Patents

Literature

508 results about "Airlock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An airlock is a device which permits the passage of people and objects between a pressure vessel and its surroundings while minimizing the change of pressure in the vessel and loss of air from it. The lock consists of a small chamber with two airtight doors in series which do not open simultaneously.

Network Security Device

ActiveUS20070261112A1Function providedFacilitate law enforcement effortDigital data processing detailsUser identity/authority verificationNetwork packetDatapath

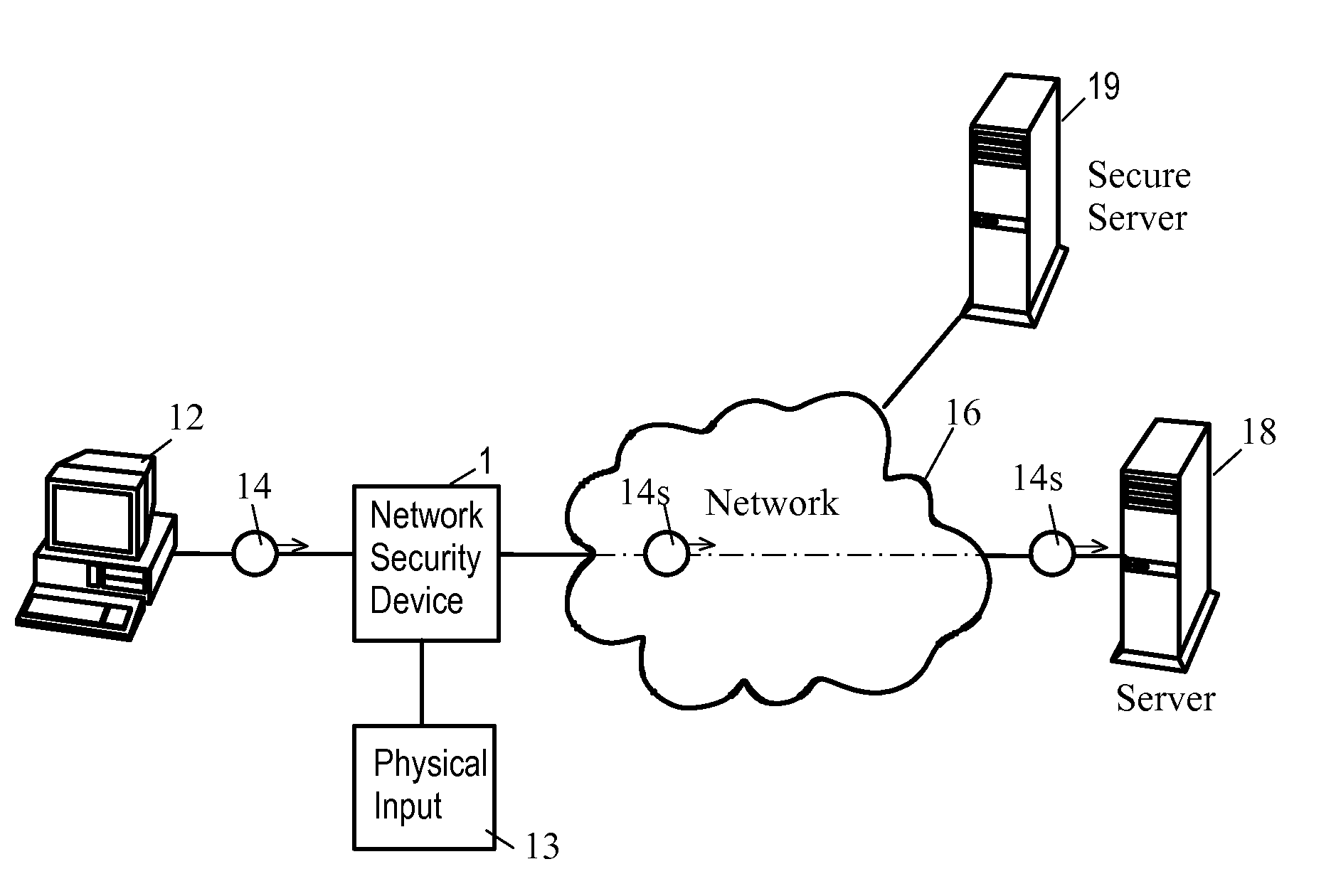

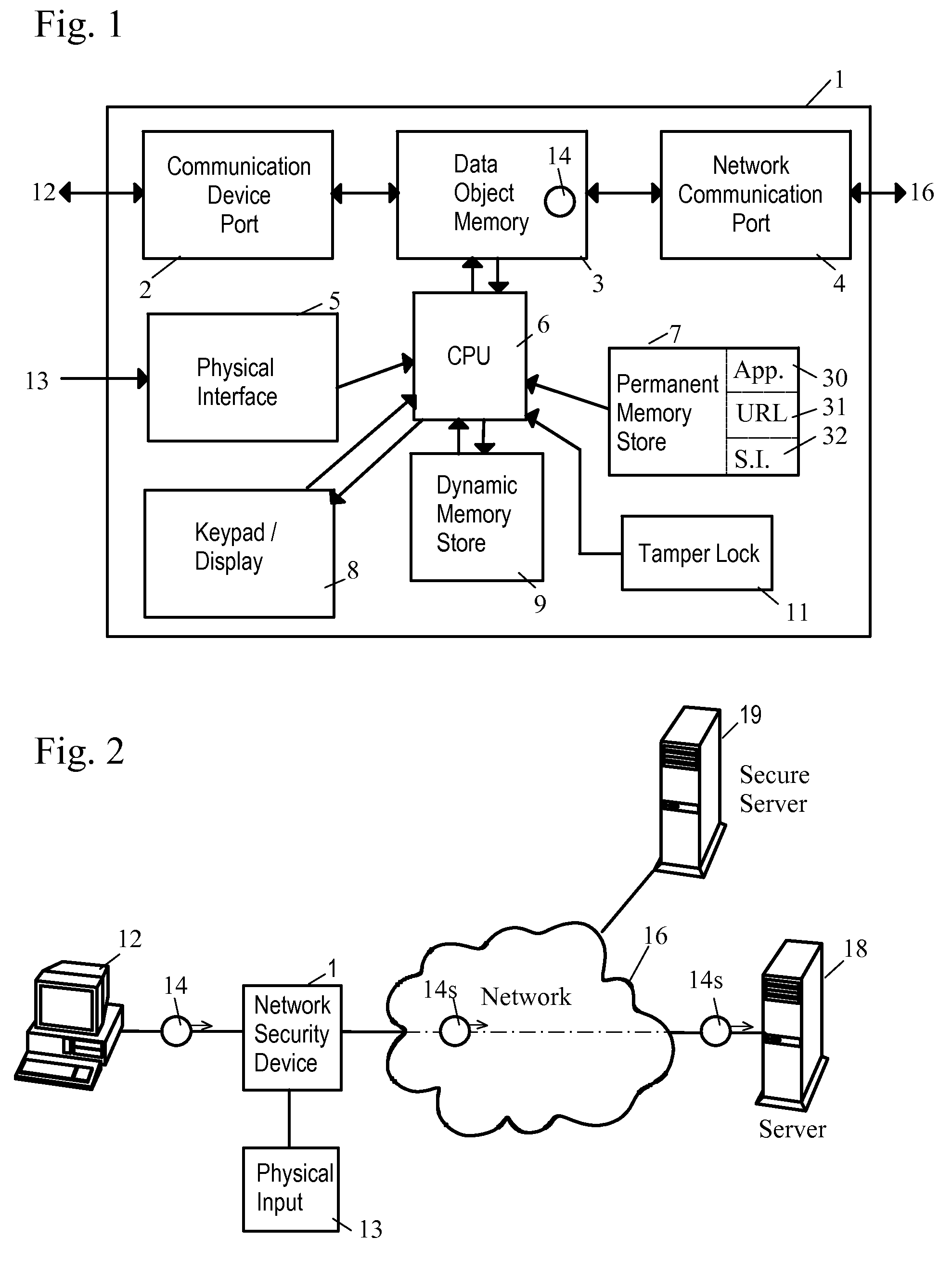

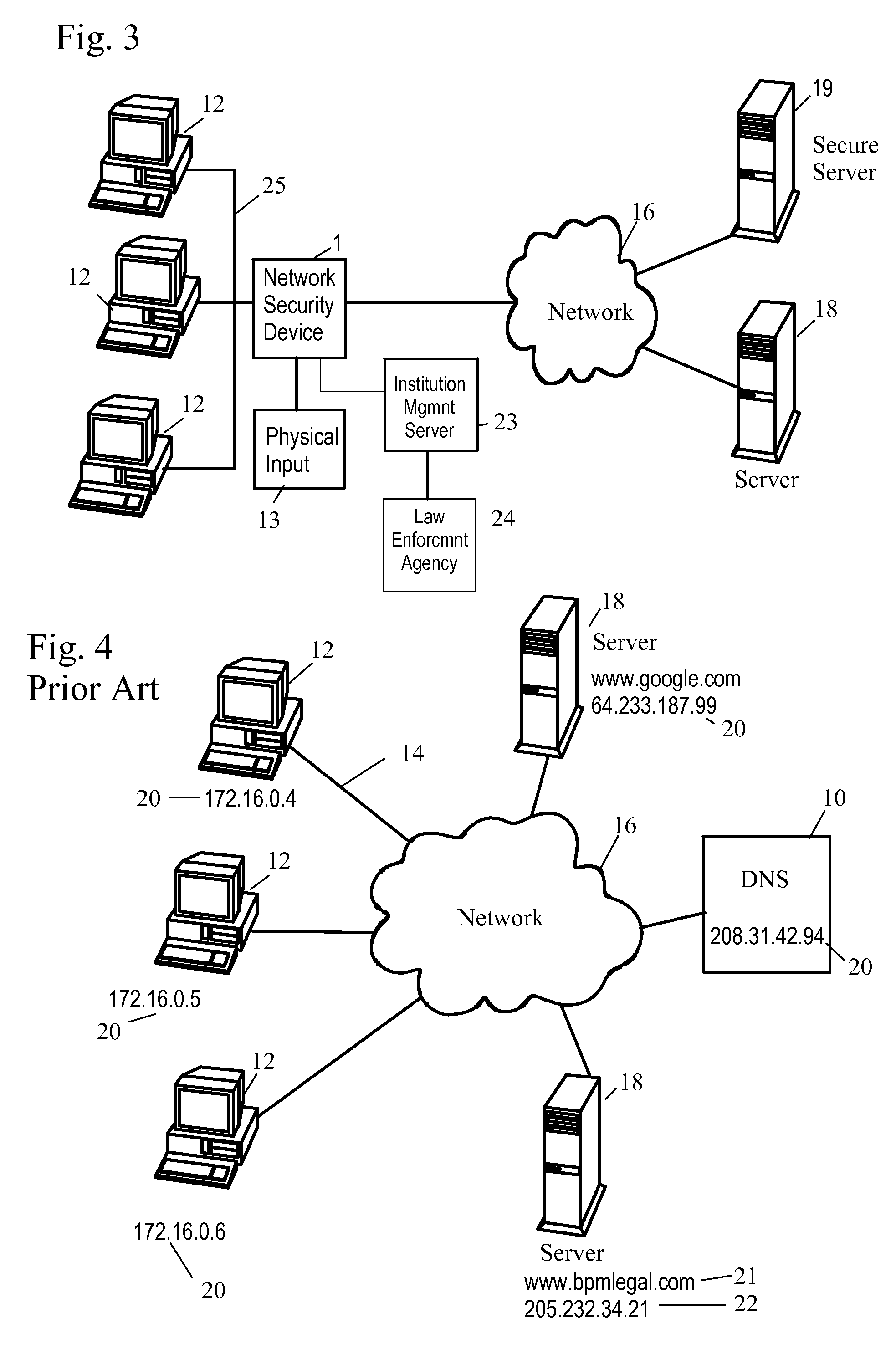

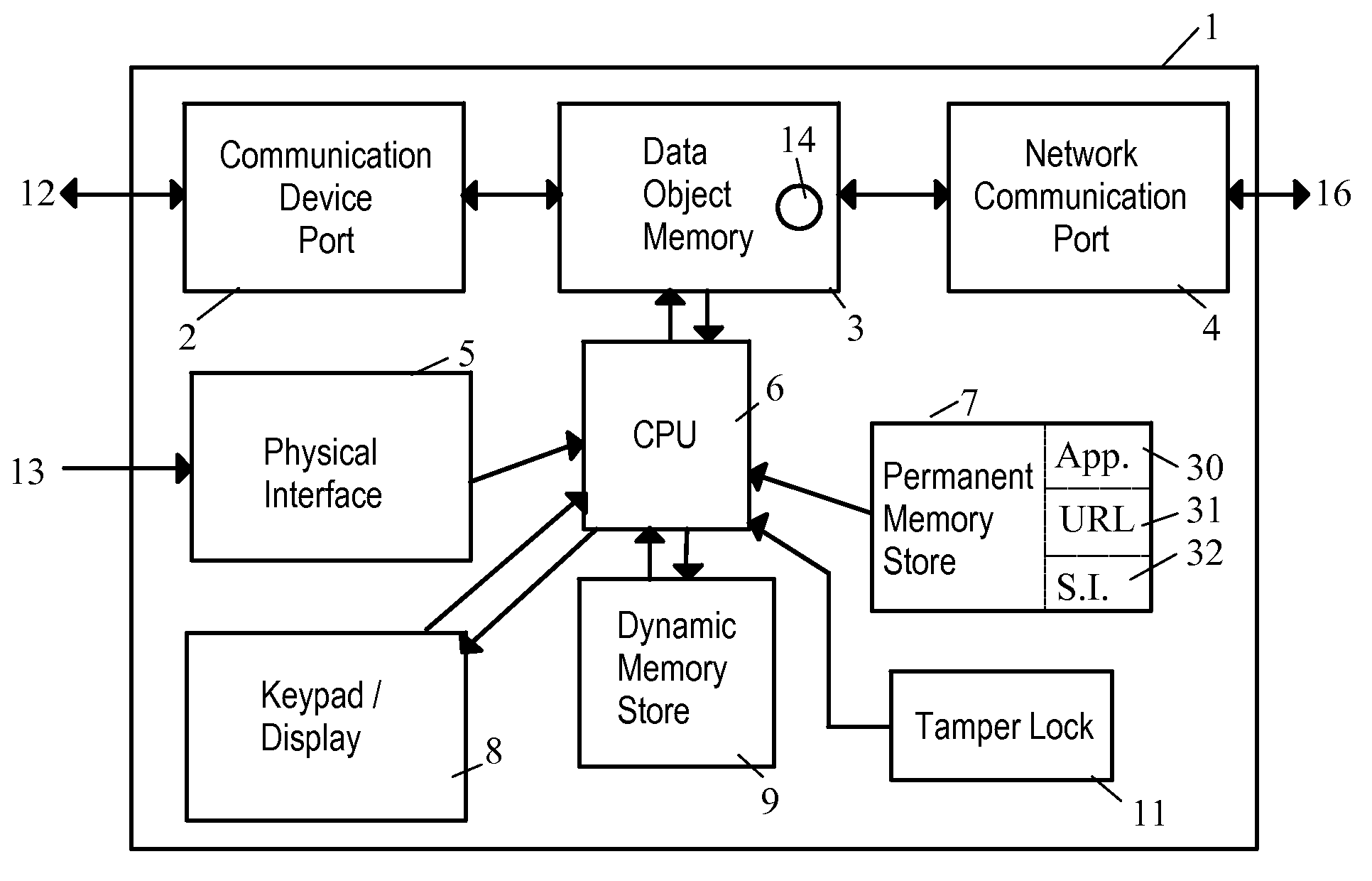

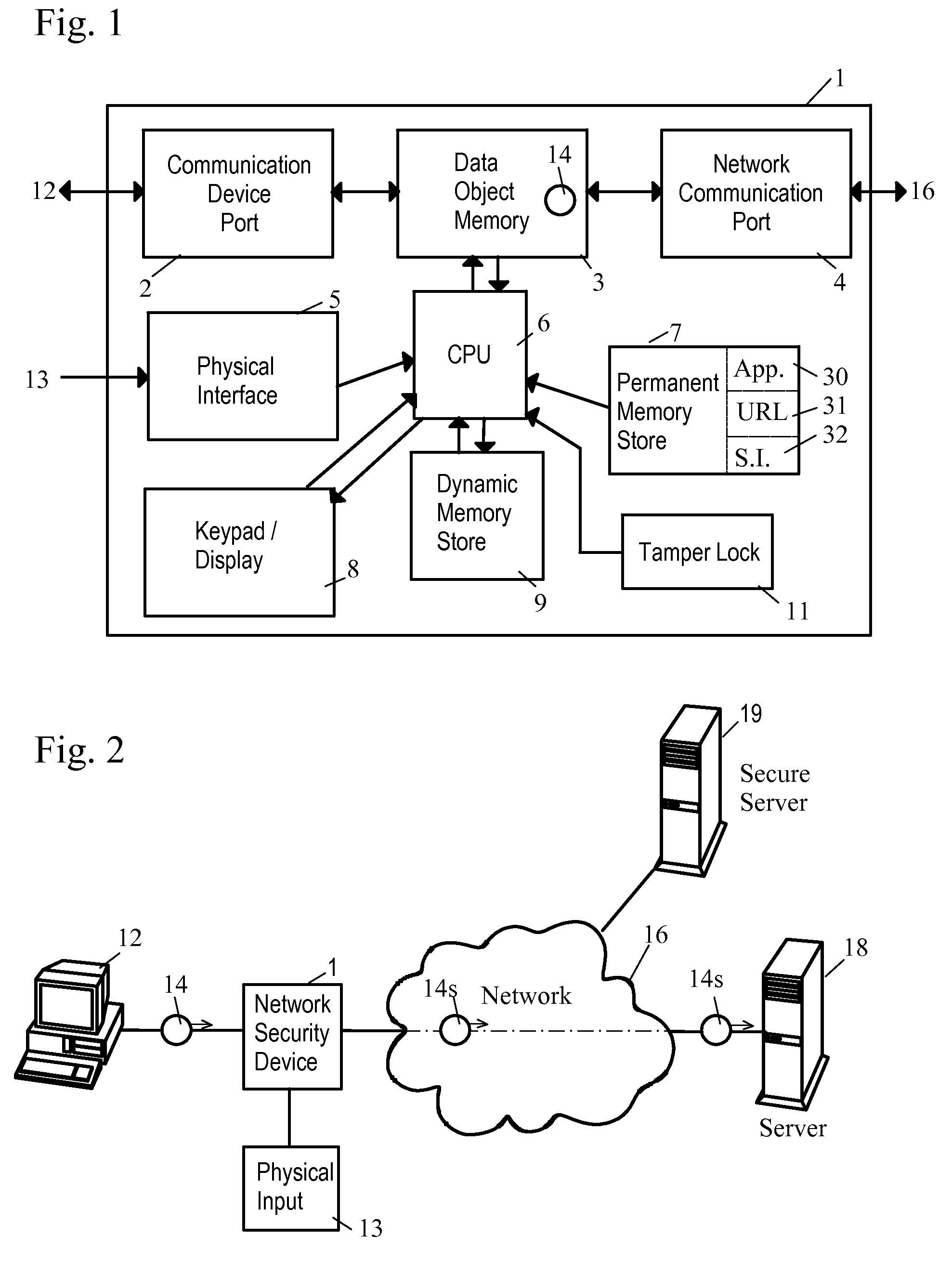

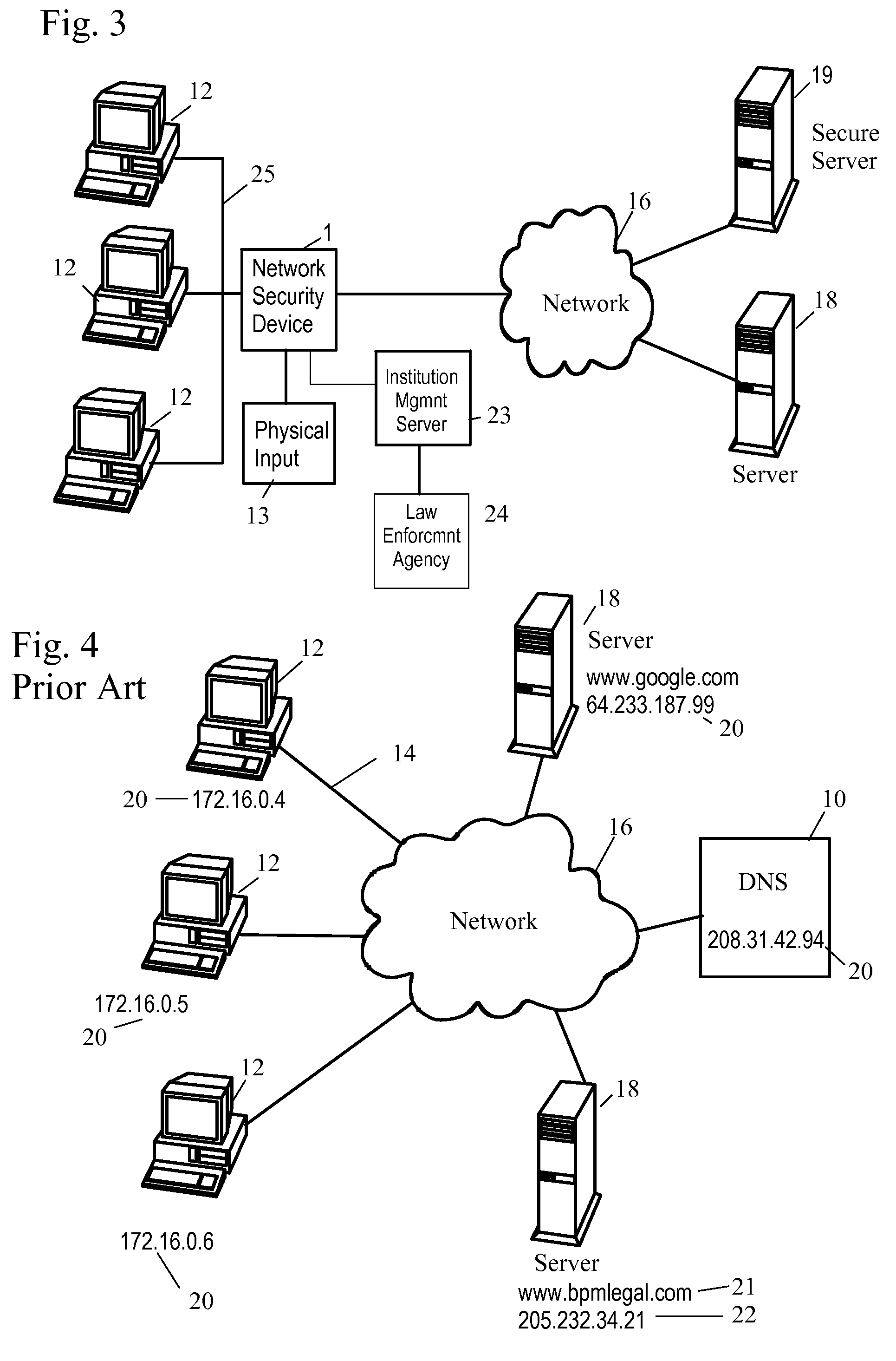

A network security device which acts as an “airlock” for traffic between a communications device and a network. Data is screened using rules based analysis by the security device to counter various threats, including viruses, phishing, attempts to “hijack” communications, communications with known malicious addresses or unknown addresses, and transmission of sensitive information. Data packets can be reassembled into files for screening, and decoded or expanded as necessary, but is never executed. The data path for the data being screened is kept separate from the operations of the network security device itself, so that the device is incorruptible—its programming cannot be compromised from outside sources. Updates for rules and entry of sensitive data for screening, etc., must be done through a physical interface, not via the normal data communications channel. The device is invisible—it cannot be “seen” by the network, and thus cannot be attacked.

Owner:ELECTRO GUARD CORP

Method and apparatus for regulating data flow between a communications device and a network

ActiveUS7890612B2Digital data processing detailsComputer security arrangementsTraffic capacityData stream

A network security device which acts as an “airlock” for traffic between a communications device and a network. Data is screened using rules based analysis by the security device to counter various threats, including viruses, phishing, attempts to “hijack” communications, communications with known malicious addresses or unknown addresses, and transmission of sensitive information. Data packets can be reassembled into files for screening, and decoded or expanded as necessary, but is never executed. The data path for the data being screened is kept separate from the operations of the network security device itself, so that the device is incorruptible—its programming cannot be compromised from outside sources. Updates for rules and entry of sensitive data for screening, etc., must be done through a physical interface, not via the normal data communications channel. The device is invisible—it cannot be “seen” by the network, and thus cannot be attacked.

Owner:ELECTRO GUARD CORP

Drainage system

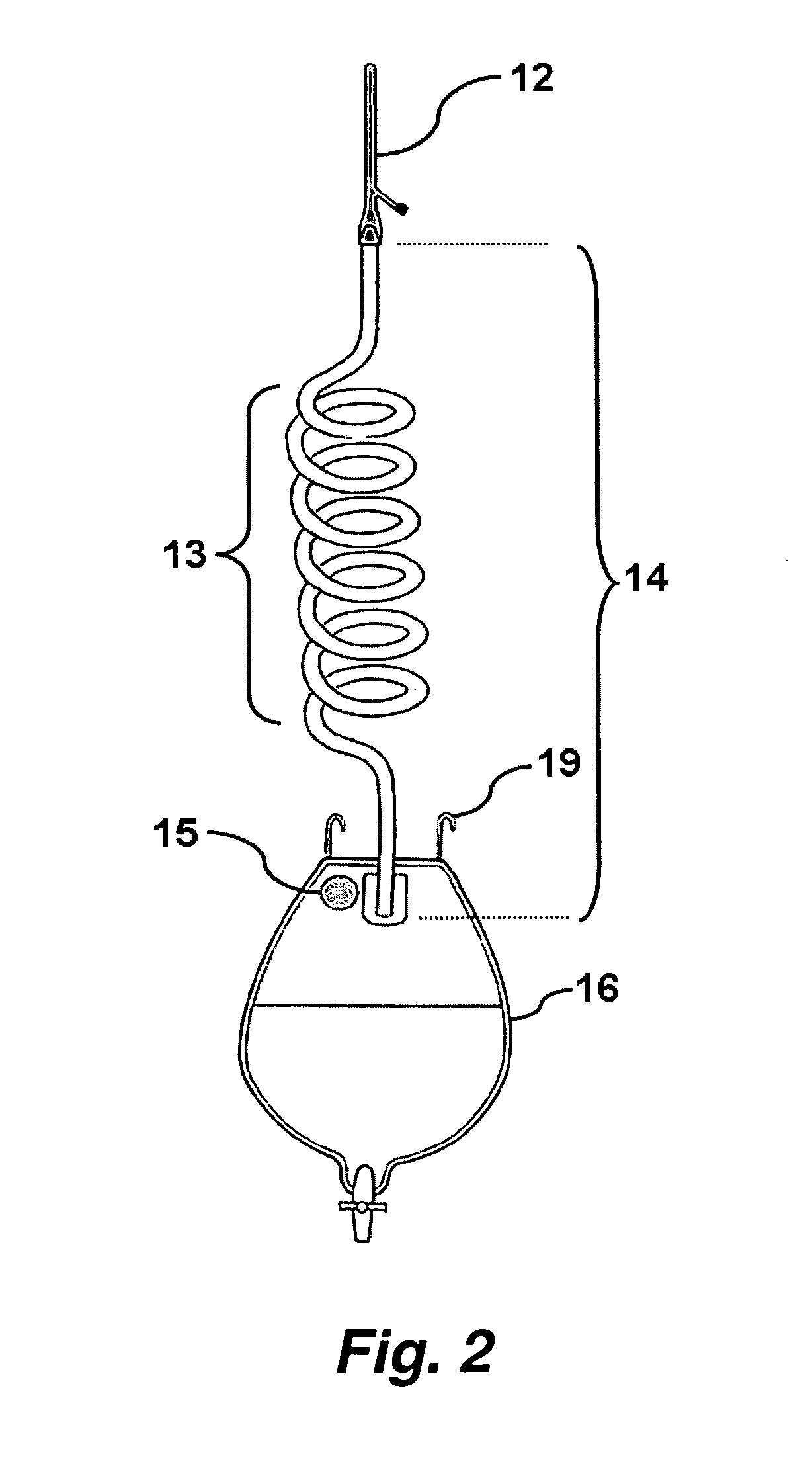

InactiveUS20060271019A1Easy to drainReducing and eliminating airlockWound drainsCatheterBladder drainageUrine output

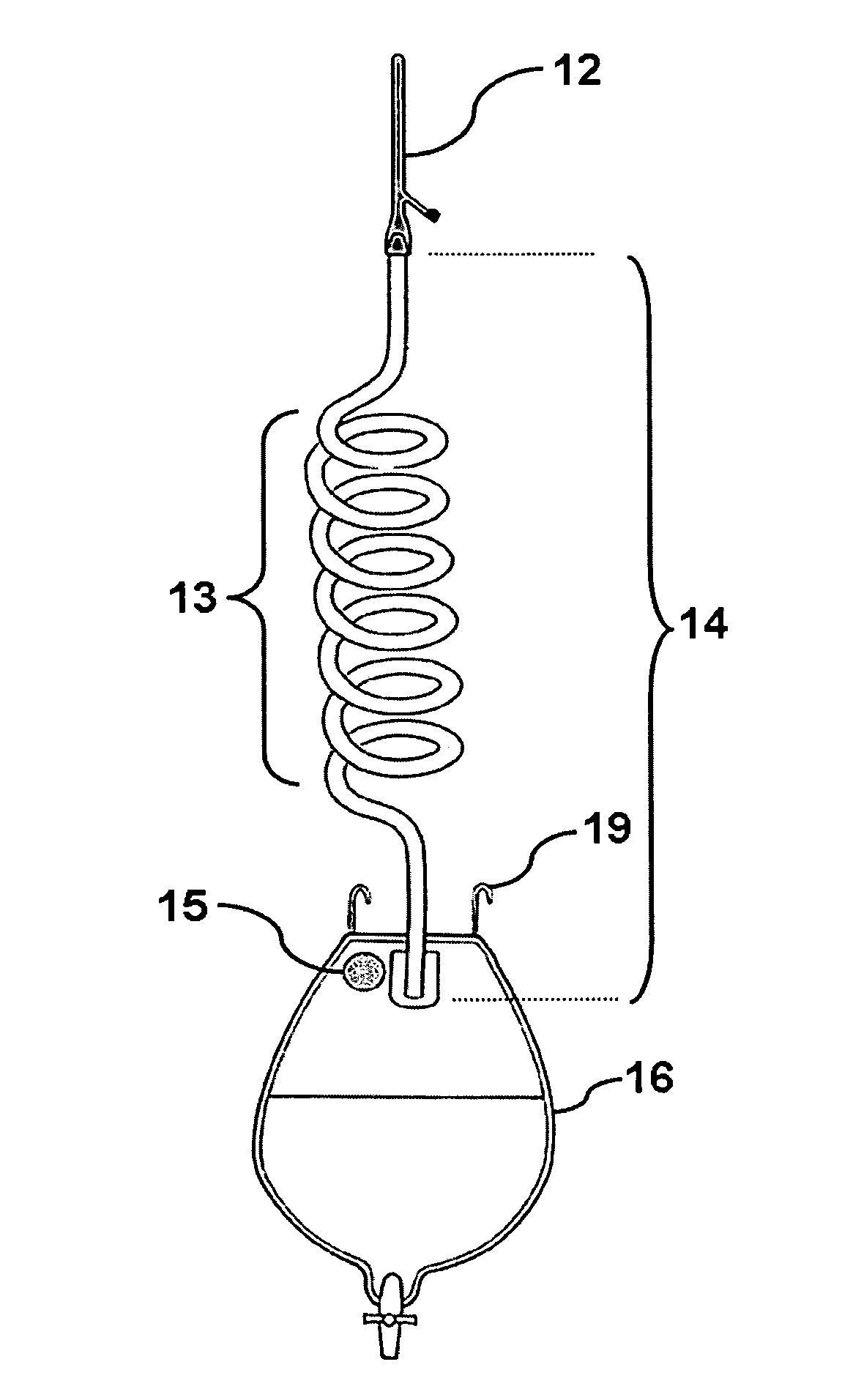

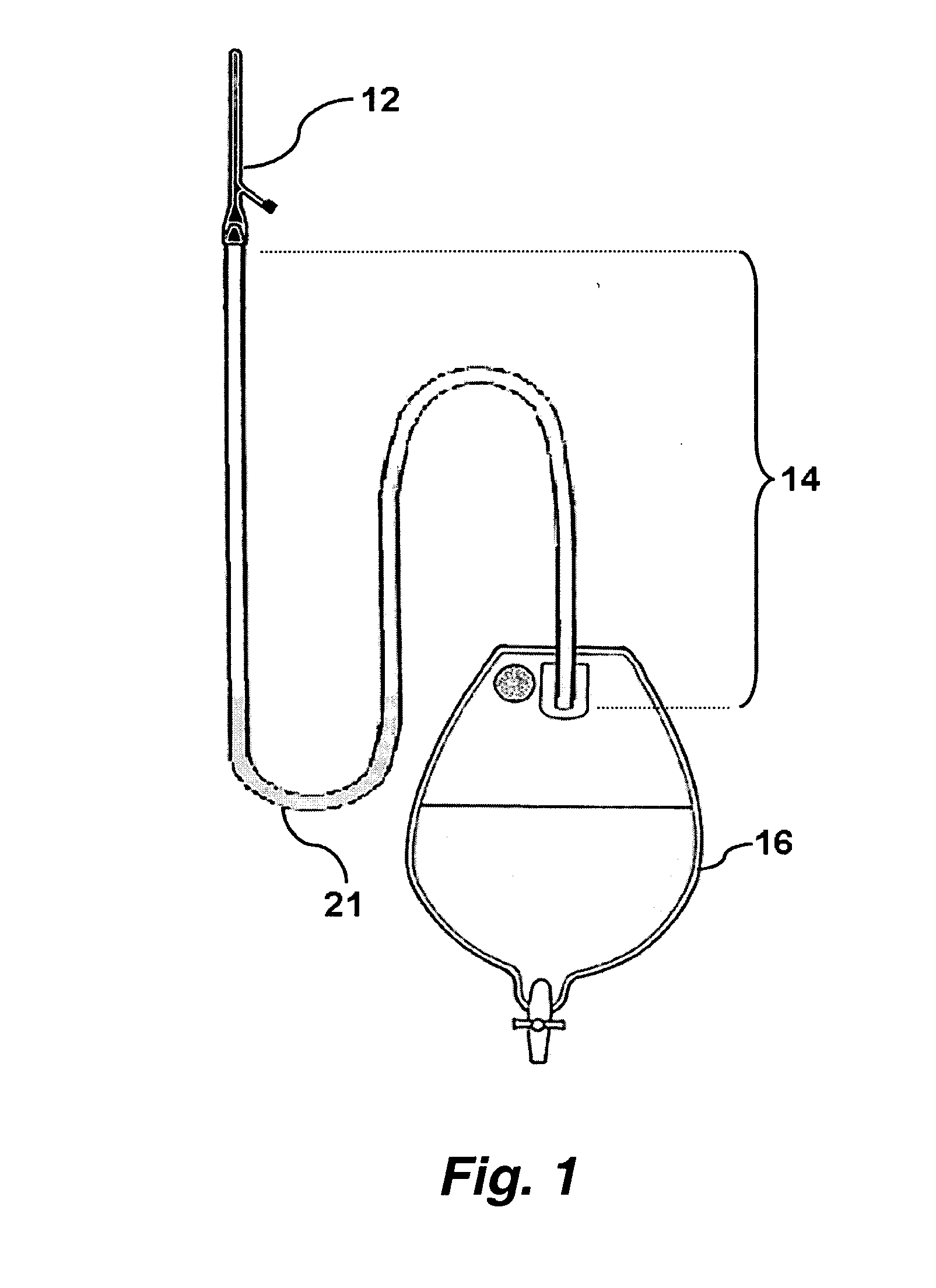

This invention provides improved medical drainage devices. In certain embodiments this invention provides a system for improved drainage from a bladder in a patient where the system comprises: a fluid collection apparatus; a drainage receptacle; and a connecting tube comprising a means for reducing or eliminating airlocks in the connecting tube and thereby providing sufficiently low backpressure such that a patient having a urinary bladder drained with said system maintains an average residual bladder urine volume of less than about 50 cubic centimeters over a period of at least four hours after initial drainage without manipulation of components of said system.

