Patents

Literature

400results about How to "Difficult to handle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

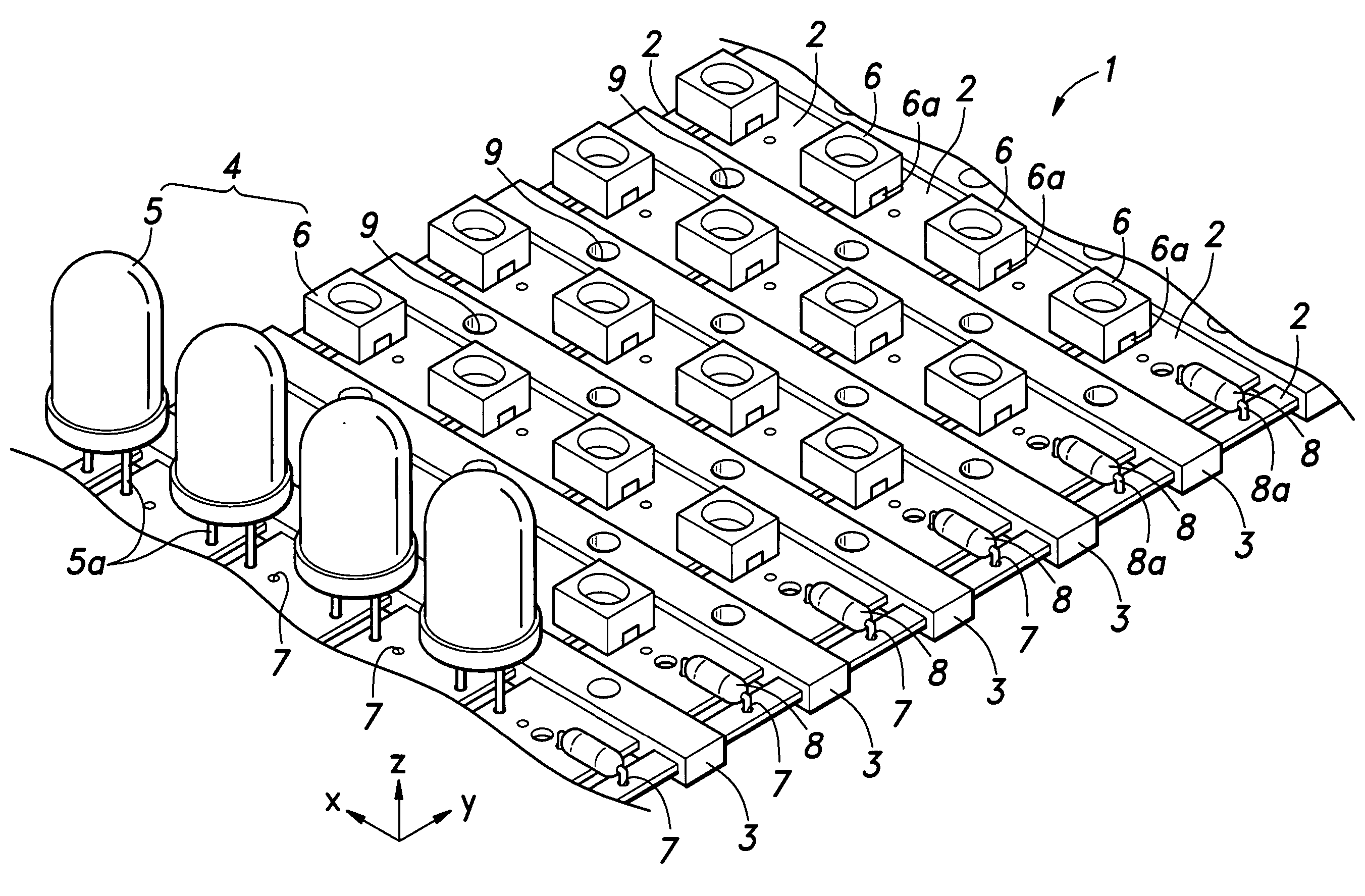

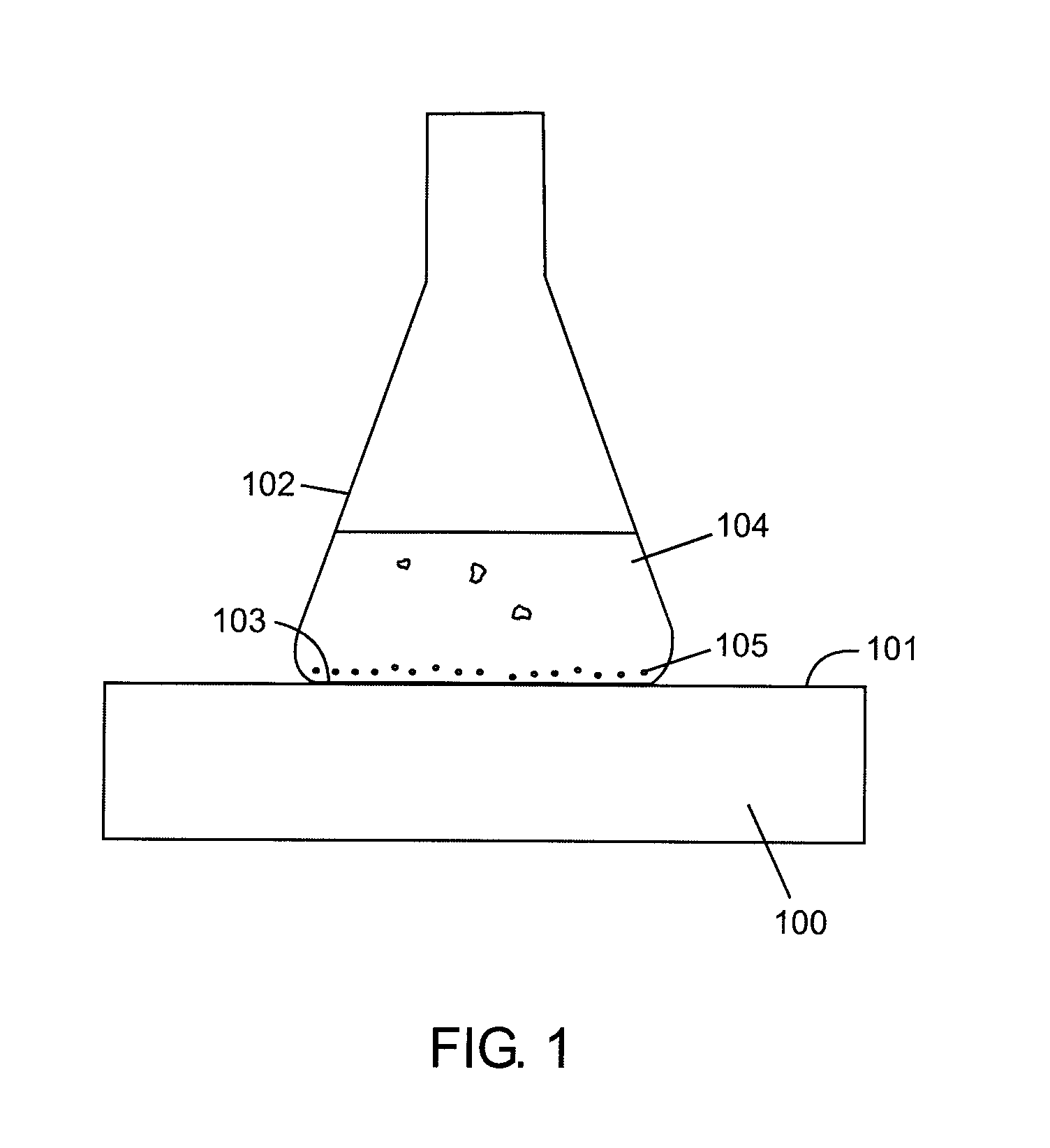

Light emitting module

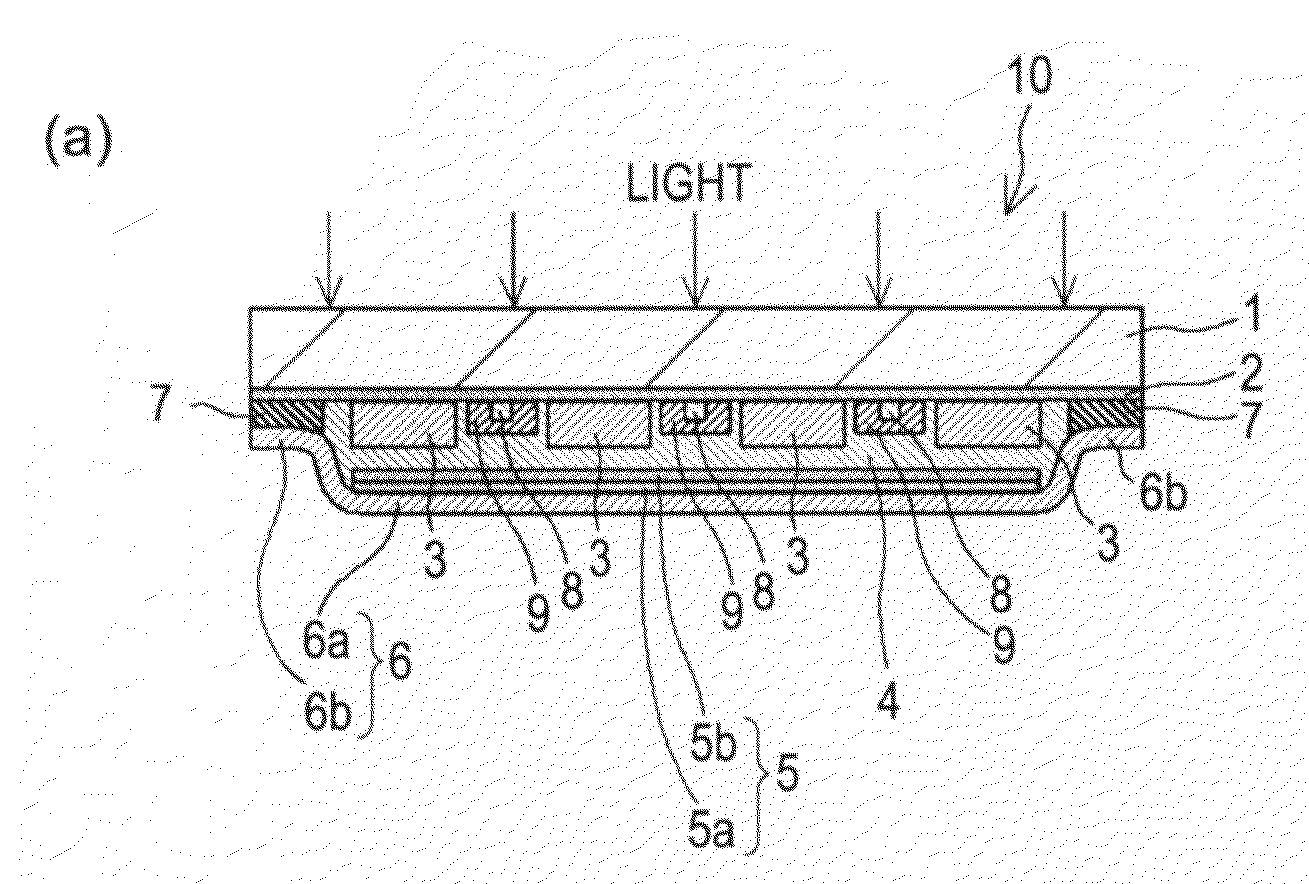

InactiveUS7201511B2Improve cooling effectDifficult to handlePlanar light sourcesLighting support devicesJoint componentElectrical conductor

