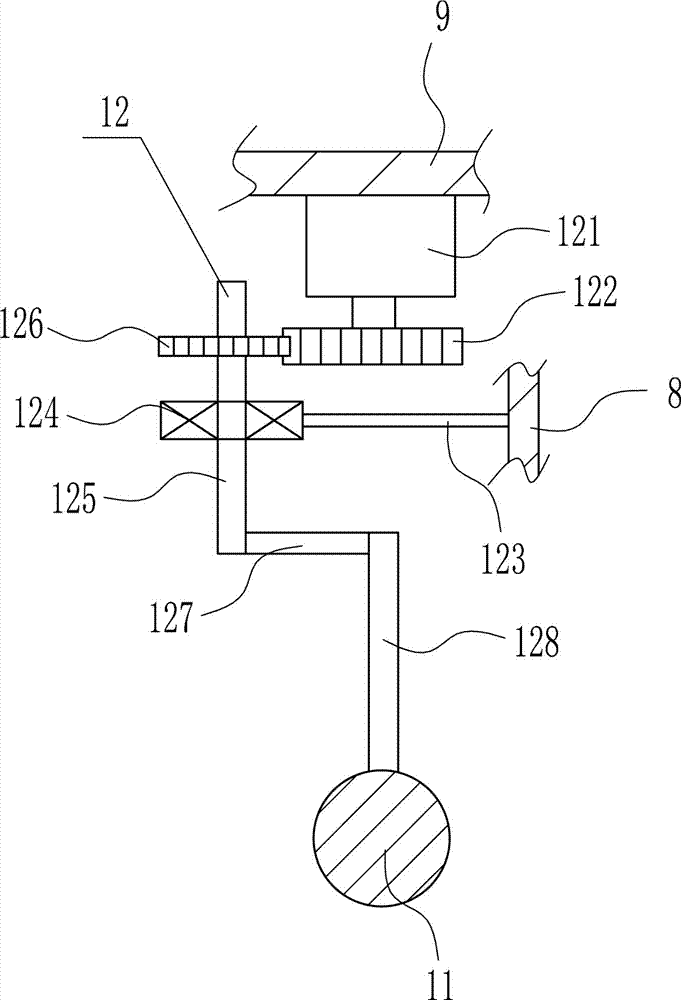

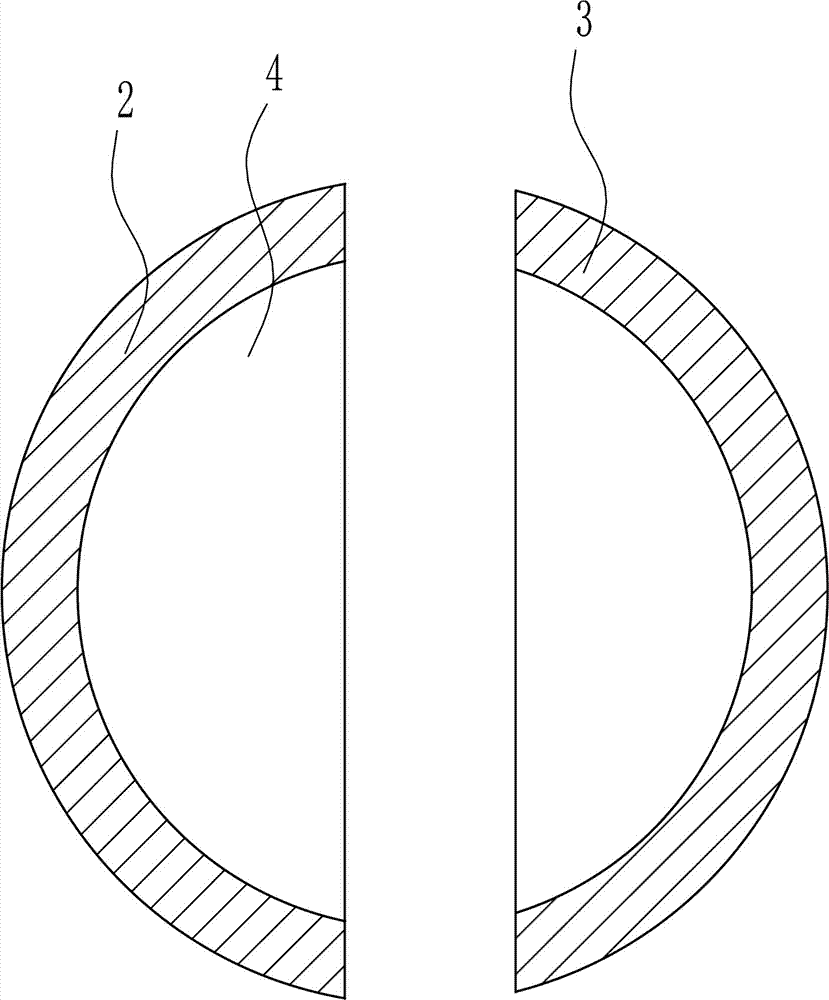

Traversing reverse circulating drilling method of horizontal directional drilling pipeline and special drilling bit

InactiveCN102003140AReduce consumptionImprove drilling efficiencyPipe laying and repairDrill bitsSlurryDirectional drilling

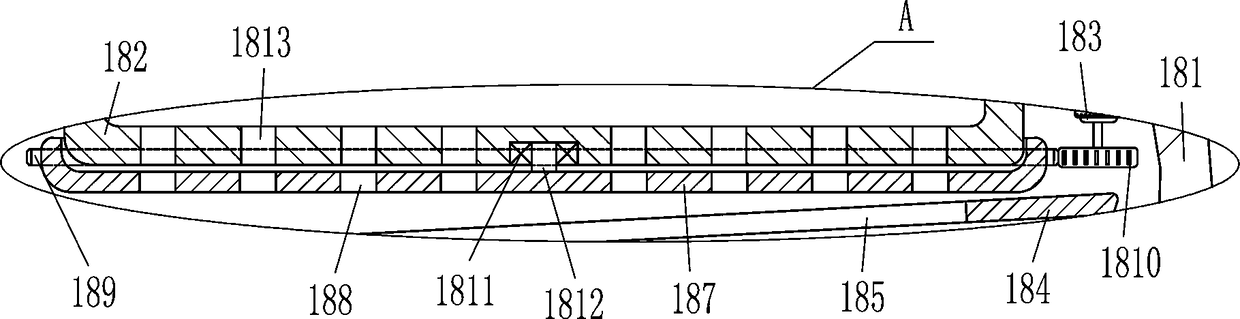

The invention provides a traversing reverse circulating drilling method of a horizontal directional drilling pipeline and a special drilling bit, which are suitable for laying oil-gas pipelines and municipal pipelines. The drilling method comprises the following steps of: mounting a gravel pump at the outer end of a drilling machine or a pit, wherein hollow cavities are formed in the drilling bit and the drilling stem in use; arranging a slag suction port communicated with a borehole circular space on a reaming drilling bit; sleeving a roller cone seat with a roller cone outside the body of the reaming drilling bit, wherein the position of the roller cone corresponds to that of the slag suction port; arranging a plug for blockage at one end of the reaming drilling bit; and circularly flowing slurry according to a flowing direction from a slurry pond to the borehole circular space, the reaming drilling bit, the drilling stem, the gravel pump and the slurry pond during drilling so as to reach the aim of deslagging. The method and the drilling bit of the invention can be adopted to effectively remove drilling slag and gravel in the horizontal borehole and solve various problems in the traversing construction of the large-diameter horizontal directional drilling pipeline.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

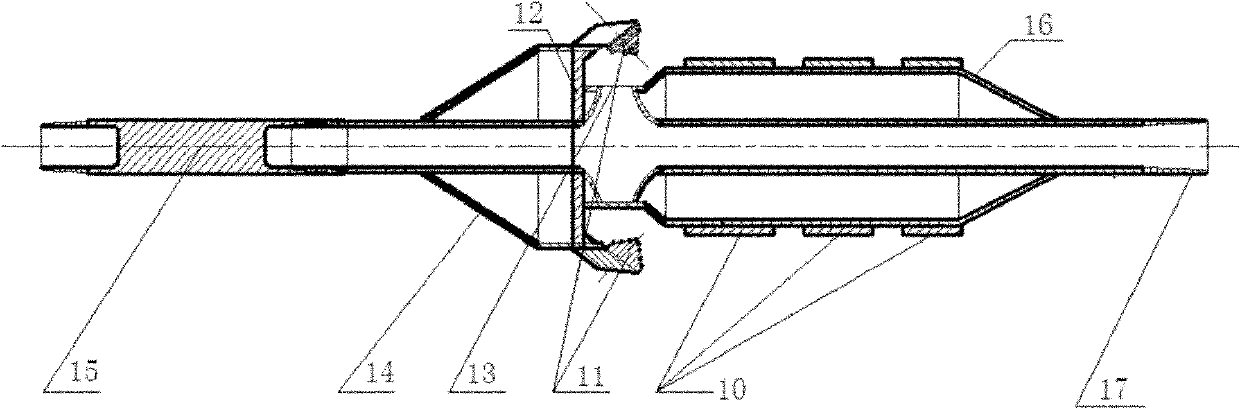

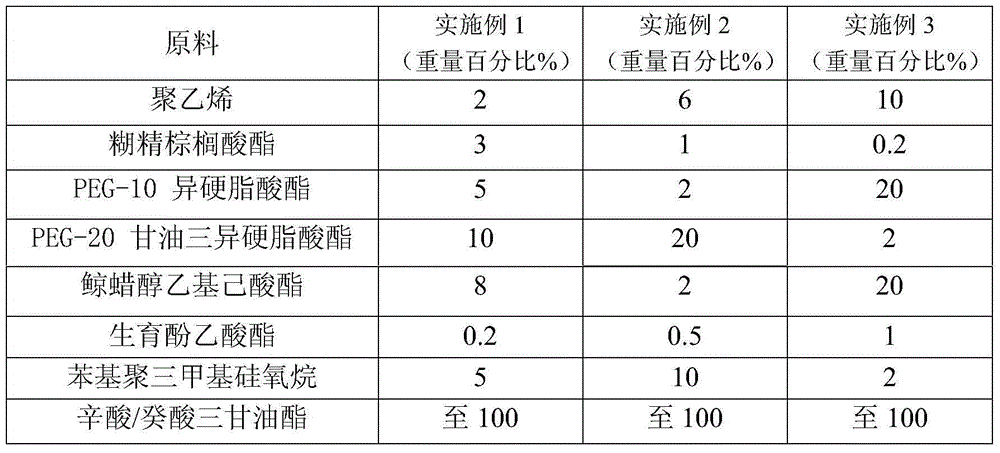

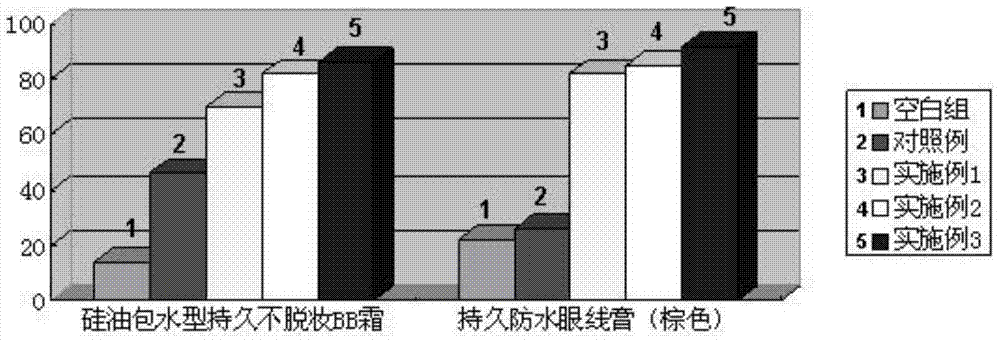

Mild and highly effective wash-free makeup removal cream and preparation method thereof

ActiveCN104800100AThe product is mild in natureGood flushing abilityCosmetic preparationsMake-upTocopheryl acetateCetyl alcohol

The invention relates to a mild and highly effective wash-free makeup removal cream. The mild and highly effective wash-free makeup removal cream is characterized in that the mild and highly effective wash-free makeup removal cream consists of the following components in percentage by weight: 2 to 10 percent of polyethylene, 2 to 20 percent of cetyl alcohol ethylhexoate, 2 to 20 percent of PEG-10 isostearate, 2 to 20 percent of PEG-20 glyceryl triisostearate, 0.2 to 1 percent of tocopheryl acetate, 2 to 10 percent of phenyl trimethicone, 0.2 to 3.0 percent of dextrin palmitate and the balance of caprylic / capric triglyceride. The makeup removal cream disclosed by the invention has the advantages of high makeup removal capability, mild properties, high safety and convenience and easiness in carrying.

Owner:FOSHAN WIN COSMETIC

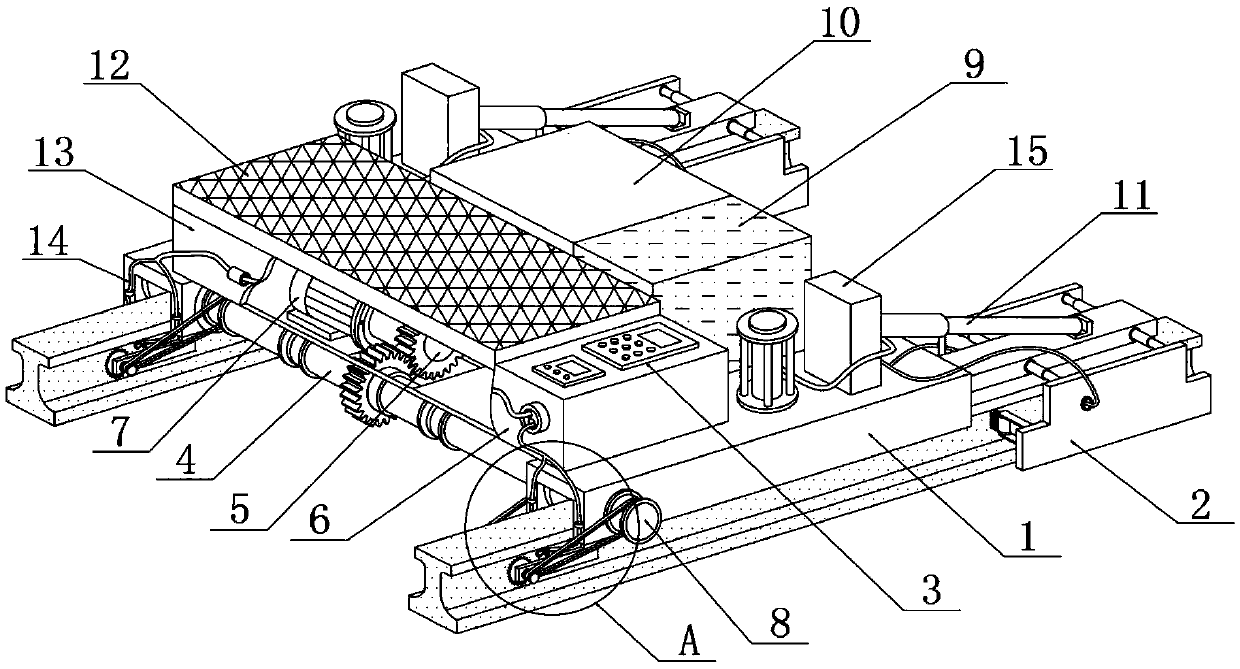

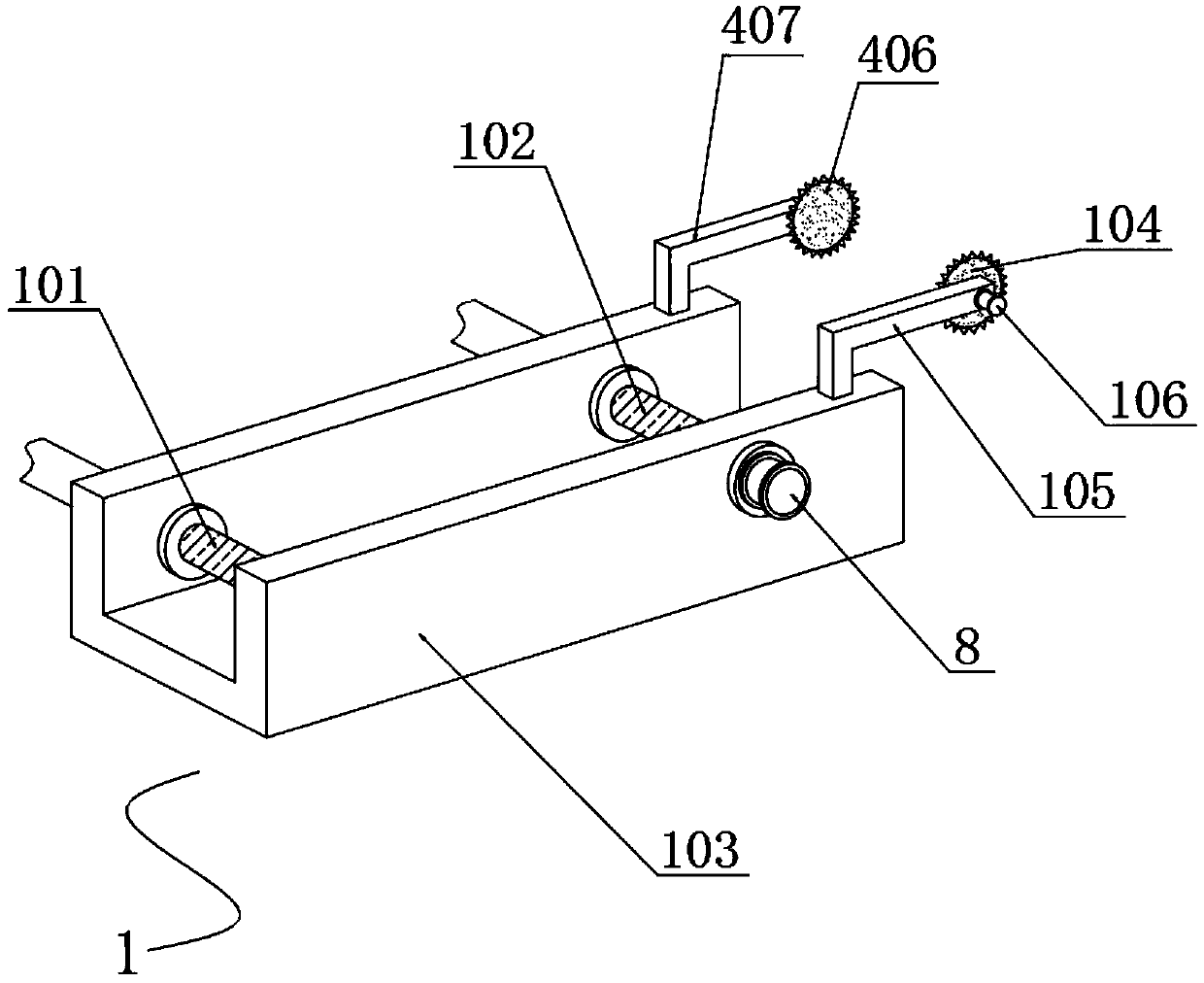

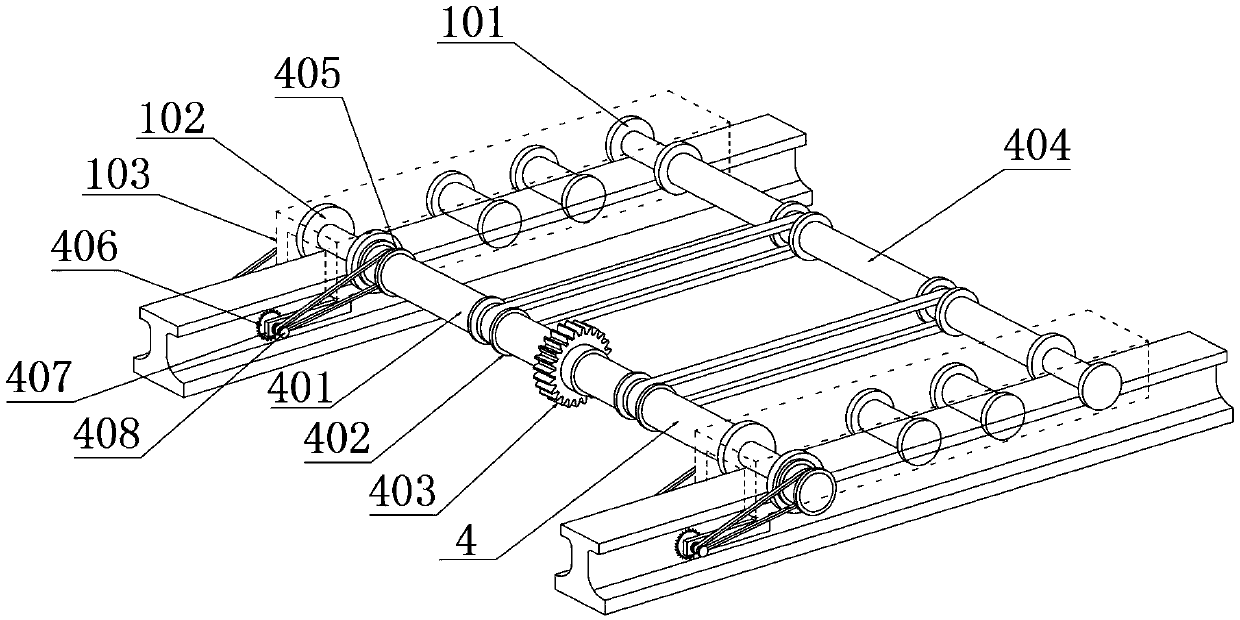

Self-propelled rust-removal grinding device for rail maintenance and with dust removal function

ActiveCN109629355AAffect the quality of useImprove rust resistanceRailway track constructionSpray nozzleEngineering

The invention discloses a self-propelled rust-removal grinding device for rail maintenance and with a dust removal function and relates to the technical field of rail rust removal. The device comprises two symmetrically-arranged walking mechanisms and fan boxes arranged at the upper ends of the walking mechanisms and used for placing fans, and control panels are arranged on the upper surfaces of the fan boxes. According to the device, the walking mechanisms are adopted for achieving self-propelled grinding, the upper surface, inner side and outer side of a rail are synchronously ground, one-time dust removal is achieved, and the dust is thoroughly cleared away; in cooperation with a blowing head, dust can be blown away, and the situation is avoided that since the dust falls on the rail, the application quality of the rail and spraying of an anti-rust solution in the later period are influenced; by adopting a sweeping mechanism, the ground rail is swept, in cooperation with a spray nozzle and a brush roller, the two side faces are sprayed with the anti-rust solution, the anti-dust effect of the rail is improved, and the service life of the rail is prolonged; the device is provided with a solar cell panel, and the cruising capacity during outdoor work is improved, so that the device continuously works.