Owner:RGT UNIV OF CALIFORNIA

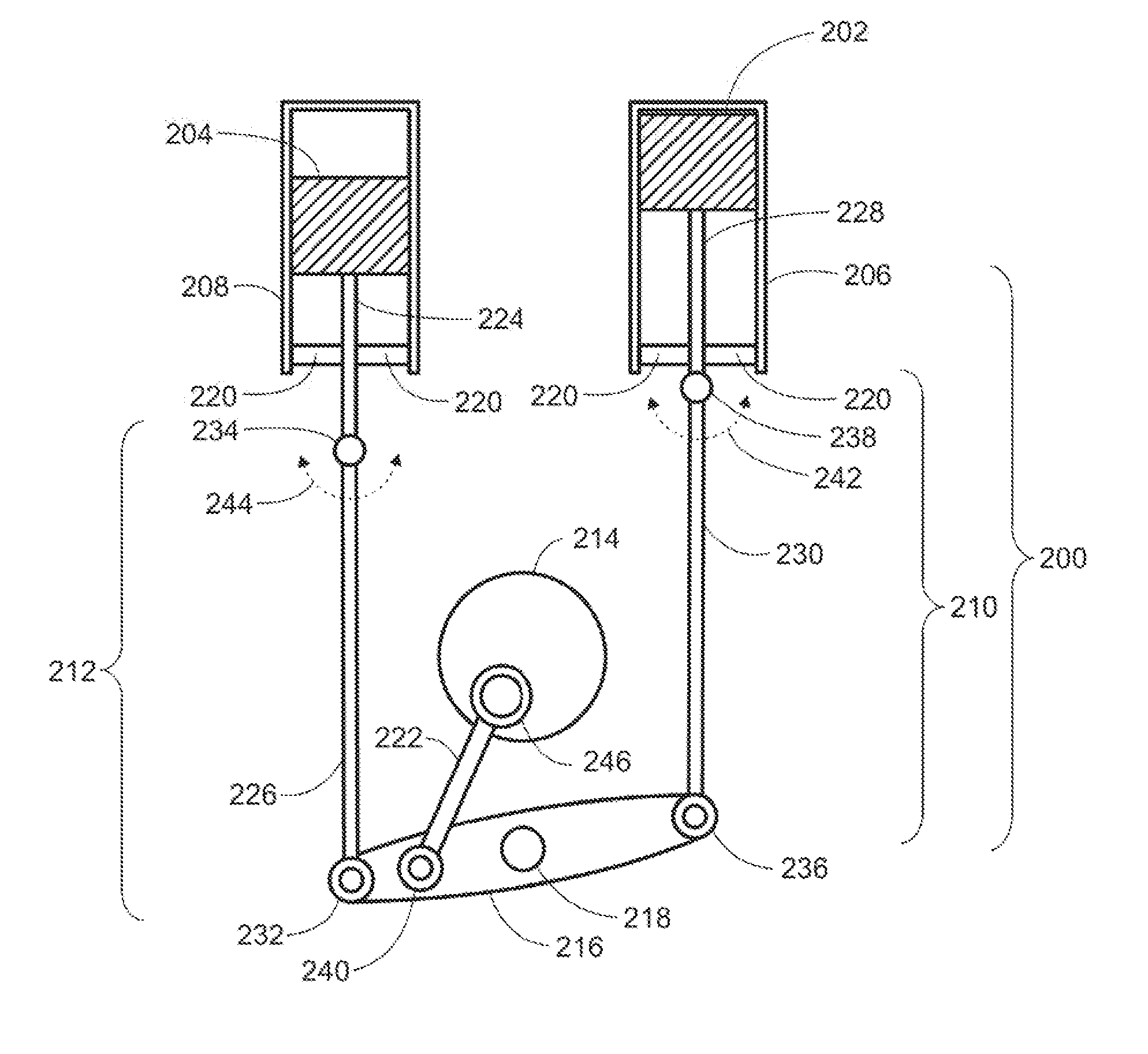

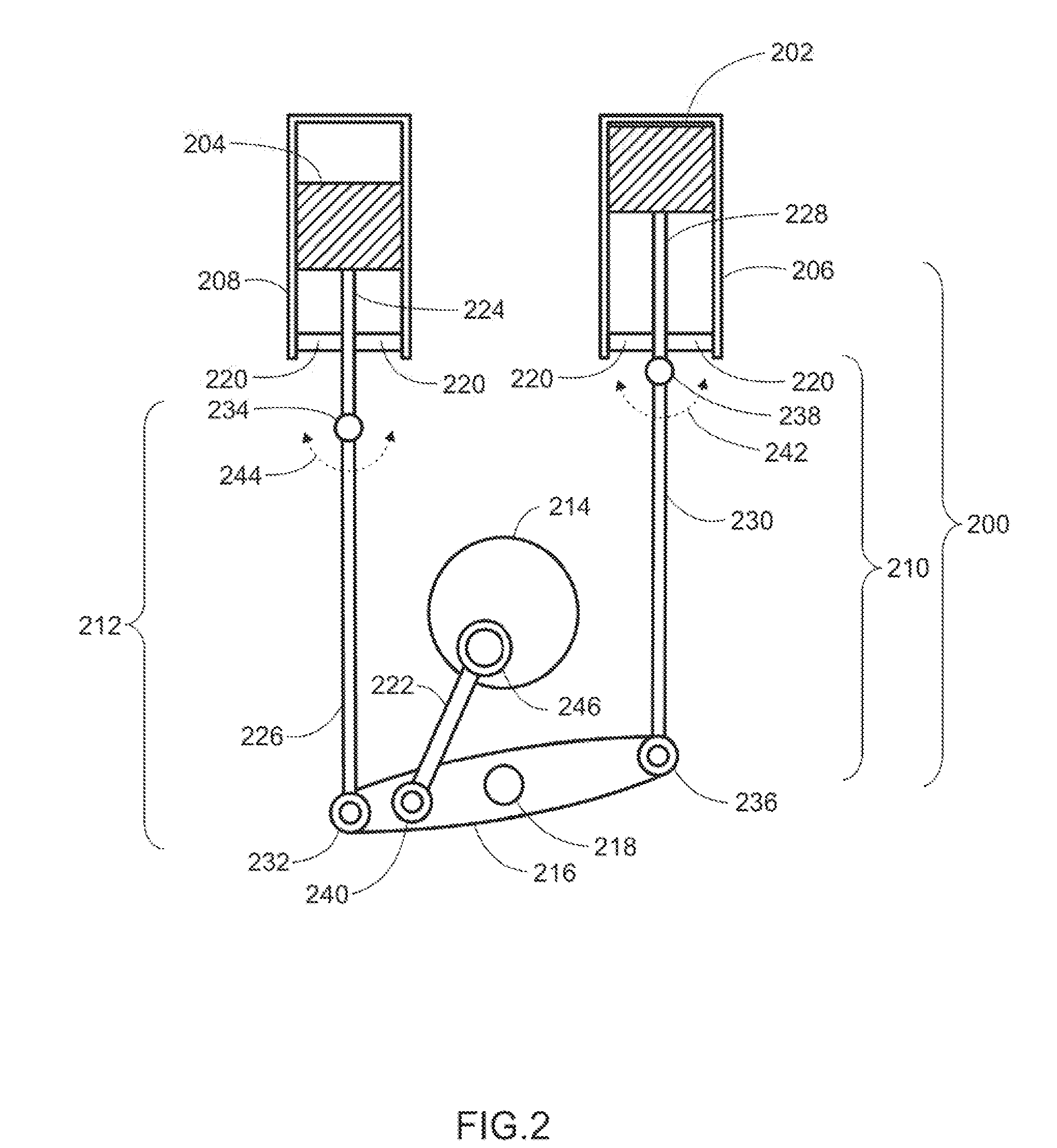

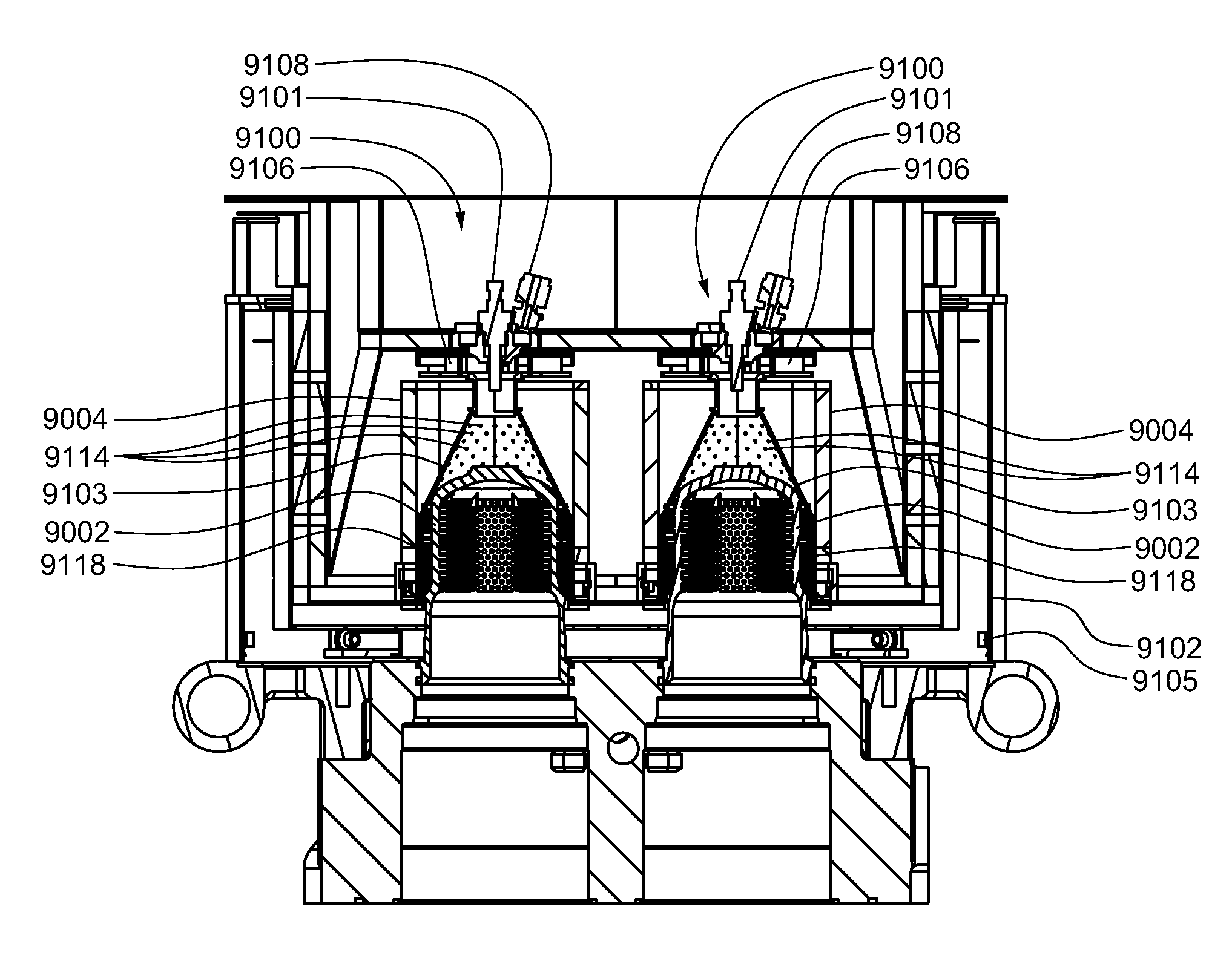

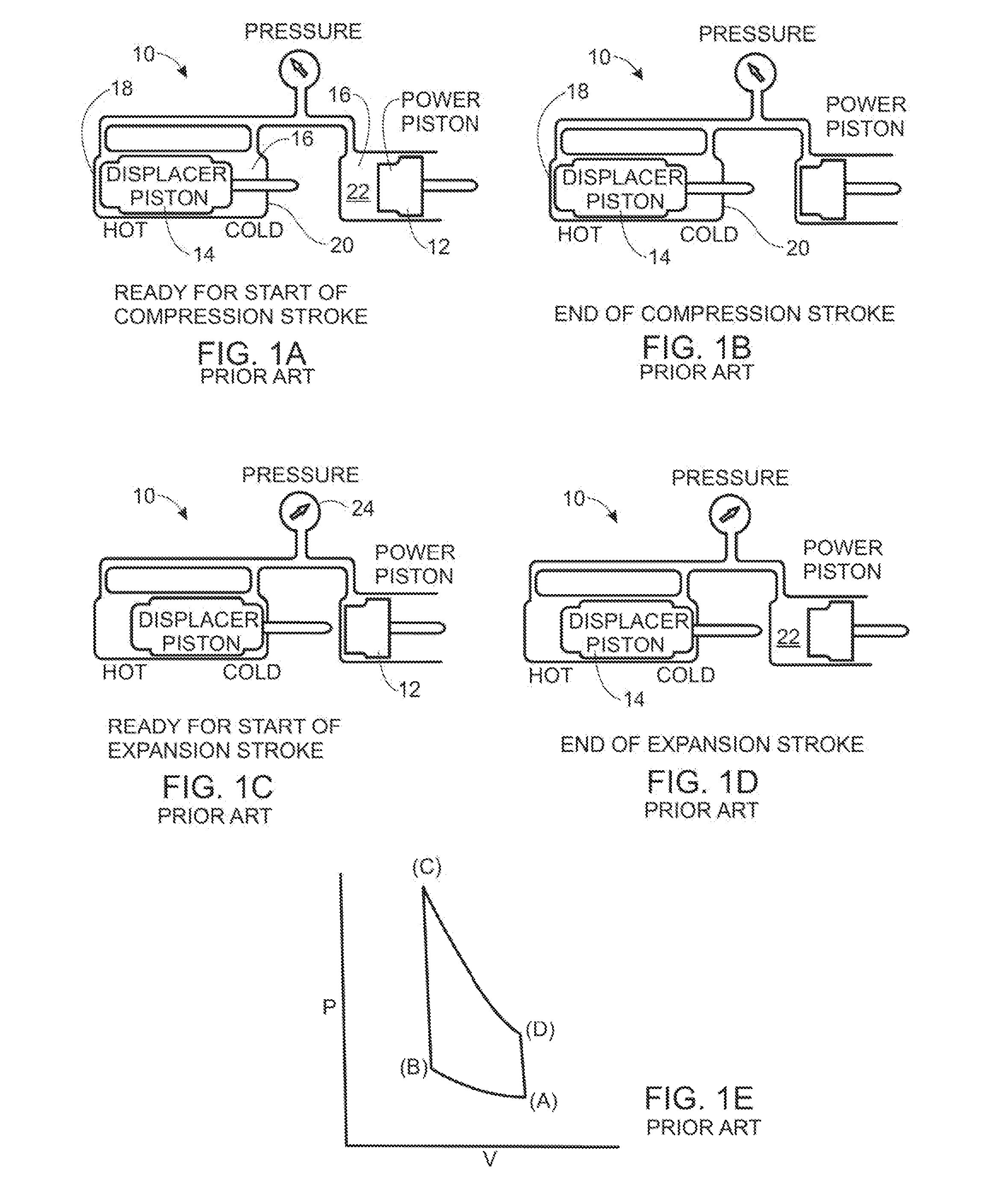

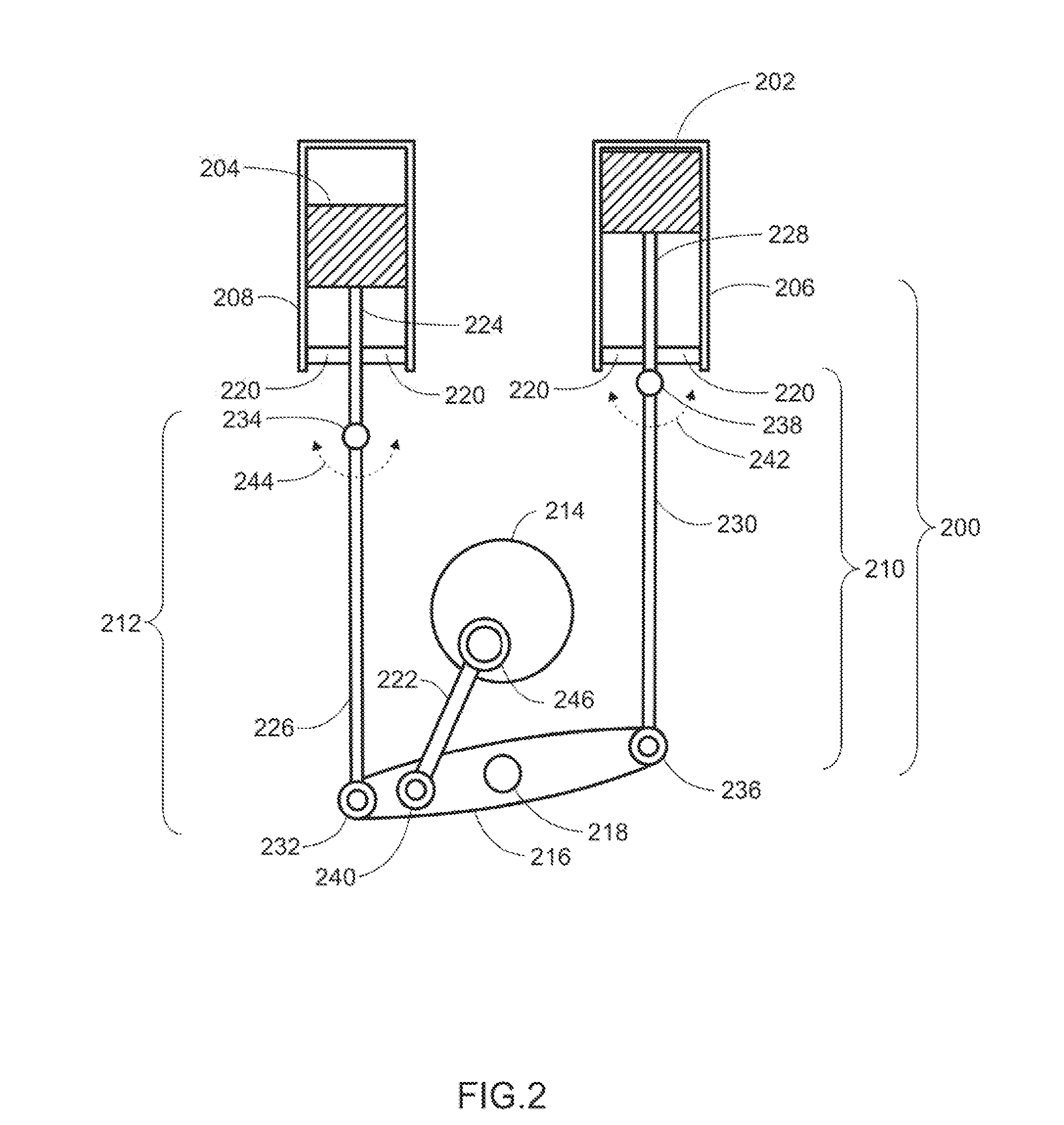

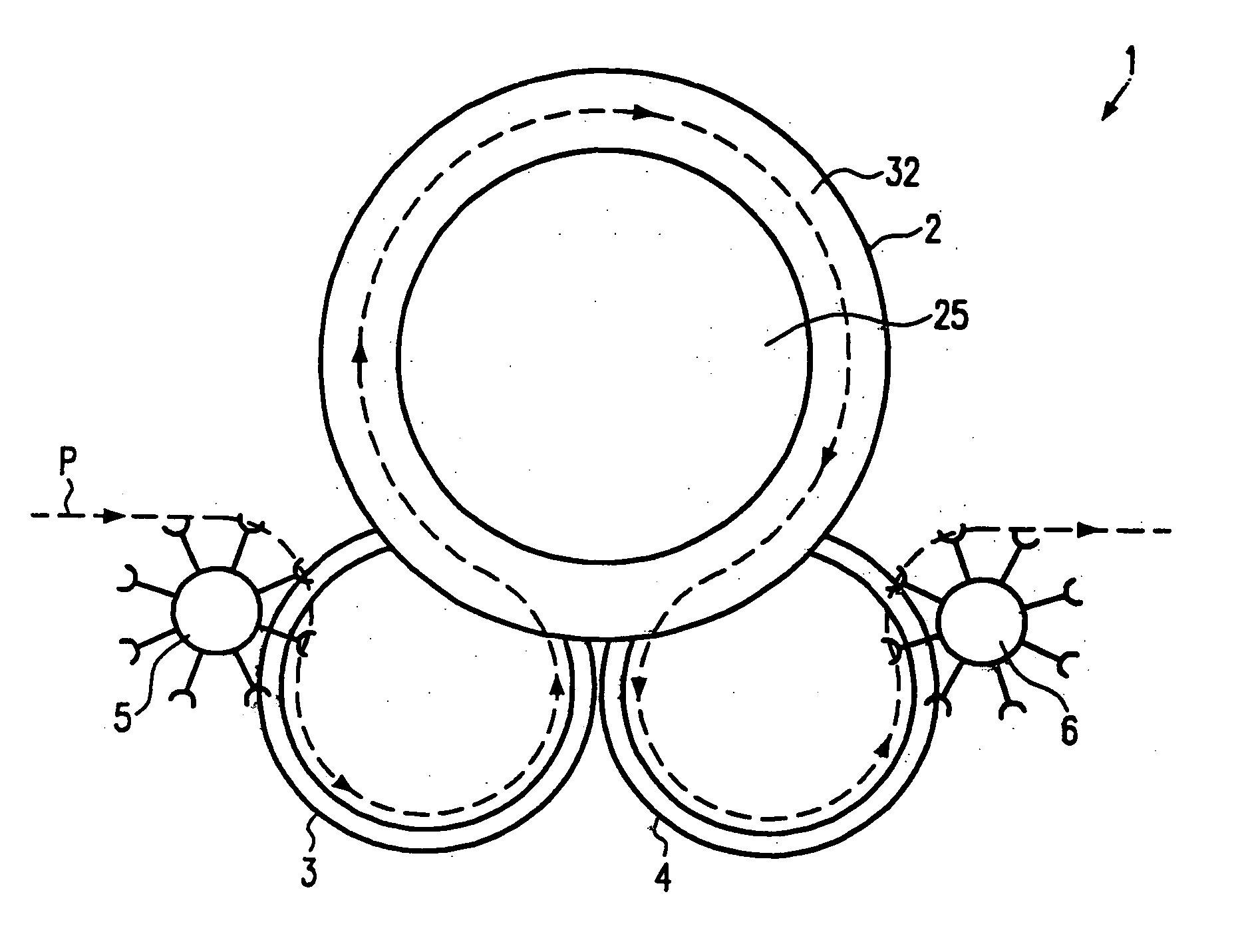

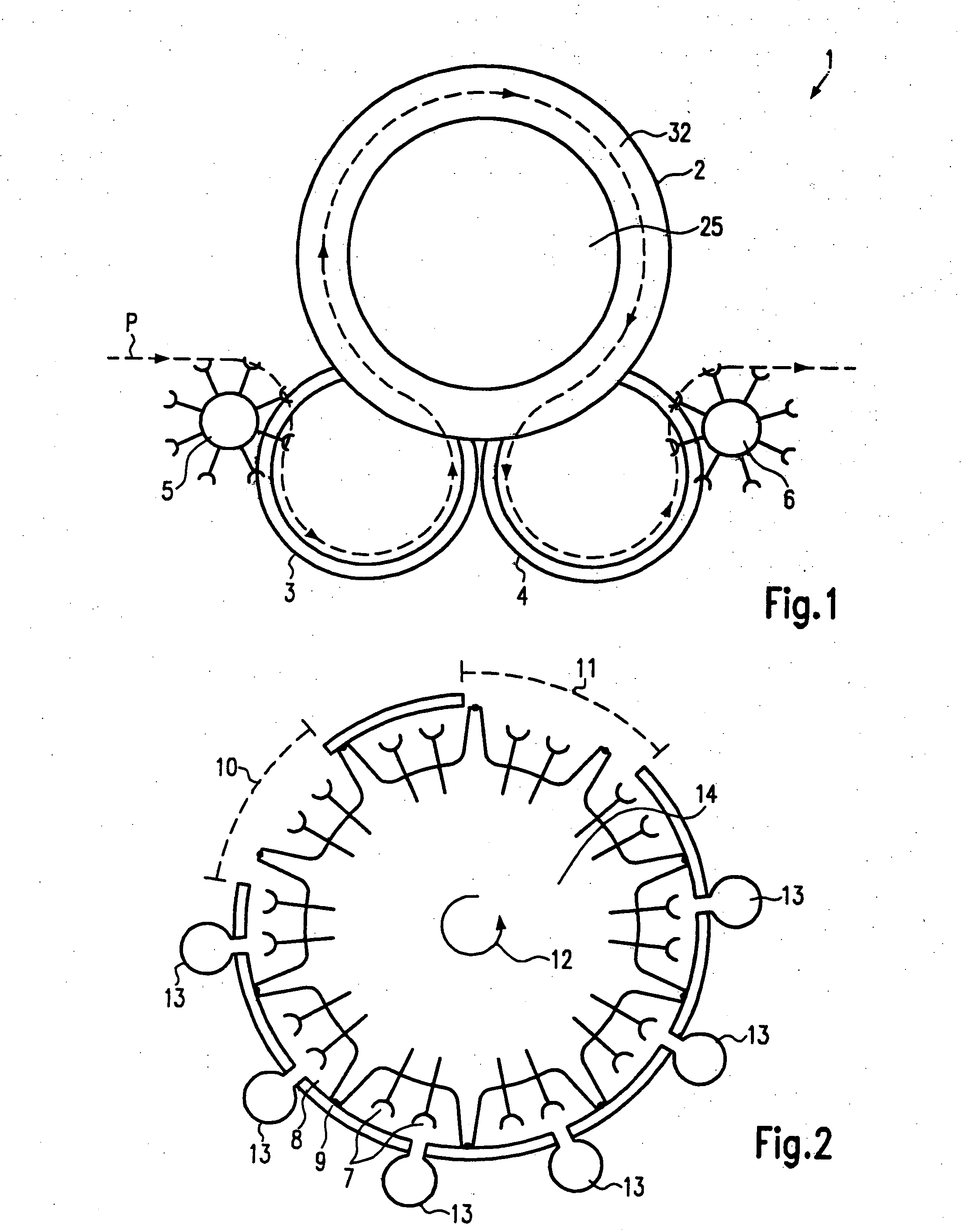

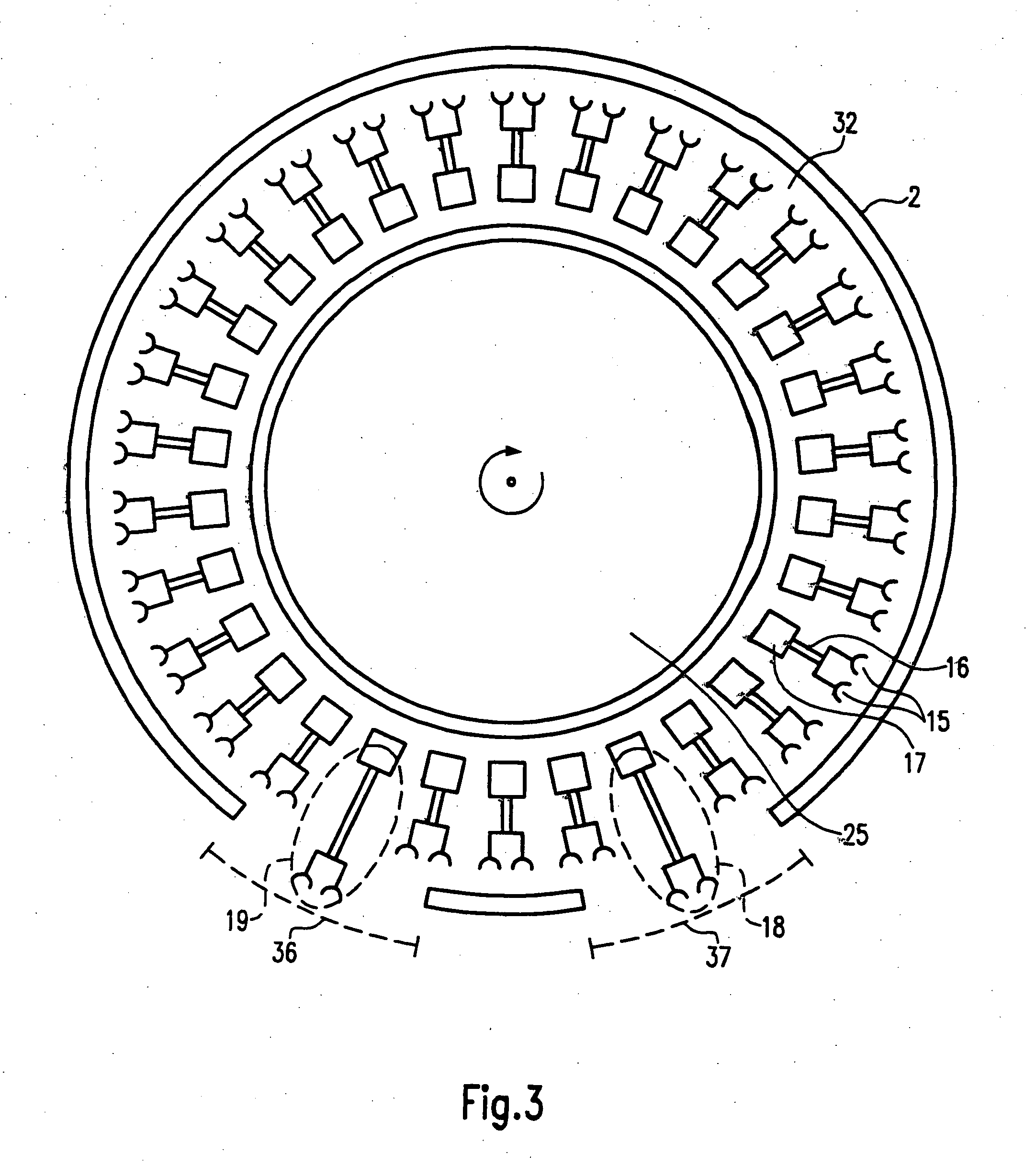

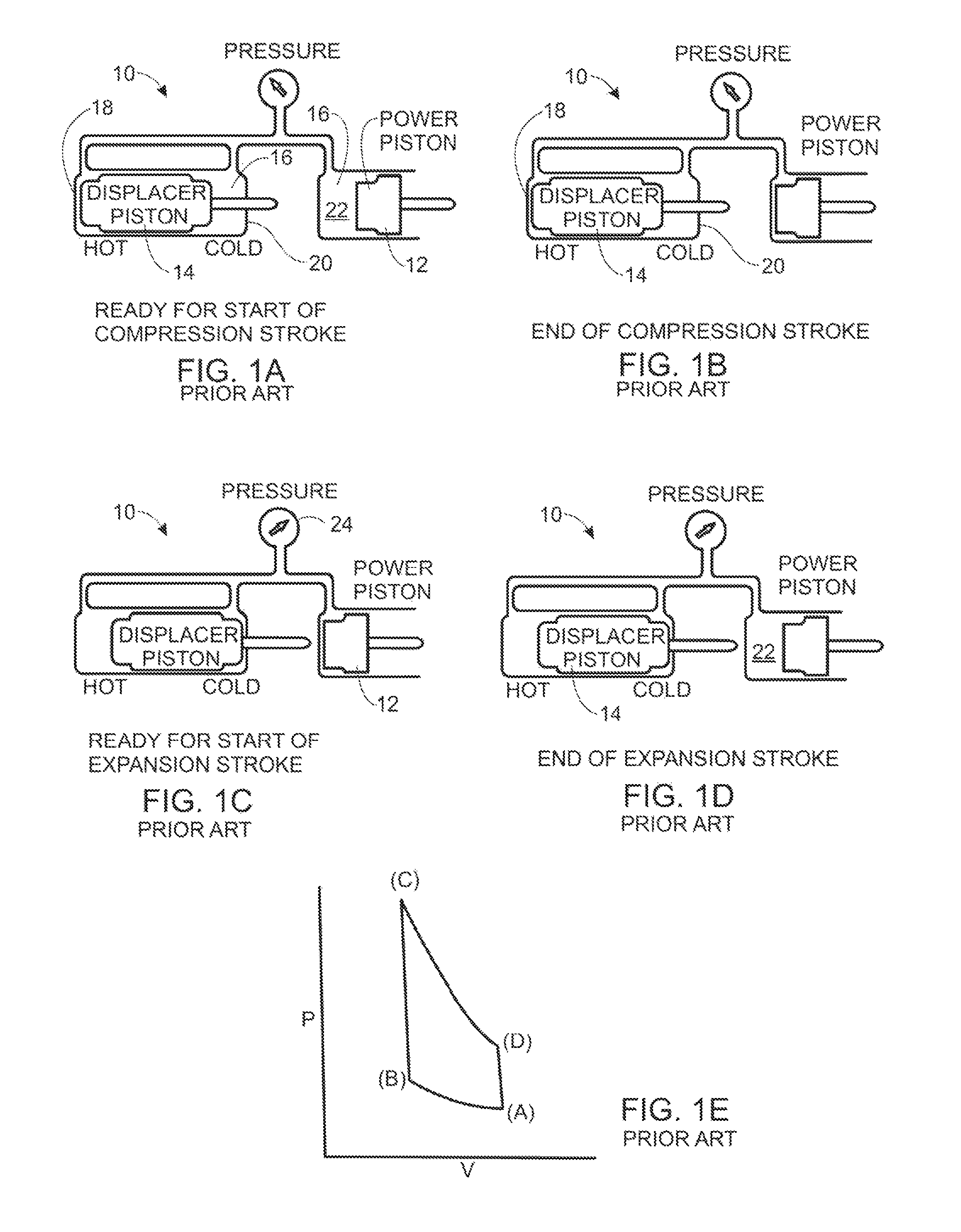

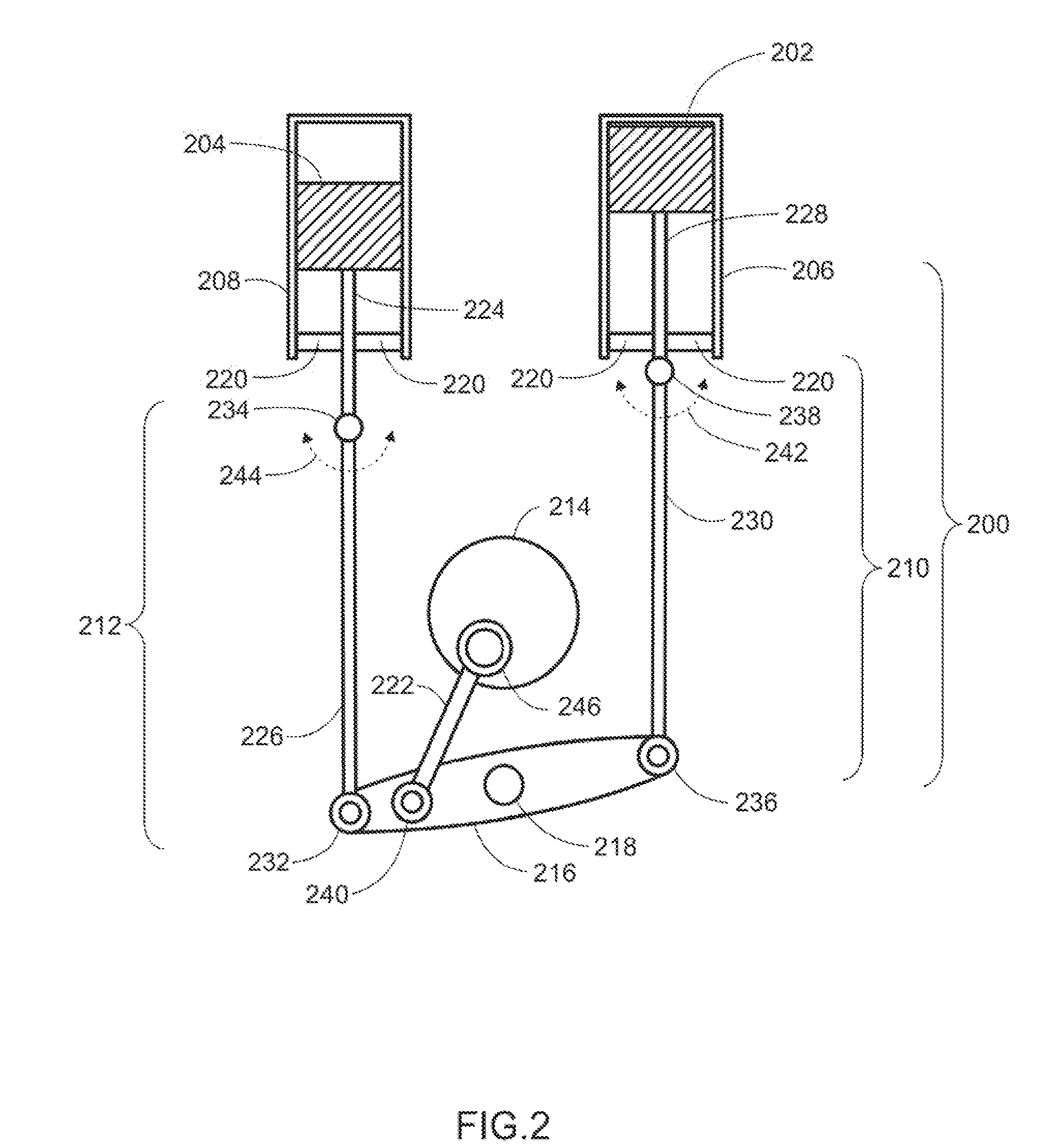

Stirling cycle machine

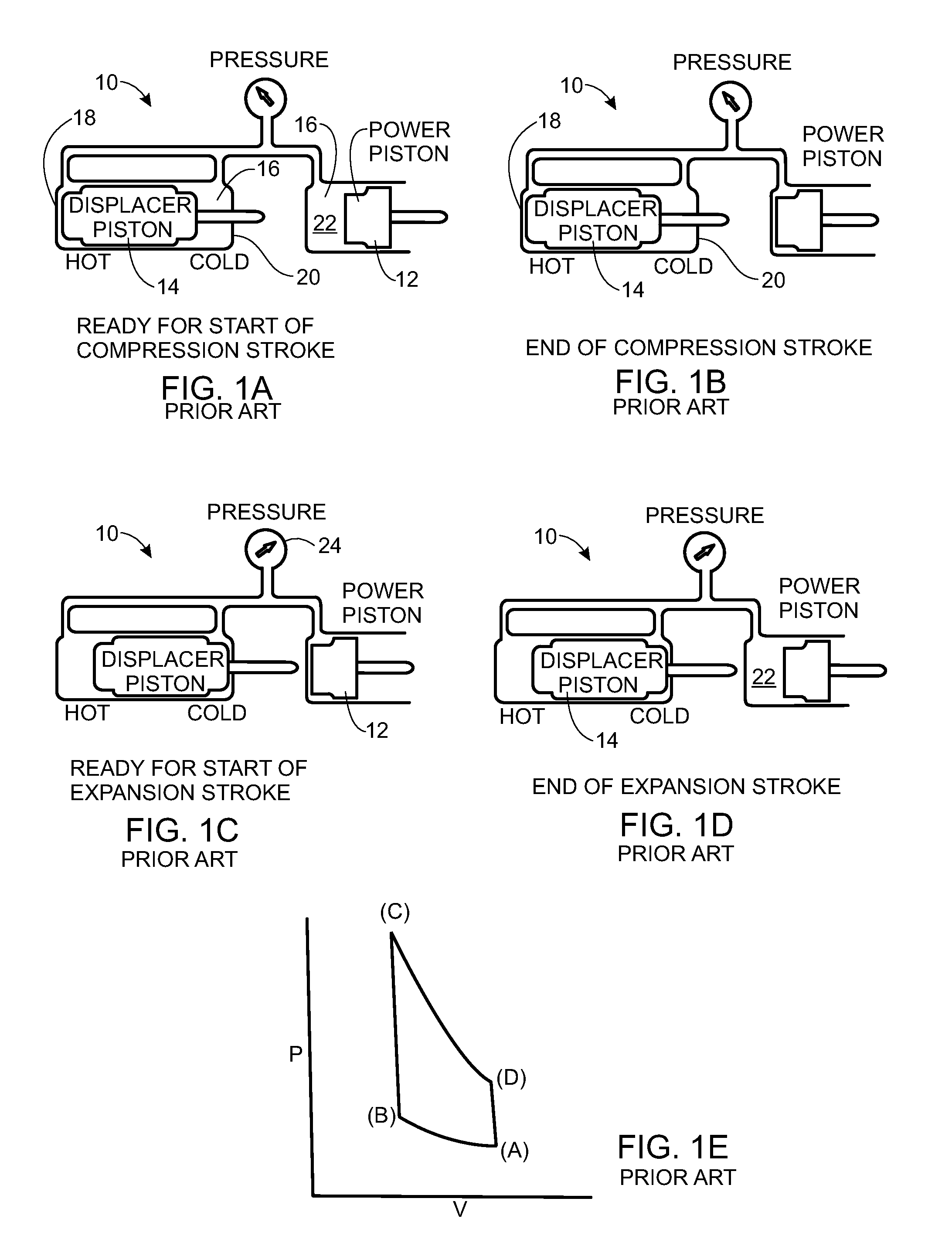

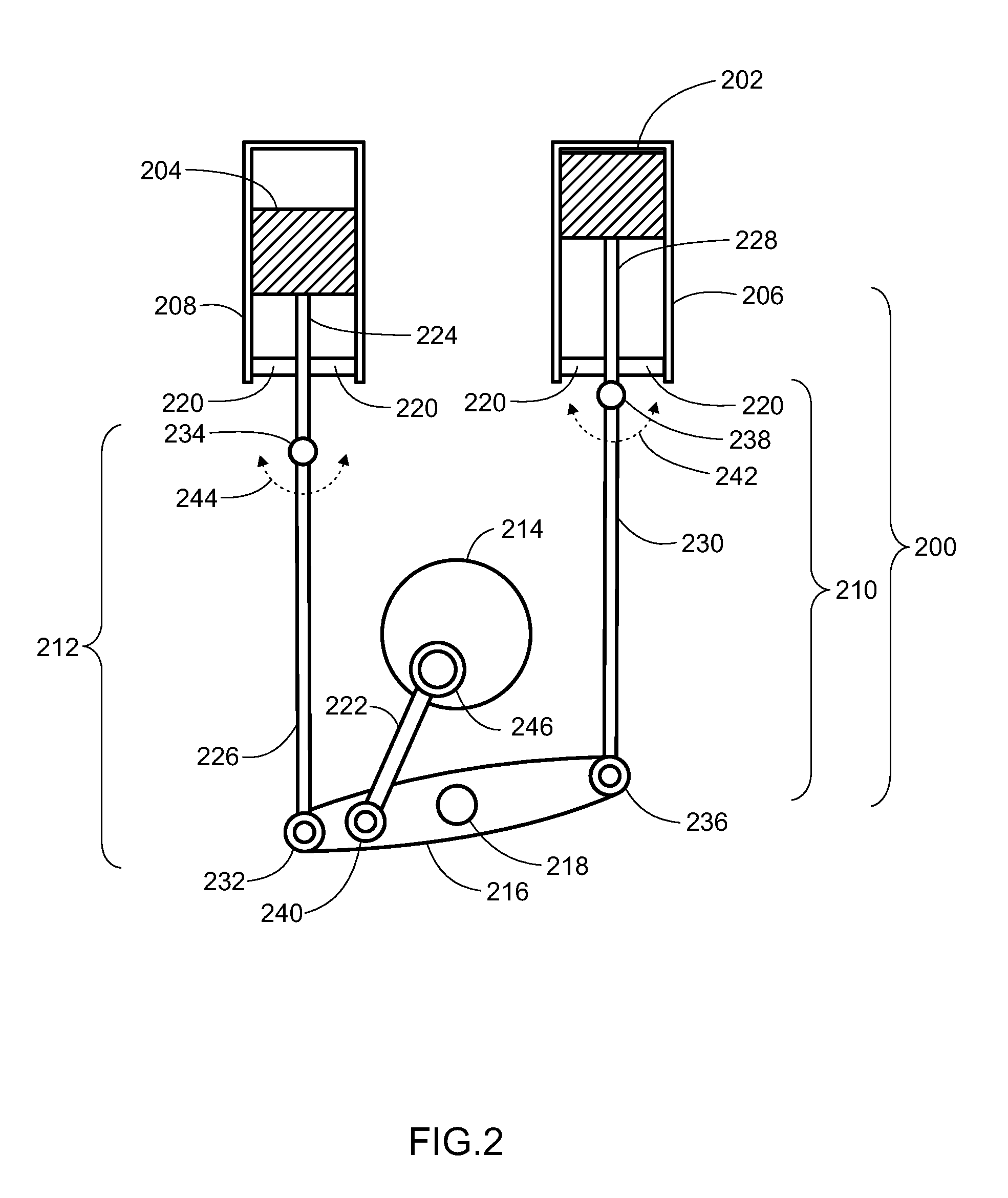

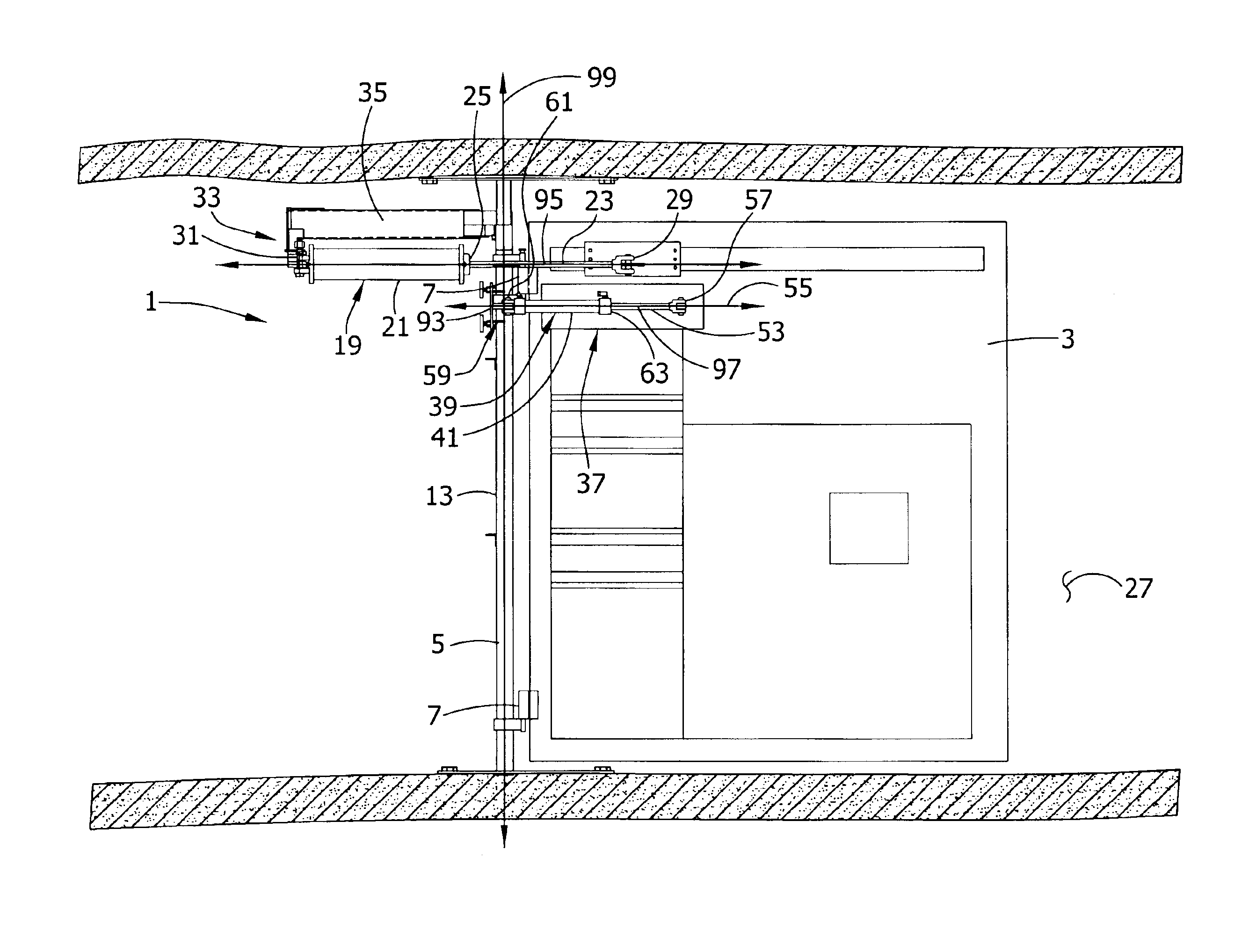

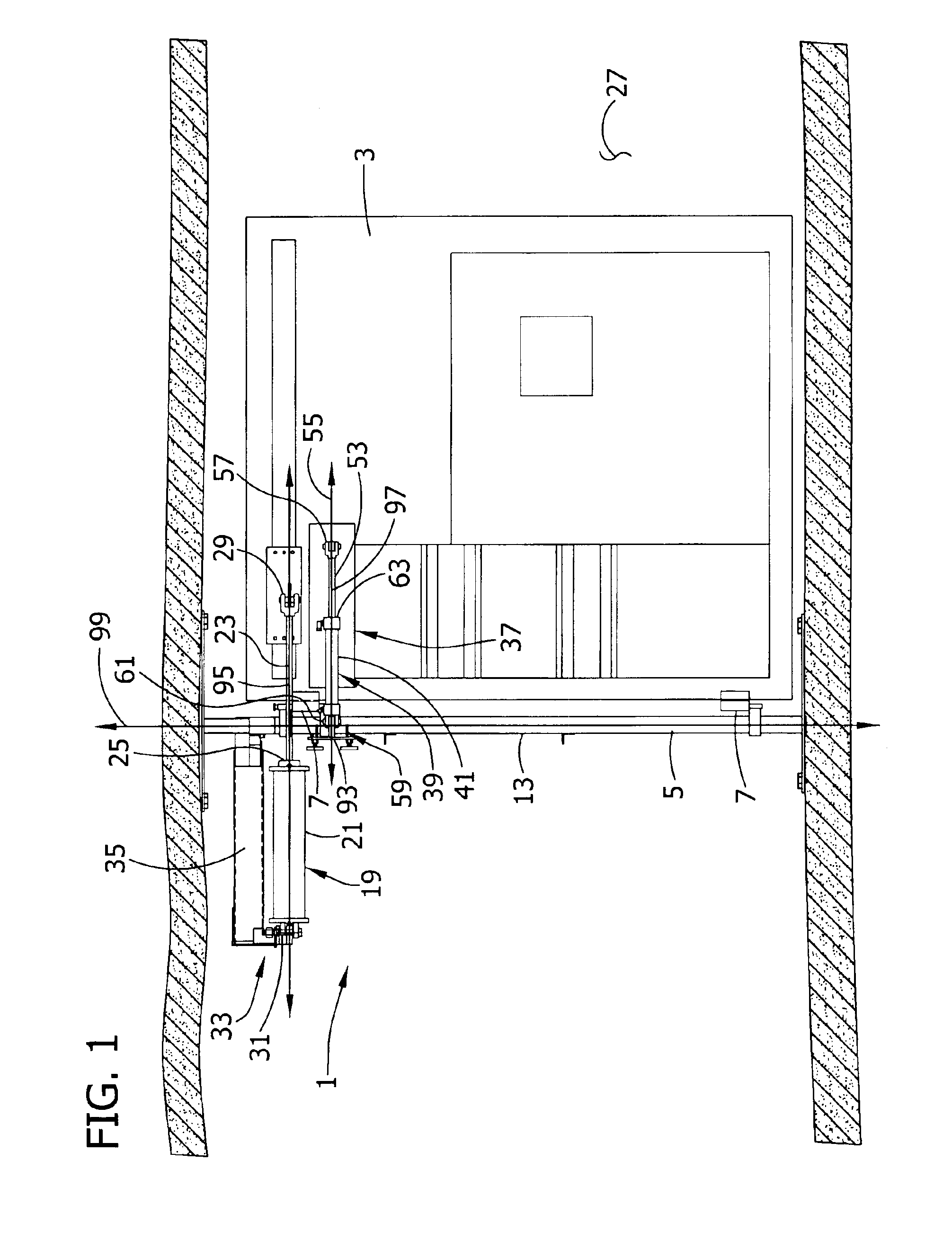

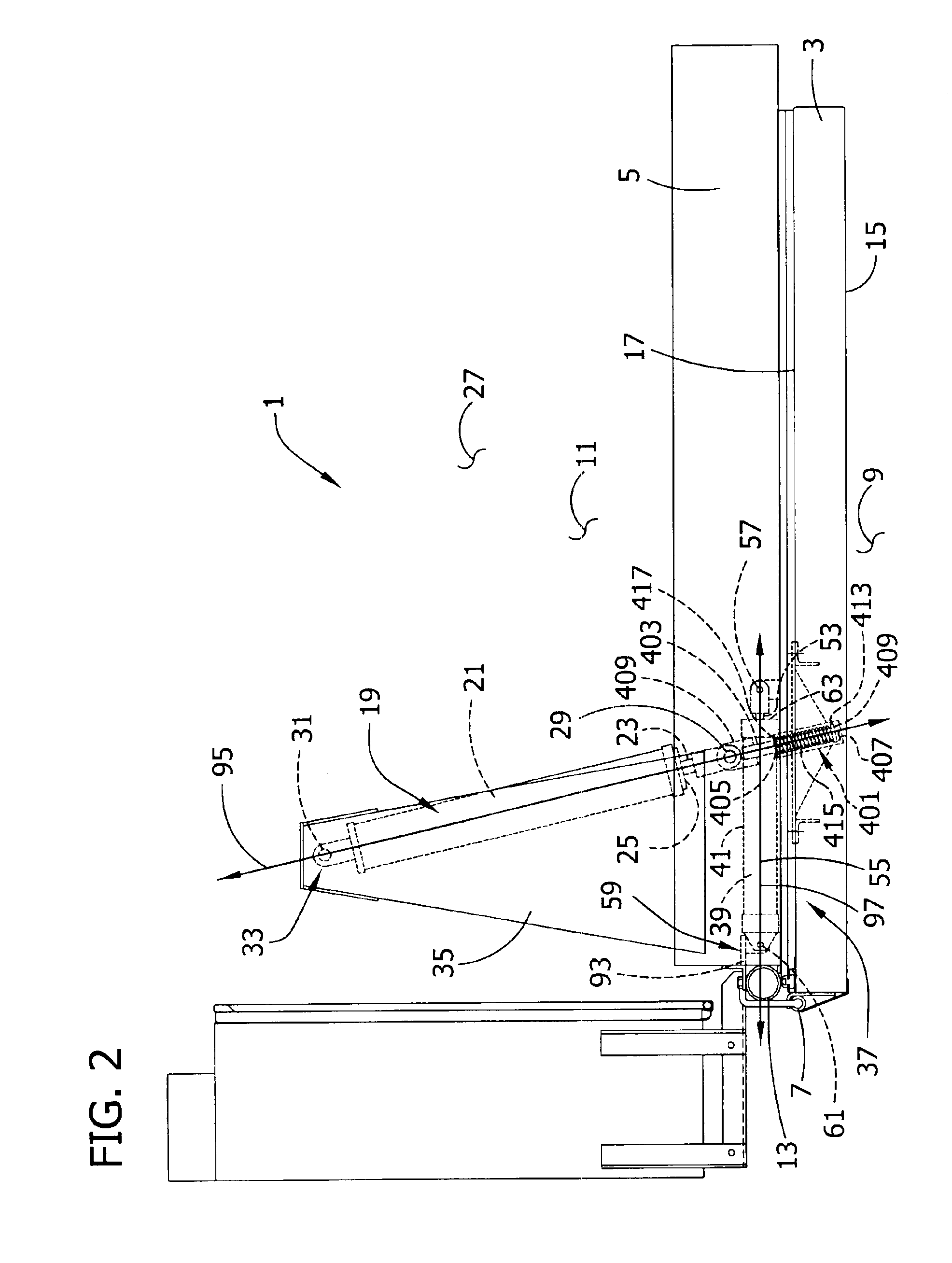

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. An airlock is included between the workspace and the crankcase and a seal is included for sealing the workspace from the airlock and crankcase. A burner and burner control system is also included for heating the machine and controlling ignition and combustion in the burner.

Owner:NEW POWER CONCEPTS

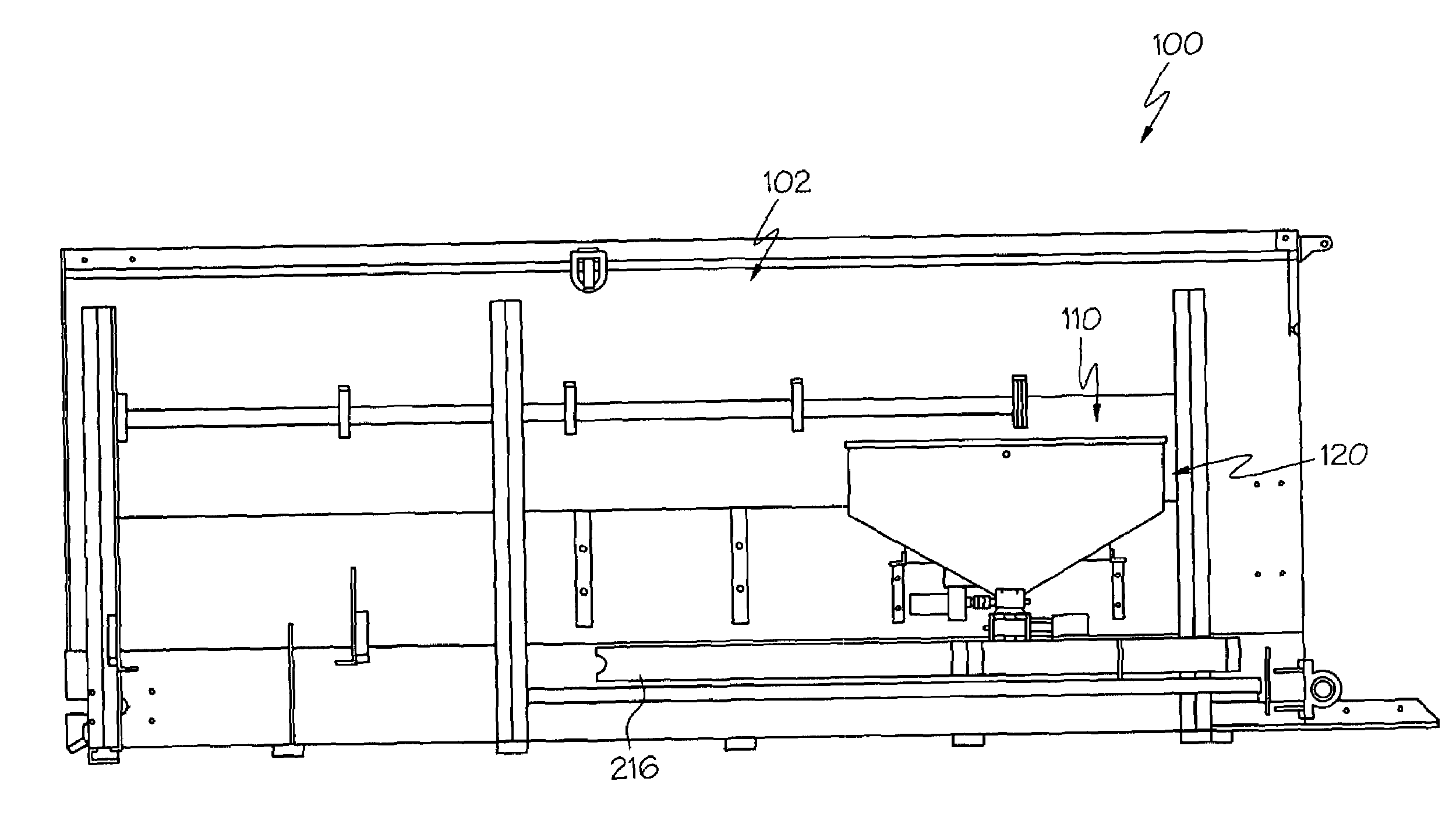

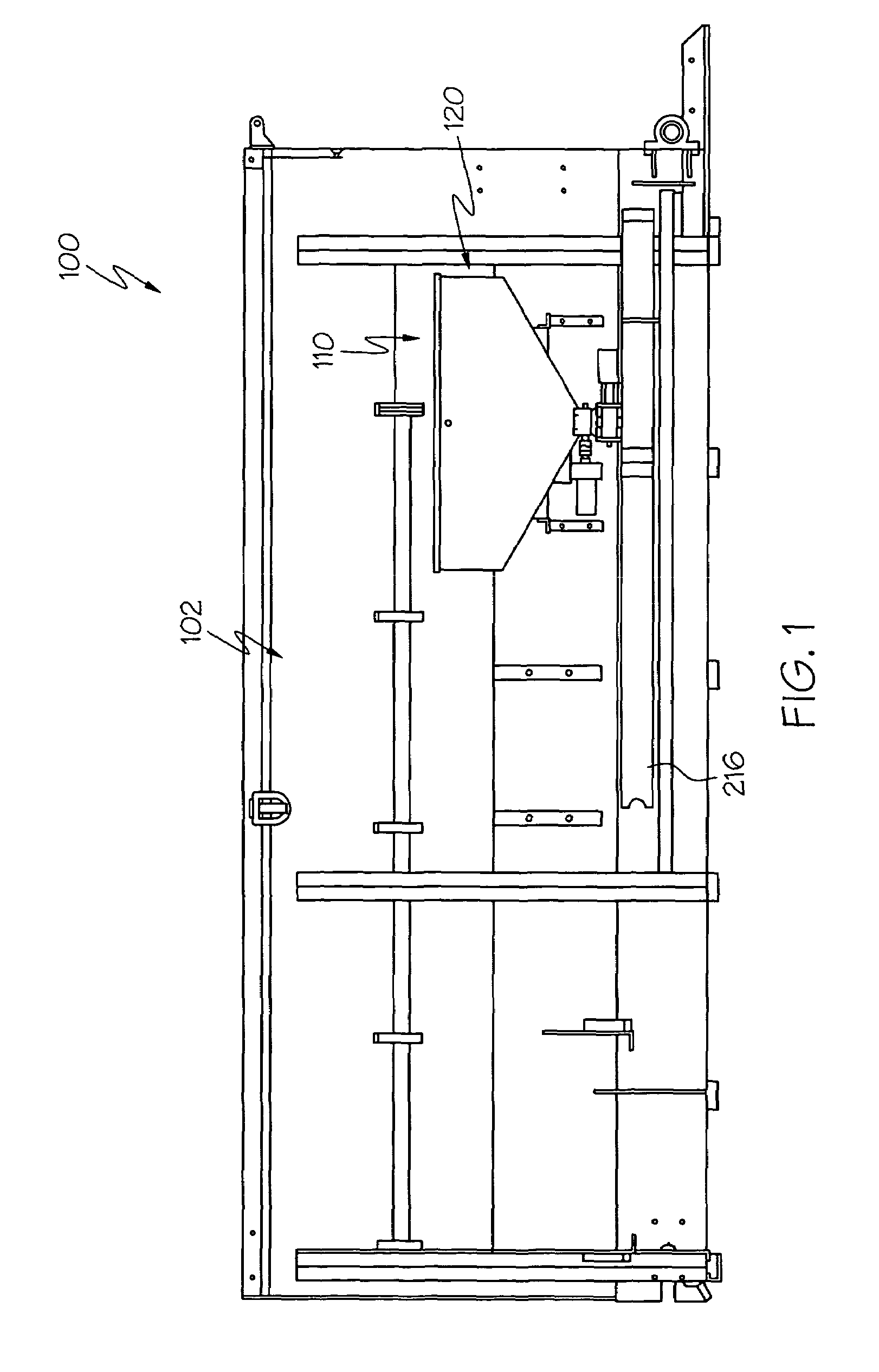

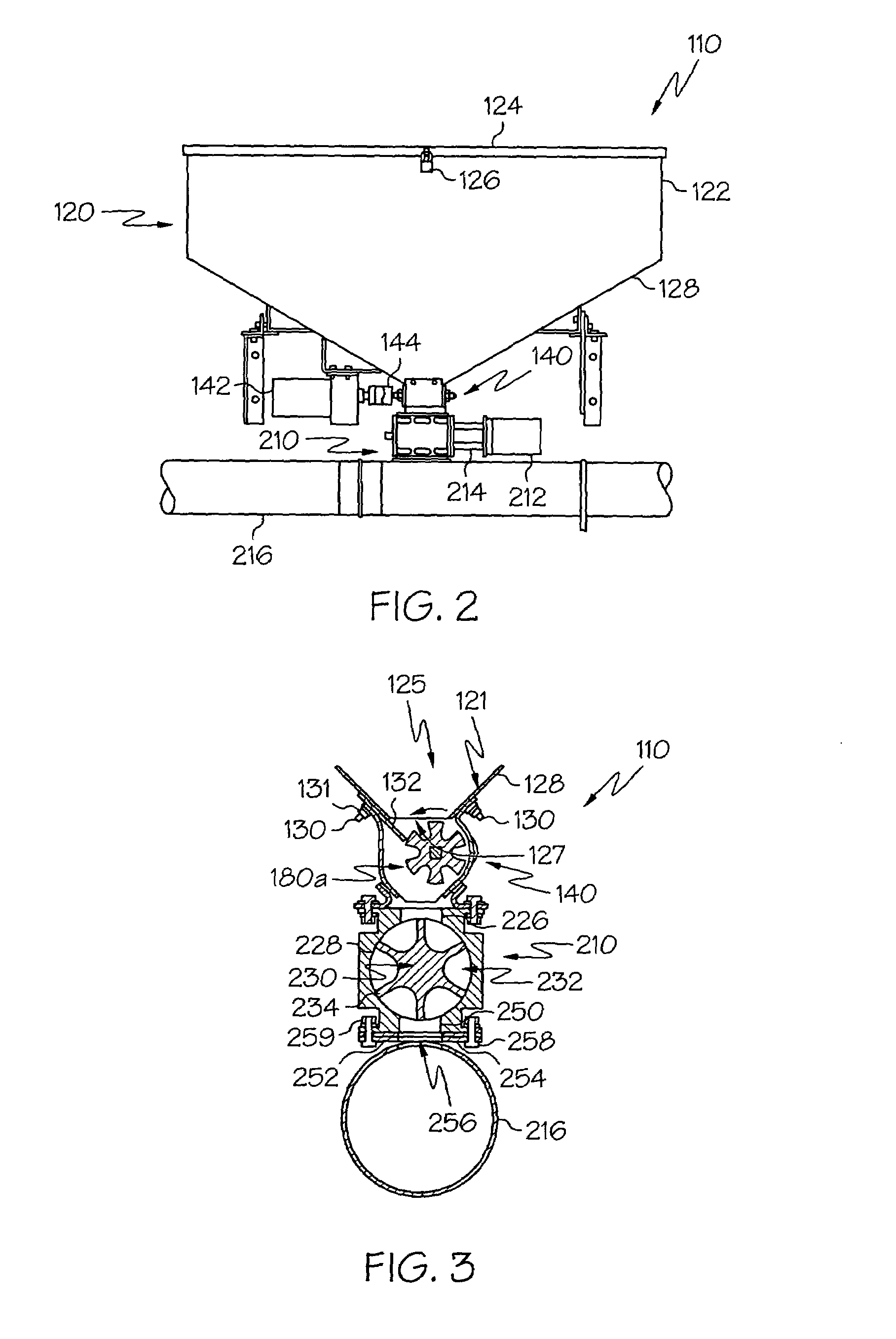

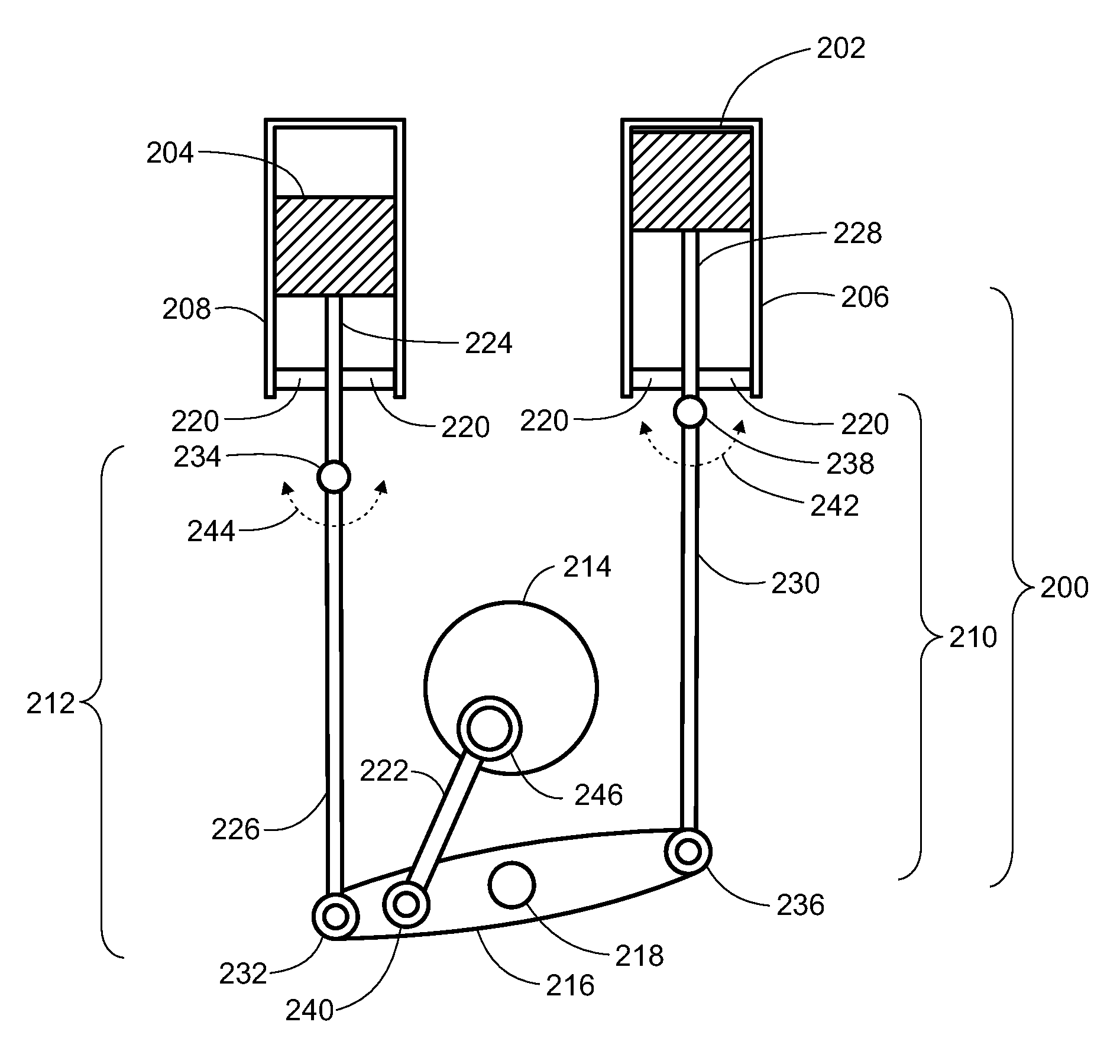

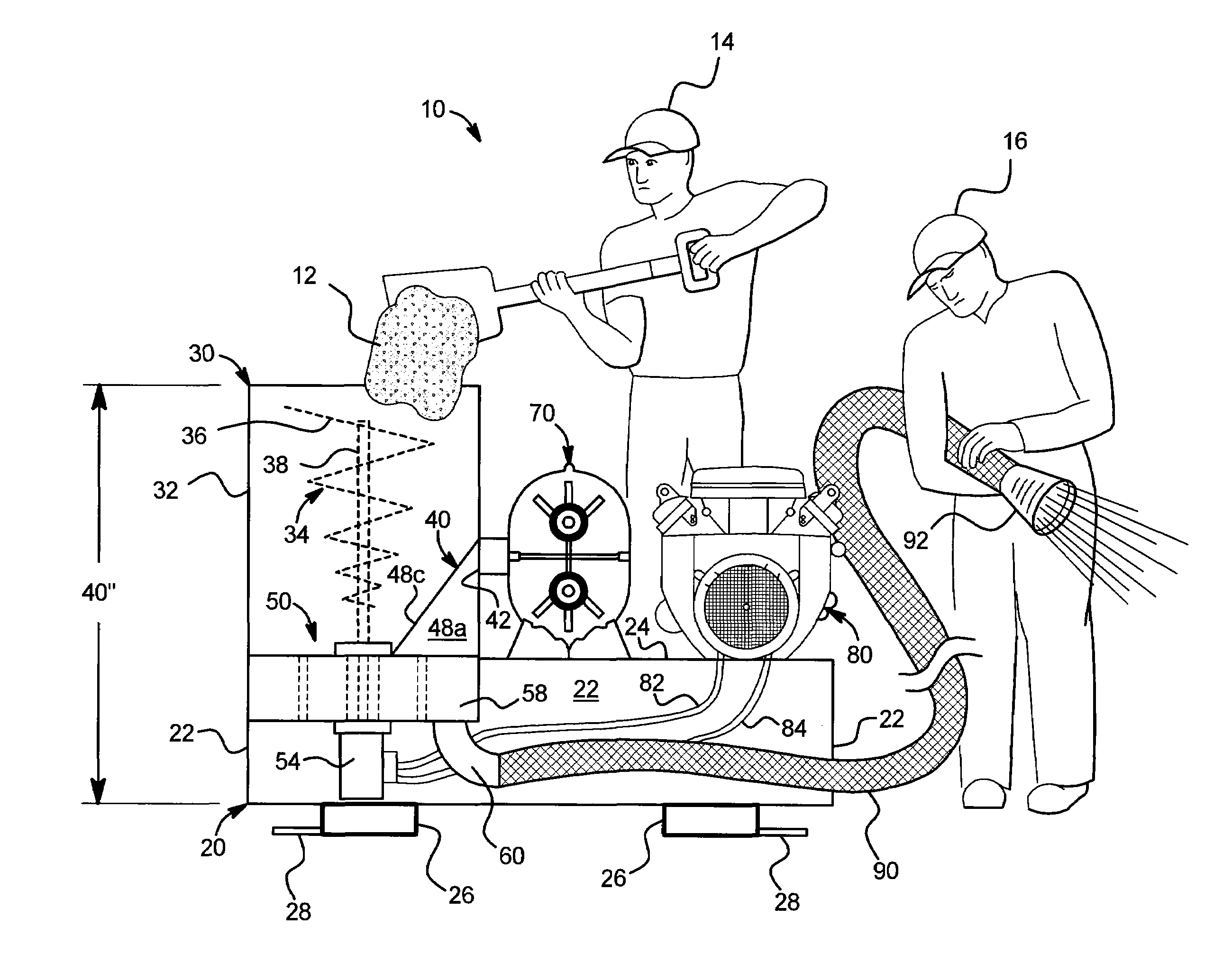

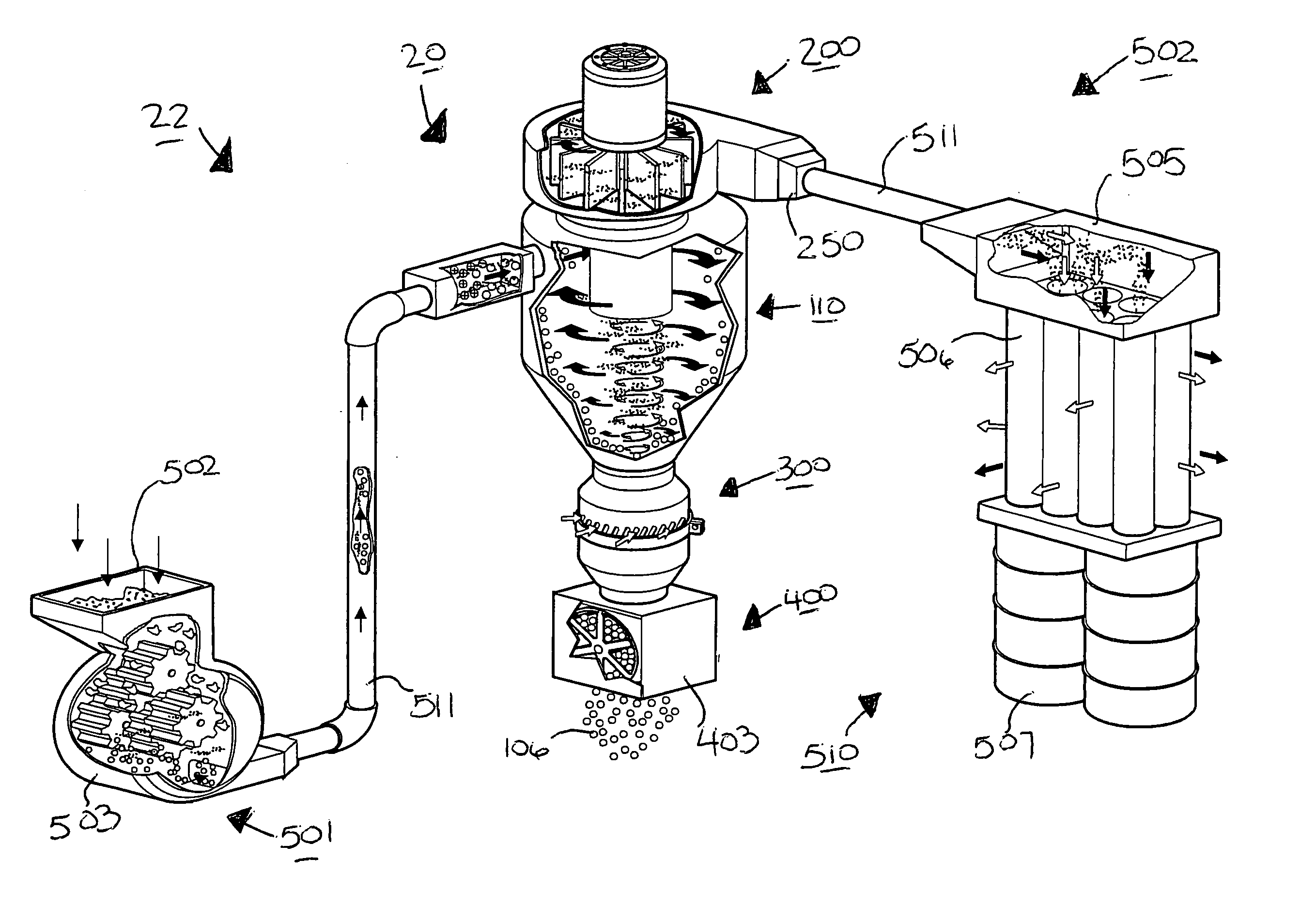

Bulk material discharge assembly with feeding apparatus

Bulk material discharge assemblies comprise a bulk material hopper, a conduit for delivering an air stream to entrain with bulk material from the bulk material hopper, and a feeding apparatus for introducing additive to the conduit. The feeding apparatus comprises an additive hopper and an airlock positioned adjacent the conduit. In addition, metering apparatus are provided that comprise an axle and first and second metering wheels. A noncircular perimeter of the axle and the shape of each hub opening of each of the metering wheels cooperate to nonrotatably mount each metering wheel to the axle. The first and second metering wheel are adapted to be selectively mounted in at least one of a first relative position and a second relative position. Still further, apparatus for dispensing additive are provided that comprise an additive hopper including at least one partition for dividing the additive hopper into at least two containment areas that are substantially isolated from one another and a metering device mounted to the additive hopper.