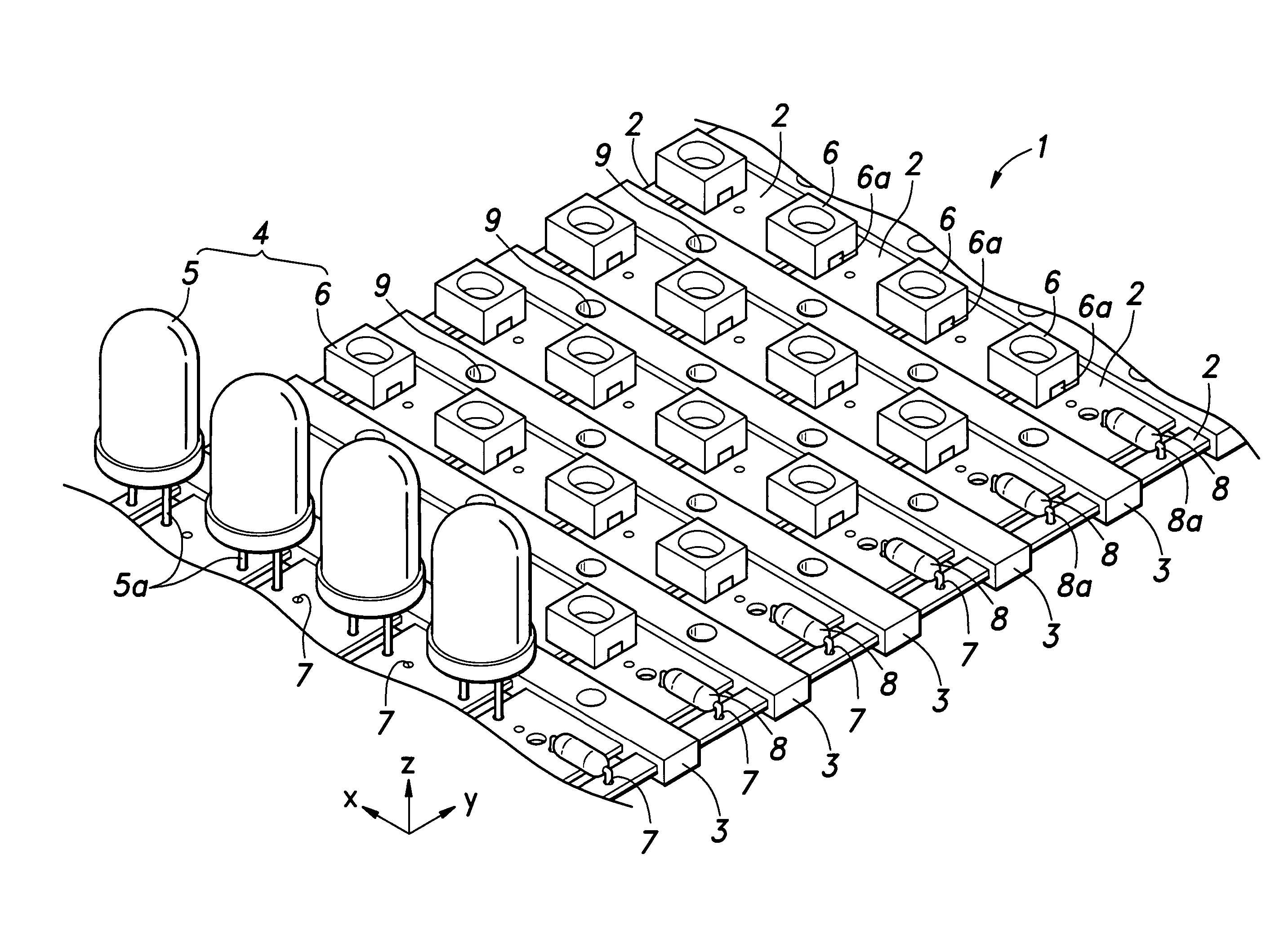

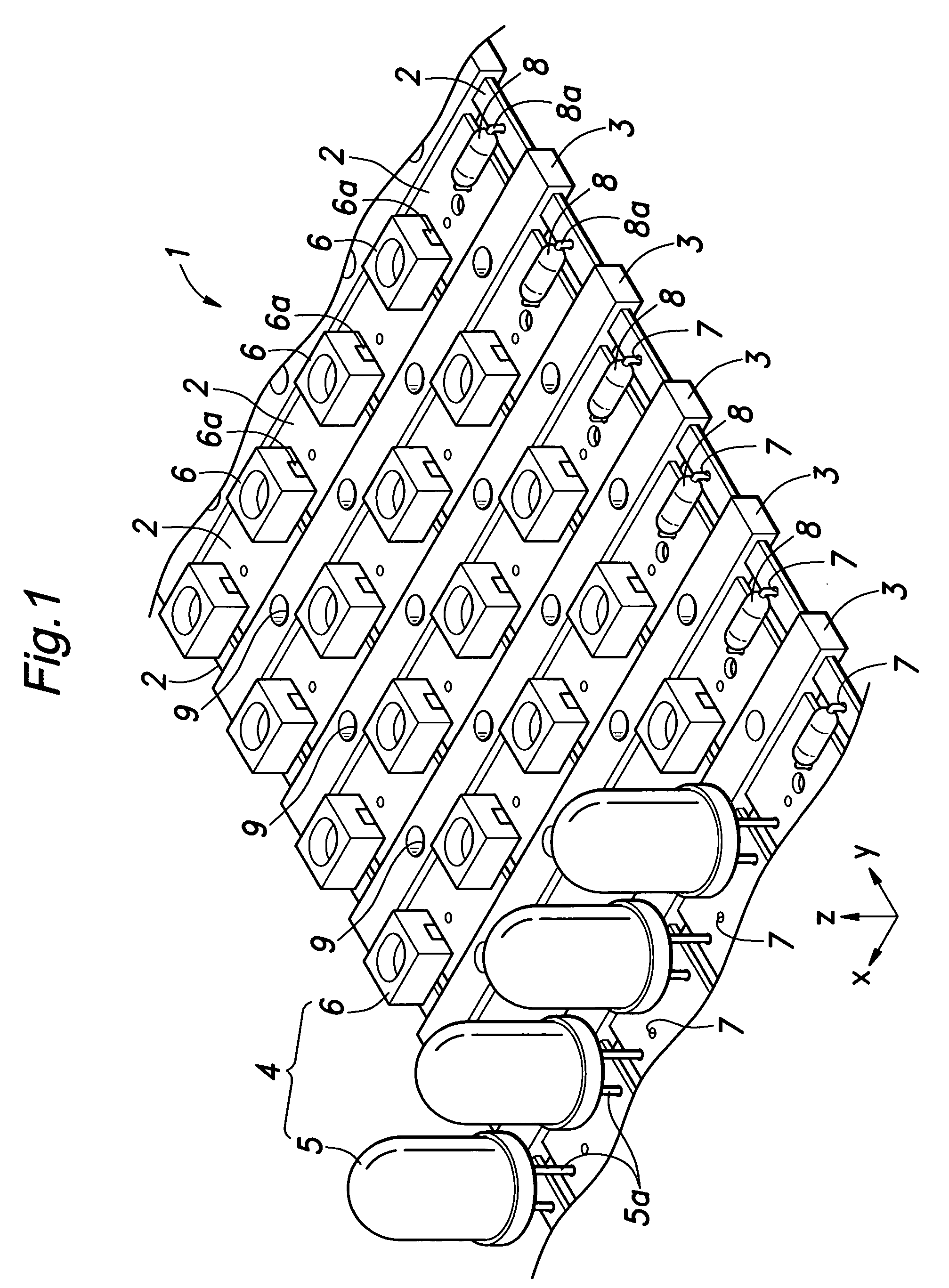

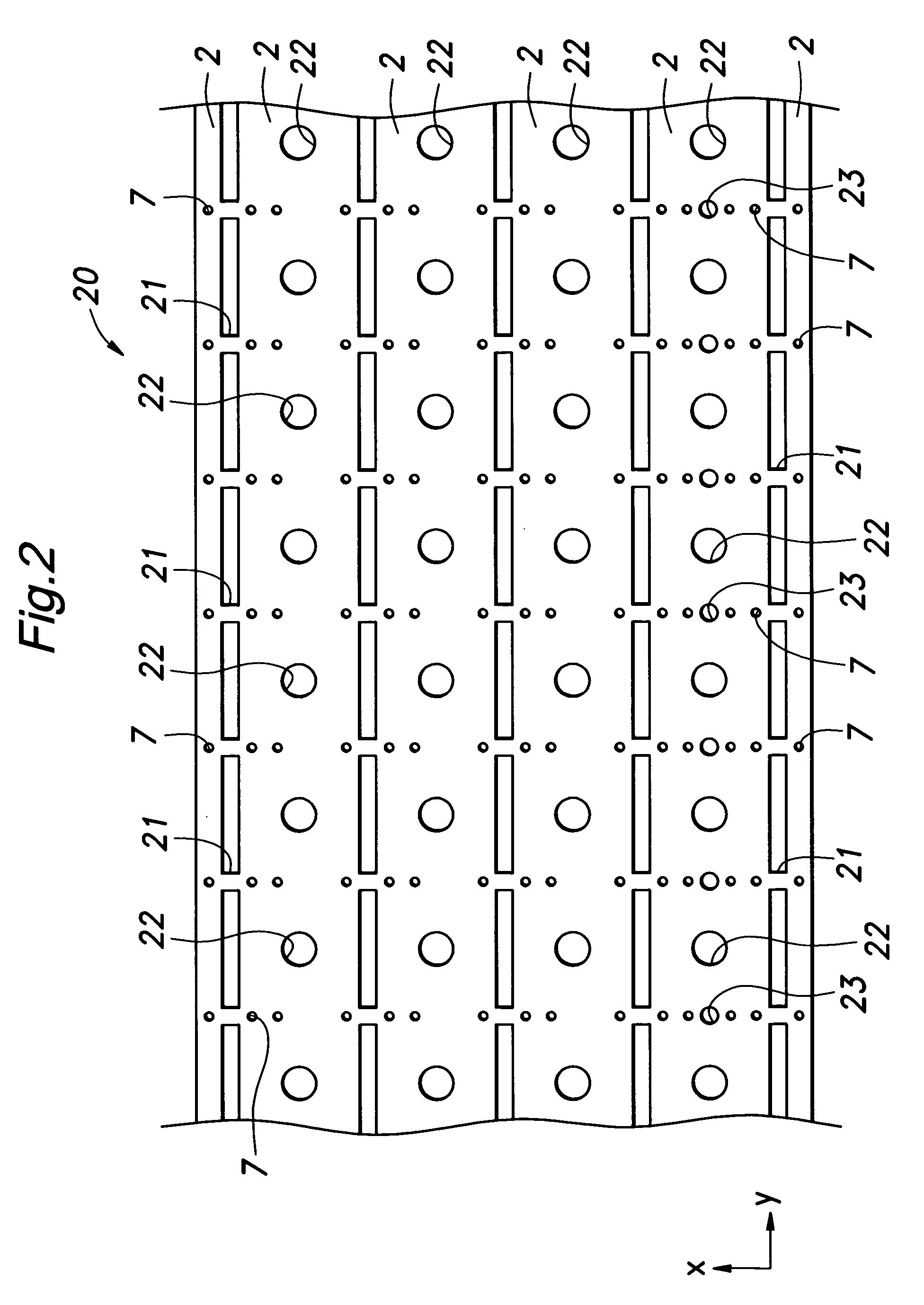

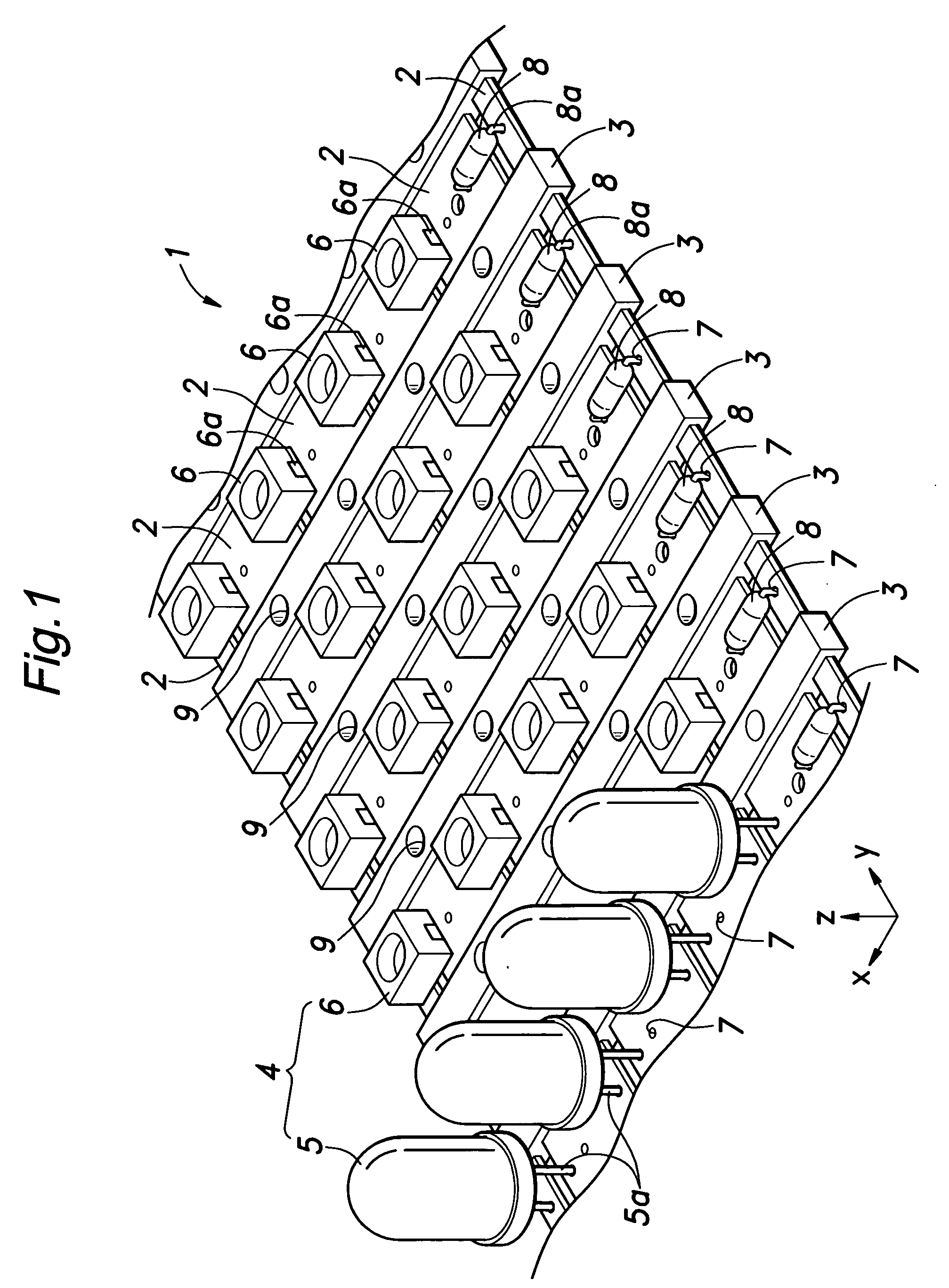

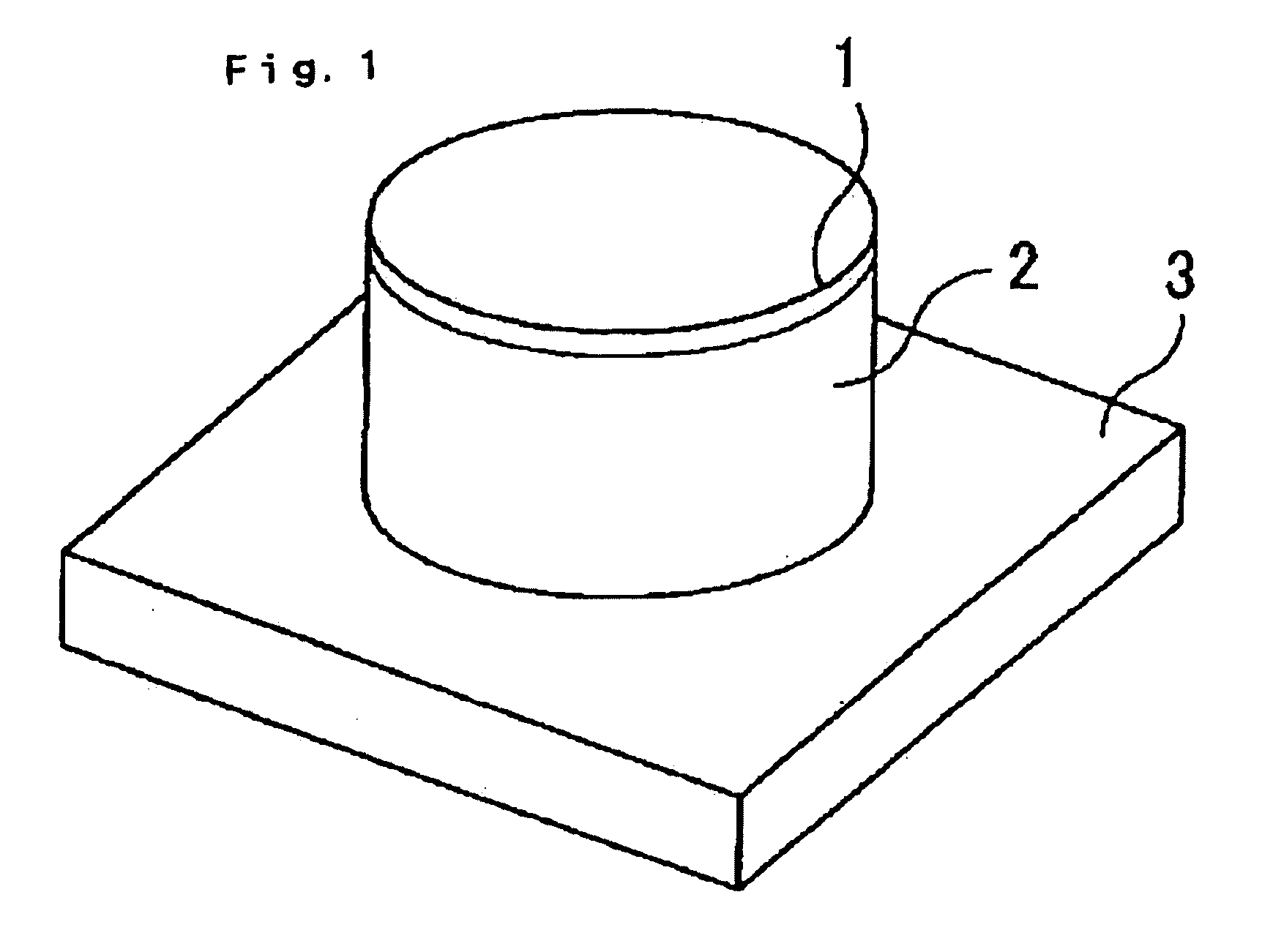

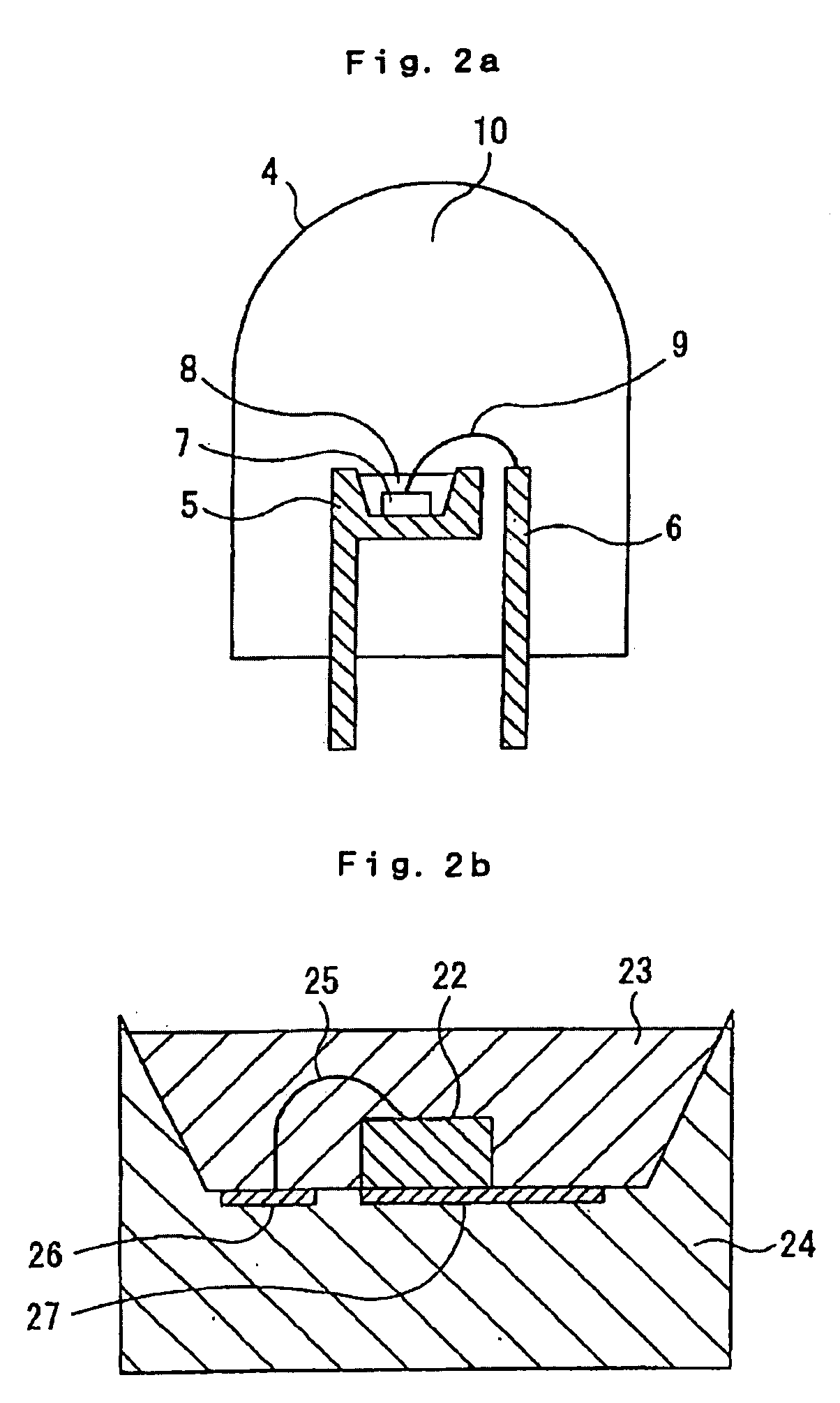

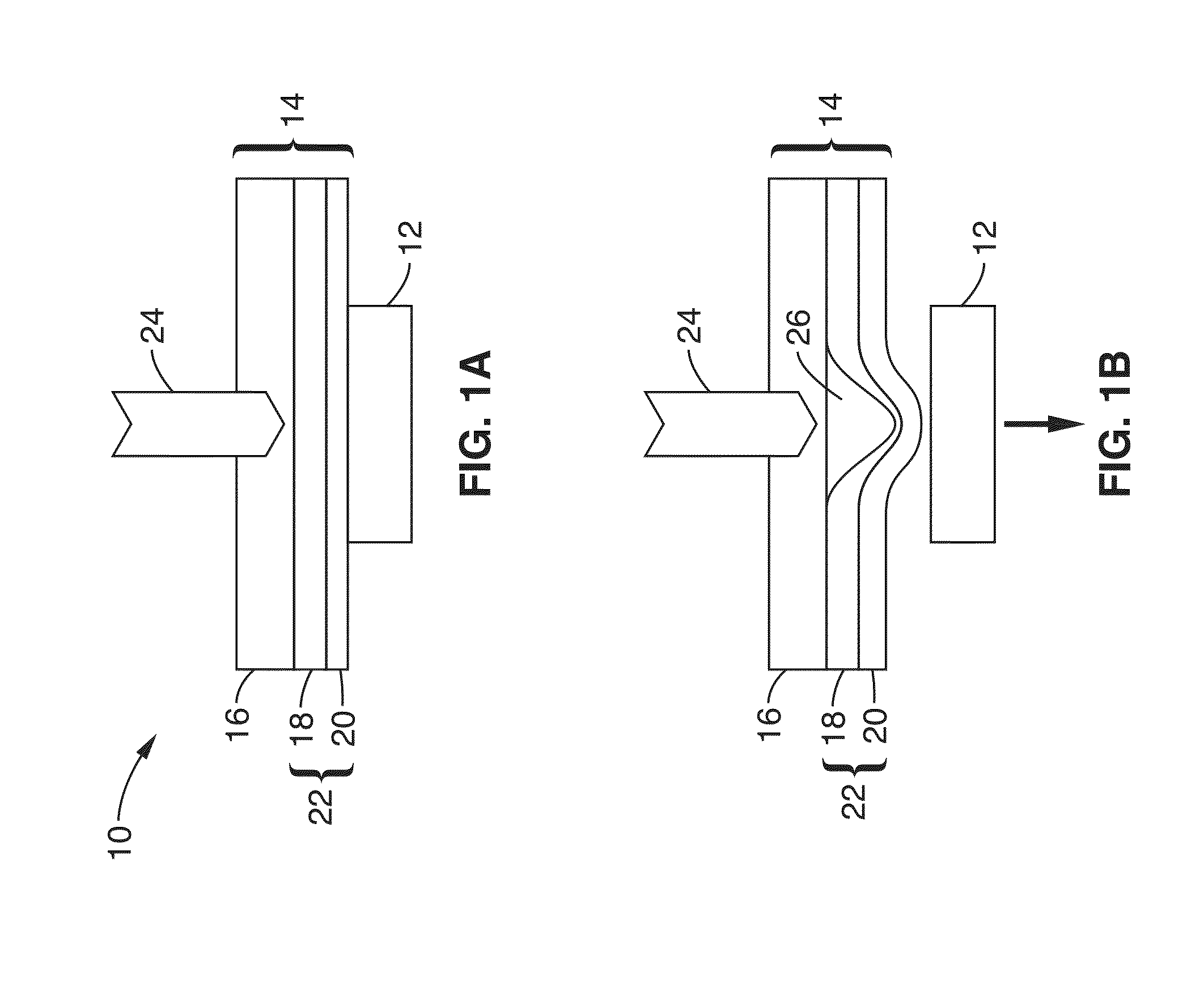

The present invention provides a light emitting module, comprising: a plurality of thin plate-shaped conductors (2) spaced apart from each other in a first direction; at least one light source (4) connected between at least one pair of adjoining ones of said conductors; and at least one insulating joint member (4) for mechanically joining said plurality of conductors, wherein said at least one insulating joint member exposes both sides of at least a portion of said conductors where said light source is mounted.

Owner:MORIYAMA SANGYO

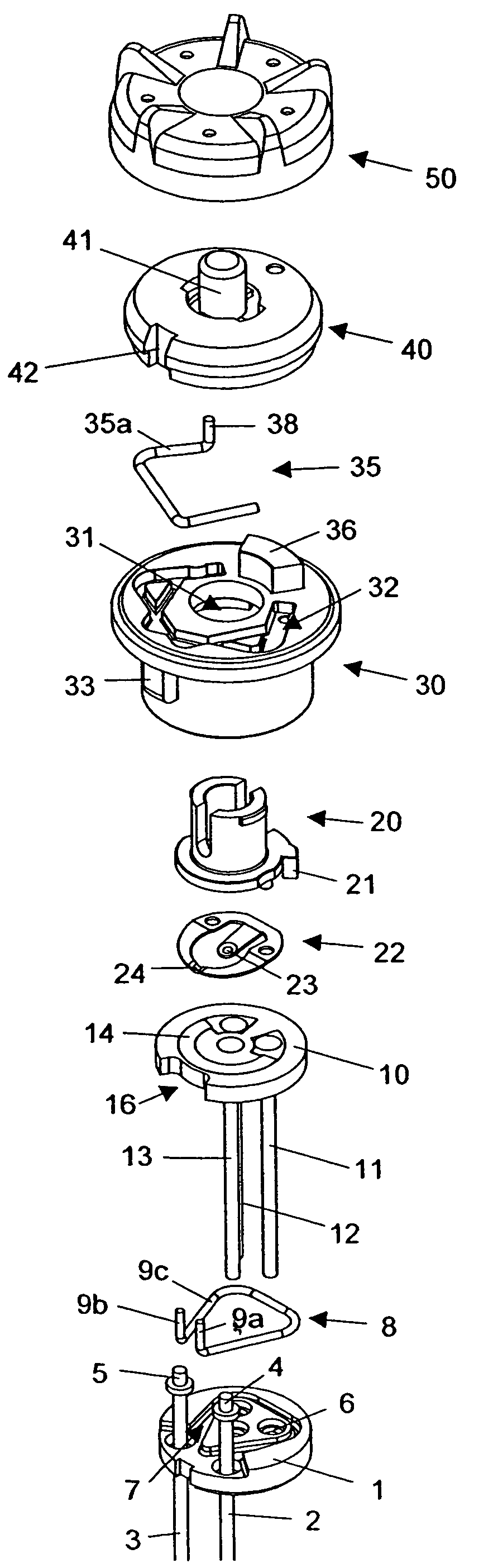

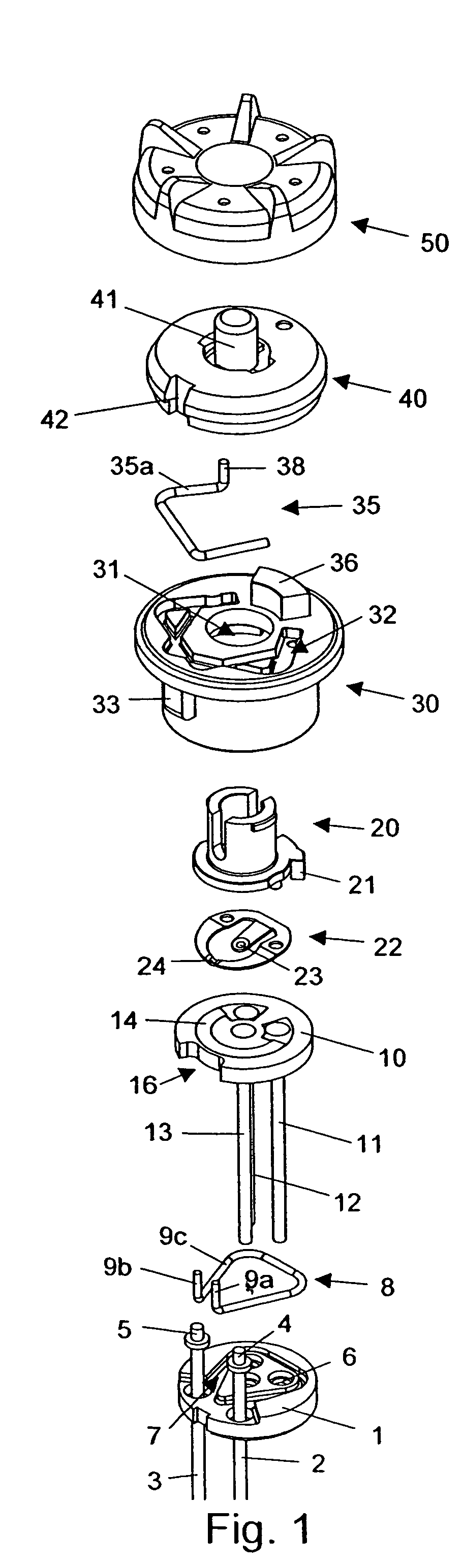

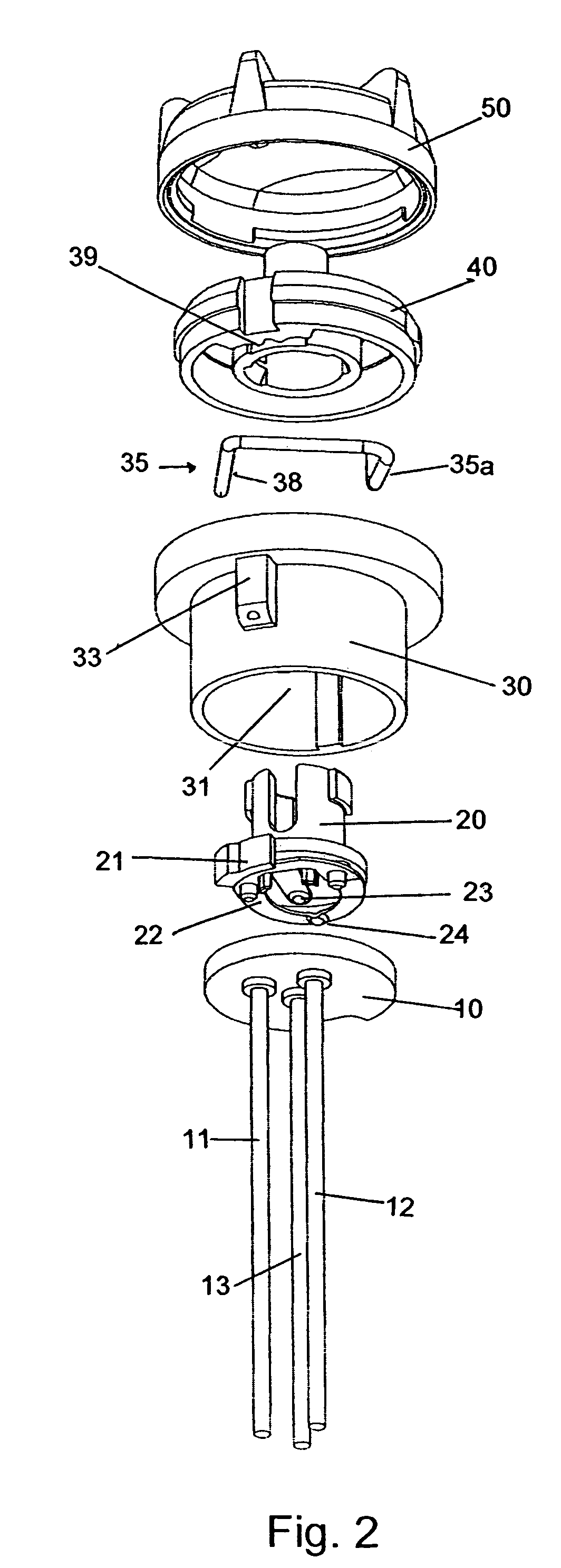

Integrated volume control and switch assembly

ActiveUS7012200B2Simple designCost efficientContact operating partsResisitors with sliding contactRotational axisMiniaturization

An integral volume control and switch assembly comprising a resilient conductive member serving for switching between a first and second switch state and a resilient tactile member serving for providing a user with a tactile feedback upon change of switch state. The resilient tactile member and the resilient conductive member are formed by separate members. Hereby the assembly can be further miniaturised without the resilient tactile member and the resilient conductive member being too small to handle in a manufacturing process. In addition, it is possible to adjust angular position of the rotatable member where switch function and tactile feedback occurs. Preferably the resilient tactile member and the resilient conductive member are spatially separated along a rotational axis of the rotatable member. The assembly according to the invention is suitable for hearing aids.

Owner:SONION ROSKILDE

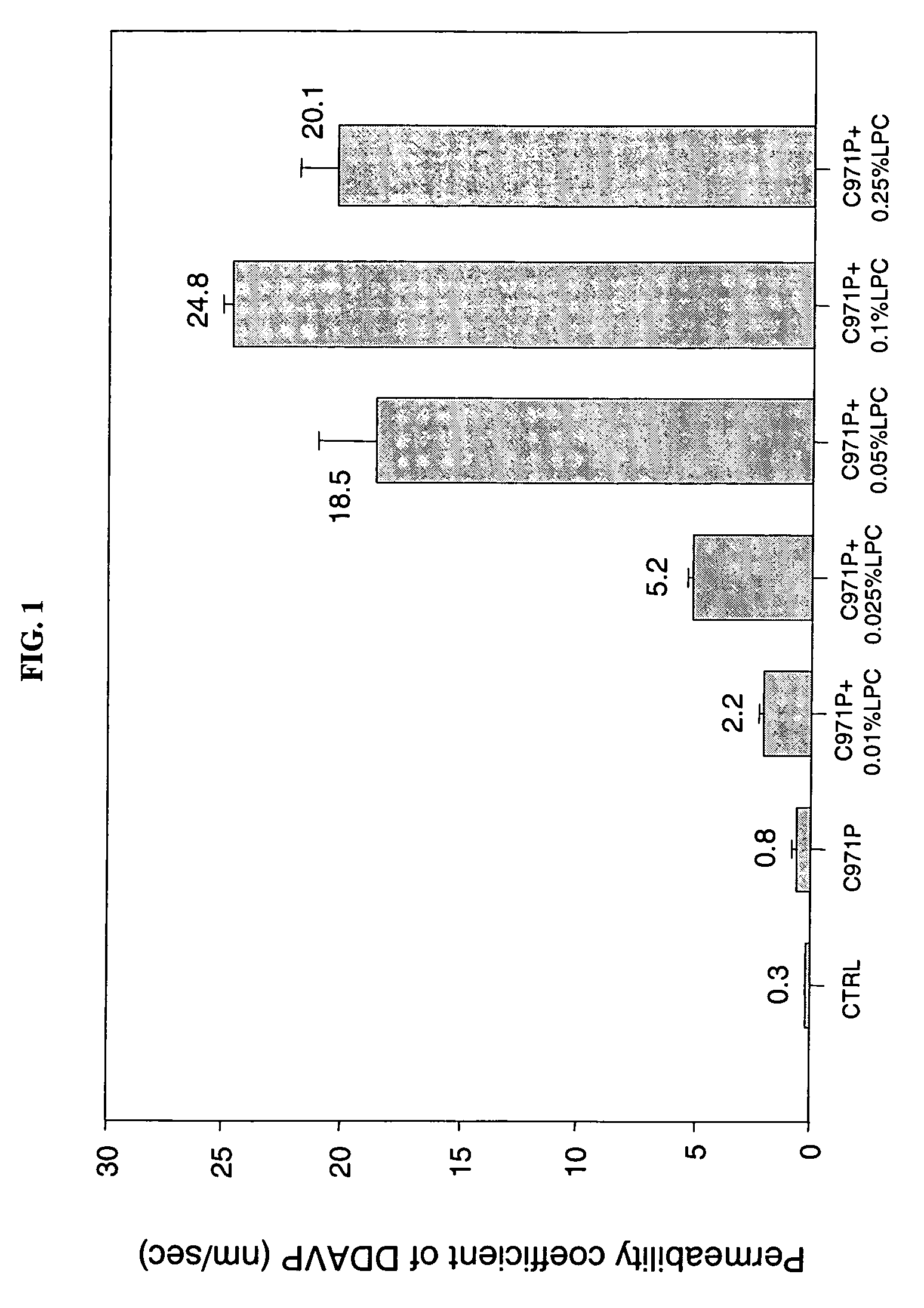

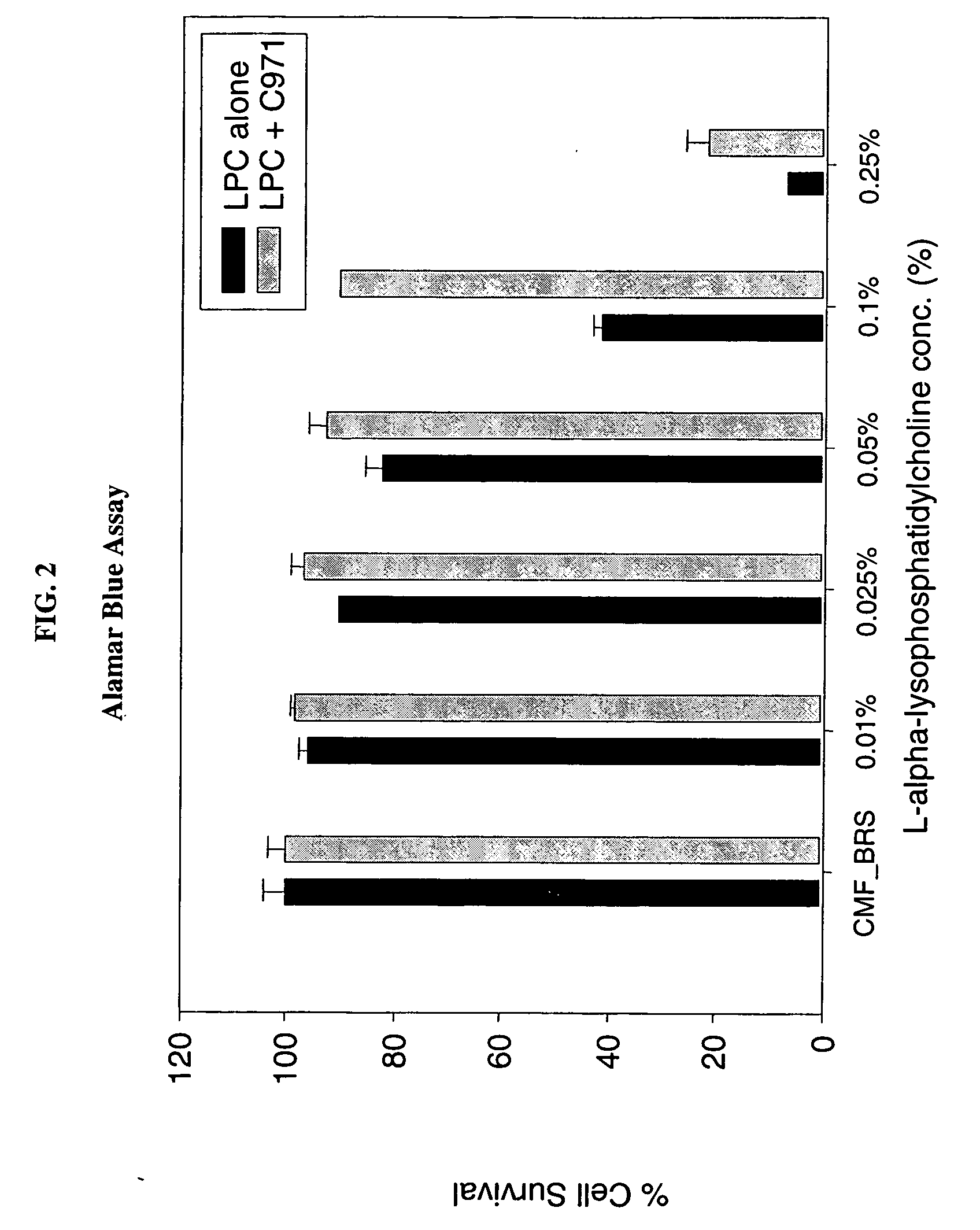

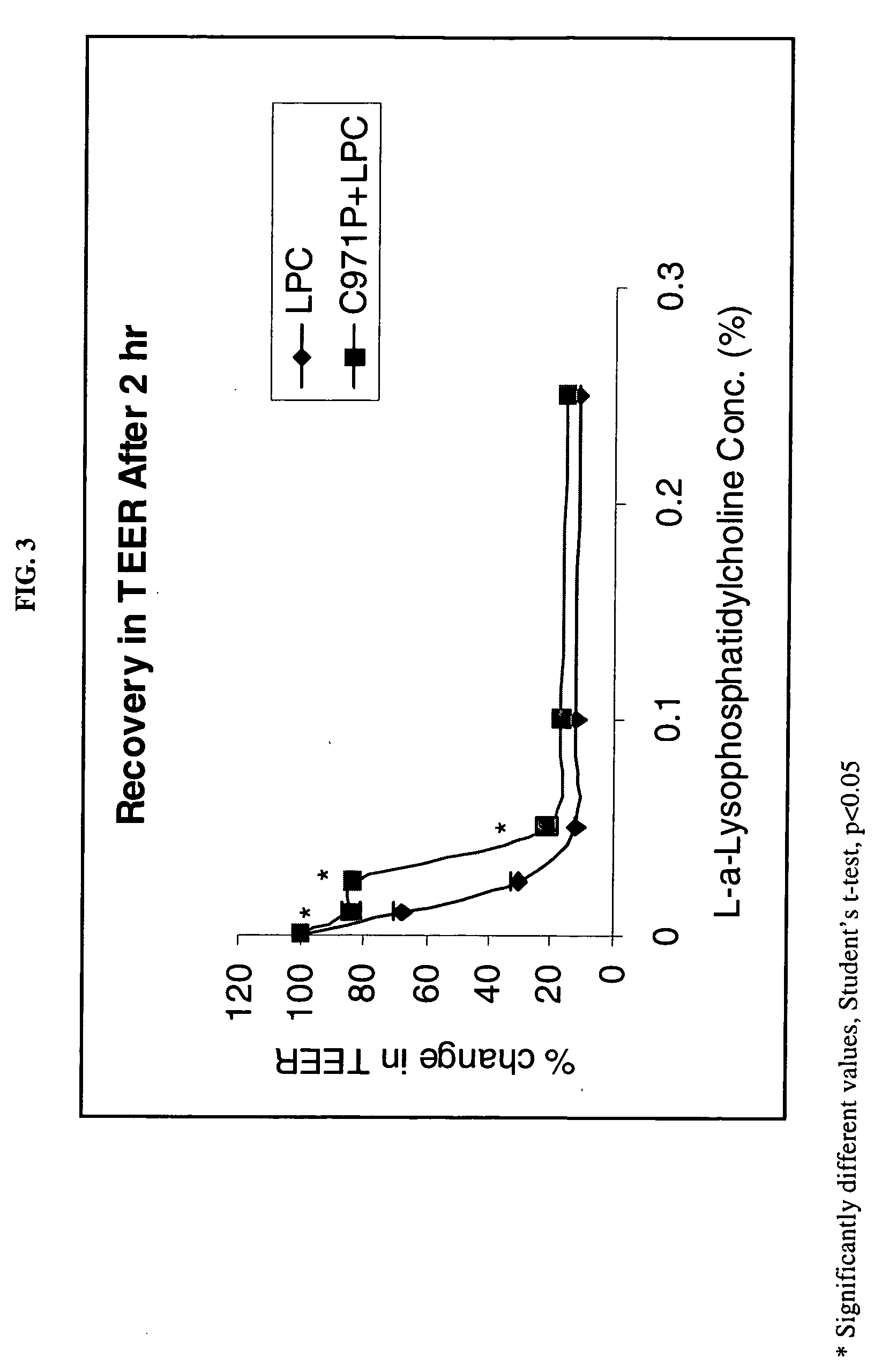

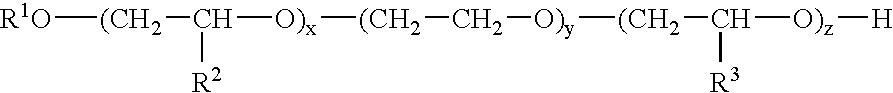

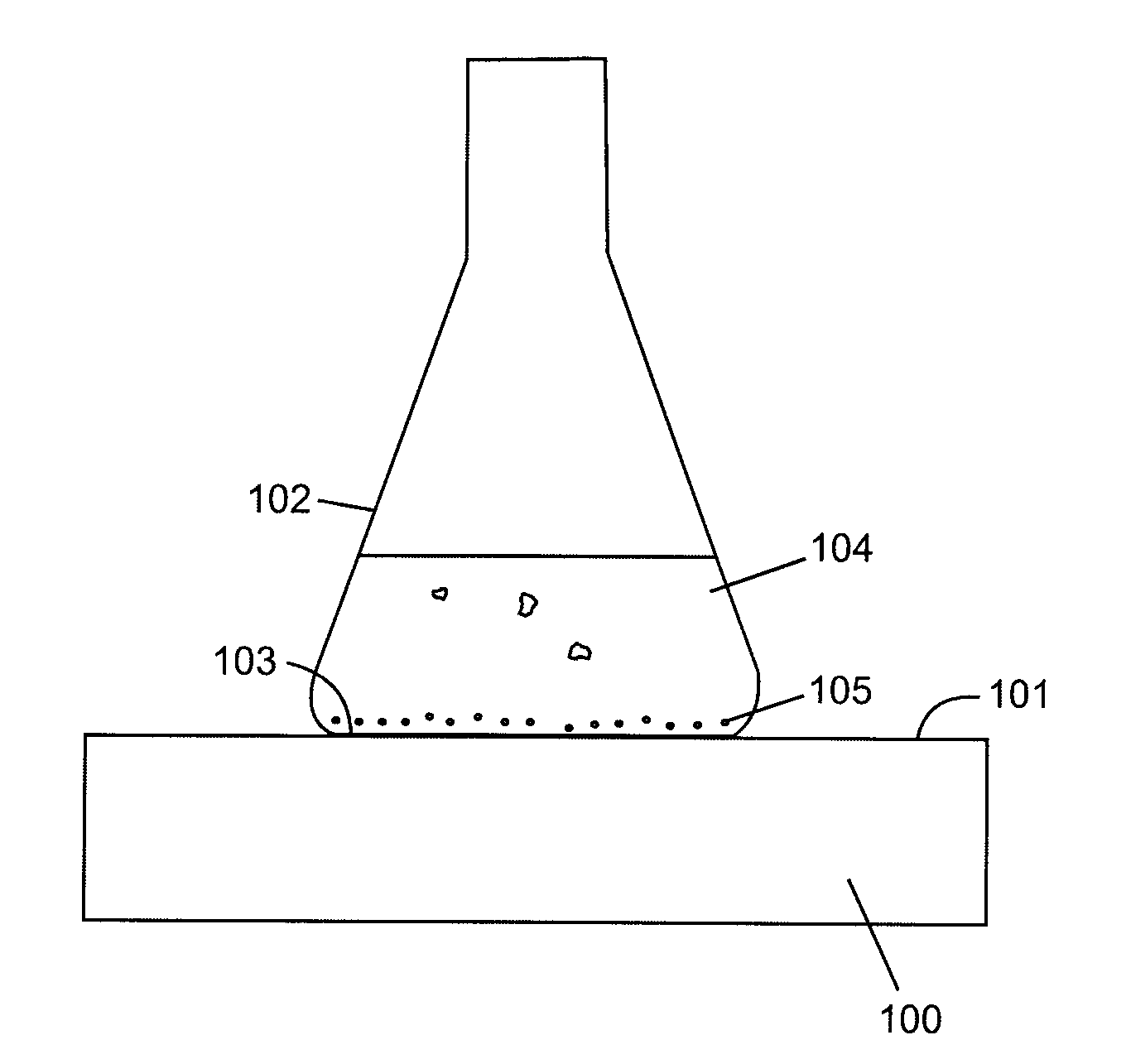

Composition for enhancing absorption of a drug and method

InactiveUS20050244502A1Avoid stimulationDifficult to handlePowder deliveryDispersion deliveryNoseCytotoxicity

A composition for enhancing absorption of a pharmaceutical which may have poor oral bioavailability, which composition has surprisingly little cytotoxicity, is provided which is in the form of a liquid or semi-solid or solid containing an admixture (1) a mucoadhesive polymer which is a polyacrylic acid polymer, preferably Carbopol 971P, and (2) an absorption or permeation enhancer which preferably is L-α-lyso-phosphatidylcholine (LPC), and which composition is free of polysaccharides. A method for improving bioavailability of a drug which has poor absorption properties is also provided wherein the above bioadhesive composition is administered with said pharmaceutical to the mucosal membrane of the GI tract, nose, oral cavity, sublingual, buccal, and vaginal mucosa. A method for reducing the cytotoxic effect of an absorption enhancer such as LPC is also provided wherein a mucoadhesive polymer as described above is administered with the LPC to a patient in need of treatment.

