A kind of preparation method of sugarcane fruit wine

A technology of sugarcane and fruit wine, applied in the field of fruit wine fermentation, can solve the problems that the production process is difficult to achieve large-scale industrial production, S. Processing time and cost, unique taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

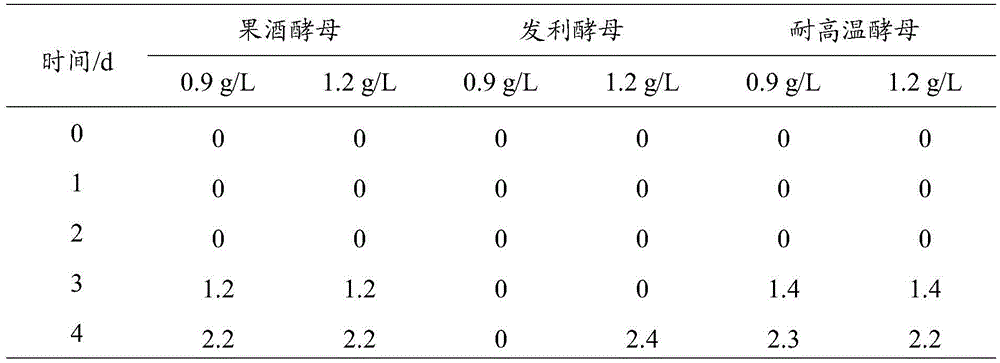

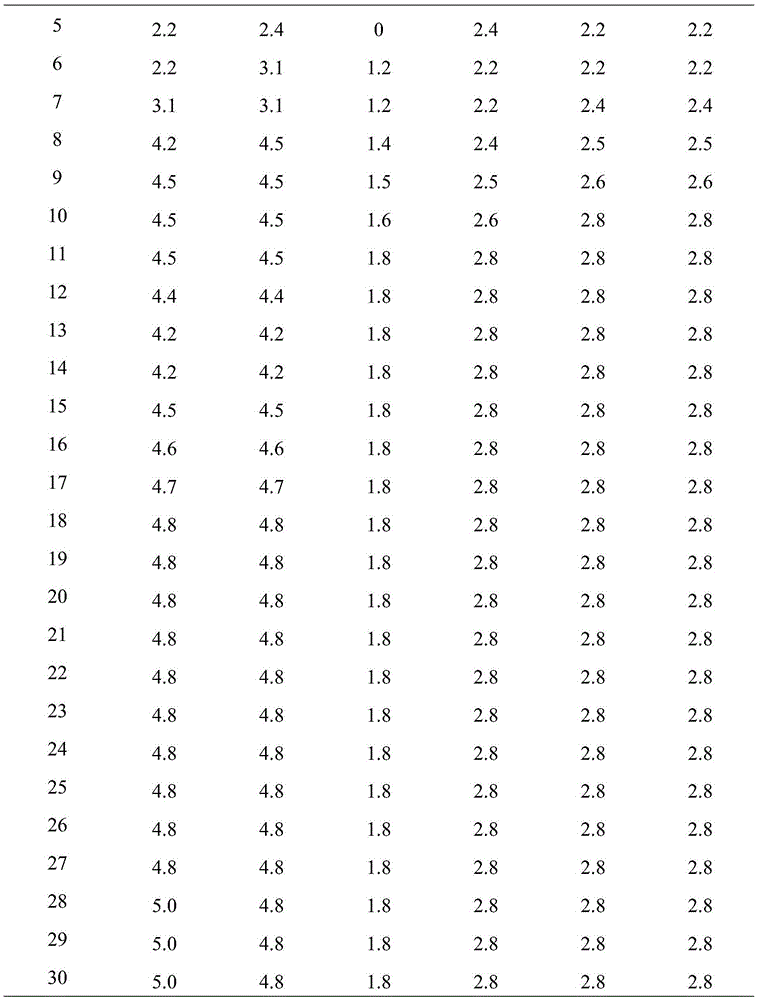

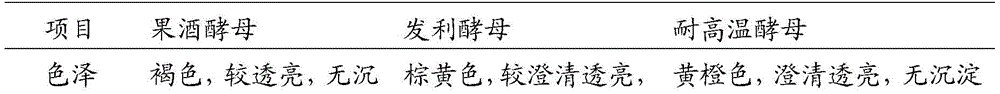

Embodiment 1

[0030] Embodiment 1 prepares sugarcane fruit wine

[0031] 1. Disinfect and sterilize the production equipment;

[0032] 2. Squeeze raw sugarcane crude juice of whole stem cane with 5% inclusion rate, use 100-mesh filter cloth for coarse filtration, filter out bagasse and impurities, and then use 300-mesh filter cloth for fine filtration to obtain 160 kg of sugarcane raw juice;

[0033] 3. Sterilize the raw sugarcane juice at 70°C for 25 minutes to obtain sugarcane juice, remove the flocs suspended in the upper layer of the sugarcane juice, and transfer the supernatant to the fermentation tank;

[0034] 4. Cool the sugarcane juice in the fermenter to 32°C, adjust the sugar content of the sugarcane juice to 18°Bx, and obtain the fermentation liquid;

[0035] 5. Use 30°C sterile water to activate Saccharomyces cerevisiae active dry powder, the activation method is 30°C water bath for 35 minutes, the weight ratio of Saccharomyces cerevisiae active dry powder to the sterile water...

Embodiment 2

[0038] Embodiment 2 prepares sugarcane fruit wine

[0039] 1. Disinfect and sterilize the production equipment;

[0040] 2. Squeeze raw sugarcane crude juice of whole stem cane with 15% inclusion rate, use 250-mesh filter cloth for coarse filtration, filter out a little bagasse and impurities, and then use 400-mesh filter cloth for fine filtration to obtain 160kg of sugarcane raw juice;

[0041] 3. Sterilize the raw sugarcane juice at 100°C for 35 minutes to obtain sugarcane juice, remove the flocs suspended in the upper layer of the sugarcane juice, and transfer the supernatant to the fermenter;

[0042] 4. Cool down the sugarcane juice in the fermenter to 32°C, adjust the sugar content of the sugarcane juice to 25°Bx, and obtain the fermentation liquid;

[0043] 5. Use sterile water at 40°C to activate Saccharomyces cerevisiae active dry powder, wherein each 1g of yeast active dry powder is activated with 50mL of sterile water at 40°C. In the fermentation broth, the inocul...

Embodiment 3

[0046] Embodiment 3 prepares sugarcane fruit wine

[0047] 1. Disinfect and sterilize the production equipment;

[0048] 2. Squeeze raw sugarcane crude juice of whole stem cane with 10% inclusion rate, use 200-mesh filter cloth for coarse filtration, filter out a little bagasse and impurities, and then use 350-mesh filter cloth for fine filtration to obtain 160kg of sugarcane raw juice;

[0049] 3. Sterilize the raw sugarcane juice at 100°C for 35 minutes to obtain sugarcane juice, remove the flocs suspended in the upper layer of the sugarcane juice, and transfer the supernatant to the fermenter;

[0050] 4. Cool down the sugarcane juice in the fermenter to 32°C, adjust the sugar content of the sugarcane juice to 23°Bx, and obtain the fermentation liquid;

[0051] 5. Use 32°C sterile water to activate Saccharomyces cerevisiae active dry powder, the activation method is 32°C water bath for 30 minutes, the weight ratio of Saccharomyces cerevisiae active dry powder to the steril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com