Owner:成都中轨轨道设备有限公司

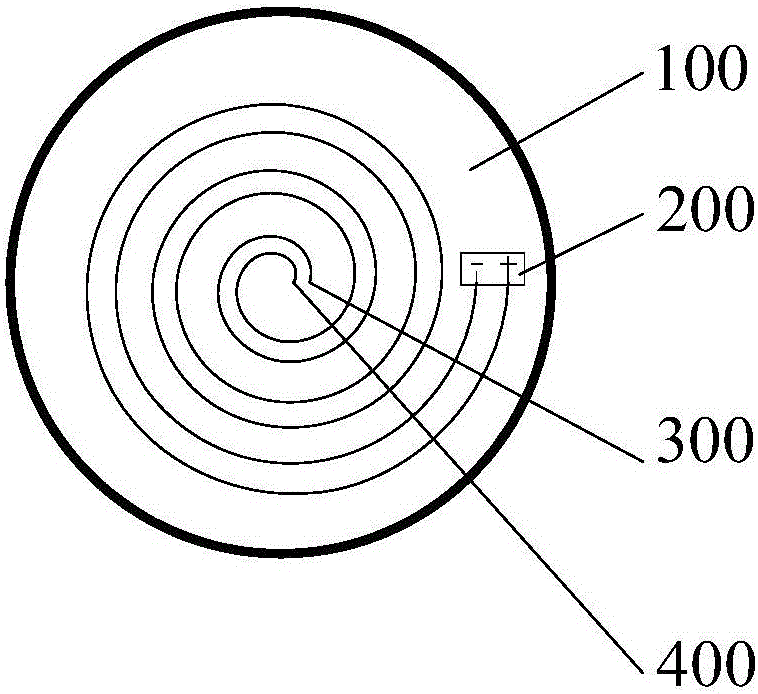

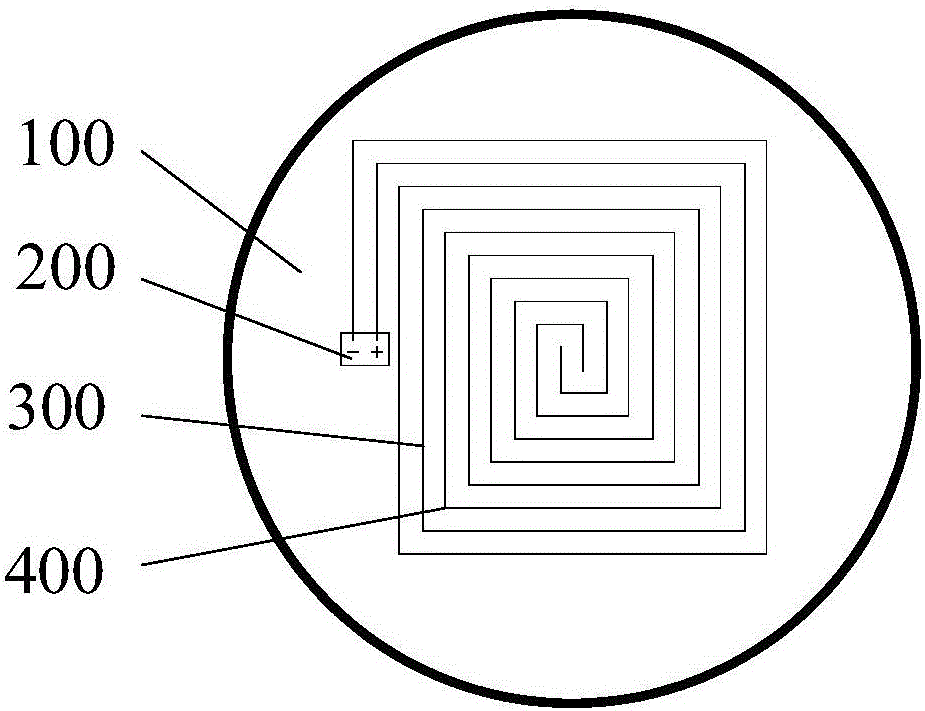

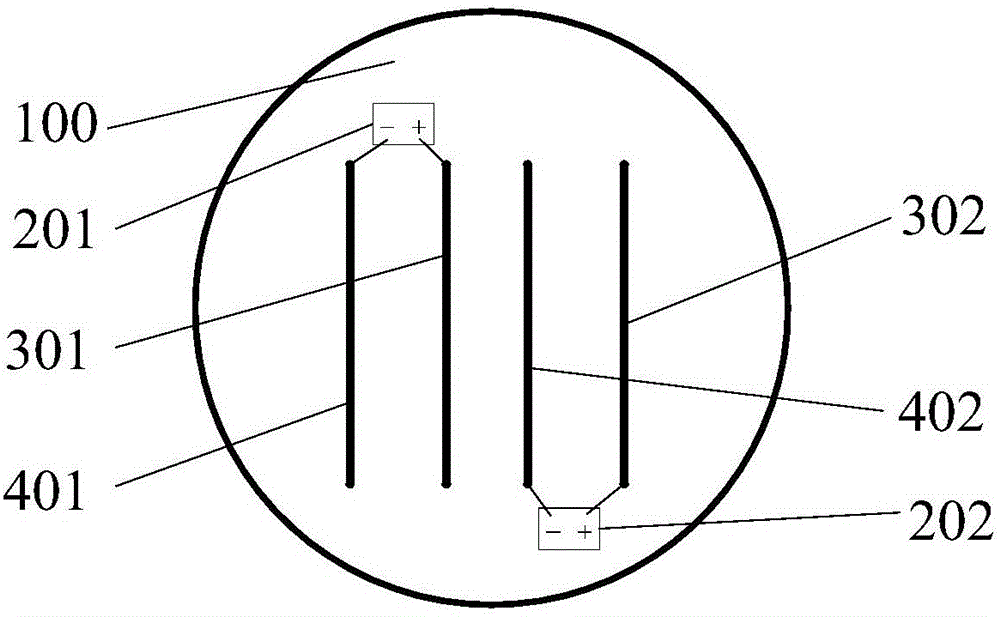

Micro-current facial mask

InactiveCN105686959AComprehensive removal of facial skin dirtFully absorbedCosmetic preparationsToilet preparationsNutrientFacial skin

The invention relates to a micro-current facial mask which comprises a facial mask body and at least one micro-current power supply on the facial mask body. By arranging the micro-current power supplies on the facial mask body, the facial mask body presents a potential difference, and therefore a loop is formed among facial skin, a positive power supply and a negative power supply, micro-currents are formed, the blood circulation of facial blood vessels is accelerated under the effect of the micro-currents, and the nutrients of the facial mask are more sufficiently absorbed by facial skin; on the other hand, grease and other dirt of facial pores are taken out of facial skin along with currents under the effect of the micro-currents, and the skin cleaning effect is achieved.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

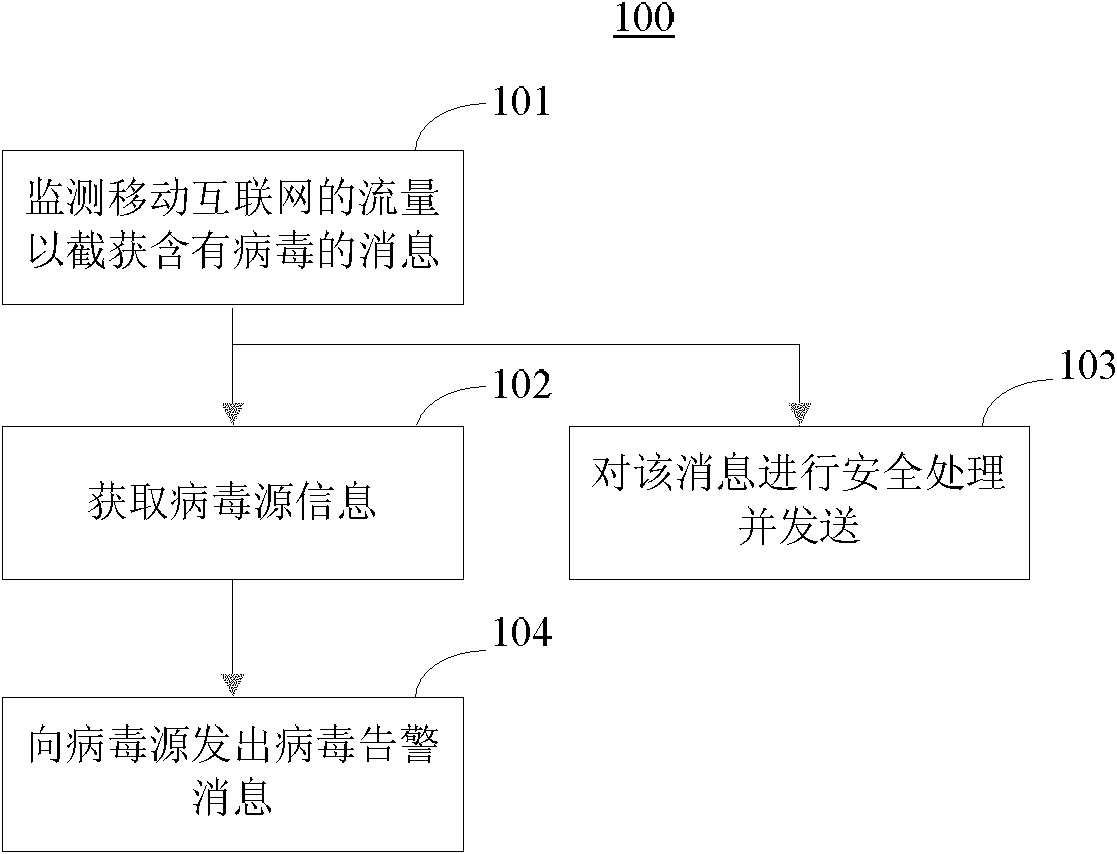

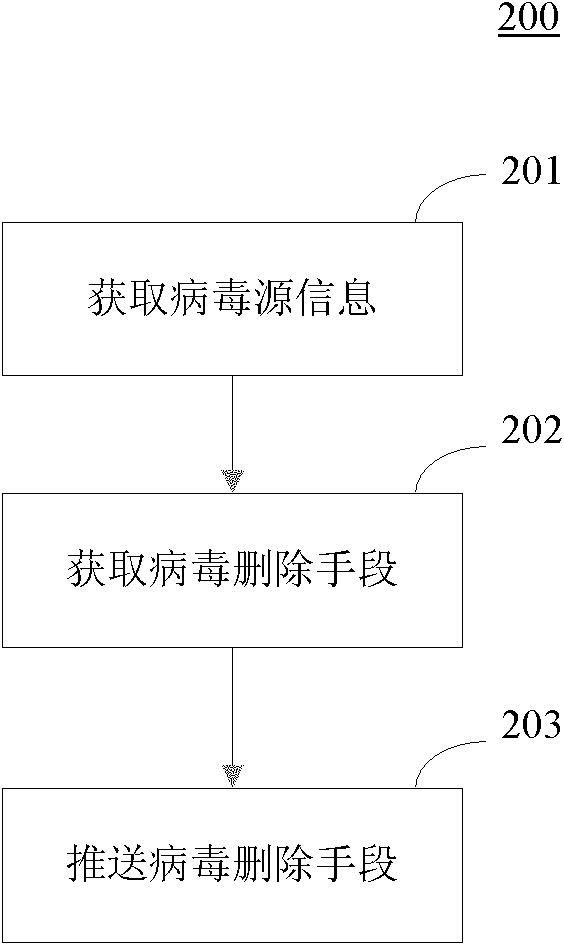

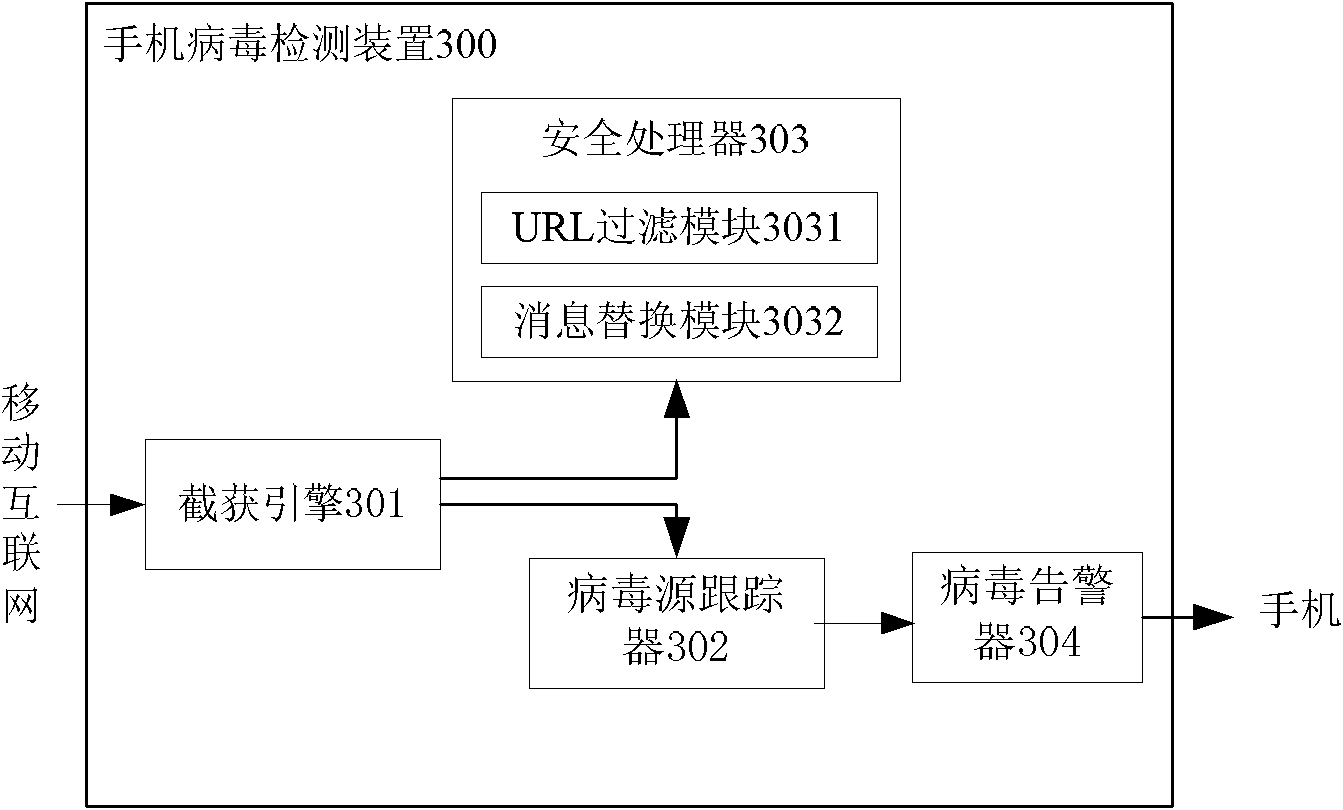

Method and device for detecting and clearing mobile terminal viruses

InactiveCN102594780ATimely detectionAvoid spreadingTransmissionSecurity arrangementRelevant informationComputer science

The invention discloses a method and a device for detecting and clearing mobile terminal viruses. The clearing device of the mobile terminal viruses comprises a virus source tracker for obtaining related information of the mobile terminal infected with the viruses, the related information of the mobile terminal at least includes identity information of the mobile terminal; a searcher for obtaining means for deleting the viruses according to the viruses which infect the mobile terminal; and a virus pusher for sending the means to the mobile terminals. The method and the device for detecting and clearing mobile terminal viruses in the present invention have the advantages of being convenient in deployment, timely in detection of the mobile terminal infected with the viruses, and thorough in clearing the viruses.

Owner:SIEMENS AG

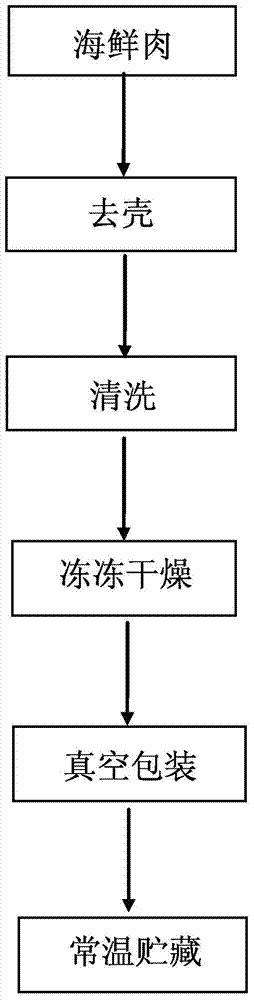

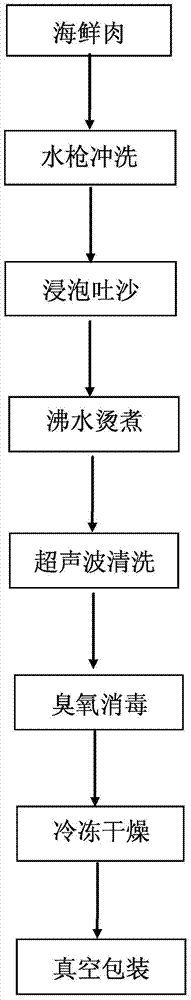

Manufacturing method for freeze-drying seafood

ActiveCN104770460AImprove hygieneEfficient killingMeat/fish preservationBivalves processingFood safetyFreeze-drying

The invention discloses a manufacturing method for freeze-drying seafood. The manufacturing method includes the following step of water gun flushing, sand splitting through soaking, boiling through boiling water, ultrasonic cleaning, ozone disinfecting, freeze drying and vacuum packaging. The manufacturing method has the advantages that dirt and impurities on the surface of seafood meat can be removed efficiently and comprehensively, microorganisms and parasites in the seafood meat are killed, a good fresh keeping effect is obtained through the complete freeze drying process, and the freeze-drying seafood meat conforming to the food safety national standard is obtained. The manufacturing method is suitable for freeze-drying manufacturing of seafood of a shellfish kind such as oysters, green sea snails, whelks, pearl sea snails, oyster drills, marine clams, abalones and dried scallop, a sleeve fish kind, a sea fish kind, a shrimp kind and the like.

Owner:北海市银海区蓝海牧场贝类养殖农民专业合作社

Centrifugal magnetic separation iron removal device for construction waste

The invention discloses a centrifugal magnetic separation iron removal device for construction waste. The centrifugal magnetic separation iron removal device comprises a base substrate and a materialcollection tank. A strip-shaped supporting groove with a crossed cross section is formed in the end face of a supporting top plate. A supporting sliding block matched with the strip-shaped supportinggroove and connected with the strip-shaped supporting groove in a left-right sliding manner is installed in the strip-shaped supporting groove. Two spiral suspenders and two limiting guide rods penetrate the supporting sliding block. Multiple iron sleeves are distributed on the side wall of a rotating vertical shaft. Electromagnetic iron bars are mounted on the inner sides of the iron sleeves. A transverse movement screw sleeve matched with a transverse movement screw rod is mounted on the transverse movement screw rod. A rotating sleeve is rotationally mounted on a supporting cross plate through a bearing. A limiting sliding sleeve is arranged on the supporting cross plate. The device is simple in structure, capable of repeatedly removing iron from waste materials, high in removal rate, convenient to operate, capable of completely separating iron from waste materials, controlled by the motor drive, easy to operate and high in practicability.

Owner:杨玲玲

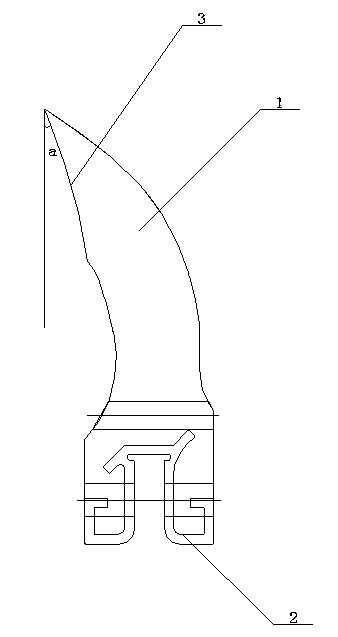

CARP optimizing and cleaning device

The invention provides a CARP optimizing and cleaning device, and relates to the field of machine manufacturing. The CARP optimizing and cleaning device comprises a polyurethane blade (1) and an aluminum alloy insert (2). The polyurethane blade (1) is embedded in the aluminum alloy insert (2). An oblique contact face (1-1) is arranged on the inner side face of the upper end of the polyurethane blade (1), and the included angle alpha between the contact face (1-1) and the perpendicular line is 20-30 degrees. According to the friction coefficient between the blade and a belt, material property of the CARP optimizing and cleaning device and characters of conveyed materials, the shape and size of the blade are designed through difference, the contact area and sweeping angle of a cleaner are guaranteed, materials which fall down on the belt can be completely eliminated, the blade is made of the polyurethane material, so that wear resistance of the blade is ensured, and the service life of the blade is guaranteed.

Owner:MARTIN ENG KUNSHAN

Makeup removing cream and preparation method thereof

InactiveCN105411993AClear allExcellent makeup removal performanceCosmetic preparationsMake-upEthylhexyl palmitateVegetable oil

The invention provides makeup removing cream. The makeup removing cream is prepared from 15%-40% of vegetable oil, 10%-30% of surfactant, 2%-10% of polyethylene, 20%-35% of ethylhexyl palmitate, 0.2%-1% of antioxidant, 0.2%-1% of oil soluble spice and 0.3%-1% of additive, and the sum of percentage of the components is 100 percent, wherein the plant oil is selected from any two of olive oil, palm oil, jojoba oil, camellia-seed oil and black sesame oil. The prepared makeup removing cream has the good advantages of being fresh, cool, free of stimulation, high in makeup removing force, mild, moist, convenient to use and free of residue after washing; meanwhile, the invention further provides a preparation method of the makeup removing cream.