Owner:BRISTOL MYERS SQUIBB CO

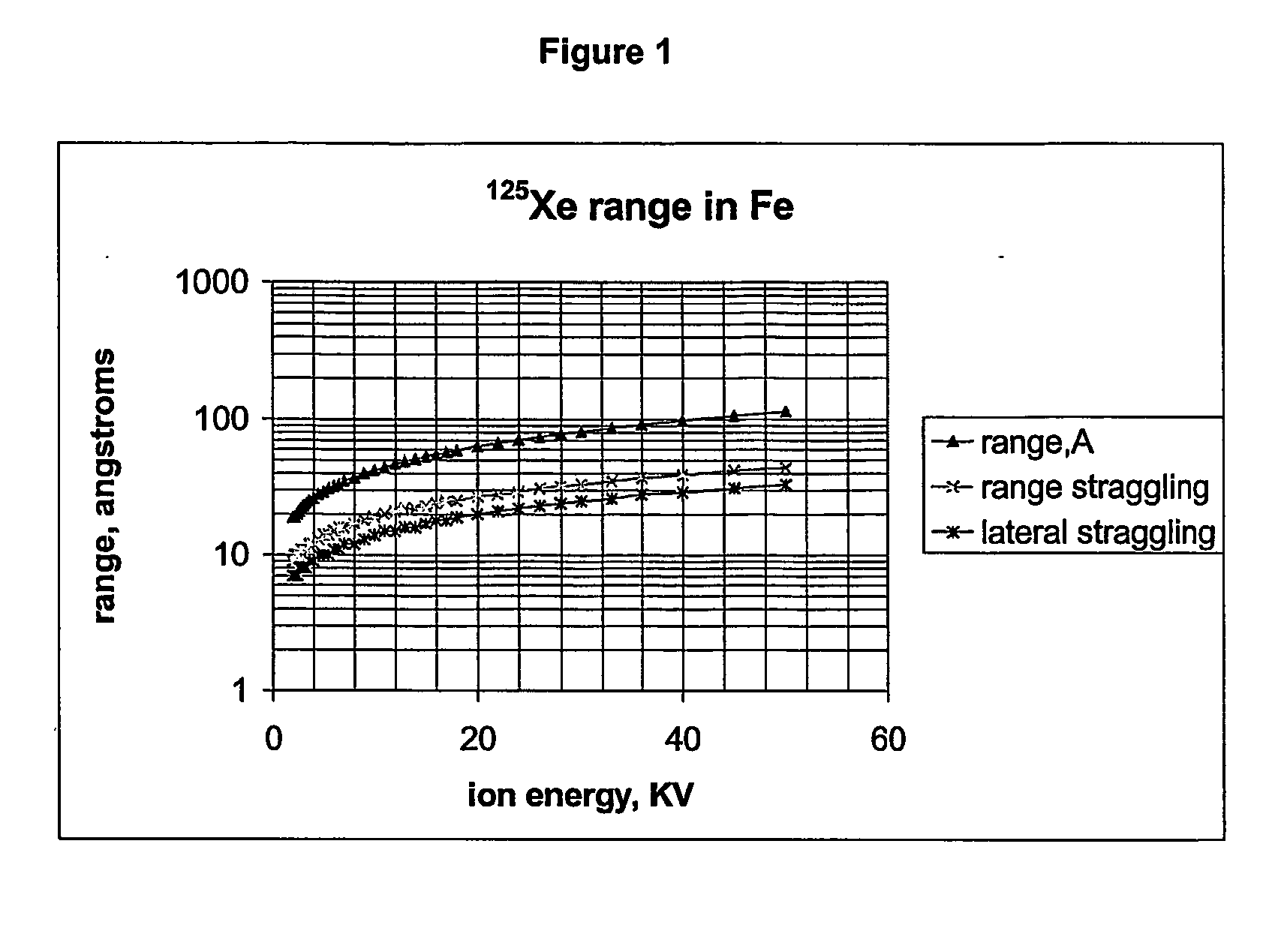

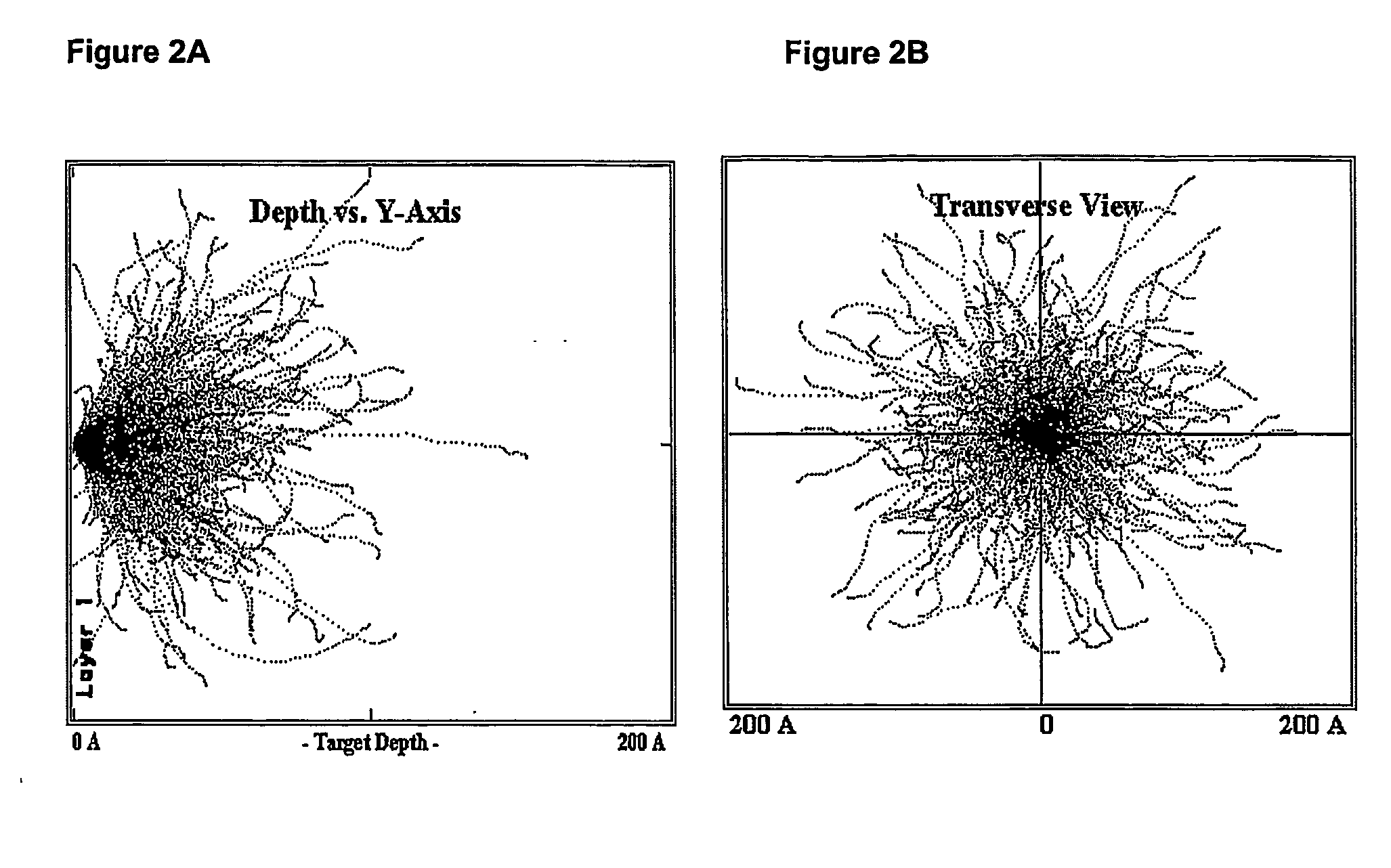

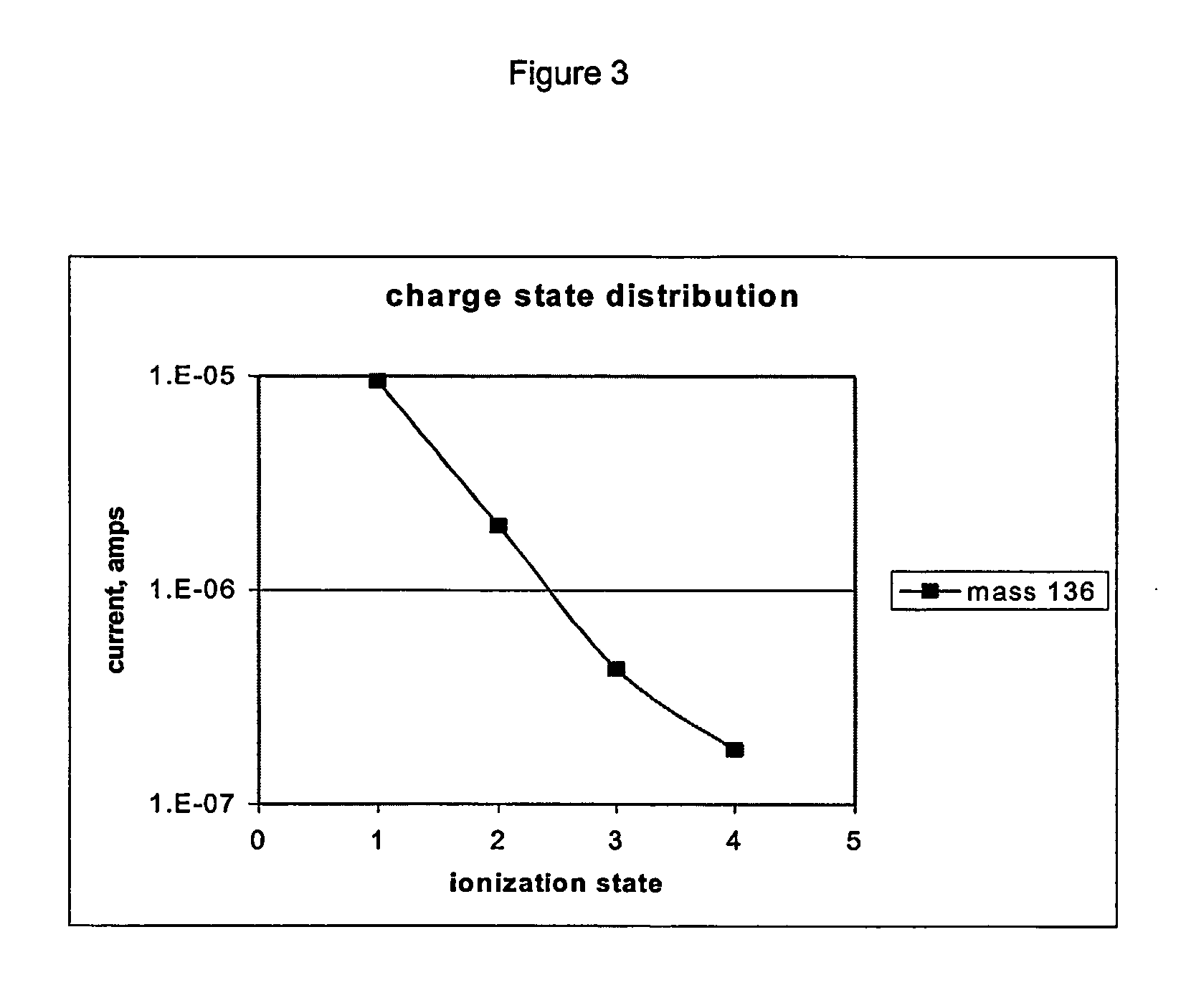

Radioactive ion

InactiveUS20050118098A1Minimize difficultyEfficient methodIn-vivo radioactive preparationsConversion outside reactor/acceleratorsMedicineInsertion stent

The present invention relates to a method for implantation of Xe isotopes in a matrix for production of 125I sources that do not shed radioactive atoms. 125Xe implanted at 12 kV in steel, titanium and gold does not evolve after more than 10 half-lives (380 h) and 125I from the decay of implanted 125Xe is equally stable for 2 half-lives (120 d). The matrix having radioxenon implanted is useful as a medical device, for instance as a “seed” for radiotherapeutic uses or in production of stents. Methods of treatment utilizing such devices are also encompassed by the present invention.

Owner:THE UNIV OF ALBERTA +1

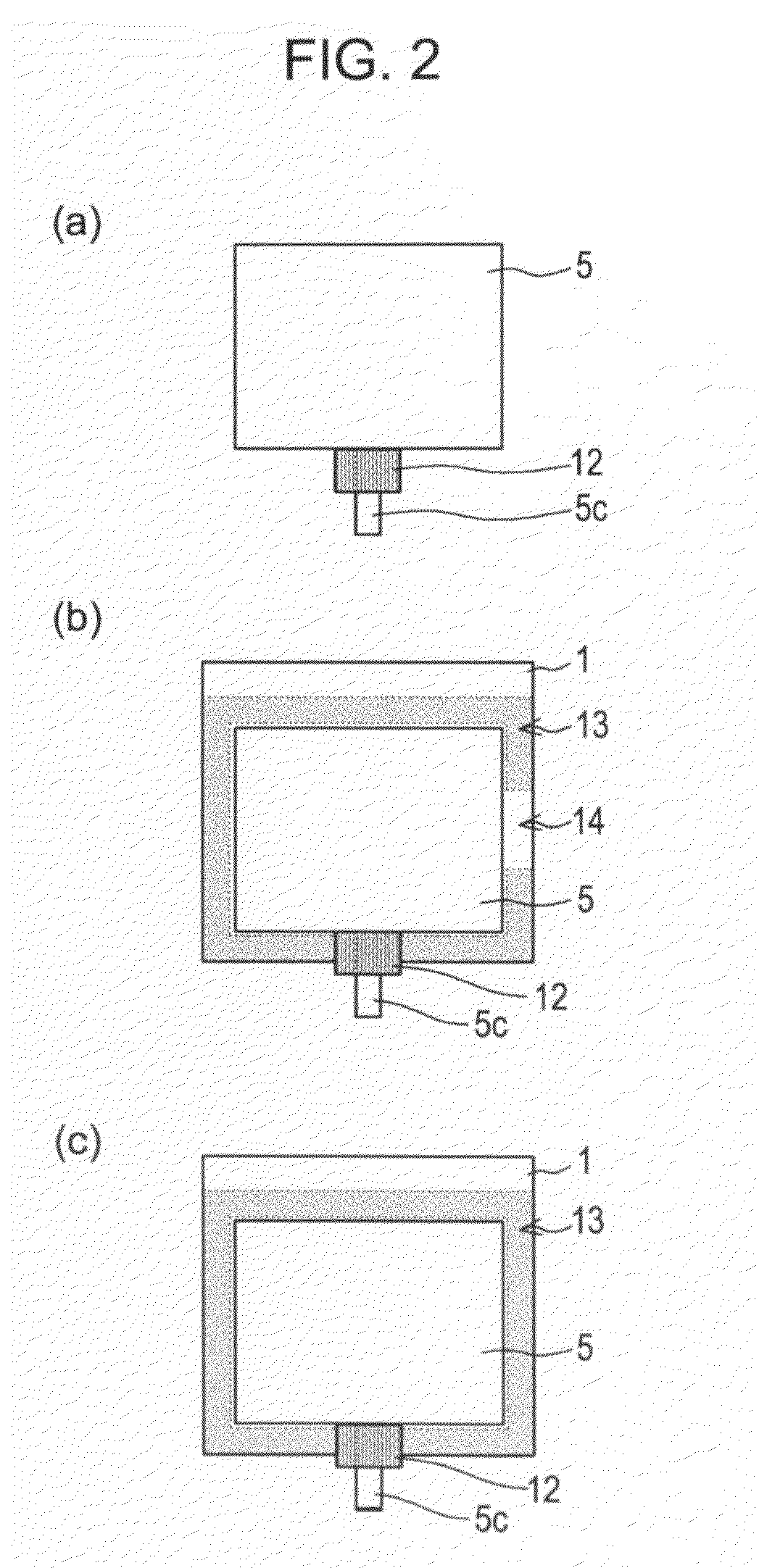

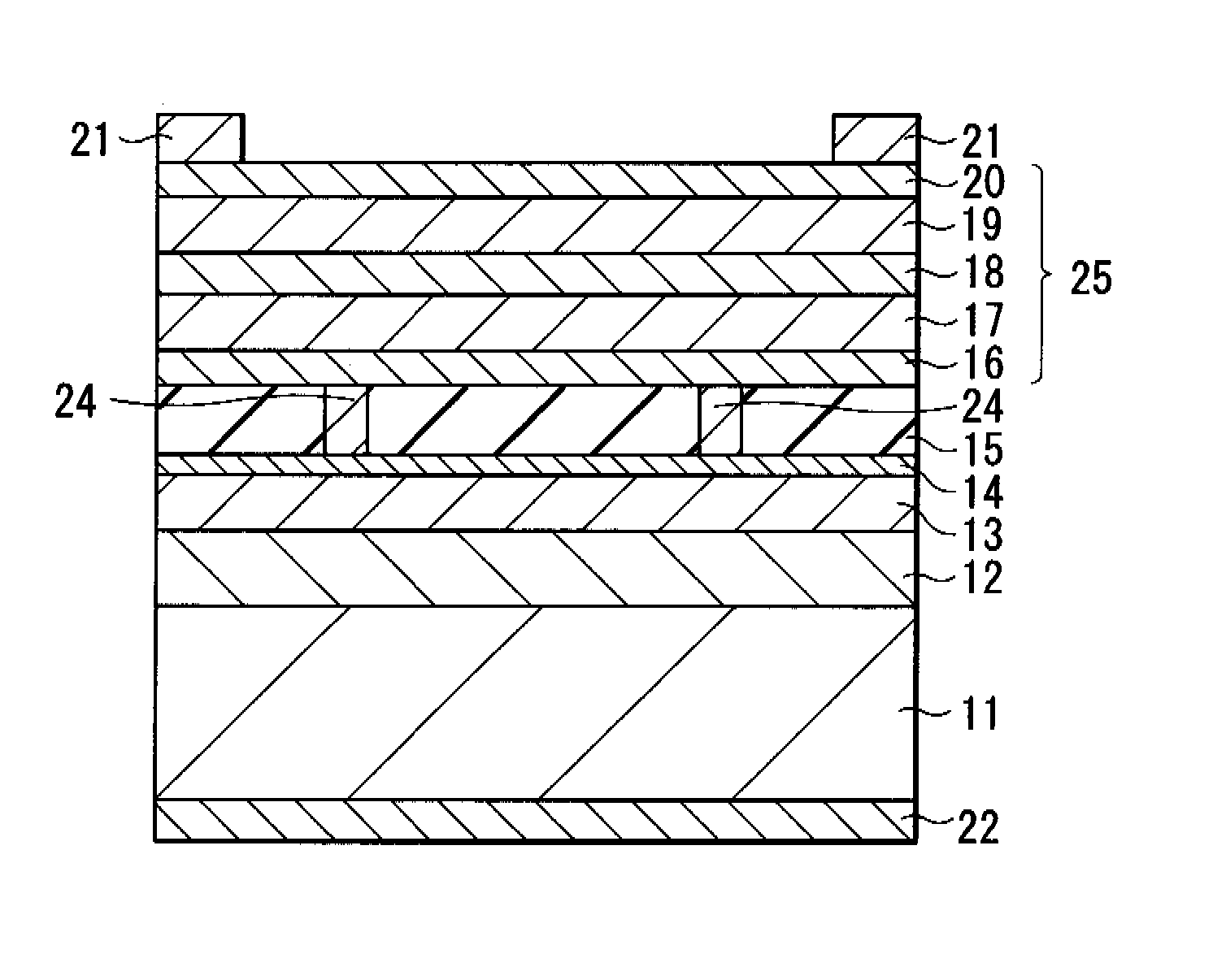

Micro-light-emitting diode backlight system

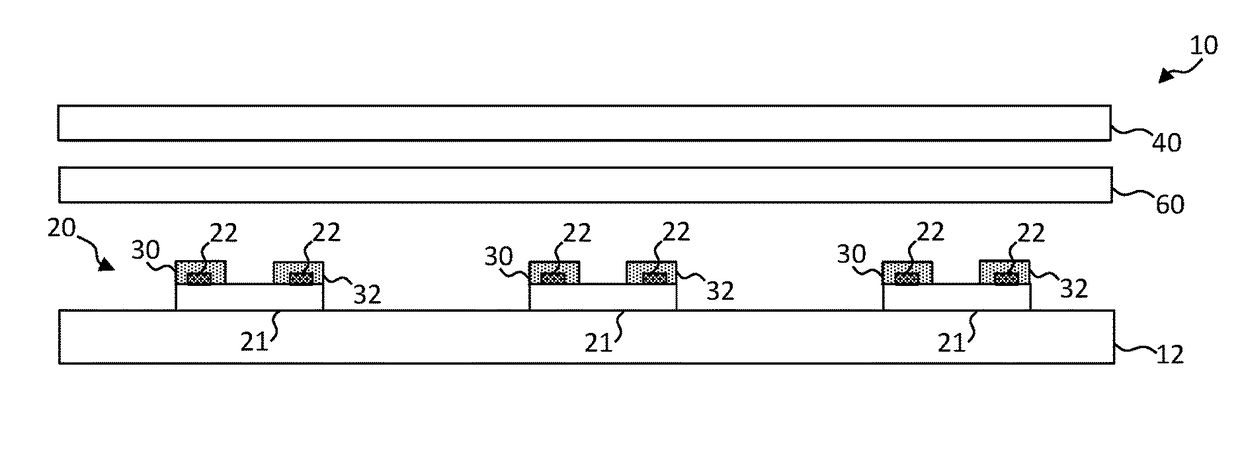

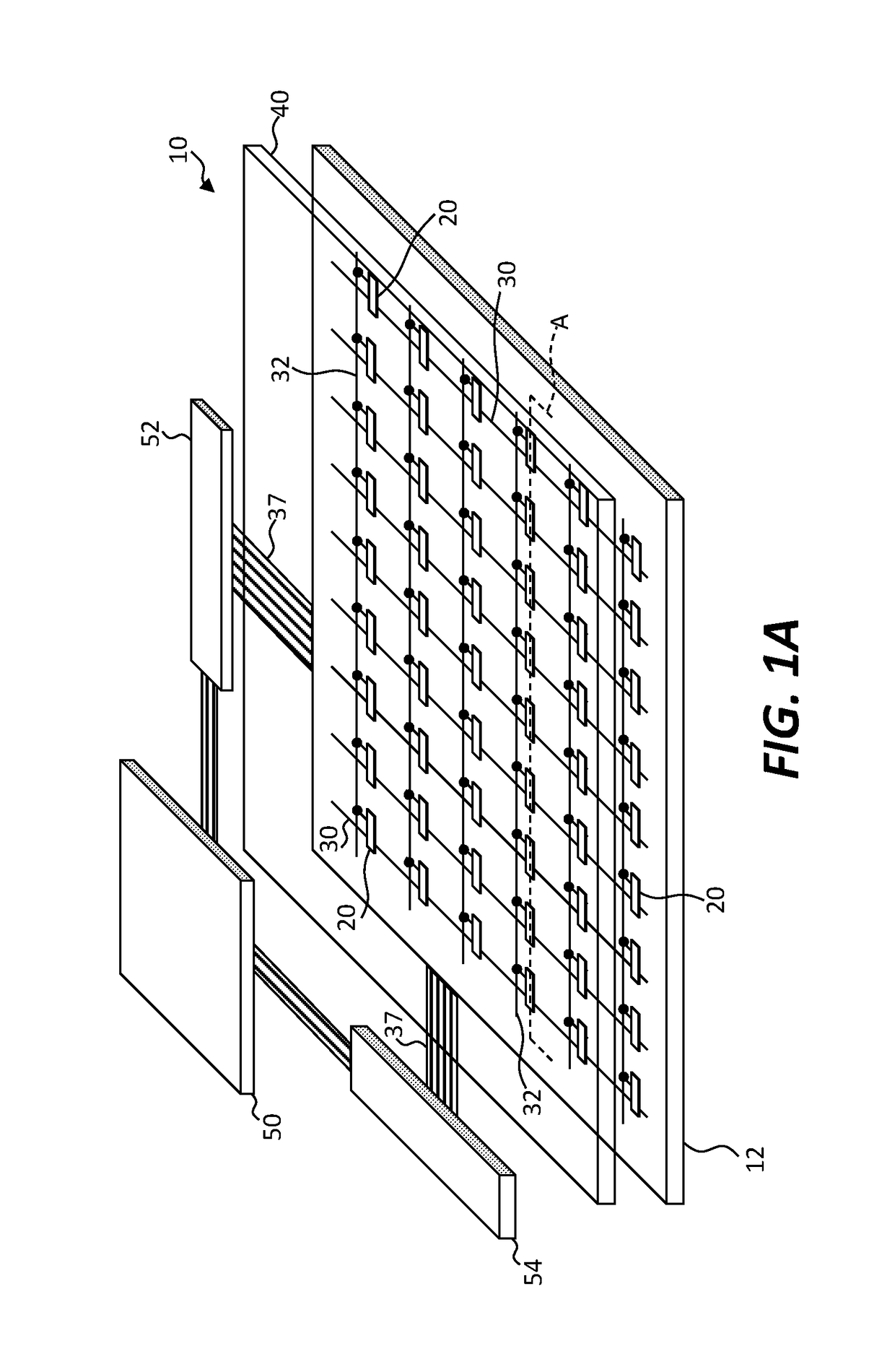

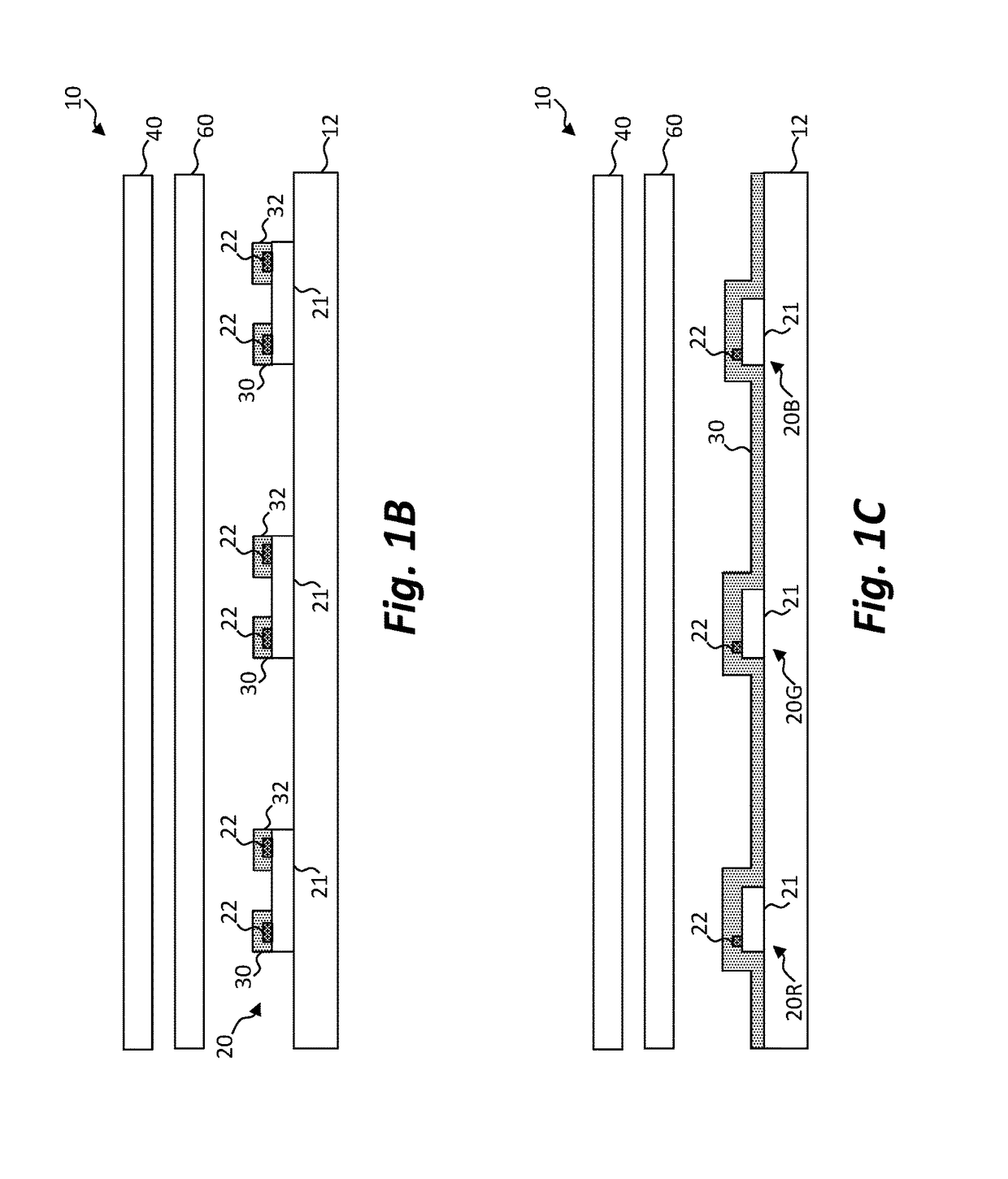

ActiveUS20170167703A1Improve light uniformityReduce power consumptionLight source combinationsElectrical apparatusContact padPower flow