Owner:FINN CORP

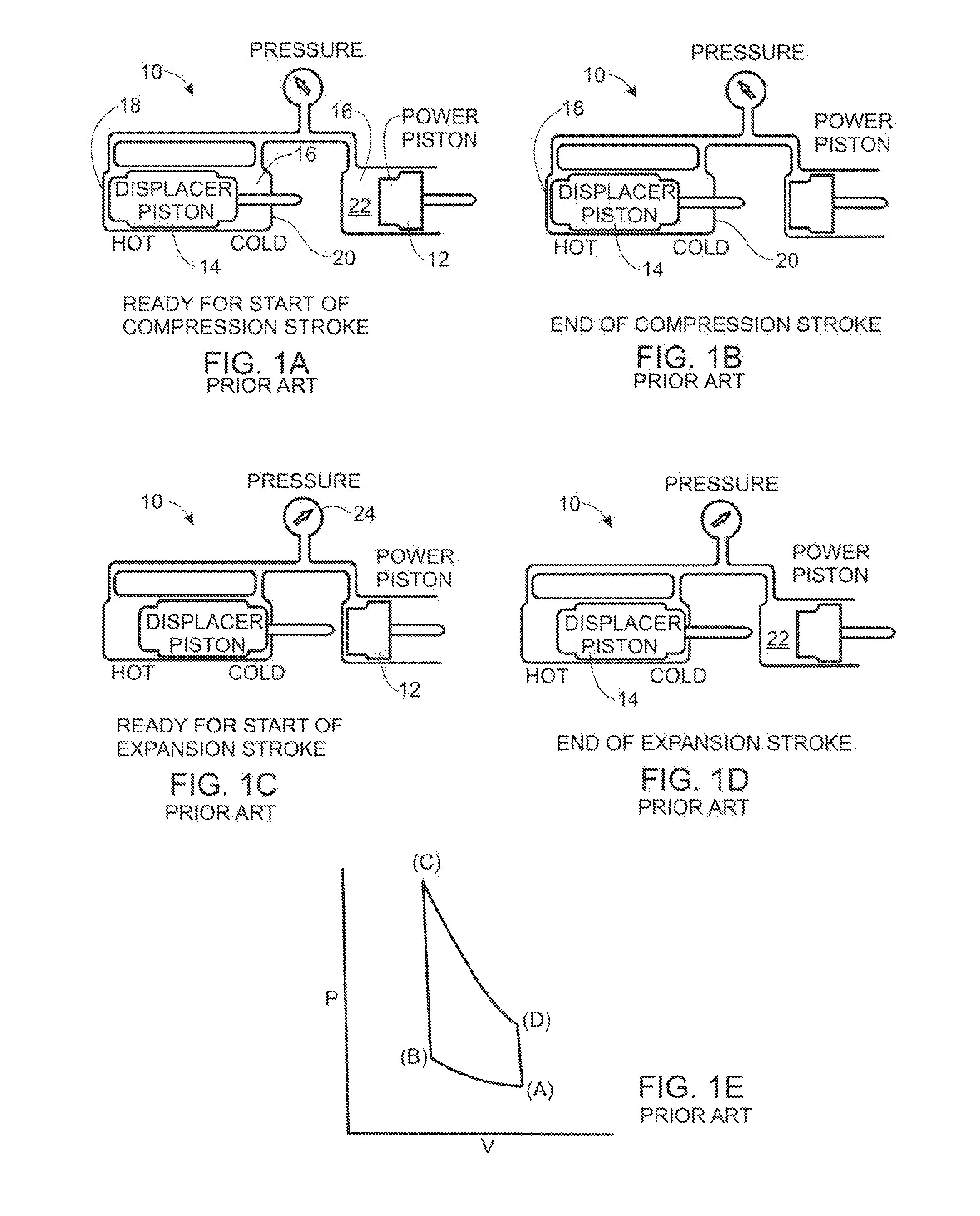

Stirling cycle machine

An external combustion engine is disclosed. The external combustion engine containing a working fluid and including a burner element for heating the working fluid of the engine, at least one heater head defining a working space containing the working fluid, at least one piston cylinder containing a piston for compressing the working fluid, a cooler for cooling the working fluid, a crankcase. The crankcase includes a crankshaft for producing an engine output, a rocking beam rotating about a rocker pivot for driving the crankshaft, a piston rod connected to the piston, a rocking beam driven by the piston rod, and a connecting rod connected at a first end to the rocking beam and at a second end to a crankshaft to convert rotary motion of the rocking beam to rotary motion of the crankshaft. The external combustion engine also includes an airlock space separating the crankcase and the working space for maintaining a pressure differential between the crankcase housing and the working space housing and an airlock pressure regulator connected between the crankcase and one of the airlock space and working space.

Owner:DEKA PROD LLP

Pneumatically-powered mine door installation with hydraulic checking system

InactiveUS6938372B2Increase air pressureReduce air pressureBuilding braking devicesServomotorsControl systemPower control system

A mine door assembly has a frame. At least one door leaf is mounted on the frame for swinging movement between open and closed positions. Movement of the door leaf is powered by a pneumatic actuator. The door installation also has a hydraulic checking system for controlling the speed of the door leaf as it moves back and forth between open and closed positions. A pneumatically-powered control system may be provided to control the door installation. The pneumatic control system may comprise a calibrated vent to shorten the delay in the response of the door leaf to direction from the control system to stop moving. The pneumatic control system may also comprise a limit valve to prevent the door installation from opening when a second door installation is open, thereby preventing both door installations in an air lock from being open at the same time.