Owner:CANTON DAMEKISS DAILY CHEM FACTORY LIMITED

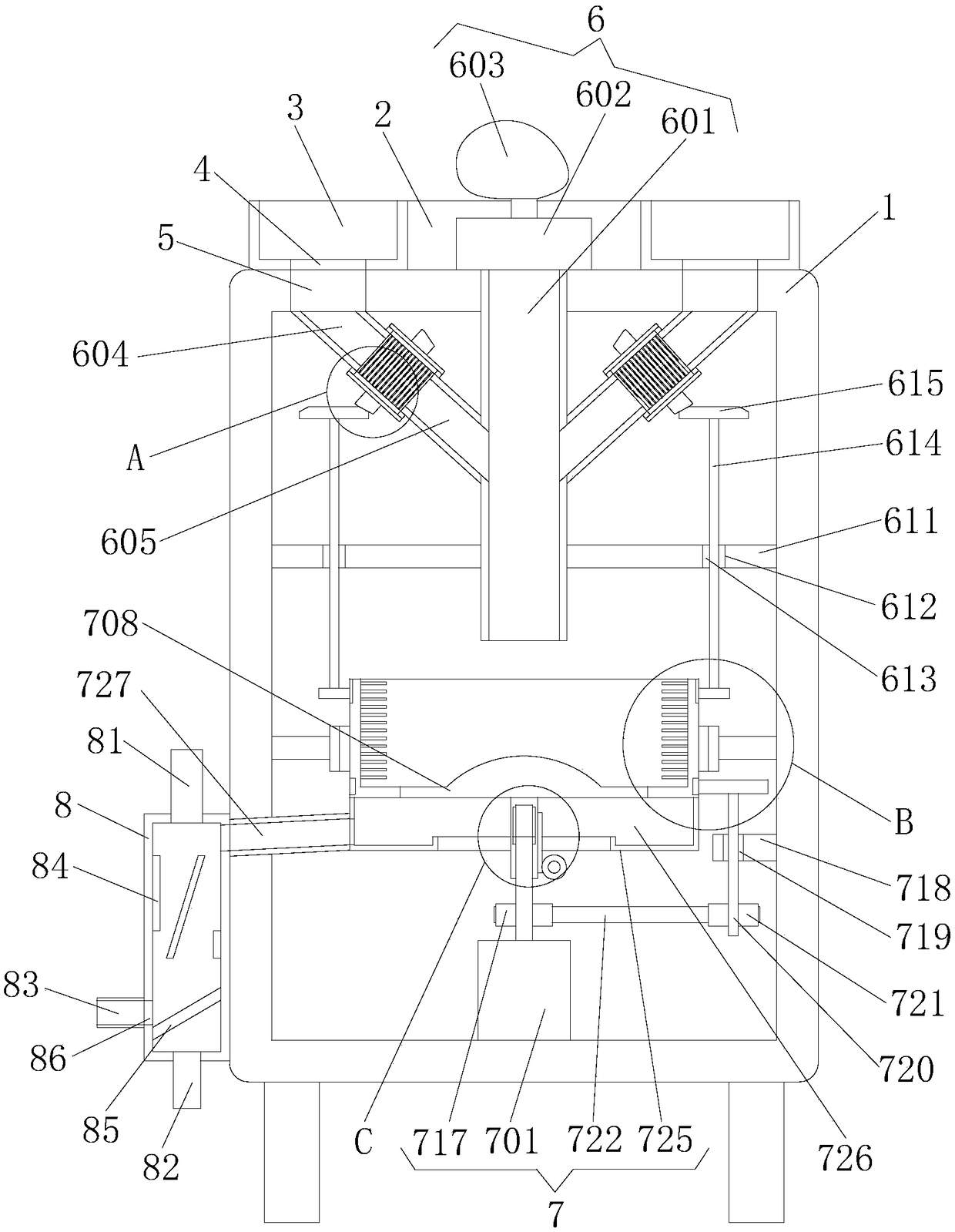

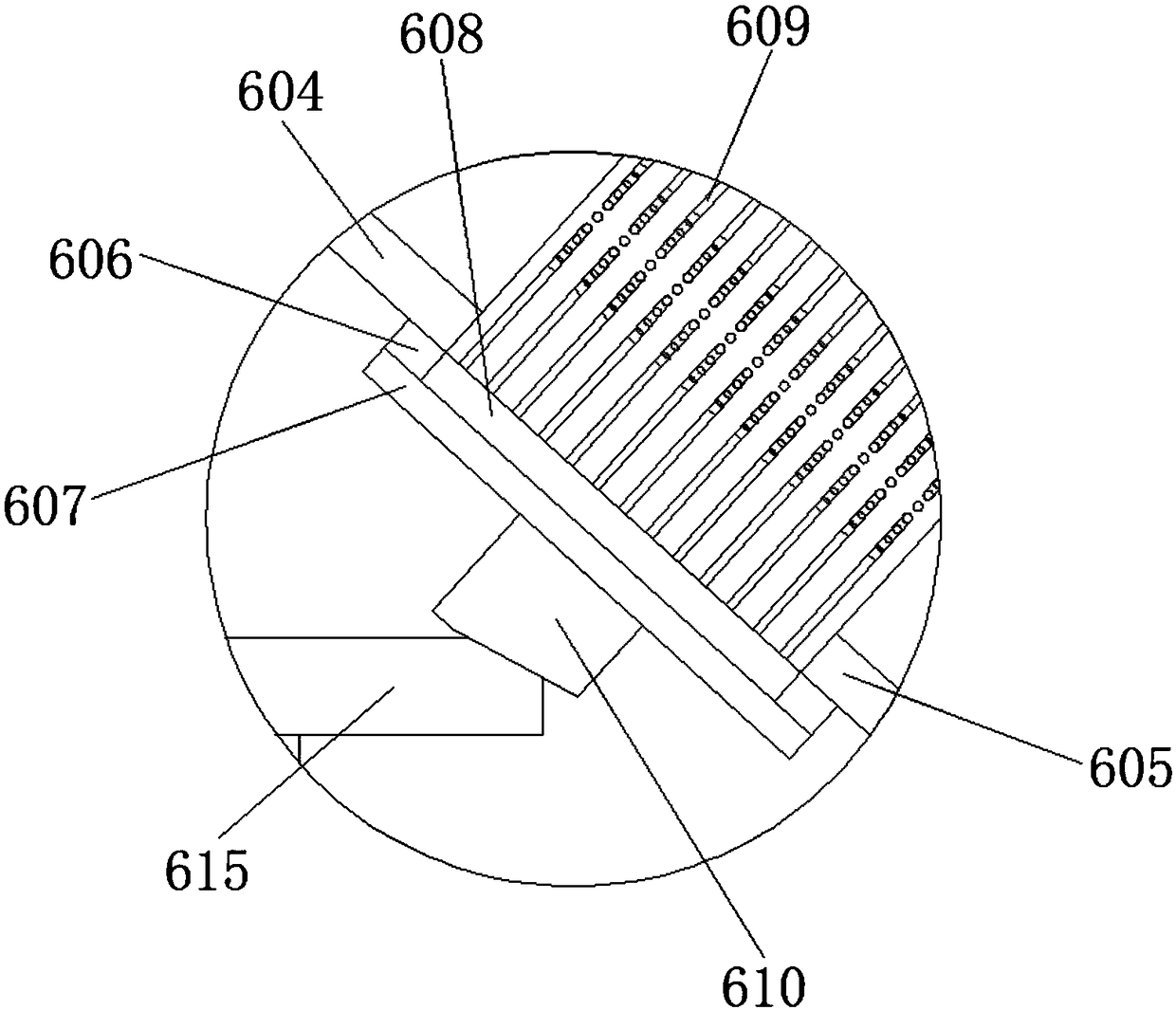

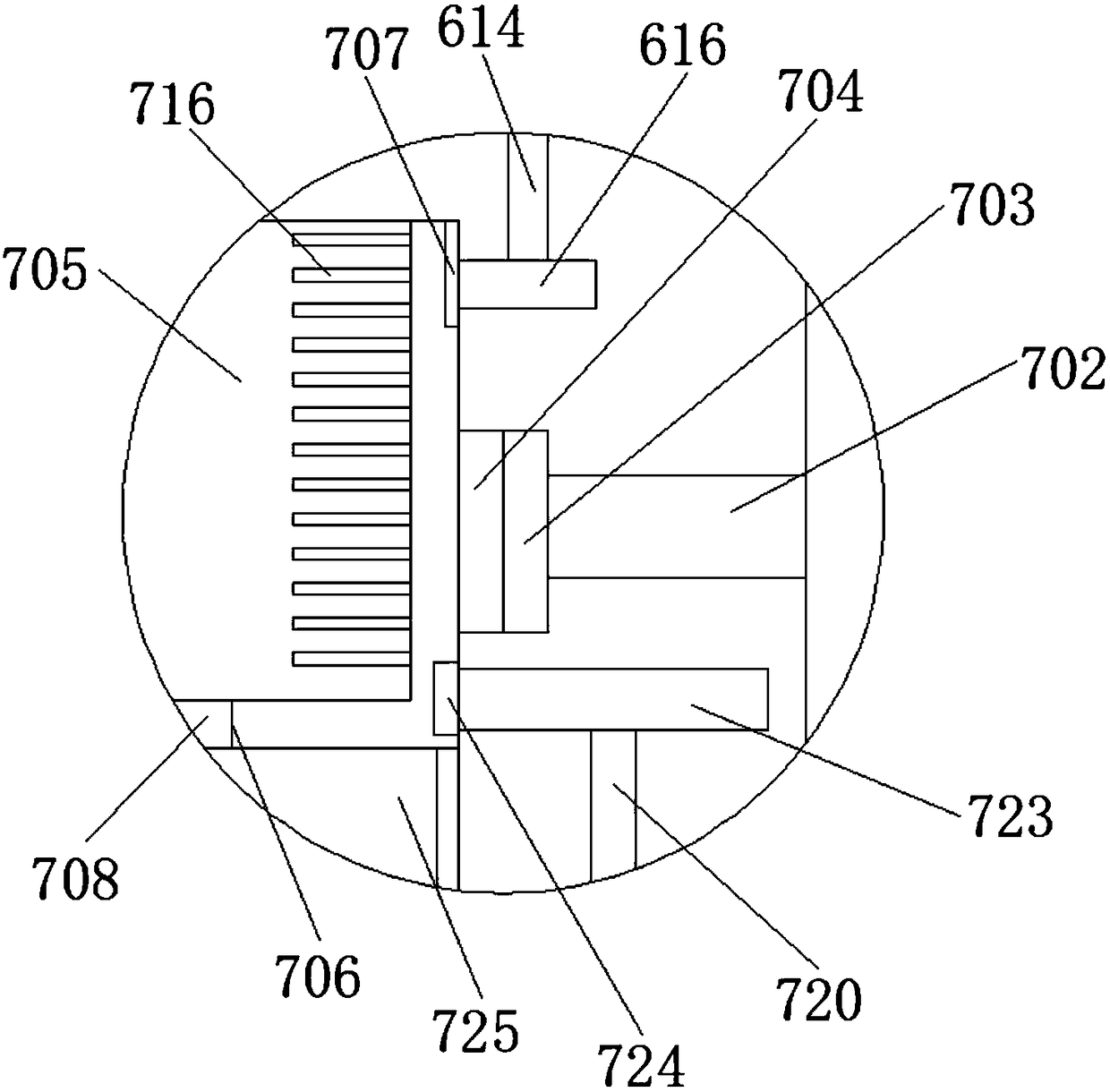

Classification recycling treatment equipment for building solid waste garbage and classification recycling treatment method

InactiveCN112044568AReduce labor intensityWill not harmGrain treatmentsStone-like material working toolsRebarProcess engineering

The invention discloses classification recycling treatment equipment for building solid waste garbage and a classification recycling treatment method. The classification recycling treatment equipmentcomprises a mounting bottom frame, rotating rollers, a cutting and crushing device and a cleaning and sorting device, the cutting and crushing device is arranged at the front end of the mounting bottom frame, and the rotating rollers are arranged between the inner walls of the mounting bottom frame and are linearly arranged; and a material falling opening is formed in the front side of the mounting bottom frame, and the cleaning and sorting device is arranged at the material falling opening and located on the lower side of the cutting and crushing device. The problems that in a process of recycling building solid waste garbage at present, prefabricated floor slabs need to be crushed manually by means of tools such as hammers and electric drills, and reinforcing steel bars need to be separated from concrete manually are solved.

Owner:郭亚征

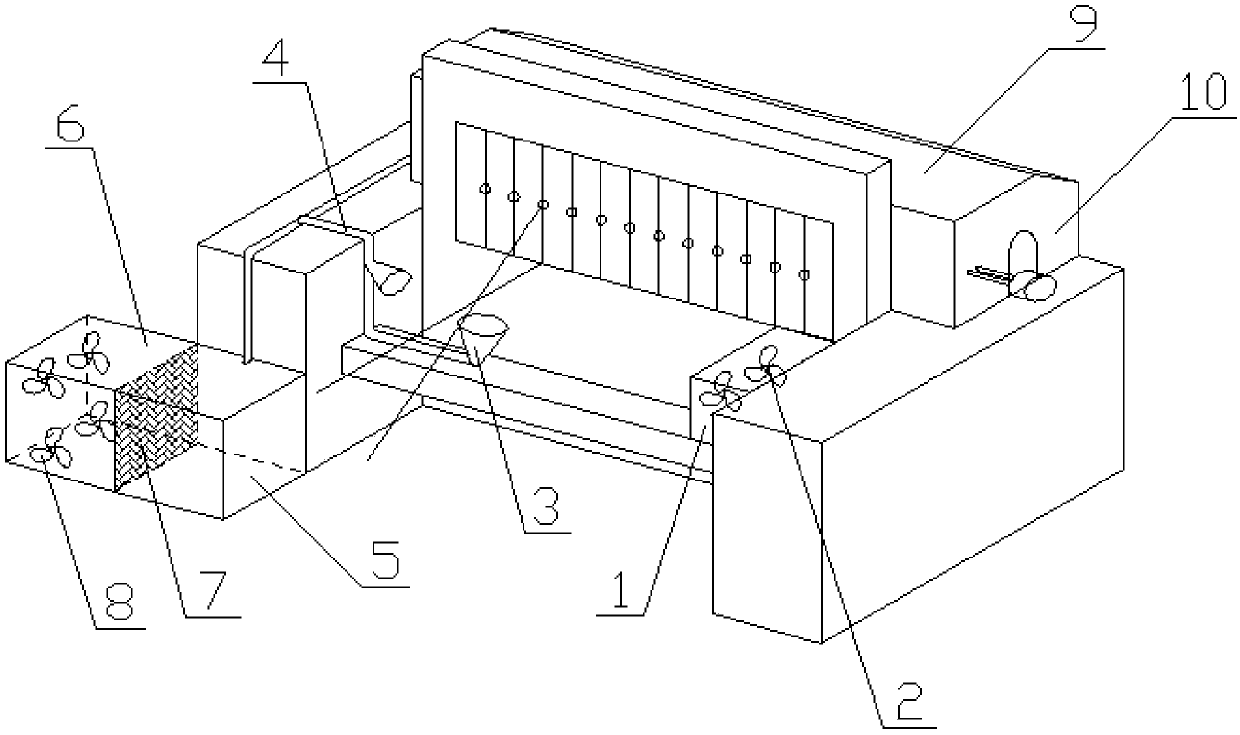

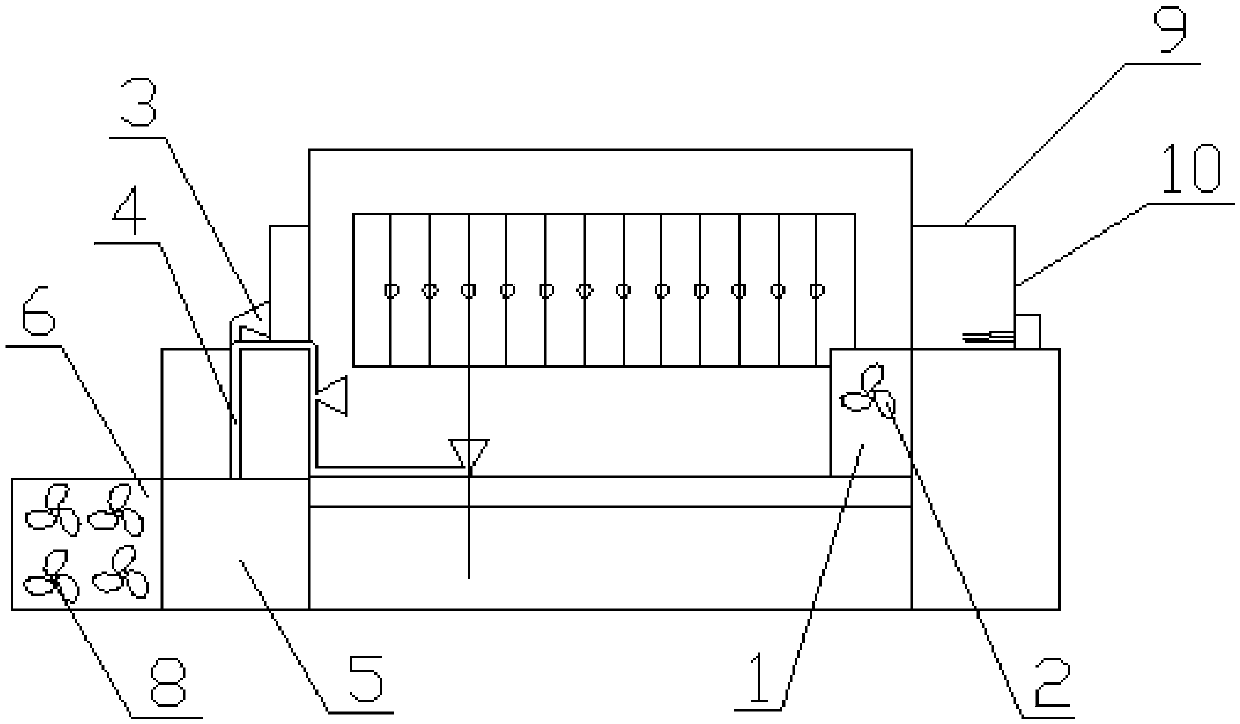

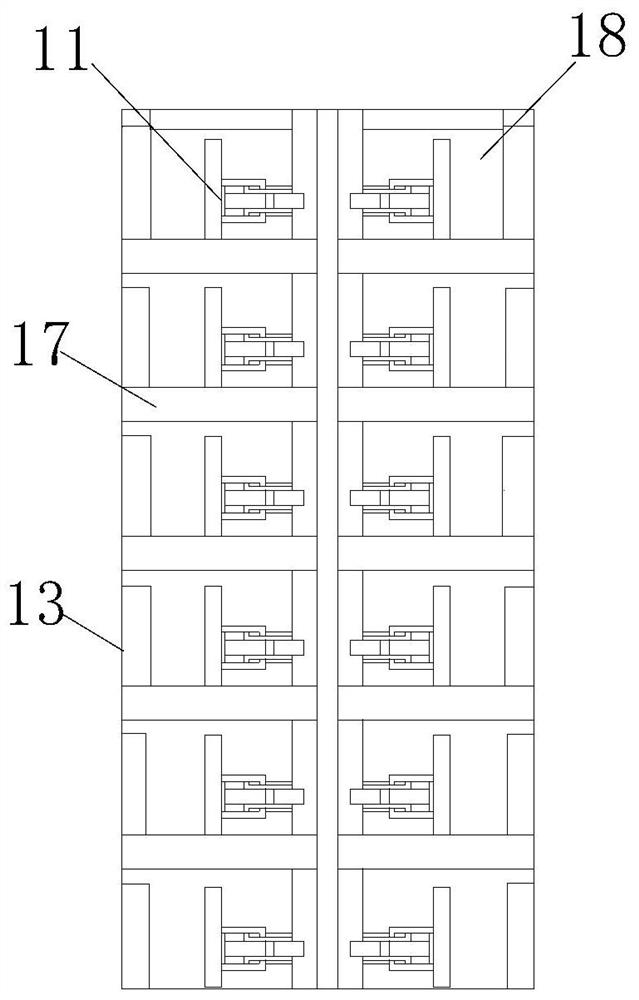

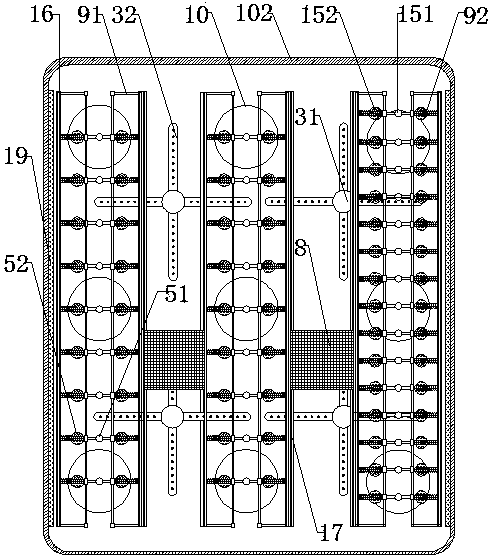

Self-cleaning system of air-jet loom

The invention relates to a self-cleaning system of an air-jet loom. The self-cleaning system comprises a blowing device, a collecting device and a protective cover device, the blowing device and the collecting device are correspondingly arranged on a left wall plate and a right wall plate on the lower portion of a rear opening of a heald frame of the air-jet loom, and the protective cover device encloses a main nozzle and a front opening of the heald frame of the air-jet loom. The blowing device comprises a blowing port and a blowing structure, and an air outlet of the blowing structure is formed in the inner side of the edge of the blowing port. The collecting device comprises a plurality of collecting ports, pipelines, a cotton collecting box and a fan, the collecting ports are connectedwith the cotton collecting box through the pipelines, the cotton collecting box is connected with the inside of the fan and separated from the fan by a filter screen, a negative-pressure structure isarranged in the fan, and the collecting ports face the air-jet loom. The protective cover device comprises a cover plate and two baffle plates, wherein the two baffle plates are arranged at the leftend and the right end of the cover plate. The system can effectively clean flyings and droppings generated by the front opening and the rear opening of the heald frame, air-jet weft insertion, reed beating-up and the like, and cleanness of a fabric interweaving environment is ensured.