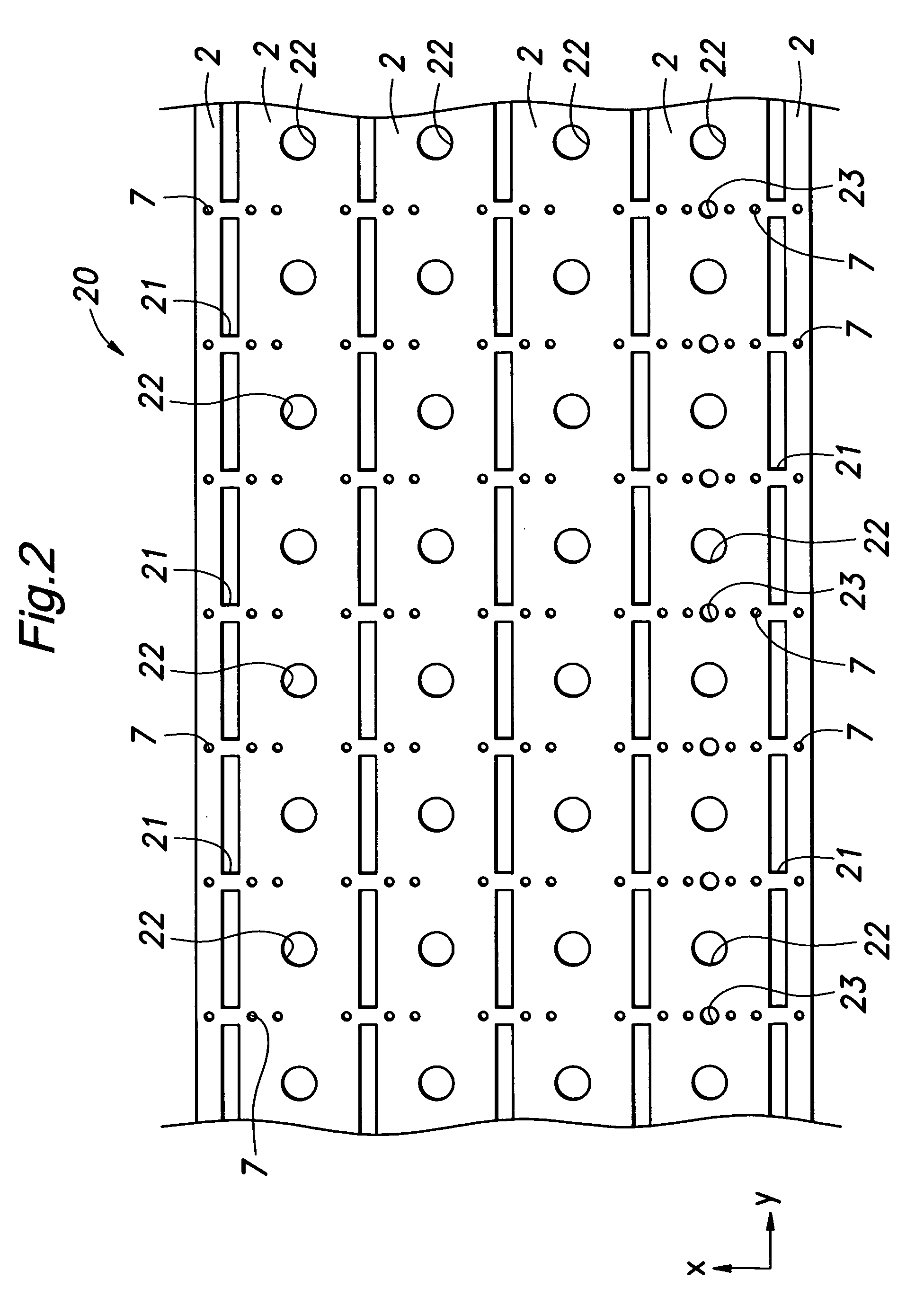

A backlight system includes a backplane and a plurality of bare die light emitters disposed on the backplane. Each light emitter has a light-emitter substrate and contact pads on the light-emitter substrate through which electrical current is supplied to cause the light emitter to emit light. A plurality of first and second backplane conductors are disposed on the backplane for conducting control signals to control the light emitters through the contact pads. A plurality of light valves is disposed to receive light from the light emitters. The number of light valves is greater than the number of light emitters.

Owner:X DISPLAY CO TECH LTD

Process for making functionalized films for cleaning products

InactiveUS7727946B2Difficult to handleLow costOrganic detergent compounding agentsOrganic/inorganic per-compounds compounding agentsWater solubleCleaning product

Owner:MONOSOL LLC +1

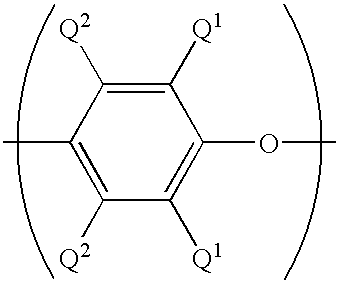

Moldable poly(arylene ether) thermosetting compositions, methods, and articles

A moldable thermosetting composition comprises a poly(arylene ether), a thermosetting resin, a toughening agent, and an amine cure agent. The compositions may be conveniently prepared without solvents, and the poly(arylene ether) may be provided in the form of an easily dissolved solid concentrate with the thermosetting resin.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Light emitting module

InactiveUS20050239342A1Improve cooling effectEasy to handlePlanar light sourcesSemiconductor/solid-state device detailsElectrical conductorEngineering

The present invention provides a light emitting module, comprising: a plurality of thin plate-shaped conductors (2) spaced apart from each other in a first direction; at least one light source (4) connected between at least one pair of adjoining ones of said conductors; and at least one insulating joint member (4) for mechanically joining said plurality of conductors, wherein said at least one insulating joint member exposes both sides of at least a portion of said conductors where said light source is mounted.

Owner:MORIYAMA SANGYO

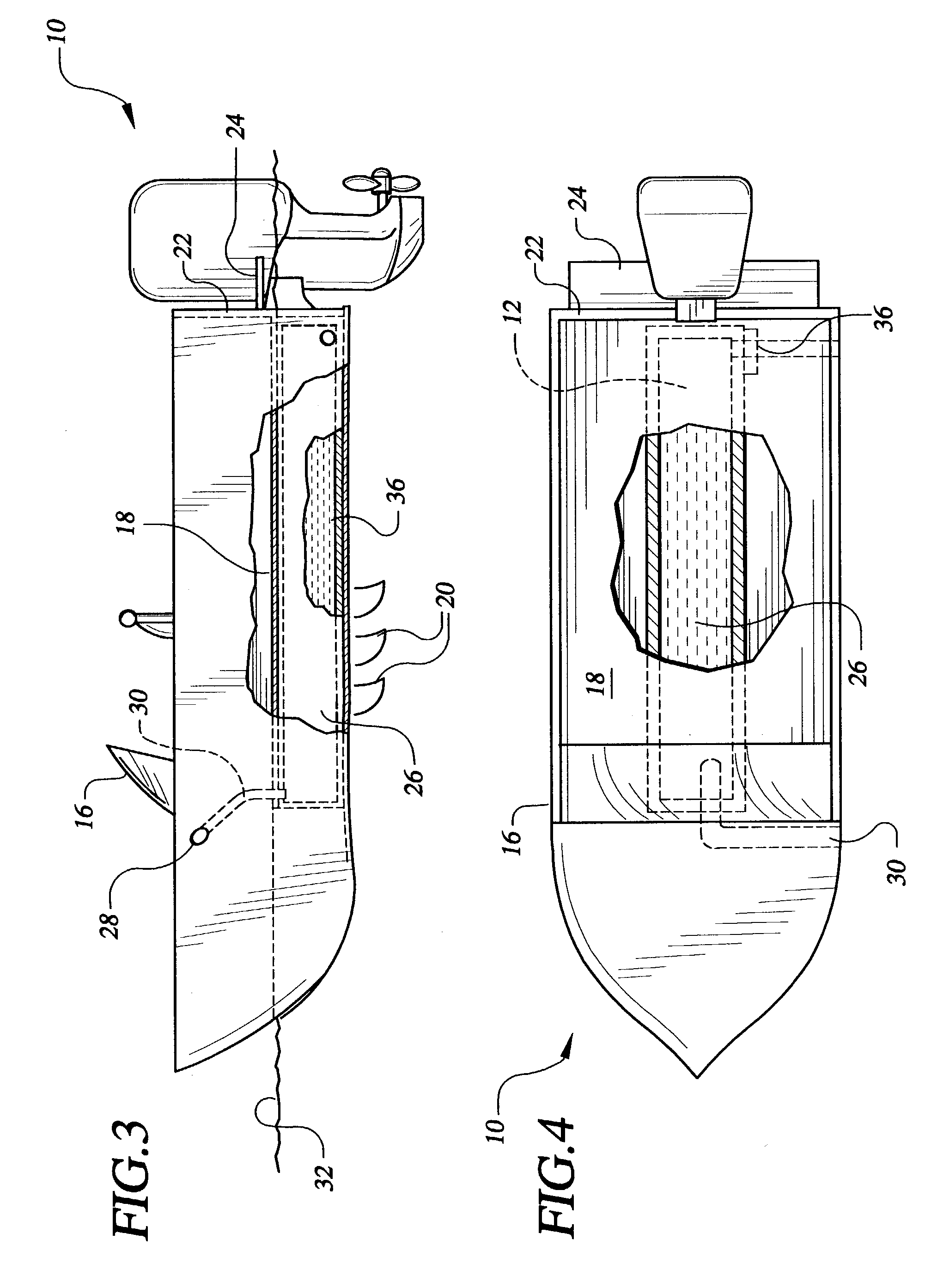

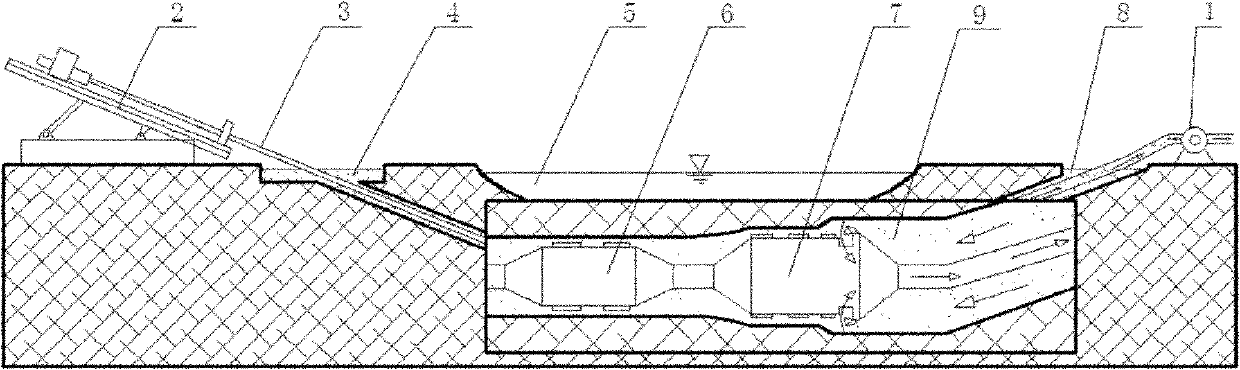

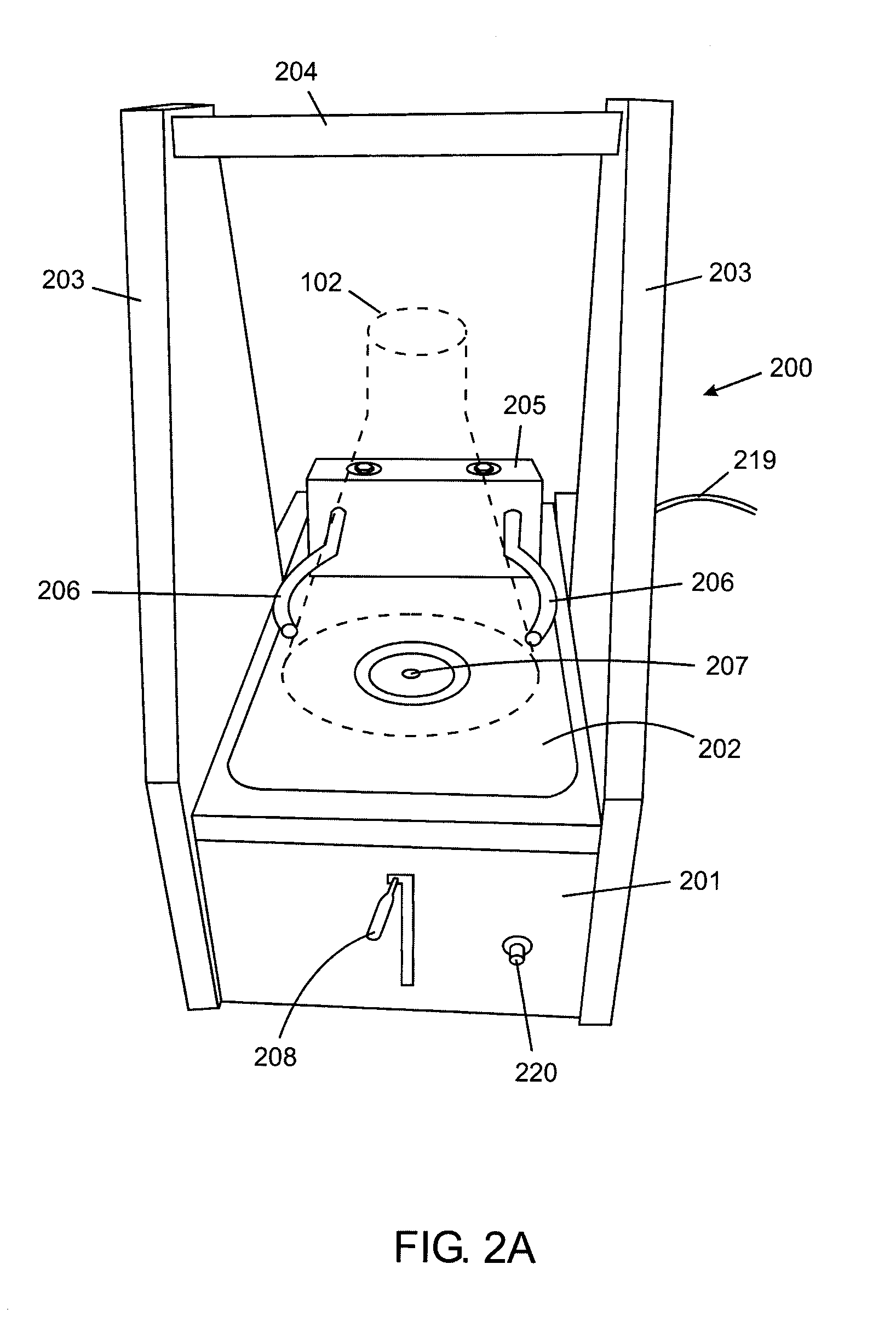

Boat wake system

InactiveUS6953002B2Enhance wake sizeIncrease speedWatercraft hull designVessel partsKeelLiquid water

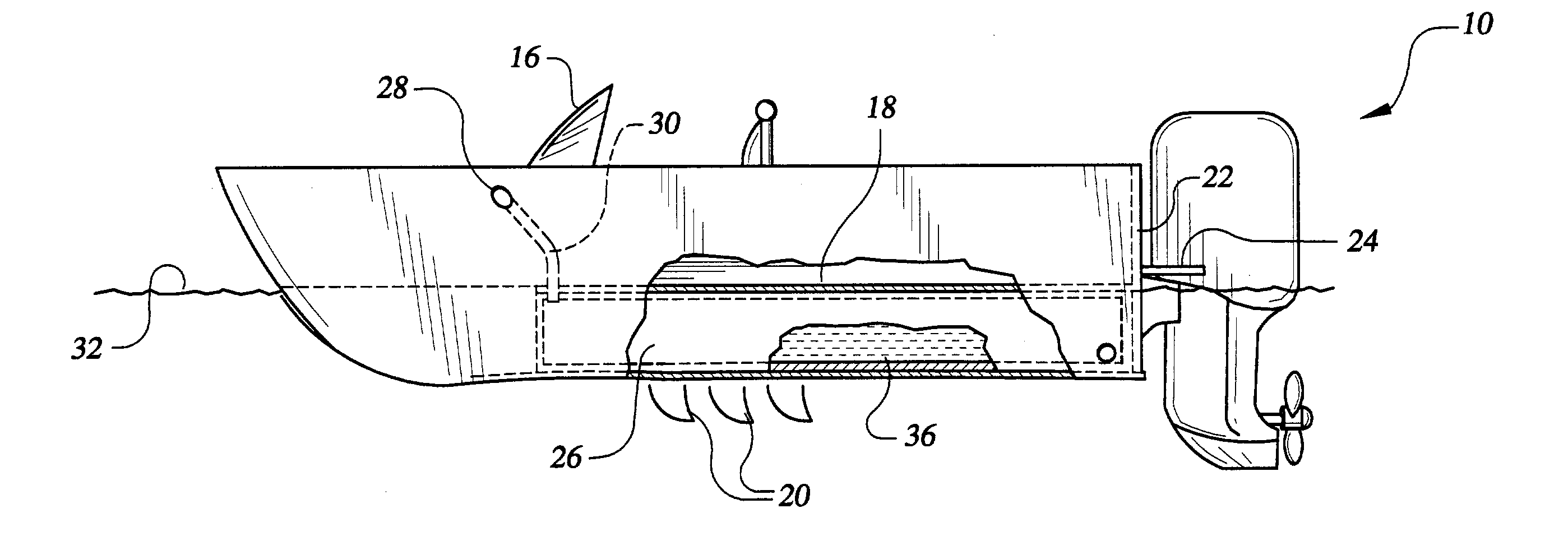

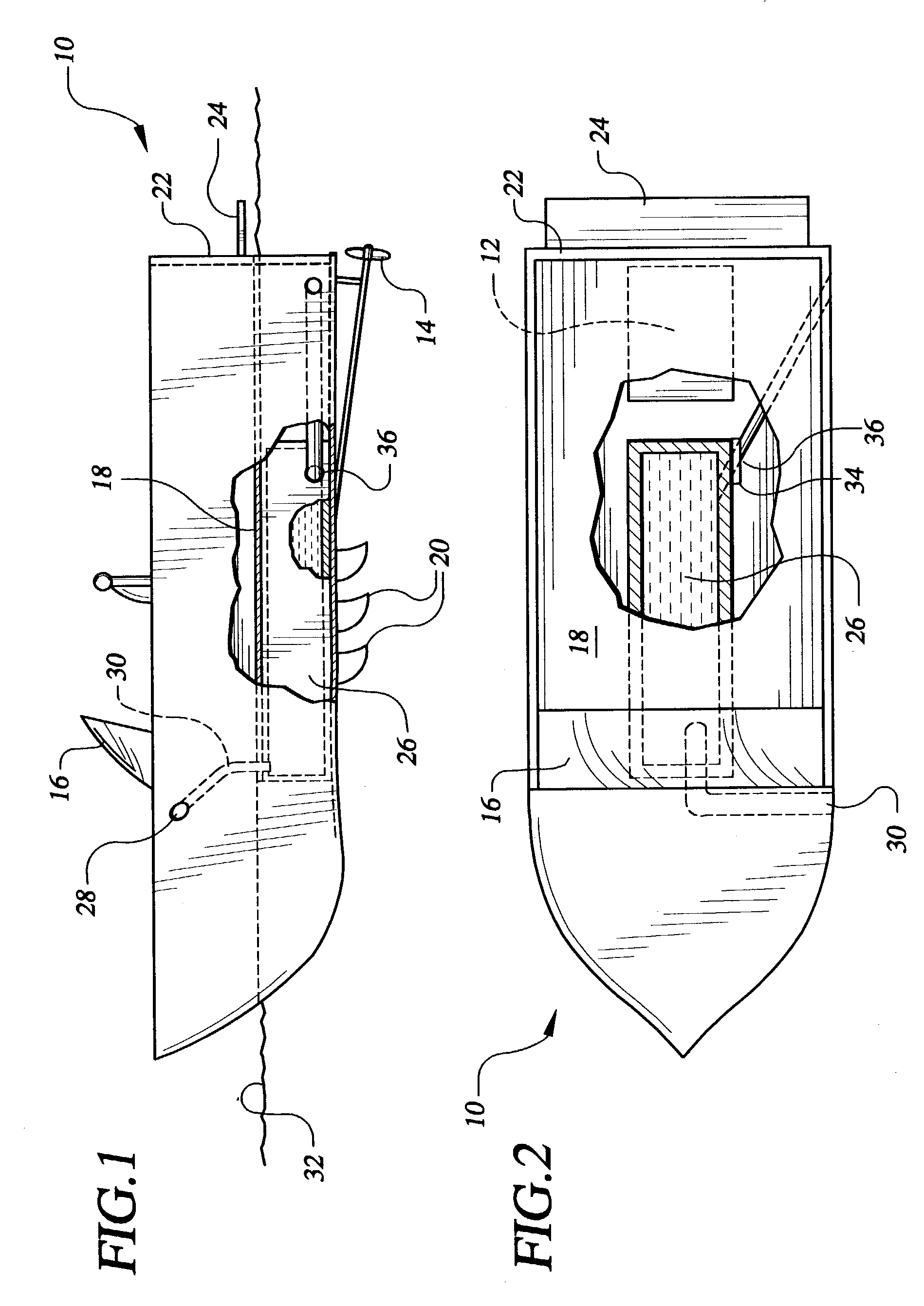

A water craft having a bow and a stern including an engine of sufficient thrust to create an enlarged wake at the stern of the boat as the boat moves along the surface of a body of water.The water tight compartment is positioned to carry water below the water line and essentially astride the centerline or keel of the boat. The compartment is adapted to contain liquid water in an amount sufficient to enhance or equalize the size of the boat wake.The compartment extends from a point forward of the transom and engine, and extends to a point forward of the midpoint between the bow and the stern, and terminates short of the bow while serving to exert downward force on the bow against the water when the water craft is underway and the compartment carries water.

Owner:MIKE MURPHYS ENTERPRISES

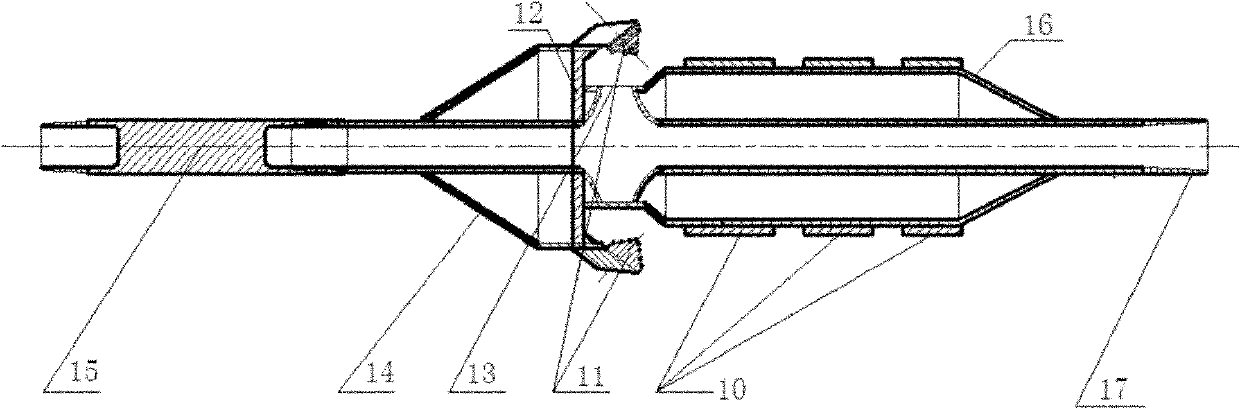

Injector device with mechanism for preventing accidental activation

InactiveUS20150174325A1Prevent premature lossDifficult to handleAutomatic syringesInfusion needlesStored energyInjection site

There is provided an injector device comprising a housing (26), a drug container (10) positioned in the housing; a drug delivery mechanism associated with the drug container, the drug delivery mechanism comprising a stored energy source; an activation member (18) coupled to the housing, the activation member configured to contact the injection site in use and movable relative to the housing to an activation position to activate the drug delivery mechanism; and a removable cap (134) coupled to the activation member and to the housing, wherein in a first position a first portion of the housing engages the activation member to prevent the activation member from moving into the activation position, and wherein a portion of the cap engages the housing to retain the first portion of the housing in the first position such that the activation member is prevented from moving into the activation position until the cap is uncoupled from the activation member.