Owner:JACK KENNEDY METAL PRODS & BUILDINGS

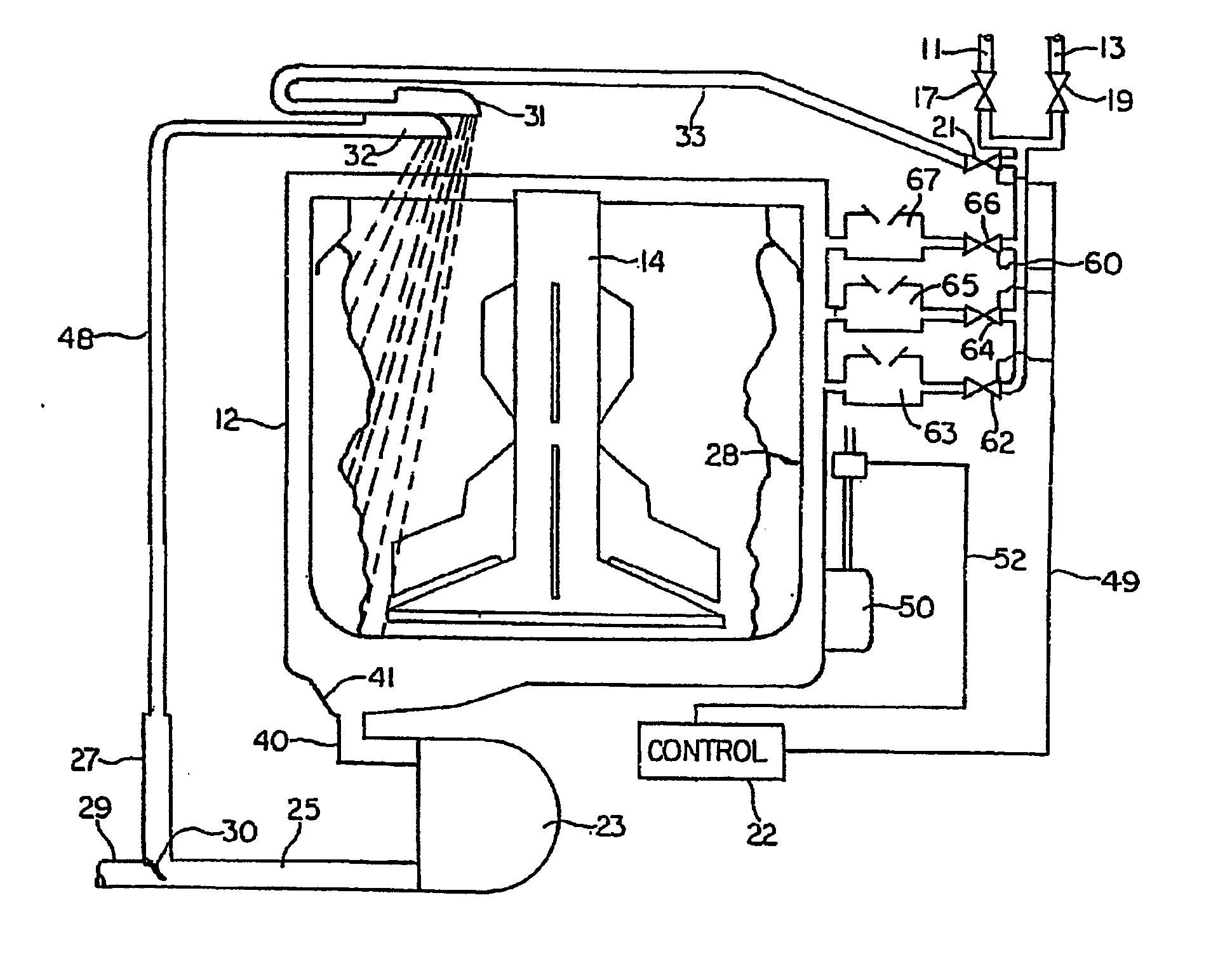

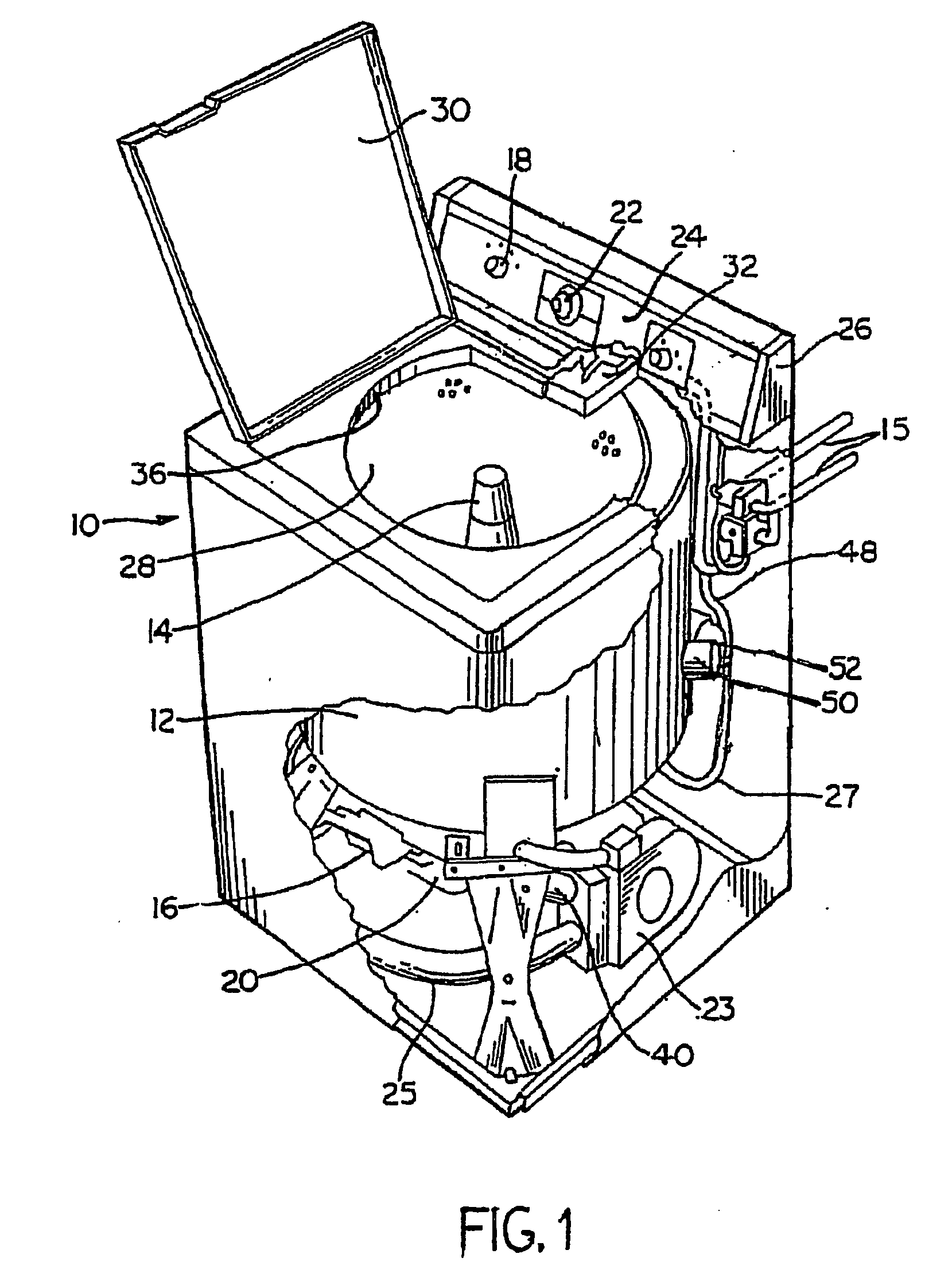

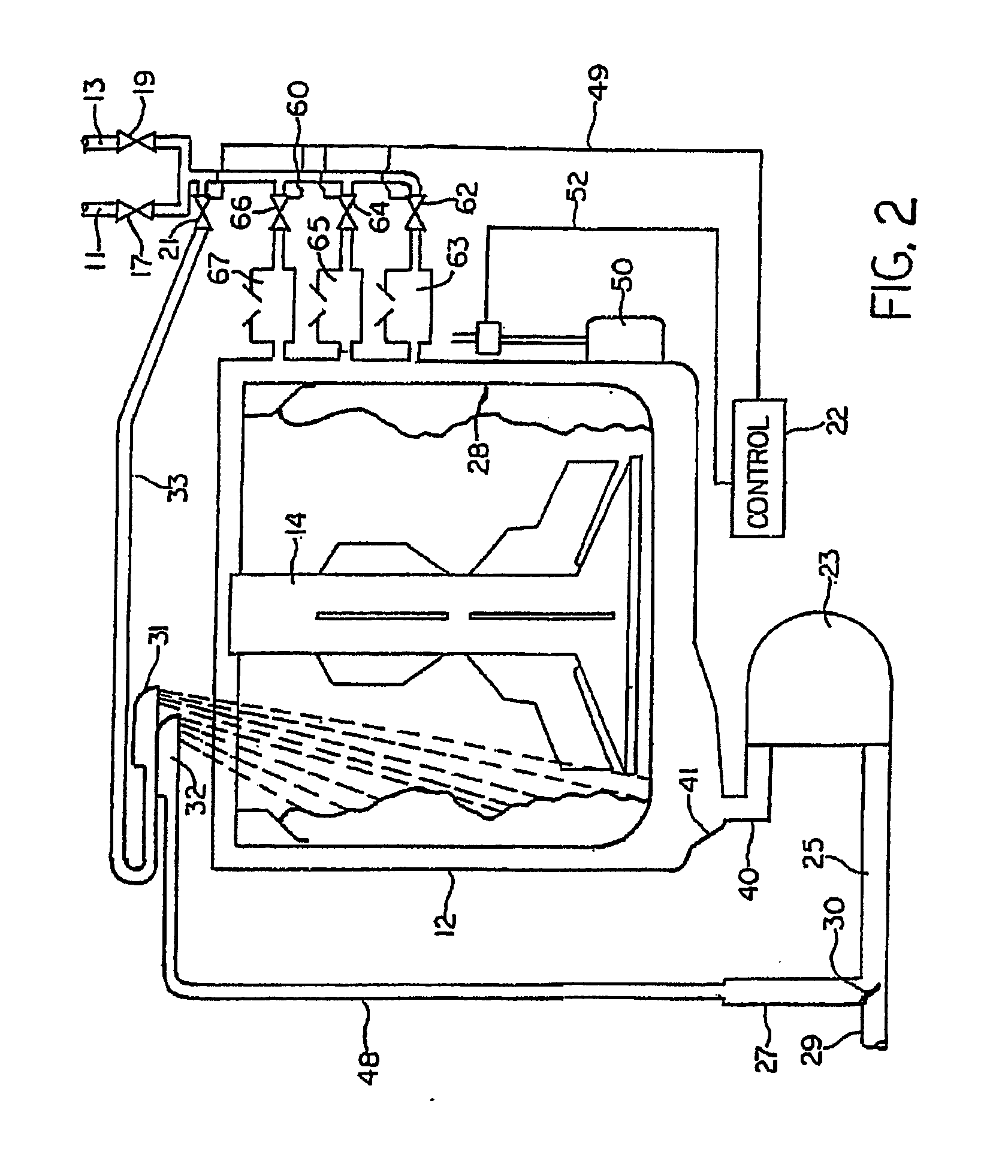

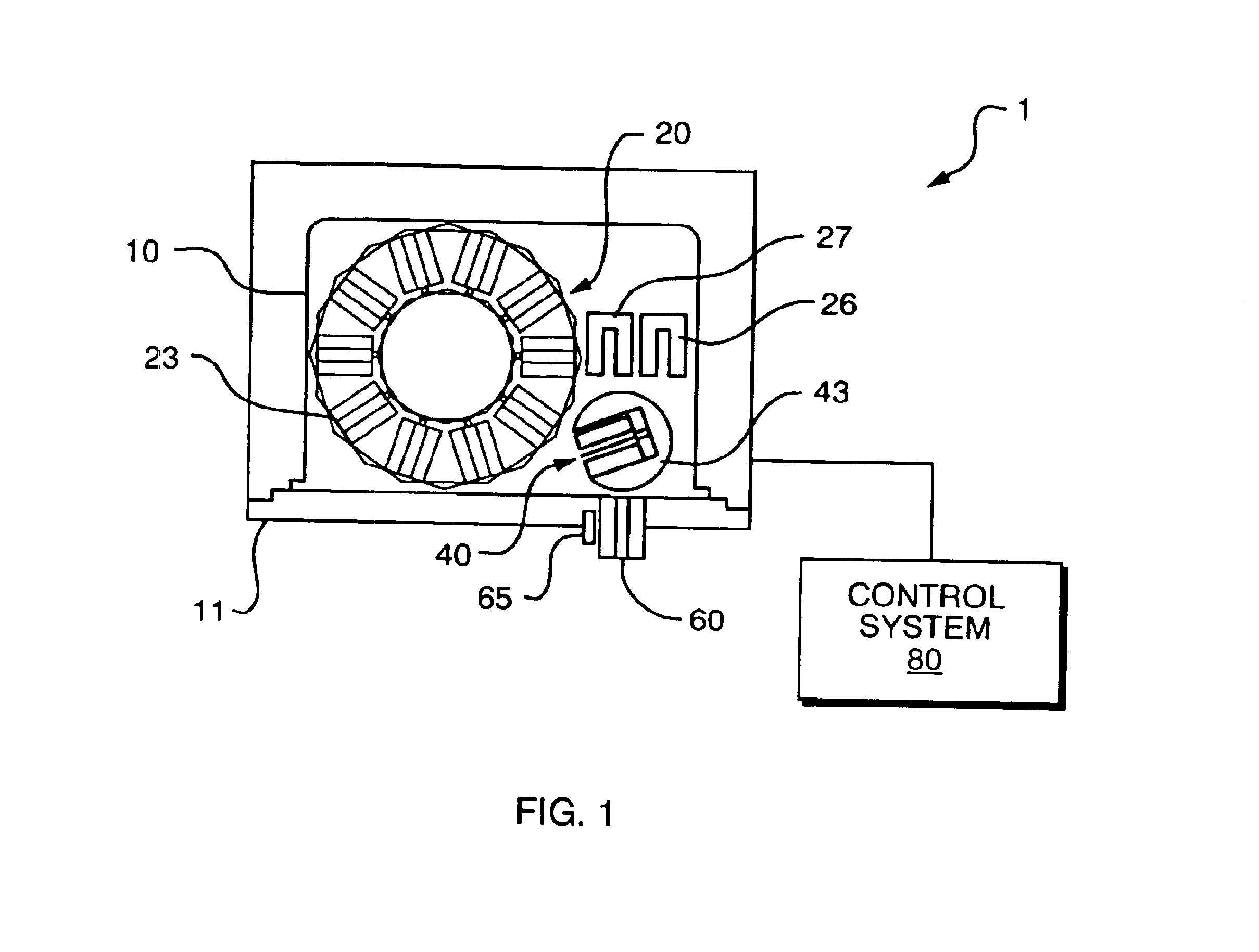

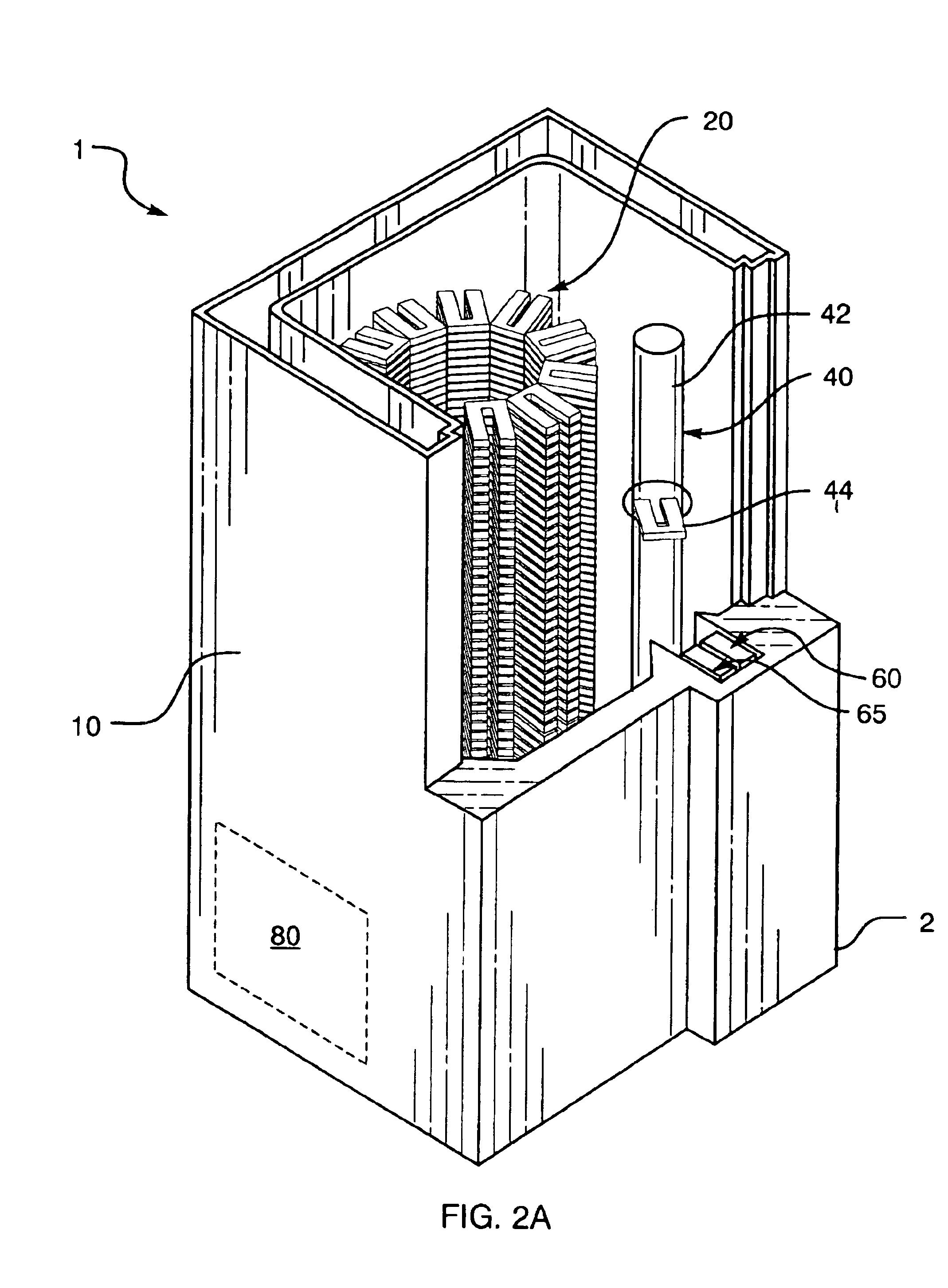

Stain removal process control method using BPM motor feedback

ActiveUS20070107138A1Easy to cleanOther washing machinesTextiles and paperProcess engineeringPre treatment

Owner:WHIRLPOOL CORP

Stirling cycle machine

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. An airlock is included between the workspace and the crankcase and a seal is included for sealing the workspace from the airlock and crankcase. A burner and burner control system is also included for heating the machine and controlling ignition and combustion in the burner.

Owner:NEW POWER CONCEPTS

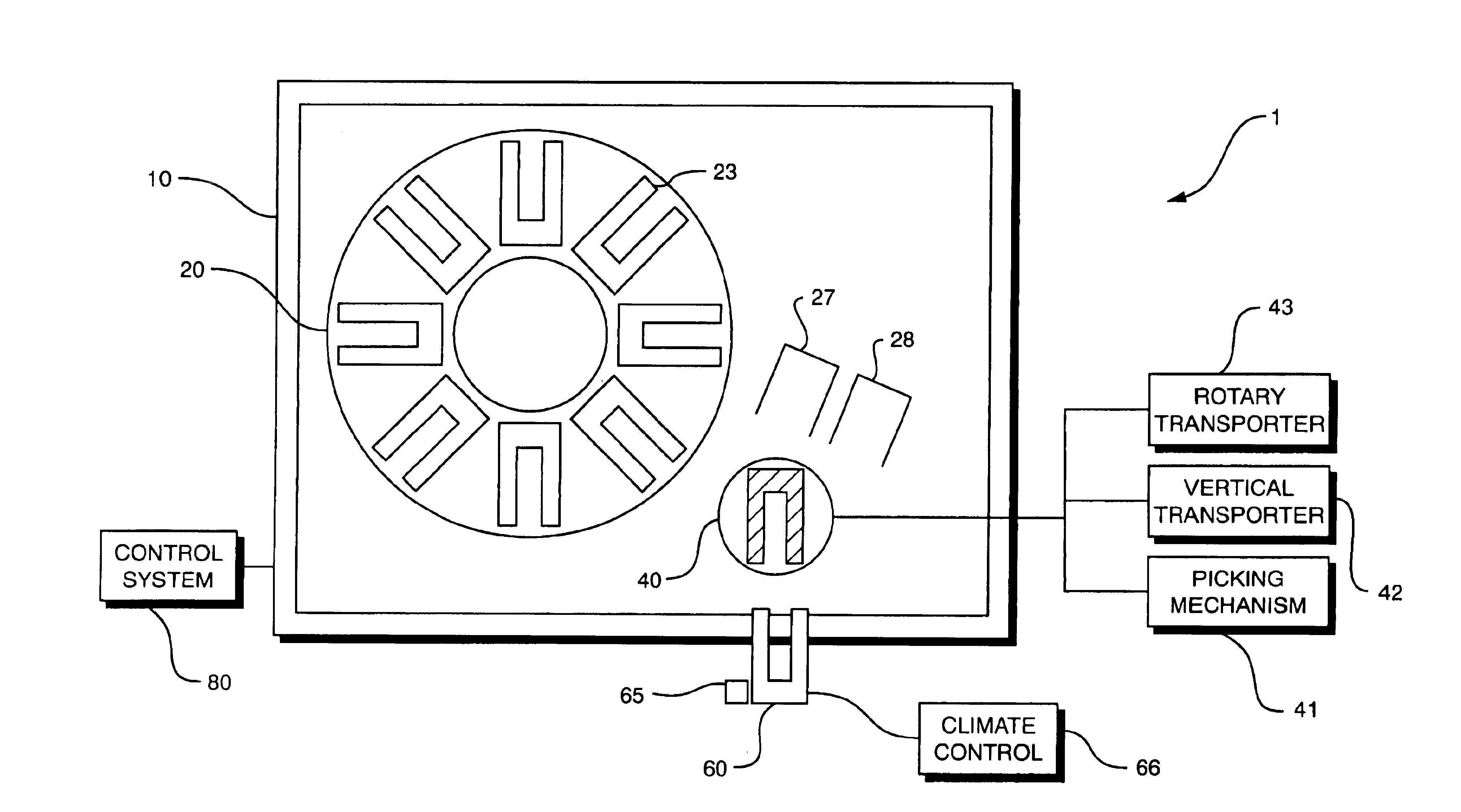

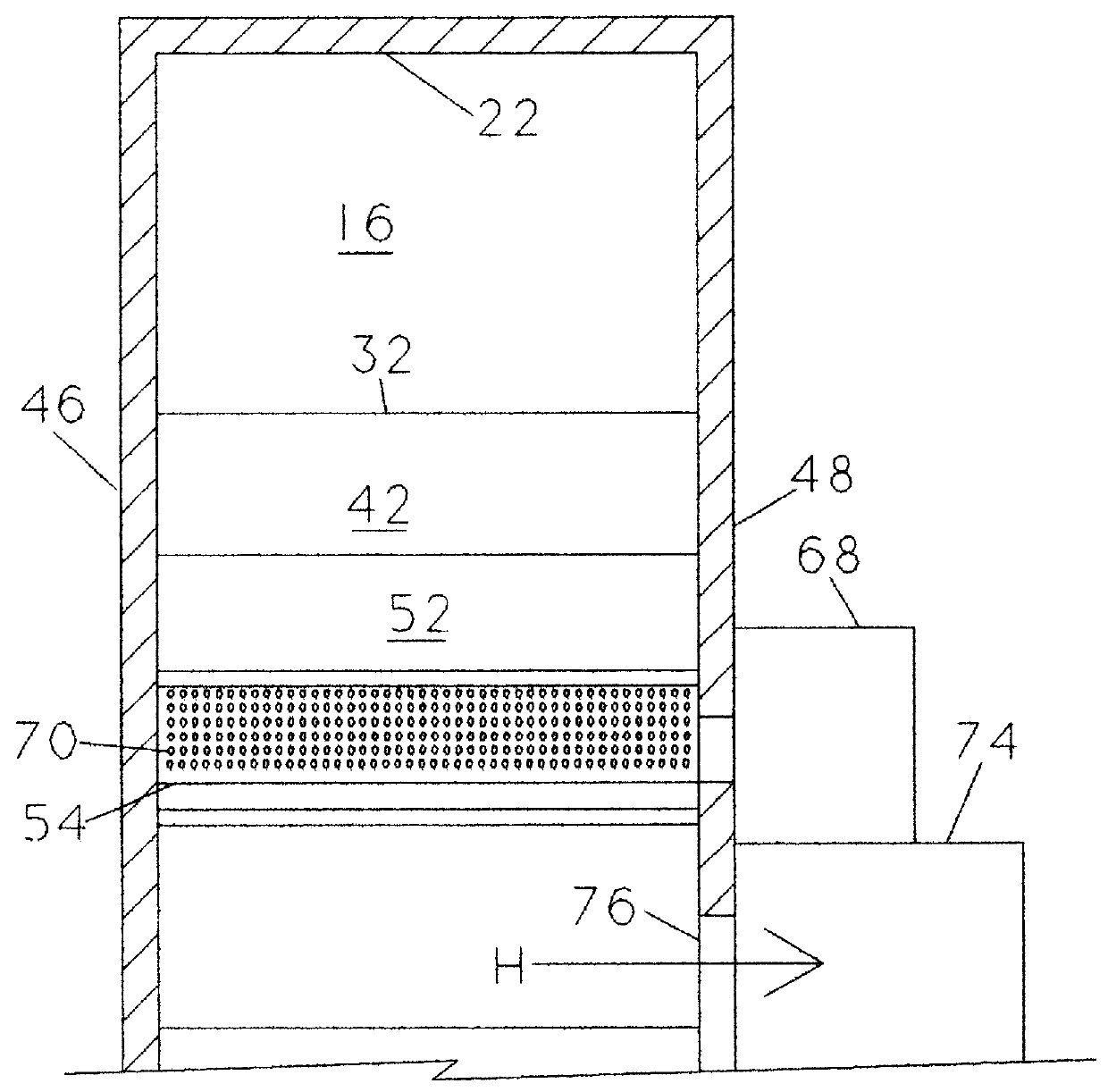

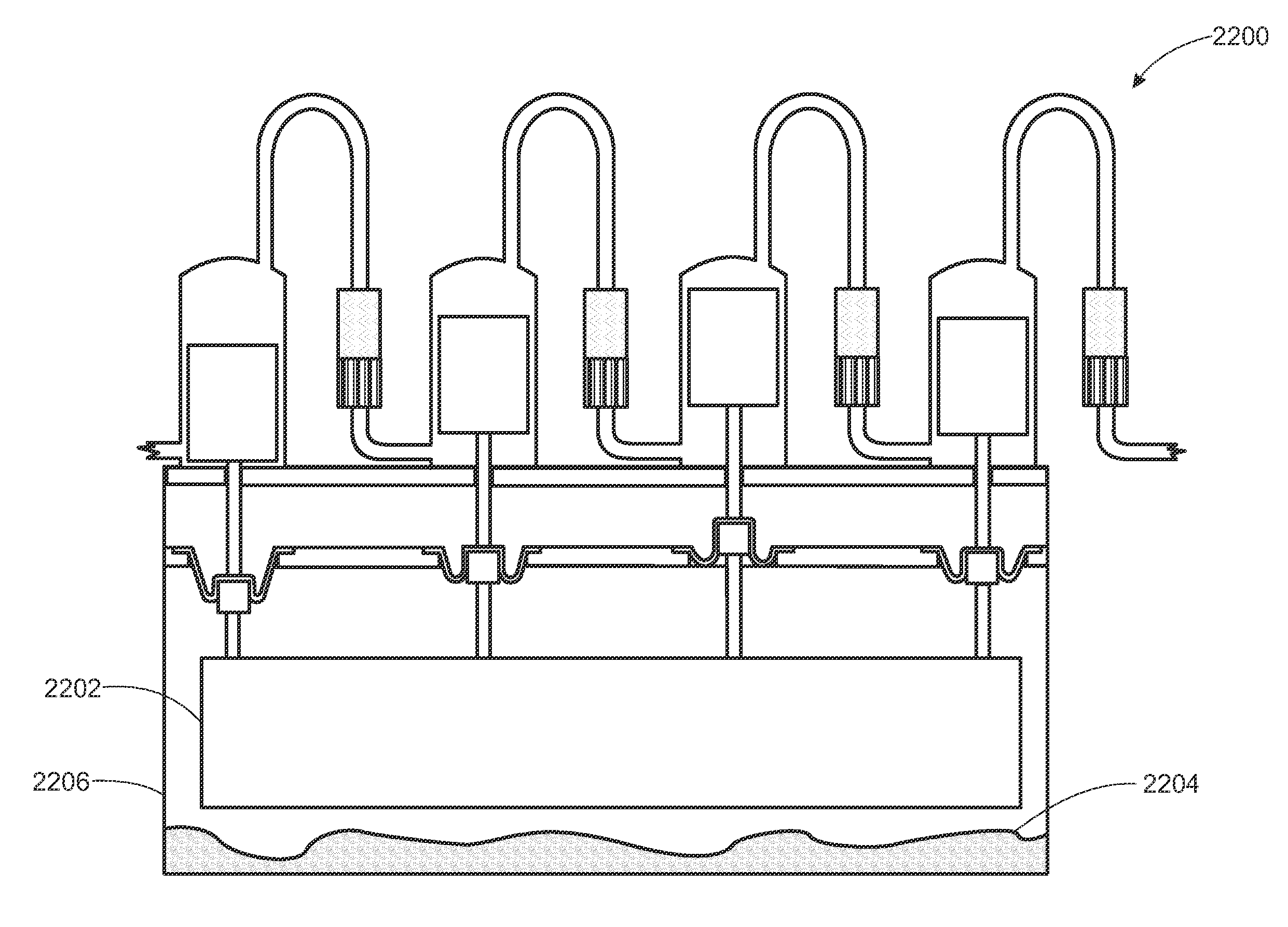

Automated storage and retrieval apparatus for freezers and related method thereof

InactiveUS6941762B2Meet needsLow production costPreparing sample for investigationDomestic refrigeratorsEngineeringNitrogen gas

An automated cold storage apparatus, and related method thereof, provides a sample process management system that is a revolutionary approach to the storage and retrieval regarding critical samples. The system—a significant technological breakthrough in laboratory automation—is the first ultra low temperature robotic system capable of being validated. Samples in containers are stored and retrieved robotically through an airlock climate-control chamber that is automatically dehumidified by a dry gas purge, such as a carbon dioxide or nitrogen purge or the like. This purge rapidly reduces ambient humidity to a desirable relative humidity (RH), e.g., less than about 15% RH, virtually eliminating the accumulation of frost. Microplates are systematically identified using barcode technology, for example. Once through the climate-controlled chamber, the containers (i.e., samples) are robotically transferred to the rotary mechanism. This mechanism transports the containers to a derived nest location upon the storage means, such as a carousel or to one of the stationary addresses.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

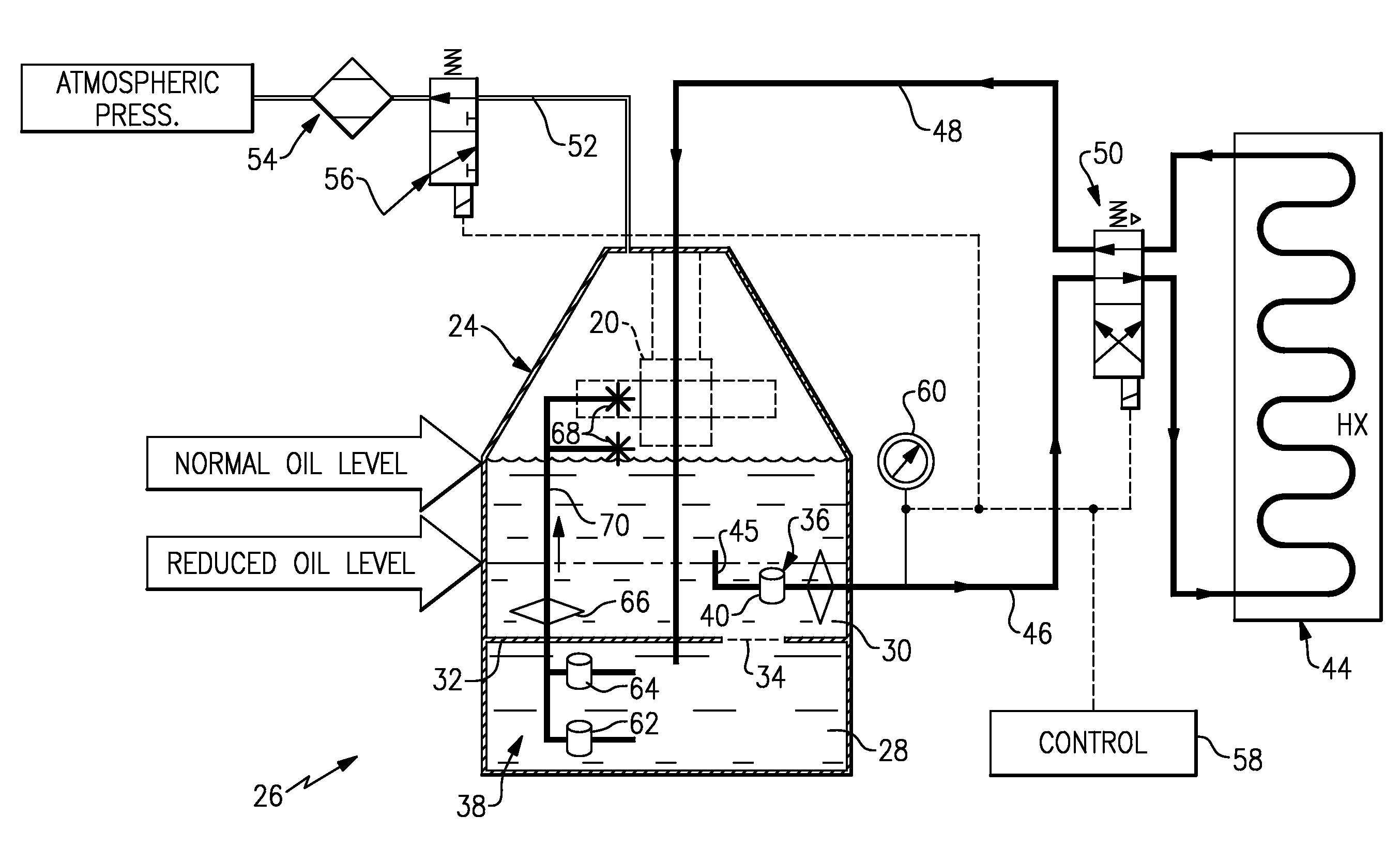

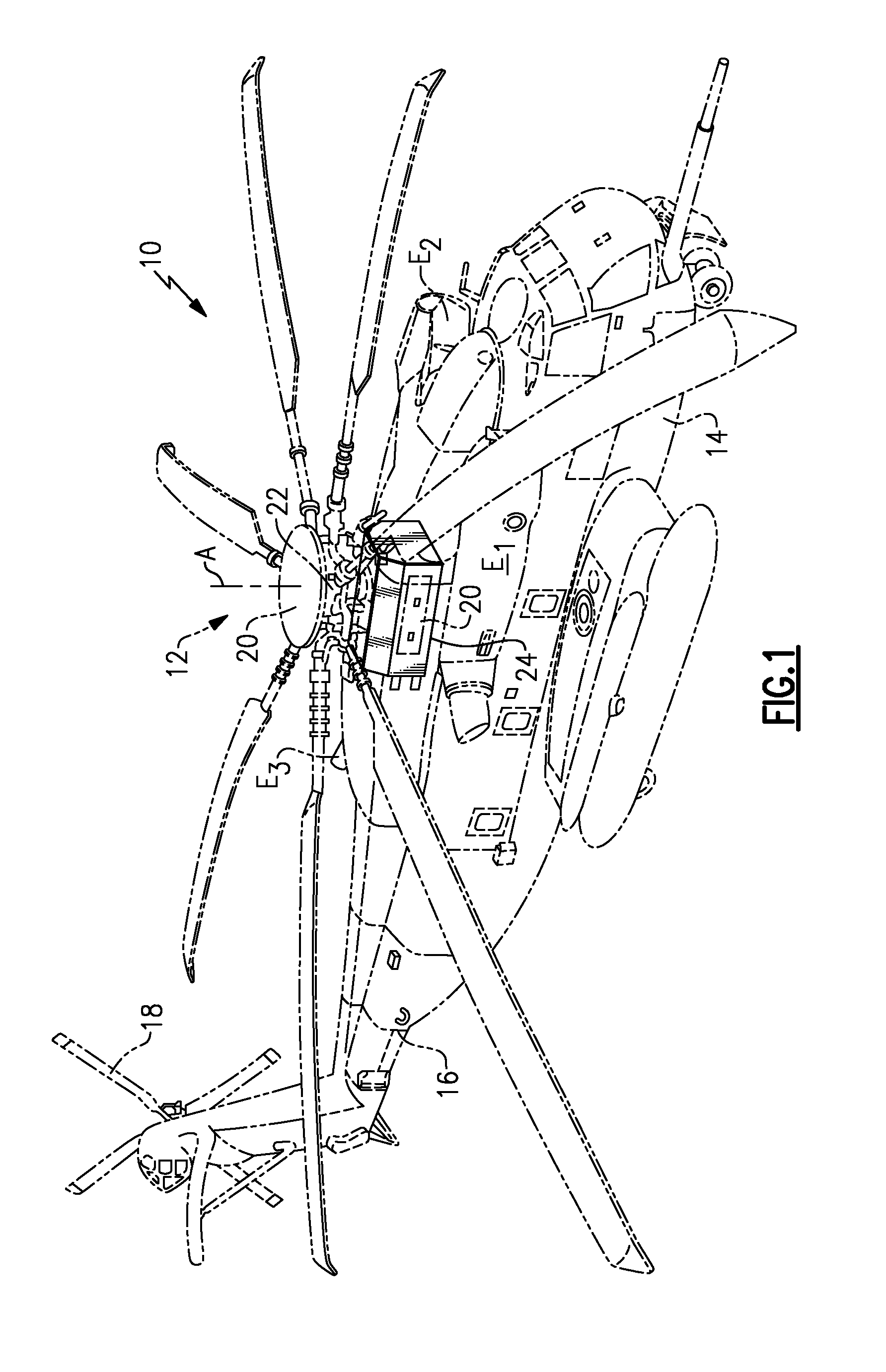

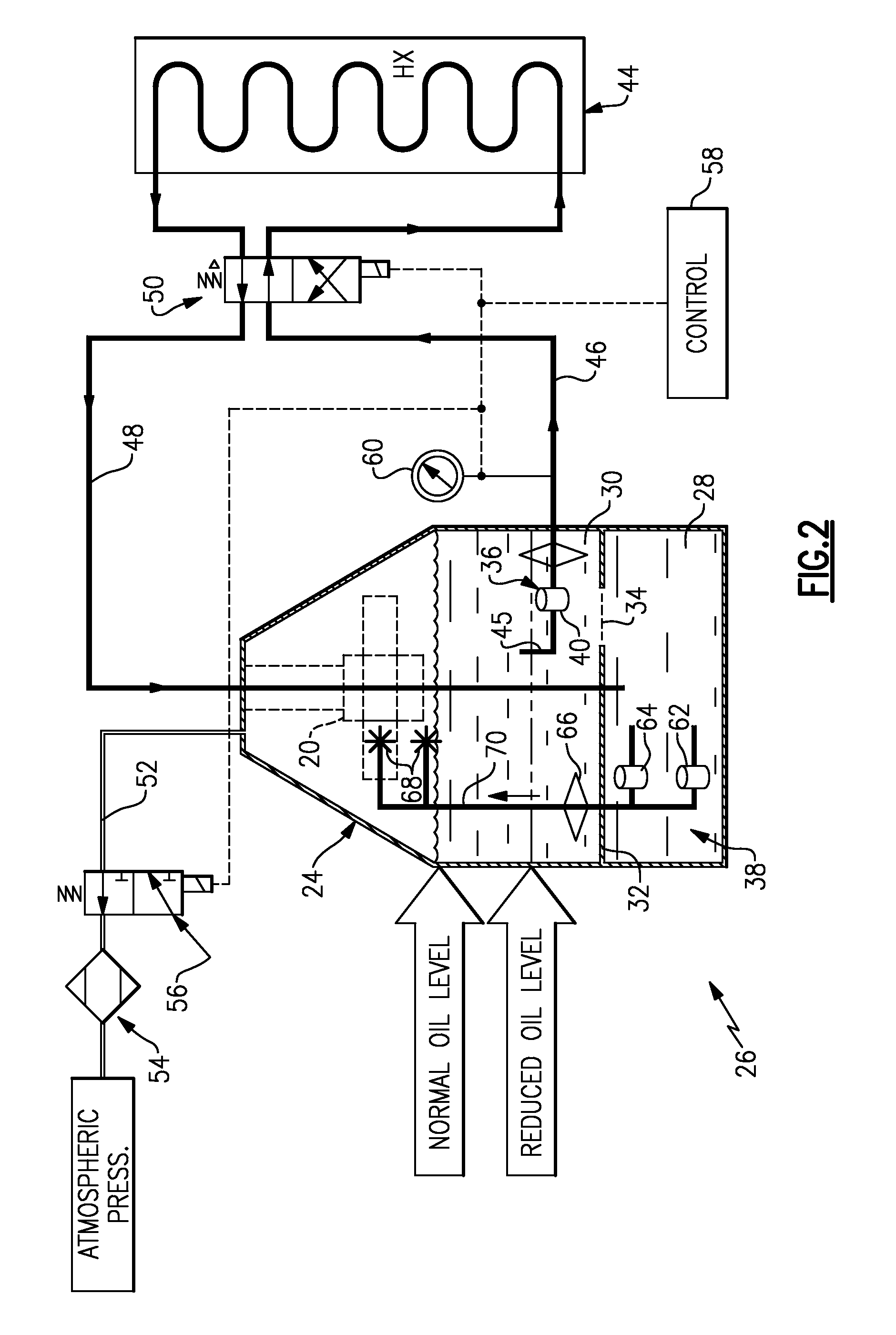

Lubrication system with prolonged loss of lubricant operation

ActiveUS20100025159A1Facilitates operation of powerPreventing and minimizingAircraft componentsMachines/enginesLubricationAirlock

A lubrication system includes an external pump system which pumps air out of the housing and develop negative pressure therein in response to a loss of lubrication condition. The negative pressure operates as an air lock to minimize or prevent lubricating oil loss from the housing while an internal lubrication system continues to distribute lubricating oil—which although now increasing in temperature—still operates to lubricate the gearbox components. For further ballistic tolerance, the housing is a compound housing that reduces or closes the penetration and further minimizes lubricating oil and negative pressure loss. The housing may be still further hardened by an armor layer.