Owner:SUZHOU JIANGSAI TEXTILE TECH CO LTD

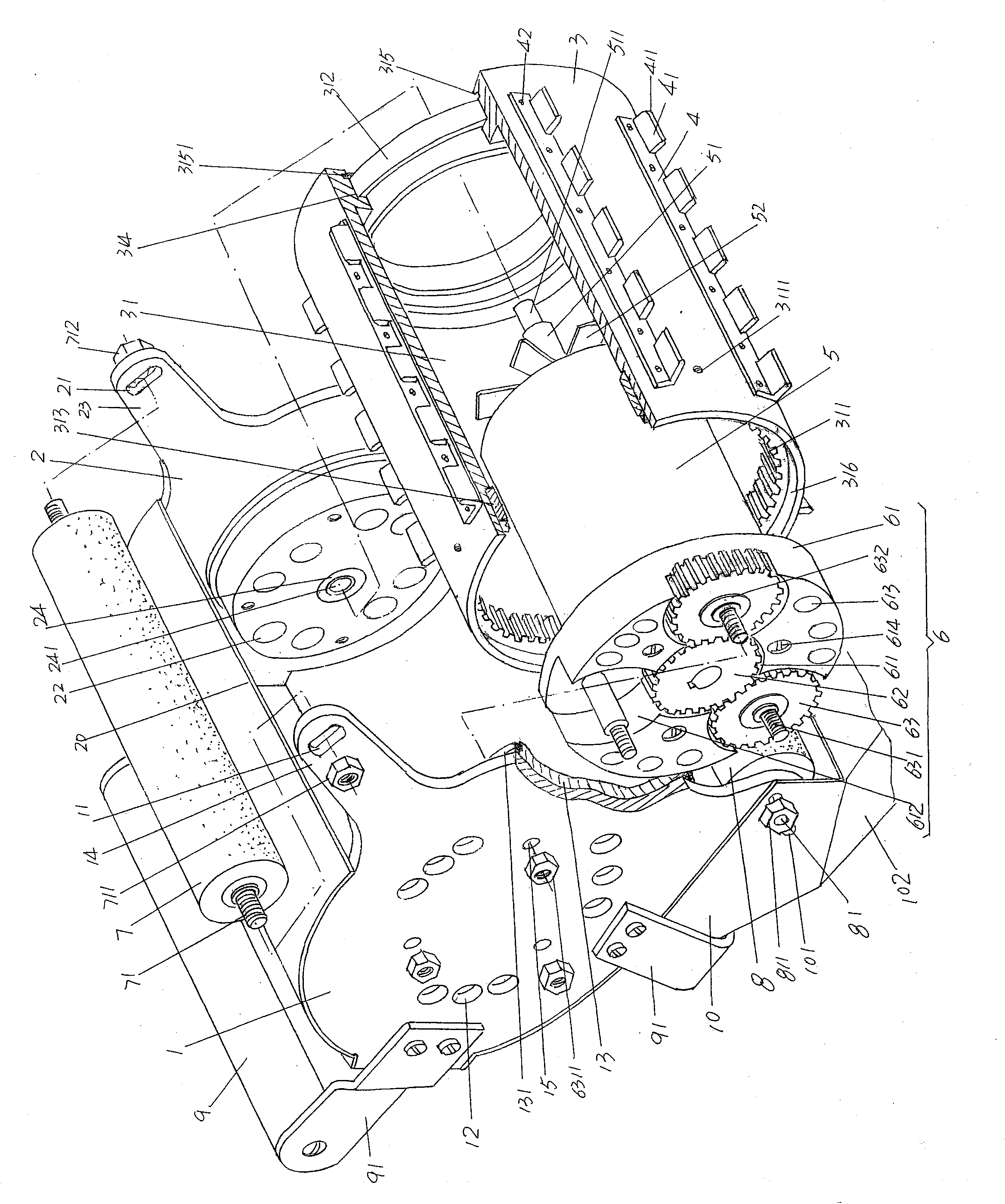

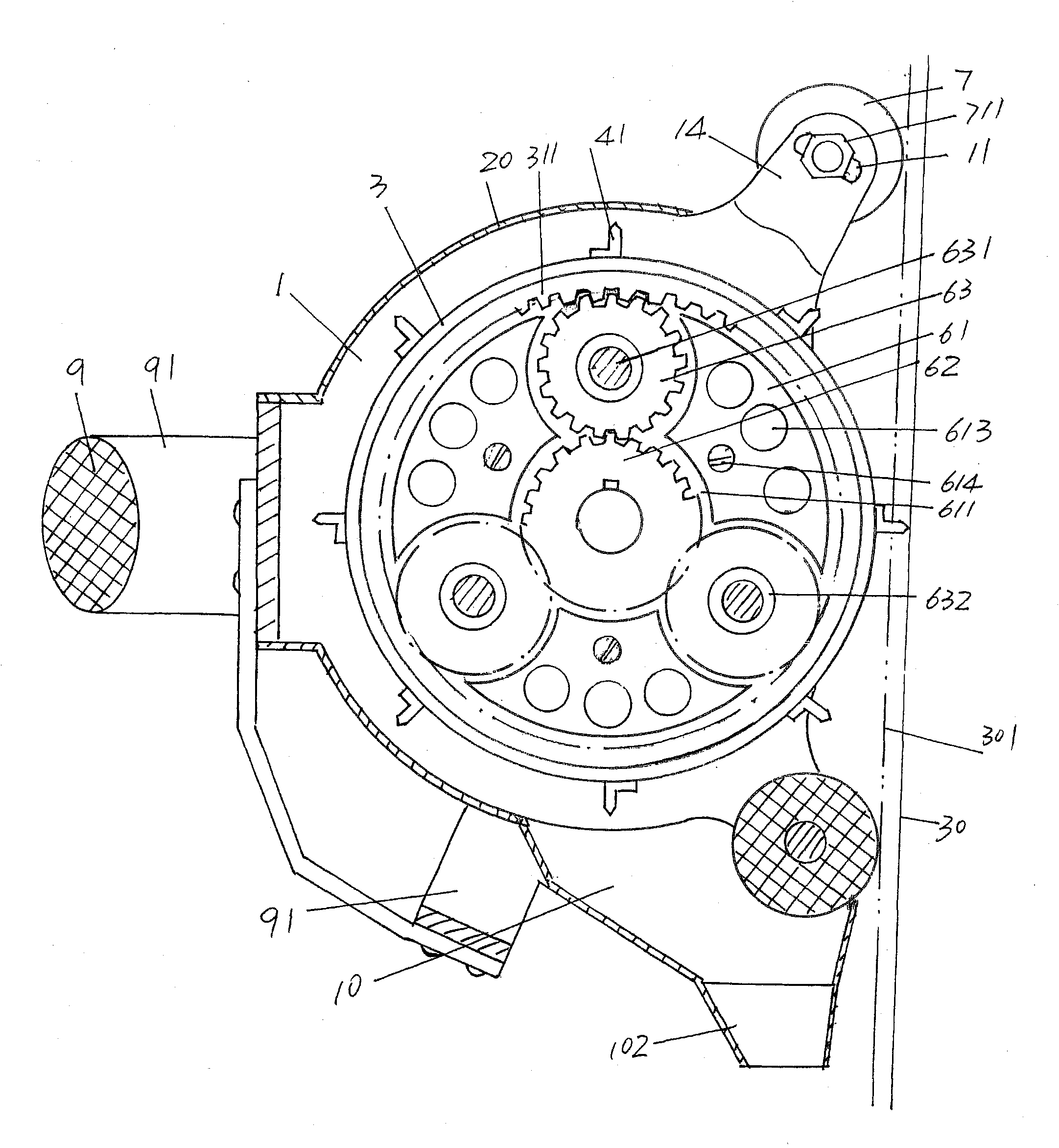

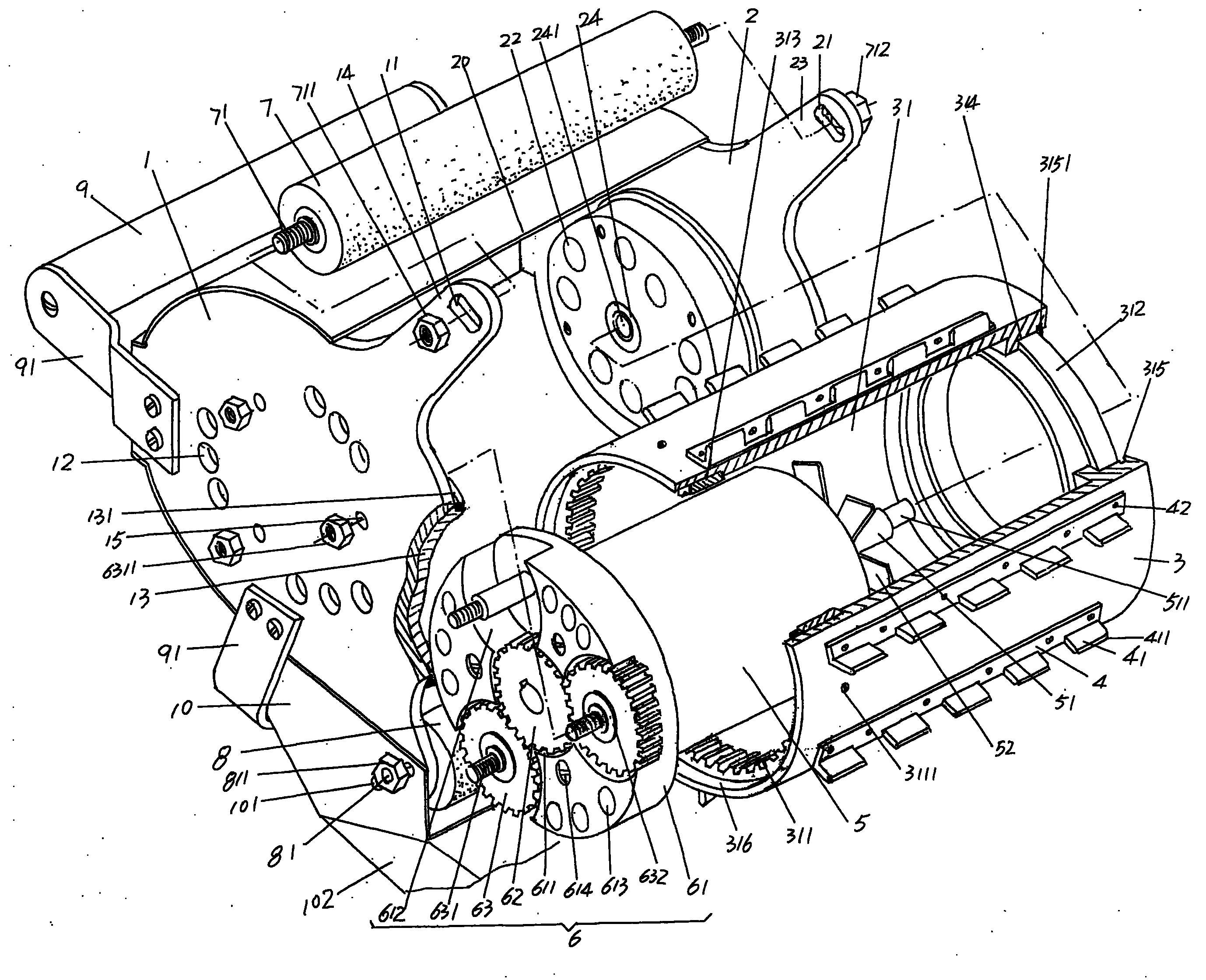

Device for eliminating wall surface coating

The invention relates to a device for eliminating a wall surface coating, which belongs to apparatus for decoration constructions of wall surface of buildings. The device comprises a first supporting plate, a second supporting plate, a roller, a group of planer tool posts, a motor, a transmission mechanism meshed with a gear ring, an upper guide roll, a lower guide roll and a pair of handles, wherein one end of the roller is fixedly provided with the gear ring while the other end is fixedly provided with a roller bearing, and the second supporting plate is fixed with the roller bearing; the planer tool posts are arranged on the outer wall of the roller at intervals, and planer tools are arranged at intervals on each planer tool post; the motor is arranged in a roller cavity, and the right end of a motor shaft is arranged on the second supporting plate; the transmission mechanism is arranged at one end of the motor, facing the first supporting plate and is connected with the left end of the motor shaft; the upper guide roll and the lower guide roll are fixed on the first supporting plate and the second supporting plate; and the two handles are fixed with the first supporting plate and the second supporting plate respectively. The device has the advantages that the device has a compact structure, a small volume and ideal equitability, is favorable for reducing the operating strength of constructors, is convenient to replace, is favorable for comprehensively and uniformly eliminating an obsolete mortar bed, a coating or an oil paint on a wall body without generating missed planing and white flying phenomena, and is helpful for combining a new decorative layer with the wall body reliably.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

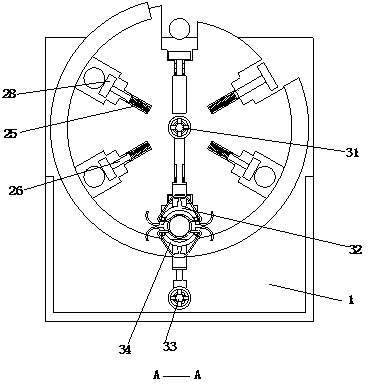

Equipment for cleaning and disinfecting medical scissors by using telescopic roller

The invention relates to the technical field of medical instruments, and discloses equipment for cleaning and disinfecting medical scissors by using a telescopic roller. The equipment comprises a cleaning box, the inner top of the cleaning box is fixedly connected with an ejector rod, the inner wall of the cleaning box is fixedly connected with a tightening wheel, and the position, located below the tightening wheel, of the inner wall of the cleaning box is fixedly connected with a support rod; and a sliding rod is slidably connected into the support rod, the bottom of the sliding rod is sleeved with the scissors, the inner wall of the cleaning box is slidably connected with a fixing block, the inner wall of the cleaning box is slidably connected with a sliding block, the top of the sliding block is fixedly connected with a fixing spring, and the front face of the sliding block is movably connected with a driving rod. According to the equipment for cleaning and disinfecting the medicalscissors by utilizing the telescopic roller, the driving rod is driven by the sliding block to move, the tightening wheel is driven by the driving rod to rotate, and the tightening wheel and the sliding rod are matched for use, so that the effects of automatically opening the medical scissors and being convenient to clean are achieved.

Owner:广州逸彬科技有限公司

Steel pipe galvanizing pretreatment equipment

InactiveCN111139491AQuality assuranceImprove pickling qualityHot-dipping/immersion processesSurface cleaningEngineering

The invention belongs to the technical field of metal treatment, and particularly relates to steel pipe galvanizing pretreatment equipment which comprises a cleaning frame. Conveying units are arranged between the inner walls of the cleaning frame; a cleaning unit is arranged between the conveying units; and a drive unit is arranged on the inner wall of the lower side of the cleaning frame. The steel pipe galvanizing pretreatment equipment provided by the invention can solve the following problems existed in existing steel pipe acid pickling operation before galvanizing: (1) a steel pipe is simply placed into an acid pickling pool so as to be soaked, an oxidation layer and stains on the surface of the steel pipe cannot be cleaned during steel pipe soaking, and the surface of the steel pipeneeds to be wiped and cleaned after the steel pipe is taken out from the acid pickling pool, so that the steel pipe soaking operation and the comprehensive surface cleaning operation cannot be accomplished integrally, and the cost of steel pipe galvanizing is increased; and (2) in traditional steel pipe acid pickling operation, steel pipes in batch are concentratedly placed in the acid picking pool, and the single feeding quantity is large, so that the surfaces of the steel pipes cannot be ensured to comprehensively contact an acid pickling solution.

Owner:平顶山市中开防腐有限公司

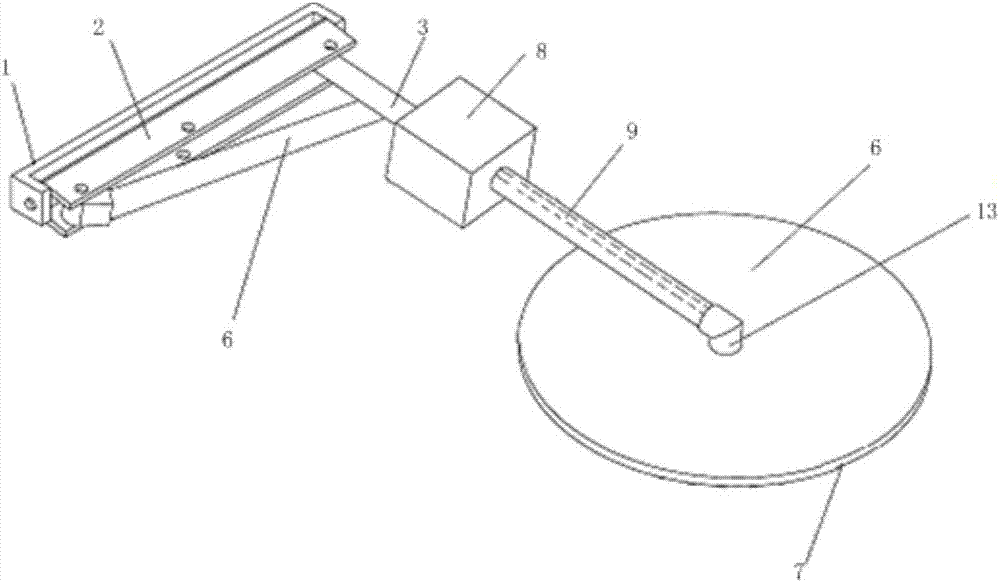

Automatic orchard obstacle-avoiding mowing machine

The invention relates to an automatic orchard obstacle-avoiding mowing machine. The automatic orchard obstacle-avoiding mowing machine comprises a primary machine frame, and a secondary machine frameis rotationally arranged in the primary machine frame; the automatic orchard obstacle-avoiding mowing machine also comprises a first hollow rod and an elastic supporting rod, one end of the secondarymachine frame is hinged to one end of the first hollow rod, and the other end of the secondary machine frame is hinged to one end of the elastic supporting rod; a second hollow rod is perpendicularlyand fixedly connected to the other end of the first hollow rod, a cutter disc shaft arranged in the axial direction of the second hollow rod is arranged in the second hollow rod, and is sleeved with an obstacle avoiding wheel, and a cutter disc is fixedly connected on the cutter disc shaft; the other end of the elastic supporting rod is hinged to the side wall of the first hollow rod; the automatic orchard obstacle-avoiding mowing machine also comprises a driving device, and the driving device is arranged on the firs hollow rod. By means of the automatic orchard obstacle-avoiding mowing machine, fruit-tree inter-row weeding and inter-plant weeding operation can be carried out at a time; fruit trees can be automatically avoided during weeding, weeds close to roots of fruit trees are weeded;the structure is simple, and the theory is novel.

Owner:XIAN UNIV OF TECH

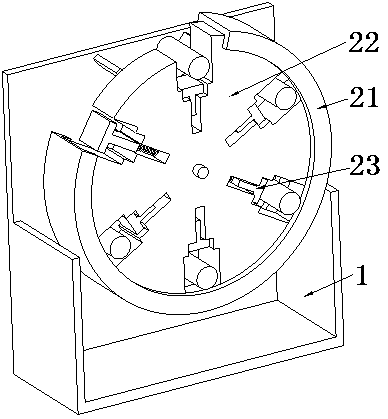

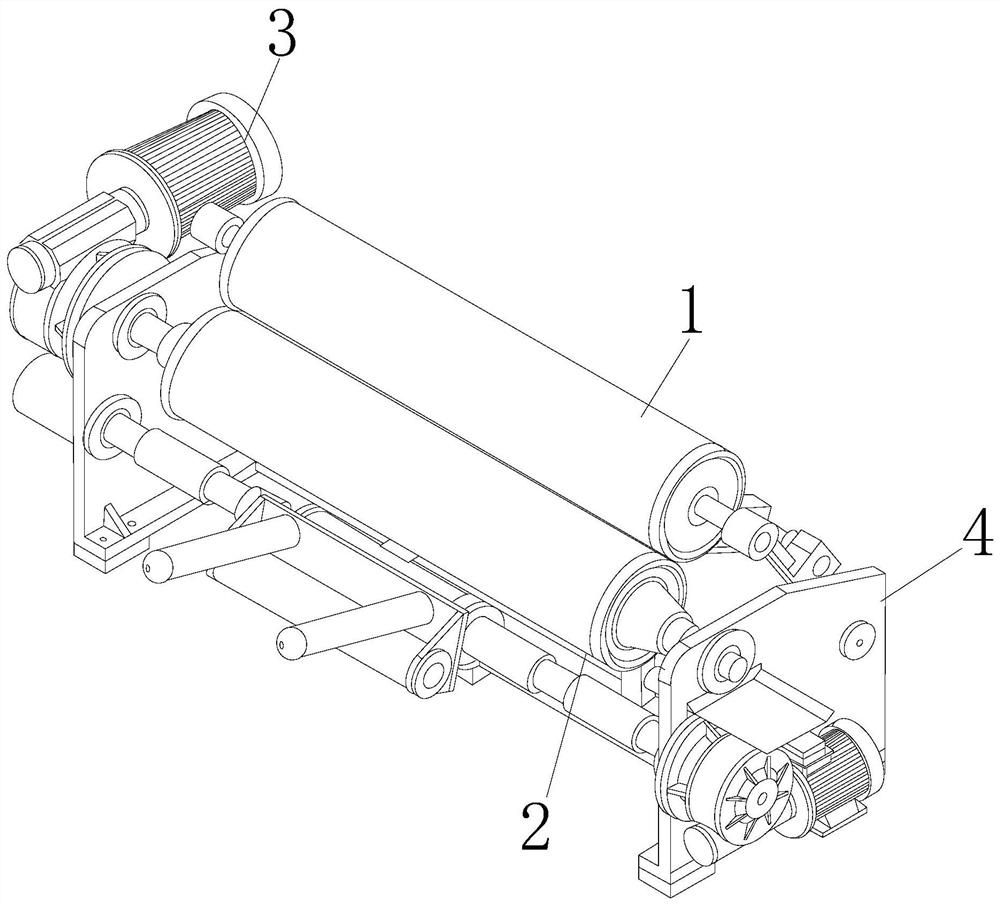

Film-pressing roller assembly of thin film processing assembly line

InactiveCN111703004AAvoid deformationAffect qualityDirt cleaningCleaning using toolsElectric machineryThin membrane

The invention discloses a film-pressing roller assembly of a thin film processing assembly line. The film-pressing roller assembly structurally comprises rollers, a scraper structure, a rack and a motor, the rollers are mounted on the inner side of the rack, the scraper structure is arranged below the rollers, and the signal output end of the motor is electrically connected with the connecting ends of the rollers. The film-pressing roller assembly is provided with mounting plates, sectional cavities and partition plates, cylindrical structures matched with the rollers are formed by the structures, and every three supporting devices are evenly distributed on the inner side in a circumference and used for abutting against the inner surfaces of the rollers, so that the rollers are not prone to deforming; and through matching of elastic air bags inside the supporting devices and opening cavities, telescopic rods move upwards during film pressing, connecting rods can further deform to pushjacking rods to deform, and the elastic air bags deform to jack the mounting plates so as to prevent the phenomenon that the rollers deform under high pressure, and consequently, the apparent qualityof a product is affected or the thickness is uneven.