Owner:OVAL MEDICAL TECH

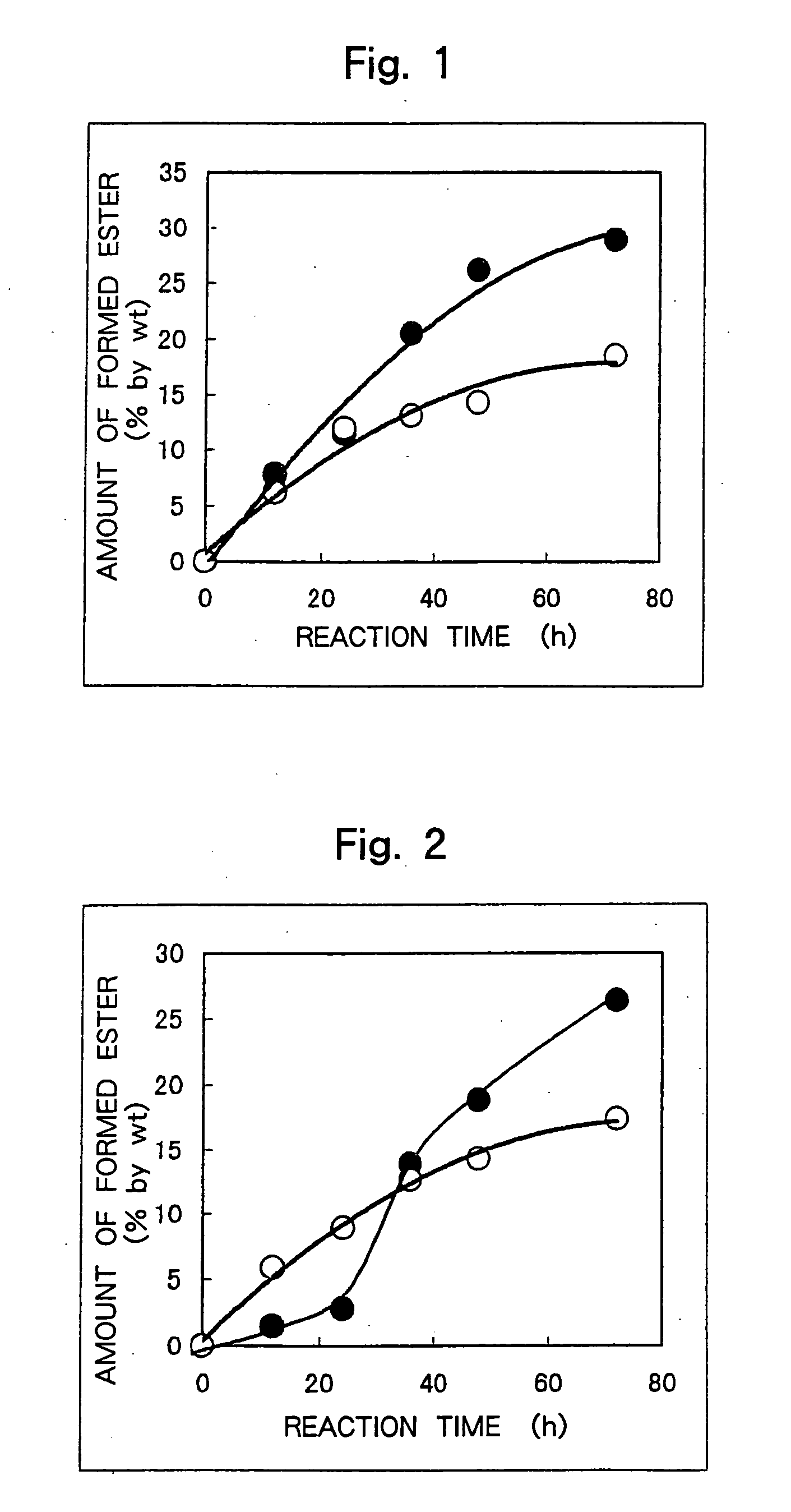

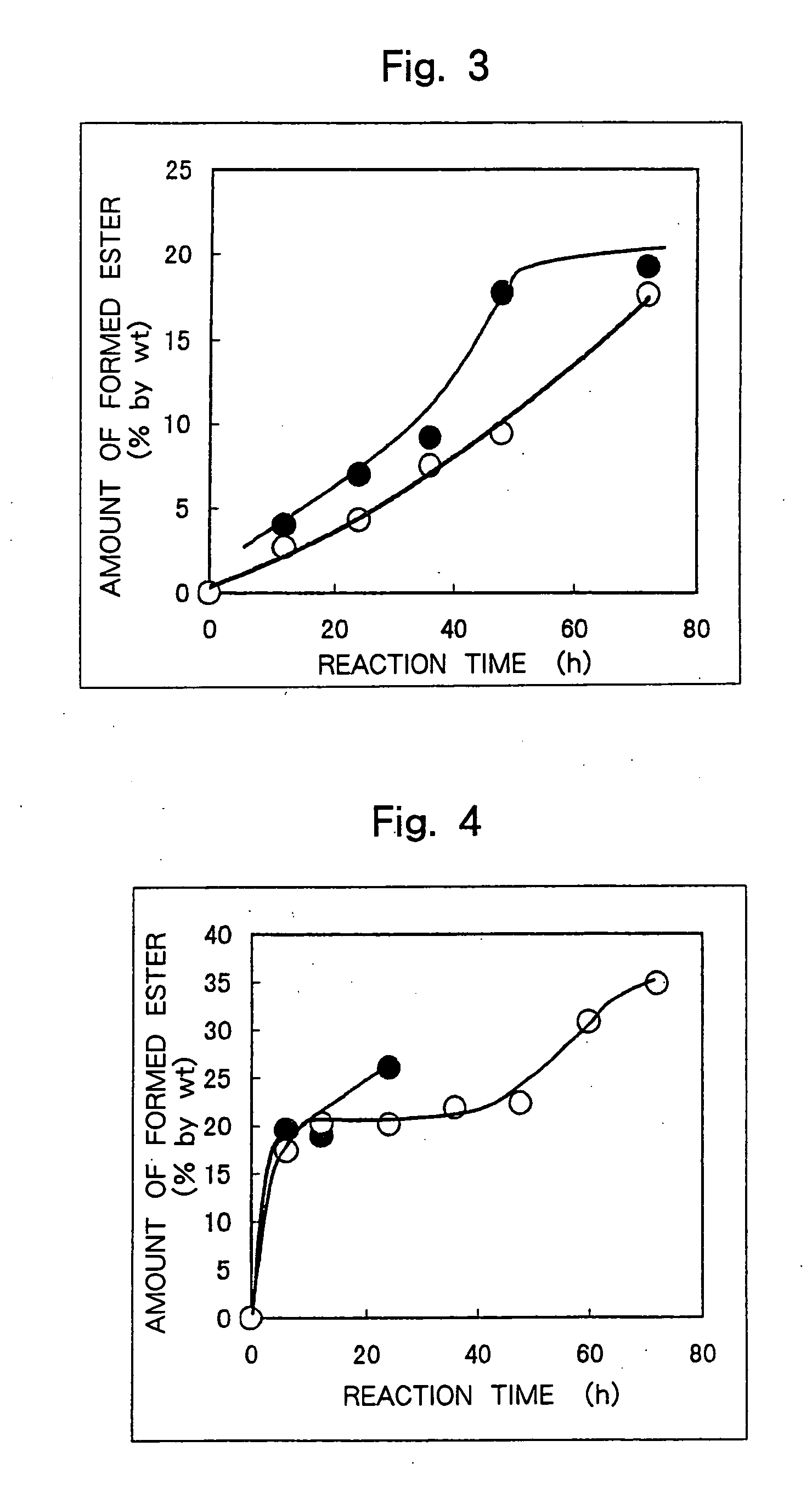

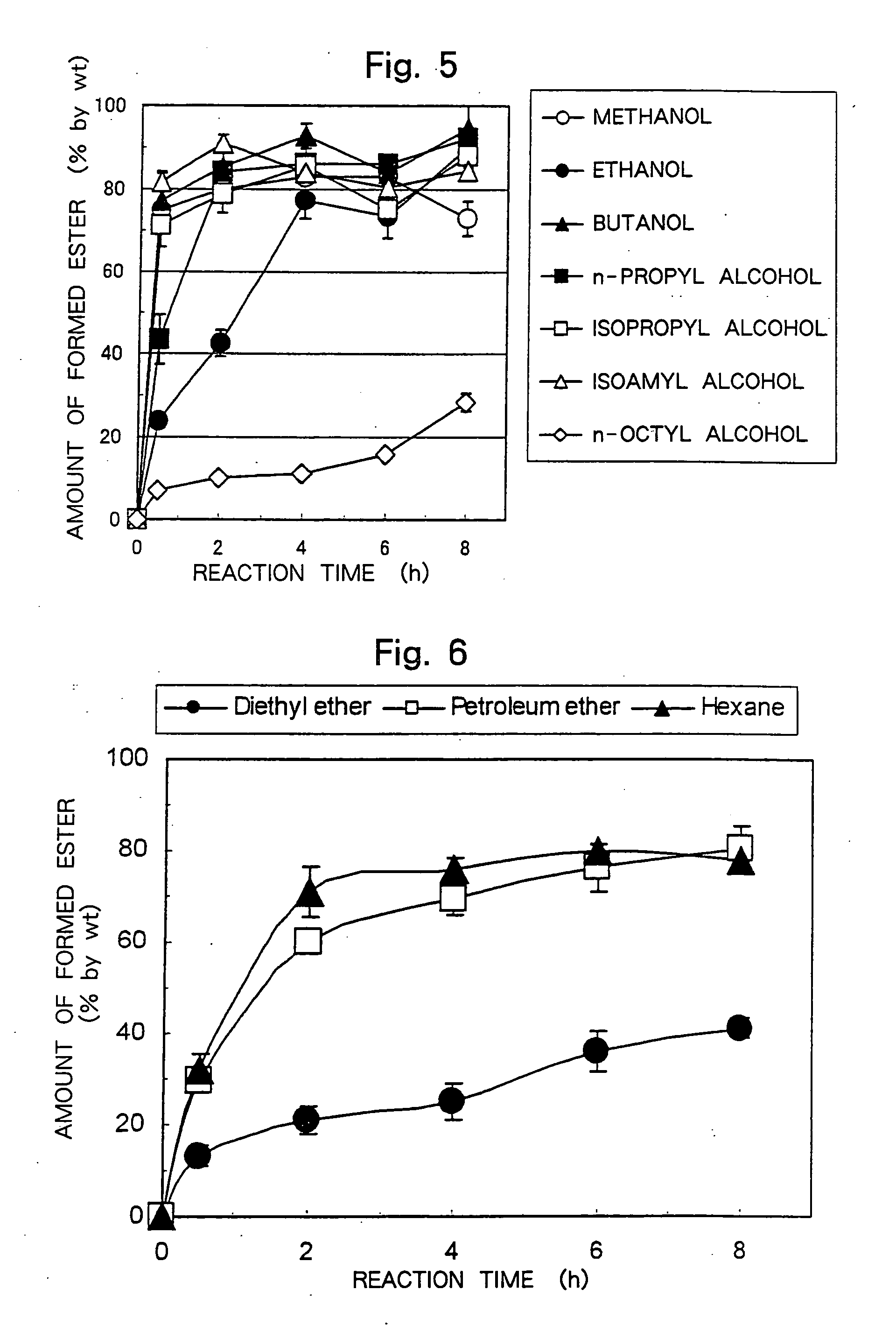

Method of producing bio-fuels

InactiveUS20050084941A1Reduce in quantityEfficient use ofFatty oils/acids recovery from wasteFatty acid esterificationAlcoholBiofuel

A method of producing bio-fuels by causing an enzyme to act on the oils and fats in a waste clay to decompose them into a fatty acid which is then reacted with a lower alcohol to form an ester that can be used as a bio-fuel. An environment friendly bio-fuel is obtained from the starting waste clay through a decreased number of steps without requiring cumbersome operations.

Owner:MIZUSAWA INDAL CHEM LTD

Nitrogen-containing alloy and method for producing phosphor using the same

InactiveUS20090140205A1Suppress rapid progressHigh performanceLuminescent compositionsFluorescenceNitrogen gas

There is provided a method for industrially producing a phosphor with high performance, in particular, high brightness. There is also provided a nitrogen-containing alloy and an alloy powder that can be used for the production method. A method for producing a phosphor includes a step of heating a raw material for the phosphor under a nitrogen-containing atmosphere, in which an alloy containing two or more different metal elements constituting the phosphor is used as the whole or part of the raw material for the phosphor, and in the heating step, the heating is performed under conditions such that the temperature change per minute is 50° C. or lower.It is possible to suppress the rapid progress of a nitridation reaction in heat treatment in producing the phosphor using an alloy for a phosphor precursor as the whole or part of the raw material, thereby industrially producing the phosphor with high performance, in particular, high brightness.

Owner:MITSUBISHI CHEM CORP

Cleaning composition

InactiveUS20050233925A1Skin careEliminates slippery propertyOrganic detergent compounding agentsSurface-active detergent compositionsSurface cleaningDistilled water

A hard surface cleaning composition for removing cooked-, baked- or burnt-on soils from cookware and tableware, the composition comprising a soil swelling agent and a spreading auxiliary and wherein the composition has a liquid surface tension of less than about 24.5 mN / m and a pH as measured in a 10% solution in distilled water of at least 10.5. The composition can be used as pre-treatment prior to the dishwashing process. The composition provides excellent removal of polymerised grease from metal and glass substrates.

Owner:FOLEY PETER ROBERT +5

Functionalized films

InactiveUS20060257596A1Avoid contactMore economicallyEnvelopes/bags making machineryOrganic detergent compounding agentsWater solubleAqueous solution

Process for making a functionalized substrate in the form of a water-soluble film carrying a coating of a functional composition, the process comprising applying to at least one side of the film an aqueous solution comprising one or more functional materials to form the coating wherein the coating is formed from a plurality of layers in a stepwise manner and / or the aqueous solution comprises a film insolubilizer agent.

Owner:MONOSOL LLC +1

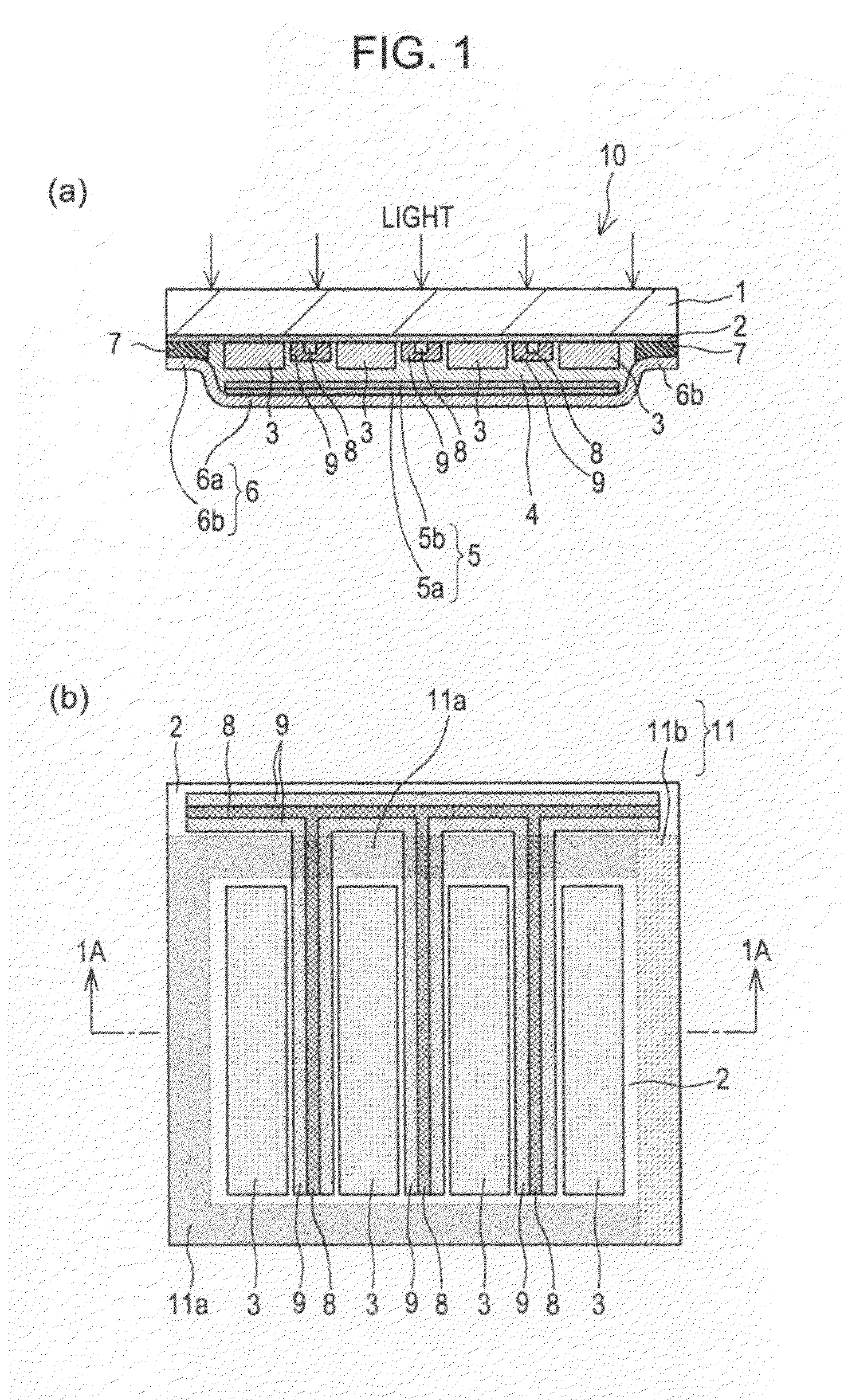

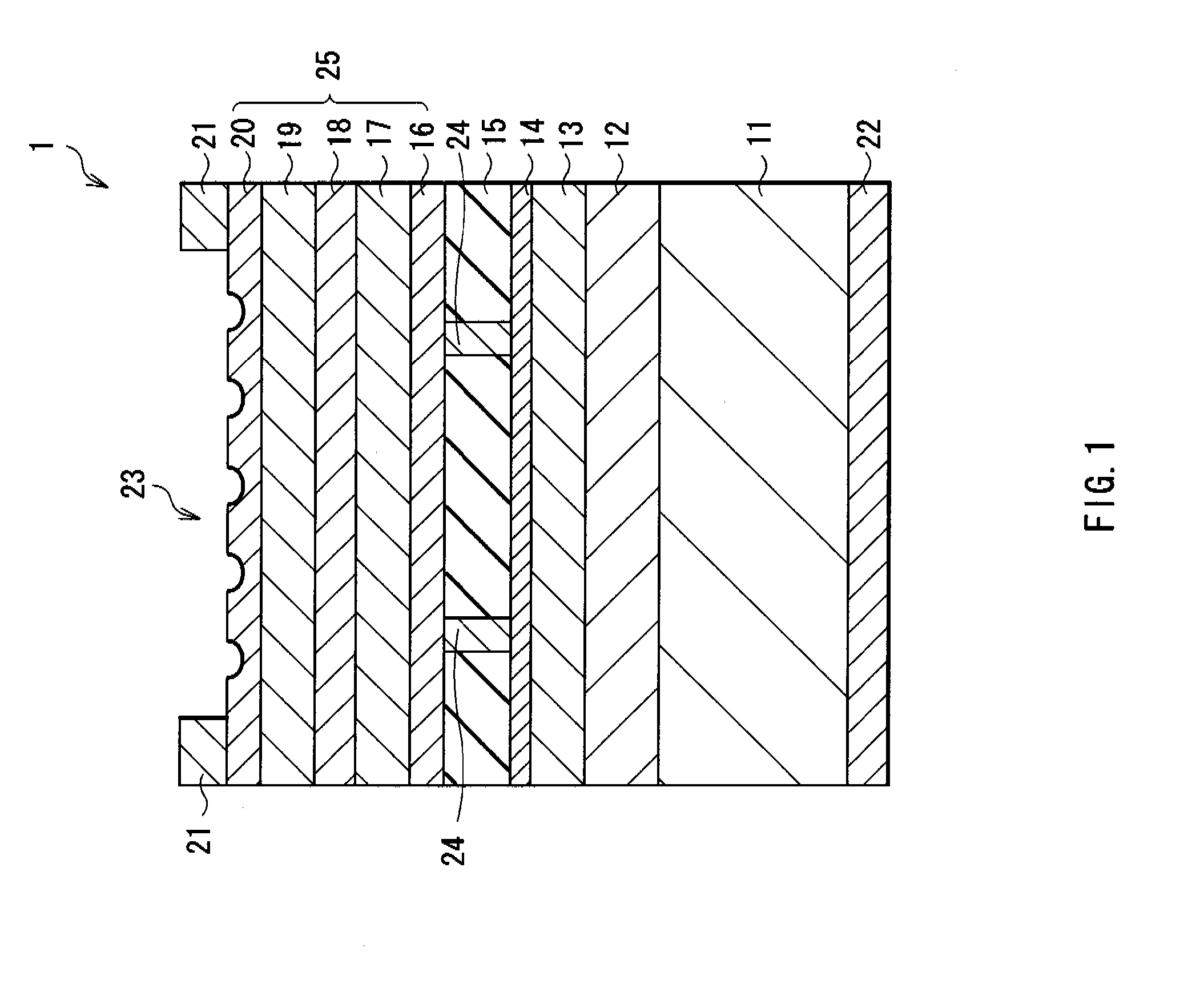

Functional Device and Method for Making the Same

InactiveUS20090272433A1High productivityDifficult to handleElectrolytic capacitorsFinal product manufactureSolventProduction rate

To provide a functional device suitable for dye-sensitized solar cells and the like and having a structure suited for thickness reduction, and a method for making the same with good productivity. A dye-sensitized photovoltaic device 10 is constituted by a transparent substrate 1 formed of glass or the like, a transparent conductive layer 2 formed of FTO or the like, semiconductor electrode layers (negative electrodes) 3 supporting a photosensitizing dye, an electrolyte layer 4, a film-shaped counter electrode (positive electrode) 5, a film-shaped packaging member 6 replacing a counter substrate of the related art, a sealing member 7, power-collecting wiring 8, a wiring protecting layer 9, and the like. As the material of the film-shaped packaging member 6, a material that has high barrier property of suppressing passage of solvents, gasses, water, and the like and excellent resistance to organic solvents and heat is preferred. The device 10 is sealed by joining the transparent substrate 1 to the film-shaped packaging member 6 but a part 11b of a joint 11 is left unjoined before introduction of an electrolytic solution so as to function as an introduction port and joined after the introduction of the electrolytic solution, thereby requiring no end seal.

Owner:SONY CORP

Peracetic teat dip

InactiveUS20060177518A1Effective antimicrobialSafe to handle and notBiocideHydroxy compound active ingredientsAcetic acidMastitis

A teat dip formula is disclosed for use on dairy animals with the objective of reducing or preventing mastitis. The teat dip formula preferably includes up to about 5000 ppm of peracetic acid in solution made in situ by mixing acetic acid and hydrogen peroxide. Other constituents of the formula may include effective amounts of a skin conditioning agent or agents, a surfactant or surfactants and urea. A method of preparing and applying the formula is disclosed.

Owner:GEA WESTFALIASURGE INC

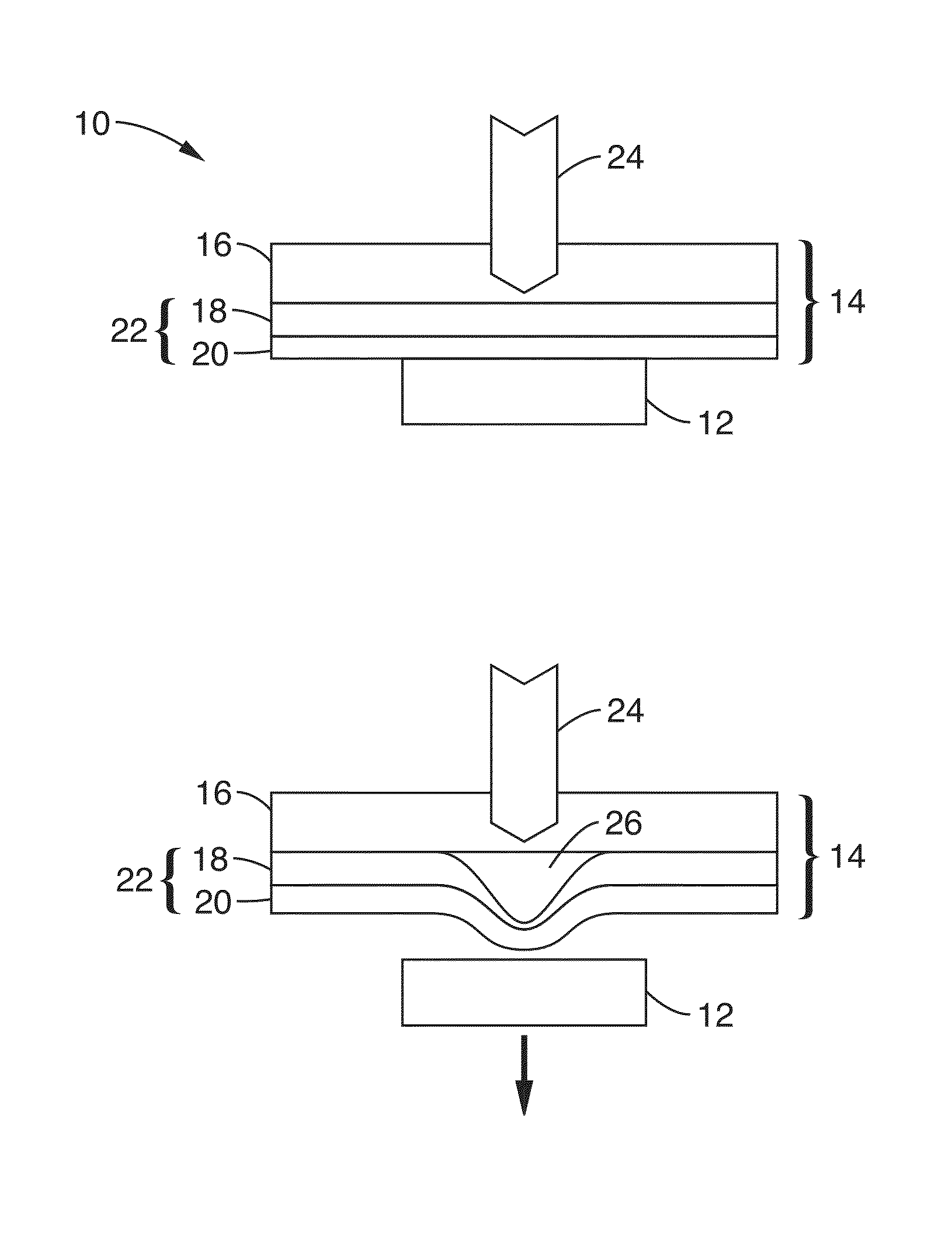

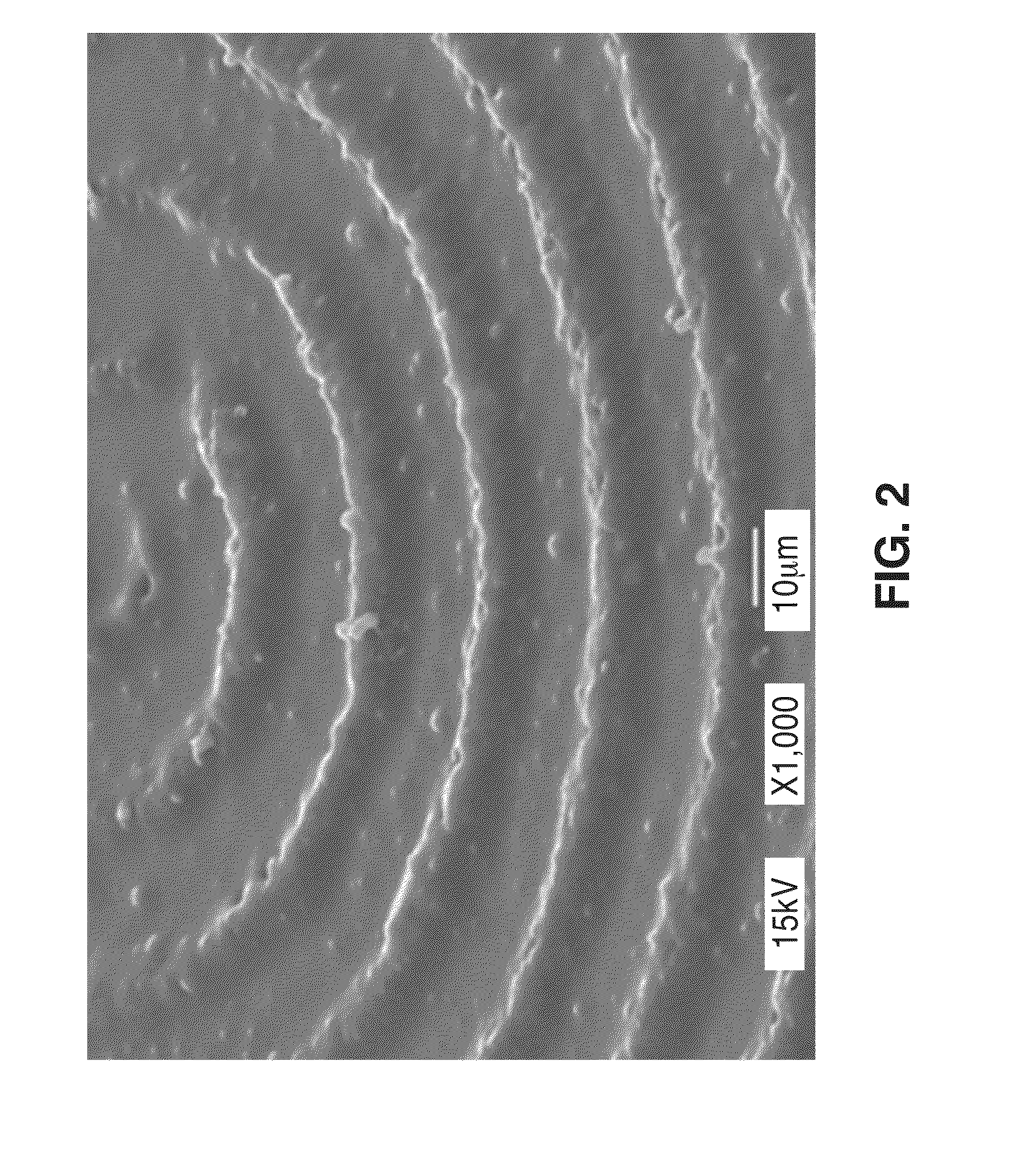

Selective laser-assisted transfer of discrete components

InactiveUS20140238592A1Easy to packDifficult to handleMechanical working/deformationLamination ancillary operationsEngineeringLaser assisted

Electronic components are often assembled using robotic equipment, such as pick-and-place machines, that is not optimized for components such as ultra-thin semiconductor bare dice. Selective laser-assisted die transfer is described based on the unique blistering behavior of a multilayer dynamic release layer when irradiated by low energy focused laser pulse(s) in which the blister creates translation of the article being placed. Accurate placement results are provided with negligible lateral and angular displacement.