Owner:SIKORSKY AIRCRAFT CORP

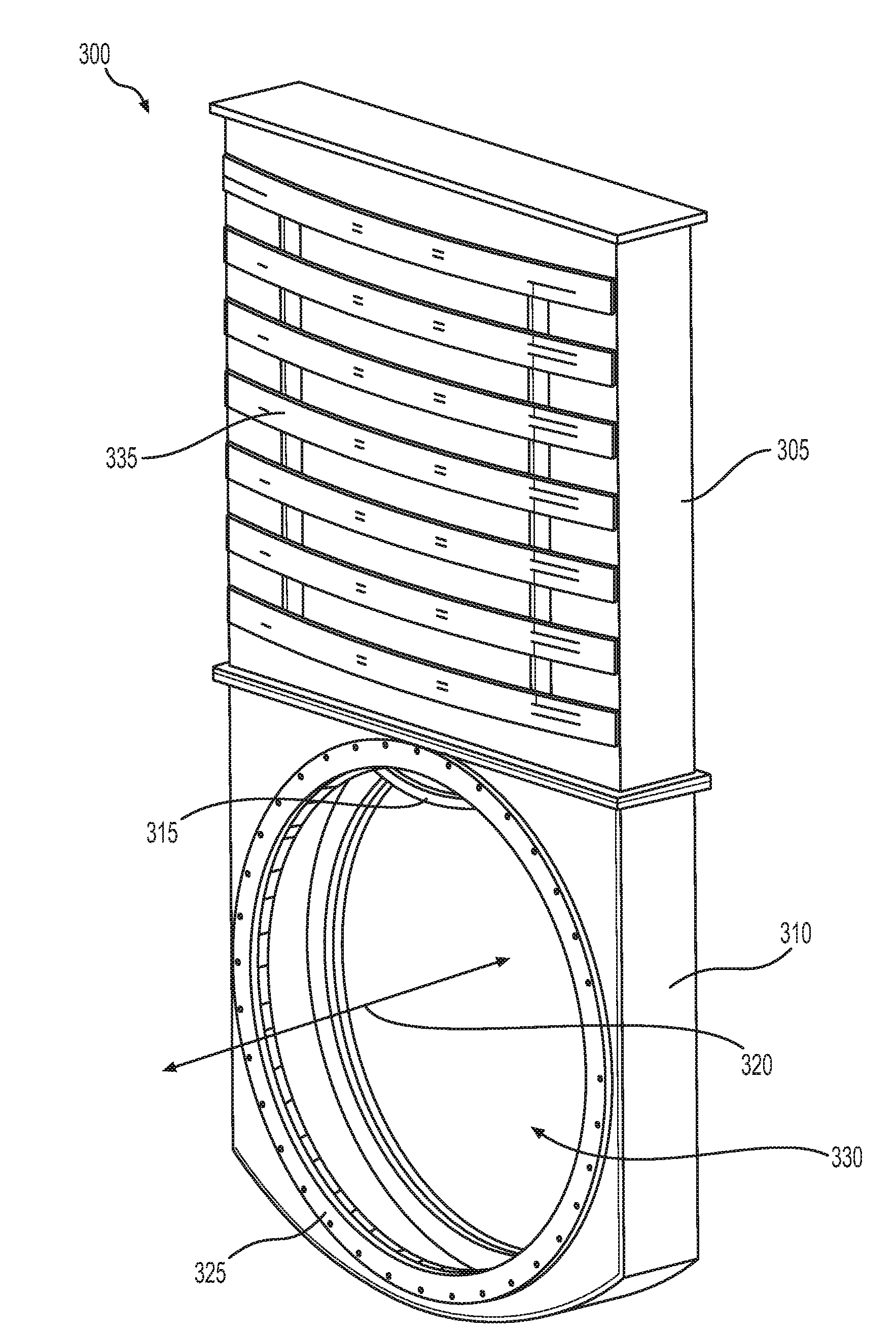

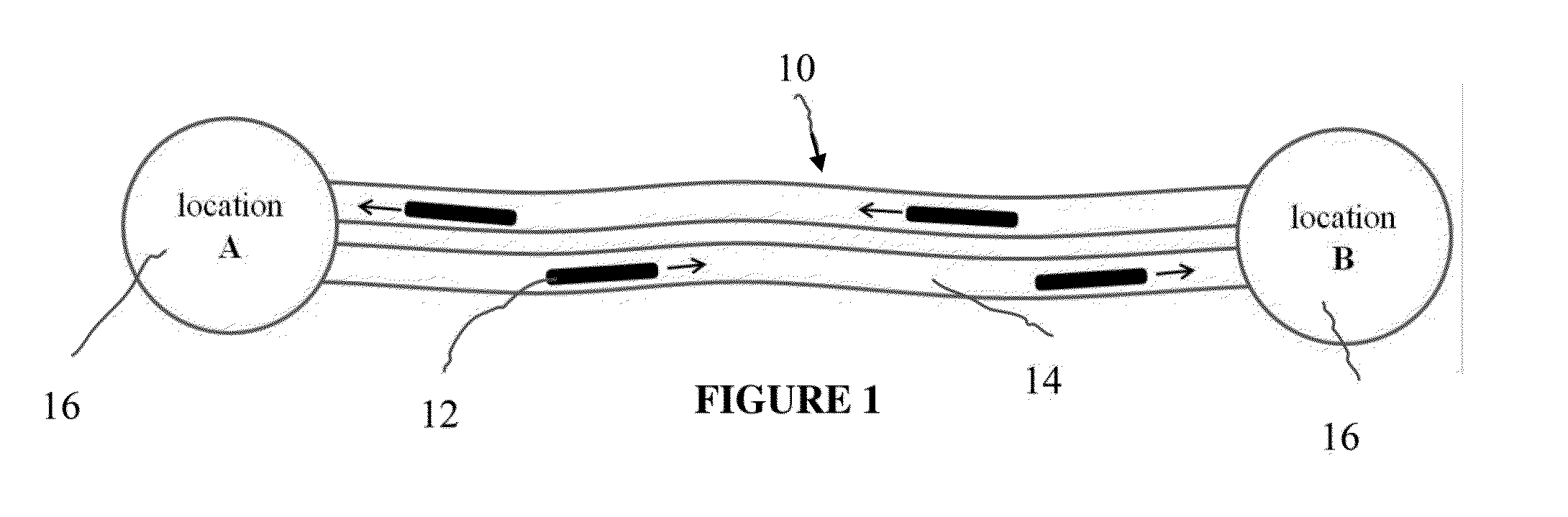

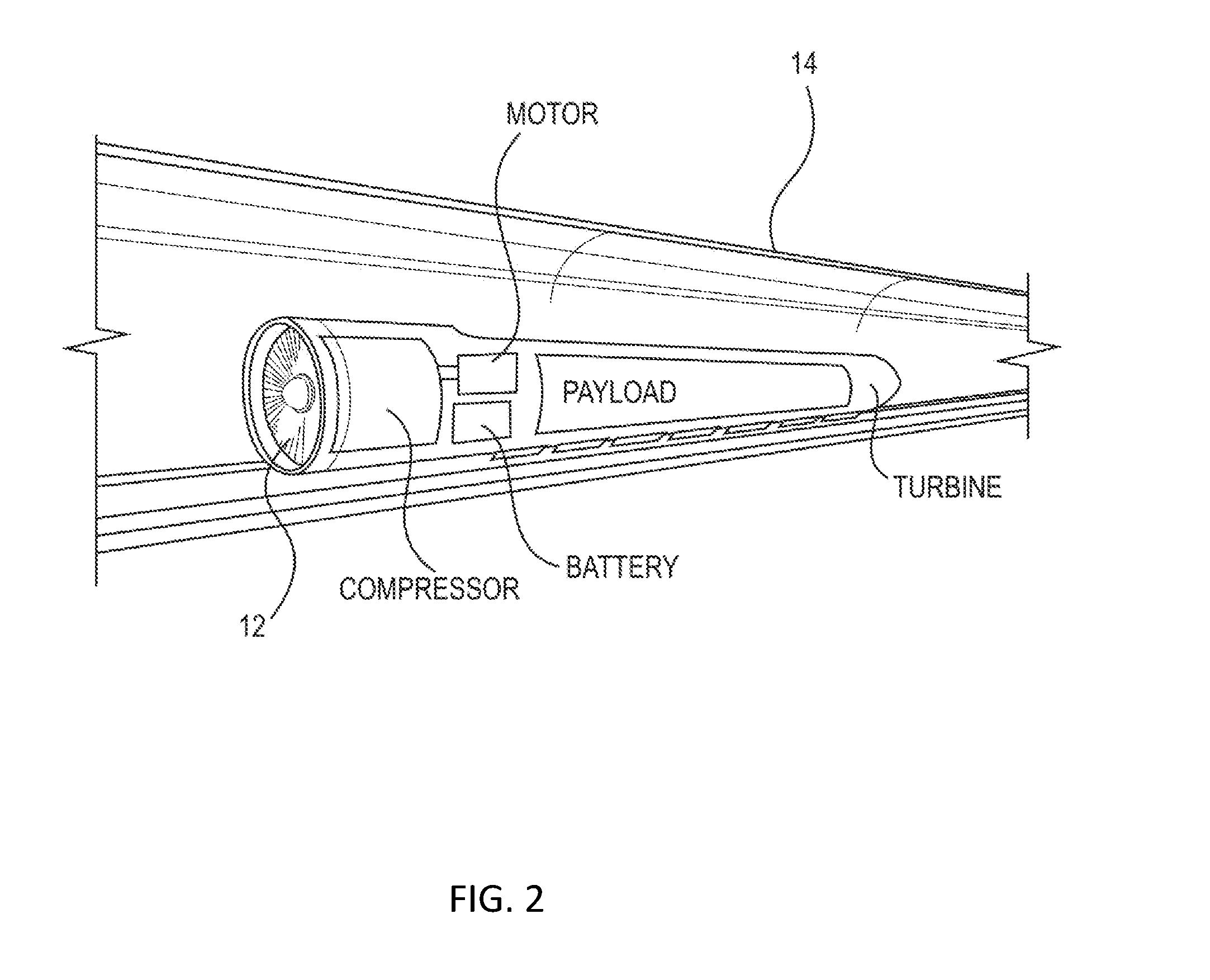

Gate valves and airlocks for a transportation system

ActiveUS20160230899A1High strengthIncrease stiffnessDiaphragm valvesEngine diaphragmsLevitationTransit system

A high-speed transportation system, the system including at least one transportation tube having at least one track, at least one capsule configured for travel through the at least one tube between stations, a propulsion system adapted to propel the at least one capsule through the tube; a levitation system adapted to levitate the capsule within the tube, and at least one tube sealer arranged along the at least one tube and configured to create an airlock in the at least one tube. In embodiments, the tube sealer may include a gate valve and / or an airbag.

Owner:HYPERLOOP TECH INC

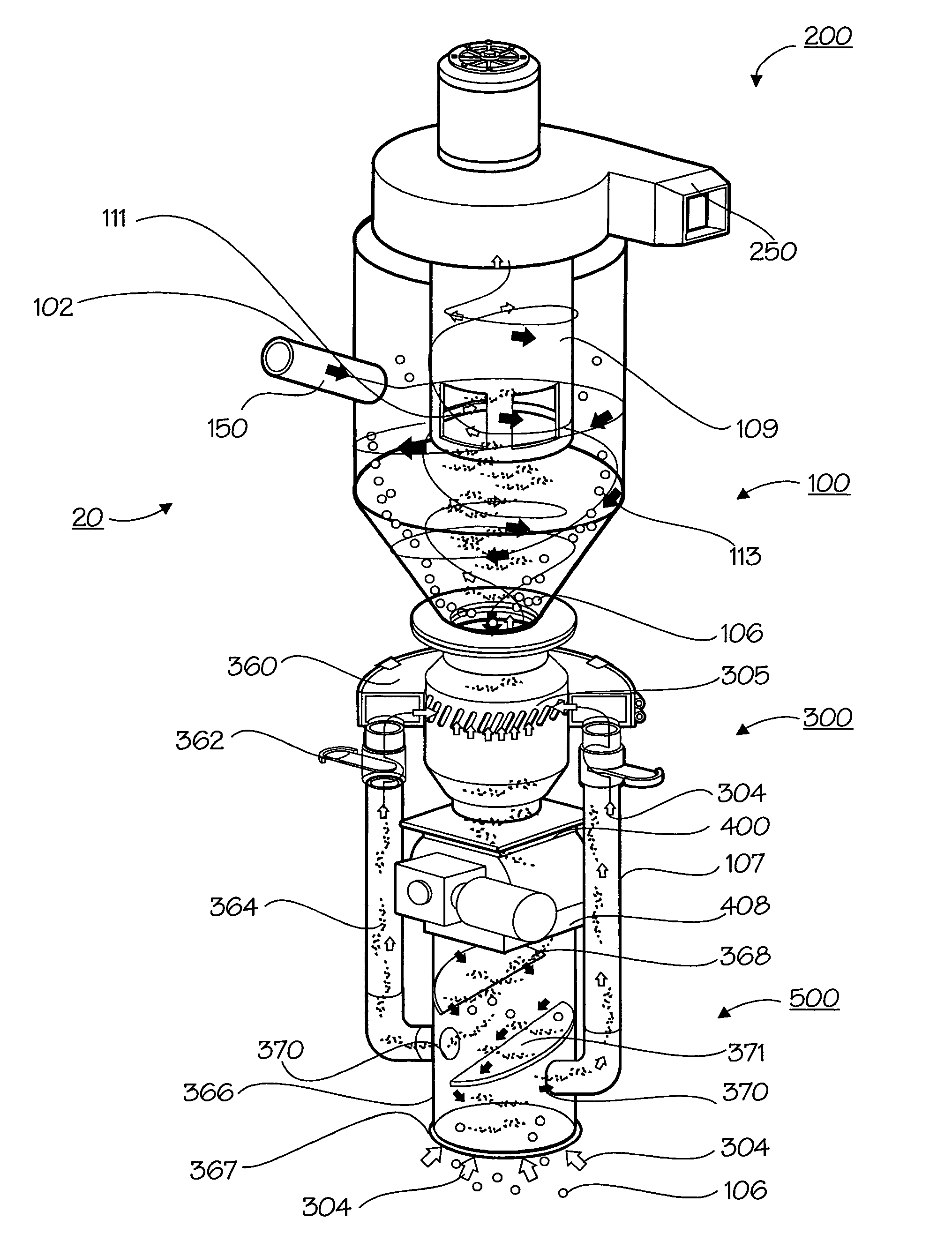

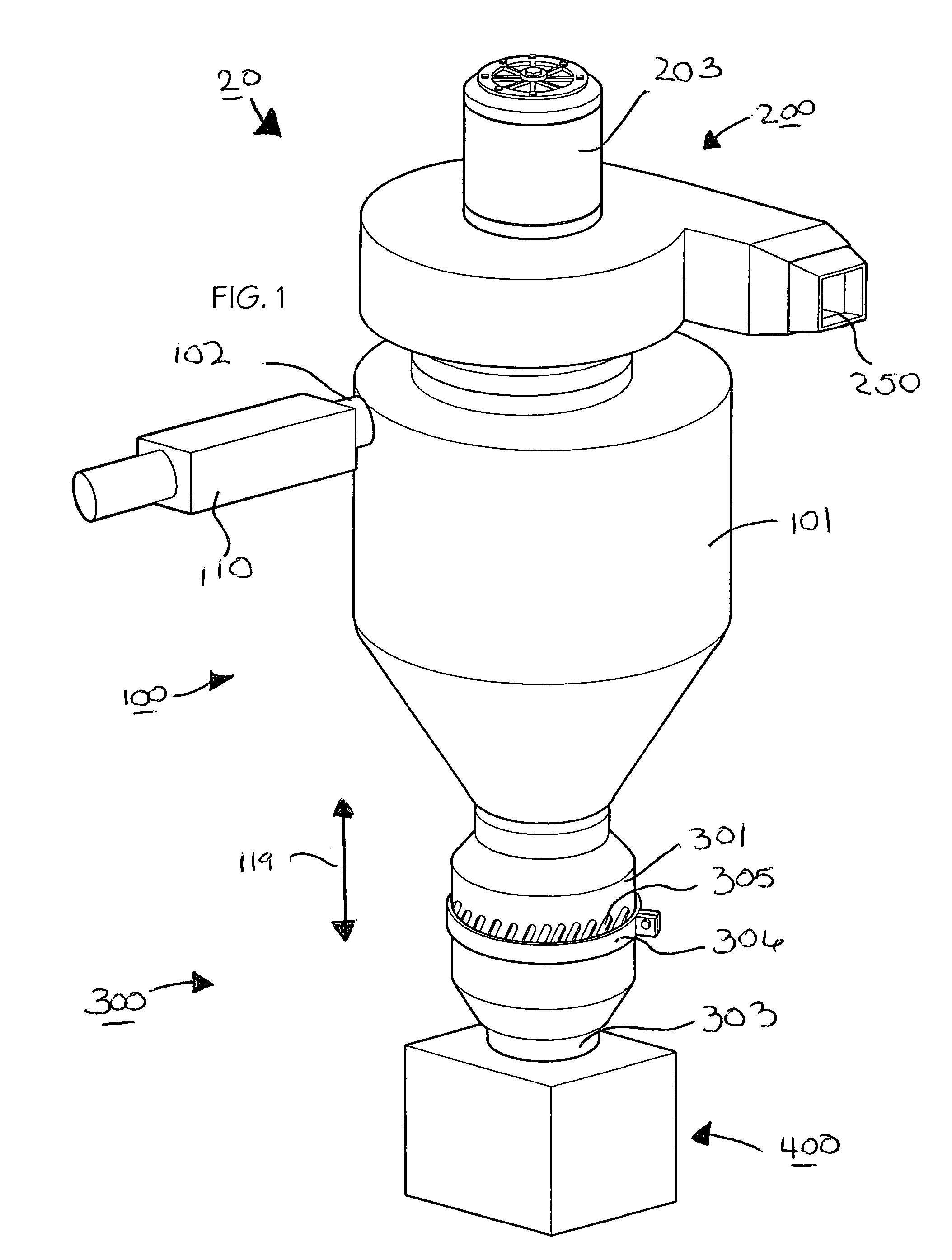

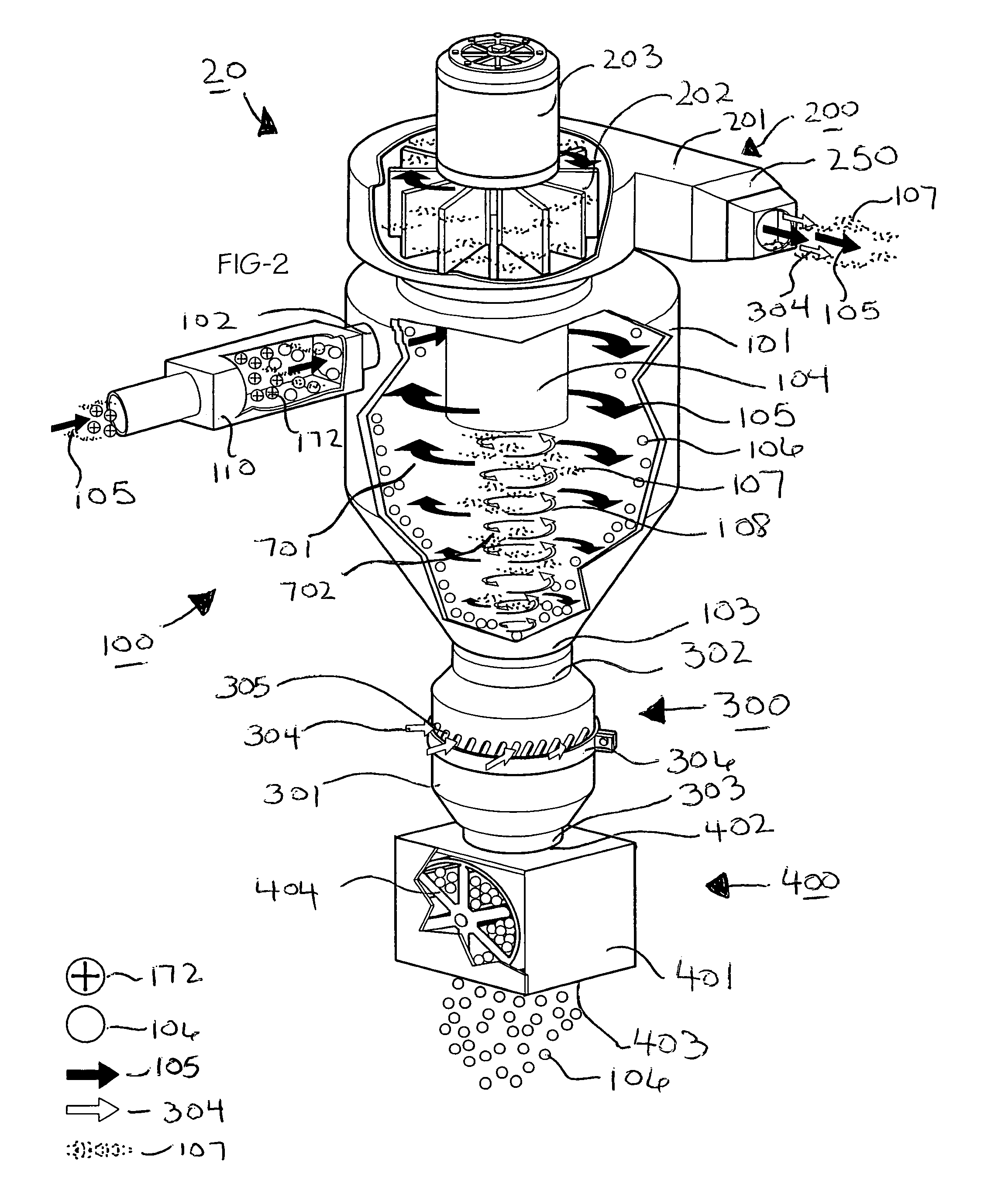

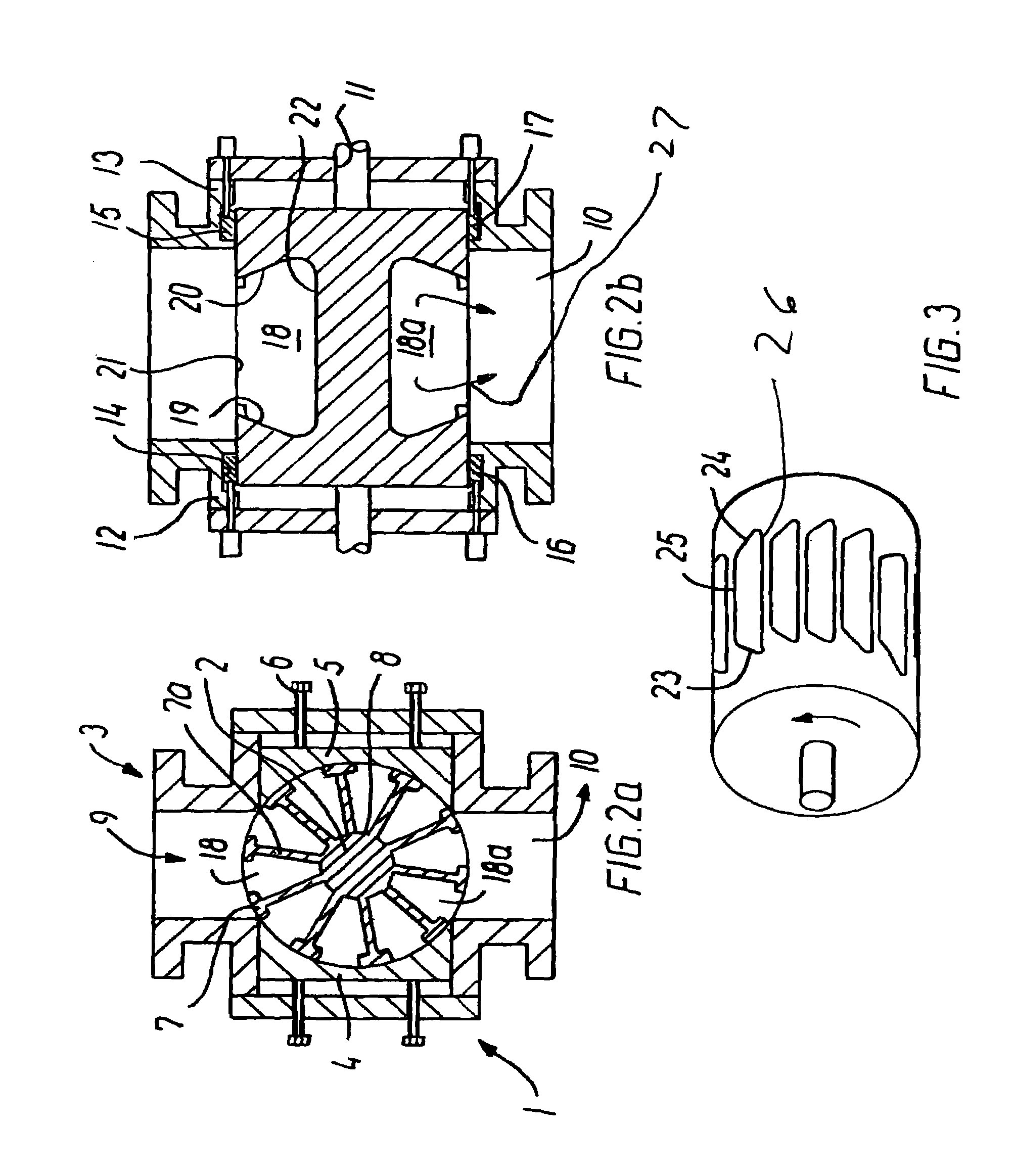

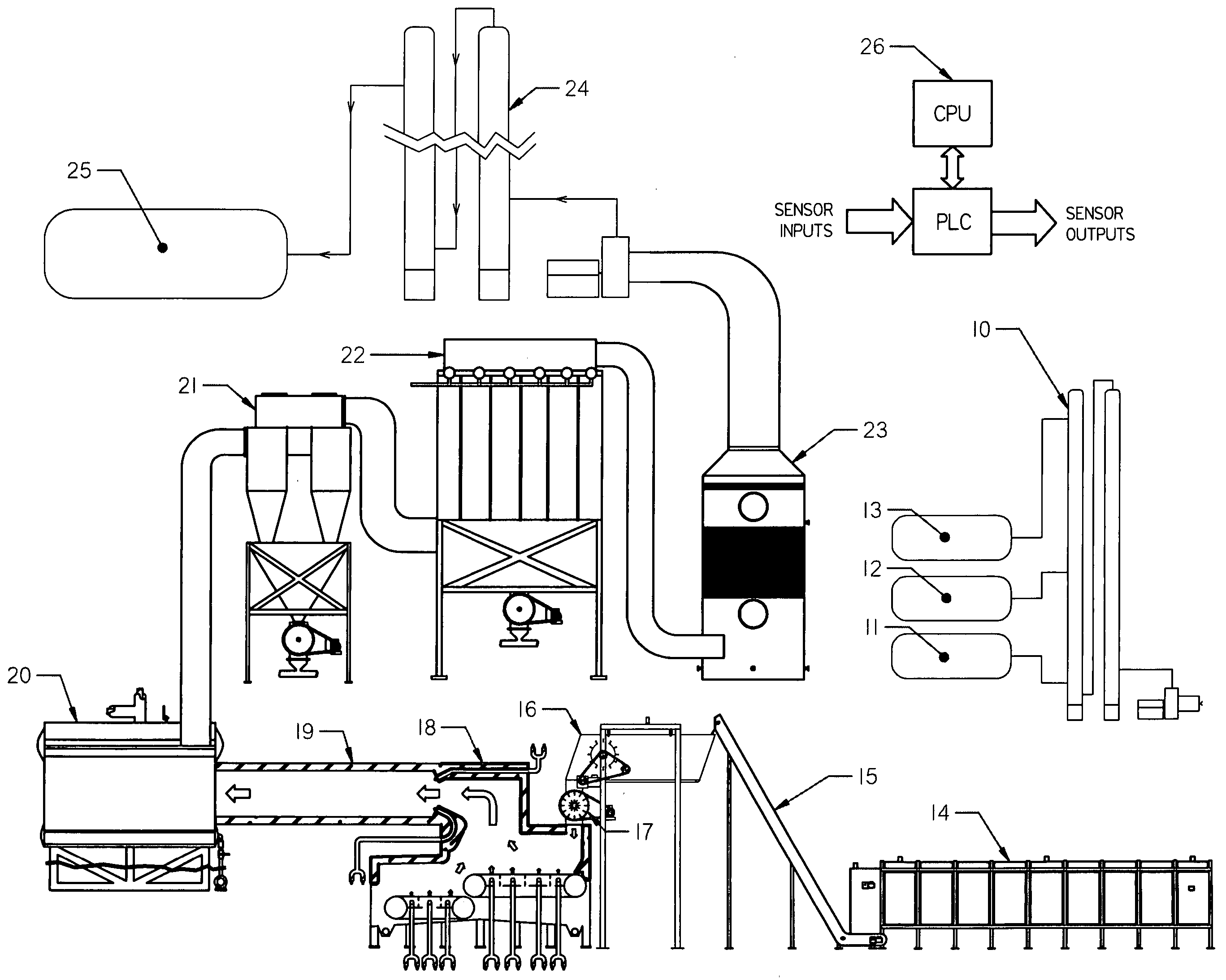

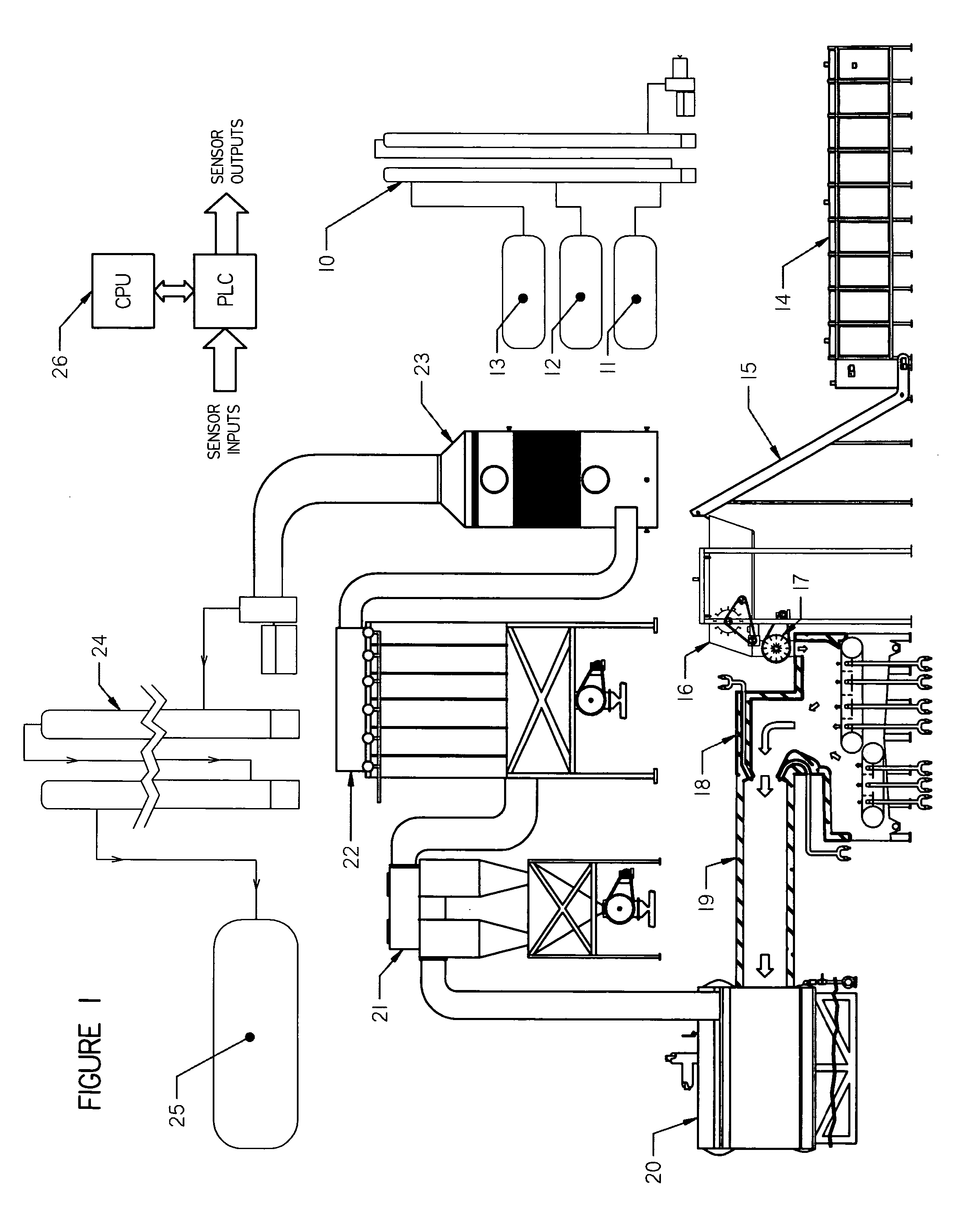

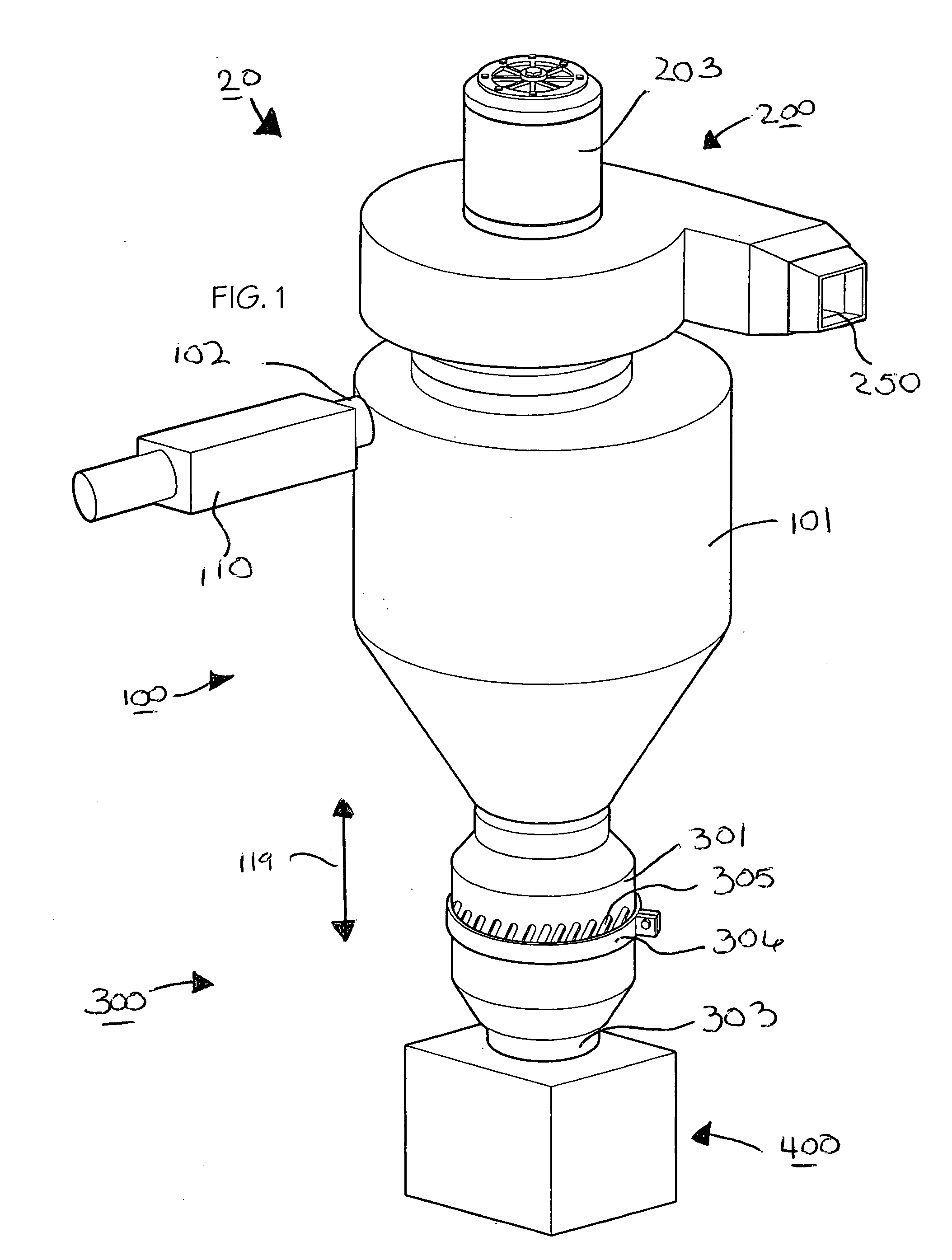

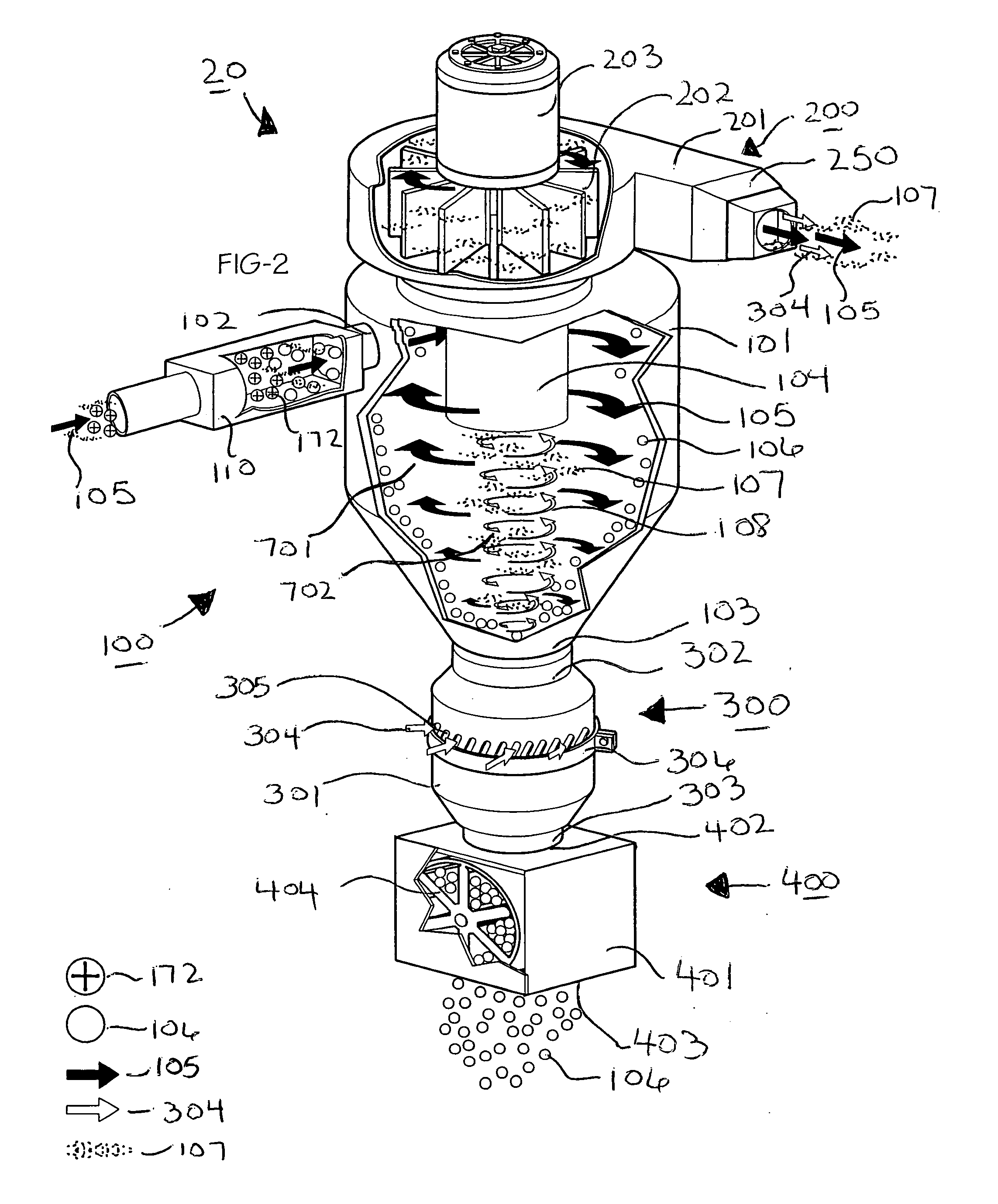

Material classifier

ActiveUS7108138B2Increase in sizeIncrease volumeCombination devicesAuxillary pretreatmentCycloneEngineering

A material classifier includes a cyclone including a cyclone inlet, a cyclone outlet, a blower and a blower discharge; an air diffuser connected at a diffuser inlet to the cyclone outlet and at a diffuser outlet to an air lock such that the cyclone and air diffuser are in fluid communication; wherein the diffuser including a central cylindrical portion including an air inlet for admitting controlled amounts of diffuser air around substantially the entire cylinder outer periphery of the central cylindrical portion, wherein the material classifier separating fine particles from coarse particles and discharging the fine particles together with air out the blower discharge, and discharging the coarse particles through the air lock, such that varying the amount of diffuser air one can control the size of the fine particles being separated from the coarse particles.

