Continuous coupled solid-state fermentation method and biological reactor

A biological reaction device, solid-state fermentation technology, applied in the field of fermentation industry to save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

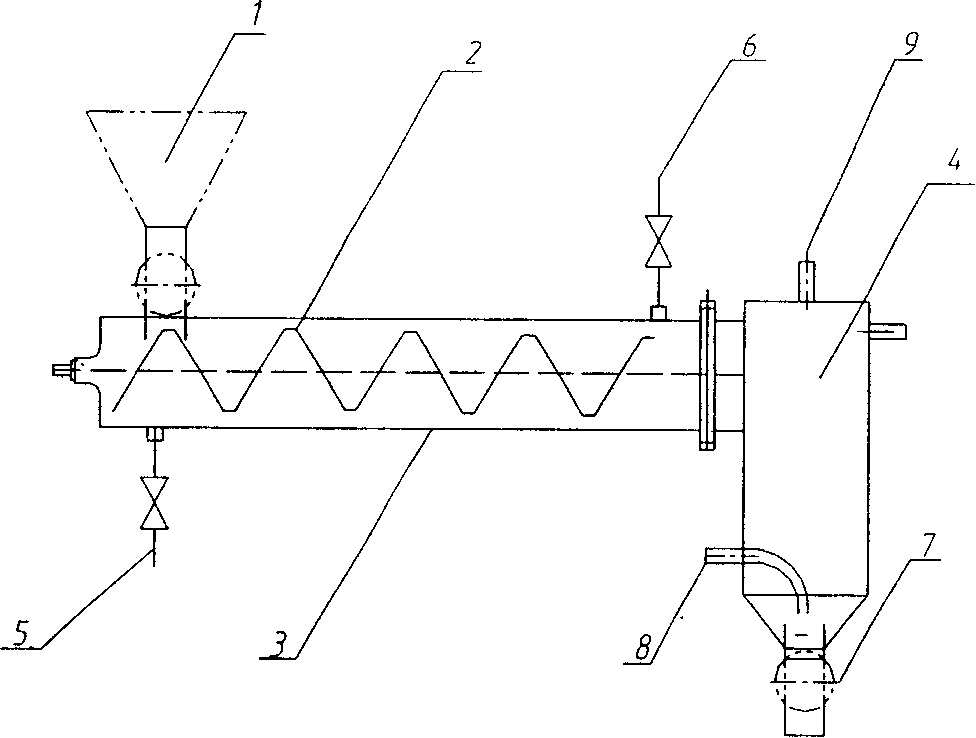

[0022] Example 1: Continuous fermentation of enzymatic hydrolysis, fermentation and air stripping coupled with steam-exploded straw fermentation to produce cellulose ethanol

[0023] Material preparation: cut the corn stalks to a length of 2-3 cm, maintain 1.4 MPa in the steam explosion tank for 5 minutes, release the pressure instantly, and obtain the steam explosion straw.

[0024] Sterilization: Steam-exploded straw is sterilized in another container at 121-125°C for 15-20 minutes. Vertical tank and horizontal tank are sterilized, enter steam from (5)(8), exhaust steam from (6)(9), maintain the pressure at 121-125°C for 15-20min.

[0025] Mixing, feeding and enzymatic hydrolysis: by passing CO before feeding 2 Air in the replacement tank, (5)(8) intake, (6)(9) exhaust. The sterilized and cooled steam-exploded straw is mixed with cellulase at a ratio of 20μ / g-steam-exploded straw, and the water content is adjusted to 65-75%. According to the ratio of adding 1g of yeast fo...

Embodiment 2

[0027] Example 2: Enzymolysis, fermentation and gas-solid separation coupled continuous fermentation of steam-exploded wheat straw solid-state fermentation to produce hydrogen

[0028] Material preparation: cut the wheat straw to a length of 15-20 cm, maintain 1.4 MPa in the steam explosion tank for 5 minutes, release the pressure instantly, and obtain the steam explosion wheat straw.

[0029] Sterilization: Put the steam-exploded wheat straw into the sterilizer for sterilization, the sterilization temperature is 121-125°C, and the sterilization time is 15-20min; the solid-state fermentation reactor is sterilized by steam, and the steam is from (5) (8 ) enters, flows out from (6)(9), and maintains at 121-125°C for more than 30 minutes.

[0030] Enzymatic hydrolysis: prepare cellulase into a 100μ / ml solution, and then mix the solution with sterilized and cooled steam-exploded wheat straw at a ratio of 20μ / g. Adjust the temperature of the horizontal tank to maintain 35±1°C. Op...

Embodiment 3

[0034] Example 3: Fermentation, gas stripping coupled continuous fermentation for the production of ethanol by solid-state fermentation of sweet sorghum

[0035] Material preparation: remove the sorghum ears, sorghum leaves and roots from the mature harvested sweet sorghum stalks and crush them;

[0036] Sterilization: Put the crushed sweet sorghum stalks into a sterilizing pot for sterilization, the sterilization temperature is 121-125°C, and the sterilization time is 15-20min; the solid-state fermentation reactor is sterilized by steam, and the steam is from (5) Enter, flow out from (6), maintain 121-125°C for more than 30 minutes.

[0037] Fermentation: Mix Angel yeast (purchased in the market) with sterile water, the mixing ratio is 1g of yeast plus 40mL of sterile water, activate at 35°C for 25-30min, and then place it at room temperature for 45-60min after activation; In the sterilized container, mix the sweet sorghum with the activation solution according to the ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com