Owner:潘景阳

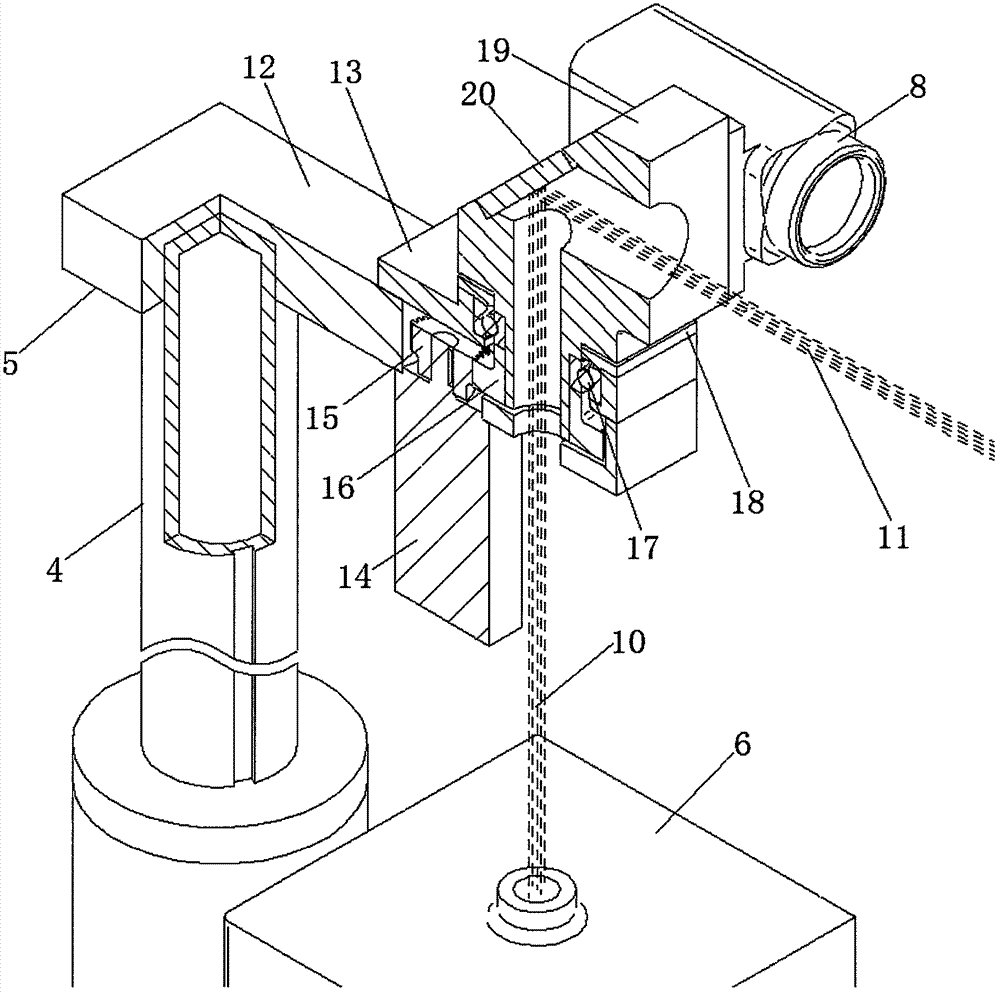

Laser sterilizing insect-killing device

InactiveCN107439511ARealize intelligent controlIncrease flexibilityLavatory sanitoryInsect catchers and killersLaser scanningEngineering

The invention belongs to the field of sterilizing insect-killing devices, and particularly provides a laser sterilizing insect-killing device. The problem that the conventional laser sterilizing insect-killing devices are single in wavelength and poor in safety can be solved. The laser sterilizing insect-killing device has a plurality of power-adjustable lasers capable of outputting different laser wavelengths, can selectively emit laser light with different wavelengths, can effectively eliminate multiple kinds of harmful bacteria and pests, has an enlarged use range, has a control system and an infrared video camera, can monitor if persons or animals enter the laser scanning range or not in real time, instantly stops emitting laser light once the persons or animals are found, and can ensure the safety of the persons or animals.

Owner:BEIJING RECI LASER TECH

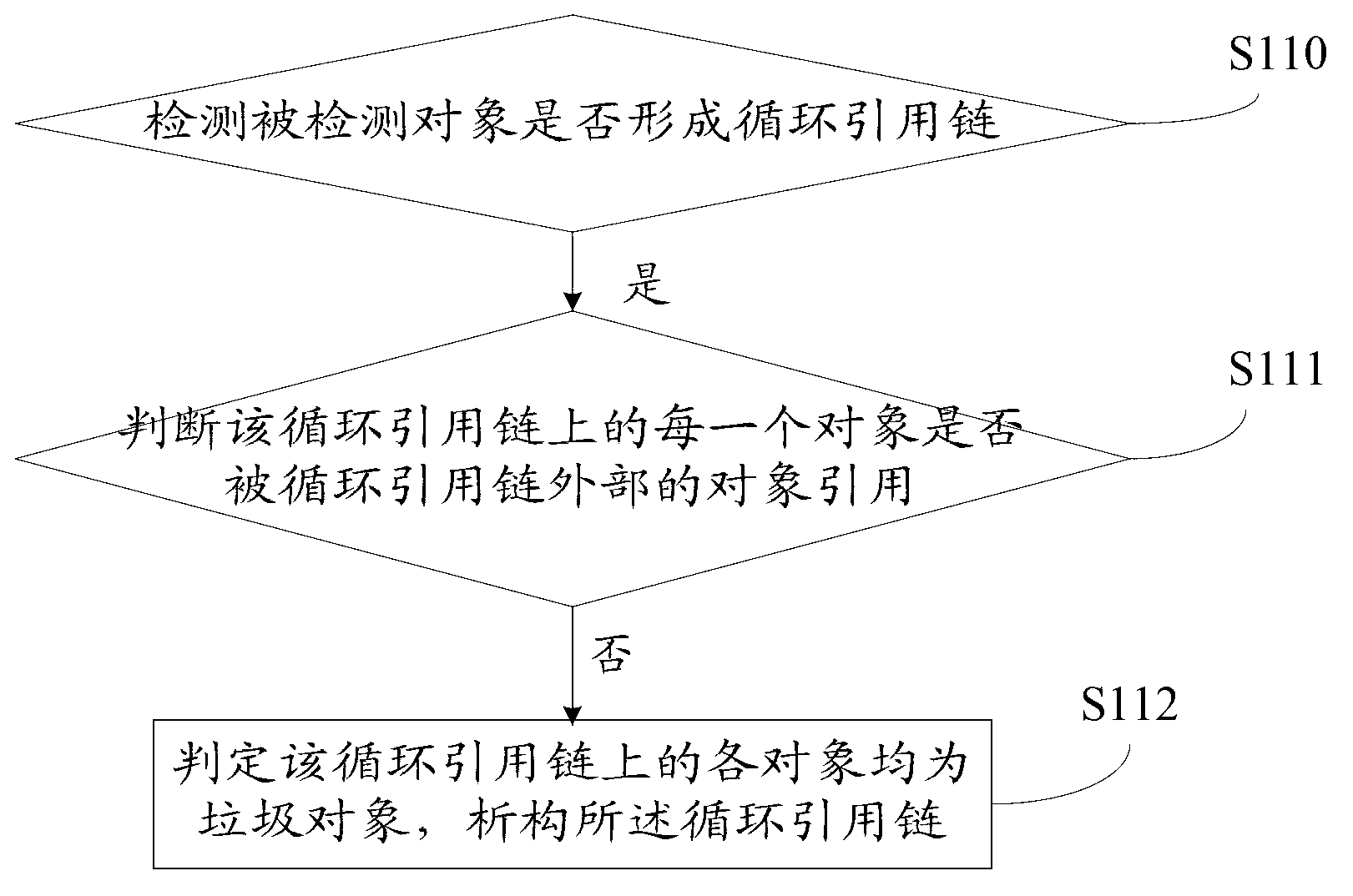

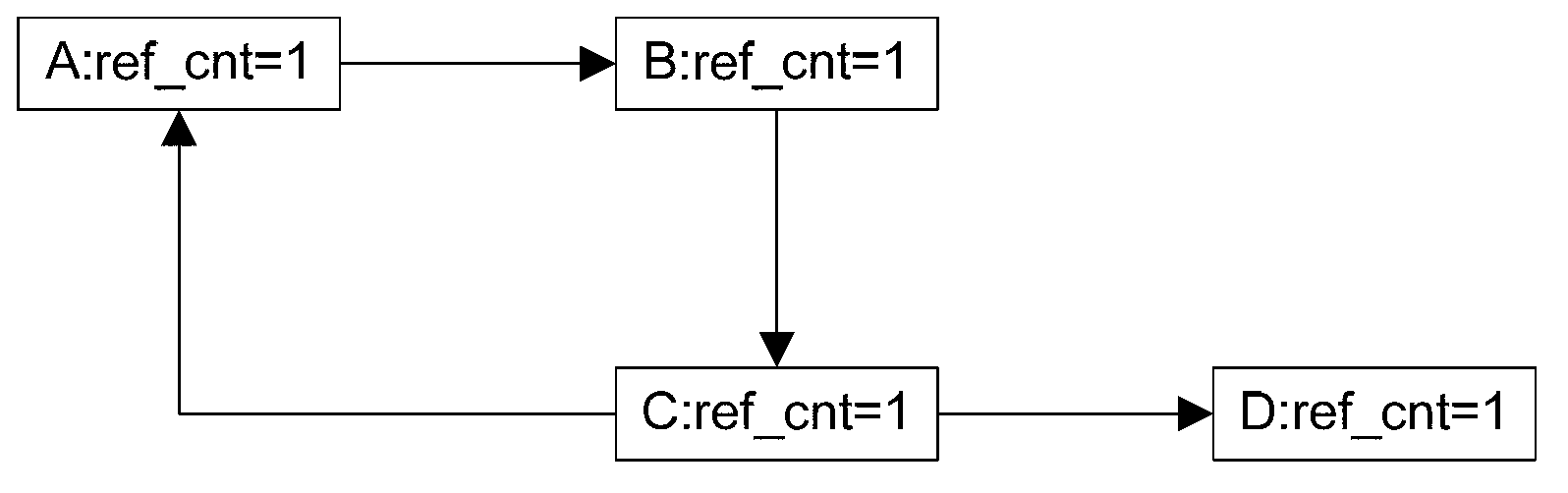

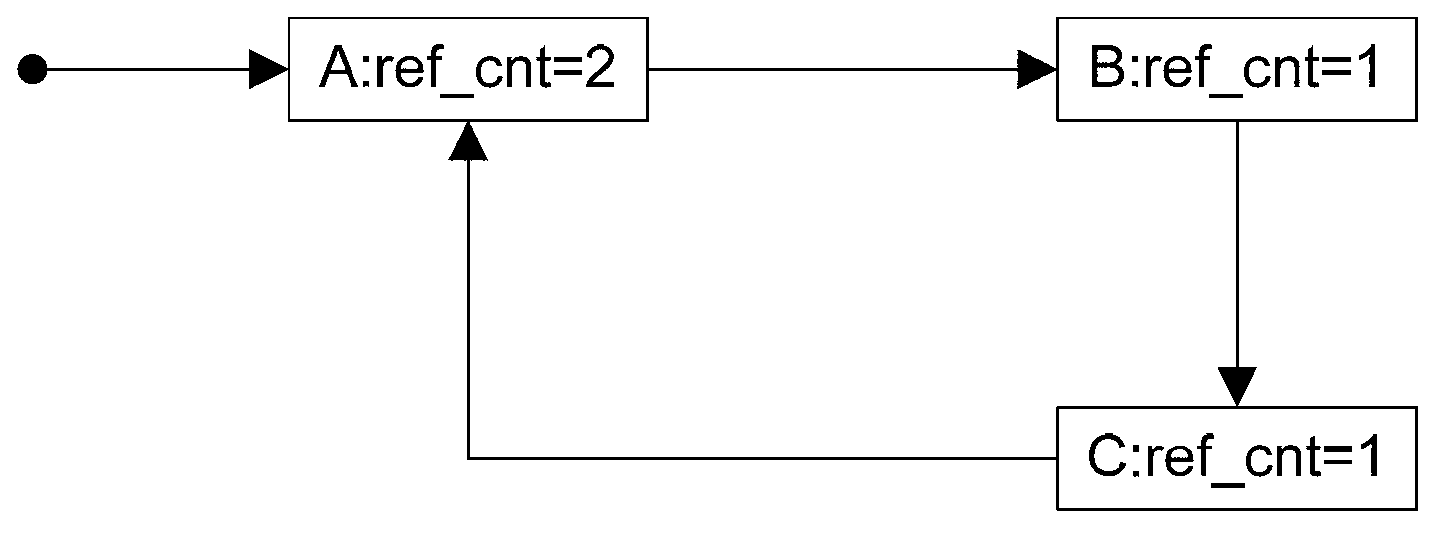

Garbage object detecting method and device

ActiveCN103226476AImprove accuracyClear allSpecific program execution arrangementsCircular referenceComputer science

The invention relates to the technical field of computer applications and particularly relates to a garbage object detecting method and device. The garbage object detecting method comprises the following steps of: detecting whether a circular reference chain is formed by objects to be detected, if so, judging weather each object on the circular reference chain is referenced by an object outside the circular reference chain, and if not, judging that all the objects on the circular reference chain are garbage objects, and destructing the circular reference chain. The garbage object detecting device comprises a detecting module and a destructing module. By using the garbage object detecting method and device provided by the invention, the problem that the garbage objects on the circular reference chain can not be circularly referenced by using a reference counting method can be effectively solved, the garbage disposal accuracy is improved, and more garbage is removed, thus more resources are released.