Owner:SIMPSON PETER

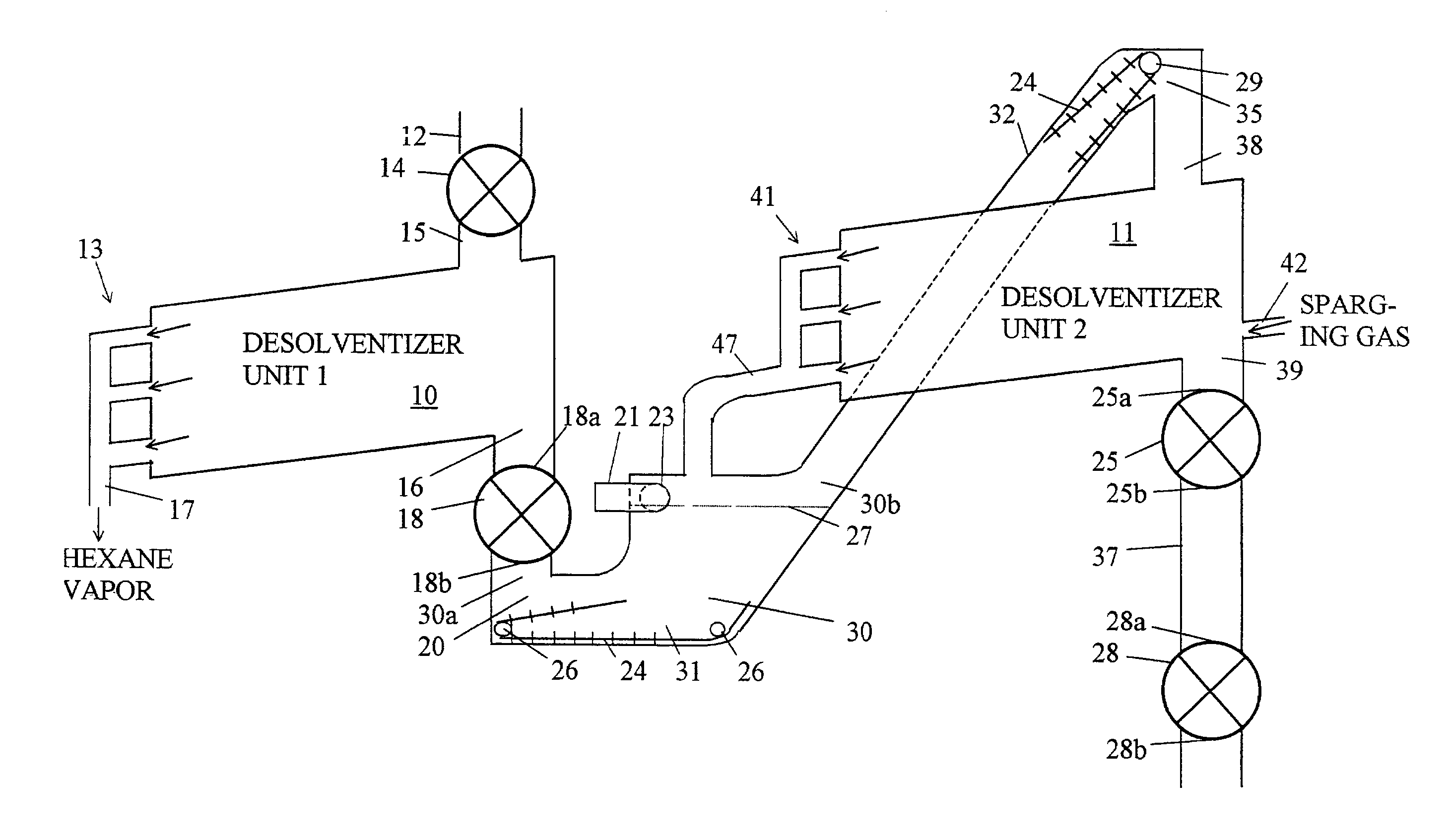

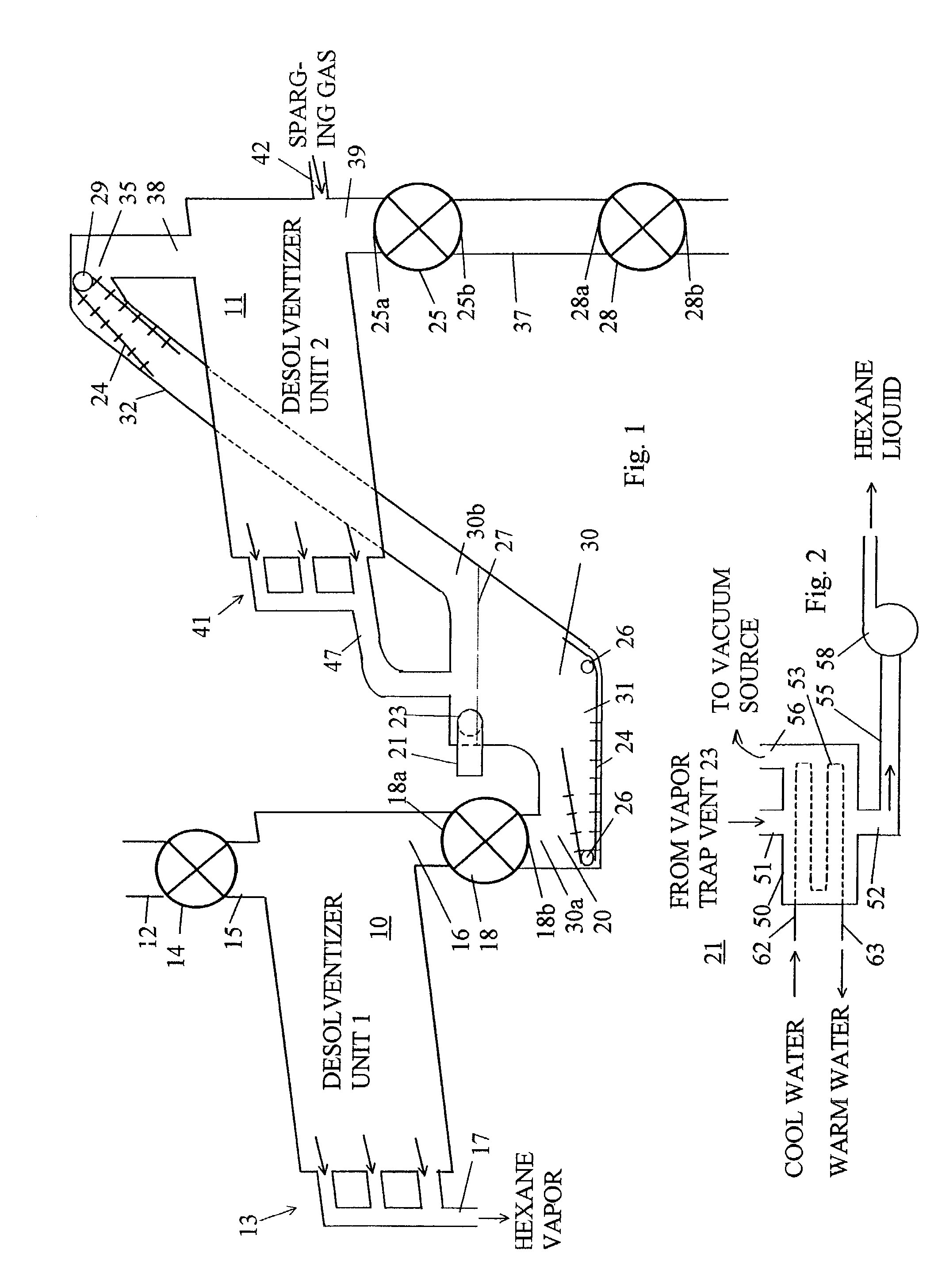

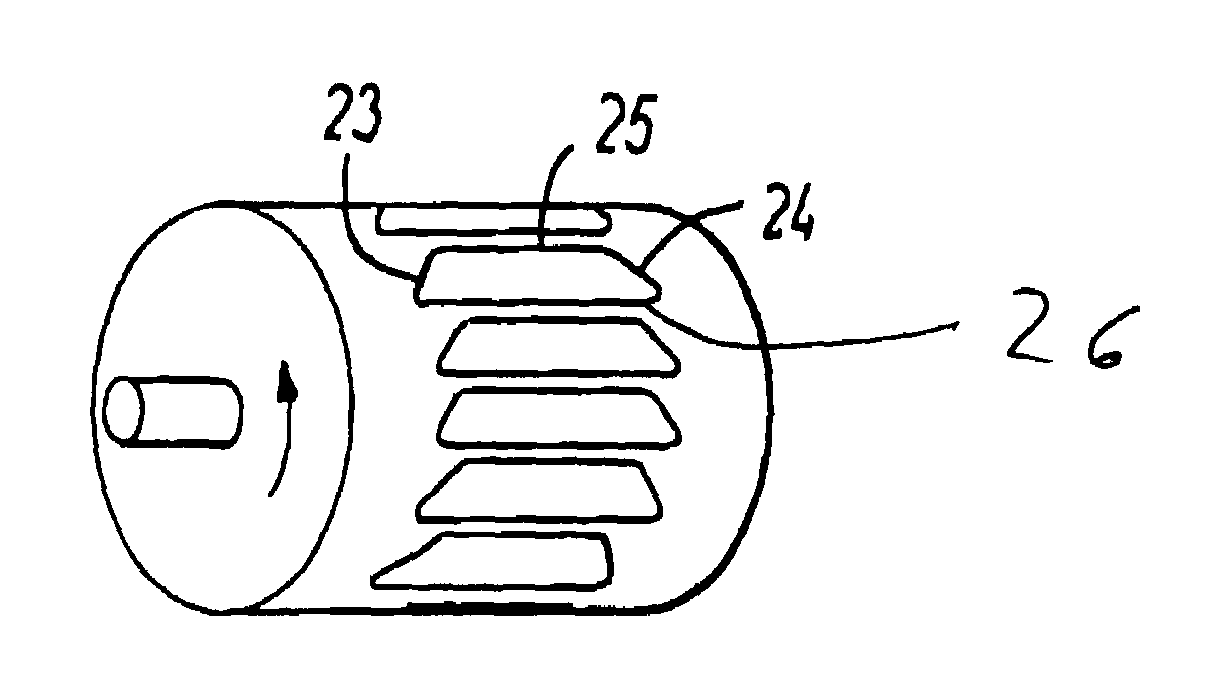

Two stage apparatus for desolventizing food grain meal

A desolventizing system for removing solvent from a quantity of solvent-laden particles such as flakes comprises first and second desolventizer units, each having an inlet port for receiving solvent-laden particles, an outlet port for discharging at least partially desolventized particles, and a solvent vapor port. A solvent trap is connected between the outlet port of the first desolventizer through a first airlock, and to the inlet port of the second desolventizer unit. Particles entering the solvent trap through the first airlock are conveyed to the inlet port of the second desolventizer. The second desolventizer unit has an airlock connected to the outlet port of the second desolventizer unit. The solvent trap has a vent preferably in the upper part of the trap for connection to a vacuum source that maintains a partial vacuum within both the solvent trap and the second desolventizer unit allowing liquid solvent and water permeating particles within the second desolventizer unit to vaporize efficiently at a relatively low temperature. Solvent vaporized in each desolventizer unit can be drawn out through the solvent vapor port of the desolventizer unit for further processing and later reuse.

Owner:CROWN IRON WORKS

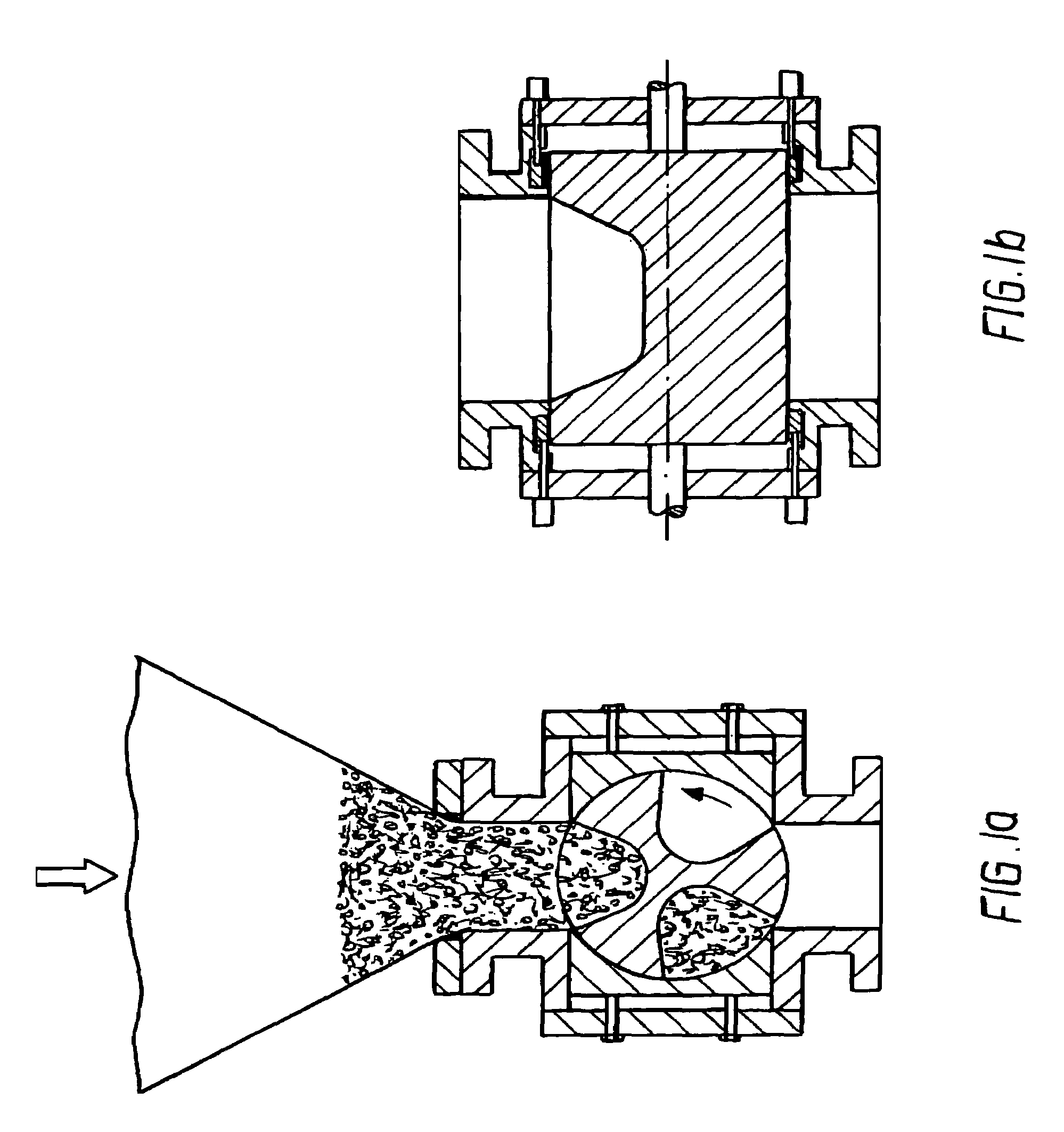

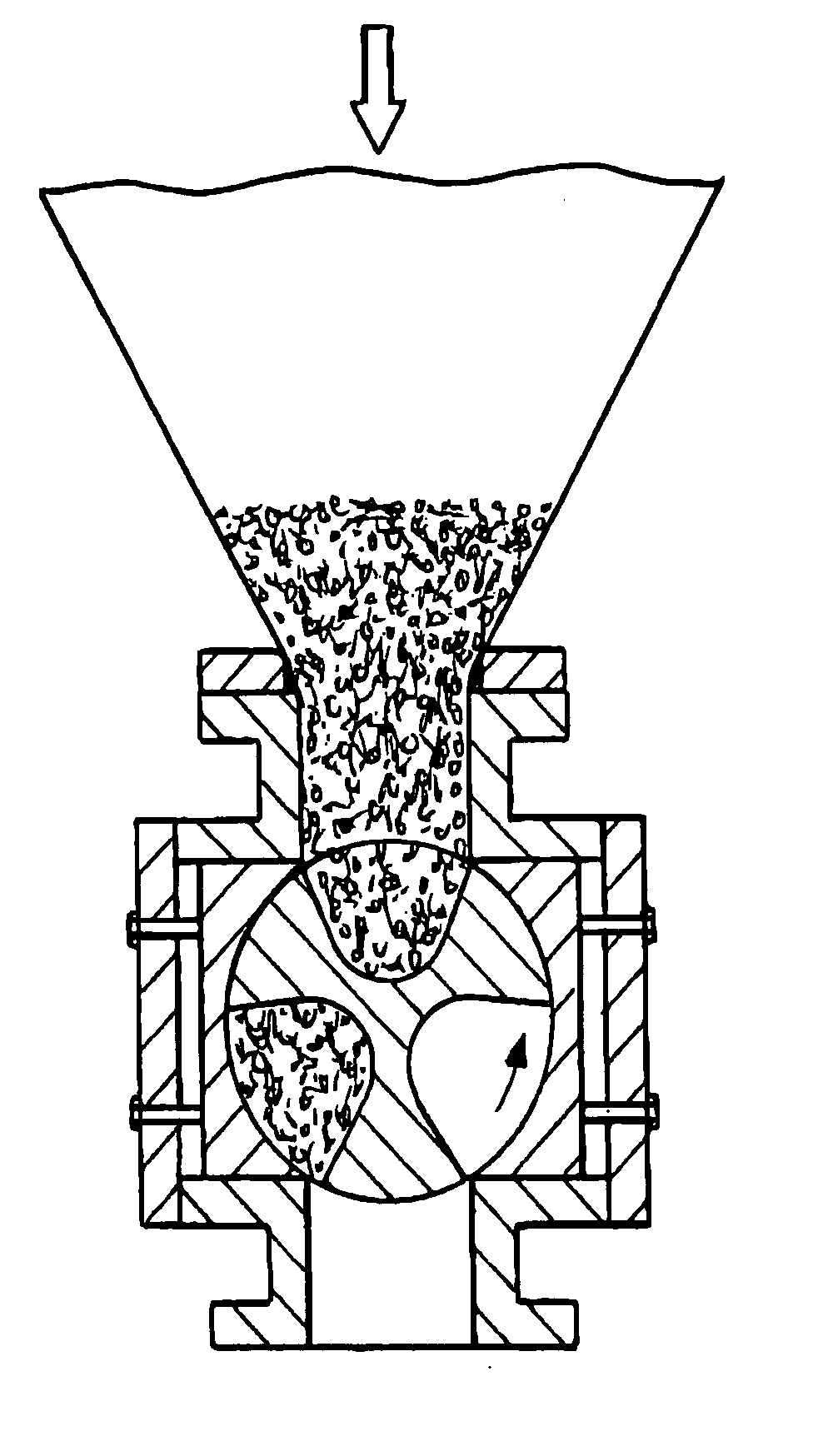

Rotary airlock valve

ActiveUS6966466B2Reduce wearDifficult to handleMovable measuring chambersBulk conveyorsLeading edgeThermal expansion

A rotary airlock valve has a plurality of material receiving pockets having leading edges that are narrower than the trailing edges thereof, preferably having walls tapering inwardly so as to define a narrowed pocket opening for directing any material expansion due to pressurization to a center of a discharge outlet, to reduce wear and increase seal life.

Owner:ASJ HLDG

Device and Process for Plasma Coating/Sterilization

InactiveUS20080032059A1Simple designImprove efficiencyElectric shock equipmentsElectric discharge tubesPlasma coatingEngineering

A device for treating containers such as bottles, preferably PET containers, such as PET bottles, with a plasma, whereby the device is designed for sterilizing and / or coating the containers. In addition, the device also relates to a method for treating containers, preferably PET containers such as PET bottles, with a plasma, whereby the treatment comprises sterilization and / or the coating of the containers. Also provided is an airlock for containers such as bottles, in particular PET containers such as PET bottles, having cells to receive the containers, at least one cell being designed to receive at least two containers.

Owner:KRONES AG

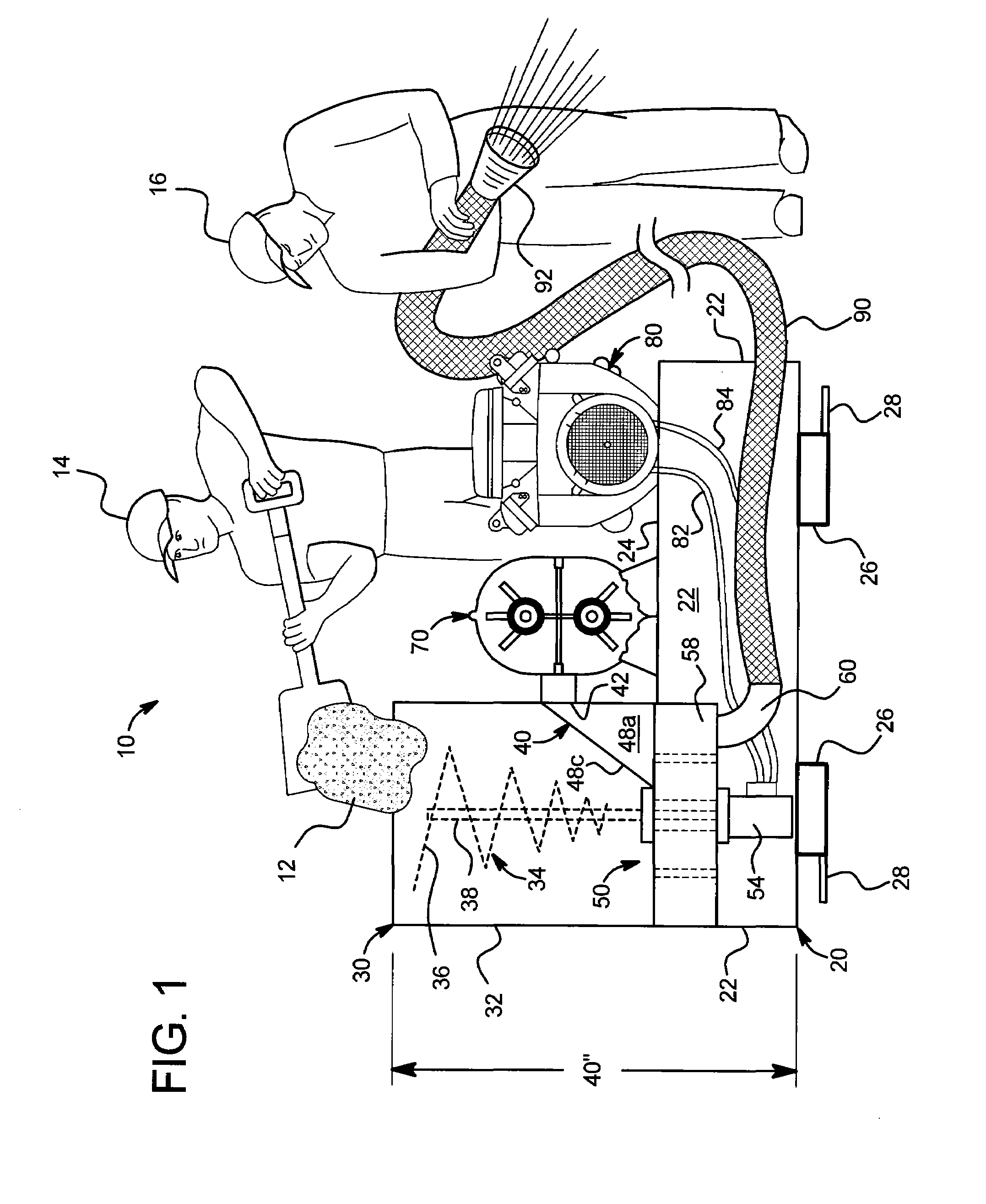

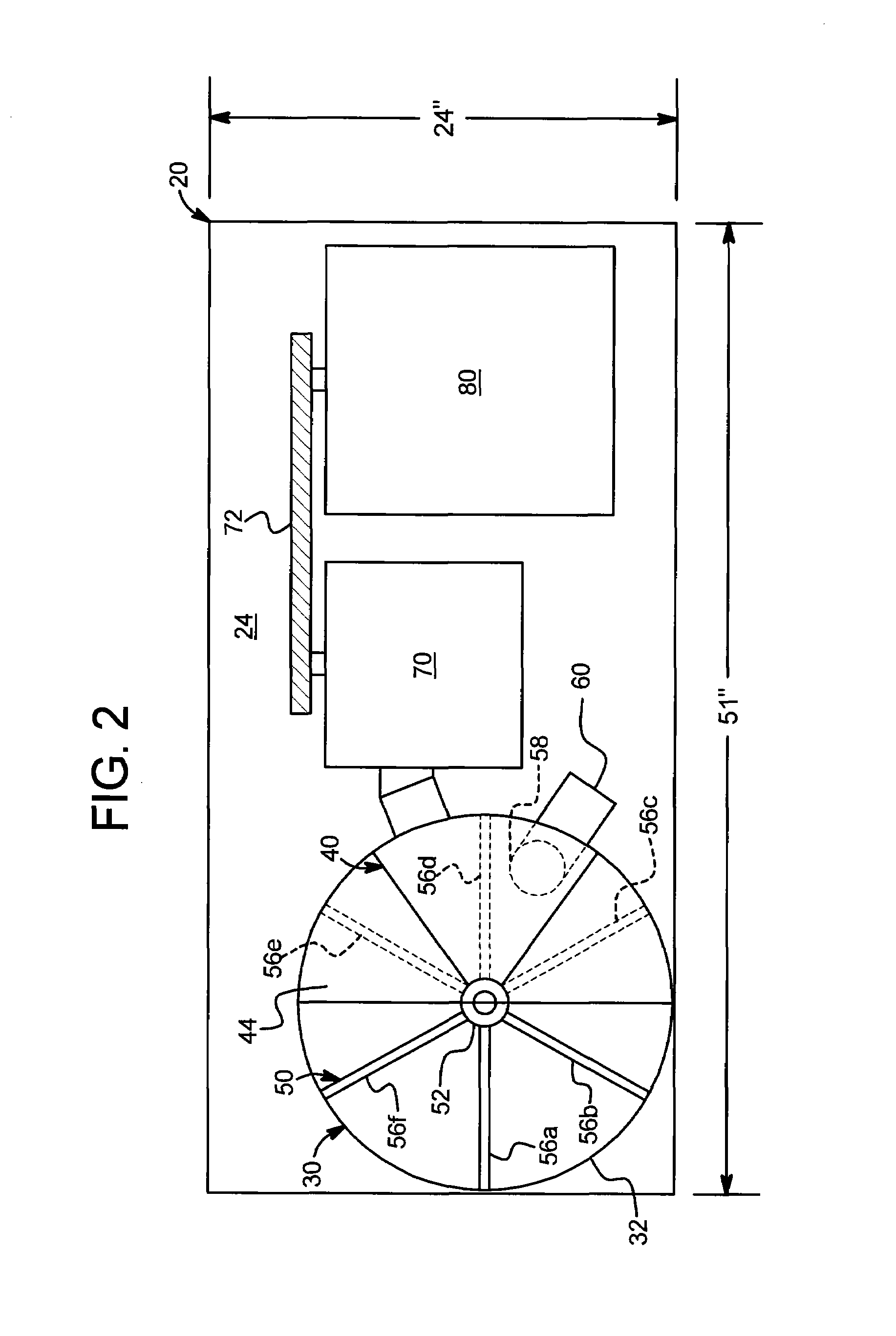

Portable pneumatic blower

A portable unit for pneumatically blowing landscaping and / or building materials, such as bark, mulch, fertilizer, compost, wood chips, grass clippings, leaves, gravel / stone, straw, hay, sawdust and combinations thereof is provided. The unit is transportable by: a car trailer, truck trailer, garden tractor trailer; on stakes of a stake bed truck; by a three point hitch; by a forklift and any combination thereof. The unit includes a hopper having an integral airlock feeder in one preferred embodiment. The unit either includes an on-board power supply device, such as an engine, or provides connections for receiving power remotely.

Owner:FINN CORP

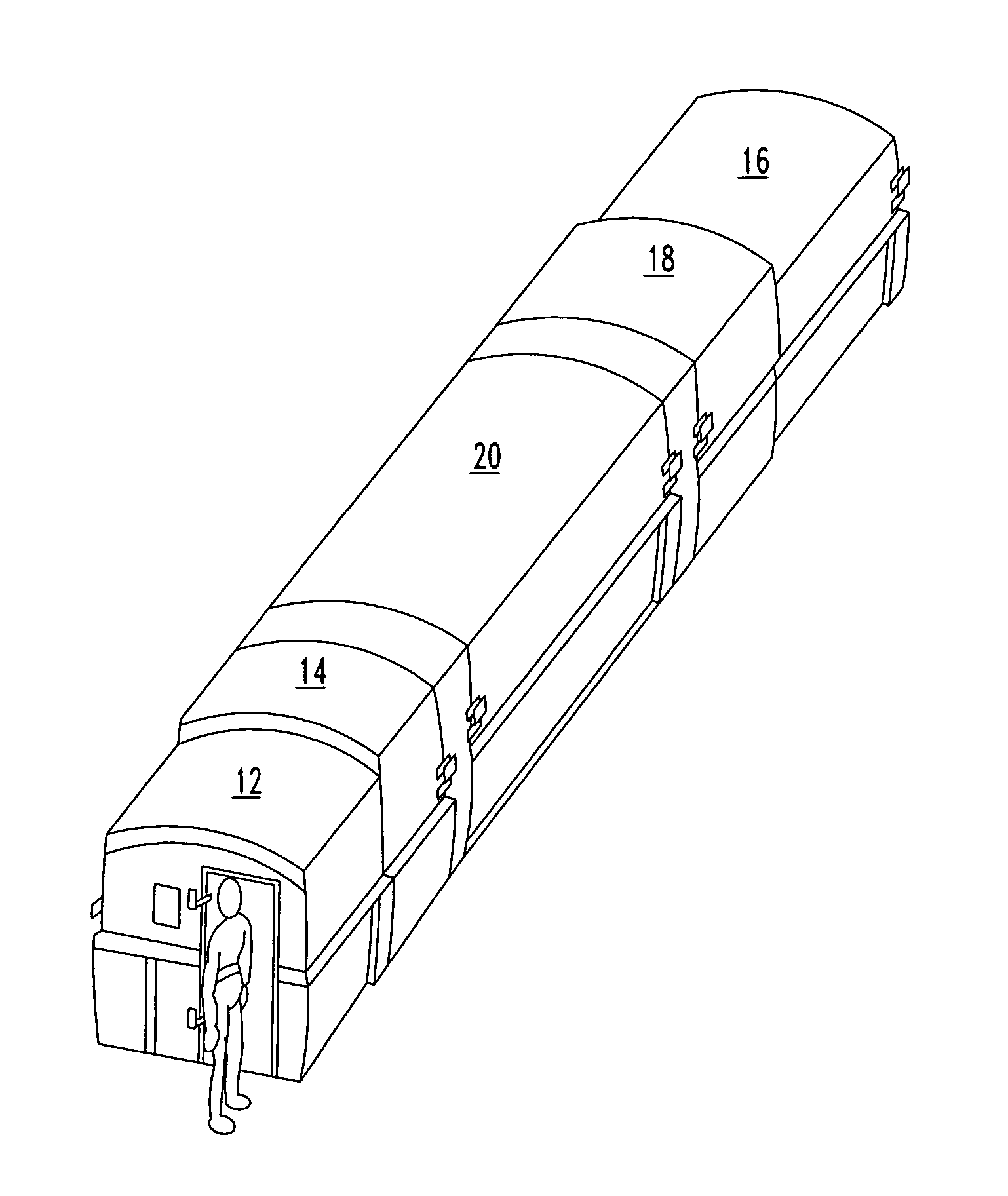

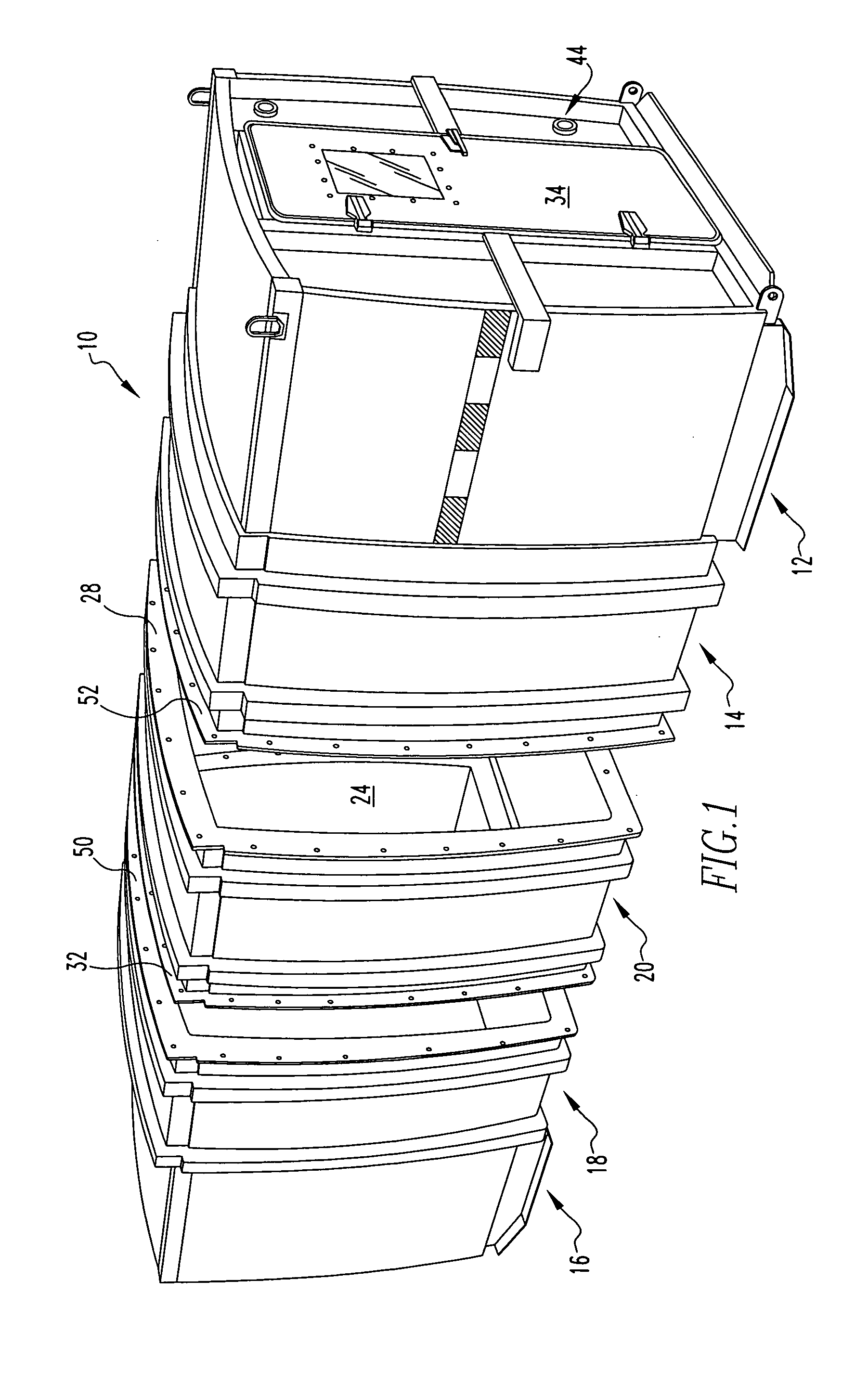

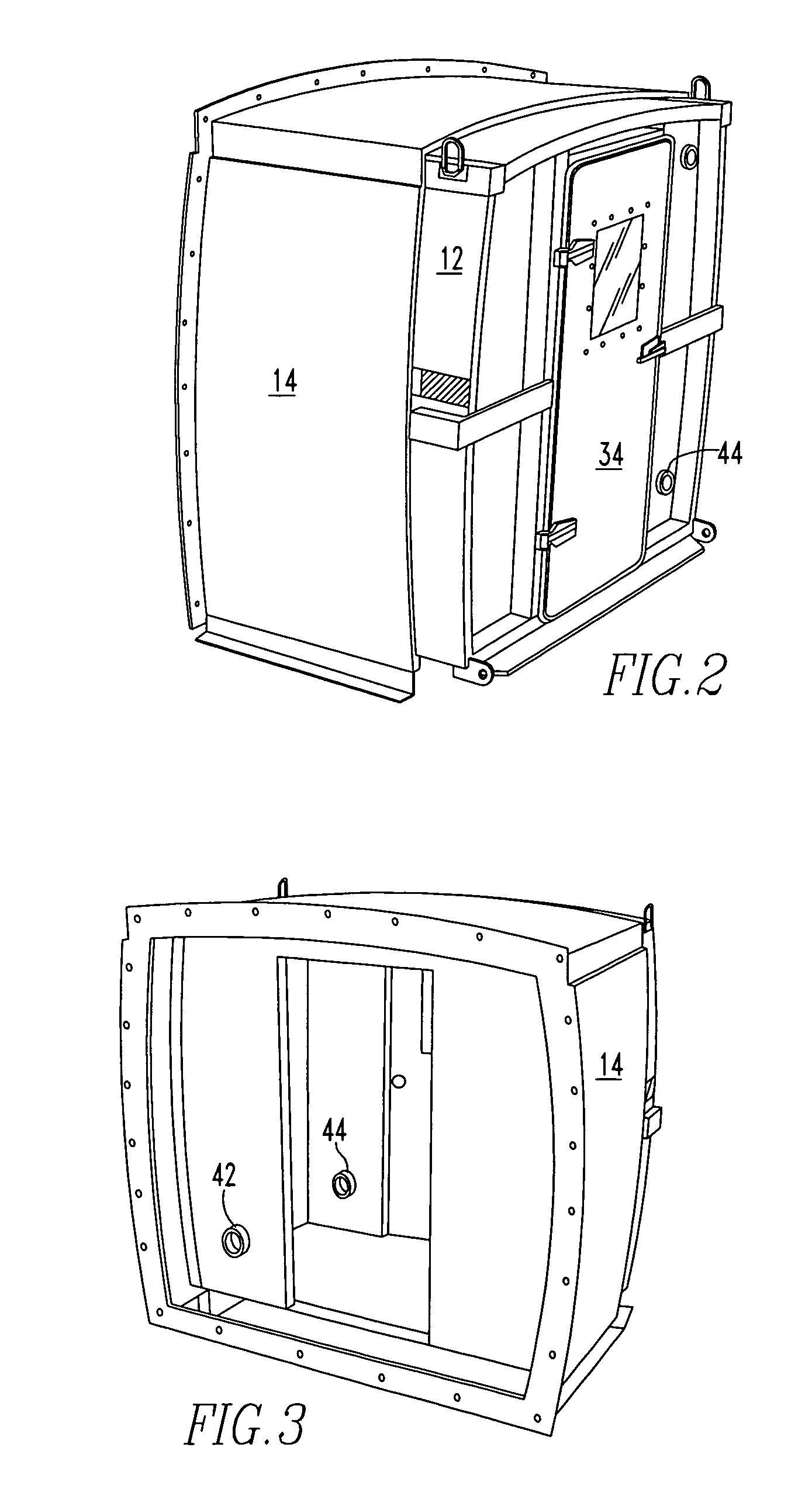

Modular shelter and method

A shelter to protect users from an external environment has an inner front module having an airlock and an outer front module which is slidingly attached to the inner front module. The shelter has an inner rear module and an outer rear module sliding attached to the inner rear module. When the outer front module and the inner front module are in an extended state and the outer rear module and the inner rear module are in an extended state and the outer front module and outer rear module are attached, they form an airtight chamber in which users are protected from the external environment. A method for constructing a shelter to protect users from an external environment.