Owner:NORTH DAKOTA STATE UNIV RES FOUND

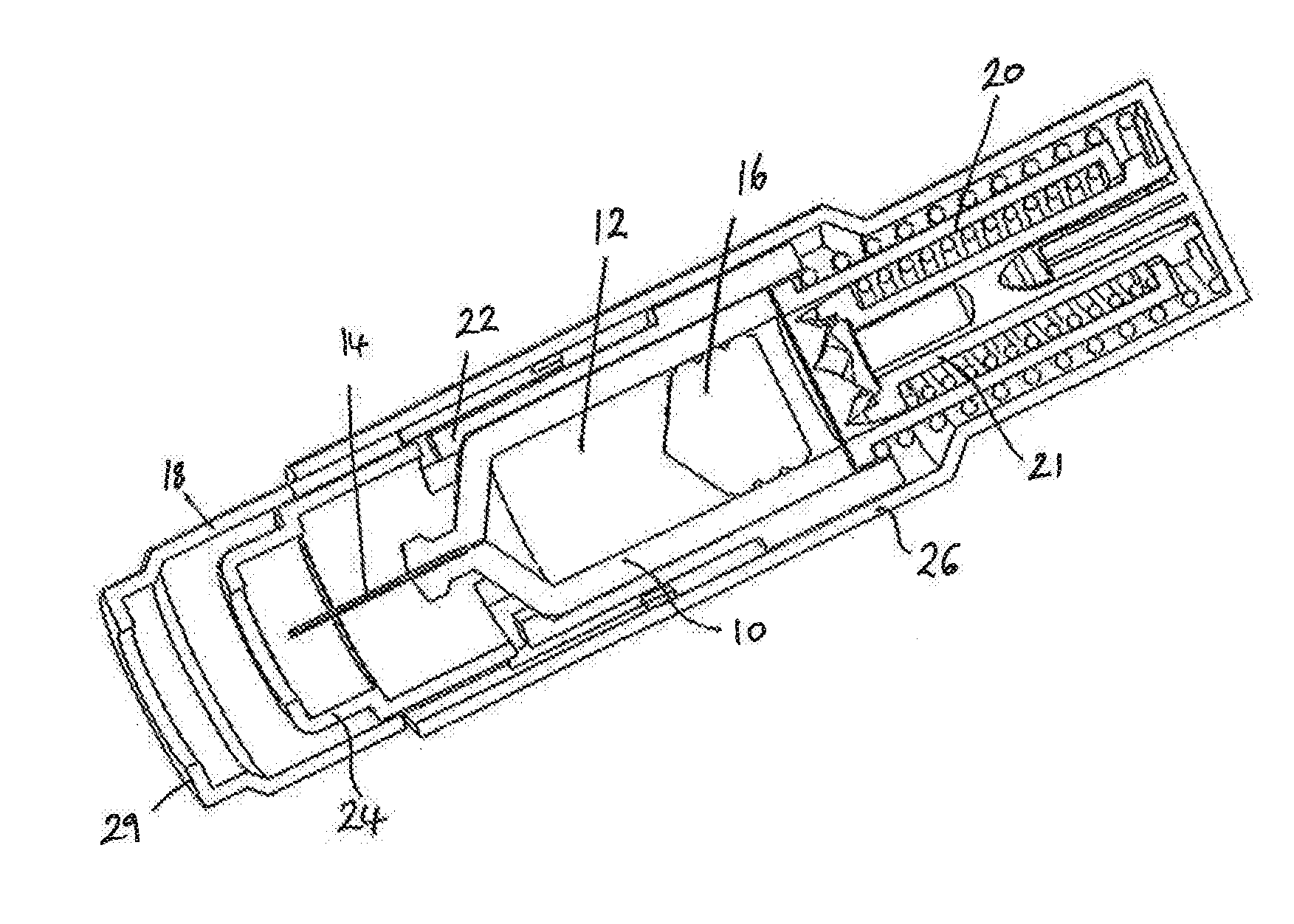

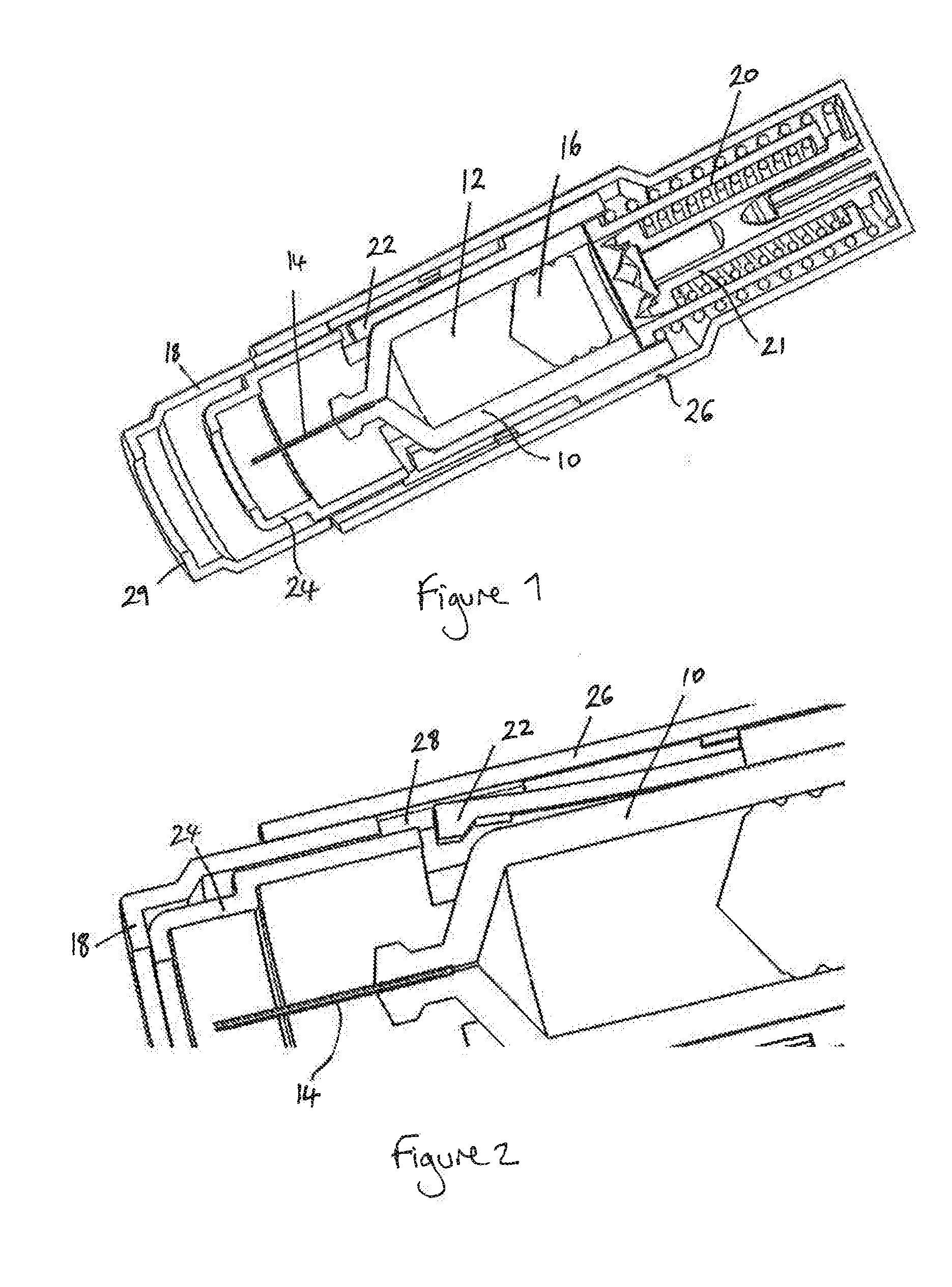

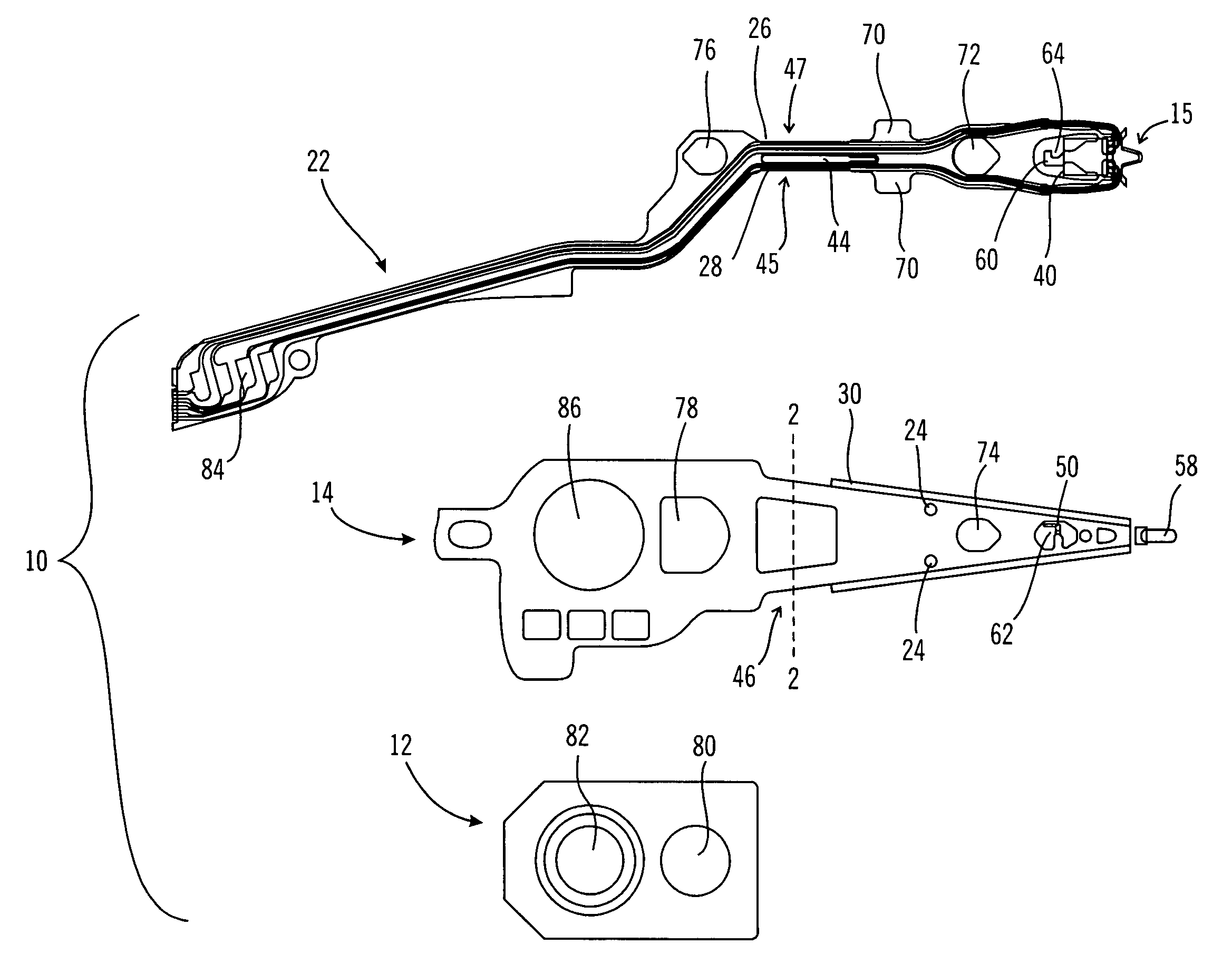

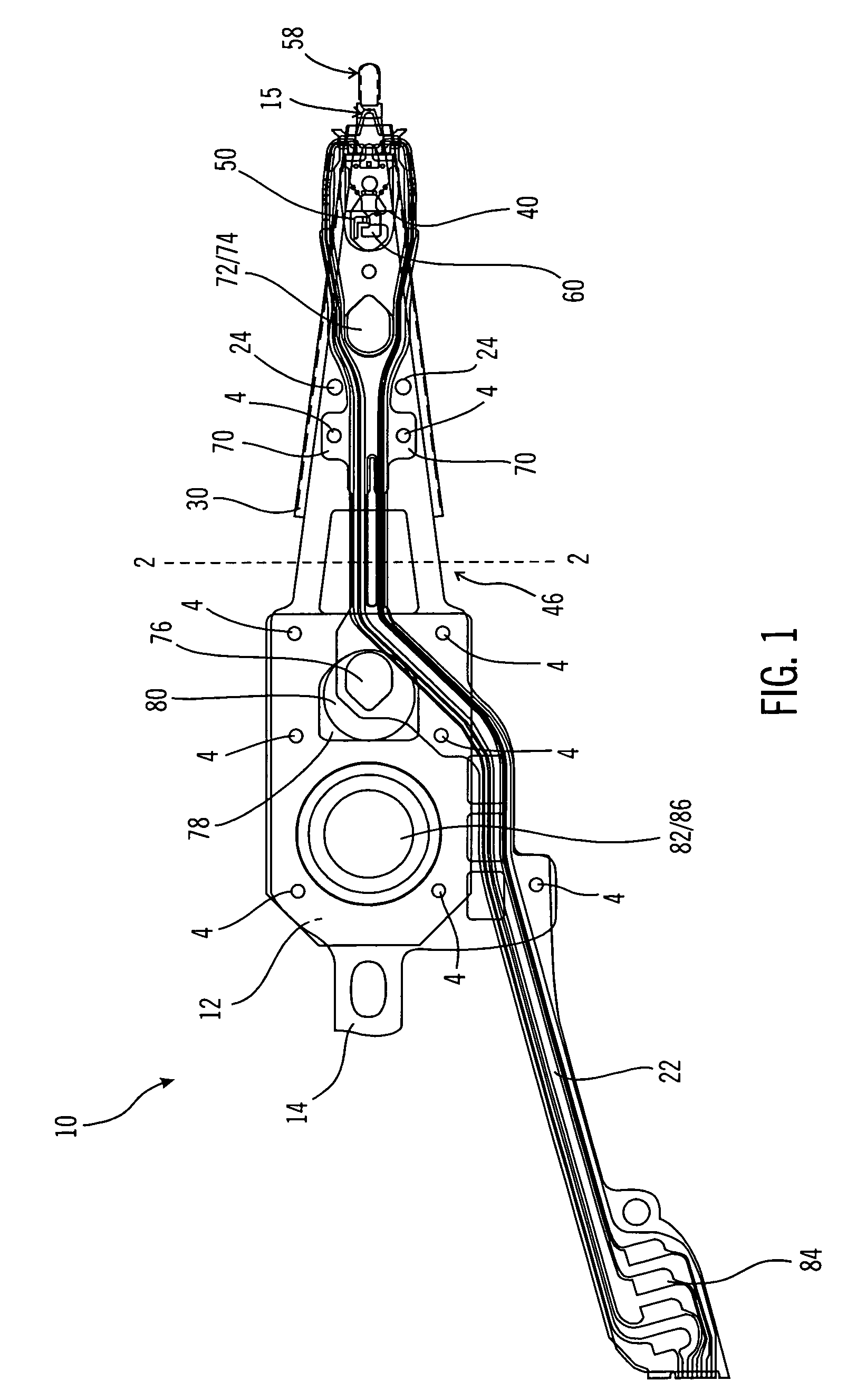

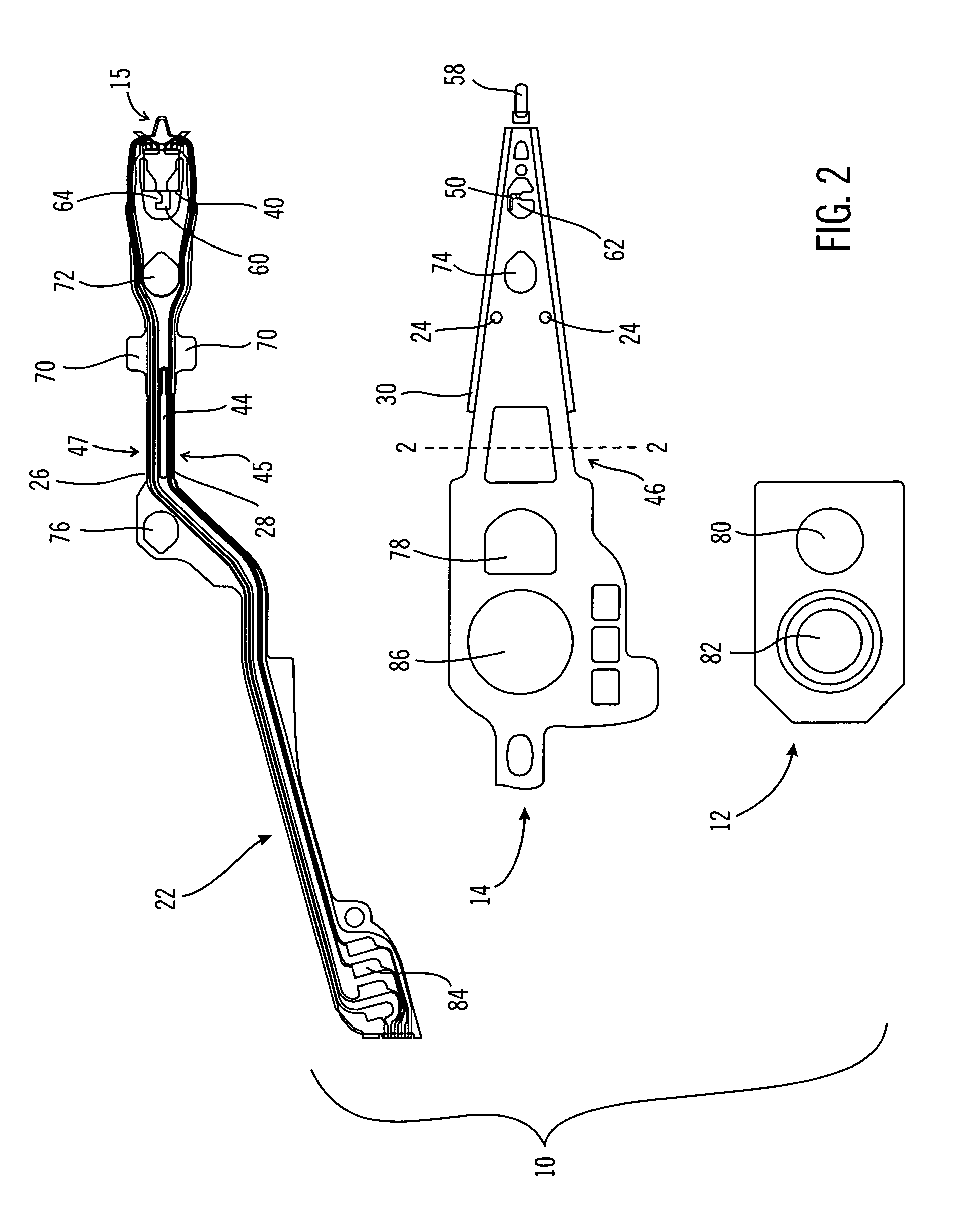

Integrated lead suspension for high density drive

InactiveUS6965501B1Avoid damageImprove dynamic performanceRecord information storageIntegrated arm assembliesLeading edgeInsulation layer

The integrated lead suspension assembly comprises several improvements. An oversized terminating pad for the electrical traces and a smaller adjacent insulation layer on the flexure assembly enable laser solder ball bonding of the pads to the read / write terminal contacts on the slider without clamping operation. Consequently, the tip of the load beam can be made narrow for a structure that provides for head loading and unloading functions, which improves the dynamic performance of the suspension assembly. The flexure assembly is configured such that it requires no permanent bending in its forming process, and any permanent bending required is done to the load beam. The limiter that limits the travel of the flexure assembly is formed on the load beam and it is bent to the functional position only after attachment of the flexure assembly to the load beam. The limiter is configured and positioned at the leading edge side of the slider to optimize the unloading process and to minimize the possibility of disengagement of the limiter and the flexure assembly during high shock environment. Asymmetric backing branches are provided for the read and write traces in the flexure assembly located at the hinge area of the load beam, the widths of which are sized to optimize the dynamic signal performance of the read and write traces without impact on the vertical stiffness of the suspension. Low profile flanges at 30°–60° that bend from the plane of the load beam are provided along the edges of the load beam to optimize bending stiffness and flow induced vibration. Dimples are provided along the load beam to facilitate insertion of a plastic head separation tool.

Owner:WESTERN DIGITAL TECH INC

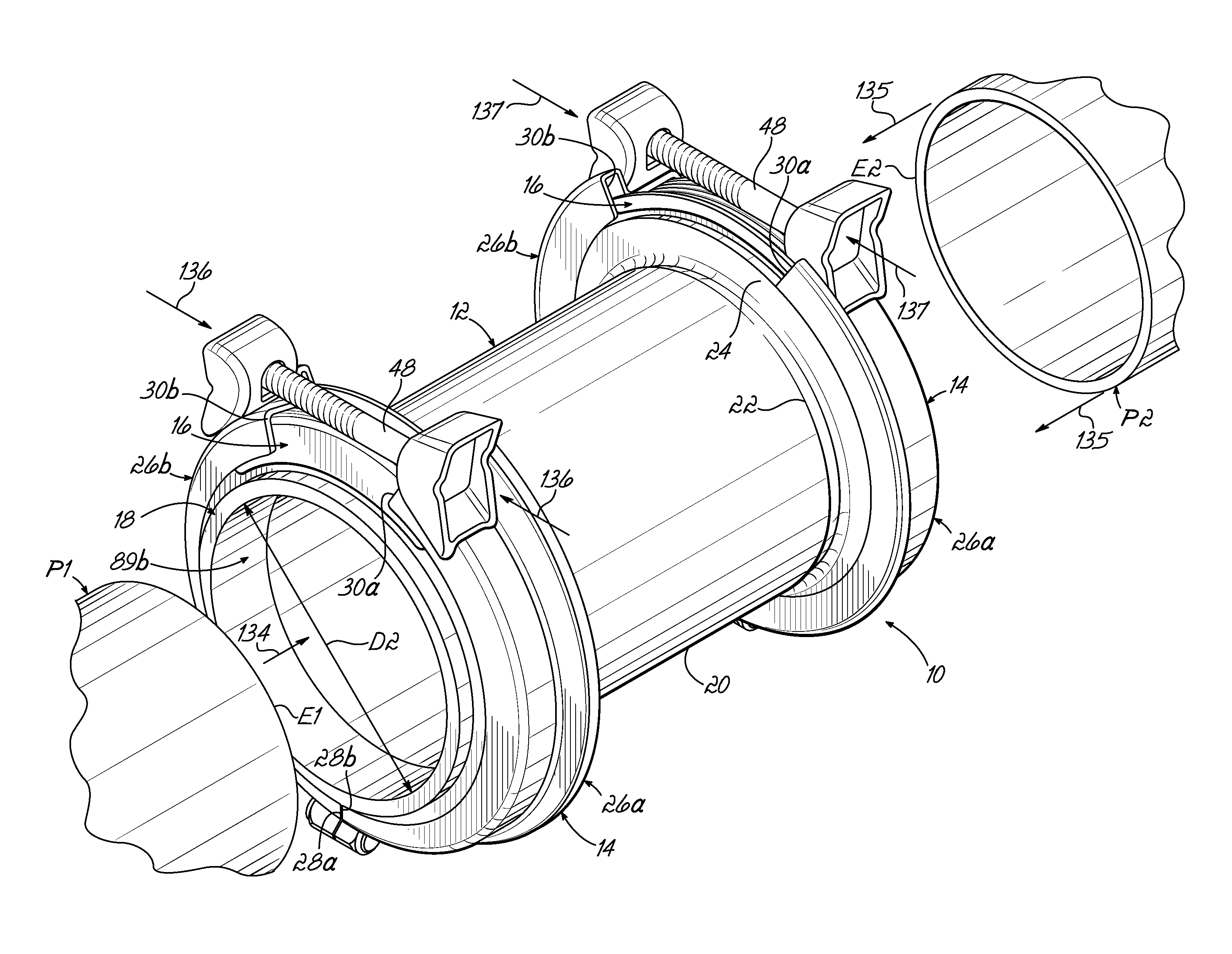

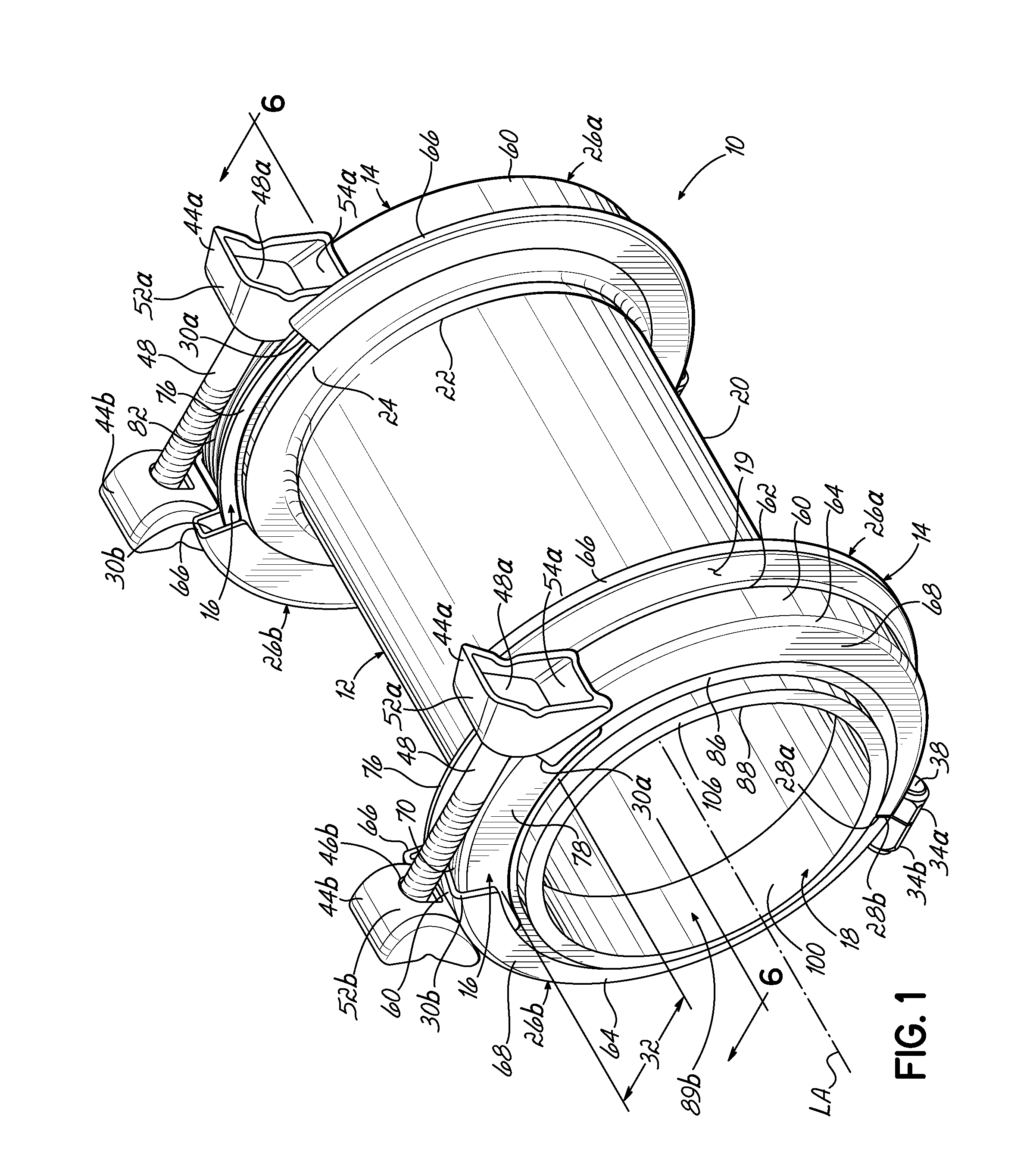

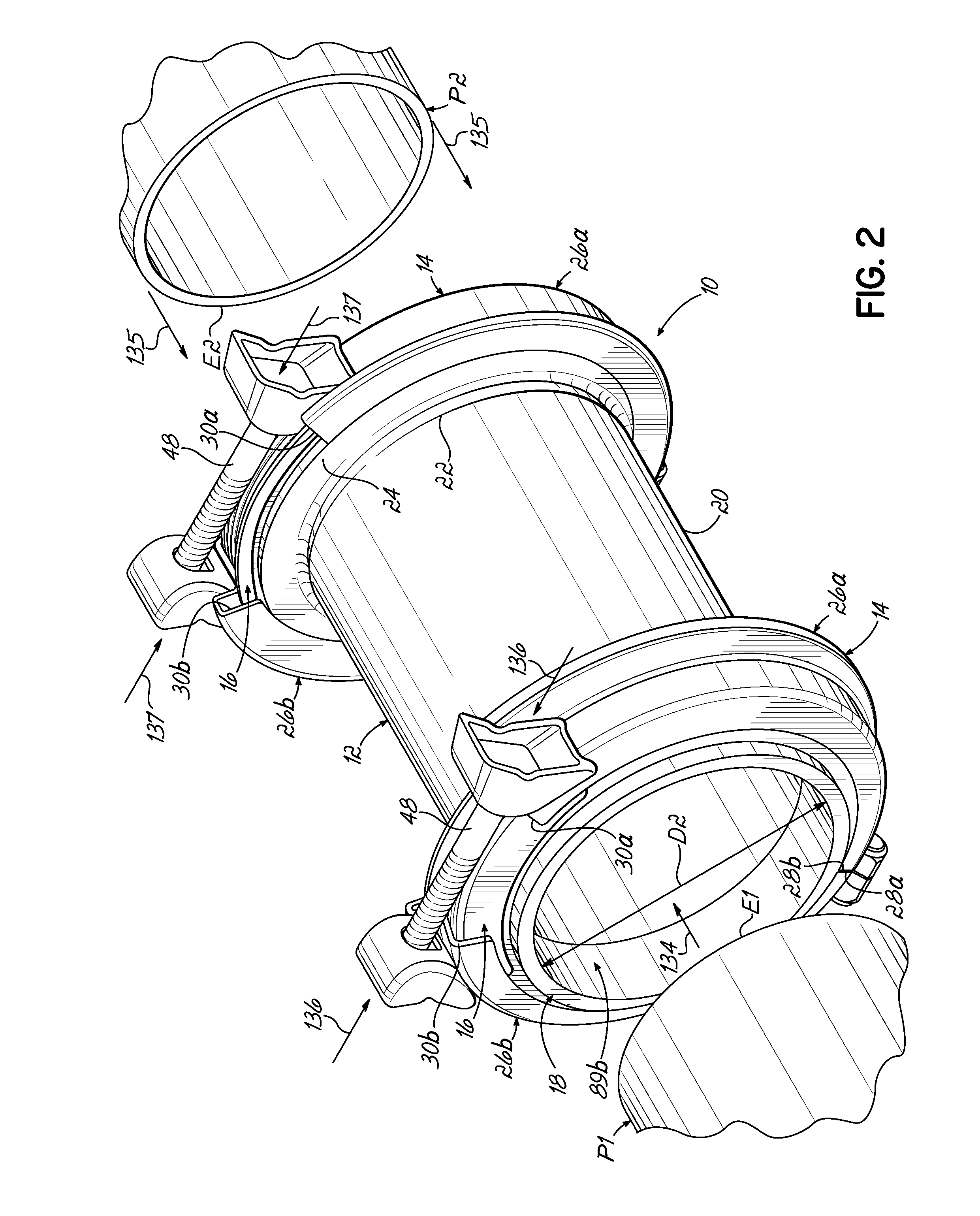

Split-Ring Gland Pipe Coupling with Corrugated Armor

ActiveUS20120205909A1Improve performanceEnhance assemblySleeve/socket jointsEngine sealsEngineeringSplit ring

A pipe coupling for coupling adjacent ends of a pair of pipes includes a sleeve, a split-ring gland positioned around one of the ends of the sleeve, and at least one annular gasket positioned within the split-ring gland and configured to be compressed by the split-ring gland for sealing one pipe end to the sleeve. The split-ring gland includes two partially circular gland members with spaced ends defining a gap. The pipe coupling includes an armor positioned to span the gap between the spaced ends to provide a generally closed annular periphery about the gasket. The armor includes a corrugated portion having a plurality of corrugations engaging the split-ring gland and the gasket during compression of the gasket. The armor is cold formed to improve structural strength and durability.