Owner:张永强

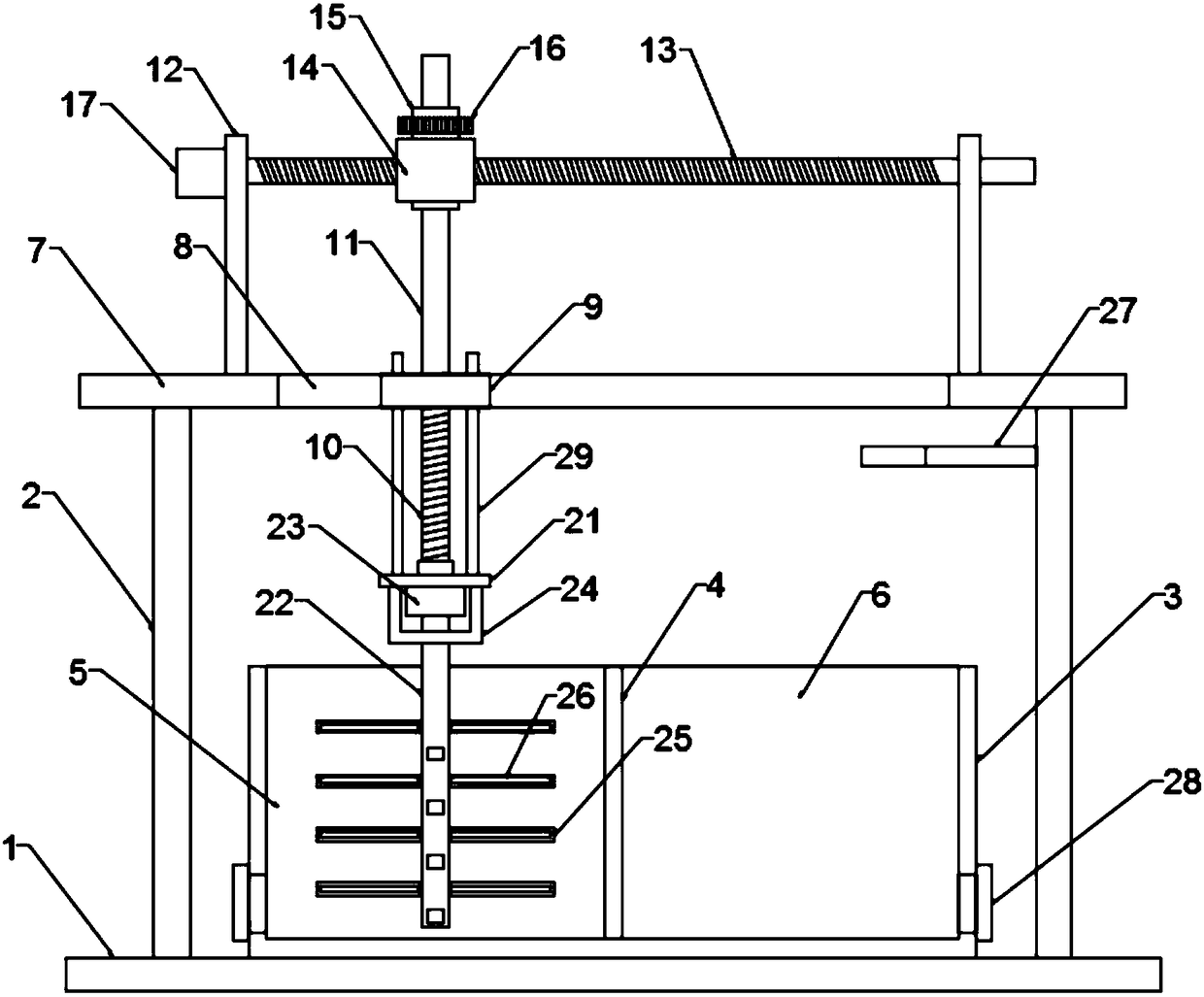

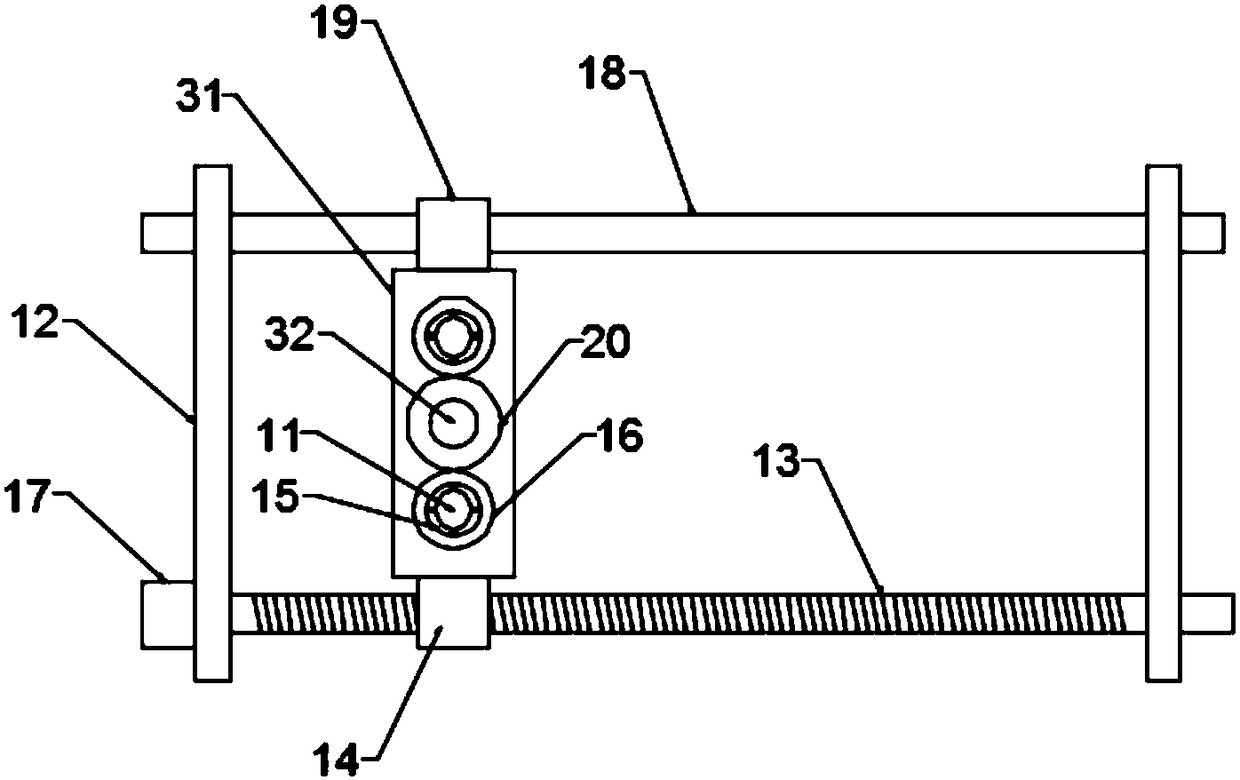

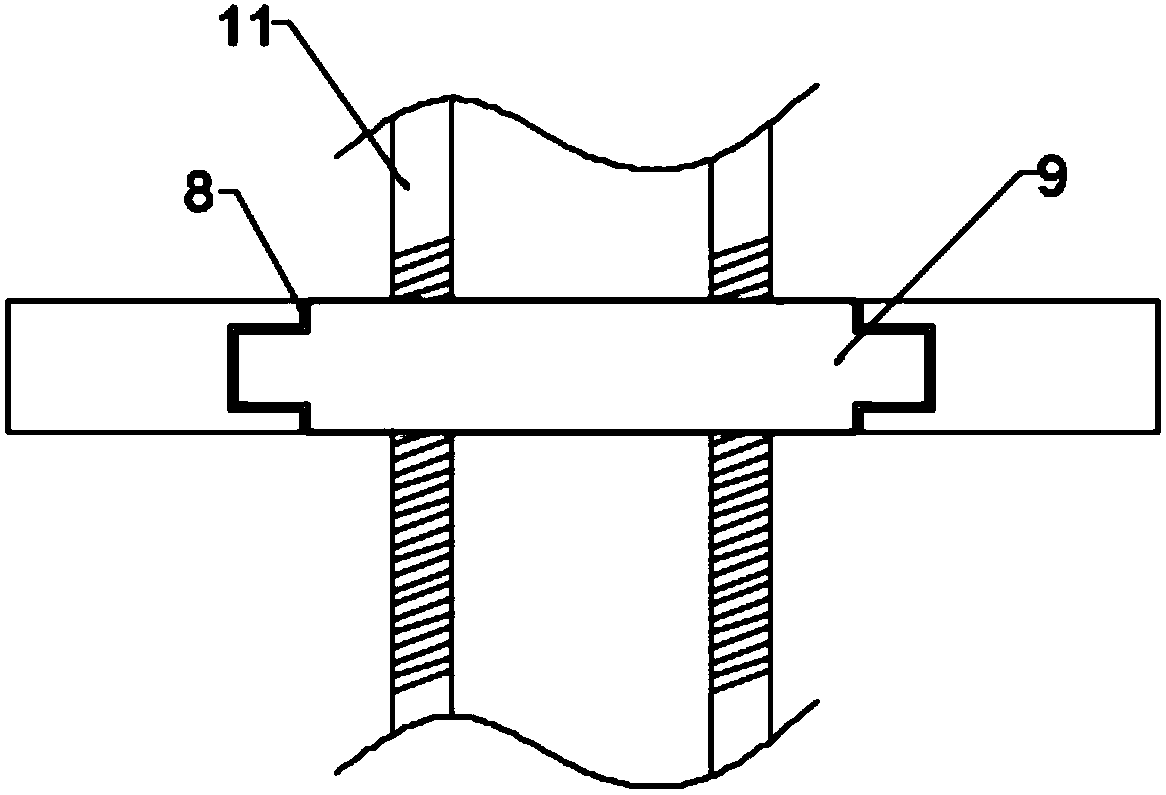

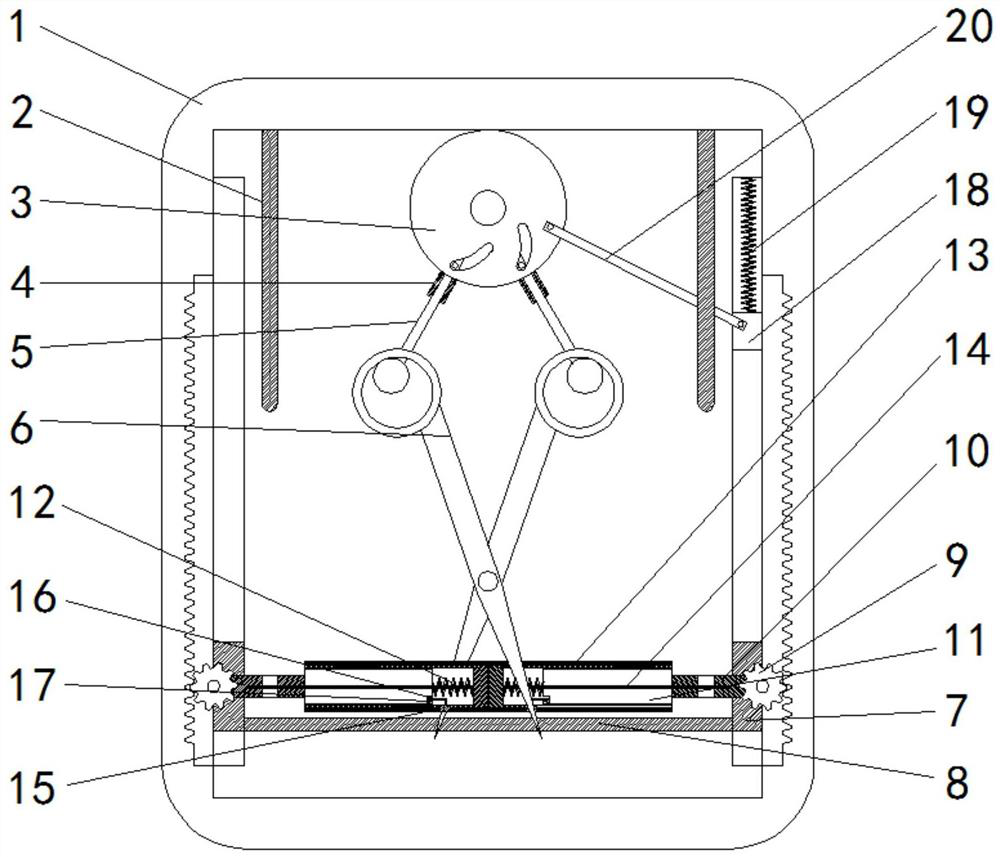

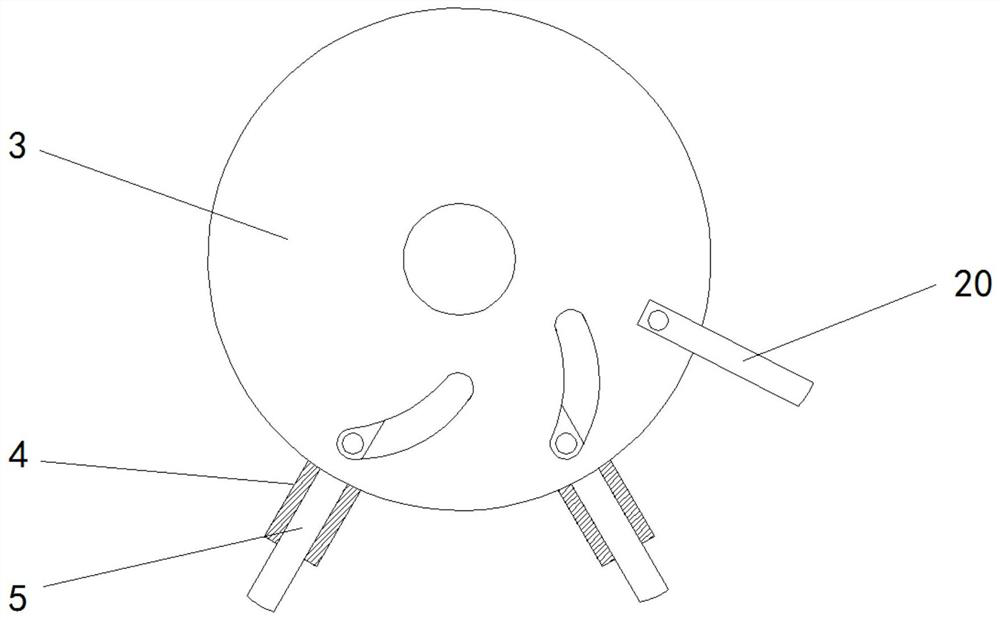

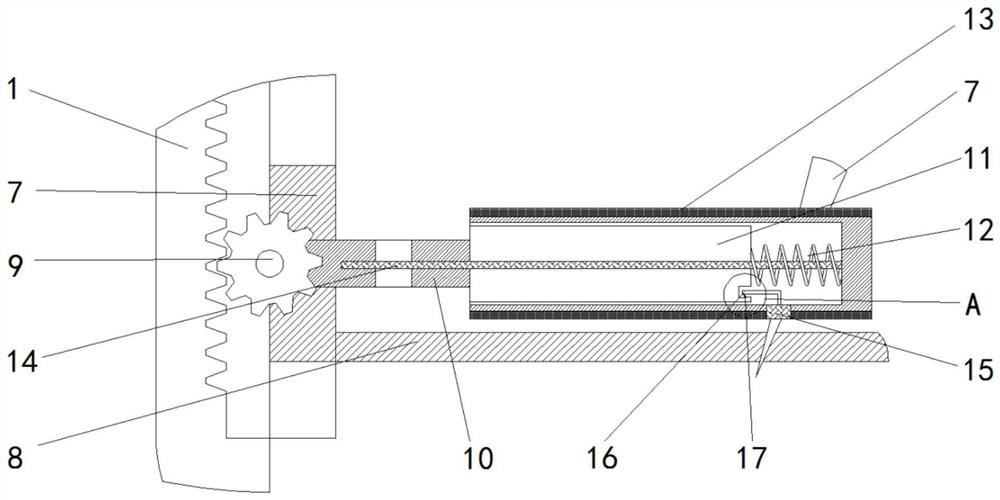

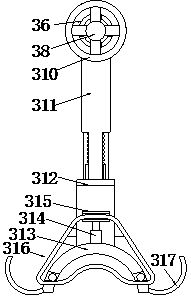

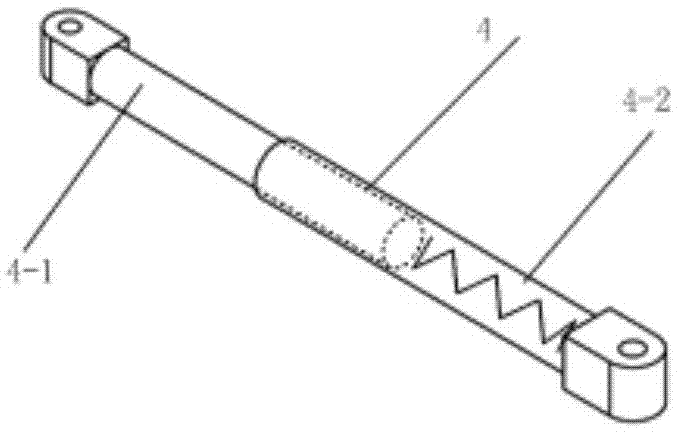

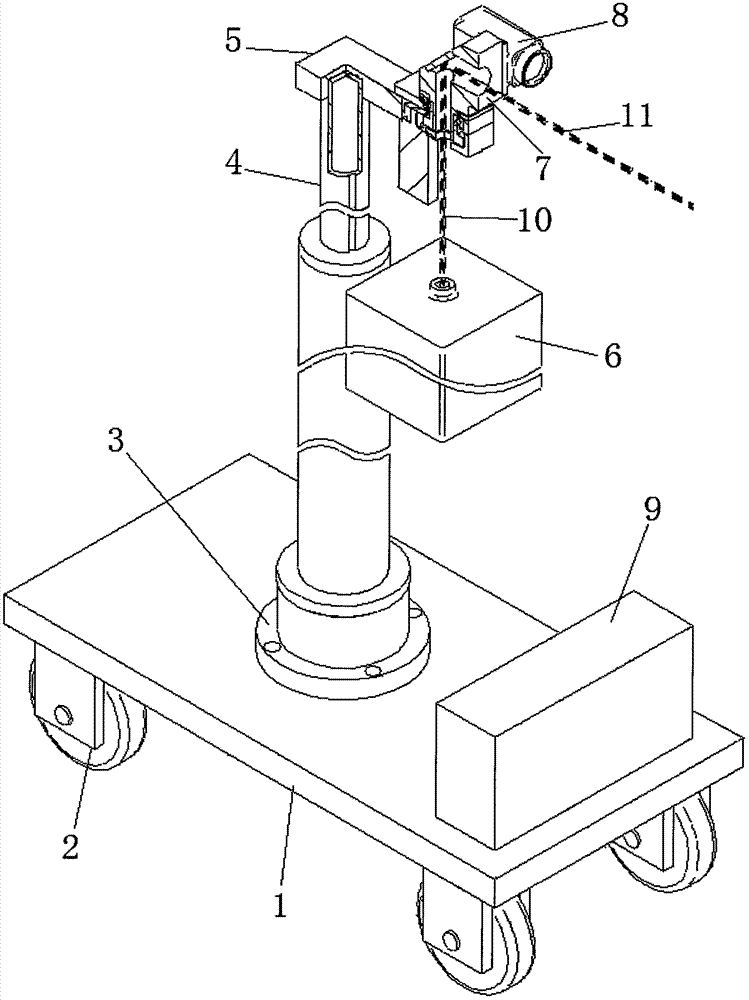

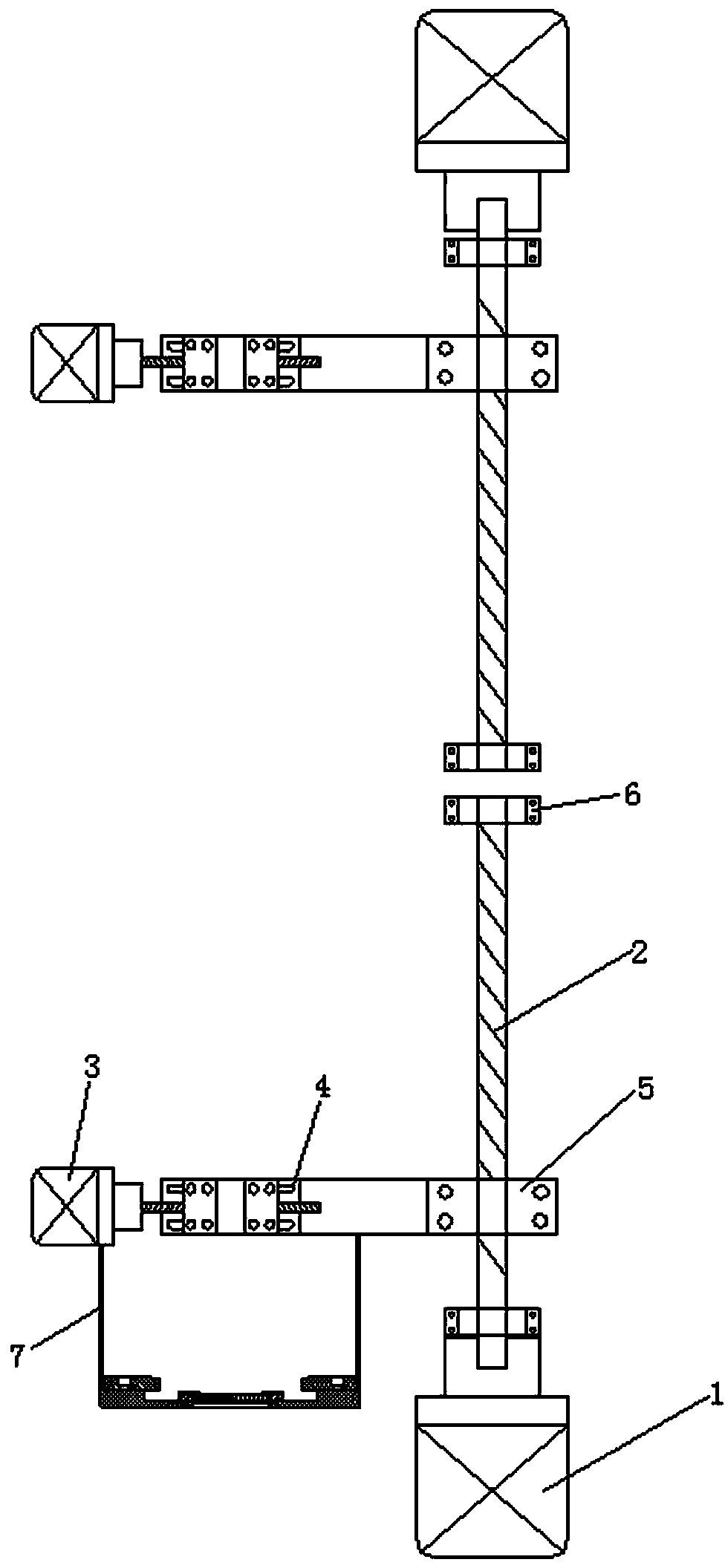

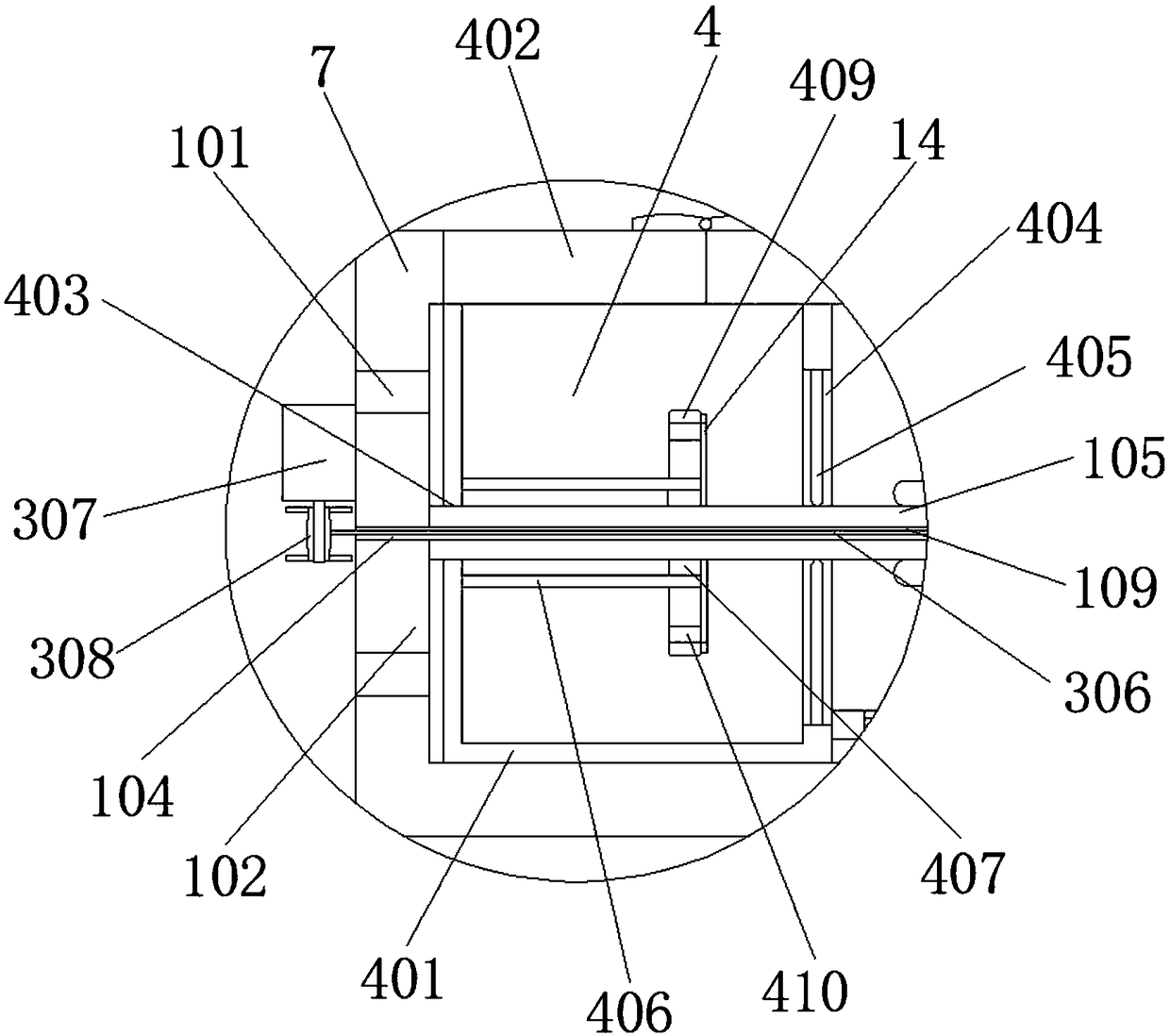

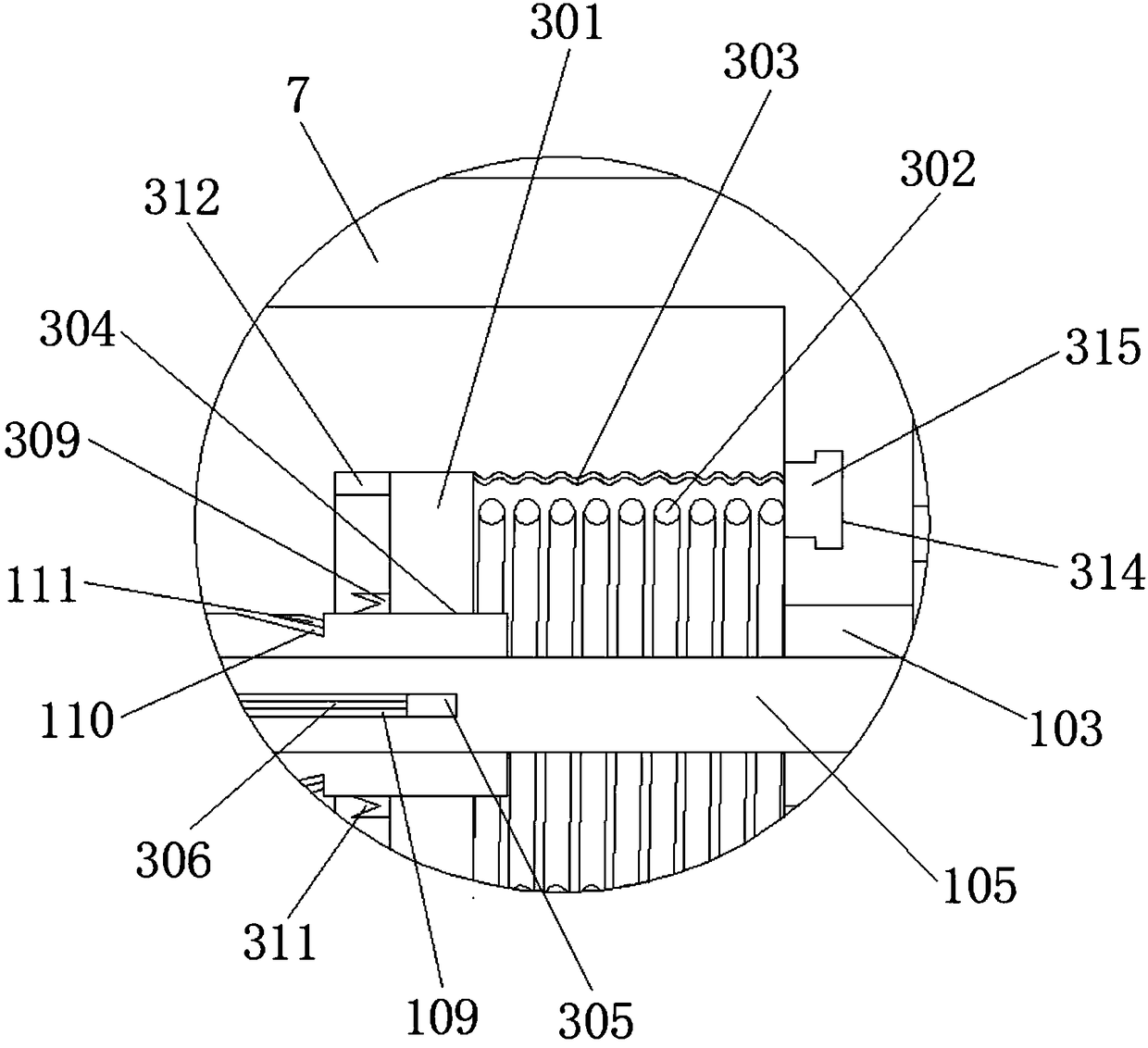

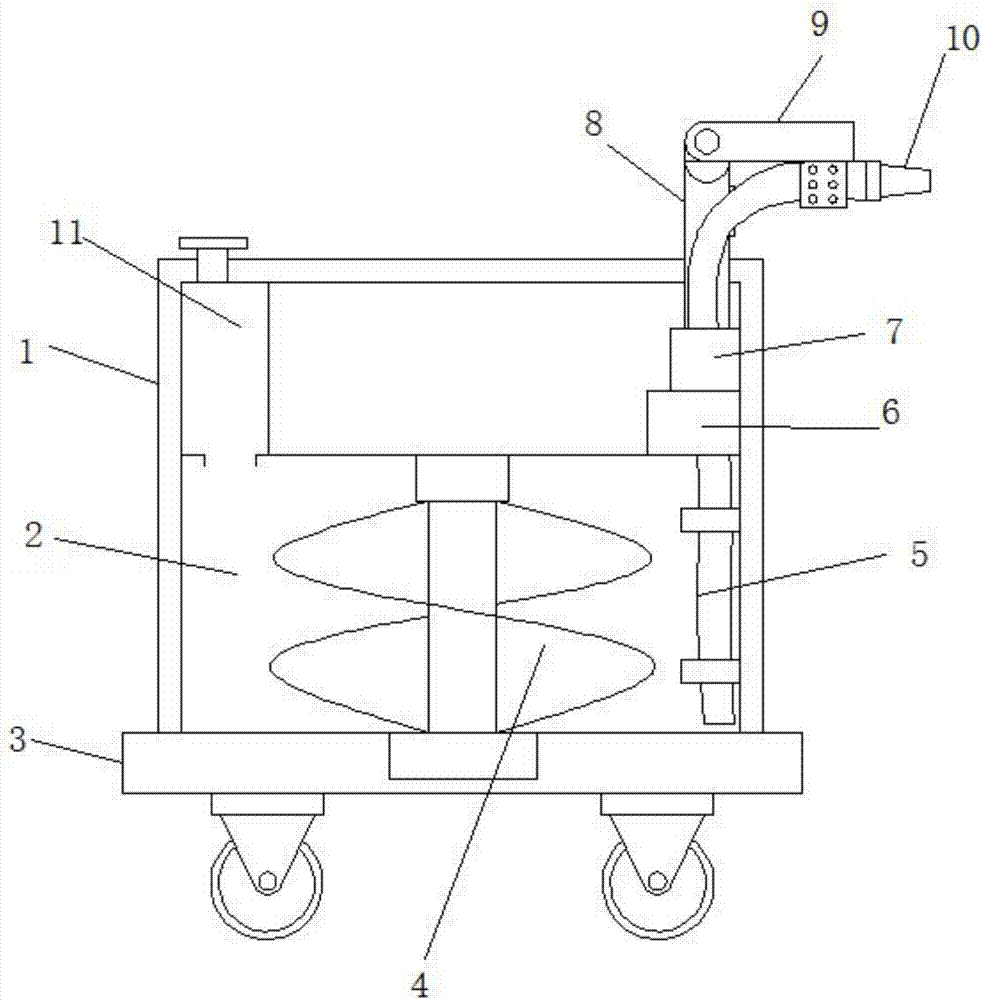

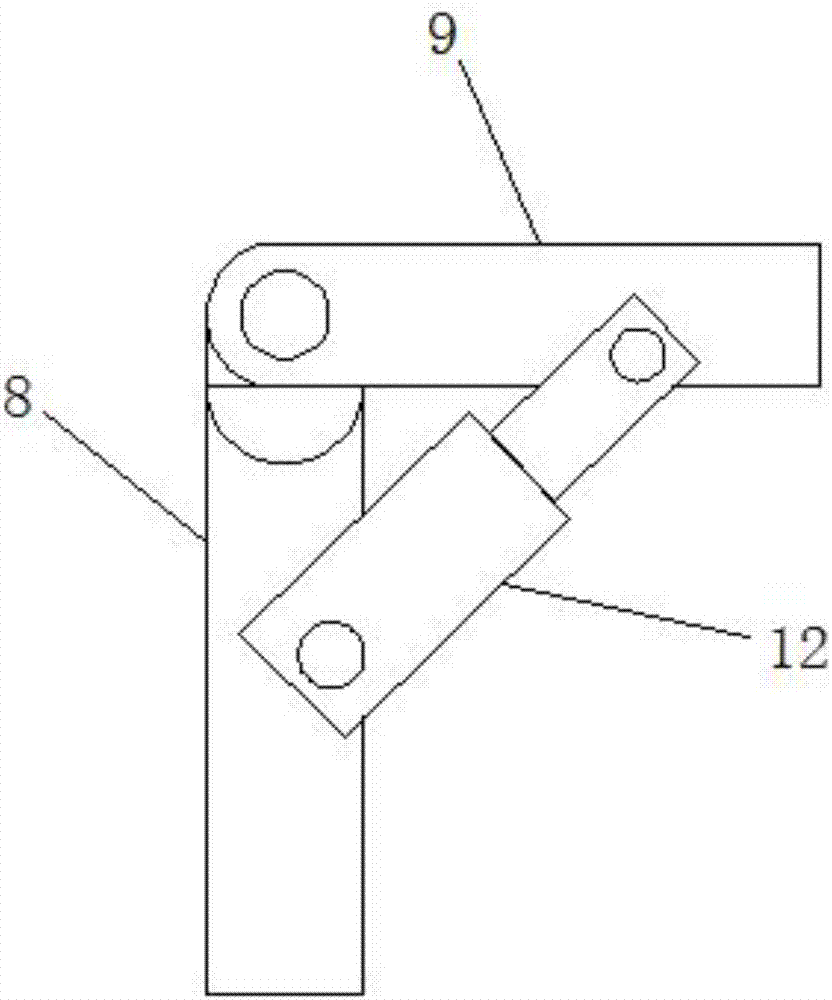

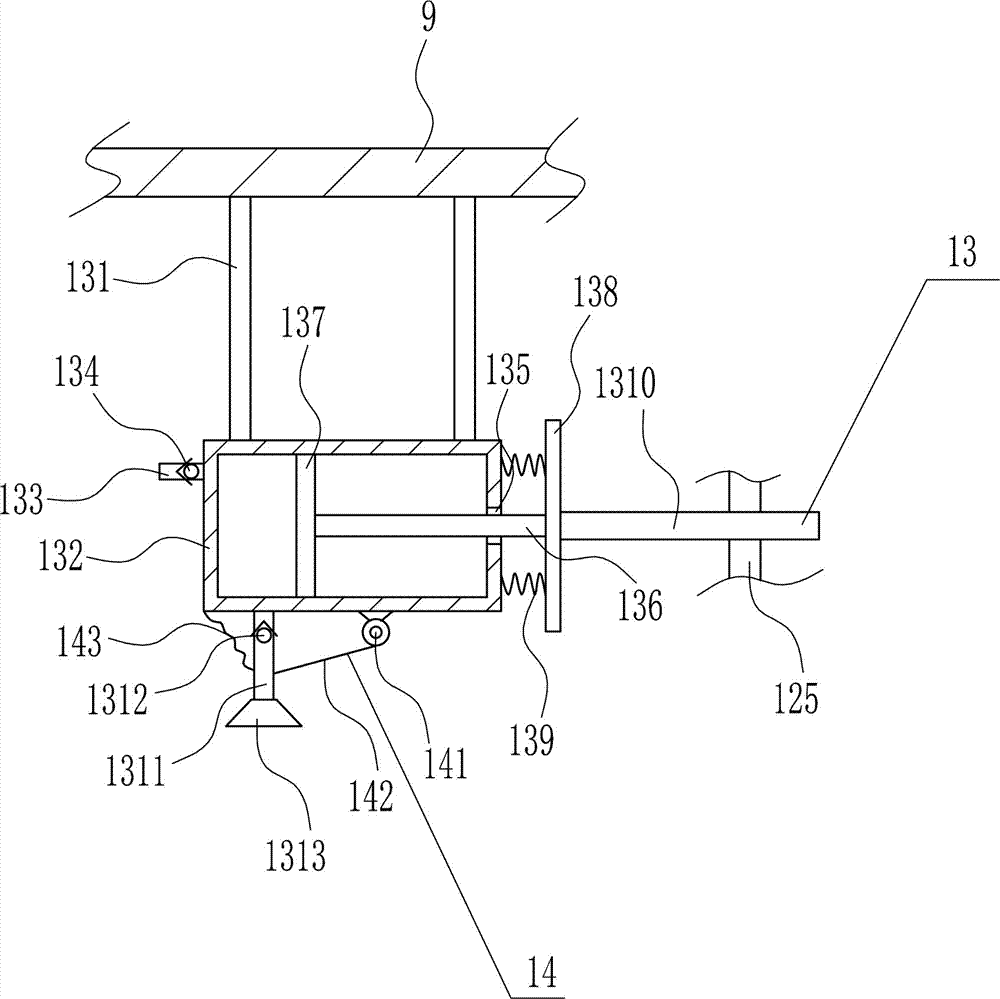

Oilfield automatic feed descaling and dewaxing device with movable lifting mechanism

The invention relates to the technical field of an oilfield automatic feed descaling and dewaxing device, in particular to an oilfield automatic feed descaling and dewaxing device with a movable lifting mechanism. The oilfield automatic feed descaling and dewaxing device comprises a blade assembly, a rubber scraper assembly and a movable lifting mechanism, wherein the movable lifting mechanism comprises two groups of symmetrically arranged movable assemblies; each group of movable assemblies comprises a first motor, a lead screw, a second motor and a pressing device; the lead screw is longitudinally connected with the first motor; the pressing device is transversely connected with the second motor and is connected with one end of the lead screw through a nut seat; and the other end of the lead screw is provided with a bearing seat. According to the oilfield automatic feed descaling and dewaxing device, the lead screw is driven by the first motor to do spiral movement so as to drive the pressing device connected with the lead screw to do up-down vertical movement, so that the automatic feed descaling and dewaxing device can be used for timely, effectively and comprehensively removing a large amount of accumulated wax, oil and scales attached to the outer surfaces of a pumping rod, an oil pipe and a drill stem and is convenient to operate and use, and the descaling and dewaxing effect is favorably improved.

Owner:JIANGSU JUNXINYI GASOLINEEUM MACHINERY

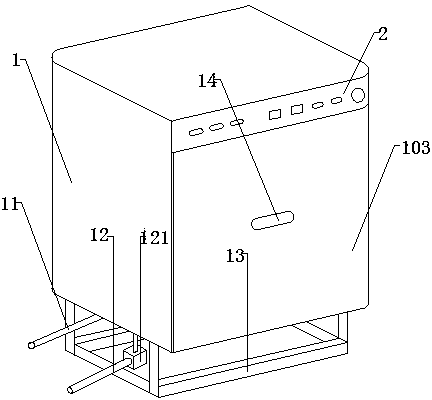

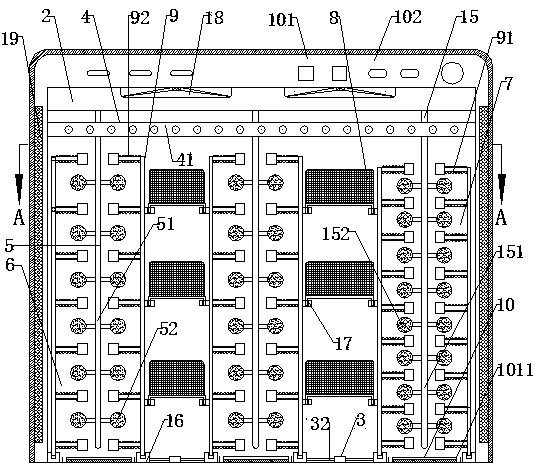

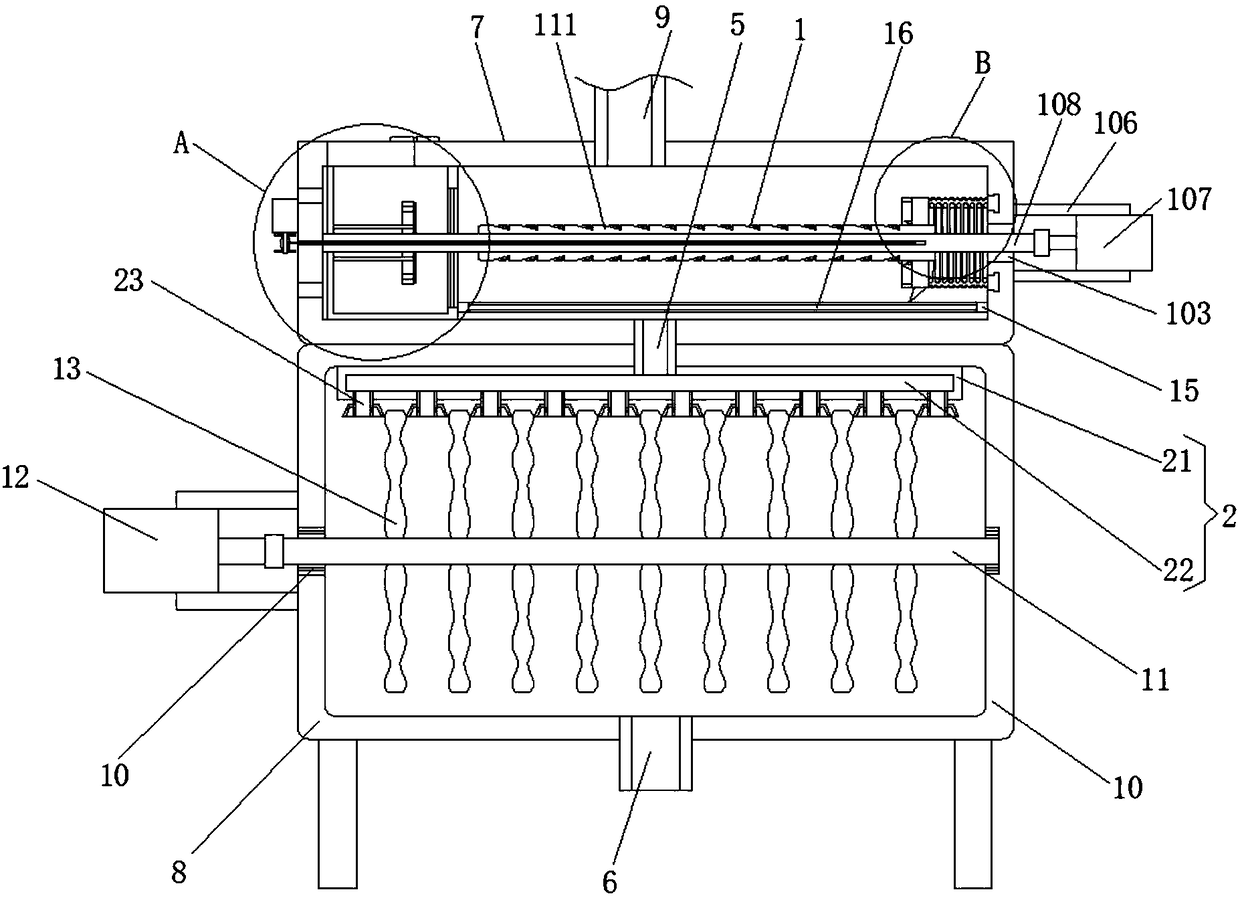

Environment-friendly dish-washing machine

ActiveCN104323747AEasy to placePlace safeTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention discloses an environment-friendly dish-washing machine, comprising a box body, wherein an upper injection unit and a lower injection unit are arranged at the upper end and the lower end in the box body; a heating device and an air-drying device are arranged at the bottom and the top in the box body; sterilizing devices are arranged on two lateral walls of the box body; a first shelving unit and a second shelving unit are arranged in the box body, and each of the first and second shelving units comprises two opposite frames; a rotational scrubbing unit and a vibrating scrubbing unit are respectively arranged between the two opposite frames of each of the first and second shelving units; a first lead rail is arranged at the bottom of each frame; each frame is composed of a plurality of layers of parallel elastic clamping layers; each elastic clamping layer is provided with a plurality of clamping springs; a plurality of grid grooves are formed between two frames on the contrary; two sides of the bottom of each grid groove are movably connected with a second lead rail; the second lead rails are fixedly arranged on the side surfaces of the frames. The environment-friendly dish-washing machine is convenient to push and pull, clean in cleaning, good in drying and air-drying effect, free of bacterial residue, thorough in sterilizing, convenient to insert, firm, and free of a dead angle in injection, and cleaned tableware is healthy and sanitary.