Owner:STRATA PRODS WORLDWIDE

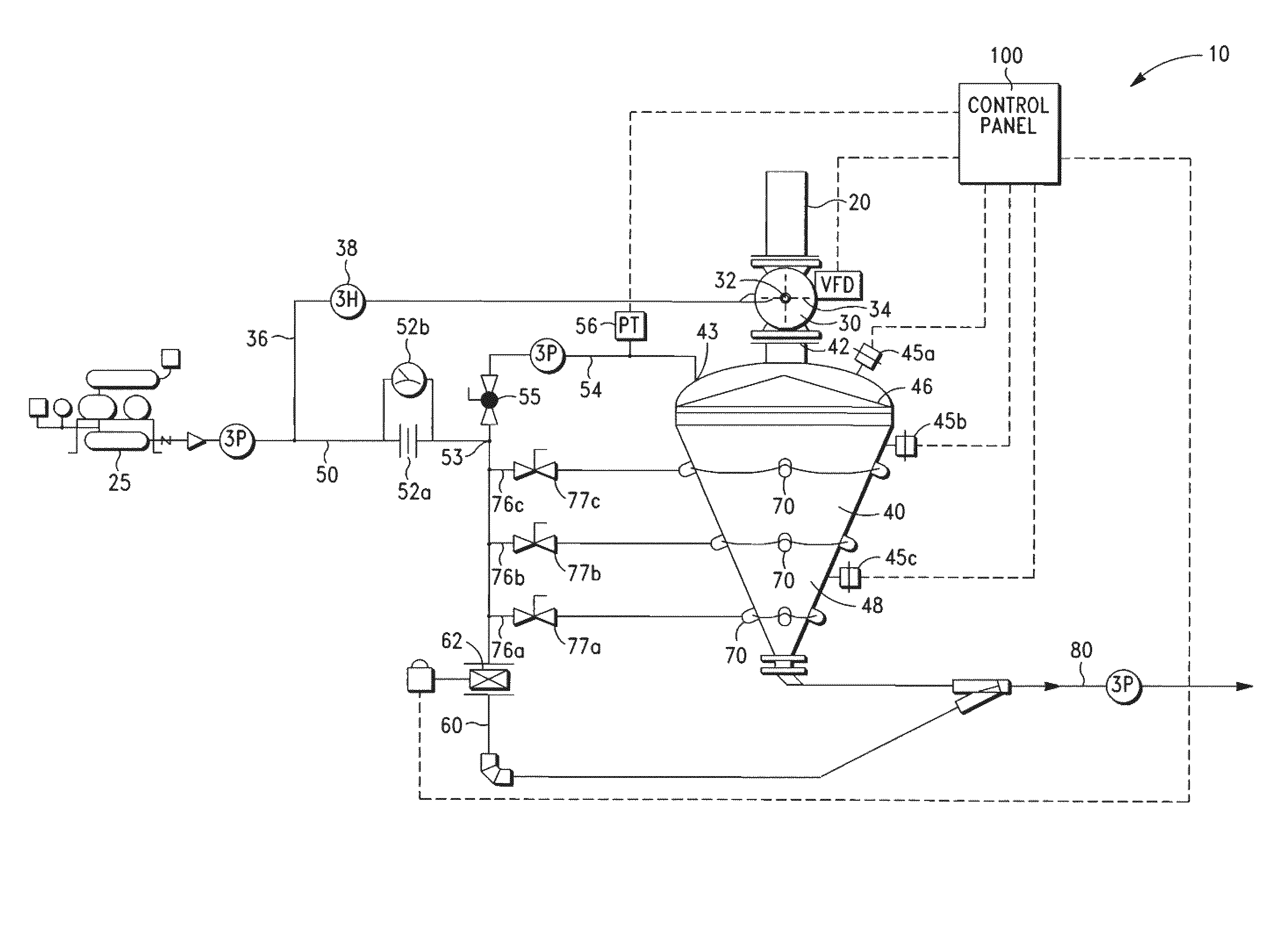

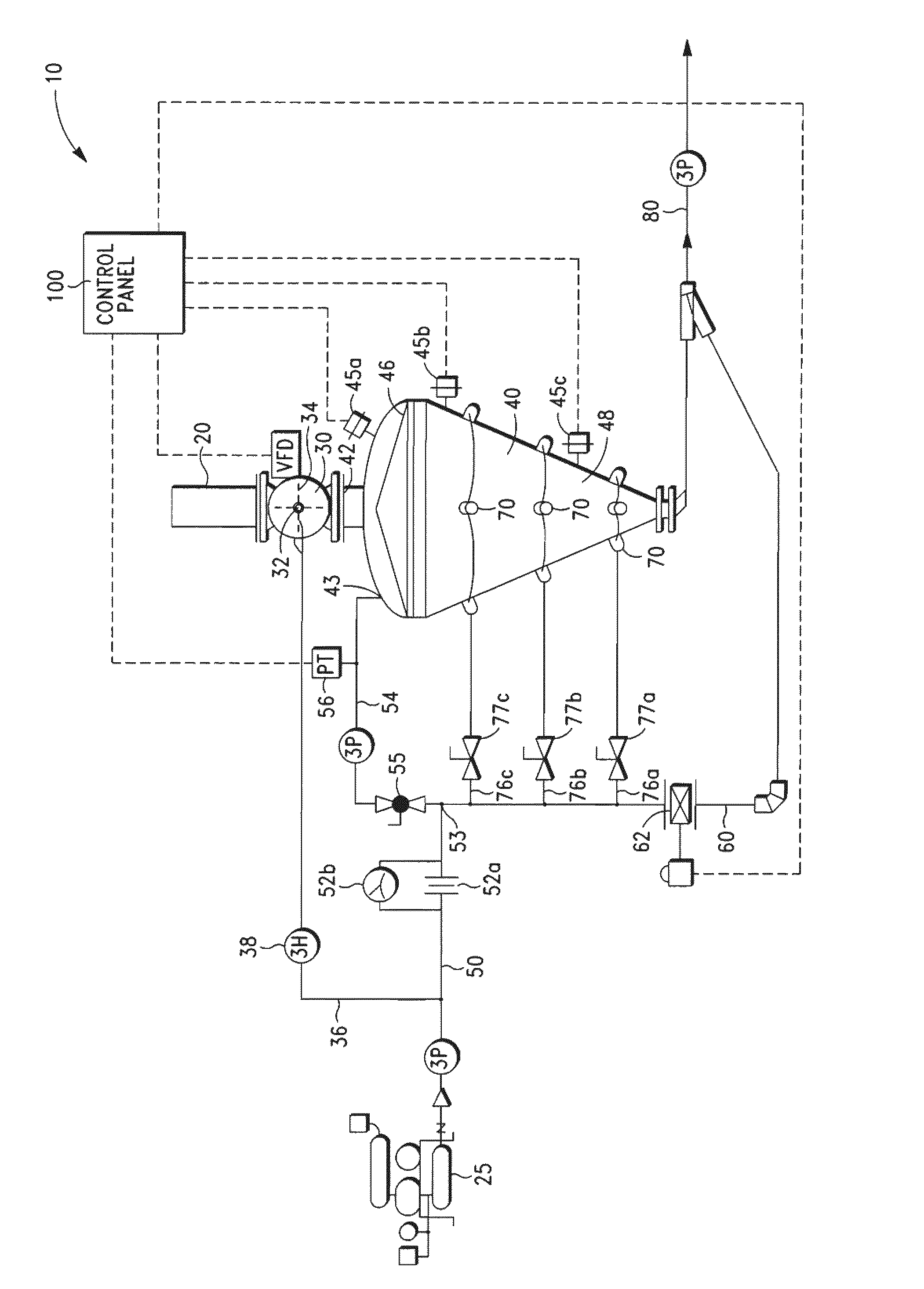

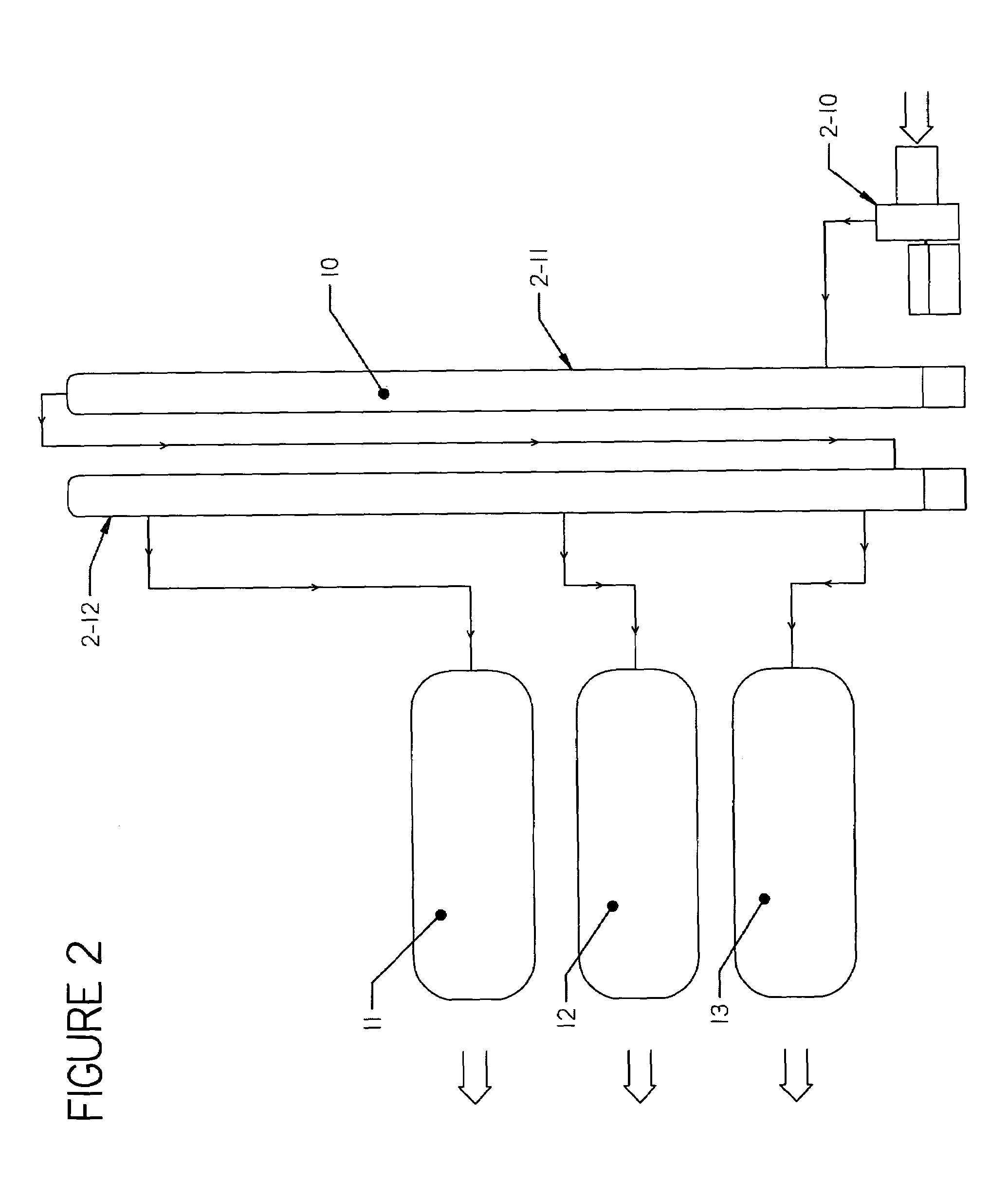

Continuous semi-dense pneumatic conveying system and method

A continuous semi-dense phase conveying system comprising a vessel having a gas inlet, a particulate material inlet, and a gas and particulate material outlet, which has an operating pressure of about 15 psig or less. The system includes a rotary airlock valve for feeding particulate material into the vessel and a pressurizing gas supply which branches into a feed gas line and a bypass line. A pneumatic conveying line coupled to the gas and particulate material outlet of said the and coupled to the bypass line. The pressure of the vessel is controlled using a bypass valve on said bypass line and optimize the flow of gas and particulate matter through the pneumatic conveying line.

Owner:MAGNUM SYST

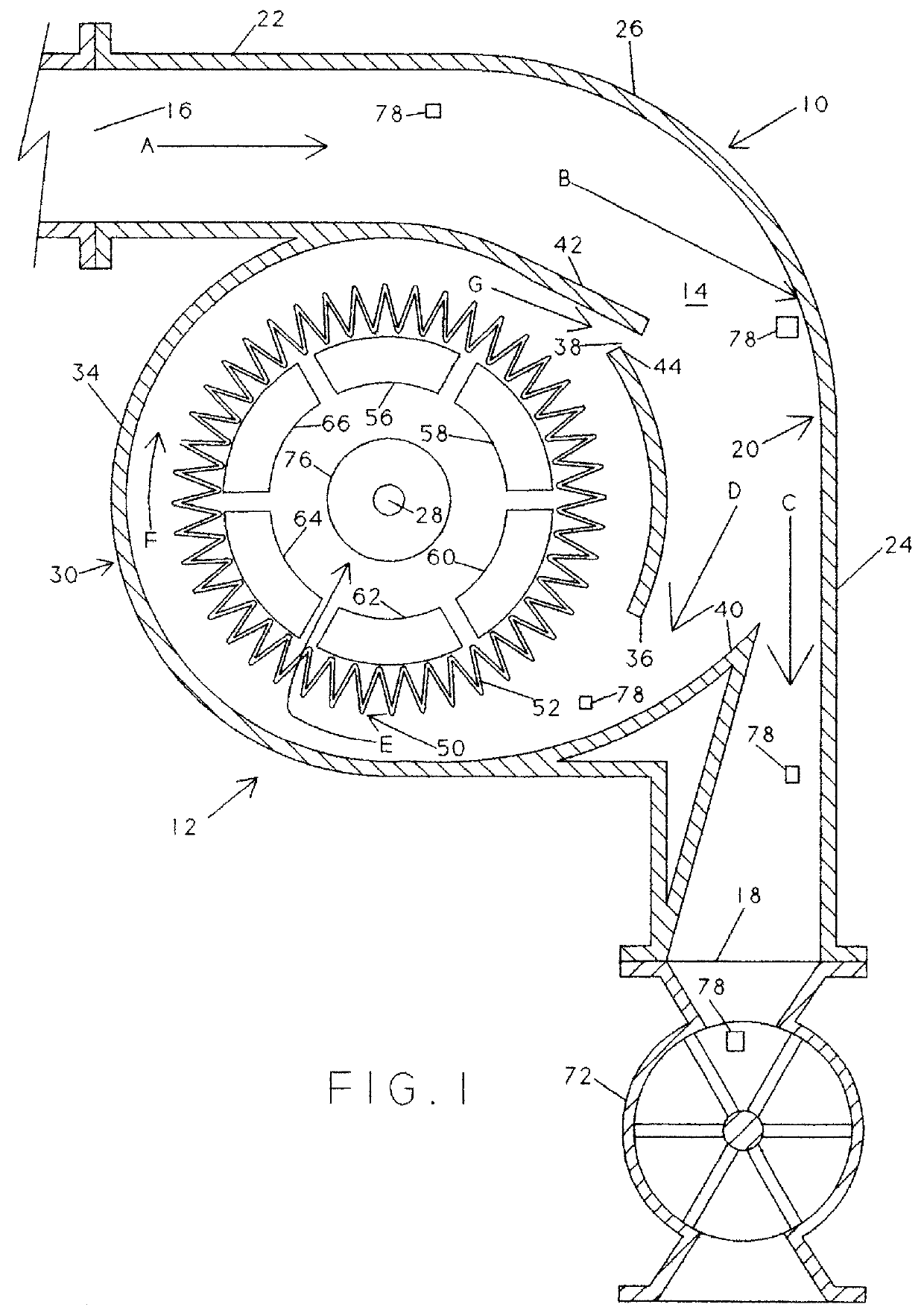

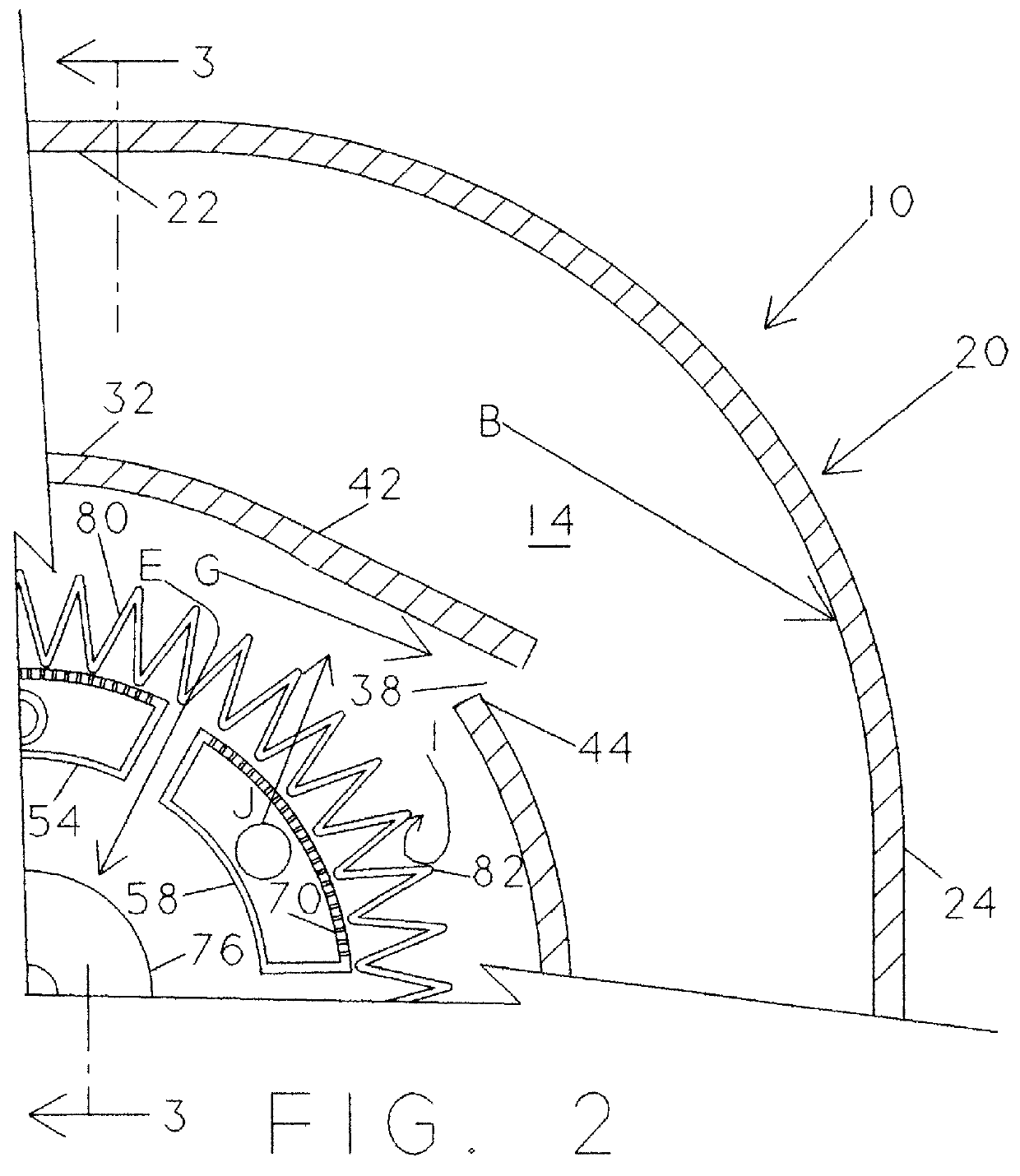

Cyclonic dust collector

InactiveUS6032804AReduce rateSmall sizeCombination devicesGas current separationCycloneHigh velocity

A method and apparatus for collecting and removing dust from dust laden air has a housing defining a chamber having an inlet for the dust laden air, a first outlet for dust free air and a second outlet for the collected dust, the inlet and second outlet being connected by a curved wall. A filter cartridge is mounted in the chamber at the axis of the curved wall and is at least partially enclosed within and inner wall which, together with the outer wall forms a cyclonic passage for the air passing therethrough. High velocity air flow is directed into the chamber wherein at least some of the dust will strike the chamber wall at high velocity causing a rapid change in kinetic energy and detraining the dust from the air, this dust then falling from the air stream and removed from the chamber through an air lock or similar device. The air then revolves around and is drawn through the filter removing the remaining dust therefrom. Periodically, bursts of reverse flow air are sent through segments of the filter to cause dust lodged therein to be reentrained in the flowing air and carried to the dust exit.

Owner:PELLETRON CORP

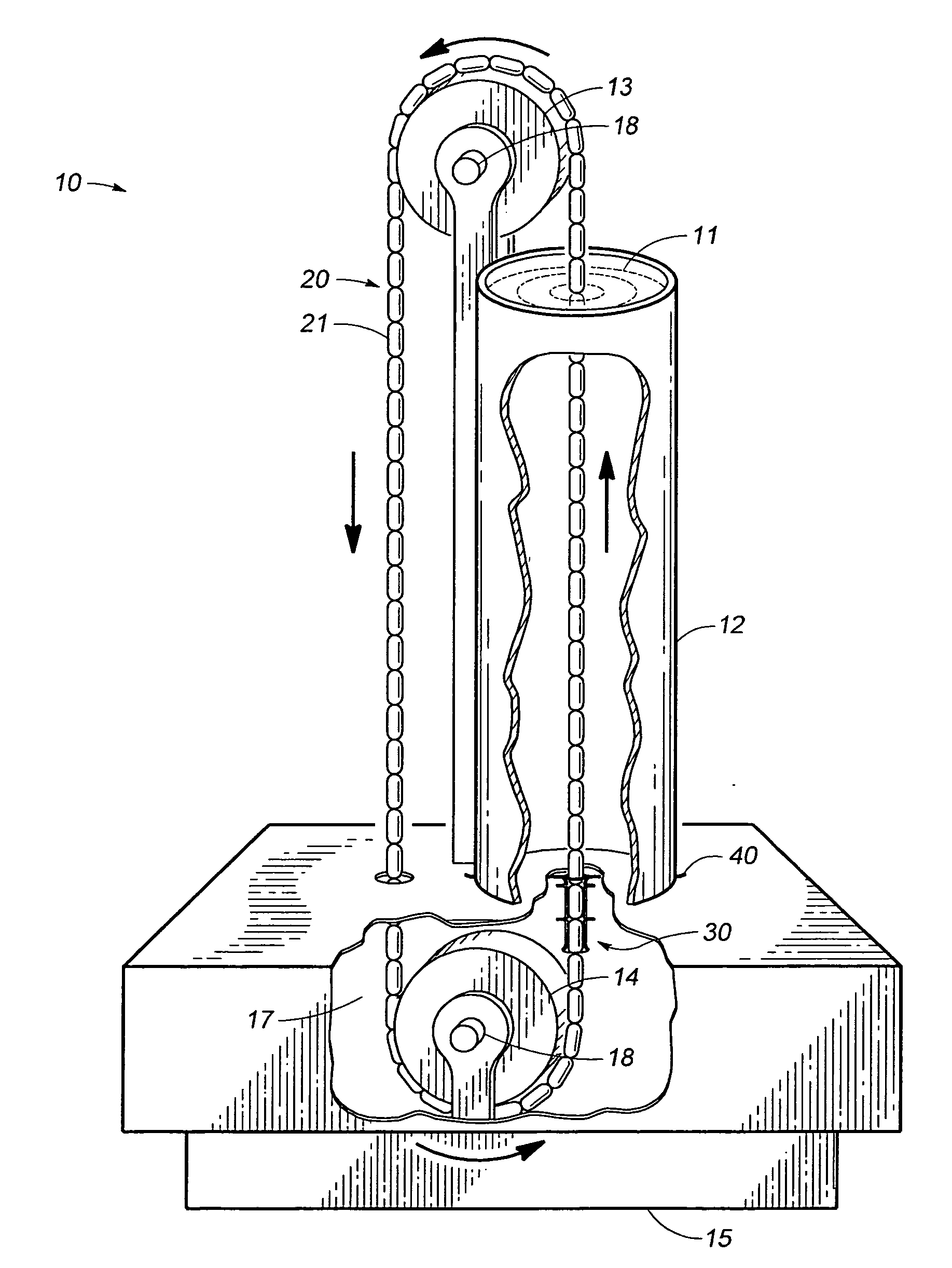

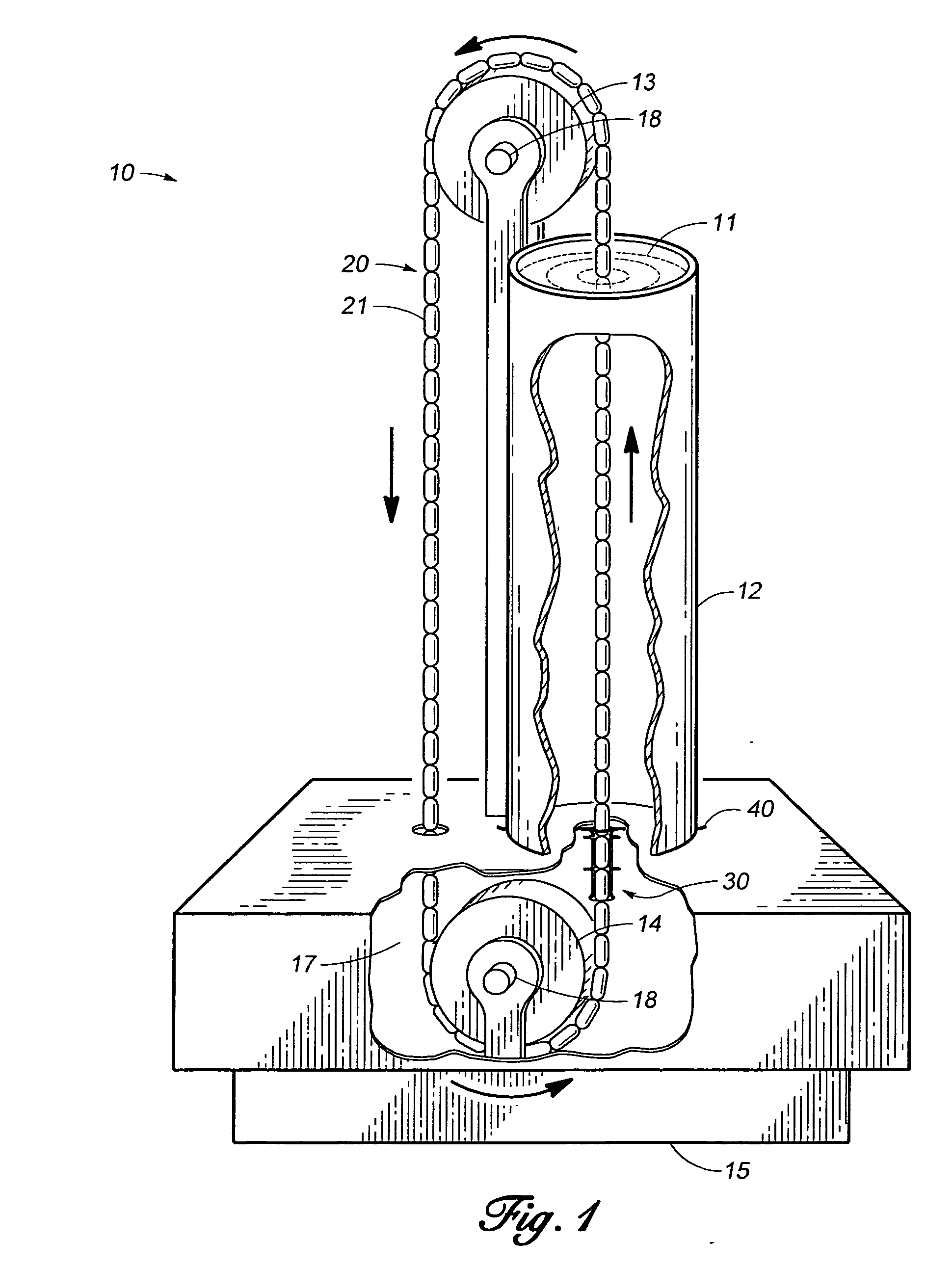

"Closed Loop" Economy of Motion Machine

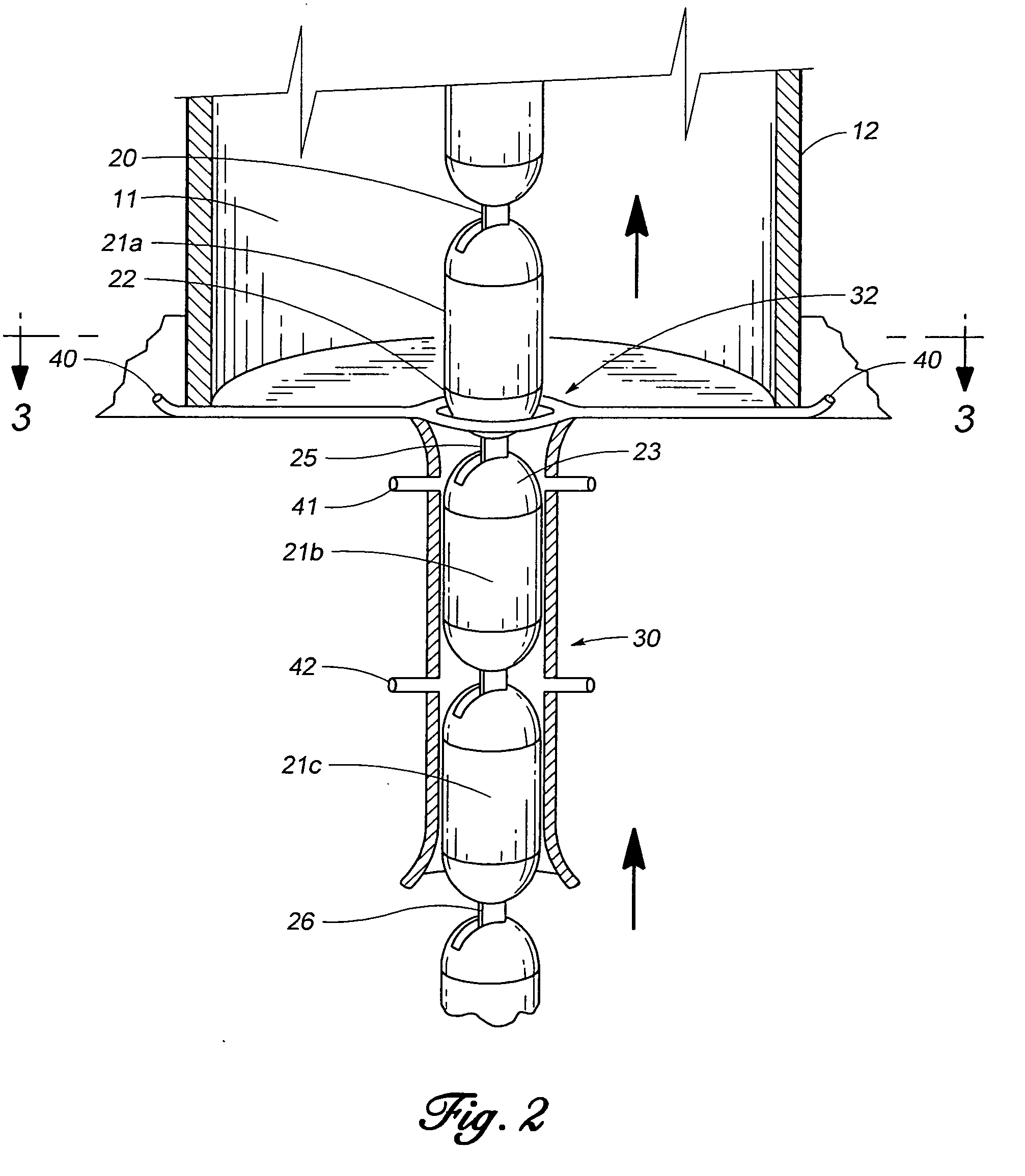

InactiveUS20100223922A1Preventing working fluid lossIncrease power generationHydro energy generationMachines/enginesDifferential pressureMechanical wear

A means and apparatus for fluid containment providing for closed loop operation of an apparatus within a column of liquid. The apparatus extracts power from a buoyant source within the contained column of liquid and is comprised of an endless chain of movable buoyant objects, a means to convert the movement of the chain into useful work and a tank filled with a constant volume column of liquid. The buoyant objects comprising the chain sequentially enter the bottom of the liquid column through an airlock seal of the current invention, move up through the column and emerge at the surface. The emerging buoyant objects leave the tank and are directed to the tank bottom where each buoyant object repeats the cycle. As the chain of buoyant objects cycles through the displaced column of liquid, the volume of liquid remains constant, with one buoyant object of the chain entering the bottom of the liquid column as one is exiting at the top surface. The invention provides for closed loop operation of the apparatus and increased control fluid flow rates within the apparatus to addresses liquid leakage due to mechanical wear at seals and to provide a controlled method for removal of friction generated heat within the apparatus. Chambered sections within the apparatus create fluid flow restriction zones where differential pressure can be controlled to further reduce the force requirement for injecting each buoyant object (a.k.a. displacing element) into the bottom of the contained column of liquid.

Owner:MCGAHEE VINCENT DEPAUL

Stirling cycle machine

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. An airlock is included between the workspace and the crankcase and a seal is included for sealing the workspace from the airlock and crankcase. A burner and burner control system is also included for heating the machine and controlling ignition and combustion in the burner.