Owner:SENSUS SPECTRUM LLC

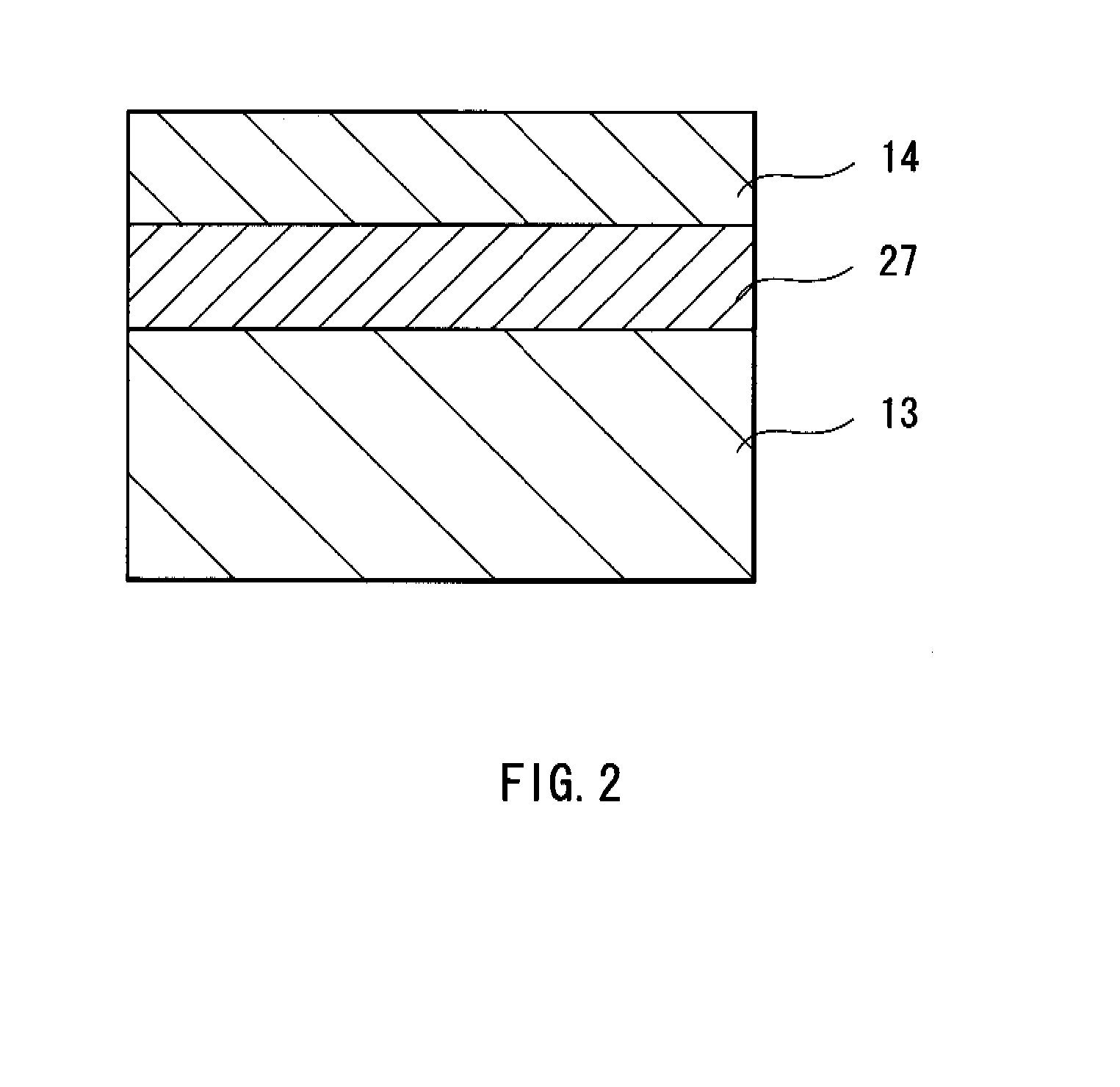

Semiconductor light-emitting device and method of manufacturing the same

InactiveUS20080173885A1Reduces tendency to flakeEnhance layeringSemiconductor/solid-state device manufacturingSlide valveHigh reflectivityLength wave

A semiconductor light-emitting device includes: a semiconductor layer including a light-emitting region and having an emission surface on its surface; an insulating layer arranged on a surface of the semiconductor layer opposite to; a first metal layer deposited on a surface of the insulating layer opposite to a surface where the semiconductor layer is arranged; a contact portion buried in a part of the insulating layer, the contact portion electrically connecting the semiconductor layer and the first metal layer; and a second metal layer having higher reflectivity with respect to a light-emitting wavelength than the first metal layer, the second metal layer arranged on a surface of the first metal layer opposite to a surface where the insulating layer is arranged, wherein a metal of which the first metal layer is made has higher adhesion to the insulating layer than a metal of which the second layer is made.

Owner:SONY CORP

Metallic Pigment and Coating Material Containing the Same

InactiveUS20080081864A1Improve corrosion resistanceImprove adhesionPigmenting treatmentChemical recyclingNitrogenDouble bond

Disclosed is a metallic pigment which enables to provide a coating film with very brilliant appearance and excellent corrosion resistance at the same time. Also disclosed is a coating material containing such a metallic pigment. Specifically disclosed is a metallic pigment which is composed of aluminum particles as the base particles whose surfaces are covered with a coating-layer composed of one or more layers. The outermost layer of the coating-layer contains a polymer which is obtained by polymerizing a monomer having a basic group and at least one polymerizable double bond. The monomer may preferably contain nitrogen. The metallic pigment may preferably be provided with a surface modification layer. Also specifically disclosed is a coating material containing such a metallic pigment.

Owner:TOYO ALUMINIUM KK

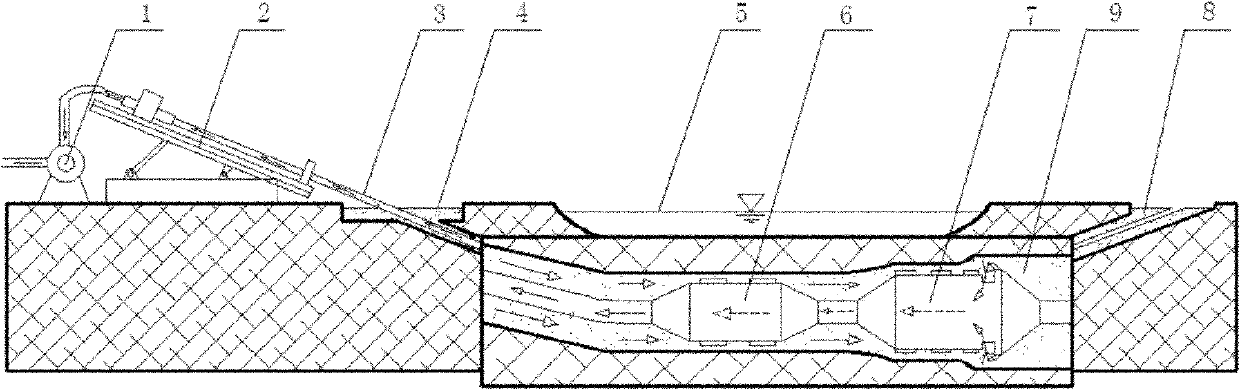

Traversing reverse circulating drilling method of horizontal directional drilling pipeline and special drilling bit

InactiveCN102003140AReduce consumptionImprove drilling efficiencyPipe laying and repairDrill bitsSlurryDirectional drilling

The invention provides a traversing reverse circulating drilling method of a horizontal directional drilling pipeline and a special drilling bit, which are suitable for laying oil-gas pipelines and municipal pipelines. The drilling method comprises the following steps of: mounting a gravel pump at the outer end of a drilling machine or a pit, wherein hollow cavities are formed in the drilling bit and the drilling stem in use; arranging a slag suction port communicated with a borehole circular space on a reaming drilling bit; sleeving a roller cone seat with a roller cone outside the body of the reaming drilling bit, wherein the position of the roller cone corresponds to that of the slag suction port; arranging a plug for blockage at one end of the reaming drilling bit; and circularly flowing slurry according to a flowing direction from a slurry pond to the borehole circular space, the reaming drilling bit, the drilling stem, the gravel pump and the slurry pond during drilling so as to reach the aim of deslagging. The method and the drilling bit of the invention can be adopted to effectively remove drilling slag and gravel in the horizontal borehole and solve various problems in the traversing construction of the large-diameter horizontal directional drilling pipeline.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

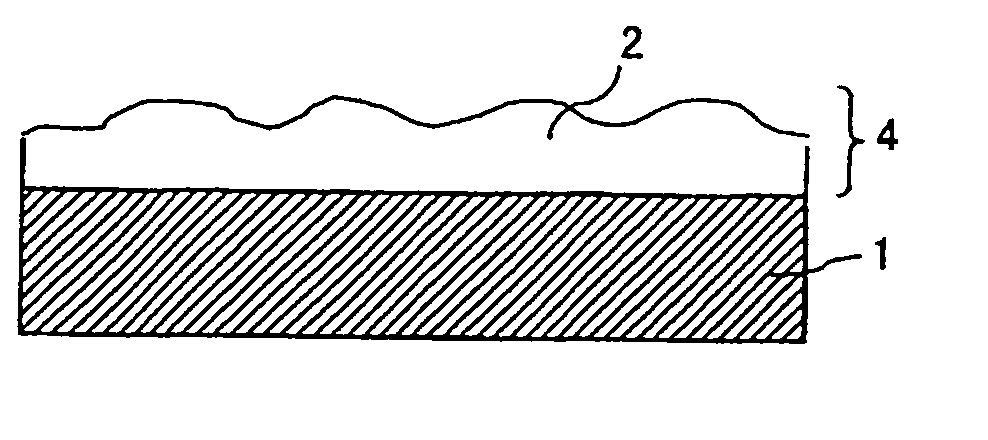

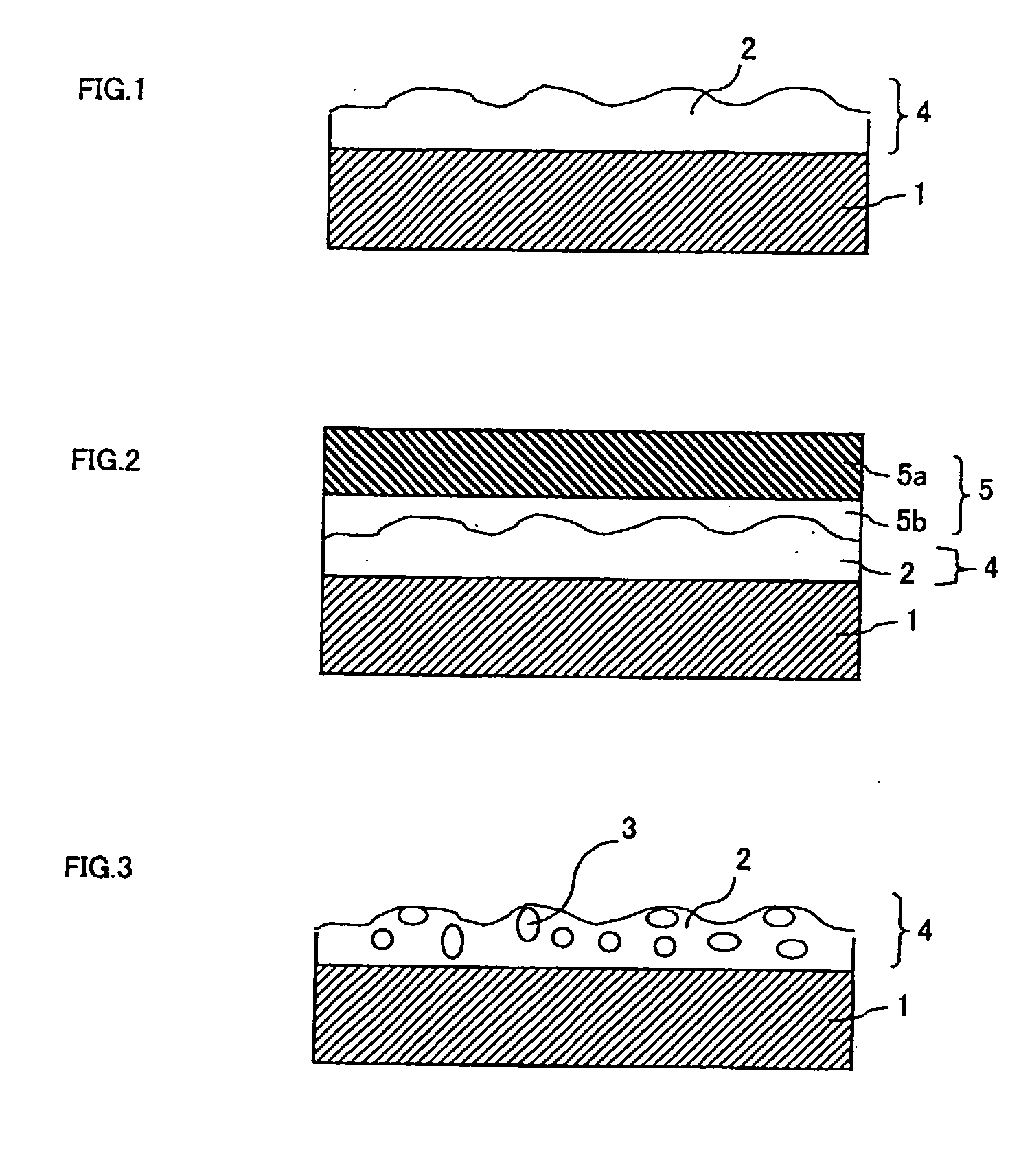

Light-diffusing sheet, optical element and image viewing display

InactiveUS20050162743A1Low optical degradationImprove balanceDiffusing elementsSynthetic resin layered productsImideRough surface

A light-diffusing sheet includes a transparent film and a light-diffusing layer formed on at least one side of the transparent film. The light-diffusing layer is composed of a resin coating layer having a rough surface. The transparent film comprises (A) a thermoplastic resin having a substituted and / or unsubstituted imide group at a side chain and (B) a thermoplastic resin having a substituted and / or unsubstituted phenyl group and a nitrile group at a side chain.

Owner:NITTO DENKO CORP

Heat-preserving composite foam concrete and preparation method thereof

InactiveCN101805203AImprove thermal insulationLight weightSolid waste managementCeramicwareFoam concreteFoaming agent

The invention discloses a formula of heat-preserving composite foam concrete, which comprises the following components based on parts by weight: 500-1000 parts of concrete, 500-1000 parts of admixture, 5-20 parts of additive, 1-30 parts of polyurethane grains, 5-20 parts of foaming agent and 500-900 parts of water. The preparation method the foam concrete comprises the following steps of: preparing foaming agent water solution, smashing the polyurethane into grains, and adjusting the sizes of the grains as required, wherein the diameters of the grains are 1-3mm; adding the polyurethane grains into the concrete, the residual water after preparing the foaming agent water solution, the additive and the admixture, and evenly stirring to obtain slurry; mixing and stirring the slurry with the foam prepared by the foaming agent water solution; and maintaining, pouring and shaping into the cast-in-situ foam concrete. The invention solves the problems of the coordination between the intensity of the foam concrete and the heat-conducting property and the treatment of the waste polyurethane. The foam concrete can guarantee the intensity and has better heat-insulating effect.

Owner:建研建材有限公司 +1

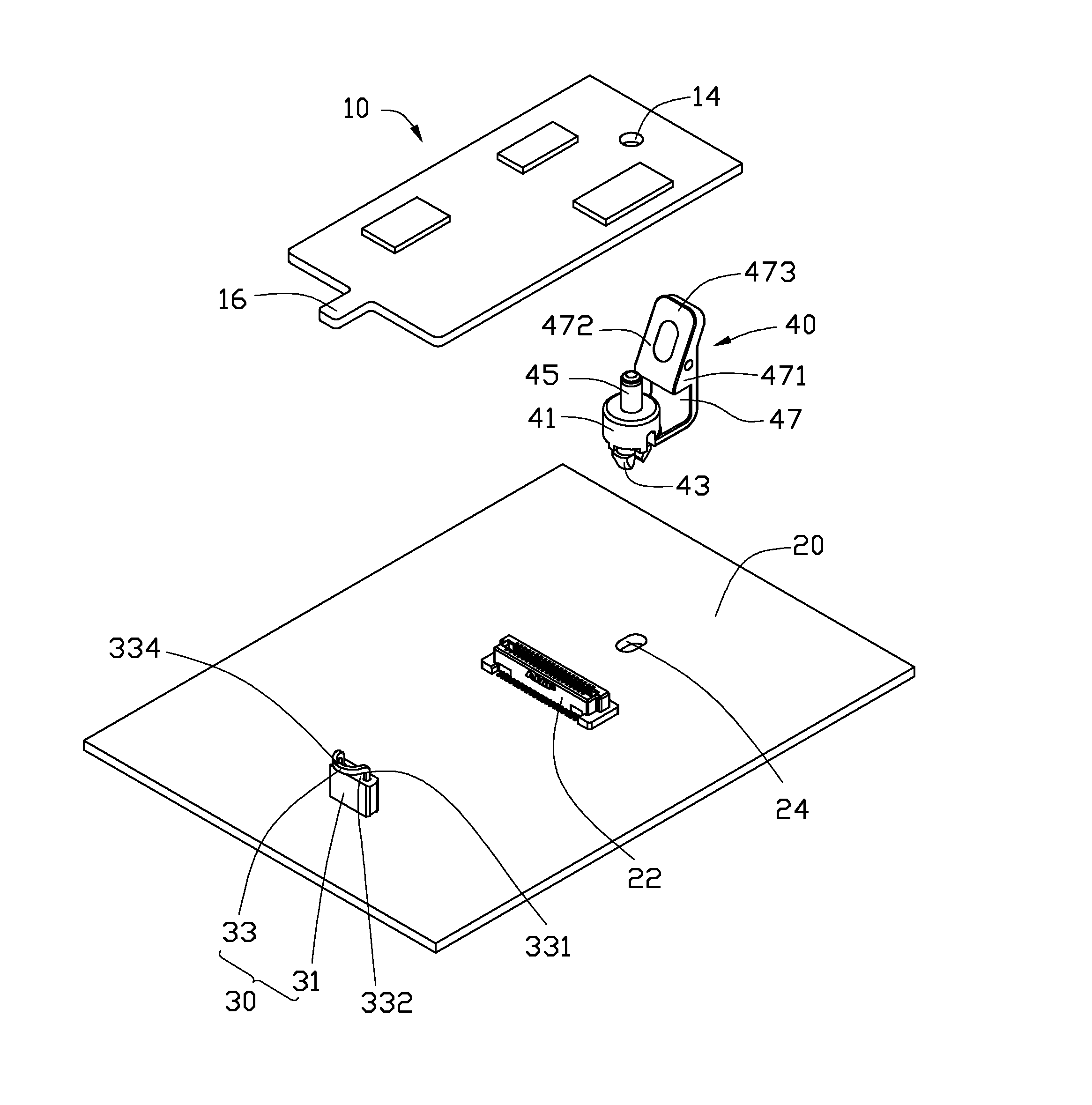

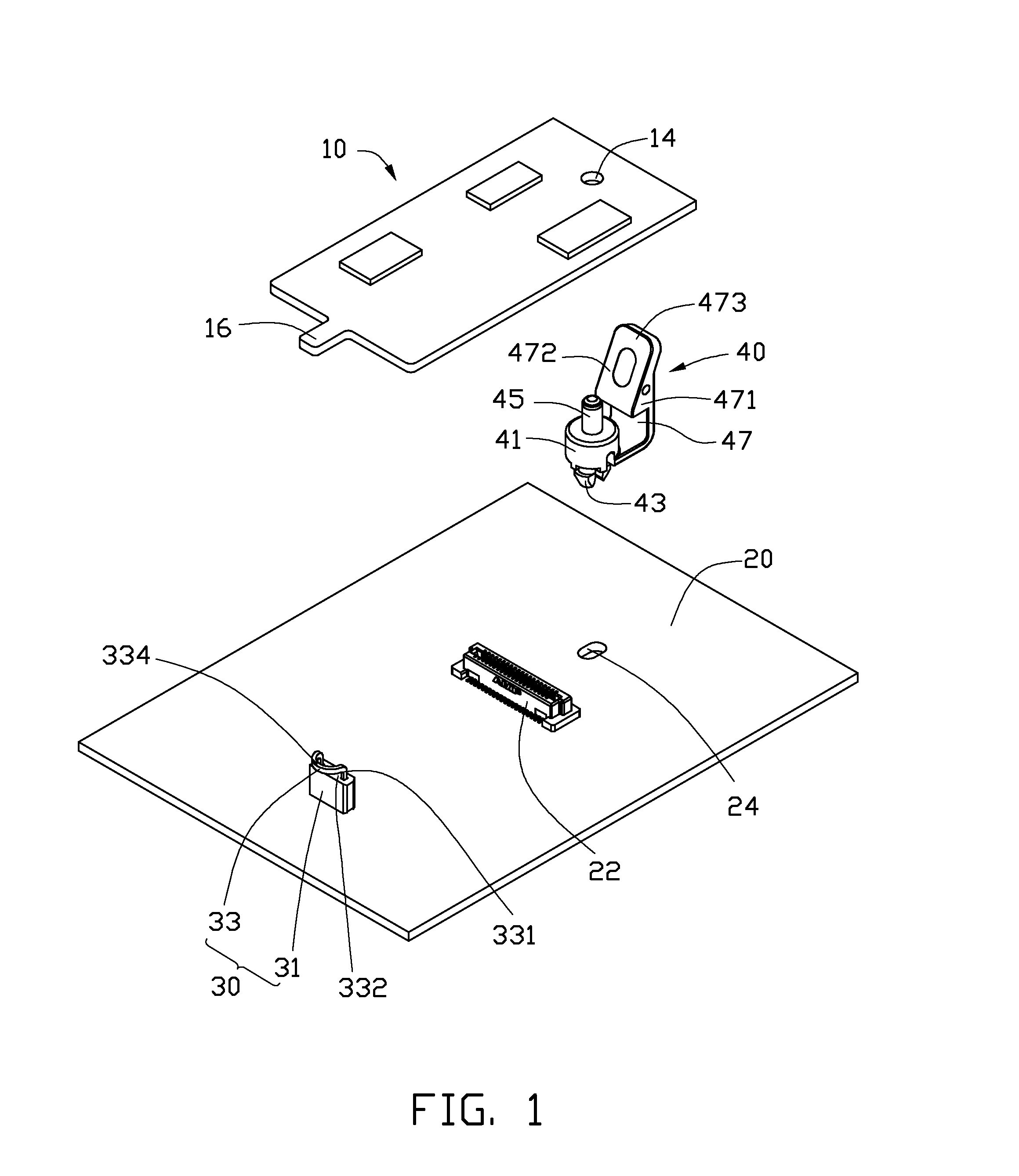

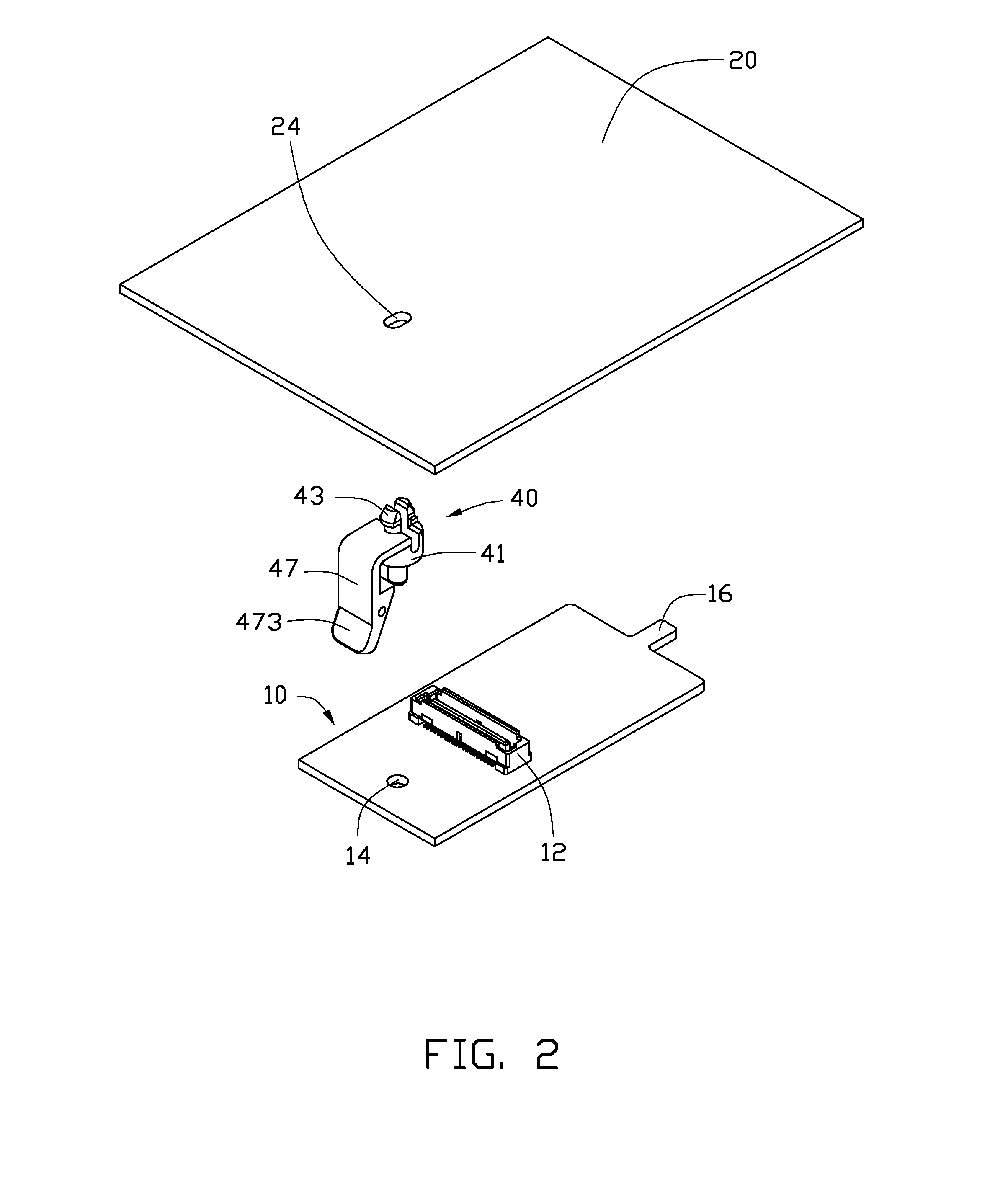

Fixing apparatus for expansion card

InactiveUS20130058054A1Difficult to handleTedious installationDigital data processing detailsElectrical apparatus contructional detailsExpansion cardEngineering

An apparatus for fixing an expansion card includes a circuit board, a fixing device, and a latching device. The expansion card includes a protrusion formed on a first end of the expansion card, and a positioning hole defined adjacent to a second end of the expansion card away from the first end. The fixing device is mounted to the circuit board for supporting the first end of the expansion card, and defines a through hole for allowing the protrusion of the expansion card to extend through the through hole. The latching device is mounted to the circuit board for supporting the second end of the expansion card, and includes a post for engaging in the positioning hole of the expansion card, and a resilient hook for engaging with a top of the expansion card.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Fertiliser coating containing micronutrients

ActiveUS20150376076A1Different and undesired coatingImprove storage characteristicsAmmonium nitrate fertilisersOrganic fertilisersChemical reactionChelation

A single-step method for preparing a free-flowing, non-dusting micronutrient-coated particulate solid fertiliser material, the method comprising applying a single fluid onto particulate solid fertiliser material at ambient temperature without chemical reaction or chelation, said single fluid comprising a suspension of one or more micronutrient materials in an oil.