Owner:王金青

Forced cyclone sand removal device structure

InactiveCN111151387ASolve the accumulationEnsure a closed environmentReversed direction vortexEngineeringStructural engineering

The invention discloses a forced cyclone sand removal device structure. The forced cyclone sand removal device structure comprises an inverted cone cyclone body, wherein the inverted cone cyclone bodycomprises an upper cyclone barrel body; the lower end of the upper cyclone barrel body is connected with a lower cone angle cyclone barrel body; a mixed phase liquid inlet is formed in the upper right end of the upper cyclone barrel body; a liquid phase outlet is formed in the just upper end of the upper cyclone barrel body; a sand outlet is formed in the bottom end of the lower cone angle cyclone barrel body; a sand dredger is arranged at the sand outlet; a throttling sand removal atomizing nozzle is arranged at the upper end of the inner wall of the lower cone angle cyclone barrel body; theright side of the liquid phase outlet is connected with a liquid phase sand removal protector; and the left side of the sand dredger is connected with a rotating power device. According to the forcedcyclone sand removal device structure, the sand dredger is designed to effectively prevent sand from being blocked, the arranged liquid phase sand removal protector can effectively and thoroughly remove fine sand in a liquid phase, and the arranged throttling sand removal atomizing nozzle can save a large amount of water resources by utilizing the atomizing design while removing the sand in the inverted cone cyclone body.

Owner:GUANGDONG POWER GRID CO LTD +1

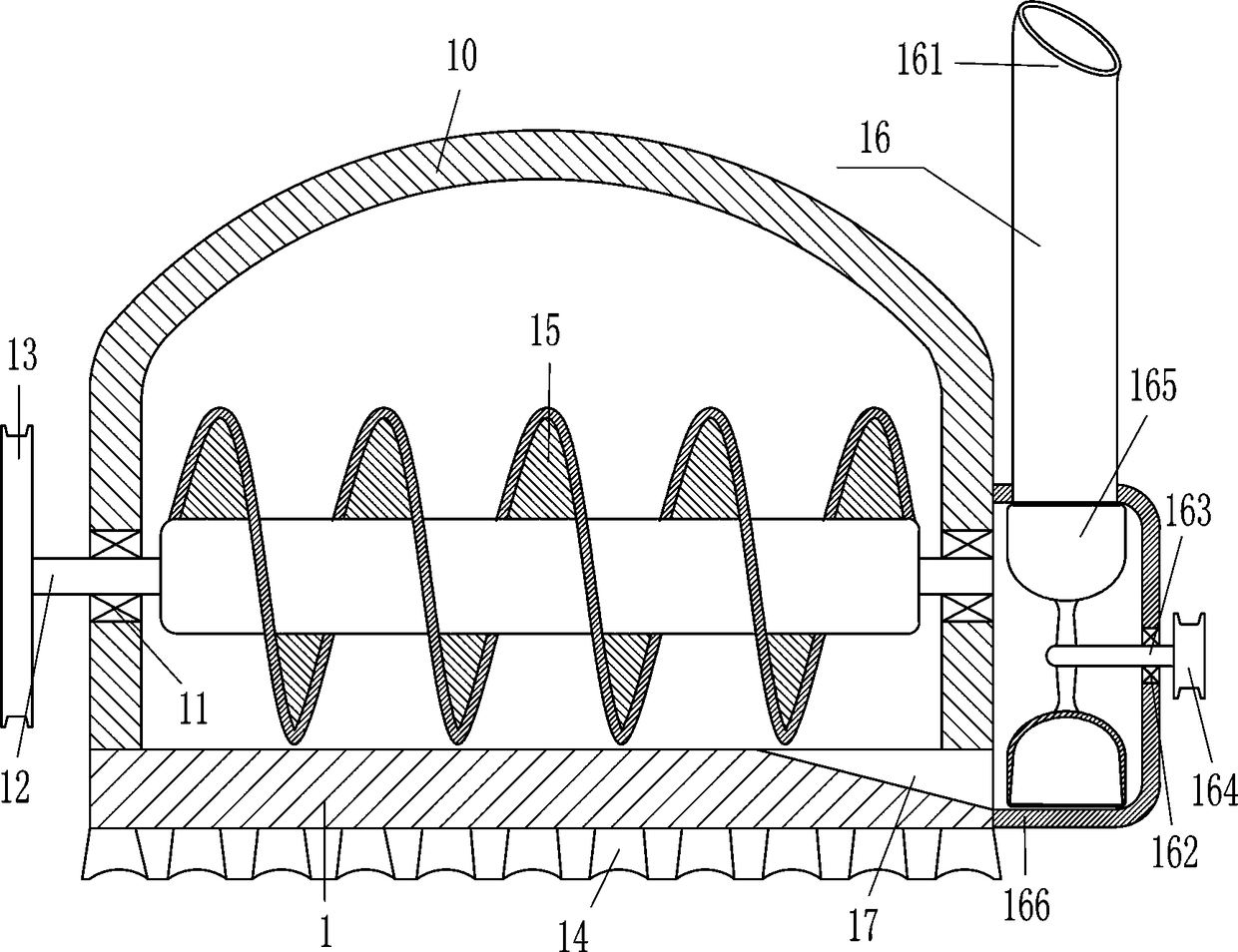

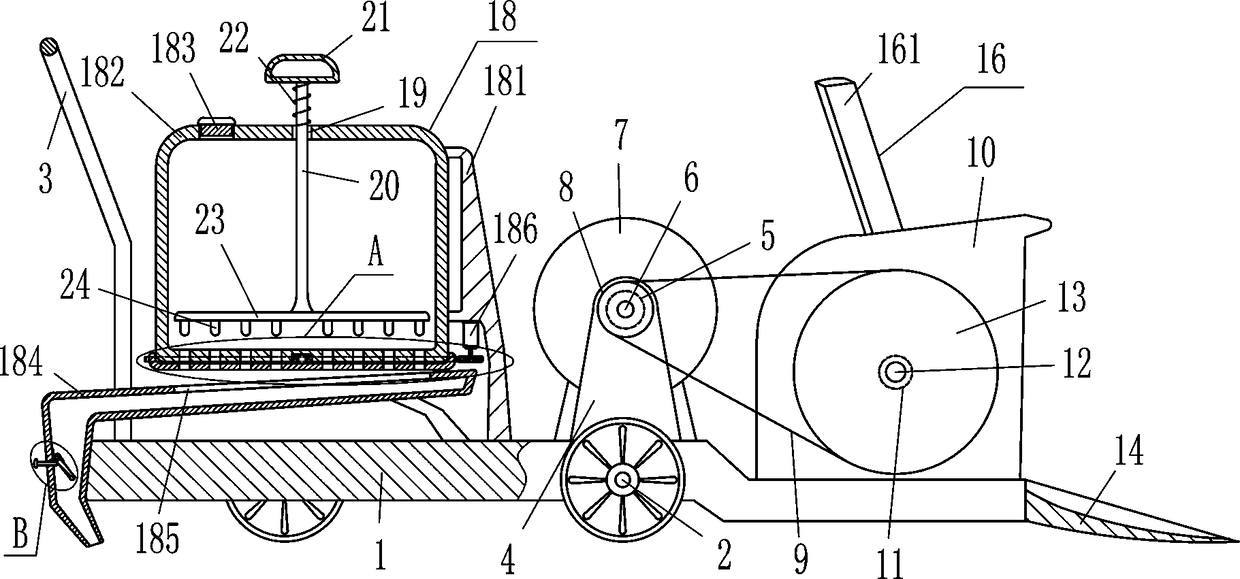

Clearing machine for accumulated snow on garden road

The invention relates to a clearing machine, in particular to a clearing machine for accumulated snow on a garden road. The technical problems are solved by the clearing machine for accumulated snow on the garden road, wherein the clearing machine can clear off the accumulated snow more rapidly, and is high in working efficiency, short in consumed time and low in labor intensity. In the technicalimplementation scheme, the clearing machine for the accumulated snow on the garden road comprises a bottom plate, wheels, a pushing hand, a supporting plate, a first bearing pedestal, a first rotatingshaft, a double-shaft motor, a first belt wheel, a first flat belt and others; the wheels are rotatably connected to the front and back sides of the middle and the front and back sides of the left ofthe bottom plate respectively, and the pushing hand is installed on the left side of the top of the bottom plate. By pushing the machine, a shoveling plate can shovel up the snow, then the shoveled snow is discharged to the two sides of the road through a snow discharging device, it is not needed to manually shovel the snow to the sides of the road, hands are prevented from being ached, working efficiency is high, salt is scattered onto the road through a salt scattering device after the snow is shoveled, and therefore the snow which falls onto the road is melt more rapidly and not easily accumulated.