Owner:NEW POWER CONCEPTS

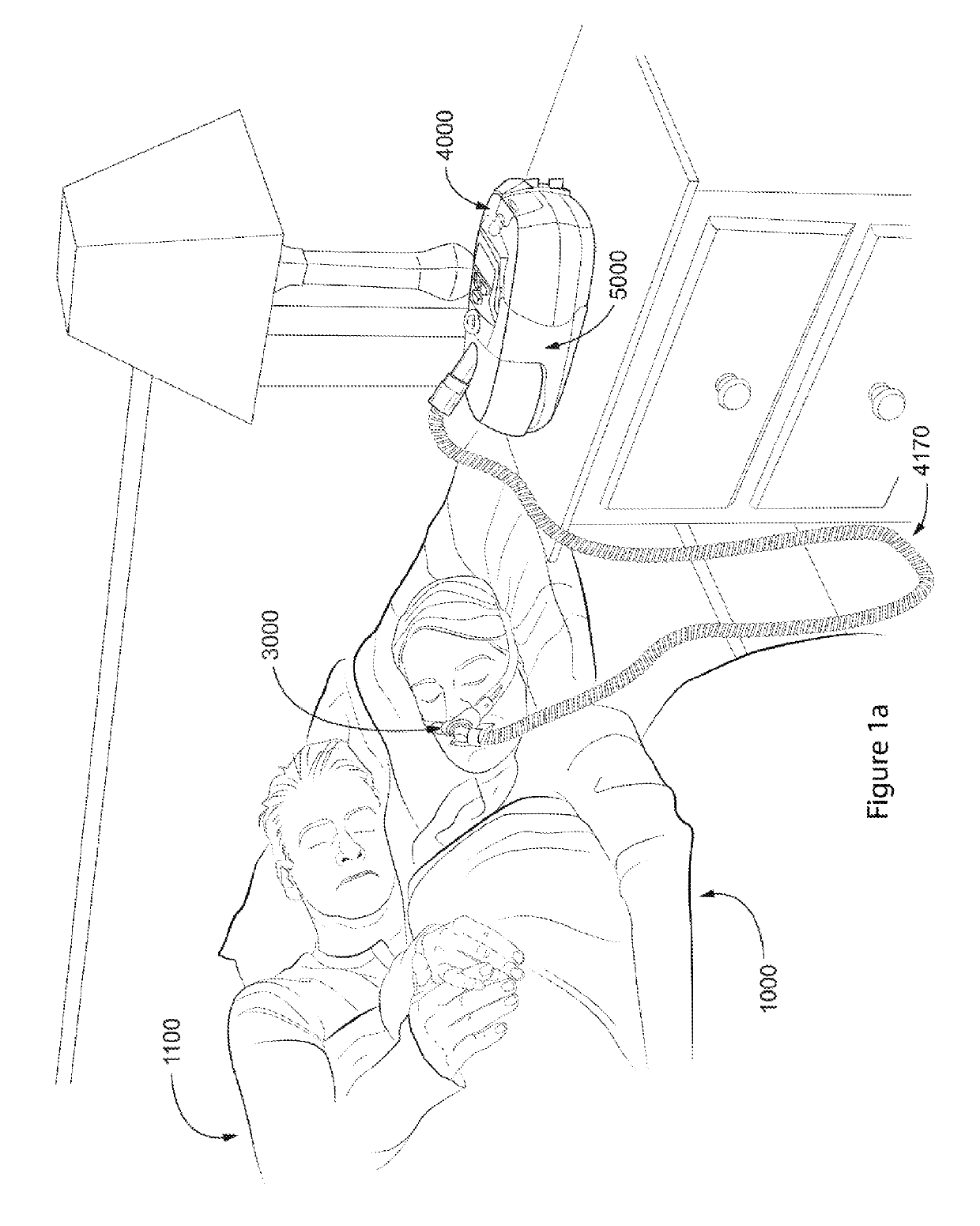

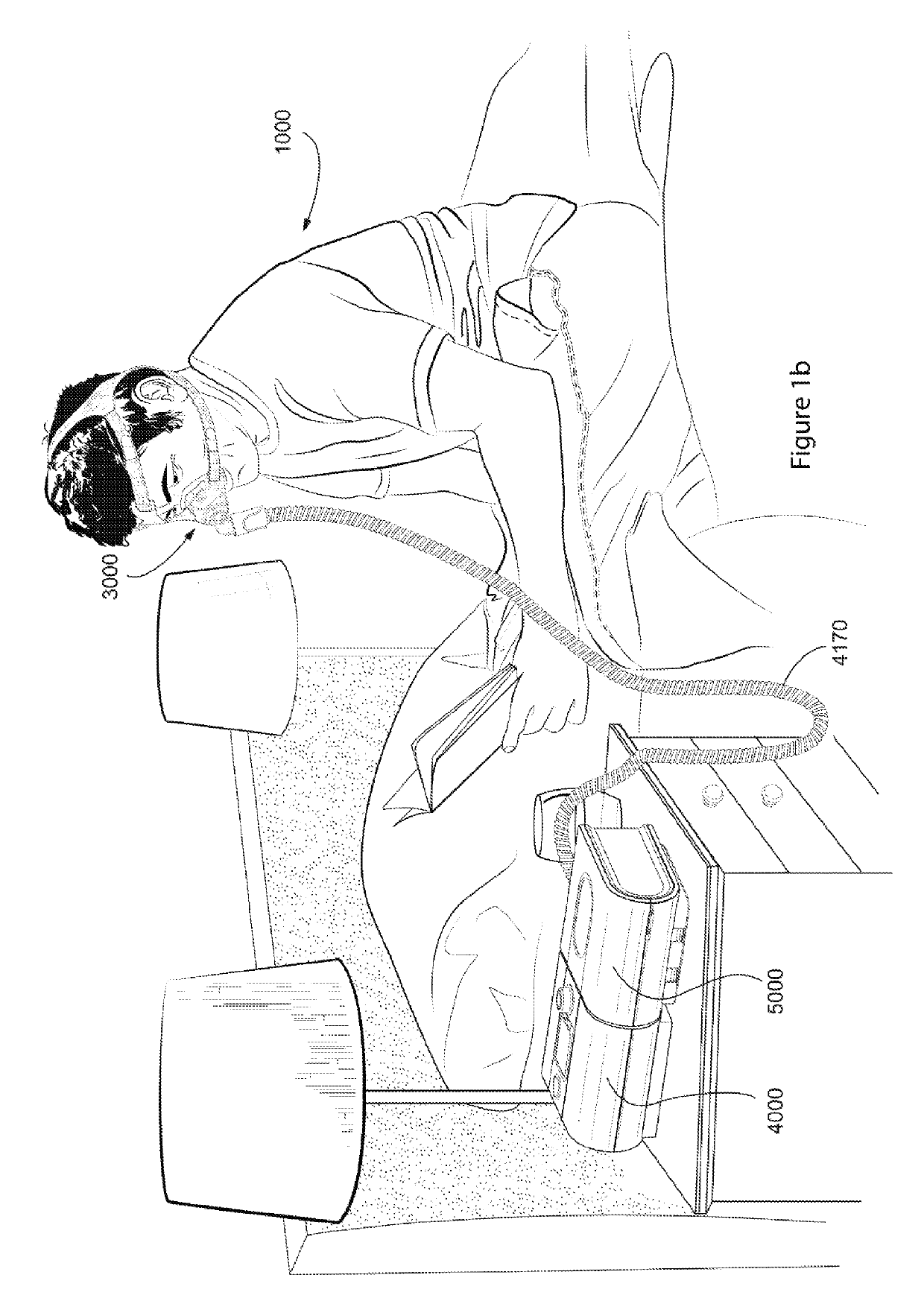

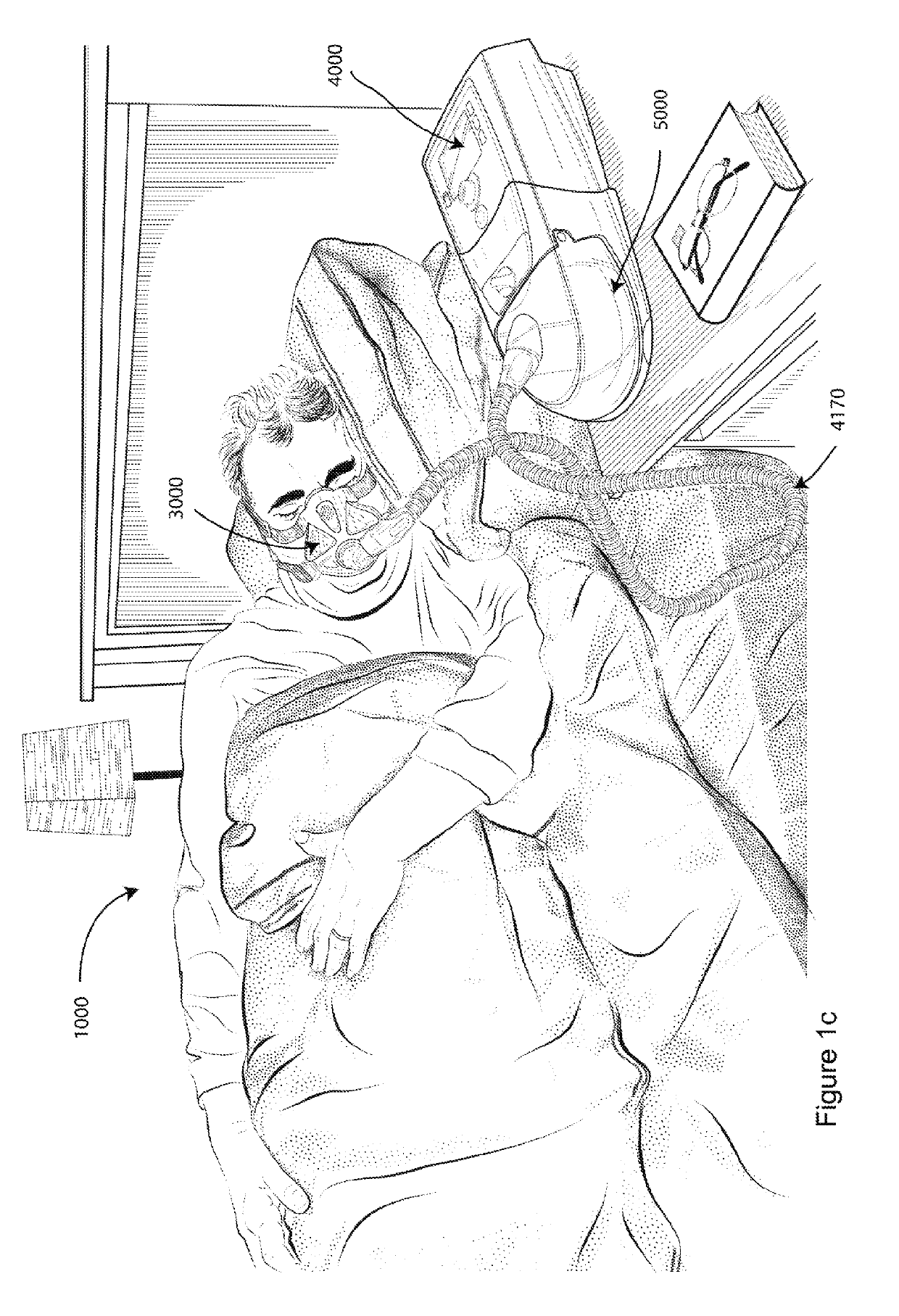

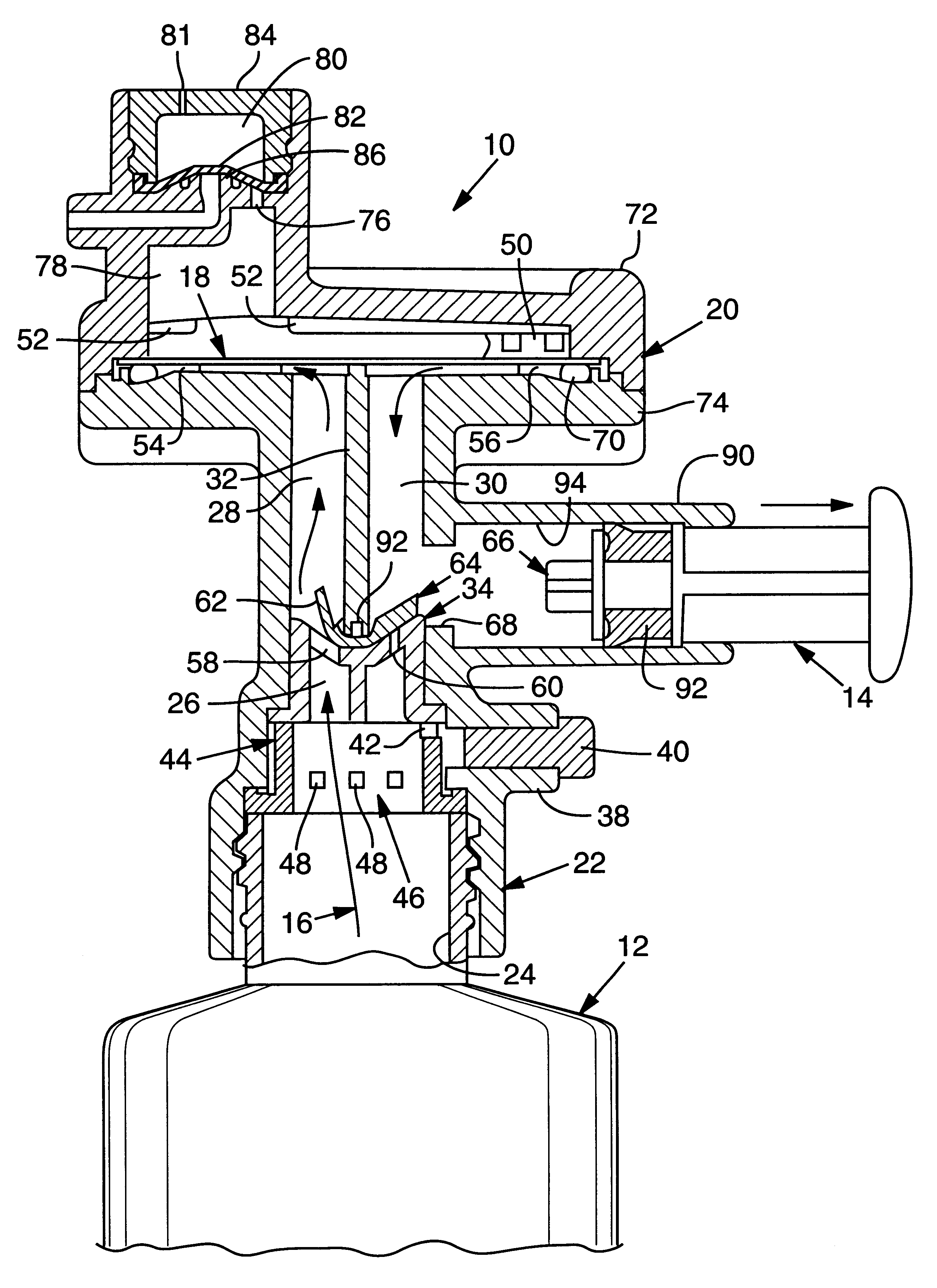

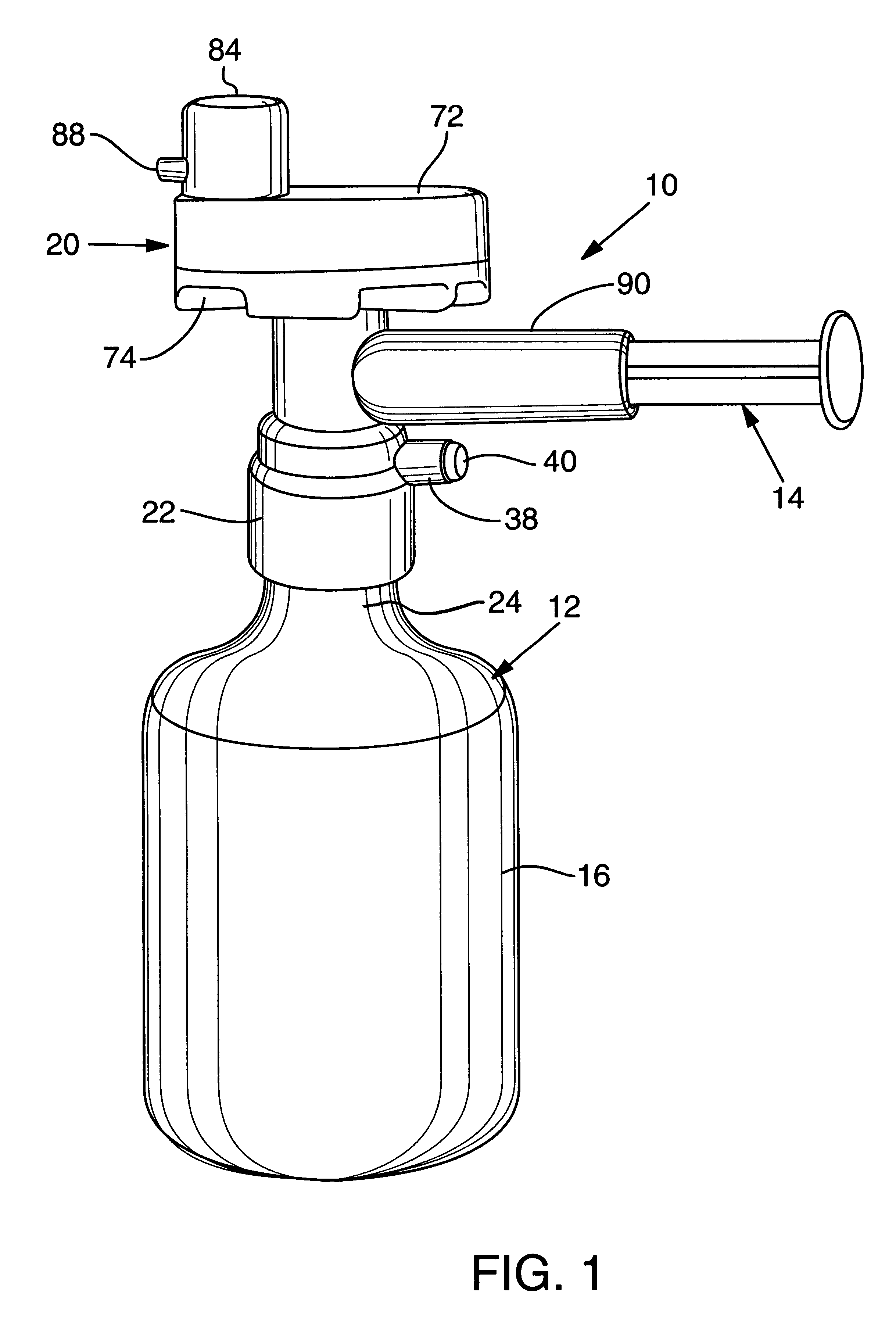

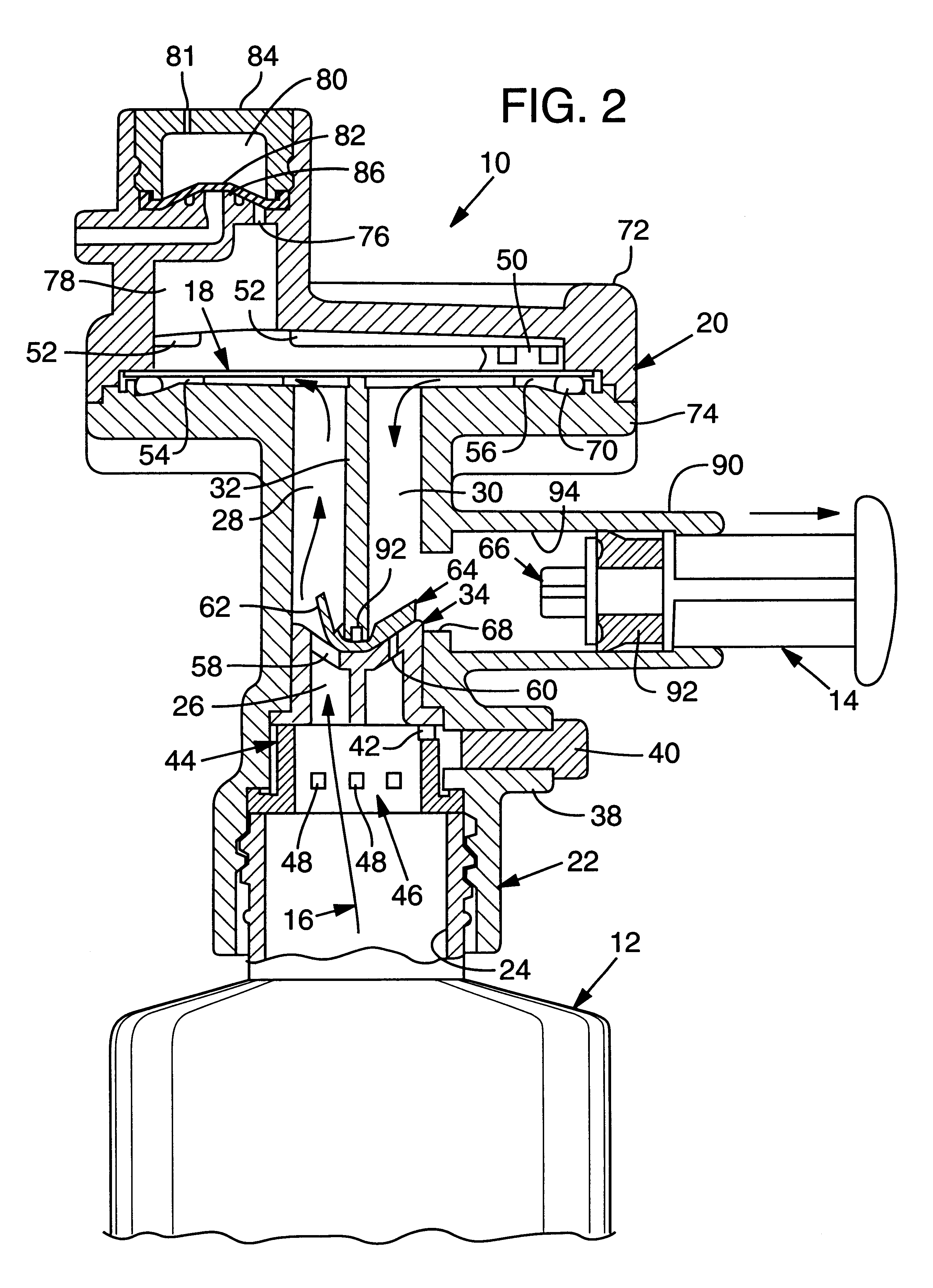

Humidifier reservoir

ActiveUS10342950B2Improve efficacyImprove manufacturabilityRespiratorsLighting and heating apparatusPre compressionEngineering

Owner:RESMED LTD

Method and apparatus for removing air locks within manually operated micro-filtration devices

Currently microfiltration devices use hydrophillic membranes to sterilize liquids. Air locks may develop on the upstream side of the filter membrane within these apparatus. The present invention provides a method and apparatus for removing an air lock from the upstream side of a microfilter in a device for dispensing a sterile liquid from a storage container by forcing the liquid through a microfilter. The device comprises a first inlet passageway communicating between the storage container and a chamber on the upstream side of the filter closable by a first valve, a second outlet passageway communicating between the storage container and a chamber on the upstream side of the filter closable by a second valve, and the method comprises the steps of: a) creating a partial vacuum in the chamber upstream of the microfilter to thereby open the first valve and draw the liquid from the storage container through the first passageway into the chamber and into contact with the upstream side of the filter; b) closing the first and second valves and increasing the air pressure in the upstream chamber; and c) opening the second valve thereby releasing air under pressure from the upstream chamber through the second passageway.

Owner:WEBB GARTH T

Oxygen-based biomass combustion system and method

InactiveUS7007616B2Heat loss from heating unnecessary oxidant is minimizedReduce heat lossSolidificationLiquefactionCombustion chamberOxygen

An oxygen-based biomass solid fuel combustion system and method has an air separator for separating oxygen from air providing a supply of oxygen for feeding oxygen to a solid fuel combustion chamber. An airlock feeds a metered amount of solid fuel to the solid fuel combustion chamber. A burner stage having a firetube for collecting fuel gases from the solid fuel combustion chamber combusts the collected fuel gases with further oxygen from the separator and heats a boiler to generate steam. A heat utilization device (e.g. an electrical generator) may be connected to the steam boiler. Nitrogen-free diluent gases (e.g. argon and carbon dioxide) are used to control combustion process temperatures. The usable heat energy and useful byproducts are extracted from the different stages of the process.

Owner:MUNIZ CESAR A

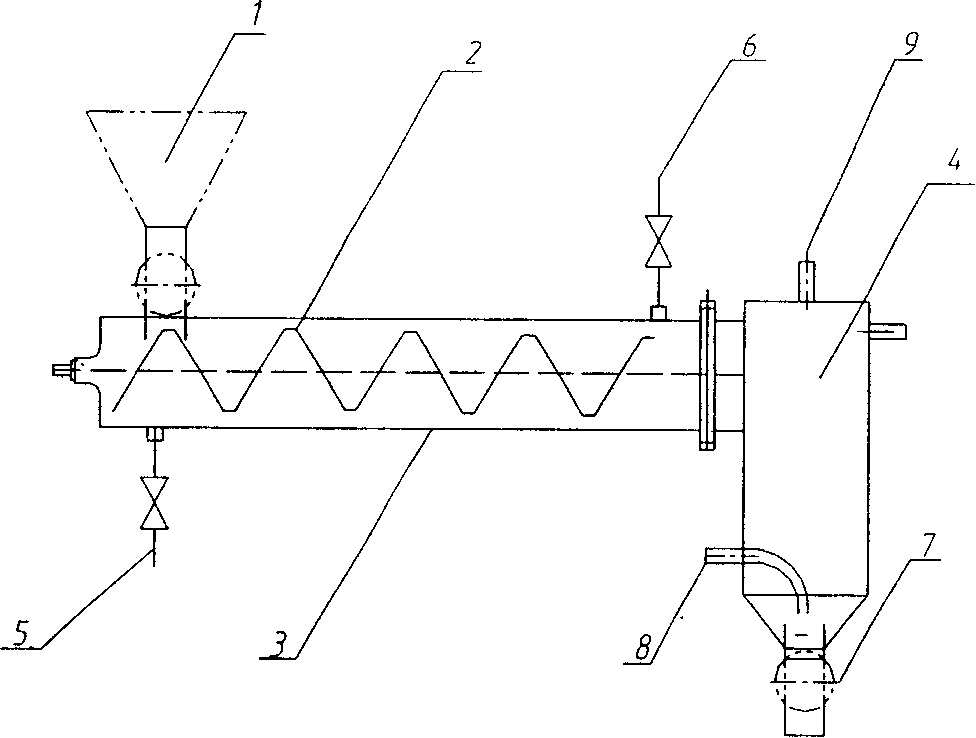

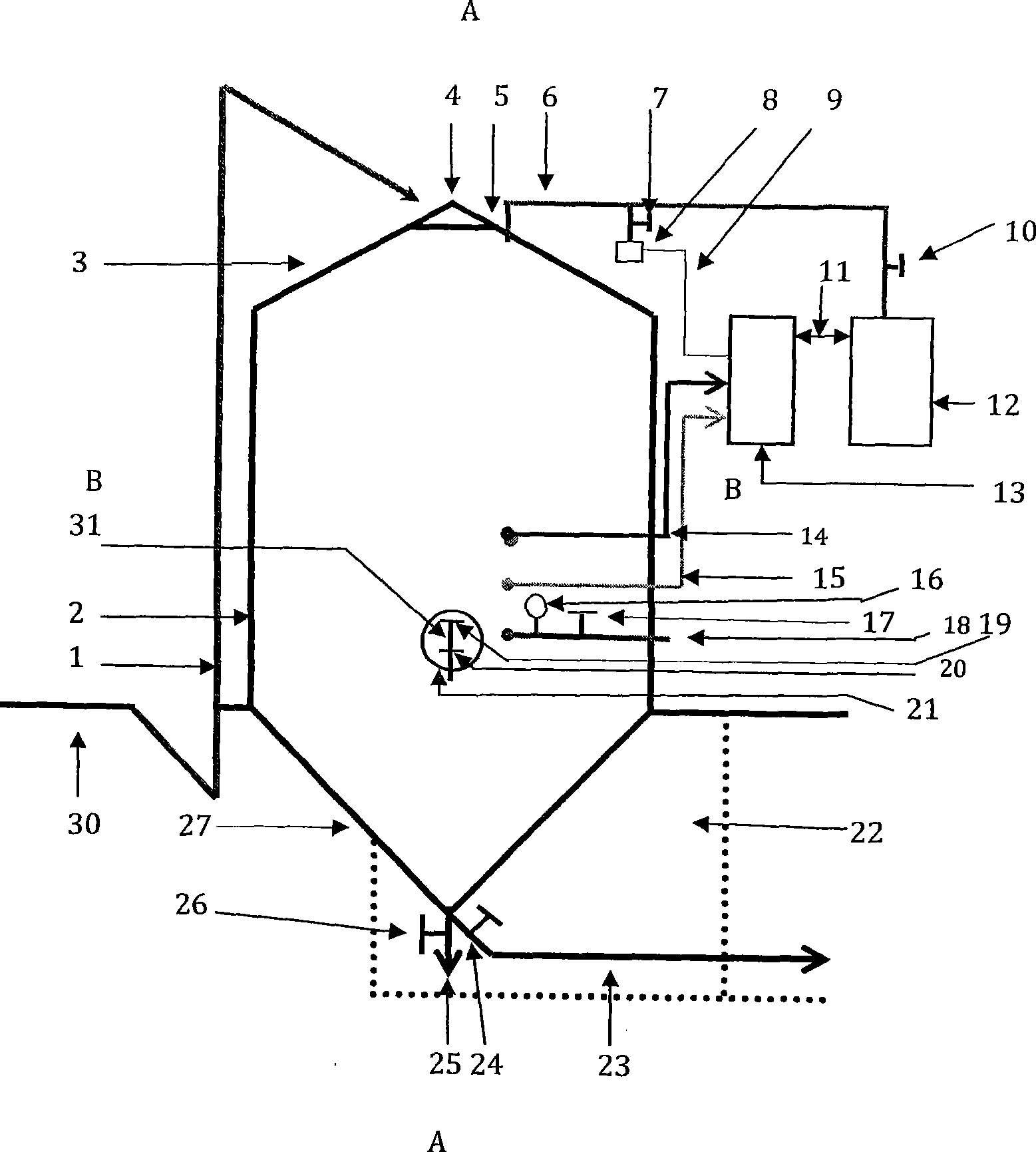

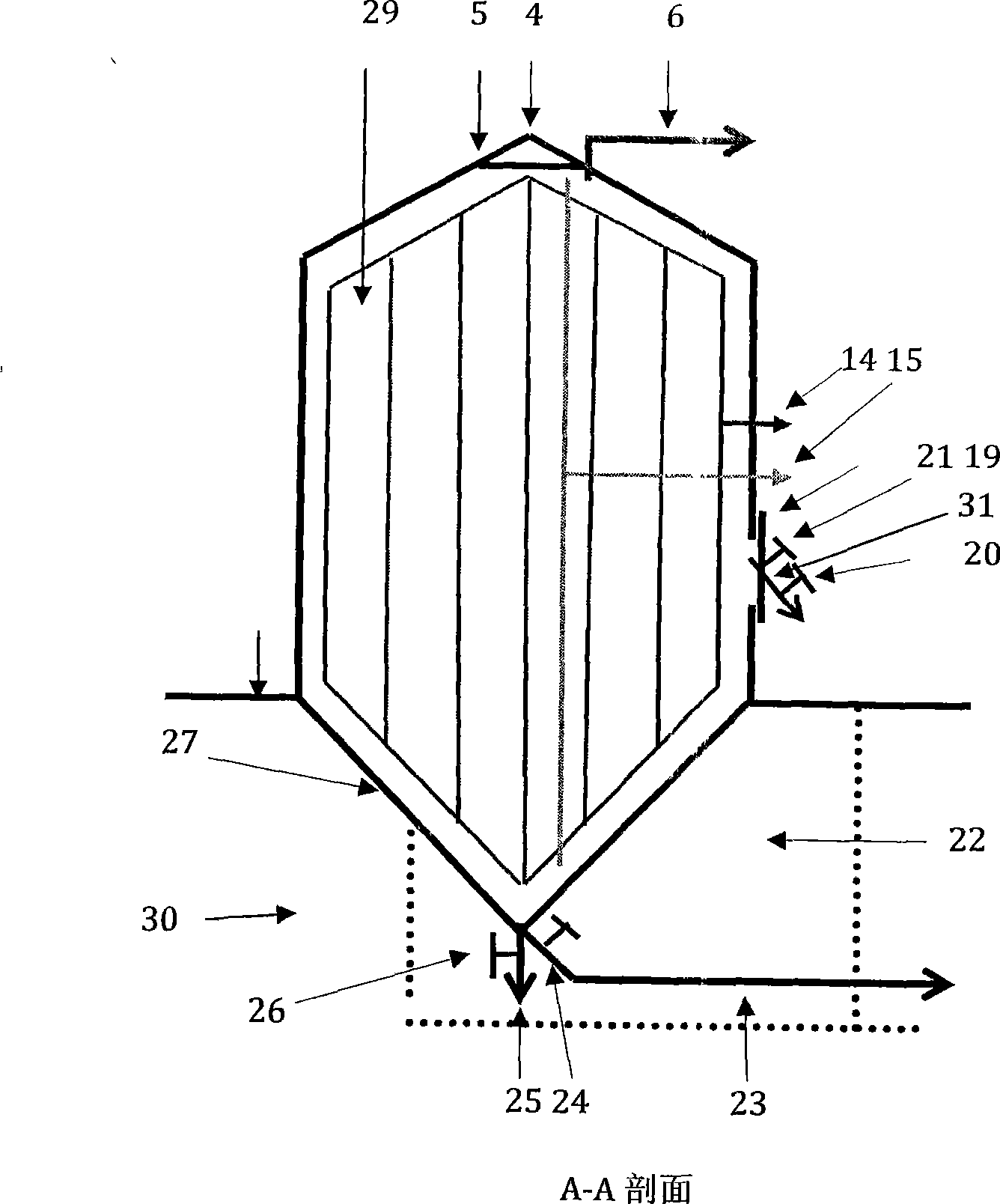

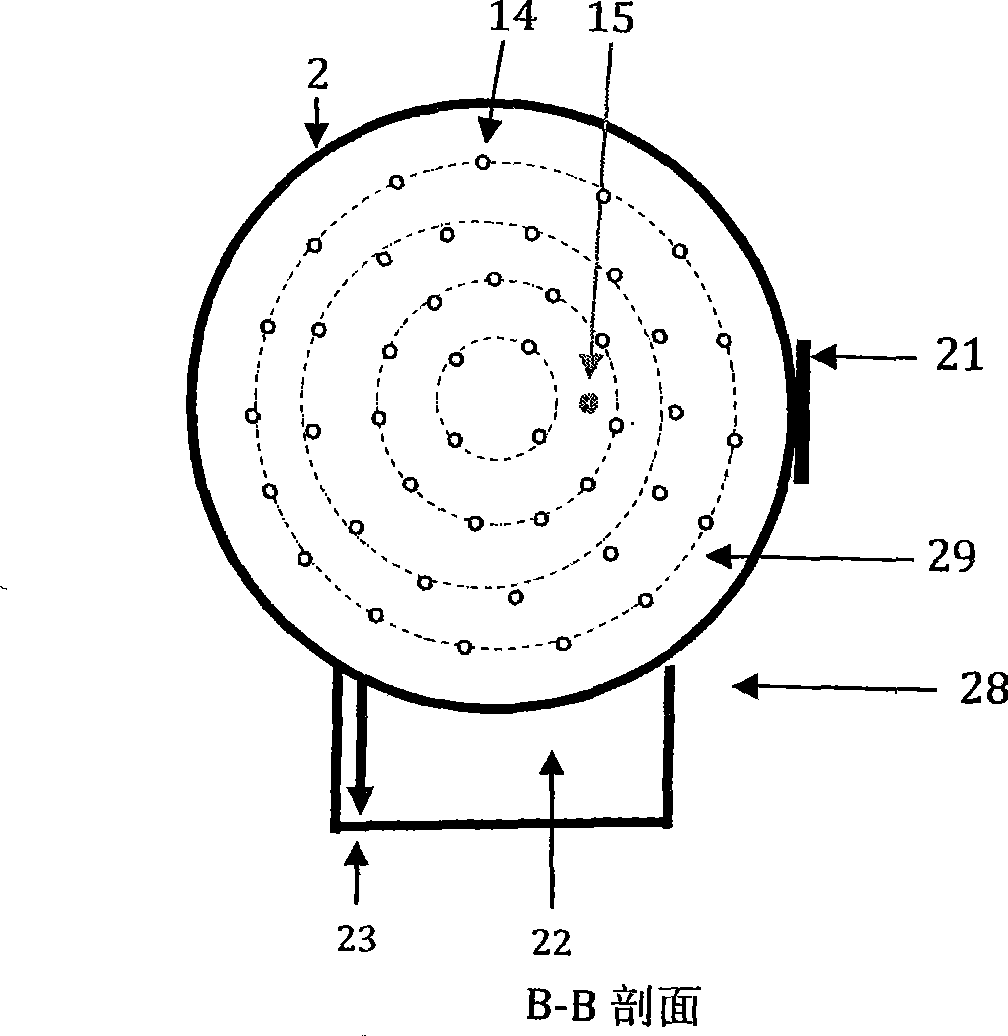

Continuous coupled solid-state fermentation method and biological reactor

InactiveCN101177693AReduce vaccinationSave manpower and material resourcesFermentationEnzymatic hydrolysisAlcohol

The invention discloses a continuous-coupling solid fermentation method and a solid bioreactor thereof. The invention has the operation method that: material is fermented in a horizontal tank first and then extracted in a vertical tank; or the material first finishes an enzymatic hydrolysis process in the horizontal tank, and then is fermented and extracted in the vertical tank. The bioreactor is characterized in that: a material inlet is provided with an airlock that can cause the material to continuously enter a fermentation tank and separate the fermentation tank with outside; the enzymatic hydrolysis, the fermentation and the extraction processes of the material are integrated into one reactor and are continuously done. The invention is suitable for the solid fermentation processes such as biomass alcohol, biomass hydrogen-production, fermentation alcohol by sweet sorghum, fermentation xanthan by inert carrier, etc.; the method realizes the continuously fermentation and coupling of every process stage; compared with fermentation in batch, the steps of reactor inoculation, cleaning and sterilization, etc., are reduced and the middle operation are also spared, thus saving manpower and material; in addition, the whole process has no turning and stirring device for solid material, thus avoiding the damage to mycelium.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

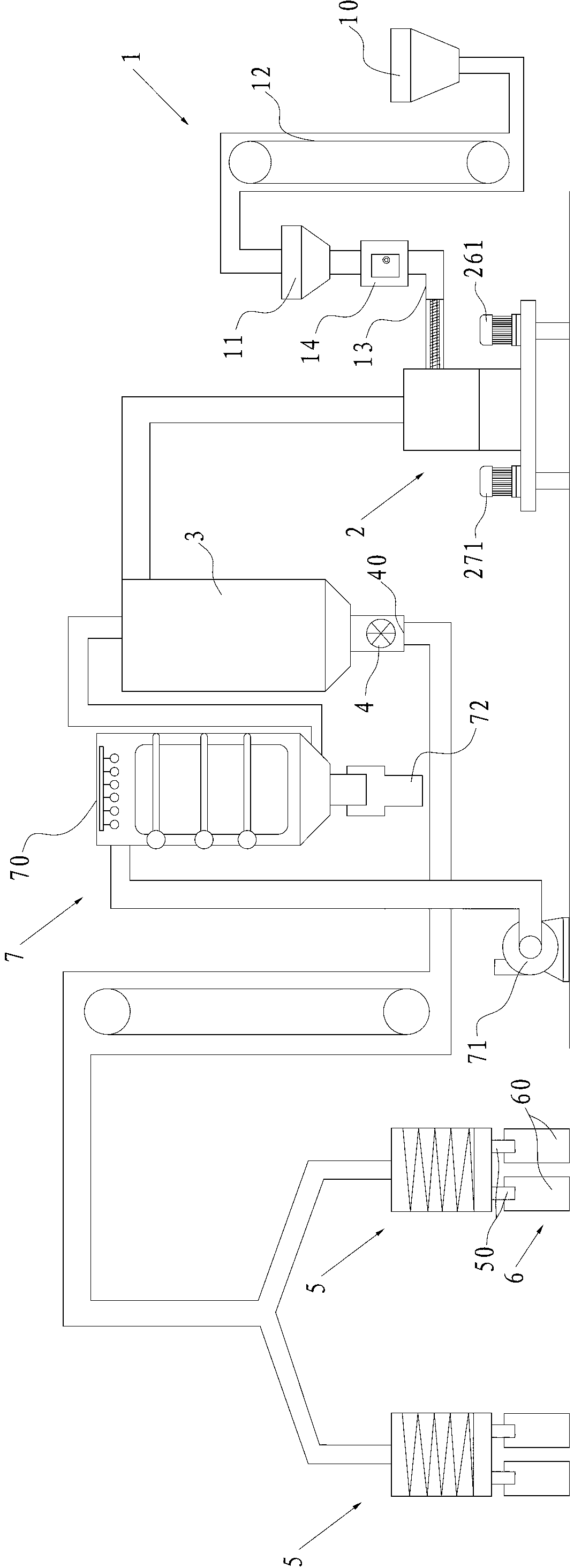

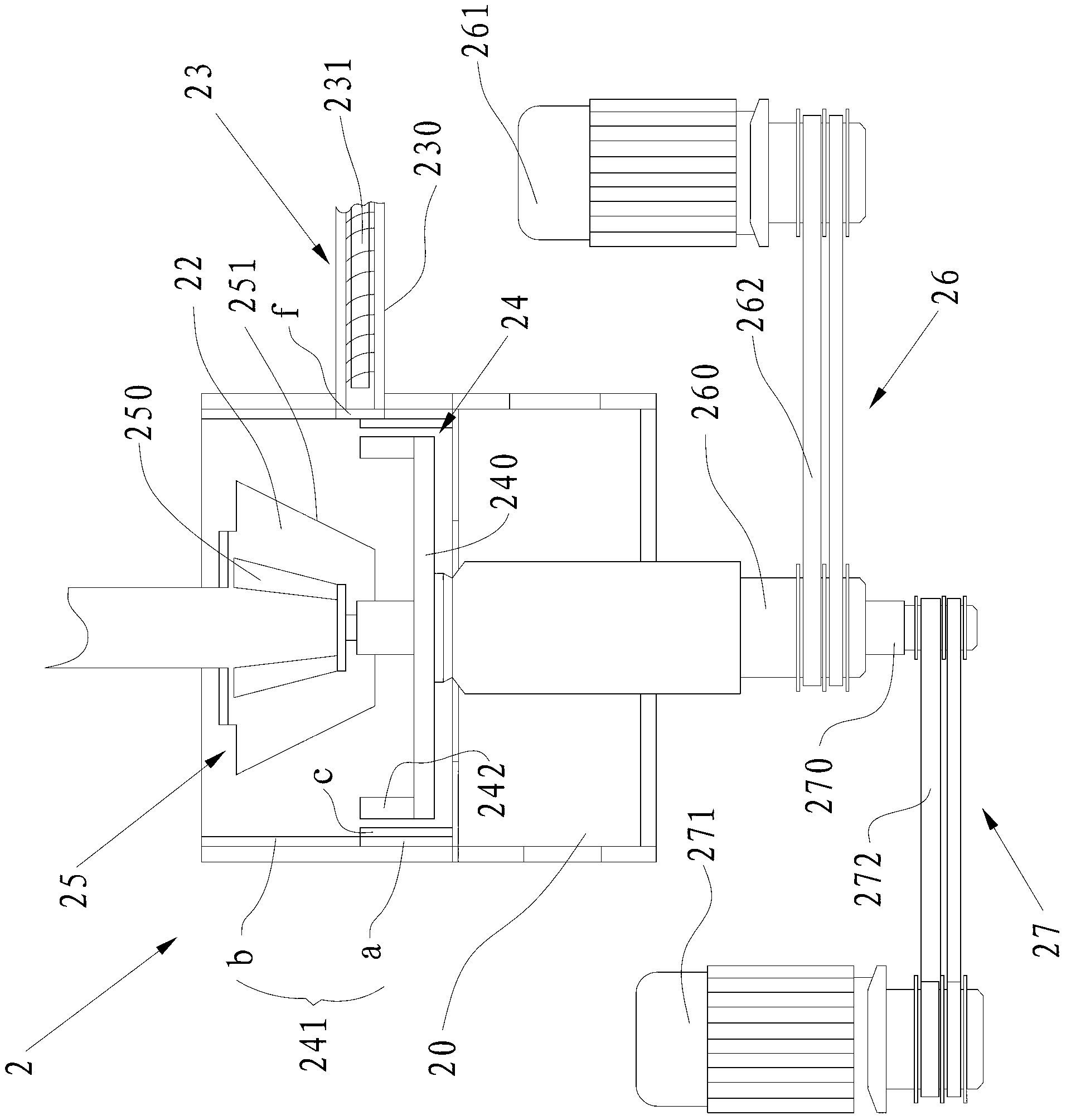

Production equipment for extracting cotton protein from cottonseed meal

The invention relates to production equipment for extracting cotton protein from cottonseed meal. The production equipment comprises a feeding mechanism, a particle crashing mechanism, a midway feed bin, an airlock, a sieving mechanism and a material receiving mechanism, wherein an air outlet of the airlock is communicated with the sieving mechanism; the particle crashing mechanism is an airflow scroll type crashing mechanism, and is provided with an air inlet chamber, a crashing chamber and a grading chamber which are communicated with each another; and the airflow scroll type crashing mechanism comprises a feeding device communicated with the crashing chamber, a crashing device arranged inside the crashing chamber, a grading device arranged inside the grading chamber, as well as a first driving device and a second driving device which respectively drive the crashing device and the grading device. According to the production equipment, cottonseed meal particles with different sizes can be crashed, and the finenesses of the cottonseed meal particles after being crashed are uniform, so that the phenomenon that the compositions of the cotton protein are damaged is reduced, the working requirement of the sieving mechanism is reduced at the same time, and the equipment cost is saved.

Owner:张家港市华丰油脂有限公司

Material classifier

ActiveUS20050242007A1Increase in sizeIncrease volumeCombination devicesAuxillary pretreatmentCycloneEngineering

The present invention a material classifier includes a cyclone including a cyclone inlet, a cyclone outlet, a blower and a blower discharge; an air diffuser connected at a diffuser inlet to the cyclone outlet and at a diffuser outlet to an air lock such that the cyclone and air diffuser are in fluid communication; wherein the diffuser including a central cylindrical portion including an air inlet for admitting controlled amounts of diffuser air around substantially the entire cylinder outer periphery of the central cylindrical portion, wherein the material classifier separating fine particles from coarse particles and discharging the fine particles together with air out the blower discharge, and discharging the coarse particles through the air lock, such that varying the amount of diffuser air one can control the size of the fine particles being separated from the coarse particles.

Owner:SIMPSON PETER

Method for long term storage of grain without deterioration and equipment thereof

InactiveCN101485356ALong shelf lifeThe solution will not deteriorateSeed preservation by dryingEngineeringNitrogen gas

The invention relates to a method for prolonging storage tenure of grains and bean grains to prevent deterioration, and equipment thereof. The equipment comprises a grain store, wherein the grain store can ensure vacuum degree and can be sealed; a vacuum pump assembly is arranged outside and communicated with the grain store; a pipeline and a valve are arranged on the store wall to fill nitrogen into the grain store; the store wall is provided with an entry inspection door; an air lock store is arranged on a cover board of the entry inspection door, is communicated with the grain store through an air lock valve and the outside through a sampling valve; a discharge valve, a discharge pipeline and a conveying pipeline with a turnover valve are arranged in the center of the bottom of the store; and an electroheat low-temperature drying system, a temperature sensor and a humidity sensor are arranged in the grain store, and the temperature sensor and the humidity sensor can detect temperature and humidity in the grain store respectively, so that oxygen and humidity during the period of grain storage can be controlled by the vacuum technology, and the grains are enforced to be in natural dormancy. Therefore, speed of natural exhaustion of the grains can be controlled to achieve the aim of prolonging the tenure of storage of the grains to prevent deterioration, and the grain store has low cost, easy construction and wide application range.

Owner:胡屹博 +2

Rotary airlock valve

ActiveUS20050098586A1Reduce wearDifficult to handleMovable measuring chambersBulk conveyorsLeading edgeTrailing edge

A rotary airlock valve has a plurality of material receiving pockets having leading edges that are narrower than the trailing edges thereof, preferably having walls tapering inwardly so as to define a narrowed pocket opening for directing any material expansion due to pressurization to a center of a discharge outlet, to reduce wear and increase seal life.

Owner:ASJ HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com