Owner:YARA UK LTD

Process for isolating microorganisms from samples and system, apparatus and compositions therefor

InactiveUS20100144005A1Lessen and eliminate effectEasy to moveBioreactor/fermenter combinationsBiological substance pretreatmentsIsolate - microorganismParticle physics

A process for isolating microorganisms from samples, particularly Shigella spp. from food samples, and a system, apparatus and composition therefor are provided. Magnetic particles are used to capture microorganisms and a system having separate magnetically-based apparatuses for collecting, concentrating and retrieving is used to isolate the magnetic particles having bound microorganisms. The apparatus for concentrating magnetic particles utilizes a small magnet assisted by vibration to concentrate collected particles at a localized region on the bottom of a container. The process, system and apparatus of the present invention are simple and inexpensive providing improved magnetic particle recovery adaptable to large scales.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF HEALTH

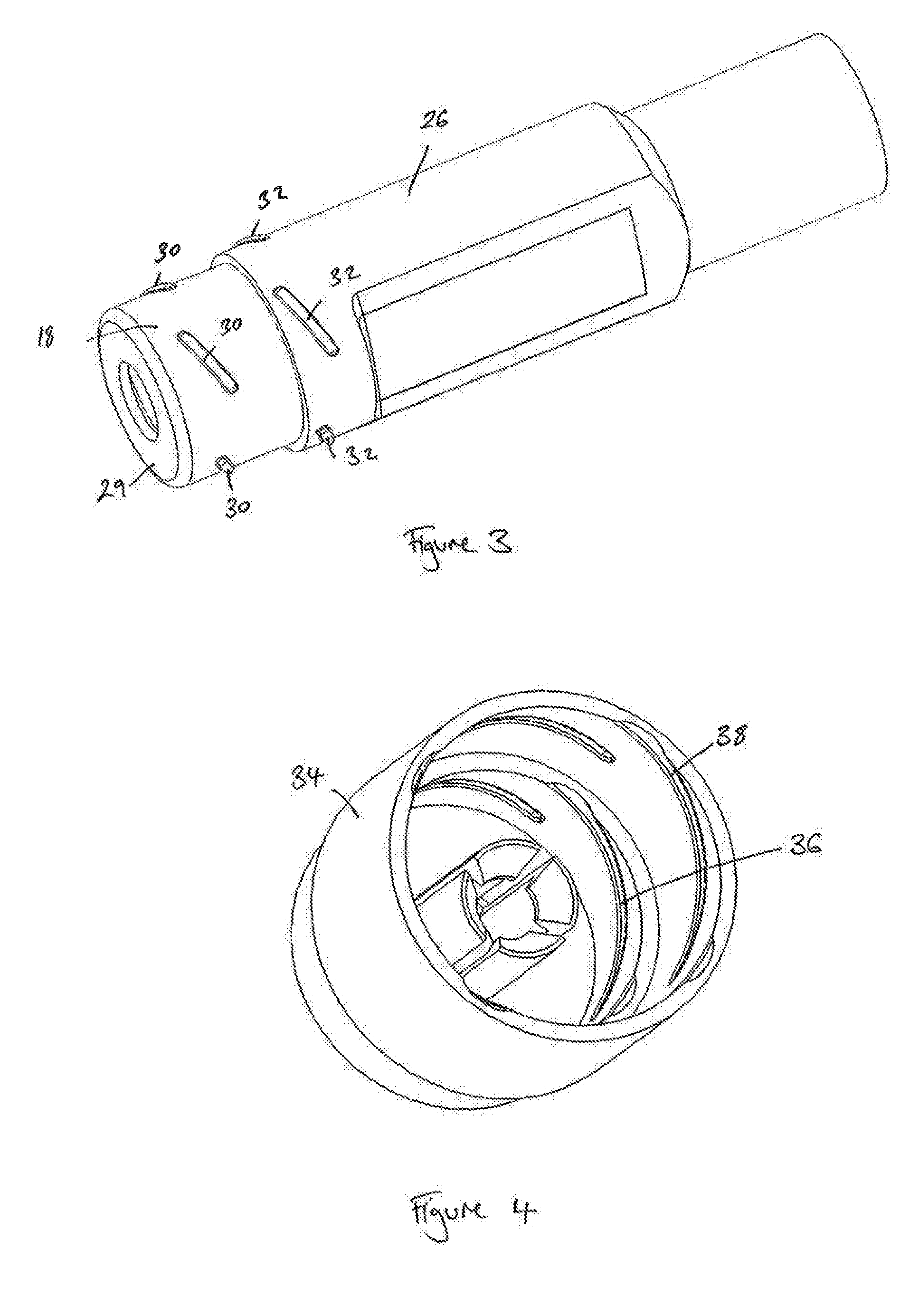

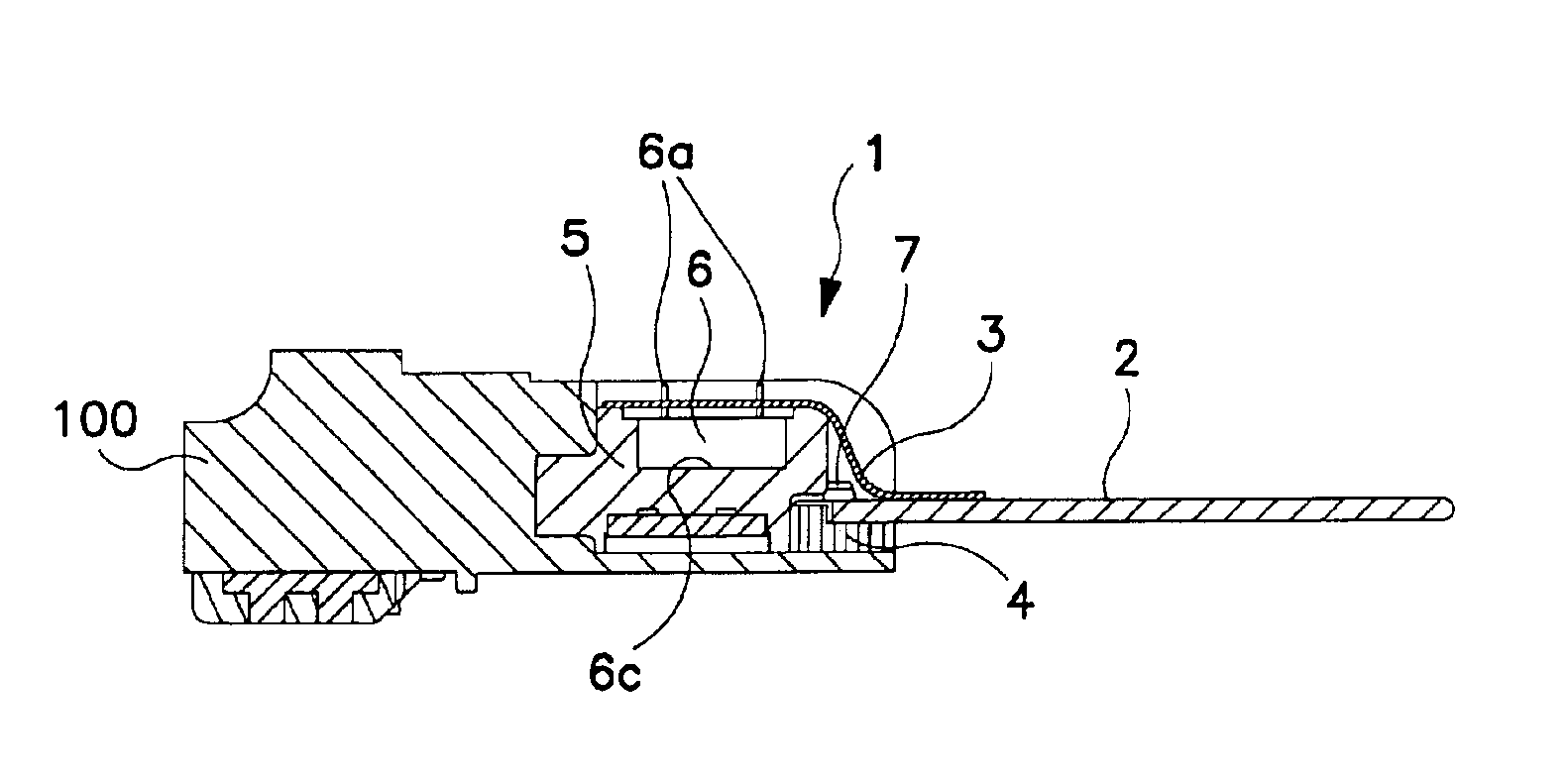

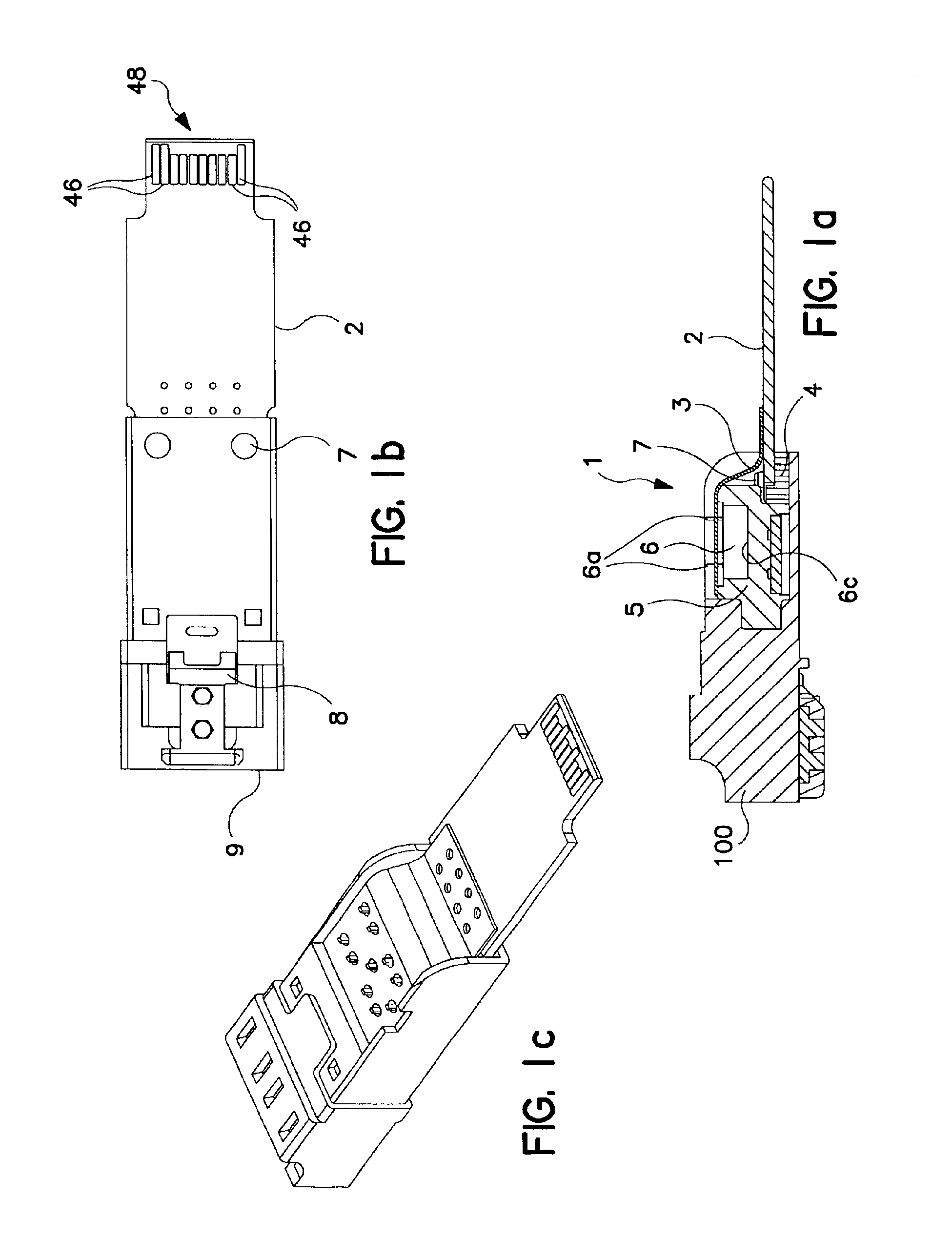

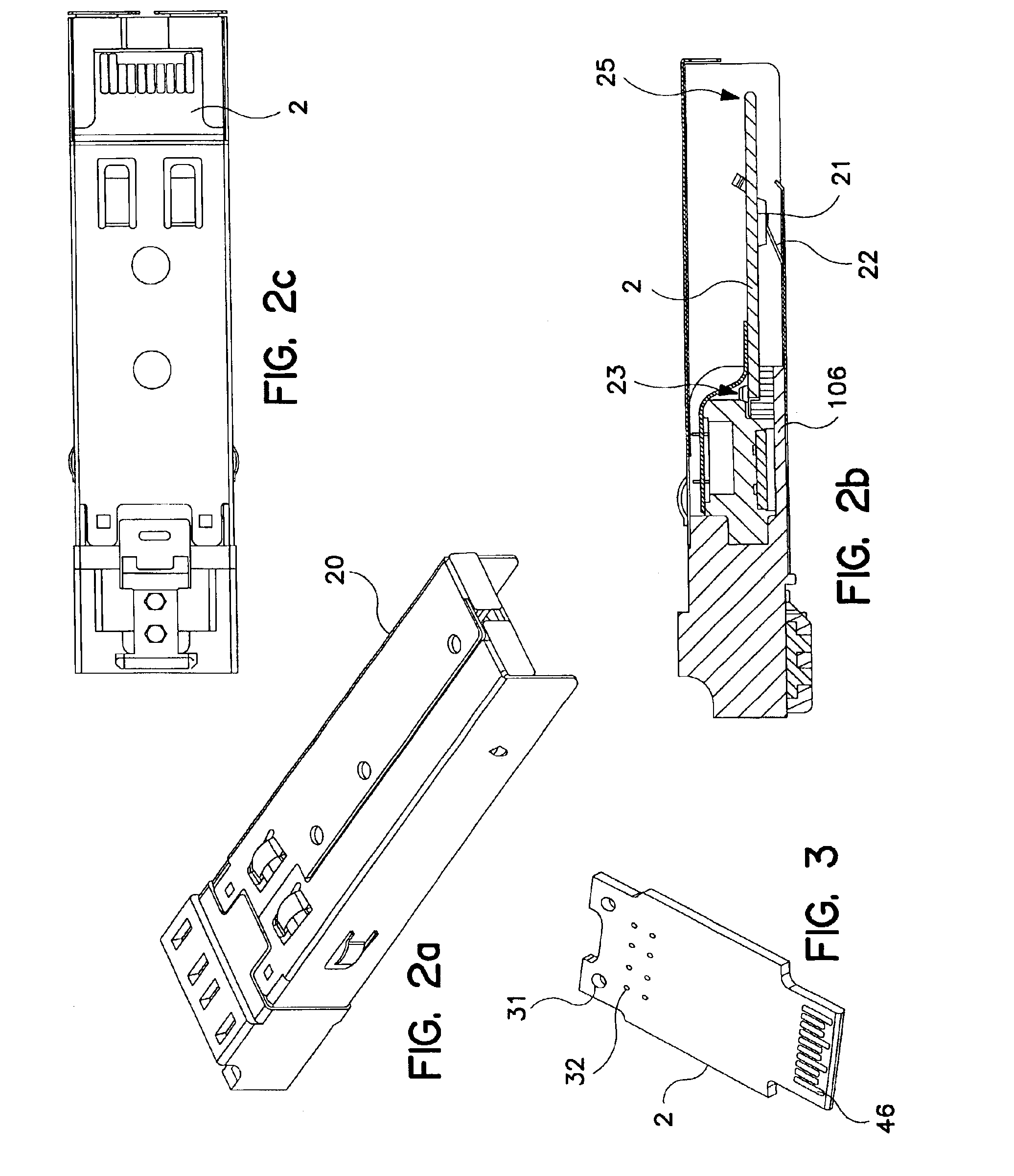

Transceiver for LC connector

A testable optical subassembly comprising a unitary structure of an optically-clear moldable material having at least the following features: (a) an optical path for transmitting optical signals between a fiber and an optoelectric device (OED); (b) a ferrule-receiving bore for receiving a ferrule and aligning a fiber held therein to the optical path; and (c) an OED-receiving cavity for receiving a lead frame and aligning an OED mounted thereon to the optical path along one or more axes.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

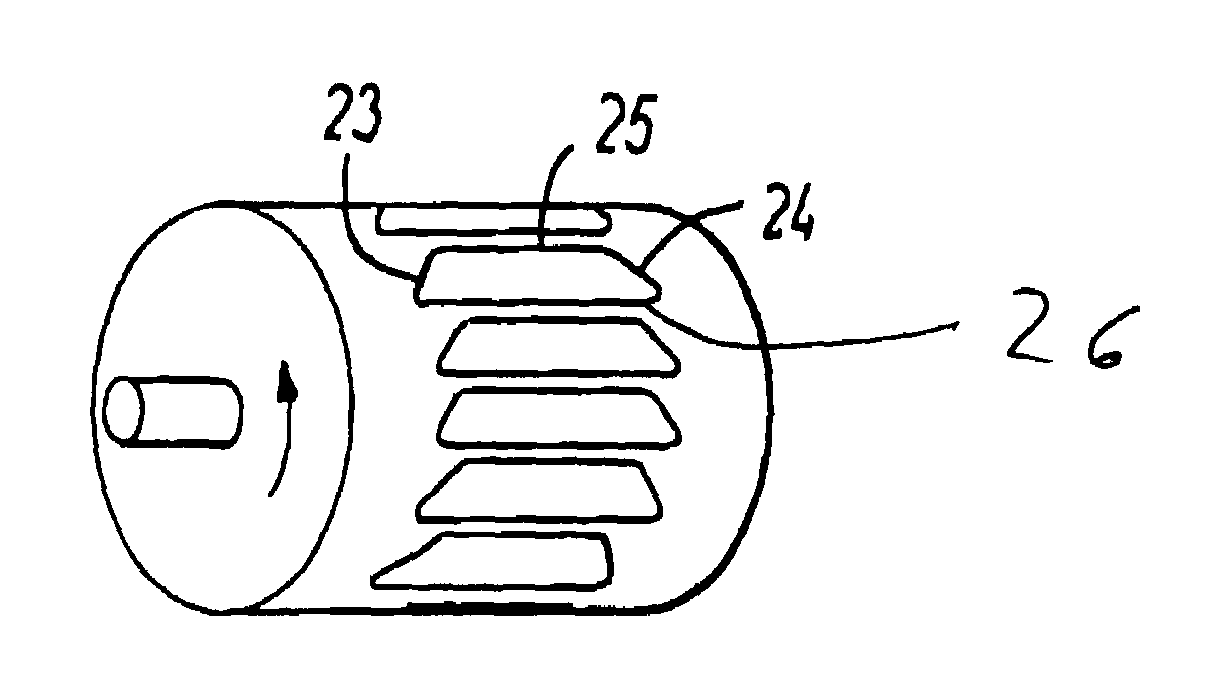

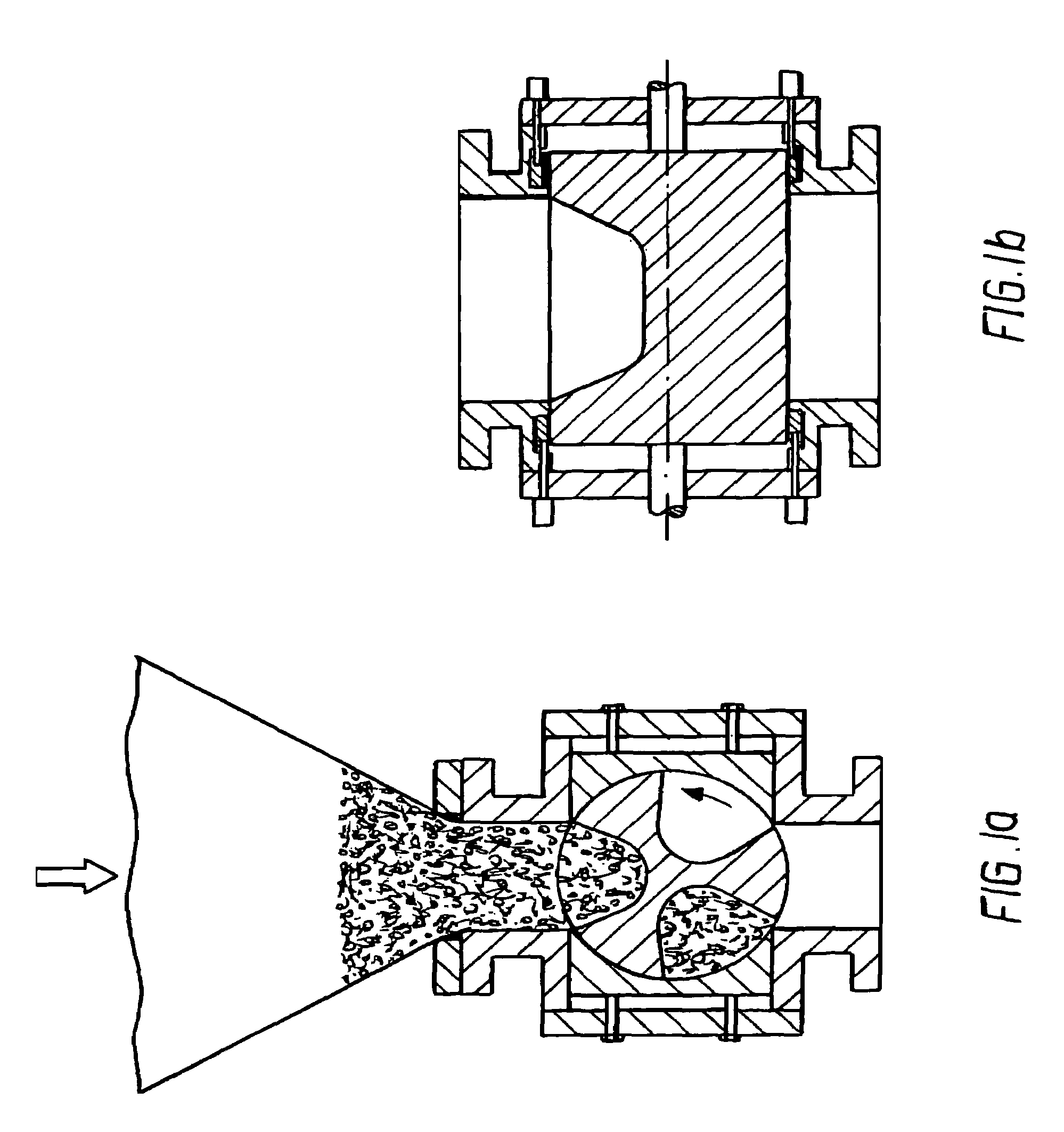

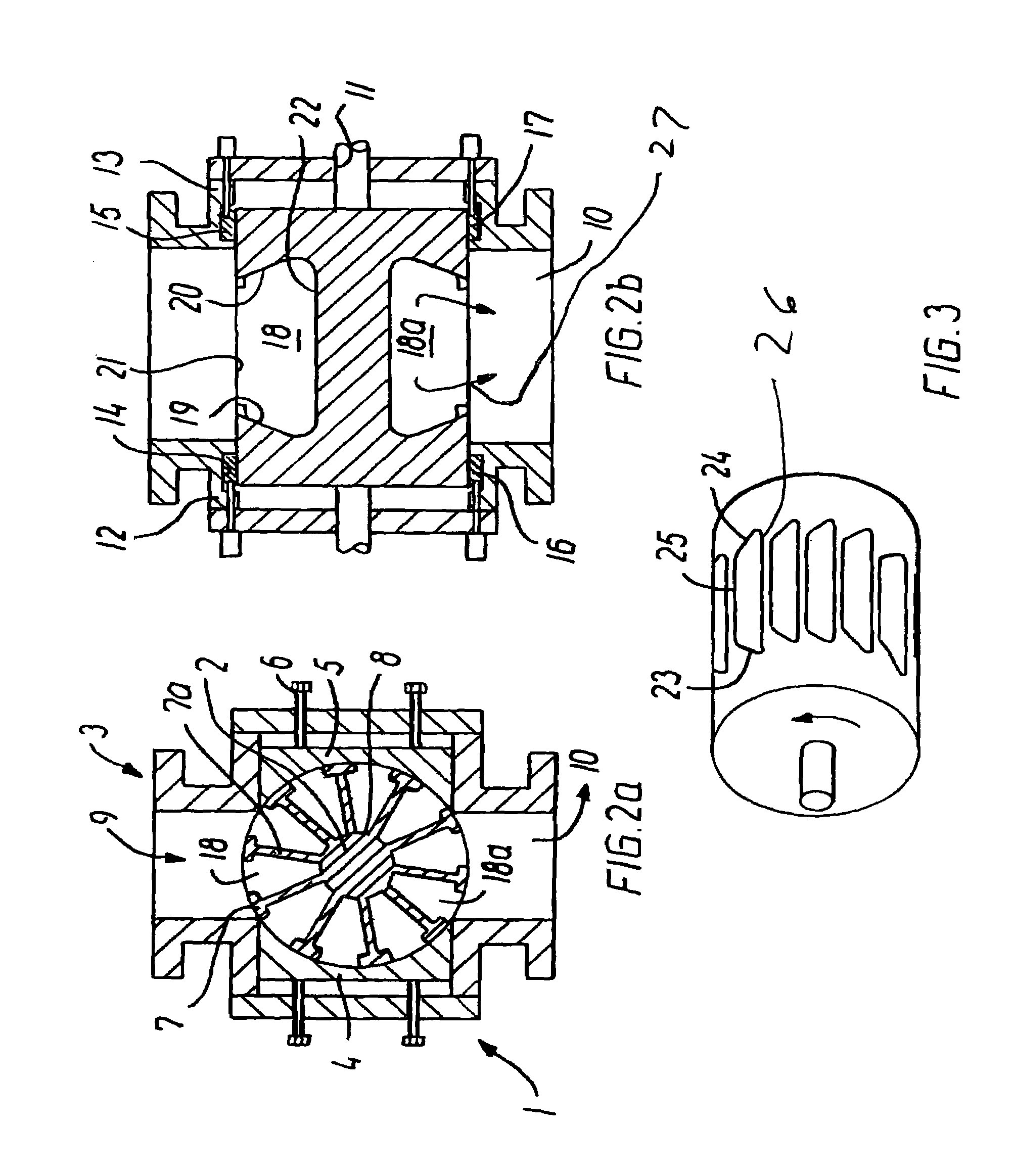

Rotary airlock valve

ActiveUS6966466B2Reduce wearDifficult to handleMovable measuring chambersBulk conveyorsLeading edgeThermal expansion

A rotary airlock valve has a plurality of material receiving pockets having leading edges that are narrower than the trailing edges thereof, preferably having walls tapering inwardly so as to define a narrowed pocket opening for directing any material expansion due to pressurization to a center of a discharge outlet, to reduce wear and increase seal life.

Owner:ASJ HLDG

R-Fe-B sintered magnet

ActiveUS20040094237A1Inferior squarenessInsufficient coercive forceInorganic material magnetismRare-earth elementMetallurgy

An R-Fe-B base sintered magnet having a composition of 12-17 at % of R (wherein R stands for at least two of yttrium and rare earth elements and essentially contains Nd and Pr), 0.1-3 at % of Si, 5-5.9 at % of B, 0-10 at % of Co, and the balance of Fe, containing a R2(Fe,(Co),Si)14B intermetallic compound primary phase and at least 1% by volume of an R-Fe(Co)-Si grain boundary phase, and being free of a B-rich phase exhibits a coercive force of at least 10 kOe despite a reduced content of heavy rare earth.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com