Owner:吴开英

Solid perfume with refreshing and bacterium inhibiting effects and preparation method thereof

InactiveCN109646380AClear allProtection from oxidative damageCosmetic preparationsAir-treating devicesEucalyptus oilButylated hydroxytoluene

The invention provides solid perfume with refreshing and bacterium inhibiting effects and a preparation method thereof. The solid perfume is prepared from, by weight, 4-10 parts of pine oil, 3-8 partsof cinnamon essential oil, 4-10 parts of lavender essential oil, 5-10 parts of flavoring rose essence, 2-5 parts of eucalyptus oil, 5-15 parts of chequer-shaped indocalamus leaves, 1-4 parts of butylated hydroxytoluene, 4-10 parts of propylene glycol, 3-8 parts of chamomile, 2-6 parts of modified chitosan and 1-5 parts of an adsorbent. The solid perfume produced according to the accessories and the preparation method are lasting in fragrance, is not likely to melt, and has the refreshing effect which is not achieved by common perfume, use is safe and effective, the air refreshing and sterilizing effects are achieved, and the solid perfume is especially suitable for being used in cars, clothes storage cabinets, hotels and other narrow spaces and is the preferred object of people living athome and taking a trip.

Owner:汪键

Printing and dyeing sewage treatment device with flocculate removing function

ActiveCN108455802AWith deflocculation functionDeal with impactTreatment involving filtrationMultistage water/sewage treatmentFiberDrive motor

The invention discloses a printing and dyeing sewage treatment device with a flocculate removing function and relates to the field of biotechnology. The printing and dyeing sewage treatment device with the flocculate removing function comprises a flocculate removing box, a reaction box, a water inlet pipe, load-carrying bearings, a reaction shaft, a driving motor, reaction discs, a connection pipe, a discharging pipe, a fiber collection mechanism, a shunting mechanism, an axial material peeling mechanism and a discharging mechanism, wherein the upper surface of the reaction box is fixedly connected with the lower surface of the flocculate removing box; the left wall and the right wall of the reaction box are movably connected with the left end and the right end of the reaction shaft respectively through the load-carrying bearings; the driving motor is fixedly mounted on the left side of the reaction box through a connection rod. The printing and dyeing sewage treatment device with theflocculate removing function has the advantages that the fiber collection mechanism in the flocculate removing box is capable of collecting fibers in the sewage, sharp parts of a flocculate collectiongroove and a flocculate collection rod are used for hanging the fibers and collecting the fibers, and the influence of excessively high fiber content on the biological sewage treatment can be avoided.

Owner:绍兴市柯桥极润贸易有限公司

Disease and insect elimination device for forestry planting

The invention discloses a device for eliminating diseases and insects for forestry planting, which comprises a casing, wherein a pesticide storage box is arranged inside the casing, and the pesticide storage box is connected to the inner bottom wall of the casing, and the bottom of the casing is connected to a fixing seat The bottom of the bottom, and two sets of moving wheels are installed on the side away from the shell on the fixed seat, the side of the shell is provided with a liquid medicine configuration box, and the side of the liquid medicine allocation box close to the pesticide storage box is connected to the inside of the pesticide storage box In the pesticide storage tank, a water pipe is provided on the side away from the liquid medicine configuration tank, and one end of the water pipe passes through the pesticide storage tank. In the present invention, by arranging the stirring paddle in the pesticide storage box, the pesticide and water are mixed more thoroughly, and the rotating plate and the bracket can be rotated, and then the telescopic rod drives the rotating plate to rotate, so that the pesticide nozzle can spray the pesticide up and down , the spraying of pesticides is more thorough, the removal of pests is more perfect, and the effect of cleaning pests is better.

Owner:阳新县茂盛林木苗圃科技有限公司

A mild and non-washing makeup remover cream and its preparation method

ActiveCN104800100BClear allHigh makeup removal abilityCosmetic preparationsMake-upCapric triglyceridesPalmitates

A mild and non-washing cleansing cream, characterized in that it consists of the following components in weight percentage: 2% to 10% of polyethylene, 2% to 20% of cetyl ethyl hexanoate, PEG‑10 isostearate 2%~20%, PEG‑20 Glyceryl Triisostearate 2%~20%, Tocopheryl Acetate 0.2%~1%, Phenyl Trimethicone 2%~10%, Dextrin 0.2% to 3.0% of palmitate, and the balance is caprylic acid / capric triglyceride. The cleansing cream of the invention has good cleansing ability, mild property, high safety, and is convenient and easy to carry.

Owner:FOSHAN WIN COSMETIC

Mechanical part rust removal device capable of working at multiple angles

ActiveCN111604787ASpeed up rust removalGuarantee the effect of grinding and rust removalGrinding wheel securing apparatusGrinding carriagesServoManufacturing engineering

The invention discloses a mechanical part rust removal device capable of working at multiple angles. The mechanical part rust removal device comprises a base, a middle cylinder, a servo motor, a workpiece clamp body and a driving gear, wherein the middle cylinder is welded and fixed to the center of the top of the base; a top gear is meshed with a driven gear; the driven gear is welded and fixed to one end of a horizontal shaft; the driving gear is welded and fixed to the middle of the horizontal shaft; and the top end of the driving gear is connected with the lower end surface of a horizontalring. According to the mechanical part rust removal device capable of working at multiple angles, a novel structural design is adopted, so that the device can carry out comprehensive multi-angle friction rust removal on mechanical parts; and the structure provided with a workpiece clamp can be driven by a grinding driving structure through a transmission structure to rotate in a forward and reverse alternating mode, small-amplitude displacement in the vertical direction can be carried out in the forward and reverse alternating rotation process, and the grinding and rust removal effect on thesurfaces of the mechanical parts is guaranteed in cooperation with a rotary grinding structure.

Owner:绍兴市魏达机械有限公司

Kiwi fruit no-injury hair removing equipment

The invention belongs to the technical field of food processing mechanisms, and discloses kiwi fruit no-injury hair removing equipment. The kiwi fruit no-injury hair removing equipment comprises a machine housing, wherein the lower surface of a feeding ring is fixedly connected to the upper surface of the machine housing; an annular groove is formed in the upper surface of the feeding ring; inletsare respectively formed in the left side and the right side of the bottom wall of the annular groove; a material opening is formed in the position corresponding to each inlet, on the top wall of themachine housing; a fed material preprocessing mechanism is arranged on the upper side of the inner part of the machine housing; and a disk type brushing and removing mechanism is arranged on the lowerside of the inner part of the machine housing. According to the kiwi fruit no-injury hair removing equipment disclosed by the invention, the fed material preprocessing mechanism is arranged, so thatin the feeding process of kiwi fruits, preprocessing hair removing can be performed, quick hair removing is realized through the gravity and the rotation of a connecting ring, and the kiwi fruit no-injury hair removing equipment is simple in structure.

Owner:杨国宝

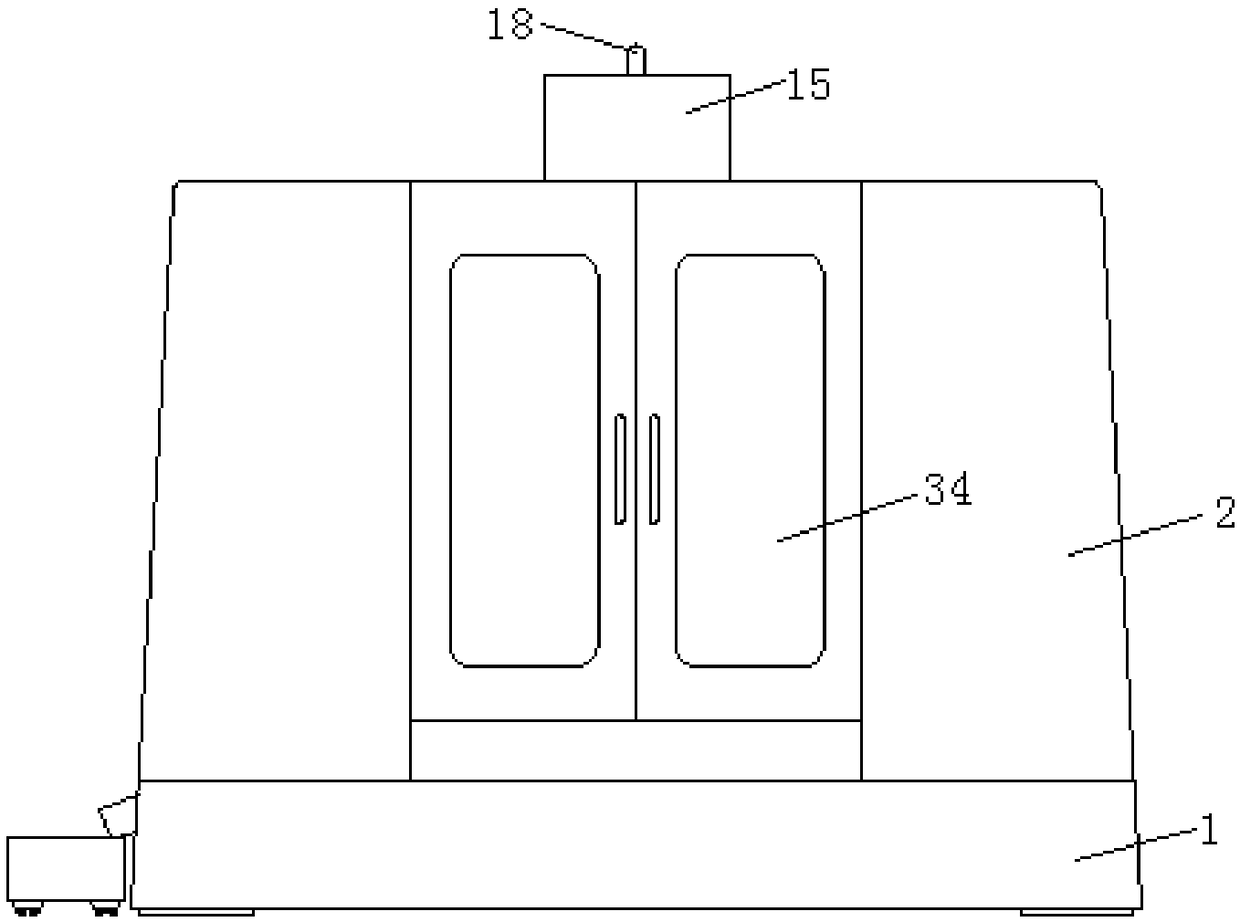

Five-axis linkage engraving and milling machine

PendingCN108747535AIncrease the cleaning areaReduced service lifeFeeding apparatusMaintainance and safety accessoriesEngravingEngineering

The invention discloses a five-axis linkage engraving and milling machine comprising an engraving and milling machine base. The upper surface of the engraving and milling machine base is fixedly connected to engraving and milling machine baffles, and the upper surface of each engraving and milling machine baffle is fixedly connected to slide ways; each slide way is internally provided with a slider, and the side, close to the engraving and milling machine baffles, of the upper surface of the engraving and milling machine base is movably connected to an engraving and milling machine workbench;the inner side walls of the engraving and milling machine baffles are fixedly connected to a Y-axis moving table of which the interior is movably connected to a Y-axis movable rod; and the outside surface of the Y-axis movable rod is movably connected to a Z-axis moving table rod. According to the five-axis linkage engraving and milling machine, through arrangement of screw clamping blocks, ejector rod holes, ejector rods and ejector rod springs, slag discharge screws are inserted into screw fixing sleeves, so that the screw clamping blocks are clamped into the ejector rod holes, and the slagdischarge screws are fixed; the screw clamping blocks are pushed out of the ejector rod holes by pressing the ejector rods, thereby facilitating maintenance of the slag discharge screws; and thus, thepurpose of facilitating removal is achieved.

Owner:HANGZHOU KINGNET ELECTROMECHANICAL

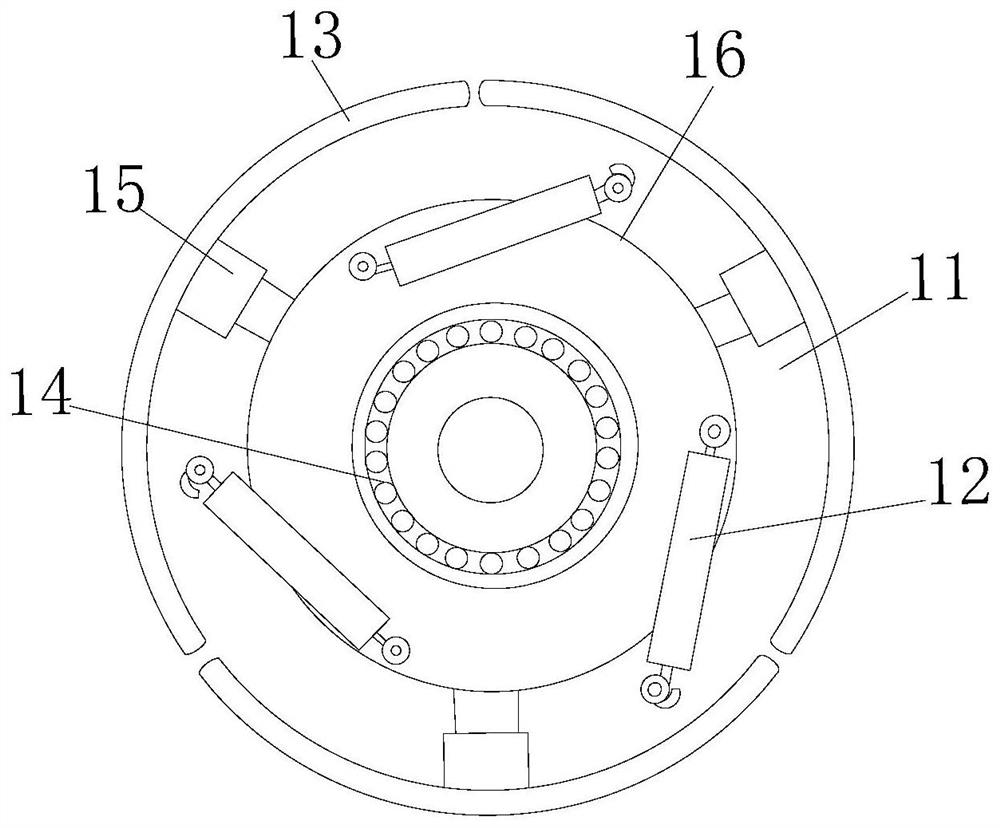

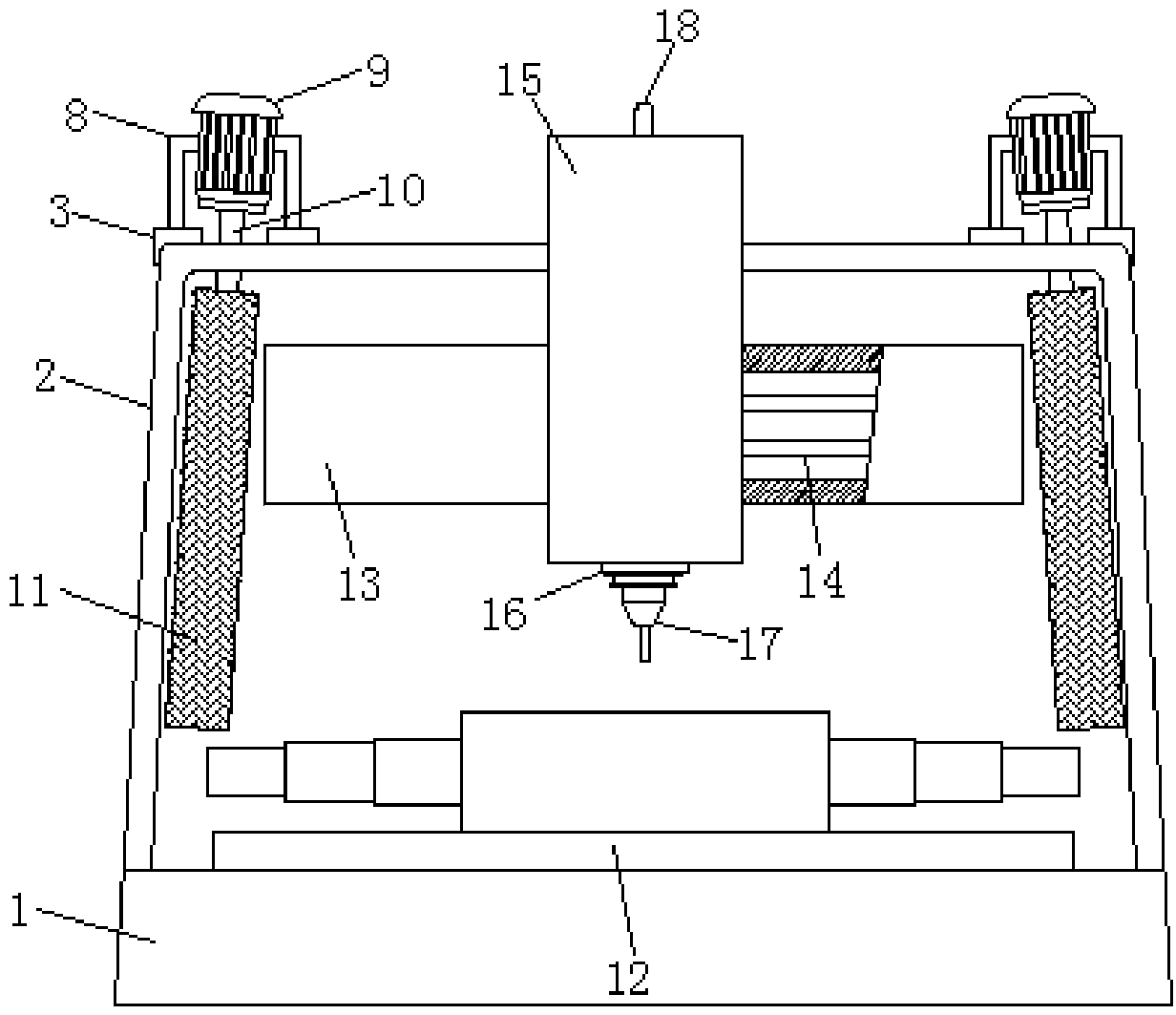

Efficient grinding equipment for brake clutch plate production

ActiveCN106956210AWill not affect the surrounding environmentClear allGrinding carriagesGrinding drivesTransverse planeEngineering

The invention relates to grinding equipment for brake clutch plate production, in particular to efficient grinding equipment for brake clutch plate production. In order to solve the technical problems, the invention provides the efficient grinding equipment for brake clutch plate production, and the efficient grinding equipment is small in labor intensity, is low in working efficiency, is not liable to damage during grinding, and does not affect the ambient environment. The efficient grinding equipment for brake clutch plate production comprises a base, a first placing plate, a second placing plate, a right side plate, a first slide rail, a first slide block, a mounting plate, a transverse plate, a grinding ball and the like, wherein the left side of the top of the base is equipped with the first placing plate in a bolt connection mode; and the right side of the top of the base is equipped with the second placing plate in the bolt connection mode. By regulating the distance between the first placing plate and the second placing plate, the efficient grinding equipment can be used for fixing brake clutch plates of different sizes; and moreover, a dust removal device can be used for removing dust.

Owner:东营宝丰汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com